Patents

Literature

135results about How to "Abrasion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

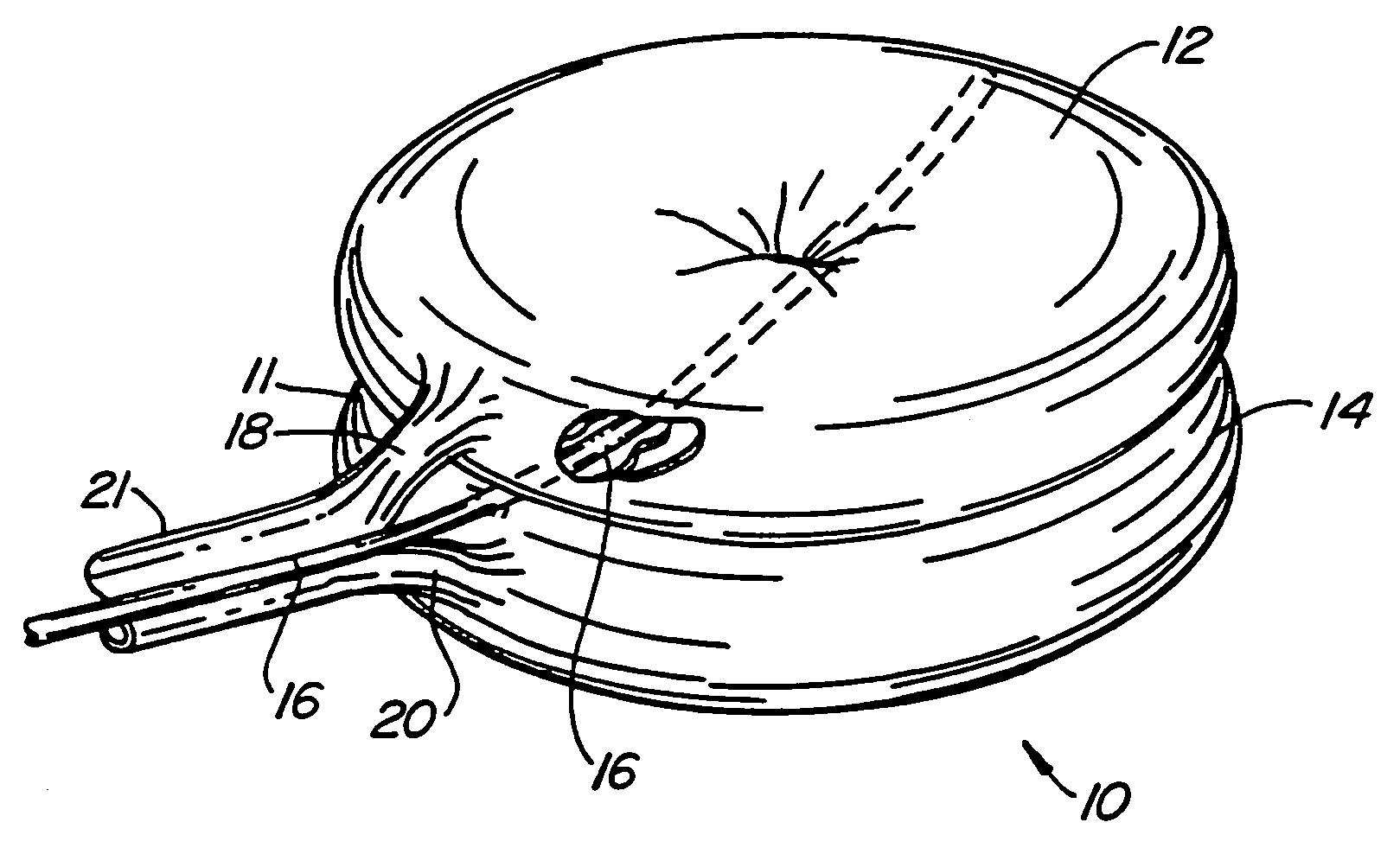

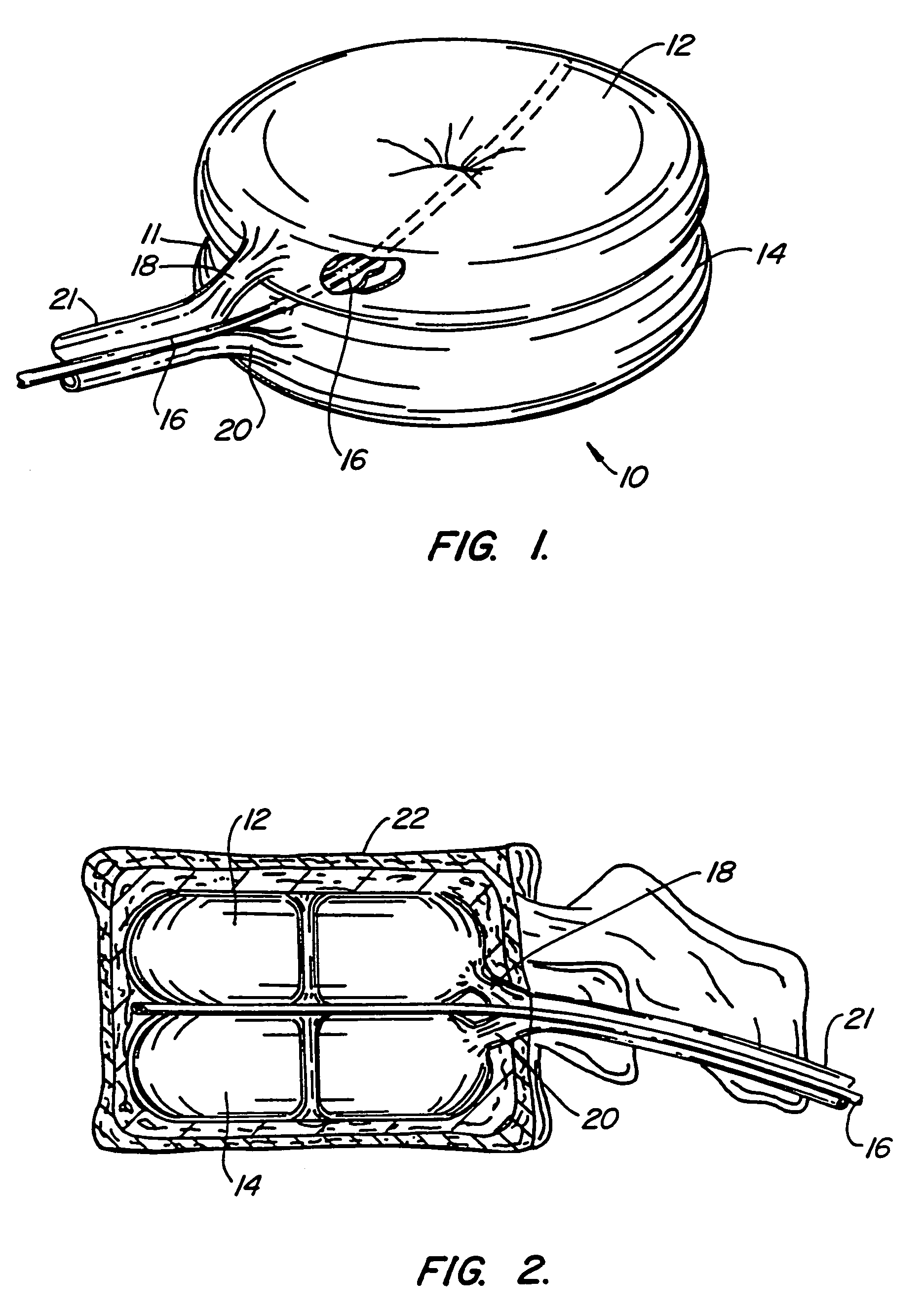

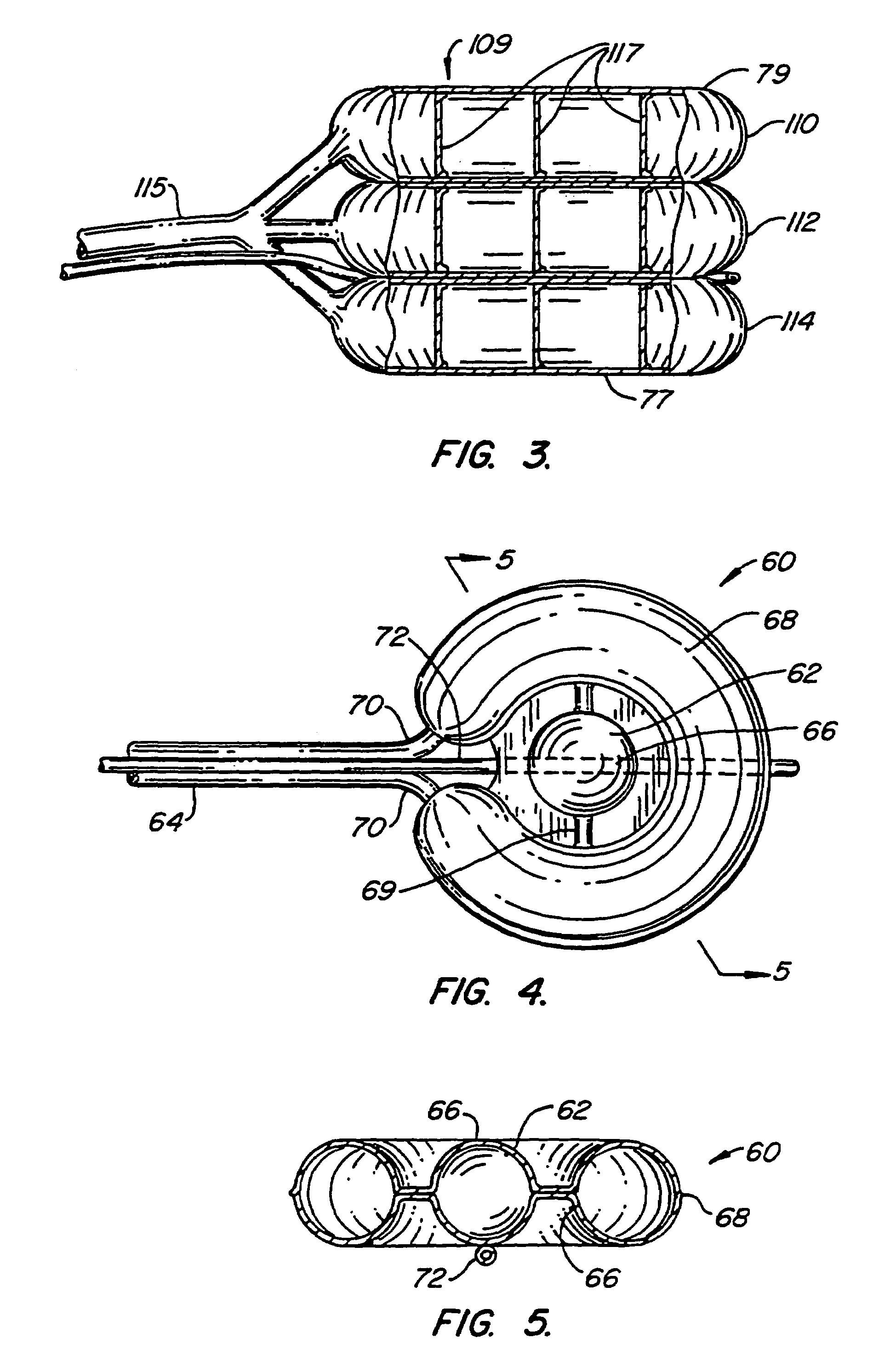

