Patents

Literature

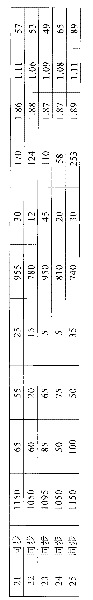

42results about How to "Prevent transverse cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

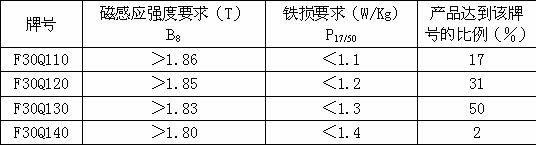

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

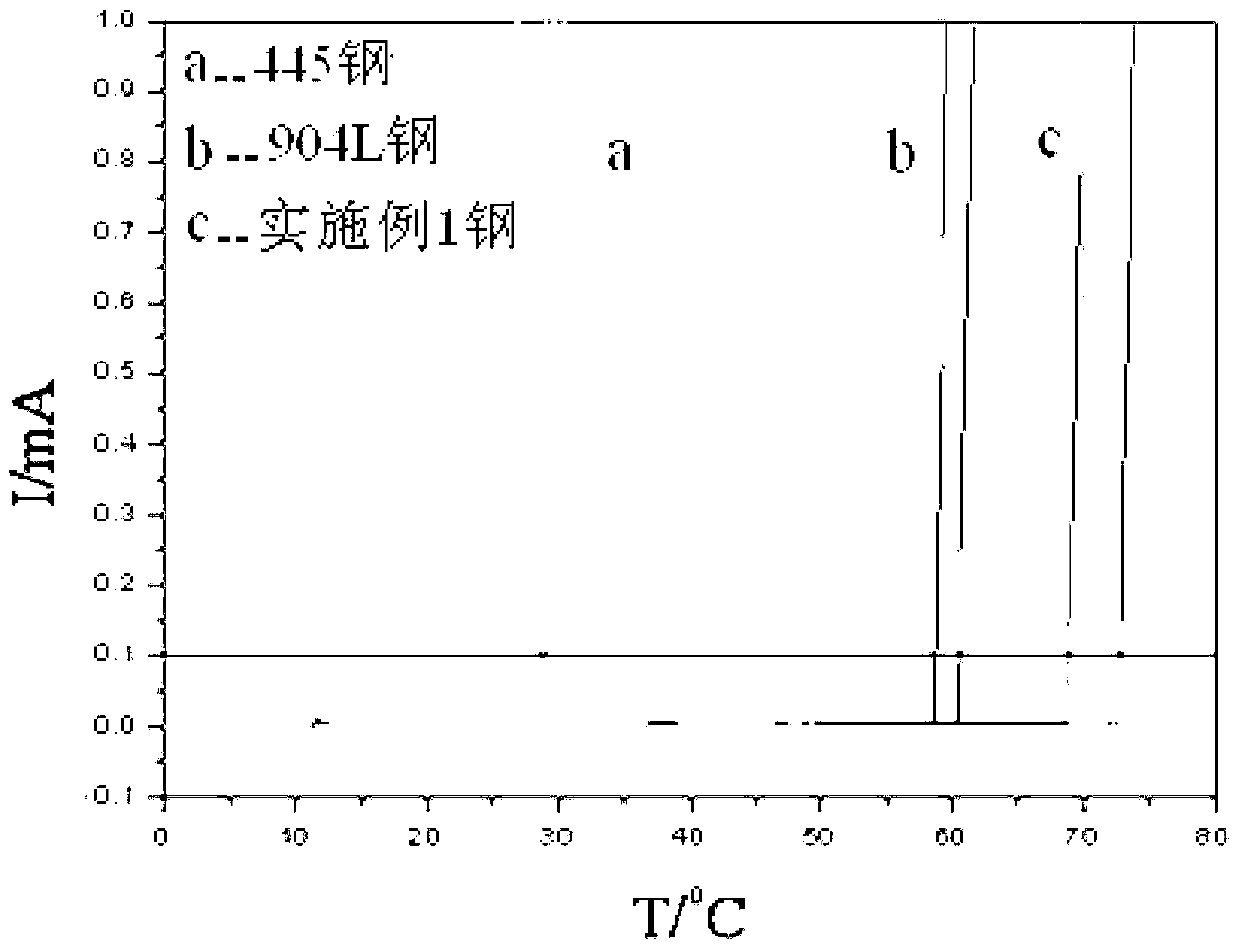

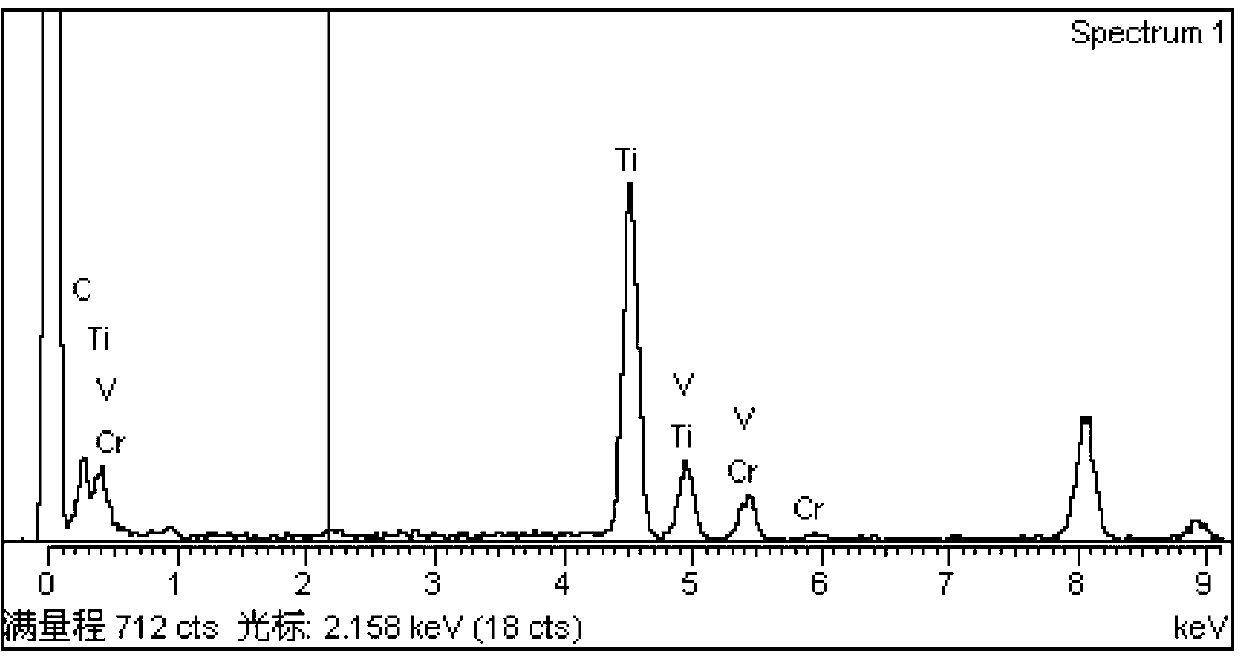

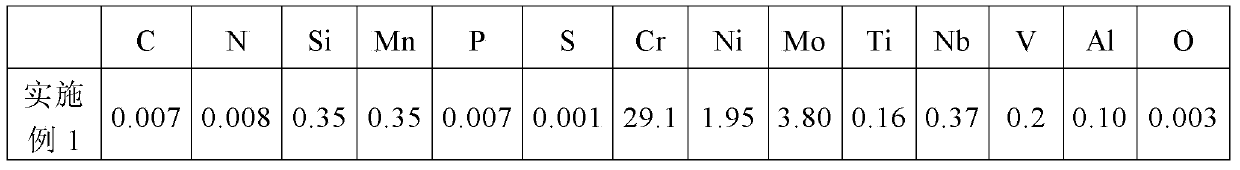

High-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and manufacturing method thereof

ActiveCN103276307AImprove corrosion resistanceImprove low temperature toughnessTransition temperatureImpurity

The invention discloses a high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate and a manufacturing method thereof. The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate comprises, by weight, 0.005 to 0.015% of C, 0.005 to 0.020% of N, 0.2 to 0.5% of Si, 0.2 to 0.5% of Mn, less than or equal to 0.035% of P, less than or equal to 0.010% of S, 25 to 28% of Cr, less than or equal to 4.0% of Ni, 2.0 to 4.0% of Mo, 0.1 to 0.3% of V, 0.10 to 0.30% of Ti, 0.2 to 0.4% of Nb, less than or equal to 0.005% of Al, less than or equal to 0.005% of O, and the balance Fe and unavoidable impurities, wherein based on Cr content, Mo content, Ti content, Nb content, C content and N content respectively represented by Cr, Mo, Ti, Nb, C and N, Cr+3.3*Mo is greater than or equal to 35% and Ti+Nb is greater than or equal to 16(C+N). The high-corrosion resistance high-toughness high-chromium ferrite stainless steel plate has a ductile-brittle transition temperature below -40 DEG C, pitting potential above 1000mv, a critical pitting temperature above 70 DEG C, a corrosion rate below 0.2g / m<2>h in boiling hydrochloric acid having a concentration of 1wt%, yield strength above 380MPa, tensile strength above 520MPa, an elongation rate A50mm above 25% and Vickers hardness of 180 to 220, and can be used in various harsh environments.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

