Patents

Literature

57results about How to "Solve the overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

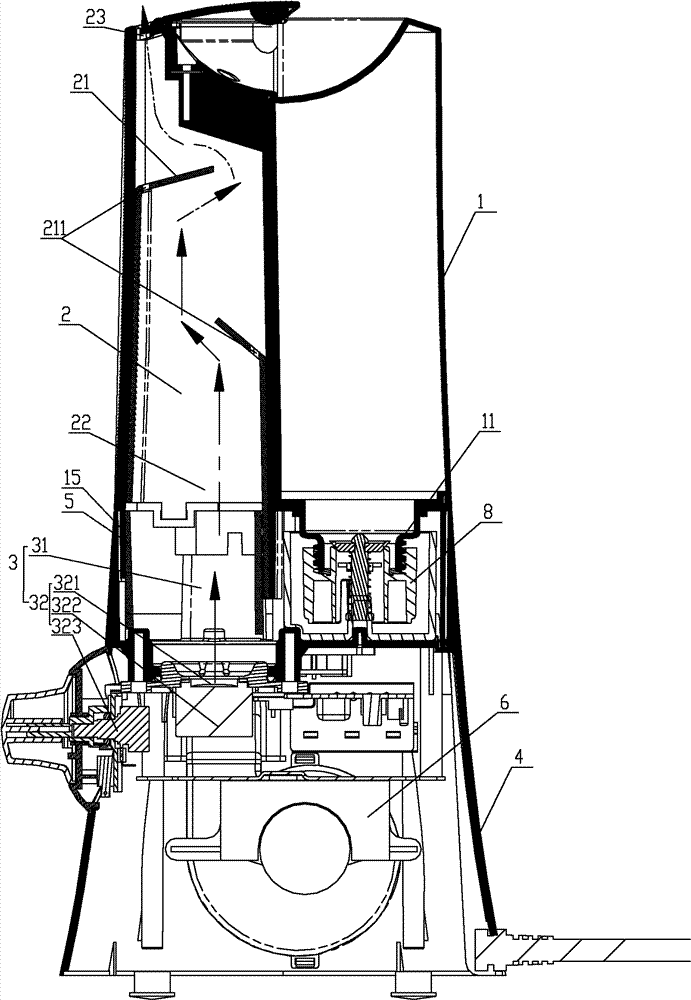

Humidifier

InactiveCN102095235AAddressing Leaky DefectsReduce complexityEngine sealsSpace heating and ventilation safety systemsEngineeringFog

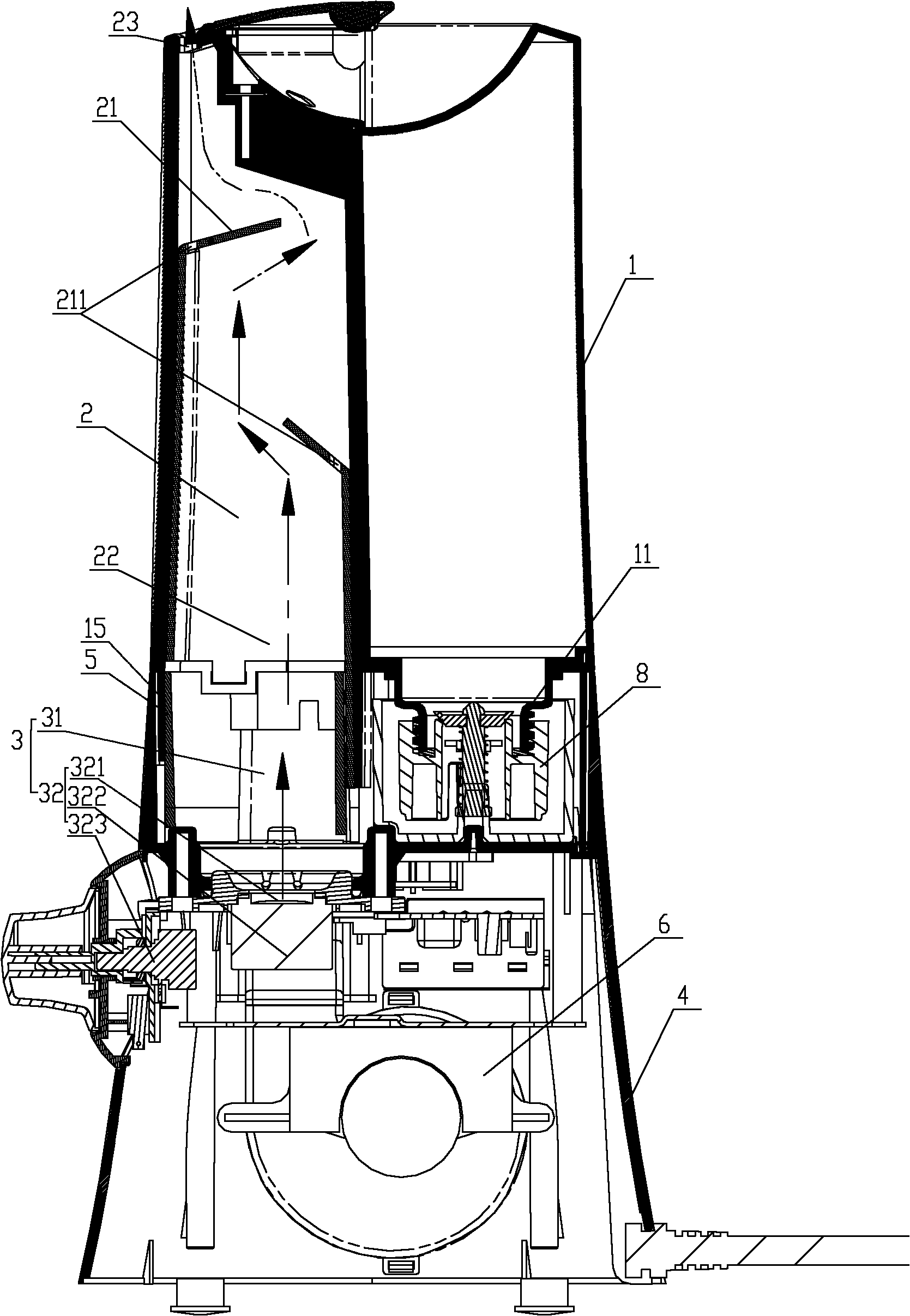

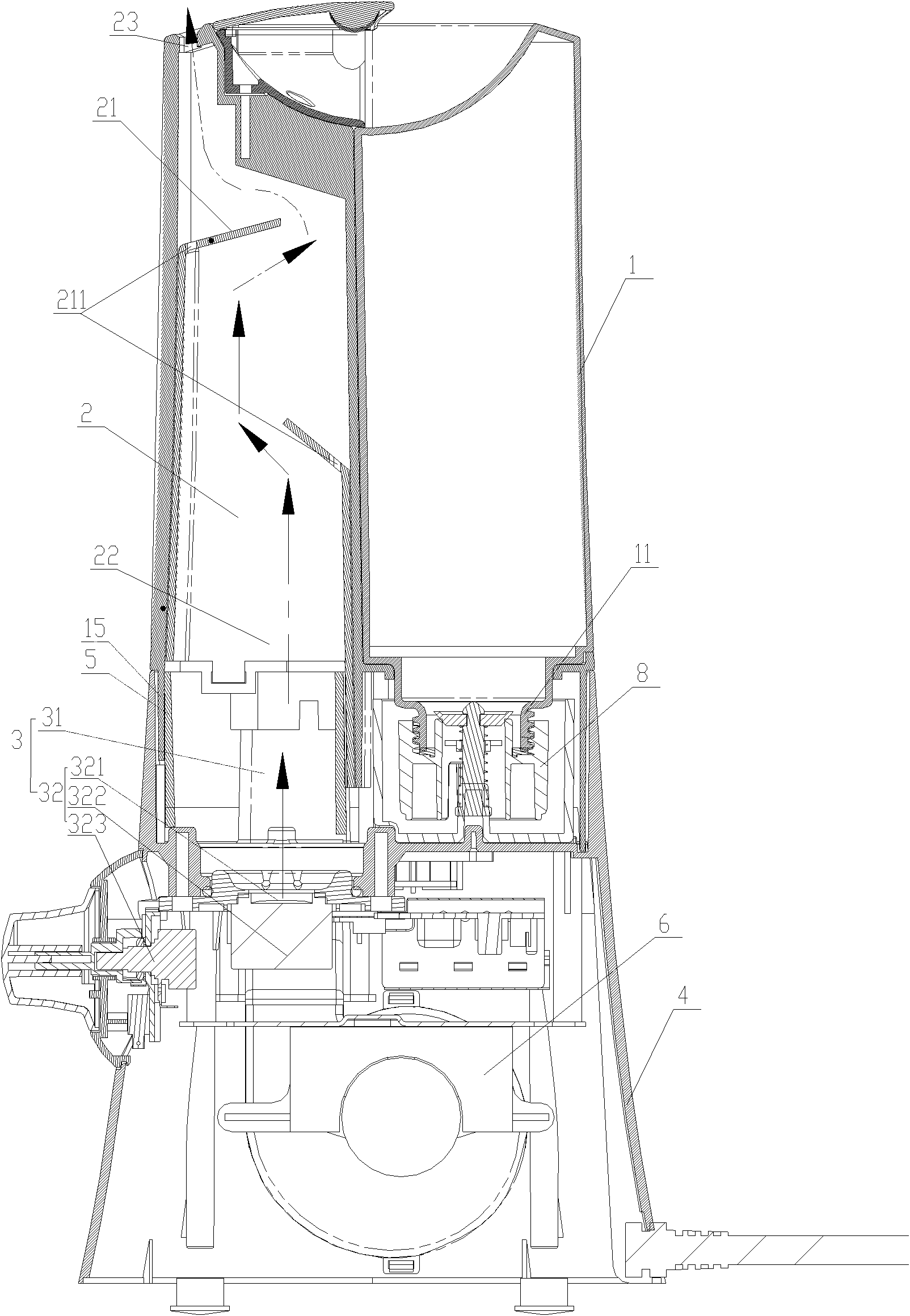

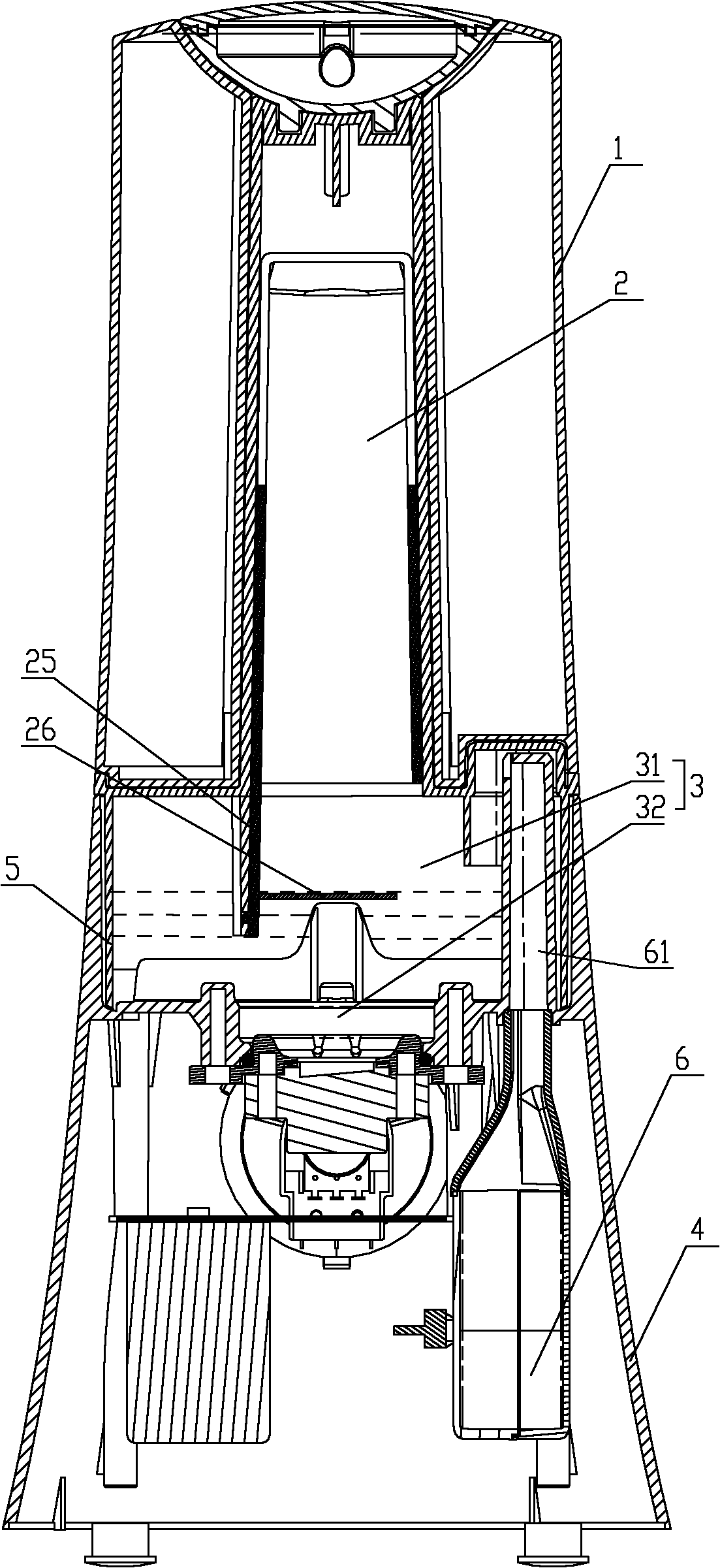

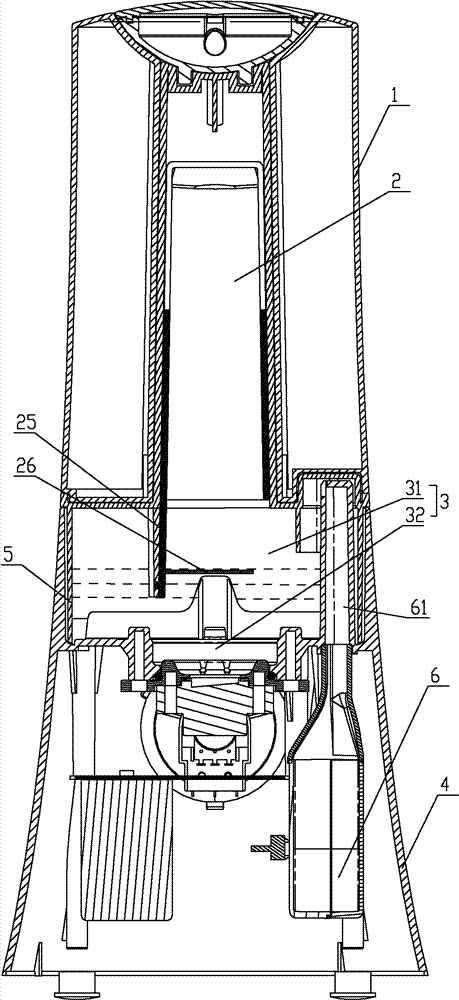

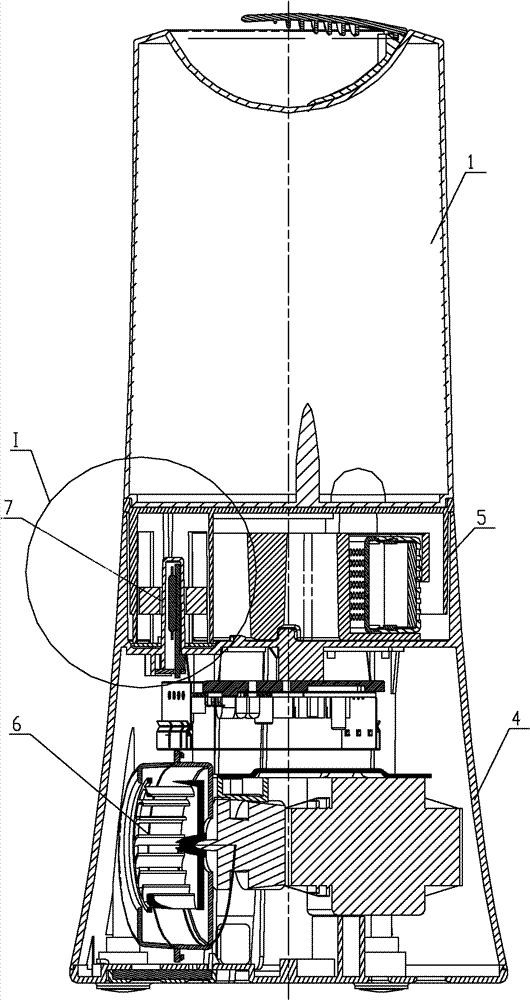

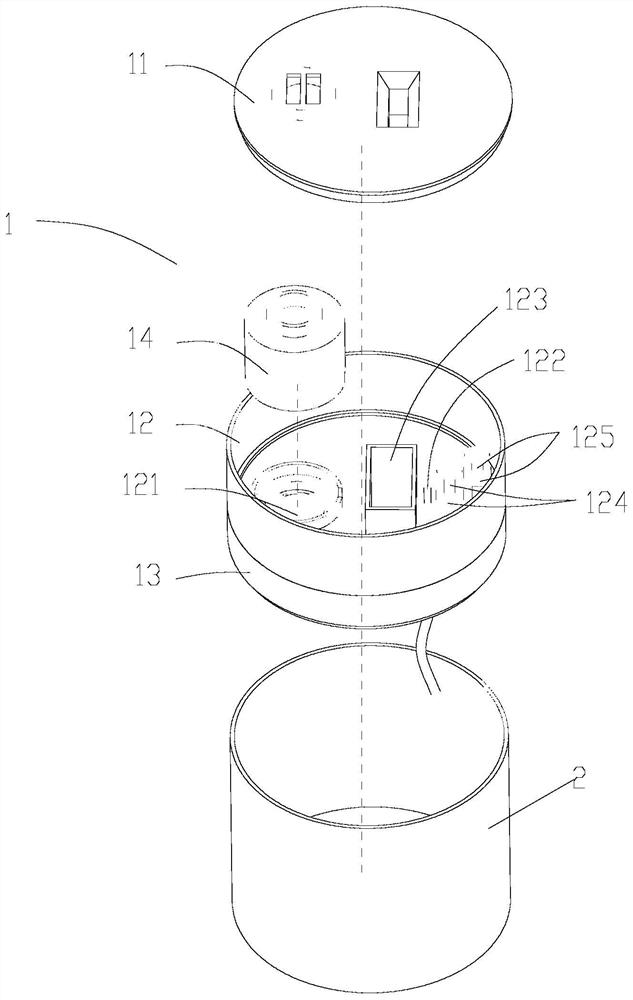

The invention relates to a humidifier, which comprises a base, a water tank and a water fog diffusing tube. An ultrasonic water fog generating mechanism, an air supply mechanism and a control mechanism are arranged in the base; the ultrasonic water fog generating mechanism comprises a water trough arranged on the upper part of the base; an ultrasonic oscillator is arranged at the bottom of the water tank; a leakage protective hood for enclosing the space above the ultrasonic oscillator is arranged above the ultrasonic oscillator; the leakage protective hood is peripherally inserted into the water trough and is immerged in the water; the water fog diffusing tube is hermetically connected with the leakage protective hood and is communicated with the space in the leakage protective hood; anda fog baffling plate is arranged in the water fog diffusing tube. The invention provides a humidifier which has no water fog leakage at the matching position of the water tank and the water trough, and has simple structure and good leakage protective effect.

