Patents

Literature

90results about How to "Avoid irreversible demagnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

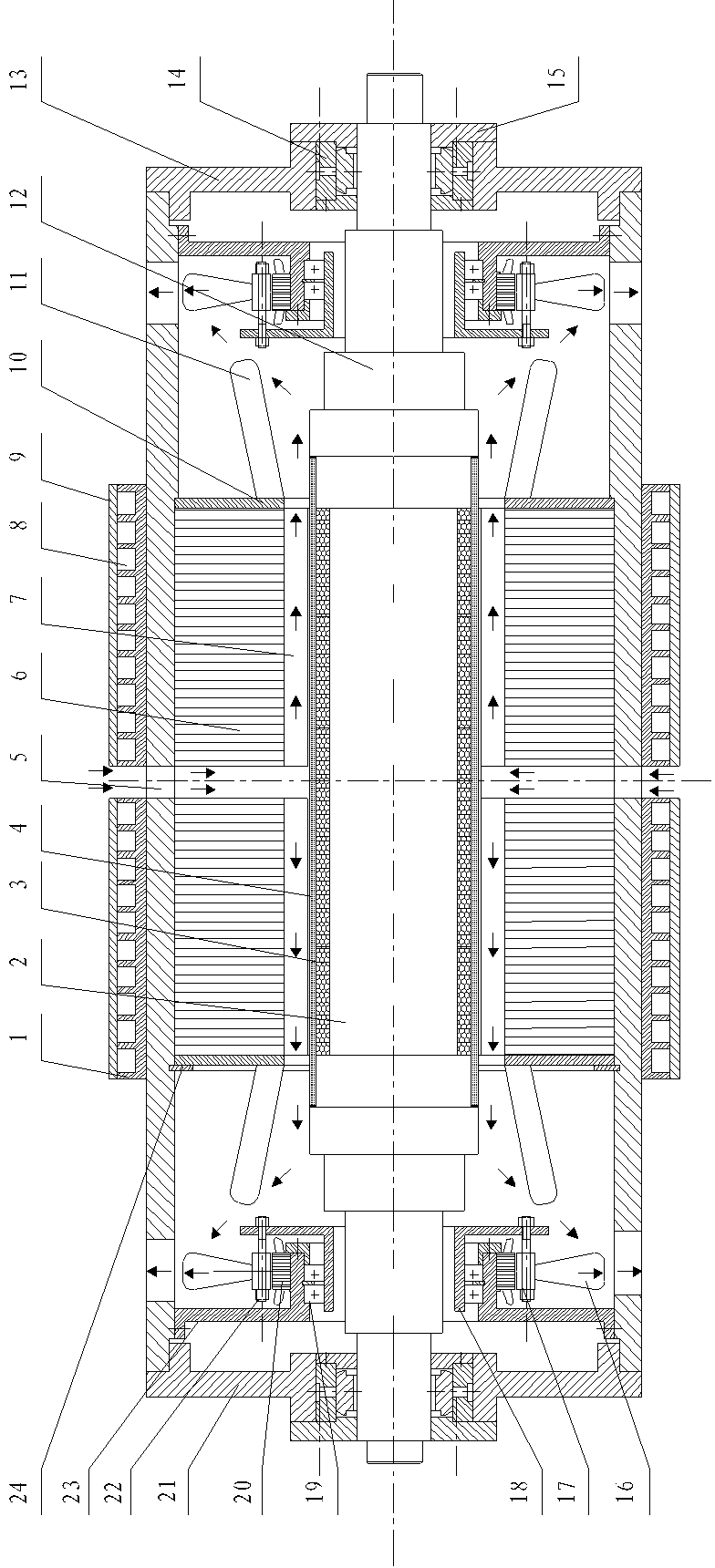

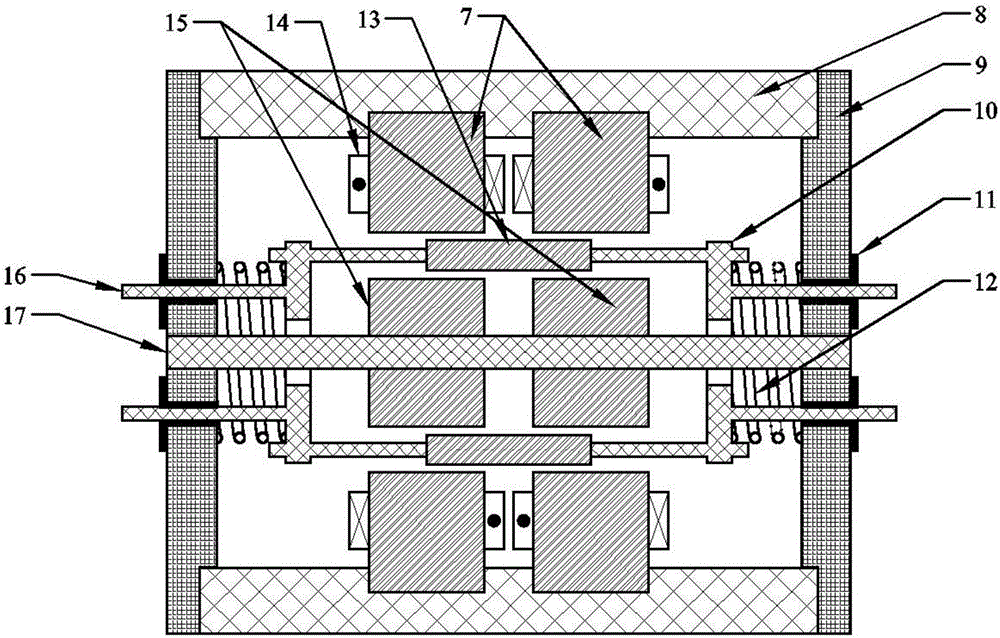

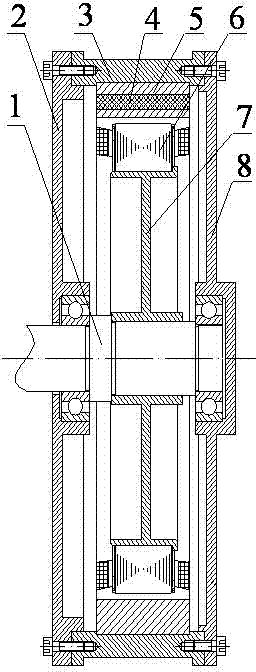

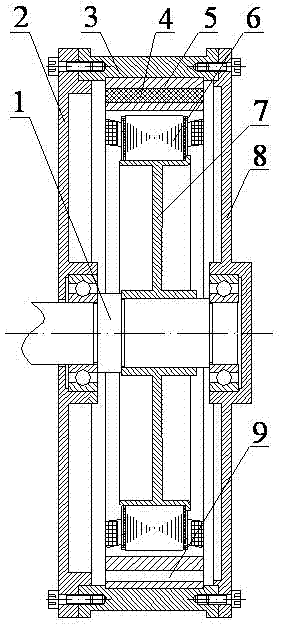

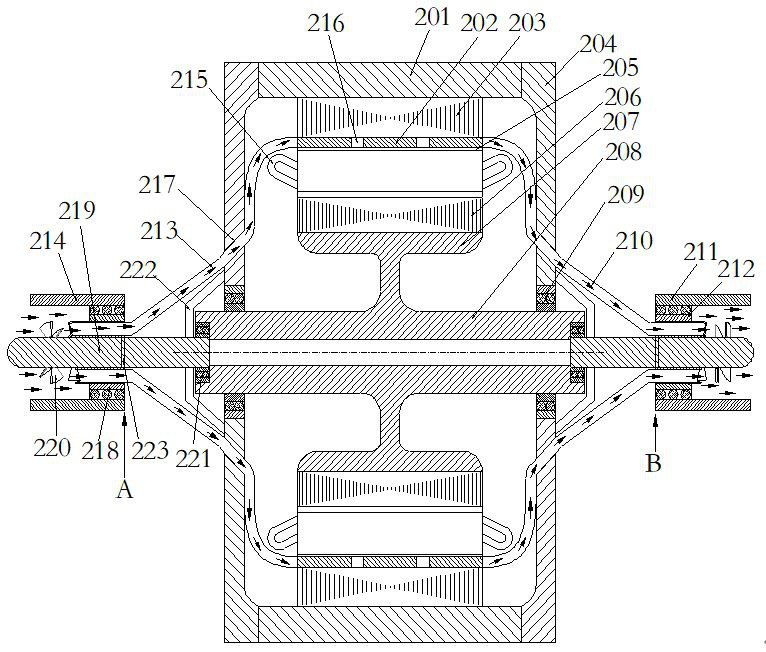

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

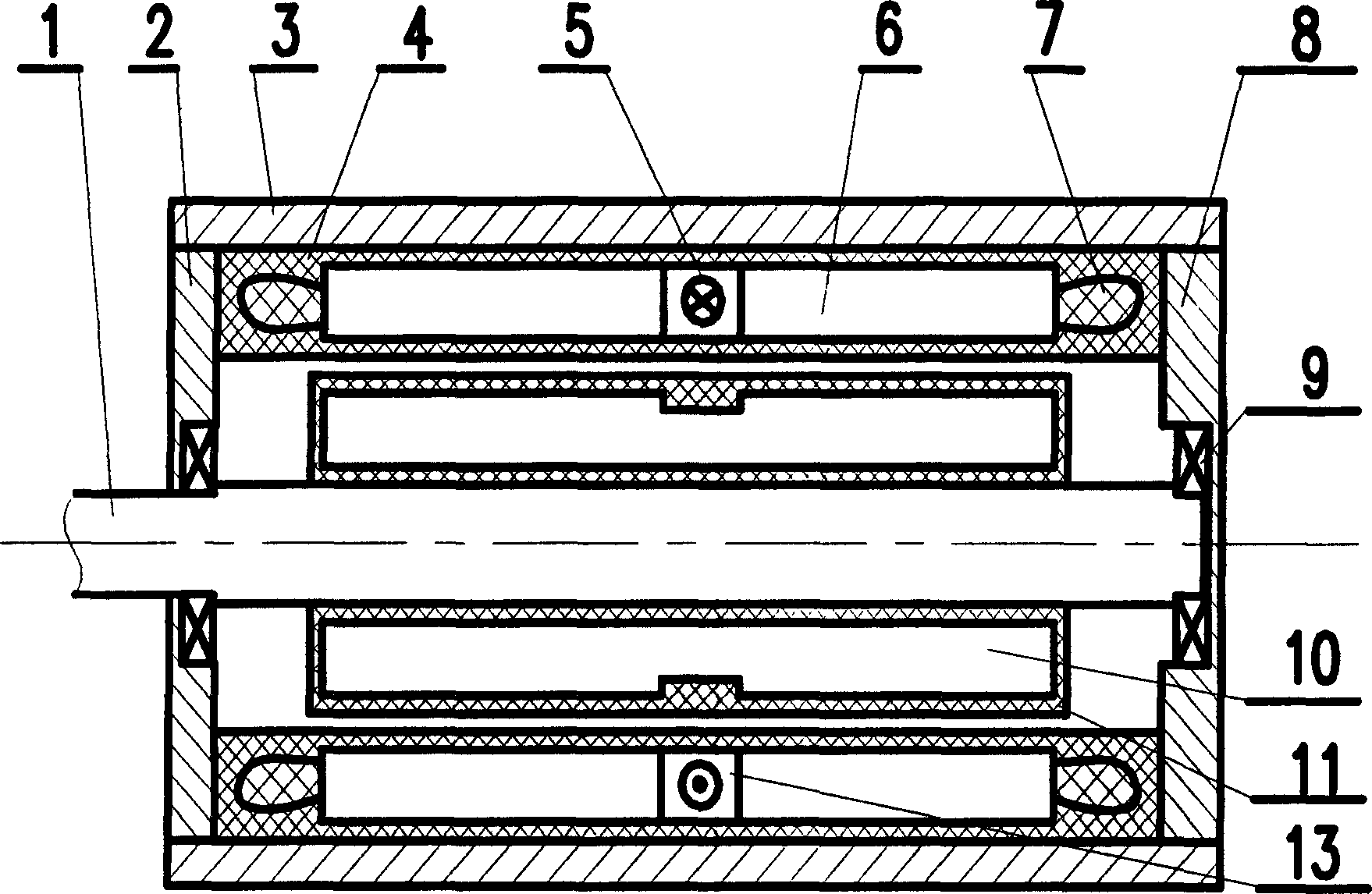

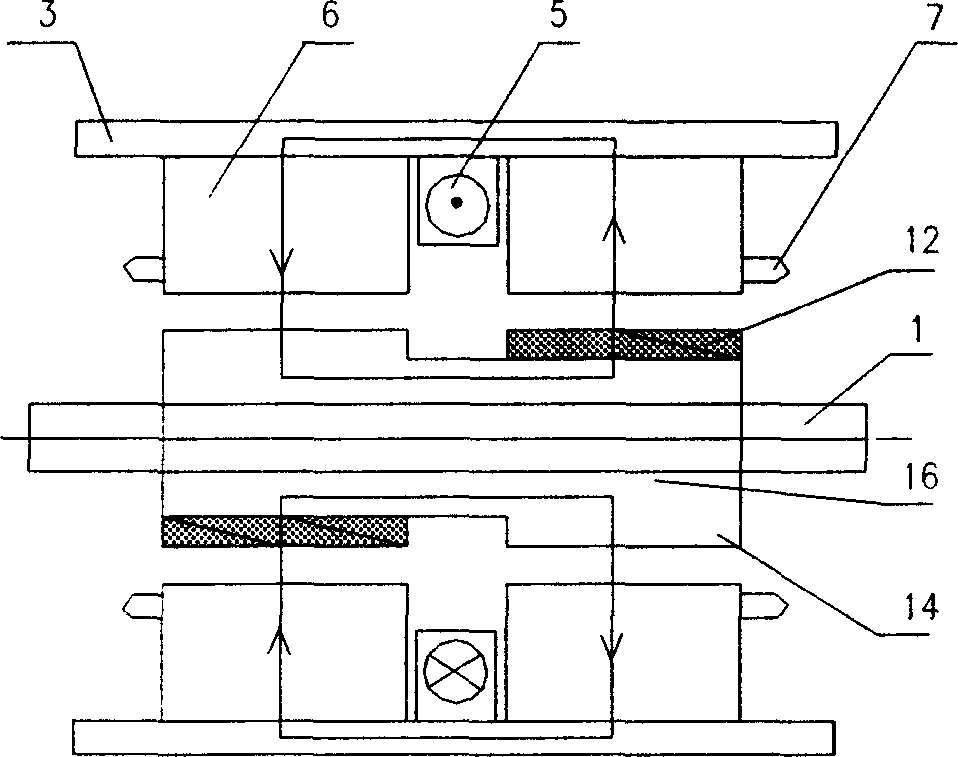

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

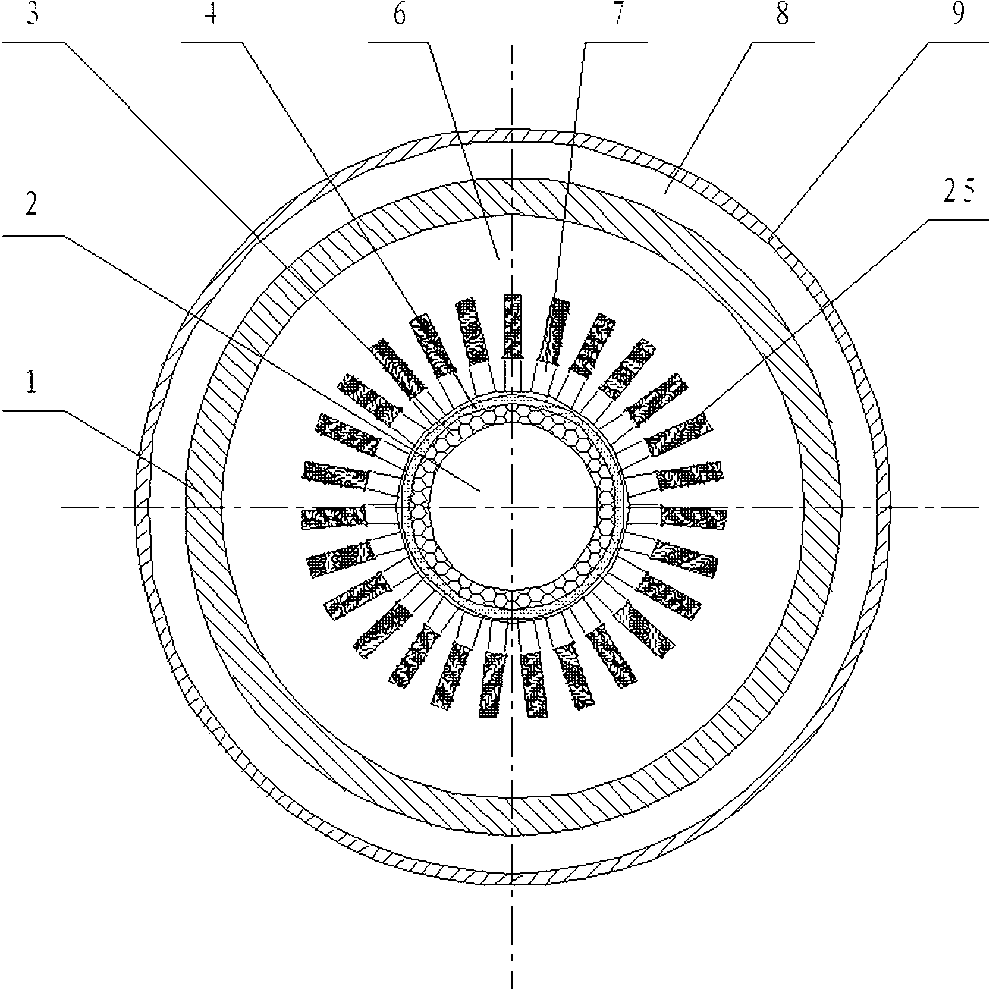

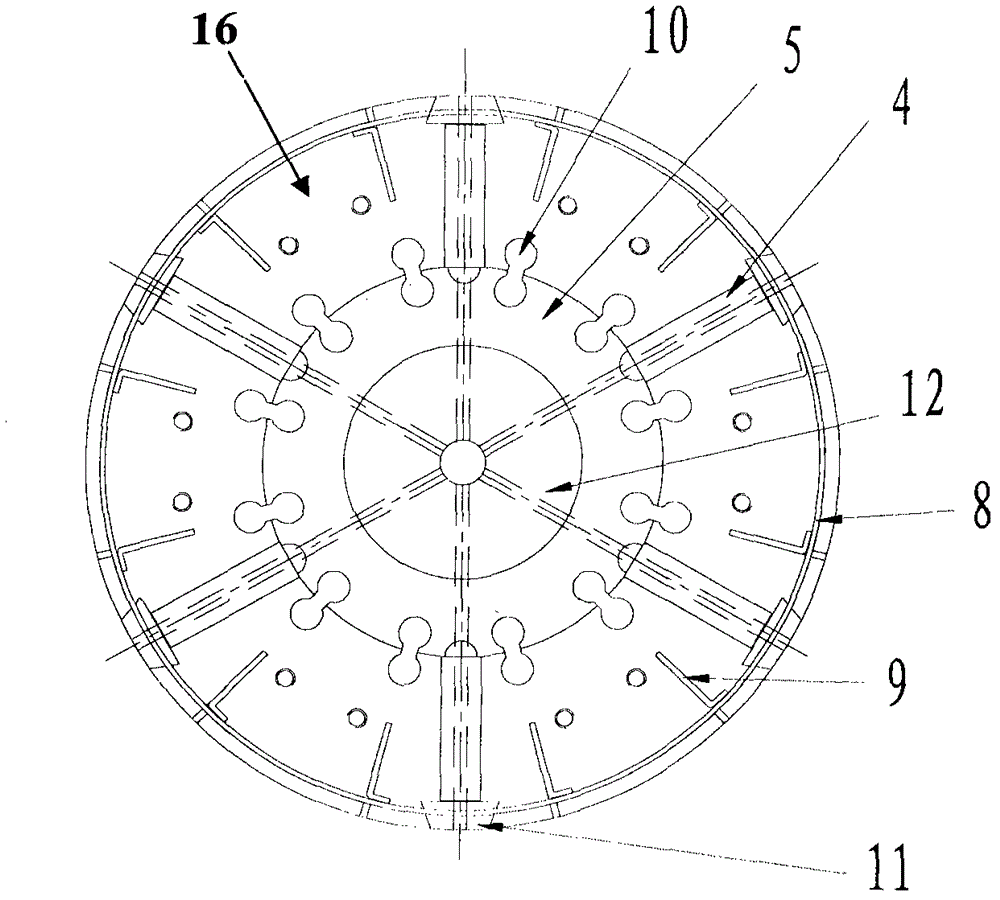

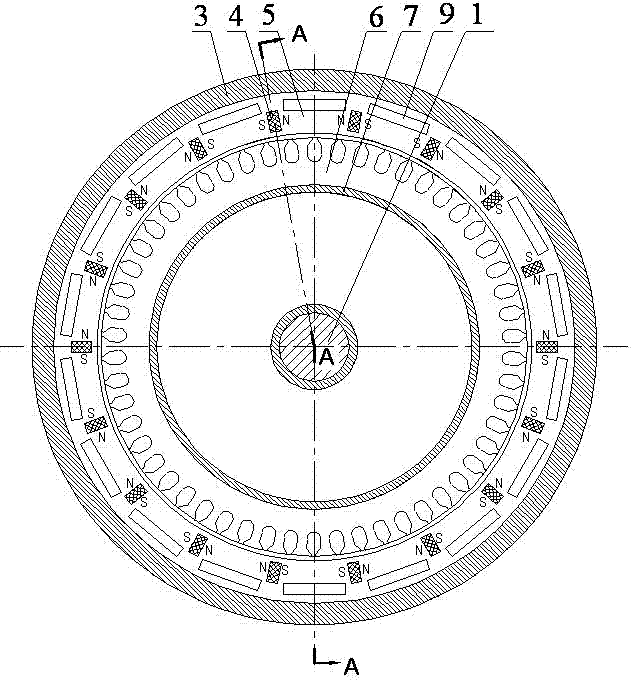

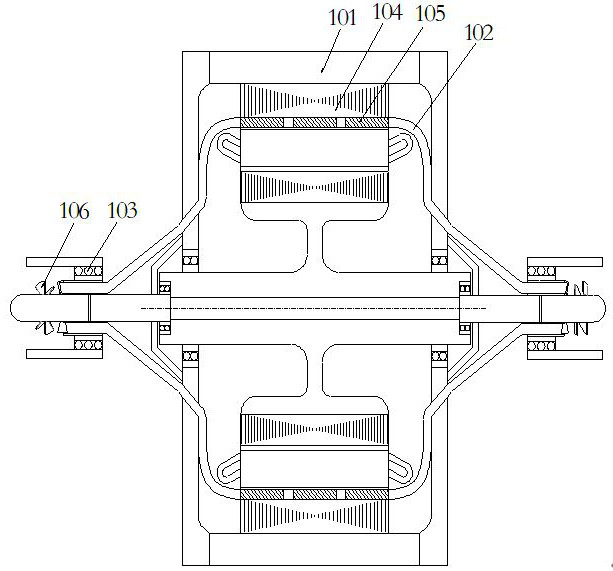

Permanent magnet synchronous motor

InactiveCN102723834AEliminate axial tensionAvoid harmMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The present invention provides a permanent magnet synchronous motor, belonging to the technical field of motors. The permanent magnet synchronous motor is characterized by: adoption of a solid shuttle-shaped rotor structure; a large radial air gap and an axial non-constant air gap; a permanent magnet adopting a radial buried structure; a starting squirrel cage embedded on the rotor; and the rotor and a stator both provided with corresponding ventilation ducts that facilitate cooling air which passes through the large radial air gap to take away heat of the surface of the solid rotor and heat of the stator itself. The permanent magnet synchronous motor in the invention not only solves a problem of starting difficulty in a permanent magnet motor having a conventional laminated rotor, but also solves a problem of heat dissipation difficulty in a permanent magnet motor having a conventional solid rotor. The permanent magnet synchronous motor in the invention with a starting torque from 2.0 to 3.0 further overcomes a problem of easy demagnetization of the permanent magnet caused by a too high temperature of the rotor.

