Patents

Literature

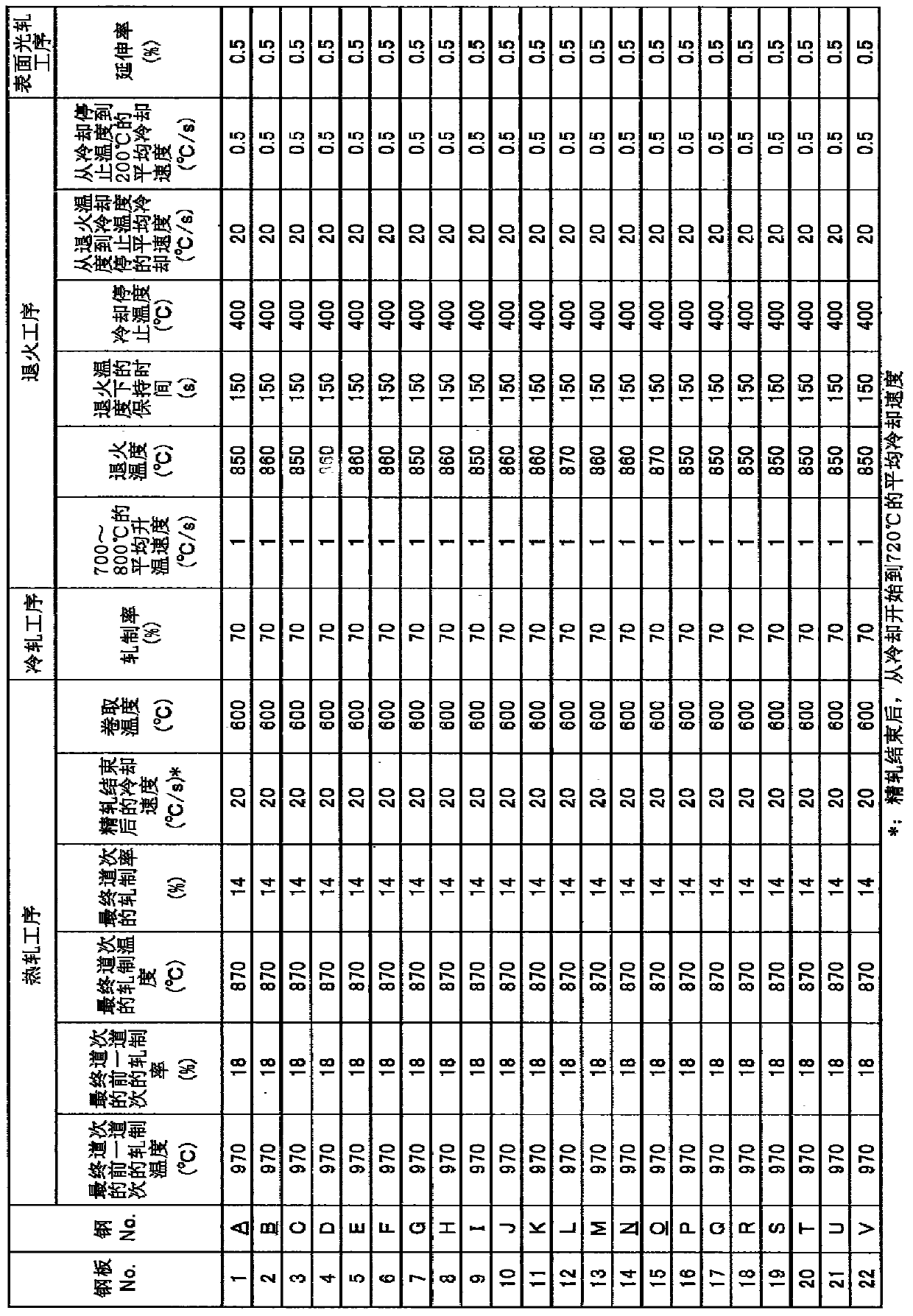

97results about How to "Helps to reduce weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength steel sheet and process for production thereof

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

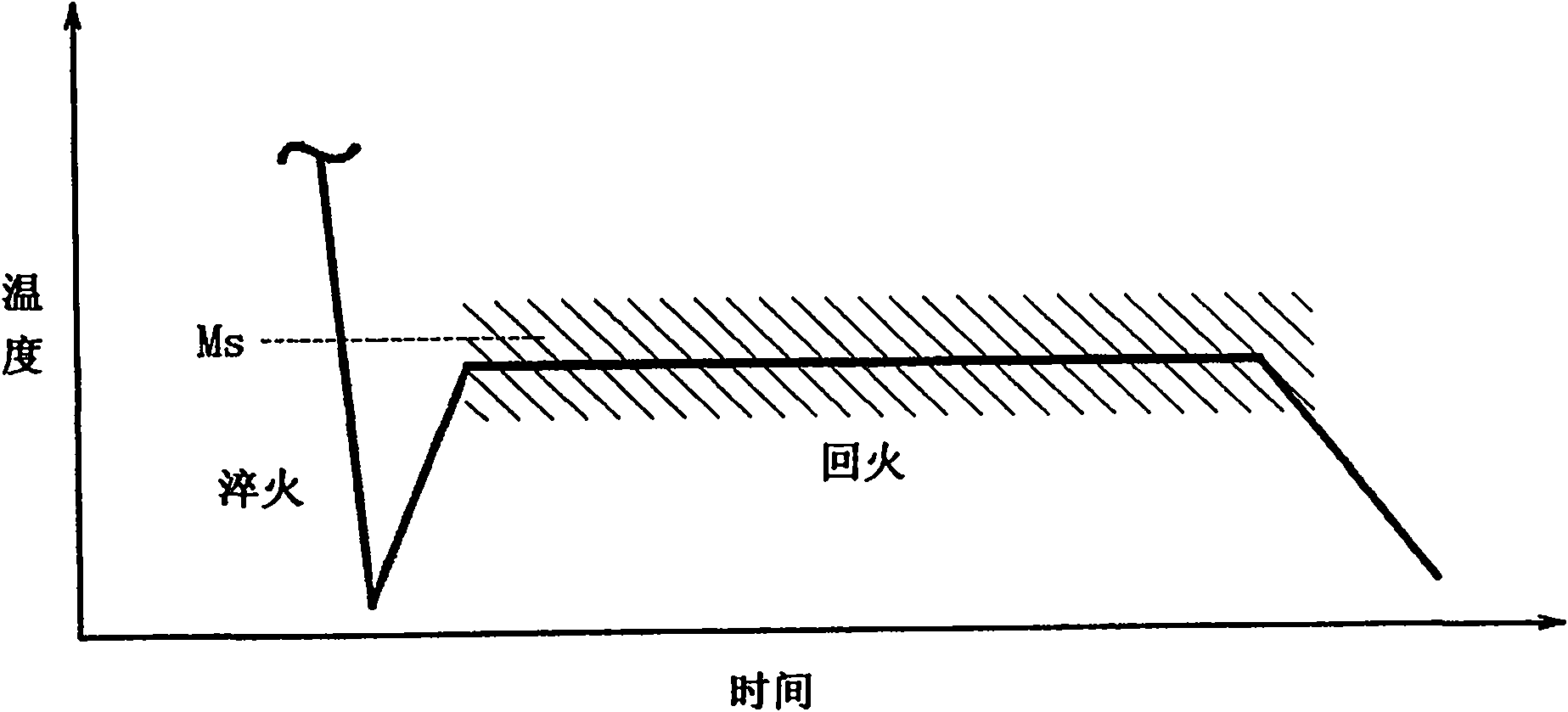

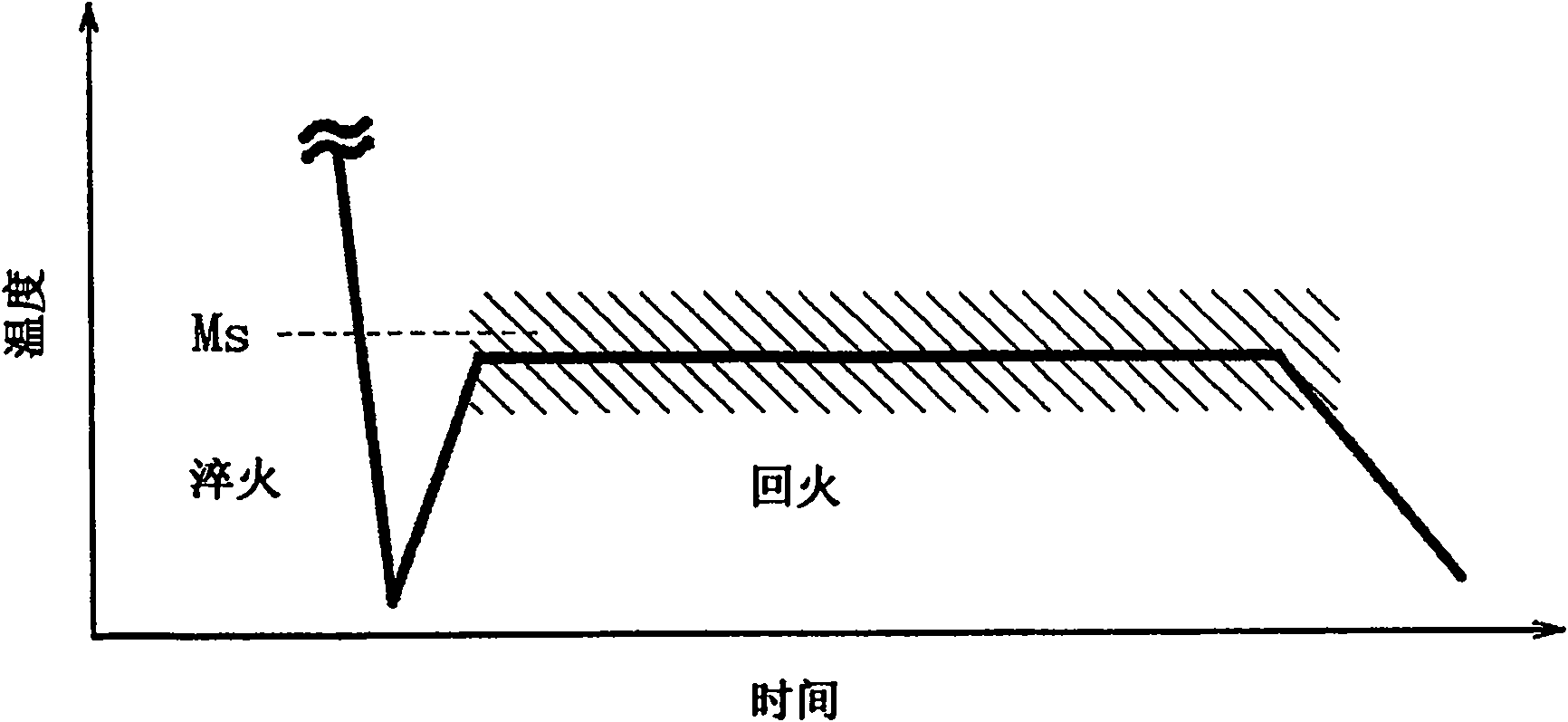

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

High-strength steel sheet and process for production thereof

ActiveCN101932746AHigh strengthEasy to processHot-dipping/immersion processesFurnace typesSheet steelCarbide

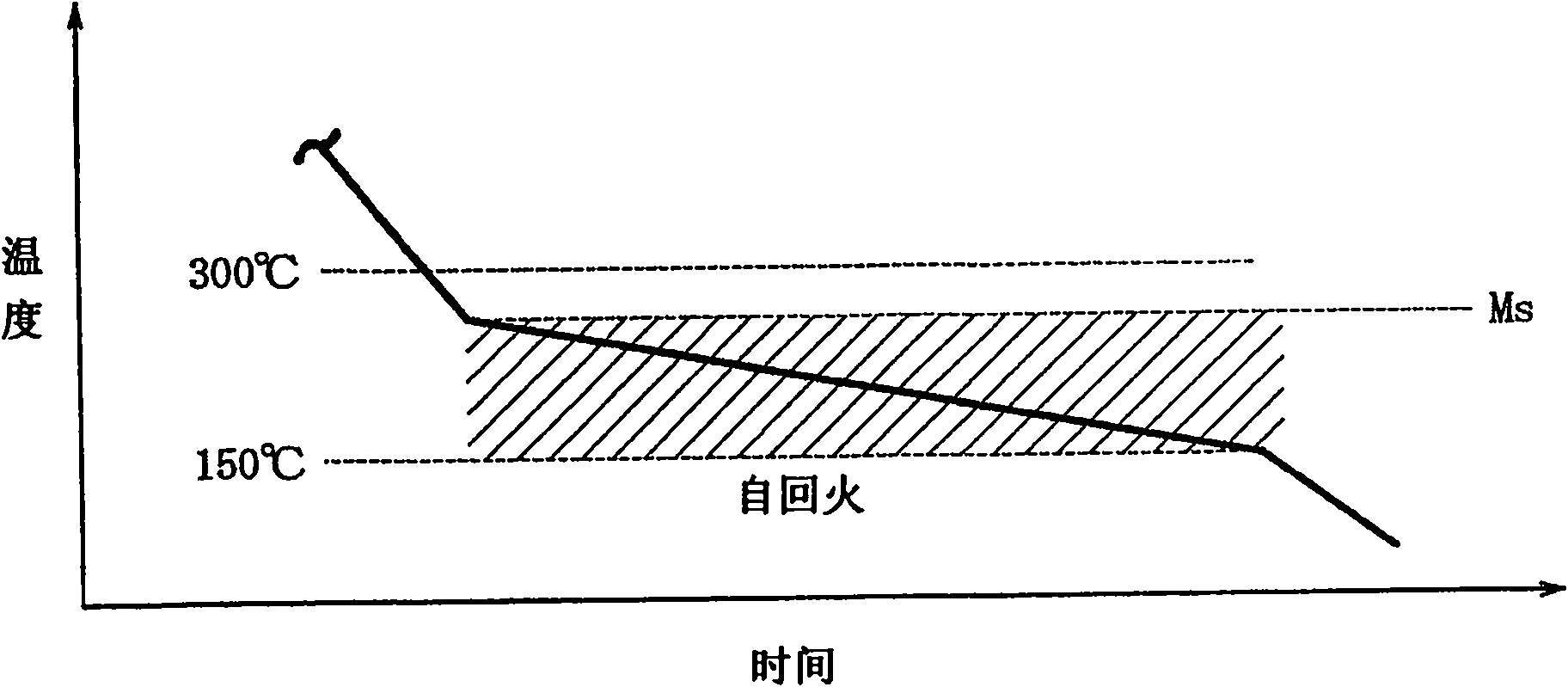

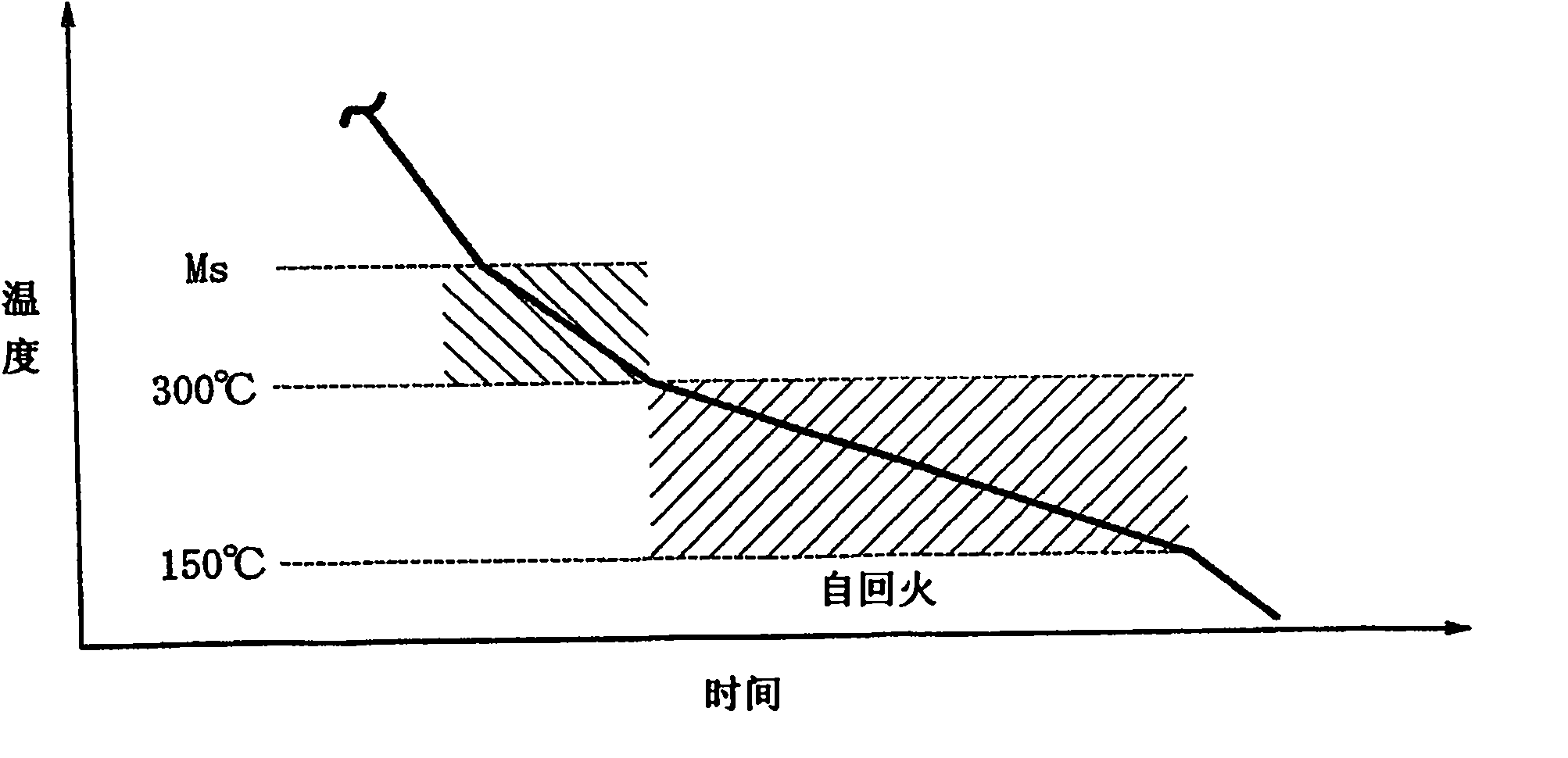

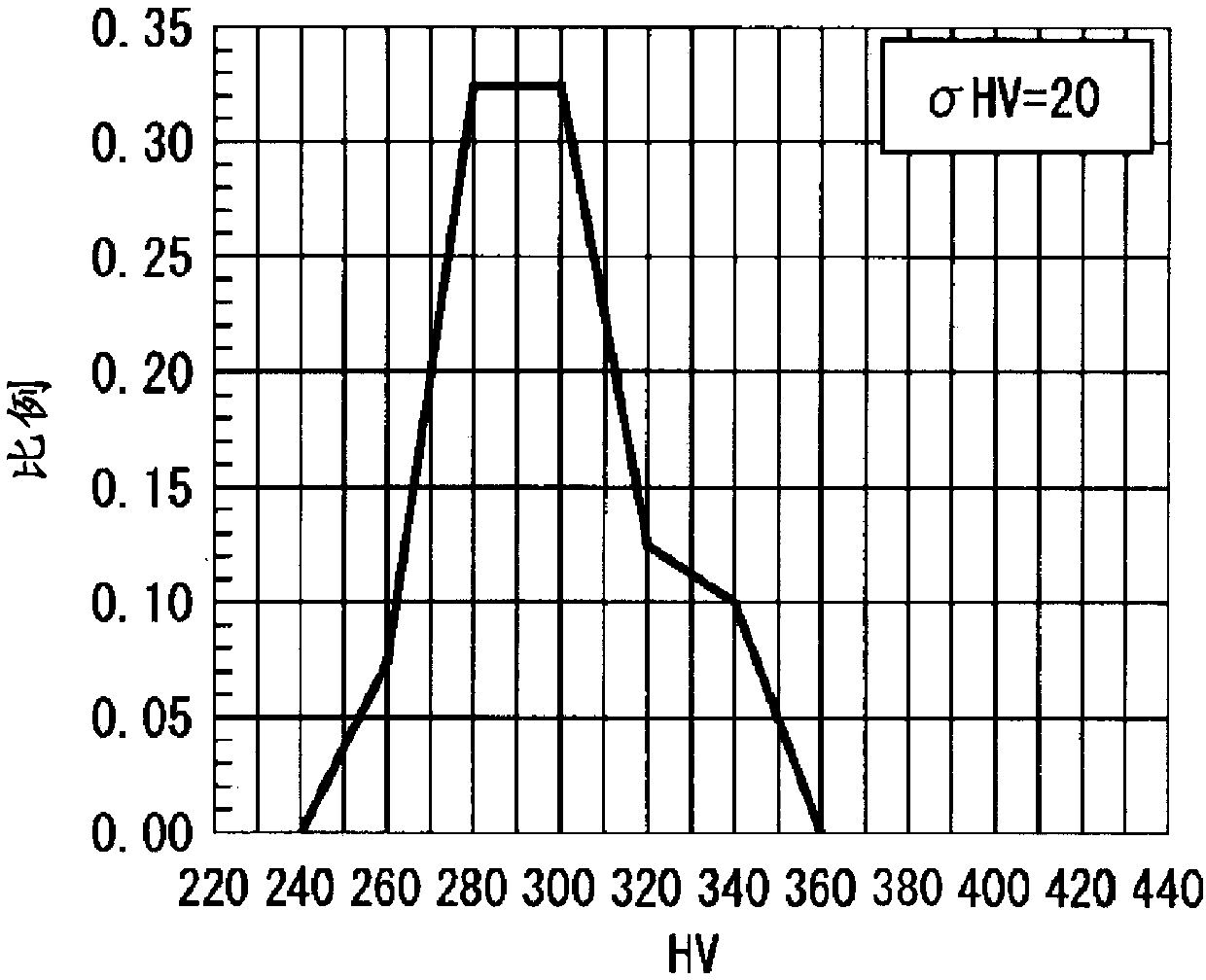

Provided is a high-strength steel sheet having both high strength and excellent formability which exhibits a tensile strength of 900 MPa or above. The steel sheet has both a composition which contains by mass C: 0.1 to 0.3%, Si: 2.0% or less, Mn: 0.5 to 3.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, ferrite: 5 to 80%, autotempered martensite: 15% or more, bainite: 10% or less, retained austenite: 5% or less, and as-quenched martensite: 40% or less and in which the average hardness of the autotempered martensite is 700HV or below and the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

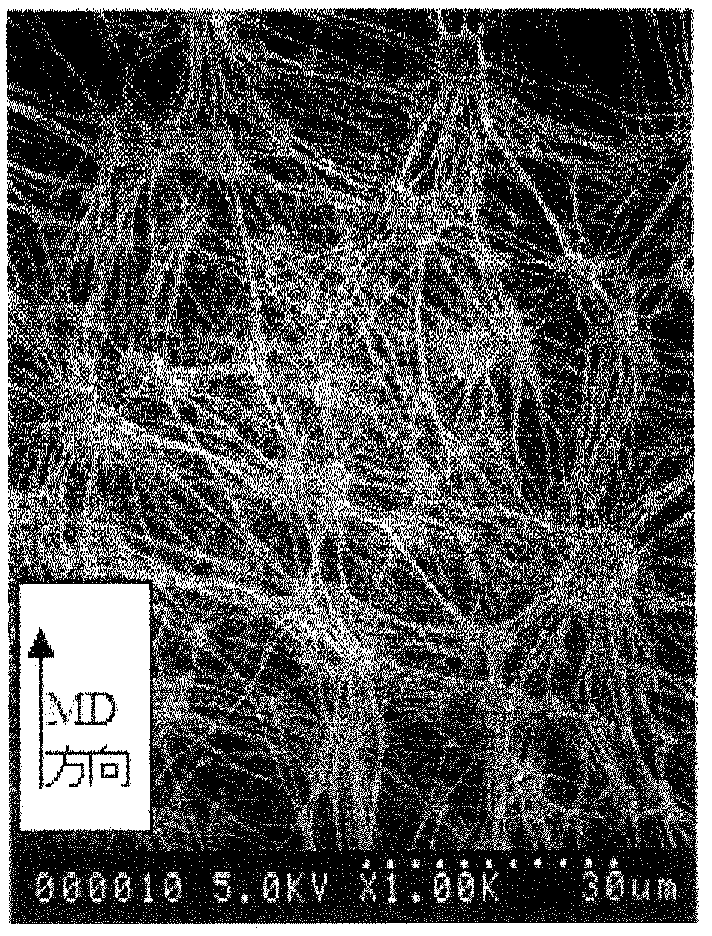

High carbon steel pipe having excellent cold workability, machinability, and quenching properties, and method for manufacturing same

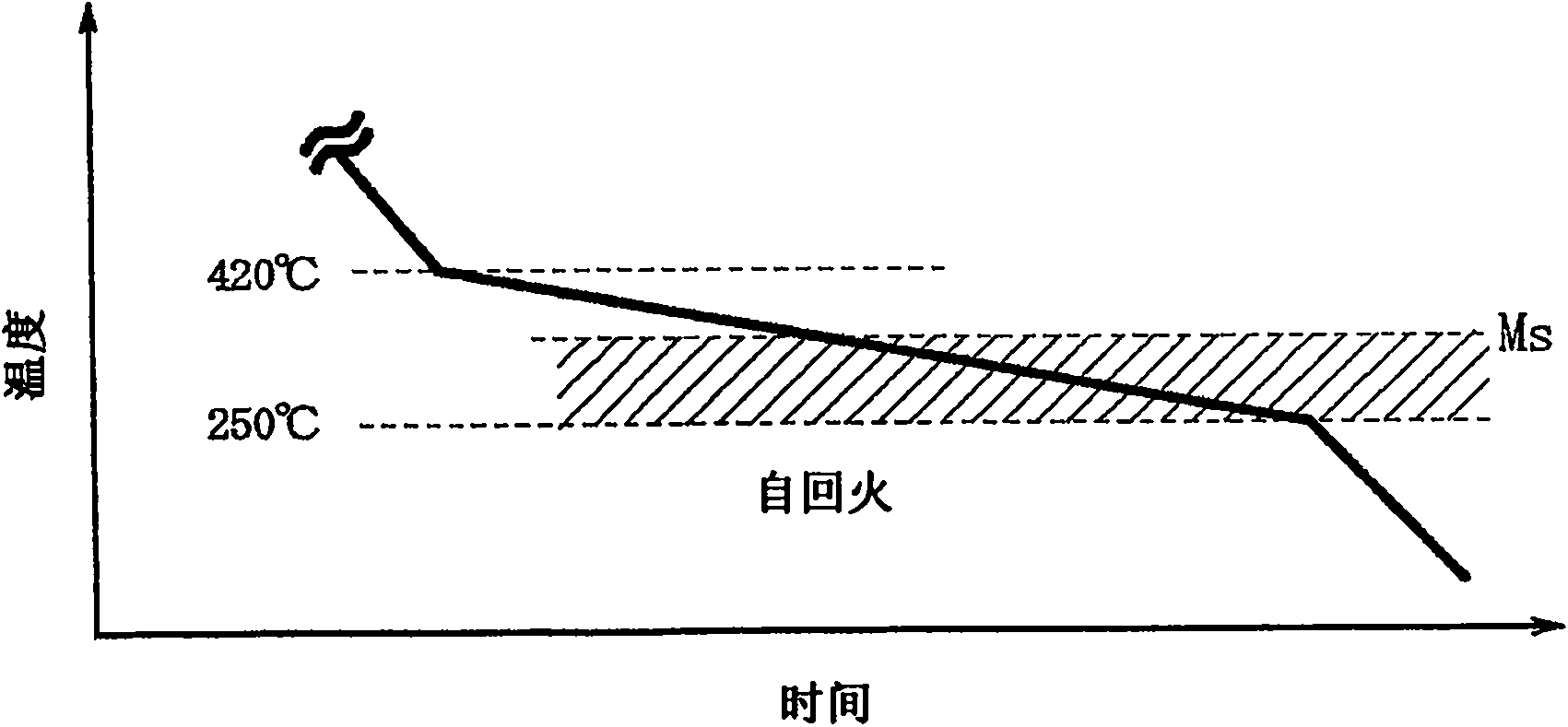

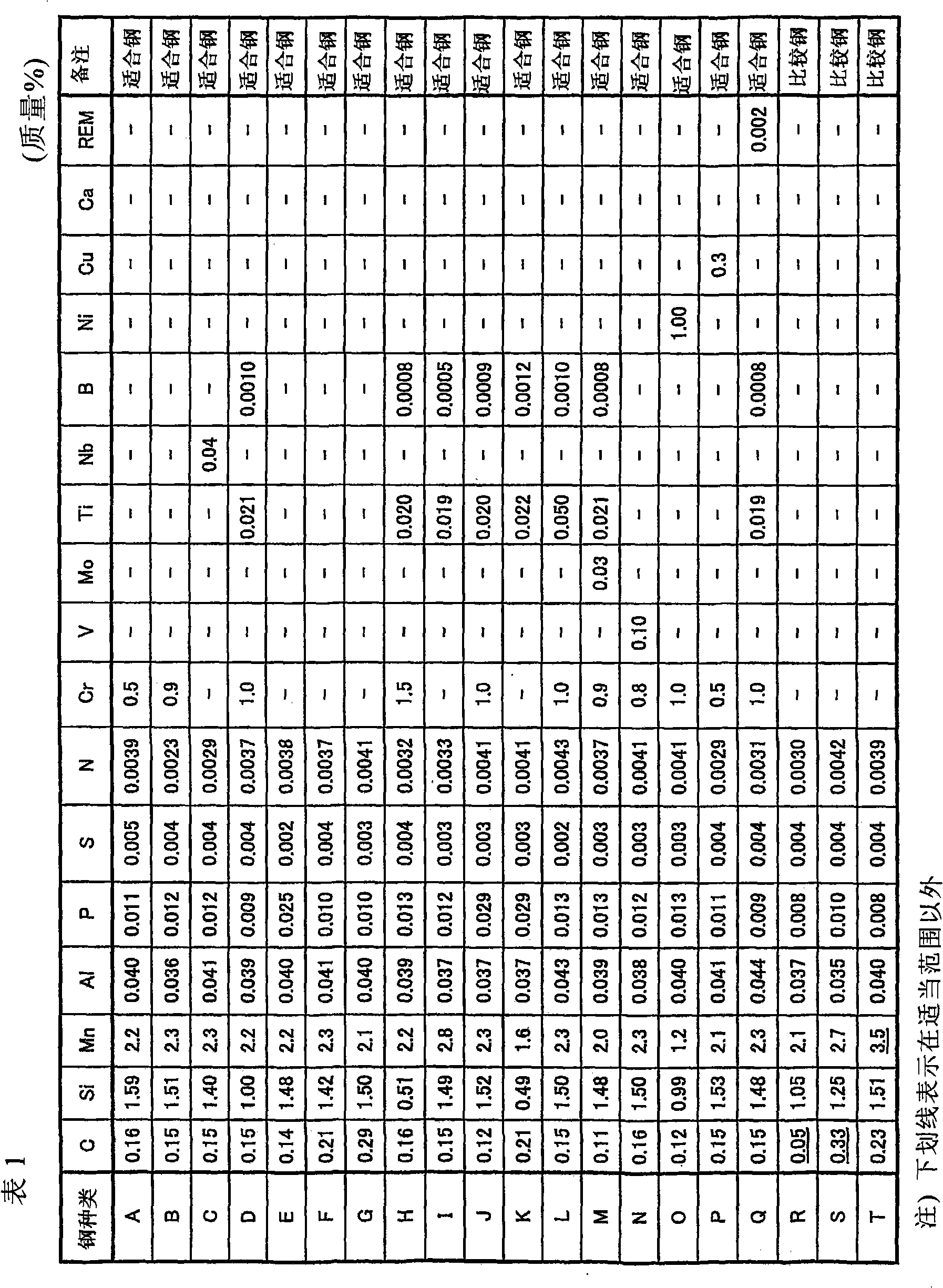

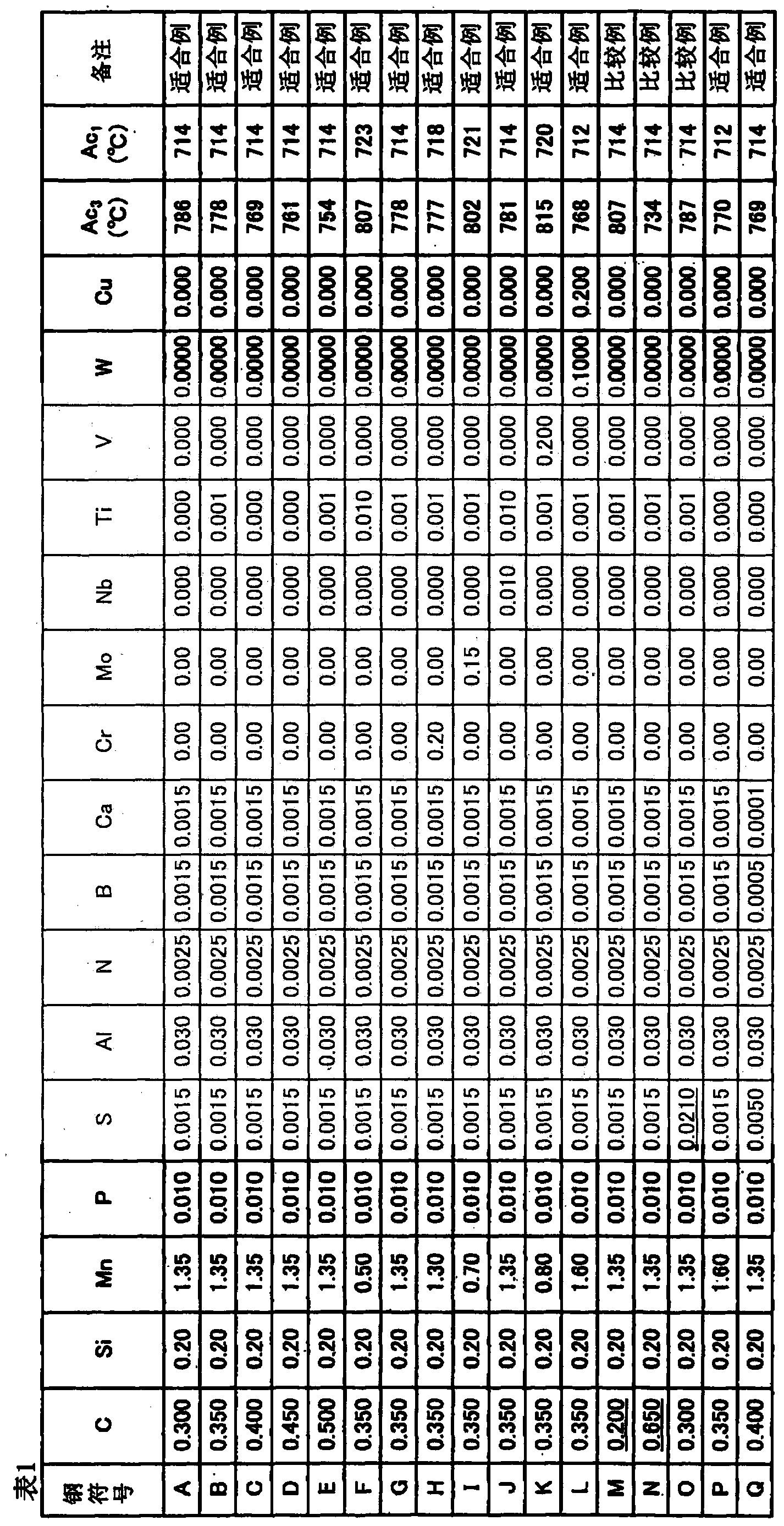

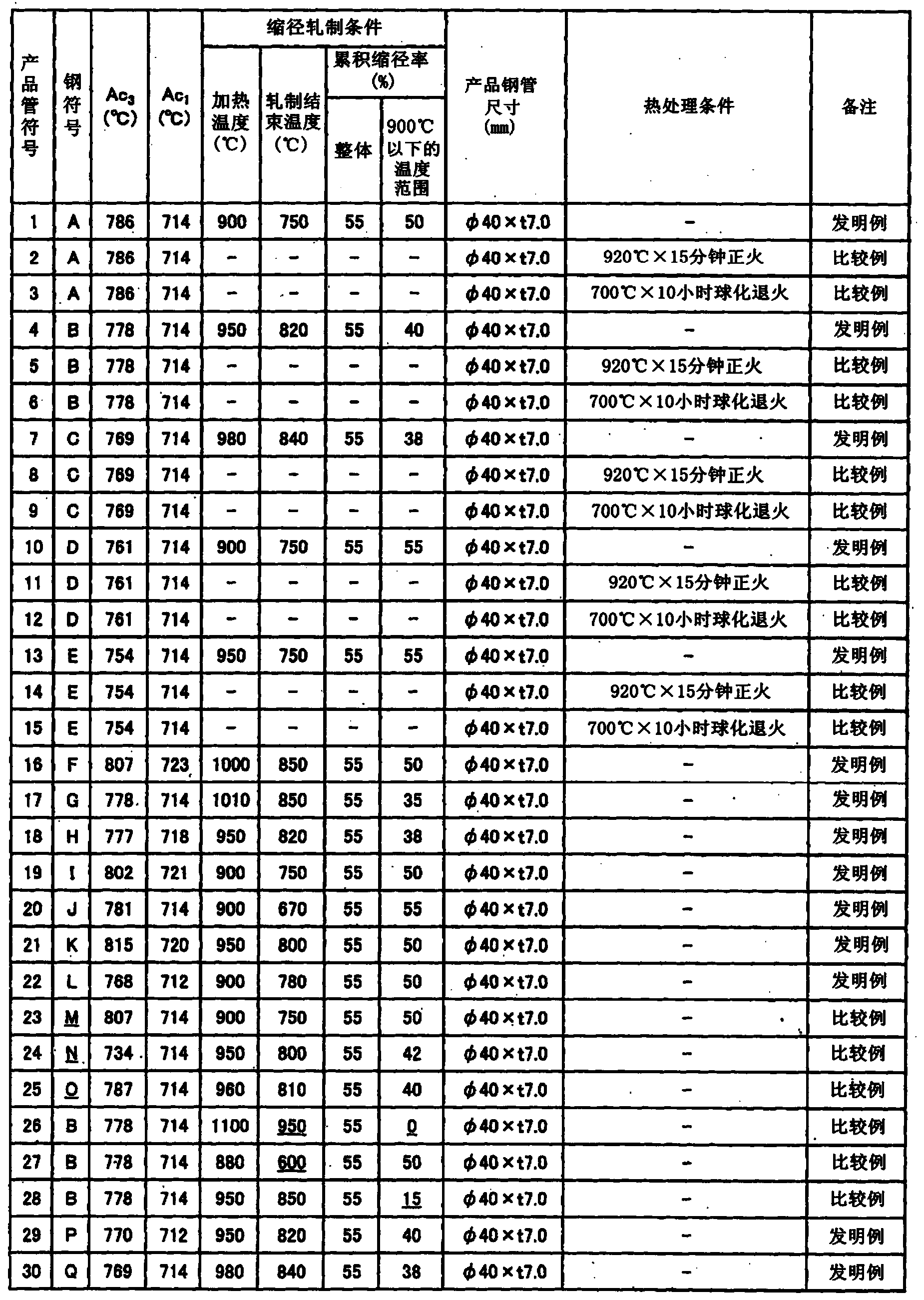

ActiveCN104411846AHelps to reduce weightSimple and cheap to manufactureFurnace typesHigh frequency current welding apparatusMetallurgy% diameter reduction

