Patents

Literature

194results about How to "Reduce axial height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

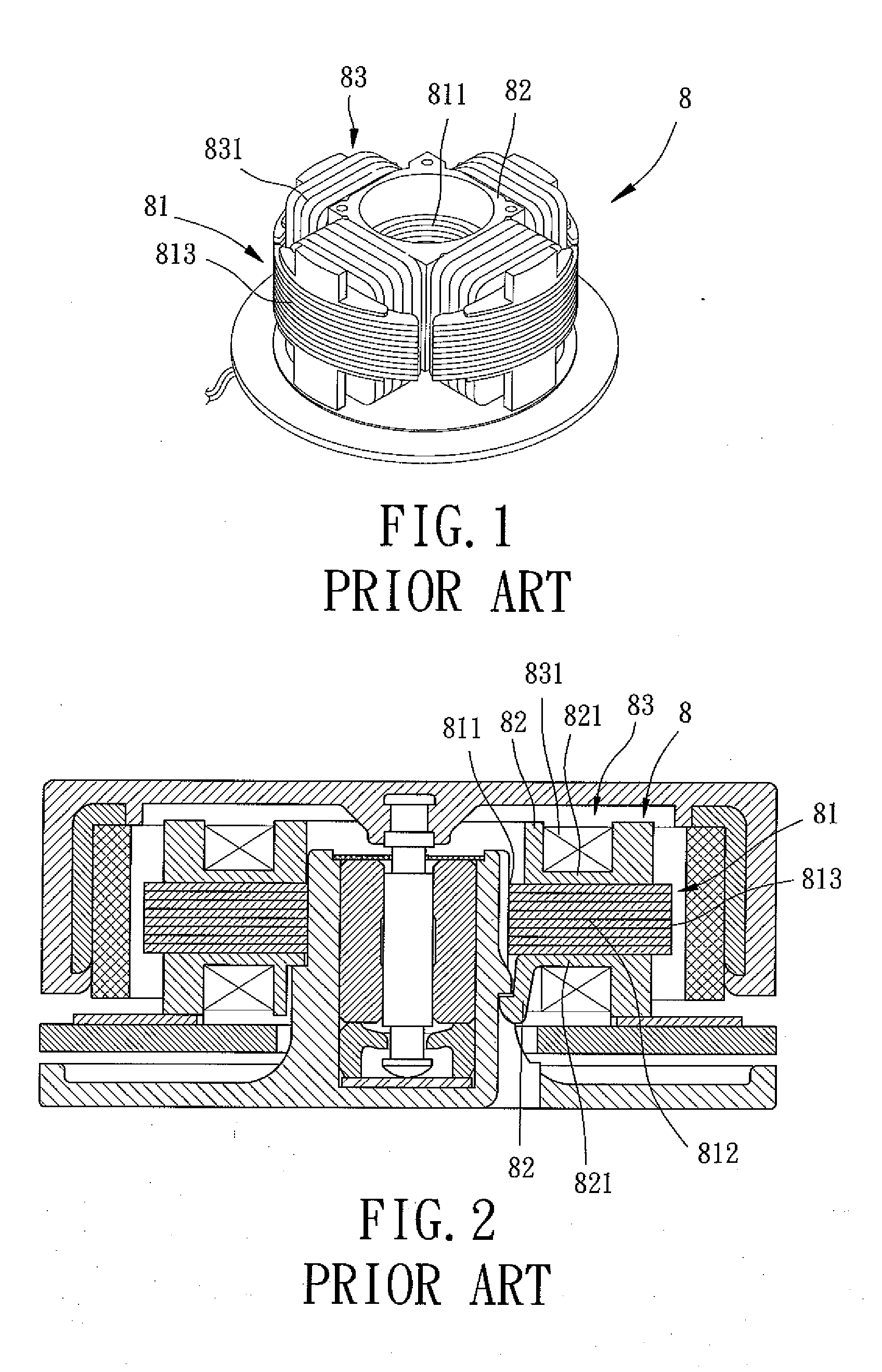

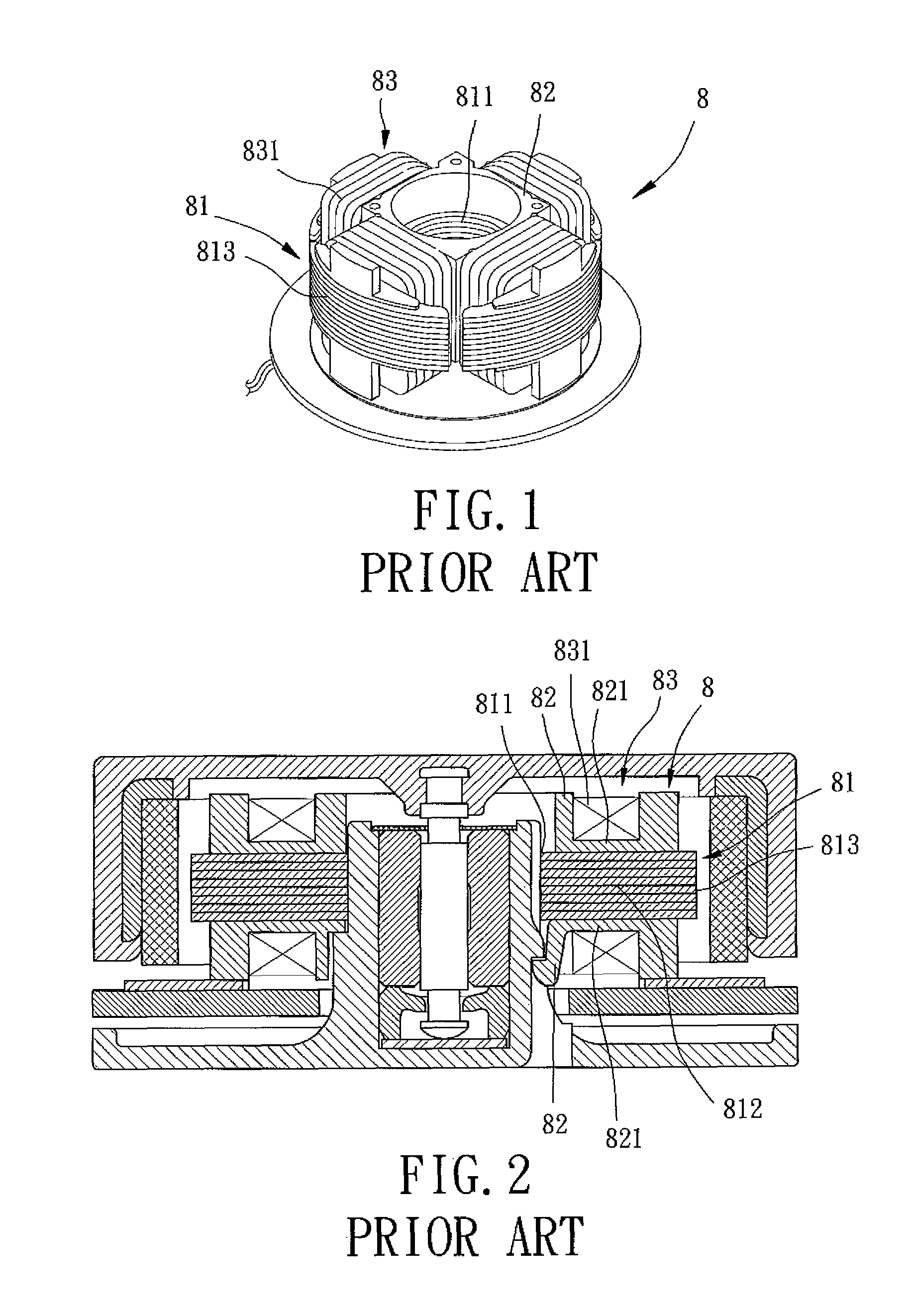

Motor

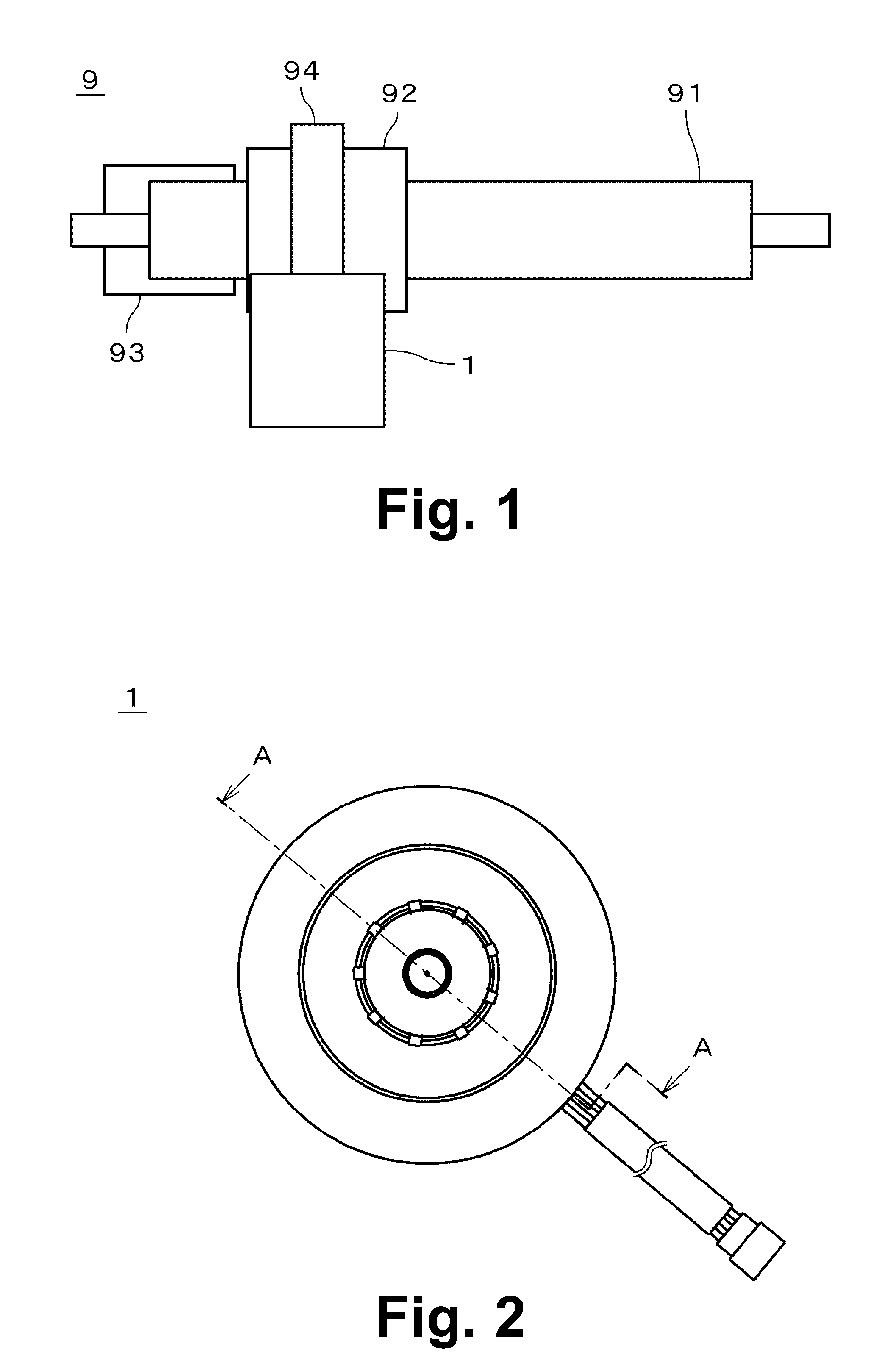

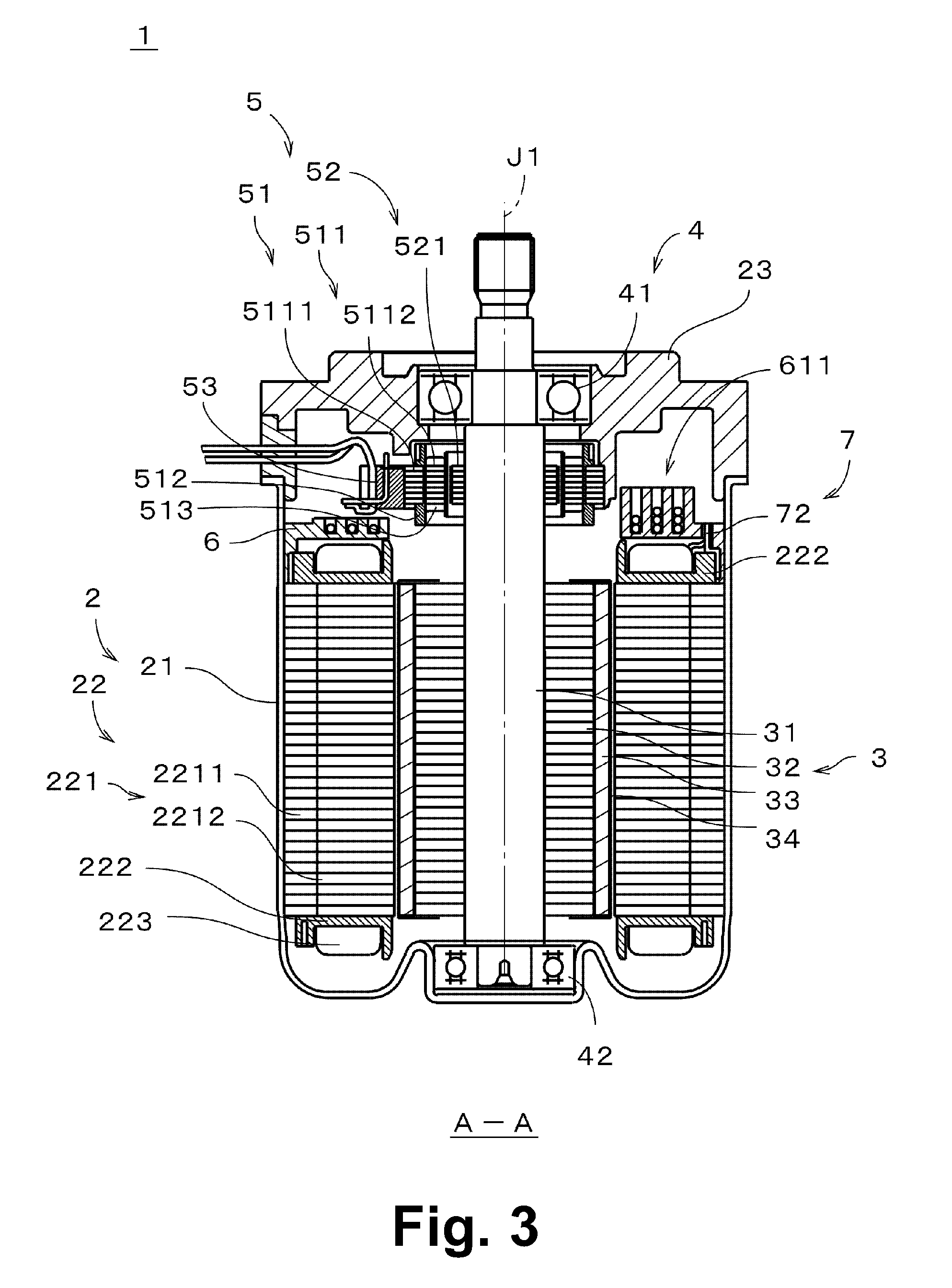

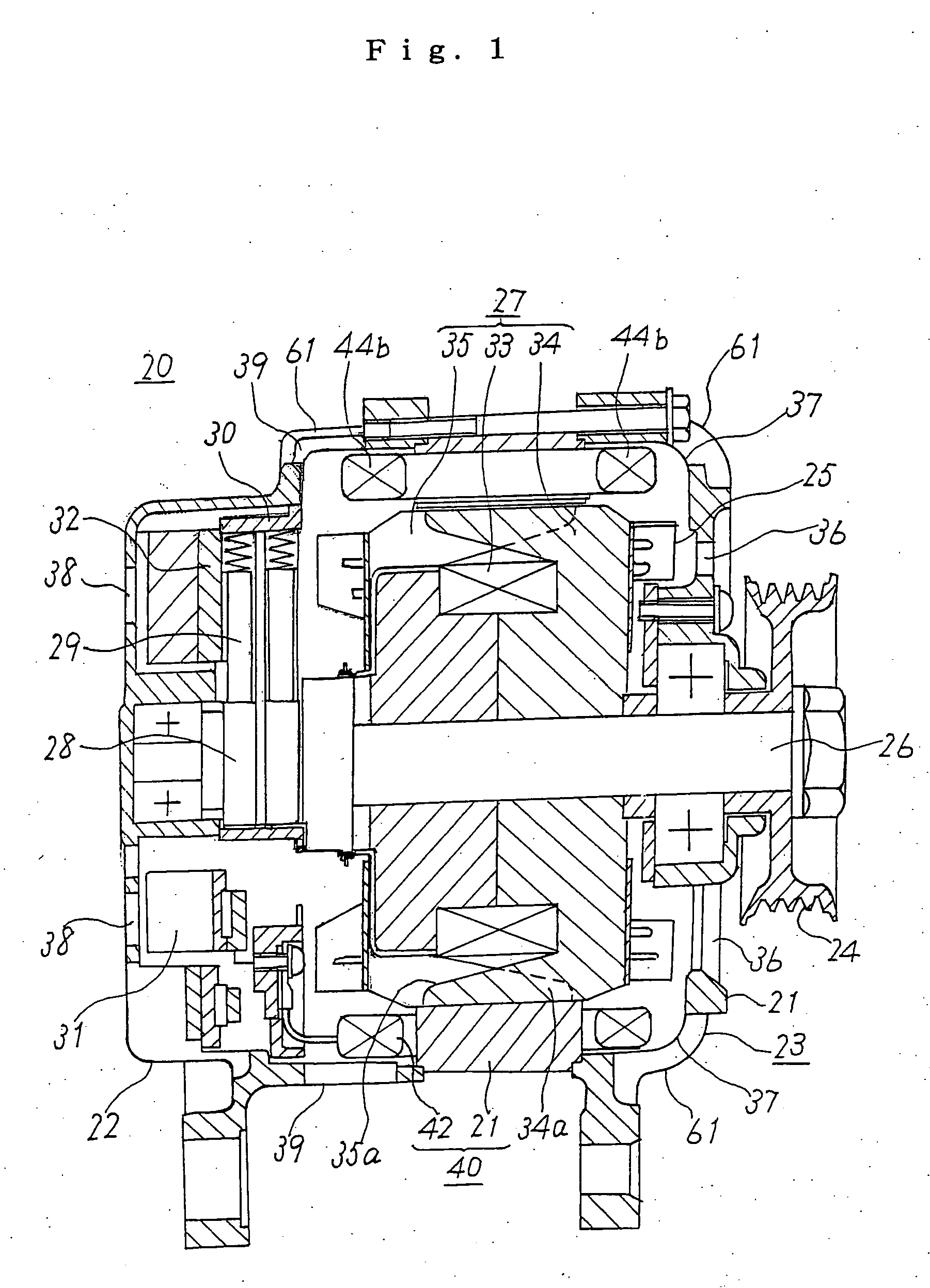

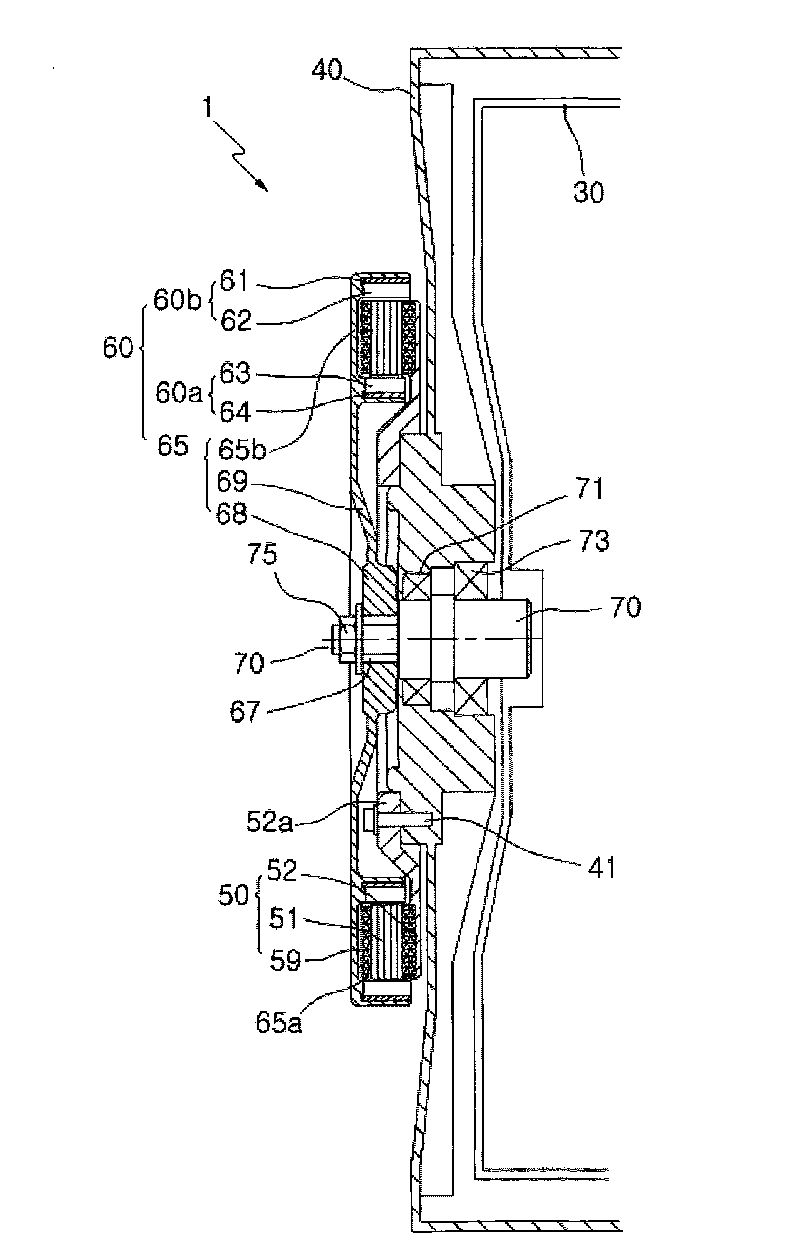

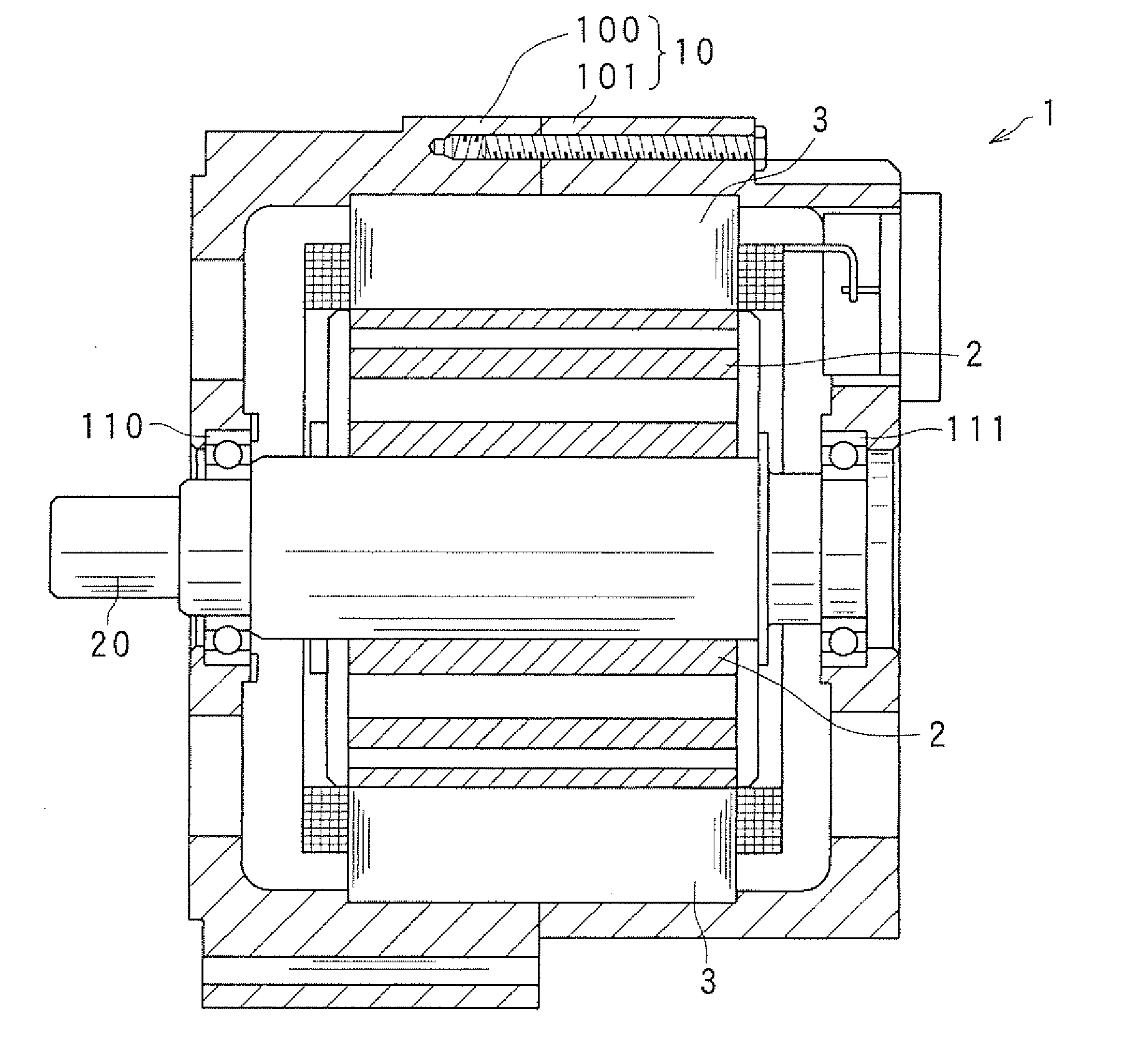

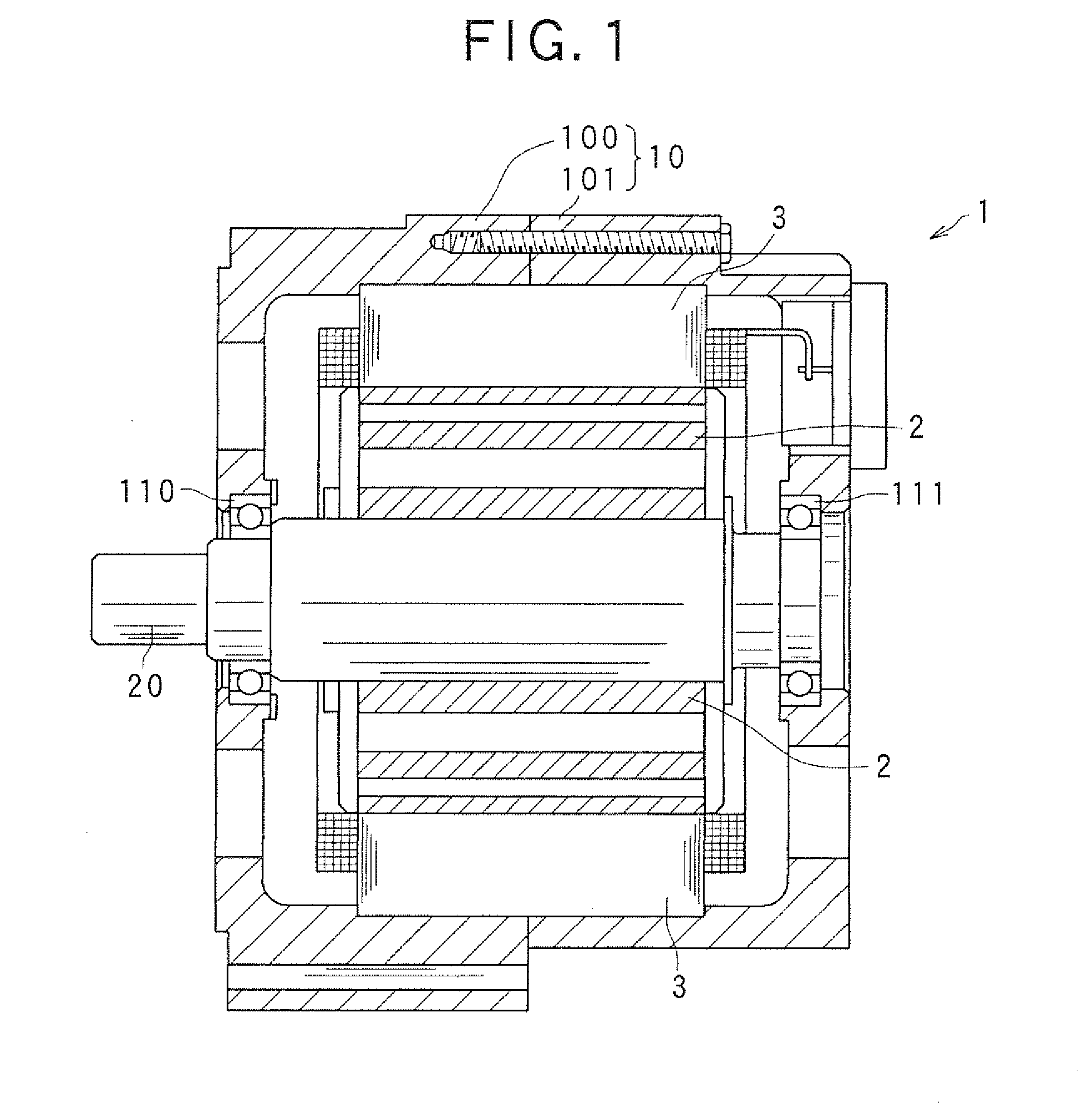

ActiveUS20070278876A1Reliable motorReduce axial heightWindingsMagnetic circuit stationary partsEngineeringElectric motor

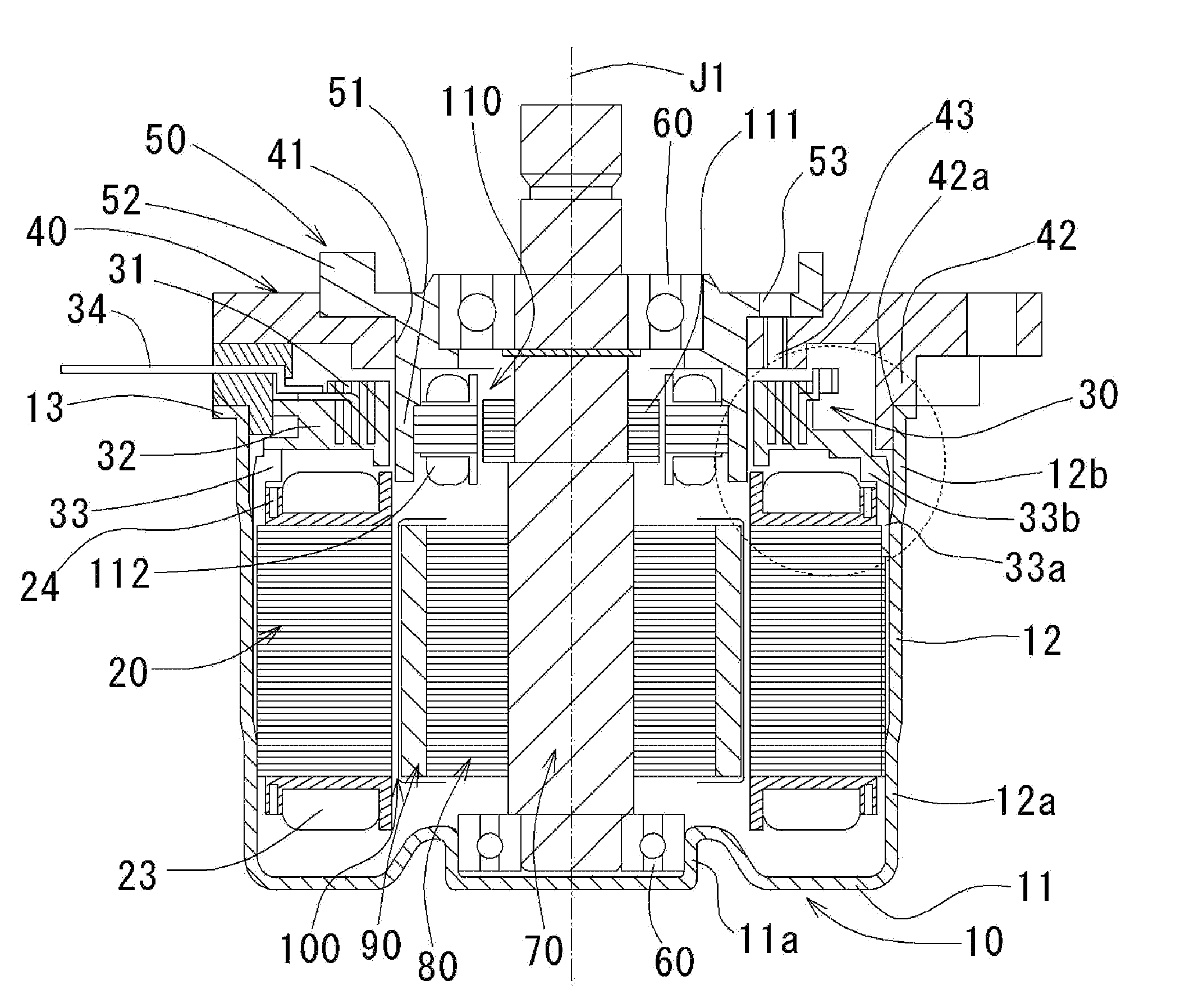

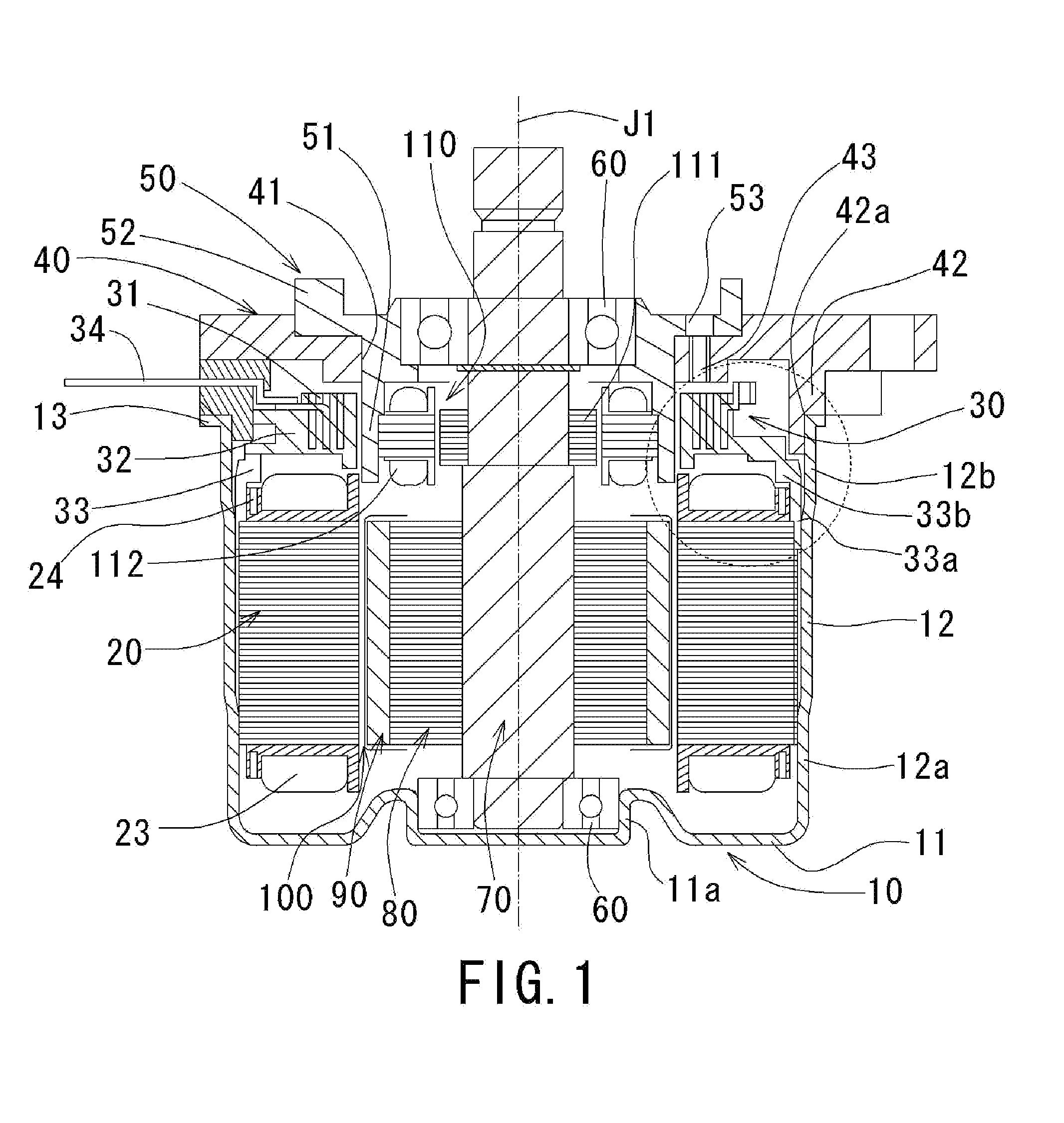

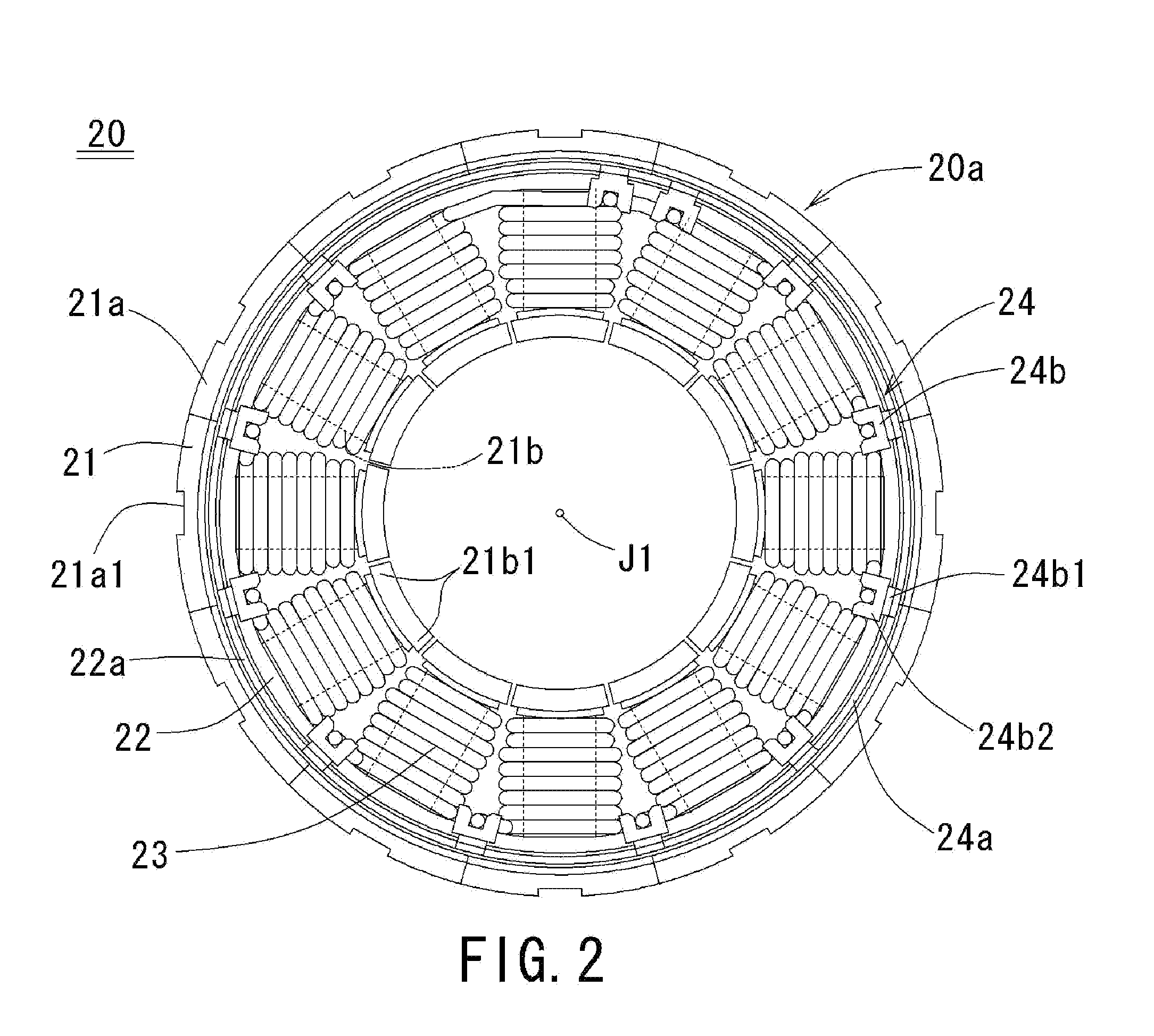

A motor includes a stator and a bus bar supported axially above the stator. The bus bar includes a concave portion arranged in a lower surface thereof facing toward coils of the stator. In a gap defined between the coil and the concave portion, a portion of the wire extracted from the coil and wound in the circumferential direction (i.e., a crossover wire portion) is accommodated. The bus bar includes a wire-positioning hole through which the wire is led to a terminal to be connected with the wire.