Owner:贺发民

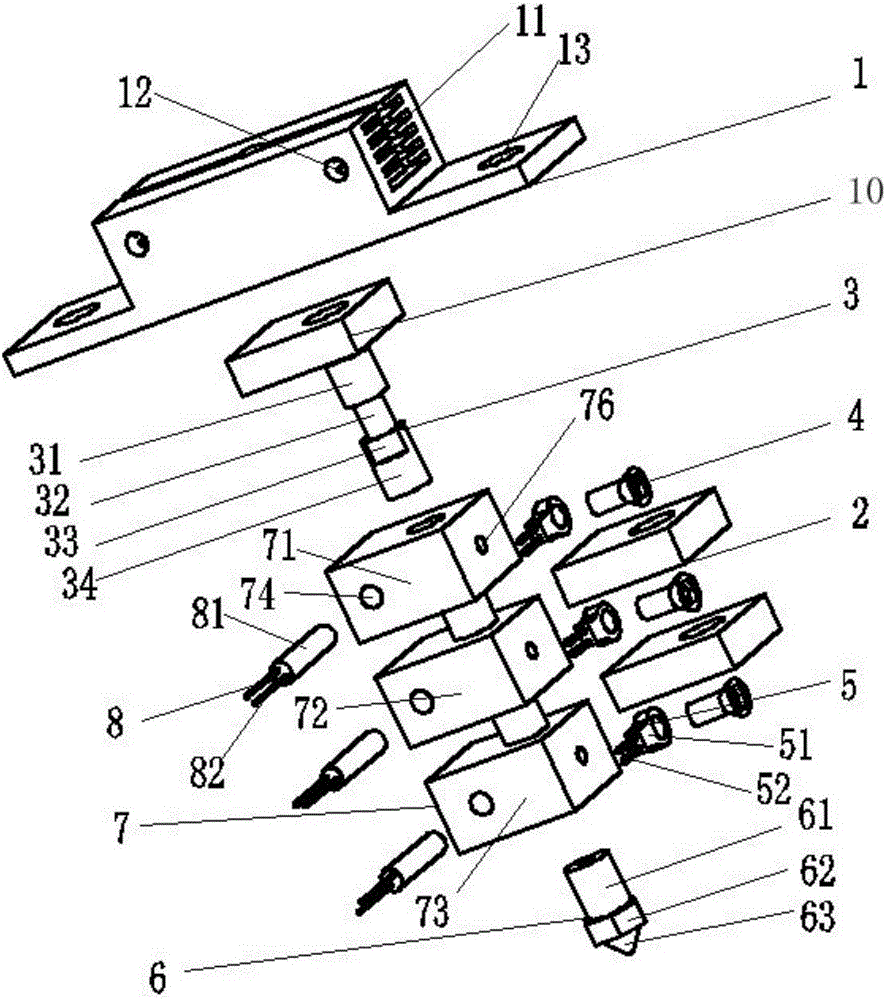

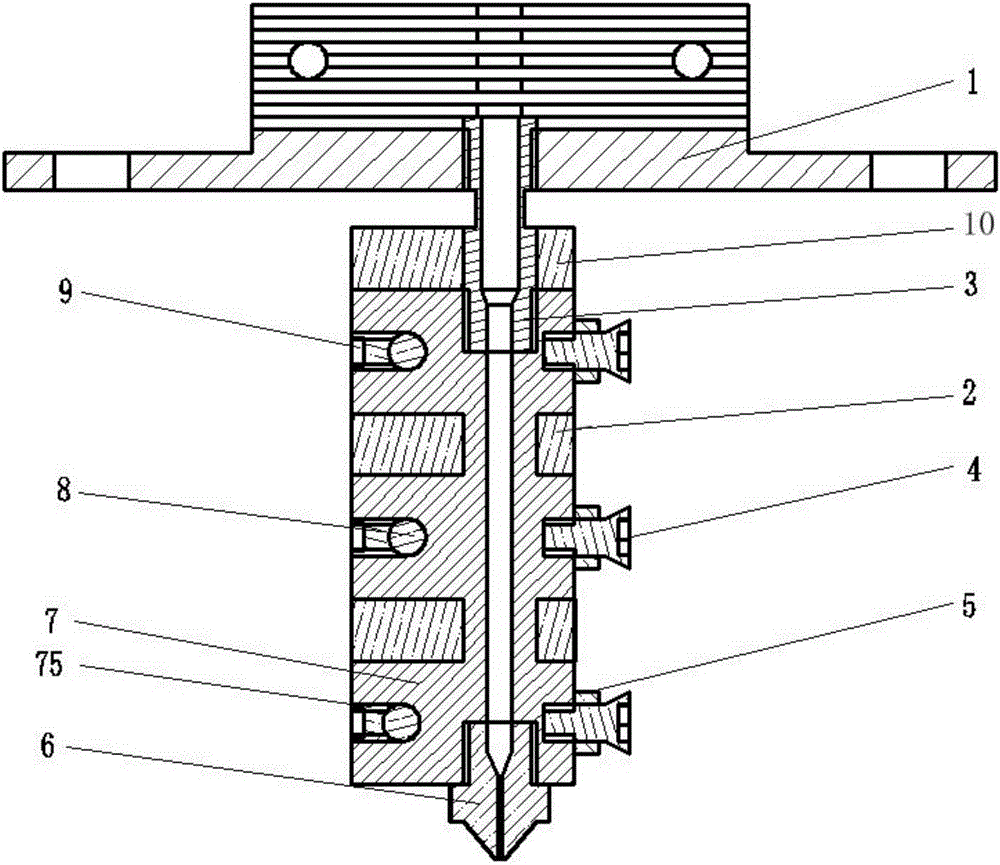

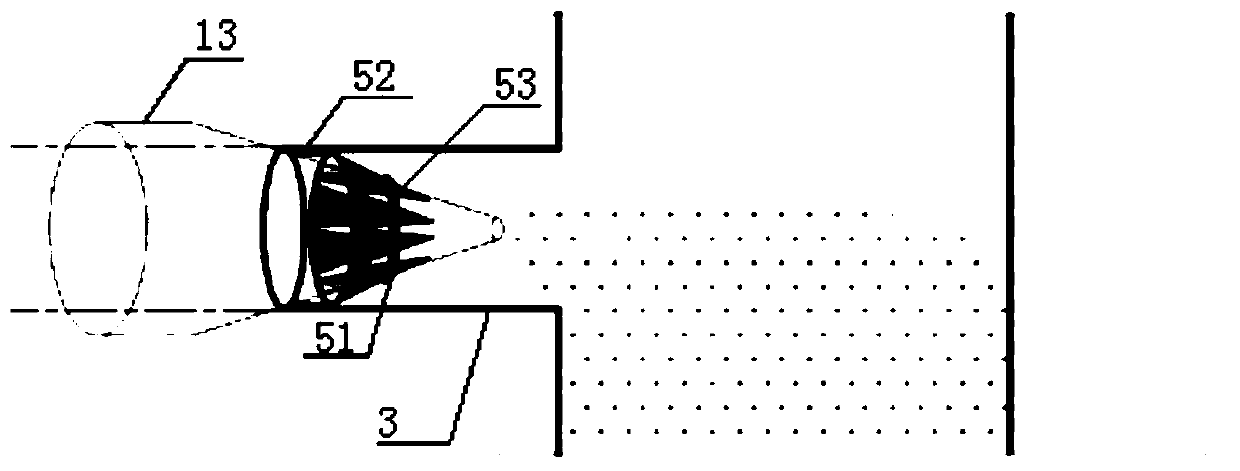

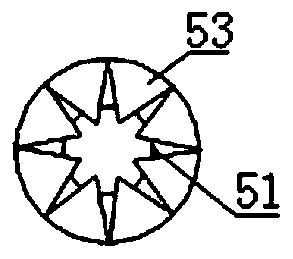

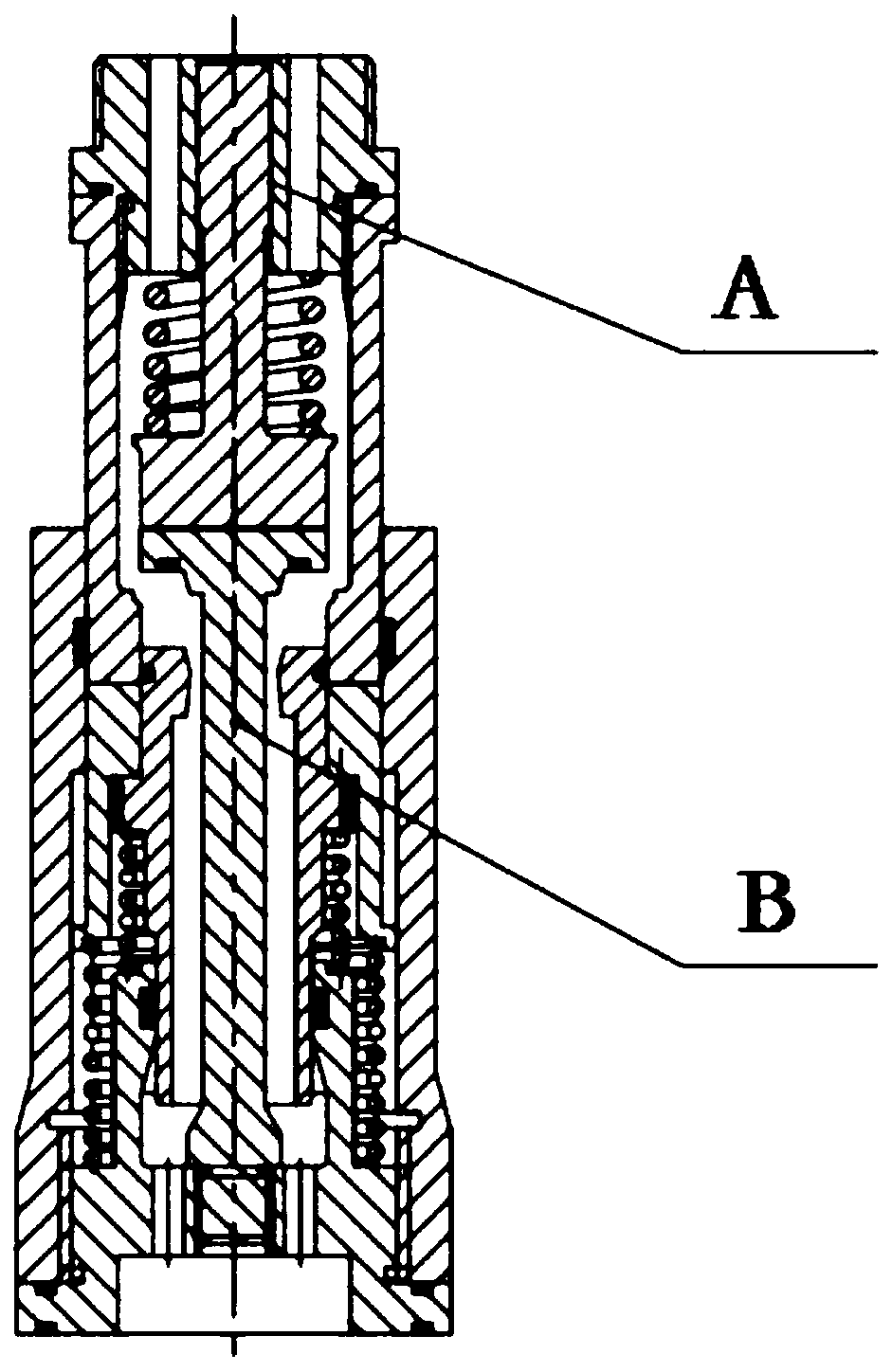

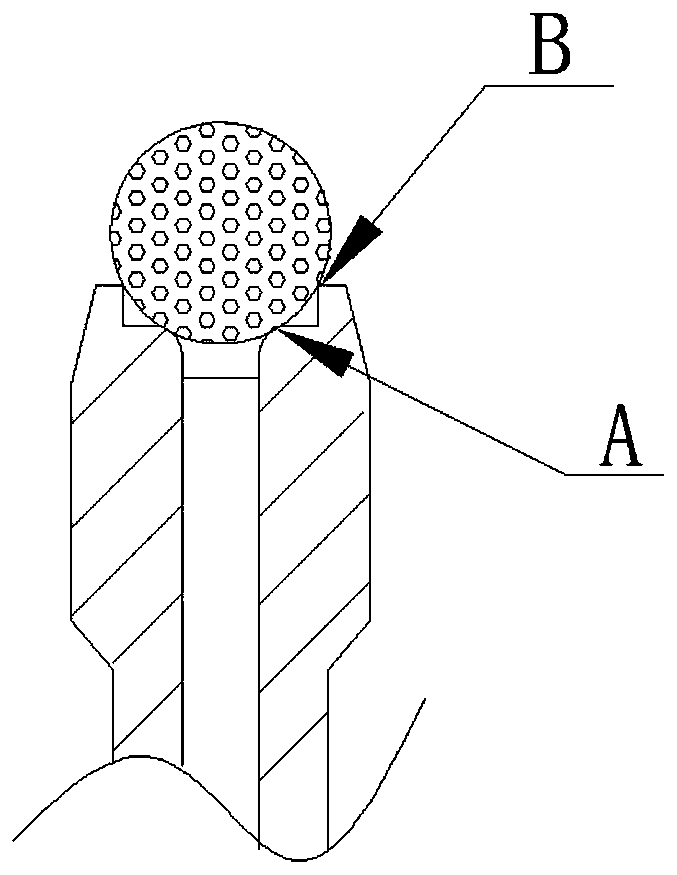

Extrusion head device based on fused deposition modeling technology

InactiveCN105235218ASmall temperature differenceExcellent extrusion qualityAdditive manufacturing apparatusTemperature controlThermal insulation

The invention provides an extrusion head device based on a fused deposition modeling technology. The extrusion head device comprises an extrusion head body with a melting channel, and further comprises a heat-insulation thermal insulation structure, wherein a heating assembly and a temperature measuring assembly are arranged on the extrusion head body; the upper end of the extrusion head body is connected with a heat dissipation device; the lower end of the extrusion head body is provided with a spray nozzle; a heat insulation structure is arranged between the extrusion head body and the heat dissipation device; and the heat-insulation thermal insulation structure covers outside the extrusion head body. The extrusion head device solves the technical problems in the prior art that temperature control is single, temperature measurement is in accurate, energy consumption is high, unstability is easily caused, different material filament materials are adopted, varying condition adaption is poor and the like. The spray nozzle and the extrusion head are an integrated structural design, so that molten material filaments can be prevented from overflowing and the material filaments can be kept at a stable temperature in the spray nozzle. The extrusion head device has the advantages such as stable sectional temperature control regulation, accurate temperature measurement, low energy consumption, an adjustable filament feeding speed, a wide material filament range and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

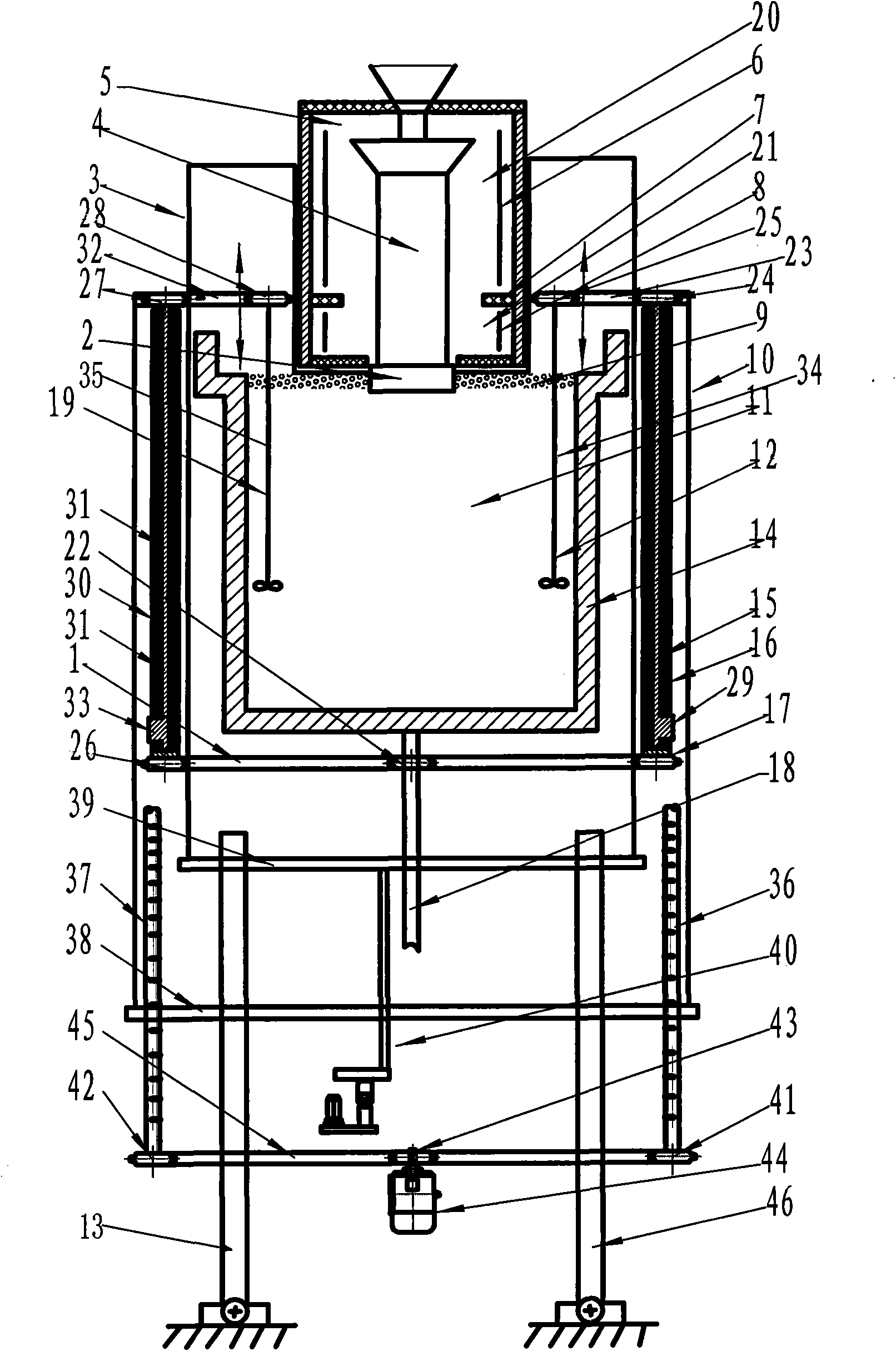

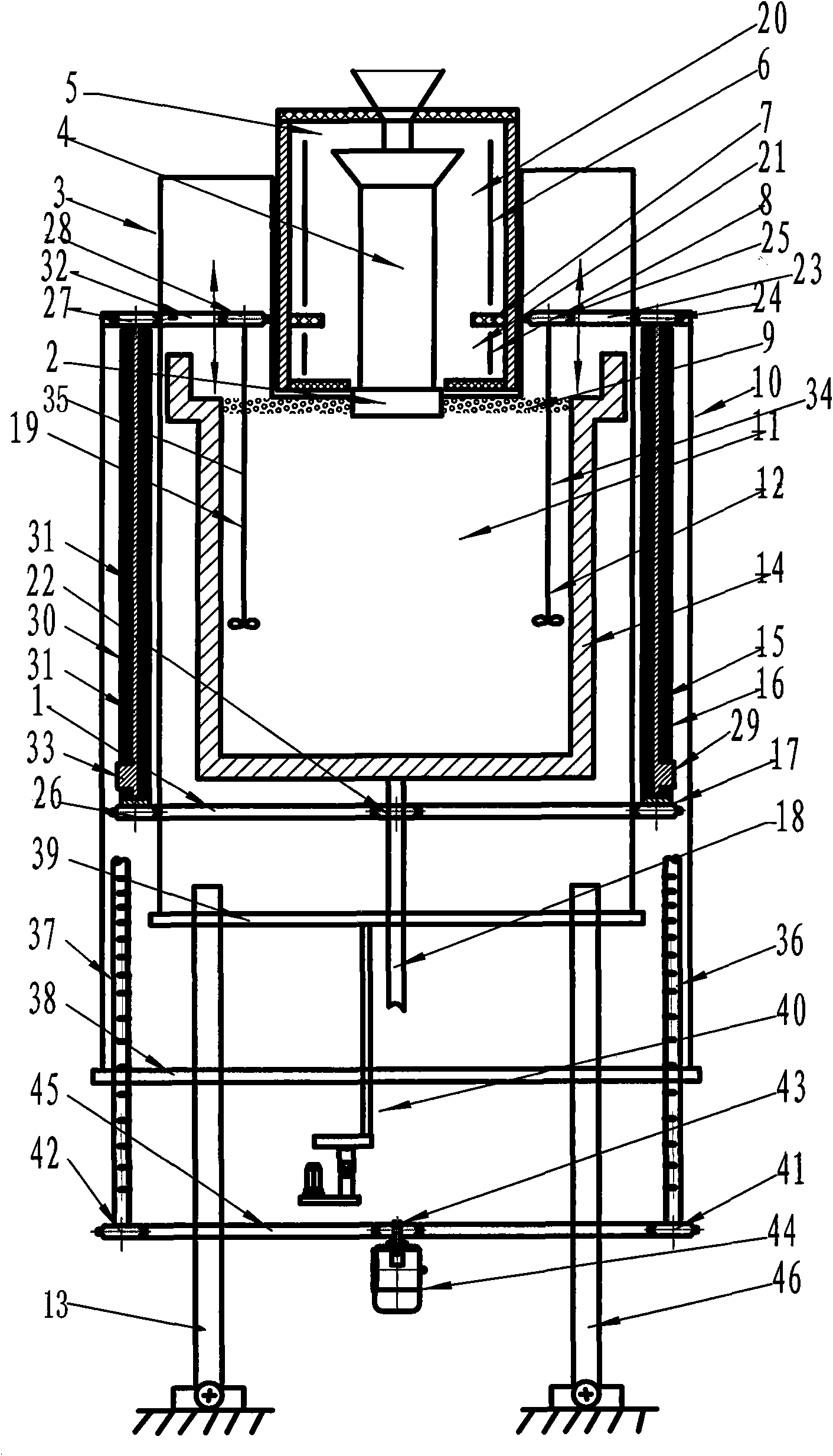

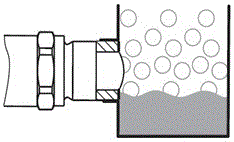

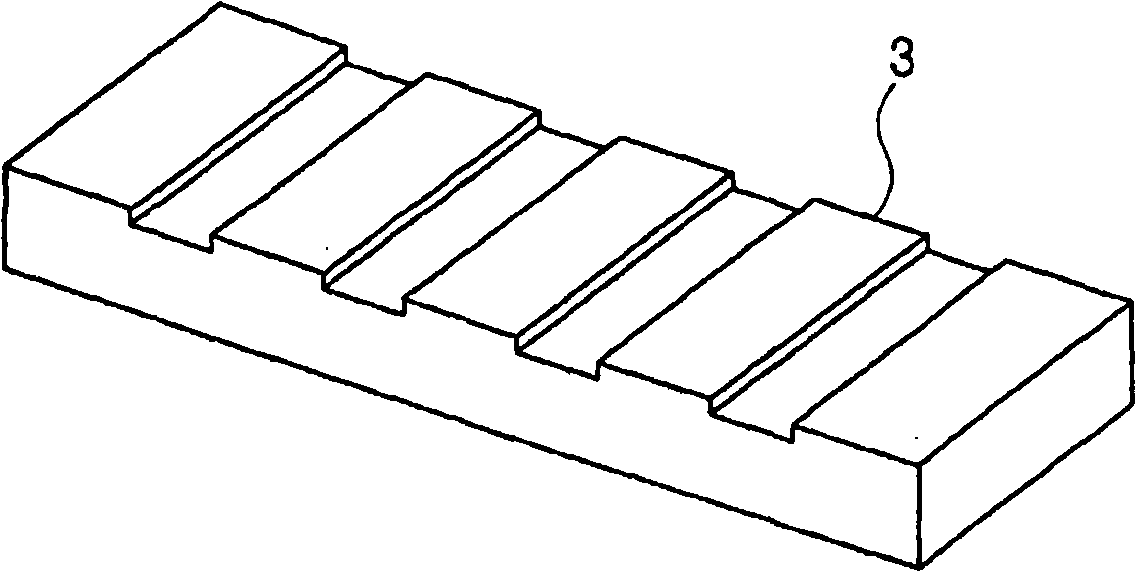

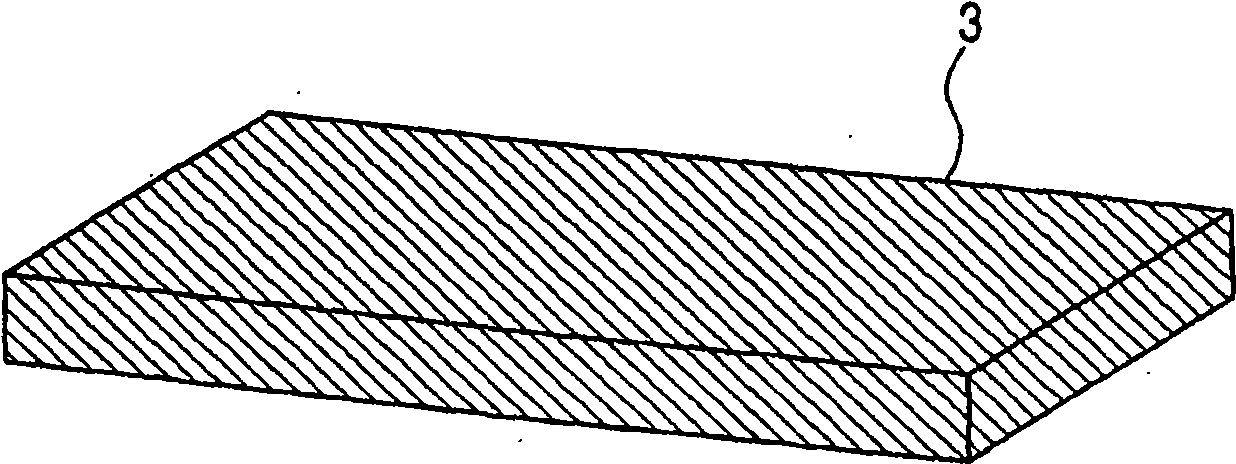

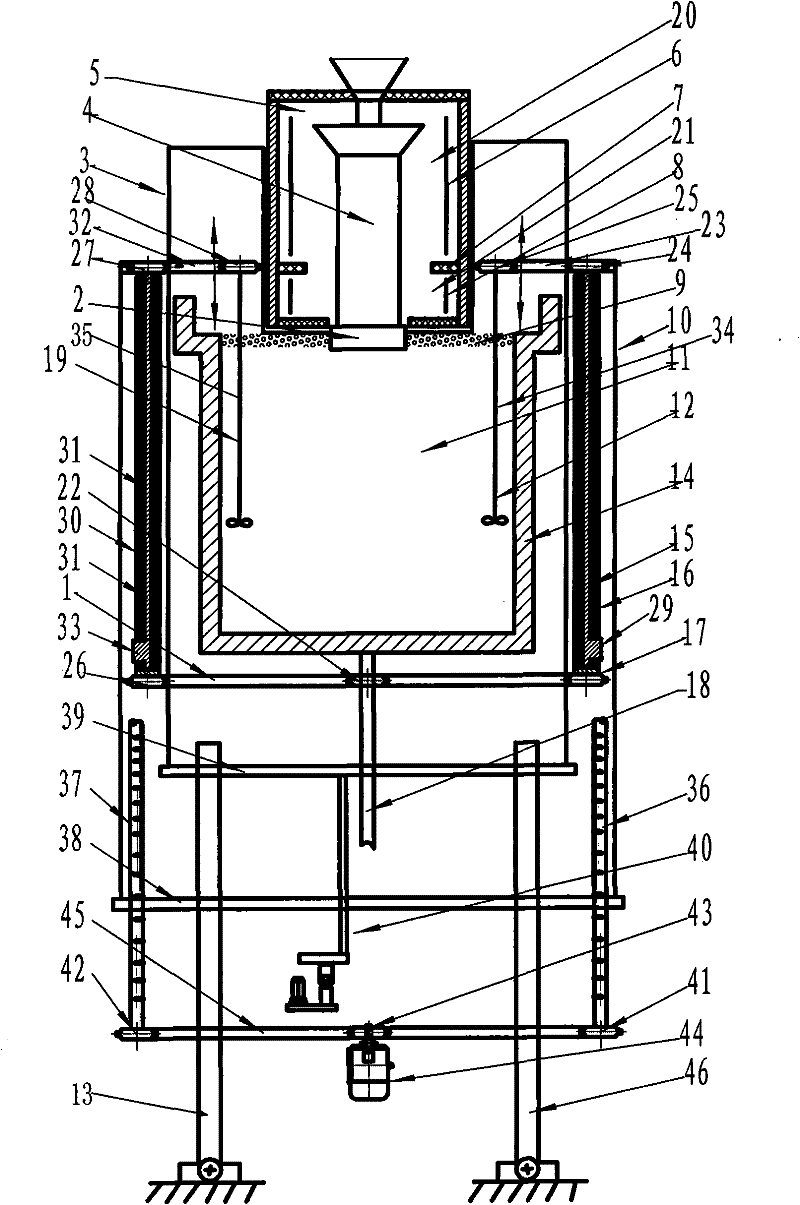

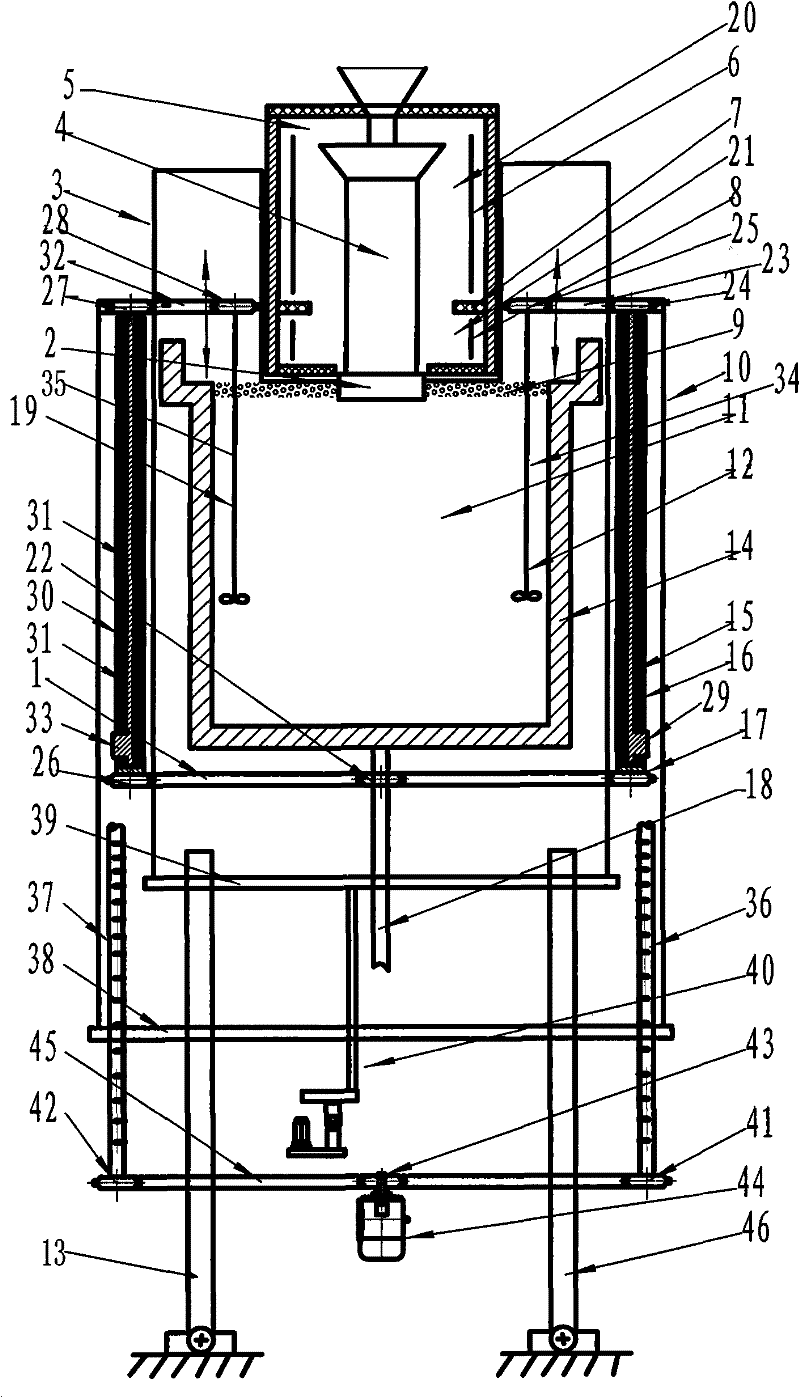

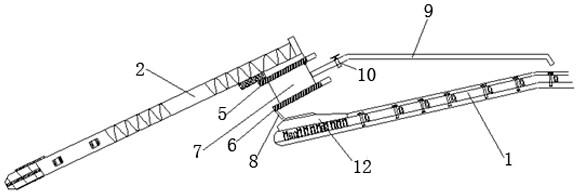

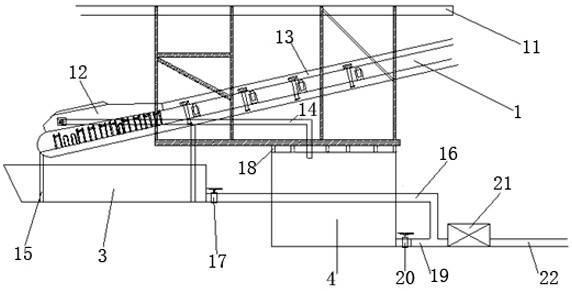

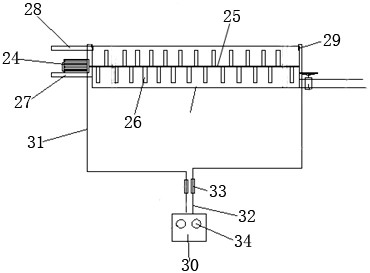

Liquid metal cooling and directional condensing equipment with tin boiler stirrer

InactiveCN101954475AImprove heat transfer effectUniform temperatureFrom frozen solutionsLiquid metalDirectional solidification