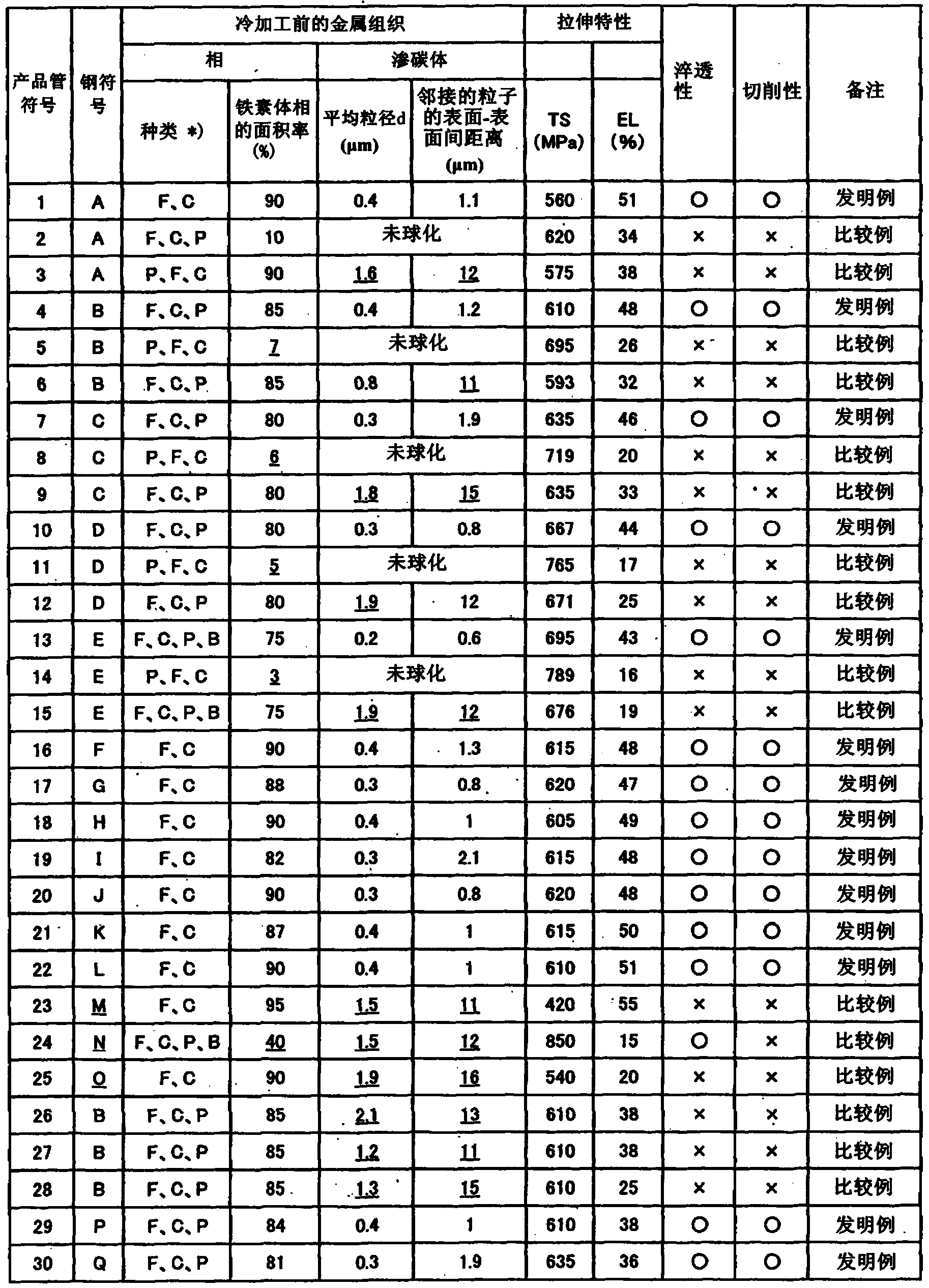

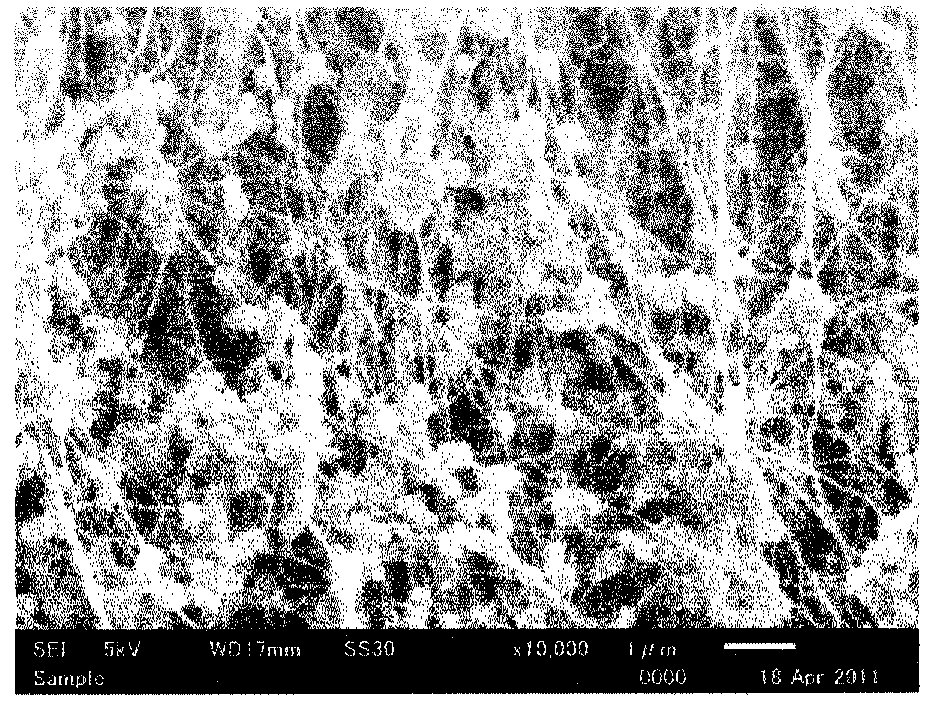

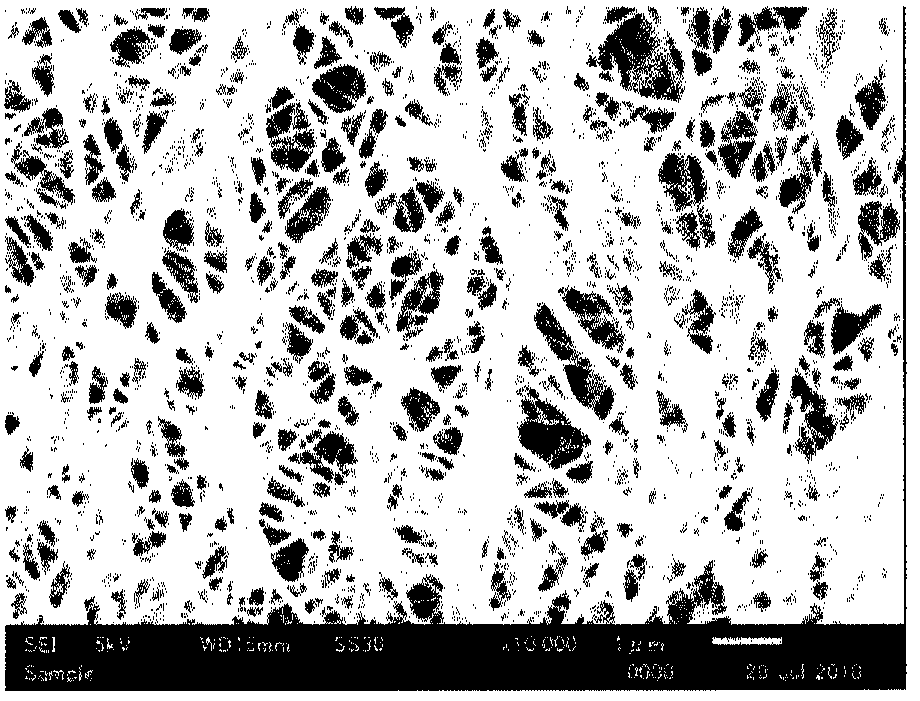

Provided are a high carbon resistance-welded steel pipe having excellent cold workability, machinability, and quenching properties; and a method for manufacturing the same. Specifically, a high carbon steel pipe having a composition containing, by mass, 0.25 to 0.60% of C, 0.01 to 2.0% of Si, 0.2 to 3.0% of Mn, 0.001 to 0.1% of Al, 0.001 to 0.05% of P, 0.02% or less of S, 0.0010 to 0.0100% of N, 0.0003 to 0.0050% of B, and 0.0001 to 0.0050% of Ca, with the remainder made up by residual Fe and unavoidable impurities, is used as a material steel pipe. Heating and soaking is performed to Ac3 transformation point or above, and diameter-reducing rolling is subsequently performed at a rolling finishing temperature of 900°C or above (Ac1 transformation point) and a cumulative diameter reduction ratio of 30 to 70% in a temperature range no greater than 900°C. This makes it possible to obtain, without performing spheroidizing annealing, a structure in which cementite particles having an average particle diameter (d) from 0.1 mum to less than 0.5 mum and in which the average distance (L) between the surfaces of adjacent cementite particles is 0.5 to 10 mum are dispersed in a ferrite phase. In particular, machinability is significantly improved.

Owner:JFE STEEL CORP

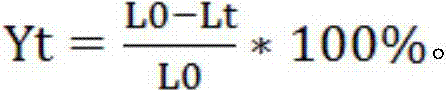

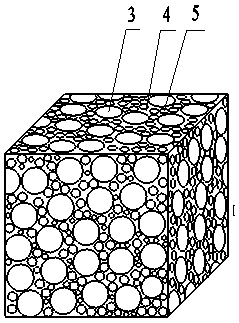

Porous polytetrafluoroethylene film and air filter filtration material

ActiveCN103649189AImprove PF valueSmall weight per unit areaSemi-permeable membranesDispersed particle filtrationAir filterFiltration

Provided is a porous polytetrafluoroethylene (PTFE) film which has a PF value of 36 or more and a weight per unit area of 0.90 g / m2 or less. In this connection, the PF value is equal to {-log(PT(%) / 100) / (PL(Pa) / 9.8}*100. In the formula, PT (permeability) is determined by PT (%) = 100 - CE (%); CE (collection efficiency) is determined by the value that is measured using a dioctylphthalate having a particle diameter of 0.10-0.20 [mu]m at a permeation flow rate of 5.3 cm / second; and PL (pressure loss) is determined by the value that is measured at a permeation flow rate of 5.3 cm / second. This porous PTFE film is suitable as an air filter filtration material.

Owner:NITTO DENKO CORP

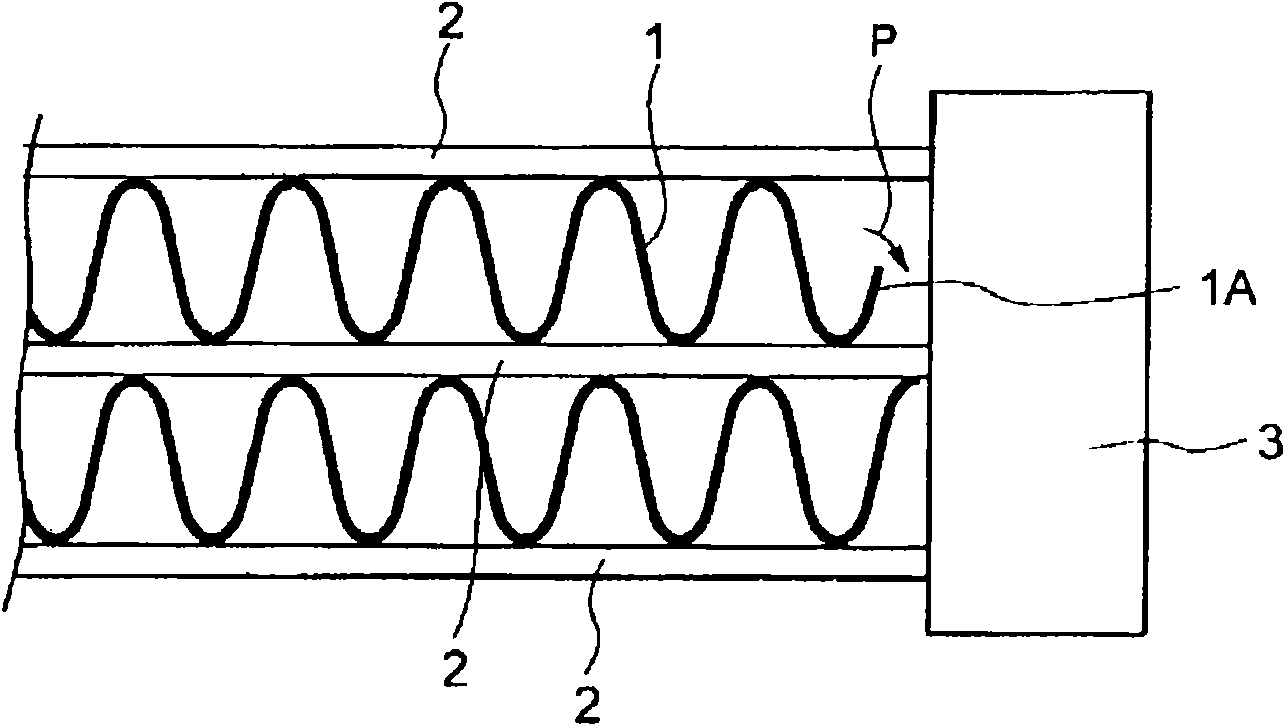

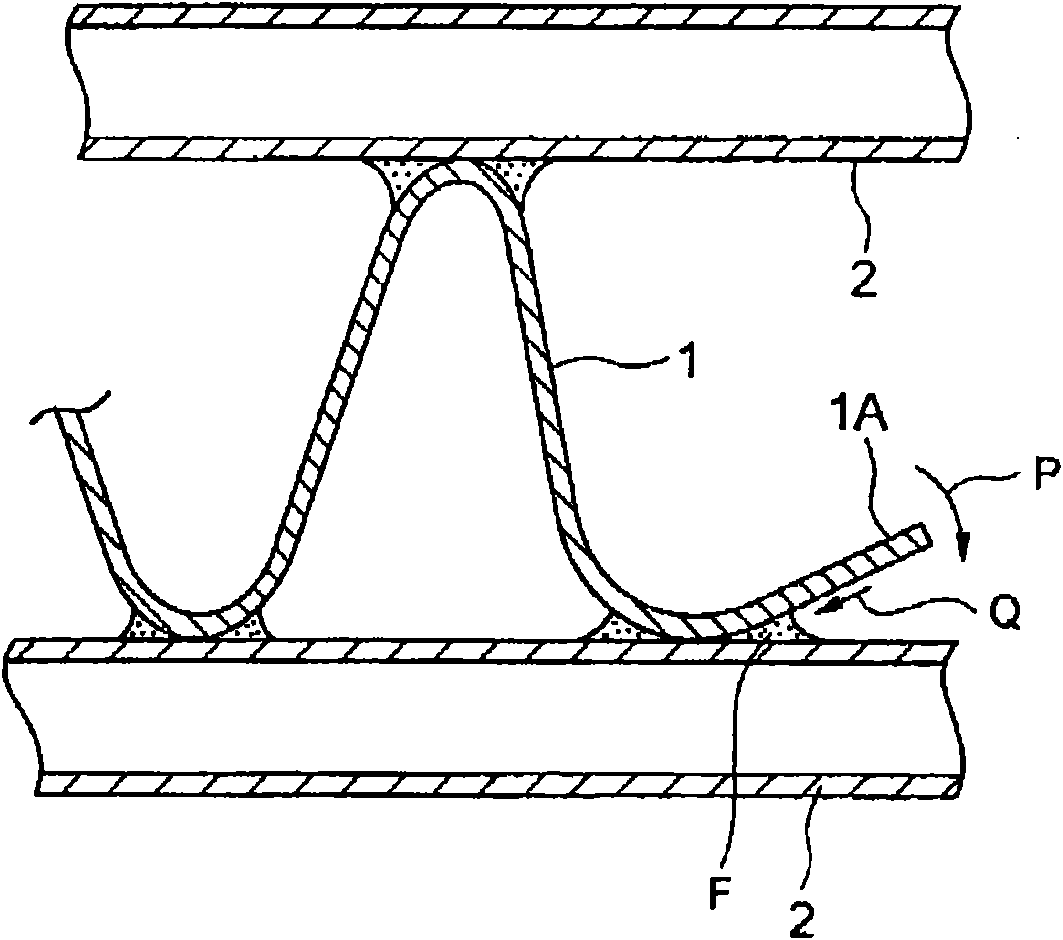

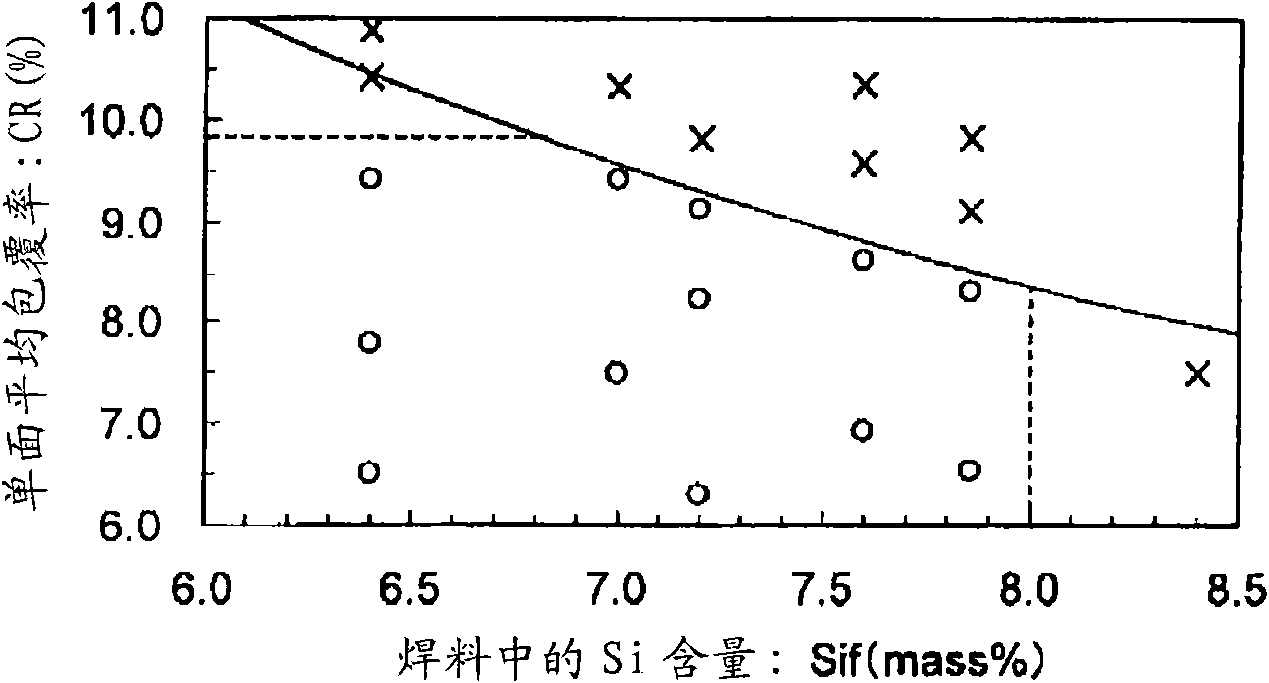

Thin brazing sheet fin component for high temperature brazing and method for manufacturing heat exchanger using the same

InactiveCN101839665APrevent tipping and deformationPrevent reduction in commodity valueWelding/cutting media/materialsWelding/soldering/cutting articlesBrazingHeat exchanger

The present invention provides a thin brazing sheet fin component for high temperature brazing and a method for manufacturing a heat exchanger using the same. According to the invention, the thin brazing sheet fin component with a thickness less than 85 mu m is used. Even the brazing is performed at a high temperature higher than 610 DEG C, the tilting deformation at the end of the fin is not caused. Al-Mn series alloy which is used as a core material is composed of the following components: 0.7-1.5% of Mn, 0.3-0.8% of Si, 0.05-0.75% of Fe, and the balance of Al substantially. The solder which is used for jointing with two surfaces of the core material is Al-Si series alloy with Si content of 5.5-8.0%. Furthermore the average coating rate of a single surface of the solder is 6.0-9.8%. Furthermore the relationship between the silicon content (Sif) in the solder and the average coating rate (CR) of a single surface of the solder is adjusted so that the following formula is satisfied: Q=Sif(mass%)*CR(%)<=67.

Owner:FURUKAWA SKY ALUMINUM CORP

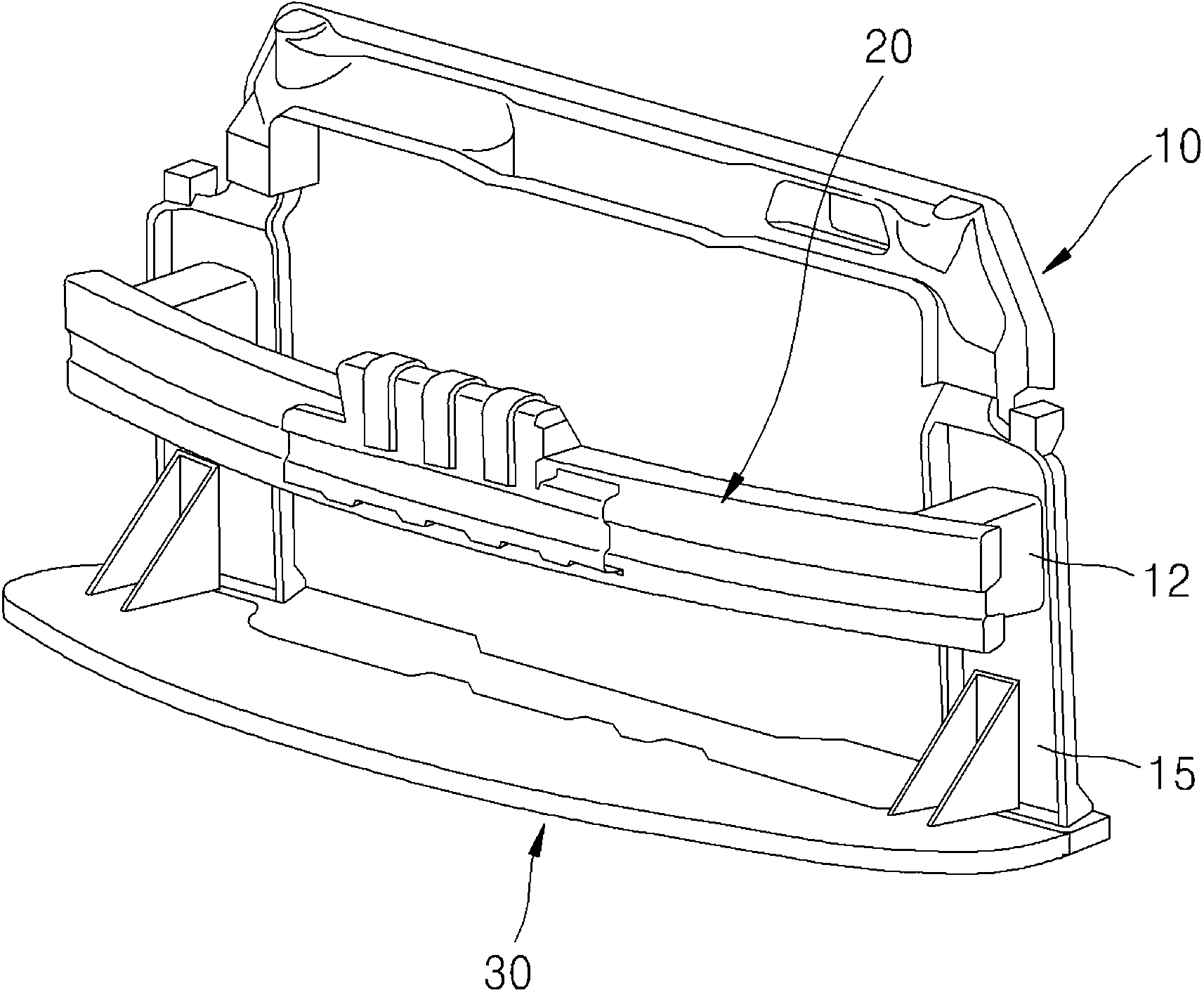

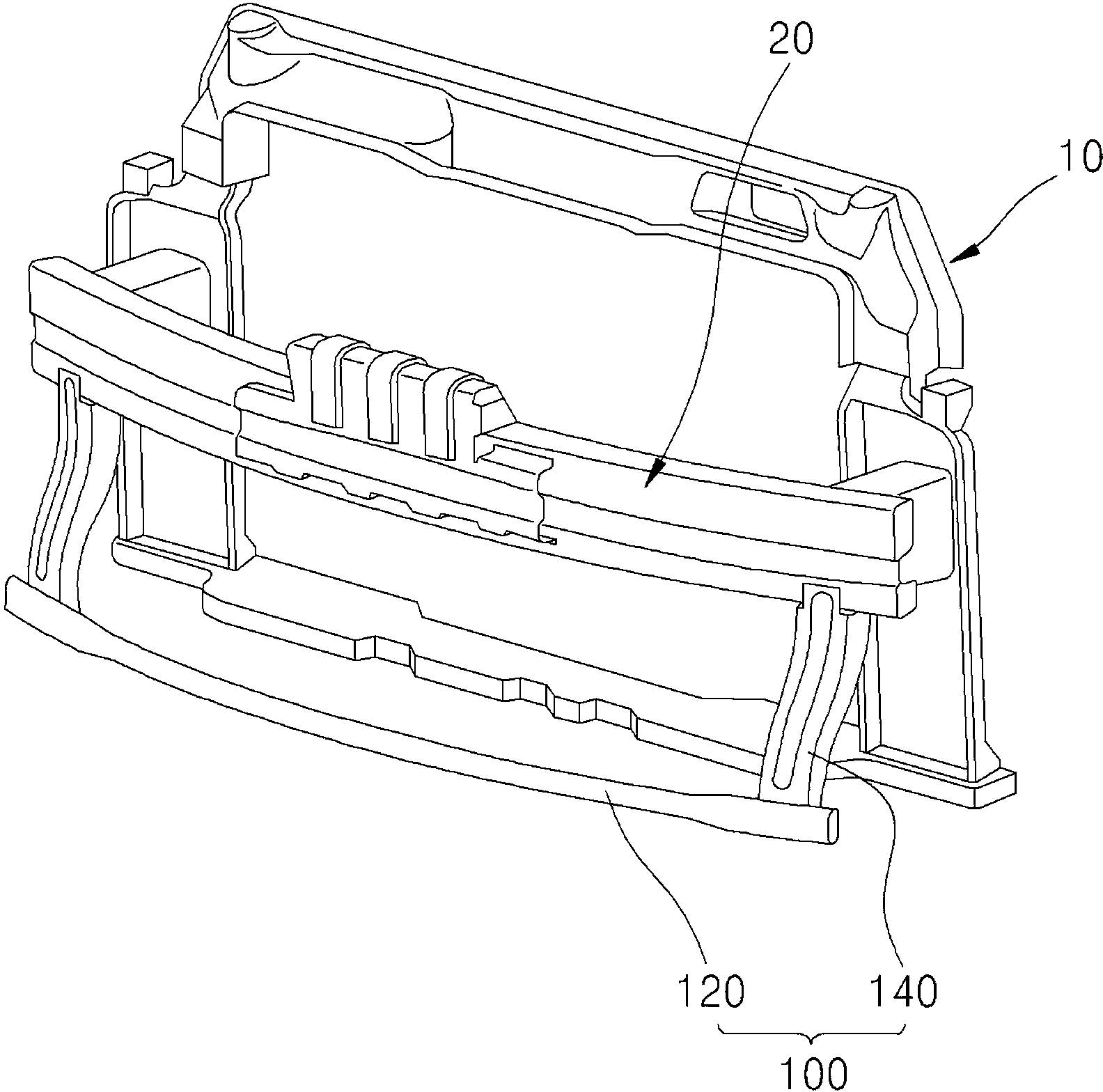

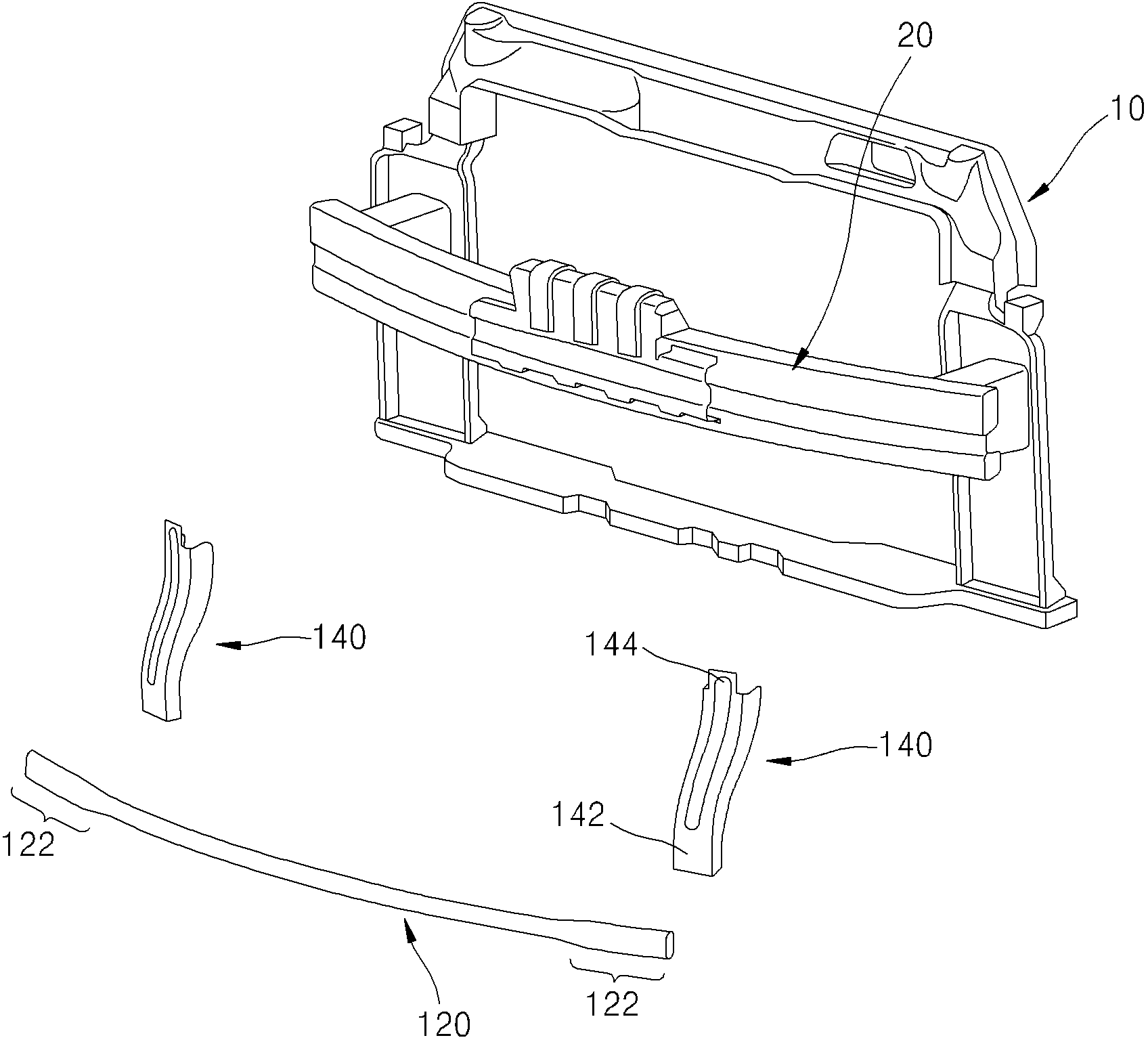

Bumper lower stiffener with improved performance using ultra high strength steel pipe and manufacturing method thereof

InactiveCN102939221AHelps to reduce weightImprove performanceBumpersEngineeringUltimate tensile strength

The present invention relates to a bumper lower stiffener formed at the lower portion of the front bumper of a vehicle and a manufacturing method thereof. More specifically, the present invention relates to a bumper lower stiffener manufactured using a steel pipe formed by hot pressing and a manufacturing method thereof. The present invention provides a method for manufacturing the horizontal member of the bumper lower stiffener, which includes a cutting step of cutting a steel pipe added with quenching elements at a predetermined length; a heat treatment step of heating the cut steel pipe at a molding temperature; a hot pressing step of hot-pressing the heated steel pipe with press molds into the shape of the horizontal member having plane surface sections at the both sides thereof; and a cooling step of rapidly cooling the formed horizontal member in the state that the press molds are closed.