Owner:NIPPON DENSAN CORP

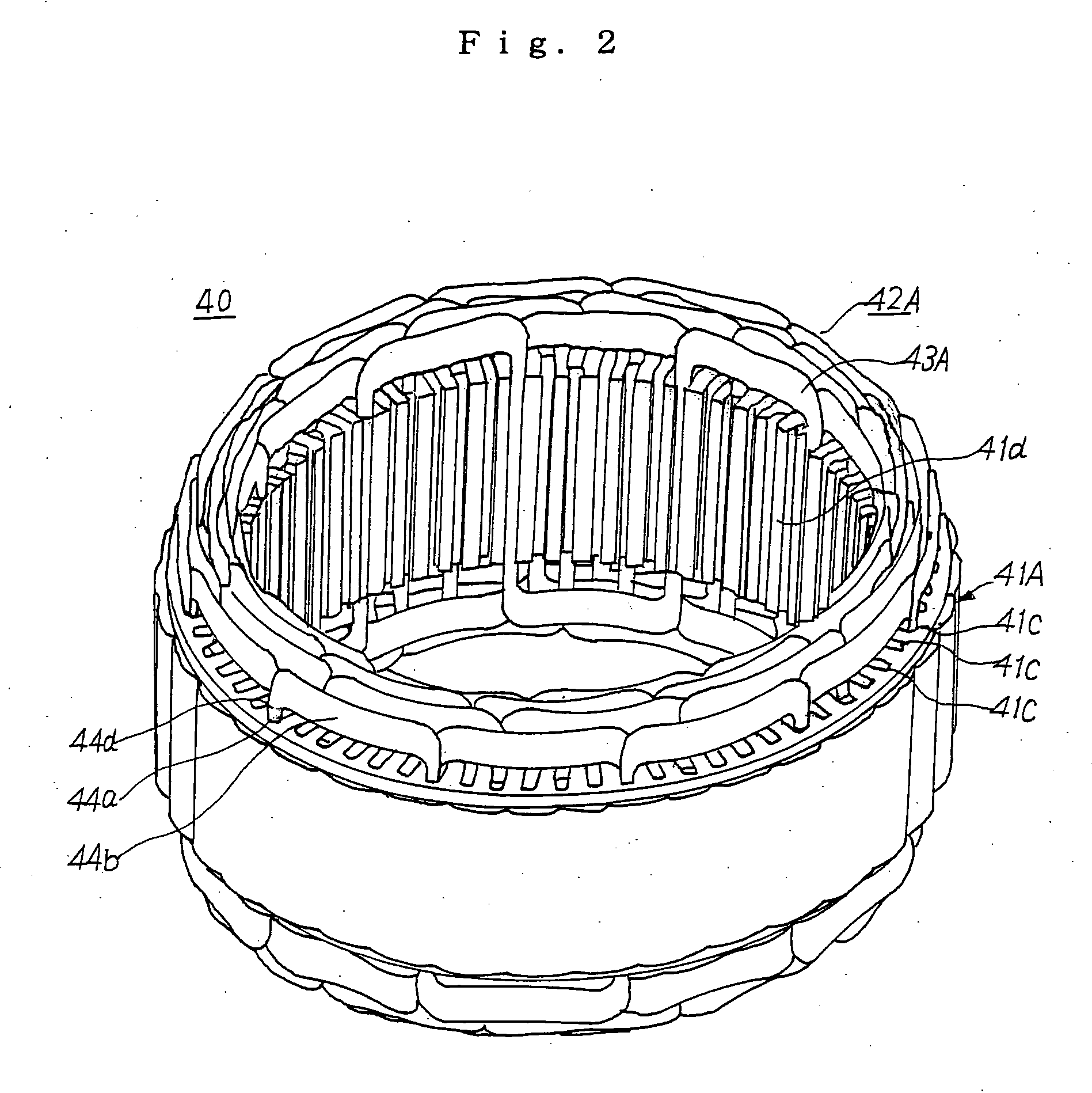

Motor

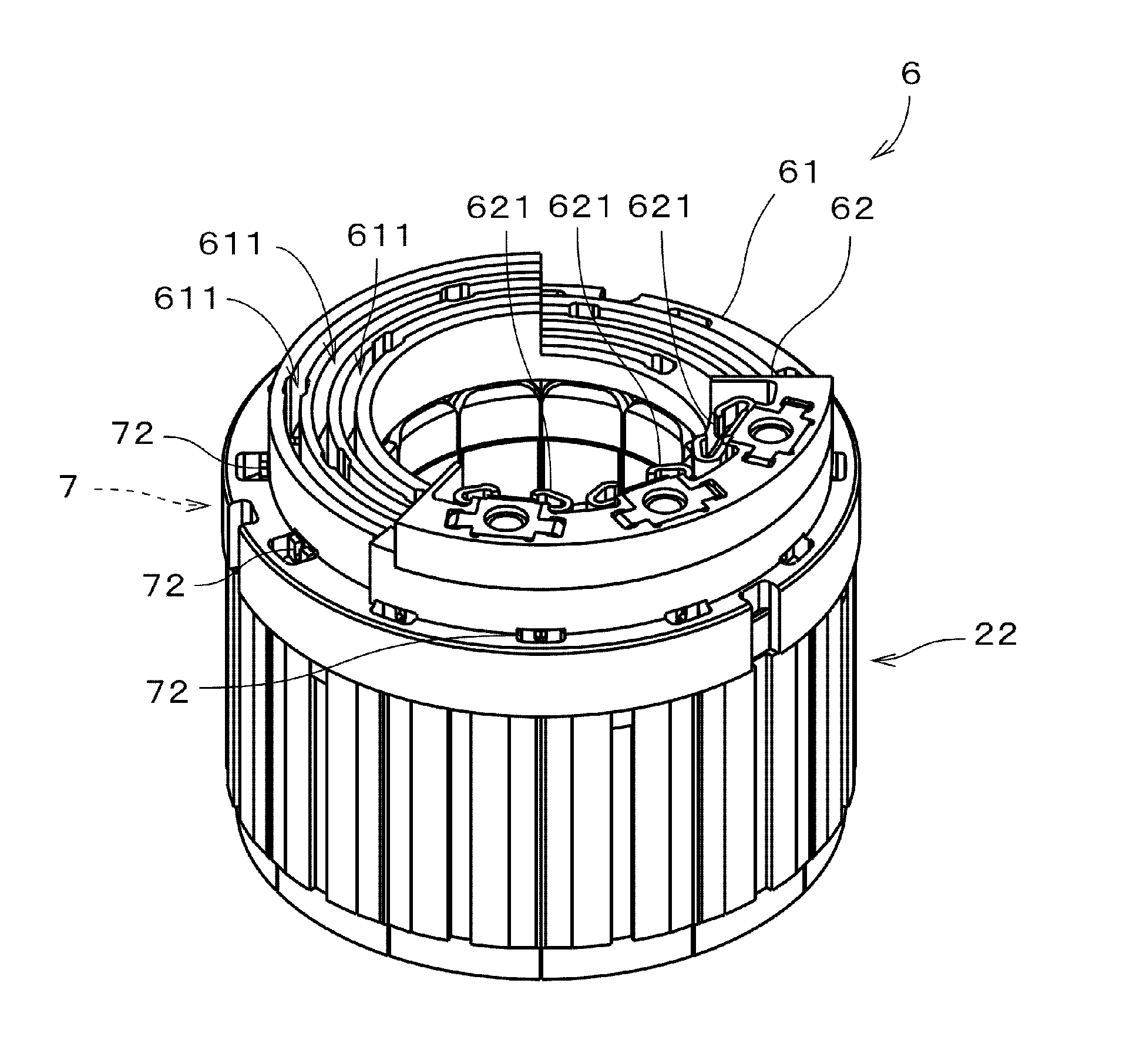

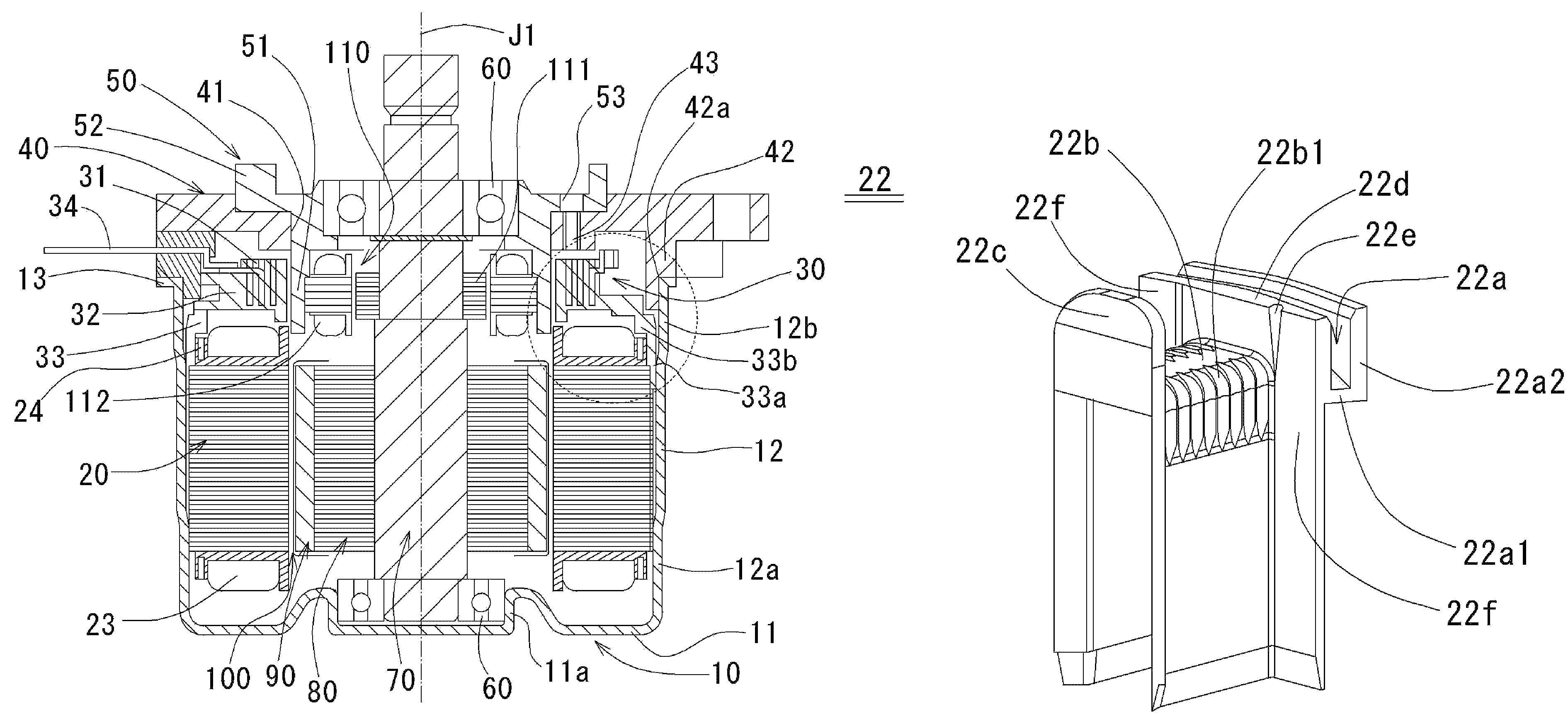

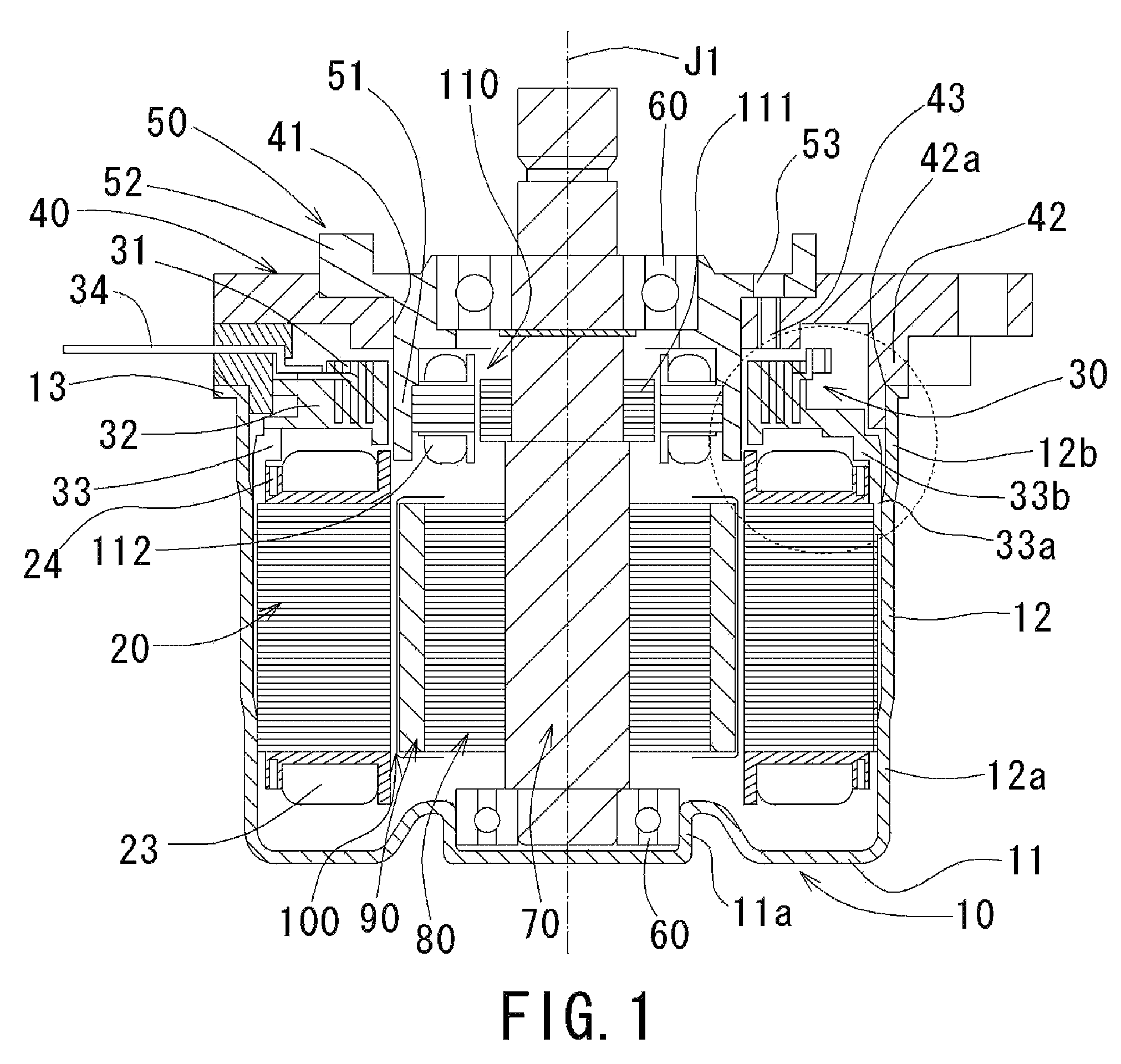

ActiveUS20100201213A1Space minimizationMinimized dimensionWindingsStructural associationEmbedded systemElectric motor

A motor includes a plurality of bus wires of a common phase which are put together before being guided in a common passage to minimize the space arranged to guide the bus wires. Also, the bus wires of a common phase are easily insulated from those of different phases, and an axial height of the motor is reduced. Further, a radial width necessary to guide the bus wires is reduced, and an axial height of the motor including a sensor portion which detects a rotary position of the motor is reduced. Also, the bus wires are easily extended from the armature, and an amount of work required to connect the bus wires and the terminals is reduced. Furthermore, the connection terminal portion does not interfere with the bus wires when they are being guided.

Owner:NIPPON DENSAN CORP

Motor

ActiveUS7663287B2Reliable motorReduce axial heightWindingsMagnetic circuit stationary partsElectrical wiringElectric motor

A motor includes a stator and a bus bar supported axially above the stator. The bus bar includes a concave portion arranged in a lower surface thereof facing toward coils of the stator. In a gap defined between the coil and the concave portion, a portion of the wire extracted from the coil and wound in the circumferential direction (i.e., a crossover wire portion) is accommodated. The bus bar includes a wire-positioning hole through which the wire is led to a terminal to be connected with the wire.

Owner:NIDEC CORP

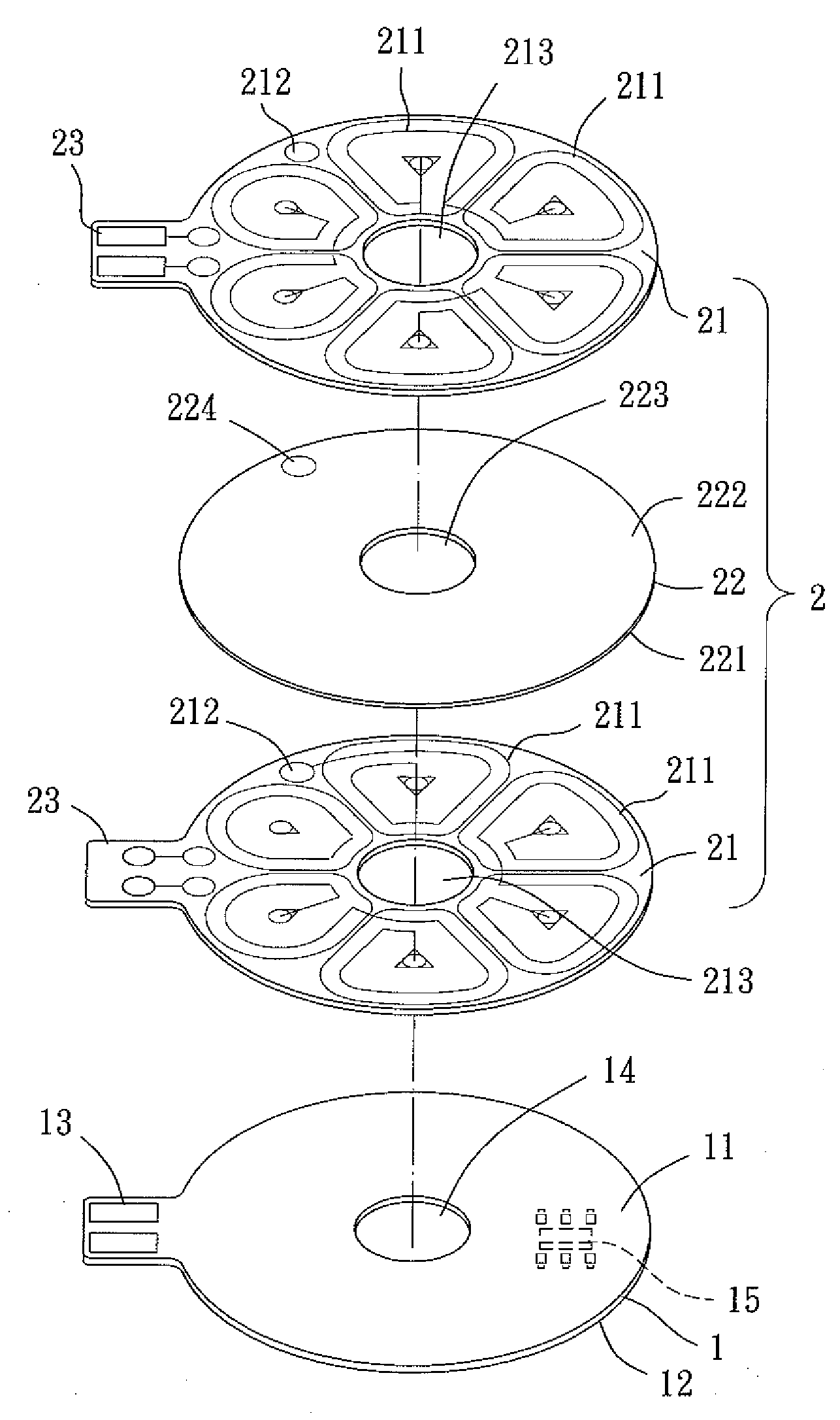

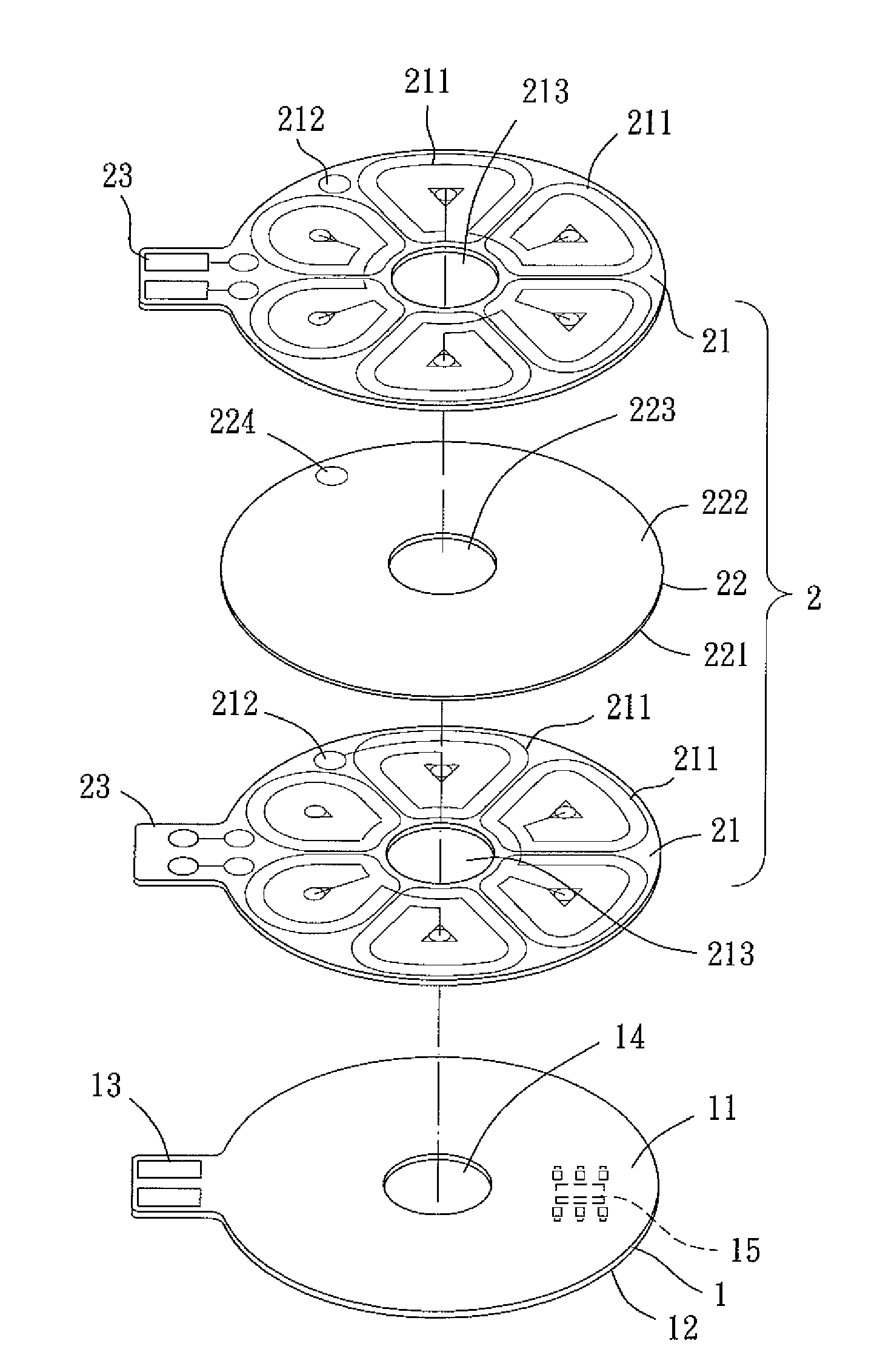

Coil Unit for Motor Stator

ActiveUS20110057536A1Reduce axial heightLower the volumeSynchronous machinesAsynchronous induction motorsEngineeringFan coil unit

A coil unit for a motor stator includes a plurality of layout layers. At least one coil and a conductive portion electrically connected to the at least one coil are formed on a surface of each layout layer. The conductive portions of two adjacent layout layers are electrically connected to each other. An insulting layer is provided between two adjacent layout layers. The coil unit can be coupled to a face of a substrate to form a motor stator with reduced axial height and reduced volume.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Coil unit for motor stator

ActiveUS8193678B2Reduce axial heightLower the volumeSynchronous machinesAsynchronous induction motorsElectric motorStator

A coil unit for a motor stator includes a plurality of layout layers. At least one coil and a conductive portion electrically connected to the at least one coil are formed on a surface of each layout layer. The conductive portions of two adjacent layout layers are electrically connected to each other. An insulting layer is provided between two adjacent layout layers. The coil unit can be coupled to a face of a substrate to form a motor stator with reduced axial height and reduced volume.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

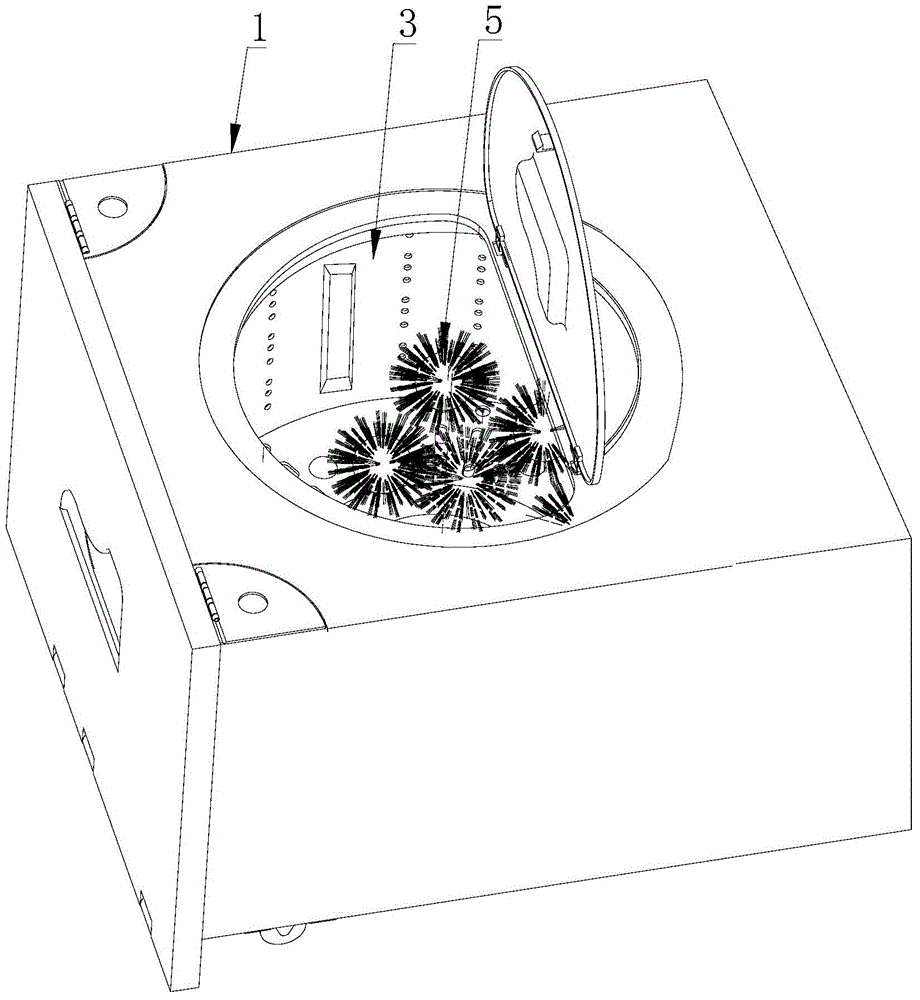

Washing device

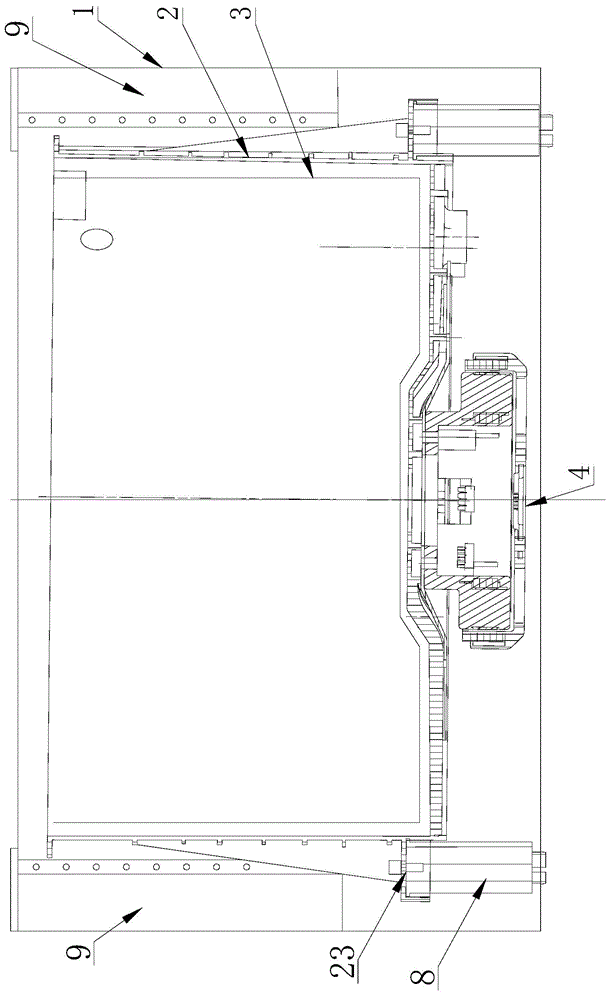

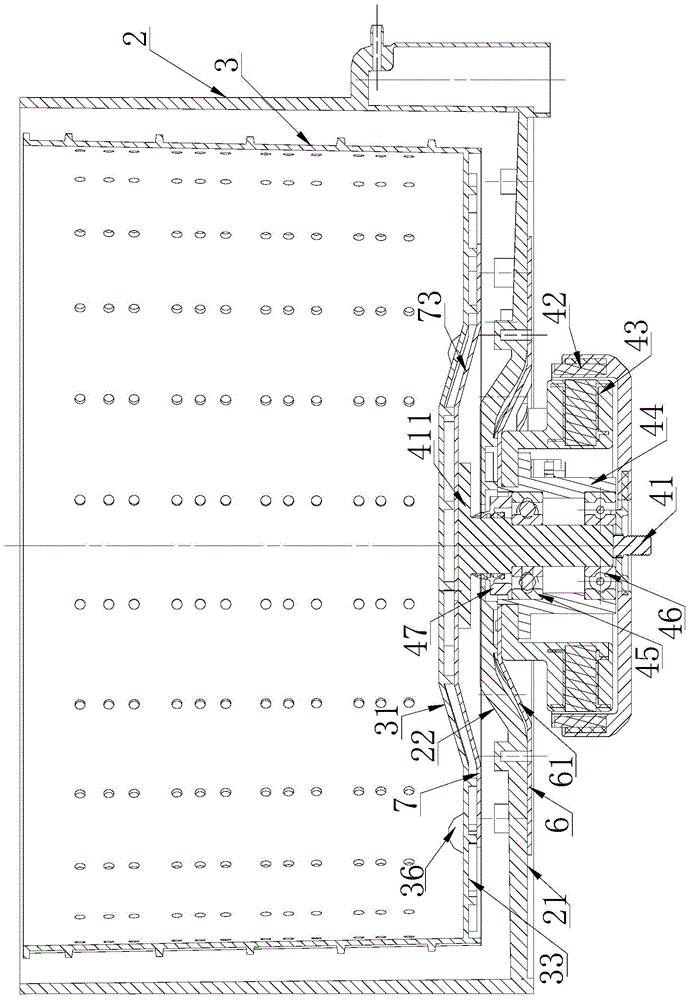

ActiveCN105624965AImprove washing efficiencySimple structureBrushing washing machinesOther washing machinesEngineering

The invention provides a washing device comprising an outer barrel, an inner barrel and a motor. The outer barrel, the inner barrel and the motor are arranged coaxially and vertically, the center of the bottom of the outer barrel is recessed from exterior to interior to form an inverted first groove, the motor is at least partly arranged in the first groove, the center of the bottom of the inner barrel is recessed from exterior to interior to form an inverted second groove, the first groove is at least partly arranged in the second groove. The motor is at least partly arranged in the first groove, the first groove is at least partly arranged in the second groove which is formed in a way that the bottom of the inner barrel protrudes upwards, on the premise that the washing capacity of the inner barrel is not reduced, the whole height of the washing device is reduced. At the same time, the inner barrel of the washing device is inside provided with a plurality of brushes which can move freely, the brushes move along with the rotation of the inner barrel, and brush goods in the inner barrel. The washing device is simple in structure and substantial in effect, and is suitable for promotion and application.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

