Preparation method of magnetic nitrogen-doped carbon materials

A nitrogen-doped carbon and magnetic technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as the difficulty of controlling the amount of nitrogen doping, achieve low cost, mild reaction conditions, and ensure magnetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

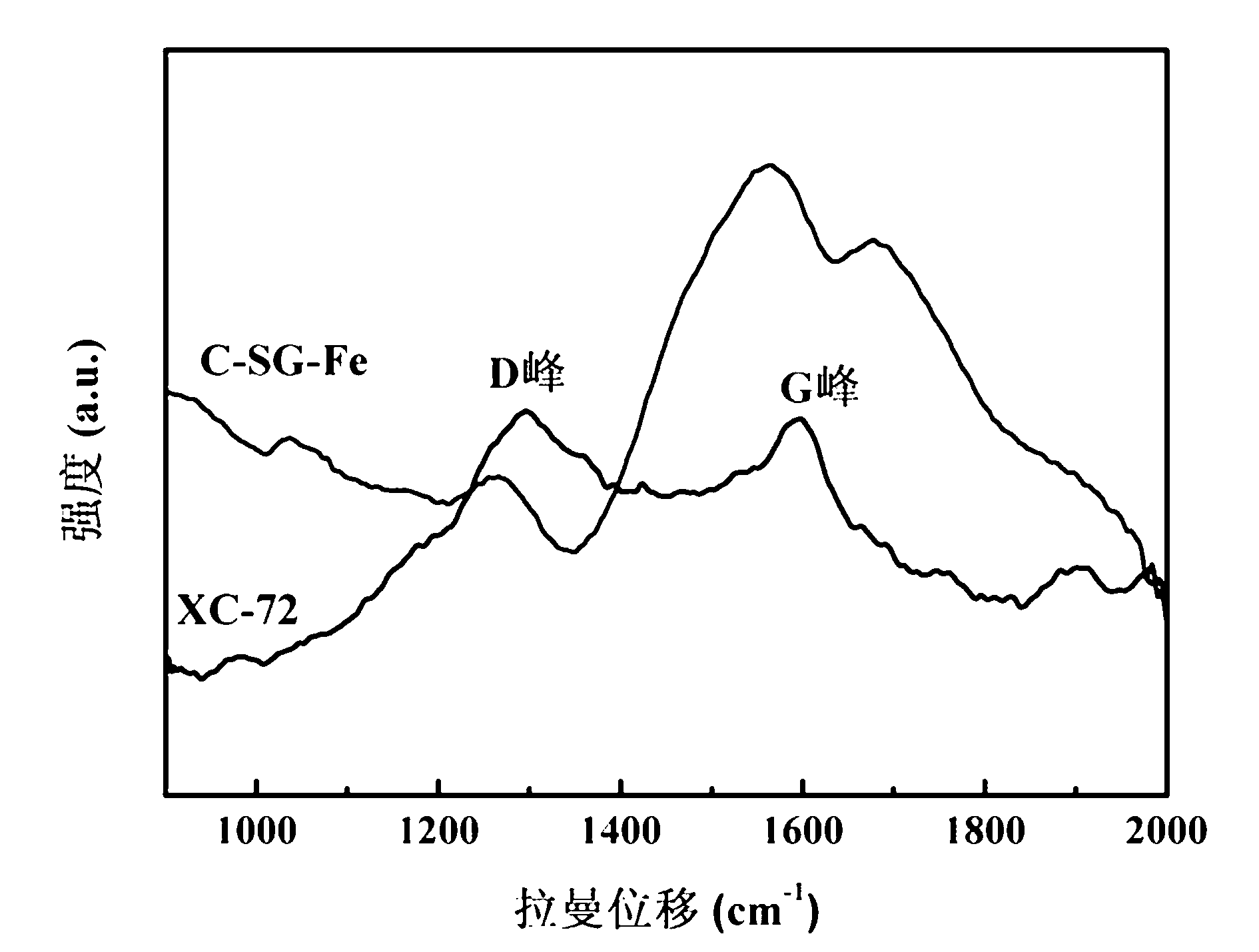

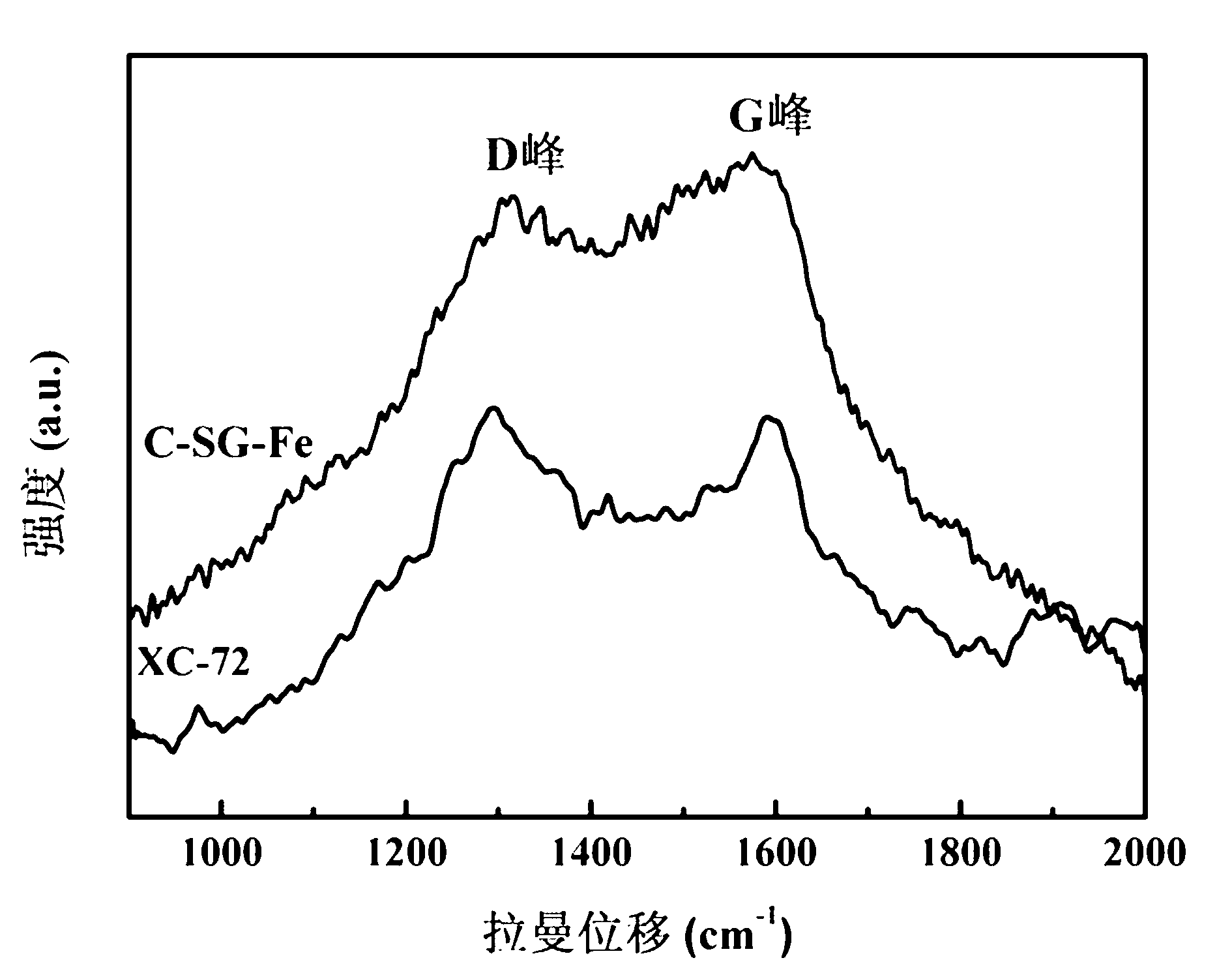

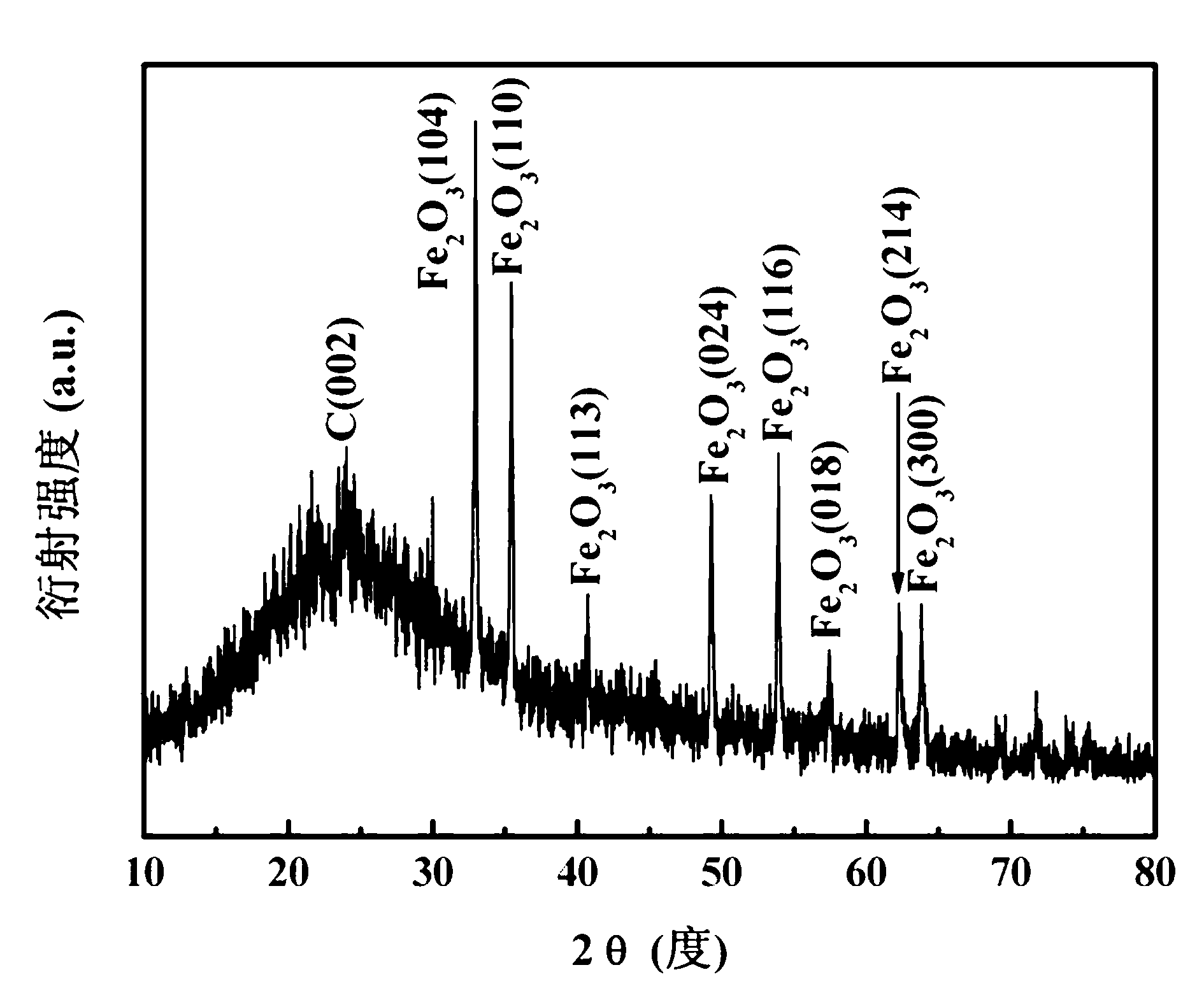

Embodiment 1

[0027] (1) Mix absolute ethanol and deionized water at a volume ratio of 1:1 to form a mixed solvent of 40mL, and adjust the pH of the solution to 2 with concentrated hydrochloric acid;

[0028] (2) 0.60g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 1.50 g of sucrose were added to the mixed solvent in turn, and stirred for 20 minutes;

[0029] (3) Add 0.033g glycine to the mixed solvent and stir for 0.5 hours;

[0030] (4) Put the mixed system in a blast oven, evaporate the solvent at 60°C, and then carbonize at 80°C for 40 hours to obtain a carbonized product;

