Design method and device of air-cooled exhaust steam pipeline with high-level arrangement of steam turbine

An exhaust pipe and design method technology, which is applied in the electric power field, can solve the problems of not considering the influence of the exhaust pipe and the amplification of the influence of the exhaust pipe, so as to optimize the overall design process, improve the safety and reliability, and enrich the design factors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

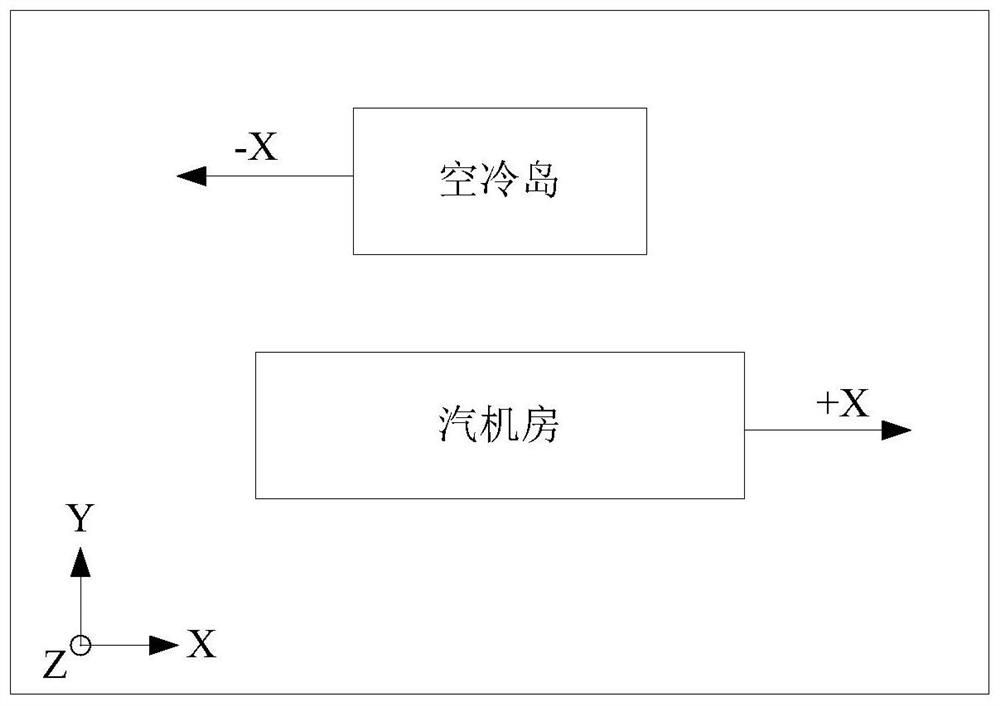

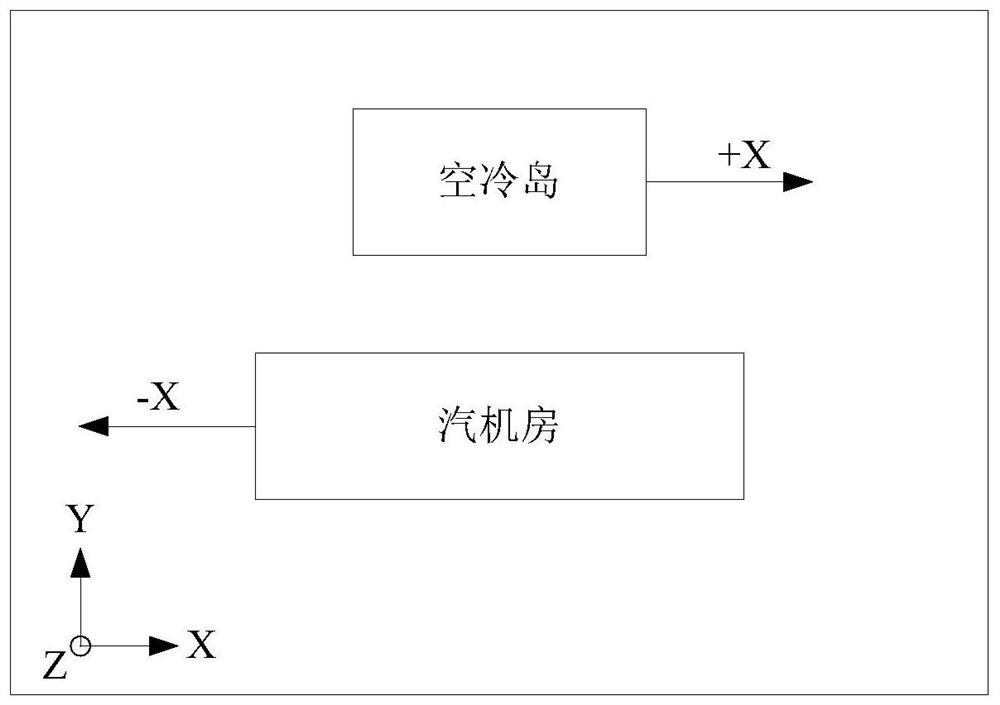

