Patents

Literature

265 results about "Rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rework (or re-work) is the term for the refinishing operation or repair of an electronic printed circuit board (PCB) assembly, usually involving desoldering and re-soldering of surface-mounted electronic components (SMD). Mass processing techniques are not applicable to single device repair or replacement, and specialized manual techniques by expert personnel using appropriate equipment are required to replace defective components; area array packages such as ball grid array (BGA) devices particularly require expertise and appropriate tools. A hot air gun or hot air station is used to heat devices and melt solder, and specialised tools are used to pick up and position often tiny components.

Thermal interface adhesive and rework

InactiveUS20050256241A1Printed circuit assemblingNon-macromolecular adhesive additivesEpoxyDevice material

A reworkable conductive adhesive composition, and method of making such, comprising an epoxy based conductive adhesive containing conductive metal filler particles dispersed in a solvent-free hybrid epoxy polymer matrix. In an additional embodiment an improved method of removing cured conductive polymer adhesives, disclosed here as thermal interface materials, from electronic components for reclamation or recovery of usable parts of module assemblies, particularly high cost semiconductor devices, heat sinks and other module components.

Owner:IBM CORP

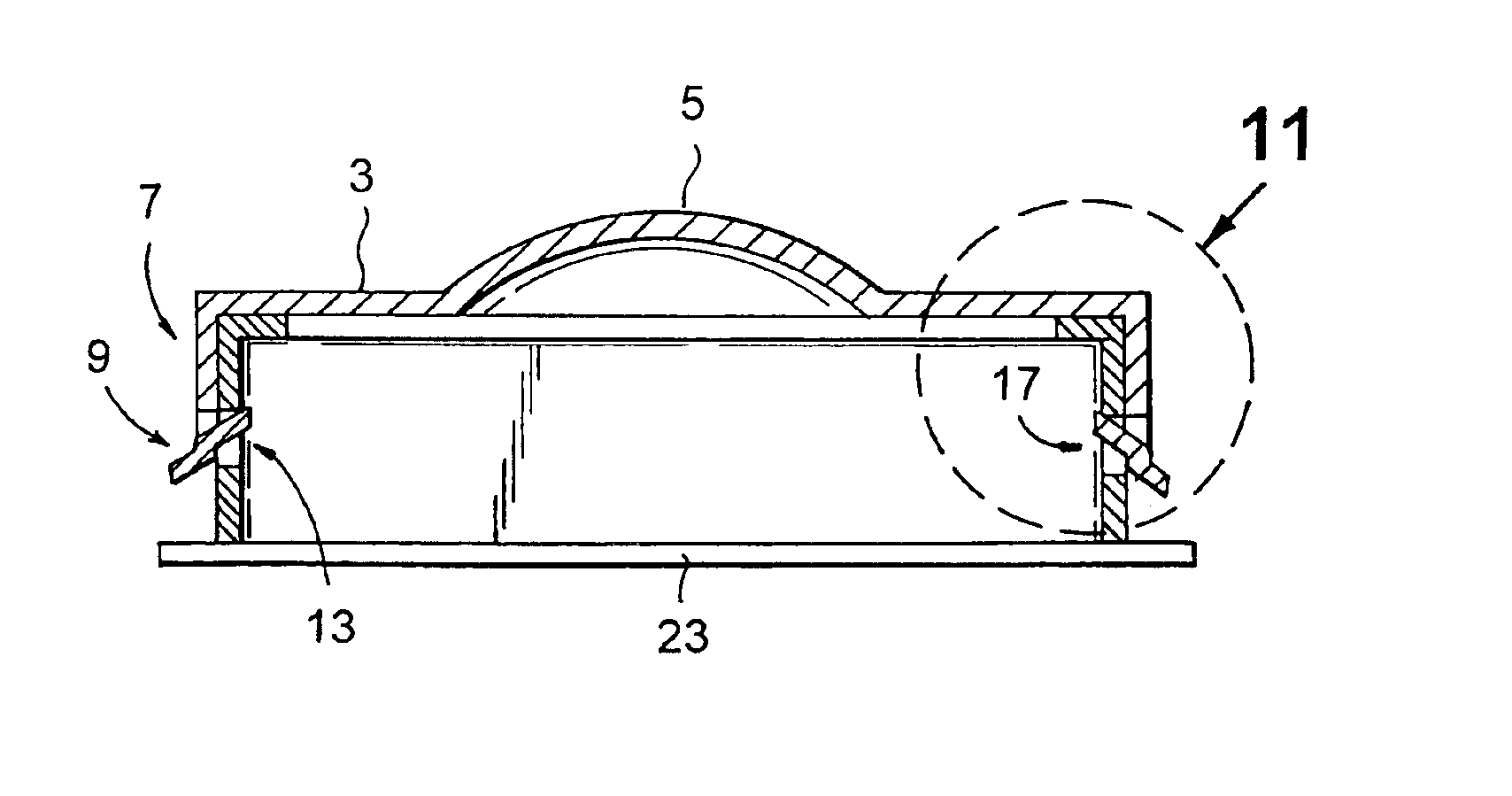

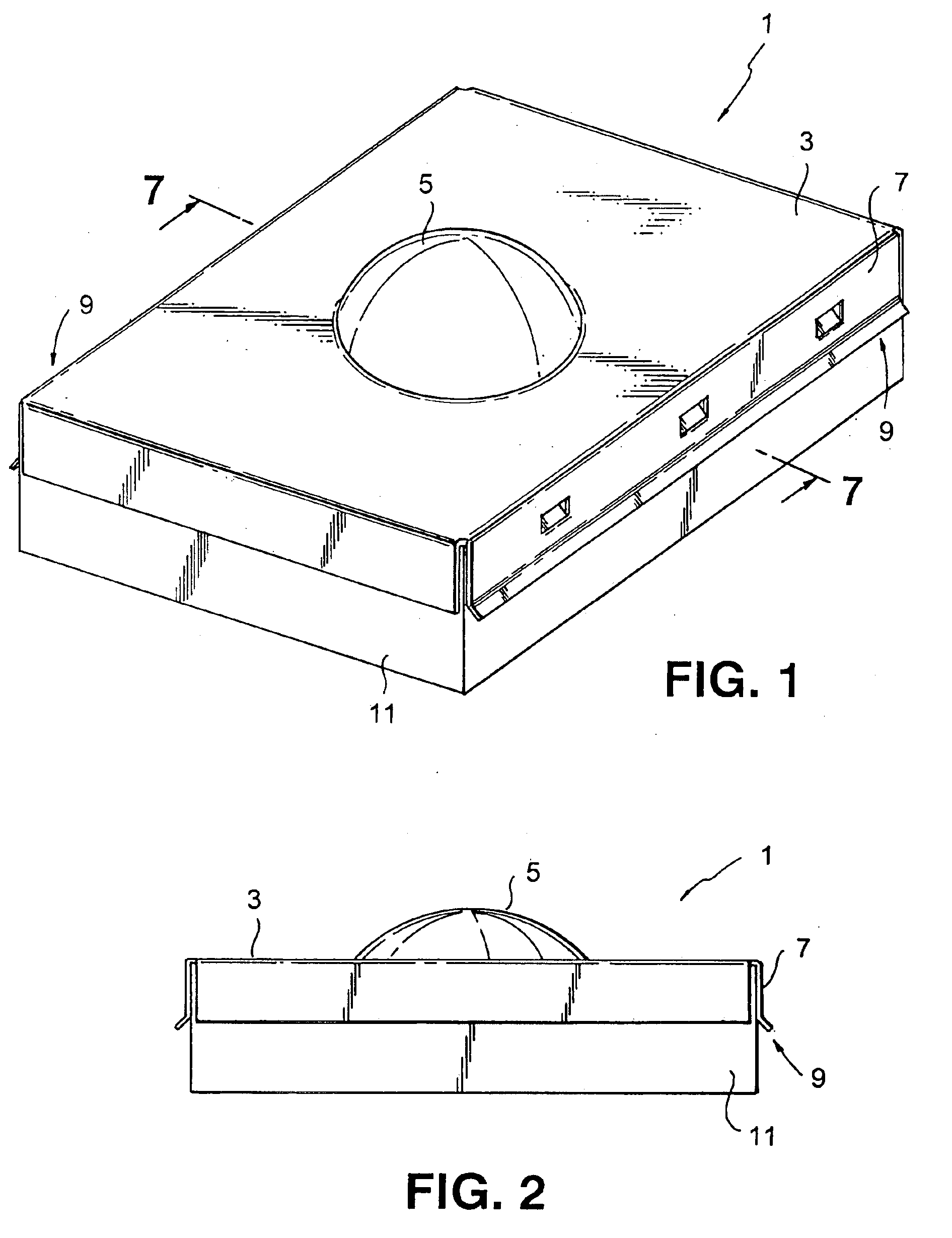

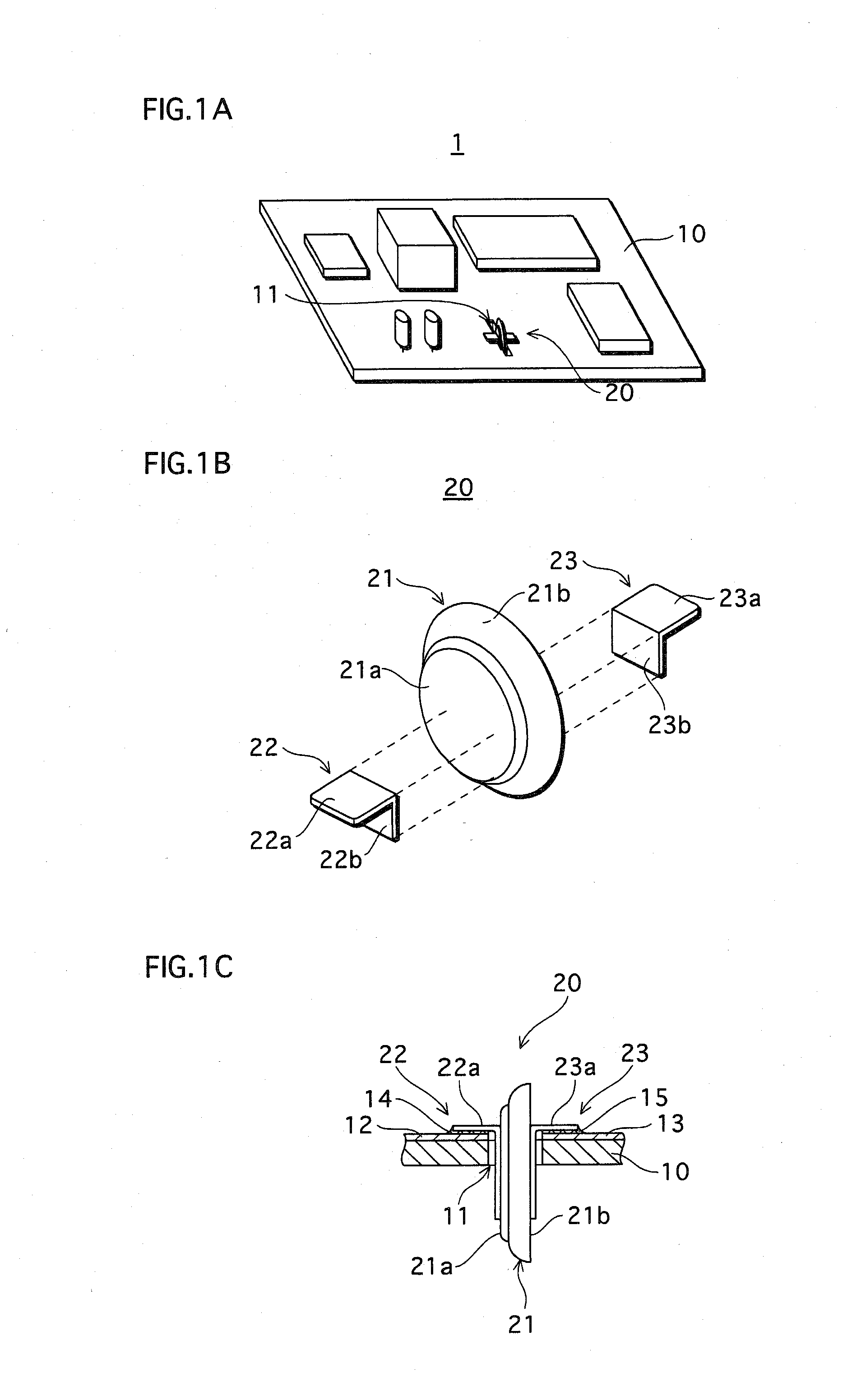

Two-piece electrical RF shield and method of manufacturing the same

InactiveUS6870091B2Cost efficientEasily adaptElectrically conductive connectionsMagnetic/electric field screeningElectricityEngineering

A two-piece RF interference shield and method of manufacturing the same that is cost efficient and easily adapted for use with existing electrical devices. The RF shield includes a bottom portion mounted to the circuit board and a top portion which fits onto the bottom portion. The RF electrical interference shield can be mounted to circuit boards (e.g., by soldering) to prevent electrical components from causing RF interference. The RF shield of the present invention also allows for easy removal of the top of the RF shield so as to provide access to the interior for rework or repair of the electrical components covered by the shield, without having to unsolder the bottom portion of the shield. The two-piece shield for shielding an electrical component comprises a top portion and bottom portion that are fitted together so as to enclose the electrical components to be shielded. The top and bottom portions snap together, e.g., by way of barbs located on one of the portions that fit into corresponding holes or slots located on the other portion.

Owner:INTERPLEX IND

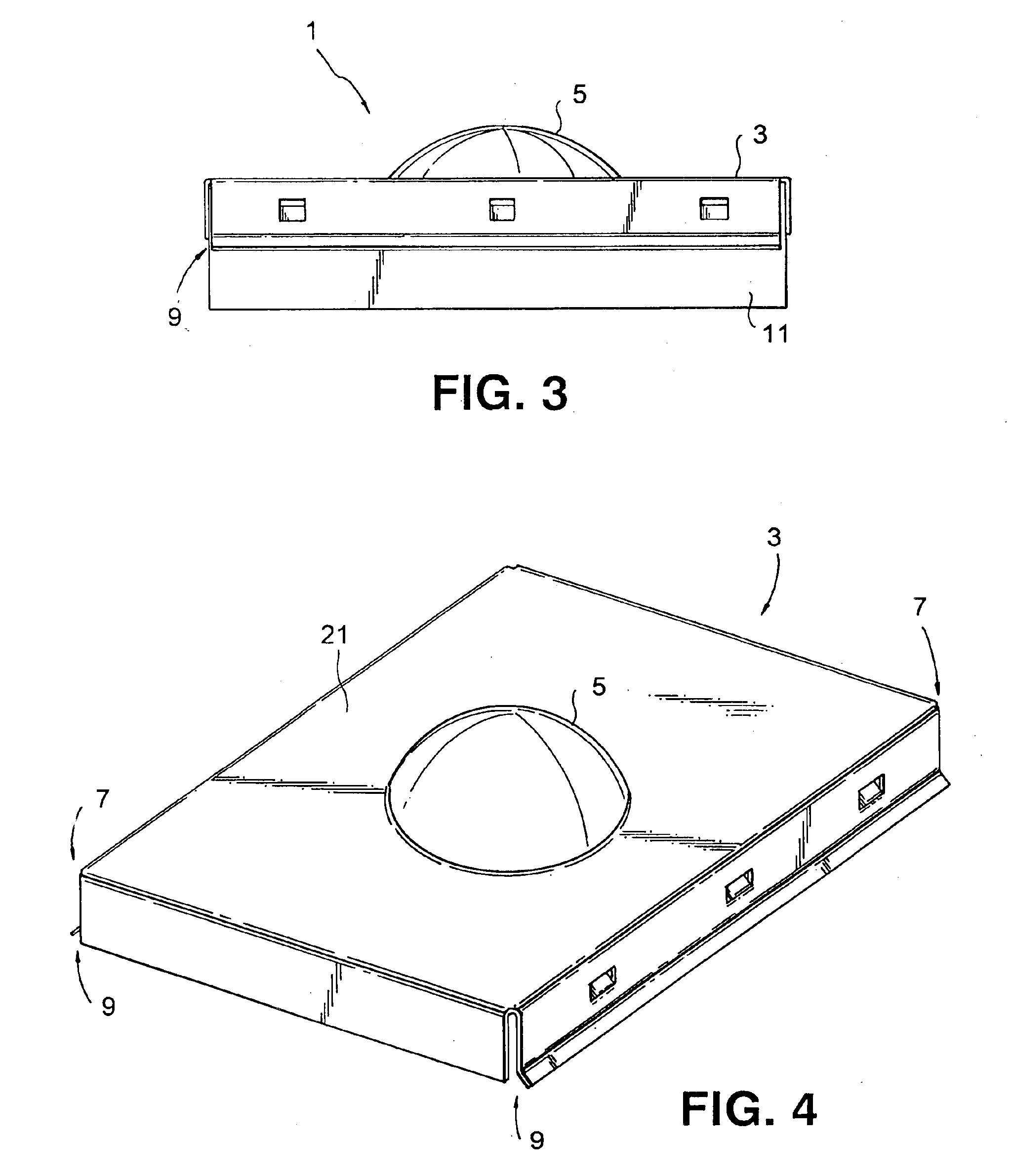

System in package

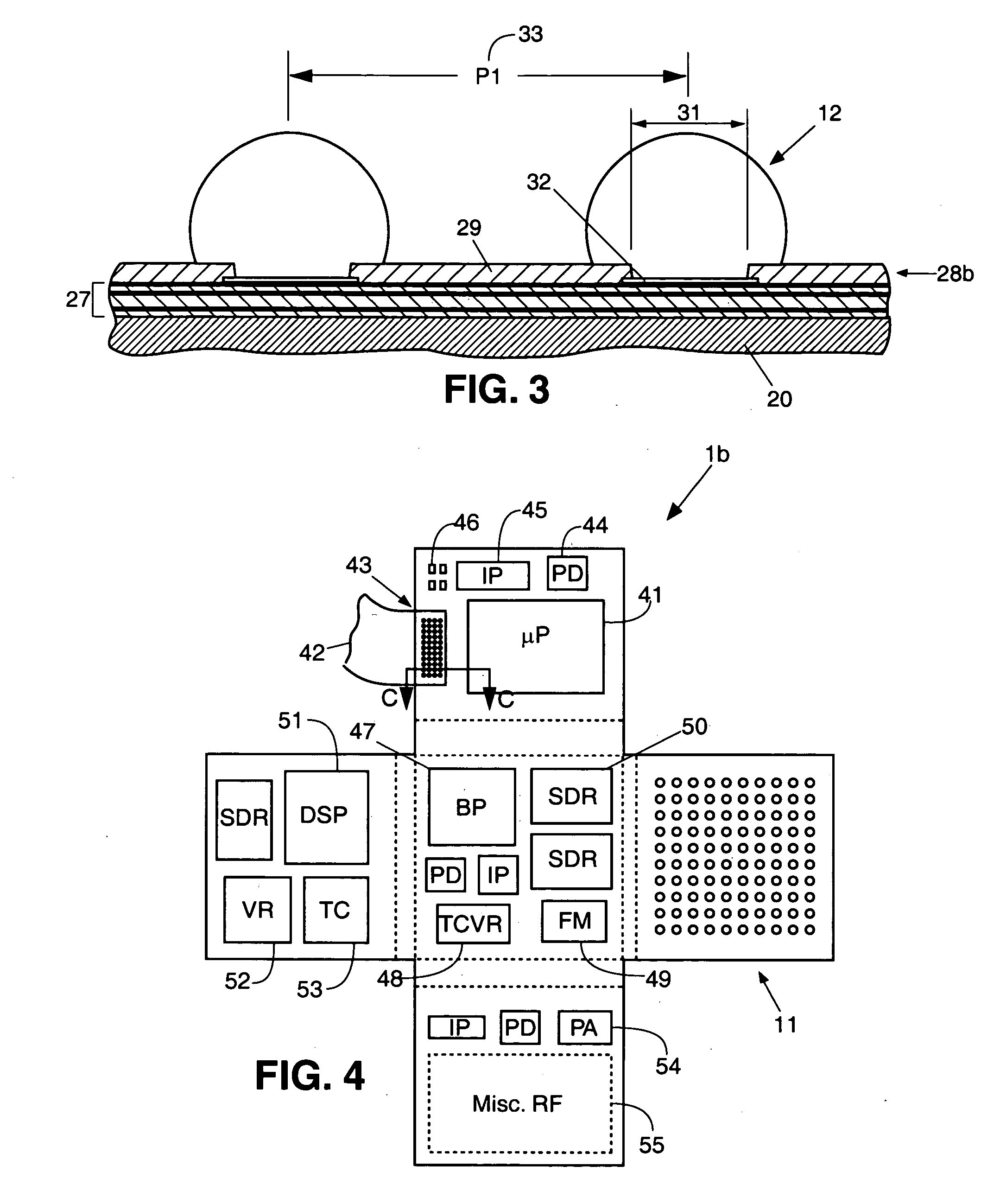

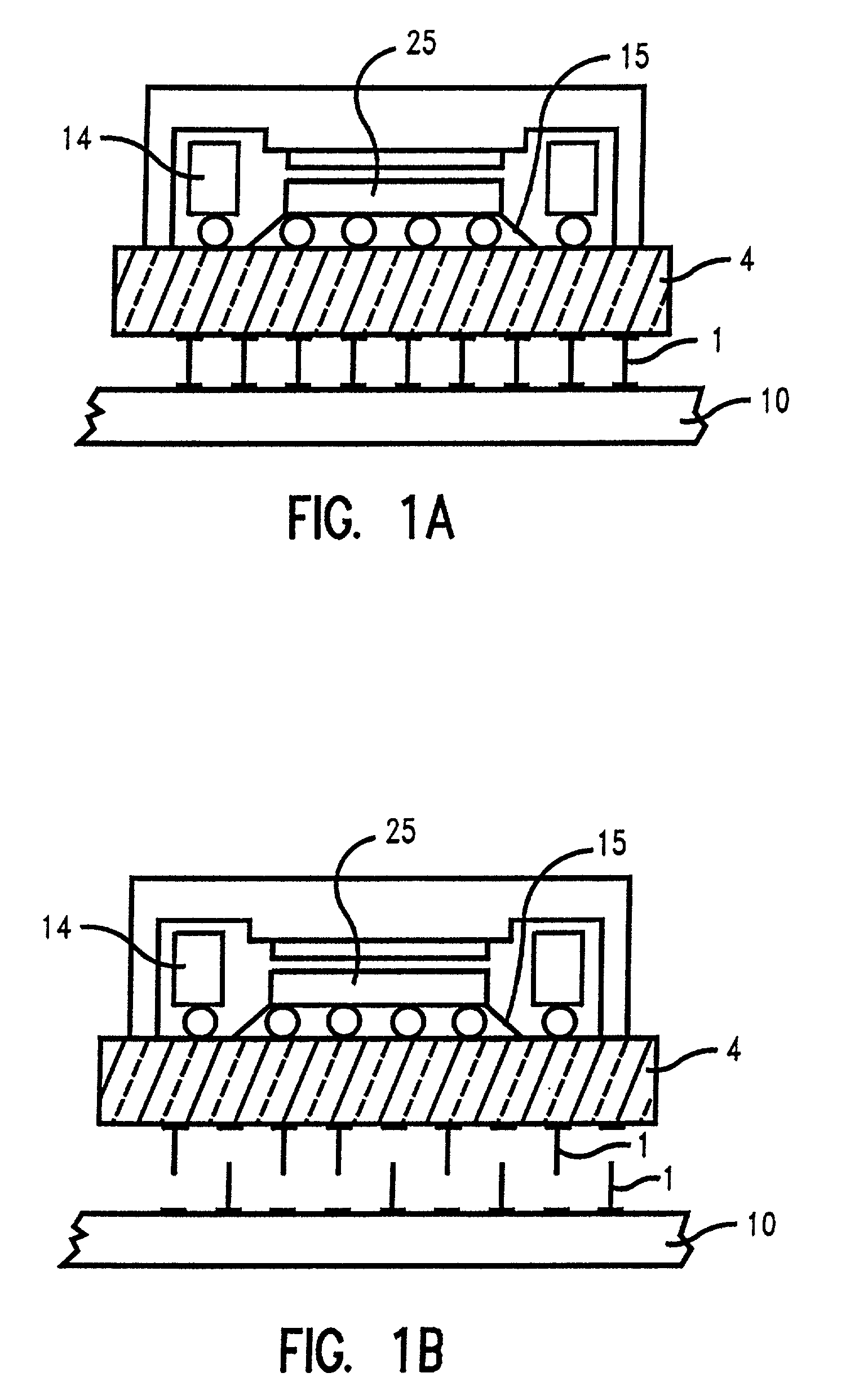

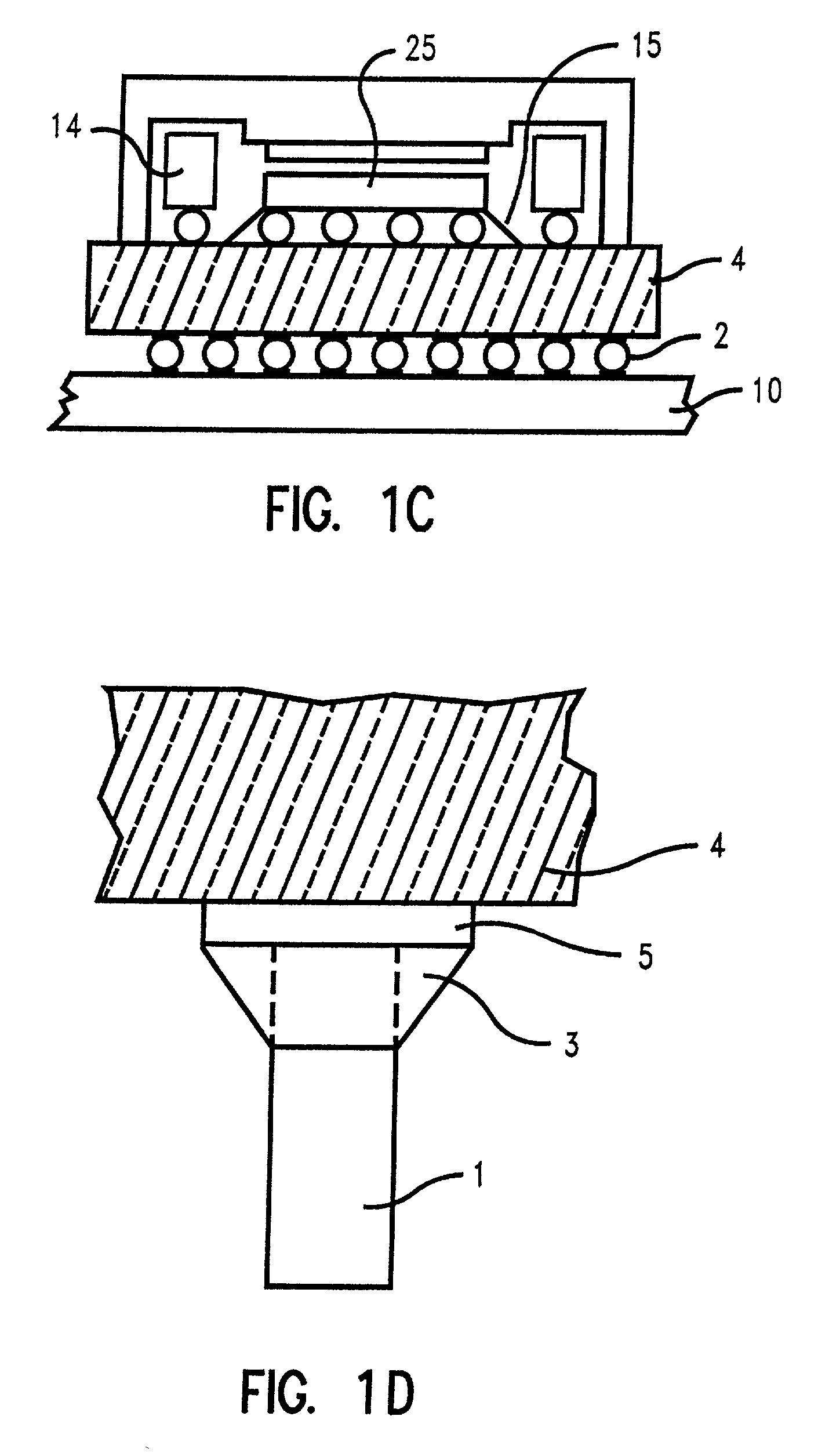

InactiveUS20050184376A1Improve cooling effectIncrease speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper conductorBand shape

A system in package (SIP) is fabricated on a sheet of copper foil. An interconnection circuit is fabricated on the foil using copper conductors and a dual damascene structure for each conductive layer. The preferred dielectric material is an amorphous fluorinated polymer called Cytop. Input / output traces of the interconnection circuit terminate in wells filled with solder. Chips are bumped and direct attached by inserting the bumps into the wells. The preferred bumps are gold stud bumps, and the preferred wells contain solder paste to a depth of approximately 15 microns. Imprinting is the preferred method for patterning; it enables 6-micron wide traces, 6-micron diameter vias, and a cost per well of around 0.02 cents. Stripline structures are described for a 4-layer stackup that can support operating frequencies of at least 10 GHz. New methods are proposed for testing the completed assembly and for rework of any chips that prove defective. After the assembly is fully tested and reworked in sheet form the copper foil is folded to form a stacked die package or system in package. 5-high and 9-high stacks are illustrated. The copper foil provides a low impedance thermal path for cooling every chip in the SIP.

