Patents

Literature

204 results about "Rotational stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotational stability. Property of a body for which a small angular displacement sets up a restoring torque that tends to return the body to its original position.

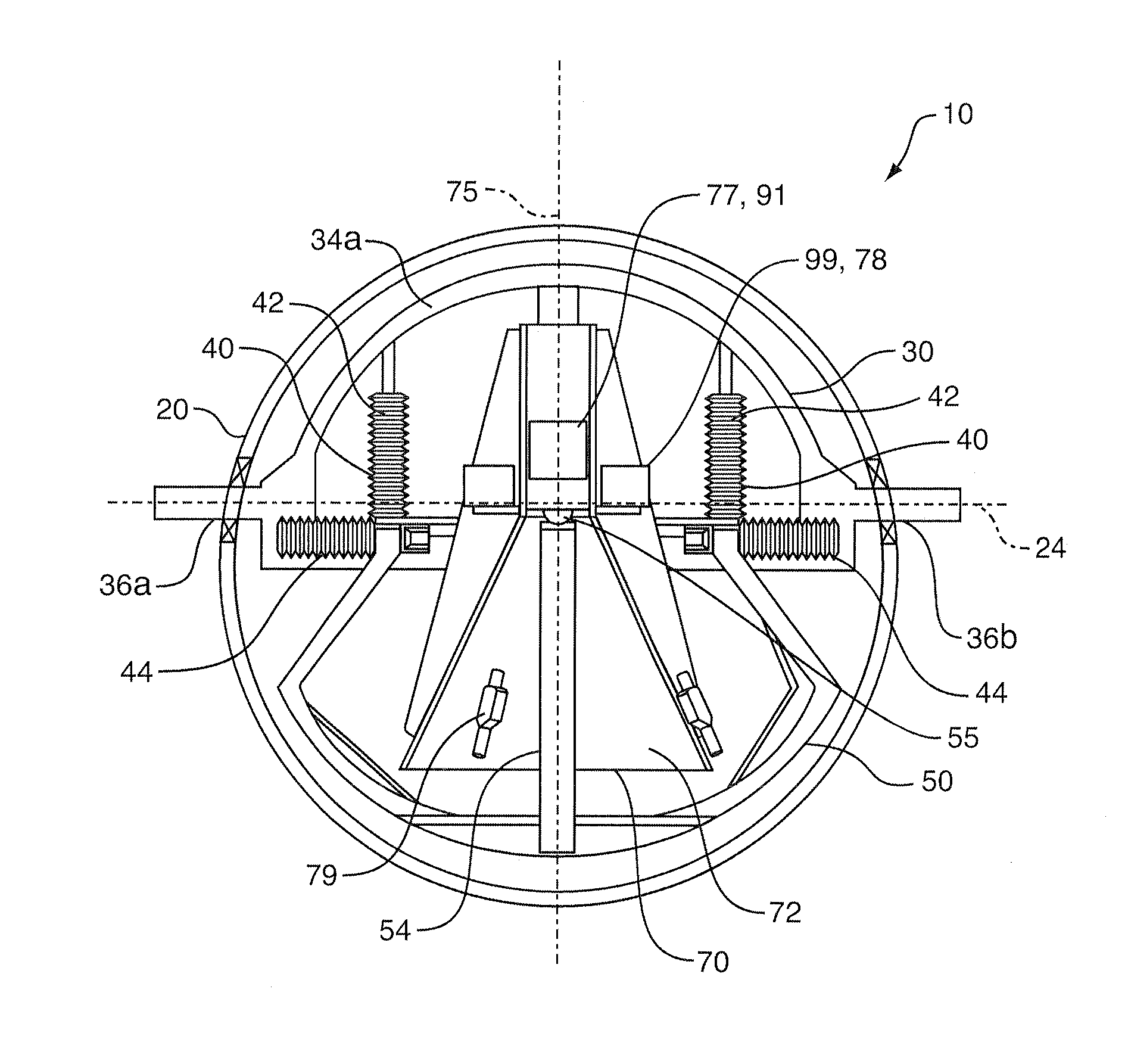

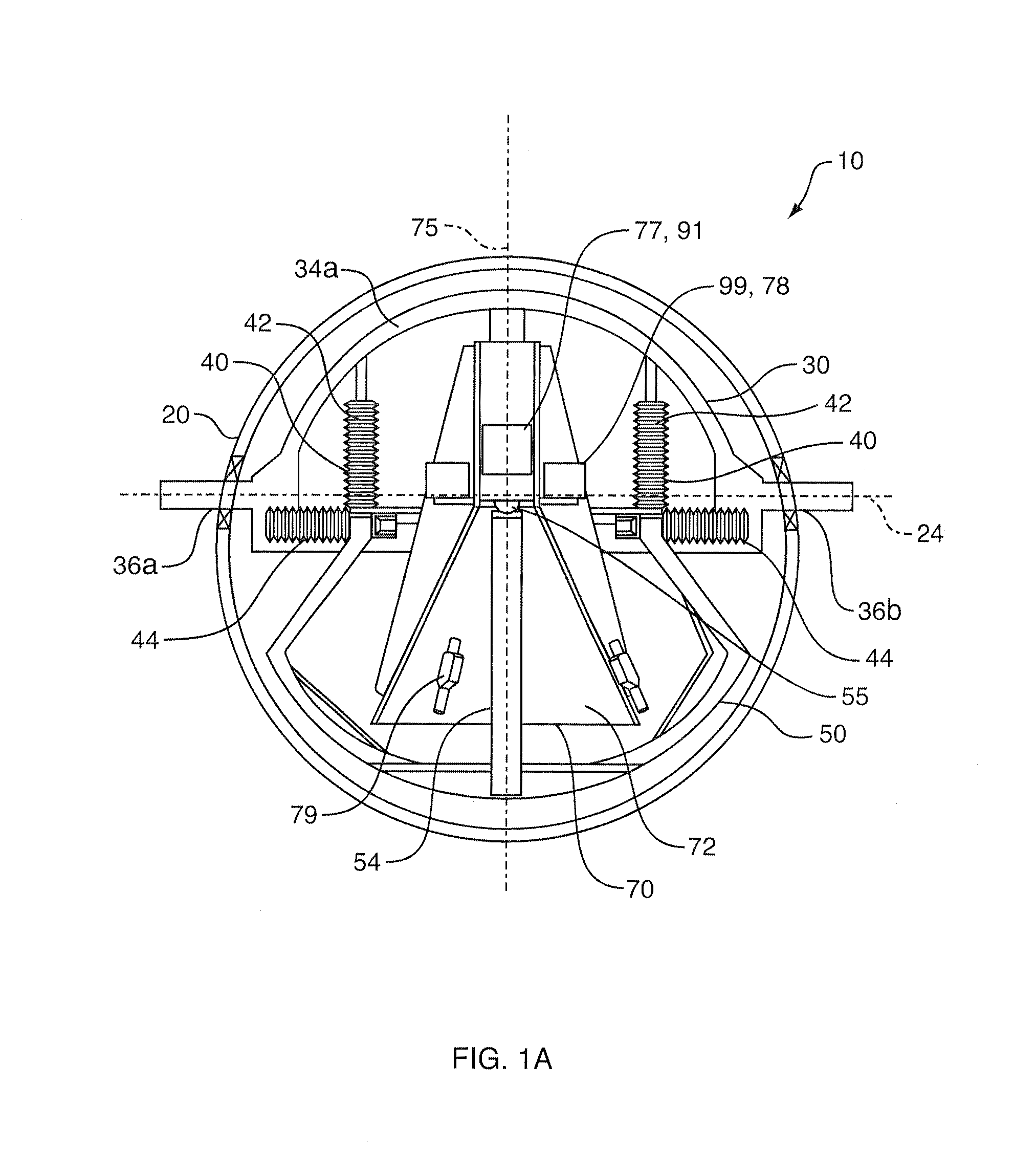

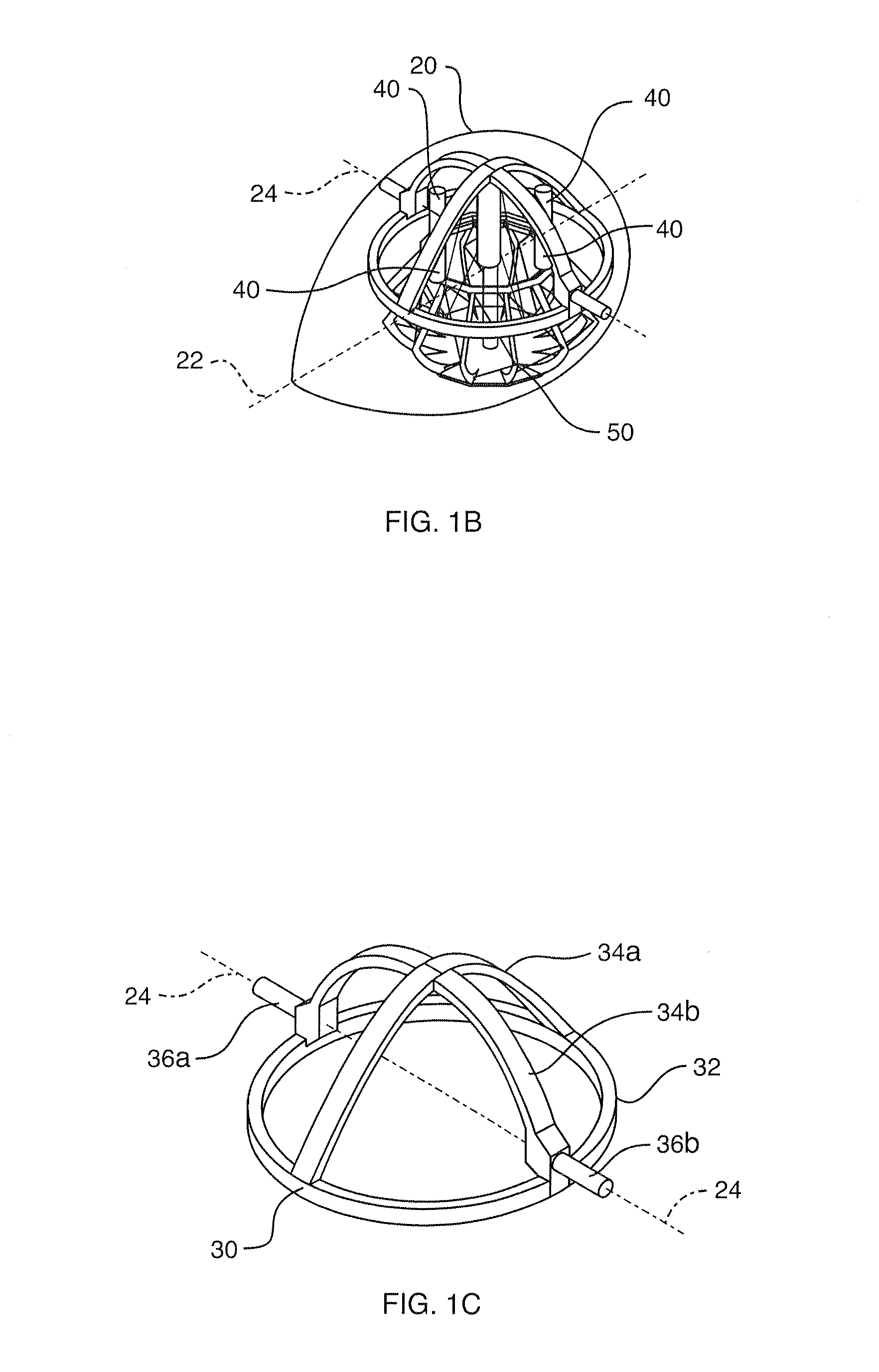

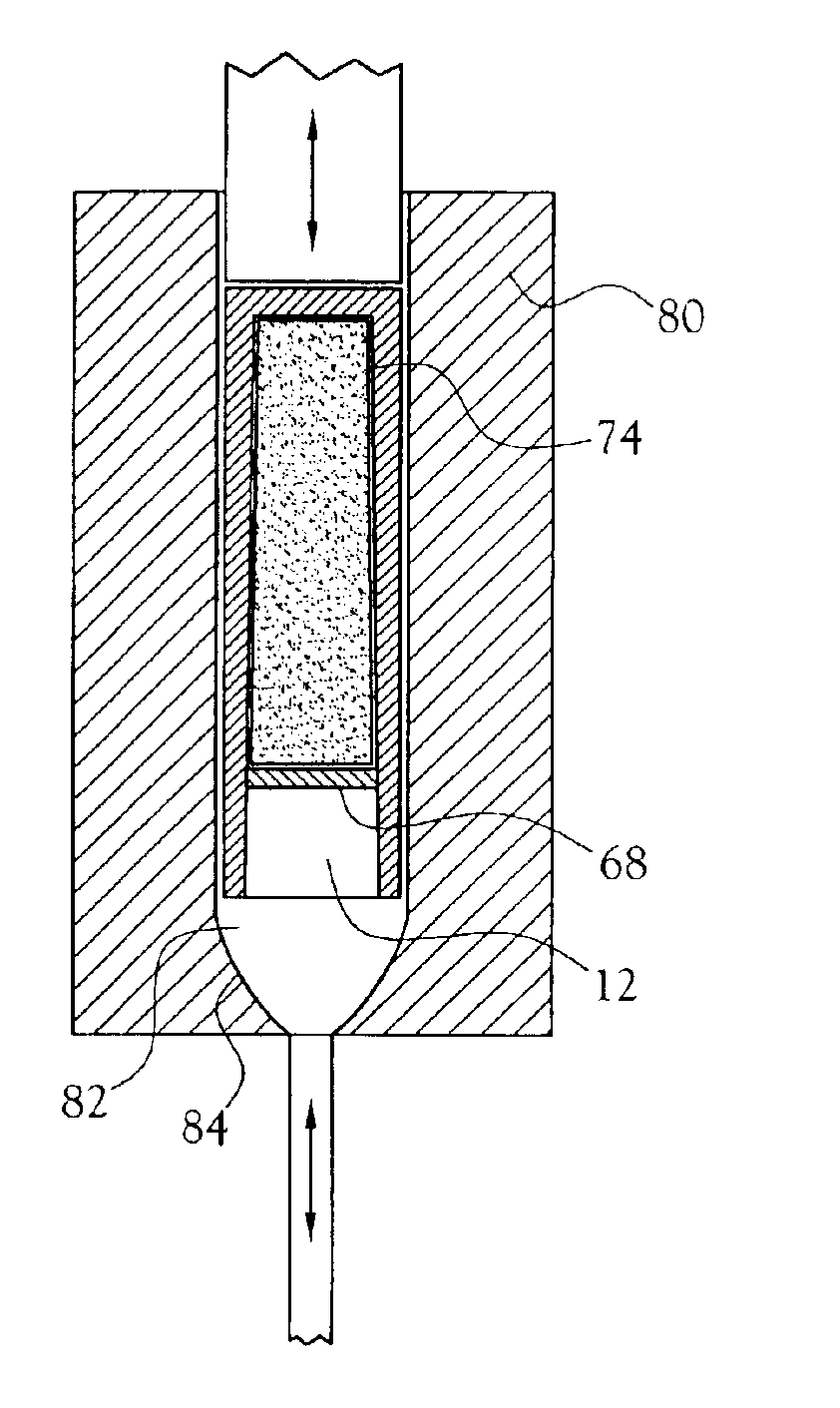

Stabilization system for sensors on moving platforms

ActiveUS20110175604A1Improve mass balanceSmall biasAcceleration measurementFrequency analysisRotational stabilityAir bearing

A stabilized field sensor apparatus collects field data, in particular magnetic field data, with reduced motion noise. The apparatus includes a tear drop shaped housing, a tow frame in the housing, a plurality of vibration isolating dampers spaced around the frame, a base assembly mounted to the dampers, a support pedestal having a bottom end fixed to the base assembly and an upper free end, a single spherical air bearing connected to the upper free end of the pedestal, an instrument platform with a lower hollow funnel having an upper inside apex supported on the air bearing for a one point support, principal and secondary gyro stabilizers for maintaining pivotal and rotational stability, and at least one field sensor mounted to the instrument platform for collecting the field data while being stabilized against motion noise including vibration, pivoting and rotation from the base assembly, from the tow frame and from the housing. Stabilization of the instrument platform is enhanced by preserving accurate balance through a dynamic balancing system whereby small masses are moved under computer control to maintain the center of mass of the instrument platform at the center of rotation of the spherical air bearing. The dynamic stabilization process is made more precise by actively vibrating the instrument platform by a set of linear vibrators.

Owner:VALE LIMITED

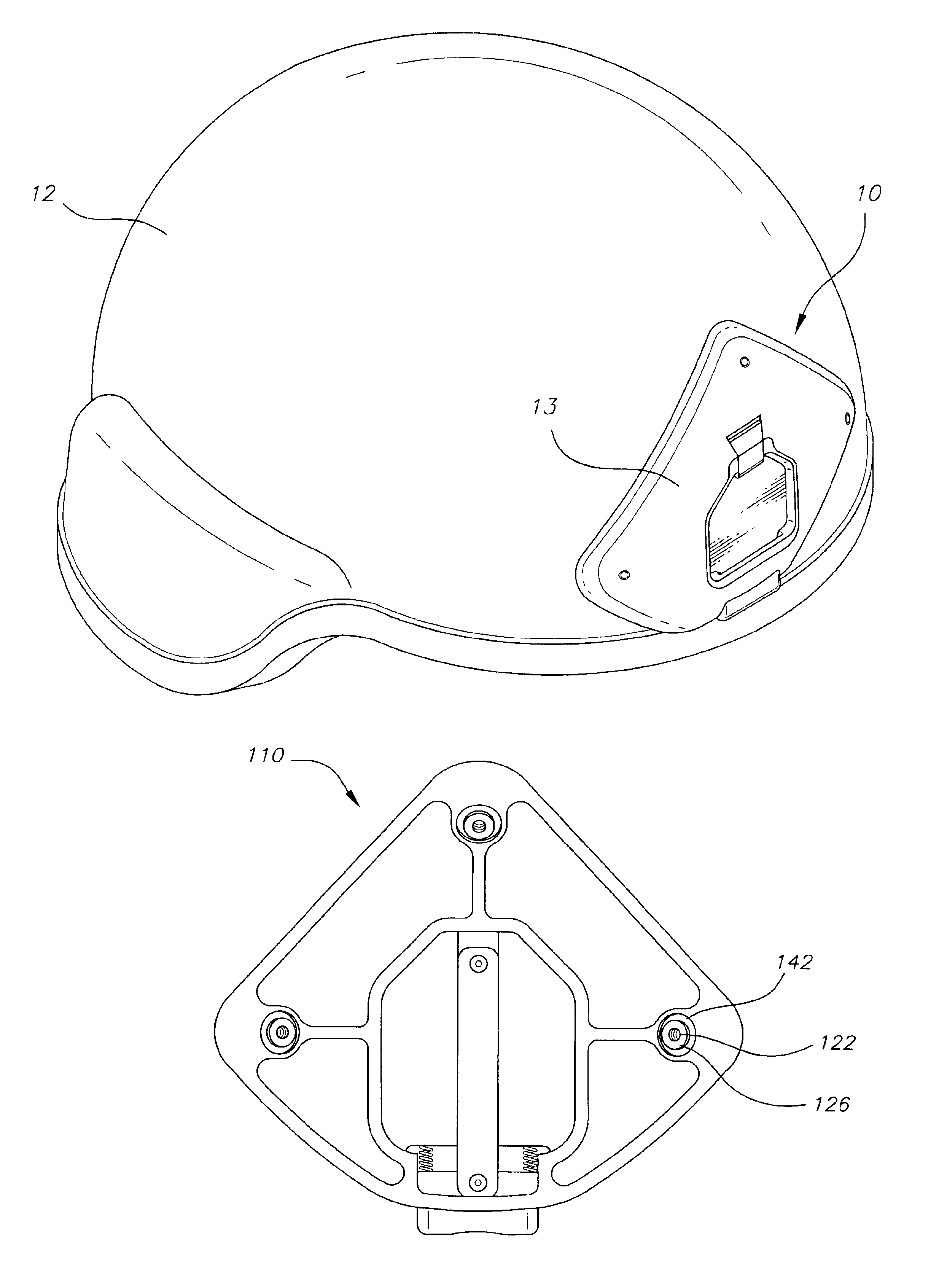

Shroud plate attachment

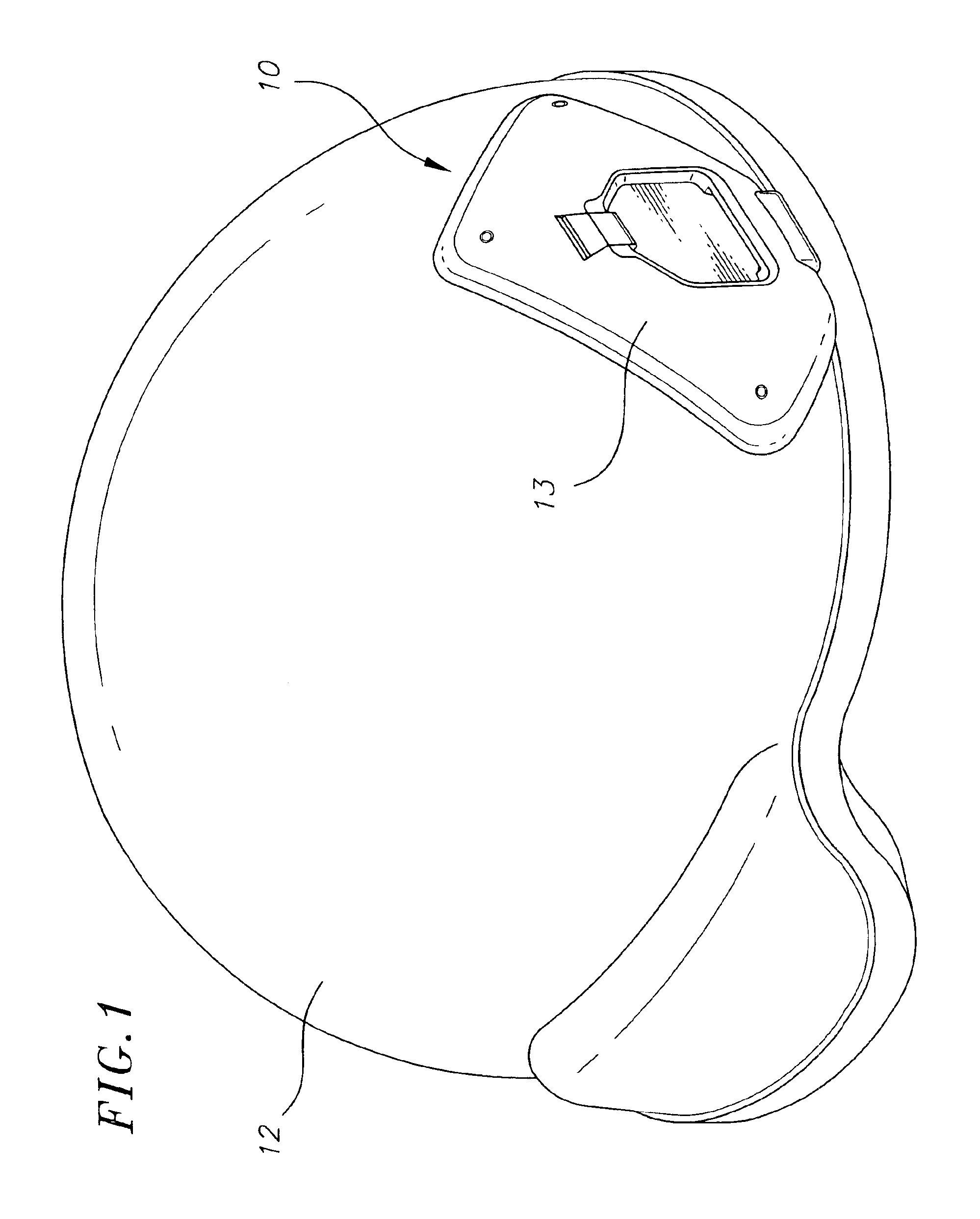

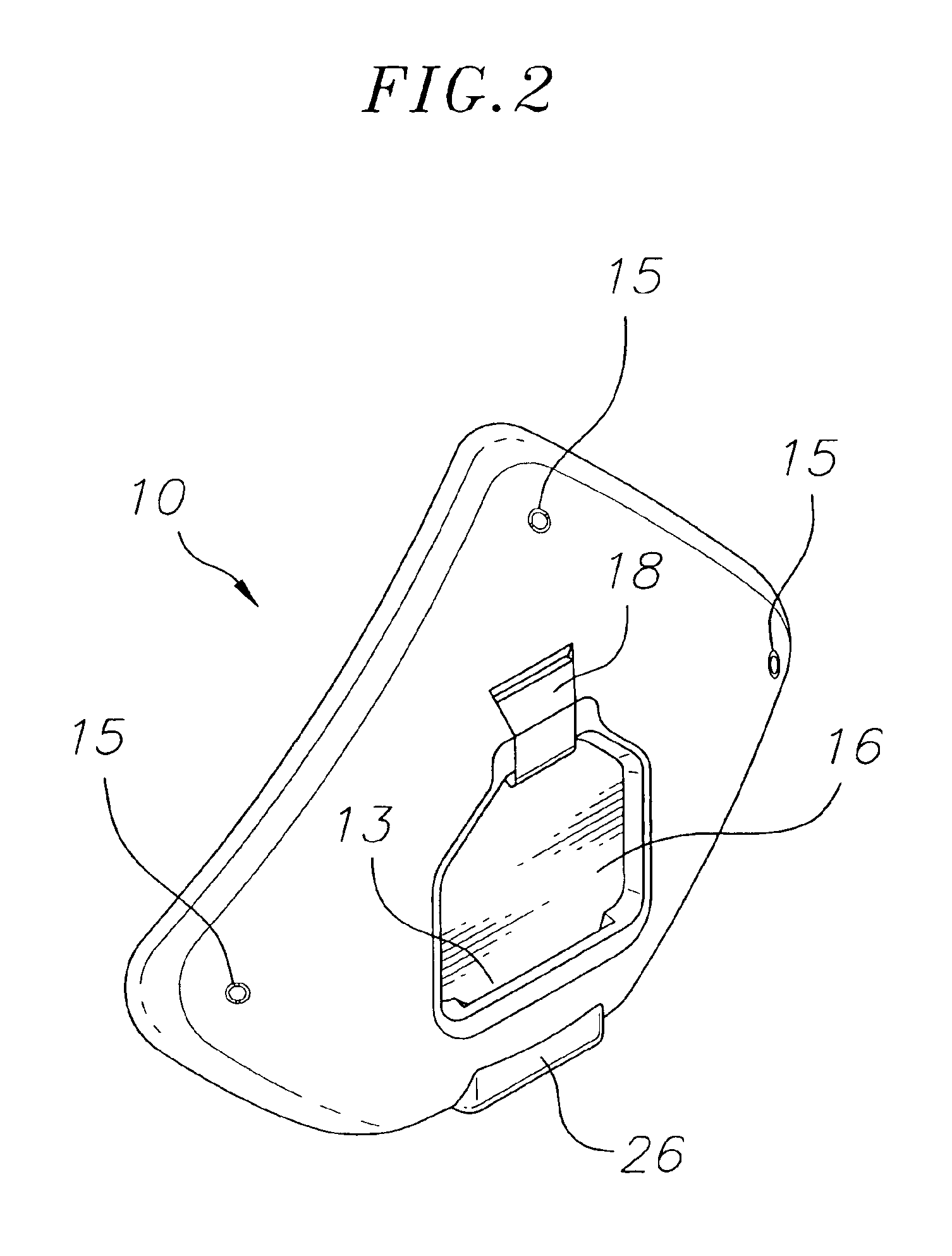

A shroud plate for headgear is provided that may comprise a shell, an insert, a lock, a release mechanism wherein the shell extends around at least a portion of the insert has a smooth surface with rounded edges and corners and is shaped to match the contour of the headgear, and at least one attachment point wherein the attachment point is laterally movable within a restricted area. Further, the shroud plate may be attachable to headgear at a single attachment point and may be given rotational stability by an elevated ridge or a plurality of legs which may extend over or wrap around an edge of the headgear.

Owner:NOROTOS

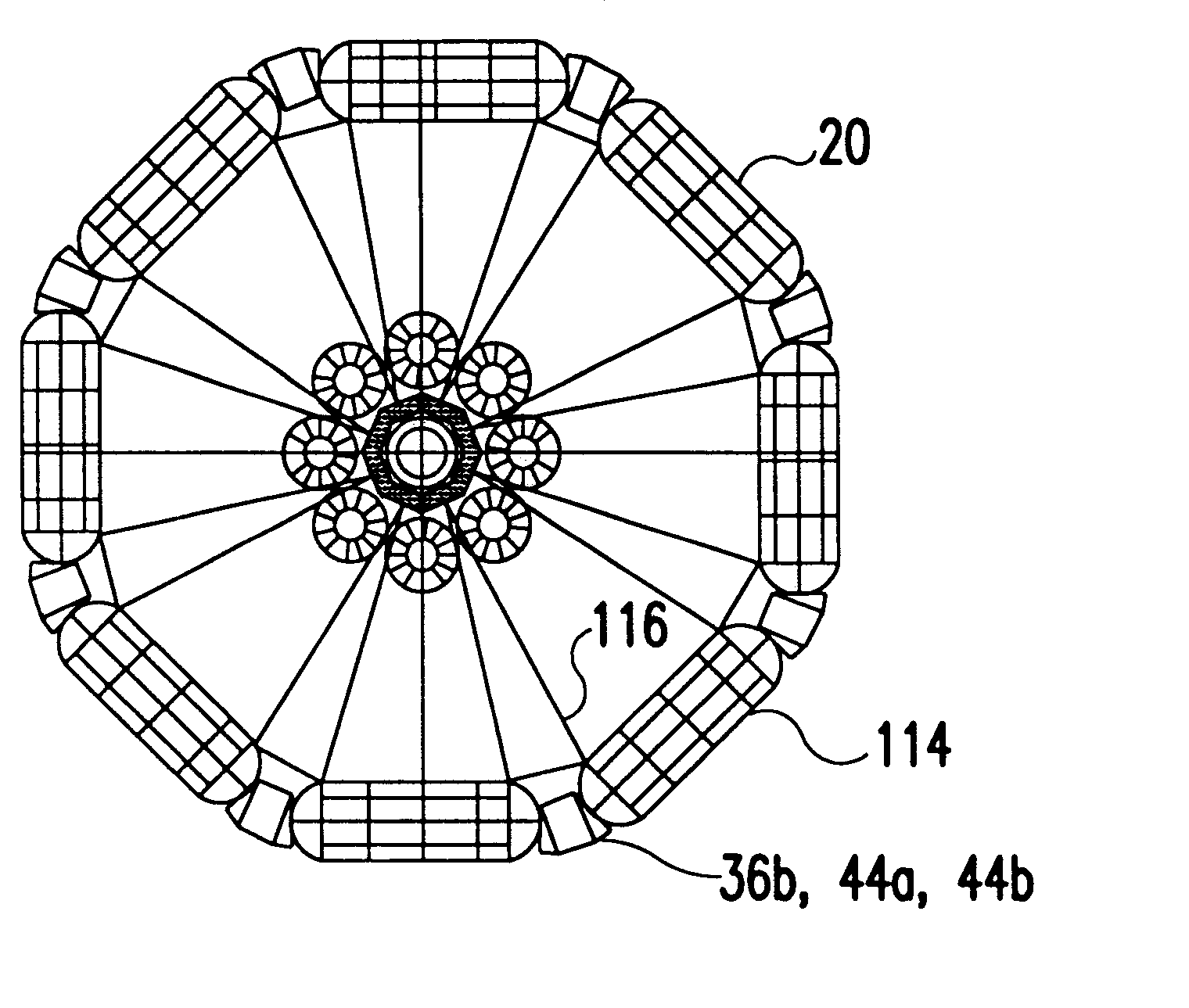

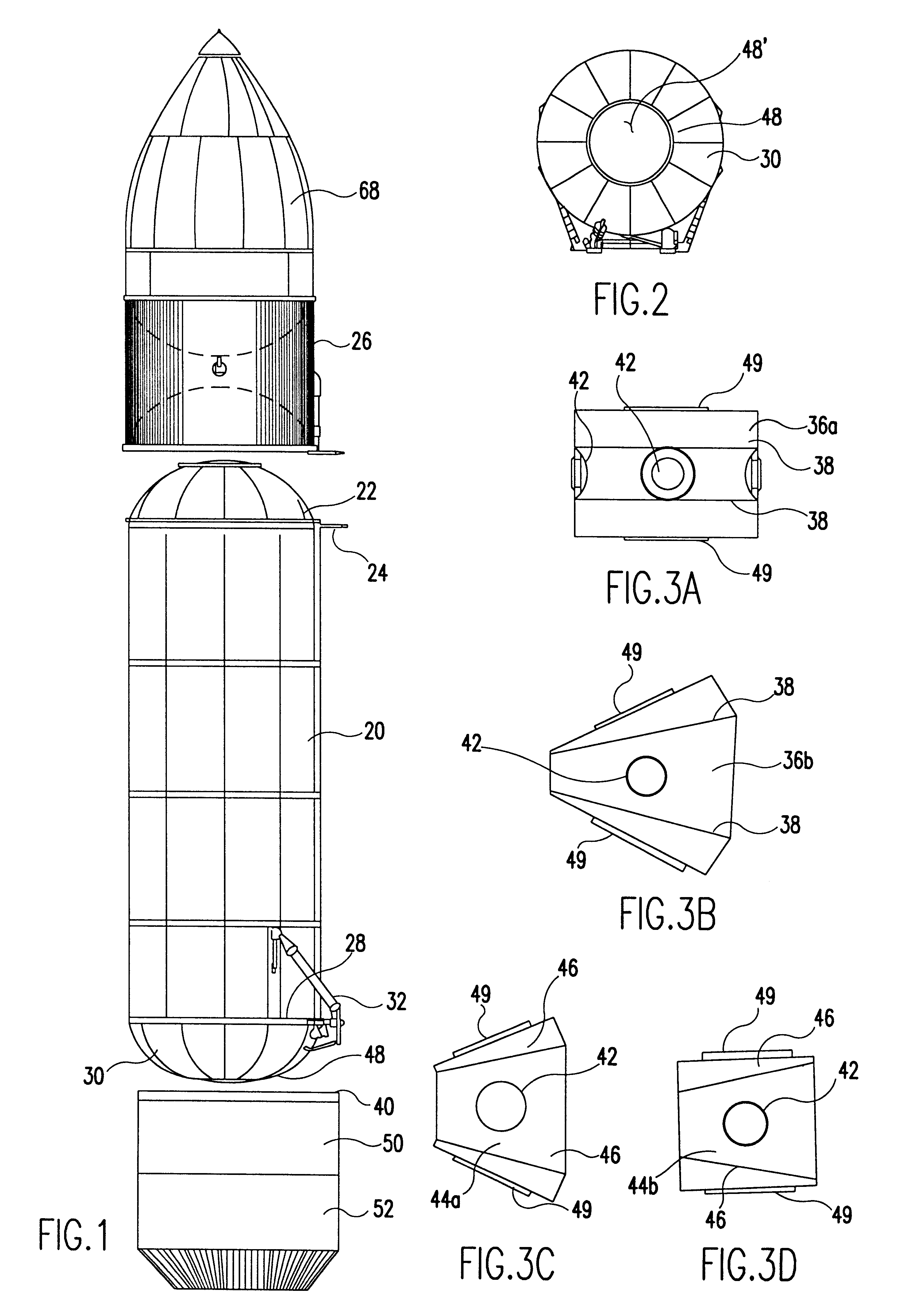

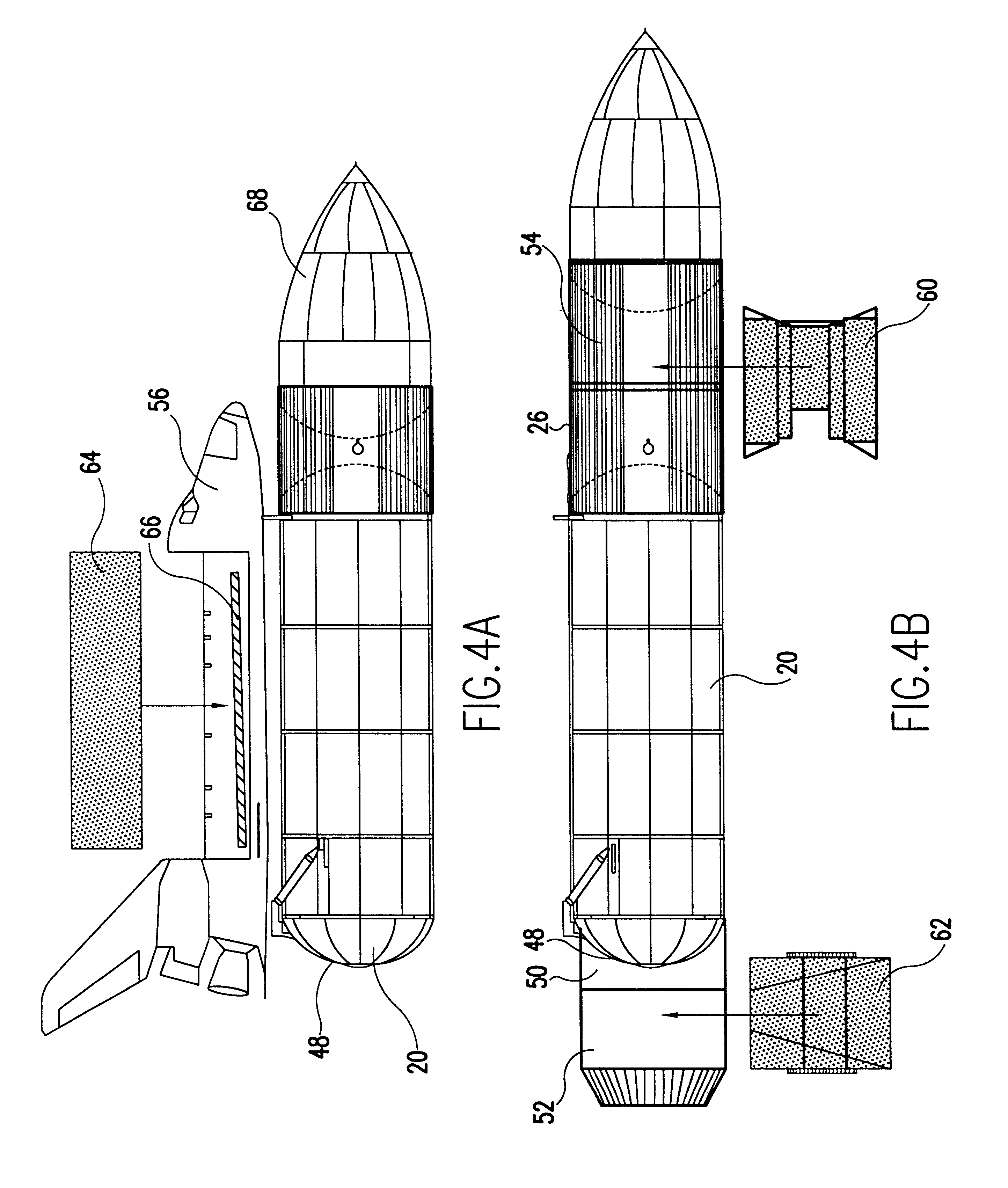

Centrifugal gravity habitation torus constructed of salvaged orbital debris

InactiveUS6206328B1Provide securityEasy to assembleCosmonautic crew accomodationsProtection against meteoritesAviationRotational stability

An aerospace hardware derelict item is salvaged in space, modified, and reused to provide manned facilities in orbit. The hardware packages added onto the salvaged discarded item enhances its value, and incorporates at least the subsystems required to effectively reuse portions of previously discarded launch vehicle components, and other derelict objects in space. The hardware, and technique used reduces the cost of launching comparable hardware to orbit, because of the reuse, and provides a human habitation in orbit. The salvaged items include the external tank of the space shuttle, other derelict orbital hardware, the add-on cargo pod in two forms, and the ability to convert the derelict into a cost effective reusable item. The salvaged hardware is initially capable of contributing mass, length, interior volume, strongback, rotational stability mass, interior pressurized volumes, artificial gravity, and stability with the addition of simple subsystems for salvage, and interior development packages.

