Patents

Literature

432 results about "Drop-shaped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

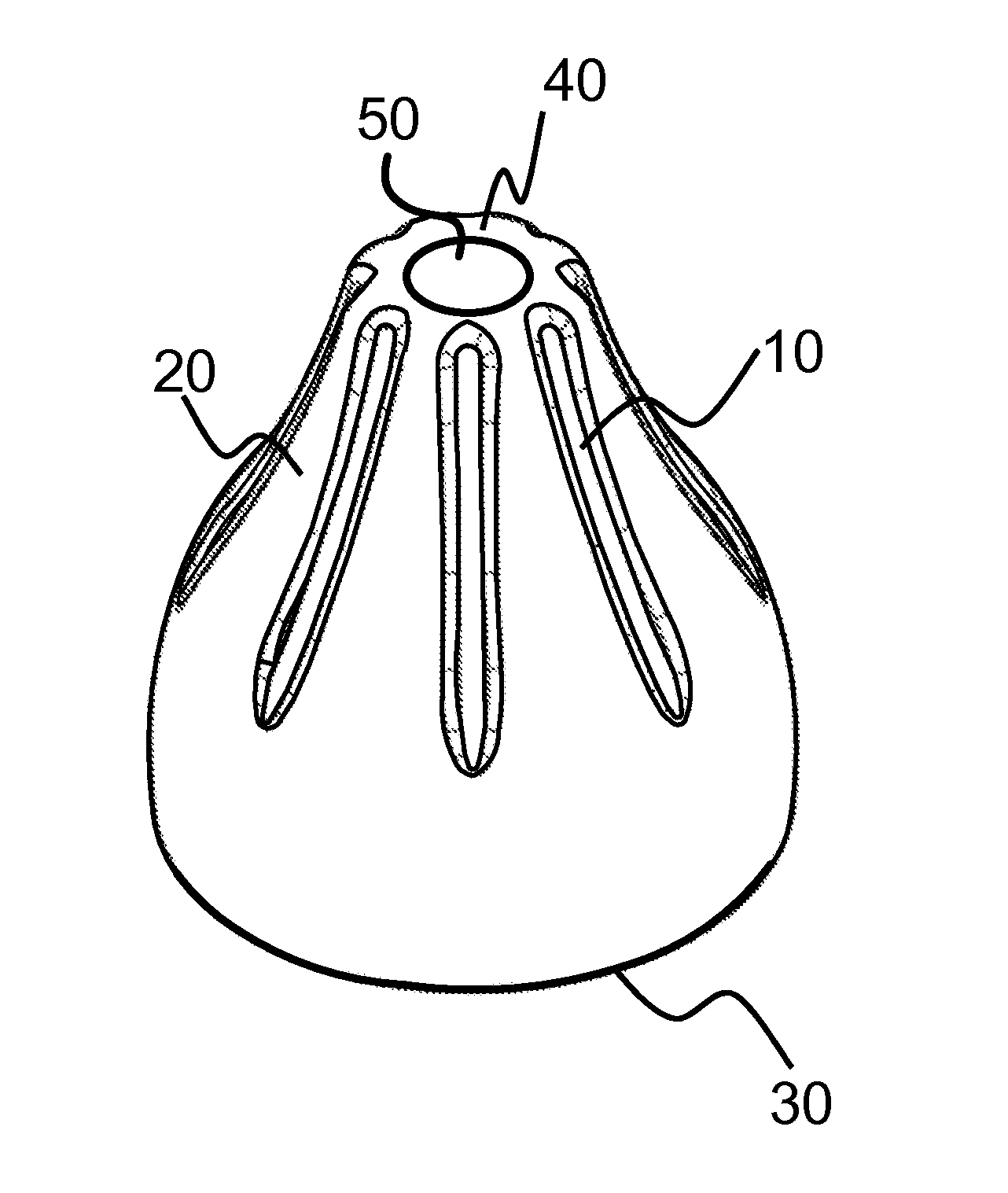

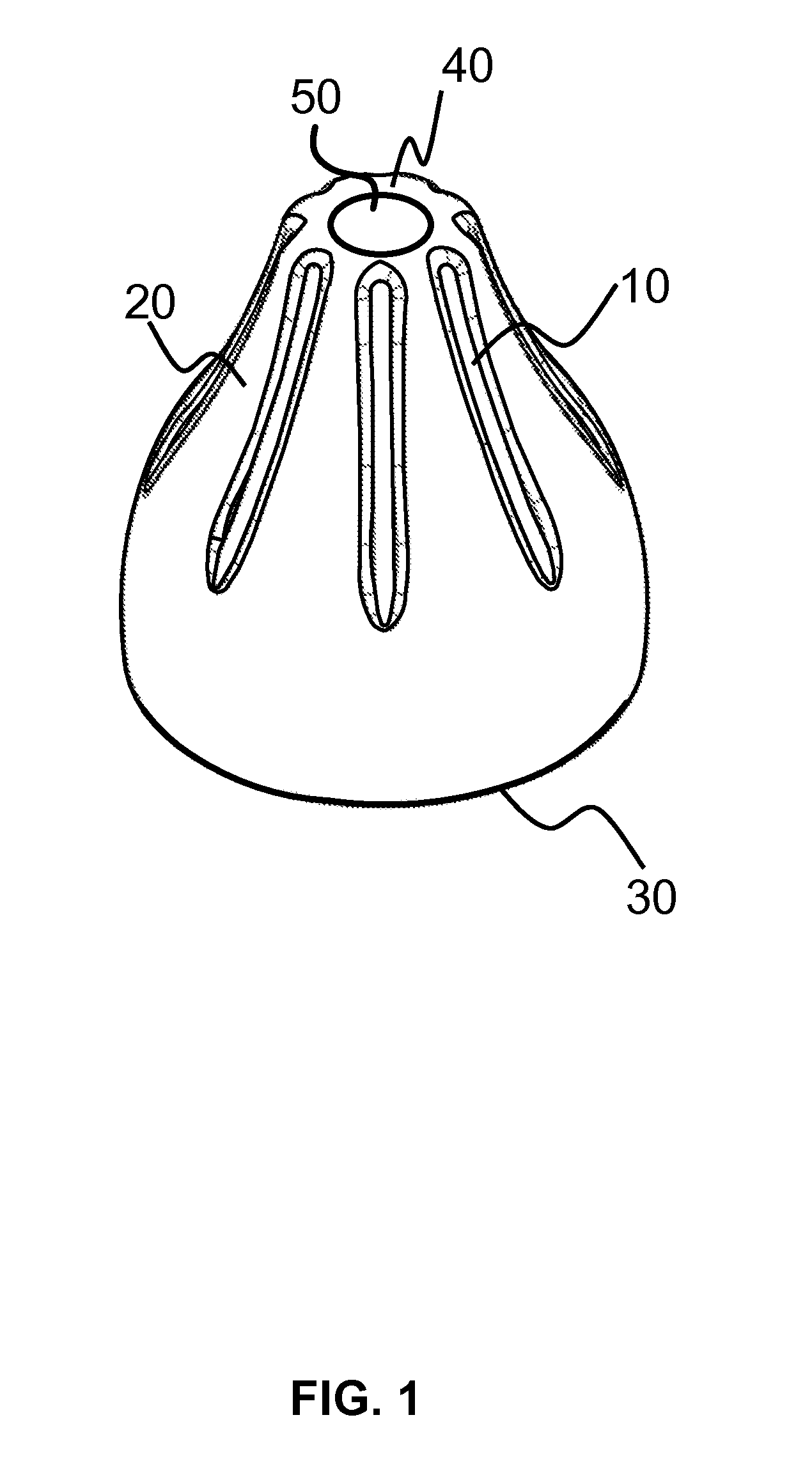

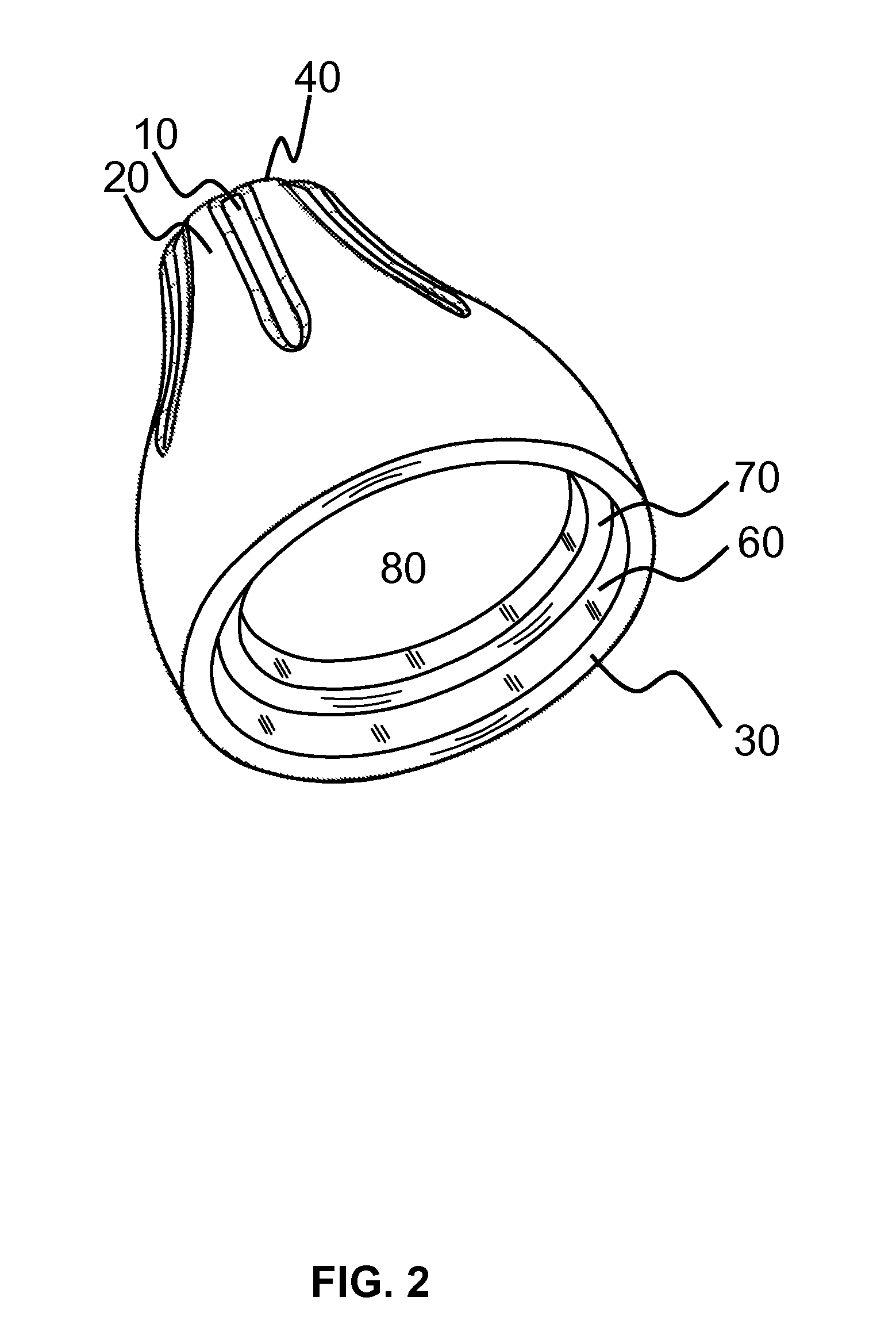

Partially Occluding Ergonomic Earbud Adapter

A partially occluding ergonomic earbud adapter is formed from low durometer materials. The exterior of the adapter is frustoconical and tear-drop shaped and formed with several fluted recesses which set apart finger-like flanges extending from an open base toward the tip of the adapter. The ergonomic flanges grip the inside of the ear canal as a result of elastic restoring forces of the flanges against each other and against the ear canal to form an ergonomic seal partially occluding sound from the ear canal while providing isolation. The inside wall of the adapter is formed to enclose and secure the earphone in a parabolic concavity formed by an undercut rib at the base. The cavity is abutted by a cylindrical channel extending through the adapter to an orifice at the tip to deliver high fidelity audio into a user's ear canal from the headset or another audio listening device.

Owner:VASQUEZ RAFAEL

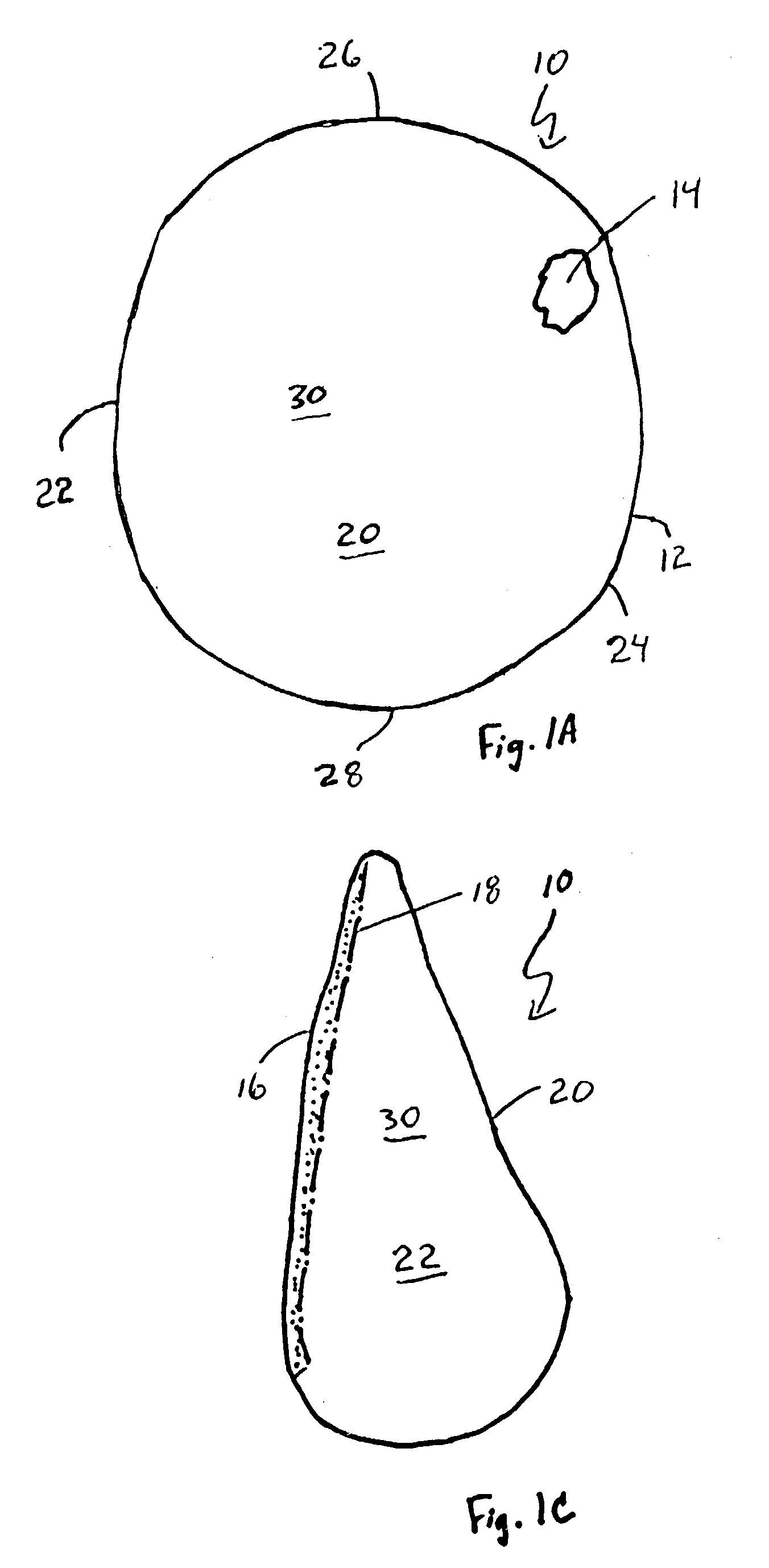

Non-rotating breast implant

InactiveUS7105116B2Precise positioningNatural appearanceMammary implantsMouldsWrinkly skinWrinkle skin

A non-rotating anatomical-shaped breast implant having a front side with a smooth surface and a rear side with a textured surface. A smooth surface ripples or wrinkles little, if at all. Rippling or wrinkling of the implant may undesirably produce a visible or palpable waviness on the skin of the breast. A smooth surface is more likely to produce the look and feel of a natural breast. A rear side with a textured surface is desirable because tissue growth of the body, after the implant has been implanted, engages the textured surface to anchor the implant in place such that the front side with the smooth surface remains matched with the front side of the body and such that the anatomical-shaped breast implant with its tear drop shaped fullness remains at a natural position within the breast. The disclosure further includes a method for minimizing the rotation of an implant within the body and a method for making an implant envelope that has different thicknesses.

Owner:BELLIN HOWARD T

Needle tip

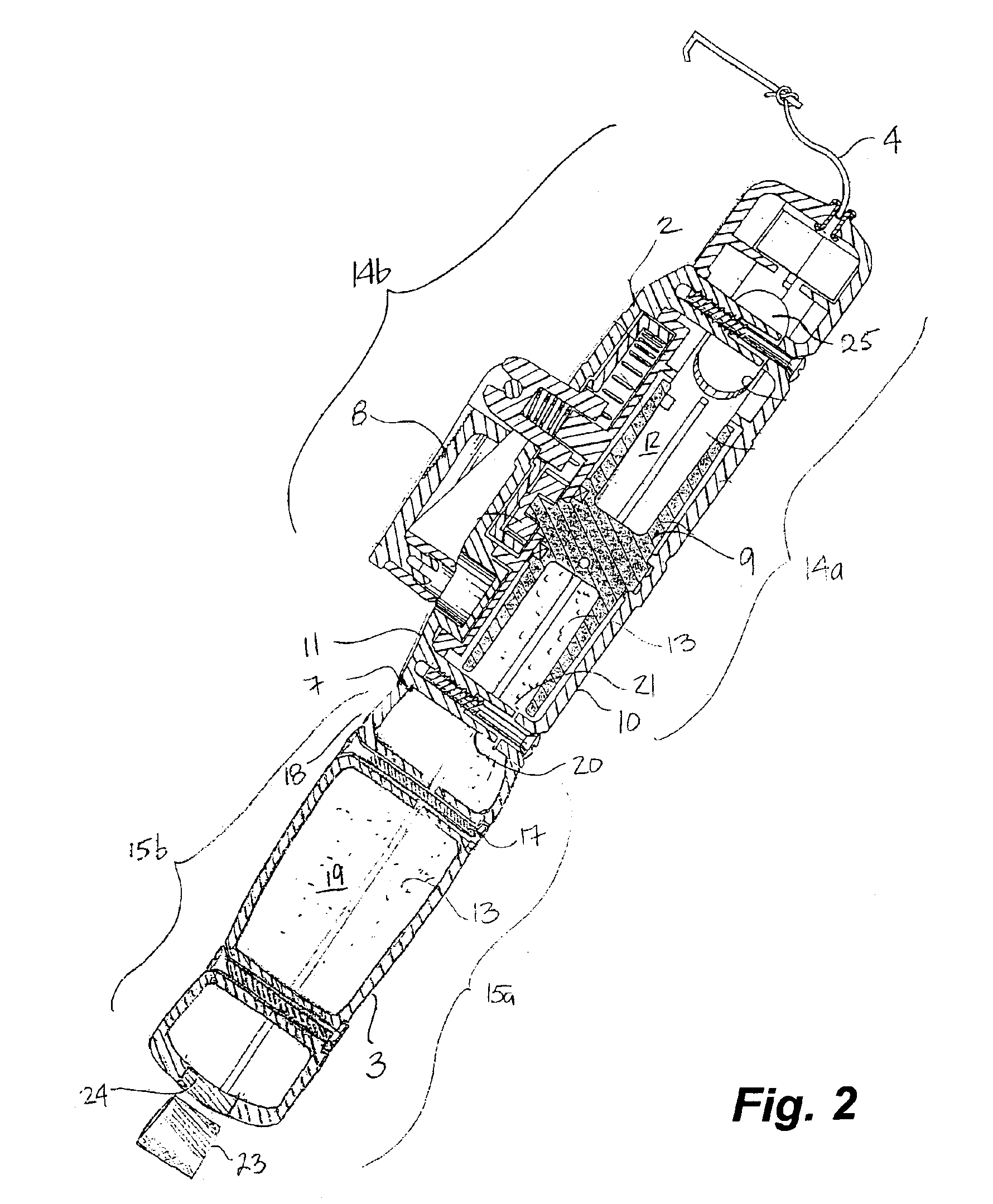

The present invention provides a needle tip for needles of cannulae for penetrating materials and transferring fluids. The needle tip incorporates at least one conduit for transferring the fluids, at least one blade portion and at least one aperture in fluid communication with the conduit, an aperture being disposed generally opposite a blade portion. The at least one blade portion preferably comprises of concave surfaces joining in a cutting surface. A needle tip according to the invention may have more than one conduit, more than one blade portion, and more than one aperture. Preferably, the needle tip comprises of a tear-drop shape in cross section. The needle tip is simple to make and can be advantageously used in single-use applications. Preferably the needle tip is comprised of polymeric material. Preferably the needle tip is manufactured by fluid-assisted moulding.

