Patents

Literature

690results about How to "Improve anti-seepage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

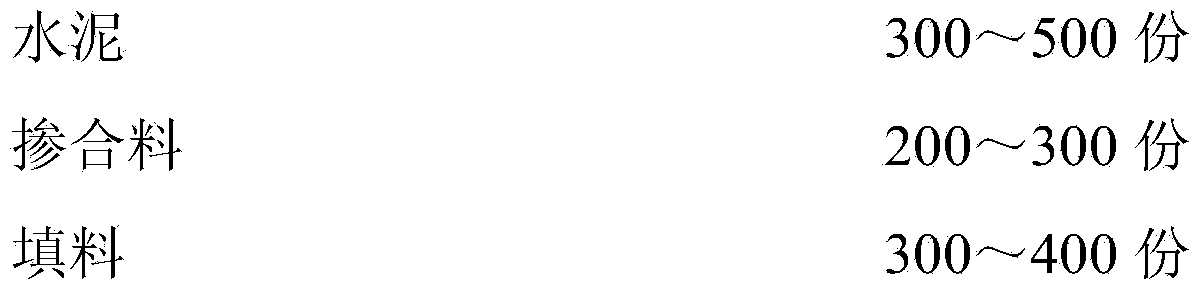

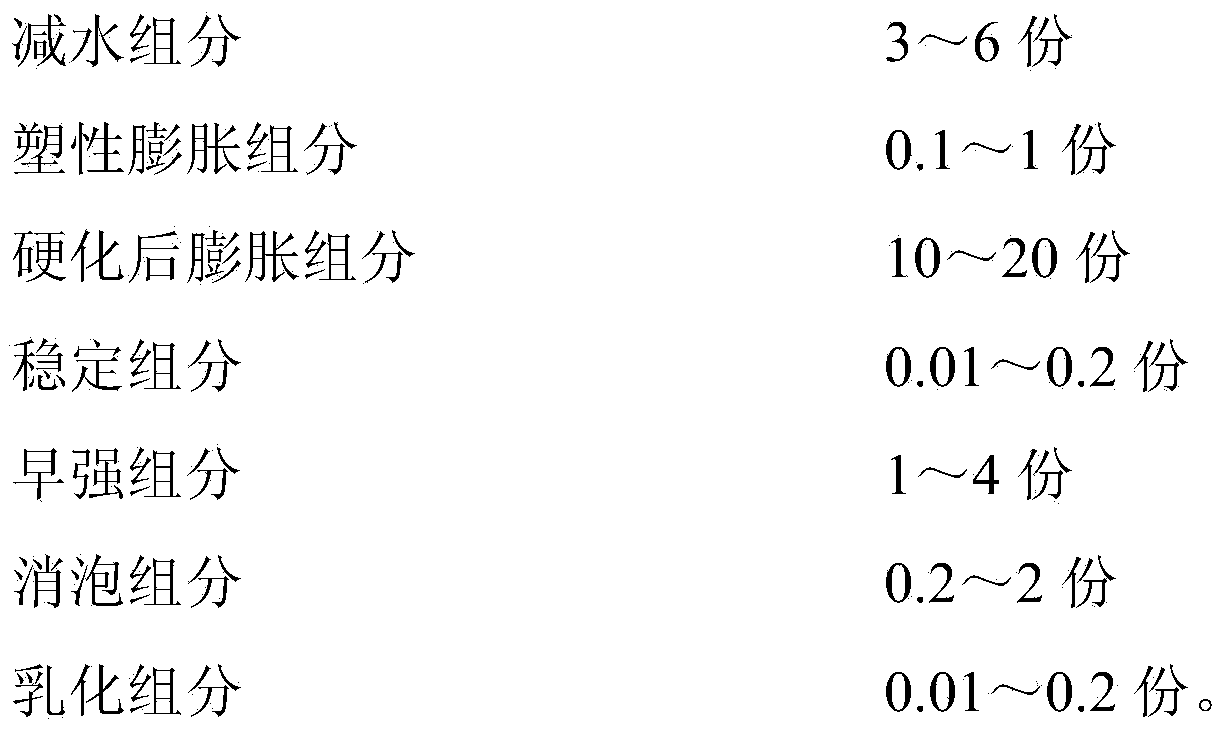

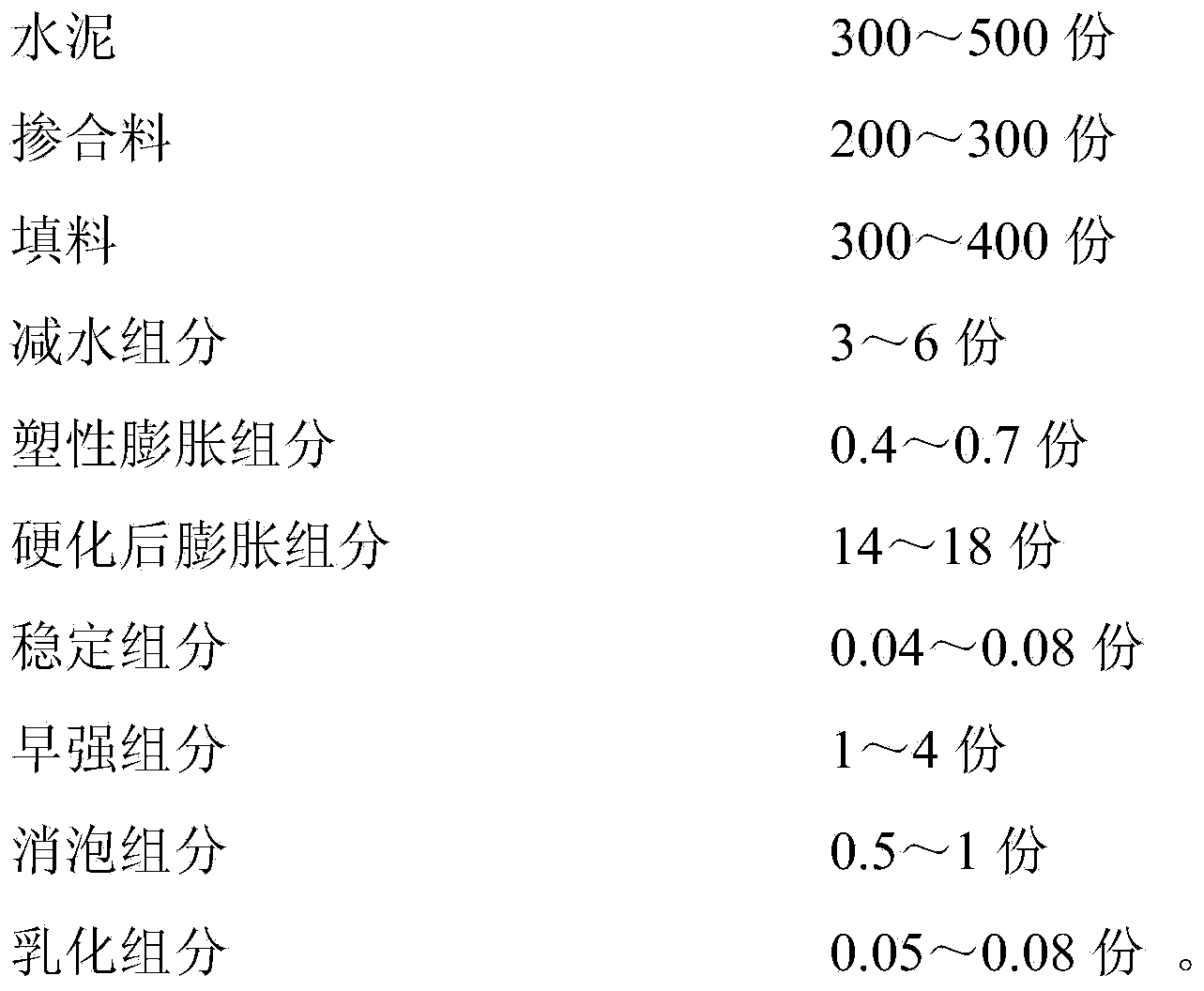

Cement-based grouting material used for strengthening repairing as well as preparation method and application thereof

InactiveCN103880372AHigh injectabilityImprove anti-seepage performanceSwelling ratioCompressive strength

The invention relates to a cement-based grouting material used for strengthening repairing as well as a preparation method and application thereof. The cement-based grouting material comprises the following components in parts by weight: 300-500 parts of cement, 200-300 parts of admixtures, 300-400 parts of fillers, 3-6 parts of water-reducing components, 0.1-1 part of plastic swelling component, 10-20 parts of hardened swelling components, 0.01-0.2 part of stable component, 1-4 parts of early strength components, 0.2-2 parts of defoaming components and 0.01-0.2 parts of emulsifying component. The cement-based grouting material disclosed by the invention has performance advantages such as higher injection-molding performance, initial fluidity not greater than 17s, impermeability not exceeding 1mm, wear resistance not exceeding 10cm<3> / cm<2>, compressive strength within 2 hours not lower than 5MPa, compressive strength within 1 day not lower than 30 MPa, and the like. The cement-based grouting material has composite swelling, the free swelling ratio within 3 hours is 0.02%-2% and grouting is full and dense; the viscosity is low, the volume stability is good and durability is good; the cement-based grouting material does not contain VOC (volatile organic compounds), and is environment-friendly.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

