Patents

Literature

34results about How to "Rich design method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

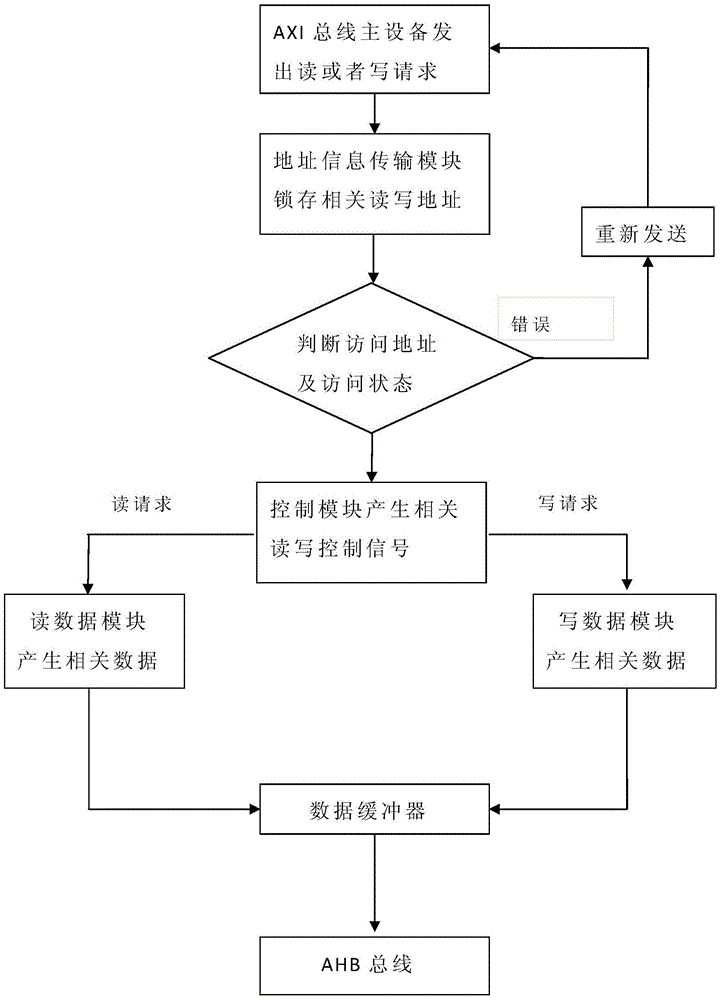

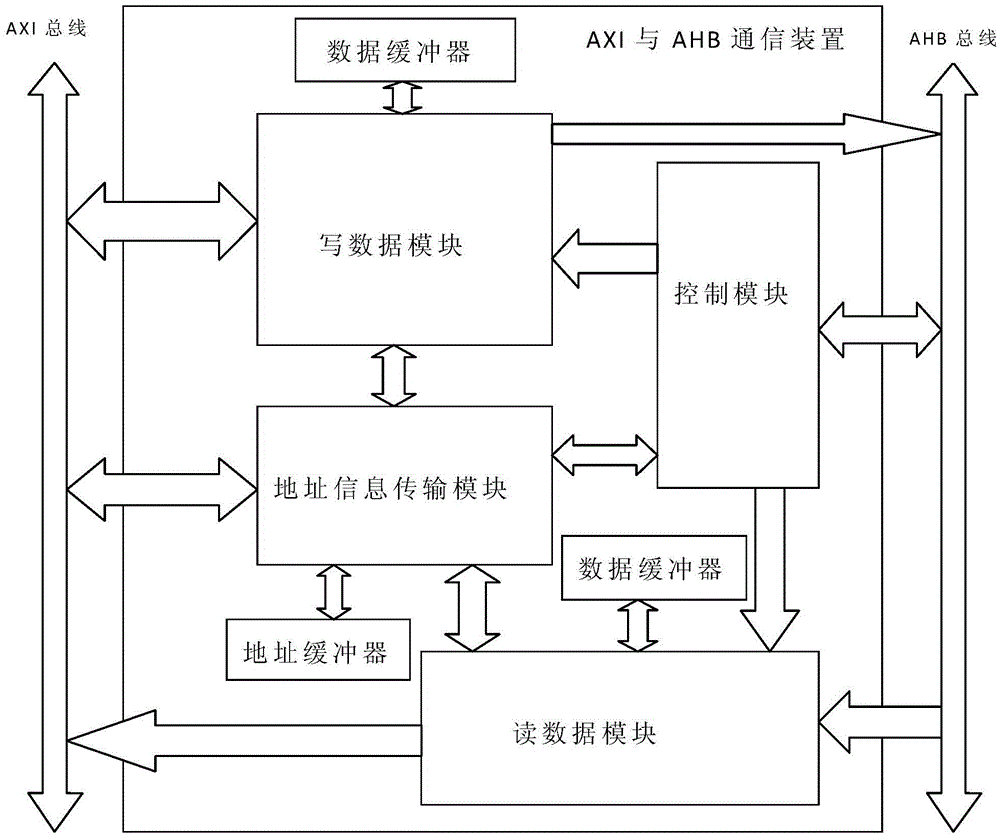

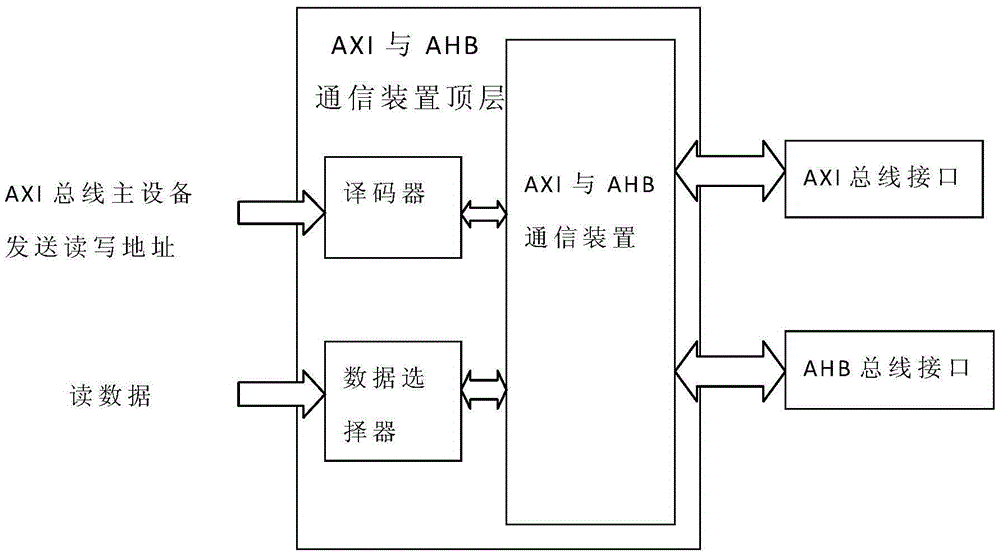

Method and device for communication between AXI (advanced extensible interface) bus and AHB (advanced high-performance bus)

ActiveCN103605632ARich design methodIncrease flexibilityGeneral purpose stored program computerElectric digital data processingControl signalEmbedded system

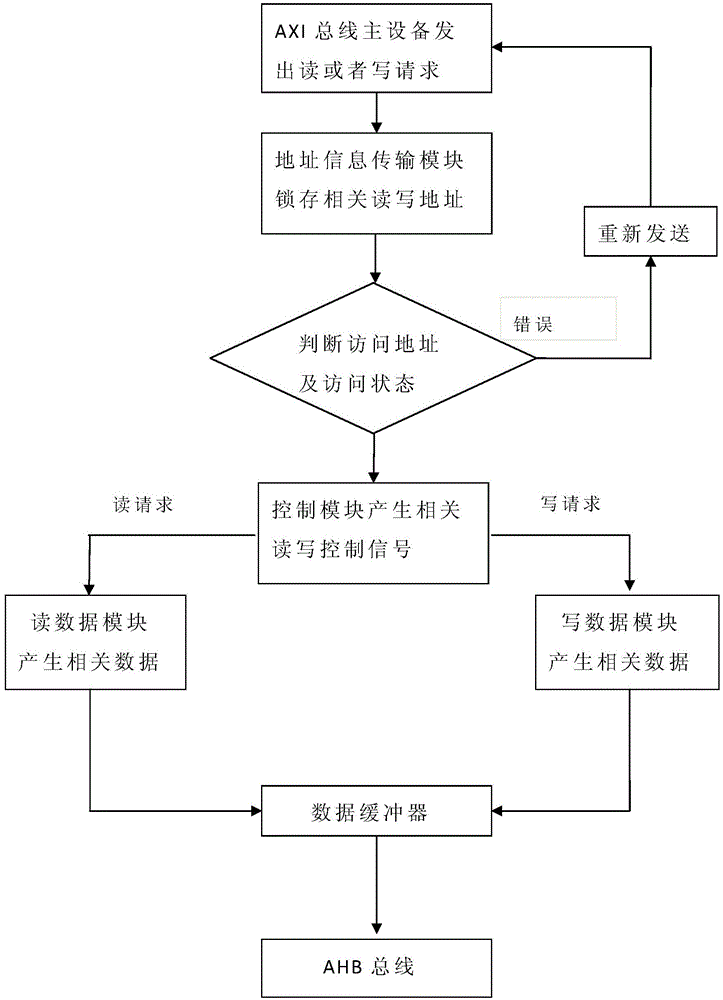

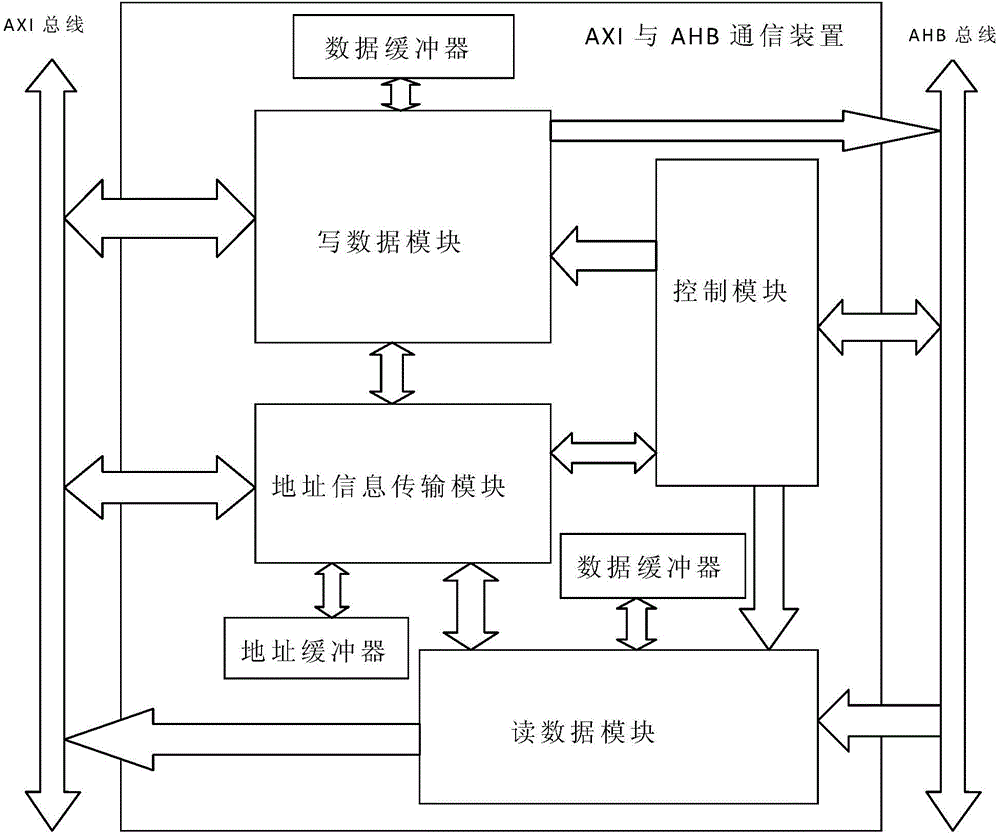

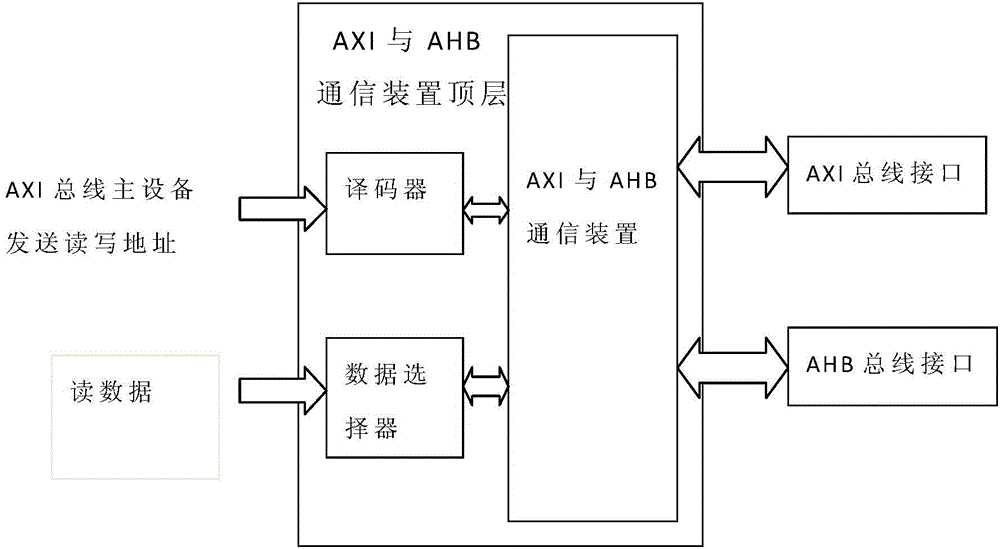

The invention discloses a method for communication between an AXI (advanced extensible interface) bus and an AHB (advanced high-performance bus). By using the method, reading and writing operation between the AXI bus and the AHB is finished, and the communication between the AXI bus and the AHB is realized. The method comprises the following steps that after main equipment of the AXI bus sends outa reading and writing request, a reading and writing address is latched by an AXI bus and AHB communication bridge, effective addresses are kept in a transmitting process, and reading and writing control signals are latched; the AXI bus and AHB communication bridge decodes the latched address and generates selection signals, and only one selection signal can be activated in a transmitting process, namely the unique AHB is selected to perform reading and writing operation from the equipment; during writing operation, the AXI bus and AHB communication bridge sends data transmitted from the AXIbus to the AHB by using a data buffer; and during reading operation, the AXI bus and AHB communication bridge sends the data on the AHB to the AXI bus by using the data buffer.

Owner:SHANDONG UNIV

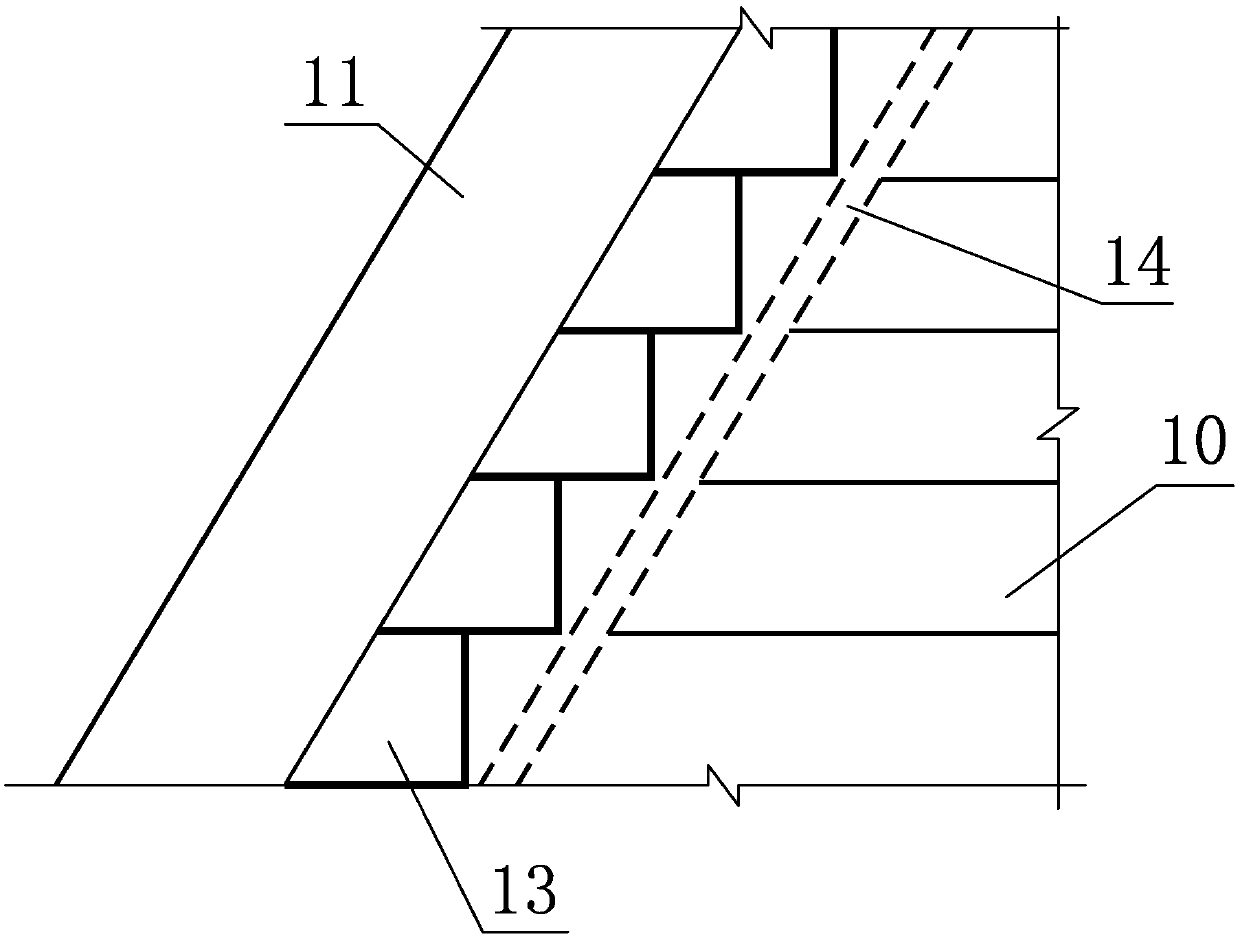

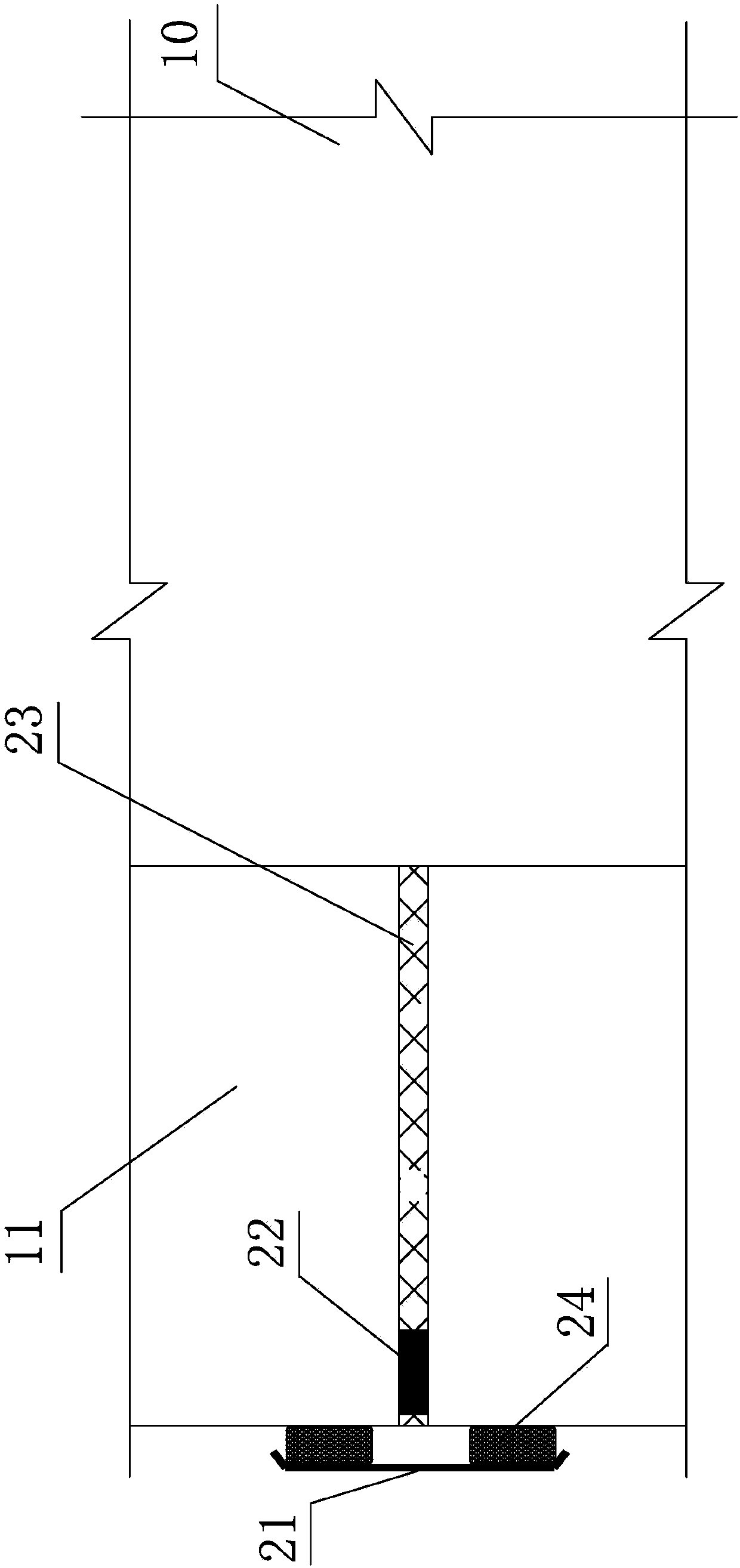

Impermeable drainage system for cement-sand-gravel dam

PendingCN108049370ARich design methodEasy constructionBarrages/weirsClimate change adaptationEngineeringSlurry

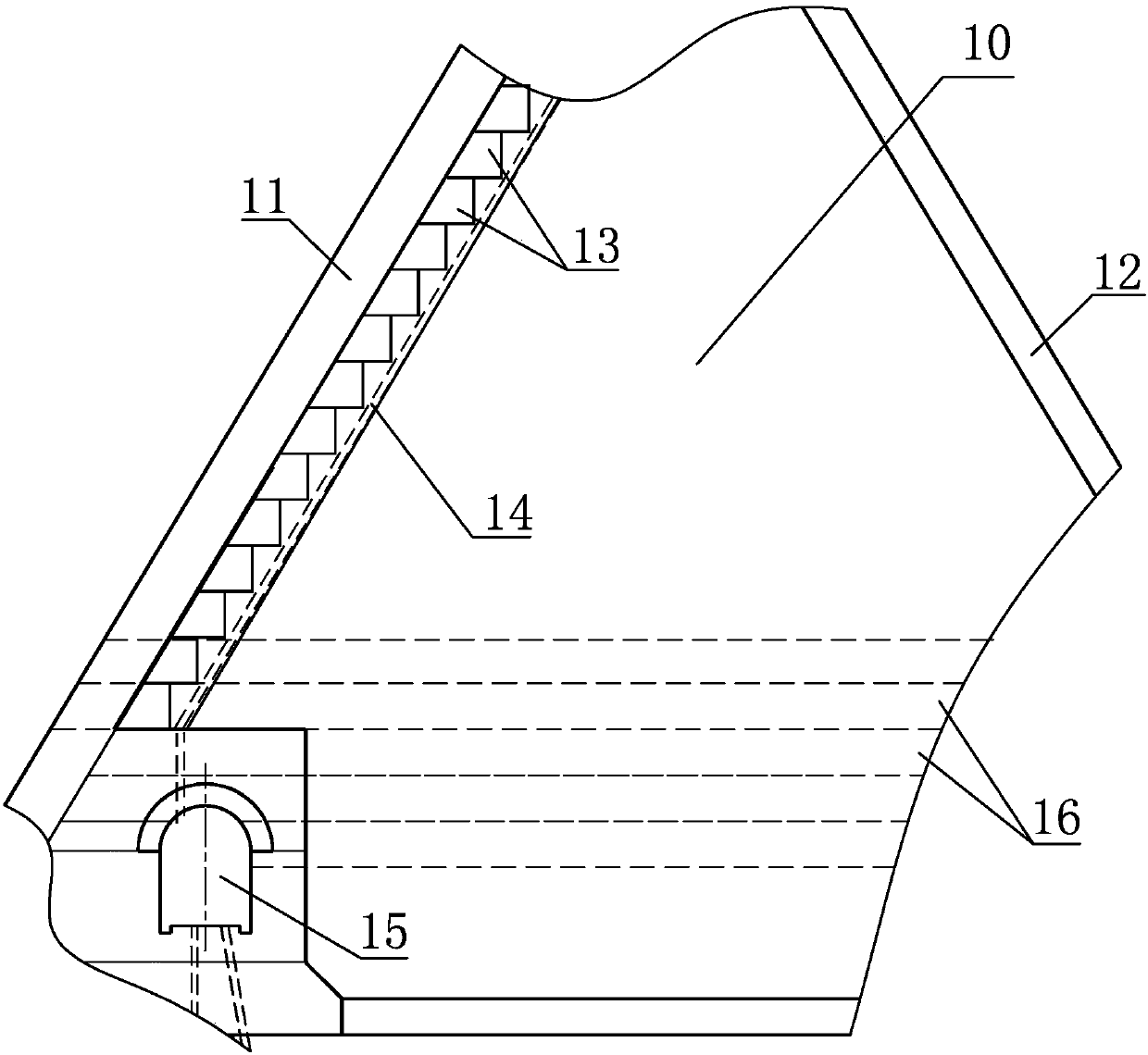

The invention provides an impermeable drainage system for a cement-sand-gravel dam. The impermeable drainage system is provided with an upstream impermeable layer and a drainage layer, wherein the upstream impermeable layer is arranged on the upstream of the cement-sand-gravel dam and covers the whole upstream dam face in a laminating manner, the upstream impermeable layer is cut into a pluralityof blocks by transverse seams in the axis direction of the dam, water-stop structures are arranged at the transverse seam positions, at least one part of each water-stop structure is arranged on the surface of the upstream impermeable layer, the upstream impermeable layer is made of slurry-adding vibrating cement sand gravels or slurry enriching cement sand gravels, the drainage layer is arrangedon the downstream side of the upstream impermeable layer of the cement-sand-gravel dam and is adjacent to the upstream impermeable layer, and drainage pipes are arranged on the downstream side of thedrainage layer in the axis direction of the dam and drain leakage water penetrating the upstream impermeable layer. According to the impermeable drainage system, the cement-sand-gravel dam is more economical and environmentally friendly, and meets higher engineering design requirements for compressive strength larger than 20 MPa, anti-freeze strength meeting F300 and impervious strength larger than W10, construction is convenient and fast, the dam body impermeable effect and the dam inner drainage effect can be improved effectively, and the design method of the cement-sand-gravel dam is perfected.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +3

Method for presenting three-dimensional pattern on clothing

ActiveCN102555468ARich design methodVarious processing methodsTypewritersSpecial data processing applicationsTextile printerStereoscopic imaging

The invention discloses a method for presenting a three-dimensional pattern on clothing. The method comprises the following steps of: processing a self-selection picture by using Photoshop software to acquire Mask and Texture, importing into three-dimensional image making software 3Dmrc, and synthesizing to generate a three-dimensional image; inputting the made three-dimensional pattern into a computer in a digital mode; compiling and processing by using a printing, color separation and drawing system of the computer; selecting different dye solutions according to a fabric to be dyed; and controlling a micro piezoelectric type ink-jet nozzle by using the computer to directly eject a special dye solution onto the fabric or a garment so as to form the fabric or the clothing on which the three-dimensional pattern can be presented. By the method, a three-dimensional pattern design technology and a digital printing technology are combined organically, so that a three-dimensional imaging technology is applied in the designing and processing of the clothing, the clothing has attractive patterns, underlying three-dimensional patterns, interestingness and artistic quality, and clothing designing and processing methods are enriched.