Owner:SSB TECH

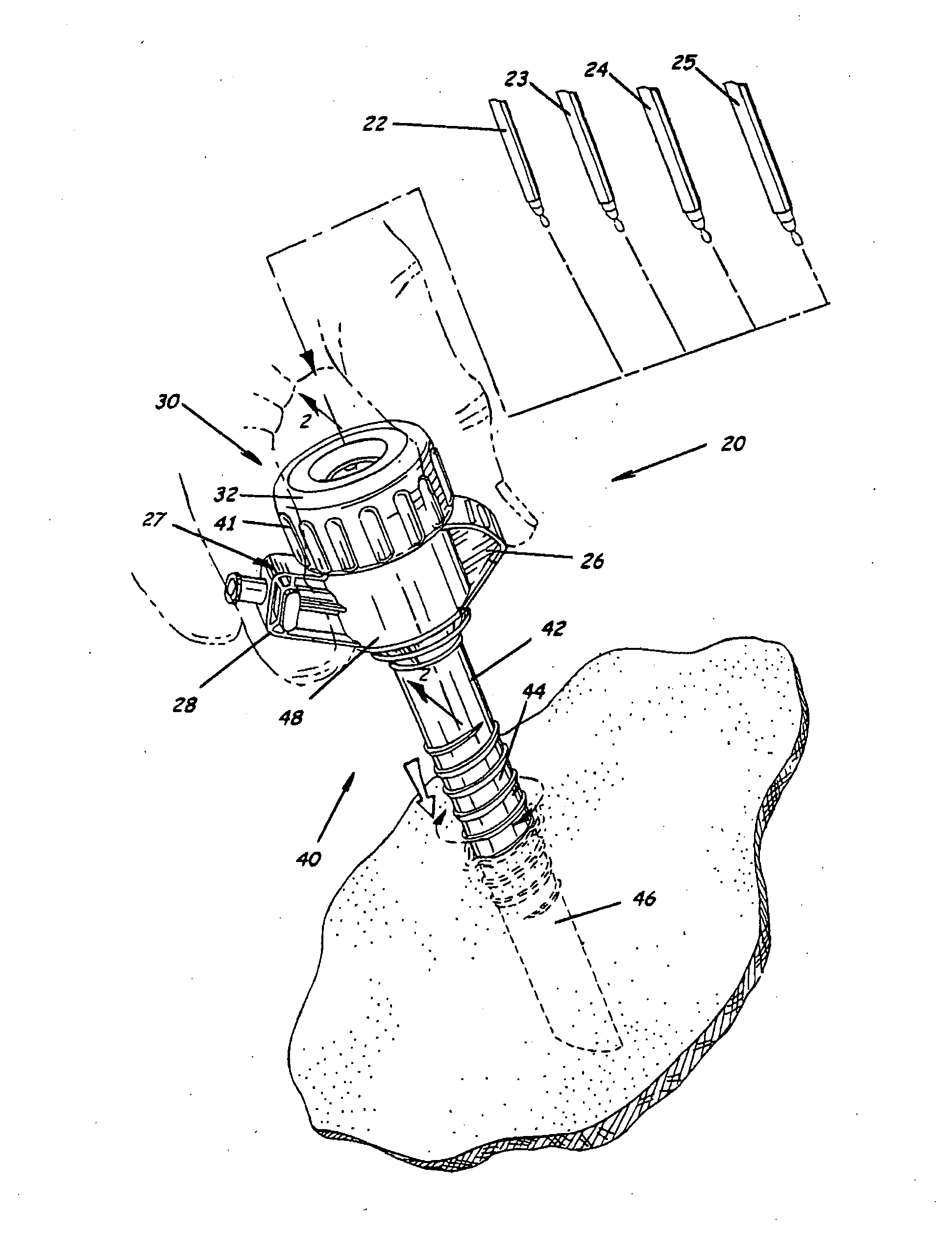

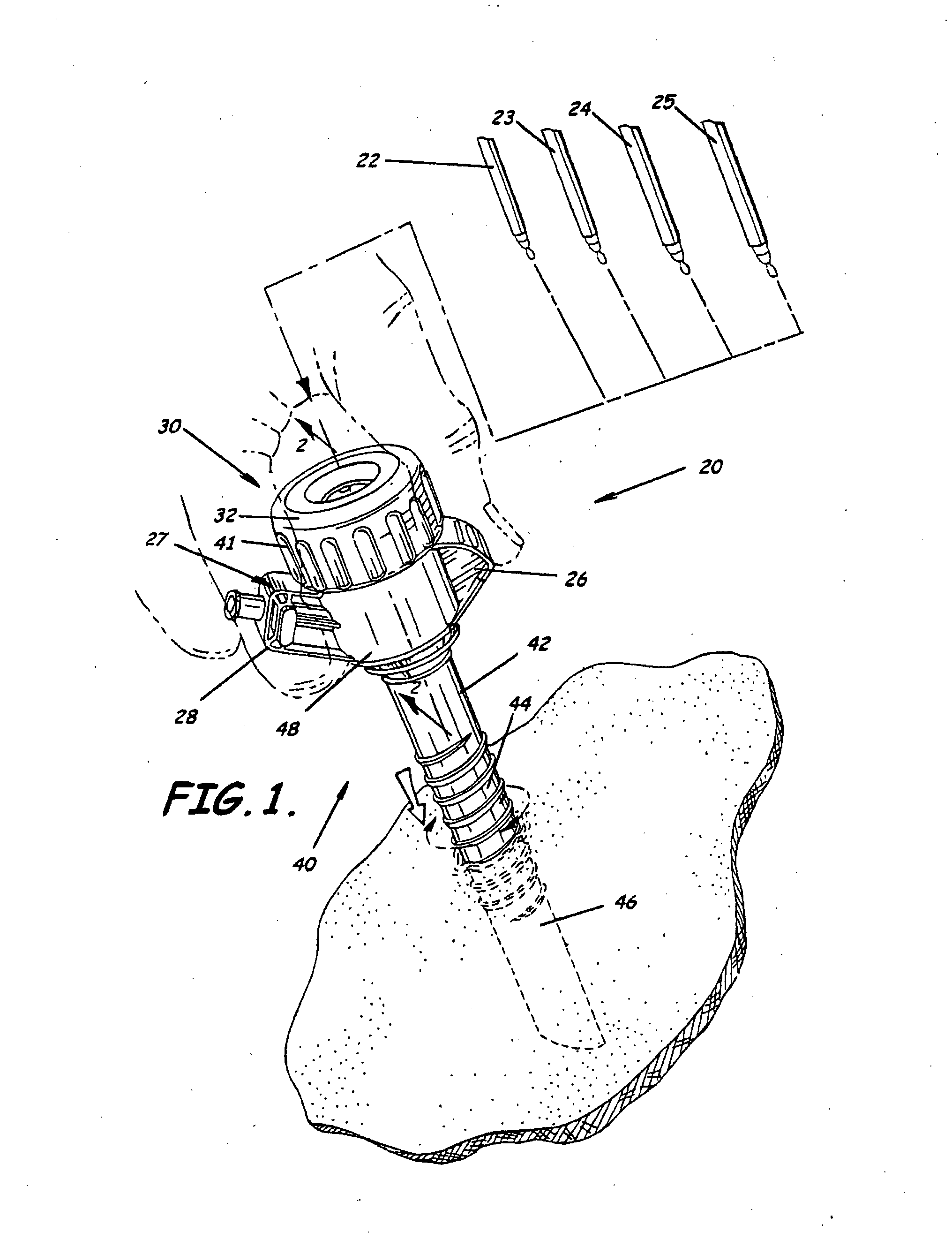

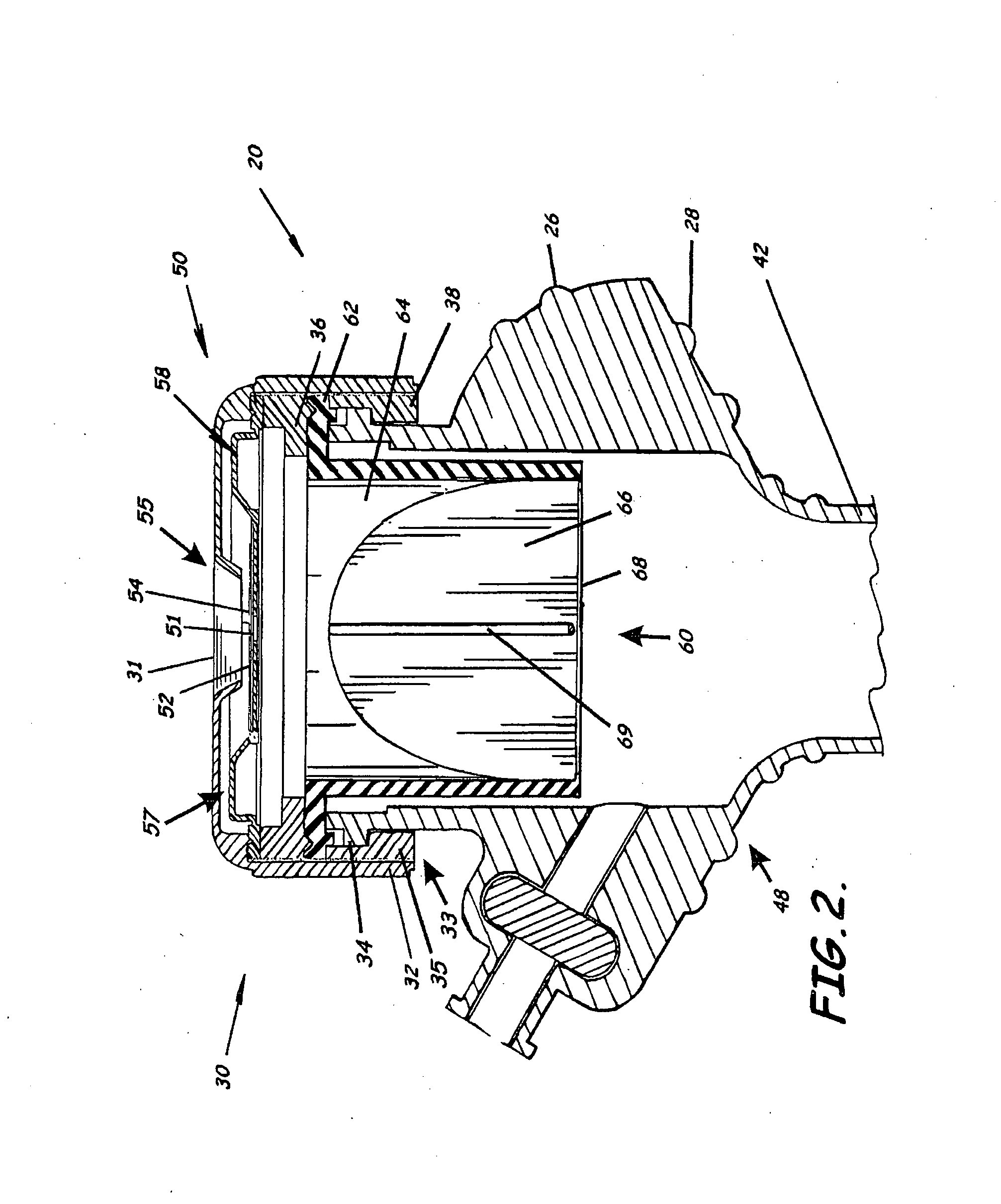

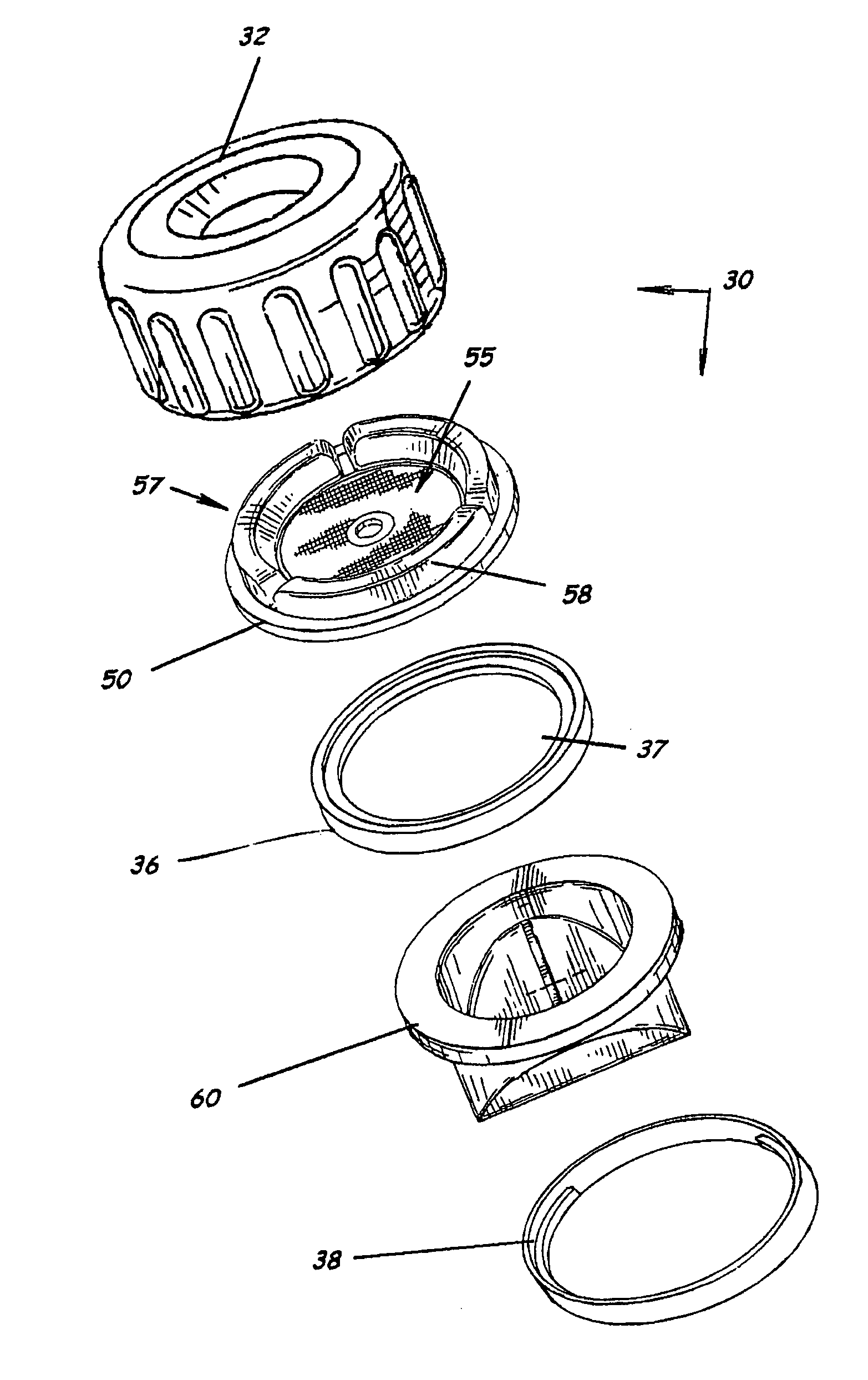

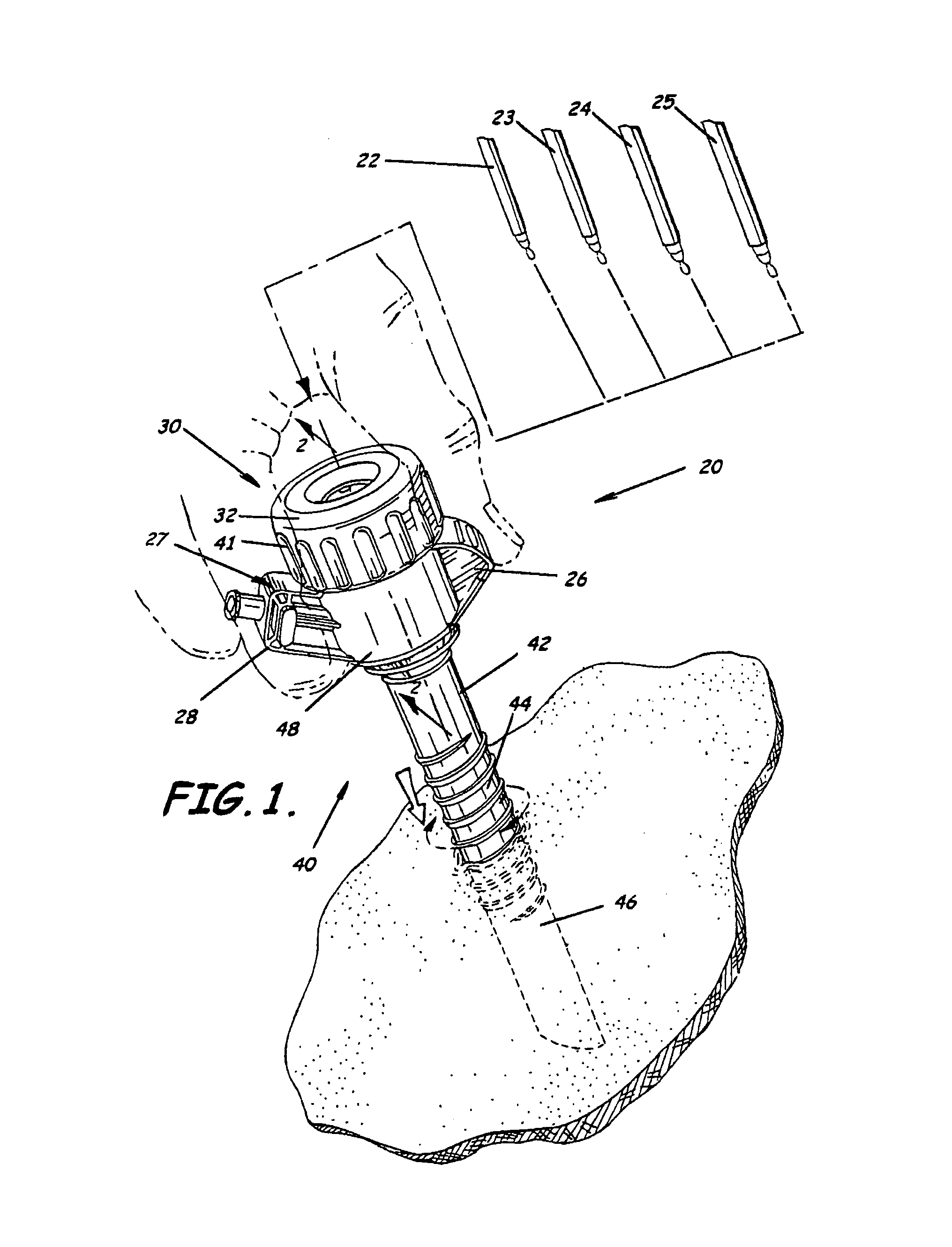

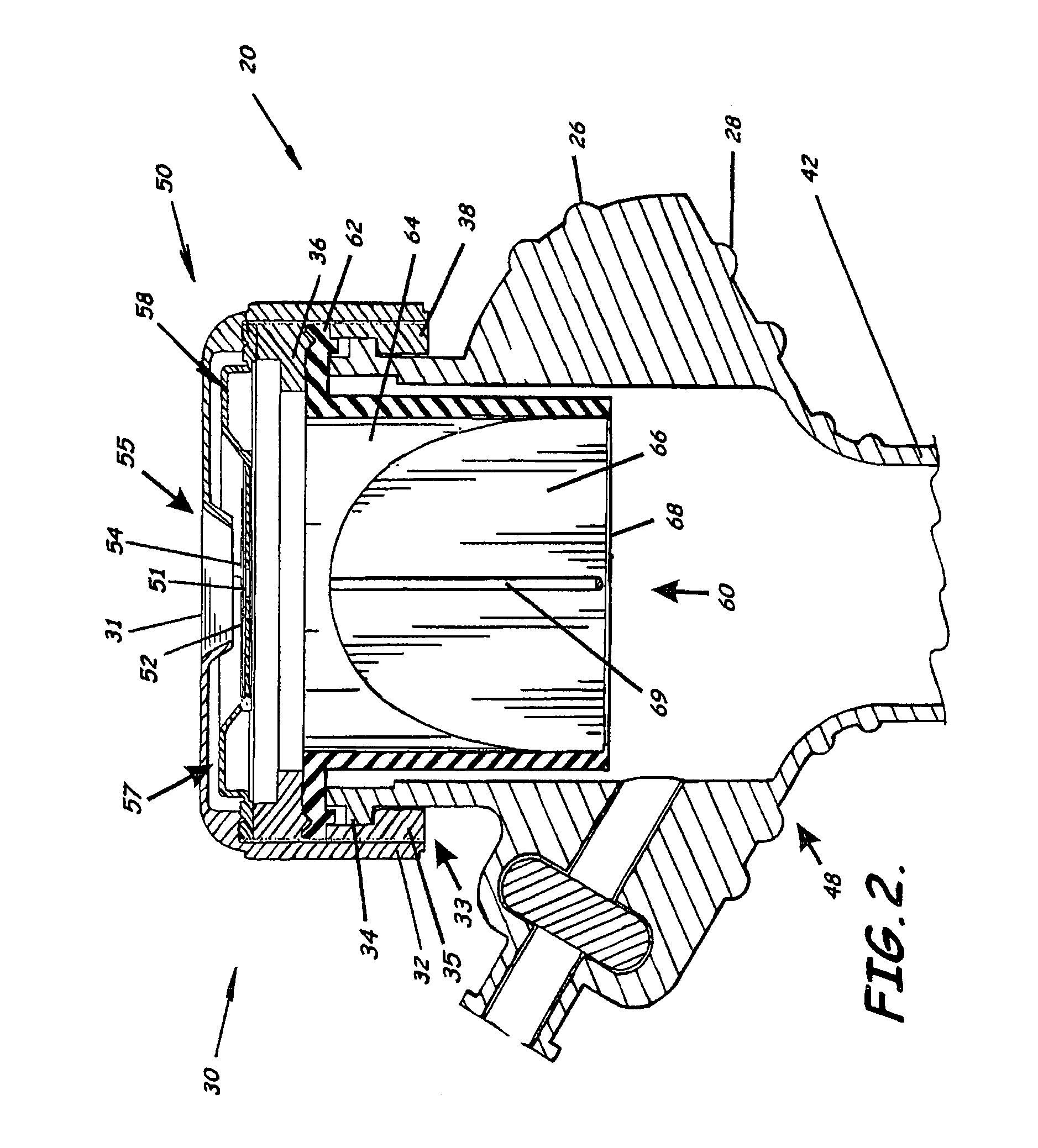

Trocar and cannula assembly having conical valve and related methods

ActiveUS20080033363A1Easy to insertEasy to retractCannulasInfusion syringesFriction reductionProximate

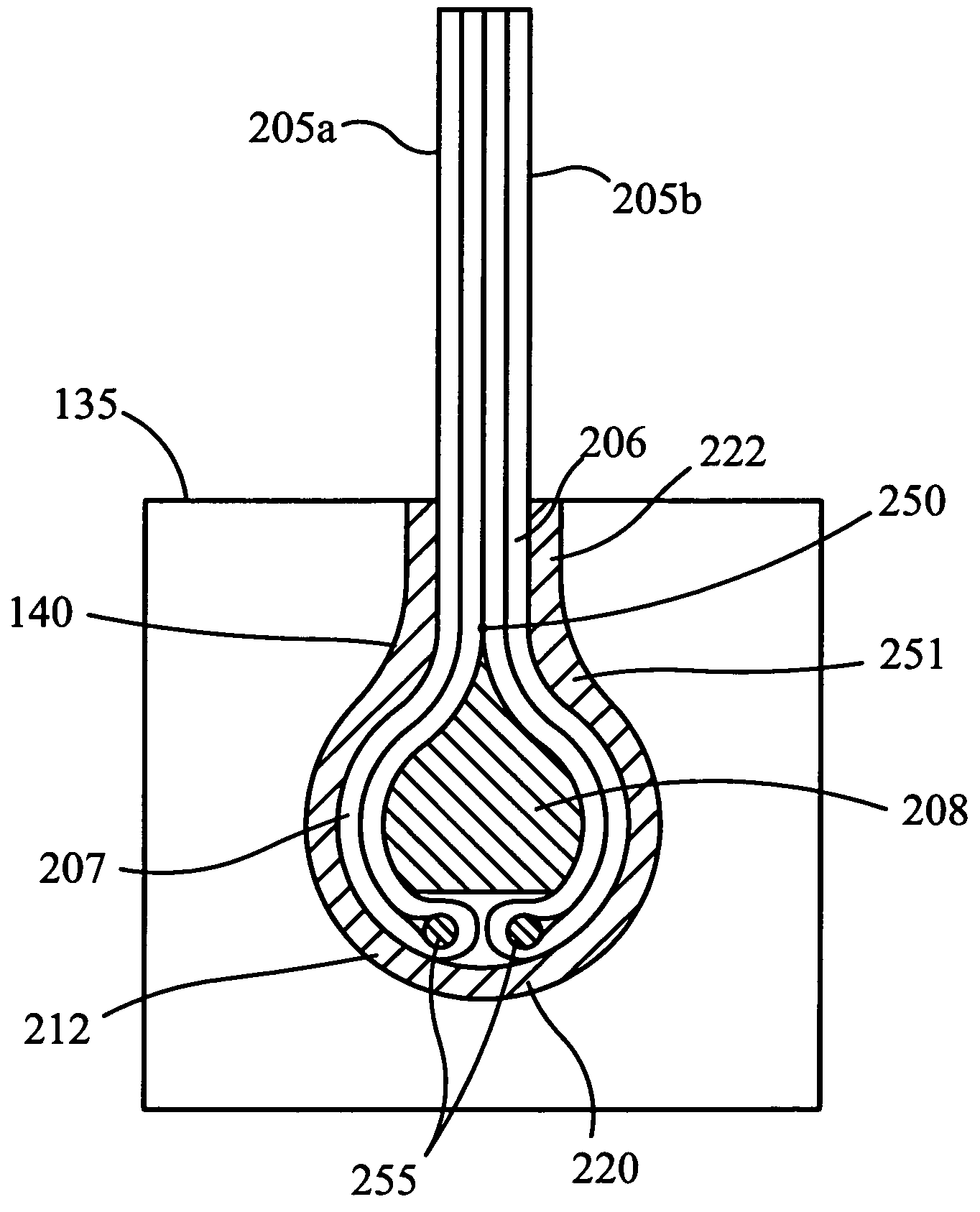

A trocar system for endoscopic surgery, cap assembly, and related methods are provided. The cap assembly includes a valve housing with an opening formed in line with an axis of the valve housing and also includes a valve positioned adjacent the opening of the valve housing. The valve body includes a proximal valve section including a valve ring positioned within the valve housing, and a distal valve section extending axially from the proximal valve section. The distal valve section includes a valve extension having a proximal and distal end portions, and a substantially conically shaped medial portion connected to and extending therebetween, wherein a plurality of friction-reduction features, preferably tear-drop shaped knobs, are disposed proximate the distal end portion and extending a distance in the medial portion of the valve. A valve opening is positioned in the distal end portion of the valve extension, adapted to individually and separately receive the elongate tools so that when any one of the elongate tools of varying diameter is positioned therethrough, electrostatic adhesion between the valve and the tool is minimized and a seal is maintained between peripheries of the valve extension surrounding the valve opening and outer peripheries of the inserted elongate tool.

Owner:KARL STORZ ENDOVISION INC

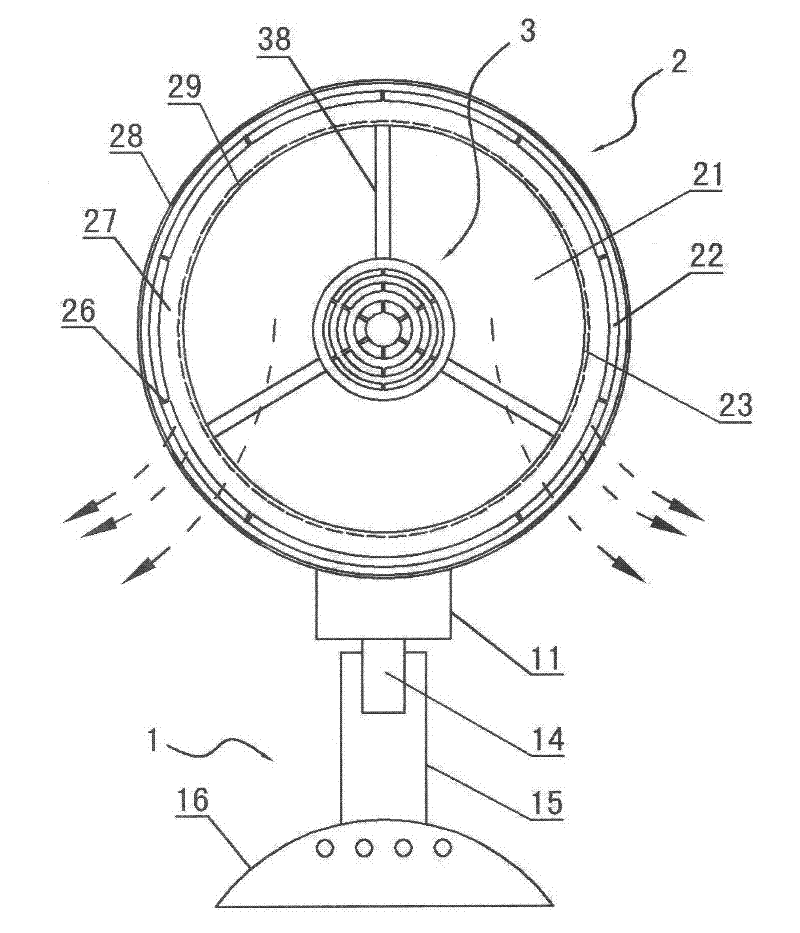

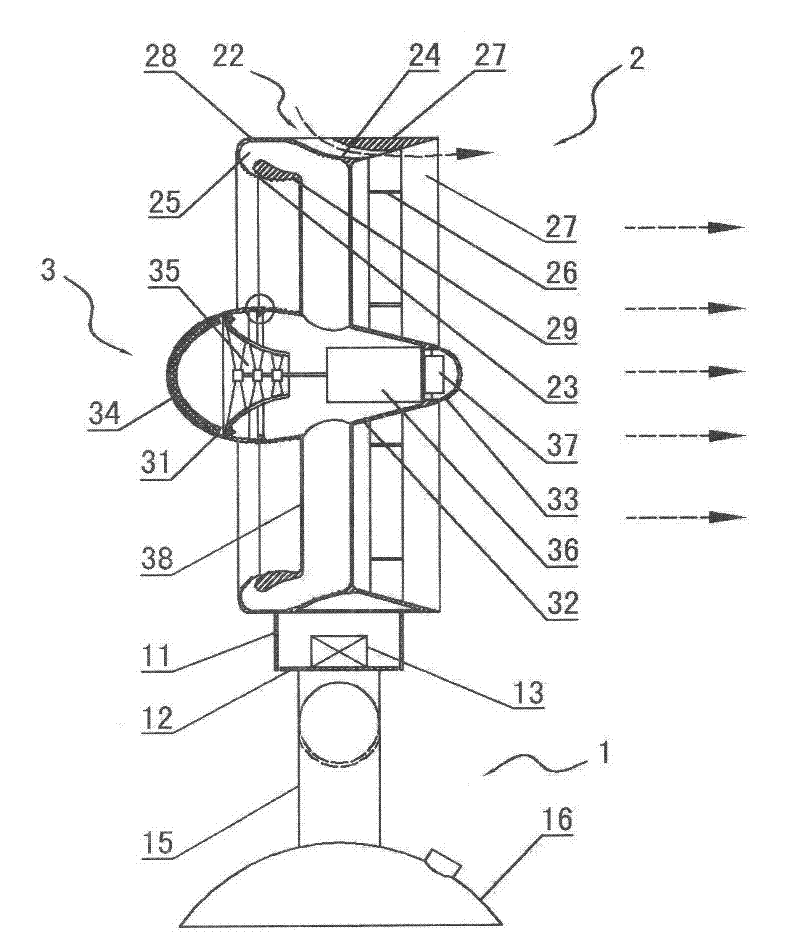

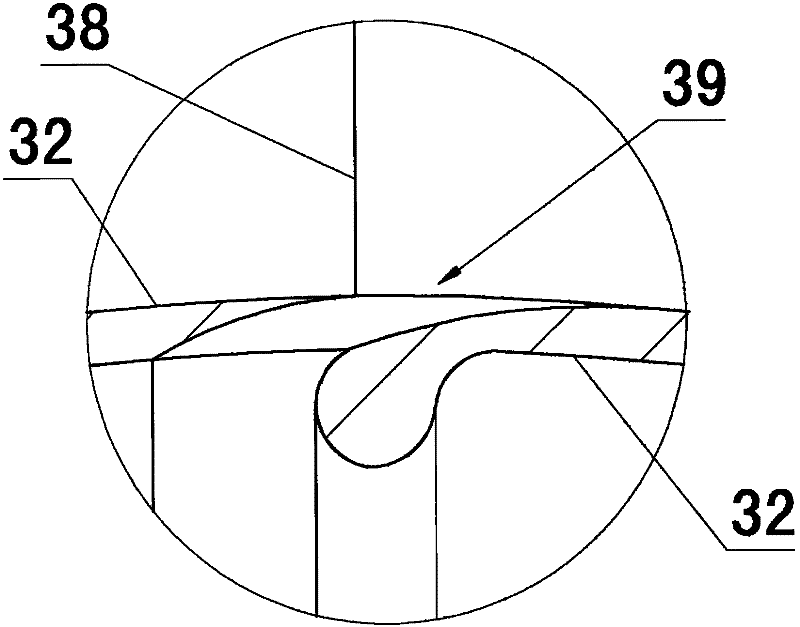

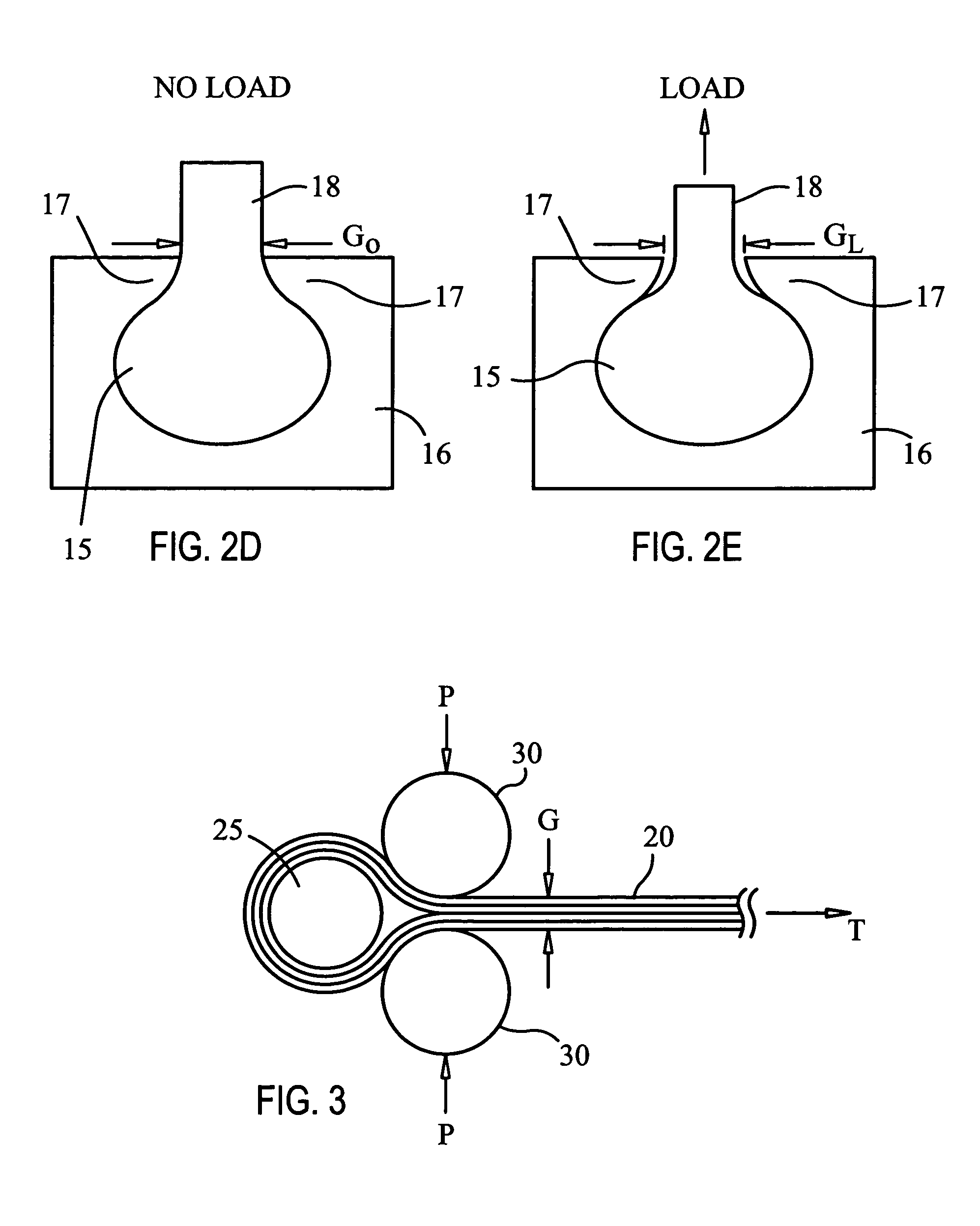

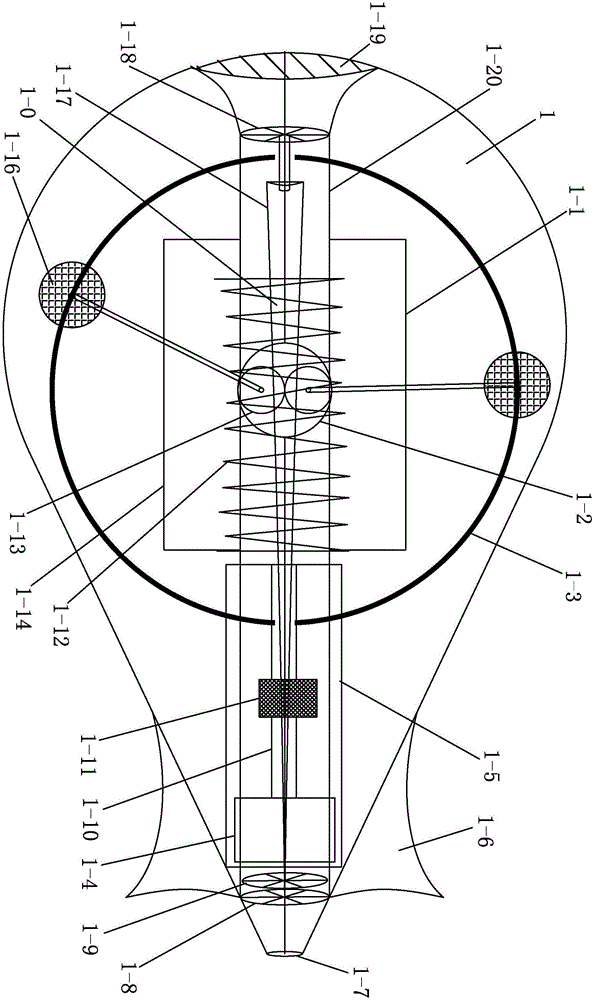

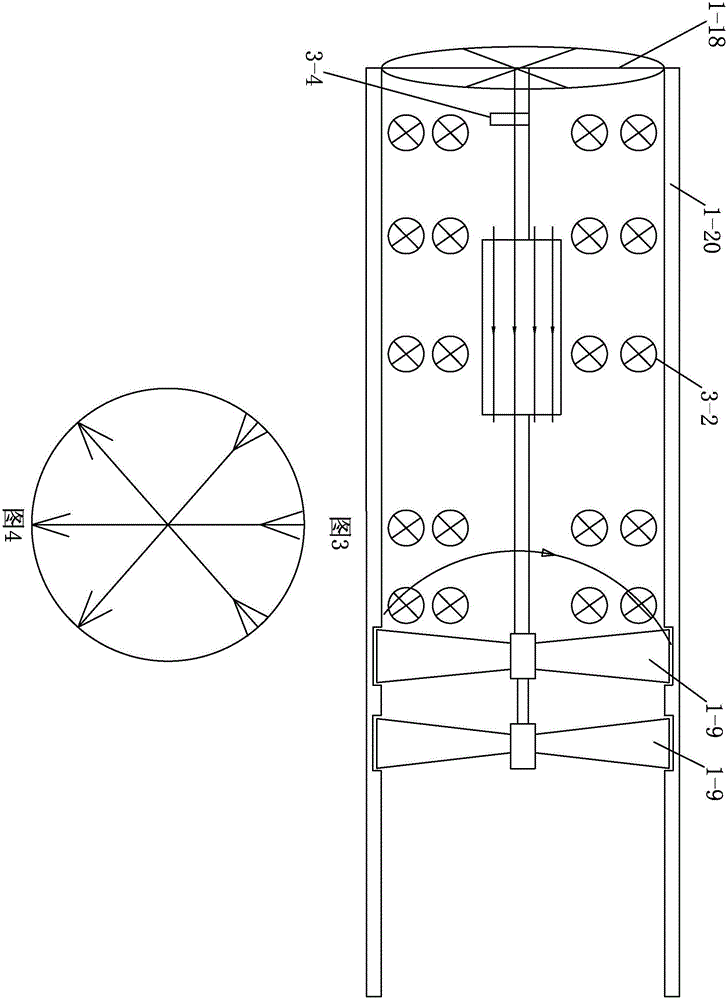

Bladeless fan with double air nozzles

InactiveCN102242737AAvoid the phenomenon of weak windJet pumpsPump installationsEngineeringDrop-shaped

The invention relates to a bladeless fan with double air nozzles. The fan consists of a base, an air flow injection device and an air supercharging device, wherein the air flow injection device is positioned above the base; the air supercharging device is of a water drop shape which is large in middle and small in two ends, is installed at the axial position of the air flow injection device, and is communicated with an air channel on the air flow injection device through an air pipe; a circle of annular first air injection openings are arranged surrounding the air channel; the middle part of the air supercharging device is provided with a shell; one end of the shell is connected with an intake cover, and the other end of the shell is connected with a dust-proof shell; and the shell is provided with a second air injection opening. Through the first air injection openings and the second air injection opening arranged coaxially, the weaker air force phenomenon at the middle part of a fanis avoided effectively.

Owner:何凤香

Cigarette blast bead and preparation method thereof

The invention relates to a cigarette blast bead and a preparation method thereof. The preparation method comprises the steps of mixing and hot-melting the gel shell materials of, by weight part, 10 parts of water, 1-2 parts of gelatin, 1-2 parts of Arabic gum, 0.2-1 parts of modified starch, 0.5-2 parts of chitosan and 0.1-0.5 part of sodium alginate, and keeping mixing during the melting process to obtain shell gel solution; mixing, by weight part, 1-2 parts of essence and 5-10 parts of light liquid paraffin to obtain core gel solution; in a concentric dropping device, feeding the core gel solution from the inner layer and the shell gel solution from the outer layer to form concentric fluid column flowing inside coolant so that drops can shrink into beads under the action of surface tension to obtain primary wet beads; performing calcification, dyeing, oil absorption and drying on the primary wet beads to obtain the cigarette blast bead. The drop shaping manner solves the problems of shell thickness non-uniformity and lack of roundness during existing national blast bead production and enables the finished cigarette blast bead to be attractive in appearance and uniform in shell thickness, and when pinched up, being uniform in stress and good in hand feeling.

