Patents

Literature

194results about How to "Guaranteed Magnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

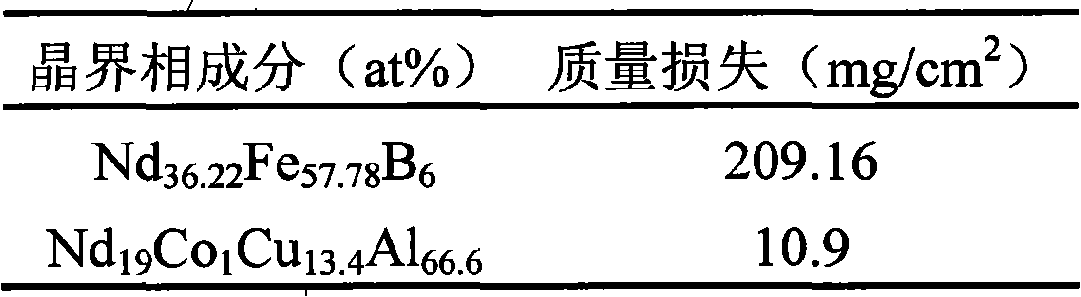

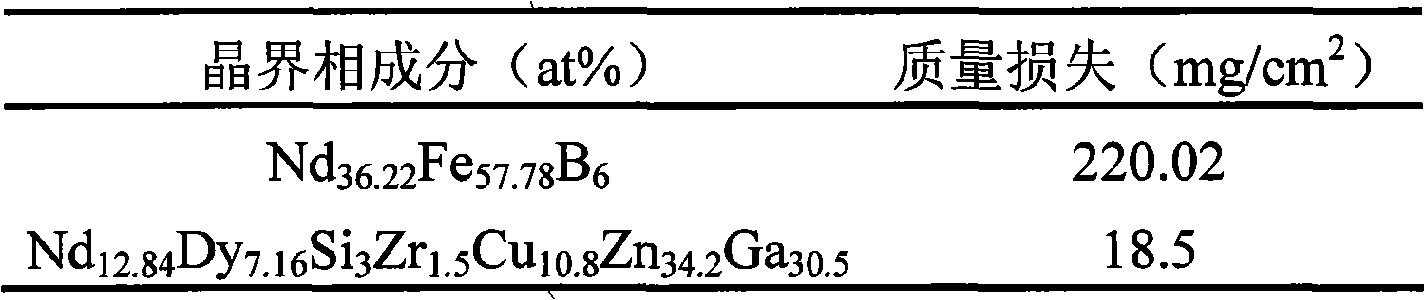

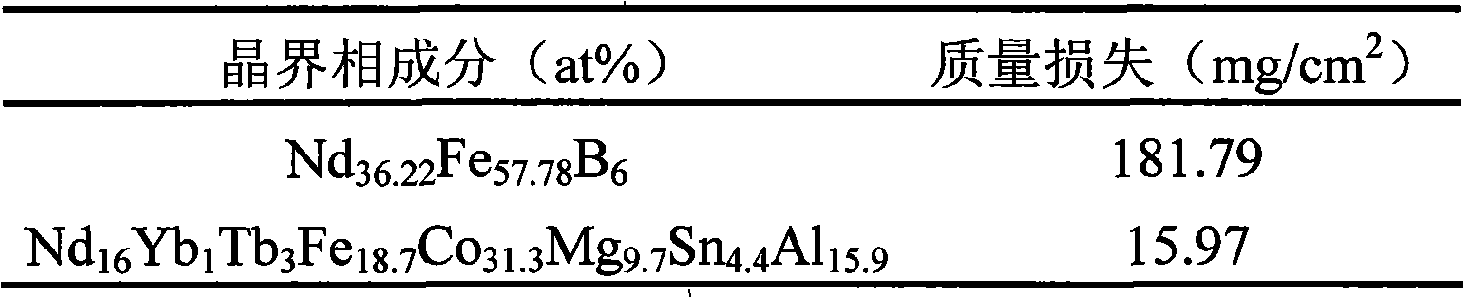

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

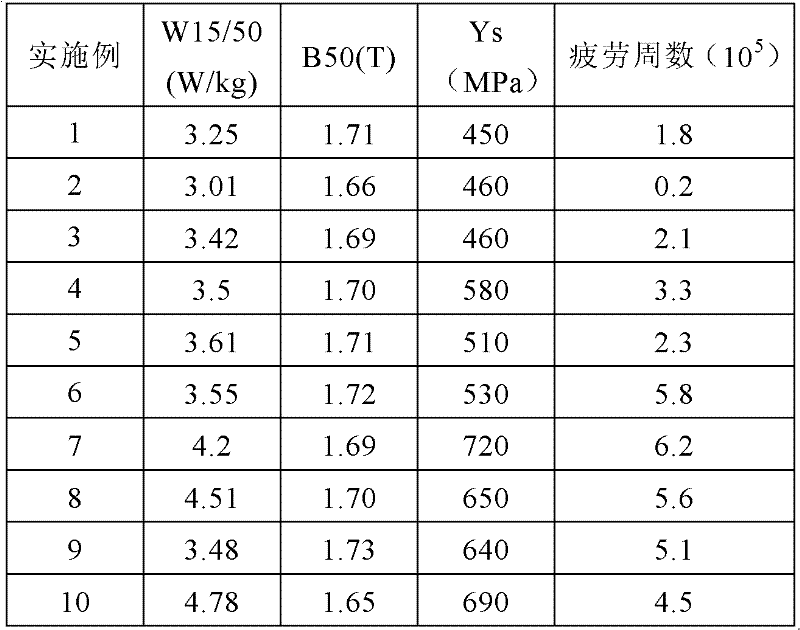

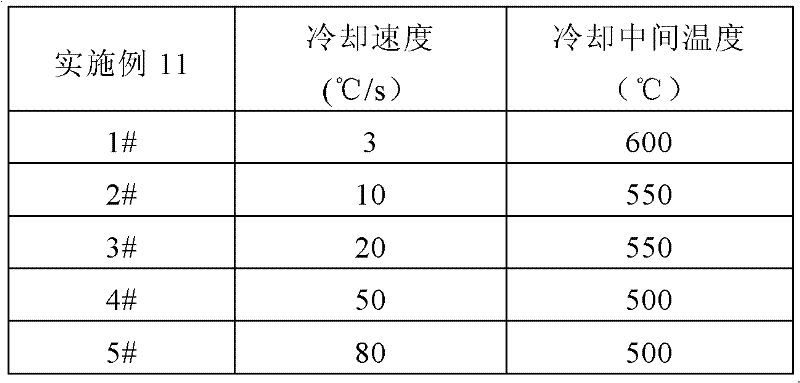

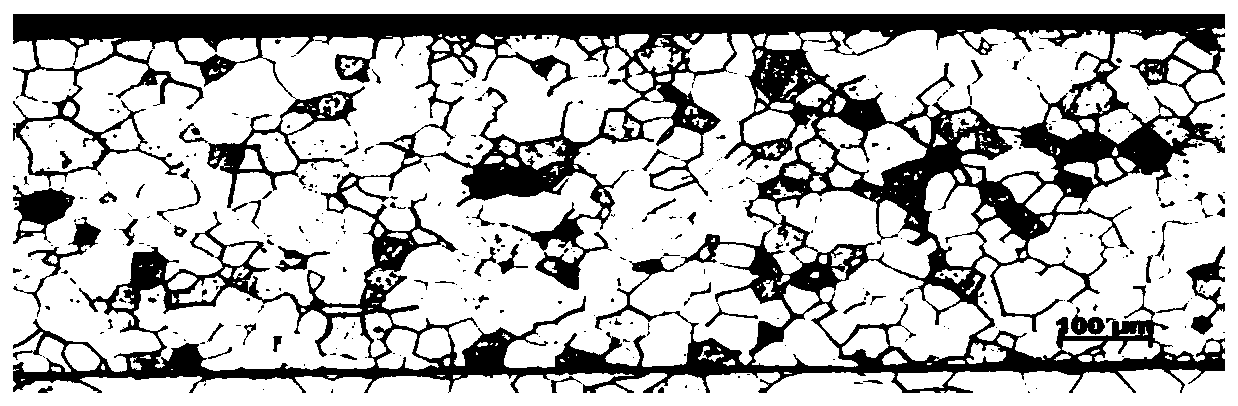

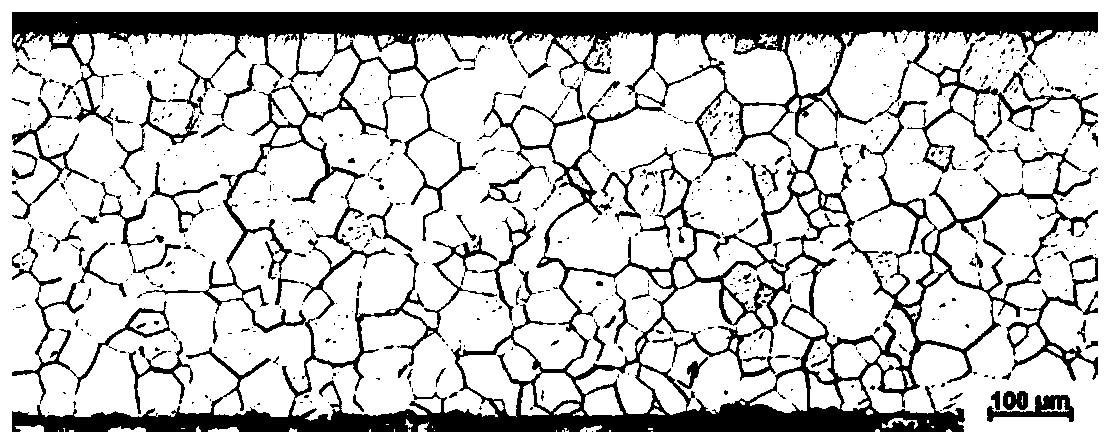

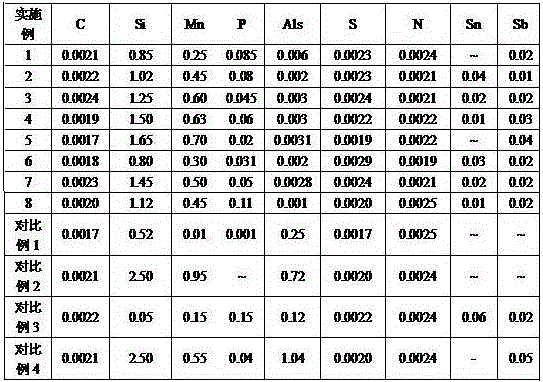

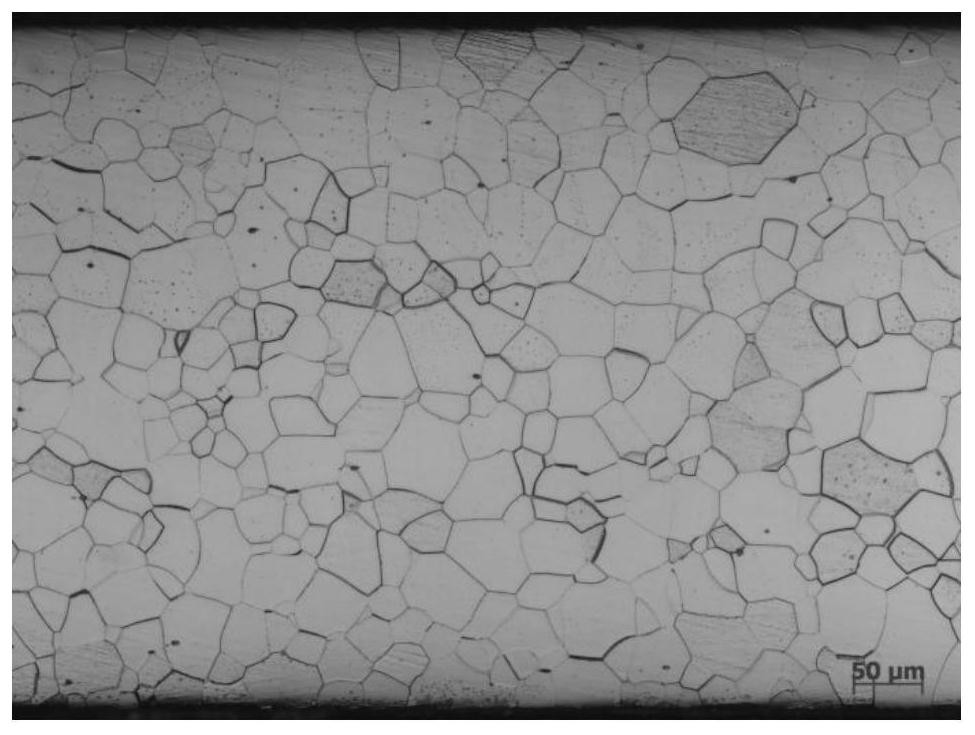

High-strength non-oriented electrical steel with high magnetic induction and manufacturing method thereof

InactiveCN102453838AHigh strengthSolve the problem of difficult rollingReduction rateElectrical steel

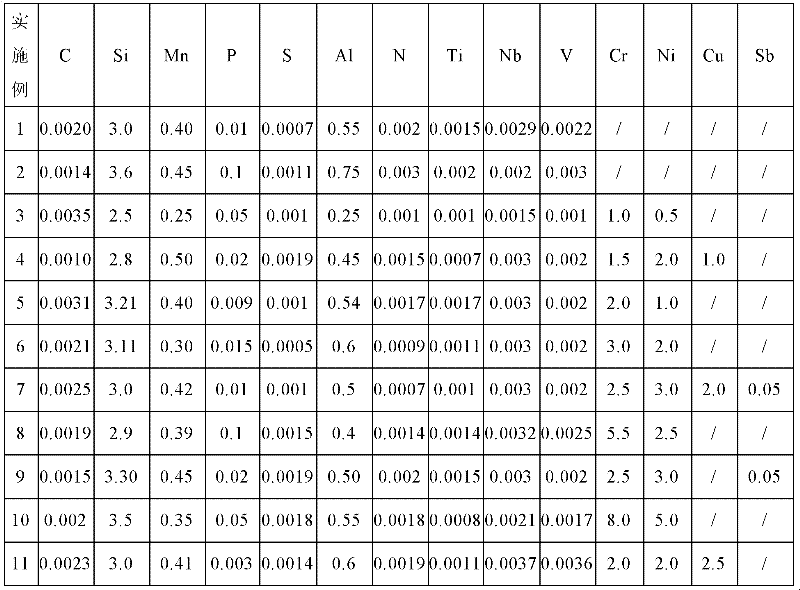

High-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof. The method comprises the following steps of: 1) smelting and casting, wherein the electrical steel comprises the following components by weight: not more than 0.0040% of C, 2.50-4.00% of Si, 0.20%-0.80% of Al, 1.0-8.0% of Cr, 0.5-5.0% of Ni, not more than 0.50% of Mn, not more than 0.30% of P, not more than 0.0020% of S, not more than 0.0030% of N, not more than 0.0030% of Ti, not more than 0.010% of Nb, not more than 0.010% of V, not more than 0.010% of C+S+N+Ti, and the balance of Fe; smelting, RH vacuum treatment, casting; 2) hot rolling; 3) normalization at a temperature of 850-950 DEG C for 0.5-3 min, slow cooling to 650-750 DEG C with a speed of 5-15 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C; 4) pickling and cold rolling with a total reduction rate of not less than 70%; 5) annealing at 800-1000 DEG C for 5-60 seconds, slow cooling to 650-750 DEG C with a speed of 3-10 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C. The method of the invention produces non-oriented electrical steel with both high strength and high-efficient magnetic properties without the increase of manufacturing difficulties.

