Patents

Literature

277results about How to "Improve assembly productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

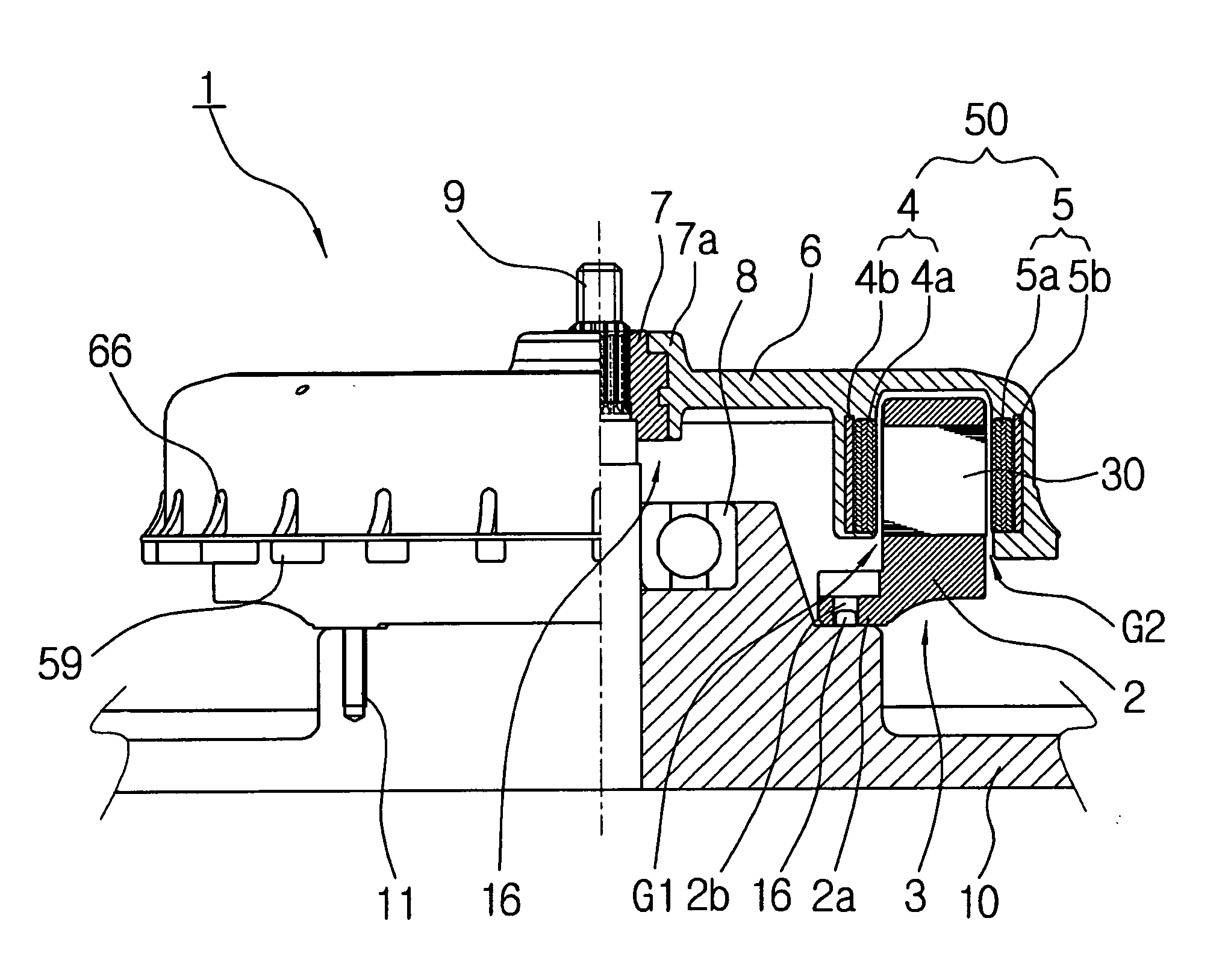

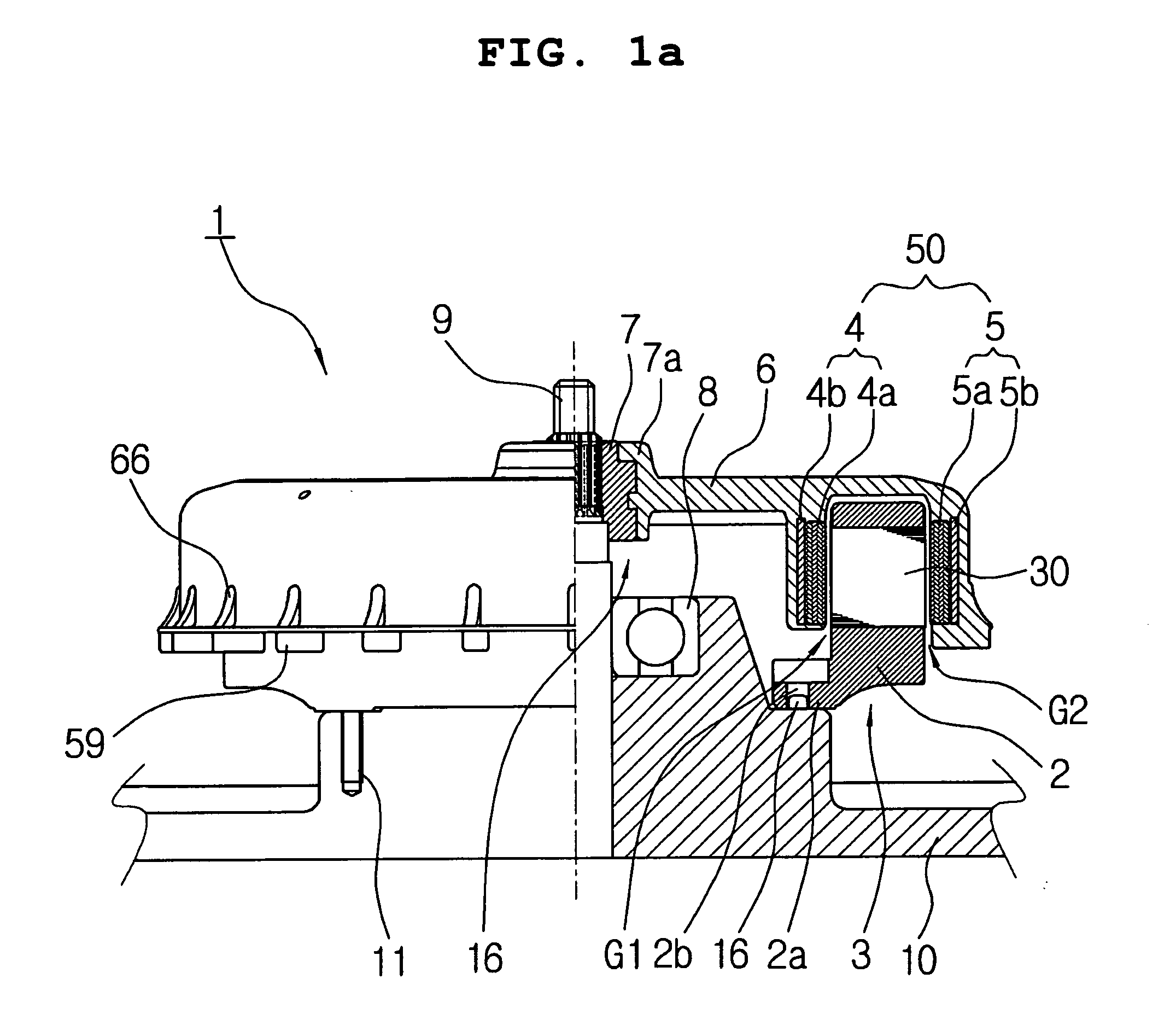

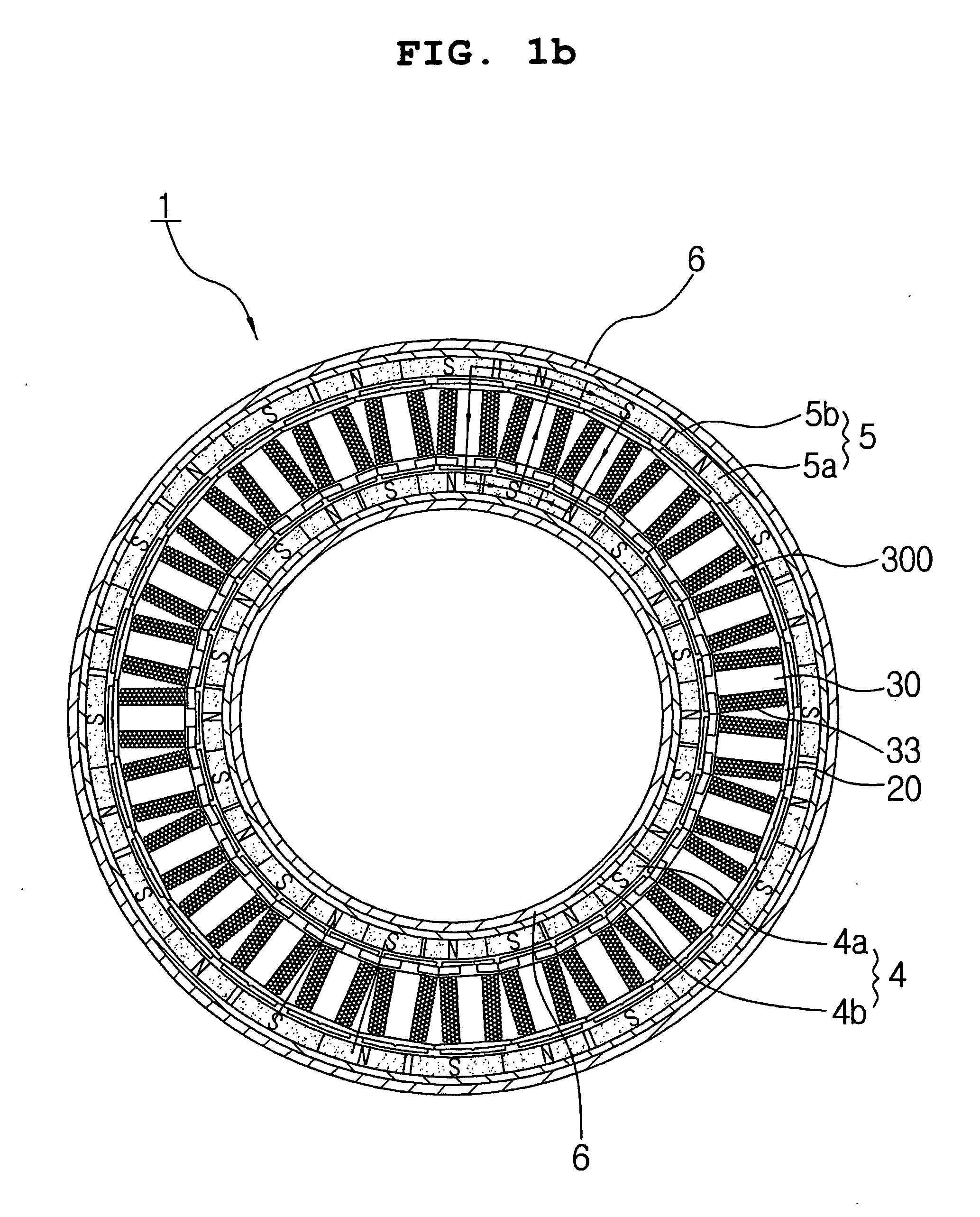

Method of making integrated stator, brushless direct-current motor of radial core type double rotor structure using the integrated stator, and method of making the same

InactiveUS20070236099A1Improve assembly productivityImprove support strengthSynchronous generatorsMagnetic circuit rotating partsStatorEngineering

Provided are a radial core type brushless direct-current (BLDC) motor and a method of making the same, having an excellent assembly capability of division type stator cores in a double rotor structure BLDC motor. The BLDC motor includes a rotational shaft, an integrated double rotor including an inner rotor and an outer rotor, and a rotor supporter wherein a trench type space is formed between the inner rotor and the outer rotor, and an end extended from the inner rotor is connected with the outer circumferential surface of a bushing combined with the rotational shaft, and an integrated stator wherein one end of the stator is disposed in the trench type space and an extension axially extended from the other end of the integrated stator is fixed to the housing of the apparatus. In the integrated stator, U, V, W phase coil assemblies are formed of a number of core groups including a number of division type cores, wherein for each phase coil assembly, the division type core groups of the U, V, W phase coil assemblies are alternately disposed in an annular form in sequence of the phases, and the respective division type core groups are integrally formed into a single body in annular form by a stator support.

Owner:AMOTECH

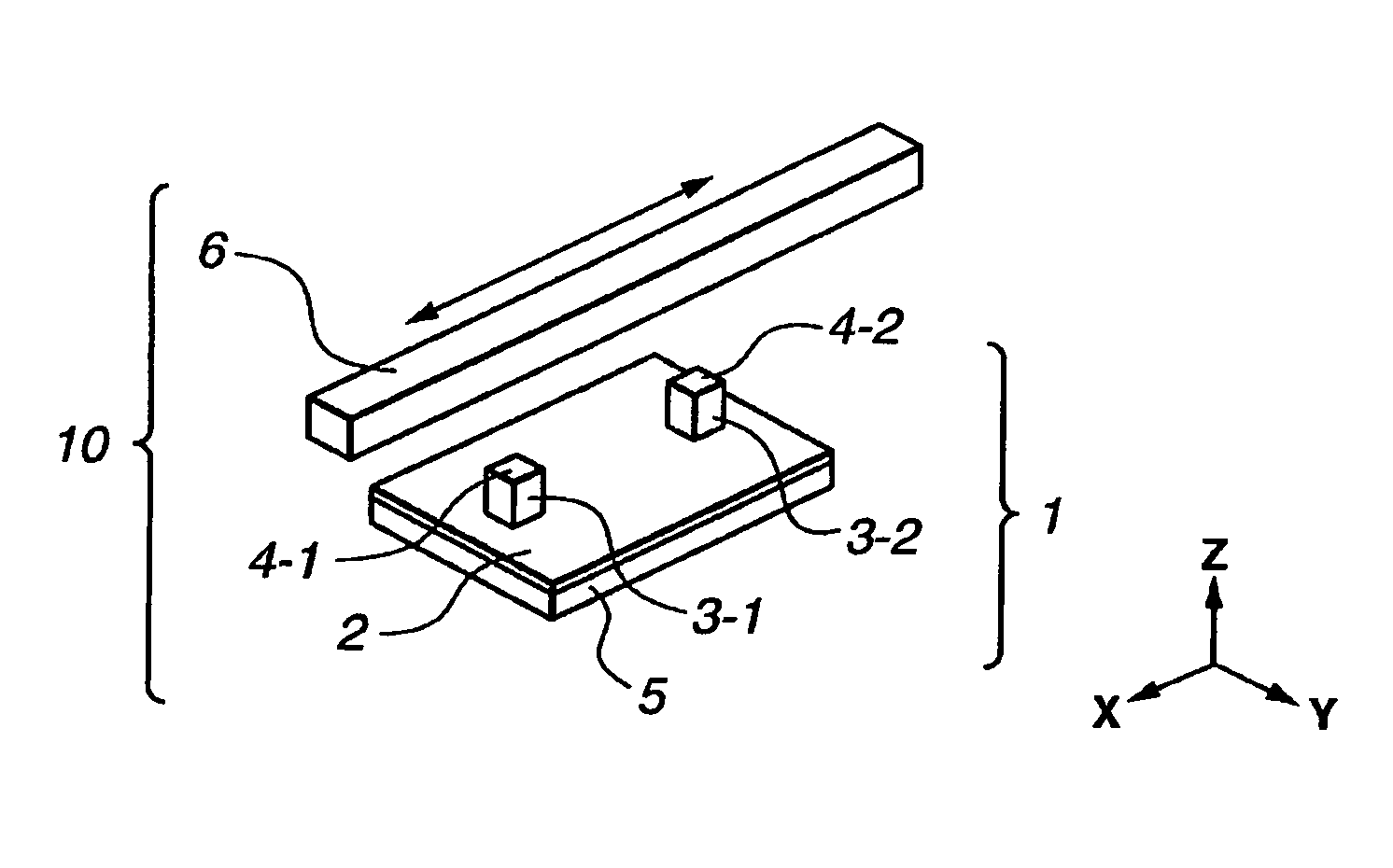

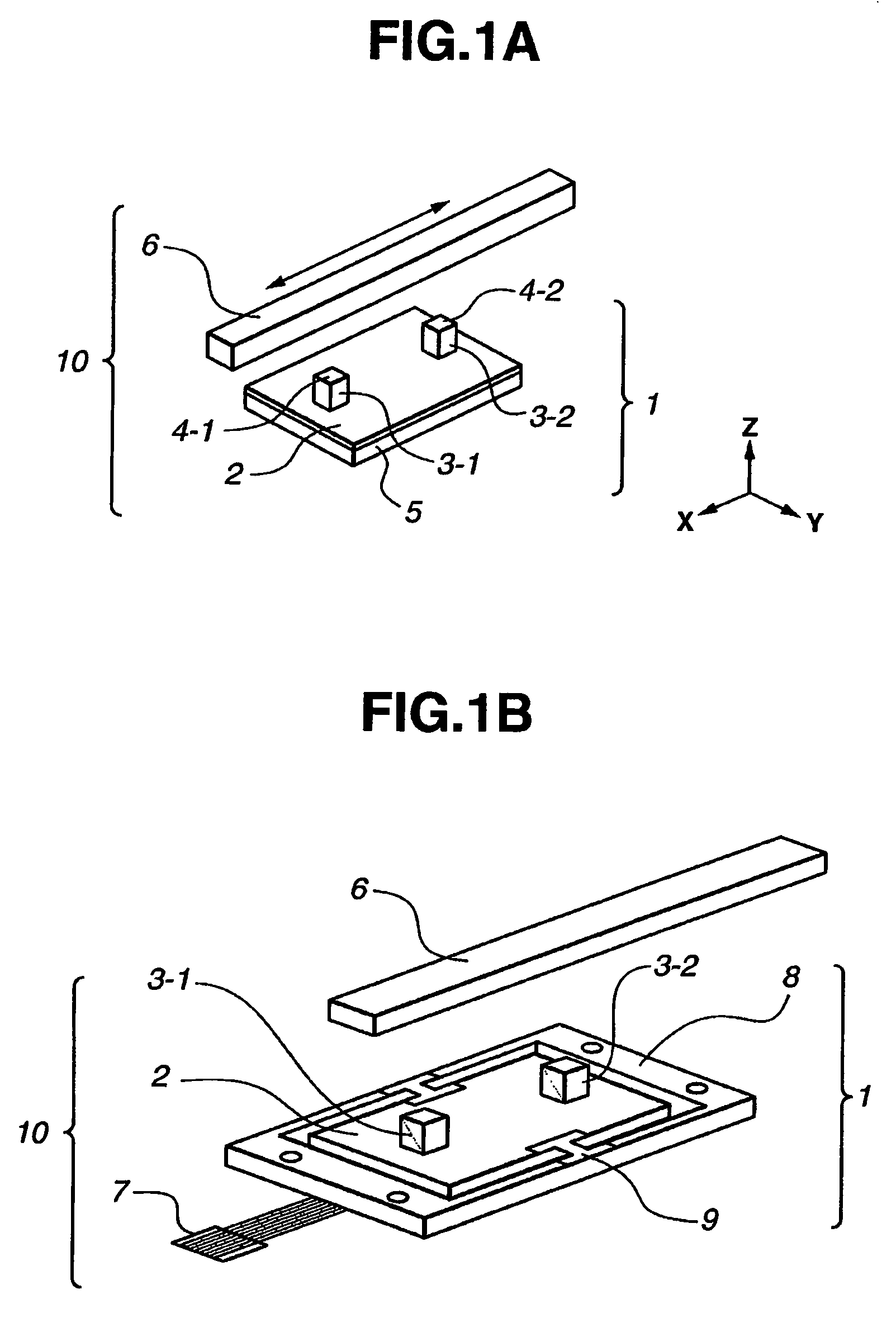

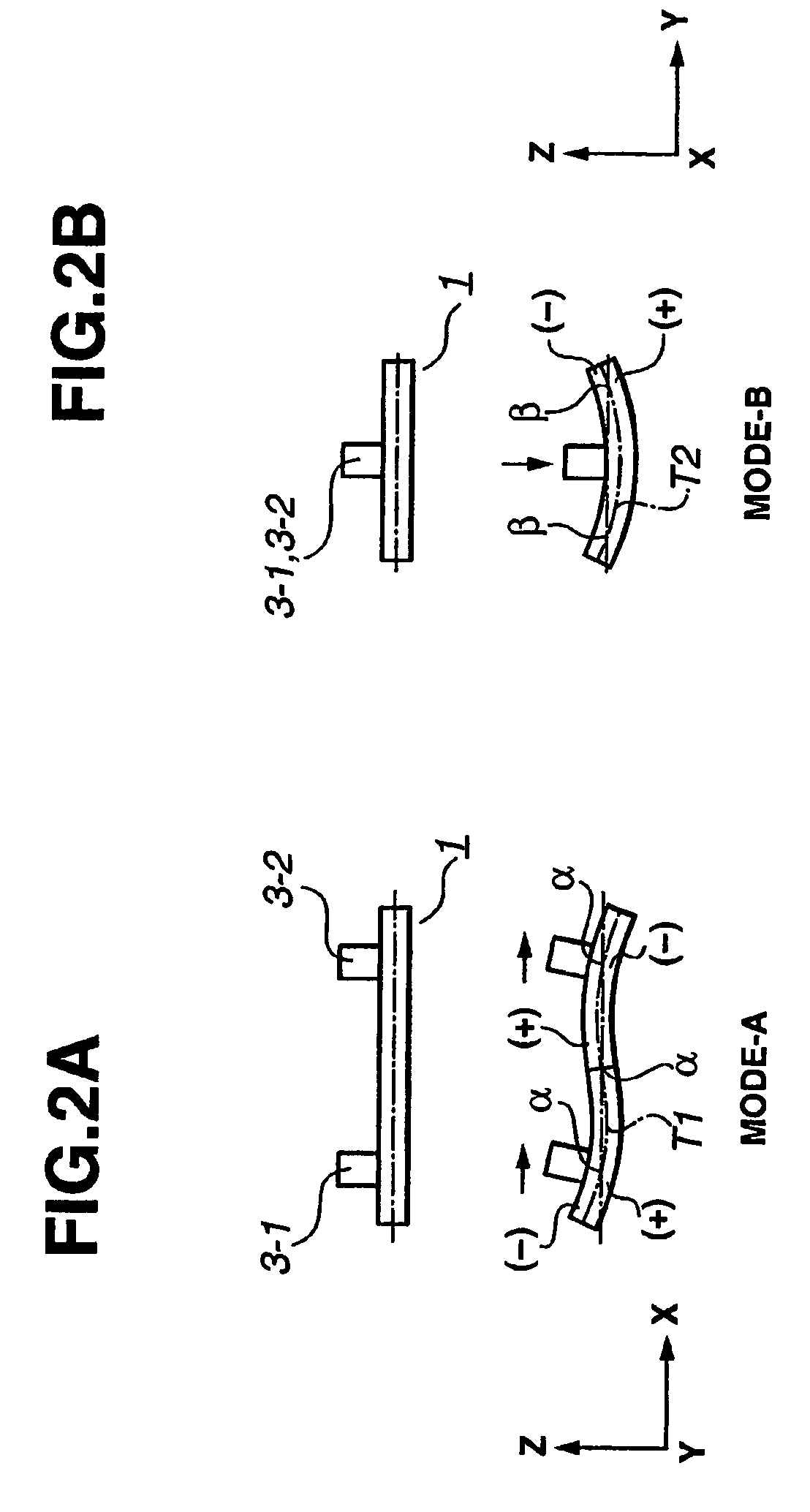

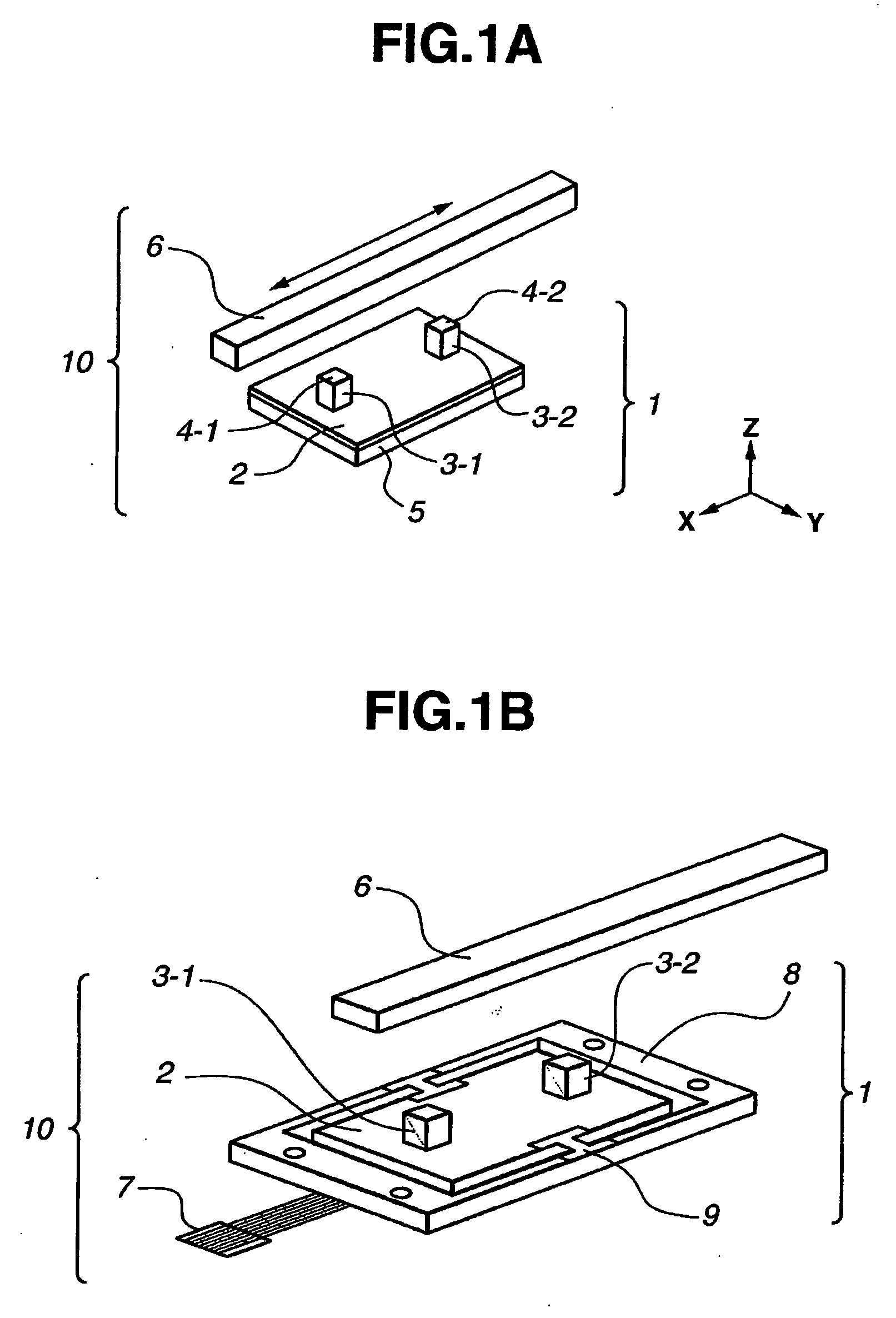

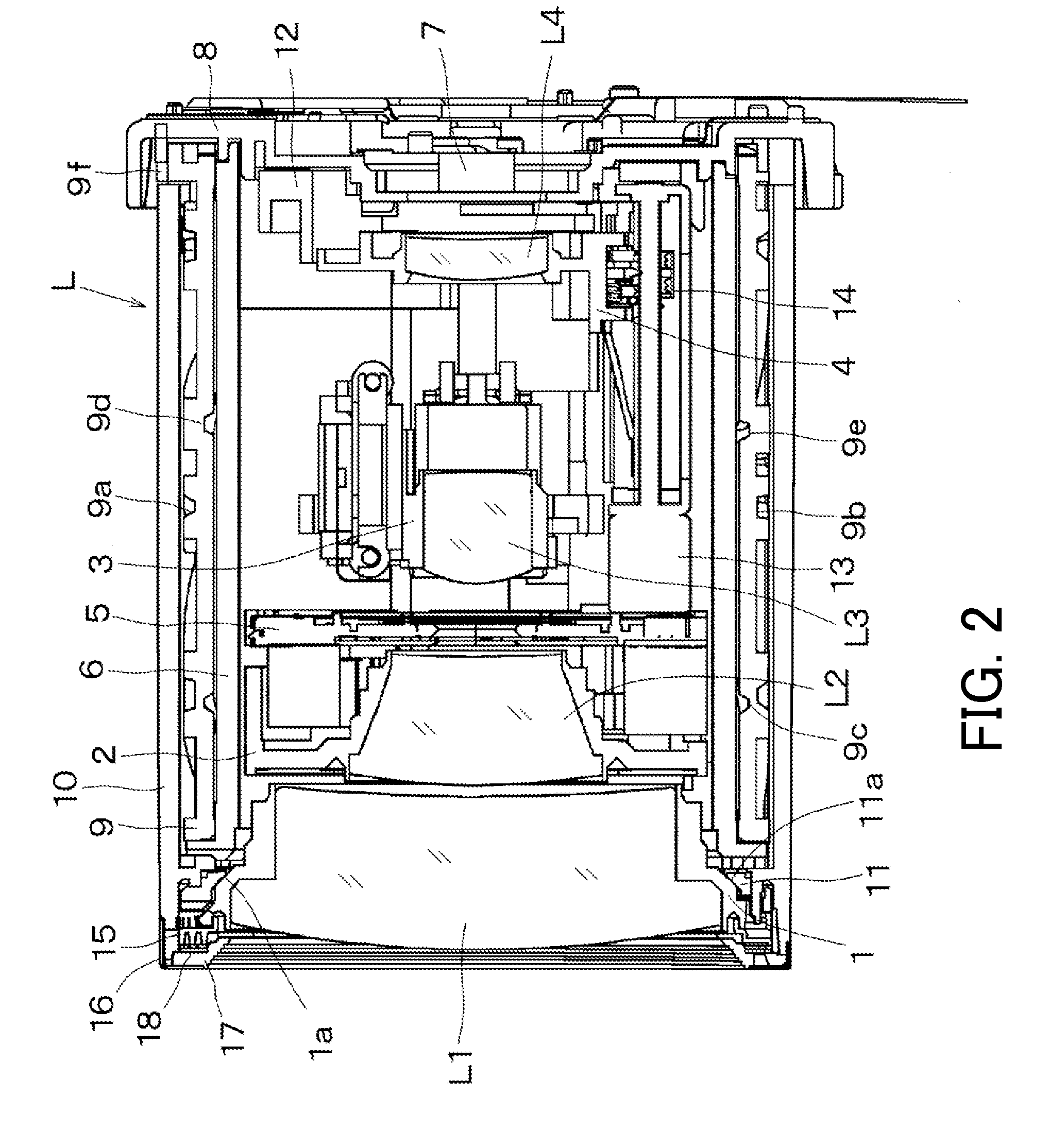

Vibration-type driving device, control apparatus for controlling the driving of the vibration-type driving device, and electronic equipment having the vibration-type driving device and the control apparatus

ActiveUS7109639B2Reduce in quantityImprove assembly productivityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsMechanical energyEngineering

A vibration-type driving device comprises a vibration element including a driving member and an electro-mechanical energy conversion element having an electrode and arranged to displace the driving member with a driving signal supplied to the electrode, and a driven element that is kept in contact with the driving member of the vibration element. According to the driving signal supplied to the electrode of the electro-mechanical energy conversion element, the vibration element excites vibrations in two flexural vibration modes in which a direction of generation of a node in one mode is perpendicular to that in the other mode. With the use of the two flexural vibration modes, the natural vibration frequency of the vibration element can be prevented from increasing, and the position of a node occurring in one flexural vibration mode and the position of an antinode occurring in the other flexural vibration mode can be made to coincide with each other, so that the amount of displacement of the driving member can be made large.