Owner:JIANGJUN TOBACCO GROUP CO LTD

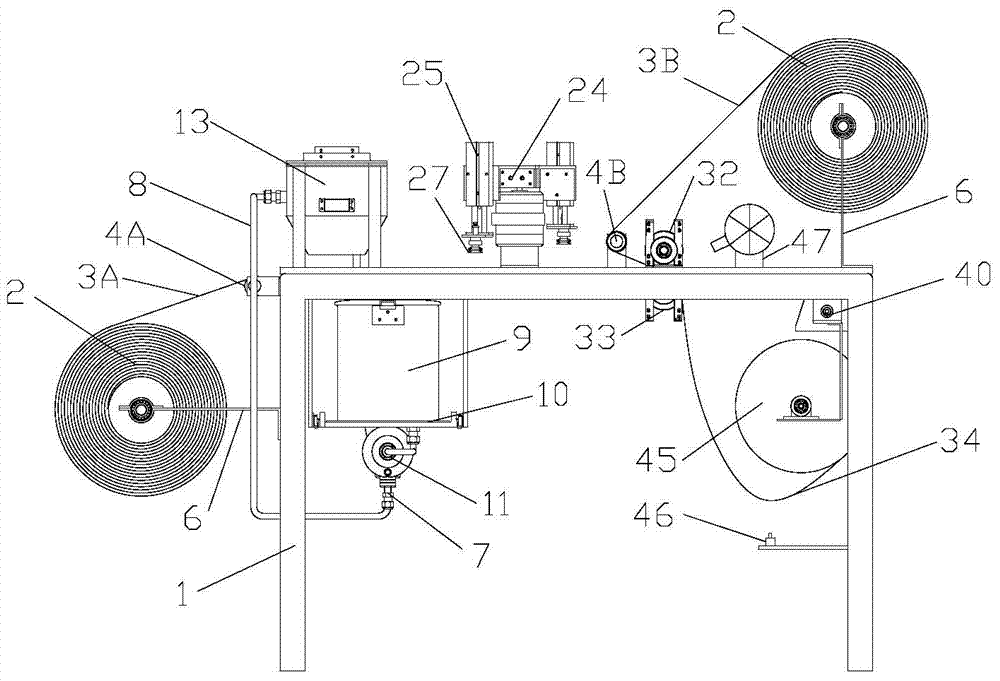

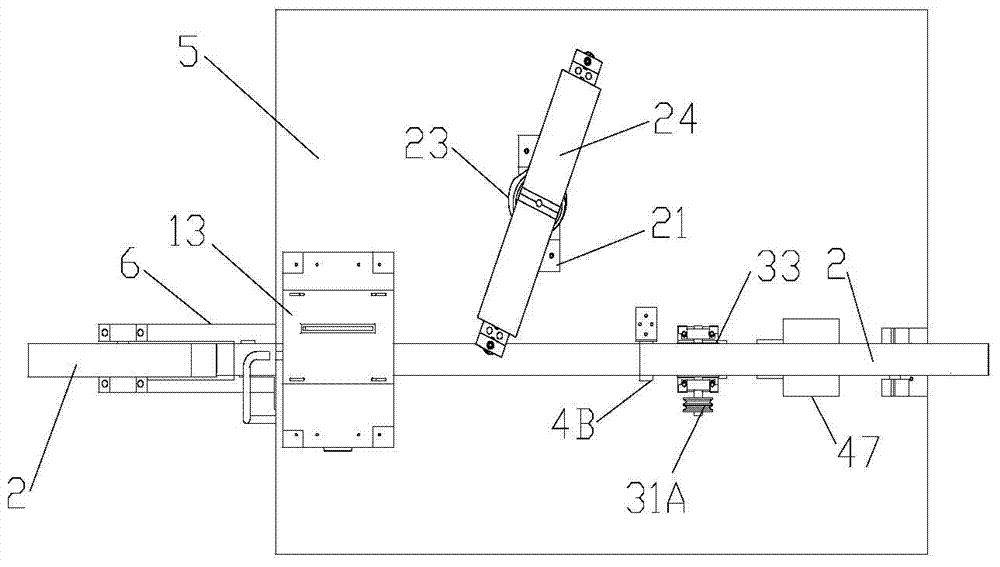

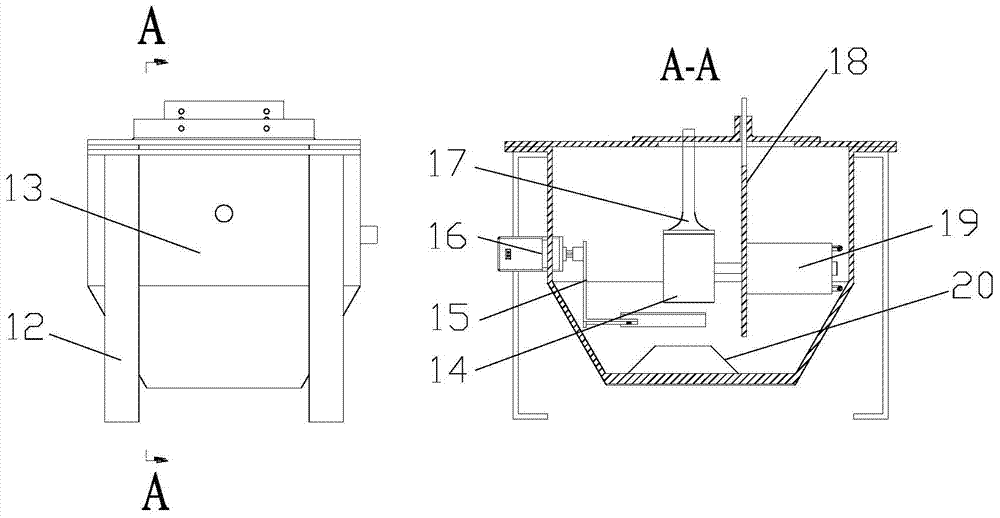

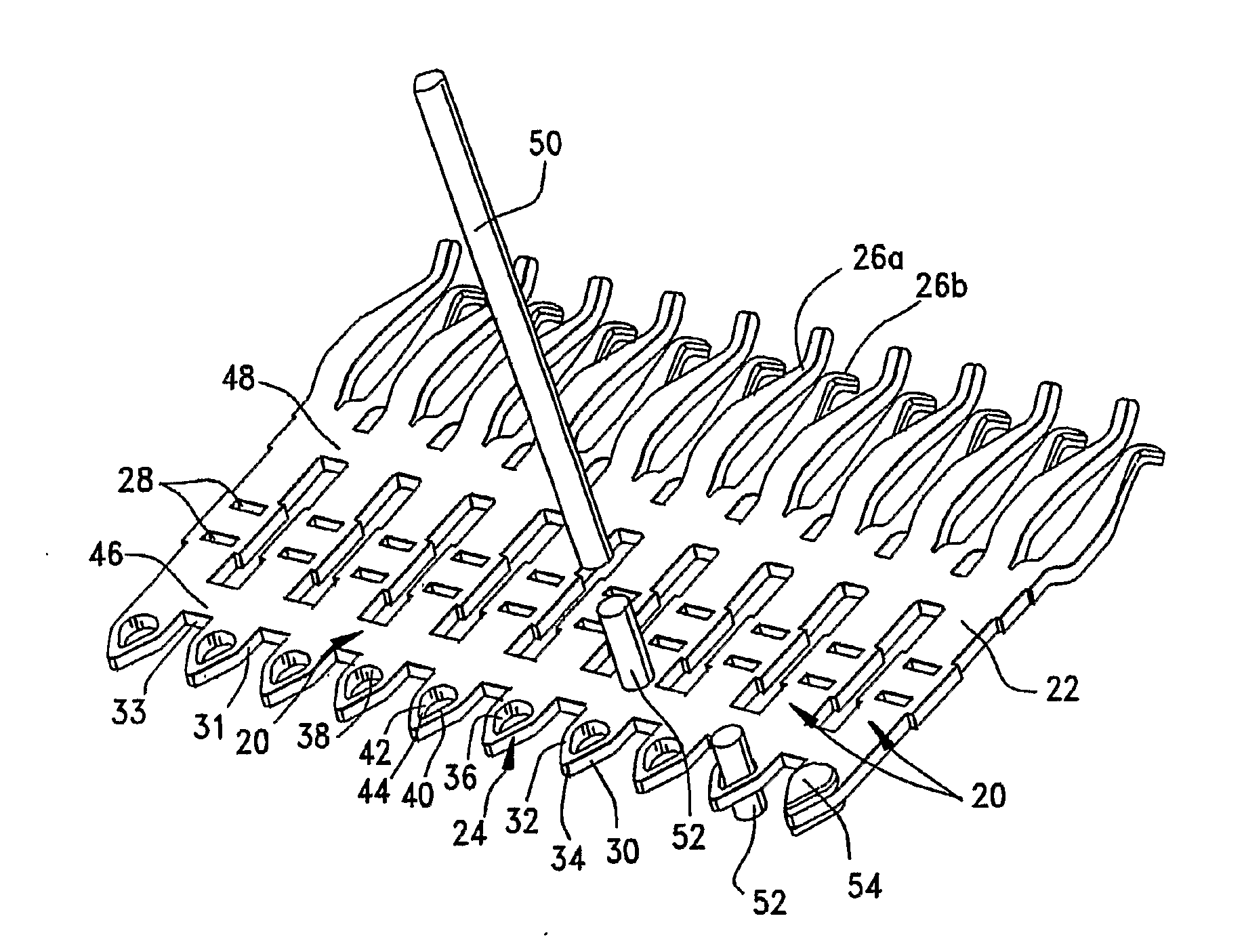

Method and device for producing corn orientated seed tape

InactiveCN103609227AGuaranteed OrientationMeet the tensile strength requirementsSeed arrangmentsPaper tapeEngineering

The invention relates to a method and a device for producing a corn orientated seed tape and particularly relates to the field of agricultural machinery. The device is characterized by comprising a rack, a gluing unit, an adsorption seed putting unit, a sticking unit and a winding unit, wherein the gluing unit is used for coating glue on a paper tape in a micro-drop shape in a manner of rotating a rotary gluing brush at a high speed; the adsorption seed putting unit comprises a swinging motor, a rotary arm, a linear air cylinder and a vacuum suction opening; the vacuum suction opening adopts a porous plane to guarantee an orientation effect of corn seeds in an adsorption and putting process; the sticking unit comprises a paper tape reversing wheel, a roller upper roll, a roller lower roll and a roller working frame; the roller upper roll and the roller lower roll are in transmission in a cross fit manner by a belt wheel and the speeds of fitted parts are the same; the winding unit comprises a winding motor, a moving motor, a screw rod mechanism and a winding disc. A height sensor is used for measuring the suspension height of the seed tape and a signal is fed back to the moving motor and the winding motor in time; the spiral winding of the seed tape can be realized.

Owner:CHINA AGRI UNIV

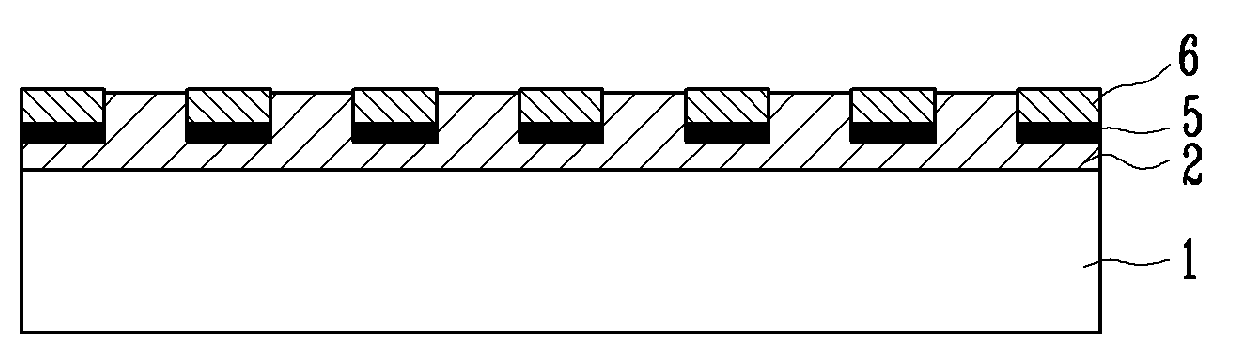

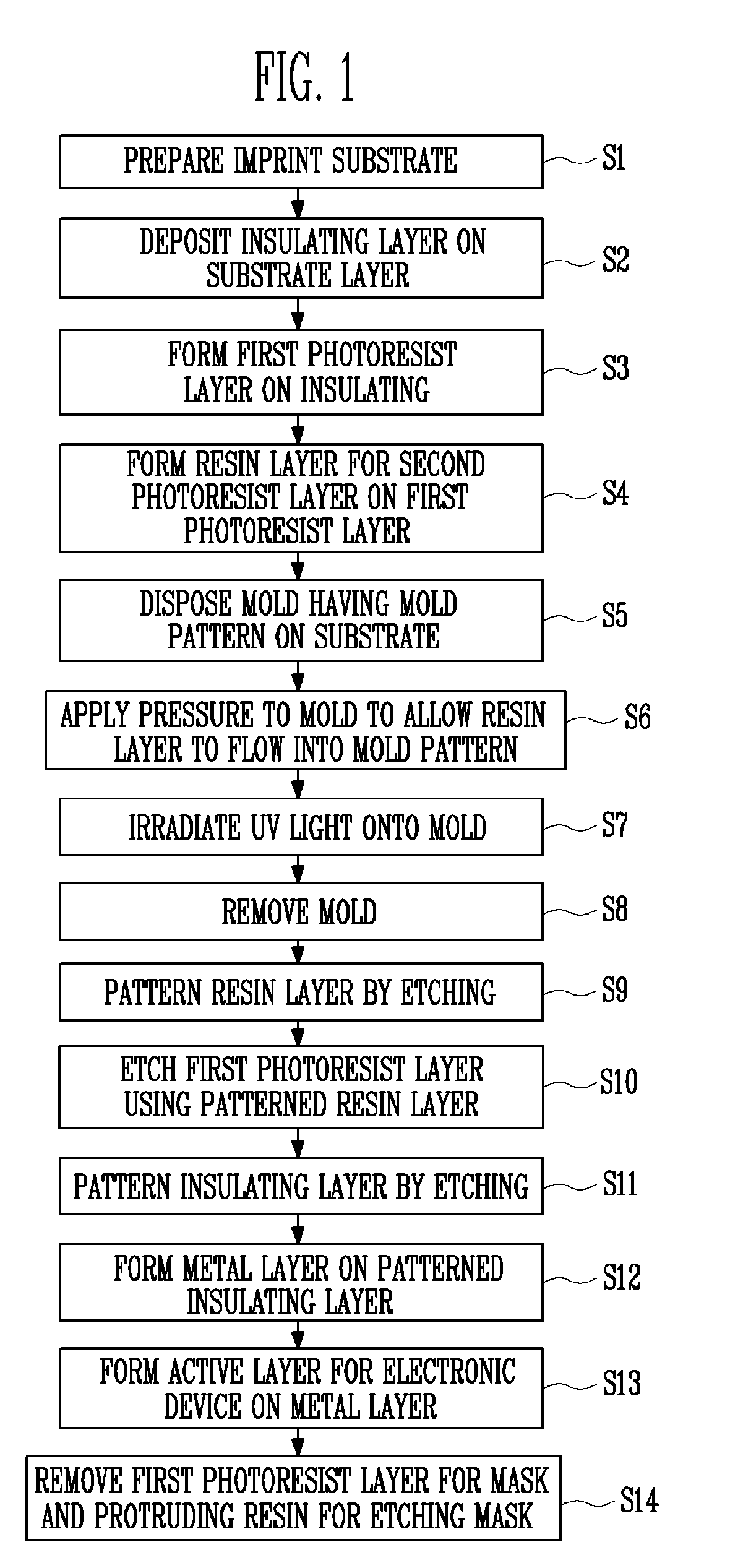

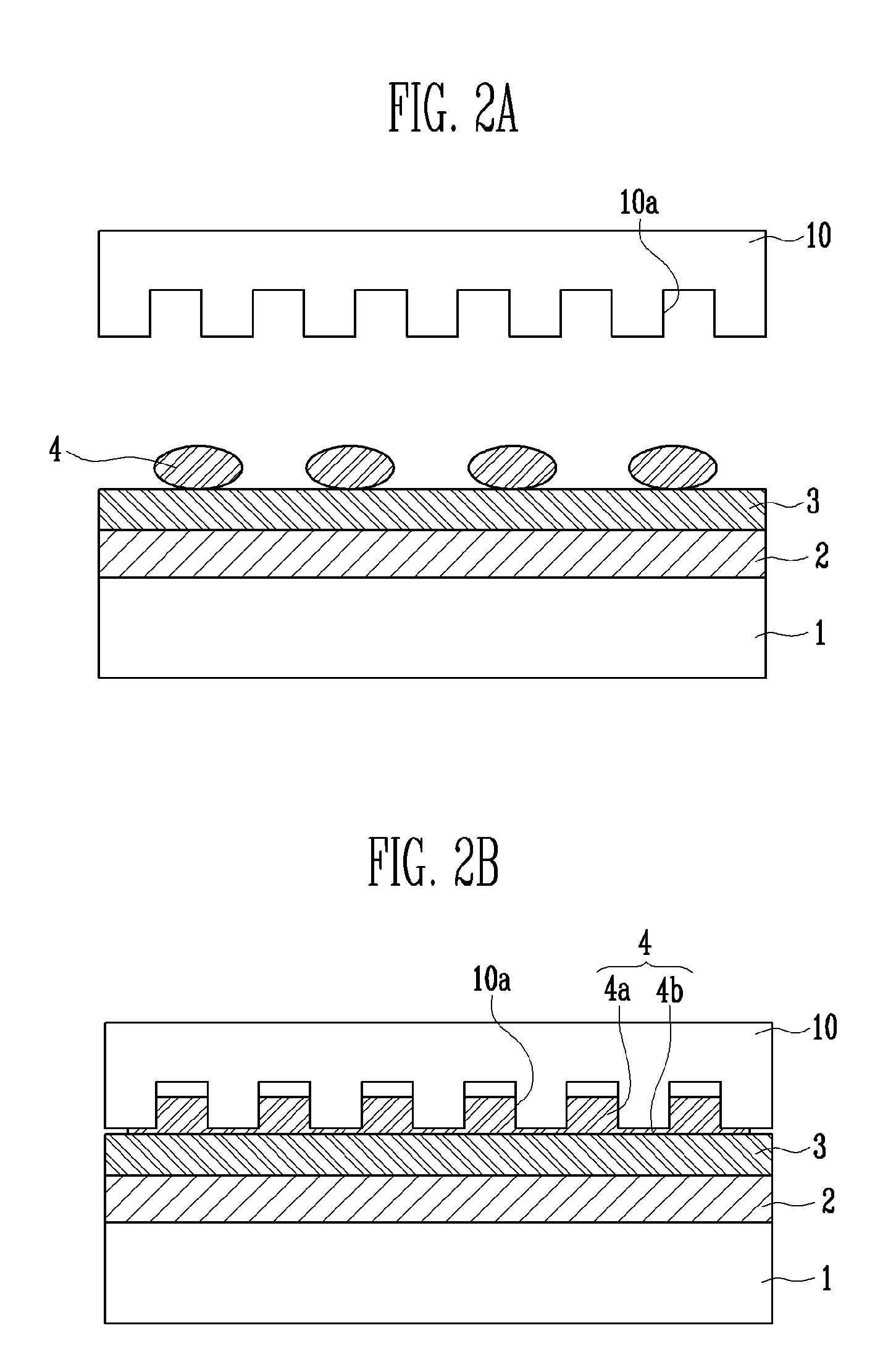

Method of manufacturing nanoelectrode lines using nanoimprint lithography process

Provided are a method of manufacturing nanoelectrode lines. The method includes the steps of: sequentially forming an insulating layer, a first photoresist layer, and a drop-shaped second photoresist on a substrate; disposing an imprint mold having a plurality of molding patterns over the second photoresist; applying pressure to the mold to allow the second photoresist to flow into the mold patterns; irradiating ultraviolet (UV) light onto the mold to cure the second photoresist; removing the mold from the cured second photoresist and patterning the second photoresist; patterning the first photoresist layer using the patterned second photoresist as a mask; patterning the insulating layer; and forming a metal layer between the patterned insulating layers. In this method, metal electrode lines are formed between insulating layers using an imprint lithography process, so that nanoelectronic devices can be freed from crosstalk between the metal electrode lines.