Owner:SHANXI NORTH MACHINE BUILDING

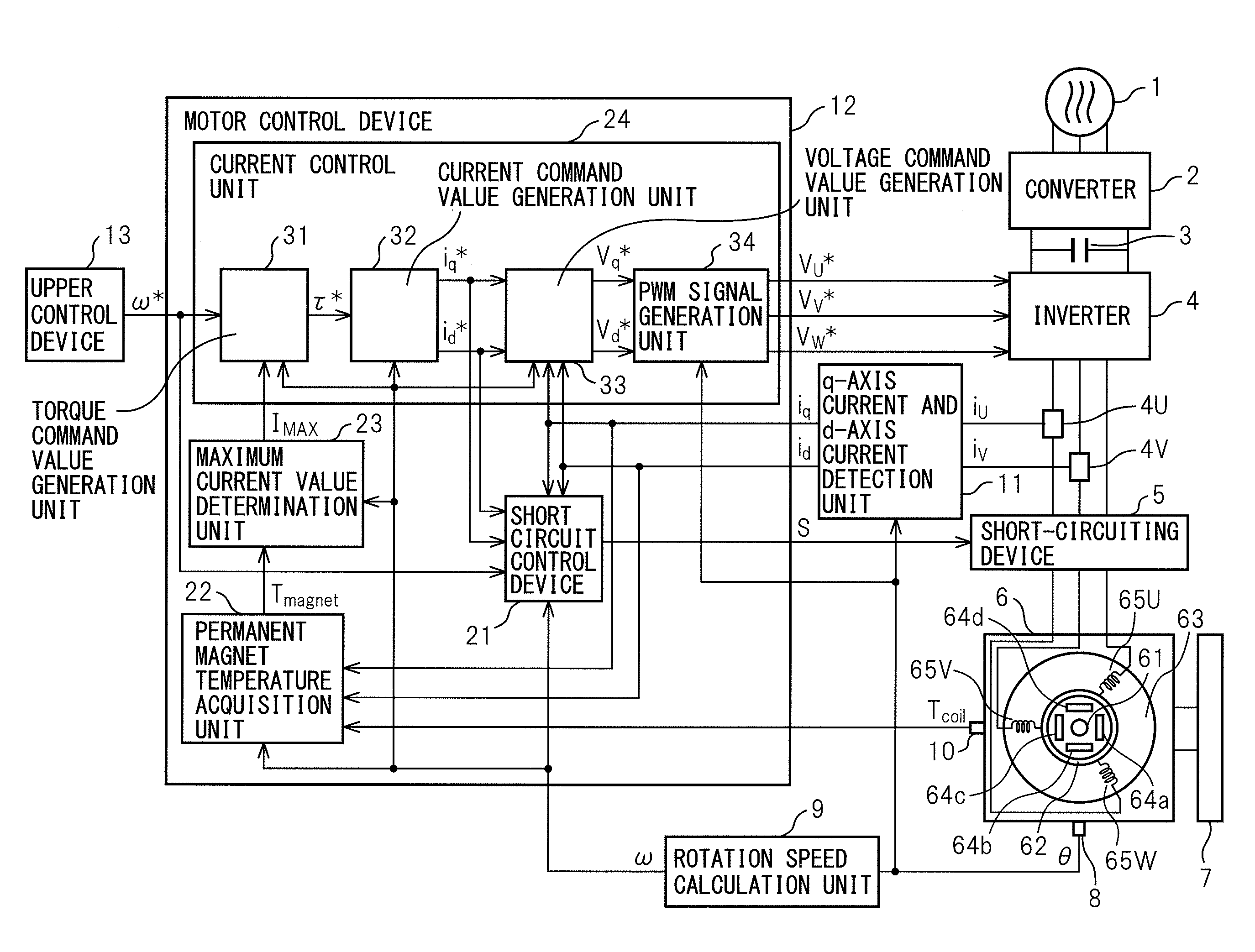

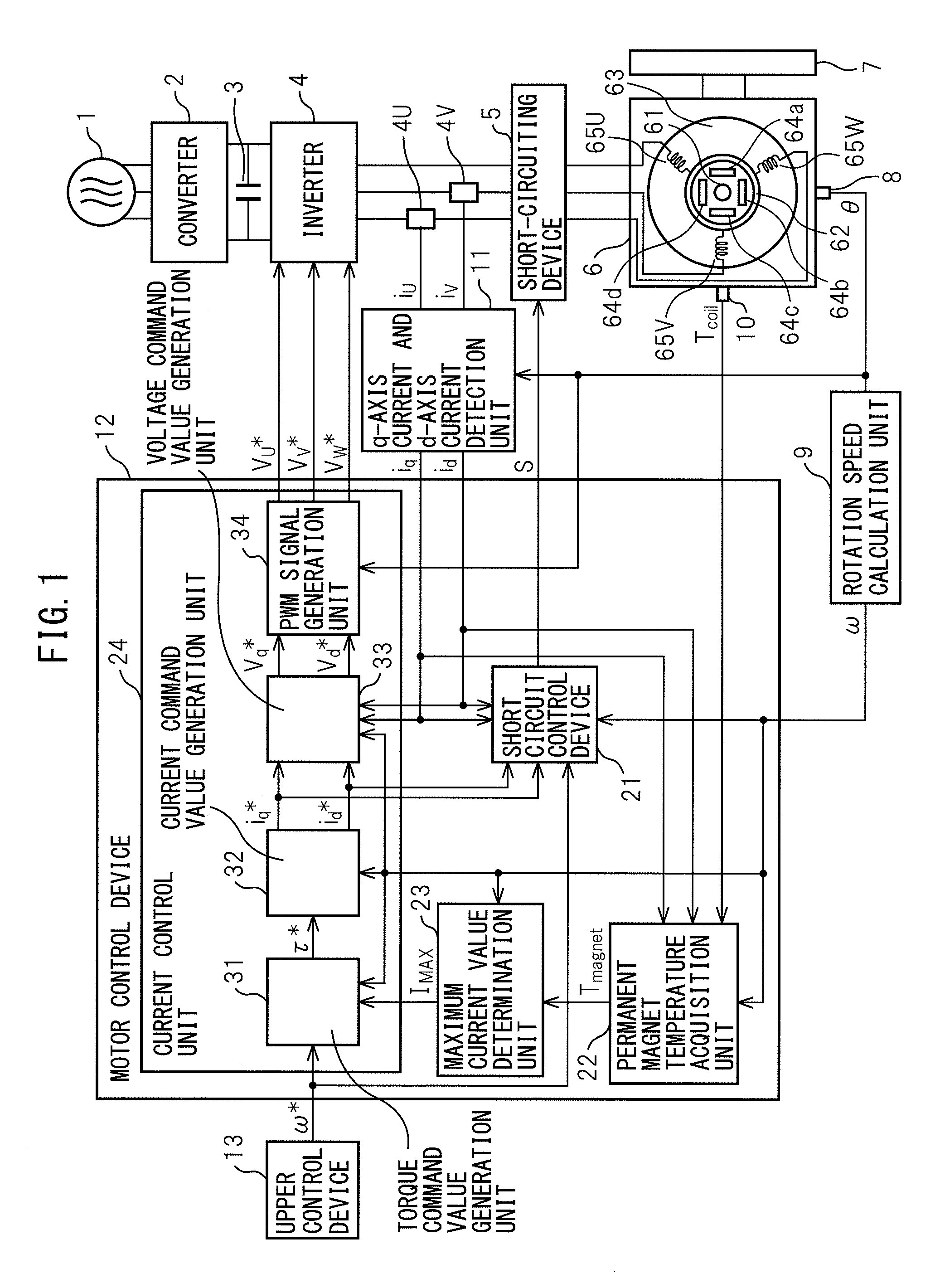

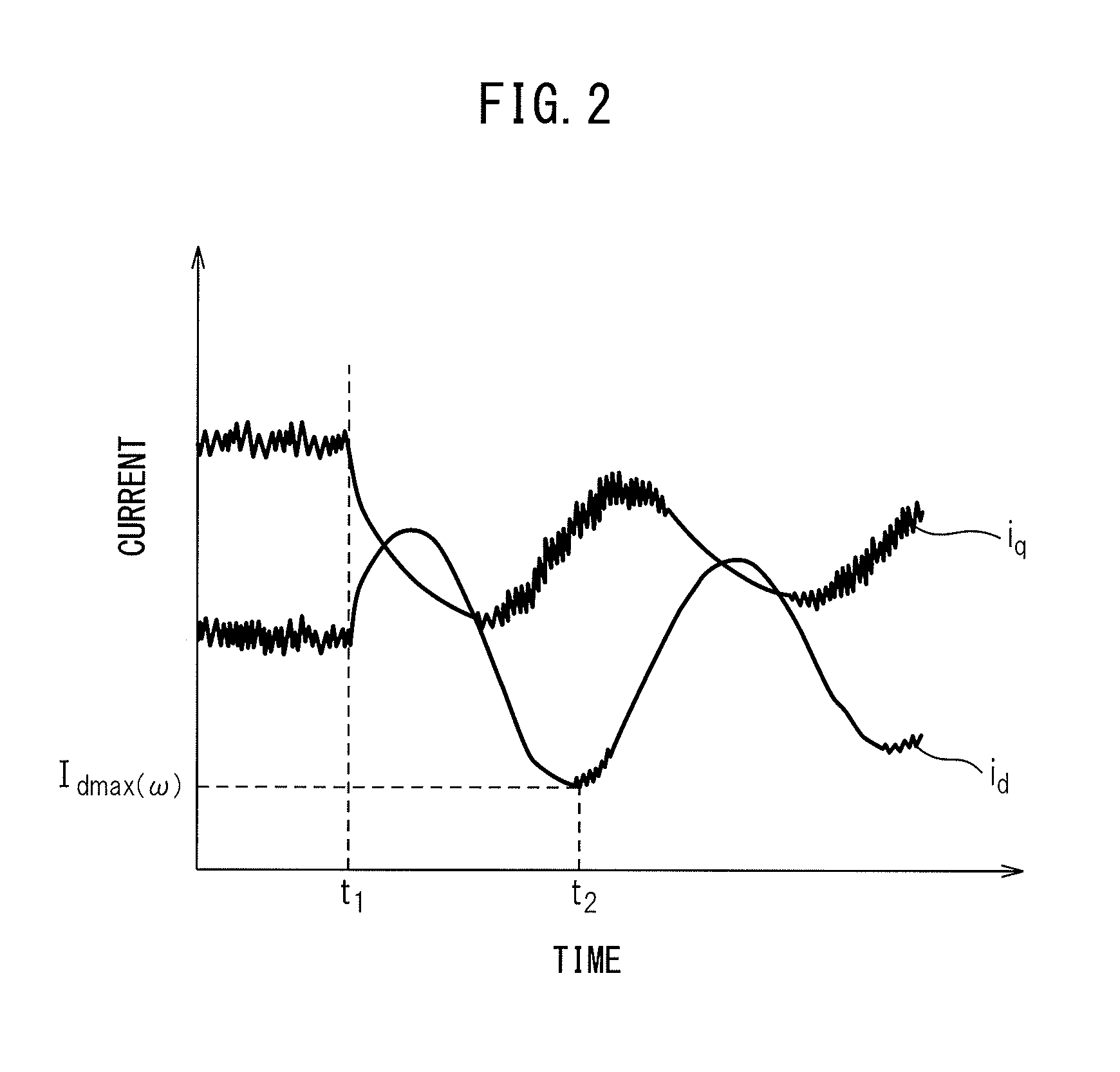

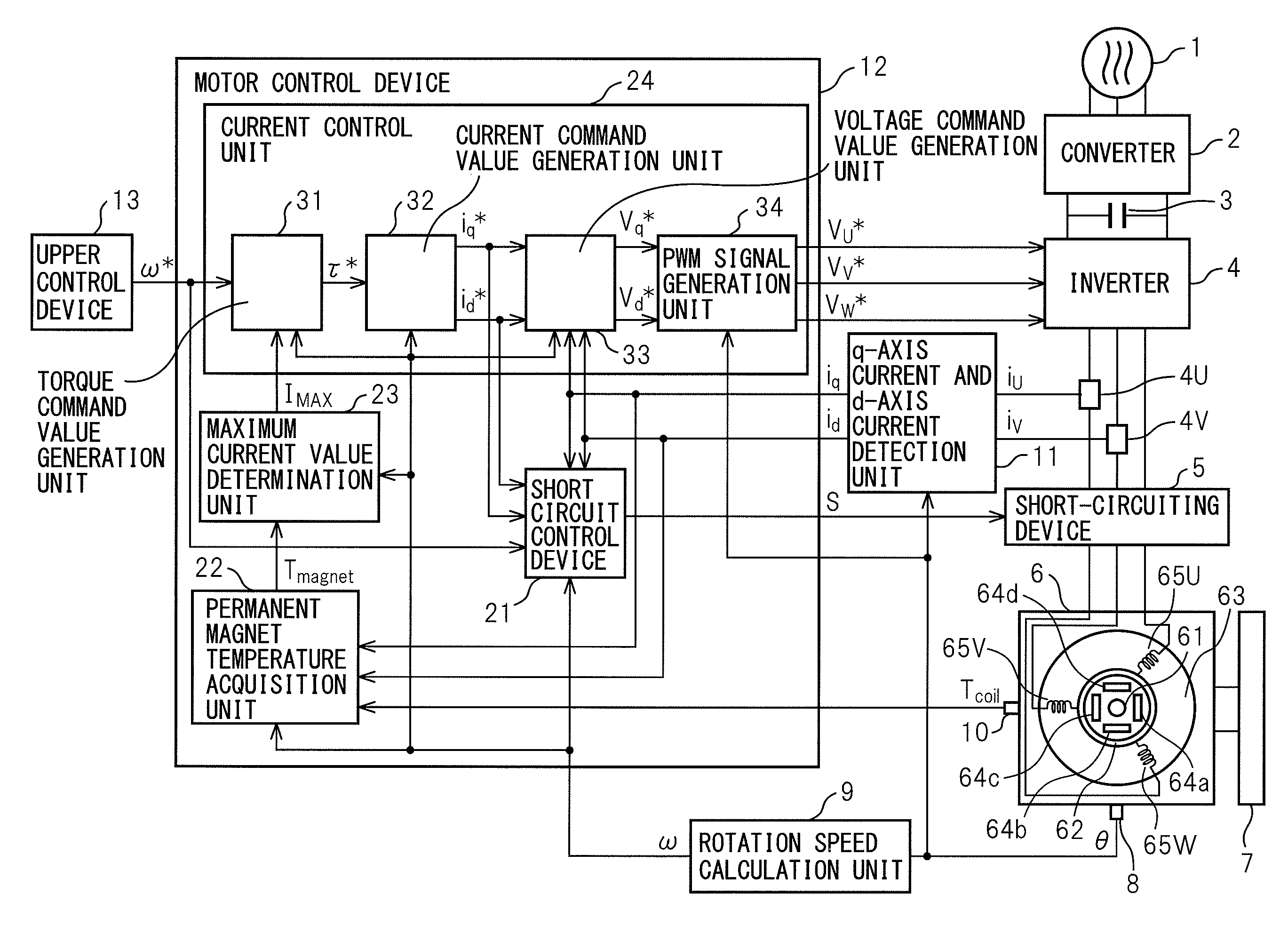

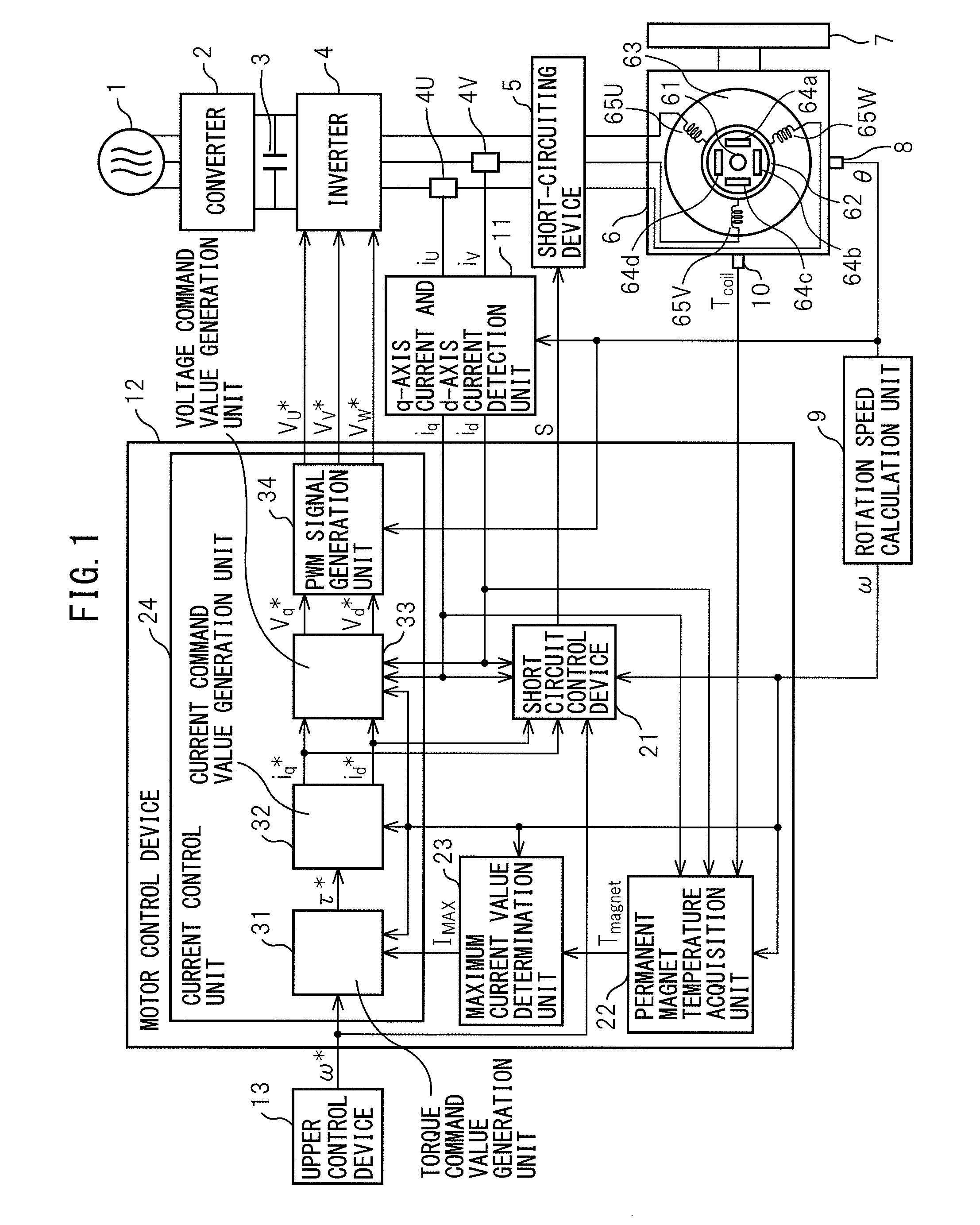

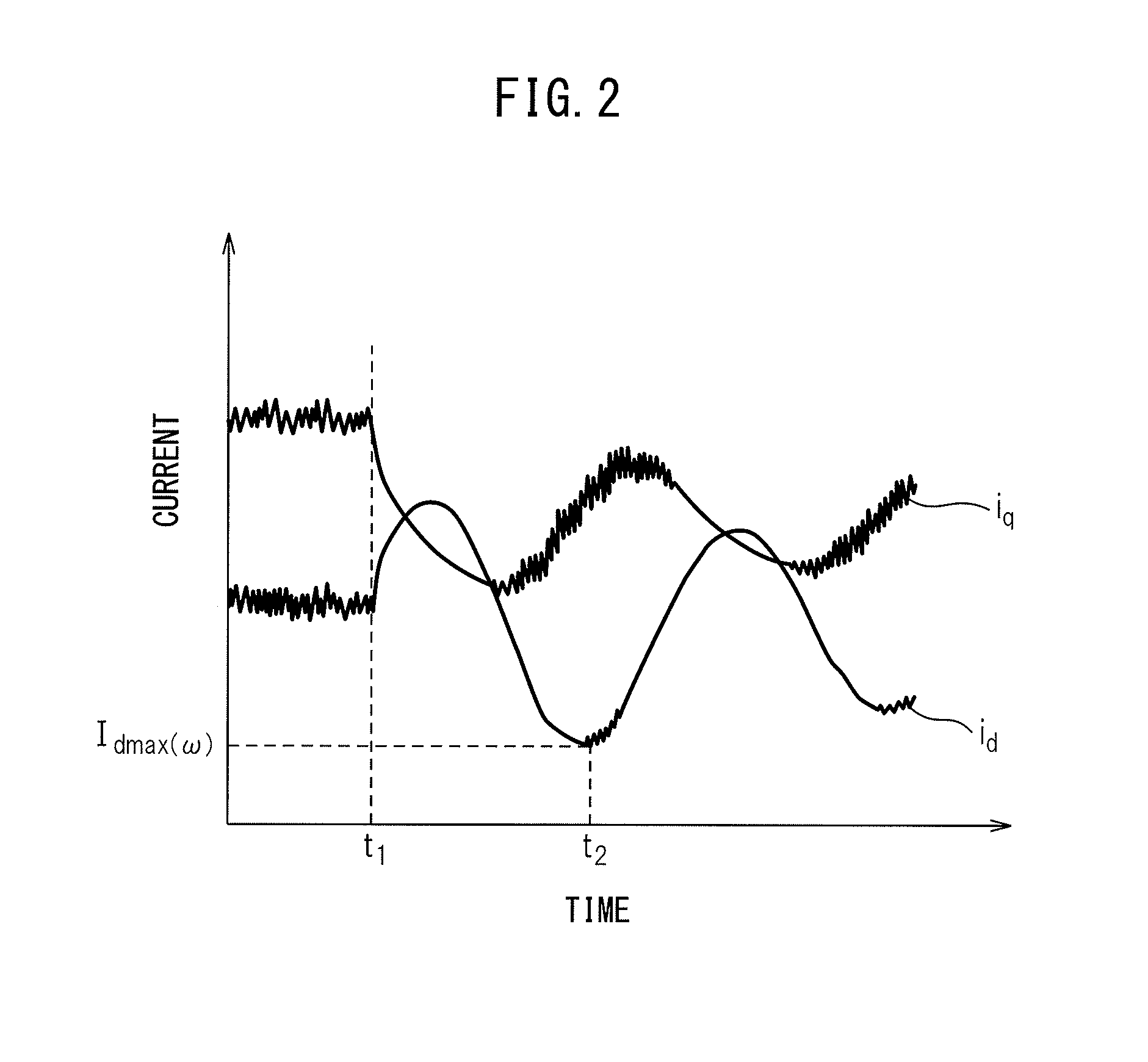

Control device of permanent magnet synchronous motor for preventing irreversible demagnetization of permanent magnet and control system including the same

ActiveUS20140062362A1Avoid irreversible demagnetizationElectronic commutation motor controlSynchronous motors startersControl systemPermanent magnet synchronous motor

A maximum current value determination unit determines the maximum current value of a permanent magnet synchronous motor in order to prevent irreversible demagnetization of a permanent magnet of the permanent magnet synchronous motor that may occur by transient current occurring at the time of short-circuiting of three phases, based on one of a set of irreversible demagnetization causing current value corresponding to permanent magnet temperature and the transient current occurring at the time of the short-circuiting of three phases, and a set of irreversible demagnetization causing magnetic field intensity corresponding to the permanent magnet temperature and demagnetization field intensity of the permanent magnet of the permanent magnet synchronous motor occurring at the time of the short-circuiting of three phases. A current control unit controls the current of the permanent magnet synchronous motor so that the current value of the permanent magnet synchronous motor is less than the maximum current value.