Owner:TAYLOR THOMAS C

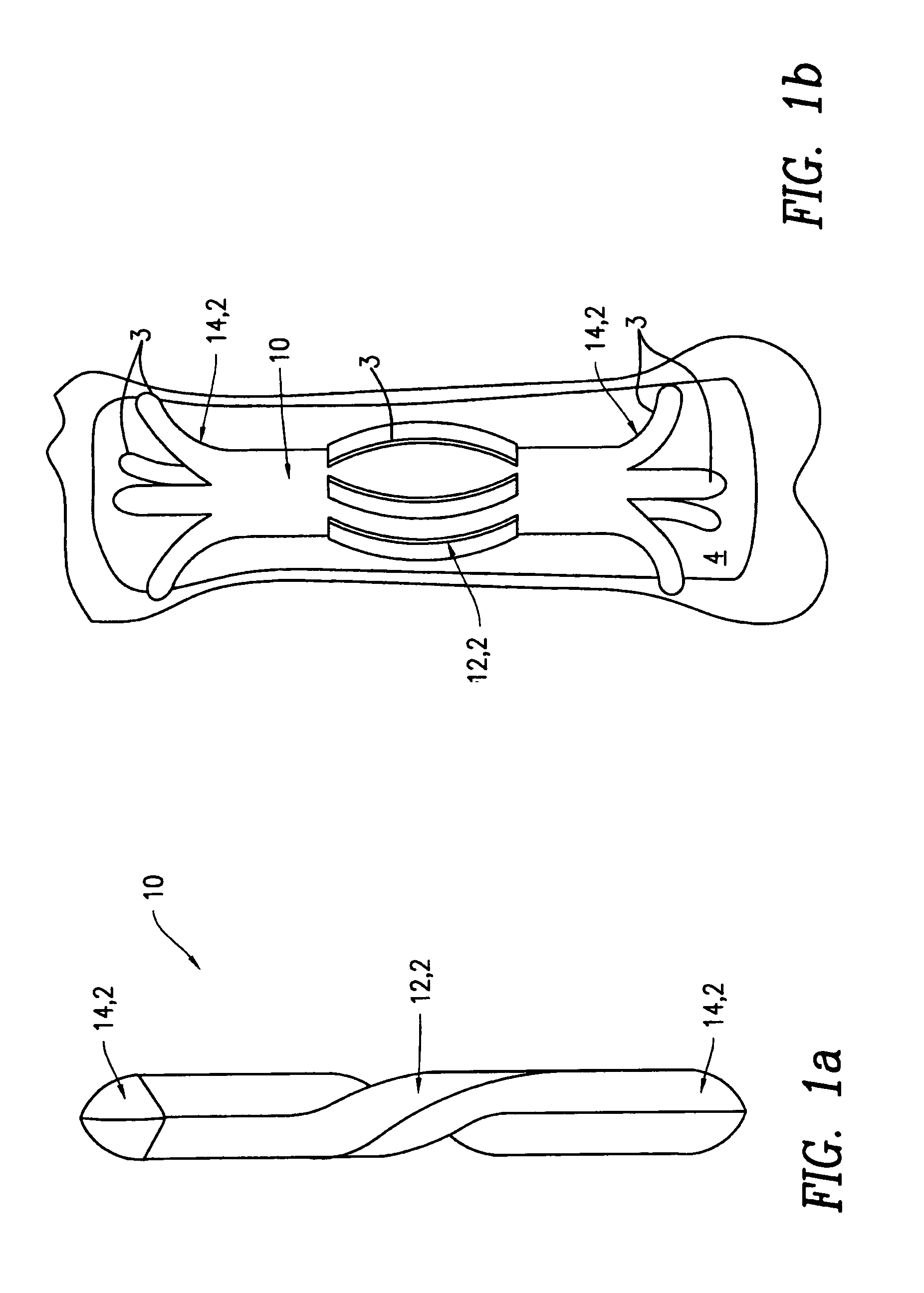

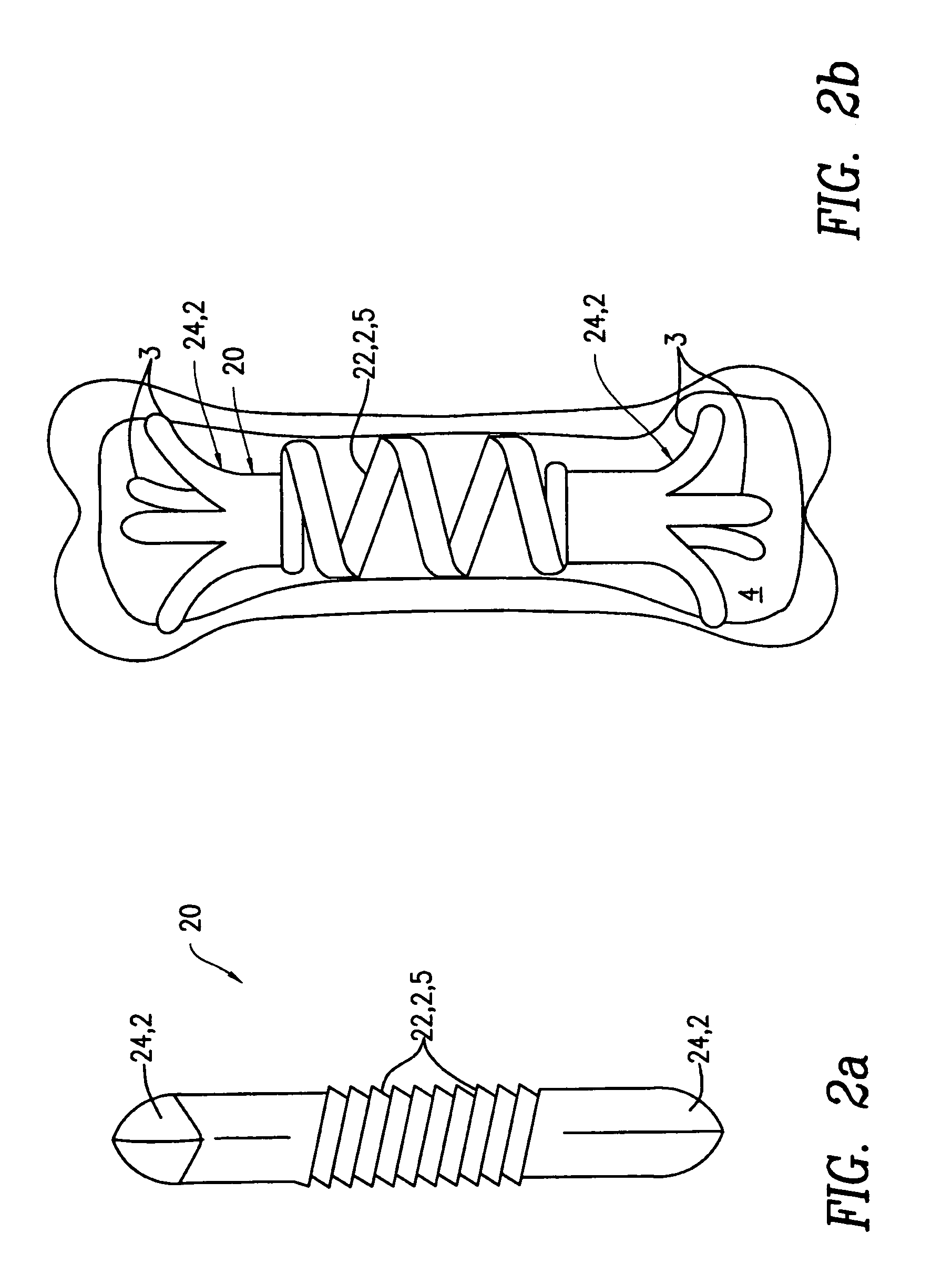

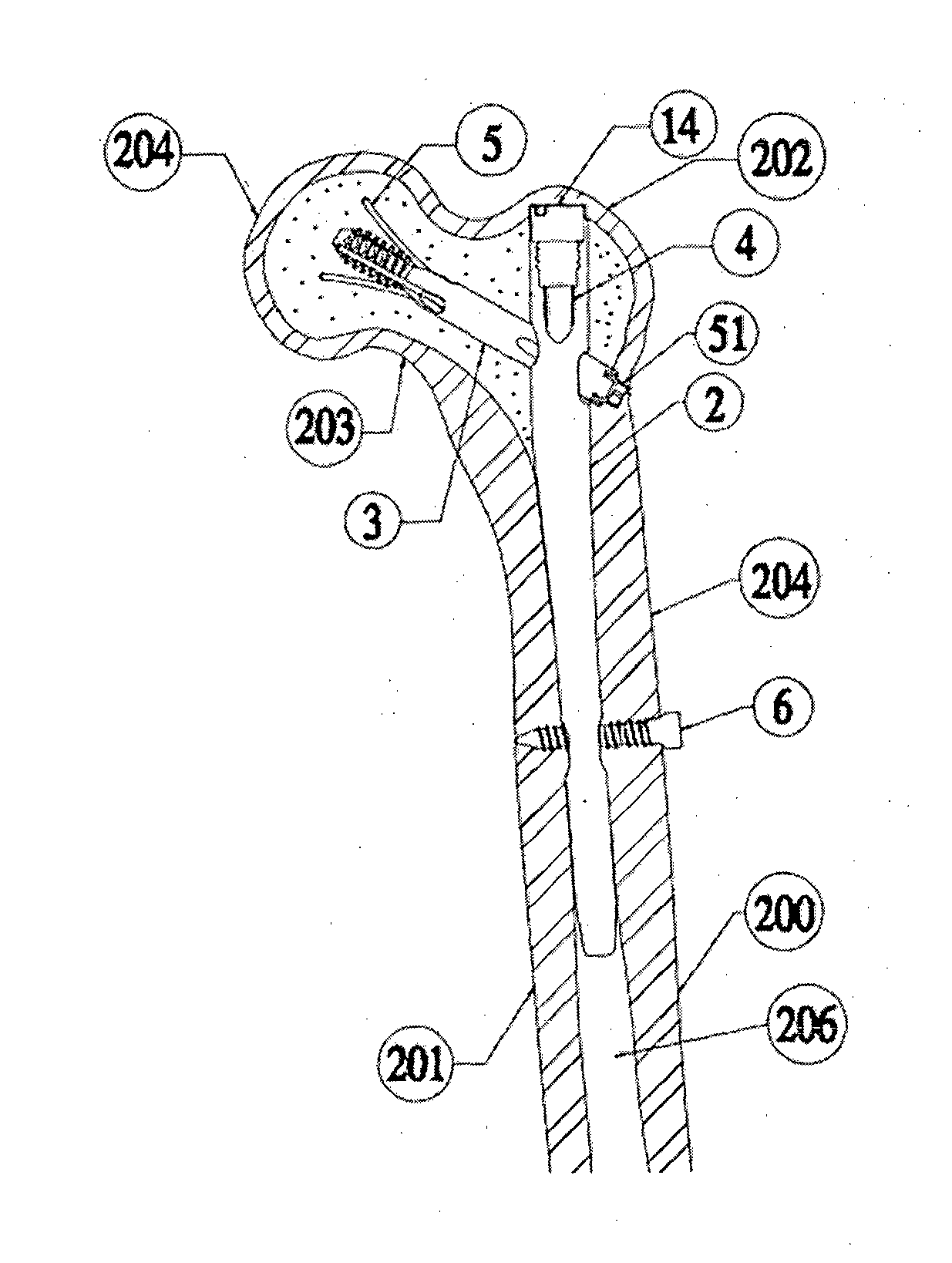

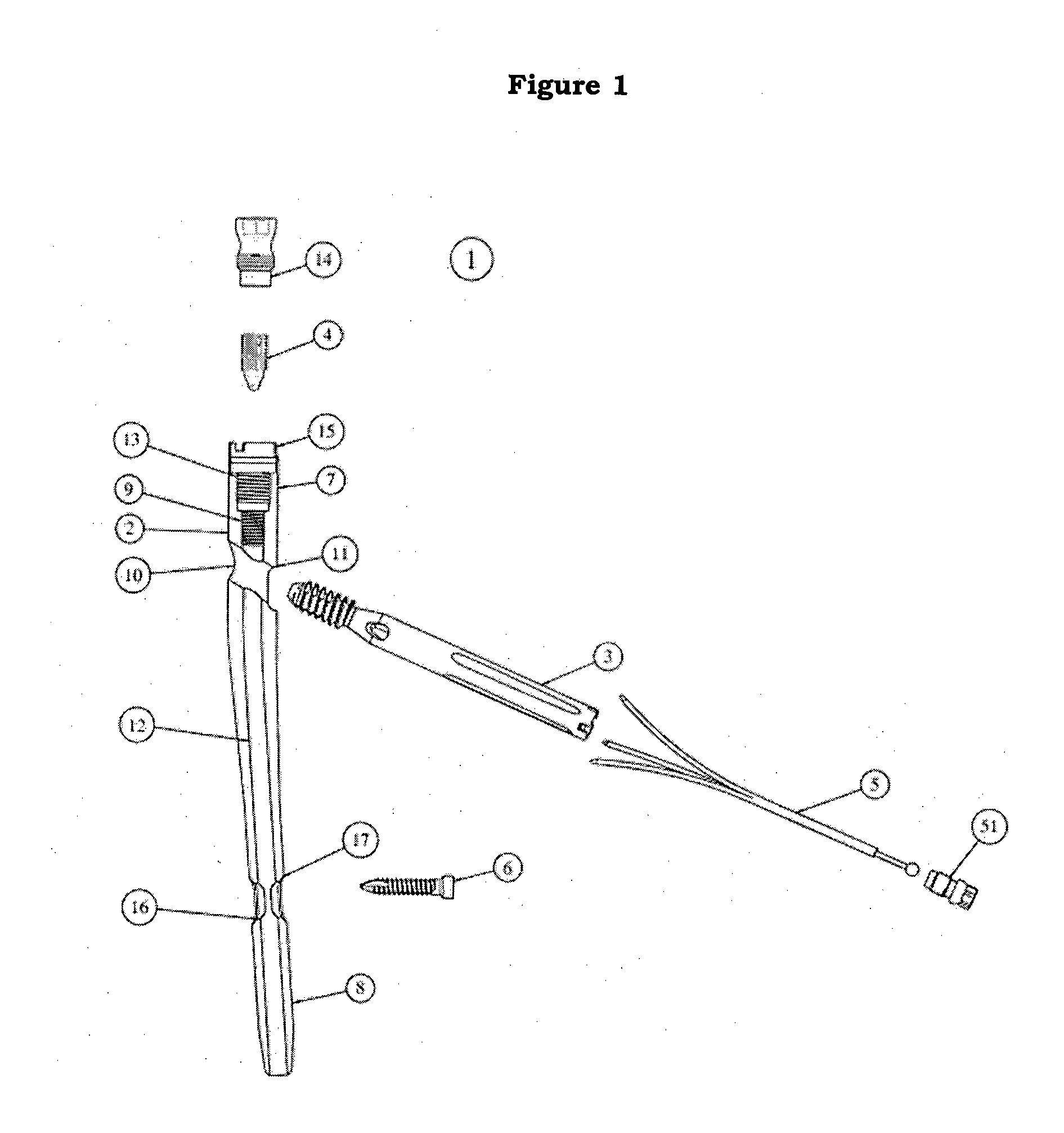

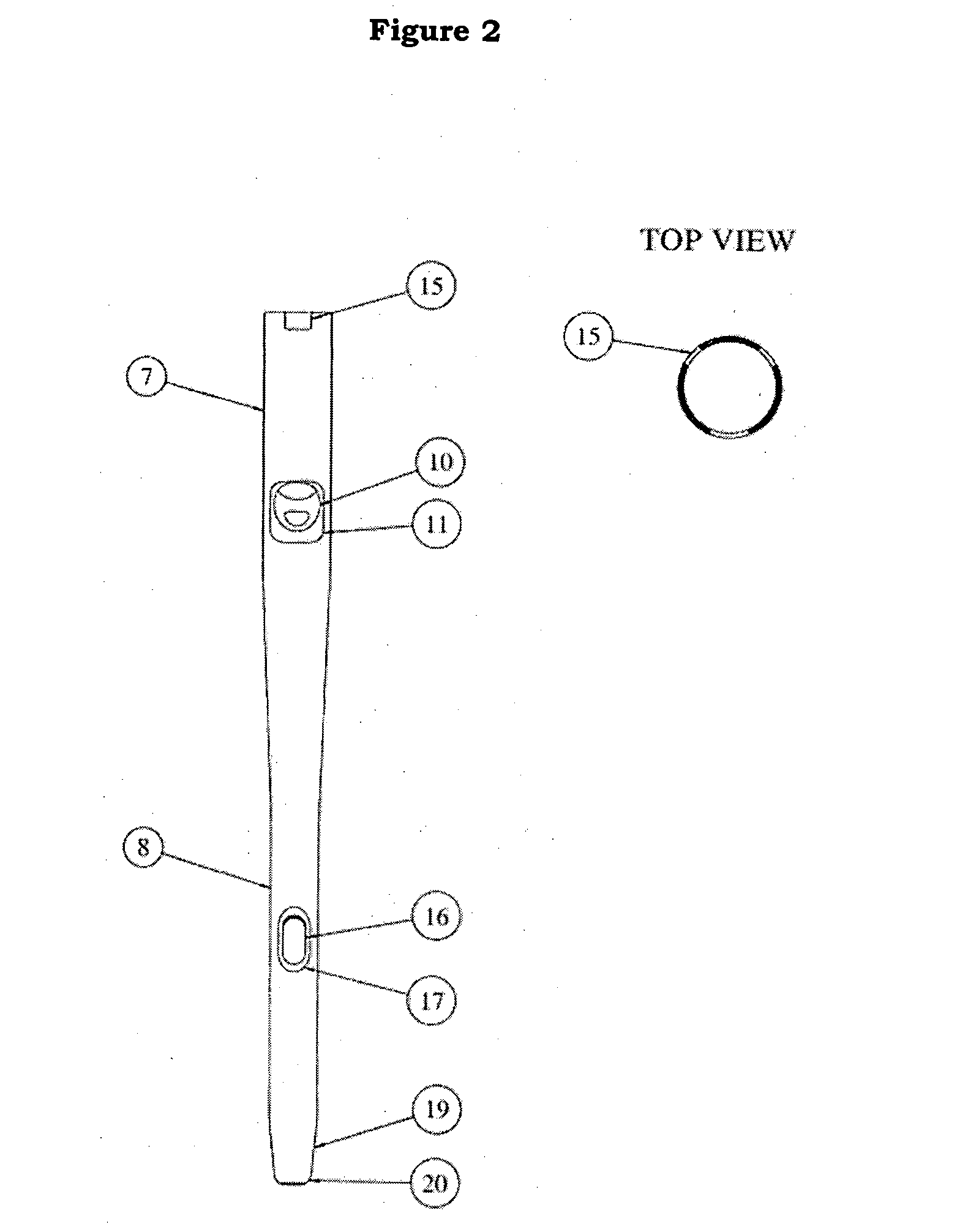

Fixation device

The present invention relates to a bone fixation device having a fixation member using a shape memory effect to secure bone fractures, including but not limited to, femur, tibia and humerus fractures. The fixation member can be malleable at a room temperature, but become rigid at a body temperature because of the shape memory effect, such as derived from a super-elastic property found in such as a nickel titanium alloy. The fixation member can be formed on one or more of the shaft portion and the two end portions of a nail member for securing bone fractures, such as by providing translational and rotational stabilities. The fixation member is also capable of providing a continuous and controllable compression force over the fractured bone, if needed.

Owner:THE UNIVERSITY OF HONG KONG

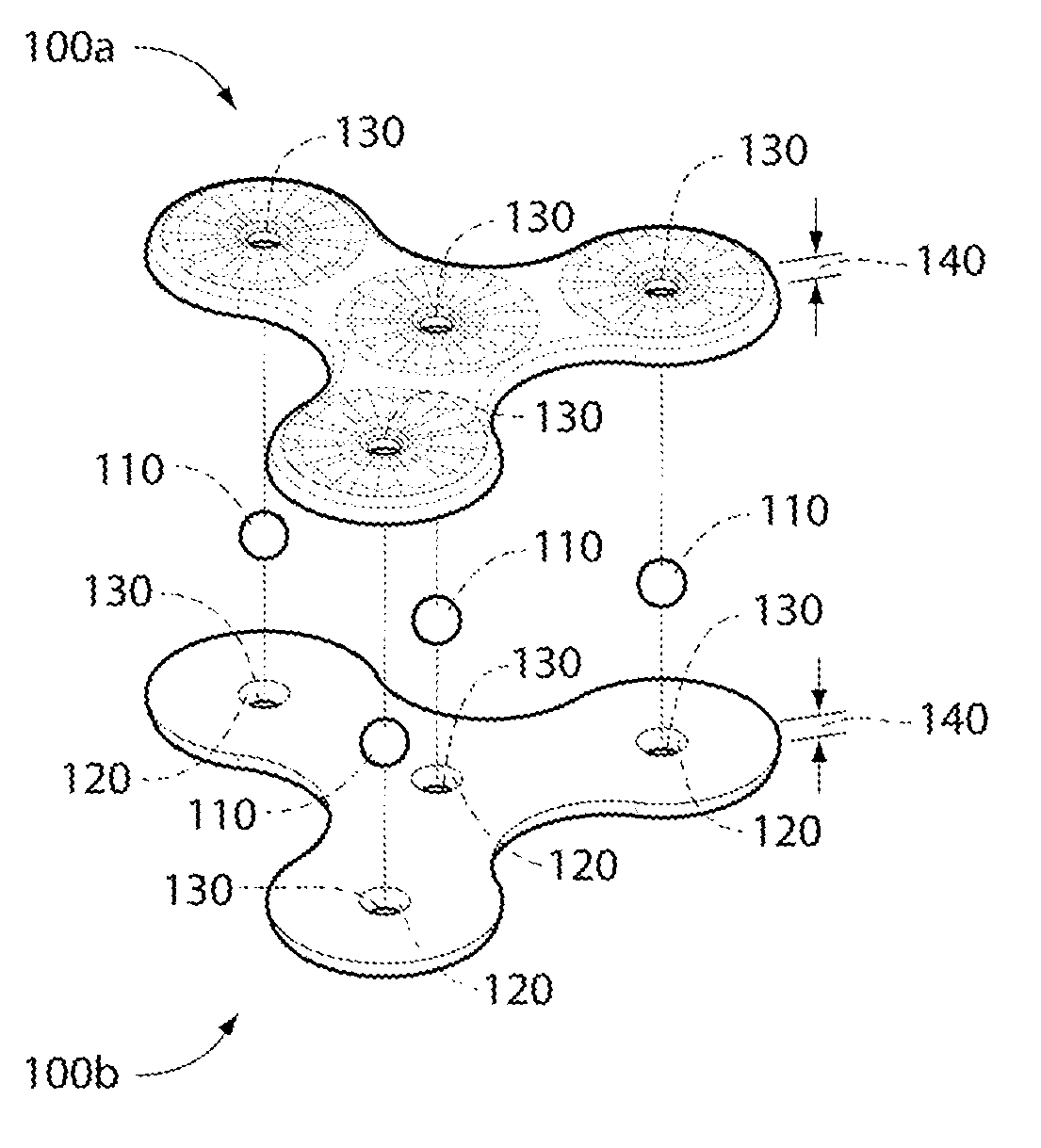

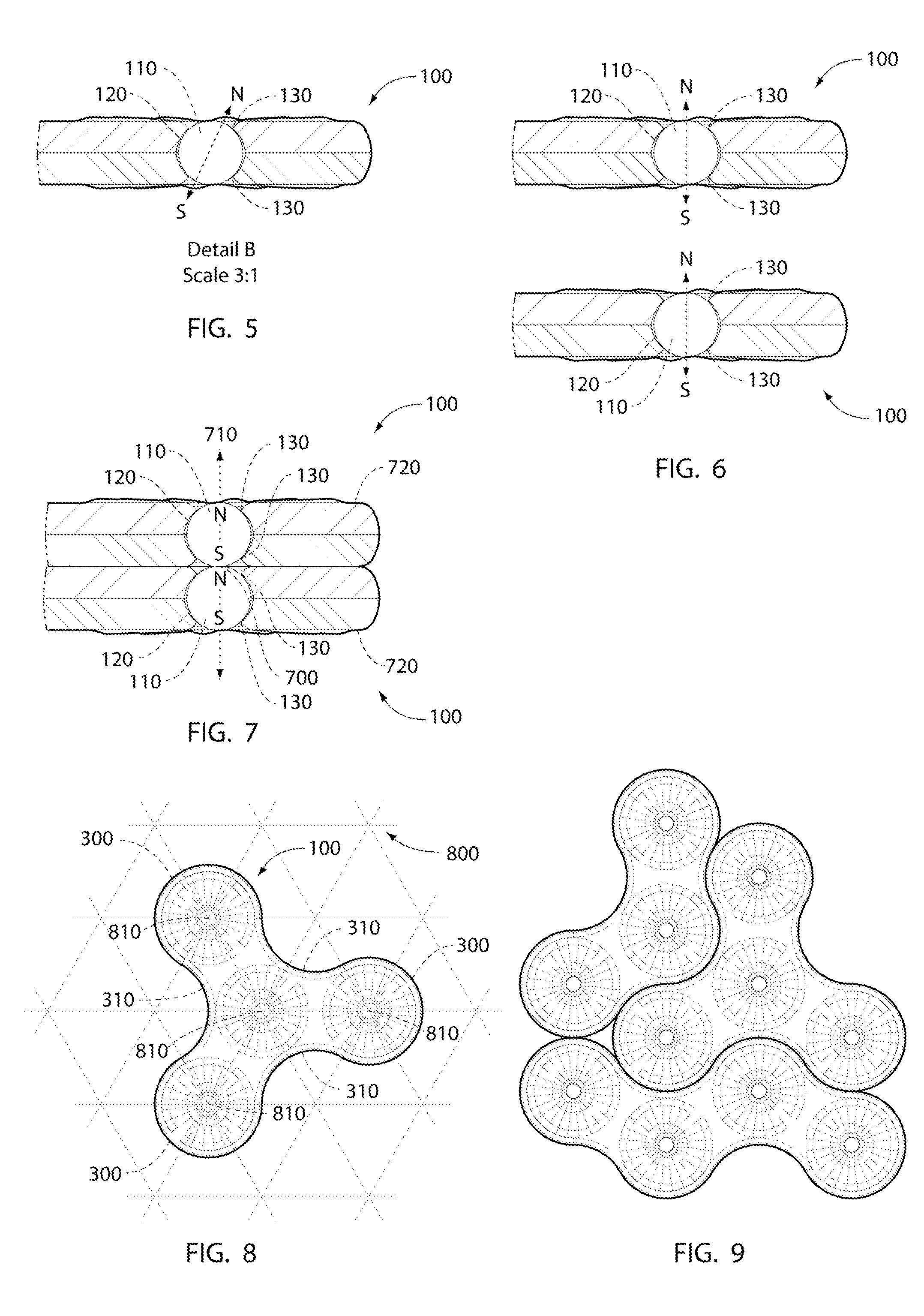

Magnetic construction system and method

ActiveUS20140213139A1Increasing magnetic coupling forceImprove abilitiesToy vehiclesMagnetic tension forceRotational stability

A magnetic construction system comprised of plural multi-shaped structural bodies each containing one or more captured magnets, wherein each magnet is free to rotate within its respective retaining pocket to align in magnetic polarity with rotatable magnets in adjacent structural bodies. Surface geometry around each magnet may include a radial detent feature which provides lateral and rotational stability between magnetically coupled structural bodies, or a radial recess which allows free rotation of respective structural bodies about the polar axis of magnetic coupling.