Owner:BAOSHAN IRON & STEEL CO LTD

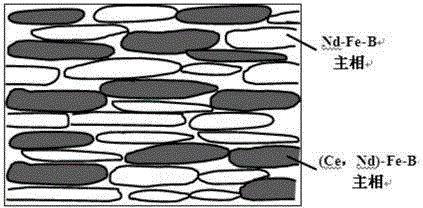

Methods for manufacturing cerium-rich anisotropy nano-crystalline rare-earth permanent magnets

ActiveCN104576028AShort thermal deformation timeShorten the production cycleInorganic material magnetismInductances/transformers/magnets manufactureCeriumIngot

The invention discloses a method for manufacturing cerium-rich anisotropy nano-crystalline rare-earth permanent magnets. The method includes (1), proportioning materials according to a chemical formula of (Ce<x>, RE<1-x>)Fe<100-a-b-c>BTM<c>; (2), melting the materials to obtain alloy ingots; (3), crushing the alloy ingots, and then rapidly quenching melt to obtain rapidly quenched magnetic powder; (4), carrying out hot-pressing on the rapidly quenched magnetic powder for 1-10 minutes at the temperatures ranging from 500 DEG C to 800 DEG C under the pressures ranging from 100MPa to 300MPa, and then enabling the rapidly quenched powder to thermally deform for 3-10 minutes at the temperatures ranging from 600 DEG C to 900 DEG C under the pressures ranging from 50MPa to 200MPa. The invention further provides a method for manufacturing the cerium-rich anisotropy nano-crystalline rare-earth permanent magnets according to chemical formulas of (Ce<x>, RE<1-x>)Fe<100-a-b-c>BTM<c> and NdFe<100-a-b-c>BTM<c>. The methods have the advantages that processes can be simplified, the cost can be reduced, and the obtained cerium-rich anisotropy nano-crystalline rare-earth permanent magnets are excellent in magnetic performance.

Owner:SICHUAN UNIV

Nano-molybdenum disulfide magnetic lubricant and preparation method thereof

ActiveCN105087105AGuaranteed MagneticStable ratioMaterial nanotechnologyAdditivesLubricationMolybdenum disulfide

The invention discloses a nano-molybdenum disulfide magnetic lubricant and a preparation method thereof, and particularly relates to a nano-Fe3O4@IF-MoS2-graphene. In the lubricant, the mass ratio of Fe3O4 to IF-MoS2 to graphene is 1:(2-20):(0.02-0.5), furthermore, each component is of a specific size and structure. The preparation method comprises the following steps: firstly, dispersing nano-Fe3O4 to the surface of graphene oxide; and then, in-situ synthesizing an MoS3 precursor outside Fe3O4, and reducing and desulfurizing to obtain the nano-molybdenum disulfide magnetic lubricant. The prepared lubricant product has the advantages of high yield, good purity, good dispersion, excellent magnetism and excellent lubricity, and has important application values in the fields of precision machinery lubrication, long-term lubrication and the like.

Owner:HEFEI UNIV OF TECH

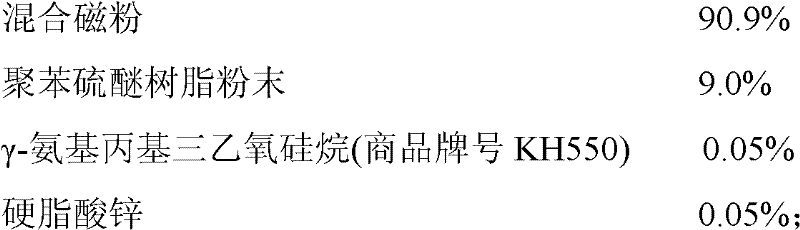

Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

ActiveCN102504534AExcellent overall performanceExcellent magnetic propertiesMagnetic powderNeodymium iron boron

An injection molding permanent magnet composite material containing polyphenylene sulfide includes the following components by mass: 78% to 91% of mixed magnetic powder, 8% to 21% of polyphenylene sulfide resin and 0.05% to 1% of coupling agents. The mixed magnetic powder includes the following components by mass: 50% to 96% of neodymium iron boron permanent magnetic powder, 1% to 49% of samariumiron nitrogen permanent magnetic powder and 1% to 45% of ferrite permanent magnetic powder. A preparation method of the injection molding permanent magnet composite material includes the following processing steps: (1) preparing multi-element composite magnetic powder, (2) mixing and pelleting and (3) injection molding.

Owner:SICHUAN UNIV

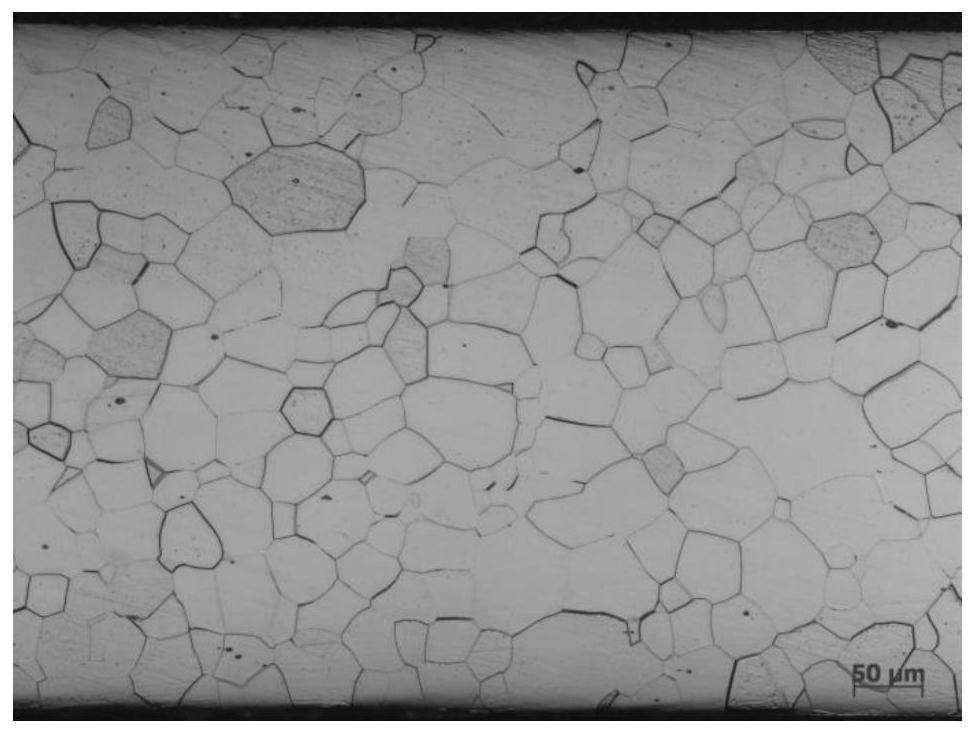

Preparation method of samarium-cobalt (SmCo) system sintered materials

ActiveCN102651263AImprove microstructureGood orientationInductances/transformers/magnets manufactureMagnetic materialsPositive pressureAlloy

The invention relates to a preparation method of samarium-cobalt (SmCo) system sintered materials. The preparation method comprises the steps of alloy smelting, alloy cast strip preparation through rapid quenching, magnetic powder preparation through combination of a hydrogenated disproportionation method and an airflow grinding method, orientation and forming, positive pressure sintering and solid dissolving and aging treatment. The preparation method has the advantages that through the innovation of the ingot casting and powder making process, the microstructure of a magnetic body is optimized to the greatest degree, the magnetic body mainly consists of columnar crystals, the orientation is easy, and in addition, the performance of the magnetic body is stable; and in the hydrogenated disproportionation process of alloy cast sheets, hydrogen enters gap positions in SmCo crystal lattices, and the crystal lattice expansion is caused, so the pulverization is realized under the condition of ensuring the crystal particle integrity, the oxidation in the powder making process is reduced, the magnetic body with low oxygen content is obtained, and the magnetic performance of the magnetic body is ensured.

Owner:NINGBO STAR MATERIALS HI TECH

Iron base amorphous alloy and preparation method thereof

InactiveCN106702291AHigh saturation magnetic inductionGood Amorphous Formation AbilityTransformerVolumetric Mass Density

The invention provides an iron base amorphous alloy expressed in a formula (I), wherein a, b, c, d and e respectively represent the atomic percentage contents of corresponding components: a is not bigger than 84.0 and not smaller than 80.5, b is not bigger than 9.0 and not smaller than 3.0, c is not bigger than 15.0 and not smaller than 8.0, d is not bigger than 0.3 and not smaller than 0.001, e is not bigger than 0.4, and the sum of a, b, c, d and e is 100; and M is an impurity element. In the iron base amorphous alloy provided by the invention, the saturation induction density of an alloy material is not lower than 1.62 T. The invention further provides a preparation method of the iron base amorphous alloy; further, the excellent soft magnetic properties can be obtained after proper heat treatment; the alloy material can be used for manufacturing iron core materials of power transformers, generators and engines; and FeaSibBcPdMe (I).

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

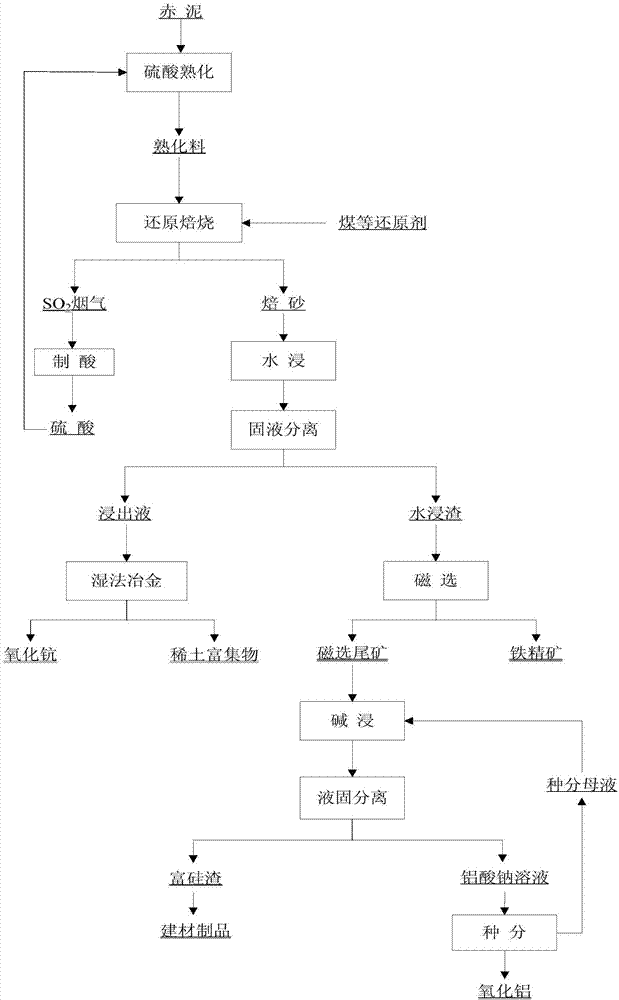

Method for high-value comprehensive utilization of red mud

ActiveCN107326182AEfficient separationEase of industrial productionSulfur compoundsMagnetic separationRed mudRare earth

The invention discloses a method for extracting aluminum, ferrum, rare earth and scandium from red mud, and belongs to the field of high-value comprehensive utilization of red mud. The method comprises the steps that after the red mud and a proper amount of concentrated sulfuric acid are evenly mixed and cured, rapid reduction roasting is conducted on the mixture with a reducing agent at a certain temperature for desulfuration, and regeneration and recycling of sulfuric acid is achieved through acid making with smoke containing SO2; water leaching is conducted on reduced roasted sand for extracting rare earth and scandium, and a water extract is concentrated, separated and purified through wet metallurgy, so that an Sc2O3 product and a rare earth-enriched product are obtained; and magnetic separation is conducted on water leaching residues, so that iron ore concentrate and magnetic separation tailings are obtained, and alkaline leaching is conducted on the magnetic separation tailings, so that aluminum oxide is prepared. According to the method, based on the principle that each component in the red mud is separated out in each step, effective separation can be achieved, the technique for each step is an existing industrial production technique, and industrial production can be achieved easily.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

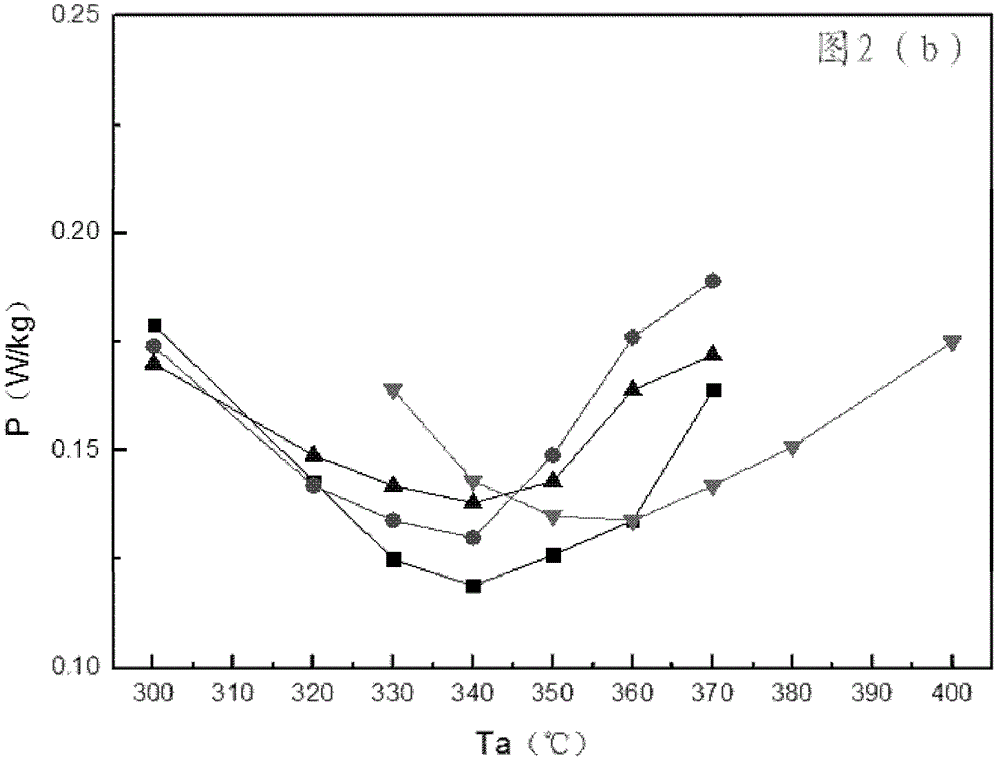

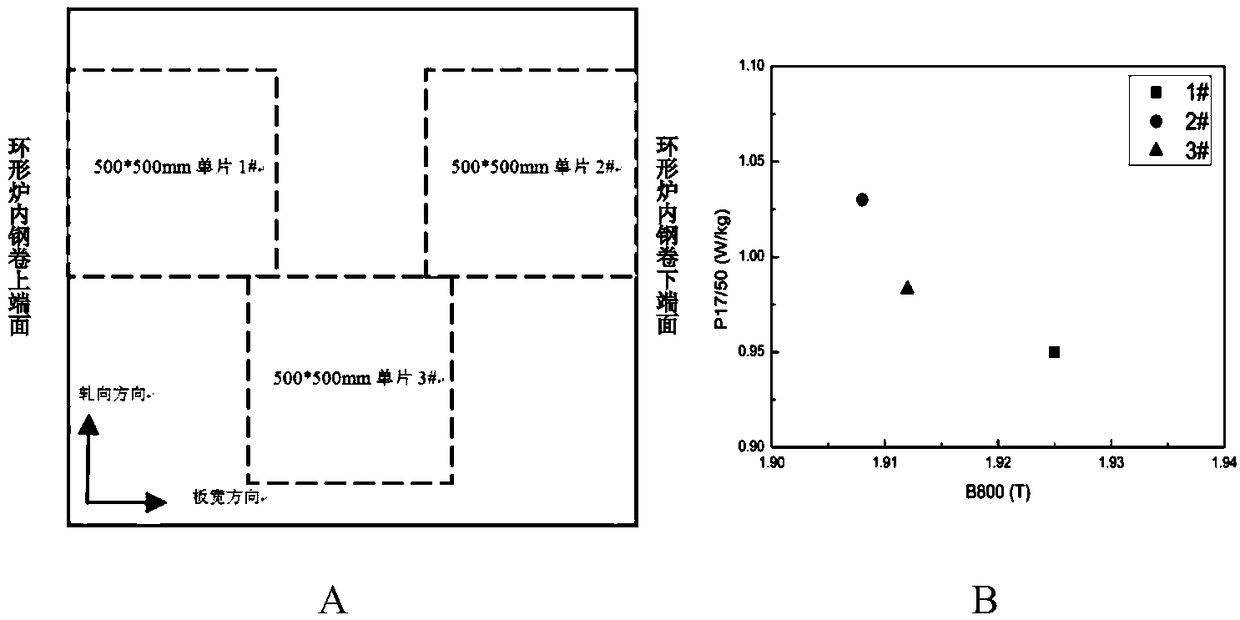

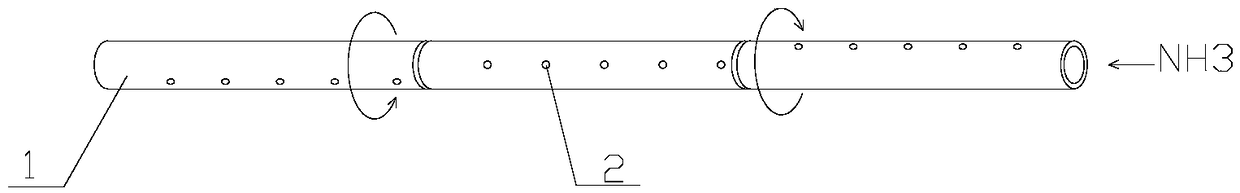

Production method of low temperature and high magnetic induction oriented silicon steel for improving magnetic uniformity in direction of plate width