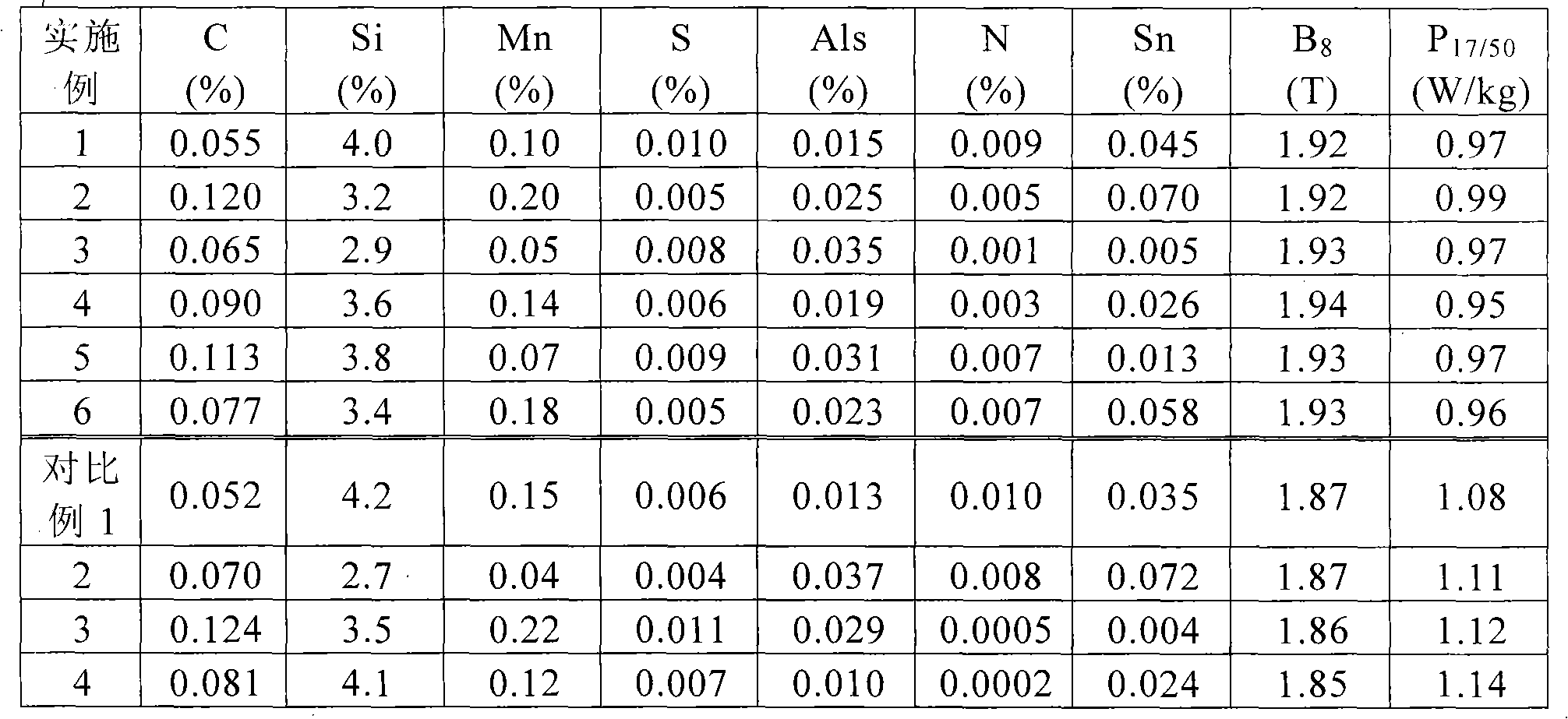

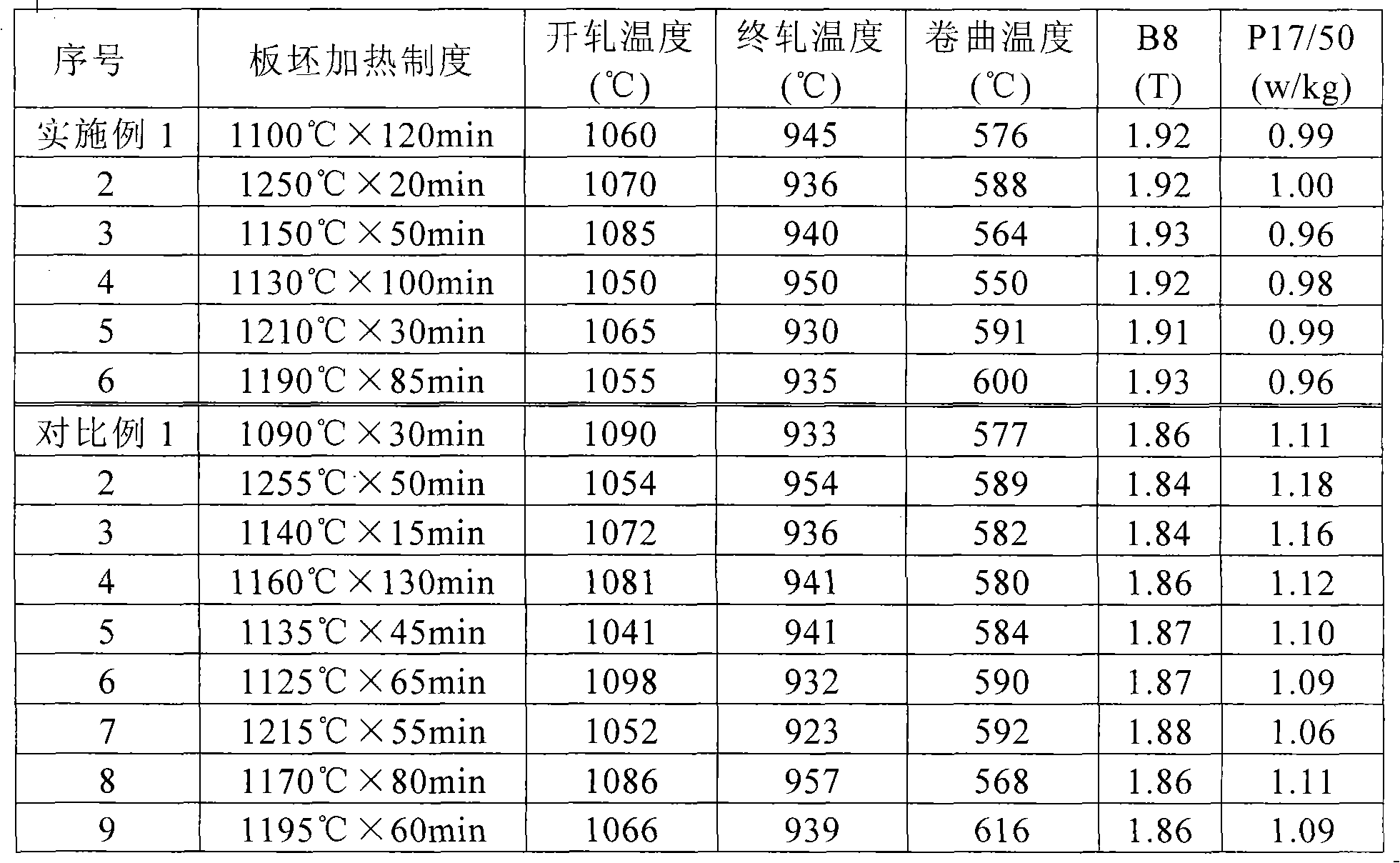

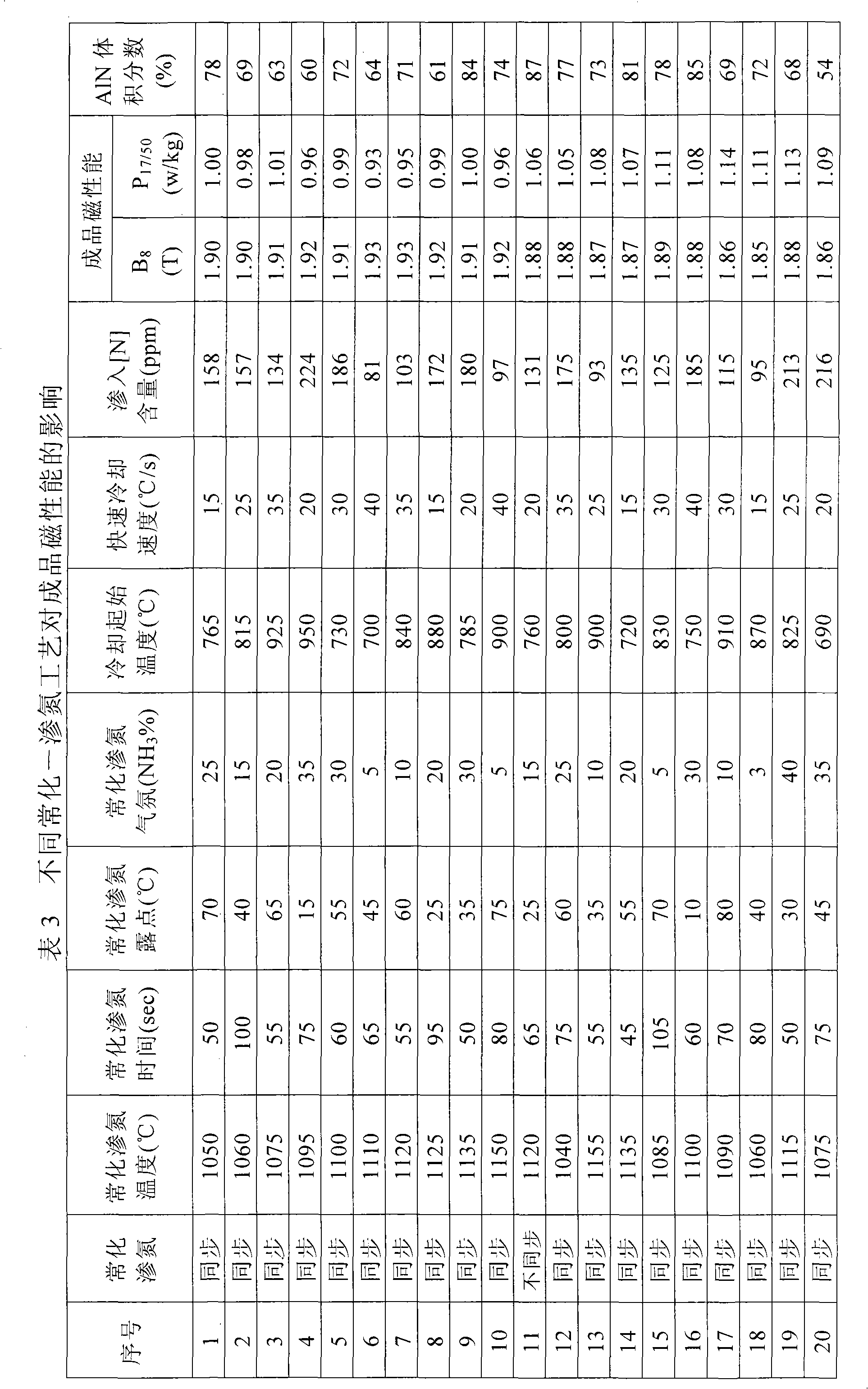

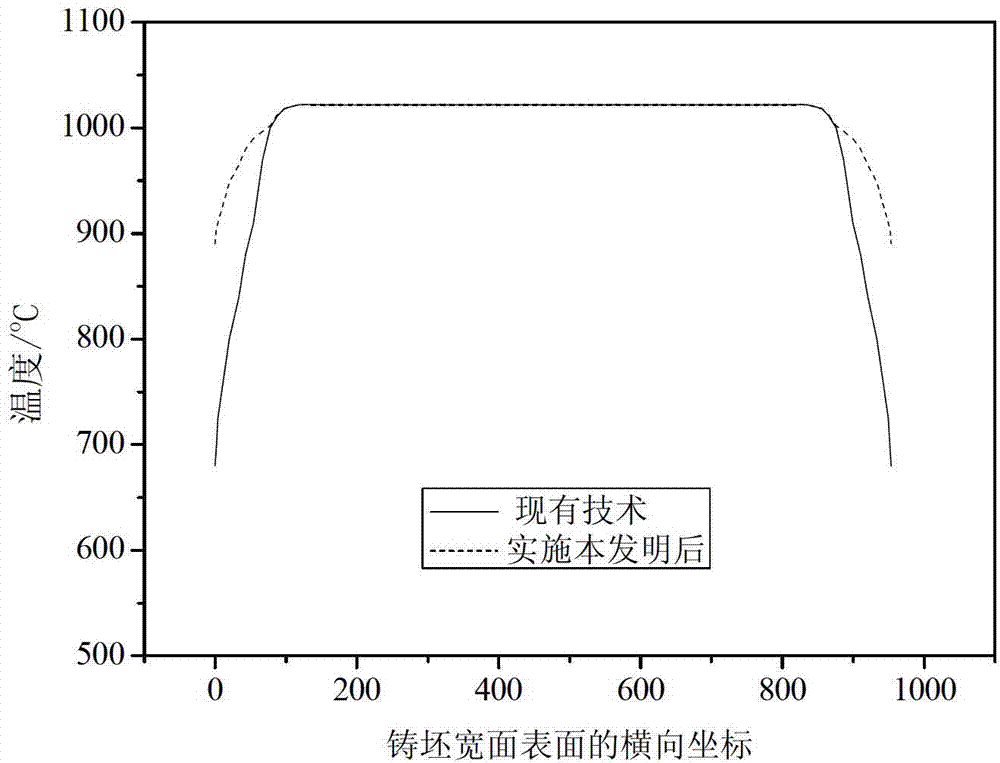

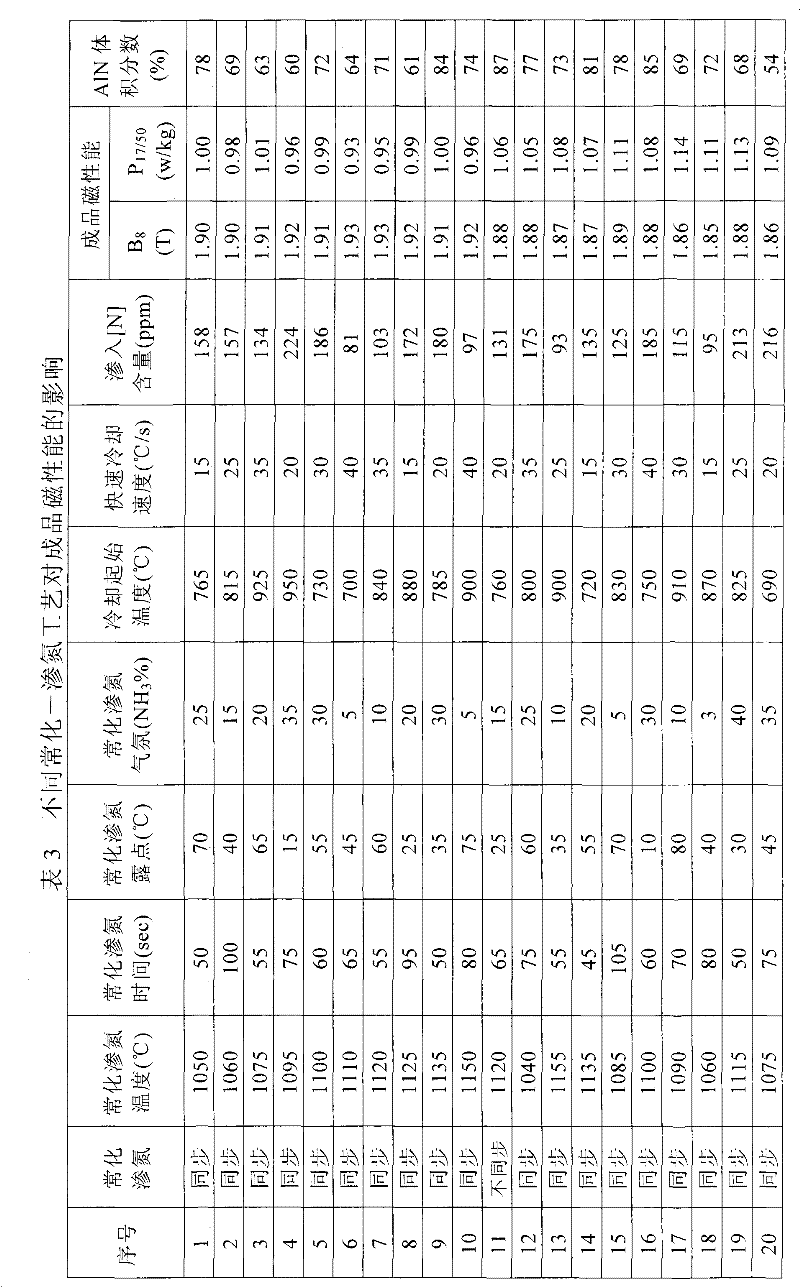

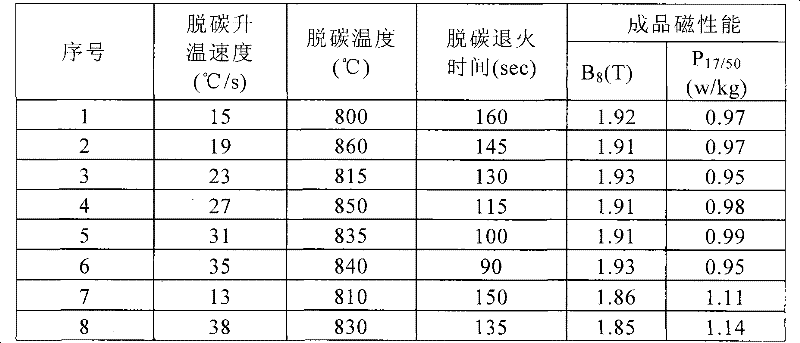

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

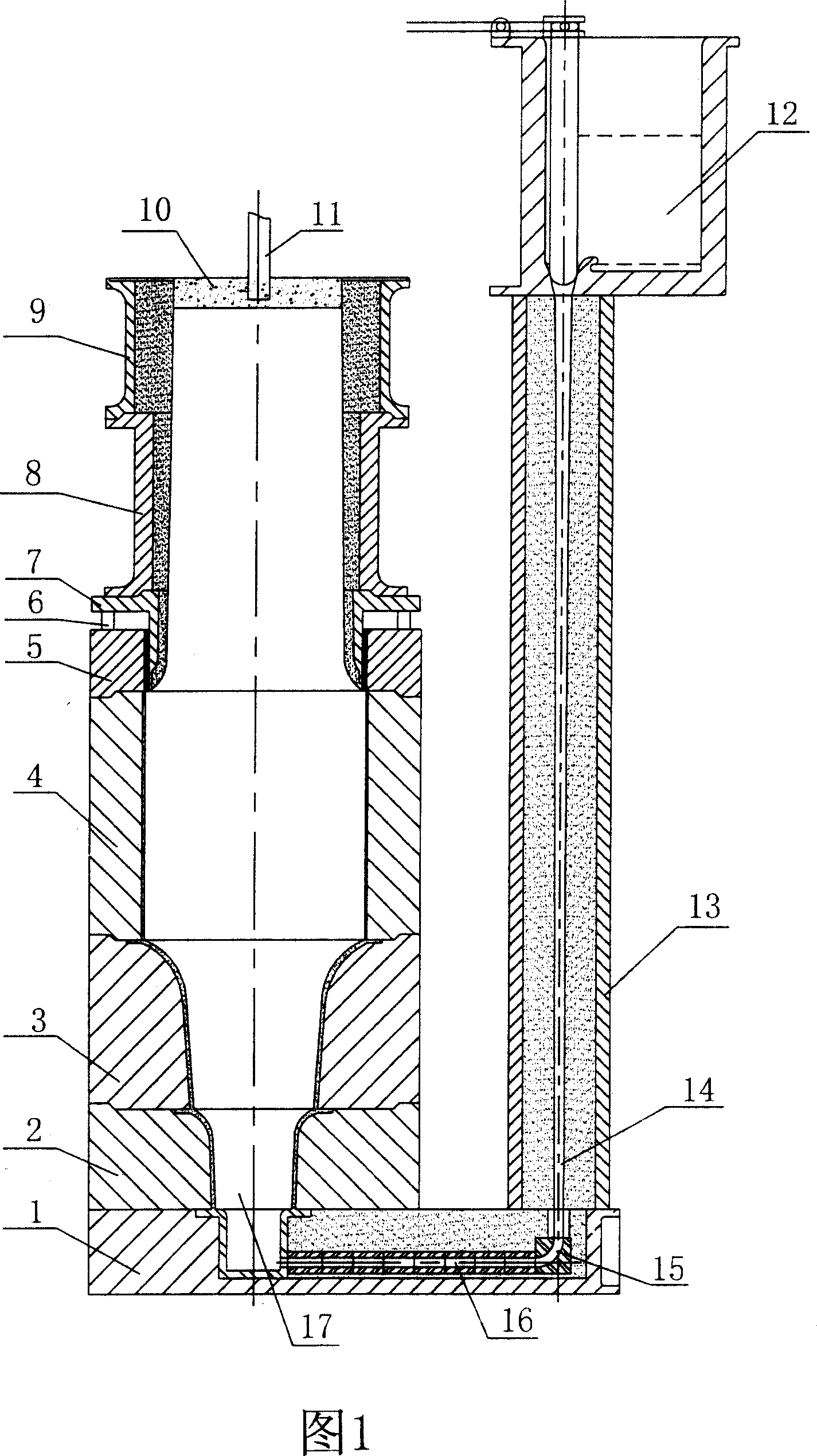

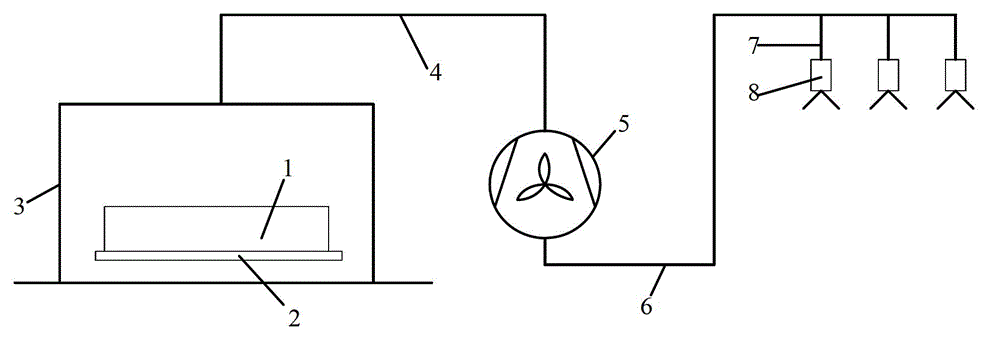

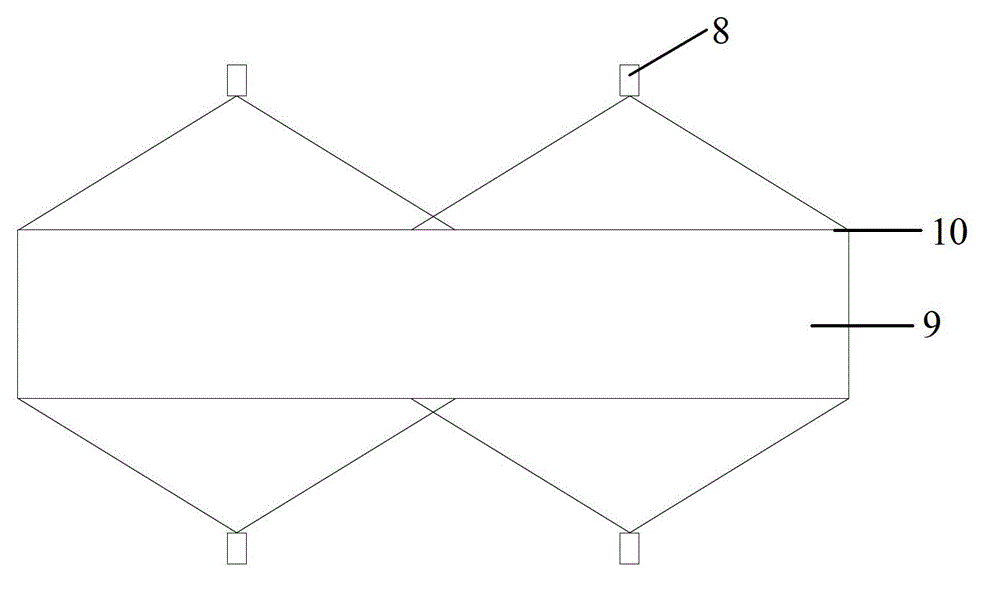

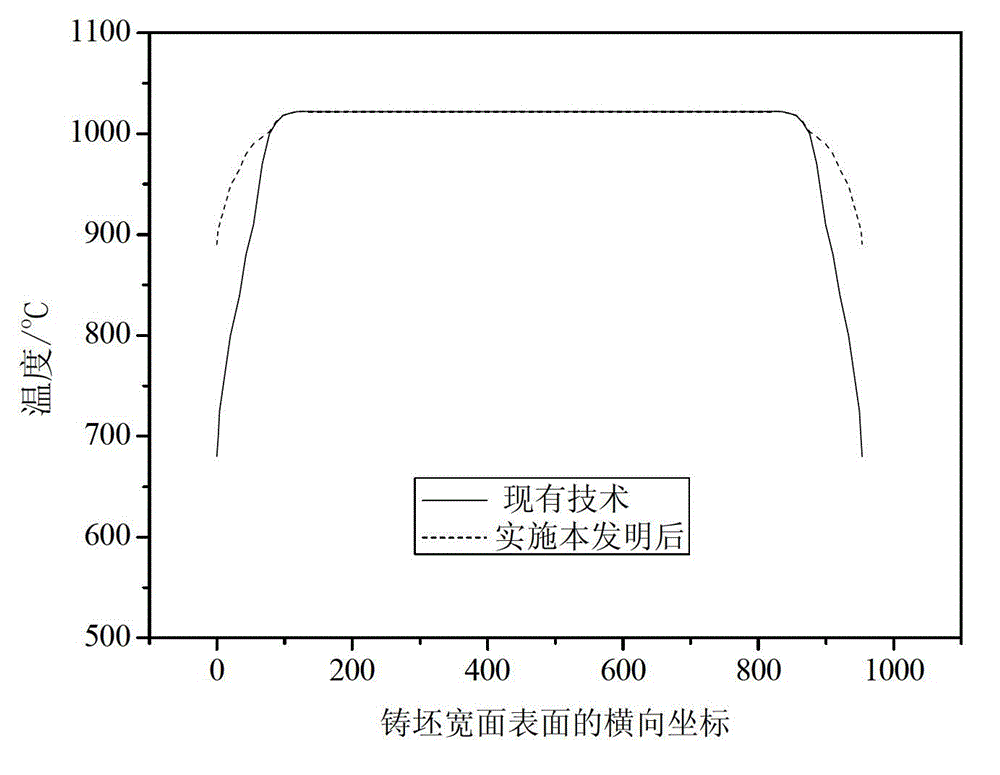

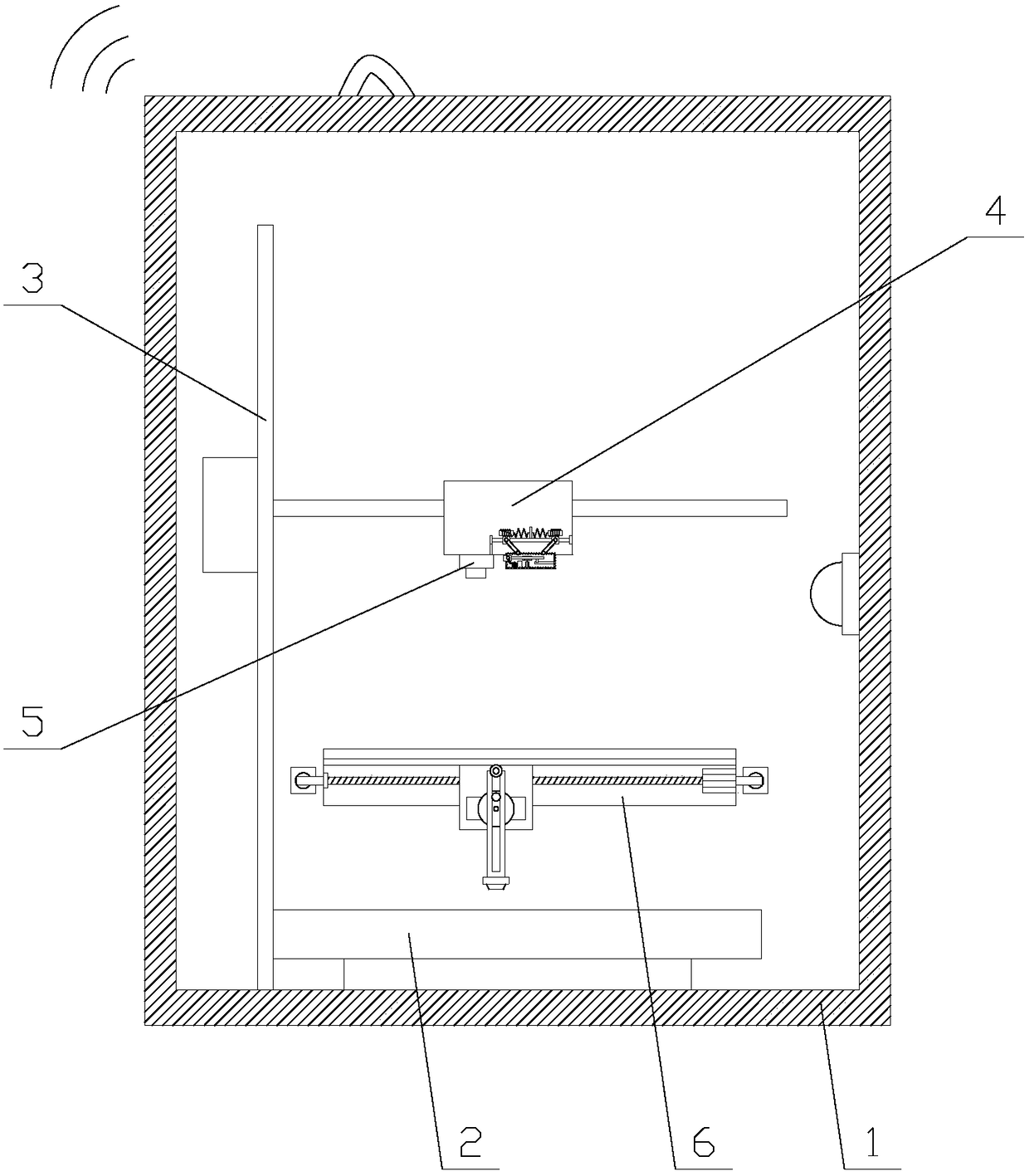

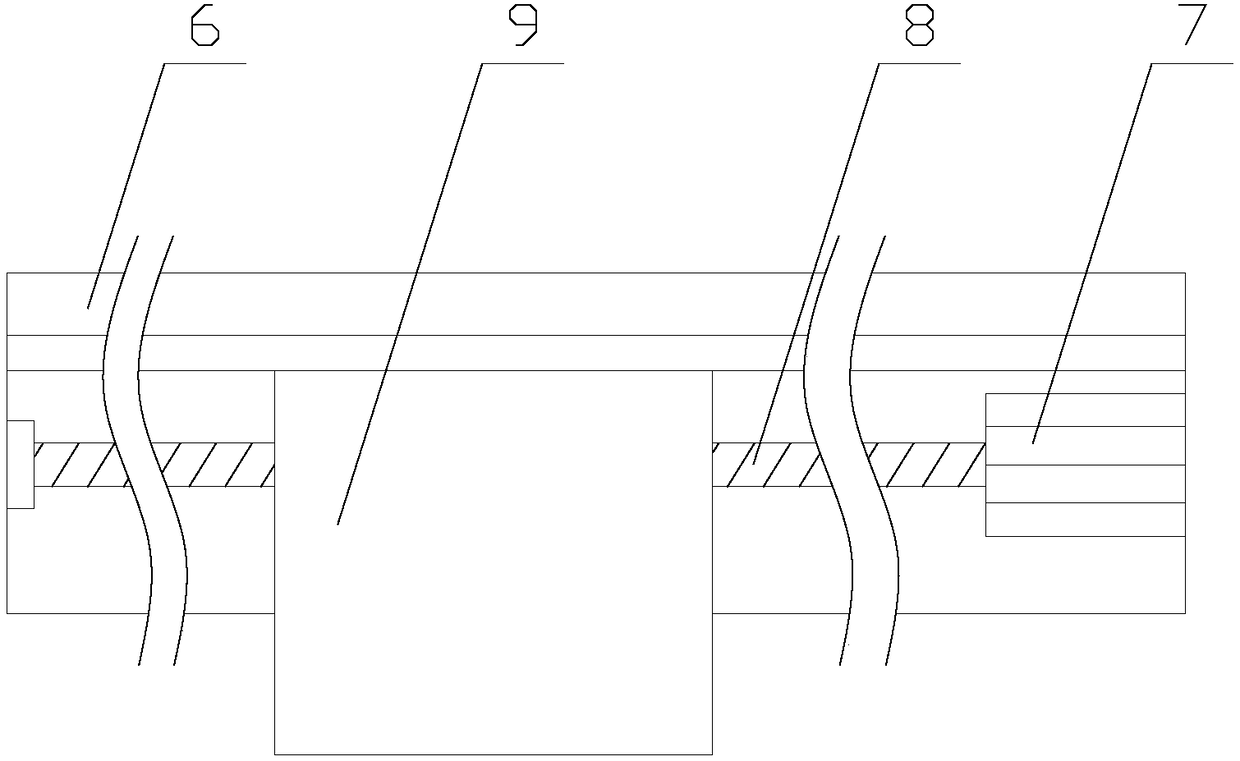

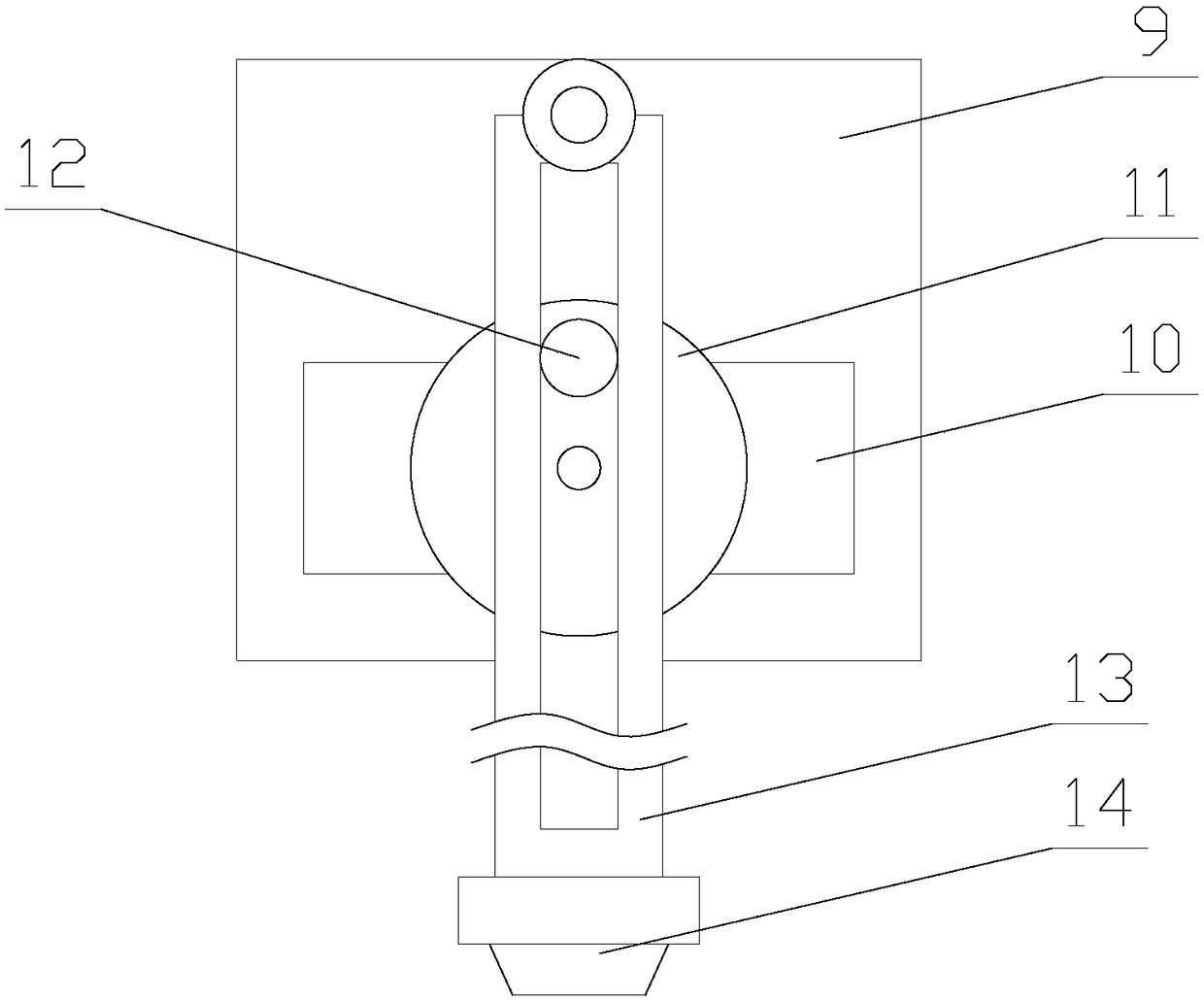

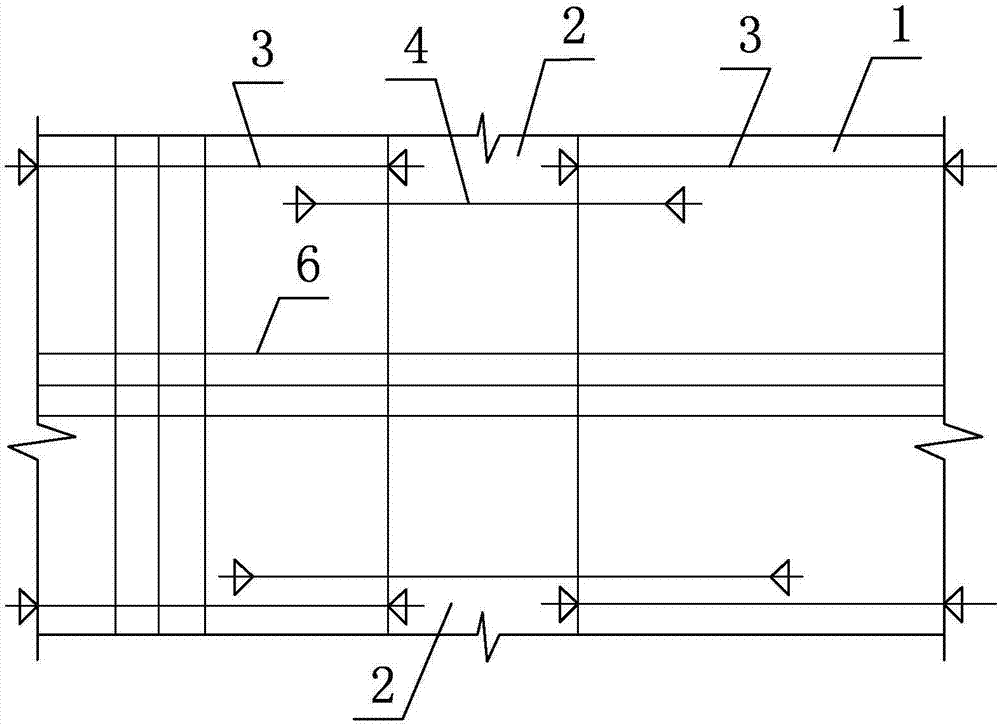

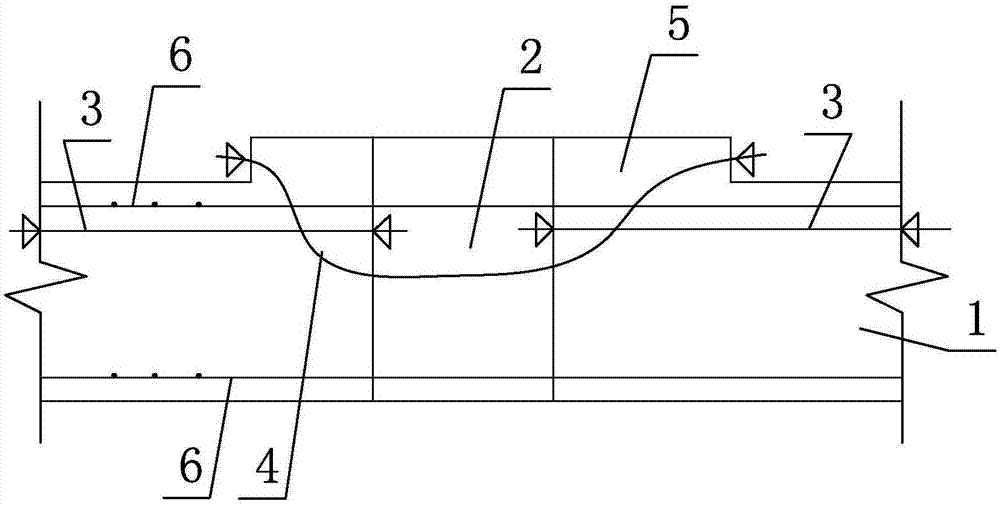

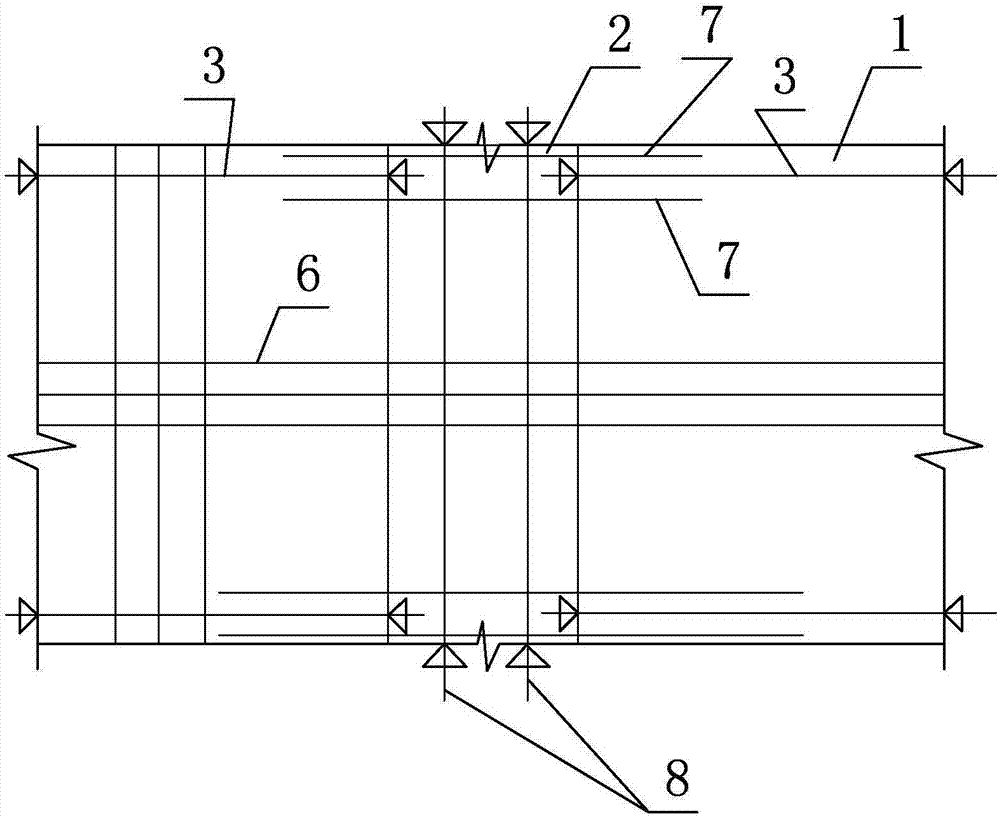

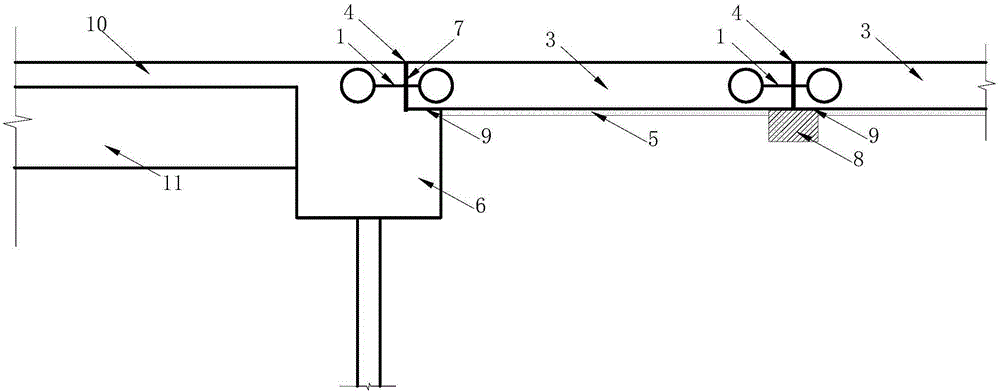

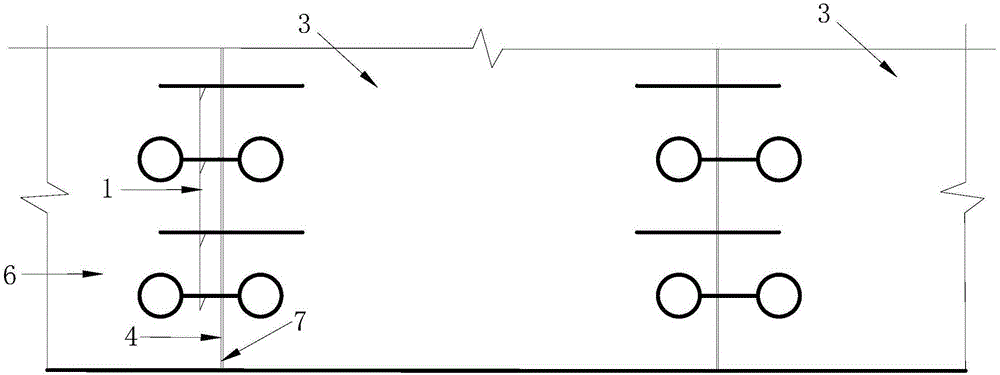

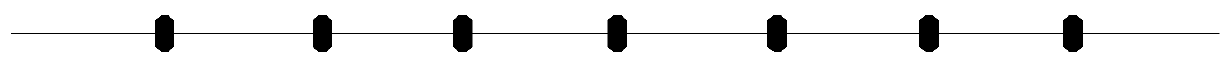

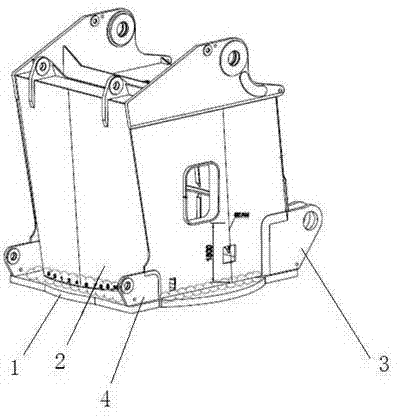

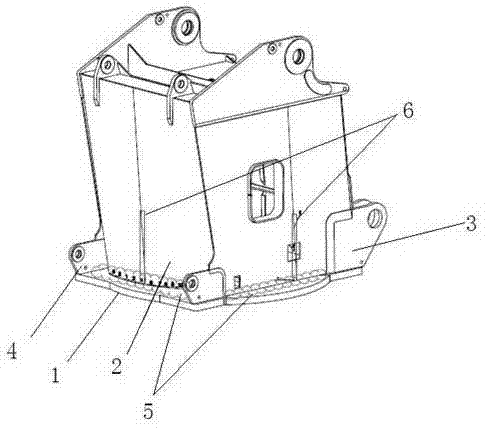