Owner:CANON KK

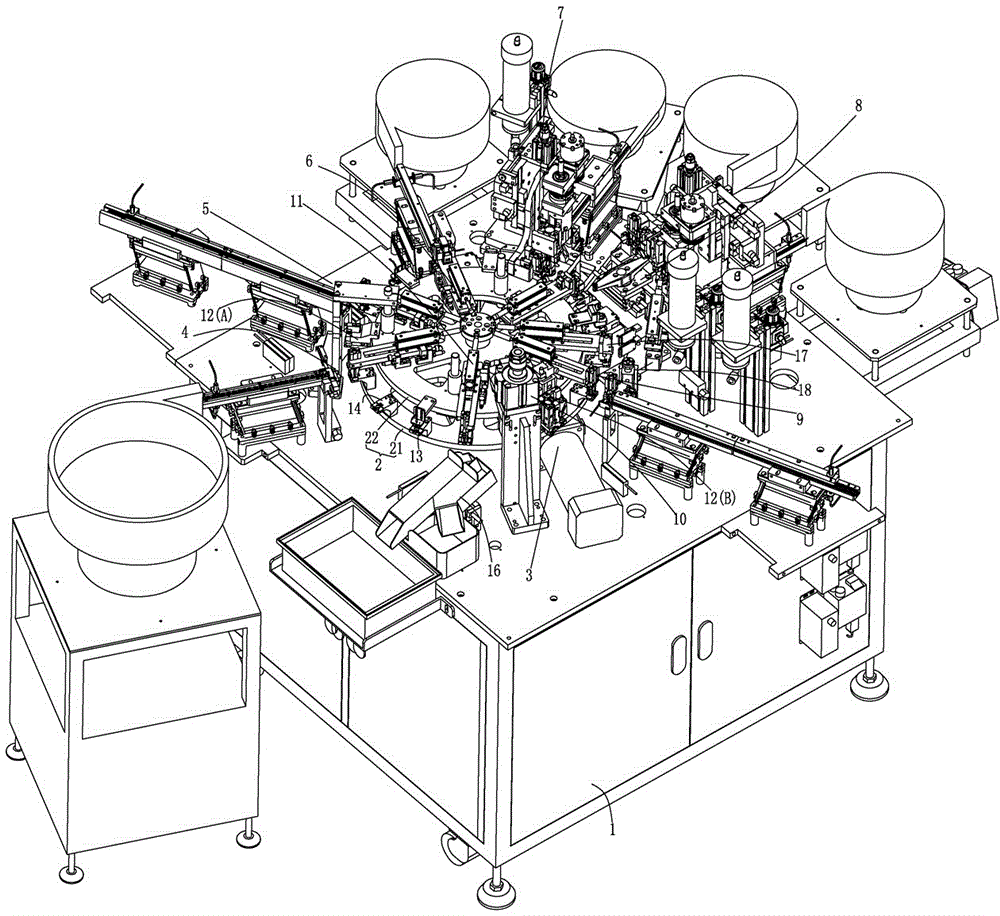

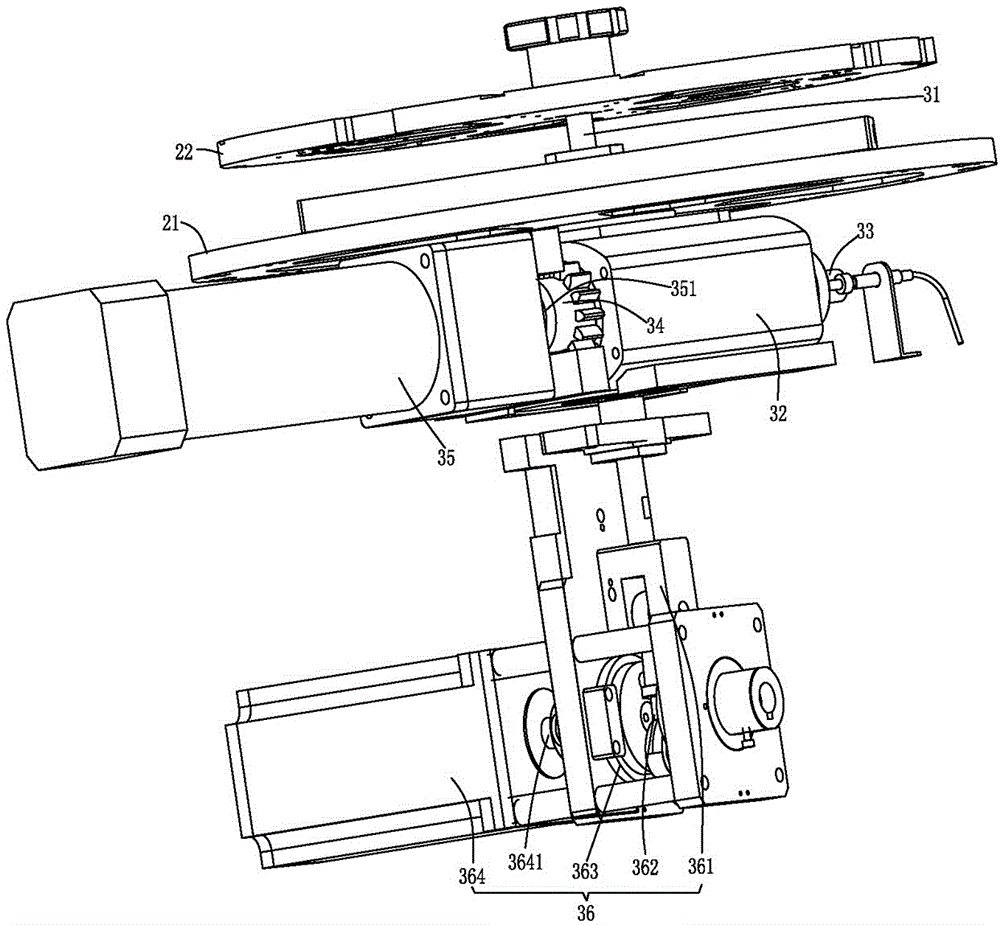

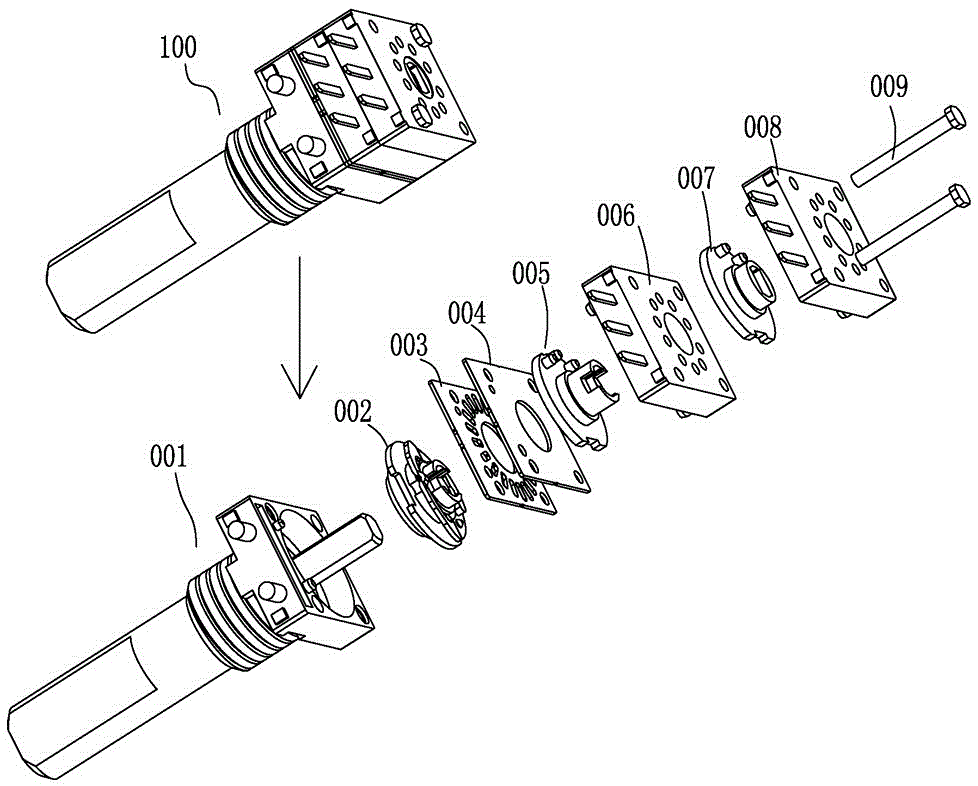

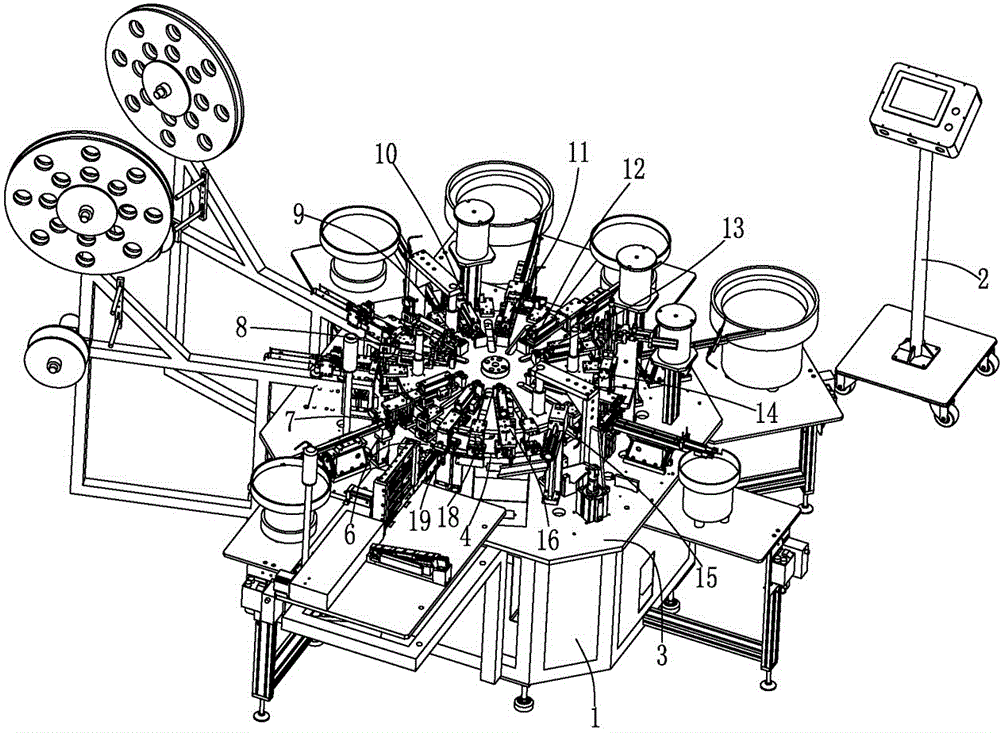

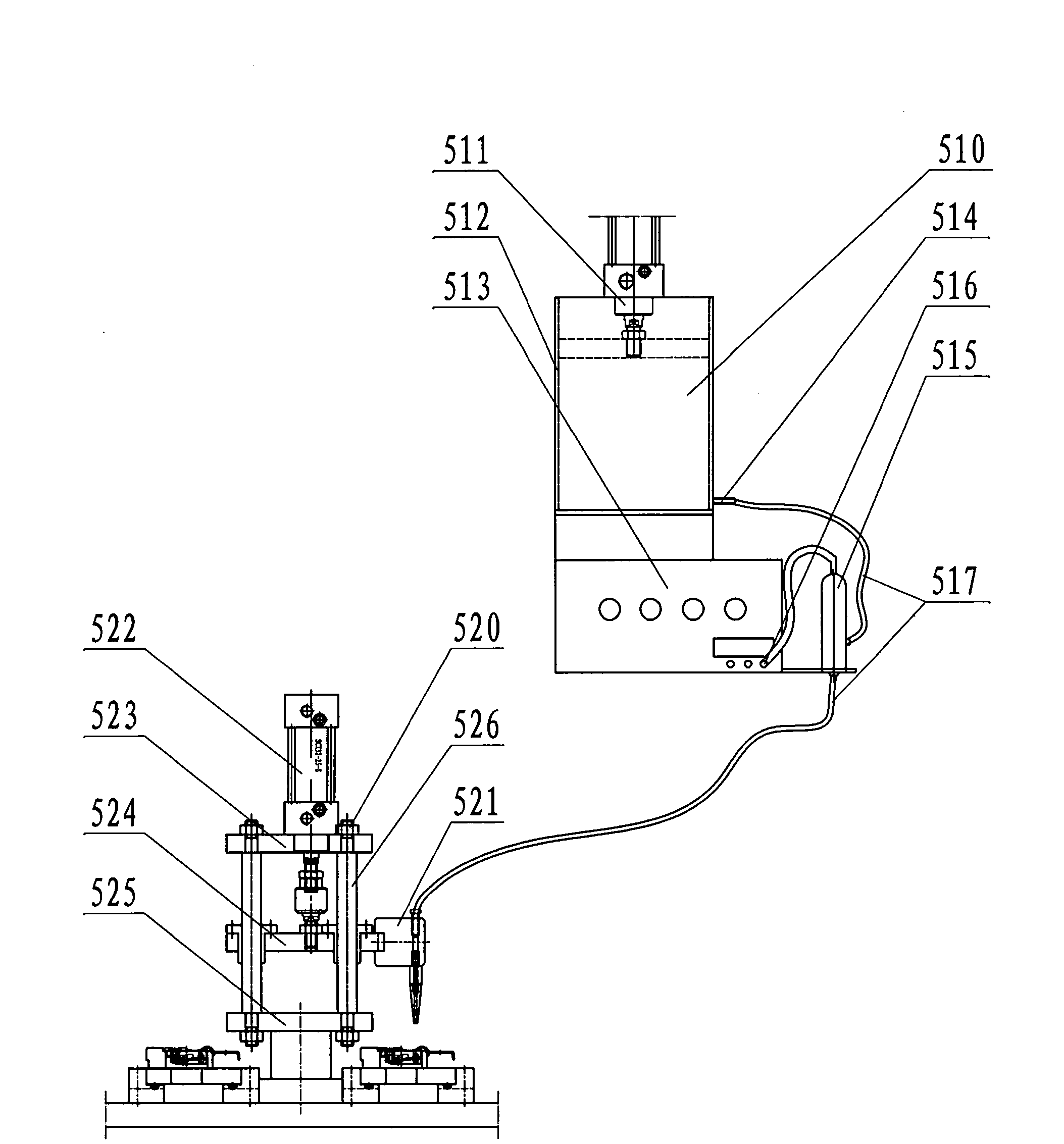

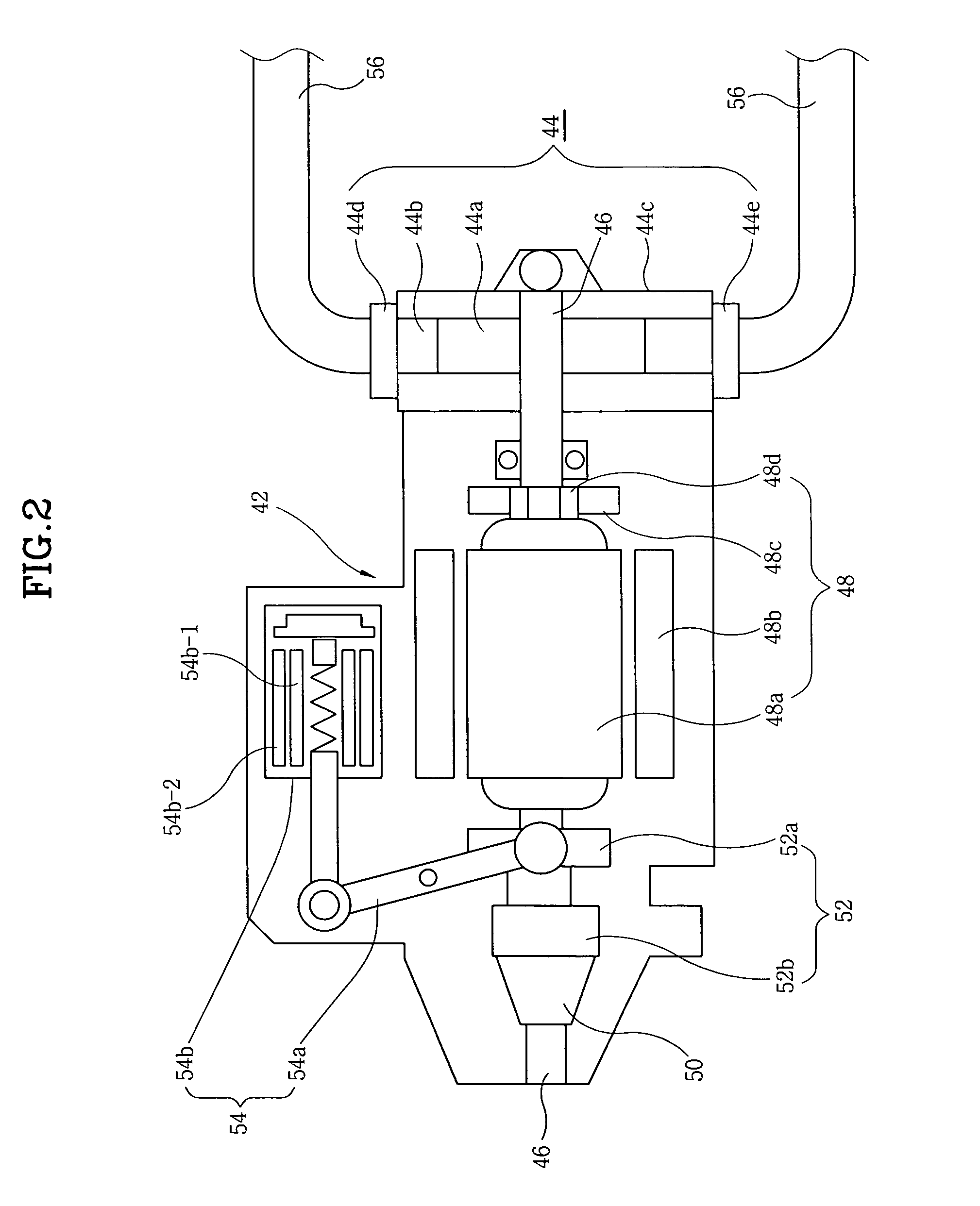

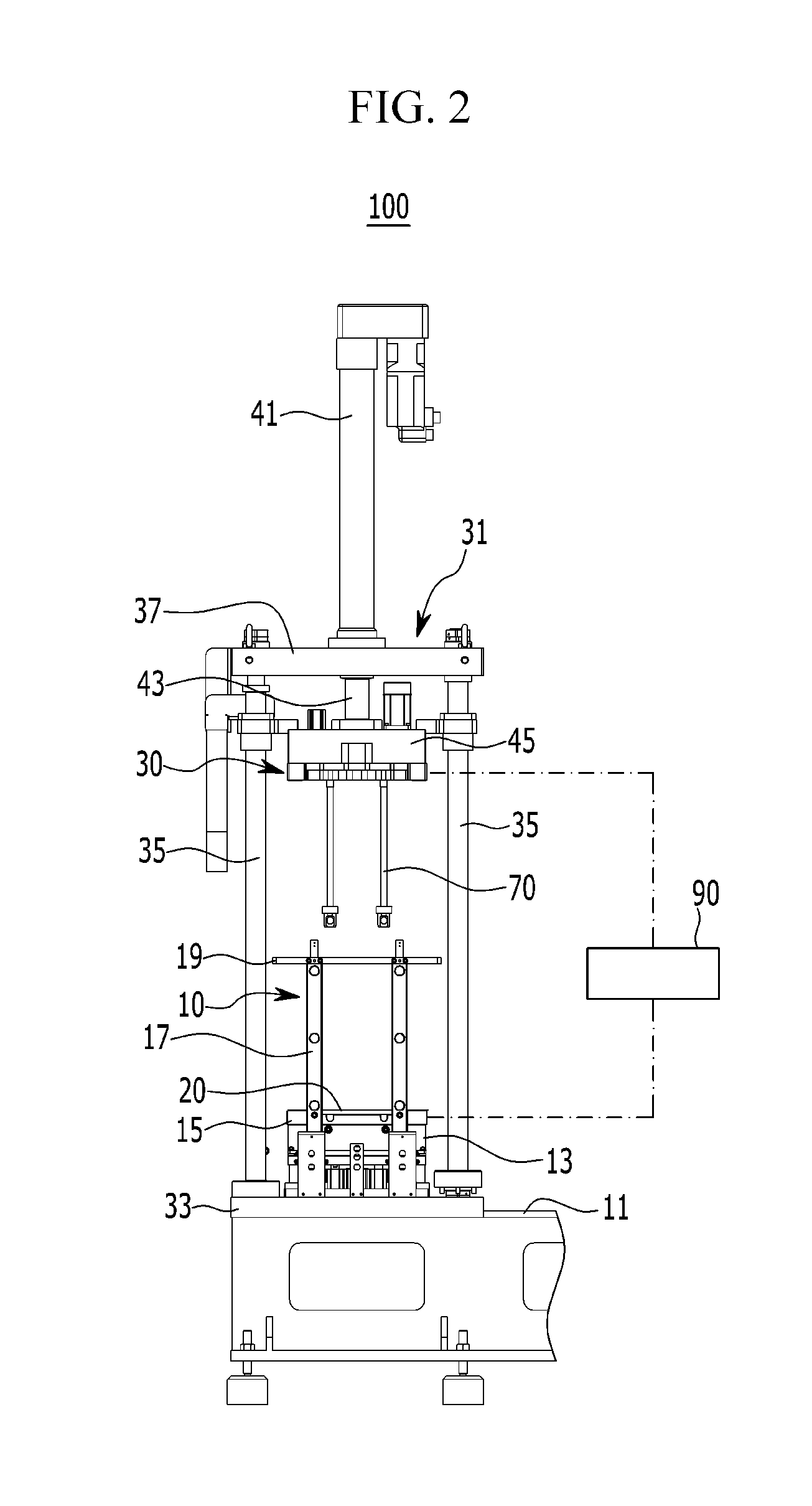

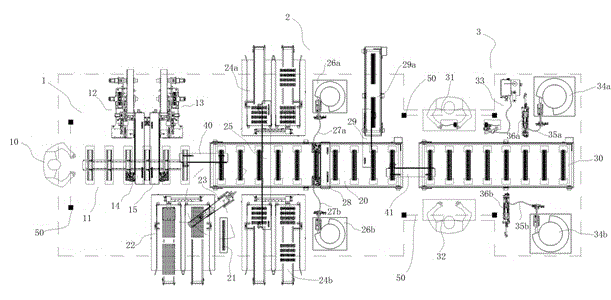

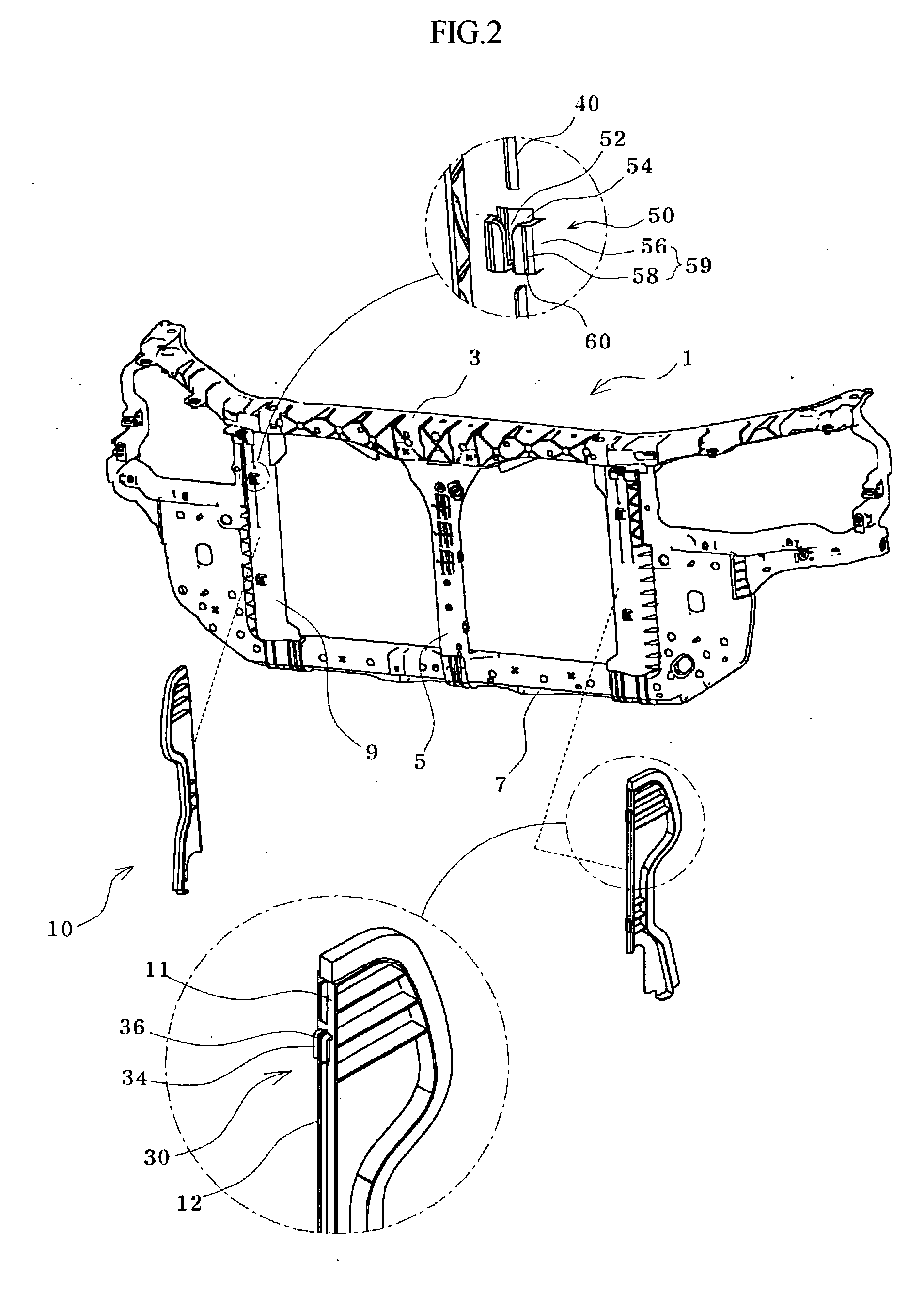

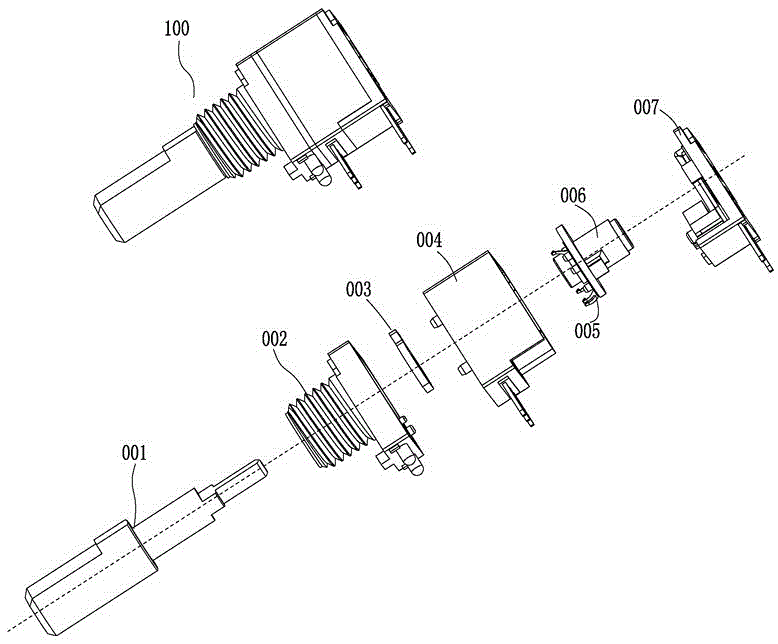

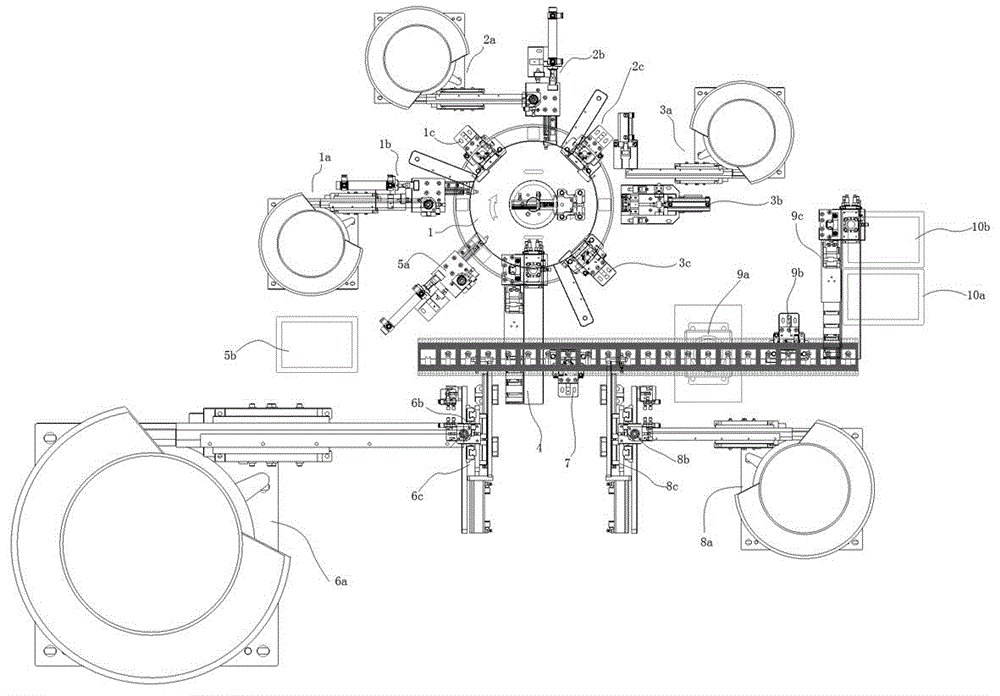

Automatic assembling machine for assembling vehicle-mounted encoder

ActiveCN106736540AImprove assembly yieldHigh degree of automationAssembly machinesMetal working apparatusEngineeringCam

Disclosed is an automatic assembling machine for assembling a vehicle-mounted encoder. The automatic assembling machine comprises a rotating table assembly, a cam indexer assembly, a support feeding mechanism, a manual pendulum shaft core and shaft sleeve feeding mechanism, a first rotor feeding mechanism, a first drive plate feeding mechanism, a second rotor and second drive plate assembling mechanism, a manual pendulum body feeding mechanism, a riveting mechanism and a discharging mechanism, wherein the rotating table assembly, the cam indexer assembly, the support feeding mechanism, the manual pendulum shaft core and shaft sleeve feeding mechanism, the first rotor feeding mechanism, the first drive plate feeding mechanism, the second rotor and second drive plate assembling mechanism, the manual pendulum body feeding mechanism, the riveting mechanism and the discharging mechanism are arranged on the top of a machine box. The automatic assembling machine further comprises two shape trimming assemblies and a plurality of detection assemblies, wherein the shape trimming assemblies are used for shape trimming of supports. A plurality of station clamps are arranged on the circumferential edge of a rotating table of the rotating table assembly in an array mode. A rotating pendulum assembly is further arranged on the top of the machine box in a matched mode. The feeding mechanisms are matched with the movement of the rotating table assembly to conduct feeding in sequence, the riveting mechanism conducts riveting on parts of the encoder to form an encoder finished product, the discharging mechanism enables the encoder finished product to be discharged into a collecting box, the shape trimming assemblies conduct opening shape trimming and inward extrusion shape trimming on the supports, and the rotating pendulum assembly is used for transmitting a second rotor and second drive plate assembly assembled by the second rotor and second drive plate assembling mechanism to the matched station clamp.