ActiveCN109023148AGuaranteed MagneticImprove magnetismSolid state diffusion coatingContinuous annealingConveyor belt

The invention discloses a production method of low temperature and high magnetic induction oriented silicon steel for improving magnetic uniformity in the direction of the plate width. The productionmethod produces and obtains the low temperature and high magnetic induction oriented silicon steel through seven steps of smelting, hot rolling, pickling normalization, cold rolling, continuous annealing and nitriding, high temperature annealing and stretching leveling annealing. When a steel belt passes through a reduction zone, a primary cooling zone and a nitriding zone of a conveyor belt sequentially after decarbonization and annealing are completed, the angle of small holes of injection holes of a nitriding branch pipe I, a nitriding branch pipe II and a nitriding branch pipe III are adjusted freely and correspondingly towards the steel plate; and the injection mode of nitriding branch pipes under and above the steel belt is designed symmetrically. By adjusting the structure of a nitriding tube in a nitriding annealing section, the production method realizes the differential control over the nitriding amount in the direction of the plate width and a primary grain area, and the problem of magnetic inhomogeneity in the direction of the plate width caused by the uneven temperature of the upper and lower end faces of a circular furnace in a current process is solved.

Owner:武汉钢铁有限公司

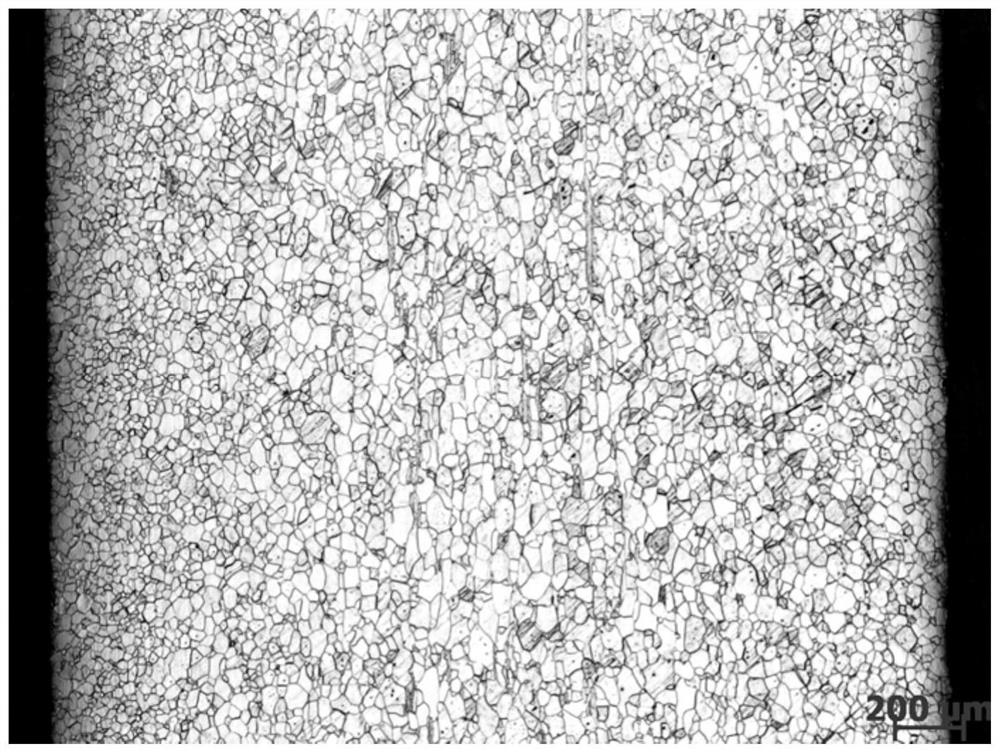

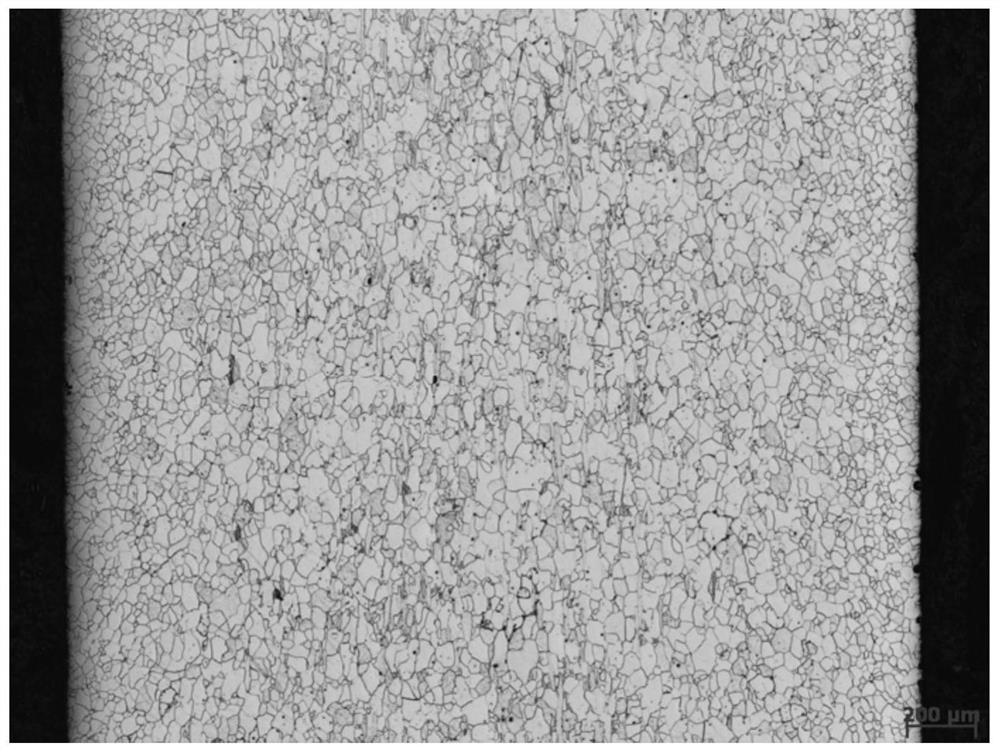

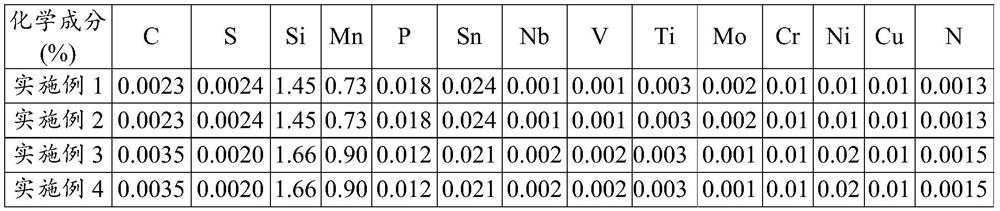

High-grade non-oriented silicon steel and production method thereof

ActiveCN112609130AStrong magnetismReduce manufacturing costFurnace typesMagnetic materialsContinuous rollingSilicon

The invention discloses high-grade non-oriented silicon steel and a production method thereof. The non-oriented silicon steel comprises the following chemical components including, by mass, 0.002%-0.004% of C, less than or equal to 0.003% of S, 1.4%-1.7% of Si, 0.7%-0.95% of Mn, less than or equal to 0.03% of P and 0.015%-0.035% of Sn, and 11*([Si]-1.4%)=14*([Mn]-0.7%). According to the production method of the non-oriented silicon steel, the heating temperature of a continuous casting billet is 1120 DEG C-1150 DEG C, the finish rolling temperature of finish rolling is 890+ / -15 DEG C, the rolling reduction of finish rolling of the last pass is larger than or equal to 30%, the total rolling reduction of finish rolling of the last two passes is larger than or equal to 50%, and the coiling temperature is 650+ / -20 DEG C; and normalization treatment is not needed before acid continuous rolling, the obtained non-oriented silicon steel is good in magnetic performance, the surface of the non-oriented silicon steel is free of corrugated defects, and the requirements of the low-cost high-grade non-oriented silicon steel are met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

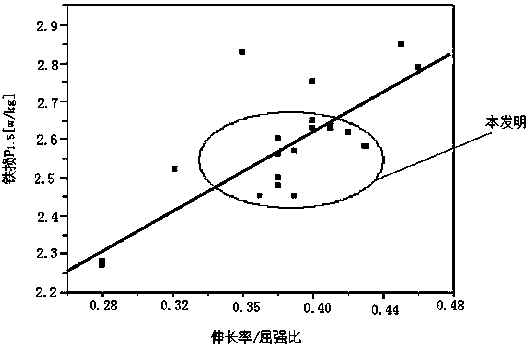

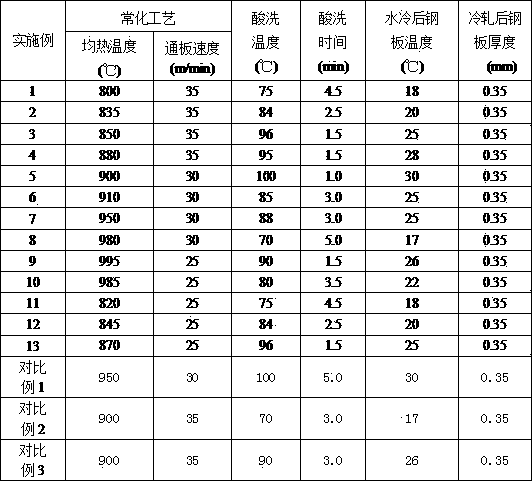

Non-oriented electrical steel for inverter compressor and production method thereof

The invention discloses non-oriented electrical steel for an inverter compressor, which comprises the following chemical components in percentage by weight: 0.001-0.015% of C, 2.0-2.5% of Si, 0.15-0.55% of Al, 0.15-0.55% of Mn, 0.01-0.039% of Cr, less than or equal to 0.12% of Sn, less than or equal to 0.08% of P, less than or equal to 0.015% of S and less than or equal to 0.008% of N. A production technology comprises the following steps: smelting by a clean steel technology, and performing continuous casting to obtain a blank; heating the continuous-cast blank; performing rough rolling, finish rolling, reeling, normalizing, acid pickling, cold rolling, decarbonization and soaking; and cooling, coating and finishing according to a conventional way. According to the non-oriented electrical steel and production technology disclosed by the invention, on the premise of guaranteeing the magnetic performance (P1.5 / 50 is less than or equal to 2.65w / kg, B50 is greater than or equal to 1.68T), relatively good mechanical performance is also realized, namely that the ratio of elongation to yield ratio is 0.37-0.43; and meanwhile, the requirements for high-speed stamping and magnetic performance in manufacturing of an iron core of an inverter compressor are met.