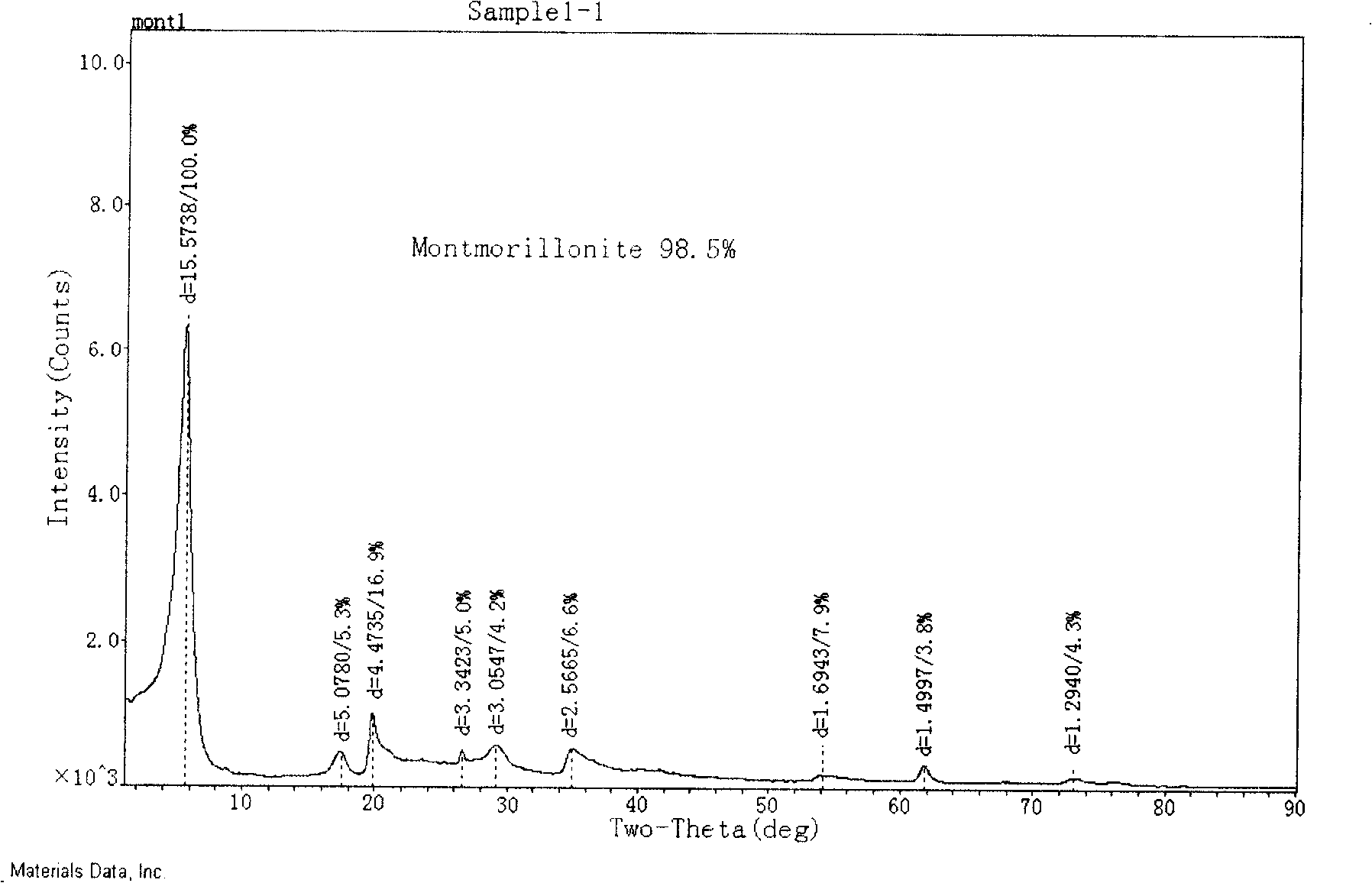

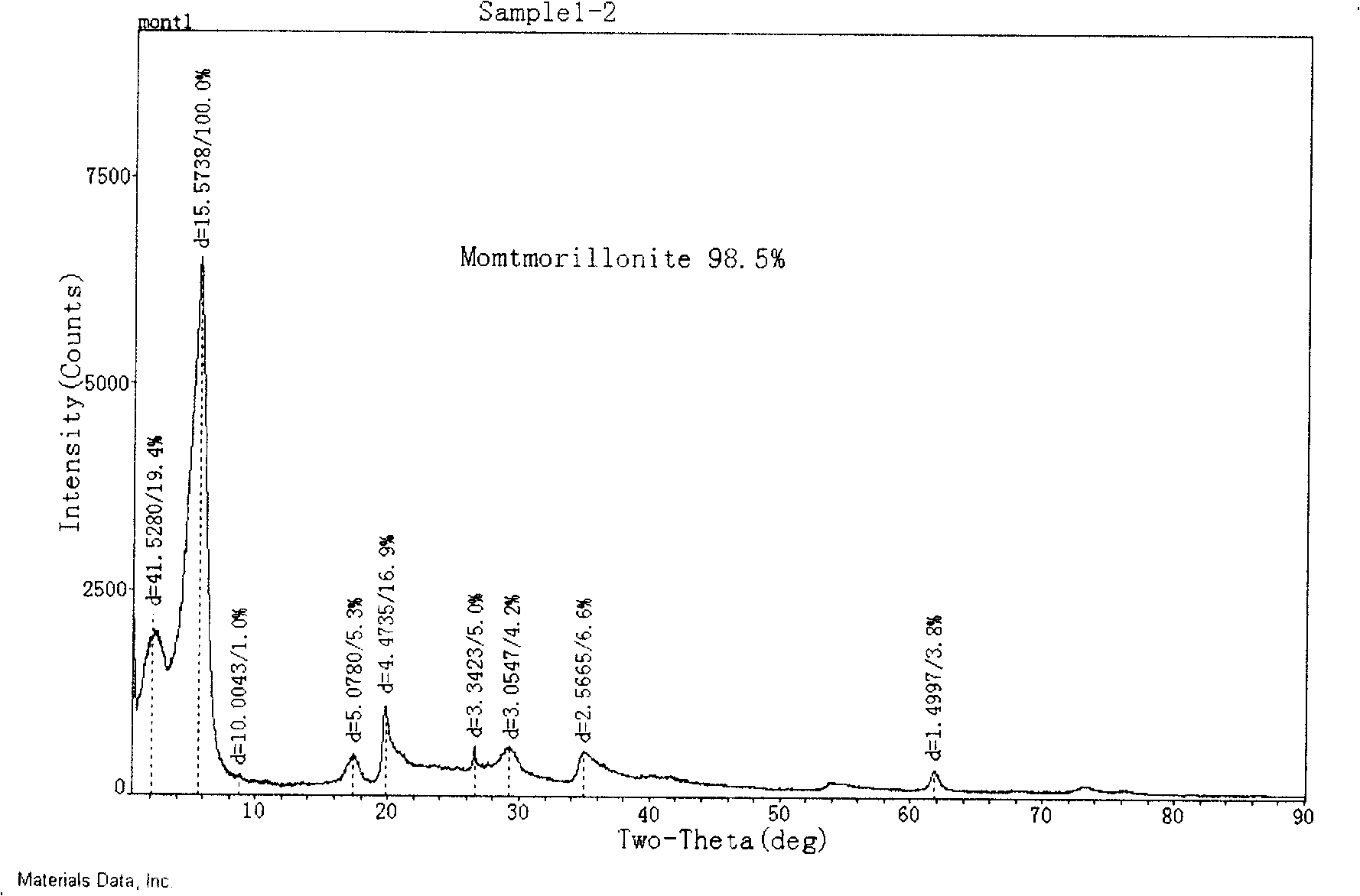

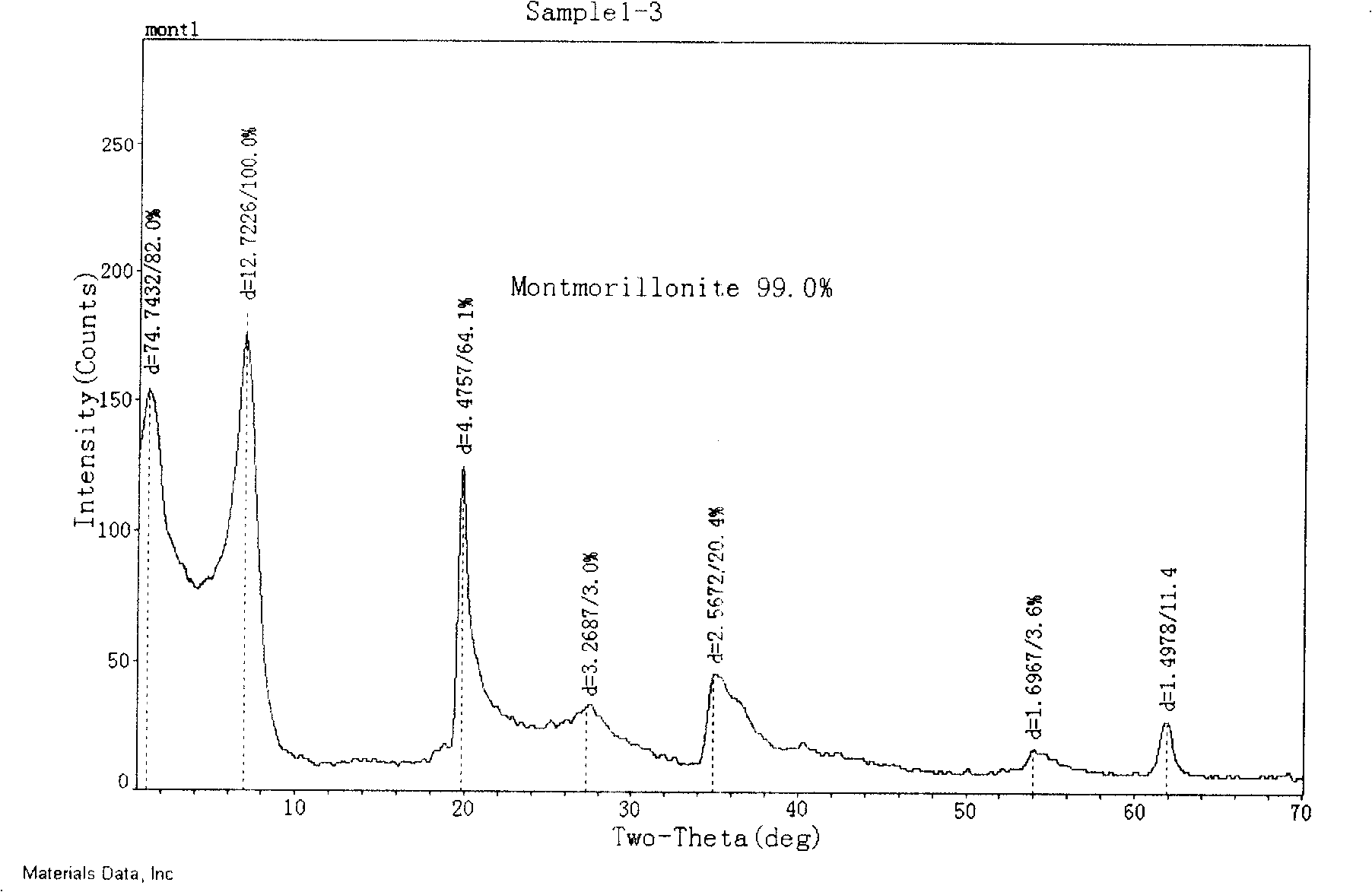

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

Use of wax in oil-based drilling fluid

InactiveUS20100173805A1Quantity minimizationDesired viscosityTransportation and packagingMixingWaxWell drilling

Compositions and methods for improving the performance of invert drilling fluids are provided. In particular, waxes are used in drilling fluid compositions to improve the performance of organophilic clays within a drilling solution as well as to improve seepage control.

Owner:ENGINEERED DRILLING SOLUTIONS

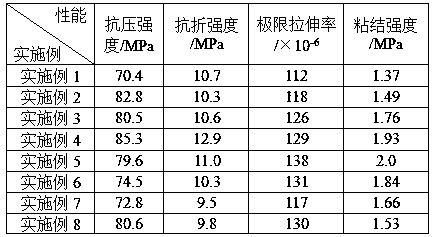

A high-strength anti-seepage concrete

InactiveCN102260059AInhibition of water seepageHigh strengthSolid waste managementUltimate tensile strengthWater reducer

A composition used for high-strength impermeable concrete. The composition contains sand, stone, cement, water reducer, water and reinforced impermeable sand. The reinforced impermeable sand includes aeolian sand and binder covering the surface of the aeolian sand. The reinforced impermeable sand can fill the gap between the sand and the stone, and well combine various components in the composition, and suppress the seepage phenomenon of the molded concrete, thereby greatly improving the strength and impermeability of the concrete.

Owner:BEIJING RECHSAND SCI & TECH GRP

Vitrified micro-bead heat preserving and insulating material and method of preparing same

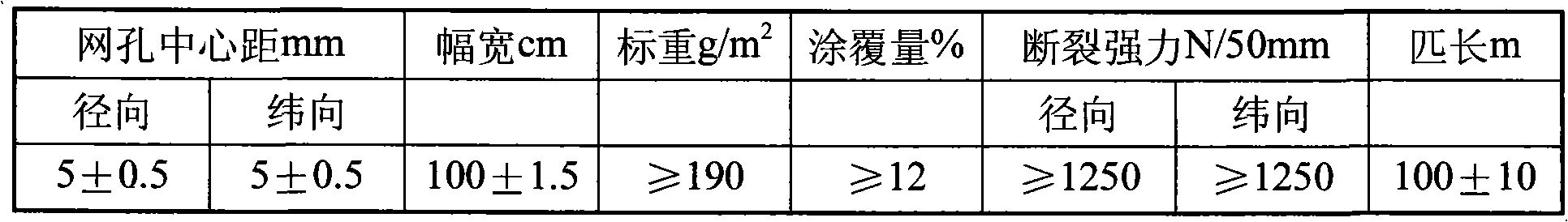

InactiveCN101665343AImprove thermal insulation performanceOvercoming the Achilles heel of flammabilitySolid waste managementCrack resistanceNew energy

The invention relates to vitrified micro-bead heat preserving and insulating material, in particular to heat preserving and insulating material for the wall and the roof of a building and a method ofpreparing the same, belonging to the field of the building energy saving technology. The heat preserving and insulating material comprises dry vitrified micro-bead heat preserving and insulating power, flexible seepage-prevention and crack-resistance mortar and alkali-resisting glass-fiber mesh cloth or hot-dip galvanized electrically-welded mesh; the dry vitrified micro-bead heat preserving and insulating power comprises the following raw materials by weight portion: 38-50 portions of special cement, 2-5 portions of pulverized coal ash, 8-10 portions of master batch and 35-55 portions of vitrified micro-beads; the flexible seepage-prevention and crack-resistance mortar comprises the following raw materials by weight portion: 28-40 portions of common silica cement, 3-6 portions of pulverized coal ash, 7-10 portions of polymer and 45-60 portions of quartz sand. The invention provides the new energy-saving and consumption-reducing environmental-friendly building material which has low thermal conductivity, good heat preserving and insulating effect, high strength, seepage prevention effect, crack resistance, fire resistance and stable performance, is convenient to use and easy to popularize and can be widely used for preserving and insulating the heat of the wall and the roof of the civil and industrial building.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Acrylate grouting liquid and preparation method thereof

The invention provides an acrylate grouting liquid composed of a liquid A and a liquid B, which both contain acrylate as main ingredient. The formulation and weight proportions of the liquids A and B are as follows: liquid A: acrylate aqueous solution 40-50 parts, acrylic ester cross-linking agent 5-7 parts, accelerator 0.5-5 parts, alkali metal hydroxide additive 0.4-0.5 parts, and water 1.5-3 parts; liquid B: initiator 0.3-0.6 parts, alkali metal hydroxide additive 1-1.5 parts and water 40-50 parts. The liquids A and B are prepared before use, and mixed in the field at equal volume under room temperature to form a gel. In the invention, the acrylic ester is used as cross-linking agent so that the grouting liquid is free of amido groups and doesn't cause environmental pollution; and the alkali metal hydroxide is added so that the grouting liquid exhibits certain expandability in water and exhibits good anti-seepage effect.

Owner:北京朗巍时代科技有限责任公司 +1

Anti-freeze aerated concrete brick

The invention discloses an anti-freeze aerated concrete brick. The anti-freeze aerated concrete brick is prepared from the following raw materials in parts by weight: 35-40 parts of fly ash, 15-20 parts of cement, 15-20 parts of wollastonite powder, 5-10 parts of modified straw ash, 2-4 parts of gypsum, 0.05-0.1 part of aluminum powder, 2-4 parts of urea, 0.01-0.03 part of oxyparaffin soap, 1-2 parts of sugar calcium, 4-6 parts of calcium formate, 0.1-0.5 part of polyethylene wax powder, 4-6 parts of calcium carbonate, 0.2-0.4 part of calcium nitrate, 0.1-0.2 part of sodium acetate and right amount of water.

Owner:潘逸东

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

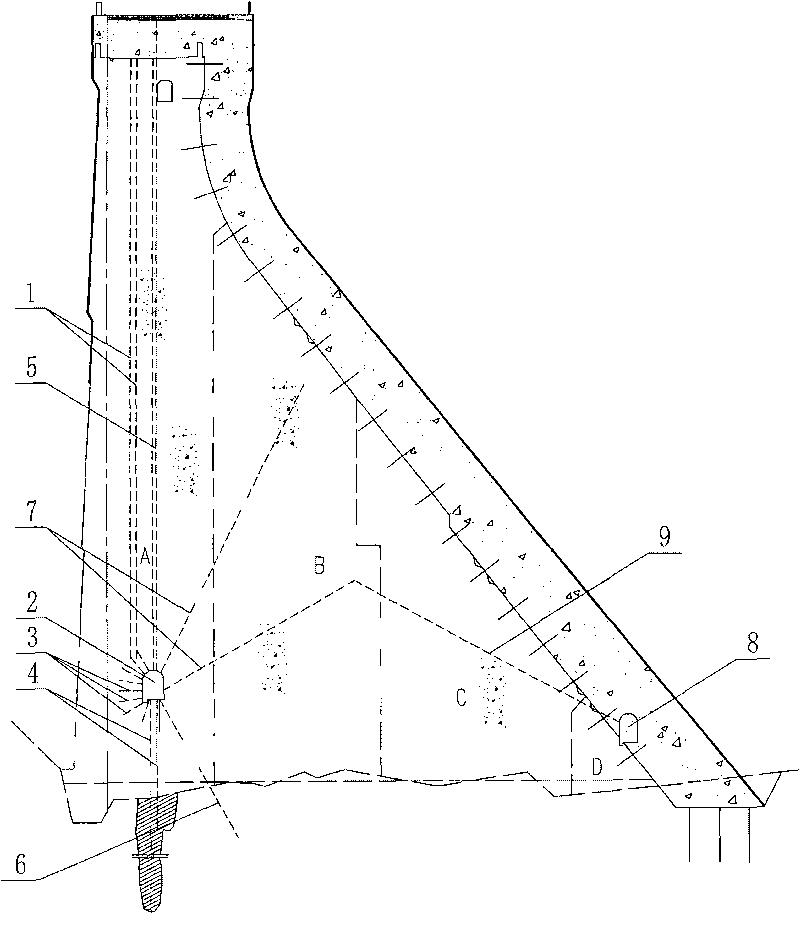

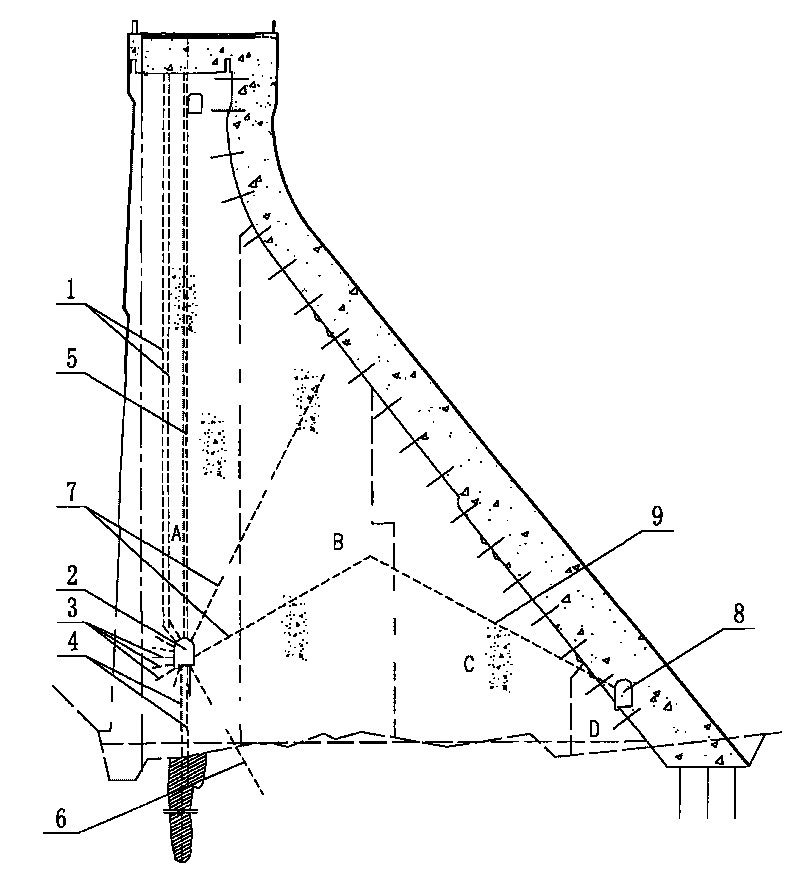

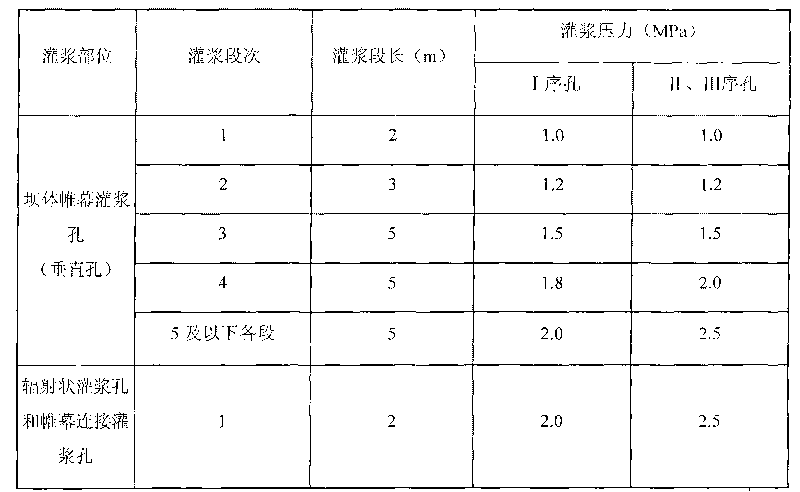

Construction method for dam body seepage preventing curtain grouting

ActiveCN101736719AIncreasing the thicknessIncreased durabilityMarine site engineeringWater dischargeSlurry

The invention relates to a construction method for dam body seepage preventing curtain grouting and provides a construction method for the dam body seepage preventing curtain grouting. The grouting is carried out by a technology of dense holes, high pressure, fine cement wet grinding and concentrated slurry, and the seepage preventing ability, the corrosion resistance and the durability of a dam body curtain are improved; the seepage is prevented in a way of front blockage and rear discharge, the downstream seepage escapement point elevation of a dam body and the uplifting pressure in a dam are reduced, and the problems of frozen thawing and frozen expansion of concrete are solved. The construction method for the dam body seepage preventing curtain grouting comprises the following steps of: a. downwards drilling a group of curtain grouting holes at the top of the dam; b. drilling radial grouting holes on the upstream surface in a basic gallery; c. downwards drilling curtain connection grouting holes extending into a dam foundation in the basic gallery; d. carrying out grouting by high pressure, fine cement wet grinding and concentrated slurry; and e. drilling a water discharge structure which is communicated with the basic gallery in the dam body. The invention is mainly used for the seepage prevention and discharge reinforcement processing of the concrete dam.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Composite nano silicon dioxide/quartz stone plate product and preparation method thereof

InactiveCN102531468ALarge specific surface areaA high proportion of surface atomsPolyester resinAccelerant

The invention discloses a composite nano silicon dioxide / quartz stone plate product and a preparation method thereof. The composite nano silicon dioxide / quartz stone plate product is prepared from the following components and raw materials in parts by weight: quartz stone sand, pigment, a silane coupling agent, nano silicon dioxide, unsaturated polyester resin, a curing agent and a certain amountof accelerant by the steps of mixing, adding to a mold, carrying out vibration compaction, curing, determining thickness, grinding and polishing and carrying out other working procedures. The invention also discloses a preparation process of the composite nano silicon dioxide / quartz stone plate product. According to the invention, the prepared composite nano silicon dioxide / quartz stone plate is a composite quartz stone plate product which is a large network structure formed by tight embedding and chemical bond cross-linking of all the components; and the prepared composite quartz stone plateproduct has the advantages of high silicon dioxide content, high strength and hardness, ultraviolet aging and thermal aging resistance, high fire retardancy and high heat insulating property, compactand glabrous surface and durability. The use range of the quartz stone plate is enlarged.