Owner:FERGUSON JOSHUA WILLARD

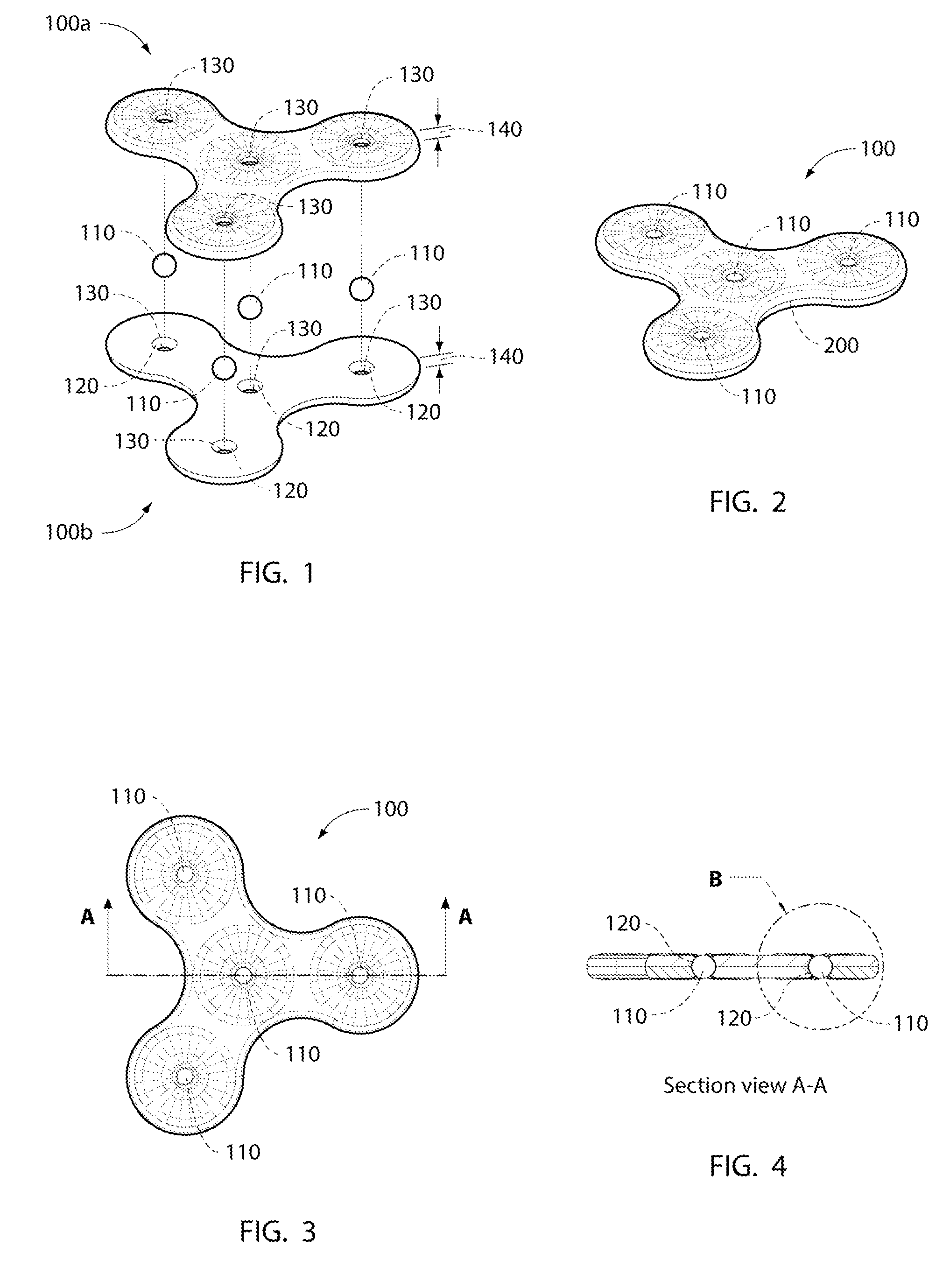

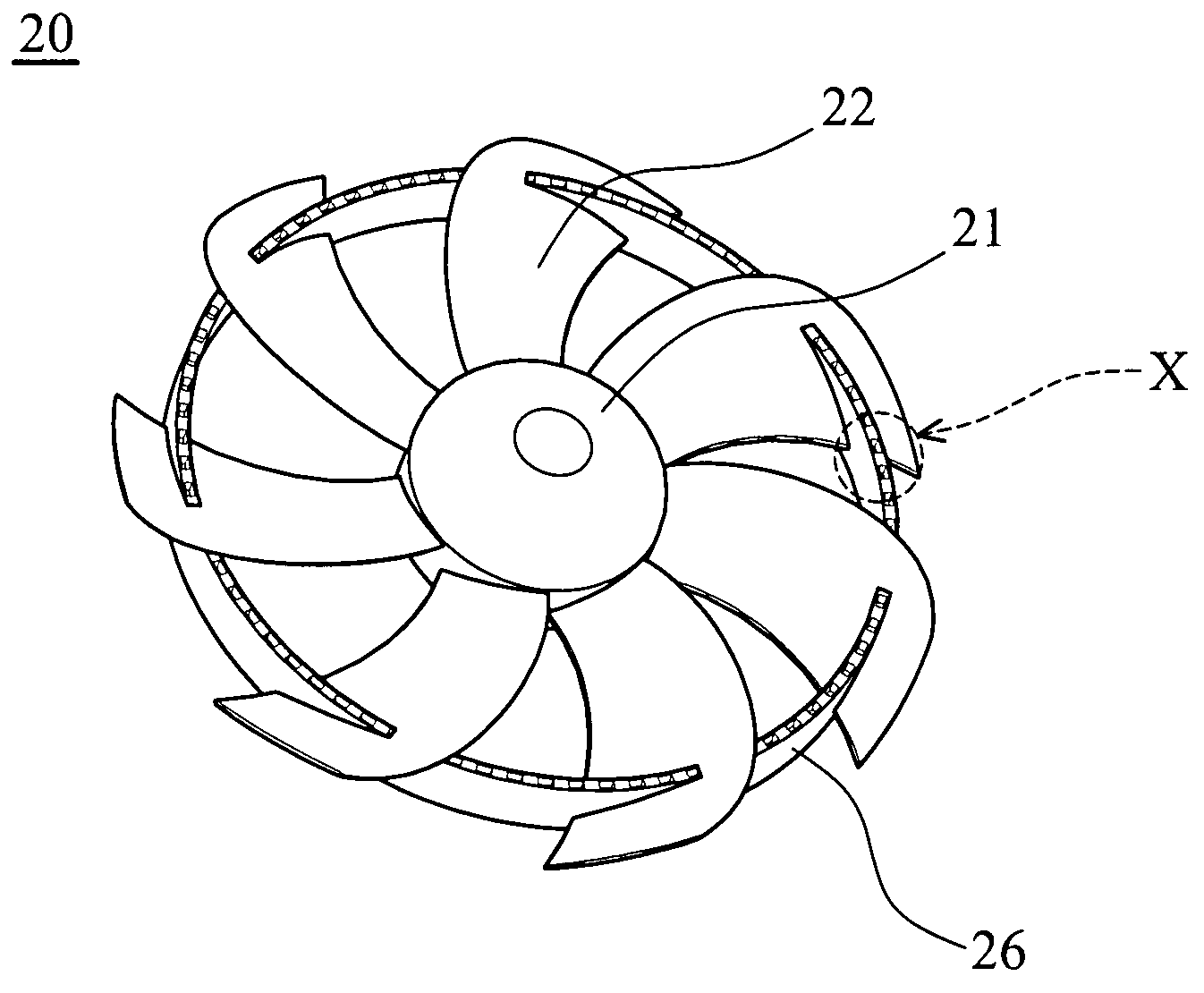

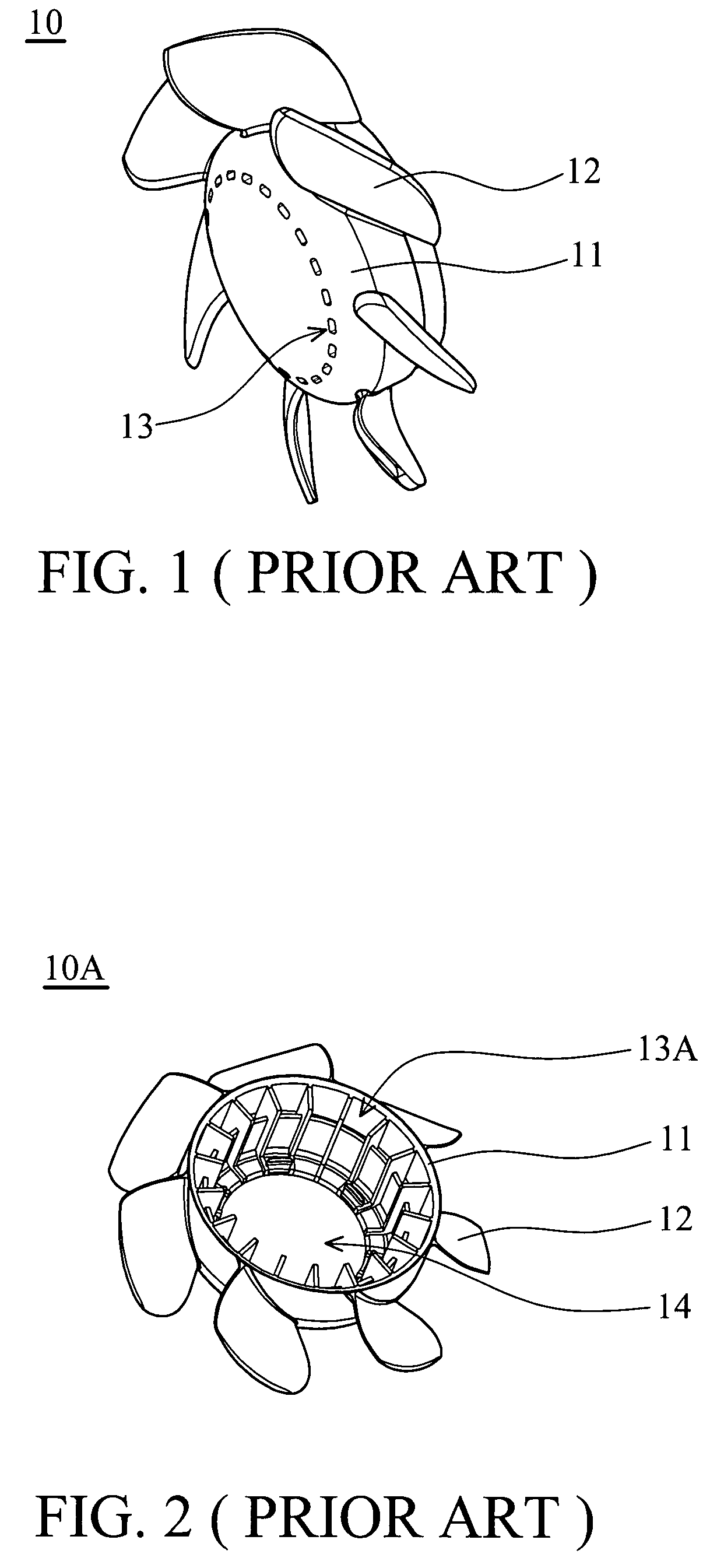

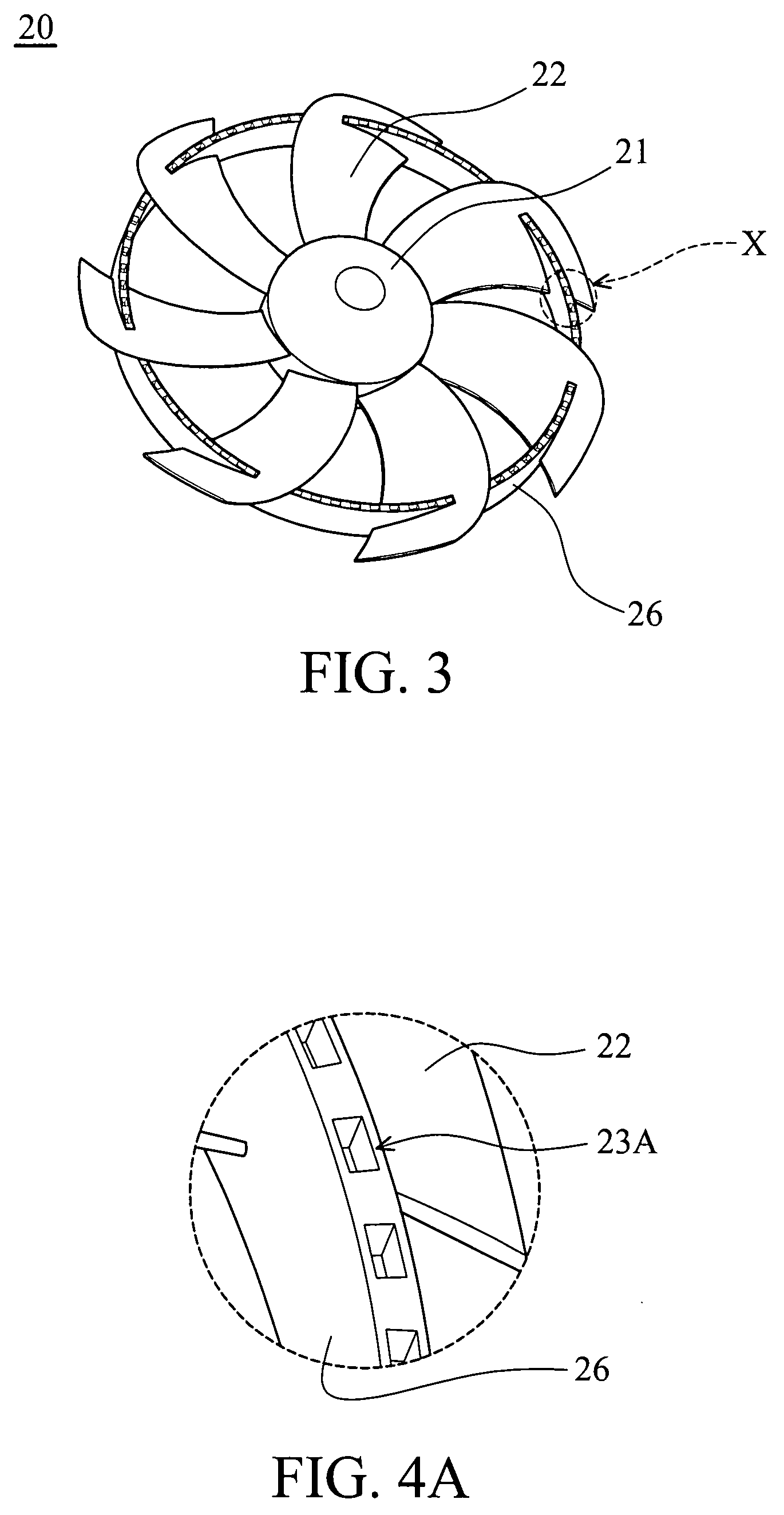

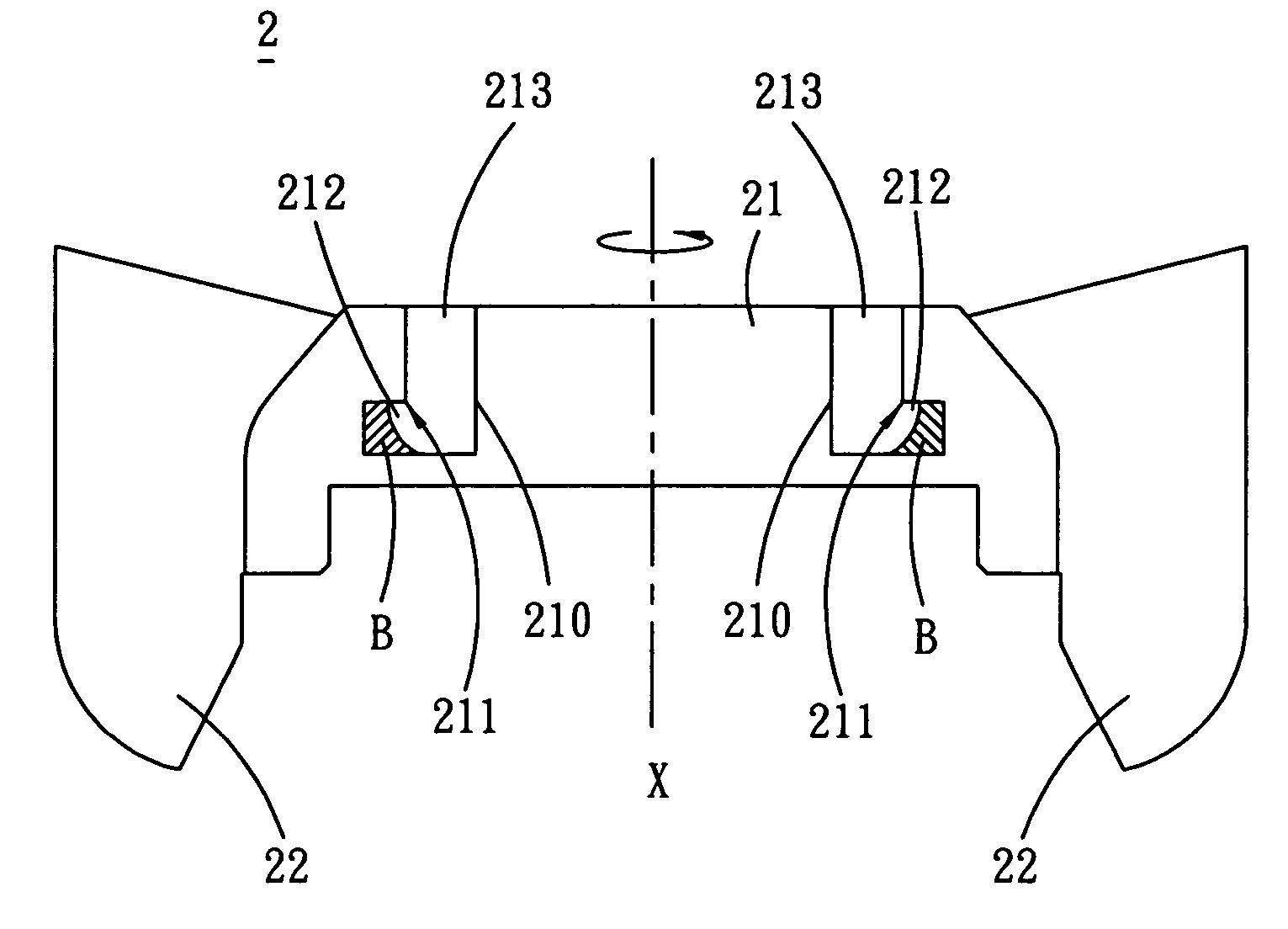

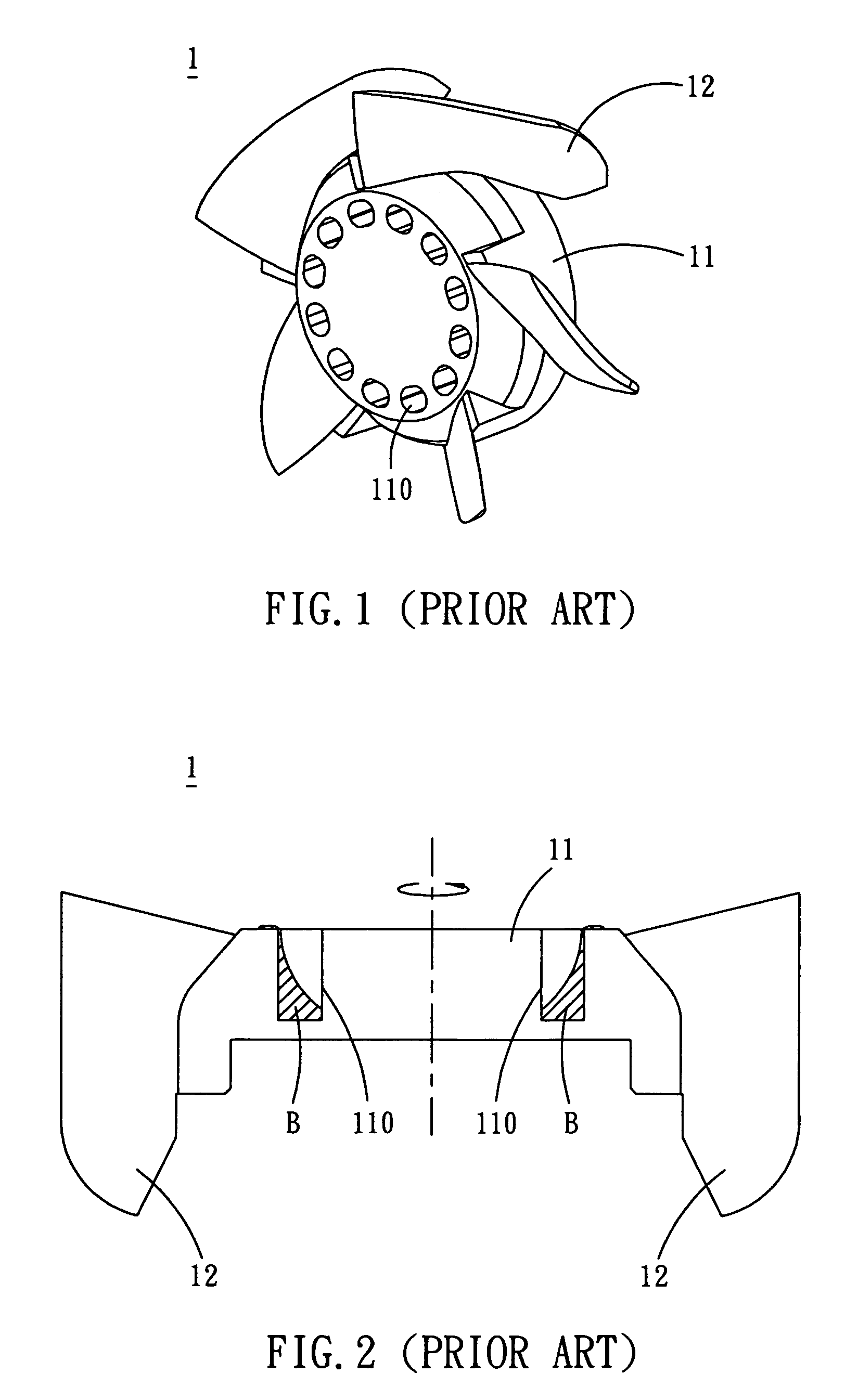

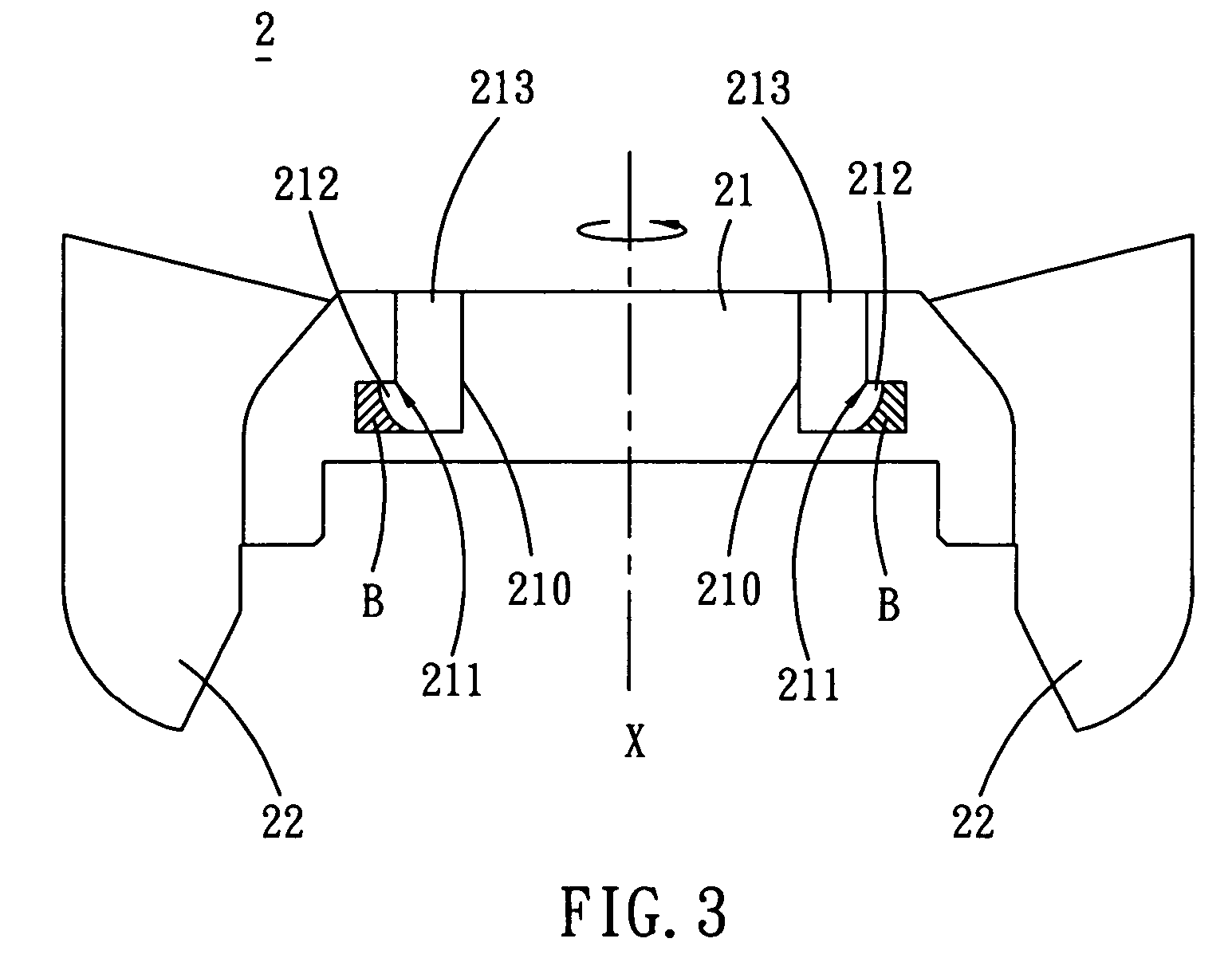

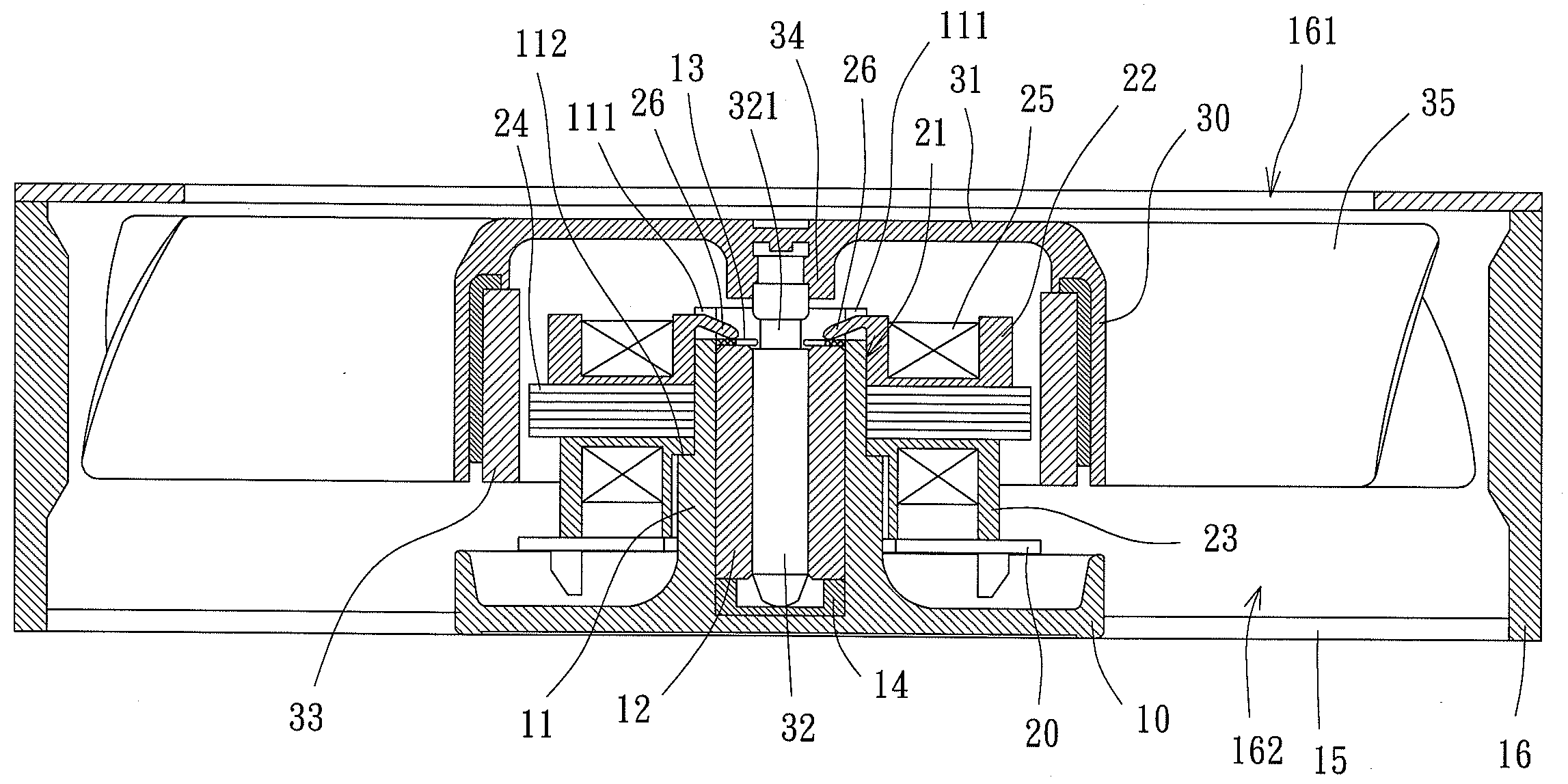

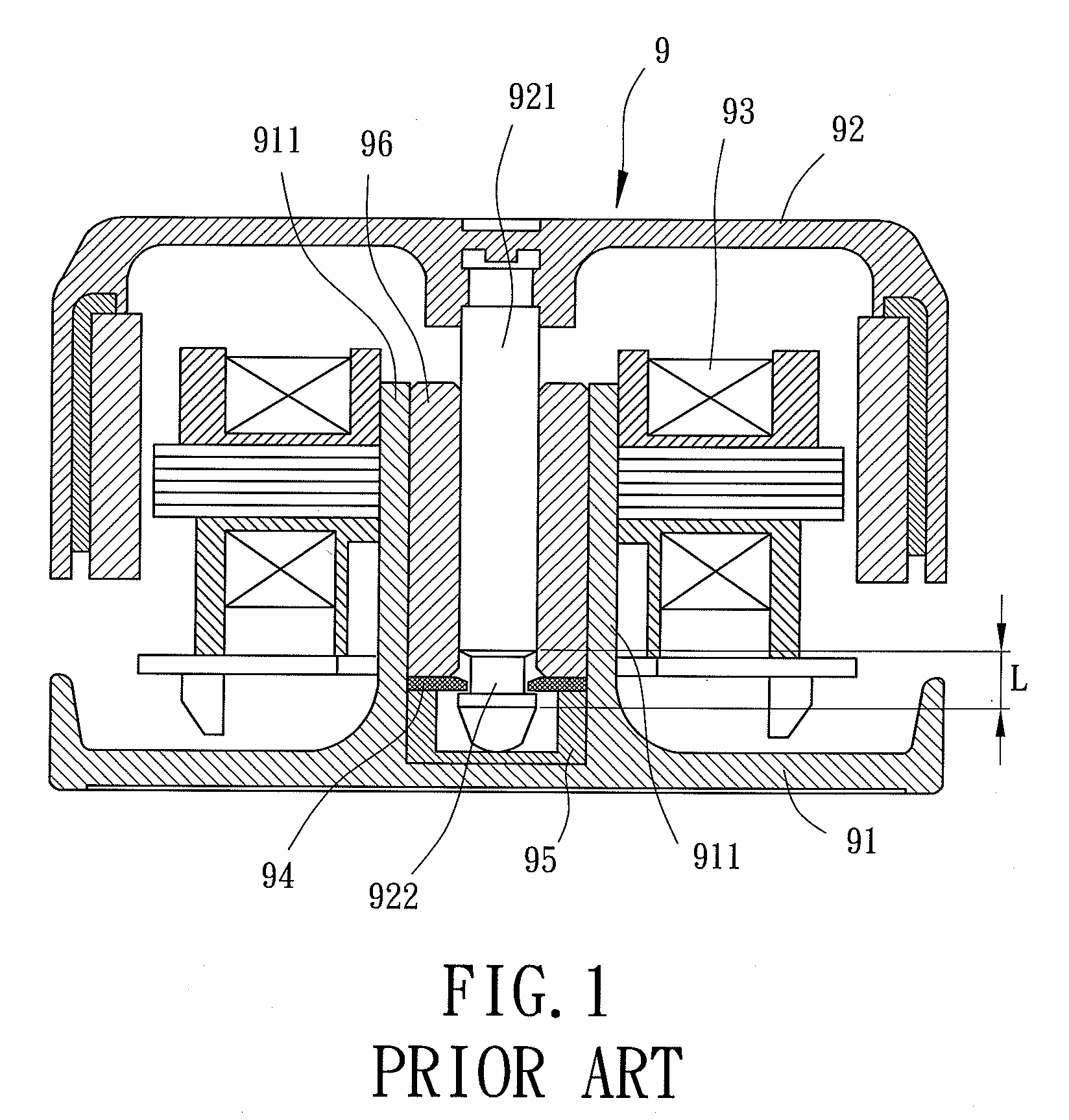

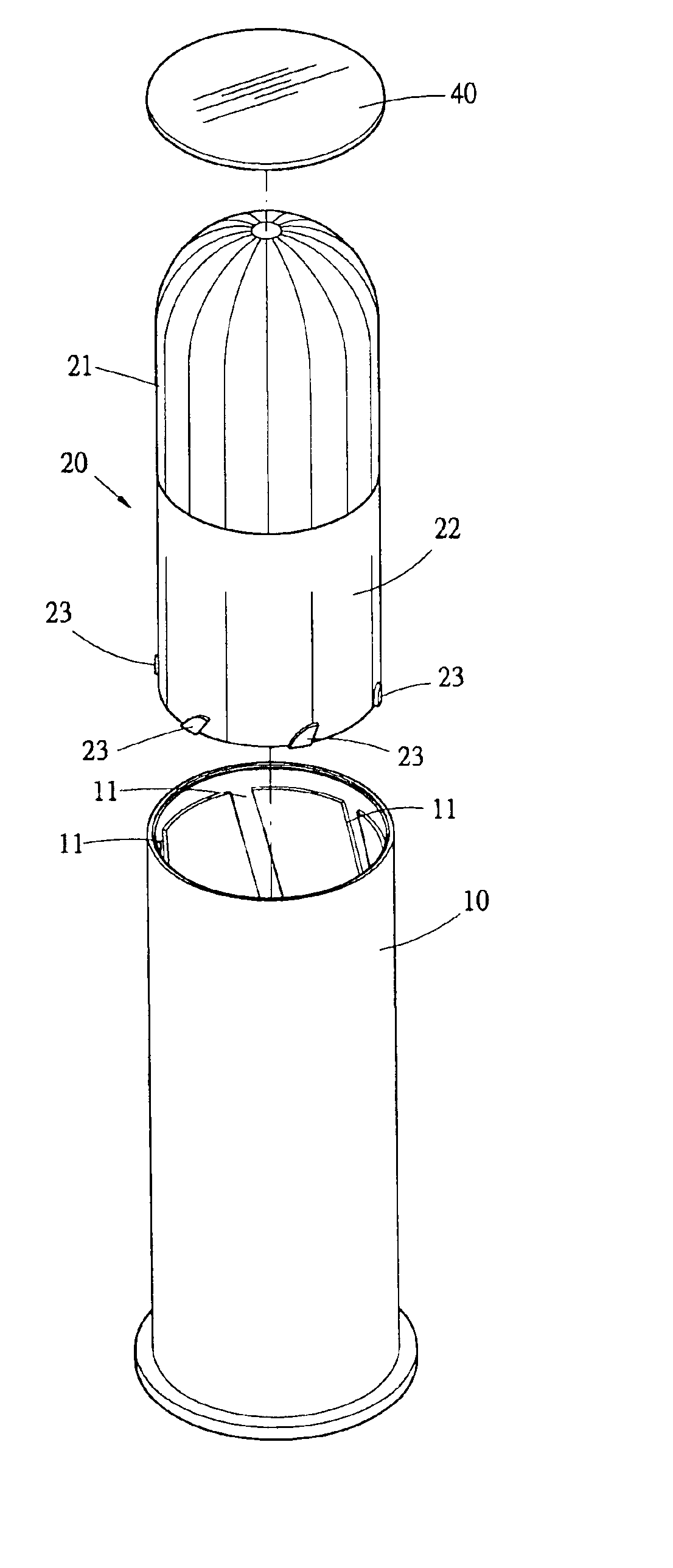

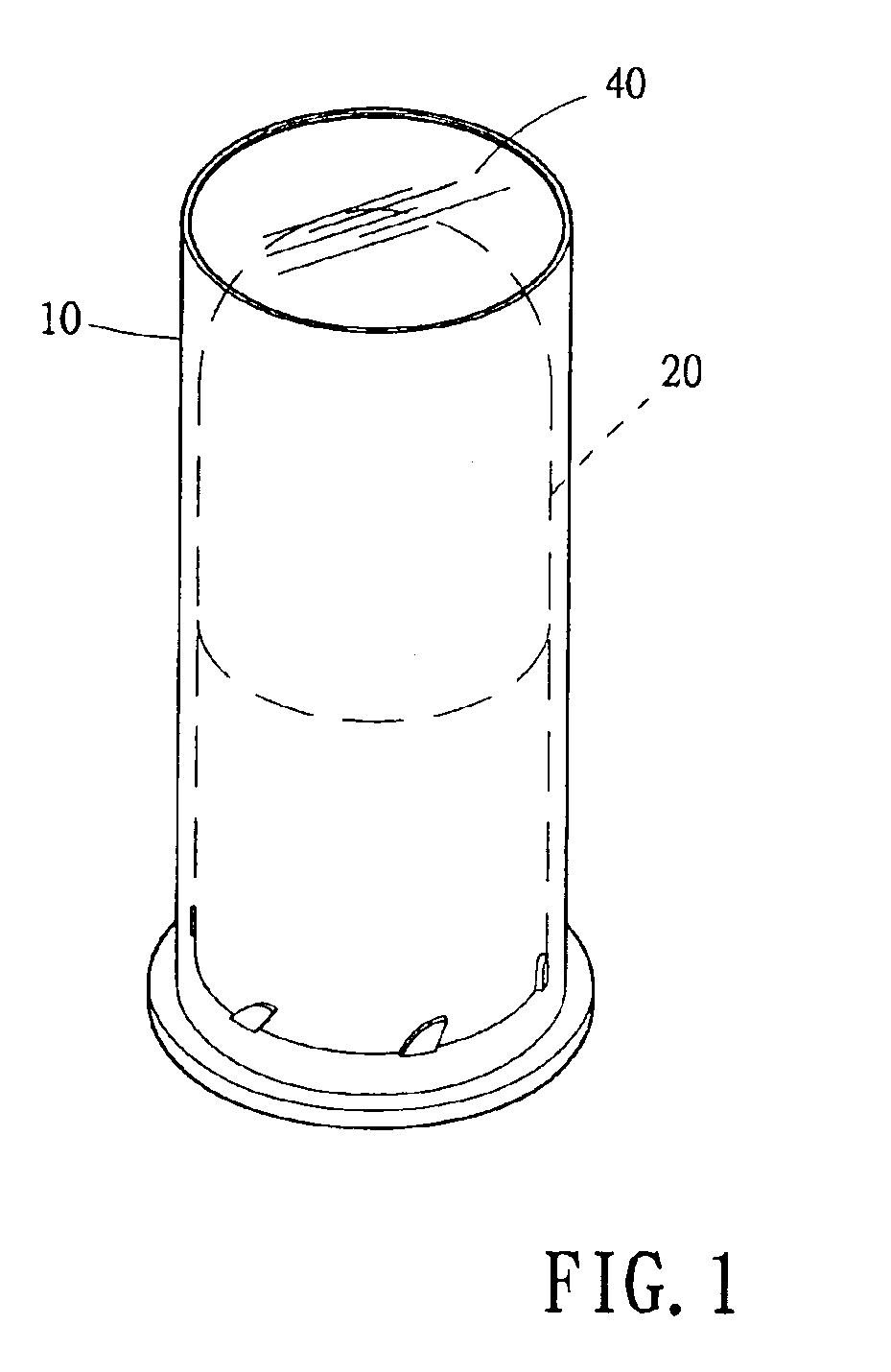

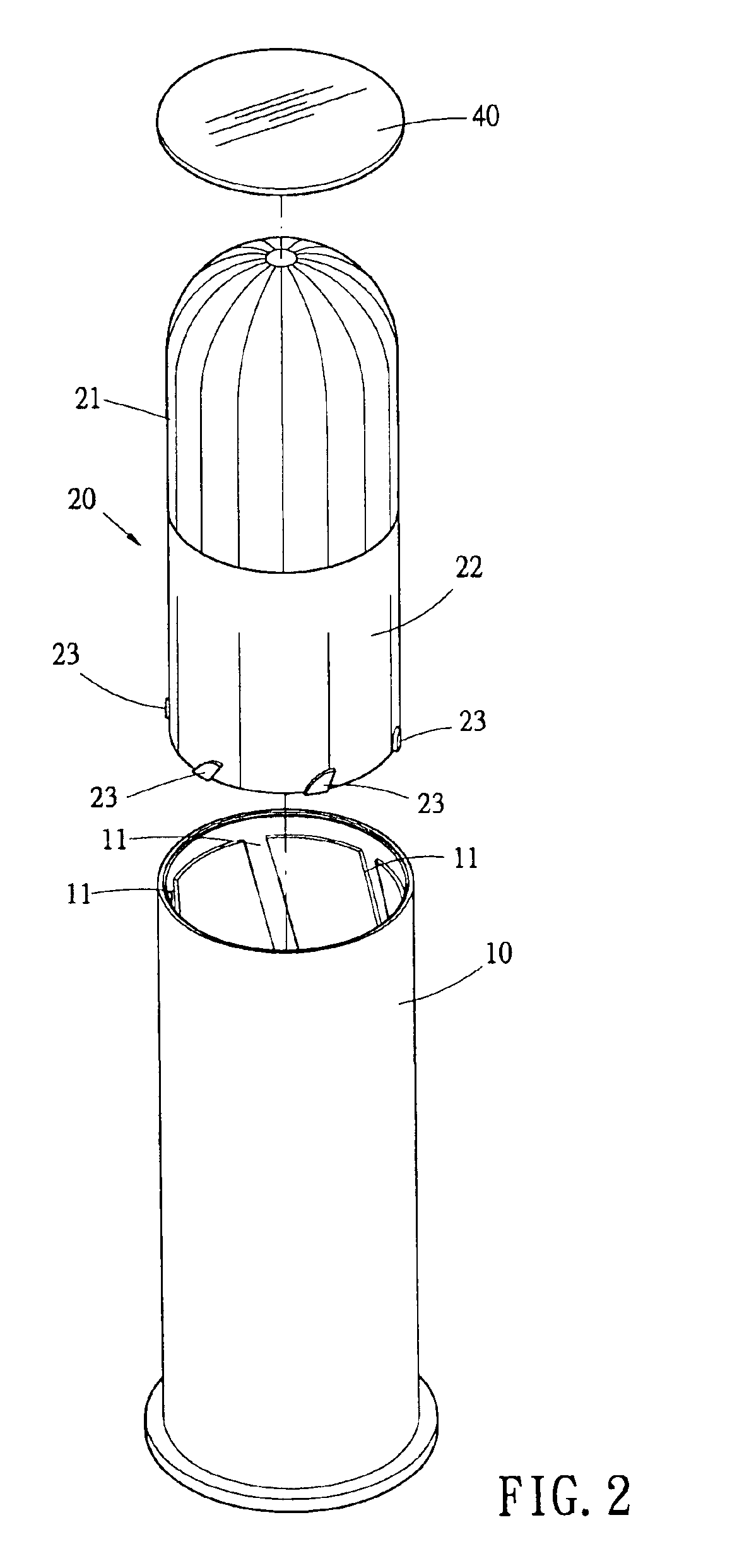

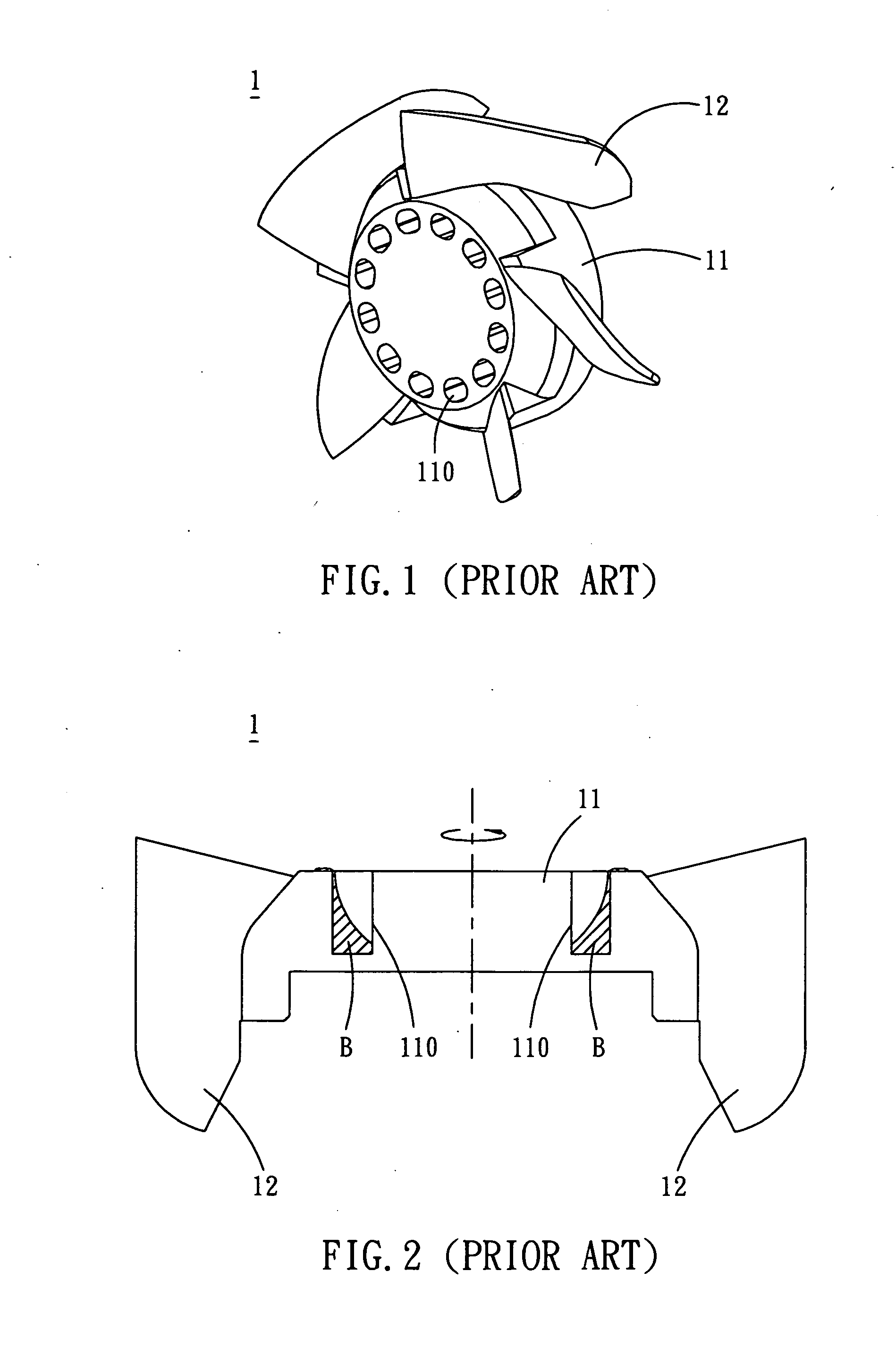

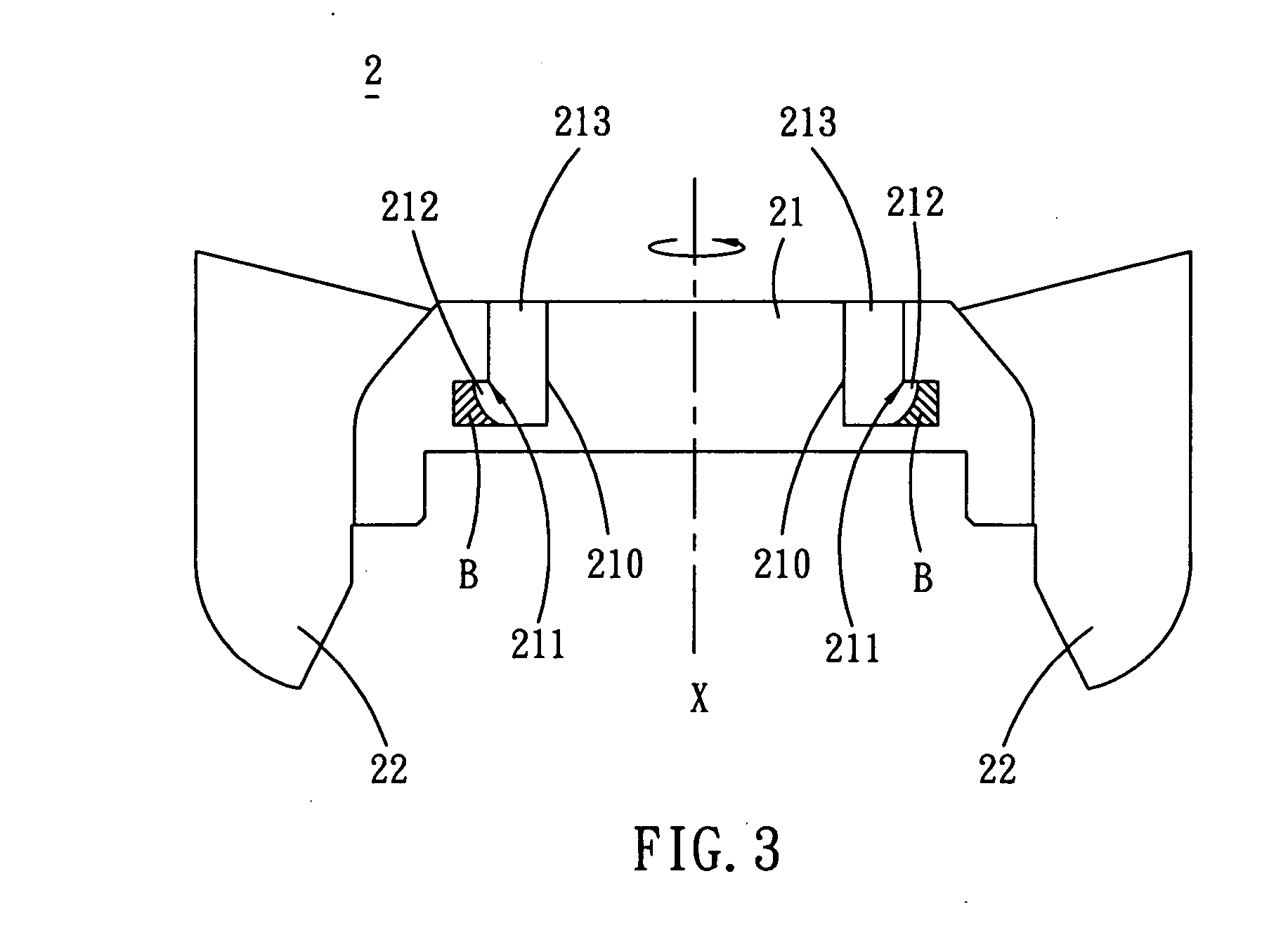

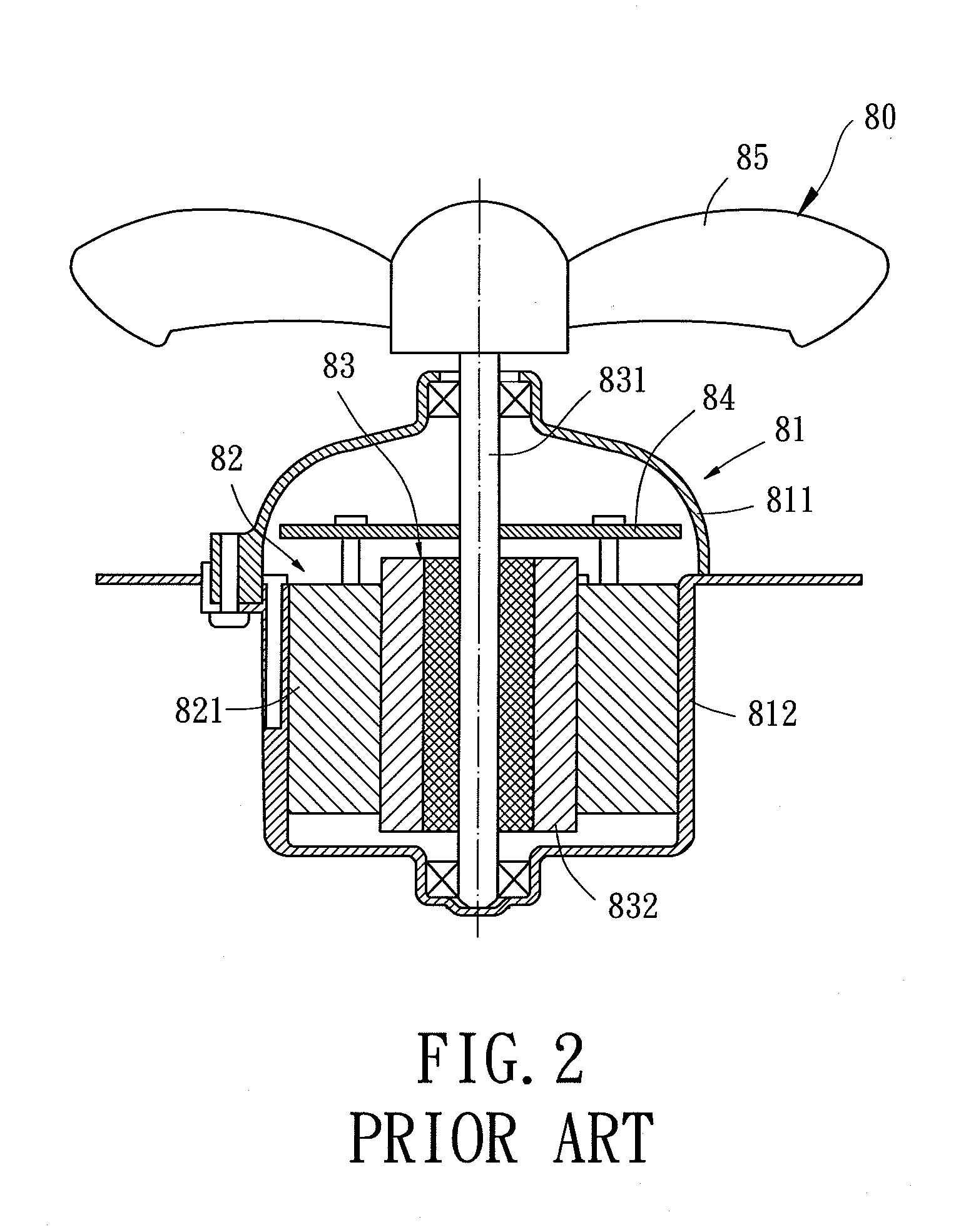

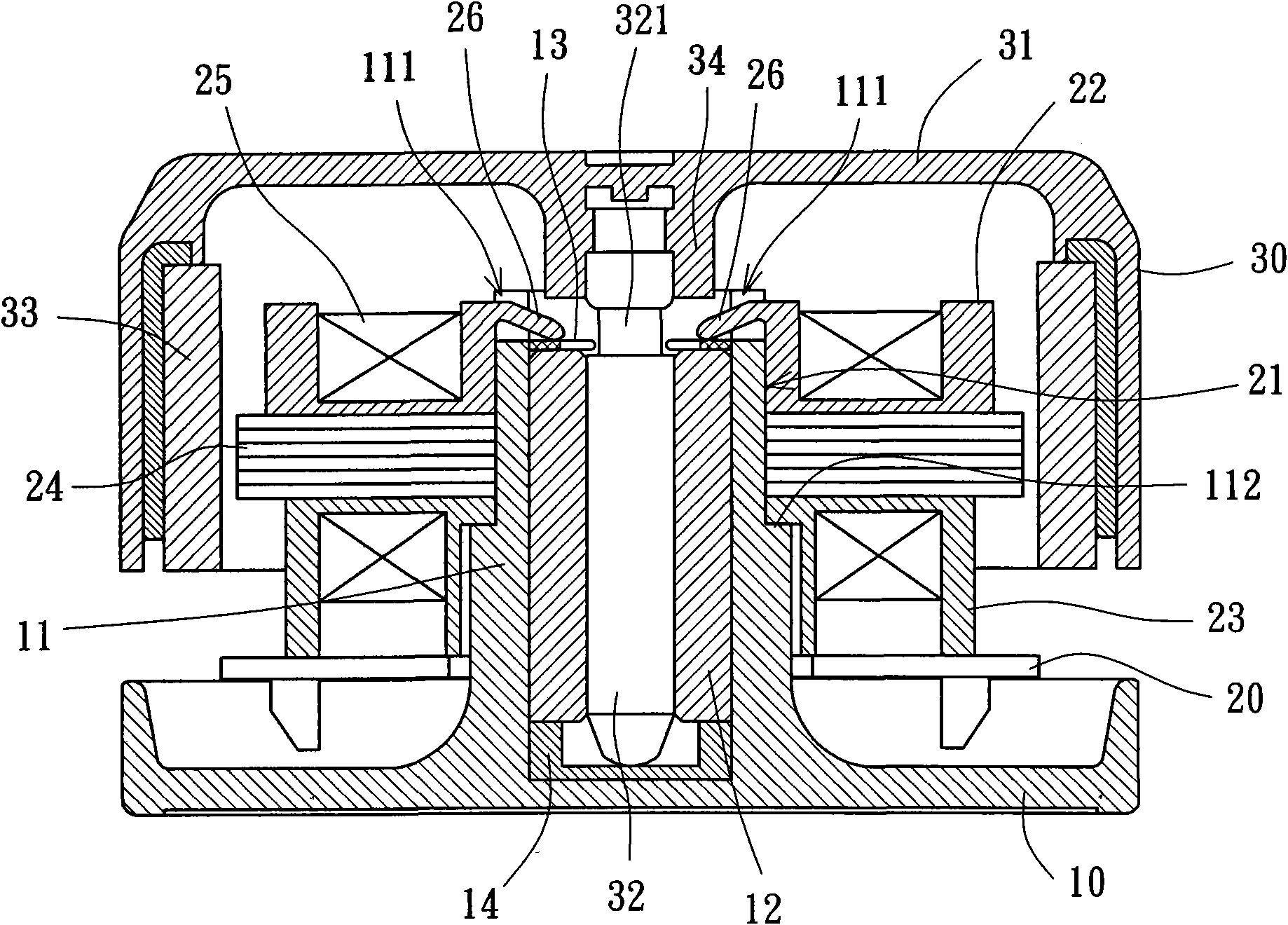

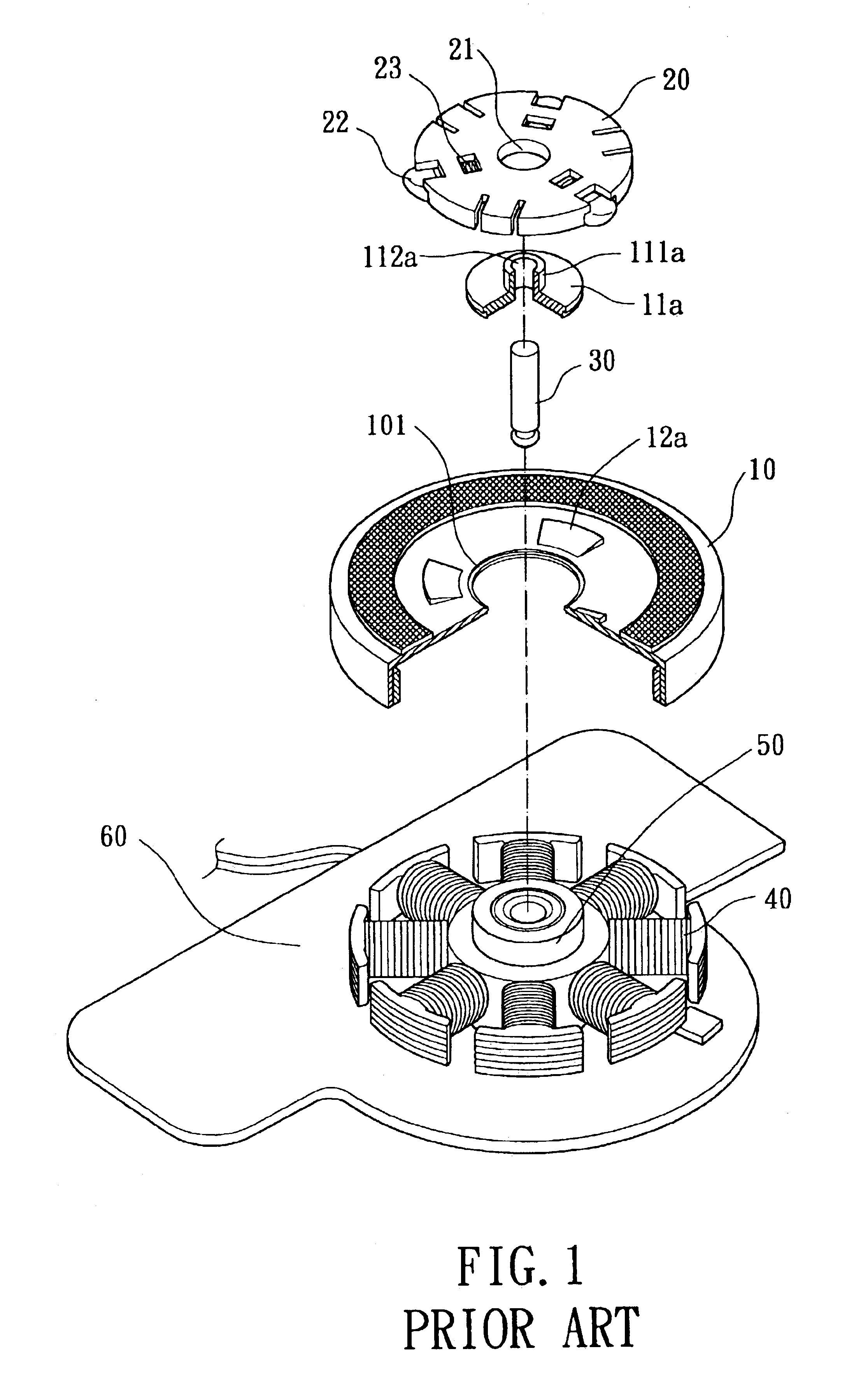

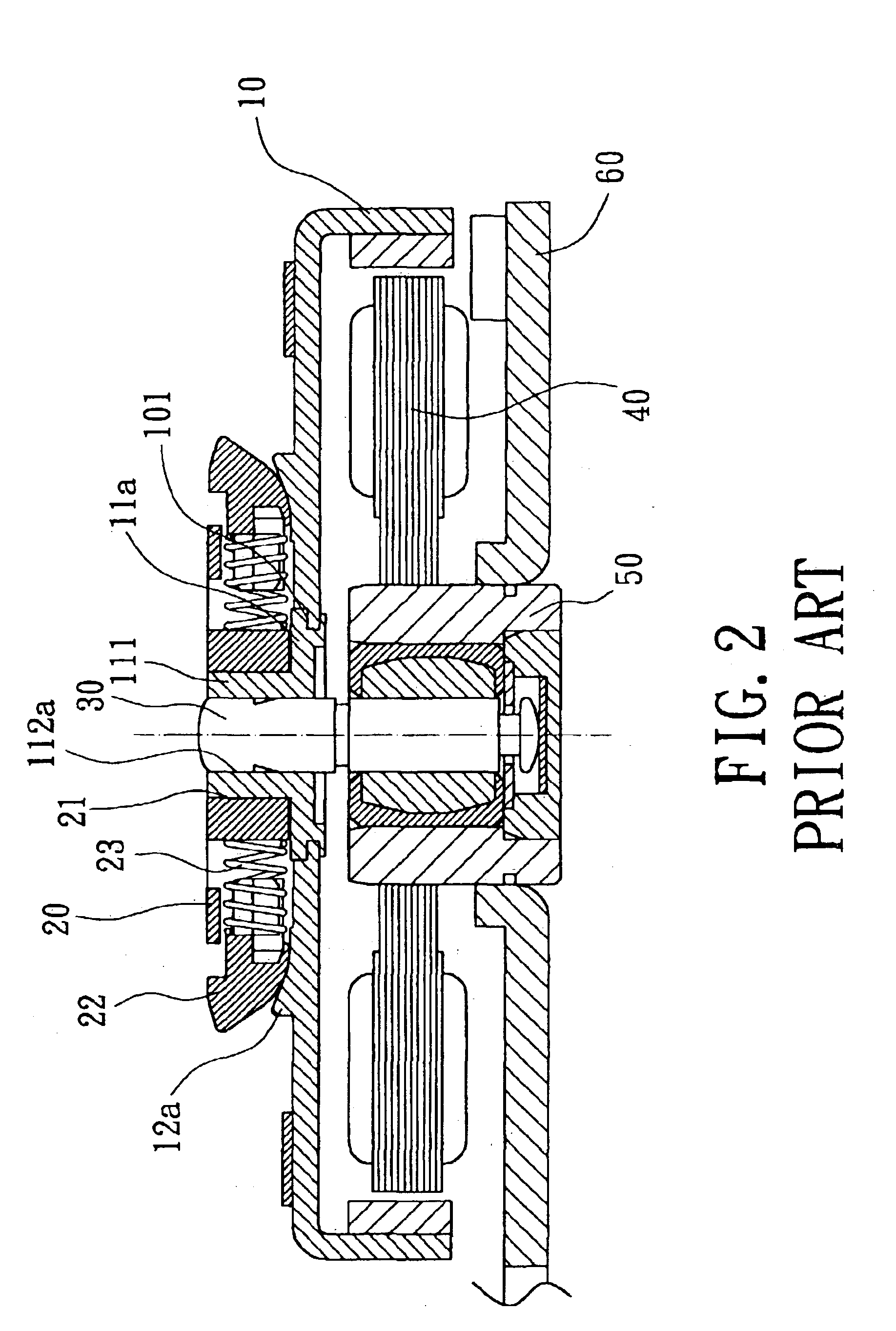

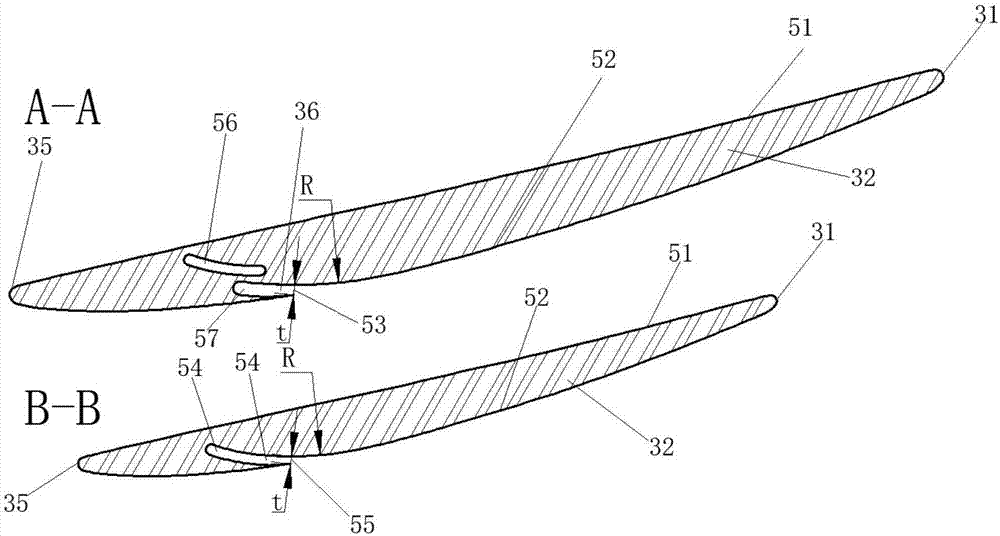

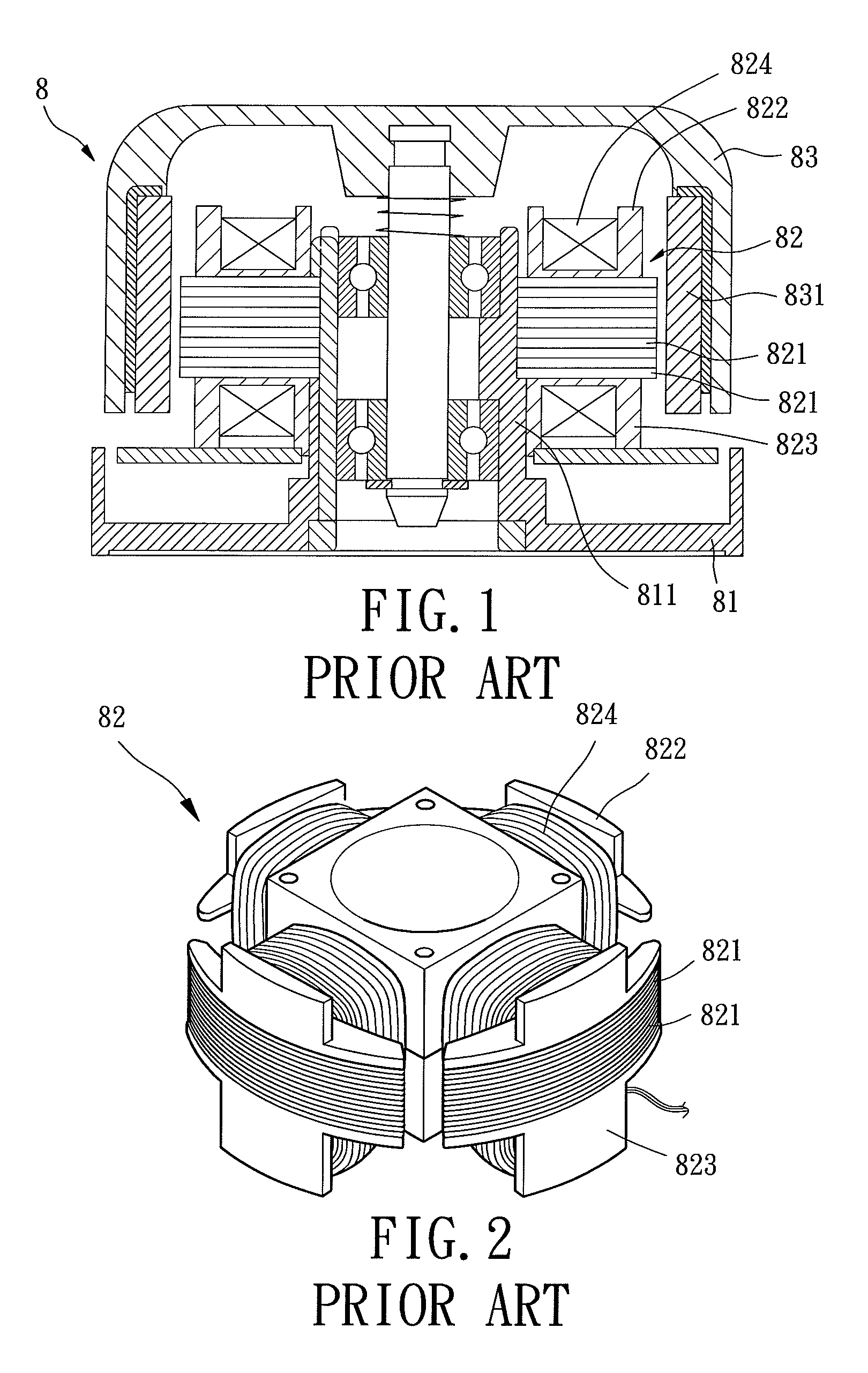

Fan and impeller thereof

InactiveUS20080056899A1Extend the lifespanImprove reliabilityPropellersRotary propellersImpellerRotational stability

An impeller includes a hub, a plurality of blades, and an annular structure. The blades are disposed around the hub. The annular structure is connected to the blades. The annular structure includes a plurality of apertures. A balance material is filled in the apertures to achieve rotational balance of the impeller. Furthermore, a fan with the described impeller is provided. The fan and the impeller improve rotational stability, reliability and product life.