Owner:ELECTRONICS & TELECOMM RES INST

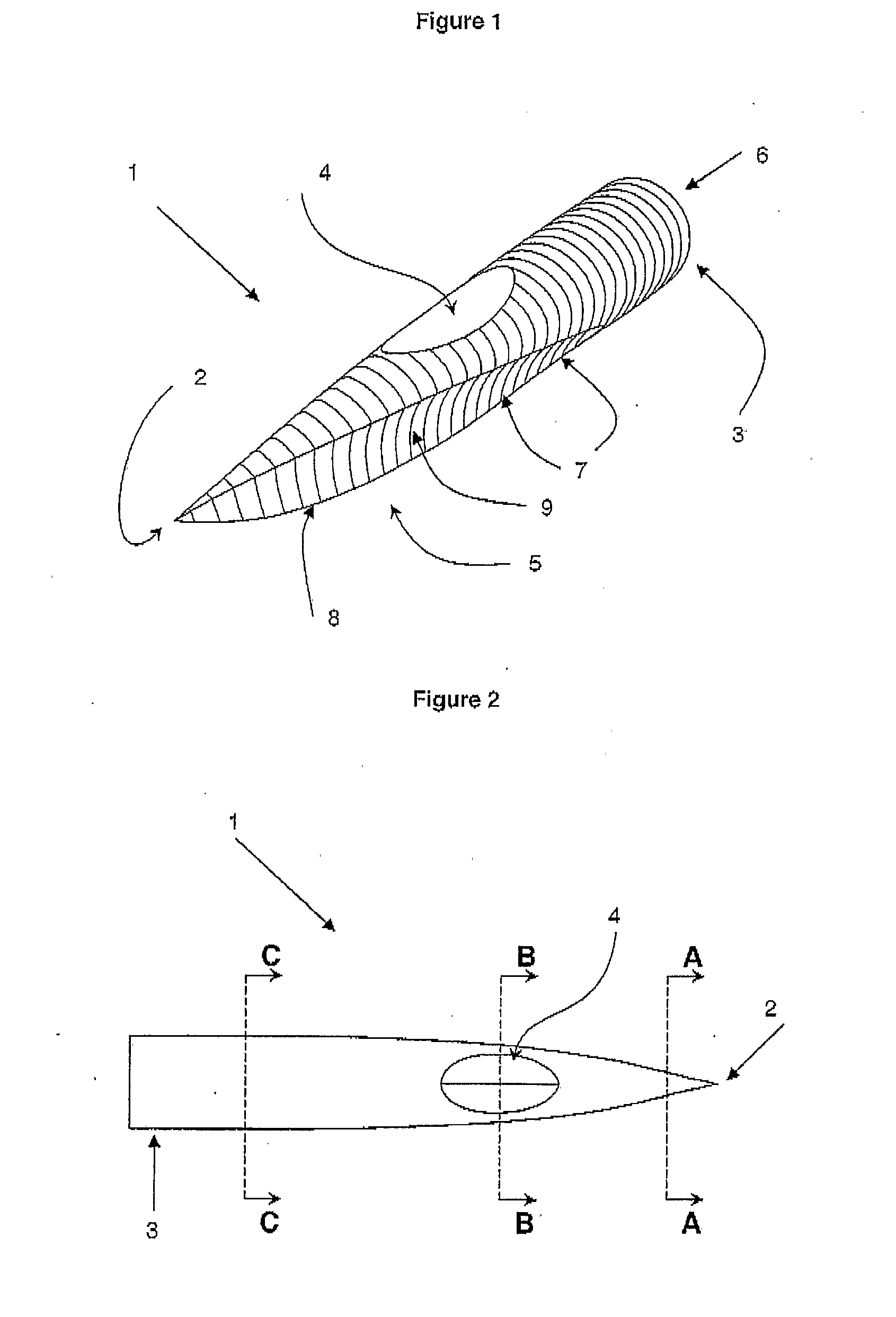

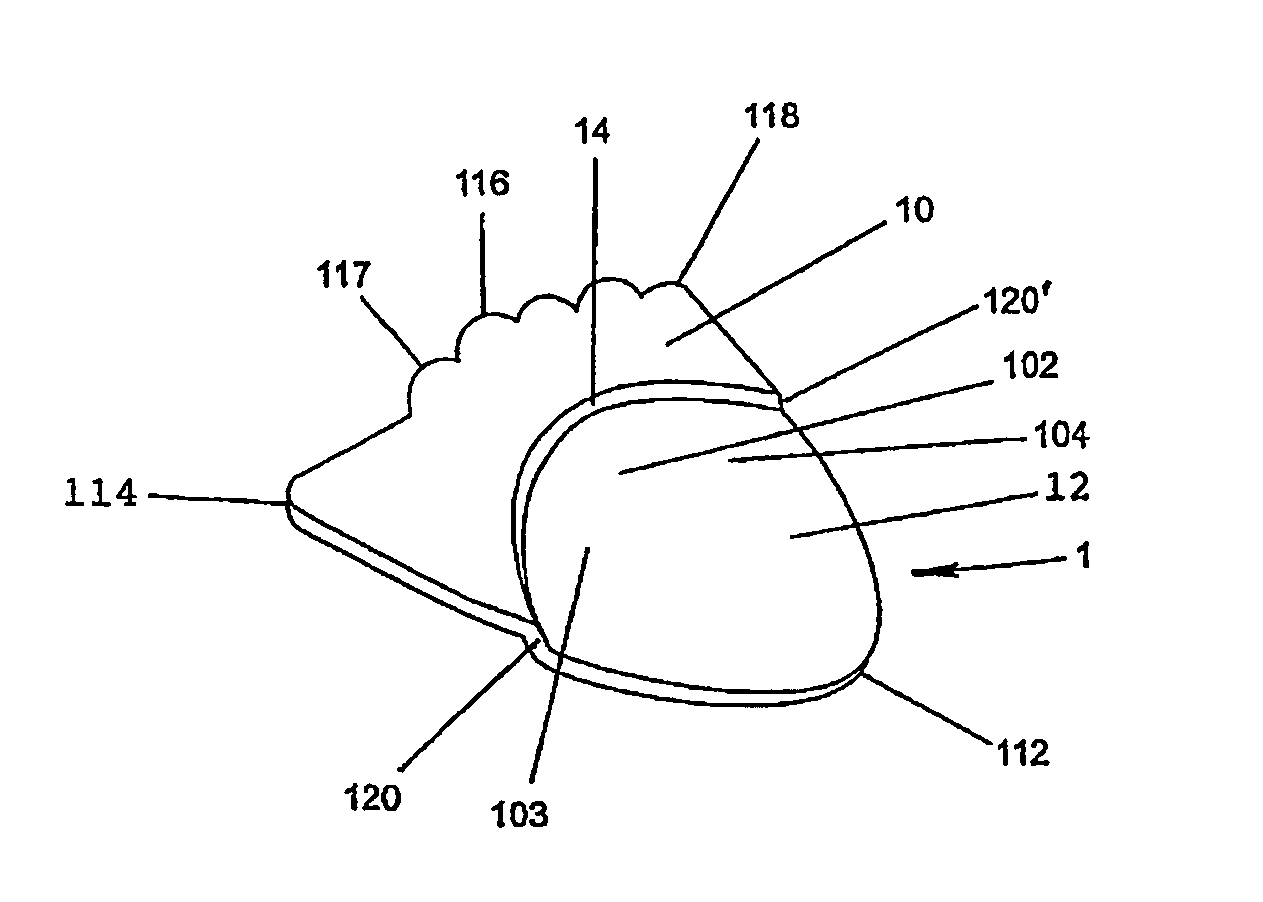

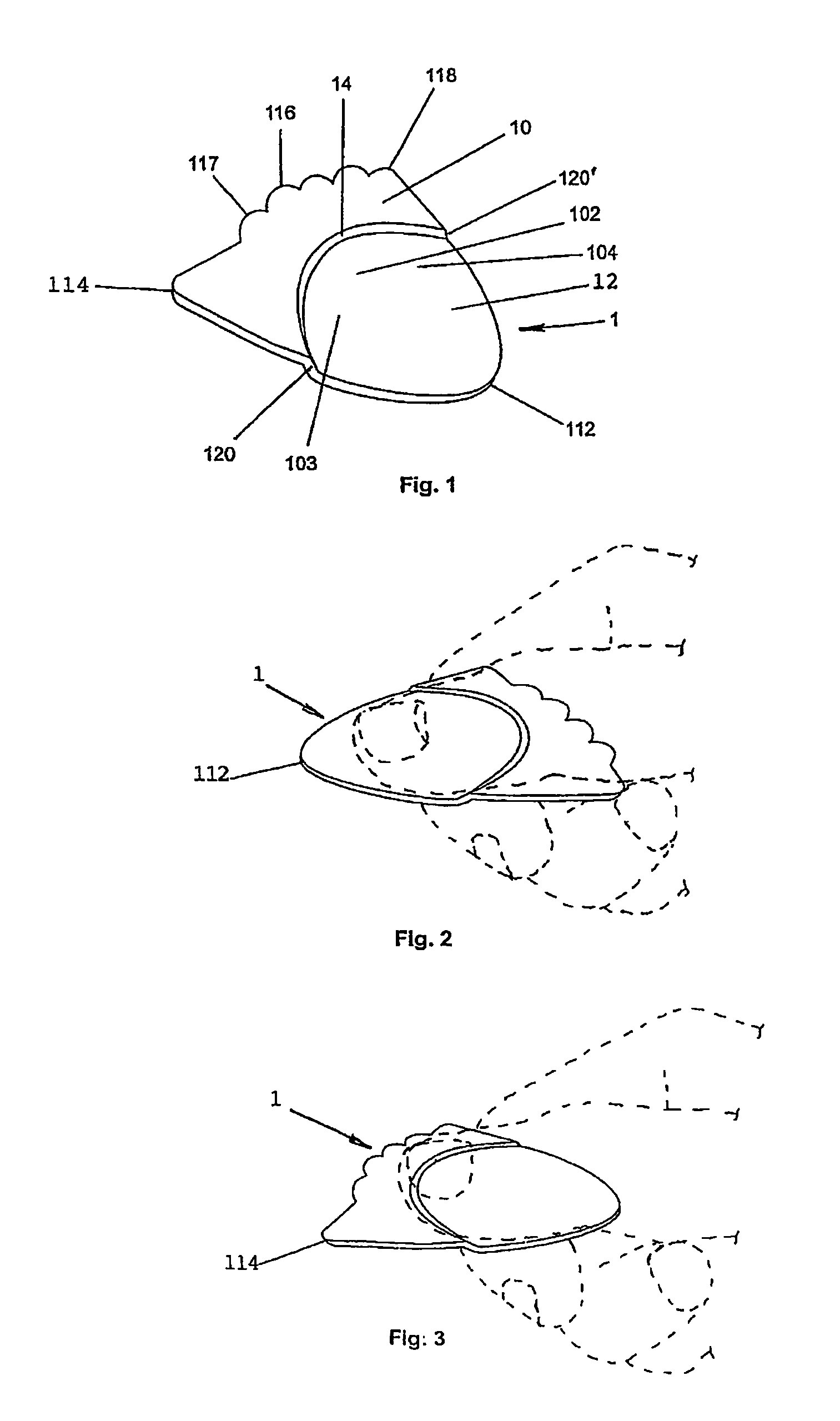

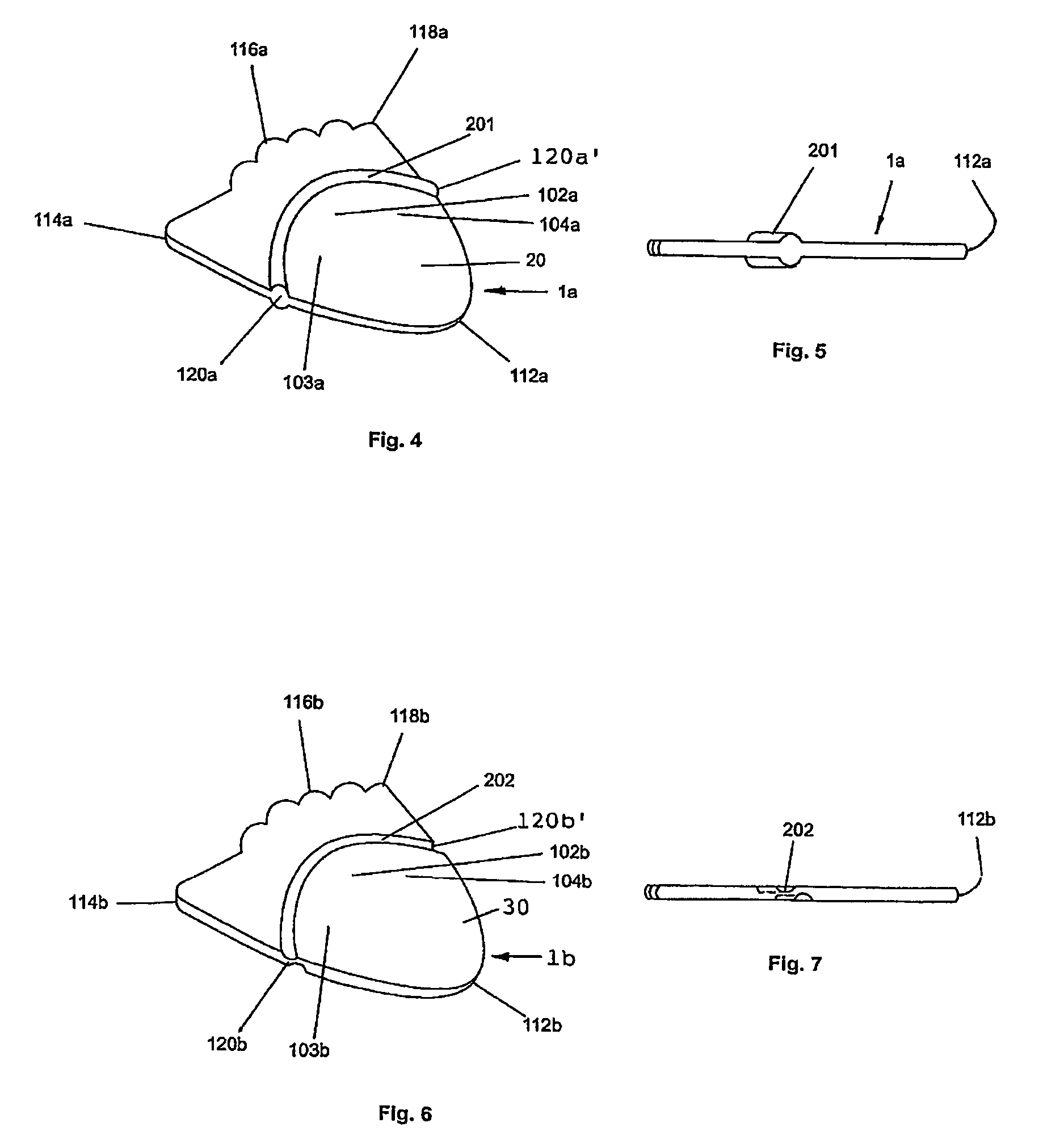

Plectrum

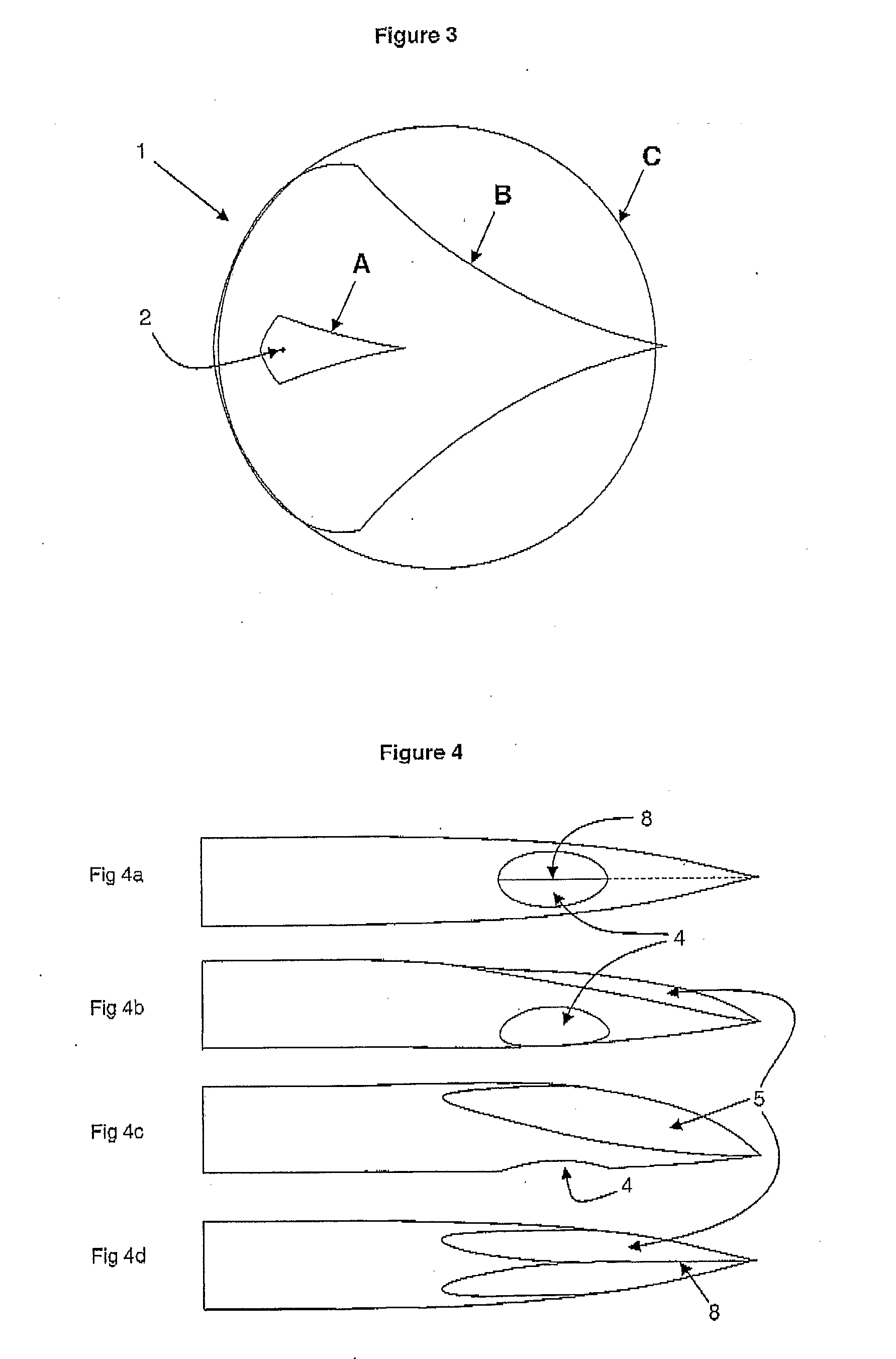

The present invention relates to a plectrum (1) having two portions (10, 12) being offset transversely but connected integrally by a stepped member (14). One portion (12) may have a tear-drop shaped playing edge (112), while the other portion may have a pointed edge (114) at one corner and another short pointed edge (118) at the second corner. A scallop playing edge (116) is typically joined to the short pointed edge (118). The stepped edge (14) is preferably in the shape of an arc. Other embodiments of the present invention include a plectrum (1a, 1b, 1c, 1d) having a planar body (20) with a tear-drop shaped playing edge (112a, 112b, 112c, 112d), a pointed playing edge (114a, 114b, 114c, 114d) and a short pointed edge (118a, 118b, 118c, 118d). A scallop shaped edge (116a, 116b, 116c, 116d) may be joined to the short playing edge (118). On the faces of the plectrum is preferably a ridge (201), a groove (202) or a combination of a ridge (201) and a groove (202) on the same or opposed face. The ridge or groove is optionally disposed across the center of the plectrum and is in the form of an arc. The curved stepped edge (14) or the edges of the curved ridge (201) or groove (202) seek to provide a positive grip on the plectrum. The curved edges are also formed to fit comfortably with the curve of the user's thumb or finger.

Owner:LEONG WENG ONN

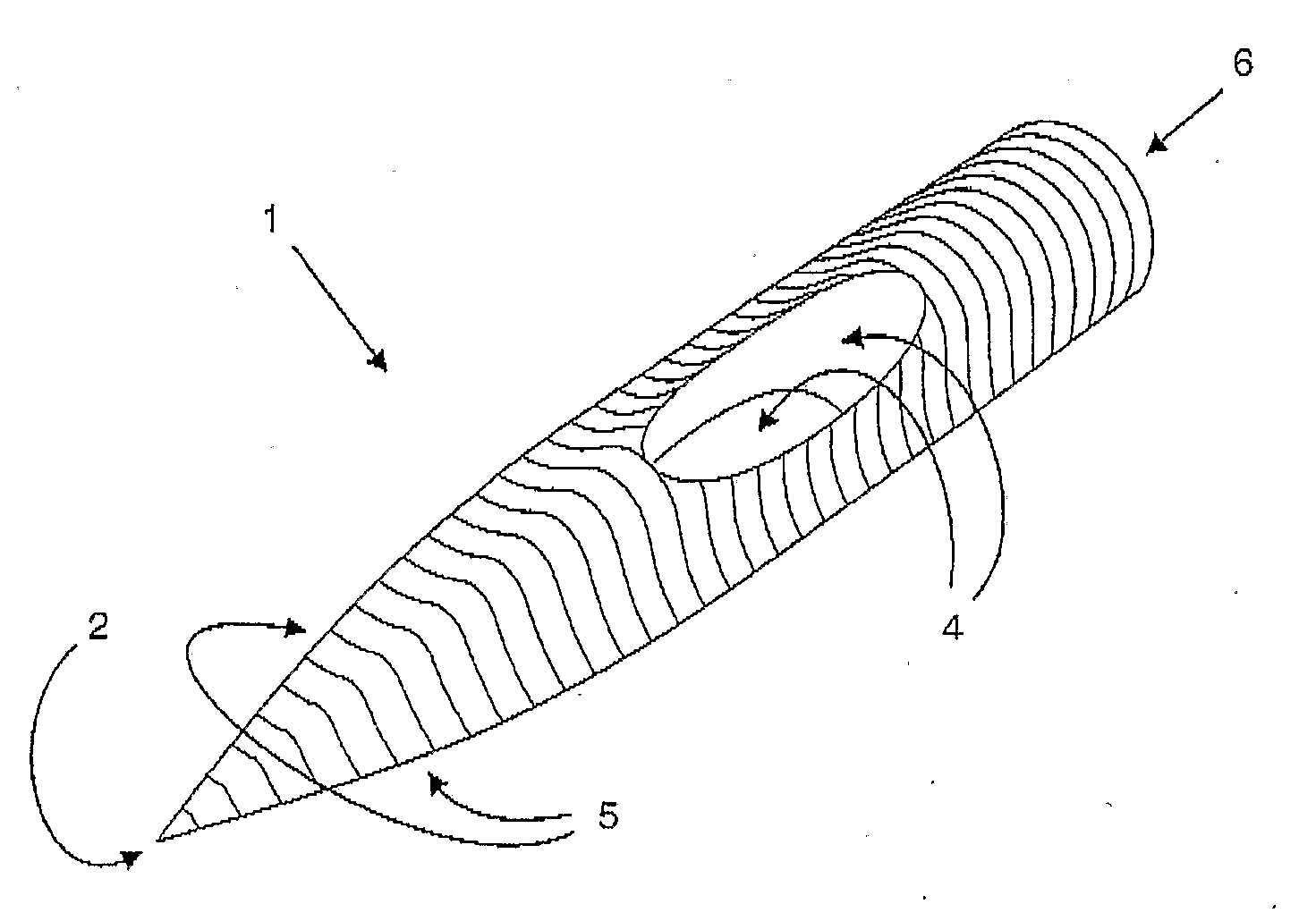

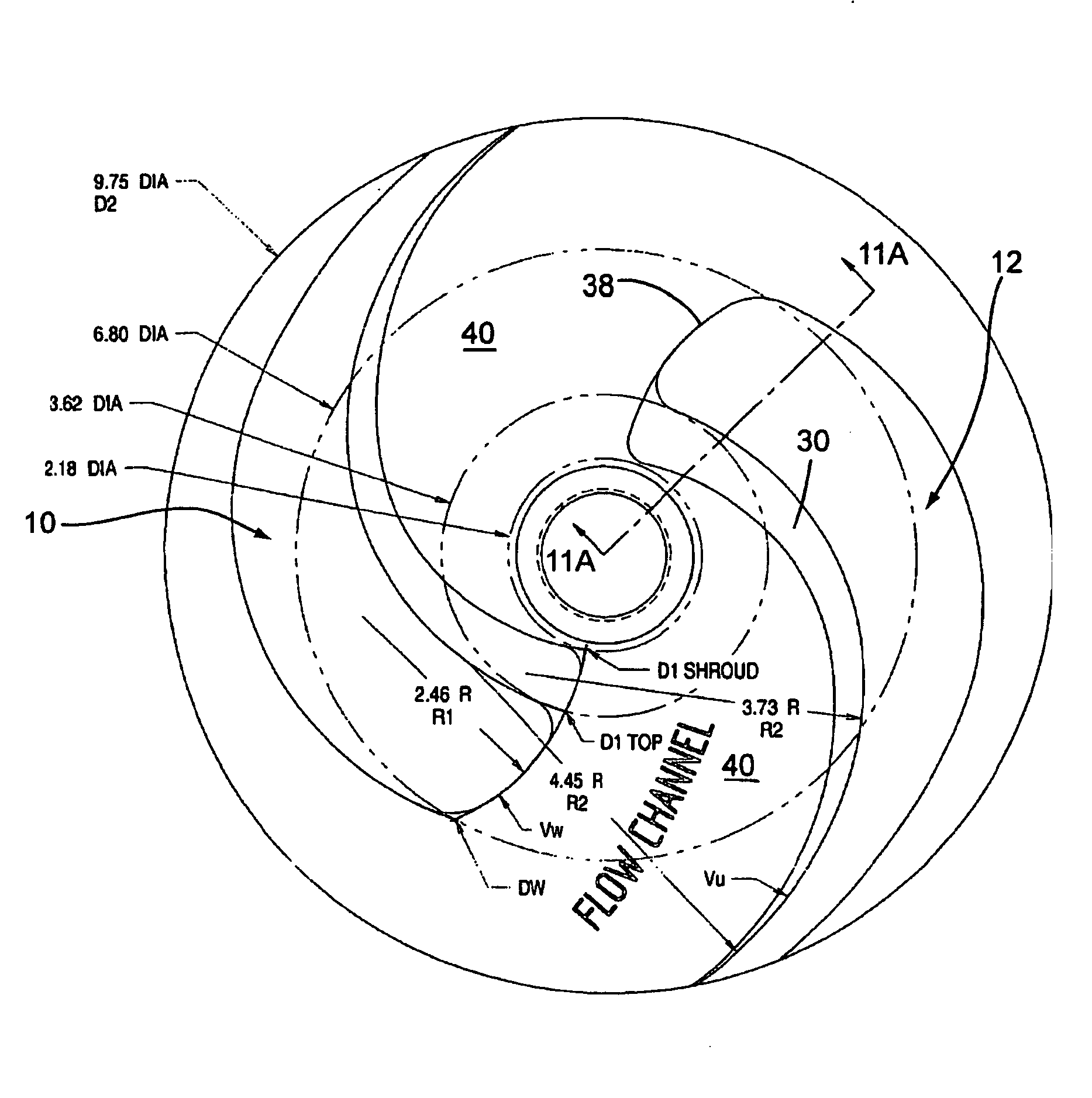

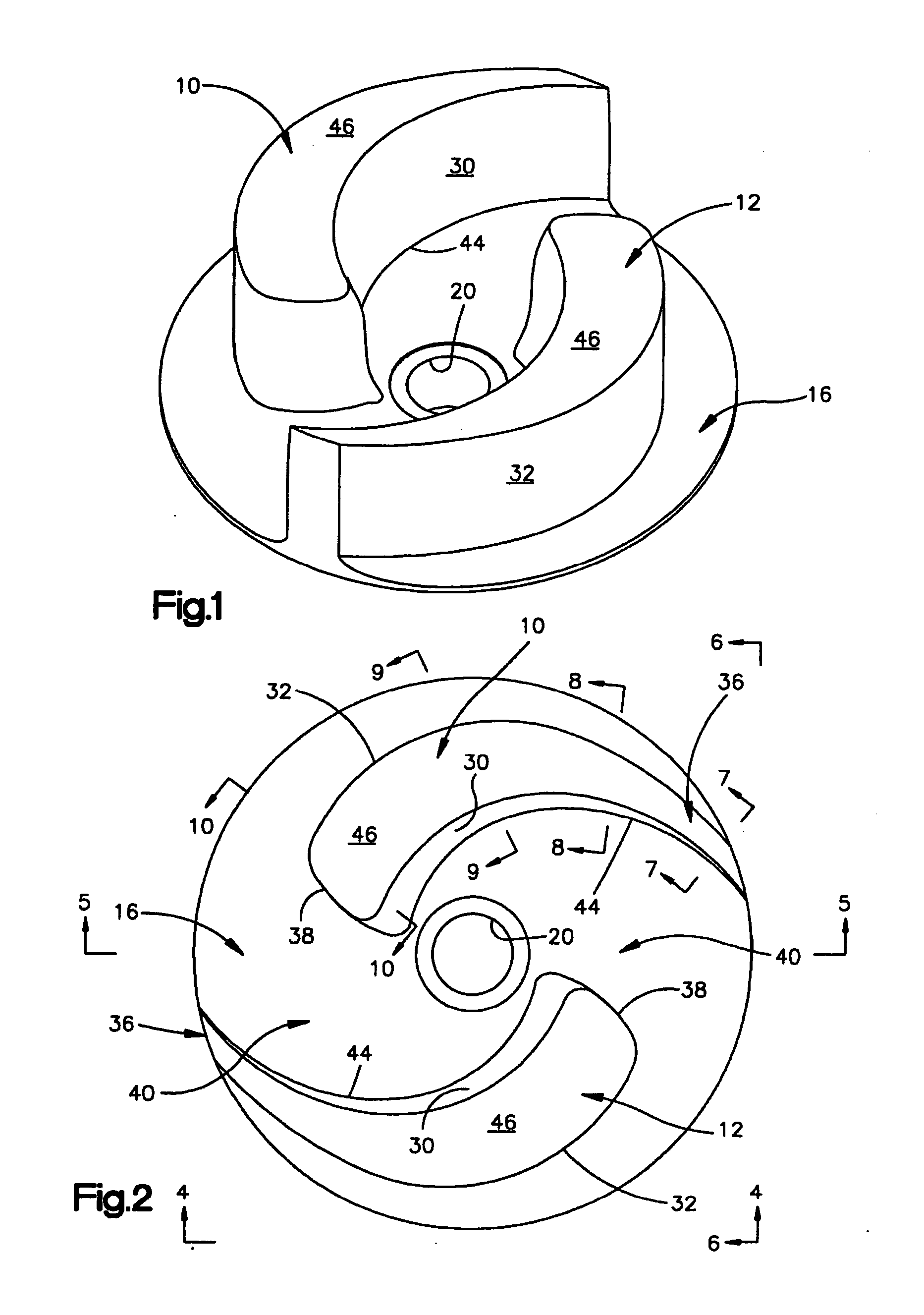

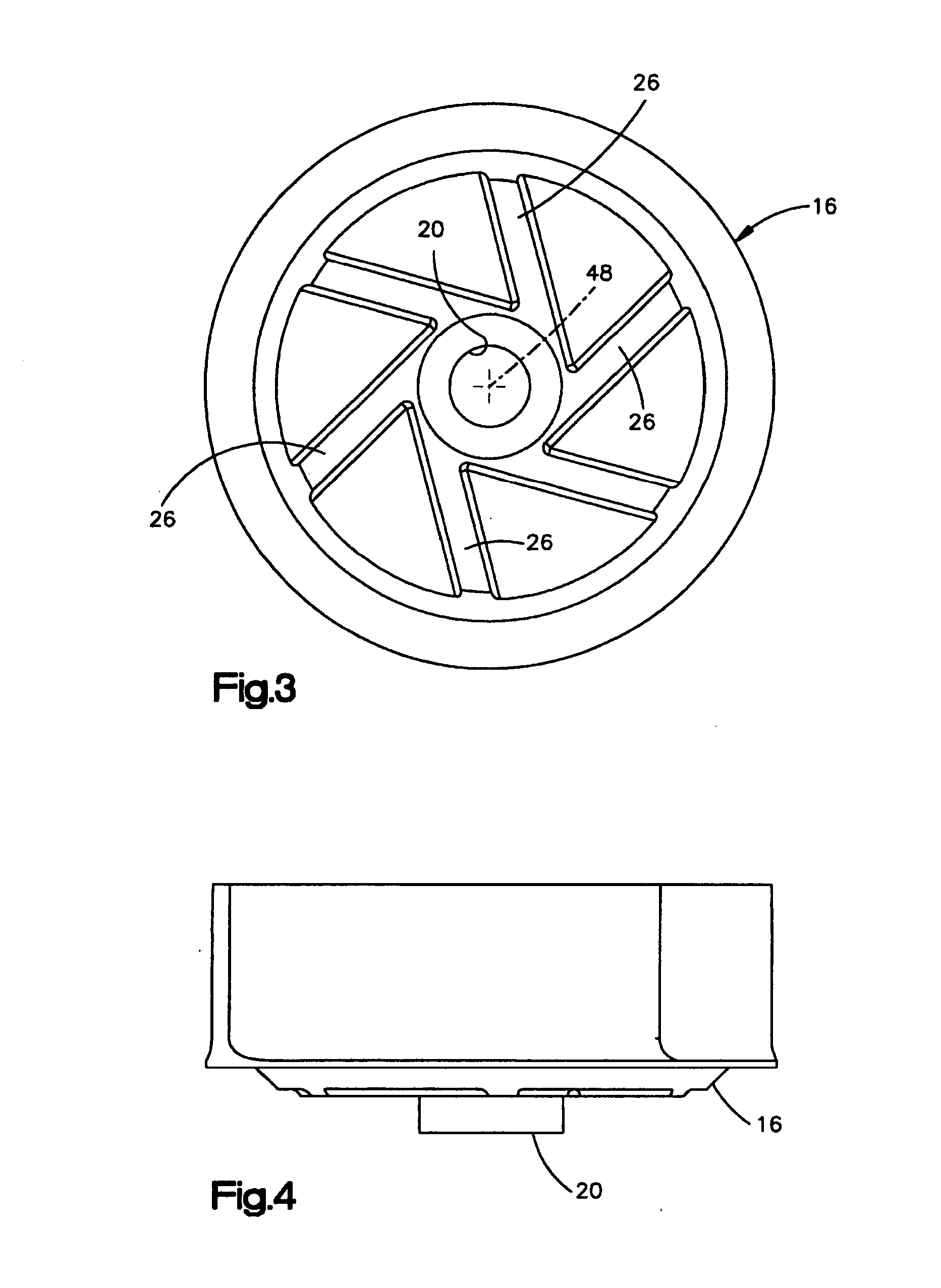

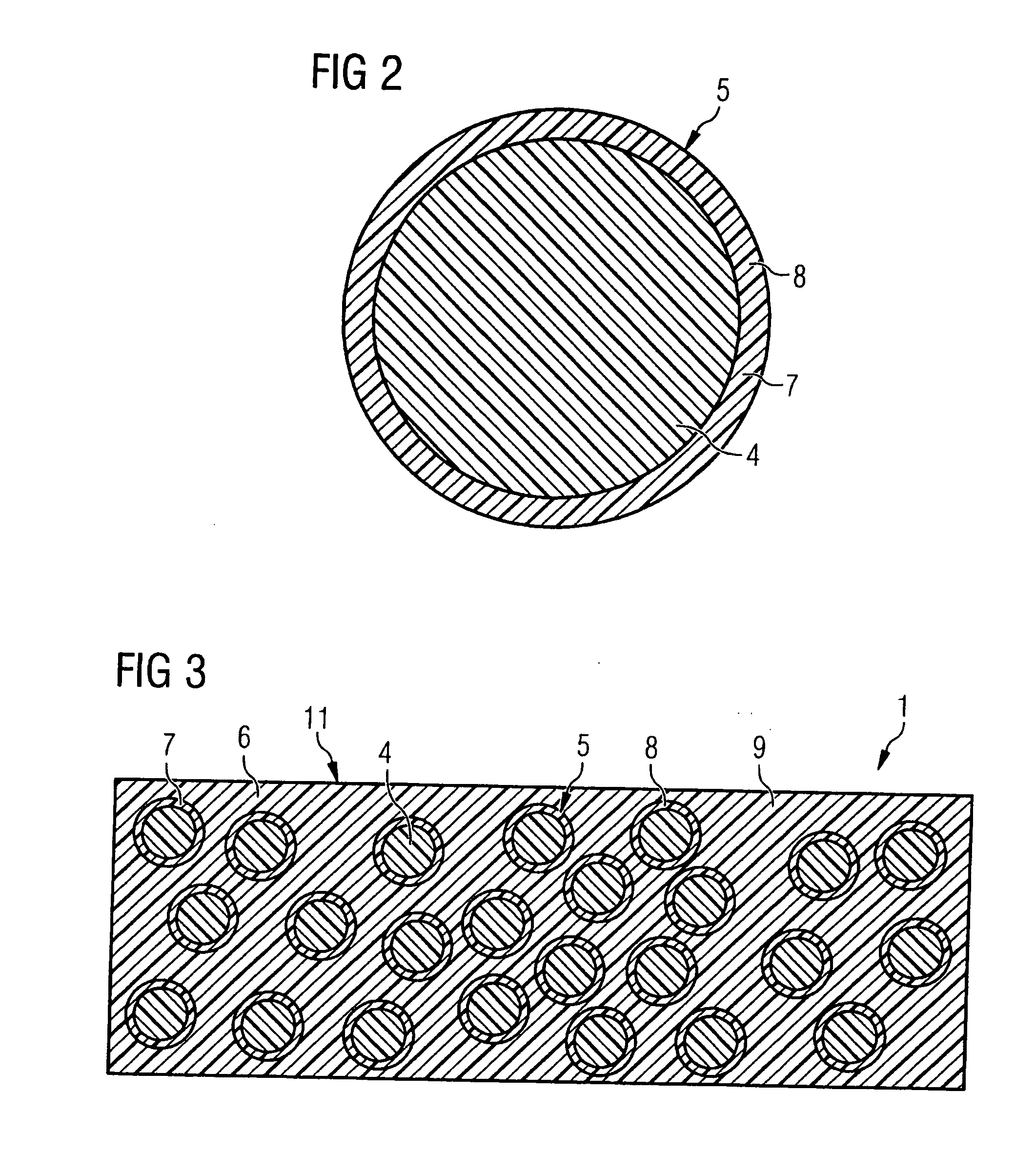

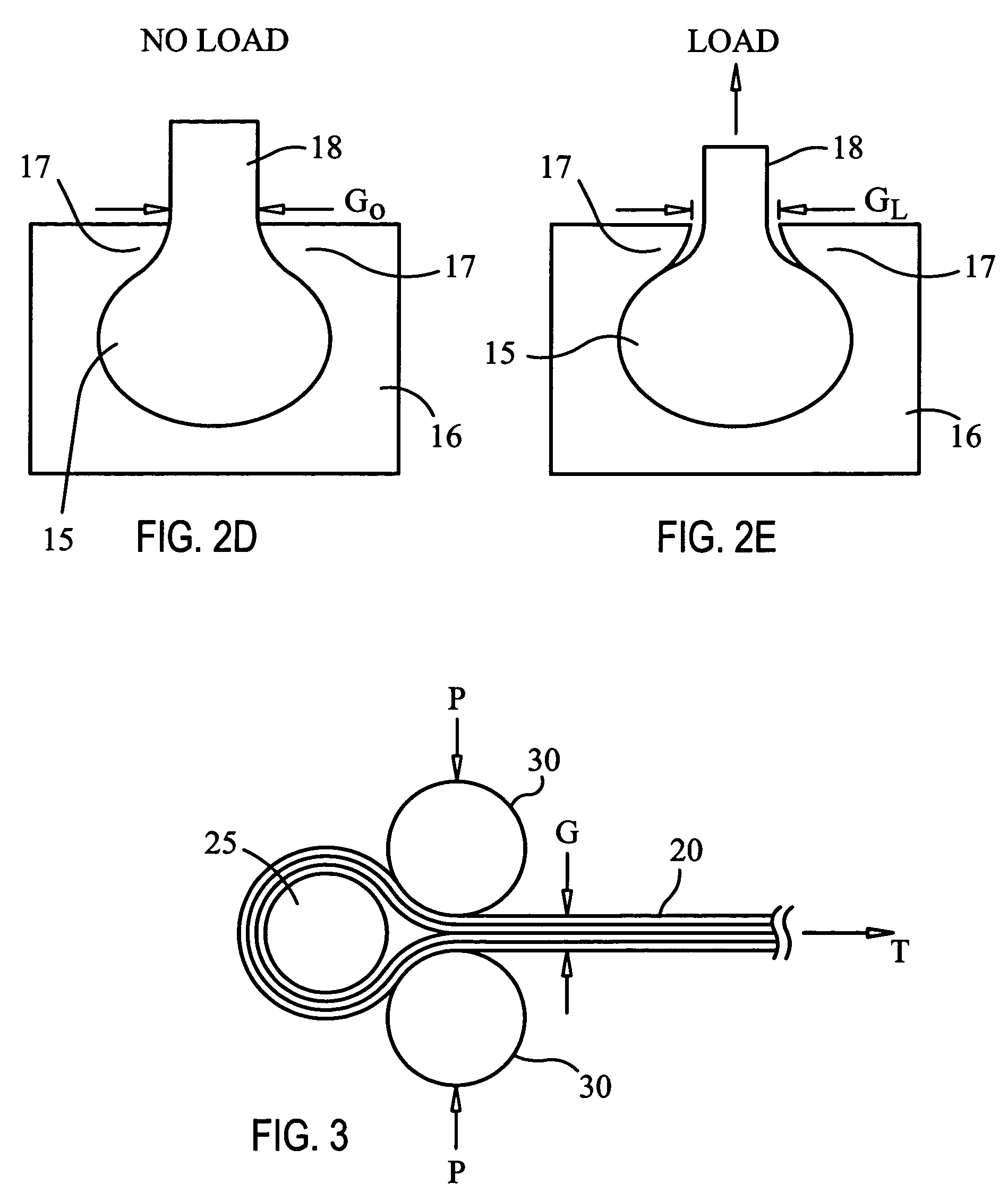

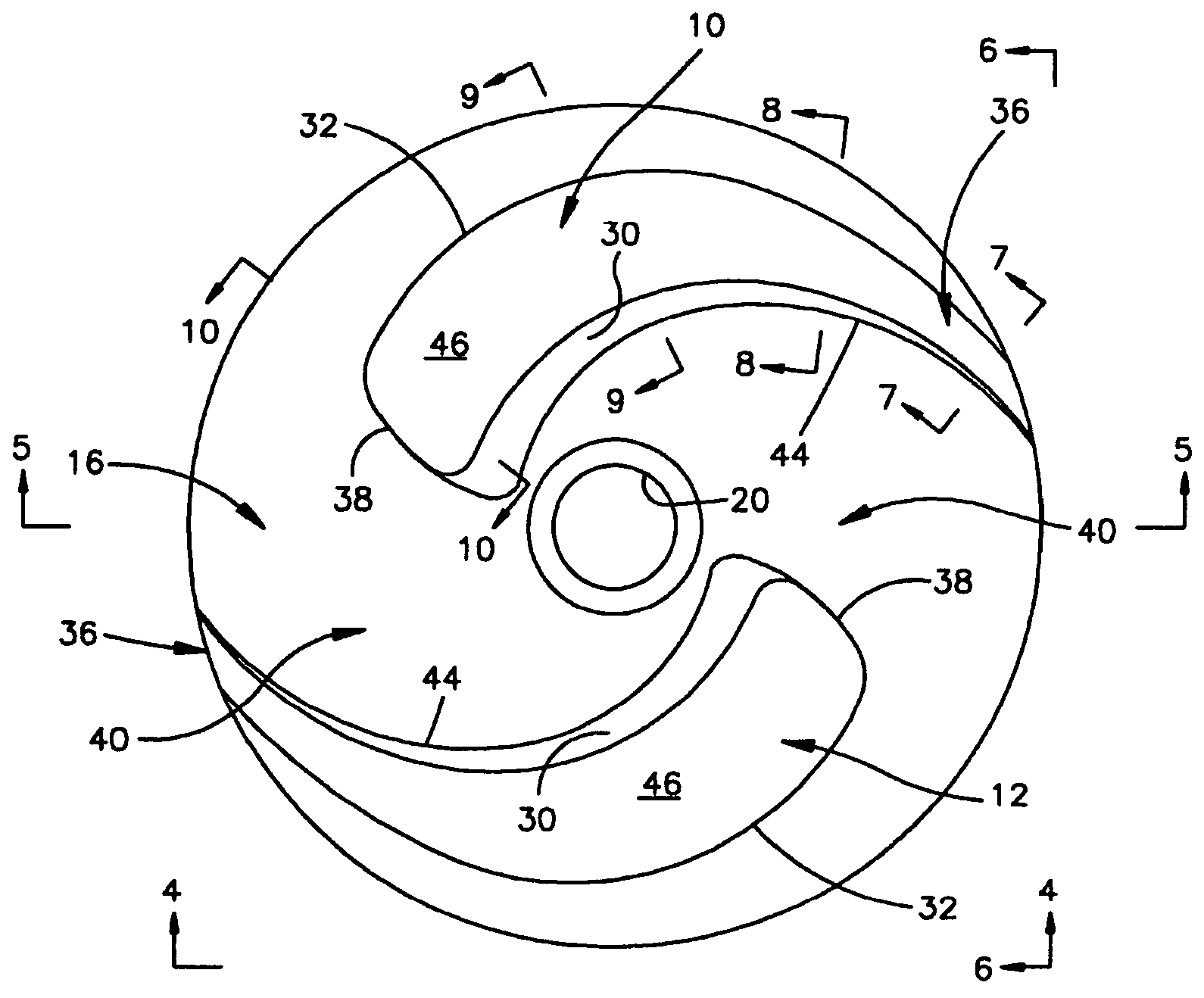

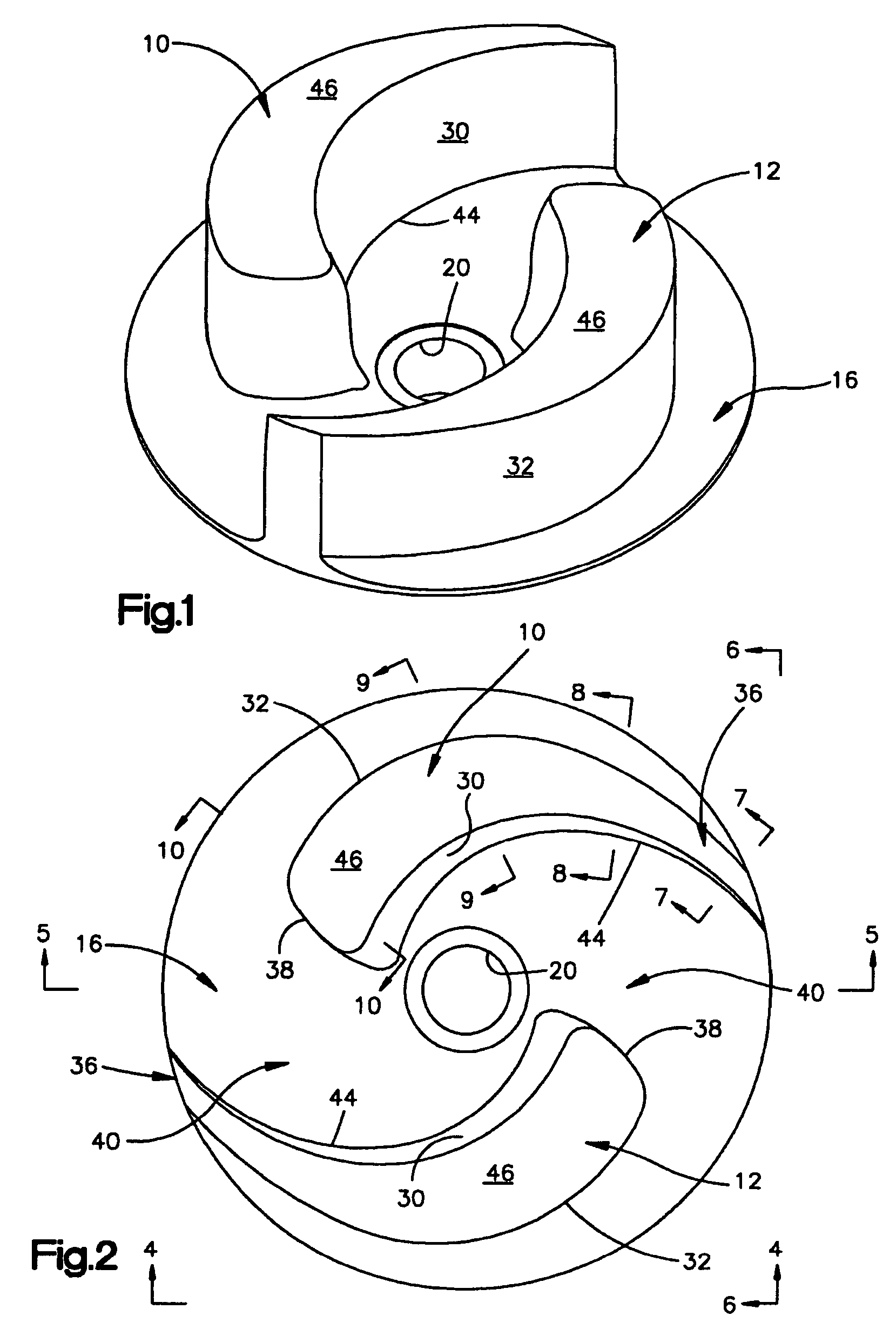

Impeller

ActiveUS20100239417A1Improve hydraulic efficiencyEasy to pumpSpecific fluid pumpsPropellersLeading edgeTrailing edge

A pump impeller for a centrifugal pump The impeller is defined by a shroud rotatable about an axis of rotation At least two pump vanes extend axially from the shroud, each of the vanes configured as a blunted tear drop shape and having an inside wall and an outside wall, the leading edges of which are interconnected by a blunt wall The trailing edges of the inside and outside walls merge together A substantially constant width flow channel is defined between the blunted wall of one vane and a confronting surface defined by an inside wall of the other vane The vanes are tapered in the axial directions by inclining the inside wall of each vane radially outwardly.