Owner:FANUC LTD

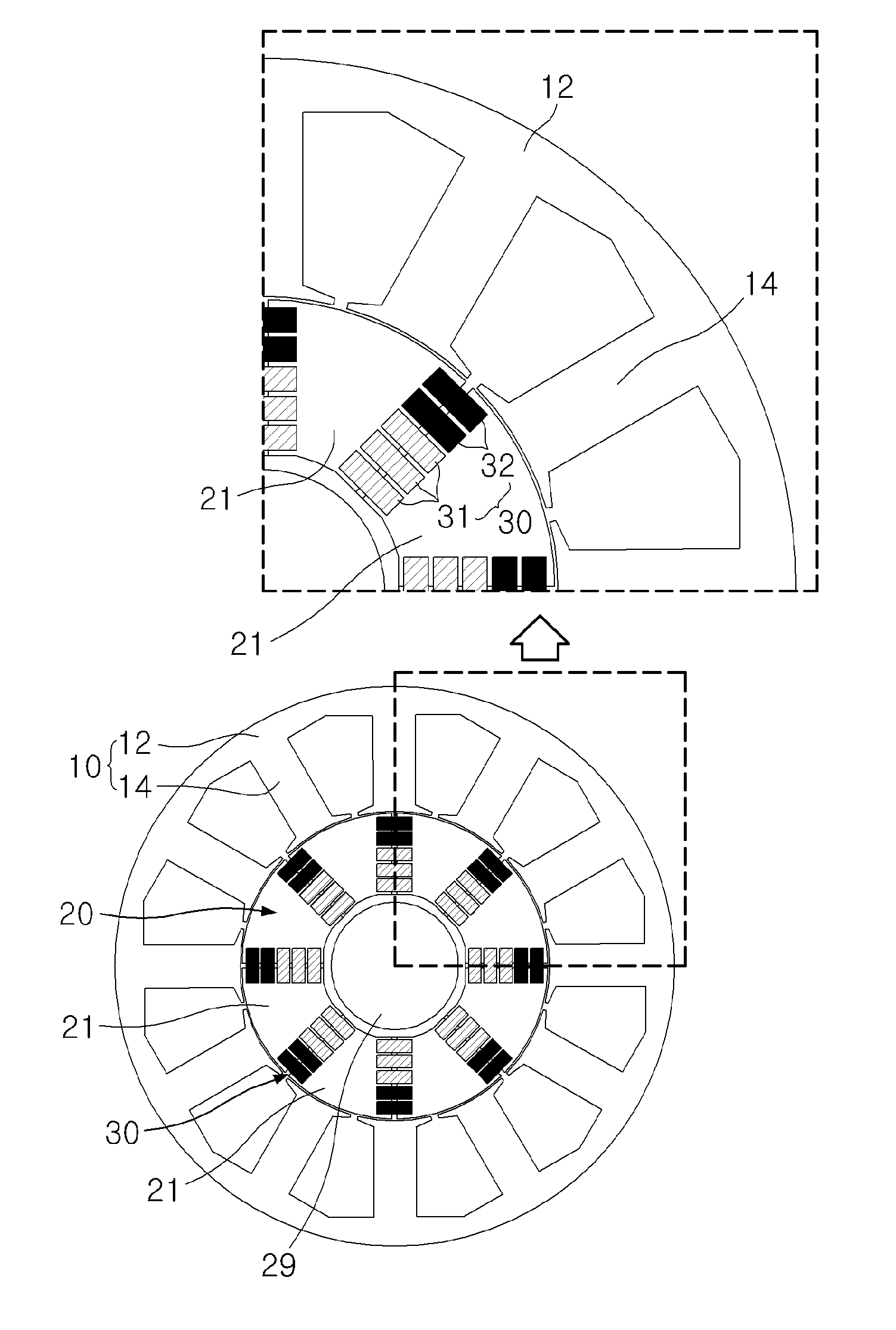

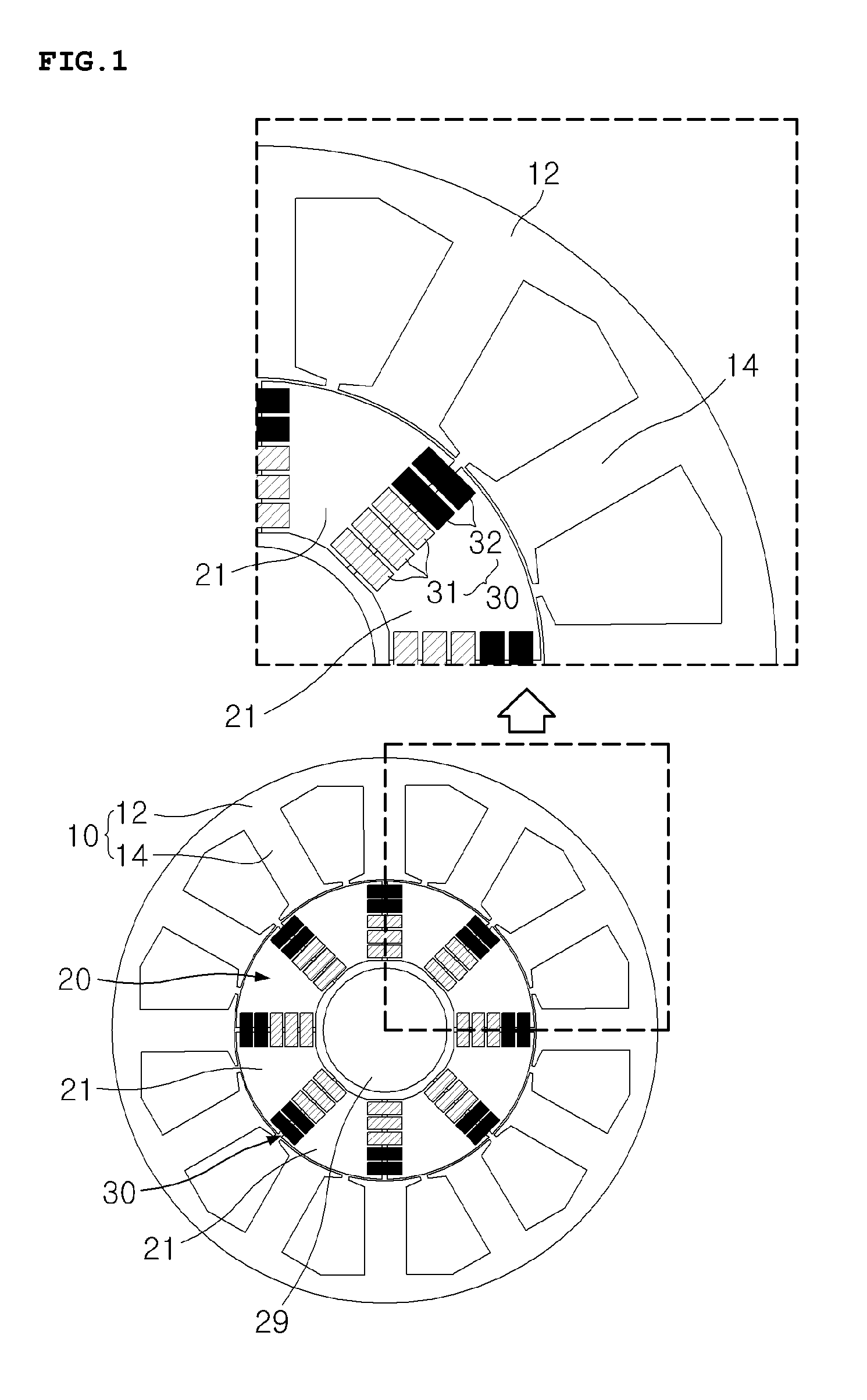

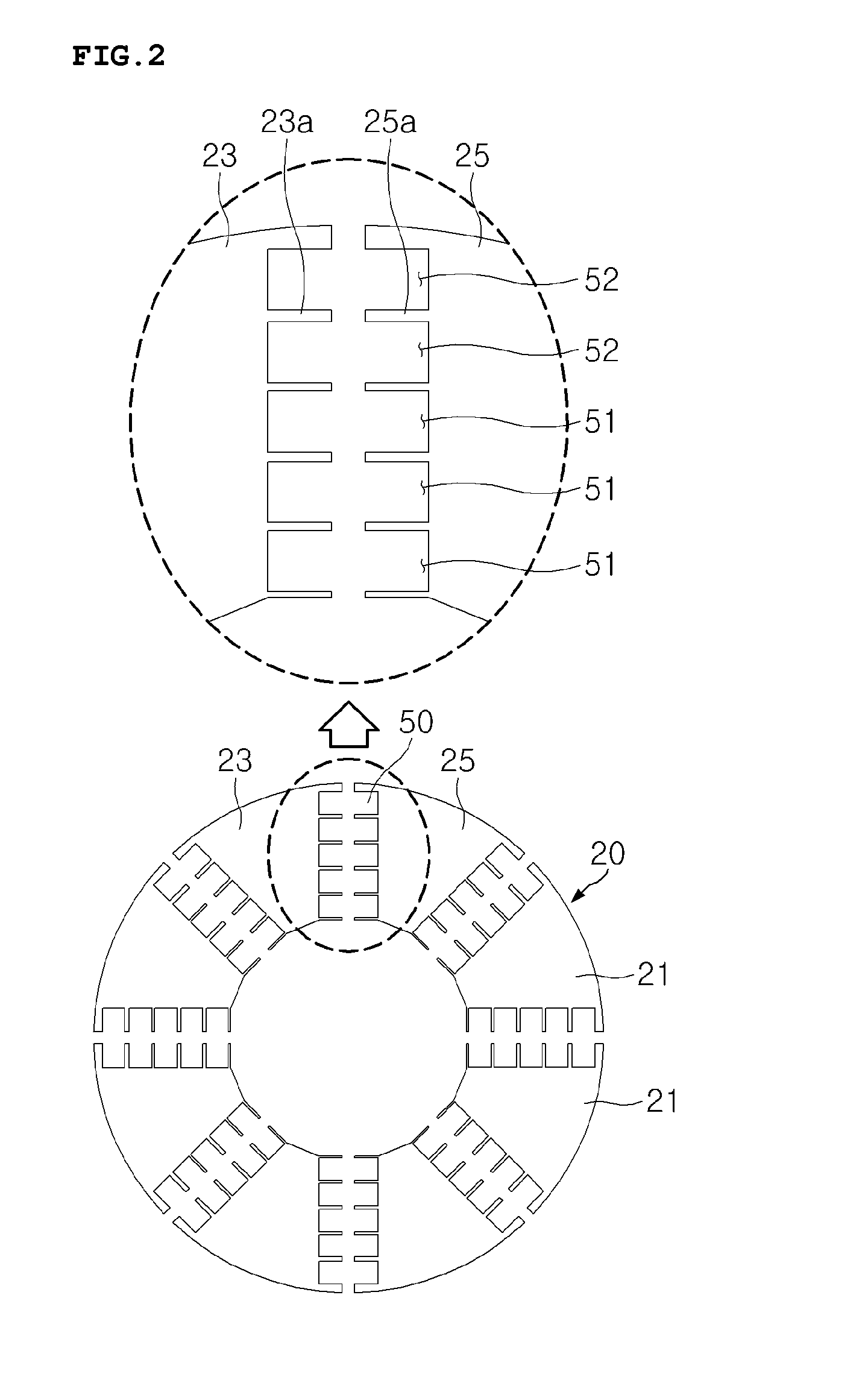

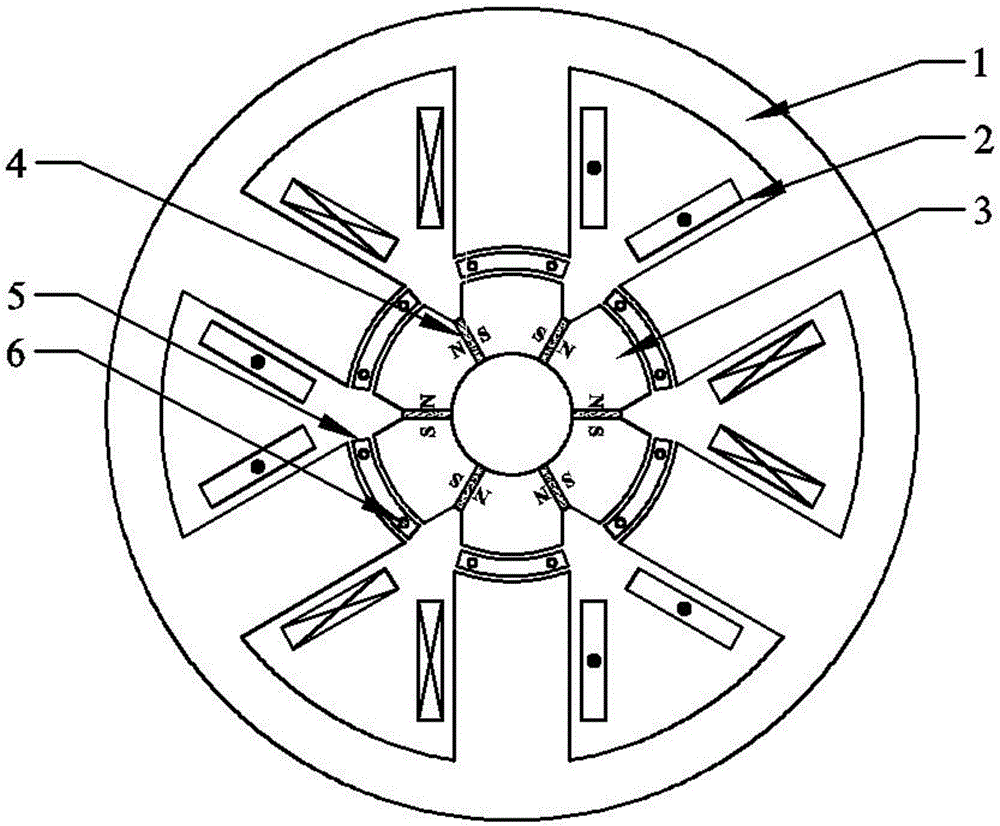

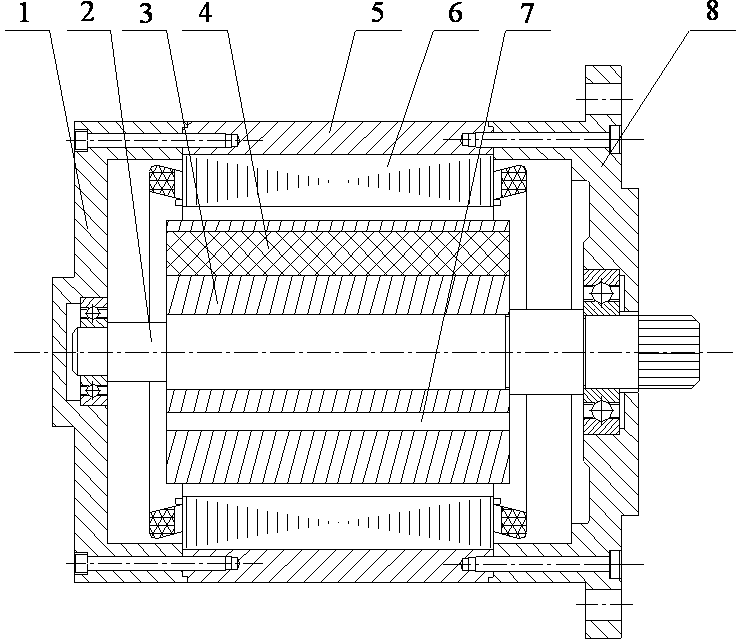

Interior Permanent Magnet Motor

ActiveUS20150028707A1Avoid irreversible demagnetizationMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsPhysicsMagnet

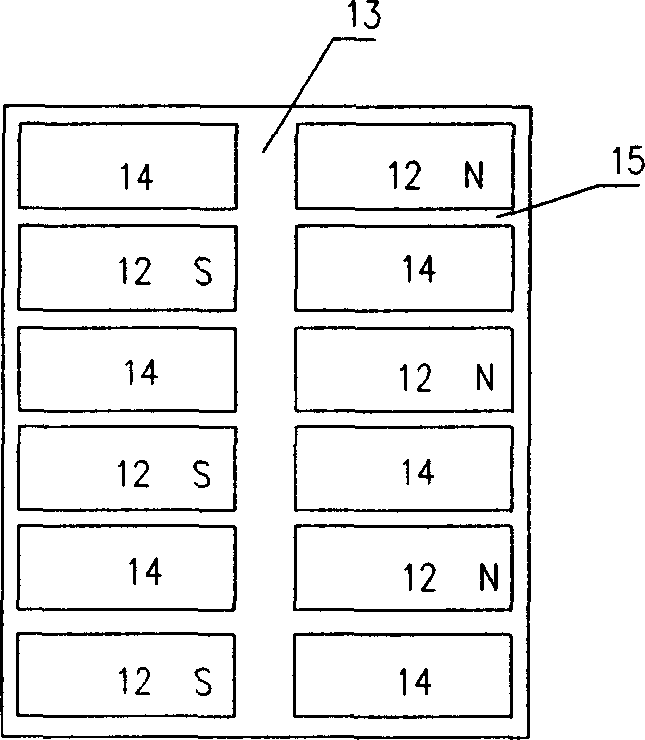

An interior permanent magnet motor includes a stator having teeth on which a coil is wound, a rotor rotatably provided inside the stator, the rotor including a plurality of rotor sectors, and at least two permanent magnet recesses formed between the rotor sectors. Ferrite permanent magnets are embedded in predetermined ones of the permanent magnet recesses that are formed in an inner portion of the rotor. Rare-earth permanent magnets are embedded in the other ones of the permanent magnet recesses that are formed in an outer portion of the rotor.

Owner:KOMOTEK

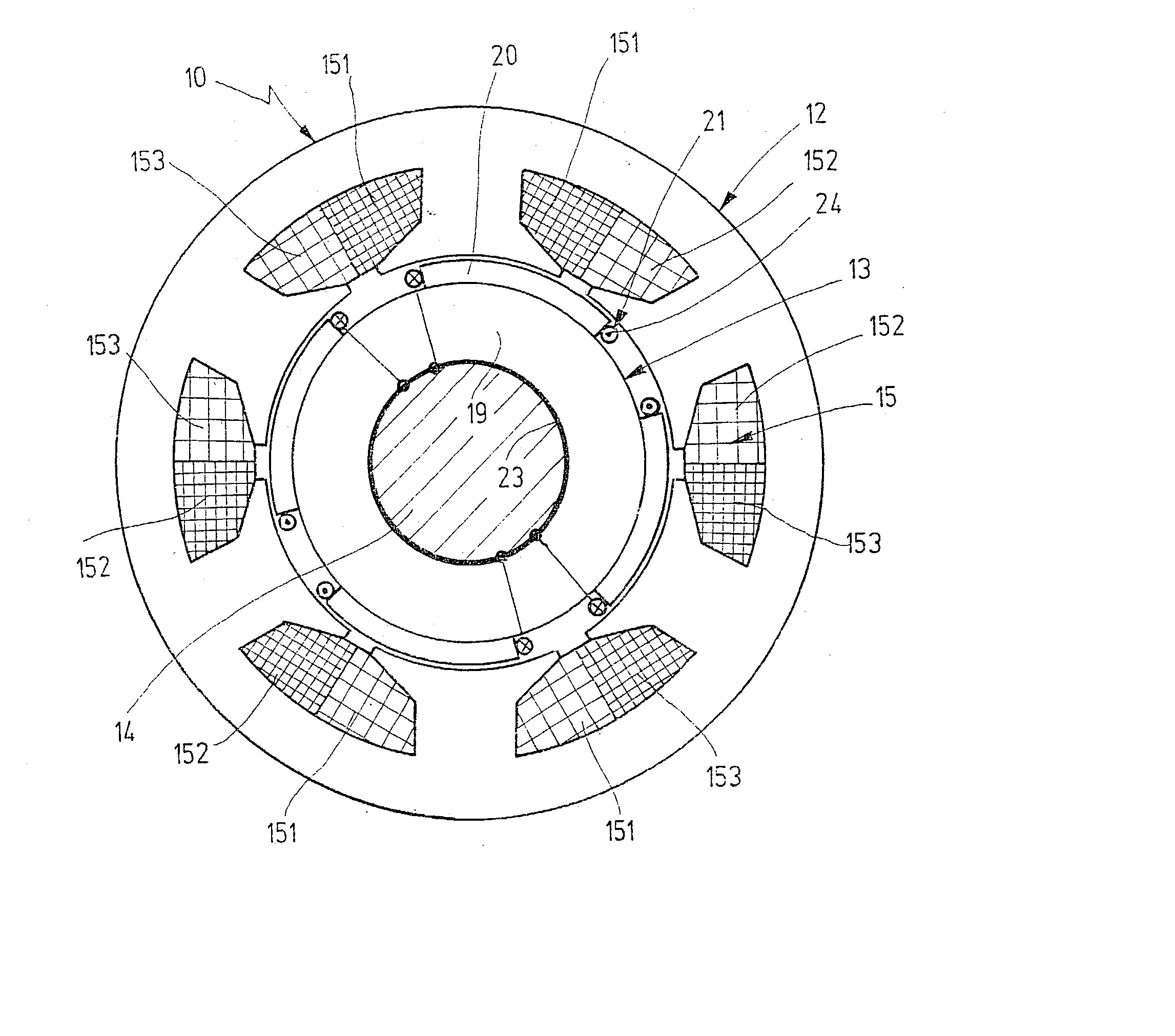

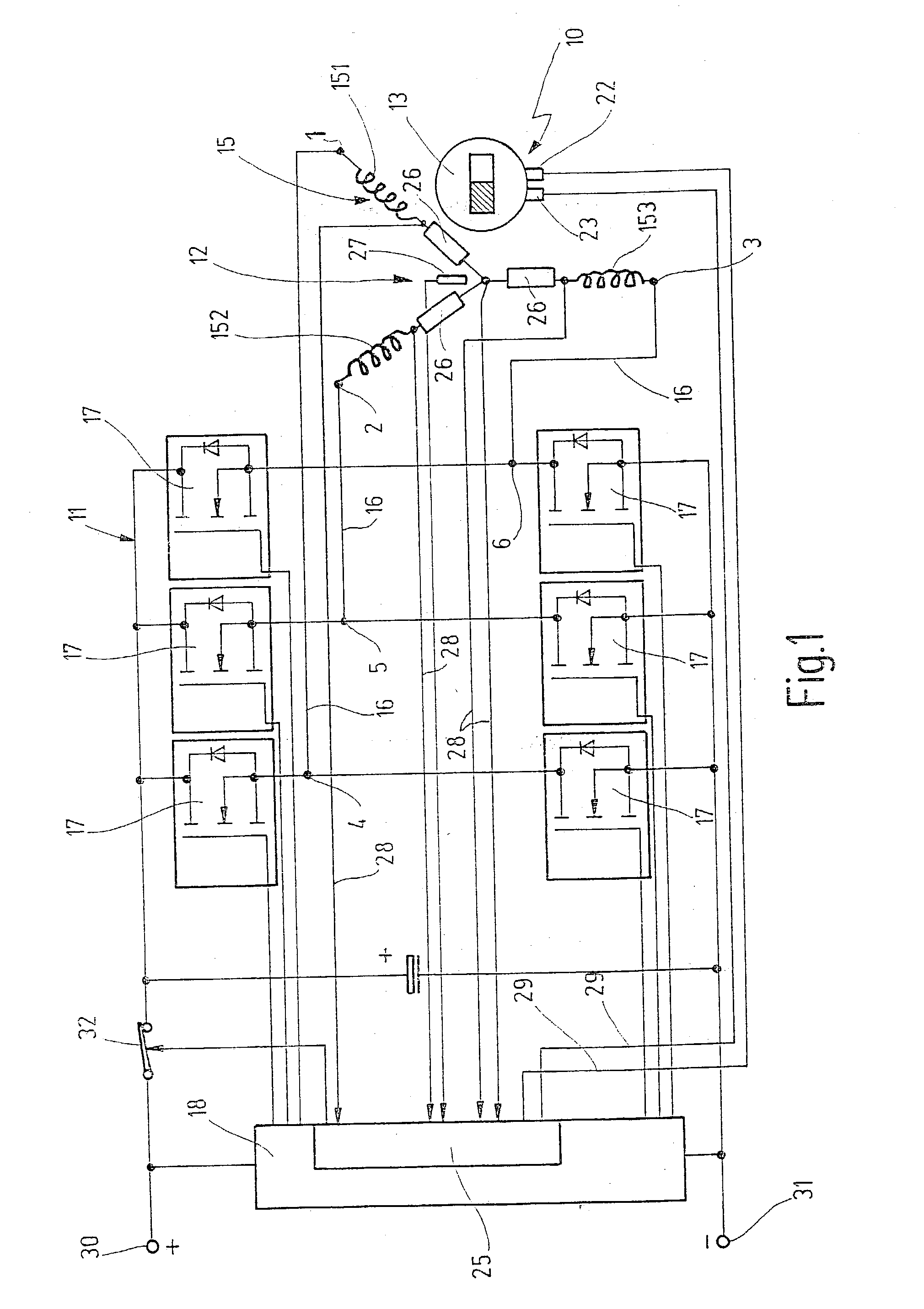

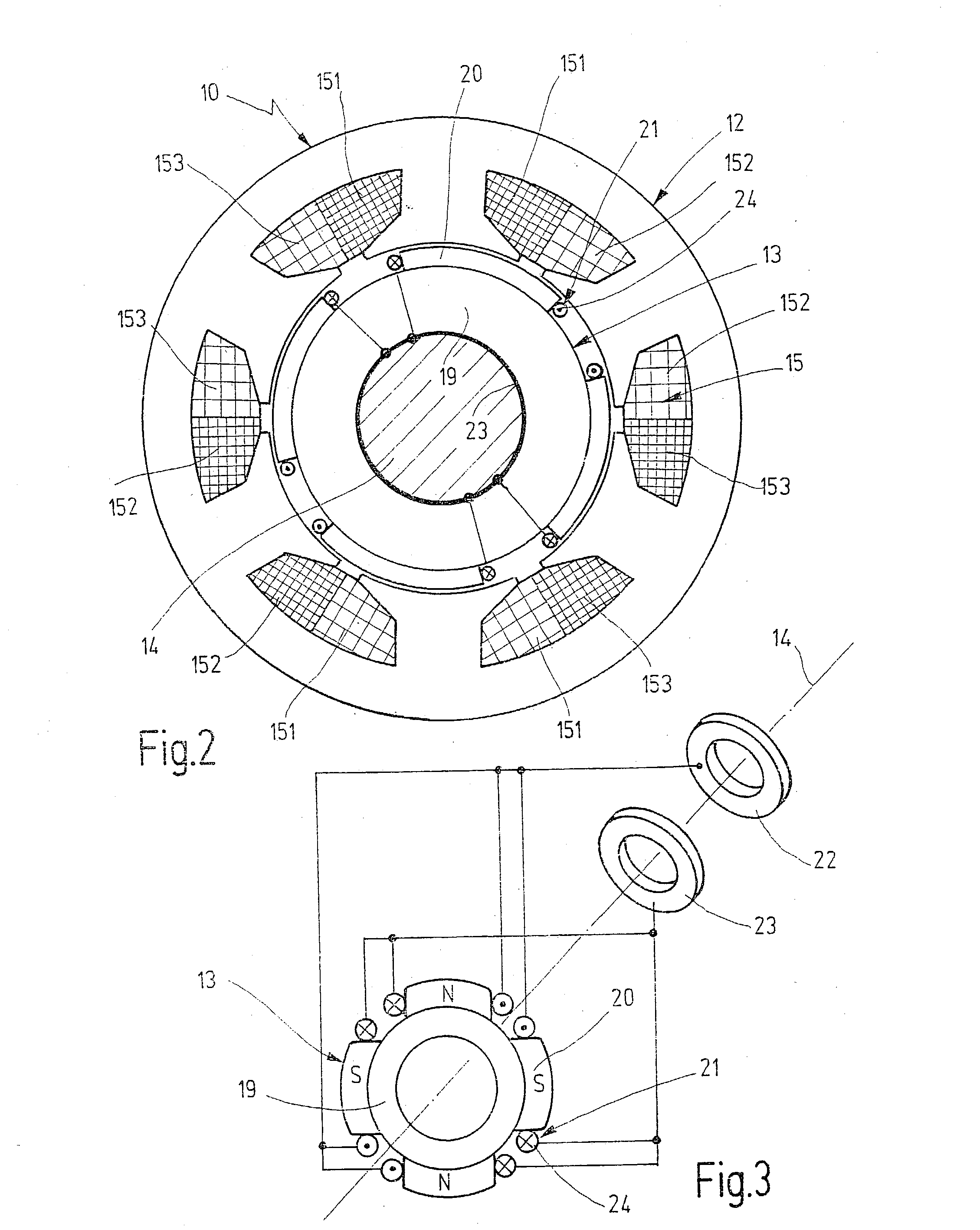

Brushless dc drive

InactiveUS20030173850A1Avoid irreversible demagnetizationDecrease in the magnetic fieldWindingsAC motor controlSynchronous motorPhysics

In a brushless direct-current drive with a synchronous motor (10), which has a stator (12) that supports a multi-phase stator winding (15) and a rotor (13) equipped with permanent magnet poles (20), and with a switch unit (11), which precedes the stator winding (15), for commutating the stator winding (15), in order to produce a fail-silent behavior, a field excitation winding (21) is disposed in the rotor (13), which winding can be supplied with current in the event of a malfunction so that it generates a magnetic flux oriented in the opposite direction from the magnetic flux of the permanent magnet poles (20) (FIG. 2).