Owner:吉林吉瑞莱板材科技有限公司

Foaming agent used in ultra-low density anti-seepage foamed concrete, and preparation method thereof

The invention relates to a foaming agent used in ultra-low density anti-seepage foamed concrete, and a preparation method thereof. The foaming agent comprises components of, by mass: 8 to 18 parts of sodium polyoxyethylene fatty alcohol sulfate, 0.1 to 7 parts of sodium dodecylsulfate, 0.5 to 7 parts of sodium dodecylbenzene sulfonate, 4 to 15 parts of pure acrylic emulsion or styrene-acrylate emulsion, 3 to 6 parts of fatty alcohol polyoxyethylene ether, 0.5 to 2 parts of hydroxyethyl cellulose or hydroxy propyl methylcellulose, 0.1 to 5 parts of modified silicon resin or modified nano-gradebentonite, 0.1 to 0.5 parts of a thickener, and balance of water. The anti-seepage foamed concrete foaming agent provided by the invention has stable property, high foaming multiple, and good workability with a substrate. The agent can be used in a foamed concrete product with a density of 100 to 600kg / m<3>. The raw materials are easy to obtain, and the cost is low. The foaming agent can be stored for a long term with out deteriorating. With the agent, foamed concrete properties such as strength and softening coefficient can be improved.

Owner:梁材

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190AStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberAdhesive

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

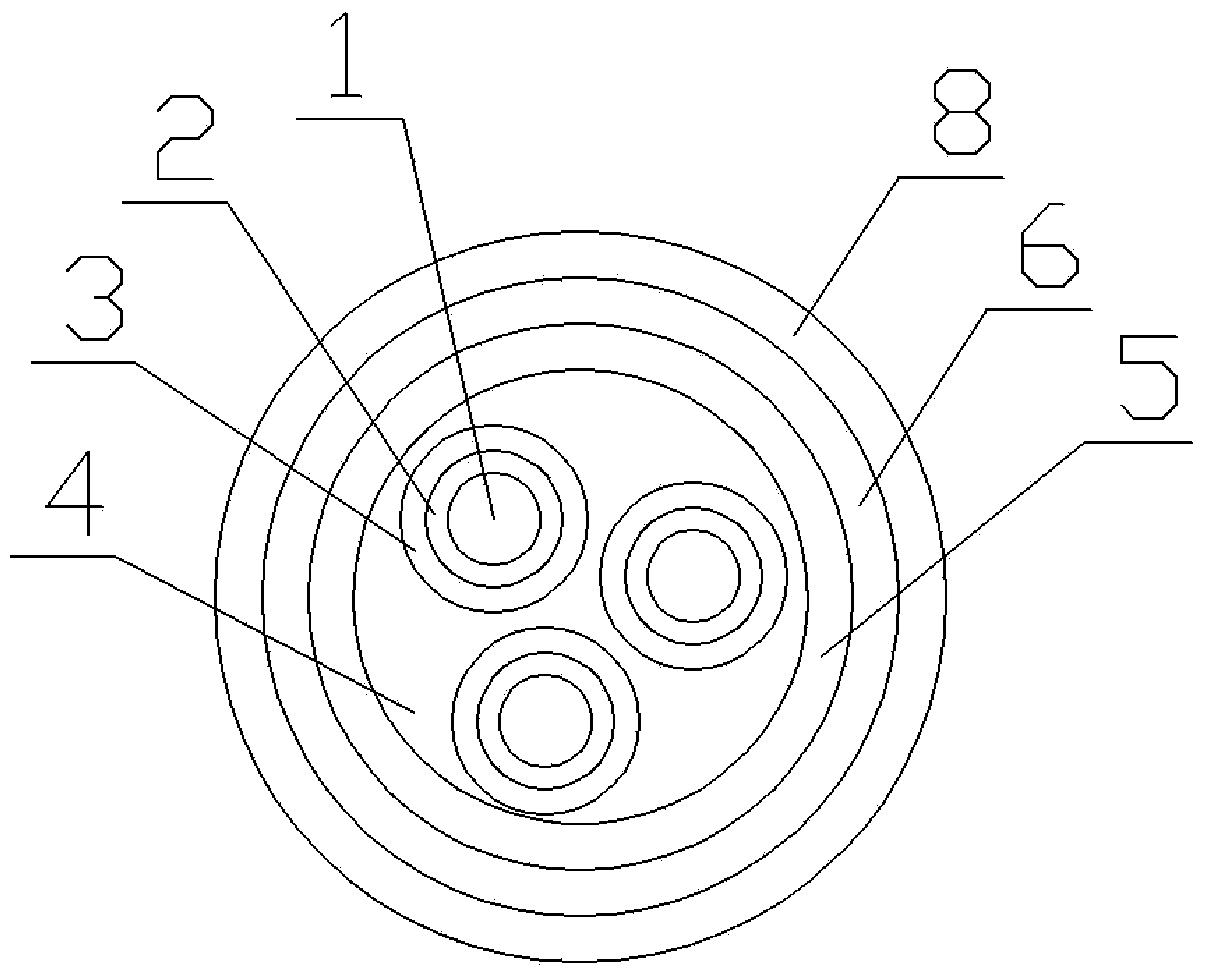

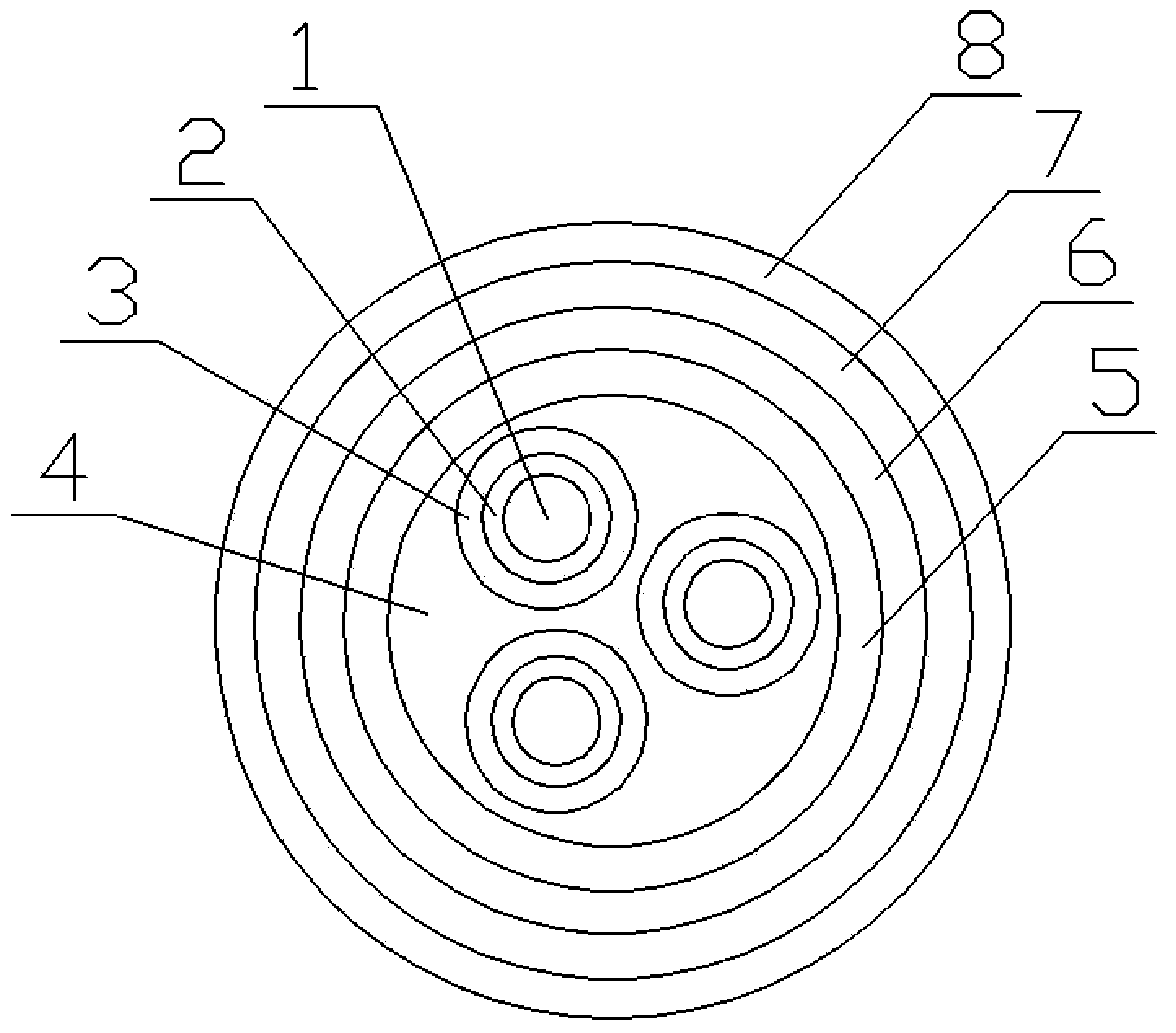

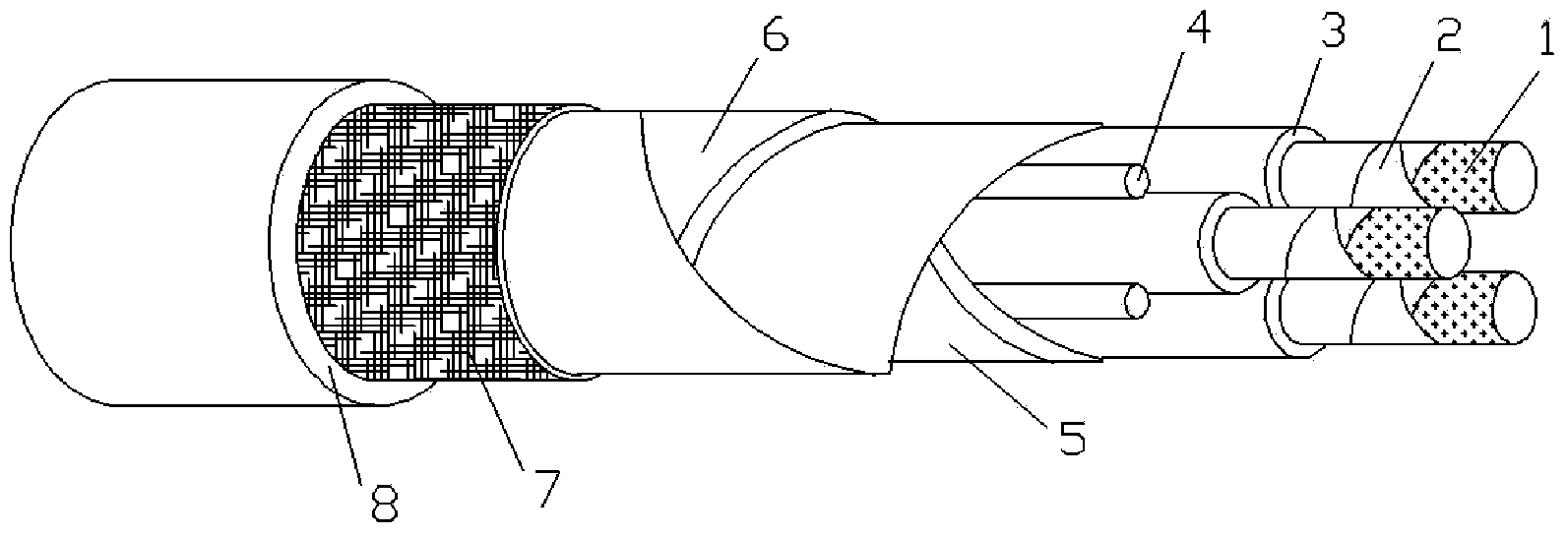

Flexible fireproof cable

ActiveCN104299691APrevent crushingHigh strengthNon-insulated conductorsFlexible cablesGlass fiberElectrical conductor

The invention provides a flexible fireproof cable. The flexible fireproof cable comprises cable cores, a thermal-collapse-resistant filling layer, a waterproof layer, an outer blocking layer and a sheath layer, wherein each cable core comprises a conductor, an inner blocking layer and an insulating layer from interior to exterior, at least one cable core is wrapped with the waterproof layer, the filling layer is arranged between the waterproof layer and the cable cores, the filling layer is formed by weaving ceramic silicon sealing strips and glass fiber in a winding mode, and the waterproof layer is wrapped with the outer blocking layer and the sheath layer in sequence. According to the flexible fireproof cable, on the premise that a high fireproof level is achieved, traditional technologies such as the wrapping technology and the cabling technology are adopted for all the important structures such as the inner blocking layers, the outer blocking layer and the thermal-collapse-resistant filling layer, and the problems that an existing fireproof cable is high in price, complicated in technology, large in manufacturing difficulty because special devices are needed, not convenient to construct because a metal sheath is hard and low in fireproof performance are effectively solved.

Owner:JINAN SHENGTONG POWER CABLE

Earth-rock dam deep-base seepage-control water-stopping structure for water conservancy and hydropower project

ActiveCN101200885APrevent leakageImprove impermeability and durabilityMarine site engineeringEmbankment damWater seepage

The present invention discloses an anti-seepage sealing structure of the deep foundation of the earth-rockfill dam of a water conservancy and hydropower project, which can effectively prevent the seepage of the dam. The anti-seepage sealing structure of the deep foundation of the earth-rockfill dam of the water conservancy and hydropower project includes the anti-seepage layer of the dam body which is stretched from the top of the dam body to the bottom of the dam body, and the anti-seepage layer of a dam base, which is jointed with the anti-seepage layer of the dam body, is arranged in the dam base of the bottom of the dam body. By arranging the anti-seepage layer of the dam base in the dam base, the anti-seepage sealing structure can effectively prevent water seepage in the dam, thus increasing the anti-seepage property and durability of the whole dam and the foundation. Moreover, according to the different distributions of permeable layers from strong to weak in the dam base, the anti-seepage layers are arranged accordingly, thus improving the rationality of the anti-seepage structure, and particularly, the present invention is suitably applied on water conservancy and hydropower dams.