Owner:GORMAN RUPP COMPANY

Test method for bending performance of fabric

ActiveCN102788729AEasy to operateEasy to useMaterial strength using tensile/compressive forcesImage processing softwareEngineering

The invention relates to a test method for bending performance of a fabric. According to the invention, a fabric to be tested is cut into a preset dimension and is flattened through ironing, then the fabric is bent to form a water-drop shape and put at a prescribed position on a testing table, and an image pickup mechanism located in front of the water-drop shaped fabric is used for shooting the bent fabric; after shooting, a shot image of the water-drop shaped fabric is introduced into AutoCAD image processing software, width, length and an area of the water drop and the ratio of the width of the water drop to the length of the water drop (a bending resistance coefficient) are respectively calculated by using the functions of distance querying and area querying of the software, and bending performance of the fabric is evaluated based on the calculated width, length, area and ratio. Directed at the disadvantages that price of an apparatus is extraordinarily expensive, test results are different from actual mechanical characteristics of a fabric and only one sample can be tested each time in conventional test methods for bending performance of a fabric, the invention provides the novel test methods for bending performance of a fabric, and the method has the advantages of simple operation, convenient usage and capacity of simultaneously testing bending performance of a plurality of samples or a fabric with a plurality of angles.

Owner:XIAMEN SINO TECH TESTING TECH

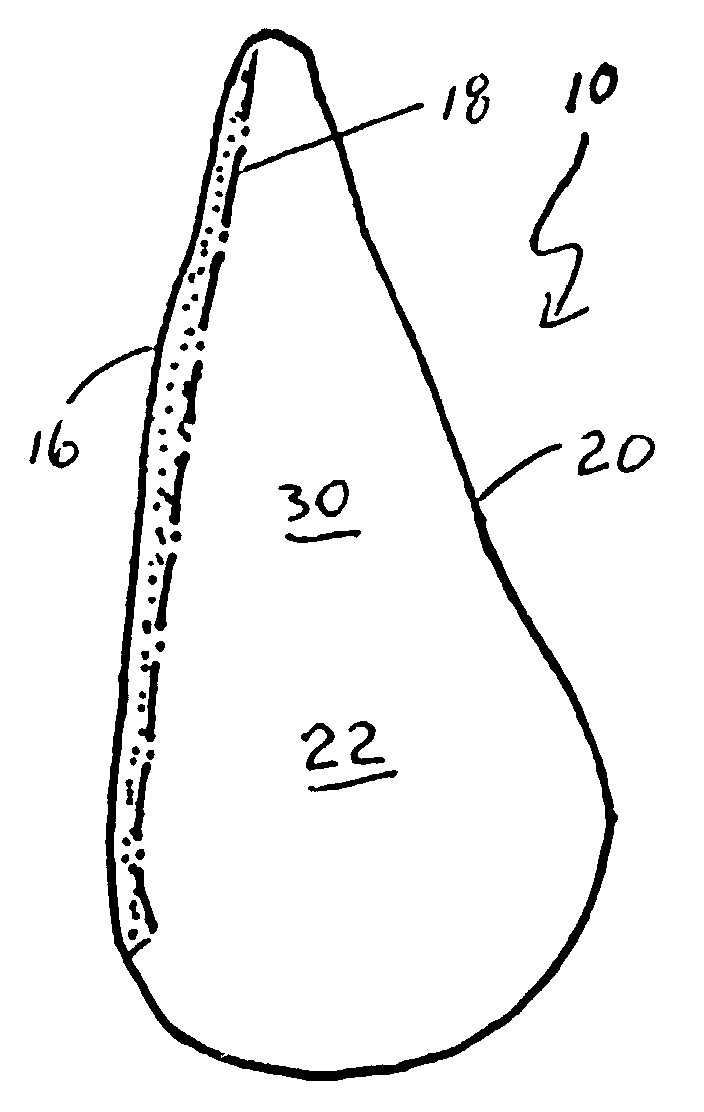

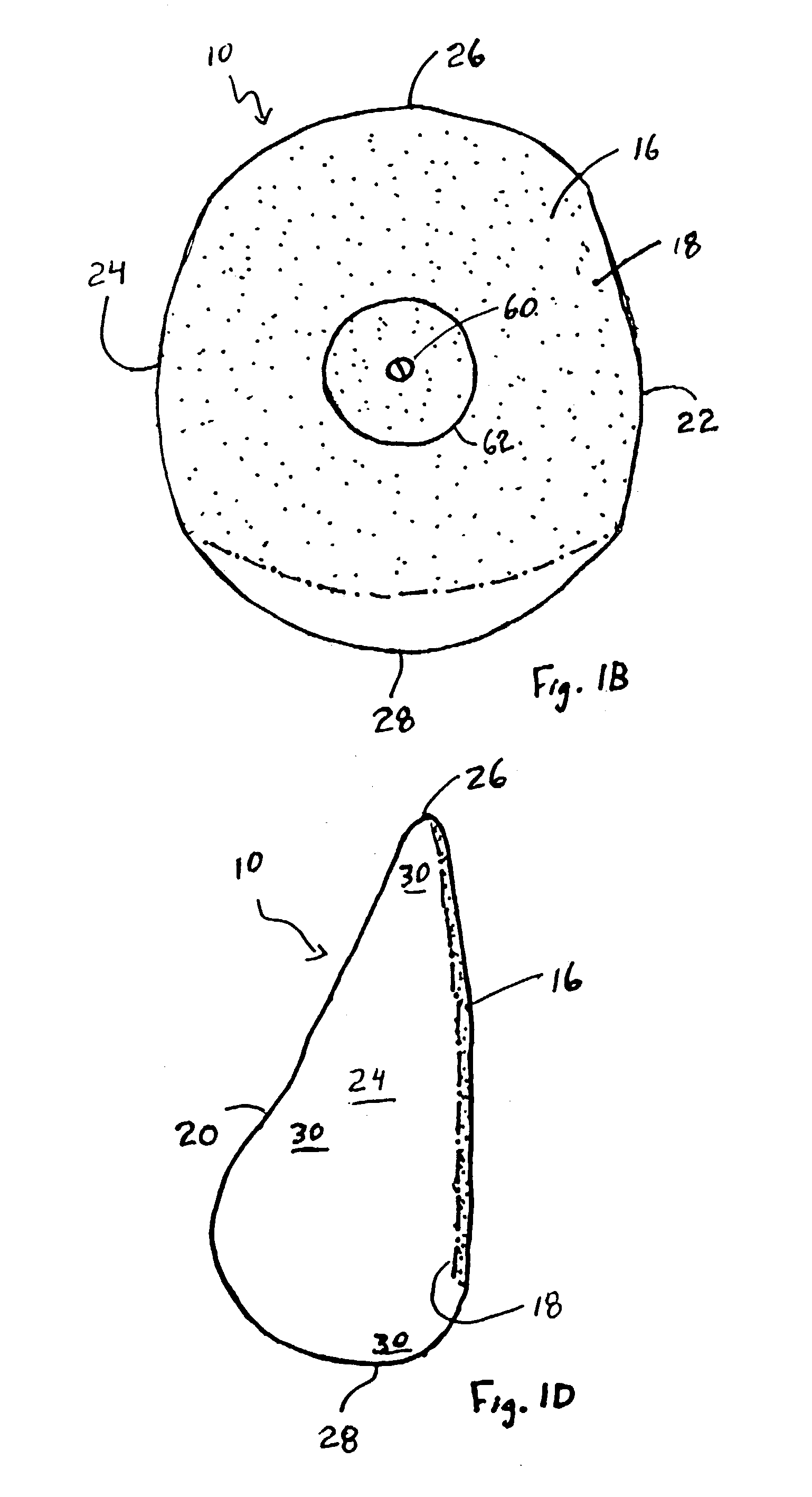

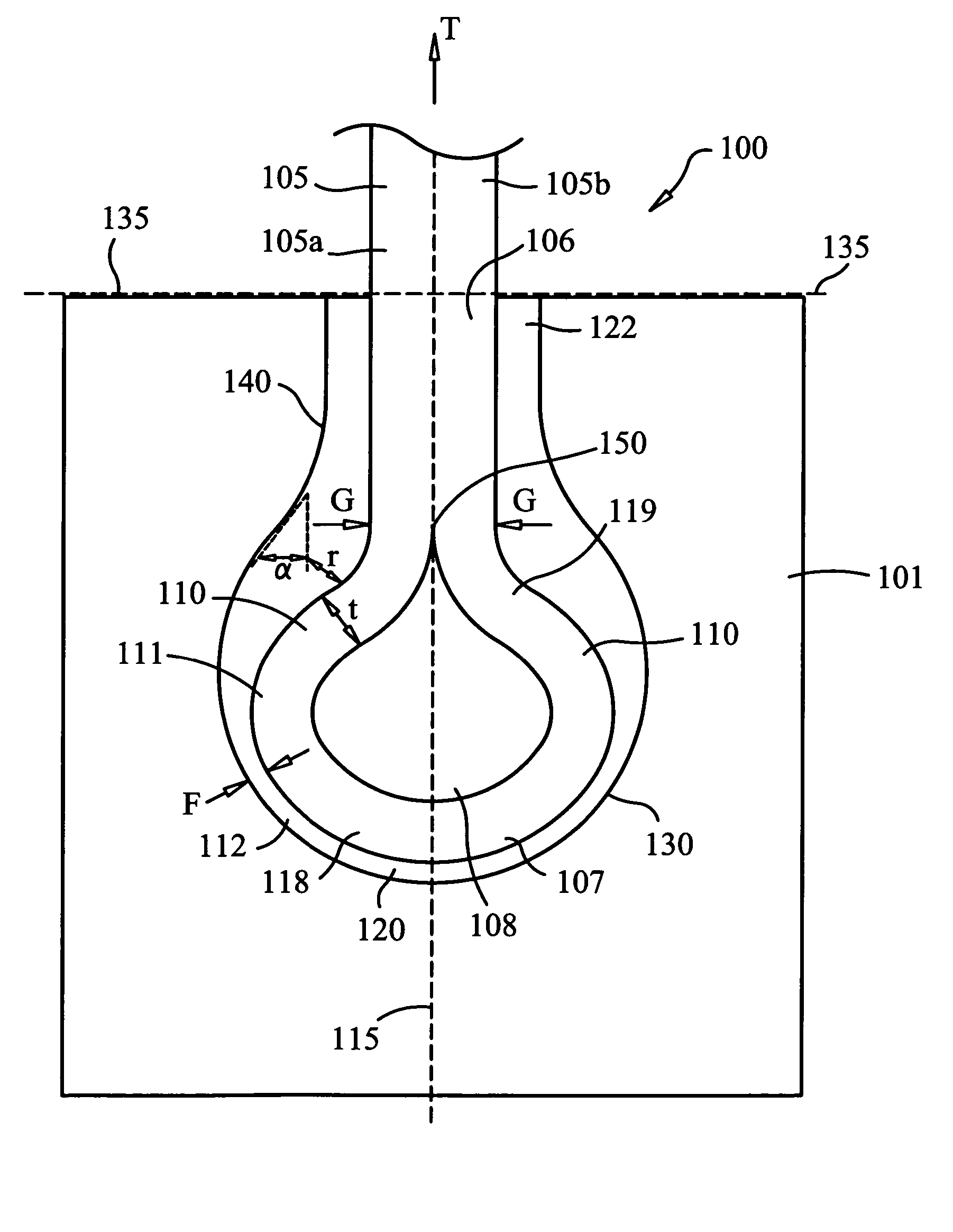

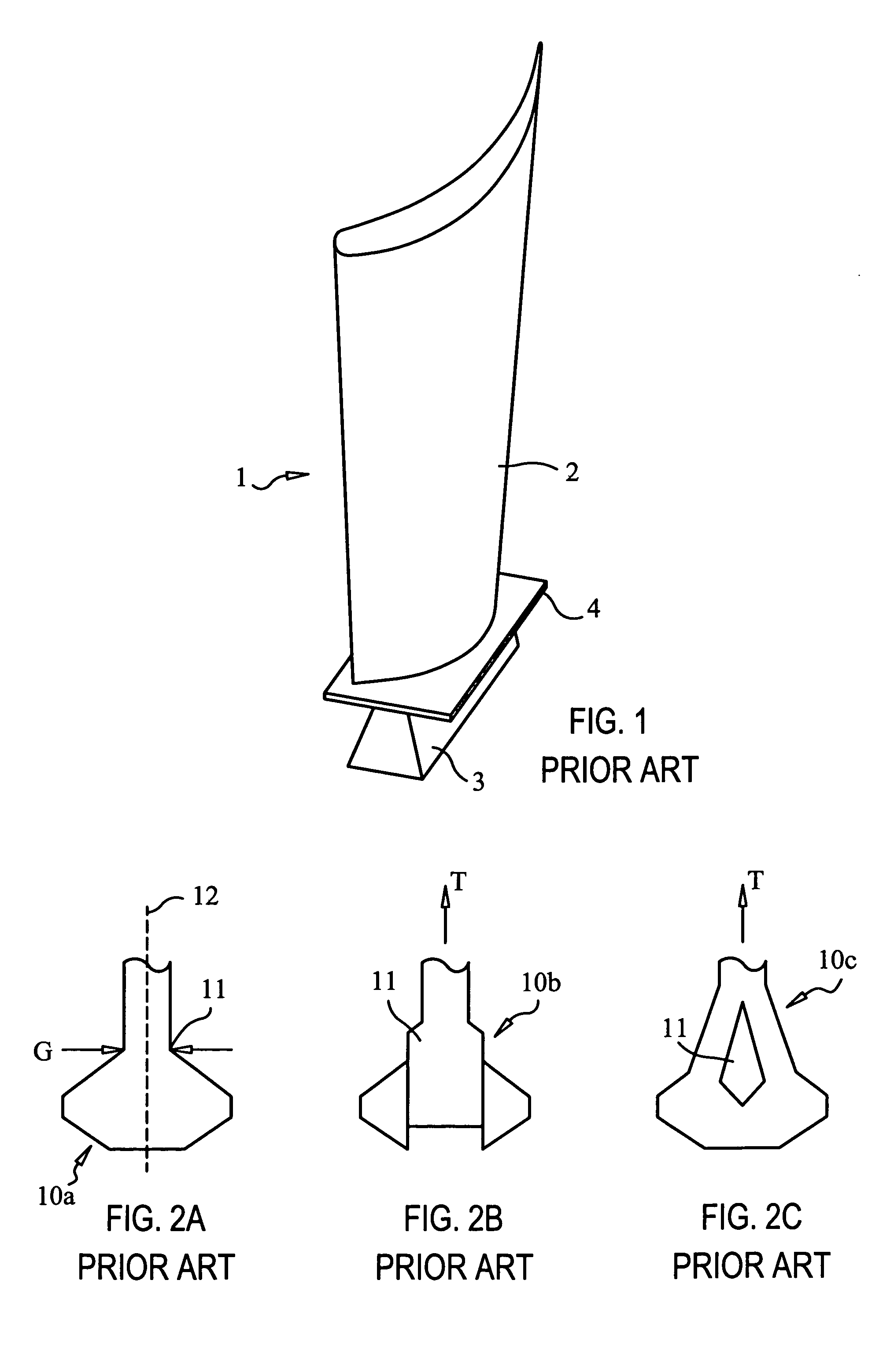

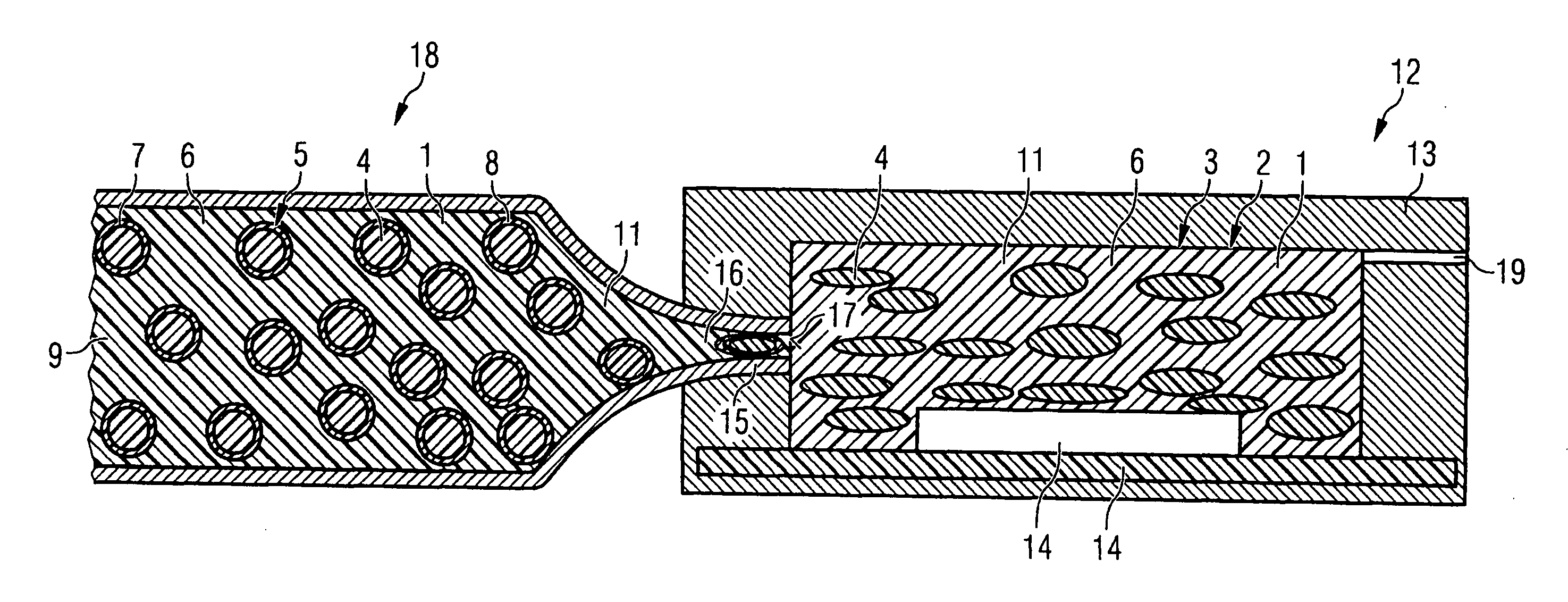

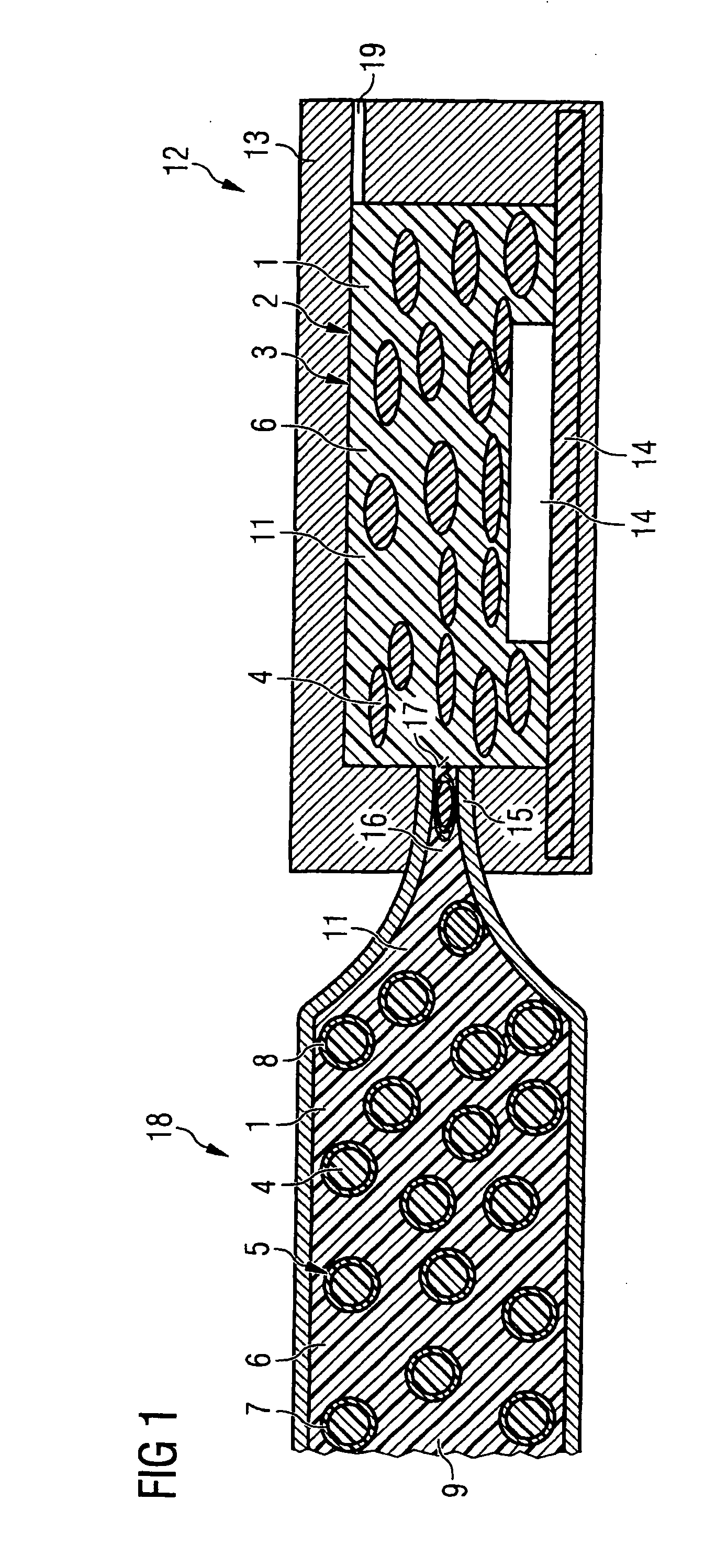

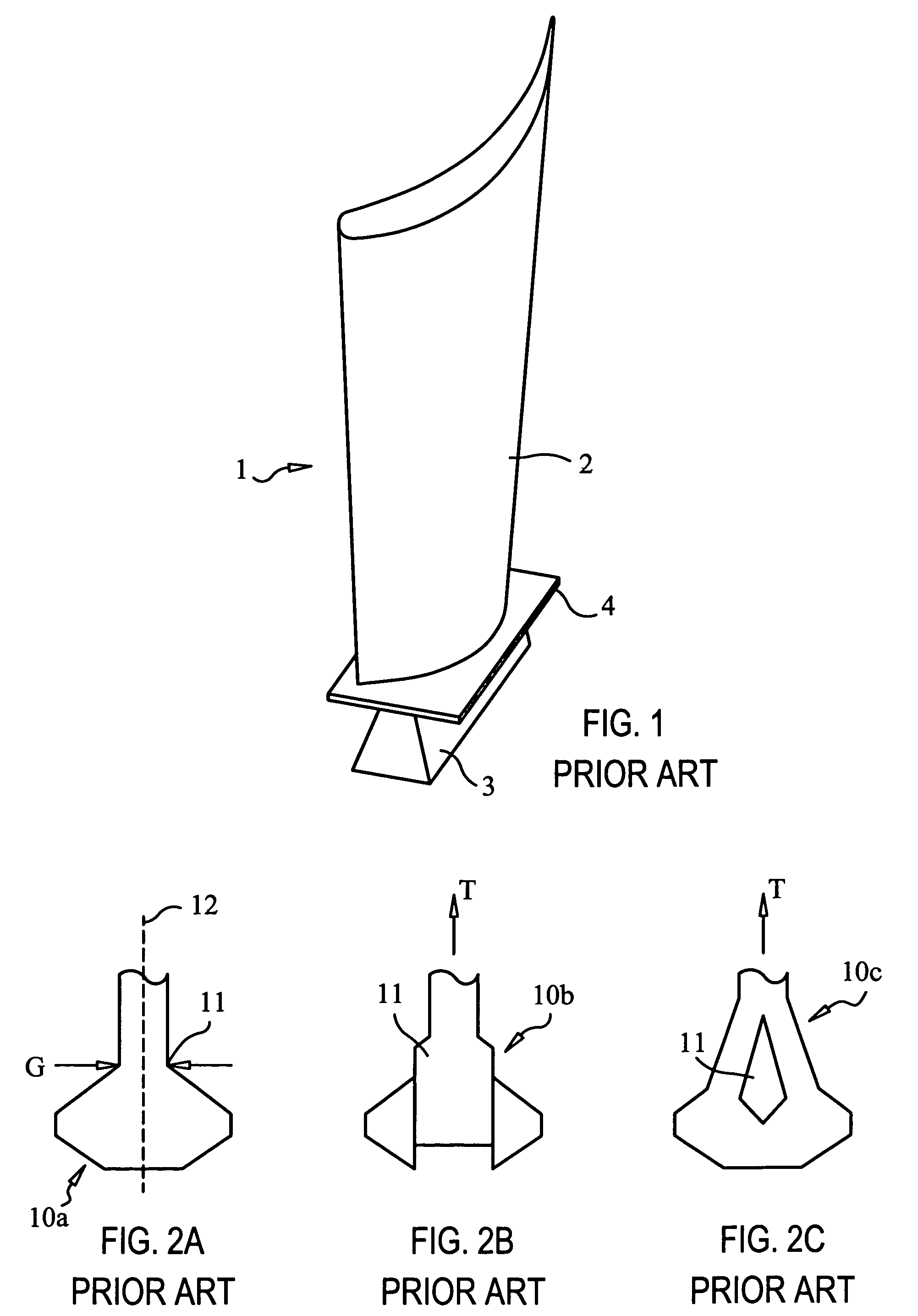

Laminated turbomachine airfoil with jacket and method of making the airfoil

InactiveUS20050260078A1Avoid separationIncreasing the thicknessPropellersRotary propellersEngineeringProviding material

An improvement for a turbomachinery blade having an airfoil portion, a neck portion, and a root portion, the neck portion extending from the root portion, and the airfoil portion extending from the neck portion, and the root portion being tear-drop shaped, includes a jacket attached to the root portion and extending along a portion of the neck portion. Additionally, a process of forming a turbomachinery blade includes steps of providing a laminate of a material; providing a blade insert; wrapping the laminate around to insert to form a blade having a root portion, a neck portion extending from the root portion, and an airfoil portion extending from the neck portion; and providing for a jacket secured around the root portion and a portion of the neck portion extending from the root portion, the jacket having such shape as to prevent delamination of the laminates at a critical point due to centrifugal force acting on the blade.