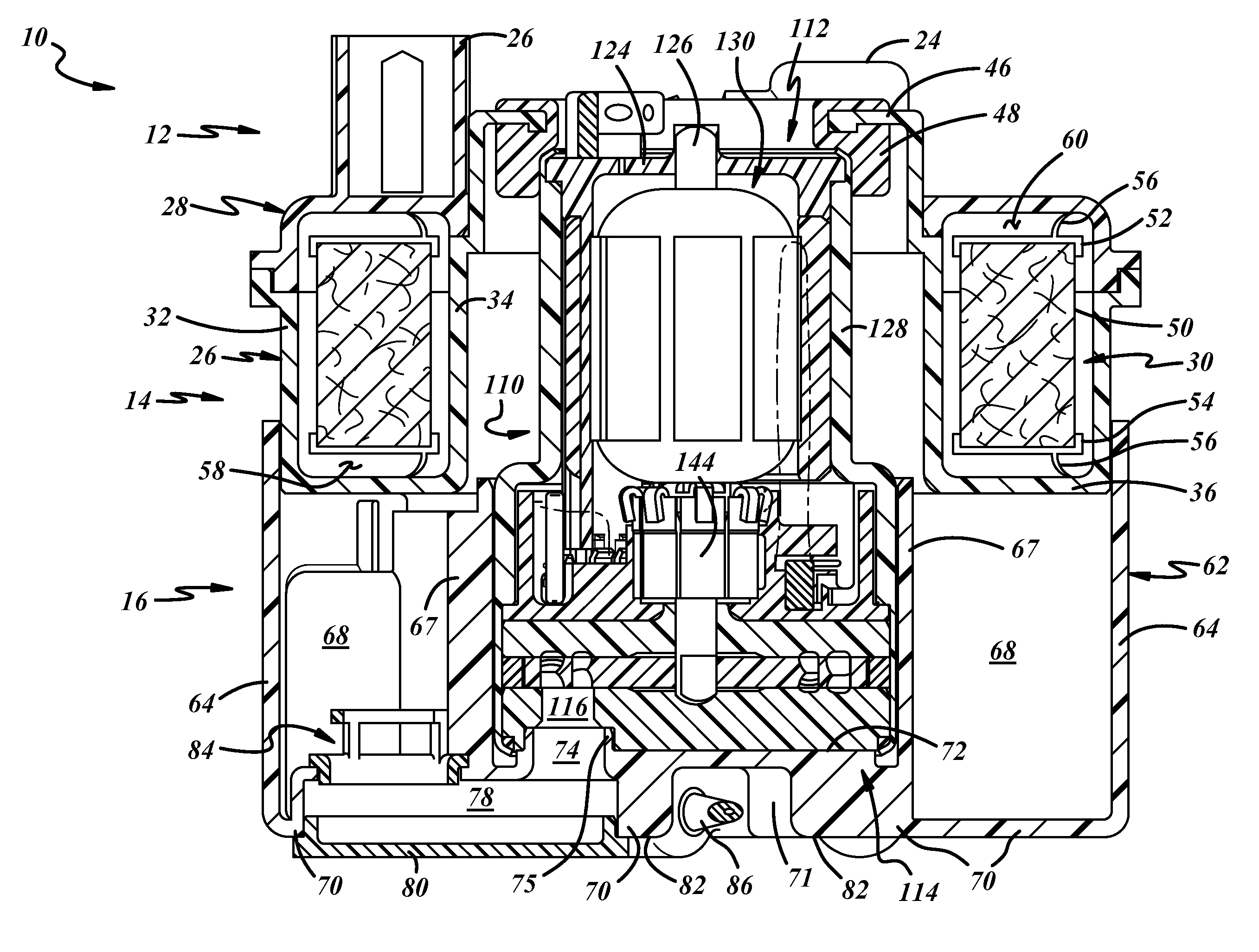

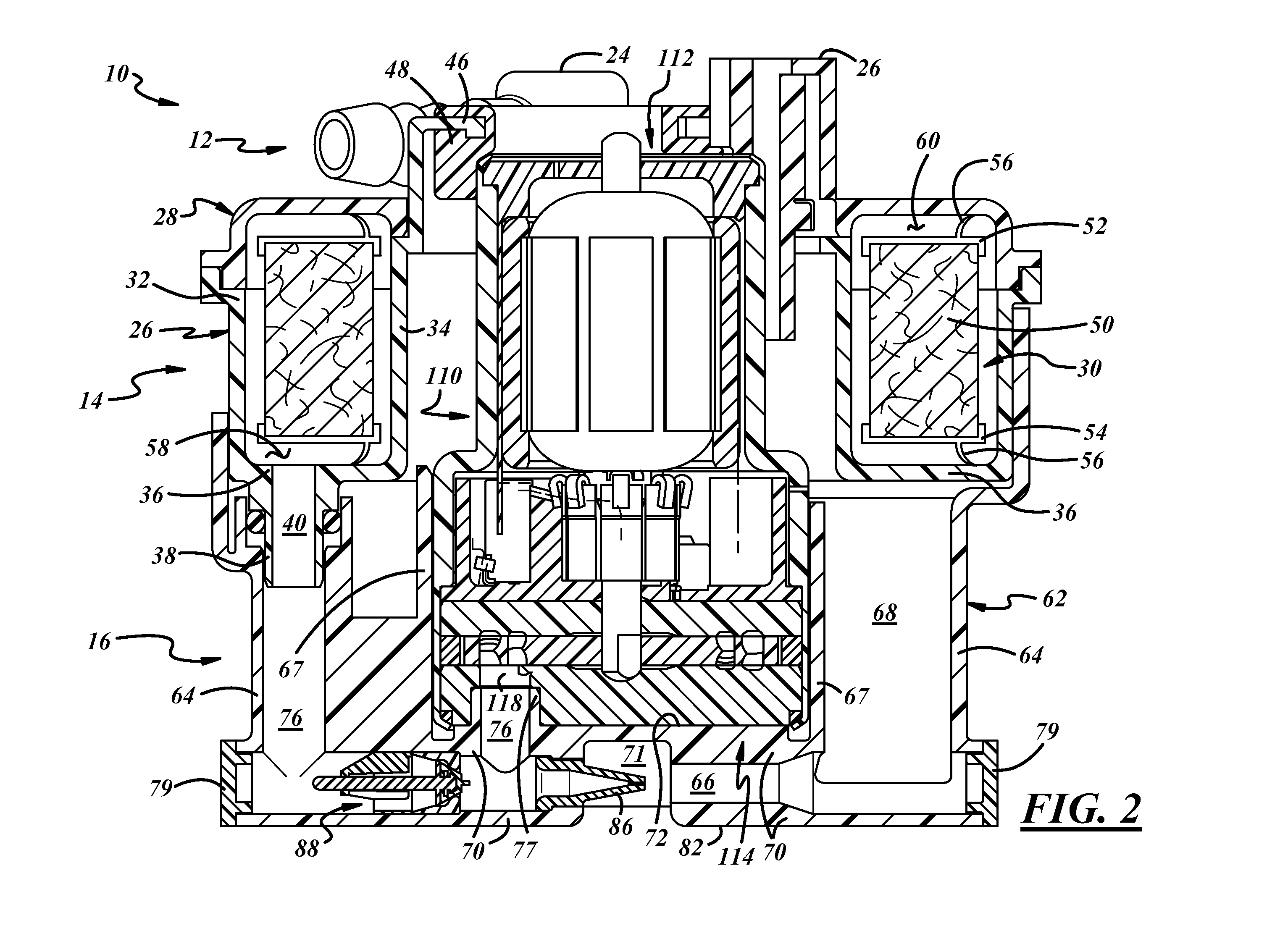

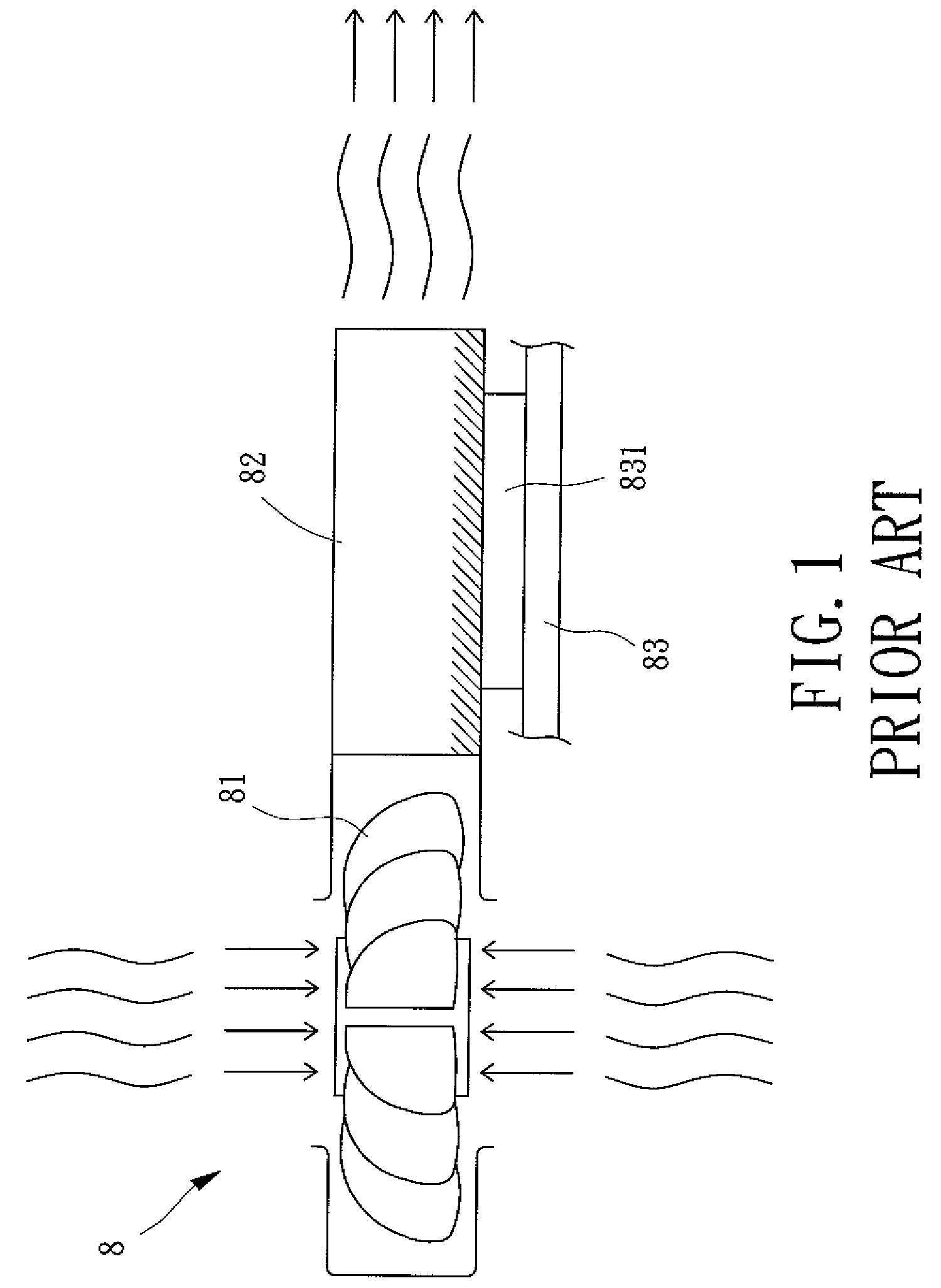

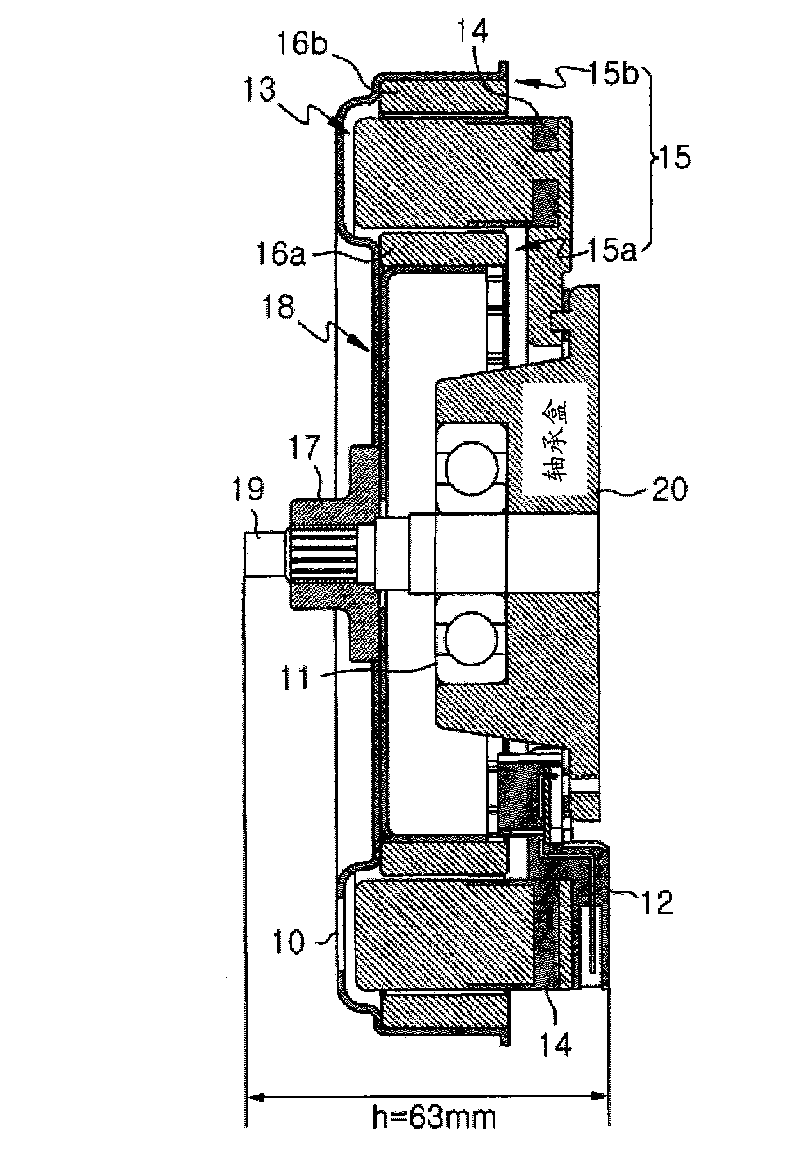

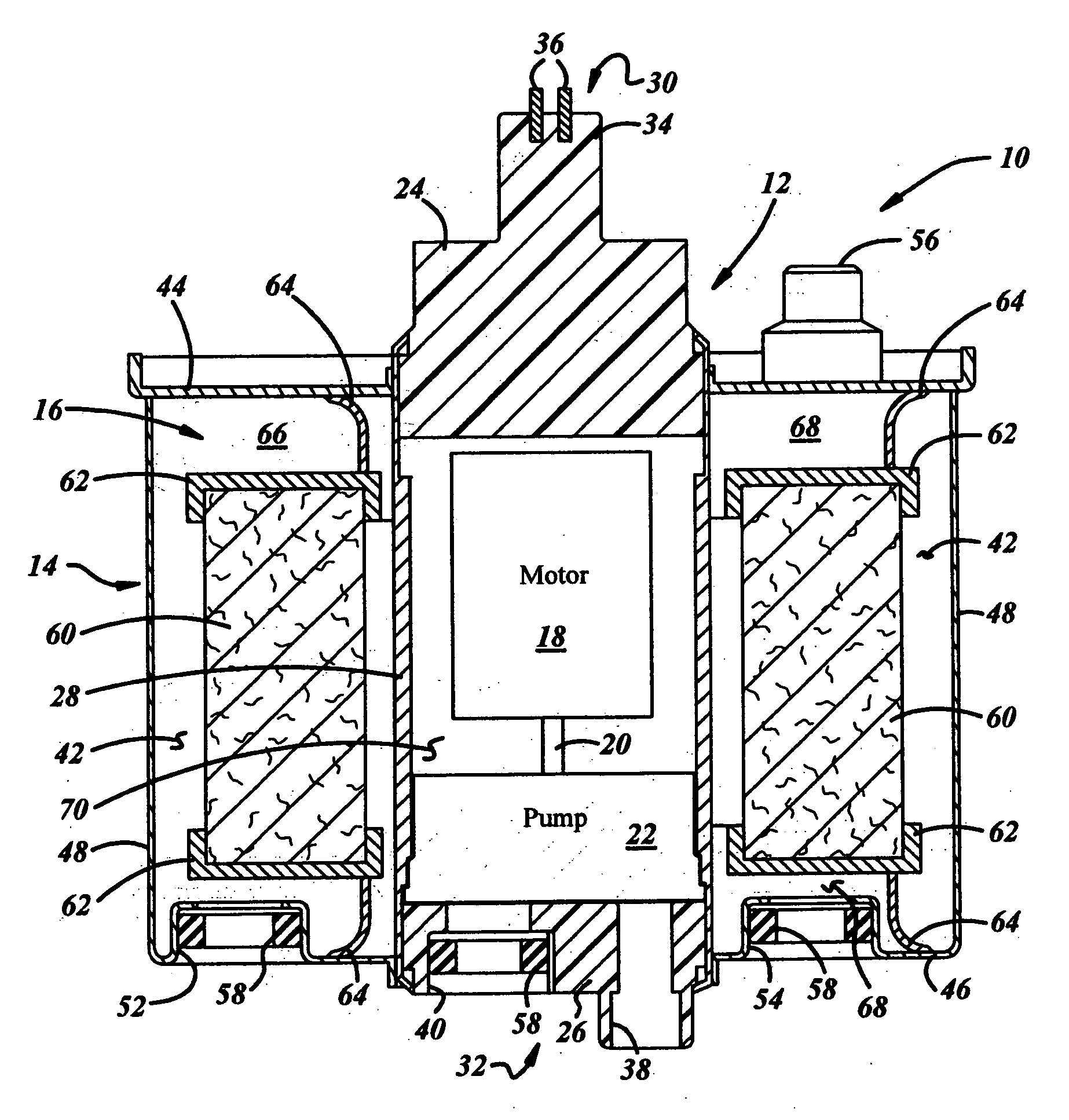

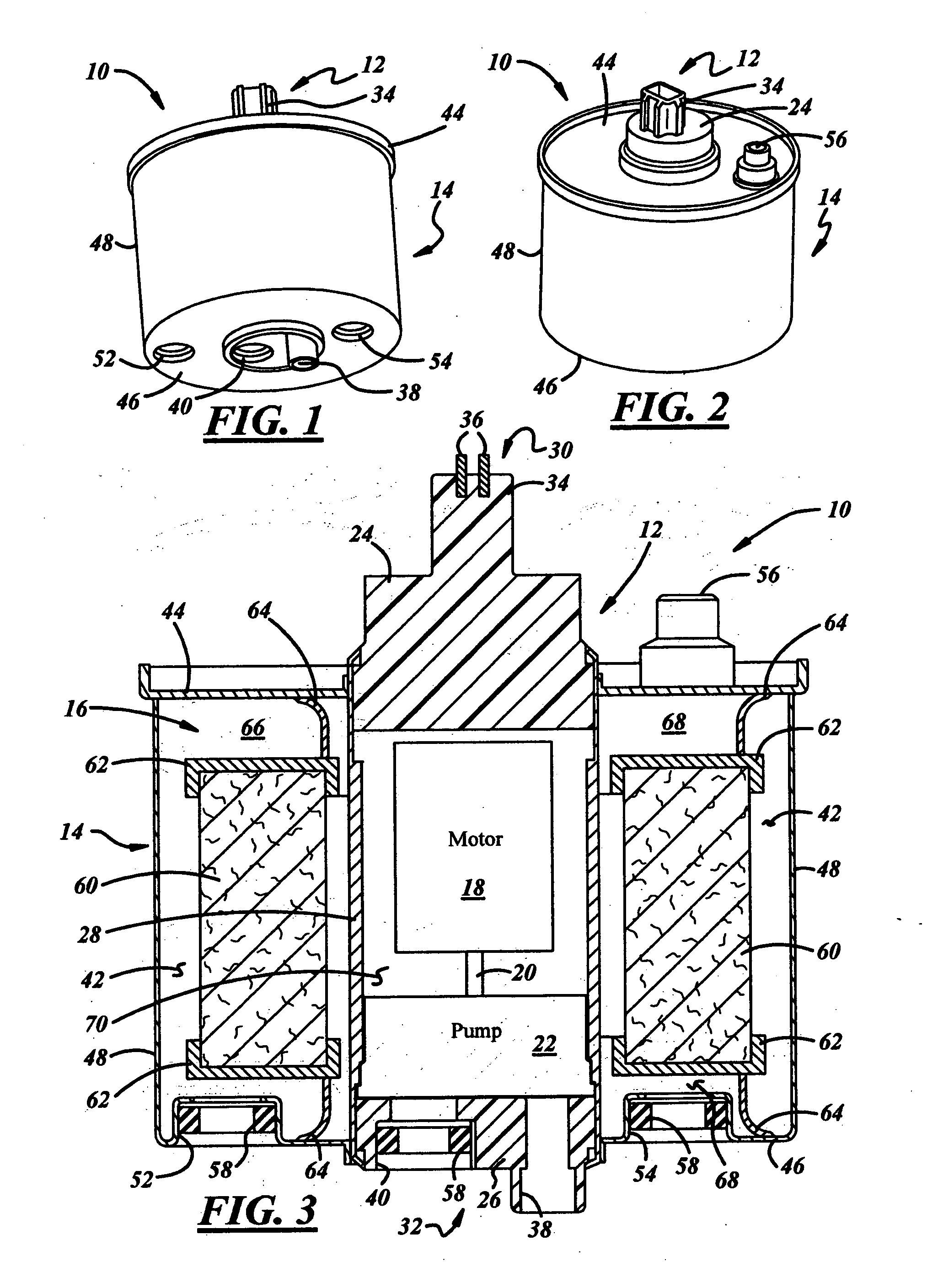

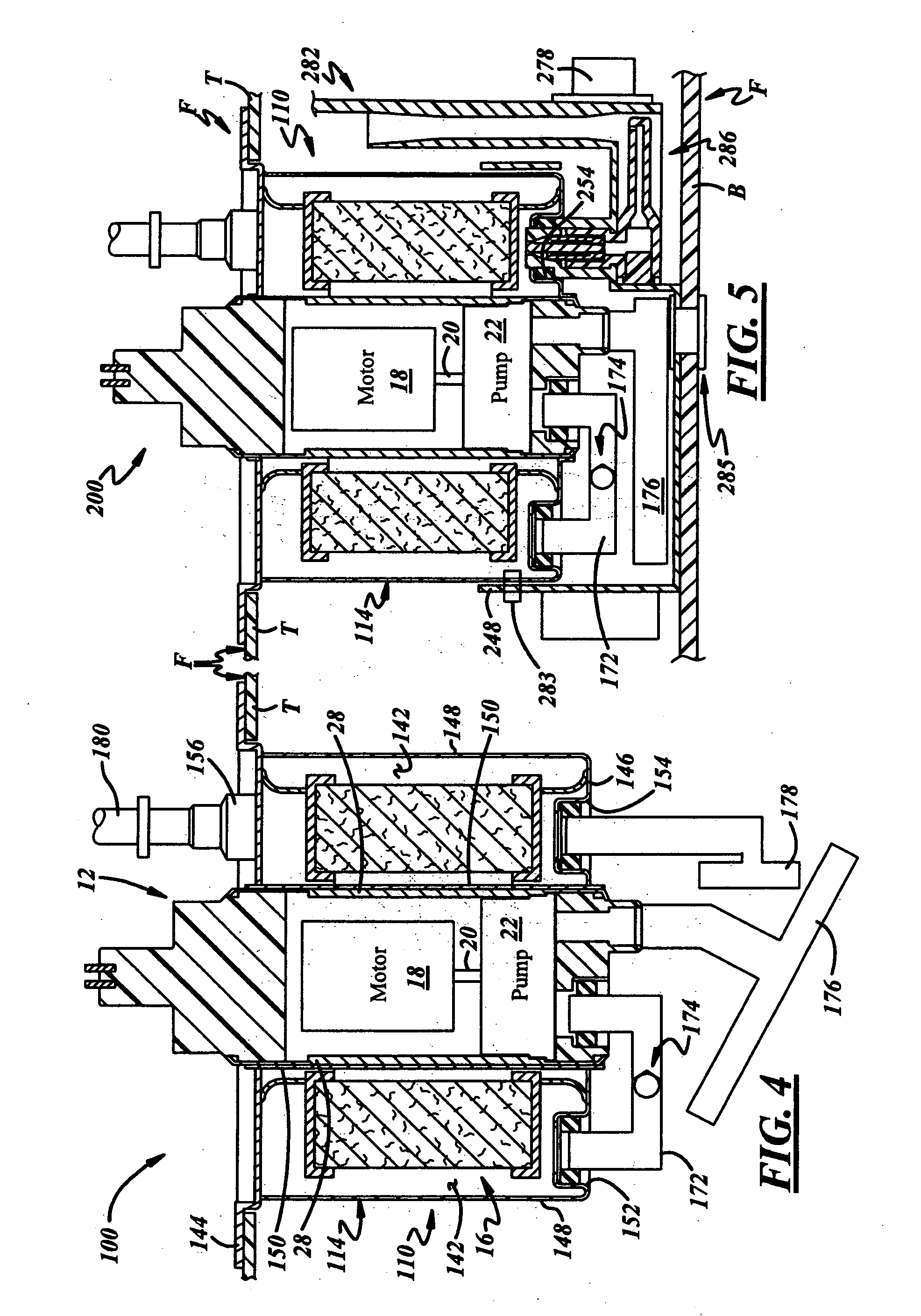

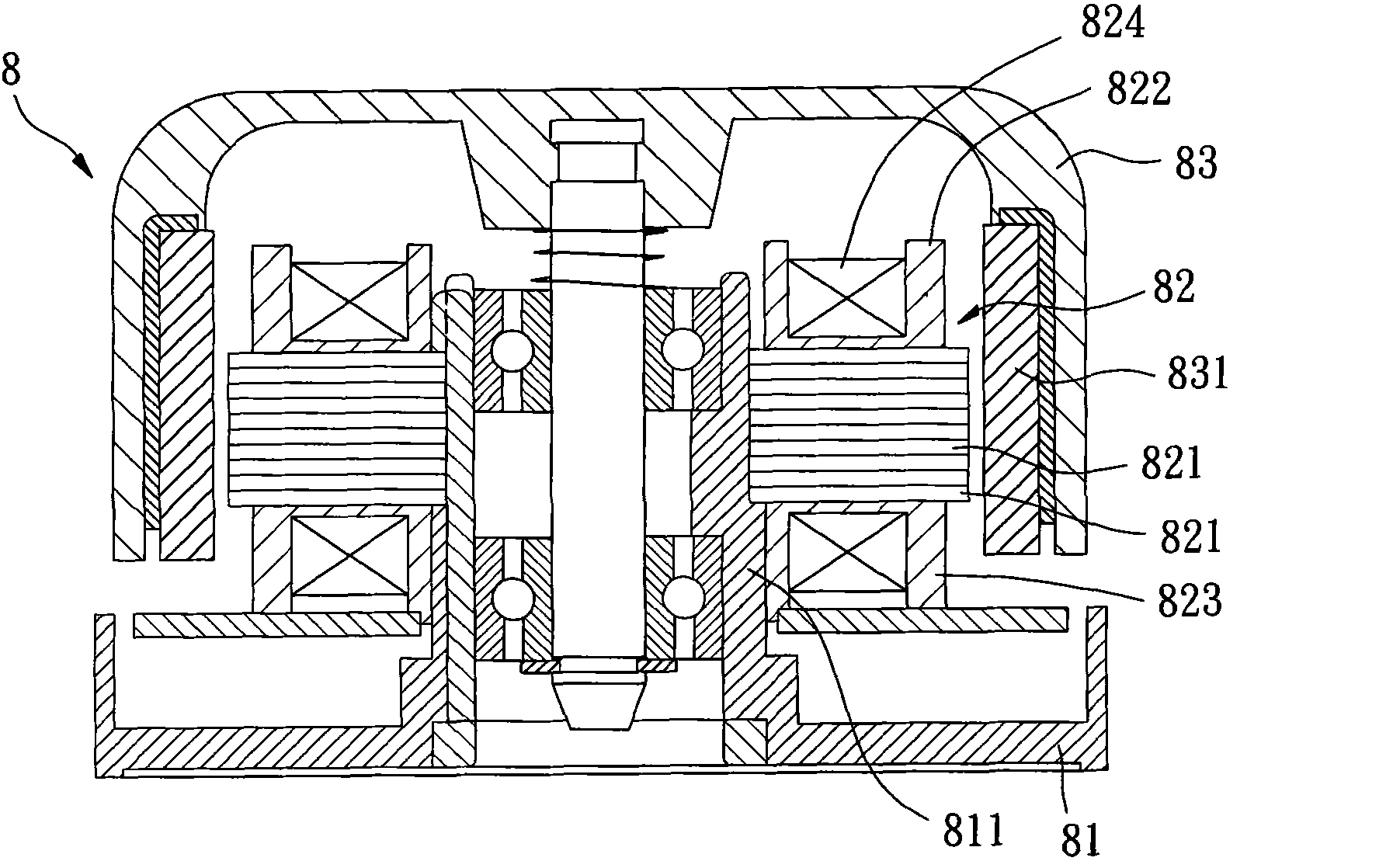

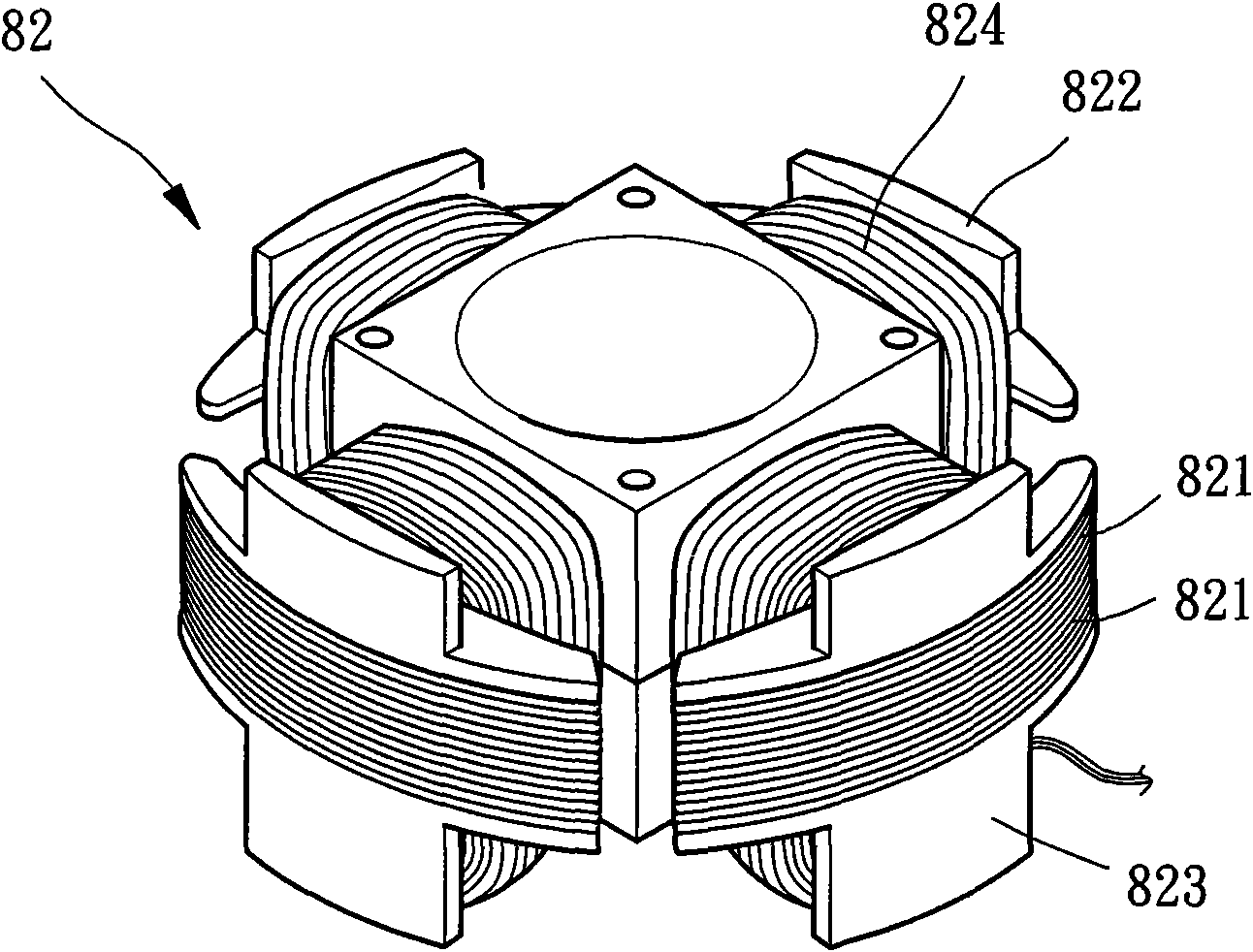

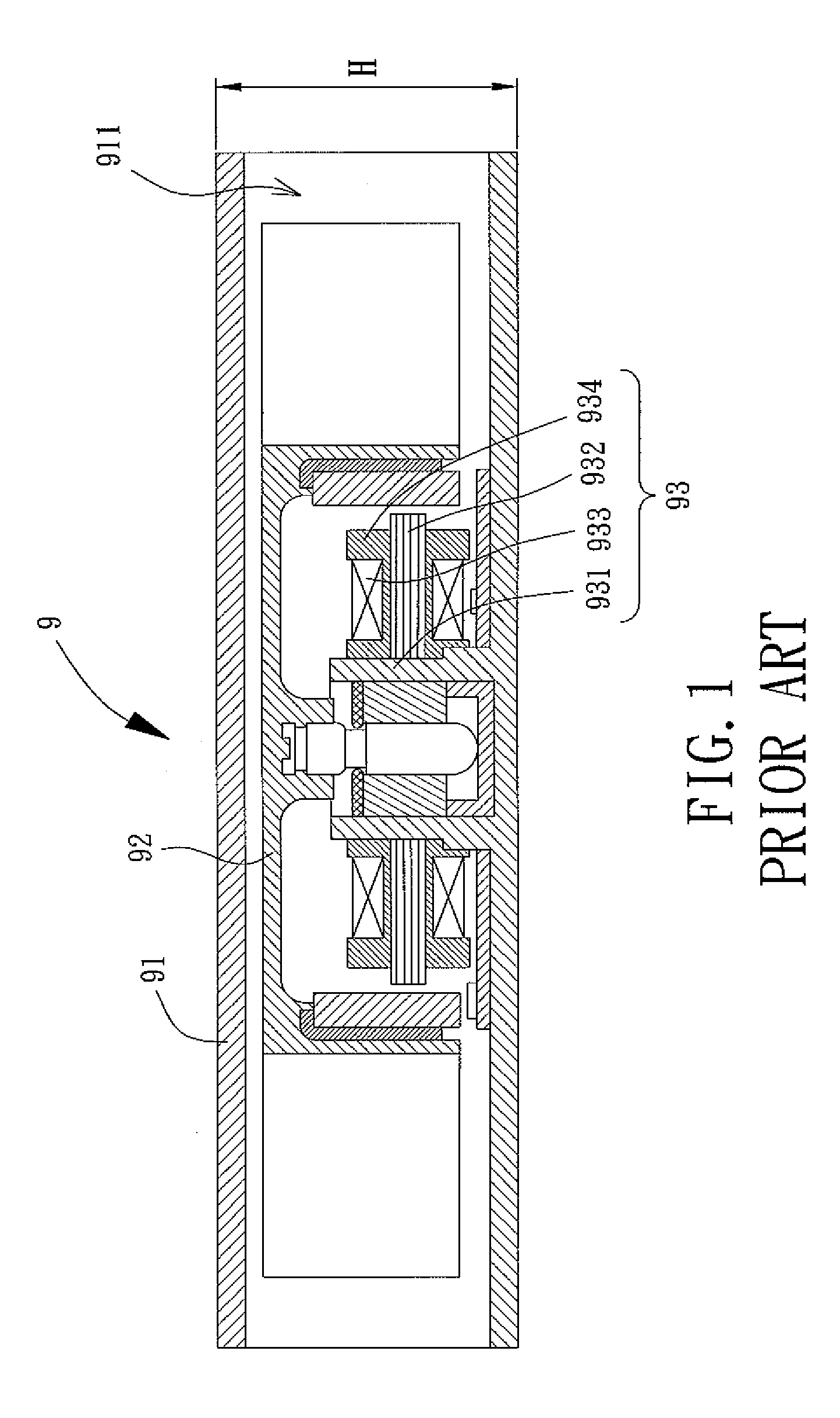

Fuel pump assembly for a fuel pump module

InactiveUS20080298985A1Improve cooling effectEasy to cleanCircumferential flow pumpsTransverse flow pumpsFuel pumpElectric motor

A fuel pump assembly includes a fuel pump, and an electric motor for rotatably driving the fuel pump and including a motor armature and a commutator positioned between the motor armature and the fuel pump.

Owner:TI GRP AUTOMOTIVE SYST LLC

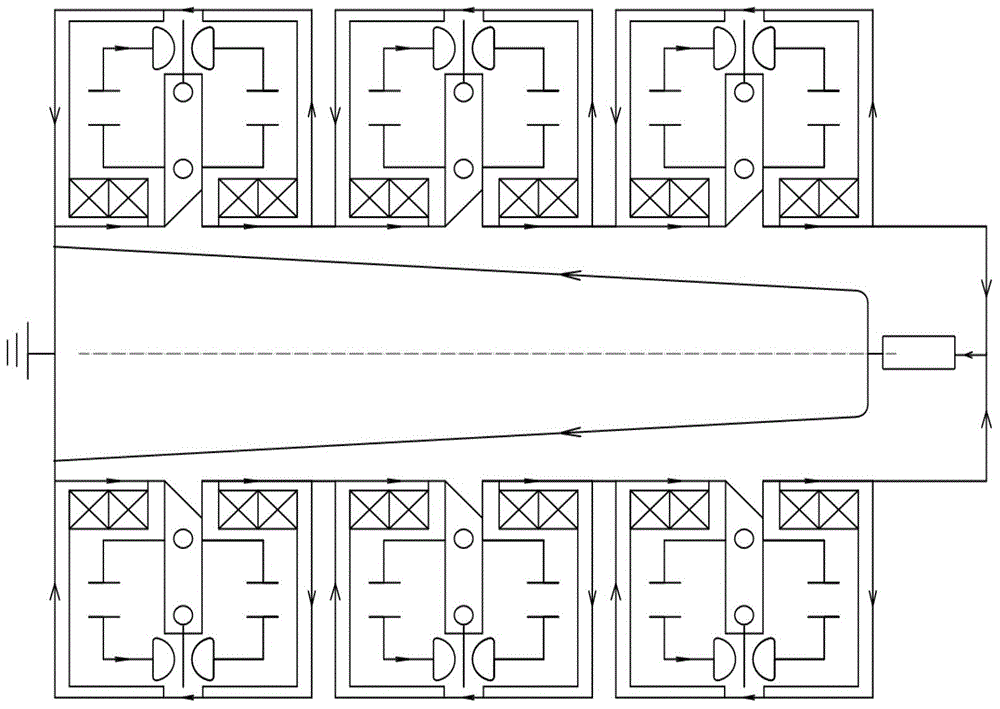

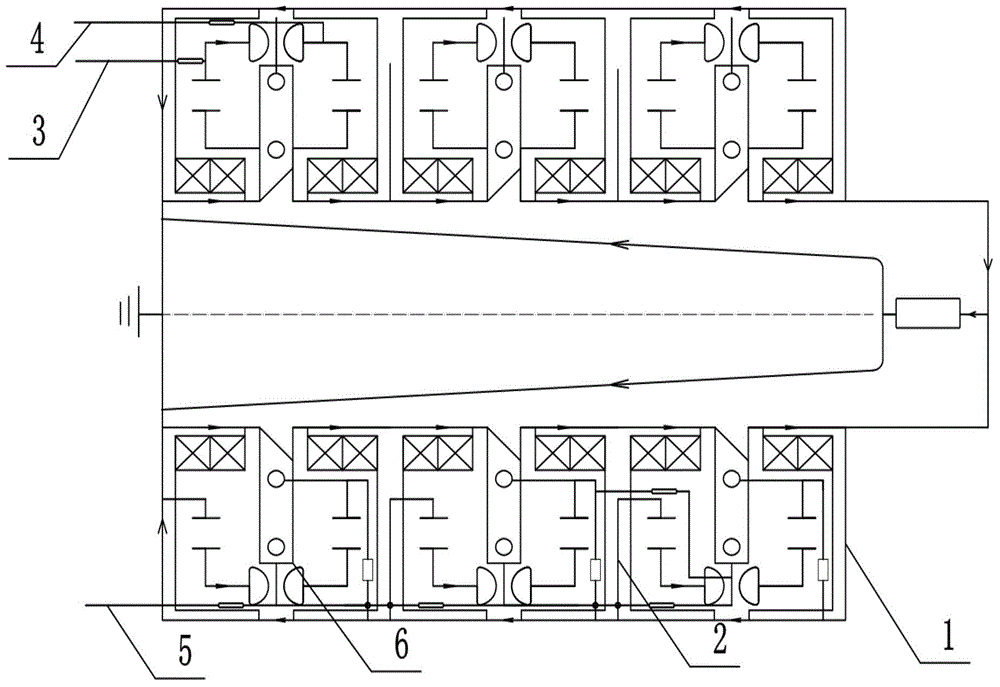

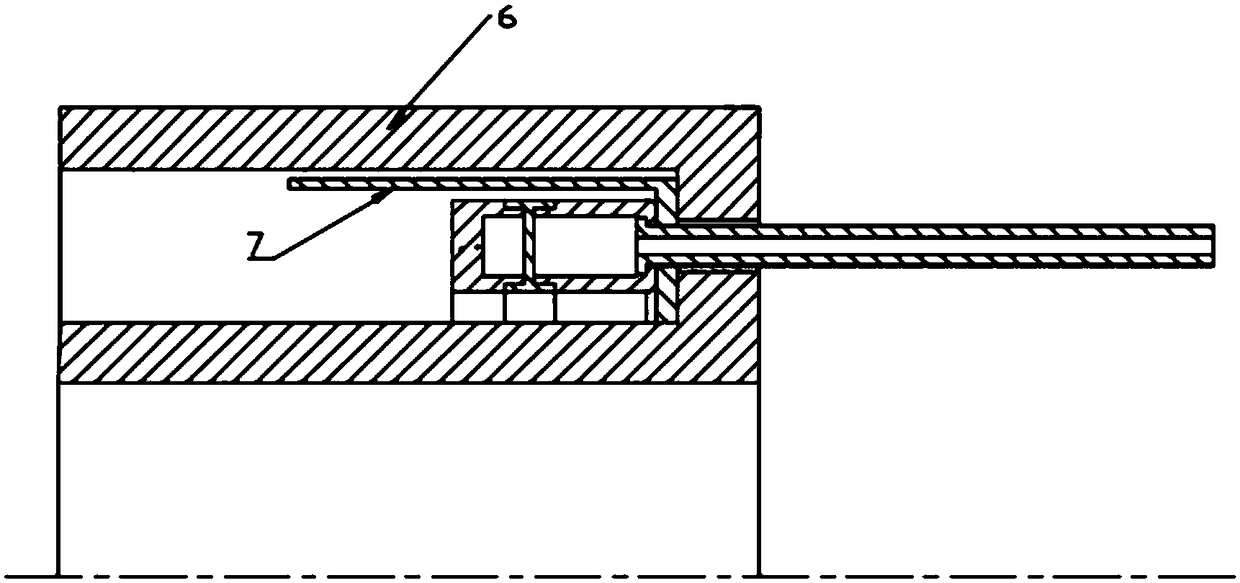

Multi-stage series-connected LTD of common cavity, and trigger method thereof

ActiveCN105187031AReduce the number of channelsConvenient ArrangementPulse generation by energy-accumulating elementComputer moduleNon magnetic

The invention relates to a multi-stage series-connected linear transformer driver (LTD) and a trigger method of the LTD. The LTD comprises multiple series-connected stacked LTD modules, wherein all the LTD modules are disposed in a common non-magnetic metal housing. The technical problems of complicated trigger circuits, high manufacturing cost and difficulty in guaranteeing a trigger sequence by use of a conventional multistage series-connected LTD are solved. The multi-stage LTD modules are connected in series and stacked in a common housing, 3 to 4-stage LTD modules can share one trigger pulse, and all the LTD modules can share one charging cable, such that the number of introduced trigger cables and the number of charging cables are substantially reduced, conventionally quite complicated line arrangement is simplified, and the equipment operation reliability is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