Owner:POWERCHINA CHENGDU ENG

Water-based reinforced type fog sealing layer material for asphalt pavement, and preparation method and construction method of water-based reinforced type fog sealing layer material for asphalt pavement

InactiveCN104164818AImprove permeabilityLow costIn situ pavingsPaving gutters/kerbsWater basedOrganic solvent

The invention relates to the technical field of highway maintenance, and discloses a water-based reinforced type fog sealing layer material for an asphalt pavement, and a preparation method and a construction method of the water-based reinforced type fog sealing layer material for the asphalt pavement. The fog sealing layer material comprises a lower water-penetration-preventing sub-layer and an upper anti-skidding wear-resisting sub-layer, wherein materials for preparing the lower sub-layer contain an emulsifier, water, an organic solvent, a dispersant, an additive, a penetrating agent, a viscosifier and asphalt, and materials for preparing the upper sub-layer contain an emulsifier, water, an organic solvent, a dispersant, an additive, a penetrating agent, a viscosifier, an ultraviolet-resistant aging agent and asphalt. The construction method of the fog sealing layer material is a layered spreading method and comprises the following steps: mixing mixed liquor of the materials for preparing the lower sub-layer with a sand material to obtain a mixture, spreading the mixture on the asphalt pavement to form the lower water-penetration-preventing sub-layer, drying, spraying mixed liquor of materials for preparing the upper sub-layer on the lower water-penetration-preventing sub-layer, and spreading the sand material to form the upper anti-skidding wear-resisting sub-layer. The water-based reinforced type fog sealing layer material for the asphalt pavement, the preparation method and the construction method d of the water-based reinforced type fog sealing layer material for the asphalt pavement, disclosed by the invention, are used for pavement preventive maintenance, can improve the waterproof performance, anti-skidding performance, firmness and ultraviolet resistant aging performance, and are environmentally-friendly and economical.

Owner:CHANGAN UNIV

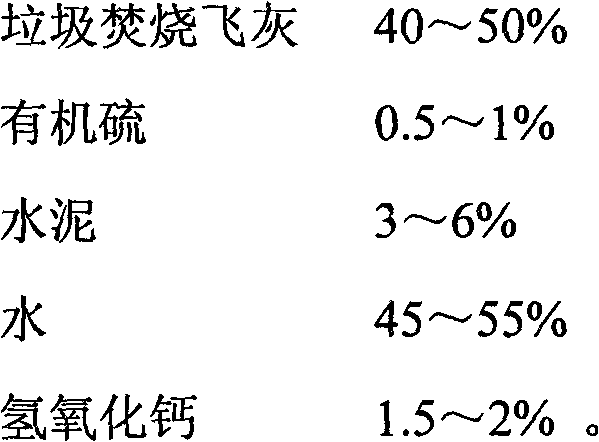

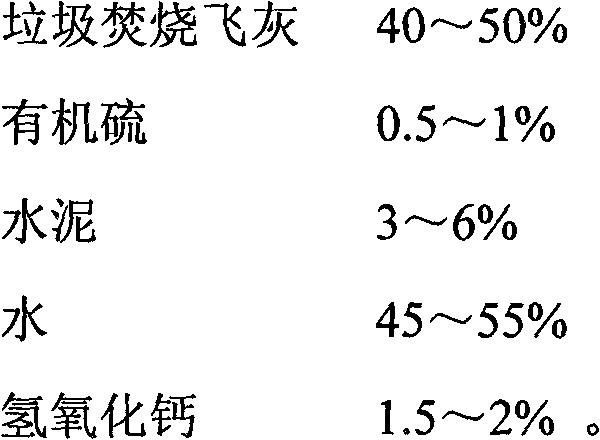

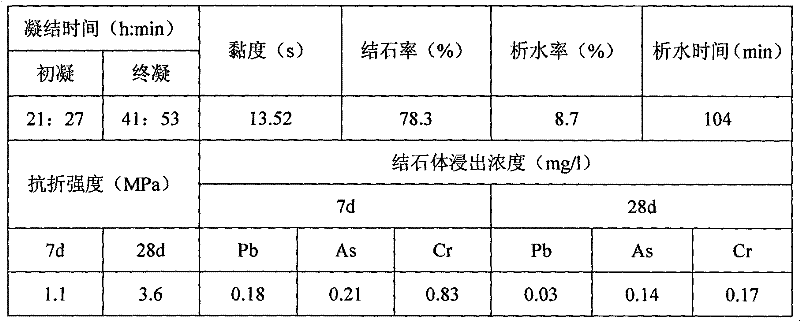

Grouting material for impervious curtain of refuse landfill and preparation method of grouting material

The invention relates to a grouting material for an impervious curtain of a refuse landfill and a preparation method of the grouting material. The grouting material comprises the following components in percentage by mass: 40 to 50 percent of MSWI (Municipal Solid Waste Incineration) fly ash, 0.5 to 1 percent of organic sulfur, 3 to 6 percent of cement, 45 to 55 percent of water, and 1.5 to 2 percent of calcium hydroxide. The method for preparing the grouting material comprises the following steps of: (1) weighing raw materials; (2) mixing the MSWI fly ash, the water and the organic sulfur, and uniformly stirring for 5 to 10 minutes; and (3) interfusing the cement and the calcium hydroxide, and uniformly stirring for 3 to 5 minutes. According to the grouting material, the problems of material selection difficulty, high cost, poor fluidity, low stability and poor impermeability of a conventional grouting material can be solved. The preparation method has the advantages of short processroute, simple operation, time saving and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

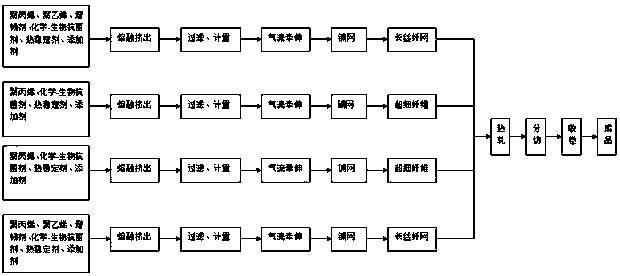

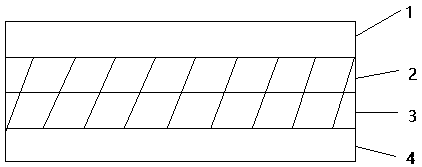

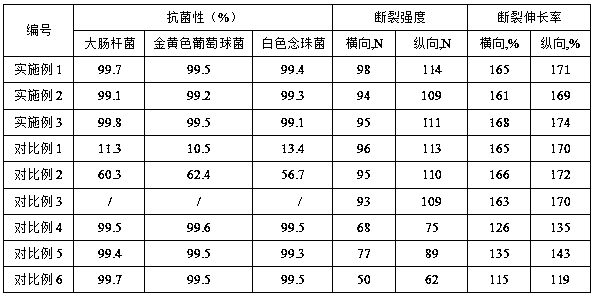

Antibacterial and bacteria-isolation SMMS composite non-woven fabric

InactiveCN110774693AWith strengthImprove tear resistanceFlame-proof filament manufactureSynthetic resin layered productsPolyhexamethylene guanidinePhysical chemistry

The invention relates to an antibacterial and bacteria-isolation SMMS composite non-woven fabric. The SMMS composite nonwoven fabric is formed by compounding a first spunbond non-woven fabric layer, afirst meltblown layer, a second meltblown layer, and a second spunbond non-woven fabric layer, wherein the first spunbond non-woven fabric layer and the second spunbond non-woven fabric layer are respectively an upper surface layer and a lower surface layer, the first meltblown layer and the second meltblown layer are intermediate layers, the spunbond non-woven fabric layers and the meltblown layers are all obtained by using polypropylene as a raw material and adding an antibacterial agent for processing, and the antibacterial agent is a chemical and biological compound antibacterial agent ofpolyhexamethyleneguanidine and gamma-polyglutamic acid. The SMMS composite non-woven fabric has the antibacterial and bacteria-isolation functions, the use of the spunbond non-woven fabric layers asthe upper and lower surfaces can ensure that the non-woven fabric has certain strength, good tear resistance, and good wear resistance, the intermediate layers adopt double-layer meltblown, permeability resistance is ensured while the air-permeability and bacteria-isolation performance are good, the resistance to bacteria is not produced, and the use is safe and reliable.