Owner:武汉钢铁有限公司

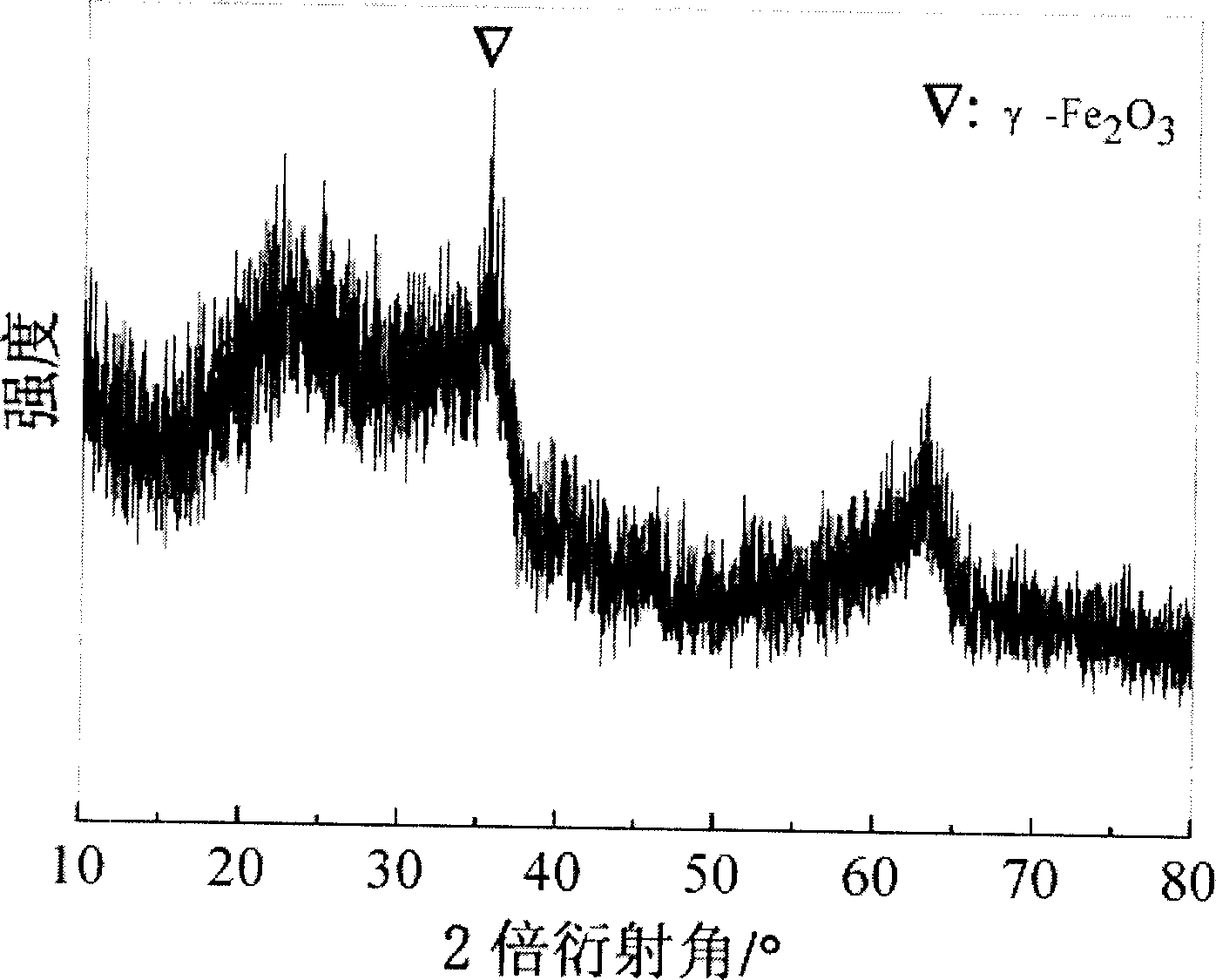

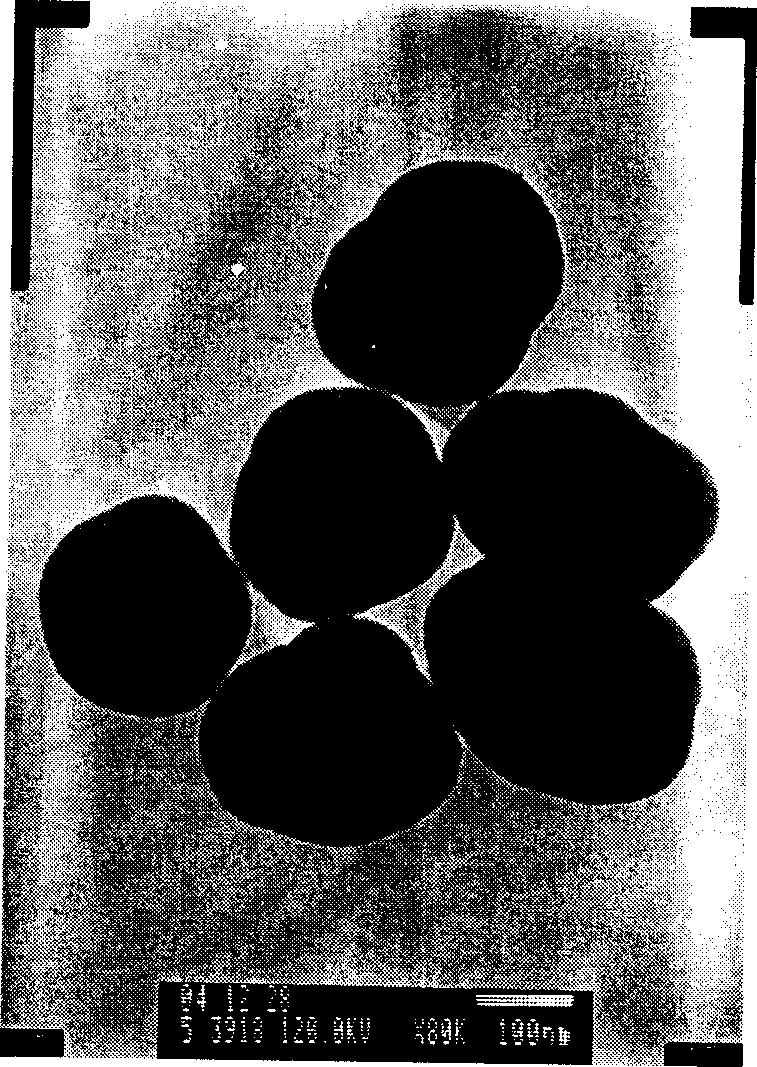

High temperature resistant magnetic carrier, its preparation process and application

InactiveCN1736603AInhibition transitionGuaranteed MagneticCatalyst carriersInorganic material magnetismSorbentComposite oxide

The invention discloses a thermostable magnetic carrier and the method for preparation and the application, belonging to the art of magnetic composite material. The thermostable magnetic carrier is a core- shell structure of XmOn / gamma- Fe2O3- SiO2. Prepare magnetic the core of gamma- Fe2O3- SiO2 composite oxide firstly, and then coat with multiple outer layer of XmOn oxide. The carrier can support plural of catalyst activity and absorption activity, and is characterized in that it is thermostable. And it is suit for the production or treatment of magnetic catalyst, magnetic absorption in high temperature.

Owner:TSINGHUA UNIV

Non-oriented silicon steel for sheet billet production and manufacturing method thereof

The invention discloses non-oriented silicon steel for sheet billet production and a manufacturing method thereof and belongs to the technical field of production of non-oriented silicon steel. The non-oriented silicon steel comprises the chemical components in percent by weight: less than or equal to 0.005% of C, less than or equal to 1.50% of Si, greater than or equal to 0.40% but less than or equal to 0.70% of Mn, greater than or equal to 0.050% but less than or equal to 0.55% of Als, greater than or equal to 0.0010% but less than or equal to 0.0030% of S, greater than or equal to 0.0010% but less than or equal to 0.0030% of N, less than or equal to 0.0015% of Ti and the balance Fe and inevitable impurities. By carrying out process treatment such as smelting, continuous casting, heating, hot continuous rolling, rolling, pickling, cold rolling, product annealing, straightening and withdrawing, insulating layer coating and stress-relief annealing on the raw materials of the componentsby adopting a sheet billet production flow, the non-oriented silicon steel which is low in iron loss and high in magnetic polarization with the Si content of being less than 1.5% and the Al content of being within 0.05-0.5% is obtained under a condition of not adding noble metals. After stress-relief annealing, the decreasing proportion of the iron loss is relatively high, so that the electromagnetic property of the non-oriented silicon steel can be further improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method of magnetic nitrogen-doped carbon materials

ActiveCN103295756ANo pollution in the processGuaranteed MagneticInductances/transformers/magnets manufactureHydration reactionPtru catalyst

The invention provides a preparation method of magnetic nitrogen-doped carbon materials. The method includes: using concentrated hydrochloric acid to adjust pH of mixed solvent of anhydrous ethanol and deionized water to 1-3, sequentially and fully dissolving or dispersing oxidation carbonization agent (ferric chloride hexahydrate), carbon source (saccharides), nitrogen source (glycine or melamine), mixing well, evaporating solvent, carbonizing at 60-80 DEG C for 40-50 hours, grinding carbonized products, and carbonizing the ground carbonized products at 180-200 DEG C for 4-6 hours to obtain the magnetic nitrogen-doped carbon materials which are promising in application prospect in fields such as fuel cell catalysts and super capacitors. The preparation method is mild in reaction condition, low in cost, simple to operate, and easy to control nitrogen contents in the nitrogen-doped carbon materials.

Owner:合肥碳艺科技有限公司

Rare earth permanent magnet powder, preparation method thereof, bonded permanent magnet containing same and device

ActiveCN105206366AGuaranteed MagneticGuaranteed anti-corrosion performancePermanent magnetsInorganic material magnetismRemanenceMetallurgy

The invention discloses rare earth permanent magnet powder, a preparation method thereof, a bonded permanent magnet containing the same and a device. The rare earth permanent magnet powder is composed of Fe<100-x-y-z>Nd<y>Q<z>N<x>, wherein the Q is B or B and C, the x is larger than or equal to 0.8 and smaller than or equal to 3.5, the y is larger than or equal to 5 and smaller than or equal to 15, and the z is larger than or equal to 4 and smaller than or equal to 10. The main phase of the rare earth permanent magnet powder is of an Nd<2>Fe<14>B structure, and one or more of the coercive force and the maximum magnetic energy product of the rare earth permanent magnet powder are over 95% of the performance of a corresponding magnet without nitrogen elements. According to the rare earth permanent magnet powder, the preparation method thereof, the bonded permanent magnet containing the same and the device, the main phase structure of the rare earth permanent magnet powder is the Nd<2>Fe<14>B phase, and it can be guaranteed that the rare earth permanent magnet powder has certain residual magnetism and the coercive force; the N elements are introduced, and it is defined that one or more of the coercive force and the maximum magnetic energy product of the rare earth permanent magnet powder are over 95% of the performance of a corresponding magnet without nitrogen elements, so that influences on the Nd<2>Fe<14>B structure of introduction of the N is lowered, the anti-corrosion property of the rare earth permanent magnet powder is improved without greatly lowering the magnetic performance, and the stability of the magnet is guaranteed.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Magnetic printing method and printing product thereof

InactiveCN102442097AVariety of materialsHigh selectivityOther printing matterPattern printingEngineeringElectrical and Electronics engineering

The invention relates to the technical field of printing, and discloses a magnetic printing method and a printing product thereof. The magnetic printing method comprises the following steps: magnetic ink is printed on a printed material, and is mixture of a magnetic material and ink; an image-character plate is suspended outside the printed material so as to be parallel to the plane of the printed material, the magnetic material is orderly arranged according to the direction of the magnetic field under the action of the magnetic field, wherein the image-character plate is a plate printed with images and / or characters to be formed; the parts of the images and / or the characters on the image-character plate are provided with a magnetic substance absorbing with the magnetic material in the magnetic oil; and the printed material is dried, and the magnetic ink on the printed material is set. The invention aims at providing the magnetic printing method and the printing product thereof so as to lead the image-character color blocks printed with the magnetic ink of the printed material to have the visual effect of embossment.

Owner:王玉珠 +1

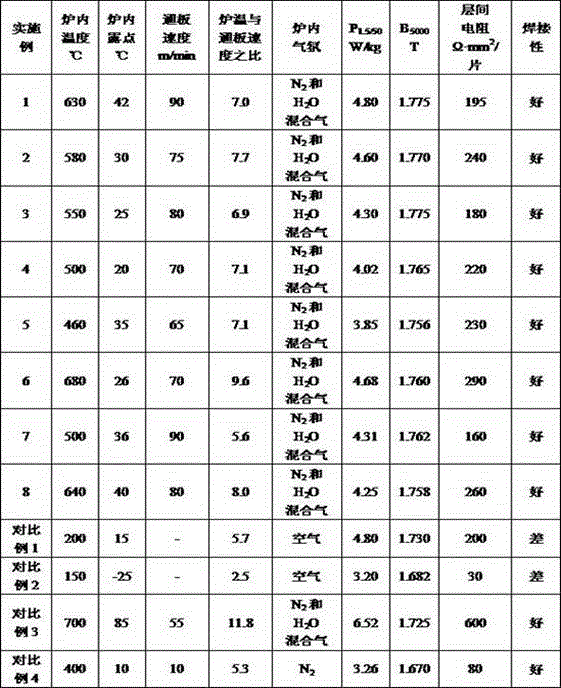

Non-oriented electrical steel good in weldability and magnetism and production method

ActiveCN106756491AGuaranteed MagneticMaintain interlayer resistanceSolid state diffusion coatingPorosityElectrical steel

Non-oriented electrical steel good in weldability and magnetism is composed of, by weight, 0-0.0030% of C, 0.8%-1.7% of Si, 0.2%-0.8% of Mn, 0-0.0050% of S, 0.01%-0.15% of P, 0-0.030% of Al, 0-0.0050% of N, 0-0.05% of Sn and / or Sb. A production method comprises the steps that steel making, hot rolling, pickling and cold rolling are conducted, and then the thickness of a finished product is achieved; after the finished product is subjected to annealing, bluing treatment is conducted; and sampling, reeling, packaging and inspection are conducted. According to the non-oriented electrical steel good in weldability and magnetism and the production method, the weldability of the product is improved while interlamination resistance is kept, weld porosity, broken welding and other defects are decreased; through control over the atmosphere, temperature and dew point of oxidation and bluing, unit speed and bluing temperature of a non-oriented electrical steel sheet, the interlamination resistance is improved, meanwhile, magnetism deterioration caused by surface oxidation can be reduced to the smallest extent, and the magnetism of the finished product is ensured, specifically, a 0.50 mm sheet B50 is larger than or equal to 1.75 T, and P1.5 / 50 is smaller than or equal to 5.0 W / kg.