Owner:HYUNDAE STEEL CO LTD

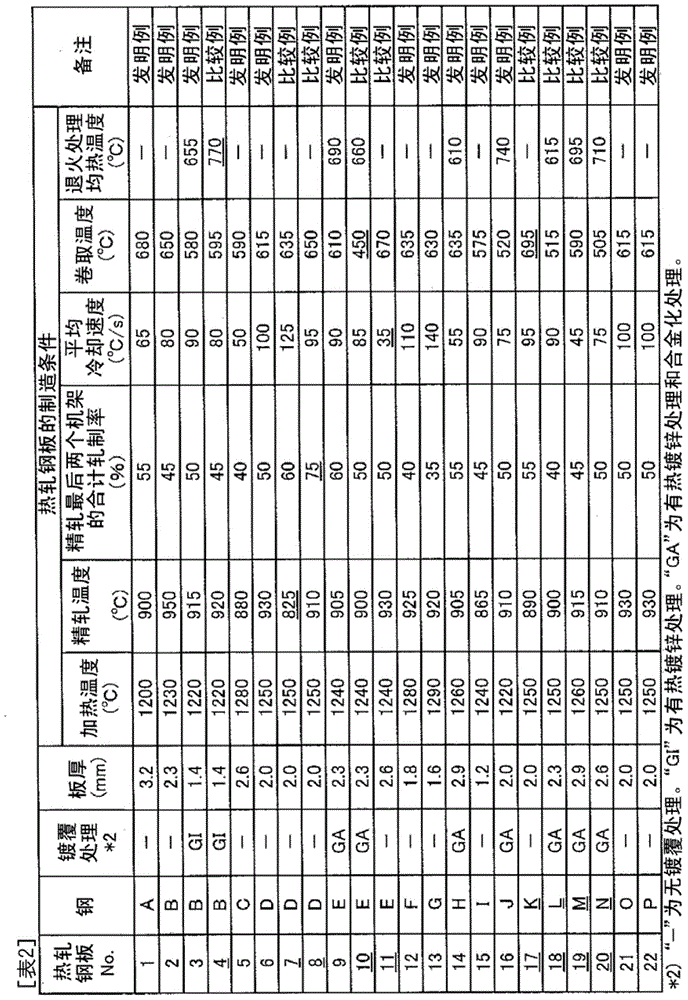

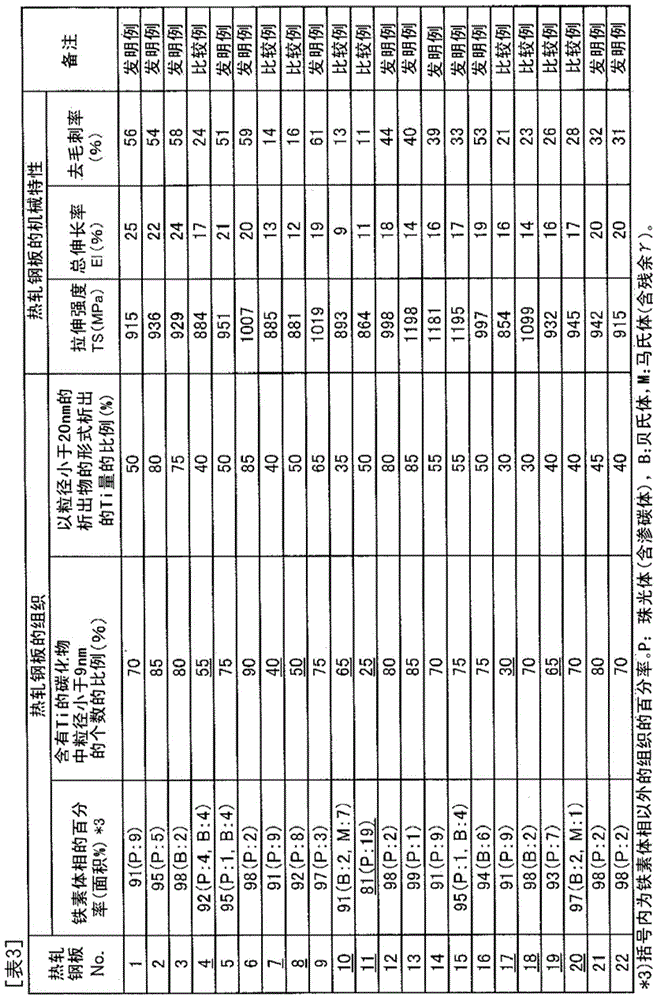

High-strength hot-rolled steel sheet

InactiveCN107849651ACheap manufacturingHigh yield ratioHot-dipping/immersion processesFurnace typesSheet steelChemical composition

Owner:NIPPON STEEL CORP

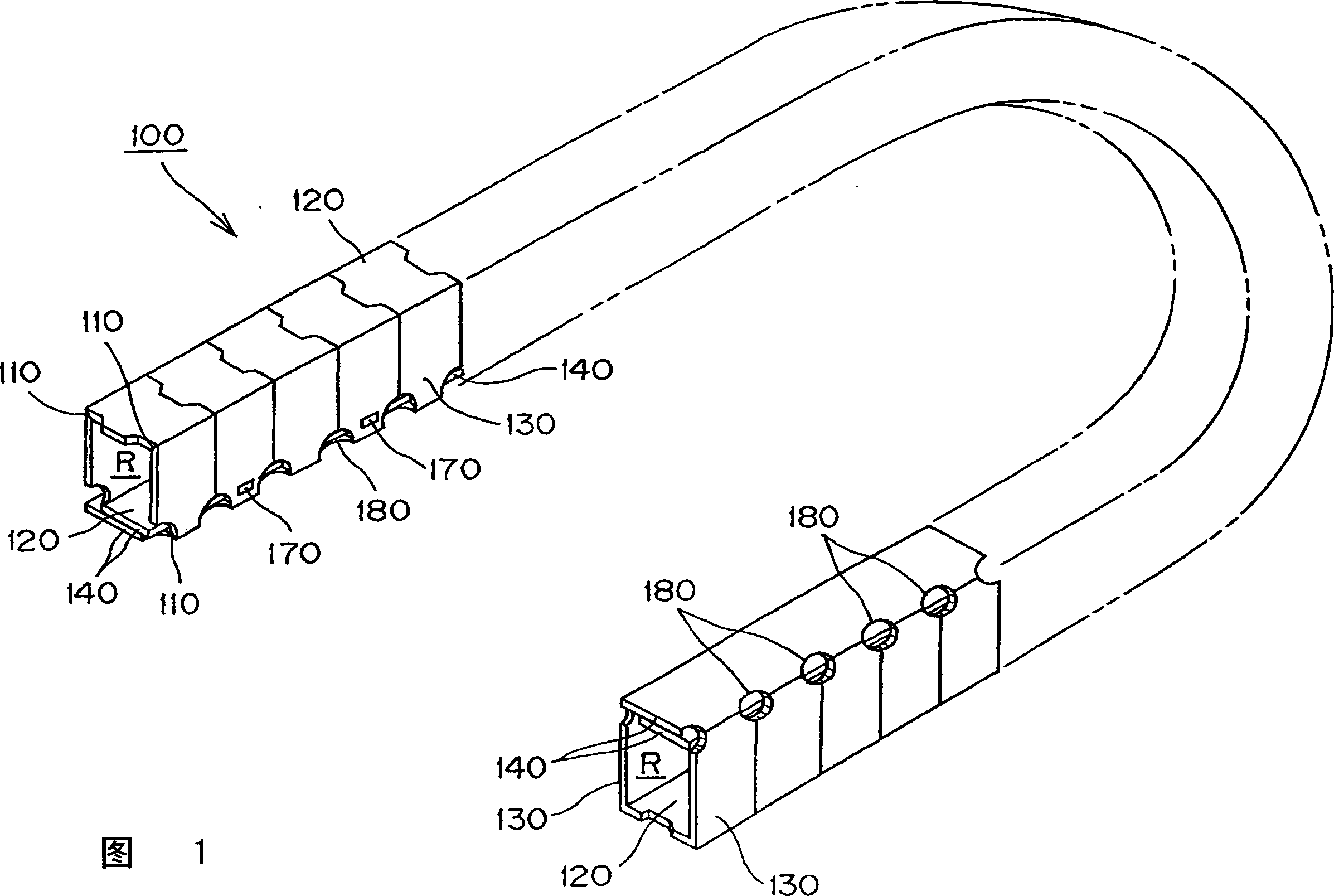

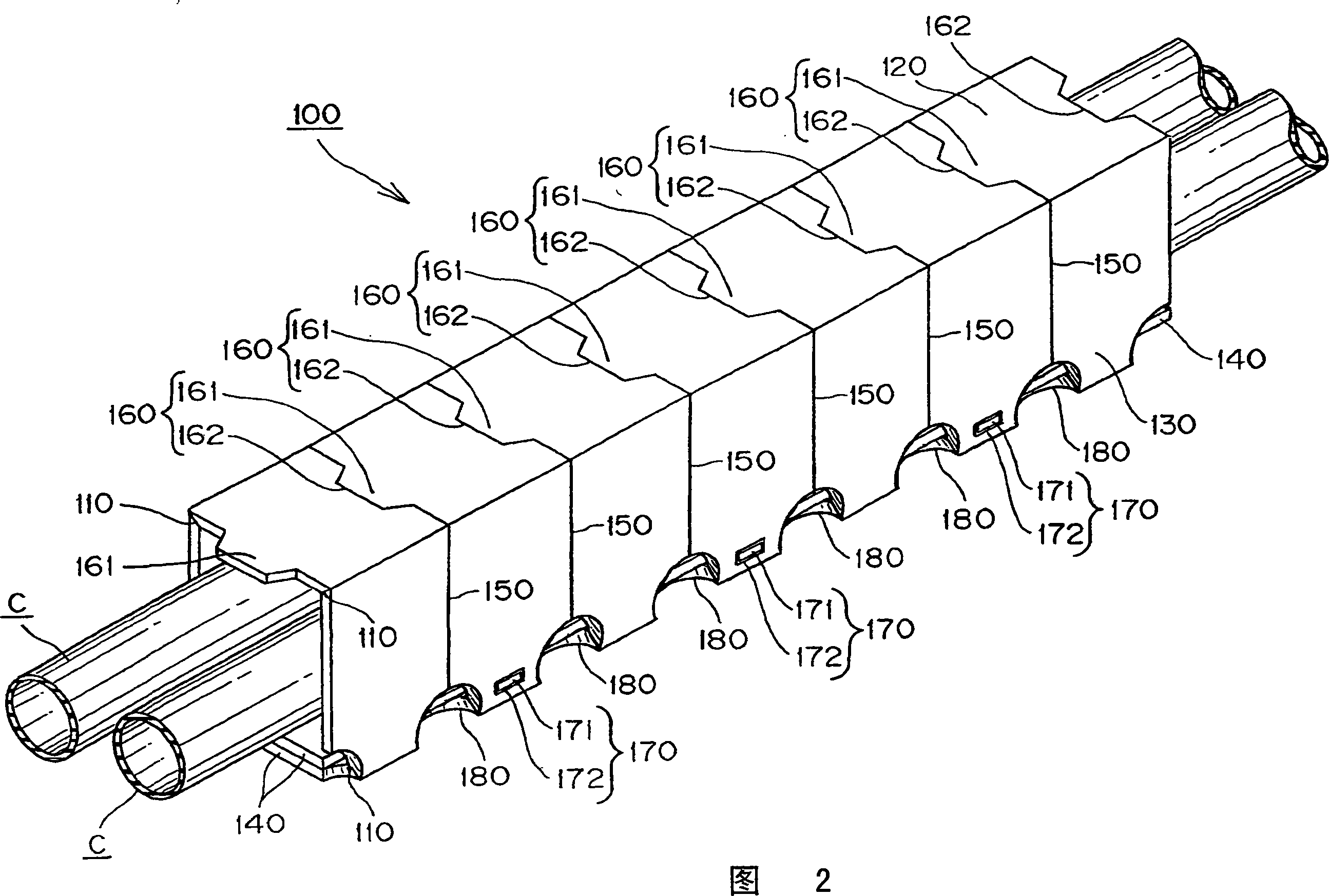

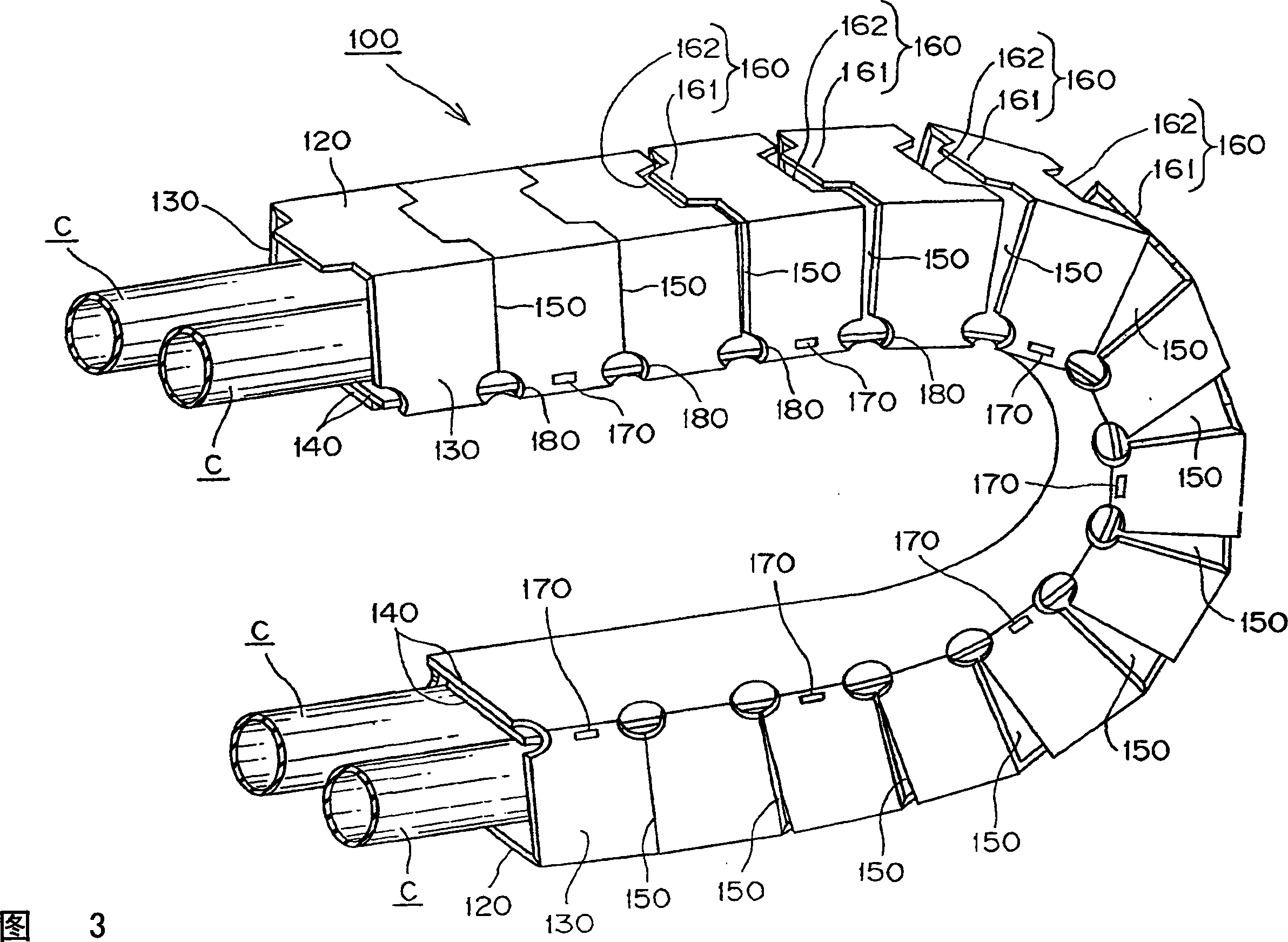

Folding assembly type cable protection and guide device

InactiveCN101113774AAvoid assembly manufacturing burdenEasy to manufactureHauling chainsElectrical apparatusElectrical and Electronics engineeringMetal mold

A folding assembly type cable protection and guide device is provided in which a cable is accommodated into a cable accommodating space. The cable protection and guide device can be easily manufactured by extrusion molding without requiring different metal molds to accommodate different size cables. Assembly is simplified. Dimensional stability of the cable accommodating space is ensured during both linear and flexion movement which provides smooth linear and flexion movement of the device. The long body cable accommodating space is a rectangularly shaped space surrounded by a synthetic resin film tape. The synthetic resin film tape is assembled through a plurality of folding V grooves which extend along a longitudinal direction of the tape to allow for repeated linear and flexion movement.

Owner:TSUBAKIMOTO CHAIN CO

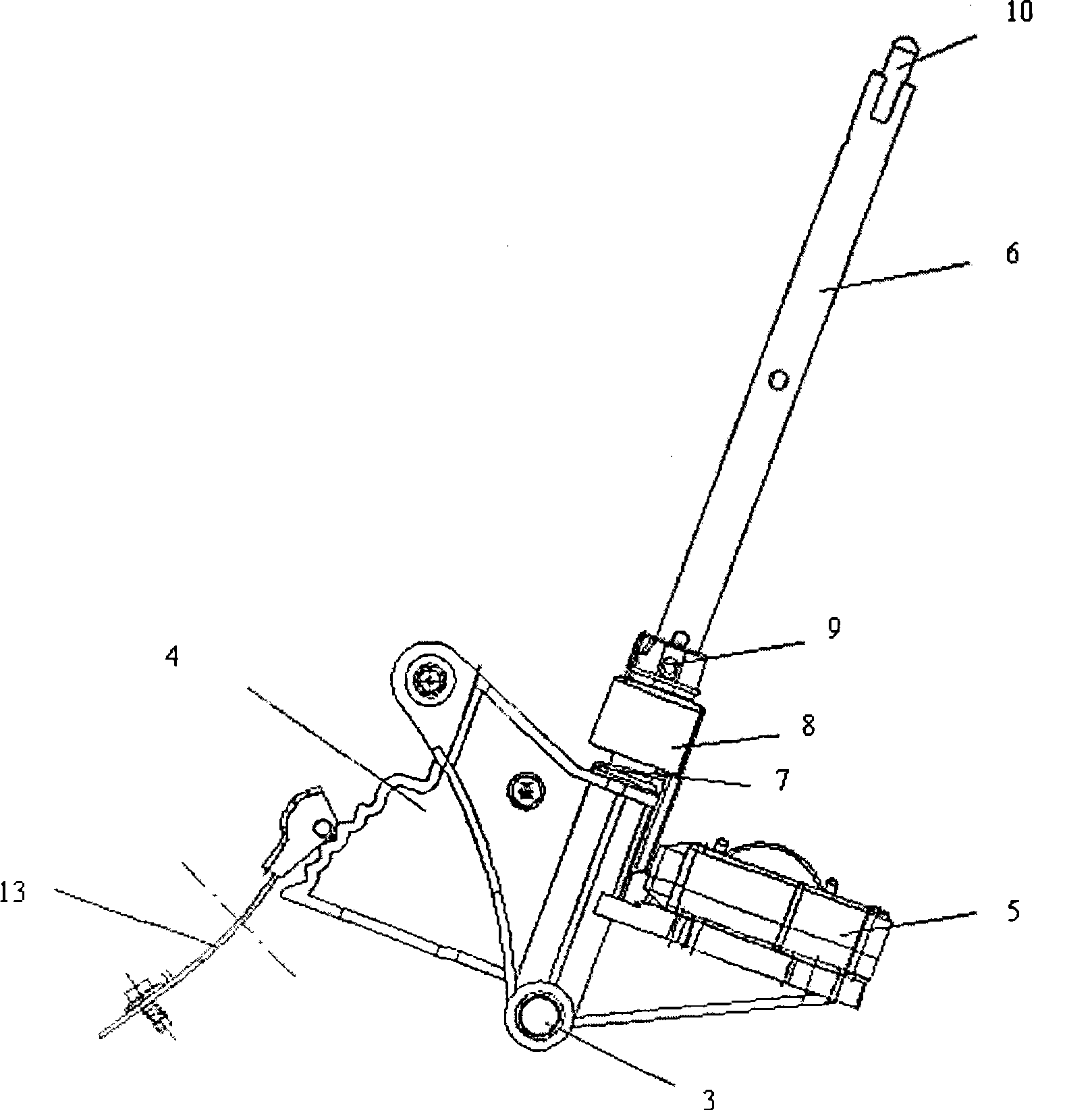

Automatic locating and unlocking device of gearshift

A limit unlocking device of an automatic gear shifting device comprises a base, a flat spring which has one end installed on the base, and a gear shifting component; wherein, the base is provided with a semi-cambered spacing step hole, the upper edge of which is corresponding to a spacing groove having six gears from P gear to L gear of an automobile; a stop block of the gear shifting component has a wave-shaped surface provided with at least six wave troughs which are respectively corresponding to the six gears from the P gear to the L gear, and the other end of the flat spring presses on the wave-shaped surface of the stop block; the lower end of a power transmission core bar is connected with a spacer pin, and a flat pin is connected below the spacer pin and presses on a return spring; one end of the spacer pin passes through the spacing step hole on the base and is blocked in the spacing groove at the upper edge by the force of the return spring. The device has the advantages of simple structure, little impact noise, good durability and hand feeling, etc.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

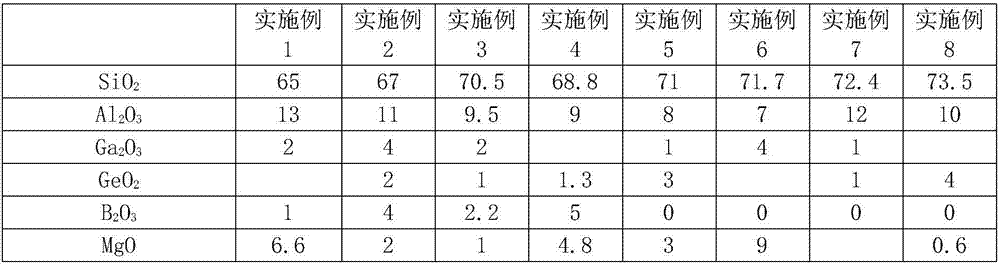

Alkali-free silicate glass and preparation method and application thereof

ActiveCN107382052AHelps to reduce weightHigh expansion coefficientGlass shaping apparatusGlass productionAlkali freeSilicate glass

The invention relates to the field of glass and particularly relates to alkali-free silicate glass and a preparation method and application thereof. The alkali-free silicate glass comprises, by mole, 65-75 mol% of SiO2, 11-17 mol% of Al2O3, Ga2O3 and GeO2, 0-8 mol% of B2O3, 0-15 mol% of MgO, 2-10 mol% of CaO, 0.5-14 mol% of SrO and BaO, 0-10 mol% of TiO2, 0.01-2 mol% of Ta2O5 and 0.01-0.5 mol% of Tl2O3. The alkali-free silicate glass has high thermal stability and dimensional stability, a high strain point, a high specific modulus, a low melting temperature, a low liquidus temperature and low density and is suitable for large-scale industrial production.

Owner:ZHENGZHOU UNIV

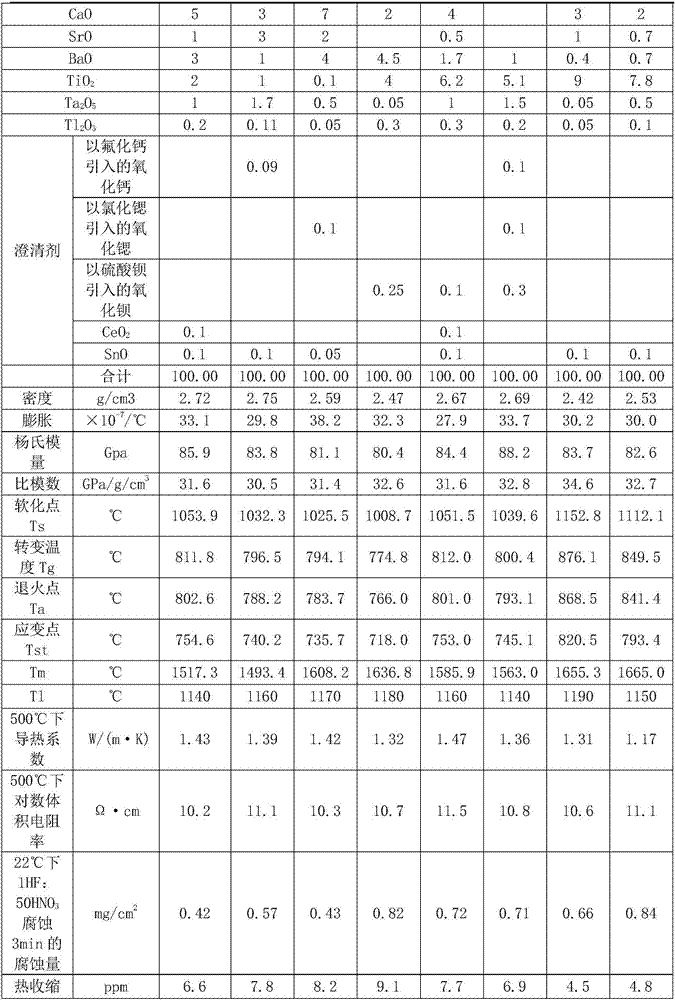

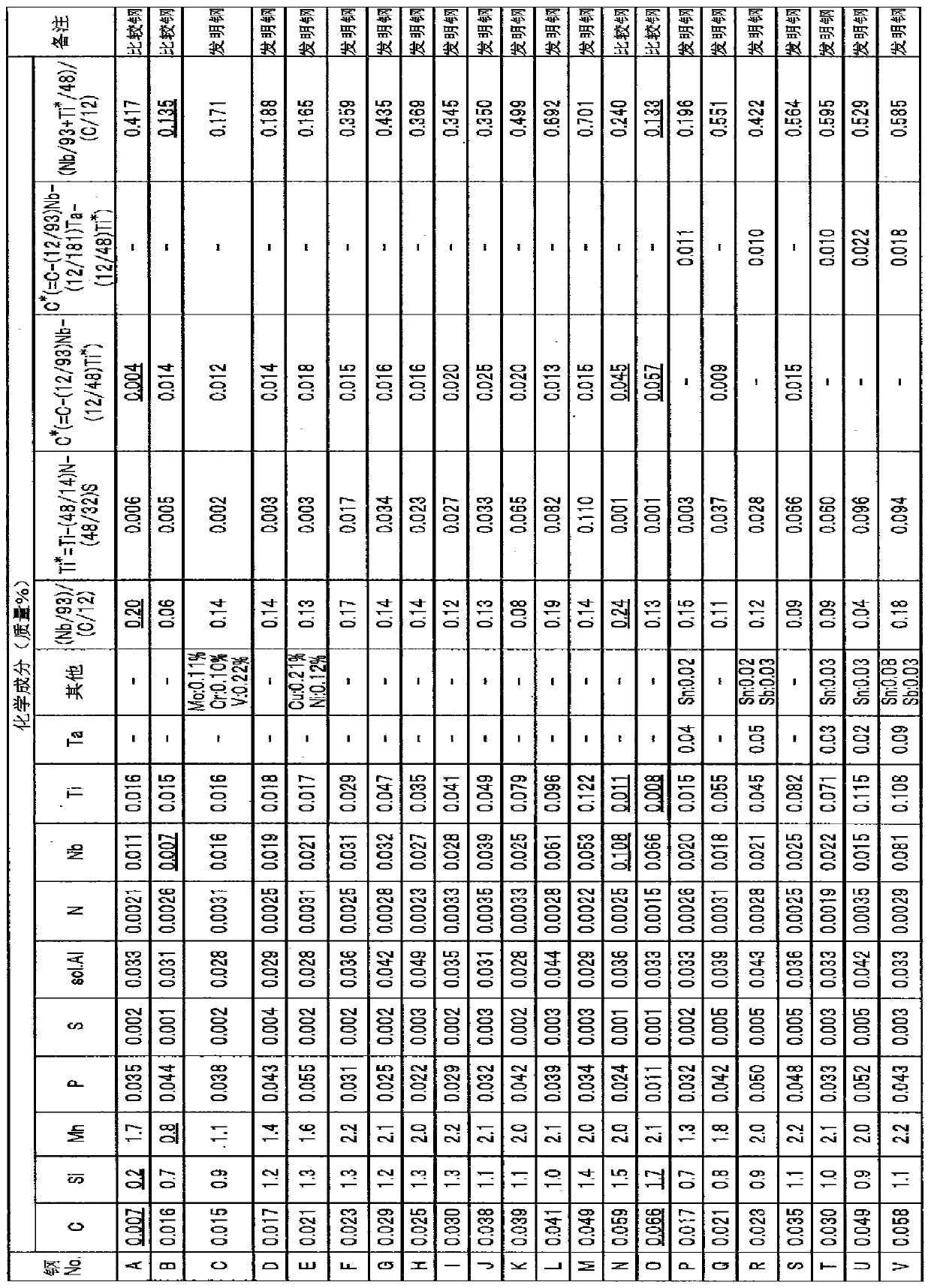

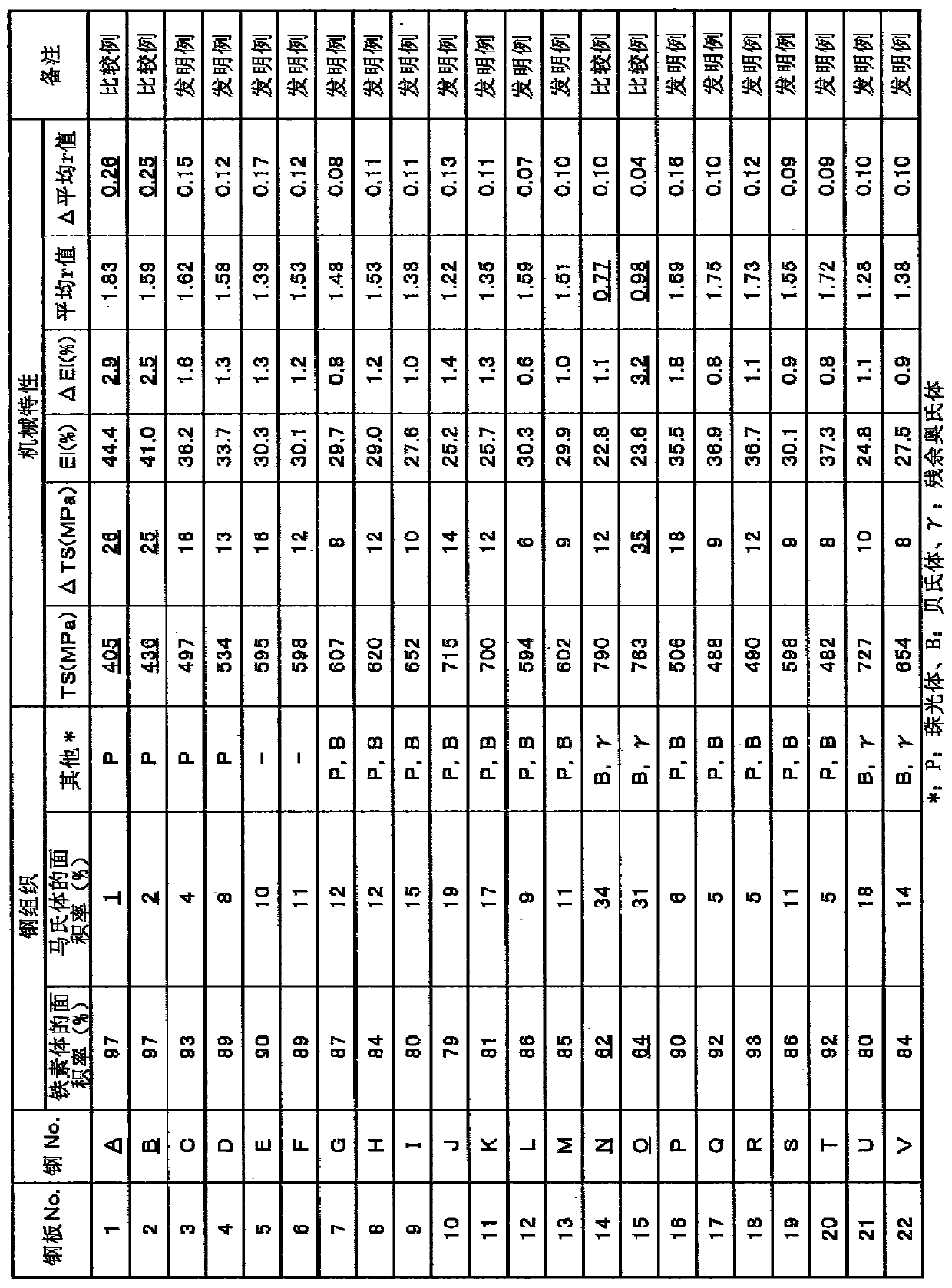

High-strength cold-rolled steel plate having excellent deep drawability and in-coil material uniformity, and method for manufacturing same

ActiveCN103857817AExcellent deep drawabilityGood material uniformityFurnace typesMetal rolling arrangementsSheet steelHigh intensity

Proposed are a high-strength cold-rolled steel plate having an excellent deep drawability and in-coil material uniformity, and a method for manufacturing same. The component composition is as follows, in weight%: C: 0.010 to 0.060%, Si: more than 0.5 to 1.5%, Mn: 1.0 to 3.0%, P: 0.005 to 0.100%, S: 0.010% or less, sol.Al: 0.005 to 0.500%, N: 0.0100% or less, Nb: 0.010 to 0.100%, and Ti: 0.015 to 0.150%, wherein (Nb / 93) / (C / 12) < 0.20, 0.005 <= C* <= 0.025, and (Nb / 93 + Ti* / 48) / (C / 12) >= 0.150 (where C* = C - (12 / 93)Nb - (12 / 48)Ti*, Ti* = Ti - (48 / 14)N - (48 / 32)S) are satisfied; and the remainder is iron and unavoidable impurities. The structure has a ferrite phase representing no less than 70% in area ratio, and a martensite phase representing no less than 3% in area ratio. The tensile strength is no less than 440 MPa and the average r value is no less than 1.20.

