Production method of non-oriented silicon steel and non-oriented silicon steel

A technology of oriented silicon steel and a production method, applied in the direction of manufacturing converters, etc., can solve the problem of high production cost, and achieve the effects of low production cost, reduced difficulty and reduced requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

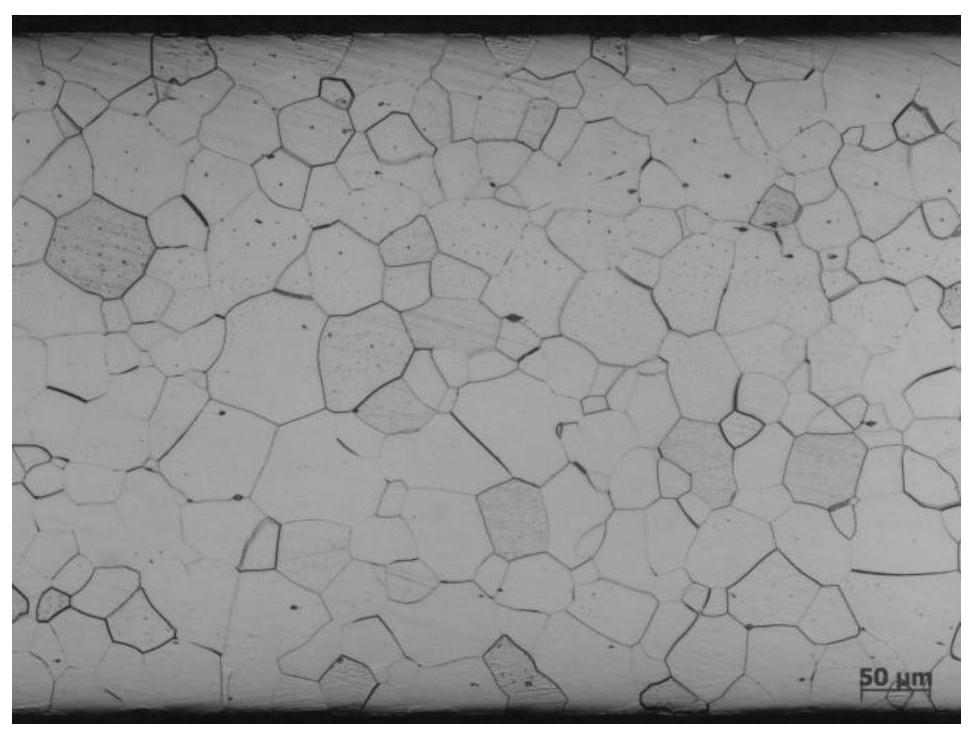

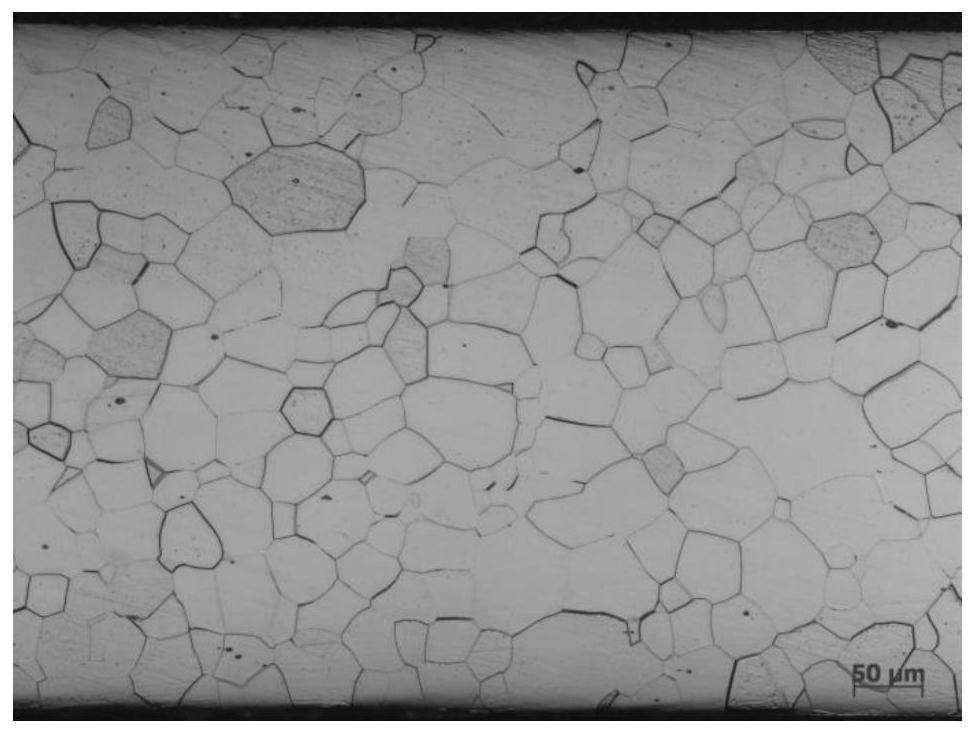

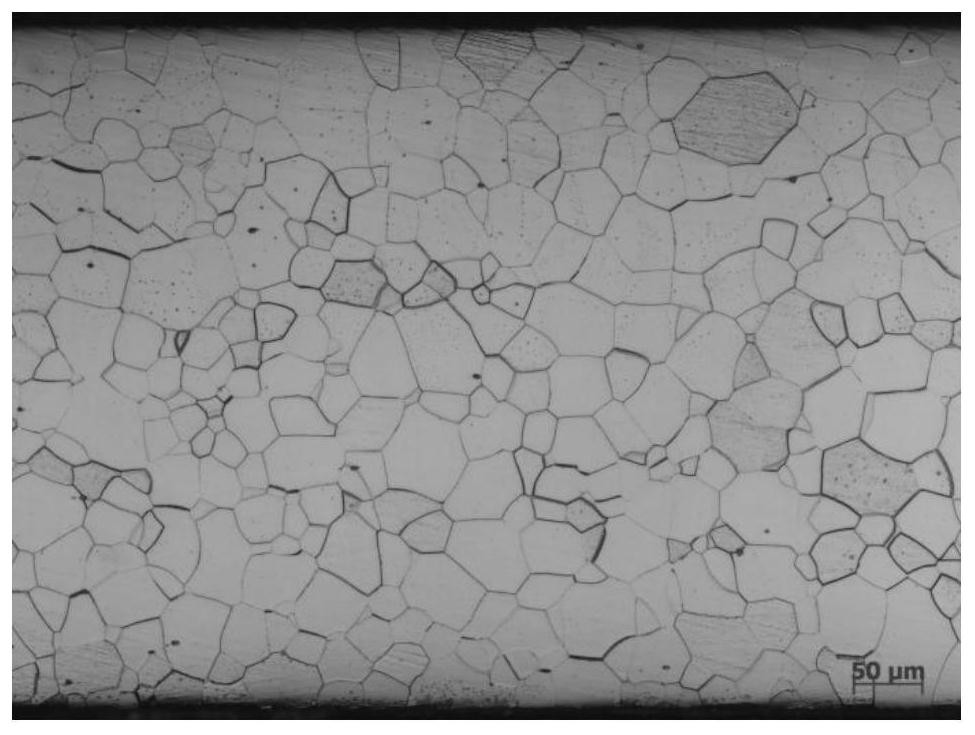

Image

Examples

Embodiment 1-4 and comparative example 1

[0126] Examples 1-4 and Comparative Example 1, the converter smelting steps are: the tapping in the aforementioned molten iron desulfurization step (that is, the molten iron after desulfurization) is moved into the converter, and clean scrap steel is mixed in the converter, and the addition of scrap steel accounts for 20-25% of the sum of steel scrap and molten iron. After desulfurization, the molten iron and steel scrap are smelted into molten steel in the converter; during the tapping process, lime is added first, and then the final product contains Sn: 0.015% into the tapping molten steel Add enough tin ingots; after tapping, add slag surface deoxidizer to molten steel.

[0127] (3) RH refining process

Embodiment 1

[0130] In embodiment 1, as shown in Table 1, S≤0.0030% when the molten steel reaches RH refining, add super Low-titanium ferrosilicon, low-titanium ferrophosphorus and metal manganese, the mass percentage of the actual chemical composition of the RH refining steel is shown in Table 1;

Embodiment 2

[0131] In Example 2, as shown in Table 1, when the molten steel reaches RH refining, 0.0030%<S≤0.0045%, according to Si:0.40% in the final product, Sn:0.020%, P:0.04~0.06%, Mn:0.15~ Add ultra-low titanium ferrosilicon, tin ingot, low titanium phosphorus ferrophosphorus and metal manganese to molten steel at 0.25%, and the mass percentage of the actual chemical composition of the steel produced by RH refining is shown in Table 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com