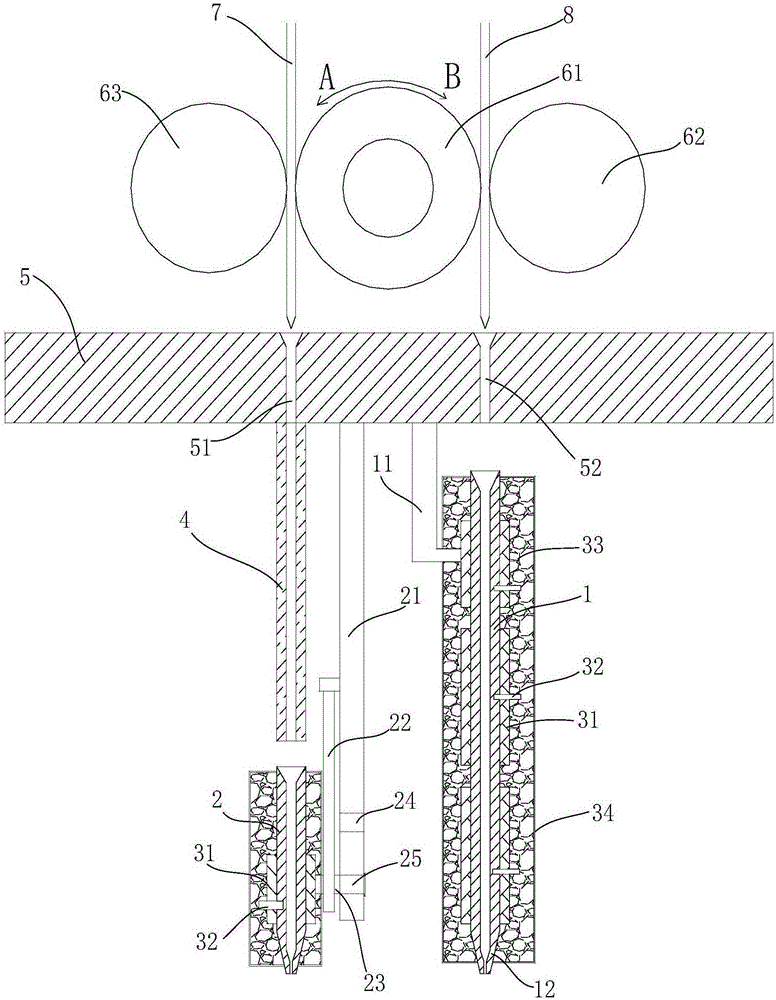

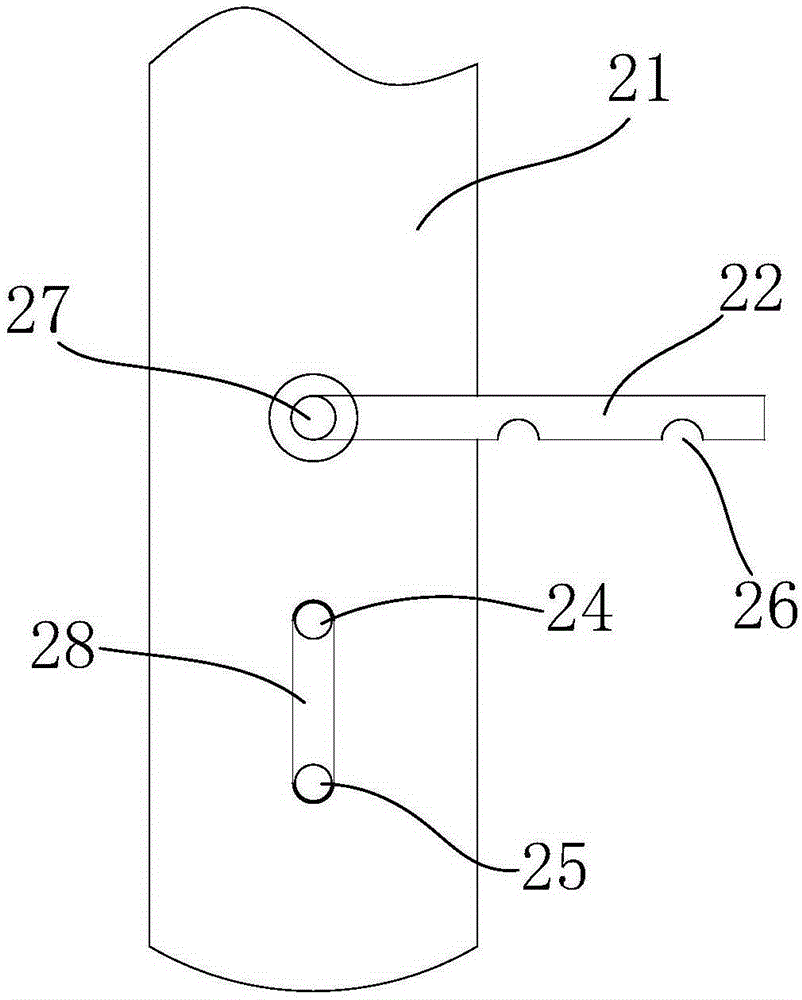

The invention discloses liquid metal cooling and directional condensing equipment with a tin boiler stirrer, which comprises a mould heating and insulating furnace, a ceramic mould, a chilling tray, a drawing bracket, a container, a floating insulation baffle, a first stirrer, a second stirrer and a stirrer drive mechanism, wherein an upper heating area and a lower heating area are reserved in the mould heating and insulating furnace, the ceramic mould is arranged in the mould heating and insulating furnace, and the chilling tray is connected with the ceramic mould and driven by the drawing bracket to move up and down; the container is arranged below the mould heating and insulating furnace and filled with liquid metal tin, and the floating insulation baffle is arranged on the liquid surface of the liquid metal tin; and the first and second stirrers capable of rising and descending are symmetrically arranged in the container. The liquid metal cooling and directional condensing equipment with the tin boiler stirrer solves the problem of overflowing of the liquid metal tin and prevents the liquid surface of the liquid metal tin from rising and contacting the heating furnace; and due to vertical movement of the stirrers, the heat exchange of the liquid metal tin is speeded up, so that the temperature of the liquid metal tin is uniform.

Owner:SHENYANG RES INST OF FOUNDRY

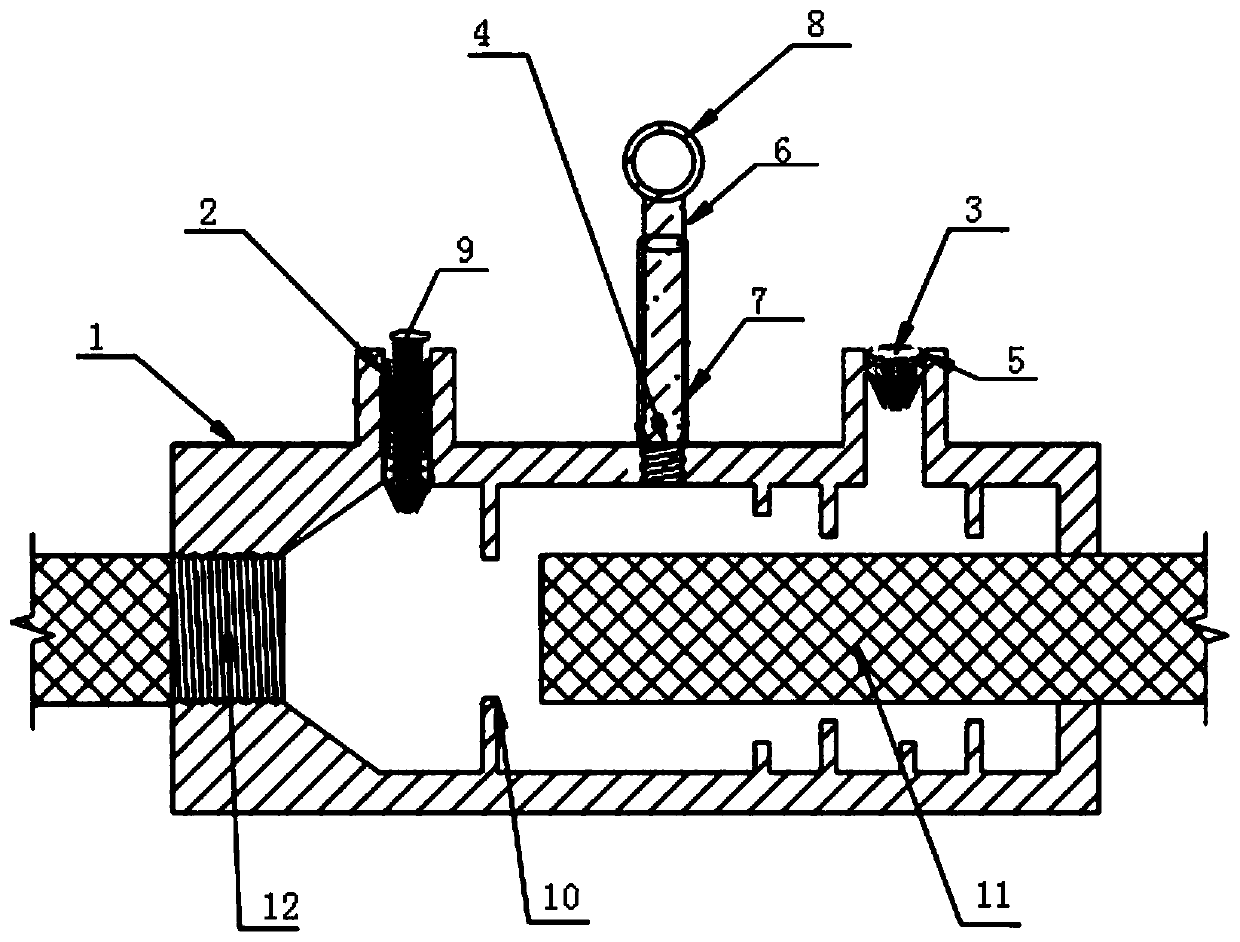

Grouting sleeve with double inspection holes and application method

The invention discloses a grouting sleeve with double inspection holes and an application method, and relates to the technical field of grouting detection. A second inspection hole is formed between agrout outlet and a grouting hole of the grouting sleeve, the grout outlet is used as a first inspection hole, and the grout outlet and the grouting hole are closed by blocking self-locking pieces. The second inspection hole is detachably closed through rigid blocking pieces, the blocking self-locking pieces comprise self-locking heads and connecting parts, the self-locking heads are connected with the grouting sleeve through the connecting parts, the self-locking heads comprise locking plates and elastic stretch rings, and the elastic stretch rings control the opening and closing of the self-locking heads by limiting the opening and closing of the locking plates. The grouting sleeve with the double inspection holes can effectively detect top defects, middle defects and horizontal defectscan be effectively detected, and a detection method is accurate, simple and fast; and the double inspection holes can further be used for repairing the slurry replenishing quality of the sleeves withthe grouting defects, and the grouting quality is ensured.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

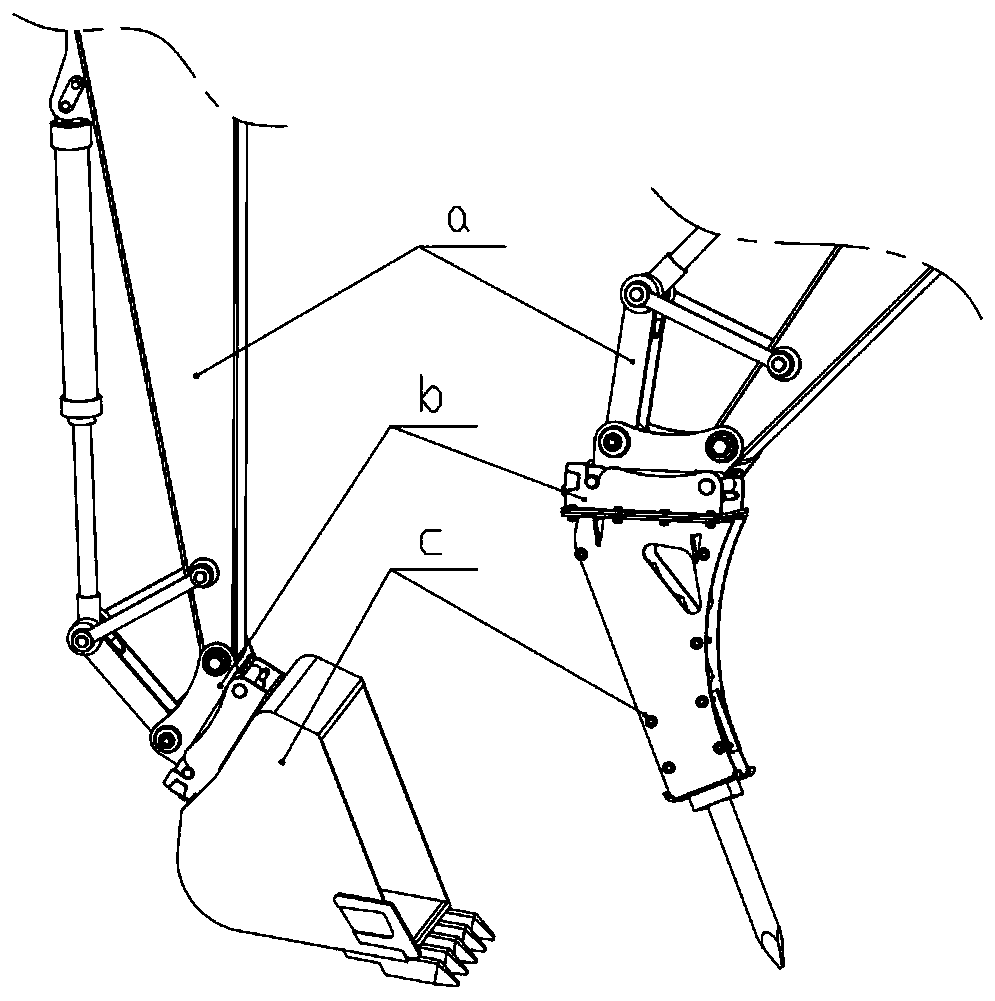

Automatic abut-joint hydraulic valve element, hydraulic quick changing device and rescue device

ActiveCN110848193ASimple structureClear principleServomotor componentsMechanical machines/dredgersMarine engineeringEmergency rescue

The invention provides an automatic abut-joint hydraulic valve element, a hydraulic quick changing device and a rescue device. The automatic abut-joint hydraulic valve element, the hydraulic quick changing device and the rescue device are applied in the occasion that a hydraulic power oil path needs to be automatically in abut joint. Flush end face connection is adopted, in the valve element abutjoint process, a prepared abut-joint manner is adopted, a male joint end has a certain pre-abut-joint length, and the anti-pollution and anti-overflow aims in the abut-joint process can be achieved. The valve element can be used for the work accessory quick changing device in the emergency rescue device. The manual participation in rapid joint connection is solved, and high efficiency and safety of the rescue work can be ensured.

Owner:UNIV OF SCI & TECH BEIJING

Temperature self-moulding skin-nursing material and skin-nursing membrane and preparation method thereof

ActiveCN106074217AFor a perfect fitGood curing effectCosmetic preparationsToilet preparationsSkin surfaceMaterials science

The invention relates to a temperature self-moulding skin-nursing material in skin nursing products such as masks, eye masks and lip masks, and a skin-nursing membrane and a preparation method thereof. The temperature self-moulding skin-nursing material comprises the following materials: a) a temperature self-moulding material formed by temperature-sensing gel; and b) a skin-nursing functional material capable of being mixed in the material a) and used for nursing the skin. The solidification temperature of the temperature self-moulding skin-nursing material containing the temperature-sensing gel is 20-30 DEG C and above, and the liquefaction temperature is 25-10 DEG C and below. The temperature self-moulding skin-nursing material is suitable for different skin surface shapes, and has good combination degree to skin, and has the advantage of convenient usage.

Owner:NANJING SKY LONG PHARMA +4

Pressure limiting valve assembly and cooking utensil

PendingCN110840245ARealize breathing exhaust effectRealize the breathing exhaust effect of cooking utensilsPressure-cookersWorking pressureExhaust pipe

The invention belongs to the technical field of cooking utensils, and particularly relates to a pressure limiting valve assembly and a cooking utensil. The pressure limiting valve assembly comprises an exhaust pipe and a pressure limiting valve, wherein the pressure limiting valve is provided with a valve element; the exhaust pipe is provided with an exhaust channel; the exhaust end of the exhaustpipe extends in the axial direction of the exhaust pipe to form an annular step; and the annular step is matched with the valve element to form multiple sections of exhaust sealing structures distributed in the exhaust direction. According to the pressure limiting valve assembly, through the design of the multiple sections of exhaust sealing structures, the cooking utensil has the breathing-typeexhaust effect, that is, a heating system performs continuous full-power heating, instantaneous exhausting is performed after the pressure of the pressure limiting valve assembly rapidly reaches the working pressure in a fully-sealed state, sealed pressure increase is continued after the pressure is lower than the working pressure by exhausting, instantaneous exhausting is performed after the working pressure is reached, and the process is circulated.

Owner:绍兴市吉柏尼机电有限公司

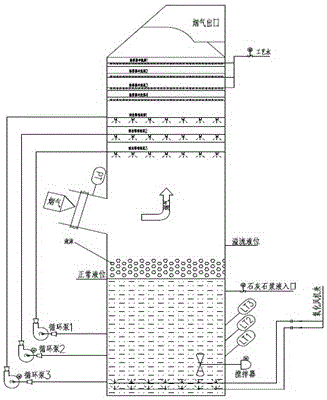

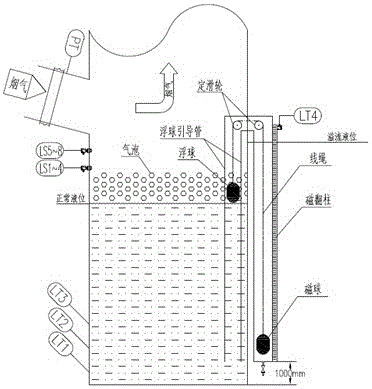

Warning device for accurately measuring liquid level and false liquid level of absorption tower

The invention provides a warning device for accurately measuring liquid level and false liquid level of an absorption tower. According to structural and technological characteristics of the desulfurizing absorption tower, the liquid level of the absorption tower is measured by transforming a traditional magnetic turning plate liquid level meter into a split structure. Based on accurate liquid level measurement of the absorption tower, one electric conducting liquid level switch is further arranged, along an outer circle of the absorption tower at 90 degrees, at two height positions below an overflow port respectively and is used for detecting bubble height and giving an alarm. In addition, three pressure transmitters arranged at the bottom of the absorption tower and used for measuring the liquid level of the absorption tower serve as standby and auxiliary measures of the measuring device. By adopting the three measures, the liquid level of the absorption tower can be accurately measured, and an alarm is given in time when the false liquid level is ultrahigh. The warning device can ensure that relevant devices of the absorption tower operate under designed working conditions, the operating efficiency of the devices is improved, energy consumption is reduced, and safe and efficient operation of the desulfurizing absorption tower is ensured.

Owner:周佳平

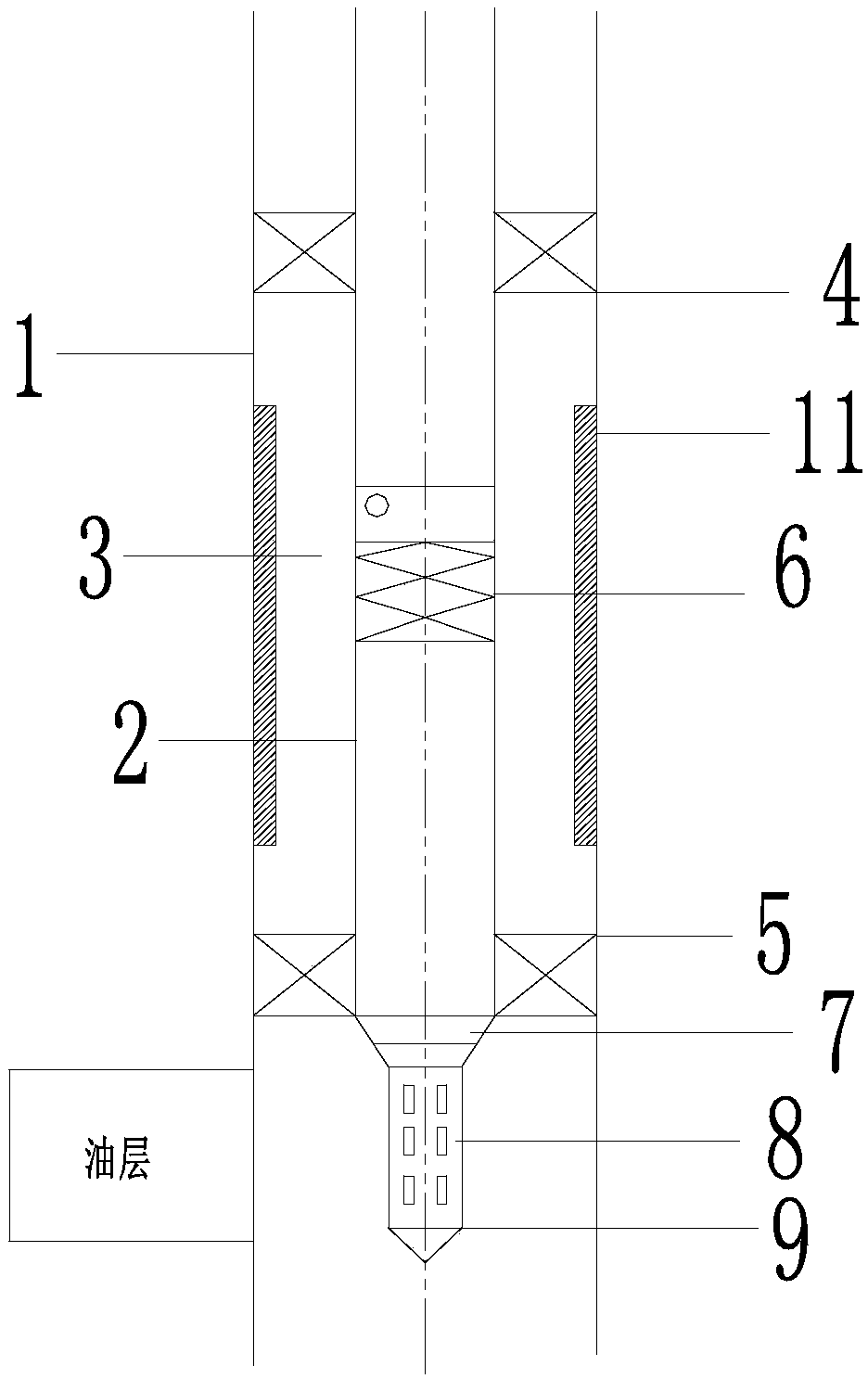

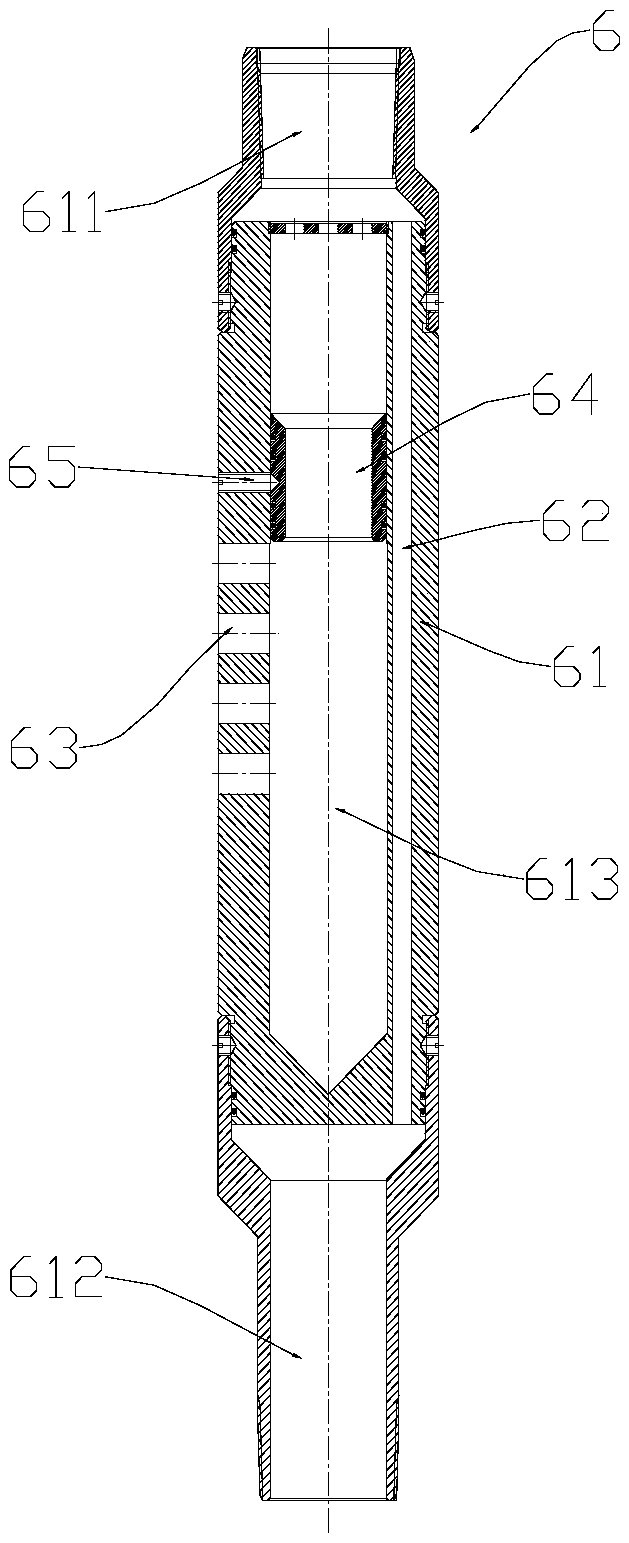

Casing subsidy section pressure-bearing detection process pipe string and method

InactiveCN108643888ARealize detectionRealize the testing process of pressure bearing capacitySurveyConstructionsPetroleum engineering

The invention provides a casing subsidy section pressure-bearing detection process pipe string and method. The pipe string comprises a casing, an oil pipe, a first packer, a second packer, a flow guiding device and a drain device. A subsidy section is arranged on the inner wall of the casing. The oil pipe is arranged in the casing in a sleeved mode, and forms an annular space with the casing. Thefirst packer is arranged above the subsidy section of the casing. The second packer is capable of passing through the subsidy section of the casing and is arranged under the subsidy section of the casing. The flow guiding device is connected to the oil pipe and corresponds to the position of the subsidy section of the casing. The flow guiding device has at least two working states, when the flow guiding device is in the first working state, the interior of the oil pipe is separated from the annular space, and when the flow guiding device is in the second working state, the interior of the oilpipe communicates with the annular space. The drain device is connected to the tail end of the oil pipe, and is used for draining fluid in the oil pipe. Through the design of the pipe string, the detection of the subsidy section of the casing can be effectively realized, and the problem of the overflow of the pipe string can be solved.

