Production method for embedded permanent magnet rotor of tangential and radial resultant magnetic field driving motor

A technology for driving motors and permanent magnet rotors, which is applied in the manufacture of stator/rotor bodies, etc. It can solve the problems of irreversible demagnetization, reduced efficiency of driving motors, etc., and achieves the effects of compact structure, high magnetic field strength, and high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

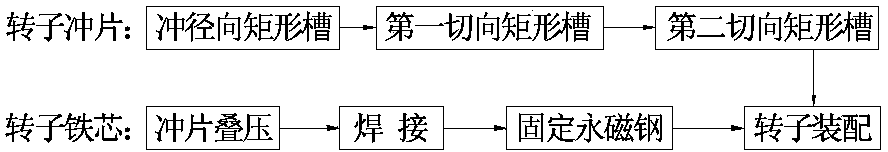

[0009] The production method of a permanent magnet rotor embedded in a tangential and radial synthetic magnetic field drive motor is characterized in that: punching and cutting a ring-shaped rotor punch, the rotor punch is evenly distributed with an even number of radial rectangular grooves running through the thickness of the rotor punch, the diameter There is a 1.5mm disconnected part between the outer end of the rectangular groove and the outer circle of the rotor punch, and a first tangential rectangular groove penetrating through the thickness of the rotor punch is provided between the inner ends of two adjacent radial rectangular grooves. Slots, the first tangential rectangular slots are used as magnetic isolation air gaps, the width of which is not less than 3mm, multiple first tangential rectangular slots are all tangent to the same circle, and are not connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com