Owner:广东钺河智能科技有限公司

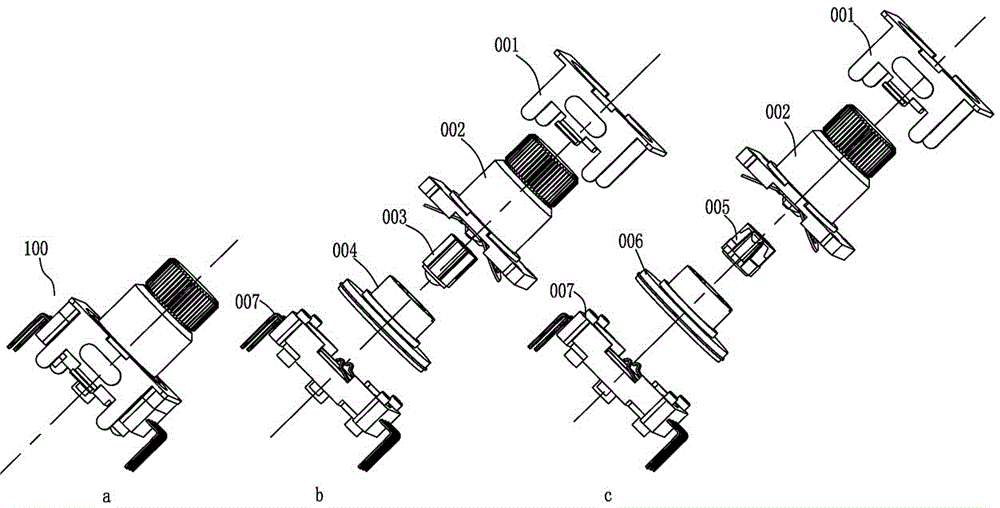

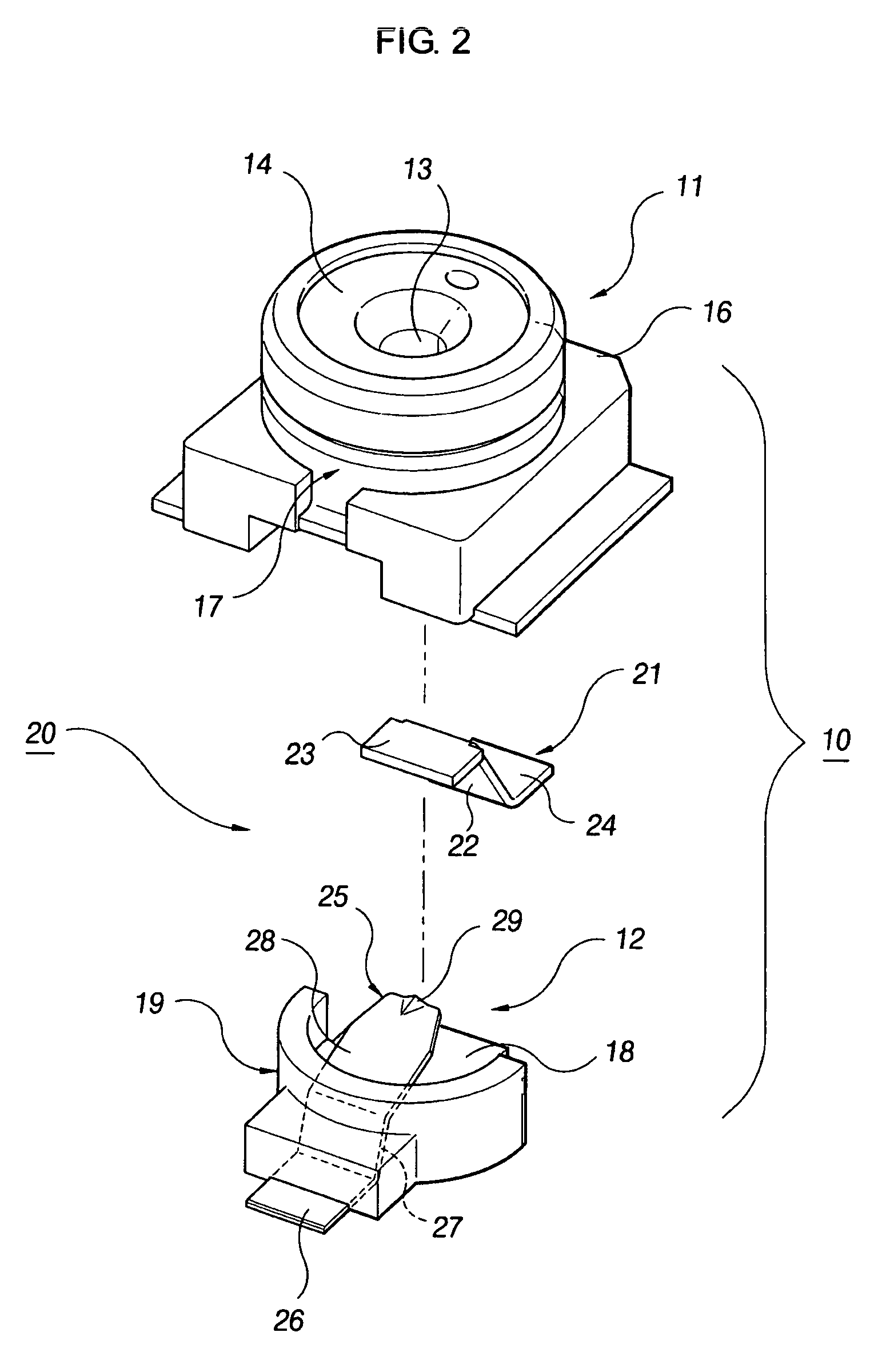

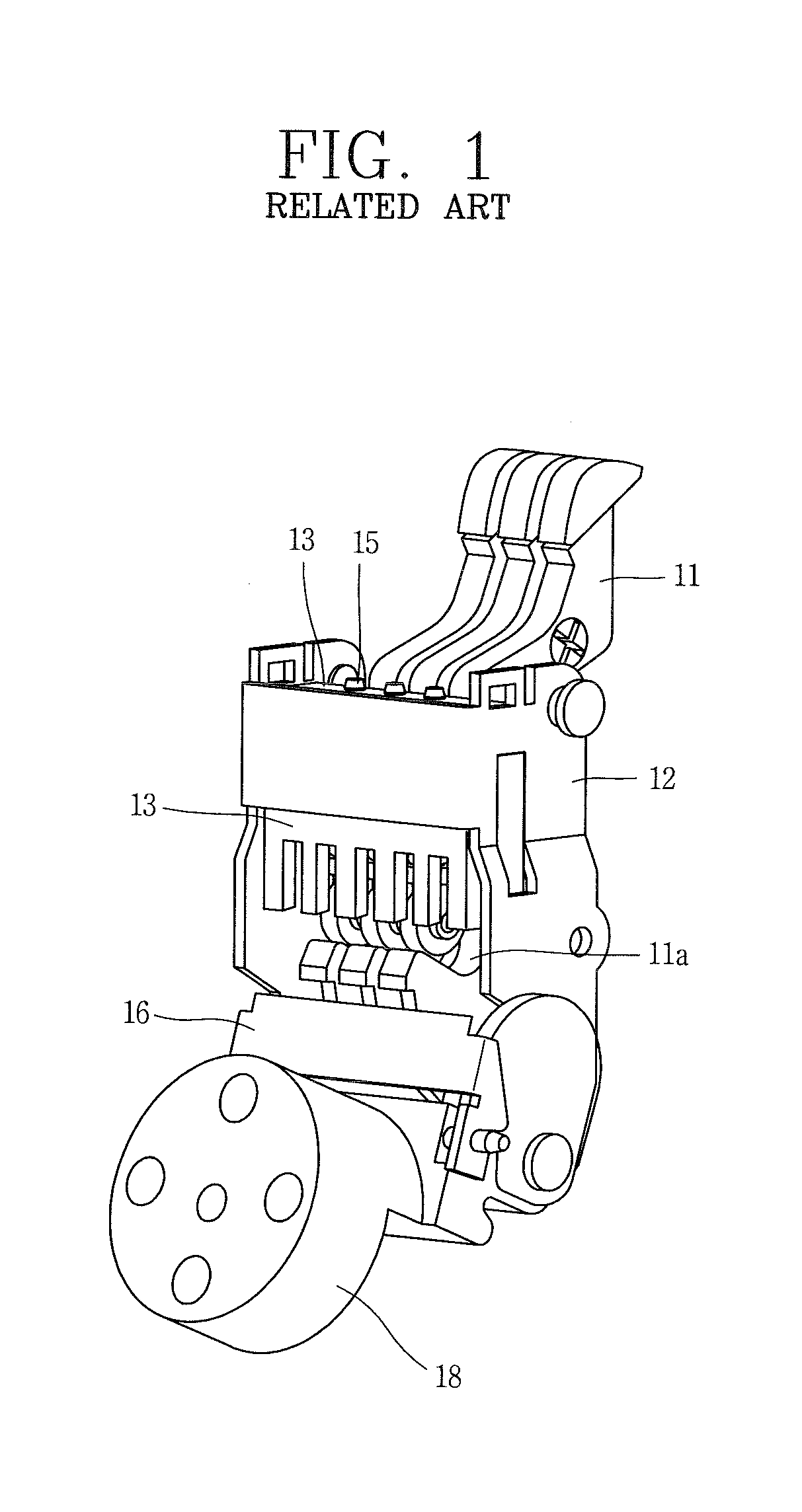

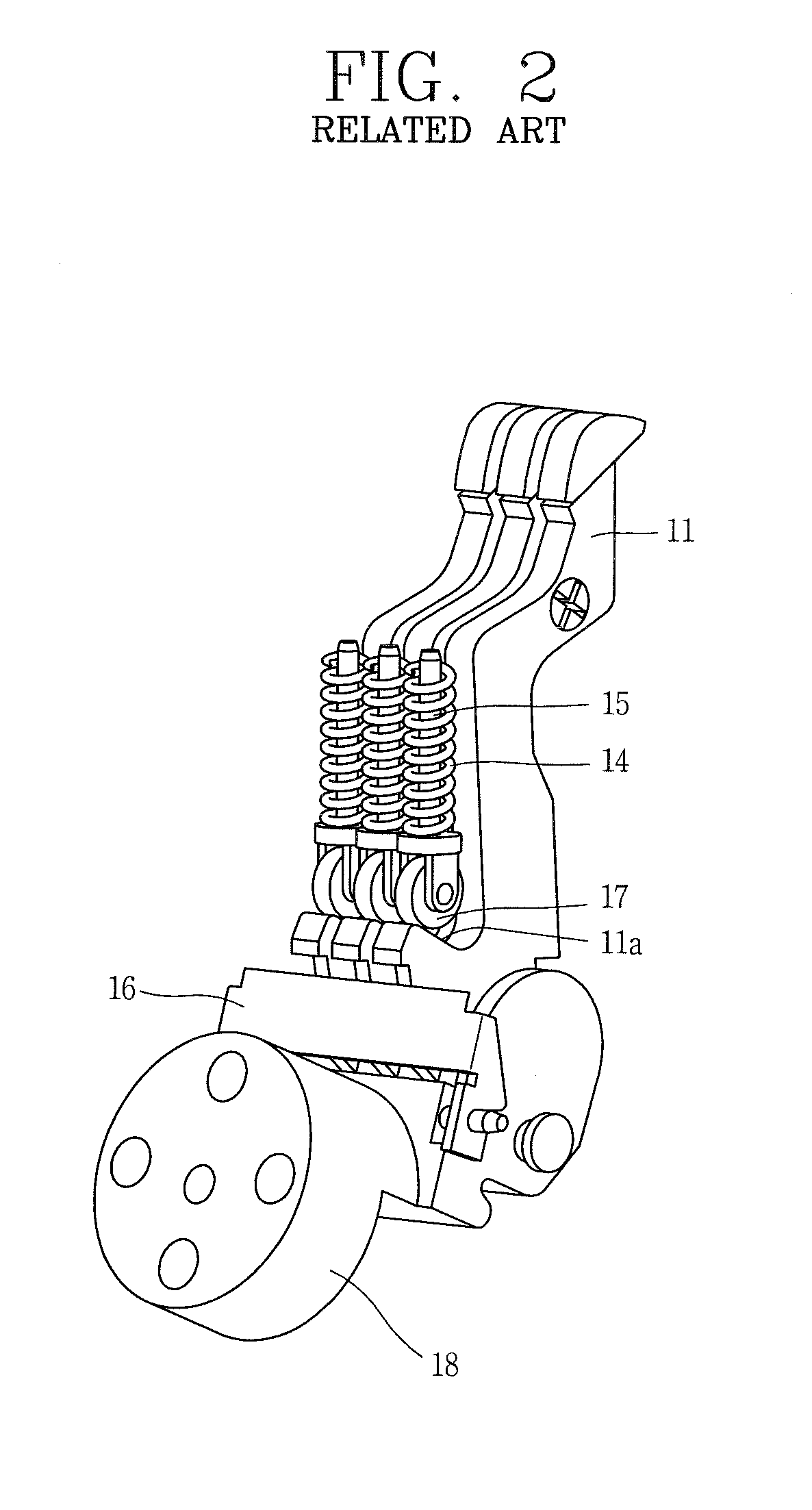

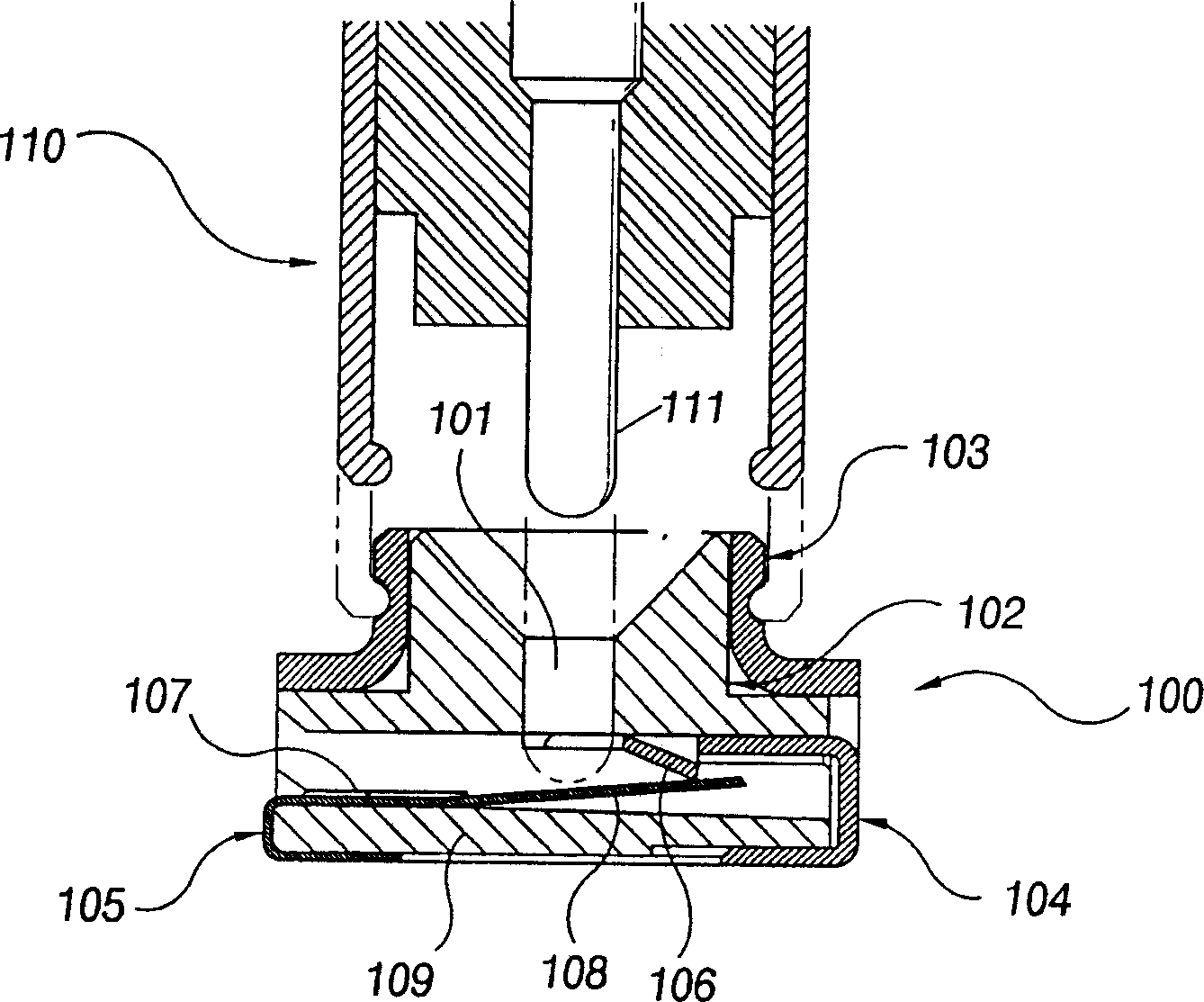

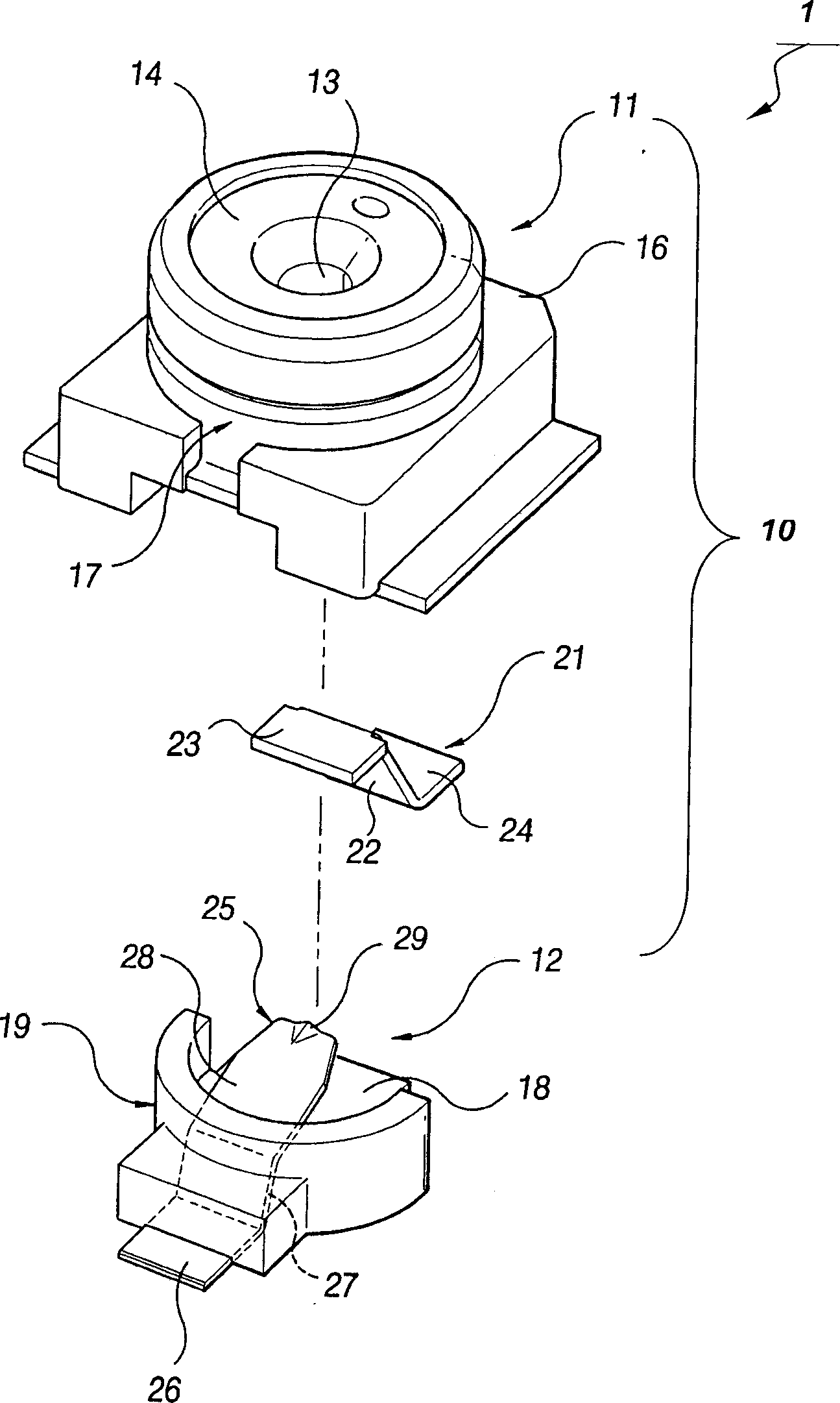

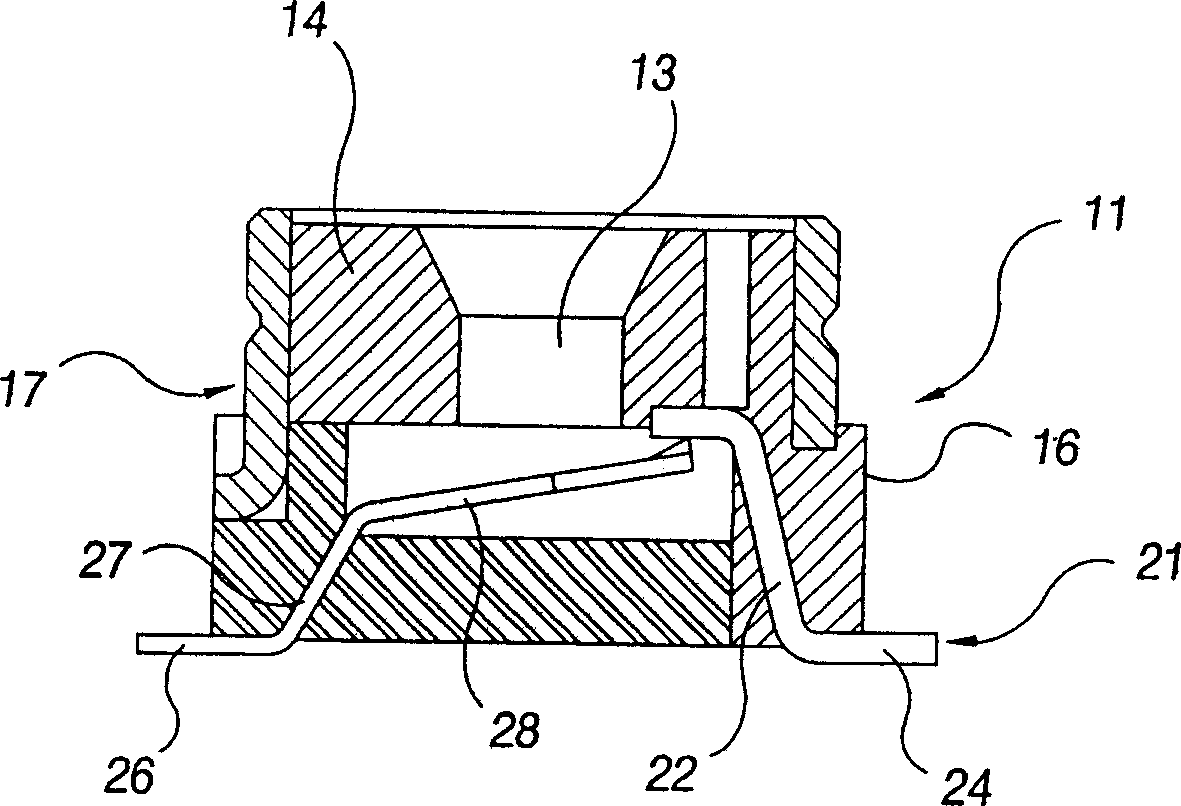

Coaxial connector with RF switch

InactiveUS6932615B1Poor contact with preventedAvoid high pressureTwo pole connectionsCoupling device detailsElectrical conductorHemt circuits

The present invention relates to coaxial connector with an RF switch. In particular, a housing 10 covered with an external conductor 17 is composed of upper and lower housings 11 and 12. A fixed terminal 21 connected to an RF circuit is insert molded in the upper housing 11, and a movable terminal 25 that is selectively brought into contact with the fixed terminal 21 is insert molded in the lower housing 12. The movable terminal 25 comprises a fixed portion 26 fixed to the lower housing 12; a waist portion 27 extending upwardly from the fixed portion 26 at a first angle α1 and molded to the lower housing 12; and an elastic piece 28 bent from the tip end of the waist portion 27 at a second angle α2, extending into a space 15 of the housing, and being contact with the fixed terminal 21.

Owner:HECTO

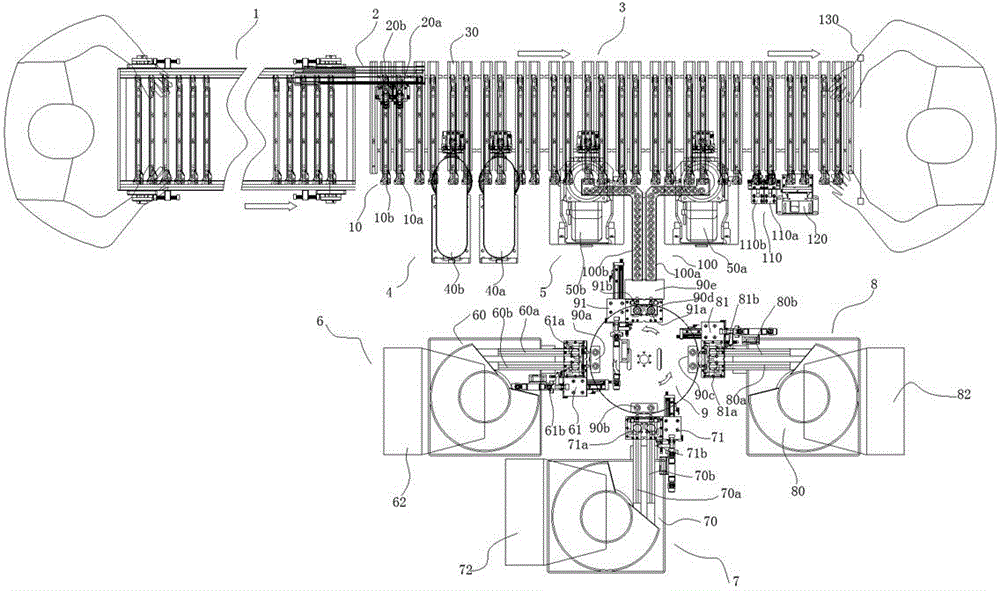

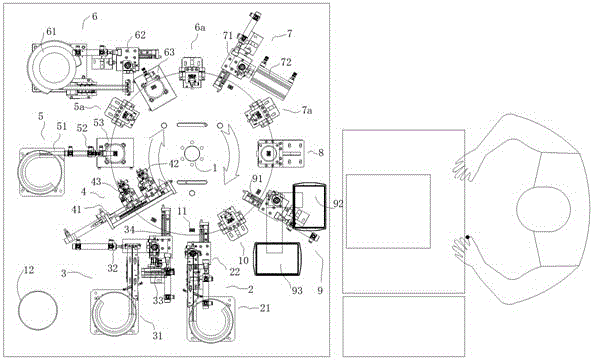

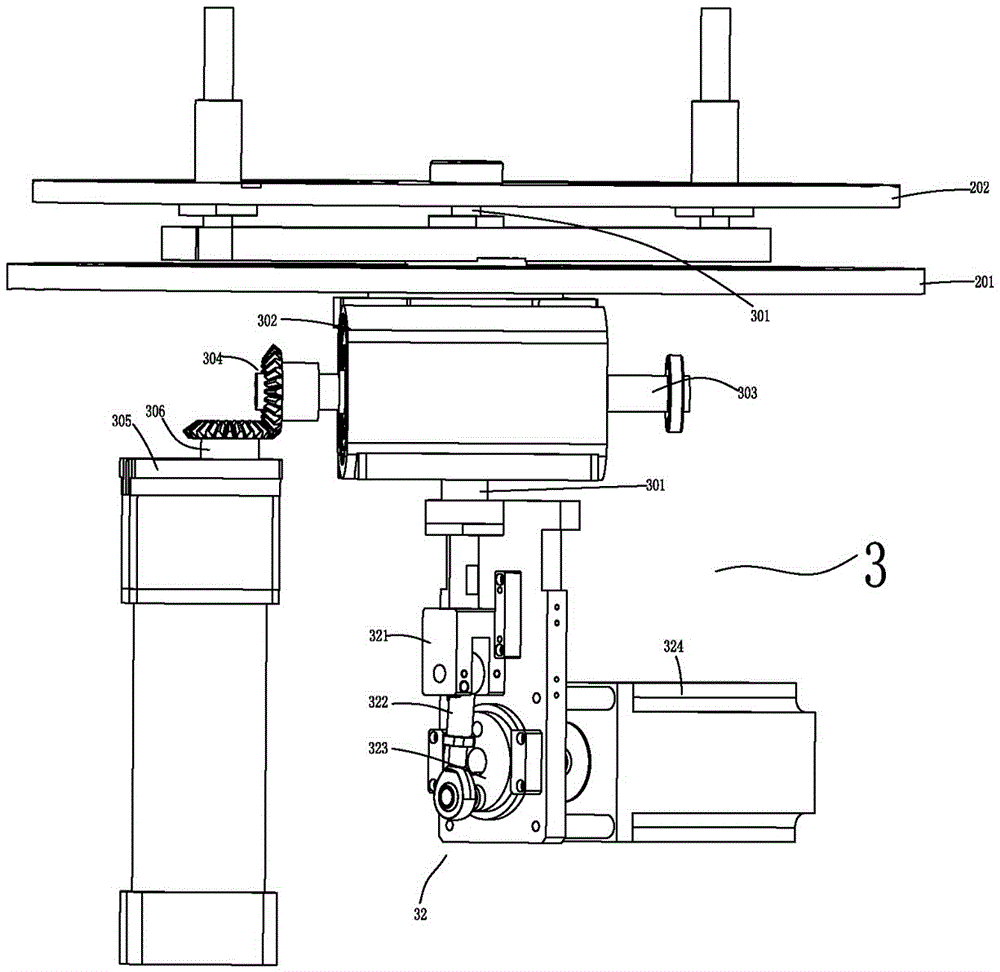

Automatic assembly machine for assembling encoder for intercom

ActiveCN106736538AHigh degree of automationImprove assembly productivityAssembly machinesMetal working apparatusEngineeringCam

The invention discloses an automatic assembly machine for assembling an encoder for an intercom. The automatic assembly machine includes a case, a controller, a rotation disc, a cam divider assembly, an upper manual placement mechanism, a stopping base mounting mechanism, a first film sheet mounting mechanism, a second film sheet mounting mechanism, a first rubber rotation sheet mounting mechanism, a first body mounting mechanism, a second rubber rotation sheet mounting mechanism, a second body mounting mechanism, an oil coating mechanism, a riveting mechanism, a discharging mechanism and detection assemblies; a plurality of working station clamps are movably arranged on a circumferential edge of the rotation disc; In assembly, the upper manual placement mechanism transfers a manual placement shaft core sleeve to a matched working station clamp, and then the stopping base, the first film sheet, the second film sheet, the first rubber rotation sheet, the first body, the second rubber rotation sheet, the second body are mounted successively, the oil coating mechanism performs oil coating after the second body is mounted, the riveting mechanism rivets all the parts through rivets to form a finished product, and the discharging assembly sends the finished product to a collection box. The automatic assembly machine is easy to use, is high in assembly efficiency, is high in yield, is simple to maintain, and is long in service life.

Owner:广东钺河智能科技有限公司

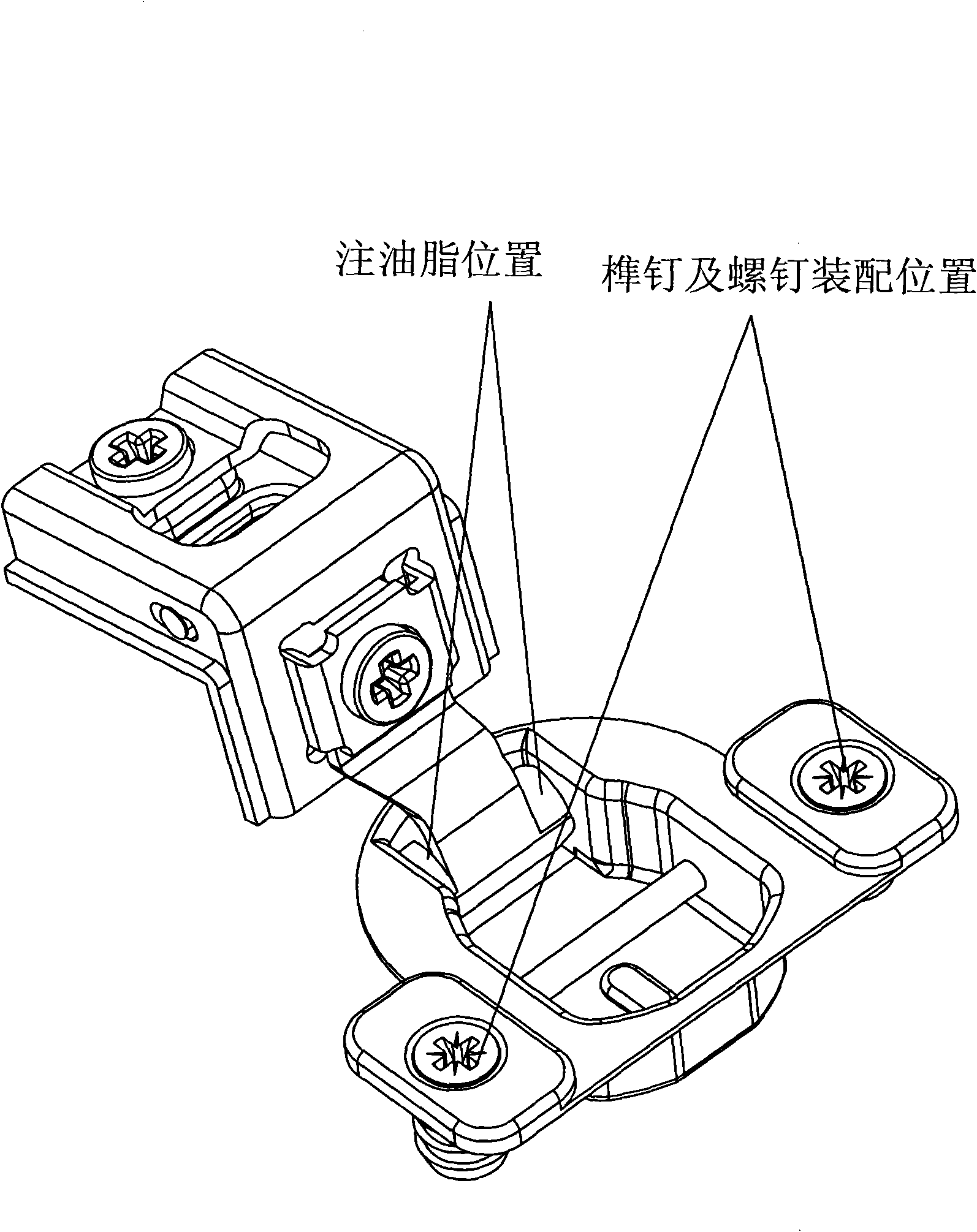

Automatic assembly equipment for hinge pre-installed tenon and oil injection process

InactiveCN102267047ARealize fully automatic assemblyImprove assembly productivityProportioning devicesLubricating pumpsSequence controlQuality assurance

The invention adopts the dowel pressing process, presses the metal screw into the center hole of the plastic dowel, the outer diameter of the screw is slightly larger than the diameter of the center hole of the dowel, and utilizes the elastic deformation and plastic deformation of the plastic dowel to make the screw and the dowel Tightly combined, so that it is firmly fixed on the fixed pocket of the hinge, and at the same time, the quantitative oil injection process is adopted to automatically inject the lubricating grease into the lubricating point quantitatively. The automatic assembly equipment of the present invention includes a dowel grasping mechanism, a dowel vibrating feeding mechanism, a dowel pre-installing mechanism, a screw vibrating feeding mechanism, a grease injection mechanism, a movable clamp cycle stepping and carrying mechanism and a microcomputer control system. Action sequence is controlled by microcomputer control system. The invention realizes the fully automatic assembly of dowel pre-installation and oil injection process, improves the assembly production efficiency and ensures the assembly quality.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