Owner:浙江新千禧纺织股份有限公司

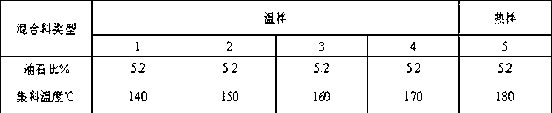

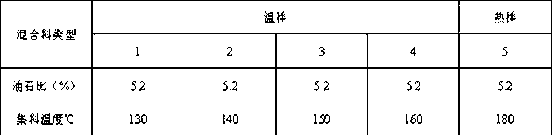

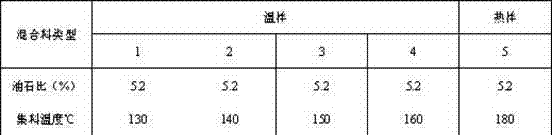

Marshall design method of Evotherm warm-mix asphalt mixture

ActiveCN102839587AOvercoming the inability to design warm mix asphalt mixtureOvercome the problem of not compactingClimate change adaptationRoads maintainencePerformance indexEngineering

The invention relates to a Marshall design method of an Evotherm warm-mix asphalt mixture, comprising the following steps: (1) selecting a Marshall design method of a warm-mix asphalt mixture to design the graduation and oil-stone ratio of the warm-mix mixture; (2) selecting aggregates with different temperatures, conducting a rutting test on the selected aggregates with different temperatures and an asphalt with same temperature of the warm-mix asphalt, and determining the discharge temperature and compaction temperature of the warm-mix asphalt with the bulk density of a test piece of the warm-mix asphalt as a standard; and (3) conducting a high temperature test, a low temperature test, and a water stability test of the warm-mix asphalt at the temperatures, and evaluating by taking technical indexes of the warm-mix asphalt of the same type. According to the invention, the warm-mix asphalt mixture can be designed without a gyratory compactor, the bulk density of the warm-mix asphalt mixture is represented as the core sample density of the rutting plate drilled core, and the technical indexes of the warm-mix asphalt of the same type are taken as the performance index for evaluation; and the design method is simple and reasonable and is convenient for laboratories and field laboratories without the gyratory compactor, thus the design method of the warm-mix asphalt mixture is expanded.

Owner:SHANXI PROVINCIAL RES INST OF COMM

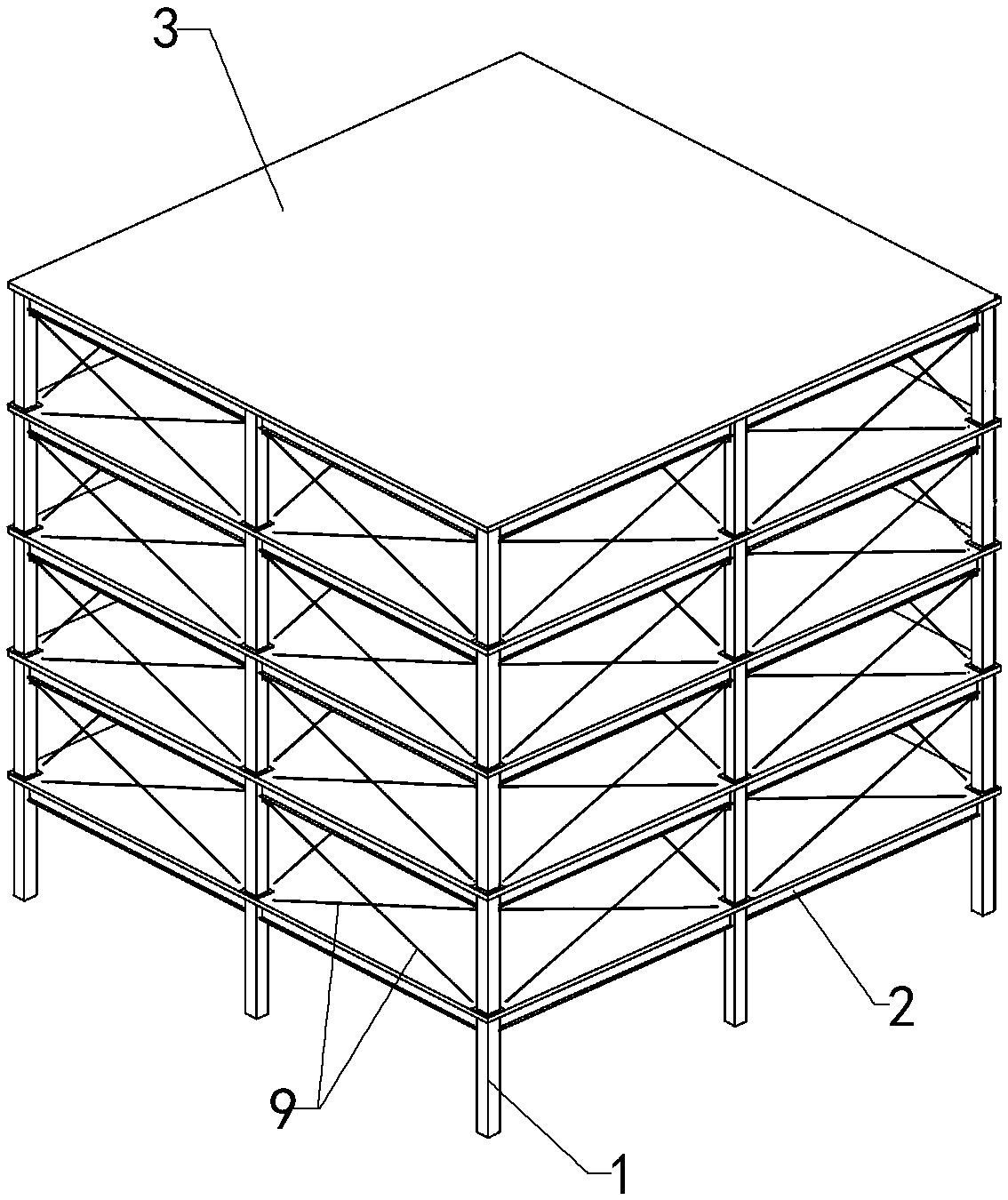

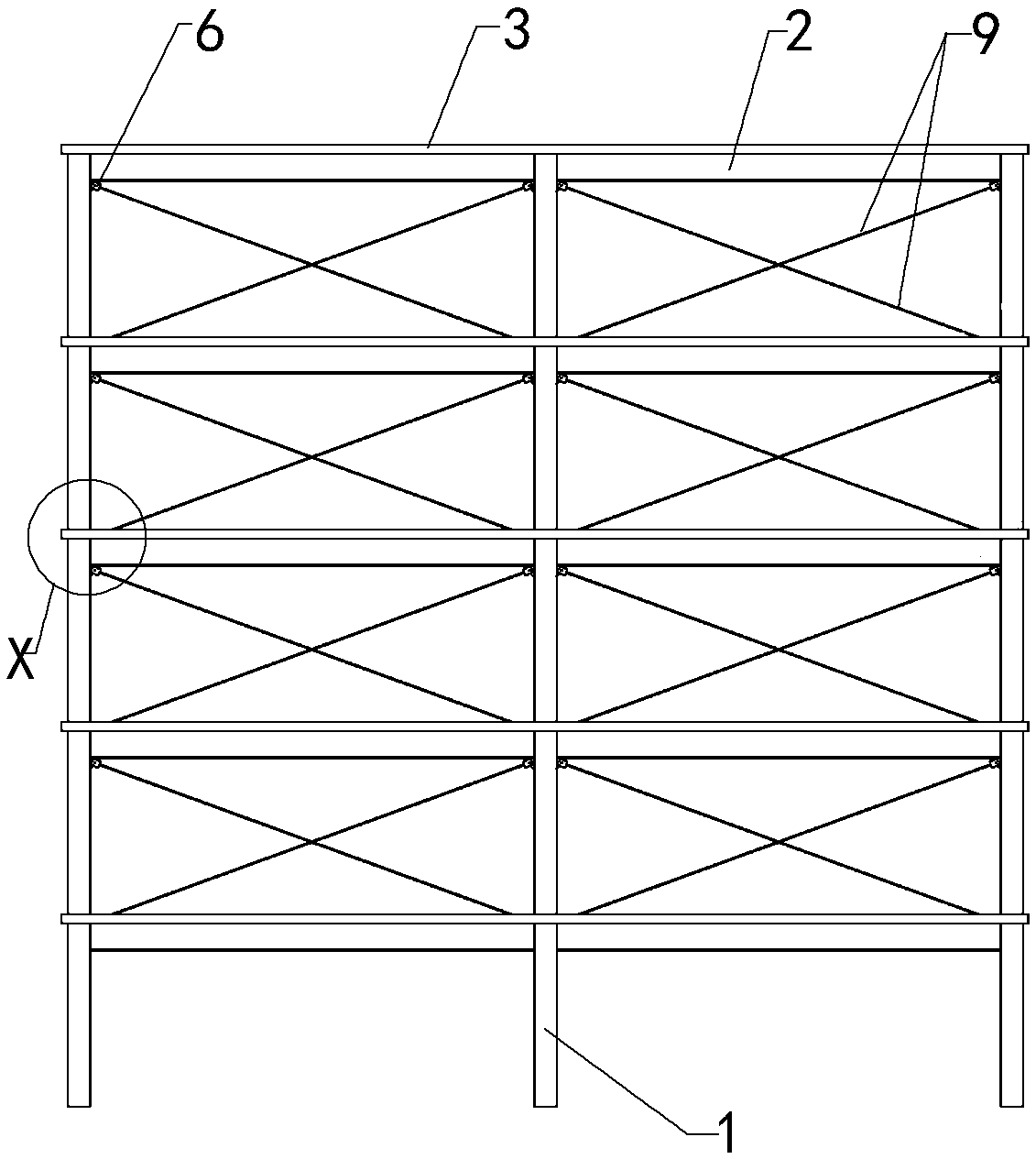

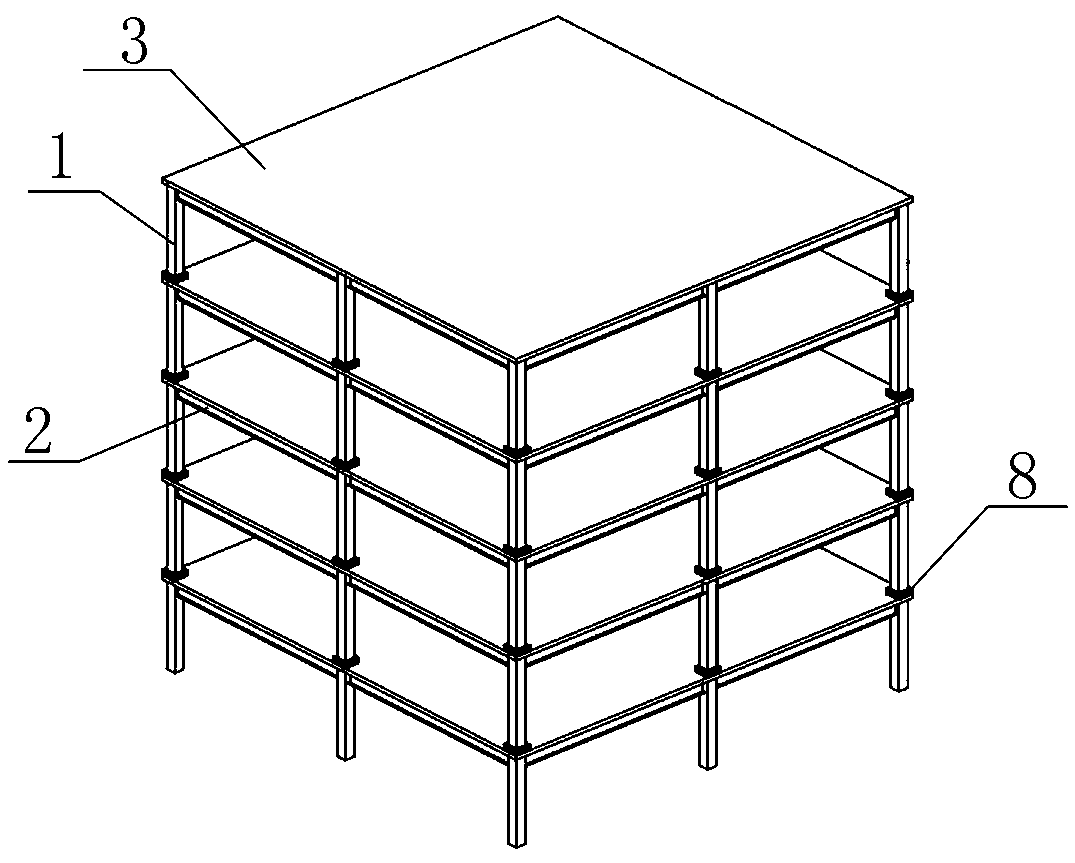

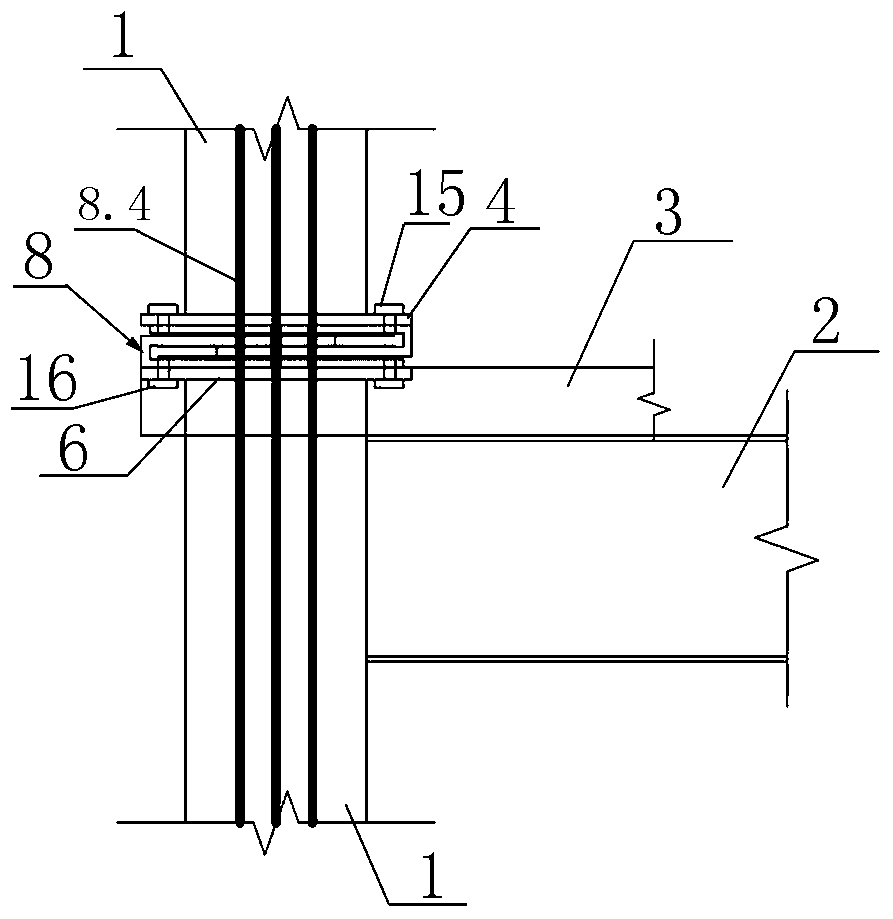

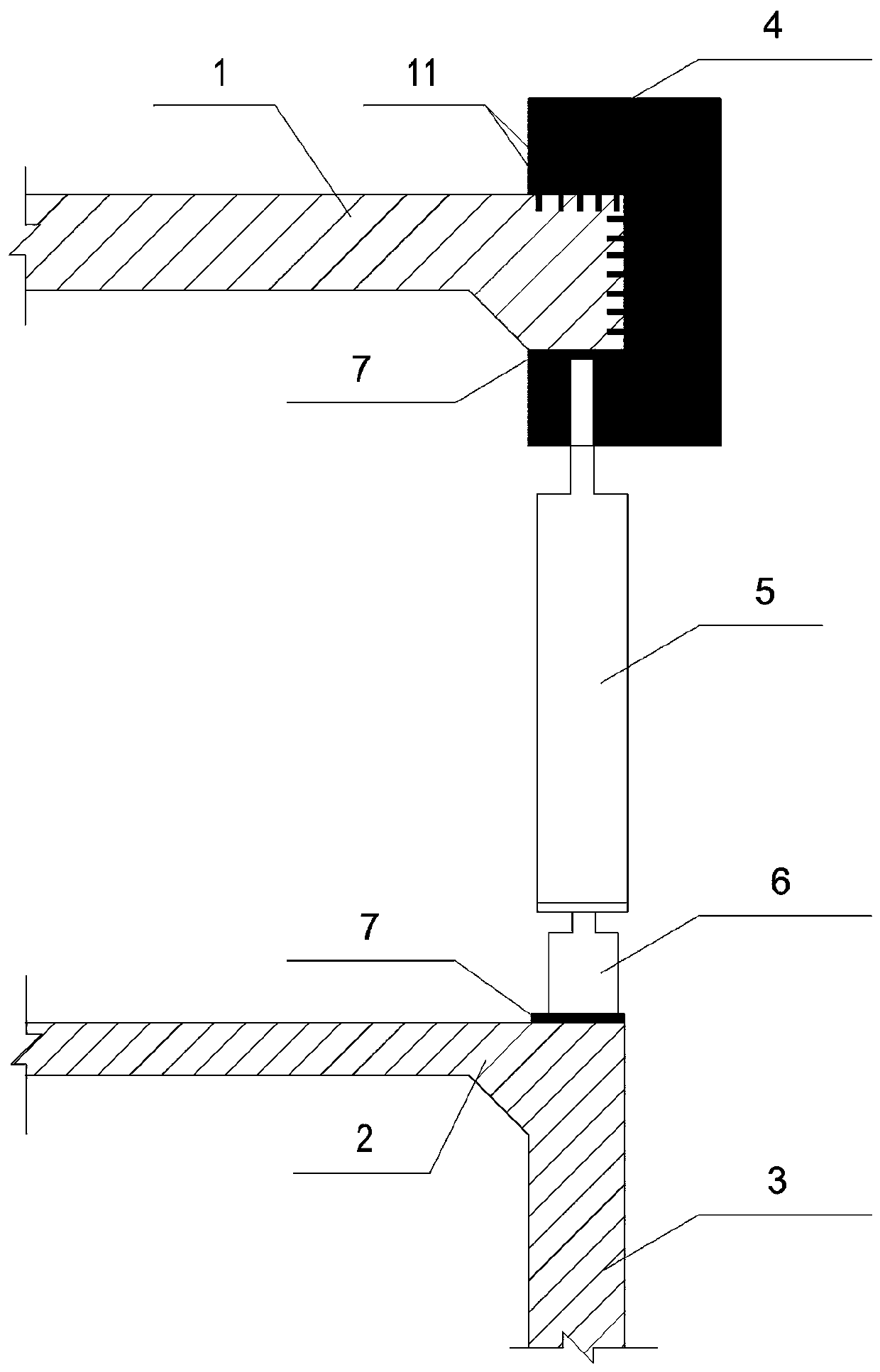

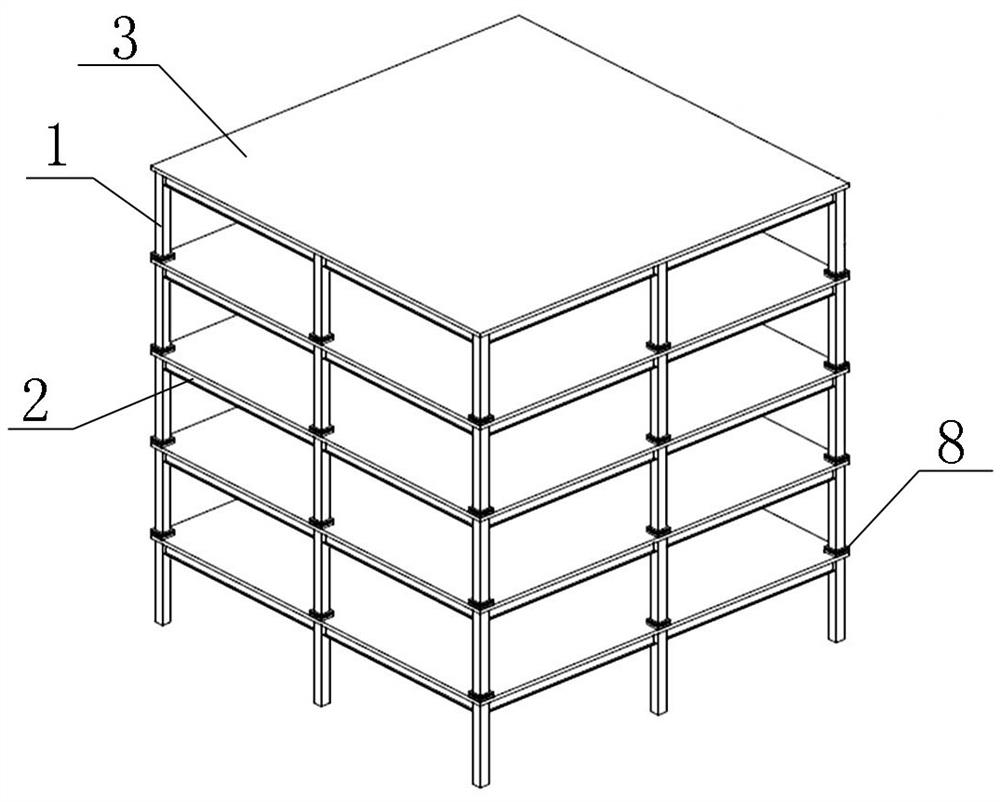

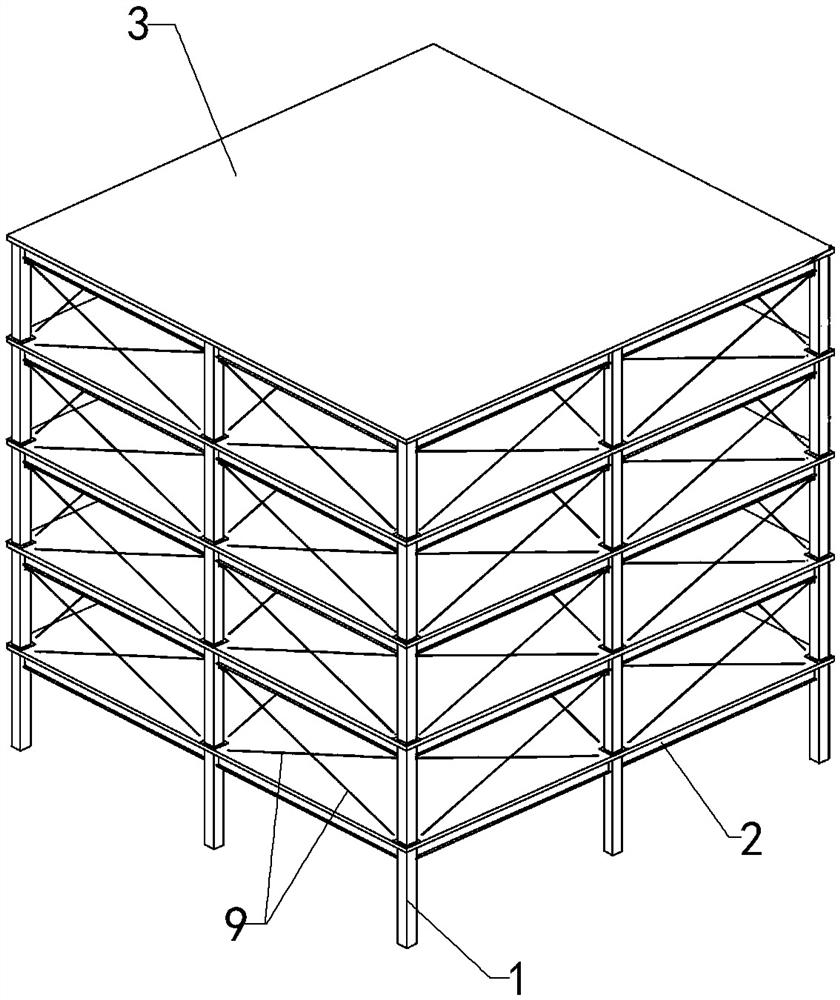

Prestressed support friction damping assembled steel structure system and design method thereof

ActiveCN110528679ANo pollution in the processImprove construction efficiencyProtective buildings/sheltersSpecial data processing applicationsPre stressEngineering

The invention relates to the technical field of structural engineering, and discloses a prestressed support friction damping assembled steel structure system and a design method. The system is formedby stacking layered frame structures up and down, each layered frame structure includes steel columns, steel beams and floor plates, the steel columns between the upper and lower adjacent layered frame structures are disconnected at the connection positions of the floor plates on the lower layer, connection through self friction is achieved, and meanwhile, high-strength cables are connected between the adjacent layered frame structures; and the top ends of the steel columns are provided with upper flange plates so as to be fixedly connected to the steel beams, the bottom ends of the steel columns are provided with lower flange plates, the lower flange plates are in contact with the upper surfaces of the floor plates of the adjacent layered frame structure on the lower layer, the upper surfaces of the floor plates are provided with friction coating layers and limiting devices, and the limiting devices are steel plate strips arranged along the edges of the floor plates. By means of the system, the layers are connected through the high-strength cables and the mutual friction between the columns, construction is convenient and efficient to achieve, and the stress performance is good.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