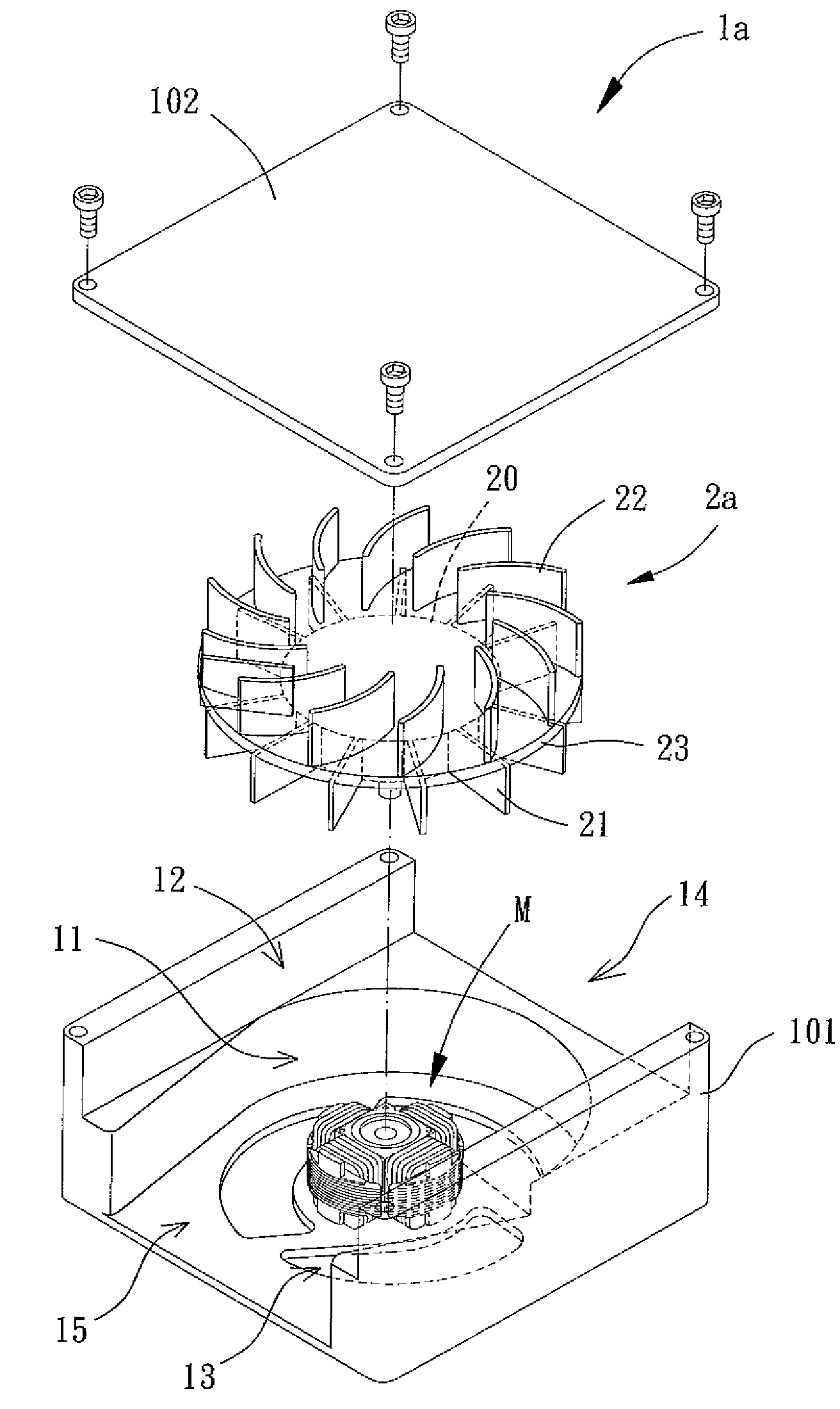

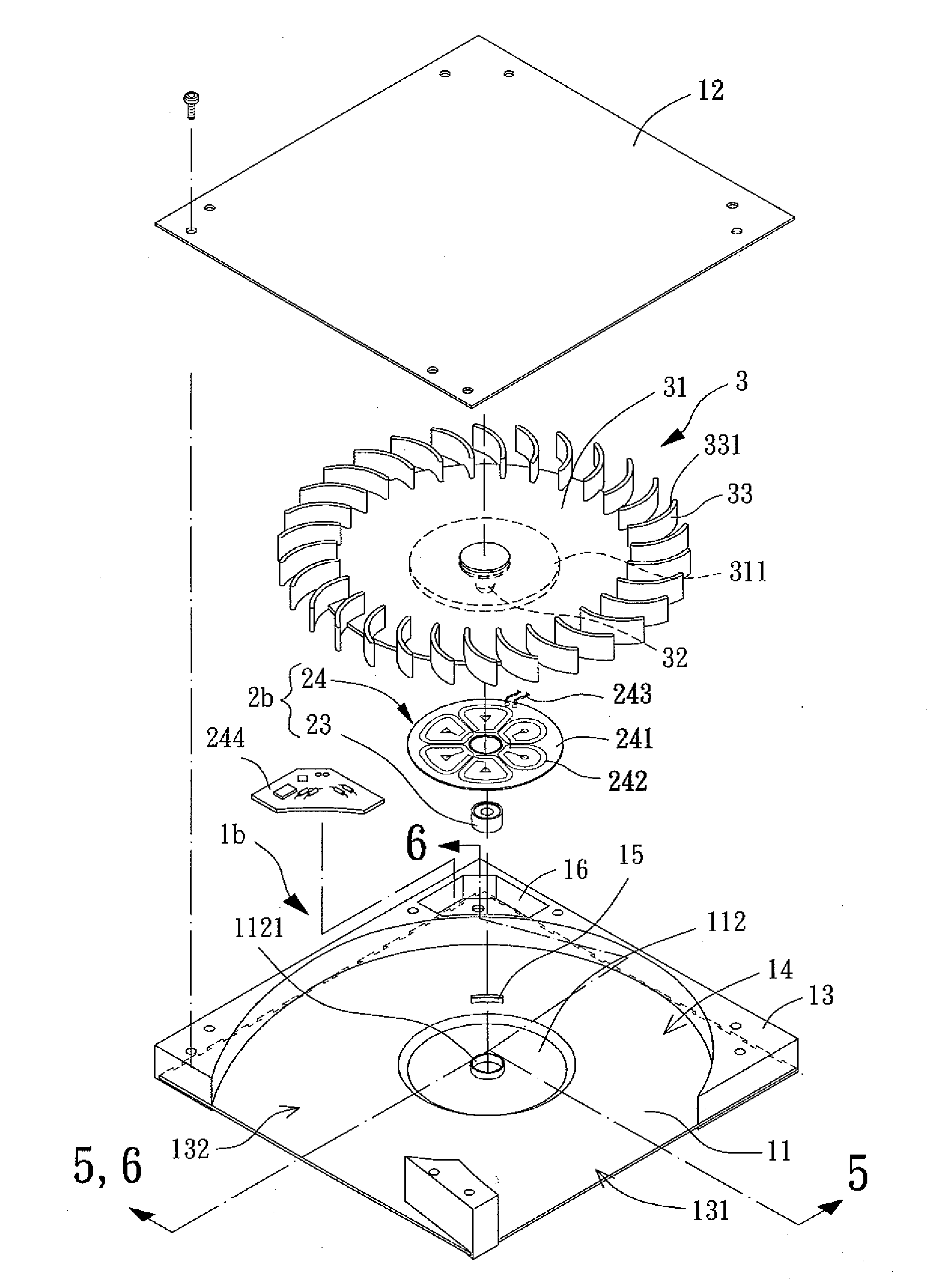

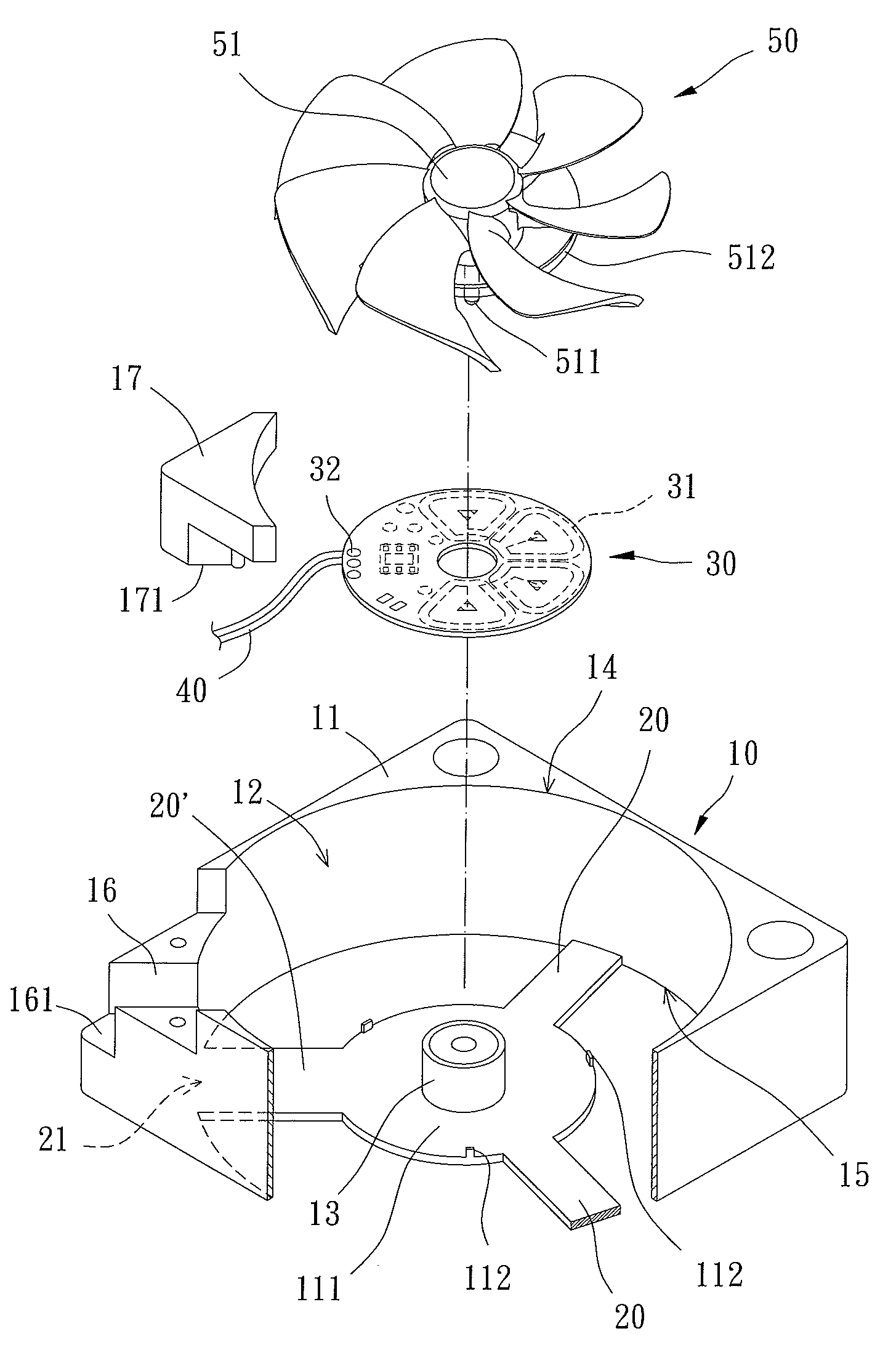

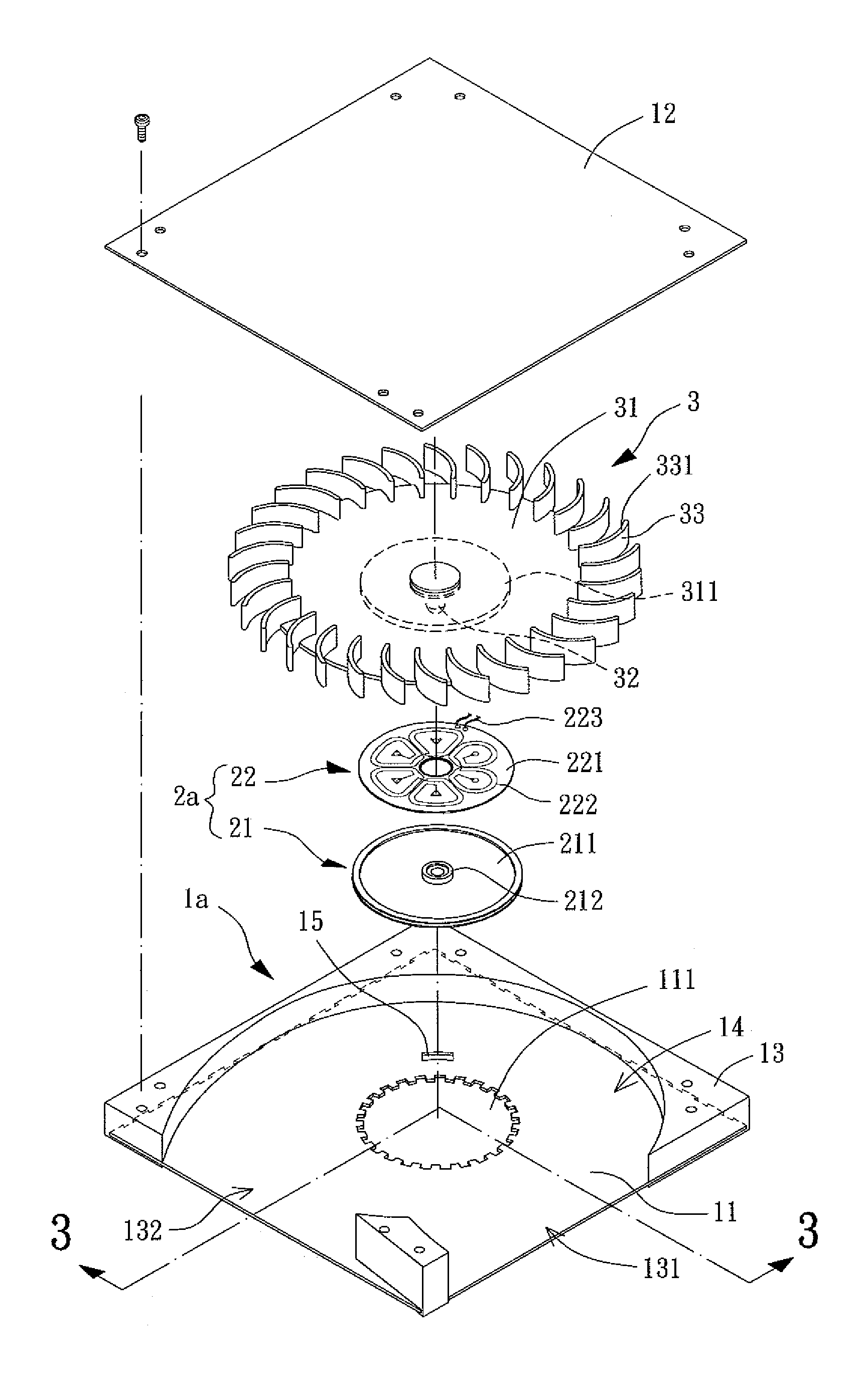

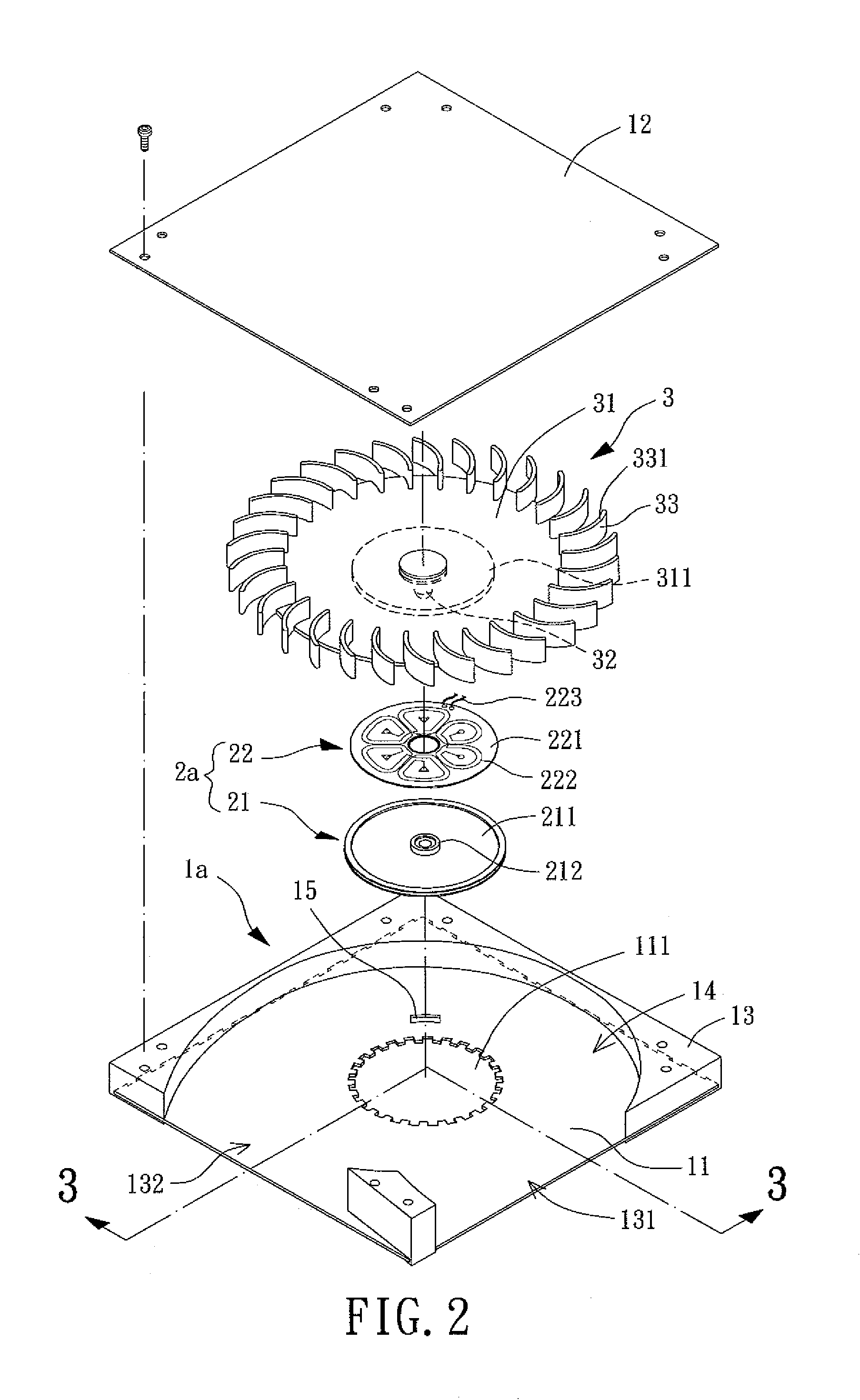

Fan module

ActiveUS8684661B2Improve cooling effectAvoid turbulenceCircumferential flow pumpsPump componentsImpellerInterior space

A fan module includes a housing and an impeller. The housing has an axial air inlet, a radial air inlet and at least one radial air outlet. The impeller is rotatably disposed in the housing and has a first air-guiding blade, a second air-guiding blade and a partitioning member. The partitioning member separates an interior space of the housing into a first air channel and a second air channel. The first air-guiding blade is located in the first air channel, and the second air-guiding blade is located in the second air channel.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Alternator for a vehicle

InactiveUS20060145558A1Efficient conductionImproving electrolytic corrosion resistibilitySynchronous generatorsWindings insulation shape/form/constructionInsulation layerAlternator

An ac generator for a vehicle is constituted so that the thickness in insulation layers of conductors in the slot-in portions located in the slot is smaller than the other to permit a metal portion of conductors to be much larger and to increase a density of conductors in the slots, causing heating from electrical conductors to efficiently conduct to a laminated core and a housing. On the contrary, the thickness in insulating layers of the cross-over portions is larger than the other to assure insulation capability among the coils and to prevent conductors of the cross-over portion axially exposed from the core to air from water immersion to improve an electrolytic corrosion resistibility without disposing unnecessary space among coils.

Owner:MITSUBISHI ELECTRIC CORP

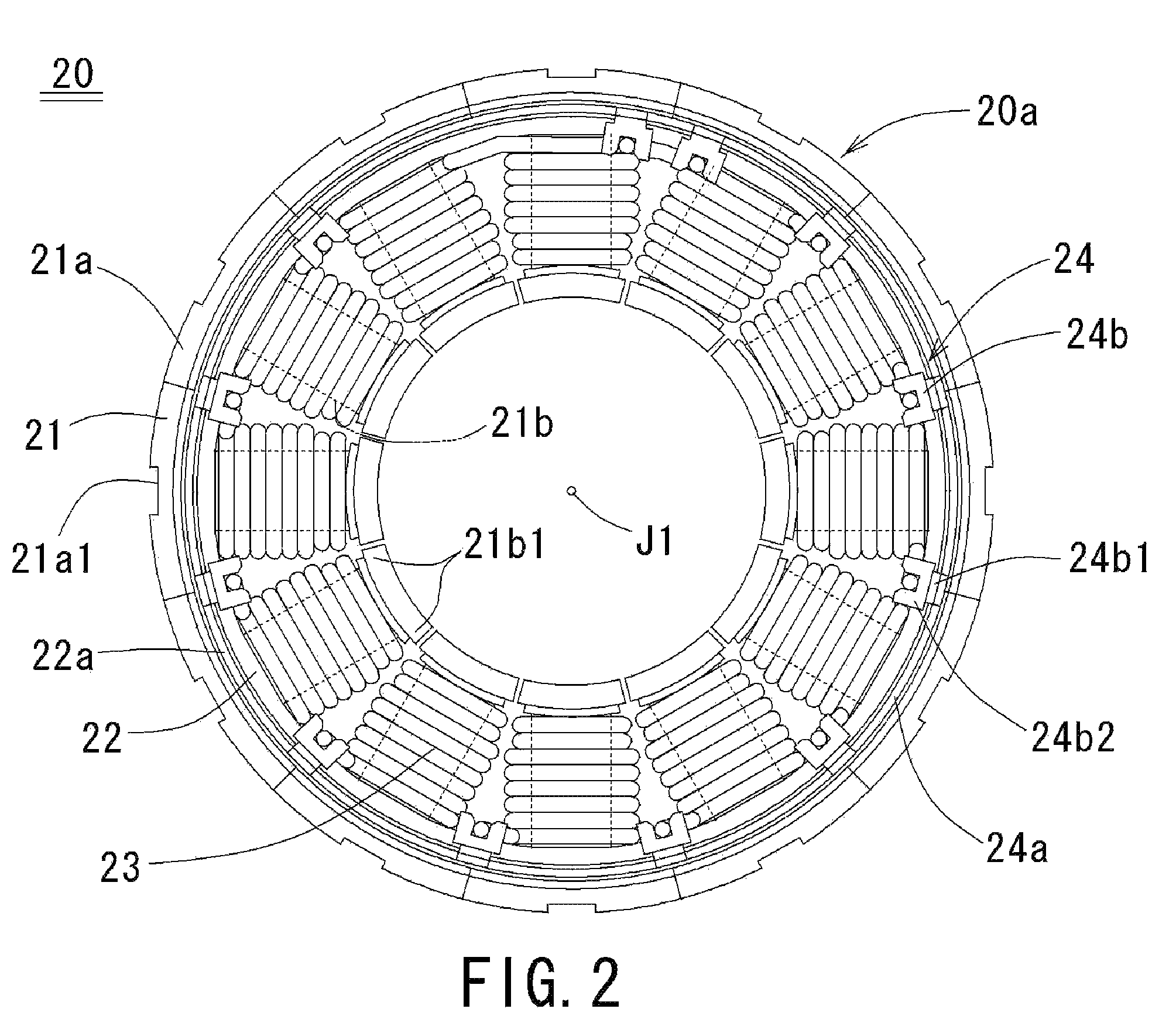

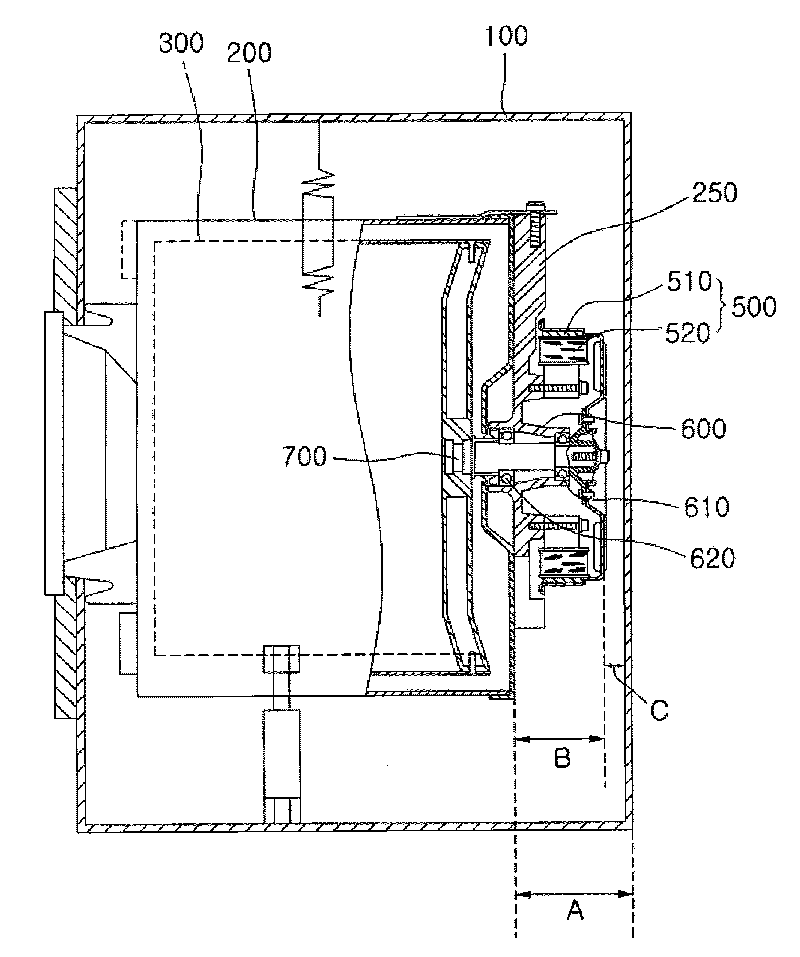

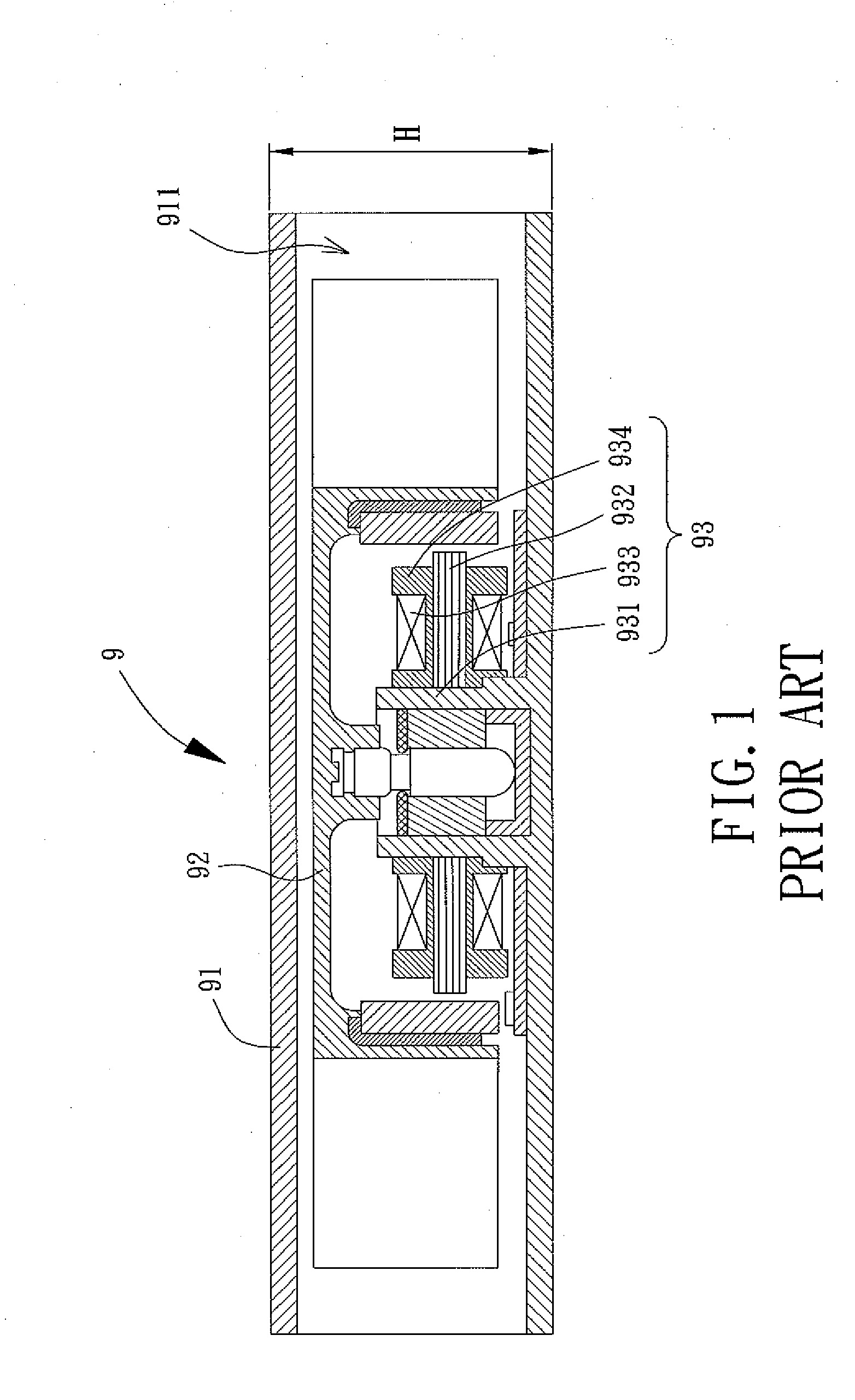

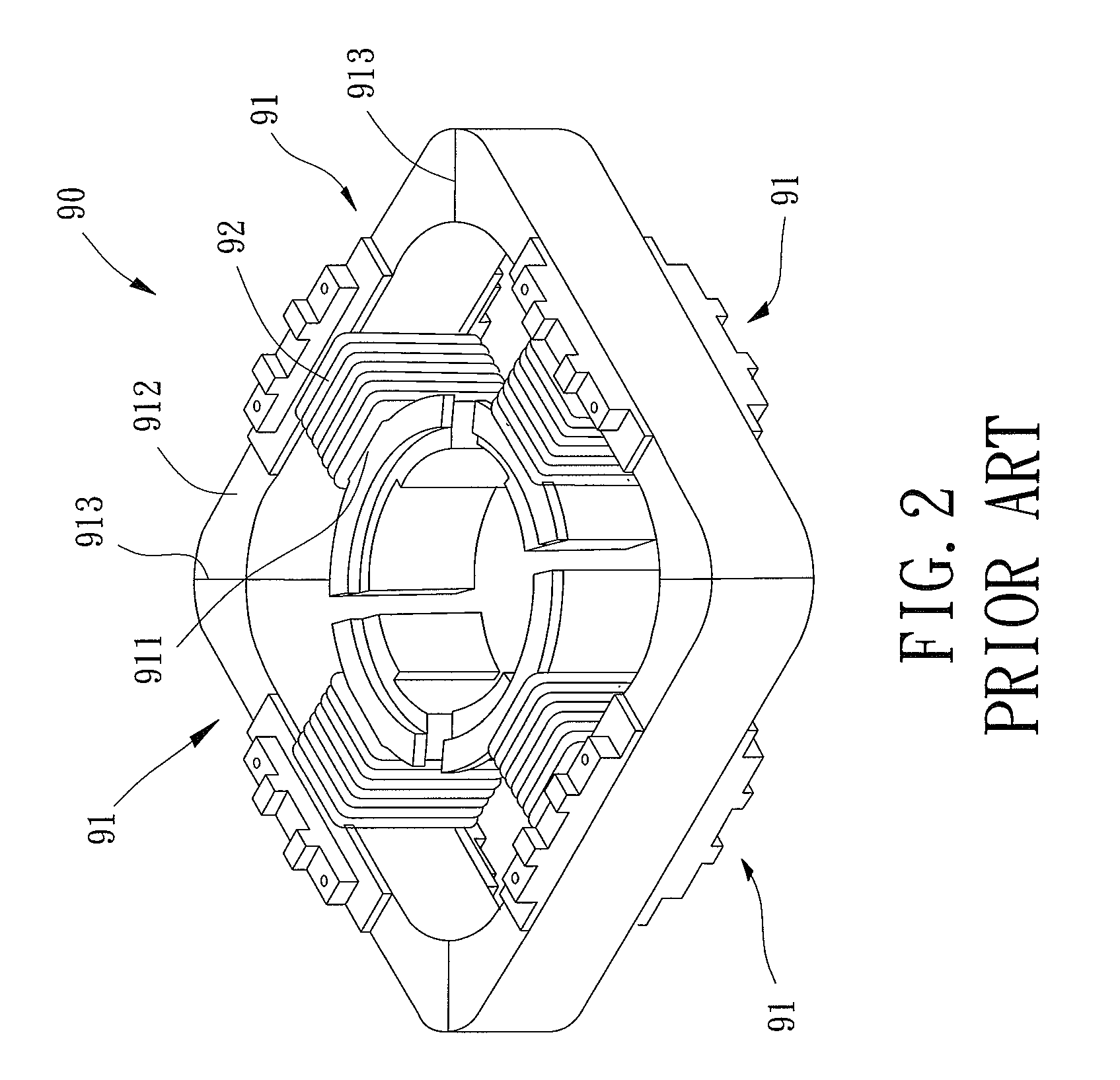

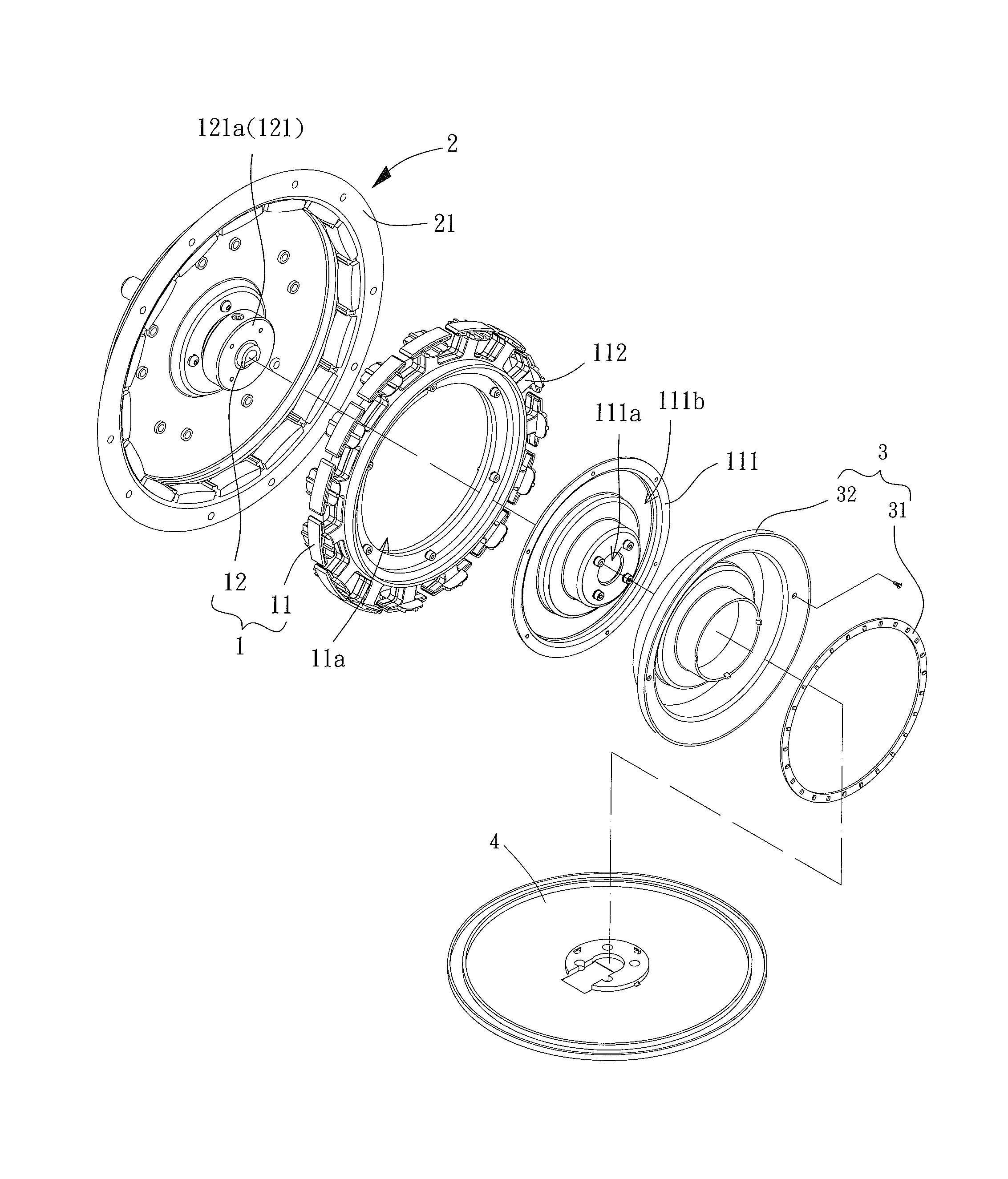

Slim type stator, slim type motor having the stator and direct drive apparatus for drum-washing machine

ActiveCN101764442AImprove assembly productivityReduce axial heightWindingsOther washing machinesBobbinCoupling

Provided is a slim type stator that is used to make a BLDC (Brushless Direct-Current) motor having a stator of a division core structure and a double rotor for use in a drum-washing machine, a slim type motor having the same, and a direct drive apparatus for use in the drum-washing machine. The stator includes: an annular division stator core assembly that is assembled in an annular form by winding a three-phase coil on a number of bobbins that are molded on respective outer circumferences of a number of division cores to thus surround a middle portion of each bobbin wherein each bobbin includes first and second flanges formed at one side of the bobbin and the other side thereof, respectively, and a coupling protrusion and a coupling groove that are formed at both side ends of the first flange that is disposed inward, and wherein the coupling protrusion and the coupling groove are mutually coupled between adjoining division stator bobbins; and a stator holder that molds the division stator core assembly that is formed in an annular form by winding the coils on the bobbins by an insert molding that uses a thermosetting resin, excepting inner and outer side surfaces of each division core of the division stator core assembly.

Owner:AMOTECH

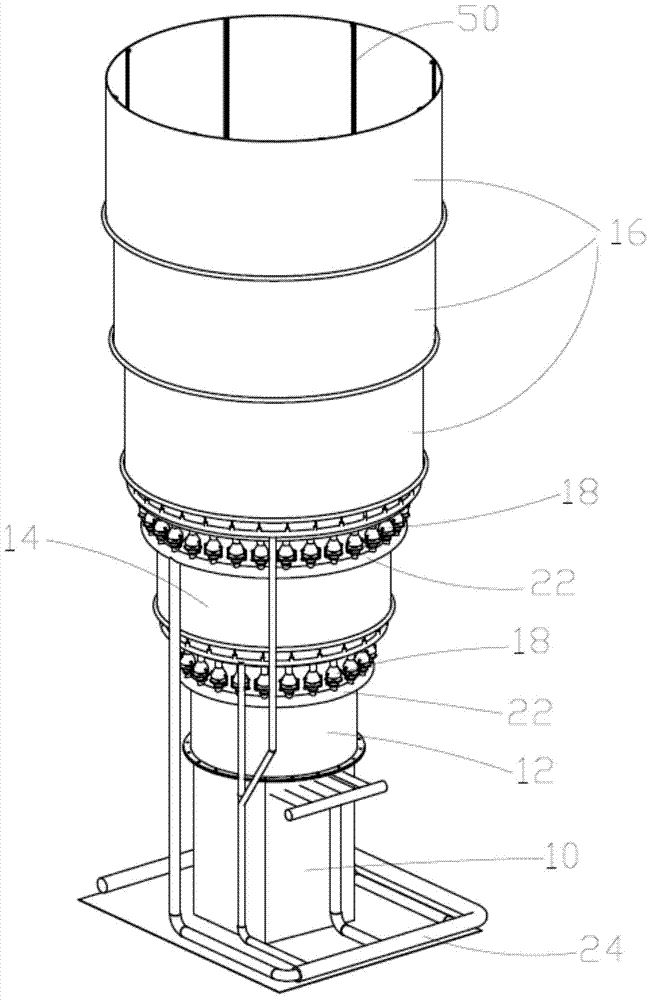

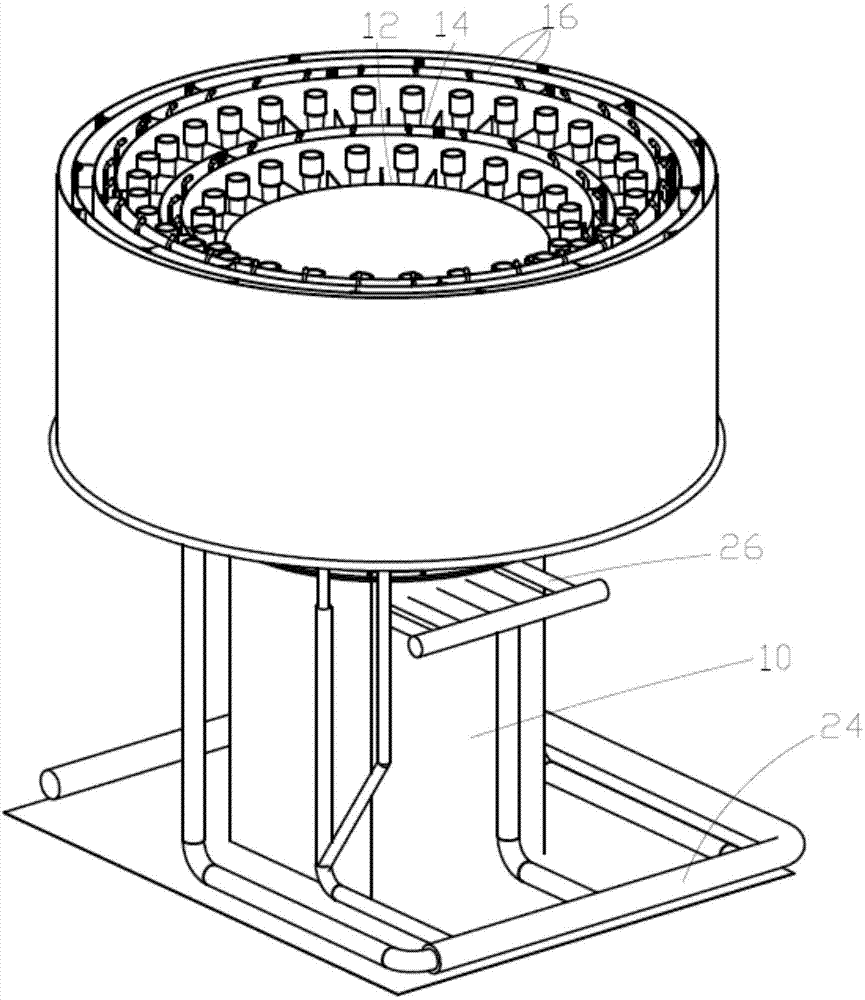

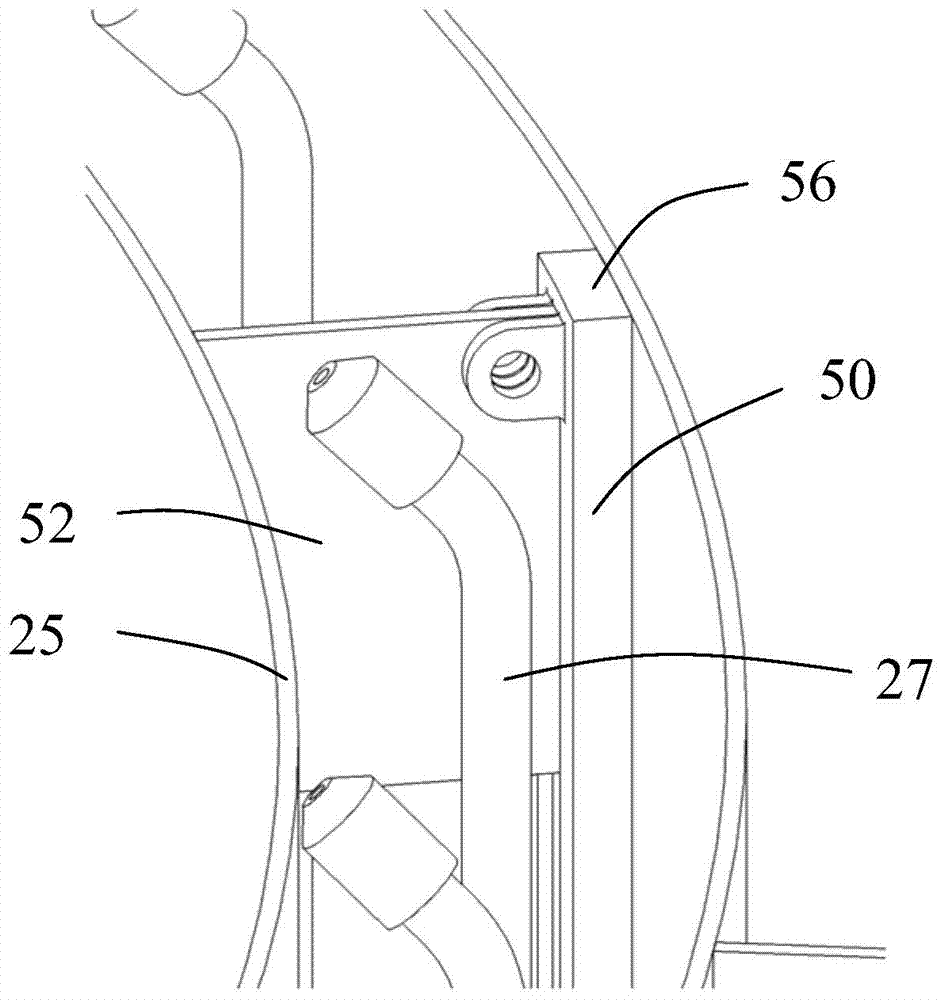

Easily-transported injected combustion apparatus

ActiveCN104764015AReduce axial heightSave spaceIncinerator apparatusGaseous fuel burnerEngineeringElectrical and Electronics engineering

The invention provides an easily-transported injected combustion apparatus. The easily-transported injected combustion apparatus comprises multiple layers of protective covers which are distributed along the vertical direction; each layer of the protective cover is circumferentially closed to form a flame cavity with upper and lower opening ends; in the vertical direction, the peripheral face of at least one layer of lower protective cover is circumferentially provided with several alternate first Venturi combustors; and in two layers of neighboring protective covers in the vertical direction, the radial dimension of the previous layer of the protective cover is greater than that of the next layer of the protective cover, and a slide rail structure is installed between two layers of the protective covers, so two layers of the protective covers can be relatively slid in the vertical direction.