Owner:PETROCHINA CO LTD

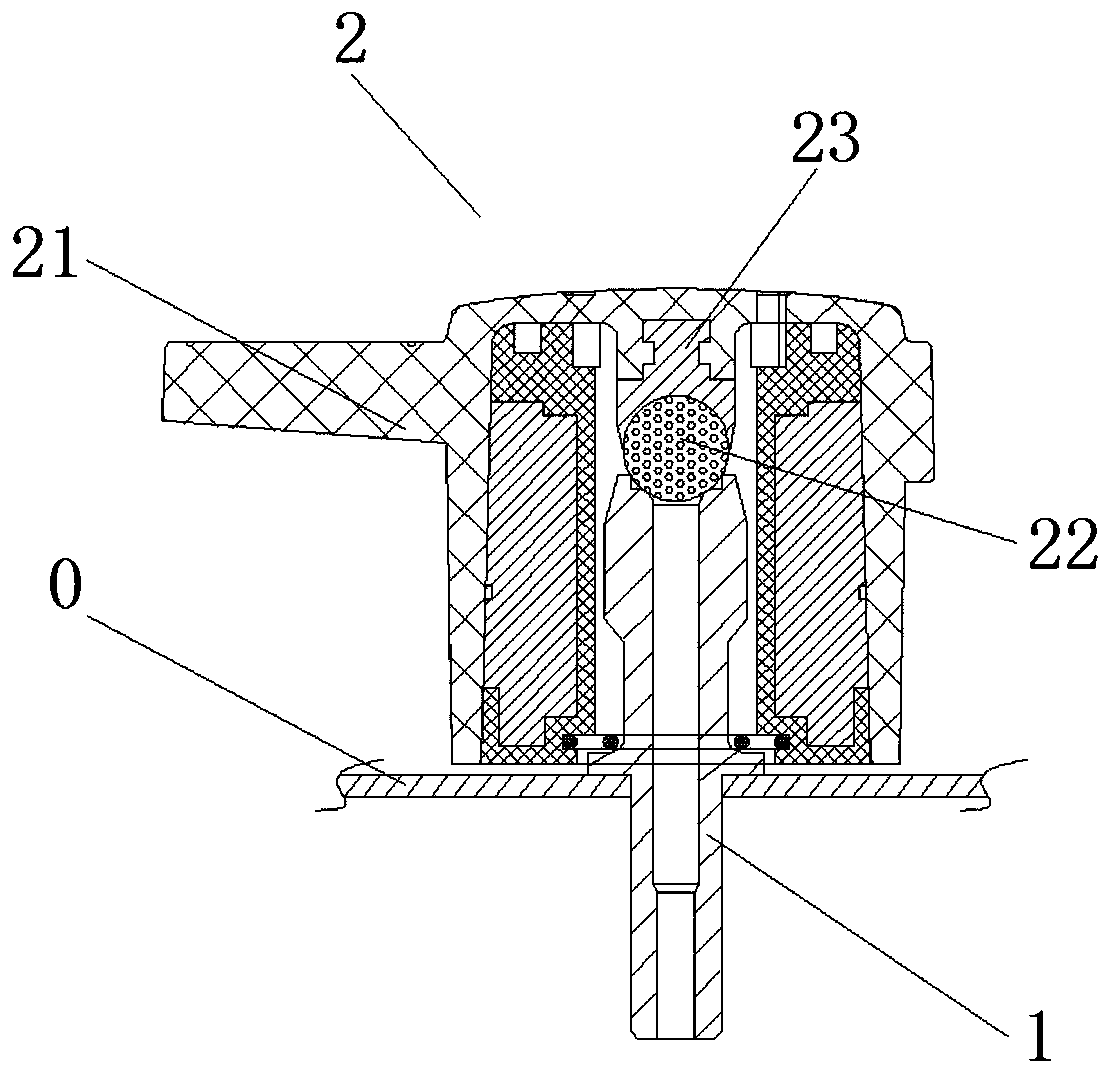

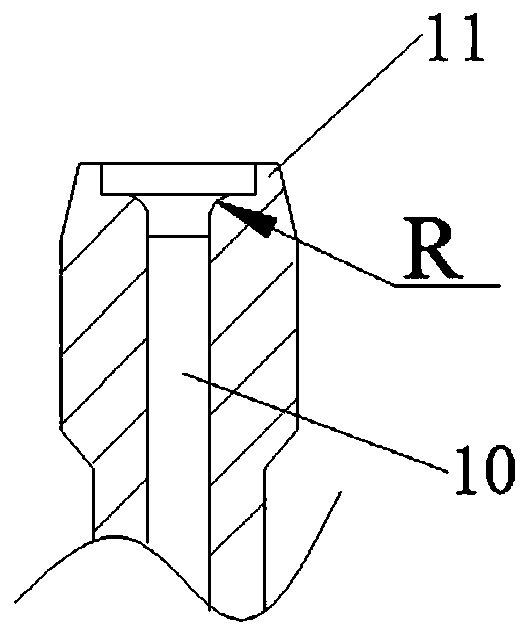

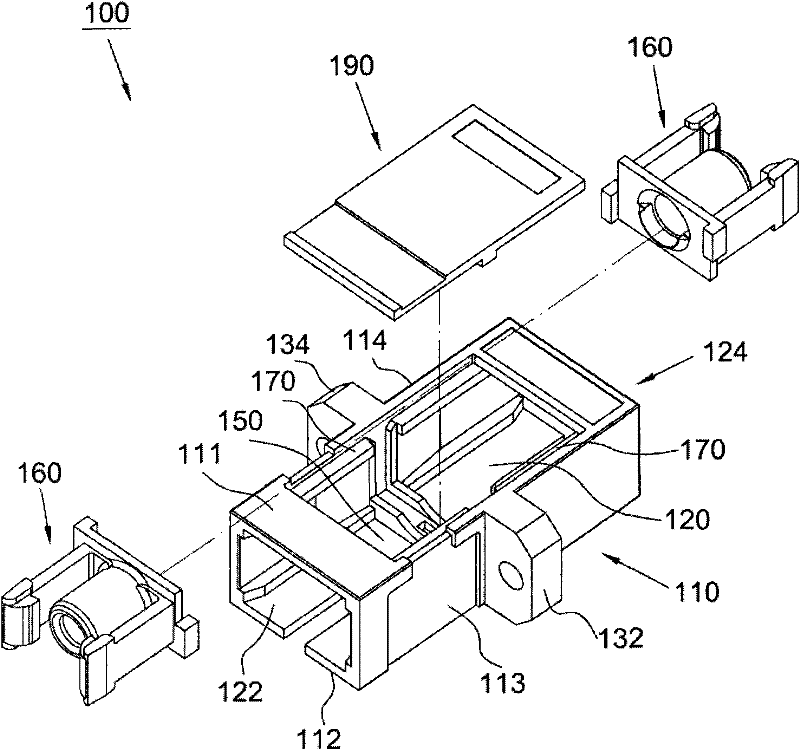

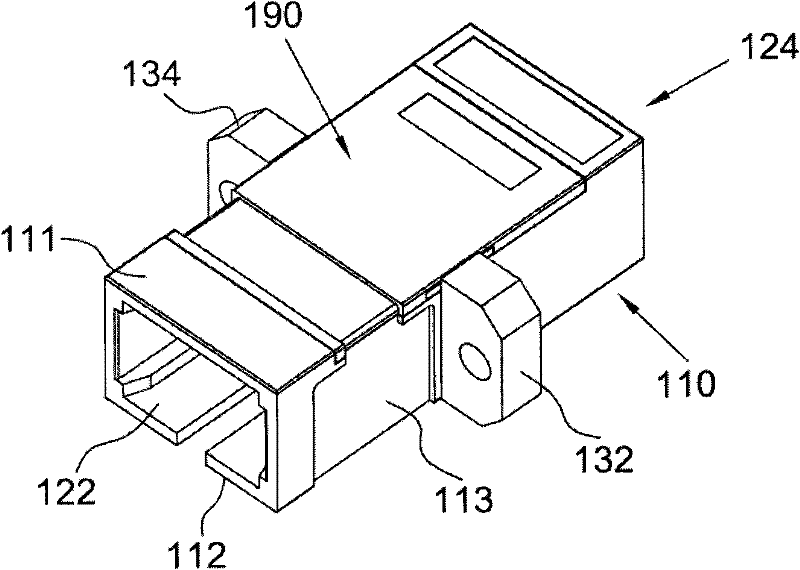

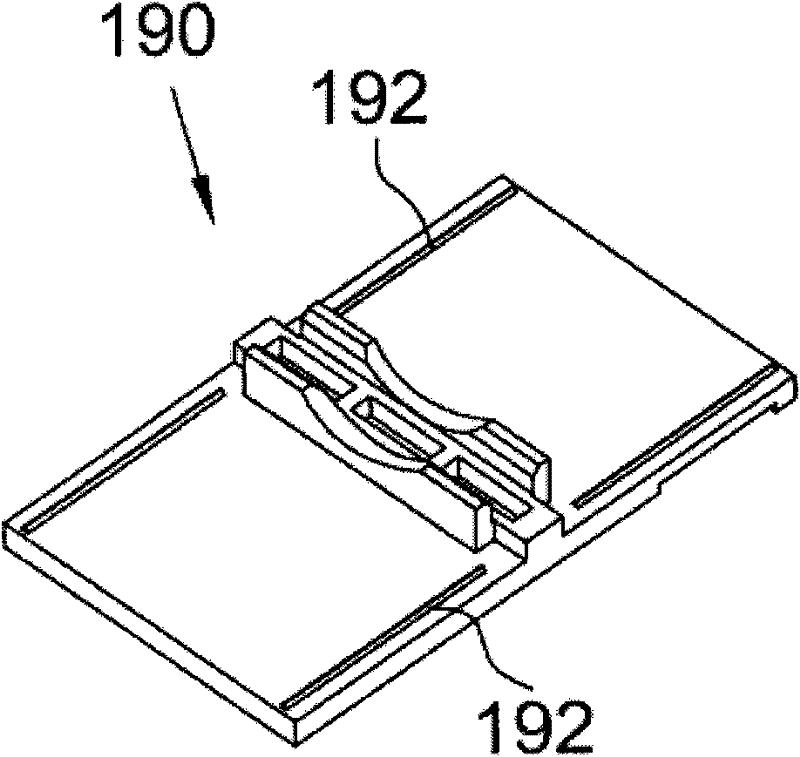

Single-piece fiber adapter

ActiveCN102207588ASolve the problem of molten protrusion overflowSolve the overflowCoupling light guidesFiberEngineering

The invention provides a single-piece fiber adapter, which comprises a body, an inner housing, and a cover plate. The body has an axial cavity, which is defined and composed of a first wall, a second wall, a third wall and a fourth wall; the first wall is opposite to the third wall, and is connected with the second wall and the fourth wall. Both of two axial ends of the axial cavity of the body have openings, and the first wall is provided with an access opening. Protrude portions are formed respectively on the second wall and the fourth wall, wherein a dent facing the access opening is formed on each of the protrude portions. The inner housing is placed within the axial cavity of the body through the access opening of the first wall. The cover plate is used for covering the access opening of the first wall, wherein a plurality of protrusions that are corresponding to the dents are formed on the cover plate. When the protrusions on the cover plate are fused and the cover plate covers the access opening, the dents on the body are used for accommodating the fused protrusions. According to the fiber adapter provided in the invention, the problem of overflow of fused protrusions can be solved.

Owner:PROTAI PHOTONIC +1

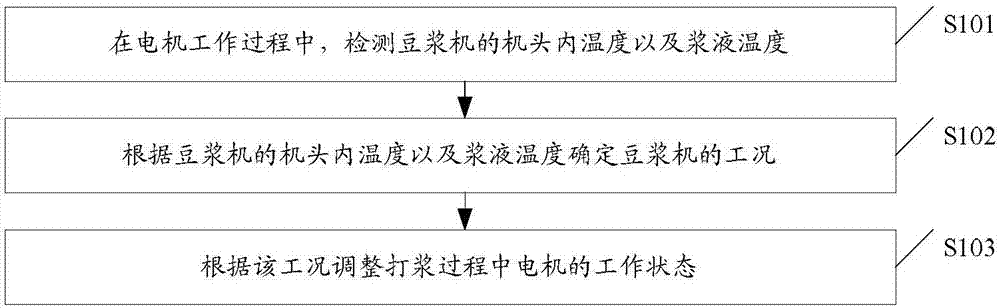

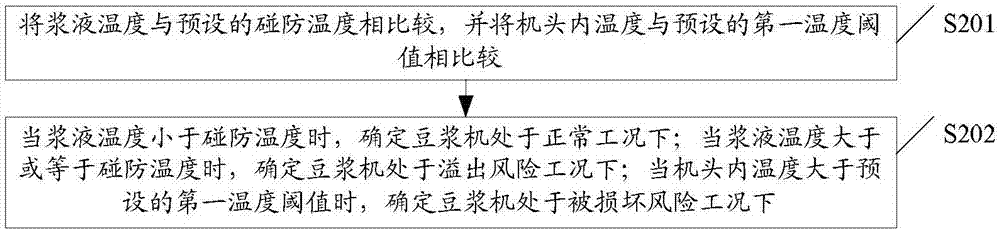

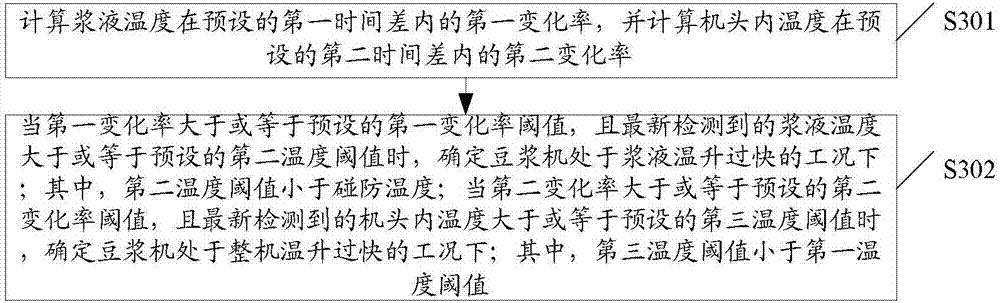

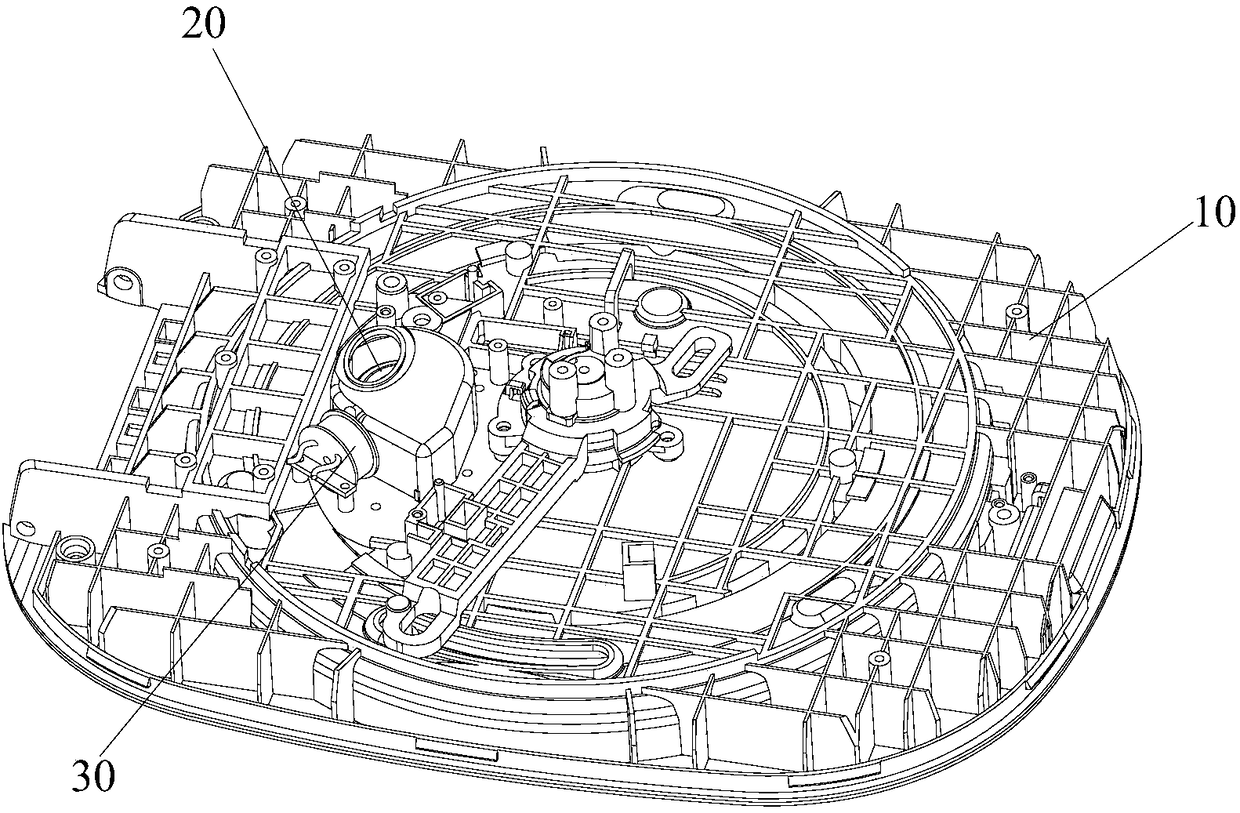

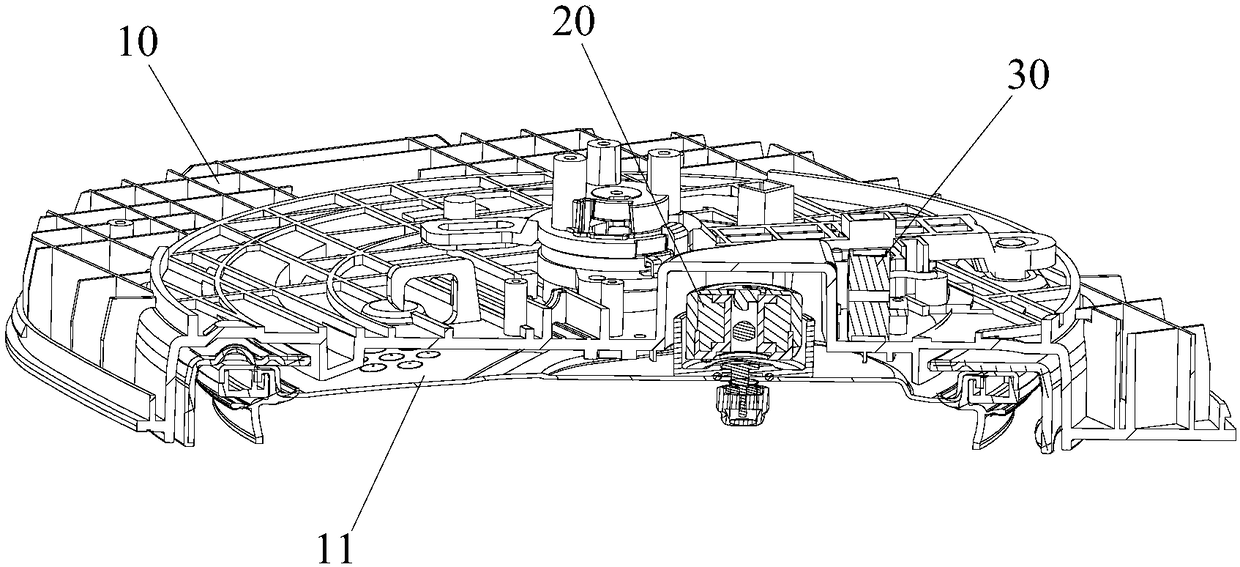

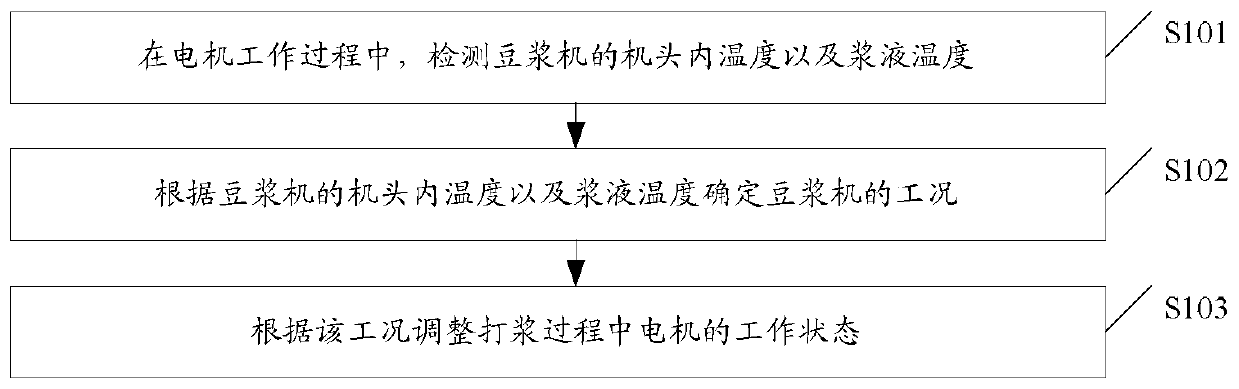

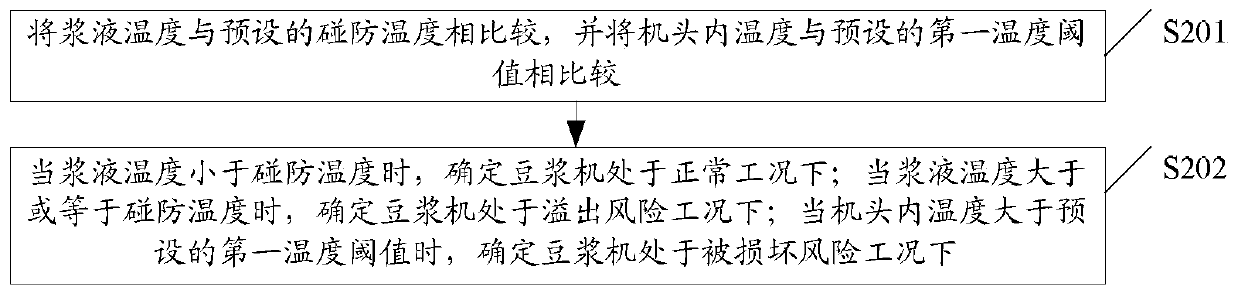

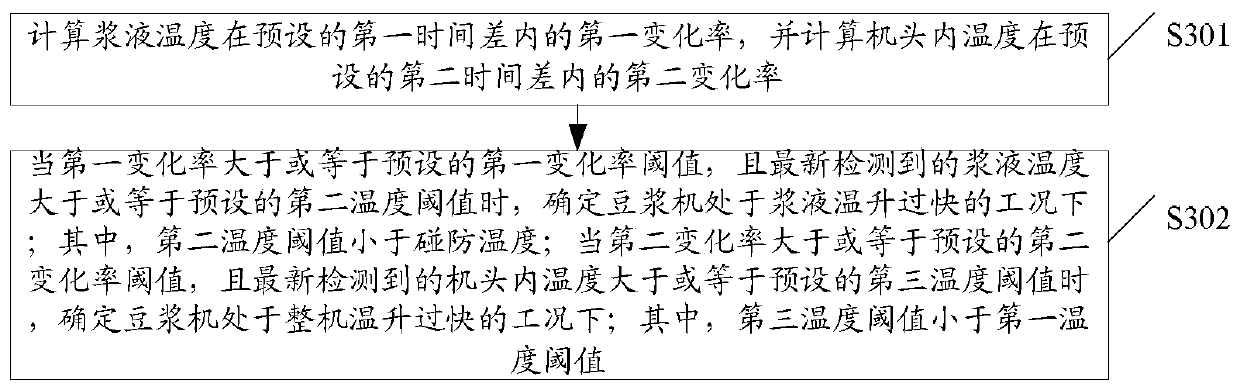

Soybean milk maker control method

ActiveCN107374403ASolve the overflowAvoid security issuesTemperatue controlKitchen equipmentEngineeringSlurry

An embodiment of the invention discloses a soybean milk maker control method. The soybean milk maker control method includes detecting internal temperature of a head of a soybean milk maker and temperature of soybean milk, determining working status of the soybean milk maker according to the internal temperature of the head of the soybean milk maker and the temperature of soybean milk, and regulating motion states of a motor during juicing according to the working status. According to the embodiment, by the soybean milk maker control method, the risk of spilling and potential safety hazard of the soybean milk maker can be detected in time and working performance of the whole soybean milk maker is improved.