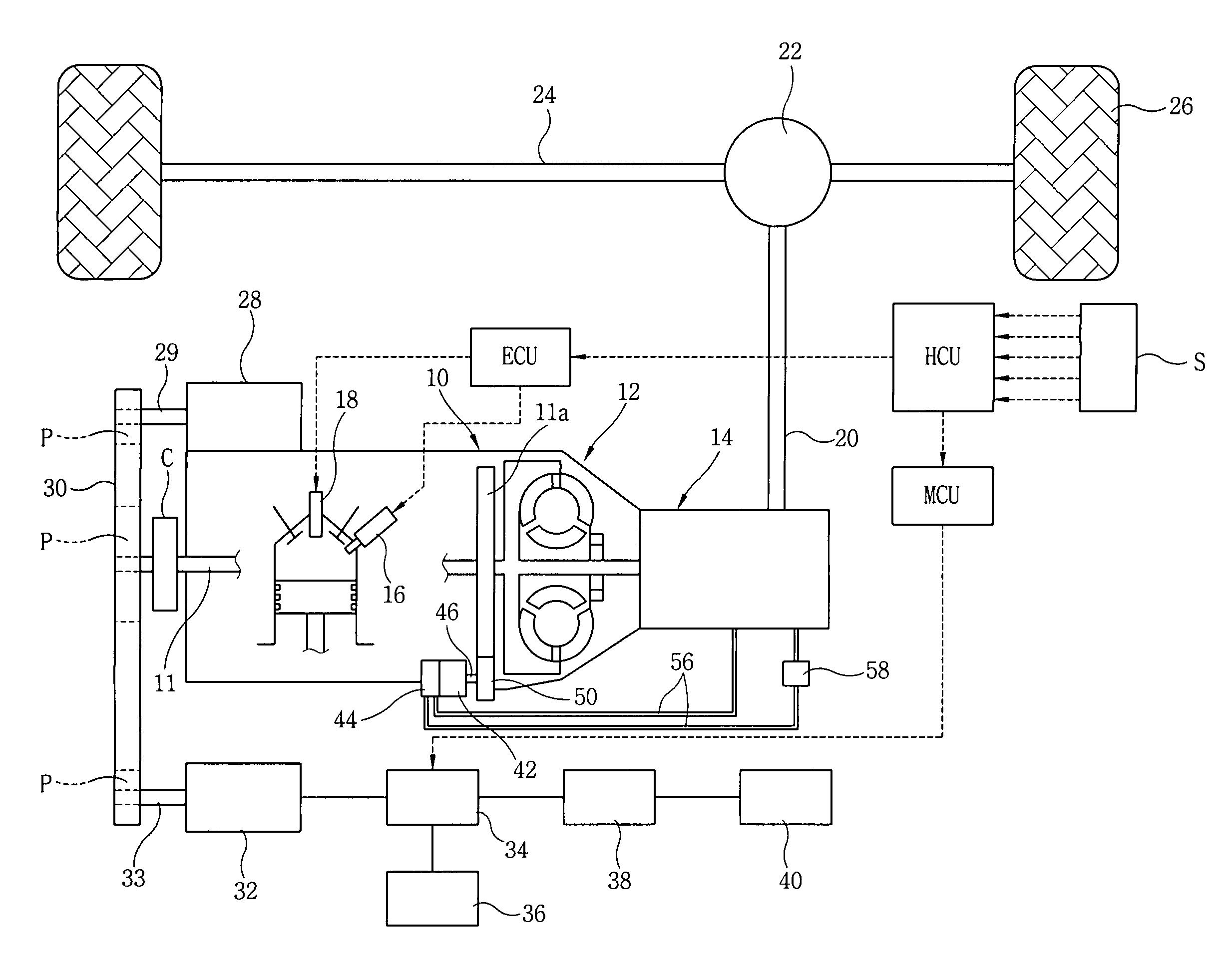

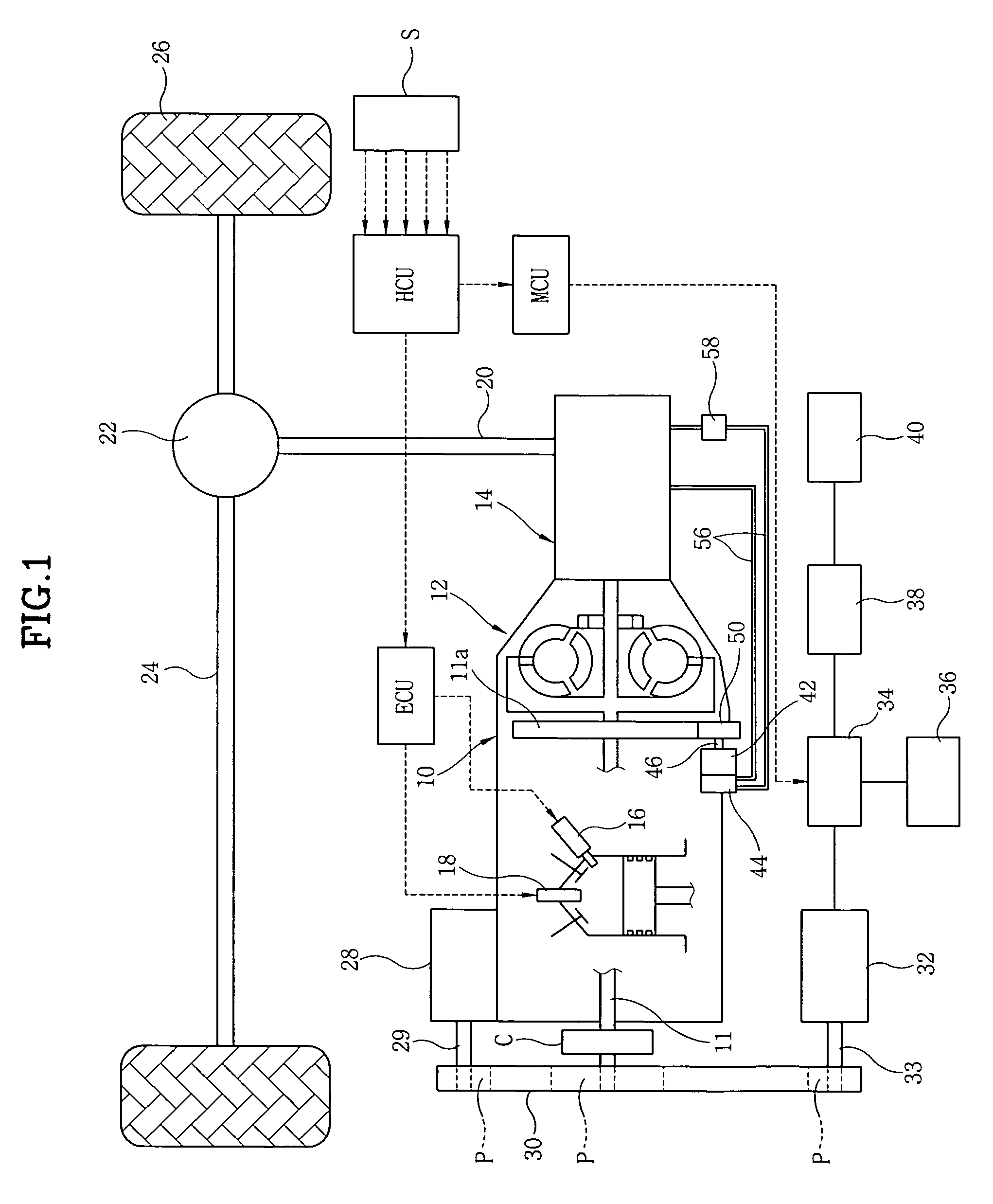

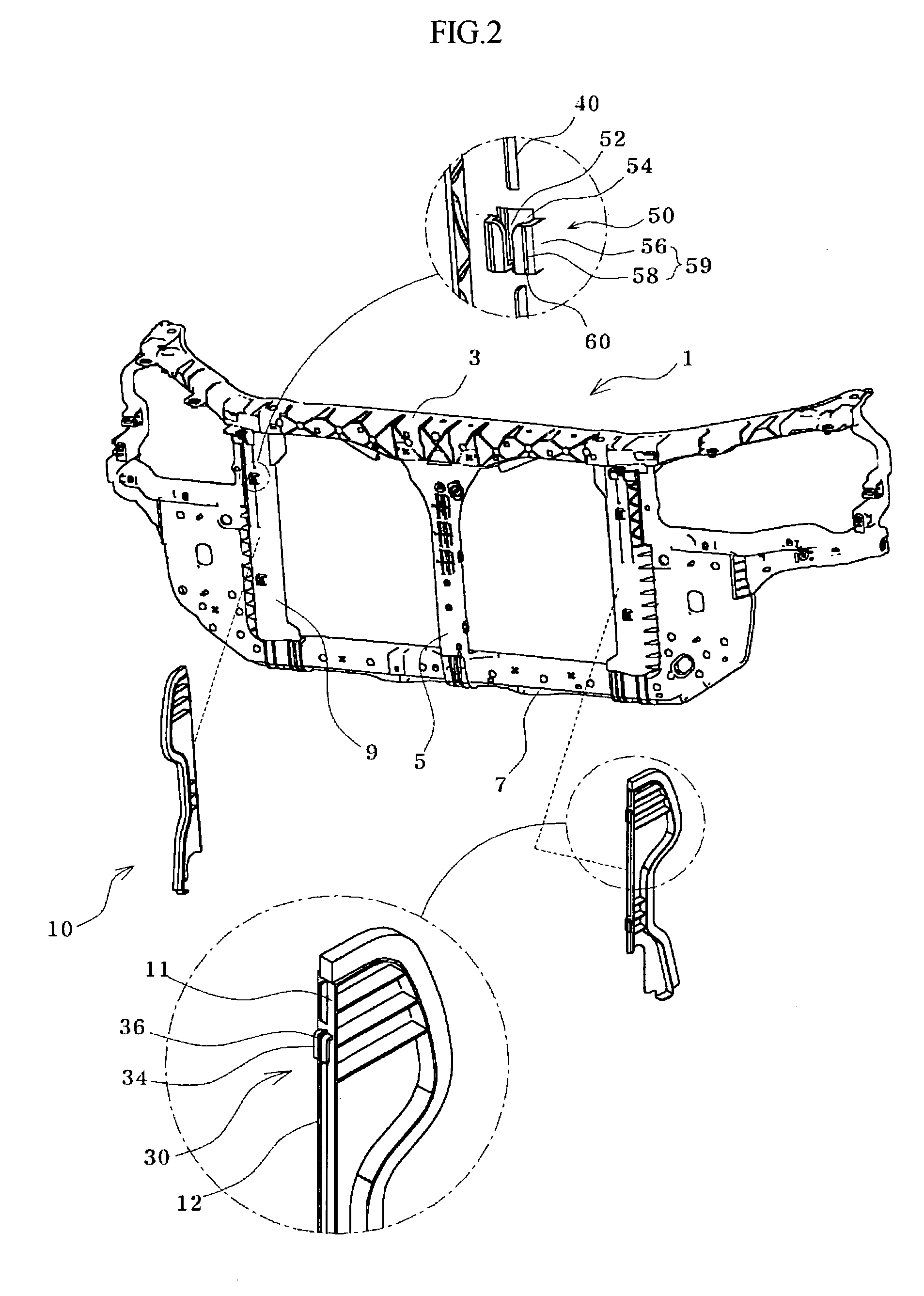

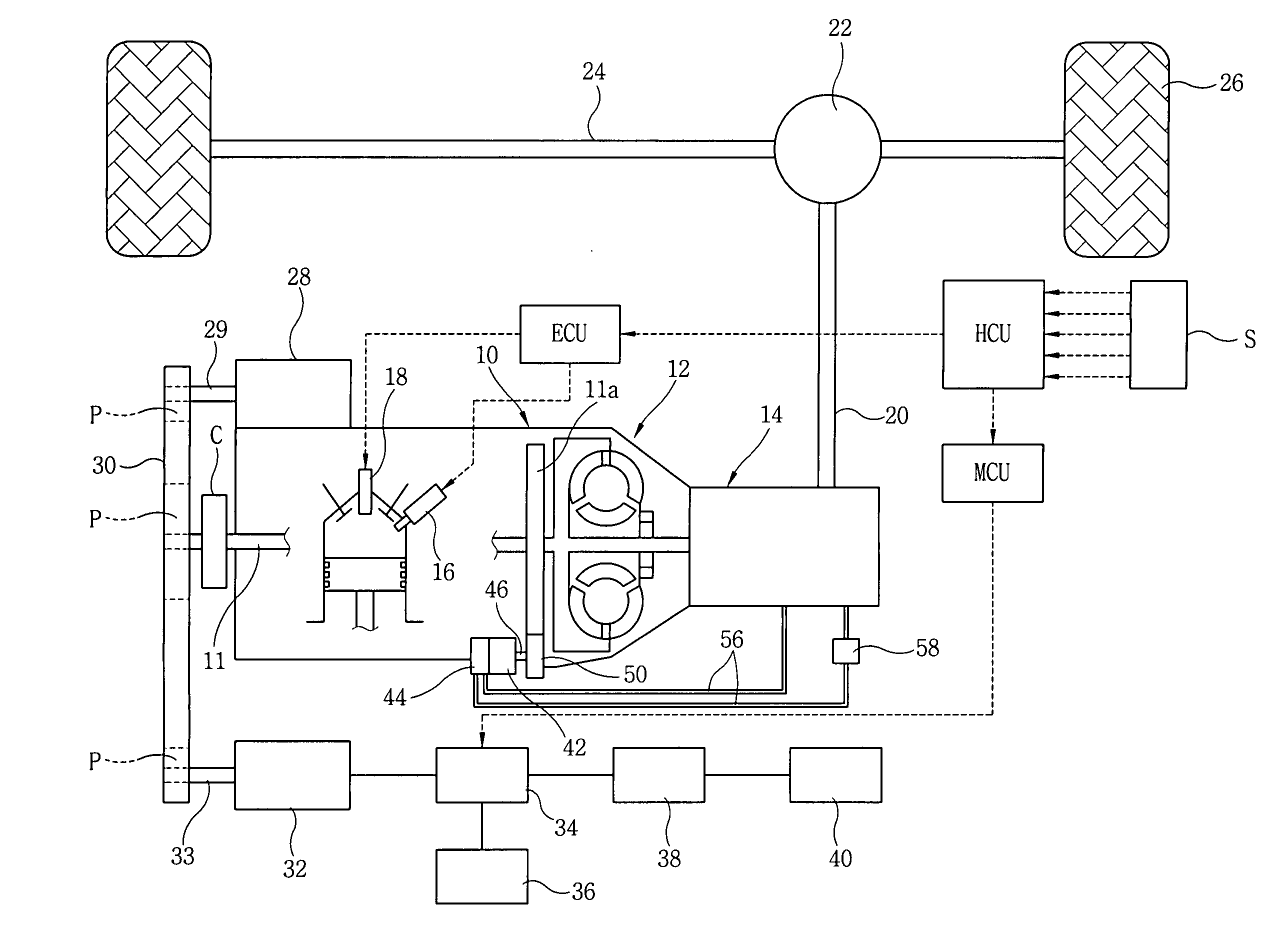

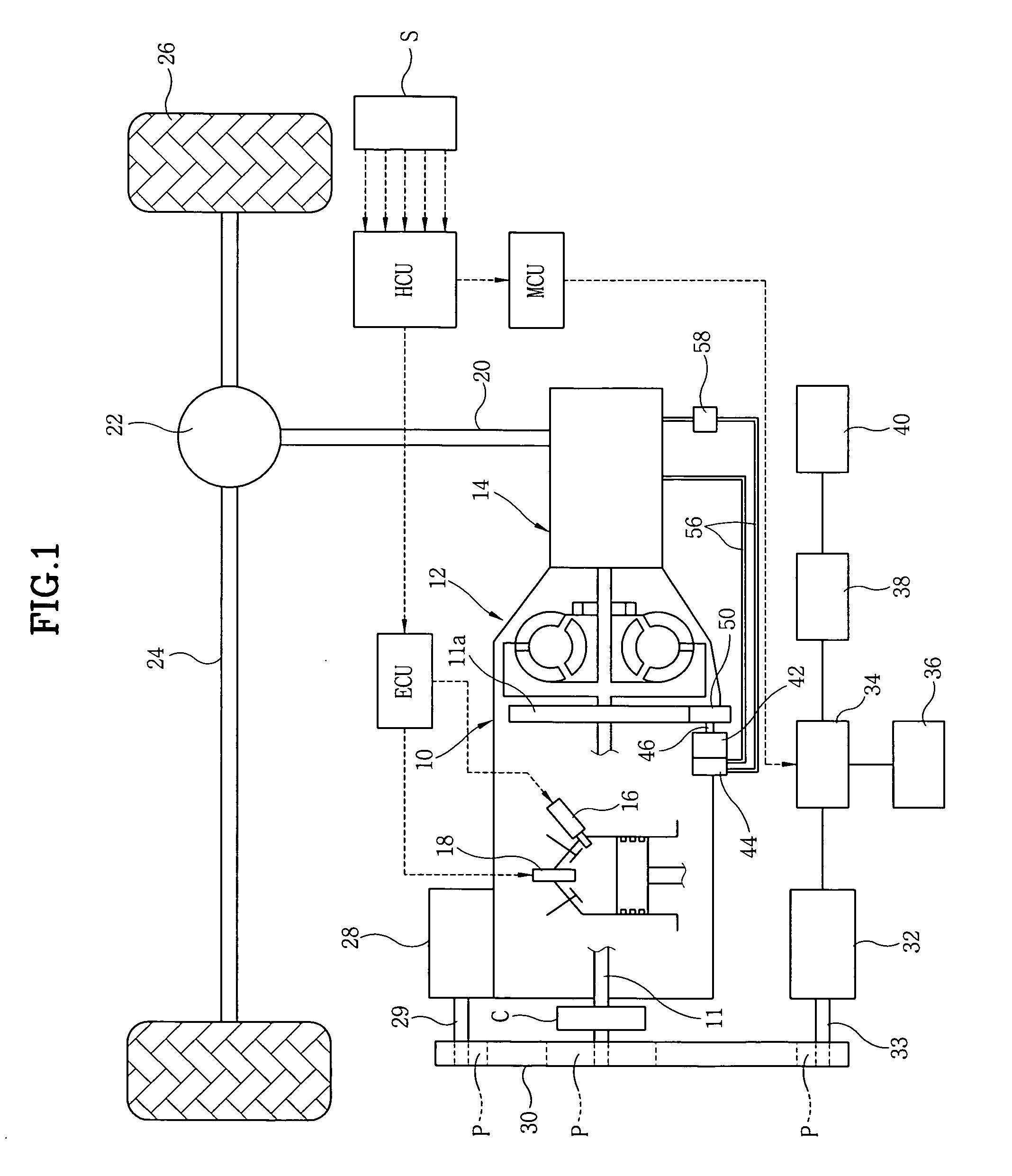

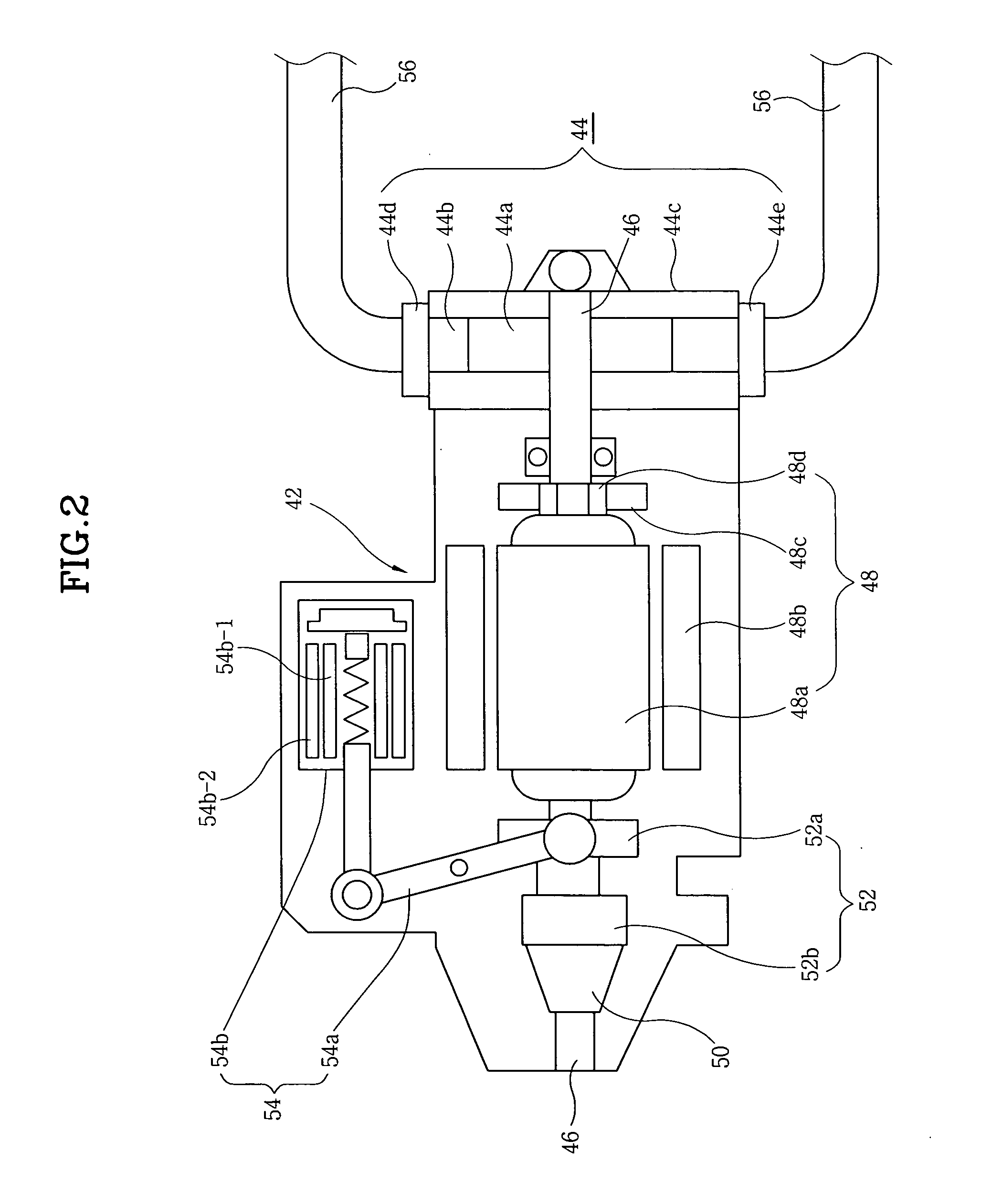

Starter with electric oil pump for hybrid vehicle

ActiveUS7357213B2Reduce spacingImprove assembly productivityHybrid vehiclesPower operated startersProduction rateModularity

The present invention provides a hybrid vehicle, which has both the function of supplying hydraulic oil to a transmission when the idle operation of an engine is stopped, and the function of providing start force when the engine is cold started, thus reducing space occupied by components, and enhancing assembling productivity due to modularized components.

Owner:HYUNDAI MOTOR CO LTD

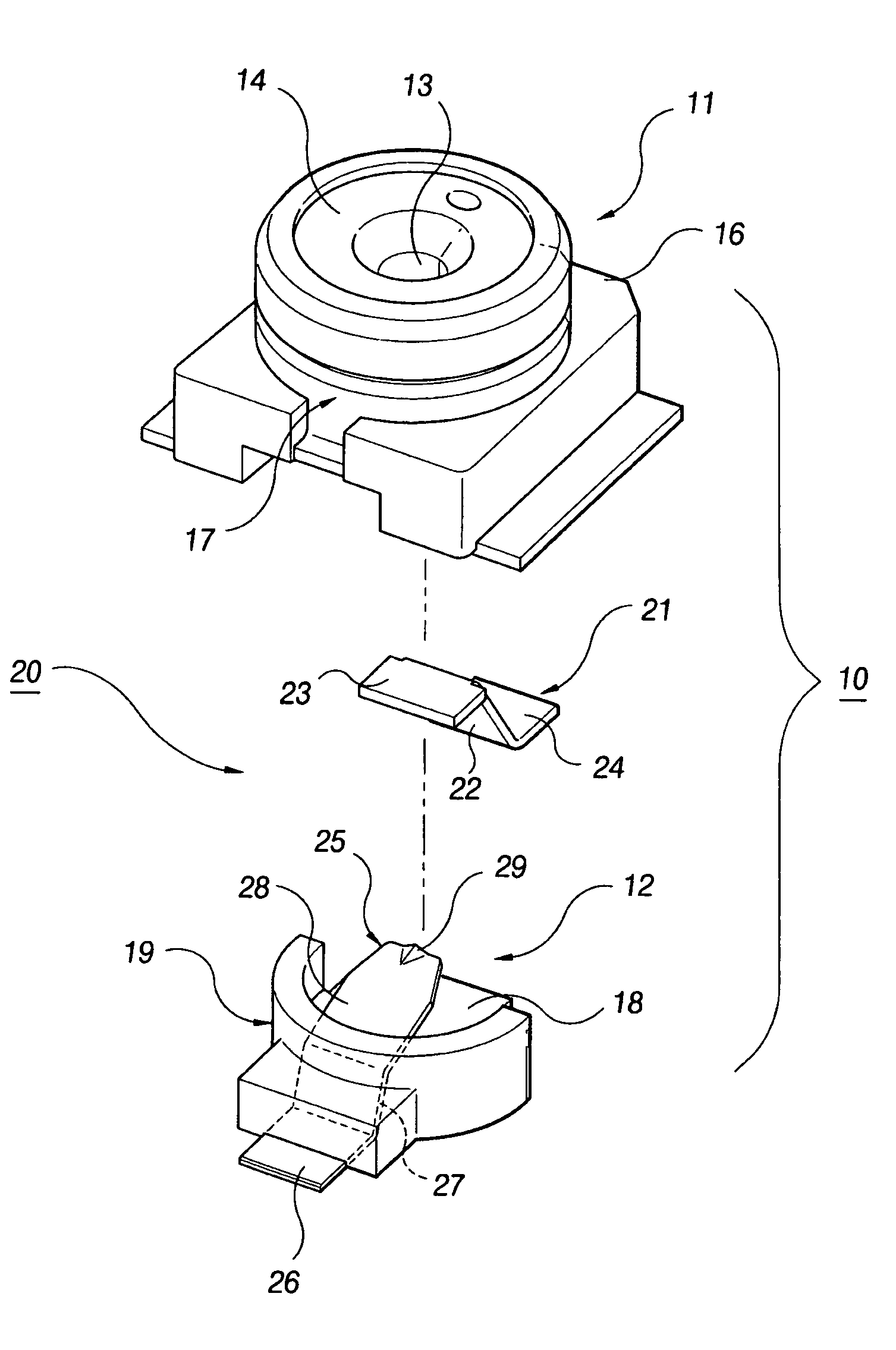

Vibration-type driving device, control apparatus for controlling the driving of the vibration-type driving device, and electronic equipment having the vibration-type driving device and the control apparatus

ActiveUS20050242686A1Simple arrangementReduce in quantityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsDriven elementFlexural vibration

A vibration-type driving device comprises a vibration element including a driving member and an electro-mechanical energy conversion element having an electrode and arranged to displace the driving member with a driving signal supplied to the electrode, and a driven element that is kept in contact with the driving member of the vibration element. According to the driving signal supplied to the electrode of the electro-mechanical energy conversion element, the vibration element excites vibrations in two flexural vibration modes in which a direction of generation of a node in one mode is perpendicular to that in the other mode. With the use of the two flexural vibration modes, the natural vibration frequency of the vibration element can be prevented from increasing, and the position of a node occurring in one flexural vibration mode and the position of an antinode occurring in the other flexural vibration mode can be made to coincide with each other, so that the amount of displacement of the driving member can be made large.

Owner:CANON KK

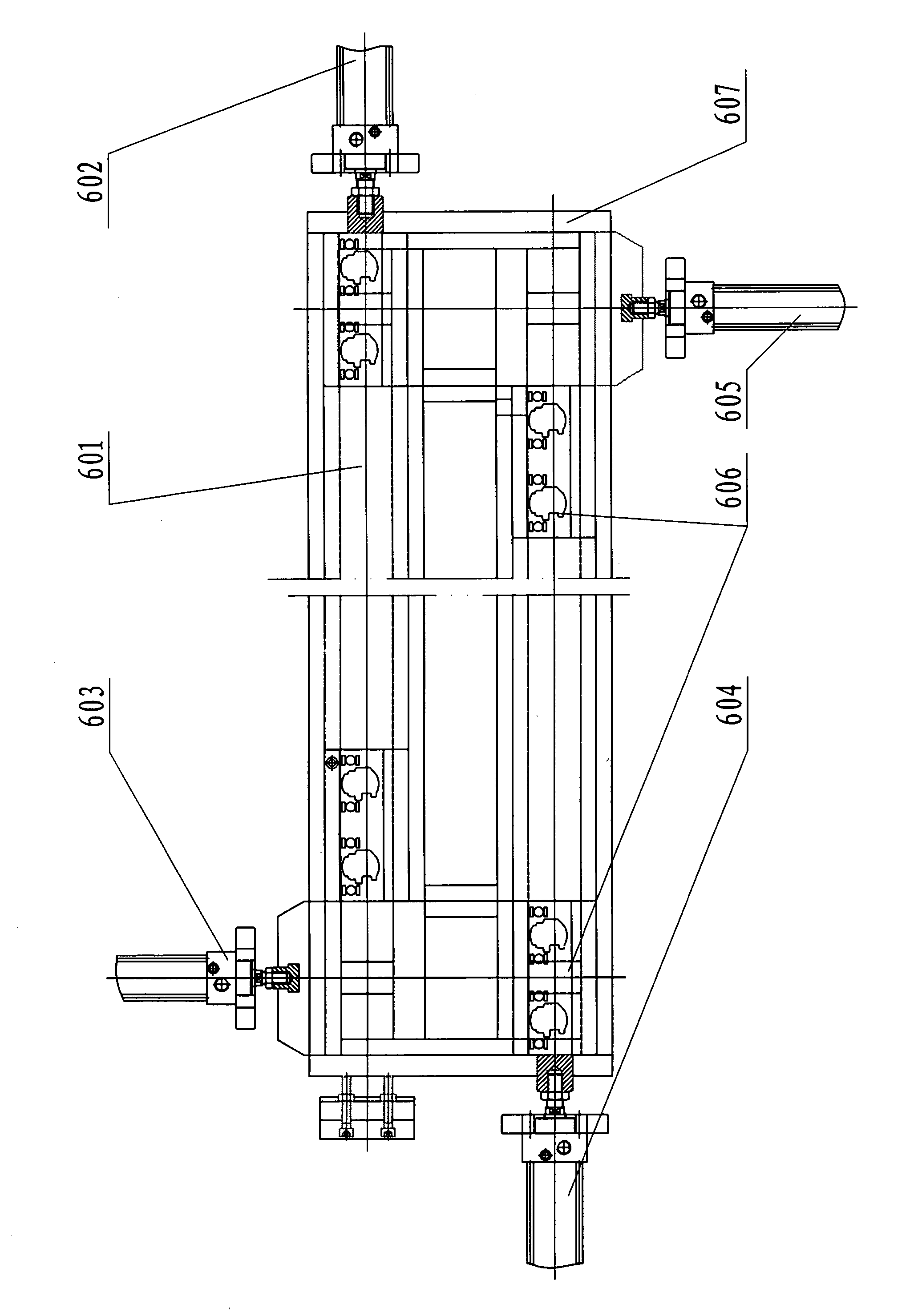

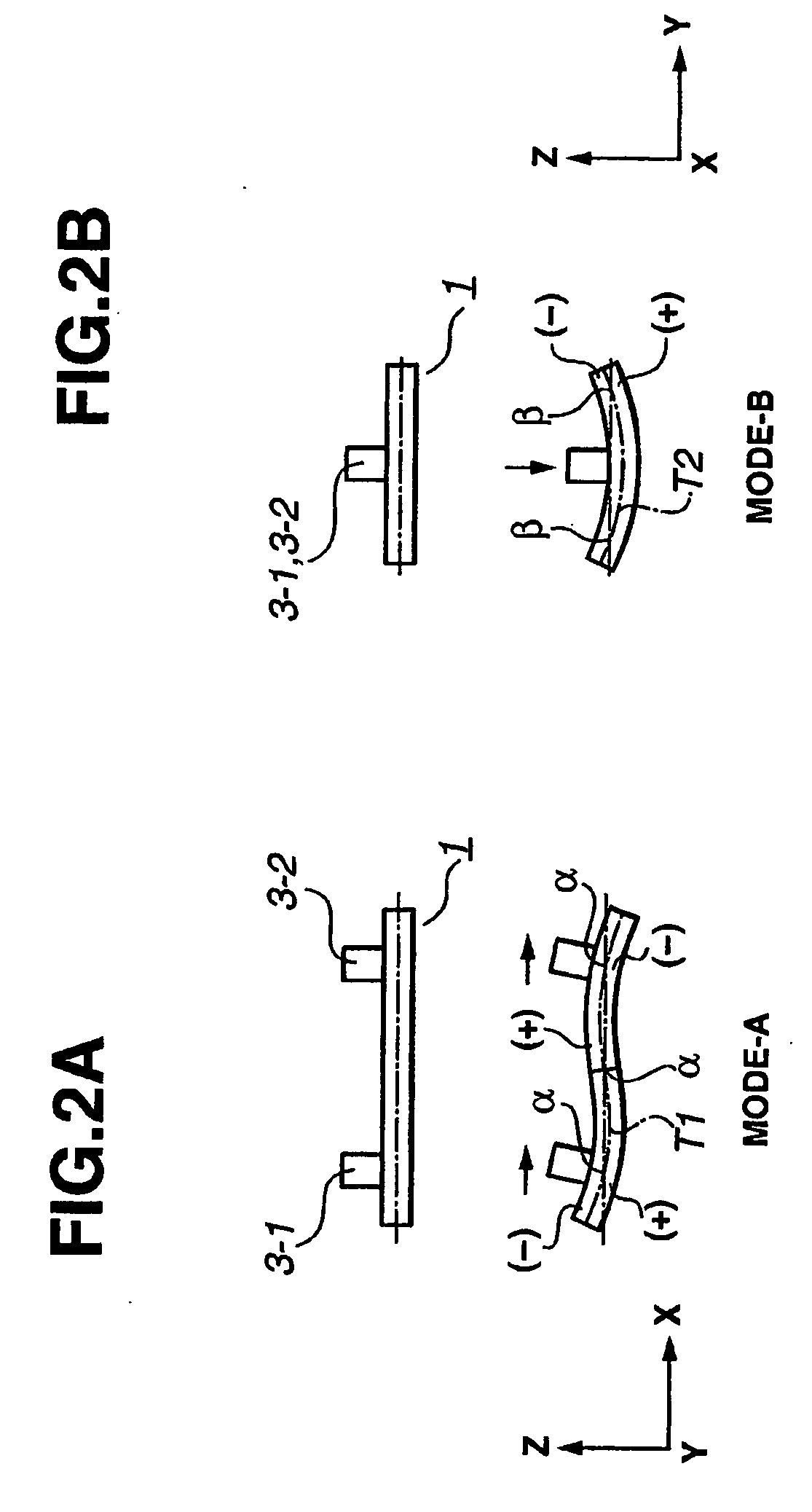

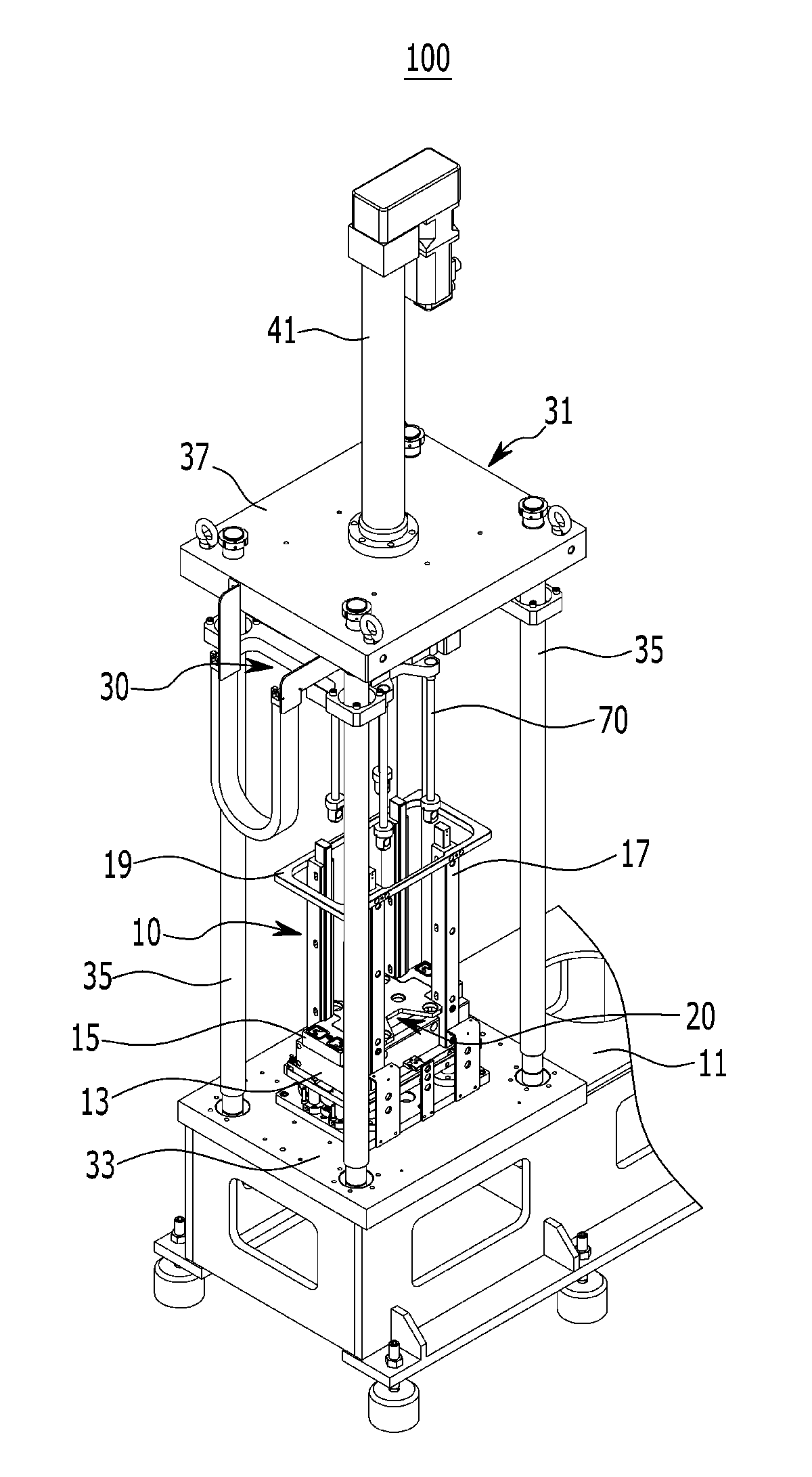

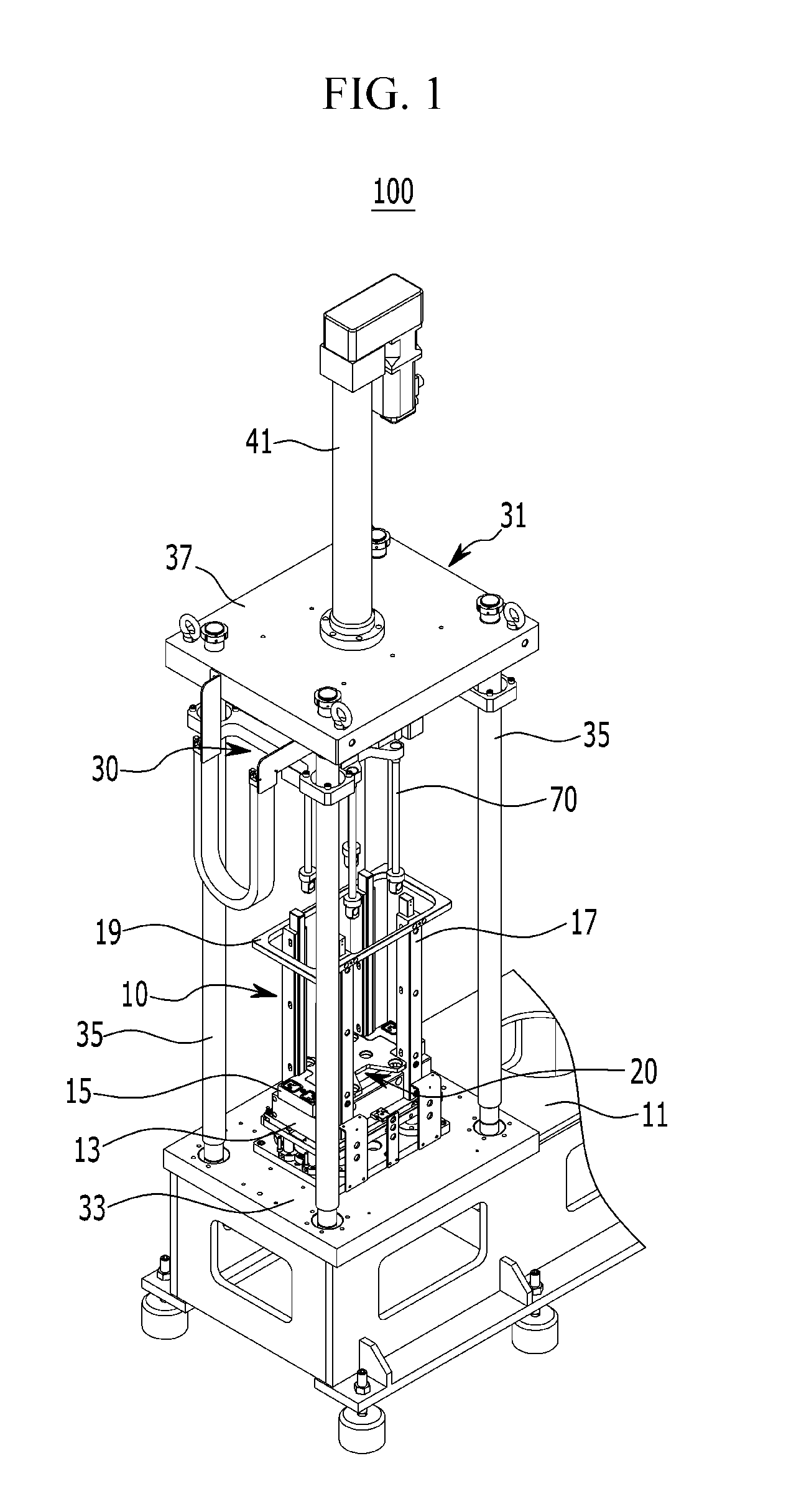

Apparatus for assembling fuel cell stack

ActiveUS20170033392A1Improve assembly productivitySimplify the assembly processFuel cellsMetal working apparatusFuel cellsMechanical engineering

An apparatus for assembling a fuel cell stack is provided. The apparatus exerts a force on fuel cell components stacked on a stacking guide and couples a pressed stacked body formed of the pressed fuel cell components by a fastening member. The apparatus includes a lift plate that is disposed on an inner bottom of the stacking guide and a press body that is installed on a press frame to be movable in a vertical direction, and exerts a force onto the fuel cell components stacked on the lift plate. A plurality of fixing rods are disposed on the press body and are fastened to the lift plate, and coupled the press body integrally to the lift plate with the pressed stacked body disposed therebetween.