Owner:SALMON TECH

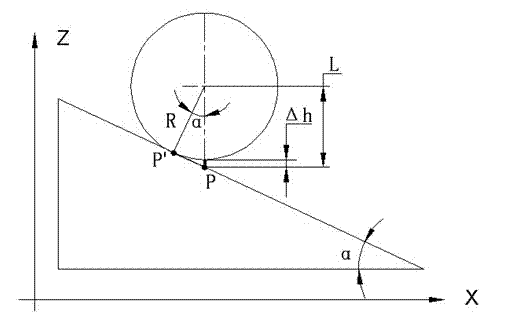

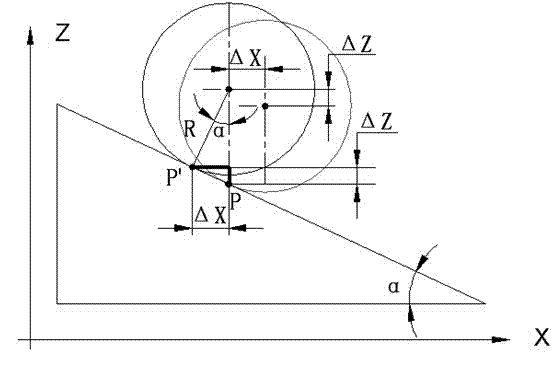

On-line measuring method for radials profile of compressor disc-like part of engine

InactiveCN102814512AAvoid errorsHas measurement limitationsAuxillary equipmentMeasurement/indication equipmentsReworkProcessing

The invention belongs to the field of automatic detection, particularly relates to an on-line measuring method for the radials profile of a compressor disc-like part of an engine. The method comprises the following steps that the measuring path of a measuring head is planned; the radius of sphere of the measuring head is corrected; characteristic points on the profile of a compressor disc are selected as measuring points; the motion program of the measuring head is edited; the motion track of the measuring head is optimized in virtual simulation software; the motion program of the measuring head is run; the measuring head traverses all the measuring points; the mean value of the measured values of the measuring points after errors are compensated is compared with the design theoretical value of the compressor disc part; when the measured values are within the design tolerance zone scope of the part, the processing size of the measured compressor disc part is considered to be qualified; otherwise, the processing and measurement are carried out again, until the size of the part is qualified. According to the method, a traditional manufacturing mode in the current industry that a design characteristic is matched with a set of measuring tooling is changed, so that the tooling manufacturing cost and the rework hours are saved, the one-time qualified rate of product processing is improved, the new product development cycle is shortened and the production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

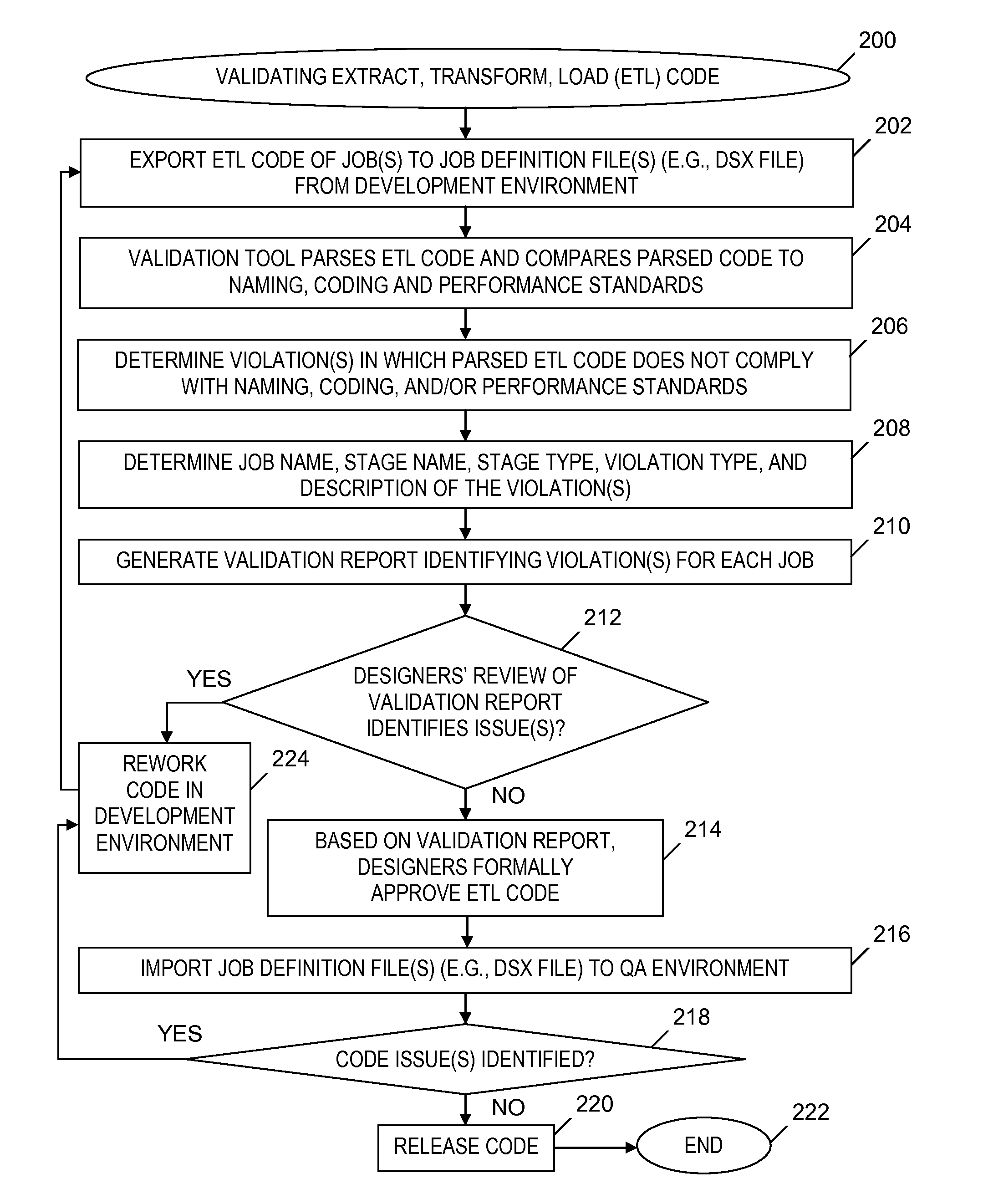

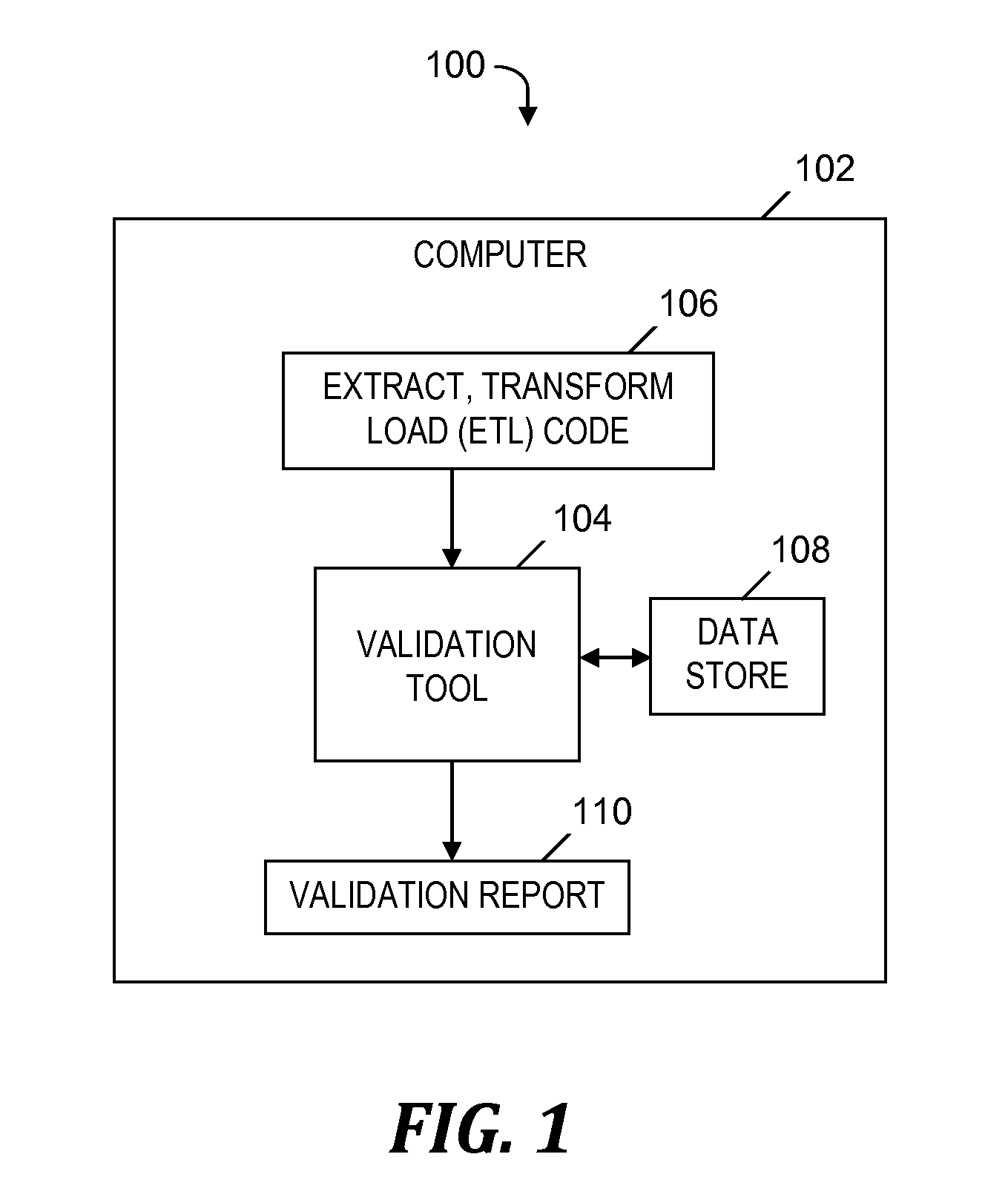

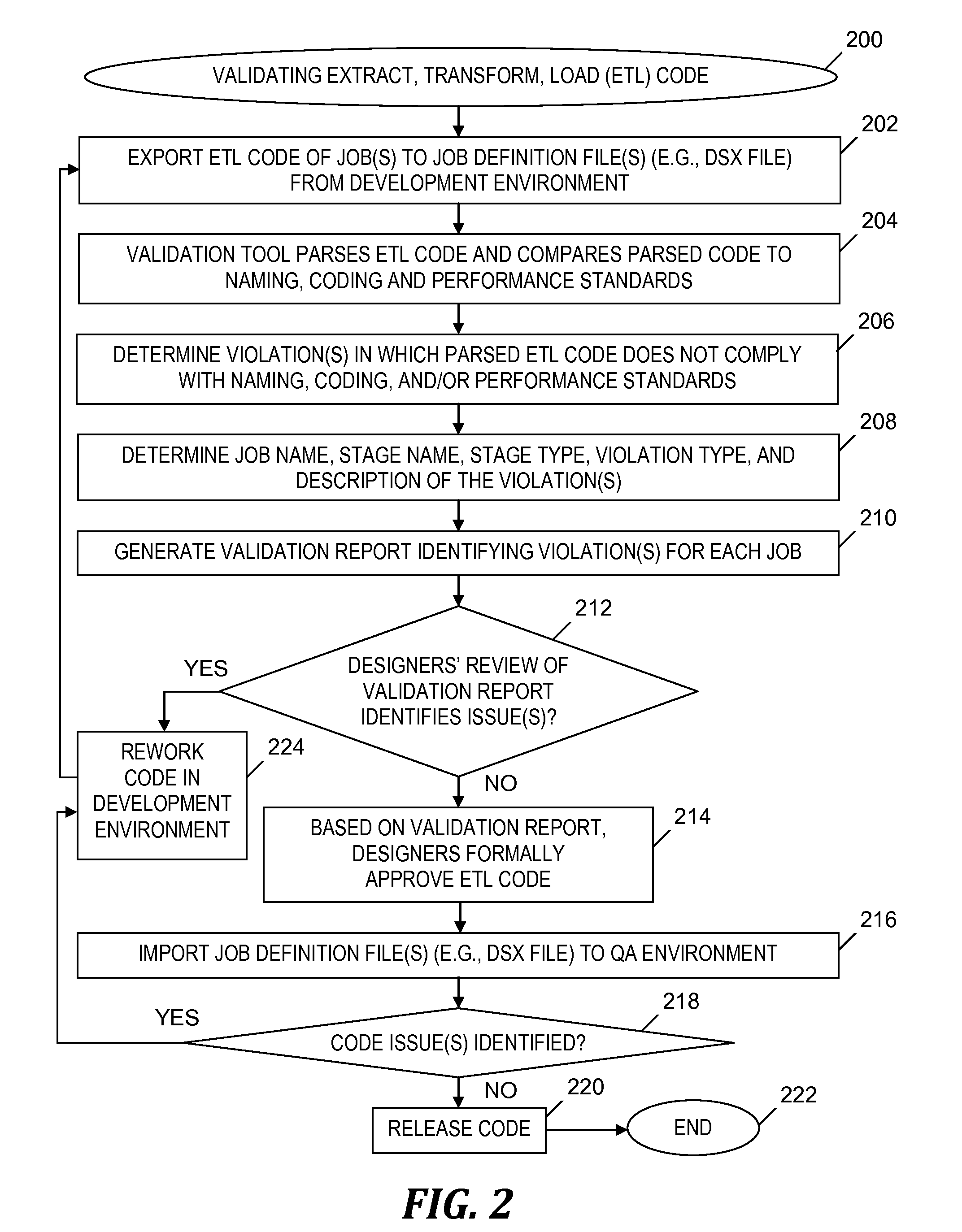

Validating code of an extract, transform and load (ETL) tool

InactiveUS20160019132A1Facilitates effective reviewLow costSoftware testing/debuggingSpecific program execution arrangementsProgramming languageRework

An approach for validating code for an extract, transform and load (ETL) tool is provided. Naming, coding, and performance standards for the code is received. The code is exported to a job definition file and parsed. Violations of the standards are determined by determining the parsed code does not match the standards. A report identifying the violations is generated. Based on a review of the report and a rework of the code to comply with the standards, the reworked code is exported to another job definition file and parsed, the parsed reworked code is determined to not include the violations of the standards, and a second report is generated that indicates that the reworked code does not include the violations. An approval of the reworked code is received based on the second report.

Owner:MAPLEBEAR INC

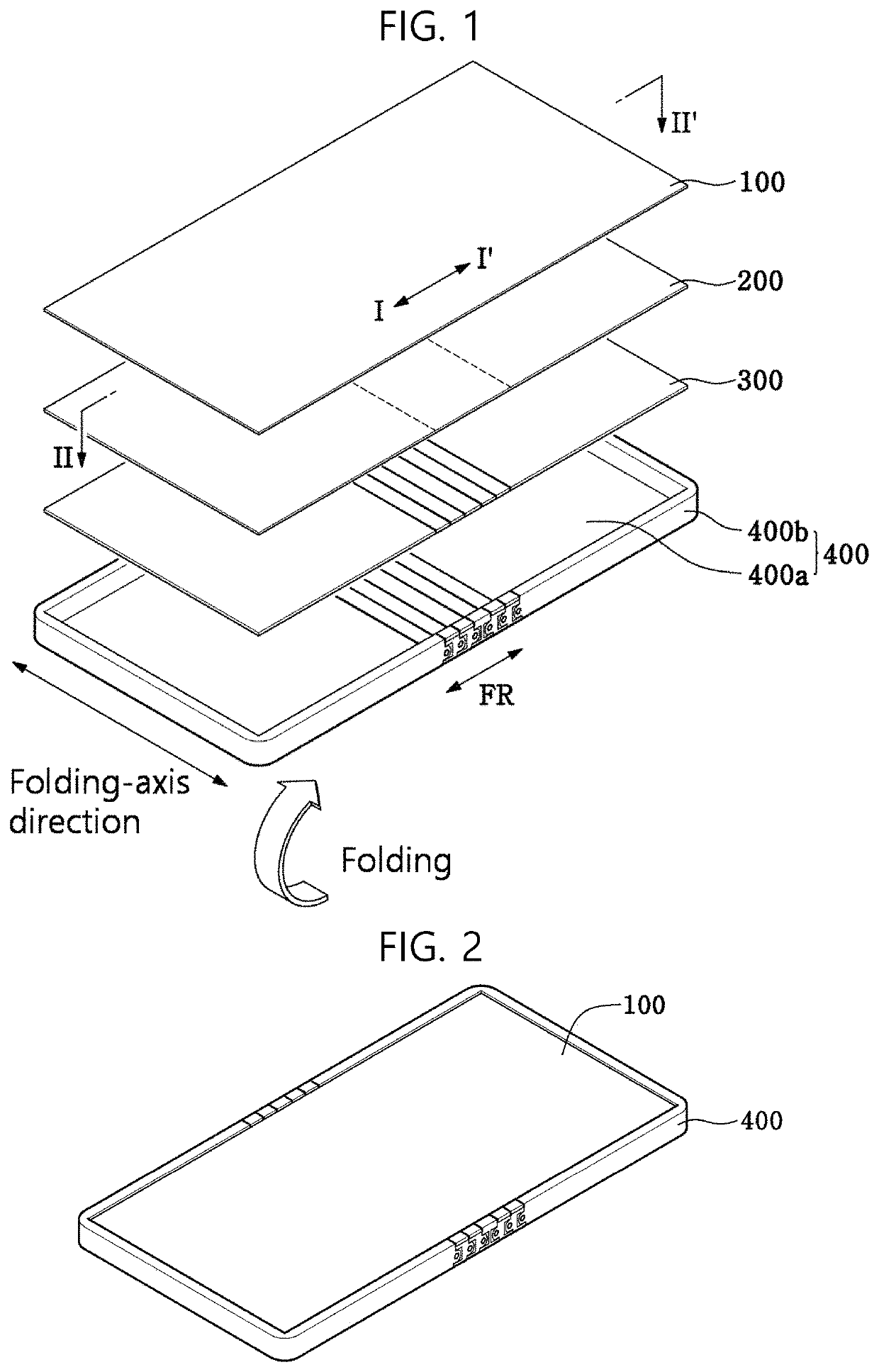

Flexible display device and electronic device including the same

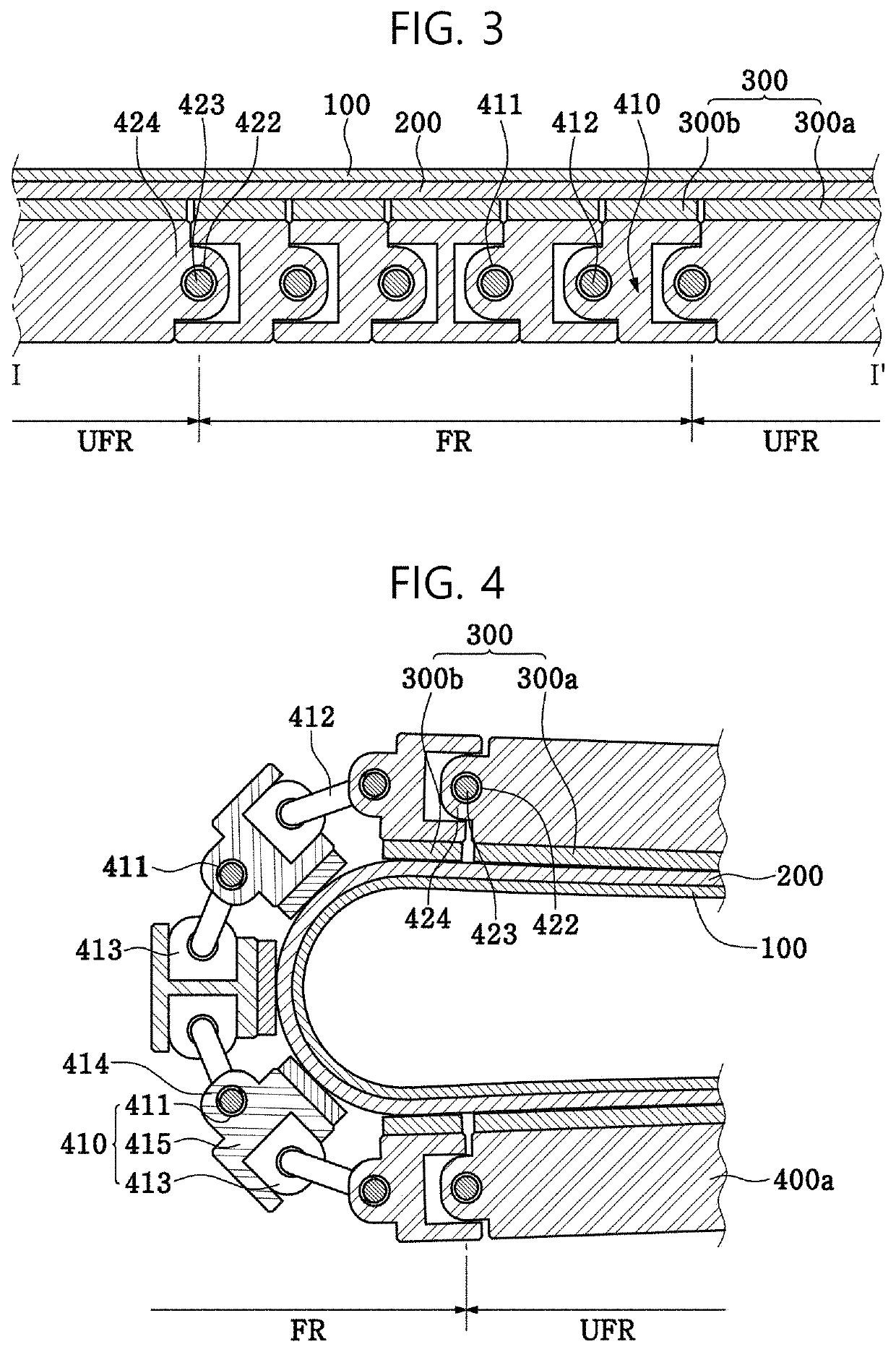

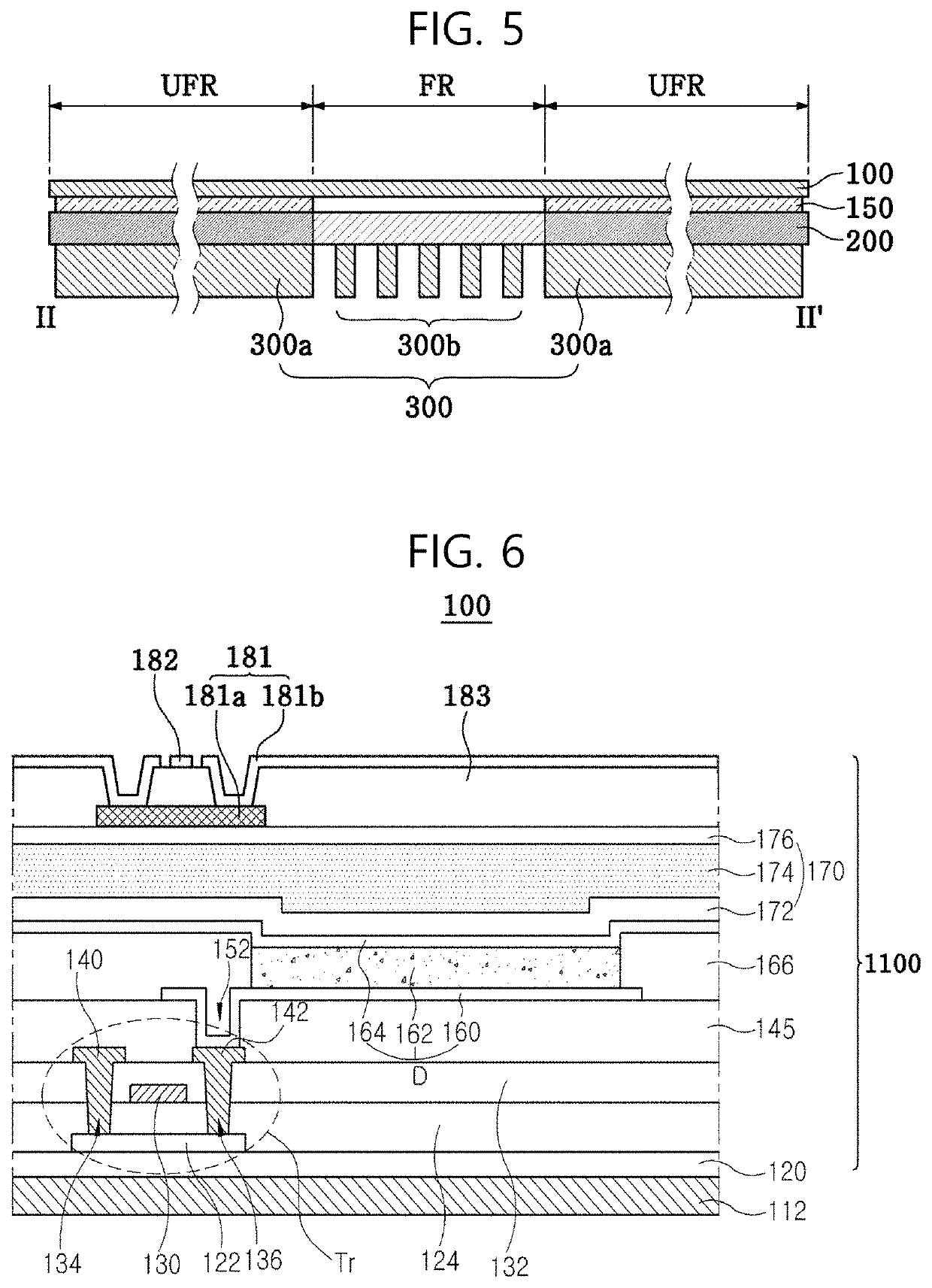

ActiveUS10727435B2Stable supportAvoid damageMagnetic/electric field screeningCasings with display/control unitsReworkSoftware engineering

A flexible display device and an electronic device including the same are disclosed. The flexible display device includes a magnetic body group, which is adhered to a lower plate provided under a display panel by the force of magnetic attraction. Therefore, the flexible display device has improved reliability in spite of frequent folding and unfolding operations and is capable of facilitating a rework process.