Owner:JOYOUNG CO LTD

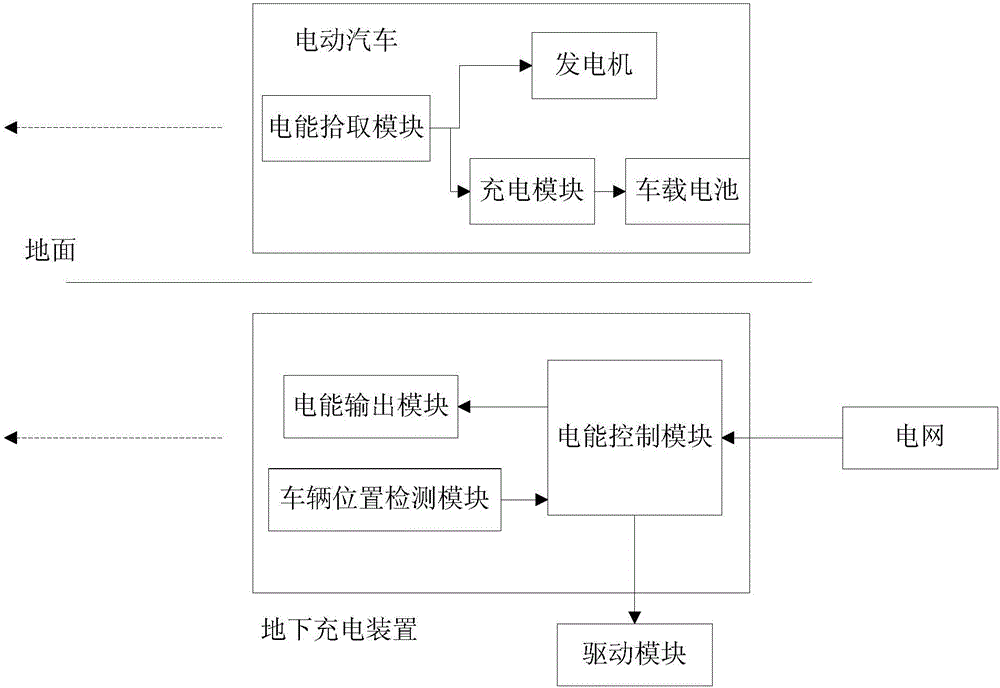

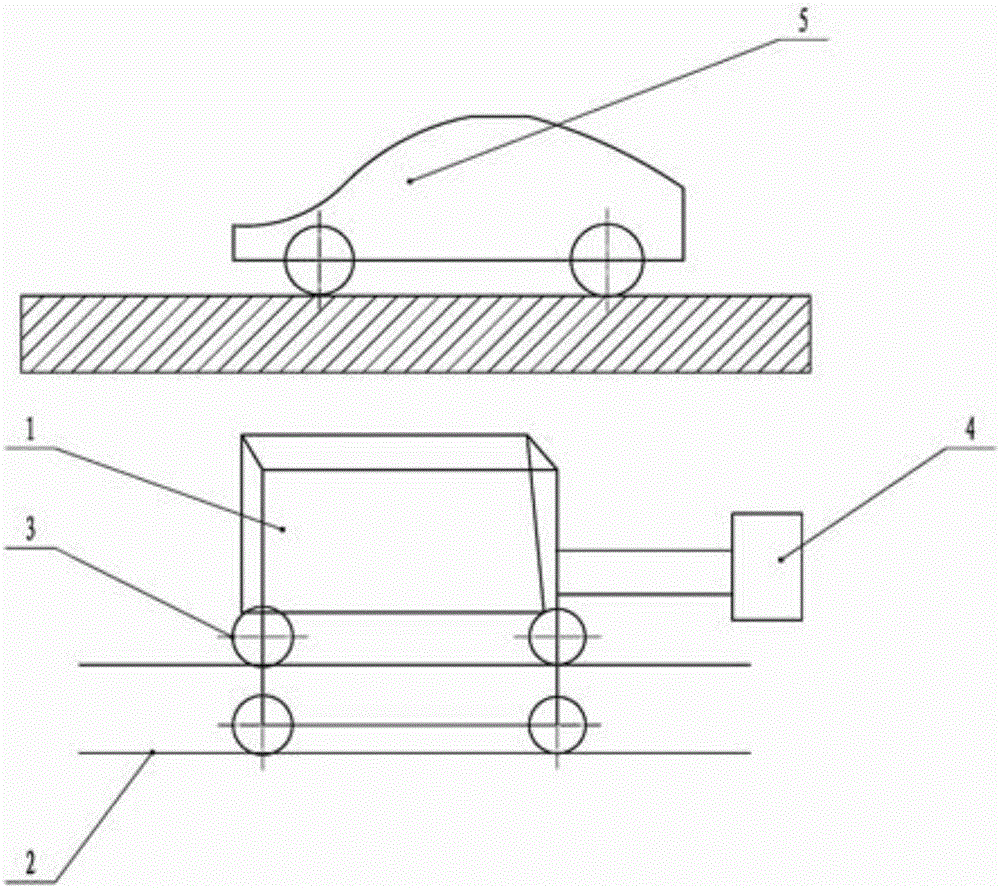

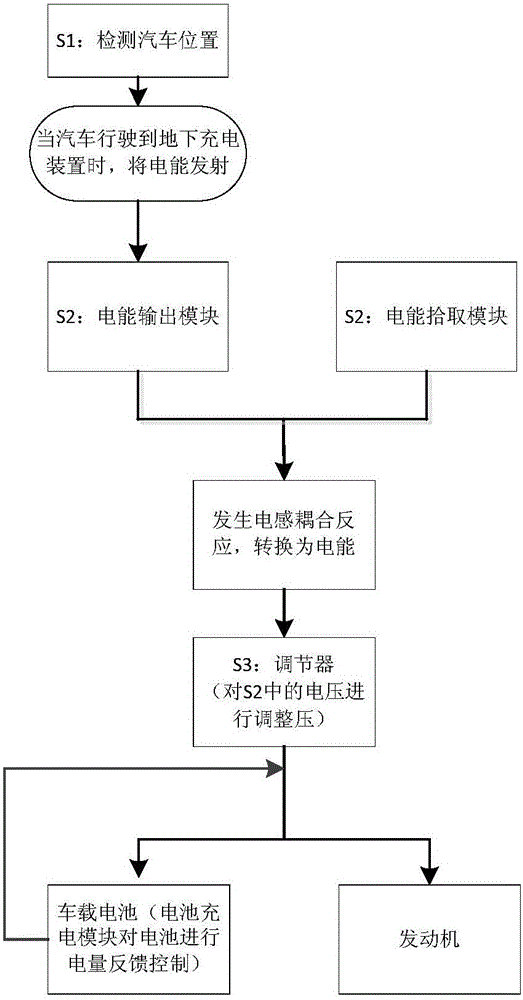

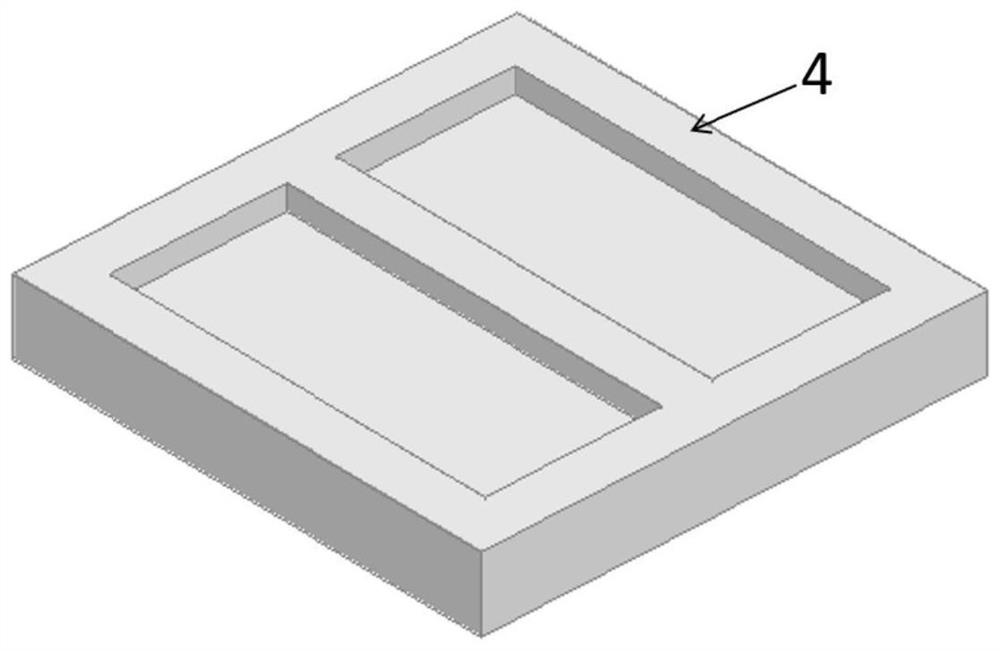

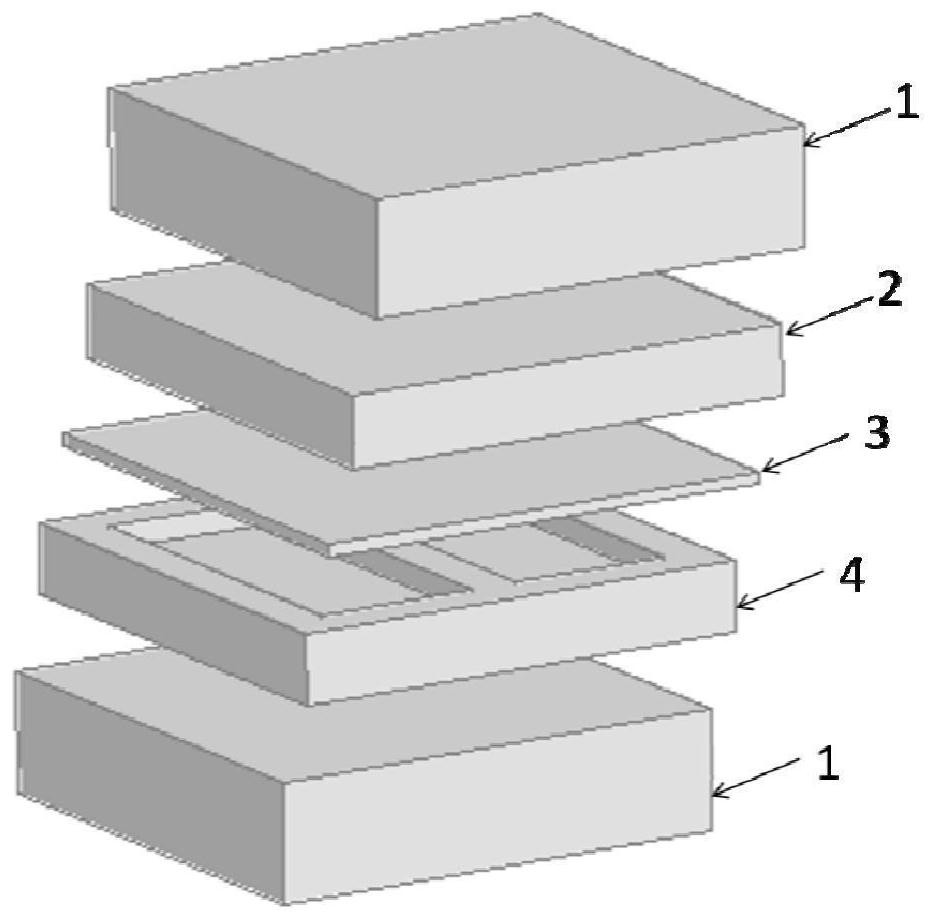

On-line electric vehicle (OLEV) system capable of controlling energy output based on sensor

InactiveCN106004485ALow costImprove the efficiency of inductive couplingCharging stationsElectric vehicle charging technologyBattery chargeElectrical battery

The invention discloses an on-line electric vehicle (OLEV) system capable of controlling energy output based on a sensor. The OLEV system comprises an underground charging device embedded underground and a vehicle-mounted receiving device arranged on the vehicle. The underground charging device comprises an electric energy control module, an electric energy output module, a vehicle position detection module and a driving module. According to the detected vehicle position, when the vehicle drives to the position where the underground charging device is embedded, the electric energy control module transmits the electric energy through the electric energy output module and controls the underground charging device to move along with the vehicle along a rail through the driving module. The vehicle-mounted receiving device comprises an electric energy picking module and a battery charging module which is used for conducting charging management on a vehicle-mounted battery. When it is detected that the electric quantity of the vehicle-mounted battery is larger than the rated capacity, charging to the vehicle-mounted battery is stopped. By the adoption of the OLEV system, the underground charging device is made to move along with the electric vehicle, the cost for building the underground charging device is reduced, reasonable charging is conducted by sensing the electric quantity of the vehicle-mounted battery, and the over-charging problem of the vehicle-mounted battery is solved.

Owner:HOHAI UNIV CHANGZHOU

Humidifier

InactiveCN102095235BAddressing Leaky DefectsAvoid crackingEngine sealsSpace heating and ventilation safety systemsFogWaste management

The invention relates to a humidifier, which comprises a base, a water tank and a water fog diffusing tube. An ultrasonic water fog generating mechanism, an air supply mechanism and a control mechanism are arranged in the base; the ultrasonic water fog generating mechanism comprises a water trough arranged on the upper part of the base; an ultrasonic oscillator is arranged at the bottom of the water tank; a leakage protective hood for enclosing the space above the ultrasonic oscillator is arranged above the ultrasonic oscillator; the leakage protective hood is peripherally inserted into the water trough and is immerged in the water; the water fog diffusing tube is hermetically connected with the leakage protective hood and is communicated with the space in the leakage protective hood; and a fog baffling plate is arranged in the water fog diffusing tube. The invention provides a humidifier which has no water fog leakage at the matching position of the water tank and the water trough, and has simple structure and good leakage protective effect.

Owner:贺发民

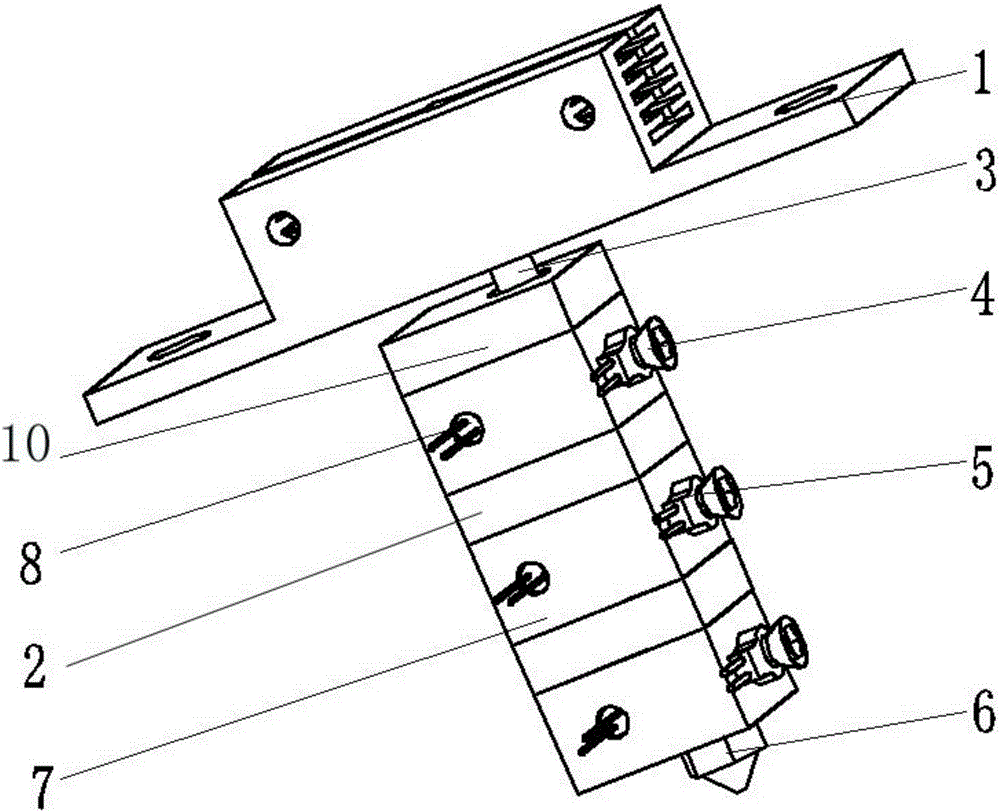

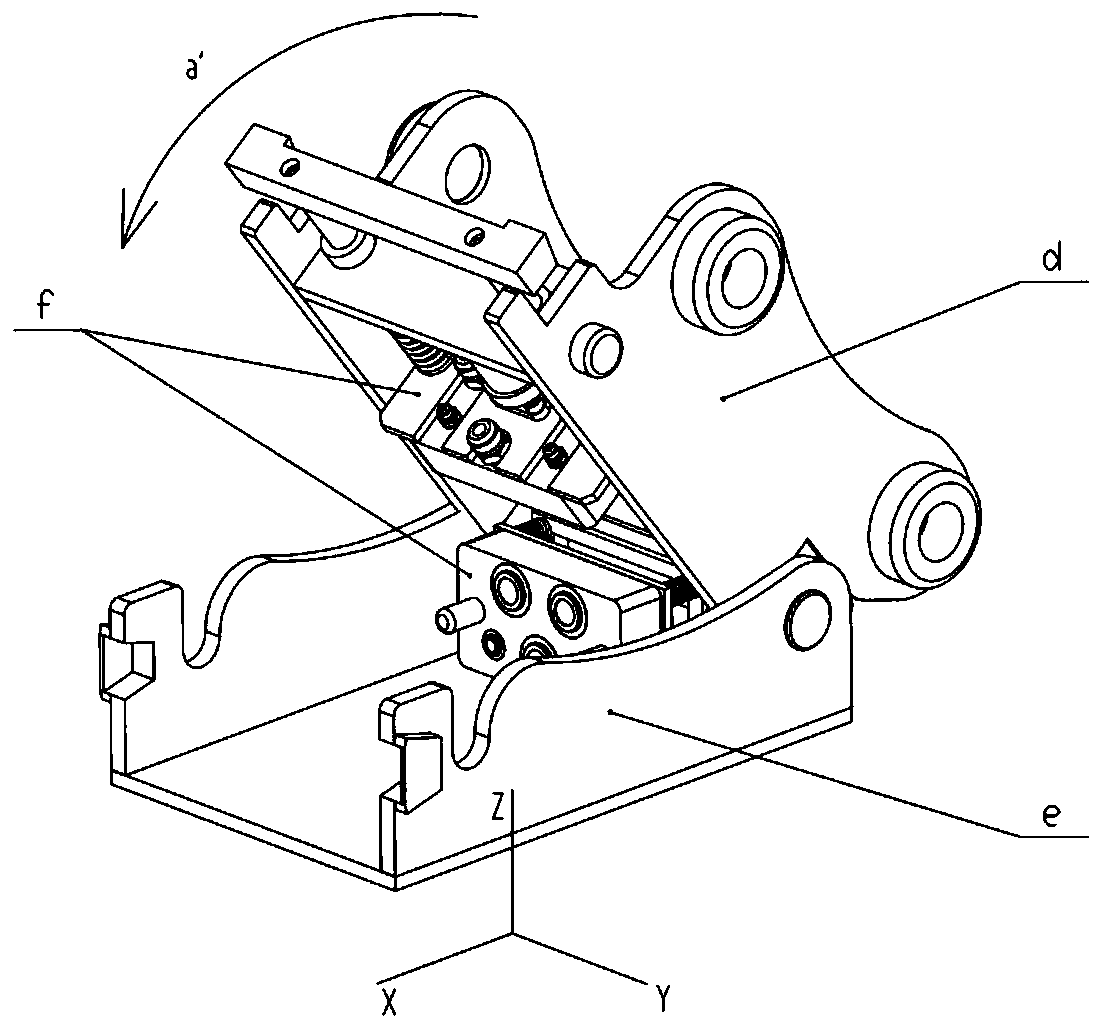

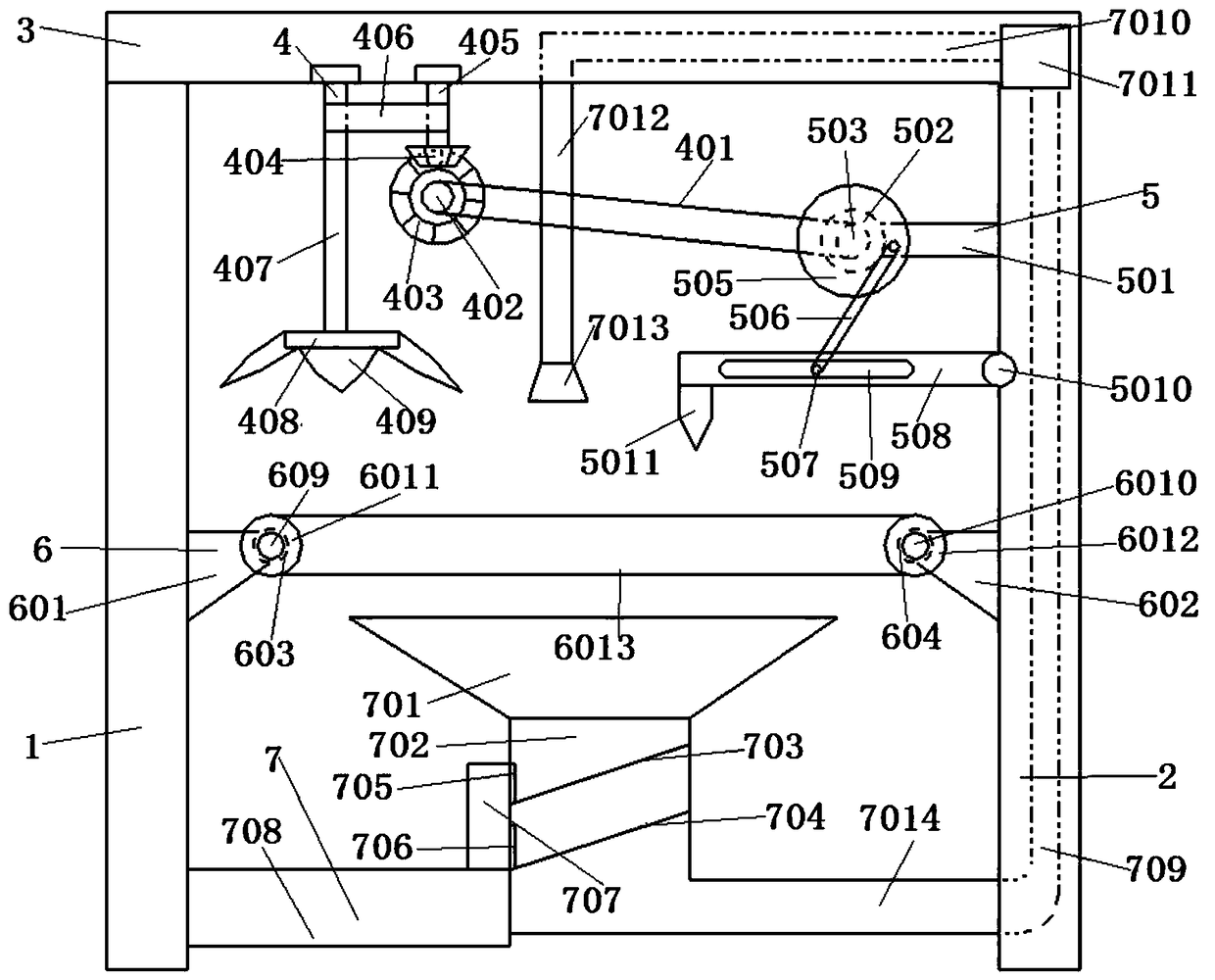

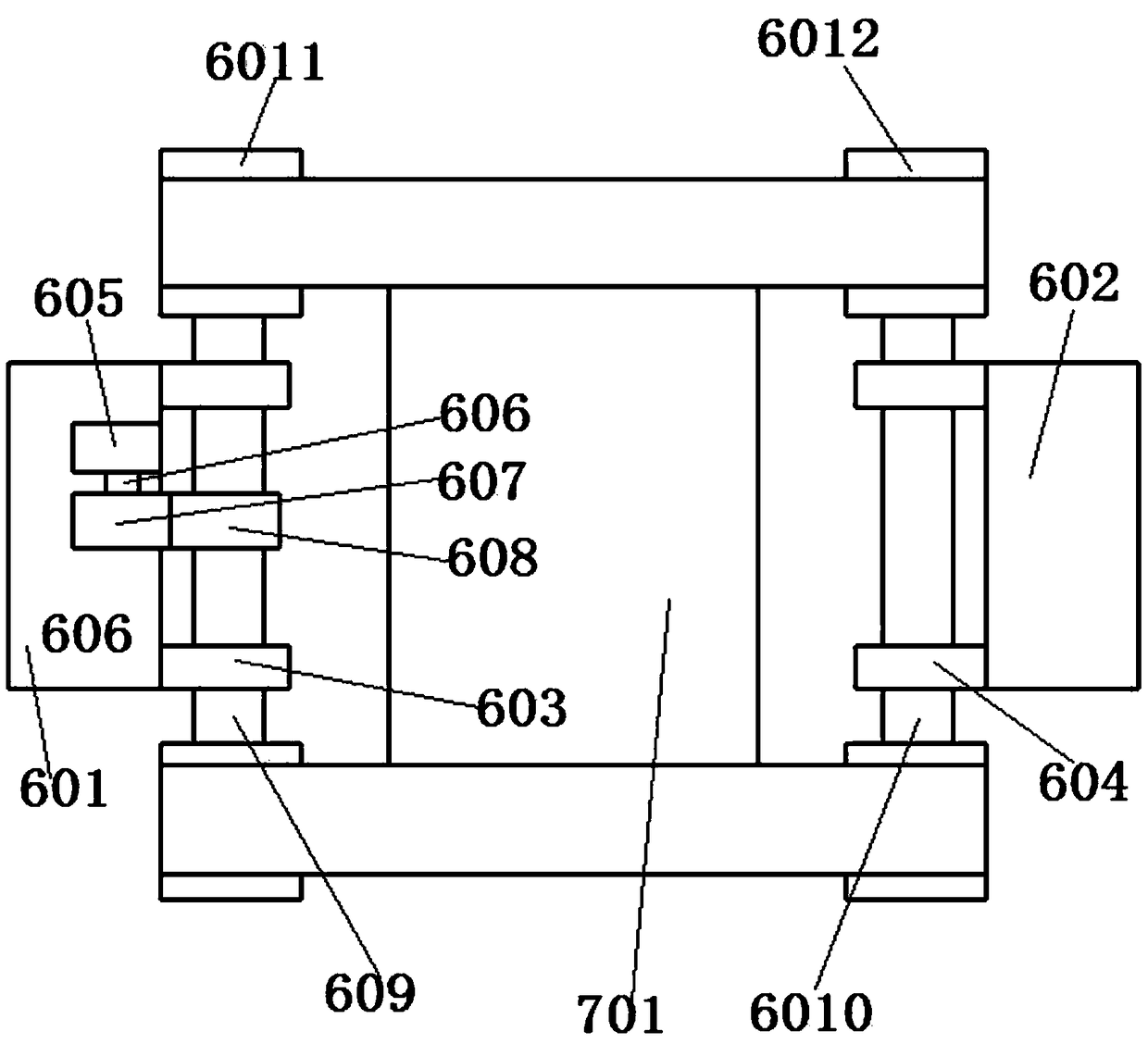

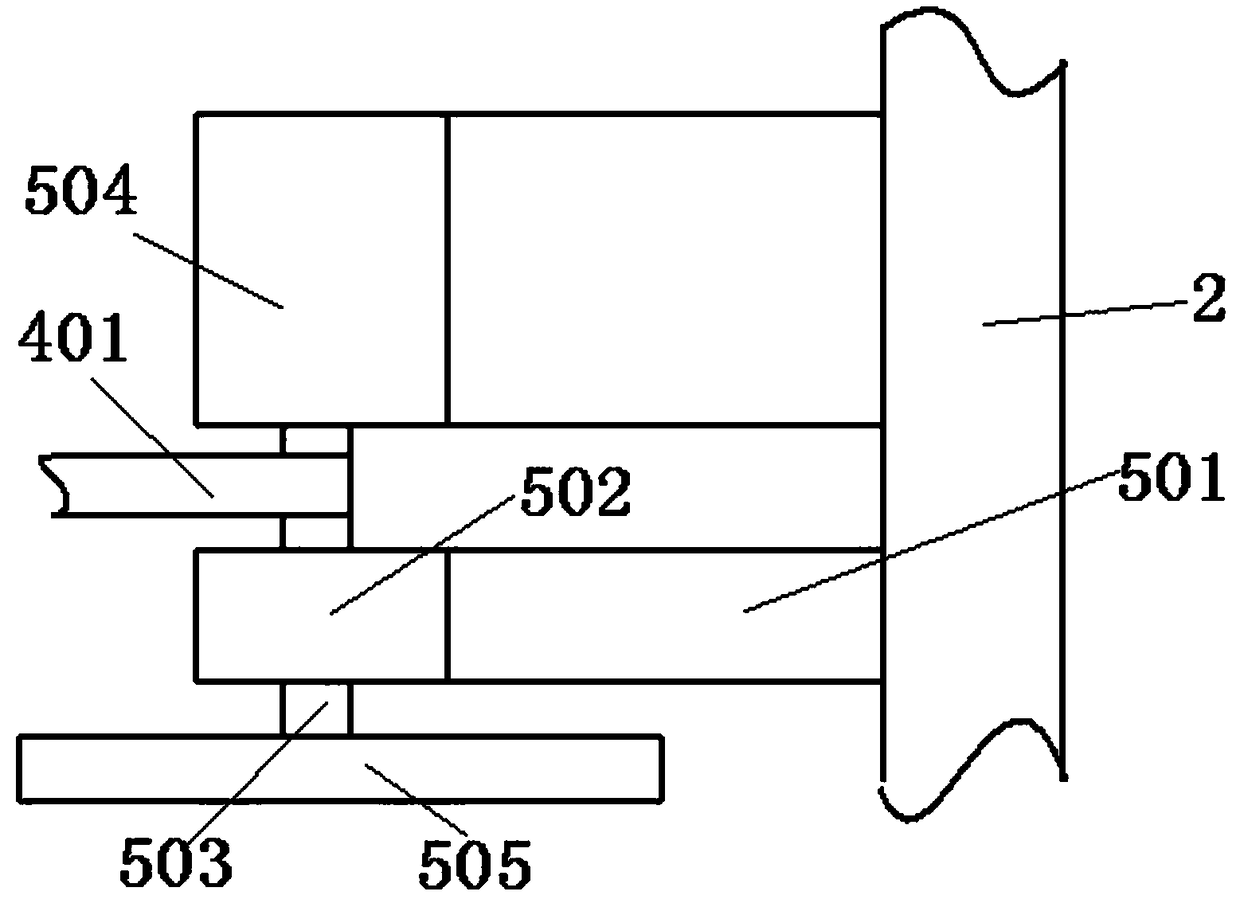

Printing device based on double material wire extruding mechanisms

ActiveCN105235219ASolve the overflowReduce heat lossAdditive manufacturing apparatusLocking mechanismEngineering

The invention provides a printing device based on double material wire extruding mechanisms. The printing device comprises a wire feeding mechanism, a moving mechanism, a locking mechanism, a supporting mechanism, a building material wire extruding head and a support material wire extruding head, wherein the building material wire extruding head and the support material wire extruding head are arranged on the supporting mechanism; the support material wire extruding head is provided with a working position and an idle position higher than the working position; and the moving mechanism is used for enabling the support material wire extruding head to switch between the working position and the idle position and the support material wire extruding head is fixed at the working position or the idle position through the locking mechanism. When the building material wire extruding head works, the support material wire extruding head is moved to the idle position through the moving mechanism, and locked by the locking mechanism and the support material wire extruding head is higher than the building material wire extruding head, so that the support material wire extruding head is prevented from interfering and influencing printing of a forming surface.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

