Impermeable drainage system for cement-sand-gravel dam

A technology of cemented sand and gravel dam and cemented sand and gravel, which is applied in water conservancy projects, marine engineering, climate change adaptation and other directions, can solve the problems of difficult control of construction quality, slow construction progress, and inappropriate discovery of specific locations, so as to improve drainage. Effect, convenient and fast construction, easy to find the effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

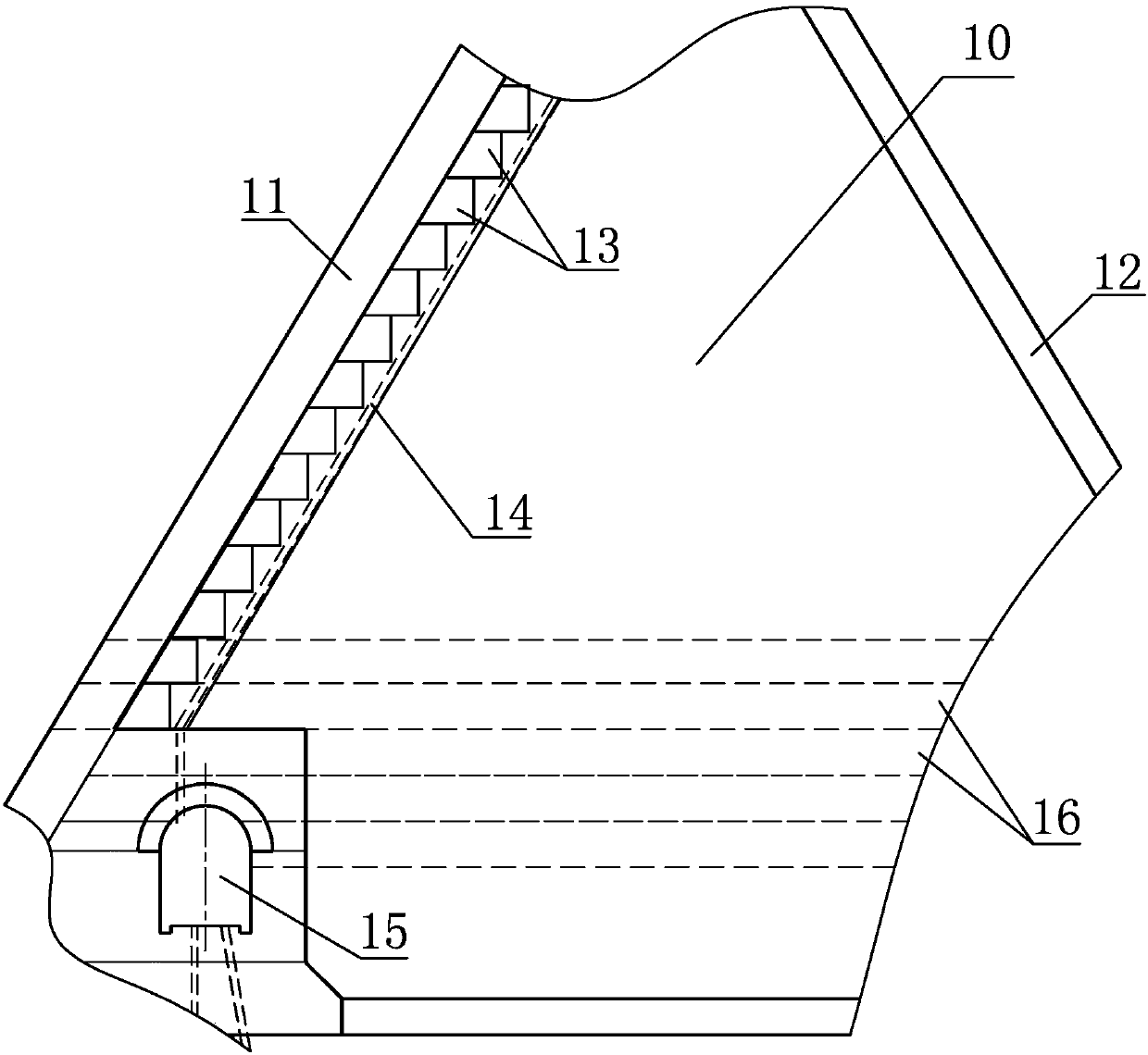

[0065] Example: anti-seepage and drainage system of a 50.6m high cementitious gravel dam.