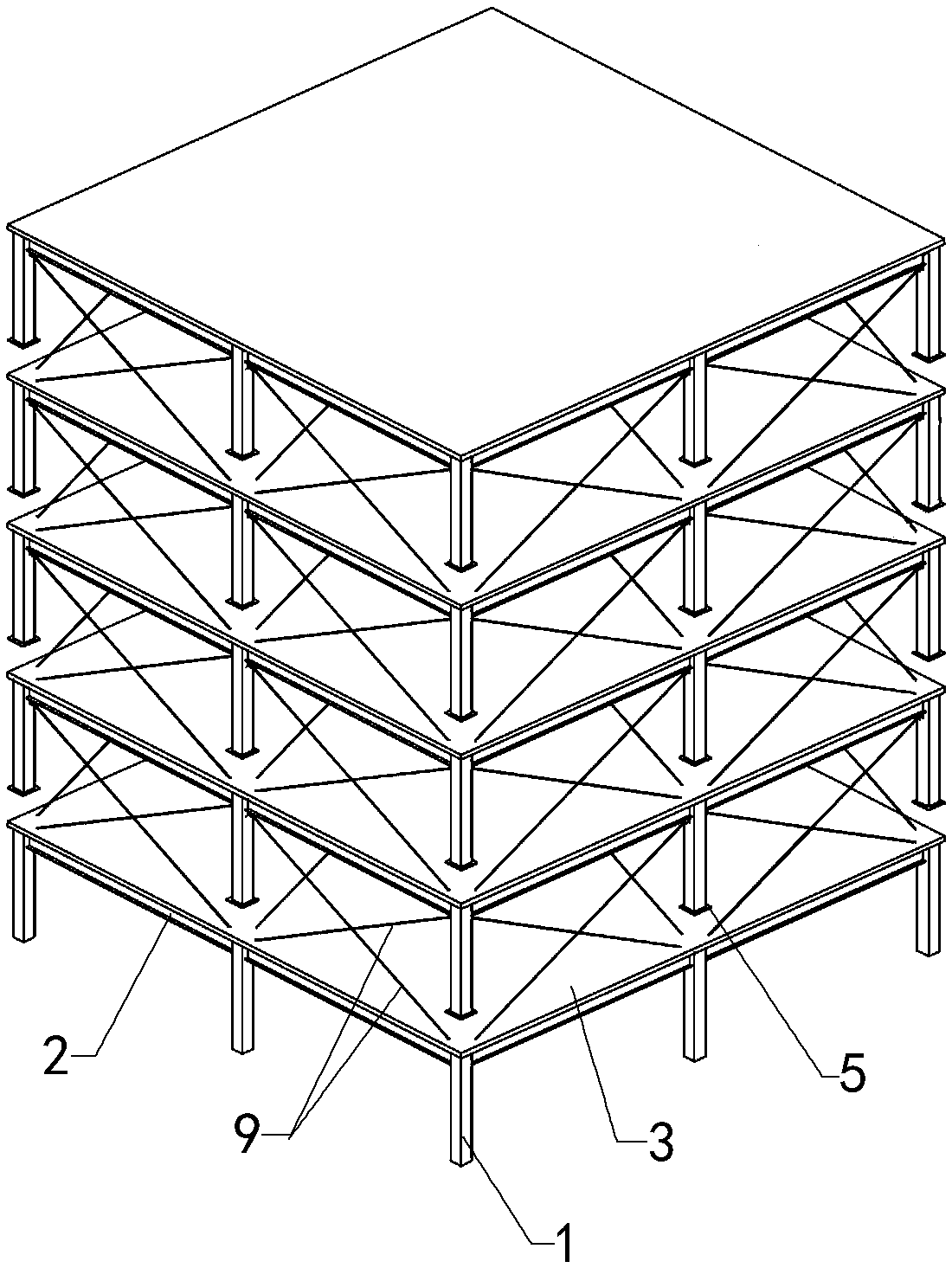

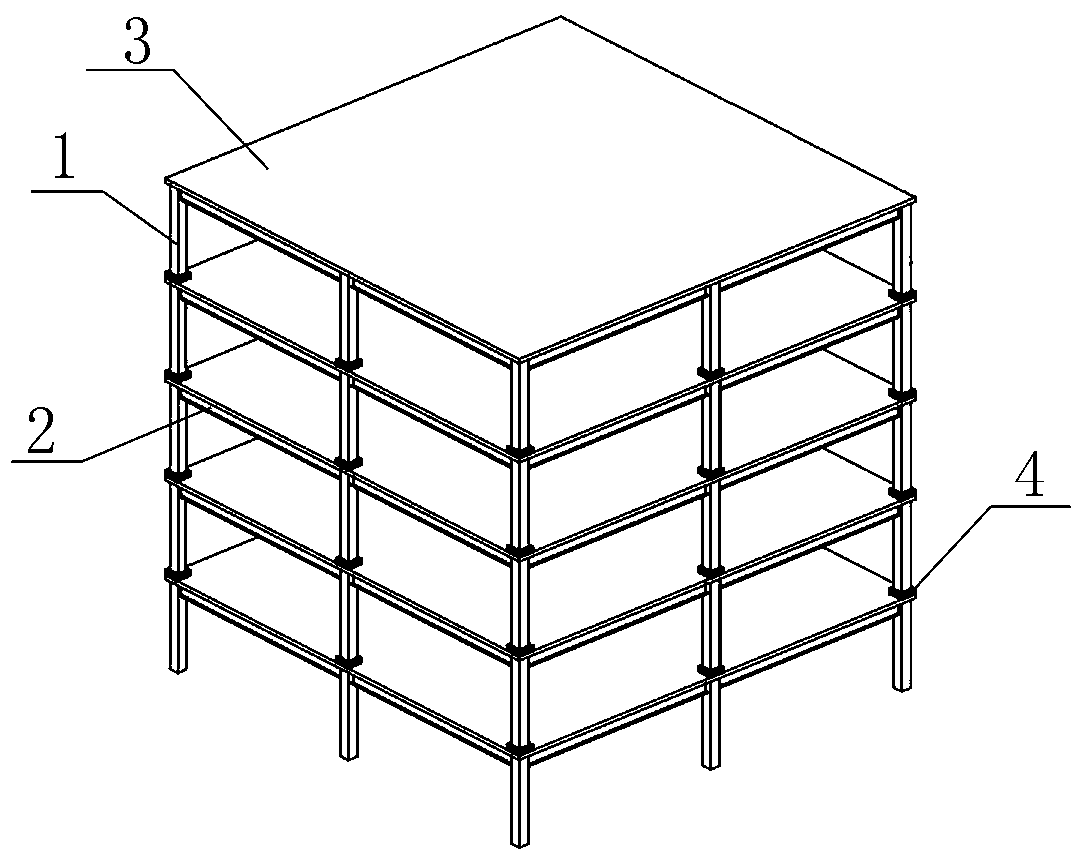

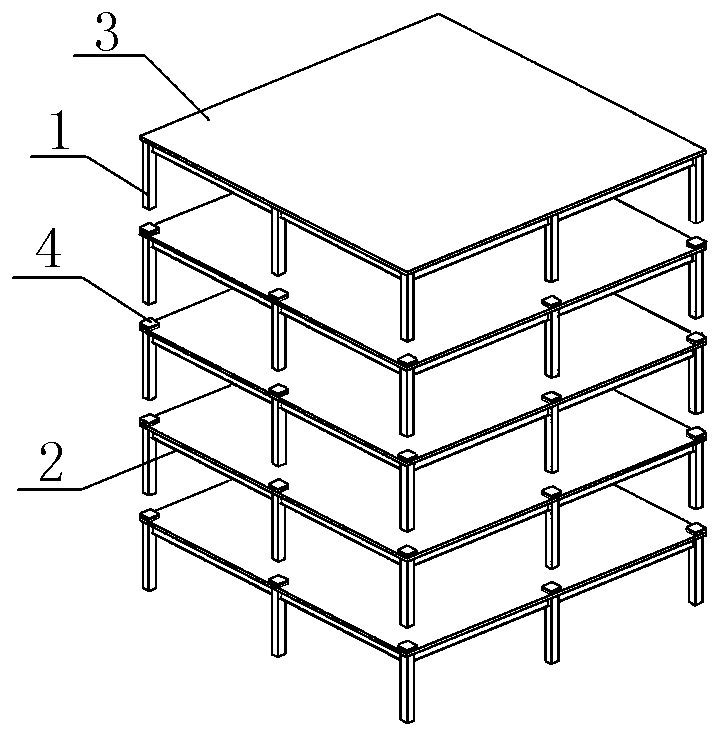

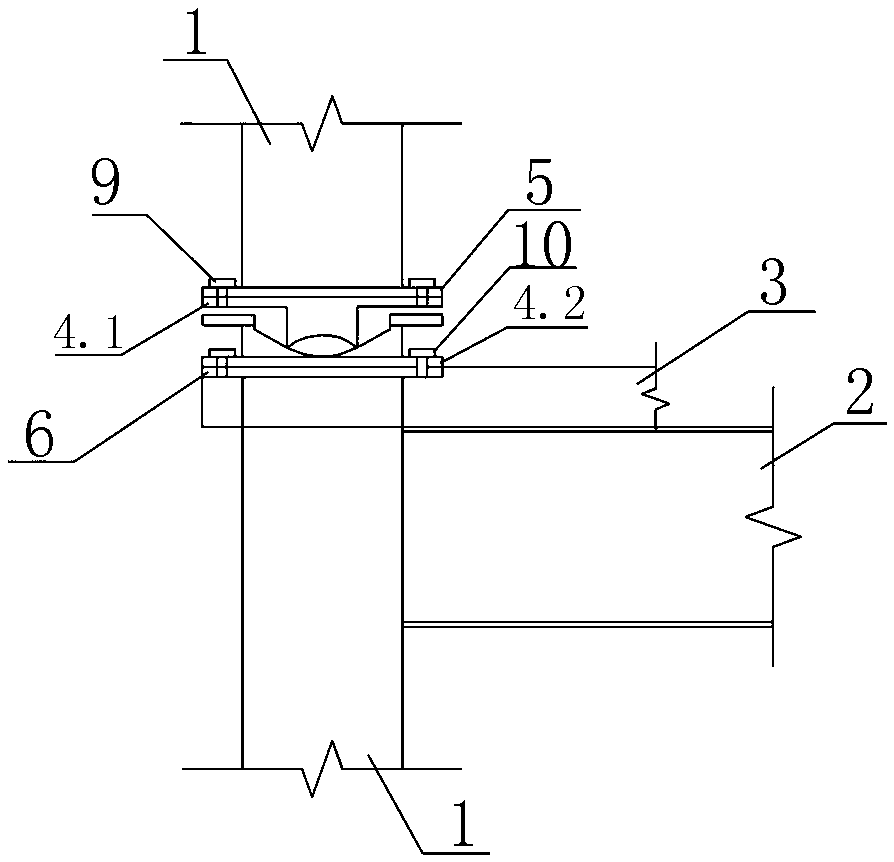

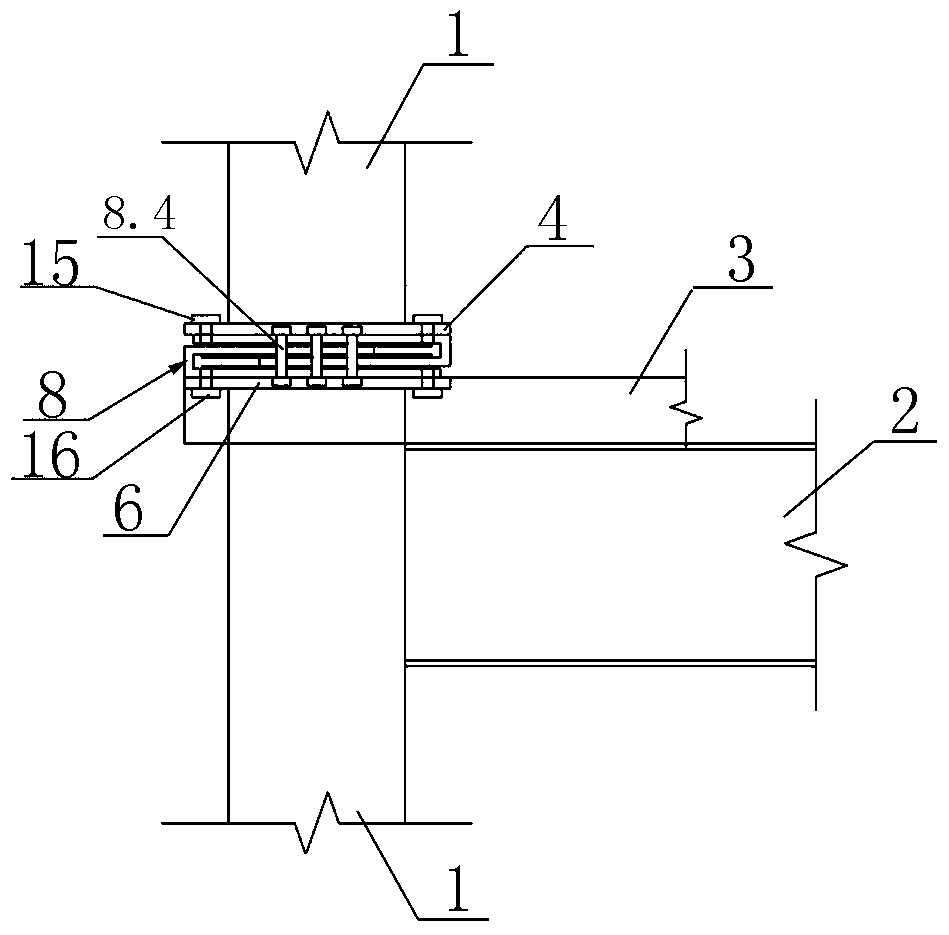

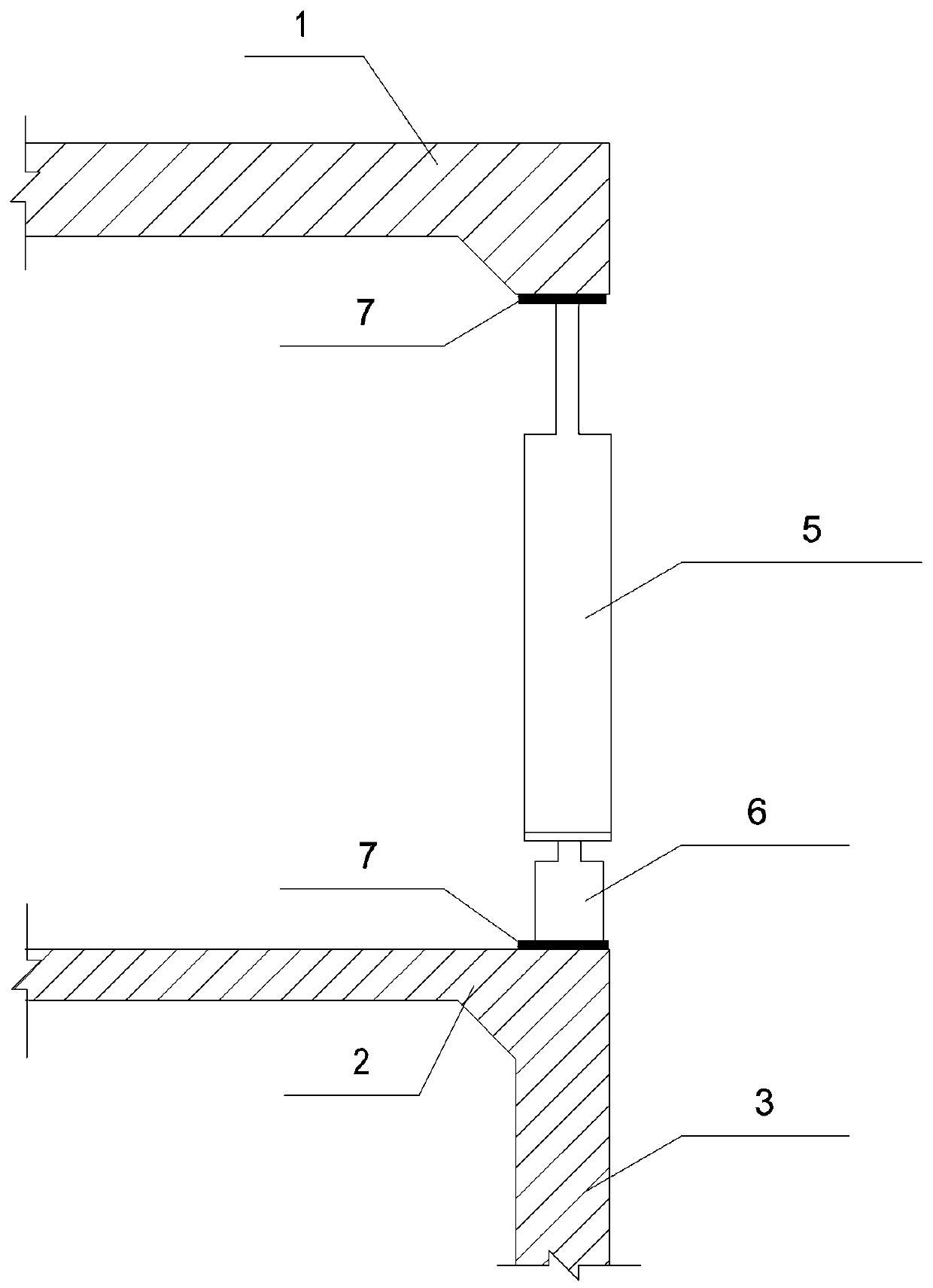

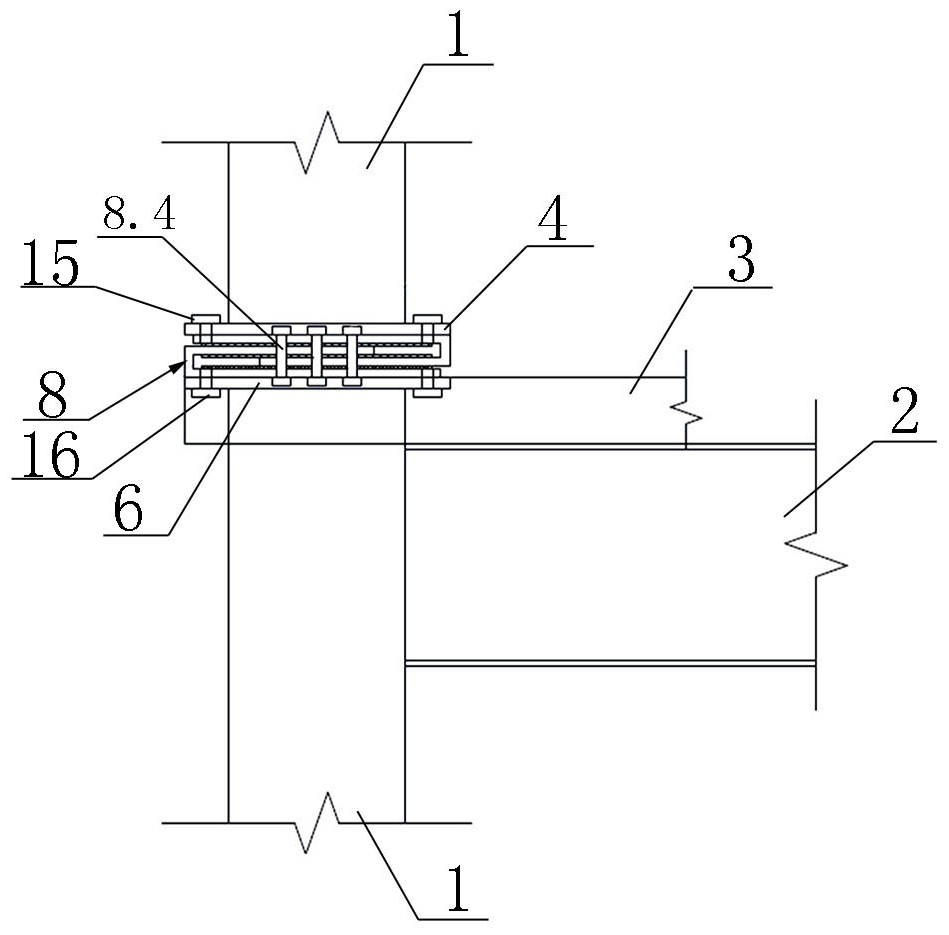

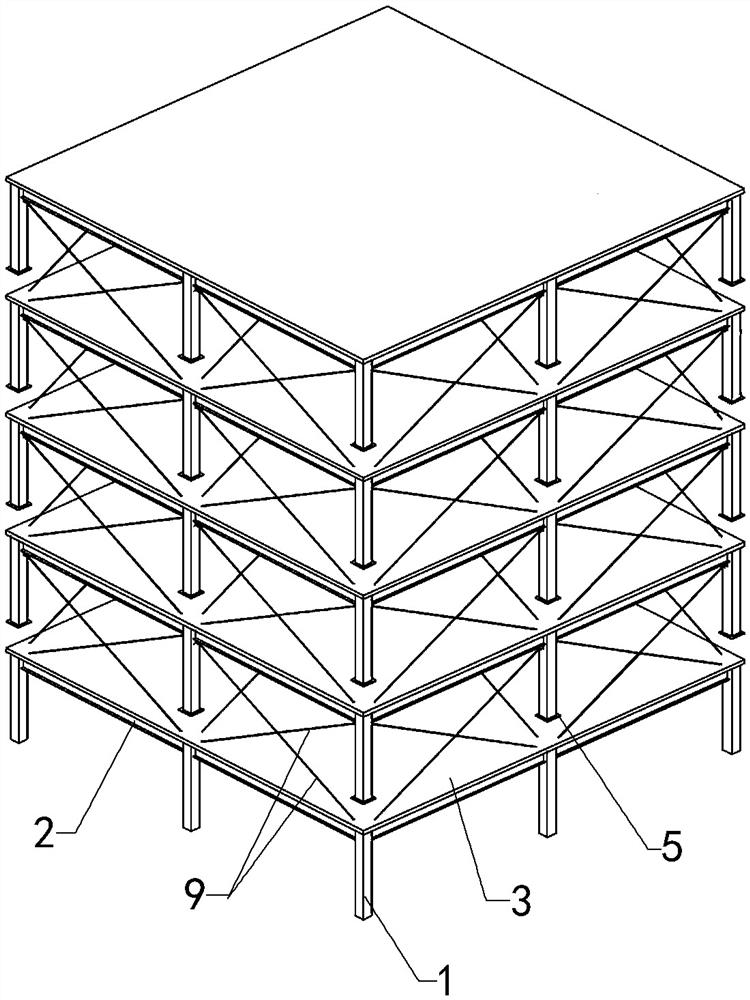

Friction pendulum connected fabricated steel structure system and design method thereof

ActiveCN110409606AImprove bearing capacityImprove reset abilityProtective buildings/sheltersSpecial data processing applicationsSteel frameEngineering

The invention discloses a friction pendulum connected fabricated steel structure system and a design method thereof. The friction pendulum connected fabricated steel structure system comprises at least two layers of steel frame structures and a group of friction pendulum shock isolation devices; steel columns of each layer of steel frame structure are disconnected at the joint with the lower floor; the friction pendulum shock isolation devices are correspondingly arranged between the steel columns of every two layers of steel frame structures; each friction pendulum shock isolation device comprises an upper connection plate and a lower connection plate; the middles of the bottom surfaces of the upper connection plates are connected with plugging blocks; the bottom surfaces of the pluggingblocks are convex curved surfaces which are convex downwards; lugs are arranged on the top surfaces of the lower connection plates; plugging slots are formed in the tops of the lugs; the bottom surfaces of the plugging slots are concave curved surfaces which are concave downwards; the plugging blocks are correspondingly plugged in the plugging slots; the tops of the plugging blocks are higher thanthe tops of the plugging slots; and distances are reserved between the side walls of the plugging blocks and the side walls of the plugging slots. The friction pendulum connected fabricated steel structure system is capable of solving the technical problems that the existing fabricated steel structure buildings are complicated in connection joints, large in field workload and low in constructionefficiency, the joints of the frame structures are rigidly connected and the seismic resistance of the frames is relatively bad are solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