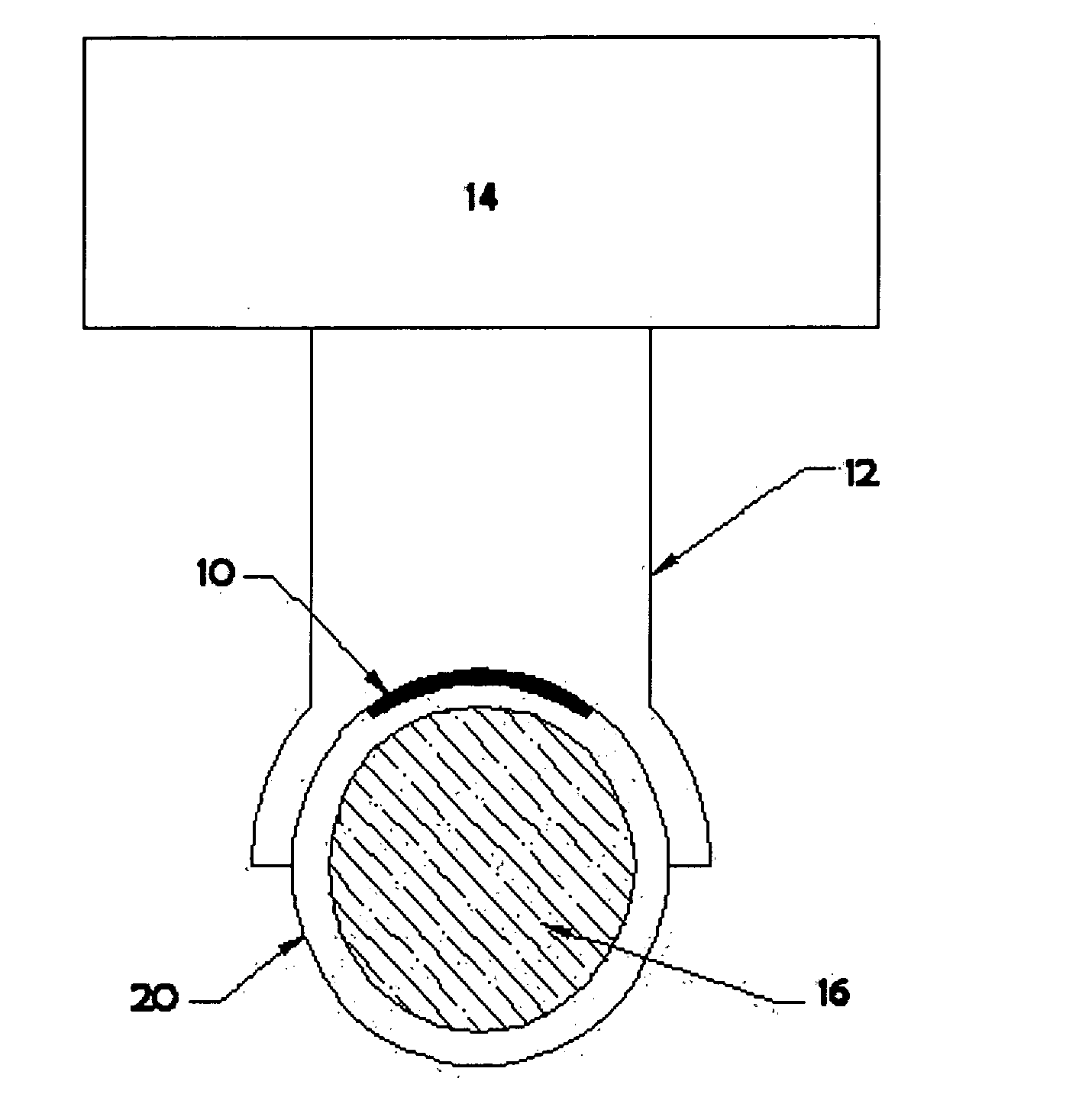

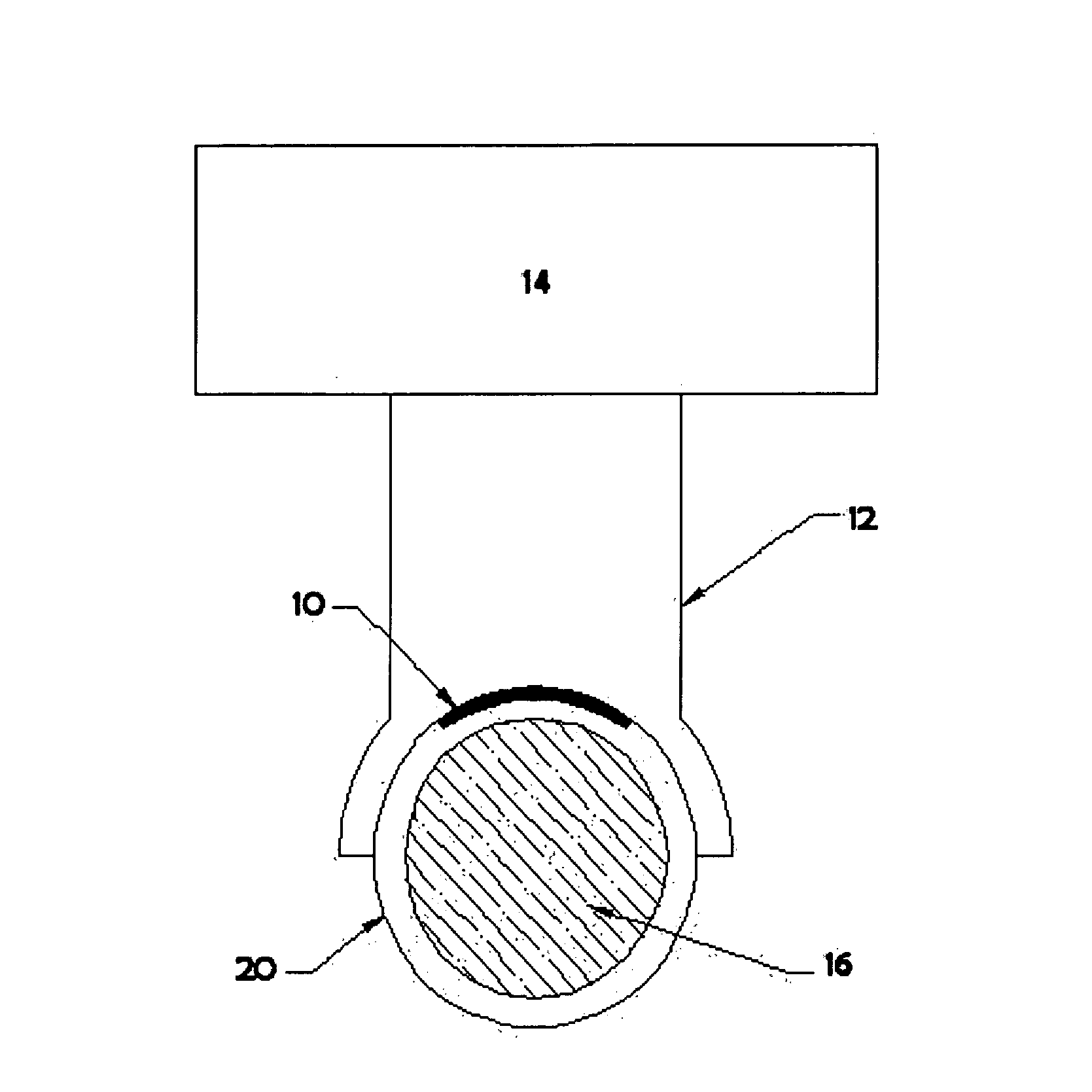

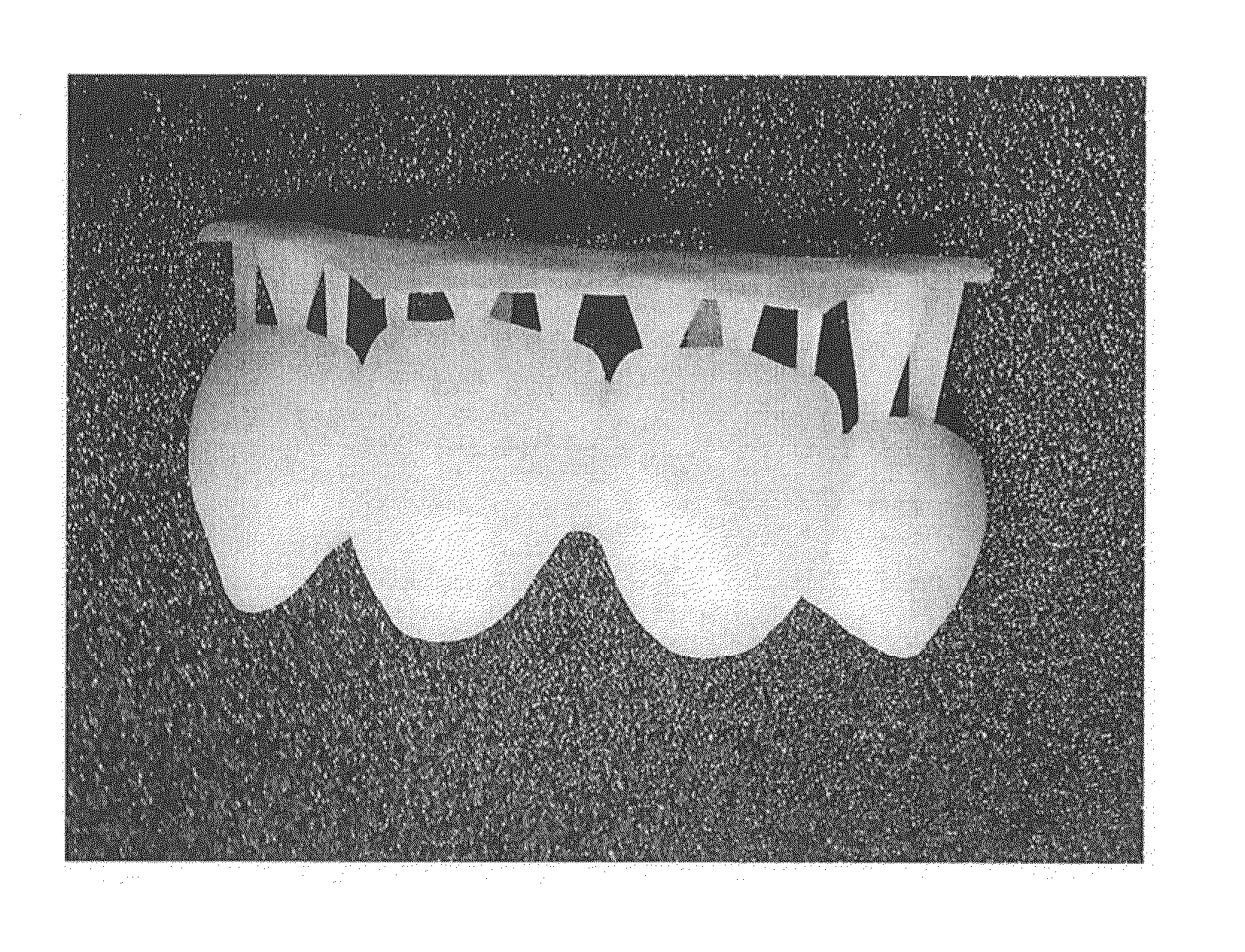

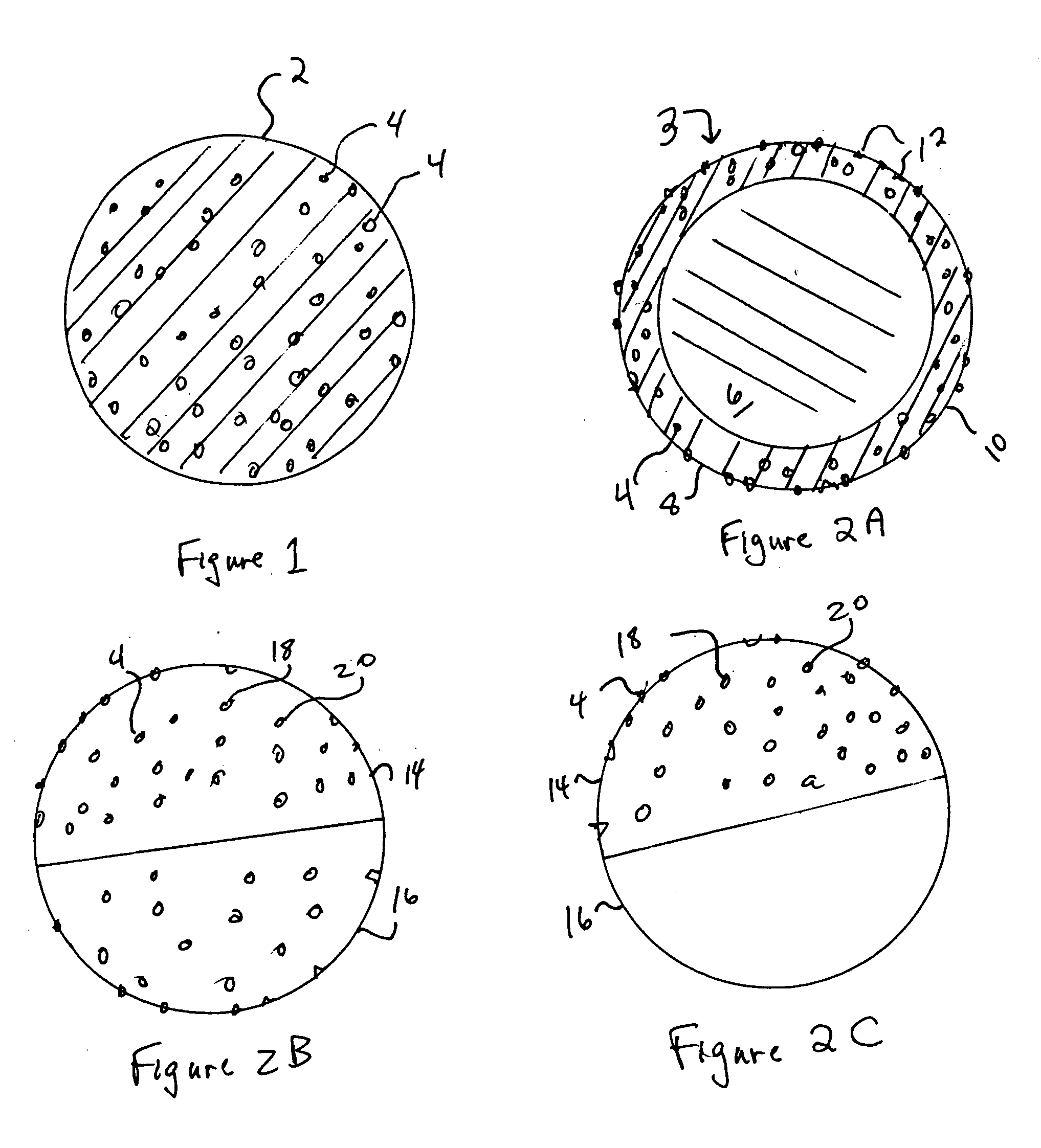

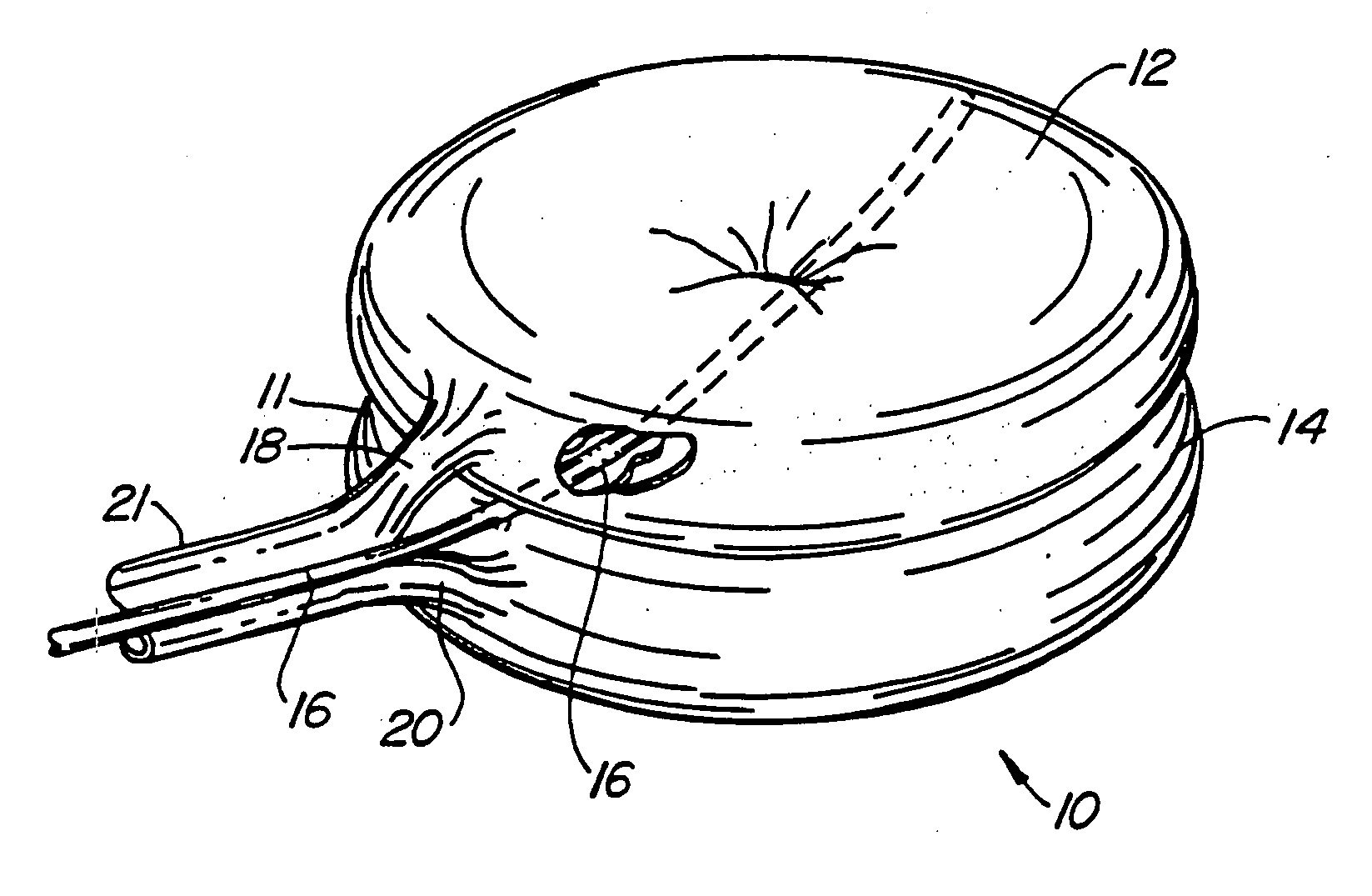