Owner:SHENZHEN WISDOM ENERGY TECH CO

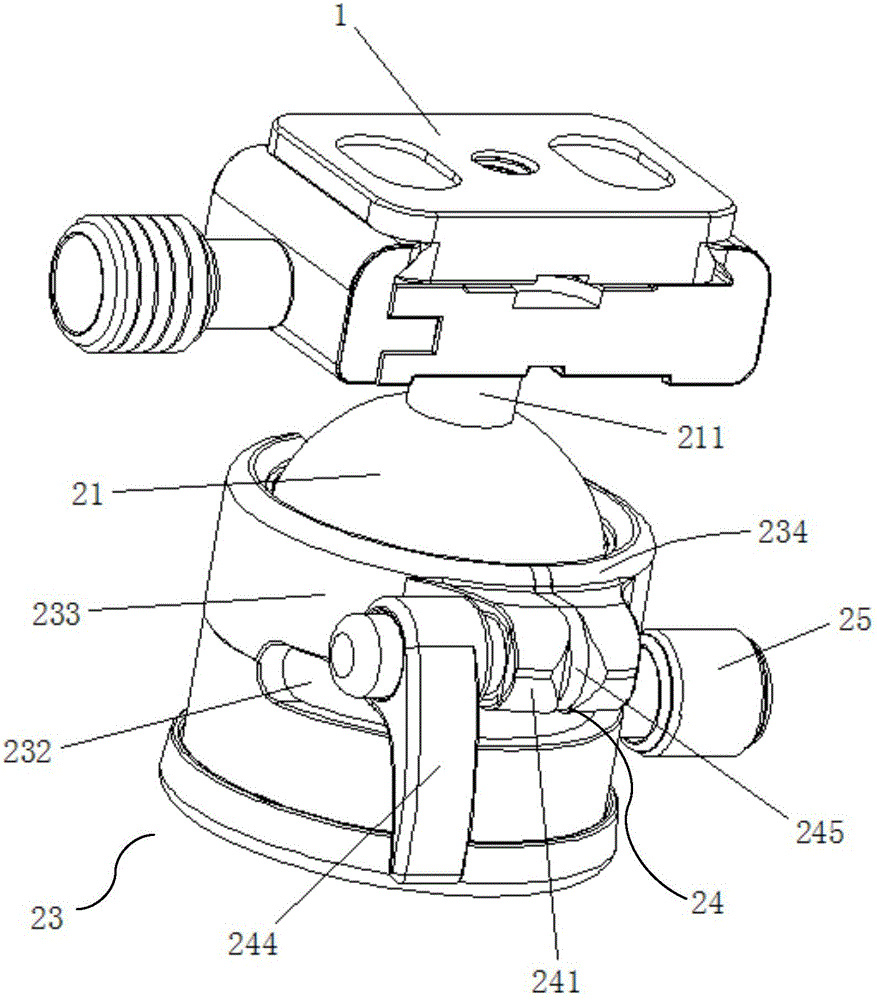

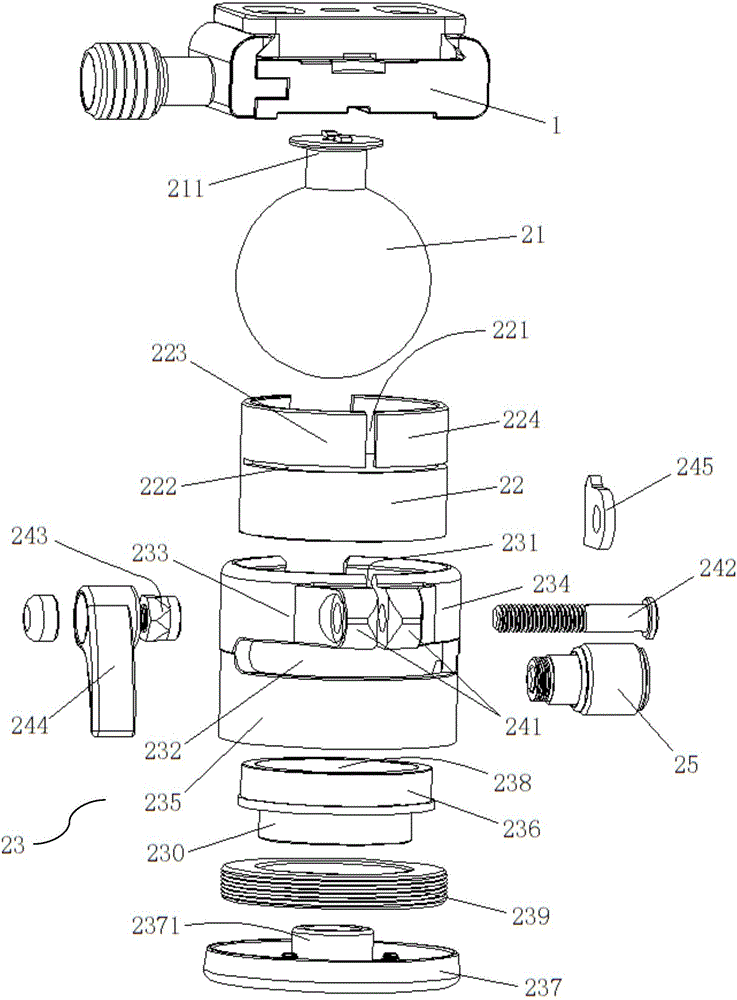

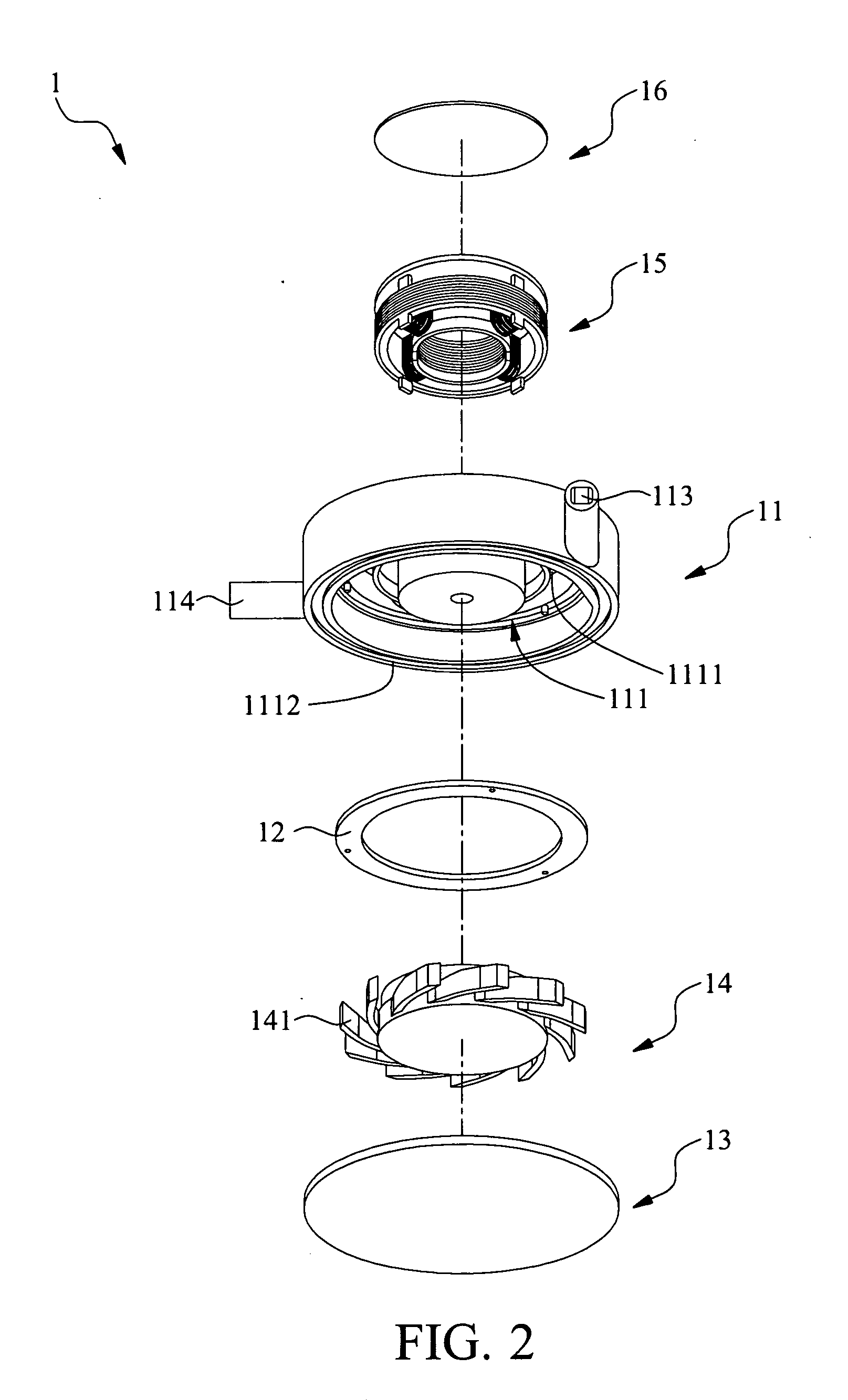

Low-axial-height universal spherical pan-tilt device

ActiveCN105864593AReduce axial heightReduce manufacturing costStands/trestlesCamera body detailsLocking mechanismTripod head

The invention relates to a low-axial-height universal spherical pan-tilt device which comprises a fast mounting seat and a low-axial-height universal seat. The low-axial-height universal seat comprises a universal ball, an internal locking sleeve and an external locking seat, the universal ball and the internal locking sleeve are mounted in the external locking seat, the internal locking sleeve sleeves the universal ball, and the fast mounting seat is mounted on a connection seat of the universal ball. The internal locking sleeve is provided with longitudinal and transverse internal locking avoidance ports, the the external locking seat is provided with longitudinal and transverse external locking avoidance ports, left and right holding portions are formed on the internal locking sleeve, and left and right locking portions are formed on the external locking seat. When the universal ball is locked, a screw locking mechanism on the left and right locking portions is operated to enable the left and right locking portions to drive the left and right holding portions to draw together and be tightened inwards, and then the left and right holding portions tightly hold the universal ball in an attached manner, so that the angle of the fast mounting seat can be adjusted and locked arbitrarily, conveniently and rapidly. The low-axial-height universal spherical pan-tilt device is stable, reliable and ingenious and compact in structure, and the axial height and cost are reduced.

Owner:张秀珠

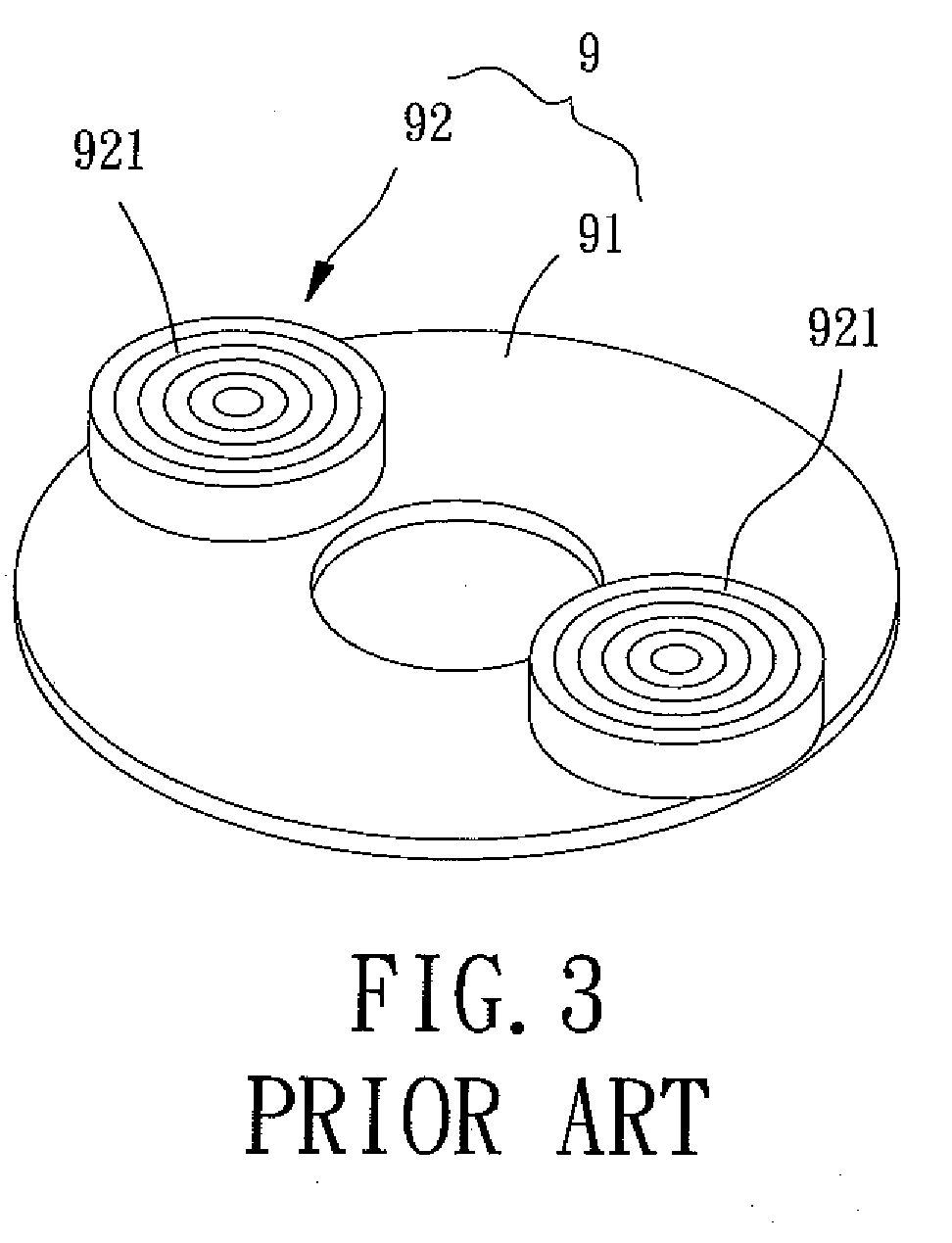

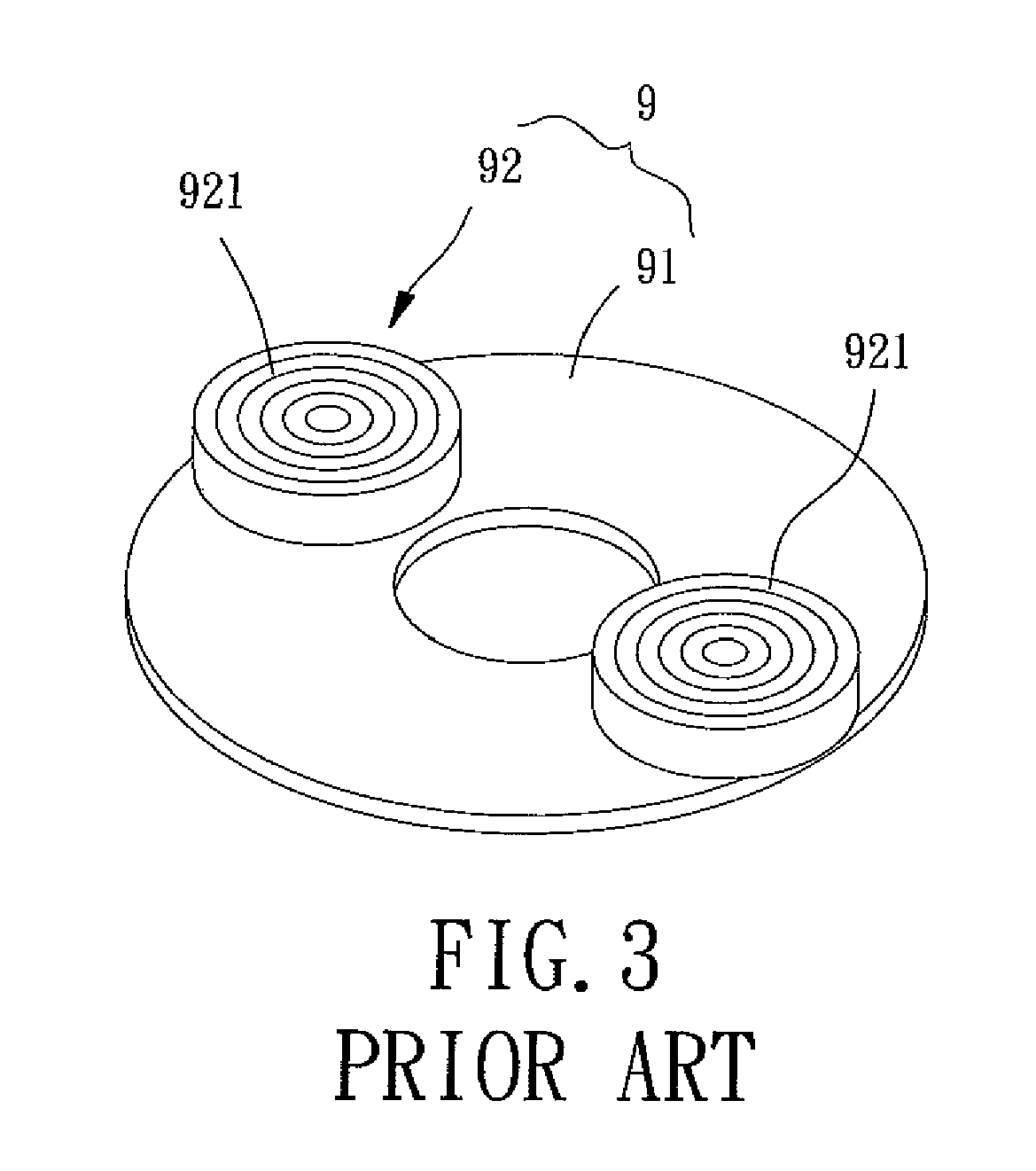

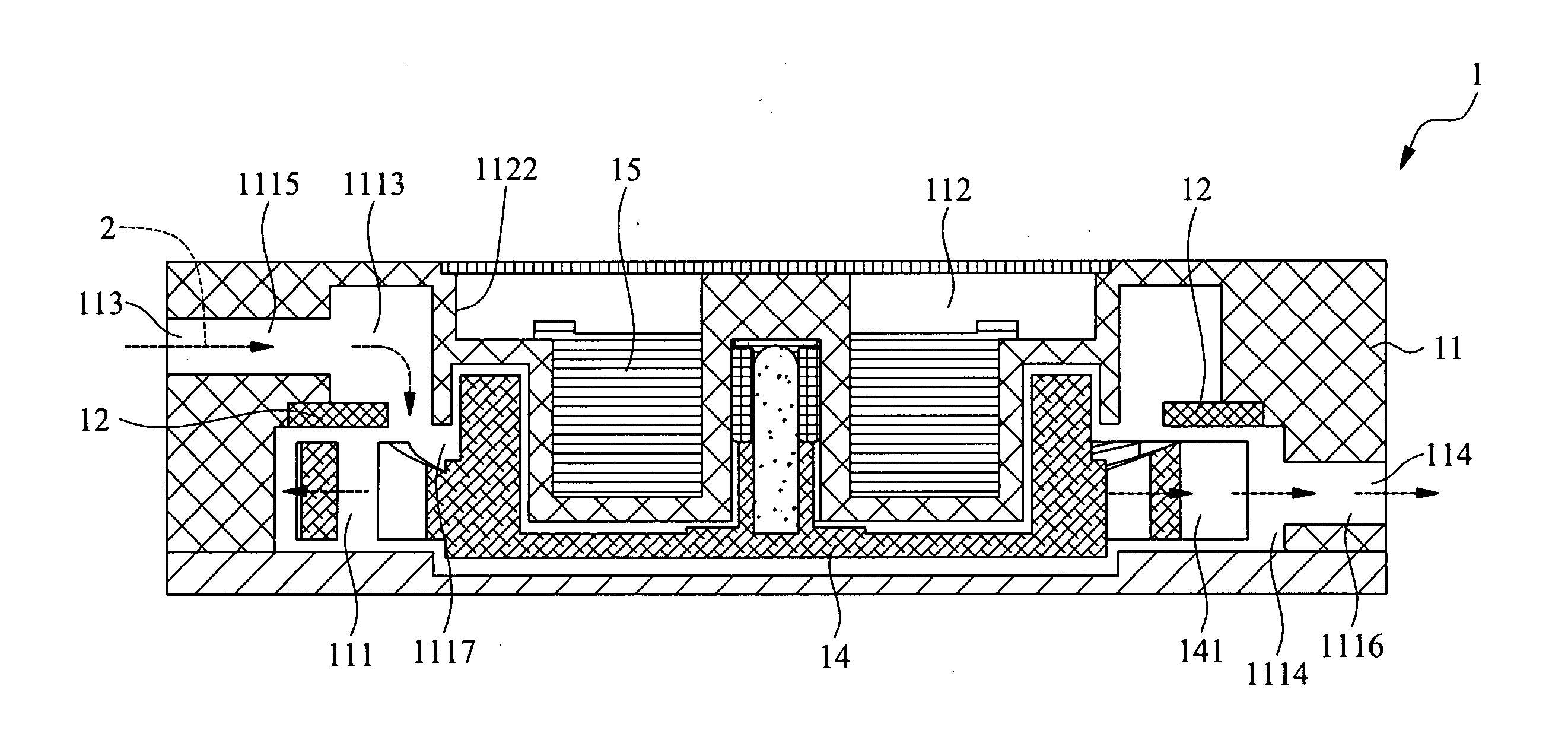

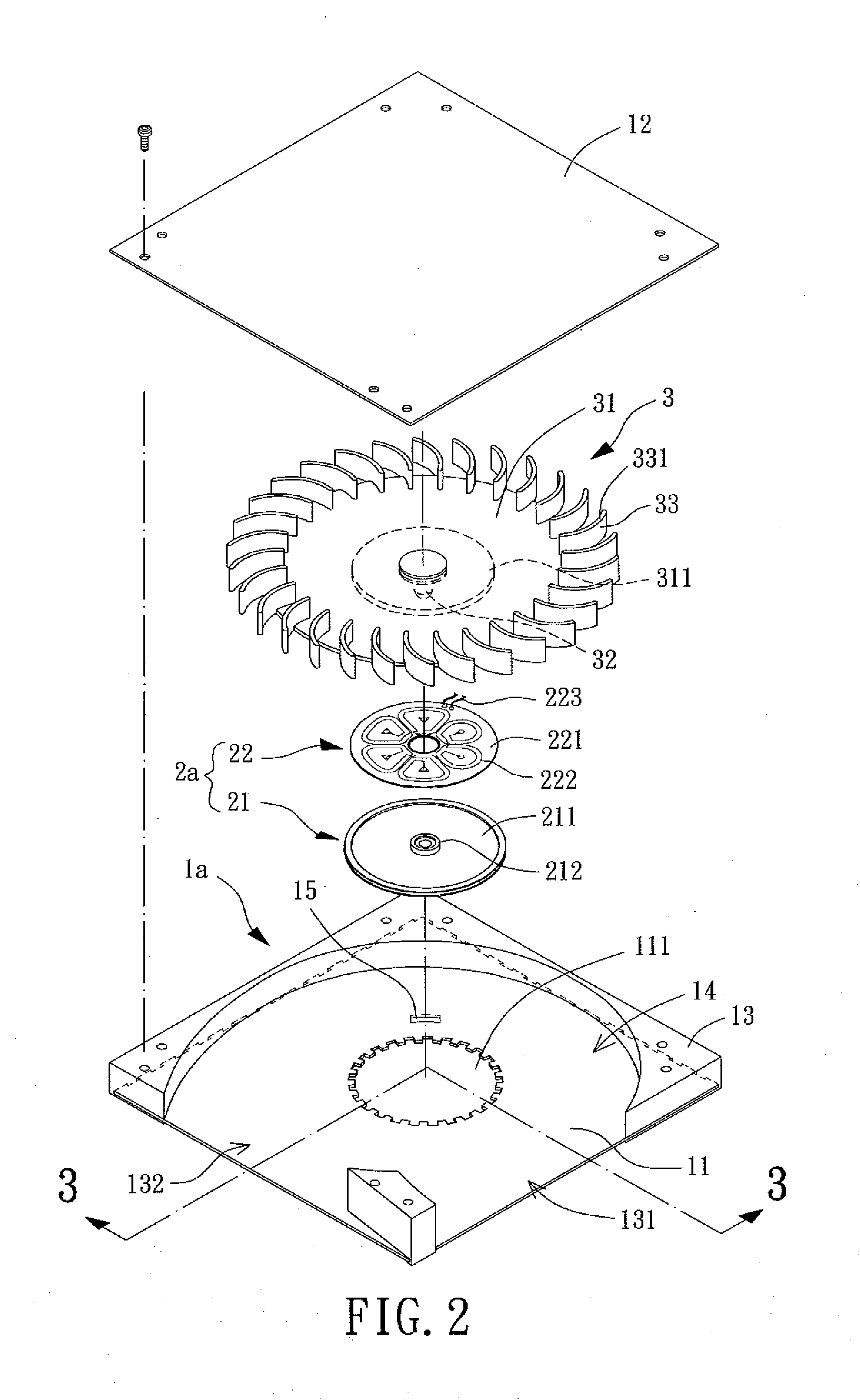

Micropump structure

ActiveUS20100322801A1Simple structureReduce axial heightPump componentsReaction enginesPropellerEngineering

A micropump structure including a main body, at least one water room partitioning board, at least one fan propeller and at least one drive unit. The main body has at least one water room, an inlet and an outlet. The inlet and the outlet are disposed on a circumference of the main body in communication with the water room. The water room partitioning board is disposed in the water room to divide the water room into at least one water incoming section and at least one water discharging section. The fan propeller is disposed in the water room. The drive unit is disposed in the main body. By means of the water room partitioning board, the flow guiding efficiency of the micropump is greatly enhanced and the axial height of the micropump is reduced so that the working efficiency is promoted and less room is occupied.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

