Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

A thrust bearing, oil film lubrication technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as increased power consumption, reduced support capacity, affected normal operation, etc., to reduce frictional power consumption, improve mechanism performance, The effect of perfecting the design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

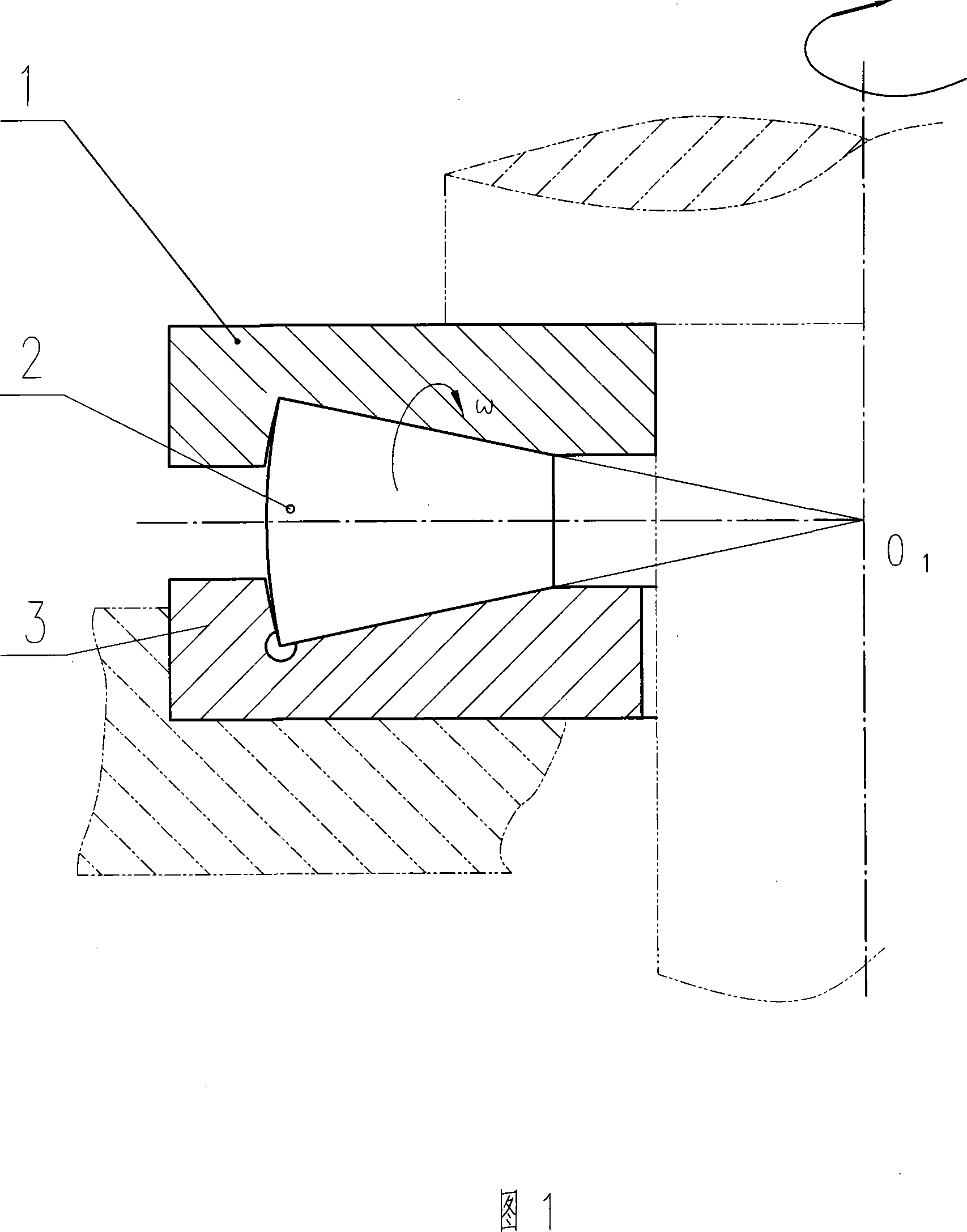

[0040]As shown in Figure 1, the structure of the tapered roller thrust bearing is that the rolling elements - tapered rollers 2 are arranged between the shaft ring 1 and the seat ring 3, and the tapered rollers are arranged equidistantly by the cage (not shown in the figure). show). The design and manufacture of the shaft ring, seat ring and tapered roller, that is, the raceway and rib, are exactly the same for the shaft ring and seat ring.