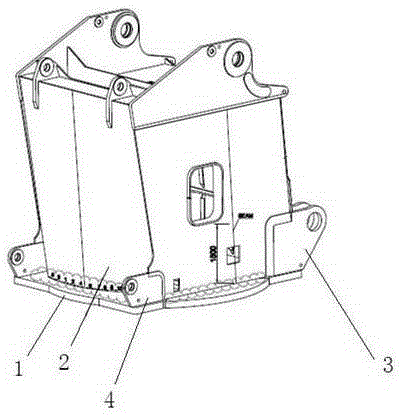

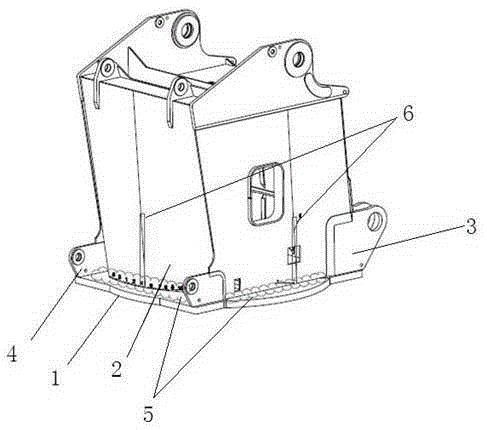

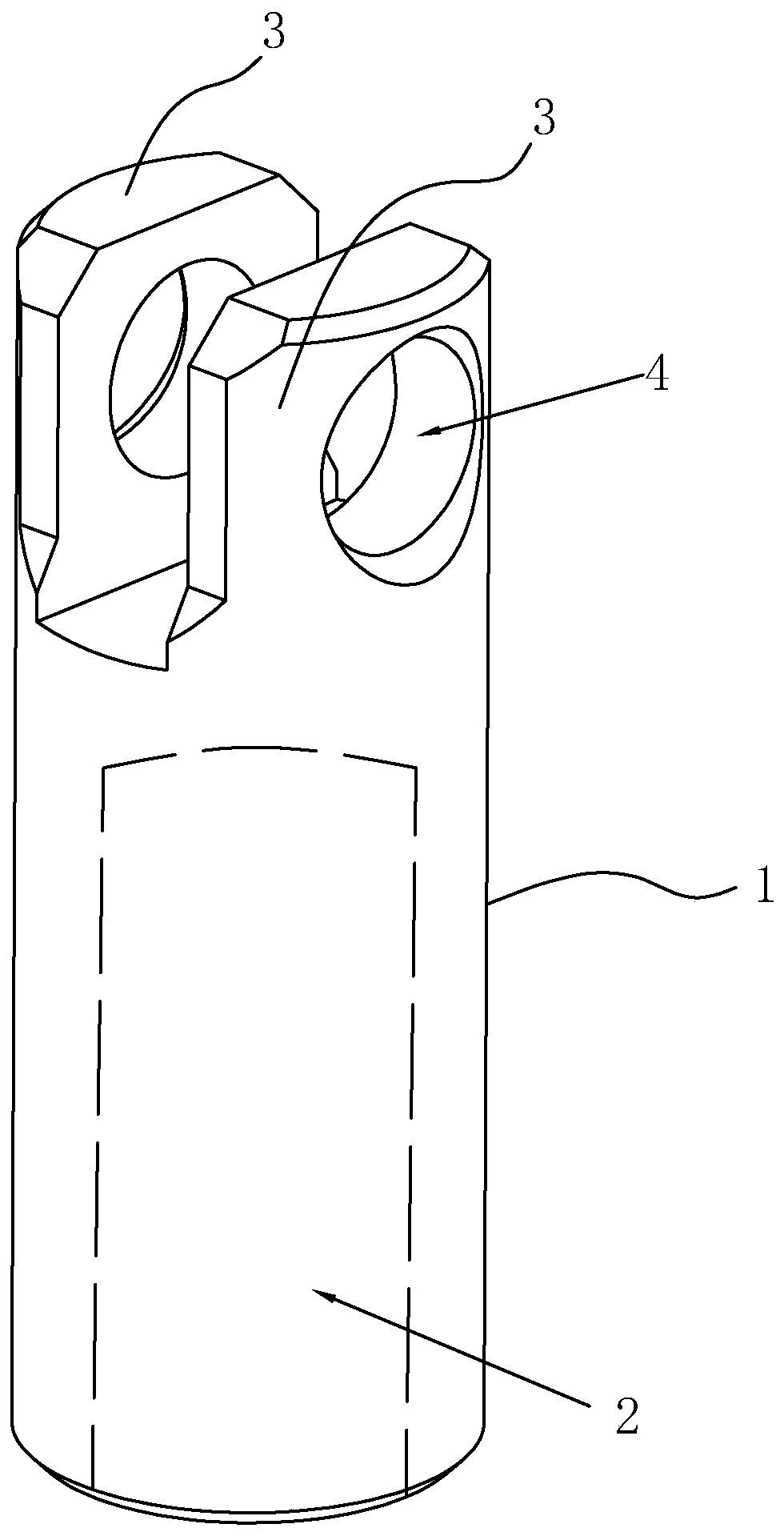

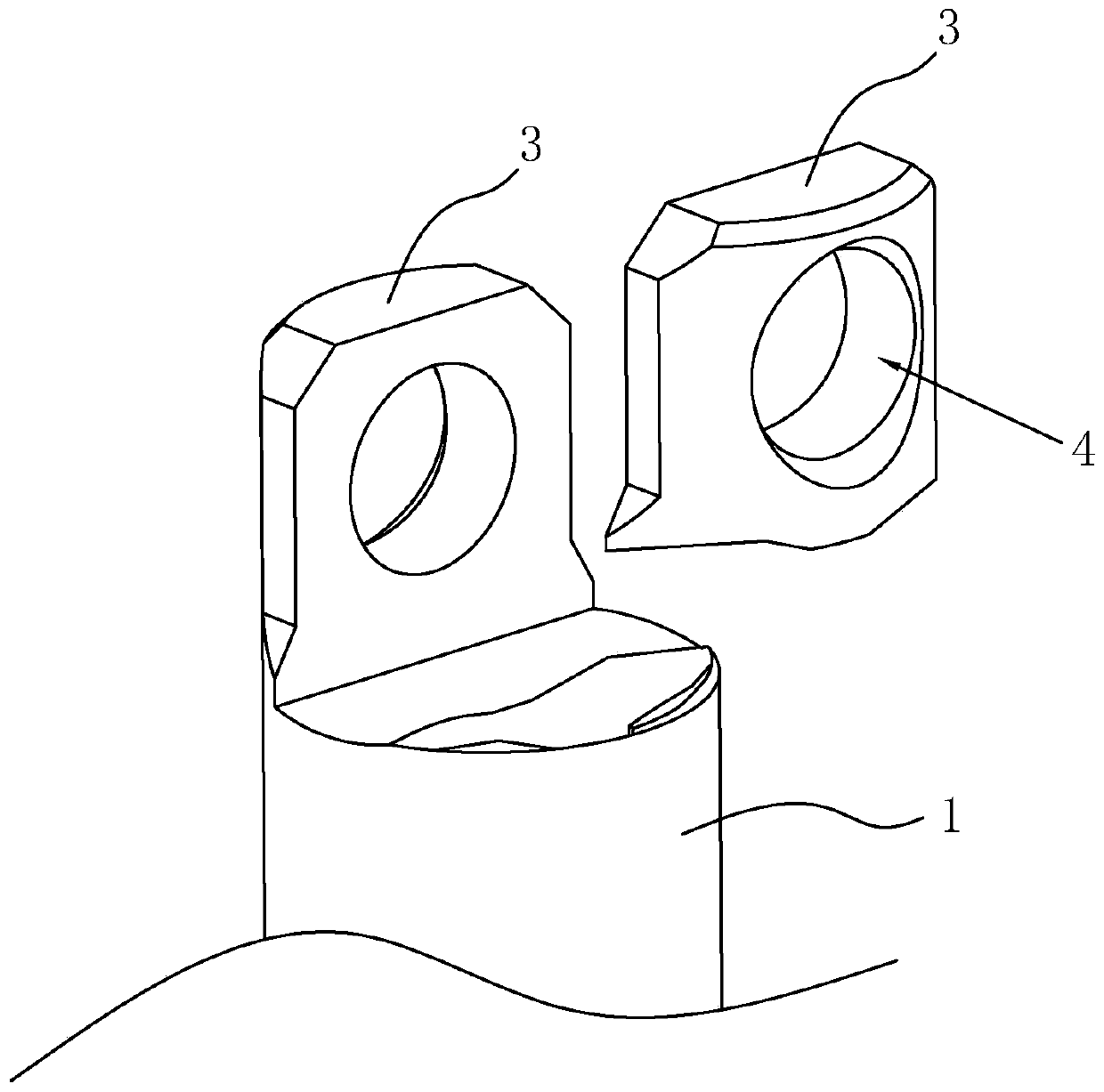

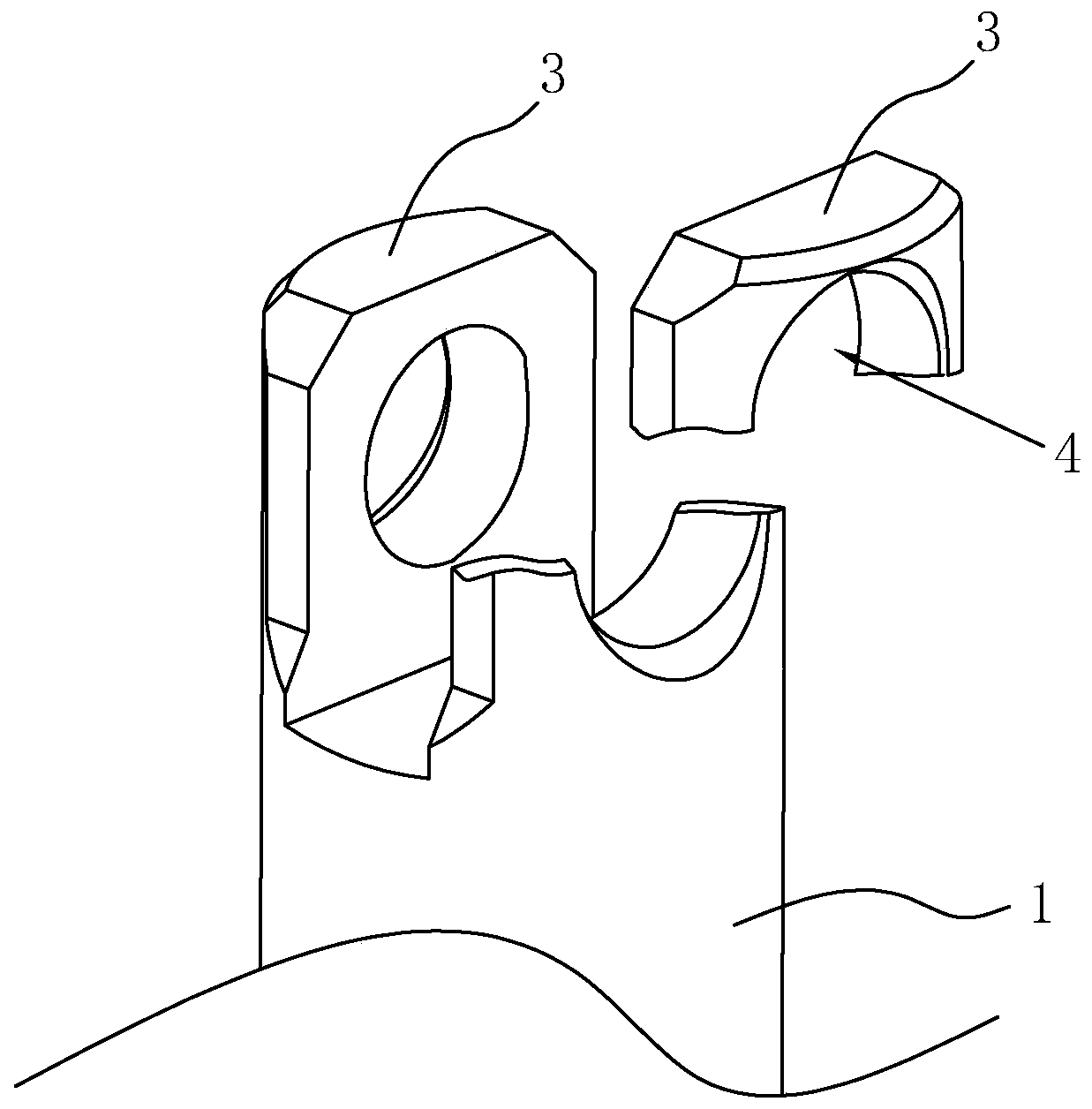

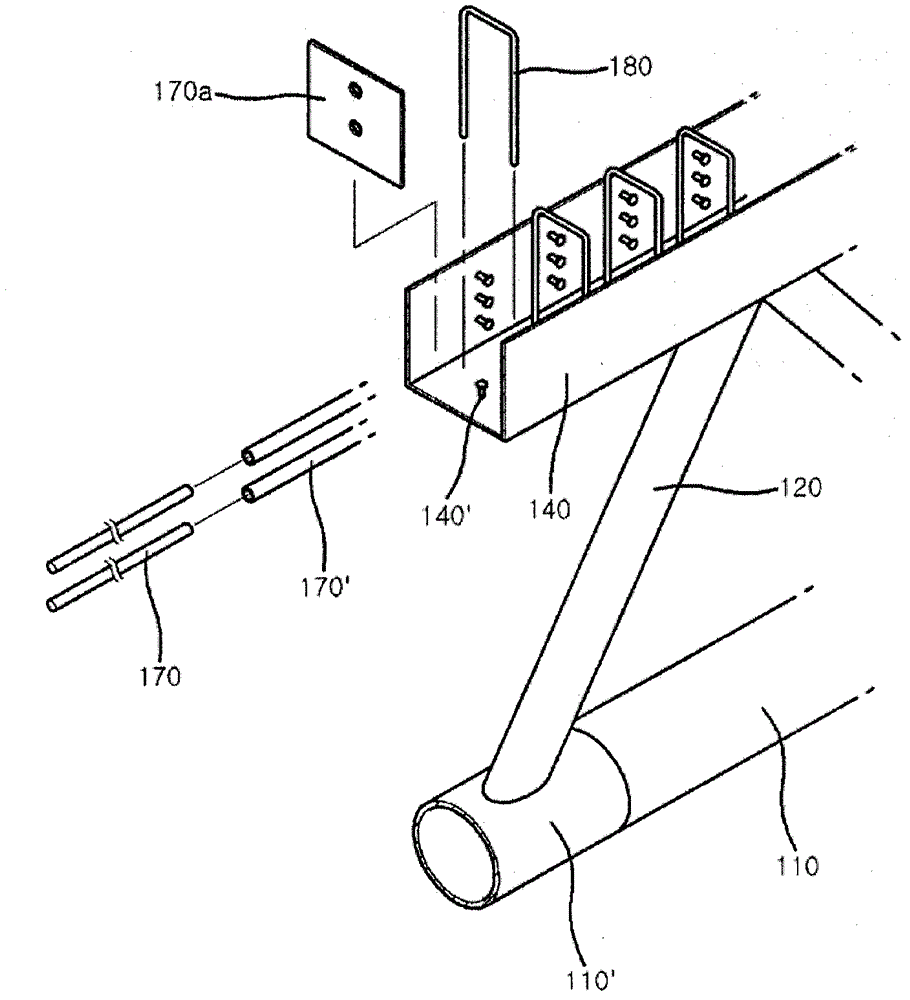

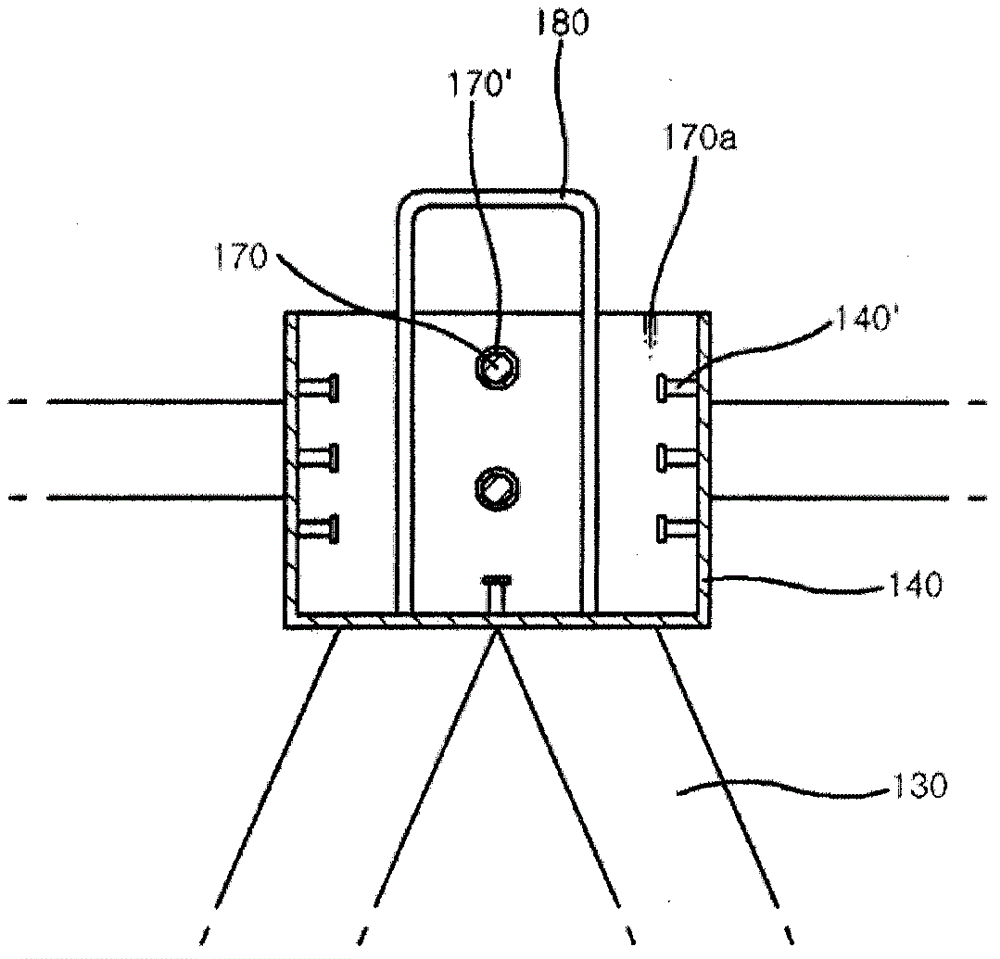

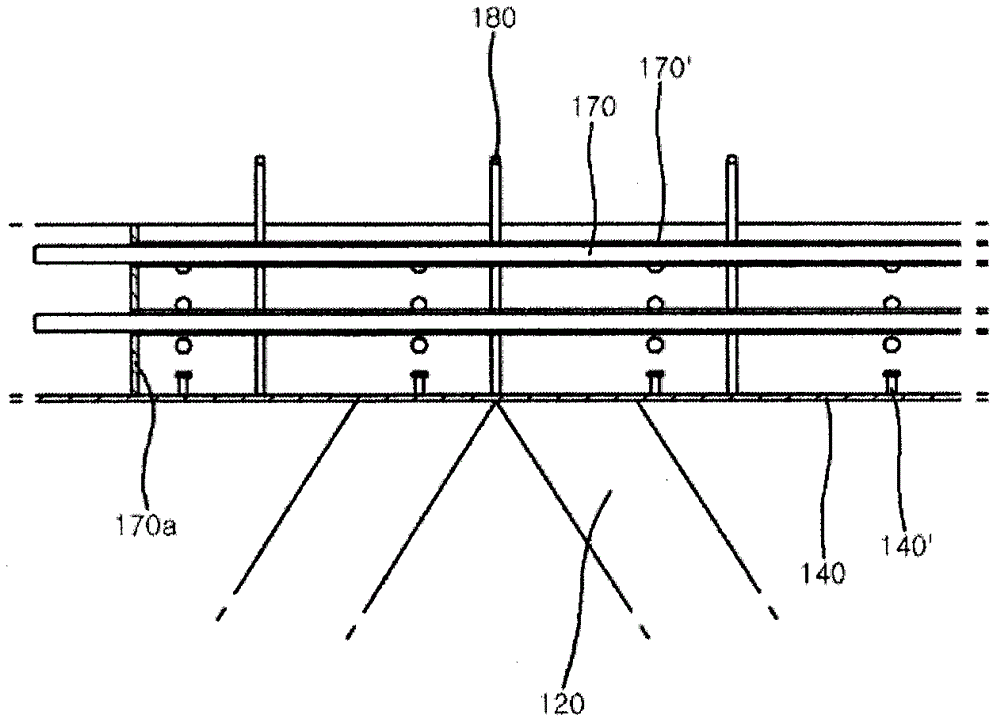

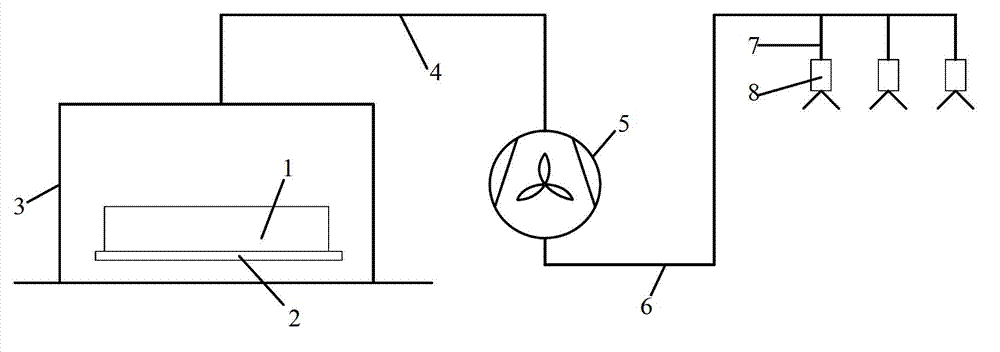

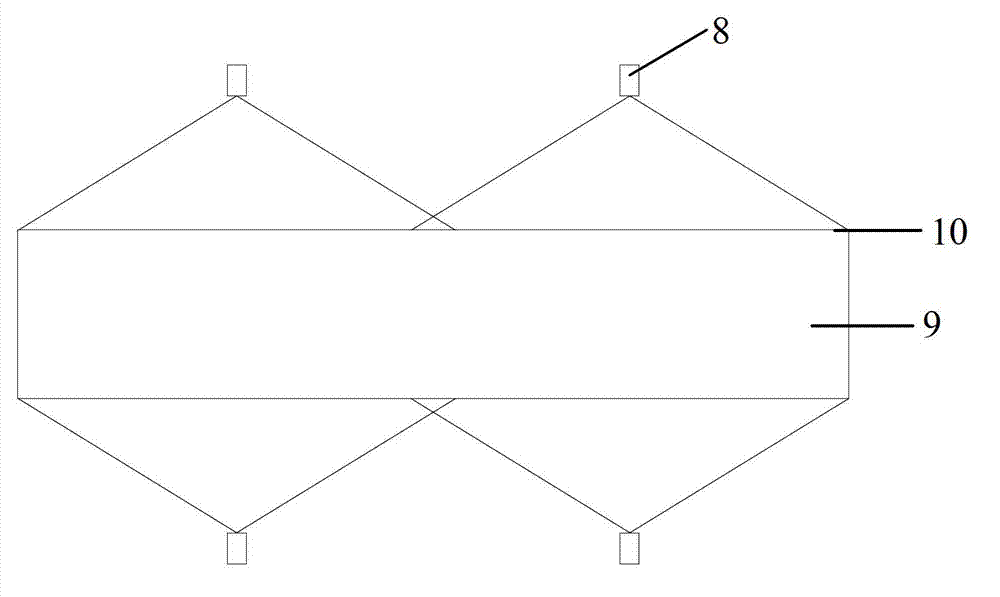

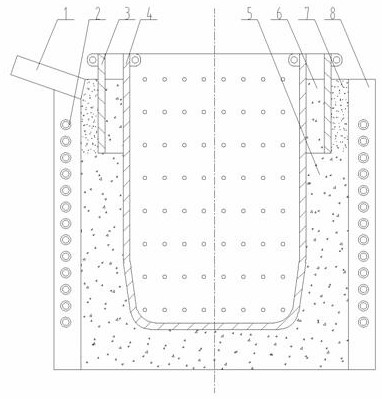

Method and device for deceasing transverse corner cracks of casting blanks

The invention relates to a method and device for decreasing transverse corner cracks of castling blanks. The method includes the steps of S1, disposing a smoke hood above a conveying roller way for cut casting blanks to collect high-temperature air; S2, delivering the collected high-temperature air under pressure; S3, delivering the high-temperature air to air nozzles disposed in a second casting blank cooling area and at corners of the casting blanks; and S4, allowing the high-temperature air to pass through the air nozzles to cover the corners of the casting blanks. The device comprises the smoke cover (3), a first heat-resistant pipe (4), a booster fan (5), a second heat-resistant pipe (6), heat-resistant branch pipes (7) and the air nozzles (8). The high-temperature compressed air can be blown to the corners of the casting blanks to prevent excessively fast cooling of the corners of the casting blanks, so that the corners of the casting blanks can be kept at the temperature higher than the upper limit of a low-temperature brittleness area before entering a straightening area, precipitation of various carbo-nitrides from the corners of the casting blanks is avoided, corner plasticity of the casting blanks is improved and transverse cracking of the corners of the casting blanks is effectively prevented during straightening.