Owner:FLORIDA TURBINE TECH

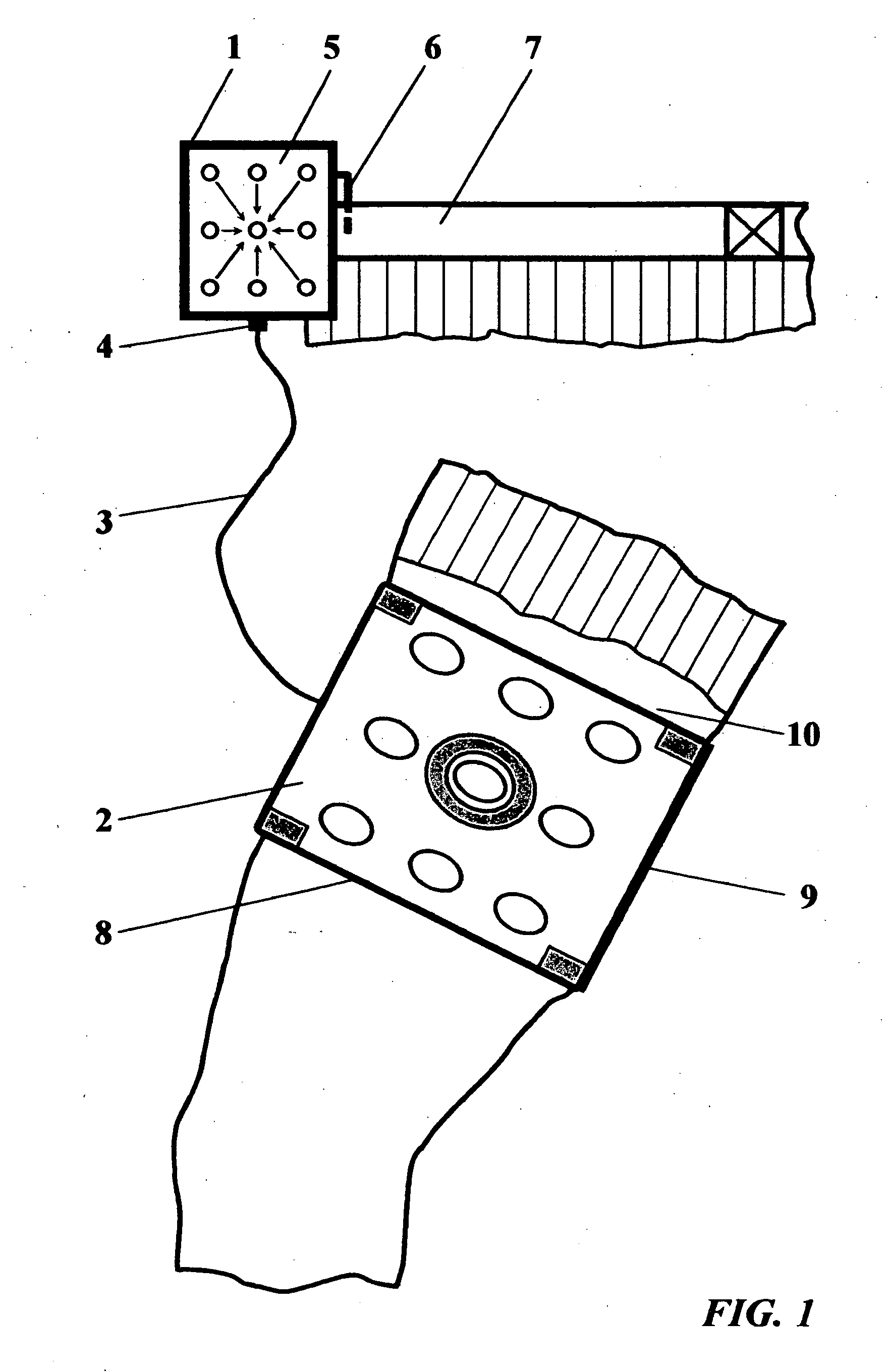

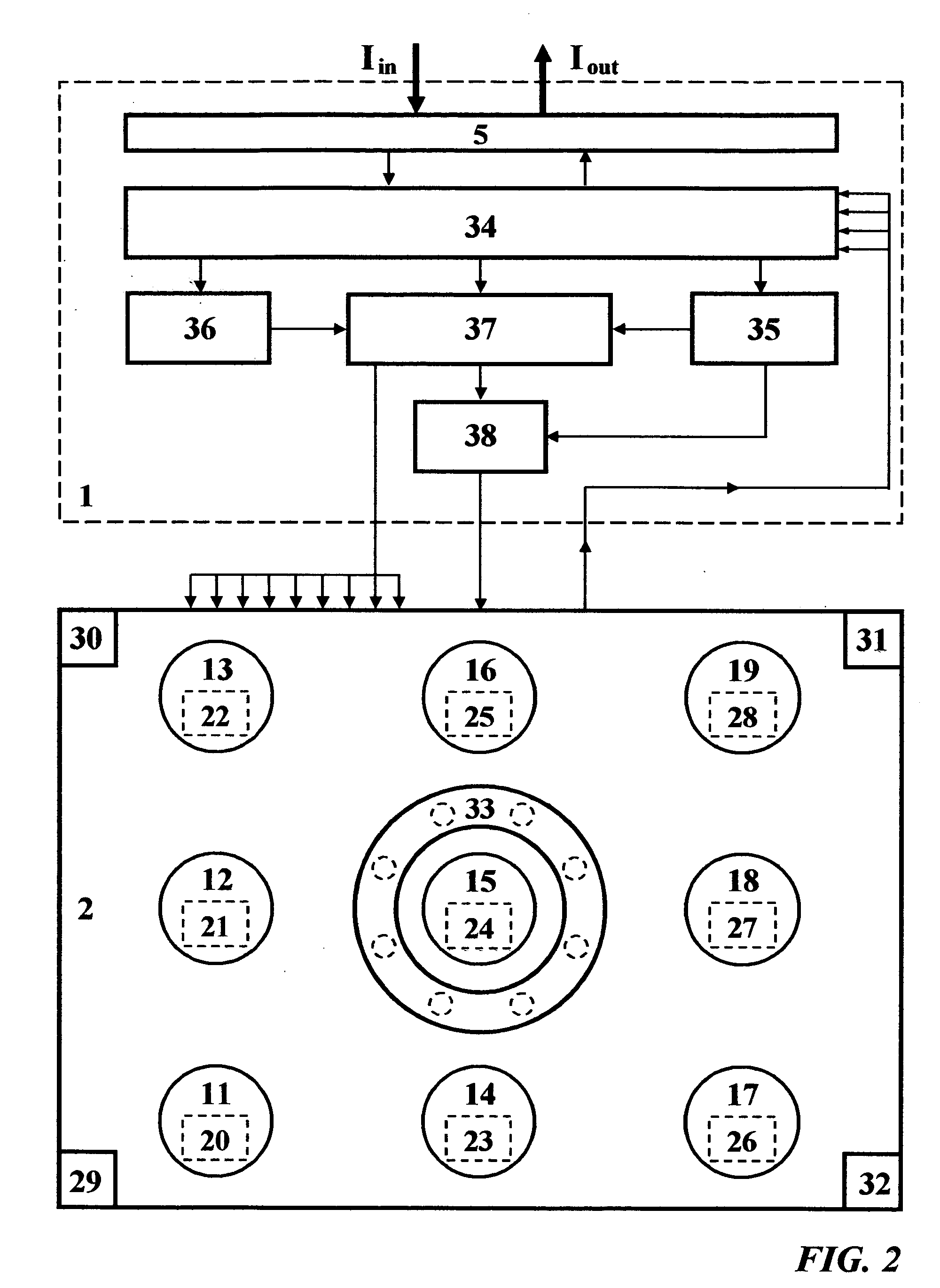

Method of dynamic binary temperature therapy

In a dynamic contrast temperature system including a thermocycling block and an organism zone multi-modules temperature applicator a method of spatiotemporal temperature-physiological optimizing includes modules structure arranging and modulating a module temperature action with a law, a range and a frequency providing a cooling phase and a heating phase of a “drop-shaped” form law so, that each two side by side disposed the modules form a temperature pair with a modulated binary temperature action gradient, and a modulation comparative phase provides a phase shift to a comparative phase of an independent periodic additional action process; and gradient-wave therapeutically optimized changing the modulation parameters in dependence on the changes of the organism physiological characteristics.

Owner:REMCO INT ,

Trocar and cannula assembly having conical valve and related methods

ActiveUS7842013B2Easy insertion and retractionLow costCannulasInfusion syringesFriction reductionEngineering

A trocar system for endoscopic surgery, cap assembly, and related methods are provided. The cap assembly includes a valve housing with an opening formed in line with an axis of the valve housing and also includes a valve positioned adjacent the opening of the valve housing. The valve body includes a proximal valve section including a valve ring positioned within the valve housing, and a distal valve section extending axially from the proximal valve section. The distal valve section includes a valve extension having a proximal and distal end portions, and a substantially conically shaped medial portion connected to and extending therebetween, wherein a plurality of friction-reduction features, preferably tear-drop shaped knobs, are disposed proximate the distal end portion and extending a distance in the medial portion of the valve. A valve opening is positioned in the distal end portion of the valve extension, adapted to individually and separately receive the elongate tools so that when any one of the elongate tools of varying diameter is positioned therethrough, electrostatic adhesion between the valve and the tool is minimized and a seal is maintained between peripheries of the valve extension surrounding the valve opening and outer peripheries of the inserted elongate tool.

Owner:KARL STORZ ENDOVISION INC

Plastic housing composition for embedding semicondutor devices in a plastic housing and use of the plastic housing composition

InactiveUS20070054530A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialPlastic materials

A plastic housing composition for embedding semiconductor devices in a plastic housing includes a multicomponent plastic material, where at least one component is distributed in the plastic material in drop-shaped and / or spherical units. The drop-shaped and / or spherical units are surrounded by dimensionally stable sheaths made from a plastic sheath material. The multicomponent plastic further includes a reactive curing system that cures when the plastic sheaths are torn open. The dimensionally stable plastic sheath material is deformation-sensitive, so that the sheaths tear open under mechanical deformation loading, which initiates and / or accelerates the curing process.

Owner:INFINEON TECH AG

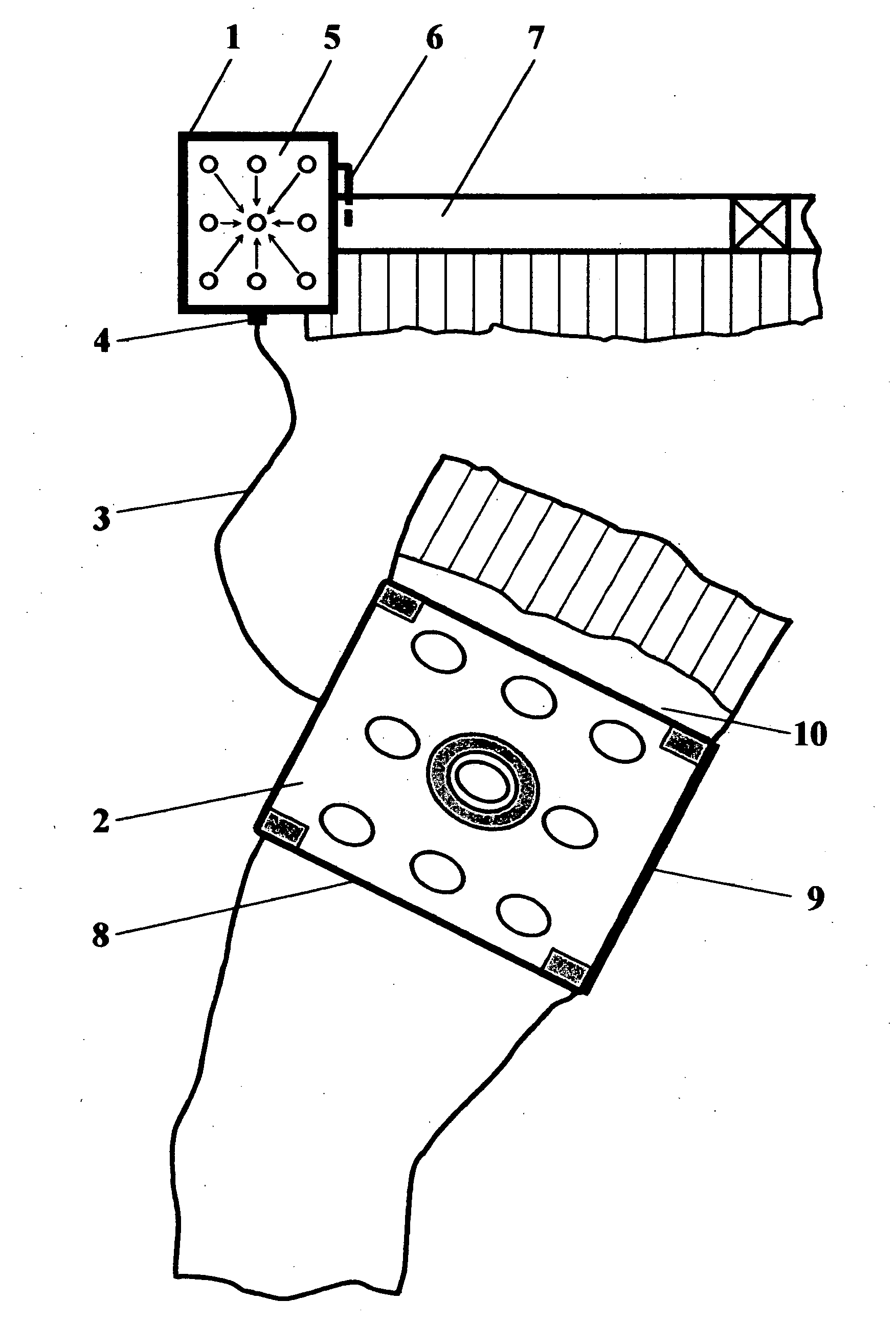

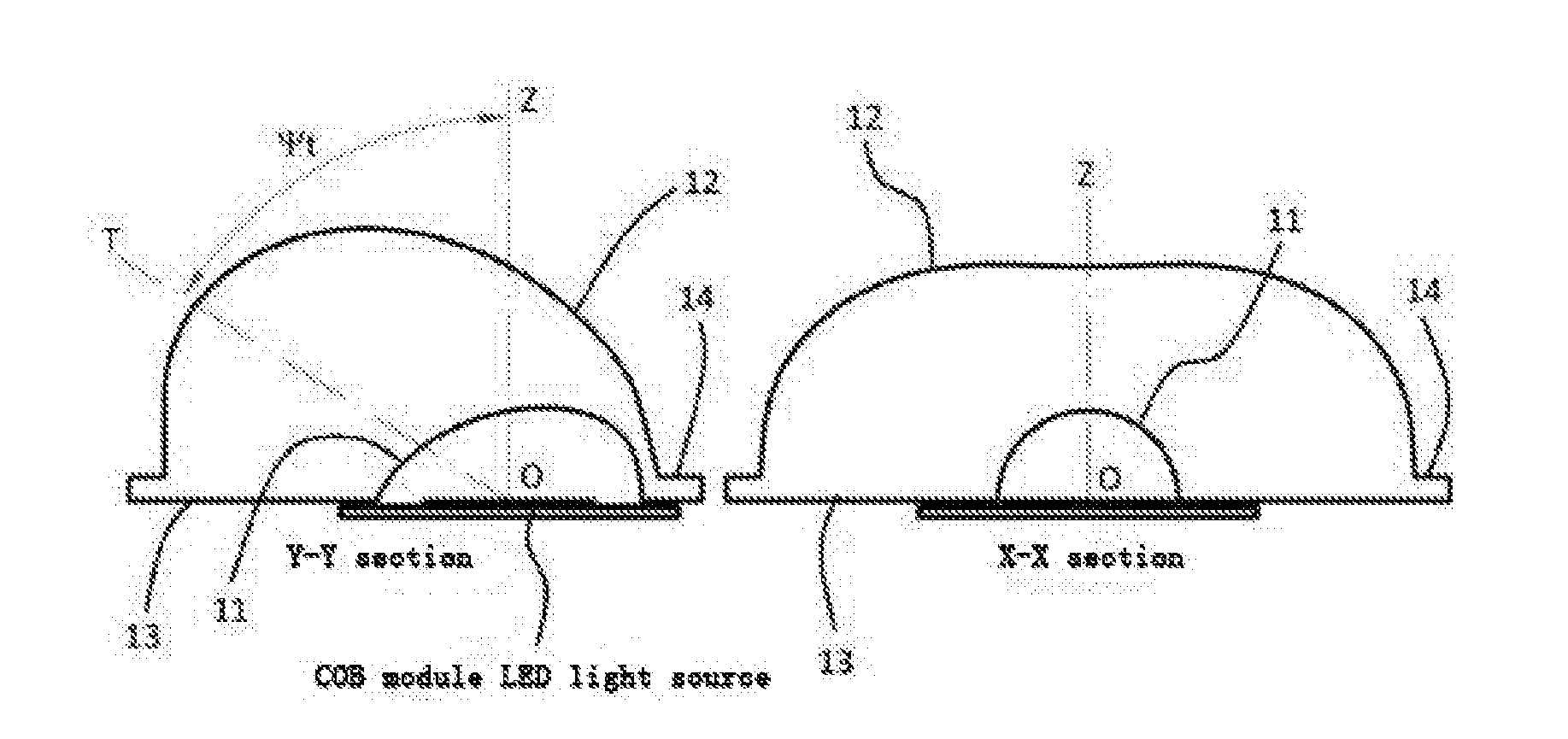

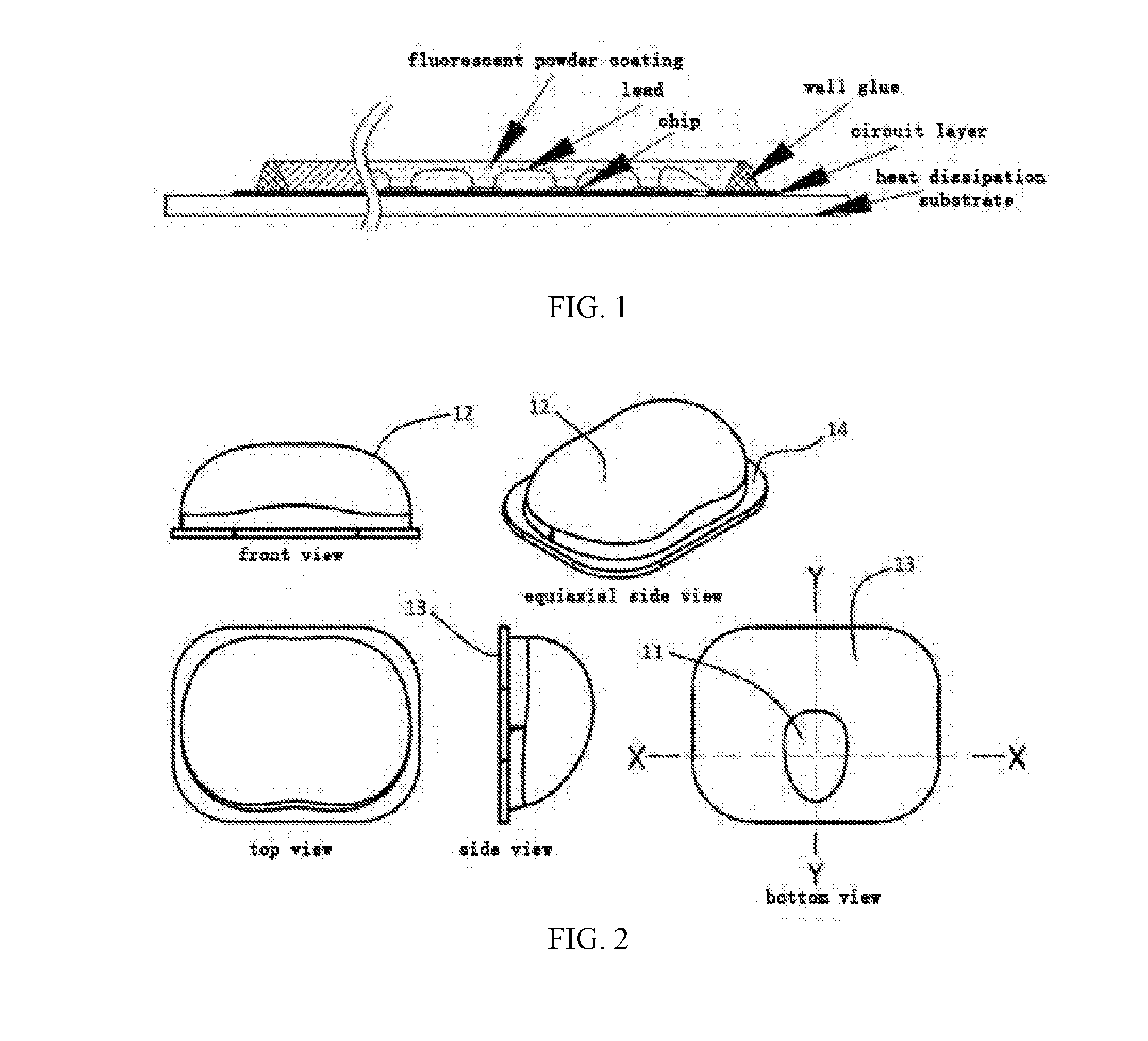

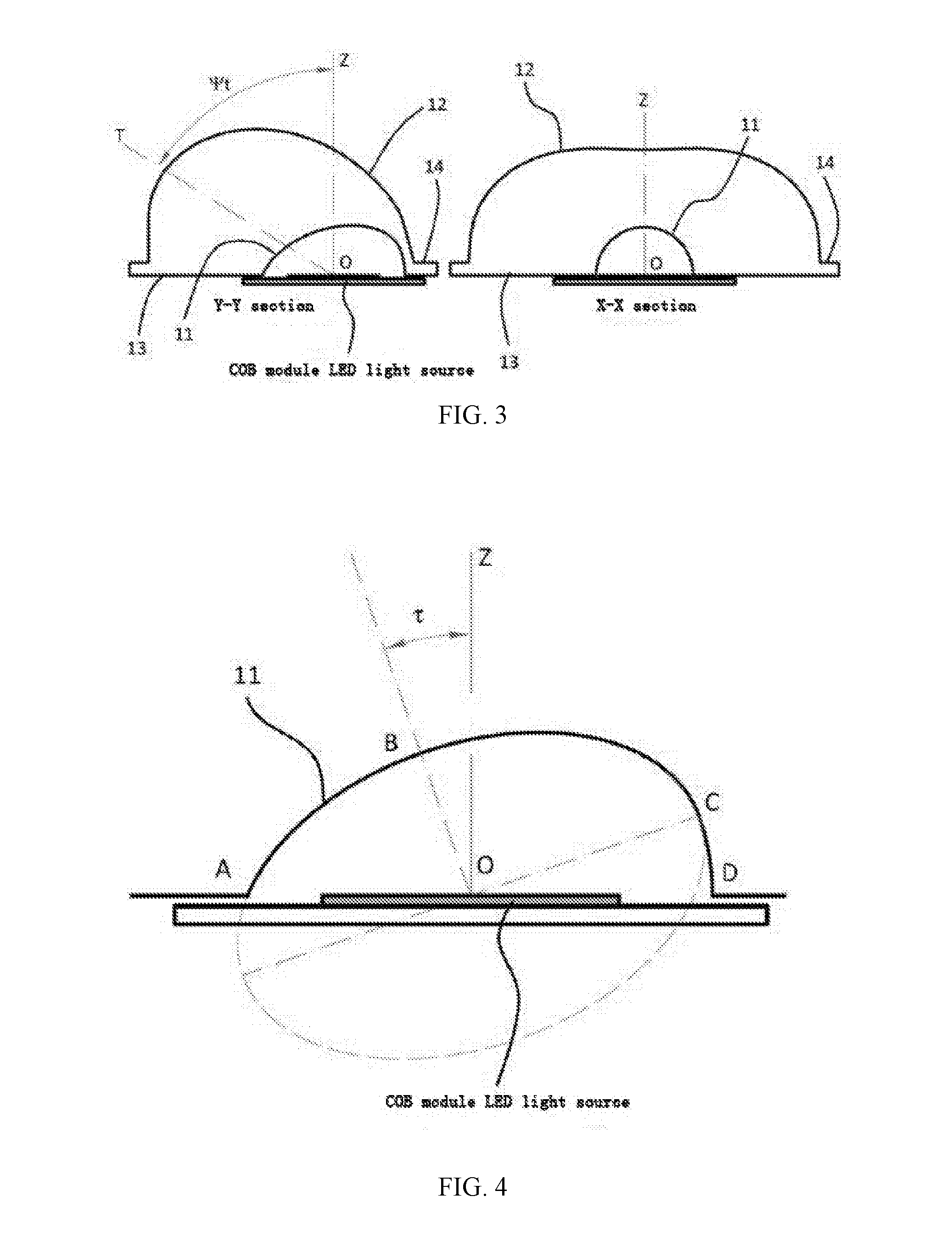

Light distribution method for cob module LED street lamp lens capable of illuminating 3 - 5 lanes

ActiveUS20160201876A1Improve efficiencyLow costMechanical apparatusPoint-like light sourceDistribution methodOptoelectronics

The invention relates to a light distribution method for a COB module LED street lamp lens capable of illuminating 3 or 5 lanes. The light distribution method is characterized in that the light emitted by a COB module LED light source is firstly refracted by a drop-shaped refraction lens and then refracted secondarily by a light distribution curved surface lens to achieve an optimal irradiation effect. The light distribution method provides a foundation for the use of a single COB module LED light source in an urban road, and has the advantages of low cost and high efficiency.

Owner:HONGLI LIGHTING GRP

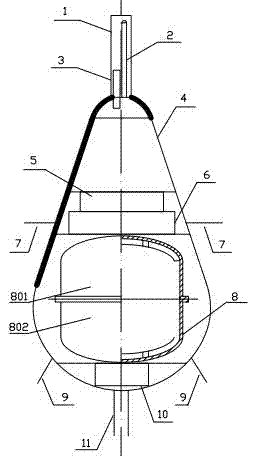

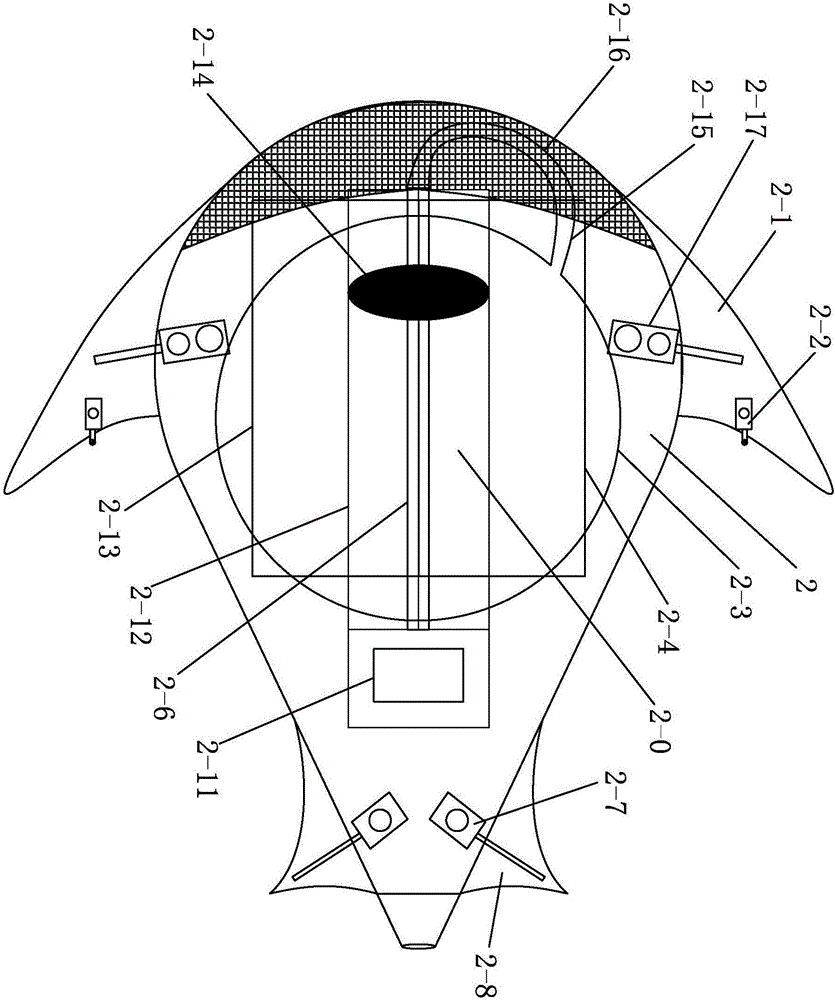

Abysmal sea communication relay buoy

The invention discloses an abysmal sea communication relay buoy which comprises a shell body. A wall-collision device and an antenna are symmetrically arranged at one end of the shell body and a cable guide tube is connected with the other end of the shell body. A conductance temperature depth (CTD) sensor, an acoustic transponder main machine, a pressure resistant tank and an acoustic transponder transducer are arranged sequentially in the shell body from top to bottom. Upper shake-reducing boards are symmetrically arranged at the periphery of the middle portion of the shell body. Lower shake-reducing boards are further symmetrically arranged at the periphery of the bilge portion of the shell body. According to the abysmal sea communication relay buoy, a shell is designed in a water-drop-shaped solid of revolution with the size gradually increased from top to bottom, devices with large weight are arranged at the bottom of the shell, so that in serious sea environment, the abysmal sea communication relay buoy is high in moving stability, capable of maintaining an efficient and long working state, compact in structure and convenient to process. The cable guide tube is arranged at the bottom of the shell body, a cable used for connection can be arranged in the cable guide tube, and therefore the abysmal sea communication relay buoy is rapid and convenient to arrange and recycle and high in work efficiency.

Owner:中国船舶重工集团公司第七〇二研究所

Laminated turbomachine airfoil with jacket and method of making the airfoil

InactiveUS7300255B2Avoid separationIncreasing the thicknessPropellersRotary propellersProviding materialEngineering

An improvement for a turbomachinery blade having an airfoil portion, a neck portion, and a root portion, the neck portion extending from the root portion, and the airfoil portion extending from the neck portion, and the root portion being tear-drop shaped, includes a jacket attached to the root portion and extending along a portion of the neck portion. Additionally, a process of forming a turbomachinery blade includes steps of providing a laminate of a material; providing a blade insert; wrapping the laminate around to insert to form a blade having a root portion, a neck portion extending from the root portion, and an airfoil portion extending from the neck portion; and providing for a jacket secured around the root portion and a portion of the neck portion extending from the root portion, the jacket having such shape as to prevent delamination of the laminates at a critical point due to centrifugal force acting on the blade.

Owner:FLORIDA TURBINE TECH

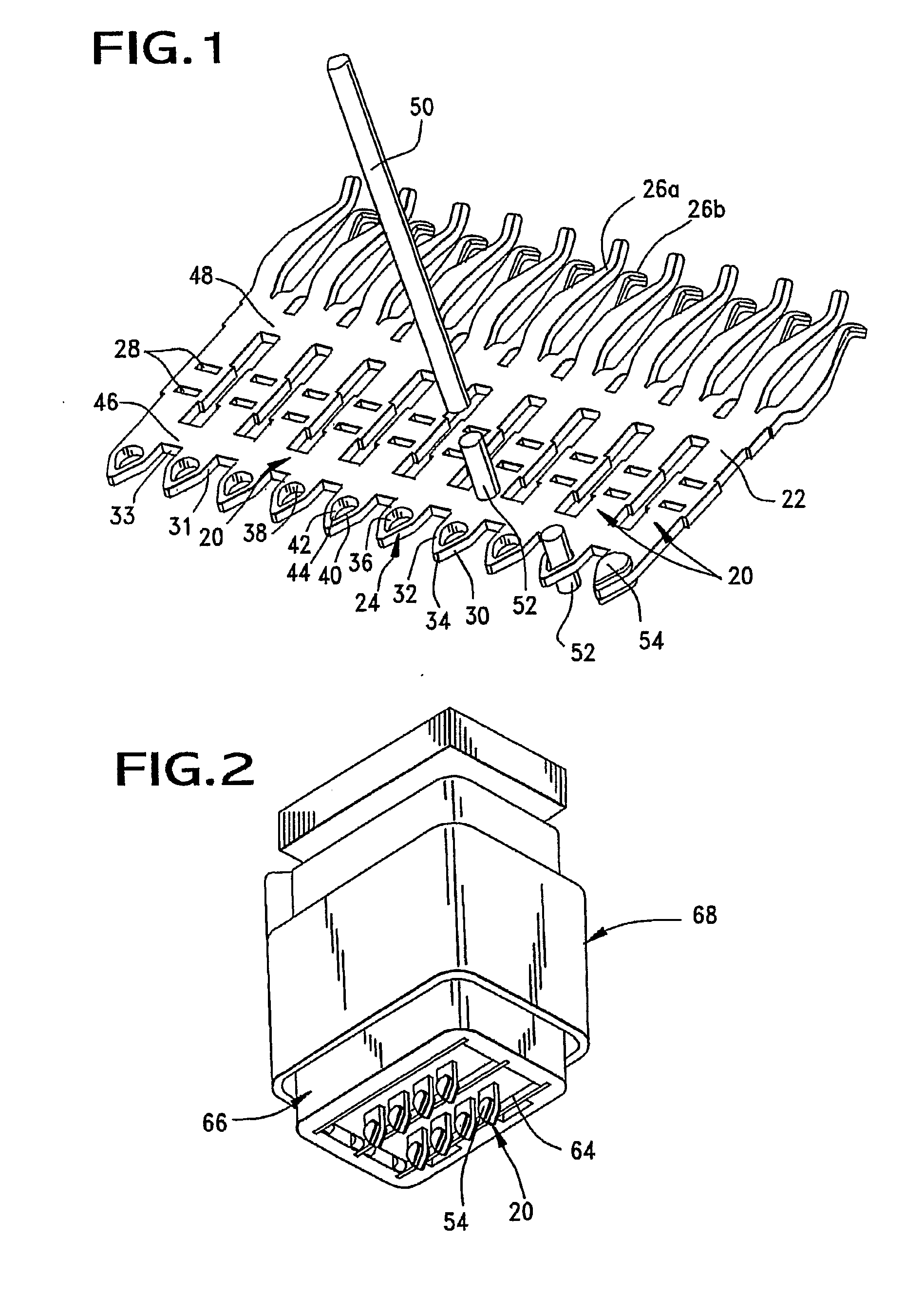

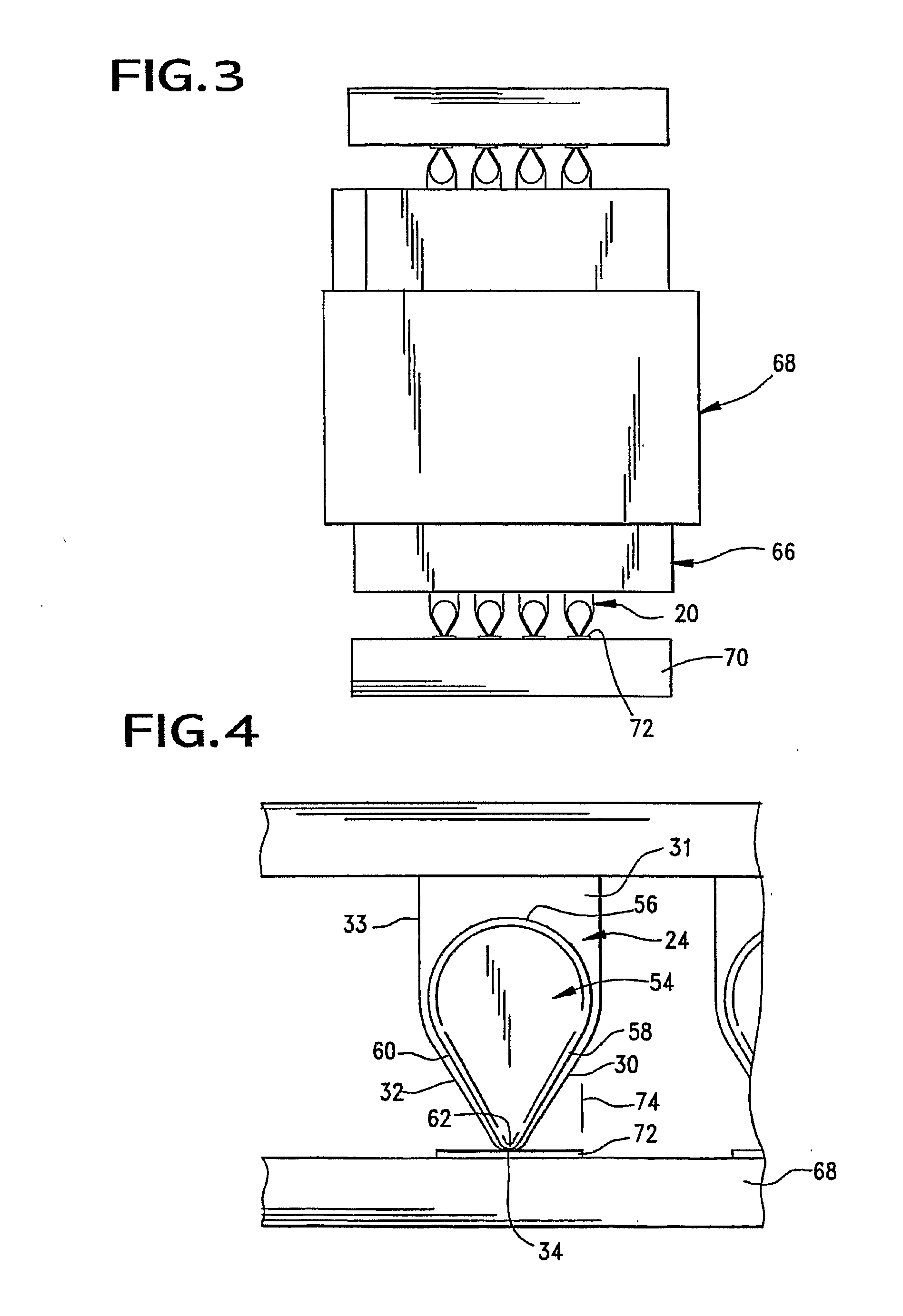

Method Of Attaching A Solder Element To Contact And The Contact Assembly Formed Thereby

A method of attaching a solder element to a contact and the contact assembly formed thereby. The contact assembly is used in a connector. The solder element is either staked or stapled to the contact. The solder element can take a variety of shapes and disclosed herein is a tear-drop shape, a “wolf's head” shape and a circular shape. An over-stress feature is also provided for when the contact assembly is mounted to a printed wiring board.