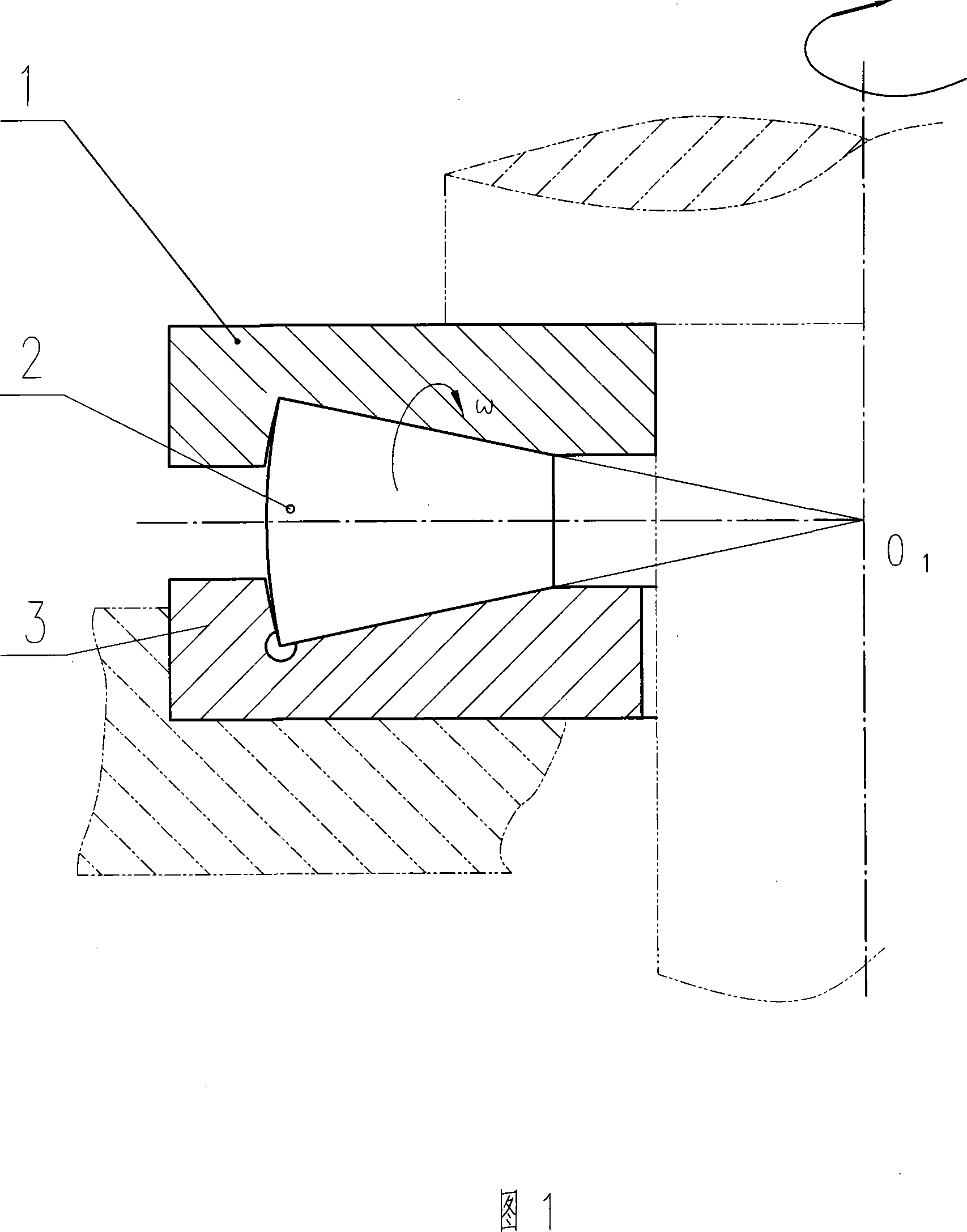

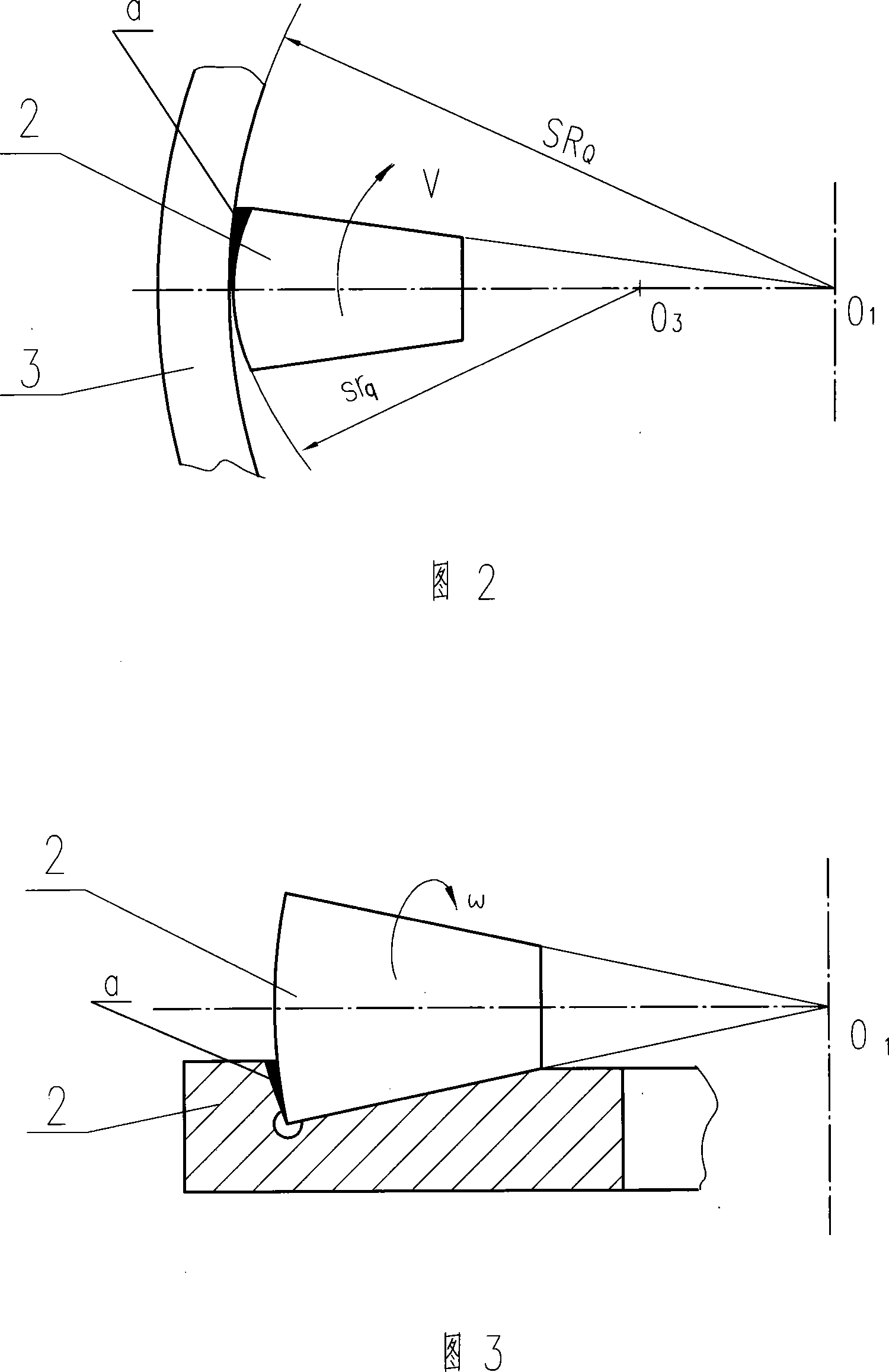

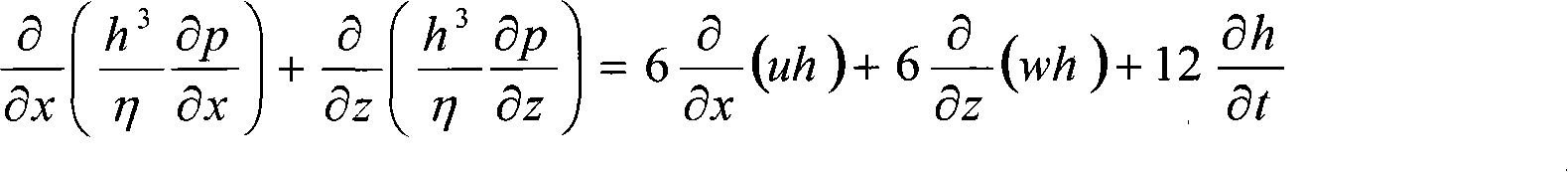

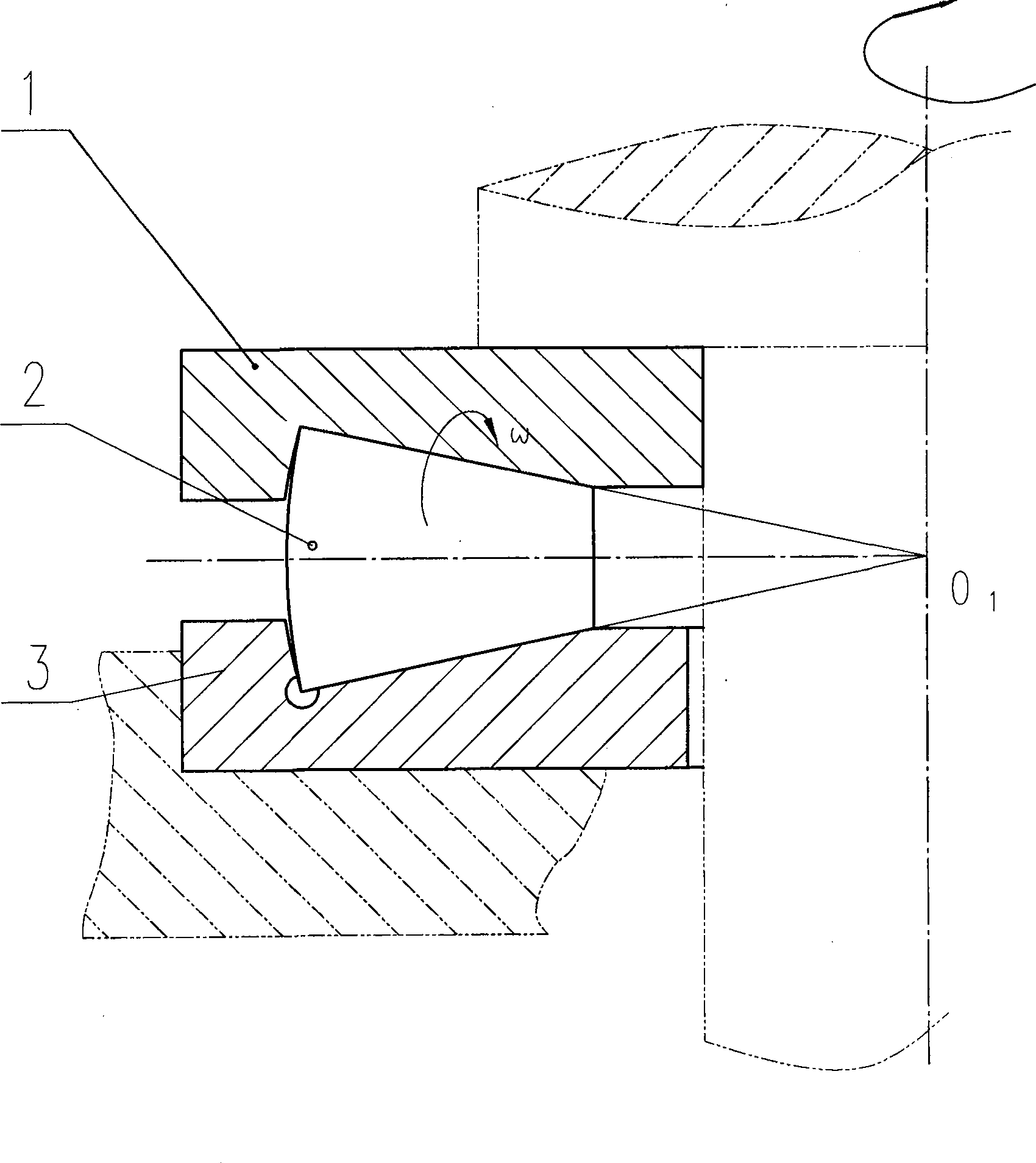

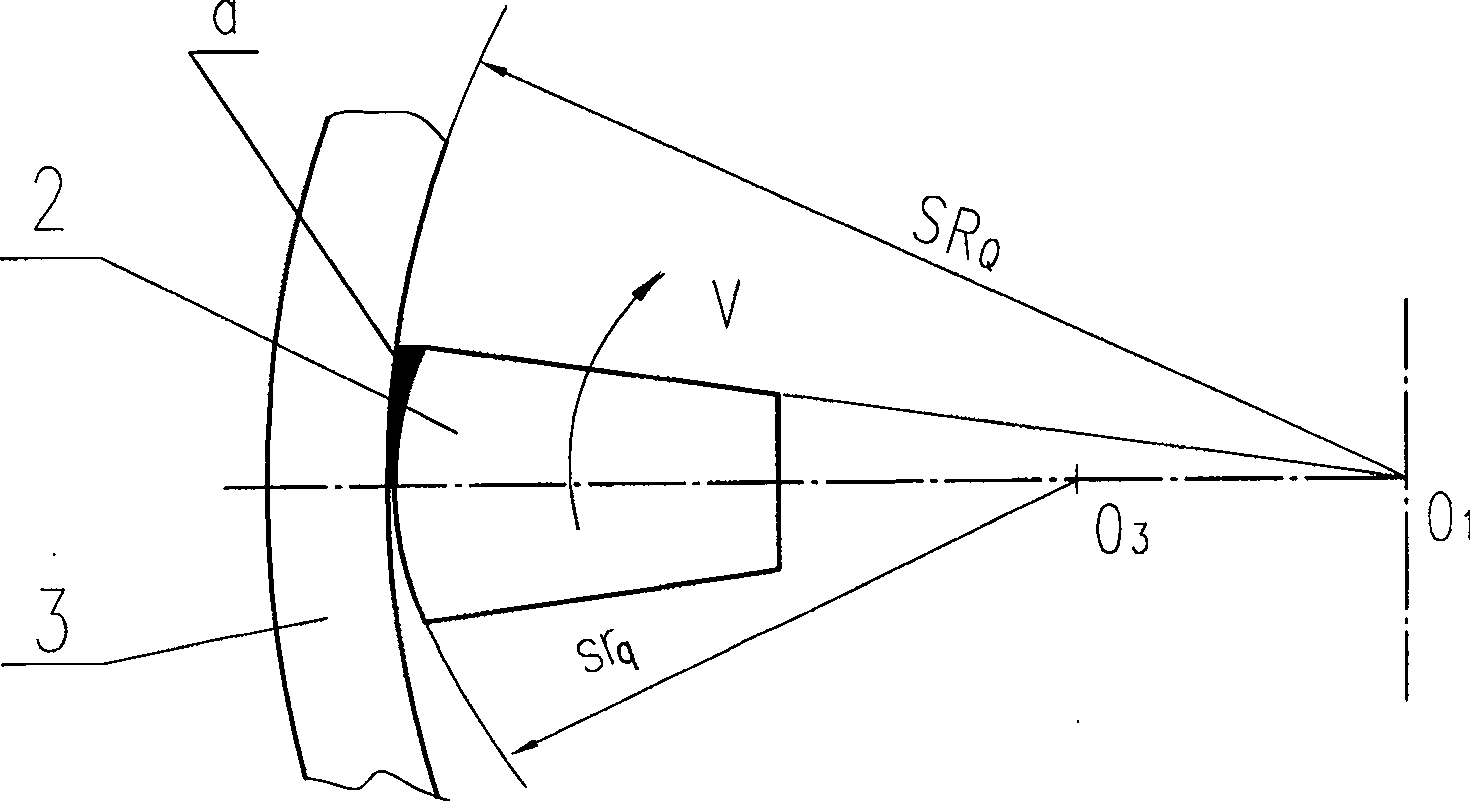

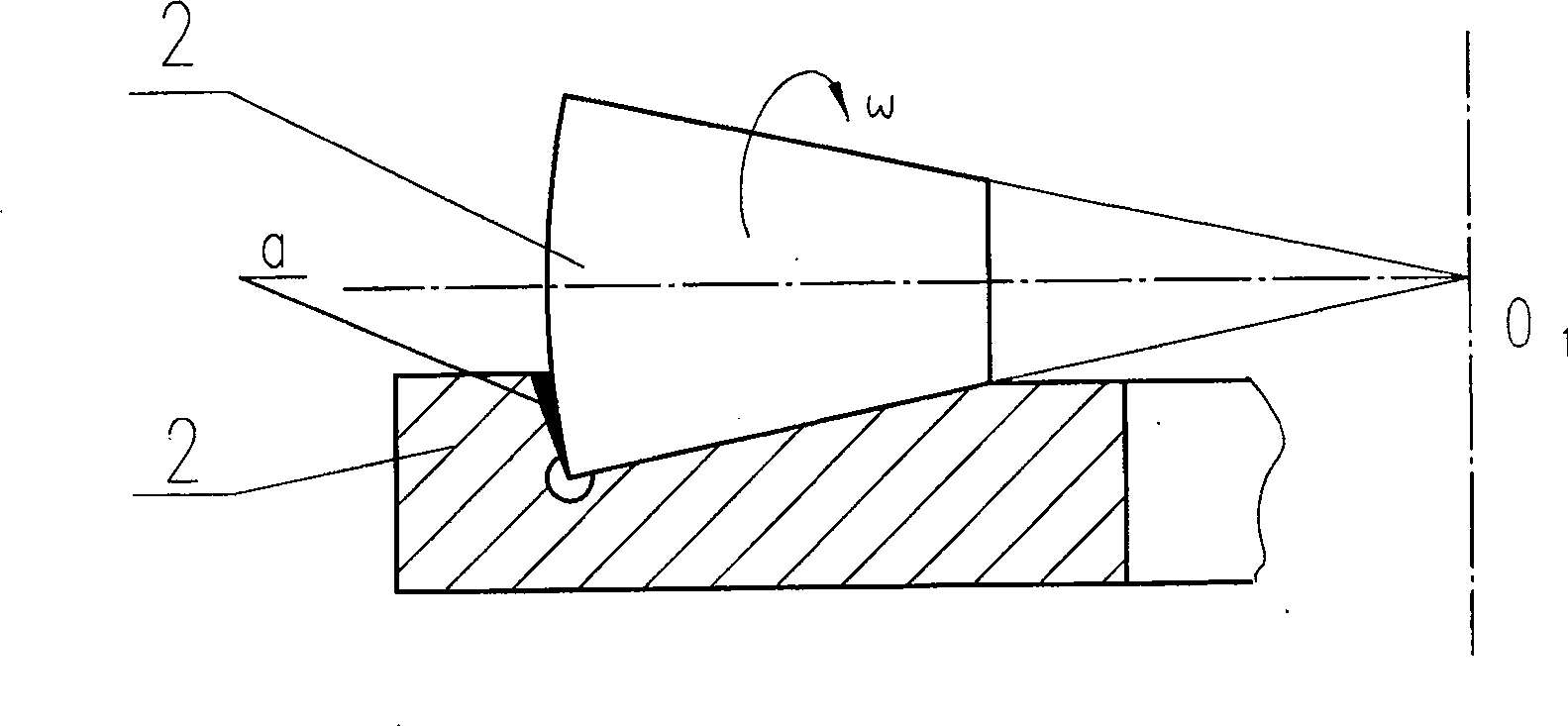

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN101092992AImprove performanceRich design methodBearing componentsRolling-element bearingThrust bearing

This invention discloses a film lubrication method for thrust bearing roller cone races and ribs, which forms a wedge clearance between the large end surface of a roller and inside wall of a ring rib and fills it with lubrication oil, when the shape, size of the clearance and axial load, glide speed and viscosity of the oil are matched to each other, a dynamic pressure film is formed between the two surfaces, in which the wedge clearance is formed by cone roller spherical large end surface and the ring rib spherical ring, so it's easy to form a dynamic pressure film by selecting race SRQ of the inner surface of the race and axis ring and srq of the cone large end surface reasonably.

Owner:郭溪泉

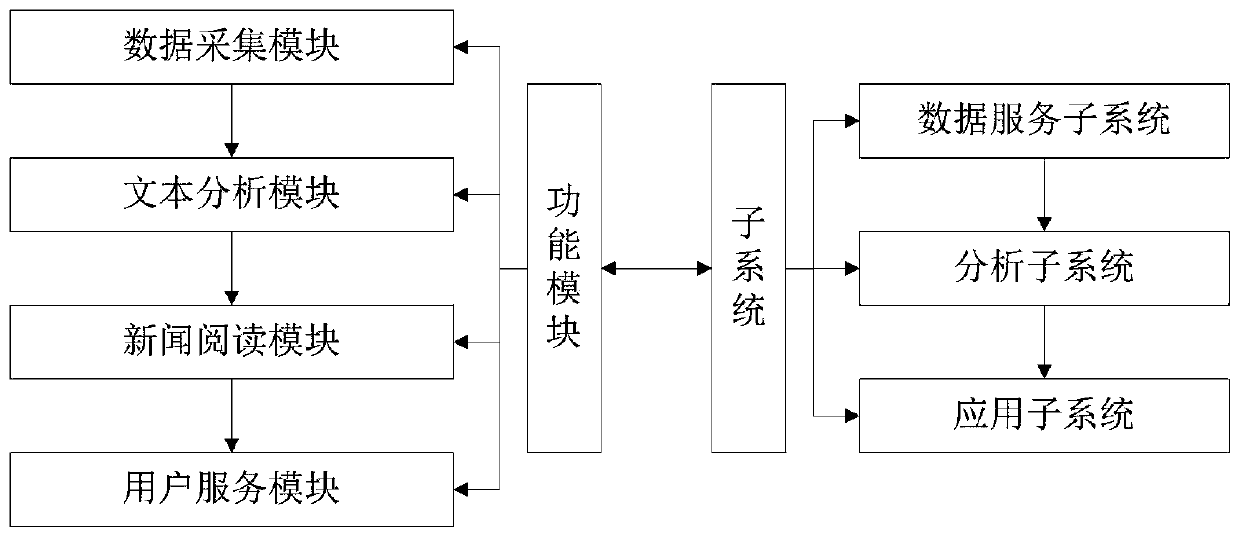

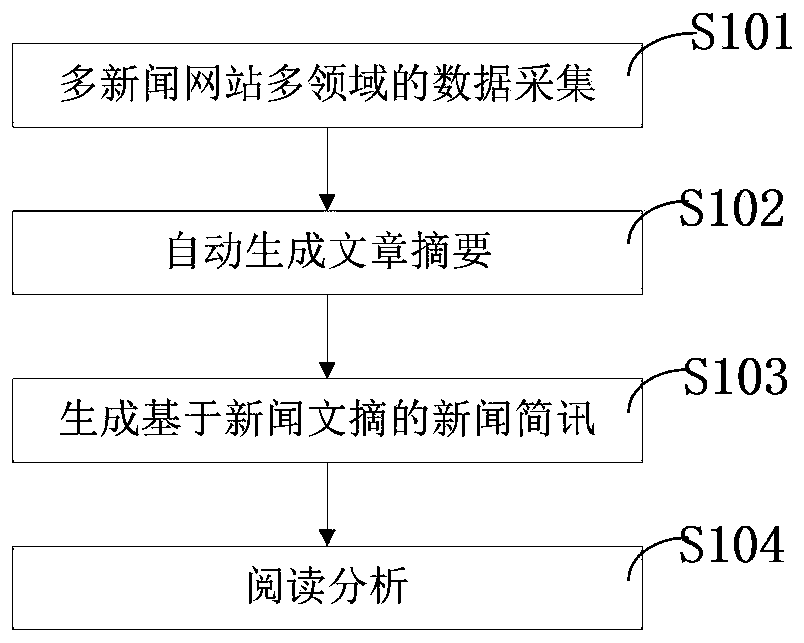

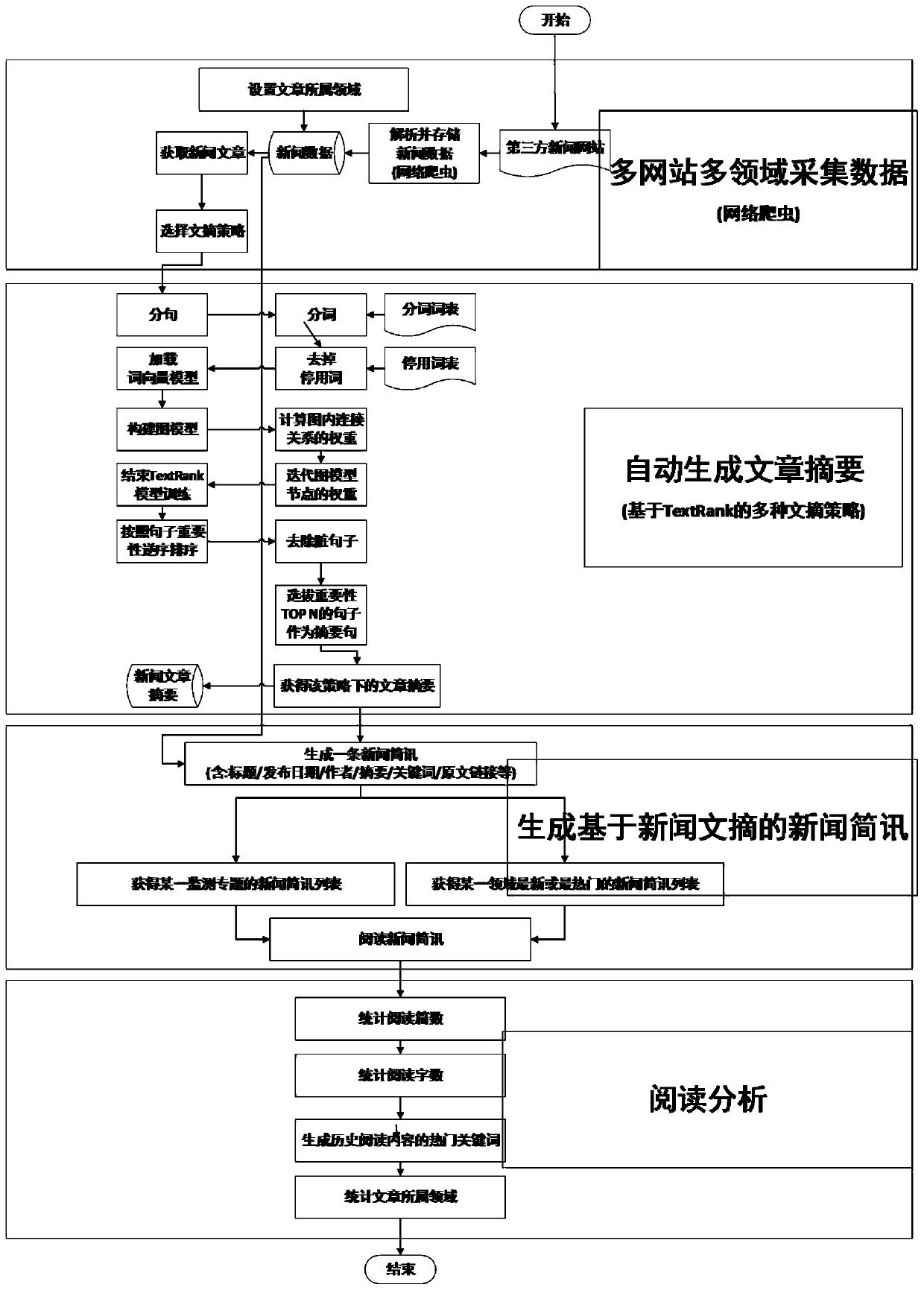

Network news summary system for automatically generating abstracts by adopting multiple strategies

ActiveCN110597981AQuick previewQuick flipWeb data indexingSpecial data processing applicationsData acquisitionSoftware development

The invention belongs to the technical field of news software development, and discloses a network news summary system and method for automatically generating abstracts by adopting multiple strategies, which are used for carrying out data acquisition in multiple fields of multiple news websites, automatically generating article abstracts, generating news short messages based on news abstracts andcarrying out reading analysis. Multiple strategy automatic abstract generation algorithms serve as the core, multiple news short messages are correspondingly generated for each original news report grabbed from the network, news short messages with large text content are removed, a user is helped to quickly preview and browse interested news reports, and the click rate and the reading rate of a news website can be increased. In addition, the use value of efficient and standard domain classification after aggregation of multiple news websites can be improved; and rapid reading of a large amountof news is achieved, and a large amount of time and energy for reading news original texts of users are saved.

