High-strength hot-rolled steel sheet

A hot-rolled steel plate, high-strength technology, applied in the field of hot-rolled steel plate, can solve the problems of increased alloy cost, etc., and achieve the effect of ensuring light weight and excellent hole expandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

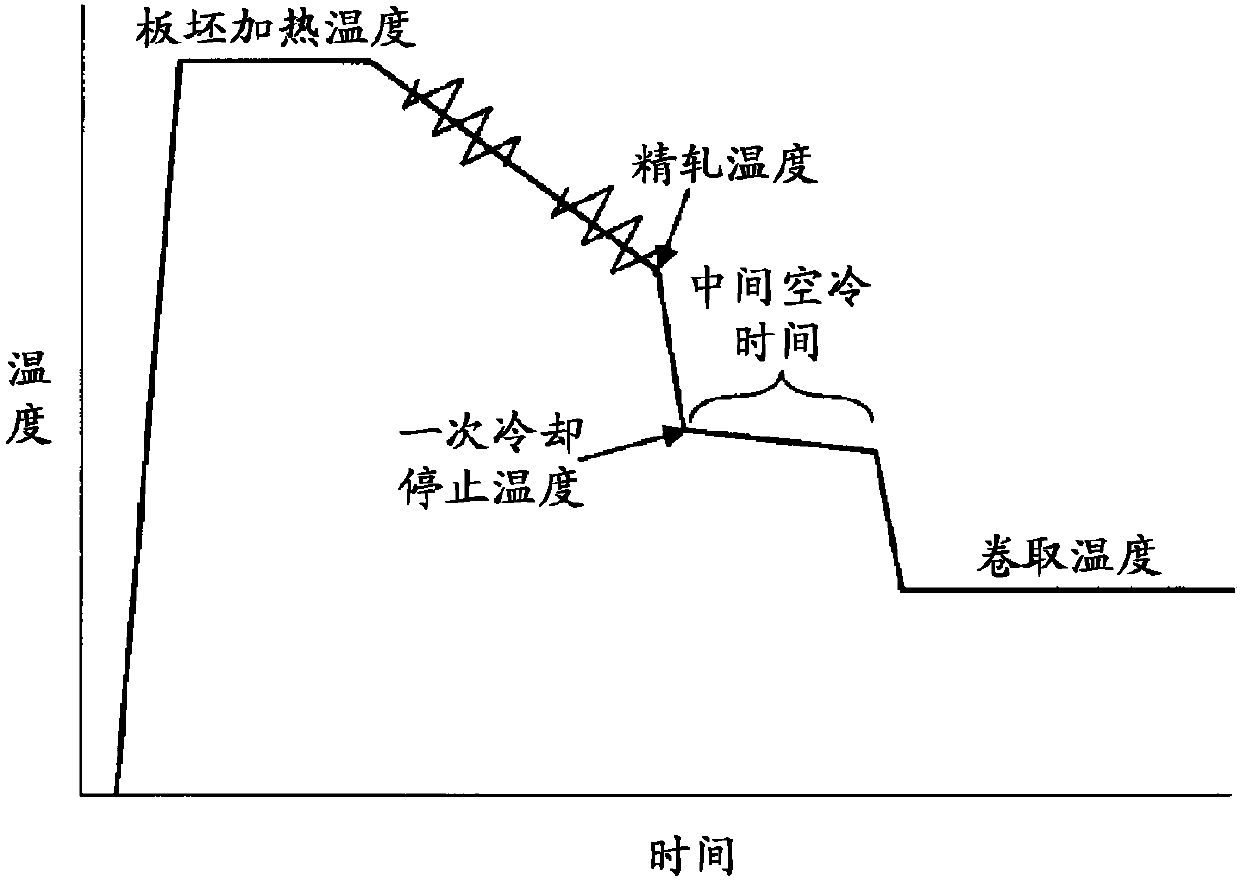

[0136] Smelt steel with the chemical composition shown in Table 1 in the laboratory, and cast a slab to figure 1 The patterns shown are heating, hot rolling, cooling, and coiling. At this time, the conditions of each step are as shown in Table 2. In Table 2, SRT, R1, R2, R3, FT, MT, t, and CT represent the following items, respectively.

[0137] SRT: Slab Heating Temperature

[0138] R1: Cumulative reduction rate above 1050°C and below 1150°C

[0139] R2: Cumulative reduction rate below 1050°C

[0140] R3: reduction ratio in the final processing pass

[0141] FT: Finishing temperature

[0142] MT: primary cooling stop temperature

[0143] t: secondary cooling time

[0144] CT: coiling temperature

[0145] The hot-rolled steel sheet thus obtained was pickled, and hot-dip galvanized for the conditions shown as "plating" in the column of "Treatment" in Table 3, and then, from a direction perpendicular to the rolling direction of the hot-rolled steel sheet, Direction to p...

