Foldable PP cellular board, preparation method thereof and trunk carpet comprising foldable PP cellular board

A technology of honeycomb panels and trunks, which is applied in the field of automotive interior parts, can solve the problems of poor carrying capacity of trunk carpets, difficulty in meeting application requirements, and no help in light weight, so as to improve commodity performance, meet high load carrying capacity and reliability Requirements for folding function, effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

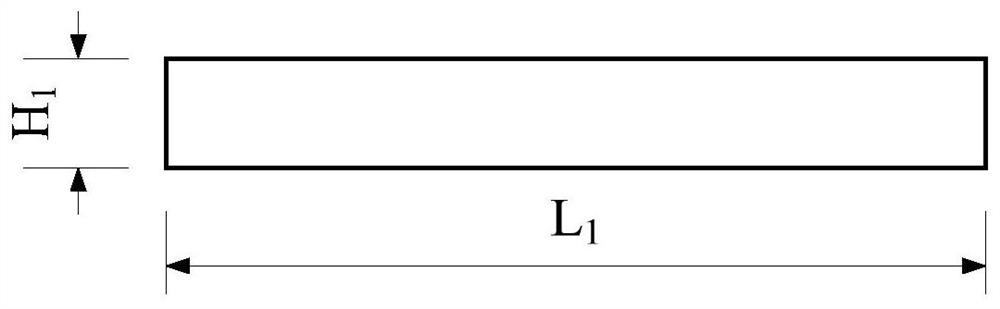

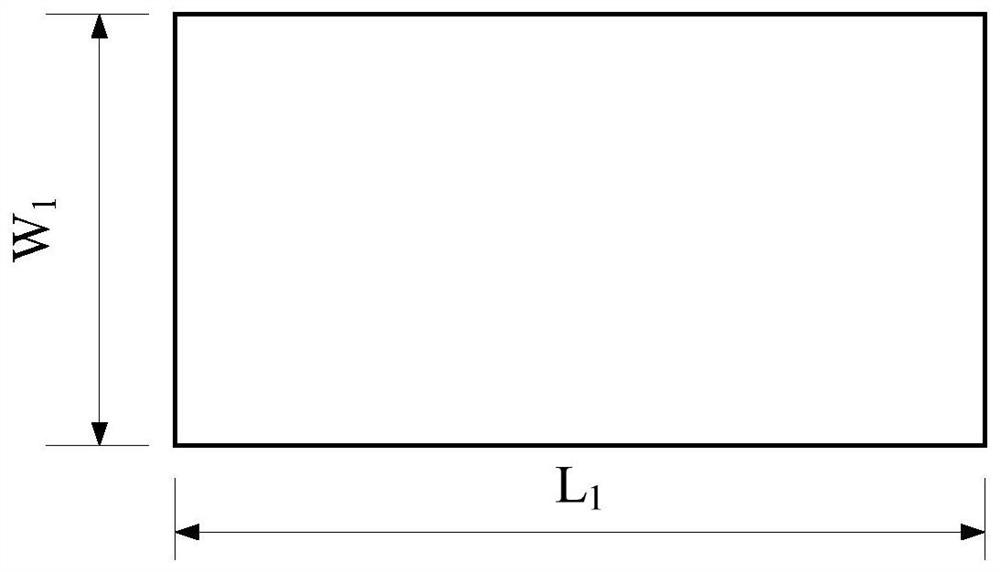

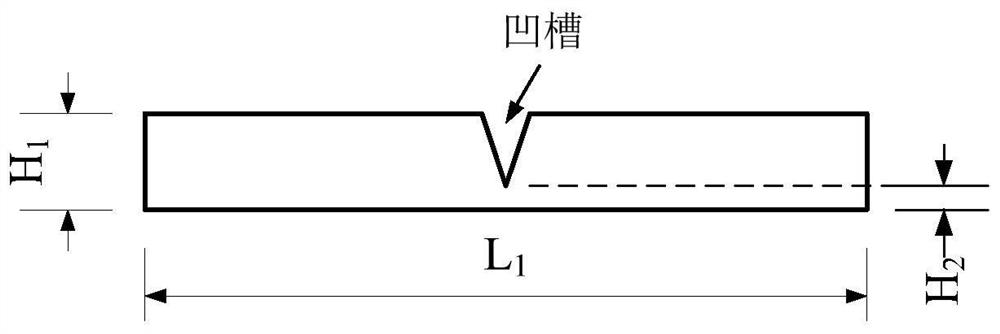

[0049] This embodiment provides a foldable PP honeycomb panel, its structure is as follows image 3 and Figure 4 As shown, including the PP honeycomb panel body, the PP honeycomb panel body is provided with a groove, the end of the groove is located at the edge of the PP honeycomb panel body, and the groove is located at the center line of the long side of the PP honeycomb panel body , and parallel to the short side of the PP honeycomb panel body;

[0050] Among them, the width W of the PP honeycomb panel body 1 800mm, length L 1 is 1000mm, the thickness H of the area except the groove 1 5mm, the thickness H at the groove 2 0.3mm, the cross-sectional shape of the groove is V-shaped, and its opening angle is 30°.

[0051] In this embodiment, the preparation method of the above-mentioned foldable PP honeycomb panel is as follows:

[0052] Put the PP honeycomb panel substrate in the mold, the mold temperature is 150°C, the mold is closed, the control pressure is 12MPa, and...

Embodiment 2

[0056] This embodiment provides a foldable PP honeycomb panel, its structure is as follows Figure 5 and Figure 6 As shown, it includes a PP honeycomb panel body, the PP honeycomb panel body includes a load-bearing area and a weakened area, the thickness of the weakened area is smaller than the thickness of the load-bearing area, a groove is arranged in the weakened area, and the end of the groove The part is located on the edge of the PP honeycomb panel body, the groove is located at the center line of the long side of the PP honeycomb panel body, and is parallel to the short side of the PP honeycomb panel body;

[0057] Among them, the width W of the PP honeycomb panel body 1 800mm, length L 1 is 1000mm; the thickness H of the load-bearing area 1 5mm; the thickness H of the weakened zone except the groove 3 3mm, the width L of the weakened zone 3 100mm; thickness H at the groove 2 0.5mm, the cross-sectional shape of the groove is V-shaped, and its opening angle is 60°...

Embodiment 3

[0063] This embodiment provides a foldable PP honeycomb panel, its structure is as follows Figure 7 and Figure 8 As shown, it includes a PP honeycomb panel body, the PP honeycomb panel body includes a load-bearing area and a weakened area, the thickness of the weakened area is smaller than the thickness of the load-bearing area, a groove is arranged in the weakened area, and the end of the groove The part is located on the edge of the PP honeycomb panel body; the groove is linear along the length direction, and the included angle with the long side of the PP honeycomb panel body is 70°;

[0064] Among them, the width W of the PP honeycomb panel body 1 800mm, length L 1 is 1000mm; the thickness H of the load-bearing area 1 7mm; the thickness H of the weakened zone except the groove 3 4mm, the width L of the weakened zone 3 150mm; thickness H at the groove 2 The cross section of the groove (the cross section perpendicular to the length direction of the groove) is V-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com