[0066] It includes the following parts:

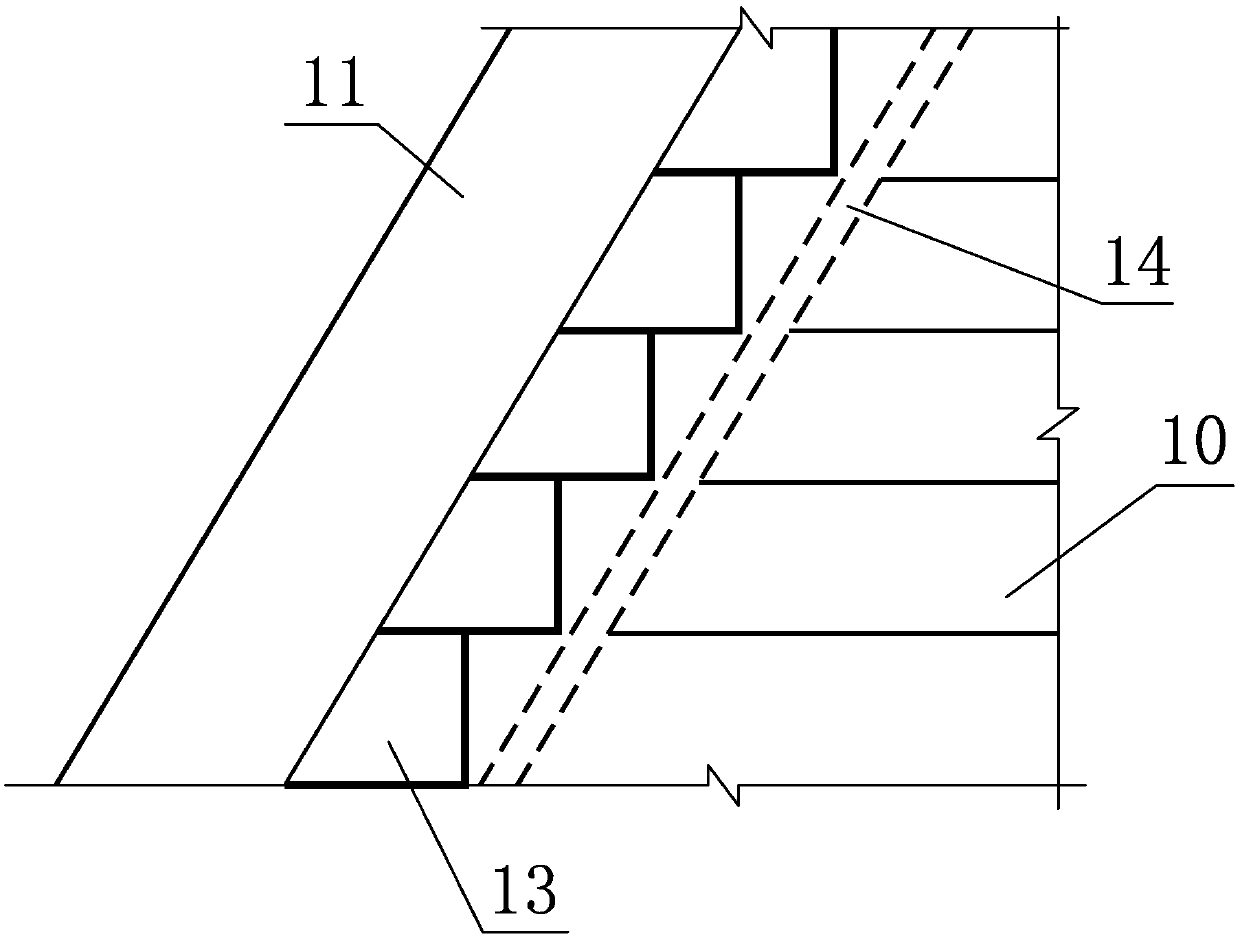

[0067] 1) Dam body anti-seepage

[0068] The dam is located in a cold region. Considering the poor corrosion resistance and freeze-thaw resistance of the cemented sand and gravel dam, an anti-seepage and protective layer are required. In this project, only an anti-seepage layer and a protective layer are provided. According to the design of the water head, the thickness of the anti-seepage layer is 1 / 30-1 / 60 of the water head. At the same time, considering the anti-freezing requirements, the upstream surface adopts a 1.5m thick cemented sand and gravel anti-seepage layer with a water-binder ratio of 0.50 and the amount of fly ash 40%.

