Aerial tube-shaped carbon fiber composite rod piece and manufacturing method thereof

A composite material and carbon fiber technology, which is used in the field of carbon fiber composite material tubular rods for aviation and their manufacturing, and can produce structural rods with a load capacity of more than 100 tons, which can solve the problem of heavy weight, high cost, and insufficient rigidity of the components themselves. requirements and other issues, to achieve the effect of super rigidity and strength, simple manufacturing method and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

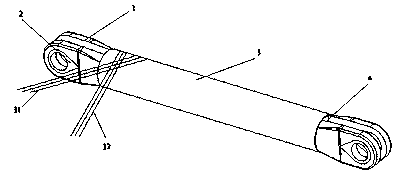

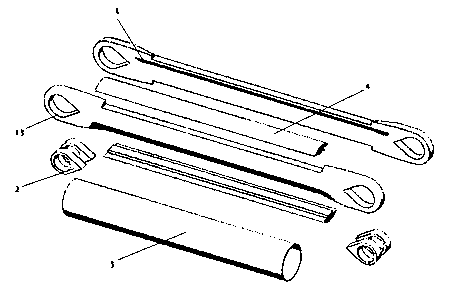

[0052] Such as Figure 1-3 Shown is a bearing rod structure of the present invention. Such as image 3 As shown, the bearing member structure includes:

[0053] Two load-carrying components 1, the two load-carrying components 1 are arranged side by side, wherein, the two ends of each load-carrying component 1 all have an ear part 13 that can be inlaid with a "water drop" type metal bushing 2;

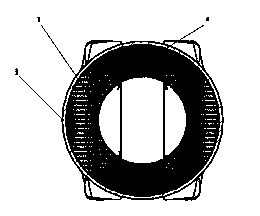

[0054] Two pieces of inner liner 4, the two pieces of inner liner 4 are respectively arranged on the upper part and the lower part of the two pieces of bearing members 1 which are closely arranged, so that the two pieces of bearing members 1 are embedded in the inner liner 4 to form a tubular structure, Such as figure 2 shown; and

[0055] A low-modulus carbon fiber tubular covering layer 3 made by weaving diagonally outside the tubular structure.

[0056] Such as figure 1 Shown is a schematic view of the formation of a bearing rod structure of the present inventi...

Embodiment 2

[0059] Such as Figure 6-8 Shown is the second bearing bar structure of the present invention. Figure 6 It is a schematic diagram of the forming of the bearing rod structure. In this structure, the opposite sides of two load-carrying members 1 are connected and fixed by rivets 5 to form a Figure 7 The cross-sectional structure shown thus simplifies the manufacturing process. Such as Figure 8 As shown, the load-bearing tubular rod for aviation is composed of the following components: two load-bearing components 1, four "drop"-shaped metal bushings 2, several high-strength rivets 5 and special adhesive between metal and resin.

[0060] Such as Figure 9 As shown, although the shape of the molding die is different, its production method is the same as that of the bearing member 1 of Example 1. The only difference is that the high modulus carbon fiber weaving method should take into account that the space of the riveted ear piece should also be filled with high modulus car...

Embodiment 3

[0062] Such as Figure 12-14 Shown is the third bearing bar structure of the present invention. Figure 12 It is a schematic diagram of forming a load-bearing bar structure in Example 3. This structure simplifies the design on the basis of the structure of Example 1, removes the inner liner, and forms such as Figure 13 The section of aeronautical load-bearing tubular member shown. Such as Figure 14 As shown, the load-bearing bar structure includes: two load-bearing members 1, four "droplet"-shaped metal bearings 2, and an outer covering layer 3, which is simpler than the structures of Embodiment 1 and Embodiment 2. Its manufacture method is almost identical with embodiment 1, embodiment 2, only is molding die 11 (see Figure 15 ) is designed to cancel the difference in the mold cavity formed by the shape of the inner liner 4 . The selection and preparation method of carbon fiber is almost the same.

[0063] The manufacturing methods of the above three load-bearing rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com