Owner:LG DISPLAY CO LTD

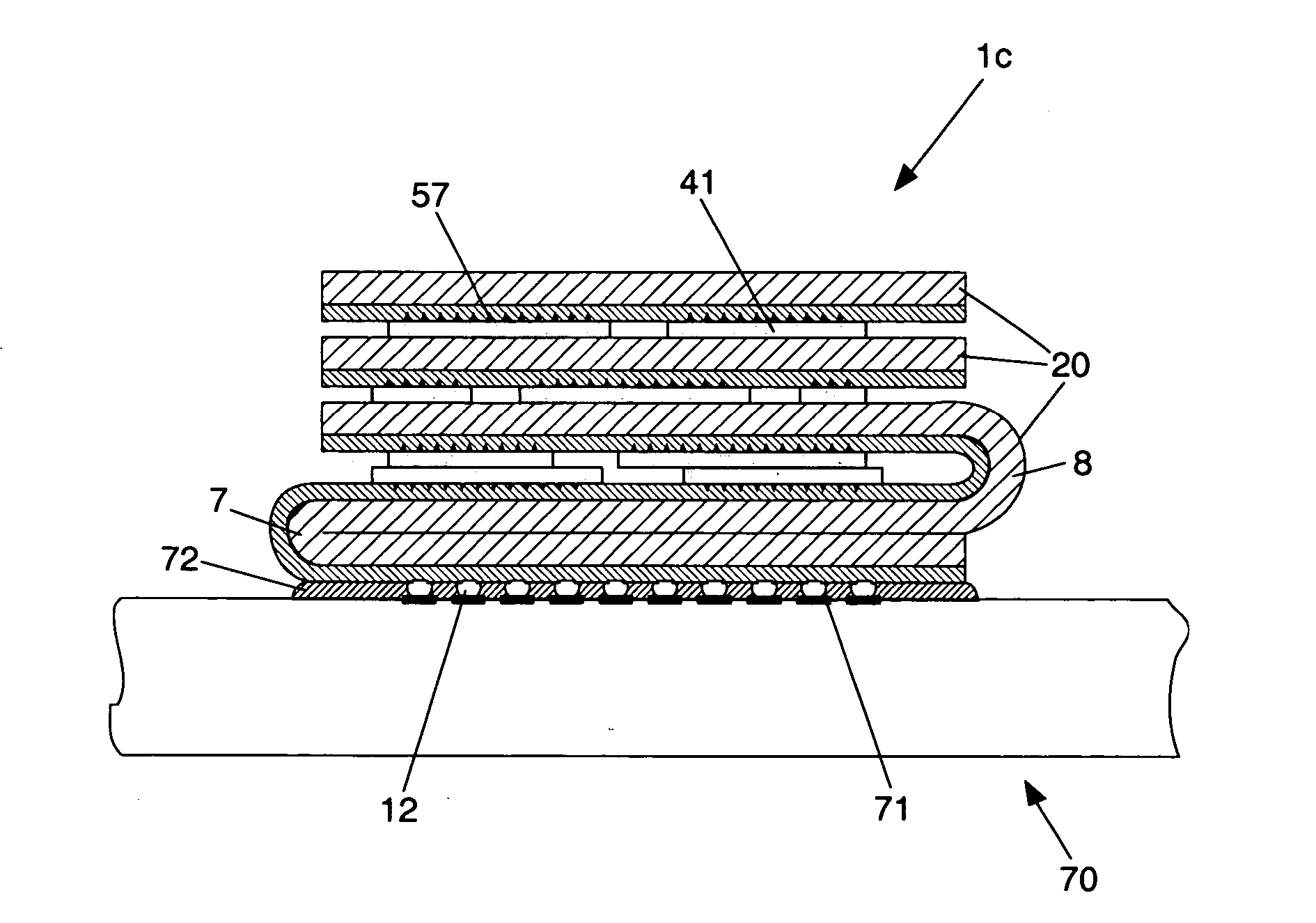

Thermal interface material for electronic assemblies

ActiveUS7718256B1Improve adhesionEasy to handleEpoxy resin adhesivesThin material handlingElastomerSurface mounting

Thermal interface materials are essential for proper operation of electronic assemblies. They are used between surface mount components and printed wiring boards and between printed wiring boards and metal heat sinks. Their function is to bond the components together and allow good heat transfer between the parts being bonded. The approach disclosed in this invention is a fully-cured, flexible, filled elastomer that is coated on both sides with a partially cured, filled adhesive, which can be conveniently made by a low cost tape casting process. This unique approach offers a combination of good adhesion to both bonding surfaces, good heat transfer, compliance to accommodate mismatched coefficient of thermal expansion, rework capability, control of flow of the adhesive during cure, and easy handling of uncured material.

Owner:NORTHROP GRUMMAN SYST CORP

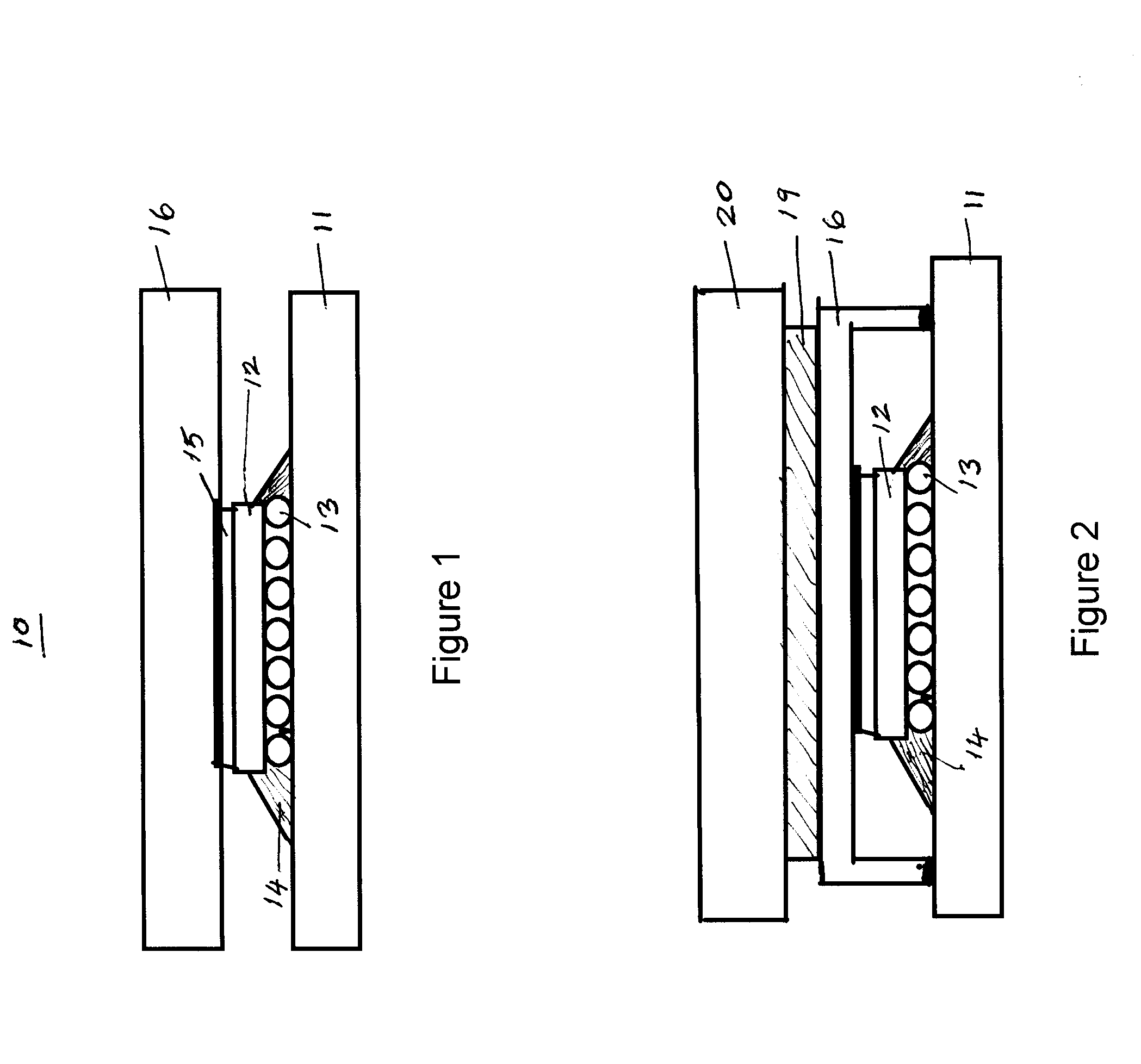

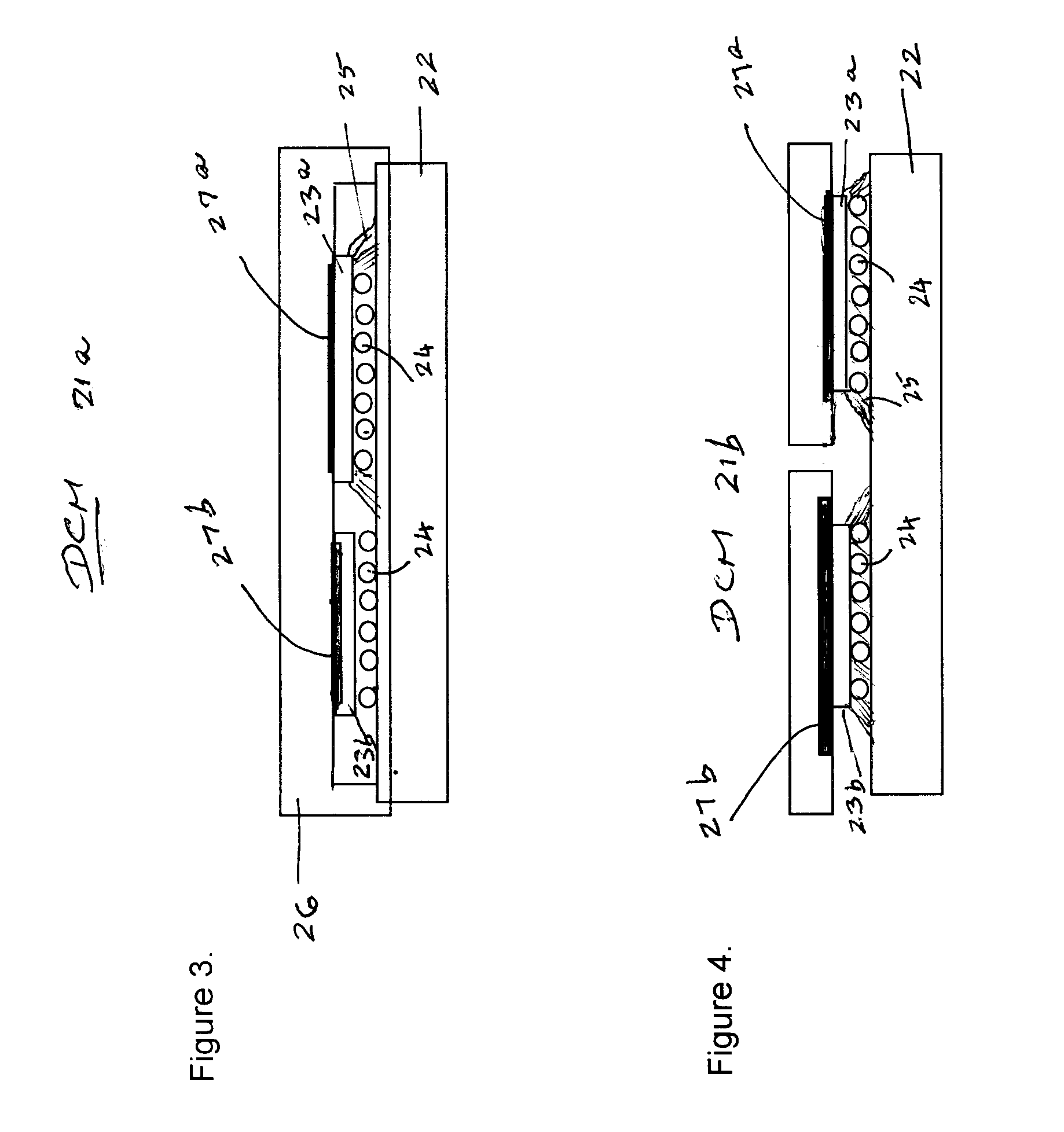

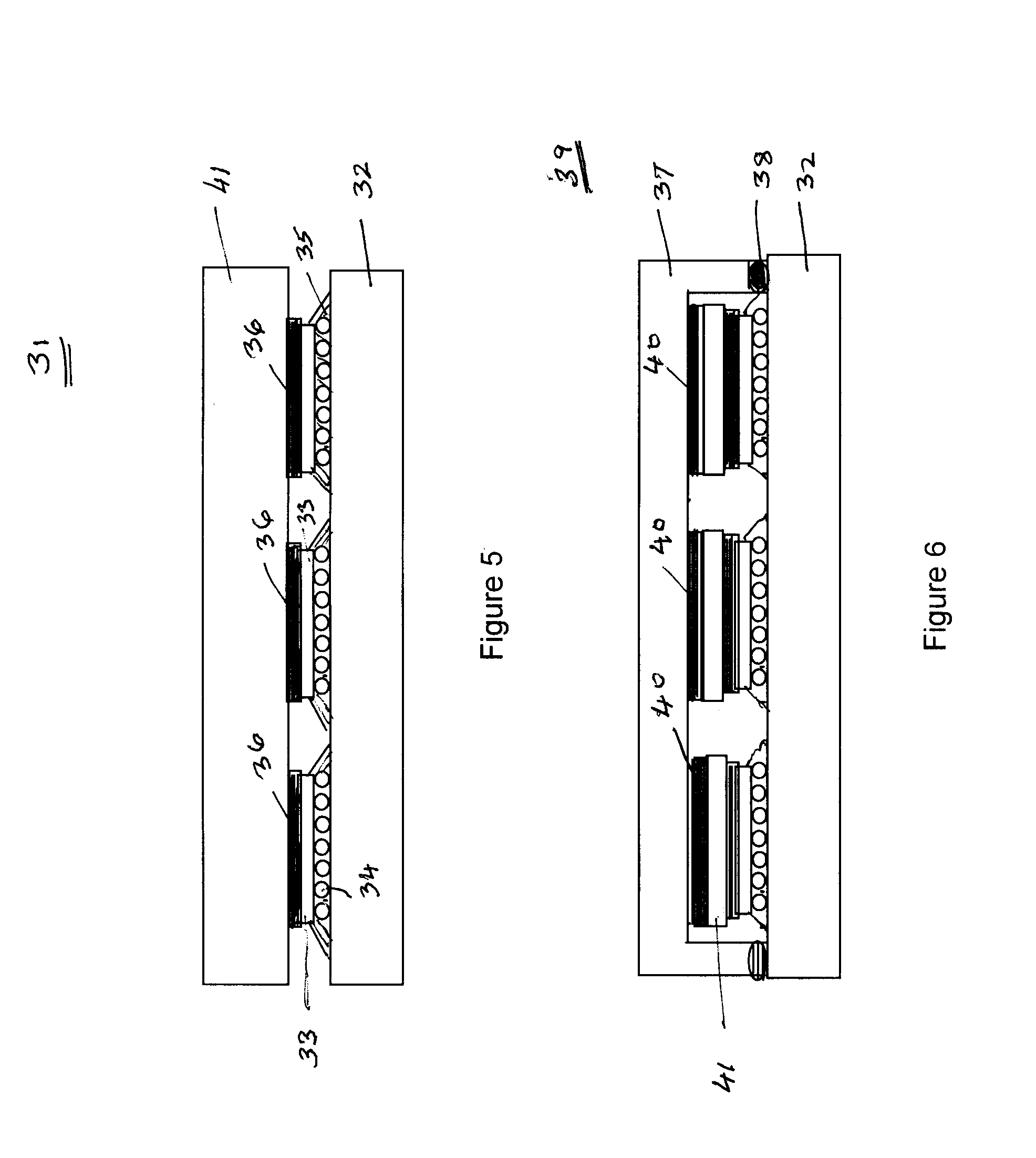

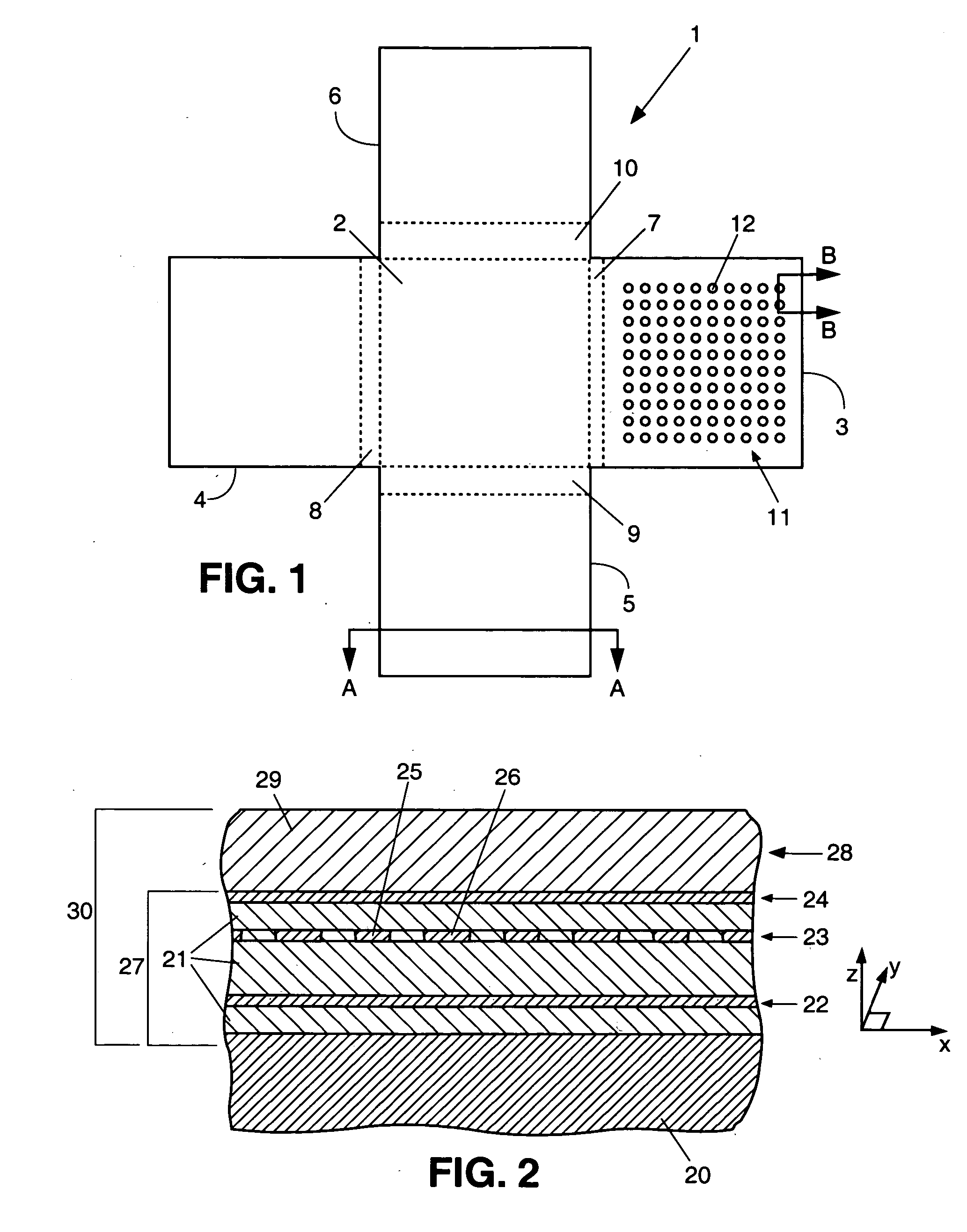

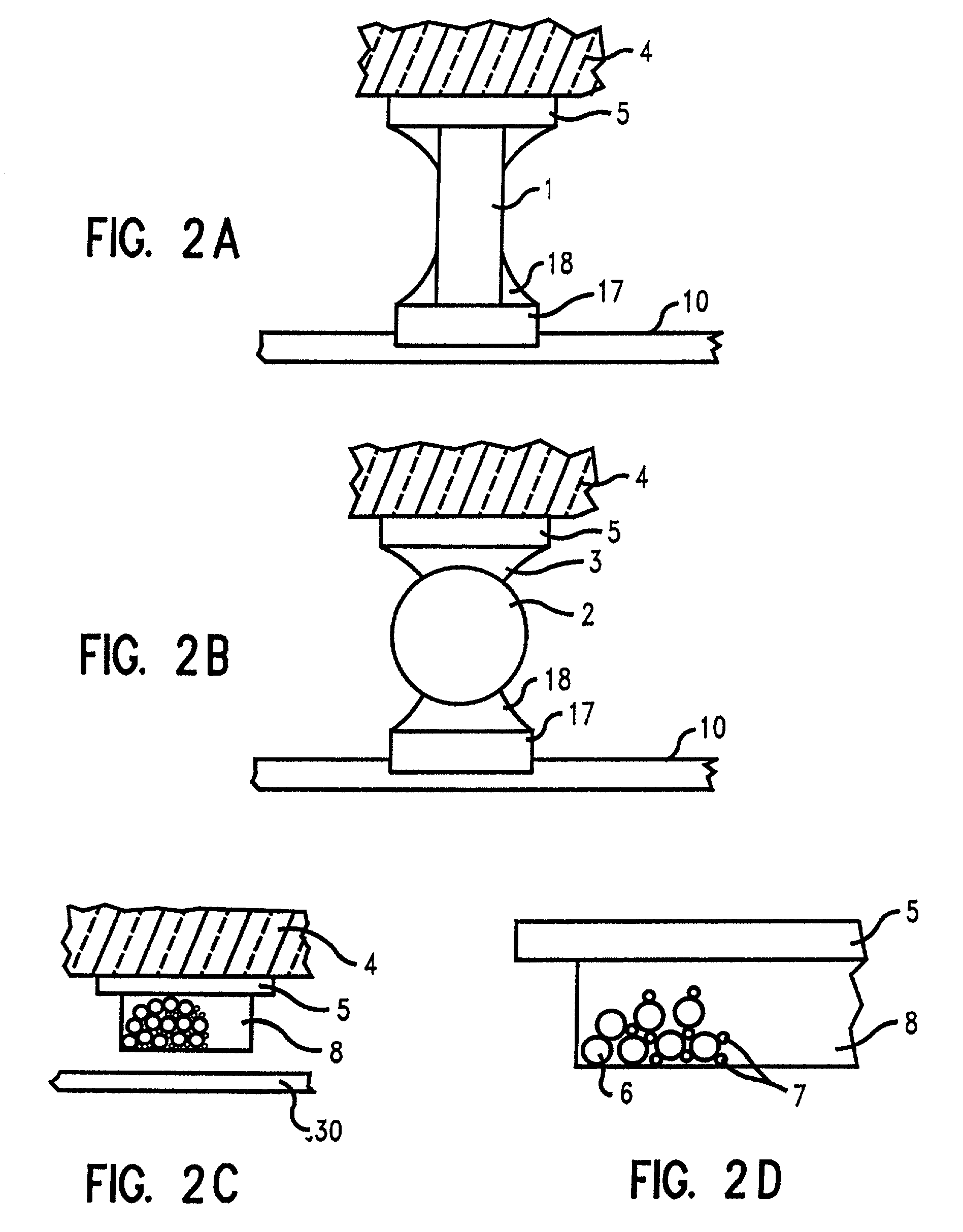

Interconnection process for module assembly and rework

An interconnection structure and methods for making and detaching the same are presented for column and ball grid array (CGA and BGA) structures by using a transient solder paste on the electronic module side of the interconnection that includes fine metal powder additives to increase the melting point of the solder bond. The metal powder additives change the composition of the solder bond such that the transient melting solder composition does not completely melt at temperatures below +230° C. and detach from the electronic module during subsequent ref lows. A Pb-Sn eutectic with a lower melting point is used on the opposite end of the interconnection structure. In the first method a transient melting solder paste is applied to the I / O pad of an electronic module by means of a screening mask. Interconnect structures are then bonded to the I / O pad. In a second method, solder preforms in a composition of the transient melting solder paste are wetted onto electronic module I / O pads and interconnect columns or balls are then bonded. Detachment of an electronic module from a circuit card can then be performed by heating the circuit card assembly to a temperature above the eutectic solder melting point, but below the transient solder joint melting point.

Owner:ULTRATECH INT INC

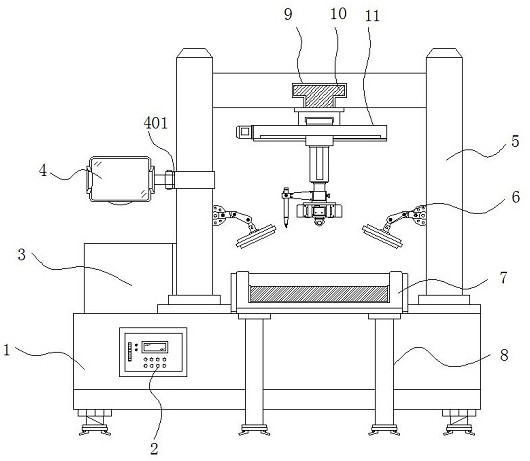

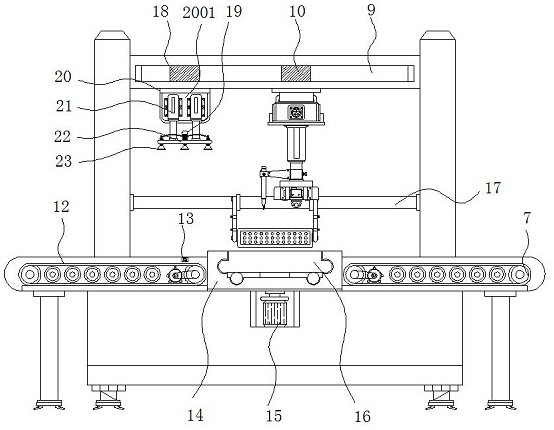

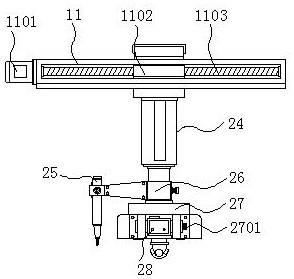

Visual inspection equipment capable of identifying flaws for large part inspection

InactiveCN112113967AFacilitate subsequent reworkImprove efficiencyOptically investigating flaws/contaminationReworkVisual inspection

The invention discloses visual inspection equipment capable of identifying flaws for large part inspection. Particularly, the equipment comprises a workbench, a feeding mechanism, an oily pen and a CCD camera, a computer operation room is arranged in the middle of one end of the top of the workbench, and a frame body is arranged at the other end of the top of the workbench; a feeding conveying belt is fixed to one side of the top of the workbench through an installation frame, and a photoelectric sensor is installed on the side, close to the feeding conveying belt, of the interior of the feeding conveying belt. The visual detection equipment capable of identifying flaws for large part detection is provided with a transverse electromagnetic sliding rail, a longitudinal guide rail, a hydraulic lifting rod and the oily pen. The oil pen can move to the flaws of the part under the synergistic effect of the transverse electromagnetic sliding rail, the longitudinal guide rail and the hydraulic lifting rod to draw circles and mark the detected flaws, follow-up rework of workers is facilitated, and the rework efficiency and accuracy are improved.