Owner:JFE STEEL CORP

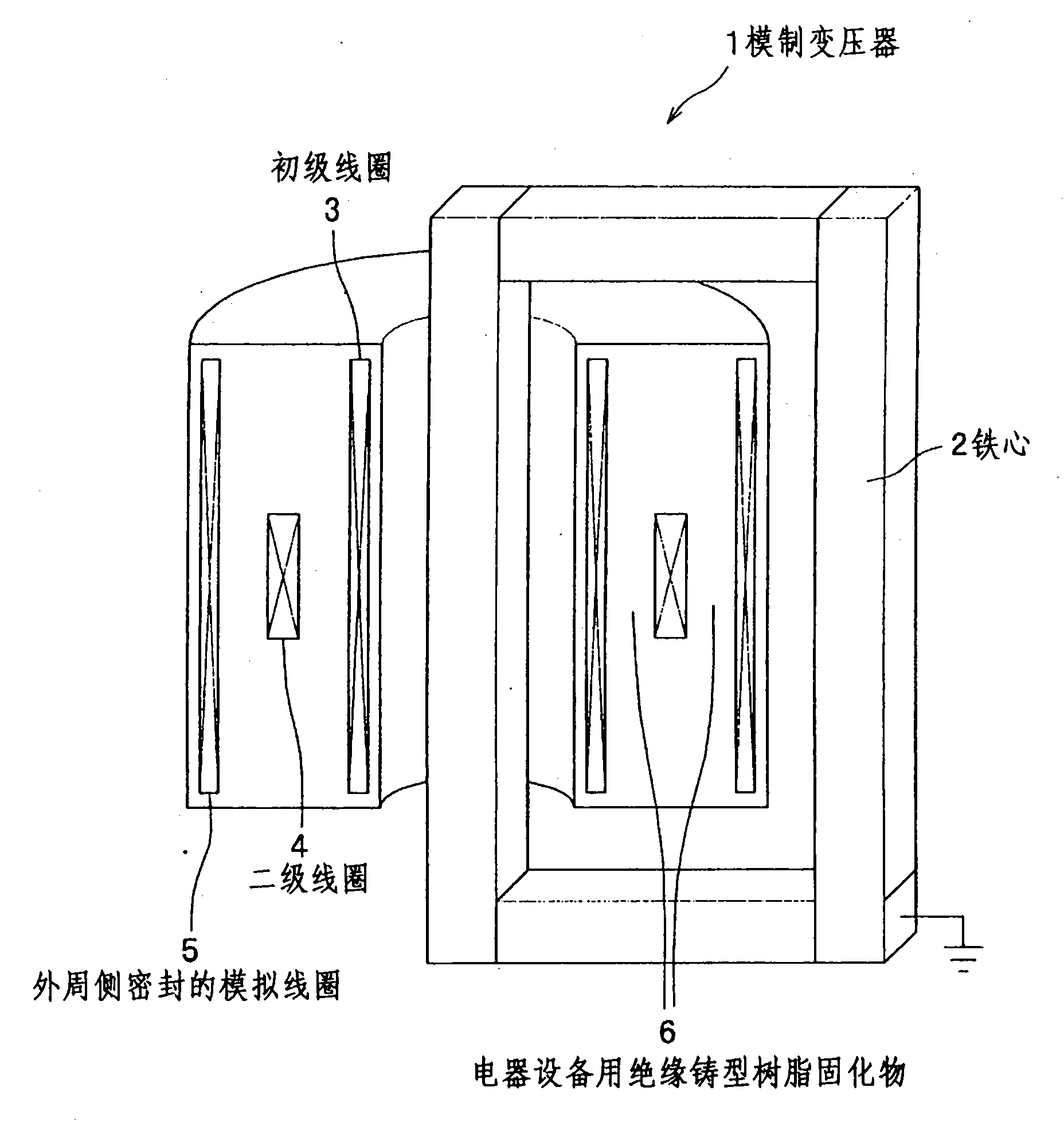

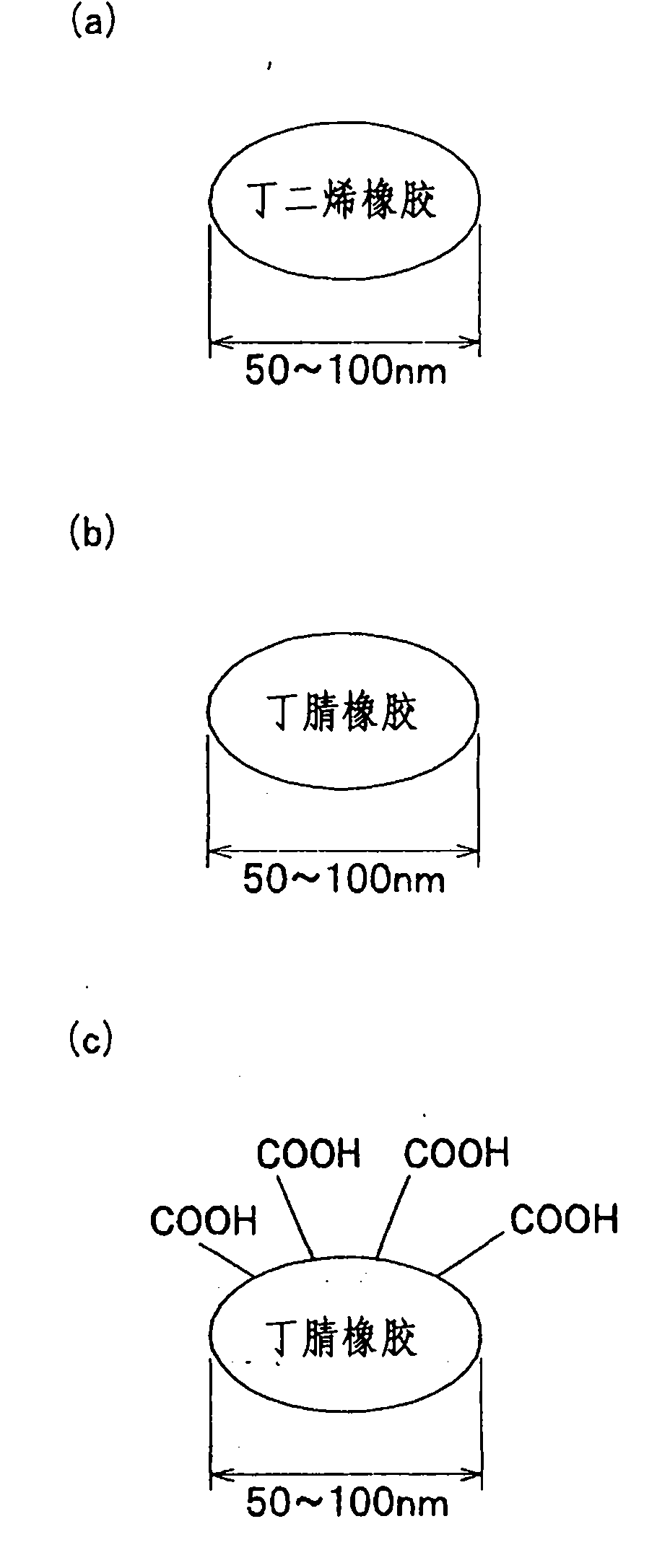

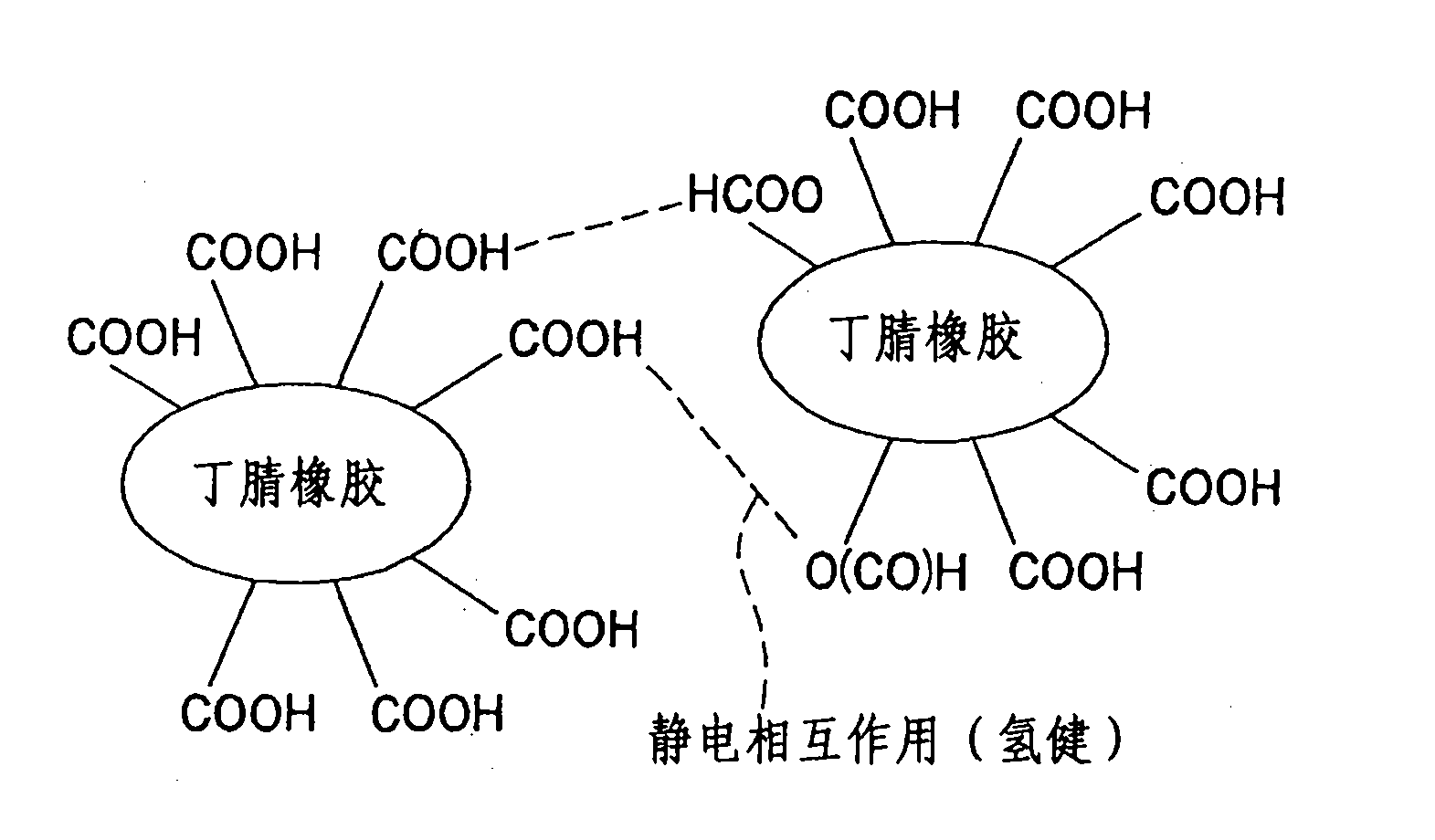

Cast insulation resin for electric apparatus and high voltage electric apparatus using the same

InactiveCN101928443ACrack suppressionLow coefficient of linear expansionRubber insulatorsPlastic/resin/waxes insulatorsElastomerEpoxy

The present invention provides a cast insulation resin for an electric apparatus having an improved fracture toughness. The cast insulation resin for an electric apparatus is a cast insulation resin used in an electric apparatus, comprising at least either a polar fine elastomer particle or a liquid elastomer having a polar molecule dispersed in an epoxy resin, and a filler formed of at least either an inorganic compound or an inorganic compound having a modified surface thereon with an organic compound. The invention also provides a high voltage electric apparatus using the same.

Owner:HITACHI IND EQUIP SYST CO LTD

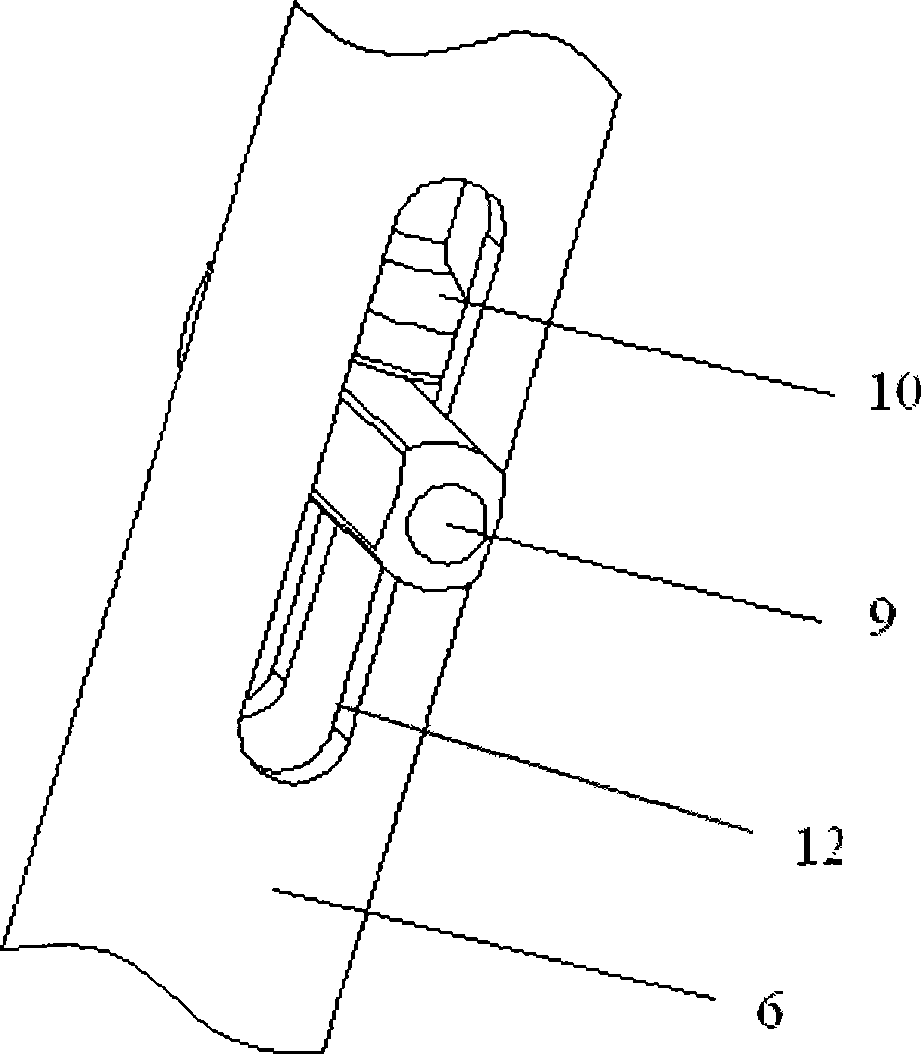

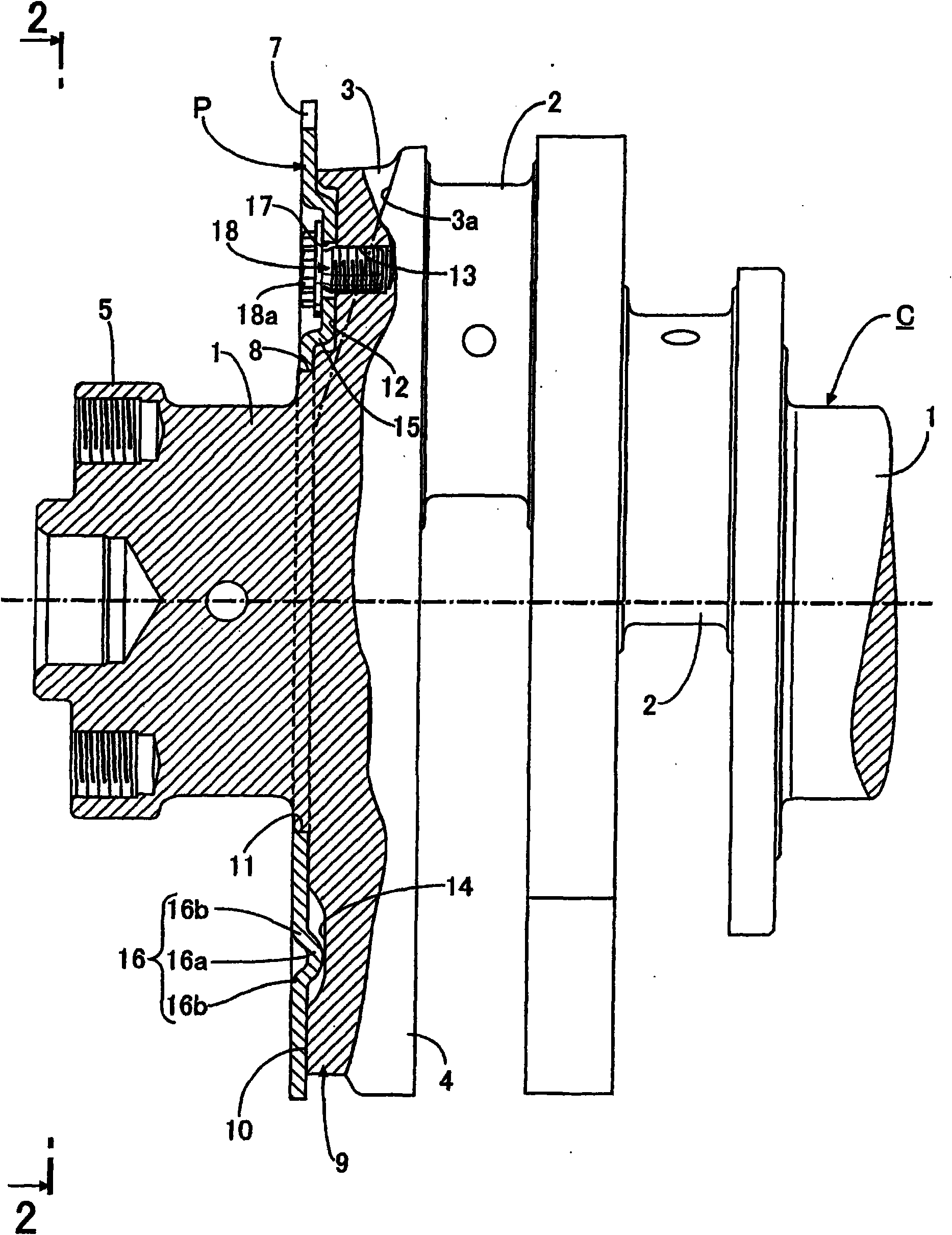

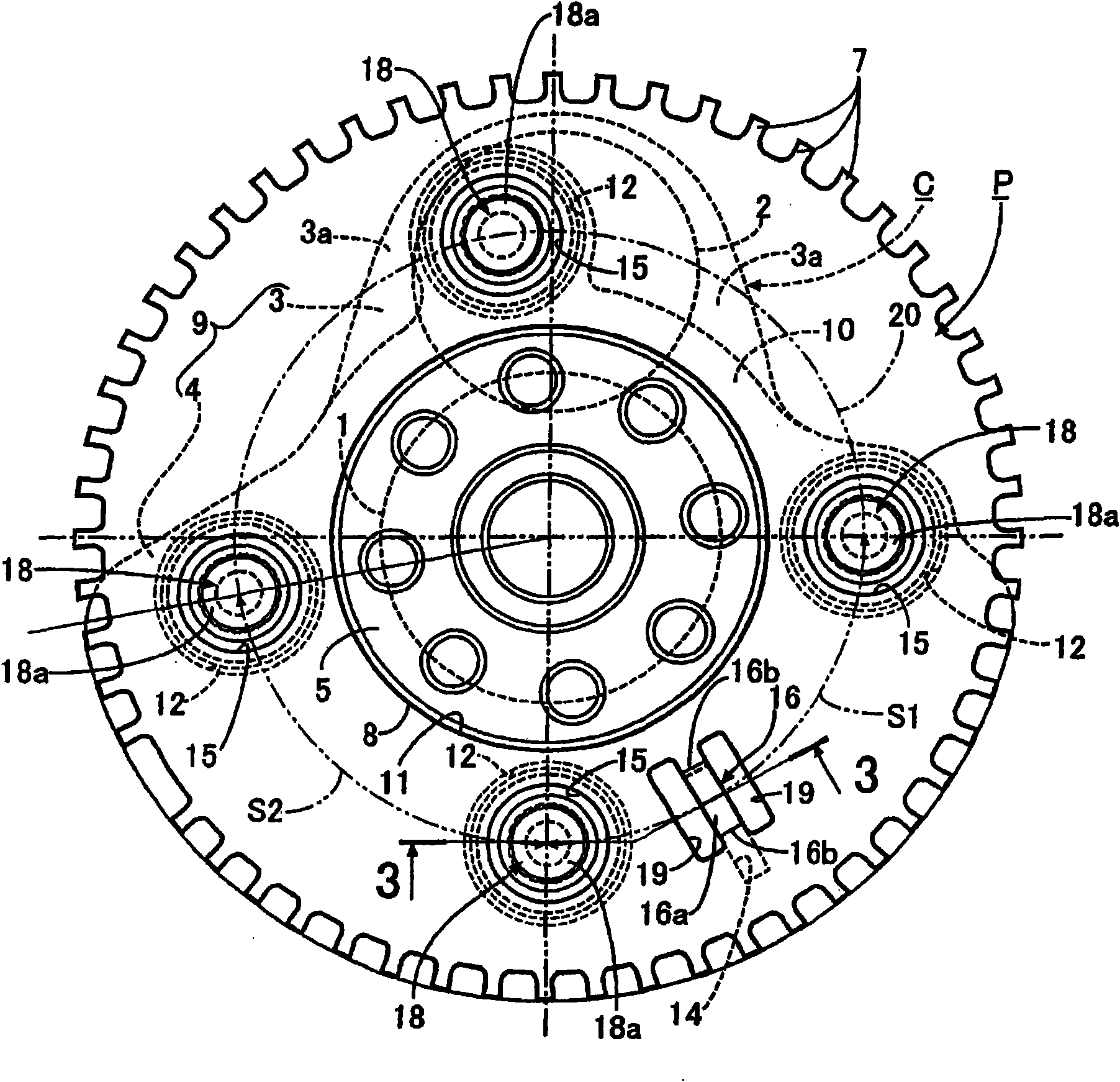

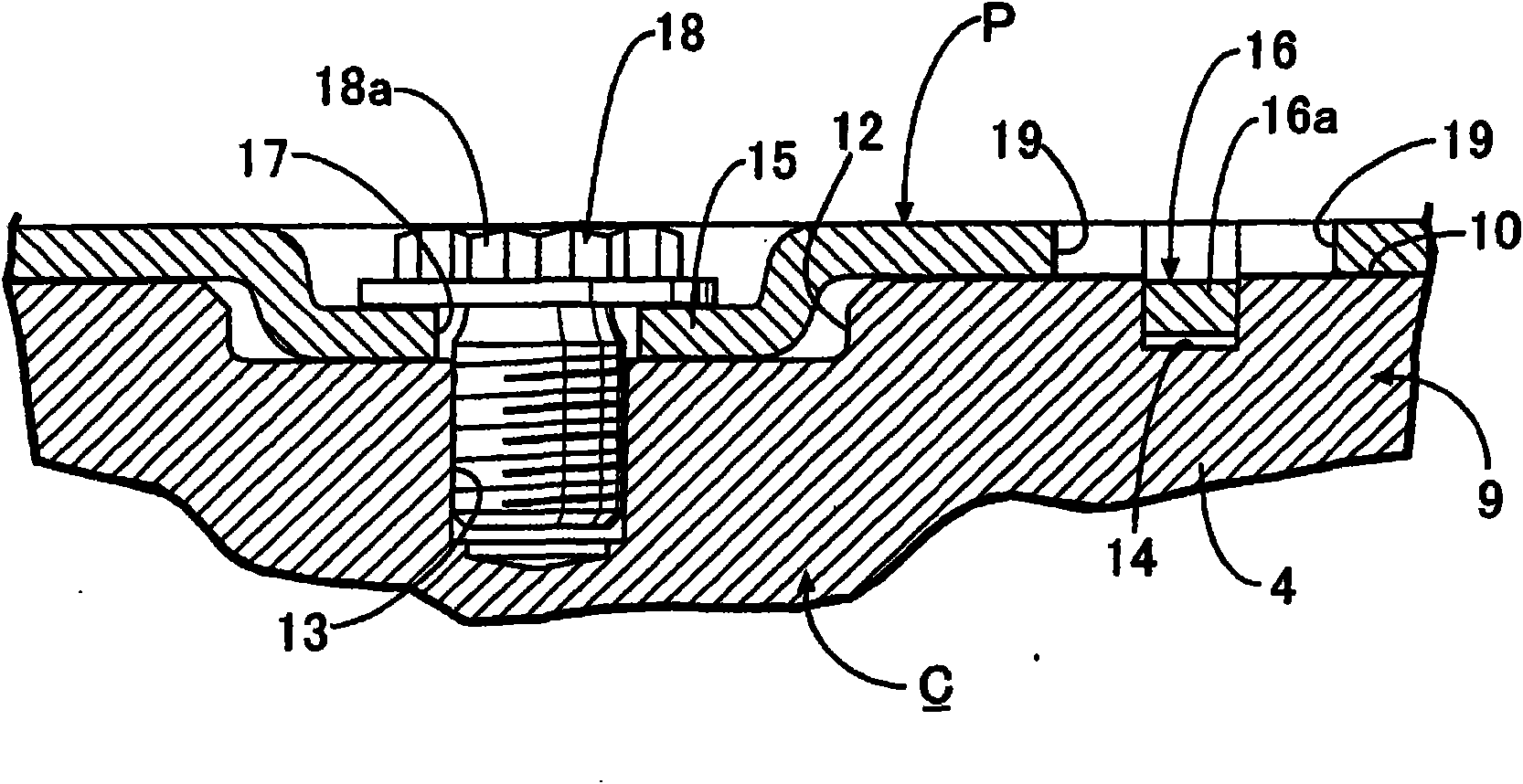

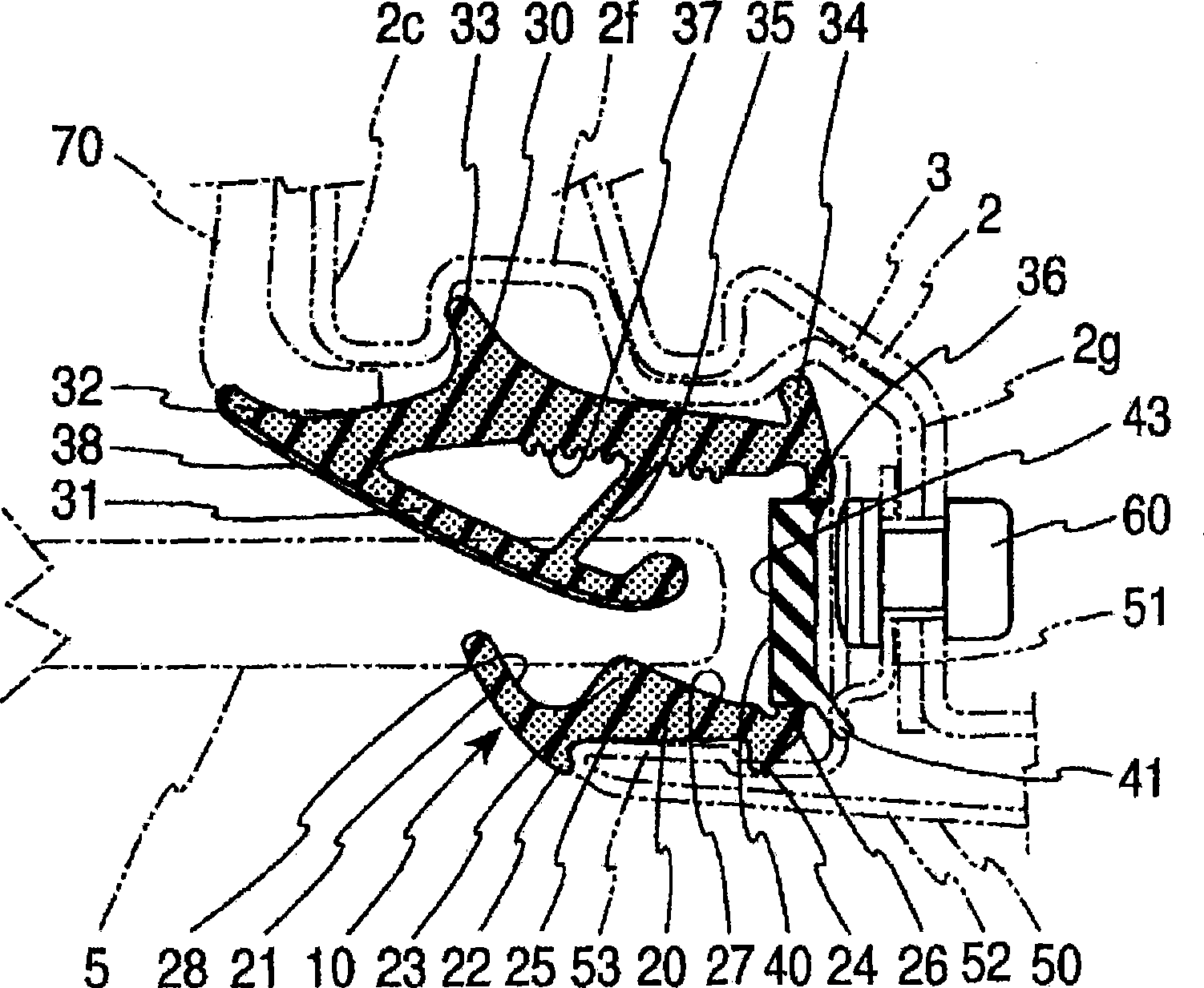

Pulser plate mounting structure

InactiveCN101600871AHigh positioning accuracyImprove productivityCrankshaftsEngine controllersProduction rateBand shape

A pulser plate mounting structure in which a key groove (14) is formed in a mounting surface (10) of a rotation wall section (9) having a crank arm (3) and a counter weight (4), a key section (16) engaging with the key groove (14) is formed on a pulser plate (P) superposed on the mounting surface (10), and the pulser plate (P) is secured to the rotation wall section (9) by a securing member (18). The key section (16) is constructed from an arcuate band-like section (16a) arcuately projecting from the pulser plate (P) toward one end face of the pulser plate and engaging with the key groove (14), and from a pair of connection sections (16b) for integrally connecting both ends of the arcuate band-like section (16a) to the pulser plate (P). The pulser plate mounting structure enables highly accurately positioning of the pulser plate on a crankshaft and provides excellent productivity of the pulser plate.