Owner:ROBERT BOSCH GMBH

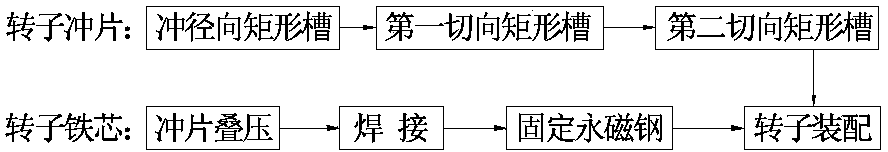

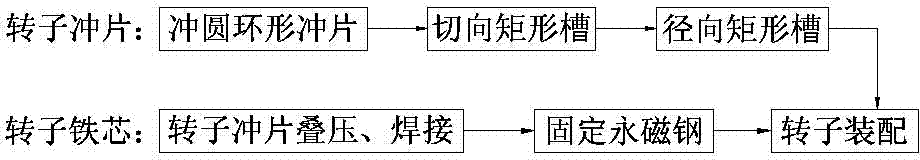

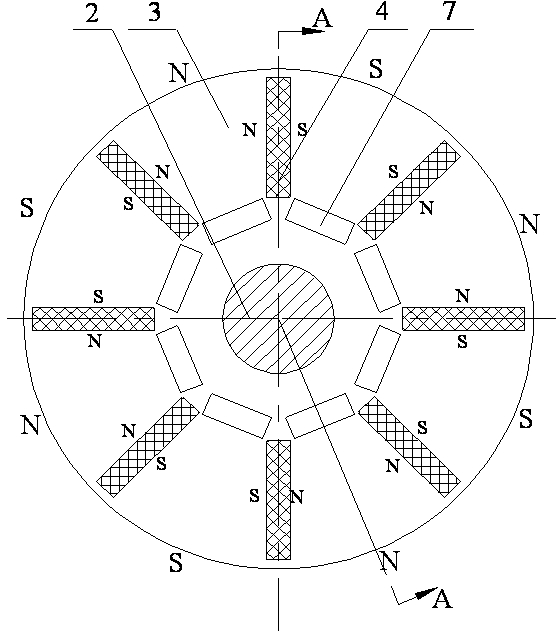

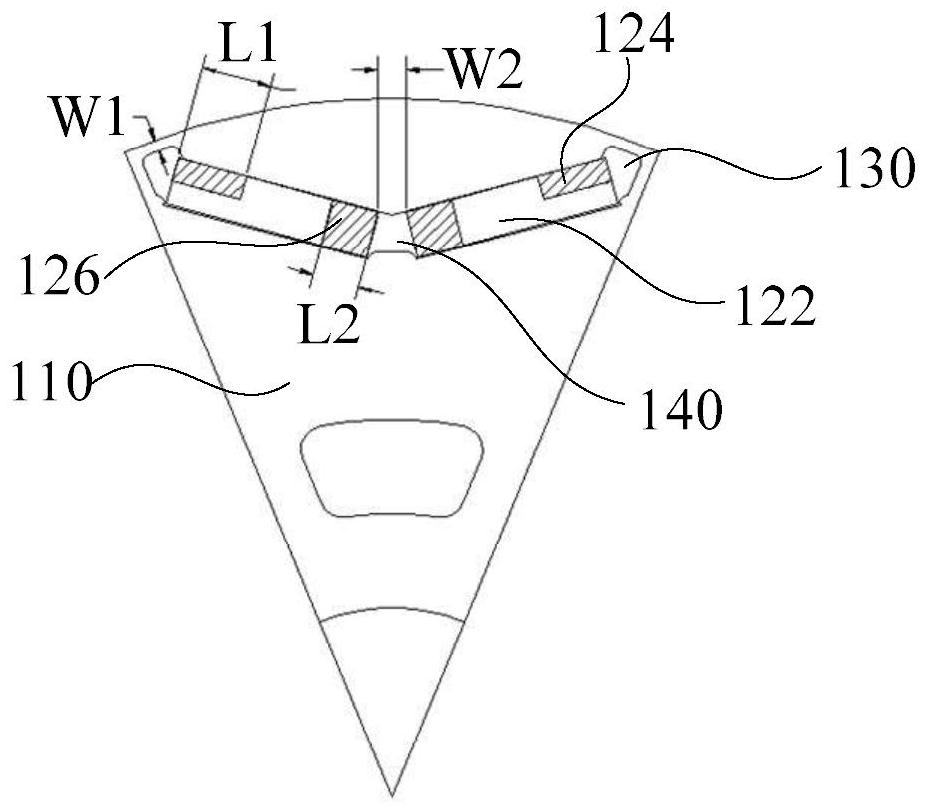

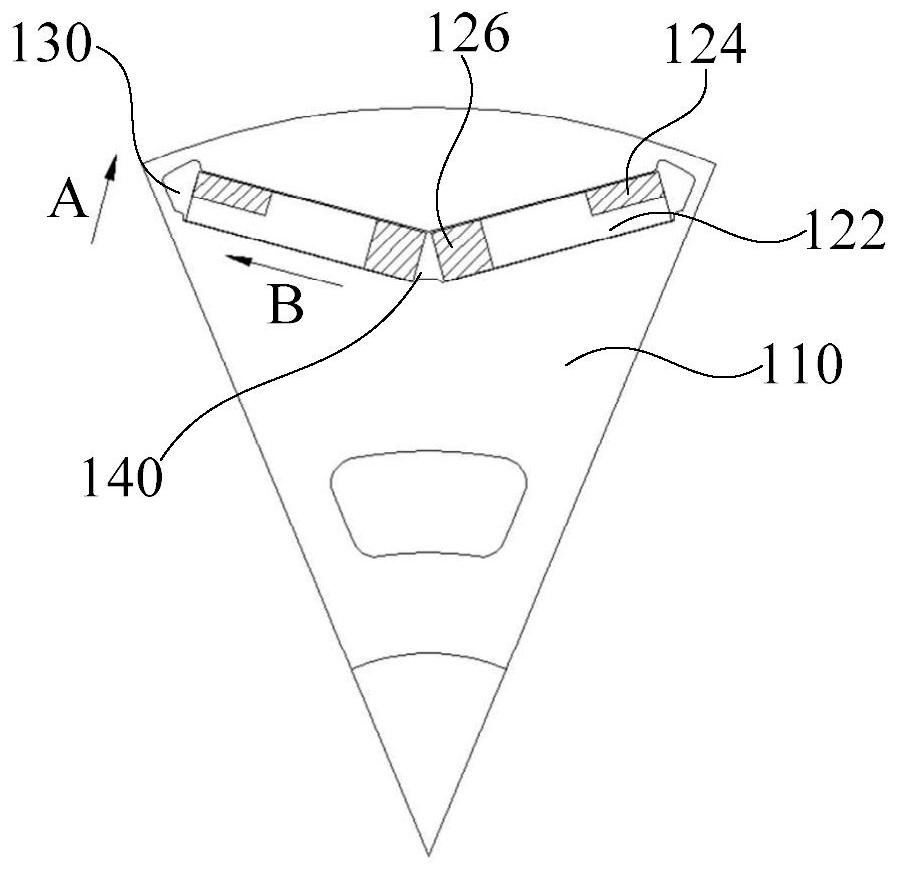

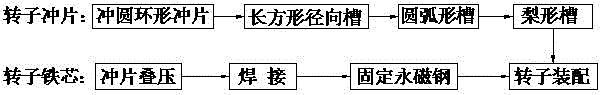

Production method for embedded permanent magnet rotor of tangential and radial resultant magnetic field driving motor

InactiveCN103762794AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

The invention provides a production method for an embedded permanent magnet rotor of a tangential and radial resultant magnetic field driving motor, and belongs to the technical field of automobile motor electric appliances. Pieces of rectangular permanent magnet steel are embedded into radial rectangular grooves and second tangential rectangular grooves of a rotor iron core respectively. Due to the fact that the tangential and radial resultant magnetic field driving motor is of a rotor magnetic bypass structure, the problem that irreversible demagnetization is generated when the permanent magnet steel bears the action of the armature reaction of an impact current can be effectively avoided, it is ensured that demagnetization does not happen on the permanent magnet steel, the magnetic field of the rotor of the driving motor is supplied by both the tangential magnetic field and the radial magnetic field, the magnetic field intensity is large, output power is high, and the embedded permanent magnet rotor has the advantages of being high in efficiency and power density, compact in structure, reliable in work and the like.

Owner:SHANDONG UNIV OF TECH

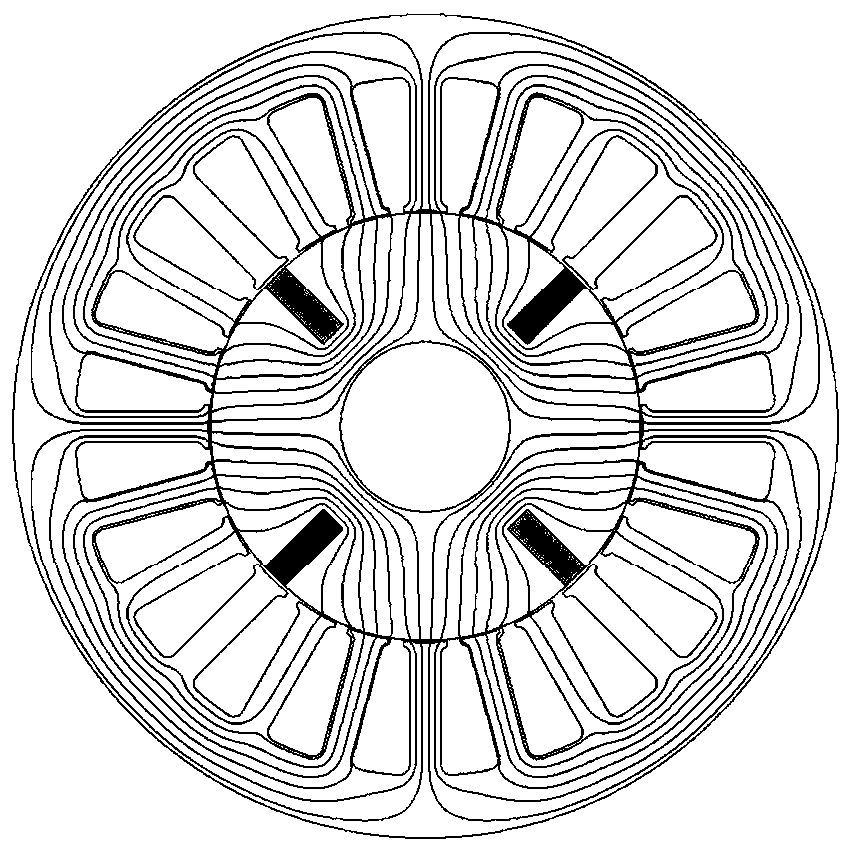

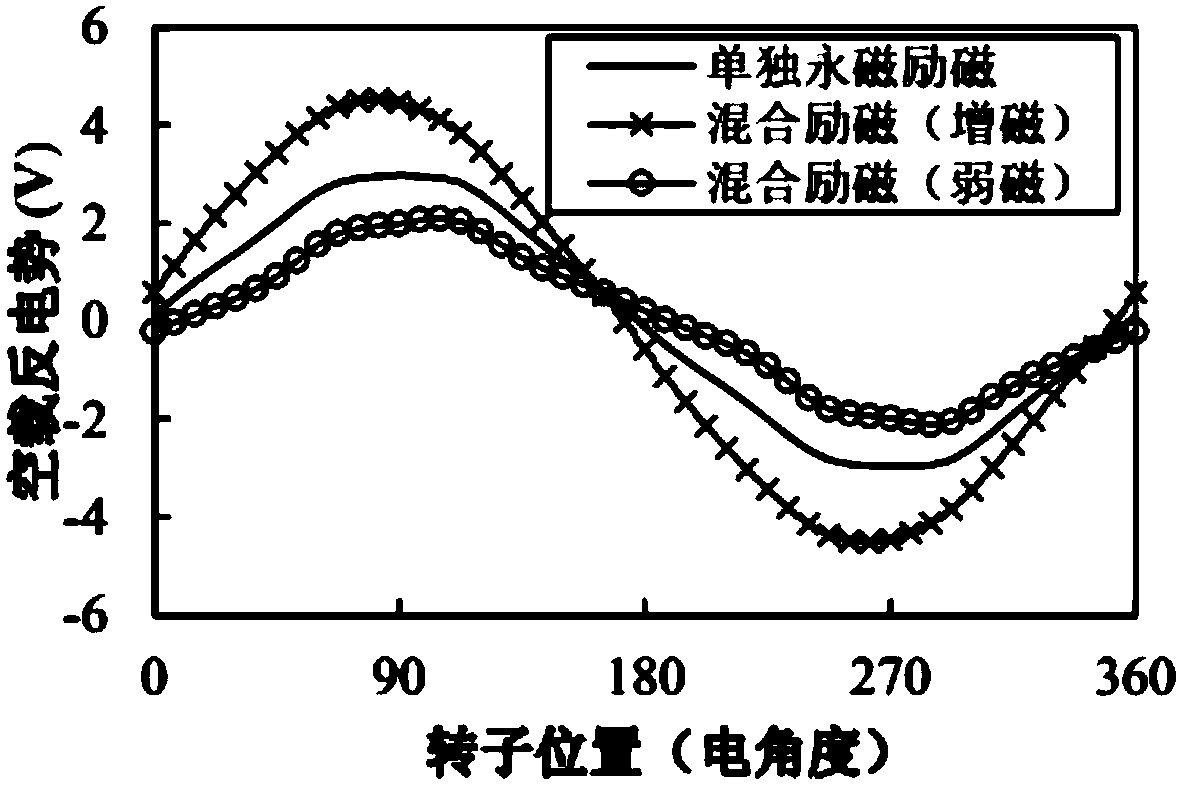

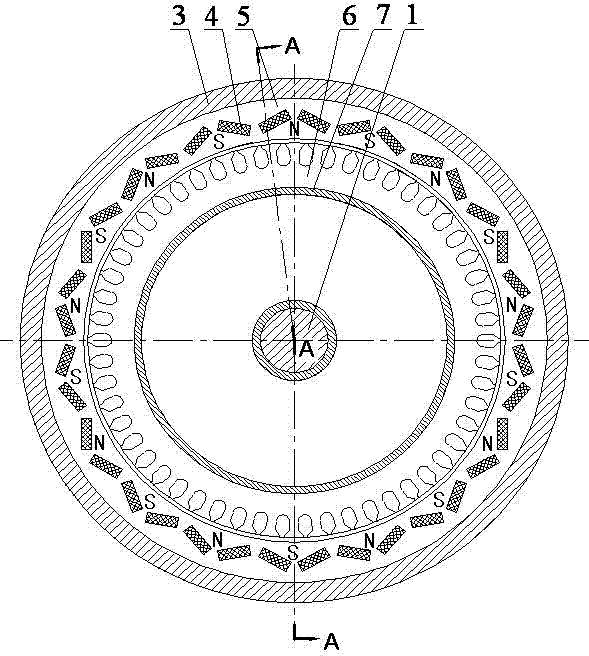

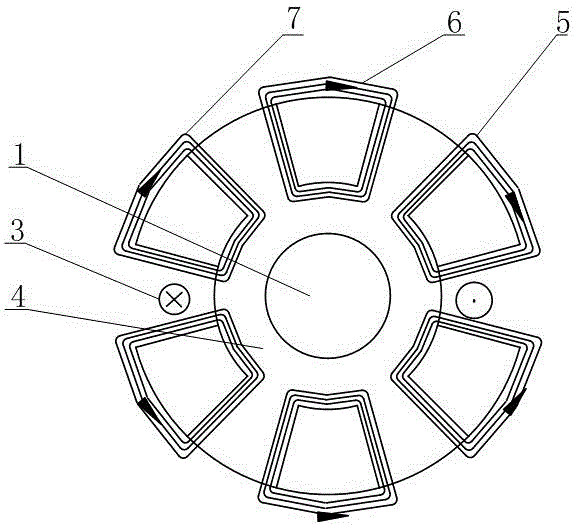

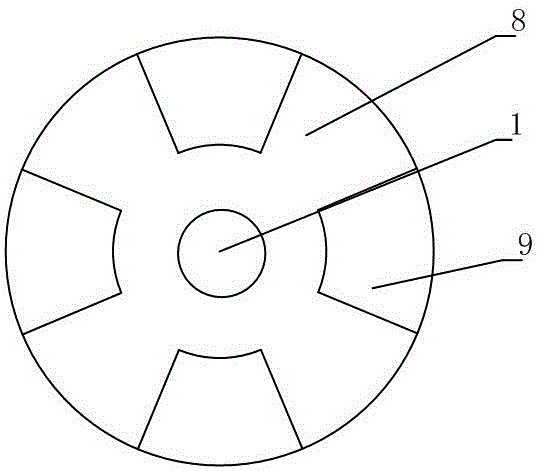

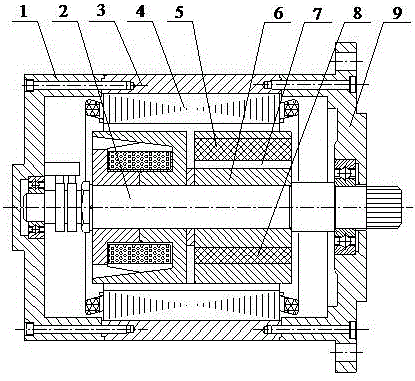

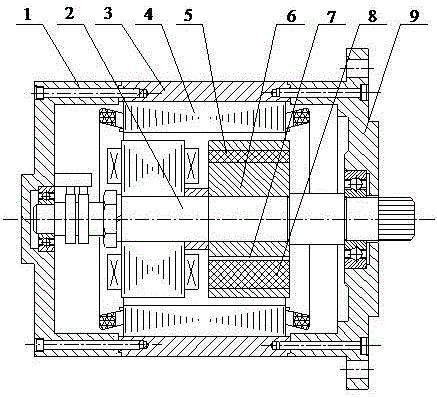

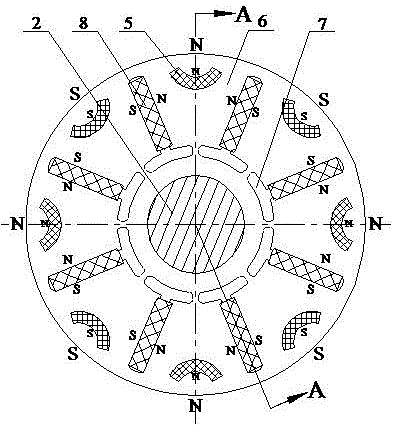

Bilaterally-excited tangential magnetic steel hybrid excited brushless motor

ActiveCN109951038ASimple and reliable brushless AC excitationAvoid demagnetizationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBrushless motorsPower flow

The invention discloses a bilaterally-excited tangential magnetic steel hybrid excited brushless motor, which comprises a stator, a rotor, tangential magnetic steel, magnetic bridges, an armature winding and an excitation winding. The armature winding and the excitation winding are both AC windings and are wound around both sides of a stator slot in the stator respectively, wherein the number of pole pairs of the armature winding is equal to the number of pole pairs of the excitation winding, and is equal to the number of pole pairs of the rotor. The tangential magnetic steel is uniformly embedded in the rotor in the circumferential direction, and the magnetization directions of every two adjacent pieces of tangential magnetic steel are opposite to each other. The magnetic bridges are disposed at the top, the bottom or the middle of each piece of tangential magnetic steel. The brushless motor, by controlling the alternating current of the excitation winding in the stator, generates anexcitation magnetic field synchronously rotating with the rotor so as to realize brushless AC excitation, and adjusts the magnetic field by controlling the magnitude and direction of the excitation component in the excitation winding current, thereby improving the output capacity of the motor and also improving motor space and a material utilization rate.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

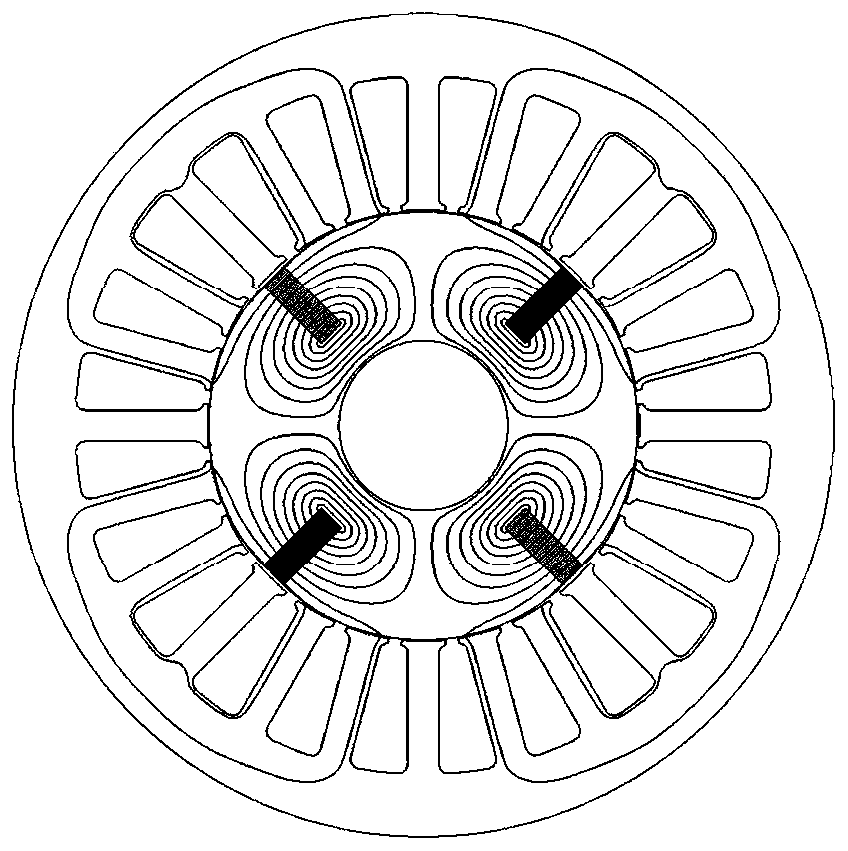

A stator-partition type consequent-pole hybrid excitation motor

ActiveCN108964396AAvoid irreversible demagnetizationAchieve magnetizationSynchronous machine detailsMagnetic circuit stationary partsConductor CoilPole number