Owner:WISDRI ENG & RES INC LTD

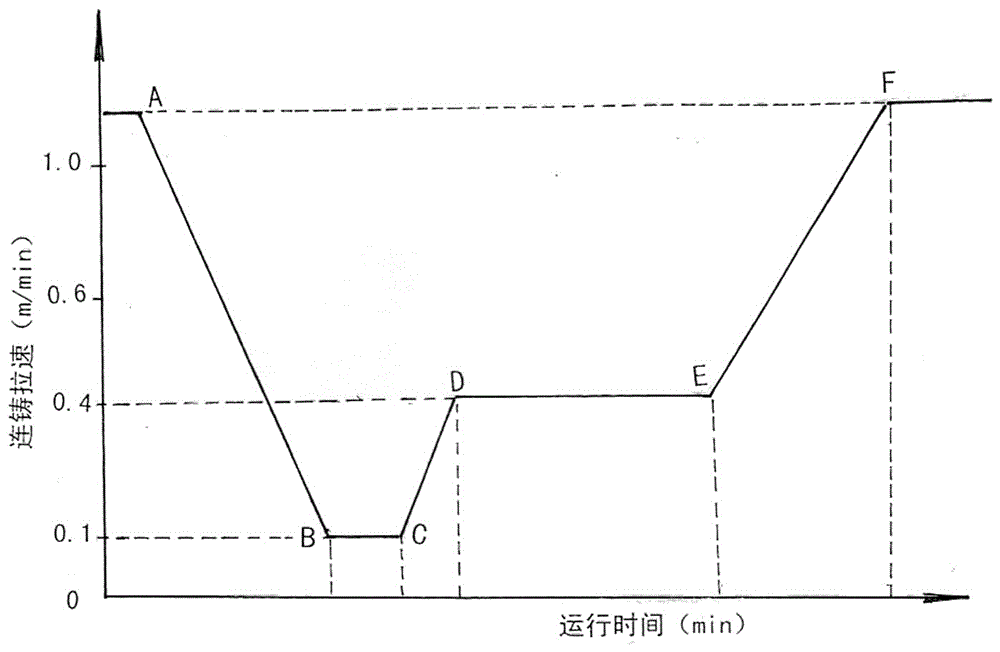

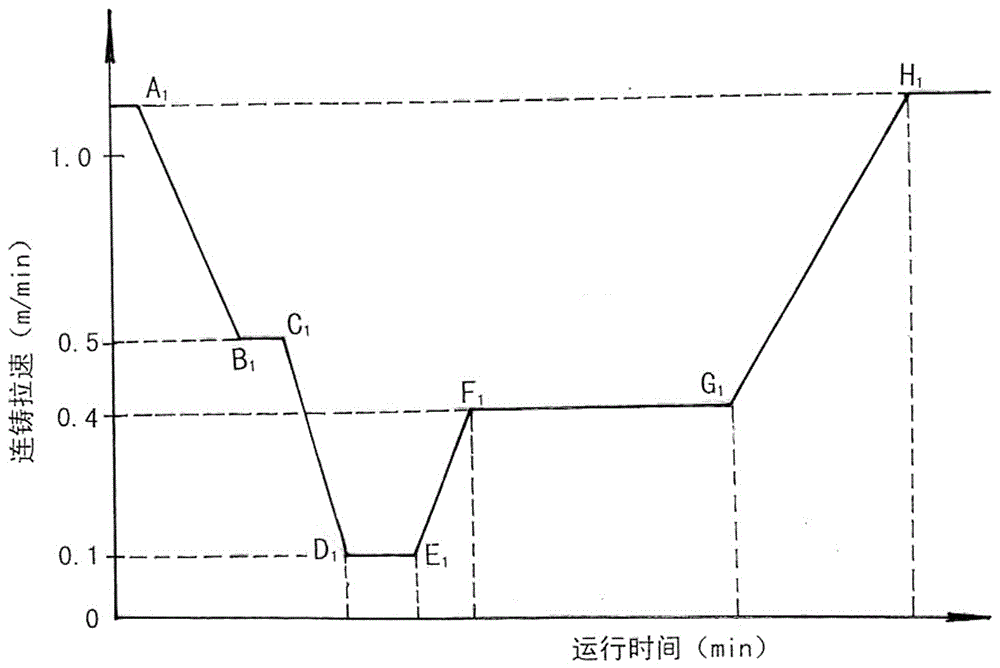

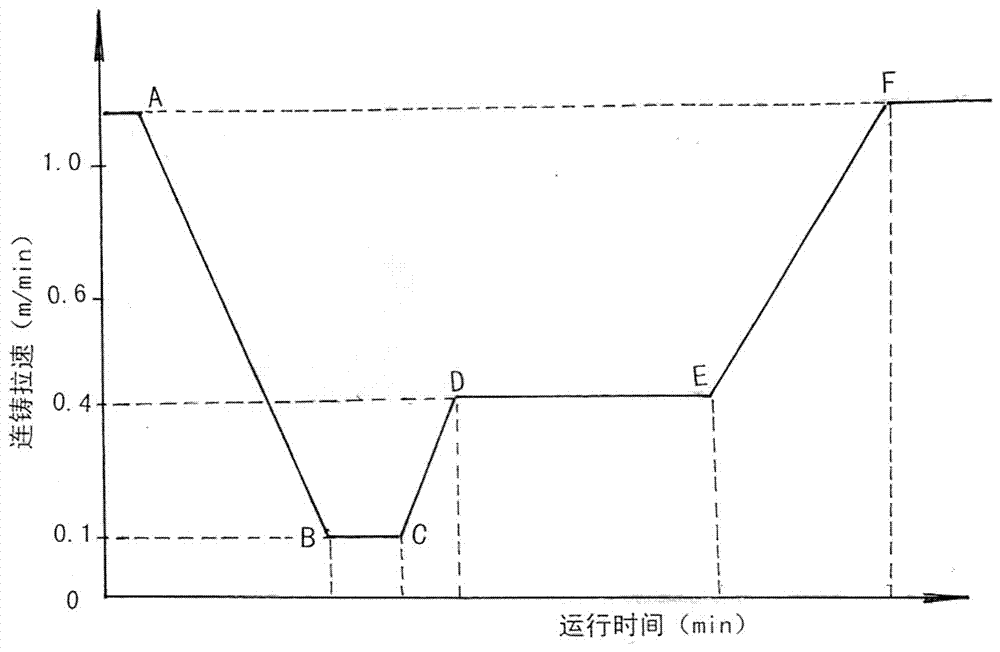

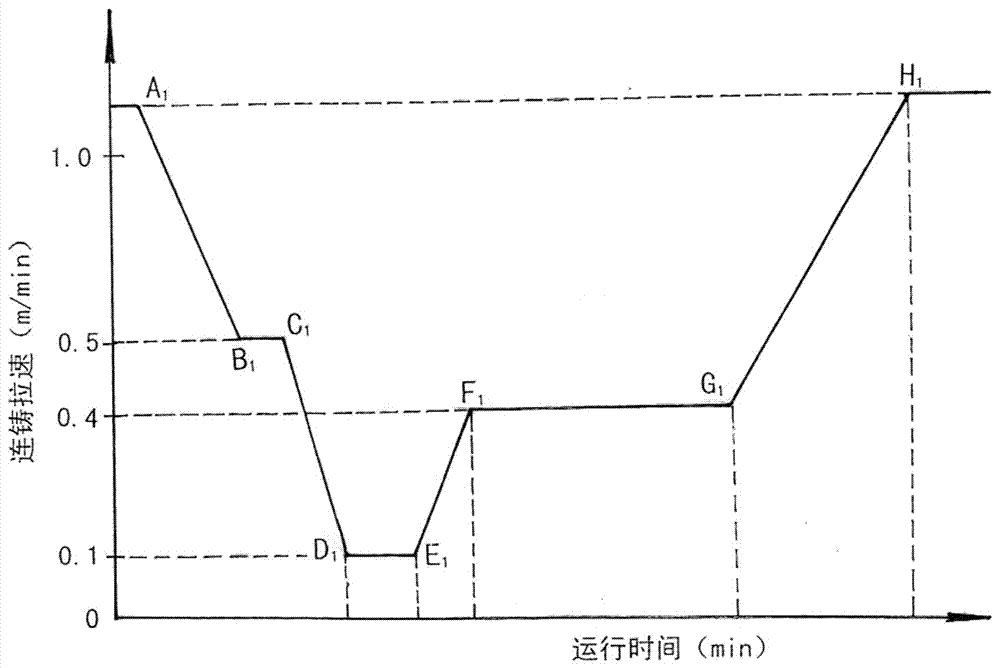

Continuous casting stop-casting blank tail discharge and top sealing method

The invention discloses a continuous casting stop-casting blank tail discharge and top sealing method. First and second stopper rods of a tundish of a two-machine and two-current continuous casting machine are opened; and first and second currents of molten steel flow into first and second crystallizers. When the height of the molten steel of the tundish is from 1130 mm to 680 mm, the continuous casting pull speeds of the first and second currents of molten steel in continuous casting are both reduced to 0.09-0.11 m / min at different accelerations; at this time, after the first and second stopper rods in the tundish are respectively closed, first and second blind plates are pushed in; first and second casting water ports are taken out from the first and second crystallizers; first and second cooling rods are put in the first and second crystallizers; and the continuous casting pull speeds are increased to 0.38-0.42 m / min for keeping by not shorter than 2 min. When the tail part of a continuous casting blank is discharged from lower ports of the crystallizers, and a foot roll section casting blank totally enters the tail part of the casting blank, the tail part of the casting blank is shrunk to form a recess area, and the tail discharge and the top sealing of the casting blank are finished. The top sealing method is excellent in tail discharge and top sealing of the casting blank, increases the molten steel yield, and has the popularization value.

Owner:湖南华菱涟源钢铁有限公司

Internet-of-Things-based intelligent printing device with good printing effect

InactiveCN108215185AImprove adhesionAvoid destructionAdditive manufacturing apparatusSpraying apparatusEngineering3d printer

The invention relates to an Internet-of-Things-based intelligent printing device with a good printing effect. The device comprises a main body, a printing platform, a stroke rod, a stroke block and anozzle, and further comprises a gluing mechanism and a wire removal mechanism, the gluing mechanism comprises a moving assembly and a swinging assembly, and the wire removal mechanism includes a lifting assembly and a wiping assembly. The gluing mechanism can uniformly glue the printing platform to enhance the adhesion of the printing platform and a first layer material and prevent the bottom of amodel from upwarping, so lateral cracks in the top structure of the model are avoided, and the printing stability and the printing success rate are improved; and the wire removal mechanism can sweepand absorb plastic filaments and plastic coagulum residual on the nozzle to prevent the influences of wires caused by dripping of excess plastics from the nozzle on the printing effect, so the practicability and the reliability of a 3D printer are improved.

Owner:惠安县冠威机械设备有限公司

Sulfuric acid resistant ferritic stainless steel and manufacturing method thereof

InactiveCN105506502AHigh sulfuric acid corrosion resistanceImprove low temperature impact toughnessAlloyAustenite

The invention relates to a sulfuric acid resistant ferritic stainless steel and a manufacturing method thereof. The sulfuric acid resistant ferritic stainless steel comprises the following chemical components by weight: 0.002-0.015% of C, 0.002-0.015% of N, 0.2-1.0% of Si, 0.2-0.5% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 28-30% of Cr, 1.5-3% of Ni, 2.0-4.0% of Mo, 0.1-0.3% of V, 0.10-0.30% of Ti, 0.2-0.5% of Nb, 0.05-0.1% of Al, with the sum of Cr+3.3*Mo being greater than or equal to 38%, and Ti+Nb being greater than or equal to 16(C+N), less than or equal to 0.005% of O, and the balance Fe and inevitable impurities. The ferritic stainless steel provided by the invention can tolerate the corrosion of various concentration sulfuric acids at a temperature of less than 60 DEG C and at a concentration of less than or equal to 98wt%, also has good impact toughness and welding performance. With a pitting resistance equivalent PREN of greater than or equal to 38, the ferritic stainless steel has corrosion resistance far superior to conventional ferritic stainless steel, and is equivalent to superaustenitic stainless steel and nickel based alloys.

Owner:BAOSTEEL STAINLESS STEEL

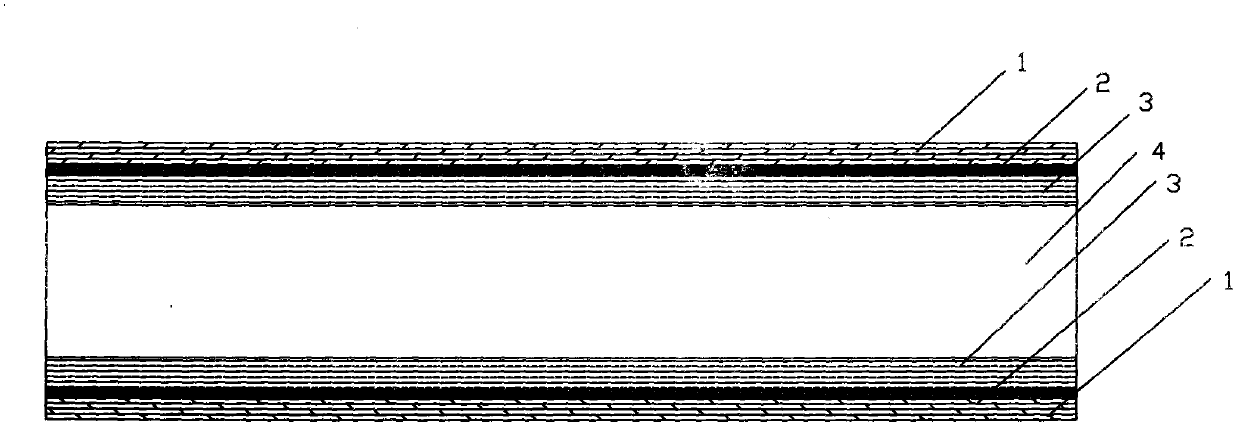

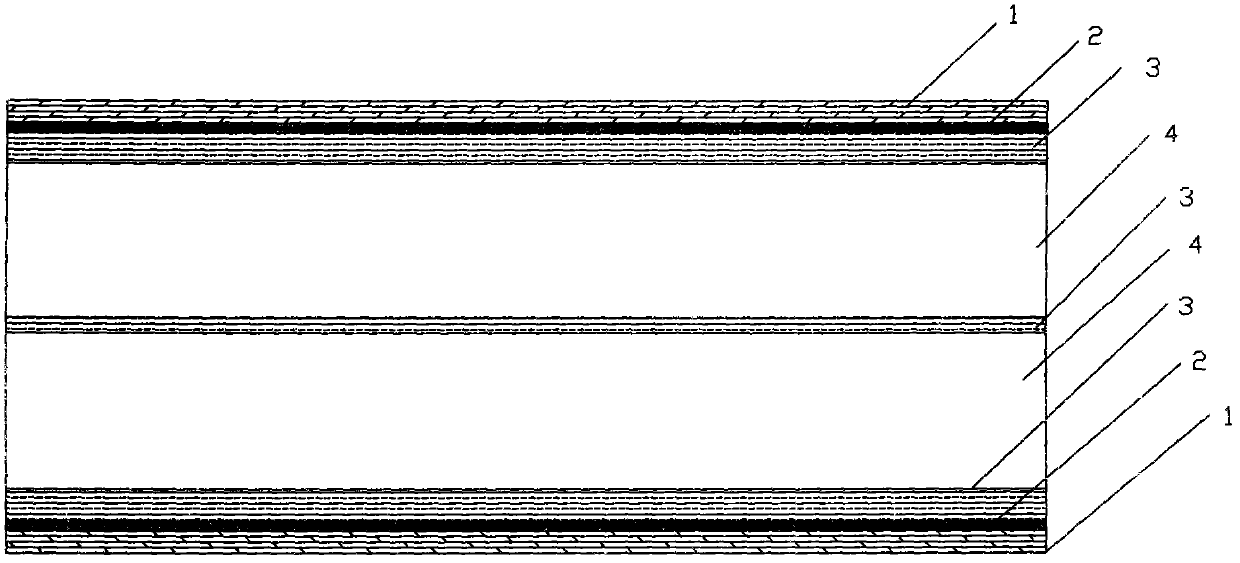

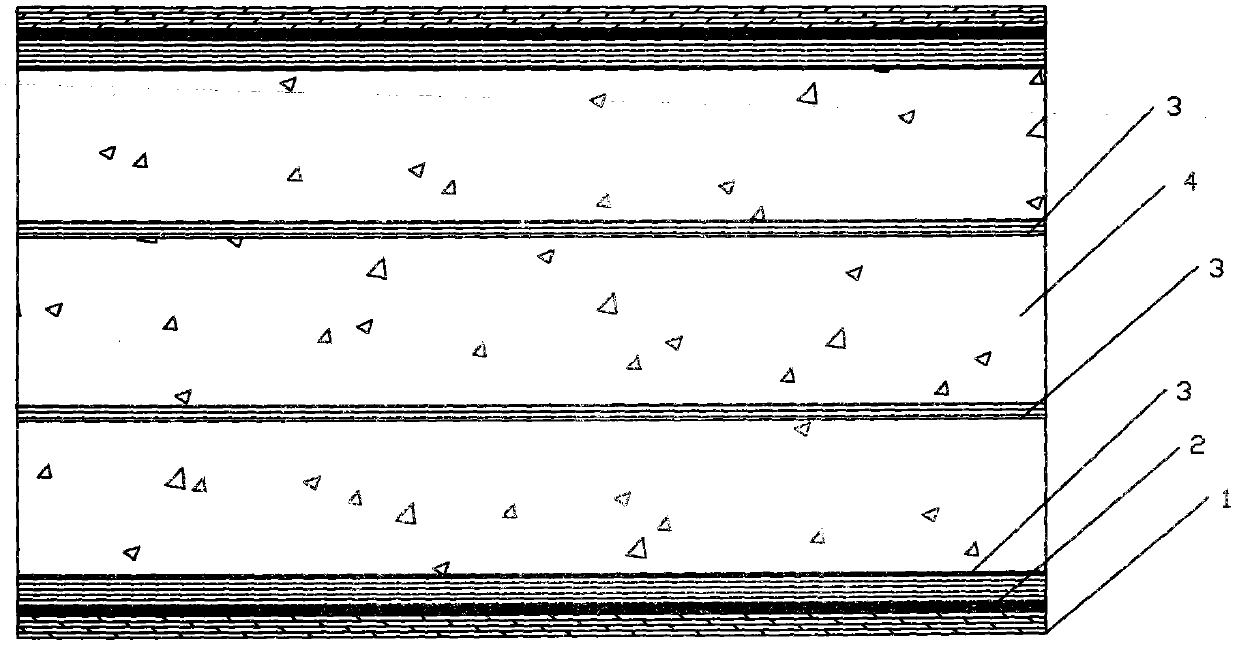

Wood and bamboo composite shaving board and process

InactiveCN102555008AImprove lateral strengthPrevent transverse crackingWood veneer joiningDomestic articlesLayered structureTransverse cracking

The invention relates to a composite shaving board, which contains wood materials and bamboo skin materials and comprises a surface layer, an inner layer and an intermediate layer. The surface layer is made of long wood single plates, a shaving layer is laid in the intermediate layer, the long wood single plates of the surface layer are longitudinally arrayed in the grain direction, short bamboo skin layers or short wood single plate layers which are transversely arrayed are arranged on inner sides of the long wood single plates, namely the inner layer, and longitudinally arrayed long bamboo skin layers are laid on inner sides of the transversely arrayed short wood single plate layers. Manufacturing process of the wood and bamboo composite shaving board includes that the long wood single plates can be spliced or longitudinally arrayed along the grain direction; the short wood single plates or bamboo curtains are transversely arrayed by the aid of gluing; and then long bamboo curtains or bamboo mats are longitudinally arrayed on the short wood single plates or bamboo curtains along the grain direction. A wood and bamboo composite board with a three-layered structure is assembled, and the shaving board layer is manufactured, the wood and bamboo composite board is provided with the transversely arrayed short bamboo skin layers or wood single plate layers, transverse strength of the composite shaving board can be improved, transverse cracking of the board is prevented, transverse nail holding force is increased, and longitudinal static bending intensity of the board is enhanced.