Owner:XIHUA UNIV

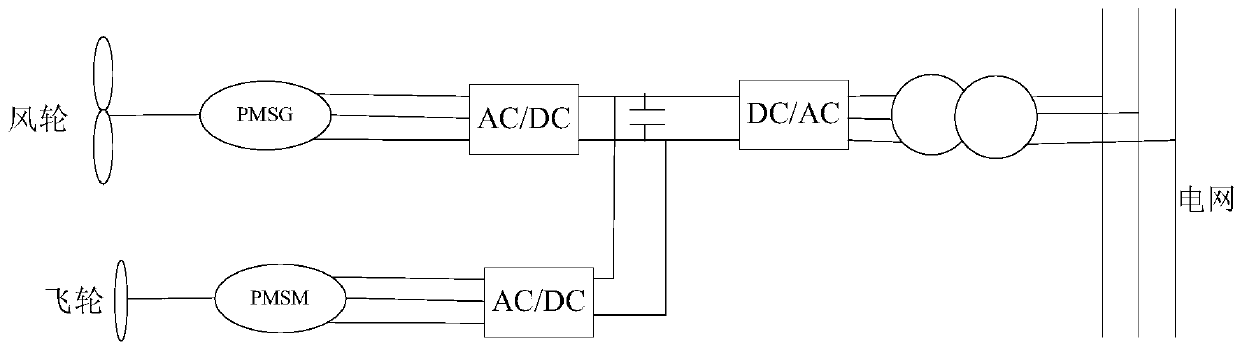

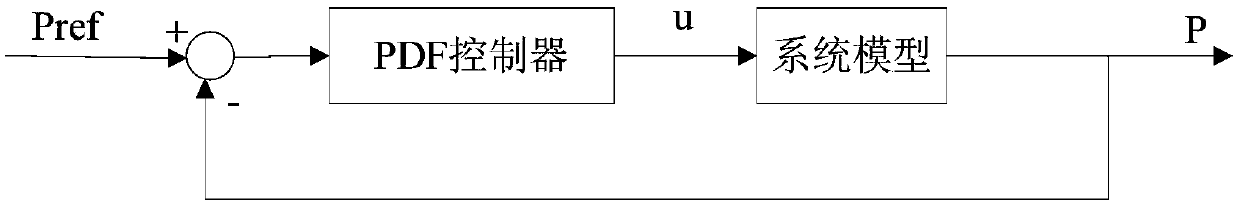

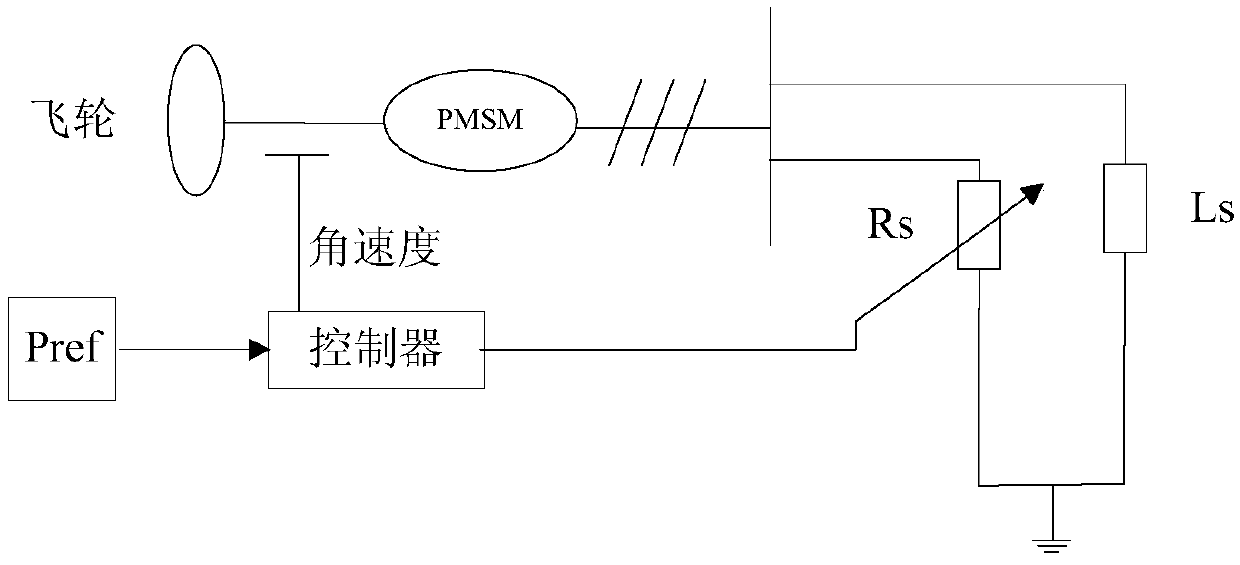

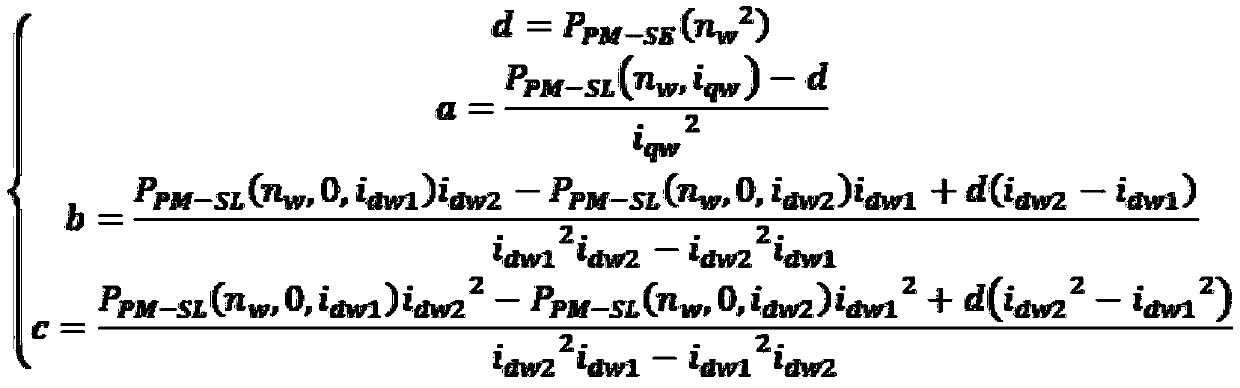

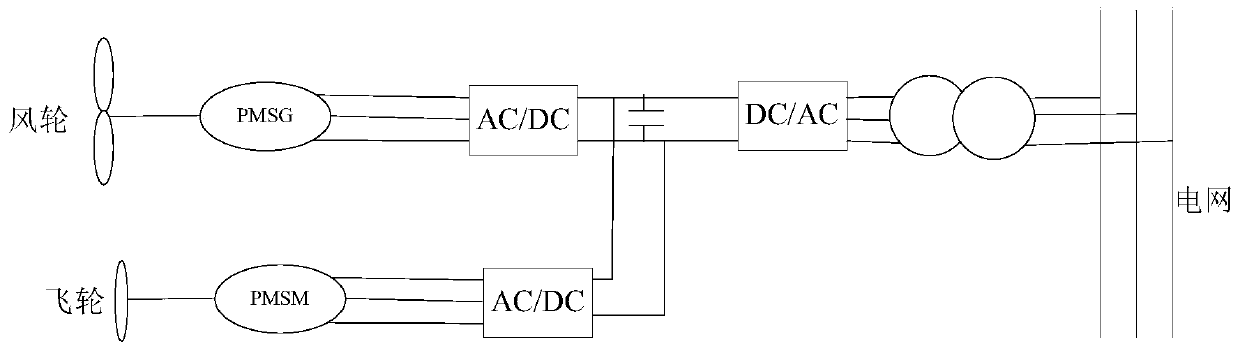

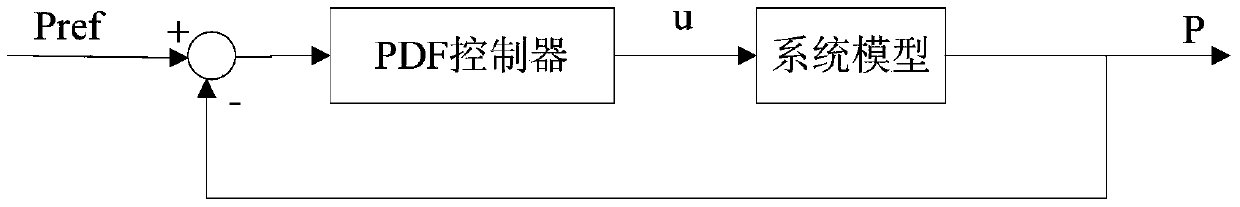

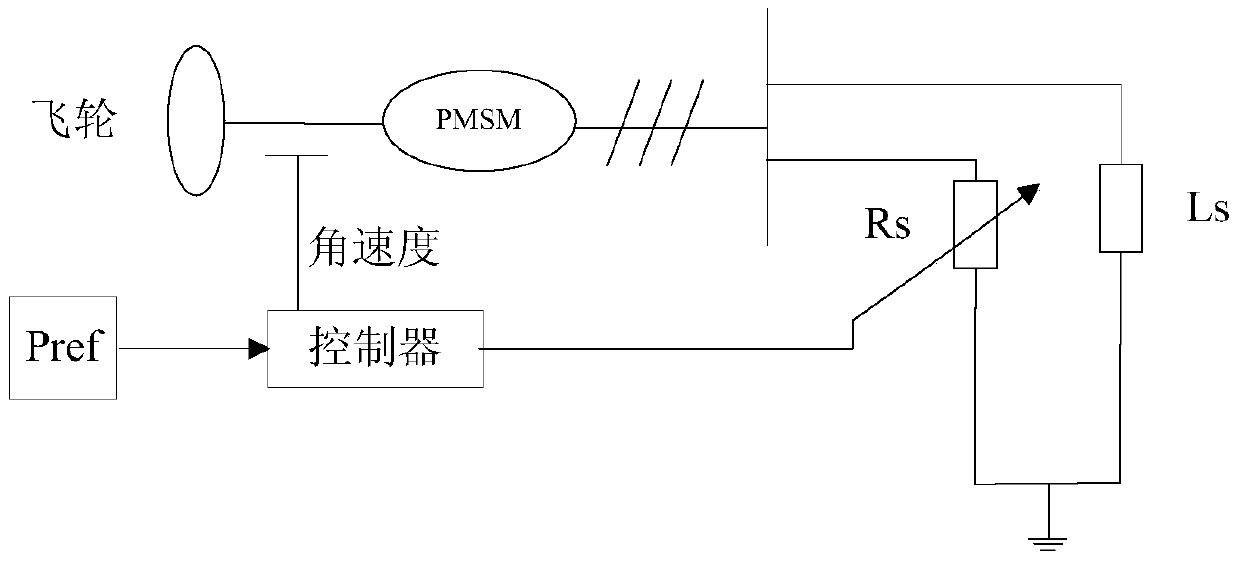

Control method and device for flywheel energy storage system

InactiveCN105515029AGuaranteed smooth powerSolve randomnessElectronic commutation motor controlVector control systemsFlywheel energy storageThermal energy storage

The invention provides a control method and a device for a flywheel energy storage system. The method comprises the steps of a, with the angular velocity, the d-axis current and the q-axis current of A, a flywheel as state variables, and the energy storage capacity of the flywheel as a control variable, constructing a model for the energy storage system of the flywheel, and discretizing the model according to the sampling time; B, constructing a performance index based on a second-order Renyi entropy, and determining an optimal input control variable increment with the partial derivative of the input control variable increment to be zero based on the performance index; C, determining a current optimal input control variable based on the optimal input control variable increment. According to the control method and device, based on the simplified energy storage model of the flywheel, a controller for the energy storage system of the flywheel can be designed. Meanwhile, the excess energy of the flywheel is stored, or the deficient energy of the flywheel is supplemented. In this way, a wind turbine generator set is ensured to transmit a smoothing power to the power grid.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

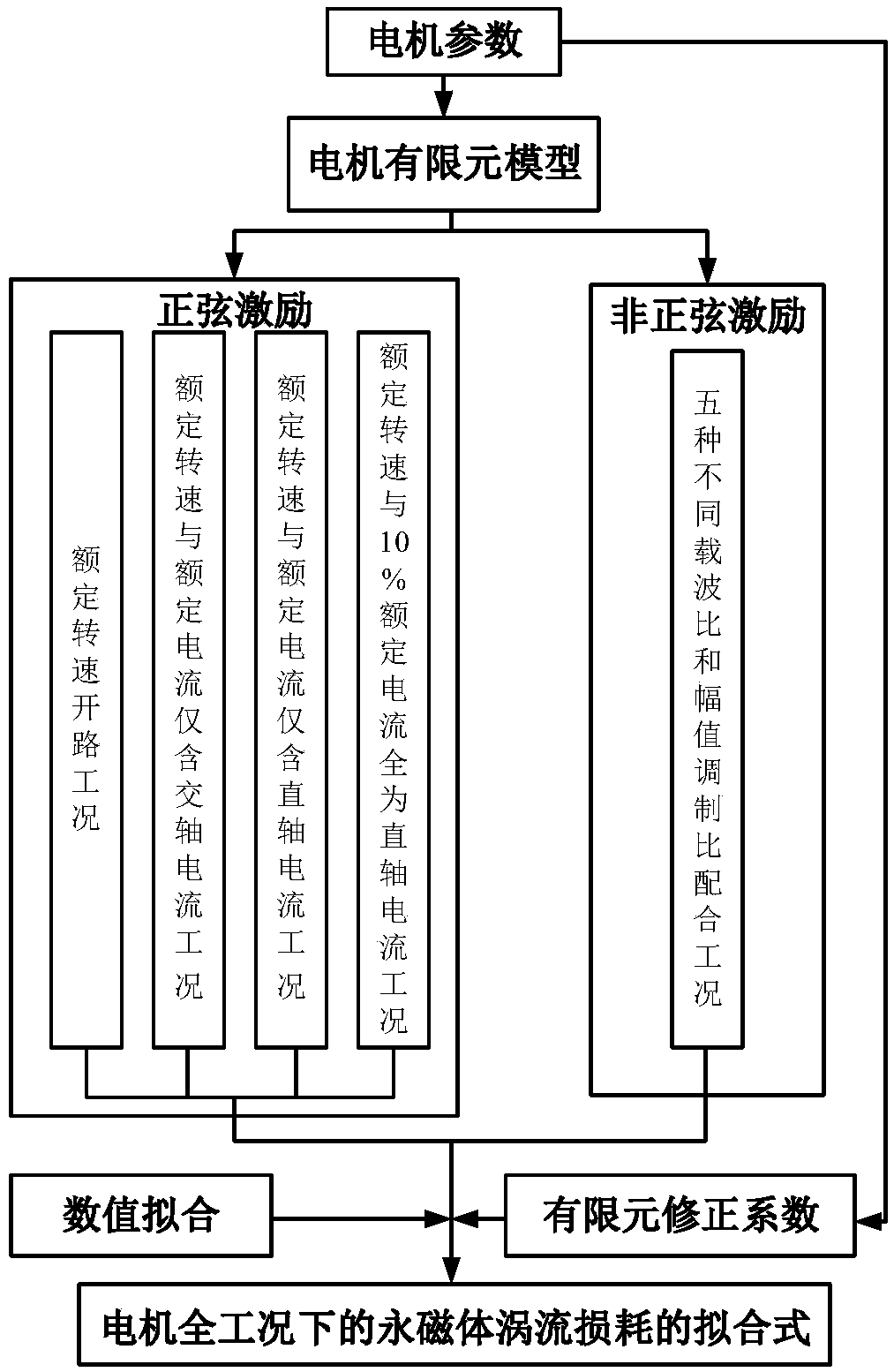

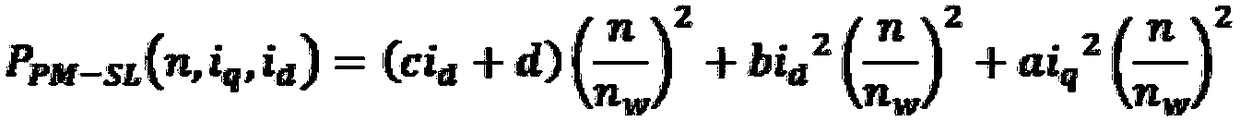

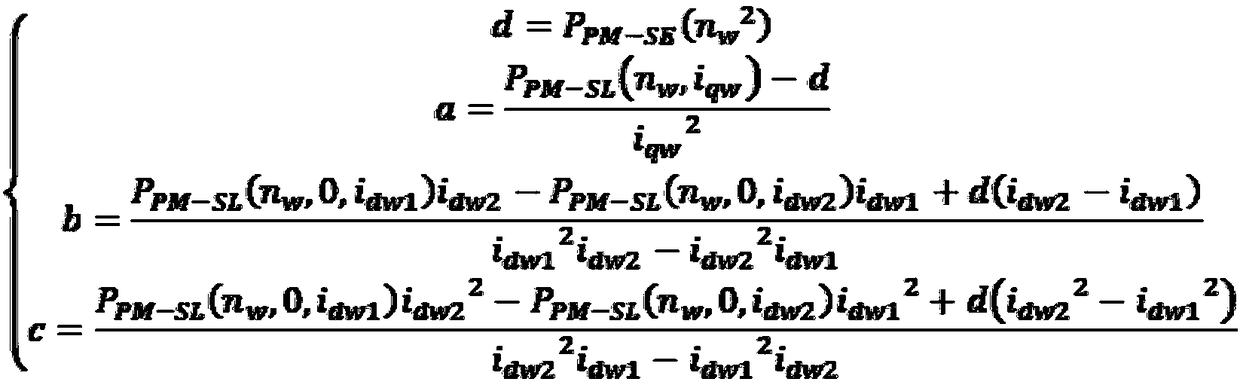

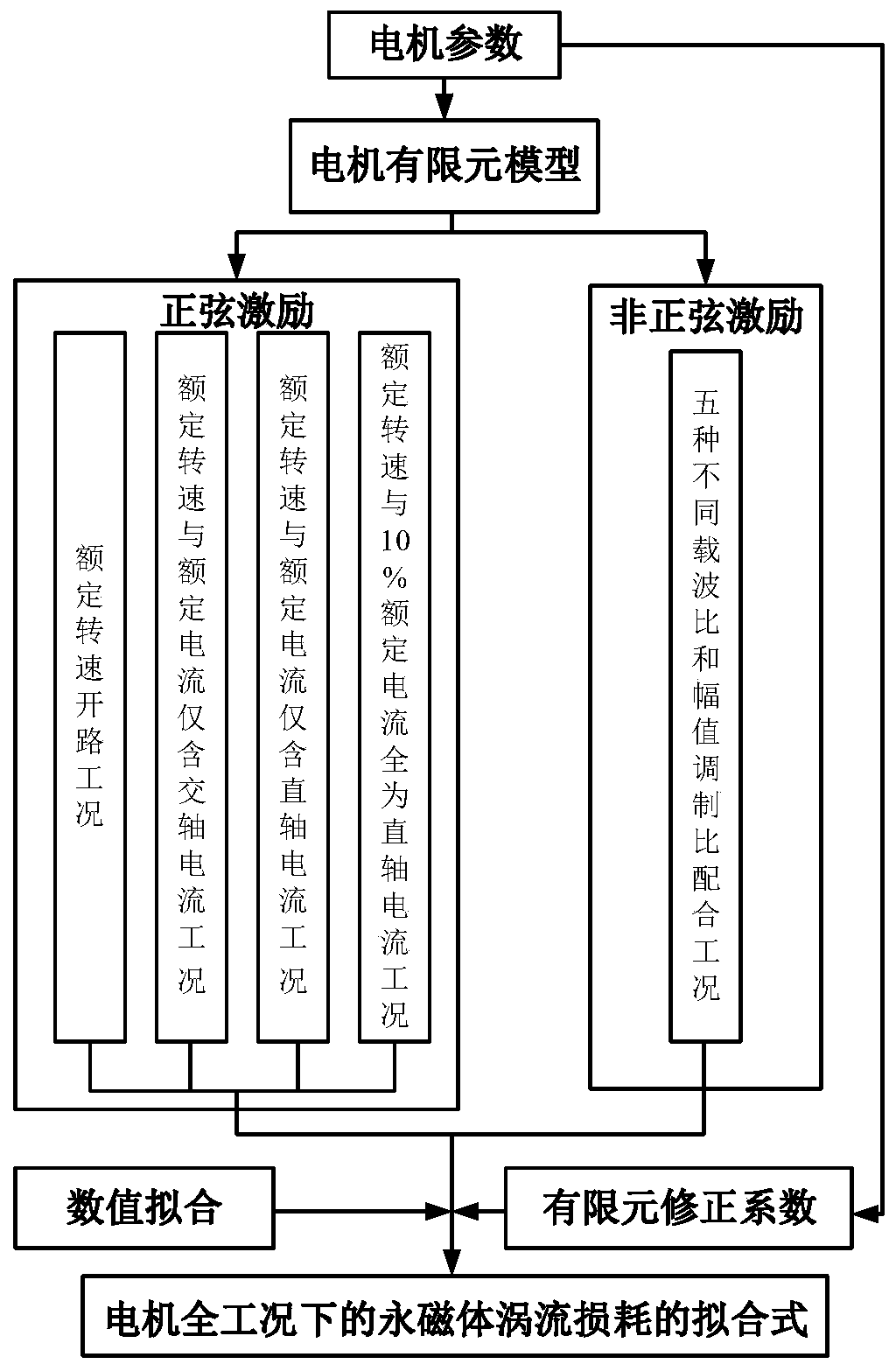

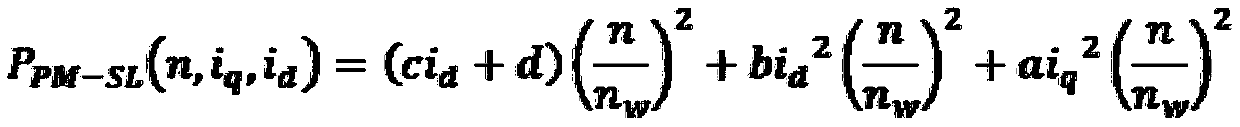

Fast calculation method for permanent magnet eddy current loss of vehicle surface-mount permanent magnet synchronous motor

ActiveCN108448990AReduce eddy current lossAvoid irreversible demagnetizationElectronic commutation motor controlVector control systemsPhase currentsElectric machine

The invention provides a fast calculation method for a permanent magnet eddy current loss of a vehicle surface-mount permanent magnet synchronous motor. The influence of phase current harmonics on thepermanent magnet eddy current loss is considered, the quick and accurate calculation of the permanent magnet eddy current loss in a whole working area can be achieved, thus a designer can select appropriate motor structural parameters and electromagnetic parameters during the design process, the permanent magnet eddy current loss is reduced, the irreversible demagnetization of a permanent magnetis avoided, and the normal working of the motor under complex and variable working conditions is ensured. At the same time, the design method of the permanent magnet synchronous motor is improved, andthe design cycle of the permanent magnet synchronous motor is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

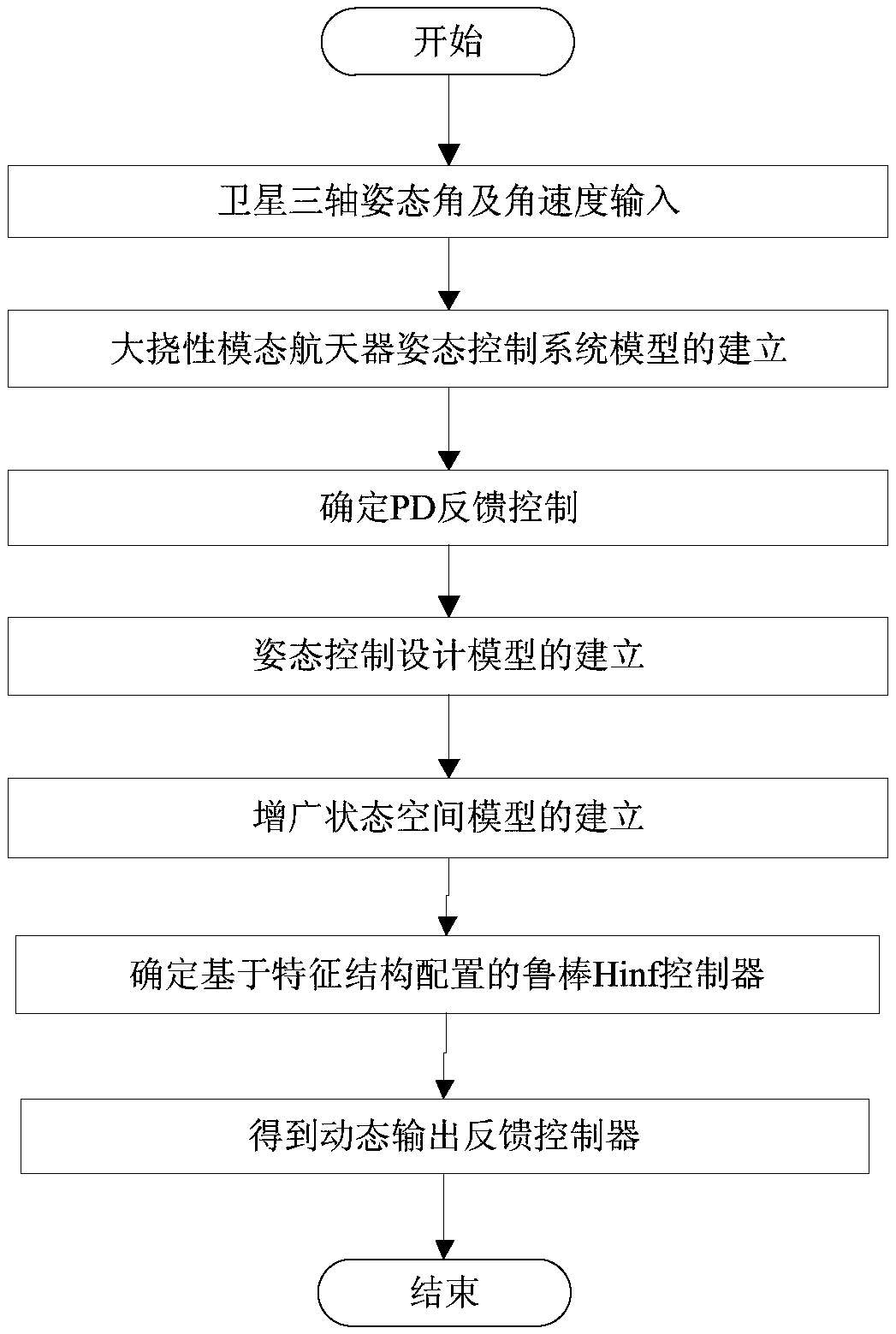

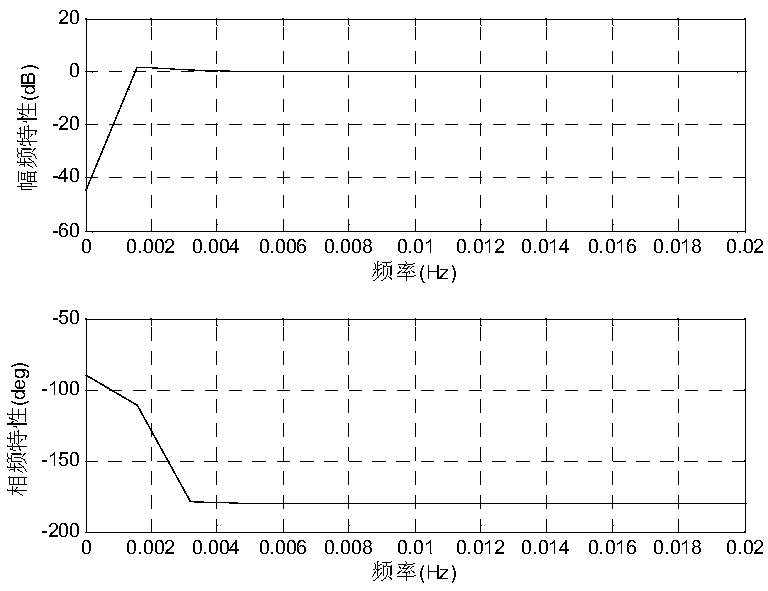

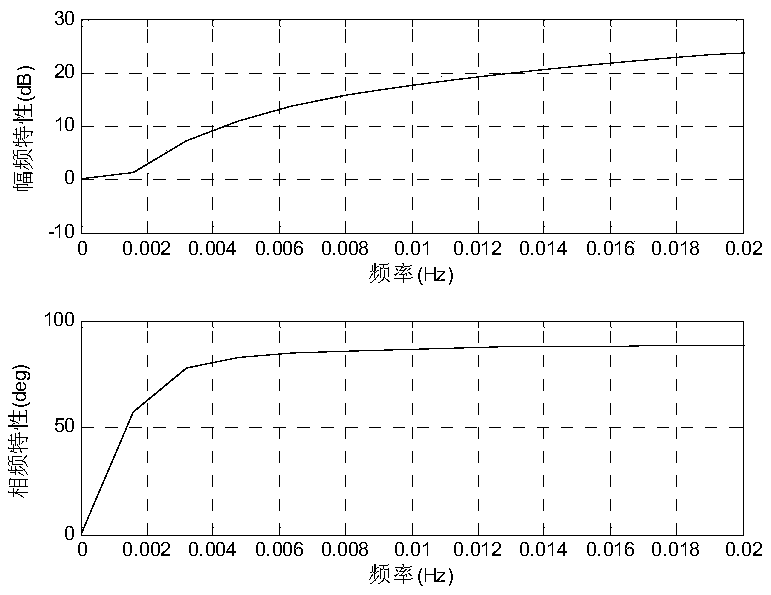

Robust Hinf spacecraft pointing control method and system based on feature structure configuration

InactiveCN109144085ARich design methodAchieve high precision pointing capabilityAttitude controlLoop controlControl system

Provided is a robust Hinf spacecraft pointing control method and system based on feature structure configuration. A controller designed by the feature structure configuration method can provide complete parameterization representation of all control laws with desired characteristics or structures for the control system, and then a reasonable constraint condition is designed according to the characteristics of a spacecraft to select free parameters in the control laws. According to the method disclosed by the invention, the satellite robust Hinf high-precision pointing control design is carriedout by mainly taking the feature structure configuration method, according to the designed closed-loop control system result, the feature value of the reasonable closed-loop system is determined andis adjusted according to the normalized structure of an existing satellite controller, the main feature value of the on-satellite closed-loop control system is consistent to that of the invention, sothat the closed-looped system has the similar motion characteristics. The in-orbit verification of the spacecraft with uncertain large-flexible structures shows that the convergence and robust stability are high, and the high-precision pointing task demand in the long-term on-orbit operation can be guaranteed, thus the reliability of the system is improved.