The invention discloses a stator-partition type consequent-pole hybrid excitation motor which comprises armature windings, exciting windings, permanent magnets, a stator where the armature windings are located, a rotor and a stator where the exciting windings are located. The stator where the armature windings are located and the stator where the exciting windings are located are respectively disposed on both sides of the rotor. When the stator where the armature windings are located is the outer stator, the stator where the excitation windings are located is the inner stator; and when the stator where the excitation windings are located is the outer stator, the stator where the armature windings are located is the inner stator. The number of teeth of the stator where the armature windingsare located is Nst, and the number of teeth of the stator where the field windings are located is Nst / 3. The tooth tips of the stator teeth where the exciting windings are located face the rotor direction, and the tooth tip of the stator tooth where each exciting winding is located has one or two permanent magnet poles, and the number of poles formed is three; and the magnetizing directions of the permanent magnets of the stator teeth where the adjacent exciting windings are located are reversed. The motor of the invention solves the problem of space restriction on the permanent magnets and the armature windings, and meanwhile realizes effective adjusting of air-gap fields through setting the set of exciting windings on the stator.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

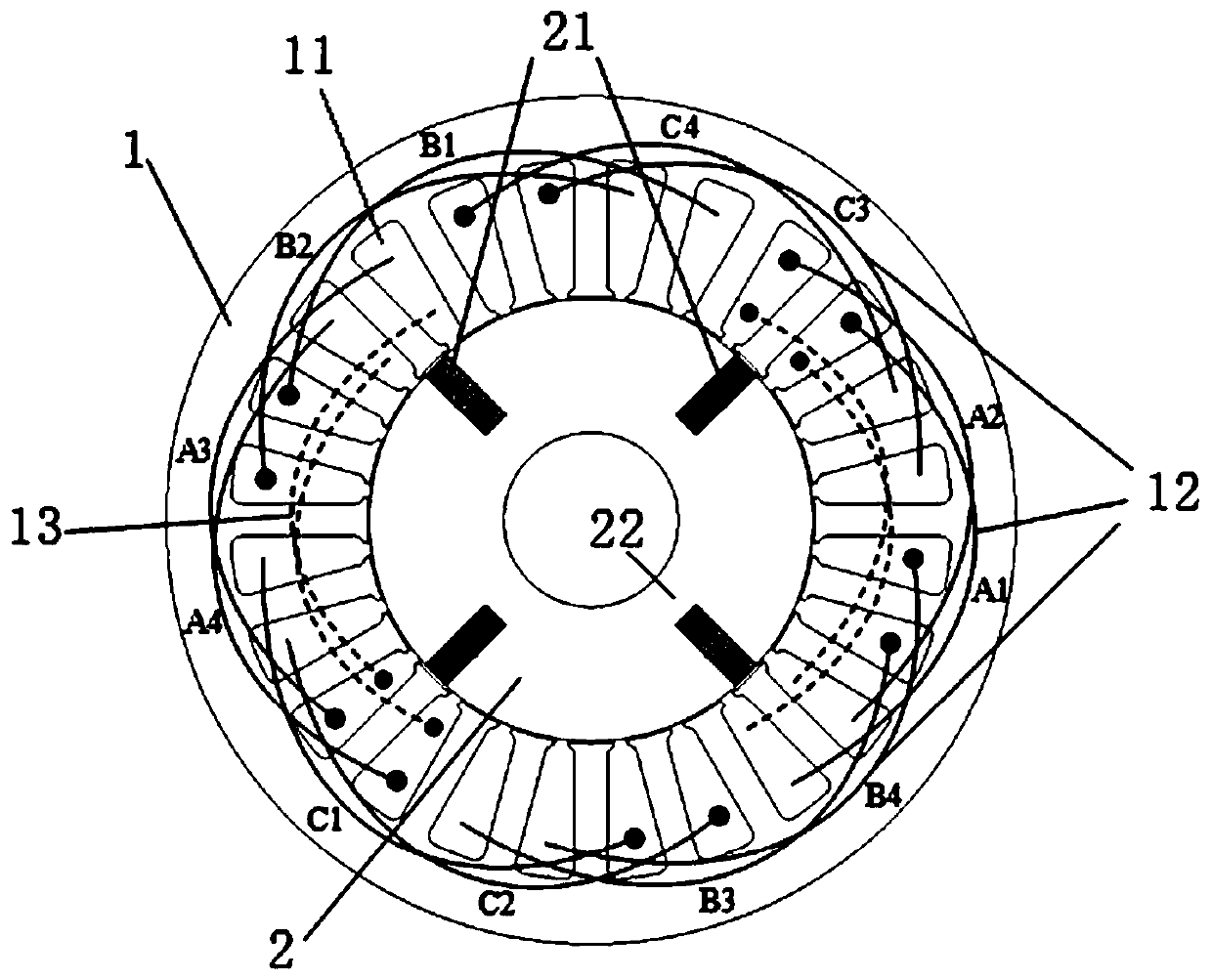

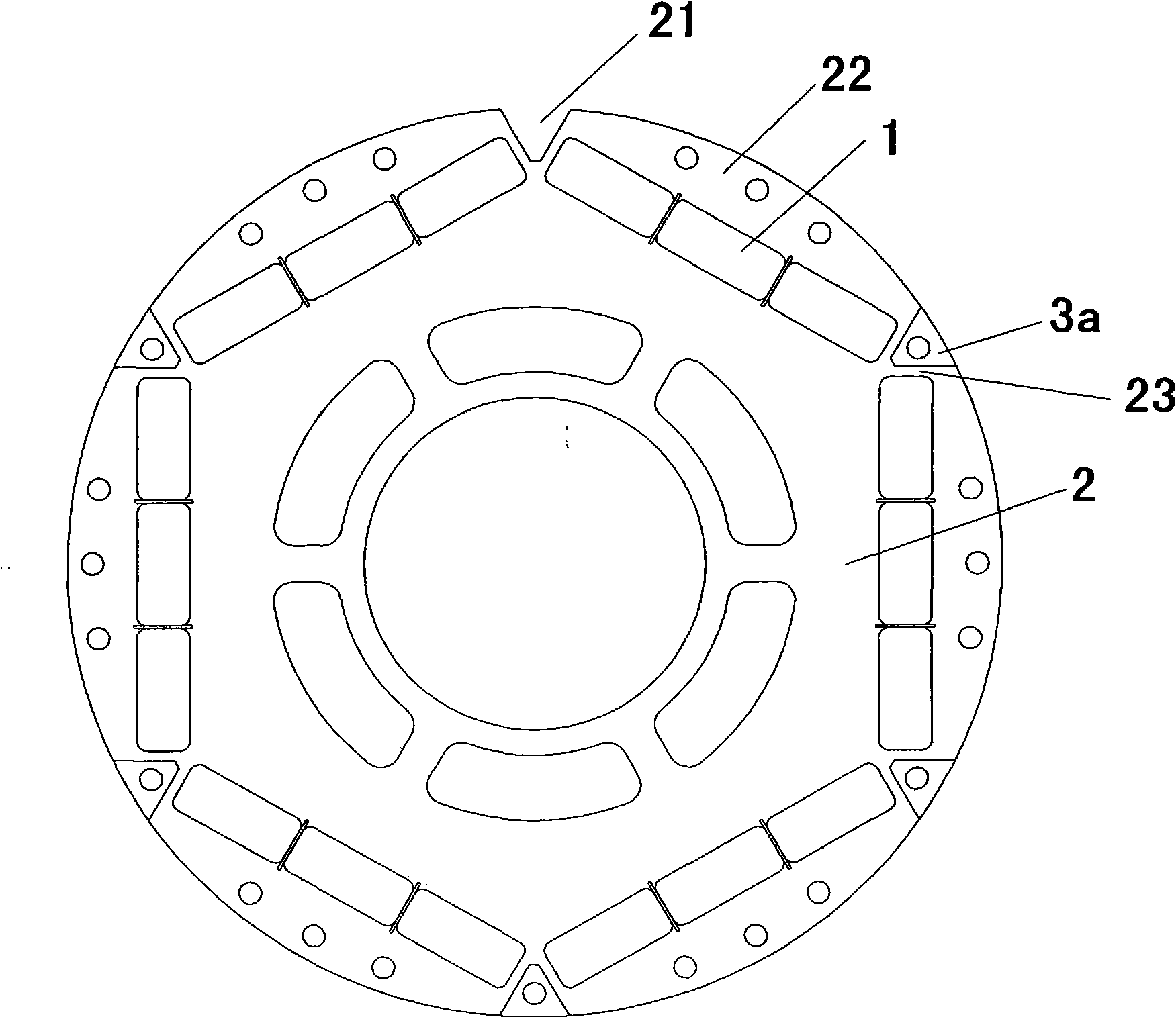

Production method for hub motor rotor with embedded radial permanent magnet steel and embedded tangential permanent magnet steel

InactiveCN103887936AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesPermanent magnet rotorPower flow

The invention provides a production method for a hub motor rotor with embedded radial permanent magnet steel and embedded tangential permanent magnet steel, and belongs to the technical field of automobile motors and electrical appliances. Rectangular permanent magnet steel is embedded in a radial rectangular groove and a second tangential rectangular groove of a rotor core respectively to form an embedded permanent magnet rotor. The structure is a rotor magnetic bypass structure, the problem that irreversible demagnetization happens to the permanent magnet steel under the action of armature reaction of impulse current can be effectively prevented, it is guaranteed that the permanent magnet steel does not lose magnetism, and meanwhile a hub drive motor rotor field is jointly provided by a radial magnetic field and a tangential magnetic field. Besides, the hub motor rotor with the embedded radial permanent magnet steel and the embedded tangential permanent magnet steel has the advantages that magnetic field intensity is high, output power is high, efficiency is high, power density is high, the structure is compact, and working is reliable.

Owner:SHANDONG UNIV OF TECH

Rotor of high-power permanent magnet motor and permanent magnet synchronous wind-driven generator using same

ActiveCN101944788AAvoid irreversible demagnetizationIncrease profitMagnetic circuit rotating partsSynchronous machine detailsWind drivenPermanent magnet synchronous motor

The invention provides a rotor of a high-power permanent magnet motor particularly suitable for a high-power permanent magnet synchronous wind-driven generator and the permanent magnet synchronous wind-driven generator using the rotor, wherein a permanent magnet embedded structure is adopted for the rotor; grooves are arranged on an iron core of the rotor between adjacent two pole permanent magnets along the axial direction of the rotor; and stuffing made of non-magnetic and non-conducting materials is arranged in the grooves and has the same cross section shape with that of the grooves. The invention can ensure that magnetic fields of the adjacent two pole permanent magnets can not be directly communicated because the stuffing is arranged between the adjacent two pole permanent magnets of the rotor, and thus, magnetic flux leakage can be avoided and the utilization rate of permanent magnet materials is enhanced; and the permanent magnets and pole pieces of the rotor are supported in the rotation course of the rotor because the stuffing is arranged between adjacent permanent magnets, and thus, a centrifugal force is prevented from acting on a magnetic flux path and the irreversible mechanical deformation of the magnetic flux path can not be caused because of excessive extrusion.

Owner:东元总合科技(杭州)有限公司

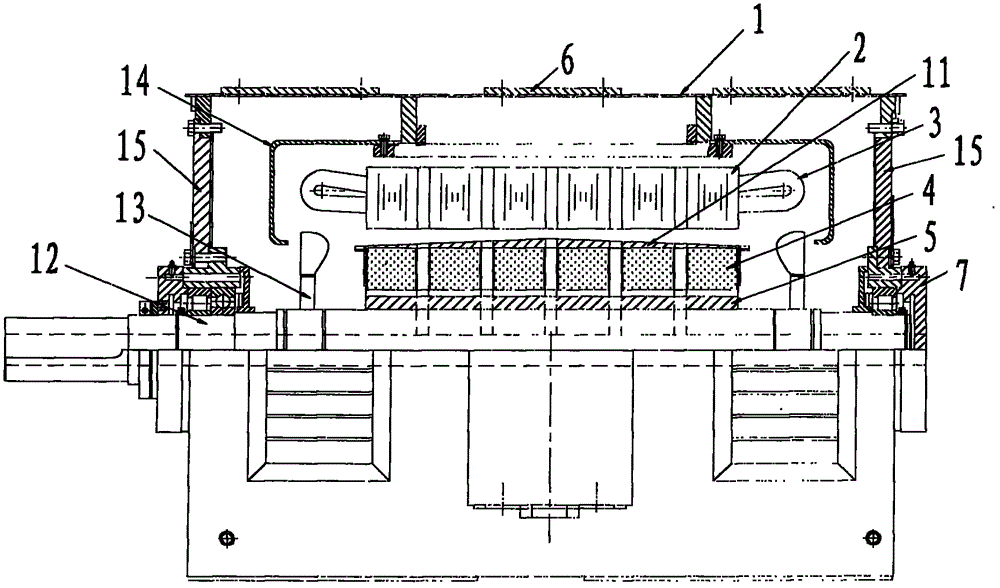

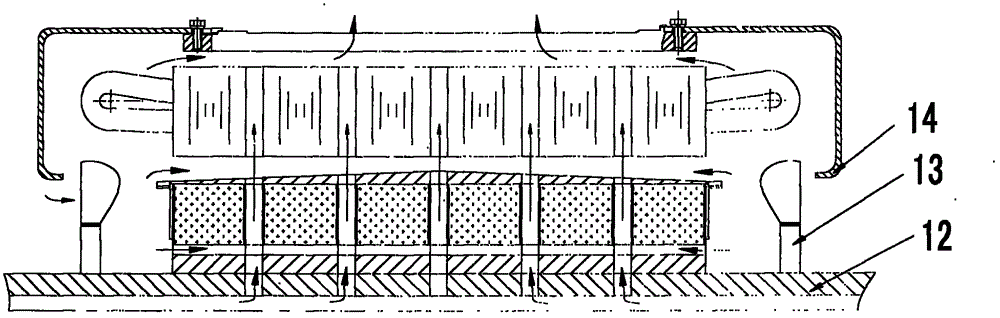

Inner stator permanent-magnet moving iron core-type linear oscillation motor

ActiveCN106849592AImprove reliabilityImprove overload capacityDynamo-electric machinesConductor CoilMagnet

The invention discloses an inner stator permanent-magnet moving iron core-type linear oscillation motor which comprises an inner stator iron core, an outer stator iron core, a rotor iron core, a cage-type rotor iron core bracket, permanent magnets, an armature winding and a resonant spring, wherein multiple permanent magnets are uniformly embedded into a yoke of each annular stator iron core of the inner stator iron core along the peripheral direction; multiple coils for forming the armature winding are wound on outer stator iron core teeth; the rotor iron core comprises multiple segments of arc-shaped iron cores; various segments of arc-shaped iron cores are fixedly connected into a whole by using the cage-type rotor iron core bracket; the whole is arranged in an air gap between the inner stator iron core and the outer stator iron core; and the resonant spring sleeves the part between the cage-type rotor iron core bracket and an end cover. The permanent magnets do not participate in reciprocating vibration, so that the security, the reliability and the robustness of the motor can be greatly improved; the permanent magnets and the armature winding are put on different stators, so that high-temperature magnetic losses of the permanent magnets can be avoided; the mass of a rotor is reduced; the requirements of a system on the rigidity of the resonant spring can be reduced; and improvement of the resonant frequency is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Built-in permanent magnet steel hub driving motor of electric vehicle

InactiveCN103887948AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorElectrical energy consumption

The invention provides a built-in permanent magnet steel hub driving motor of an electric vehicle and belongs to the technical field of automobile motor electric appliances. The built-in permanent magnet steel hub driving motor of the electric vehicle consists of a front end cover, a rear end cover, a hub casing, a rotor, a stator, a stator support and a shaft. Two pieces of completely-identical rectangular permanent magnet steel are respectively placed in two rectangular grooves forming a shape of a regular Chinese character 'ba' of a rotor iron core to form an N-pole, the other two pieces of completely-identical rectangular permanent magnet steel are respectively placed in a regular Chinese character 'ba' shaped groove formed by the other two adjacent rectangular grooves of the rotor iron core to form an S-pole, the rest can be done in the same manner to form the permanent magnet rotor with N-poles and S-poles arranged at intervals, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, and the failure rate is low.

Owner:SHANDONG UNIV OF TECH

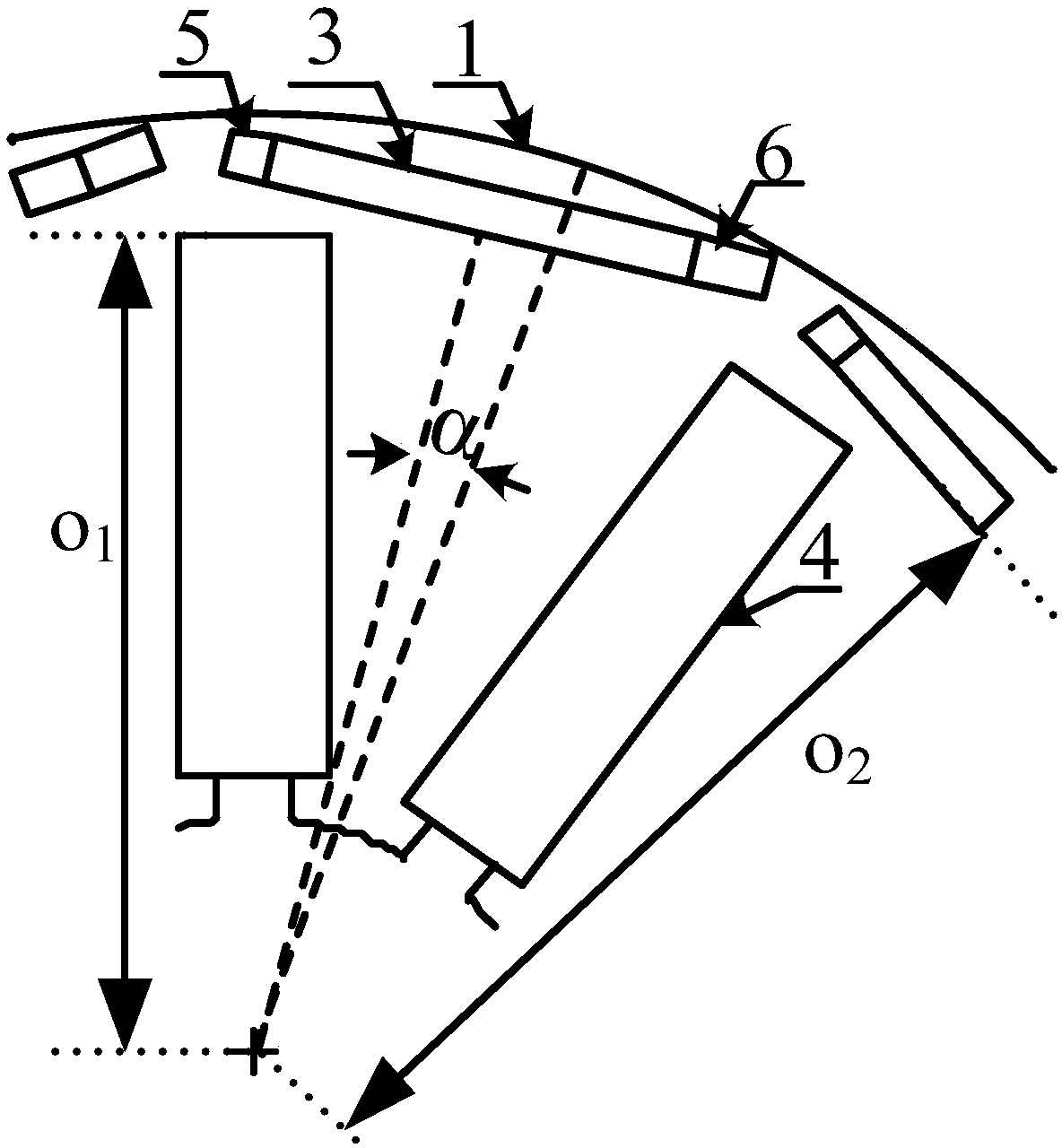

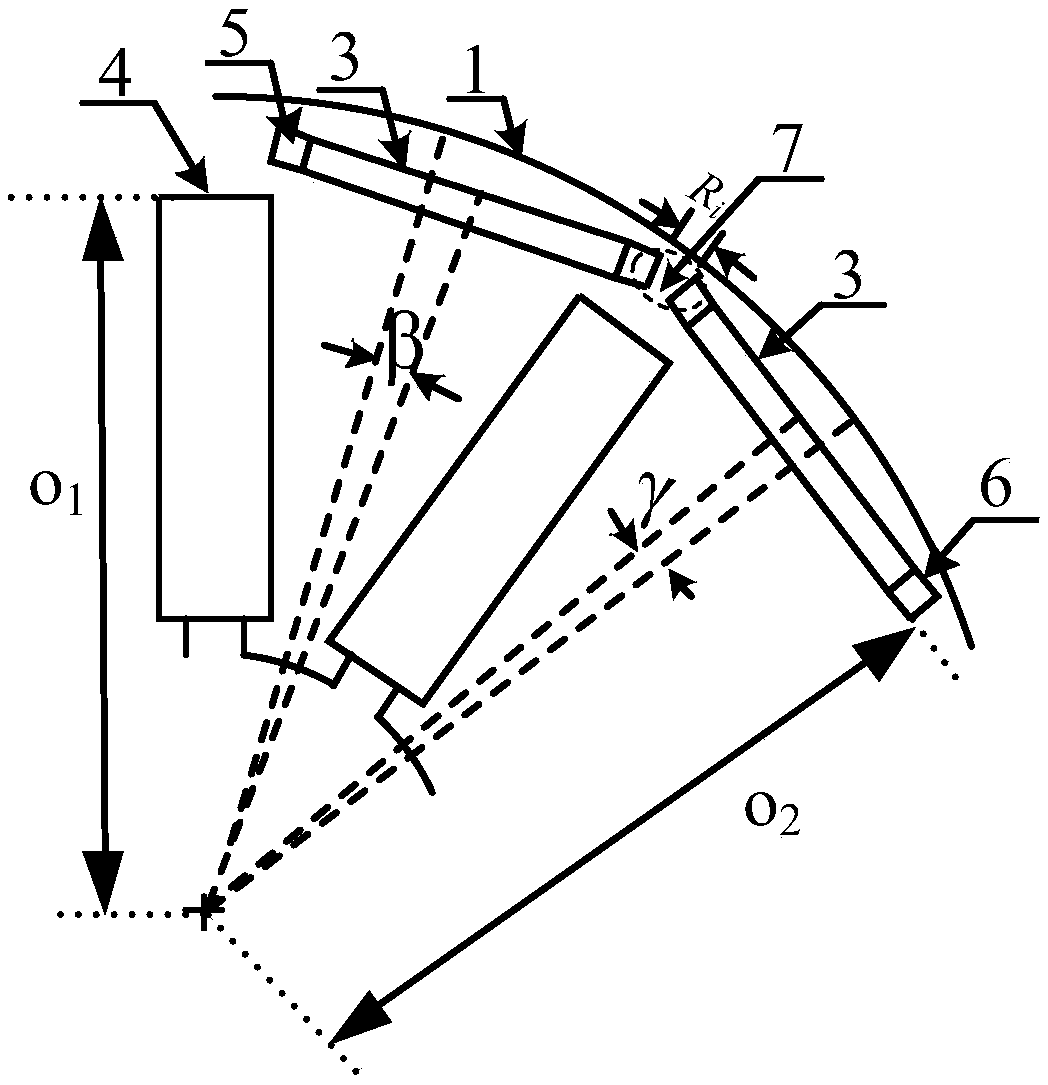

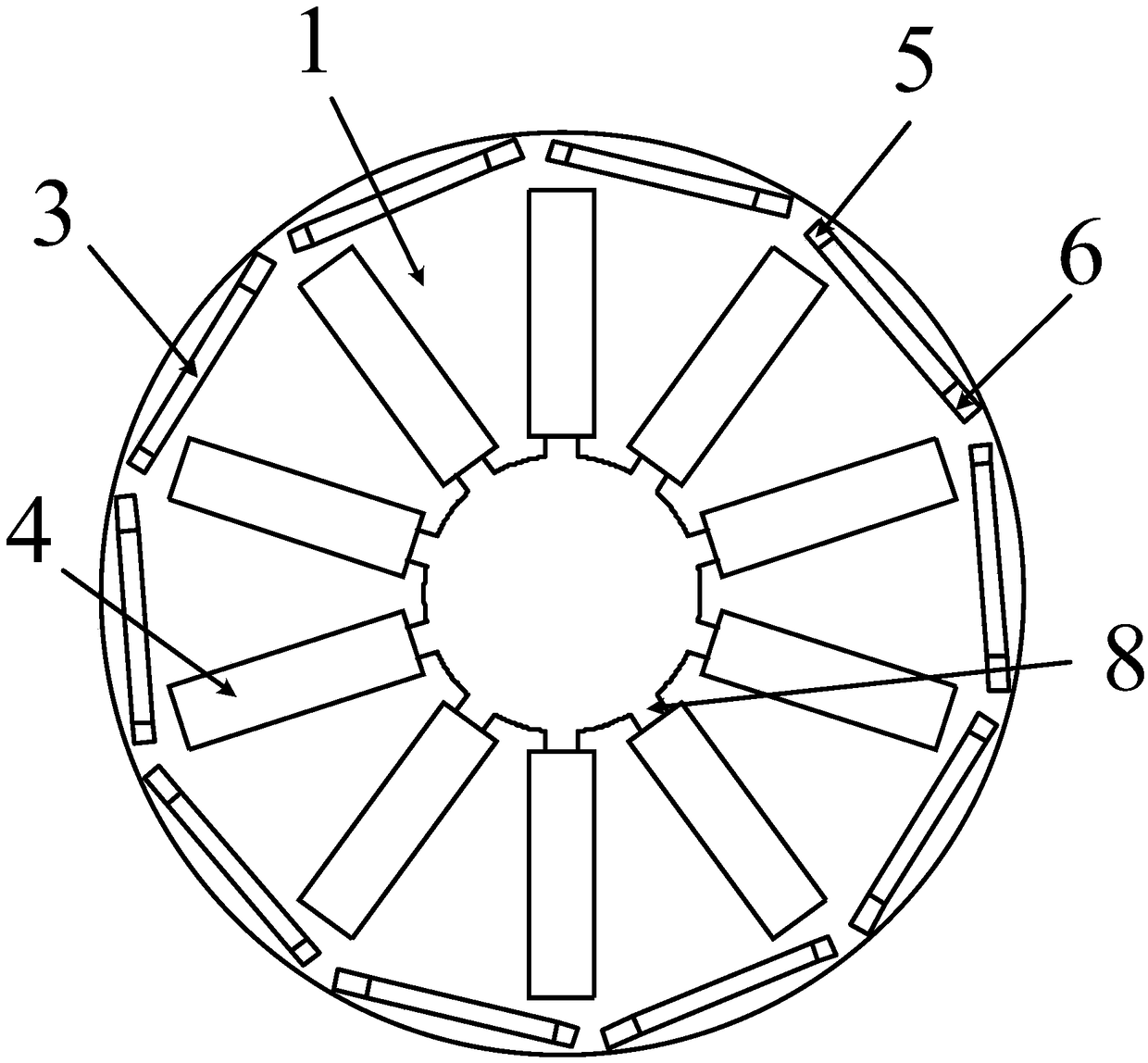

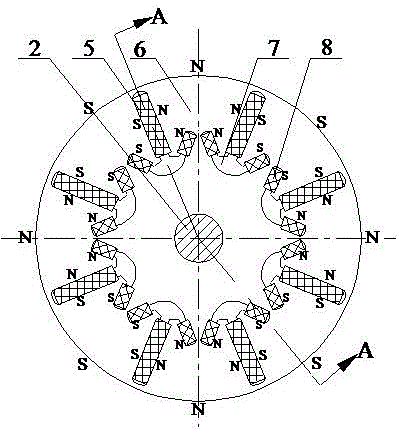

High-torque-density asymmetrical rotor structure

ActiveCN108667177ANo cost reductionLow costMagnetic circuit rotating partsEddy currentAir gap flux density