Owner:HYUNDAI MOTOR CO LTD

Full-automatic drawer sliding rail assembling machine

ActiveCN104647029AEasy to operateReduce manual labor intensityAssembly machinesDrawersChain conveyorManipulator

The invention discloses a full-automatic drawer sliding rail assembling machine which comprises a sliding rail main body storage stay wire, a first suction manipulator, a chain conveyor, reaming equipment, riveting equipment, a pin feeding device, a roller feeding device, a spacer feeding device, a rotating disc type assembly table, a second suction manipulator, a finished product roller moving stay wire, a roller axial gap detection device and an oiling device, wherein the sliding rail main body storage stay wire is arranged upstream the chain conveyor, the reaming equipment is positioned at the downstream of the first suction manipulator, and the riveting equipment is installed on the chain conveyor and is positioned at the downstream of the reaming equipment and on the same side as the reaming equipment. According to the full-automatic drawer sliding rail assembling machine, full-automatic assembly of pins, rollers and spacers into a finished roller can be realized, the finished roller can be automatically screwed and riveted on a drawer sliding rail main body, meanwhile, roller axial gap detection on a finished drawer sliding rail and anti-rust oil coating in riveting positions can be automatically completed, manual operation is matched, and the full-automatic drawer sliding rail assembling machine has the advantages of simplicity in operation, low manual labor intensity and high assembling production efficiency.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

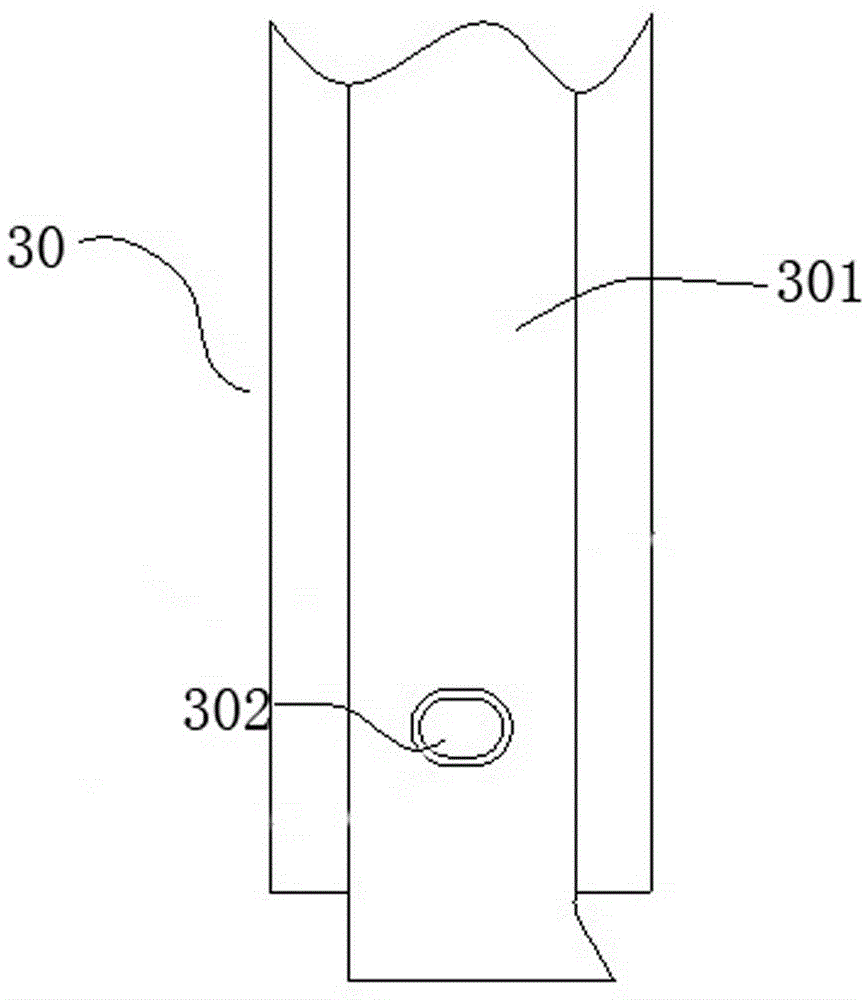

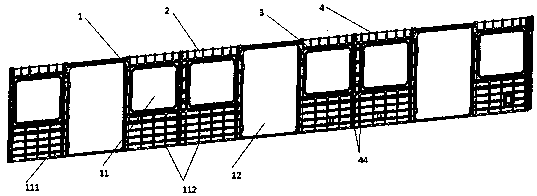

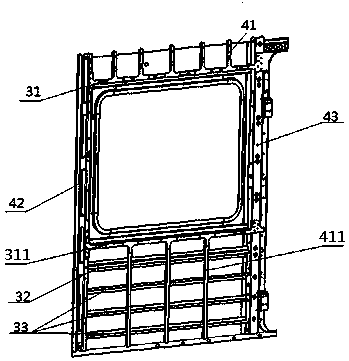

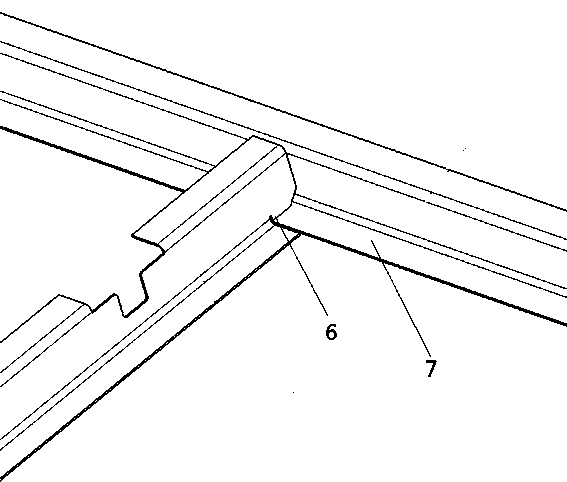

Novel stainless steel side wall structure and mounting method of novel stainless steel side wall

InactiveCN107901932AReduce welding processGuarantee the appearance qualityAxle-box lubricationRailway bodiesStructural engineeringEngineering

The invention provides a novel stainless steel side wall structure and a mounting method of a novel stainless steel side wall. The novel stainless steel side wall structure comprises a side wall skeleton. The side wall skeleton is formed by connecting a plurality of cross beams and a plurality of vertical columns in a mutually-crossing mode, and the cross beams and the vertical columns are fixed through mutual inserting; end vertical columns are arranged on the left and right sides of the side wall skeleton correspondingly; door vertical columns are arranged on the left and right sides of doorframes correspondingly; a window upper cross beam is arranged on the upper portion of each window frame, and a window lower cross beam is arranged on the lower portion of each window frame; a waist cross beam is arranged below each window lower cross beam; three lower cross beams are arranged below each waist cross beam; a window upper vertical column is connected to each window upper cross beam;skeleton connecting plates are welded inside the connecting positions of the window upper cross beams and the window upper vertical columns in the side wall skeleton; window lower vertical columns are connected among each window lower cross beam, the corresponding waist cross beam and the three corresponding lower cross beams; and skeleton connecting plates are welded inside the connecting positions of the window lower cross beams and the window lower vertical columns in the side wall skeleton. The cross beams and the vertical columns of the novel stainless steel side wall structure are fixedthrough mutual inserting connection, the deformation problem caused by welding of a skeleton is solved, the production cost is saved, and the assembly production efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

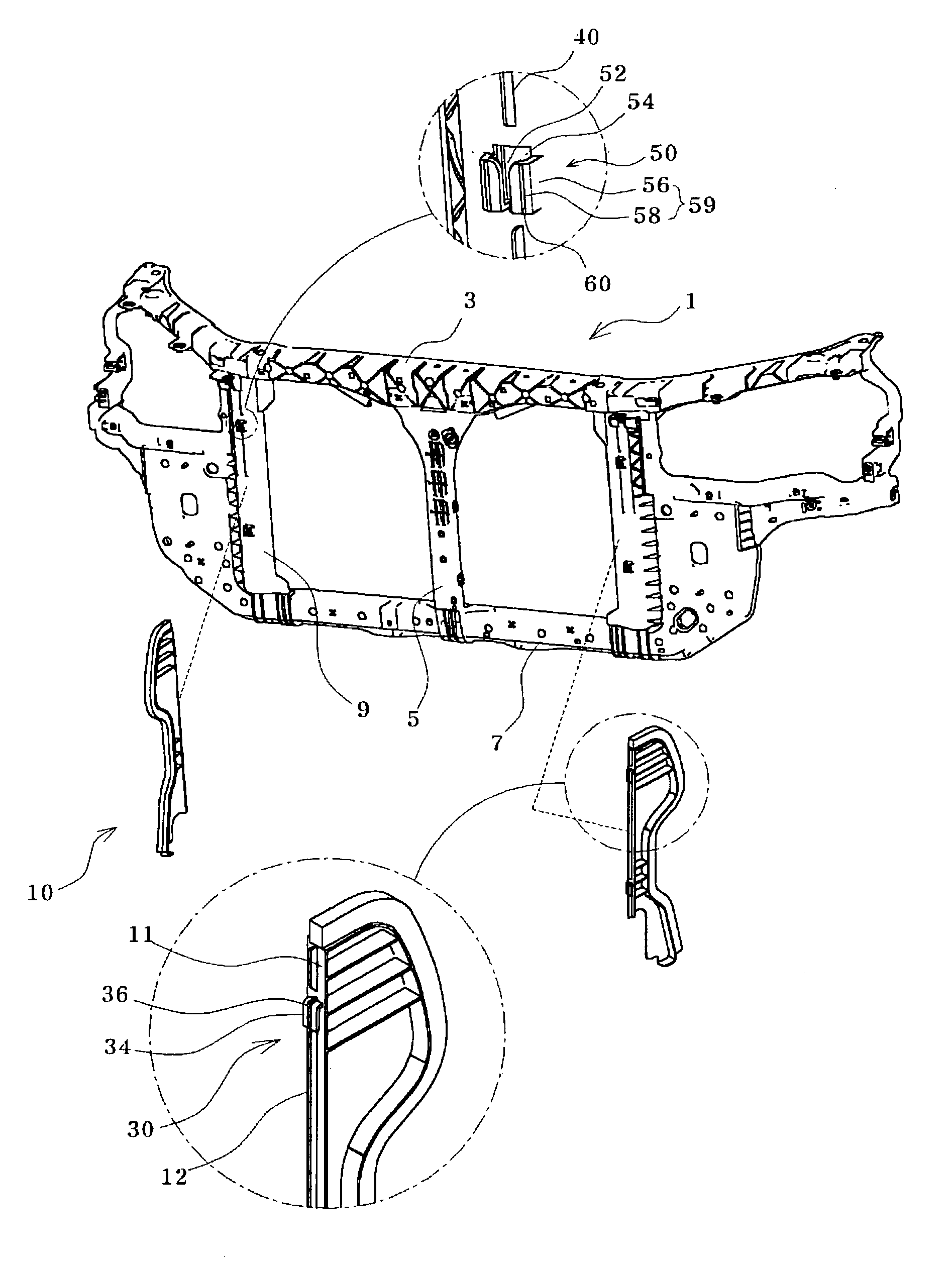

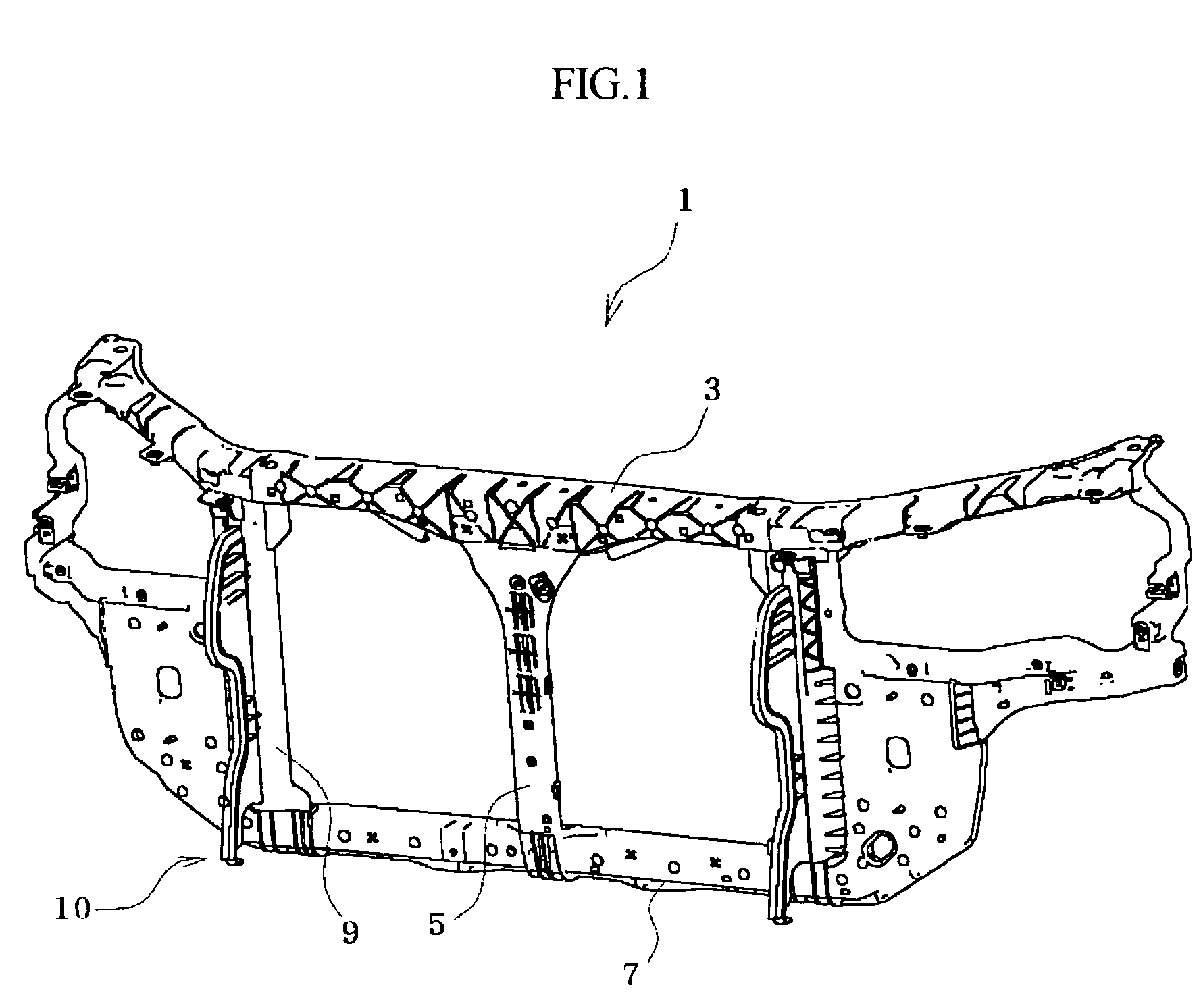

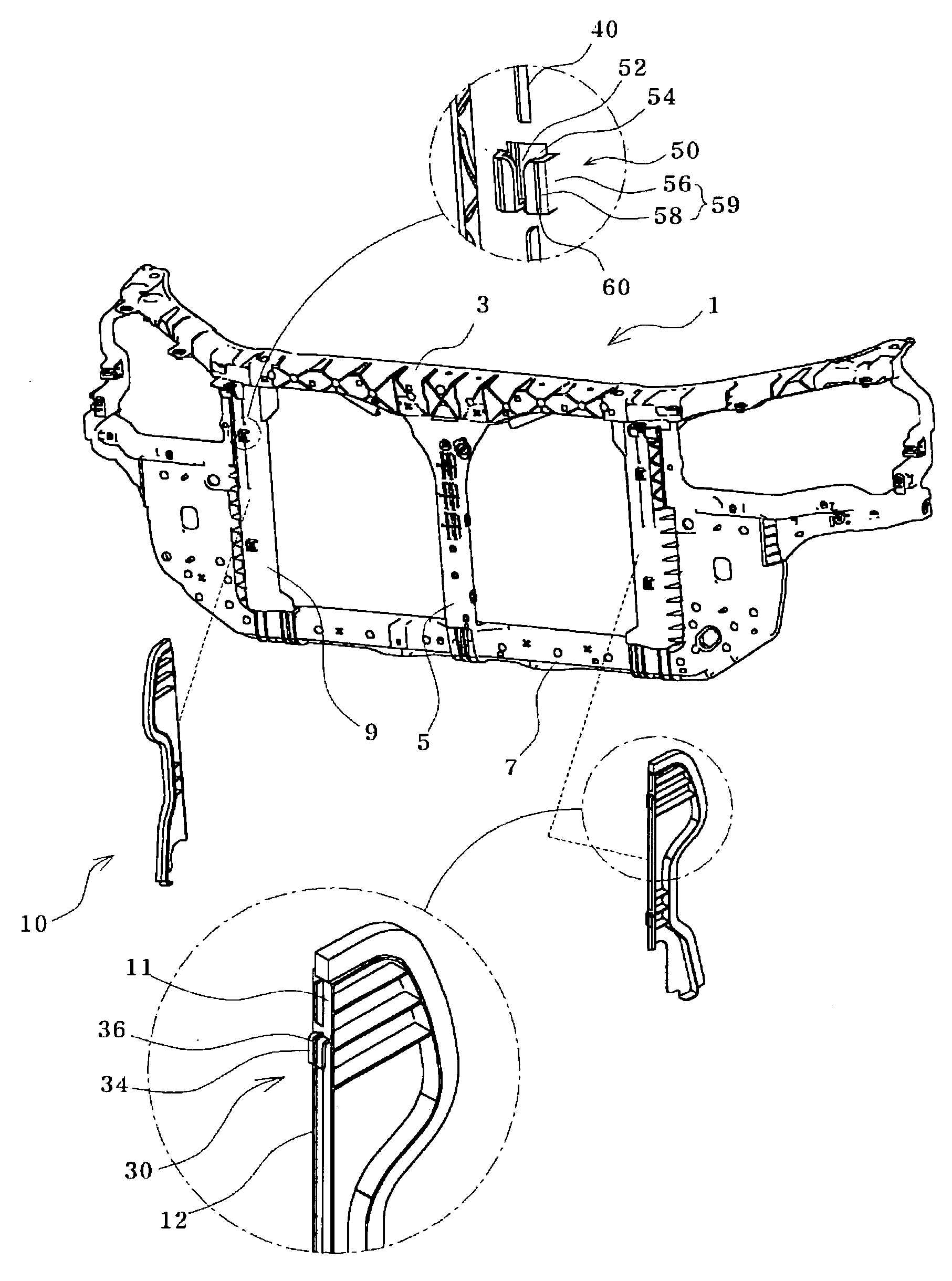

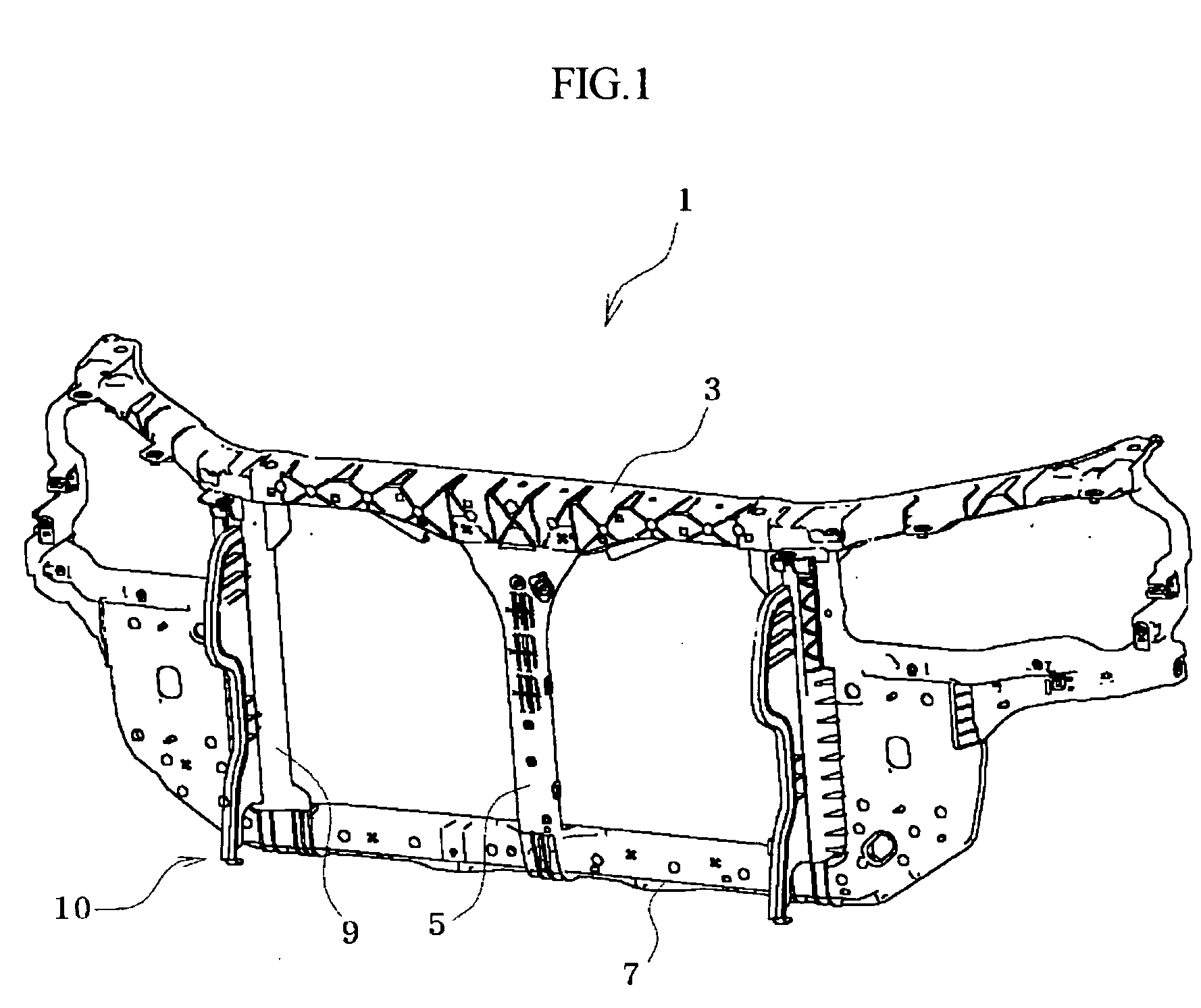

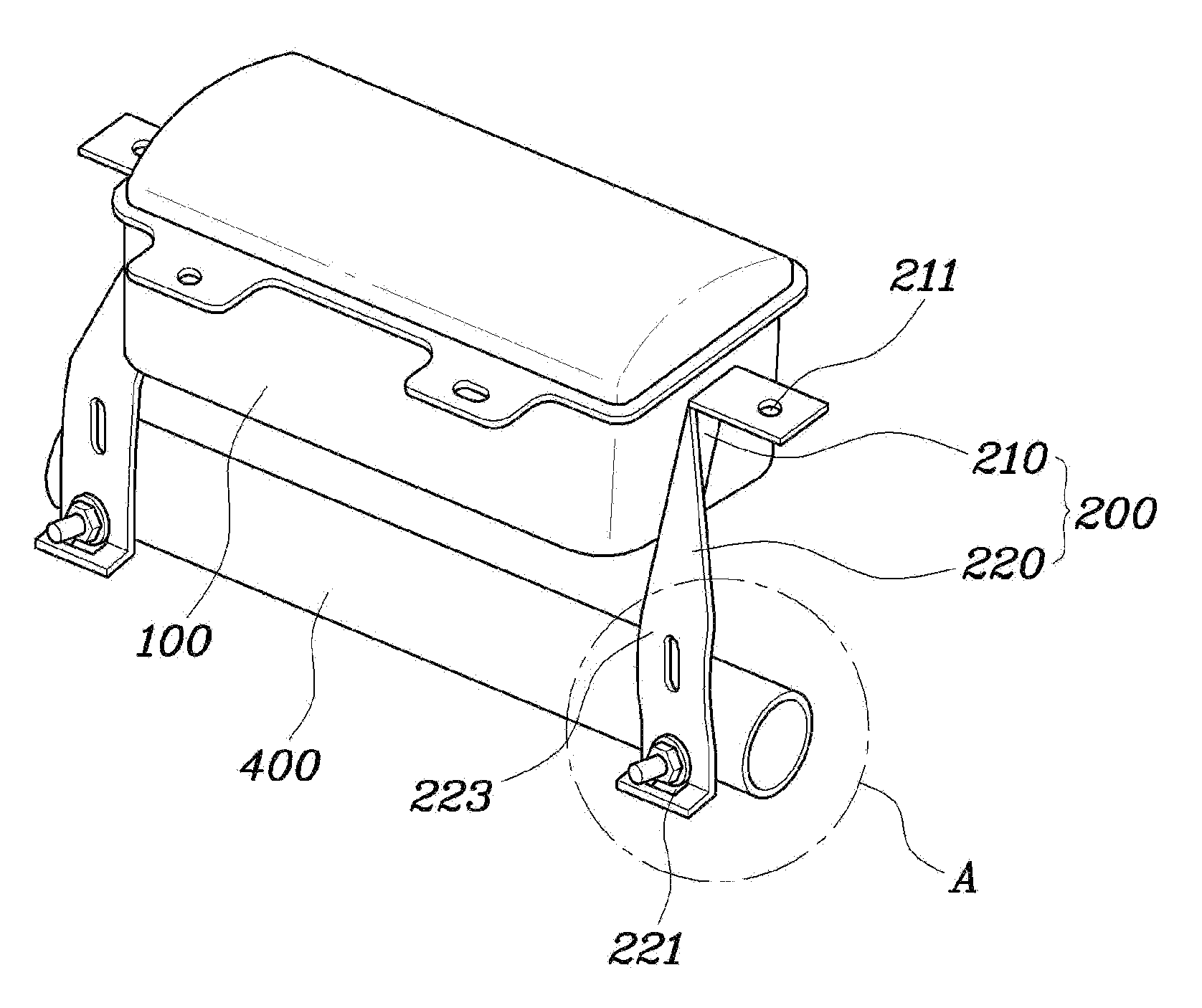

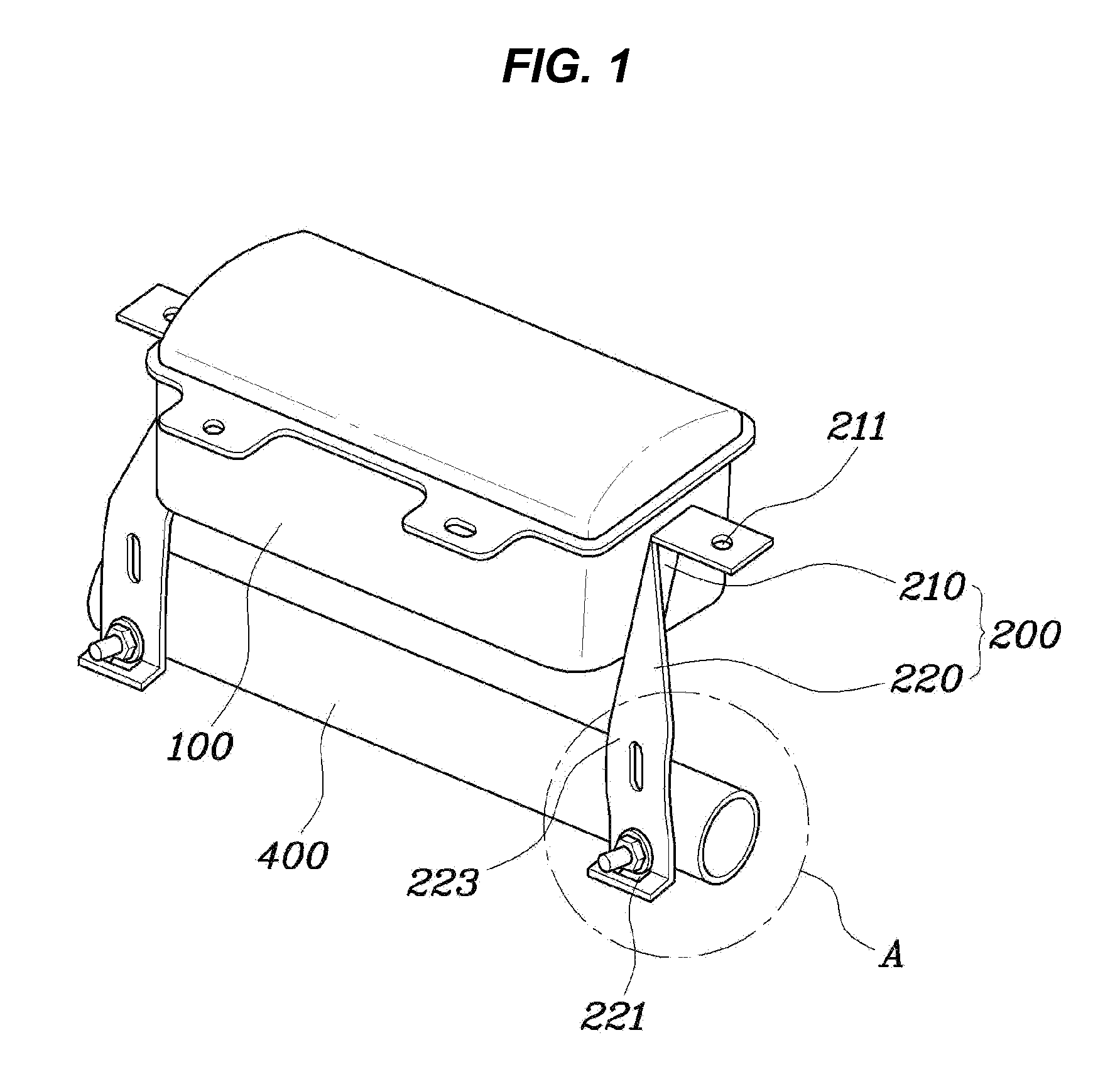

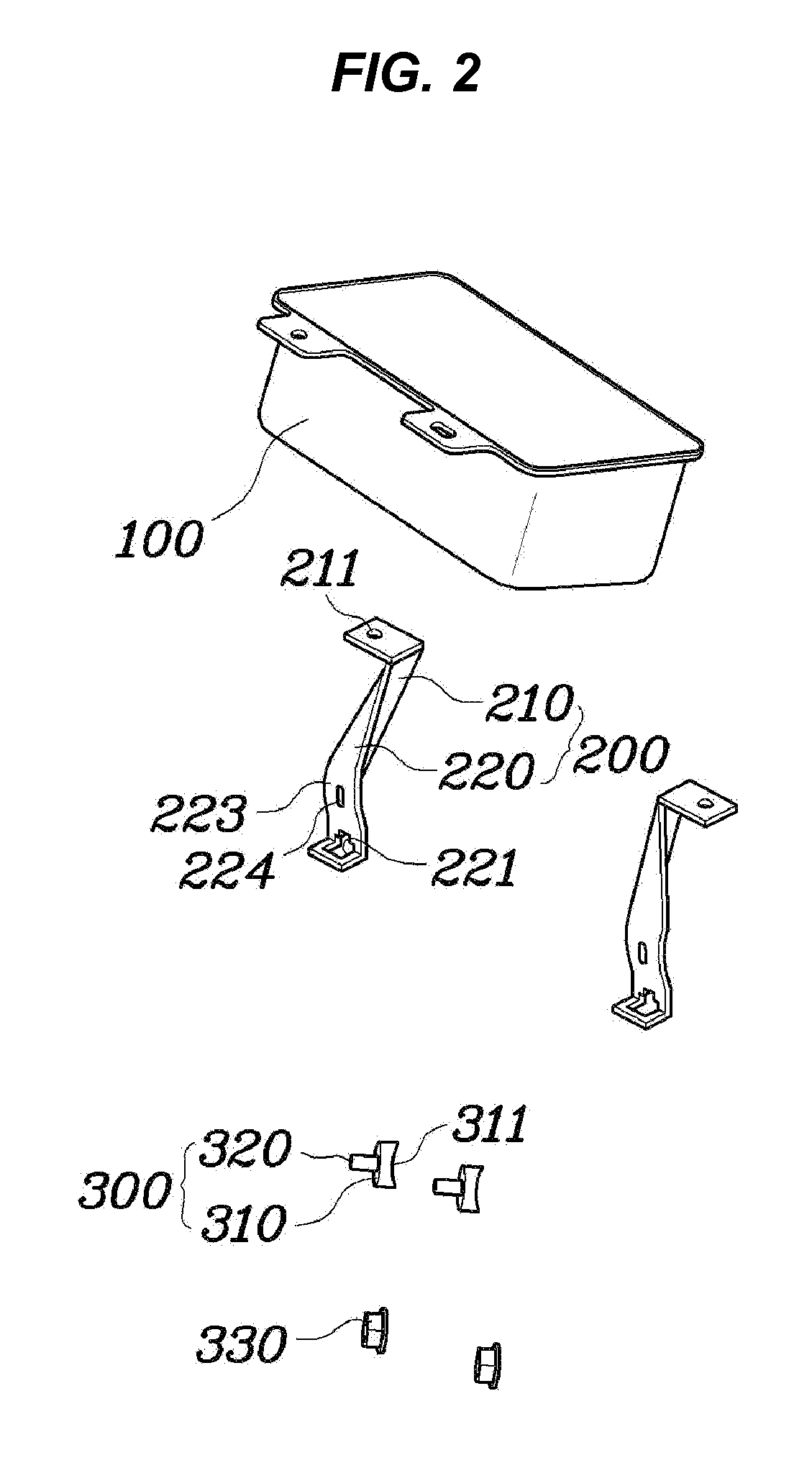

Coupling structure for air guide of front-end module

InactiveUS7073848B2Simple coupling structureReduce assemblyVehicle seatsSuperstructure subunitsCouplingTroffer

Owner:HYUNDAI MOBIS CO LTD

Starter with electric oil pump for hybrid vehicle

ActiveUS20070111849A1Reduce spacingImprove assembly productivityHybrid vehiclesPower operated startersModularityAutomotive engineering

The present invention provides a hybrid vehicle, which has both the function of supplying hydraulic oil to a transmission when the idle operation of an engine is stopped, and the function of providing start force when the engine is cold started, thus reducing space occupied by components, and enhancing assembling productivity due to modularized components.