Owner:武汉钢铁有限公司

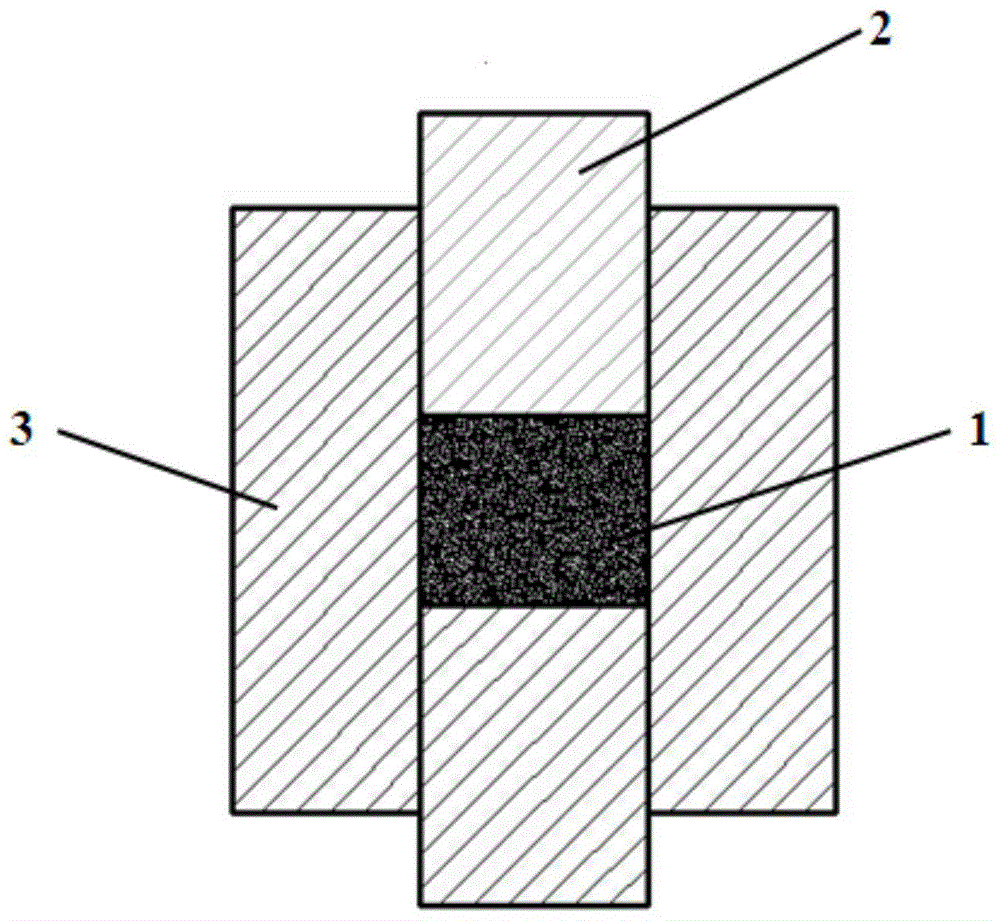

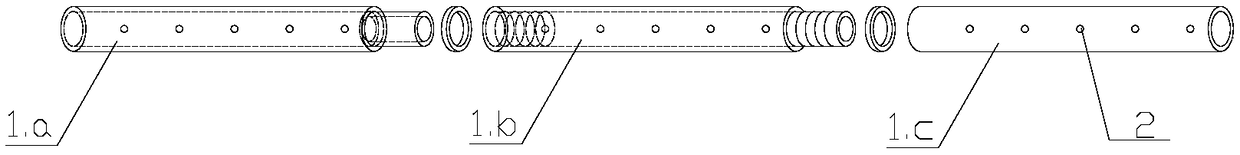

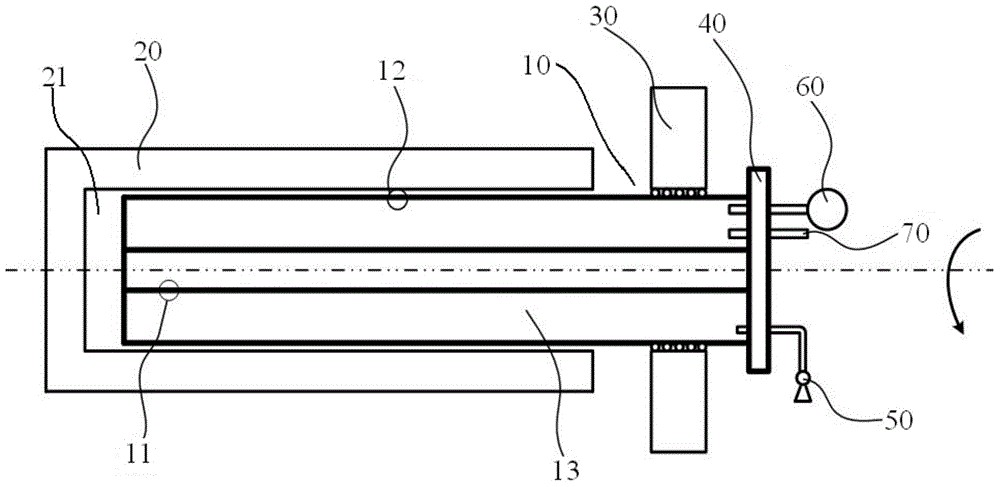

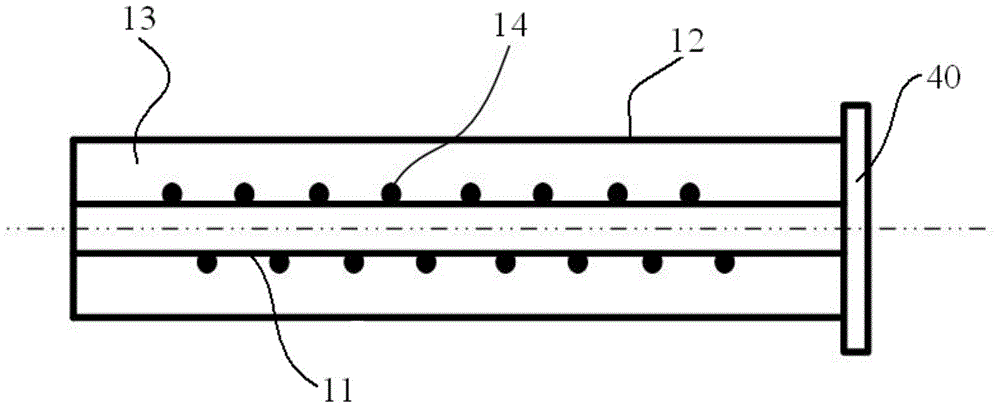

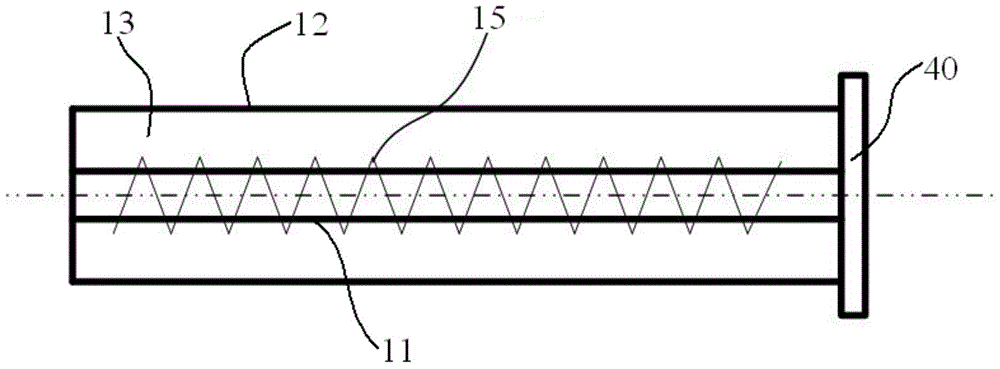

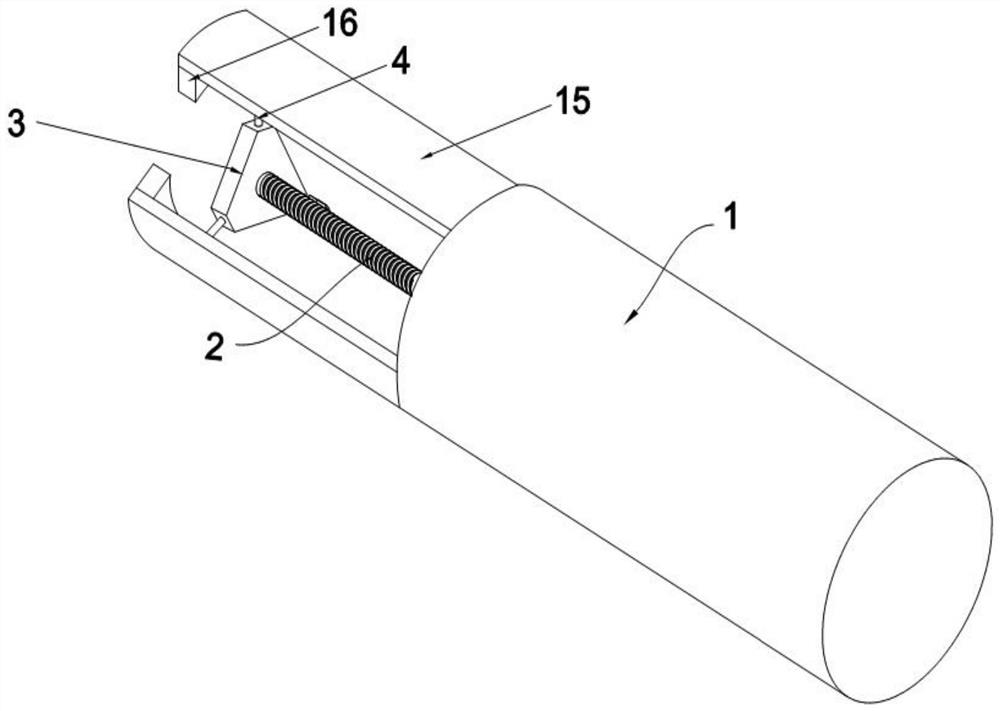

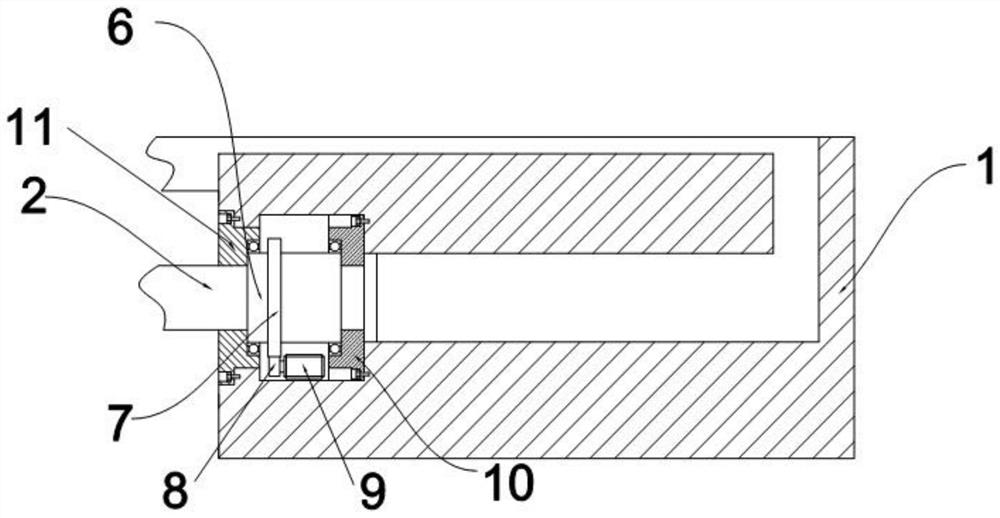

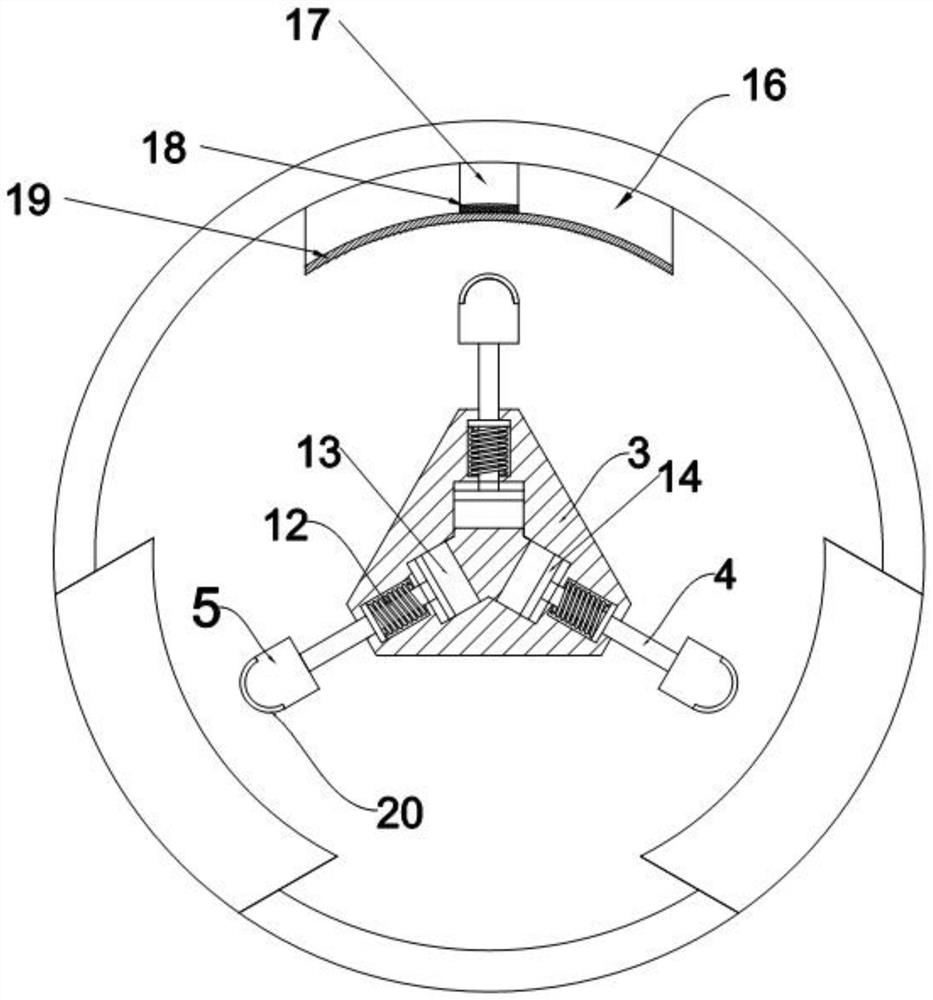

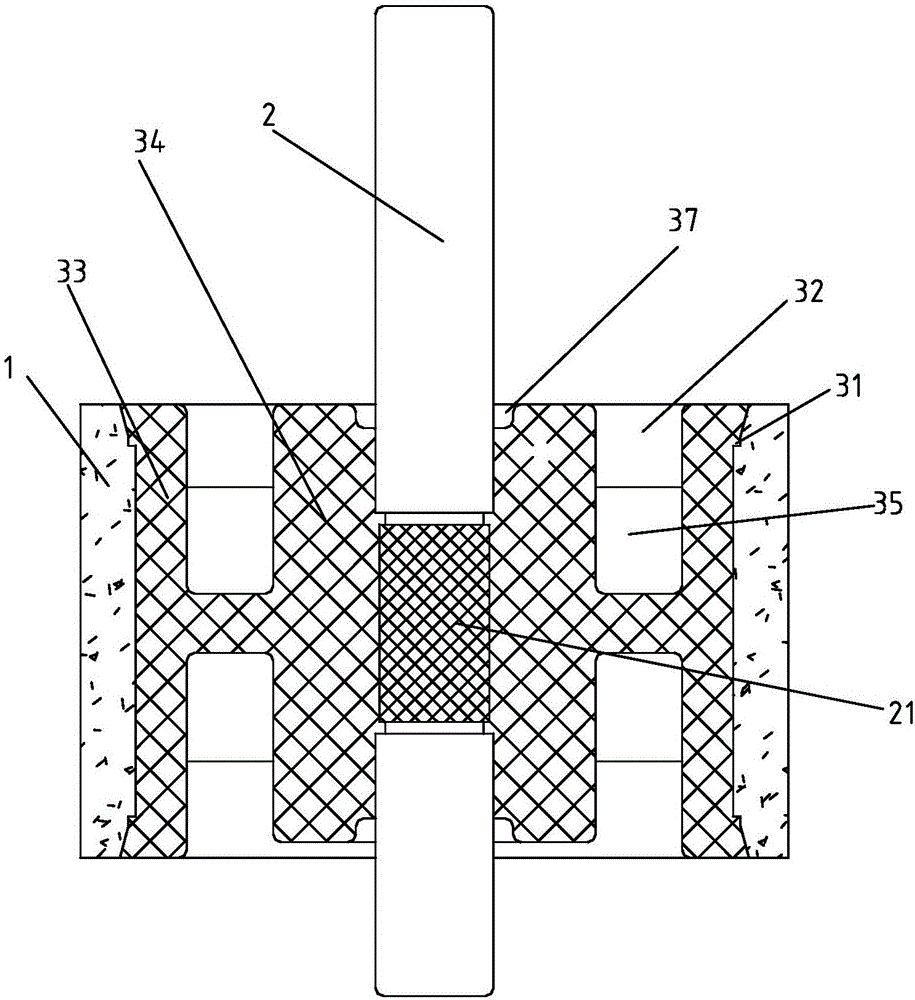

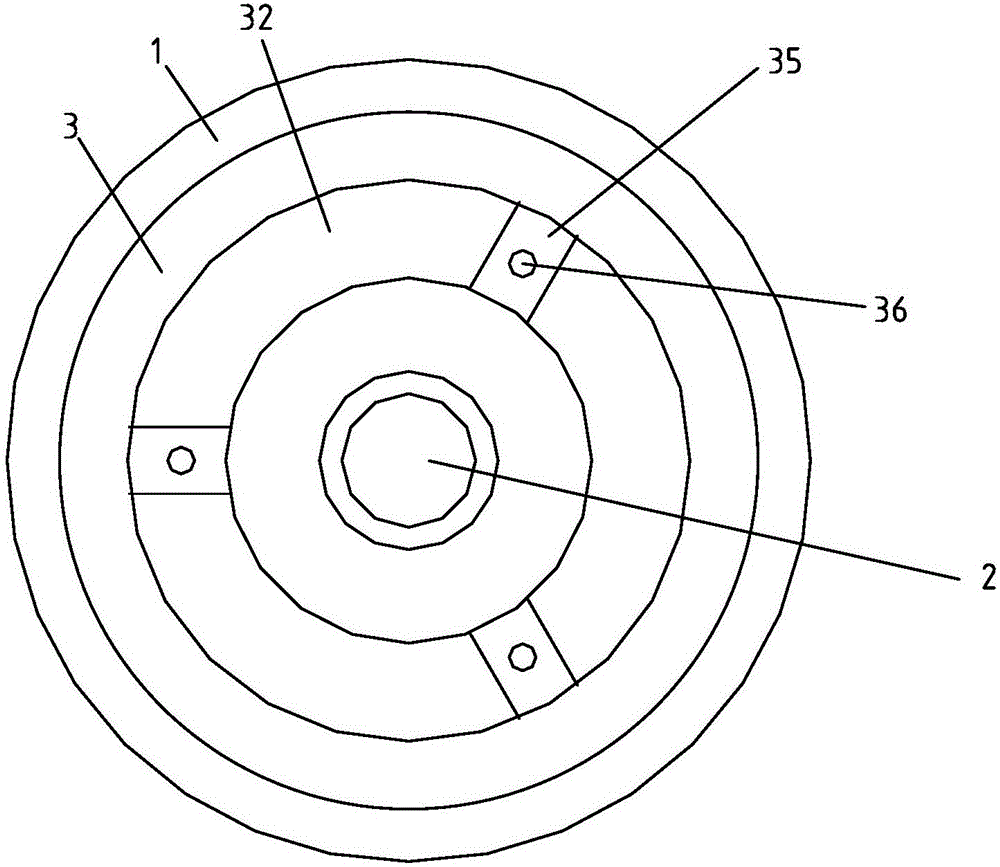

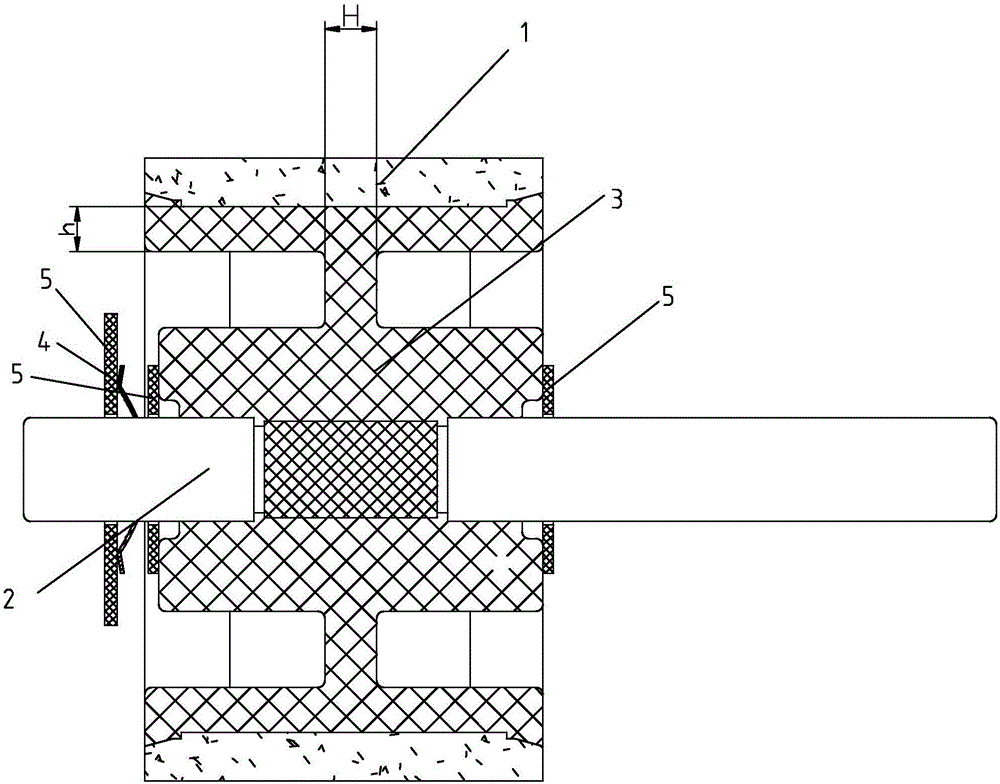

Machining and positioning method for anti-deformation thin-wall pipe fitting

ActiveCN112846851ASolve the clamping problemPracticalPositioning apparatusMetal-working holdersPipe fittingClassical mechanics

The invention discloses a machining and positioning method for an anti-deformation thin-wall pipe fitting. The inner part and the outer part of the thin-wall pipe fitting are supported when the thin-wall pipe fitting is machined, the clamping force is guaranteed through the magnetic connection of an electromagnet and a permanent magnet so that the supporting force of the permanent magnet to the inner part of the thin-wall pipe fitting is counteracted with the supporting force of an electric telescopic rod to the outer part of the thin-wall pipe fitting, coaxial clamping of the device and the thin-wall pipe fitting is achieved, deformation of the pipe fitting during machining is avoided, and the product precision and the qualified rate after machining are guaranteed.

Owner:山东华舜重工集团有限公司

PPS-rare earth permanent-magnetic granular master batch used for injection molding and preparation method of same

The invention belongs to the technical field of magnetic materials and discloses a PPS-rare earth permanent-magnetic granular master batch used for injection molding. The master batch is prepared fromraw materials including: rare earth magnetic powder, PPS powder, a reinforcing agent, a coupling agent, an antioxidant, a lubricant and the like; the invention also discloses a preparation method ofthe PPS-rare earth permanent-magnetic granular master batch used for injection molding. In the invention, a rare earth permanent-magnetic material is used as a main component, and through surface modification process, oxidization of magnetic powder is prevented, thus ensuring magnetic performance of the master batch; meanwhile, a corresponding coupling agent is added, so that binding force betweenthe magnetic powder and the binder, polyphenylene sulfide (PPS), is enhanced, and the uniformity and stability of the master batch are enhanced; a certain amount of the reinforcing agent is added tomodify the PPS, thus increasing strength of the master batch; finally, the lubricant can improve the flowability of the master batch. The PPS-rare earth permanent-magnetic granular master batch used for injection molding has high performances, high stability, high flowability and the like advantages.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

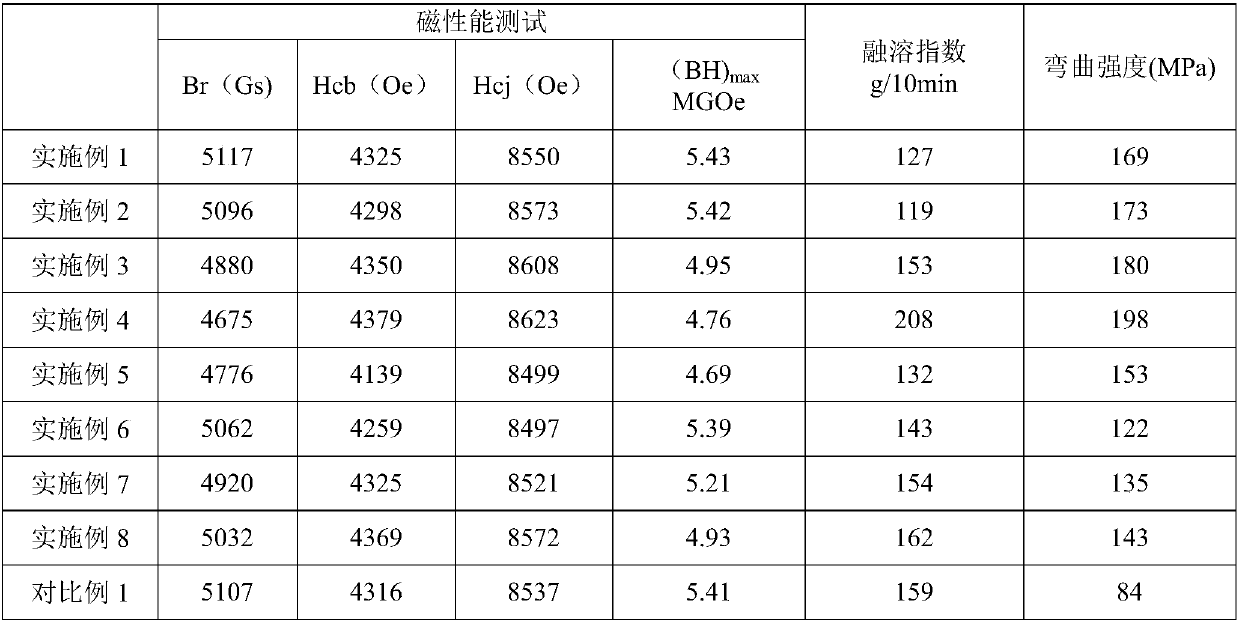

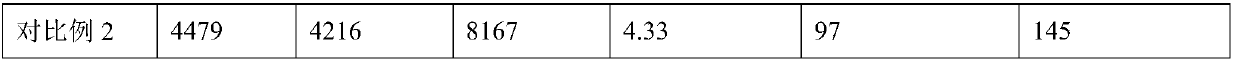

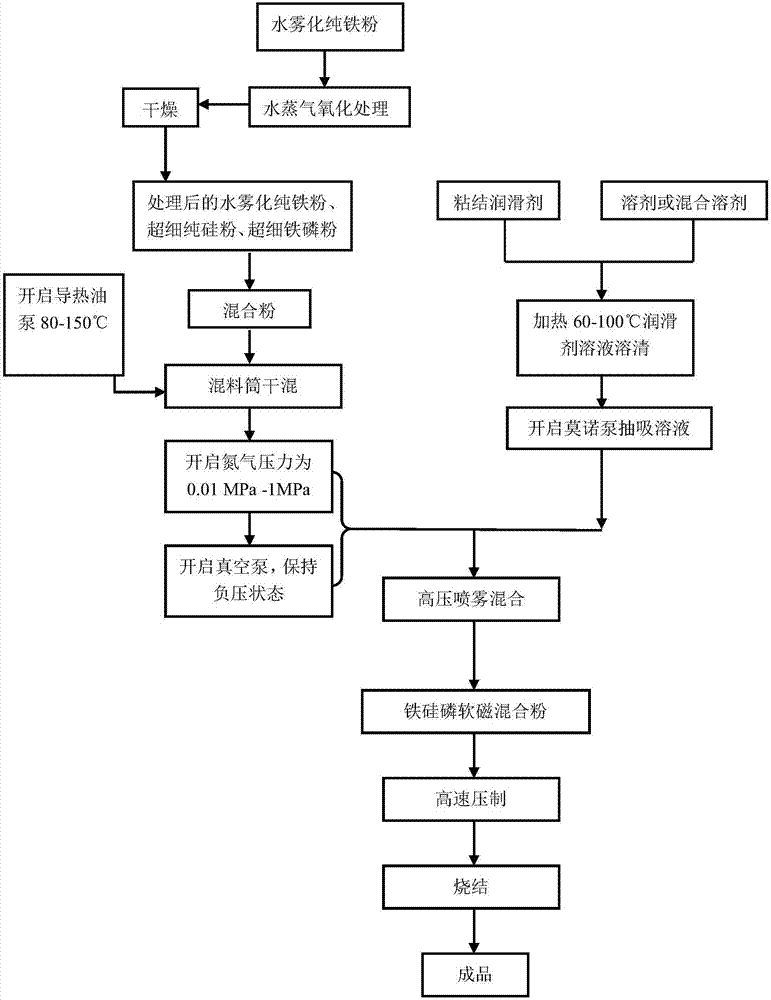

Preparation method of sintered iron powder base soft magnetic composite

ActiveCN107256752APrevent oxidationImprove permeabilityTransportation and packagingMetal-working apparatusWater vaporAlloy