Owner:DELTA ELECTRONICS INC

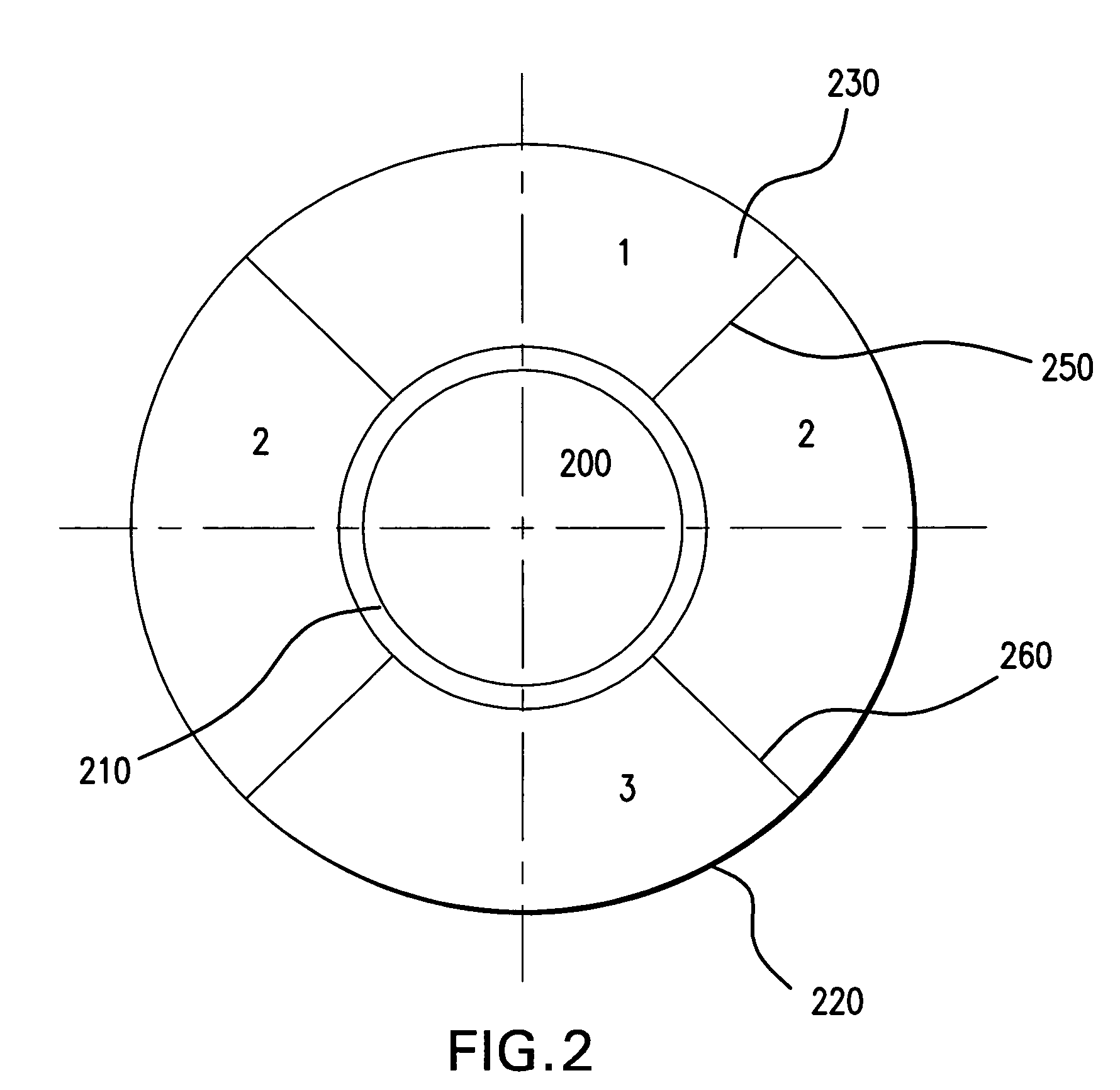

Methods and therapeutic optical devices for regulation of astigmatism

In accordance with exemplary embodiments, the present invention provides a therapeutic optical device configured to focus the central retinal image in at least one meridian and focus at least one semi-meridian of the peripheral image field in front of or behind the retina to stimulate eye and / or corneal reshaping to reduce astigmatism. In exemplary embodiments, the device further provides rotational stability.

Owner:PARAGON CRT CO LLC +1

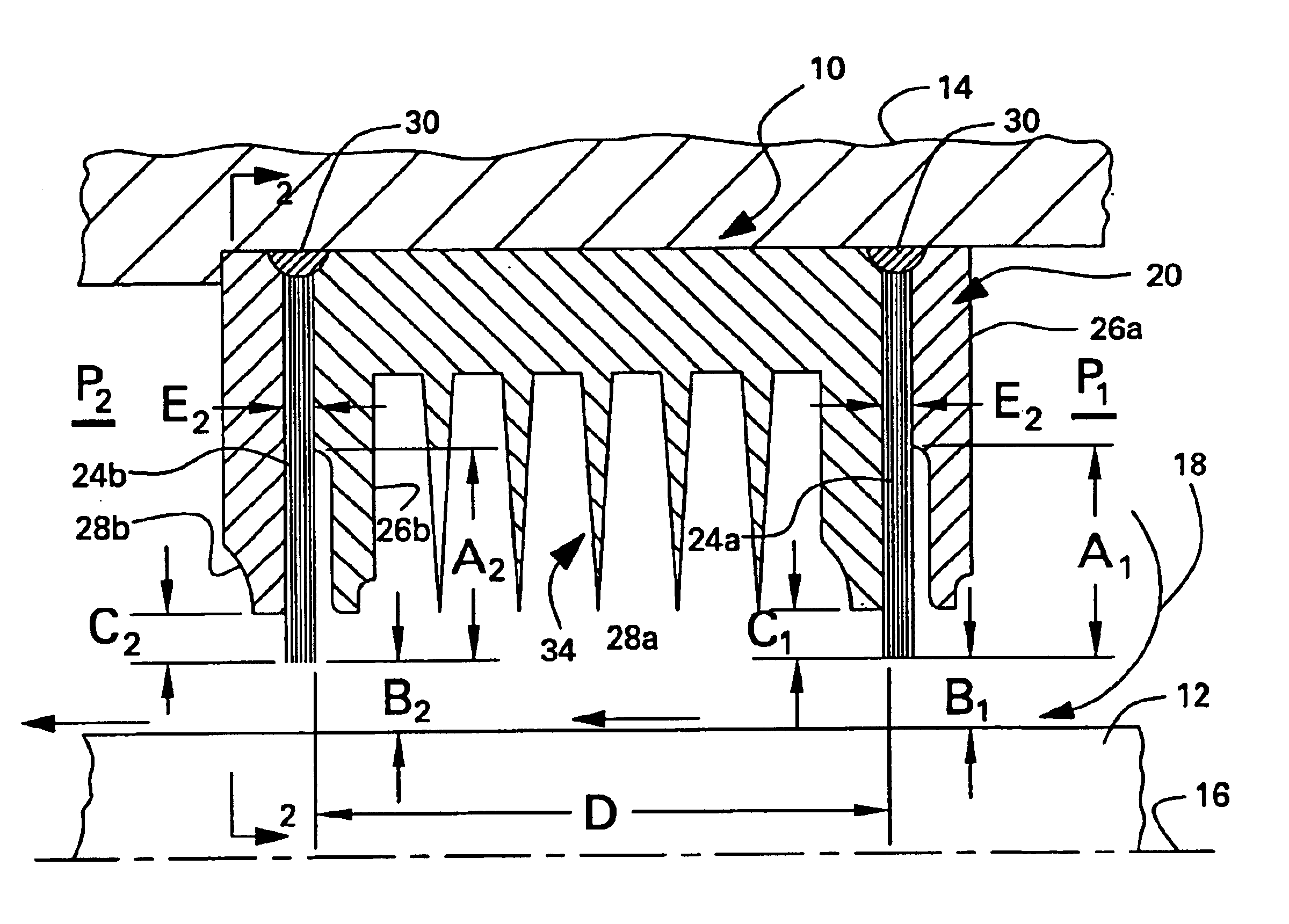

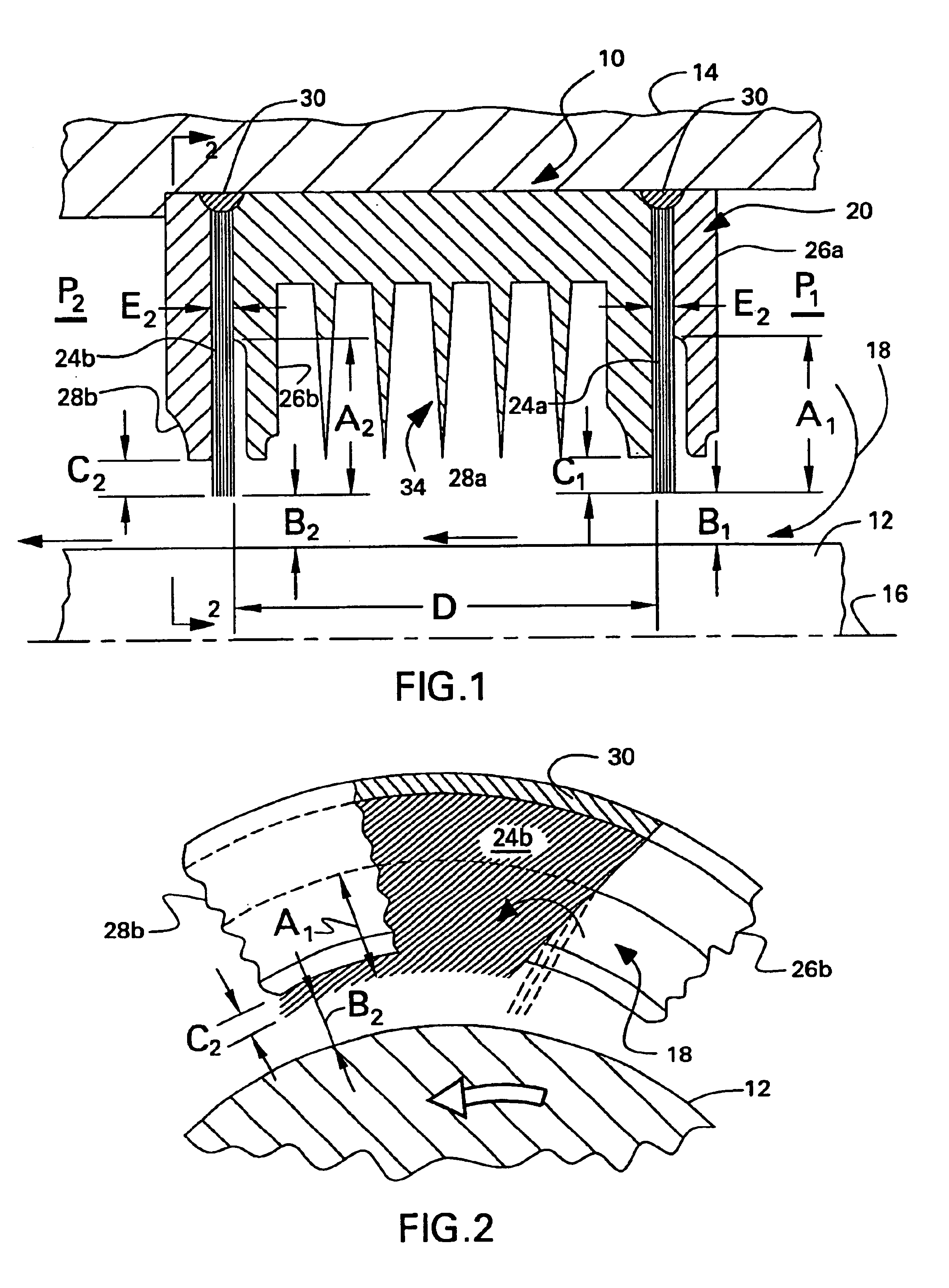

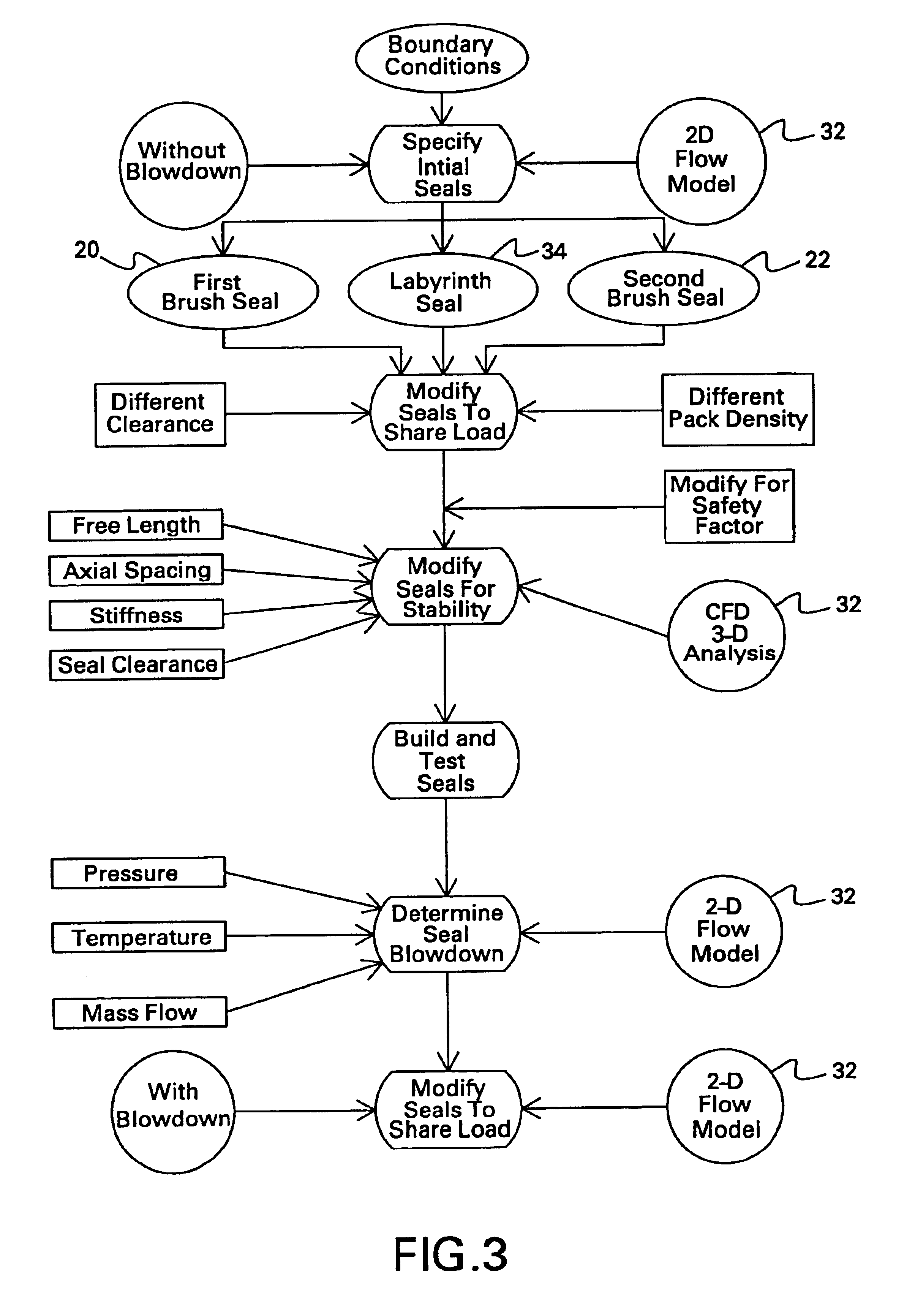

In situ load sharing brush seals

InactiveUS6854735B2Load sharingEngine sealsLeakage preventionRotational stabilityDifferential pressure

Multistage brush seals are made by initially specifying designs thereof for collectively sharing a differential pressure along an adjacent land subject to relative rotation with the seals. The seals are modified to share the loading without blowdown therefrom. The seals are further modified to ensure rotational stability with the land. The seals are built and tested under pressure to determine pressure blowdown thereof. And then, the seals are again modified to share the pressure loading under blowdown. In this way, the seals share the load in situ under the effects of blowdown.