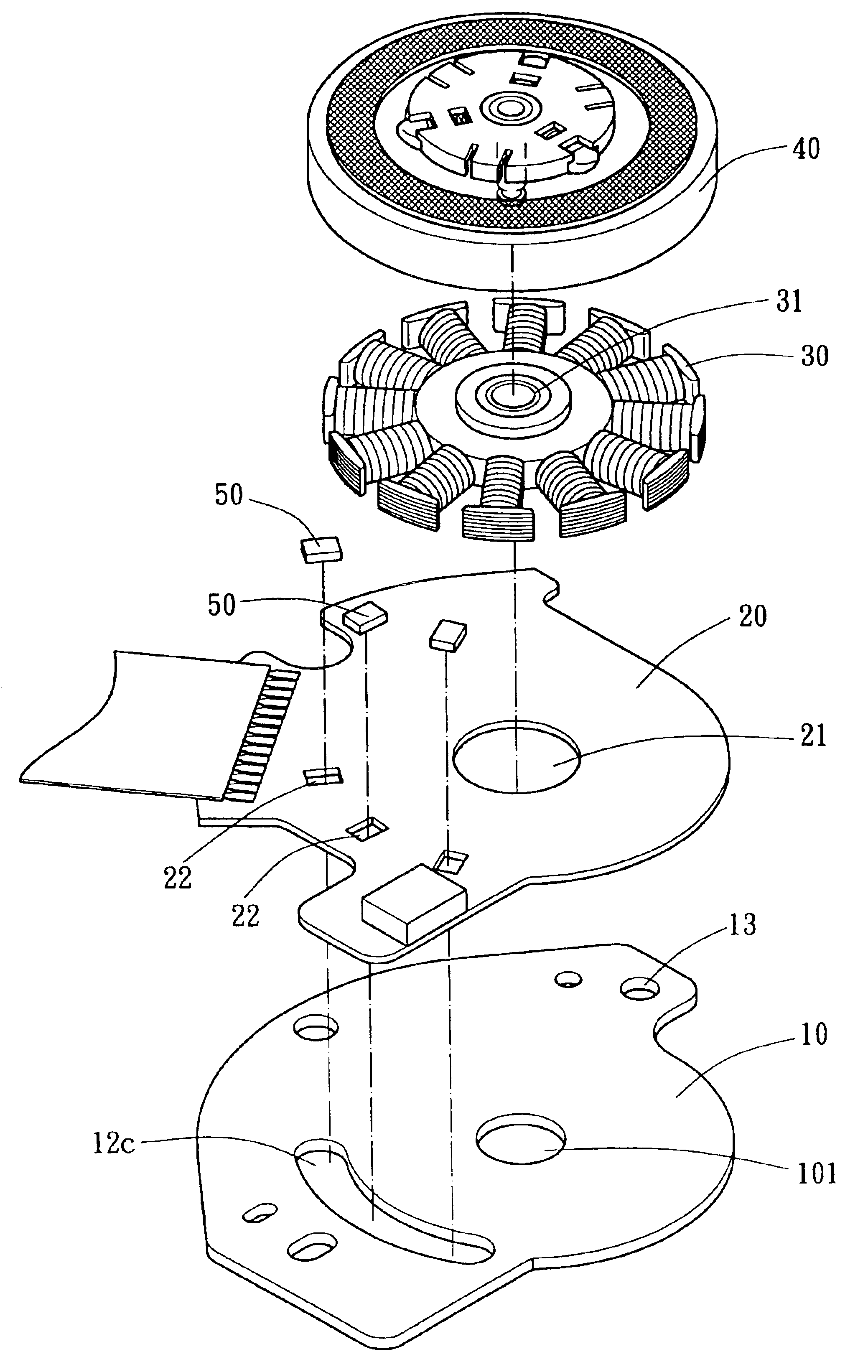

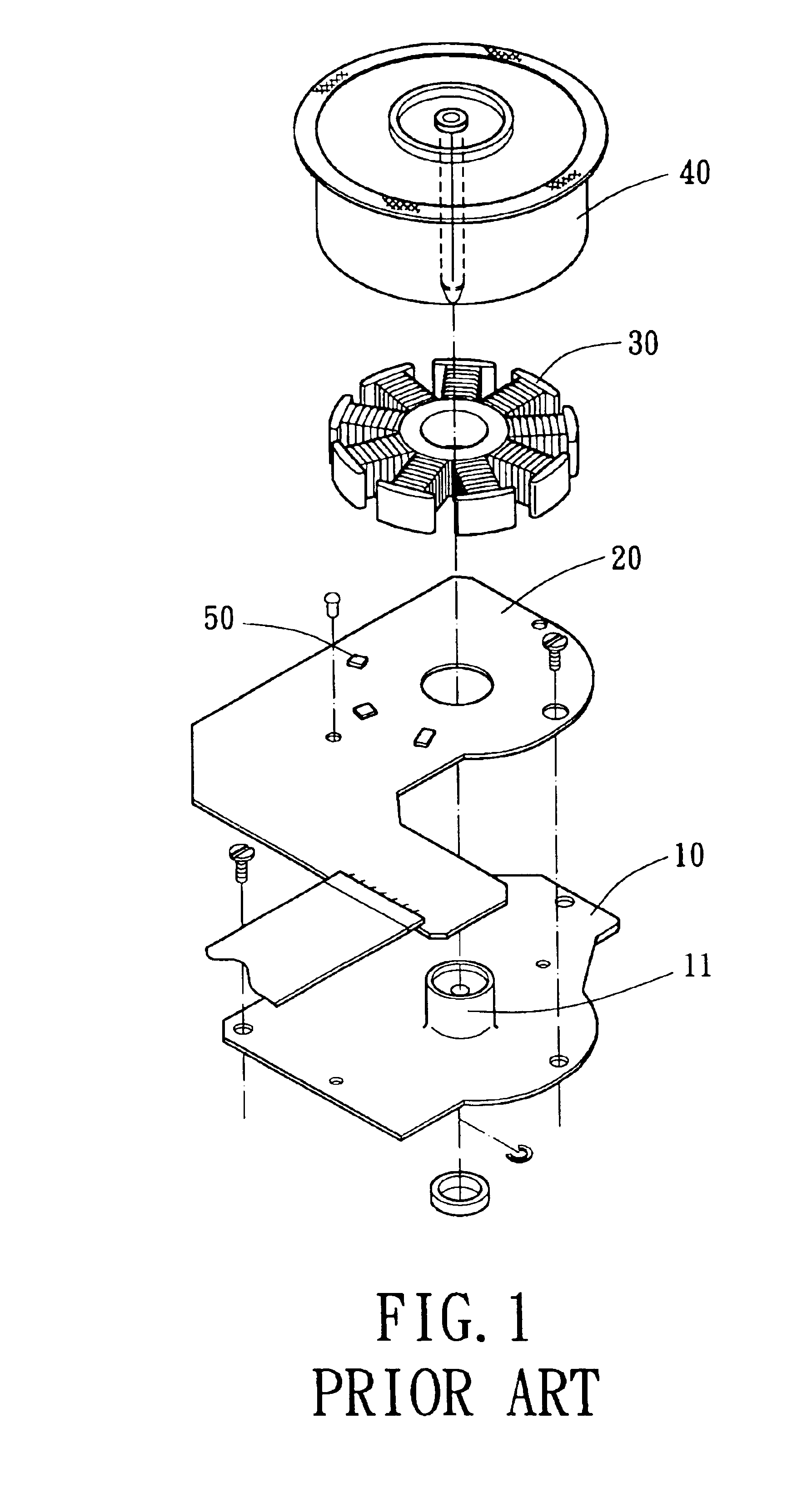

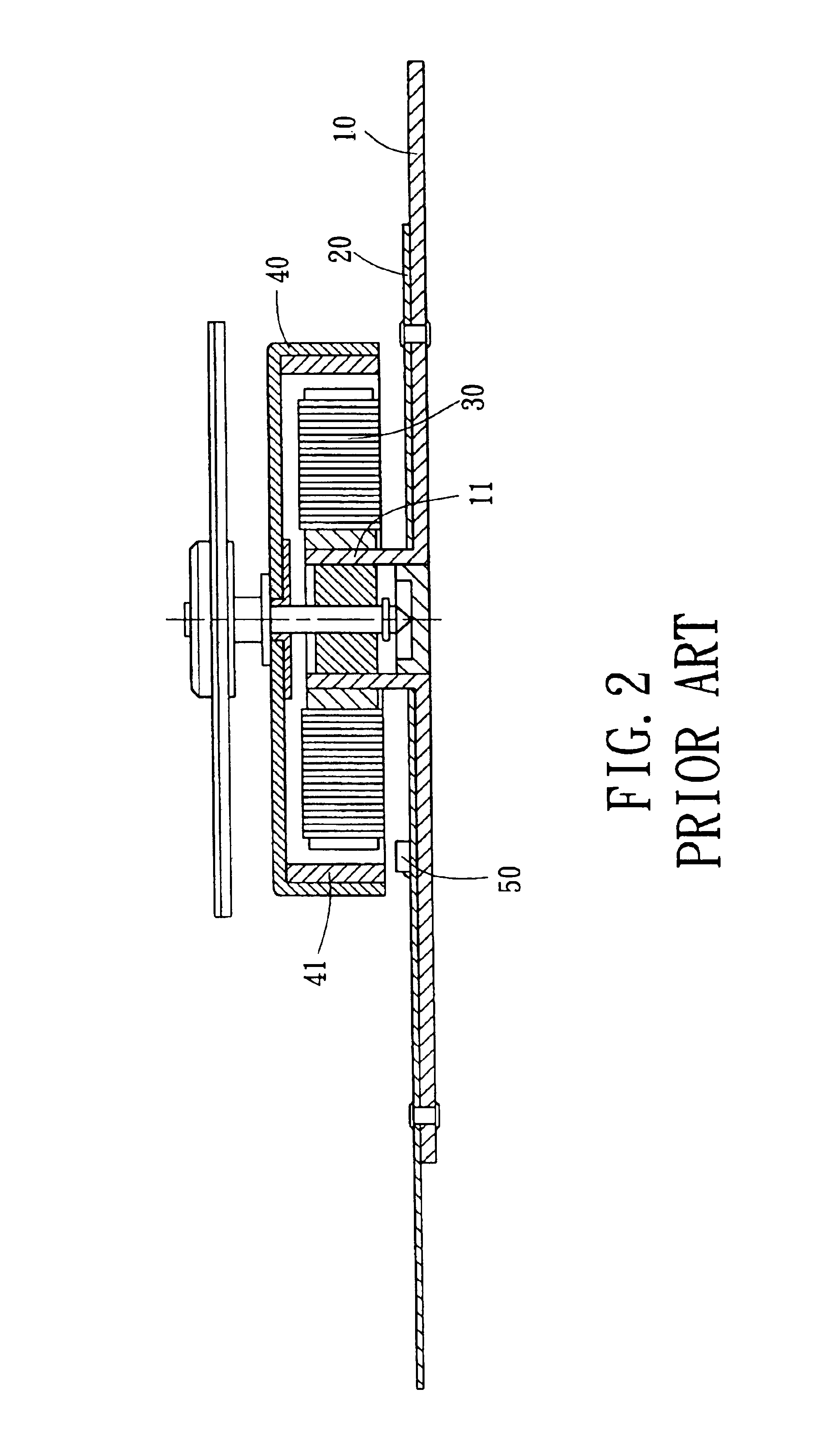

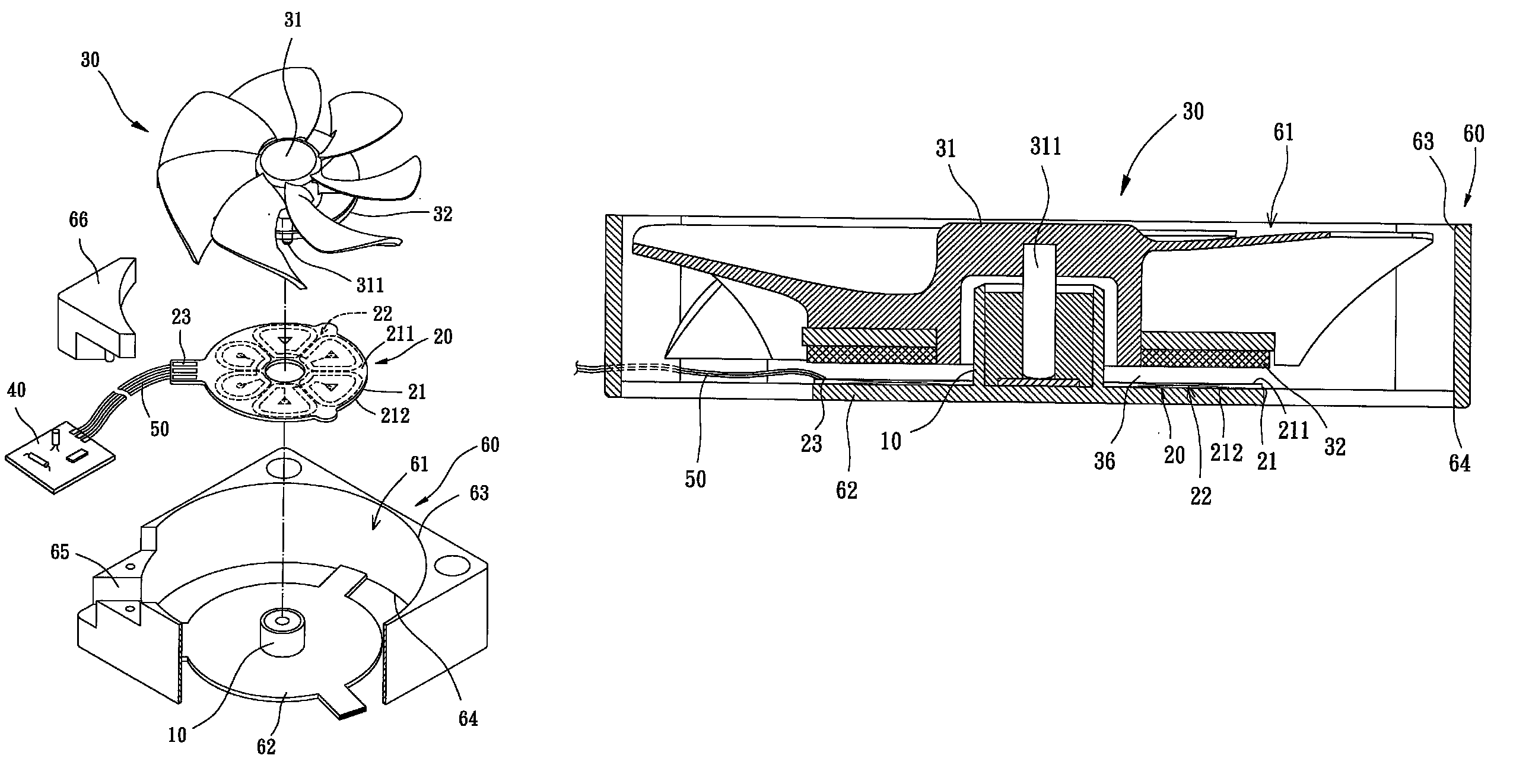

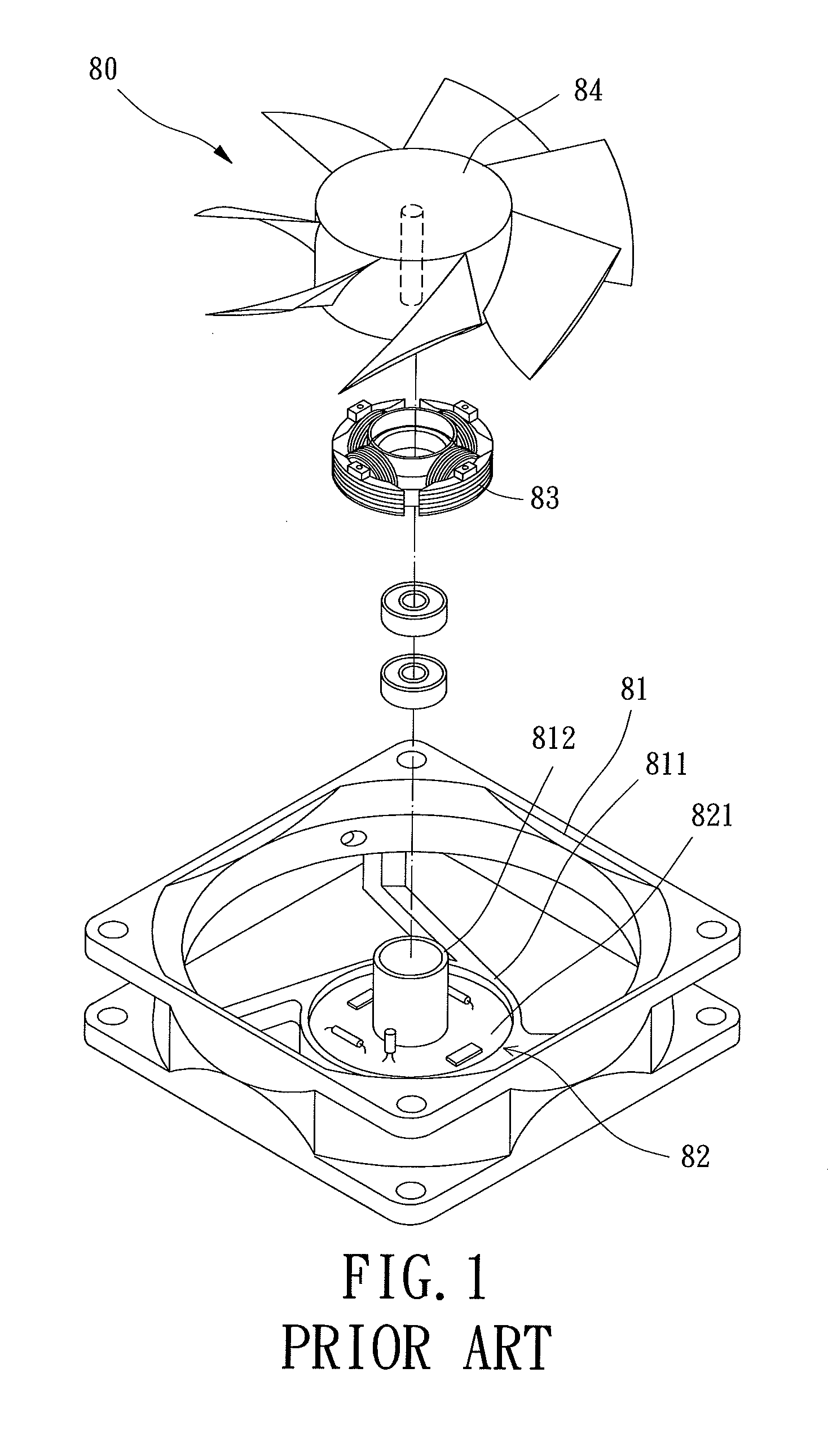

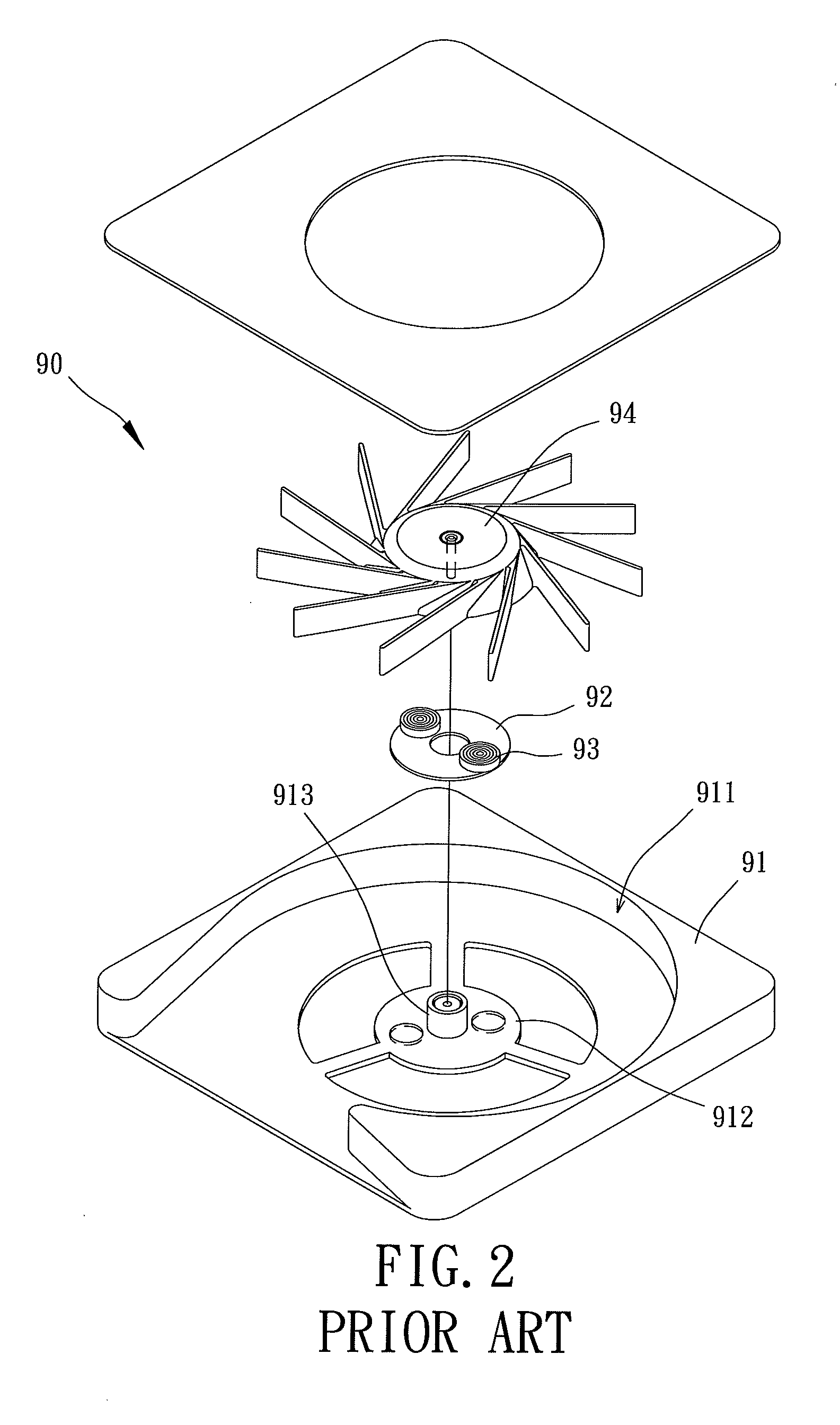

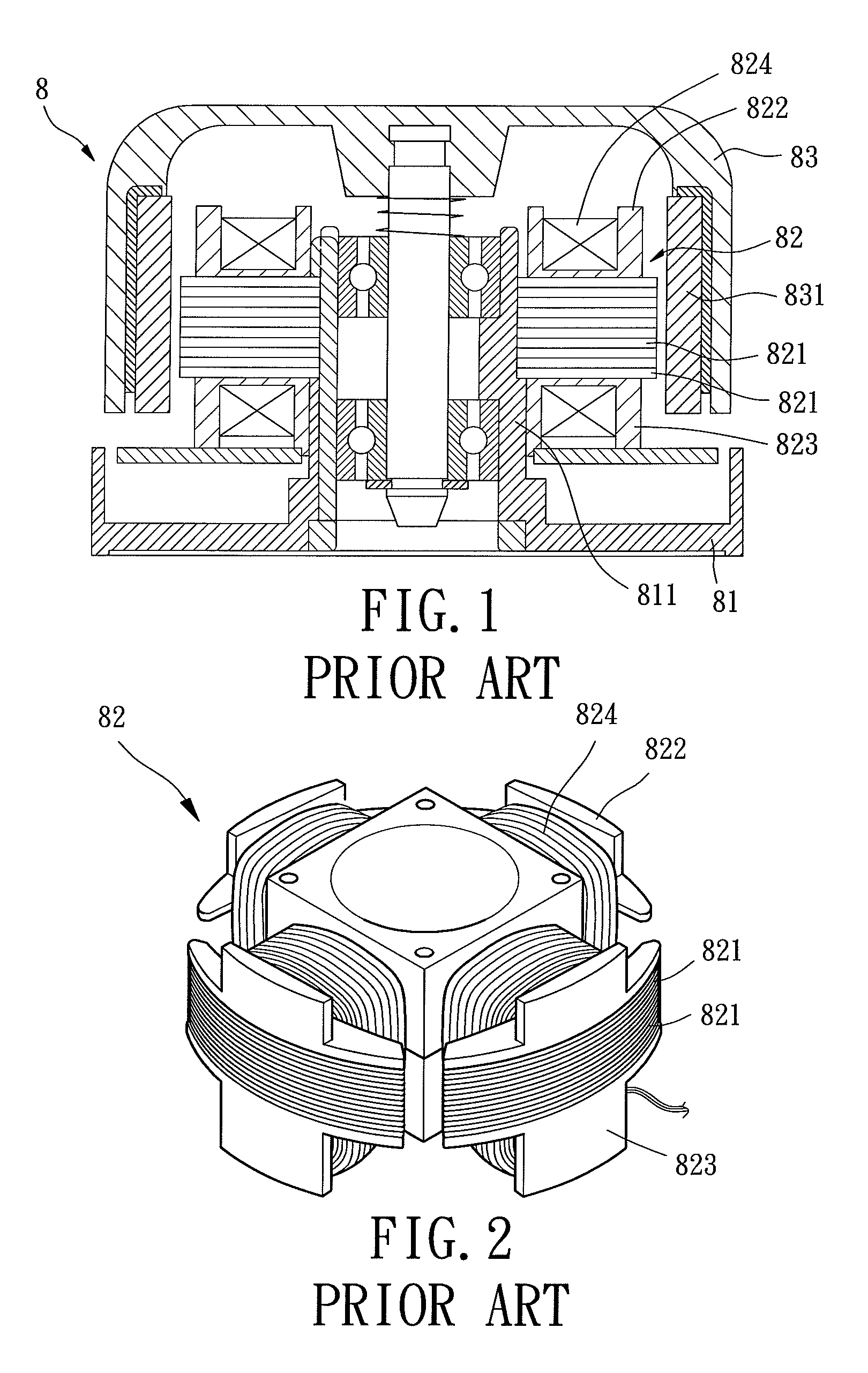

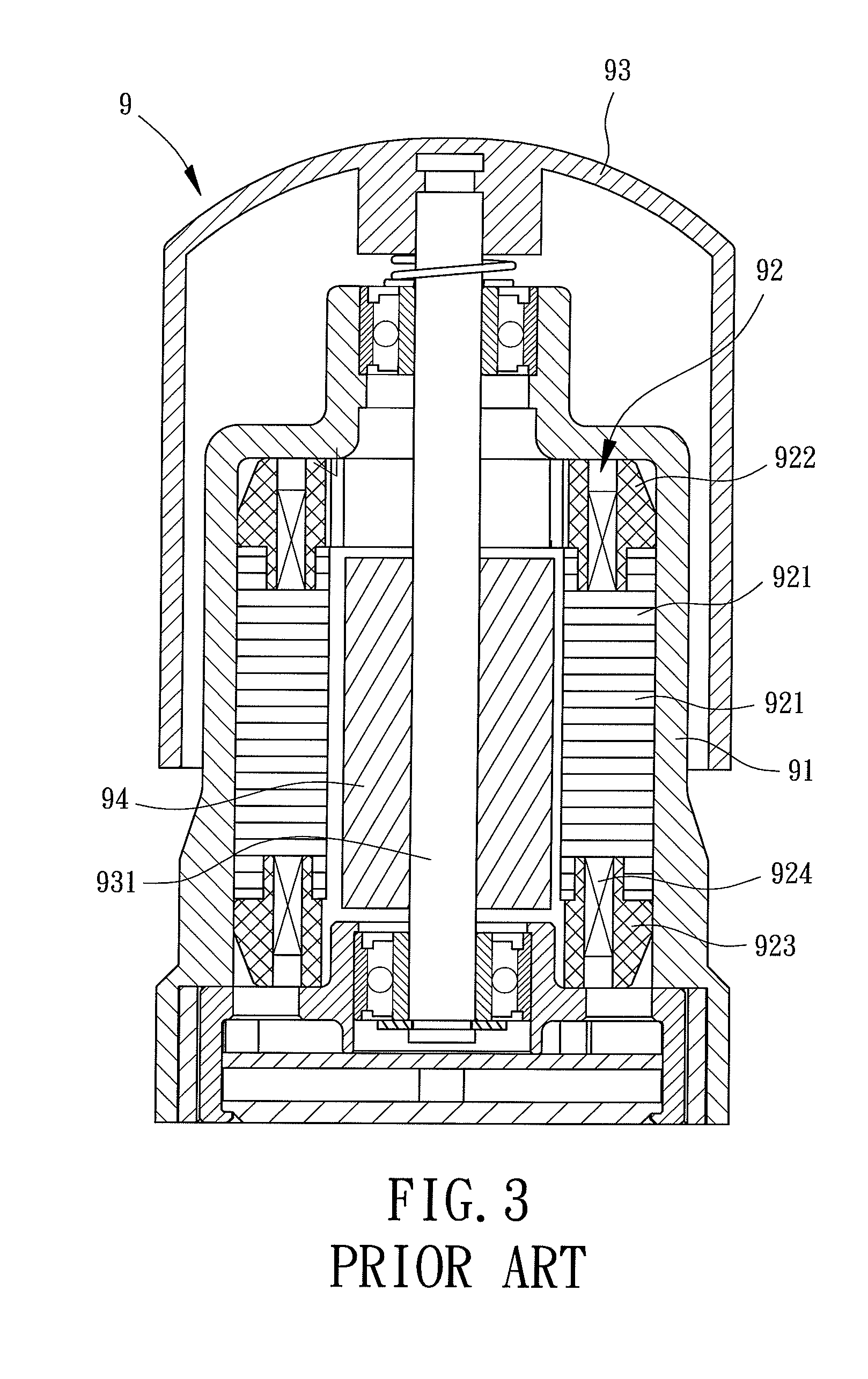

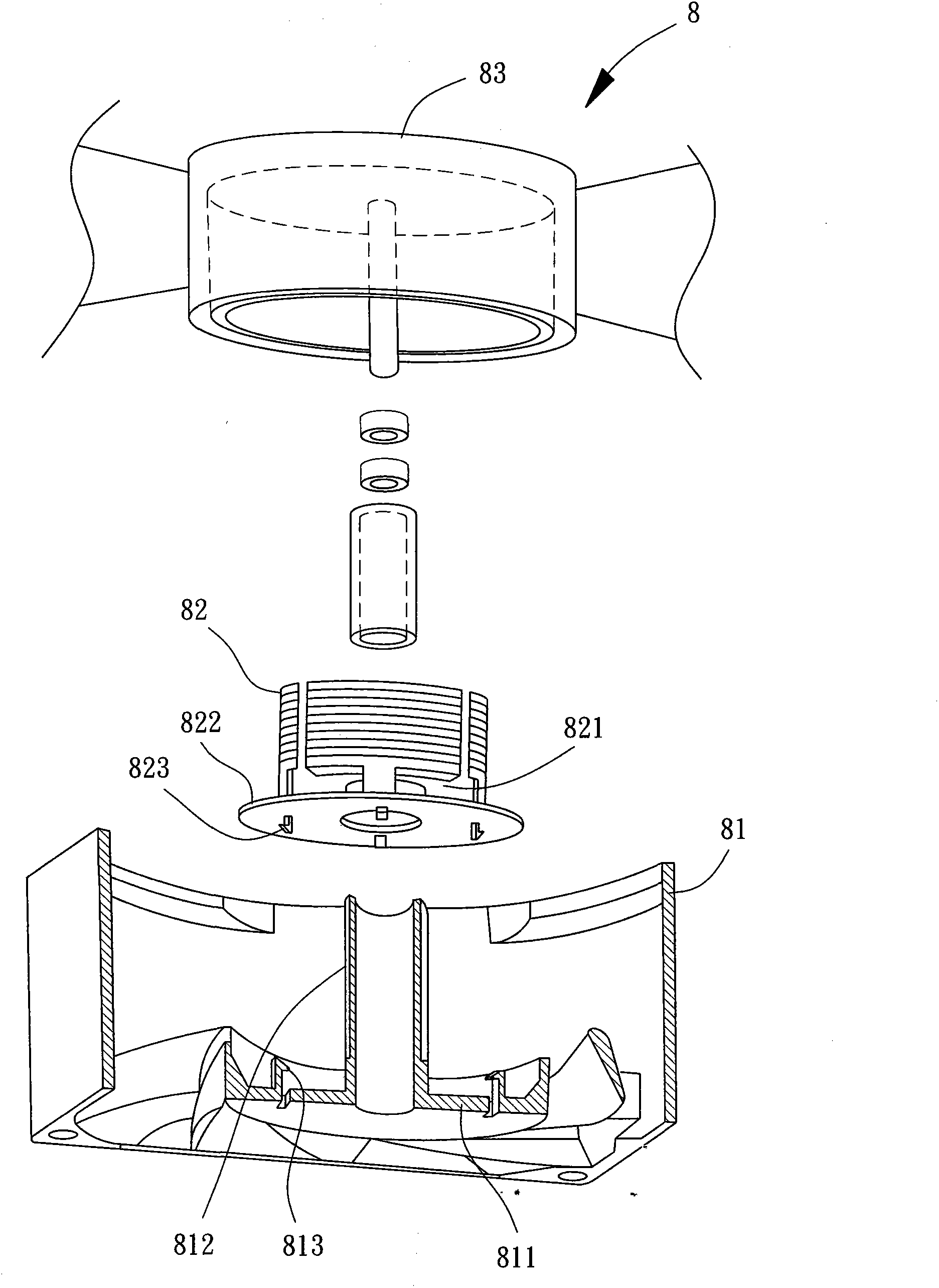

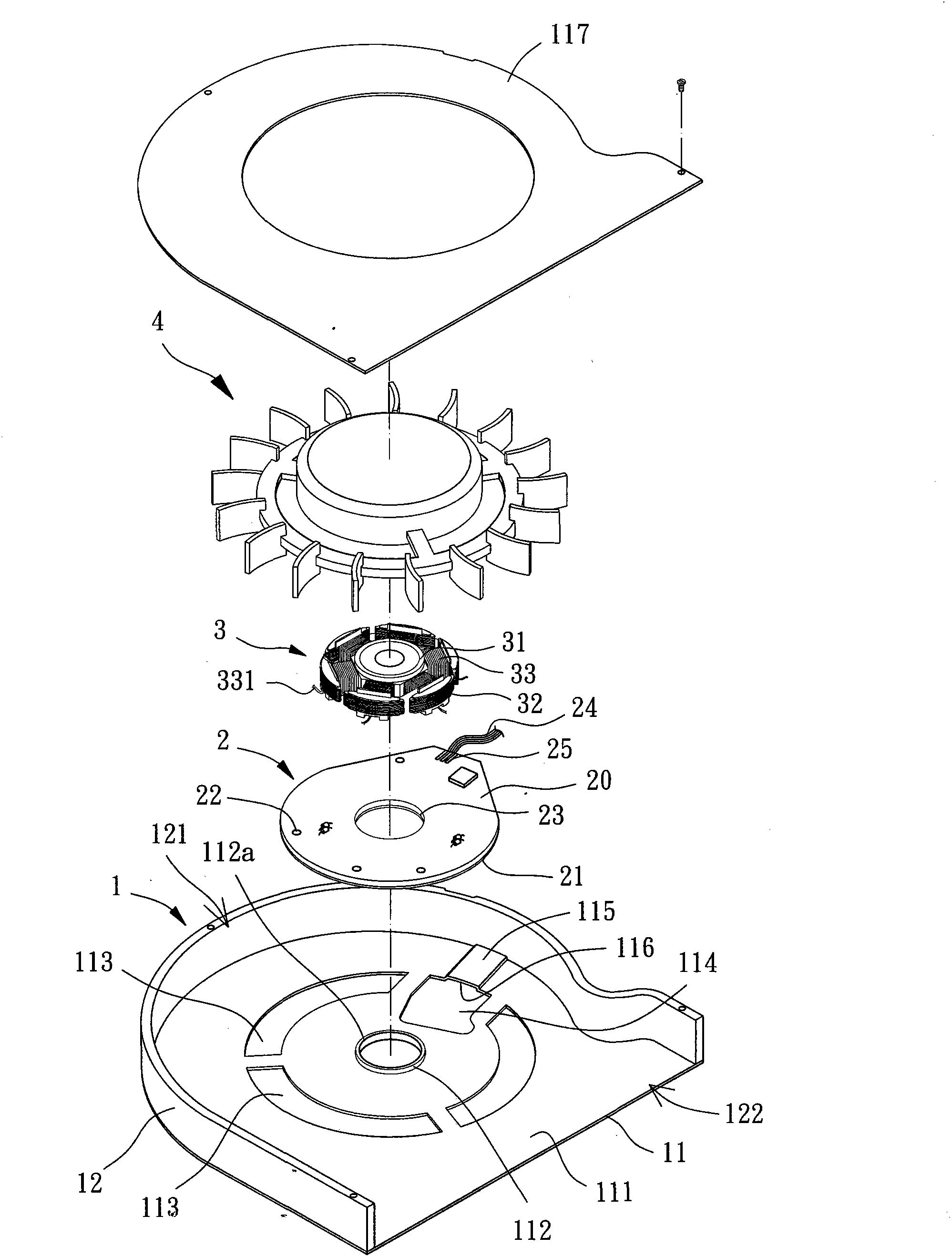

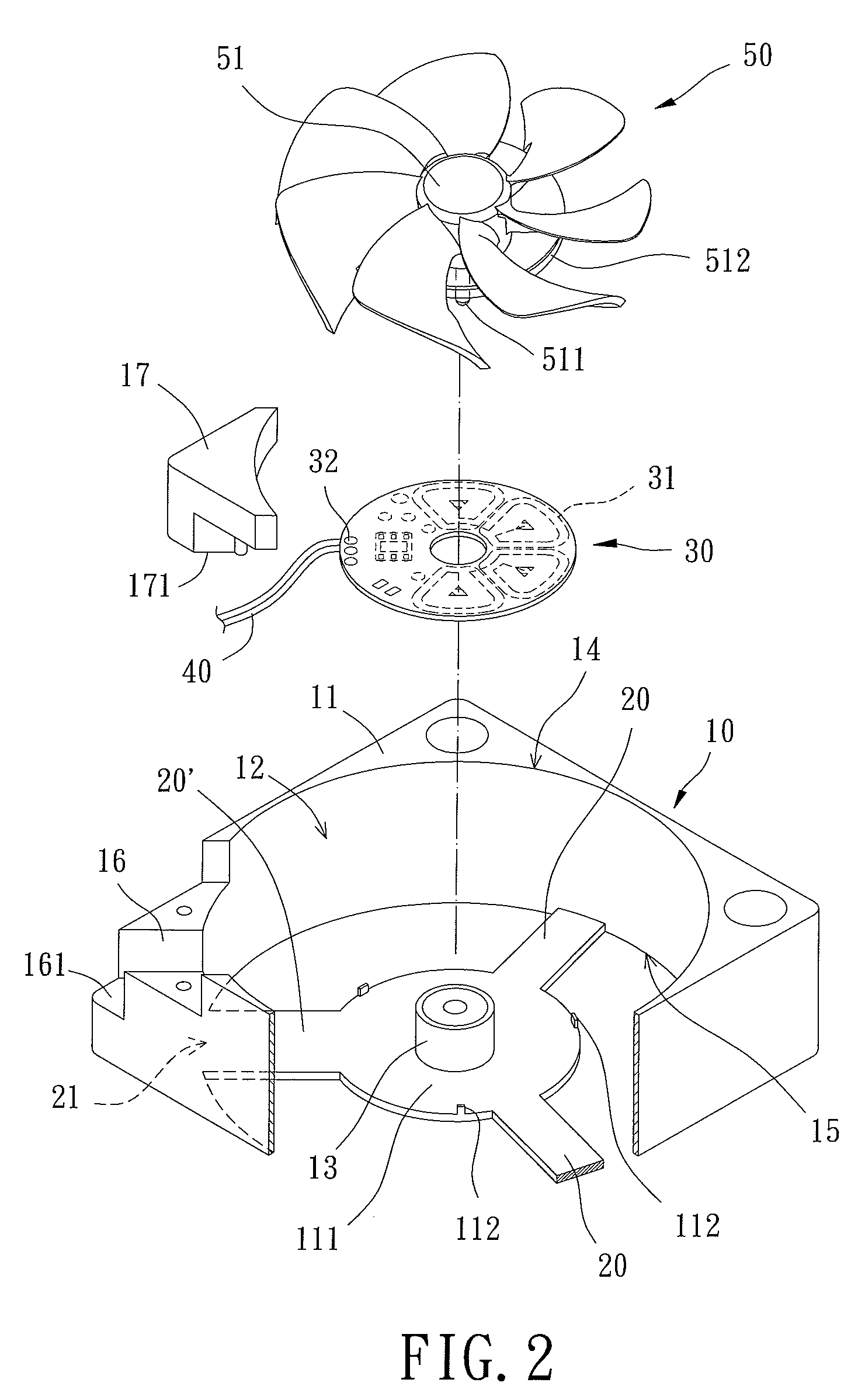

Combination structure of a motor

InactiveUS6919657B2Increase heightEasy to installRecord information storageMagnetic circuit stationary partsPrinted circuit boardMagnet

Owner:SUNONWEALTH ELECTRIC MACHINE IND

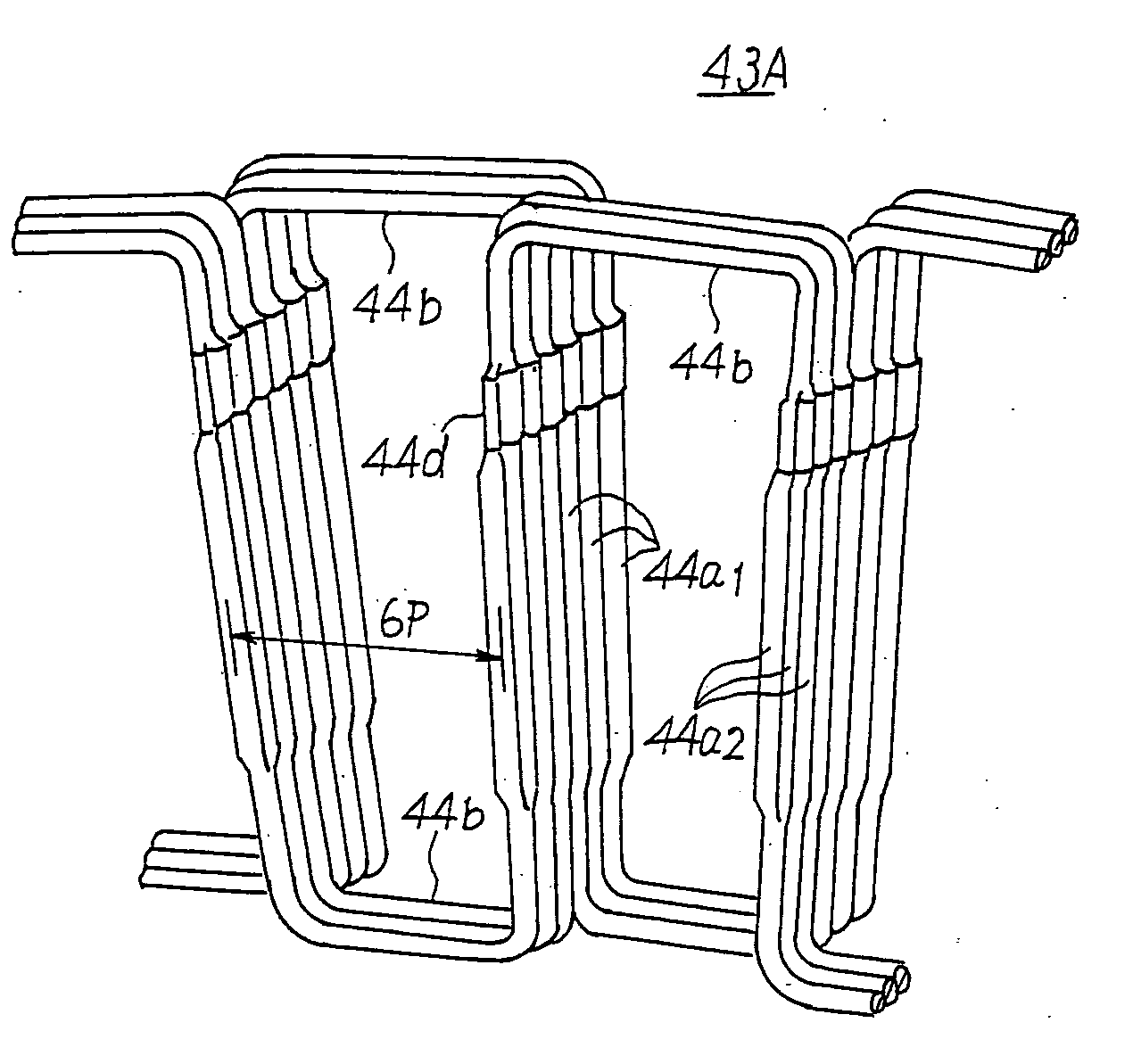

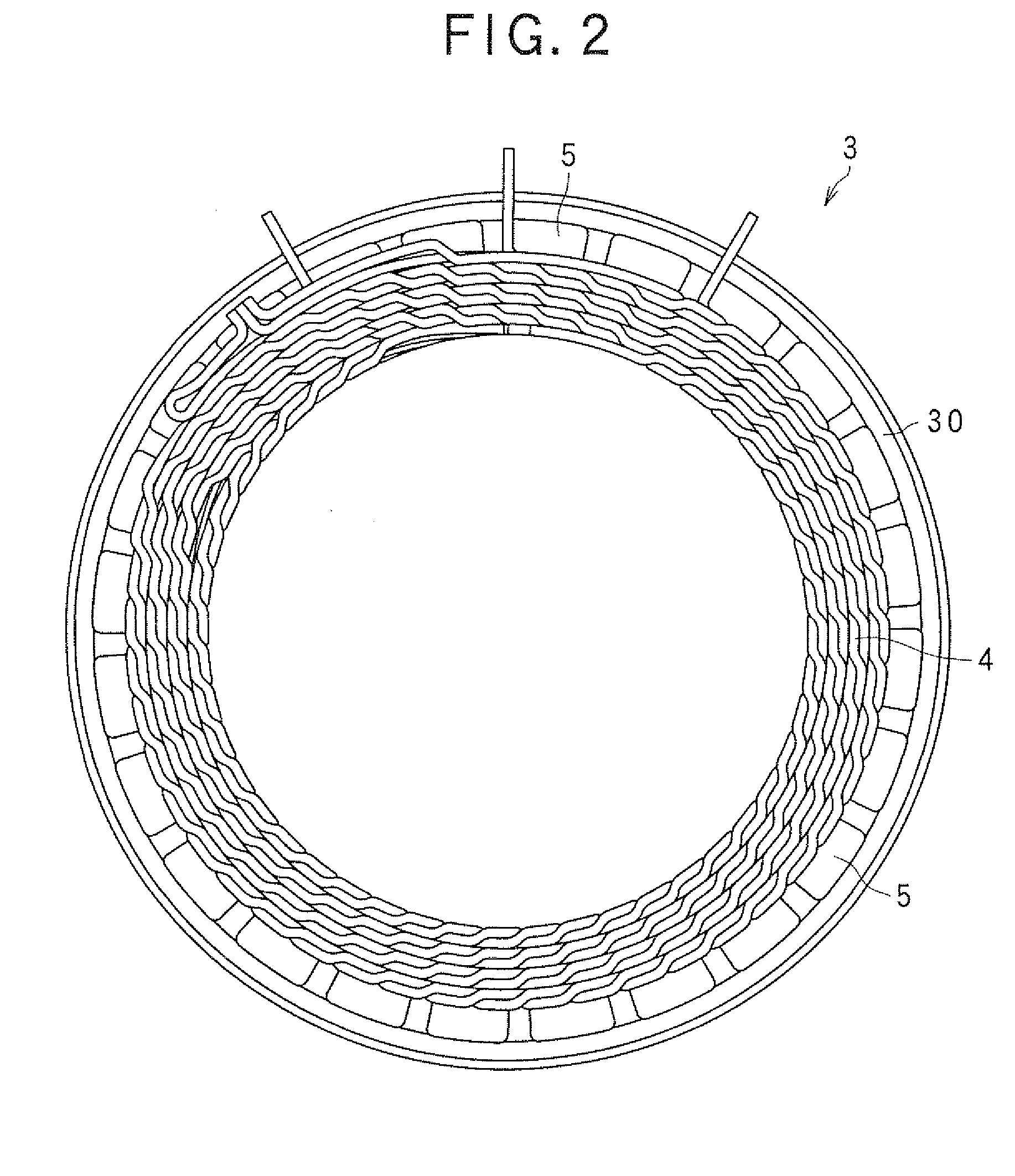

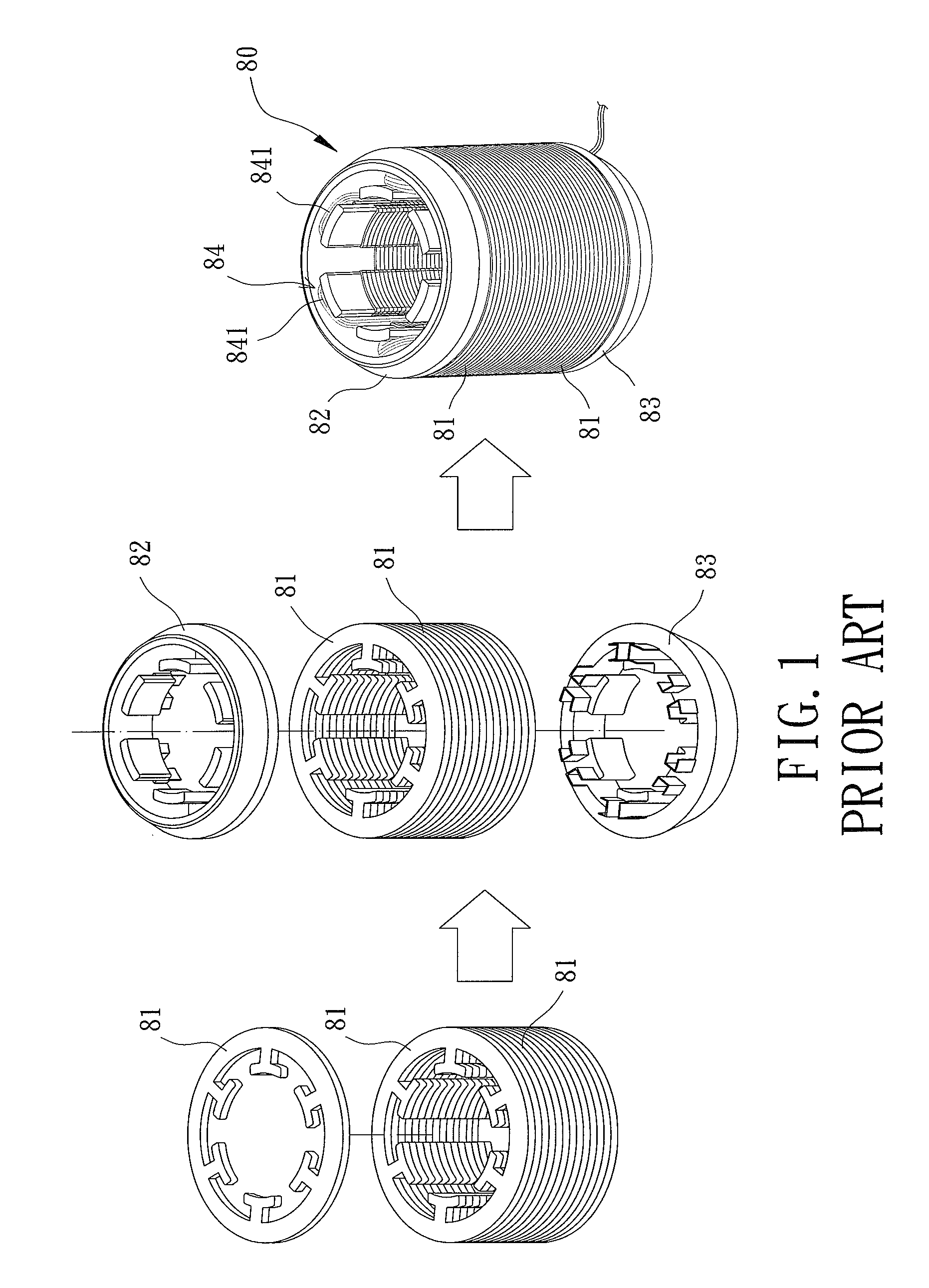

Method of manufacturing stator for dynamoelectric machine

ActiveUS20100064505A1Improve performanceGap minimizationManufacturing dynamo-electric machinesElectromagnetsElectric wireElectric motor

There is disclosed a method of manufacturing a stator for a dynamoelectric machine. The method includes a step of mounting a hollow cylindrical electric wire assembly, which includes a plurality of straight stacked portions of shaped electric wires, to a hollow cylindrical stator core that includes a plurality of slots formed in the radially inner surface thereof. The mounting step includes: (1) placing the electric wire assembly radially inside of the stator core so that each of the straight stacked portions of the electric wire assembly is radially aligned with a corresponding one of the slots of the stator core; and (2) radially expanding the electric wire assembly to insert the straight stacked portions of the electric wire assembly into the corresponding slots of the stator core.

Owner:DENSO CORP

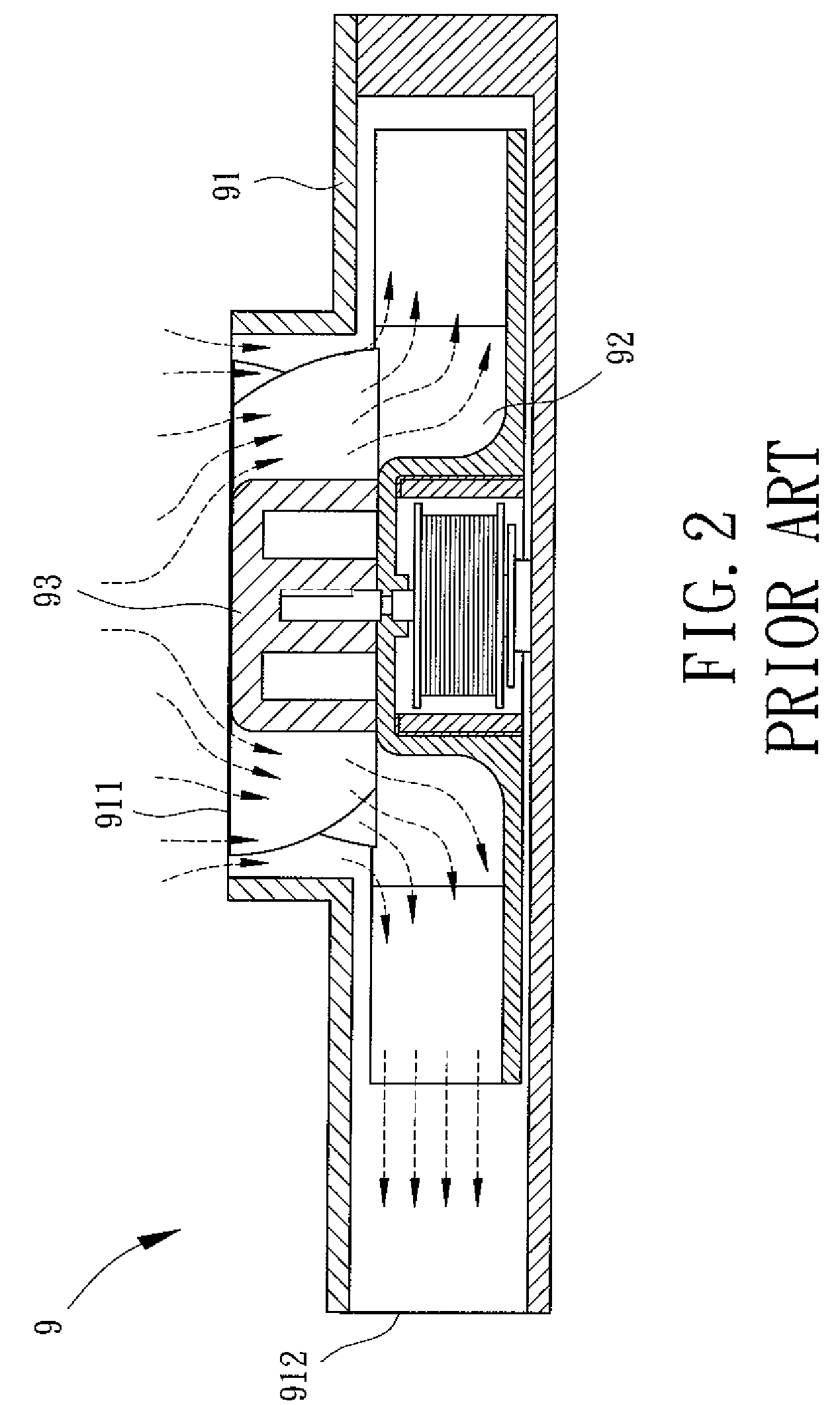

Fuel pump and filter assembly

InactiveUS20080107549A1Reduces or eliminates pump flow-through lossesImprove pumping efficiencyLoose filtering material filtersCartridge filtersEngineeringFuel pump

A fuel pump and filter assembly includes a housing supporting a filter in a filter chamber, which is at least partially defined by first and second end walls, an outer wall extending therebetween, and an inner side wall disposed radially inwardly of the outer side wall. A fuel pump assembly is carried by the housing radially inwardly of the inner side wall and includes a sleeve that extends from the first end wall of the housing to the second end wall of the housing.