Owner:HONDA MOTOR CO LTD

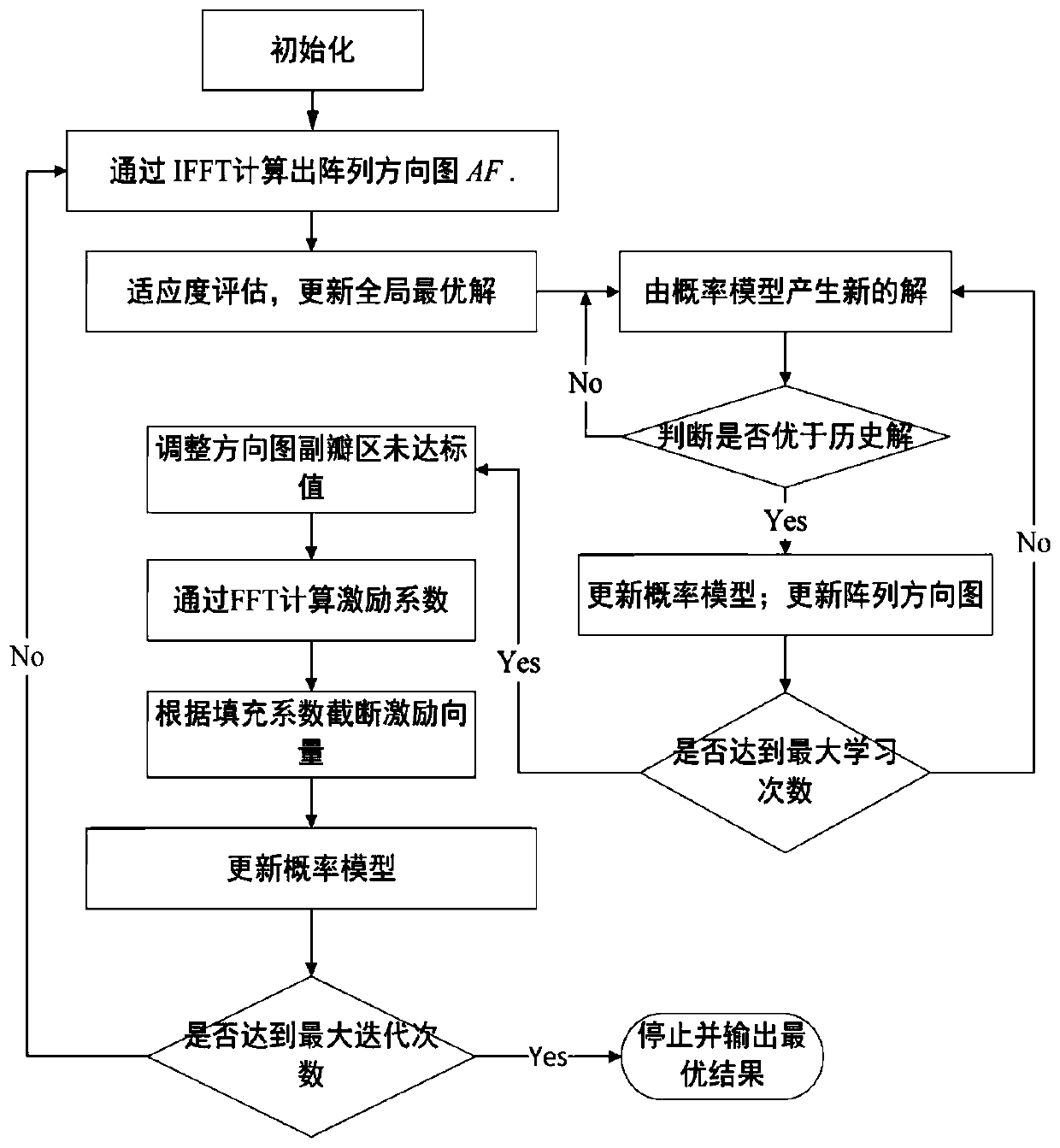

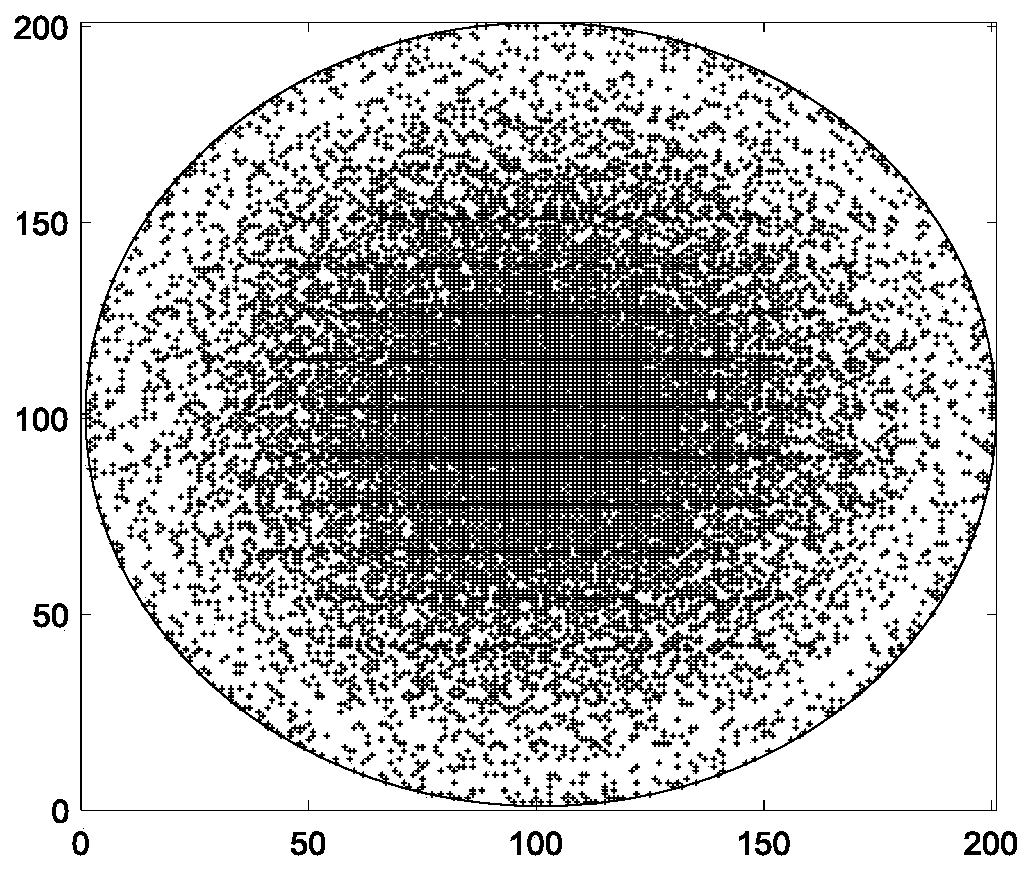

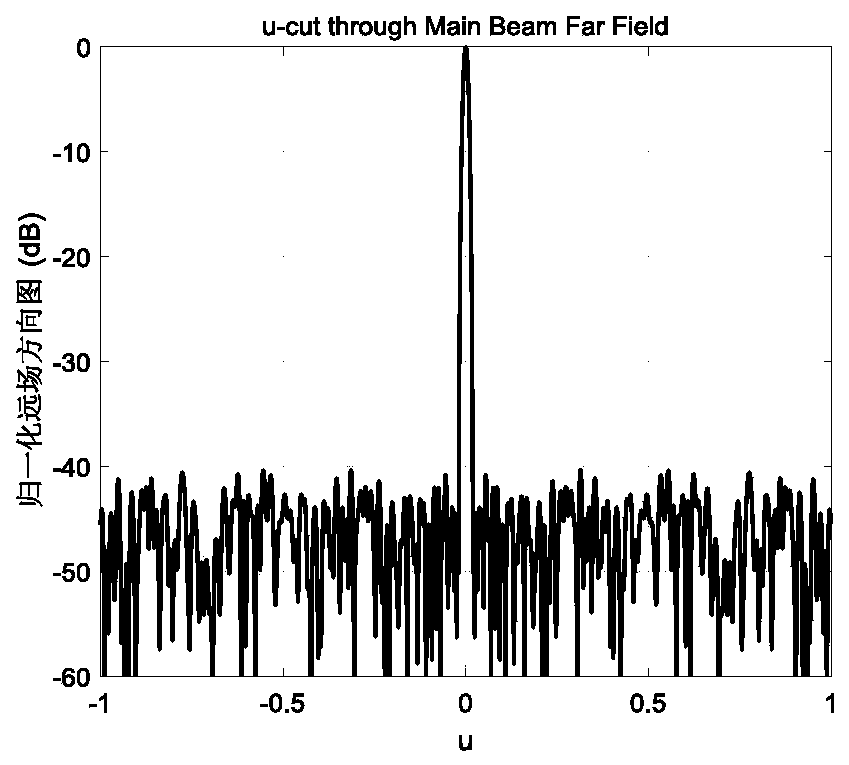

Large-scale sparse array antenna efficient comprehensive method based on adaptive probability learning

ActiveCN110427590AImprove operational efficiencyConvenient sparse synthesisComplex mathematical operationsProbability estimationArray element

The invention discloses a large-scale sparse array antenna efficient comprehensive method based on adaptive probability learning, and solves the problems of poor radiation characteristics and low efficiency caused by poor gradient density distribution of antenna units in an array aperture and high side lobe of a directional diagram in large-scale array antenna sparse array synthesis. According tothe method, the layout of a sparse array is combined with selection probability estimation of antenna units, an array comprehensive problem is combined with optimization of an adaptive probability learning model, and the method comprises the implementation steps of randomly initializing antenna array element distribution, and constructing an initial probability estimation model; rapidly calculating a far-field directional diagram through the excitation coefficient by means of fast Fourier transform; generating a new solution to participate in competition according to the probability model based on a probability learning strategy; adjusting a far-field directional diagram; array element excitation is obtained through fast Fourier transform, and updating the probability model. When the target function requirement is met or the maximum iteration frequency is reached, the optimal sparse array scheme is output, and the comprehensive problem of the large sparse array antenna is solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

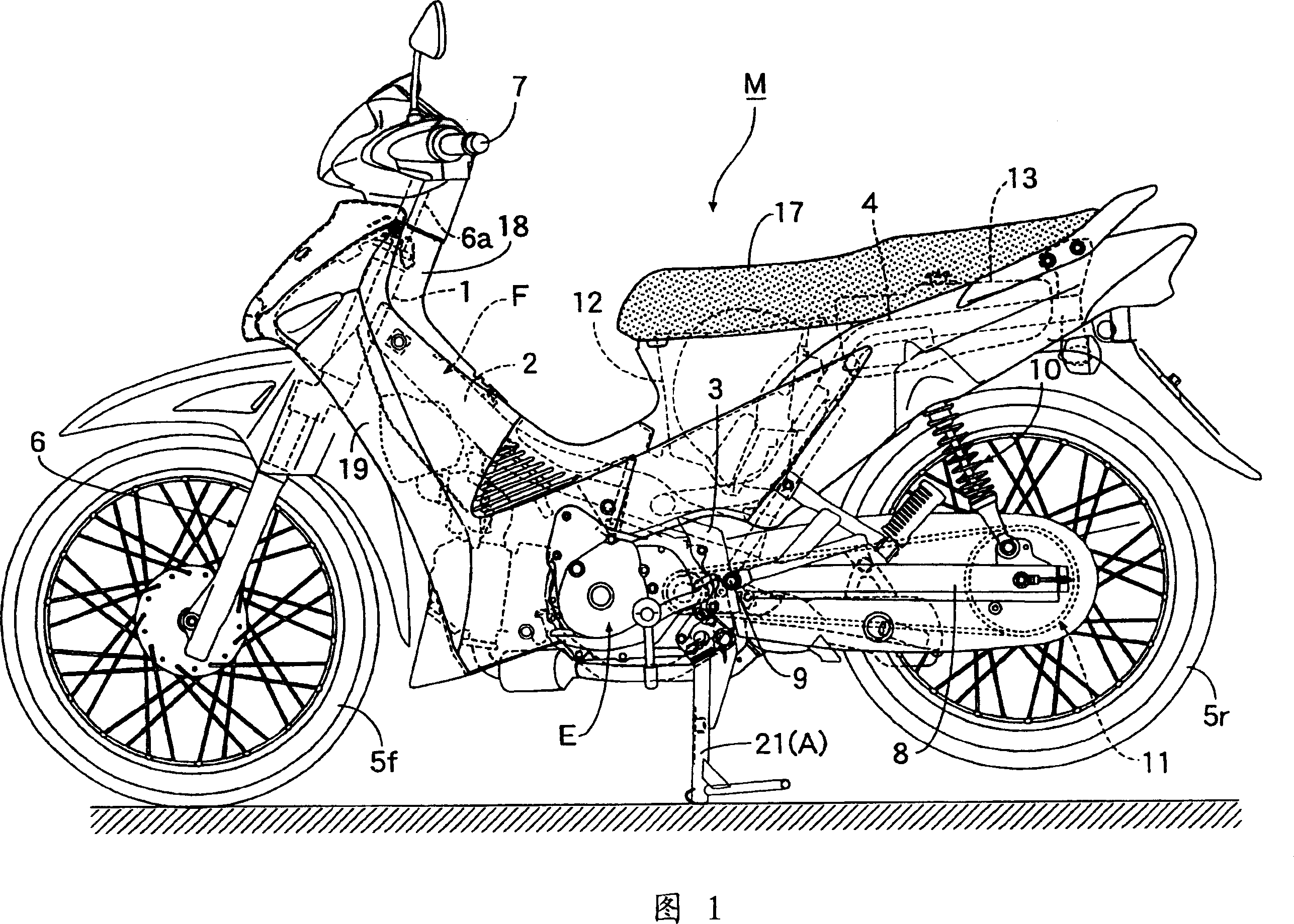

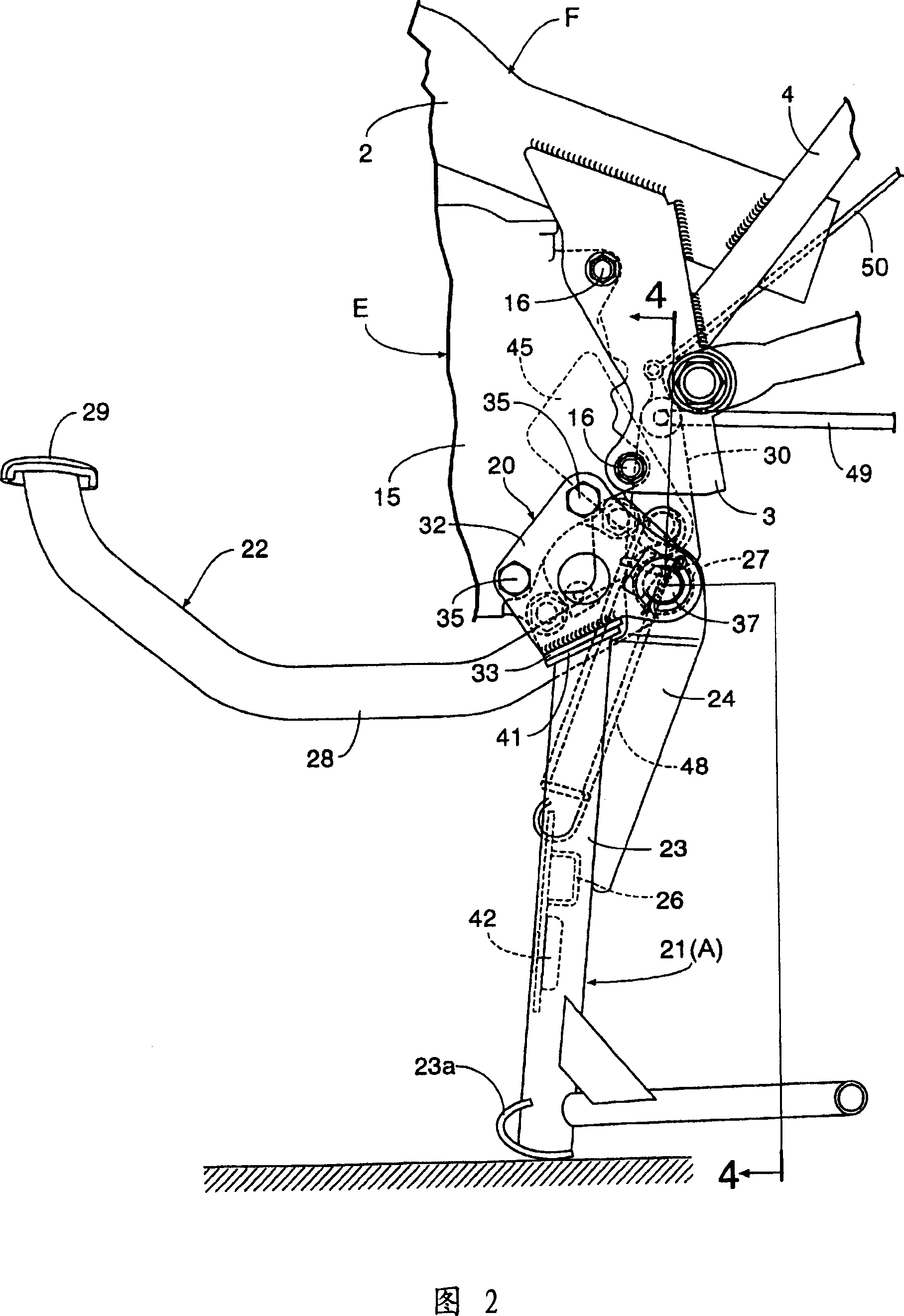

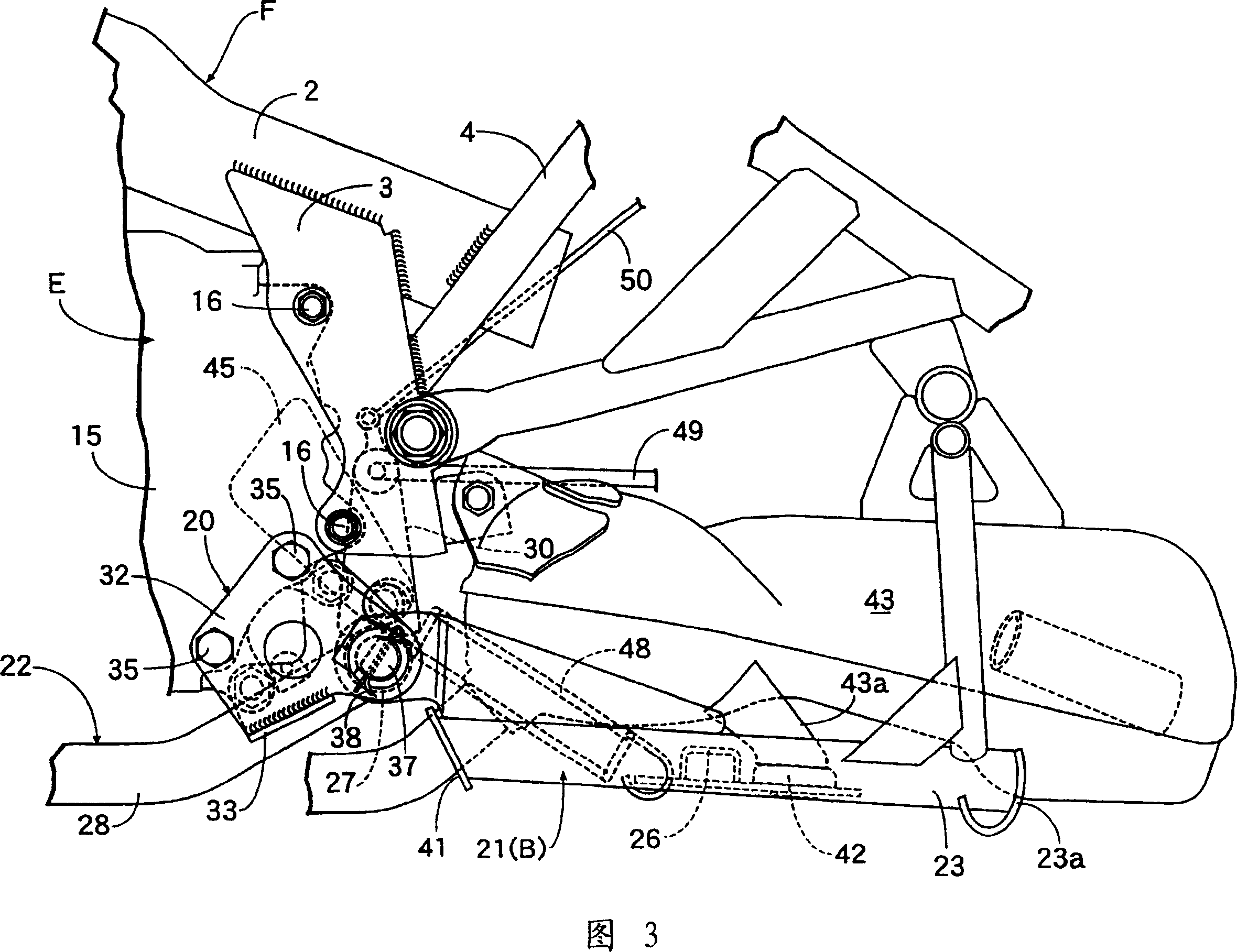

Motorcycle

The utility model relates to a two-wheeled motor vehicle, in which the support shaft of the support bracket is also used for the support of the brake pedal, so as to reduce the number of parts and reduce the weight of the two-wheeled motor vehicle. The two-wheeled motor vehicle has a door-shaped bracket (21) and a brake pedal (22) for actuating the brake of the rear wheel 5r, wherein the door-shaped bracket is pivotally supported by the bracket supporting portion (20) to ground the grounding portion (23a). Position (A) and the same leg (23a) can be rotated between the storage position (B) facing the rear of the vehicle body, wherein the bracket shaft ( 37) upper support brake pedal (22).

Owner:HONDA MOTOR CO LTD

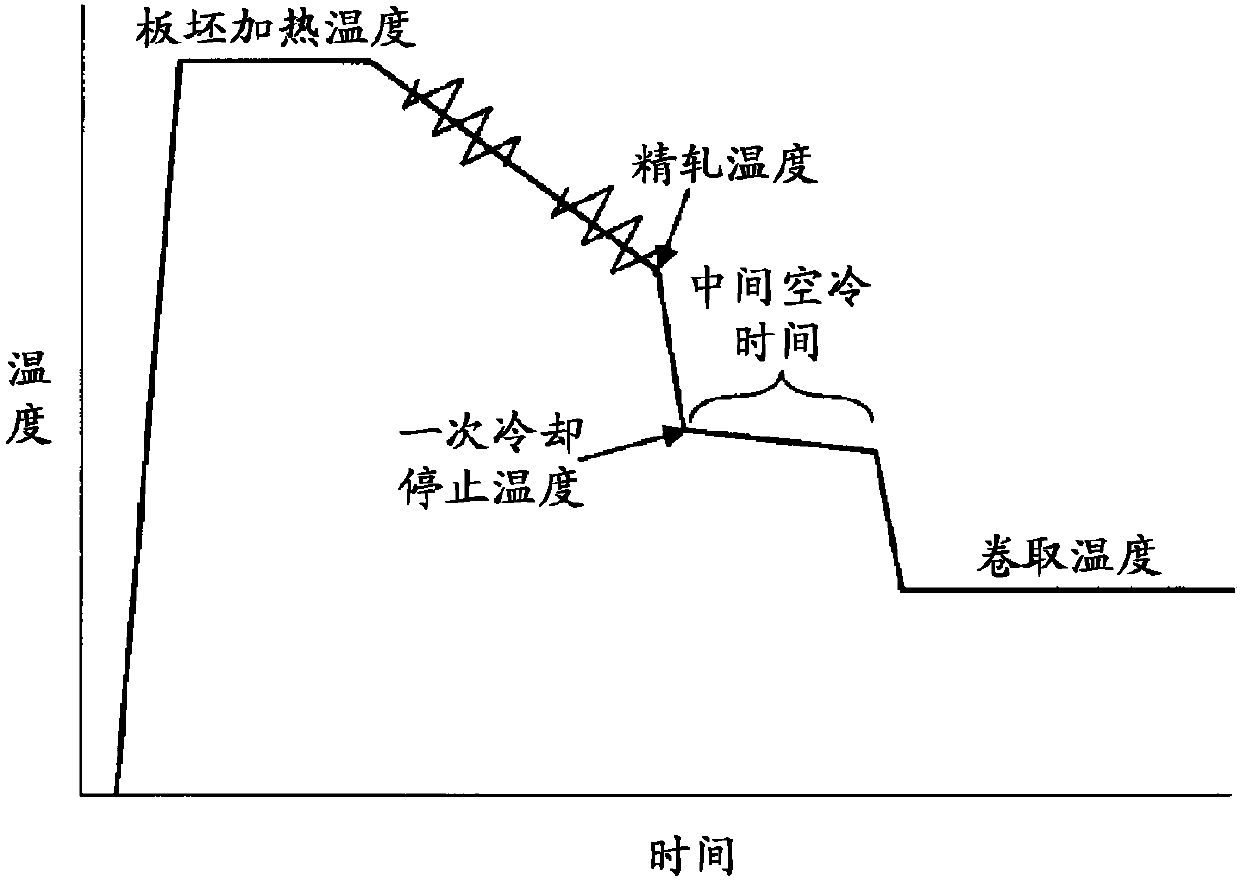

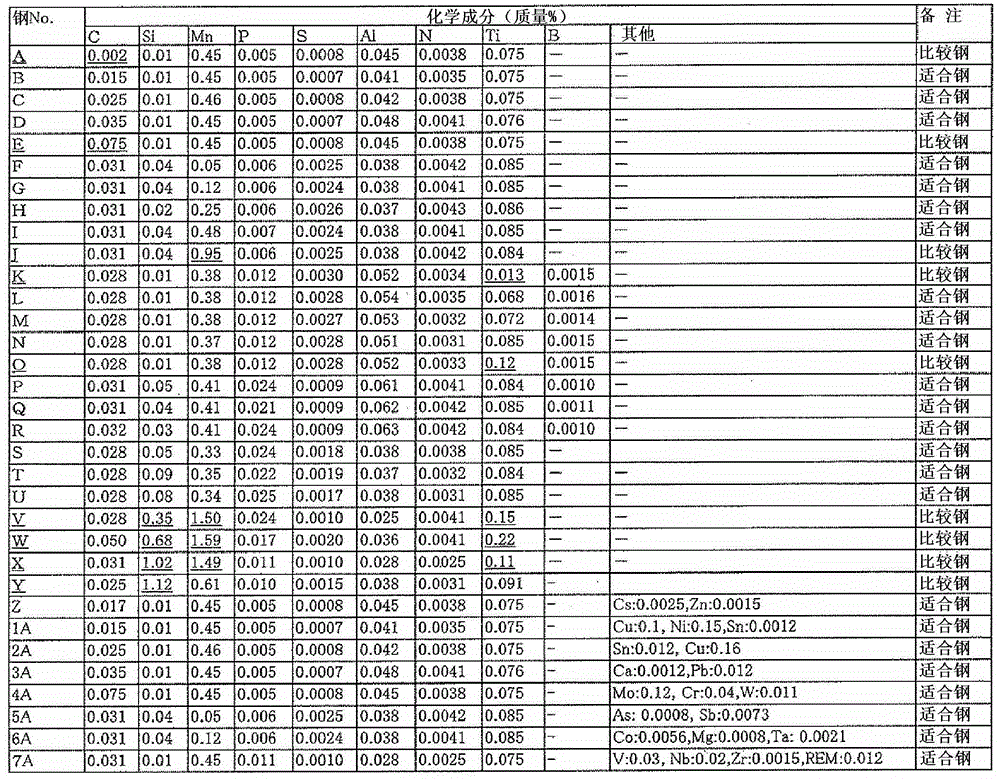

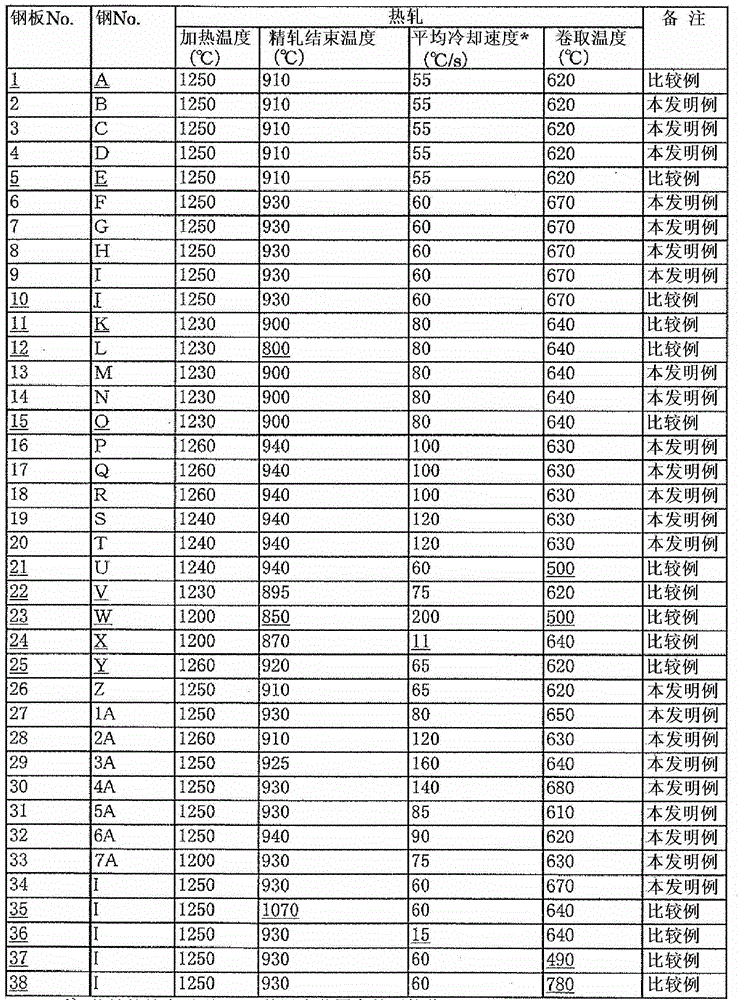

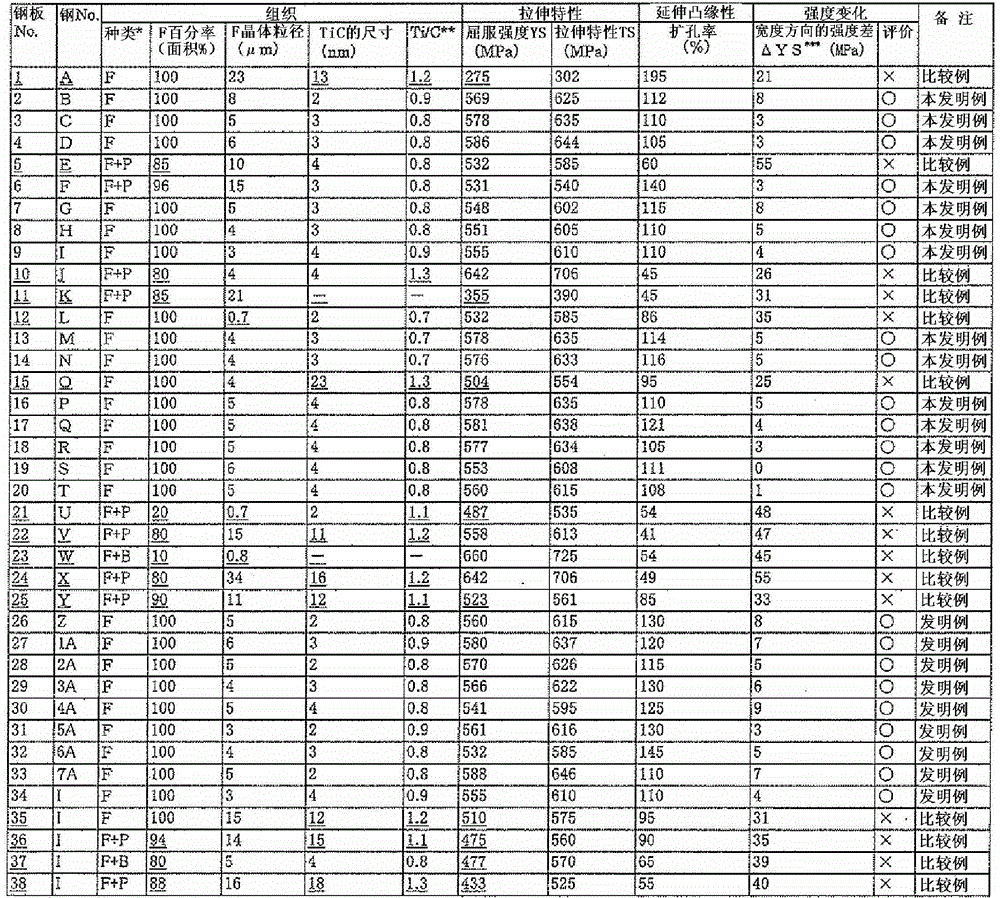

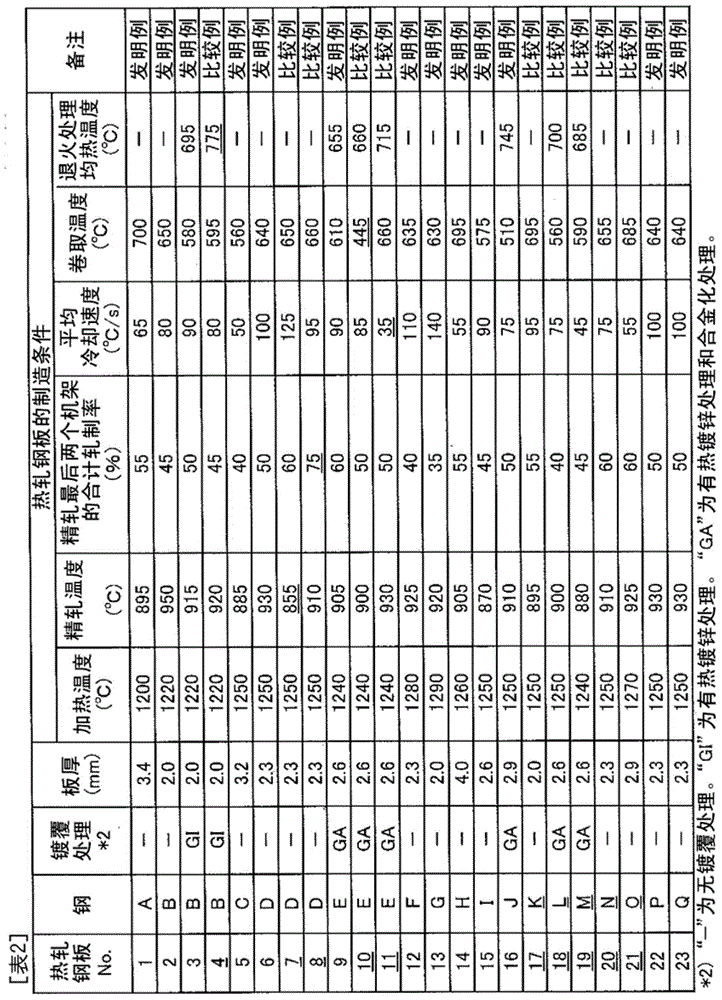

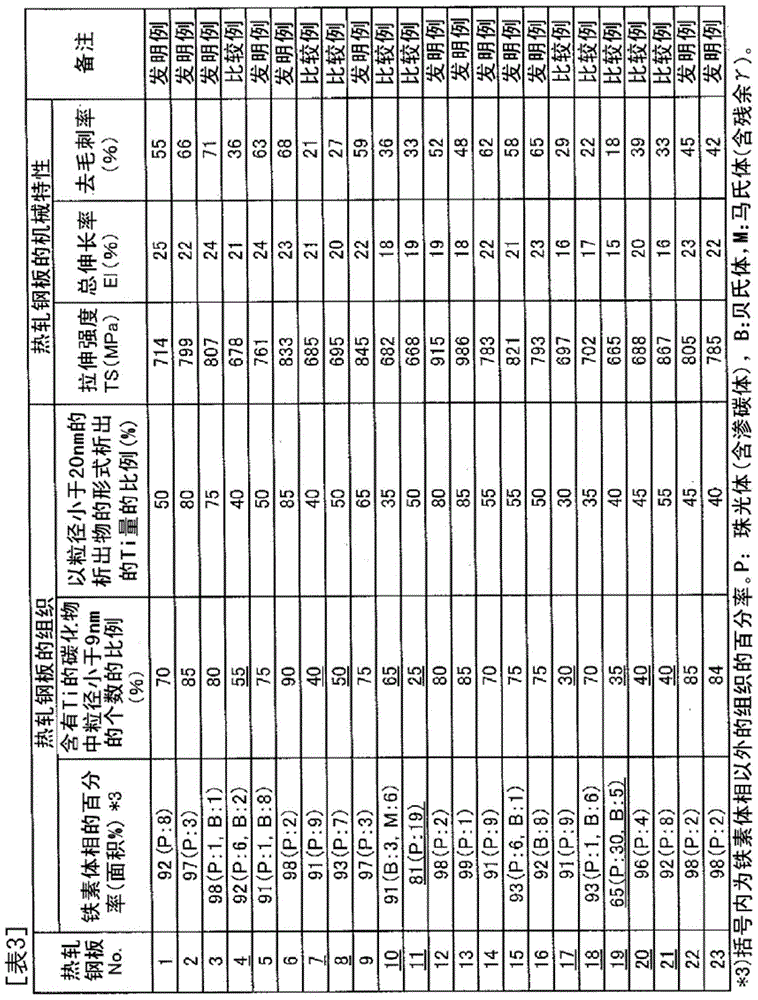

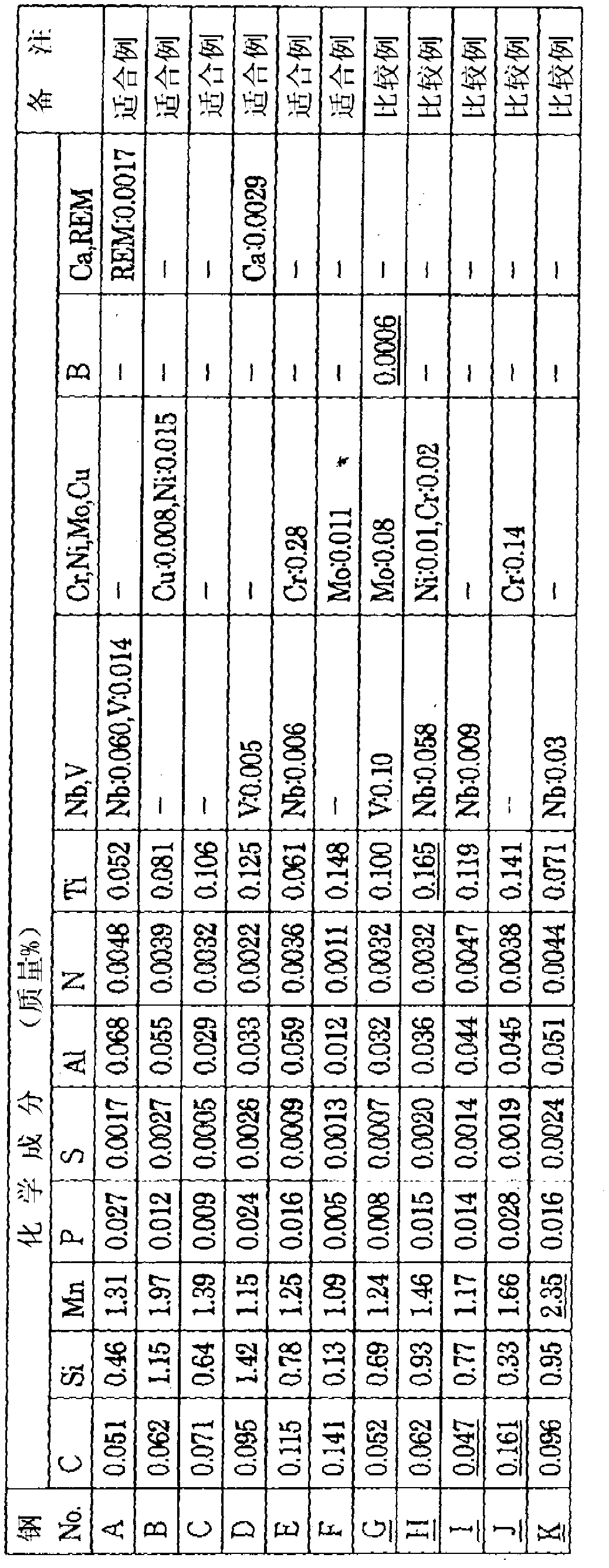

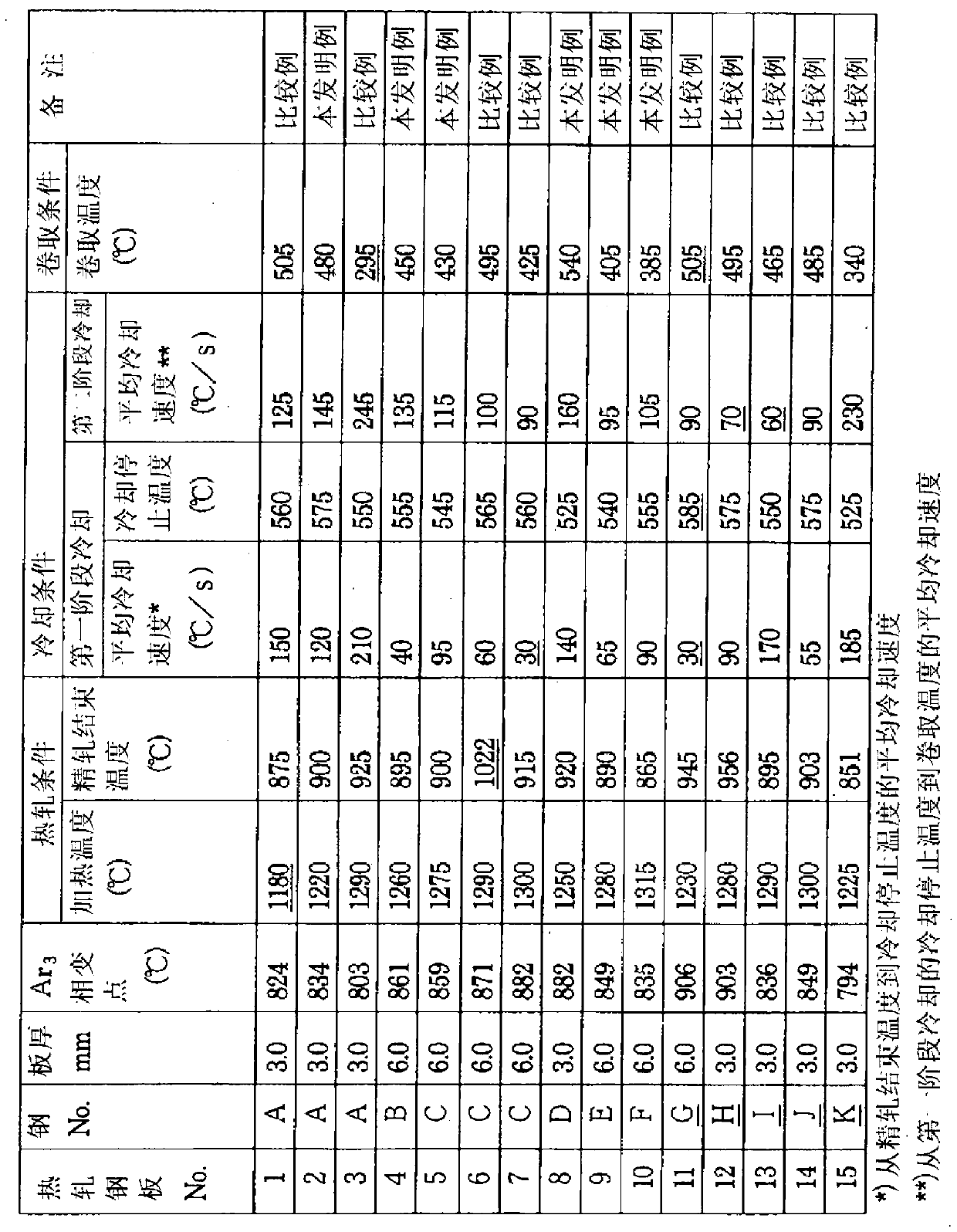

High-strength hot-rolled steel sheet and manufacturing method therefor

ActiveCN104024460ALittle change in mechanical propertiesExcellent stretch flangeabilityFurnace typesThin material handlingMean diameterManganese

