A fast calculation method for permanent magnet eddy current loss of surface-mounted permanent magnet synchronous motor for vehicles

A permanent magnet synchronous motor and eddy current loss technology, which is used in the estimation/correction of motor parameters, control of generators, motor generator control, etc. Accuracy and other issues, to avoid irreversible demagnetization, improve the design method, and shorten the design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the quick calculation method for the permanent magnet eddy current loss of the vehicle surface-mounted permanent magnet synchronous motor provided by the present invention will be further explained in detail below in conjunction with the accompanying drawings.

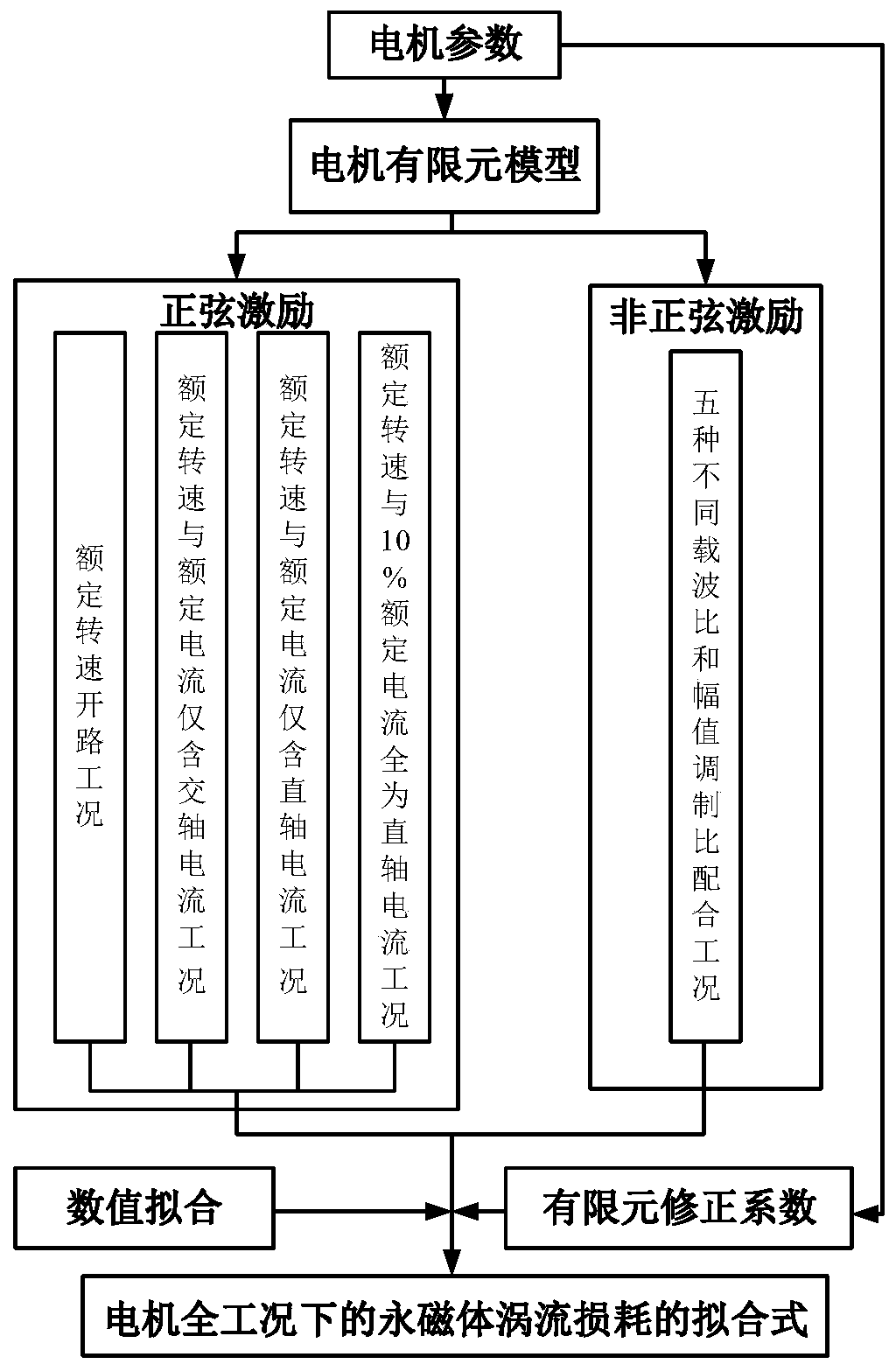

[0035] like figure 1 As shown, in an example, a surface-mounted permanent magnet synchronous motor with an outer rotor is used, and the pole slot fit is 16 / 18. The method provided by the present invention specifically includes the following steps:

[0036] Step 1. Based on the motor parameters, the finite element model of the surface-mounted permanent magnet synchronous motor is established by using the time-step finite element method.

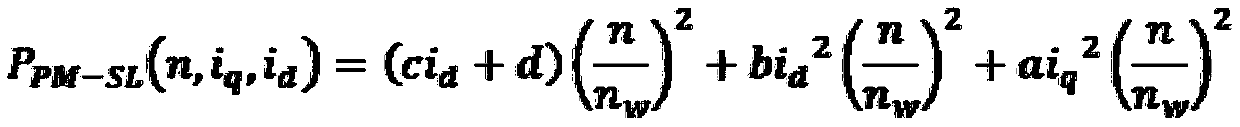

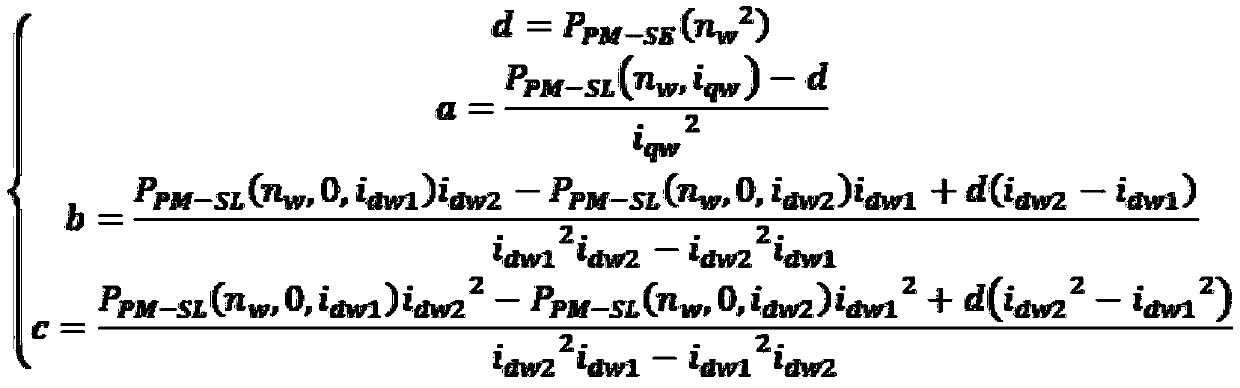

[0037] Step 2. Calculate the eddy current loss of the permanent magnet under different motor conditions under sinusoidal excitation and non-sinusoidal excitation through two-dimensional finite element, and use the numerical fitting method to obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com