Owner:TI GRP AUTOMOTIVE SYST LLC

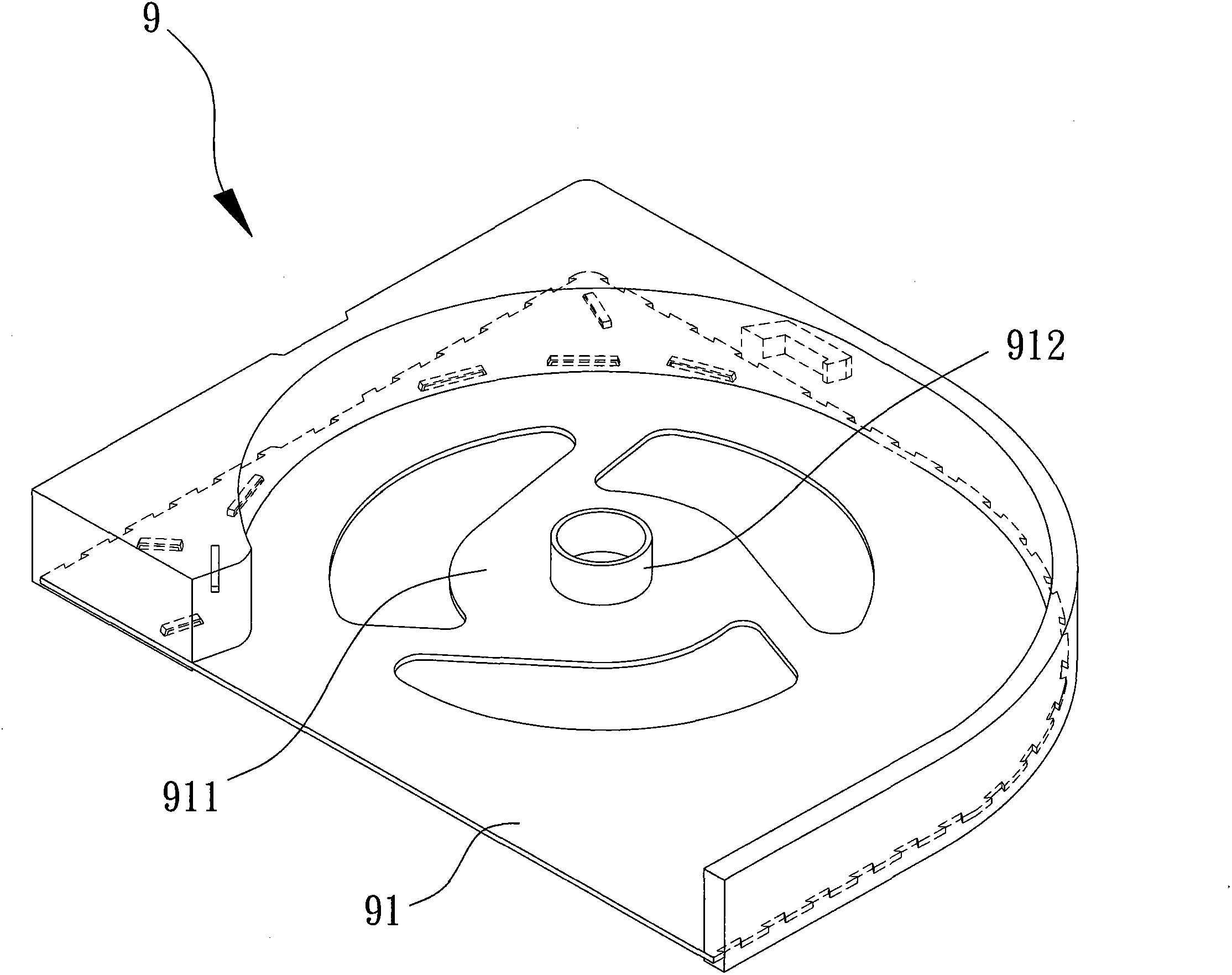

Advection Fans

ActiveUS20130171014A1Increasing air outputIncrease output pressurePump componentsReaction enginesImpellerEngineering

An advection fan includes a housing having a metal housing base and a closure member. A lateral wall is arranged between the metal housing base and the closure member and includes an air inlet and an air outlet. A horizontal air passage is defined between the metal housing base and the closure member. The metal housing base includes an engagement section. A stator includes a coil unit embedded in or abutting and attached to the engagement section of the metal housing base. The coil unit abuts the engagement face of the metal housing base. The coil unit includes a substrate and at least one coil formed on a surface of the substrate by printing circuit or electroforming process. An impeller is rotatably coupled to the shaft tube of the stator. A gap is formed between the impeller and the coil unit of the stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

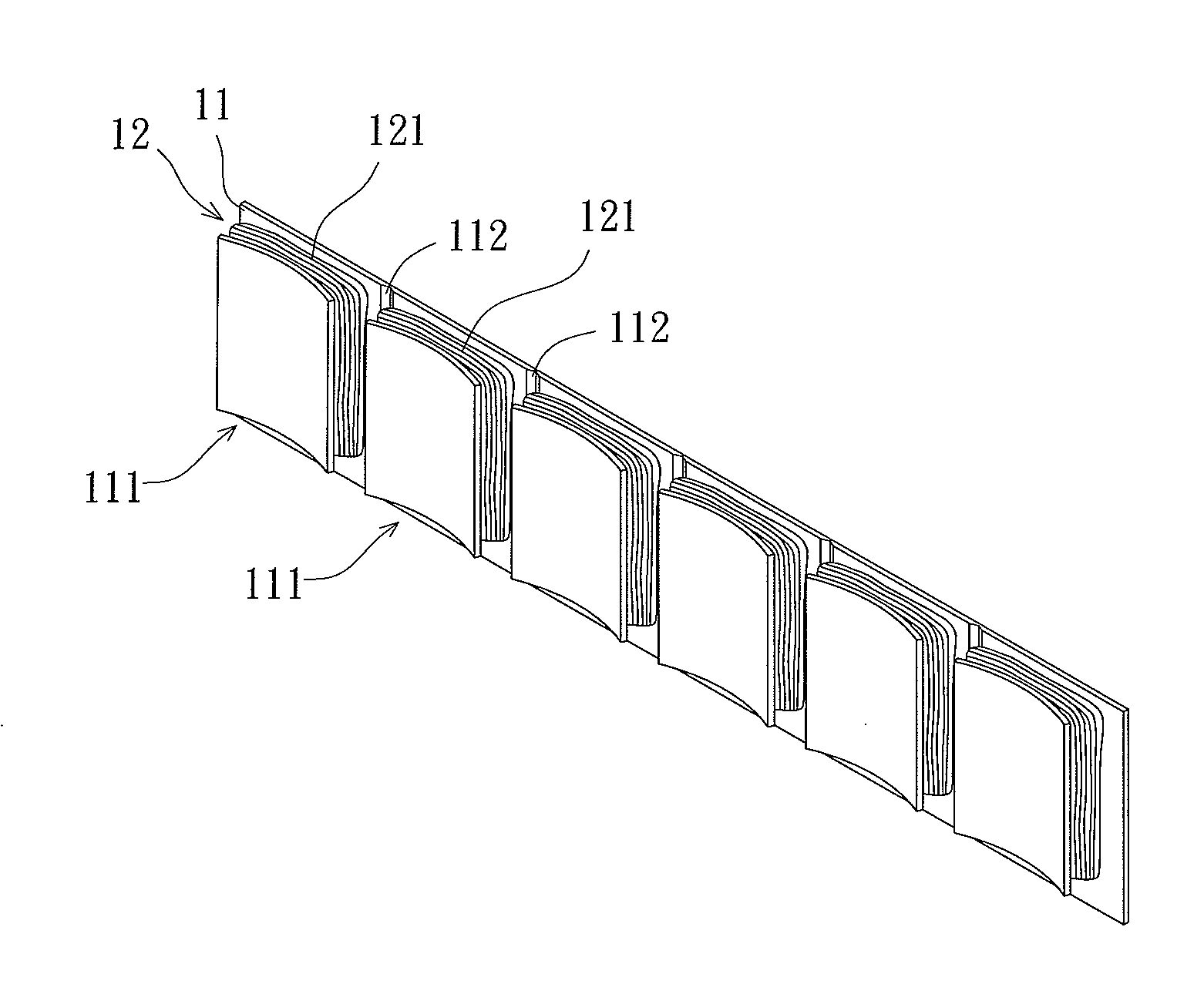

Stator Manufacturing Method for a Motor and Stator Utilizing the same

InactiveUS20100308682A1Low costReduce axial heightWindingsSynchronous machinesEngineeringElectric motor

A stator manufacturing method for a motor comprises a preliminary step configured to provide a strip plate having at least one wound portion on a surface thereof; a winding step configured to provide a coil unit and wind the coil unit around the at least one wound portion of the strip plate; a rolling step configured to roll up the strip plate into an unshaped sleeve having a central hole, wherein the at least one wound portion and the coil unit are located inside the central hole; and a shaping step configured to shape the unshaped sleeve into a shaped sleeve.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Heat-dissipating fan

ActiveUS8419385B2Reduce axial heightSimple cooling structureMagnetic circuit rotating partsPiston pumpsImpellerMagnet

A heat-dissipating fan includes a shaft seat. A coil base is coupled to the shaft seat. The coil base includes a base portion and a coil unit coupled to the base portion. The base portion includes a connection port electrically connected to the coil unit. The connection port is connected to a drive circuit. An impeller includes a hub and a permanent magnet. A shaft is coupled to the hub and rotatably coupled to the shaft seat about an axis. The permanent magnet is coupled to the hub and aligned with the coil unit. Since the coil base does not include electronic elements of the drive circuit, the axial height of the heat-dissipating fan is reduced, and the structure of the heat-dissipating fan is simplified.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

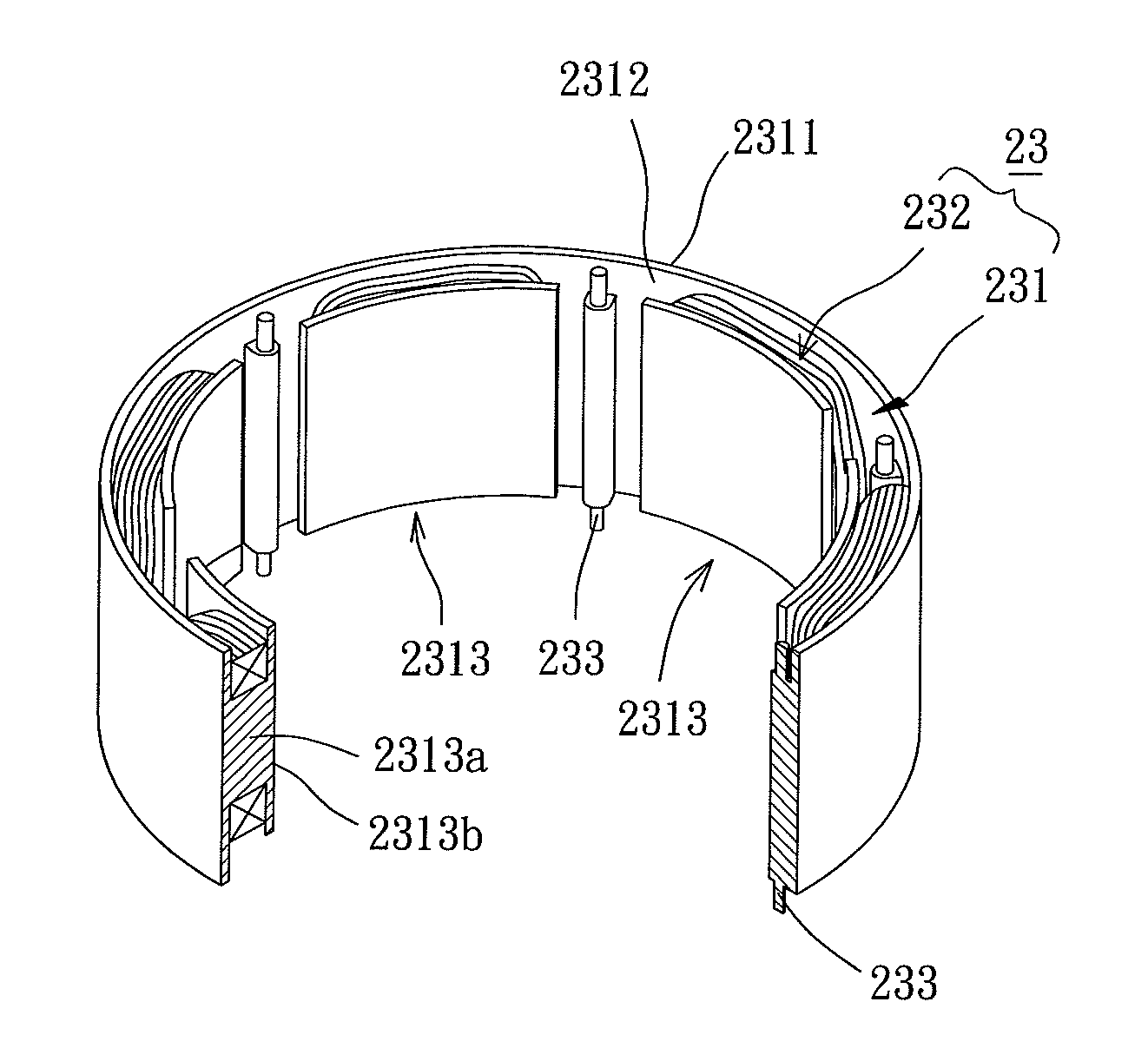

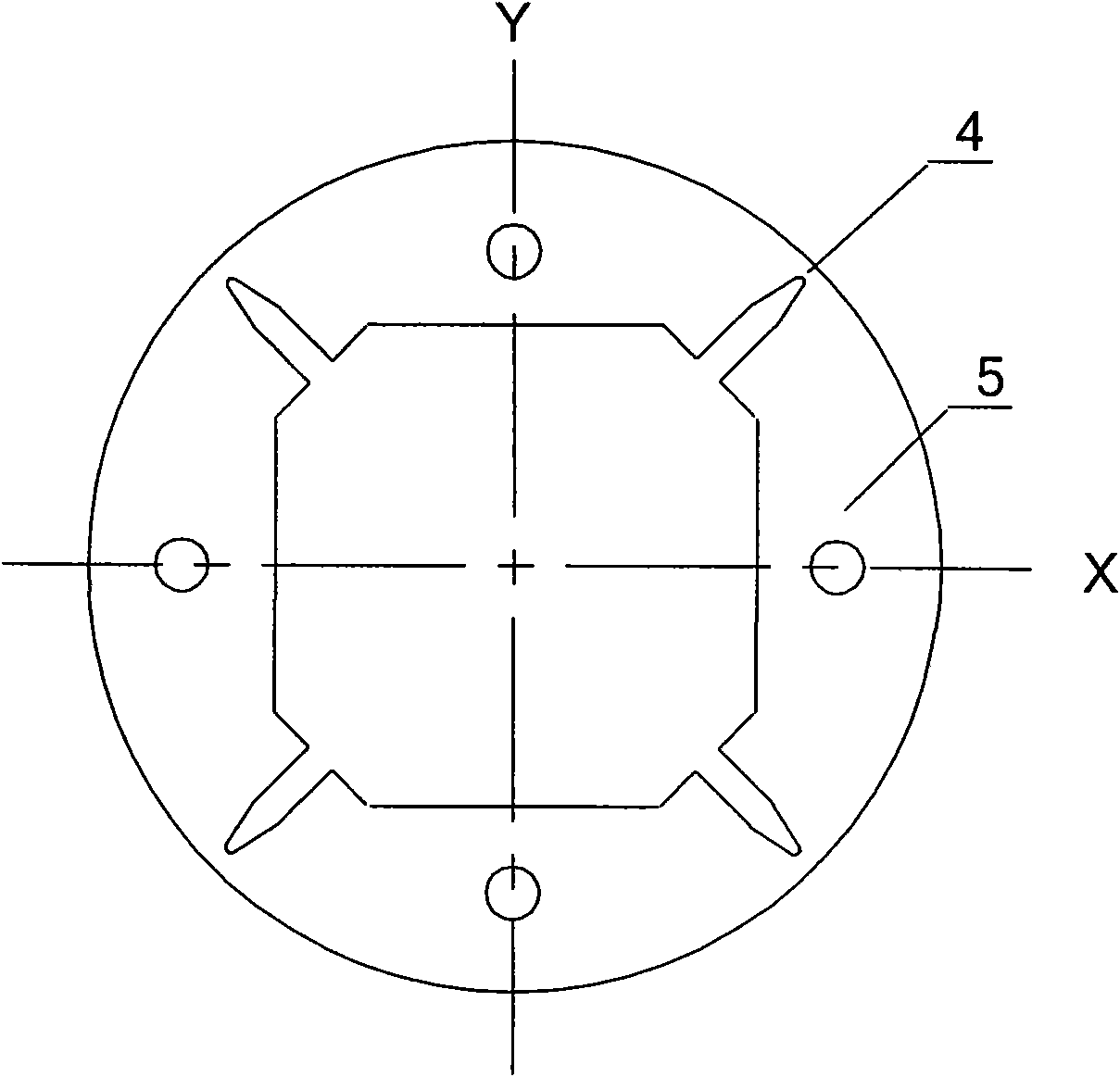

Stator and DC brushless motors including the stator

ActiveUS8030809B2Reduce axial heightSolve the stability is not highMagnetic circuit characterised by insulating materialsRotational stabilityBrushless motors

A stator for a DC brushless motor includes an annular insulating ring integrally formed from an insulating material. The annular insulating ring includes an outer peripheral face and an inner peripheral face. A plurality of winding portions extends from at least one of the outer and inner peripheral faces. A coil unit is wound around each of the plurality of winding portions. The stator can be utilized in various DC brushless motors. Since the stator does not include conventional silicon steel plates and is comprised of an annular insulating ring and a coil unit, advantages including low manufacturing costs, assembling convenience, possible reduction in the axial height, and high rotational stability are obtained.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Cooling fan and assembly method thereof

ActiveCN102996474ASimplified assembly stepsImprove the ease of assemblyPump componentsManufacturing dynamo-electric machinesImpellerInsulation layer

A cooling fan includes a fan frame, a circuit board, a stator-coil unit and an impeller. The fan frame includes a metal seat and a lateral wall. The metal seat comprises an engaging face and an engaging portion arranged on the engaging face. The lateral wall is arranged on a periphery of the metal seat and includes an air inlet and an air outlet. The circuit board includes a positioning hole. The circuit board is press fitted around the engaging portion of the metal seat via the positioning hole and adhered to the engaging face of the metal seat. The circuit board includes an insulation layer facing the metal seat. The stator-coil unit is mounted on the metal seat of the fan frame and electrically connected to the circuit board. The impeller is rotatably coupled with the stator-coil unit. Therefore, the Cooling fan and the assembly method thereof can simplify the assembling step and improve the assembling convenience, and can effectivley reduce the axial height of the cooling fan.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

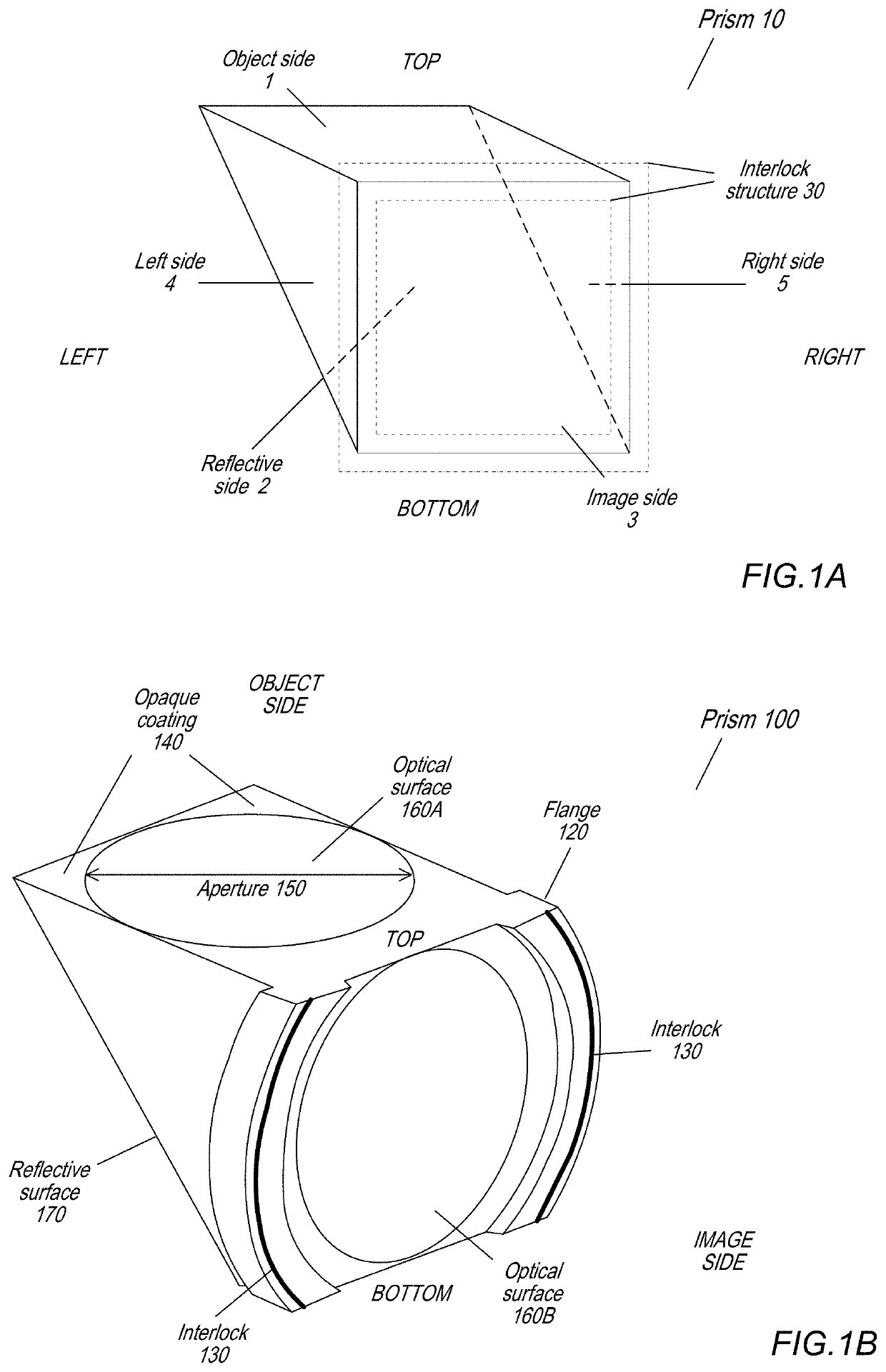

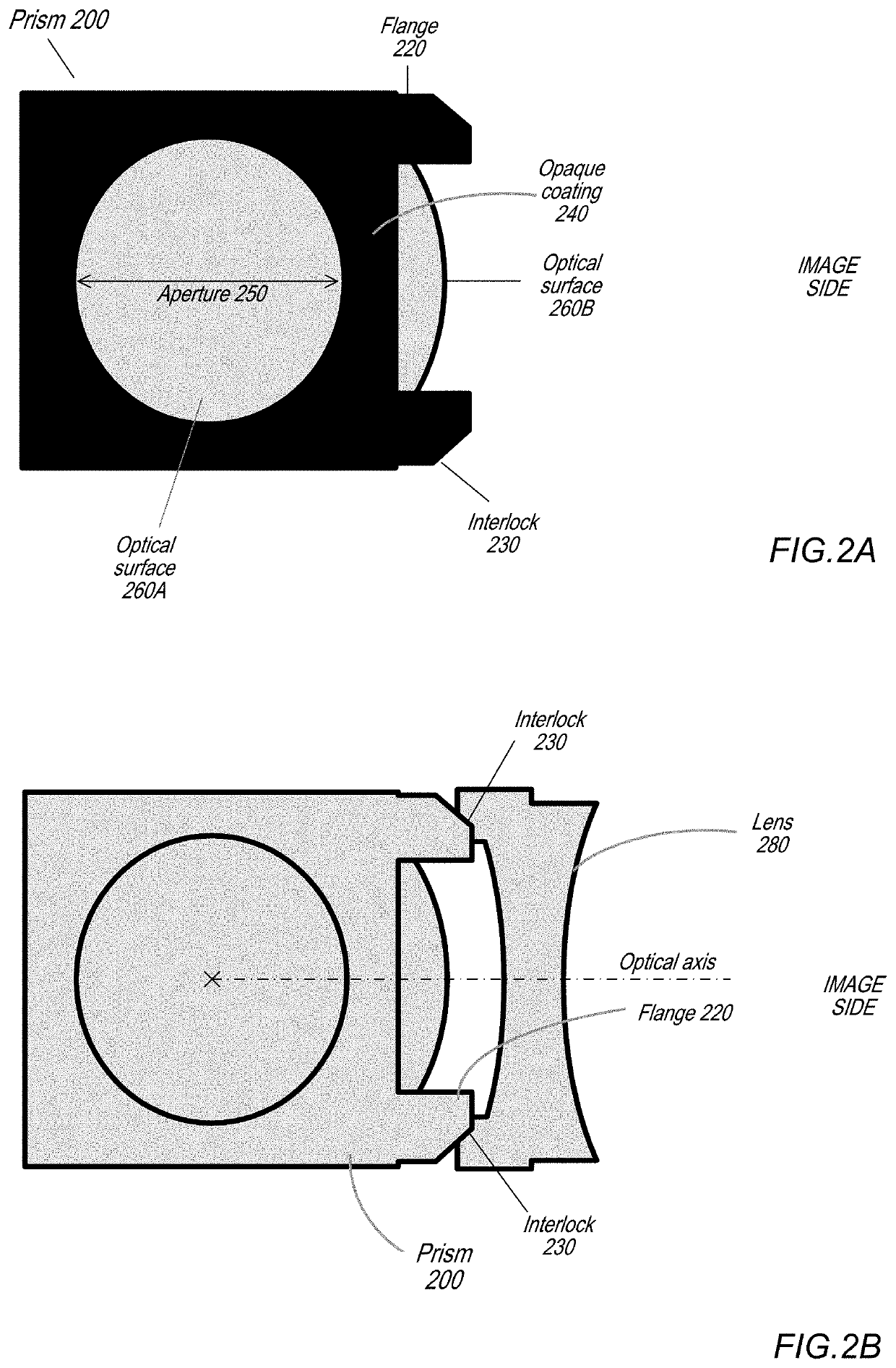

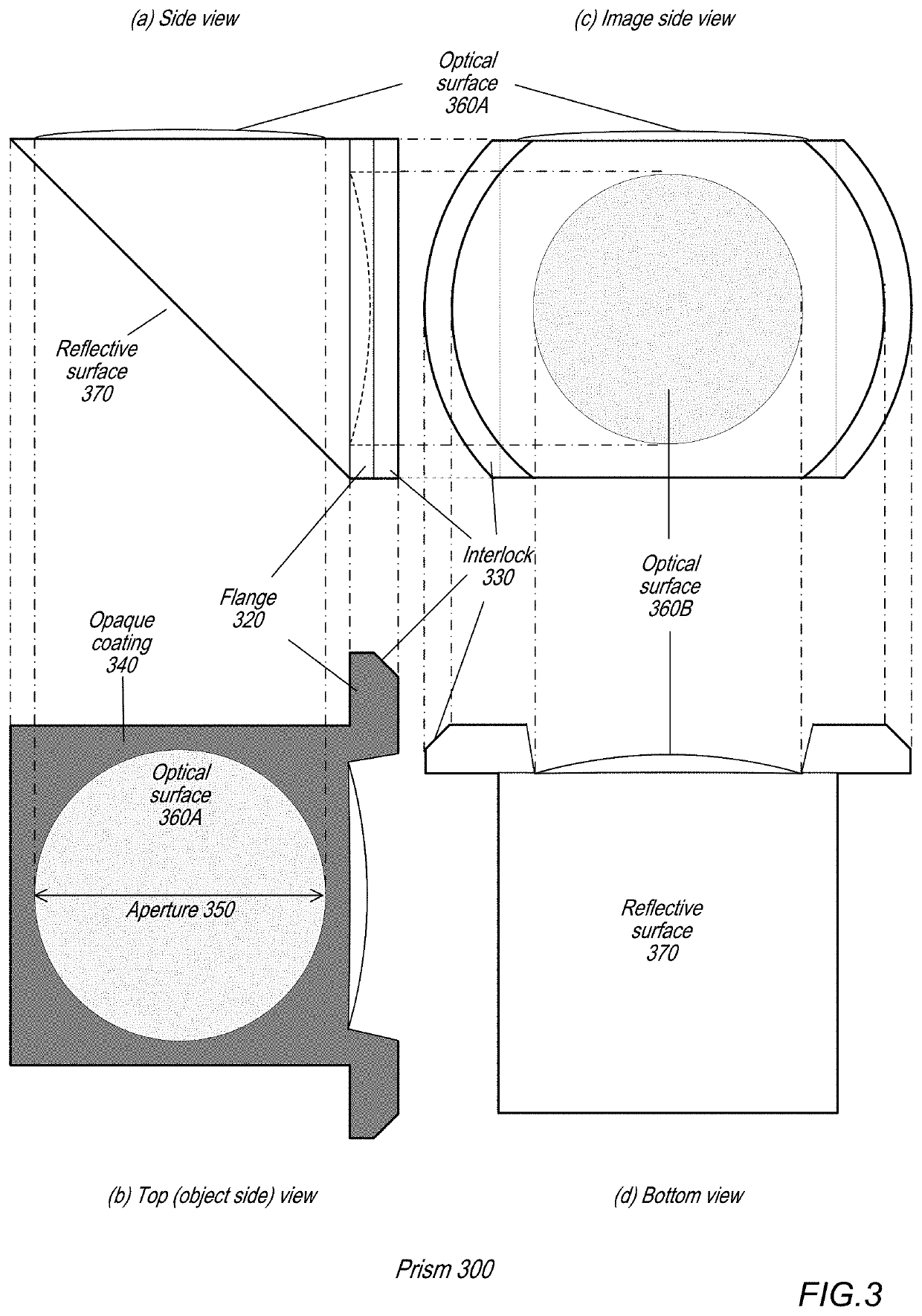

Optical prism with interlock

ActiveUS20200064527A1Lower Z heightReduce the Z-height of a cameraTelevision system detailsPrismsOptical axisRefractive lens

An optical prism that includes an interlock structure that precisely couples to a complementary structure of a refractive lens. For precision, the interlock structure may be formed at the same time and using the same technique as the optical surface of the prism. The interlock structure provides high accuracy when assembling a folded lens system by precisely aligning the object side optical surface of the lens with the image side optical surface of the prism so that the optical axis is centered in the lens. The prism may have refractive power. A portion of the object side surface may be coated with an opaque material to provide an aperture stop at that surface.

Owner:APPLE INC

Brushless DC motor and stator thereof

ActiveCN101931300AReduce manufacturing costEasy to assembleDynamo-electric machinesMechanical engineeringSilicon

The invention relates to a brushless DC motor and a stator thereof. The stator comprises an insulating ring and a coil assembly, wherein the insulating ring is an integral-forming ring body made of insulating material; the ring body is provided with an external ring surface and an internal ring surface; at least one of the external ring surface and the internal ring surface extends to form a plurality of winding parts; and the coil assembly winds around the winding parts. Thus, the stator can be used in an outer rotor motor or inner rotor motor so as to utilize the characteristic of the stator in which the traditional silicon steel sheet is omitted; and therefore, the invention has the advantages of low manufacturing cost, convenient assembling and the like, can reduce the axial height and can enhance the running stability.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

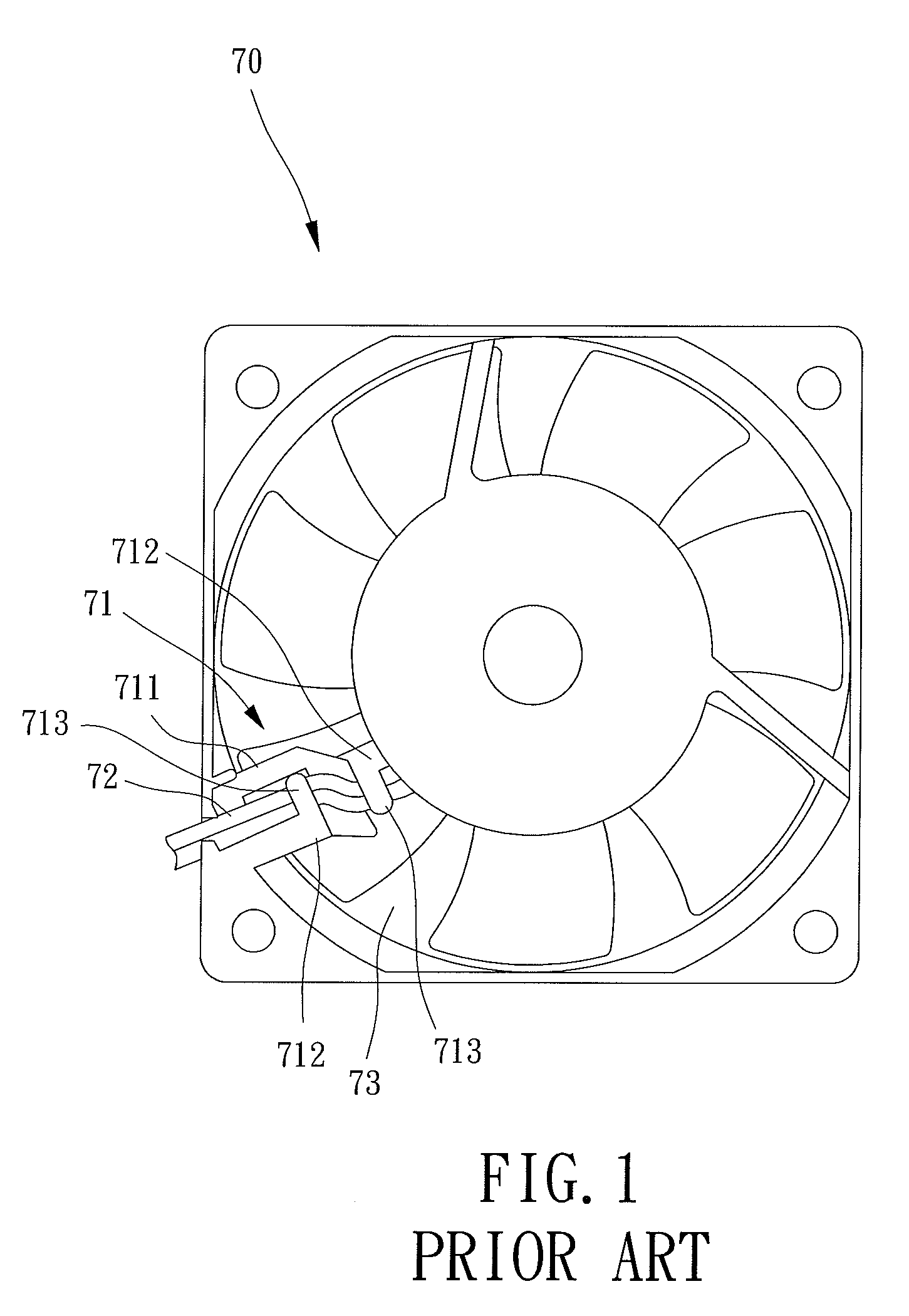

Fan

ActiveUS8297950B2Improve the ease of assemblyReduce spacingPiston pumpsPump installationsImpellerElectrical and Electronics engineering

A fan has a housing with a wire-guiding slot. One of plural connecting members is taken as a line fixed portion having a linking end facing the wire-guiding slot, with the linking end connecting to a section of a peripheral wall of the housing and the section axially aligned with the wire-guiding slot of the housing. A base is coupled to the housing. A power line has one end connected with the connection port and the other end extended beyond the housing via the wire-guiding slot. An impeller is rotatably mounted inside of the housing. Therefore, the line fixed portion can be close to the wire-guiding slot. Thus, the power line can be extended straight through the wire-guiding slot. A distance between the connection port and the wire-guiding slot is shortened to enhance assembling convenience of the power line.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