Owner:东莞市兴林木业有限公司

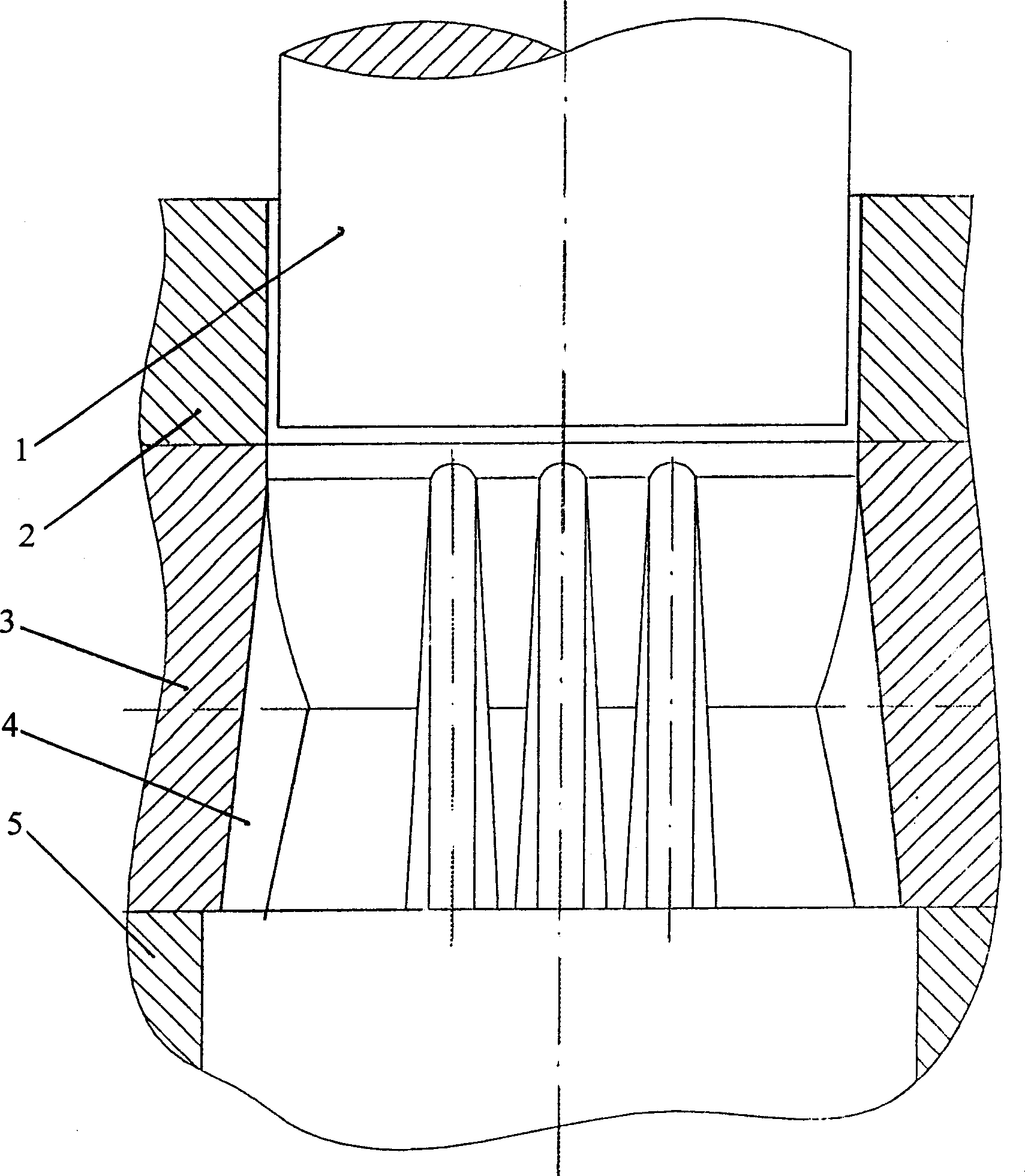

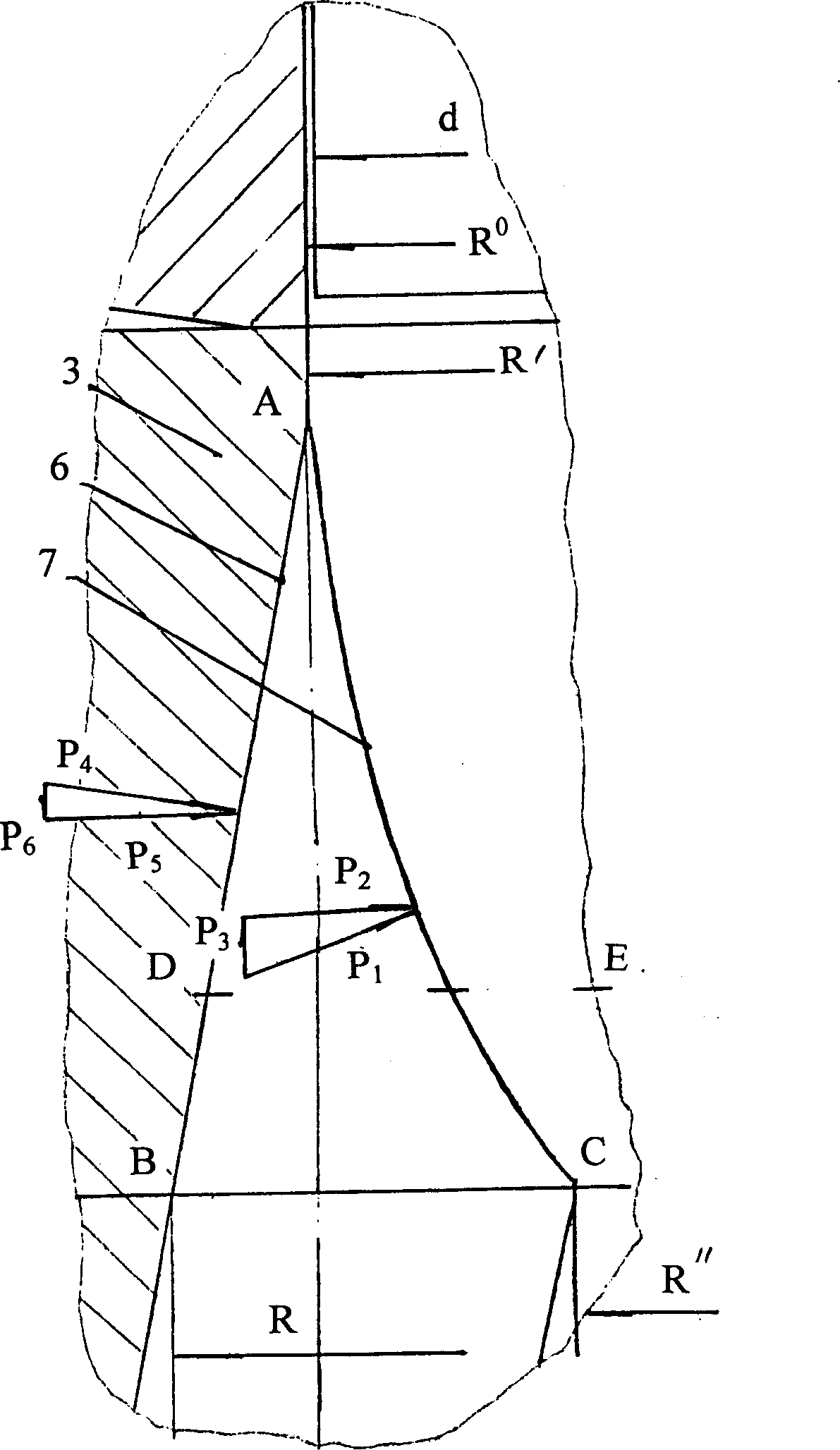

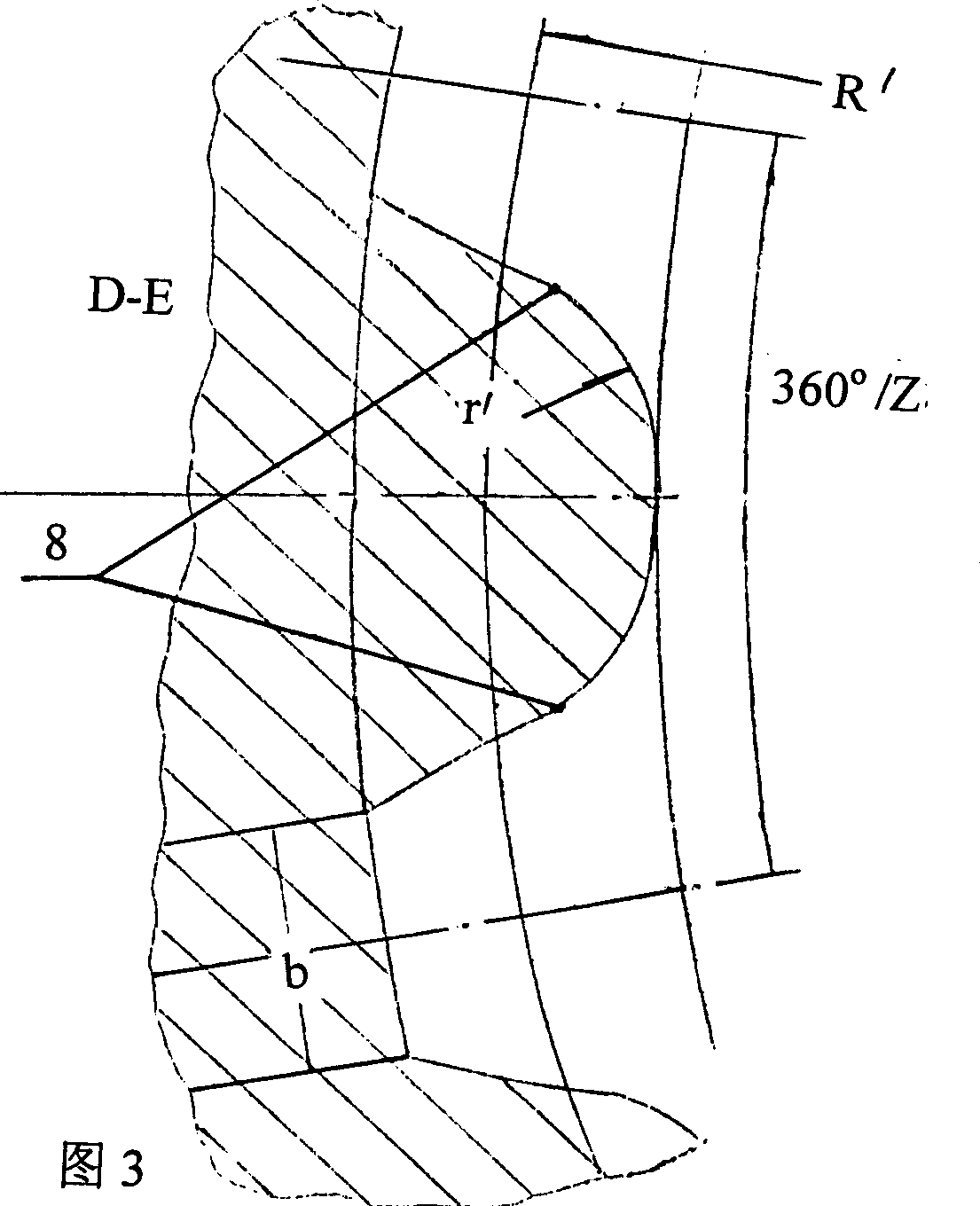

Spur gear extrusion concave die

The invention is an extrusion concave mould of straight-tooth cylindrical gear, and its character: inlet diameter of the concave mould is greater than the diameter of divided circle of a molded gear and less than that of addendum circle of the molded gear; the shape and size of the gap between teeth at the end of the molding segment of the concave mould are consistent with those of the tooth form of planar projection of the molded gear; for arbitrary cross section in molding segment of the concave mould but point of tangency from the top arc of the tooth form to the side wall between teeth, the geometrical shapes and sizes of the rest parts between teeth are consistent with those of the corresponding parts at the end of the molding segment of the concave mould, and the centre angles opposite to the circumferential pitches are the same. It needs small extruding force, and the parts of tooth form are easy to fill up, the involutes of the concave mould is uneasy to wear and its service life is long.

Owner:HEFEI UNIV OF TECH

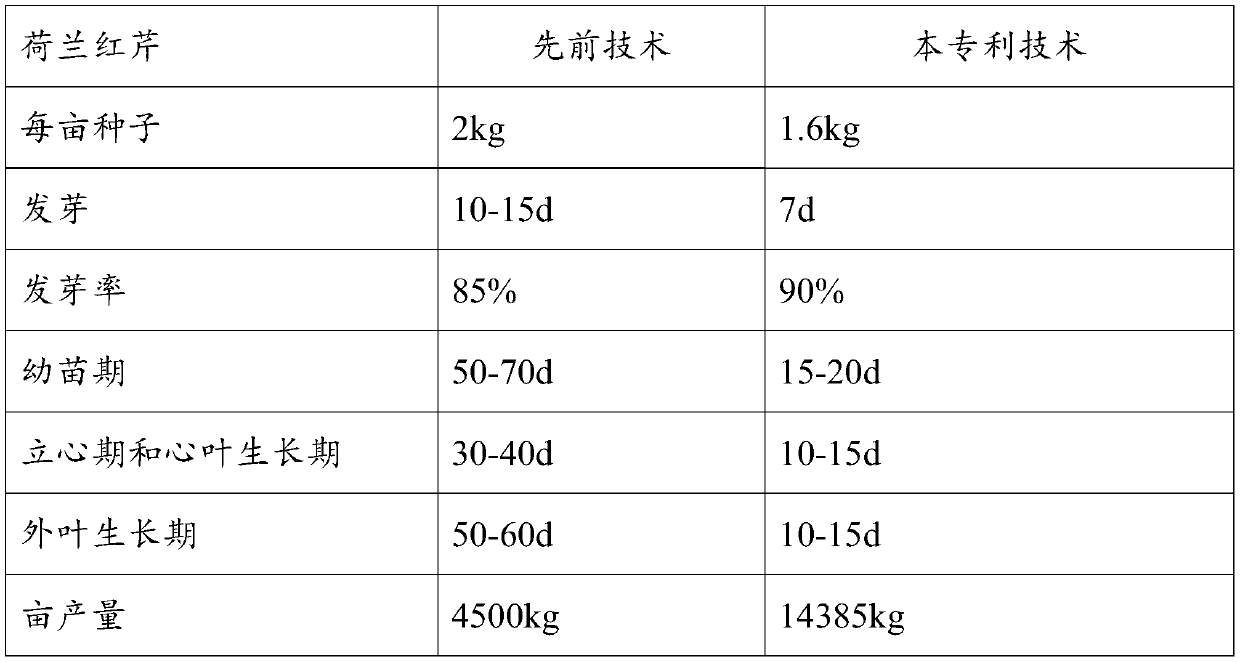

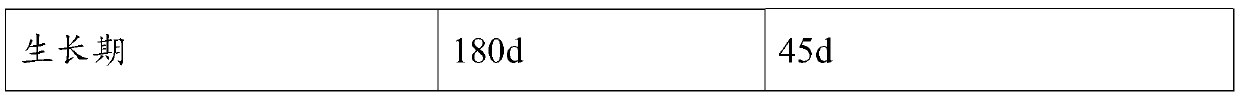

Method for cultivating red celery in plant factory

PendingCN110169317APromote hydrationSuitable humidityMagnesium fertilisersSeed and root treatmentFlavorPlant factory

The invention provides a method for cultivating red celery in a plant factory. The method includes: cultivating the red celery indoors by utilizing artificial light and a water cultivating technologyin a seed germination stage, a seedling stage, a field planting stage and a harvesting stage, controlling nutrient solution conductivity, pH (potential of hydrogen), and temperature and humidity environments of the red celery, and setting corresponding light intensity and light illumination time according to growing habits of the red celery in different stages. The method for cultivating the red celery in the plant factory has the advantages that by cultivating the red celery in different light environments, limits to the red celery from seasons and temperatures are eliminated, annual and clean production of the red celery can be realized, a germination rate of the red celery is guaranteed, a growing period of the red celery is shortened, the red celery can grow stronger, yield per unit area is increased, and excellent and stable conditions and flavor of the red celery are guaranteed.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

Post-cast strip structure of prestressed concrete plate

The invention discloses a post-cast strip structure of a prestressed concrete plate. The post-cast strip structure comprises two longitudinal post-tensioning unbonded prestressed reinforcing bars (3) arranged in precast concrete (1) on two sides of a first longitudinal non-prestressed reinforcing bar (6) and second longitudinal non-prestressed reinforcing bars (7) substituting original post-cast strips' longitudinal post-tensioning unbonded prestressed reinforcing bars (4) by adopting an equal-strength principle and in post-cast strips (2), the second longitudinal non-prestressed reinforcing bars (7) are located on two horizontal sides of the longitudinal post-tensioning unbonded prestressed reinforcing bars (3) in the precast concrete (1), and two ends of the second longitudinal non-prestressed reinforcing bars (7) extend to the precast concrete (1) of one end of a post-cast strip. By the arrangement, same bearing force can be guaranteed, cement consumption can be reduced, the construction of the post-cast strip is simplified, and concrete cracks in the post-cast strip are prevented.

Owner:浙江华展工程研究设计院有限公司 +1

30CrMnSiNi2A high-strength steel for aviation and production method thereof

ActiveCN113502434ADelay and inhibit grain growth tendencyGrain ultrafineProcess efficiency improvementAviationSmelting process

The invention provides 30CrMnSiNi2A high-strength steel for aviation and a production method thereof. The 30CrMnSiNi2A high-strength steel for aviation comprises the following chemical components in percentage by weight: 0.27 to 0.34 percent of C, 0.90 to 1.20 percent of Si, 1.00 to 1.30 percent of Mn, 0.90 to 1.20 percent of Cr, 1.40 to 1.80 percent of Ni, 0.015 to 0.03 percent of Al, 0.02 to 0.03 percent of Mo, 0.02 to 0.03 percent of V, 0.015 to 0.025 percent of Ti, 0.15 to 0.2 percent of W, less than or equal to 0.012 percent of P, less than or equal to 0.01 percent of S and the balance of Fe. According to the 30CrMnSiNi2A high-strength steel for aviation and the production method provided by the invention, a smelting process comprising electric furnace die casting, external refining and electroslag remelting which is always adopted abroad is completely replaced by the method comprising electric furnace continuous casting, external refining and electroslag remelting, so that the effect of improving the material structure property and the fatigue property is obvious. By means of the method, batch, systematic and energy-saving production can be carried out, and energy and cost are obviously saved.

Owner:青海西钢特殊钢科技开发有限公司 +1

Narrow-face copper plate taper back draft process for continuous casting sheet billet chamfering crystallizer

The invention provides a narrow-face copper plate taper back draft process for a continuous casting sheet billet chamfering crystallizer and belongs to the technical field of steelmaking-continuous casting. The length of a contour line of an applicative chamfer ranges from 35 mm to 70 mm and the applicative continuous casting billet normal work pulling speed ranges from 0.65 m / min to 1.50 m / min. When low-carbon steel with the [C] content lower than or equal to 0.08% is poured through the continuous casting sheet billet chamfering crystallizer, the narrow-face taper back draft of a copper plate ranges from 1.1% / m to 1.5% / m; when medium-carbon steel with the [C] content higher than or equal to 0.09% and lower than or equal to 0.2% is poured through the continuous casting sheet billet chamfering crystallizer, the back draft of the copper plate ranges from 1.2% / m to 1.6% / m; when high-carbon steel with the [C] content higher than 0.2% is poured through the continuous casting sheet billet chamfering crystallizer, the narrow-face taper back draft of the copper plate ranges from 1.1% / m to 1.45% / m. The narrow-face copper plate taper back draft process has the advantages that the reasonable chamfer copper plate back draft is adopted, so that great significance in guaranteeing even and stable growth of a billet shell in a chamfered position and avoiding generation of transverse cracks on the surface of a continuous casting billet is achieved.

Owner:SHOUGANG CORPORATION

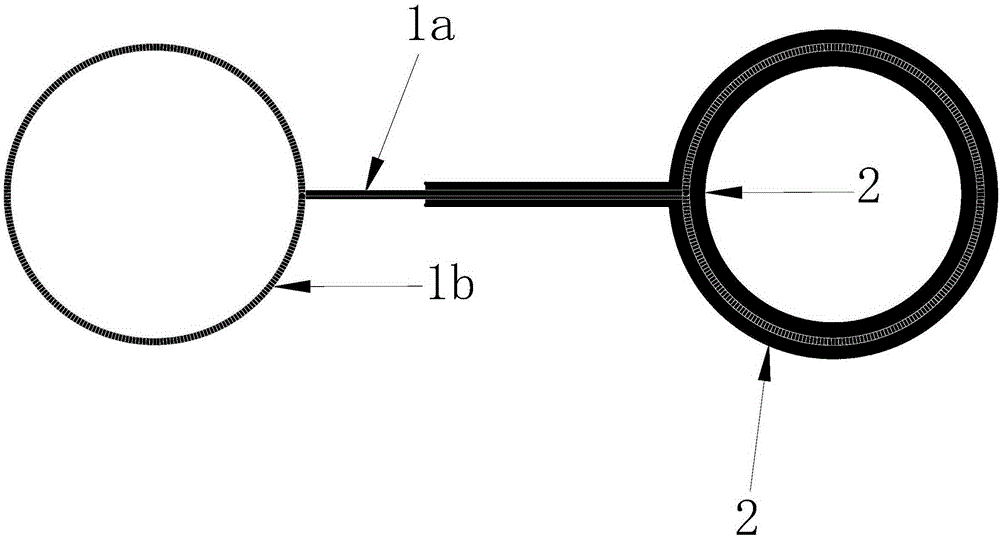

Chain type butt strap structure based on seamless bridge

ActiveCN105178171AImprove mechanical performanceImprove driving comfortBridge structural detailsChain typeEngineering

The invention discloses a chain type butt strap structure based on a seamless bridge. The chain type butt strap structure comprises a bridge abutment, a girder, a bridge deck and two or more butt straps, wherein the bridge abutment, the girder and the bridge deck form the main bridge section, and the butt straps are arranged at the end of the main bridge section in parallel and in the length direction of the main bridge section. Expansion joints are formed between the main bridge section and the butt strap closest to the main bridge section and between every two adjacent butt straps. The main bridge section and the butt strap closest to the main bridge section and every two adjacent butt straps are connected through dumbbell-shaped-structure steel bars, each dumbbell-shaped-structure steel bar is composed of a linear steel bar and two annular steel bars connected to the two ends of the linear steel bar, and the two annular steel bars are fixed inside the main bridge section and the butt strap or respectively fixed inside two butt straps. According to the invention, cracks in the joints of the butt straps at the rear part and the bridge abutment of the seamless bridge and pavement cracks in the joints of the tail ends of the butt straps and a roadbed can be eliminated, the stress performance of the butt straps of the seamless bridge can be effectively improved, and therefore the drive comfort of vehicles can be improved.