[0037] In the embodiments of the present invention, unless otherwise stated, the directional words used such as "positive direction, negative direction" generally refer to two opposite directions along the same axis on the coordinate system, for example, the positive direction of the X axis may be It is understood as the +X direction in the ground coordinate system, the negative X axis can be understood as the -X direction, the positive Y axis can be understood as the +Y direction, and the negative Y axis can be understood as the -Y direction.

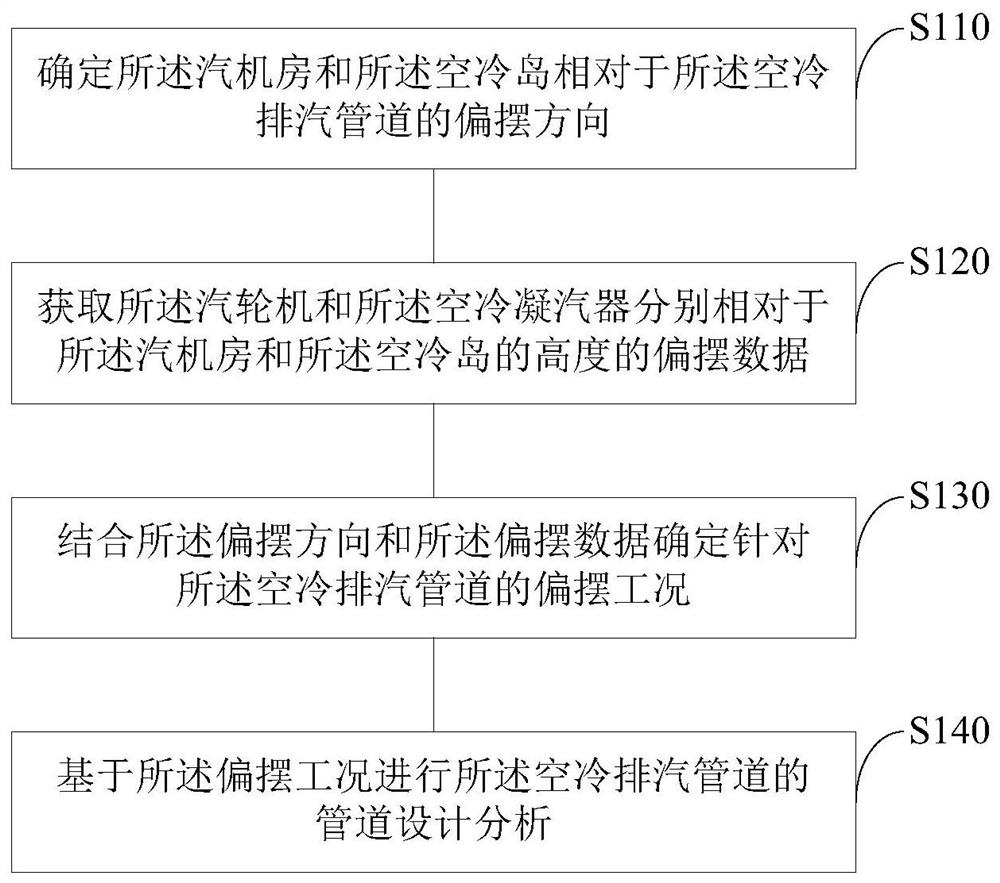

[0038] figure 1 It is a schematic flow chart ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com