Owner:HYUNDAI MOTOR CO LTD

Assembling line of corridor LED (Light-Emitting Diode) light

ActiveCN104668953ARealize semi-automatic assembly productionImprove assembly productivityMaterial gluingAssembly machinesProduction lineSemi automatic

The invention discloses an assembling line of a corridor LED (Light-Emitting Diode) light. The assembling line of the corridor LED light comprises a first assembling line used for transferring brushed aluminum, pasting a product sequence code on the back of the brushed aluminum and pasting a spacer on the front of the brushed aluminum; a second assembling line used for installing a lamp panel, a reflector and a lens on the brushed aluminum; and a third assembling line used for respectively installing an end cover and a sheet iron at the two ends of the brushed aluminum; the first assembling line is connected with the second assembling line by a manipulator; the second assembling line is connected with the third assembling line by the manipulator; the first assembling line comprises a first manual station, a first feeding line, etc.; the second assembling line comprises a second feeding line, a reflector loading device, a lamp panel loading device, etc.; the third assembling line comprises a third feeding line, a second manual station, a third manual station, etc. The assembling line of the corridor LED light disclosed by the invention can realize the semi-automatic assembling production of the corridor LED light, and has the advantages that the assembling production efficiency is high, the manual operation can be simplified and the manual labor intensity can be reduced.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Coupling structure for air guide of front-end module

InactiveUS20050275248A1Improve rigidityNot only assembly processVehicle seatsSuperstructure subunitsCouplingEngineering

A coupling structure for an air guide of a front end module includes a plurality of rib members formed at a lateral portion of the front end module, at least one support ribs protruding from a fixing surface of the air guide, and a plurality of insert blades extending at a right angle at one end of the respective support ribs. Each of the rib members is formed about an associated guidance recess, and includes a pair of lateral ribs protruding from opposite lateral sides of the guidance recess, and a pair of front ribs extending from distal ends of the lateral ribs toward each other. The support ribs are configured to be inserted along the guidance recesses of the rib members, respectively, and in such an inserted state of the support ribs, the insert blades connected thereto come into contact with inner surfaces of the front ribs of the rib members.

Owner:HYUNDAI MOBIS CO LTD

Eyeglass revolving shaft full-automatic assembly machine

InactiveCN104668954ASimplify manual operationsEasy to operate manuallyAssembly machinesEngineeringAssembly machine

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

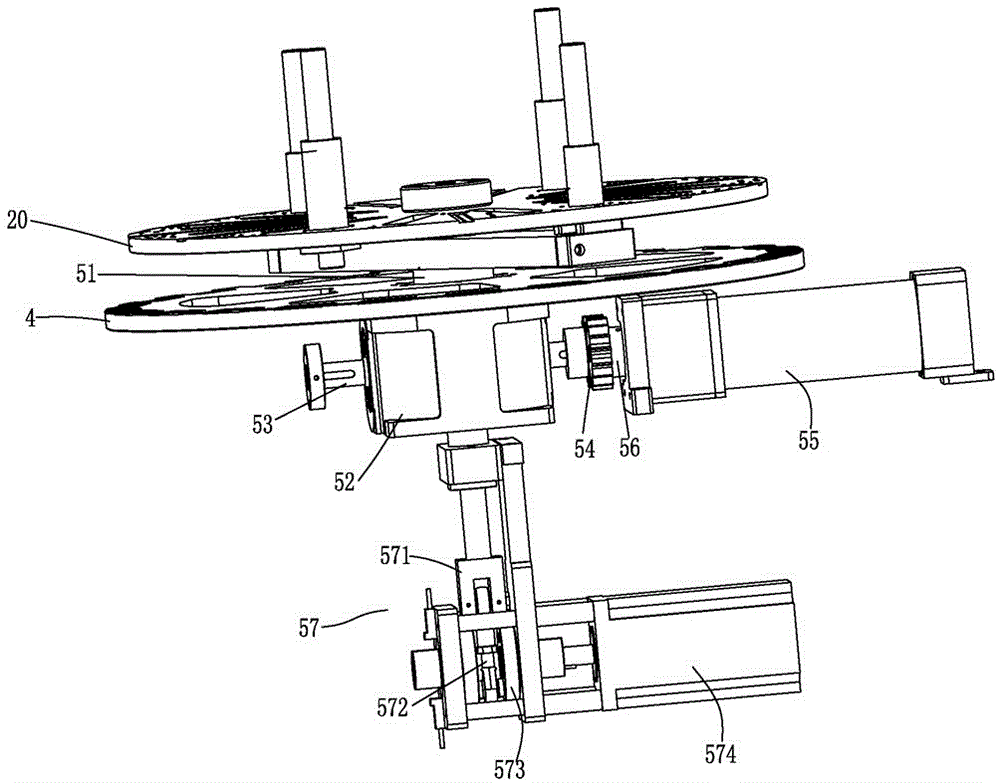

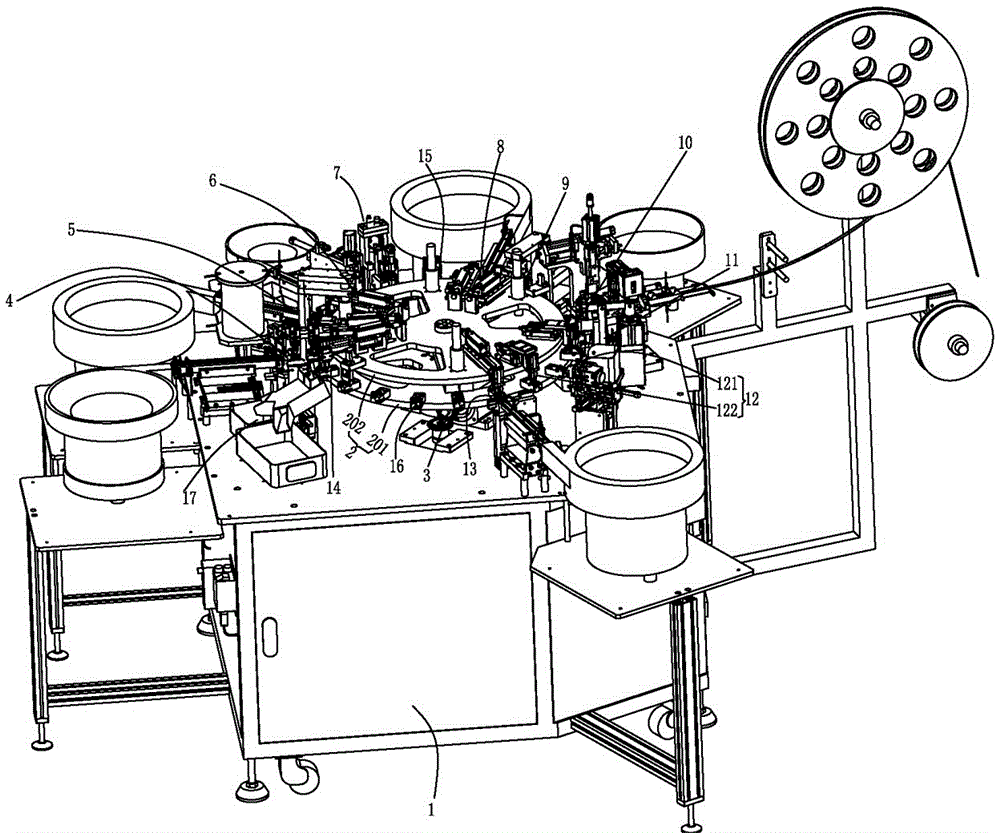

Potentiometer automatic assembly machine

ActiveCN106782964AHigh degree of automationImprove assembly productivityResisitors with sliding contactResistor manufactureEngineeringCam

The invention discloses a potentiometer automatic assembly machine, which comprises a turntable, wherein the turntable comprises a rotatable disc and a fixed disc; the rotatable disc and the fixed disc can be driven to do corresponding intermittent rotation and intermittent ascending and descending by a cam cutter assembly; a shaft core feeding mechanism, a shaft sleeve feeding mechanism, a stop baffle sheet feeding mechanism, a stop baffle sheet riveting mechanism, a body feeding mechanism, a glue rotating sheet feeding mechanism, a brush feeding mechanism, a brush riveting mechanism, a glue rotating sheet installing mechanism, a switch feeding mechanism and a material return mechanism are arranged on a machine box; a plurality of part clamps are arrayed on the rotatable disc; during the assembly, the shaft core feeding mechanism applies oil on a shaft core and feeds the shaft core to the part clamps; an assembled stop baffle sheet and the shaft core are riveted by the stop baffle sheet riveting mechanism; a brush is riveted on a glue rotating sheet by the brush riveting mechanism; the glue rotating sheet riveted with the brush, the shaft core, a shaft sleeve, the stop baffle sheet and a body are assembled by the glue rotating sheet installing mechanism; the shaft sleeve, the stop baffle sheet, the body and a switch are sequentially assembled through the shaft sleeve feeding mechanism, the stop baffle sheet feeding mechanism, the body feeding mechanism and the switch feeding mechanism.

Owner:广东钺河智能科技有限公司

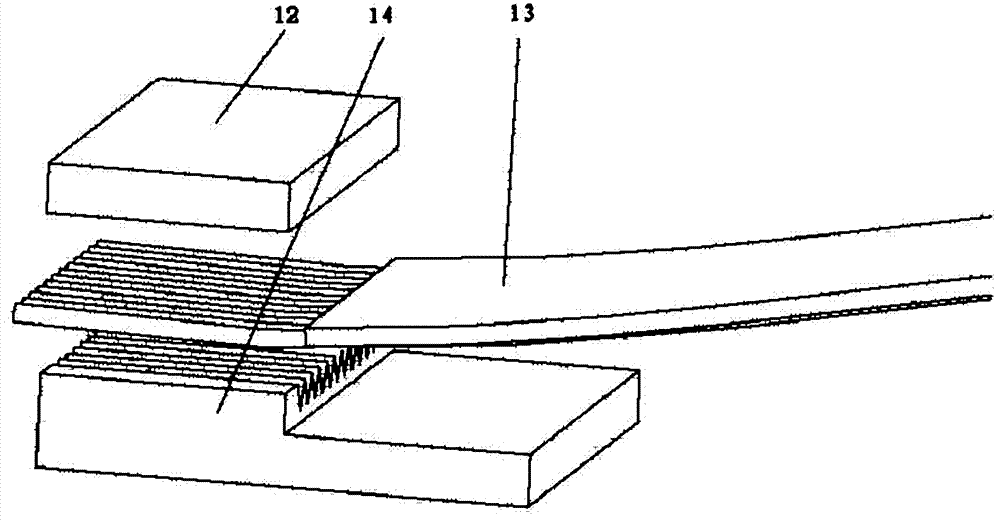

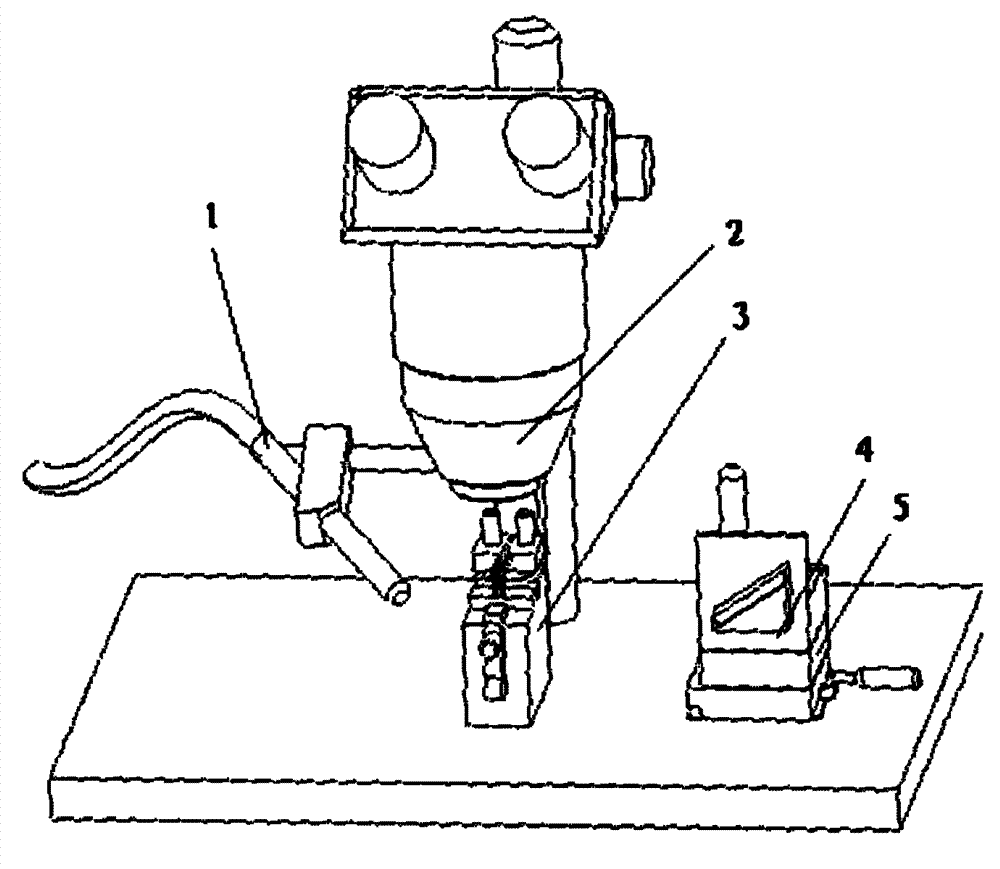

Fiber array board assembly device and fiber array board assembly platform using same

ActiveCN103358249AImprove assembly qualityIncrease profitWork holdersFastening meansFiber arrayMechanical engineering

The invention relates to a fiber array board assembly device and a fiber array board assembly platform using the same. The fiber array board assembly device comprises an L-shaped positioning base and a clamp component. The L-shaped positioning base comprises a side wall and a base. A positioning block is fixedly connected to the inner side of the side wall. A pressure block parallel to the positioning block is also movably connected to the inner side of the side wall. The pressure block can horizontally move along the inner side of the side wall. The inner side of the side wall is further provided with a clamp groove. The base is provided with a through hole. A lifting member and a support member are disposed in the through hole. A U-shaped support is disposed on two side walls of the clamp component. An elastic member is arranged between the bottom of the U-shaped support and the bottom of the clamp component. A glass pressure block is arranged between two ends of the U-shaped support. One end of the clamp component is provided with a protrusion which is clamped in the clamp groove. The lifting member controls the U-shaped support to ascend and descend through the support member.

Owner:广东安捷康光通科技有限公司

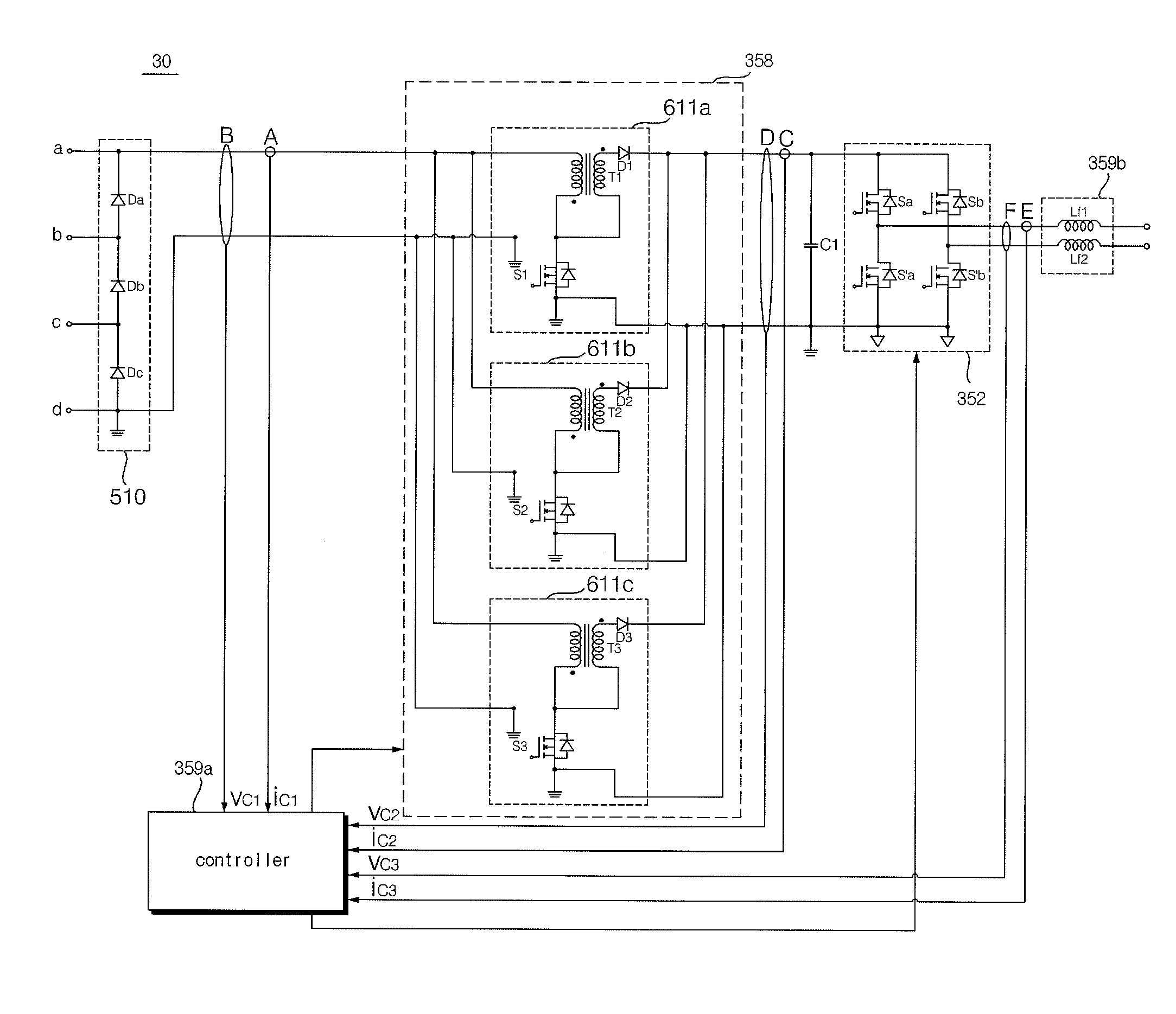

Integral inverter and solar cell module including the same

ActiveUS20150200603A1Improve assembly productivityImprove structural stabilityCasings/cabinets/drawers detailsPhotovoltaicsElectricitySolar cell

Discussed is an integral inverter usable with a solar cell module including a solar cell panel. The integral inverter includes a terminal connected to the solar cell panel, a bypass diode electrically connected to the terminal, an inverter member including a direct current (DC)-alternating current (AC) inverter electrically connected to the bypass diode and a case configured to integrate at least one of the terminal and the bypass diode with the DC-AC inverter located therein.

Owner:SHANGRAO JINKO SOLAR TECH DEV CO LTD

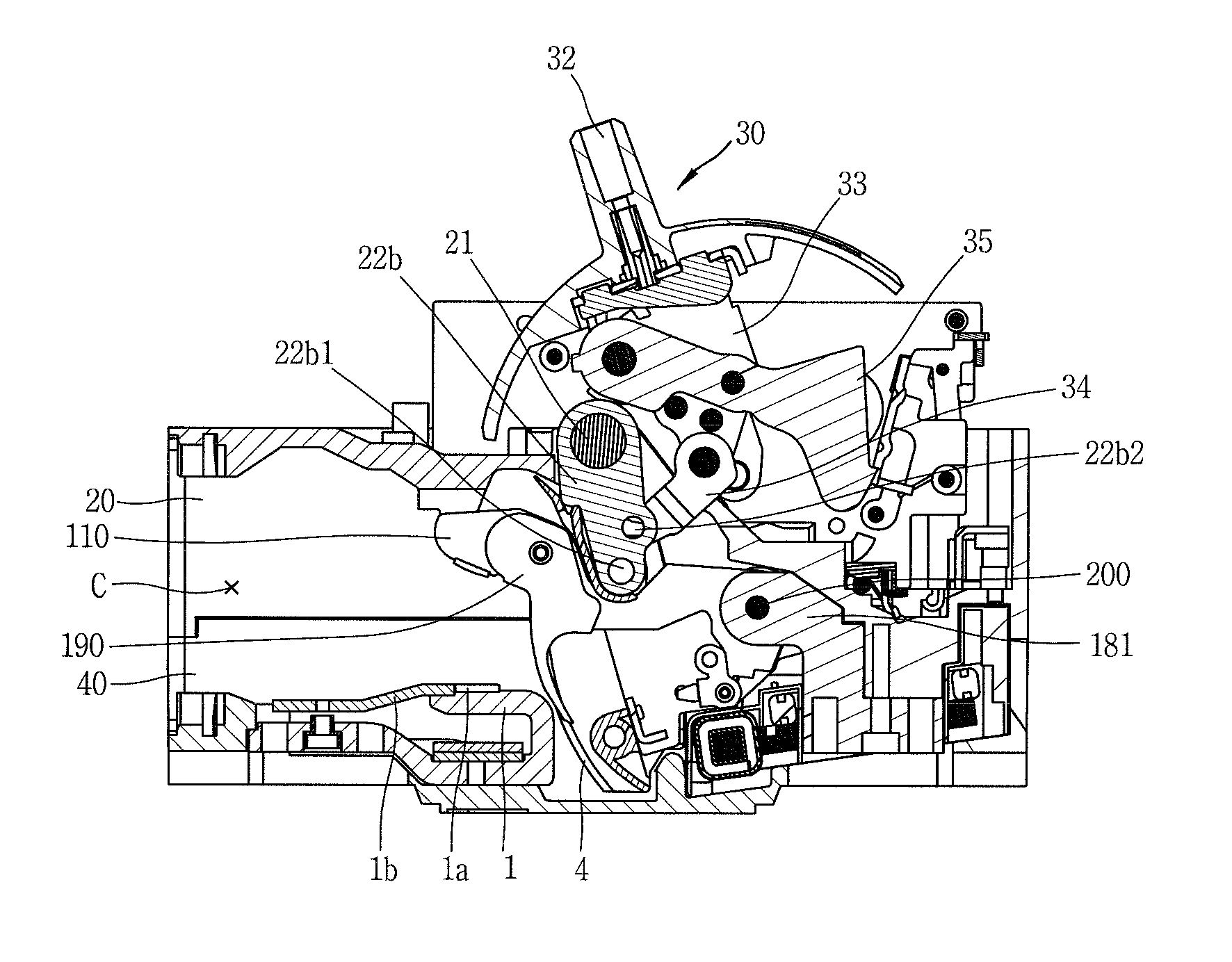

Movable contactor assembly for current limiting type molded case circuit breaker

ActiveUS20110193660A1Reduce in quantityImprove electricity efficiencySnap-action arrangementsProtective switchesElectricityCurrent limiting

A movable contactor assembly for a current limiting type MCCB comprising: a terminal base fixedly installed on a case; a plurality of movable contactors having a cam face portion; a pair of holder plates supporting the movable contactors at both sides thereof; a plurality of first springs providing an elastic force to the movable contactors; a plurality of extending plate portions provided to face the side of one end portion of each of the movable contactors; a plurality of flexible wire plates electrically connecting the movable contactors and the terminal base and having a portion bendable toward the movable contactors or toward the extending plate portions; and a second spring providing an elastic force to the flexible wire plates so as to be tightly attached to the movable contactor.

Owner:LS IND SYETEMS CO LTD

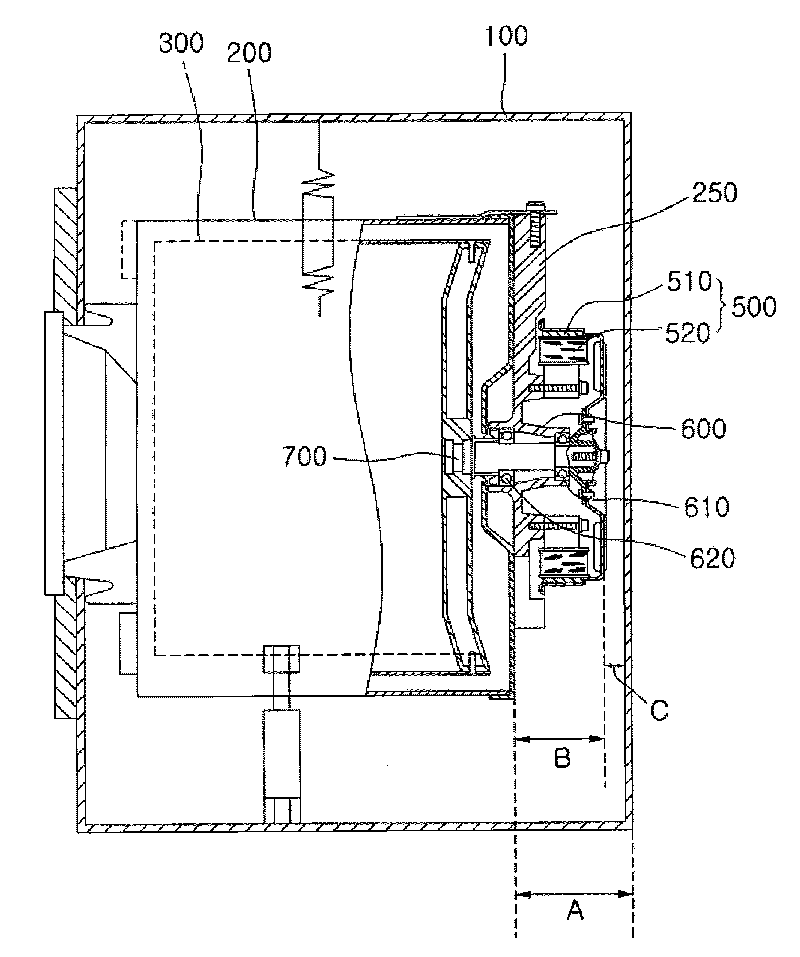

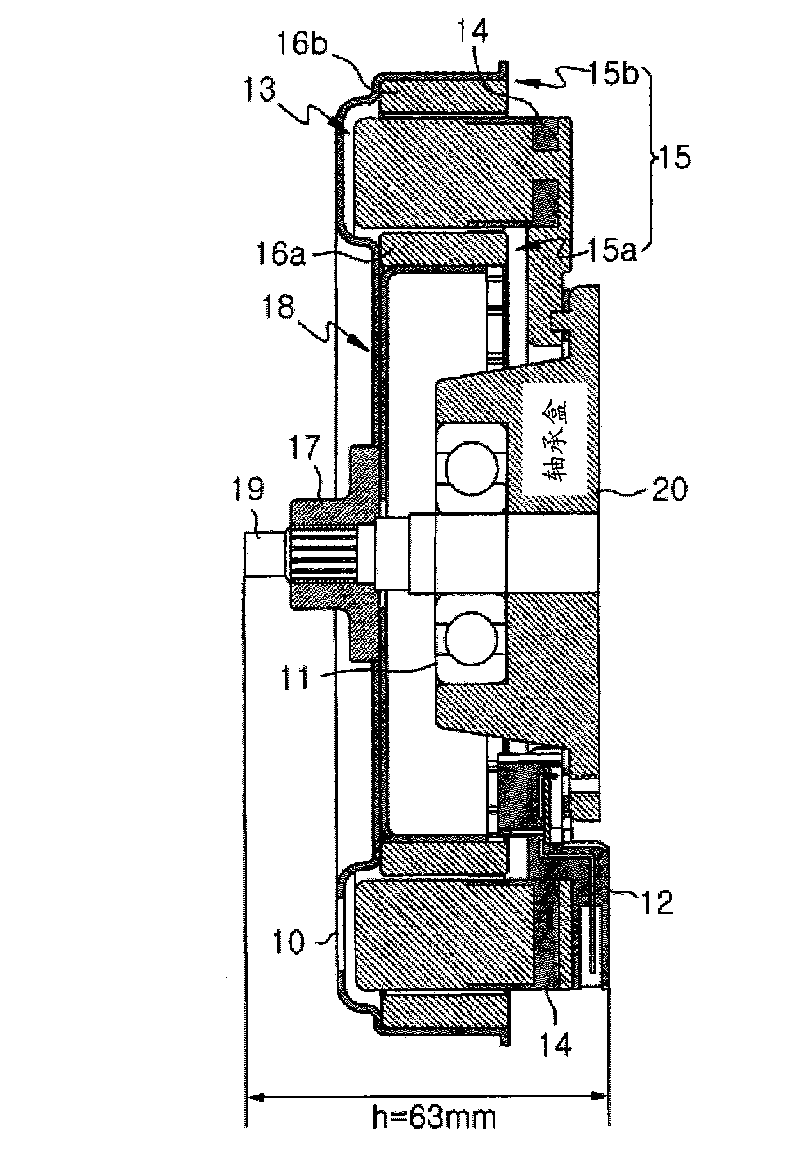

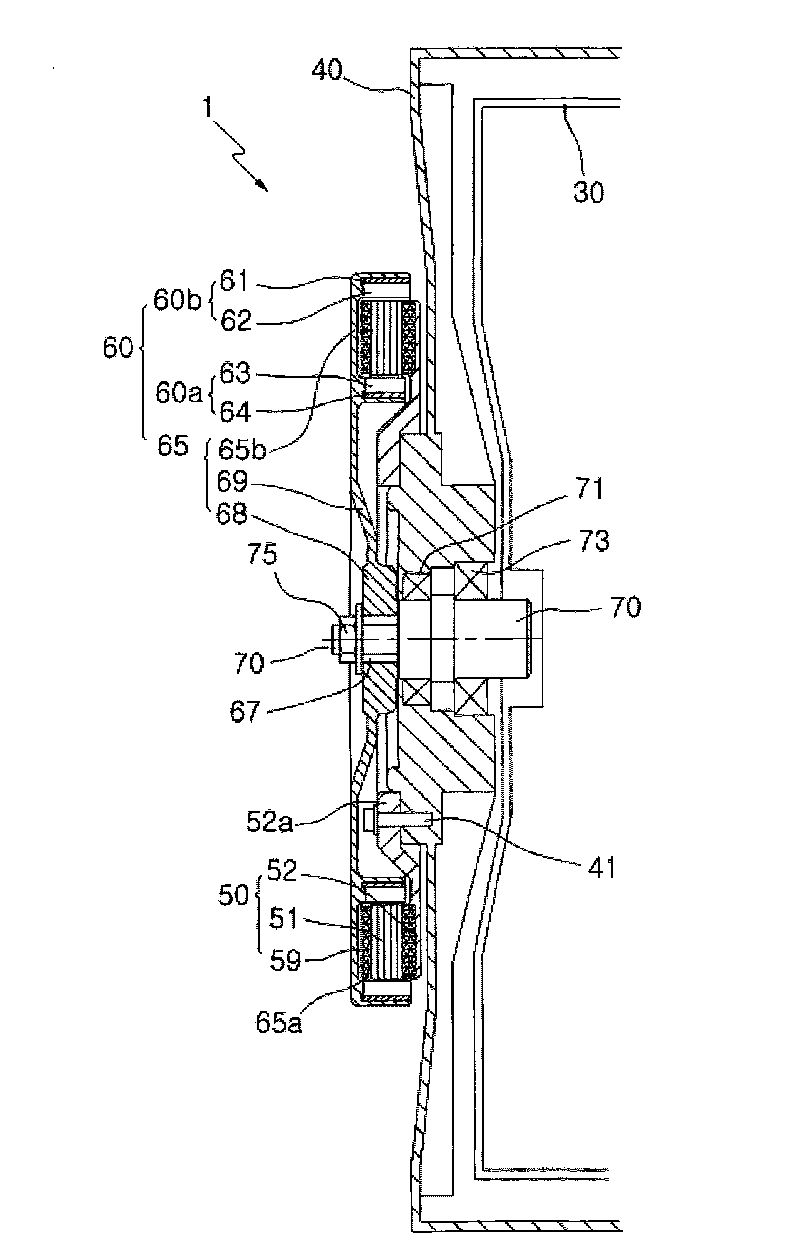

Slim type stator, slim type motor having the stator and direct drive apparatus for drum-washing machine

ActiveCN101764442AImprove assembly productivityReduce axial heightWindingsOther washing machinesBobbinCoupling

Provided is a slim type stator that is used to make a BLDC (Brushless Direct-Current) motor having a stator of a division core structure and a double rotor for use in a drum-washing machine, a slim type motor having the same, and a direct drive apparatus for use in the drum-washing machine. The stator includes: an annular division stator core assembly that is assembled in an annular form by winding a three-phase coil on a number of bobbins that are molded on respective outer circumferences of a number of division cores to thus surround a middle portion of each bobbin wherein each bobbin includes first and second flanges formed at one side of the bobbin and the other side thereof, respectively, and a coupling protrusion and a coupling groove that are formed at both side ends of the first flange that is disposed inward, and wherein the coupling protrusion and the coupling groove are mutually coupled between adjoining division stator bobbins; and a stator holder that molds the division stator core assembly that is formed in an annular form by winding the coils on the bobbins by an insert molding that uses a thermosetting resin, excepting inner and outer side surfaces of each division core of the division stator core assembly.