Owner:CHONGQING TECH & BUSINESS UNIV

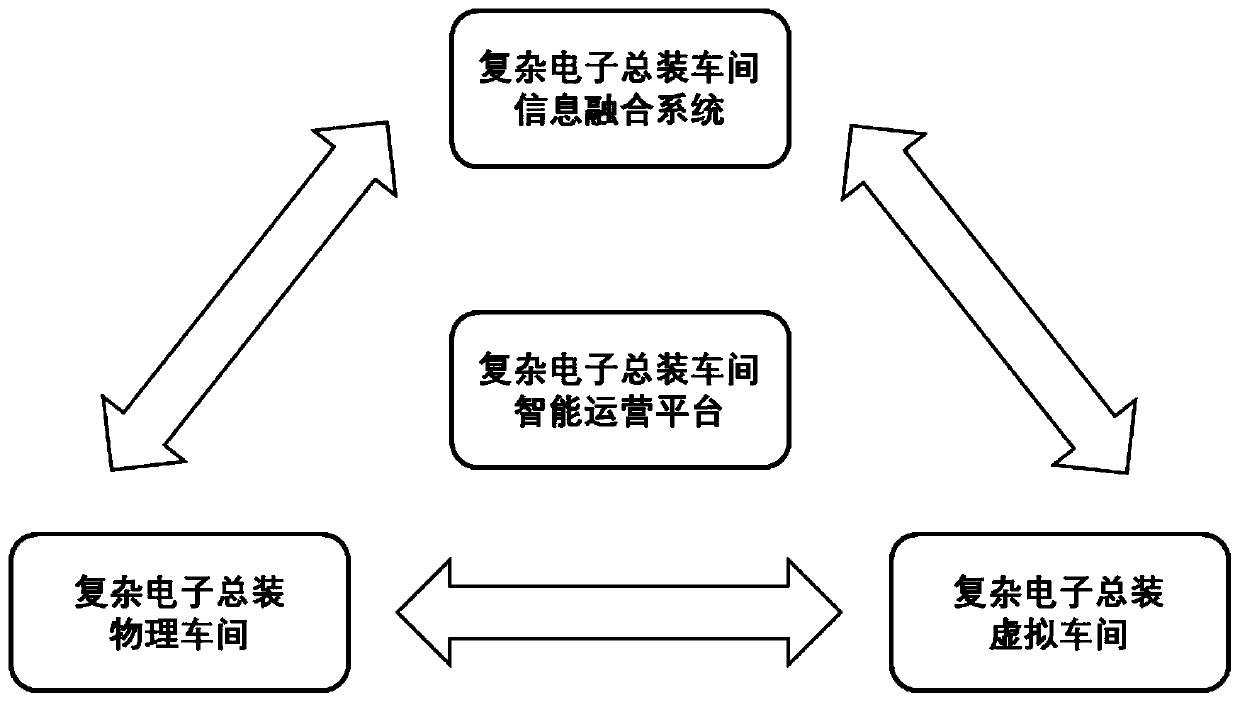

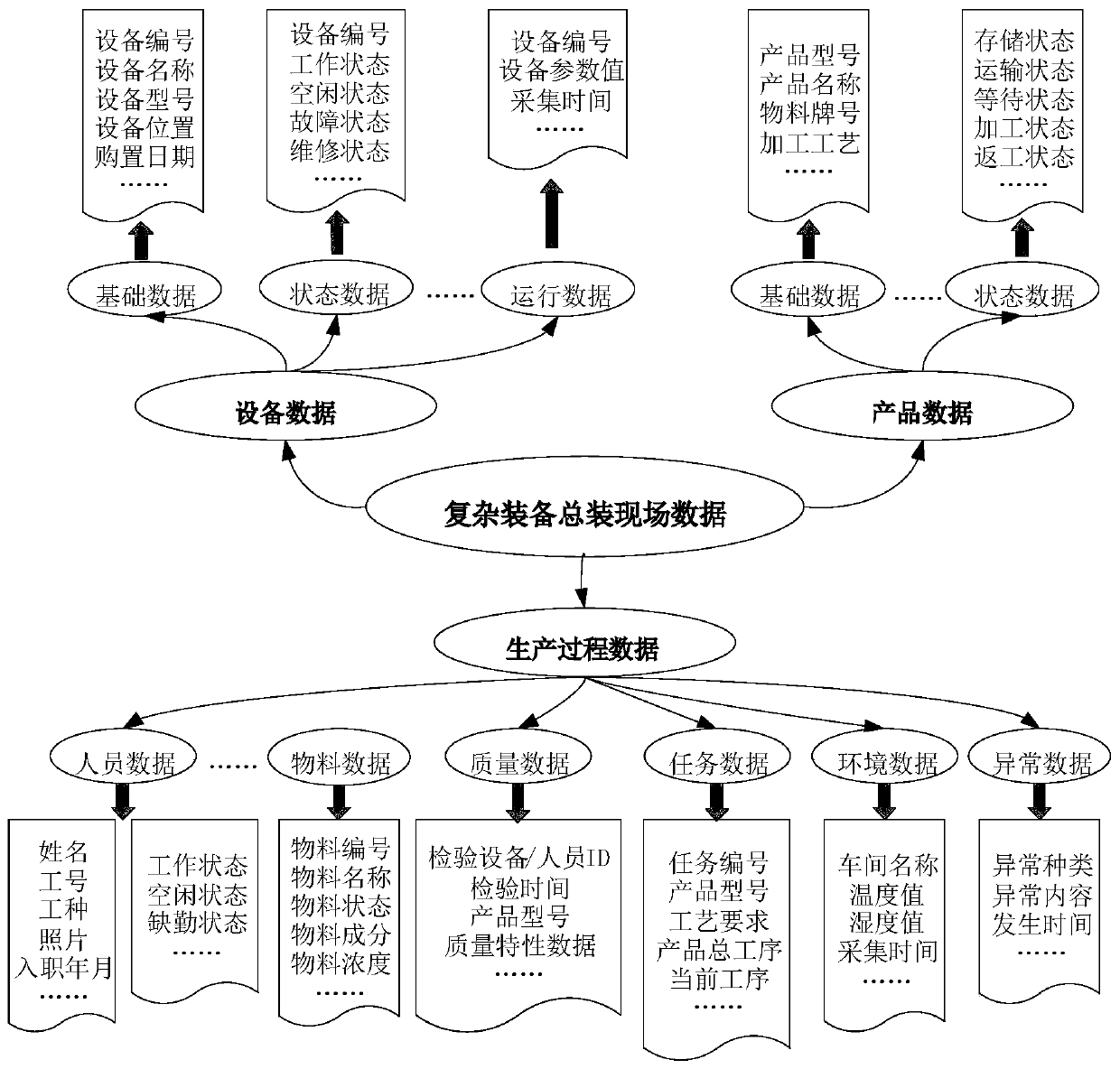

Digital twinning workshop for general assembly of complex electronic device

PendingCN111580478ARealize interconnectionRealistic depiction of running statusTotal factory controlProgramme total factory controlProduction lineGeneral assembly

Based on general assembly characteristics of an complex electronic device, in order to increase the flexibility of a production line and improve the efficiency of the production line, the invention provides a construction method for a digital twinning workshop of a general assembly of a complex electronic device, and solves the problems of low production efficiency, poor resource allocation, higherror rework rate, unstable quality, incapability of effectively meeting the requirements of a rapid production period and low one-time assembly success rate in the complex electronic device general assembly.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

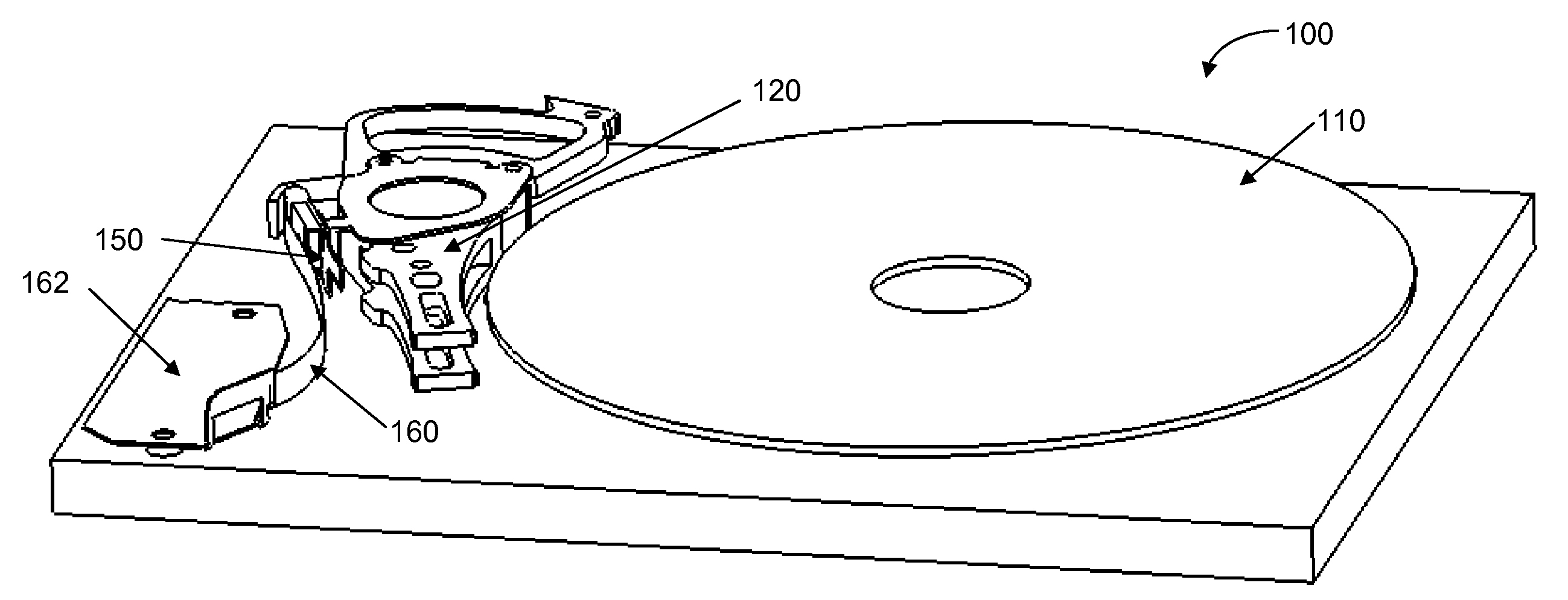

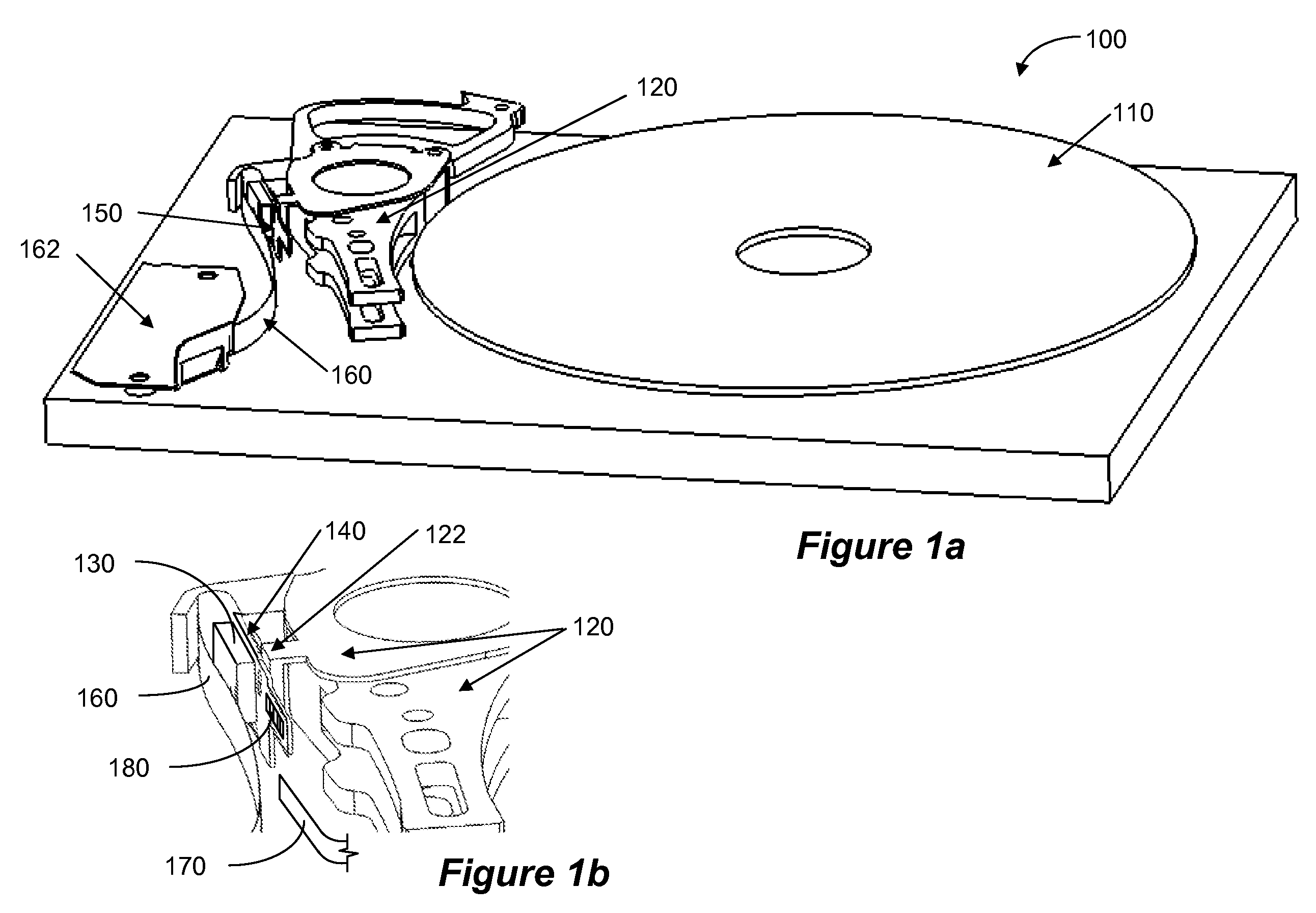

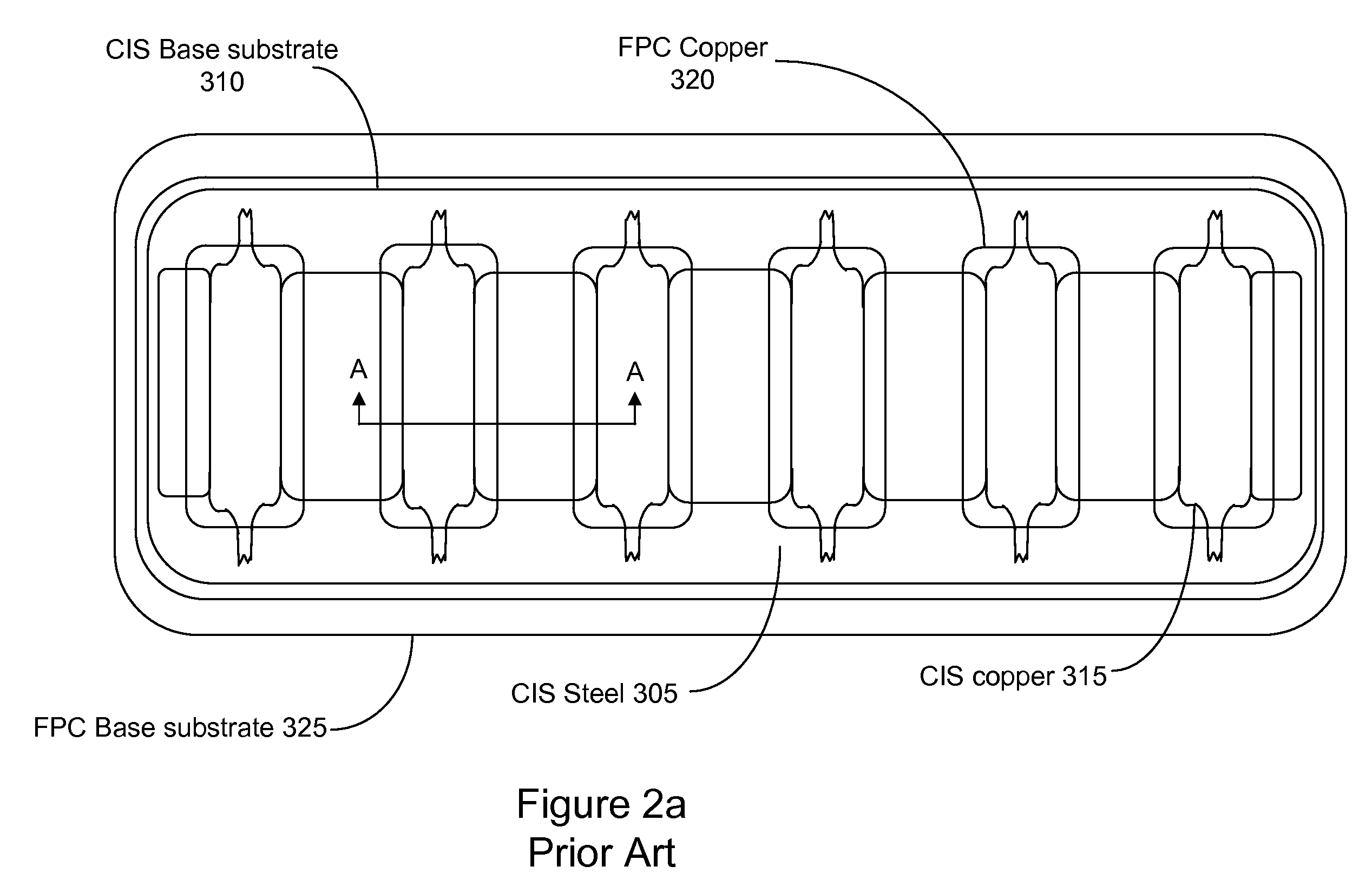

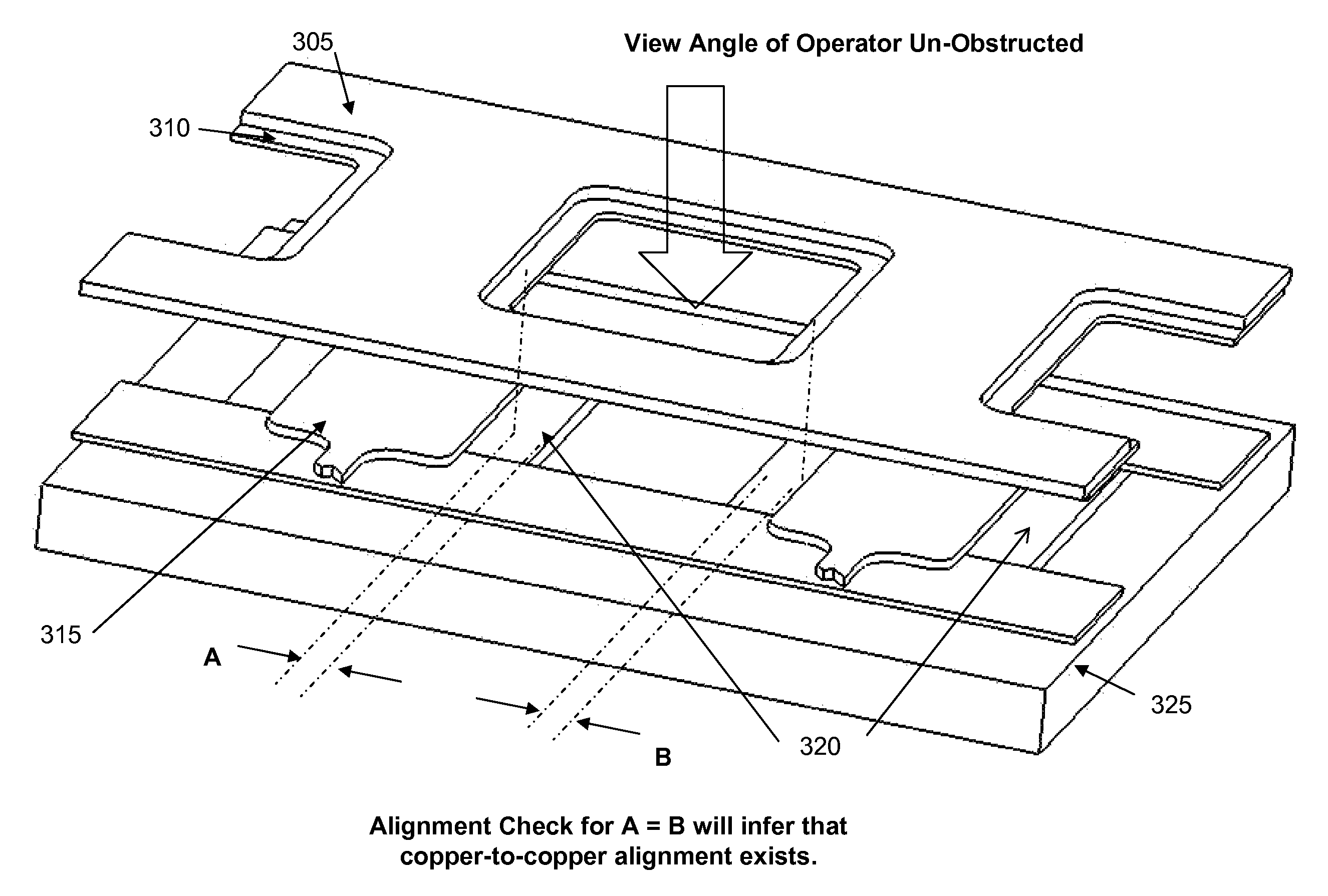

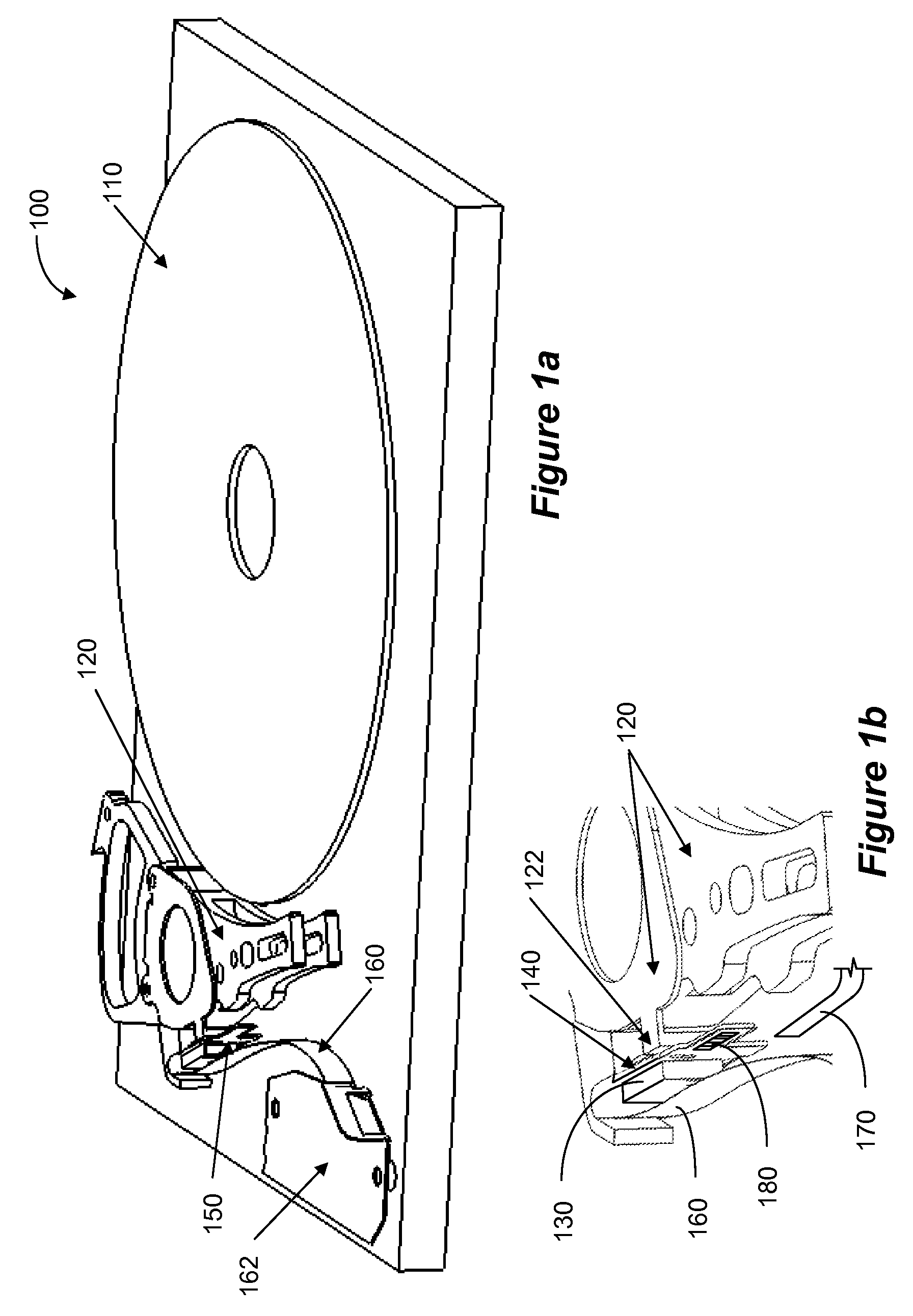

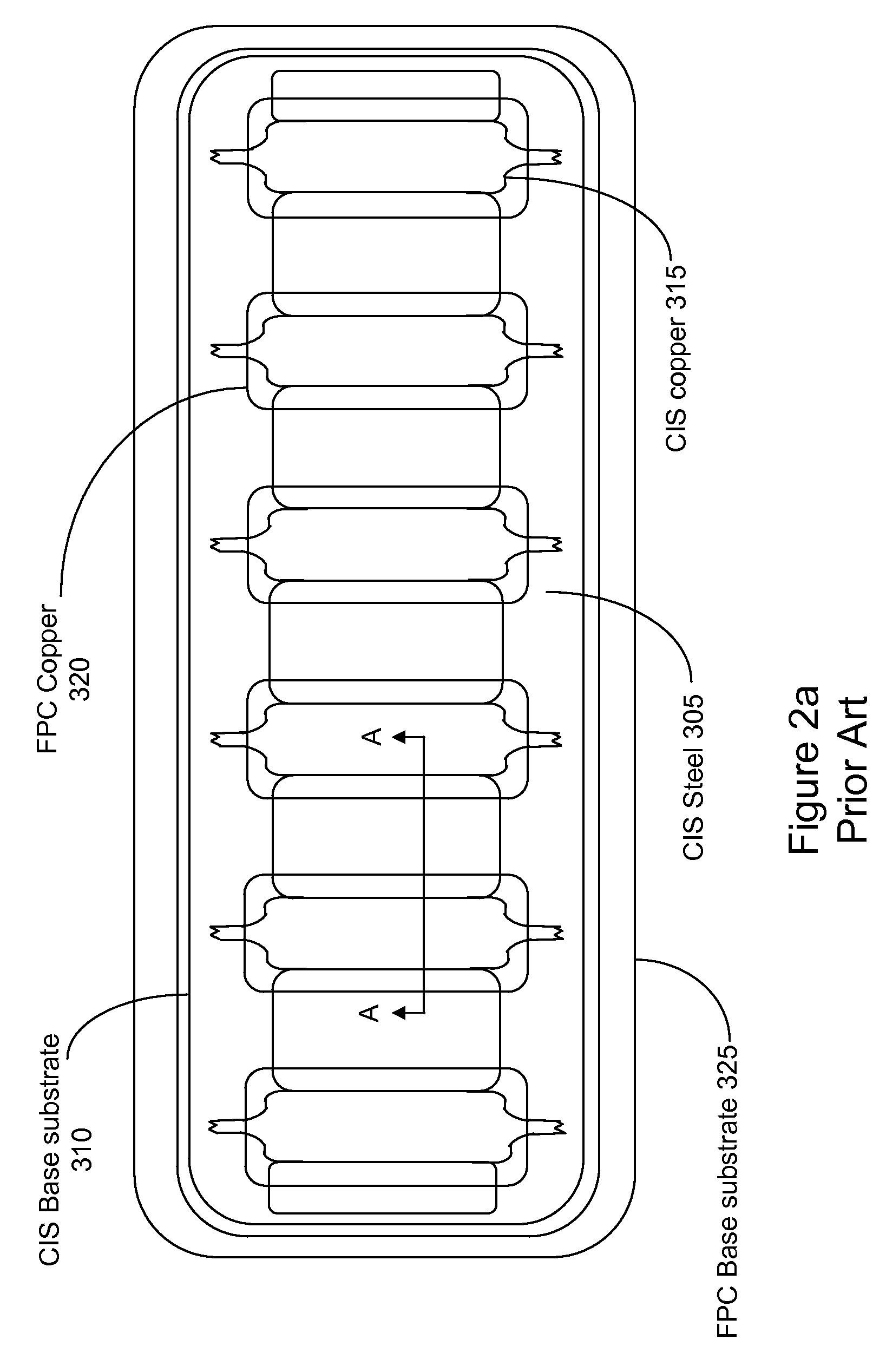

Method for mating flexure to flex-print circuit and flexure therefor

ActiveUS20080099236A1Easy visual inspectionEasy to checkContact member assembly/disassemblyIncorrect coupling preventionHard disc driveVisual inspection

Inspection windows are cut or formed into the tail section of the flexure circuit tail in a hard disk drive Head Gimbal Assembly (HGA), or CIS, to enable visual inspection of the alignment of the CIS to the head preamp circuit, or FPC. The holes are made in the steel backing and base polyimide, and are positioned between adjacent conductive pads. In addition to facilitating visual inspection, the windows also enable rework of solder. Additionally, solder wicking holes may also be provided in the conductive pads and / or the polyimide and steel backing.