The invention provides a preparation method of a sintered iron powder base soft magnetic composite, and belongs to the technical field of soft magnetic composites. The technological process includes the steps that initially, pretreatment is conducted on water atomized iron powder by means of high-temperature steam treatment, then cementation treatment is conducted by means of a double tapered spraying blender, a binder solution is atomized and evenly sprayed on materials continuously tumbling under the effect of a high-pressure gas, ultrathin pure silica powder and ultrathin iron-phosphorus alloy powder evenly adhere to the surfaces of iron powder particles, and sintered iron base powder is obtained. High-density compact is prepared by high-speed compacting through a warm mold with the mold wall lubricated, then fast sintering densification at low temperature is conducted, and finally an iron-silicon-phosphorus soft magnetic composite is obtained. The sintered iron powder base soft magnetic composite has the advantages of high magnetic permeability, low eddy-current loss and high strength, and is suitable for high-frequency application.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of non-oriented thin silicon steel strip for motor

The invention discloses a preparation method of a non-oriented thin silicon steel strip for a motor. The method is characterized in that under the guidance of a silicon steel alloying theory, the chemical compositions of silicon steel are adjusted on the basis of a large number of experiments, so as to enable alloying elements to act synergistically, enable Alpha-Gamma phase transition to occur when continuous casting plate slabs are heated and hot-rolled, promote hot-rolled tissue to be dynamically recovered and recrystallized, and eliminate coarse deformed grains (fiber-like tissue) in the middle of the strip steel; and to be matched with composition adjustment, technological parameters of hot rolling is properly controlled, so as to radically solve the problem of corrugated defects; the magnetic performance of the silicon steel can be guaranteed at the same time, and the mechanical performance of the silicon steel is improved to a certain degree; and the prepared thin silicon steel strip can be enabled to satisfy the use demand of the motor.

Owner:JIANGSU HAODA

Preparation method of MIP (molecular imprinted polymer) magnetic mesoporous silica-based microspheres

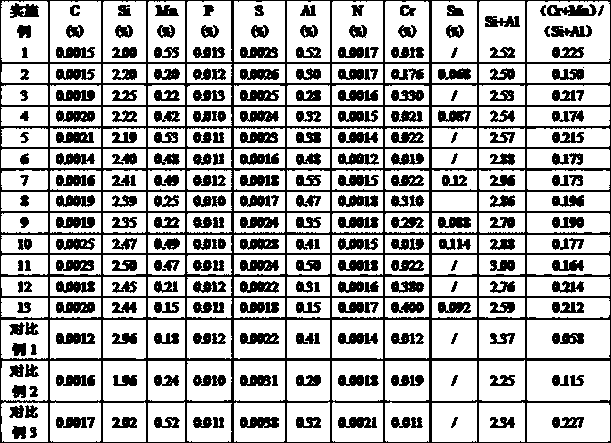

ActiveCN105754053AIncrease reaction rateLarge specific surface areaIon-exchange process apparatusOther chemical processesTetraethyl orthosilicateCitrate sodium

The invention discloses a preparation method of MIP (molecular imprinted polymer) magnetic mesoporous silica-based microspheres. According to the method, a ractopamine MIP is constructed by polymerizing surface-initiated atom transfer radicals on magnetic mesoporous silica-based microspheres, sodium citrate modified Fe3O4 magnetofluid is taken as a core, mesoporous silica spheres are prepared through hydrolysis and self-assembly of tetraethyl orthosilicate and octadecyltrimethoxysilane with long carbon chains, and the magnetic mesoporous silica-based microspheres with submicron particle size are obtained; further, the surfaces of prepared magnetic mesoporous silica-based microspheres are modified with an ATRP (atom transfer radical polymerization) initiator, then the modified magnetic mesoporous silica-based microspheres are taken as a reactor, the ractopamine MIP is generated in mesopores through adsorption, and the MIP magnetic mesoporous silica-based microspheres which can be used for separating and enriching trace substances are formed and have higher adsorption capacity and better selection for ractopamine and similar drugs of ractopamine.