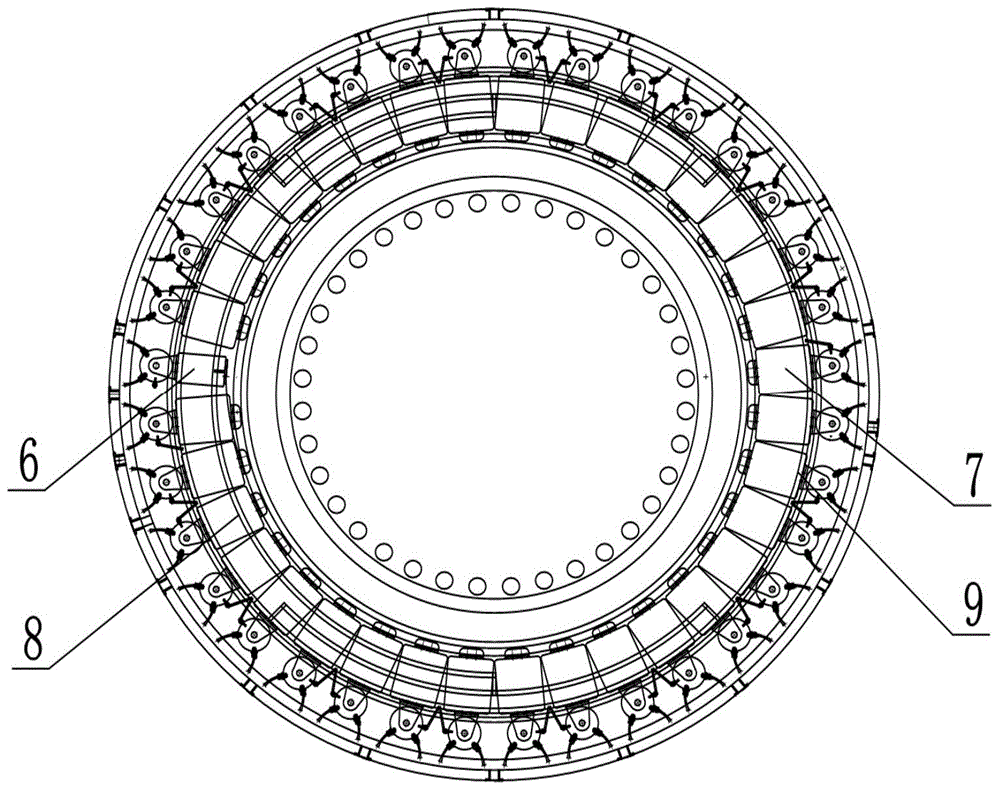

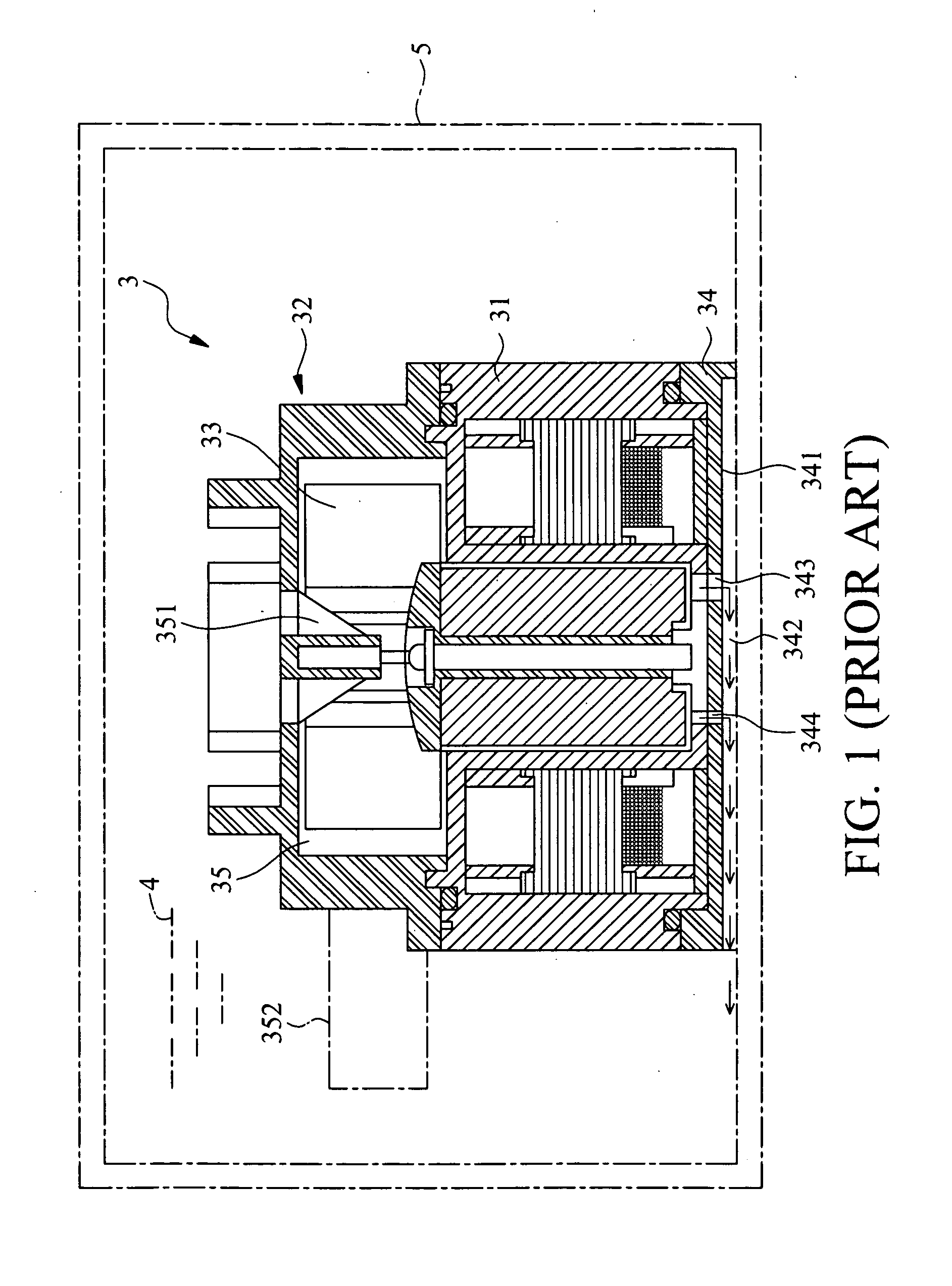

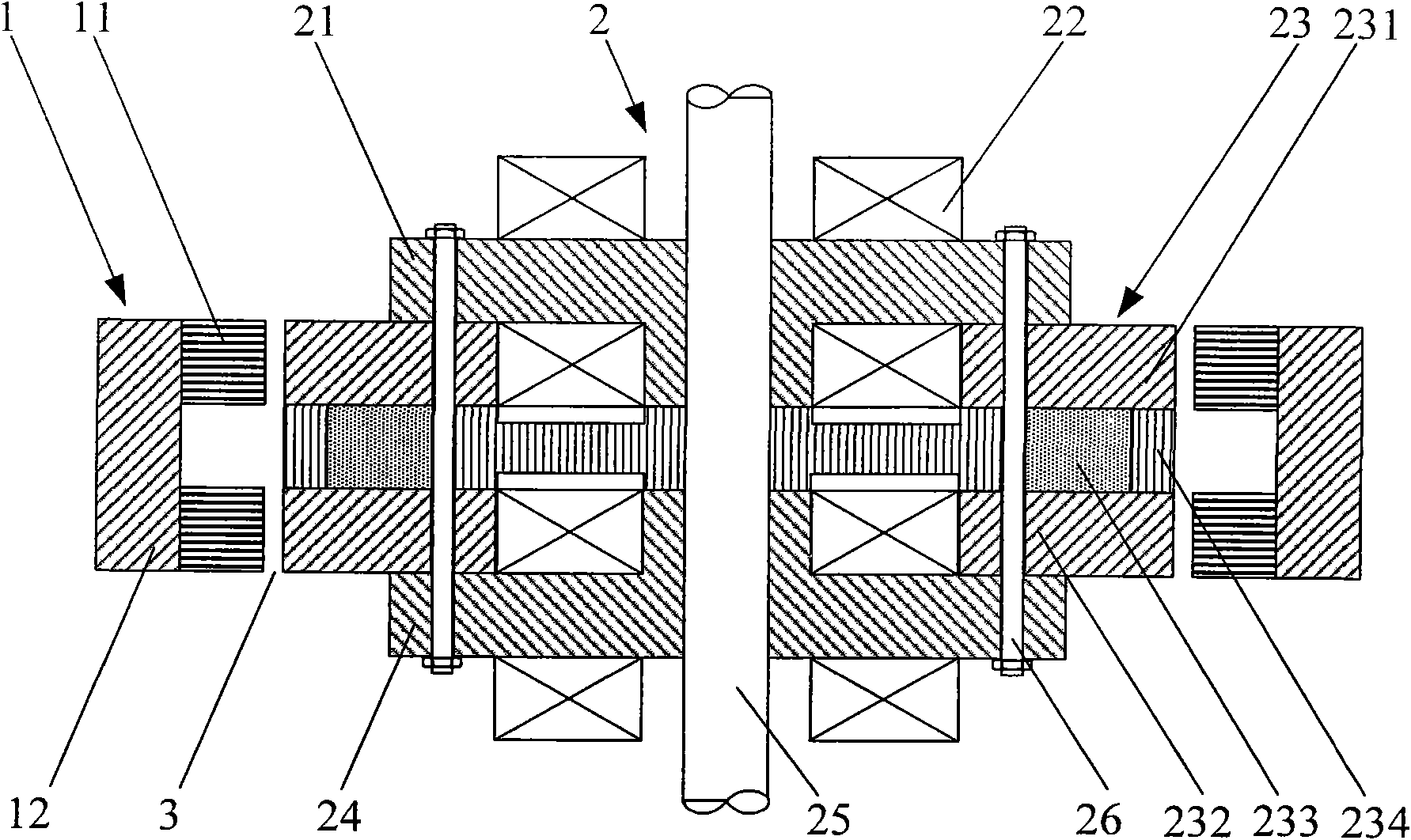

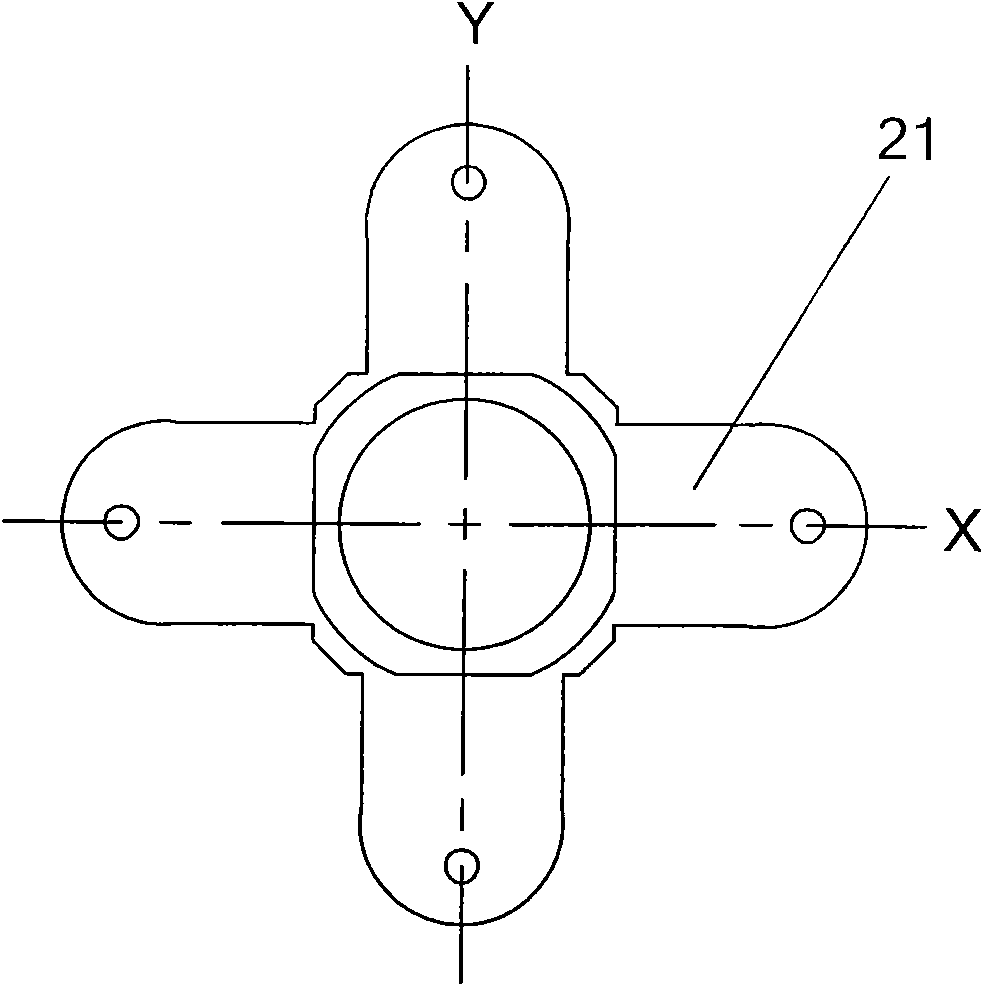

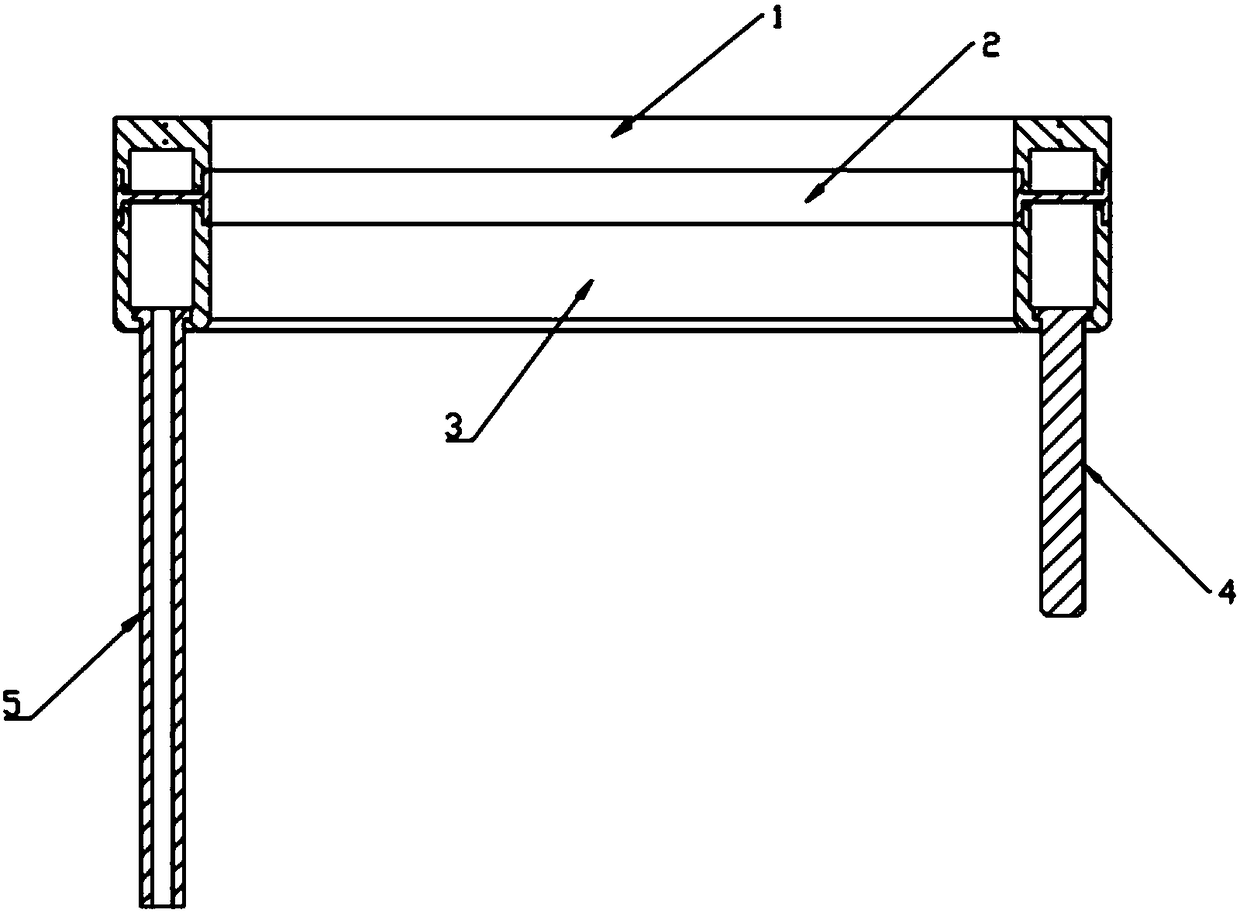

Mixed magnetic bearing with horizontal-coil uniform radial pole and low-loss outer rotor

InactiveCN101608669AReduce axial heightLight in massShaftsRotary machine partsMagnetic bearingMagnetic poles

The invention discloses a mixed magnetic bearing with a horizontal-coil uniform radial pole and a low-loss outer rotor, comprising a rotor magnetic conducting ring (1) and a stator (2), wherein the rotor magnetic conducting ring (1) consists of a rotor iron core (11) sleeved with the inner cavity of an external magnetic conducting ring (12); the stator (2) consists of a stator disc (23), an upper magnetic conducting cover board (21), a lower magnetic conducting cover board (24), eight solenoid coils (22) and a stator mounting shaft (25), wherein the solenoid coils (22) are arranged horizontally and are respectively arranged at the upper side and the lower side of the stator disc (23) by taking the upper magnetic conducting cover board (21) and the lower magnetic conducting cover board (24) as coil iron cores. In the invention, the solenoid coils are arranged horizontally, take the magnetic cover boards as the coil iron cores and are separated from magnetic poles in structure, therefore, the processing and the assembly are more convenient and the magnetic poles can fully utilize circumference area to increase the bearing capability. In addition, the horizontal-coil uniform radial pole structure is more compact, thereby effectively reducing the axial height of the bearing and reducing the weight of the magnetic bearing.

Owner:NAT UNIV OF DEFENSE TECH

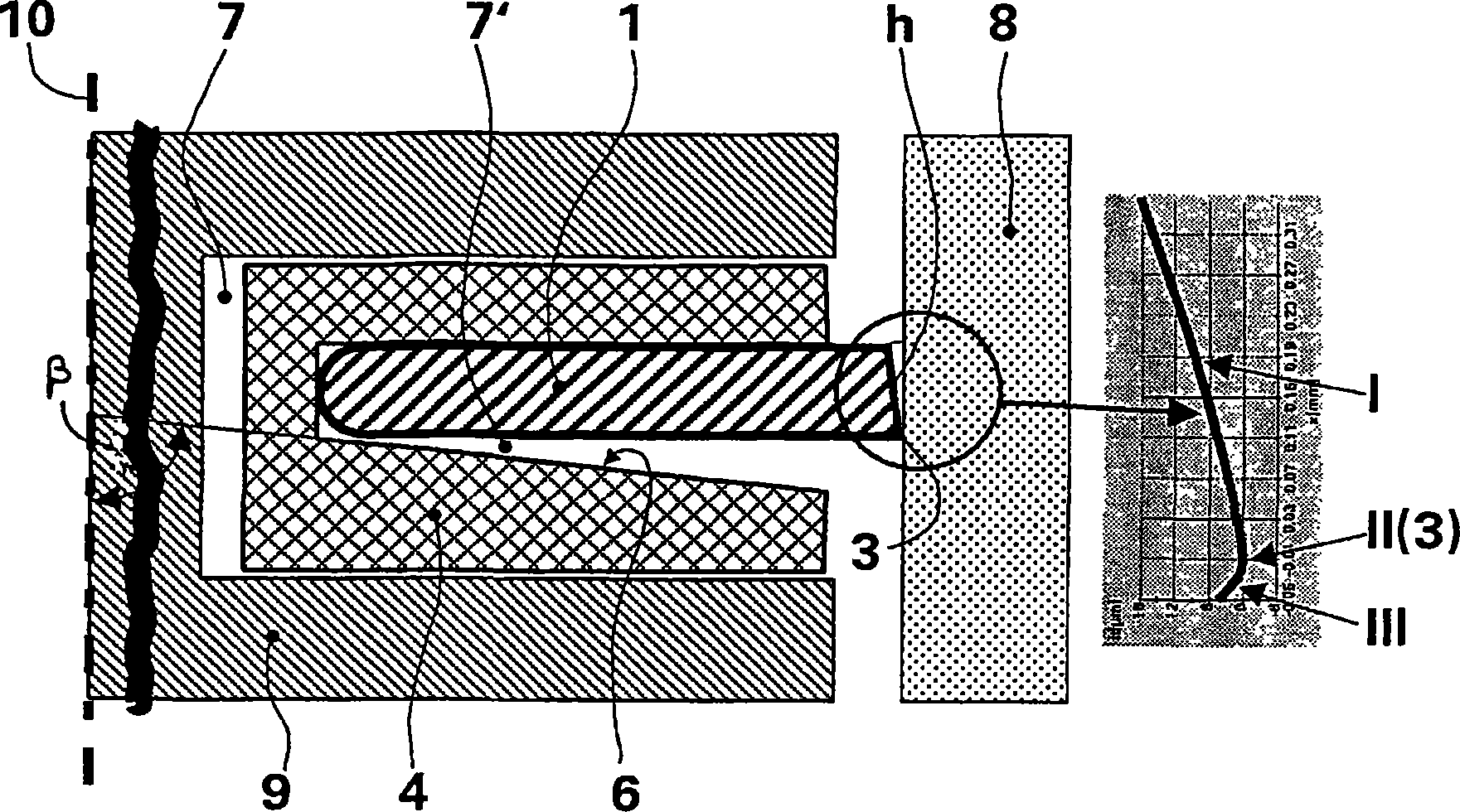

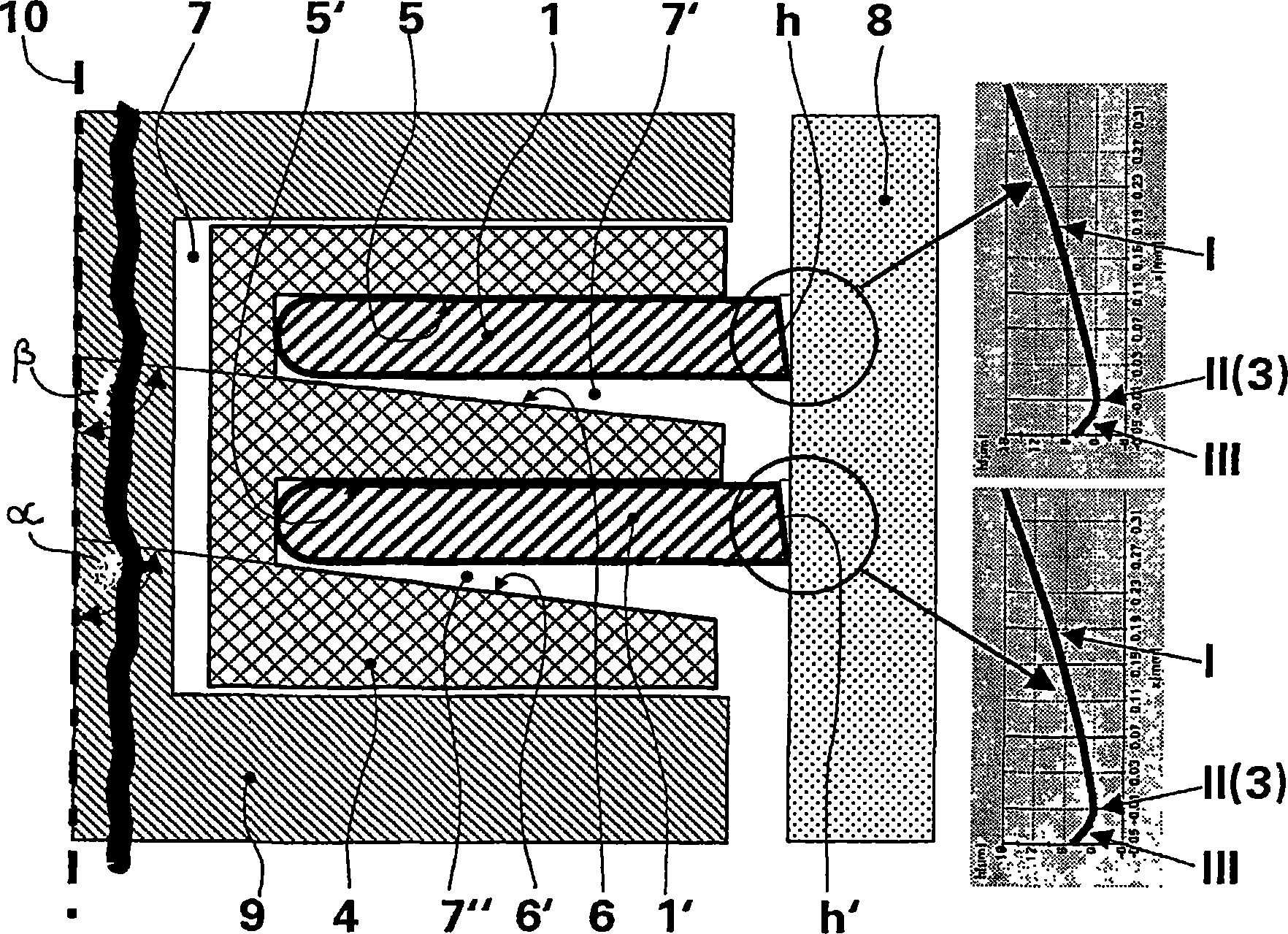

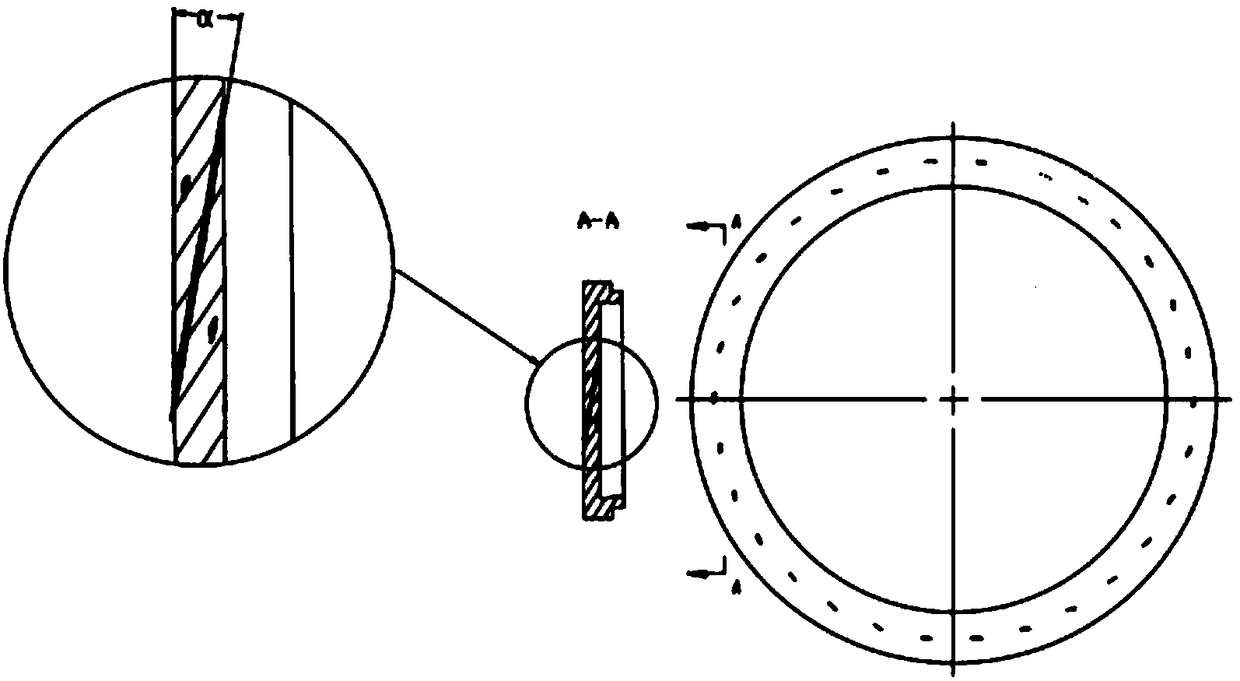

Oil scraper ring for pistons of internal combustion engines

The invention relates to an oil scraper ring for pistons of internal combustion engines, said oil scraper ring comprising a disc (1) that is provided with parallel flanks and a bearing surface (h) having an asymmetrical crowned form with a vertex line (3) extending over the periphery of the disc. A bracing spring (4) arranged in a ring groove (7) of the piston and comprising a spring groove side (6) opposing the piston head and a spring groove side (5) facing the piston head presses the disc (1) radially against the cylinder wall (8). The aim of the invention is to achieve an improved oil scraping action compared to that of prior art, while reducing the friction and the abrasion of the bearing surface. To this end, at least one of the spring groove sides (5, 6) extends at an angle (ss) in relation to the piston axis (10) in such a way that it is radially outwardly inclined to the bracing spring end oriented towards the cylinder, the bearing surface (h) of the disc (1) being embodied in such a way that it corresponds to an almost worn end contour in the started engine state, and, when the oil scraper ring (1) is mounted in the piston, the vertex line (3) of the bearing surface (h) is oriented in the direction of the ring groove side (6) opposing the piston head.

Owner:MAHLE GMBH

Advection fans

An advection fan includes a housing having a metal housing base and a closure member. A lateral wall is arranged between the metal housing base and the closure member and includes an air inlet and an air outlet. A horizontal air passage is defined between the metal housing base and the closure member. The metal housing base includes an engagement section. A stator includes a coil unit embedded in or abutting and attached to the engagement section of the metal housing base. The coil unit abuts the engagement face of the metal housing base. The coil unit includes a substrate and at least one coil formed on a surface of the substrate by a printing circuit or electroforming process. An impeller is rotatably coupled to the shaft tube of the stator. A gap is formed between the impeller and the coil unit of the stator.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Rotational flow gas outlet structure for magnetic focusing hall thruster

InactiveCN108457827AExtended stayIncreasing the thicknessMachines/enginesUsing plasmaEngineeringIonization

The invention relates to a rotational flow gas outlet structure for a magnetic focusing hall thruster and belongs to the field of hall thrusters. The rotational flow gas outlet structure solves the problem of the poor ionization characteristic of an existing high-specific-impulse krypton working medium hall thruster. The rotational flow gas outlet structure comprises a top guide plate, a middle guide plate, a gas distributor base, an installation pillar, a gas guide tube, a discharge channel and a positive pole. The top guide plate, the middle guide plate and the gas distributor base are arranged in parallel from top to bottom and are fixedly connected to form a primary buffer chamber and a secondary buffer chamber in a laser welding manner. The primary buffer chamber and the secondary buffer chamber are coaxially arranged in the discharge channel, and the top guide plate guides neutral gas through inclined holes to rotate in the discharge channel. The positive pole is arranged on theportion, close to the top guide plate, inside the discharge channel. The gas guide tube and the installation pillar are welded to both sides of the bottom of a gas distributor. By the adoption of therotational flow gas outlet structure, the utilization rate of a working medium is increased effectively, and especially the effect on the improvement of the ionization performance of the krypton working medium is outstanding.

Owner:HARBIN INST OF TECH

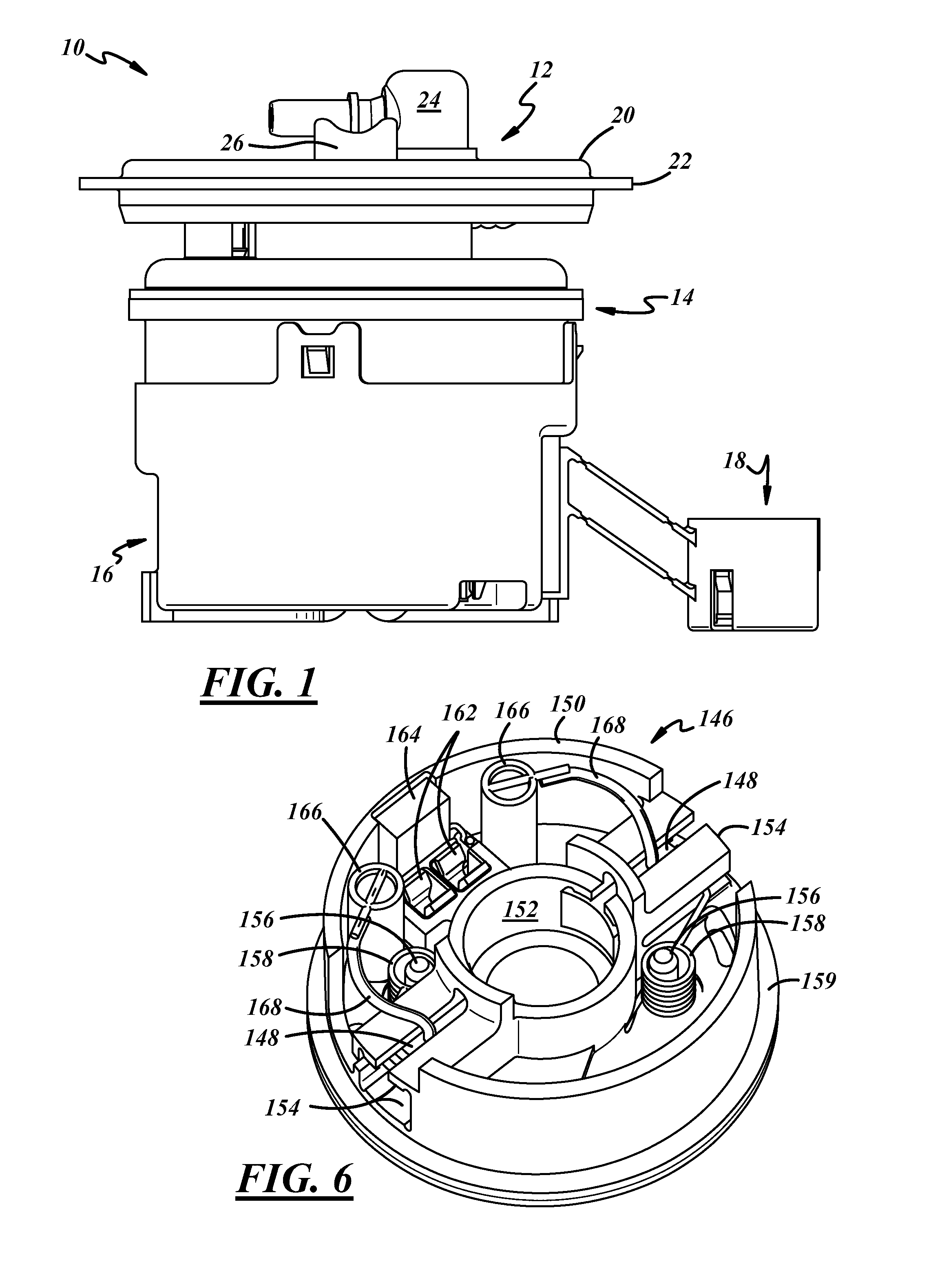

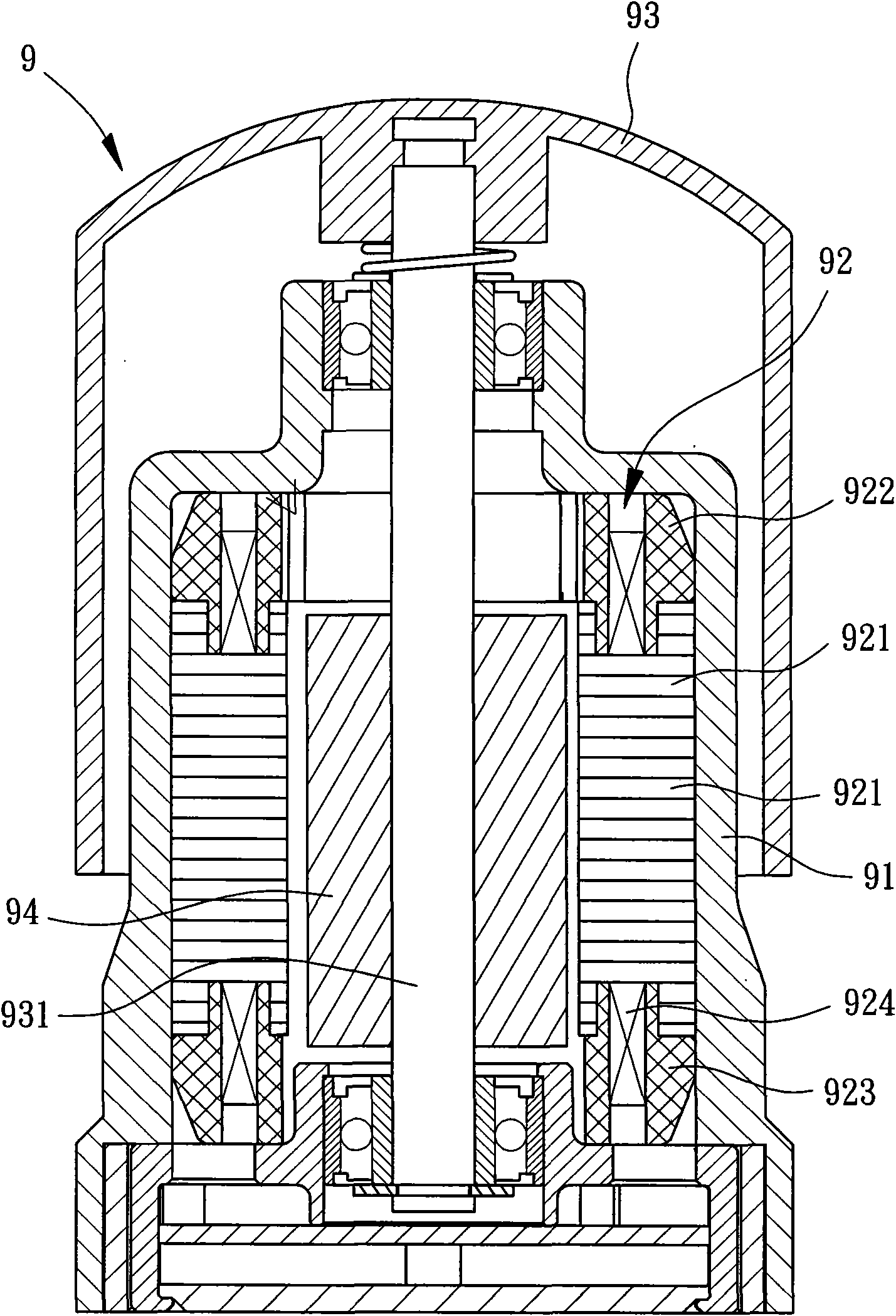

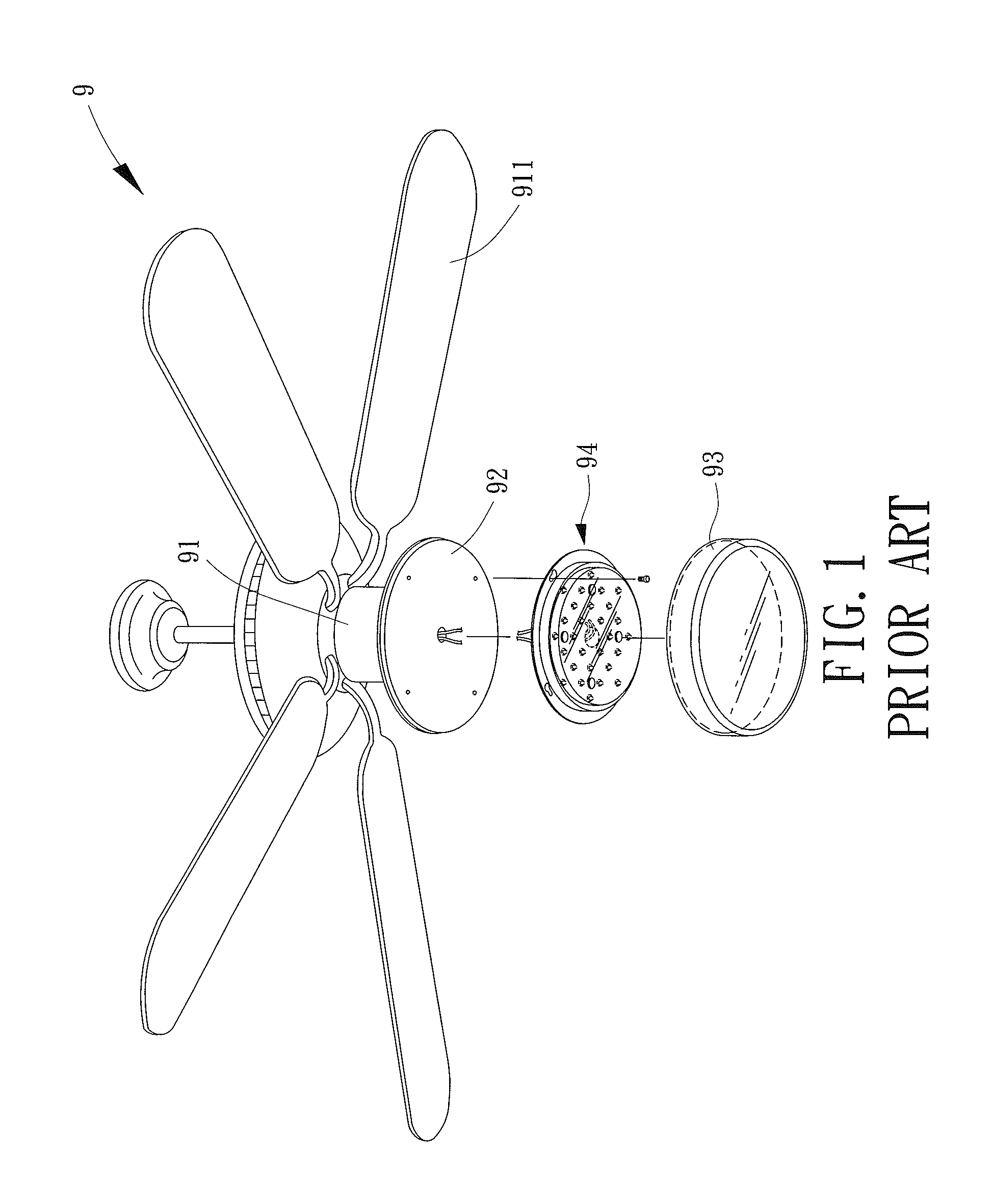

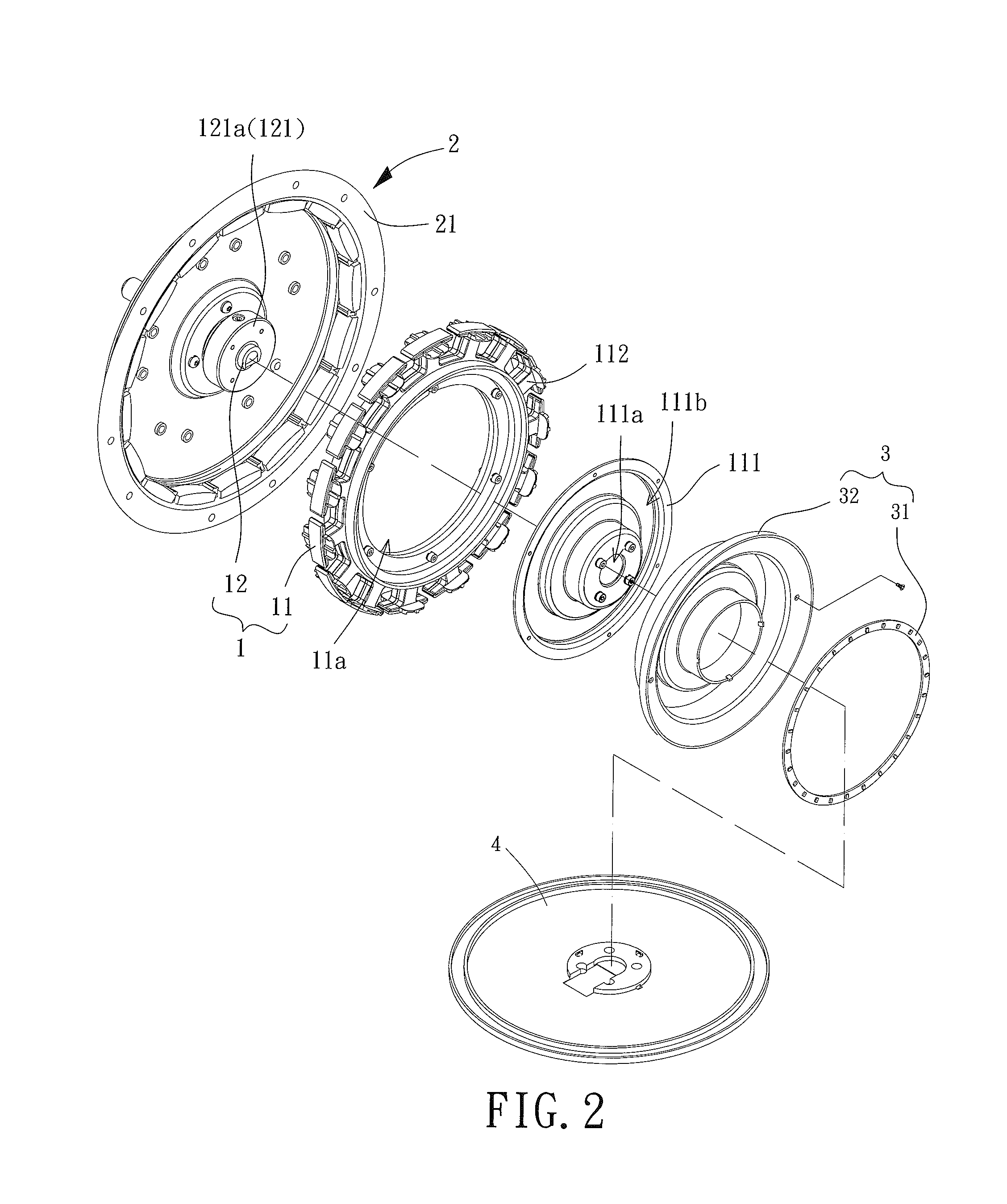

Ceiling Fan Motor

ActiveUS20160348894A1Increase profitReduce axial heightLighting support devicesPump componentsCeiling fanEngineering

A ceiling fan motor with a reduced axial height includes a stator, a rotor and a light-emitting module. The stator includes an iron core and a shaft. The iron core forms an assembly opening at a central portion thereof. The rotor is rotatably coupled with an outer periphery of the shaft and includes a housing. The light-emitting module is at least partially arranged between the iron core and the shaft, or is arranged between the iron core and the housing of the rotor, along a radial direction perpendicular to the shaft.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com