Owner:GENERAL ELECTRIC CO

Fan and impeller thereof

ActiveUS7281896B2Improve rotational stabilityIncrease reliability and lifetimePropellersPump componentsRotational stabilityImpeller

Owner:DELTA ELECTRONICS INC

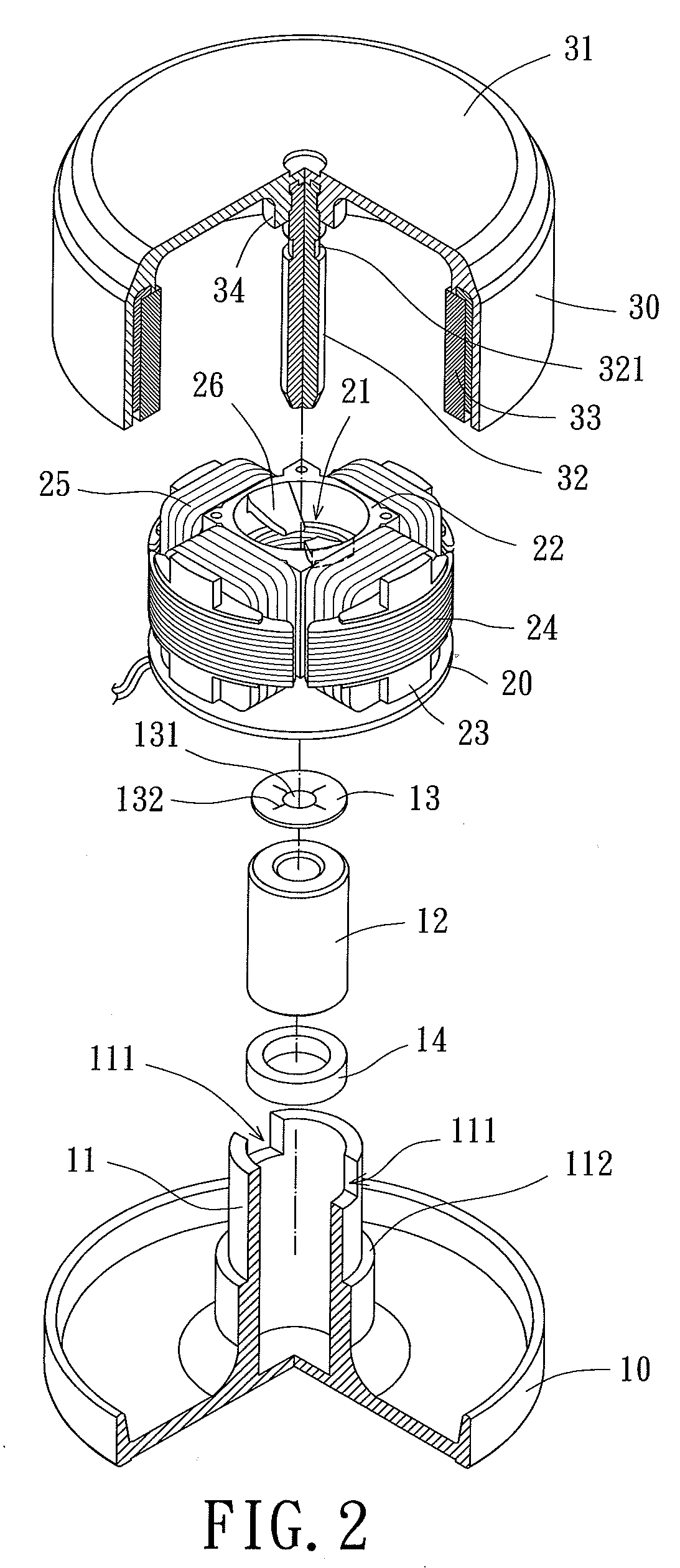

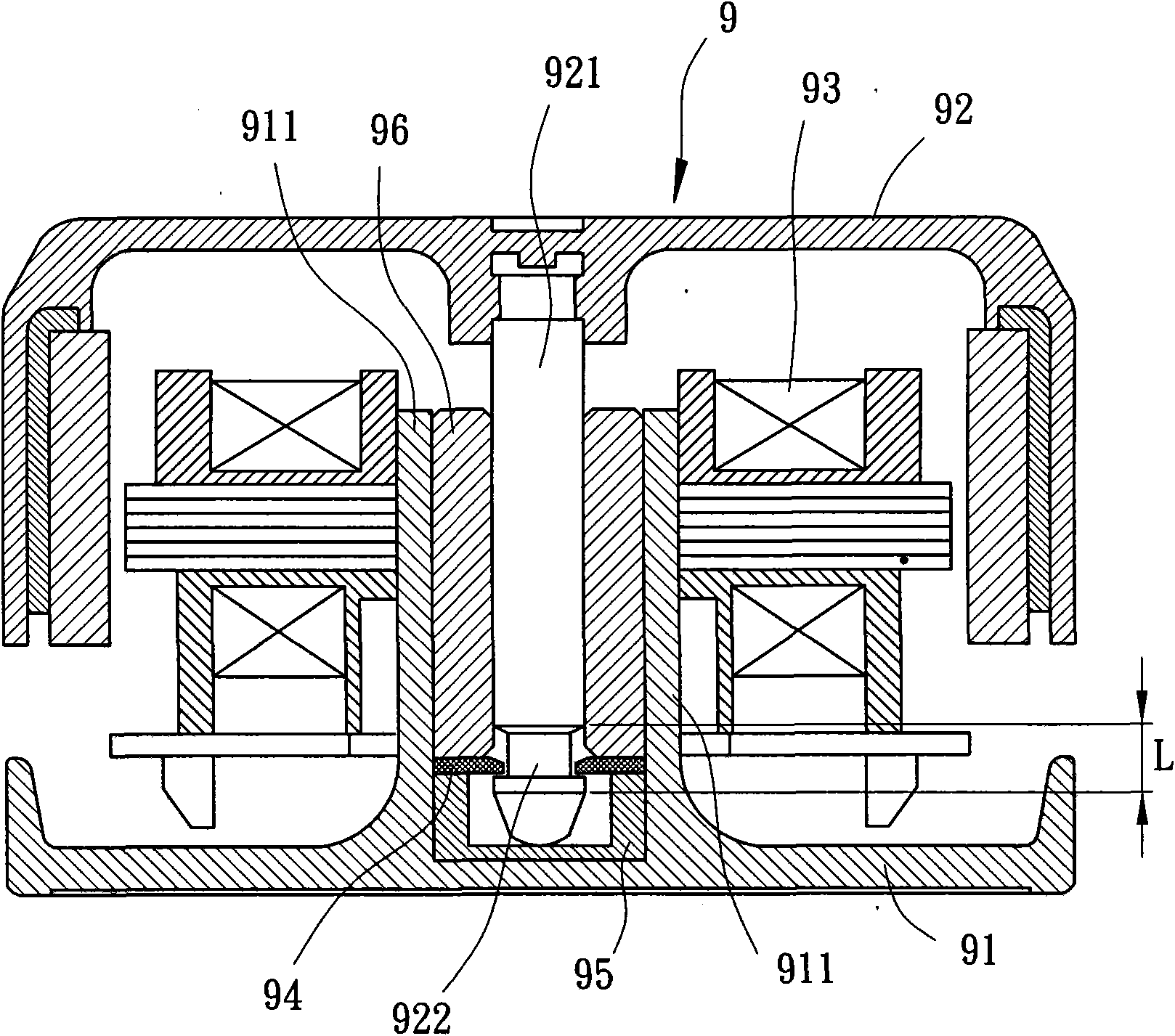

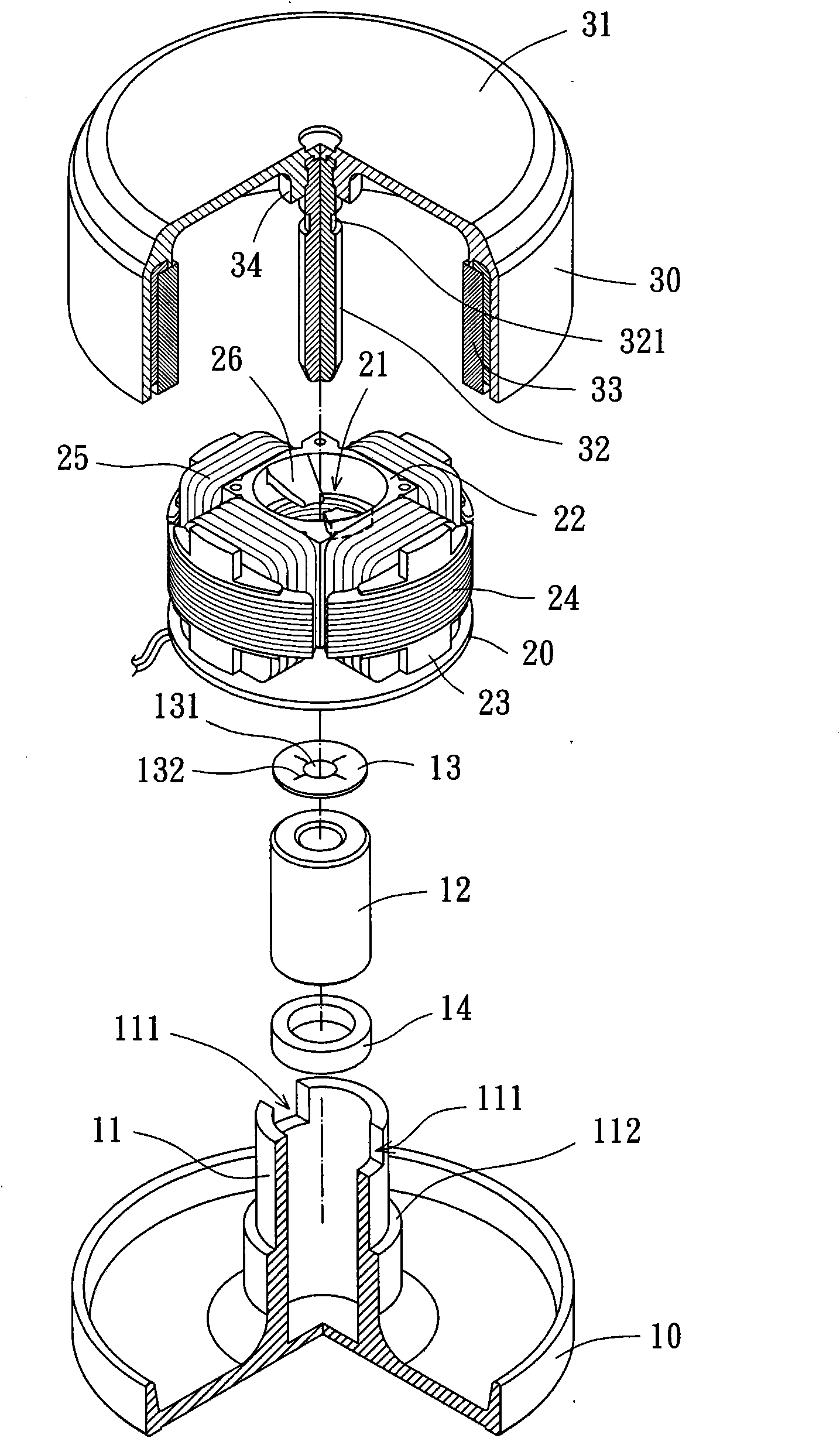

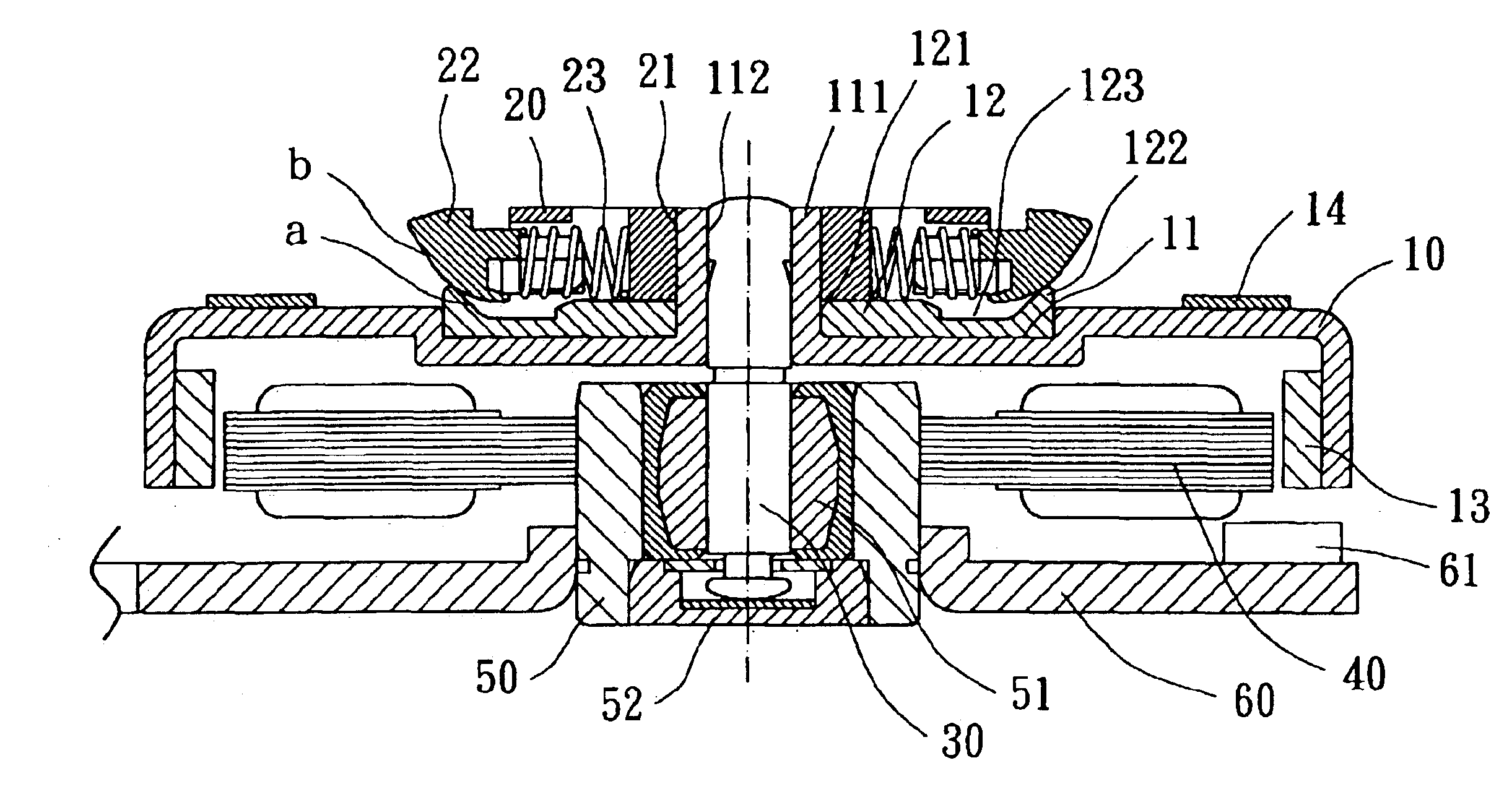

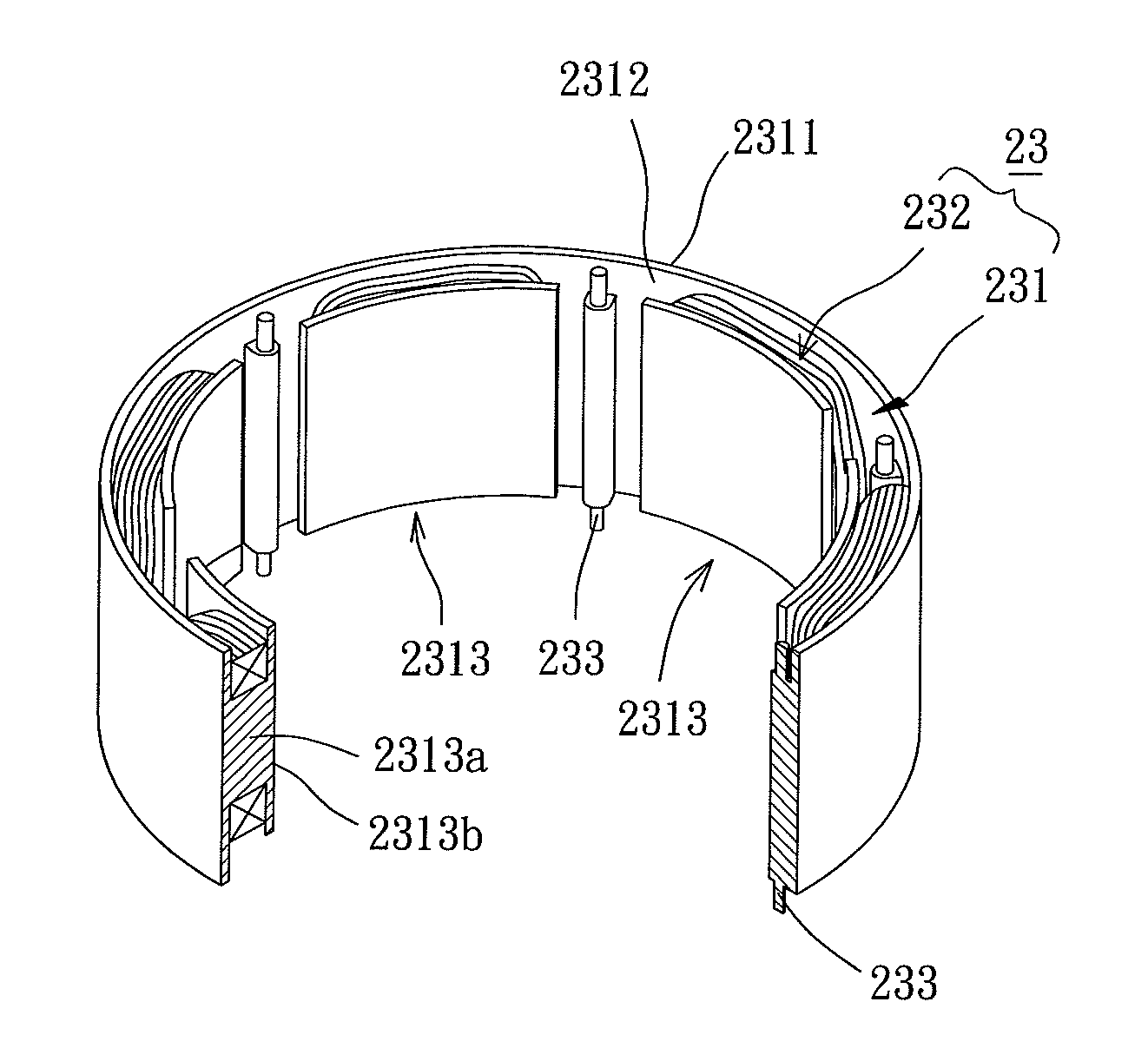

Stator Device, Motor Constructed Thereby, and Heat-Dissipating Fan Including The Stator Device

ActiveUS20100329901A1Prevent disengagementEasy to assemblePump componentsMagnetic circuitImpellerRotational stability

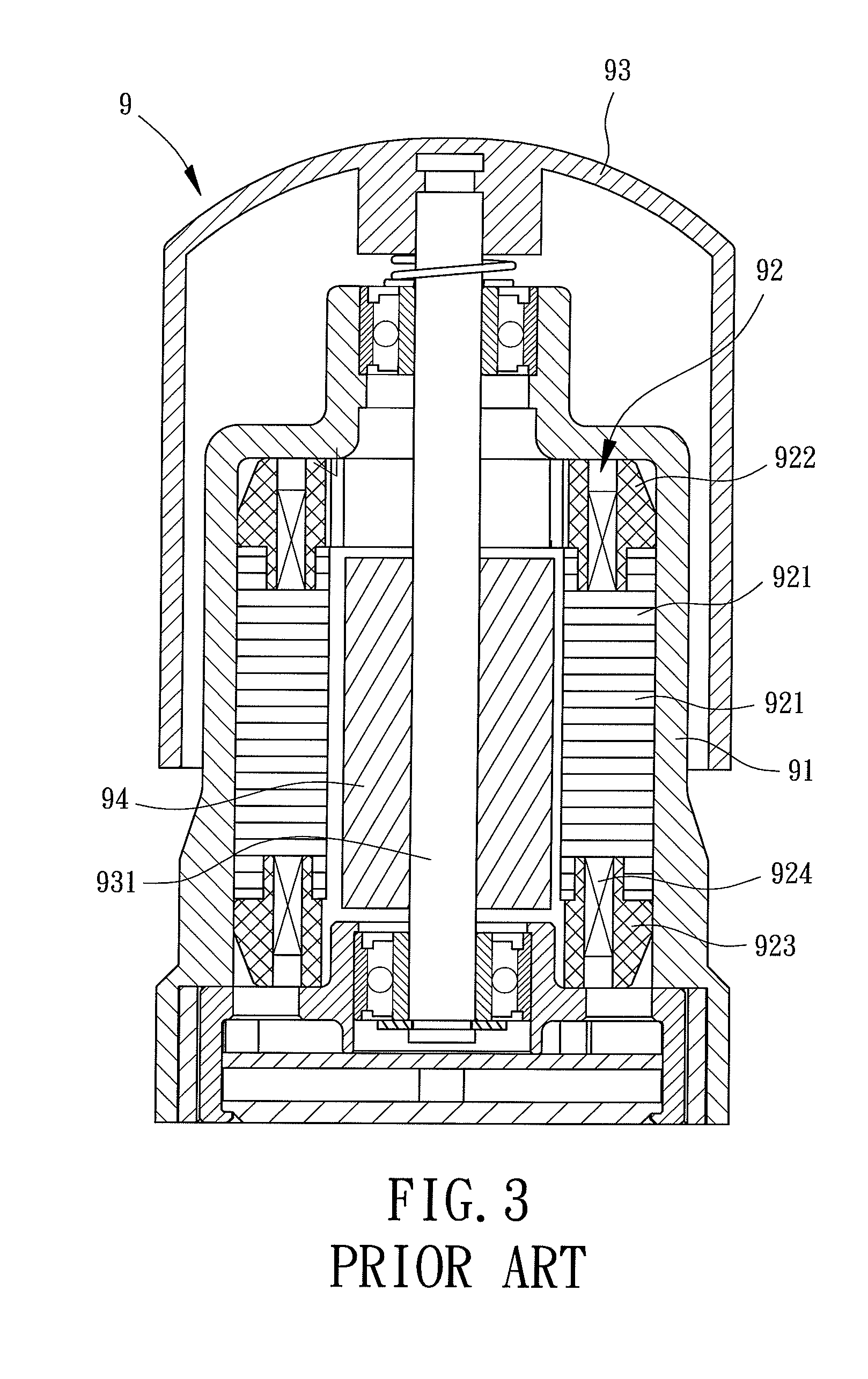

A stator device includes a base having a shaft tube receiving a bearing. The shaft tube includes a top end having at least one groove. A stator unit is mounted around an outer periphery of the shaft tube. The stator unit includes at least one limiting member extending through the at least one groove into the shaft tube. The at least one limiting member prevents the bearing from disengaging from the shaft tube, enhancing assembling convenience. The stator can be coupled with a rotor to form a motor with enhanced assembling convenience and enhanced rotational stability. The base can be interconnected by connecting members to a housing having air inlet and outlet sides. Vanes can be formed on the hub of the rotor to form an impeller. Thus, a heat-dissipating fan can be formed from the stator device.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

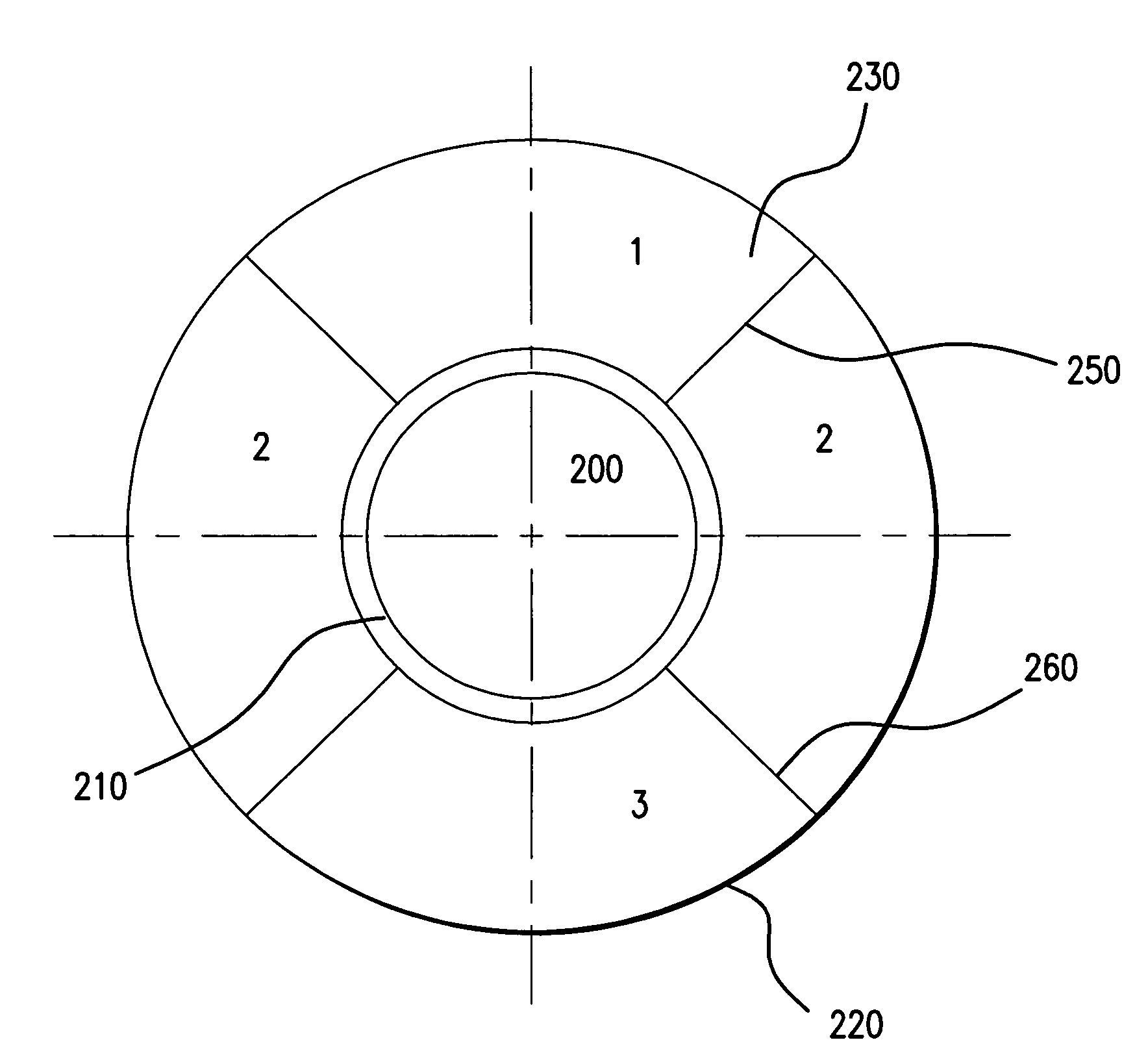

Toric lens design

This invention is related to contact lenses. In particular, the present invention is related to a toric contact lens design with thickness zones in the carrier portion of the lens for increased rotational stability.

Owner:ALCON INC

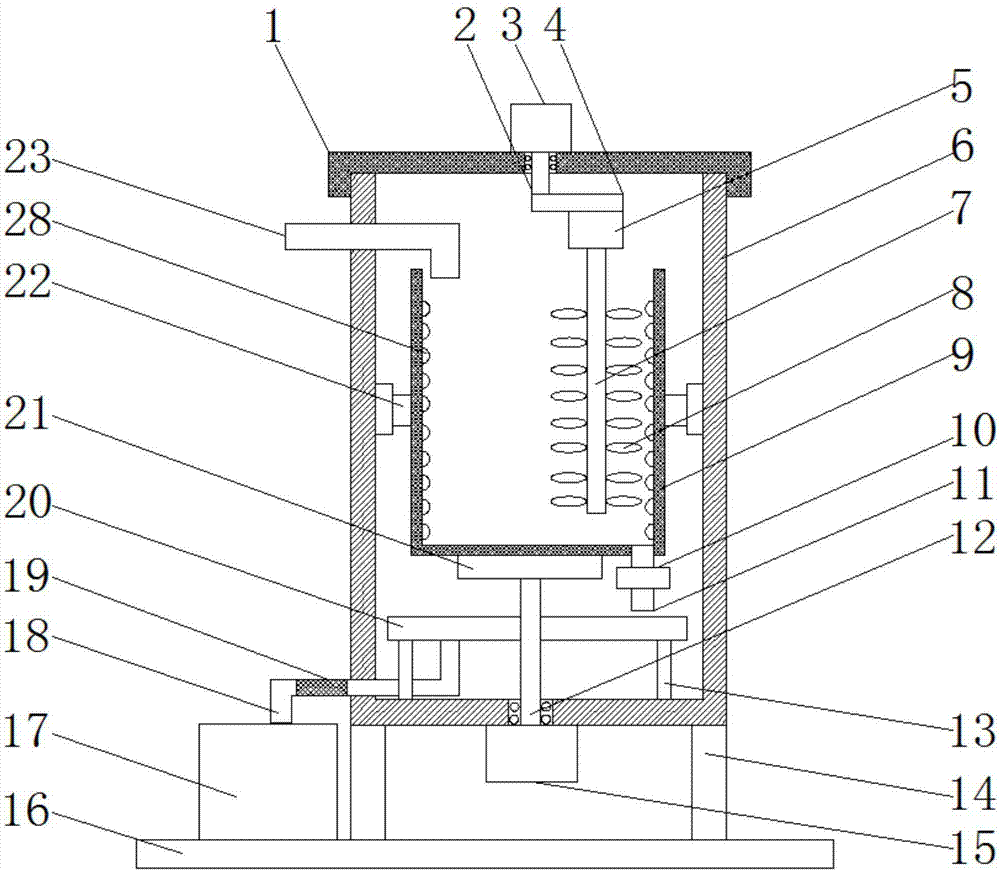

Wool cleaning device for animal husbandry

The invention discloses a wool cleaning device for animal husbandry, which comprises a second motor, a first motor, a cleaning shaft, a third motor, an auxiliary rotating device and a waste water collection tank, and the rotation of the second motor drives the cleaning blades to rotate against the cleaning tank. The wool is cleaned, and the first motor is used to rotate and then drive the support arm connected to the first rotating shaft to rotate, and further drive the second motor fixedly installed at the bottom of the support arm to rotate in the circumferential direction, so that the cleaning shaft moves in the cleaning pool along the circumferential direction Movement, use the third motor to rotate and then drive the rotating base fixedly installed on the top of the second rotating shaft to rotate, and further drive the cleaning tank to rotate to clean the wool. The auxiliary rotating device is used to improve the stability of the cleaning tank when it rotates. By setting The waste water collection tank is used to collect the filtered sewage to prevent the sewage from polluting the environment.