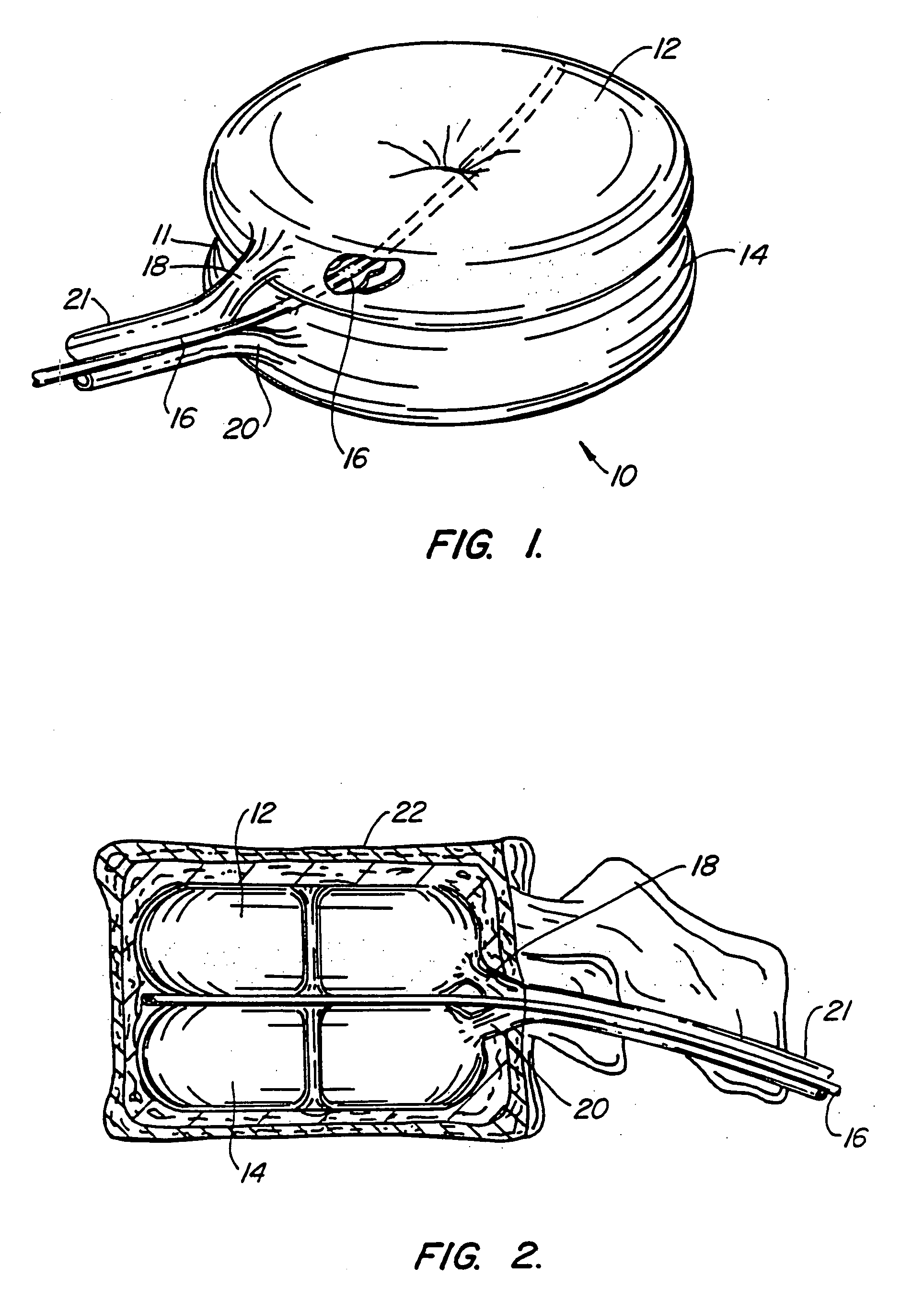

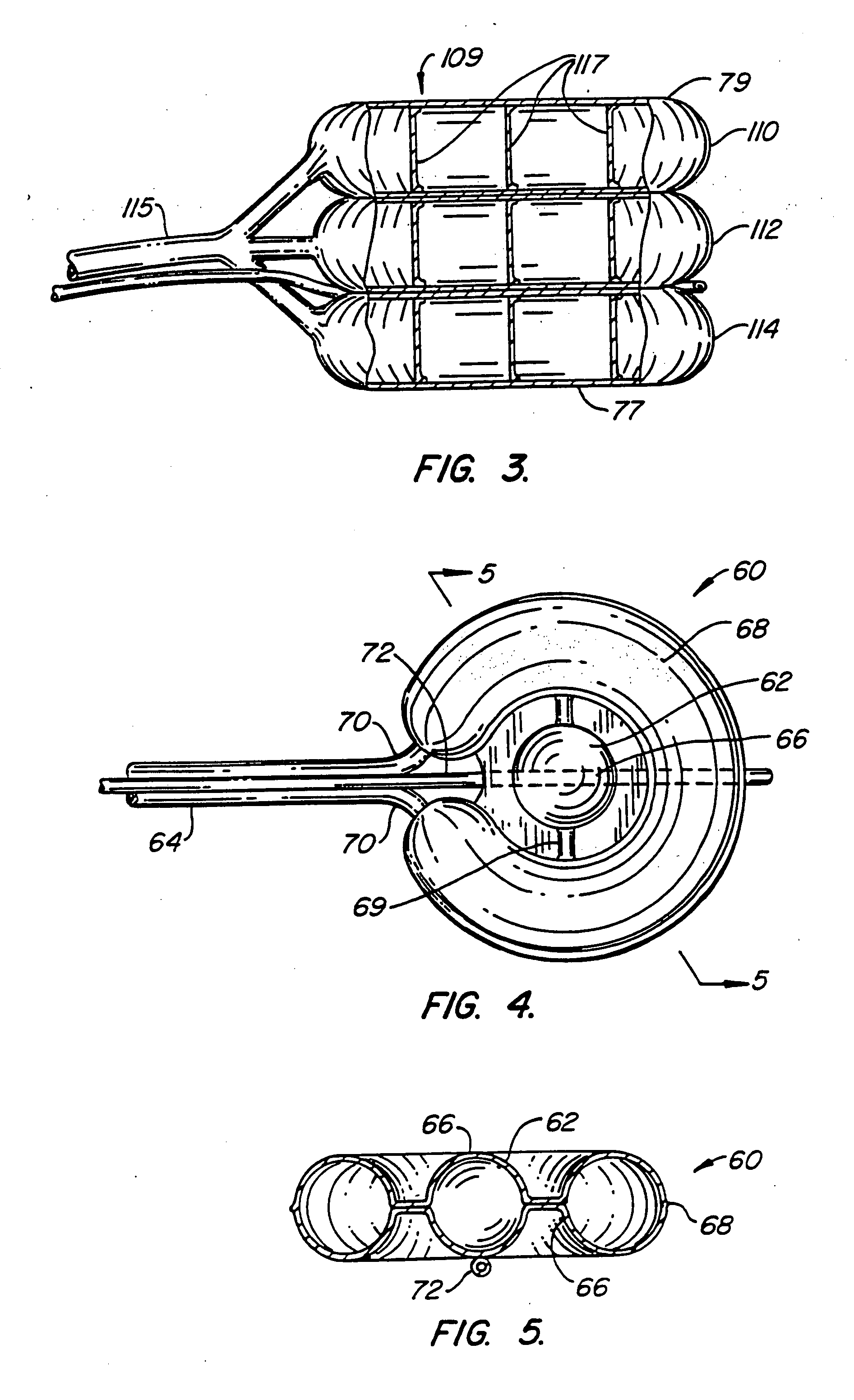

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS7261720B2Easy to compressEasy to foldSurgical furnitureInternal osteosythesisBone CortexTrabecular bone