Owner:江阴金凤特种纺织品有限公司

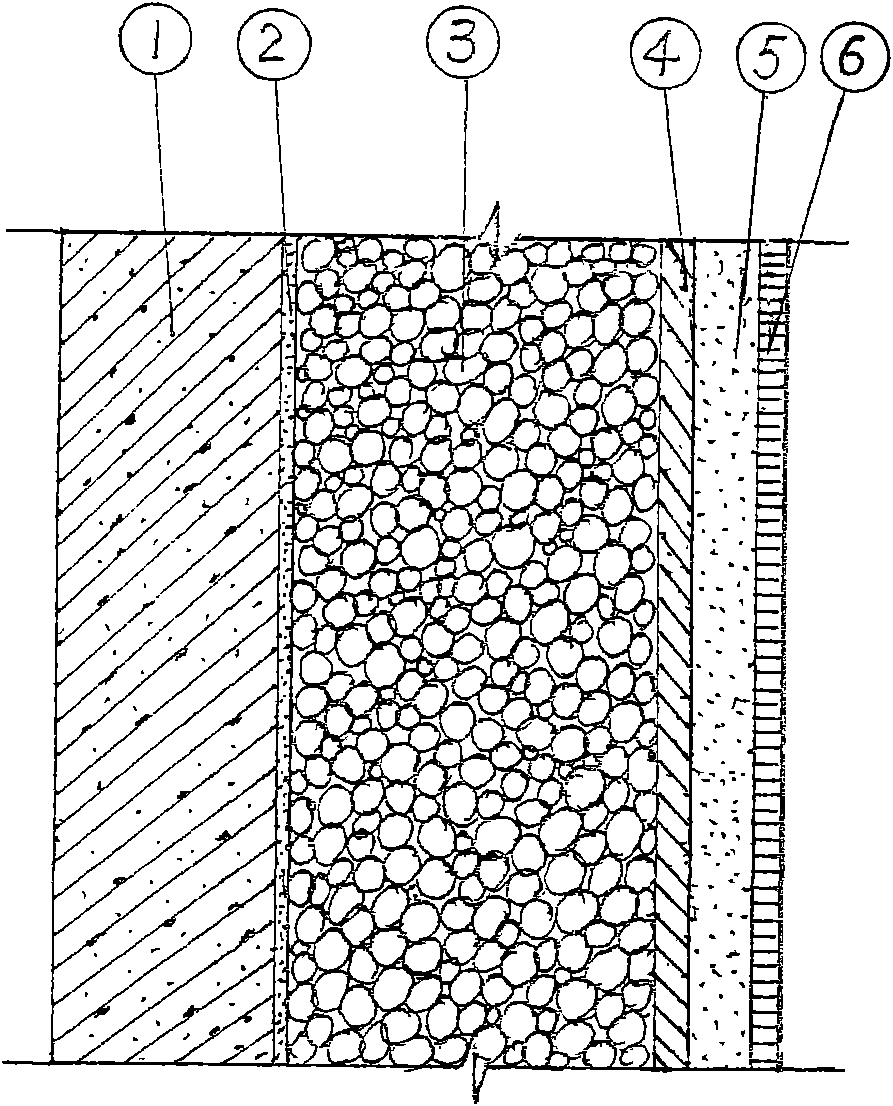

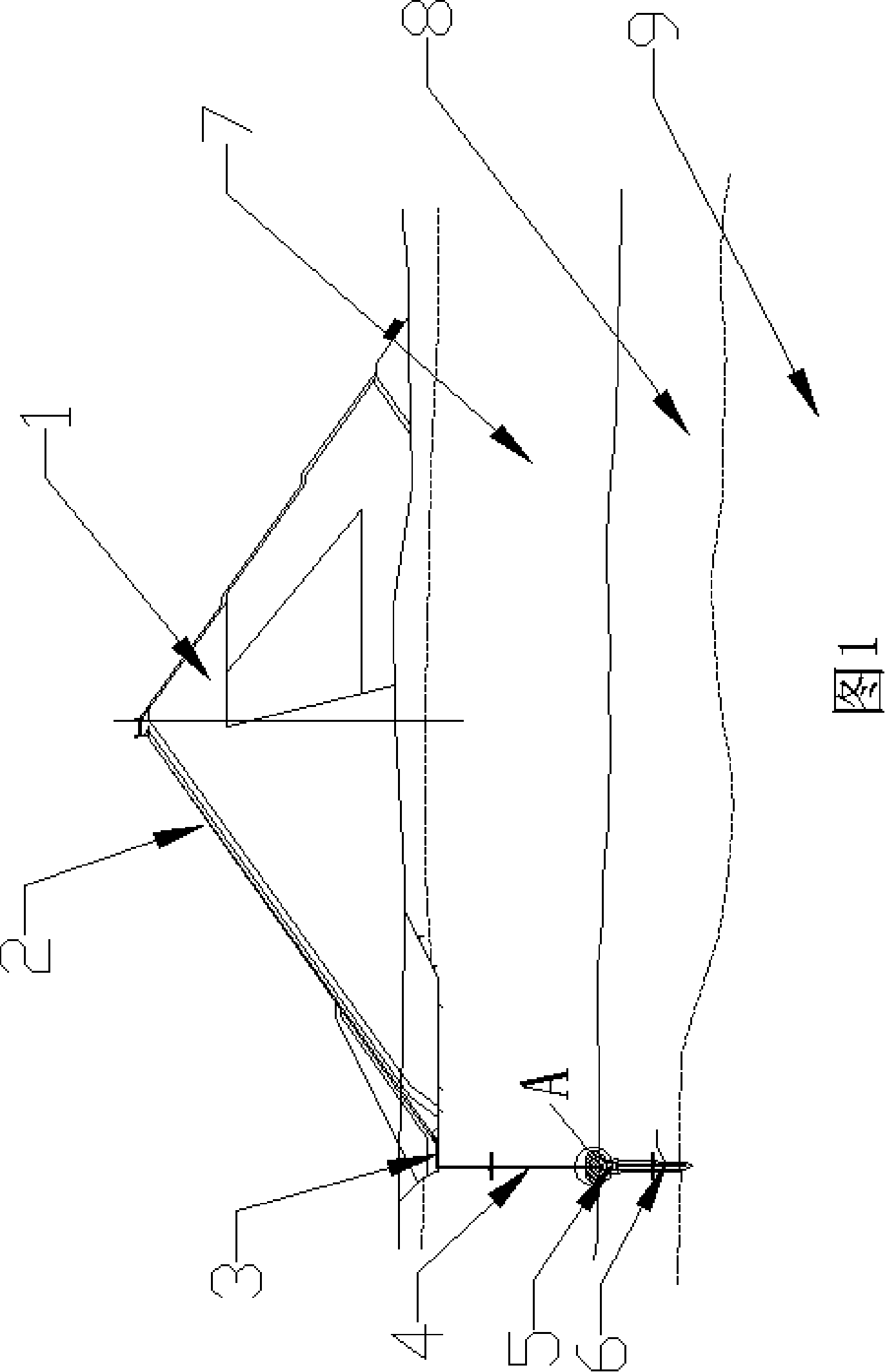

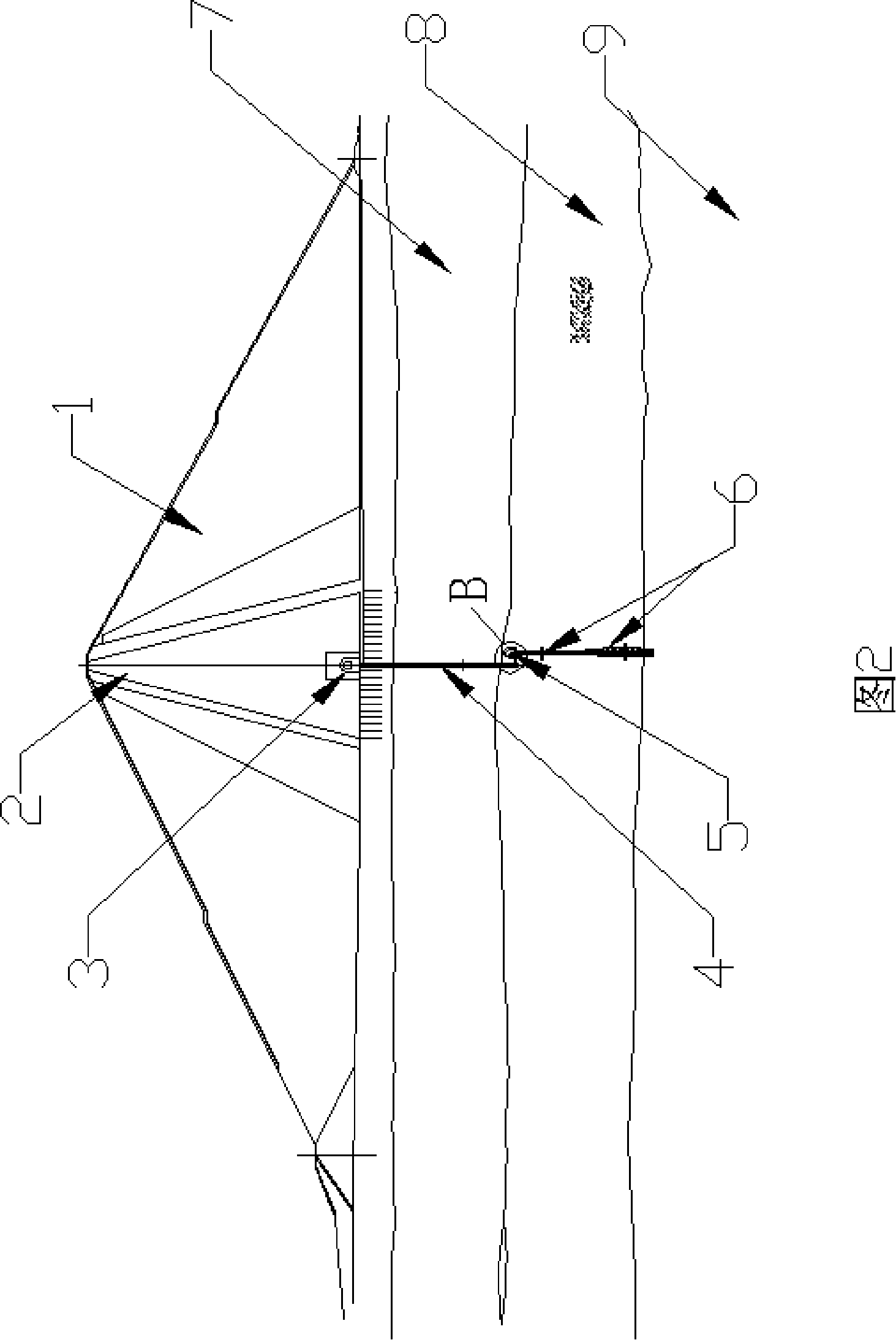

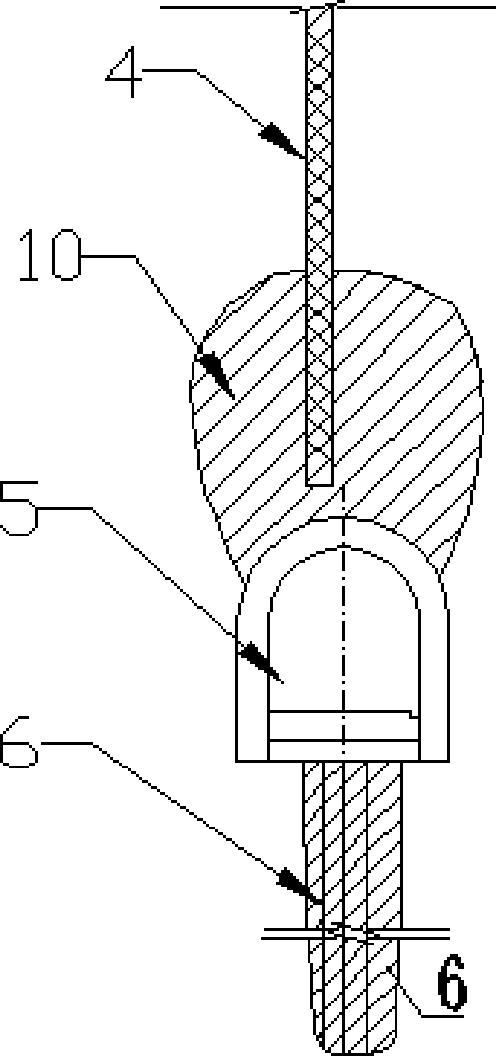

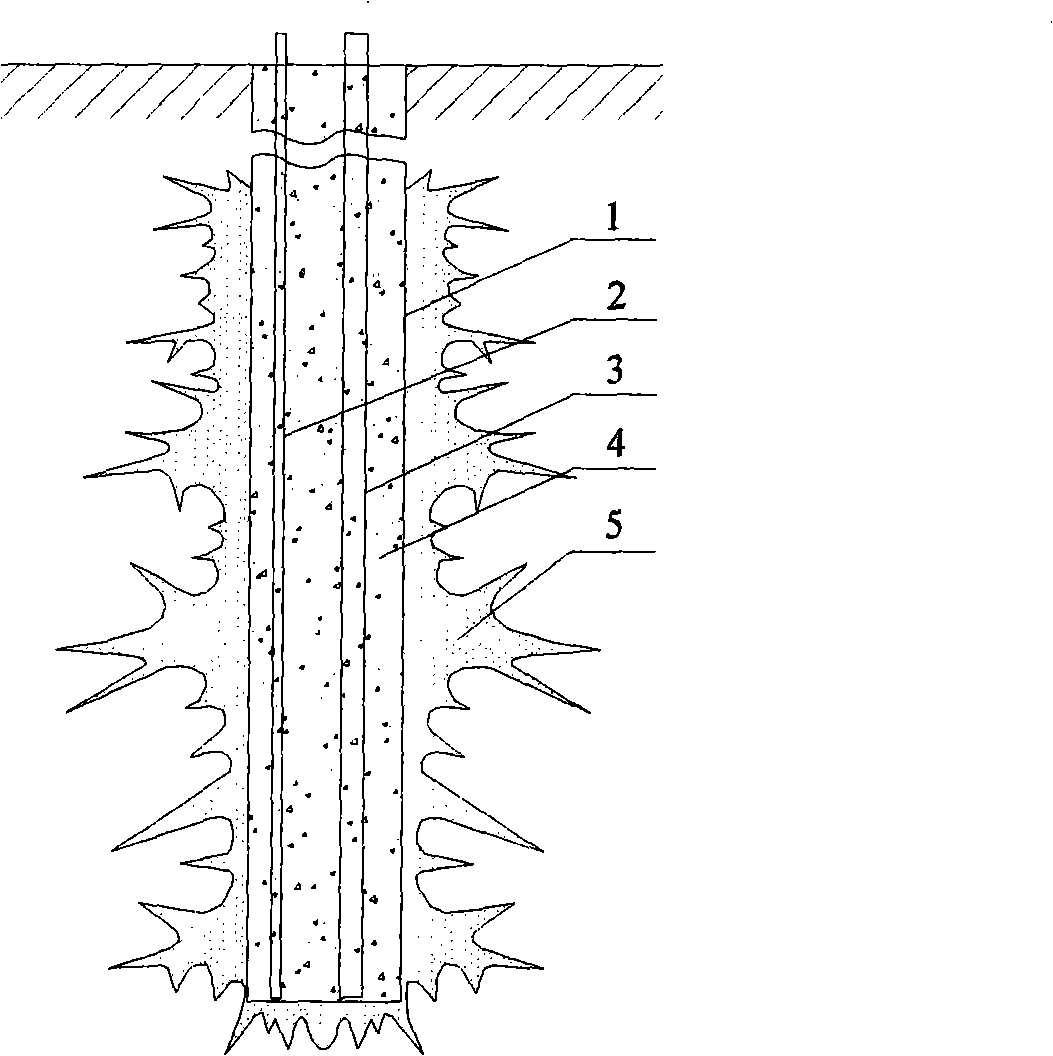

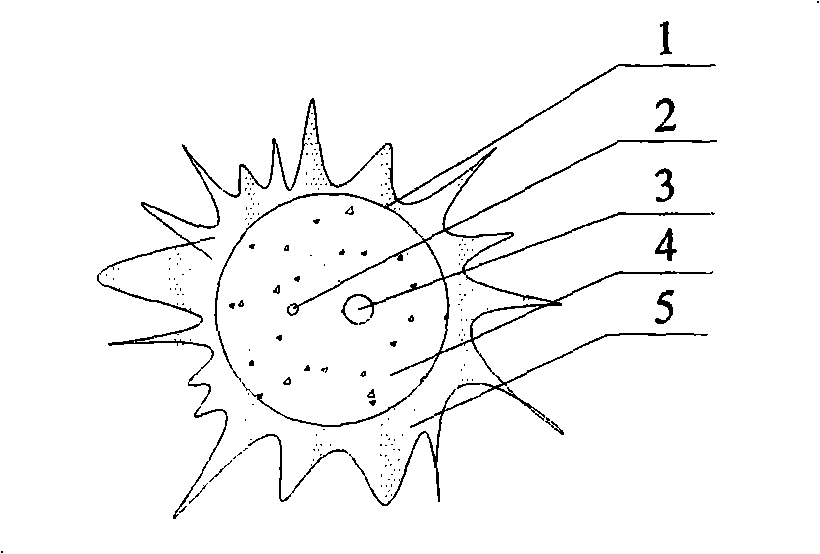

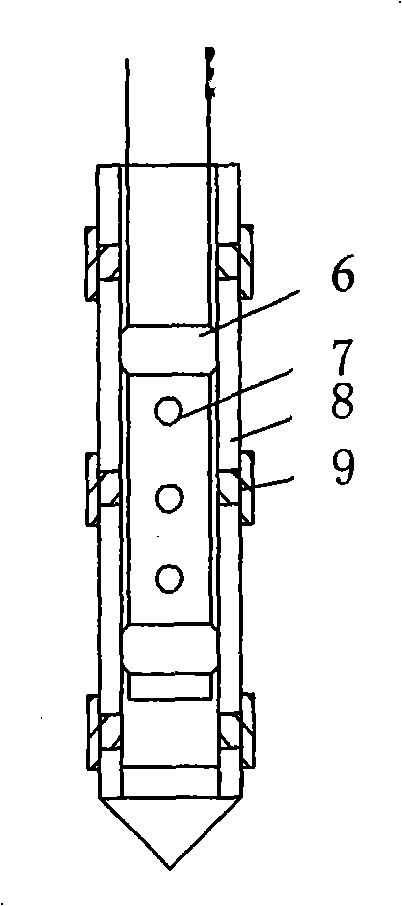

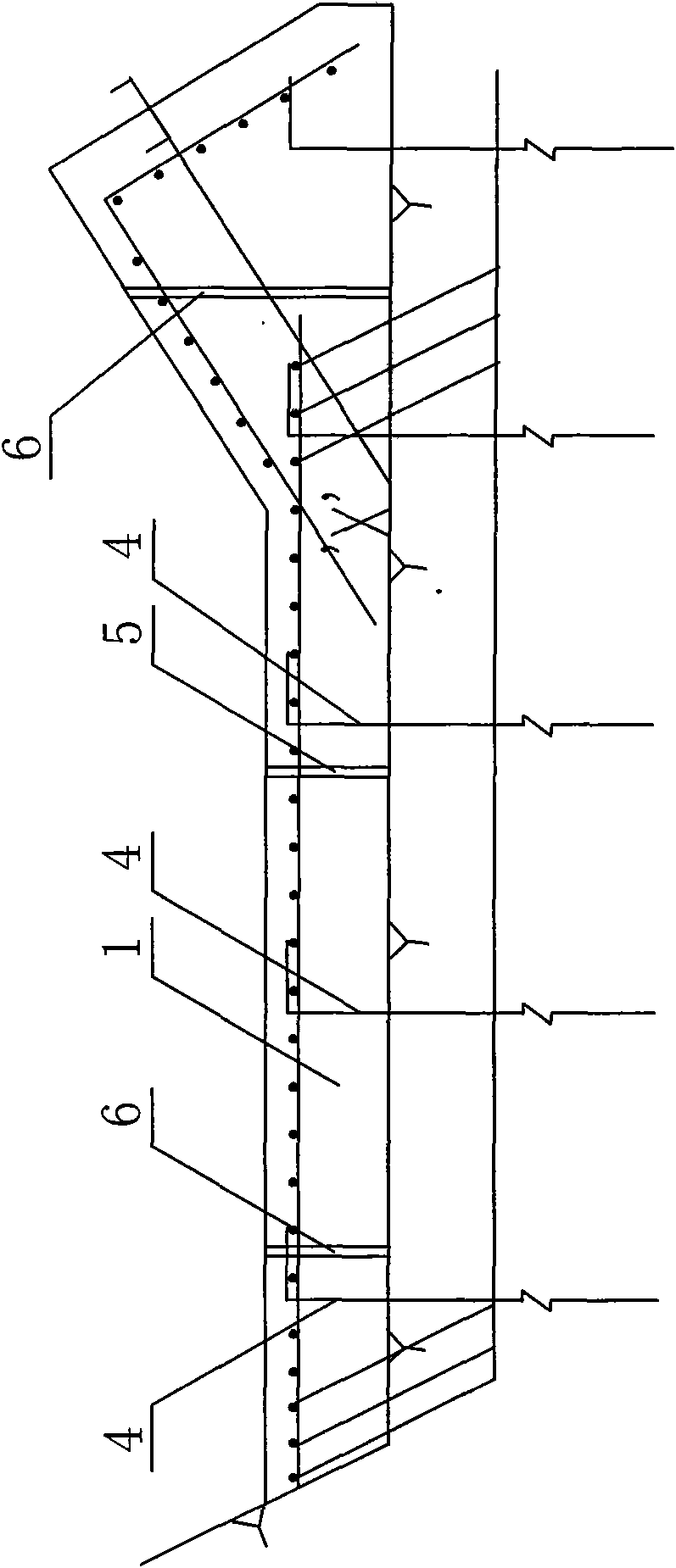

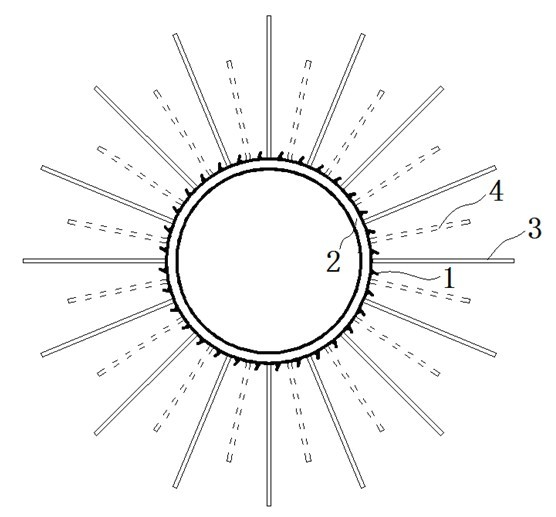

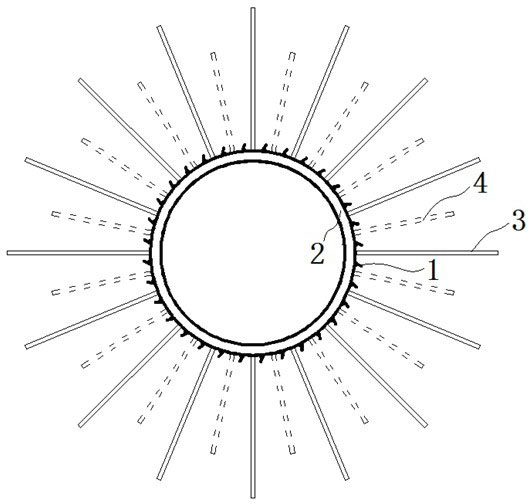

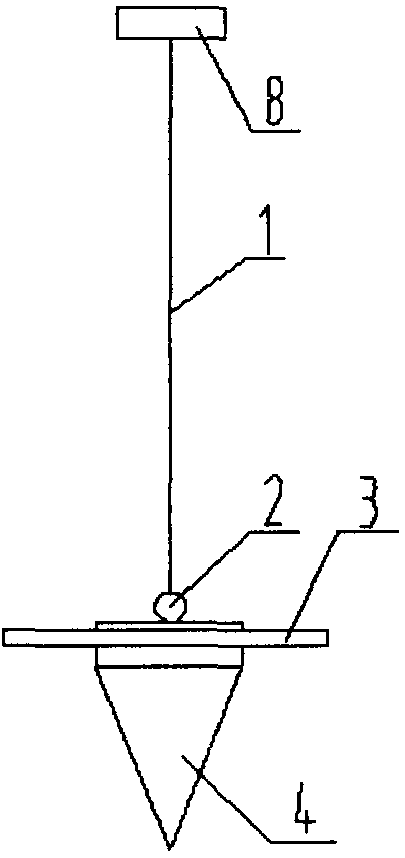

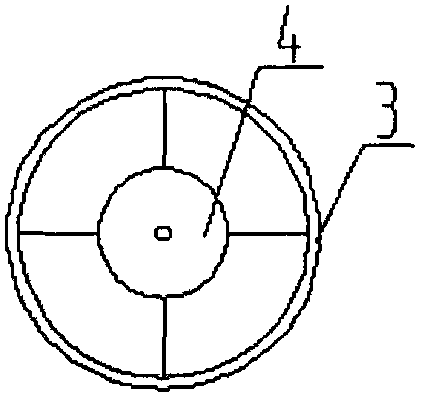

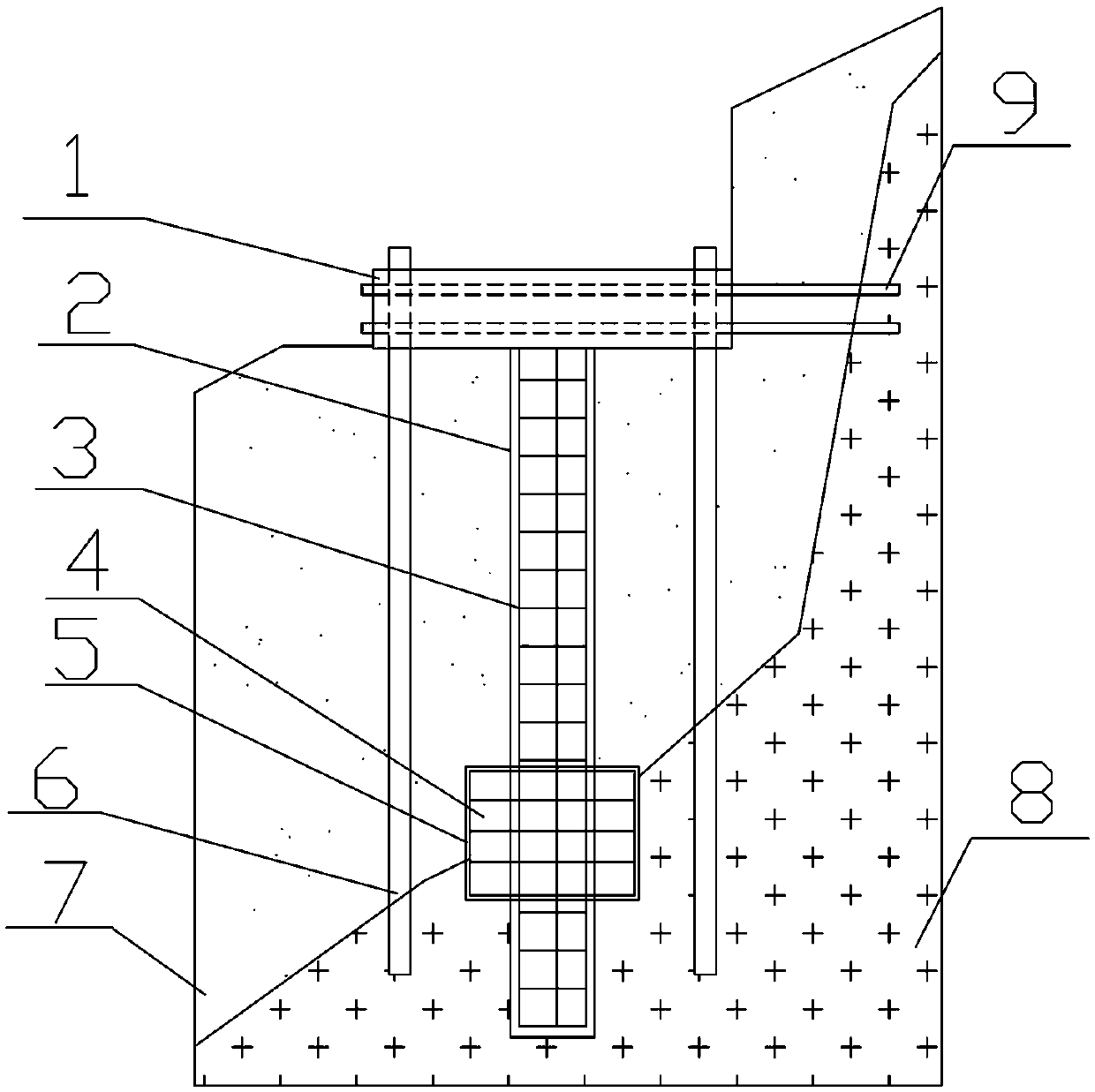

Pressure casting non-sand concrete pile

InactiveCN101294385AGuarantee flood control abilityImprove anti-seepage performanceBulkheads/pilesSleeve valvePressure casting

A pressure grouting non-fines concrete pile belongs to the construction engineering field, and is particularly applicable to strengthening river levees and reinforcing road-widening lap joints. The pressure grouting non-fines concrete pile comprises a borehole (1), a grouting pipe (2), a sleeve valve pipe (3), graded gravels or crushed stones (4) and a grouting body (5), wherein, the sleeve valve pipe (3) is composed of a sleeve valve pipe grout stop piston (6), a sleeve valve pipe grout injecting hole (7), a sleeve valve pipe screen tube (8) and a rubber bush (9). During the implementation process, a boring machine is firstly utilized to form the borehole (1) until the design depth of the non-fines concrete pile is reached, the grouting pipe (2) and the sleeve valve pipe (3) with the length of the both equal to the depth of the borehole (1) are inserted, then the graded gravels or the crushed stones (4) are filled in, and finally the grouting pipe (2) is utilized to carry out first grouting, the amount of which is equal to the grout output of the borehole (1); after the grout is initially condensed, the sleeve valve pipe (3) is utilized for carrying out secondary middle-high pressure grouting, the pressure of which is 1 to 5 MPa, and the grouting flow rate is 10 to 60 L / min. The pressure grouting non-fines concrete pile has the advantages that the design is reasonable, the construction is simple, the bearing capacity is high, and the anti-seepage capacity of the reinforced section is improved.