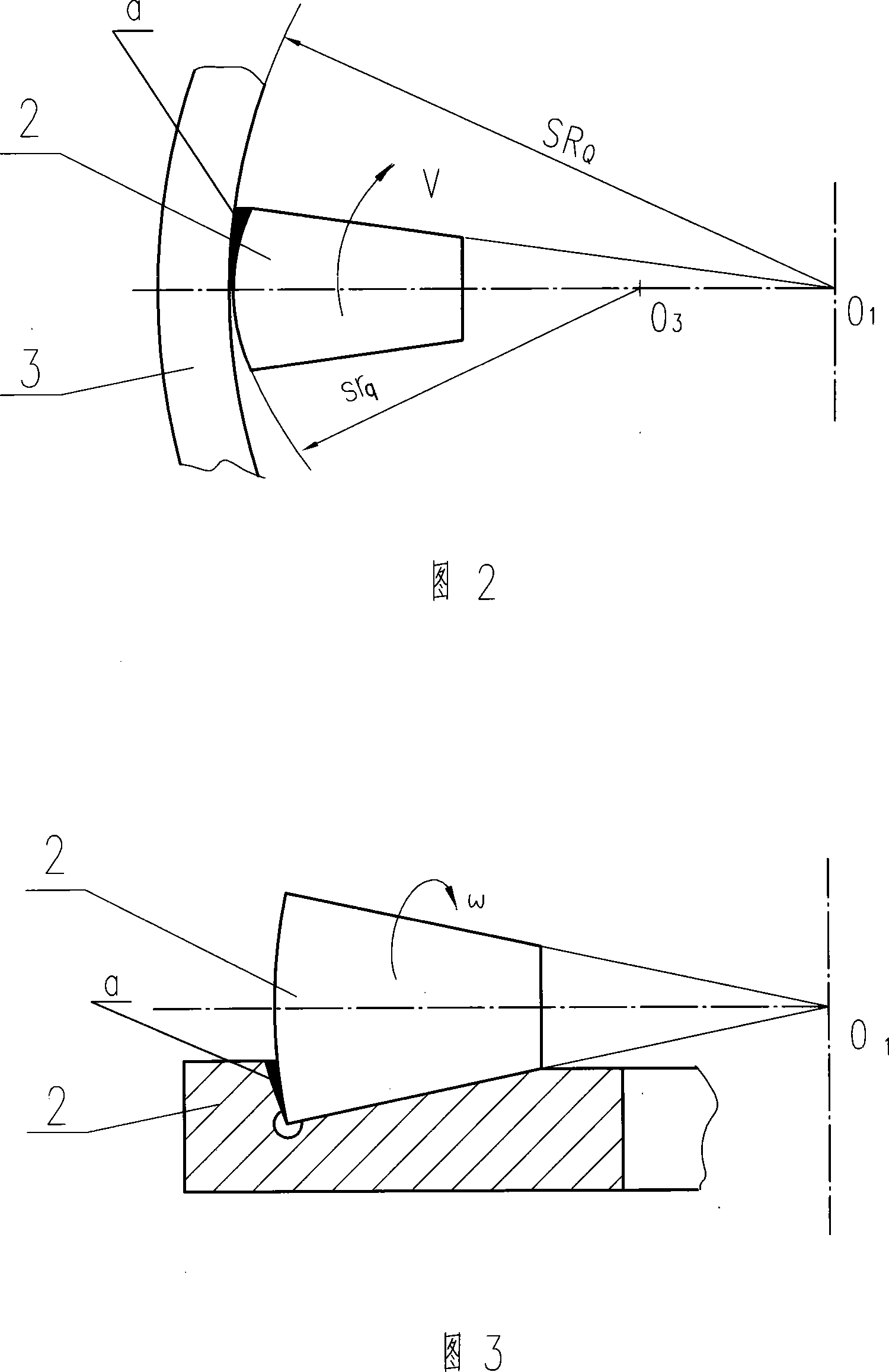

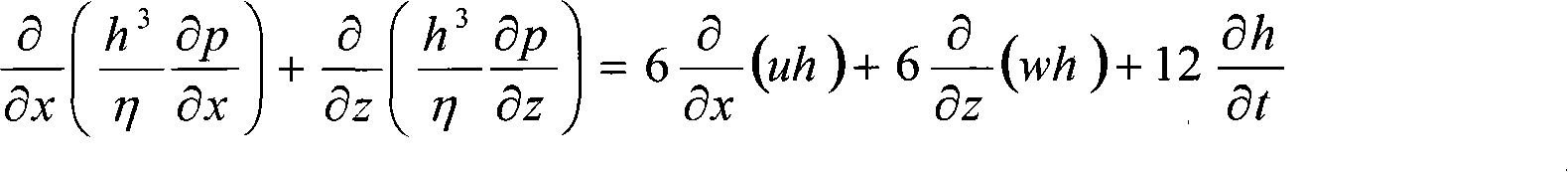

[0041] As shown in Figure 2, an oil film lubrication method for the large end surface of the thrust bearing tapered roller and the rib of the seat ring. ), a wedge-shaped gap with a large front and a small rear is formed between the front part of the large end face of the tapered roll and the inner wall of the seat ring rib, as indicated by "a" in the figure (that is, a convergent gap with a dynamic pressure effect. Wedge-shaped gap), like a water ski with a tilted front end, as long as it moves forward, it will generate buoyancy. The "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com