A balloon for use in compressing cancellous bone and marrow (also known as medullary bone or trabecular bone). The balloon comprises an inflatable balloon body for insertion into said bone. The body has a shape and size to compress at least a portion of the cancellous bone to form a cavity in the cancellous bone and / or to restore the original position of the outer cortical bone, if fractured or collapsed. The balloon desirably incorporates restraints which inhibit the balloon from applying excessive pressure to various regions of the cortical bone. The wall or walls of the balloon are such that proper inflation of the balloon body is achieved to provide for optimum compression of the bone marrow. The balloon can be inserted quickly into a bone. The balloon can be made to have a suction catheter. The balloon can be used to form and / or enlarge a cavity or passage in a bone, especially in, but not limited to, vertebral bodies. Various additional embodiments facilitate directionally biasing the inflation of the balloon.

Owner:ORTHOPHOENIX

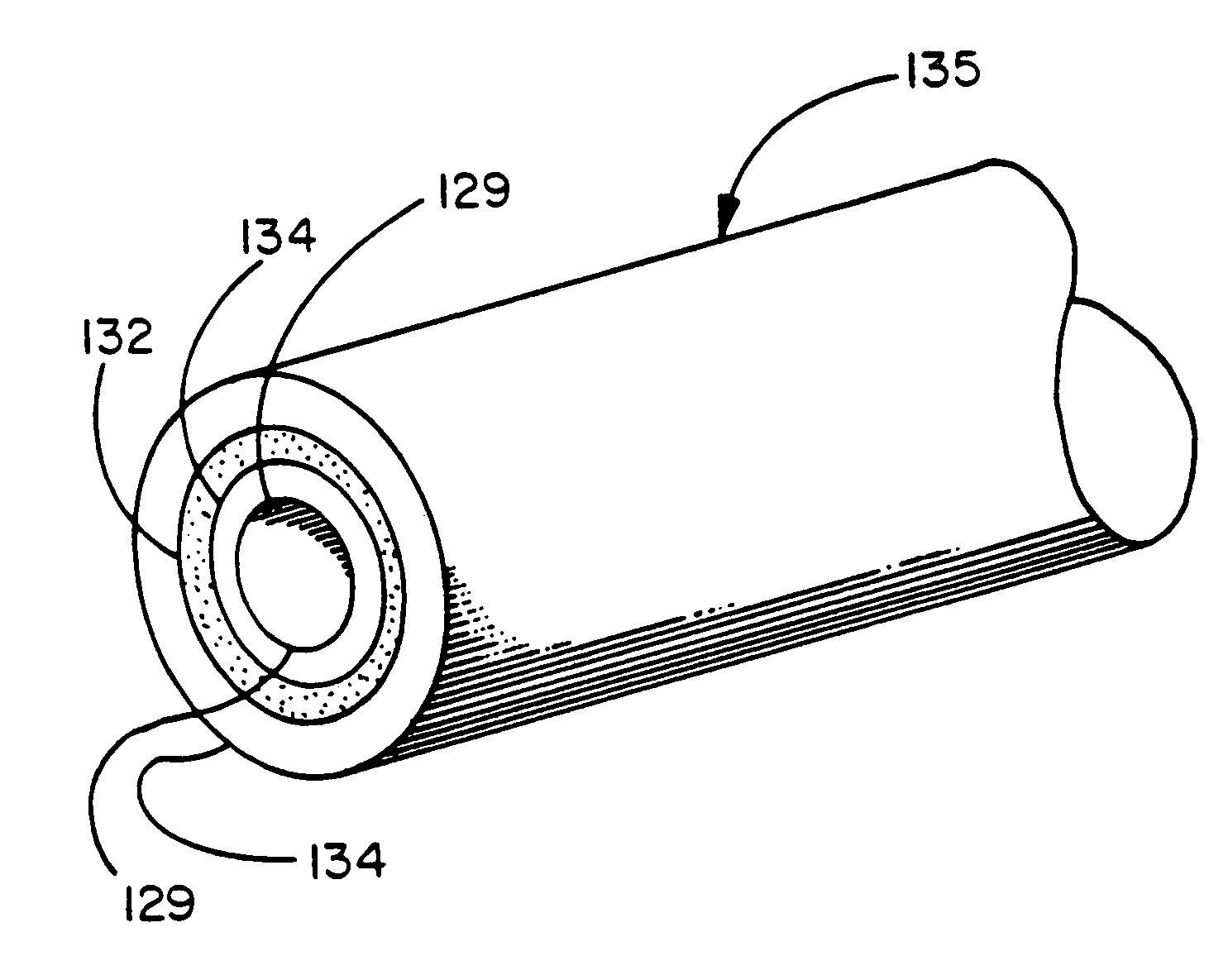

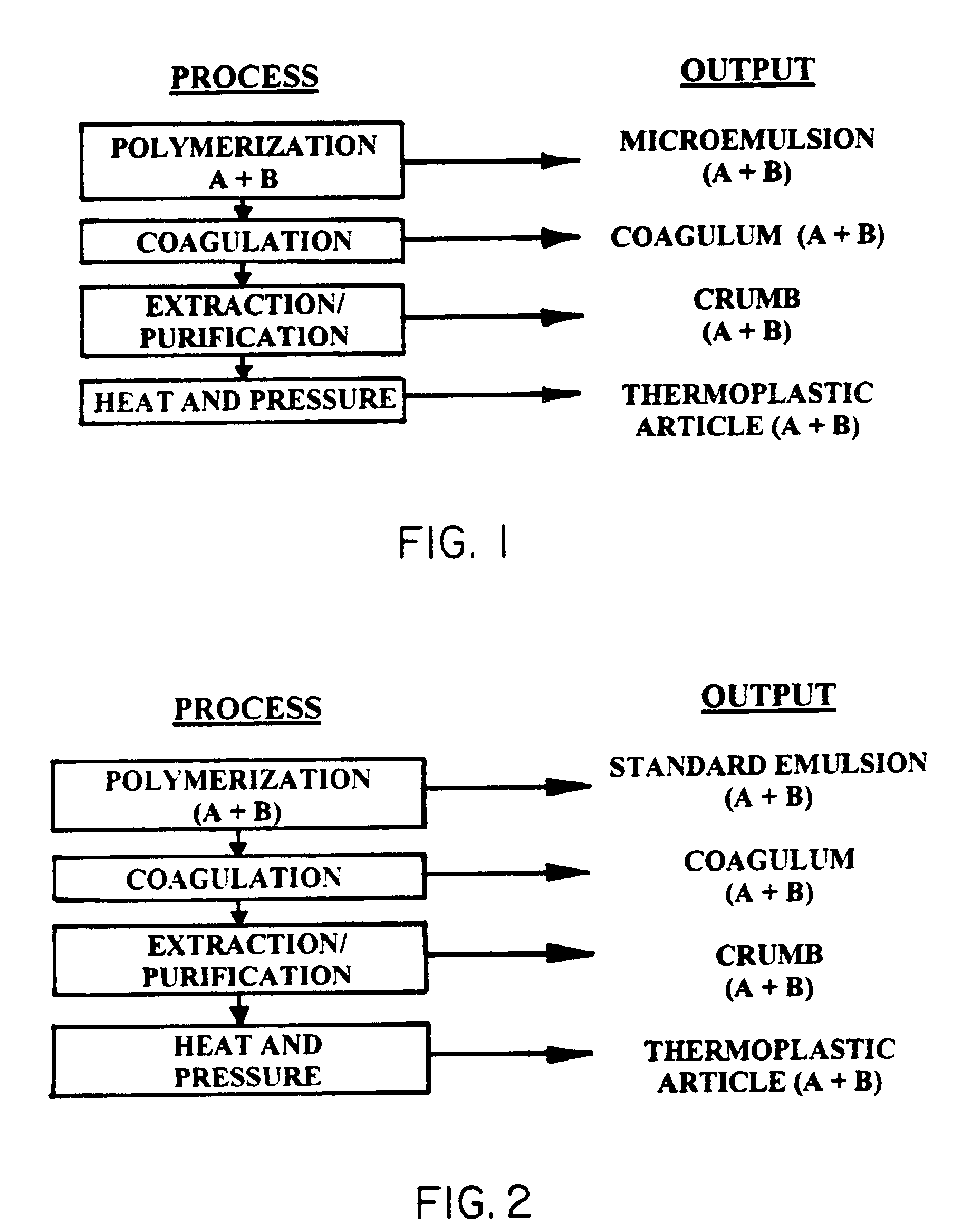

Thermoplastic copolymer of tetrafluoroethylene and perfluoromethyl vinyl ether and medical devices employing the copolymer

An improved elastomeric material is described comprising an essentially noncross-linkable amorphous copolymer of tetrafluoroethylene (TFE) and perfluoromethyl vinyl ether (PMVE) which is both a thermoplastic and exhibits exceptional mechanical properties. This material is particularly suitable for use in ultra-clean environments, and particularly for use in an implantable device, since it does not contain contaminants that previous thermoset TFE / PMVE copolymers have required. Among the improved properties of the present invention are excellent biocompatibility, high matrix tensile strength, high clarity, high abrasion resistance, high purity, adequate elasticity, and ease of processing due to the thermoplastic, and noncross-linkable structure of the copolymer. The material of the present invention is also a high strength bonding agent particularly suited for bonding porous PTFE to itself or to other porous substances at room or elevated temperatures.