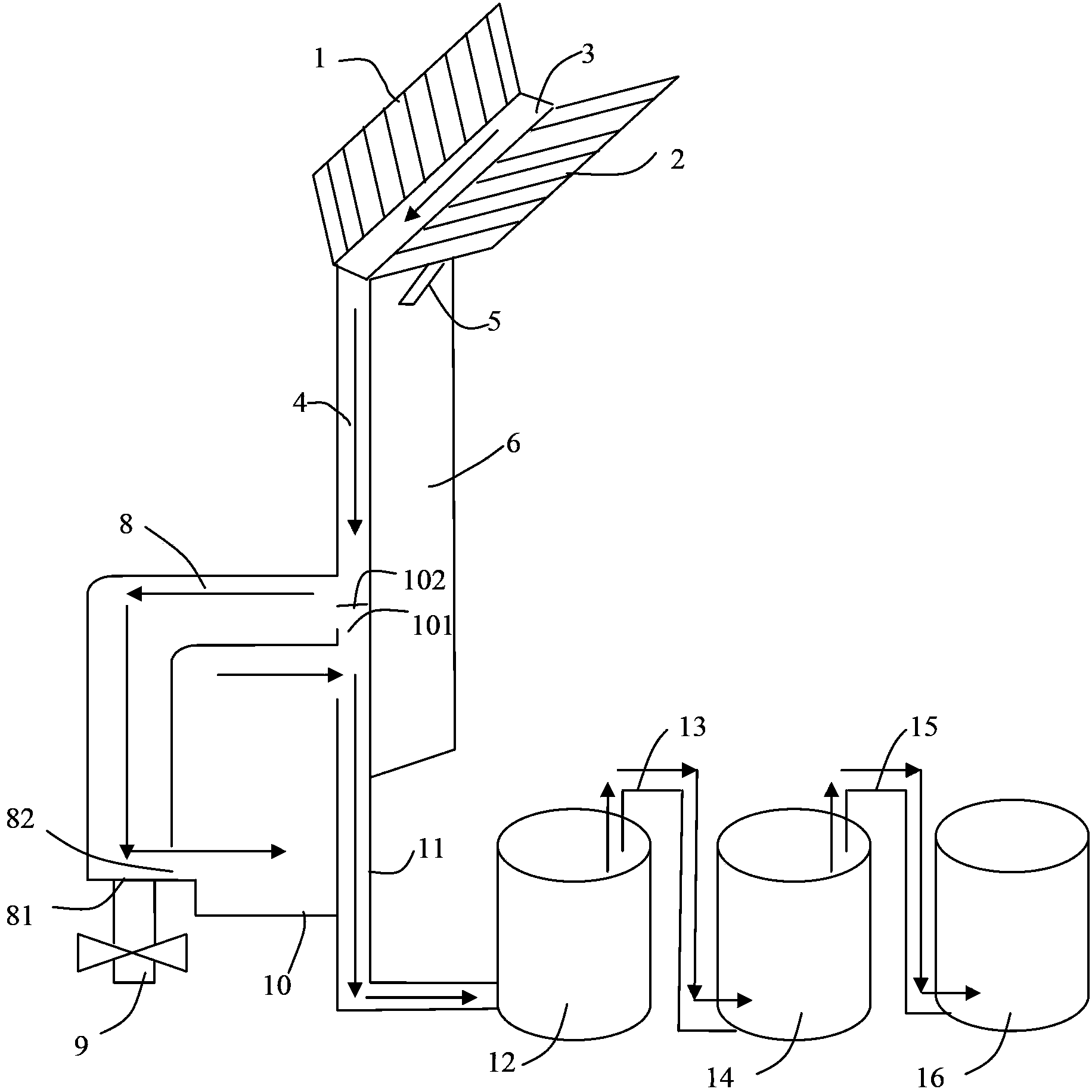

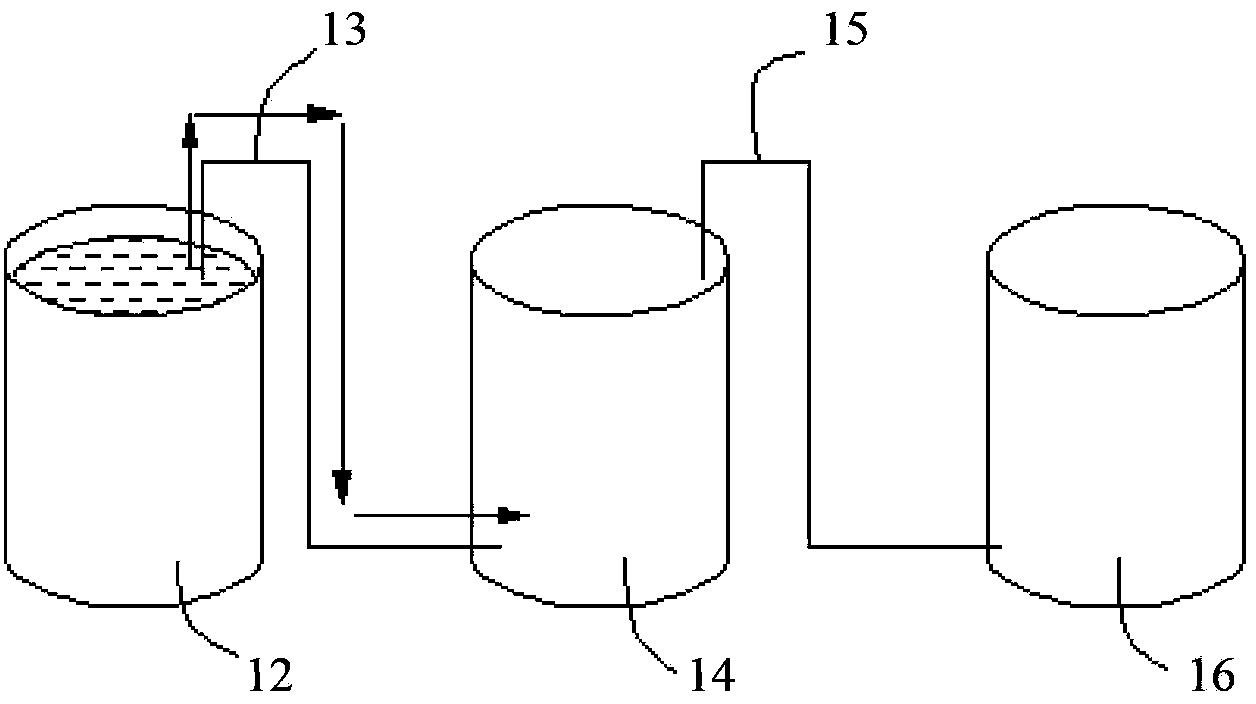

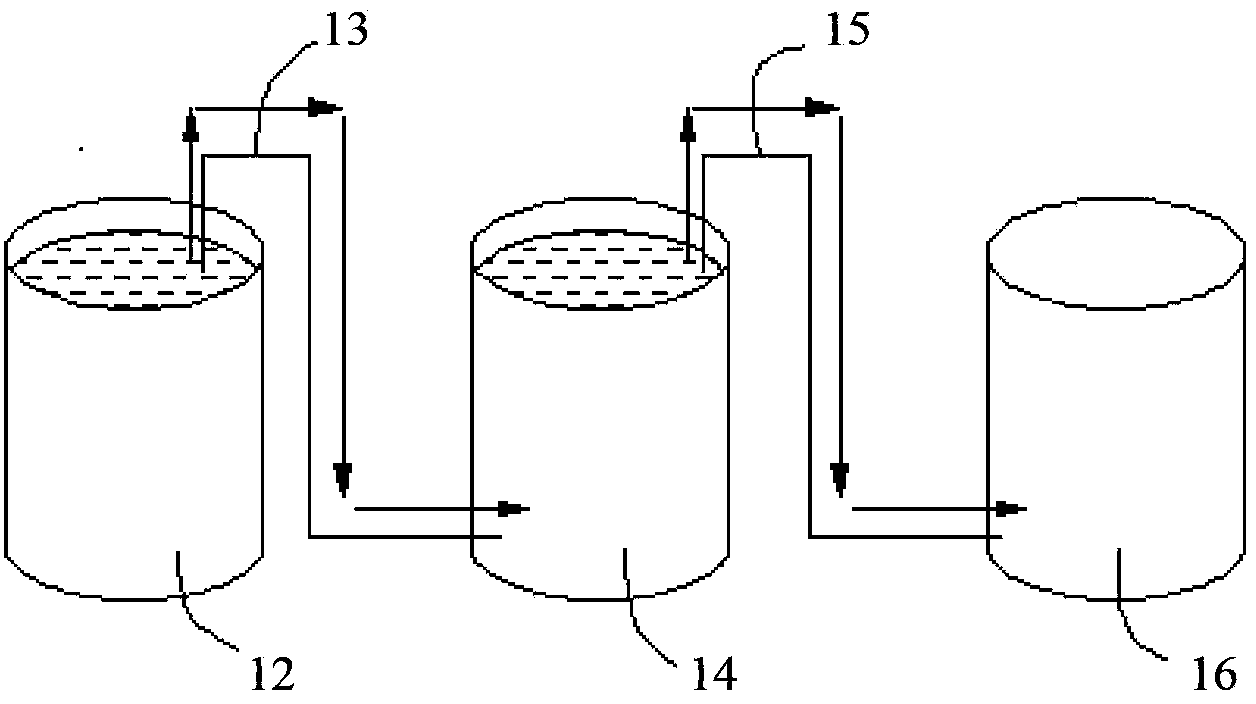

Rainwater collection system and building comprising same

ActiveCN103306333BImprove water qualitySolve the overflowRoof coveringGeneral water supply conservationCollection systemWater storage tank

The invention provides a rainwater collection system and a building comprising the same. The rainwater collection system comprises a water inlet pipe and a flow abandon device, wherein the flow abandon device comprises a flow guiding pipe, a valve and a water storage tank; the flow guiding pipe is provided with a water inlet, a first water outlet and a second water outlet; the water inlet of the flow guiding pipe are communicated with a water outlet of the water inlet pipe; the first water outlet of the flow guiding pipe is communicated with the valve; and the second water outlet of the flow guiding pipe is communicated with the bottom of the water storage tank. According to the embodiment of the invention, the rainwater collection system is provided with the flow abandon device; when the valve is opened, initial rainwater polluted seriously can be abandoned; and when the valve is closed, rainwater flows into the water storage tank, so that the rainwater collection can be realized, and the collected rainwater quality is improved.

Owner:SHENZHEN SMART SECURITY & SURVEILLANCE SERVICE ROBOT CO LTD

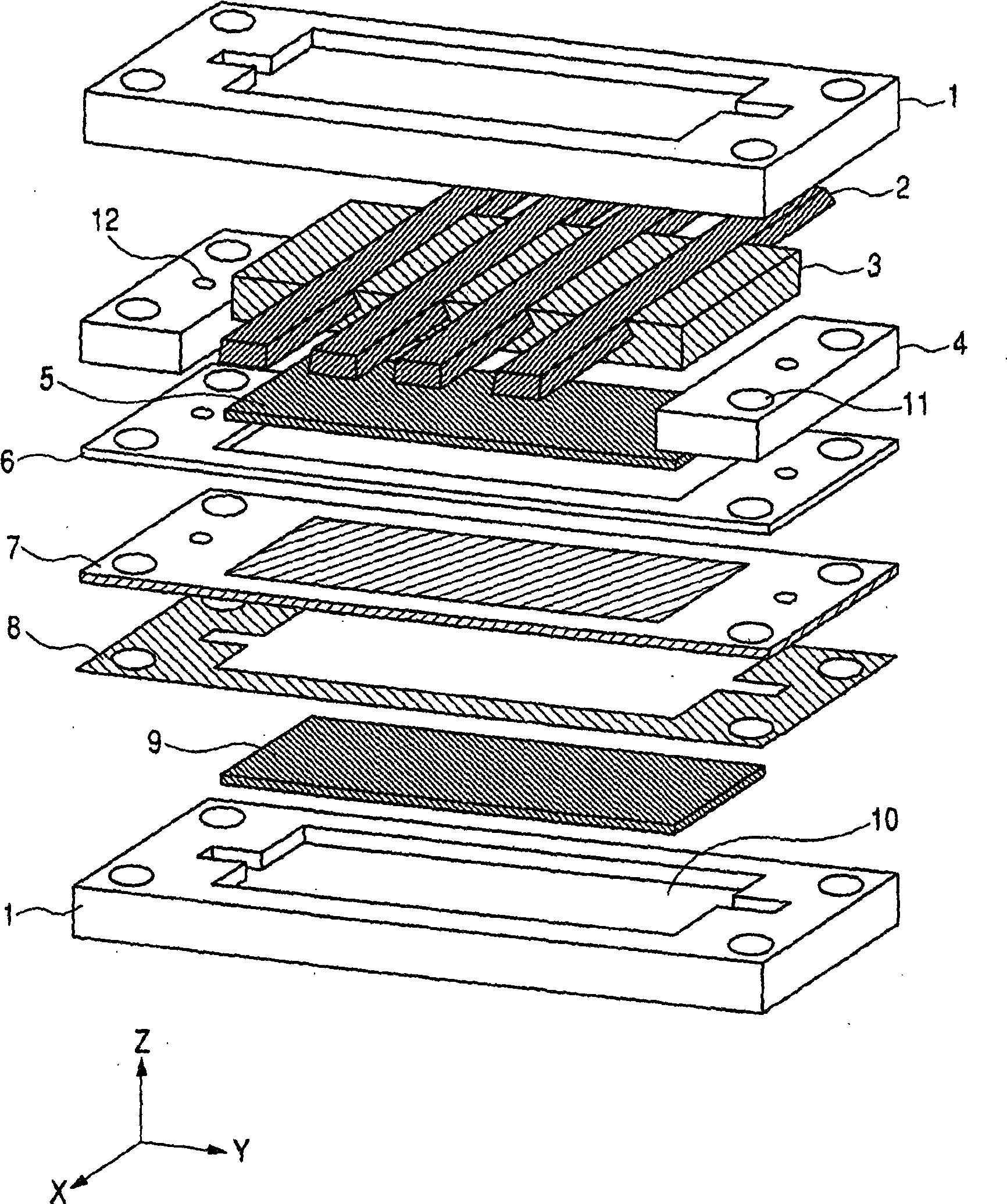

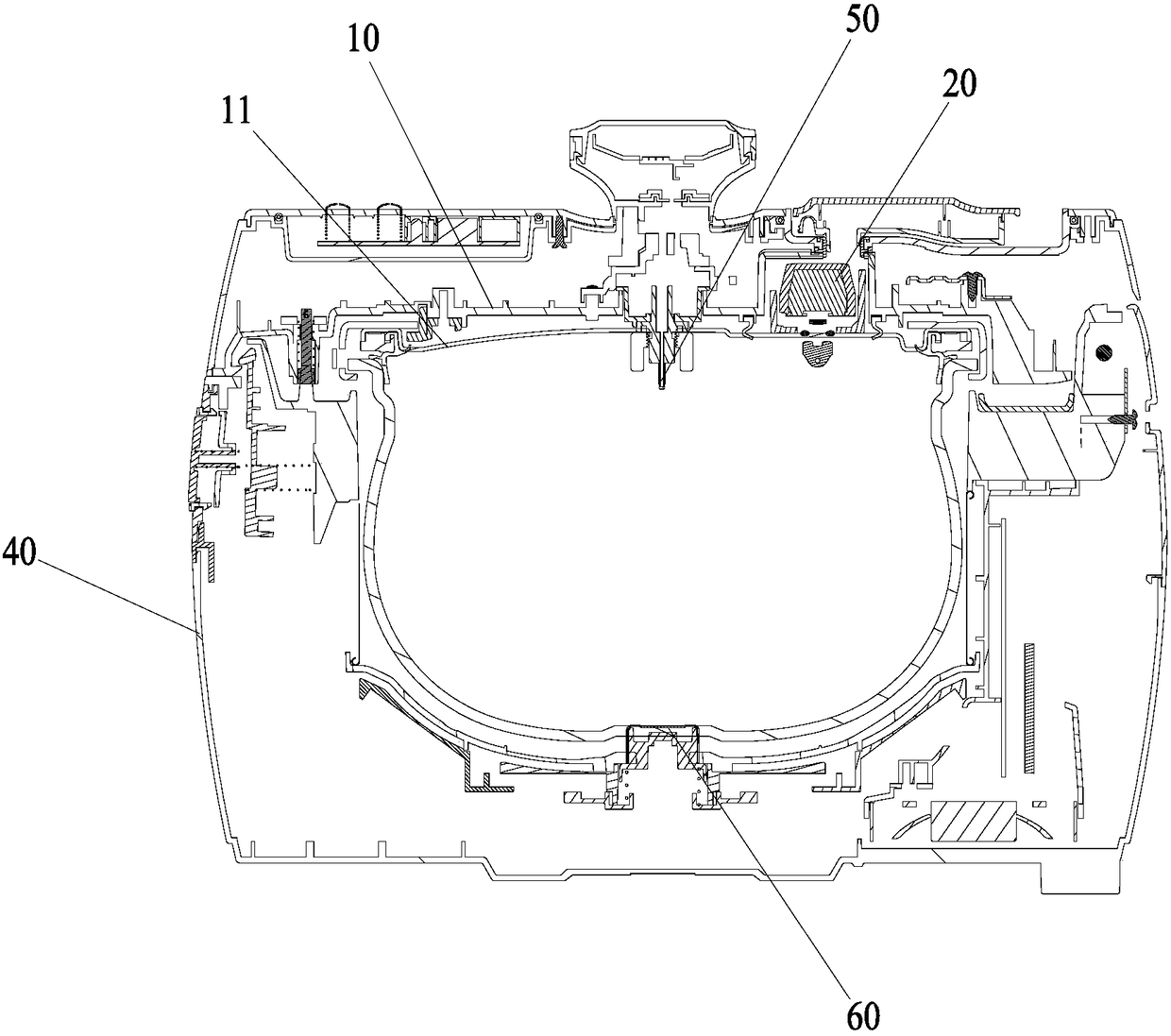

Fuel cell stack

InactiveCN101533923ASolve the overflowFuel cell heat exchangeFuel cells groupingFuel cellsElectrical and Electronics engineering

The invention provides a fuel cell stack in which at least one of a plurality of fuel cell units constituting a fuel cell stack includes a water absorbing member with a surface exposed to the atmosphere in a portion where an oxidizer flow path forming member and a separator are in contact with each other, and an area of a surface exposed to the atmosphere of the water absorbing member of the fuel cell unit the temperature of which becomes relatively lower is larger than an area of a surface exposed to the atmosphere of the water absorbing member of the fuel cell unit the temperature of which becomes relatively higher.

Owner:CANON KK

Liquid metal cooling and directional condensing equipment with tin boiler stirrer

InactiveCN101954475BImprove heat transfer effectUniform temperatureFrom frozen solutionsLiquid metalHeating furnace

The invention discloses liquid metal cooling and directional condensing equipment with a tin boiler stirrer, which comprises a mould heating and insulating furnace, a ceramic mould, a chilling tray, a drawing bracket, a container, a floating insulation baffle, a first stirrer, a second stirrer and a stirrer drive mechanism, wherein an upper heating area and a lower heating area are reserved in the mould heating and insulating furnace, the ceramic mould is arranged in the mould heating and insulating furnace, and the chilling tray is connected with the ceramic mould and driven by the drawing bracket to move up and down; the container is arranged below the mould heating and insulating furnace and filled with liquid metal tin, and the floating insulation baffle is arranged on the liquid surface of the liquid metal tin; and the first and second stirrers capable of rising and descending are symmetrically arranged in the container. The liquid metal cooling and directional condensing equipment with the tin boiler stirrer solves the problem of overflowing of the liquid metal tin and prevents the liquid surface of the liquid metal tin from rising and contacting the heating furnace; and dueto vertical movement of the stirrers, the heat exchange of the liquid metal tin is speeded up, so that the temperature of the liquid metal tin is uniform.

