Rework welding process for T-shaped connector full penetration weld of pivot steel structure of ocean engineering crane

A technology of marine engineering and welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to avoid hydrogen-induced cracks, slow down the cooling rate, and prevent the appearance of transverse cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention relates to a repair welding process for full-penetration welds of T-shaped joints of a central steel structure of a marine engineering crane. The bottom plate and side plates of the T-shaped joints of the central steel structure are made of high-strength marine steel plates E36.

[0016] The specific steps are:

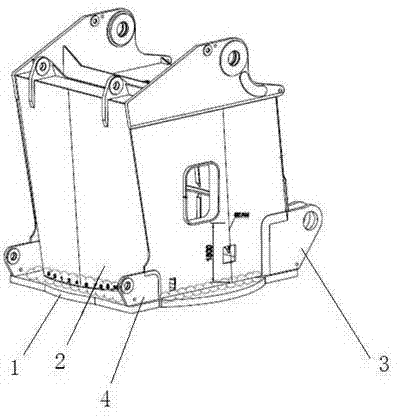

[0017] Step S1: Firstly, preheat the horizontal weld at the T-shaped joint between the bottom plate 1 and the side plate 2. The preheating adopts electric heating and attaches an electric heating block from the back of the bottom plate;

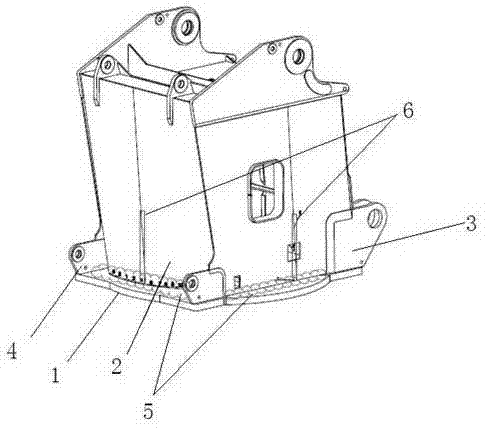

[0018] Step S2: After the preheating temperature reaches 110°C, check the defective welds at the T-joints shown by the flaw detection (see figure 2 Central cloud line area 5) Grind and remove the inner and outer sides of the T-joint by carbon arc gouging; cut a length of weld at the butt joint of side plate 2 on the extension path of the problem weld, see figure 2 Middle rectangular dotted line area 6; make th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com