Owner:GUANGDONG ENG TECH INST

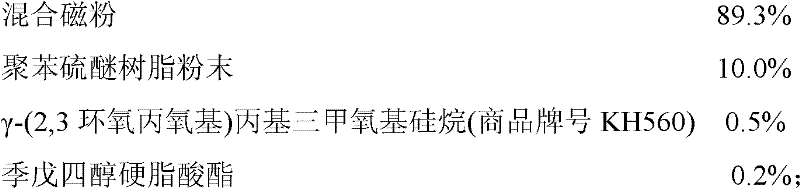

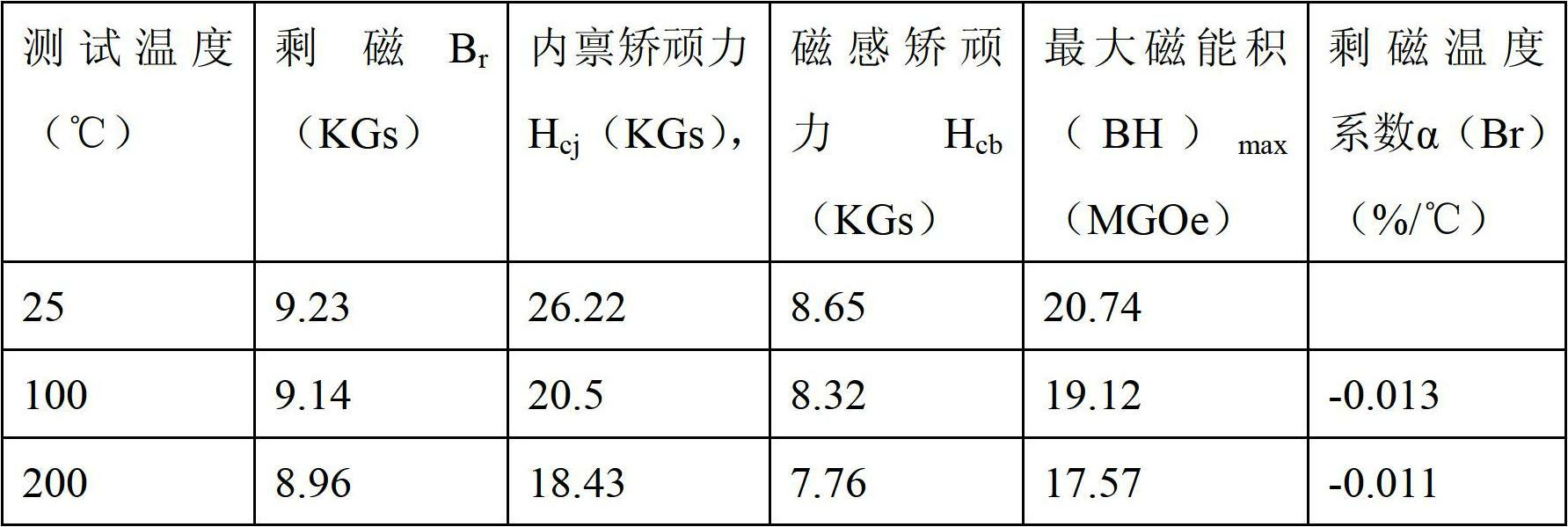

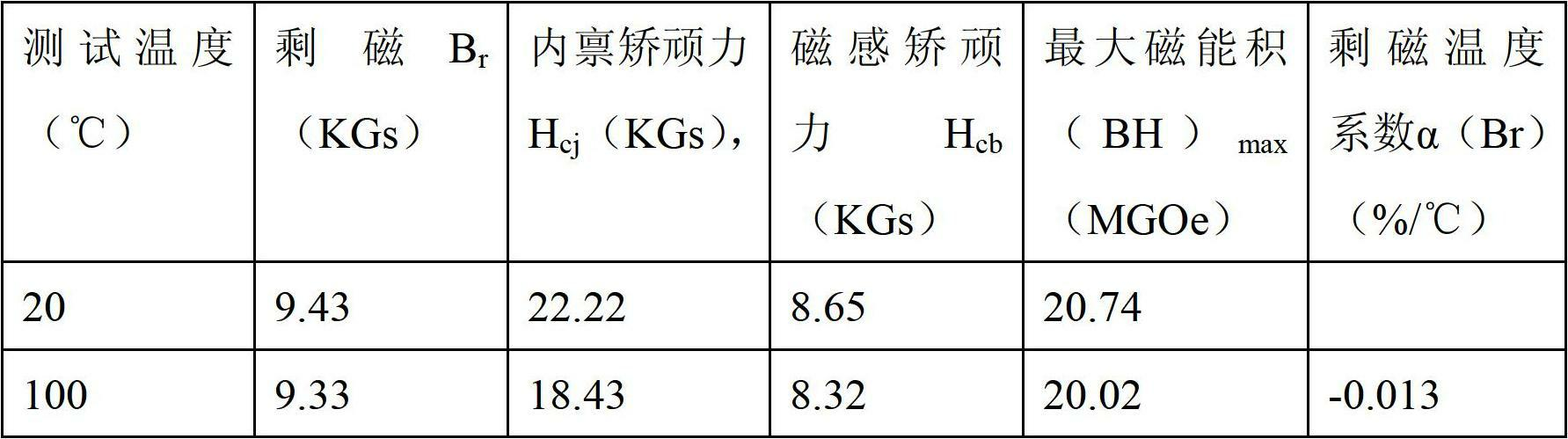

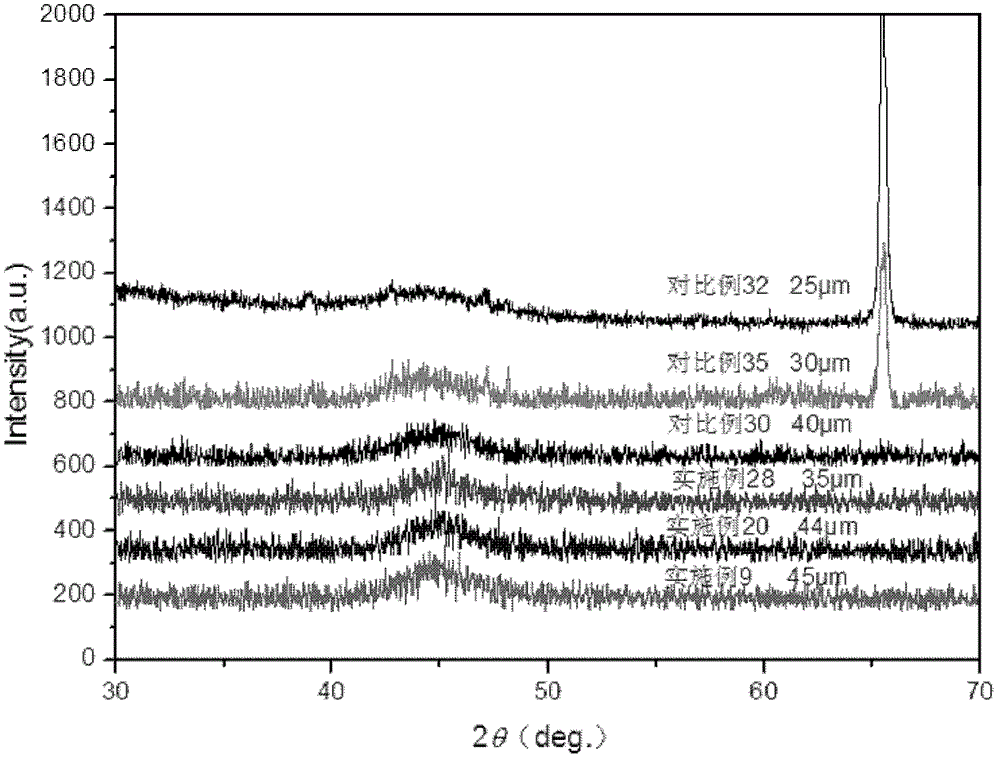

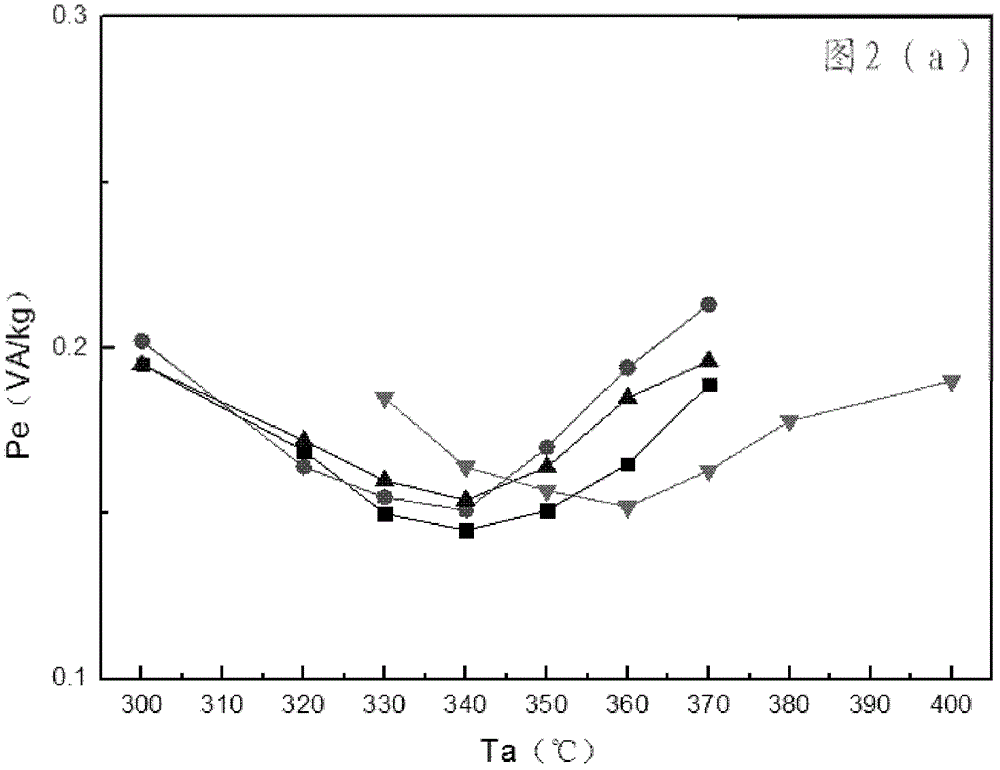

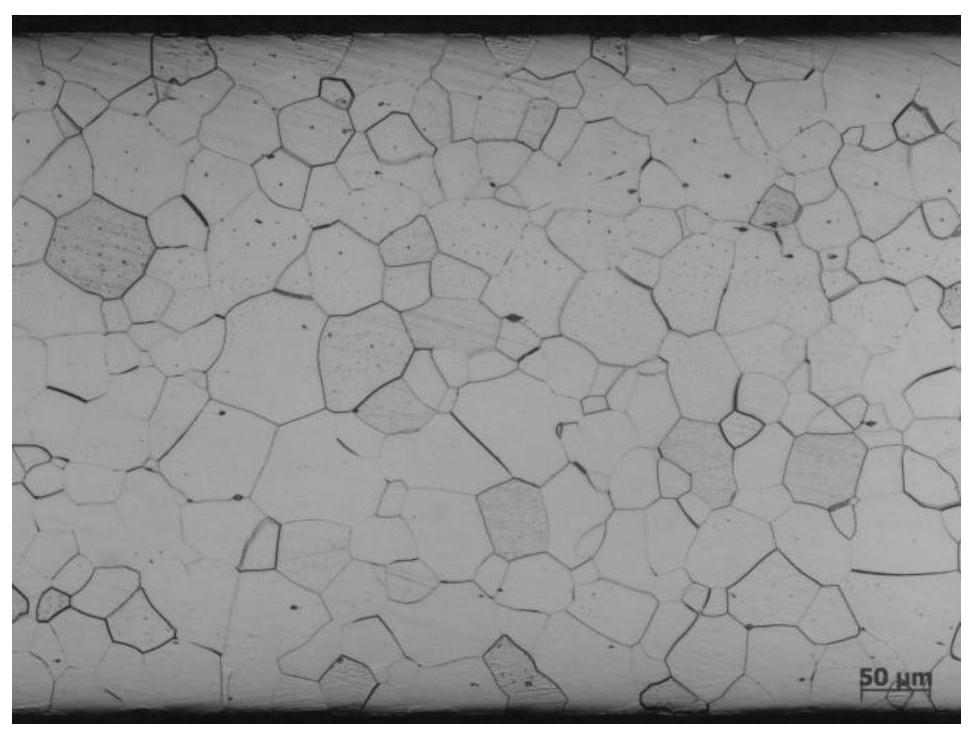

Preparation method of samarium-cobalt (SmCo) system sintered materials

ActiveCN102651263BHigh temperature coefficient of remanenceLow temperature coefficient of remanenceInductances/transformers/magnets manufactureMagnetic materialsPositive pressureAlloy

The invention relates to a preparation method of samarium-cobalt (SmCo) system sintered materials. The preparation method comprises the steps of alloy smelting, alloy cast strip preparation through rapid quenching, magnetic powder preparation through combination of a hydrogenated disproportionation method and an airflow grinding method, orientation and forming, positive pressure sintering and solid dissolving and aging treatment. The preparation method has the advantages that through the innovation of the ingot casting and powder making process, the microstructure of a magnetic body is optimized to the greatest degree, the magnetic body mainly consists of columnar crystals, the orientation is easy, and in addition, the performance of the magnetic body is stable; and in the hydrogenated disproportionation process of alloy cast sheets, hydrogen enters gap positions in SmCo crystal lattices, and the crystal lattice expansion is caused, so the pulverization is realized under the condition of ensuring the crystal particle integrity, the oxidation in the powder making process is reduced, the magnetic body with low oxygen content is obtained, and the magnetic performance of the magnetic body is ensured.