Owner:SHENYANG RES INST OF FOUNDRY

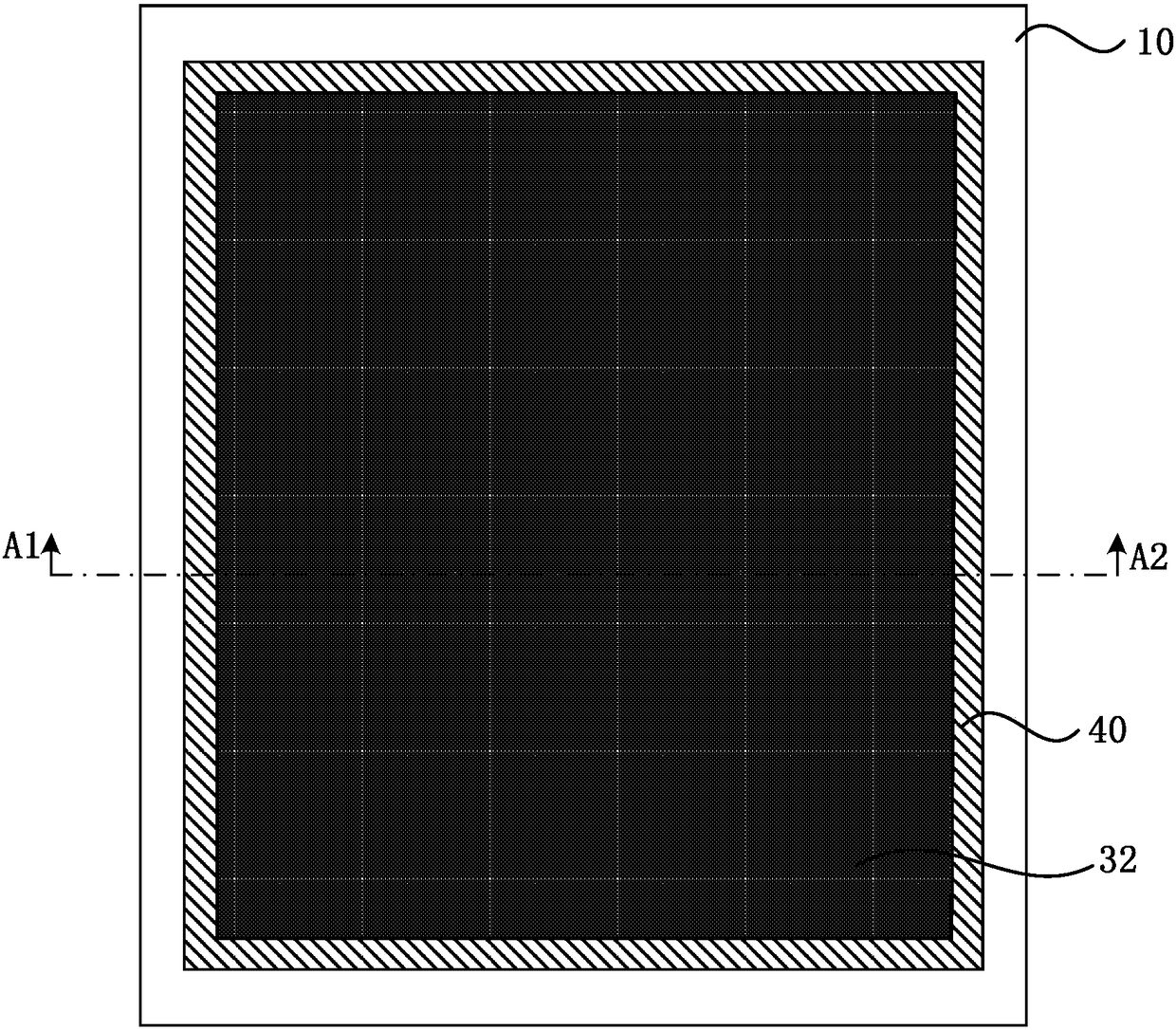

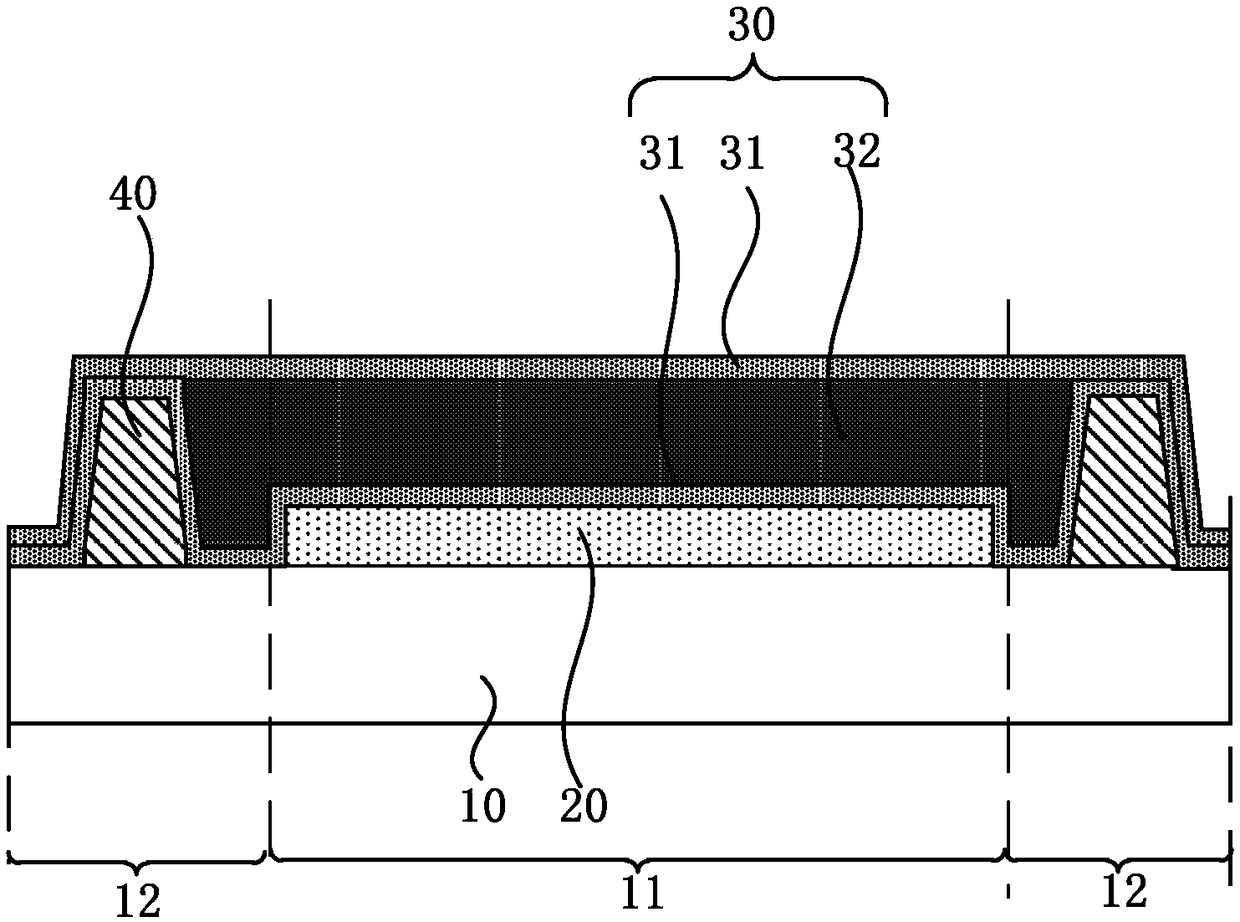

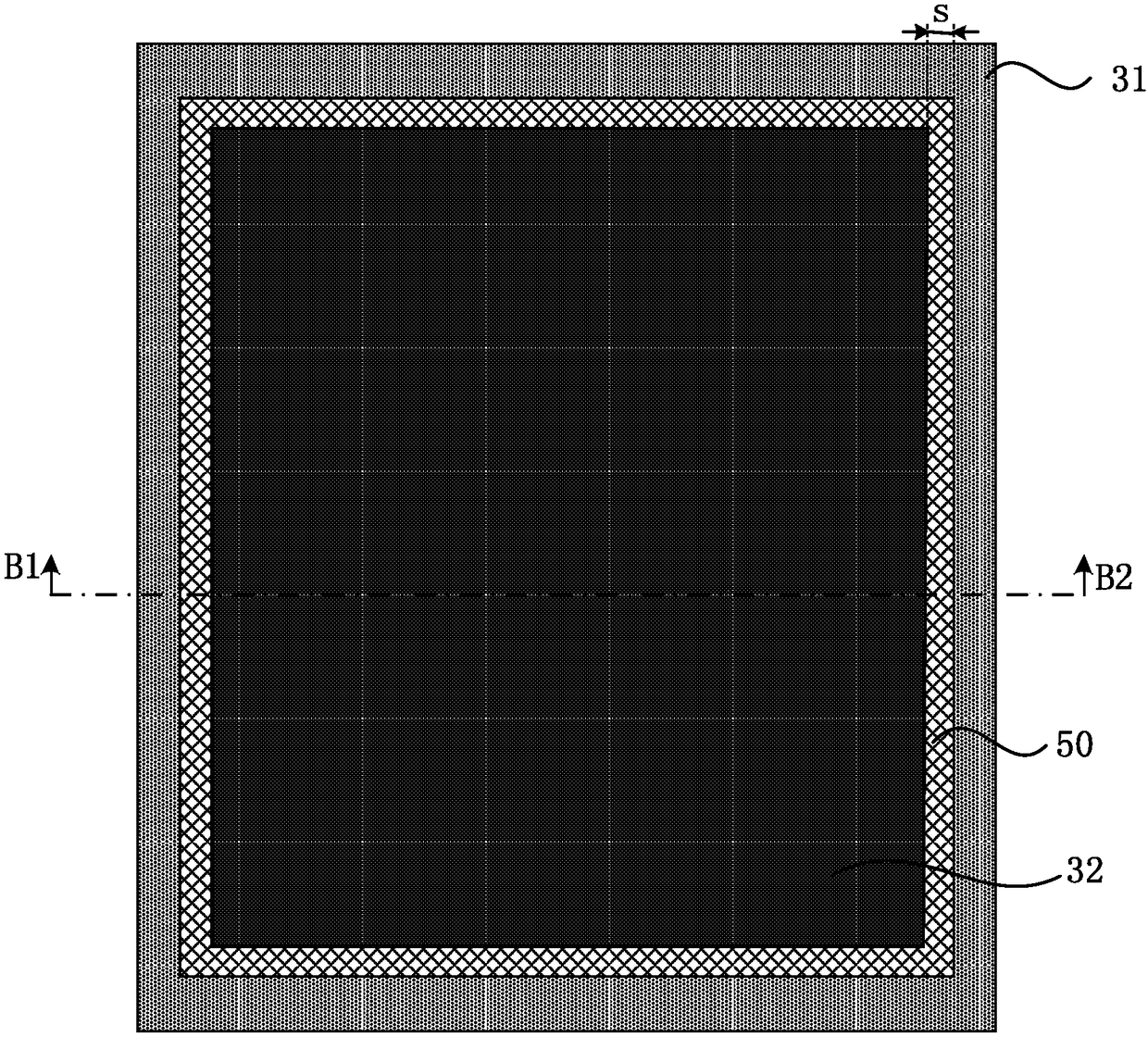

Display panel, display device and display panel manufacturing method

ActiveCN109285959AImprove bending performanceSolve the overflowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention discloses a display panel, a display device and a display panel manufacturing method. The display panel comprises a substrate, an organic light-emitting structure, a film packaging layer and a polymerization inhibiting substance, wherein the substrate includes a display area and a non-display area; the organic light-emitting structure is arranged in the display areaof the substrate; the film packaging layer covers the organic light-emitting structure; the film packaging layer includes inorganic layers and an organic layer which are arranged at intervals; the polymerization inhibiting substance is arranged in the non-display area of the substrate and surrounds the display area; and the polymerization inhibiting substance is arranged in the same layer as theorganic layer and used for preventing the polymerization reaction of organic monomers contacted with the polymerization inhibiting substance in the process of forming the organic layer and confining the organic layer in an area surrounded by the polymerization inhibiting substance. The embodiment of the invention provides a method for preventing overflow of the organic monomers without setting a retaining wall, and improves the bending characteristics of the display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

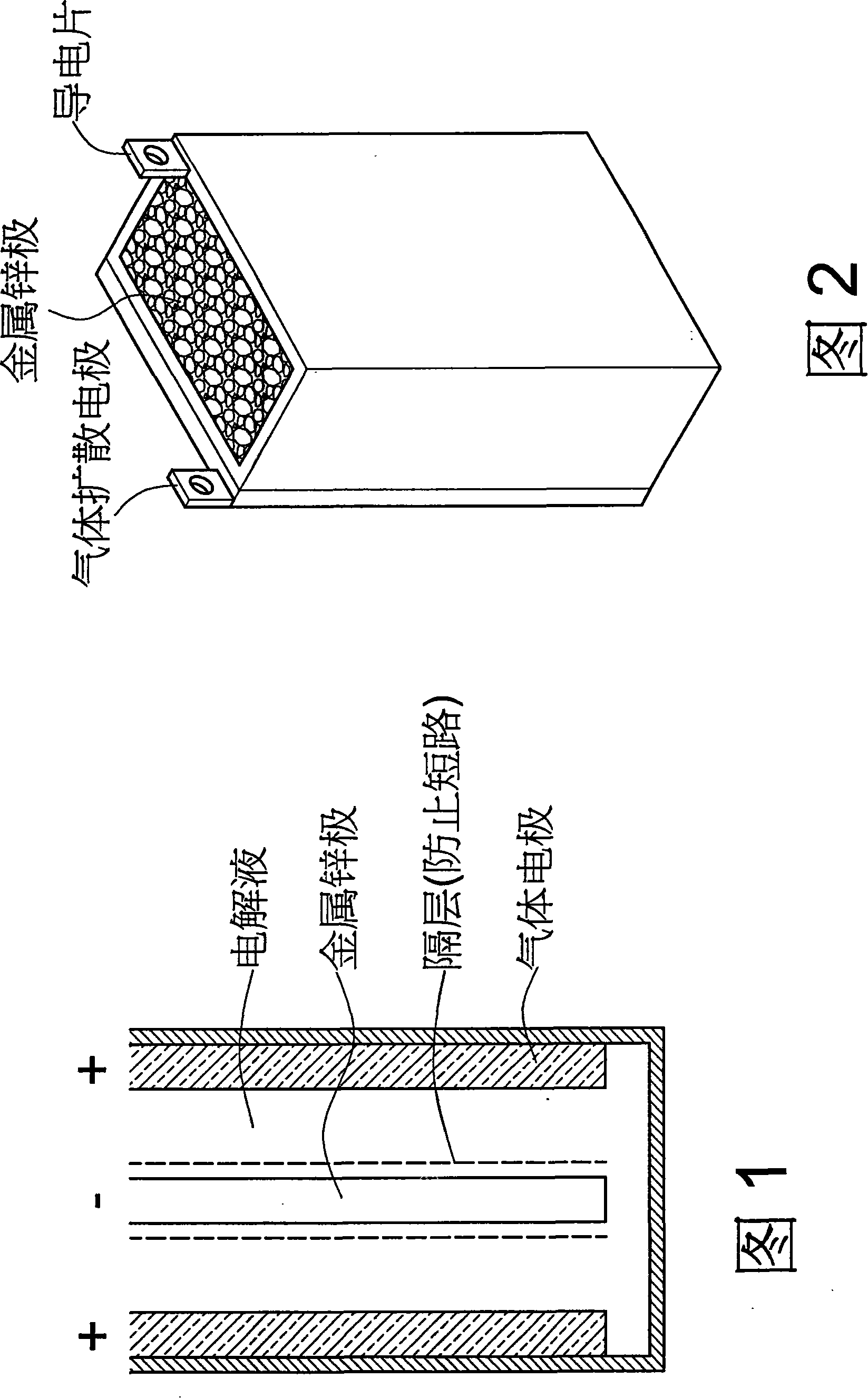

Powdered fuel cell

InactiveCN101188299ASolving Air Flow ManagementSolving Thermal Management IssuesElectrolyte holding meansReactant parameters controlIonChemistry

A powdered fuel cell includes current collectors, fuel chambers, porous membranes, electrolyte chambers and gas diffusion electrodes. The porous membranes pass oxide the formed from the reacted fuel through the holes thereof and block the unreacted powdered fuel; the electrolyte chambers provide the storage space for electrolyte so as to conduct ions and provide the collection space for the reacted oxide; and the gas diffusion electrodes, each has one side surface thereof for an oxidizing agent incoming and outgoing and catalyzed to acquire electron and ion conduction, wherein one of the current collectors and one of the gas diffusion electrodes are connected by posts, saving outer wires and being connected directly to the anode and the cathode as a loop. Thus, a power supply being capable of electricity conversion and storage and movable is realized.

Owner:林益泉

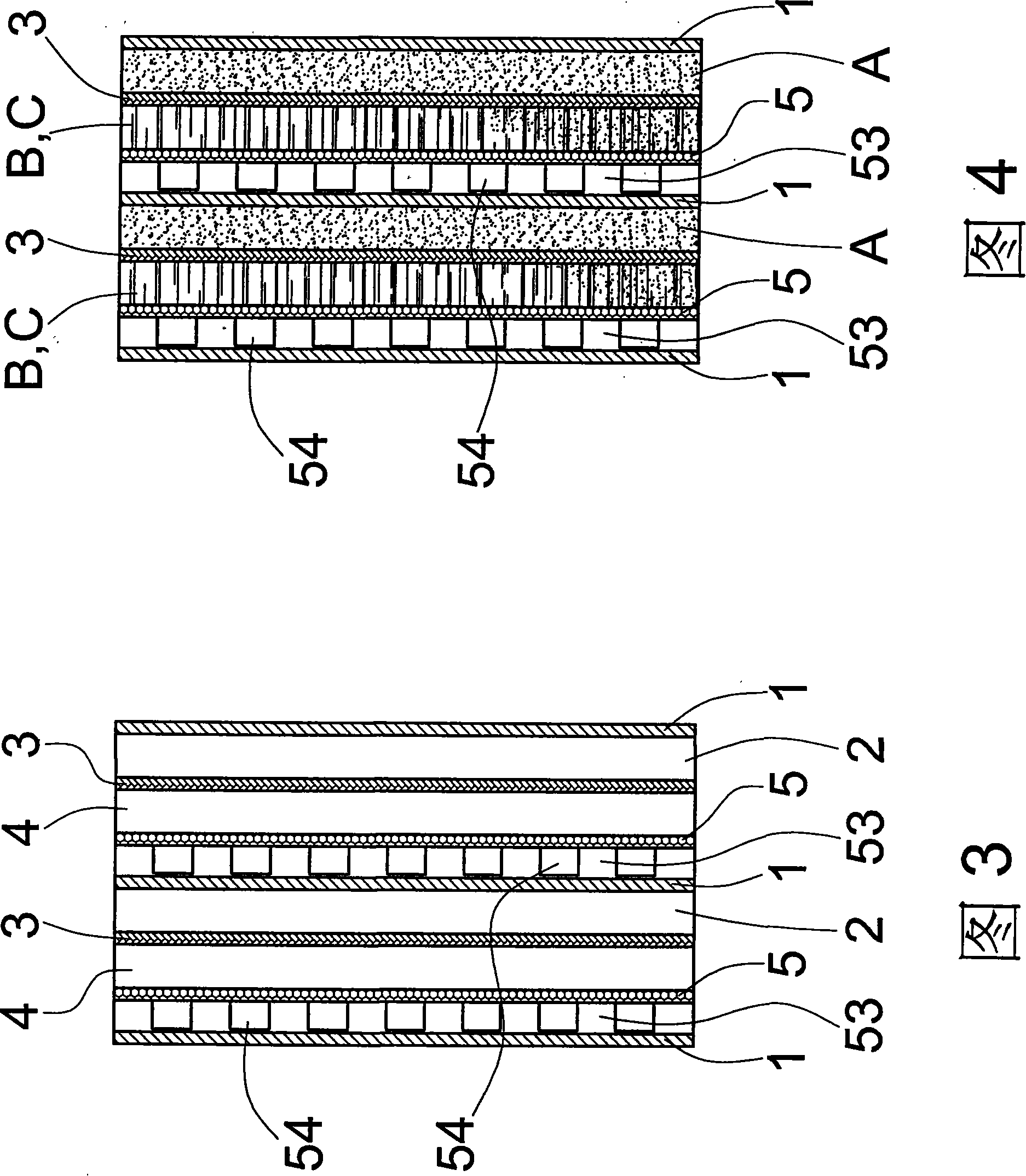

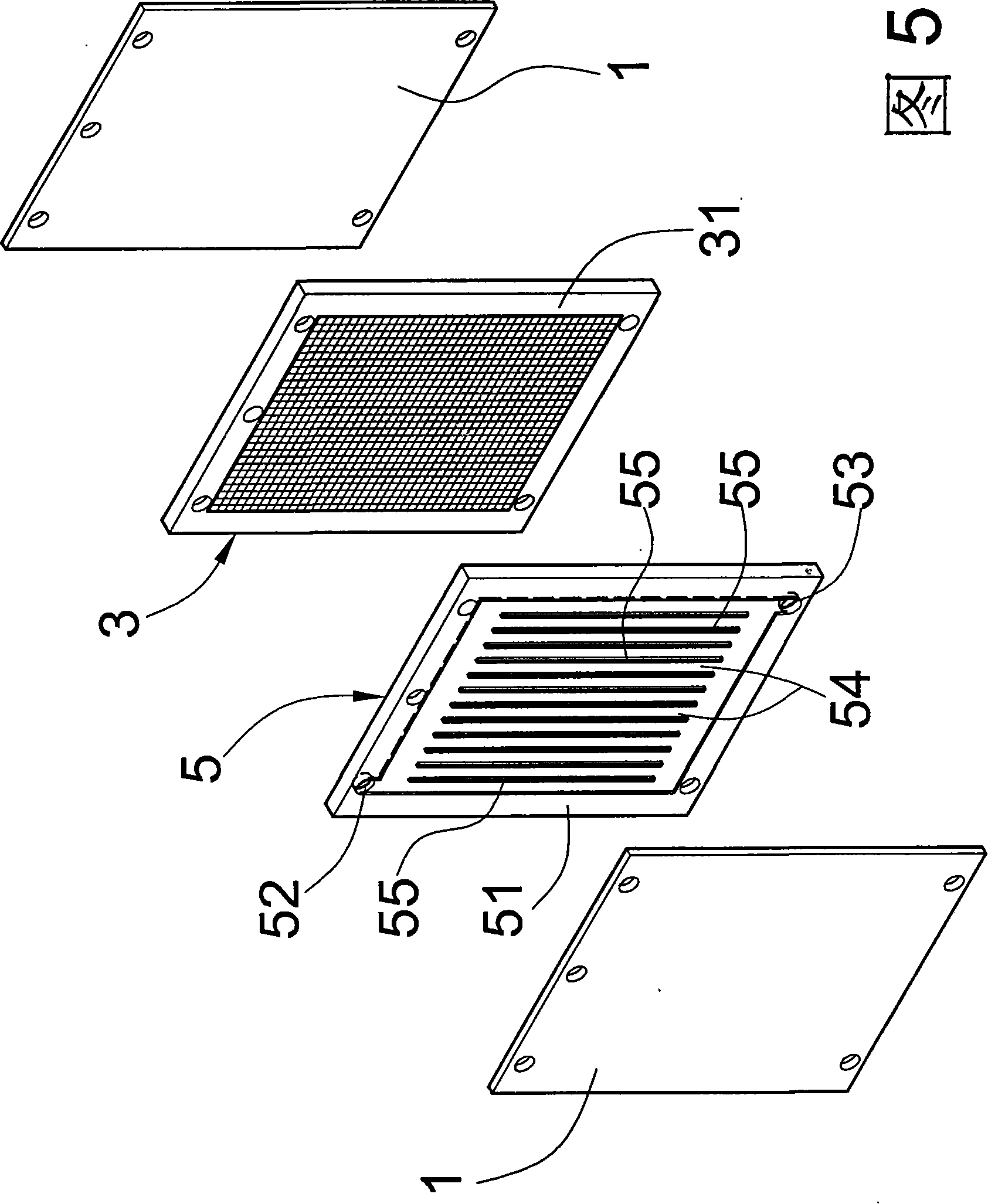

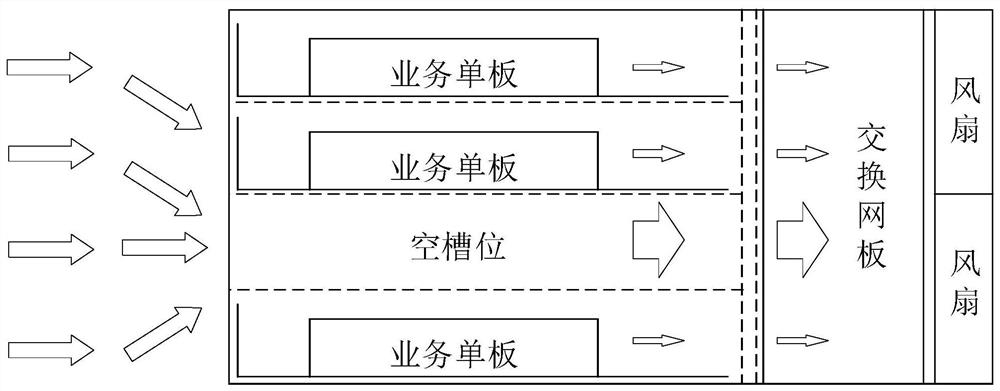

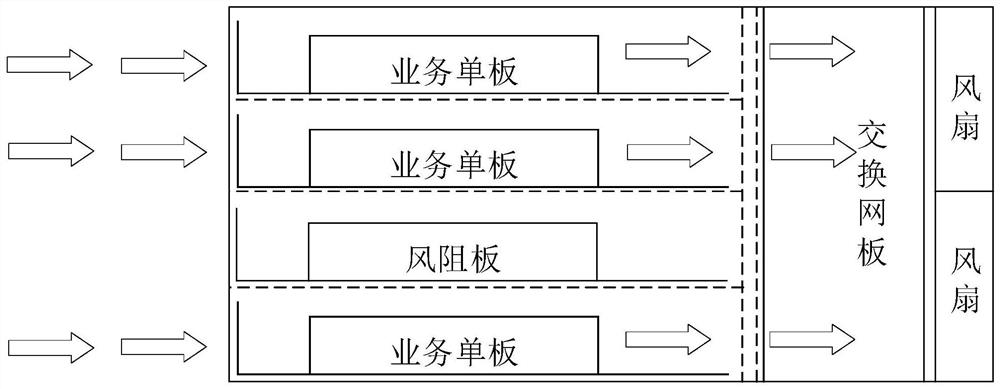

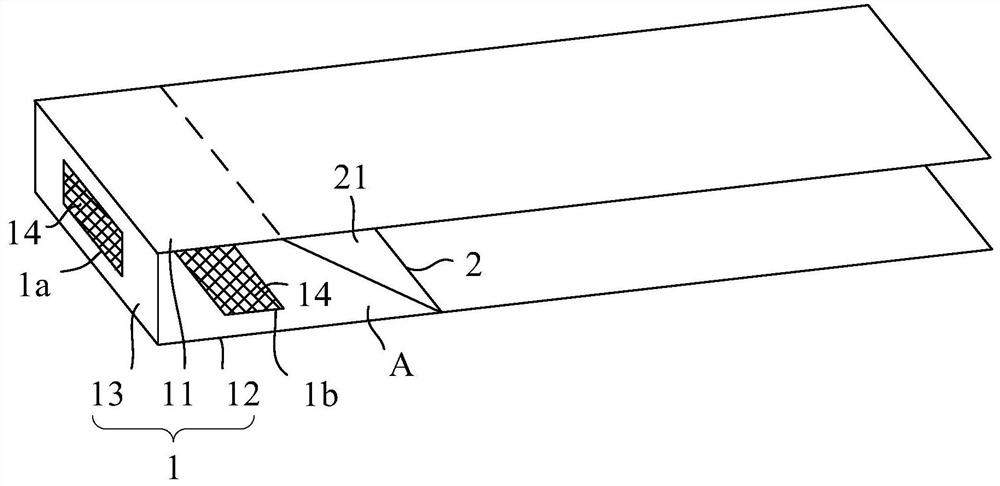

Air guide plug-in unit, cabinet, electronic equipment and manufacturing method of air guide plug-in unit

PendingCN114340301ASolve the overflowGuaranteed total air intakeCooling/ventilation/heating modificationsMechanical engineeringIndustrial engineering

The invention discloses an air guide plug-in, a cabinet, electronic equipment and a manufacturing method of the air guide plug-in. The air guide plug-in comprises a shell and a flow guide structure. The shell is provided with a first air inlet and a first air outlet, and an included angle is formed between the planes where the first air inlet and the first air outlet are located. The flow guide structure is located in the shell and is configured to guide airflow flowing into the first air inlet to the first air outlet. According to the invention, the heat dissipation capability of the electronic device can be improved.

Owner:HUAWEI TECH CO LTD

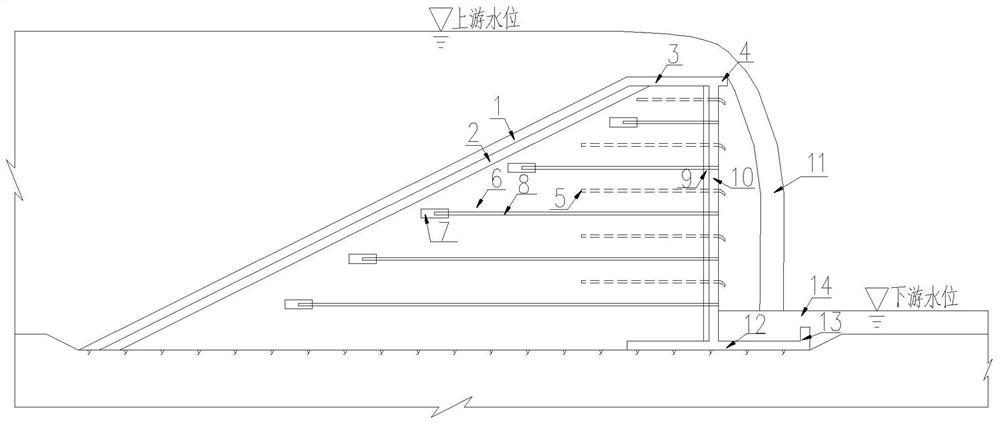

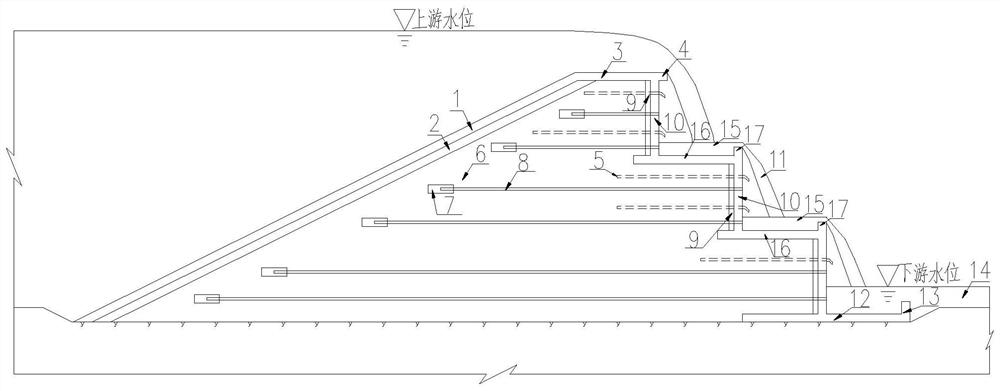

Reinforced soil retaining dam

PendingCN114319249AImprove engineering performanceImprove anti-seepage performanceBarrages/weirsEarth-fill damsSoil scienceStructural engineering

The invention relates to a reinforced soil retaining dam, and belongs to the field of retaining dams in water conservancy and hydropower engineering. The water retaining dam comprises a water retaining dam base body formed by piling reinforced soil, the upstream face of the water retaining dam base body is a slope with the top end inclining to the downstream, a cushion layer and a slope surface concrete anti-seepage face plate are sequentially arranged on the upstream face of the water retaining dam base body from inside to outside, a top concrete anti-seepage face plate is arranged at the top of the water retaining dam base body, and a top concrete anti-seepage face plate is arranged at the bottom of the top concrete anti-seepage face plate. The top concrete anti-seepage panel and the slope concrete anti-seepage panel are combined into a whole, a flip bucket is arranged at the downstream end of the top concrete anti-seepage panel, and a concrete supporting panel is arranged on the downstream slope of the water retaining dam base body. The reinforced soil retaining dam provided by the invention can overflow, and is simple in structure, high in adaptability and low in investment cost.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

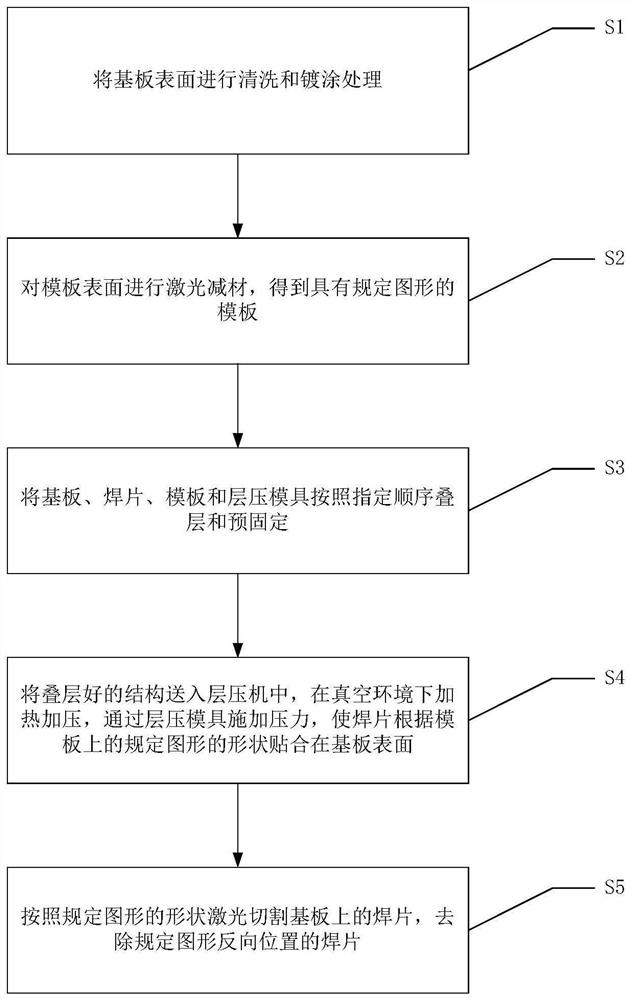

Method for selectively pressing alloy soldering lug on substrate

ActiveCN112133639ASolve the overflowSolve sizeSemiconductor/solid-state device manufacturingLaser cuttingSoldering