Owner:WL GORE & ASSOC INC

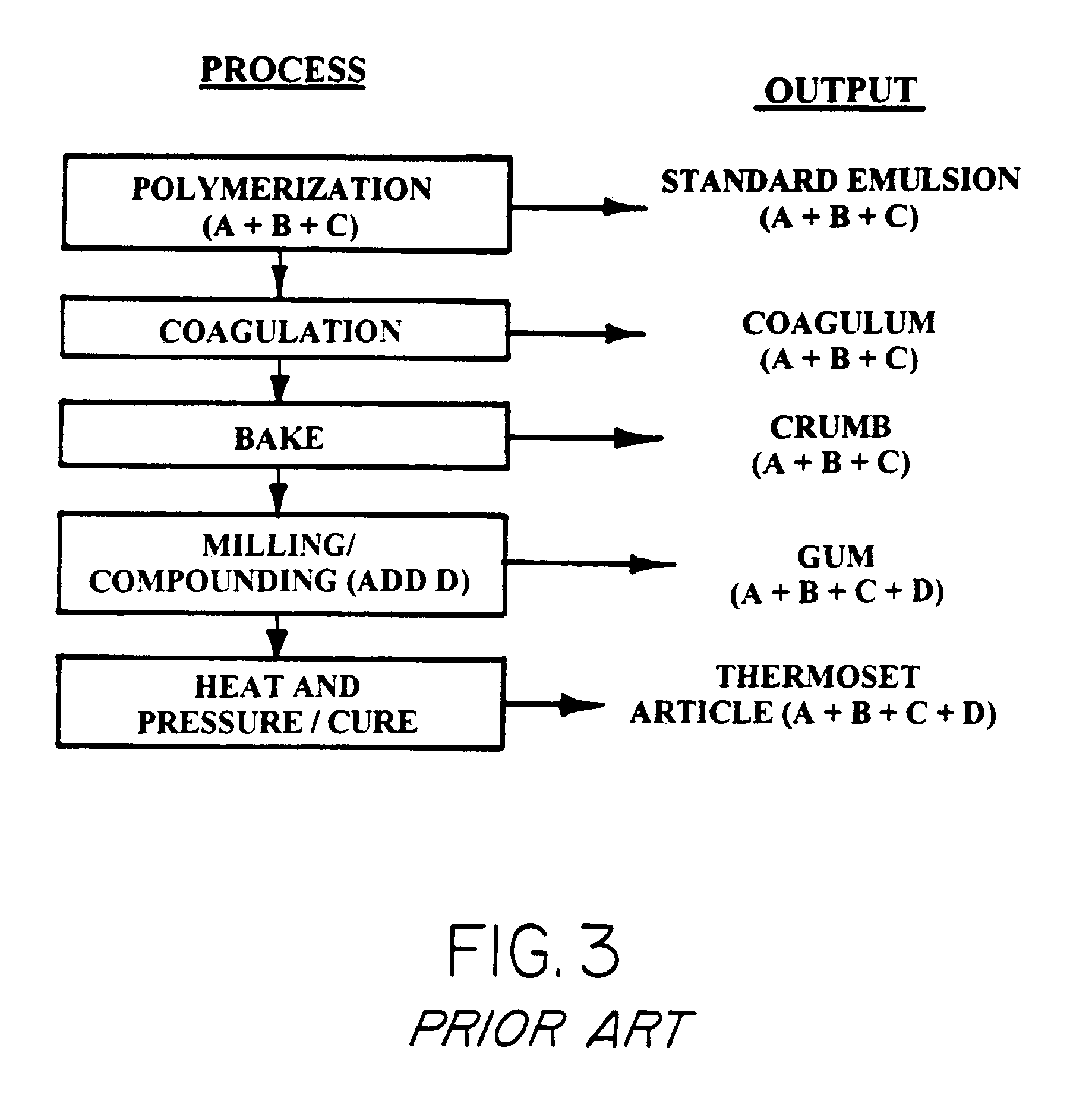

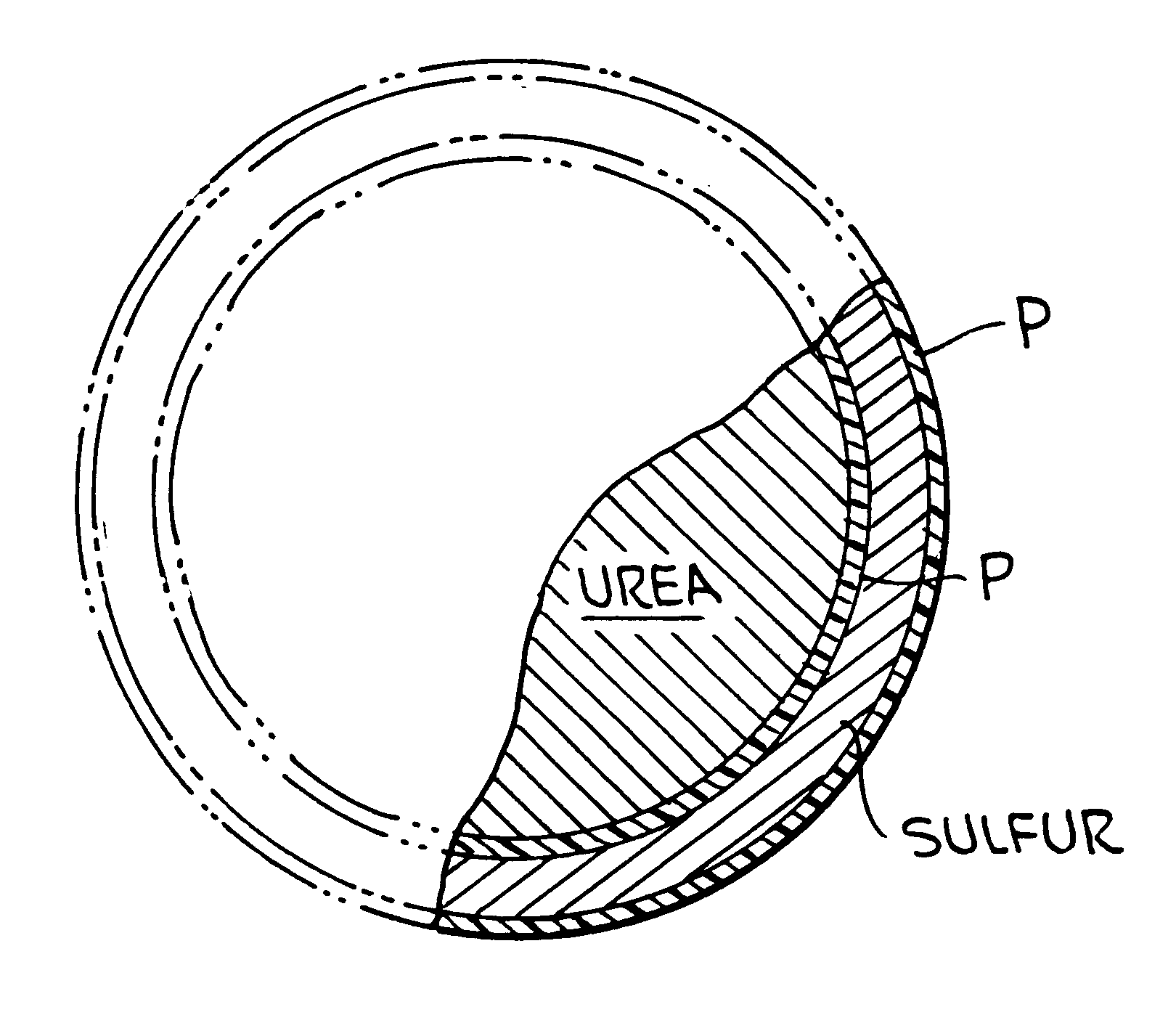

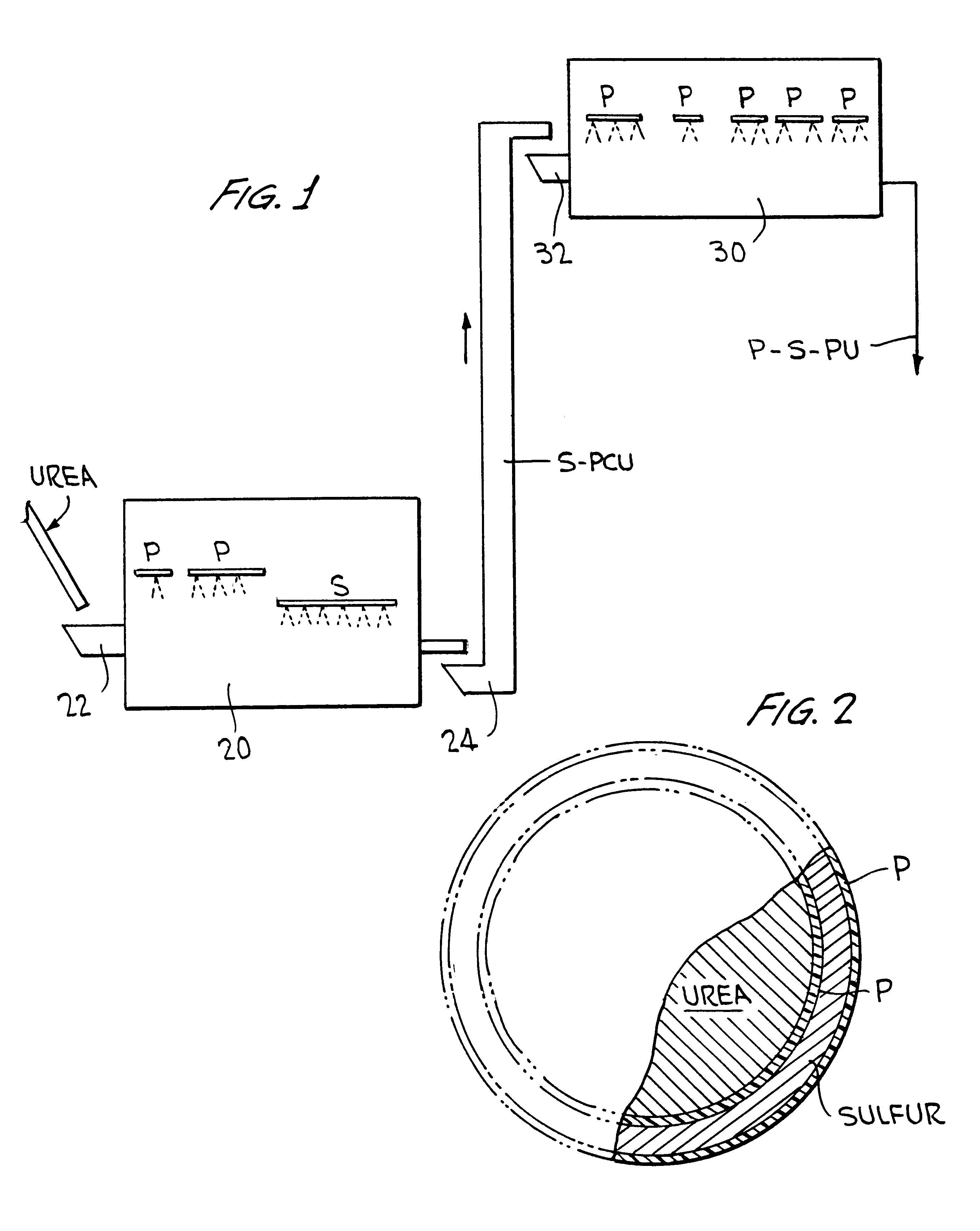

Polymer-sulfur-polymer coated fertilizers

InactiveUS6338746B1Good resistance to abrasionAvoid serious impactBiocideMaterial granulationControlled releasePositive control

The present invention described a polymer coated fertilizer, such as urea, subsequently coated with a layer of sulfur and thereafter a further coating of polymer. Preferably, the polymer coatings are formed by the direct in situ co-polymerization of the components of the polymer on the fertilizer and on the sulfur coating. The compositions provide positive controlled release characteristics, are abrasion and impact resistant and are substantially more economical to produce than polymer coated fertilizers.