The invention relates to a high-torque-density asymmetrical rotor structure. The rotor structure comprises a one-way displacement asymmetrical rotor structure and a two-way displacement asymmetrical rotor structure. Ferrite permanent magnets and neodymium-iron-boron permanent magnets are distributed on a rotor, the ferrite permanent magnets are distributed in a spoke shape, and the neodymium-iron-boron permanent magnets are distributed in a linear shape and arranged on the outer circle of the rotor. The axis of each neodymium-iron-boron permanent magnet of the one-way displacement structure anticlockwise deflects by an angle alpha from the central line of the ferrite permanent magnet adjacent to the neodymium-iron-boron permanent magnet of the one-way displacement structure; the neodymium-iron-boron permanent magnets of the two-way displacement structures clockwise and anticlockwise rotate by an angle beta and an angle gamma respectively. By means of the hybrid permanent magnet structure, the peak hybrid permanent-magnet torque and the peak reluctance torque reach the maximum at the same time at a same current angle, and the permanent-magnet utilization rate and the output torque of a motor are improved; the air-gap flux density waveform is effectively improved, the cogging torque and the torque pulsation are reduced, and the core loss and the eddy-current loss are reduced.

Owner:JIANGSU UNIV

Built-in permanent magnet rotor driving motor of electric automobile

InactiveCN103746483AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectric machine

The invention provides a built-in permanent magnet rotor driving motor of an electric automobile, and belongs to the technical field of automobile motor appliances. The built-in permanent magnet rotor driving motor comprises a front end housing, a rear end housing, a shell, a rotor and a stator, wherein permanent magnet steel is embedded in a rotor core, and the structure is a rotor magnetic bypass structure which can effectively prevent an irreversible demagnetization problem of the permanent magnet due to ultrahigh temperature or an armature reaction of impulse current, ensure that the permanent magnet steel is free from loss of excitation. The rotor field of the driving motor is provided by the permanent magnet steel, so that the built-in permanent magnet rotor driving motor is free from electric exciting windings, carbon brush and a mechanical rectifier, low in power consumption and failure rate, high in efficiency and power density, obvious in magnetic flux gathering effect, and capable of providing large enough power for the electric automobile.

Owner:SHANDONG UNIV OF TECH

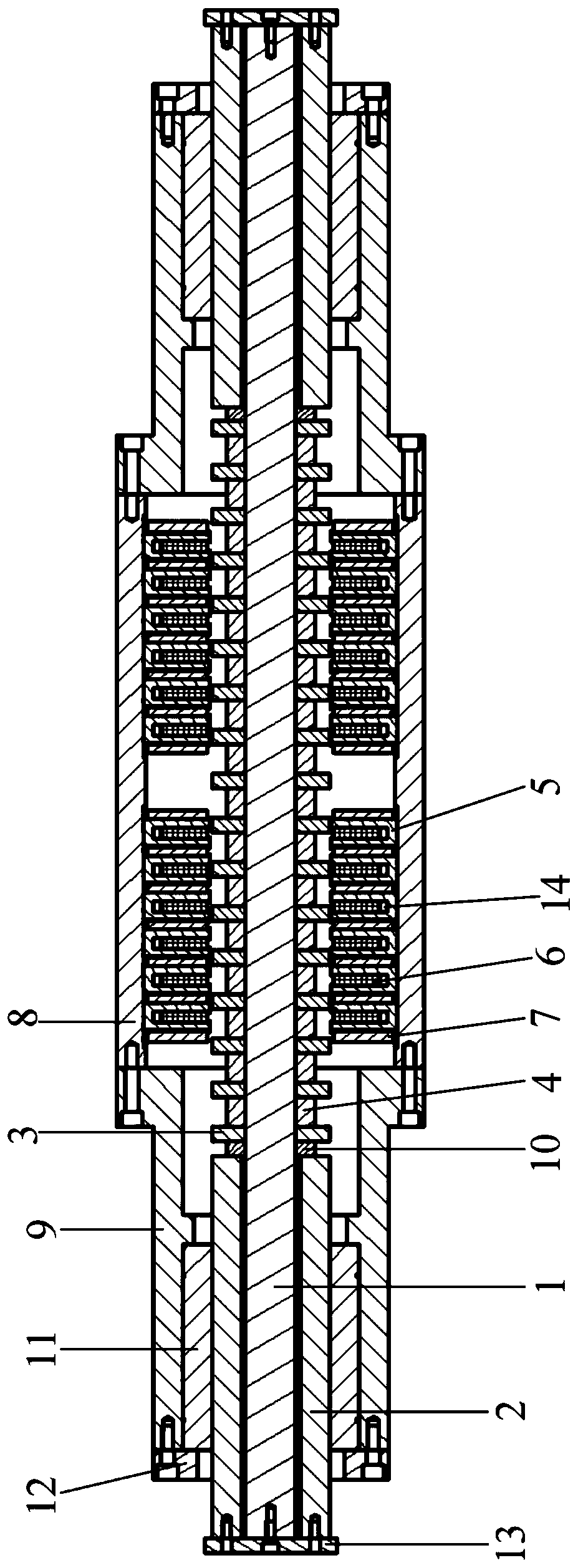

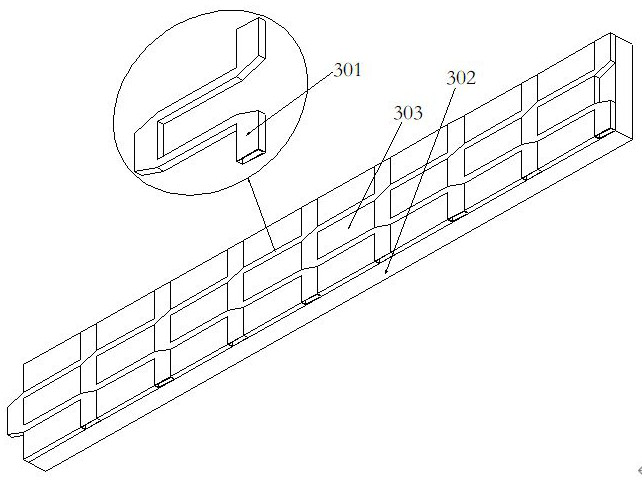

Primary permanent magnet linear motor actuator

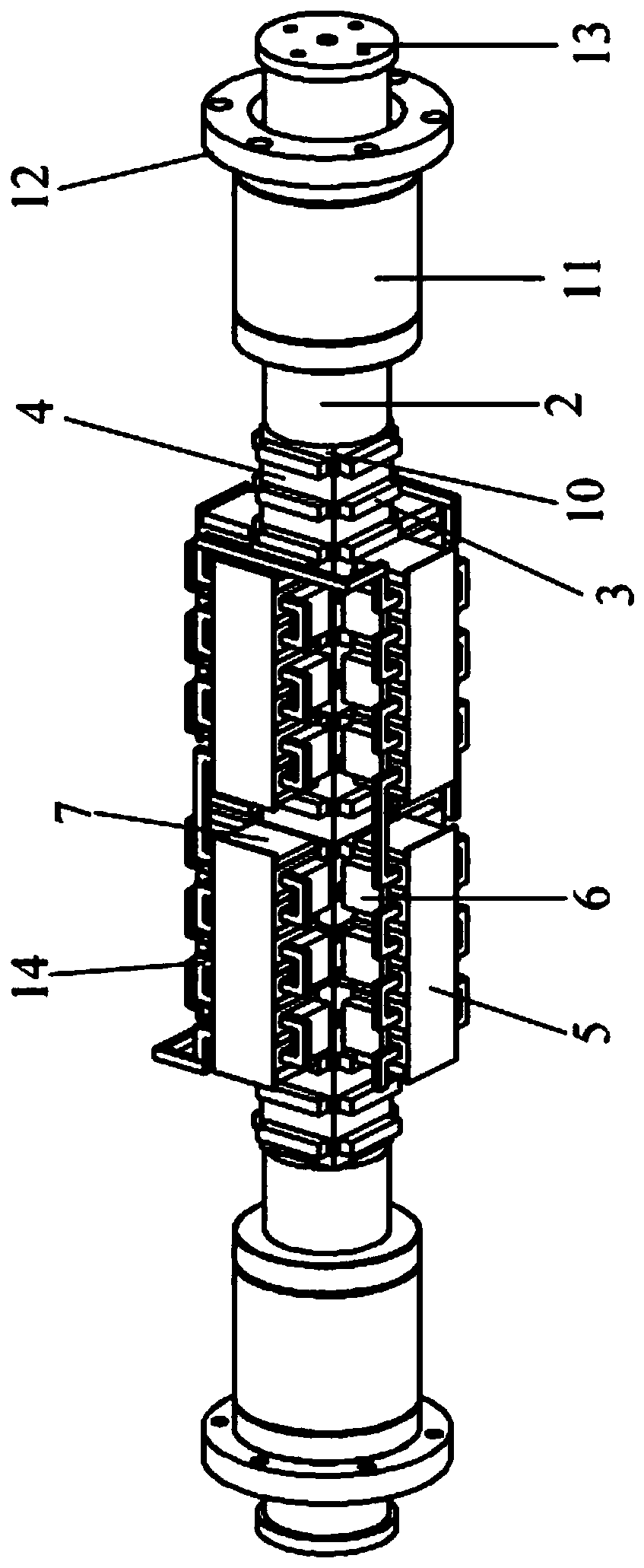

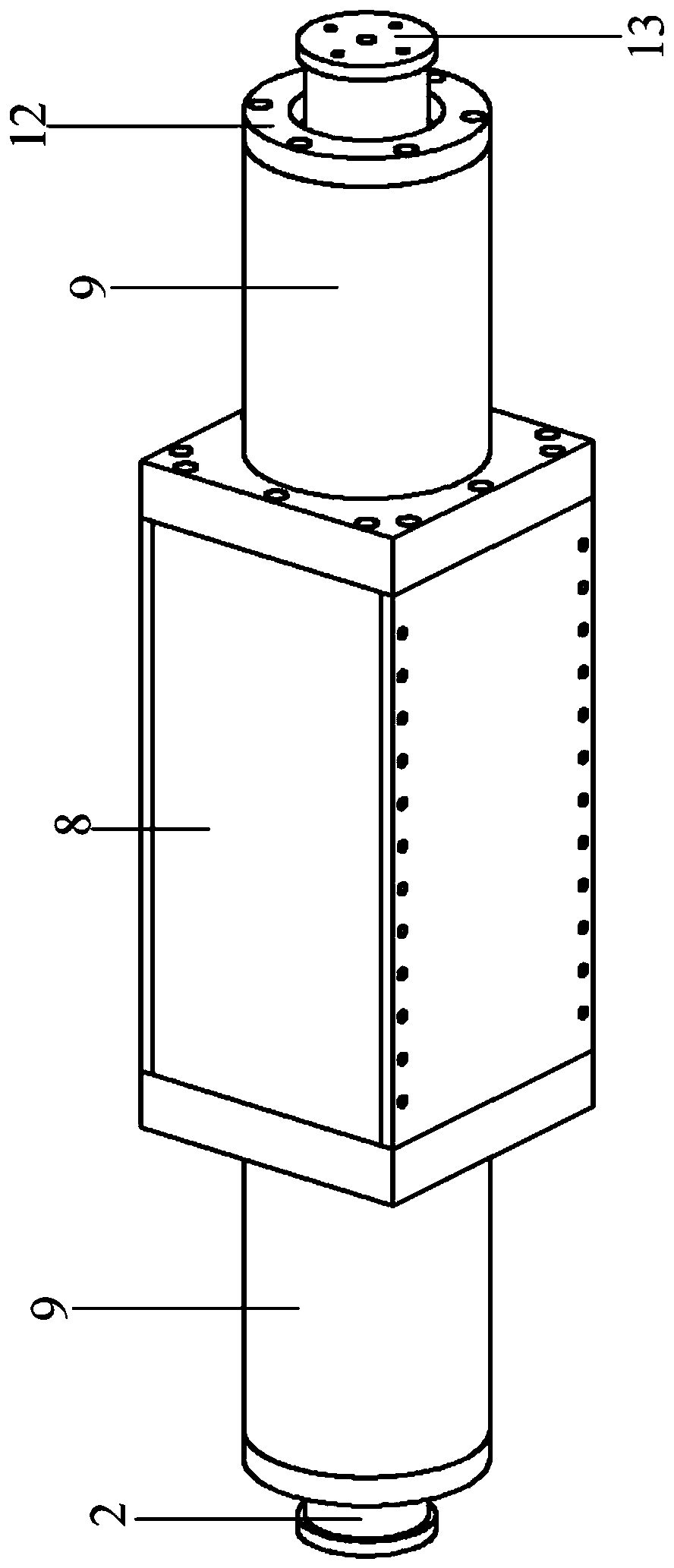

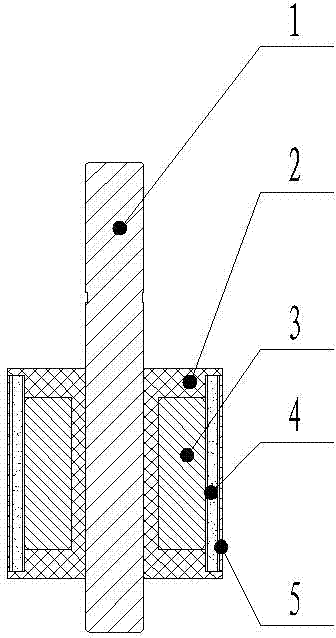

InactiveCN109787448AReduce the effect of temperature riseImprove power densityMagnetic circuit stationary partsCooling/ventillation arrangementPrimary permanentDrive shaft

The invention discloses a primary permanent magnet linear motor actuator. The primary permanent magnet linear motor actuator comprises a driving shaft, a secondary mover convex tooth block, a secondary mover channel block, primary stator iron cores, an armature winding and a permanent magnet body, wherein a secondary mover of a primary permanent magnet linear motor is arranged on a driving shaft and consists of the secondary mover convex tooth block and the secondary mover channel block arranged in the axial direction of the driving shaft at intervals; four primary stators of the primary permanent magnet linear motor are separately and symmetrically arranged on the outer side of the driving shaft; each of the primary stator comprises two primary stator iron cores; each of the primary stator iron cores is provided with a plurality of stator channels; each of the stator channel comprises a large stator channel and a small stator channel; and the large stator channels and the small statorchannels are arranged at intervals. Through creative proposal of a four-sided tubular structure, the pushing force density and the power density of the actuator can be improved, so that the driving shaft of the actuator has a simple structure and is high in robustness; and through arrangement of a built-in water cooling pipeline, the heating effect is reduced.

Owner:XIDIAN UNIV

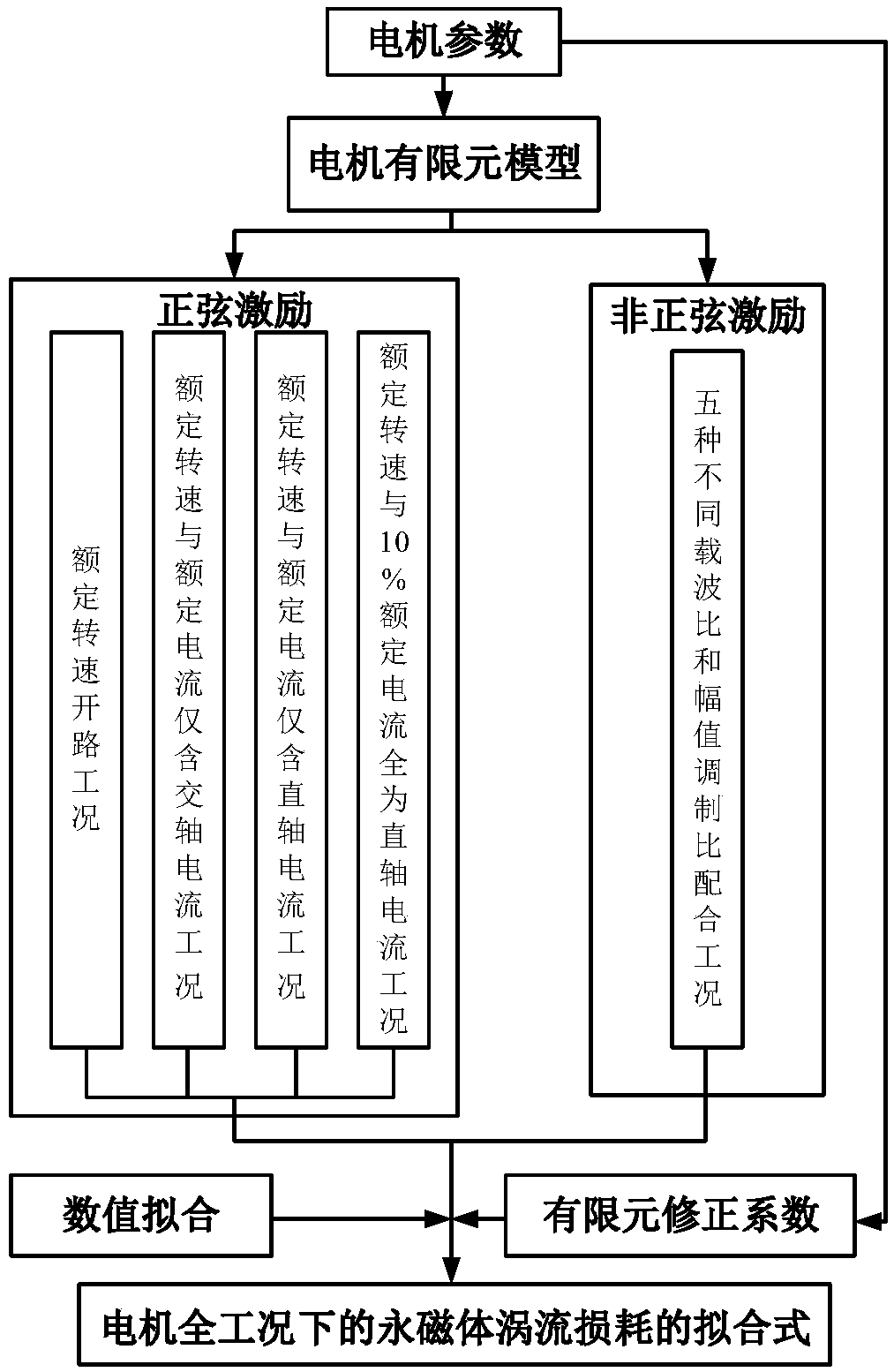

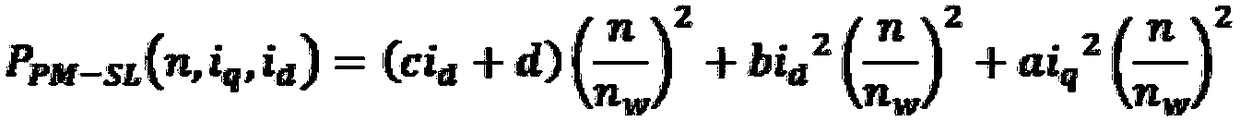

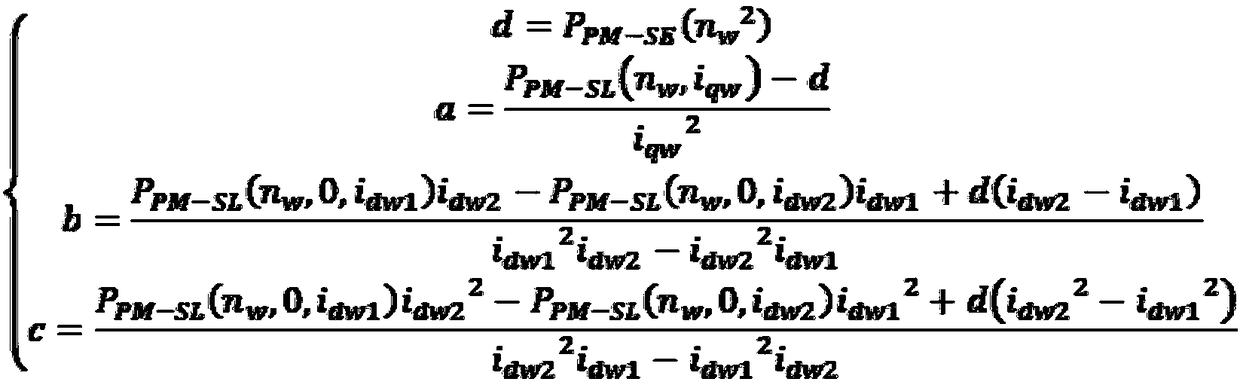

Fast calculation method for permanent magnet eddy current loss of vehicle surface-mount permanent magnet synchronous motor

ActiveCN108448990AReduce eddy current lossAvoid irreversible demagnetizationElectronic commutation motor controlVector control systemsPhase currentsElectric machine

The invention provides a fast calculation method for a permanent magnet eddy current loss of a vehicle surface-mount permanent magnet synchronous motor. The influence of phase current harmonics on thepermanent magnet eddy current loss is considered, the quick and accurate calculation of the permanent magnet eddy current loss in a whole working area can be achieved, thus a designer can select appropriate motor structural parameters and electromagnetic parameters during the design process, the permanent magnet eddy current loss is reduced, the irreversible demagnetization of a permanent magnetis avoided, and the normal working of the motor under complex and variable working conditions is ensured. At the same time, the design method of the permanent magnet synchronous motor is improved, andthe design cycle of the permanent magnet synchronous motor is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Built-in tangential permanent magnet steel hub driving motor of electric vehicle

InactiveCN103887947AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorDrive motor

The invention provides a built-in tangential permanent magnet steel hub driving motor of an electric vehicle and belongs to the technical field of automobile motor electric appliances. The built-in tangential permanent magnet steel hub driving motor of the electric vehicle consists of a shaft, a front end cover, a rear end cover, a hub casing, a rotor, a stator and a stator support. A first piece of rectangular permanent magnet steel and the other piece of rectangular permanent magnet steel are sequentially installed in radial rectangular grooves of a rotor iron core in a mode that an N-pole of the first piece of rectangular permanent magnet steel is opposite to an N-pole of the other piece of rectangular permanent magnet steel, and an S-pole of the first piece of rectangular permanent magnet steel is opposite to an S-pole of the other piece of rectangular permanent magnet steel, a tangential permanent magnet rotor with N-poles and S-poles arranged at intervals is formed, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, the failure rate is low, and the built-in tangential permanent magnet steel hub driving motor has high-efficiency, high-power-density and remarkable magnetic focusing effect and can provided enough power for the electric vehicle.