Owner:BEIJING INST OF CONTROL ENG

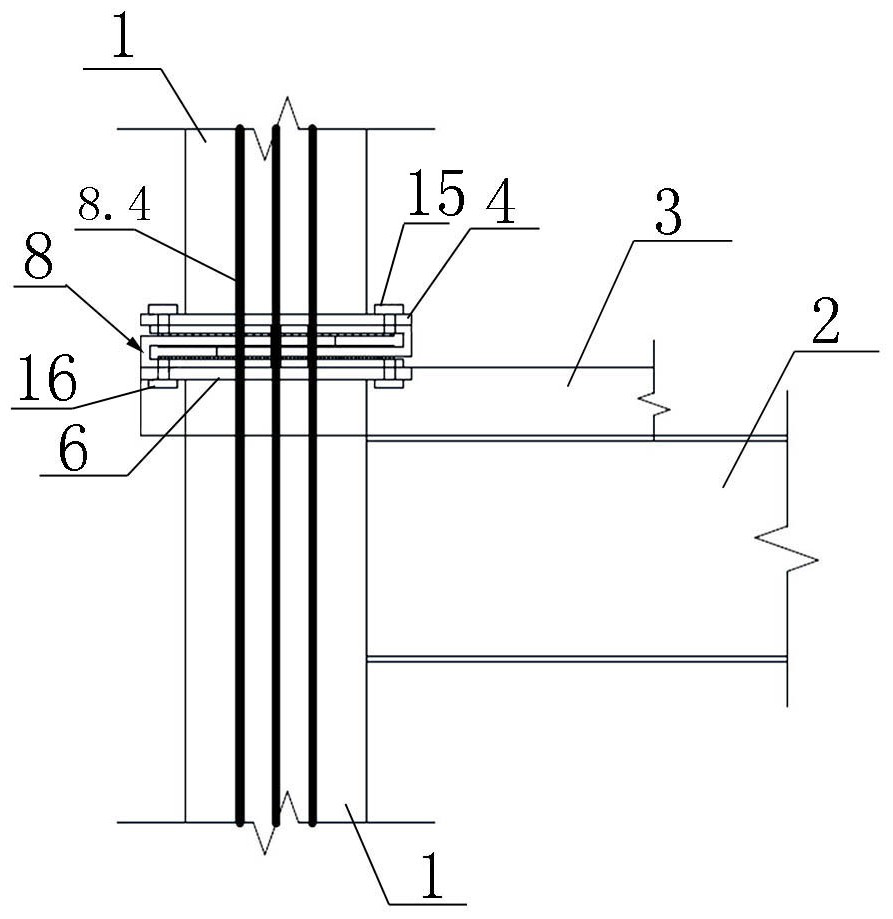

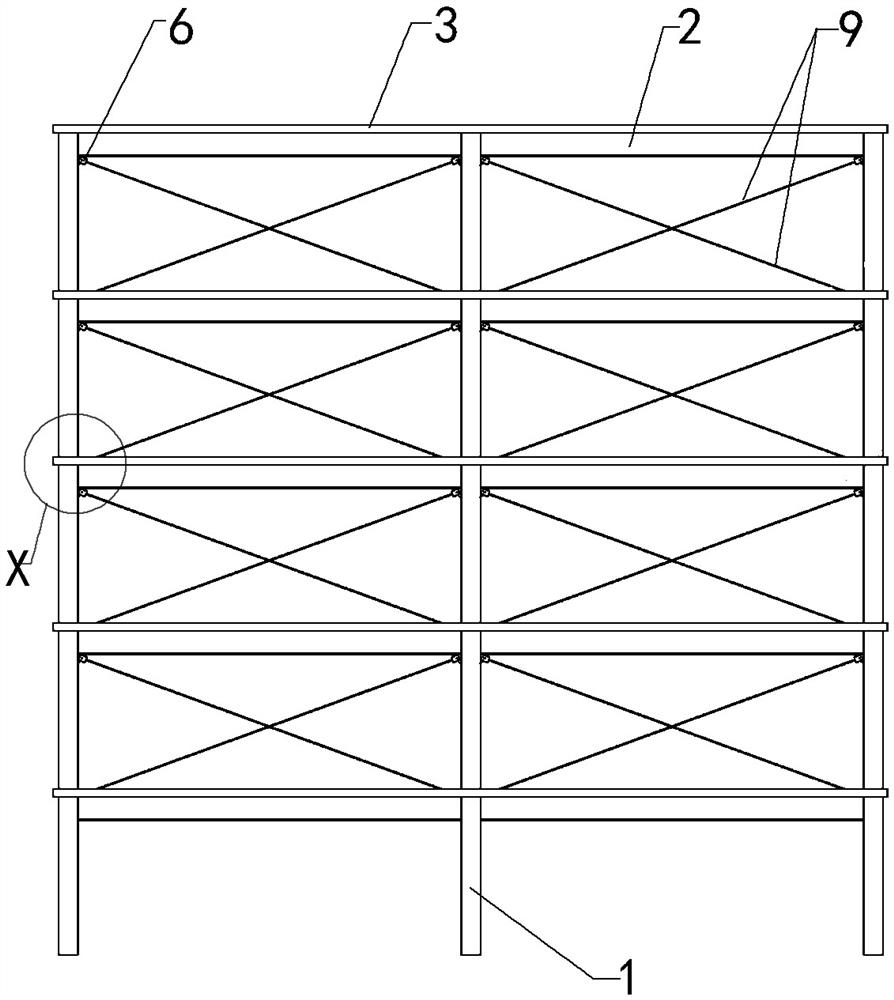

Prestressed assembly type steel frame friction damping structure system and design method thereof

ActiveCN110409604AAvoid damageReduce pollutionProtective buildings/sheltersSpecial data processing applicationsFloor slabPre stress

A prestressed assembly type steel frame friction damping structure system and a design method thereof comprise at least two layers of steel frame structures, wherein adjacent steel frame structures are disconnected at the joint of an upper-layer column and a lower-layer floor slab; the adjacent steel frame structures are connected in a sliding manner through a bidirectional sliding friction connecting device; the bidirectional sliding friction connecting device comprises an upper C-shaped plate, a lower C-shaped plate, a friction plate and a connecting piece; the plate surface of the upper C-shaped plate is provided with a first transverse strip hole; the plate surface of the lower C-shaped plate is provided with a first longitudinal strip hole; the upper C-shaped plate and the lower C-shaped plate are mutually inserted and connected with the connecting pieces in the corresponding first longitudinal strip holes through the first transverse strip holes; the upper C-shaped plate is connected with a bottom connecting plate; the lower C-shaped plate is connected with a top connecting plate; and friction plates are arranged between a first top plate and a second top plate, between a second top plate and a first bottom plate and between the first bottom plate and a second bottom plate. The prestressed assembly type steel frame friction damping structure system solves the technical problems of poor energy consumption performance and difficult construction of connecting joints of the traditional assembly type structural steel column connecting structure.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

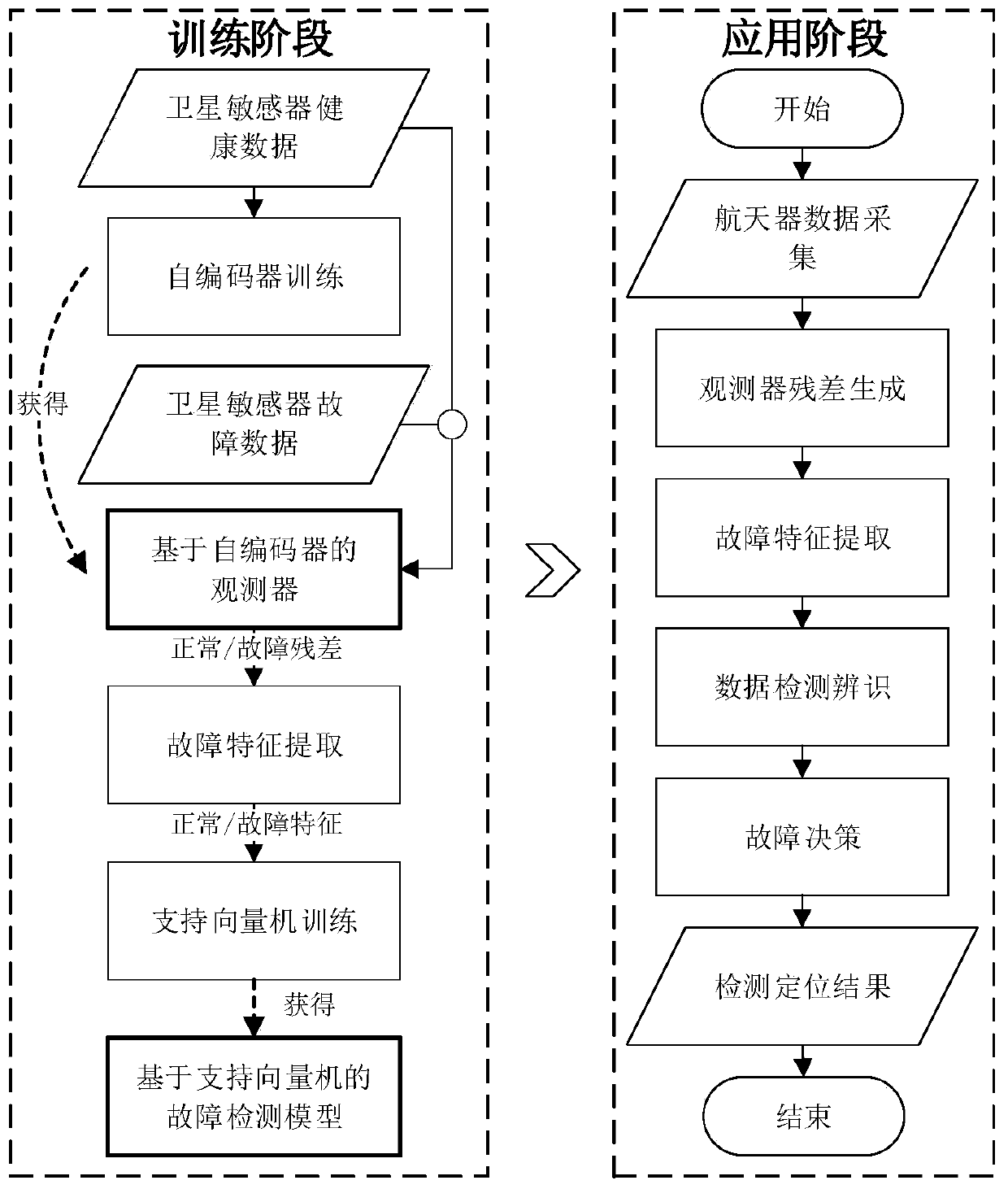

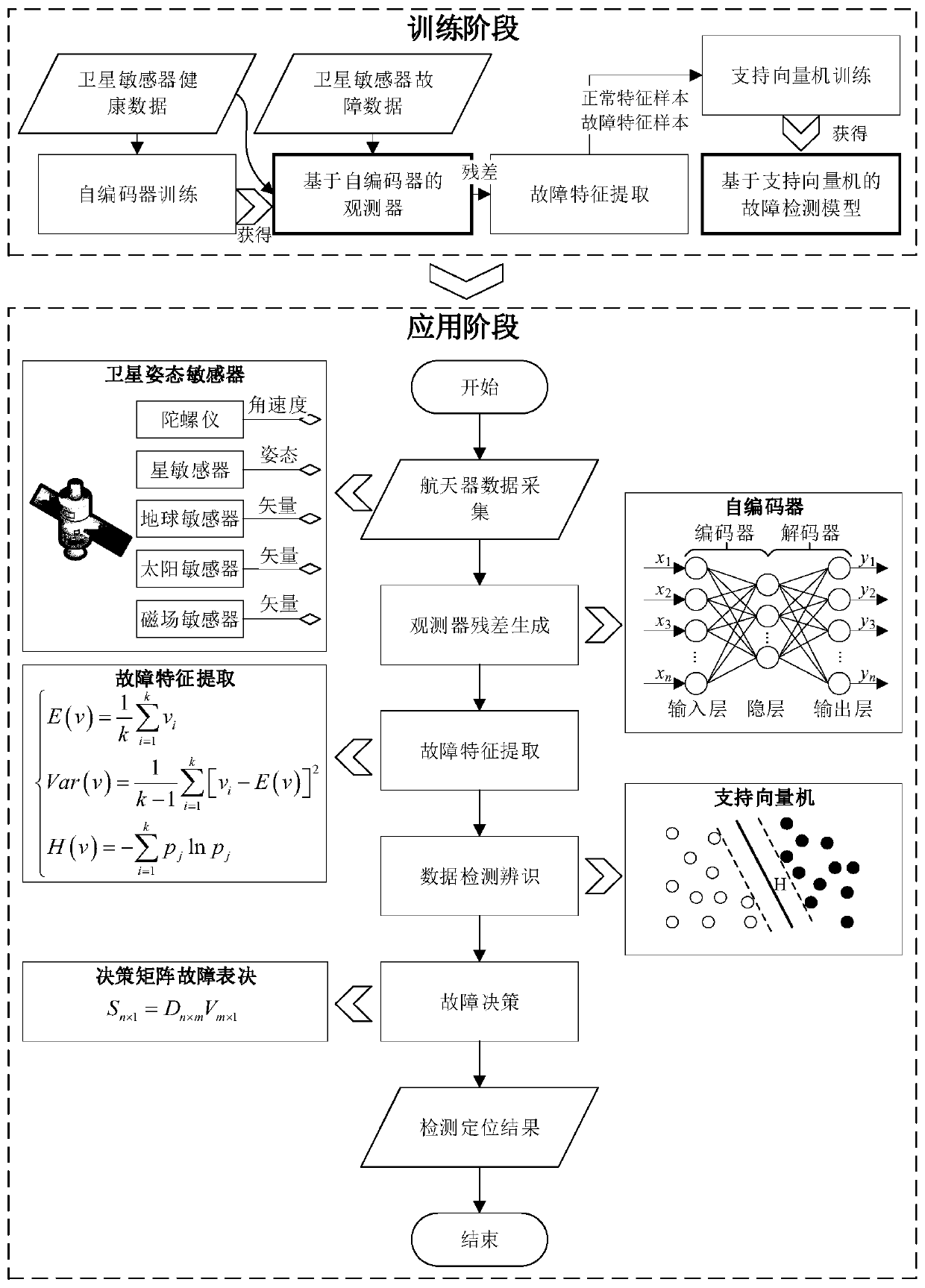

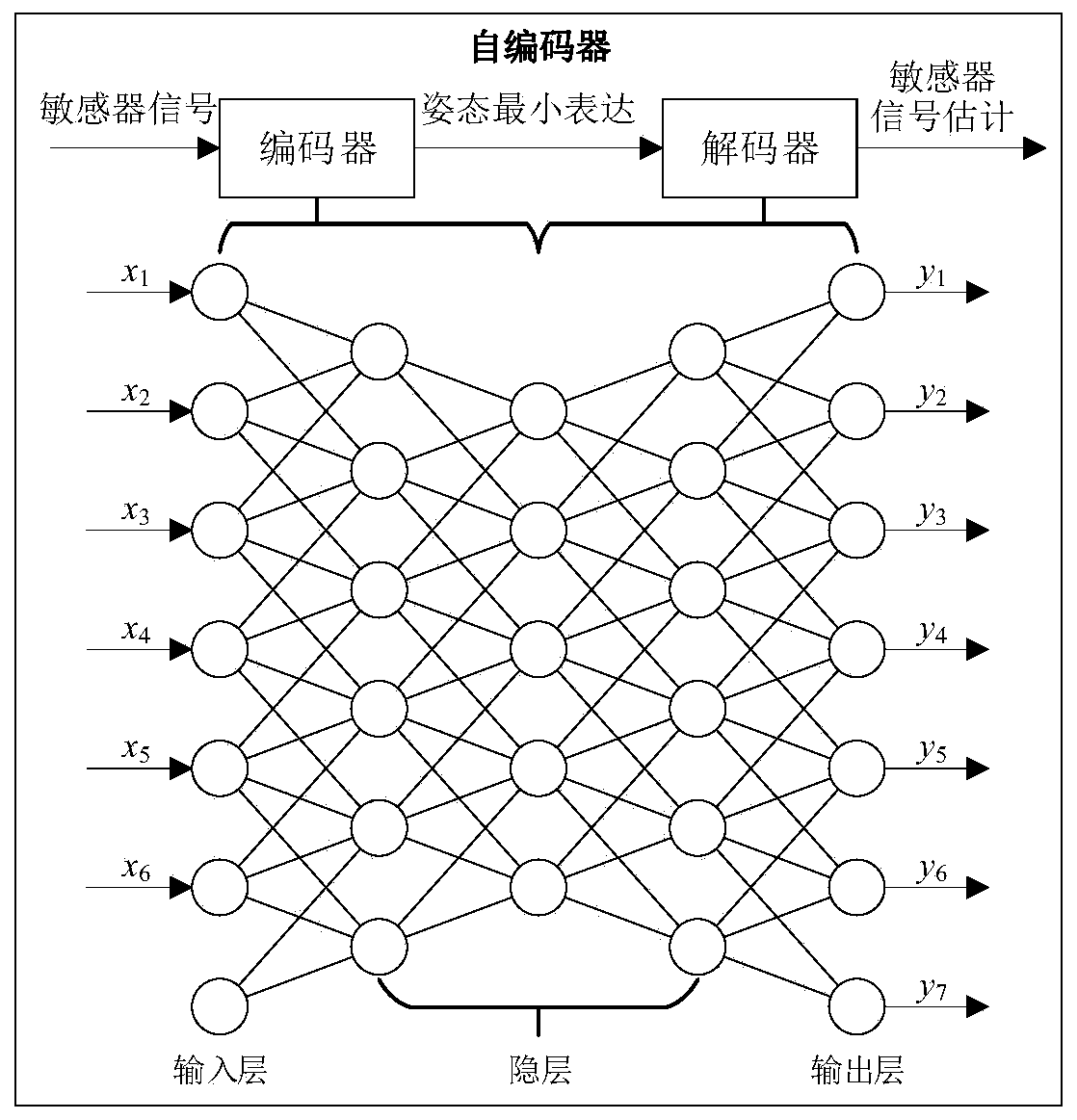

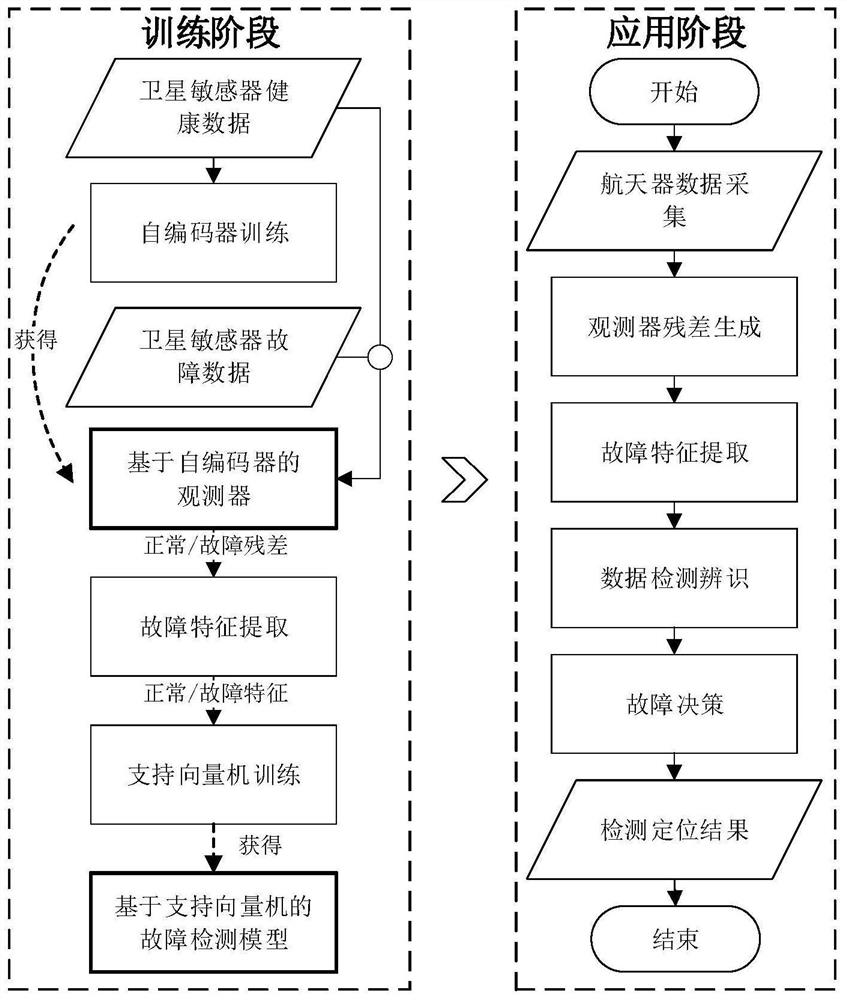

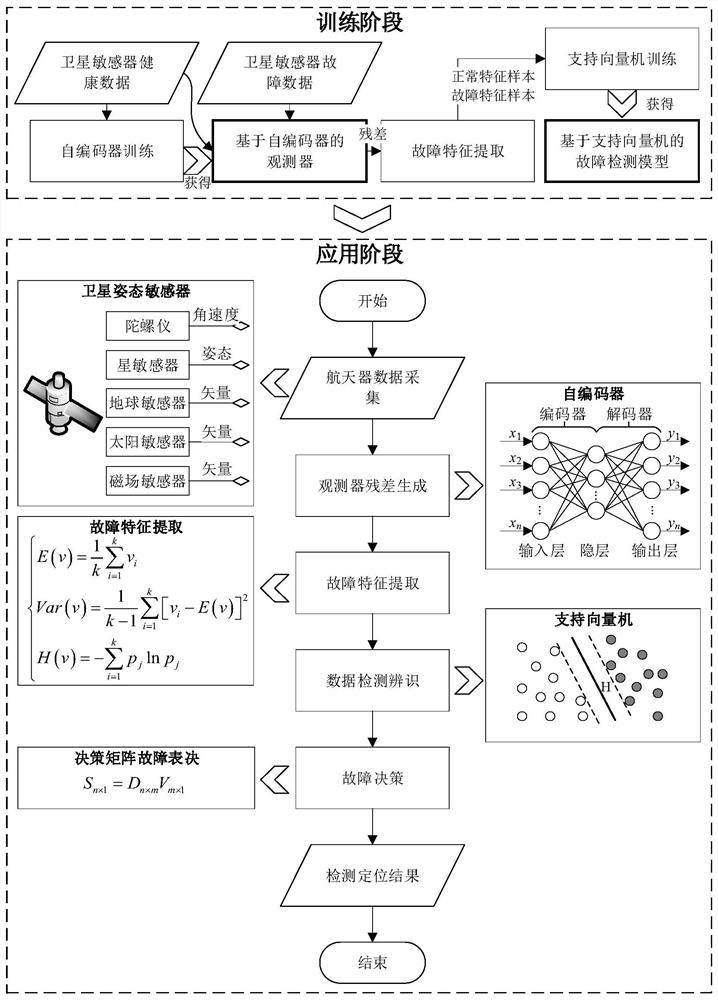

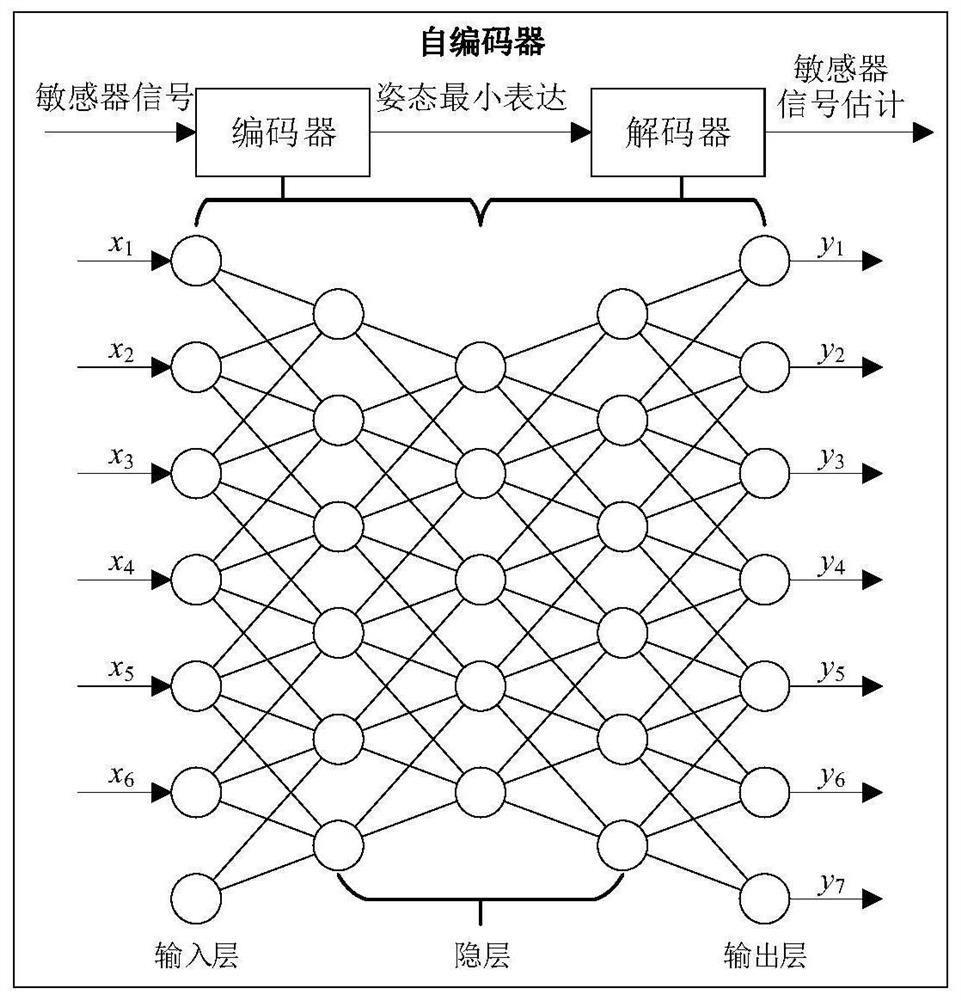

Satellite sensor fault detection and positioning method based on self-encoding observer

ActiveCN111076744AImprove portabilityRich design methodInstruments for comonautical navigationArtificial intelligenceControl theory

The invention discloses a satellite sensor fault detection and positioning method based on a self-encoding observer. According to the method, fault detection and positioning are carried out on a satellite attitude sensor based on a self-encoding observer. To be specific, according to an observer design based on an auto-encoder and a support vector machine system, self-coding observers are built according to a satellite attitude measurement method, inputs and outputs of the observers are compared to generate residual errors, the support vector machine is used for detecting faults according to mean values, mean square errors and information entropies of the residual errors, and detection results of the multiple self-coding observers are combined to locate fault sensors. According to the invention, fault detection and fault positioning can be carried out in combination with signals of a plurality of satellite attitude sensors, and the reliability and ground monitoring capability of a satellite attitude control system are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Communication method and device for axi bus and ahb bus

ActiveCN103605632BRich design methodIncrease flexibilityGeneral purpose stored program computerElectric digital data processingComputer hardwareControl signal

The invention discloses a method for mutual communication between an AXI bus and an AHB bus, which mainly completes the read and write operations between the AXI bus and the AHB bus to realize the communication between the two. After the AXI bus master sends a read and write request, the AXI bus and AHB bus communication bridge latches the read and write address, and keeps the address valid during the transmission process, including the latch of the read and write control signals; then the AXI bus communicates with the AHB bus The bridge decodes the latched address and generates a selection signal. Only one selection signal can be activated during the transmission process, that is, the only AHB slave device is selected for read and write operations; during the write operation, the AXI bus and The AHB bus communication bridge is responsible for sending the data from the AXI bus to the AHB bus through the data buffer; during the read operation, the AXI bus and AHB bus communication bridge is responsible for sending the data on the AHB bus to the AXI bus through the data buffer.