Owner:KOCH AGRONOMIC SERVICES LLC

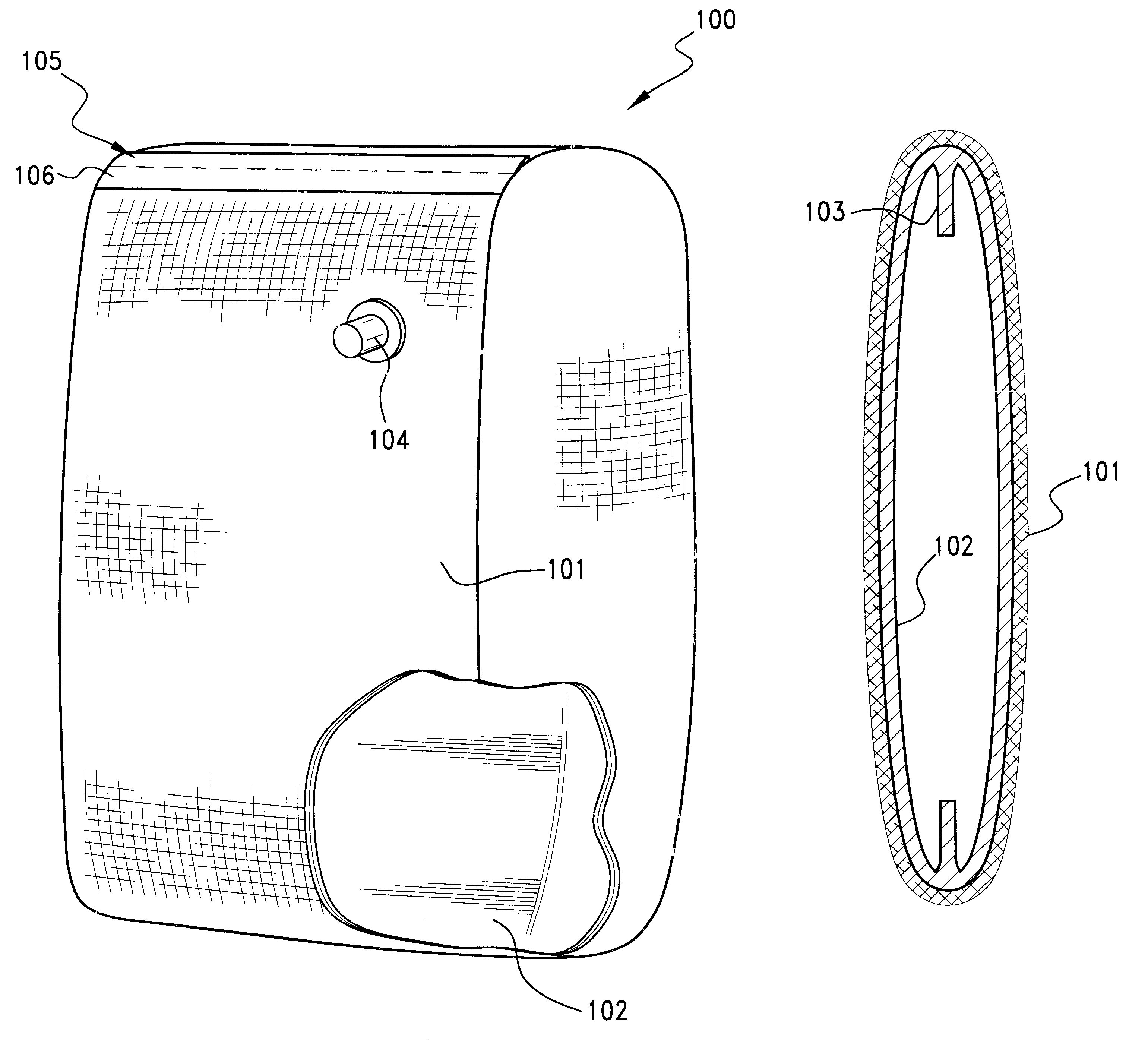

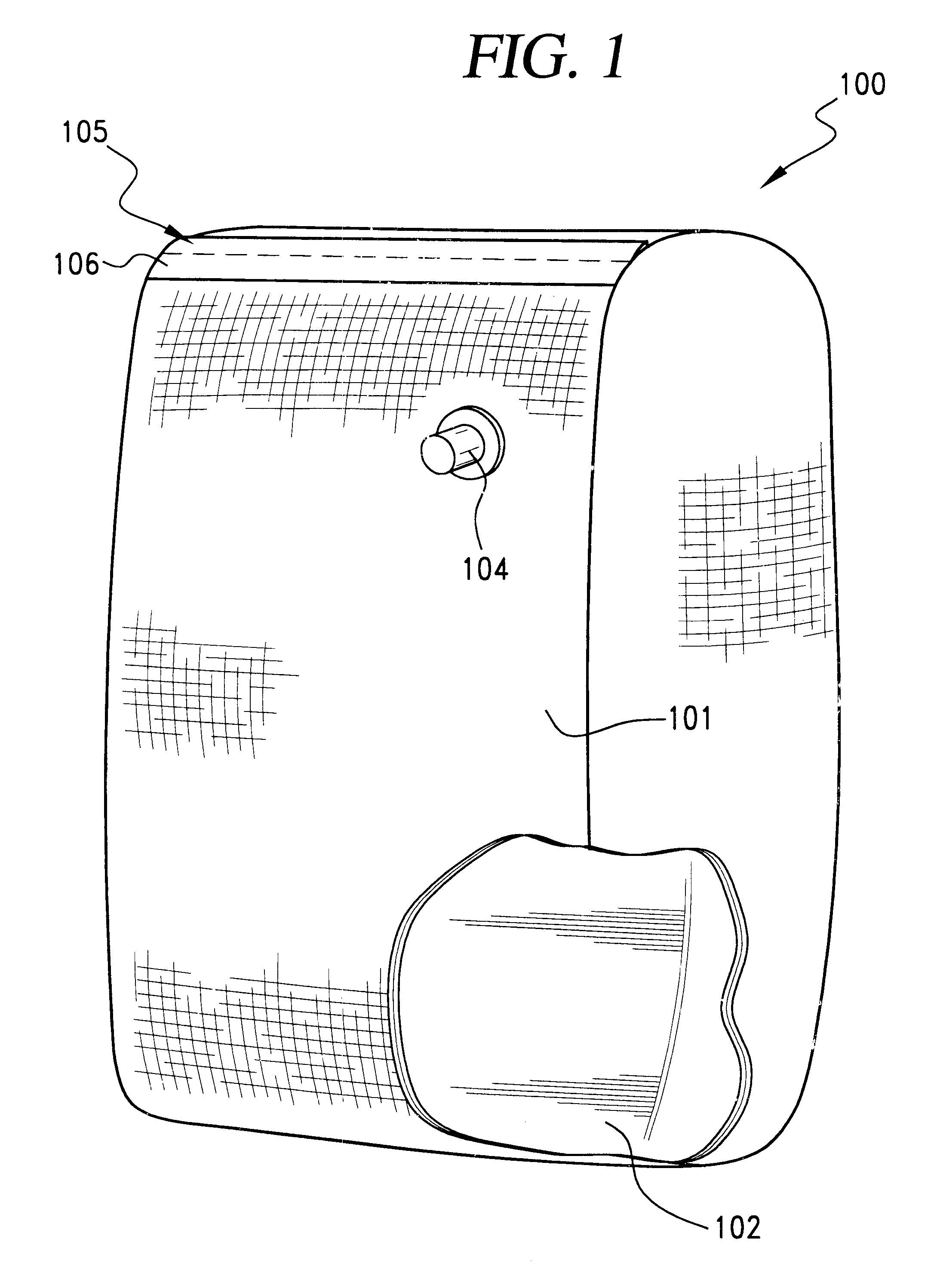

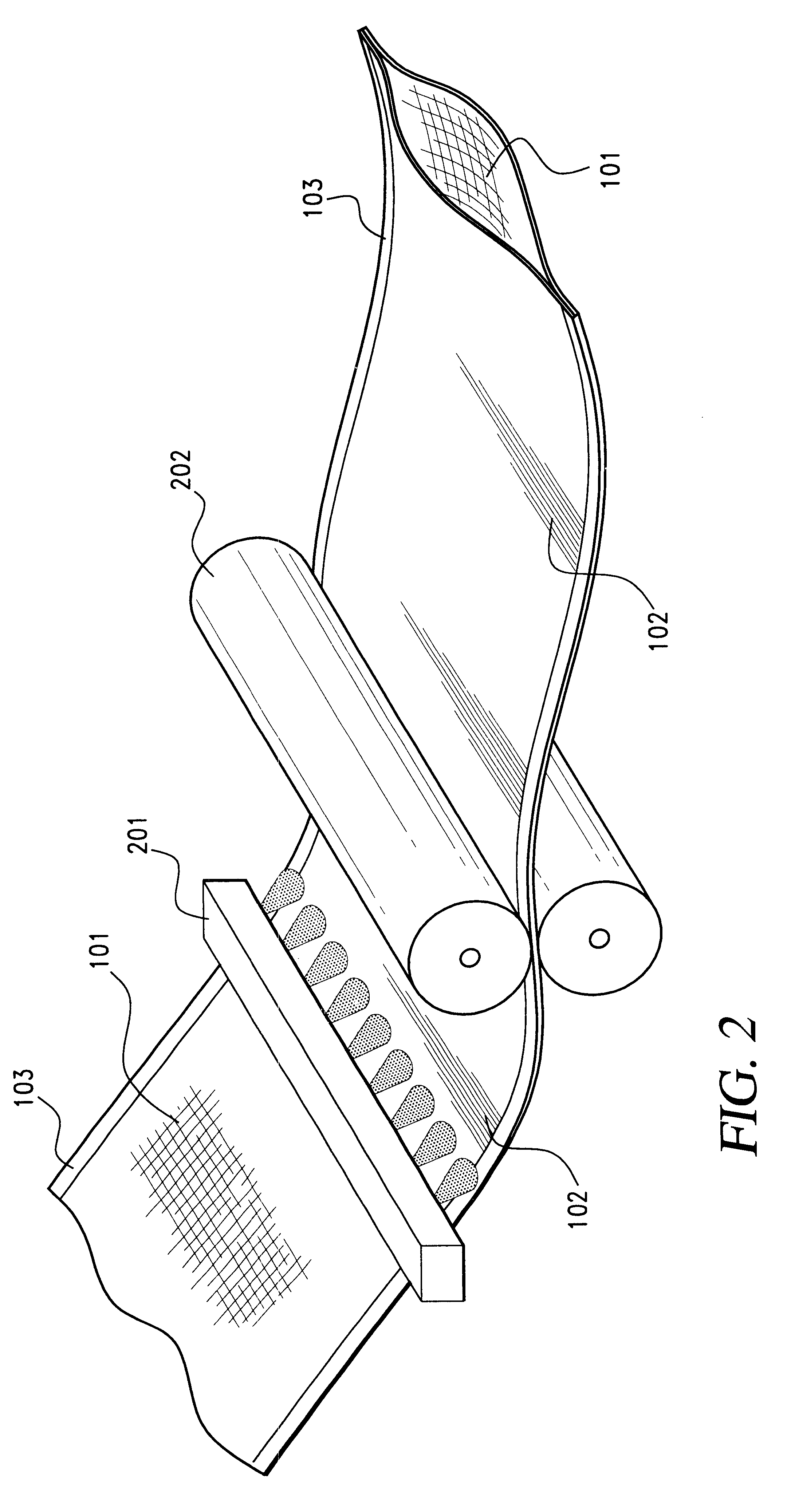

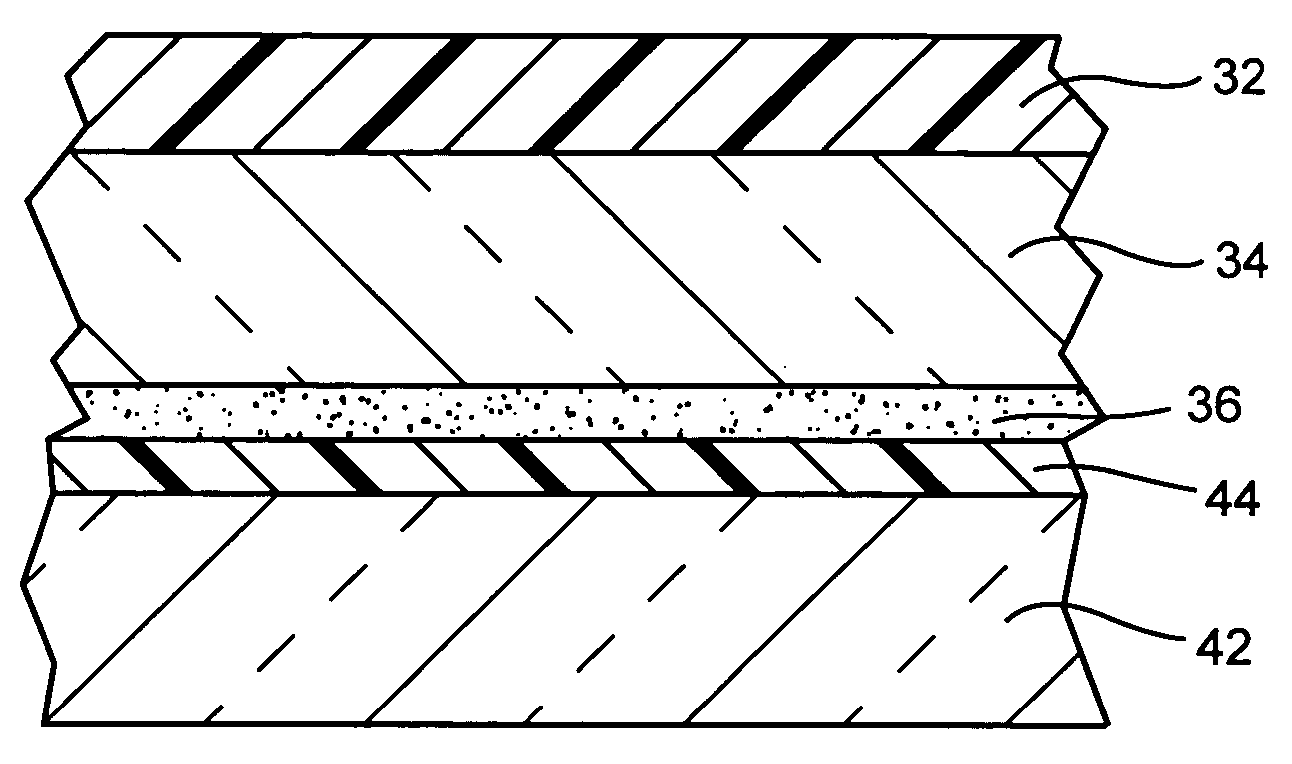

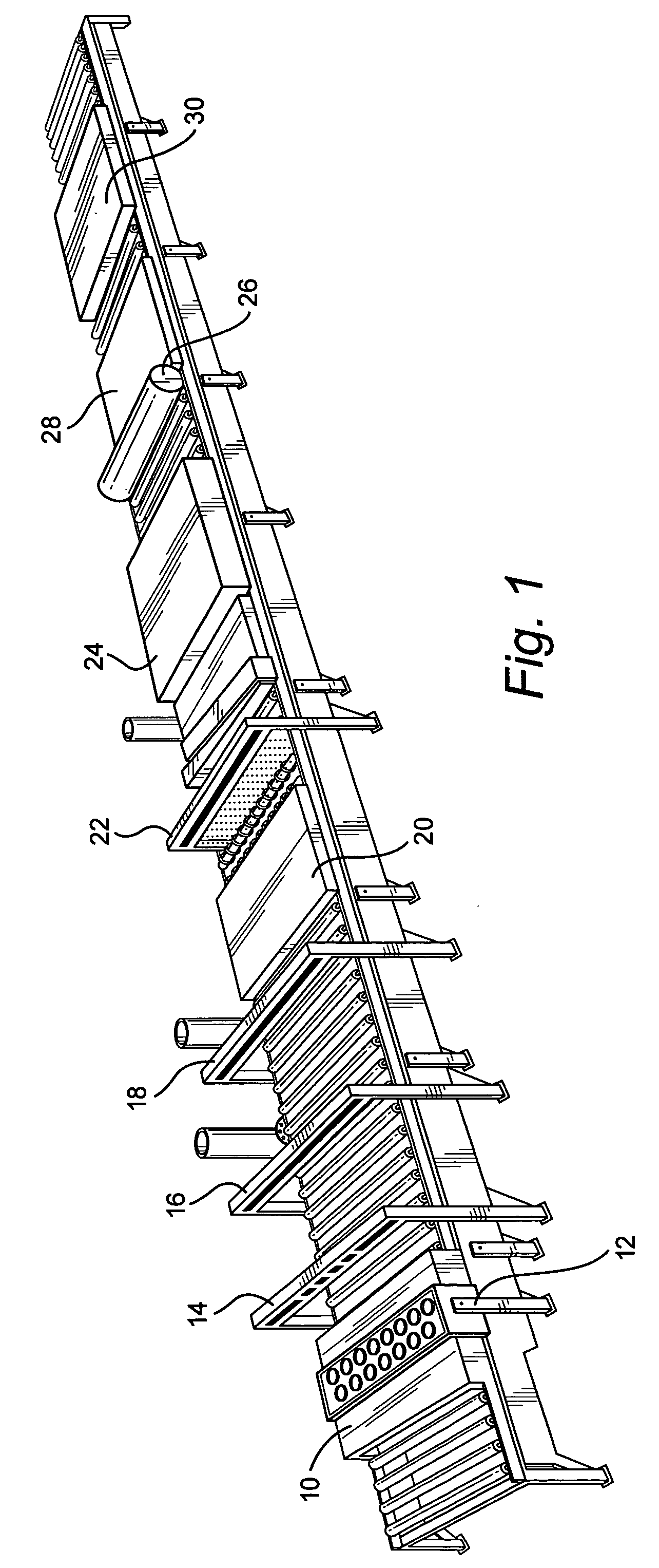

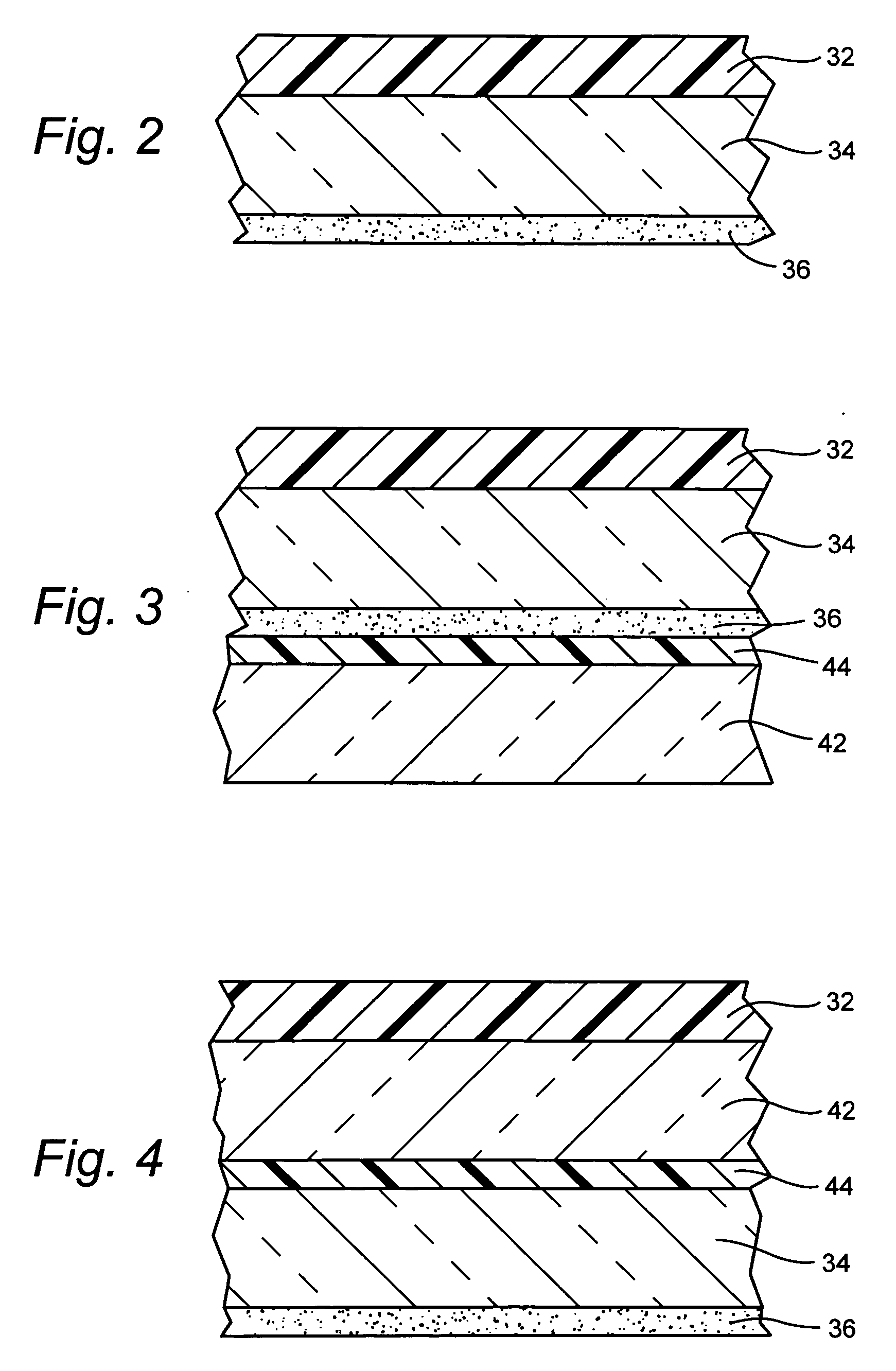

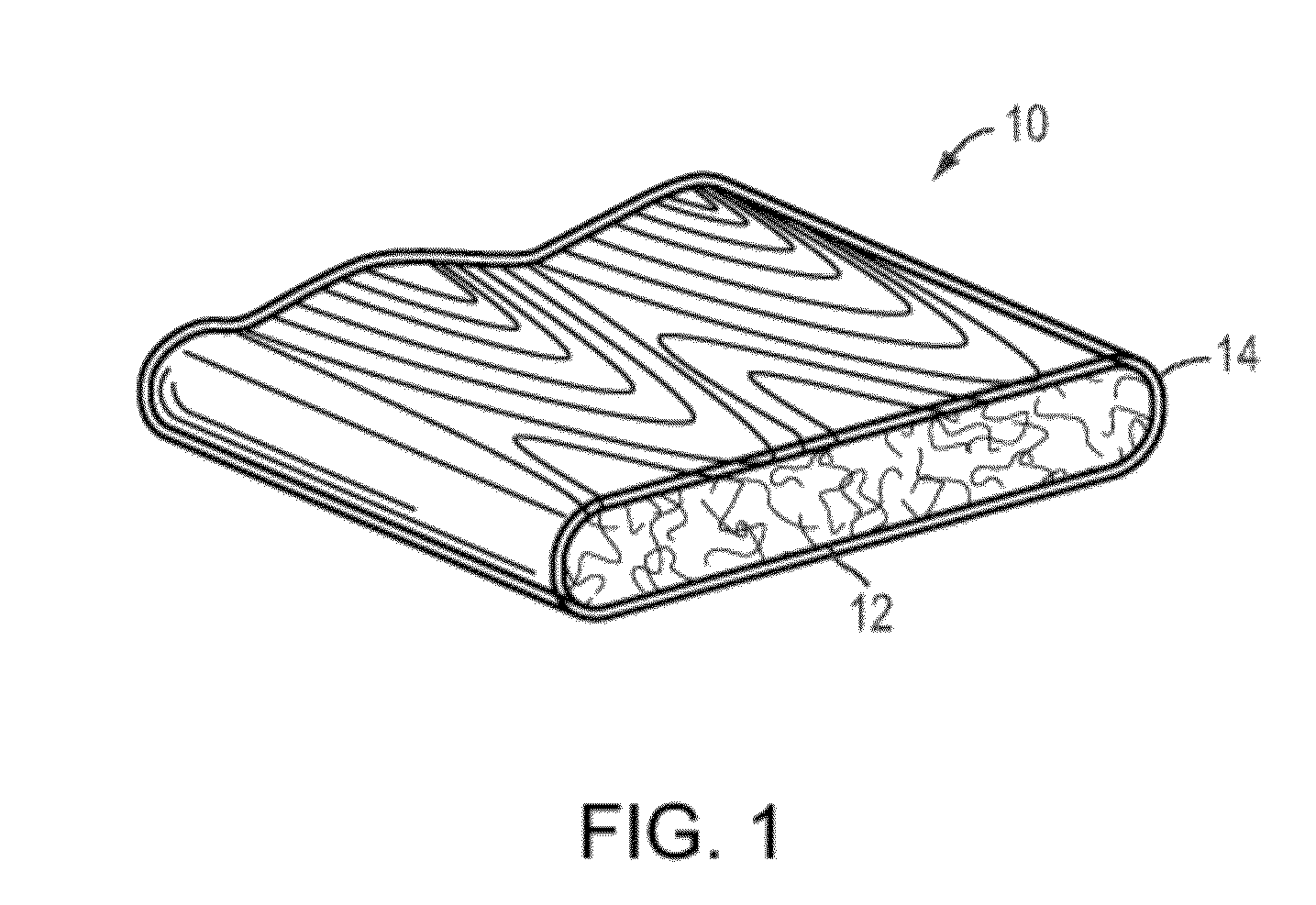

Method of making dunnage bags

InactiveUS6435787B1Abrasion resistanceReduce manufacturing costLoad securingCargo supporting/securing componentsDunnageAdhesive

A method of manufacturing an inflatable dunnage bag having a wall construction of two integrally fused layers of thermoplastic polymer, the outer layer of which is a sleeve of strips of woven polymer, the inner of layer of which is a continuous layer of gas impervious polymer. The ends of the sleeve are sealed against the escape of gas. The wall of the bag has a valve for the admittance of gas to the interior of the bag. The bag is formed by deposition of a continuous molten layer of gas impervious polymer to a sleeve of strips of woven polymer, installing a valve for admittance of gas into the wall of the sleeve and forming a gas tight seal at the ends of the sleeve. Deposition of the continuous layer of gas impervious polymer may be a two-step process wherein a molten layer of gas impervious polymer is deposited to one exterior side of the flattened sleeve, then to the other exterior side of the flattened sleeve and the sleeve turned "inside-out". The ends of the bag are sealed, may be folded, the folds secured to the exterior of the bag by adhesive and a binding strip. The dunnage so manufactured is strong, lightweight, scuff resistant, moisture resistant, reusable or easily recyclable.