Embodiment 2

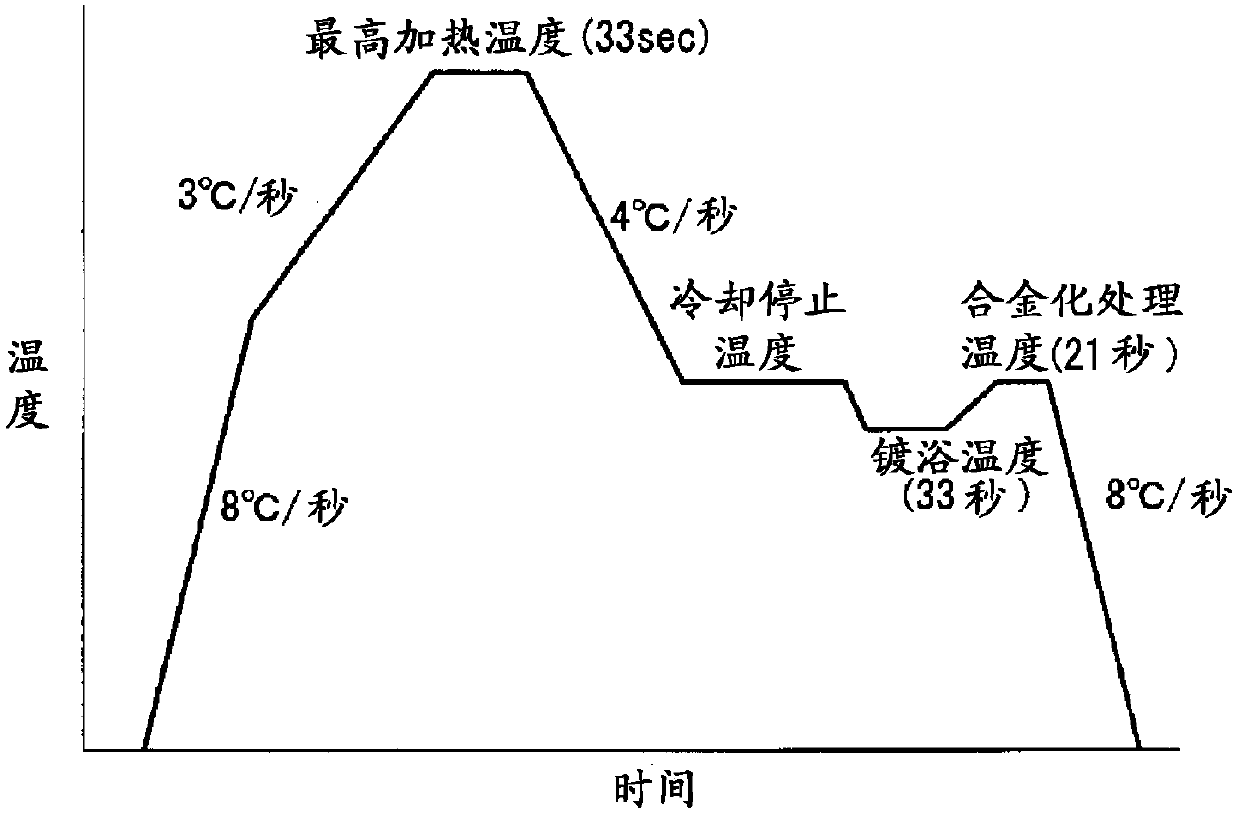

[0164] Next, among the steels having the chemical compositions shown in Table 1, five steel grades A to C and G and H were tested. figure 1 Hot rolled and cooled as shown. Thereafter, descaling treatment was carried out, and cold rolling was not carried out, and a continuous heat treatment simulator was used to carry out figure 2 The shown model simulates the heat treatment of alloying hot-dip galvanizing production line. At this time, the conditions of each step are as shown in Table 5. In Table 5, RA, LTH, DIP, and GA represent the following items.

[0165] RA: maximum heating temperature

[0166] LTH: Low temperature hold temperature

[0167] DIP: Zn bath temperature

[0168] GA: alloying temperature

[0169] From the hot-rolled steel sheets thus obtained, JIS No. 5 tensile test pieces were prepared from a direction perpendicular to the rolling direction. Using this sample, a tensile test was performed to measure yield strength (YS), tensile strength (TS), yield rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com