The invention relates to the field of microelectronic packaging, and discloses a method for selectively pressing an alloy soldering lug on a substrate, which comprises the following steps of: cleaningand plating the surface of the substrate; performing laser material reduction on the surface of the template to transfer the specified pattern to the template; laminating and pre-fixing the substrate, the soldering lug, the template and the laminating die according to a specified sequence; sending the laminated structure into a laminating machine, and heating and pressurizing in a vacuum environment, so that the soldering lug is attached to the substrate; and the soldering lugs on the substrate are cut through laser, and the soldering lugs corresponding to the specified patterns on the surface of the substrate are selectively reserved. According to the method, the alloy soldering lugs are selectively pressed on the surface of the substrate, high-quality and high-reliability integration and packaging between the chip, the module, the surrounding frame and the like and the substrate can be achieved, and the method has the advantages that the soldering lug size adjusting range is large,the line precision is high, alignment between the soldering lugs and the substrate is not needed, and disturbance displacement between the soldering lugs and the substrate is avoided.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

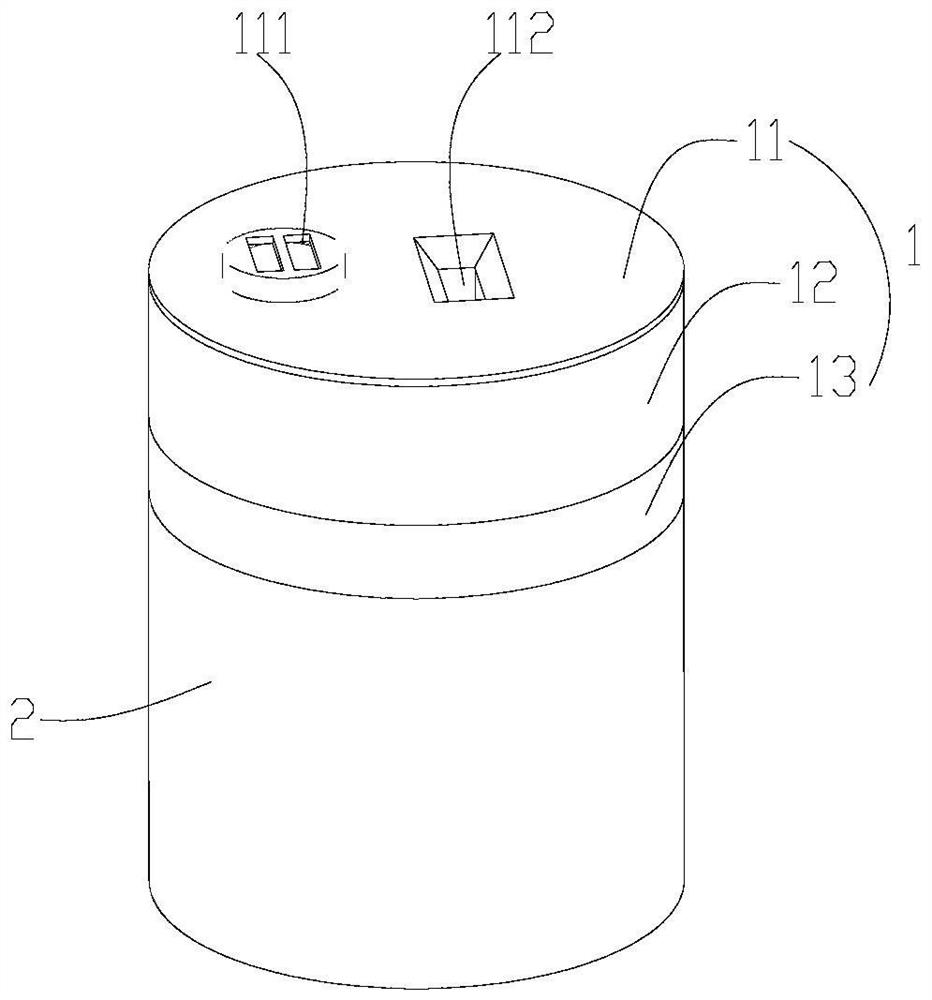

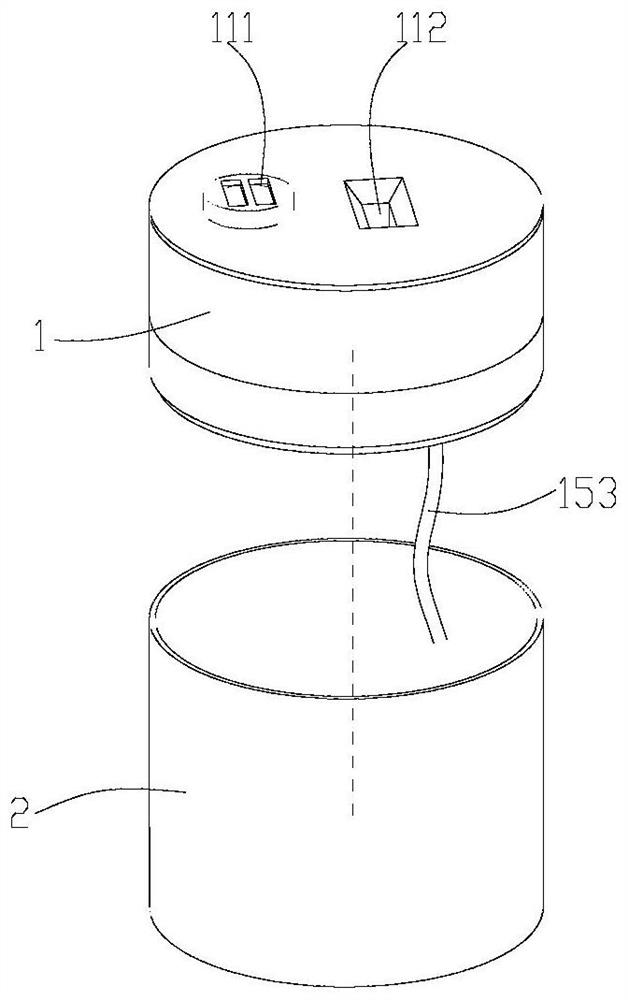

Humidifier

PendingCN114264006ASolve the risk of overflowThe water tank structure is simpleDucting arrangementsMechanical apparatusWater tanksMechanical engineering

The humidifier comprises a water tank and a main machine arranged above the water tank, the main machine comprises a water tank and a bottom cover located at the bottom end of the water tank, the bottom of the water tank is provided with a humidifying assembly and an overflow pipe downwards penetrating through the bottom cover, and the two ends of the overflow pipe are open; an opening in the upper end of the water tank extends upwards to a position below the horizontal height of the upper edge of the water tank; a water pump is arranged between the bottom of the water tank and the bottom cover, a water outlet pipe of the water pump is communicated with the water tank, and a water inlet pipe of the water pump extends out of the bottom cover downwards and extends to the bottom of the water tank through a water suction pipe. The overflow pipe is arranged in the water tank above the water tank, the overflow pipe penetrates through the bottom cover and then is communicated with the water tank, the overflow pipe in the water tank can prevent excessive water injected into the water tank, the water level in the water tank is kept below the height of the opening in the upper end of the overflow pipe, and redundant water can directly overflow the opening in the upper end of the overflow pipe; therefore, the hidden danger of water overflow is solved.

Owner:SHENZHEN LIANCHUANG ELECTRICAL APPLIANCE IND CO LTD

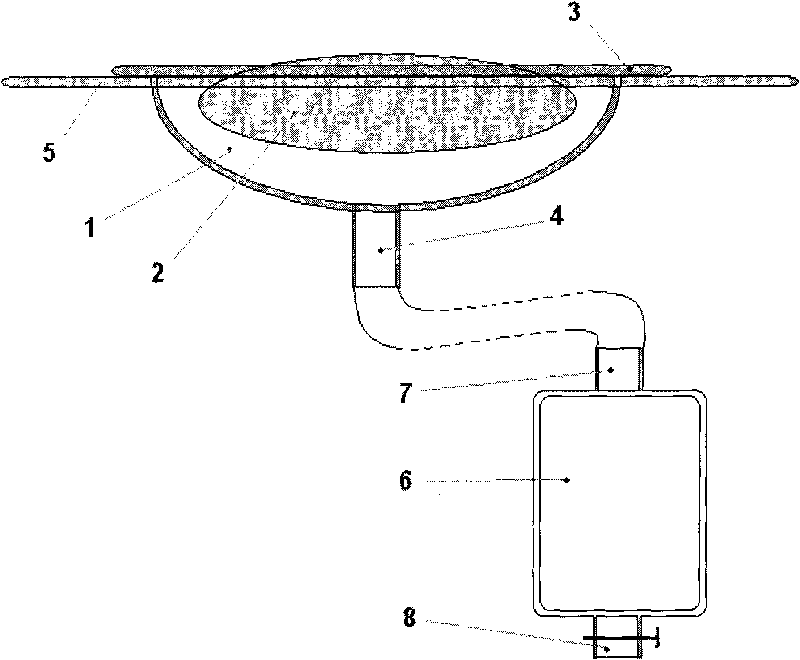

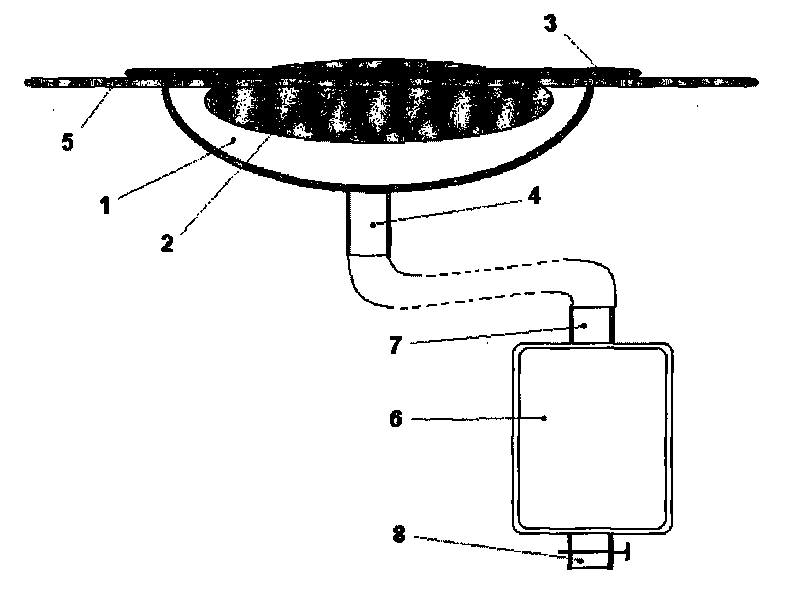

Adhesive film type catheter

InactiveCN101708143APay attention to softness and comfortAttention to suitabilityBodily discharge devicesFamily nursingMedical attention

The invention relates to a medical care and home care supply, in particular relating to an adhesive film type catheter used by the patients of urinary incontinence, which is composed of four parts of a urine collecting tank 1, a fluid guide pipe, a urine collecting bag 6 and a fixed adhesive film 5, wherein, the urine collecting tank 1 with a liquid deriving pipe 4 and a edge 3 with a certain width is provided with a sponge 2; an end 7 of the urine collecting bag 6 is connected with a soft plastic pipe for guiding into urine, the other end 8 of the urine collecting bag is connected with the soft plastic pipe with a valve, the soft plastic tube is used for deriving the urine in the urine collecting bag, and the urine collecting bag is marked with volume scales; and the fixed adhesive film 5 is provided with an opening in the middle, is used for fixing the urine collecting tank outside the urethral canal of human body (externalia), and can prevent the urine from overflowing. The urine collecting bag, the fluid guide pipe and the urine collecting bag can be used repeatedly, and the fixed adhesive film is disposal.

Owner:北京康安珂林科技有限公司

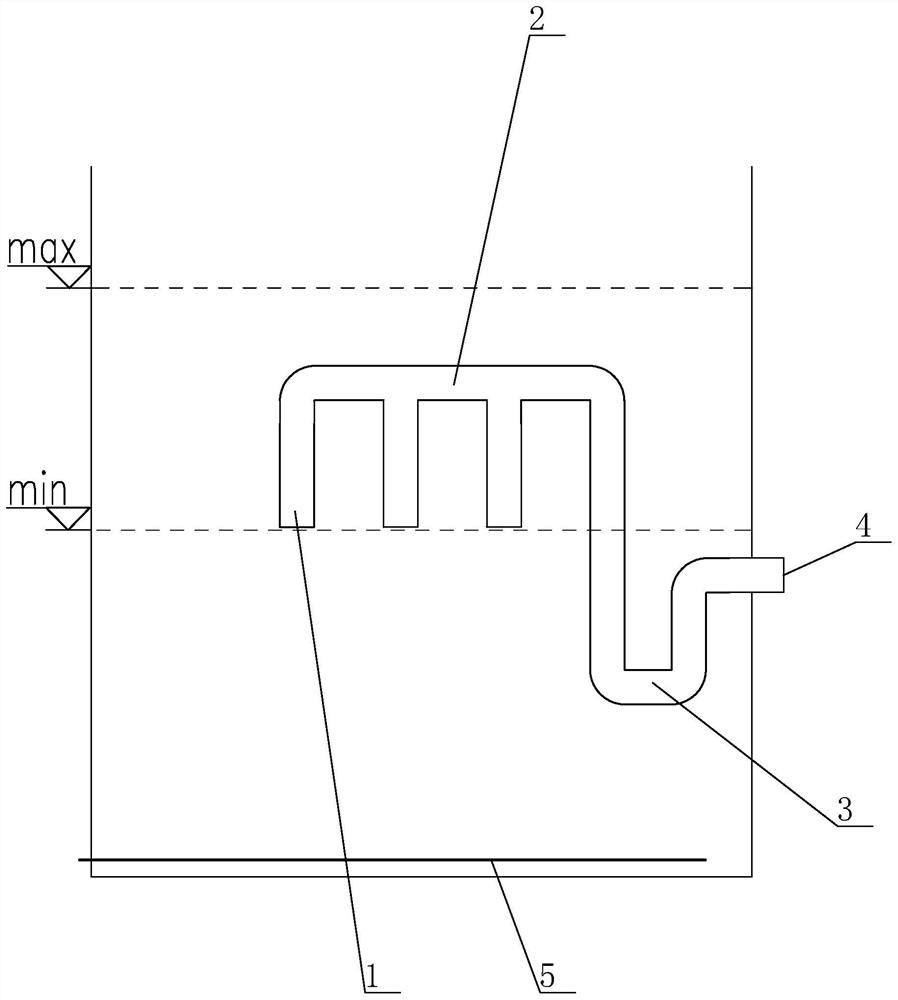

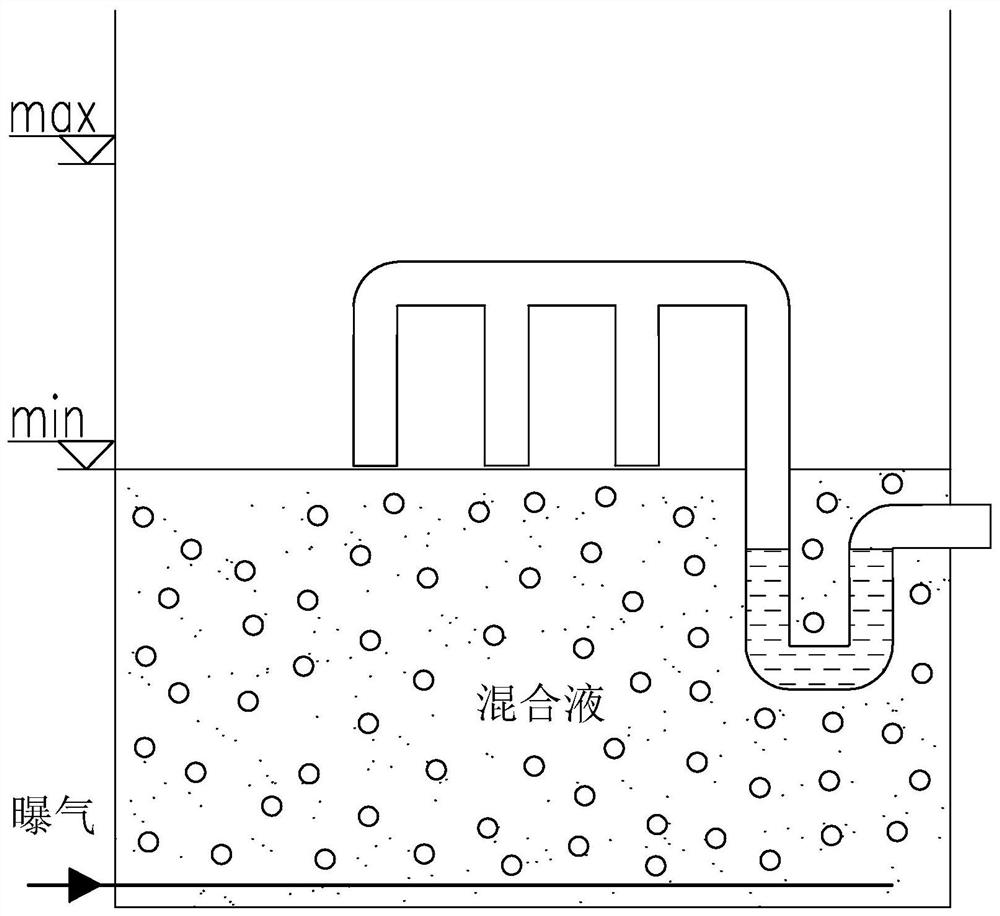

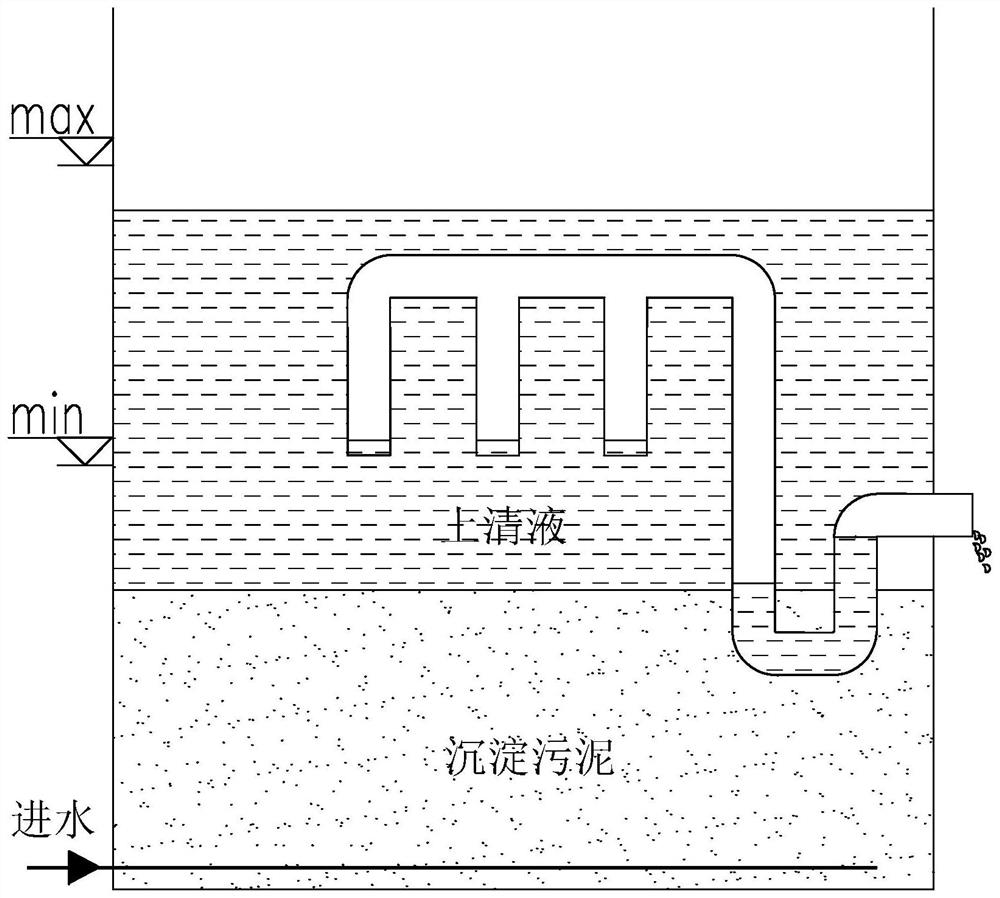

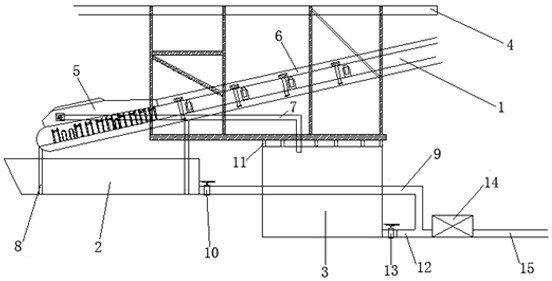

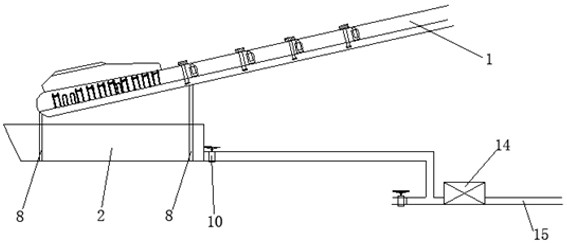

Unpowered fixed-water-level automatic drainer and drainage method thereof

ActiveCN114506922ANo outflow problemSolve the overflowBiological treatment apparatusSustainable biological treatmentSequencing batch reactorWater storage

The invention discloses an unpowered fixed-water-level automatic drainer and a drainage method thereof, and mainly relates to the field of sludge precipitation drainage. Comprising a water decanting short pipe, a water decanting main pipe and a U-shaped water storage pipe, the top of the water decanting short pipe is communicated with a water decanting main pipe, one end of the water decanting main pipe is communicated with one end of a U-shaped water storage pipe, and the other end of the U-shaped water storage pipe is a water outlet end. A plurality of water decanting short pipes can be arranged according to needs. And the water outlet end of the U-shaped water storage pipe is lower than the lowest end of the water decanting short pipe. The device has the beneficial effects that the device is applied to a UniFedSBR (Sequencing Batch Reactor) tank, namely a sewage treatment tank, the problem of overflow of a mixed solution is solved, and the device can immediately enter a water inlet precipitation stage after aeration is finished, so that the working time can be effectively saved, and the working period can be shortened. The device is free of electric equipment, pneumatic equipment and operating parts, simple in structure, reliable in operation and free of faults; and full-automatic operation can be realized according to a set water level without additional operation. The device is formed by bonding UPVC pipes and pipe fittings, and is easy and convenient to manufacture and low in cost.

Owner:山东问清环境科技有限公司

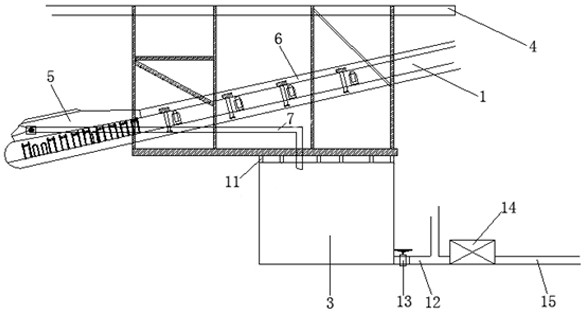

Equipment and method for quickly clearing and transporting muck of water-rich stratum shield belt conveyor

ActiveCN112963166AQuick ClearanceDoes not affect normal progressMining devicesTunnelsWater flowEnvironmental engineering

The invention discloses equipment and method for quickly clearing and transporting muck of a water-rich stratum shield belt conveyor, belongs to the technical field of shield construction, and can solve the problems that silt and water flow falling to the lower part of the belt conveyor are accumulated at a shield tail, a segment conveyor is submerged, normal tunneling cannot be performed and the like during earth pressure balance shield construction of a water-rich stratum. The equipment comprises the belt conveyor, a water collecting tank and a side drainage water collecting tank, wherein the water collecting tank and the side drainage water collecting tank are located at the bottom of the belt conveyor; a drainage hole is formed in the bottom of one end of the water collecting tank and connected with a drainage pipe I provided with a drainage valve I; a drainage hole is formed in the bottom of the side drainage water collecting tank and connected with a drainage pipe II provided with a drainage valve II; and the other end of the drainage pipe I is connected with a main drainage pipe through a slurry pump after being connected with the drainage pipe II. According to the invention, the muck and muddy water sliding from the bottom end of the belt conveyor and splashed to the position below the belt conveyor from the two sides of the belt conveyor are rapidly cleared and transported, and normal propelling of a shield tunneling machine is not affected.

Owner:THE 5TH ENG OF THE THIRD ENG GROUP OF CHINA RAILWAY +1

High-precision machine tool capable of recycling cooling liquid

InactiveCN109128997AEasy to recycleEasy to collectFeeding apparatusMetal working apparatusEnvironmental resistancePunching

The invention discloses a high-precision machine tool capable of recycling cooling liquid. The high-precision machine tool comprises a first machine tool frame and a second machine tool frame. The upper end of the first machine tool frame and the upper end of the second machine tool frame are connected through a supporting plate. The lower portion of the supporting plate is connected with a cooling assembly. The cooling assembly is in transmission connection with a punching assembly connected to the side face of the second machine tool frame. A transmission assembly is arranged below the cooling assembly, one end of the transmission assembly is connected with the first machine tool frame, and the other end of the transmission assembly is connected with the second machine tool frame. A recycling assembly is arranged below the transmission assembly. A liquid discharging pipe is arranged between the cooling assembly and the punching assembly. A liquid discharging head is connected to thelower portion of the liquid discharging pipe. The high-precision machine tool solves the problems that material scraps can block a channel through which cooling liquid flows, and the cooling liquid overflows; and the high-precision machine tool has the effects that cooling is efficient, the cooling liquid is saved and recycled, practicability is high, environment friendliness is achieved, and theservice life of the machine tool is prolonged.

Owner:安徽省临泉县智创精机有限公司

Device and method for preventing gushing of water-rich stratum and improving shield tunneling efficiency

PendingCN112943271AClean up in timeImprove tunneling efficiencyMining devicesTunnelsShield tunnelingScrew conveyor

The invention discloses a device and method for preventing gushing of a water-rich stratum and improving shield tunneling efficiency, and belongs to the technical field of tunnel shield construction. The device and method can solve the problems that a shield tunneling machine is prone to surface collapse, the shield tunneling machine is flooded, a tunnel collapses, personnel casualty accidents and the like in the construction process of penetrating through the water-rich stratum. The device comprises a belt conveyor, a screw conveyor located above the belt conveyor and a water collecting tank and a side drainage water collecting tank which are located at the bottom of the belt conveyor; the tunneling method comprises the steps of water drainage in a soil bin, solid soil pressure establishment, soil bin muck improvement, shield tunneling machine propelling, spewing prevention and rapid pressure relief and drainage and slag dredging system starting; and meanwhile, muck and muddy water accumulated at the bottom of the shield tunneling machine and falling out of the belt conveyor are effectively prevented, manual regular cleaning is not needed, and the shield tunneling efficiency is improved.

Owner:THE 5TH ENG OF THE THIRD ENG GROUP OF CHINA RAILWAY +1

Cooking utensil

ActiveCN108244996ASimple structureSolve the problem of not being able to open the coverBoiling over preventionPressure-cookersCold airEngineering

The invention provides a cooking utensil. The cooking utensil comprises a pot body, a pot lid, a driving mechanism and a controller, and the pot body is used for containing cooked food and is internally provided with a heating device; the pot lid lids the pot body and comprises a lid body and a face lid arranged on the lid body, and the lid body is provided with a pressure limiting valve; the driving mechanism is in communication with the controller, the pressure limiting valve keeps often opened, when heating is started, cold air in the pot body is exhausted, and when pressurizing is needed,the controller can control the driving mechanism to drive the pressure limiting valve to be closed. By means of the cooking utensil, the problem of an electric pressure pot in the prior art that pulpeasily overflows from a cold air rod and a cold air hole can be effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com