Owner:MOLEX INC

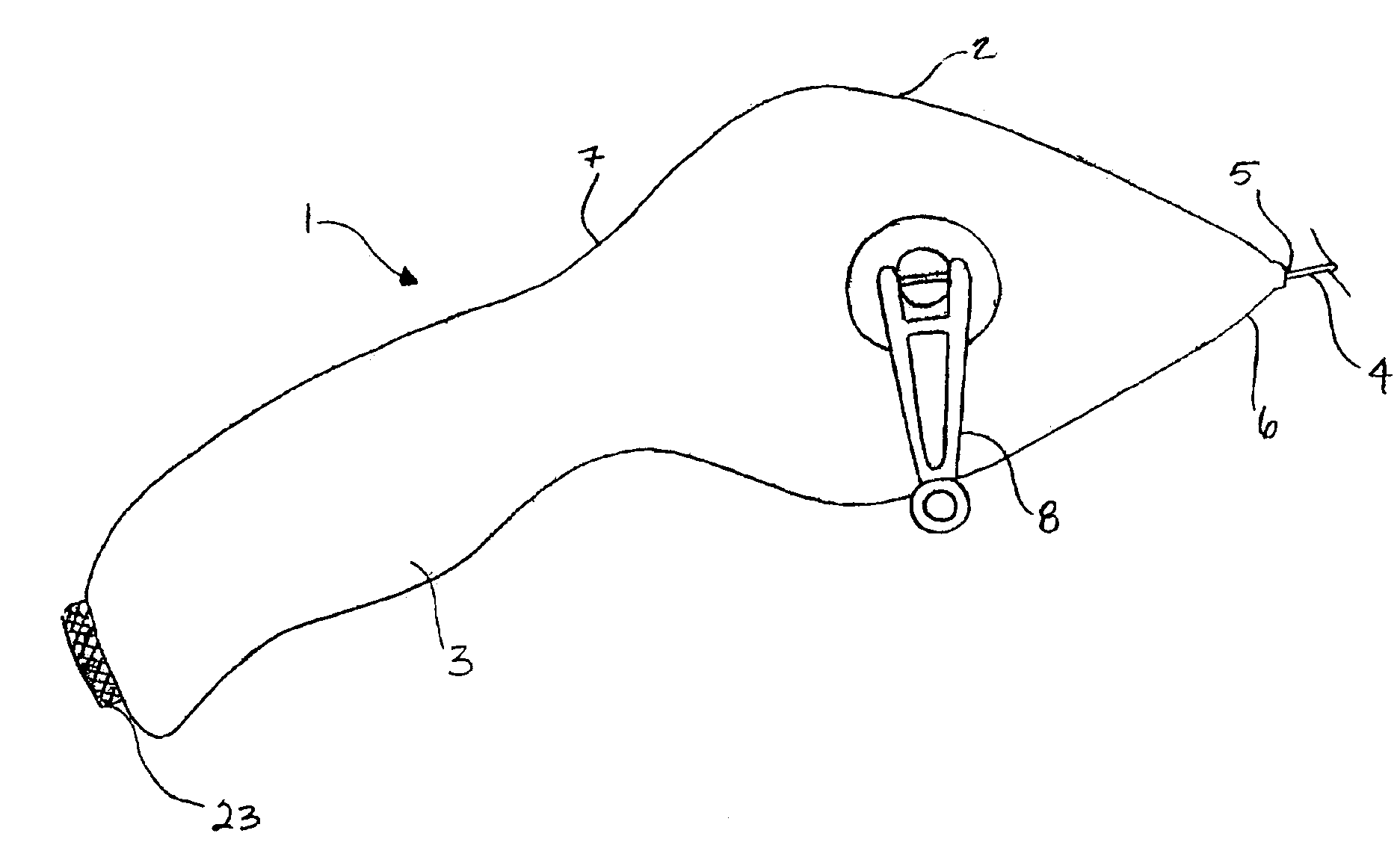

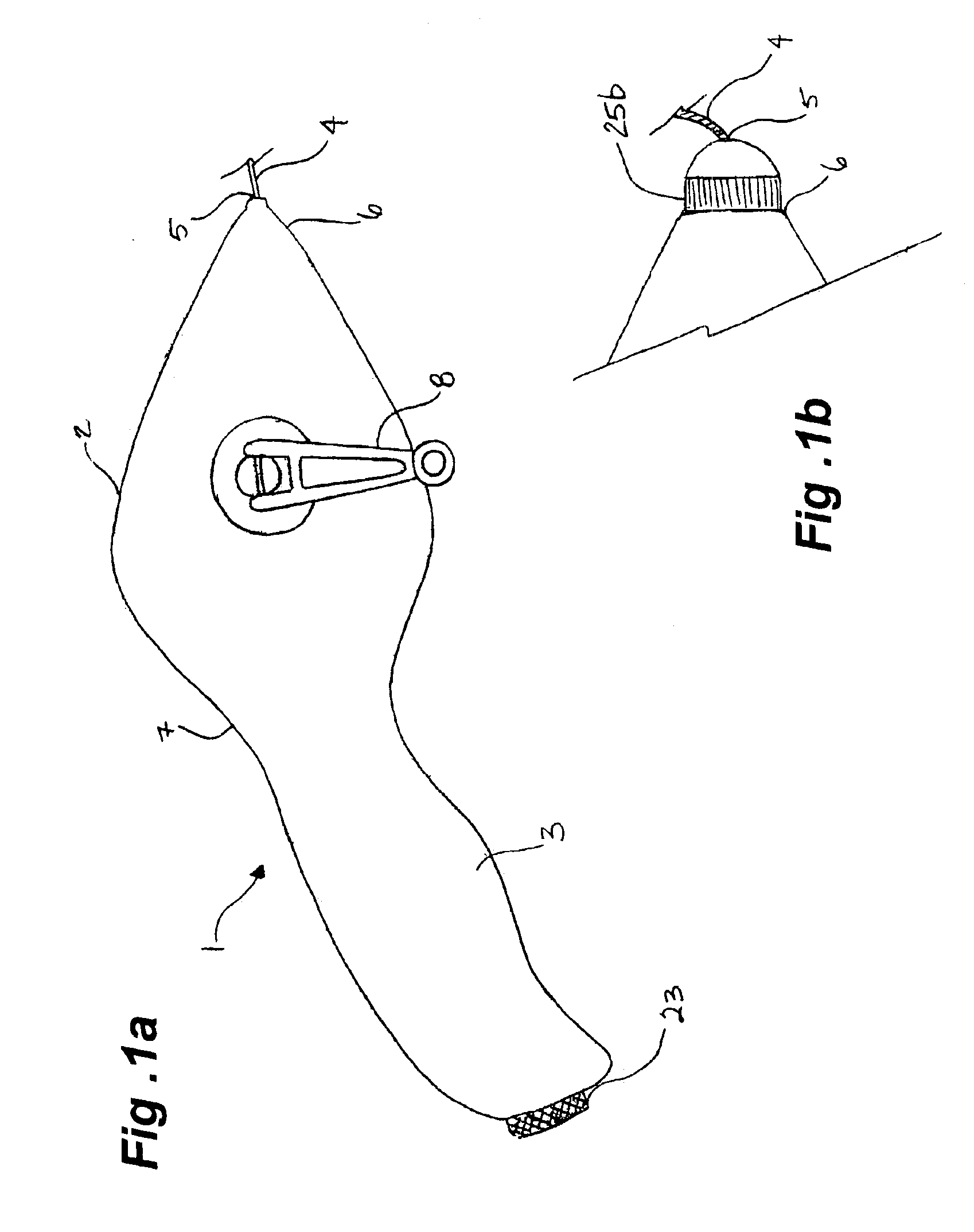

Chalk line with handle reservoir

InactiveUS6895679B2Improve ergonomicsConvenient meanOther artistic work equipmentsMeasuring tapesEngineeringDrop-shaped

A chalk line tool is provided having a tear-drop shaped body which houses a chalk line spool and chalk for coating the chalk line and a handle connected to the body and acting as a reservoir for additional chalk. The reservoir feeds the cavity in the body. The flow of chalk is controlled between the reservoir and the cavity. The handle advantageously acts to maintain the operator's hands away from the hand crank used to retract the chalk line and provides an extended reach with the tool for improved ergonomics when using the tool. The chalk line tool can be manufactured with the handle or can be retrofit with parts which are supplied as a kit.

Owner:DEKORT HENRY

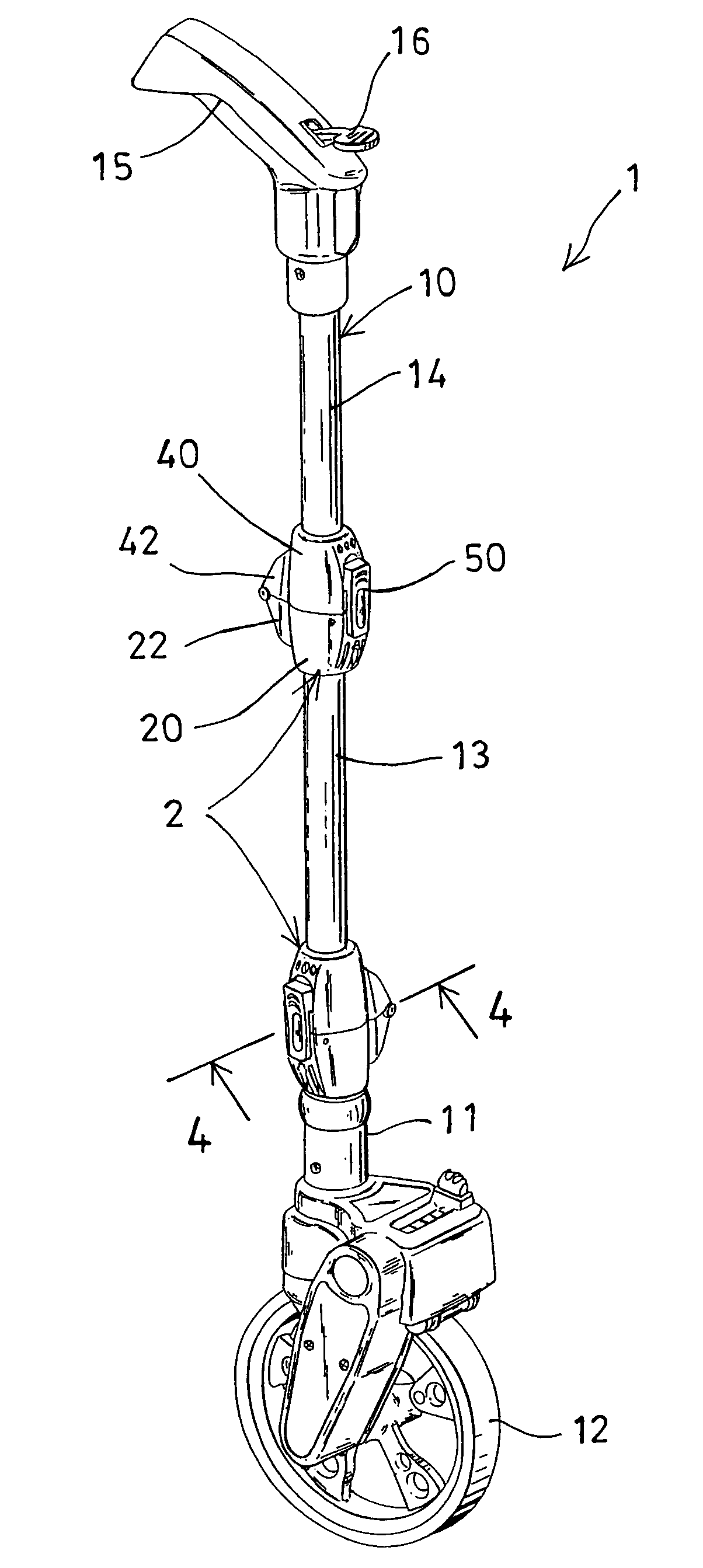

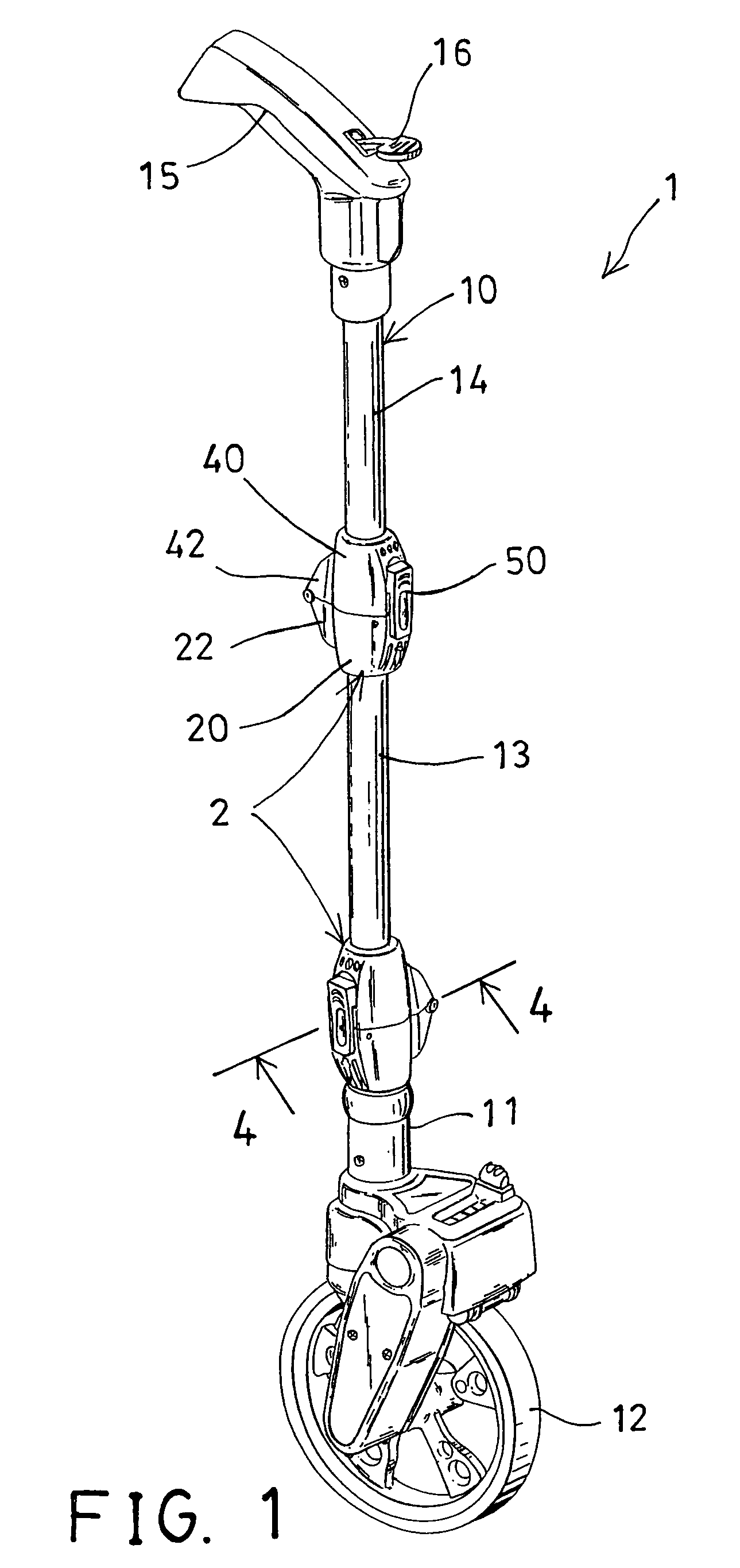

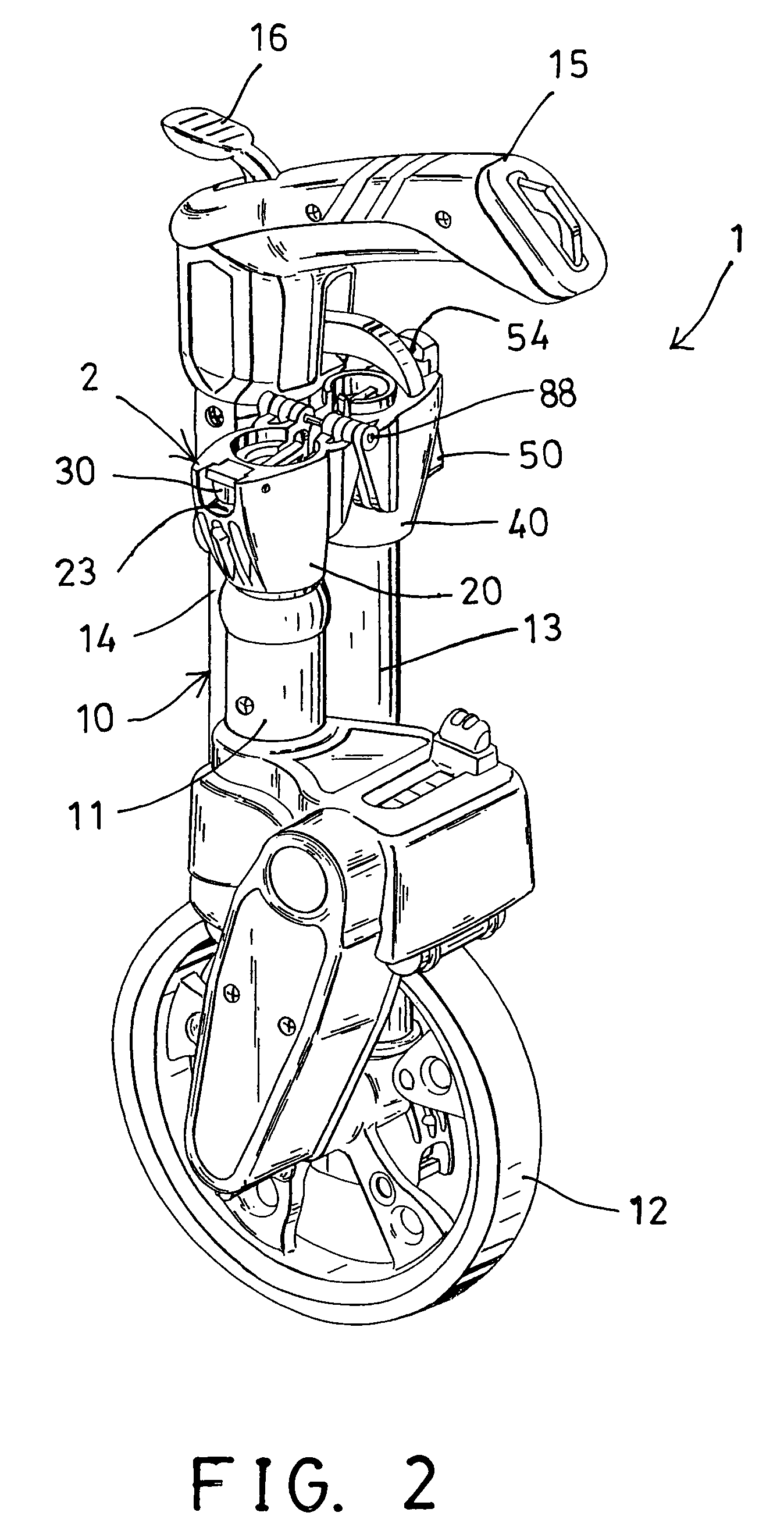

Wheeled distance measuring device

ActiveUS7555846B1Efficient foldingSelectively and solidly coupled togetherMeasuring wheelsUsing electrical meansDrop-shapedElectrical and Electronics engineering

A wheeled distance measuring device includes a longitudinal pole having two segments, a housing and a casing attached to the segments and pivotally coupled together, a latch device pivotally attached to the housing and having a latch, and a lock device pivotally attached to the casing and having a catch for engaging with the latch of the latch device and for detachably securing the segments together. The casing includes a chamber formed by a wall for receiving the lock device, and a channel formed in the wall for pivotally engaging with a water-drop-shaped pivot member of the lock device and for pivotally attaching and coupling the lock device to the casing.

Owner:WANG CHENG LIN

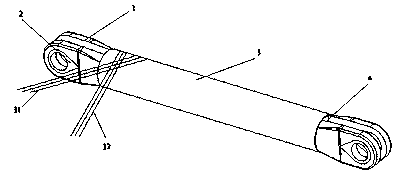

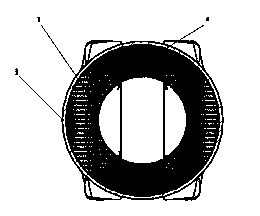

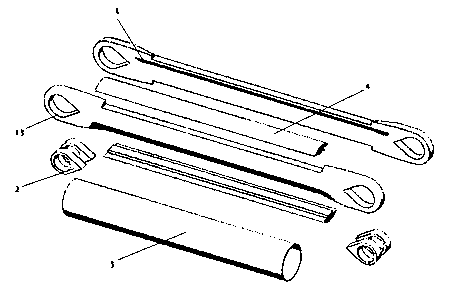

Aerial tube-shaped carbon fiber composite rod piece and manufacturing method thereof

The invention discloses an aerial tube-shaped carbon fiber composite rod piece and a manufacturing method thereof. The rod piece is a tube-shaped structure made from a composite material formed by mixing and weaving high-modulus and low-modulus fibers, wherein the fiber weaving manner is longitudinal arrangement in bearing direction and transverse reinforcement in nonbearing direction. The rod piece comprises two bearing components and metal shaft sleeves, wherein the two bearing components are arranged fixedly, closely adjacently and side by side; the two ends of each bearing component are respectively provided with an ear part; the metal shaft sleeves are embedded in the ear parts; the metal shaft sleeves are in shape of a water drop. According to the rod piece disclosed by the invention, the water-drop-shaped metal shaft sleeves are beneficial to tensile loading and also beneficial to compression-resistance unloading, so that a pull rod can greatly uniformly distribute the load on the carbon fiber composite material when bearing the pressure. The manufacturing method disclosed by the invention is simple and convenient, the provided rod piece has the characteristics of resistance to high-altitude low temperature of -55 DEG C, resistance to ground high temperature of 45 DEG C, resistance to huge tension / pressure of 100 tons, vibration resistance, large torque resistance, no deformation, ultra high rigidity and strength, light dead weight and the like, and the provided rod piece can be taken as key bearing parts on spacecrafts.

Owner:莫凡

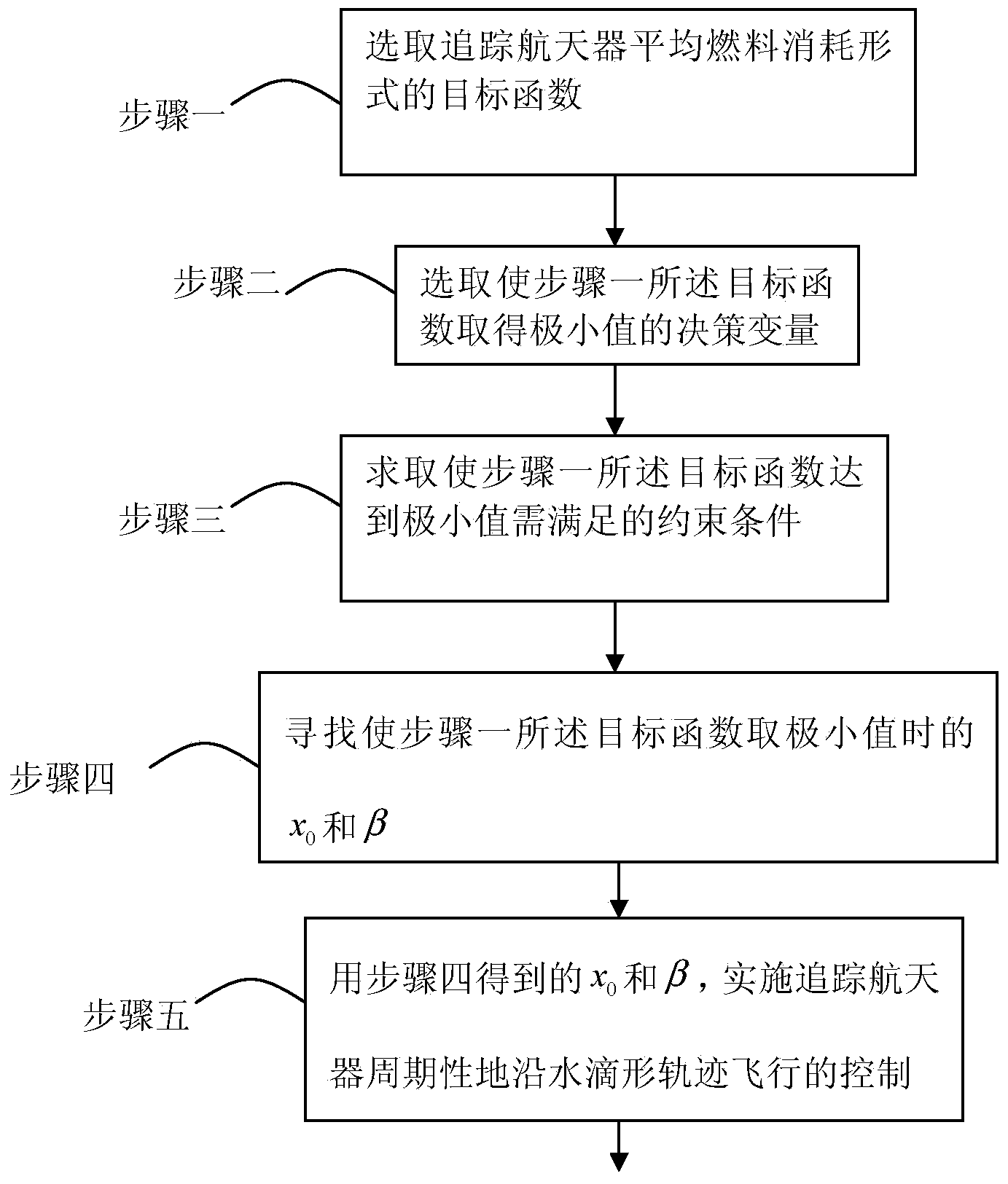

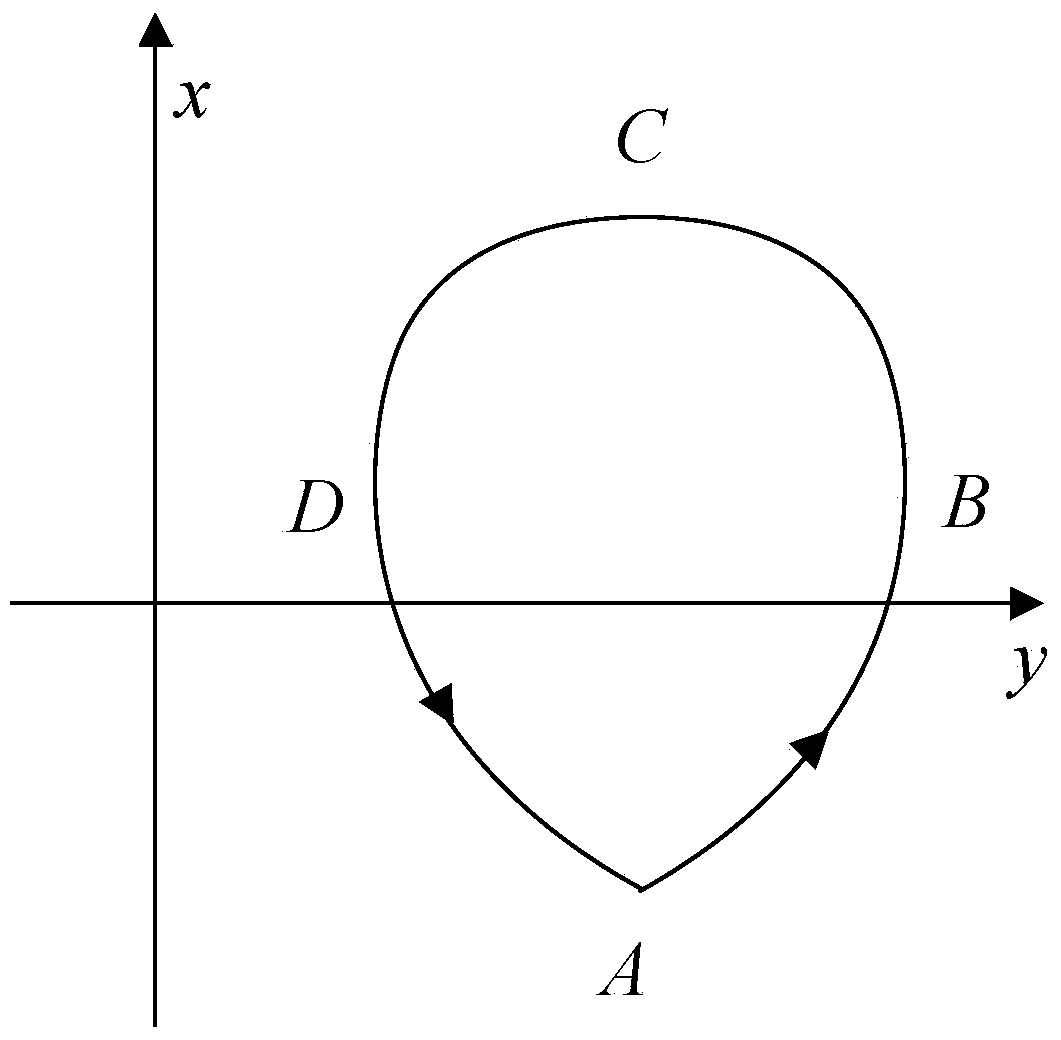

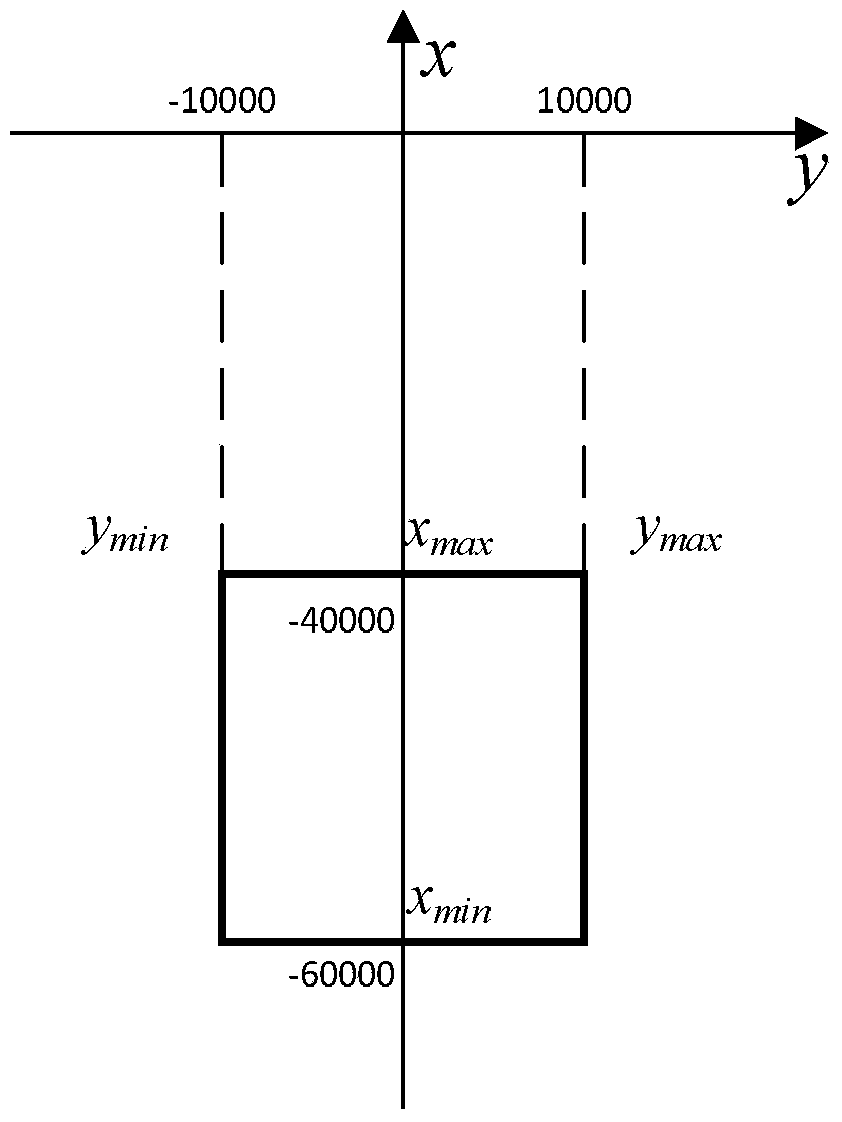

Parameter optimization-based spacecraft single-pulse drop-shaped fly-around track hover control method

The invention discloses a parameter optimization-based spacecraft single-pulse drop-shaped fly-around track hover control method, belongs to the technical field of spacecraft track control, and aims to solve the problems that the existing fixed point hover method requires the control quantity to be continuous and the existing single-pulse drop-shaped fly-around method realizes hovering without considering the fuel consumption of a tracking spacecraft hovering on the track plane of a target spacecraft due to long hovering time. According to the technical scheme, the target spacecraft is positioned on a circular high-orbit track, the relative position range has upper and lower boundaries, the single-pulse drop-shaped fly-around track scheme with parameter optimization is adopted for implementation, and the scheme with the least performance index value, namely fuel consumption, is discovered on the basis that the entire drop-shaped track meets the position range requirement of hovering in consideration of the relative motion coordinate system based on a hill equation. The method is mainly used for track control of the spacecraft.