Owner:YANCHENG INST OF TECH

Stress segmentation-type pavement structural layer

InactiveCN110055848AHigh strengthImprove toughnessPaving reinforcementsIn situ pavingsSurface layerClimate change

The invention discloses a stress segmentation-type pavement structural layer. Joint-type stress bars are laid longitudinally in a structural layer of asphalt concrete pavement, the joint-type stress bars laid on an upper layer can prevent cracks generated by traffic loads and climate change, laid on a lower layer can prevent reflection cracks of a base layer, and laid on the base layer can preventcracks appearing on the base layer in the hardening process. According to the stress segmentation-type pavement structural layer, the problem of the horizontal cracks of a road is solved, the servicelife of the road is prolonged, later supporting of the road is delayed, the thickness of a pavement surface layer is reduced, and a pavement structure of a strong-base thin surface can be realized.

Owner:CHANGAN UNIV

Continuous casting stop casting slab tail out capping method

The invention discloses a continuous casting stop-casting blank tail discharge and top sealing method. First and second stopper rods of a tundish of a two-machine and two-current continuous casting machine are opened; and first and second currents of molten steel flow into first and second crystallizers. When the height of the molten steel of the tundish is from 1130 mm to 680 mm, the continuous casting pull speeds of the first and second currents of molten steel in continuous casting are both reduced to 0.09-0.11 m / min at different accelerations; at this time, after the first and second stopper rods in the tundish are respectively closed, first and second blind plates are pushed in; first and second casting water ports are taken out from the first and second crystallizers; first and second cooling rods are put in the first and second crystallizers; and the continuous casting pull speeds are increased to 0.38-0.42 m / min for keeping by not shorter than 2 min. When the tail part of a continuous casting blank is discharged from lower ports of the crystallizers, and a foot roll section casting blank totally enters the tail part of the casting blank, the tail part of the casting blank is shrunk to form a recess area, and the tail discharge and the top sealing of the casting blank are finished. The top sealing method is excellent in tail discharge and top sealing of the casting blank, increases the molten steel yield, and has the popularization value.

Owner:湖南华菱涟源钢铁有限公司

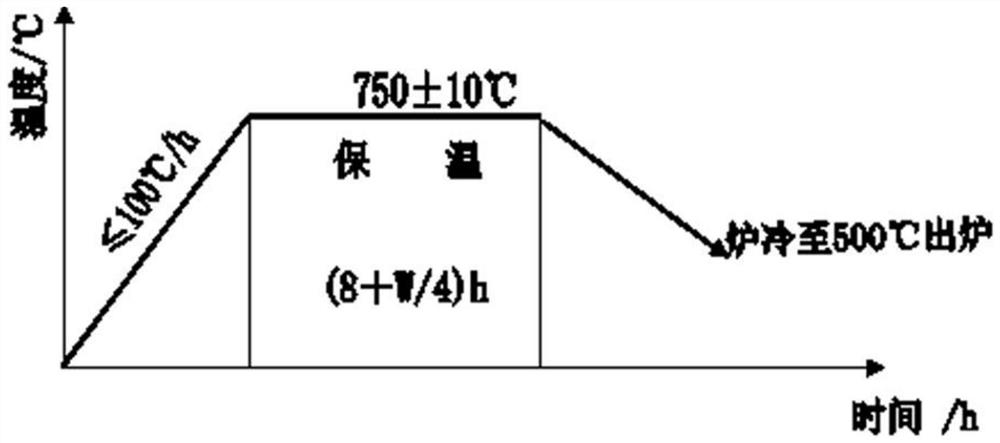

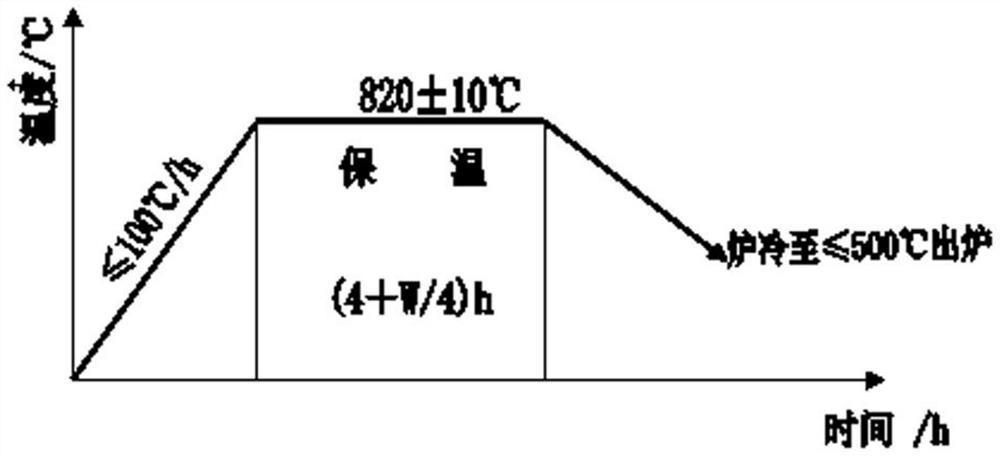

Rework welding process for T-shaped connector full penetration weld of pivot steel structure of ocean engineering crane

ActiveCN103659017APromote escapeEscape fullyWelding/cutting auxillary devicesAuxillary welding devicesButt jointFree cooling

The invention relates to rework welding process for a T-shaped connector full penetration weld of a pivot steel structure of an ocean engineering crane. A bottom plate and lateral plates of the pivot steel structure are made of a high strength steel sheet E36 for a ship, the rework welding process is characterized by comprising the following steps of heating the position of a T-shaped connector through an electric heating block at the back of the bottom plate; after a weld joint with a problem is removed, aligning to a lateral plate on an extending path, and cutting weld joints with a length at the position of a lateral plate butt joint connector; ensuring all cracks are removed, conducting heating and welding again, conducting self-cooling after heat insulation for a period of time; ensuring that transverse cracks are thoroughly removed, and completing welding of the several weld joints cut in the position of the lateral plate butt joint connector. The rework welding process for the T-shaped connector full penetration weld of the pivot steel structure of the ocean engineering crane has the advantages that the welding process with reasonable welding sequence avoiding high constraint stress is adopted so as to reduce condensation stress to avoid the transverse cracks, after the weld joint welding is completed, heat insulation processing is continuously conducted by adopting the electric heating block, and the transverse cracks are further avoided.

Owner:CHIEFNEW NANTONG HEAVY IND

Rework Welding Process of T-joint Full Penetration Weld Seam in Central Steel Structure of Marine Engineering Crane

ActiveCN103659017BPromote escapeEscape fullyWelding/cutting auxillary devicesAuxillary welding devicesButt jointFree cooling

The invention relates to rework welding process for a T-shaped connector full penetration weld of a pivot steel structure of an ocean engineering crane. A bottom plate and lateral plates of the pivot steel structure are made of a high strength steel sheet E36 for a ship, the rework welding process is characterized by comprising the following steps of heating the position of a T-shaped connector through an electric heating block at the back of the bottom plate; after a weld joint with a problem is removed, aligning to a lateral plate on an extending path, and cutting weld joints with a length at the position of a lateral plate butt joint connector; ensuring all cracks are removed, conducting heating and welding again, conducting self-cooling after heat insulation for a period of time; ensuring that transverse cracks are thoroughly removed, and completing welding of the several weld joints cut in the position of the lateral plate butt joint connector. The rework welding process for the T-shaped connector full penetration weld of the pivot steel structure of the ocean engineering crane has the advantages that the welding process with reasonable welding sequence avoiding high constraint stress is adopted so as to reduce condensation stress to avoid the transverse cracks, after the weld joint welding is completed, heat insulation processing is continuously conducted by adopting the electric heating block, and the transverse cracks are further avoided.

Owner:CHIEFNEW NANTONG HEAVY IND

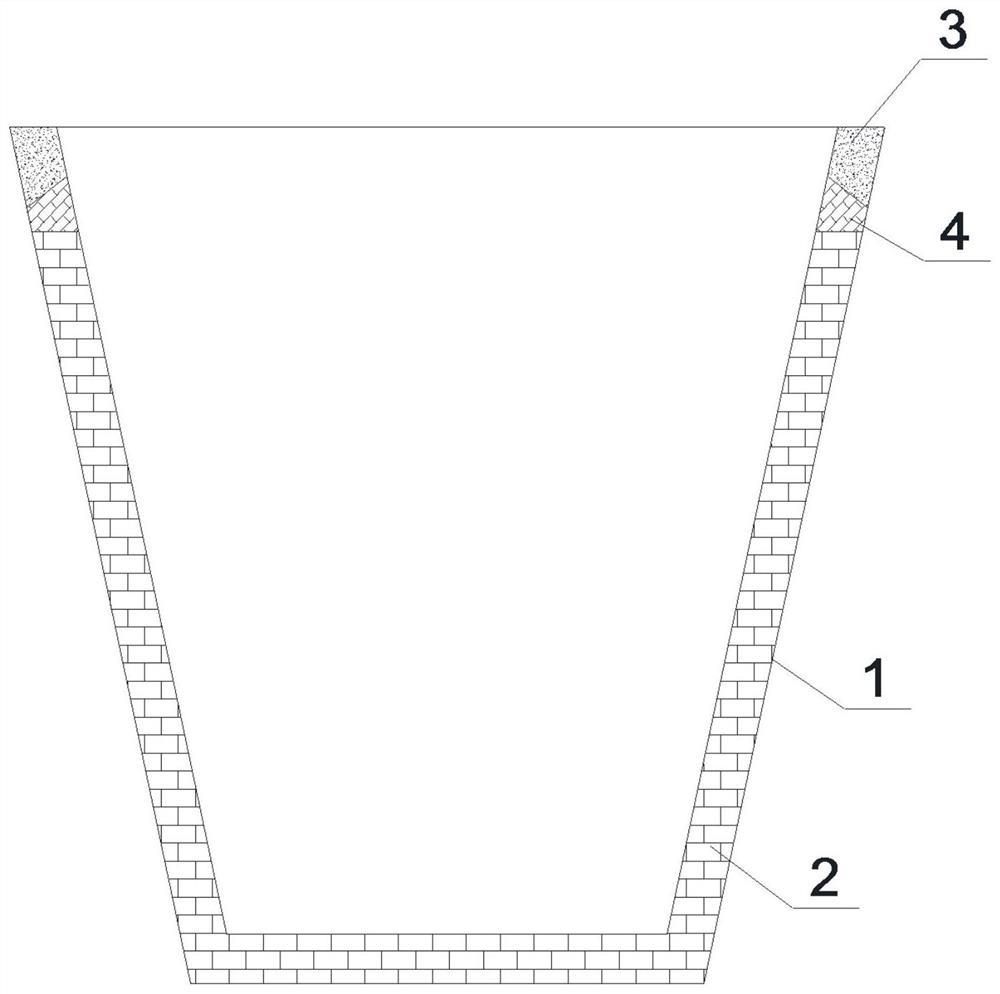

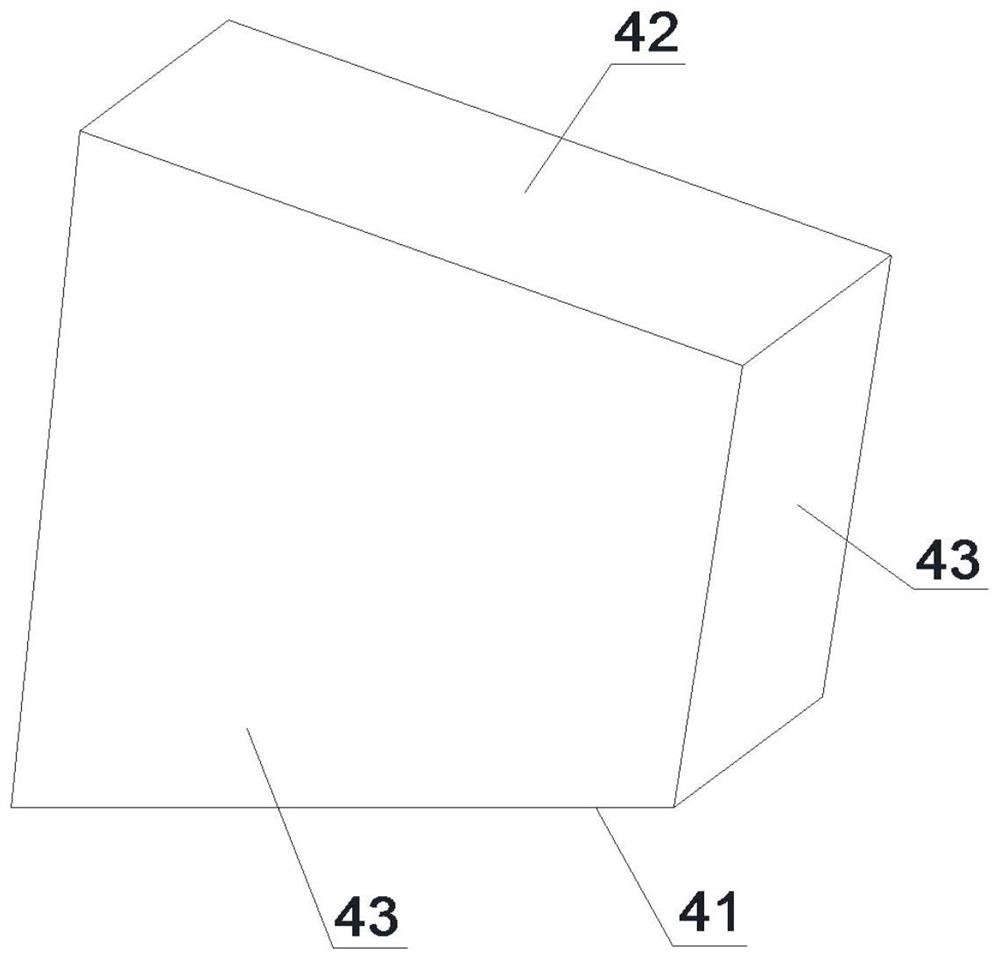

Steel ladle and steel ladle building method

The invention provides a steel ladle, and belongs to the technical field of steel ladles. According to the steel ladle, refractory bricks are arranged on the lower middle portion of a steel ladle lining, aluminum-magnesium spinel castable is arranged on the ladle edge of the upper portion of the steel ladle lining, the refractory bricks and the aluminum-magnesium spinel castable are connected through special-shaped bricks, each special-shaped brick comprises a bottom face, a top face and four side faces, the bottom faces and the top faces are both rectangular faces or trapezoid faces or sector faces, the bottom faces are horizontal faces, the top faces are inclined faces, and the height of the side faces close to the molten steel side in the vertical direction is larger than that of the side faces close to the steel shell side. By improving the structure and the material of the steel ladle, the technical problem of serious slag bonding of the steel ladle is effectively solved, the problem of damage generated in the process of treating the edge of the steel ladle is avoided, the safety risk in the production process is reduced, and the product quality is improved. The invention further provides a steel ladle building method.

Owner:BEIJING SHOUGANG CO LTD

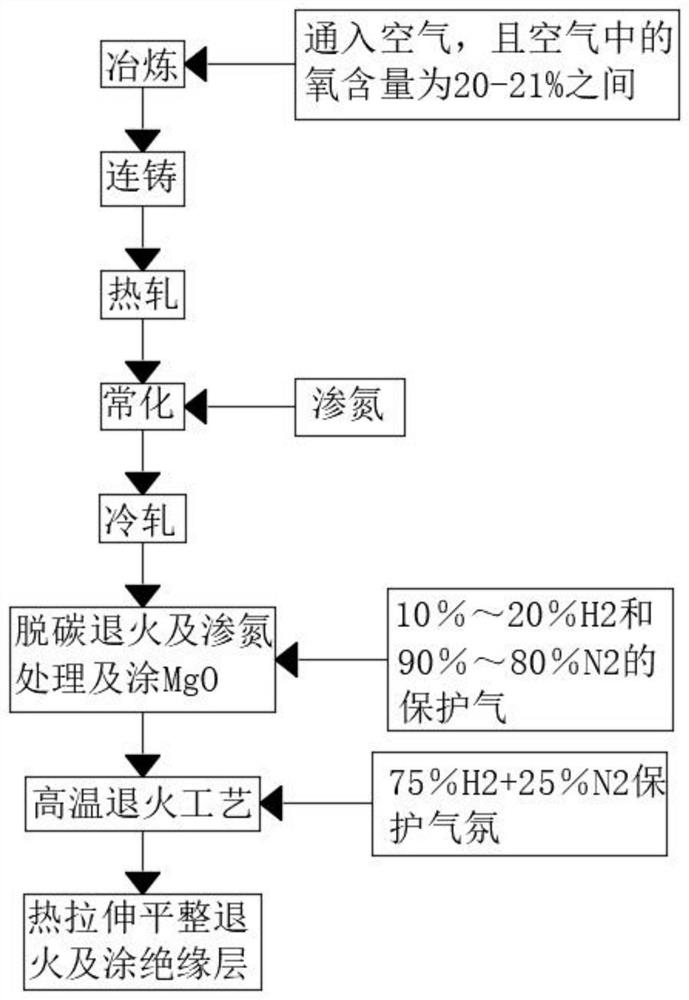

Atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism

PendingCN112626447AImprove the accuracy of atmosphere controlReduce FeO contentSolid state diffusion coatingHeat treatment process controlSmelting processNitrogen gas

The invention relates to the technical field of oriented silicon steel, and discloses an atmosphere control process of high-magnetic-induction oriented silicon steel with excellent magnetism. The atmosphere control process comprises the following steps of 1, smelting, specifically, smelting in a converter and RH refining to obtain molten steel, introducing air in the smelting process, and setting the total air inflow to be 100-300Nl / min and the oxygen content in the introduced air to be 20-21%. According to the atmosphere control process of the high-magnetic-induction oriented silicon steel with the excellent magnetism, the content of oxygen and the content of nitrogen in a certain proportion are added in different processes, the atmosphere control precision of each stage is effectively improved, therefore the obtained final high-magnetic-induction oriented silicon steel is excellent, the influence of air pressure, flow and other factors on the magnetic effect of the final high-magnetic-induction oriented silicon steel is avoided, the FeO content in the slag is reduced, the steel recovery rate is increased, the service life of a furnace lining is prolonged, the effect of reducing the production cost is achieved, accurate atmosphere control is conducted, the smelting effect is better in the smelting process of the high-magnetic-induction oriented silicon steel, and the magnetism of the smelted high-magnetic-induction oriented silicon steel is more excellent.

Owner:海安华诚新材料有限公司

A kind of low-temperature resistant micro-alloyed steel and its production process

Owner:CENT IRON & STEEL RES INST +1

Non-uniformly distributed preformed diamond compact and preparation method thereof

ActiveCN112276098AImprove wear resistanceImprove impact resistanceTurbinesOther manufacturing equipments/toolsPolycrystalline diamondAlloy

The invention relates to the technical field of diamond compacts, in particular to a non-uniformly distributed preformed diamond compact and a preparation method thereof. The non-uniformly distributedpreformed diamond compact comprises a hard alloy matrix and a polycrystalline diamond layer, wherein at least two grooves distributed around the axis are formed in the edge of the upper end surface of the hard alloy matrix; the polycrystalline diamond layer comprises a first block corresponding to the upper end surface of the hard alloy matrix up and down and second blocks in one-to-one correspondence to the grooves up and down; and the lower end surface of the polycrystalline diamond layer is connected with a connecting surface in a shape matching manner. The preparation method comprises thesteps of processing a hard alloy meter, manufacturing the polycrystalline diamond layer, manufacturing a combination body, carrying out machining and carrying out cobalt removal treatment. The product provided by the invention has relatively high wear resistance and impact resistance at the same time.