Owner:SHANDONG UNIV

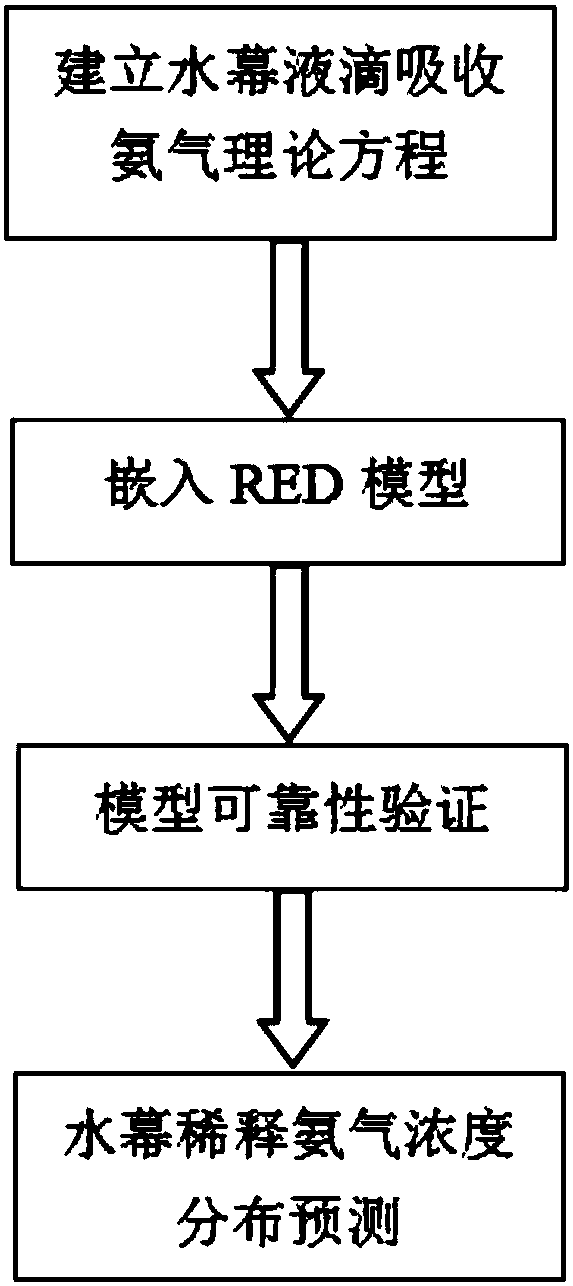

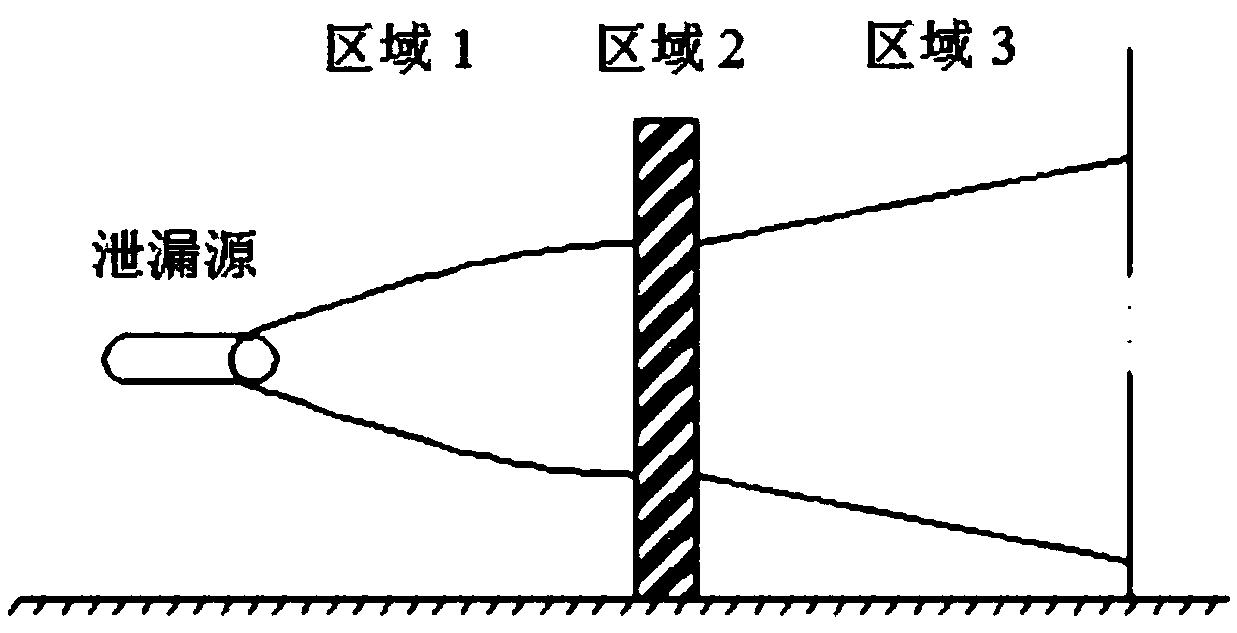

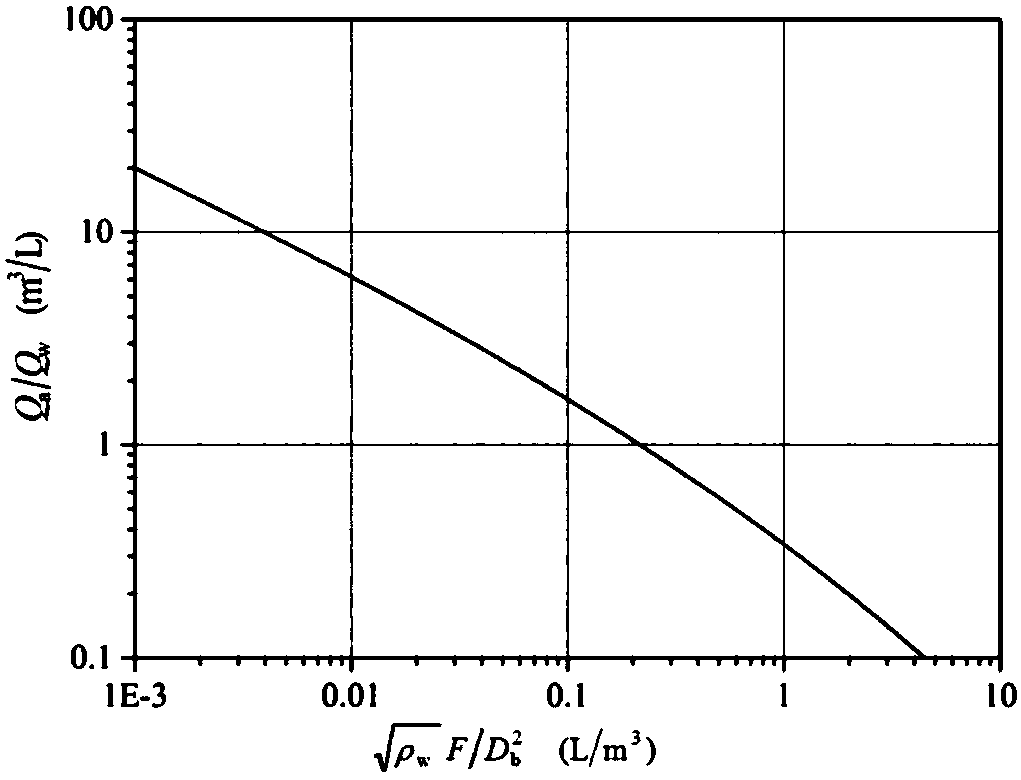

Concentration distribution prediction model of water curtain diluted ammonia by considering water curtain liquid drop absorbing ammonia mass transfer

InactiveCN108225981AReduce the prediction error of dilution ammonia effectReduce forecast errorDiffusion analysisSmoke plumeDesign methods

The invention relates to a concentration distribution prediction model of water curtain diluted ammonia by considering water curtain liquid drop absorbing ammonia mass transfer. The mass transfer process between water curtain liquid drop and ammonia cloud cluster is researched based on a double-film mass transfer theory, a theoretical calculation equation of water curtain liquid drop absorbing ammonia is built, the liquid drop absorbing ammonia concentration R is built to represent the liquid drop absorbing effect, the square root of R is coupled into the smoke plume radius r on the basis thatthe parameter R is comprehensively assessed, and the concentration distribution prediction model of the water curtain diluted ammonia is built. The built concentration distribution prediction model is testified by adopting relevant experimental data, the model can accurately calculate the ground concentration of the ammonia leaked cloud cluster in the downwind direction at a natural spreading state and a forced spreading state respectively. The design method of water curtain diluted ammonia system projects is enriched, and the effect prediction errors of the water curtain diluted ammonia aredeclined. The result shows that the built prediction model can accurately predict the concentration of the water curtain diluted ammonia in the downwind direction, the deviation is within the range accepted by the project, and the prediction result is enabled to be reliable.

Owner:TIANJIN UNIV

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN100523532CImprove performanceRich design methodBearing componentsFluid film lubricationThrust bearing

Owner:郭溪泉

A fast calculation method for permanent magnet eddy current loss of surface-mounted permanent magnet synchronous motor for vehicles

ActiveCN108448990BReduce eddy current lossAvoid irreversible demagnetizationElectronic commutation motor controlVector control systemsPhase currentsSurface mounting

The invention provides a fast calculation method for a permanent magnet eddy current loss of a vehicle surface-mount permanent magnet synchronous motor. The influence of phase current harmonics on thepermanent magnet eddy current loss is considered, the quick and accurate calculation of the permanent magnet eddy current loss in a whole working area can be achieved, thus a designer can select appropriate motor structural parameters and electromagnetic parameters during the design process, the permanent magnet eddy current loss is reduced, the irreversible demagnetization of a permanent magnetis avoided, and the normal working of the motor under complex and variable working conditions is ensured. At the same time, the design method of the permanent magnet synchronous motor is improved, andthe design cycle of the permanent magnet synchronous motor is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Control method and device for flywheel energy storage system

InactiveCN105515029BGuaranteed smooth powerSolve randomnessElectronic commutation motor controlVector control systemsFlywheel energy storageInput control

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Marshall design method for evotherm warm mix asphalt mixture

ActiveCN102839587BOvercoming the inability to design warm mix asphalt mixtureOvercome the problem of not compactingClimate change adaptationRoads maintainencePerformance indexEngineering

The invention relates to a Marshall design method of an Evotherm warm-mix asphalt mixture, comprising the following steps: (1) selecting a Marshall design method of a warm-mix asphalt mixture to design the graduation and oil-stone ratio of the warm-mix mixture; (2) selecting aggregates with different temperatures, conducting a rutting test on the selected aggregates with different temperatures and an asphalt with same temperature of the warm-mix asphalt, and determining the discharge temperature and compaction temperature of the warm-mix asphalt with the bulk density of a test piece of the warm-mix asphalt as a standard; and (3) conducting a high temperature test, a low temperature test, and a water stability test of the warm-mix asphalt at the temperatures, and evaluating by taking technical indexes of the warm-mix asphalt of the same type. According to the invention, the warm-mix asphalt mixture can be designed without a gyratory compactor, the bulk density of the warm-mix asphalt mixture is represented as the core sample density of the rutting plate drilled core, and the technical indexes of the warm-mix asphalt of the same type are taken as the performance index for evaluation; and the design method is simple and reasonable and is convenient for laboratories and field laboratories without the gyratory compactor, thus the design method of the warm-mix asphalt mixture is expanded.

Owner:SHANXI PROVINCIAL RES INST OF COMM

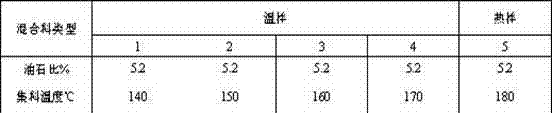

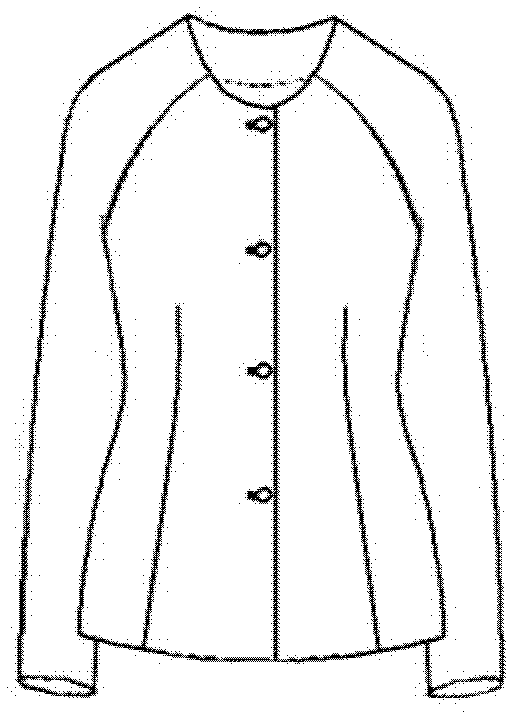

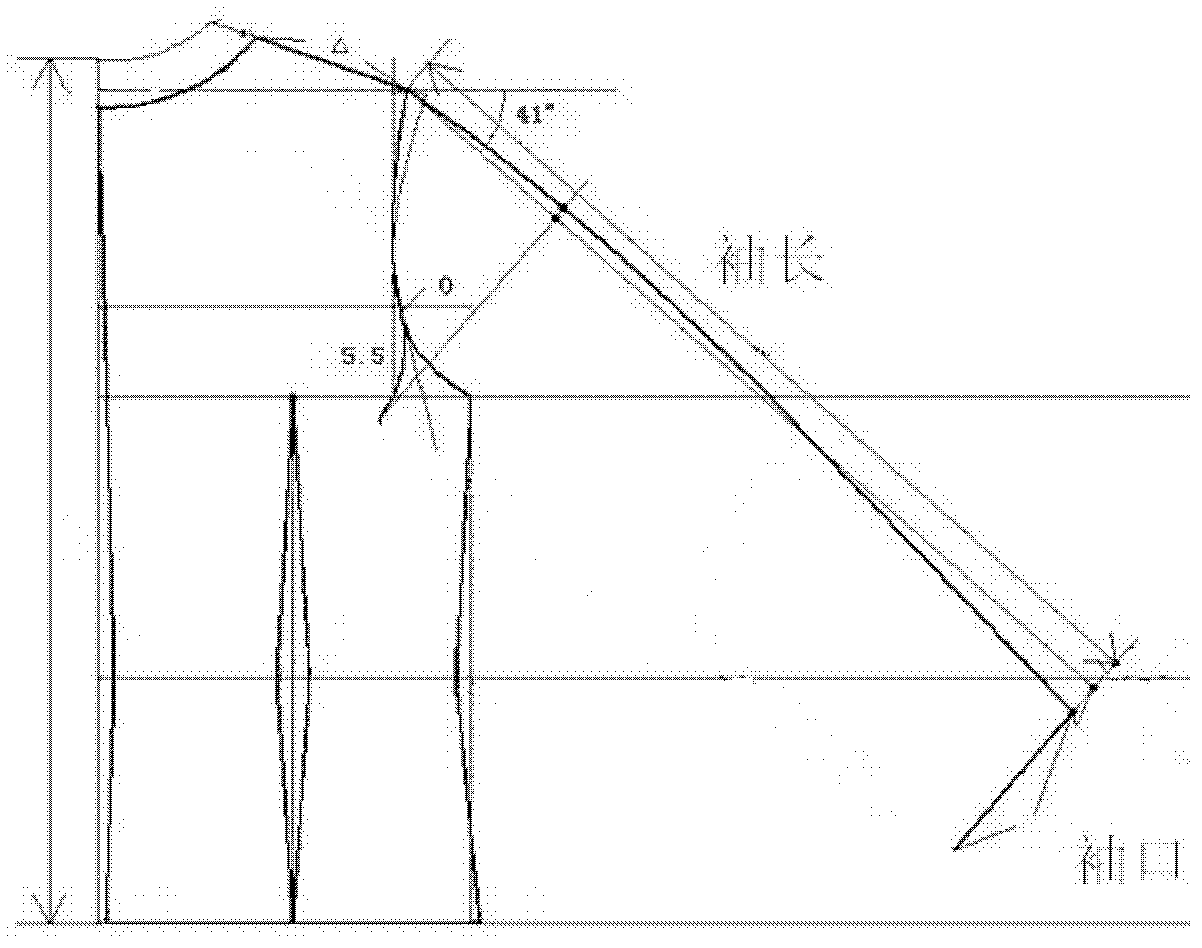

Fit raglan sleeve model design and manufacturing method

InactiveCN102488343BRich design methodThe production process is accurate and simpleGarmentsClothes making applicancesShoulder widthMathematical model

The invention relates to a fit raglan sleeve model design and manufacturing method, which comprises the following steps: building a mathematical model between the inclination angle and body and sleeve intersection and the static elegance, dynamic comfort and static and dynamic elegance and fit of the raglan sleeve; preparing a rear garment piece model, determining shoulder width, a post 1 / 4 chest width point, a waistline and a post central line and well collecting the dart of the rear piece; and determining the value of the inclination angle of the rear sleeve, the length of the sleeve and cuff; determining the intersection of the rear garment body and the garment piece, drawing a tangent line, which passes through the intersection, of a rear arm hole line, drawing a muscle line which is symmetric with the rear arm hole line below the intersection about the tangent line, and determining sleeve cap height; preparing a front garment piece model, determining the shoulder width, a front 1 / 4 chest width point, the waistline and the width of front over lap, and collecting a chest dart and a waist dart; drawing a front sleeve central line, sleeve length and cuff; and drawing a vertical line of the sleeve central line according the sleeve cap height of the rear piece, determining a point, which a tangent line serving as a symmetric axis of the front chest width point and a point on the vertical line passes through, on the front armhole curve, determining sleeve width and well drawing a front sleeve piece. The fit raglan sleeve model design and manufacturing method facilitates flexible structural design of garments.

Owner:DONGHUA UNIV +2

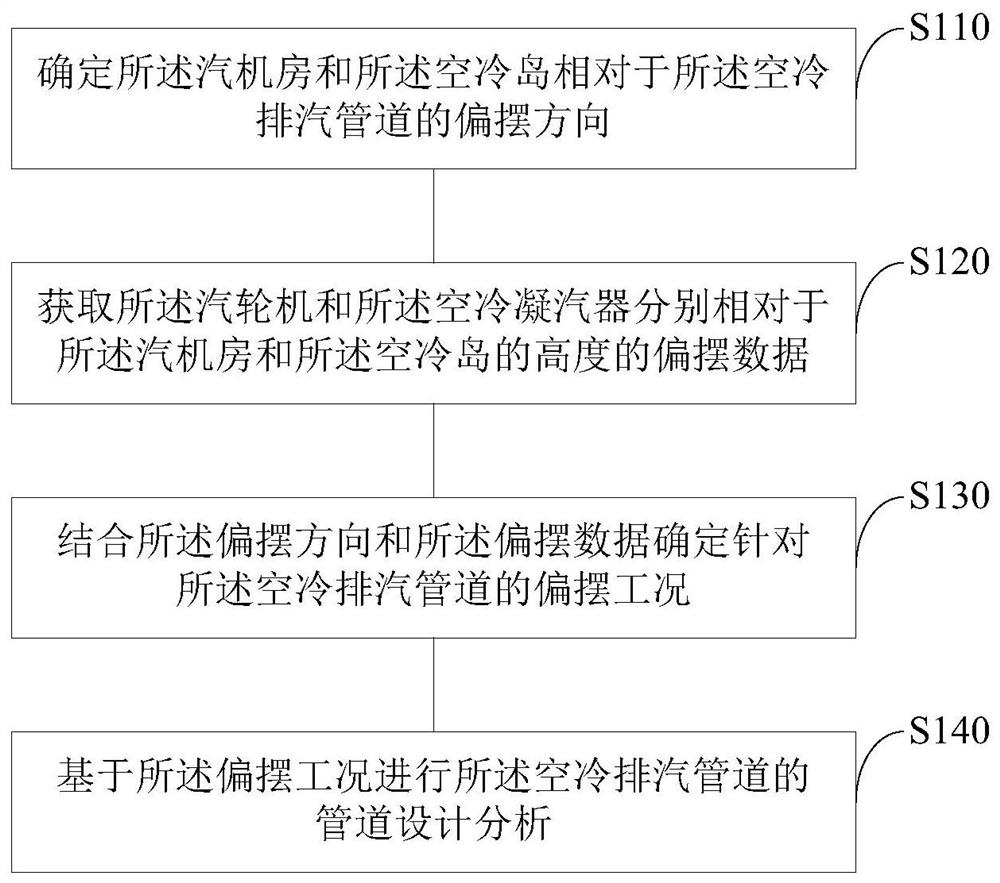

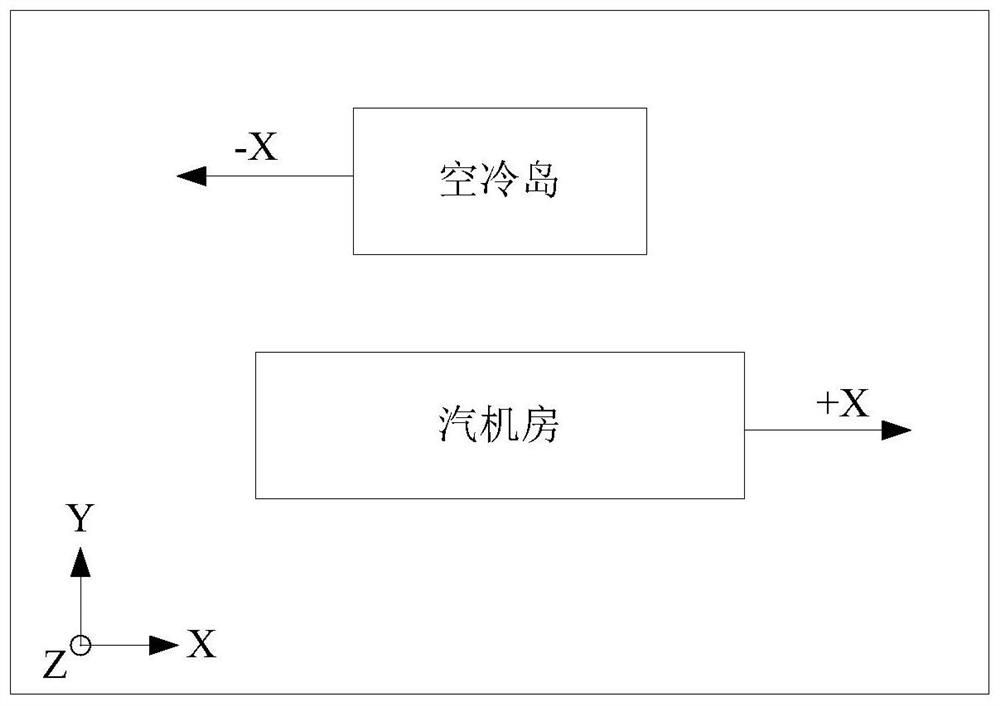

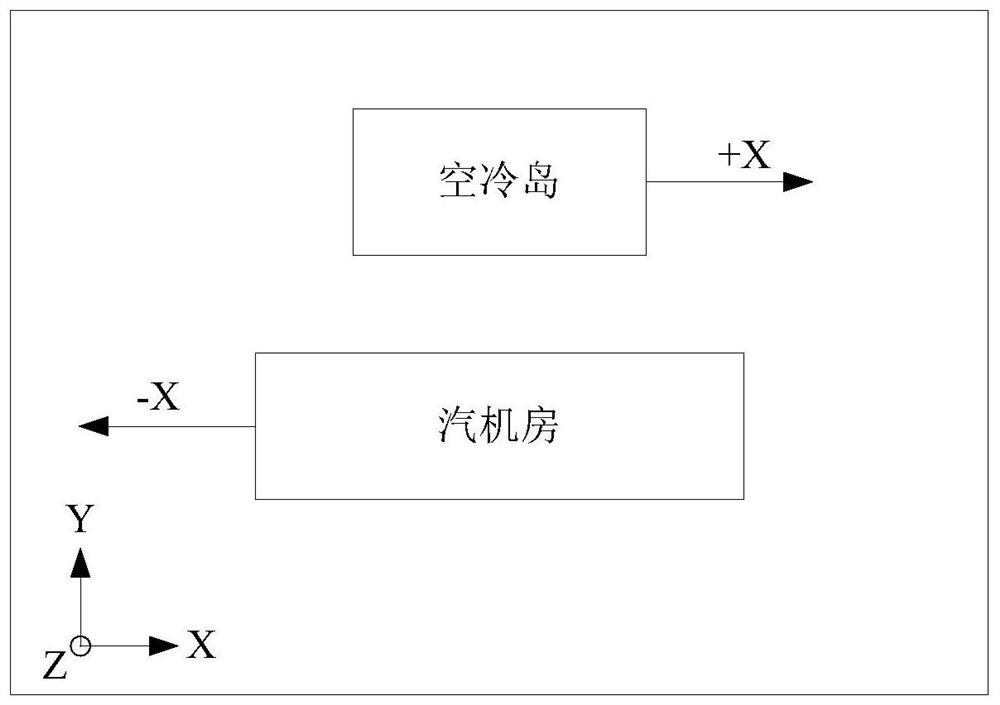

Design method and device of air-cooled exhaust steam pipeline with high-level arrangement of steam turbine

ActiveCN110195621BRich design methodImprove securityGeometric CADDesign optimisation/simulationEngineeringProcess engineering

Owner:CHINA SHENHUA ENERGY CO LTD +4

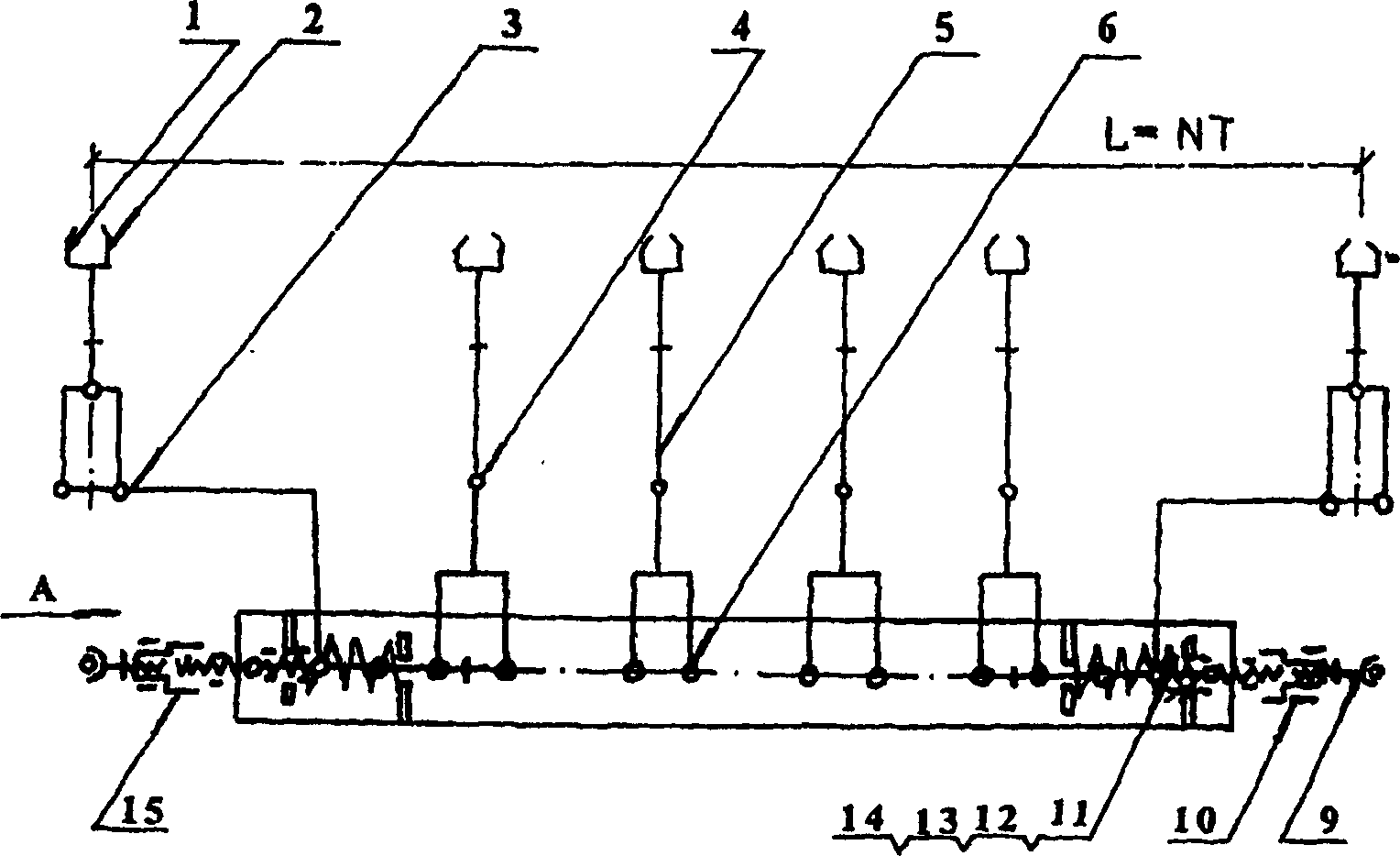

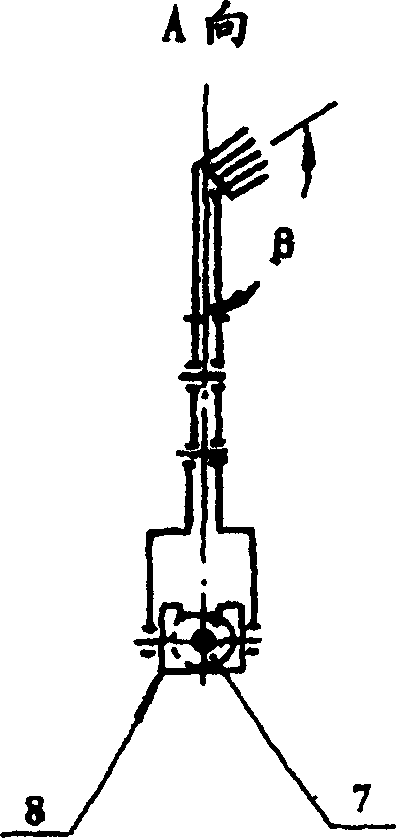

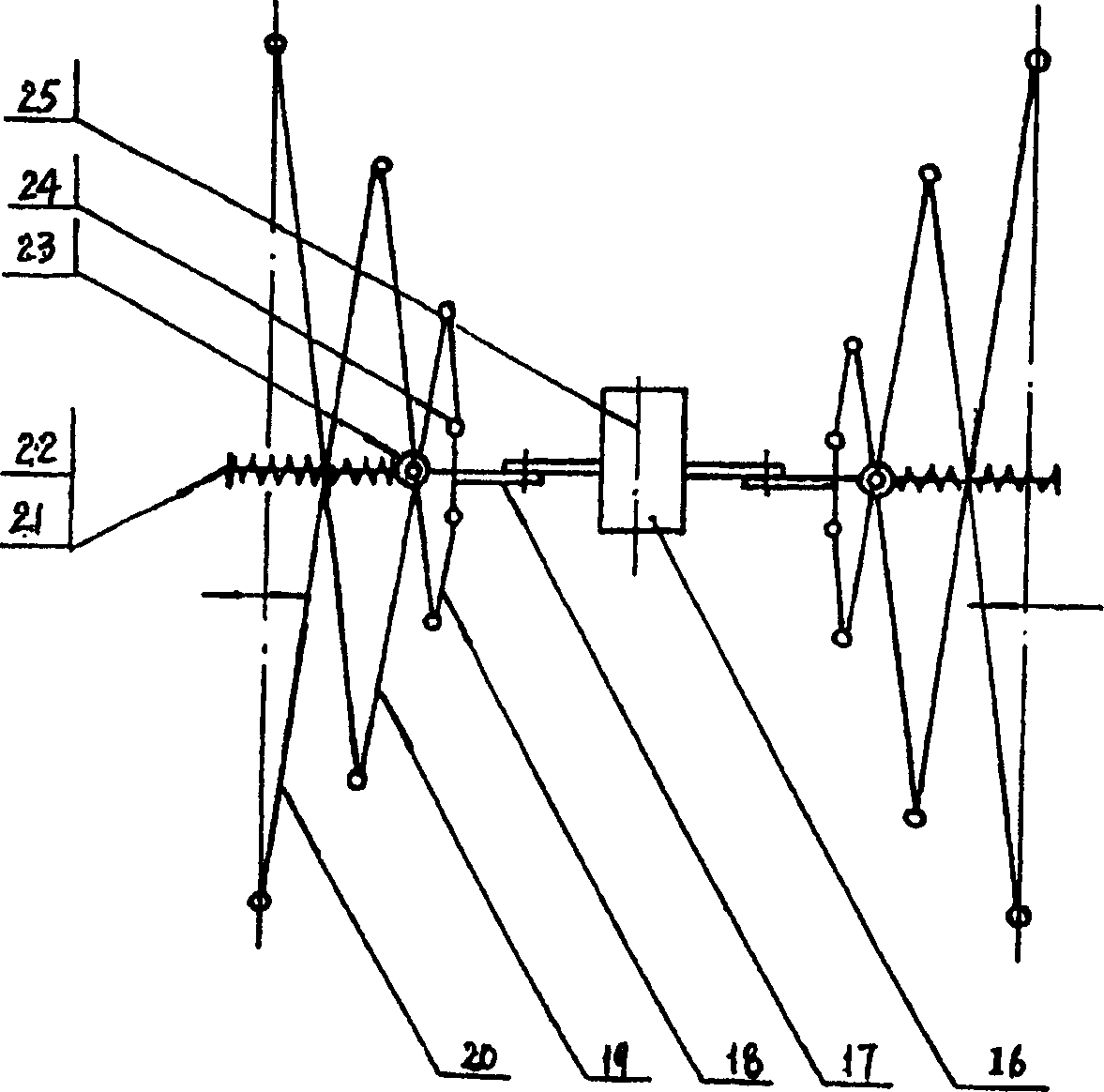

Rice transplanter with rotary multi-row movable seedling jaws

The present invention relates to a sort of rotary rice transplanter with many lines of moving claws for the seedlings, which includes: machine support, the left-and-right railway underpans, the principal axis, the moving claws for the seedlings, the rotary driver, the telescopic machine and the like, the left and right railway underpans are arranged at the two side of the principal axis, more than one rotary drivers are arranged at the principal axis, several telescopic machines is arranged in every rotary driver, a moving claw is connected on the telescopic machine. The moving seedling claw have a structure with double deck, three hinges and four levers, whose four disciplinary reciprocating actions include: rest interval, circumversion, expansion and random self-regulation. The present invention perfects the design theory and working performance in the moving theory and design method fields, the moving of the rice transplanter is stable when it works, the claw can simulate the rice-transplanting action of the man, and the depth of planting can random self-adjusted, so it has a good uniformity.