Owner:NINGBO STAR MATERIALS HI TECH

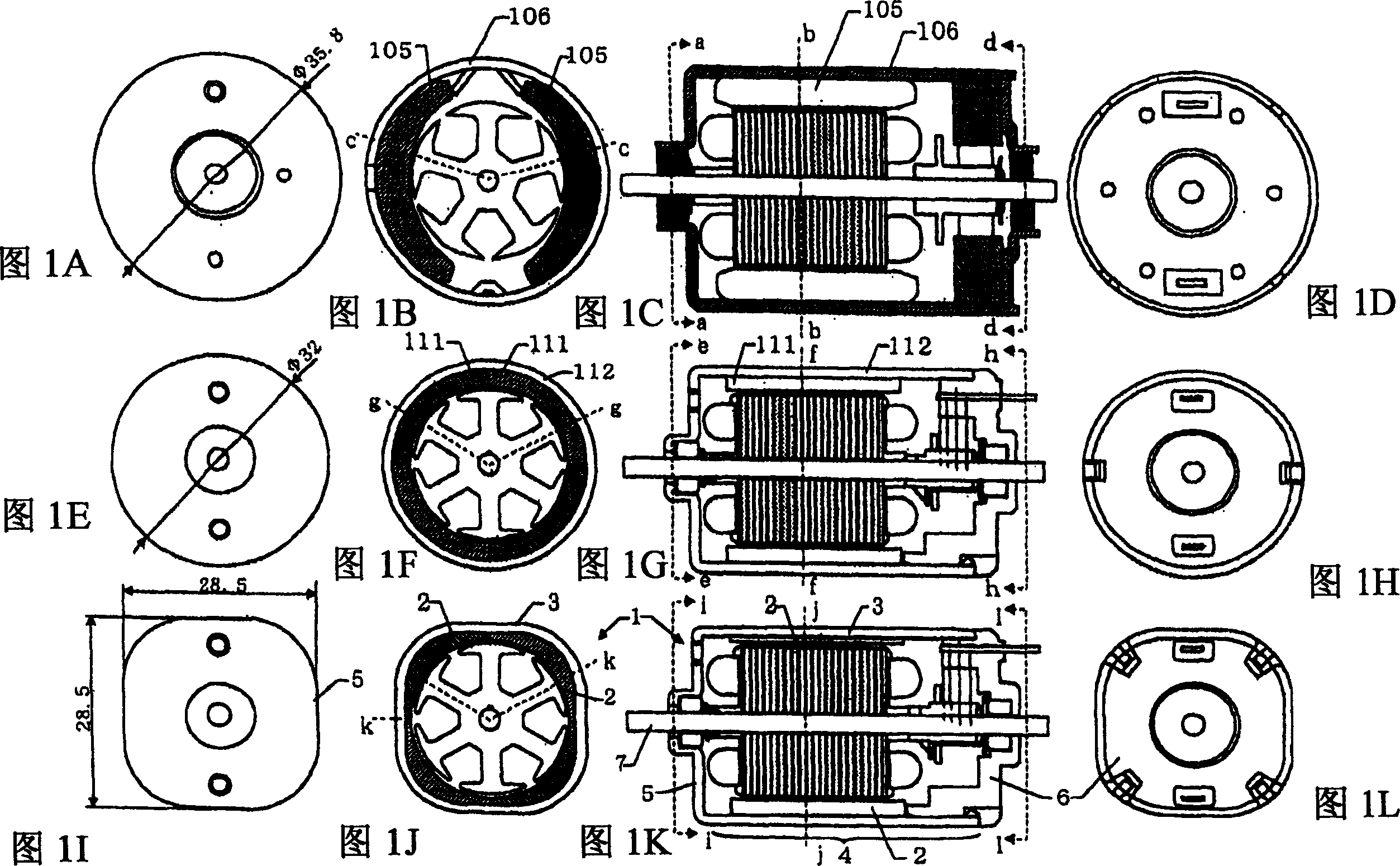

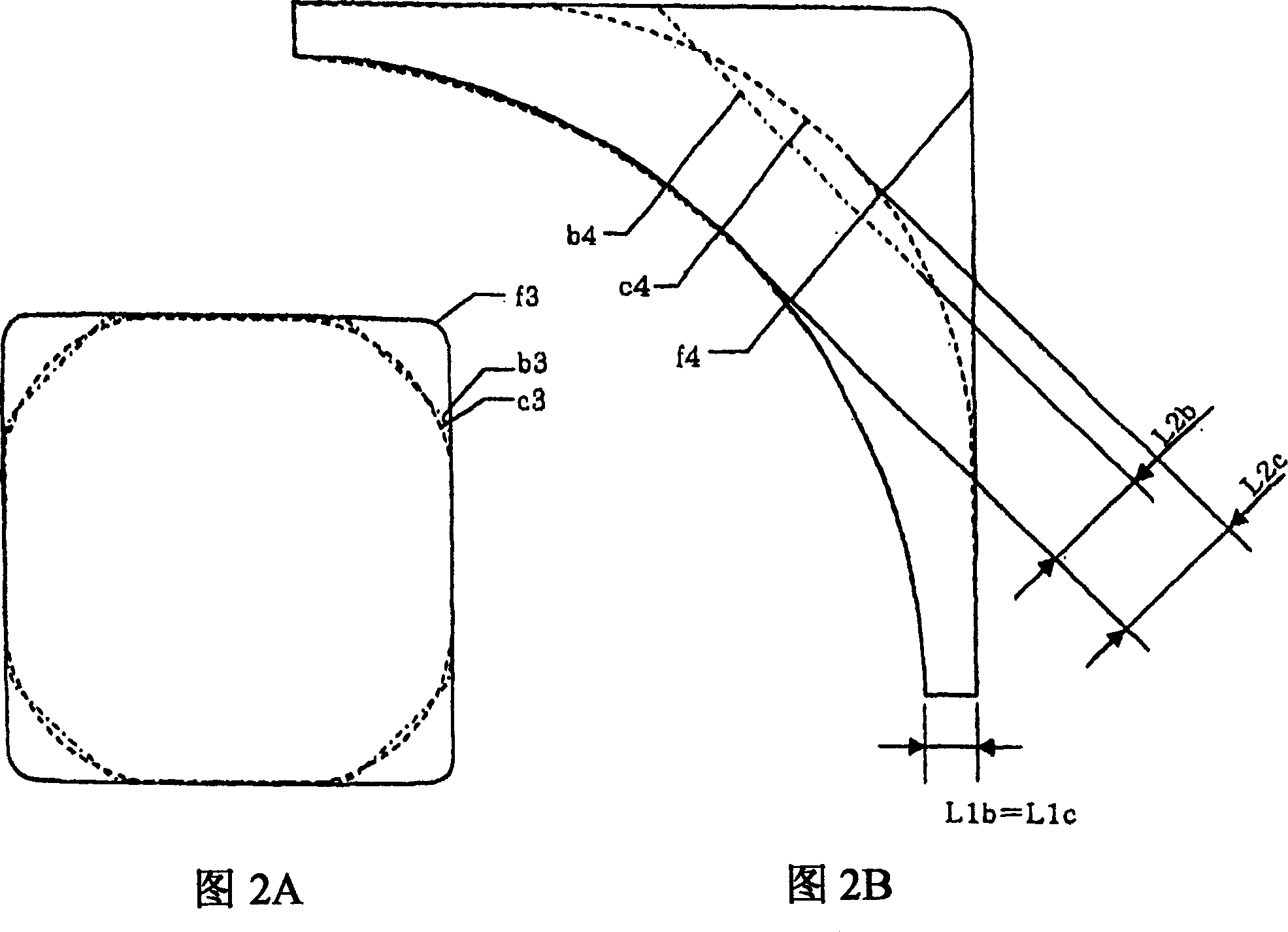

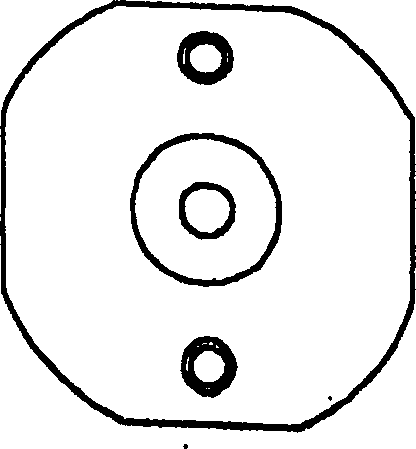

Small DC motor

ActiveCN1870398ASmall sizeGuaranteed MagneticMagnetic circuit stationary partsDC commutatorDC motorMagnet

A small DC motor includes a motor frame having a cylindrical portion, the cylindrical portion having a constant thickness and having a cross section in a shape that comprises four sides and connecting portions, each of the connecting portions connecting adjacent two of the four sides and being located inward from a corresponding corner in a quadrangle comprising the four sides; and a magnet having a circumferential surface on an inside thereof and having conformable contact with the motor frame on an outside thereof.

Owner:MINEBEA MOTOR MFG

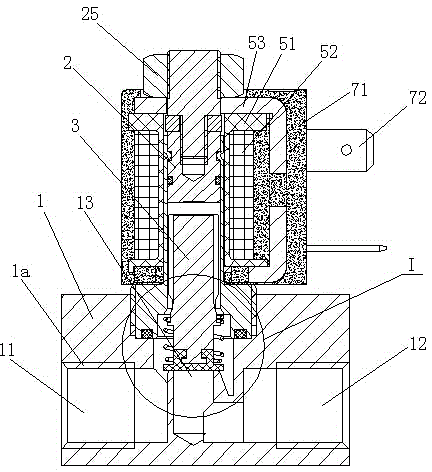

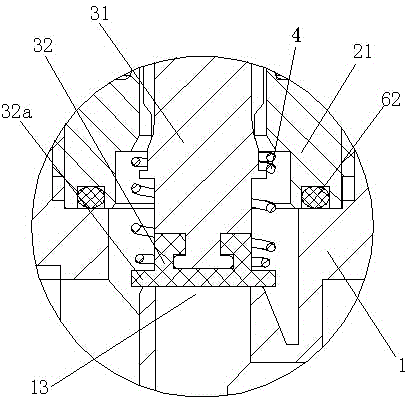

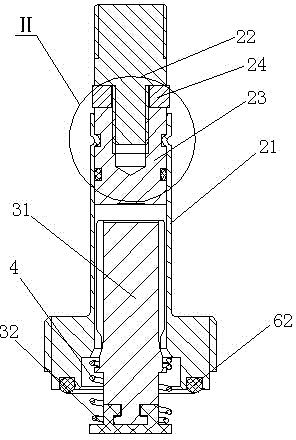

Self-holding electromagnetic valve

ActiveCN104653845AReduce manufacturing costImprove stabilityOperating means/releasing devices for valvesLift valveEngineeringNon magnetic

The invention discloses a self-holding electromagnetic valve, which comprises a valve body, wherein an inlet and an outlet are formed in the valve body, a fixed iron core assembly is assembled at the upper part of the valve body, the fixed iron core assembly consists of a sleeve, a first fixed iron core, a second fixed iron core and a permanent magnet, the center of the sleeve is vertically provided with an open hole, the first fixed iron core is made of non-magnetic-conduction stainless steel materials, the second fixed iron core is made of soft magnetic materials, the permanent magnet is arranged between the first fixed iron core and the second fixed iron core, the second fixed iron core is fixedly arranged at the upper end of the sleeve, the first fixed iron core is fixedly arranged on the second fixed iron core, a movable iron core assembly is arranged in the sleeve of the fixed iron core assembly, the lower end of the movable iron core assembly is matched with a valve opening formed in the valve body, a spring is arranged outside the lower part of the movable iron core assembly in a sleeving way, the upper end of the spring is abutted against the fixed iron core assembly, the lower end of the spring is abutted against the movable iron core assembly, a reel is arranged outside the fixed iron core assembly, and a winding and a coil magnetic conduction frame are arranged on the reel. The self-holding electromagnetic valve has the advantages that the structure is simple, the manufacturing cost is low, and the self-holding state is stable.

Owner:XINGYU ELECTRON NINGBO CO LTD

High-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and preparation method thereof

InactiveCN102832006ALow coercivityHigh saturation magnetic inductionMagnetic materialsCobaltNickel based

The invention provides a high-effective-magnetic-permeability cobalt-nickel based microcrystalline magnetic material and a preparation method thereof. The material reduces the cobalt content under the condition of guaranteeing better soft magnetic properties. The preparation method is simple in process, low in production cost and suitable for industrial production. The material comprises the following components in percentage by weight: 18-22% of Fe, 30-35% of Ni, 4-7% of Gd, 0.01-0.05% of Ho, 0.1-0.5% of V, 0.01-0.05% of Ru, 6-9% of Al, 1-3% of P1, and the balance of Co.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Magnetic rubber material and preparation method thereof

The invention discloses a magnetic rubber material. The magnetic rubber material is characterized by comprising the following components in parts by weight: 60-80 parts of standard rubber, 25-35 parts of chloroprene rubber, 20-30 parts of carbon black, 15-25 parts of dibutyl ester, 3-7 parts of zinc oxide, 1-5 parts of magnesium oxide, 40-50 parts of nickel zinc ferrite, 1.5-2.5 parts of stearic acid, 0.3-0.7 part of accelerant M, 0.5-1.5 parts of accelerant DM, 0.3-0.7 part of accelerant NA, 0.03-0.07 part of accelerant TT, 0.4-0.8 part of anti-aging agent 4010, 0.4-0.8 part of anti-aging agent RD and 1.4-1.8 parts of sulphur. The magnetic rubber material has the advantages that mixing and vulcanization steps are adopted, so that plasticity of the magnetic rubber material can be effectively improved, and the plasticity of the magnetic rubber material is more than 0.55; the magnetic rubber material is sulphurized after being magnetized, so that magnetic property of the magnetic rubber material can be permanently maintained.

Owner:NANJING DONGYA RUBBER & PLASTICS

Production method of non-oriented silicon steel and non-oriented silicon steel

ActiveCN112143974AStrong magnetismMeet the needs of low-grade non-oriented silicon steelManufacturing convertersInorganic material magnetismChemical compositionContinuous rolling

The invention discloses non-oriented silicon steel and a production method thereof. The non-oriented silicon steel is prepared by molten iron sulfur removal, converter smelting, RH refining, continuous casting, hot rolling, acid continuous rolling, annealing, coating and finishing, and comprises the following chemical components in percentage by mass: less than or equal to 0.003% of C, less than or equal to 0.008% of S, 0.35%+delta1 of Si, 0.15-0.25% of Mn, 0.04-0.06% of P, 0.015%+delta 2 of Sn, less than or equal to 0.004% of Nb, less than or equal to 0.004% of V, less than or equal to 0.005%of Ti, less than or equal to 0.004% of Mo, less than or equal to 0.03% of Cr, less than or equal to 0.03% of Ni, less than or equal to 0.03% of Cu, less than or equal to 0.003% of N and the balance of Fe and inevitable inclusions. When the thickness of the non-oriented silicon steel is 0.5 mm, P1.5 / 50 is less than or equal to 5.5 W / kg, B5000 is larger than or equal to 1.75, and sulfur removal treatment is not needed in RH refining.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

High tenacity magnetic materials and preparation method of the same

ActiveCN103093915AReduce stray magnetic fieldReduce irreversible loss of magnetic fluxMagnetic materialsManufactured materialHafnium

The invention discloses high tenacity magnetic materials and a preparation method of the high tenacity magnetic materials. The component percentages of the high tenacity magnetic materials comprise, by weight, 28-38% of neodymium (Nd), 2.8-3.8% of praseodymium (Pr), 1-4% of boron (B), 0.09-0.198% of tantalum (Ta), 0.08-0.176 % of hafnium (Hf), 0.02-0.044 % of wolfram (W) and 0.028-0.038% of scandium (Sc), and the rest is ferrum (Fe). The high tenacity magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance. The preparation method fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

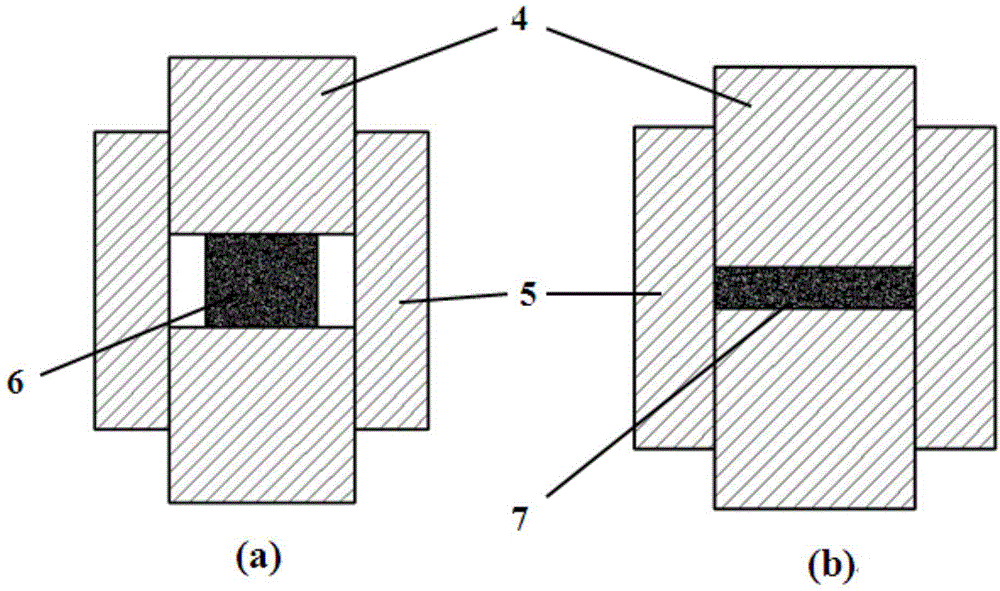

Integrated injection molding rotor and stepping motor applied to automatic control

InactiveCN106208610APrevent looseningImprove manufacturing precisionMechanical energy handlingSupports/enclosures/casingsAutomatic controlEngineering

The invention discloses an integrated injection molding rotor and a stepping motor applied to automatic control. The integrated injection molding rotor comprises a magnet ring, a rotating shaft, an injection molding body arranged between the magnet ring and the rotating shaft to facilitate that the injection molding body makes the rotating shaft and the magnet ring into a whole. The rotating shaft and the magnet ring are made into the whole through injection molding, the rotor manufacturing precision is greatly improved by arranging a speed-reducing grooved cavity and a special gate position, the machining process is simple, the made rotor assembly is small in coaxiality error, stable in quality and high in reliability, the positioning accuracy of the BY series stepping motor is remarkably improved, product noise is reduced, torque pulsations are decreased, the motor efficiency is improved, and the BY series stepping motor can be widely applied in special working and medical treatment automation equipment driving occasions having higher requirements and the field of automatic control.

Owner:CHANGZHOU CHENGLI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com