Owner:NITTO DENKO CORP

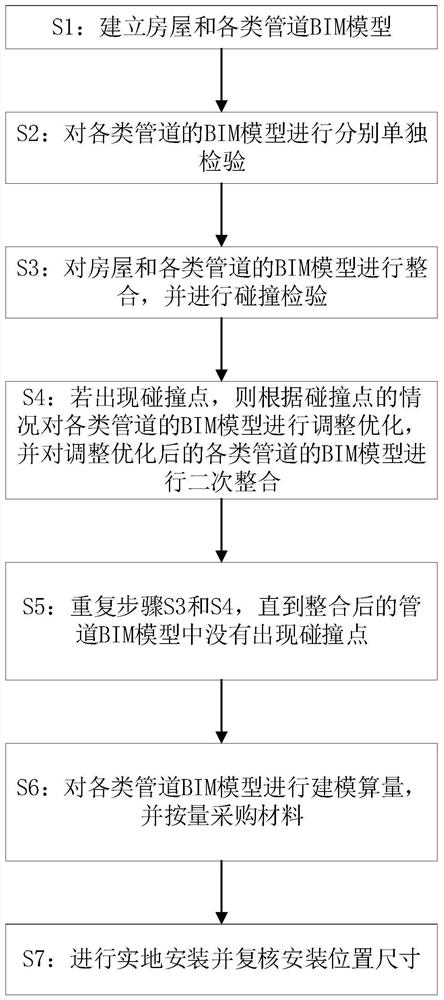

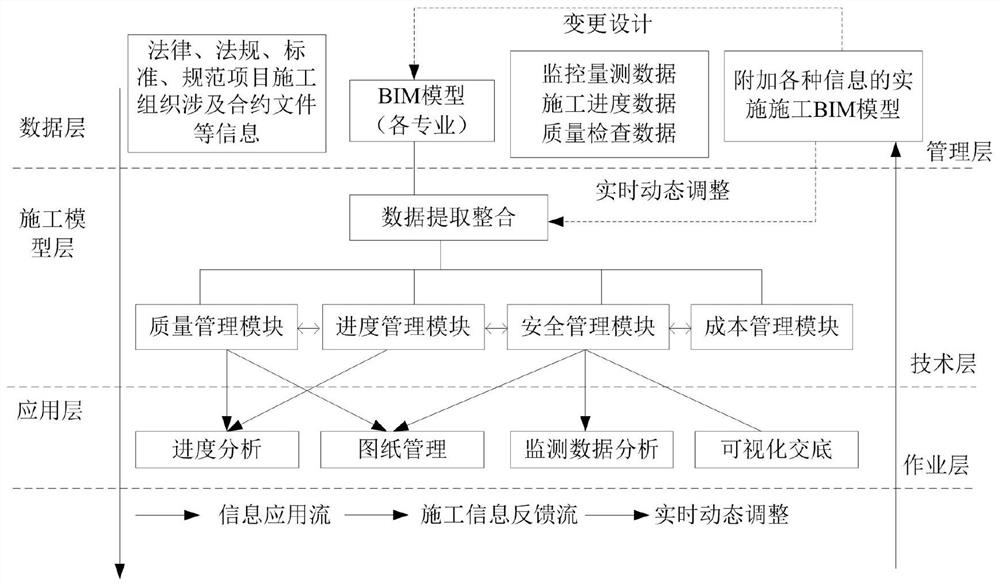

Pipeline arrangement method based on BIM model

InactiveCN112182817AReduce biasReduce subsequent rework costsGeometric CADDesign optimisation/simulationReworkProcess engineering

The invention discloses a pipeline arrangement method based on a BIM model. The pipeline arrangement method comprises the following steps: S1, building BIM models of houses and various pipelines; S2,independently inspecting the BIM models of the various pipelines respectively; S3, integrating the BIM models of the house and various pipelines, and performing collision inspection; S4, if a collision point appears, adjusting and optimizing the BIM models of the various pipelines according to the condition of the collision point, and carrying out secondary integration on the adjusted and optimized BIM models of the various pipelines; S5, repeating the steps S3 and S4 until no collision point appears in the integrated pipeline BIM model; S6, conducting modeling calculation on the various pipeline BIM models, and purchasing materials according to the quantity; S7, carrying out on-site installation, and rechecking the installation position size. The position of the pipeline can be designed in advance through the BIM model, problem points are found in advance, the subsequent rework cost is reduced, the unified BIM model can give consideration to the size of each detail position, and the deviation of the whole project is reduced.

Owner:KUNMING RAILWAY CONSTR COMPANY OF CHINA RAILWAY NO 8 ENG GRP +1

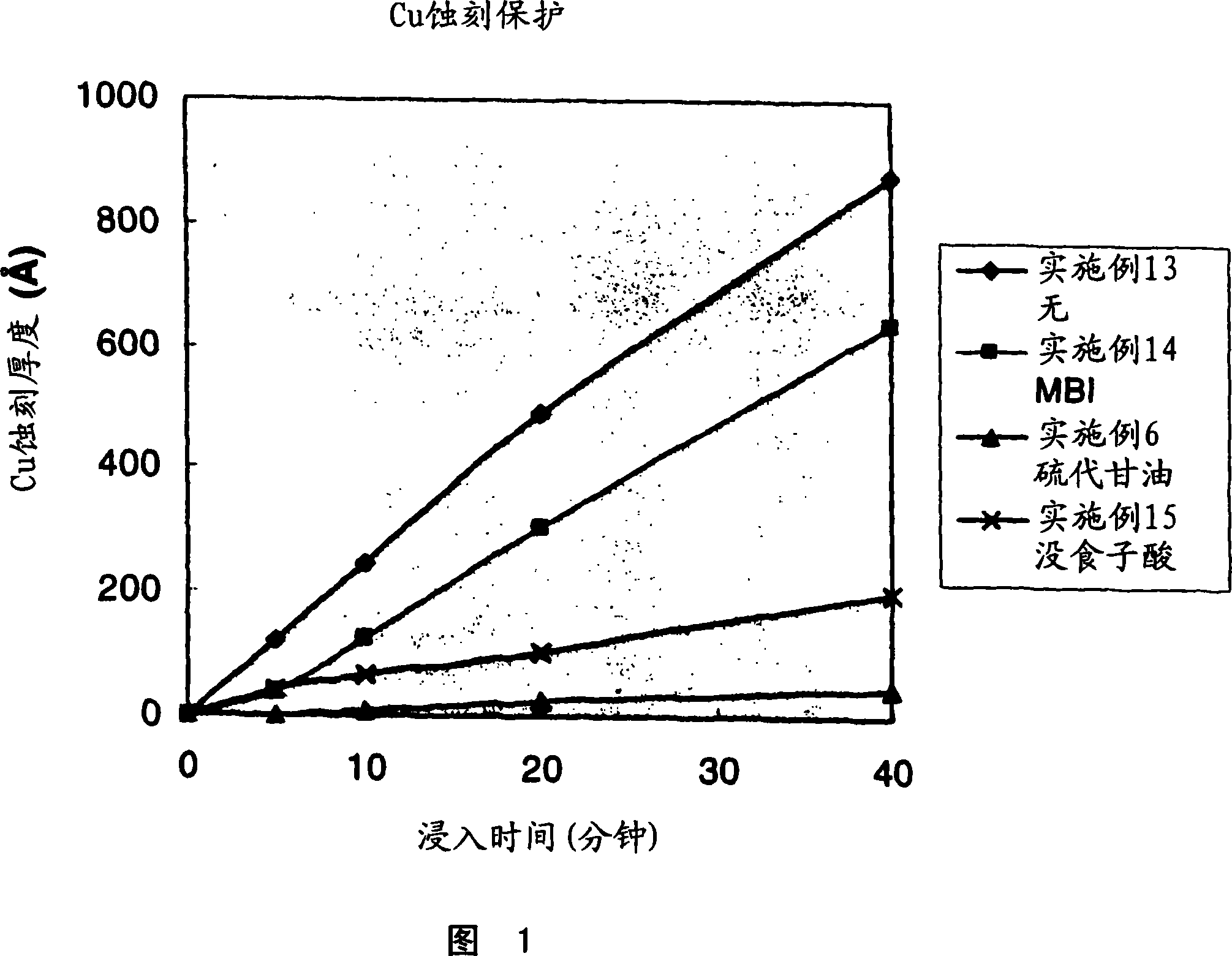

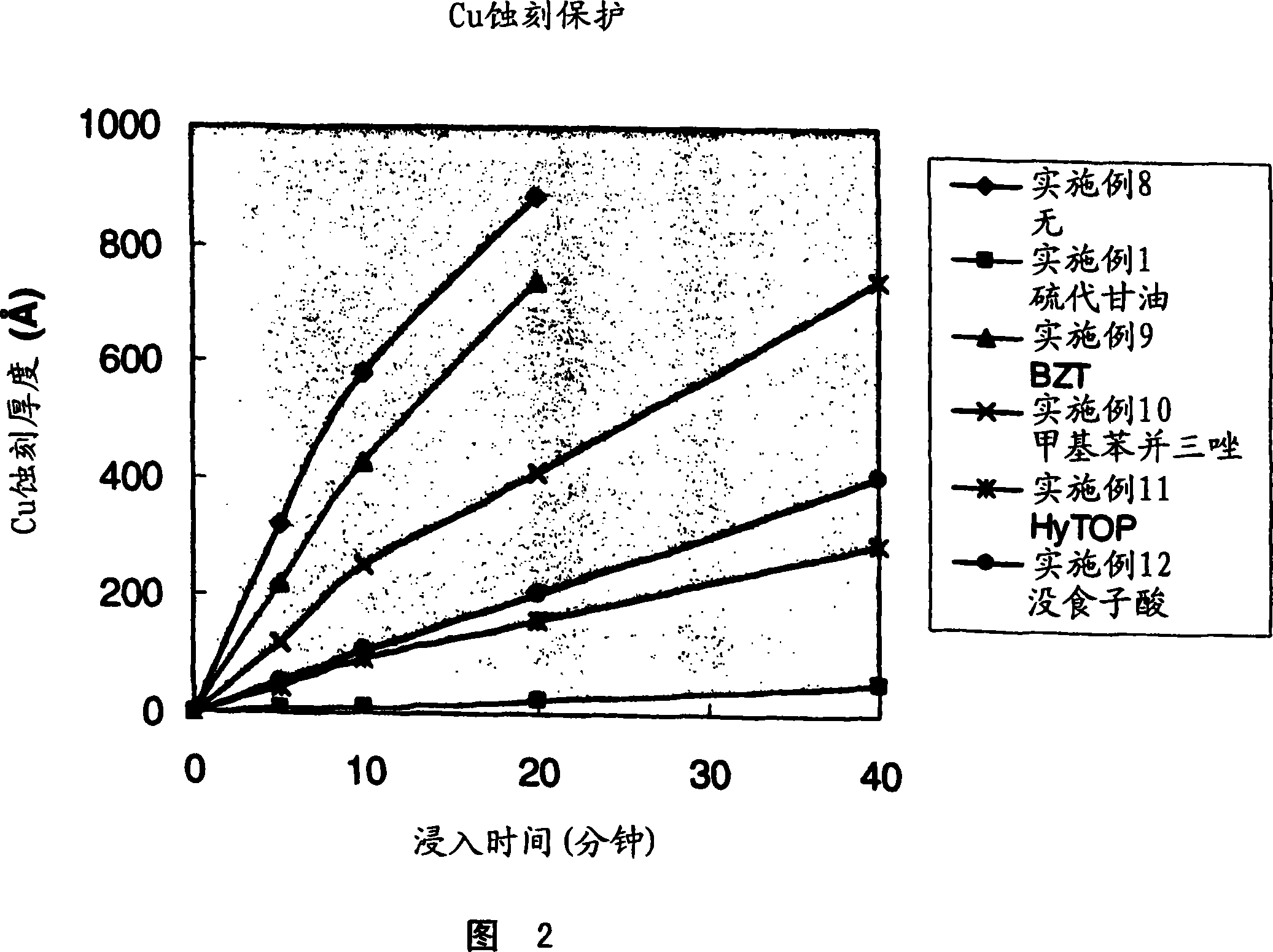

Composition and method for photoresist removal

The present invention provides a composition for removing multilayer photoresist layers on an electronic device substrate for rework of the photoresist on the substrate. The composition comprises: (i) at least three discrete solvents; (ii) at least one organic sulfonic acid; and (iii) at least one corrosion inhibitor. The present invention is also a method for using the above composition. This composition and the method succeed in removing such multilayer photoresist at temperatures less than 65[deg.]C and in contact times under three minutes, allowing high throughput on sheet type wafer tools.

Owner:AIR PROD & CHEM INC

Address label re-work station

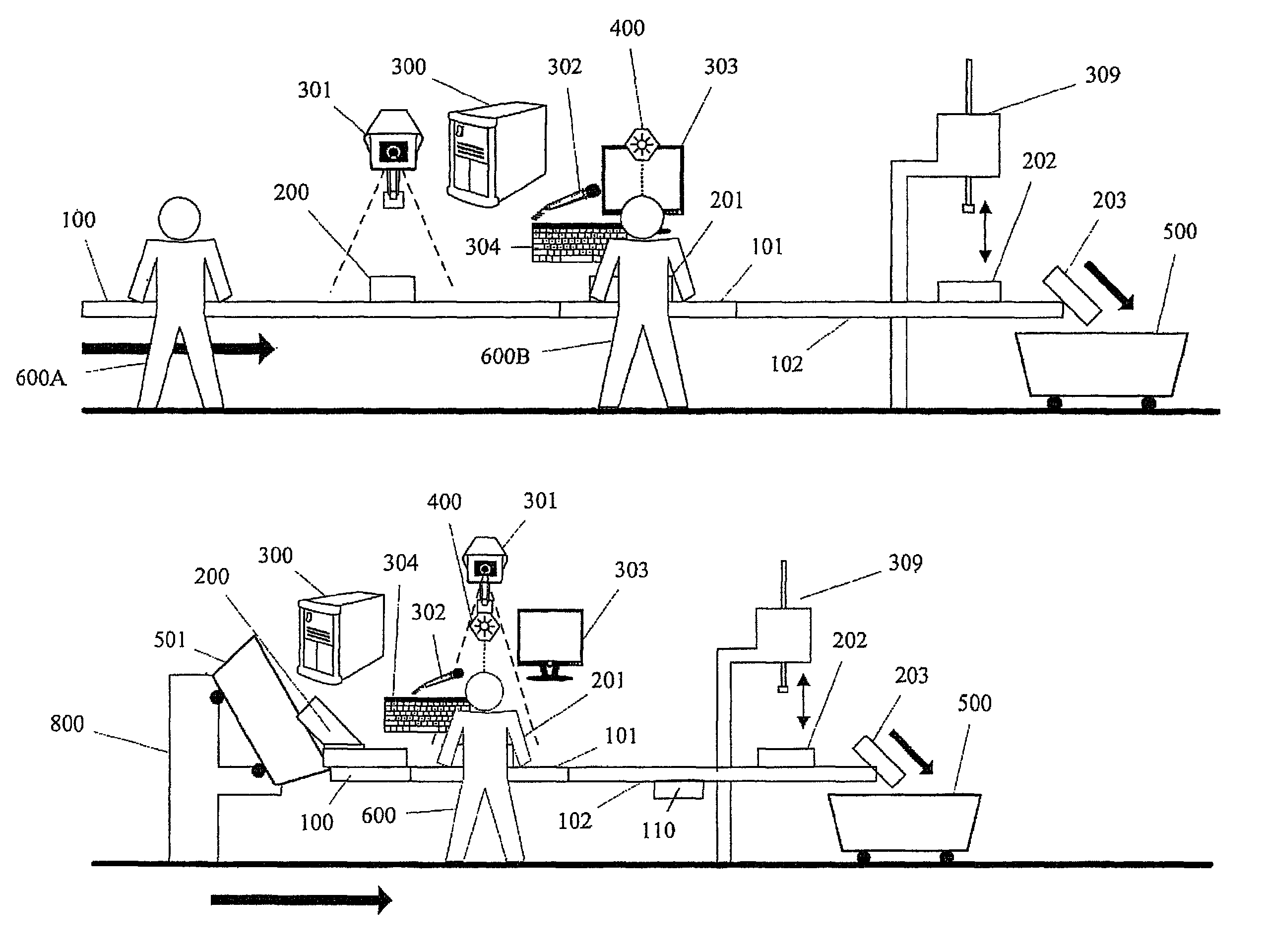

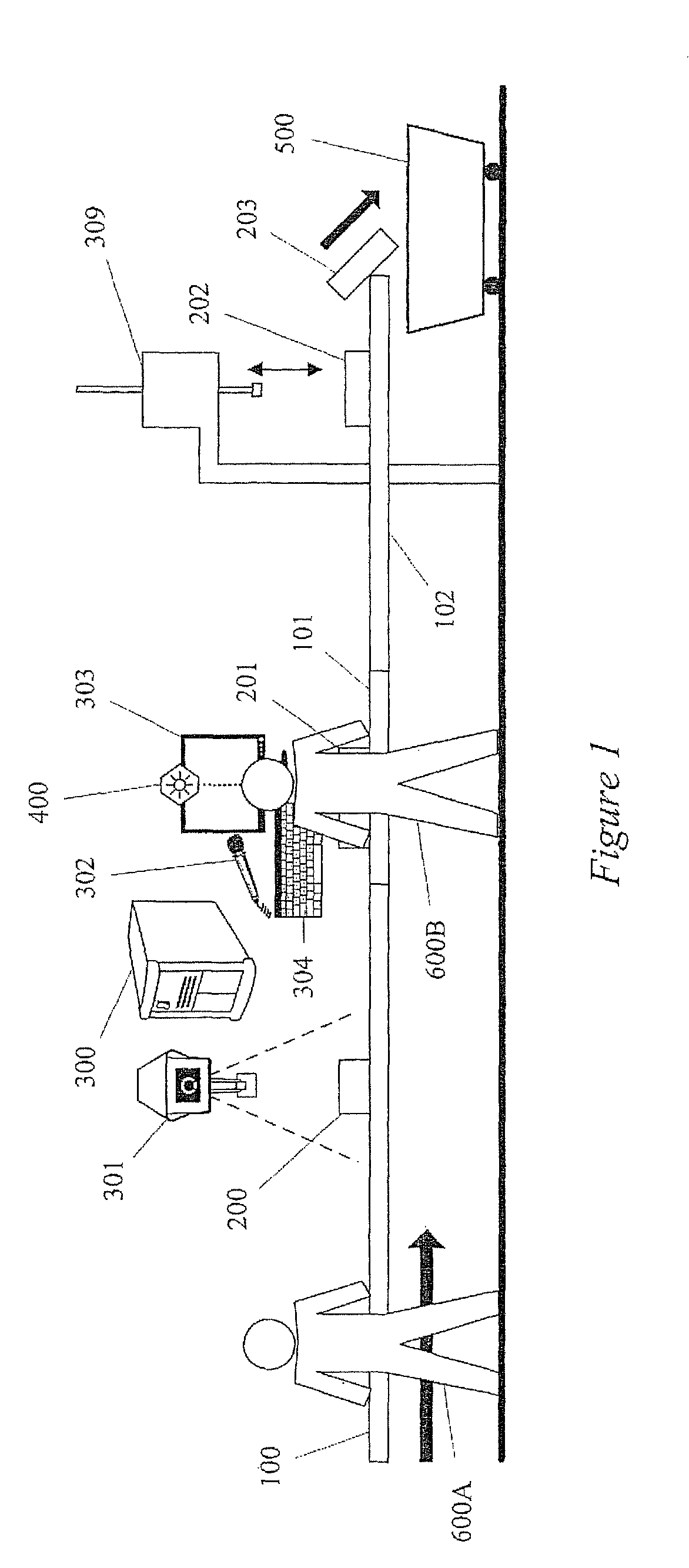

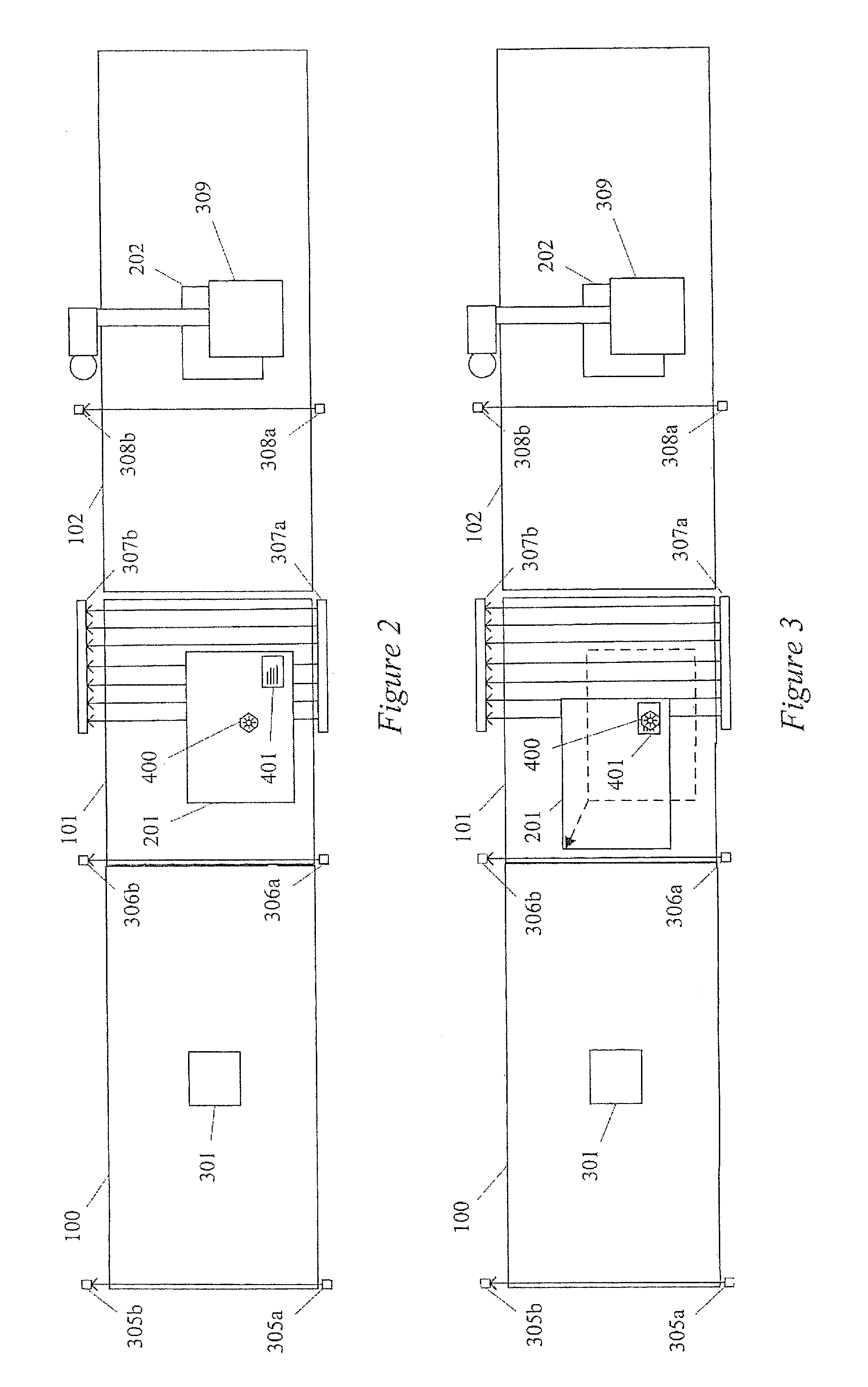

ActiveUS8260455B2Digital data processing detailsCharacter and pattern recognitionEngineeringHuman operator

An address label rework station according to the invention includes a conveyor which can simultaneously transport a series of spaced parcels along a conveyor path in a substantially horizontal stream. The station includes a camera, A work space, a microphone is usable by an operator in the work space, a targeting device directing a human operator in the work space. Station also includes a sensor system, a labeler and a printer to print shipping information. The station also includes a computer configured to receive and recognize image and voice data, generate a label with a recognized shipping address, and control the conveyer to apply a new label to the parcel by the labeler at the position selected using the targeting device.