Owner:AMOTECH

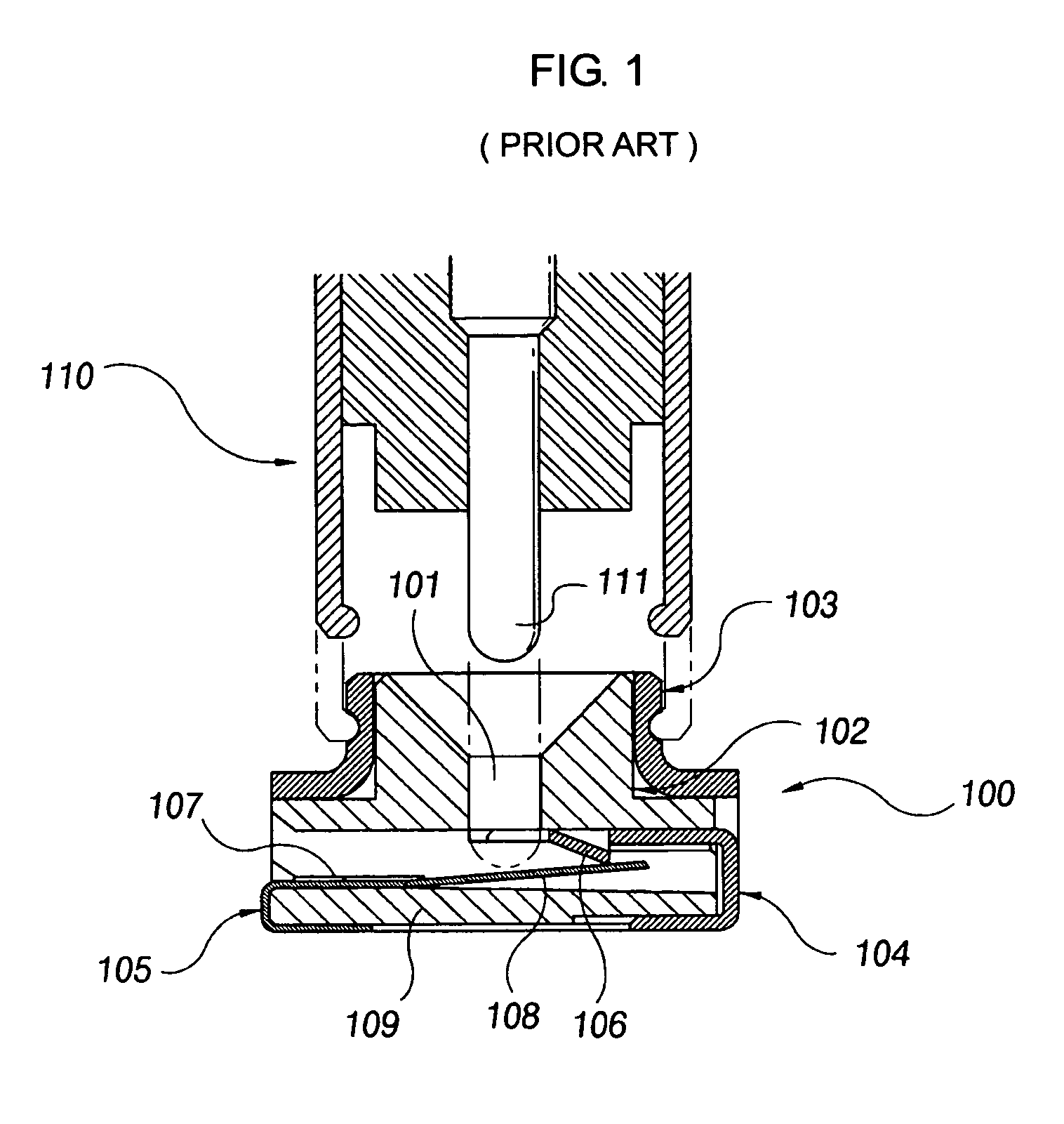

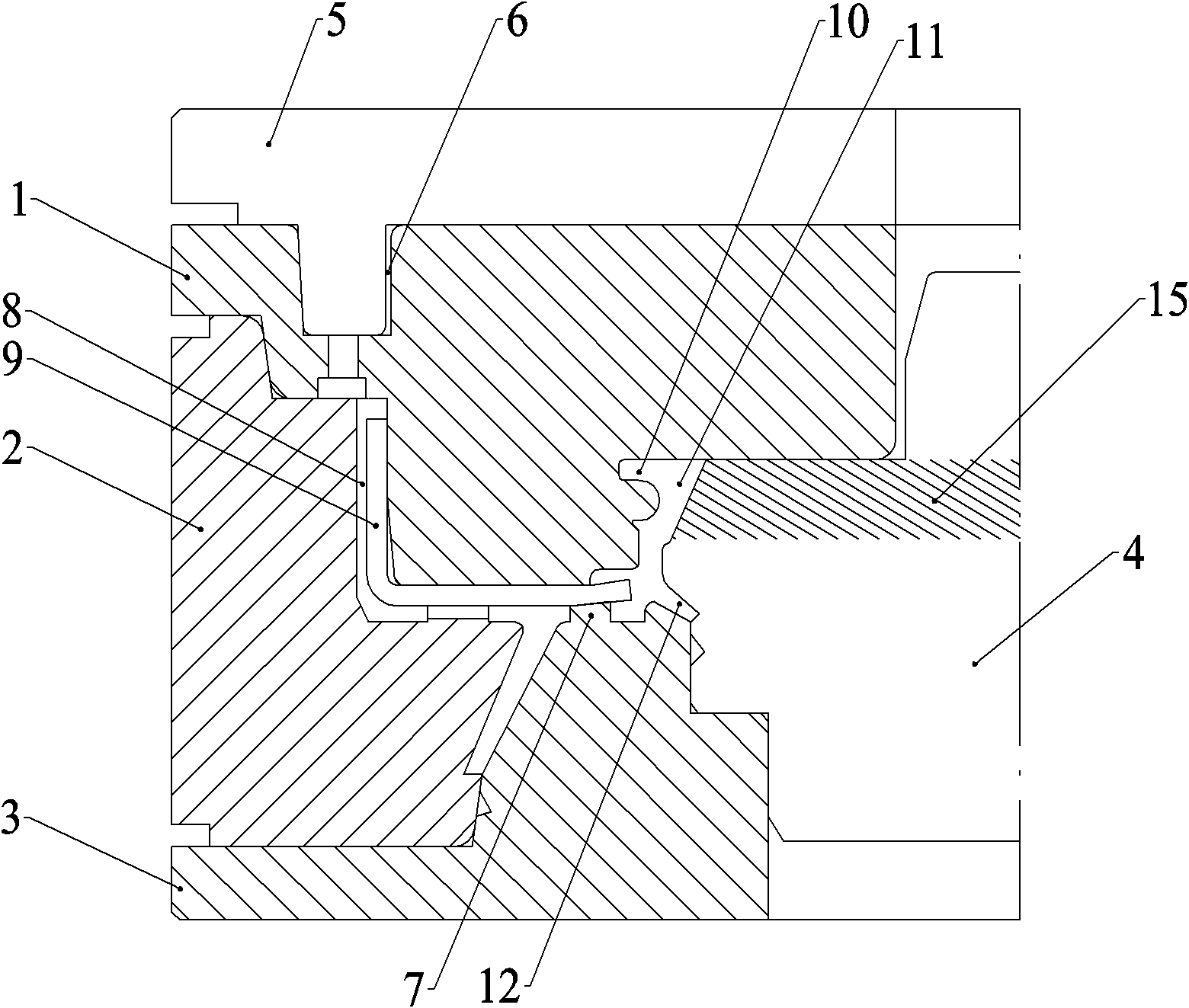

Coaxial connector with RF switch

InactiveCN1722542AAvoid it happening againGuaranteed stabilityTwo pole connectionsCoupling device detailsElectrical conductorRF switch

The present invention relates to coaxial connector with an RF switch. In particular, a housing 10 covered with an external conductor 17 is composed of upper and lower housings 11 and 12 . A fixed terminal 21 connected to an RF circuit is insert molded in the upper housing 11 , and a movable terminal 25 that is selectively brought into contact with the fixed terminal 21 is insert molded in the lower housing 12 . The movable terminal 25 comprises a fixed portion 26 fixed to the lower housing 12 ; a waist portion 27 extending upwardly from the fixed portion 26 at a first angle alpha1 and molded to the lower housing 12 ; and an elastic piece 28 bent from the tip end of the waist portion 27 at a second angle alpha2, extending into a space 15 of the housing, and being contact with the fixed terminal 21.

Owner:HTEC

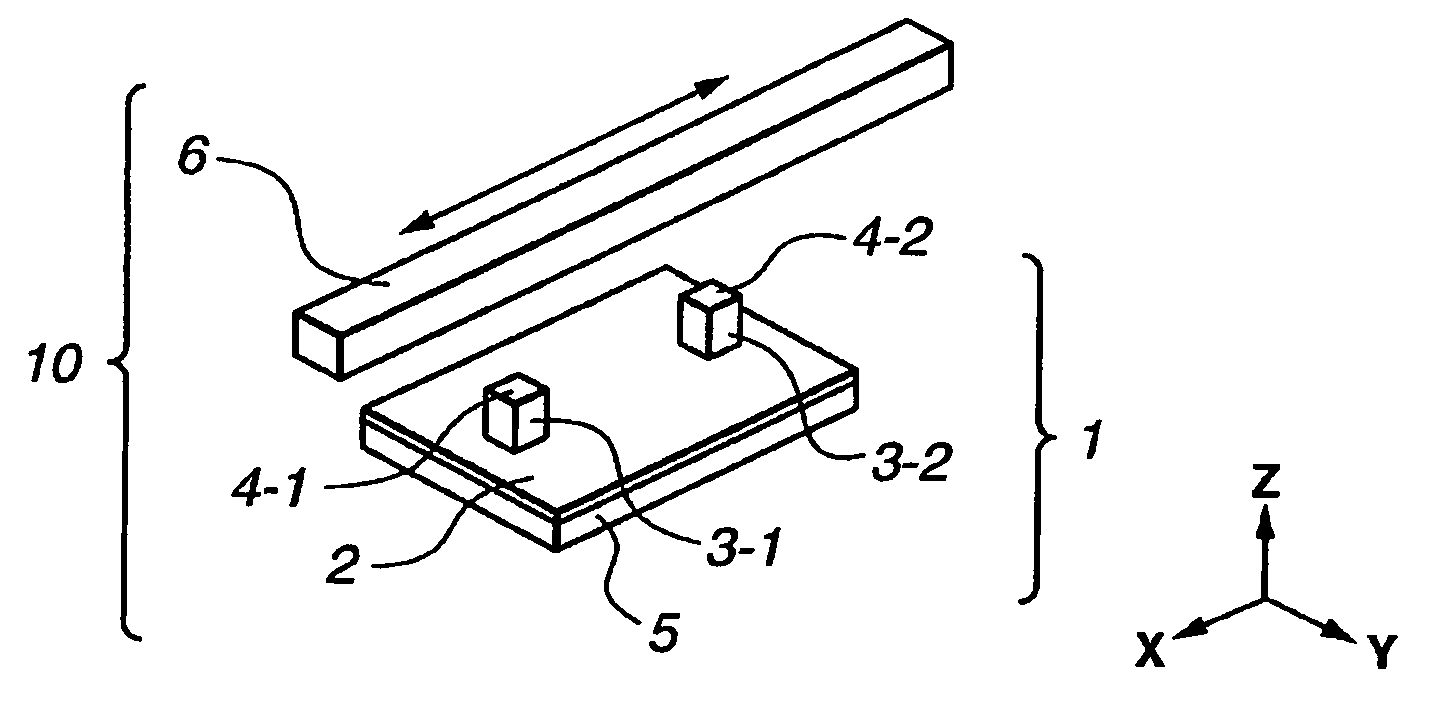

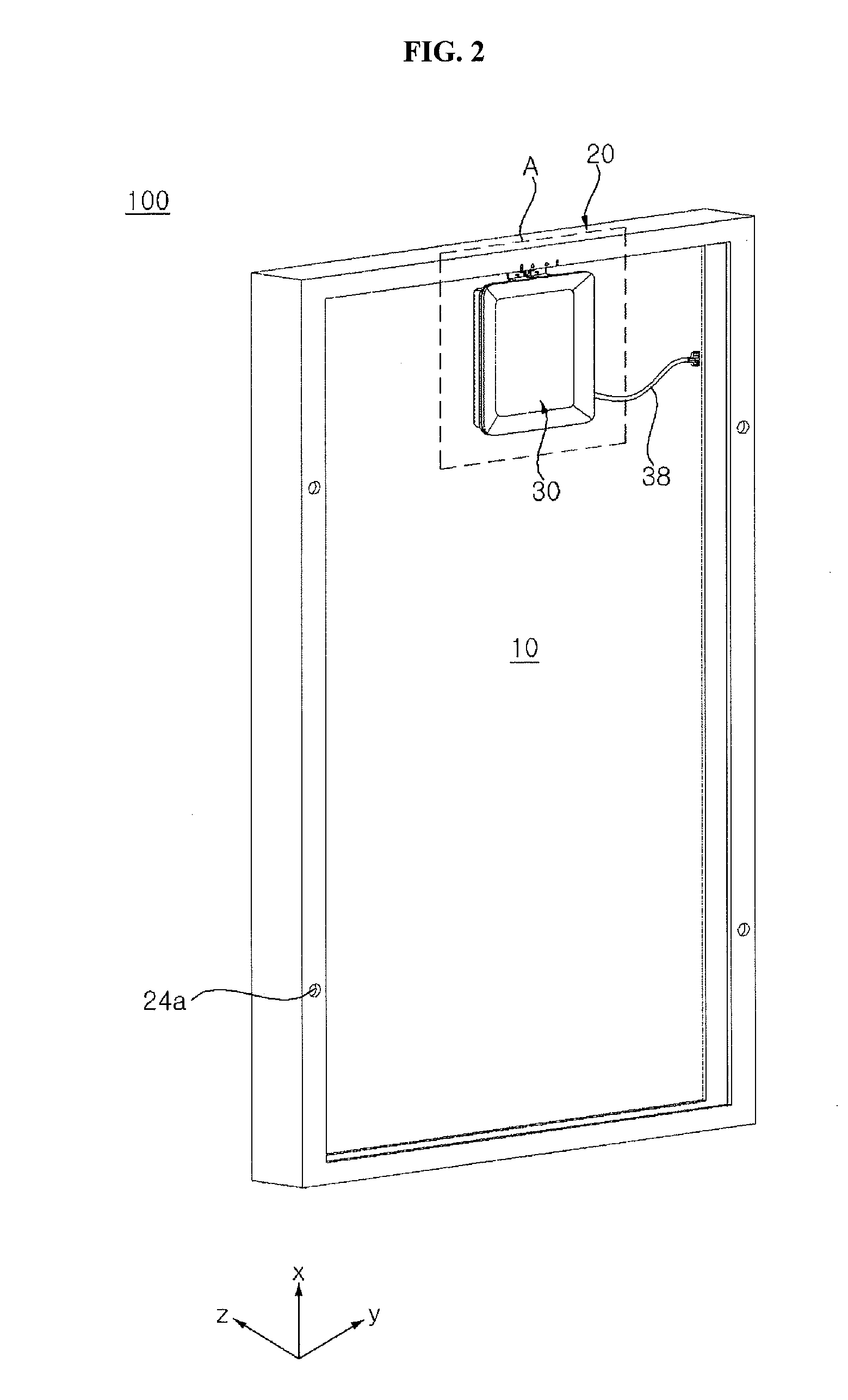

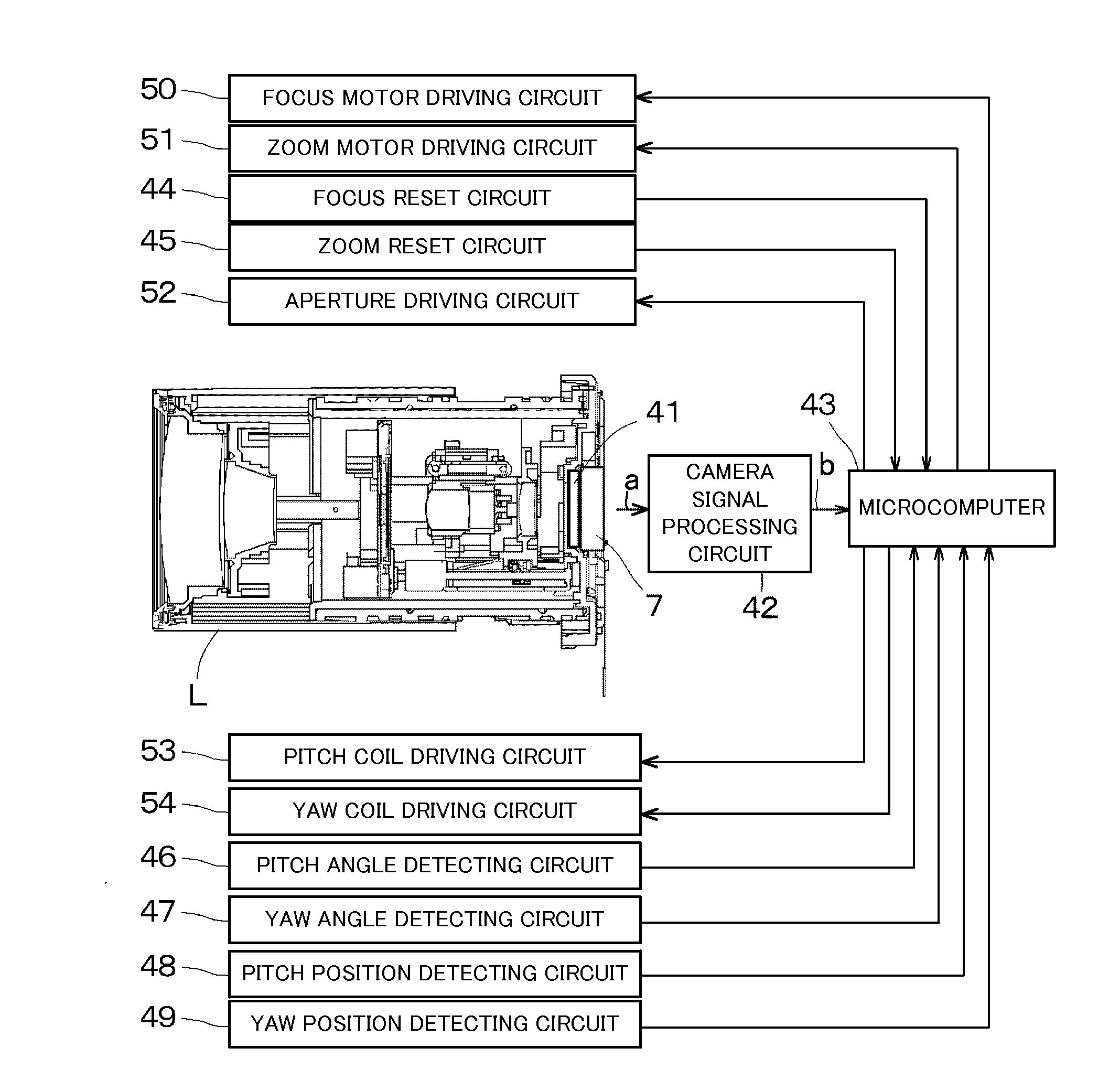

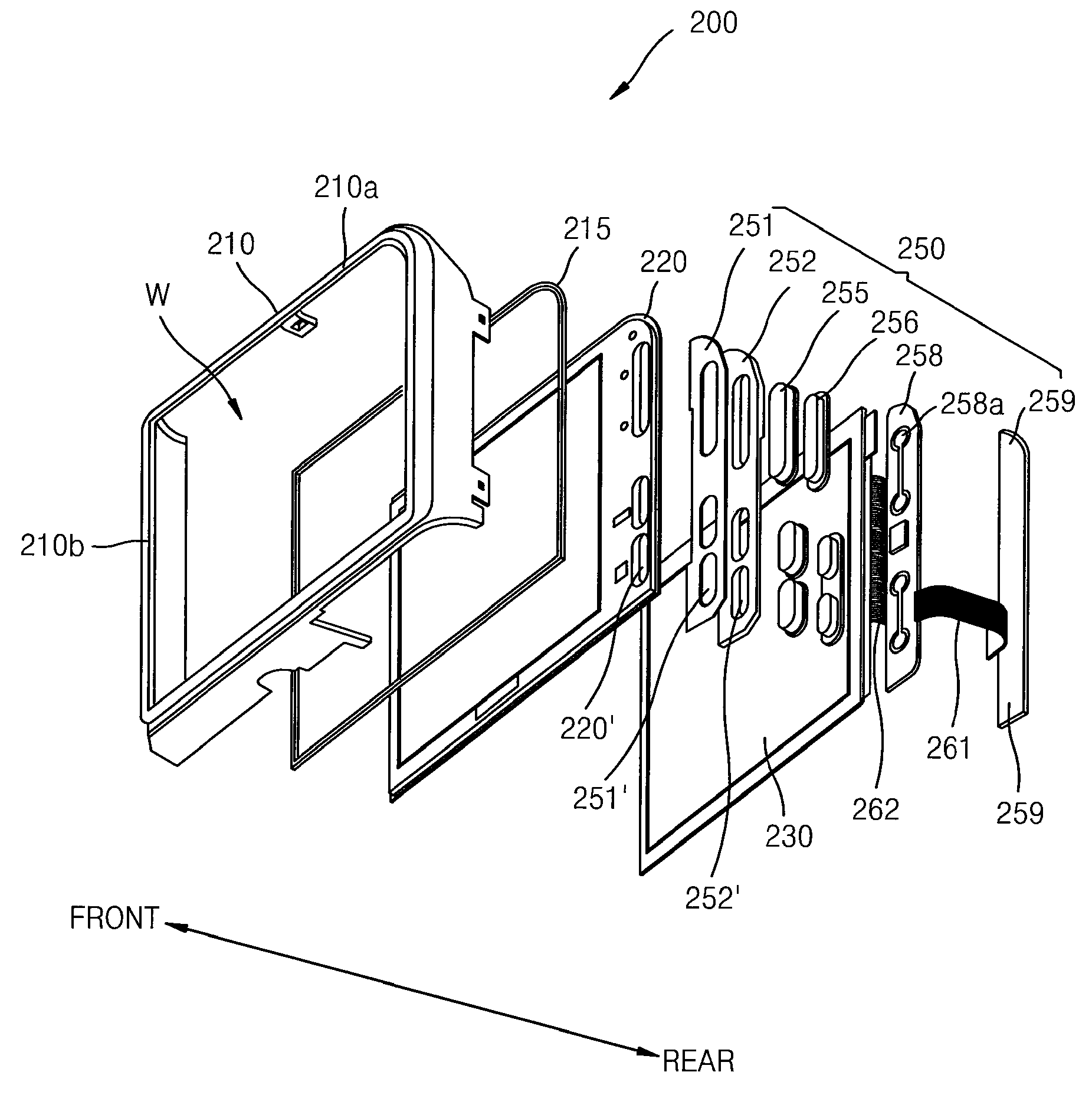

Image shake correction apparatus and image pickup apparatus

InactiveUS20100260493A1Improve assembly productivitySmall sizeCamera body detailsOptical elementsDriver/operatorOptical axis

A third group barrel 3 holding a third lens group L3 is controlled to be driven by drivers in yaw and pitch directions orthogonal to an optical axis, respectively. The Y magnet and the Y yoke of the driver in the yaw direction are fixed on the third group barrel 3, and a Y electromagnetic coil is disposed at a Y guide base 24 surrounding the third group barrel 3. As a driver in the pitch direction, a P magnet and P yoke 29 are fixed to the Y guide base 24, and a P electromagnetic coil is fixed to a P guide base at an opposed position. A Y guide bar 25 and a P guide bar 30 are overlapped with projection regions onto planes orthogonal to the optical axis of the Y electromagnetic coil and the Y magnet, and the P electromagnetic coil and the P magnet, respectively.

Owner:CANON KK

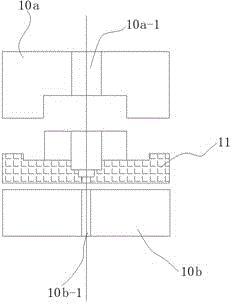

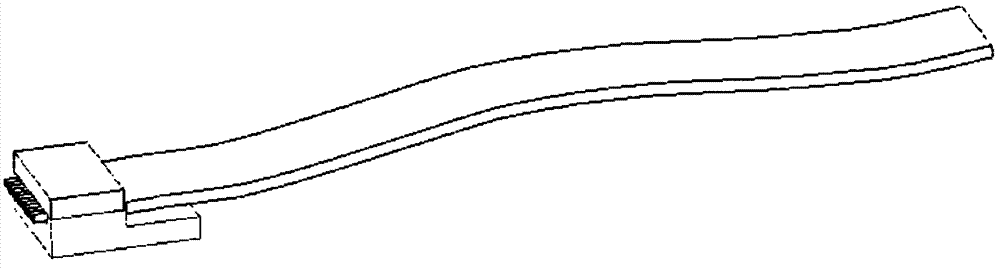

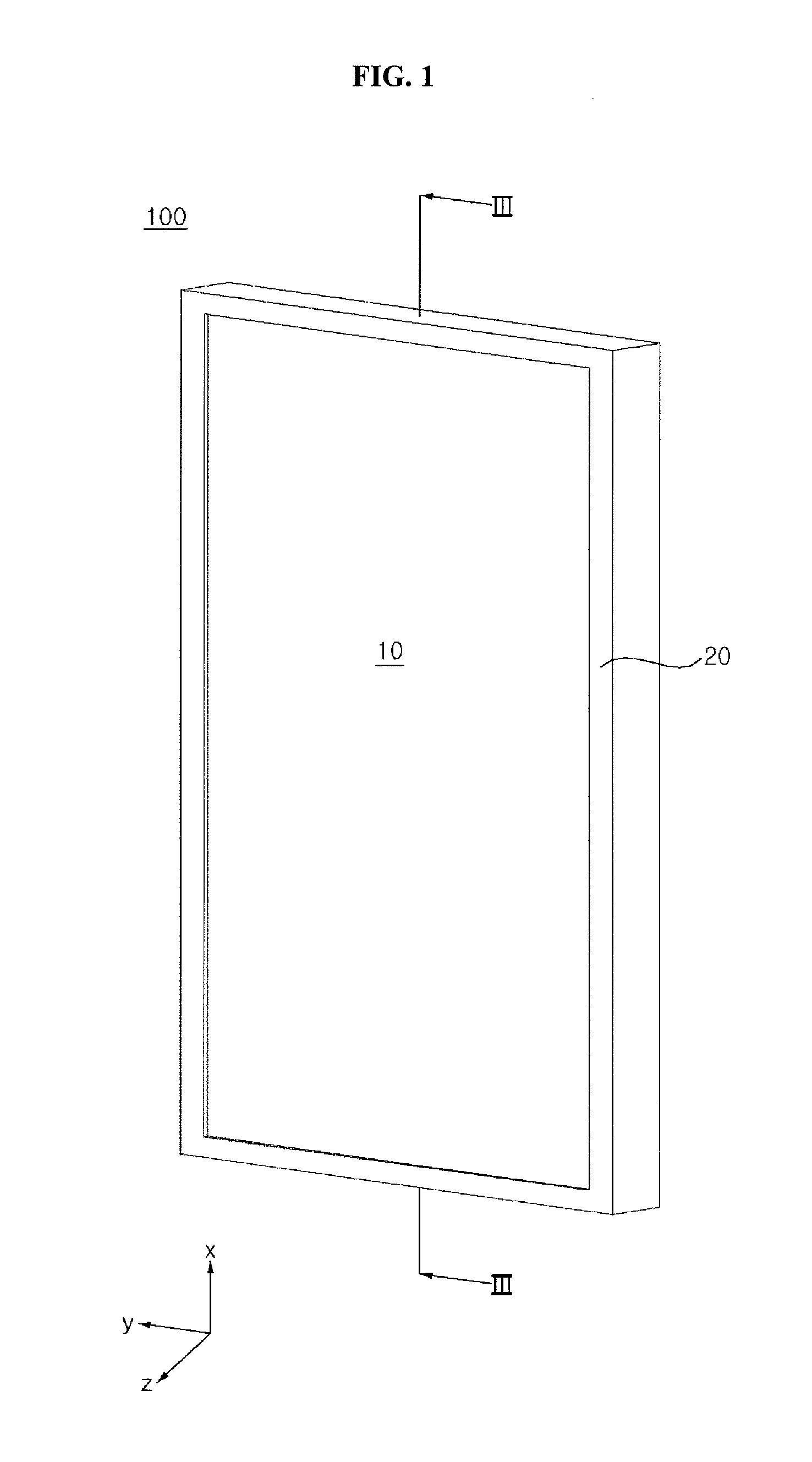

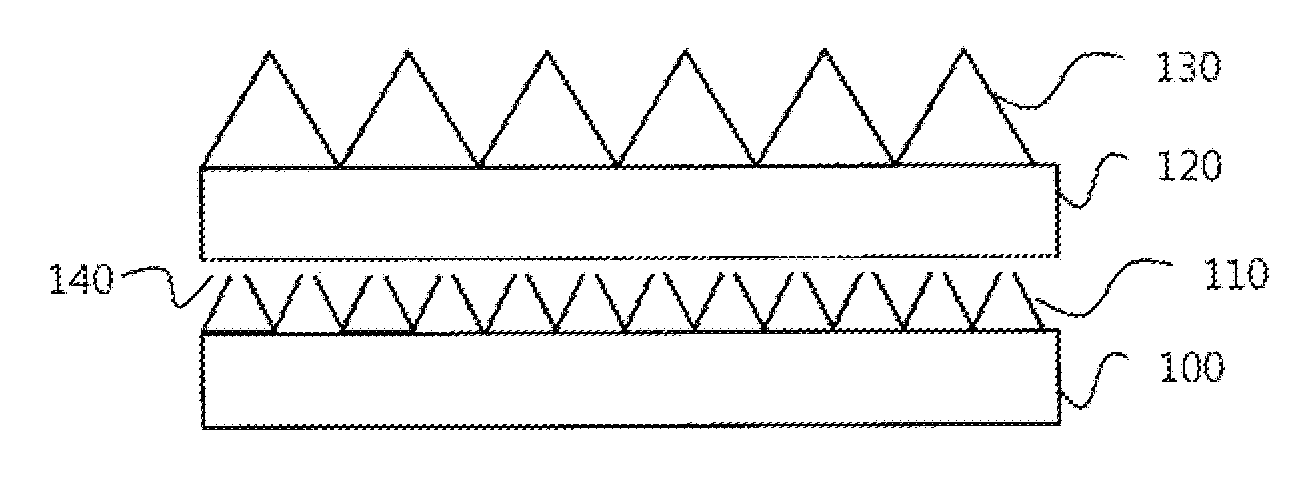

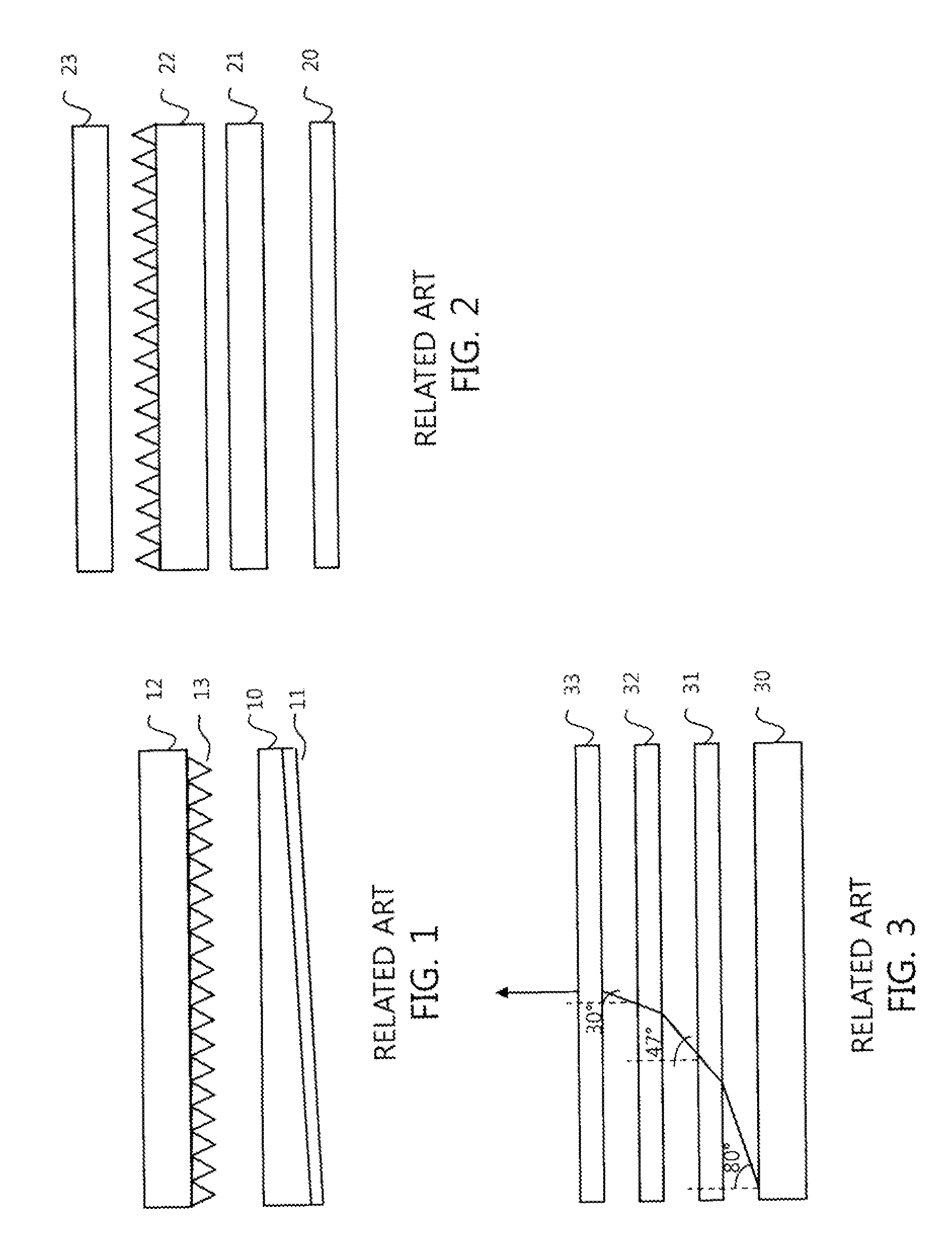

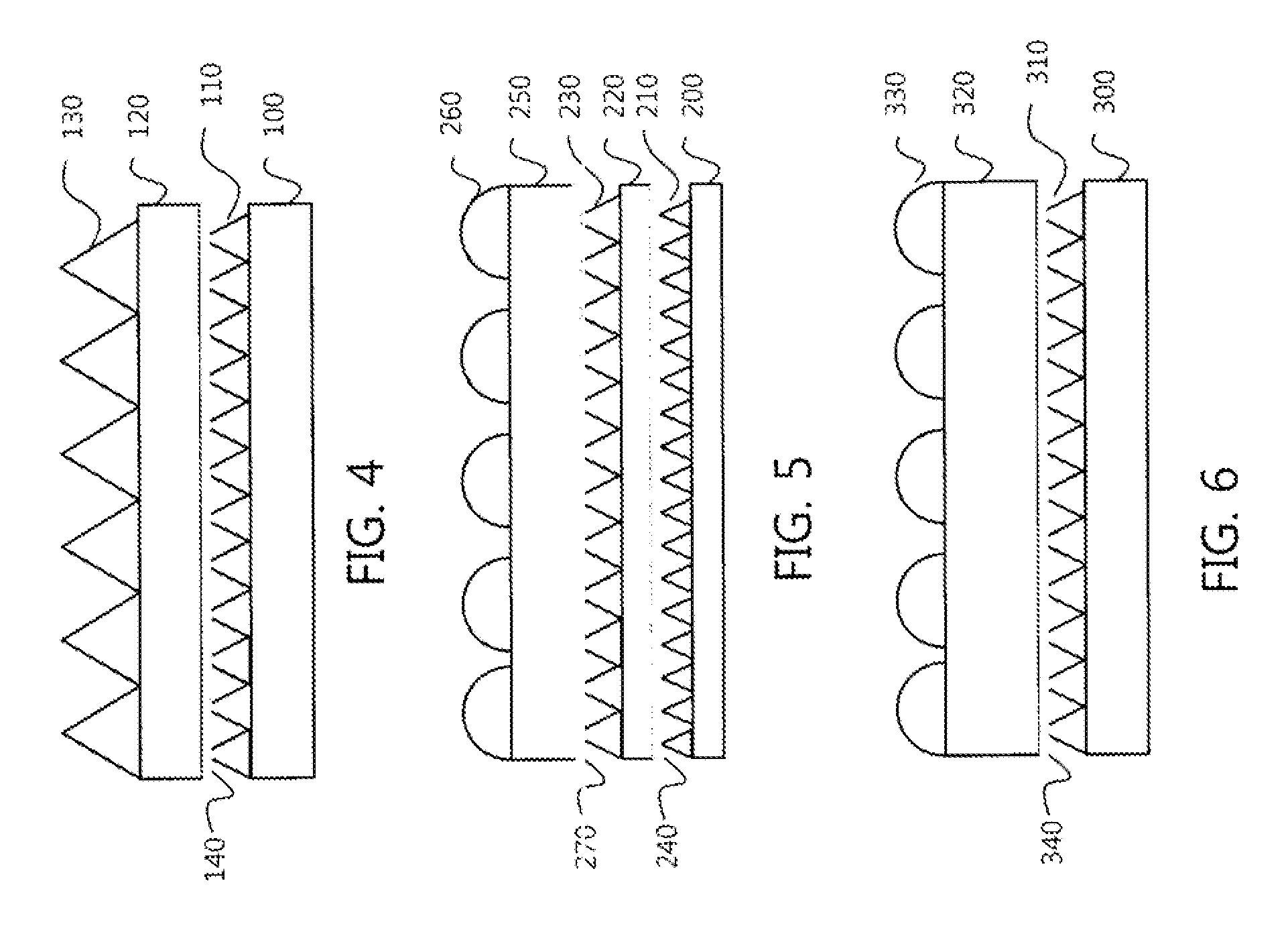

Optical film and manufacturing method thereof, liquid cristal display apparatus using the optical film

ActiveUS20130010234A1Improve assembly productivityReduce manufacturing costPrismsLamination ancillary operationsLiquid-crystal displayLight guide

An optical sheet having a single sheet structure for an edge-lighting backlight unit using a printless light guide plate, a method of manufacturing the same, and a liquid crystal display apparatus using the same are provided. The optical sheet having a single sheet structure includes a first prism sheet having a prism pattern formed on the upper surface thereof, and a second prism sheet having a prism pattern formed on the upper surface thereof. Further, prism ridges of the first prism sheet are attached to the bottom surface of the second prism sheet by means of an adhesive so that the prism pattern of the first prism sheet and the prism pattern of the second prism sheet are directed in the same direction.