[0031] (5) After the primary carbonization product is ground, it is placed in a blast oven and carbonized at 200°C for 4 hours to obtain a magnetic nitrogen-doped carbon material. The nitrogen content of the nitrogen-doped carbon material is 0.93%.

Embodiment 2

[0033] (1) Mix absolute ethanol and deionized water at a volume ratio of 1:1.5 to form a mixed solvent of 40mL, and adjust the pH of the solution to 1 with concentrated hydrochloric acid;

[0034] (2) 0.60g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 1.20 g of glucose were added to the mixed solvent in turn, and stirred for 20 minutes;

[0035] (3) Add 0.062g glycine to the mixed solvent and stir for 0.5 hours;

[0036] (4) Put the mixed system in a blast oven, evaporate the solvent at 70°C, and then carbonize at 60°C for 40 hours to obtain a carbonized product;

[0037] (5) After the primary carbonization product is ground, it is placed in a blast oven and carbonized at 190°C for 6 hours to obtain a magnetic nitrogen-doped carbon material. The nitrogen content of the nitrogen-doped carbon material was 2.1%.

Embodiment 3

[0039] (1) Mix absolute ethanol and deionized water at a volume ratio of 1:2 to form a mixed solvent of 40mL, and adjust the pH of the solution to 2 with concentrated hydrochloric acid;

[0040] (2) 0.60g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 1.80g cornstarch were added to the mixed solvent in turn, and stirred for 20 minutes;

[0041] (3) Add 0.167g glycine to the mixed solvent and stir for 0.5 hours;

[0042] (4) Put the mixed system in a blast oven, evaporate the solvent at 65°C, and then carbonize at 80°C for 48 hours to obtain a carbonized product;

[0043] (5) After the primary carbonization product is ground, it is placed in a blast oven and carbonized at 190°C for 6 hours to obtain a magnetic nitrogen-doped carbon material. The nitrogen content of the nitrogen-doped carbon material was 3.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com