Provided is a high-strength hot-rolled steel sheet that exhibits little inter-coil variability in mechanical properties and excellent stretch flangeability. By mass, said steel sheet contains more than 0.010% and no more than 0.06% carbon, up to 0.3% silicon, up to 0.8% manganese, up to 0.03% phosphorus, up to 0.02% sulfur, up to 0.1% aluminum, up to 0.01% nitrogen, and 0.05-0.10% titanium, with the remainder comprising iron and unavoidable impurities. The amounts of silicon and manganese are minimized, the amount of segregation and the like is reduced, and strength variation due to inter-coil position differences is decreased. The structure of the steel sheet is such that the area fraction of a ferrite phase is at least 95%, the mean diameter of ferrite crystal grains is at least 1 [mu]m, and TiC with a mean grain diameter of at most 7 nm is dispersed inside the ferrite crystal grains. This results in a high-strength hot-rolled steel sheet that maintains a yield strength of at least 530 MPa.

Owner:JFE STEEL CORP

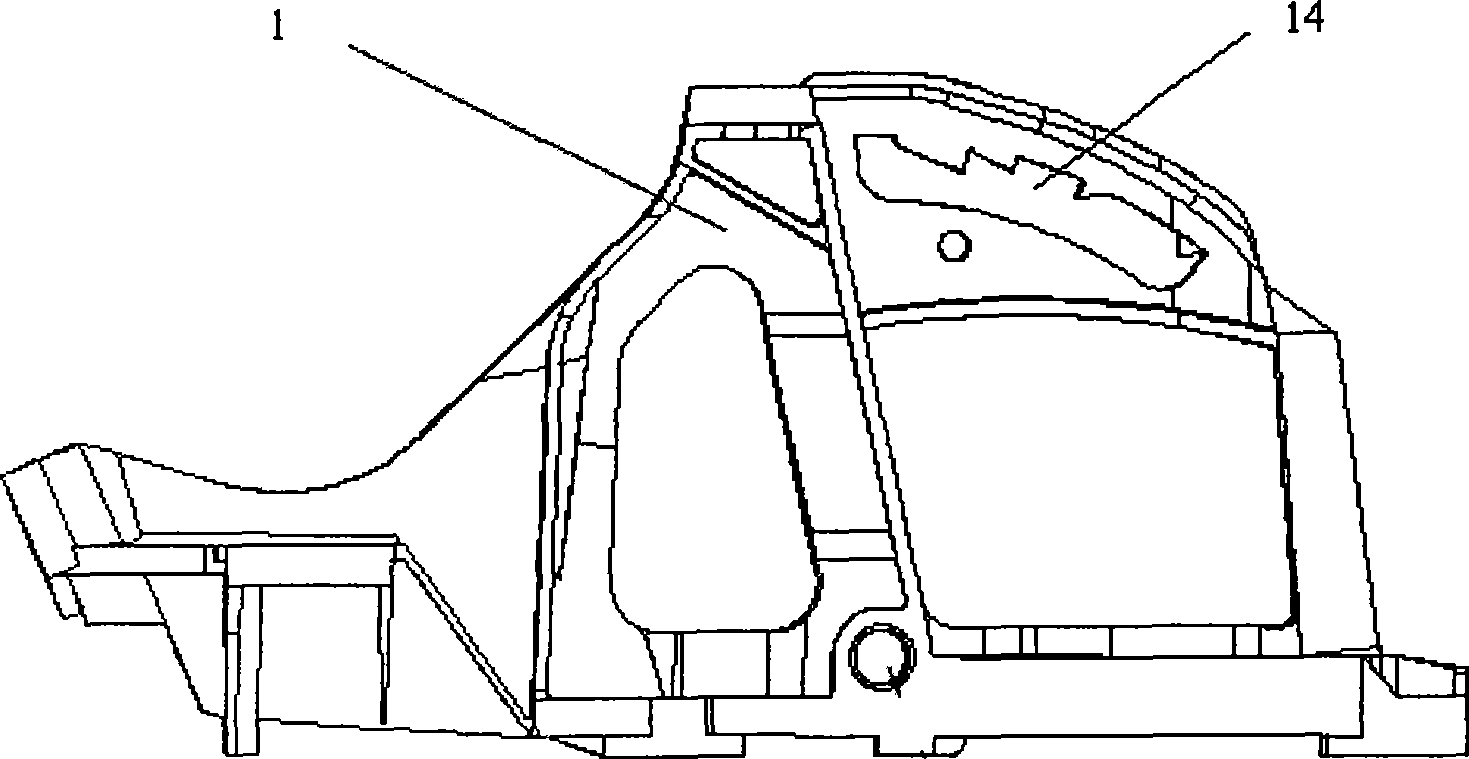

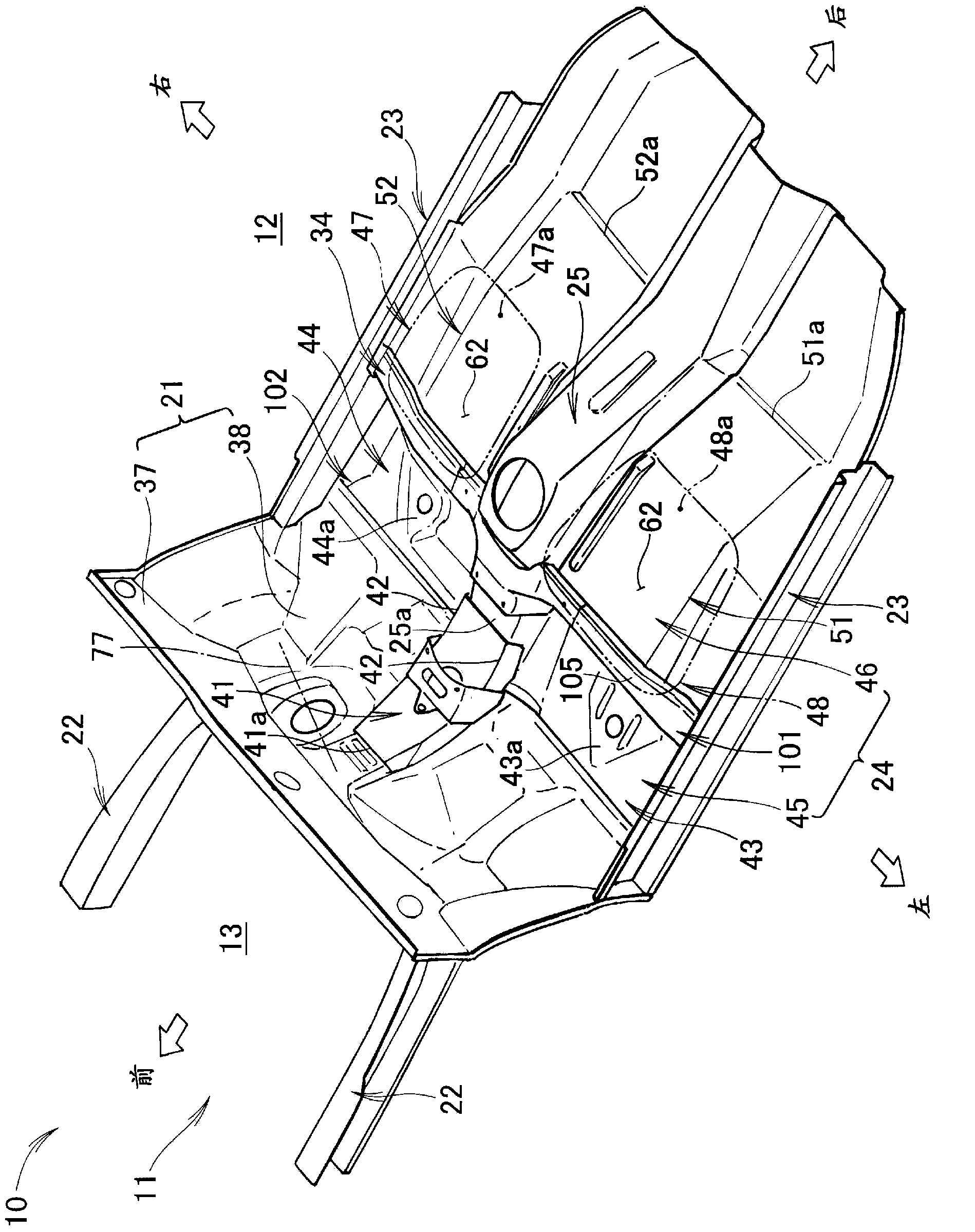

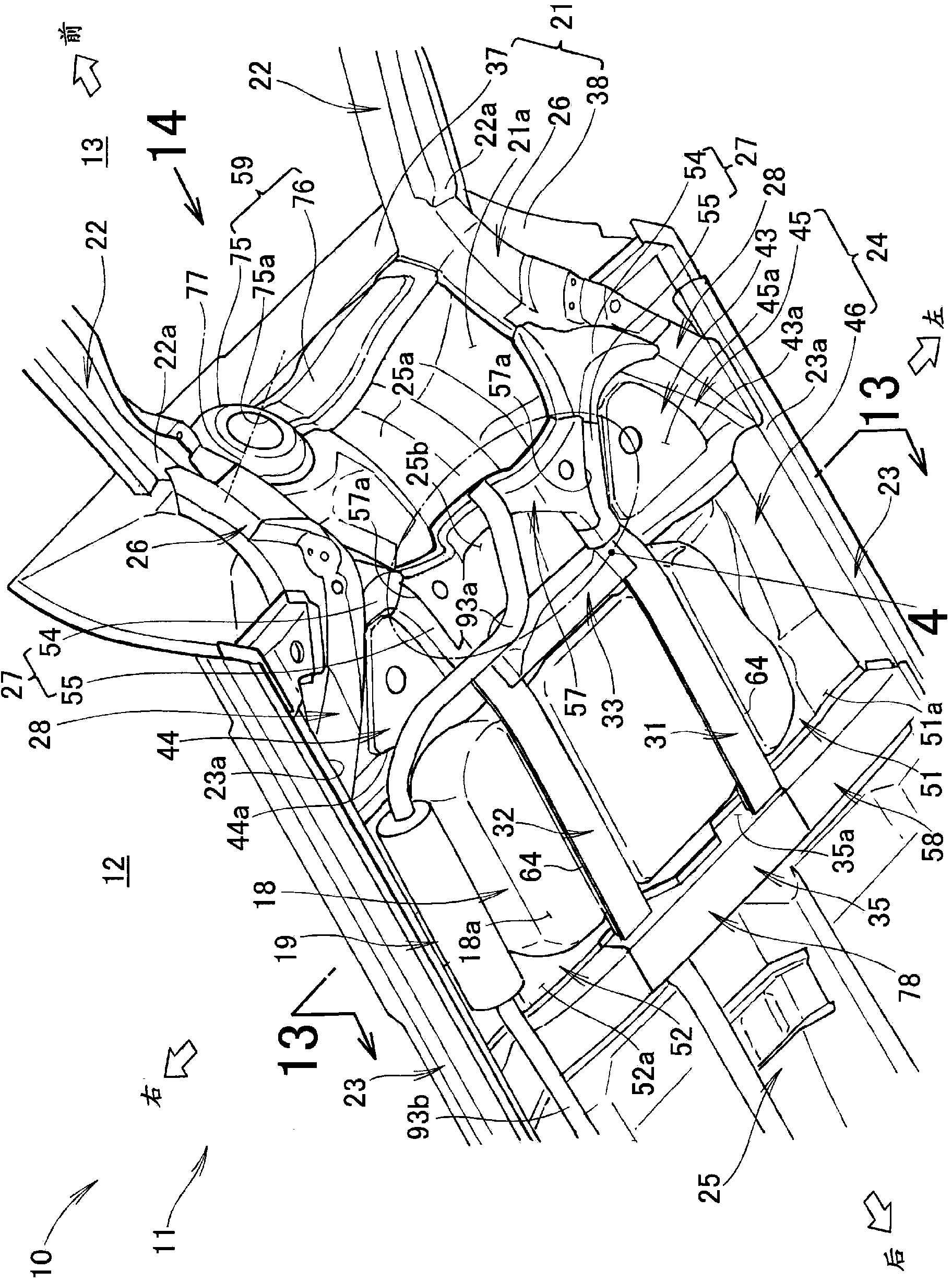

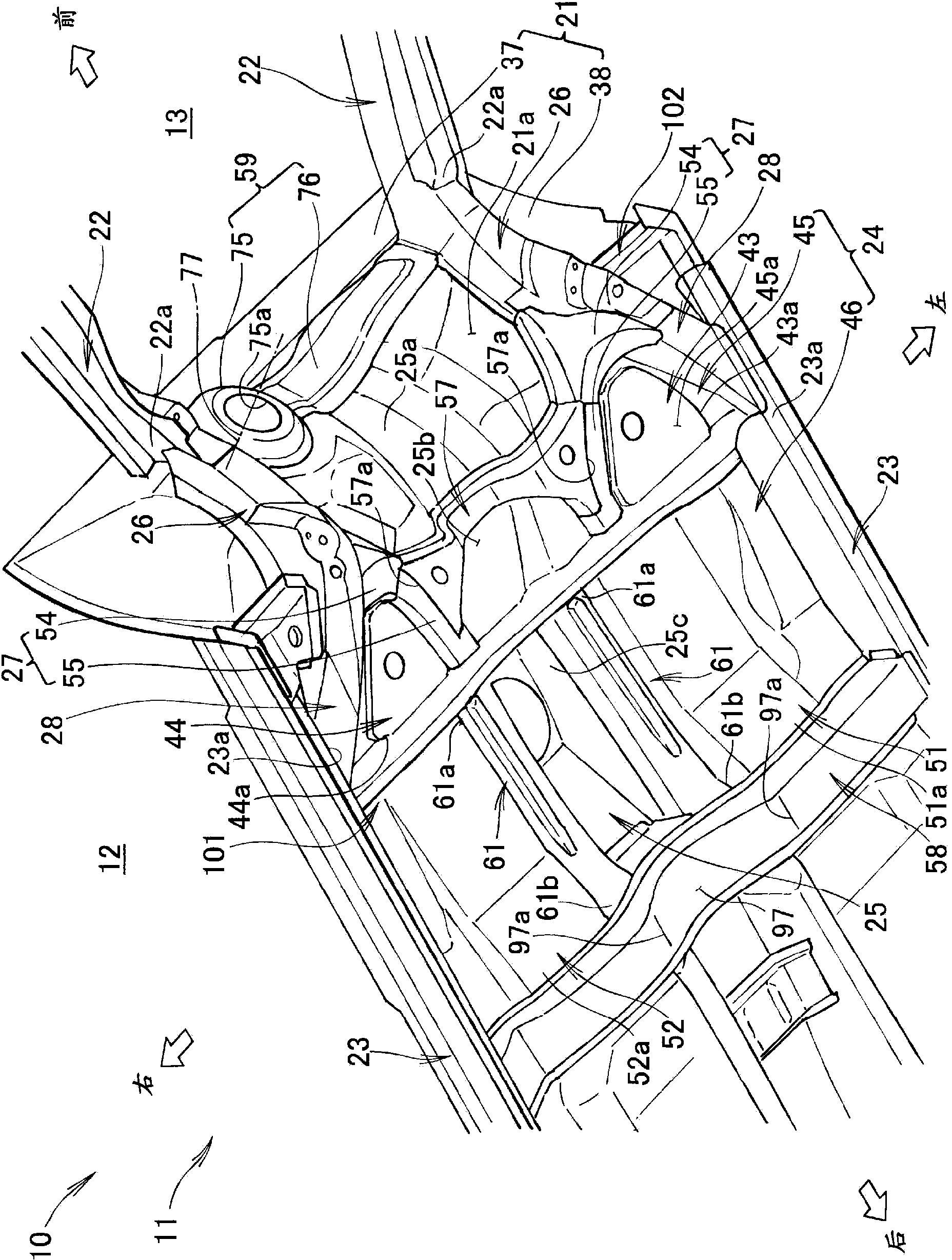

Vehicle body structure

ActiveCN103998273AFreely fixedImprove work efficiencyUnderstructuresVehicle sub-unit featuresDashboardVehicle frame

A floor panel (24) of a vehicle body (11) is provided with bulging sections (51, 52) in which seats (47, 48) are disposed to the left and right of a tunnel section (25), and a rear tunnel cross member (58) extending in the vehicle width direction at the rear ends (51a, 52a) of the bulging sections (51, 52). The vehicle body (11) is provided with left and right floor extensions (27, 27) set further toward the tunnel section (25) along a dashboard lower (21) relative to front side frames (22, 22), floor frames (31, 32) extending so as to span between the floor extensions (27, 27) and the rear tunnel cross member (58) and having a predetermined distance in the vehicle body vertical direction from a rear floor panel (46), and an energy container (18) placed below the bulging sections (51, 52) and supported on the floor frames (31, 32). The floor frames (31, 32) are fixed to the vehicle body (11) so as to be capable of being removed from below the vehicle body.

Owner:HONDA MOTOR CO LTD

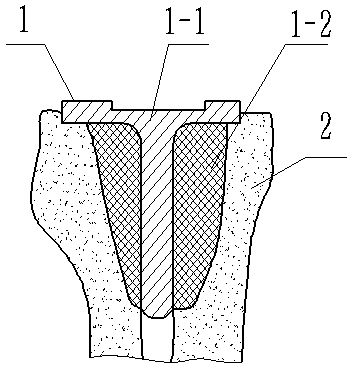

Bone implant

The invention discloses a bone implant, which comprises a porous material, a metal stem which is contained in the porous material, as well as growth factors and medicines which are contained in the bone implant, wherein the porous material is an integrated body; the porous material is a multi-stage porous material which includes at least two stages, and pores of the minimum stage are nano-scale pores; and pore cavities of various stages mutually communicate and the pores cavities in each of various stages also mutually communicate. The bone implant provided by the invention, is integrally fixed and strong in supporting capacity in the initial stage of implantation, so that a surgery becomes simple to operate and short in duration; more growth factors and medicines can be stored, so that the bone implant is more conducive to cell adhesion, differentiation and migration, and the bone implant is beneficial for promoting cell growth and accelerating tissue regeneration; and the bone implant is beneficial for rapid and sufficient transmission of tissue fluid and metabolites and for smooth growth of tissues.

Owner:CHONGQING RUNZE PHARM CO LTD

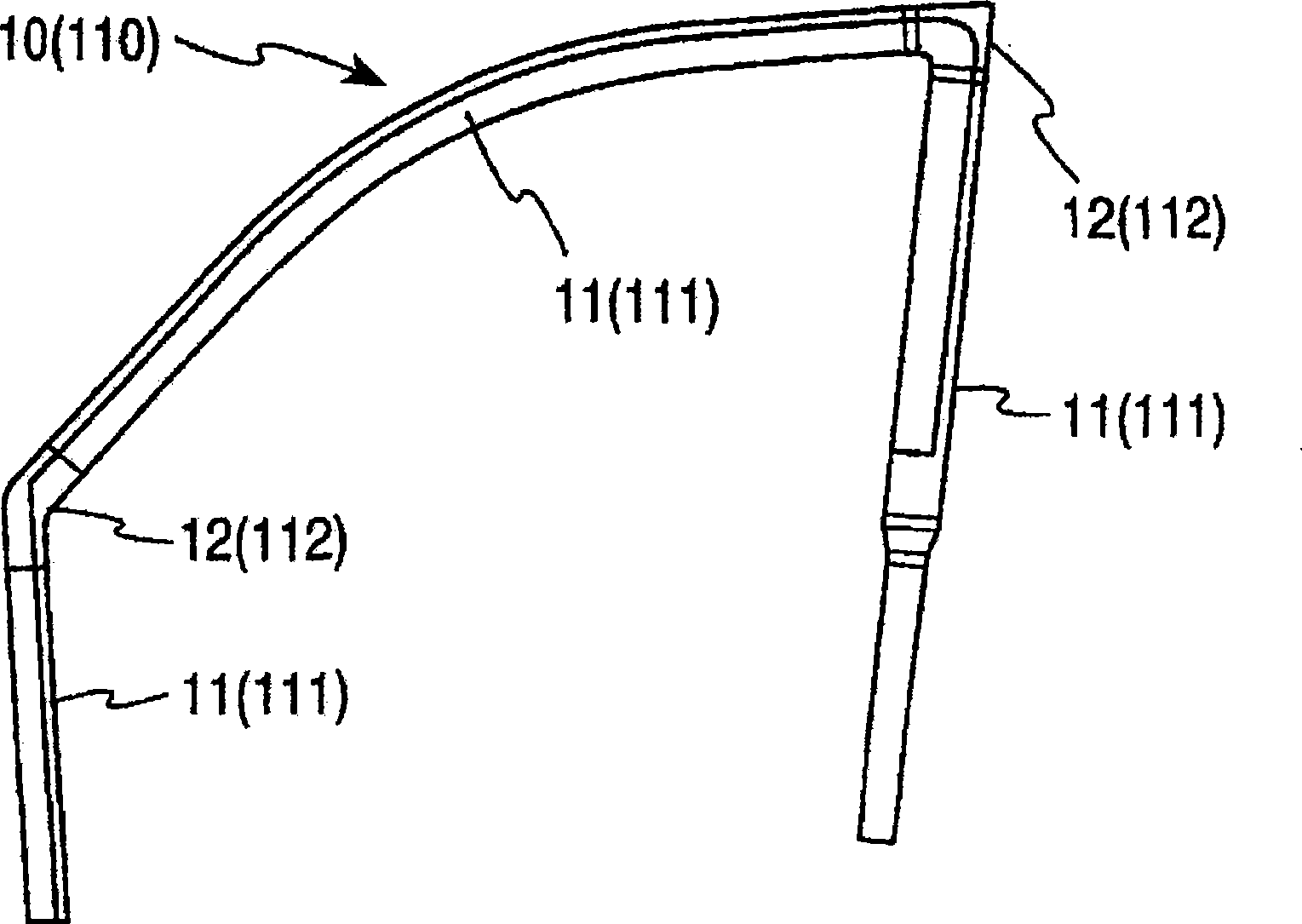

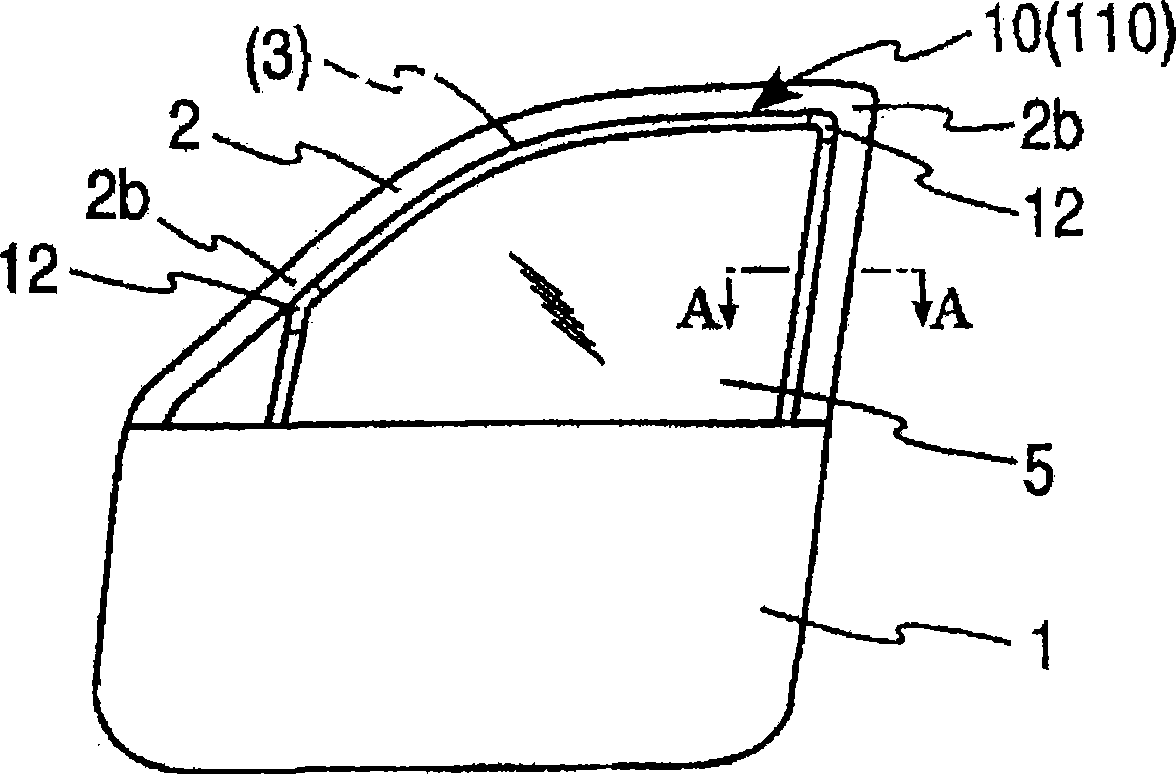

Automotive glass run

InactiveCN101376332AImprove rigidityReduce weightEngine sealsVehicle sealing arrangementsEngineeringMechanical engineering

The invention discloses an automotive glass run. A main body of automotive glass run assumes a substantially U-shaped cross section consisting of a vehicle-exterior side wall, an interior side wall, and a bottom wall and is provided with a vehicle-exterior seal lip and an interior seal lip. The bottom wall is made of a solid material or a microfoaming solid material, and the vehicle-exterior side wall and the interior side wall are made from a sponge material. A vehicle-exterior projection, which assumes a triangular cross-sectional profile and whose top inwardly protrudes so as to be able to contact a door glass, is formed on an interior surface of the vehicle-exterior side wall. A low sliding resistance material layer is formed on a surface of the vehicle-exterior projection.

Owner:TOYODA GOSEI CO LTD

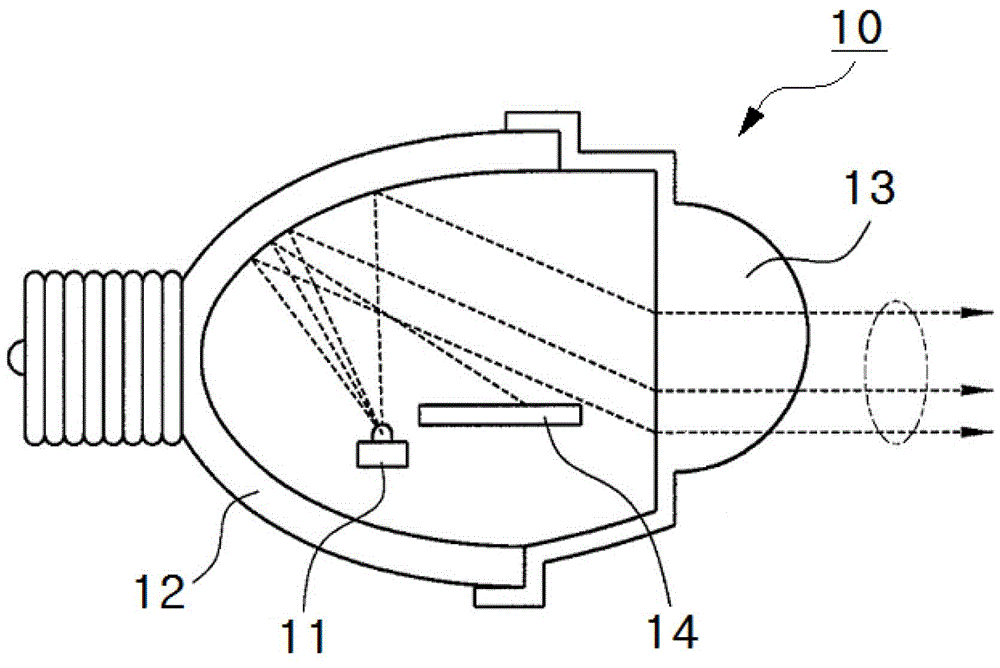

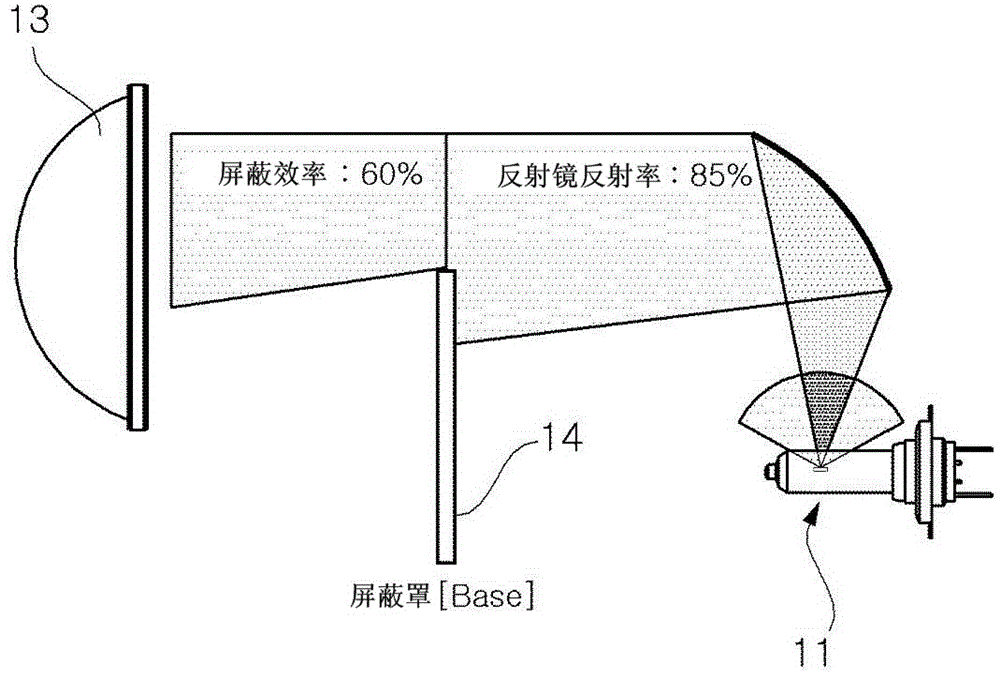

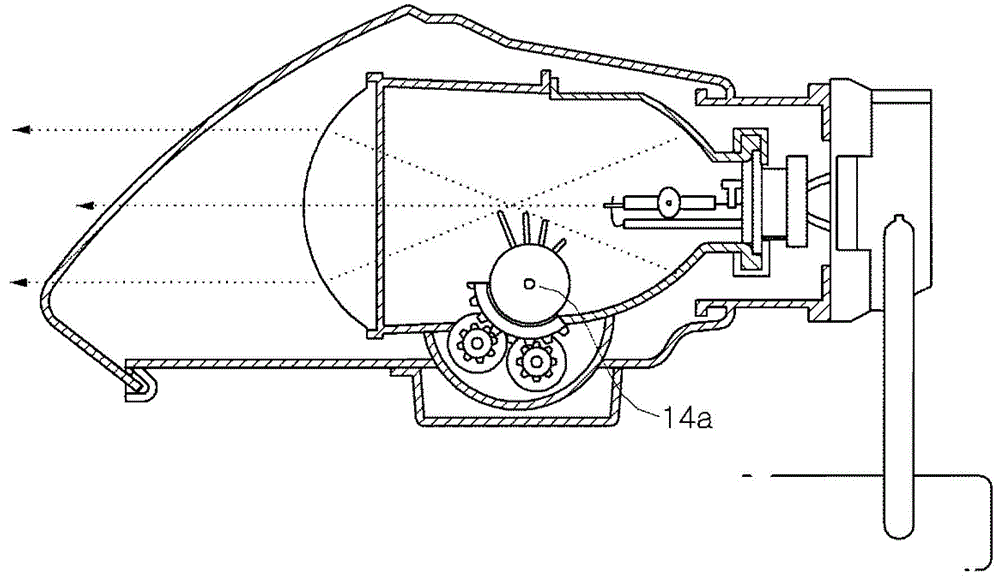

Multi-array LED chip for embodying cut-off line and head lamp having the same

ActiveCN104100899ADoes not reduce light efficiencyImprove lighting efficiencyPlanar light sourcesVehicle headlampsEngineeringLED lamp

The present invention relates to a multi-array LED chip for embodying a cut-off line, and the multi-array LED chip includes: a plurality of LED modules which emits light; and at least one low beam LED module which emits light, in which the LED module and the low beam LED module are disposed to match a cut-off line, and the LED module and the low beam LED module are individually turned on and off such that a low beam is emitted. Accordingly, a direct type of light is emitted, and thus a low beam, which complies with regulations regarding the cut-off line, is embodied, and light efficiency does not deteriorate.