Owner:洪全明

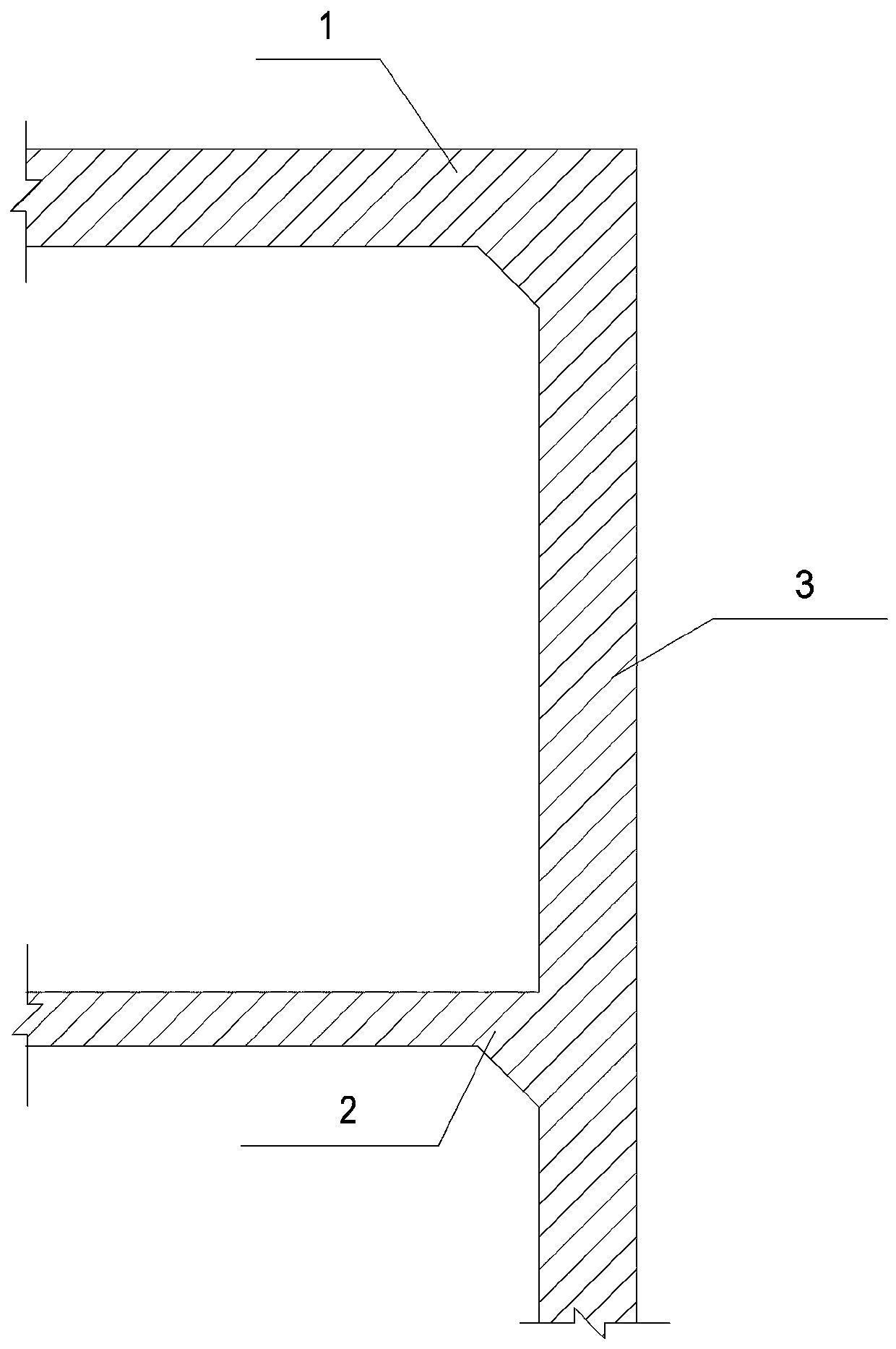

Reconstruction and extension engineering connector structure based on C-shaped grip beam and construction method thereof

PendingCN111101605AEffective structureActive connectionBuilding constructionsHydro energy generationShaped beamTension stress

The invention relates to a reconstruction and extension engineering connector structure based on a C-shaped grip beam and a construction method thereof. The connector structure comprises a newly-madestructure and accessories of the newly-made structure, wherein the newly-made structure and the accessories of the newly-made structure are arranged in a connection position of an existing structure and a newly-constructed structure; the connector structure is in rigid connection with the existing structure and the newly-constructed structure; an existing part comprises an existing structure top plate, side walls and an existing structure middle plate or bottom plate; a newly-constructed part comprises a newly-constructed structure top plate, side walls and a newly-constructed structure middleplate or bottom plate; a C-shaped beam is arranged between the existing structural top plate and the newly-constructed structure top plate; a notch faces the existing part; the upper and lower sidesclamp the existing structure top plate; the other side is in rigid connection with the newly-constructed structure top plate; and the existing structure middle plate or bottom plate is in rigid connection with the newly-constructed structure middle plate or bottom plate. The C-shaped beam clamped and connected with the existing structure top plate converts a connector structure using tensile stress as a main part in a conventional flat connection mode into a superposed component bearing combined bending-shear-torsion action; the stress integrity and deformation coordination are improved; and the integral rigidity of the connector part of new and old structures is improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

A satellite sensor fault detection and positioning method based on self-encoding observer

ActiveCN111076744BImprove portabilityRich design methodInstruments for comonautical navigationEngineeringSatellite attitude control system

The invention discloses a satellite sensor fault detection and positioning method based on an auto-encoding observer. The method performs fault detection and positioning on a satellite attitude sensor based on the self-encoding observer, including an observer design based on the self-encoding observer and a support vector machine. The system builds a self-encoding observer according to the satellite attitude measurement method, compares the input and output of the observer to generate residuals, uses a support vector machine to detect faults according to the mean, mean square error and information entropy of the residuals, and combines multiple self-encoding observations The detection result of the sensor is used to locate the faulty sensor. The invention can perform fault detection and fault location in combination with signals of a plurality of satellite attitude sensors, thereby improving the reliability and ground monitoring capability of the satellite attitude control system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Design method of a prestressed fabricated steel frame friction damping structure system

ActiveCN110409604BAvoid damageReduce pollutionGeometric CADDesign optimisation/simulationFloor slabPre stress

A prestressed assembly type steel frame friction damping structure system and a design method thereof comprise at least two layers of steel frame structures, wherein adjacent steel frame structures are disconnected at the joint of an upper-layer column and a lower-layer floor slab; the adjacent steel frame structures are connected in a sliding manner through a bidirectional sliding friction connecting device; the bidirectional sliding friction connecting device comprises an upper C-shaped plate, a lower C-shaped plate, a friction plate and a connecting piece; the plate surface of the upper C-shaped plate is provided with a first transverse strip hole; the plate surface of the lower C-shaped plate is provided with a first longitudinal strip hole; the upper C-shaped plate and the lower C-shaped plate are mutually inserted and connected with the connecting pieces in the corresponding first longitudinal strip holes through the first transverse strip holes; the upper C-shaped plate is connected with a bottom connecting plate; the lower C-shaped plate is connected with a top connecting plate; and friction plates are arranged between a first top plate and a second top plate, between a second top plate and a first bottom plate and between the first bottom plate and a second bottom plate. The prestressed assembly type steel frame friction damping structure system solves the technical problems of poor energy consumption performance and difficult construction of connecting joints of the traditional assembly type structural steel column connecting structure.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

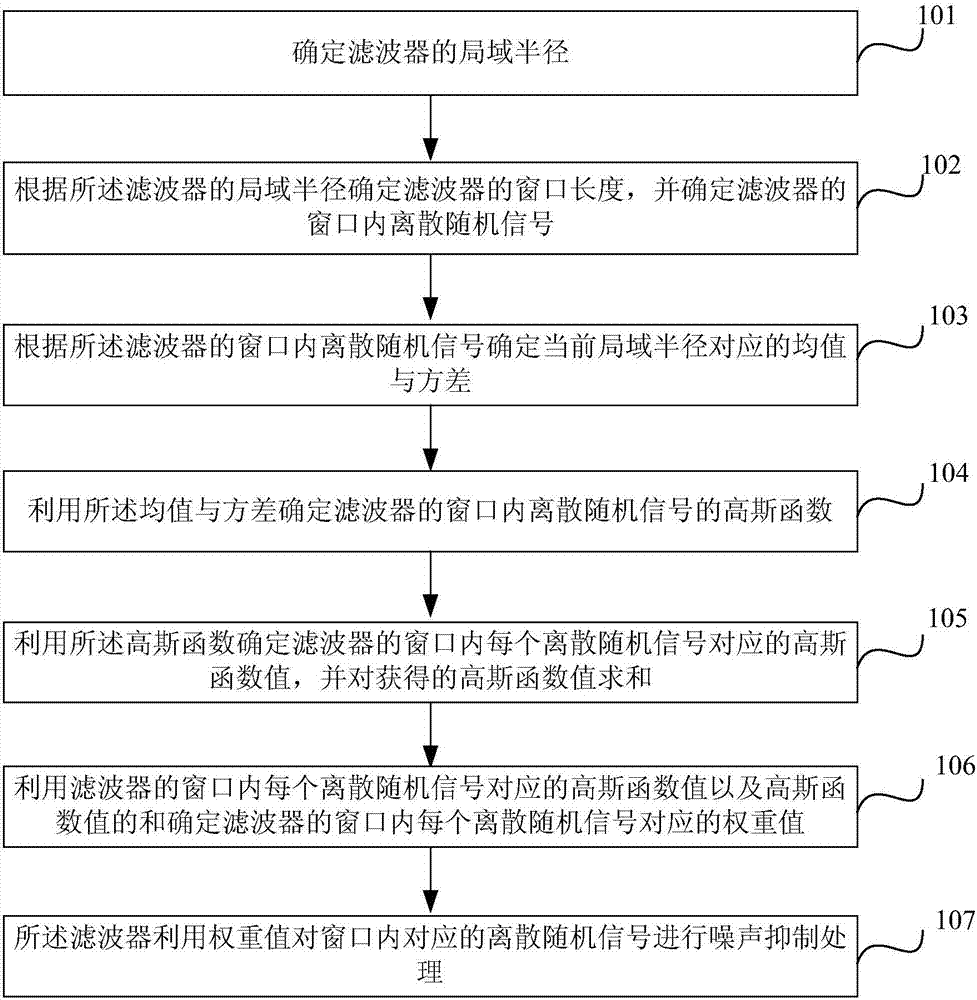

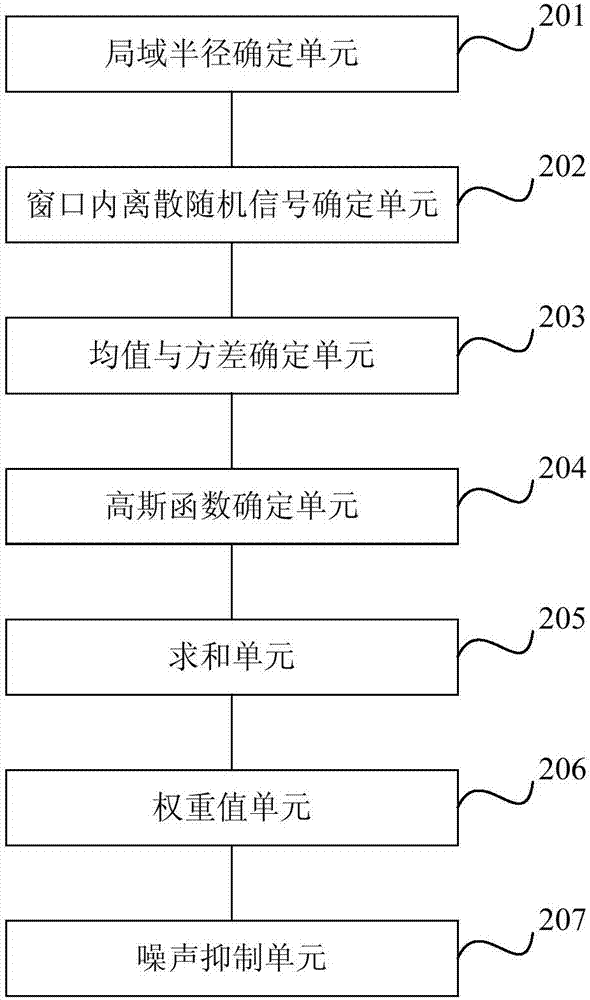

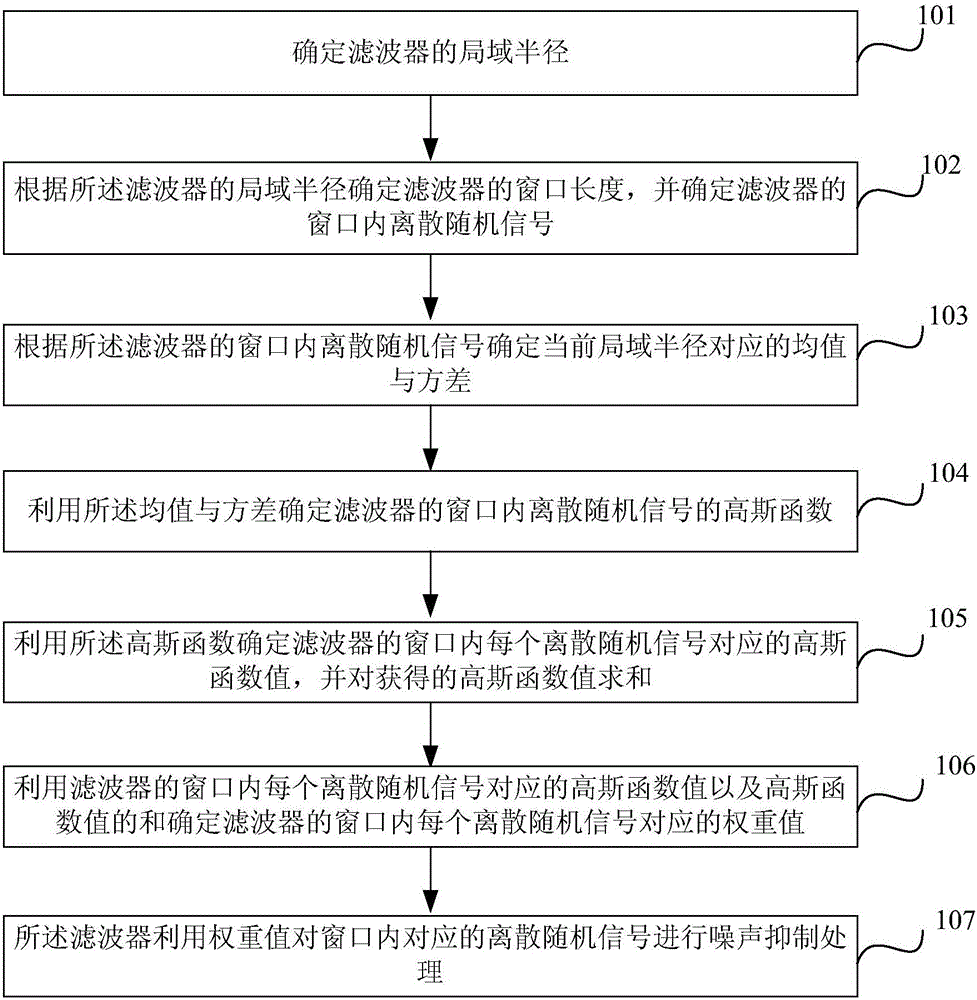

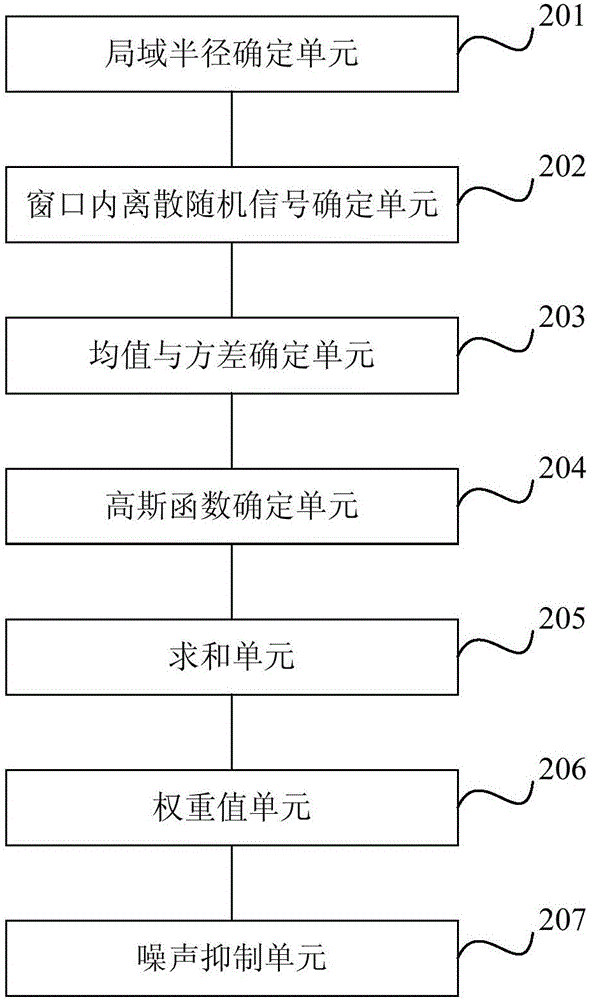

A noise suppression method and device based on Gaussian distribution weighting

ActiveCN105812068BRich design methodImprove filtering effectTransmission noise reductionSpeech analysisPattern recognitionGaussian function

The invention relates to a noise suppression method and a noise suppression device based on Gaussian distribution weighting. The noise suppression method comprises the steps of determining the local radius of a filter; determining a window length of the filter according to the local radius of the filter, and determining discrete signals in the window of the filter; determining corresponding mean values and variances according to the discrete signals in the window of the filter; determining a Gaussian function of the discrete signals in the window of the filter by using the mean values and the variances; determining the corresponding Gaussian function value of each discrete signal in the window of the filter by using the Gaussian function, and performing summation of the obtained Gaussian function values; determining the corresponding weighted value of each discrete signal in the window of the filter by using the corresponding Gaussian function value of each discrete signal in the window of the filter and the sum of the Gaussian function values; and performing noise suppression treatment on the discrete signals at the center of the window by using the weighted values by the filter.

Owner:STATE GRID CORP OF CHINA +2

Noise suppression method and device based on Gaussian distribution weighting

ActiveCN105812068ARich design methodImprove filtering effectTransmission noise reductionSpeech analysisPattern recognitionGaussian function

The invention relates to a noise suppression method and a noise suppression device based on Gaussian distribution weighting. The noise suppression method comprises the steps of determining the local radius of a filter; determining a window length of the filter according to the local radius of the filter, and determining discrete signals in the window of the filter; determining corresponding mean values and variances according to the discrete signals in the window of the filter; determining a Gaussian function of the discrete signals in the window of the filter by using the mean values and the variances; determining the corresponding Gaussian function value of each discrete signal in the window of the filter by using the Gaussian function, and performing summation of the obtained Gaussian function values; determining the corresponding weighted value of each discrete signal in the window of the filter by using the corresponding Gaussian function value of each discrete signal in the window of the filter and the sum of the Gaussian function values; and performing noise suppression treatment on the discrete signals at the center of the window by using the weighted values by the filter.

Owner:STATE GRID CORP OF CHINA +2

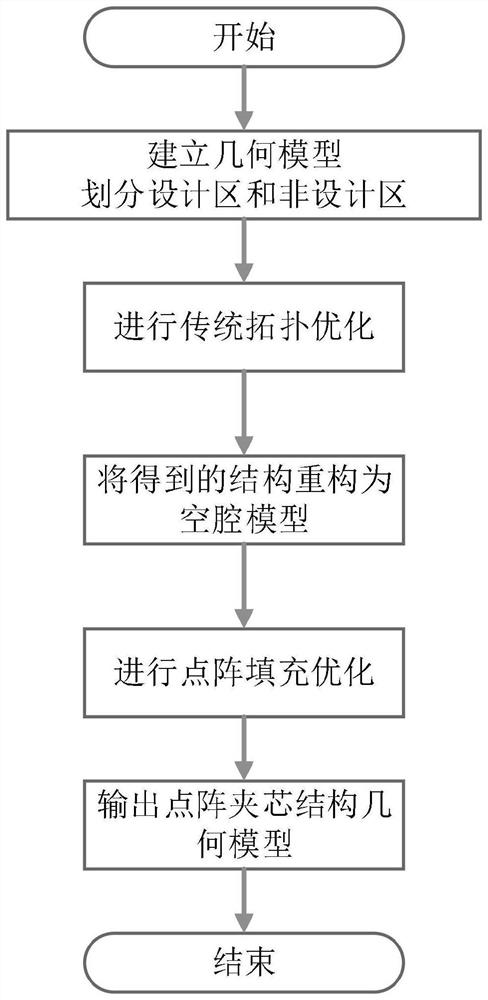

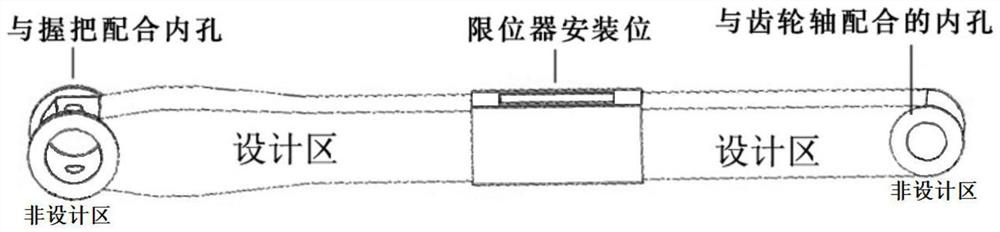

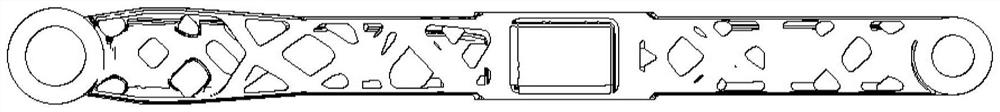

Design method and structure of dot matrix sandwich structure for additive manufacturing

PendingCN114741821ARich design methodEffective design methodGeometric CADIncreasing energy efficiencyMaximum diameterStructural engineering

The invention provides a design method and structure for an additive manufacturing lattice sandwich structure, relates to the technical field of additive manufacturing, and can provide a feasible design scheme for preparing the lattice sandwich structure by adopting an additive manufacturing process and expand the application scene of the additive manufacturing lattice structure. According to the method, an initial structure is assumed to be a solid structure for topological optimization, then the skin thickness of the initial structure is adjusted according to a topological optimization result, then a cavity part of the adjusted structure is filled with a dot matrix through dot matrix filling optimization, and design is completed. The optimization target of topological optimization is that the strain energy of the overall structure with the weight is minimum, and the constraint conditions comprise volume fraction constraint, minimum size constraint and / or maximum size constraint; the optimization target of dot matrix filling optimization is that the rigidity of the overall structure with the weight is maximum, and the constraint conditions comprise the total mass constraint, the dot matrix target length constraint, the minimum diameter constraint and / or the maximum diameter constraint.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

A prestressed support friction damping assembled steel structure system and its design method

ActiveCN110528679BNo pollution in the processImprove construction efficiencyGeometric CADDesign optimisation/simulationFloor slabPre stress

The invention relates to the technical field of structural engineering, and discloses a prestressed support friction damping assembled steel structure system and a design method. The system is formedby stacking layered frame structures up and down, each layered frame structure includes steel columns, steel beams and floor plates, the steel columns between the upper and lower adjacent layered frame structures are disconnected at the connection positions of the floor plates on the lower layer, connection through self friction is achieved, and meanwhile, high-strength cables are connected between the adjacent layered frame structures; and the top ends of the steel columns are provided with upper flange plates so as to be fixedly connected to the steel beams, the bottom ends of the steel columns are provided with lower flange plates, the lower flange plates are in contact with the upper surfaces of the floor plates of the adjacent layered frame structure on the lower layer, the upper surfaces of the floor plates are provided with friction coating layers and limiting devices, and the limiting devices are steel plate strips arranged along the edges of the floor plates. By means of the system, the layers are connected through the high-strength cables and the mutual friction between the columns, construction is convenient and efficient to achieve, and the stress performance is good.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com