Owner:SHANDONG UNIV OF TECH

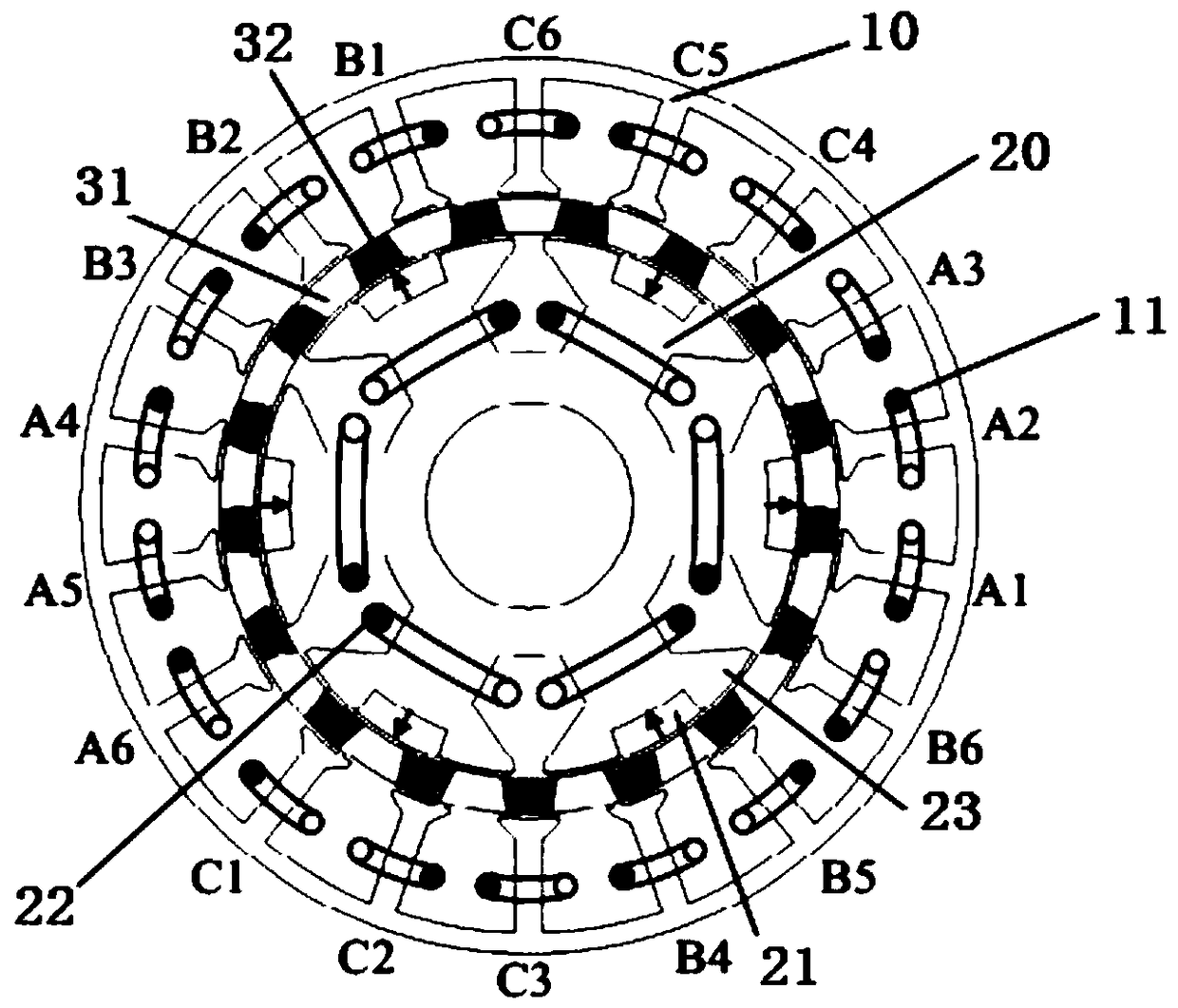

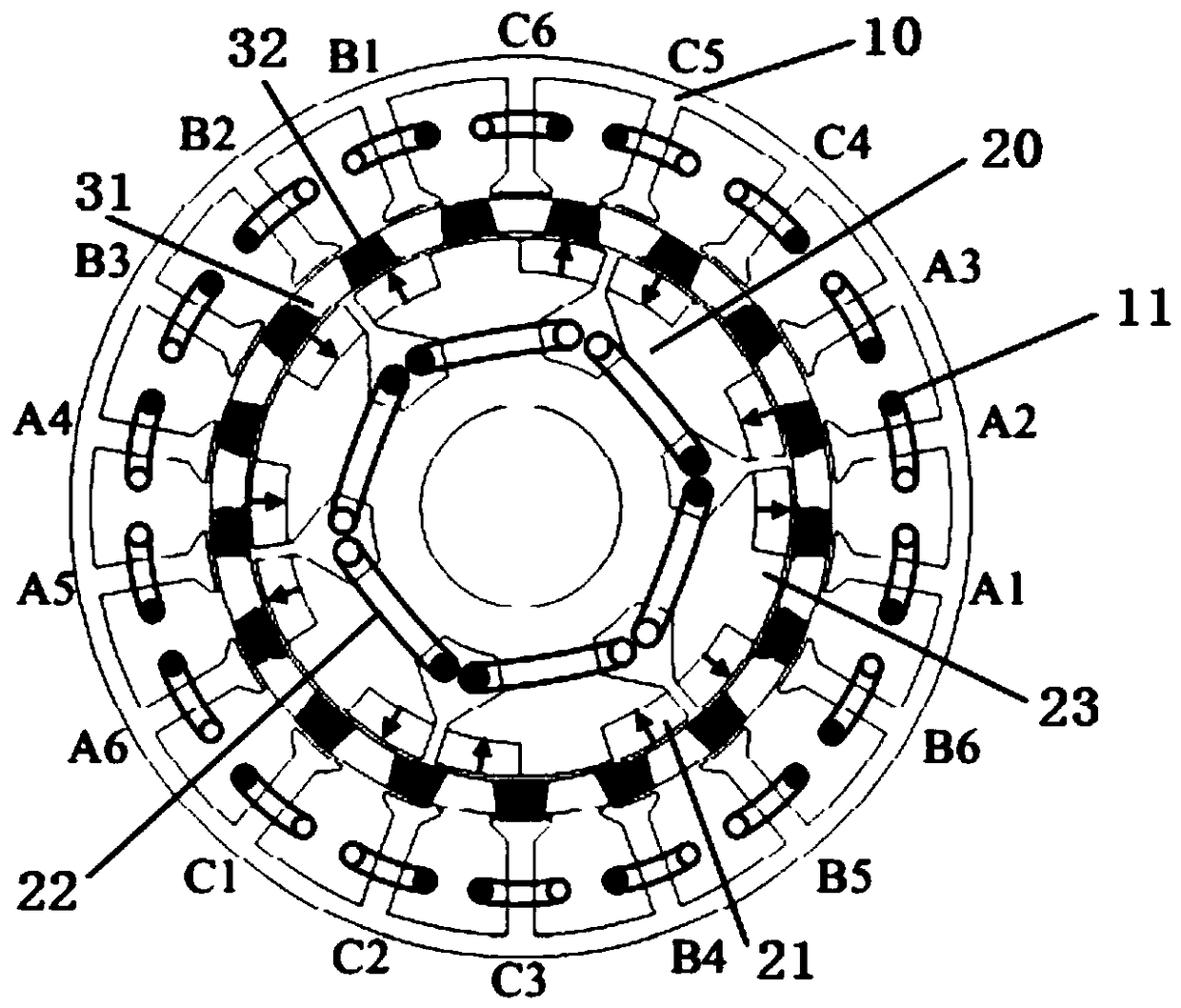

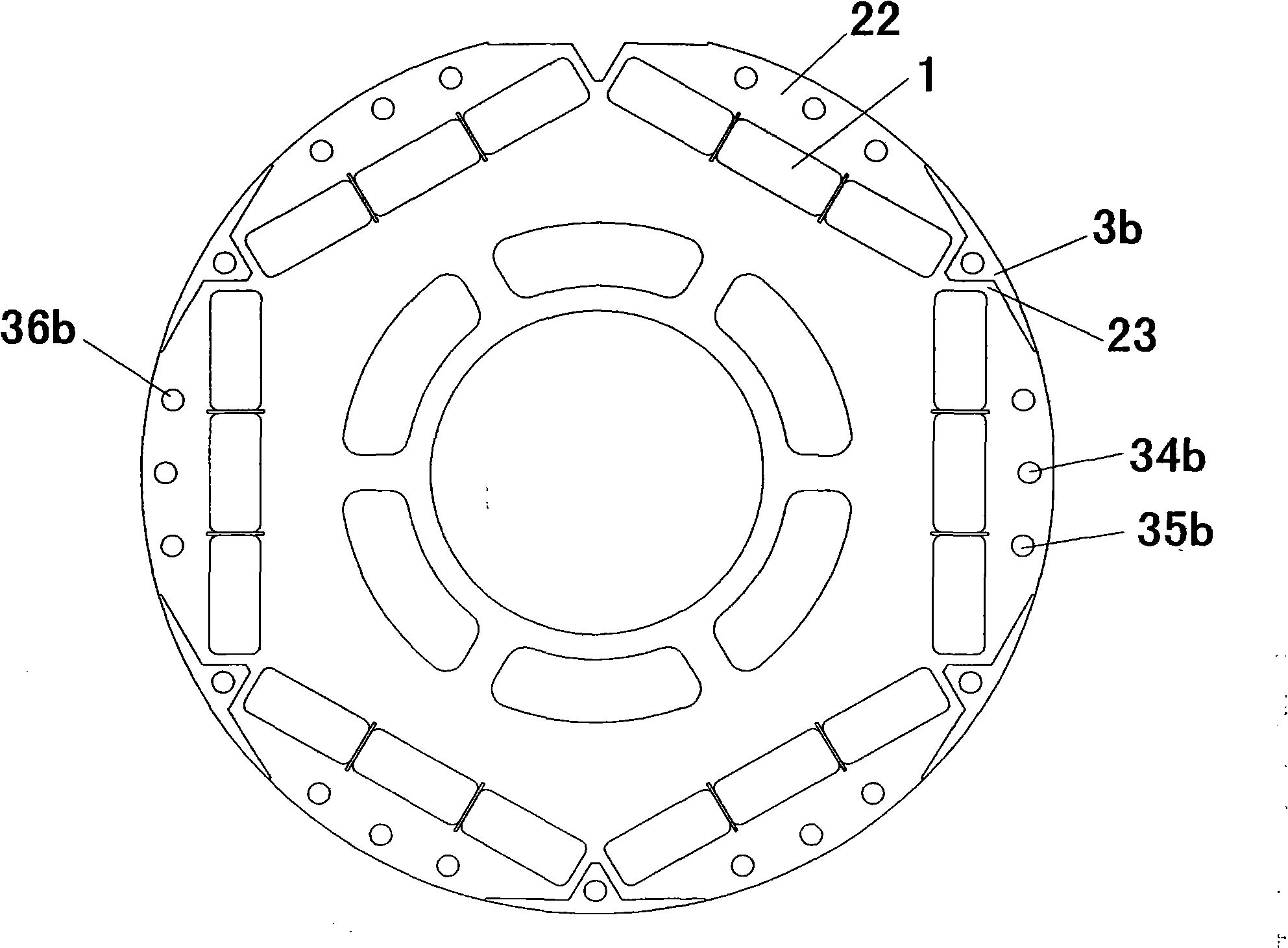

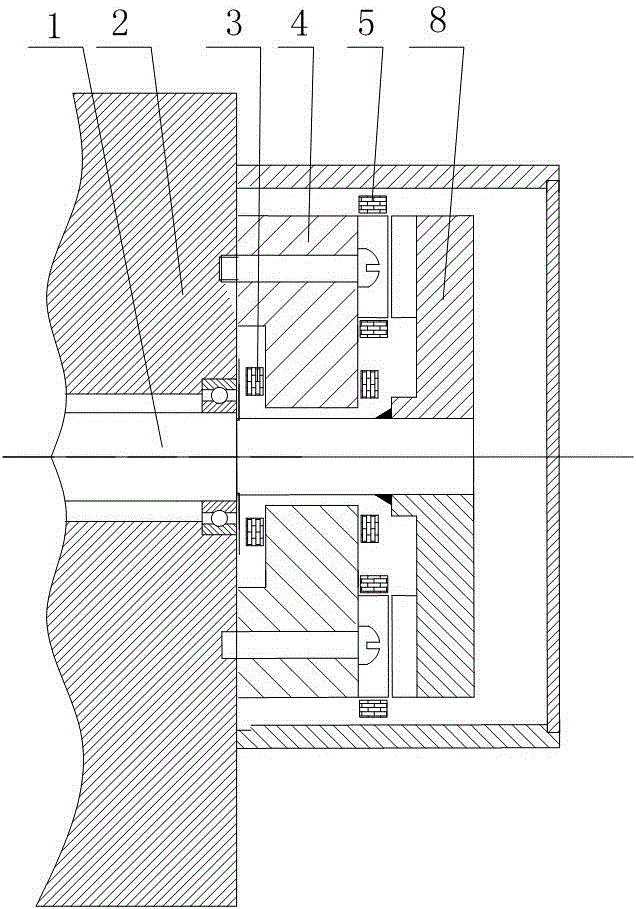

Flywheel-type motor for diesel engine

ActiveCN105703588AReduce volumeReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsExcitation currentThree-phase

The invention proposes a flywheel-type motor for a diesel engine. The flywheel-type motor comprises a crank shaft, excitation windings, a stator iron core, armature windings and a rotor iron core, wherein 2N rotor poles with circular fan-shaped bulges are arranged on the inner side end surface of a round disc of the rotor iron core, 3N stator poles with circular fan-shaped bulges are uniformly arranged on the end surface, opposite to the end surface of each stator pole, of the stator iron core, the stator iron core is provided with a groove among each three stator poles, the excitation coil is wound in the groove and wound around the three stator poles, the winding directions of adjacent excitation coils are opposite, each stator pole is provided with the one of the armature coils wound around an axial direction, an armature winding is divided into three phases, and each phase of the armature coil comprises the same-phase armature coil. By the flywheel-type motor, the size of a gap magnetic field is adjusted by adjusting the size of an excitation current, and thus, stable output voltage can be maintained on the condition of variable load and variable rotational speed of the motor.

Owner:SHANDONG UNIV OF TECH

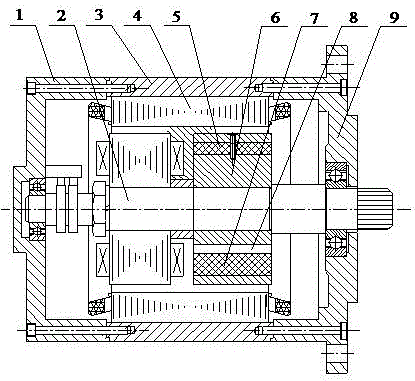

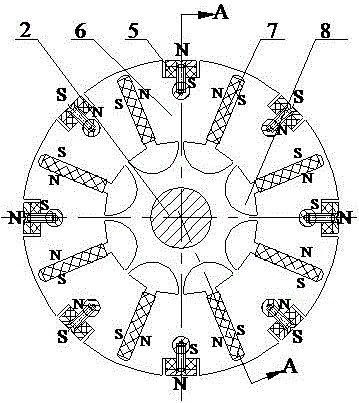

Electric automobile electromagnetic and built-in permanent magnet combined magnetic pole hybrid excitation driving motor

InactiveCN105846569AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machineMagnetic poles

The invention provides an electric vehicle electromagnetic and built-in permanent magnet combined magnetic pole hybrid excitation drive motor, which belongs to the technical field of electric vehicle motors and appliances. It is composed of a front end cover, a rear end cover, a casing, a rotor, and a stator. The rectangular permanent magnet steel is respectively embedded in the first rectangular slot and the second rectangular slot, which can effectively prevent the permanent magnet steel from being affected by the armature reaction of the impact current. Irreversible demagnetization is generated to ensure that the permanent magnet steel does not lose its magnetism. The magnetic field in the air gap of the drive motor is provided by the permanent magnet steel and the electric excitation winding, with high magnetic field strength and high output power.

Owner:SHANDONG UNIV OF TECH

Electromagnetic permanent magnet electric machine

InactiveCN1862927AGuaranteed uniformityGuaranteed symmetryMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetization

The invention relates to the electromotor, the stator iron core is mounted on the electromotor, the three phase symmetry winding is mounted on the stator iron core, the permanent magnet is fixed on the rotor iron core. The generator rotor of the invention is mounted with one loop slop locating on the half of the width. Two sides of the loop slop are mounted with the slop along the direction of the axis on the rotor, and these slops are collocated distantly along the sides of the loop slot, the slop along the axis is the adopting pole constructed by the rotor iron core soft iron. The permanent magnet are fixed on the slot along the axis, thereinto, each permanent magnet N poles located in the slot along the axis on the side of the loop slot point at the centre of the a circle of the rotor, and the S pole of each permanent magnets located on the other side of the loop slot point at the centre of the circle of the rotor, so the magnet direction formed is the magnetization along the axis.

Owner:赵克中 +2

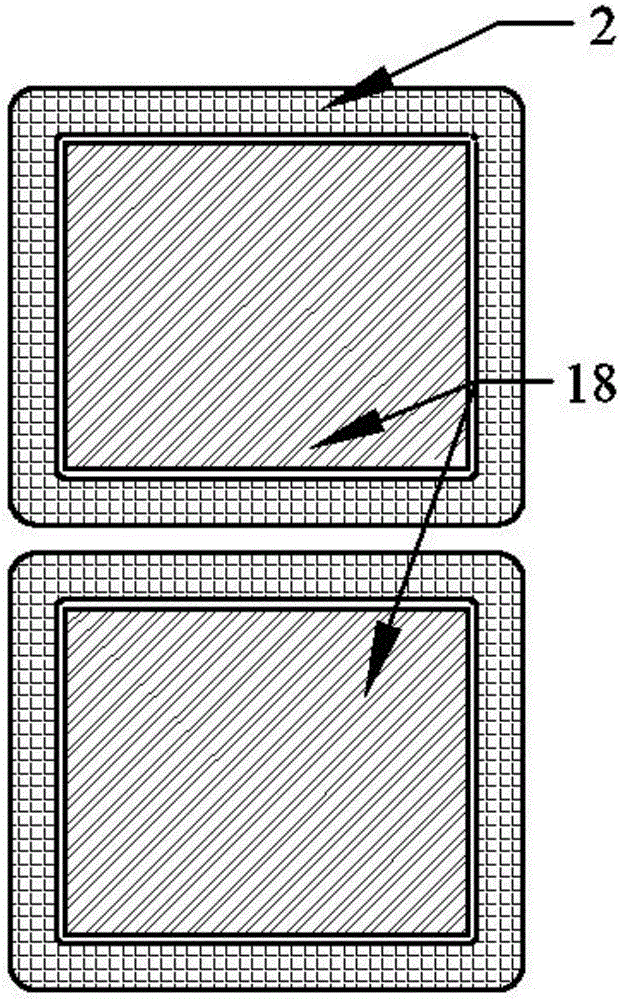

Motor rotor assembling process

InactiveCN104753266ABeating highHigh precisionManufacturing stator/rotor bodiesAdhesiveDynamic balance

The invention discloses a motor rotor assembling process, relates to the assembling process of a motor rotor and mainly solves the problems that magnetic shoe adhesive is adhered to the rotor iron core directly and currently and the stability and position are difficult to guarantee. The process includes a, adopting a special tooling fixture to fix a rotor iron core in the middle of the fixture, fixing an aluminum ring to the fixture, and guaranteeing the concentricity of the rotor iron core and aluminum ring; b, adopting a pressing fixture to press a magnetic shoe between the rotor iron core and aluminum ring with the controlled concentricity, and allowing the magnetic shoe to fit to the external circle of the rotor iron core and the internal circle of the aluminum ring; c, integrating a rotor shaft and a magnetizer conductor composed of the rotor iron core, the magnetic shoe and the aluminum ring through an injection molding part in an injection molding manner; d, turning the external circle of the permanent magnetic rotor through a lathe after injection molding, performing dynamic balancing, adjusting the dynamic balancing scale by the material increasing method, and achieving the design requirements. The process has the advantages of high efficiency, fine performances and long service life.

Owner:HUBEI HUITONG MOTILITY IND CO LTD

Salient electromagnetic and embedded permanent magnet hybrid excitation drive motor for electric automobiles

InactiveCN105958772AAvoid irreversible demagnetizationGuaranteed not to lose magnetismSynchronous machine detailsMagnetic circuit rotating partsDrive motorMagnet

The invention provides a salient electromagnetic and embedded permanent magnet hybrid excitation drive motor for electric automobiles, and belongs to the technical field of electric automobile motors and appliances. The drive motor is composed of a front end cover, a rear end cover, a case, a rotor, and a stator. Rectangular permanent magnet steel pieces are embedded into radial rectangular slots, and tile-shaped permanent magnet steel pieces are embedded into circular arc slots. The permanent magnet steel pieces can be effectively prevented from generating irreversible demagnetization under the armature reaction effect of impact current, and that the permanent magnet steel pieces do not lose magnetism is ensured. The magnetic field in the air gap of the drive motor is provided jointly by the permanent magnet steel pieces and an electric excitation winding. The magnetic field is strong, and the output power is high.

Owner:SHANDONG UNIV OF TECH

Combined permanent magnetic and electromagnetic mixed excitation driving motor

InactiveCN105914995AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsSynchronous machine detailsPhysicsDrive motor

The invention provides a combined permanent magnetic and electromagnetic mixed excitation driving motor, belonging to the automobile motor electric appliance technical field, and comprises a front end cover, a rear end cover, a casing, a rotor and a stator. Rectangular permanent magnet steels are respectively installed in tangential and radial rectangular notches. The motor can effectively prevent permanent magnet steels from generating irreversible demagnetization under the surge current armature reaction effect, and avoid loss of excitation of the permanent magnet steels; a magnetic field in driving motor air gaps is provided by the permanent magnet steels and electro-magnetic coils, and has the characteristics of great magnetic field intensity and high output power.