Owner:UNIV OF SCI & TECH BEIJING

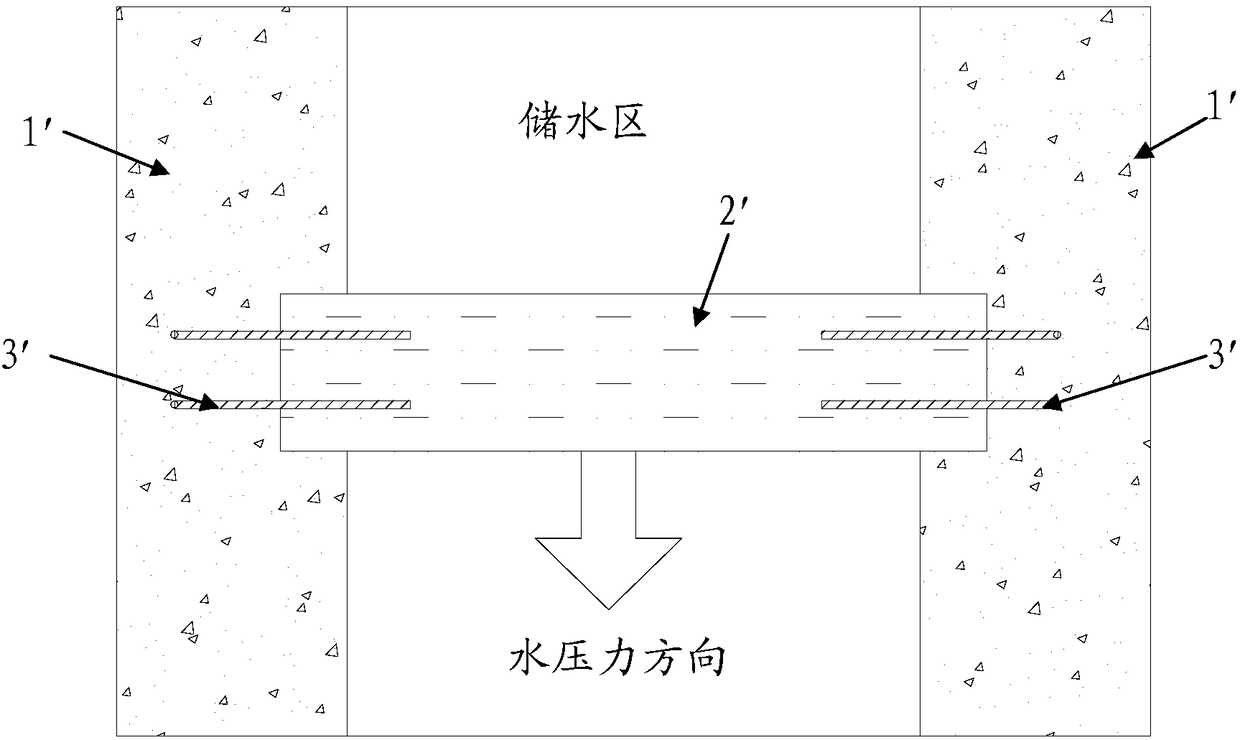

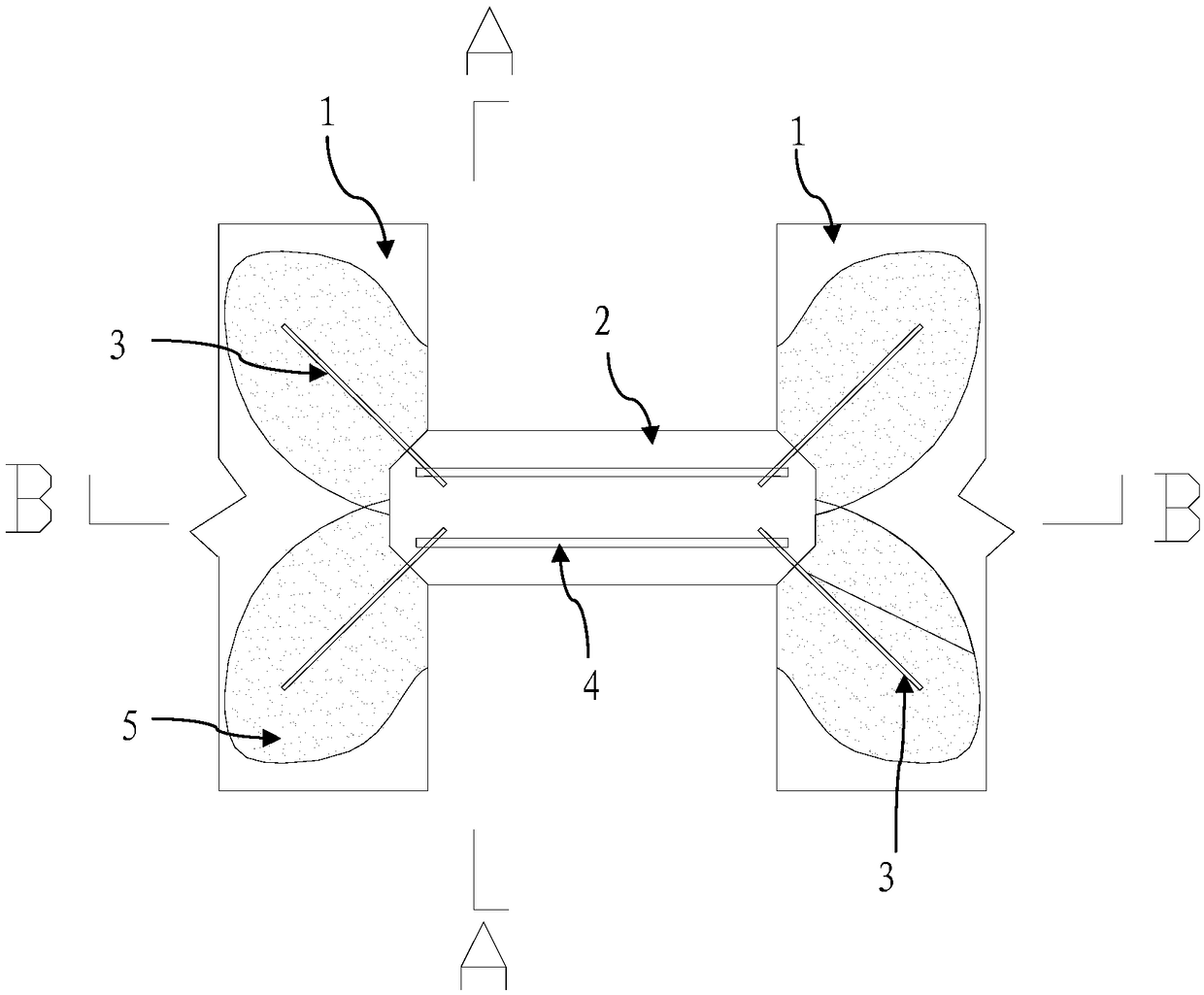

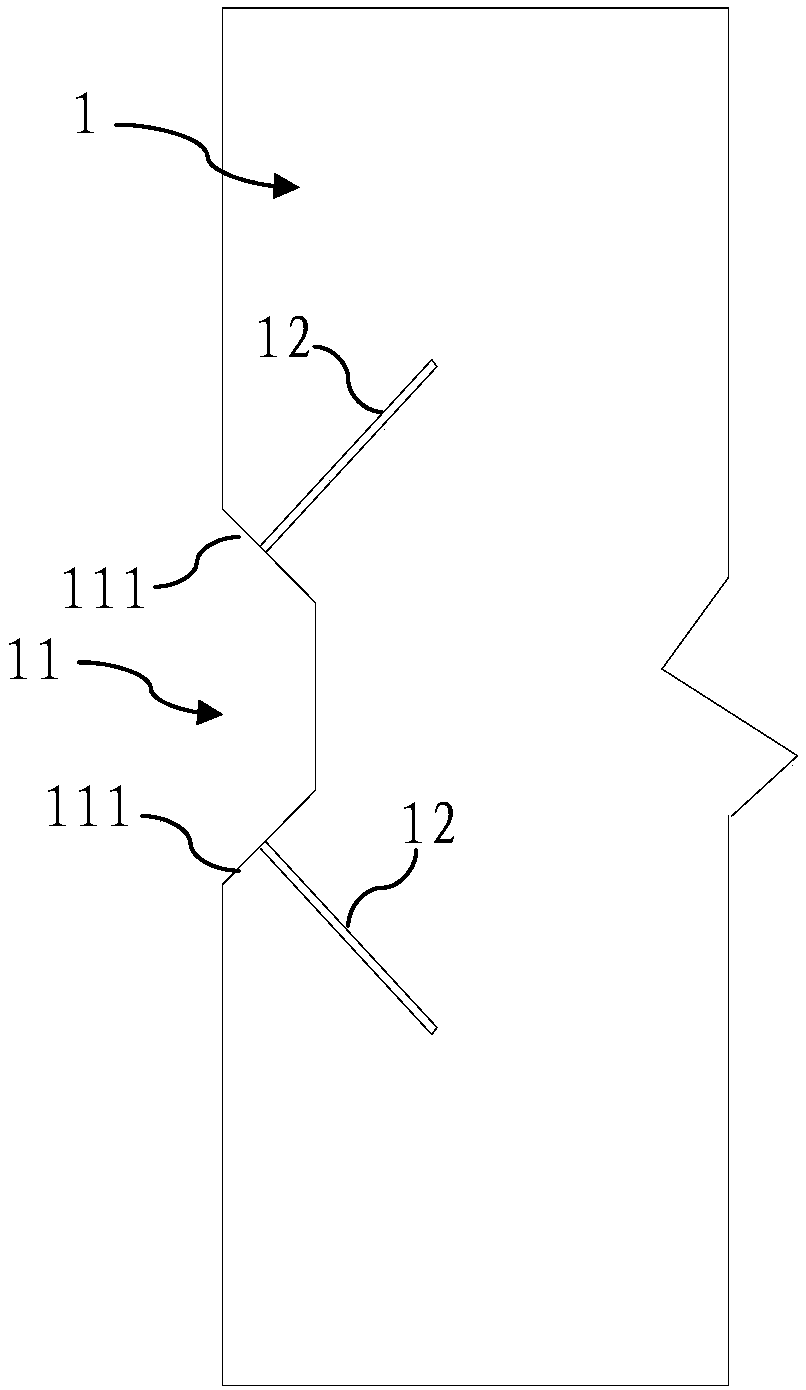

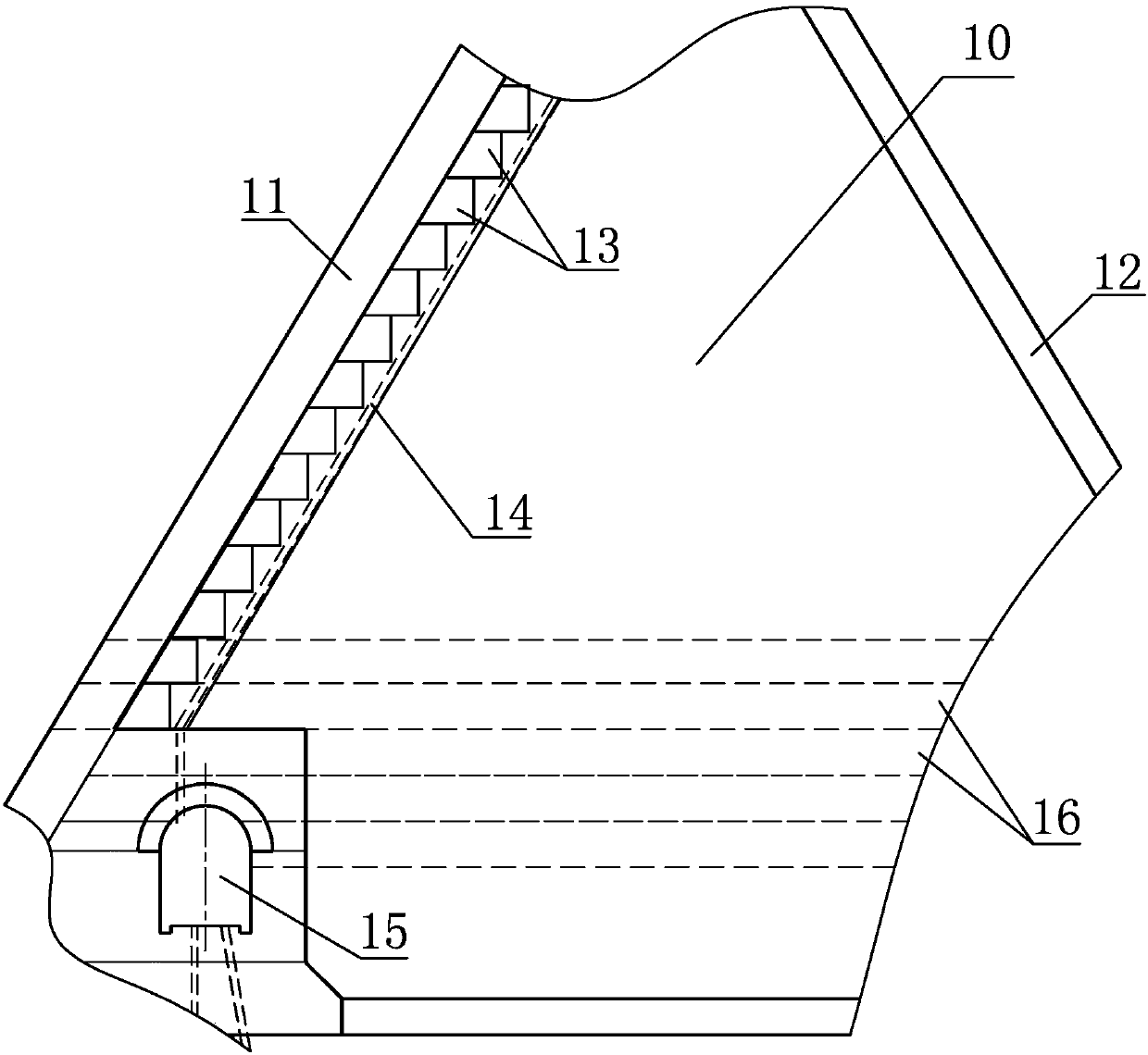

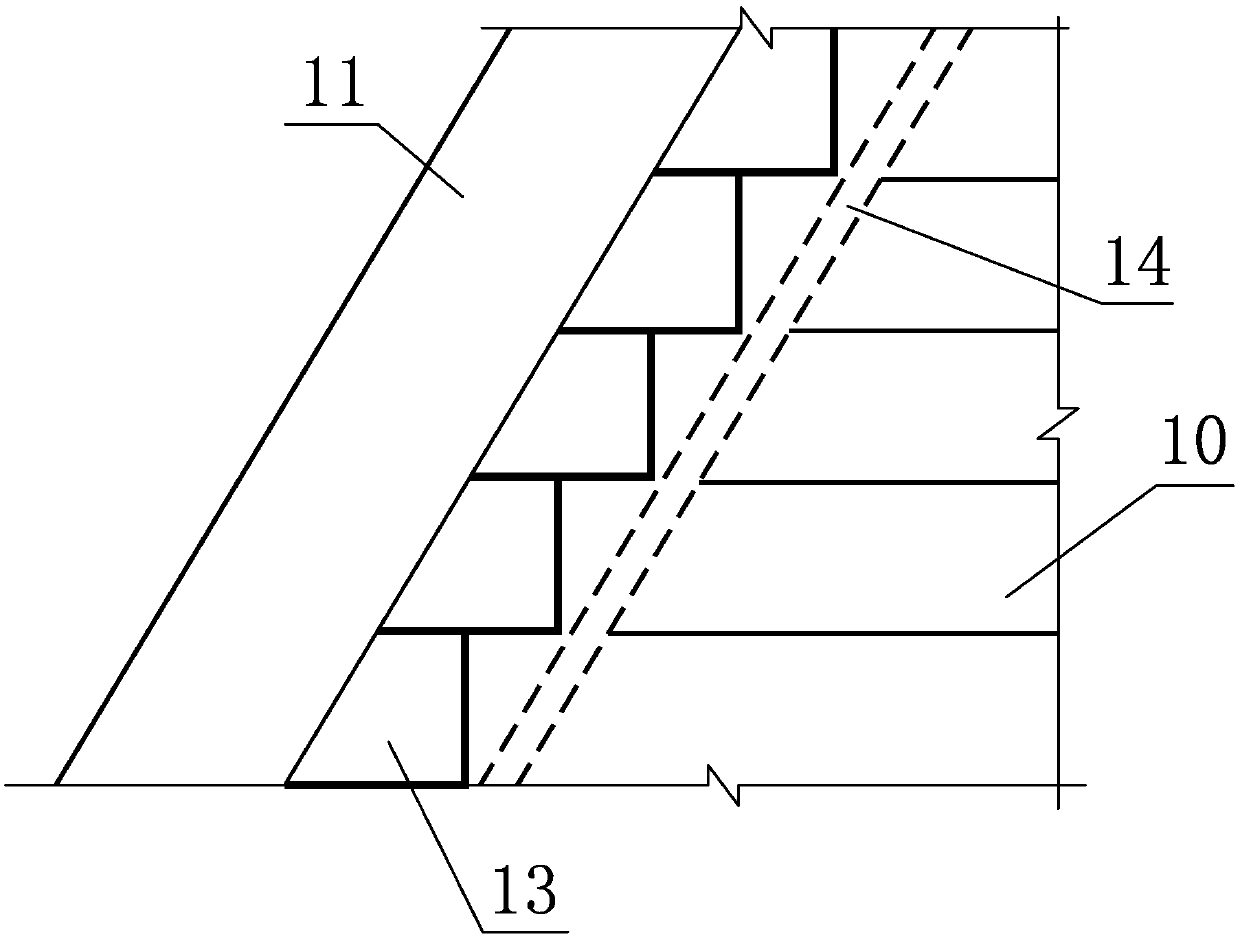

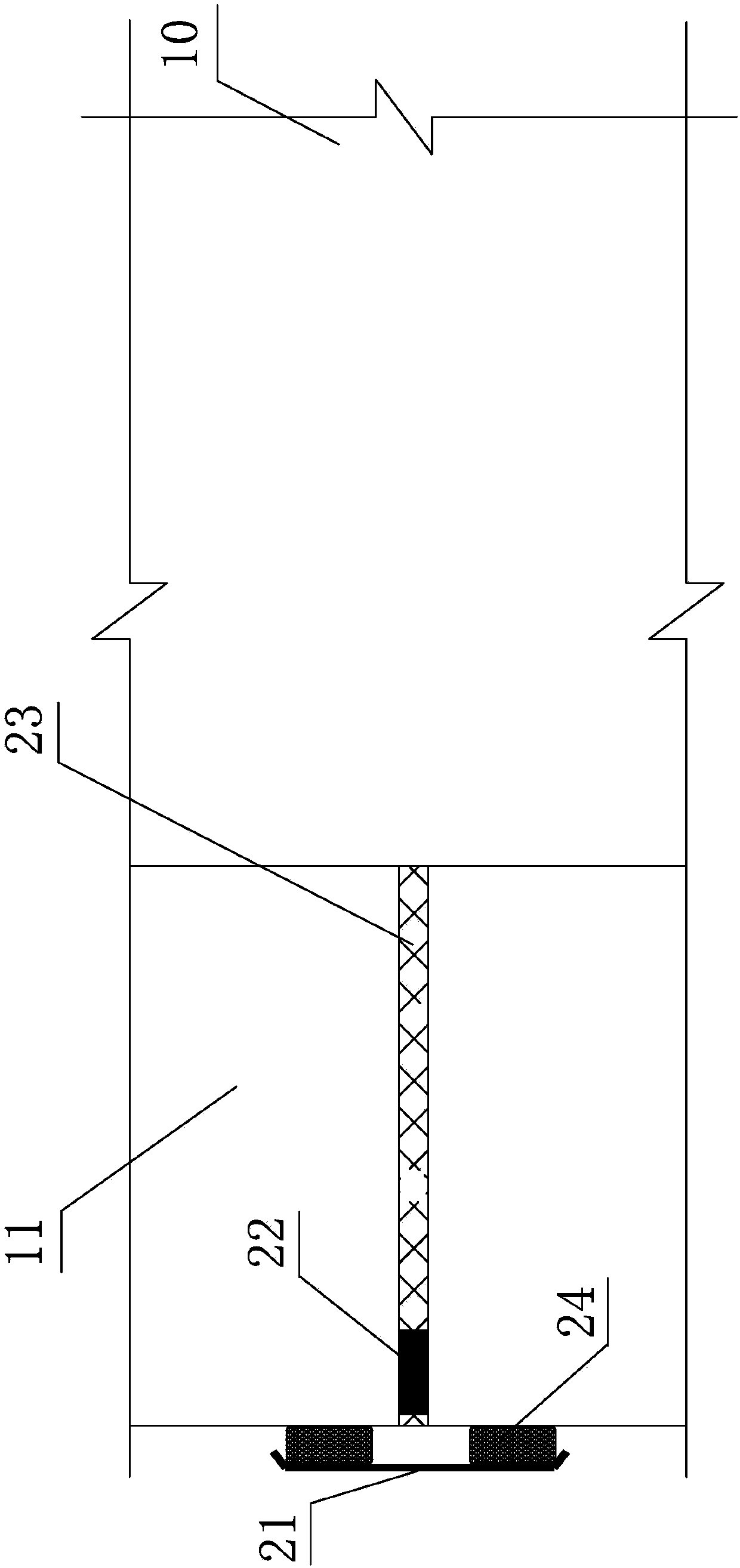

Underground reservoir artificial dam body and coal pillar dam body connecting structure and construction technology thereof

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Antimicrobial radiation-preventing formaldehyde-degrading ecological diatom wall material

The invention discloses a wall material belonging to the field of building decoration, and specifically relates to antimicrobial radiation-preventing formaldehyde-degrading ecological diatom wall material paint and a preparation process and construction process of the wall material. The wall material is prepared from the following components in percentage by weight: 21-29% of kieselguhr, 15-20% of quartz sand, 0.1% of fiber, 7-8.6% of bentonite, 3-5% of attapulgite, 12-17% of sierozem, 6-8% of water-retaining agent, 8-12% of nano titanium dioxide, 3-6.1% of nano zinc oxide, 3-5% of zeolite, 3-5% of micro silicon powder, 3-5% of grammite and 3-7% of anion powder. The wall material disclosed by the invention has the effects of adsorbing toxic and harmful gas, resisting bacteria, preventing radiation and degrading formaldehyde, and diatom ooze enables the product to have the powerful characteristics of breathing, conditioning and purifying air; and the wall material has the functions of fire resistance, flame retardance, sound insulation, noise reduction, warm keeping and heat insulation. Thus, the wall material is an ideal wall decoration material combining an environmental protection function and artistic modeling.

Owner:广东太氧谷环保科技有限公司

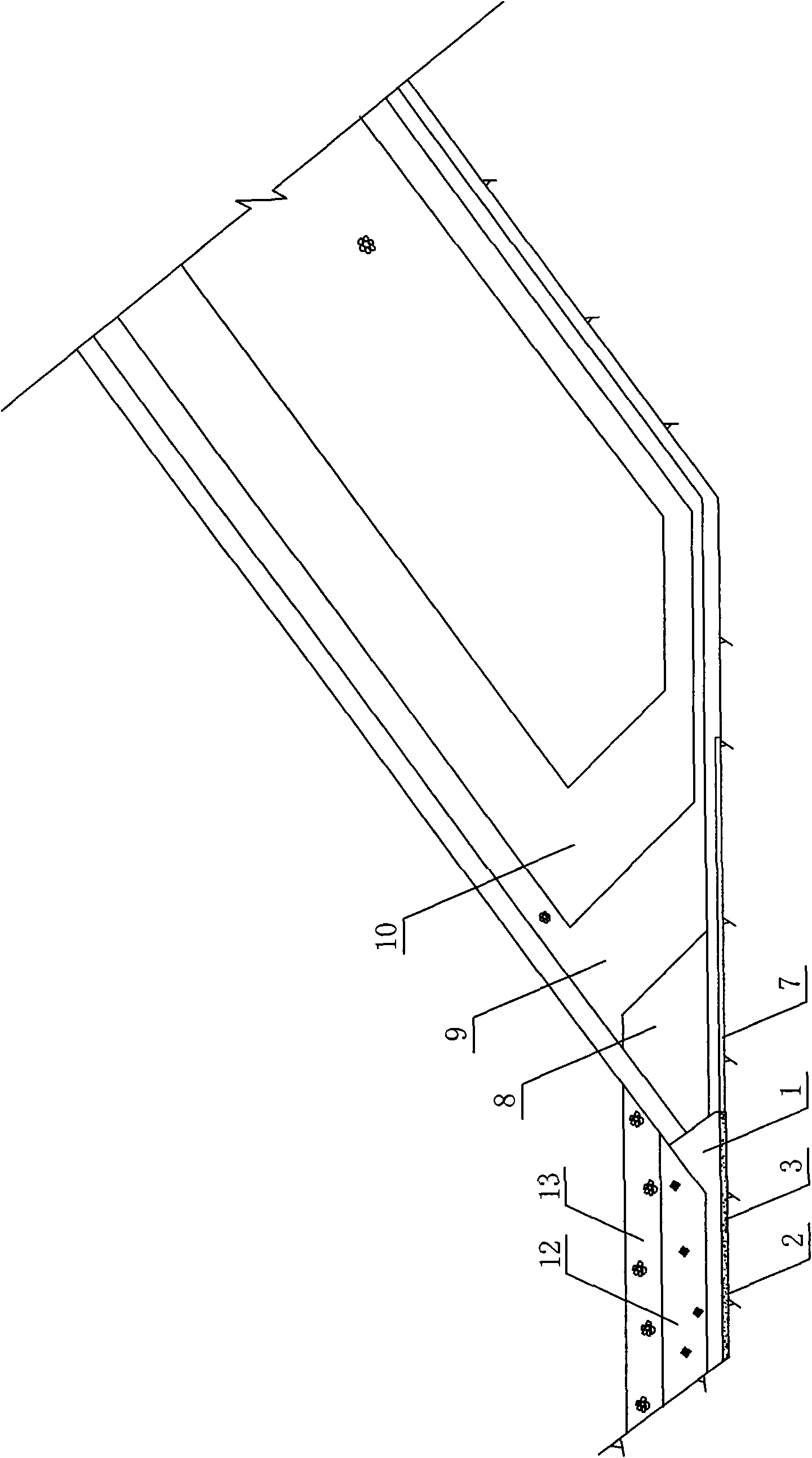

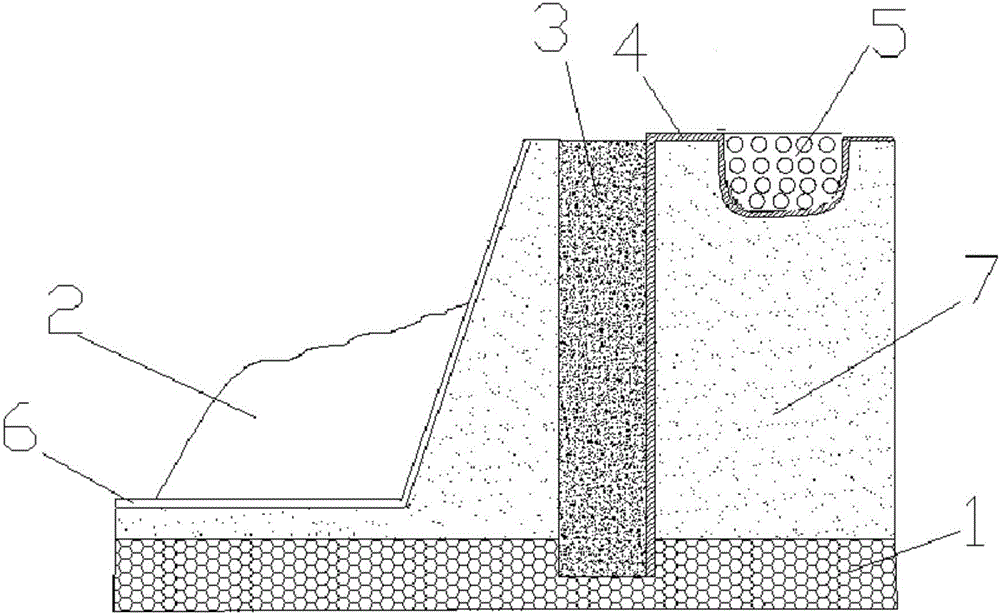

Face rockfill dam toe board structure constructed on completely weathered bed rock and construction method thereof