Owner:湖南天爱农业科技有限公司

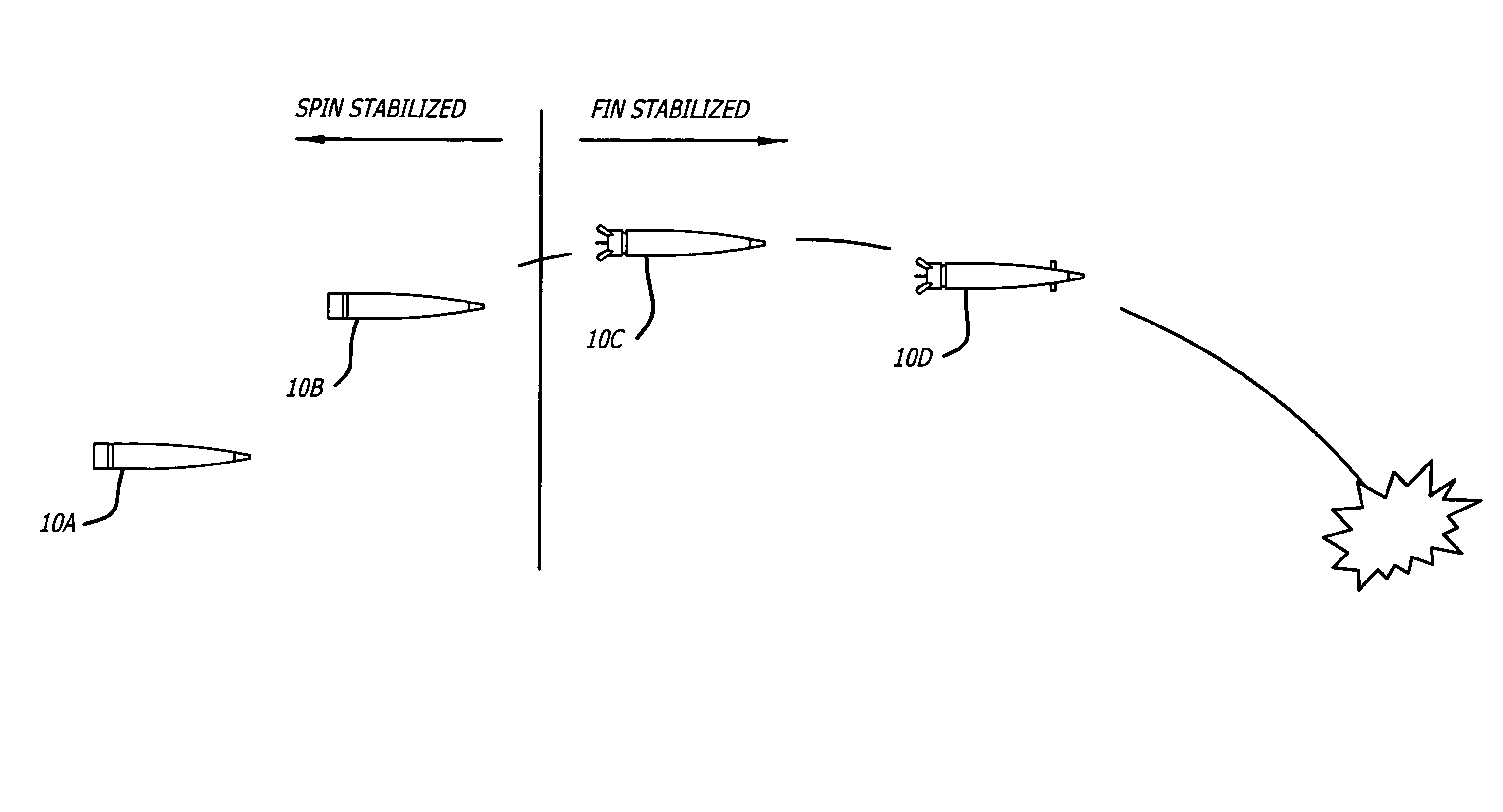

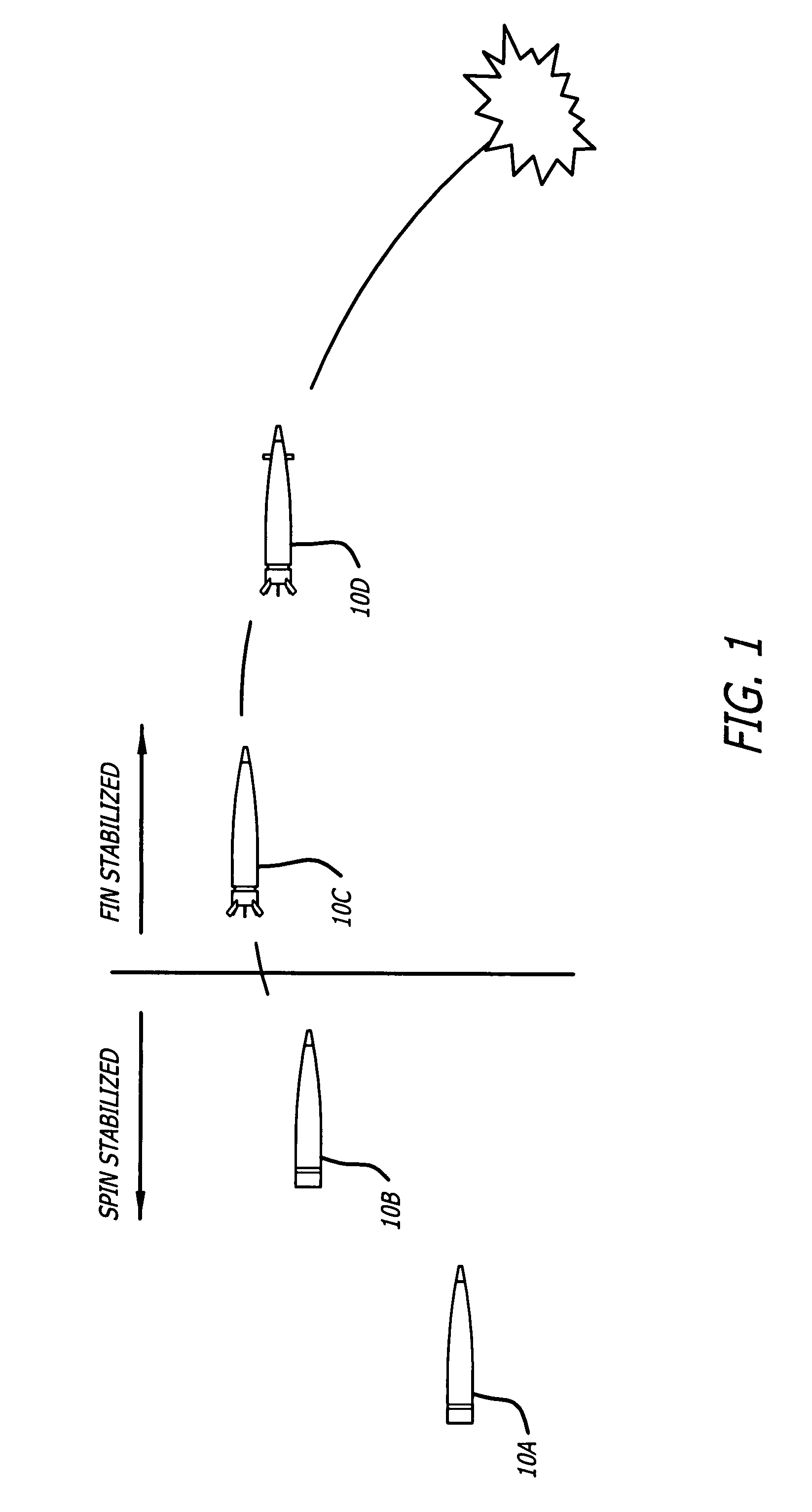

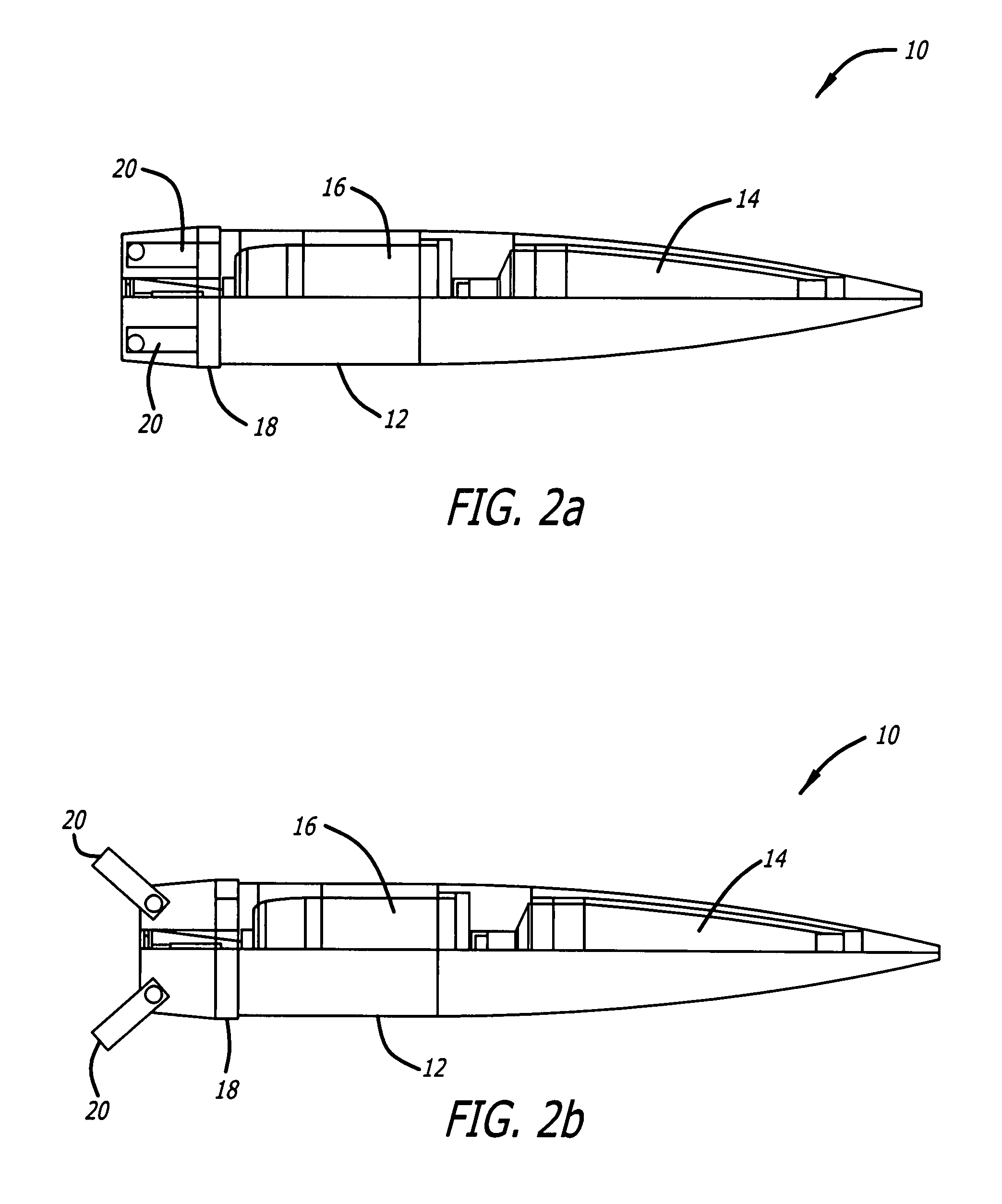

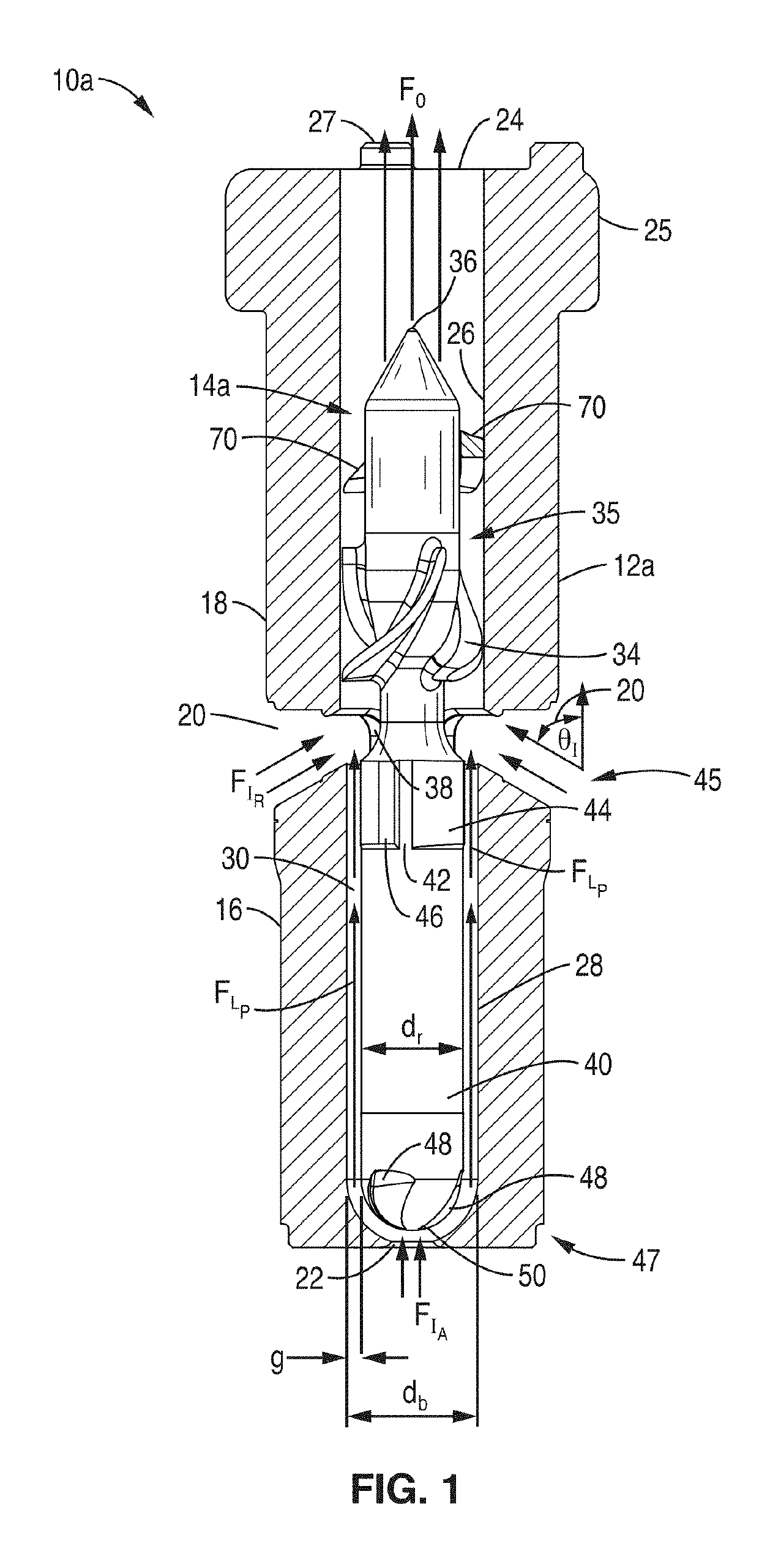

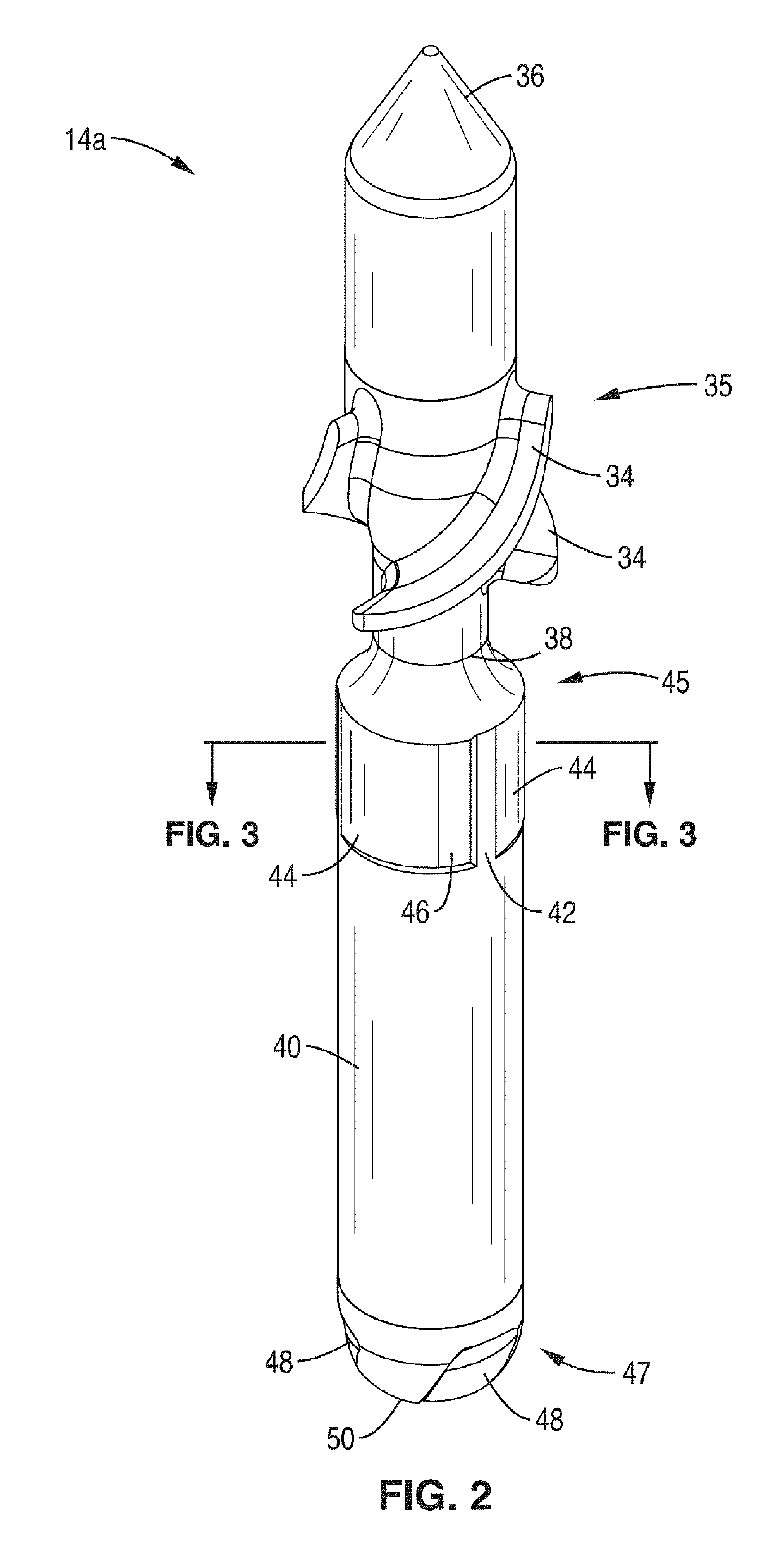

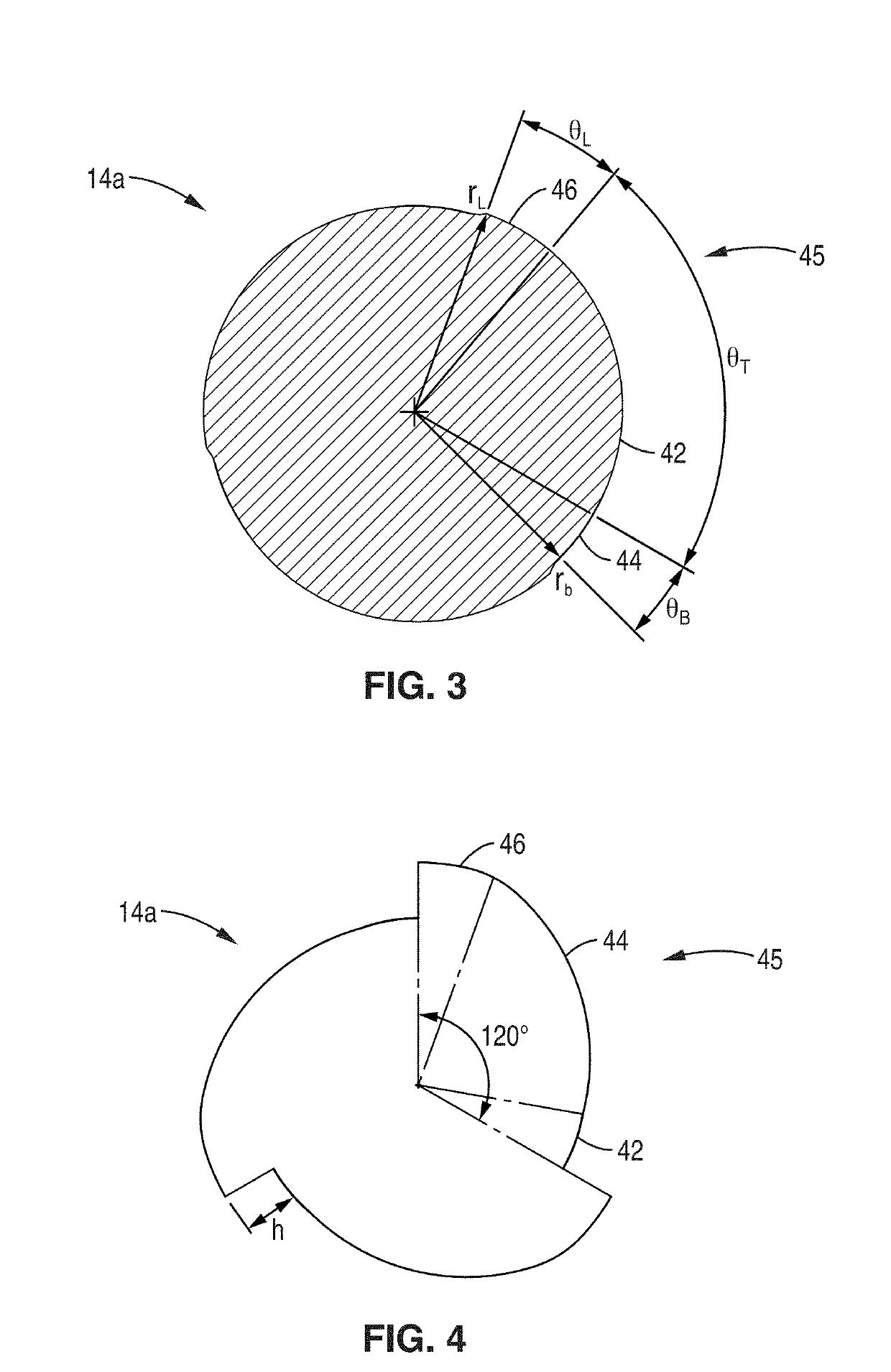

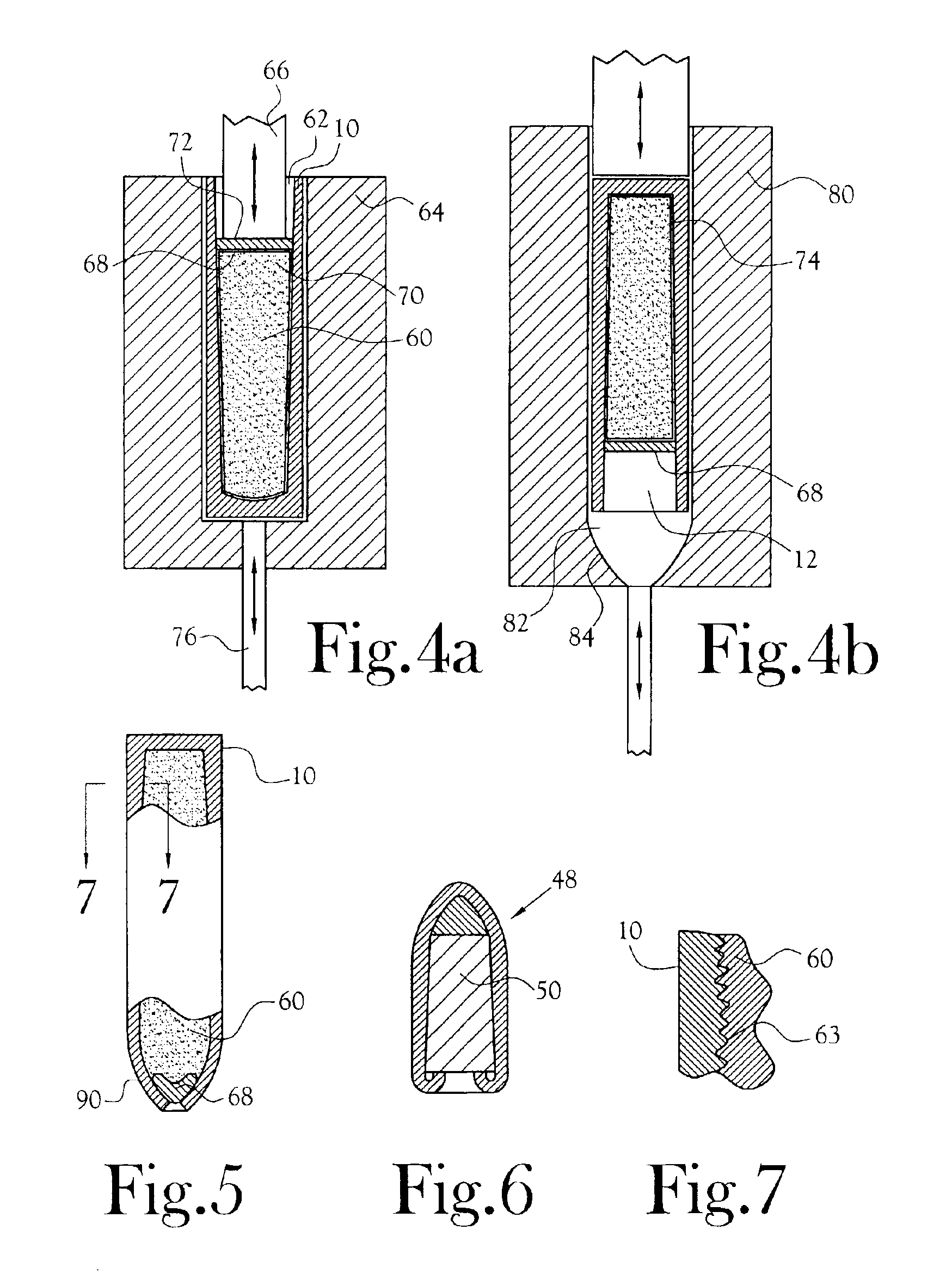

Hybrid spin/fin stabilized projectile

A hybrid spin / fin stabilized projectile. The novel projectile includes a body, a first mechanism for spin stabilizing the body during a first mode, and a second mechanism for fin stabilizing the body during a second mode. In an illustrative embodiment, the projectile includes a rifling band adapted to engage with rifling in a gun during gun launch to impart a spin rate compatible with spin stabilization to the projectile, and a plurality of folding fins attached to an aft end of the body. A fin locking mechanism locks the fins in an undeployed position during the first mode and unlocks to deploy the fins at a predetermined time to switch the projectile to fin stabilization during the second mode. The projectile also includes a mechanism for reducing the spin of the projectile to a rate compatible with guided flight during the second mode.

Owner:RAYTHEON CO

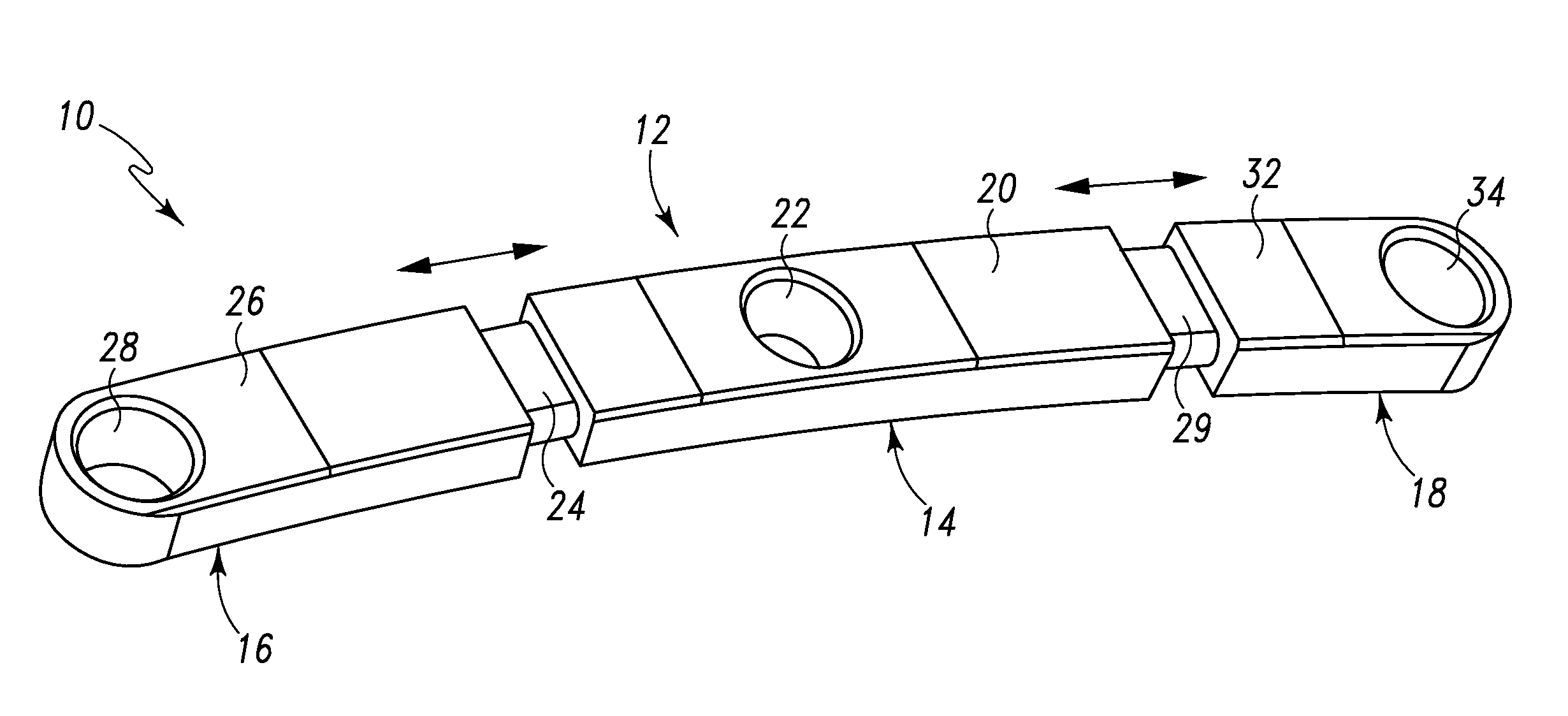

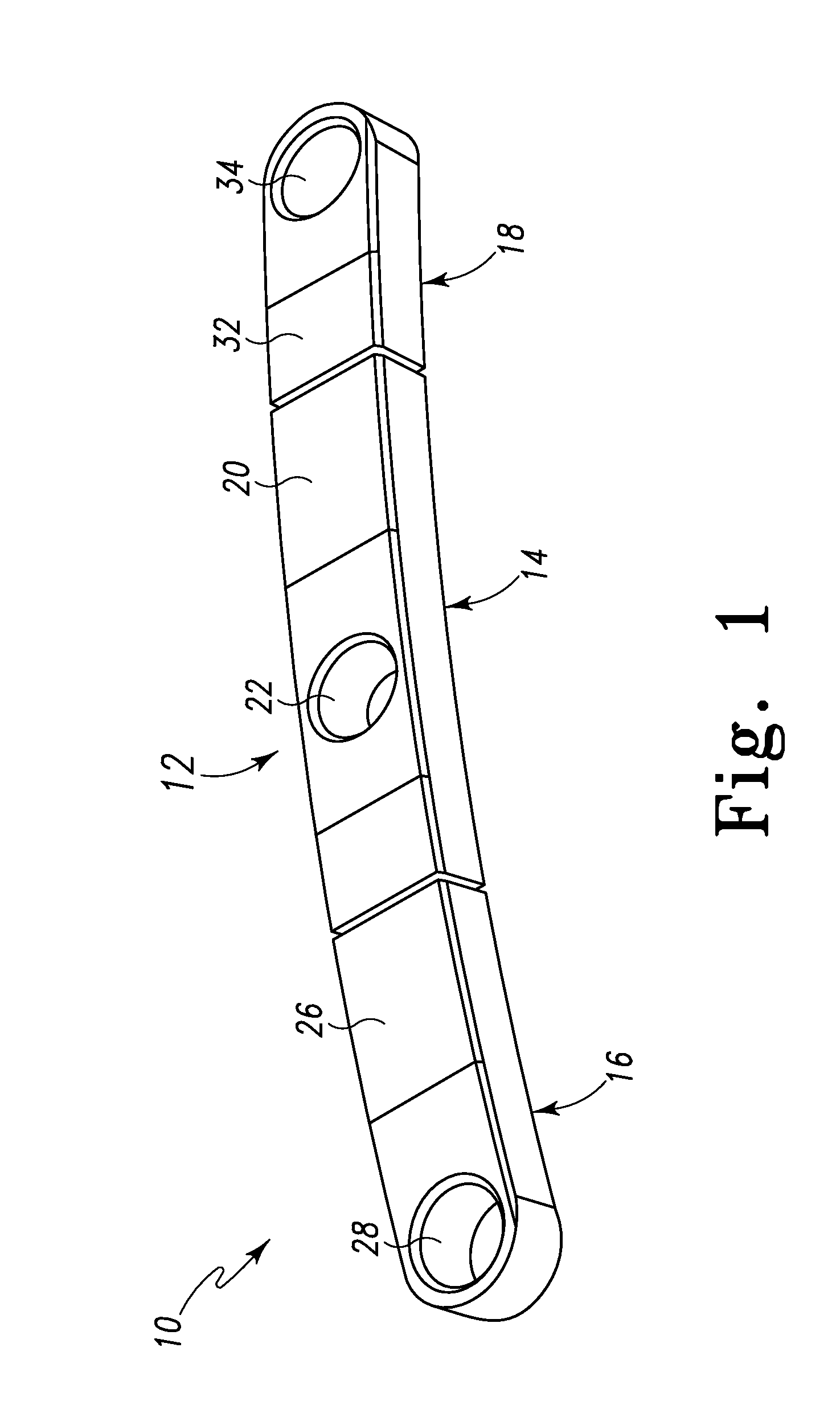

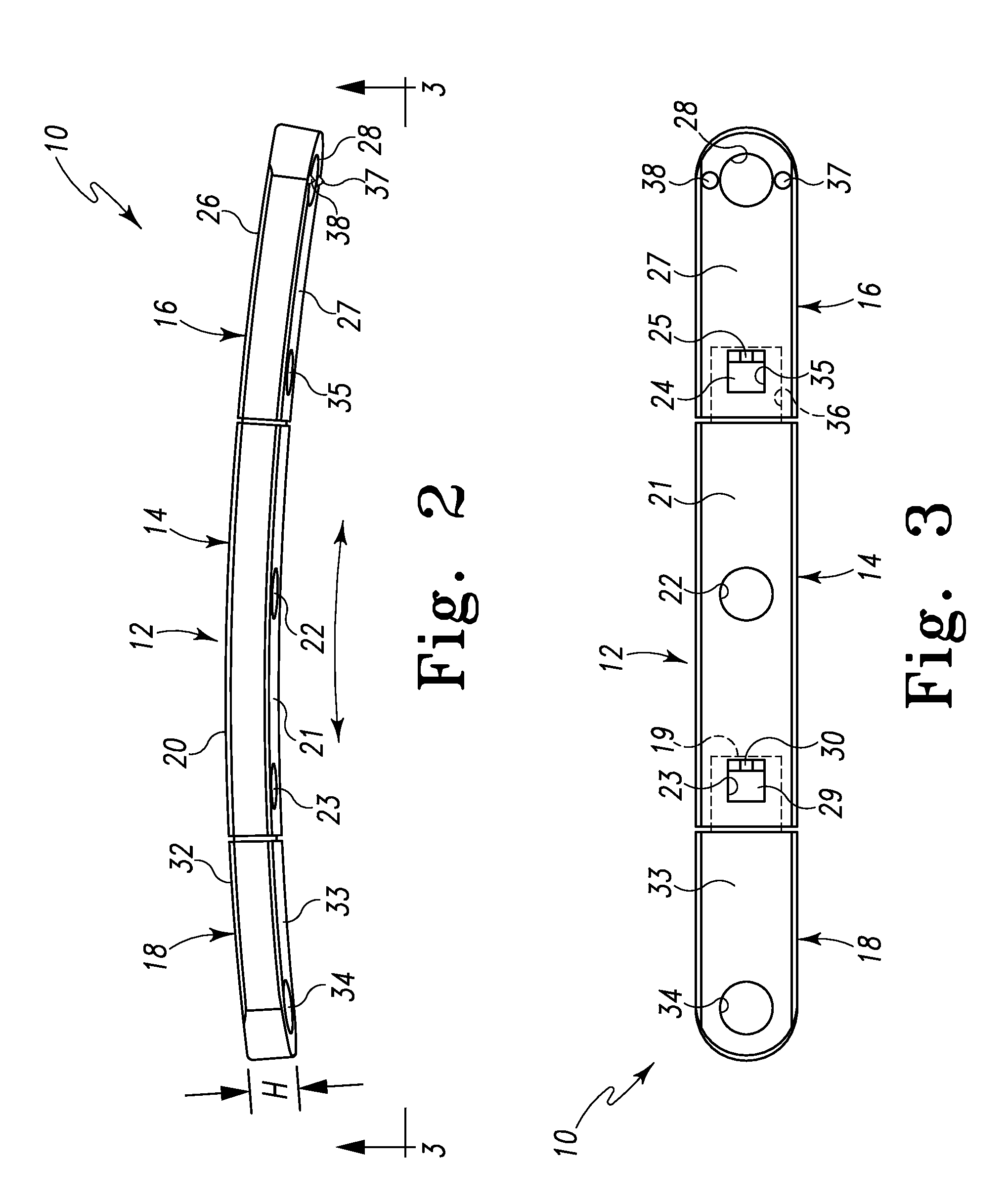

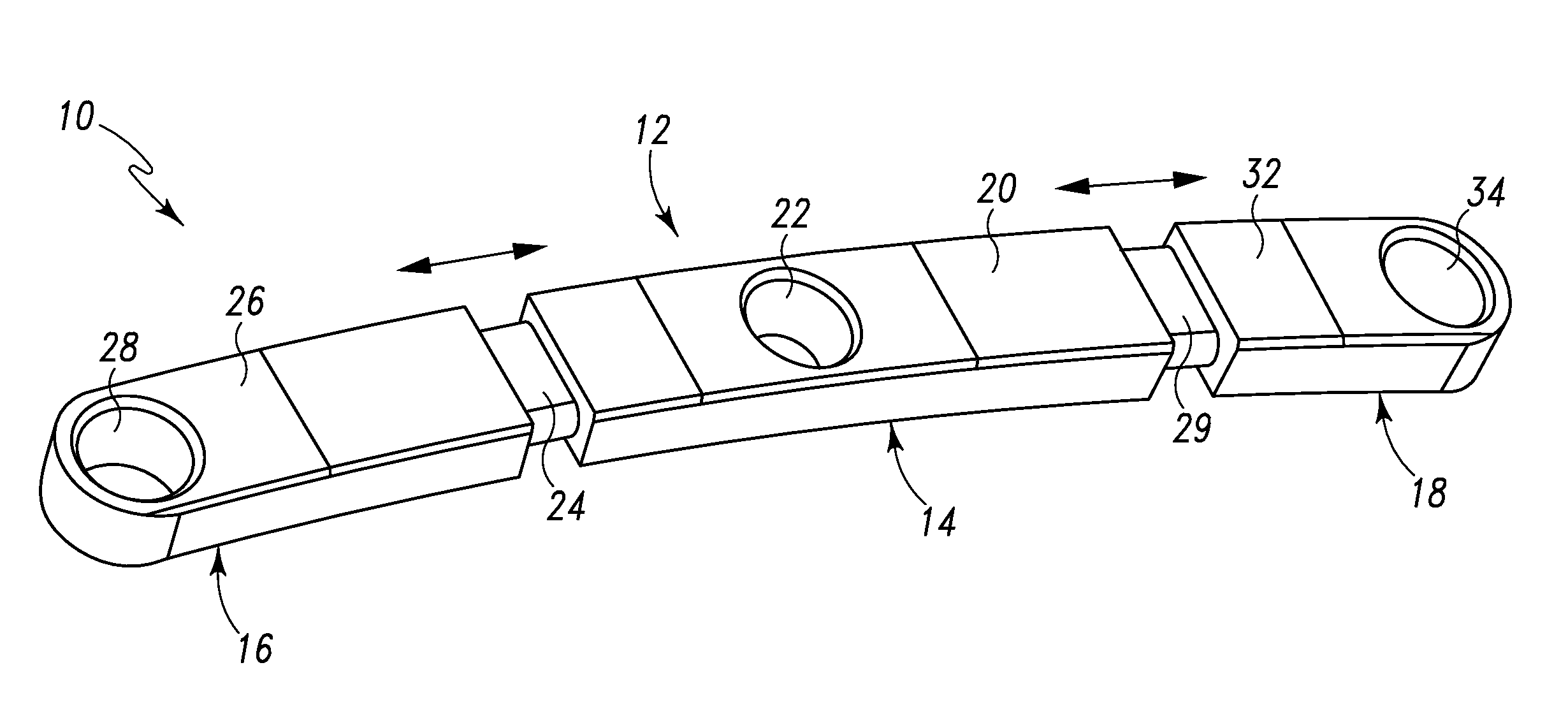

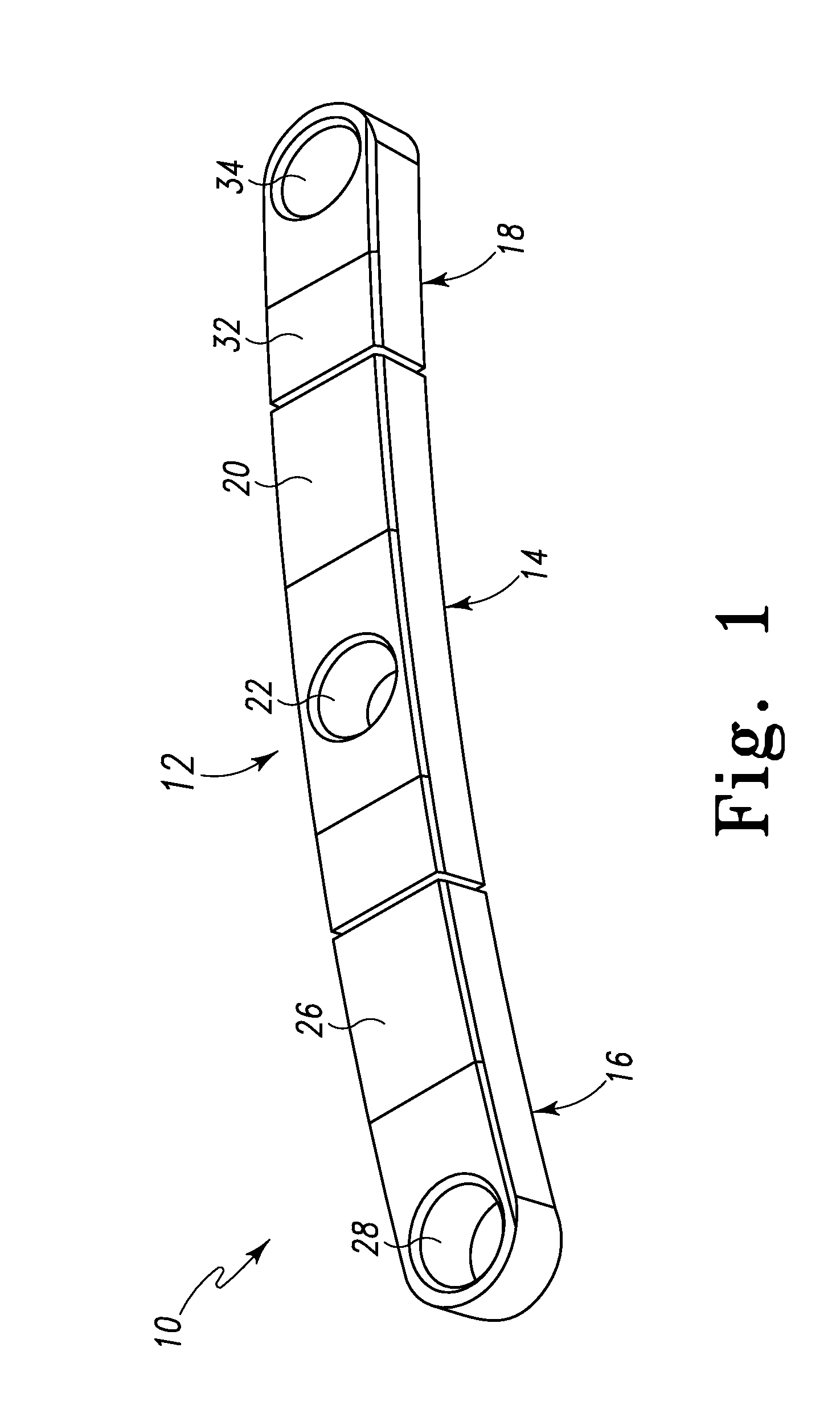

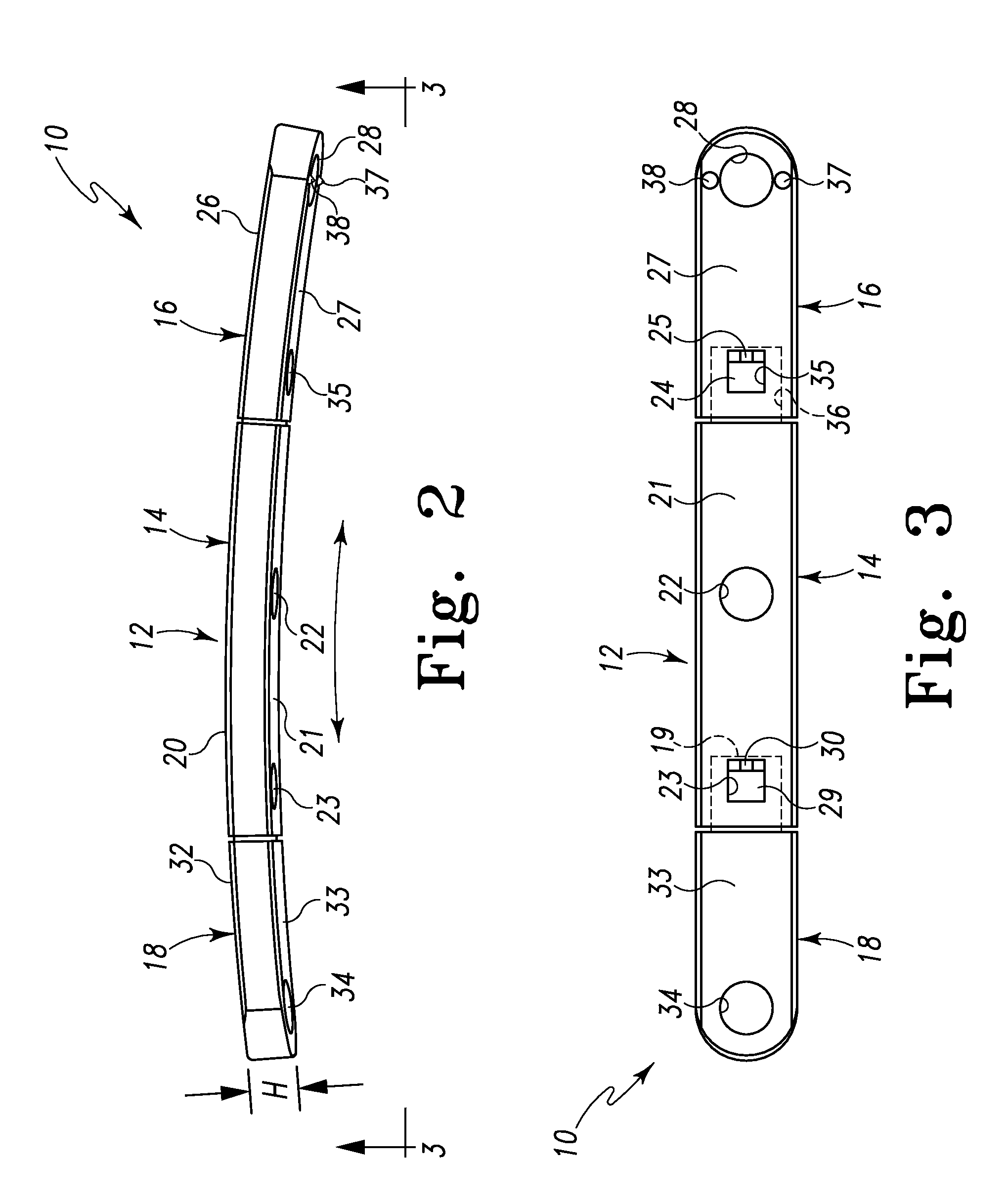

Single-sided dynamic spine plates

A dynamic spine plate is formed with only a single row of bone screw bores that extend along a generally superior / inferior axis of the spine plate, providing a single-sided dynamic spine plate. The single-sided dynamic spine plate is formed from a plurality of spine plate components that are coupled dynamically to one another. This provides a modular, single-sided dynamic spine plate. The spine plate components are coupled dynamically to one another via socket and projection interfaces, the socket and projections interfaces incorporating resilient coupling and retention structures that allow limited movement of the spine plate components relative to one another. This provides for dynamic extension of the spine plate components relative to one another. The resilient coupling structure connects the spine plate components, providing a self-biased, snap fit coupling of spine plate components. Rotation stabilizers may be provide on the present single-sided dynamic spine plate that provide rotational stability to the spine plate in addition to the bone screws that will attach the spine plate to the vertebrae.