Owner:KÖRBER SUPPLY CHAIN LLC

Method for mating flexure to flex-print circuit and flexure therefor

ActiveUS8173909B2Easy visual inspectionFacilitate visual inspection and reworkContact member assembly/disassemblyPrinted circuit aspectsHard disc driveAudio power amplifier

Owner:NITTO DENKO CORP

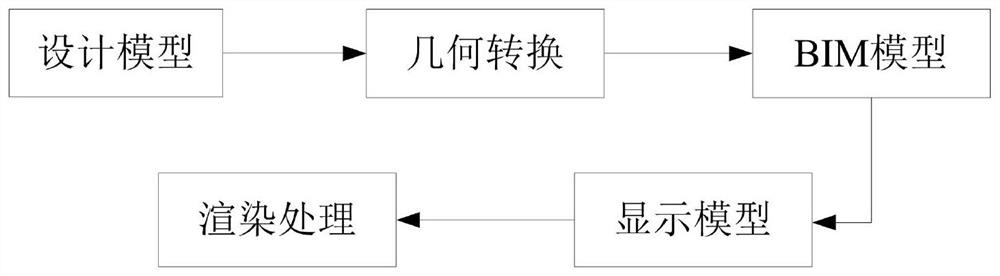

Construction management method of BIM + MR based on HoloLens

PendingCN114329695AAvoid wastingImprove quality controlGeometric CADOffice automationReworkSoftware engineering

The invention relates to a construction management method of BIM + MR based on HoloLens, and the method comprises the steps: 1, building a BIM model and information through employing Revit software according to a project construction drawing; 2, a BIM model constructed by Revit software is converted into a model format capable of being recognized by Unity through a BIM-MR plug-in at the Revit end, meanwhile, model information is extracted and reserved, and the BIM-MR plug-in at the Revit end needs to optimize the model surface number so as to meet the requirement that HoloLens equipment can bear the model surface number; step 3, establishing a BIM-MR collaborative network server, and connecting Revit software of a user PC terminal and a HoloLens device terminal so as to acquire the acquired BIM data in real time, and synchronously displaying the acquired BIM data in an MR scene of HoloLens; 4, construction is carried out based on the BIM-MR function of the HoloLens client, and positioning correspondence is carried out on the BIM model and a real coordinate system through a model positioning function; and 5, carrying out construction quality acceptance and operation and maintenance based on the BIM-MR function of the HoloLens client. The BIM information data can be better matched with the on-site entity construction part, rework is reduced, material waste is avoided, cost is saved, and construction efficiency is improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

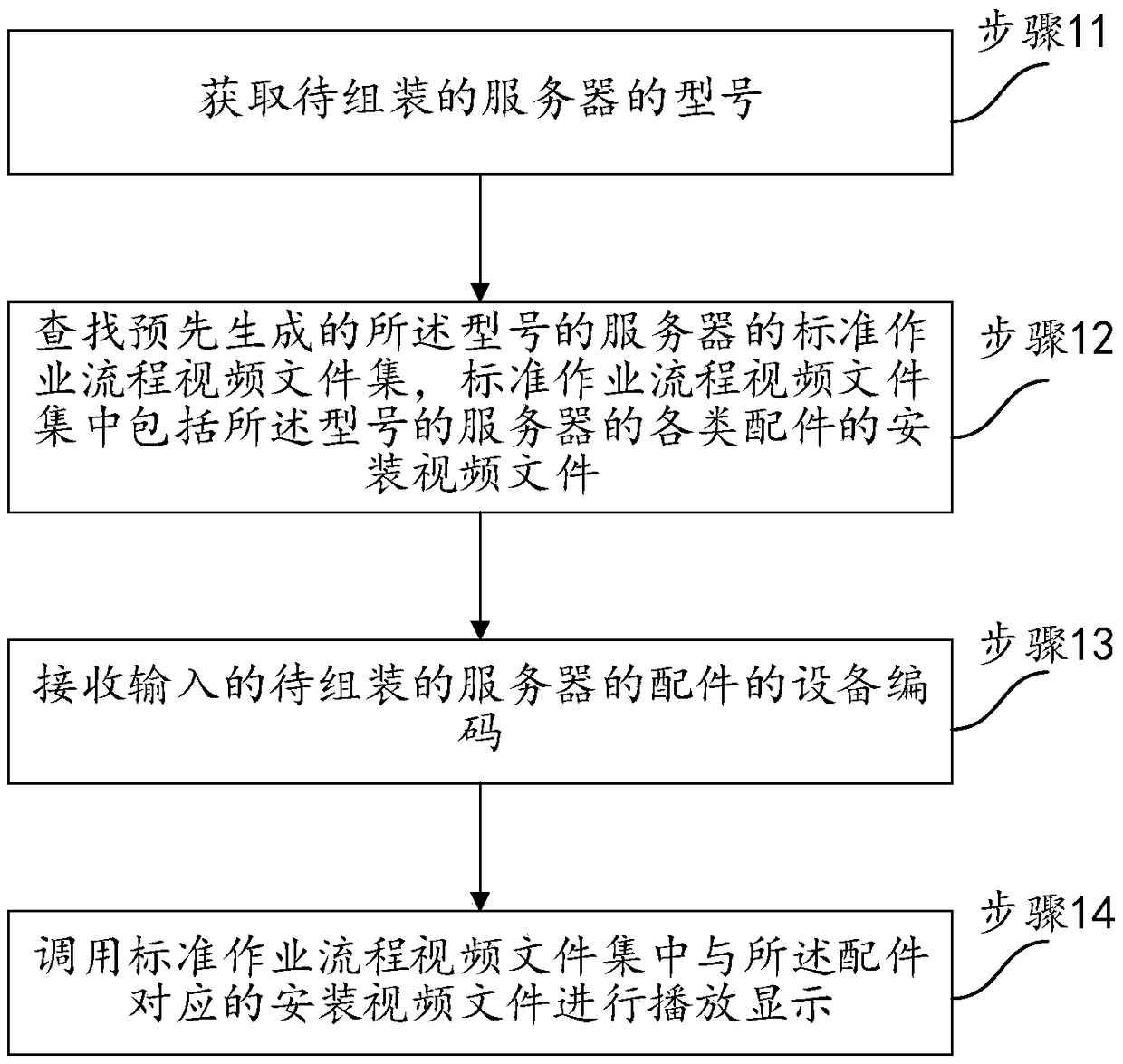

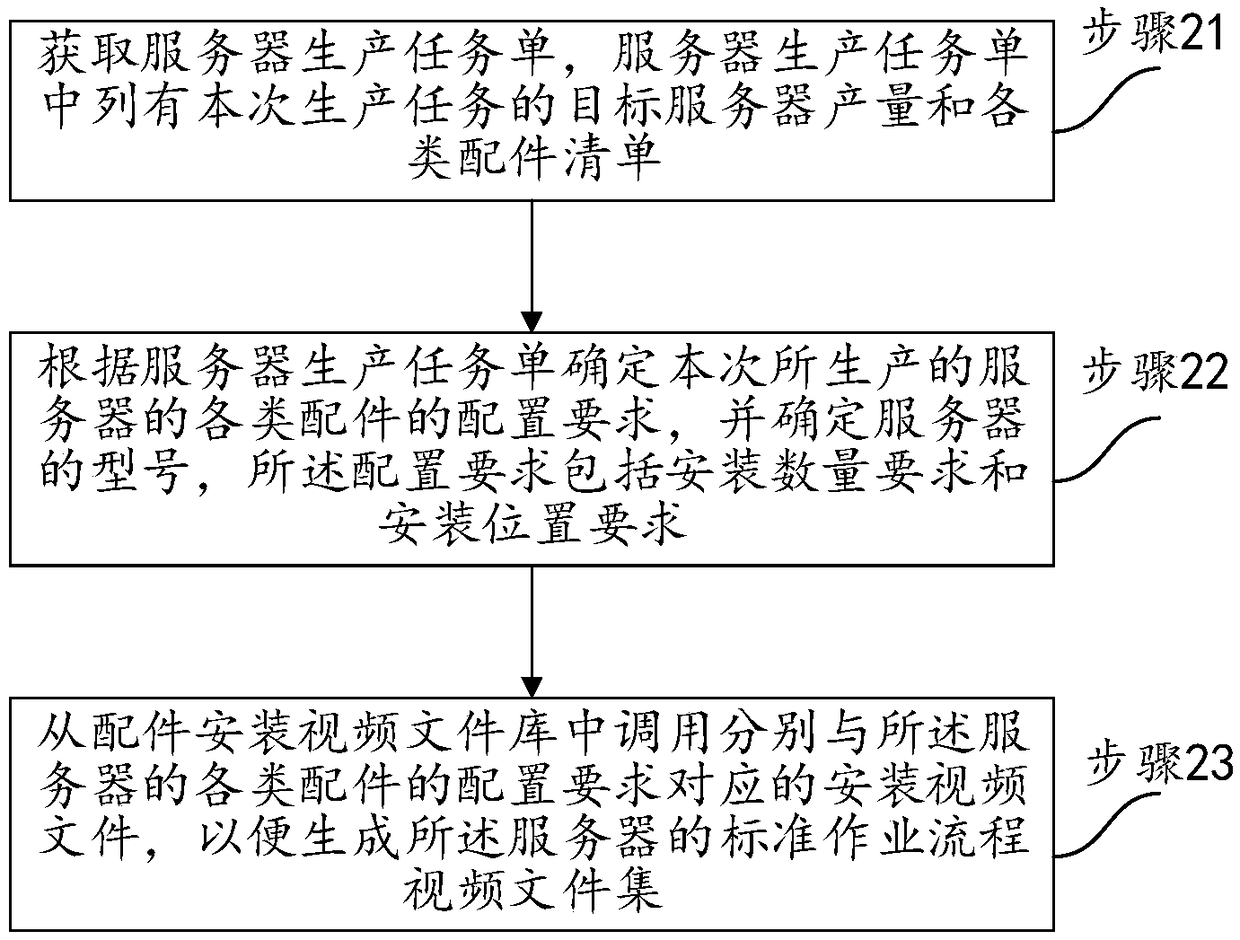

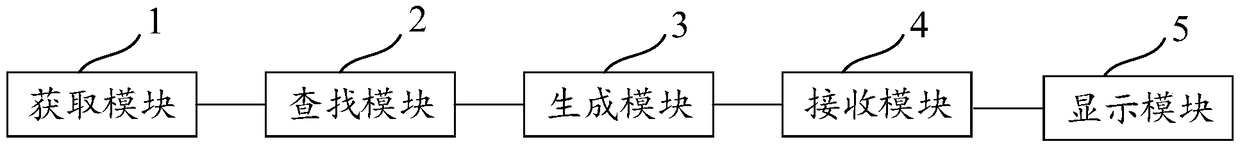

A method and a device for displaying a standard operation flow in a server production process

InactiveCN109241350AImprove assembly productivityEasy to understandVideo data browsing/visualisationDisplay deviceInstallation Error

The invention discloses a method for displaying a standard operation flow in a server production process, which comprises the following steps: obtaining a model number of a server to be assembled; Searching a standard operation flow video file set of the model server generated in advance, wherein the standard operation flow video file set includes installation video files of various accessories ofthe model server; Receiving an input device code of an accessory of a server to be assembled; calling the installation video file corresponding to the accessories in the standard operation flow videofile set for playback and display. The application adopts the mode of dynamic video to make the demonstration of the server assembly production process vivid, simple and intuitive, clear in organization, convenient for operators to understand and remember, greatly reducing the rework rate of the installation error, and effectively improving the assembly production efficiency. The invention also discloses a display device, a device and a computer-readable storage medium of a standard operation flow in the production process of a server, which also has the above-mentioned beneficial effects.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

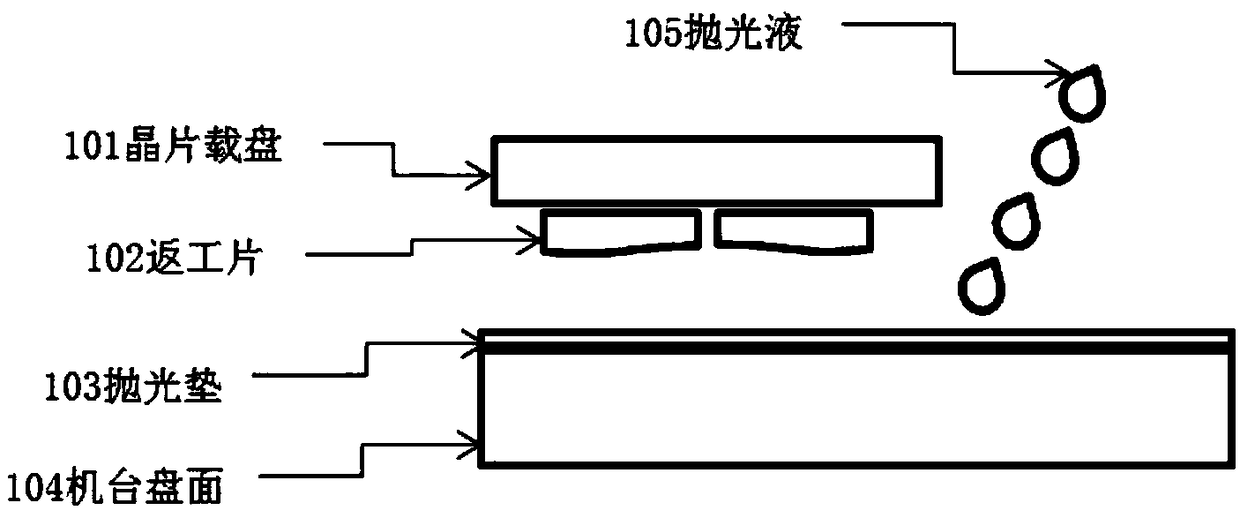

Rework process and method for sapphire single-sided polished section thickness badness

The invention discloses a rework process and method for sapphire single-sided polished section thickness badness. The rework process is characterized in that polishing is performed on a single side ofa sapphire wafer through existing equipment. The rework process comprises the following steps of: performing graph surveying and mapping on the surface of the polished sapphire wafer; measuring and analyzing to obtain sapphire wafer surface thickness unit area difference (TTV, LTV, TIR and a pit); improving a polished wafer carrier plate, a polishing pad, a machine table disc surface and a polishing solution according to the principle of analyzing a sapphire wafer surface thickness unit area (TTV, LTV, TIR and the pit) value, reducing a product wafer scrap rate and increasing a wafer rework maximum utilization rate; and re-polishing a sapphire single-polished sheet through a regulated polishing method. The integral thickness unit area difference (TTV, LTV, TIR and the pit) of the polishedsapphire re-polished sheet is measured until the wafer thickness flatness requirements are achieved.

Owner:ZHEJIANG EAST CRYSTAL BOLANTE PHOTOELECTRIC

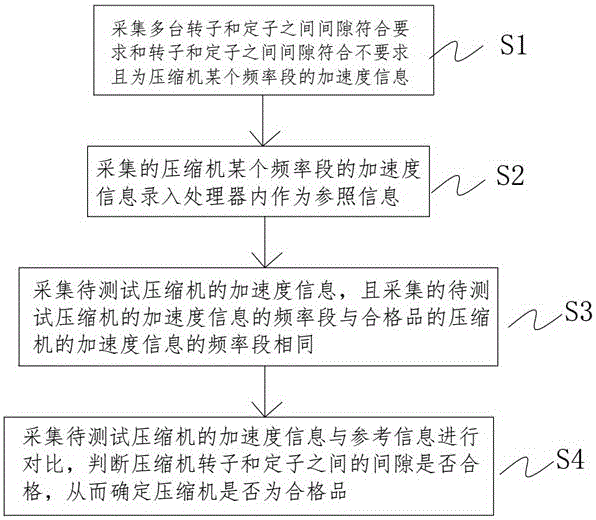

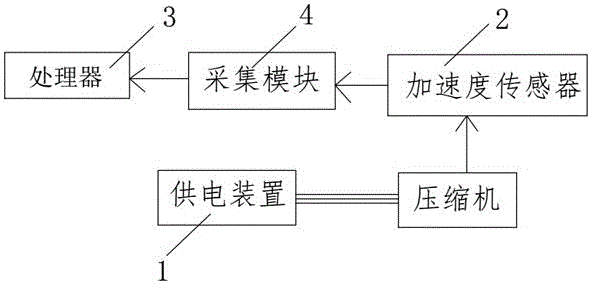

Method and device for detecting clearance between rotor and stator of compressor

ActiveCN106403880AImprove judgment efficiencyWon't breakMeasurement devicesMachines/enginesTest efficiencyEngineering

The invention discloses a method for detecting a clearance between a rotor and a stator of a compressor. The method comprises the steps of: S1, acquiring acceleration information of compressors which are qualified products and have clearances between rotors and stators conforming to requirements; S2, inputting the acquired acceleration information of the compressors into a processor to serve as reference information; S3, and acquiring acceleration information of a compressor to be tested, comparing the acceleration information with the reference information, and judging whether a clearance between a rotor and a stator of the compressor is qualified, so as to determine whether the compressor is a qualified product. The invention further discloses a device for detecting the clearance between the rotor and the stator of the compressor. According to the method and the device, a top cover of the compressor does not need to be turned off from a compressor shell body, the efficiency of judging whether the clearance between the rotor and the stator in the compressor shell body conforms to the requirement is improved, the production cost is saved, the rework cost is decreased, the testing efficiency is improved, the method and the device are suitable for batched compressor detection, and the product quality is improved.

Owner:TCL RUIZHI (HUIZHOU) REFRIGERATION EQUIP CO LTD

BIM-based large refrigeration machine room digital assembly method and system

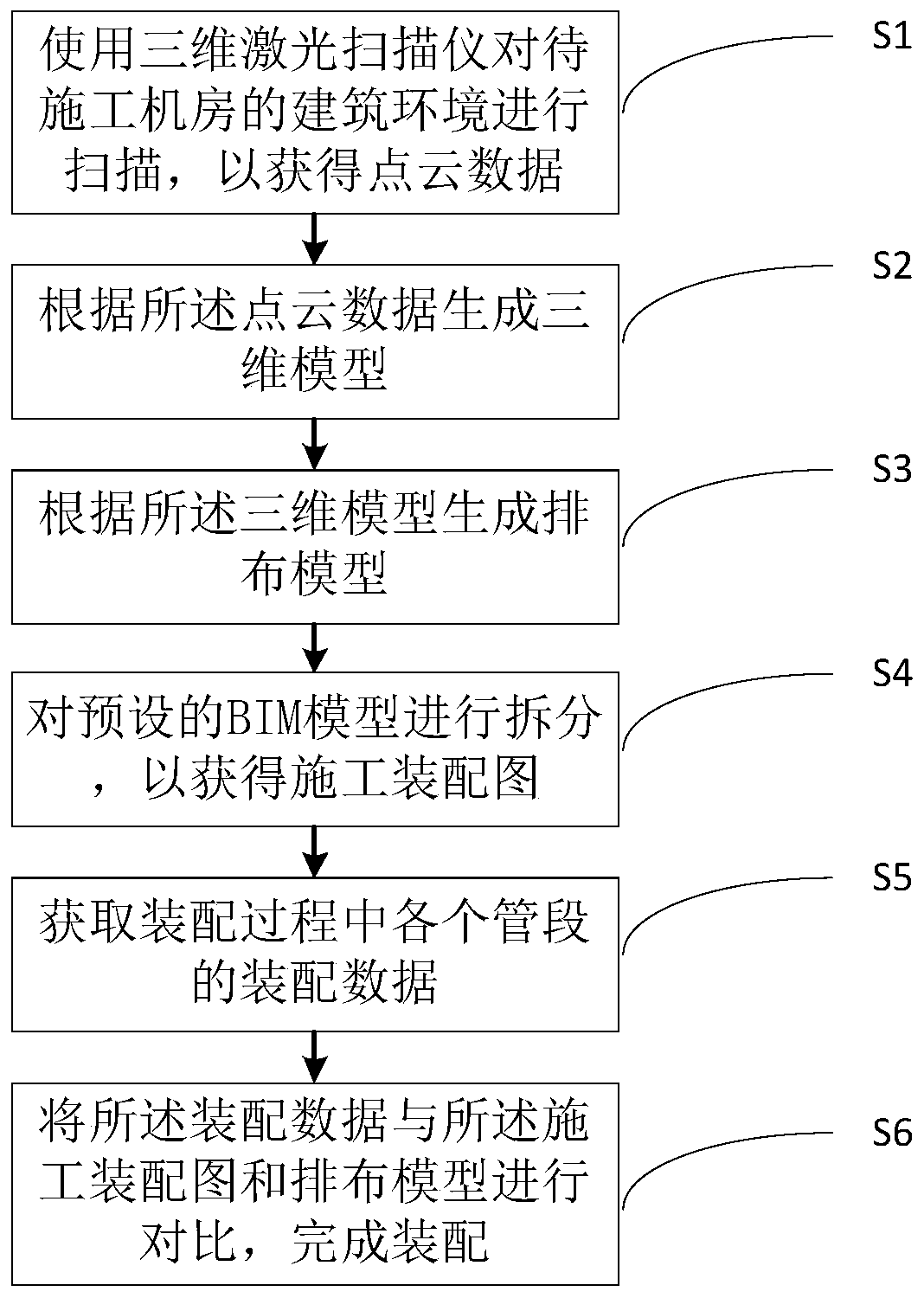

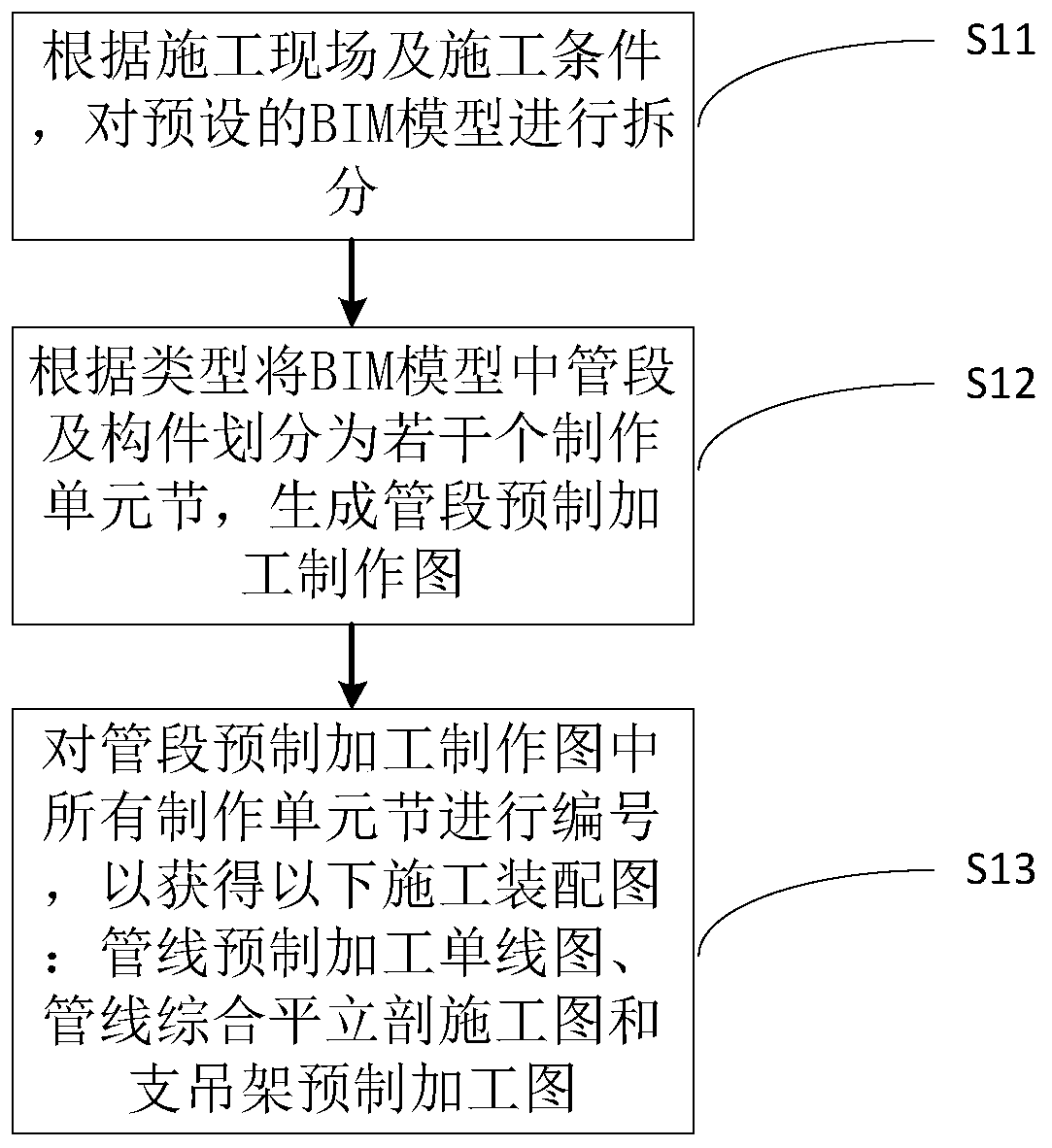

PendingCN111104709AReduce wasteImprove installation accuracyGeometric CADCo-operative working arrangementsLaser scanningMachine

According to the BIM-based large refrigeration machine room digital assembly method and system provided by the invention, The method comprises the steps of: using a three-dimensional laser scanner forscanning a building environment of a to-be-constructed machine room to obtain point cloud data; generating a three-dimensional model according to the point cloud data; generating an arrangement modelaccording to the three-dimensional model; splitting a preset BIM model to obtain a construction assembly drawing; acquiring assembly data of each pipe section in the assembly process; and comparing the assembly data with the construction assembly drawing and the arrangement model to complete assembly. According to the method, the BIM technology is adopted for leading deepening design, pipeline optimization, organization and drainage, factory prefabrication and field assembly of the refrigerating machine room. because the precision of the BIM model reaches the millimeter level, the installation precision is improved, rework caused by manpower is avoided, material waste is reduced, and the construction period is effectively shortened.

Owner:青岛国信海天中心建设有限公司

Interactive three-dimensional and VR simulation disclosure system for thermal power plant

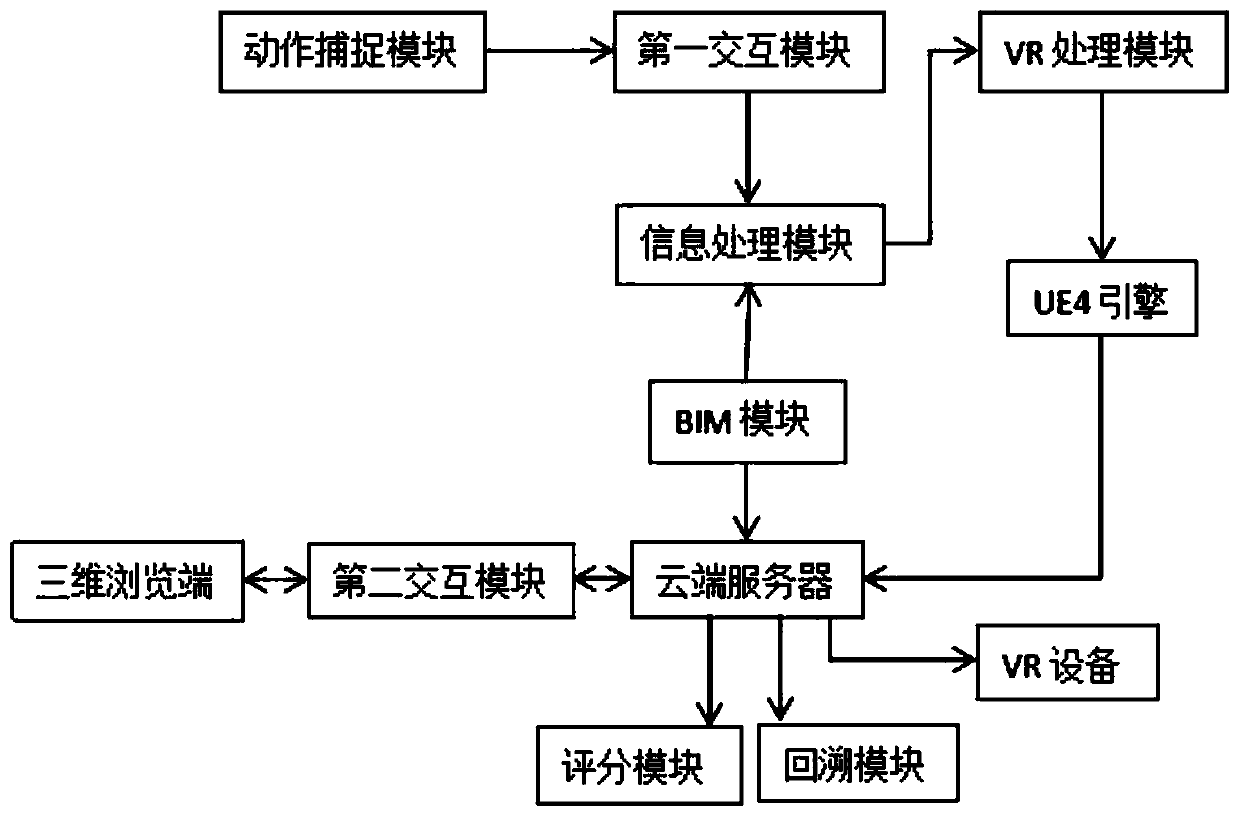

ActiveCN110766805AUnintuitive solutionSolve the problem of incomplete disclosureData processing applicationsImage data processingInformation processingPower station

The invention discloses an interactive three-dimensional and VR simulation disclosure system for a thermal power plant. The disclosure system comprises an action capture module, a first interaction module, an information processing module, a VR processing module, a UE4 engine, VR equipment, a BIM module, a cloud server, a three-dimensional browsing terminal, a second interaction module, a scoringmodule and a backtracking module. According to the invention, the BIM technology, the VR technology, the Internet, the cloud platform and other technologies are applied to the thermal power generationproject construction process so as to assist the scheme disclosure, the problems that an important technical scheme is not visual and is not thorough in disclosure are solved, the technical disclosure quality is improved, rework and cost are reduced, good economic benefits are generated, meanwhile, the time for constructors to recognize and learn technical difficulties in the power construction process is shortened, the knowledge transmission efficiency is improved, and the technology is integrated, dominated and interacted.