ActiveCN101644041AGuaranteed carrying capacitySolve the cracking problemEarth-fill damsRock-fill damsBedrockOn board

The invention relates to a face rockfill dam toe board structure constructed on a completely weathered bed rock and a construction method thereof. The invention aims at providing a face rockfill dam toe board structure constructed on a completely weathered bed rock and a construction method thereof. Due to the invention, a face rockfill dam toe board can be directly built on the completely weathered bed rock, thereby guaranteeing the safety of a dam body with the minimum project investment and the shortest construction period. The technical solution is as follows: the face rockfill dam toe board structure constructed on the completely weathered bed rock comprises a concrete toe board constructed on the completely weathered bed rock, wherein the toe board is downstream provided with an impervious connecting board; the top part of the impervious connecting board and a downstream pavement extend to filter material at the food of a downstream dam; an impervious blanket and waste residues are spread on the upper surface of the toe board; retraction gaps are arranged on the completely weathered bed rock and adjacent strongly-weathered or weakly-weathered bed rocks; and still water is arranged in the gaps. The face rockfill dam toe board structure is mainly used for face rockfill dam projects associated with deep and thick completely weathered bed rocks of two banks in conservancy andhydropower engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

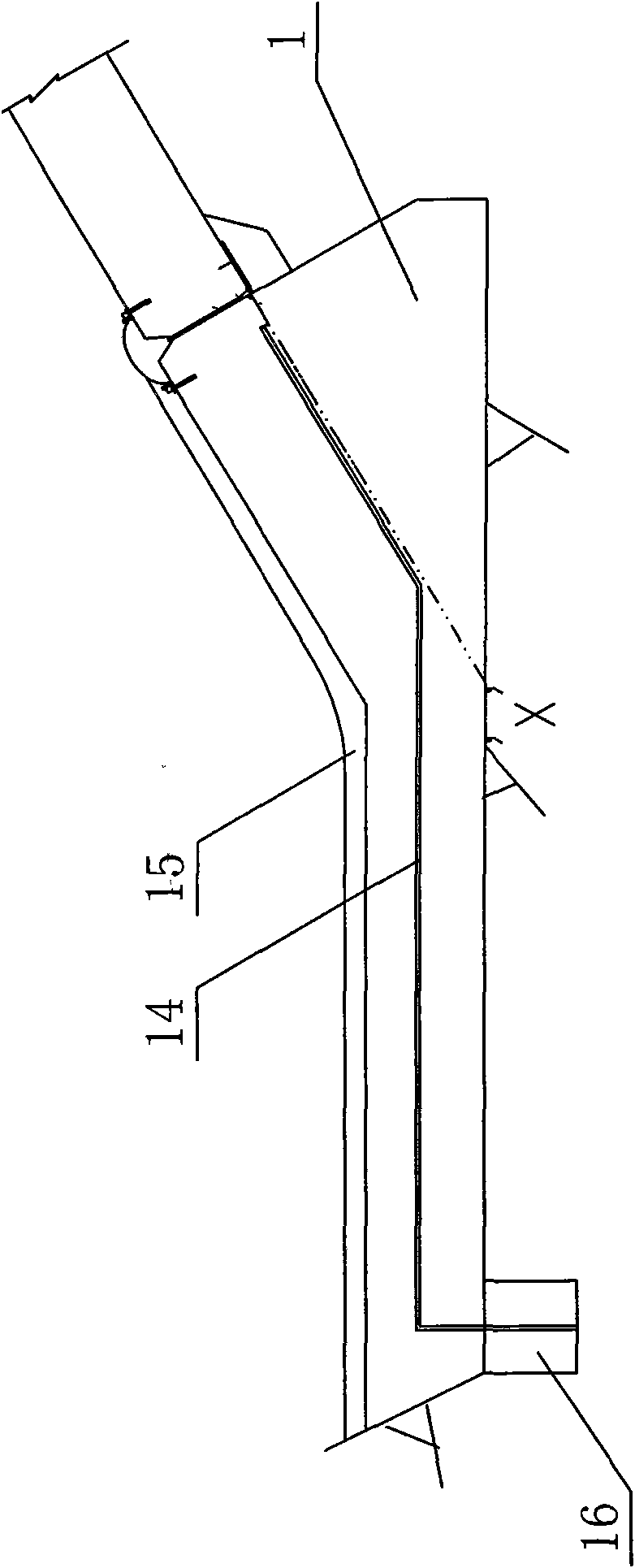

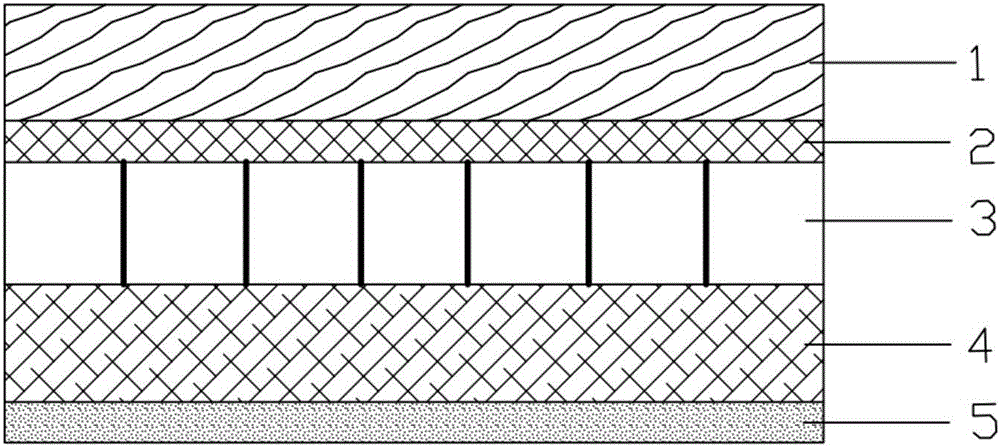

Impermeable drainage system for cement-sand-gravel dam

PendingCN108049370ARich design methodEasy constructionBarrages/weirsClimate change adaptationEngineeringSlurry

The invention provides an impermeable drainage system for a cement-sand-gravel dam. The impermeable drainage system is provided with an upstream impermeable layer and a drainage layer, wherein the upstream impermeable layer is arranged on the upstream of the cement-sand-gravel dam and covers the whole upstream dam face in a laminating manner, the upstream impermeable layer is cut into a pluralityof blocks by transverse seams in the axis direction of the dam, water-stop structures are arranged at the transverse seam positions, at least one part of each water-stop structure is arranged on the surface of the upstream impermeable layer, the upstream impermeable layer is made of slurry-adding vibrating cement sand gravels or slurry enriching cement sand gravels, the drainage layer is arrangedon the downstream side of the upstream impermeable layer of the cement-sand-gravel dam and is adjacent to the upstream impermeable layer, and drainage pipes are arranged on the downstream side of thedrainage layer in the axis direction of the dam and drain leakage water penetrating the upstream impermeable layer. According to the impermeable drainage system, the cement-sand-gravel dam is more economical and environmentally friendly, and meets higher engineering design requirements for compressive strength larger than 20 MPa, anti-freeze strength meeting F300 and impervious strength larger than W10, construction is convenient and fast, the dam body impermeable effect and the dam inner drainage effect can be improved effectively, and the design method of the cement-sand-gravel dam is perfected.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +3

Edible fungus chaff aerated brick and preparation method therefor

The invention provides an edible fungus chaff aerated brick. The aerated brick is prepared from the raw materials comprising, by weight, 30-35 parts of edible fungus chaff, 24-28 parts of fly ash, 15-20 parts of cement, 12-16 parts of lime, 3-5 parts of bamboo charcoal powder, 3-5 parts of oil foot, 12-18 parts of gypsum, 1-2 parts of aluminium powder, 1-2 parts of nekal, 16-19 parts of bentonite, 3-4 parts of lignocellulose, 2-3 parts of chitosan, 3-5 parts of sodium metasilicate, 8-10 parts of argil, 2-3 parts of rapeseed meal, 1-2 parts of ammonium persulfate and moderate water. The method employs the rapeseed meal as a raw material and the hydrophobicity of the brick is raised and the seepage-proofing effect is improved. Edible fungus chaff is employed as a raw material and waste materials can be utilized.

Owner:唐海峰

Method for improving single-layer oil tank into double-layer oil tank

ActiveCN106239932AReal-time anti-seepage detectionImprove anti-seepage performanceLarge containersDomestic articlesGlass fiberEngineering

The invention relates to a method for improving a single-layer oil tank into a double-layer oil tank. On the basis that the inner wall of the buried single-layer steel oil tank in service is derusted, an anti-corrosion reinforcing coating, a 3D through gap layer and a glass steel inner tank are sequentially manufactured, and the single-layer oil tank is quickly improved into the glass steel double-layer oil tank with a through gap layer space. The 3D through gap layer is communicated with a tank top monitoring well, and sealing performance of the inner tank and the steel outer tank in service can be monitored all day long. The inner surface of the glass steel inner tank is coated with an anti-static layer which makes direct contact with stored liquid, the anti-static layer is connected with an original steel storage tank, and the original steel single-layer storage tank is grounded so that electrostatic hazards can be avoided. The inner tank is made from a glass steel material formed by mixing resin and glass fiber. The oil tank improvement method has the advantages of being good in safety, high in strength, convenient to manufacture and the like, corrosion resistance of the oil tank is improved, the overhaul frequency is reduced, the service life is prolonged, and improvement cost is reduced.

Owner:ZHONGYI GLASS FIBER REINFORCED PLASTICS

A high-pressure waterway anti-seepage method and a high-pressure waterway annular anti-seepage curtain

InactiveCN102277858AExcellent mechanical propertiesImprove anti-seepage performanceMarine site engineeringChemical groutingReinforced concrete

The invention discloses a high-pressure waterway anti-seepage method and a high-pressure waterway annular anti-seepage curtain, which belong to the field of rock mass anti-seepage, in particular to the field of rock mass anti-seepage treatment in a relatively high water head environment. The present invention aims at the disadvantages of the existing high-pressure waterway that needs to set up hanging curtains upstream of the underground powerhouse. Consolidate grouting holes and anti-seepage grouting holes; then use 0.3Mpa~0.5Mpa pressure for anti-seepage grouting and surrounding rock consolidation grouting; finally use ultra-fine cement chemical grouting and anti-seepage grouting holes with a grouting pressure greater than 2.0MPa to improve the surrounding area. The anti-seepage performance of the rock can reduce the leakage of high-pressure waterways, and then achieve the purpose of canceling the hanging curtain. The method has reasonable process layout design, simple structure and convenient operation, and can greatly save engineering cost.

Owner:POWERCHINA ZHONGNAN ENG

Anti-floating system combining anti-floating cement soil pile and anti-floating anchor rod and construction process of anti-floating system

InactiveCN103603379AIncrease buoyancyAvoid influenceProtective foundationBulkheads/pilesBasementPull force

The invention discloses an anti-floating system combining an anti-floating cement soil pile and an anti-floating anchor rod and a construction process of the anti-floating system. The anti-floating system comprises the anti-floating cement soil pile and the anti-floating anchor rod fixedly embedded in the anti-floating cement soil pile, and the top of the anti-floating cement soil pile is connected with the lower surface of a basement bottom plate in a contact mode. The anti-floating anchor rod comprises an anchor cable, an anchor head and an anchor device, wherein the anchor head is arranged in the anti-floating cement soil pile, the anchor cable penetrates through the anti-floating cement soil pile and extends into an anchoring hole in the basement bottom plate, the anchor cable is tensioned, and the anchor device is fixed through grouting. The anti-floating system gives full play to the advantages of the anti-floating cement soil pile and the advantages of the anti-floating anchor rod, a pile and an anchor are integrated and work together, and the anti-floating system is suitable for anti-floating anchor rod construction of various soft soil layers, improves anti-pull force of the anchor rod, prevents hole wall collapse, improves the impervious performance of a connecting node of the basement bottom plate and the anchor rod, expands the use range of the soft soil layers of the anti-floating anchor rod in high-water-level environment, enables construction to be convenient to achieve and can be widely used for anti-floating processing of various underground structures.

Owner:葛建

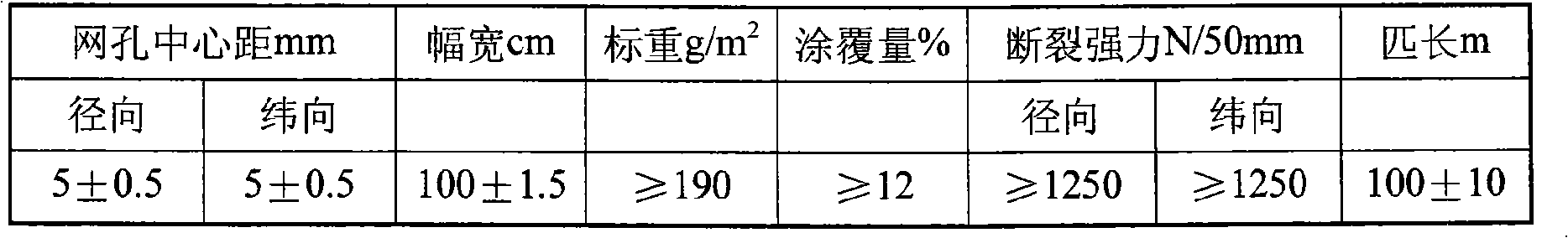

GCL vertical anti-seepage wall and preparation method thereof

ActiveCN105672365AGood anti-seepageTightly boundProtective foundationGeotextilesStructural engineeringLow permeability

The invention discloses a GCL vertical anti-seepage wall and a preparation method thereof. The GCL vertical anti-seepage wall comprises a vertical anti-seepage wall body, wherein a sodium-based geosynthetic clay liner is fixed at the outer side of the vertical anti-seepage wall body, and the sodium-based geosynthetic clay liner comprises a vertical anti-seepage structure and a top fixation structure. The anti-seepage wall disclosed by the invention has a low permeability coefficient, and is good in bonding with a soil mass, and high in anti-seepage effect.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

Construction method of bridge pile foundation in mountainous area

ActiveCN105507340AHigh strengthReduce the problem of crack growthFoundation engineeringSoil horizonGrout

The invention discloses a construction method of a bridge pile foundation in a mountainous area. The construction method comprises the following steps: (1) staking out in survey, namely locating position of the pile foundation; (2) digging a hole, namely enlarging hole on the bottom rock of a pile hole after digging the pile hole to form an enlarge hole cavity; (3) placing a steel reinforcement cage and an enlarged steel reinforcement cage, namely placing a main steel reinforcement cage in the pile hole and placing the enlarged steel reinforcement cage in the enlarged hole cavity; (4) pouring concrete, namely pouring concrete into the pile hole by adopting a guide pipe method and manufacturing a bearing platform; and (5) arranging anchor cables, namely drilling around the pile foundation, mounting a vertical anchor cable and a horizontal anchor cable, grouting by adopting a hole bottom grout returning method, and punching the vertical anchor cable and the horizontal anchor cable into the rock by passing through the soil layer. The construction method is simple; the pile foundation bearing capability is strong.

Owner:NANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com