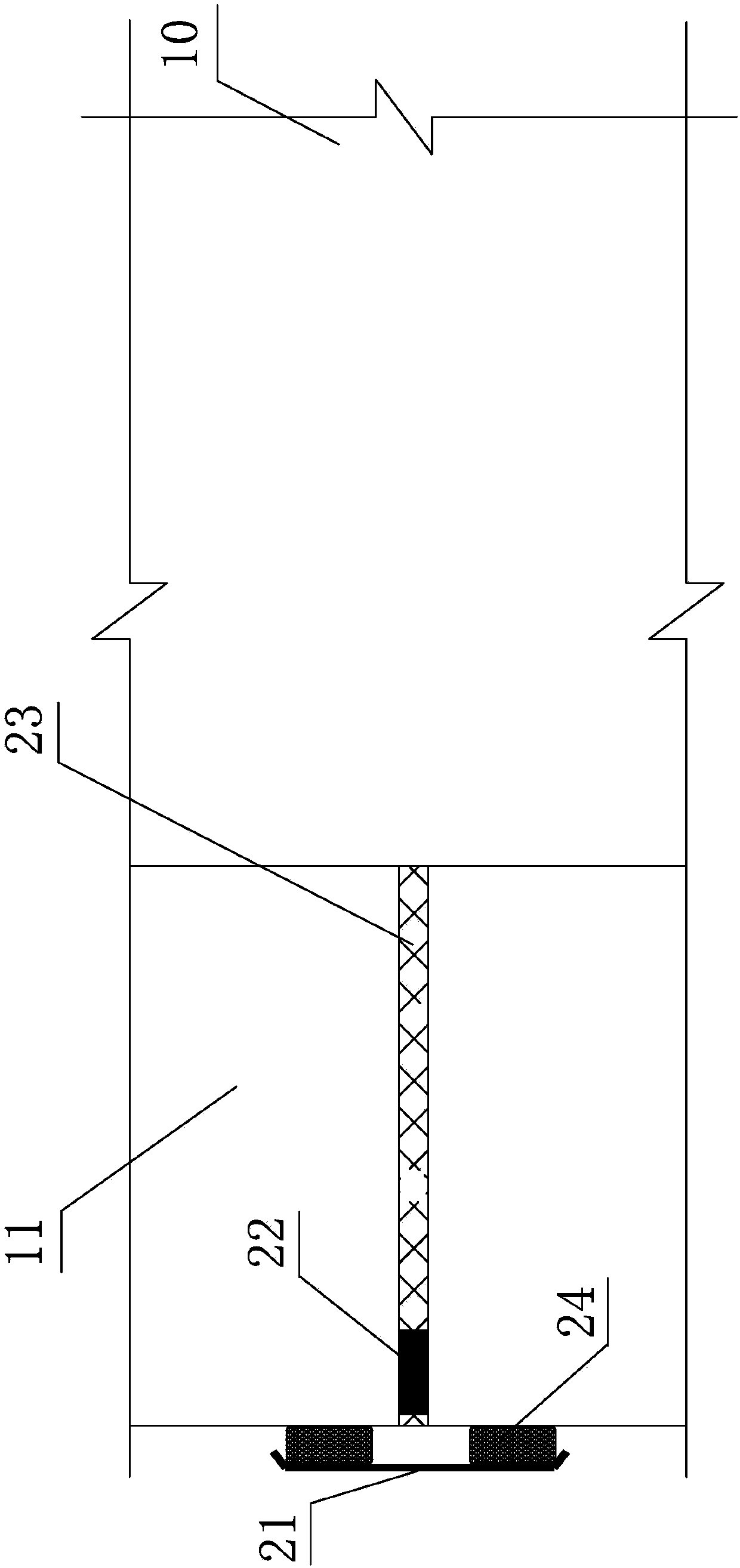

[0069] 2) Transverse seam water stop

[0070] Considering that the relative displacement of the dam body on both sides of the cemented sand gravel dam joint is relatively small, copper sheets are used to stop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com