Owner:张学义

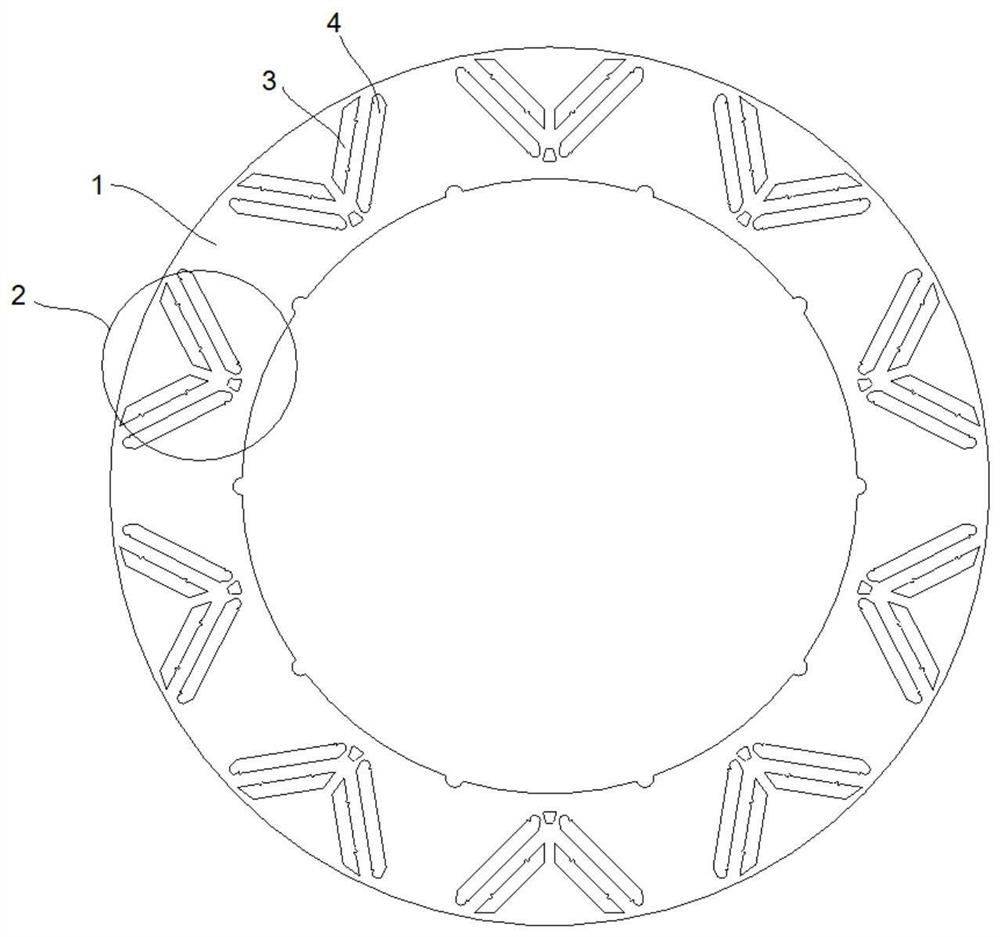

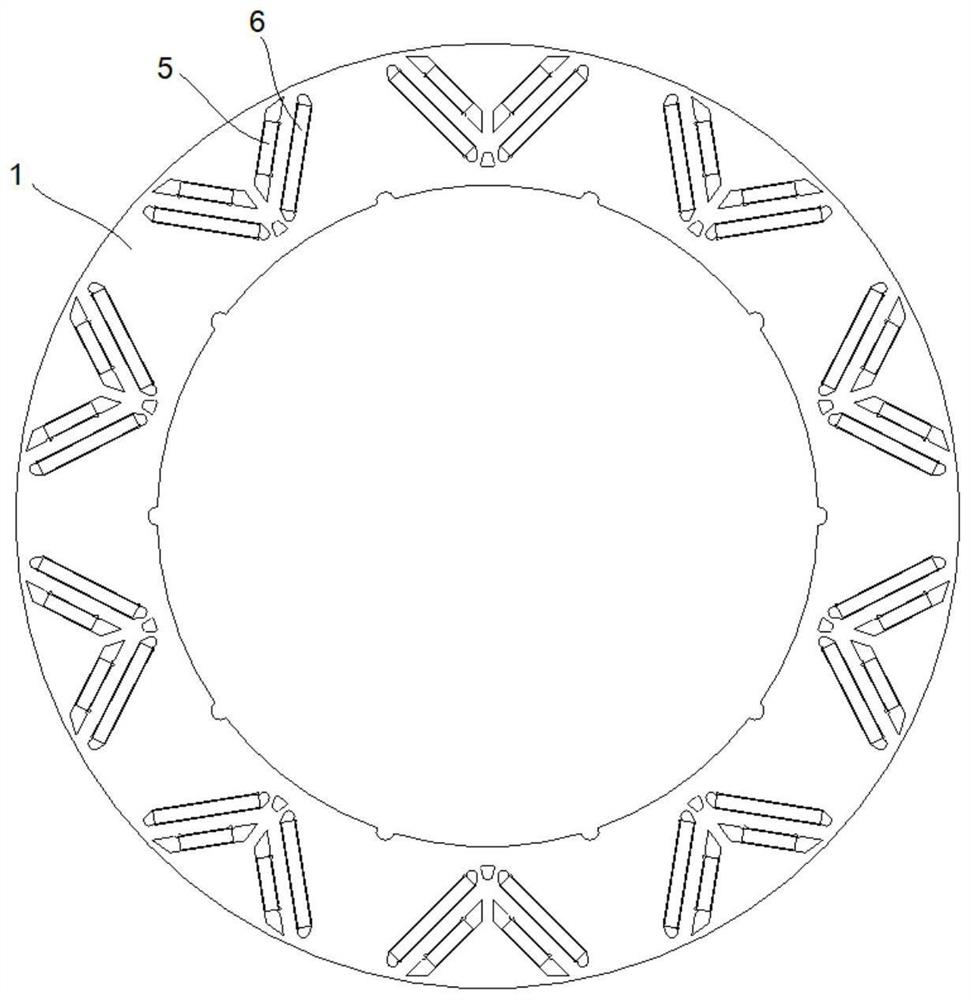

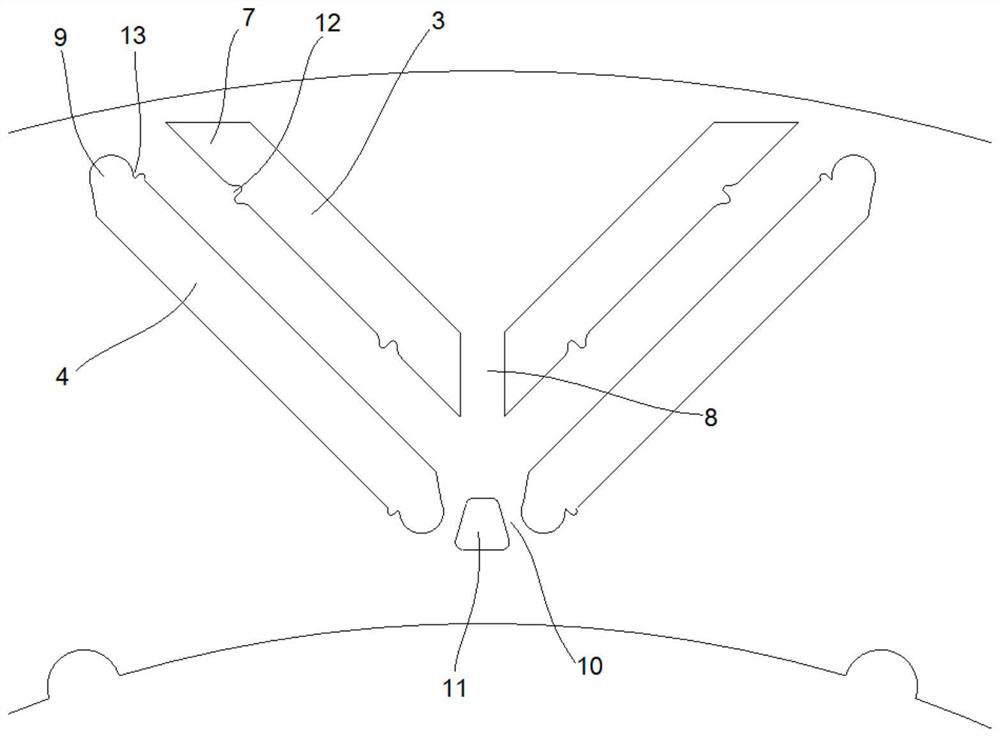

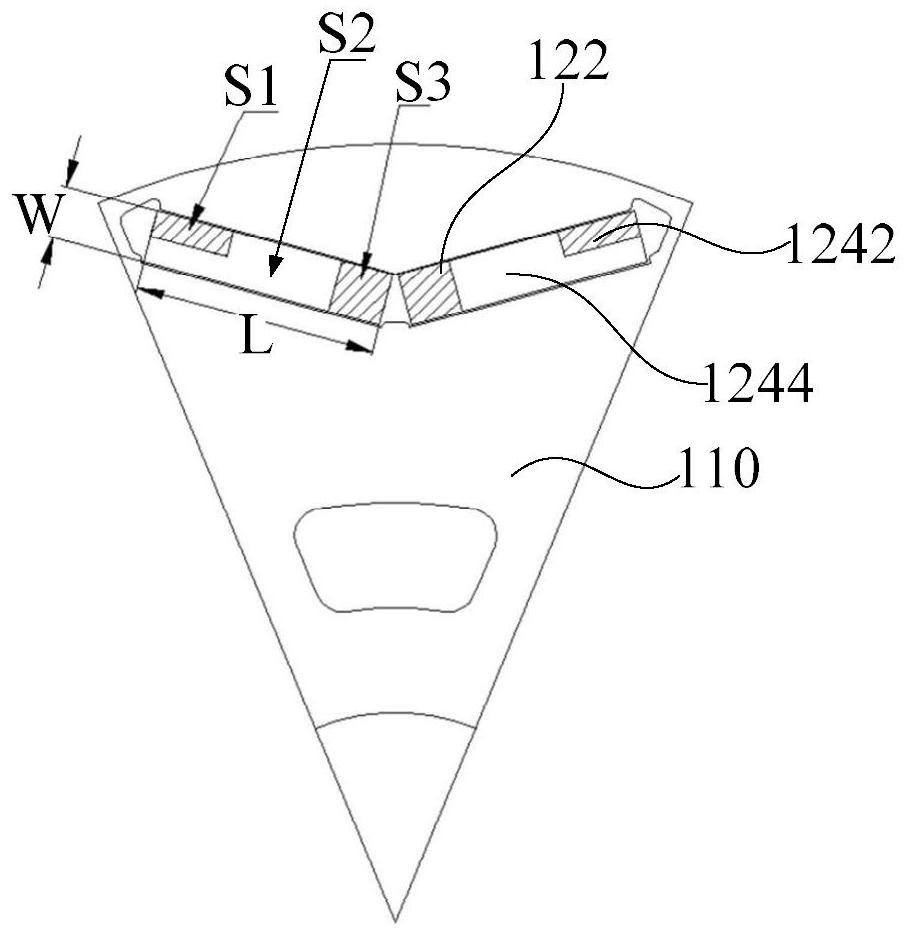

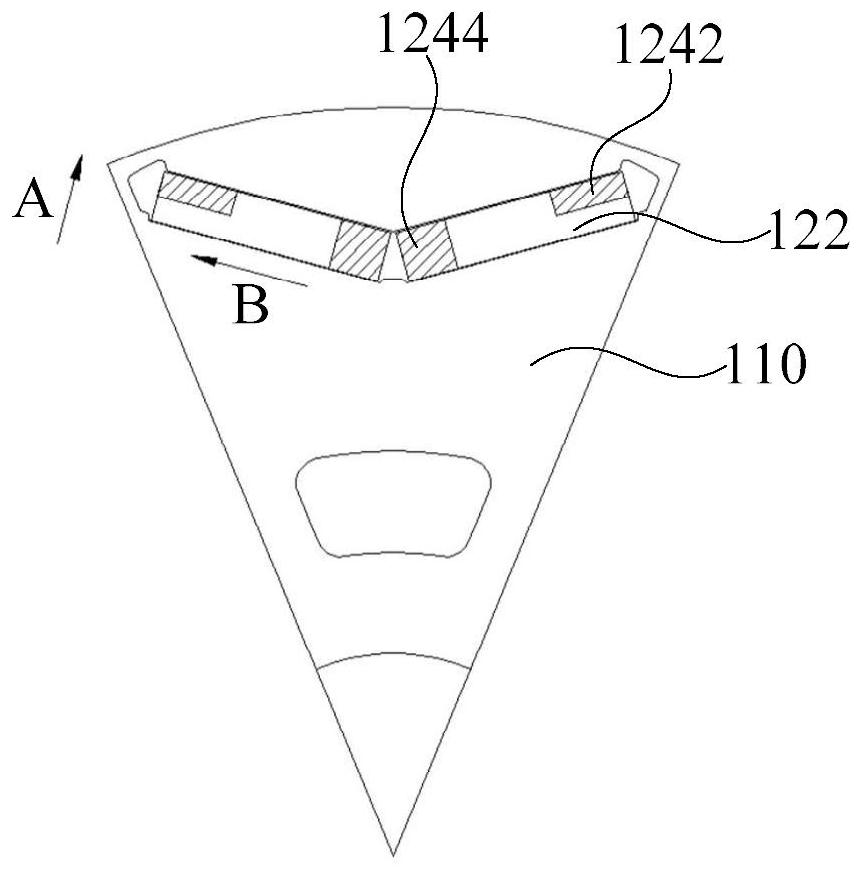

Multi-layer rotor magnetic steel structure of permanent magnet motor for high-power-density new energy automobile

PendingCN111786481AEasy to installGuaranteed mechanical strengthMagnetic circuit rotating partsNew energyElectric machinery

The invention discloses a multi-layer rotor magnetic steel structure of a permanent magnet motor for a high-power-density new energy automobile. The structure comprises a rotor core, a plurality of magnetic steel groove groups are arranged on the rotor core at interval along the circumferential direction, each magnetic steel groove group is composed of first layer V-shaped magnetic steel grooves and second layer V-shaped magnetic steel grooves, and a first layer of magnetic steel and a second layer of magnetic steel are respectively arranged in the first layer V-shaped magnetic steel groove and the second layer V-shaped magnetic steel groove; the first layer of V-shaped magnetic steel grooves are symmetrical about the radial direction of the rotor core, and the second layer of V-shaped magnetic steel grooves are symmetrically arranged at two sides of the first layer of V-shaped magnetic steel grooves; v-shaped openings of the first-layer V-shaped magnetic steel grooves face the outer ring of the rotor core, and the extending directions of the two side grooves of the first-layer V-shaped magnetic steel grooves and the extending directions of the two side grooves of the second-layerV-shaped magnetic steel grooves are correspondingly parallel. A rotor is high in structural strength, and the permanent magnet motor manufactured by the rotor is high in power density.

Owner:无锡欧瑞京机电有限公司

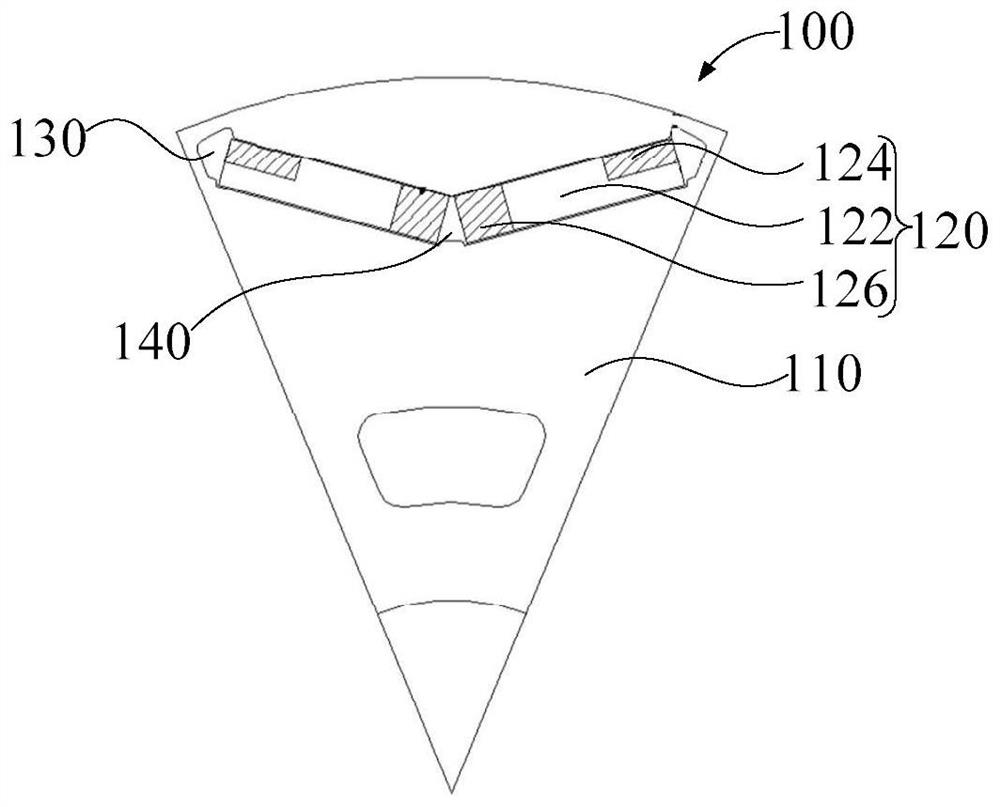

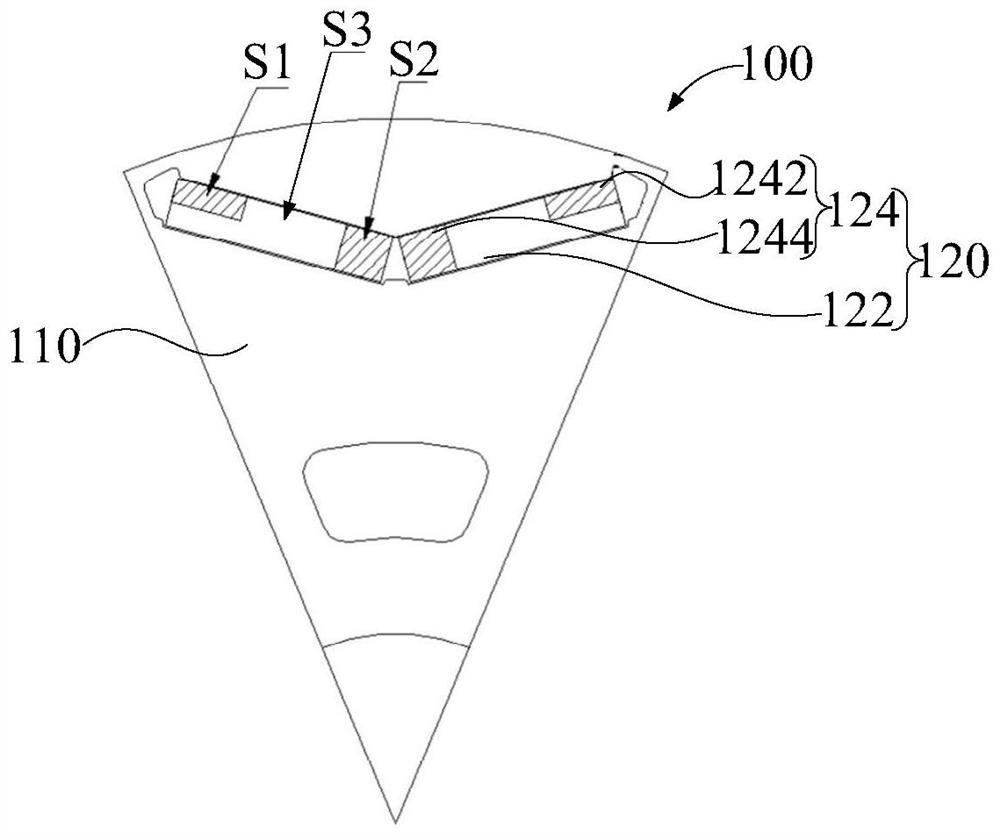

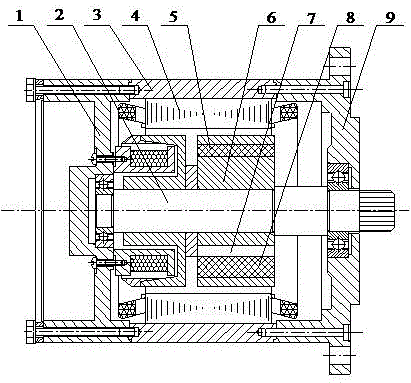

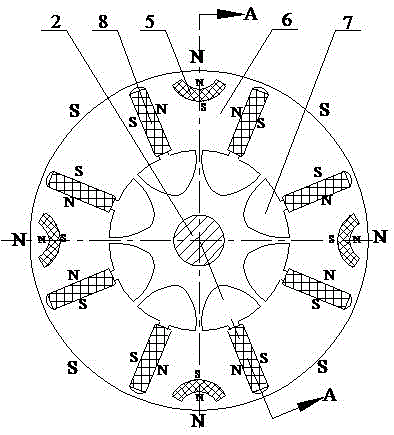

Rotor assembly, permanent magnet motor and compressor

PendingCN114709952AReduce Flux LeakageSimple structureMagnetic circuit rotating partsElectric machineryPermanent magnet motor

The invention provides a rotor assembly, a permanent magnet motor and a compressor, and the rotor assembly comprises a rotor iron core which comprises a through hole; the permanent magnet is arranged in the through hole, the permanent magnet is cut out through a surface perpendicular to the axis of the rotor iron core to obtain a first section, the included angle between the extension direction of the permanent magnet and the radial direction of the rotor iron core is larger than 0 degree and smaller than 90 degrees on the first section, the permanent magnet comprises a non-diffusion part, and the non-diffusion part comprises a first end and a second end in the extension direction, the first end is close to the circumferential side of the rotor core, and the second end is close to the axis of the rotor core; the first diffusion part is connected with the first end of the non-diffusion part; the first magnetic isolation bridge is connected with the first diffusion part and is positioned between the first diffusion part and the circumferential side surface of the rotor iron core; wherein the mass ratio of the heavy metal elements in the first diffusion part is greater than the mass ratio of the heavy metal elements in the non-diffusion part. According to the invention, the technical problems that the anti-demagnetization capability of the permanent magnet motor is weak and irreversible demagnetization is easy to occur are solved.

Owner:ANHUI MEIZHI PRECISION MFG

Method for producing combined magnetic pole and invisible magnetic pole driven motor rotor

InactiveCN105896848AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsElectric machine

The invention provides a method for producing a combined magnetic pole and invisible magnetic pole driven motor rotor, and belongs to the technical field of motors and electric appliances of electric vehicles. A permanent magnet steel is separately embedded into an oblong radial slot and an arc slot of a rotor core; the structure is a rotor magnet bypass structure, and can effectively prevent the permanent magnet steels from producing irreversible demagnetization under the action of armature reaction of impulse current and guarantee the permanent magnet steels not demagnetized; meanwhile, the magnetic field for driving the motor rotor is provided by the permanent magnet steels, so that the magnetic field intensity and the output power are high; and the motor rotor has the characteristics of high efficiency, high power density, compact structure, reliable operation and the like.

Owner:张学义

Rotor assembly, permanent magnet motor and compressor

PendingCN114759703AAvoid irreversible demagnetizationGuaranteed MagneticMagnetic circuit rotating partsElectric machineEngineering

The invention provides a rotor assembly, a permanent magnet motor and a compressor. The rotor assembly includes: a rotor core including a through hole; the permanent magnet is arranged in the through hole, and the permanent magnet comprises a non-diffusion part; the diffusion part and at least part of the non-diffusion part are arranged side by side in a first direction, and the first direction is perpendicular to a rotating shaft of the rotor iron core; wherein the mass ratio of the heavy metal elements in the diffusion part is larger than that of the heavy metal elements in the non-diffusion part. Therefore, a diffusion region with relatively high demagnetization resistance is formed in a partial region of the permanent magnet, so that the local demagnetization resistance of the permanent magnet is improved through the diffusion region, and the overall demagnetization resistance of the rotor assembly is further improved. Therefore, the possibility of irreversible demagnetization of the rotor assembly is reduced, reliable operation of the permanent magnet motor and related products within a long time is ensured, and the service life of the products is prolonged.

Owner:ANHUI MEIZHI PRECISION MFG

Composite permanent-magnet invisible magnetic pole and brushless electromagnetic hybrid excitation driving motor

InactiveCN105811704AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsSynchronous machine detailsElectric machineMagnetic poles

The invention provides a composite permanent-magnet invisible magnetic pole and brushless electromagnetic hybrid excitation driving motor, and belongs to the technical field of a motor electrical device of an electric vehicle. The hybrid excitation driving motor comprises a front end cover, a rear end cover, an enclosure, a rotor and a stator, wherein rectangular permanent-magnet steel is separately embedded into a radial rectangular groove and an arc groove in a rotor iron core, the permanent-magnet steel can be effectively prevented from generating irreversible demagnetization under the effect of armature reaction of impact current and is enabled not to loss magnetism, a magnetic field in an air gap of a driving motor is jointly provided by the permanent-magnet and an electric excitation magnetic winding, the generated magnetic field directly faces the air gap, and less magnetic leakage is achieved.

Owner:SHANDONG UNIV OF TECH

Control device of permanent magnet synchronous motor for preventing irreversible demagnetization of permanent magnet and control system including the same

ActiveUS9054617B2Avoid irreversible demagnetizationElectronic commutation motor controlAC motor controlControl systemPermanent magnet synchronous motor

Owner:FANUC LTD

Outer rotor water cooling structure of permanent magnet synchronous hub motor

InactiveCN112564422AAvoid magnetic degradationAvoid irreversible demagnetizationMagnetic circuit rotating partsCooling/ventillation arrangementImpellerElectric machine

The invention relates to the technical field of hub motors, in particular to an outer rotor water cooling structure of a permanent magnet synchronous hub motor, which comprises an outer rotor permanent magnet synchronous hub motor, an outer rotor waterway cooling pipe, a waterproof bearing and an axial flow impeller, the two ends of the outer rotor waterway cooling pipe are welded between the inner ring of the waterproof bearing and the surface of an axial-flow impeller shaft and are tightly attached to the periphery of motor permanent magnets and the inner wall of a rotor core through end covers. When the hub motor rotates, the outer rotor waterway cooling pipe and the axial flow impeller are driven to rotate, and cooling water enters the outer rotor waterway cooling pipe through the axial flow impeller to cool the permanent magnets. A rotor adopts water internal cooling, the temperature rise of the permanent magnets is low, the reduction of magnetic performance and irreversible demagnetization of the permanent magnets due to over-high temperature are avoided, and the motor is reliable in operation. The permanent magnet adopts an axial segmented structure, and omega-shaped coolingwater pipes are arranged between every two adjacent permanent magnets, so that waterways can be in full contact with the permanent magnets and the inner wall of the rotor, and the heat dissipation isimproved; the permanent magnet segmented structure can significantly reduce the eddy current loss of the permanent magnets and reduce heat generation.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com