Owner:HYUNDAI MOBIS CO LTD

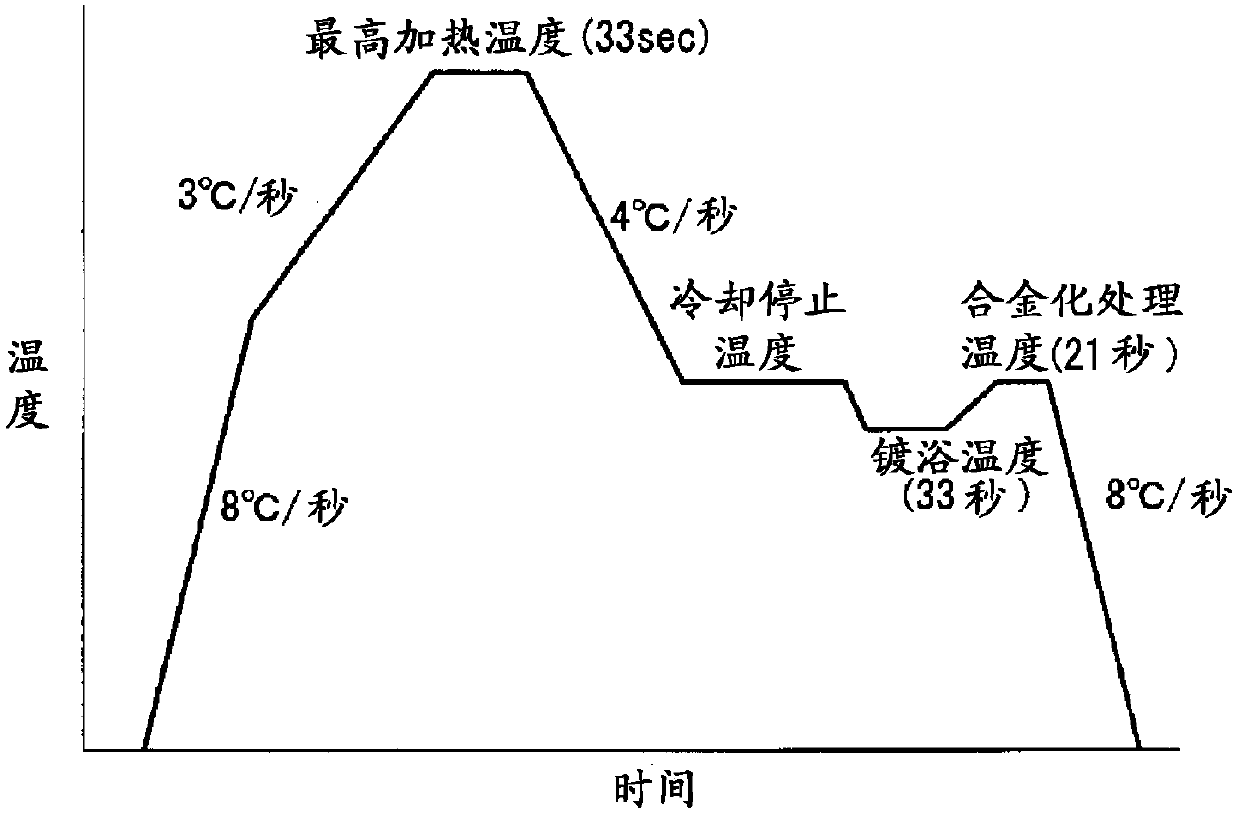

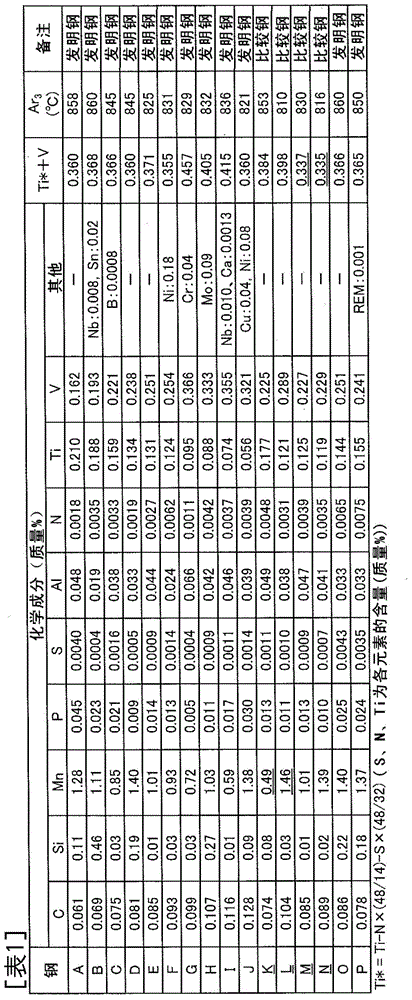

High-strength hot-rolled steel sheet and production method thereof

ActiveCN104968819AHelps to reduce weightExcellent deburring processabilityMetal recyclingHot-dipping/immersion processesCarbidePhase fraction

A high-strength hot-rolled steel sheet with excellent burring workability, and a production method thereof are provided. This high-strength hot-rolled steel sheet with excellent burring workability has a composition which includes, in mass%, C: 0.06%-0.13%, Si: less than 0.5%, Mn: greater than 0.5% and less than or equal to 1.4%, P: 0.05% or less, S: 0.005% or less, N: 0.01% or less, Al: 0.1% or less, Ti: 0.05%-0.25% and V: greater than 0.15% and less than or equal to 0.4%, such that S, N, Ti and V satisfy Ti* + V ≧ 0.35 (here, Ti*=Ti-N×(48 / 14)-S×(48 / 32), and S, N, Ti and V represent the content (in mass%) of each element), with the remainder consisting of Fe and unavoidable impurities, and is of a material in which the ferrite phase fraction exceeds 90%, carbides containing Ti are precipitated, and 70% or more of said carbides have a particle diameter of less than 9nm.

Owner:JFE STEEL CORP

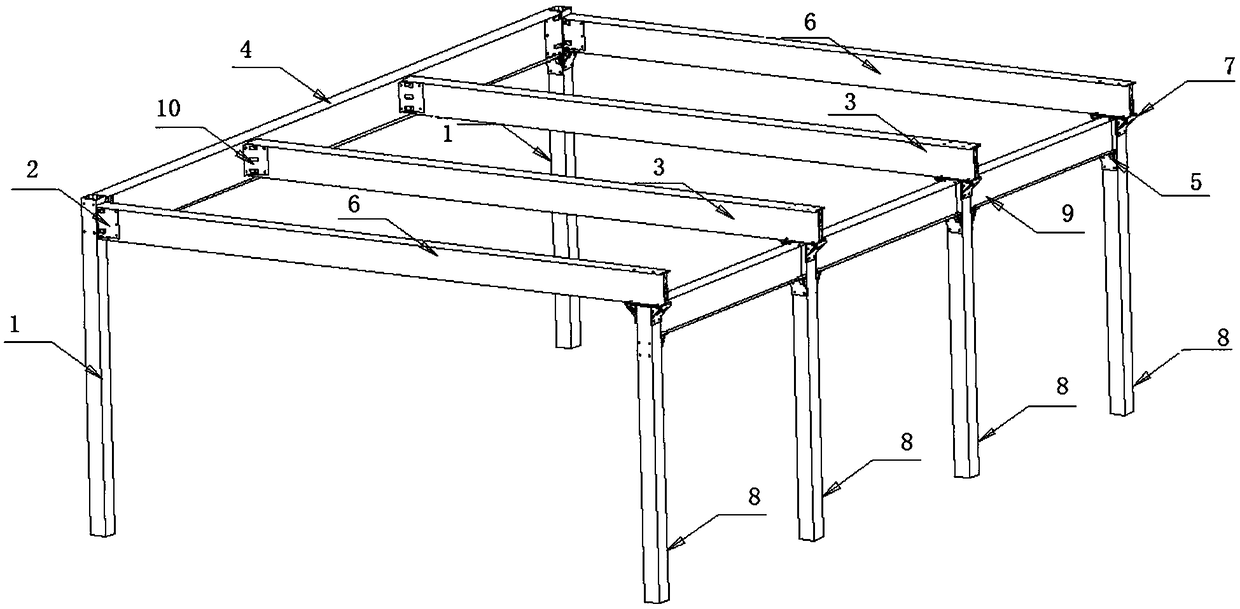

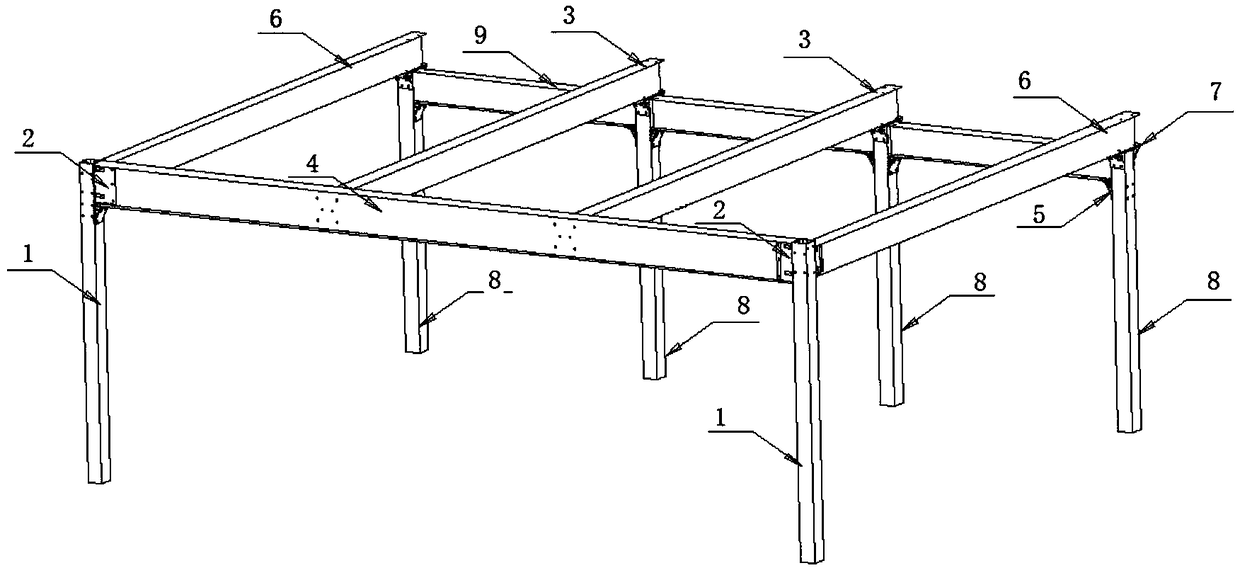

Full-aluminum stereo parking equipment frame

InactiveCN108487710ARealize pure screw fixationImprove recycling ratesBuilding constructionsParkingsStructural engineeringTorsion strength

The invention discloses a full-aluminum stereo parking equipment frame. The full-aluminum stereo parking equipment frame comprises two or more front vertical columns, two or more rear vertical columns, a front beam, a rear cross beam, two edge longitudinal beams and a middle longitudinal beam. The front beam is transverselyfixed to the top ends of the front vertical columns, the rear cross beam istransversely fixed to the top ends of the rear vertical columns, and profiles used by the front beam and the rear cross beam are II-shaped multi-cavity profiles. Stiffening ribs and reinforcing barsare designed on the inner surfaces of cavities. One ends of the edge longitudinal beams are fixedly connected with the front beam, the other ends of the edge longitudinal beams are fixedly connected with the rear cross beams, and one ends of the middle longitudinal beams are fixedly connected with the front beam. The other ends of the middle longitudinal beams are fixedly connected with the rear cross beam, and the profiles used by the edge longitudinal beams and the middle longitudinal beams are II-shaped triangular multi-cavity aluminum profiles. The II-shaped triangular multi-cavity aluminum profiles can improve the strength and stability of the middle longitudinal beams and the edge longitudinal beams, and the anti-torsion strength of the front beam and the rear cross beam can be reinforced through the II-shaped multi-cavity aluminum profiles with the stiffening ribs. Connecting components can be placed on the abdomens of the II-shaped profiles, thus the II-shaped profiles are conveniently connected with the longitudinal beams and the vertical columns through bolts, and dismounting and mounting are flexible and convenient.

Owner:ALNAN ALUMINIUM CO LTD

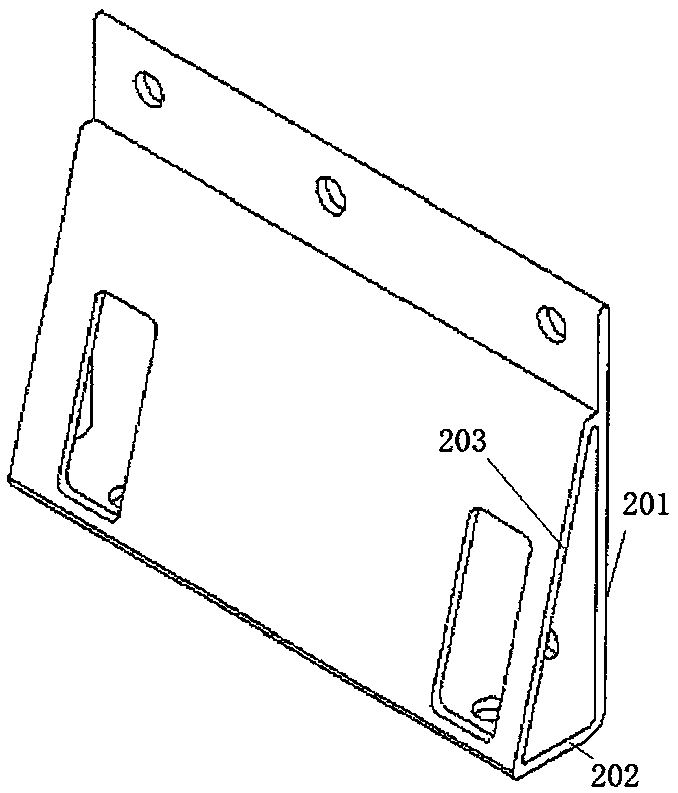

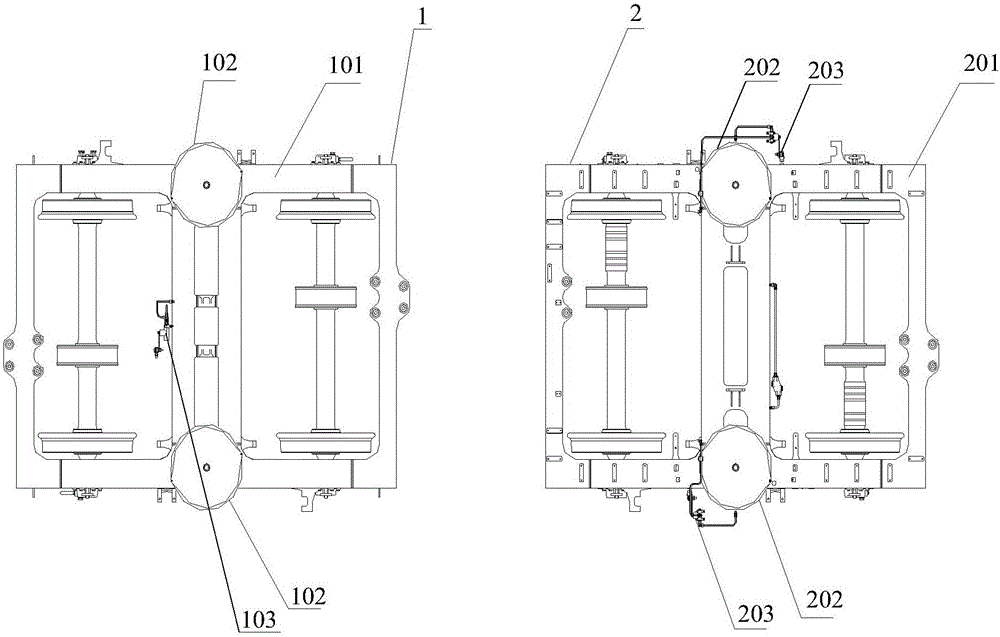

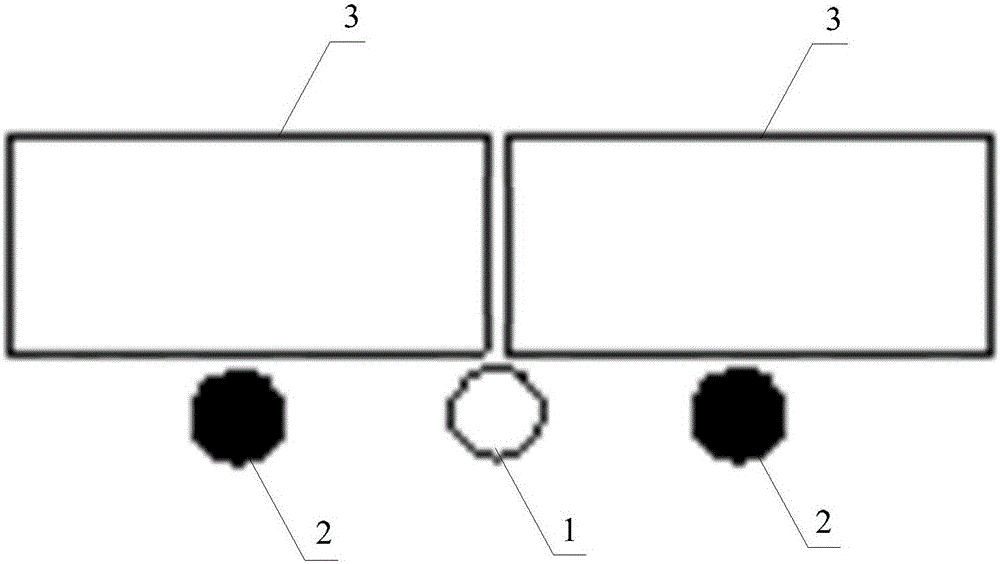

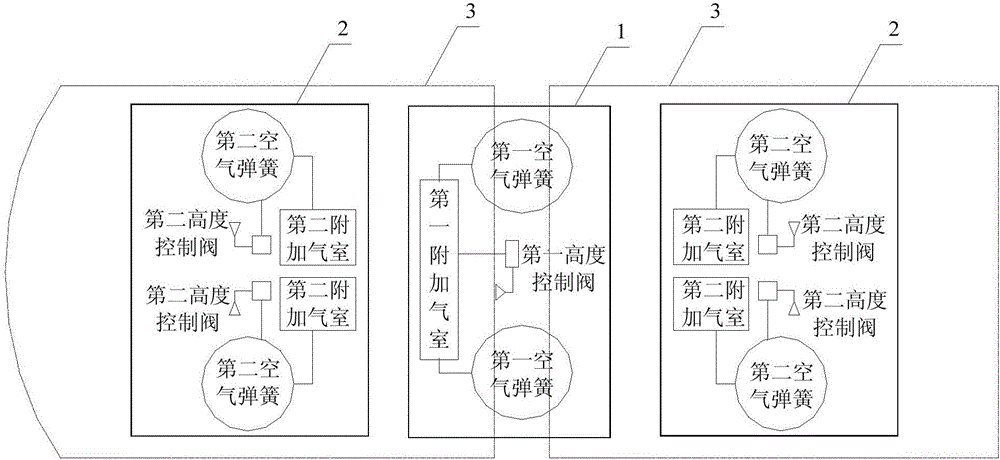

Train supporting device and train

ActiveCN106043342AReduce weightHelps to reduce weightBogiesBogie-underframe connectionsAir springAir suspension

The invention provides a train supporting device and a train. The train supporting device comprises a hinging steering frame and a supporting steering frame, wherein the hinging steering frame comprises a first framework and two first air springs positioned on the first framework; the two first air springs are jointly provided with a first additional air chamber and a first height control valve; the supporting steering frame comprises a second framework and two second air springs positioned on the second framework; each of the two second air springs is provided with a second additional air chamber and a second height control valve; the hinging steering frame is used for connecting two adjacent sections of a train body; and the supporting steering frame is positioned under a single section of the train body, and is used for supporting the single section of the train body. According to the train supporting device provided by the invention, the whole weight of the train is reduced, and the operating performance of the train is improved.

Owner:CRRC TANGSHAN CO LTD

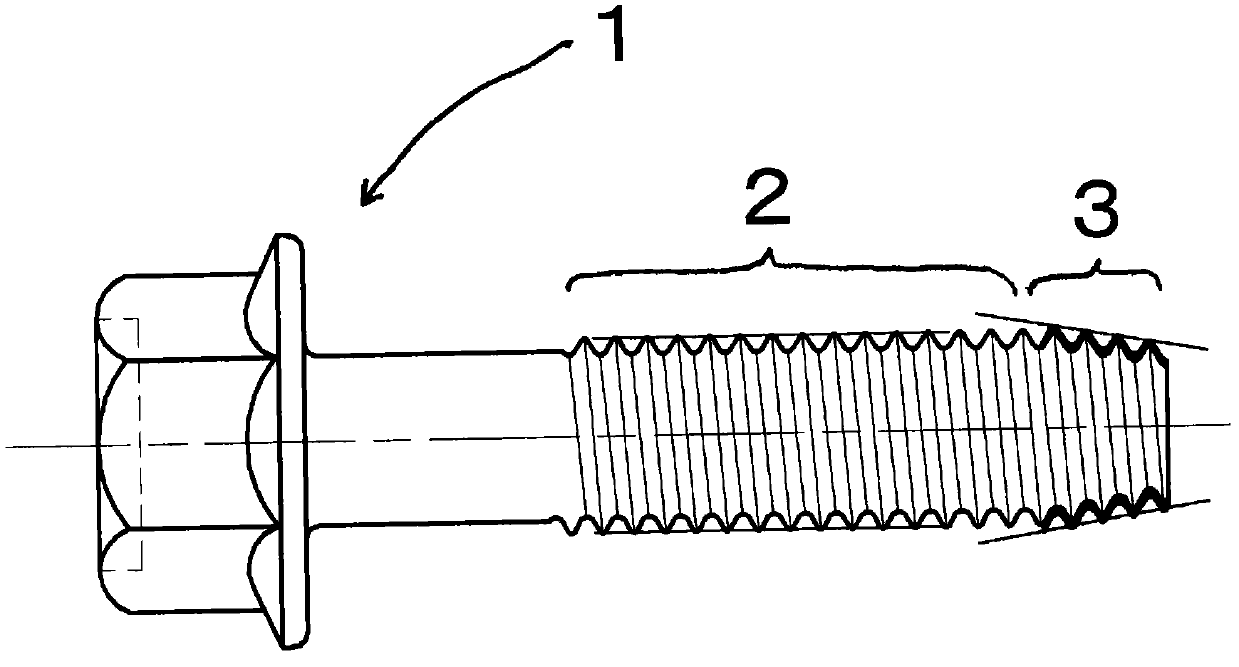

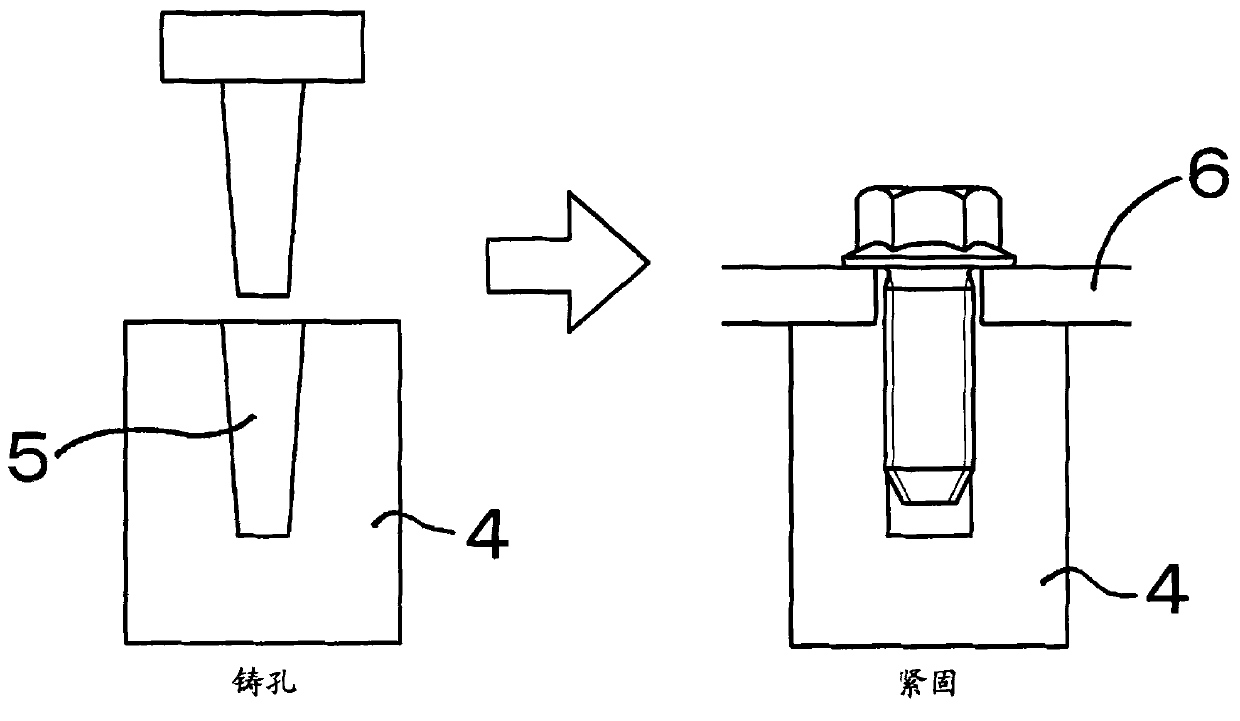

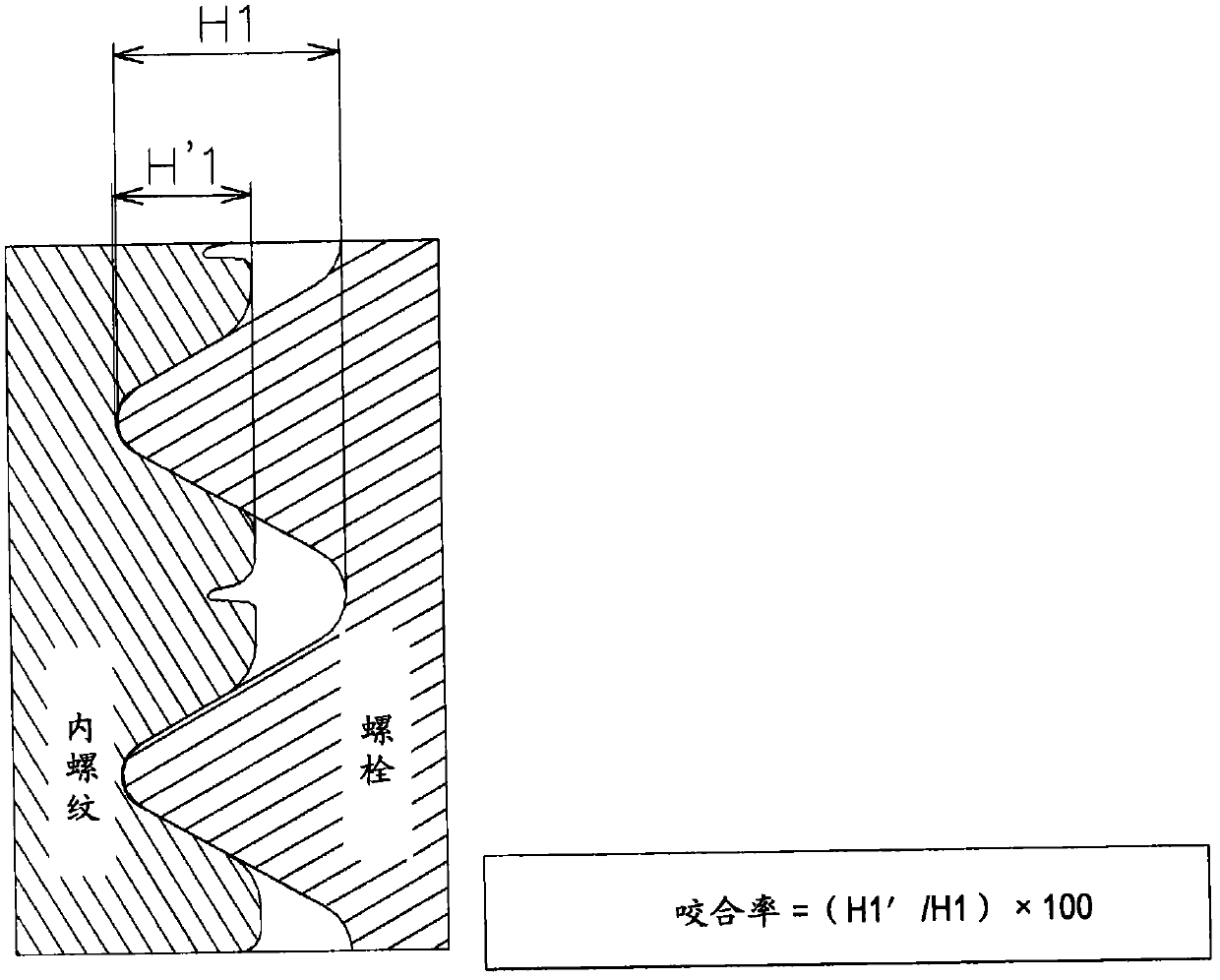

Screw fastening structure with high-strength self-forming screw

ActiveCN102027244AReduce processing stepsReduce stressSheet joiningScrewsSelf formingMiniaturization

To provide a screw fastening structure for enhancing the strength of a bolt and fatigue strength by reducing the machining process without altering the shape of an associated member, and for achieving downsizing by keeping the fitting length of a thread almost the same as that of the prior art, thus contributing remarkably to weight reduction of a vehicle. A self-forming screw (1) having a strength 14T produced by form rolling before heat treatment is employed as a fastening bolt, and the self-forming screw is driven into a member (4) having an as-cast, nonthreaded rough hole (5). In a screw fastening structure to which a fixing member (6) is fastened, the catch rate of a female screw and a male screw formed by a self-form is 75-90%, the fitting length of the screw and the rough hole is d-2.5d (d is screw diameter), and no clearance appears at the contact surface of the male and female screws because of self-forming screw fastening.

Owner:TOPURA CO LTD

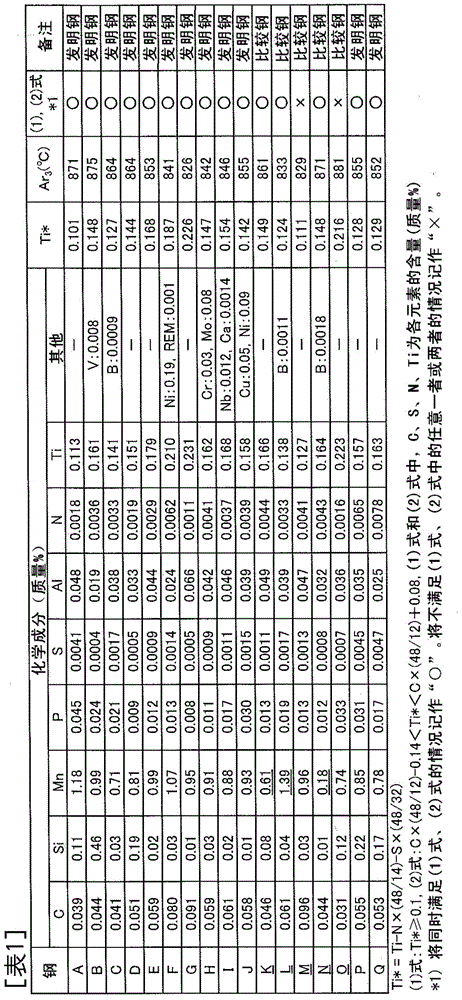

High-strength hot-rolled steel sheet and manufacturing process therefor

InactiveCN104995323AHelps to reduce weightExcellent deburring processabilityHot-dipping/immersion processesFurnace typesSheet steelCarbide

Provided are a high-strength hot-rolled steel sheet with excellent burring workability and a manufacturing process therefor. This high-strength hot-rolled steel sheet with excellent burring workability has: a composition that contains, in mass%, 0.03 to 0.1% of C, less than 0.5% of Si, more than 0.7 to less than 1.2% of Mn, up to 0.05% of P, up to 0.005% of S, up to 0.01% of N, up to 0.1% of Al, and 0.1 to 0.25% of Ti so as to satisfy the relationships Ti*≥0.1 and C×(48 / 12)-0.14<Ti*<C×(48 / 12)+0.08 [wherein Ti*=Ti-N×(48 / 14)-S×(48 / 32), and C, S, N and Ti are contents (mass%) of these elements respectively], with the balance consisting of Fe and unavoidable impurities; and a structure that has a ferrite fraction exceeding 90% and that contains Ti-containing carbide precipitates, at least 70% of which have particle diameters of less than 9nm.