Owner:中能建建筑集团有限公司 +1

lightweight BIM prefabricated part full life cycle comprehensive information management system

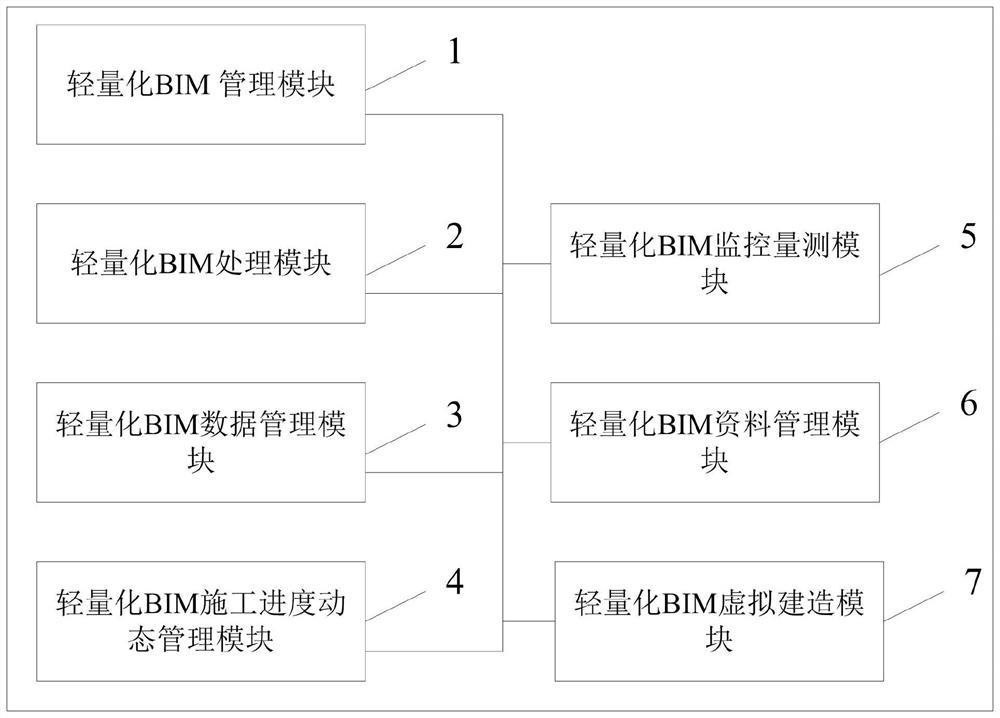

PendingCN113722797AImprove management levelRun fastGeometric CADDesign optimisation/simulationFull life cycleEngineering

The invention discloses a lightweight BIM prefabricated part full life cycle comprehensive information management system. The system comprises a lightweight BIM management module, a lightweight BIM processing module, a lightweight BIM data management module, a lightweight BIM construction progress dynamic management module and a lightweight BIM monitoring measurement module. Based on the advantages of visualization, digitization, multi-dimension, coordination, whole-process simulation and the like of the BIM technology, geometric information, functional attributes and process information of engineering objects are completely expressed, reproduced, transmitted and shared, co-governance, co-management and coordination of all participants of a construction project on the same target object and a single engineering data source can be supported. A sharing platform is provided for design construction, resource allocation, construction simulation and monitoring measurement; according to the system, the running speed of a processing computer can be increased, memory consumption is reduced, the response speed is high, and the error and rework probability caused by participation of multiple units can be reduced.

Owner:CHINA RAILWAYS CORPORATION +2

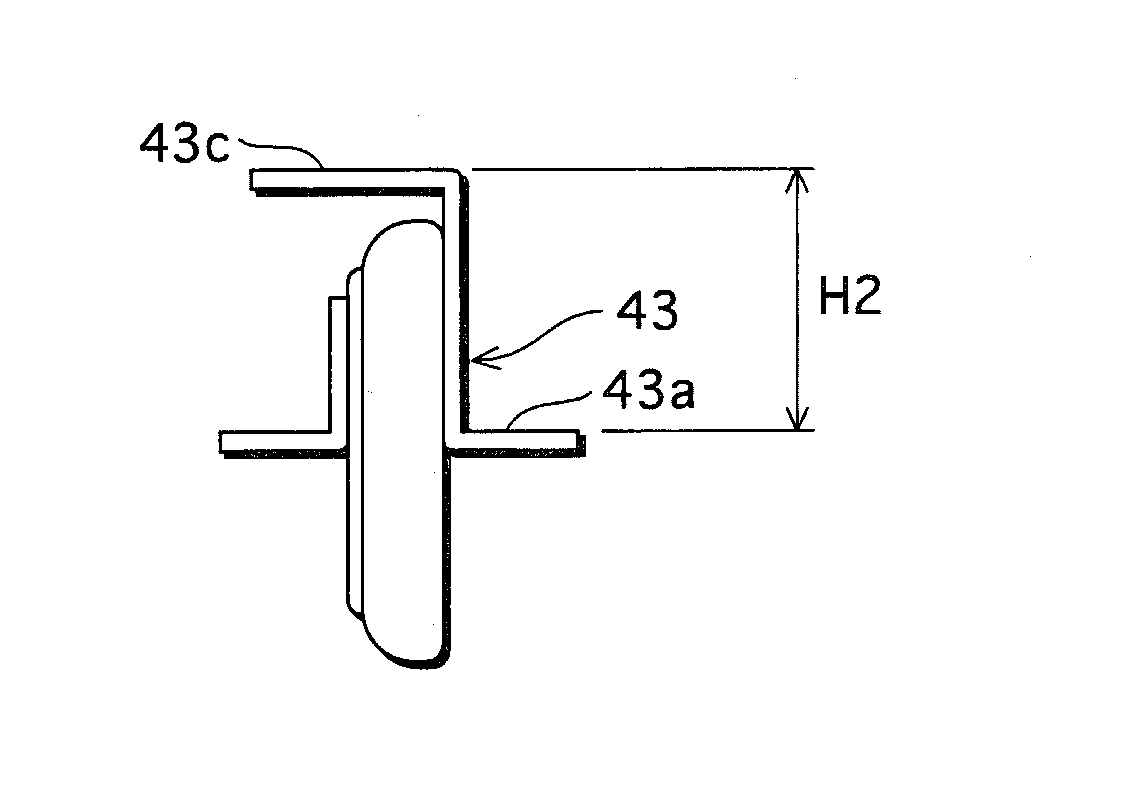

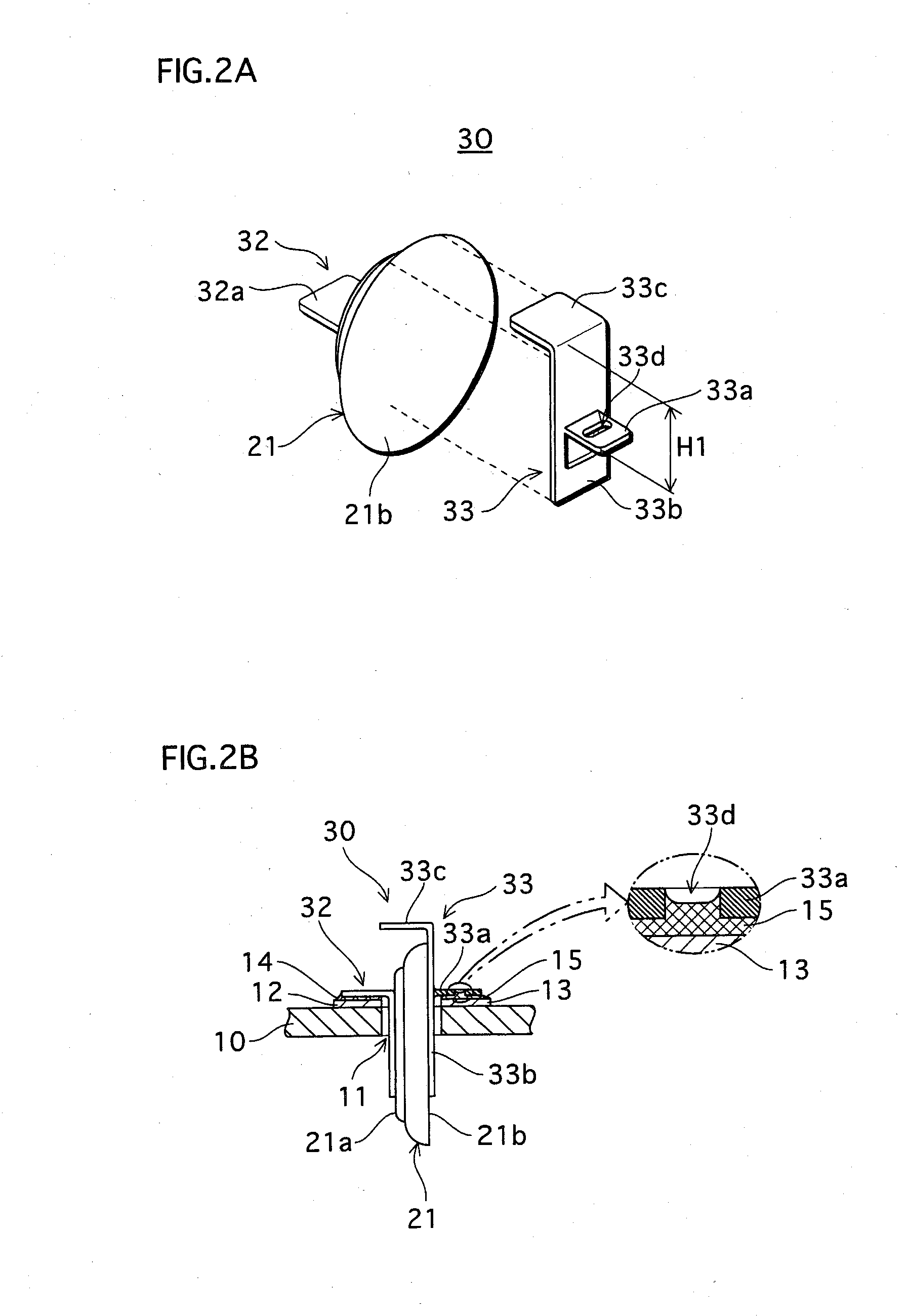

Mounting board including a flat-type electrical element and capable of being reduced in size, and lead-attached electric element that is flat in shape and has a lead bonded to each electrode face

InactiveUS20080236880A1Reduce areaIncrease in envelope volumePrinted circuit aspectsPrinted circuit manufactureLead bondingEngineering

A lead-attached electrical element and a mounting board to which the lead-attached electrical element is mounted both contribute to a reduction in the size of the mounting board as well as facilitate rework. The lead-attached electrical element is constituted from an electrical element and two leads. Each lead includes a main portion which is bonded to a respective electrode face of the electrical element, and a bent portion which is inclined with respect to the main portion. The mounting board is constituted from a PC (printed circuit) board and the lead-attached electrical element. Two conductive lands are provided on a surface of the PC board. The lead-attached electrical element has been inserted into an aperture in the PC board, and bent portions of the leads attached to the electrical element are bonded to the conductive lands so that the electrical element is suspended in the aperture by the leads.

Owner:FDK CORP +1

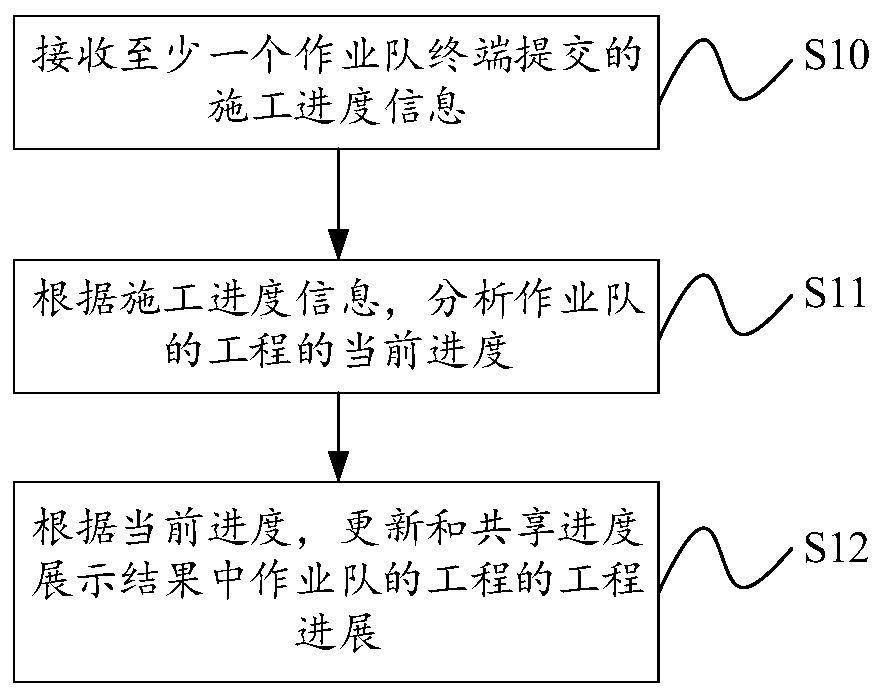

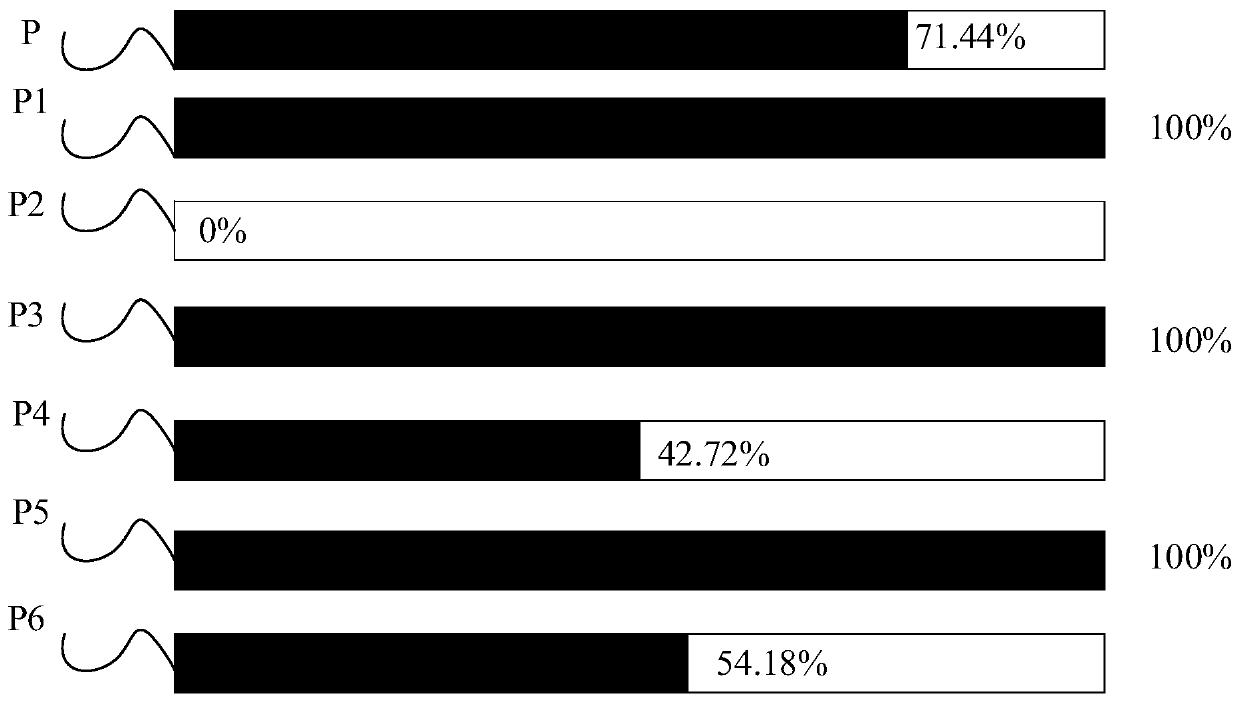

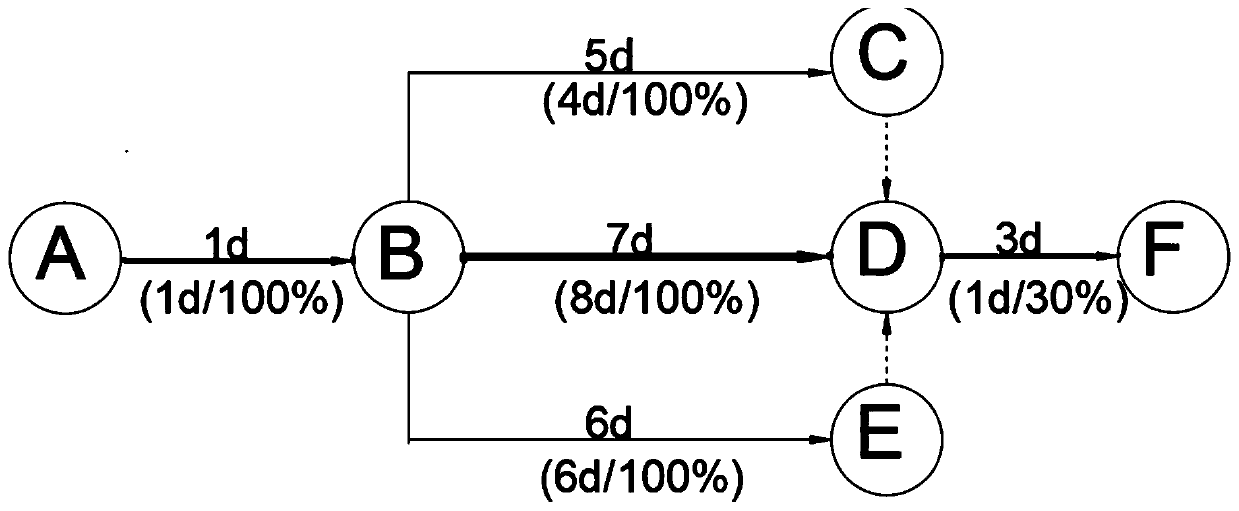

BIM-based project progress management method, apparatus and device, and storage medium

PendingCN111445218AImprove timelinessImprove collaborative construction efficiencyOffice automationReworkWork task

The invention provides a BIM-based project progress management method, apparatus and device, and a storage medium, and relates to the technical field of software. The method comprises the steps of: receiving construction progress information submitted by at least one operation team terminal, wherein the construction progress information comprises identification of an operation team, identificationof a project, progress information of a work task, use material information and the like; and analyzing the current progress of the project of the operation team according to the construction progress information, and updating the project progress of the project of the operation team in the progress display result according to the current progress. According to the method, the project progress can be obtained in time through the BIM construction management platform, the display result is updated and shared, the collaborative construction efficiency is greatly improved, rework is reduced, meanwhile, the cost is reduced, and the management timeliness is improved.

Owner:ELECTRICAL SERVICE & ELECTRIFICATION ENG +1

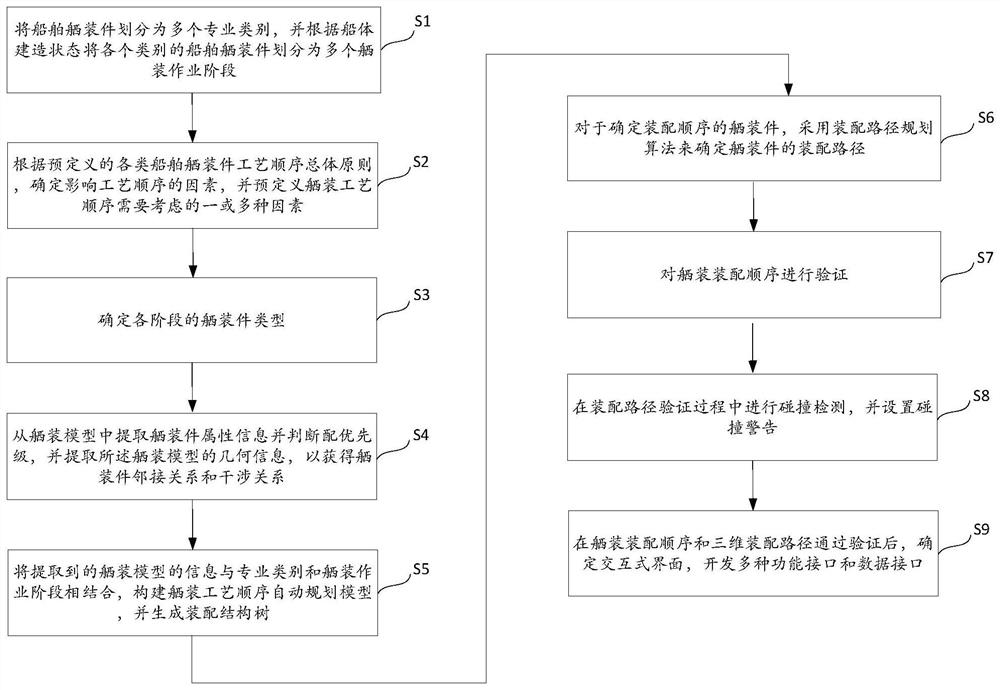

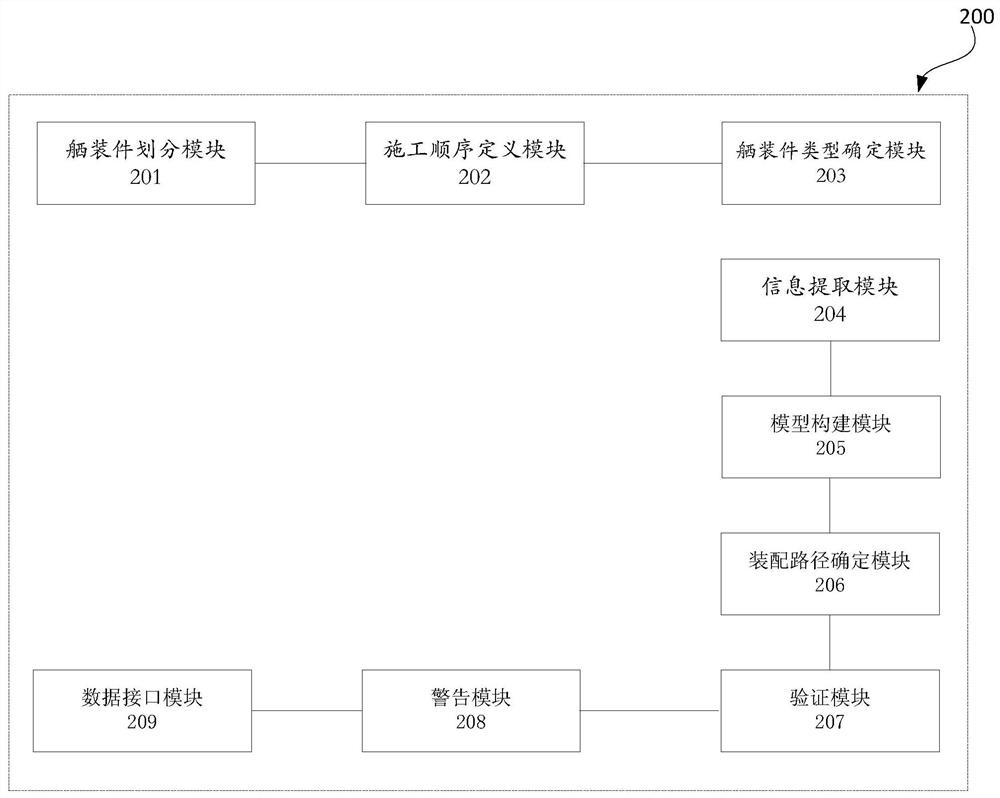

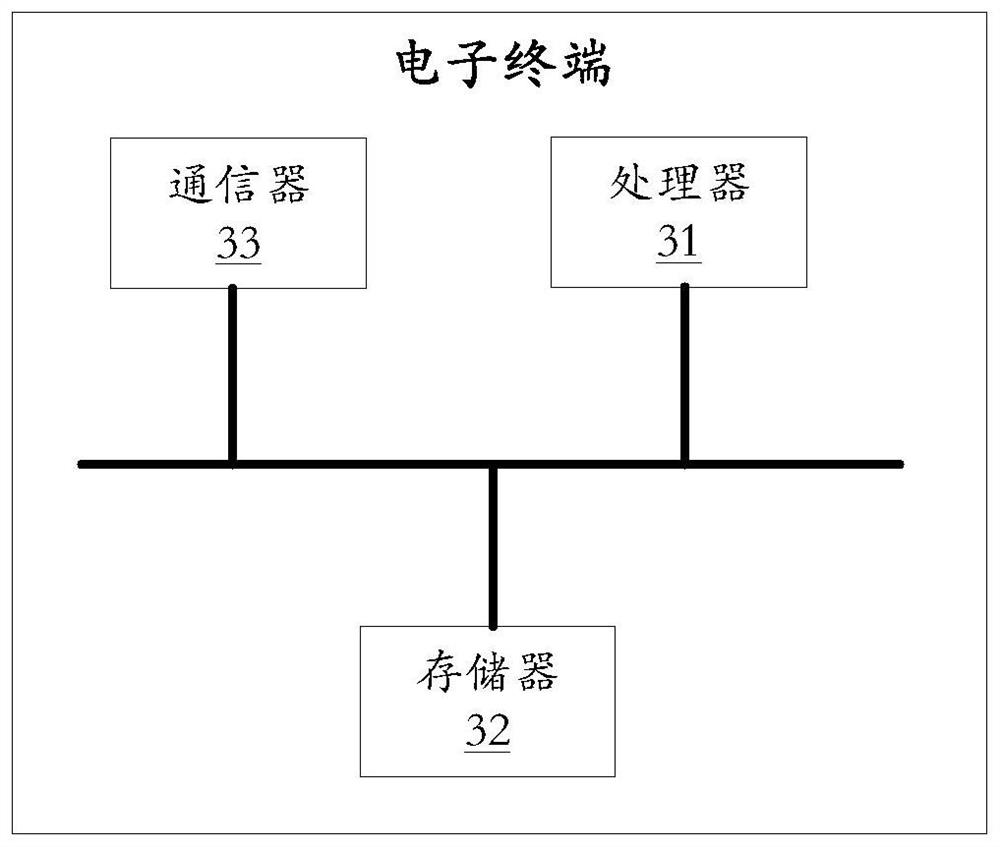

Ship outfitting process sequence automatic planning method and device, terminal and storage medium

PendingCN112036760AImprove accuracyRaise the level of digitizationResourcesManufacturing computing systemsSequence planningSequence design

The invention provides a ship fitting-out process sequence automatic planning method and device, a terminal and a storage medium, and solves the problems of unreasonable sequence, high construction difficulty, low design efficiency, frequent rework and the like in the existing ship fitting-out process sequence planning process, thereby achieving reasonability and standardization of ship fitting-out process sequence design, and improving the efficiency of ship fitting-out process sequence planning. Through the automatic planning function of the outfitting assembly sequence, the accuracy of theconstruction process is improved, the rework phenomenon is reduced, the dock or berth period is shortened, the production cost is reduced, through the automatic planning function of the ship outfitting three-dimensional assembly path, interference and collision are avoided, field assembly operation is guided, and the digital level of the outfitting construction process is improved; and the assembly efficiency is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

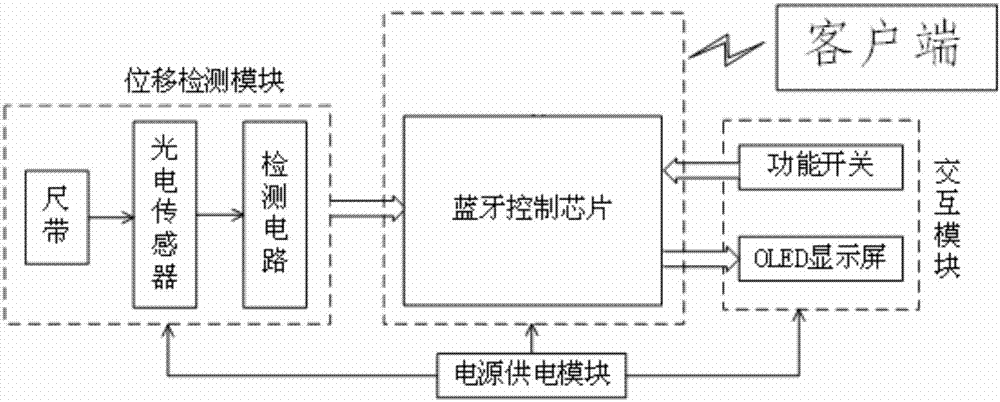

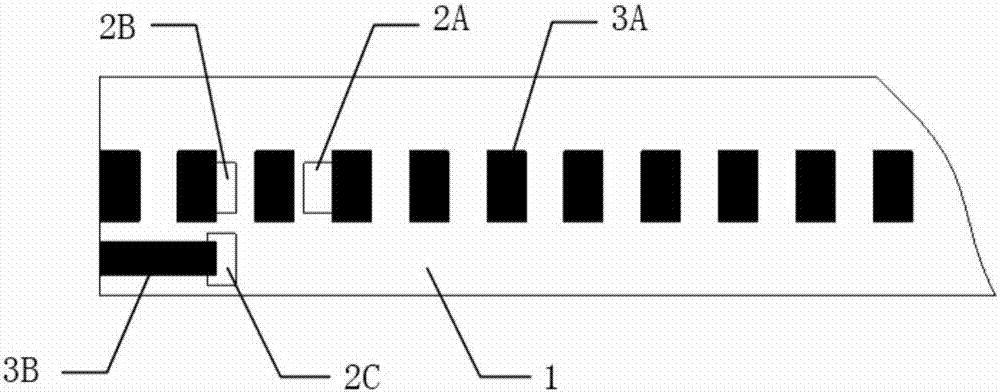

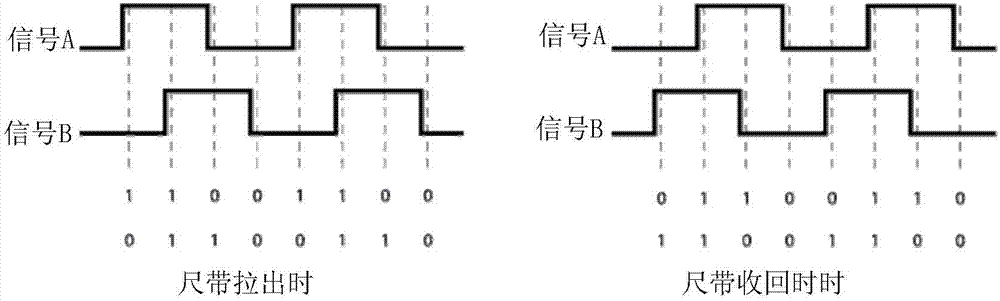

Digital measurement ruler and measurement method thereof

InactiveCN107019277ATake advantage ofAvoid reworkClothes making applicancesComputer moduleCentralized management