Owner:GLOTEC

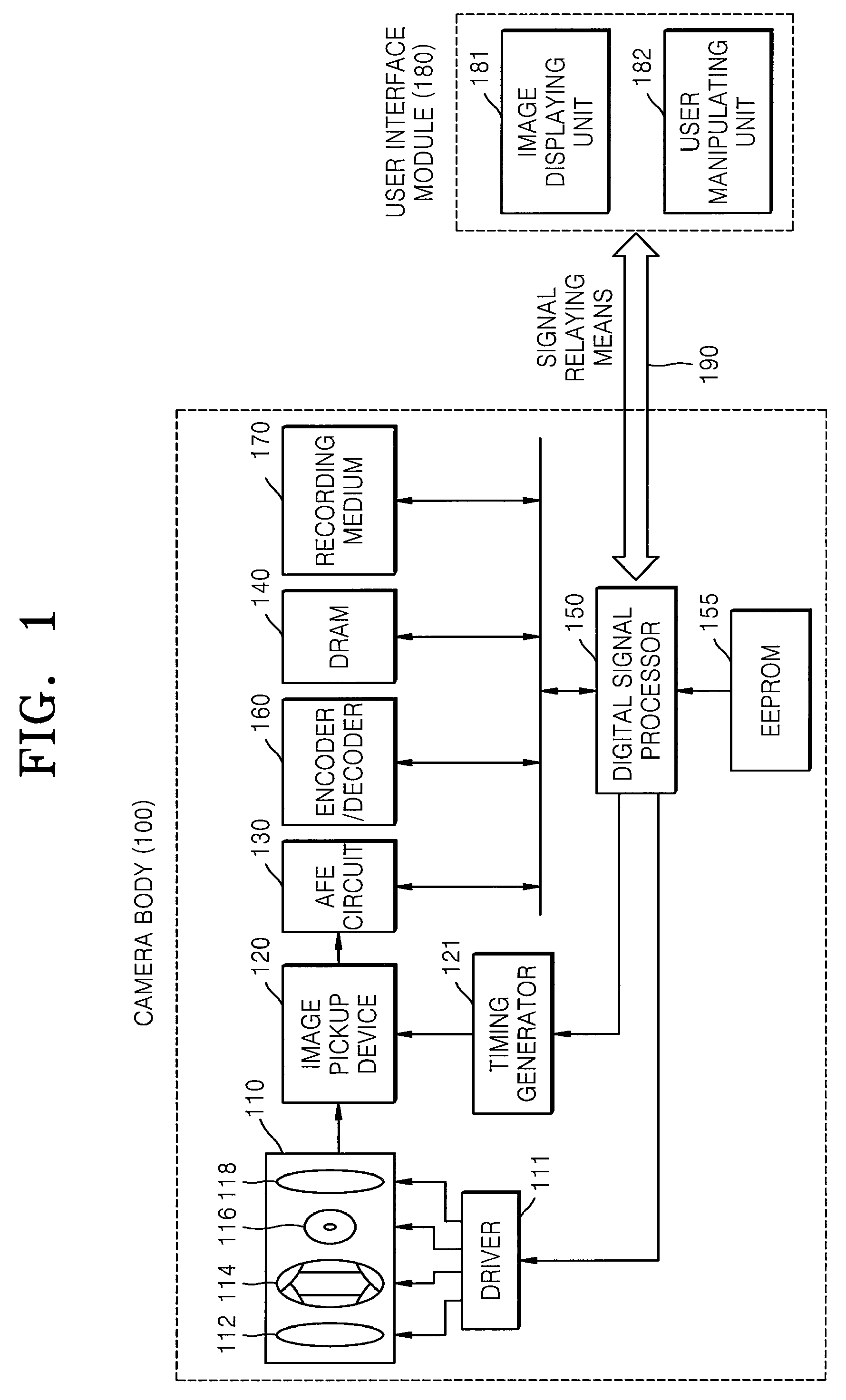

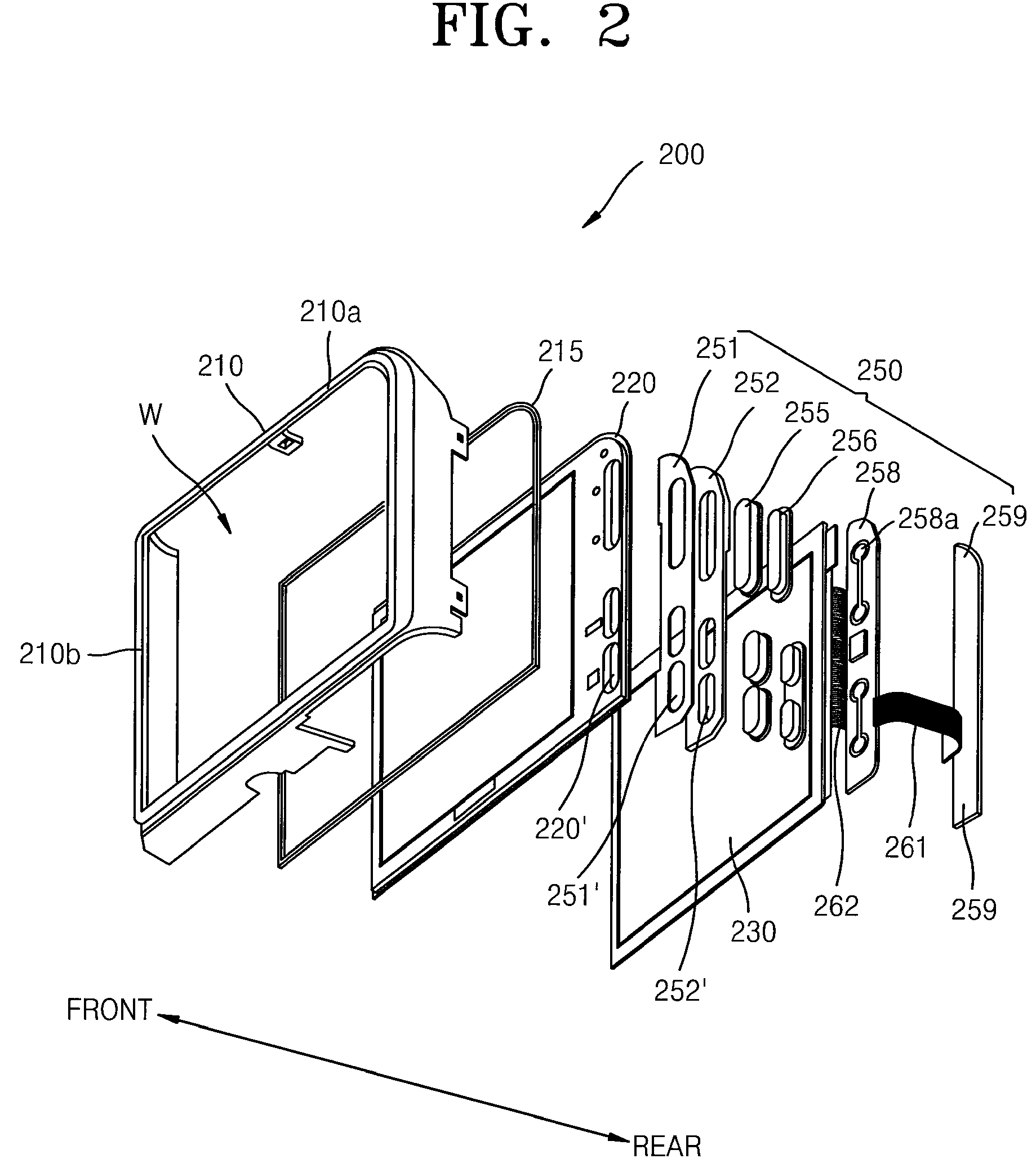

User interface module for digital camera and digital camera including the same

ActiveUS8368805B2Improve assembly productivityImprove maintainabilityTelevision system detailsColor television detailsComputer graphics (images)Projection image

Owner:SAMSUNG ELECTRONICS CO LTD

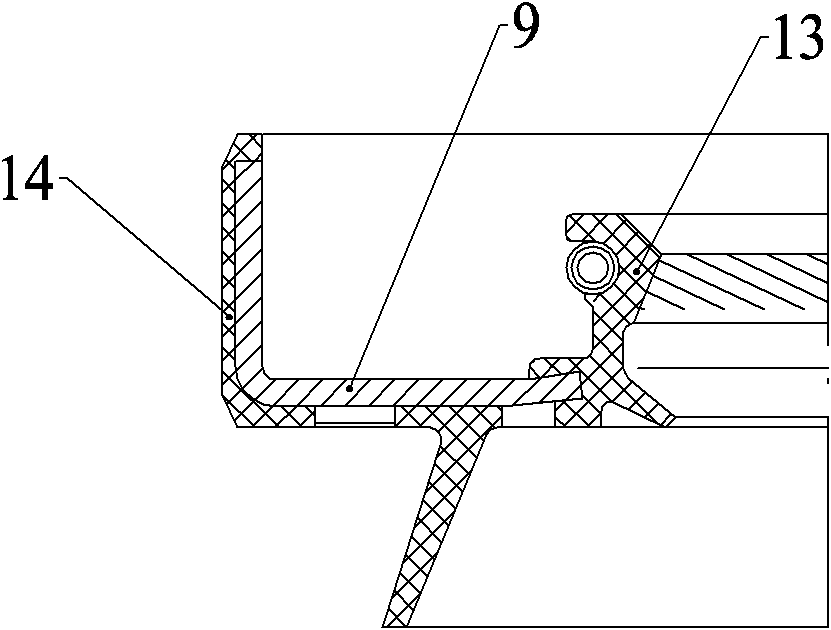

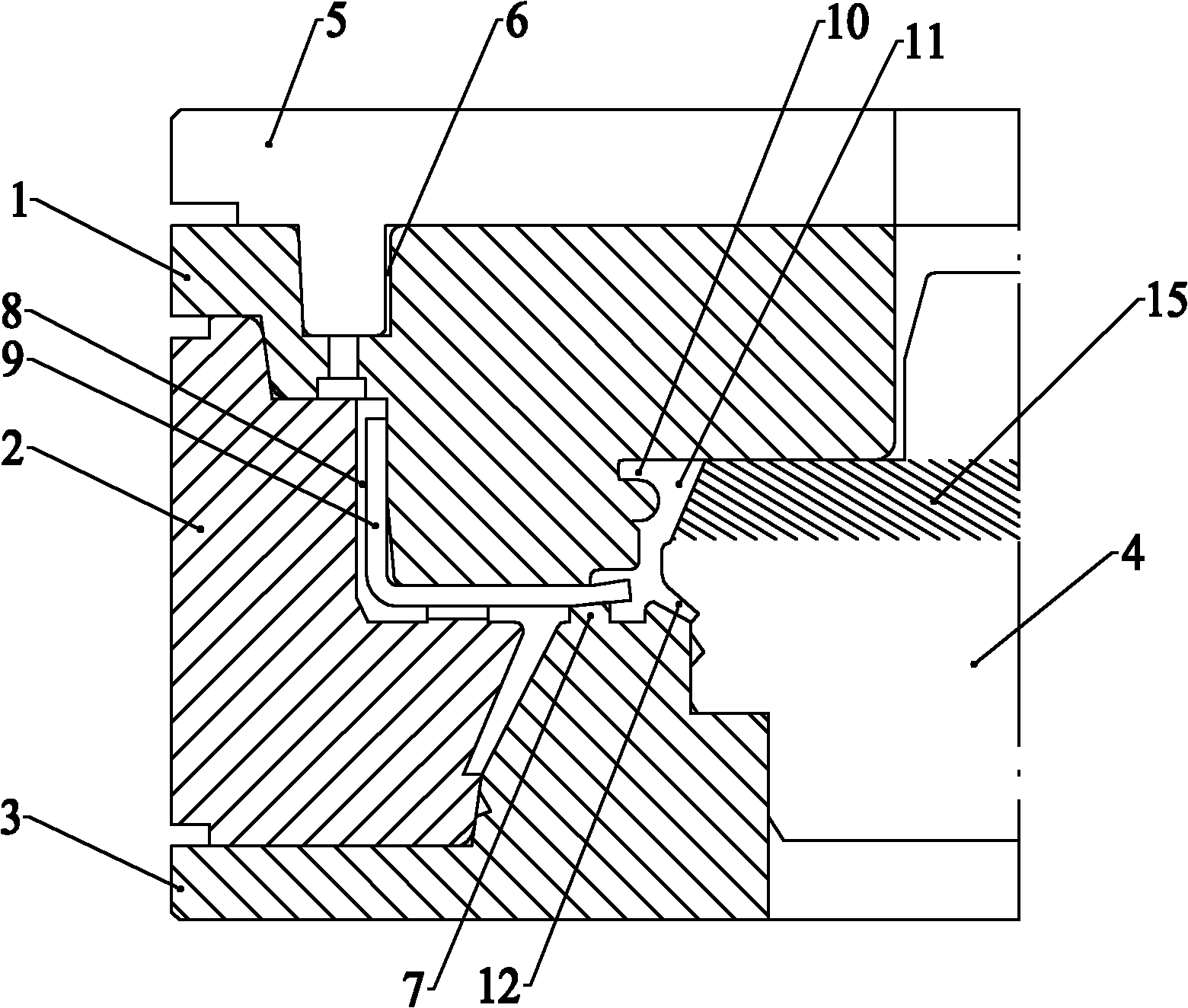

Double-rubber combined oil seal forming die and forming method thereof

InactiveCN102107494AImprove assembly productivityReduce leakageDomestic articlesVulcanizationEngineering

The invention relates to a double rubber combined oil seal forming die and a forming method thereof. The double rubber combined oil seal forming die comprises an upper die, a middle die, a lower die, a die core and a rubber pressurized die, wherein, the lower die, the upper die and the middle die are combined so as to form a first rubber cavity in an encircling manner, and the upper die and the die core supported by the lower die are combined so as to form a second rubber cavity in an encircling manner; an oil seal support framework arranged in the first rubber cavity is connected with a rubber sealign rib of the lower die in a supporting manner; the second rubber cavity is shaped in advance and then is arranged inside the second rubber cavity formed on the upper inclined surface of the die core; and after first rubbers are filled in a rubber injection cavity of the upper die the first rubbers are injected to the first rubber cavity by the rubber pressurized die through the rubber injection cavity, a first rubber body is processed through vulcanization shaping and secondary vulcanization according to a conventional rubber vulcanization shaping method. The combined oil seal forming die with the double rubbers and the forming method thereof have the advantages as follows: the operation of the die forming technology is simple, the finished product ratio is high, the oil seal structure that is formed in an injection compressing manner is more compact, and the service life of the oil seal can be prolonged.

Owner:广东京汕密封件有限公司

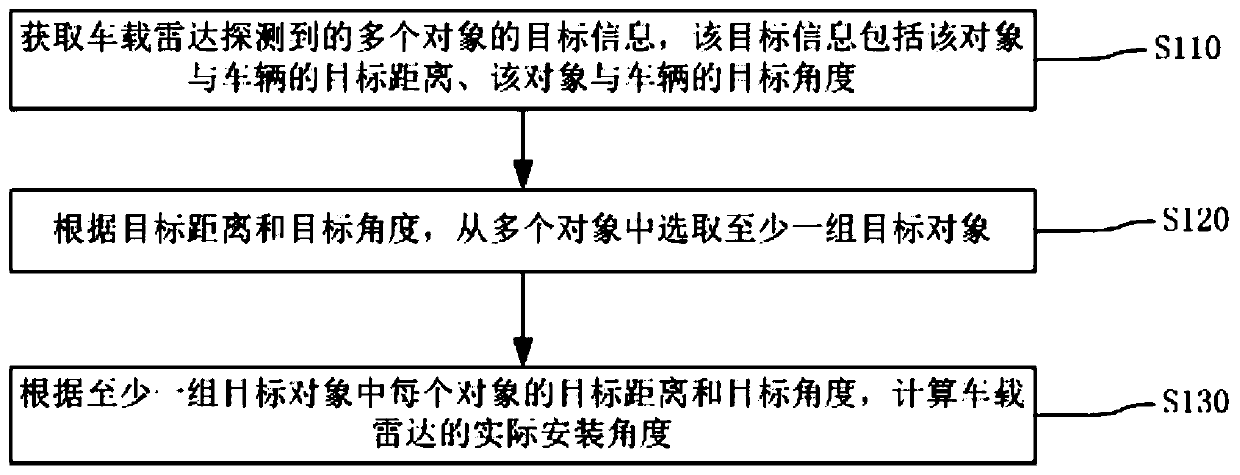

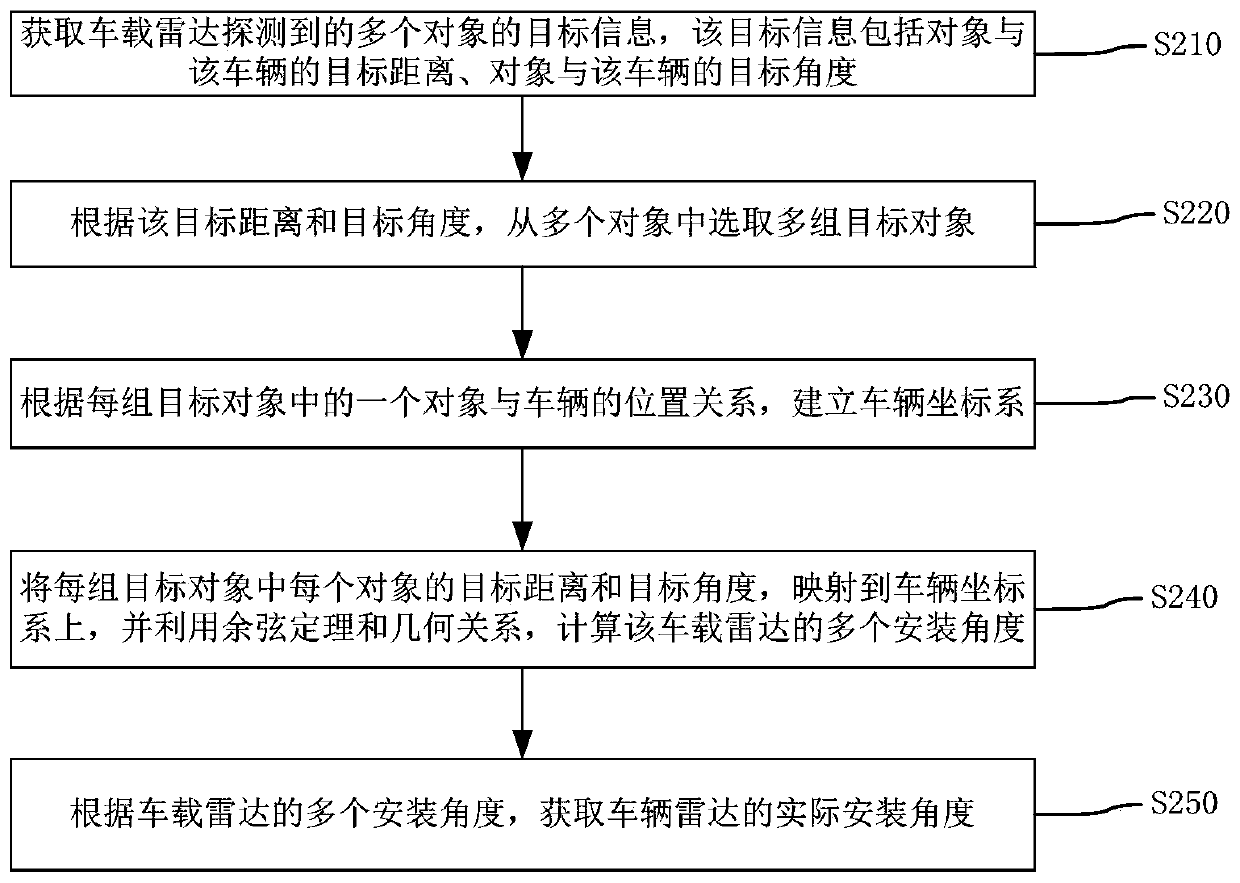

Method and device for calibrating installation angle of vehicle-mounted radar and related equipment

PendingCN111521979AImprove assembly productivityReduce manufacturing process stepsWave based measurement systemsIn vehicleEngineering

The invention discloses a method and device for calibrating an installation angle of a vehicle-mounted radar, and related equipment. The method for calibrating the installation angle of the vehicle-mounted radar comprises the following steps of acquiring the target information of a plurality of objects detected by the vehicle-mounted radar, wherein the target information comprises a target distance between the object and the vehicle and a target angle between the object and the vehicle; selecting at least one group of target objects from a plurality of objects according to the target distanceand the target angle, each group of target objects including two objects satisfying a preset condition; and calculating an actual installation angle of the vehicle-mounted radar according to the target distance and the target angle of each object in the at least one group of target objects. The method is advantaged in that dynamic calibration of the radar installation angle is achieved when the vehicle is subjected to road testing, so steps of the whole vehicle manufacturing process of the vehicle can be reduced, the time and labor can be effectively saved, and vehicle assembly production efficiency is improved.

Owner:BYD CO LTD

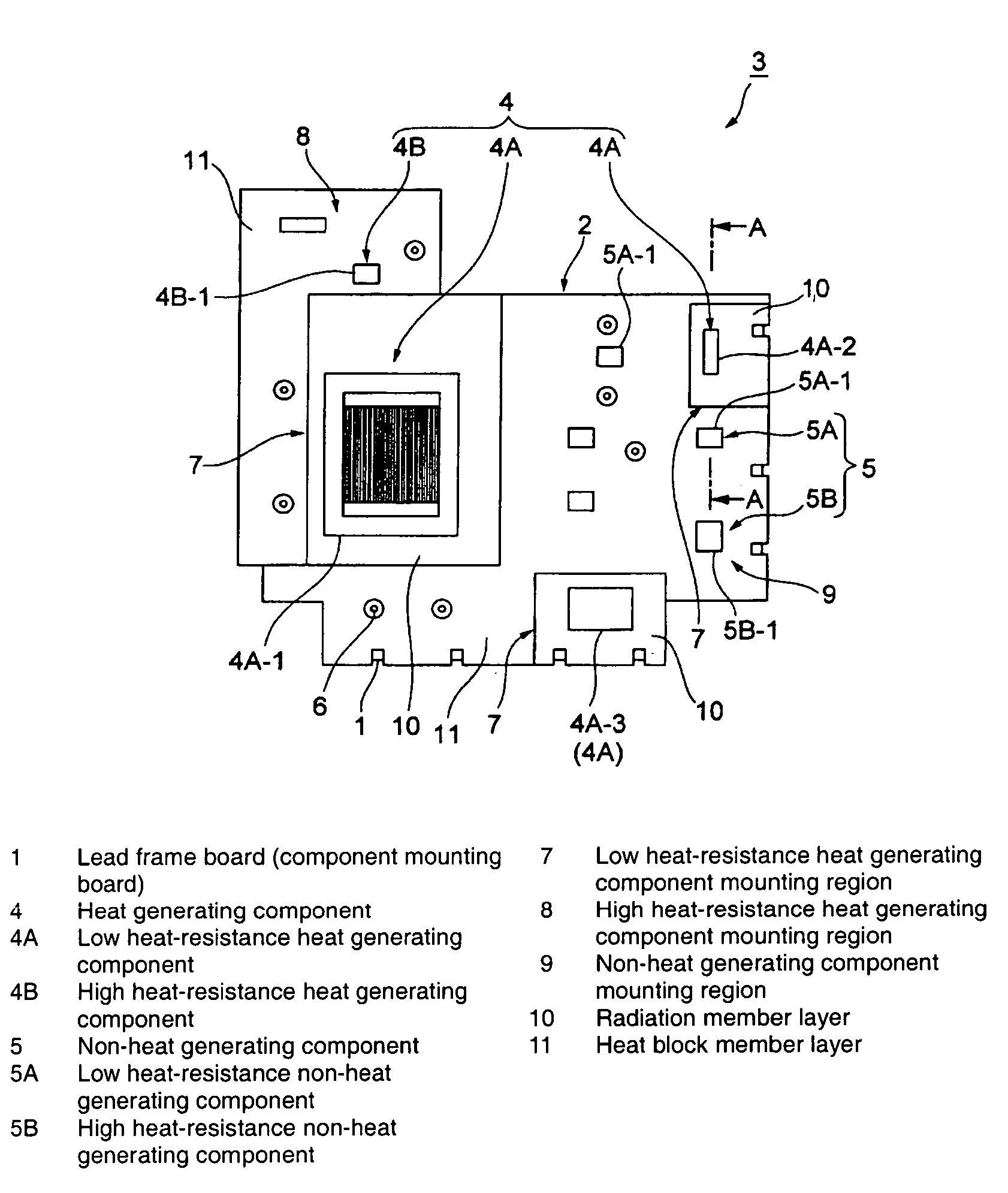

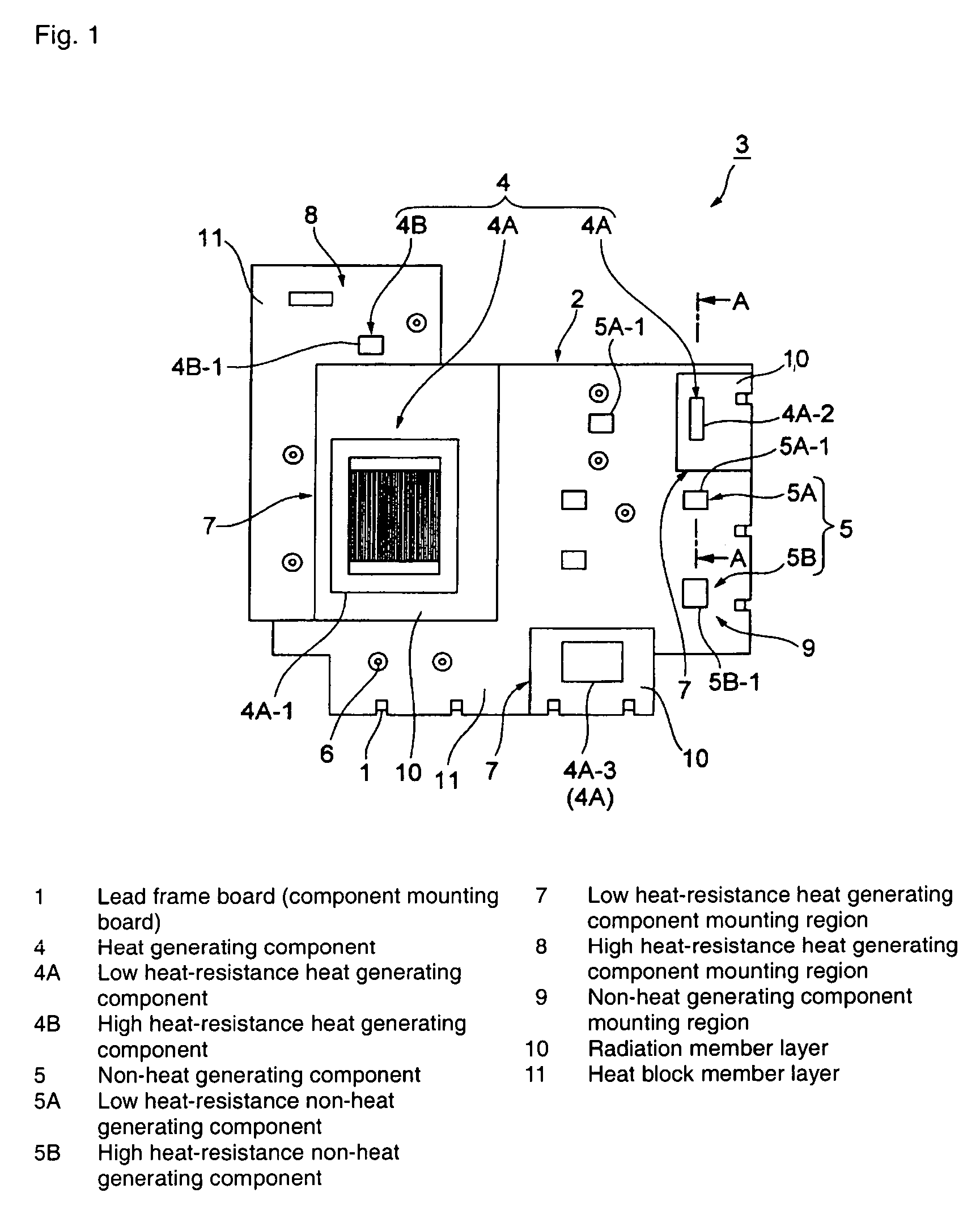

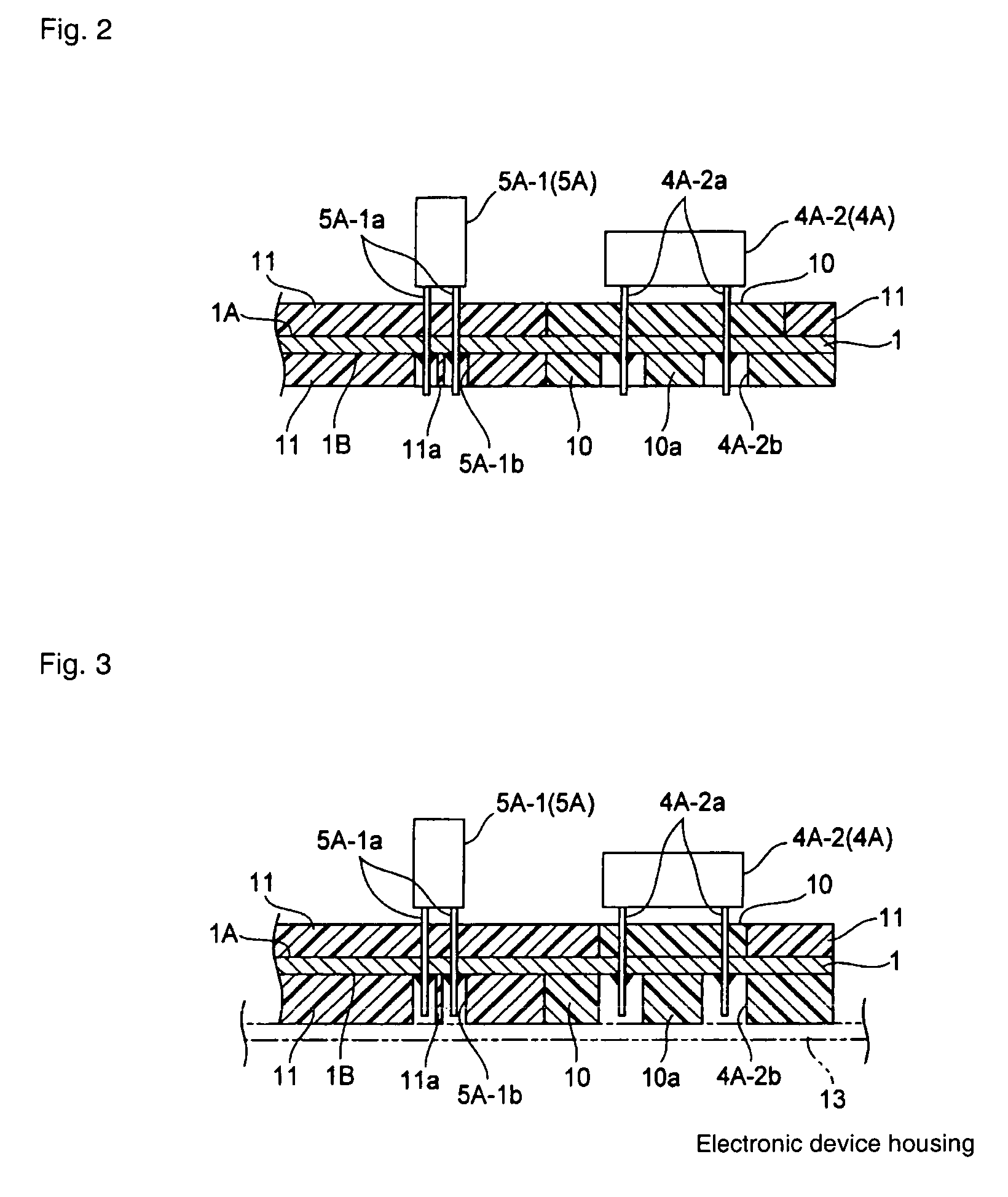

Component mounting board structure and production method thereof

InactiveUS7663891B2Low component requirementsImprove heat resistance3D rigid printed circuitsPrinted circuit aspectsHeat resistanceEngineering

In a lead frame board, while a heat radiation wall member formed by a resin having a relatively high thermal conductivity is provided in a low heat-resistance heat generating component mounting region where a low heat-resistance heat generating component is mounted, heat block wall members formed by resins having relatively low thermal conductivities are provided in a high heat-resistance heat generating component mounting region where a high heat-resistance heat generating component is mounted and in a non-heat generating component mounting region where a non-heat generating component is mounted. Thus, heat block is performed between the low heat-resistance heat generating component mounting region and the high heat-resistance heat generating component mounting region and non-heat generating component mounting region, and a heat radiation function is enhanced in the low heat-resistance heat generating component.

Owner:ORMON CORP

Lock cylinder cover assembling machine

InactiveCN104668951AImprove pass rateImprove assembly productivityAssembly machinesEngineeringManipulator

The invention discloses a lock cylinder cover assembling machine which comprises rotary disc type assembling table, a first feeding device, a first mechanical arm, a first detection sensor, a second feeding device, a second mechanical arm, a second detection sensor, a third feeding device, a pin shaft assembling device, a third detection sensor, a third mechanical arm, a fourth mechanical arm, a fourth feeding device, a first transit detecting calibration device, a fifth mechanical arm, a fourth detection sensor, a fifth feeding device, a second transit detecting calibration device, a sixth mechanical arm, a pressure cylinder device, a pressure sensor detection device and a seventh mechanical arm, and the third mechanical arm is arranged between the fifth mechanical arm and the fourth detection sensor. The lock cylinder door assembling machine has the advantages that covers, torsional springs, pin shafts, lock cylinder bodies and surface covers can be assembled into qualified finished lock cylinders fully automatically, assembly production efficiency is high, and the yield of the finished lock cylinders is high.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Airbag mounting assembly for vehicles

ActiveUS20110115200A1Easy constructionImprove productivityPedestrian/occupant safety arrangementSuperstructure subunitsEngineeringAirbag

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com