Owner:JFE STEEL CORP

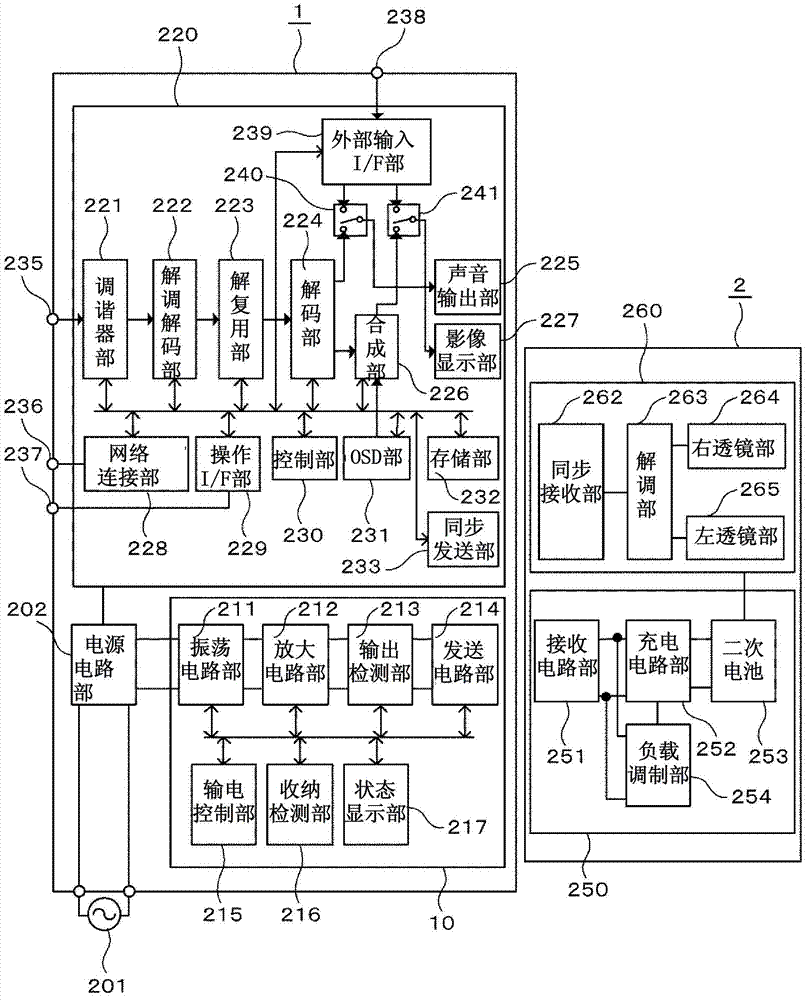

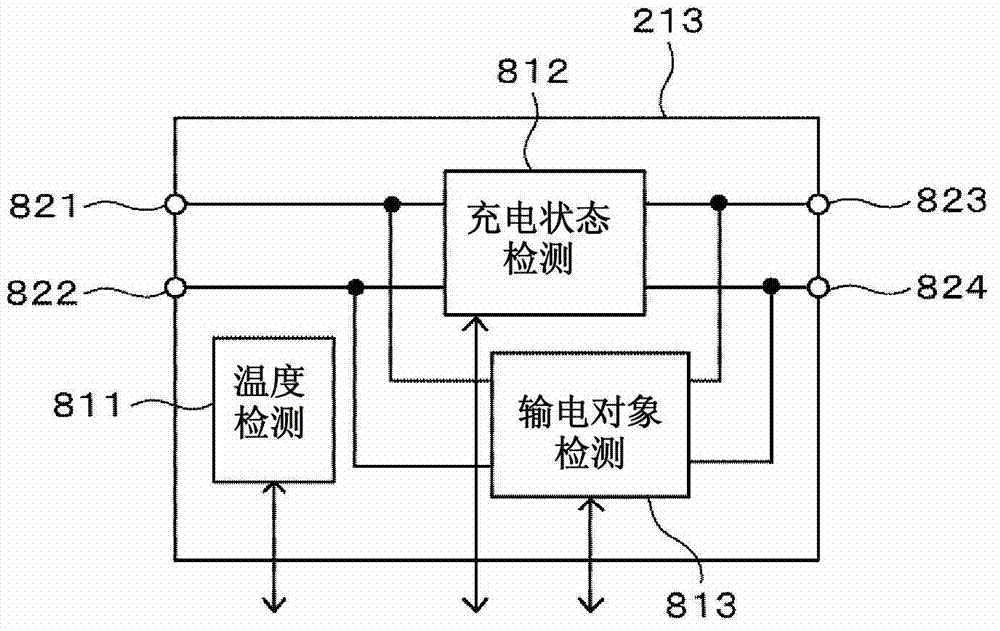

Contact-less power transmitter and contact-less power transmission system

InactiveCN103094974AHelp miniaturizationSimple structureNear-field transmissionElectromagnetic wave systemElectric power transmissionControl signal

Owner:RESONAC CORPORATION

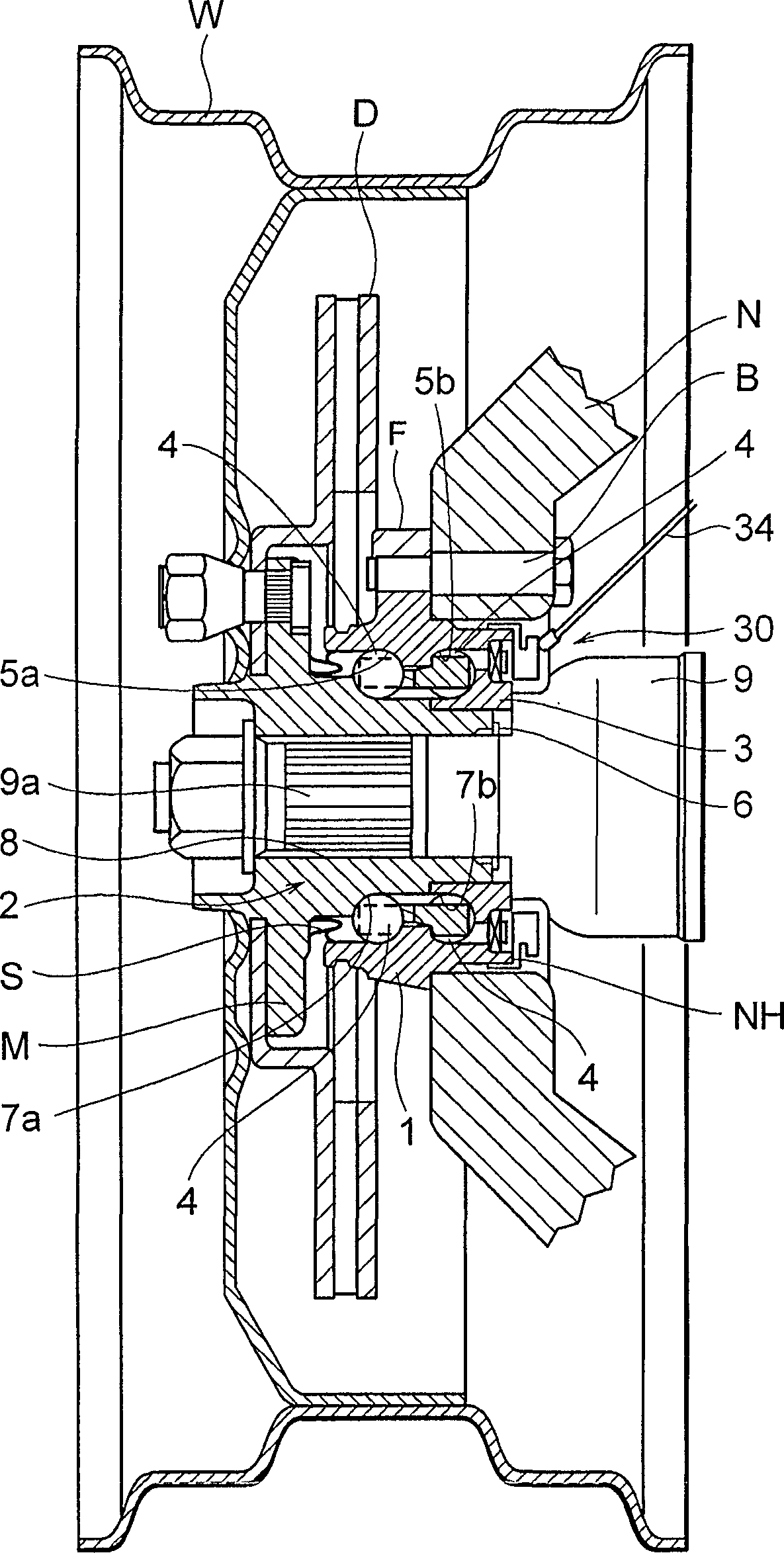

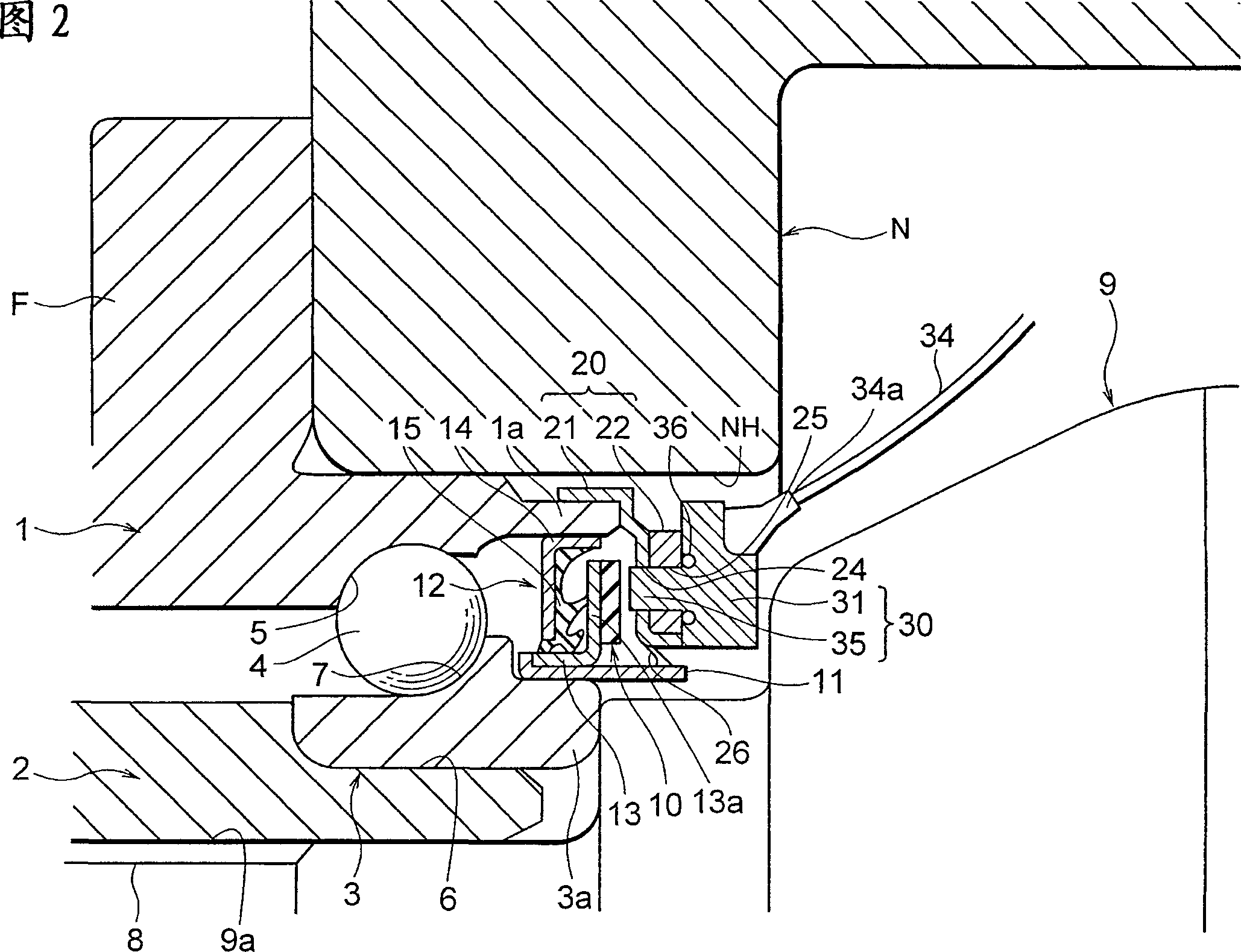

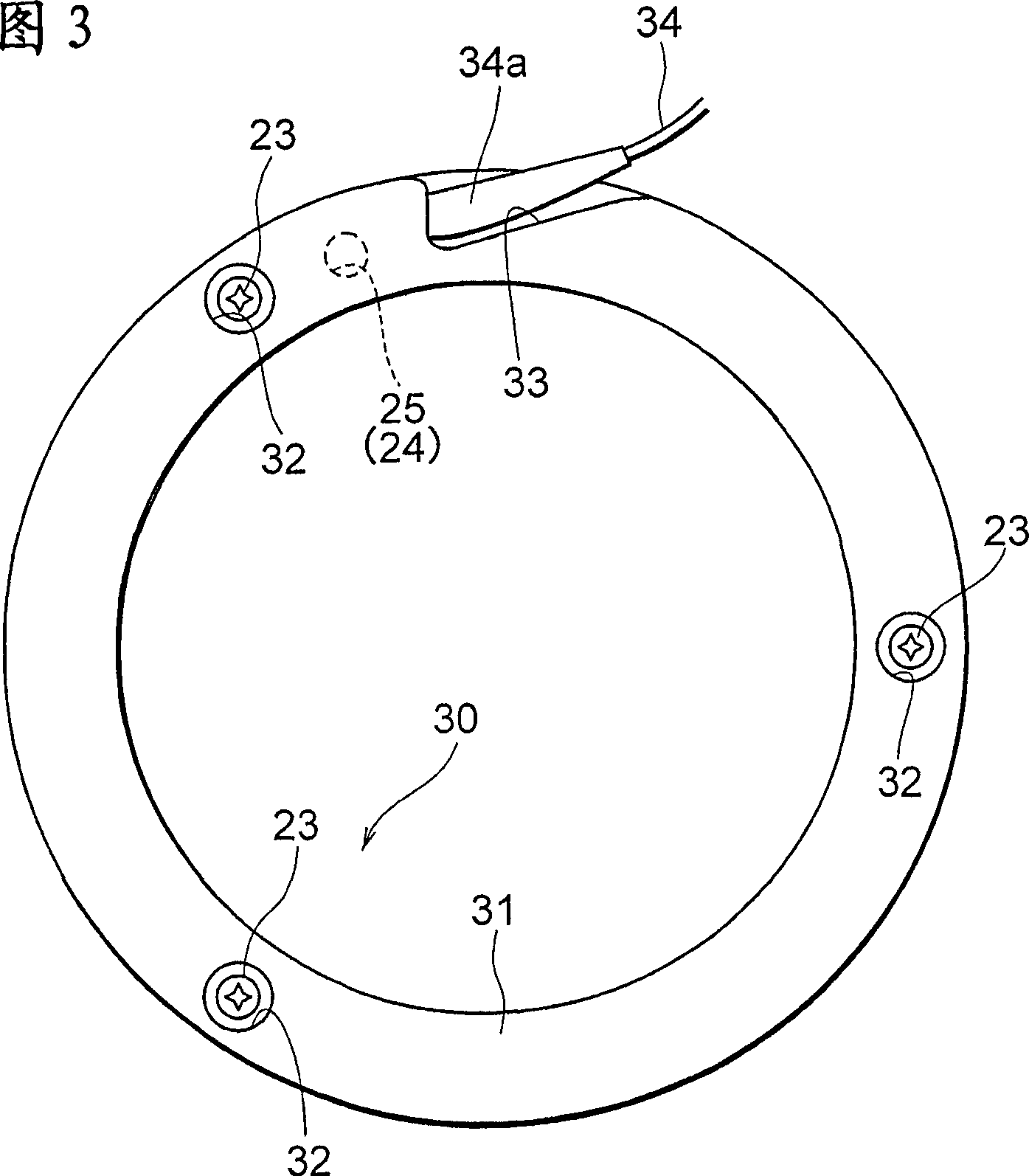

Hub unit for drive wheel

InactiveCN1882841AHigh strengthLightweight reductionRolling contact bearingsBearing assemblyConstant-velocity jointKnuckle

A rotating speed detection sensor is an active sensor, and a sensing section (35) of the sensor is directly faced to a magnetic encoder (10) without an interposed object provided between the sensing section and the magnetic encoder (10). A harness (34) (or connector) of the rotating speed detection sensor (30) is led out from a gap between a knuckle (N) and a constant velocity joint (9).

Owner:NSK LTD

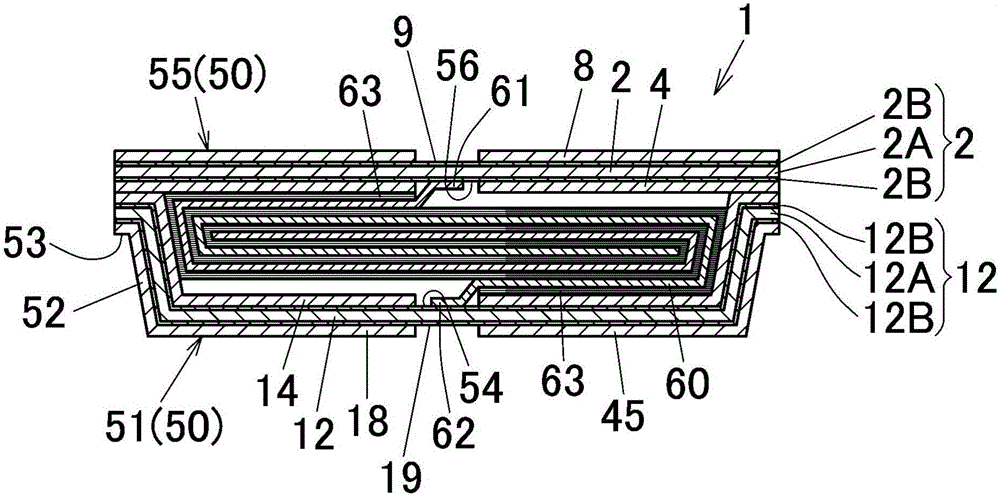

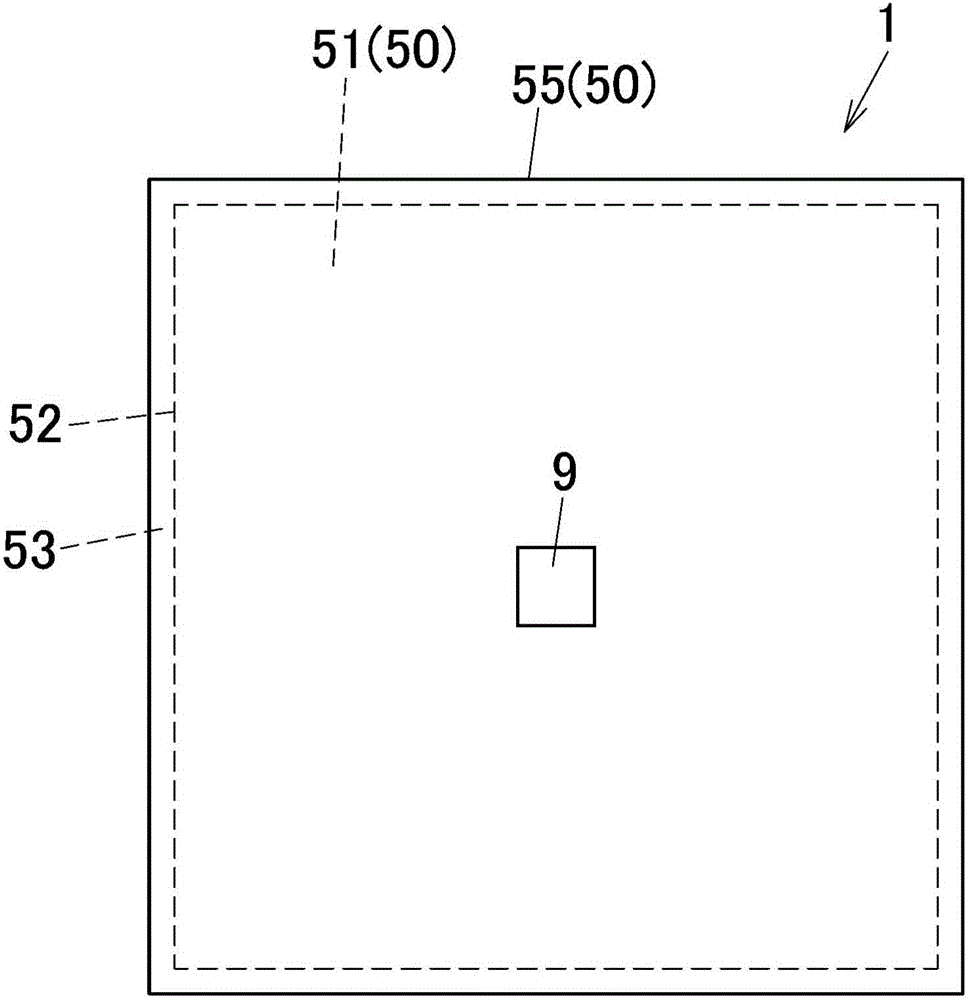

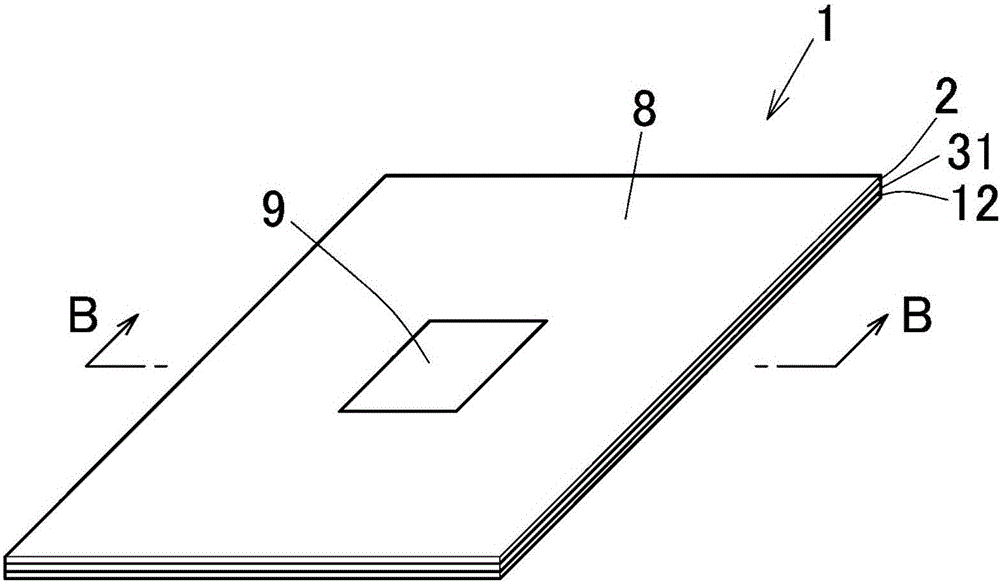

An outer package for a power storage device and the power storage device

InactiveCN106067520AImproved resistance to electrolytesHelps to reduce weightNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesConductive coatingMetal foil

The invention relates to an outer package for a power storage device and the power storage device. The outer package body according to the present invention comprises a metal layer (2) and a thermoplastic resin layer (4) laminated on one surface of the metal layer (2). A part of one surface of the metal layer (2) is provided with a conductive portion (56) which is not covered by the thermoplastic resin layer. The above metal layer (2) can use (A) a metal foil which has been subjected to a plating treatment on at least one surface thereof, (B) a metal foil composed of clad materials or (D) a metal foil with a conductive coating layer containing a conductive agent and a binder laminated on at least one surface thereof.

Owner:SHOWA DENKO PACKAGING CO LTD

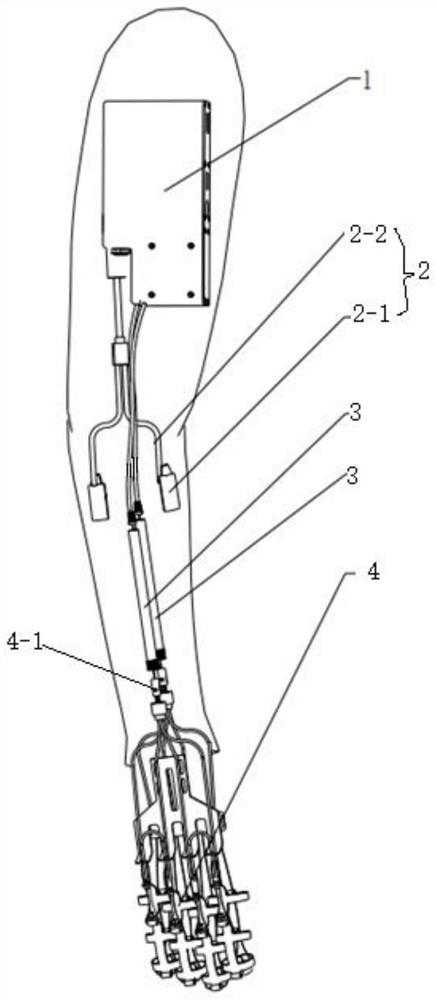

Hand action assisting device based on line driving

ActiveCN112641596AIncrease profitReduce quality problemsDiagnosticsChiropractic devicesHand partsMedizinische rehabilitation

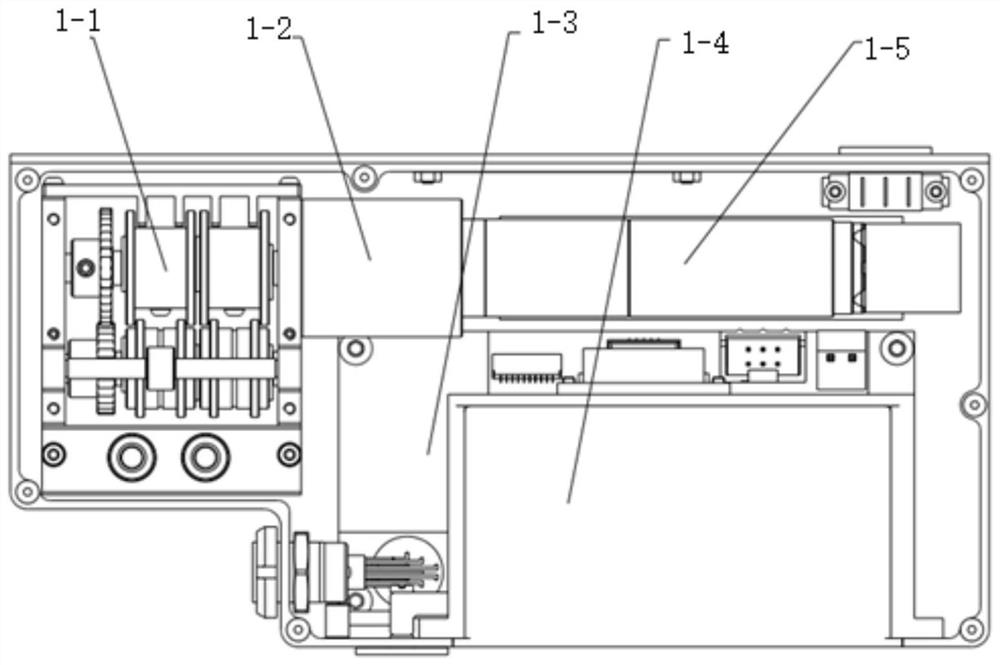

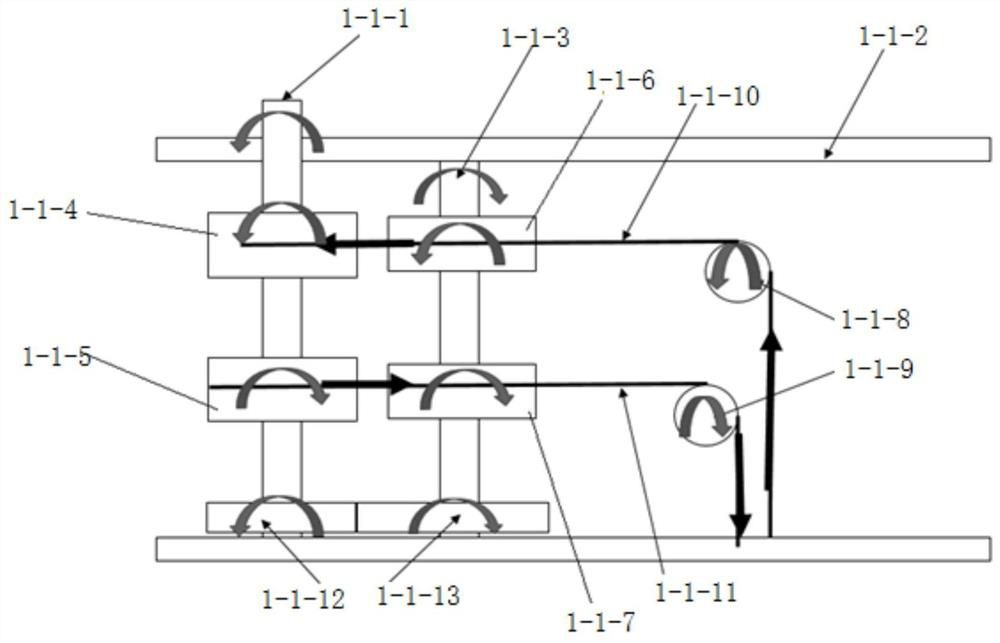

The invention relates to the technical field of medical rehabilitation instruments, in particular to a hand action assisting device based on line driving. The device comprises a sensing unit, a driving unit, a driving line pipe and a hand exoskeleton. A control circuit board receives bioelectricity signals transmitted by the sensing unit, analyzes the bioelectricity signals and transmits instructions to the driver to enable a driver to generate driving force, and the driving force is transmitted to the hand exoskeleton through a self-locking mechanism and a transmission mechanism to control the hand exoskeleton to act. The hand exoskeleton is a flexible exoskeleton glove or a rigid-flexible exoskeleton glove, and a new transmission mechanism is designed, so that two actions of stretching and bending are realized by one motor, and the paying-off speed can be adjusted within a small range. A bidirectional self-locking mechanism is rotated to eliminate a self-locking return stroke gap, the safety and the reliability of the self-locking mechanism are greatly improved; The flexible exoskeleton glove and the rigid-flexible exoskeleton glove are selectively used, so that the glove is comfortable and light to wear, and the daily life requirements are met.

Owner:SHANGHAI AI CARE MEDICAL TECH CO

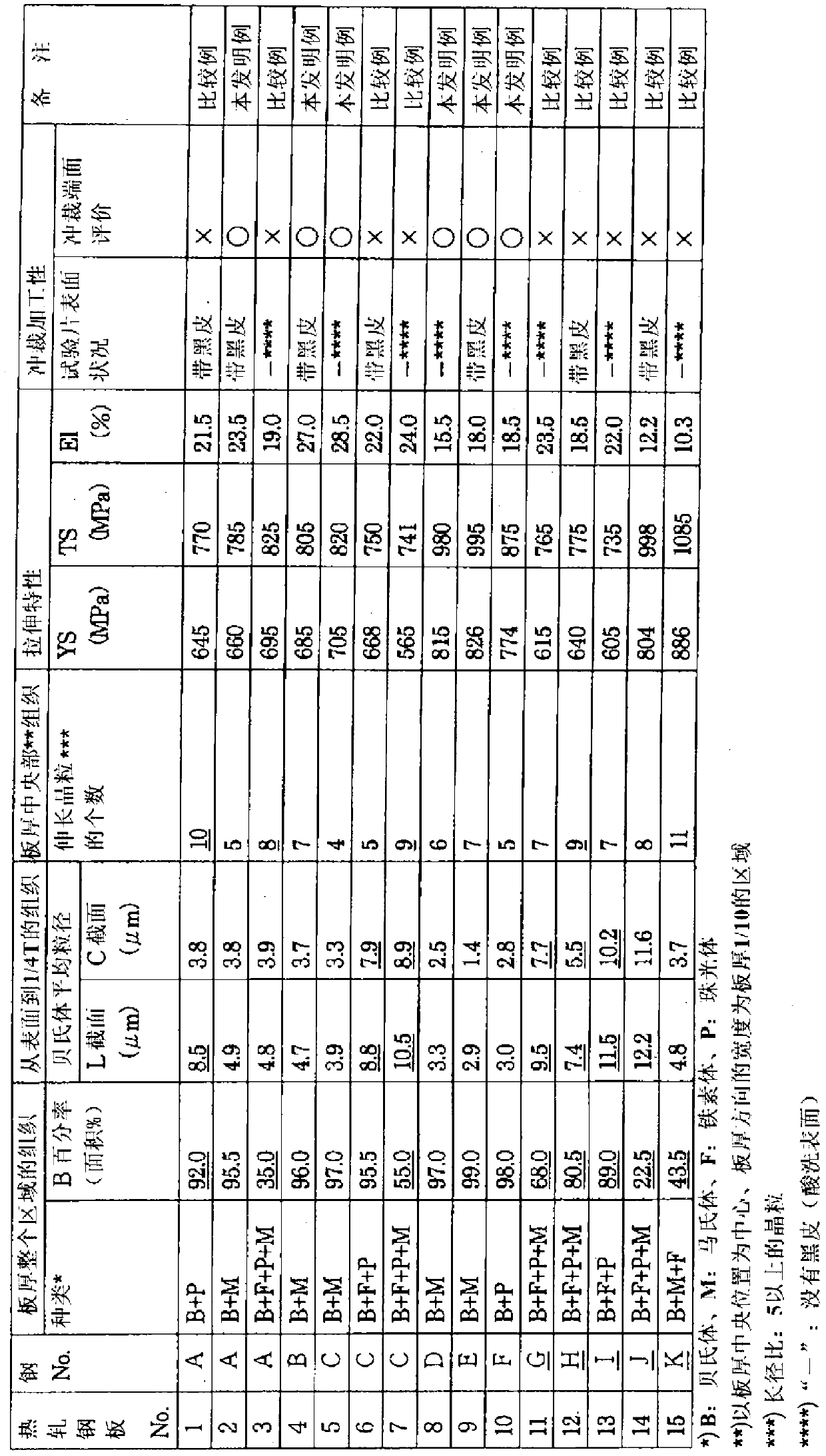

High-strength hot-rolled steel sheet having superior punchability and method for producing same

ActiveCN103108973ASimple and cheap to manufactureExcellent punchabilityFurnace typesMetal rolling arrangementsUltimate tensile strengthHot rolled

Provided is a high-strength hot-rolled steel sheet having superior punchability. The steel sheet has a composition that contains 0.050-0.15% C, 0.1-1.5% Si, 1.0-2.0% Mn, no greater than 0.03% P, no greater than 0.0030% S, 0.01-0.08% Al, 0.05-0.15% Ti, and no greater than 0.005% N, and the composition is over 95% a bainite phase by area ratio. Furthermore, the average grain size of the bainite in a region from the surface to a position at 1 / 4 of the sheet thickness is no greater than 5 [mu]m in a cross section in the L direction, and no greater than 4 [mu]m in a cross section in the C direction, and additionally, the structure is such that in the central portion of the sheet thickness, there are no greater than seven crystal grains that have an aspect ratio of at least 5 and that extend in the direction of rolling. As a result, the hot-rolled steel sheet has superior punchability and superior punched edge properties, the punched edges are fine, even ductile fractures, and the sheet has a high strength, having a tensile strength (TS) of at least 780 MPa.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com