Owner:HARBIN INST OF TECH

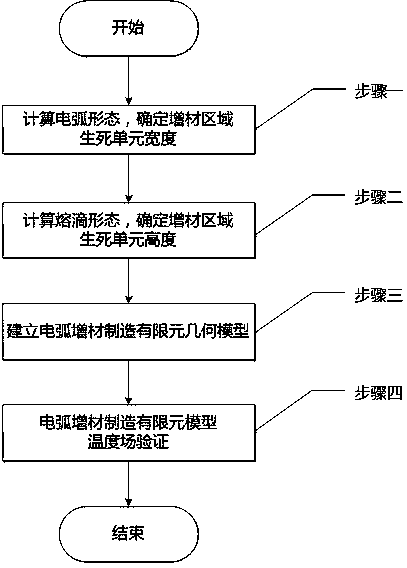

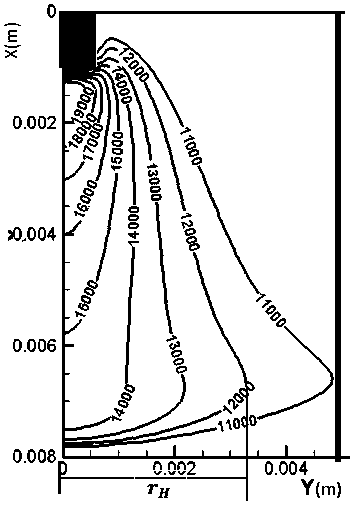

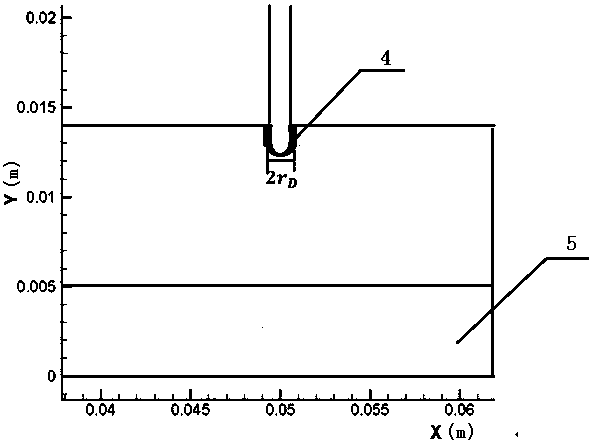

Arc additive manufacturing finite element modeling method

ActiveCN107066700AReduce the amount of experimentsImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsGeometric modelingElement modeling

The invention discloses an arc additive manufacturing finite element modeling method. The method comprises the following steps of: calculating an arc shape and determining the width of an additive area birth-death element; calculating a molten drop shape and determining the height of the additive area birth-death element; establishing an arc additive manufacturing finite element geometric model according to the width of the additive area birth-death element and the height of the additive area birth-death element; correcting the arc shape and the molten drop shape through verifying the temperature distribution of the arc additive manufacturing finite element geometric model, so as to correct the arc additive manufacturing finite element geometric model. According to the method disclosed by the invention, the geometric size of the additive area birth-death element can be determined before the arc additive manufacturing finite modeling by adopting an arc additive manufacturing simulation process, combining an arc shape simulation technology, a molten drop shape simulation technology and a finite element simulation technology and carrying out experimental verification, so as to realize the correct calculation of arc additive manufacturing finite element simulation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

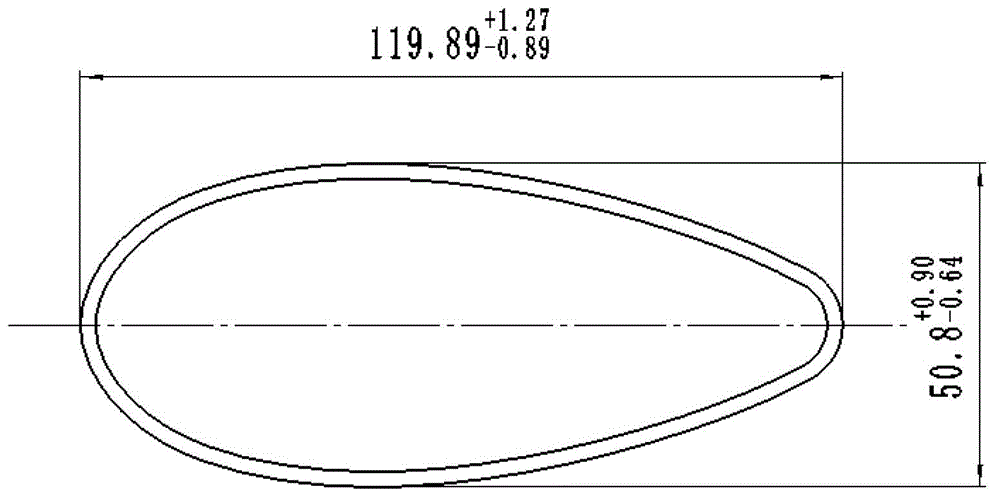

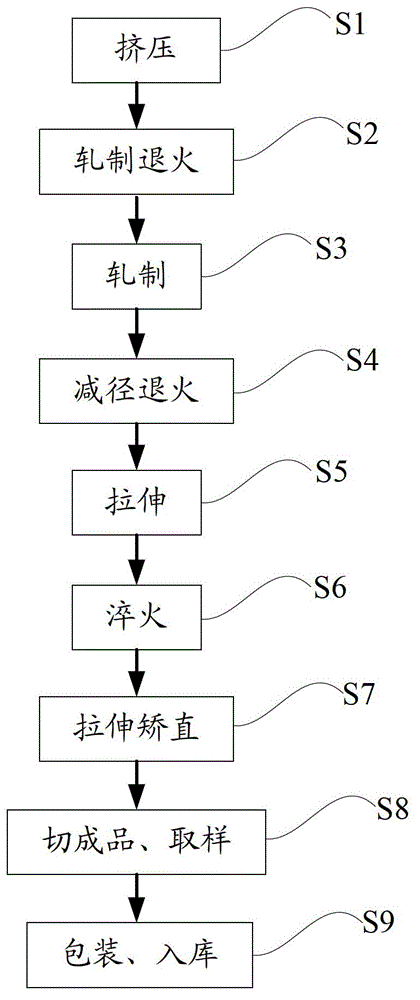

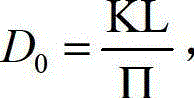

Manufacturing process of aluminum alloy water-drop-shaped thin-wall tubular material

The invention provides a manufacturing process of an aluminum alloy water-drop-shaped thin-wall tubular material, comprising the following steps of: 1) extruding: extruding a casting ingot into a circular tube blank; 2) rolling and annealing: carrying out annealing treatment on the circular tube blank; 3) rolling: rolling the circular tube blank and reducing the diameter and the wall thickness of the circular tube blank; 4) reducing the diameter and annealing: carrying out annealing treatment on the circular tube blank with the reduced diameter; 5) stretching: stretching the circular tube blank with the reduced diameter and stretching into a water-drop-shaped tube finished product; 6) quenching: carrying out quenching treatment on the water-drop-shaped tube finished product; and 7) stretching and strengthening: carrying out stretching and strengthening on the water-drop-shaped tube finished product. According to the manufacturing process, the circular tube blank is obtained by extruding the casting ingot; the manufacturing of the water-drop-shaped thin-wall tubular material can be realized through direct molding of a rolling and stretching process of the circular tube blank; the subsequent machining is reduced and the metal utilization rate is improved; and the machining difficulty is reduced and the machining time is shortened, so that the production efficiency is improved.

Owner:SOUTHWEST ALUMINUM GRP

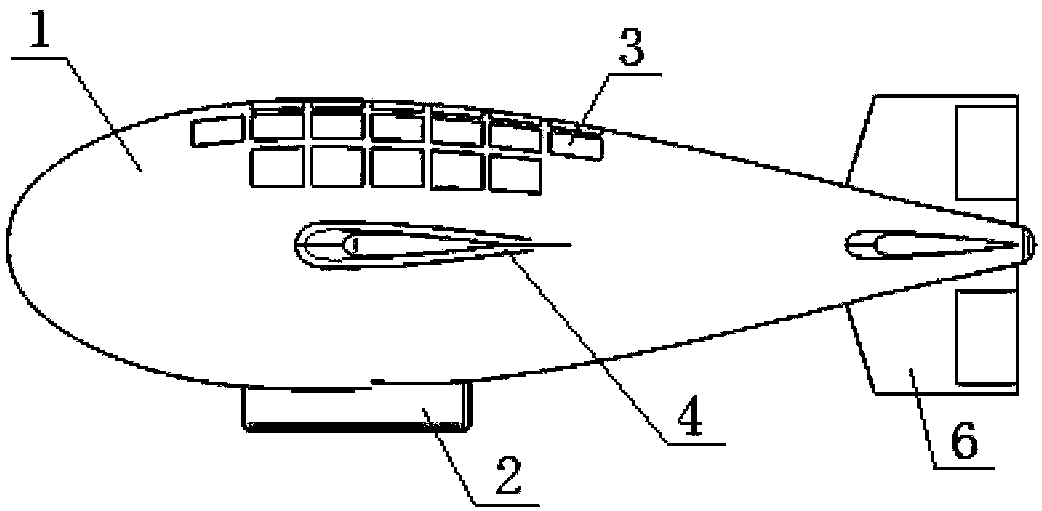

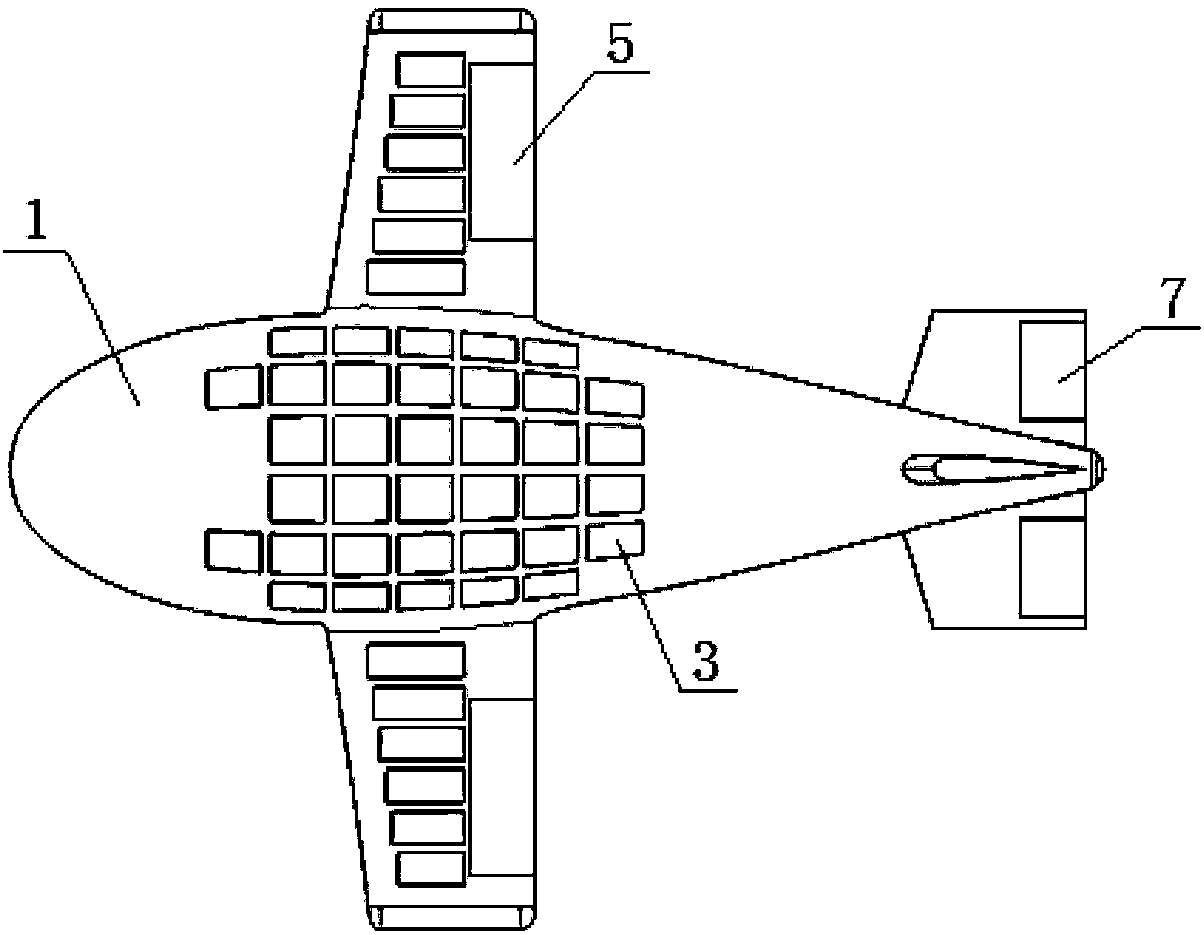

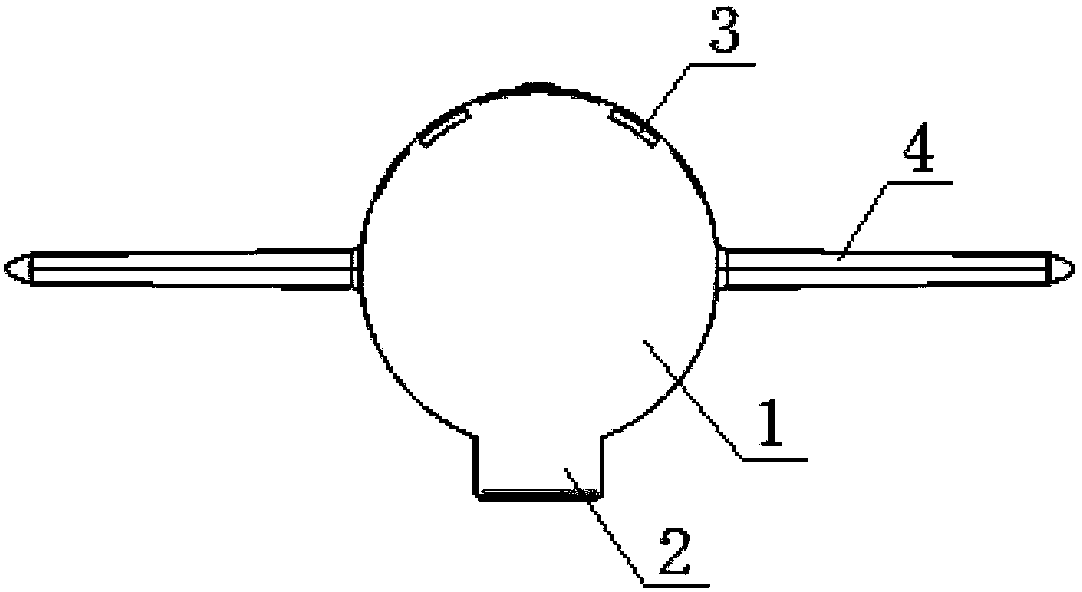

Variable density unmanned airship based on solar energy

InactiveCN108058802AReduce dependenceAchieve energy saving effectBatteries circuit arrangementsElectric powerVolumetric Mass DensityEngineering

The invention provides a variable density unmanned airship based on solar energy. The variable density unmanned airship comprises an airship body (1), lifting airfoils (4), an empennage (6) and solarcell panels (3), wherein the airship body (1) is in a drop-shaped symmetrical streamline shape, the cross empennage (6) is arranged at one end of the tip of the airship body (1), the lifting airfoils(4) are symmetrically arranged at the two sides of the airship body (1), the solar cell panels (3) are laid on one side, facing the sun, of the two lifting airfoils (4) and the airship body (1), a power device (9) for controlling the airship body (1) to float or sink is arranged inside the airship body (1), and pipelines which extend to the two ends of the airship body (1) and supply air inlet andexhaust to the airship body are connected to the two sides of the power device (9) respectively. By means of the variable density unmanned airship, extra energy sources are not needed, and the airship can be on guard in the air for a long time. Through the density change of inflation and deflation of a compressor itself, floating and sinking are achieved; the airship is powered by the solar energy, and the pollution is not caused.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

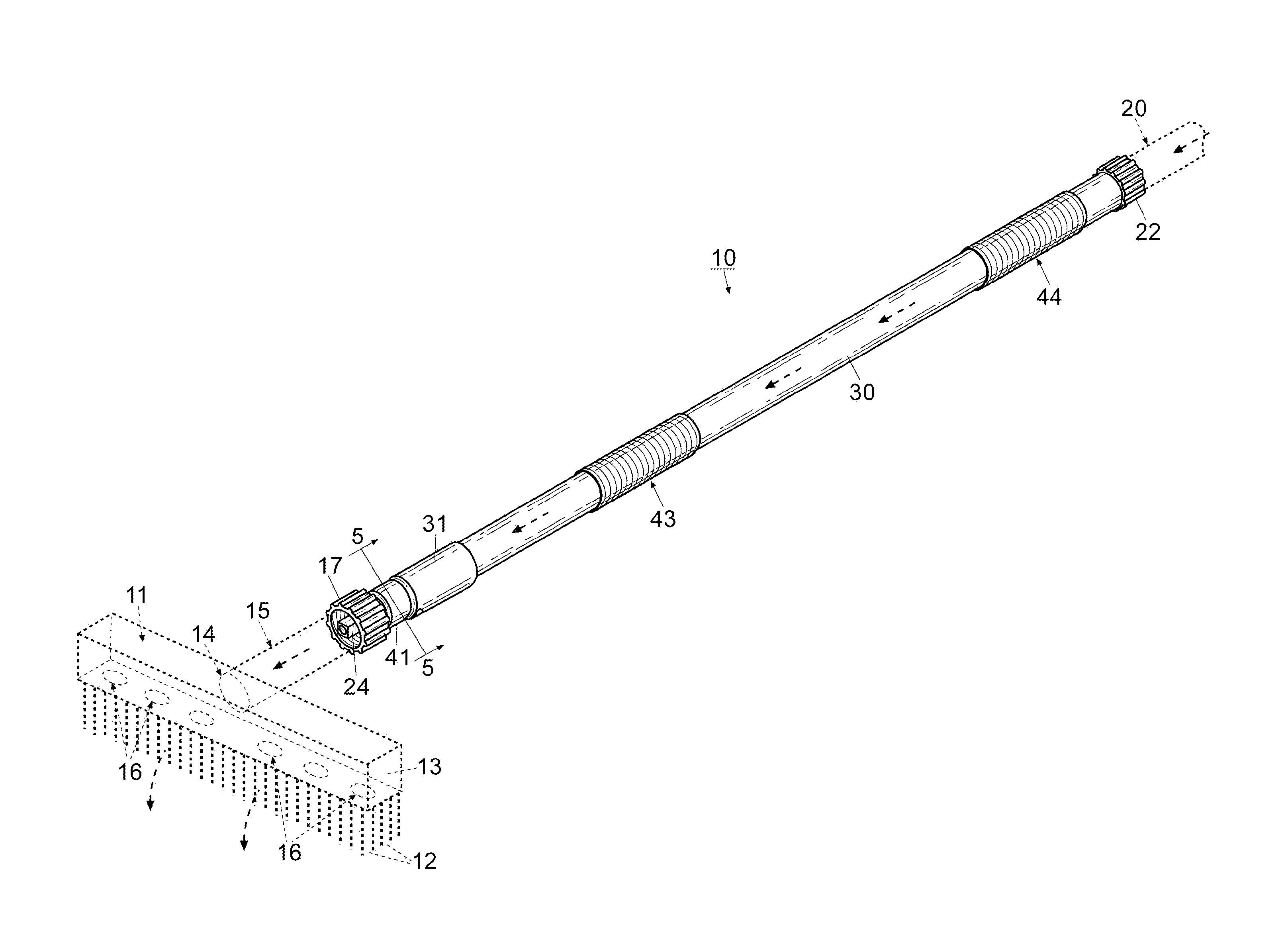

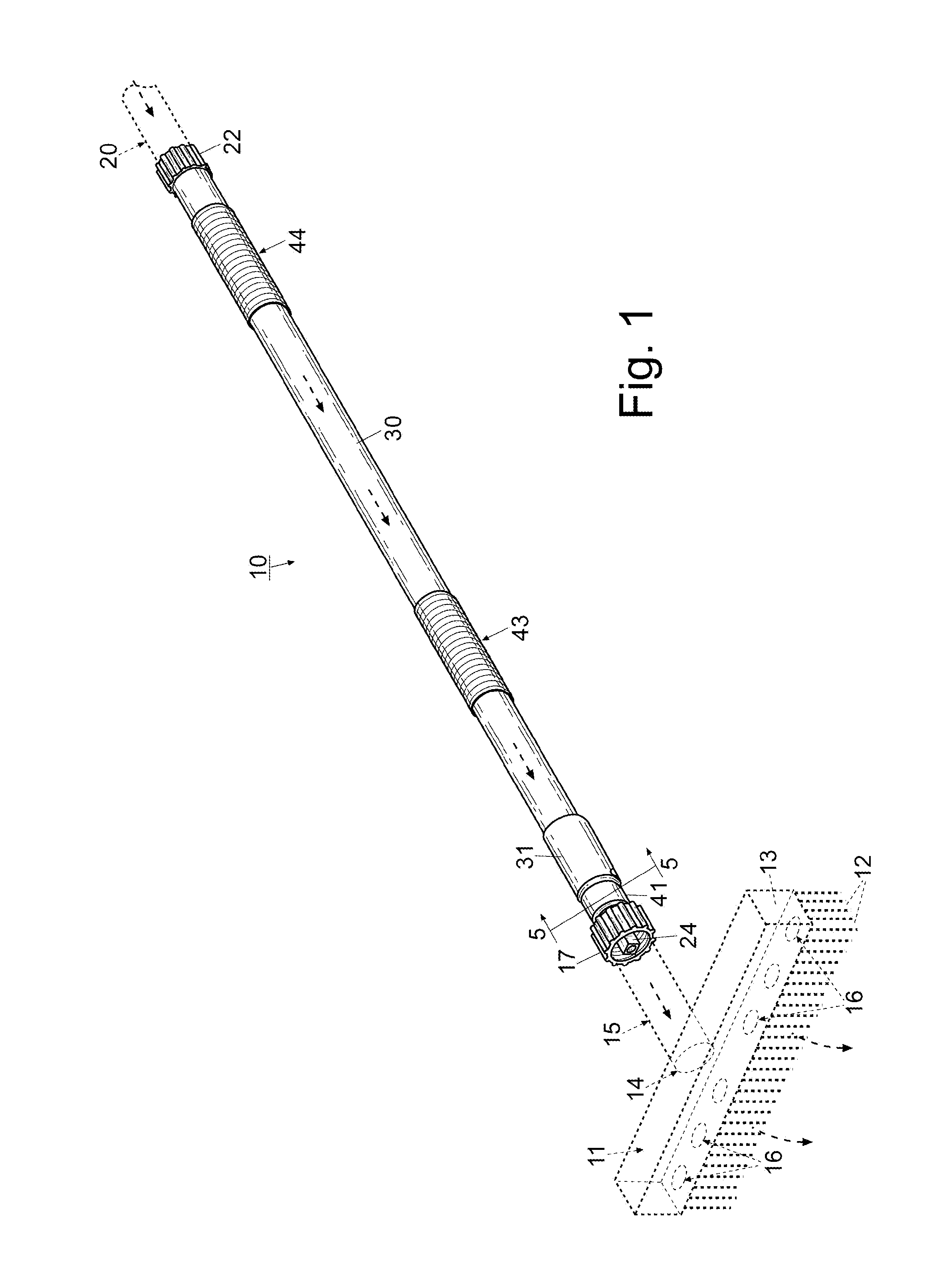

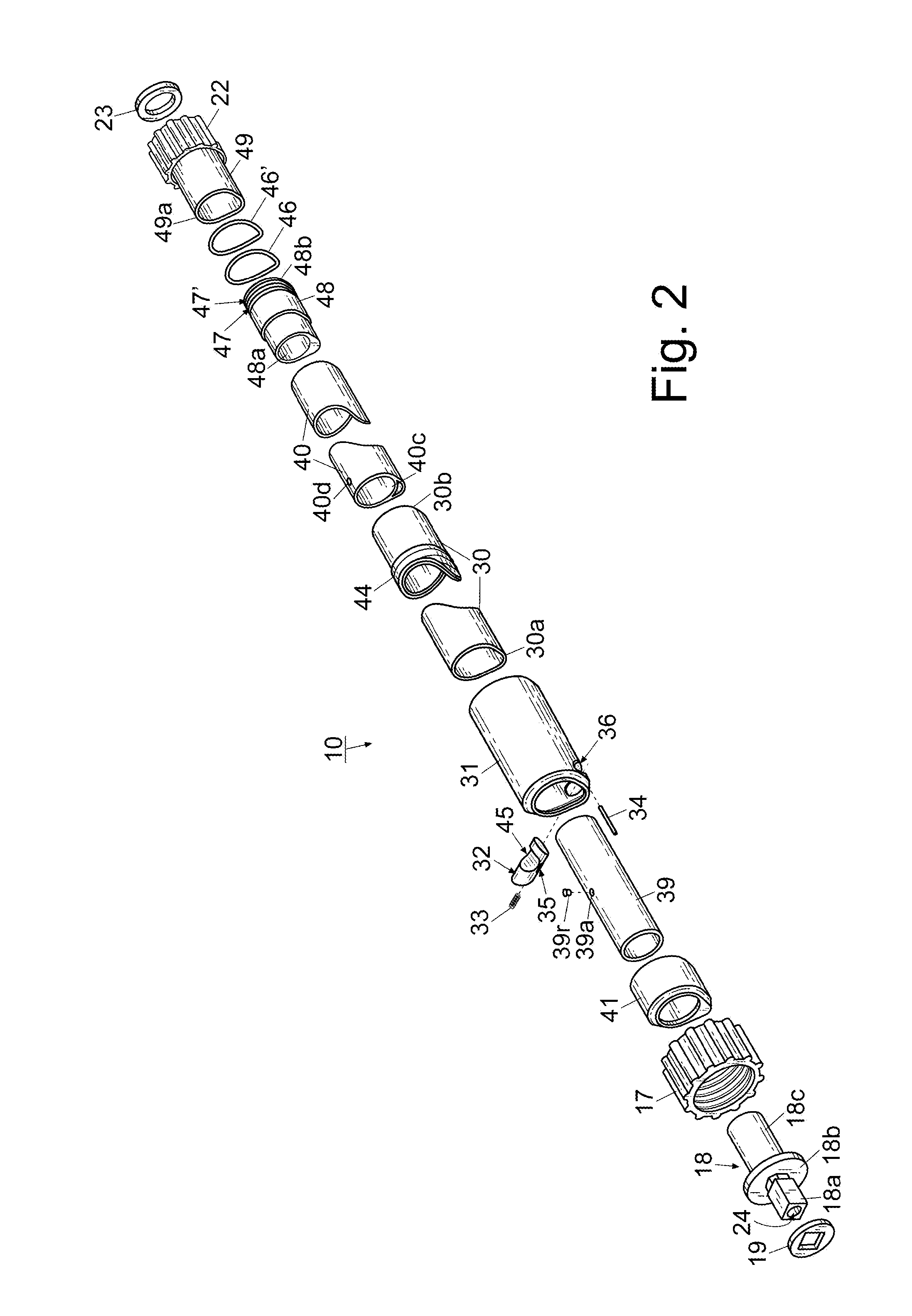

Flow thru telescoping handle and method

A flow thru telescoping handle for use with brush heads and other tools includes a telescoping handle having a tear-drop shaped cross section to increase the strength and improve its functioning capabilities. A spring loaded tension pin is mounted along the bottom of the outer section of the handle which is operated by finger pressure to engage and release it from the inner handle section. A method for adjusting the length of the telescoping handle is also described using the tension pin.

Owner:CAMCO MFG LLC

Decorative tile with diamond shining effect, colorful dry particles and preparation method of colorful dry particles

The invention discloses a decorative tile with a diamond shining effect, colorful dry particles and a preparation method of the colorful dry particles. A crystallization pre-treatment step is added for diamond shining frits, so that the frits contain crystals of a considerable quantity and the considerable sizes, a dry particle glaze mode is adopted to conduct glazing, the time required for crystal nucleation growth of crystal glaze is greatly shortened, and the temperature requirement of the crystal nucleation growth of the crystal glaze is reduced; the dry particle glaze mode is more suitable for the condition of the quick firing period for 50-90 minutes for an existing wall and floor tile roller kiln, and application occasions are added. The decorative tile utilizing the colorful dry particles is bright in color and specific in characteristics, and under irradiation of light, the decorative tile similar to a diamond is shiny and dazzling and achieves an ornamental function with finecrystal stripes of different shapes and sizes in a well-defined silver oil drop shape.

Owner:佛山市禅城区科捷陶瓷原料有限公司

Impeller

InactiveUS8025479B2Improve hydraulic efficiencyEasy to pumpSpecific fluid pumpsPropellersLeading edgeEngineering

A pump impeller for a centrifugal pump. The impeller is defined by a shroud rotatable about an axis of rotation. At least two pump vanes extend axially from the shroud, each of the vanes configured as a blunted tear drop shape and having an inside wall and an outside wall, the leading edges of which are interconnected by a blunt wall. The trailing edges of the inside and outside walls merge together. A substantially constant width flow channel is defined between the blunted wall of one vane and a confronting surface defined by an inside wall of the other vane. The vanes are tapered in the axial directions by inclining the inside wall of each vane radially outwardly.

Owner:GORMAN RUPP COMPANY

Dish-shaped underwater gliding robot

ActiveCN106347609AReduce the dissipation rateSmooth rotationUnderwater equipmentHigh energyGravity center

The invention provides a dish-shaped underwater gliding robot, which relates to an underwater detection robot, and solves the problems of poor hydrodynamic performance, high energy consumption and poor cruising ability of two underwater detection robots. The dish-shaped underwater gliding robot comprises a main casing, wherein the main casing is in a water drop shape; the main casing mainly consists of an upper half cabin and a lower half cabin in sealed butt joint; the longitudinal section of the main casing uses an NACA airfoil profile; an ascending and sinking adjustment mechanism used for controlling the ascending and sinking of the robot is arranged in the upper half cabin; an electromagnetic propulsion system used for controlling the navigation of the robot, an alternating current module used for providing a power source for the electromagnetic propulsion system, an attitude adjustment mechanism used for controlling the attitude of the robot and a gravity center adjustment mechanism used for controlling the glider tail inclination are arranged in the lower half cabin; a main control module used for controlling the attitude adjustment mechanism, the gravity center adjustment mechanism and the ascending and sinking adjustment mechanism is also arranged in the upper half cabin; a battery pack for transmitting electricity to the alternating current module and the main control module is also arranged in the lower half cabin. The dish-shaped underwater gliding robot is used for underwater navigation detection.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com