The invention discloses a digital measurement ruler and a measurement method thereof. The measurement ruler comprises a soft ruler belt, a first photoelectric sensor, a second photoelectric sensor, a detection circuit, a connecting disc, an outer shell, a Bluetooth control chip, a display screen, an LED data transmission indicator lamp, a function switch, a power supply module and a client side; the Bluetooth control chip acquires the displacement length of the soft ruler belt according to a received signal of the photoelectric sensor and controls the display screen to display data in real time. The reflective photoelectric sensor is used to detect the displacement, then the measurement accuracy is guaranteed, the design cost is also lowered; the chip resource is fully utilized, the unnecessary cost waste is avoided; the measurement data are displayed in real time, the phenomenon of rework, caused by the measurement error of the faulted measurement ruler, is avoided; the data are not artificially recorded and summarized, the working efficiency is improved, the manpower cost is lowered, and meanwhile, the centralized management and use of the data is facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

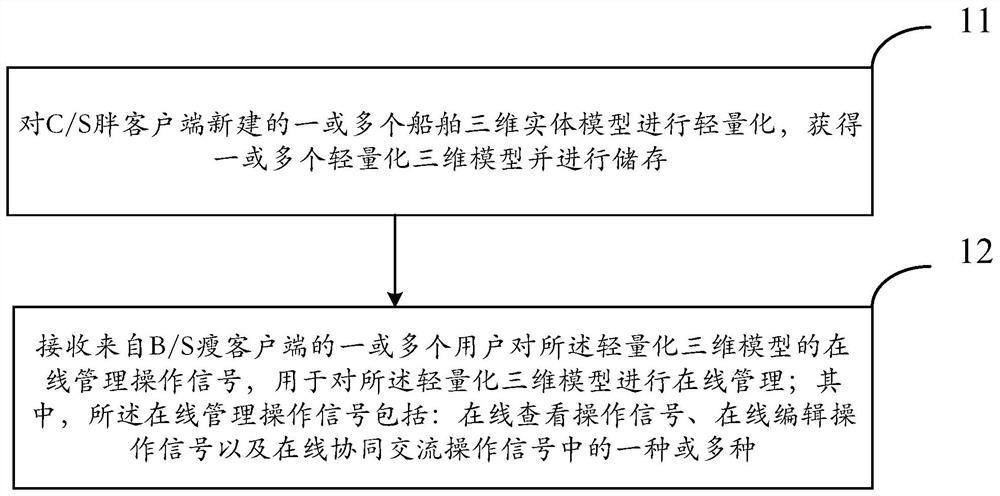

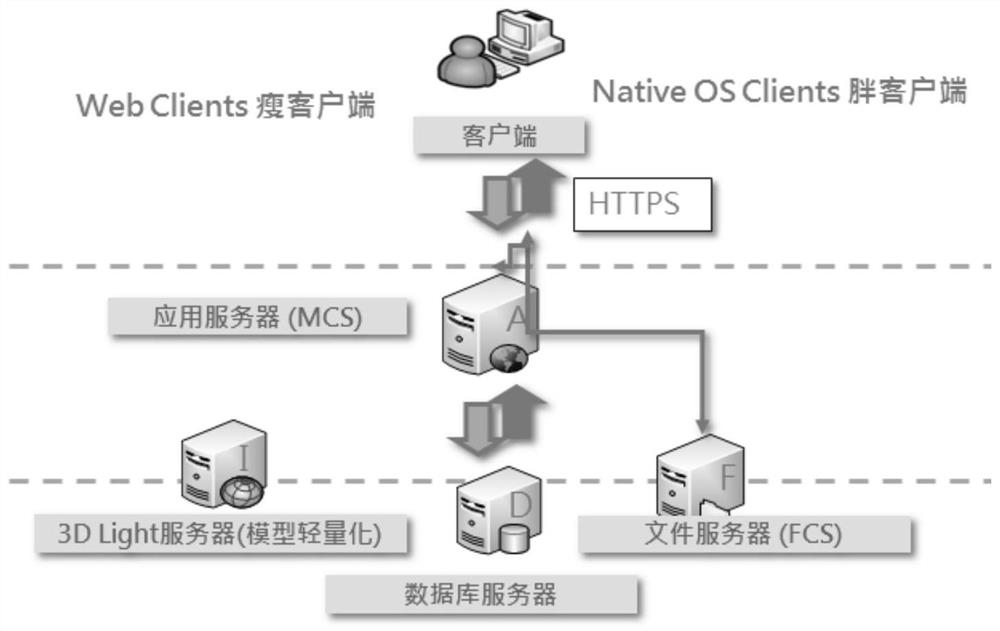

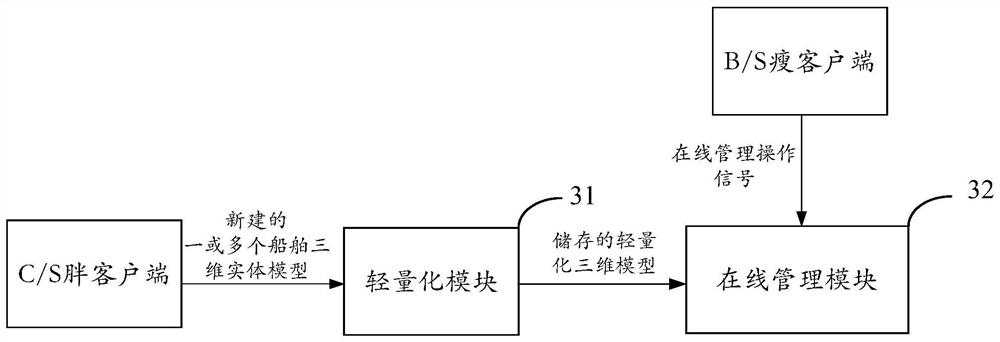

Online operation management method and system based on ship three-dimensional model and terminal

PendingCN111915276AAchieve fast and lightweightLower requirementGeometric CADOffice automationReworkIndustrial engineering

The invention provides an online operation management method and system based on a ship three-dimensional model and a terminal. The method comprises the steps: lightening a ship three-dimensional entity model newly built at a C / S fat client to acquire a light-weight three-dimensional model, and storing the light-weight three-dimensional model; receiving online management operation signals of one or more users from a B / S thin client, wherein the online management operation signals are used for carrying out online management on the lightweight three-dimensional model; wherein the online management operation signal comprises one or more of an online viewing operation signal, an online editing operation signal and an online cooperative communication operation signal. The problems that in the prior art, the requirement for field terminal application equipment is high, the application cost is high, and online cooperation between design and manufacturing cannot be achieved for a three-dimensional model are solved. Online cooperation between ship design and manufacturing is achieved, online communication between field manufacturing personnel and designers is supported, the design problem existing in the manufacturing field is rapidly solved, design change and manufacturing rework are reduced, and the production and construction cost is saved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

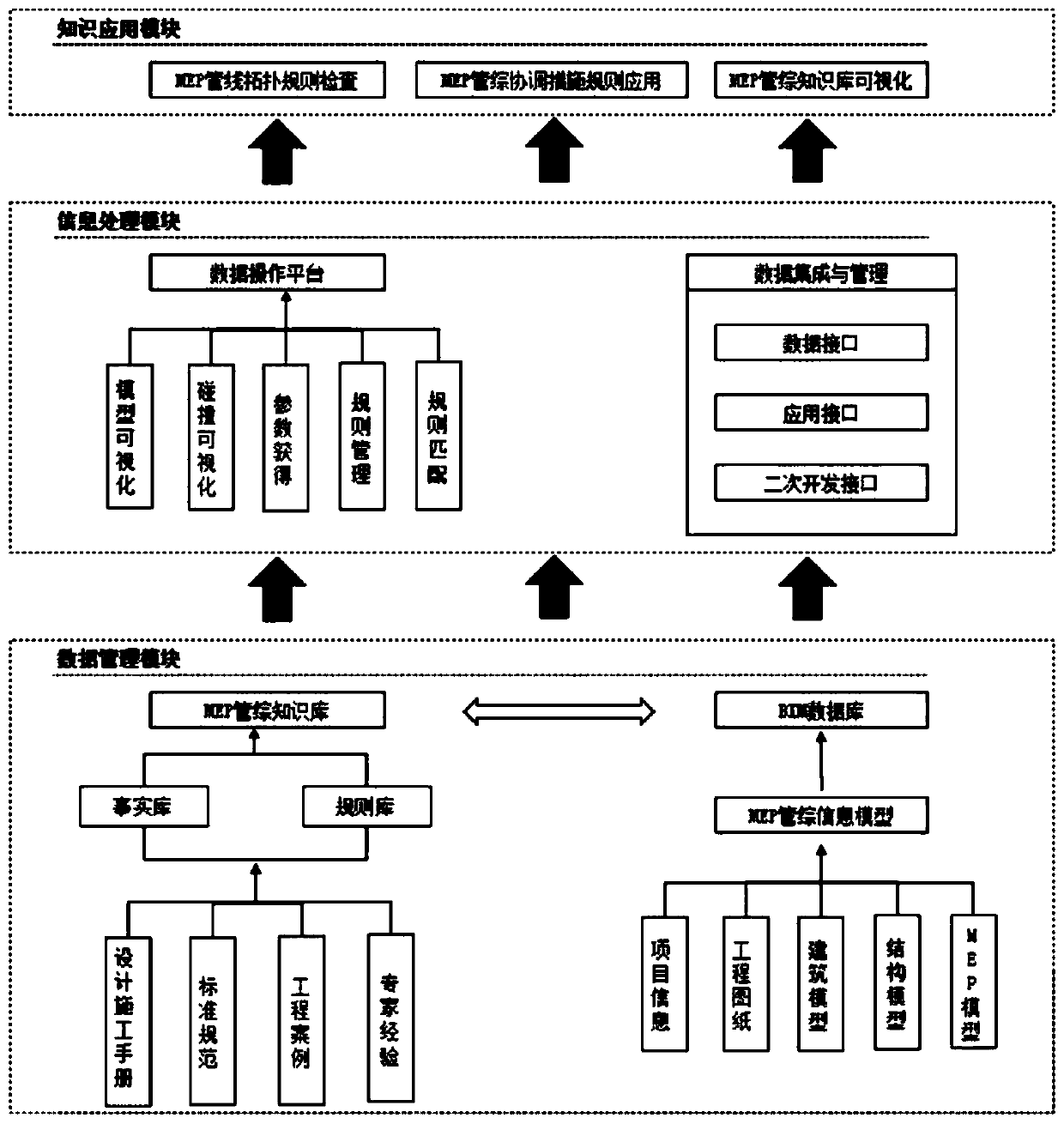

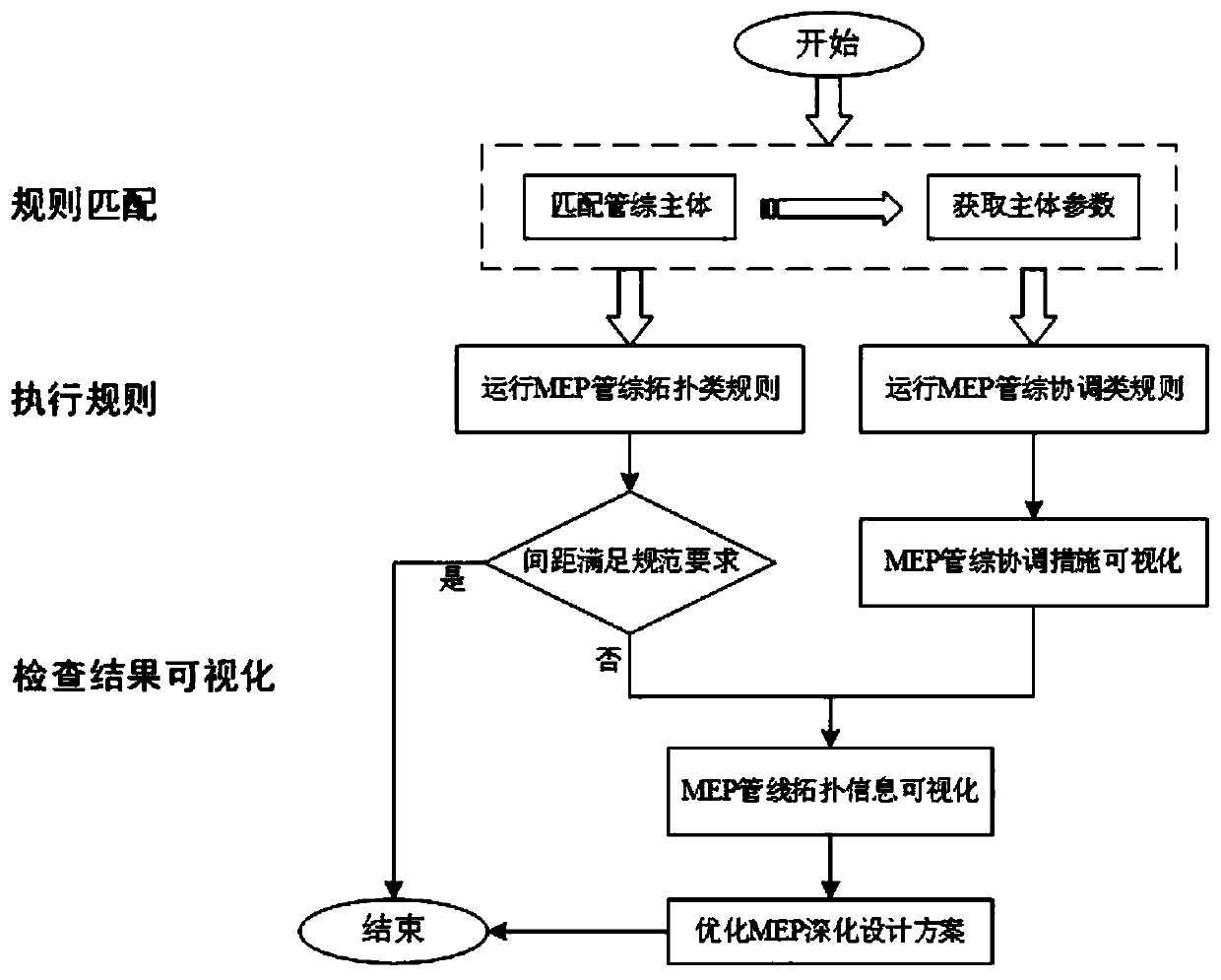

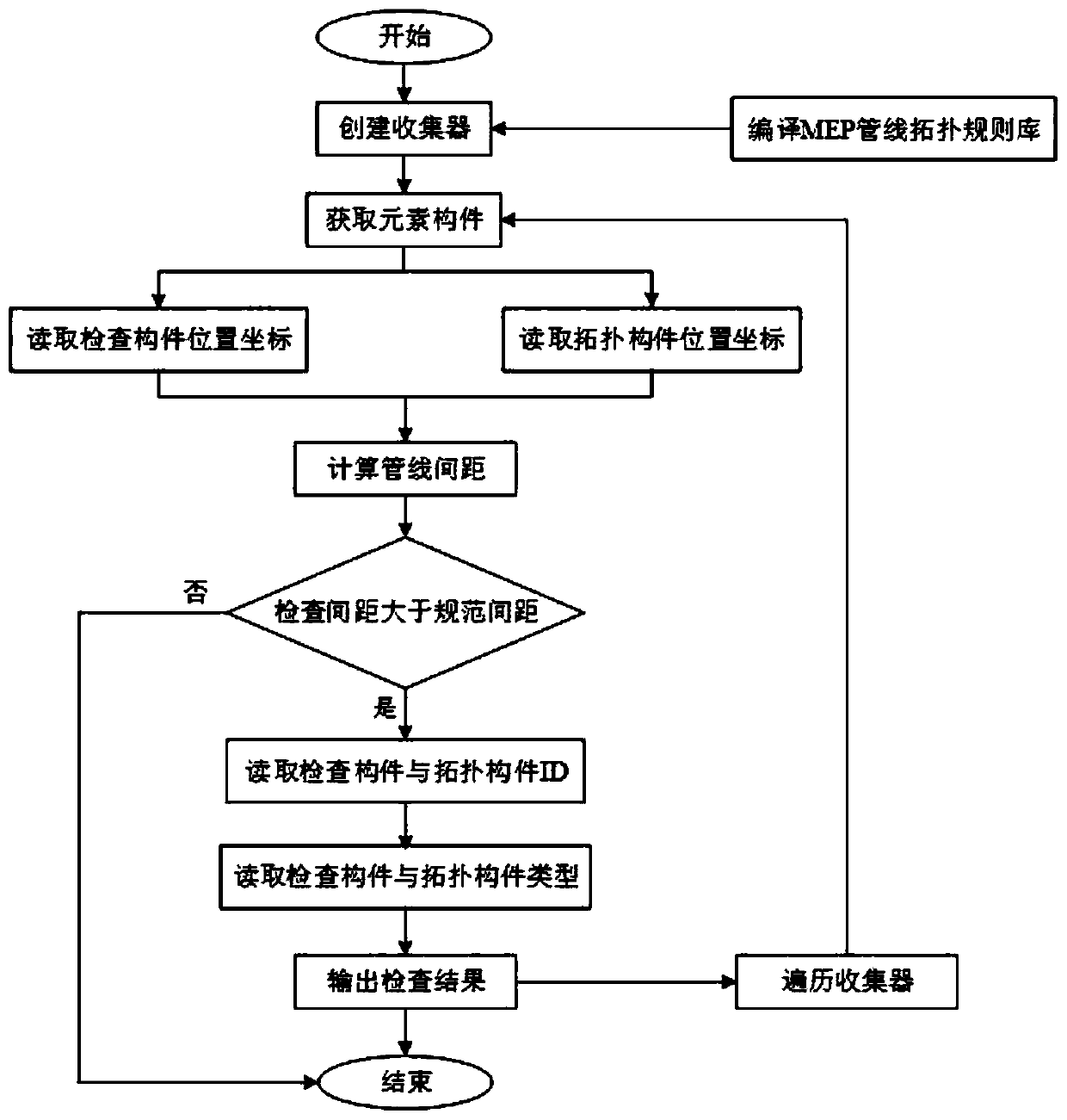

BIM-based electromechanical pipeline comprehensive specification automatic inspection system

Owner:江苏数链建筑科学研究院有限公司 +1

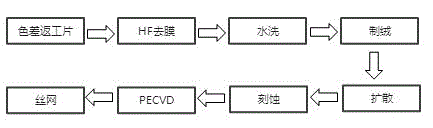

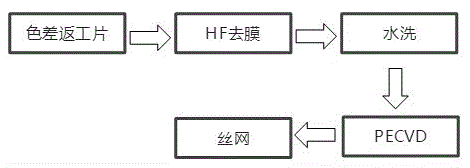

PECVD rework cell processing method

InactiveCN105575759ALittle impact on efficiencySimplify the rework processFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingCell processing

The invention discloses a PECVD rework cell processing method. According to the adopted technical scheme, after HF film removing and washing of a PECVD rework cell, PECVD coating and screen printing are carried out directly to complete a cell preparation process. The PECVD rework cell processing method has the beneficial effect that the rework process is simplified, manpower and material resources are saved for companies, and the optimized process almost has no influence on the suede and the PN junction and has little influence on the final cell efficiency.

Owner:ZHEJIANG FORTUNE ENERGY

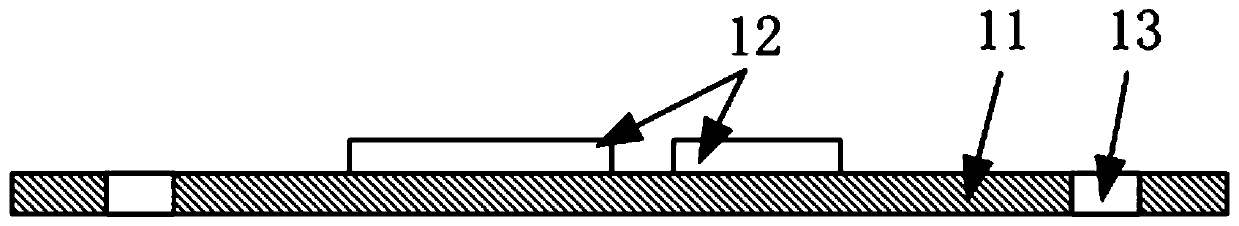

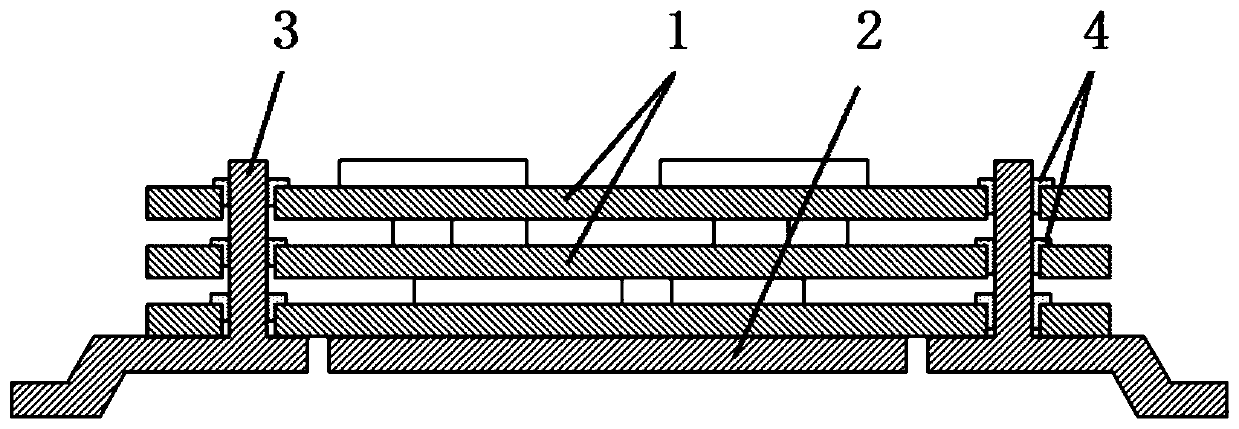

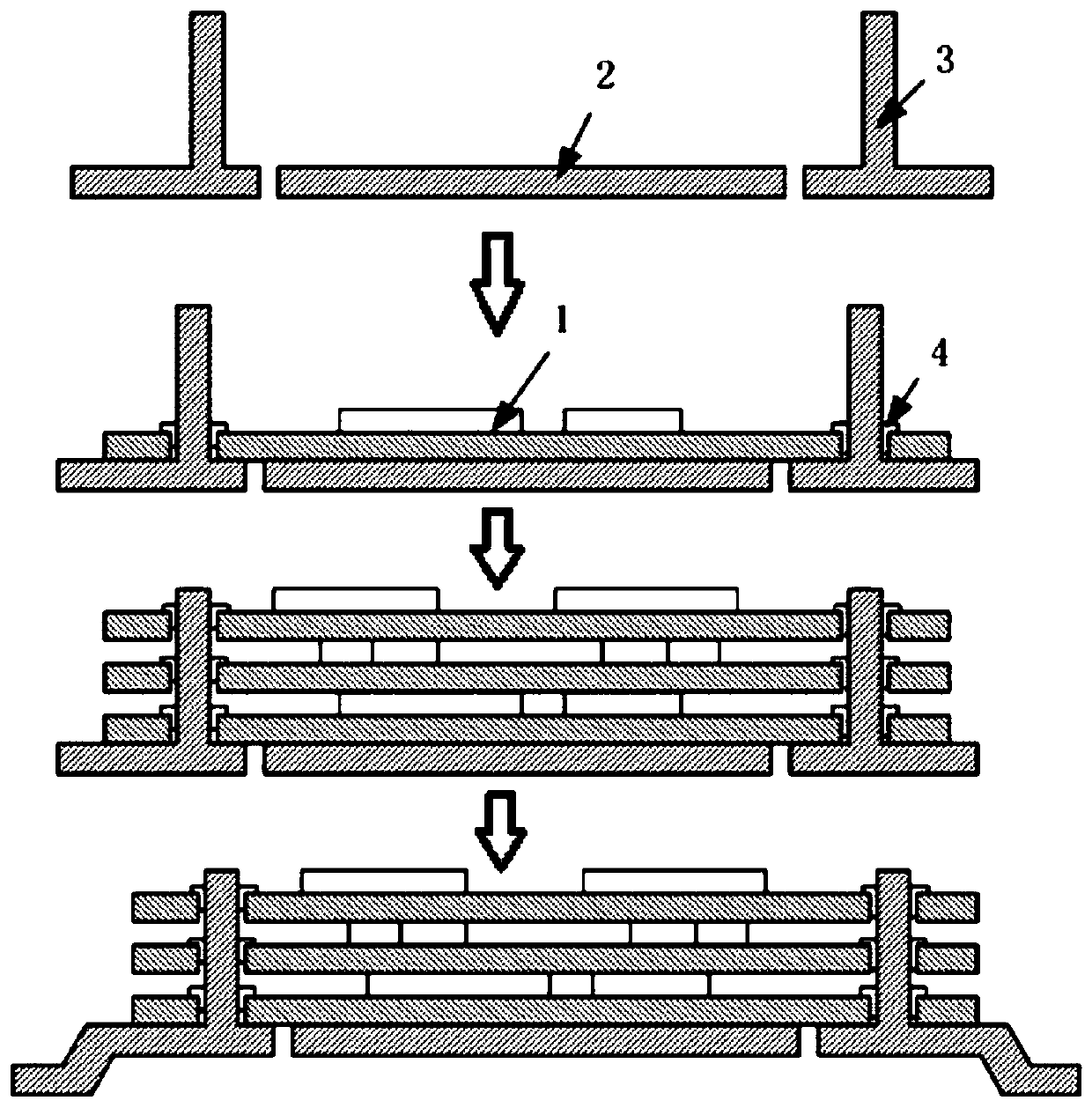

Packaging structure and packaging method of multilayer chip

InactiveCN111128977AAchieve reconnectionTo achieve interconnectionSemiconductor/solid-state device detailsSolid-state devicesMetal frameworkRework

The invention discloses a packaging structure and a packaging method of a multilayer chip. The packaging structure comprises a plurality of chip assemblies and a metal frame, wherein the chip assemblies and the metal frame are sequentially arranged in a stacked mode from top to bottom; each chip assembly comprises a substrate, a chip monomer connected to the substrate and a plurality of through holes formed in the substrate; a plurality of columnar connecting bodies are fixed on the upper surface of the metal frame; and the plurality of chip assemblies are all located above the metal frame, the through holes of the chip assemblies sleeve the columnar connecting body, and the substrates of the chip assemblies are communicated with the columnar connecting body through the welding body. According to the invention, the functions of fixing and communicating the columnar connecting body and the substrate are realized by adopting the welding body, the finished product yield of the integratedpackaging structure can be effectively improved, rework operation can be carried out on connection at the welding body position, and the preparation cost is reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com