Owner:LIFE SPINE INC

Long-distance blast banger

InactiveUS6889612B1Reduce drag coefficientExtended flight rangeAmmunition projectilesFirework flares/torchesRotational stabilityExplosive Agents

A long-distance blast banger including a cartridge loaded with a blast banger made up from plastic material. The blast banger encompasses a sound explosives cup and a delay cup. The sound explosives cup is loaded with a sound explosives agent having components including perchloryl potassium, magnesium powder and aluminum powder. A sufficient sound value is acquired through appropriate compacting of the sound explosives cup, and therefrom realizes uniform shattering of the cup into small fragments that are insufficient to cause injury. Furthermore, at least two helical grooves extending from a bottom to a top of the cartridge are defined on an inner wall thereof, and ear attachments are configured on a base of an outer wall of the blast banger so as to correspond with the helical grooves, thereby engendering a spinning stability effect during flight time of the blast banger, reducing wind resistance, and thus increasing flight range.

Owner:204TH ARSENAL MATERIEL PROD CENT THE ARMEMENT BUREAU M N D +1

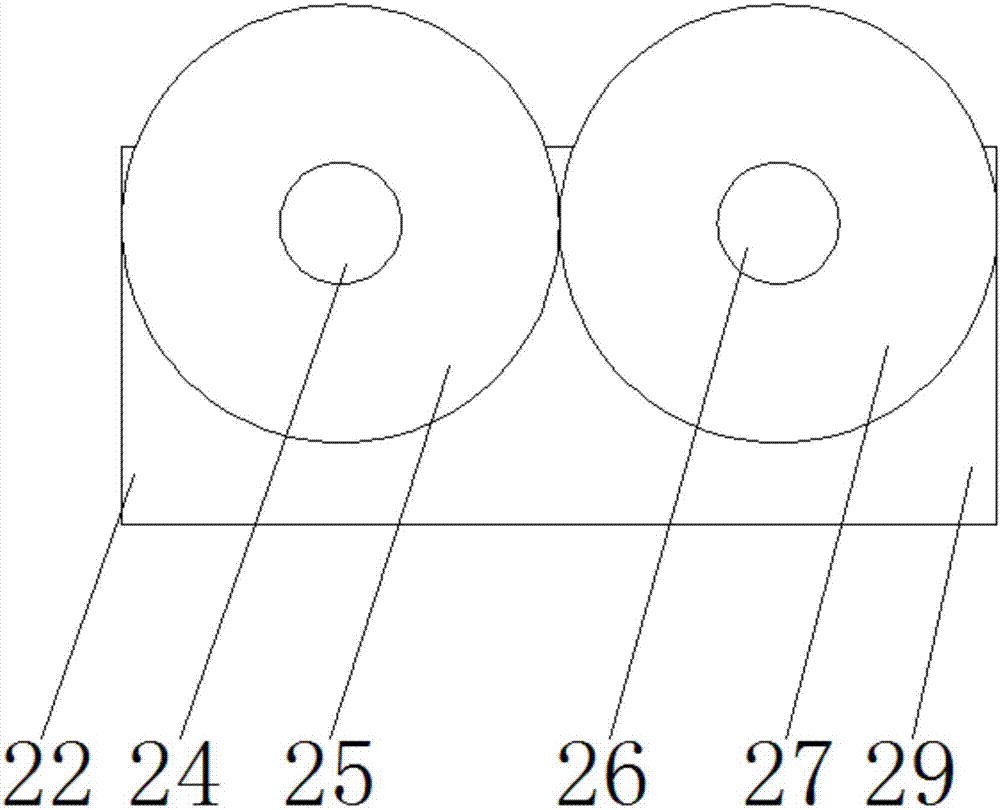

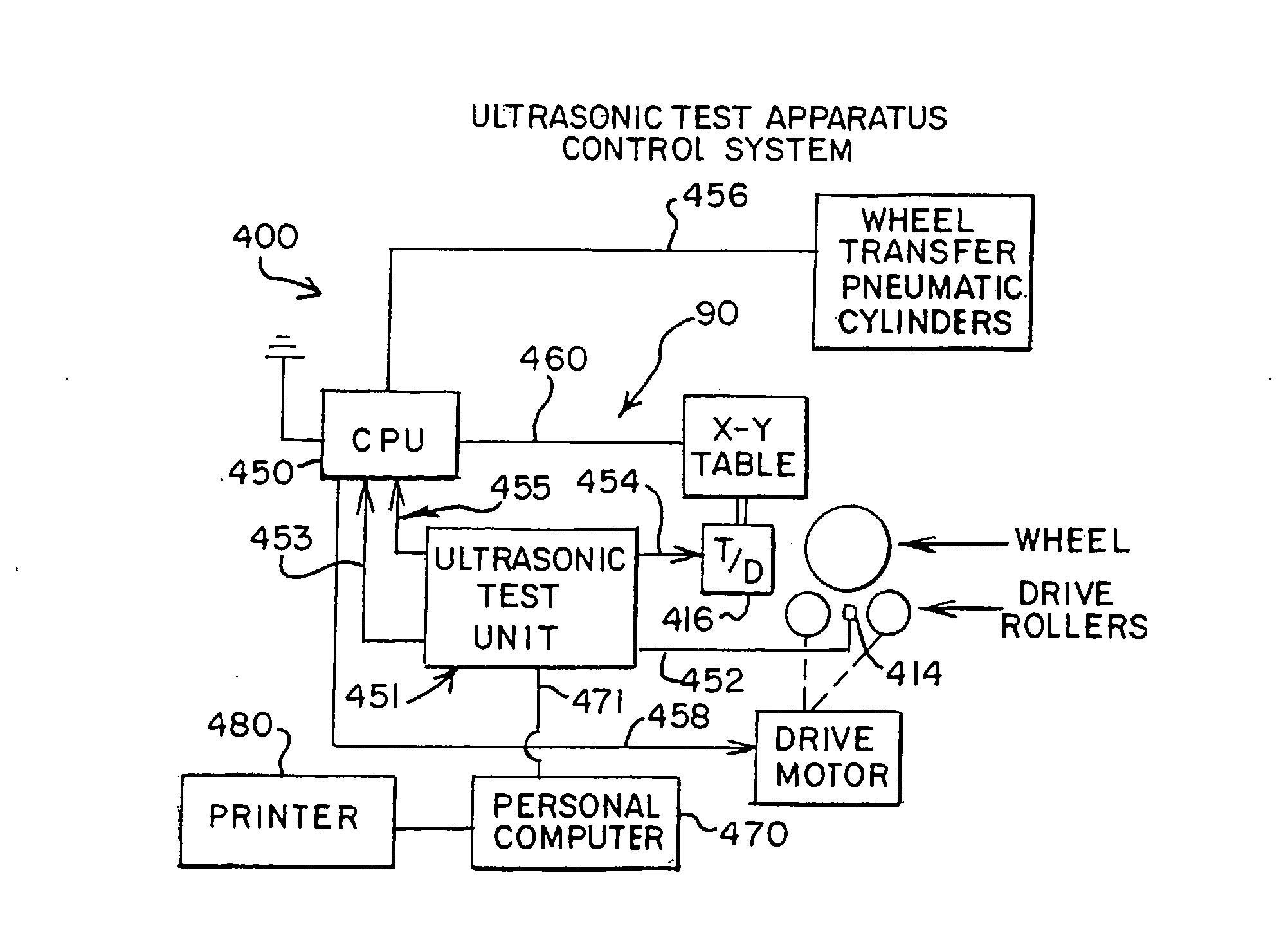

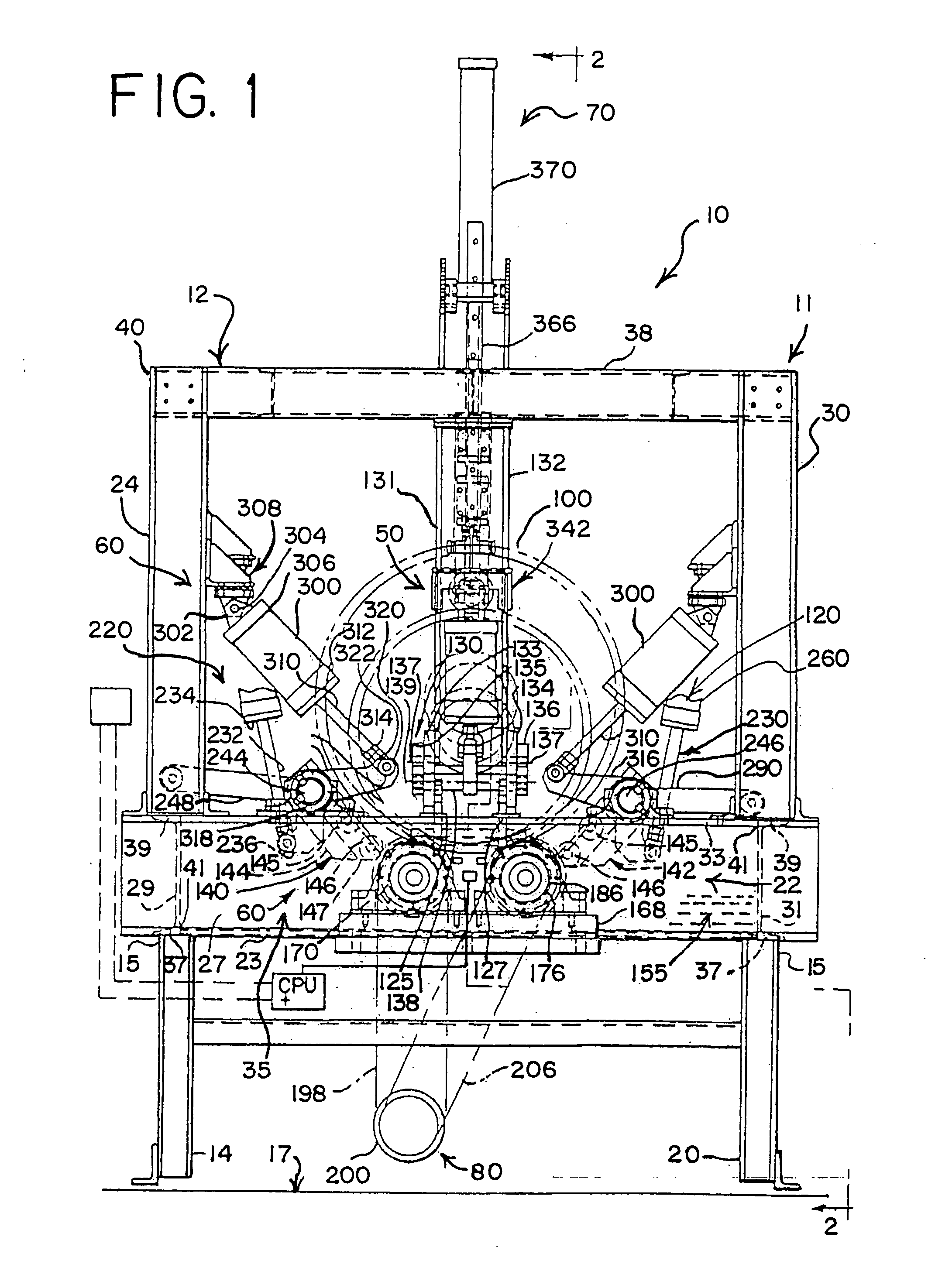

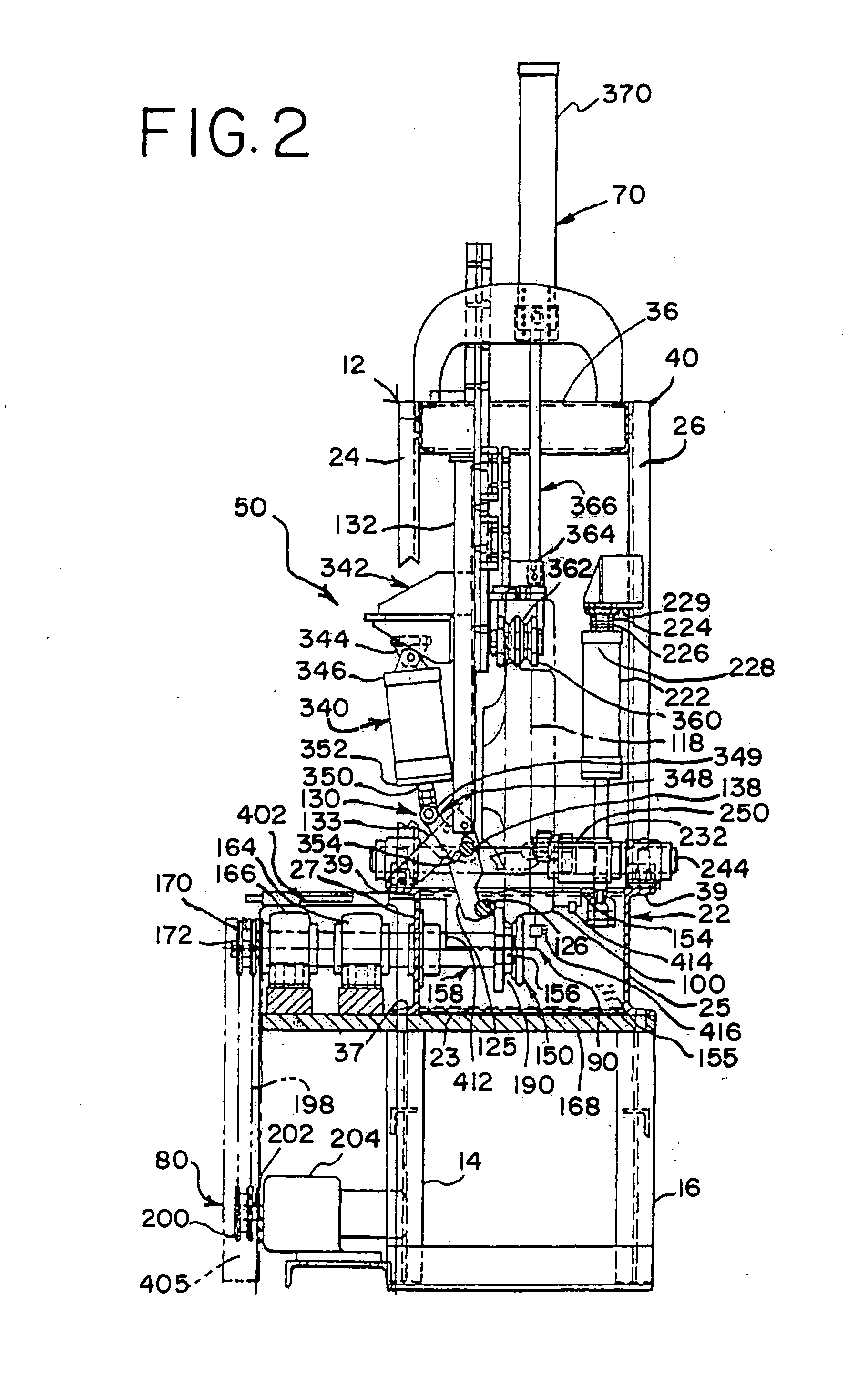

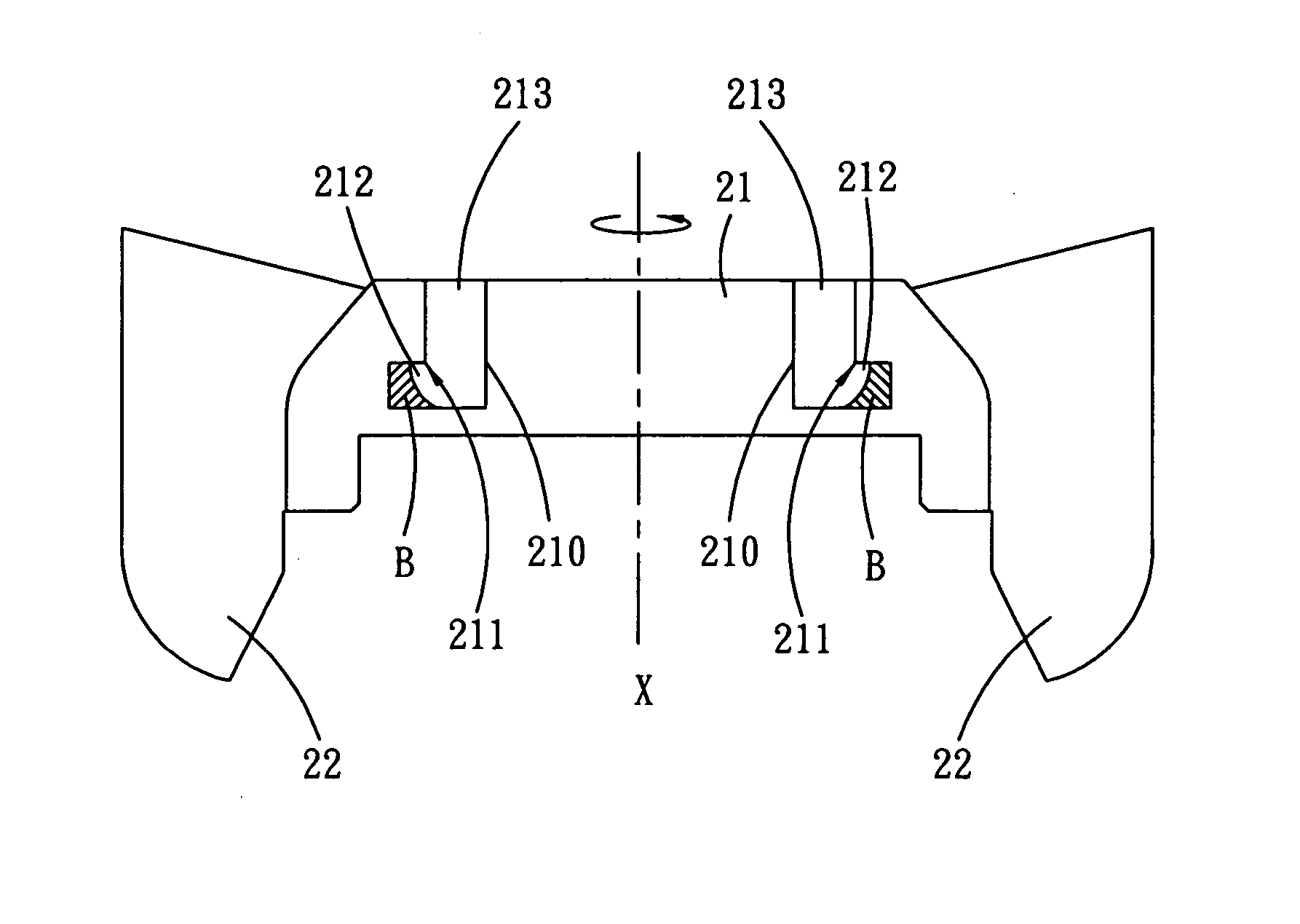

Method and apparatus for a railway wheel ultrasonic testing apparatus

ActiveUS20130019686A1Faster data collection rateAccurate and reproducible ultrasonic test dataAnalysing solids using sonic/ultrasonic/infrasonic wavesWheel-rims surveying/measuringRotational stabilityDrive wheel

A method and apparatus for collecting ultrasonic test data from a railway wheel with an ultrasonic testing apparatus is described. The railway wheel is supported by two drive rollers, each having an indentation which engages with and rotates the wheel. An indexing transducer moves across the rotating wheel, collecting ultrasonic test data while a fixed transducer correlates a reference position on the wheel to the collected test data. To maintain the accuracy of the reference position to the collected test data, it is desirable to maintain the rotational stability of the wheel, minimizing any dynamic instability caused by dimensional tolerances in the wheel. To mitigate instabilities resulting from dimensional tolerances, the indentation of the drive rollers, which engage and drive the flange of the wheel, is adjustable by the flexing design of the drive rollers to maintain frictional contact between the wheel and the drive roller. This allows the indentation to accommodate the varying dimensional tolerances of the wheel flange, mitigating the possibility of dynamic instability resulting from departure of the wheel flange from the indentation.

Owner:AMSTED RAIL CO INC

Fan and impeller thereof

ActiveUS20060269412A1Easy to separateSmooth rotationPropellersPump componentsRotational stabilityImpeller

An impeller includes a hub and at least one blade. In this case, the hub has at least one balancing portion disposed on hub and arranged with respect to a center of the hub. The balancing portion has at least one corner. The blades are disposed around the hub. In addition, a fan including the impeller is also provided. The impeller and the fan can enhance the rotation stability. As a result, the product reliability and lifetime can be increased. Furthermore, the impeller and the fan facilitate the balancing object to be separated from the tool at the corner.

Owner:DELTA ELECTRONICS INC

Inner-Rotor-Type Heat Dissipating Fan

ActiveUS20100073873A1Avoid interferencePrevent leakagePump componentsPiston pumpsRotational stabilityImpeller

An inner-rotor-type heat dissipating fan comprises a fan housing, a seal casing, an inner-rotor-type motor, an impeller and a circuit board. The fan housing includes an outer frame portion and a motor casing. The seal casing is a hollow housing made of magnetically conductive material. One end of the seal casing forms a connecting portion coupling to the motor casing. The inner-rotor-type motor is mounted inside the seal casing. The impeller is coupled to the inner-rotor-type motor and outside the seal casing. The circuit board is electrically connected to the stator. By this configuration, rotation stability of the impeller is enhanced by the inner-rotor-type motor, airflow generated by rotation of the impeller is effectively concentrated and guided by the fan housing and a sealing effect for avoiding magnetic flux leakage is provided by the seal casing. Consequently, heat dissipating efficiency is enhanced.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

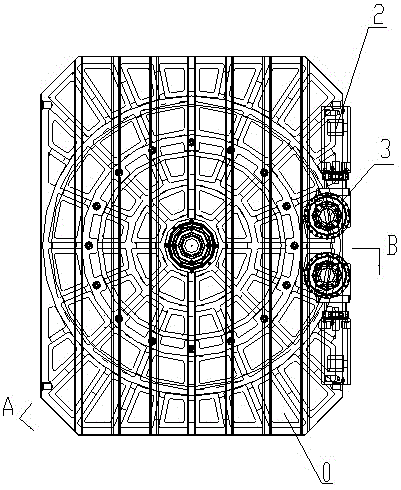

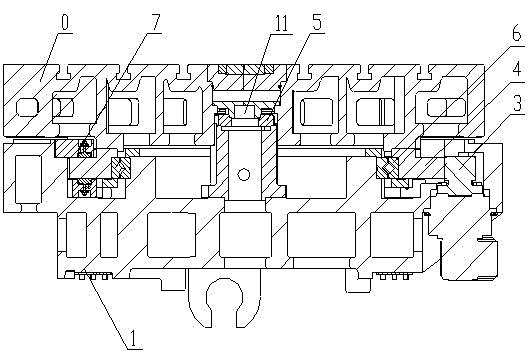

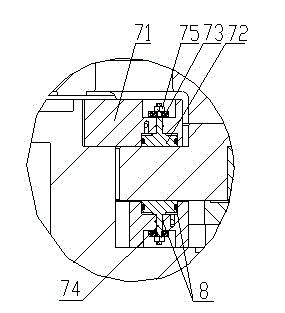

Rotary table structure and machine tool

InactiveCN102744612ASimple structureStable clampingFeeding apparatusLarge fixed membersRotational stabilityReducer

The invention discloses a rotary table structure and a machine tool, and belongs to the technical field of rotary tables. The rotary table structure mainly comprises two servo motors, two speed reducers, two driving gears, a driven gear, piston clamping mechanisms, an angle encoder and crossed roller bearings, the piston clamping mechanisms are symmetrically arranged on the upper side and the lower side of a gear ring of the driven gear, oil is fed into an oil cavity in each piston clamping mechanism after a table rotates for a required angle, upper pistons and lower pistons simultaneously clamp the driven gear, and braking and locking are carried out by the aid of friction force between each piston and a corresponding end surface of the driven gear. The rotary table structure is designed for small and medium machine tools, rotational stability and operational reliability of the table are realized by an anti-backlash effect of the piston clamping mechanisms and the double motors, and the rotary table structure is high in rotation precision and simple and compact in structure and is time-saving and labor-saving.

Owner:SHANGHAI SANY PRECISION MACHINERY

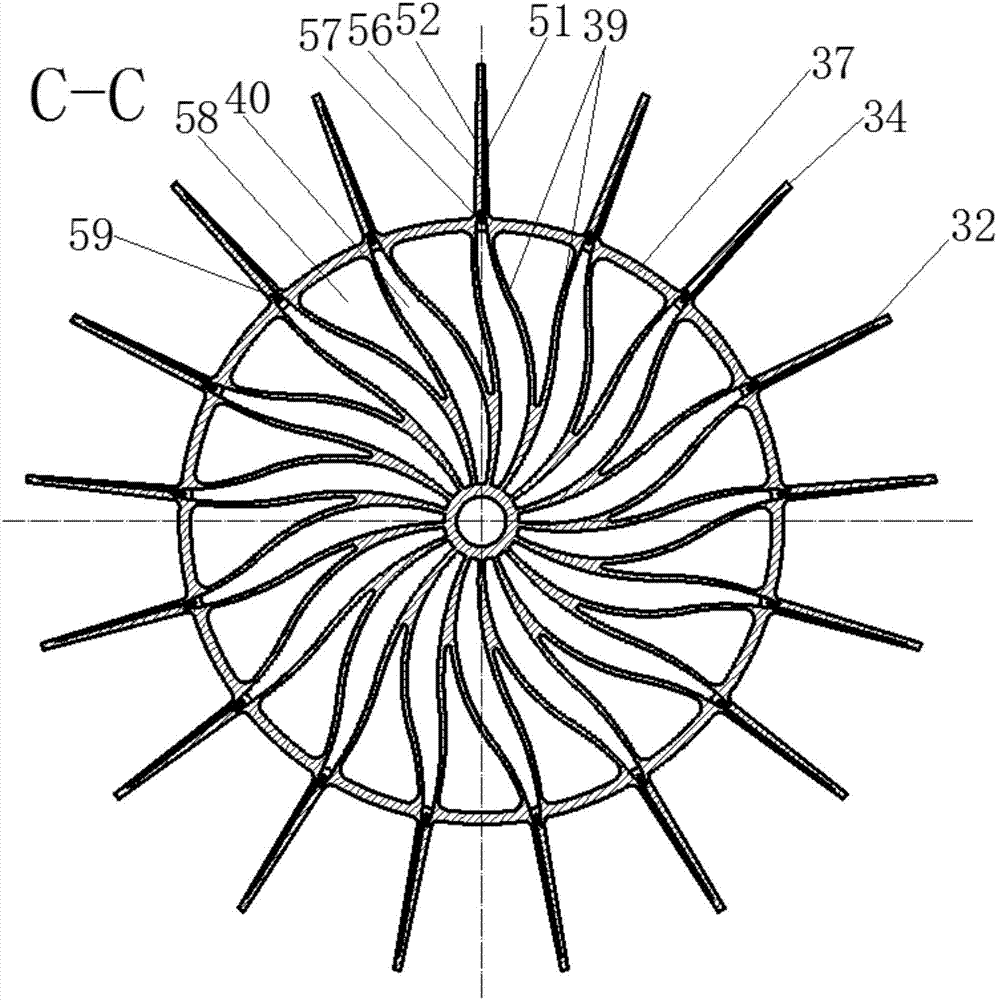

Heart assist device

ActiveUS20190125948A1Less invasive cannulationIncrease the number ofControl devicesBlood pumpsRotational stabilityRotary pump

A heart assist device comprising a rotary pump housing having a cylindrical bore, a pumping chamber and a motor stator including an electrically conductive coil located within the housing and surrounding a portion of the cylindrical bore. A rotor has a cylindrical shaft with an impeller and one or of magnets located within the shaft that are responsive to the motor stator to drive actuation of the rotor. The housing bore is closely fitted to the outer surface of the shaft forming a hydrodynamic journal bearing with an annular clearance defining a leakage flow path. One or more of radial or axial thrust bearings may be provided to provide rotation stability to the rotor and flow within the leakage flow path. The relative orientation of positions of the inflow, outflow, and leakage flow paths may be varied within the pump, such as to accommodate different intended methods for implantation and / or use.

Owner:VADOVATIONS INC

Single-Sided Dynamic Spine Plates

A dynamic spine plate is formed with only a single row of bone screw bores that extend along a generally superior / inferior axis of the spine plate, providing a single-sided dynamic spine plate. The single-sided dynamic spine plate is formed from a plurality of spine plate components that are coupled dynamically to one another. This provides a modular, single-sided dynamic spine plate. The spine plate components are coupled dynamically to one another via socket and projection interfaces, the socket and projections interfaces incorporating resilient coupling and retention structures that allow limited movement of the spine plate components relative to one another. This provides for dynamic extension of the spine plate components relative to one another. The resilient coupling structure connects the spine plate components, providing a self-biased, snap fit coupling of spine plate components. Rotation stabilizers may be provide on the present single-sided dynamic spine plate that provide rotational stability to the spine plate in addition to the bone screws that will attach the spine plate to the vertebrae.