Owner:河南亚龙金刚石制品股份有限公司 +1

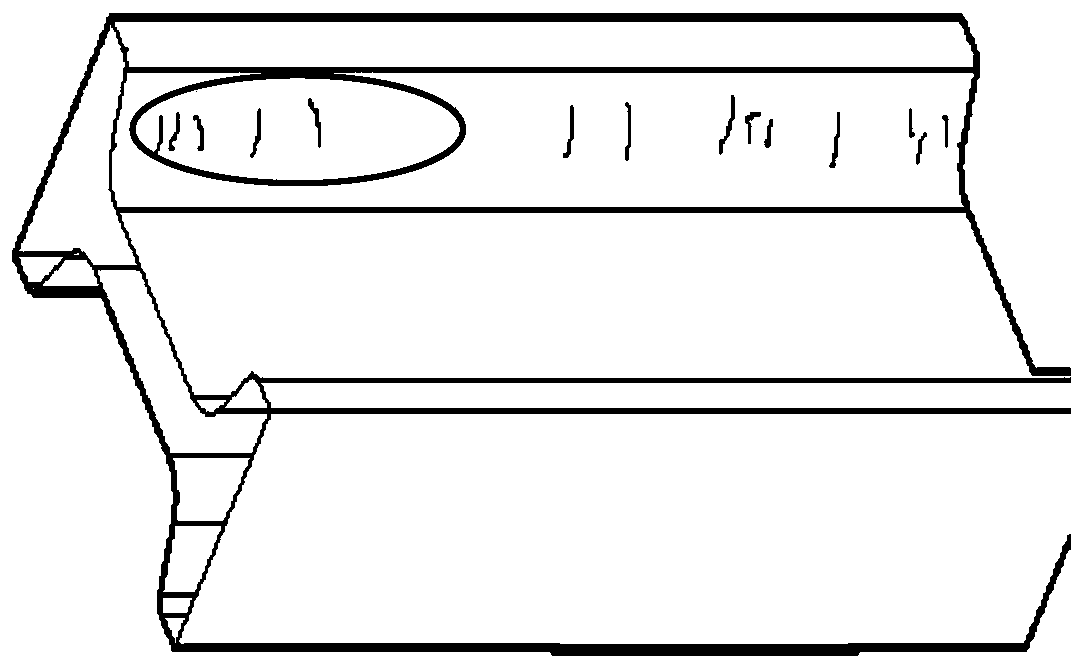

Electric hammer cylinder

PendingCN110733002AAvoid breakingImprove structural strengthPortable percussive toolsClassical mechanicsStructural engineering

The invention provides an electric hammer cylinder, and belongs to the field of electric tools. The electric hammer cylinder comprises a cylinder block; a cylinder hole is formed in one end of the cylinder block, and two connecting lugs are arranged at the other end; coaxial connecting holes are formed in the two connecting lugs; the tops of the two connecting lugs are connected as a whole througha connecting plate; and the roots of the two connecting lugs are connected as a whole, and are transited through arcs. The tops and the roots of the two connecting lugs are connected as a whole, so that the structural strength is greatly improved; meanwhile, the connecting places are transited by the arcs, the roots of the connecting lugs and the transverse direction of the connecting holes are effectively prevented from rupturing; the service life of the electric hammer cylinder is far longer than the service life of other parts of an electric hammer; and even if the other parts of the electric hammer cylinder are damaged and replaced, the electric hammer cylinder cannot generate the damage and replacement phenomenon.

Owner:温岭市百邦电动工具配件厂(普通合伙)

Truss structure having an open-section upper chord member and a production method for the same, and a truss bridge using the truss structure having an open-section upper chord member and a method for constructing the same

InactiveCN103210148BImprove rigidityHigh strengthTruss-type bridgeGirdersEngineeringBuilding construction

Owner:崔夏祯

Method and device for deceasing transverse corner cracks of casting blanks

The invention relates to a method and device for decreasing transverse corner cracks of castling blanks. The method includes the steps of S1, disposing a smoke hood above a conveying roller way for cut casting blanks to collect high-temperature air; S2, delivering the collected high-temperature air under pressure; S3, delivering the high-temperature air to air nozzles disposed in a second casting blank cooling area and at corners of the casting blanks; and S4, allowing the high-temperature air to pass through the air nozzles to cover the corners of the casting blanks. The device comprises the smoke cover (3), a first heat-resistant pipe (4), a booster fan (5), a second heat-resistant pipe (6), heat-resistant branch pipes (7) and the air nozzles (8). The high-temperature compressed air can be blown to the corners of the casting blanks to prevent excessively fast cooling of the corners of the casting blanks, so that the corners of the casting blanks can be kept at the temperature higher than the upper limit of a low-temperature brittleness area before entering a straightening area, precipitation of various carbo-nitrides from the corners of the casting blanks is avoided, corner plasticity of the casting blanks is improved and transverse cracking of the corners of the casting blanks is effectively prevented during straightening.

Owner:WISDRI ENG & RES INC LTD

Stress-decomposed pavement structure layer

InactiveCN110055848BHigh strengthImprove toughnessPaving reinforcementsIn situ pavingsArchitectural engineeringStructural engineering

The invention discloses a stress segmentation-type pavement structural layer. Joint-type stress bars are laid longitudinally in a structural layer of asphalt concrete pavement, the joint-type stress bars laid on an upper layer can prevent cracks generated by traffic loads and climate change, laid on a lower layer can prevent reflection cracks of a base layer, and laid on the base layer can preventcracks appearing on the base layer in the hardening process. According to the stress segmentation-type pavement structural layer, the problem of the horizontal cracks of a road is solved, the servicelife of the road is prolonged, later supporting of the road is delayed, the thickness of a pavement surface layer is reduced, and a pavement structure of a strong-base thin surface can be realized.

Owner:CHANGAN UNIV

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582BIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconHot Temperature

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / s. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

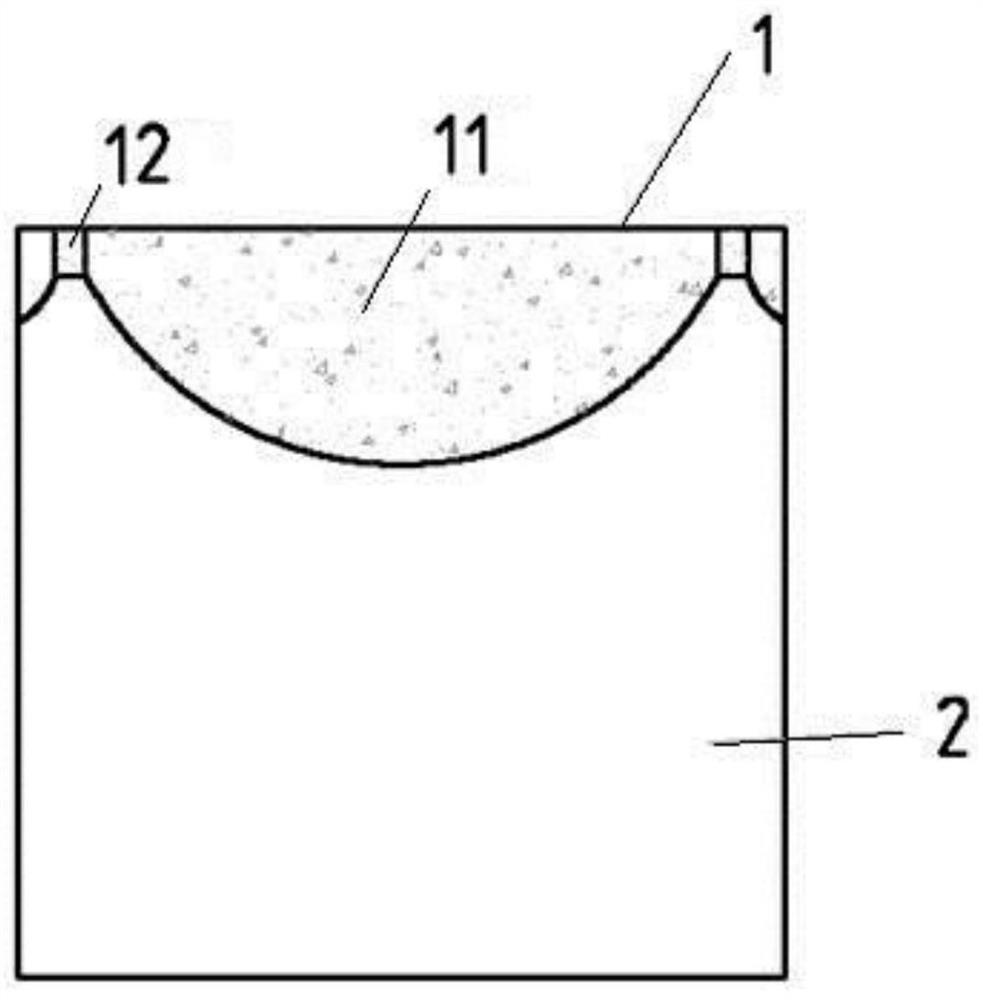

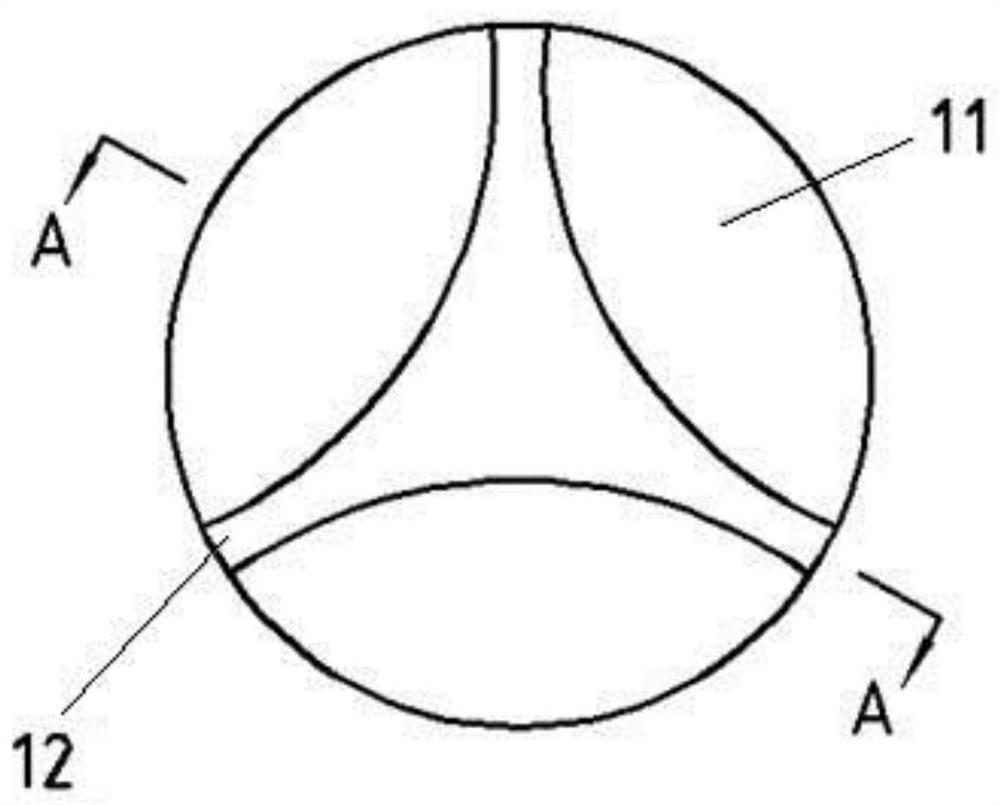

Knotting mould for crucible and knotting method

The invention discloses a knotting mould for a crucible. A furnace body wall is arranged on the outer part of an inner ring mould; an outer ring mould is arranged between the inner ring mould and the furnace body wall; the interior of a space which is formed between the furnace body wall and the inner ring mould is filled with a first magnesium oxide dry ramming material; a second magnesium oxide dry ramming material is filled between the inner ring mould and the outer ring mould; and the interior of a cavity body which is positioned between the outer ring mould and the furnace body wall is filled with a mixed dry ramming material. The knotting method comprises the following steps: 1), knotting the furnace bottom, adding the first magnesium oxide dry ramming material in batches, performing degassing and compacting by vibration, and scraping hairs; 2), knotting the furnace wall; 3), performing up-and-down vibration in corresponding positions of the inner ring mould by using a radial vibrator when material addition, compaction and knotting are carried out every three times; 4), ensuring that the space between the outer ring mould and the inner ring mould is equal uniformly; 5), filling the first magnesium oxide dry ramming material between the inner ring mould and the outer ring mould until the knotting operation is carried out completely and the first magnesium oxide dry ramming material arrives at the top of the furnace body wall; 6), performing sealing by using the mixed dry ramming material; and 7), taking out the outer ring mould and completing a knotting operation of the crucible. The knotting mould disclosed by the invention has the characteristics of preventing cracking, buffering high-temperature stress, and improving the anti-vibrating stability.

Owner:西安聚能高温合金材料科技有限公司

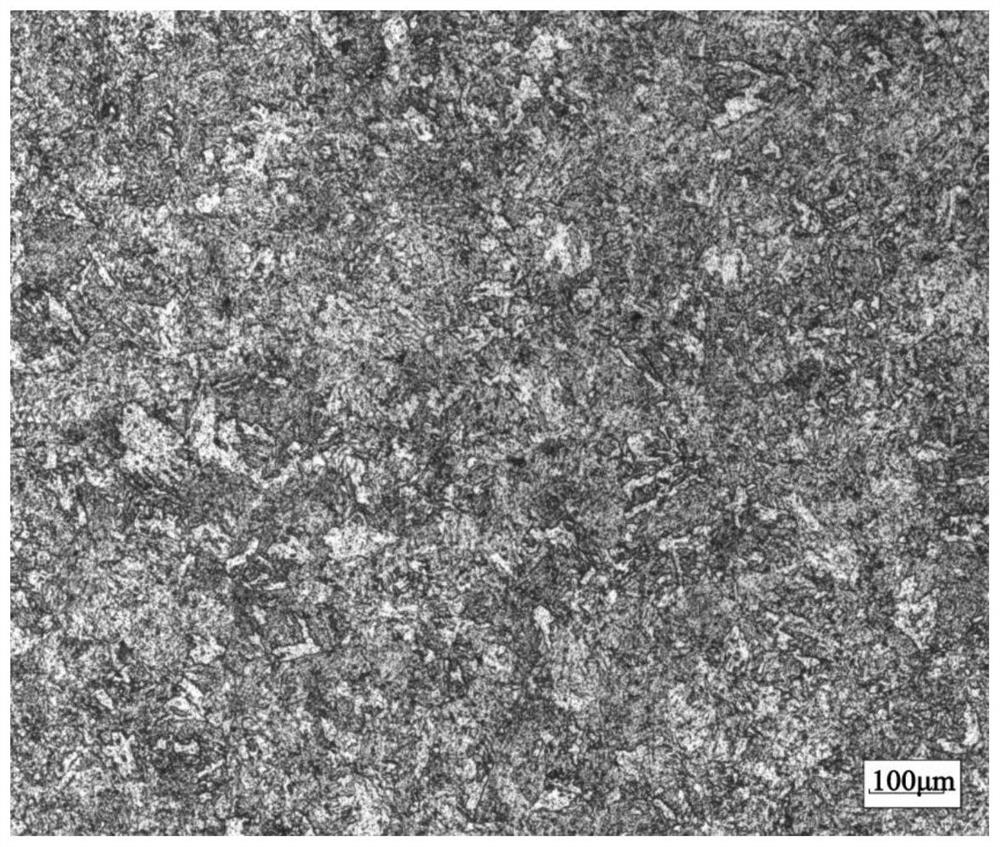

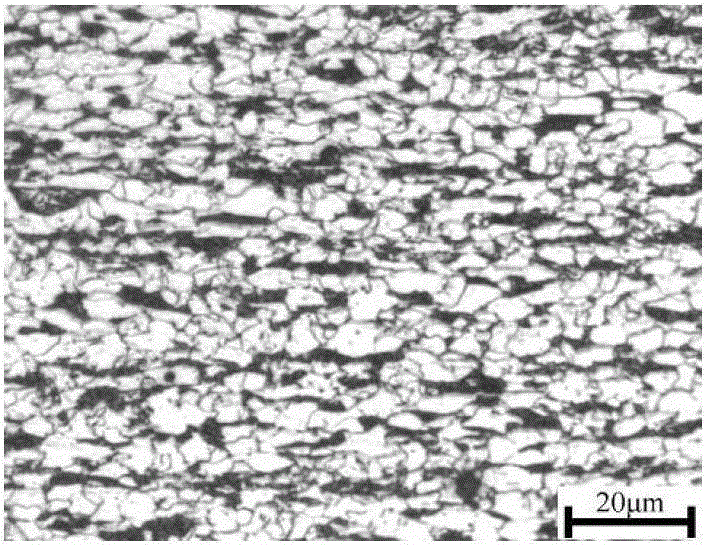

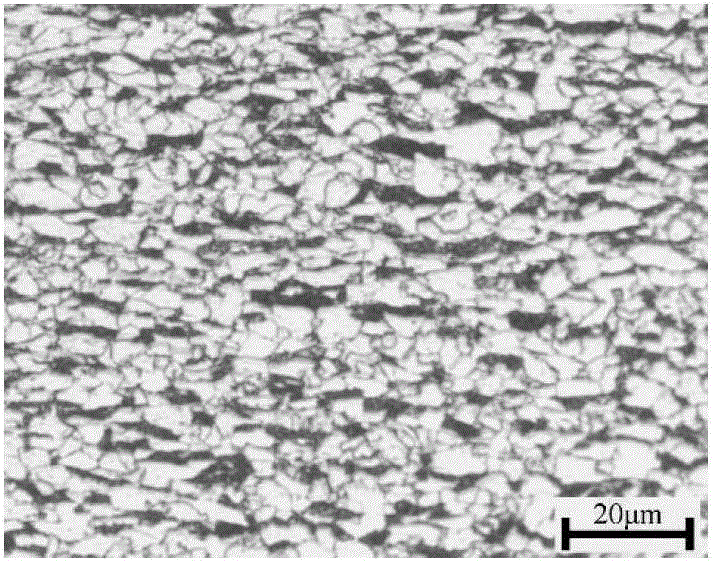

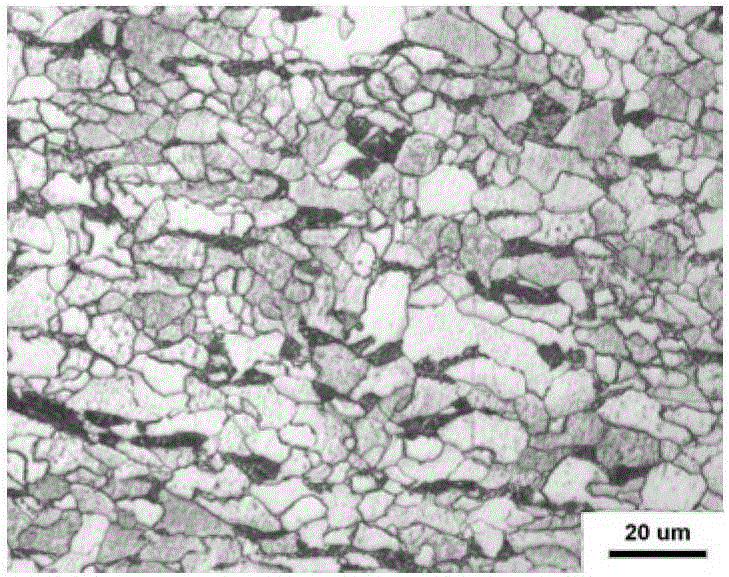

A kind of Cr alloyed steel for electric resistance welded oil casing and its manufacturing method

ActiveCN103510010BLow costResilientTemperature control deviceElectrical resistance and conductanceElectric resistance welding

The invention provides a Cr alloying electric resistance weld petroleum casing pipe steel and a manufacturing method thereof. The steel comprises the following chemical components: 0.15%-0.20% of C, 0.10%-0.35% of Si, 0.90%-1.15% of Mn, less than or equal to 0.020% of P, less than or equal to 0.008% of S, 0.010%-0.030% of Ti, 0.08%-0.28% of Cr, 0.02%-0.06% of Als, less than or equal to 0.008% of N, and the balance Fe and inevitable elements. The manufacturing method includes: smelting, continuous casting, rolling, cooling, and reeling. The heating temperature of a continuous casting sheet billet is 1100-1200DEG C. The rolling adopts two-stage control. In the first stage, the initial rolling temperature is 1050-1150DEG C, the final rolling temperature is higher than 970DEG C, and the accumulative deformation is more than 60%. In the second stage, the initial rolling temperature is lower than 990DEG C, the final rolling temperature is 780-850DEG C, and the accumulative deformation is above 70%. A rolled steel strip is cooled to 570-640DEG C at a cooling rate of 10-15DEG C / s and is subjected to reeling. The metallographic structure of the steel is ferrite-pearlite, and the pearlite volume content is 6%-40%. According to the invention, a Cr alloying design is adopted, and adding of Nb and V precious alloys is unnecessary. By controlling rolling, cooling and reeling processes, the steel plate can meet the requirements of the API SPEC 5CT standard on a J55 grade steel pipe.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com