Owner:LIFE SPINE INC

Motor, fan and stator device thereof

InactiveCN101902090AImprove the ease of assemblyLimit looseMagnetic circuit rotating partsPump installationsRotational stabilityEngineering

The invention relates to a motor and a stator device thereof, wherein the stator device comprises a shell base and a stator group; the center of the shell base is provided with a shaft tube which is internally provided with a bearing; the top end of the shaft tube is provided with as least one groove; the stator group is provided with an assembling hole which penetrates the stator group throughlyin the axial direction; the assembling hole is sleeved at the outer peripheral surface of the shaft tube, and the stator group is provided with at least one stopper which passes through the groove ofthe shaft tube and protrudes at the inner side of the shaft tube so as to restrict the bearing from loosening; and the center of the stator is provided with a rotary shaft which is pivoted on the bearing, thereby effectively improving the assembly convenience and rotation reliability of the motor and the stator device thereof. The invention is named as motor, fan and stator device thereof.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

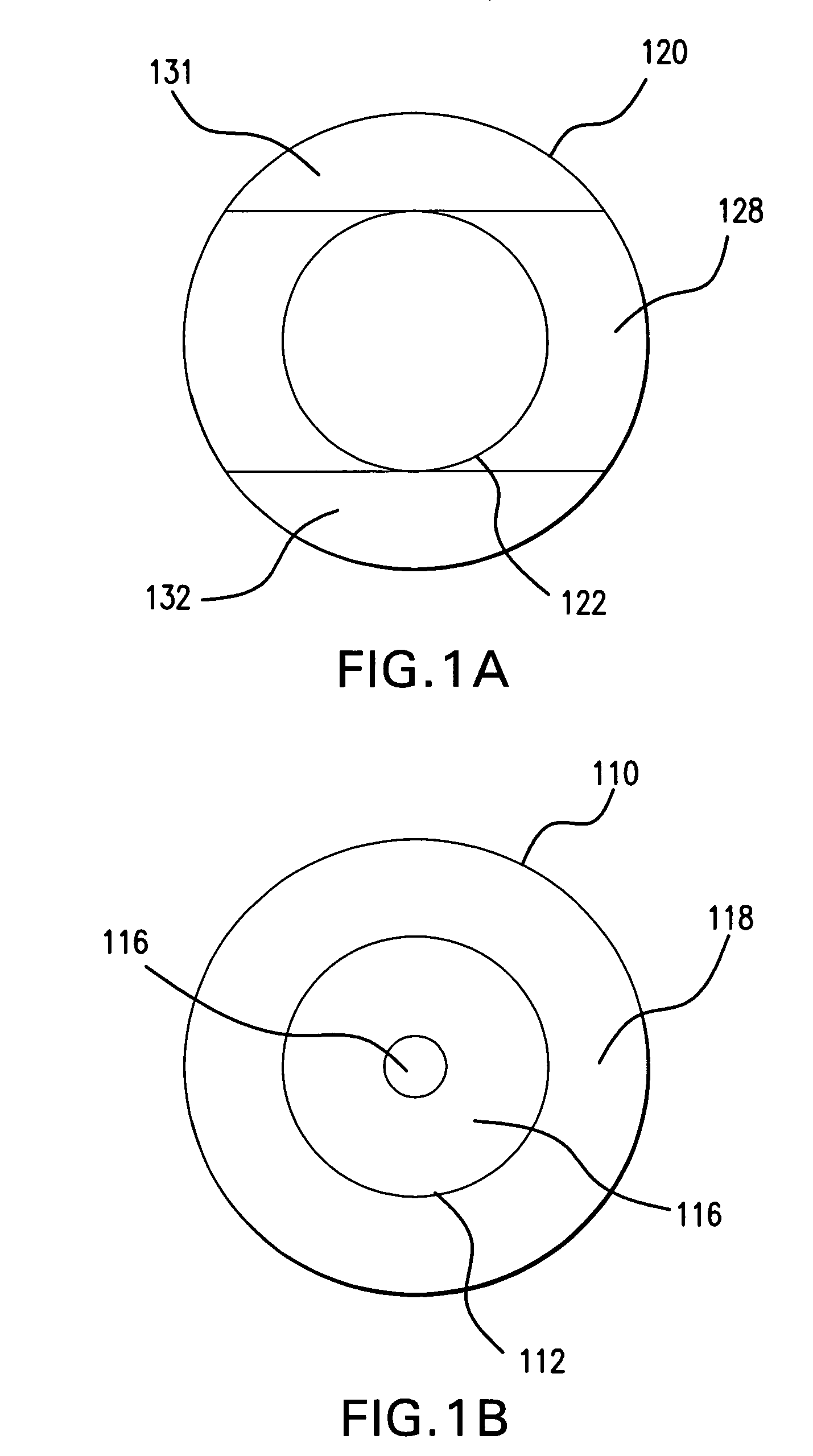

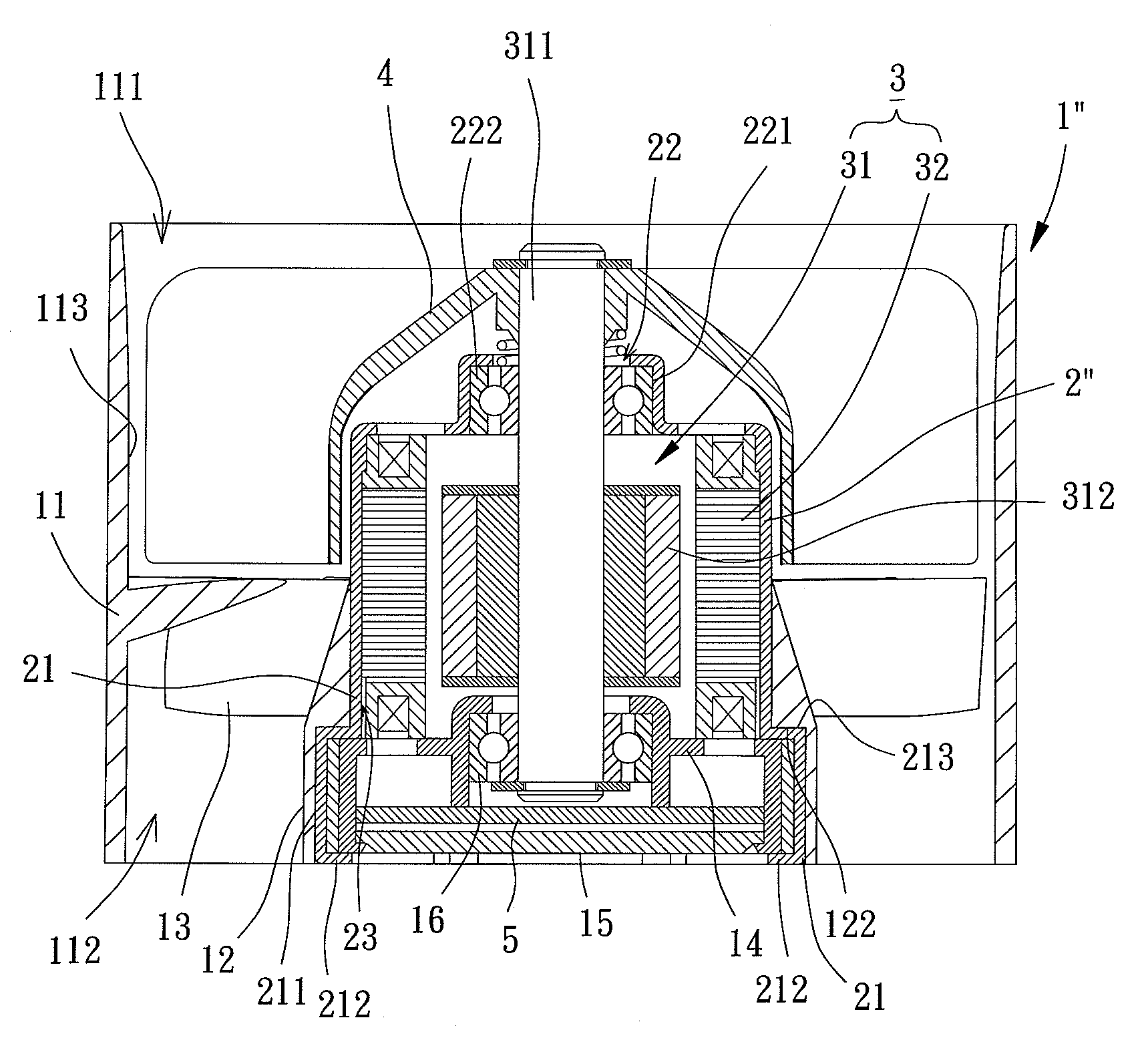

Disc carrier having a clamping device for use in an optical disc drive

InactiveUS6961949B2Improve rotational stabilityAssembled easily and rapidlyRecord information storageRecording on magnetic disksRotational stabilityEngineering

A disc carrier for an optical disc drive includes a recession integrally formed thereon and an axial tube projecting from a central portion of a bottom wall of the recession. A shaft extends through the axial tube. An engaging length between the axial tube and the shaft is increased to improve rotating stability of the disc carrier. A support member is fixed in the recession and includes a peripheral support edge along a periphery thereof. The support member is in contact with and thus supports plural clamping members of a clamping device.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

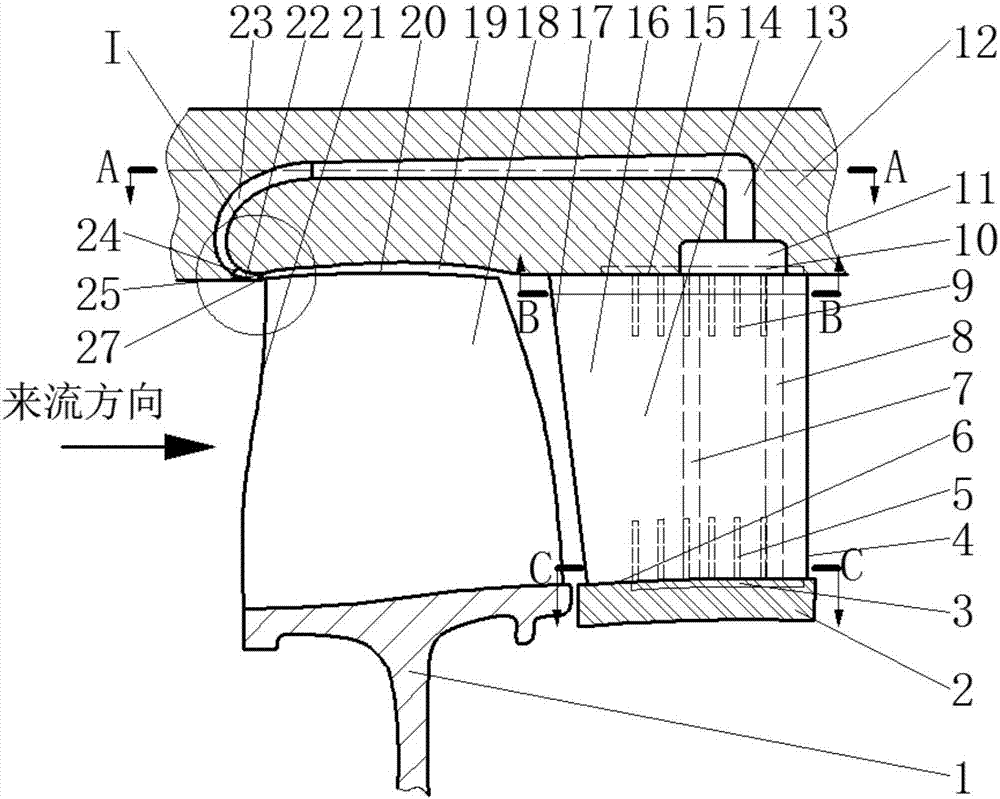

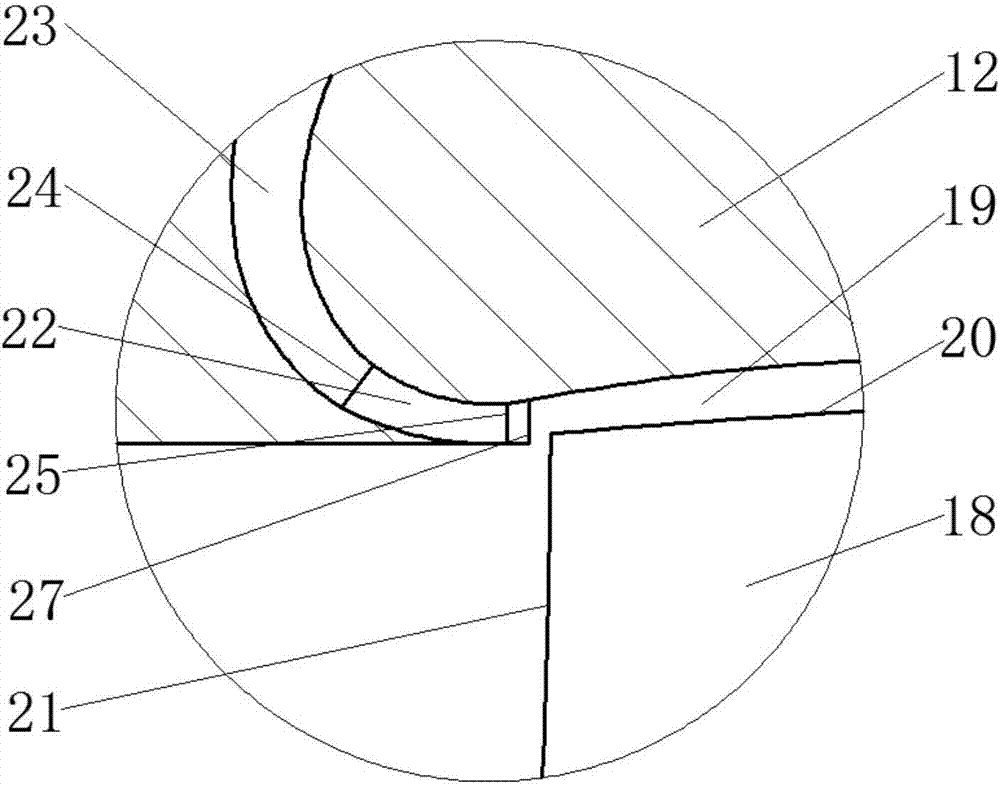

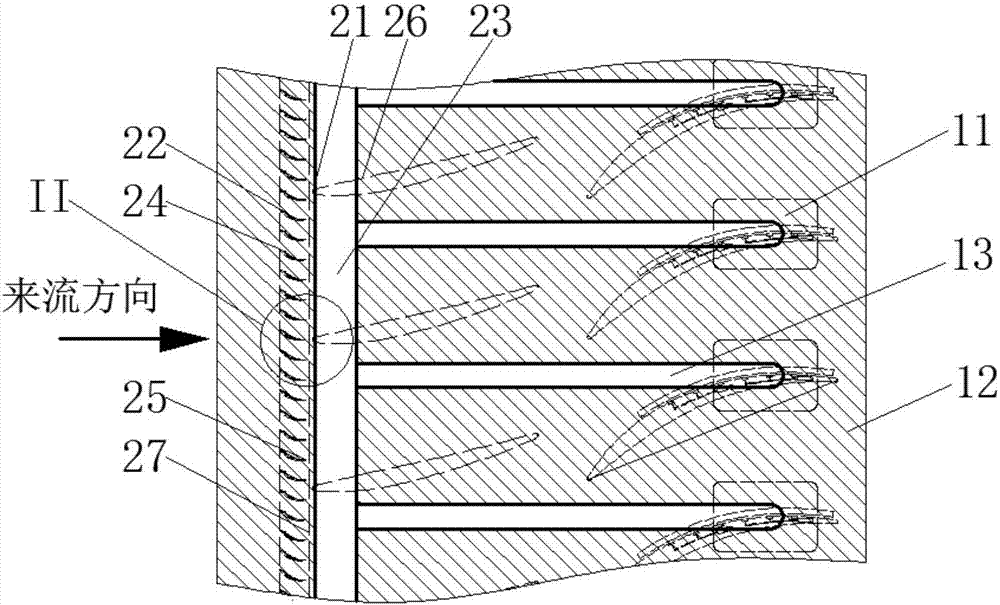

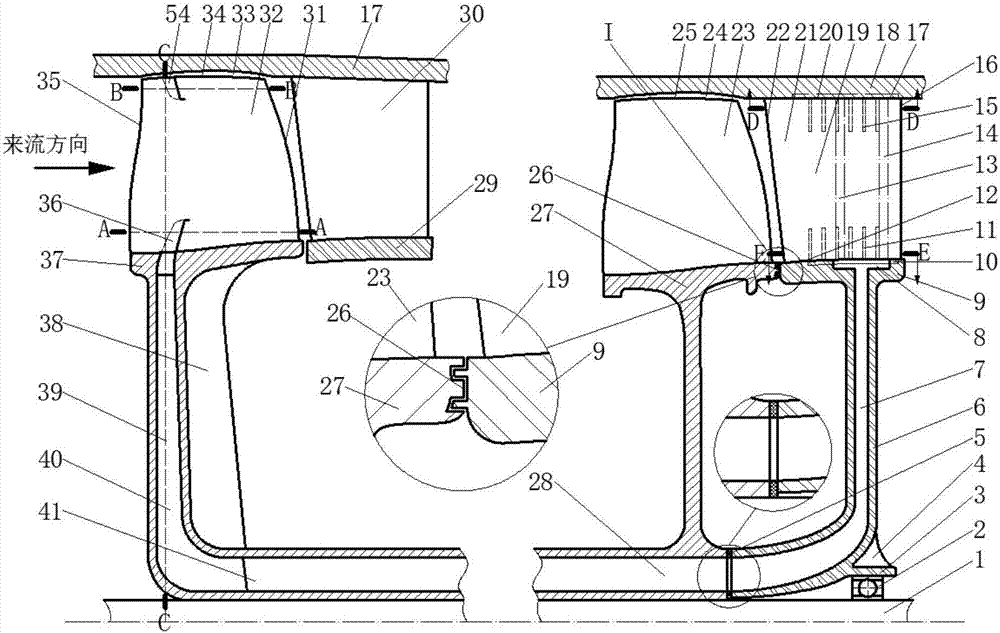

Self-circulation treatment casing for simultaneously improving stator corner region flowing

ActiveCN107202036AAvoid suction controlEasy to movePump componentsPump controlRotational stabilityDifferential pressure

The invention relates to multistage axial flow air compressor treatment casings, and discloses a self-circulation treatment casing for simultaneously improving stator corner region flowing. The self-circulation treatment casing comprises a target rotor blade, a downstream stator blade, a casing body and an air guide pipe structure located in the casing body. A flow guide cavity structure penetrating the whole circumferential direction is arranged at the position, on the front edge of a target rotor blade tip, in the casing body. Flow guide cavity outlet front guide vanes used for adjusting the jet flow direction are circumferentially and evenly arranged on the front edge of a flow guide cavity outlet, and the outlet directions of the guide vanes are consistent with the pre-rotating direction of the target rotor blade tip. According to the characteristic of stage-by-stage pressurization of a multistage air compressor, self-adaptive suction and jet flow are formed under the action of differential pressure of a downstream stator blade combined suction groove and the flow guide cavity outlet of the target rotor blade tip; separated flowing of a stator three-dimensional corner region of the air compressor is effectively restrained, and meanwhile moving blade rotating stall is prevented from happening too early through circumferentially-even jet flow with the pre-rotating direction consistent with that of the rotor blade tip; the rotor blade rotating stability and margin are increased; and the stable work condition range of the air compressor is widened.

Owner:BEIHANG UNIV

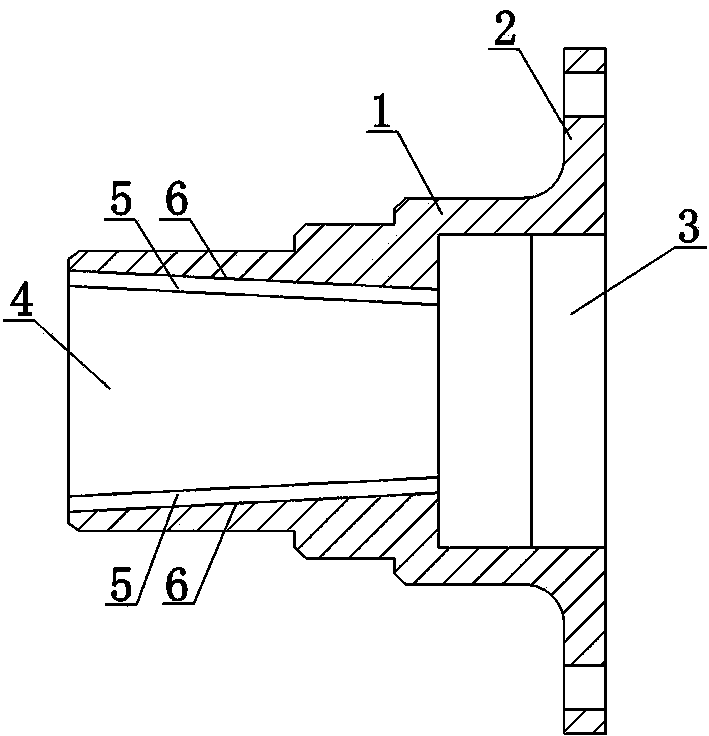

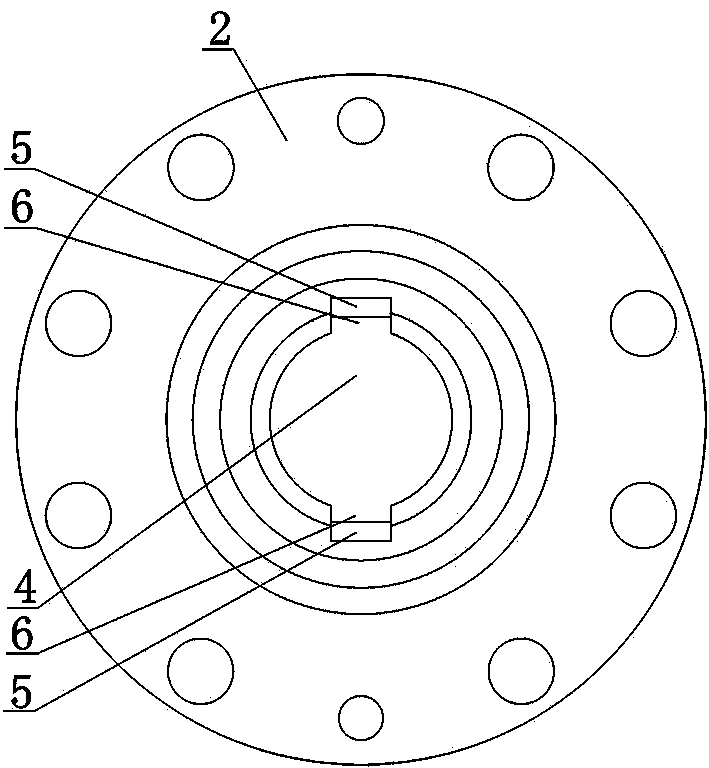

Coupler for electric bus motor and manufacturing process thereof

InactiveCN103727144AIncrease contact areaImprove connection strengthCouplings for rigid shaftsRotational stabilityGeneral assembly

The invention discloses a coupler for an electric bus motor. The coupler comprises a body (1), a flange (2) and a step-shaped through hole. A shaft fastener containing cavity (3) is formed in one end of the through hole, a conical hole (4) with the inner diameter gradually decreasing in the direction from outside to inside is formed in the other end of the through hole, and two key grooves (5) formed in the axial direction are symmetrically formed in the surface of the conical hole (4). The invention further discloses manufacturing process. The coupler for the electric bus motor and the manufacturing process thereof have the advantages that the conical hole structure further improves the coaxiality of a connecting shaft and the coupler, balance performance is good, and the rotating stability of the connecting part is enhanced. A key groove structure further reinforces the coaxiality of the connecting shaft in the conical hole and a connecting shaft fixedly connected with the flange. In the manufacturing process, location operation is simple, and locating is stable and accurate, so that processing precision of a workpiece is ensured, quality is stable and reliable, the requirement for design precision and the requirement for interchangeability of motor general assembly are ensured, and manufacturing is safe and protects the environment without pollution.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

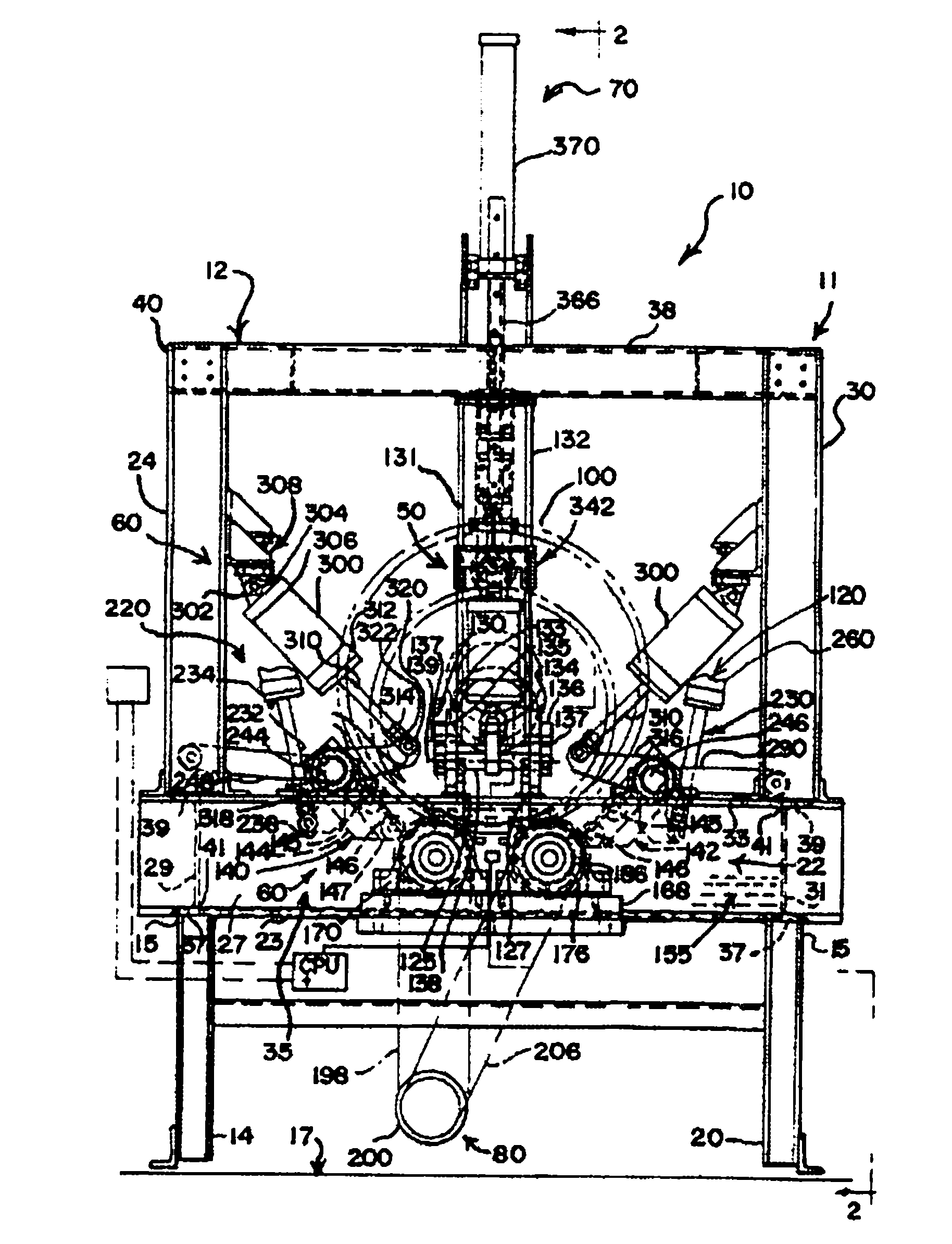

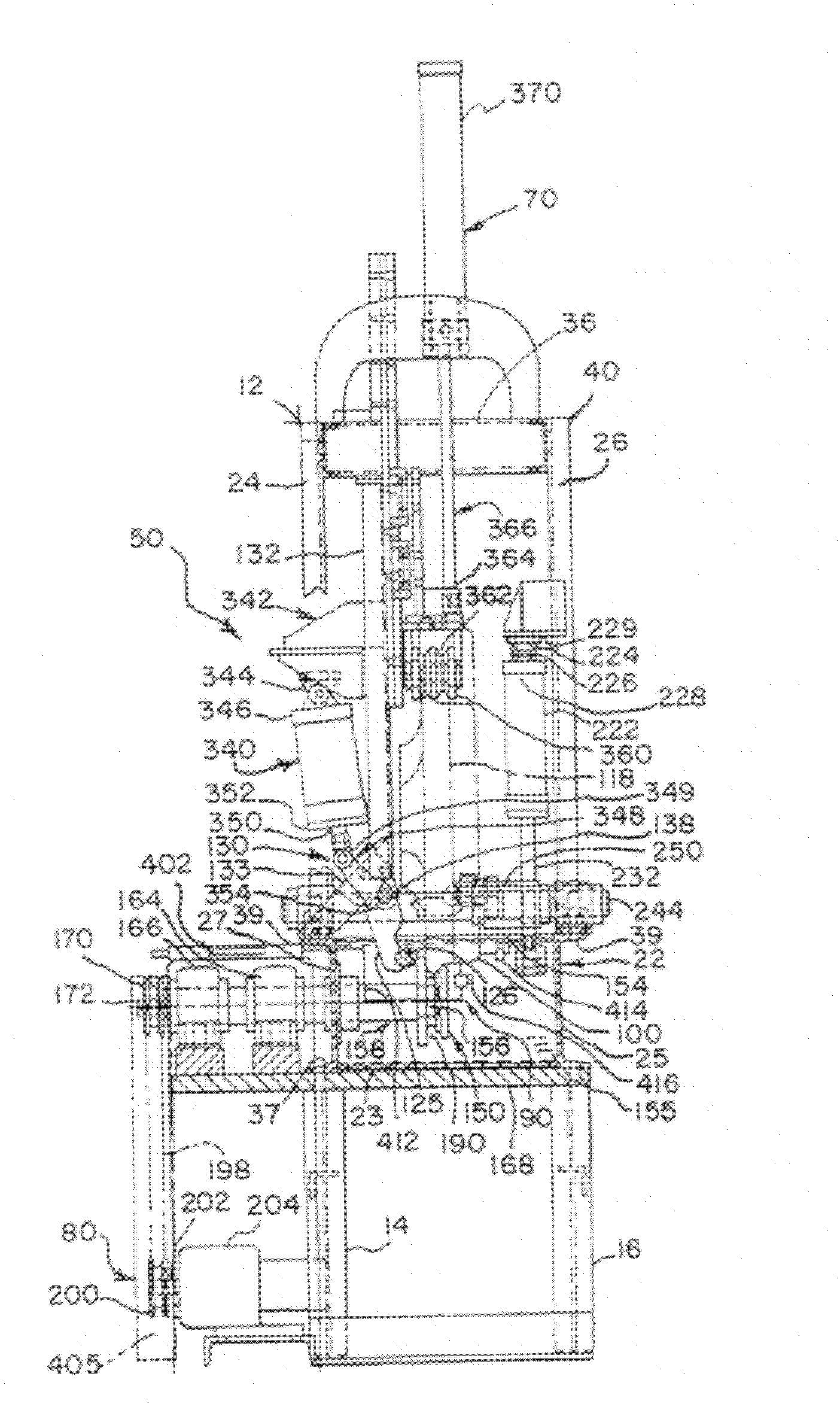

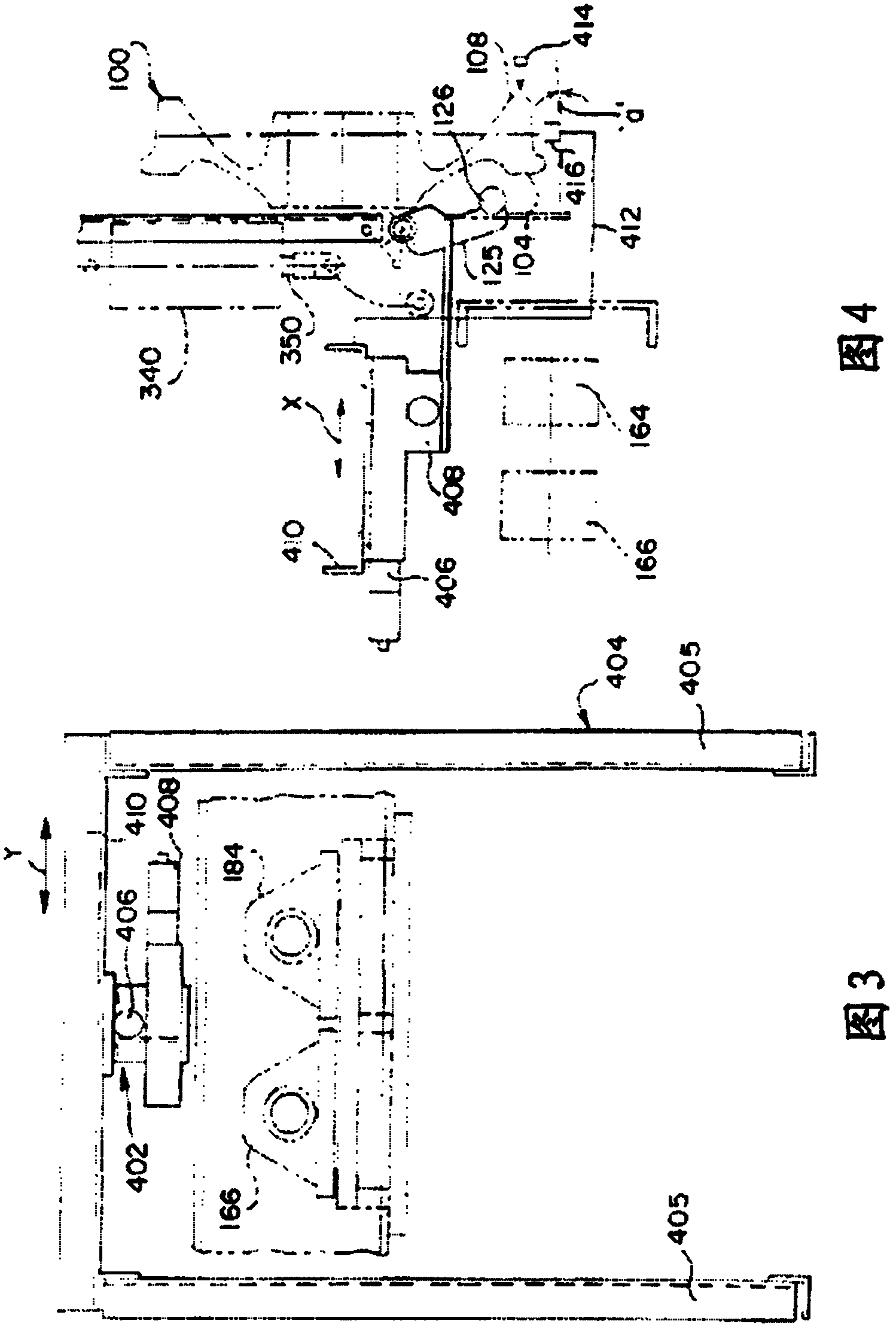

Method and apparatus for railway wheel ultrasonic testing apparatus

ActiveCN102841147AReduce vibrationReduce stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesRailway vehicle testingRotational stabilityTransducer

A method and apparatus (10) for collecting ultrasonic test data from a railway wheel with an ultrasonic testing apparatus are described. The railway wheel (100) is supported by two drive rollers (150, 152), each having an indentation (190, 192) which engages with and rotates the wheel. An indexing transducer moves across the rotating wheel, collecting ultrasonic test data while a fixed transducer correlates a reference position on the wheel to the collected test data. To maintain the accuracy of the reference position to the collected test data, it is desirable to maintain the rotational stability of the wheel (100), minimizing any dynamic instability caused by dimensional tolerances in the wheel. To mitigate instabilities resulting from dimensional tolerances, the indentation of the drive rollers, which engage and drive the flange of the wheel, are variably spaced using a resilient member to maintain frictional contact between the wheel (100) and the drive roller (150, 152). This allows the indentation to accommodate the varying dimensional tolerances of the wheel flange, mitigating the possibility of dynamic instability resulting from departure of the wheel flange from the indentation.

Owner:AMSTED RAIL CO INC

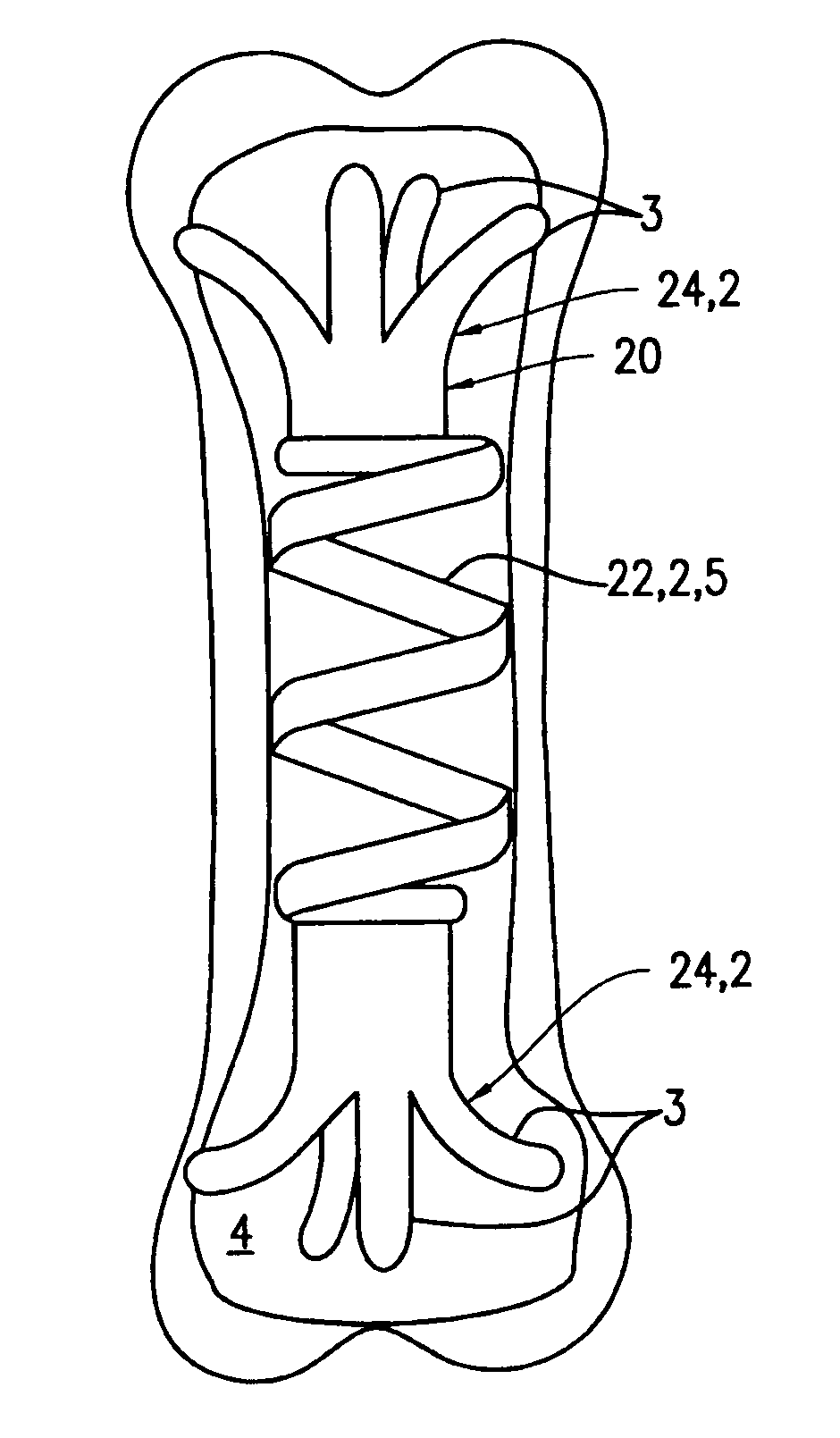

A device for bone support with improved rotational stability

ActiveUS20160256202A1Improve rotational stabilityEasy to manufactureInternal osteosythesisRotational stabilityWeight-bearing

A bone support fixating device with a longitudinally slotted hip screw which permits operative compression of the fracture and holds this compression yet allows sliding as further compression of the fracture occurs under forces of weight bearing; comprising a hollow cylindrical shaft with a screw portion at its upper proximal end and four equally spaced longitudinal grooves at its lower distal end, having three equally distant angled holes between the ends, through which three wires can be inserted, the three ‘elastic’ proximally curved wires, welded, glued or crimped distally, can be inserted into the hip screw collectively called the ‘tri-wire’; The proximal end has the wires curved outward, with all three wires equally spaced; upon pushing the tri-wire into the hip screw, the wires goes through the angle holes in the hip screw and provides three projections equally spaced; which improves the rotational stability of the proximal fracture fragment.

Owner:GENERAL SURGICAL COMPANY INDIA PVT

Rotating blade and stationary blade combined self-adaption adjustment multistage axial flow gas compressor

ActiveCN107165864AIncrease marginBroaden the range of stable working conditionsPump componentsPump controlRotational stabilityGas compressor

The invention relates to a multistage axial flow gas compressor and discloses a rotating blade and stationary blade combined adjustment multistage axial flow gas compressor which comprises a target rotor blade, a downstream stator blade, a downstream stator blade wheel disk, a target rotor blade wheel disk and a rotor wheel disk drainage cavity structure rotating synchronously with an engine shaft. Through a guiding blade in a jet flow gas flow guiding cavity, drainage gas has the same convected velocity as a rotor, and a jet flow groove further acts on an end area and a blade tip of the target rotor blade. According to the characteristics of pressurizing by stages of the multistage gas compressor, a self-adaptive suction and wall-attached jet flow is formed in a downstream stator combination suction groove and the target rotor end area and the blade tip, rotor and stator three-dimensional angular area separation flowing of the multistage gas compressor is effectively inhibited, leakage flowing of the rotor blade tip is improved, rotating stall caused by three-dimensional angular area separation, blade tip front edge overflow and tail edge countercurrent flow is effectively prevented, the rotating stability of the target rotor is strengthened, the margin is increased, and the stable working condition range of the gas compressor is widened.

Owner:BEIHANG UNIV

Tapered powder-based core for projectile

A powder-based projectile useful in the manufacture of gun ammunition comprising a jacket having an inner volume which is tapered from a maximum diameter adjacent the open end of the jacket to a minimum diameter adjacent the closed end of the jacket and a core formed outside the jacket and having a complementary tapered geometry with respect to the inner volume of the jacket. Projections from the outer surface of the core are embedded within the inner wall of the jacket to enhance the spin stability of the jacket / core combination and to enhance the frangibility of the projectile upon it striking a target. A method for the manufacture of the projectile is disclosed.

Owner:LONE STAR FUTURE WEAPONS LLC

Stator and DC brushless motors including the stator

ActiveUS8030809B2Reduce axial heightSolve the stability is not highMagnetic circuit characterised by insulating materialsRotational stabilityBrushless motors

A stator for a DC brushless motor includes an annular insulating ring integrally formed from an insulating material. The annular insulating ring includes an outer peripheral face and an inner peripheral face. A plurality of winding portions extends from at least one of the outer and inner peripheral faces. A coil unit is wound around each of the plurality of winding portions. The stator can be utilized in various DC brushless motors. Since the stator does not include conventional silicon steel plates and is comprised of an annular insulating ring and a coil unit, advantages including low manufacturing costs, assembling convenience, possible reduction in the axial height, and high rotational stability are obtained.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com