Owner:JOHN DAVID M

Fire retardant and heat resistant yarns and fabrics made therefrom

InactiveUS6358608B1Improve heat resistanceIncrease abrasionNatural mineral layered productsYarnYarnEngineering

Fire retardant and heat resistant yarns, fabrics, felts and other fibrous blends which incorporate high amounts of oxidized polyacrylonitrile fibers. Such yarns, fabrics, felts and other fibrous blends have a superior LOI, TPP and continuous operating temperature compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends are also more soft and supple, and are therefore more comfortable to wear, compared to conventional fire retardant fabrics. The yarns, fabrics, felts and other fibrous blends incorporate up to 99.9% oxidized polyacrylonitrile fibers, together with at least one additional fiber, such as p-aramid, in order to provide increased tensile strength and abrasion resistance of the inventive yarns, fabrics, felts and other fibrous blends. The yarns may be woven, knitted or otherwise assembled into a desired fabric.

Owner:CHAPMAN THERMAL PRODS

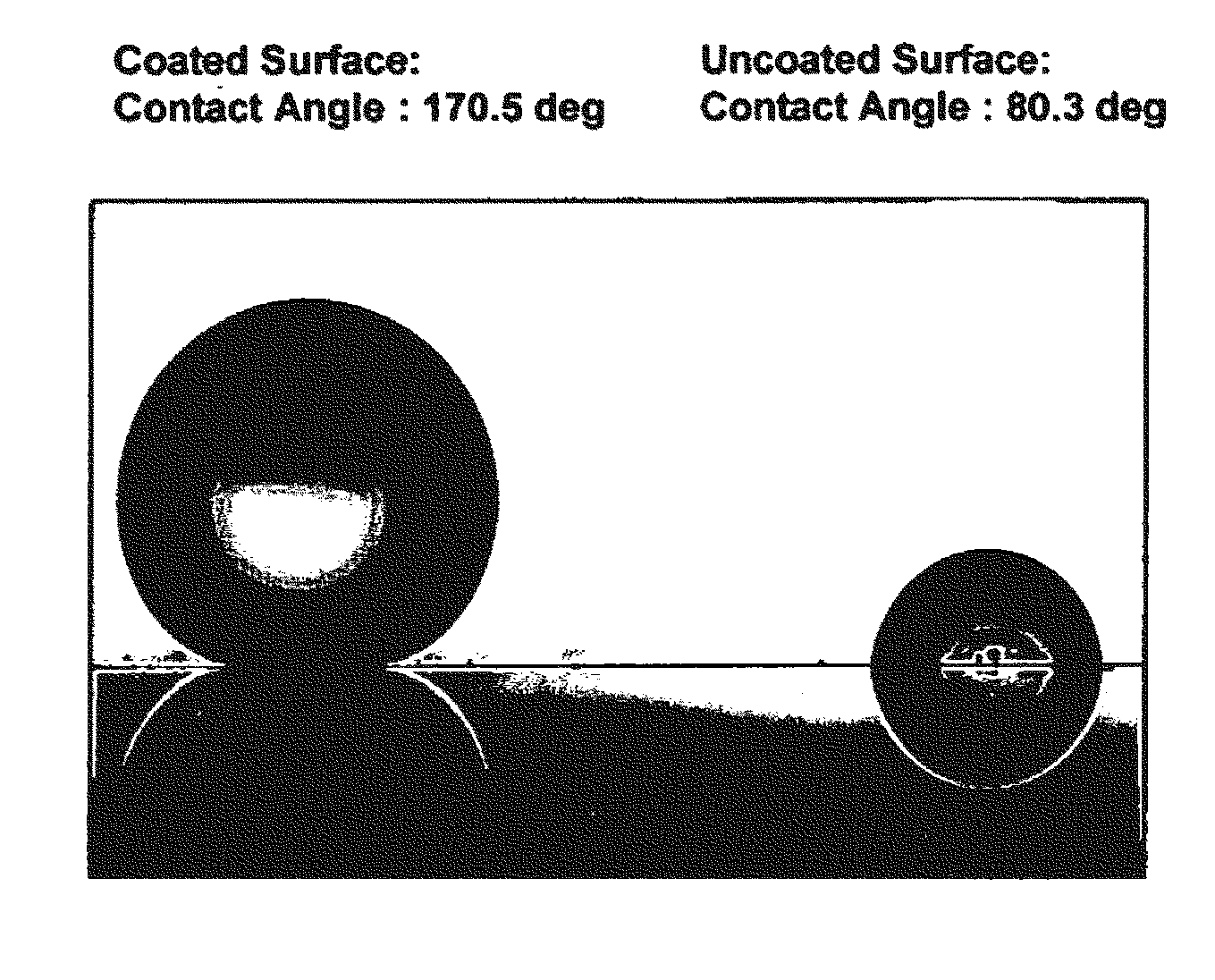

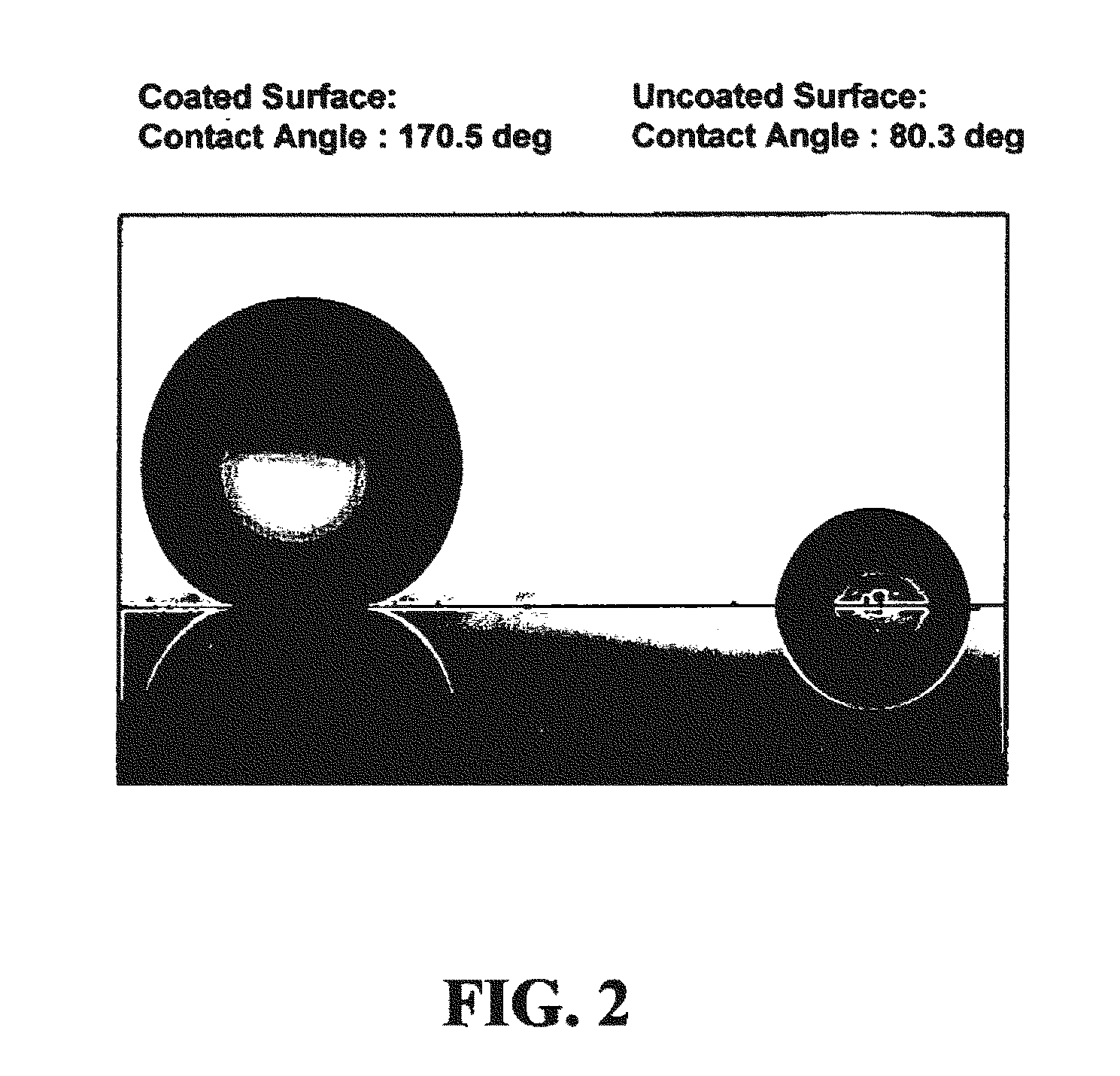

Coating compositions for producing transparent super-hydrophobic surfaces

ActiveUS20110177252A1Improves UV resistanceAbrasion resistanceMaterial nanotechnologyOrganic detergent compounding agentsNanoparticleSilsesquioxane

Owner:VGP IPCO LLC

Carpet Fiber Polymeric Blend

ActiveUS20080157425A1Improve fire resistanceImprove spinnabilityFlame-proof filament manufactureCeramic shaping apparatusYarnPolymer chemistry

The invention provides carpet fibers prepared from a blend of polymeric components, said fiber exhibiting improved properties, such as improved spinnability and improved fire resistance. The carpet fibers particularly comprise a majority of polytrimethylene terephthalate (PTT) and a minority of polyethylene terephthalate (PET). The invention further provides yarns and carpets prepared from the inventive fibers, said yarns and carpets likewise exhibiting improved properties. The invention also provides methods of improving various physical properties (such as fire resistance, spinnability, and elongation) of a polymeric composition.

Owner:ALADDIN MFG CORP

Fine-grained metallic coatings having the coefficient of thermal expansion matched to the one of the substrate

ActiveUS20070281176A1Cost-effective and convenient processIncrease stiffnessMaterial nanotechnologyRodsThermal dilatationMetal coating

Fine-grained (average grain size 1 nm to 1,000 nm) metallic coatings optionally containing solid particulates dispersed therein are disclosed. The fine-grained metallic materials are significantly harder and stronger than conventional coatings of the same chemical composition due to Hall-Petch strengthening and have low linear coefficients of thermal expansion (CTEs). The invention provides means for matching the CTE of the fine-grained metallic coating to the one of the substrate by adjusting the composition of the alloy and / or by varying the chemistry and volume fraction of particulates embedded in the coating. The fine-grained metallic coatings are particularly suited for strong and lightweight articles, precision molds, sporting goods, automotive parts and components exposed to thermal cycling. The low CTEs and the ability to match the CTEs of the fine-grained metallic coatings with the CTEs of the substrate minimize dimensional changes during thermal cycling and prevent premature failure.

Owner:INTEGRAN TECH

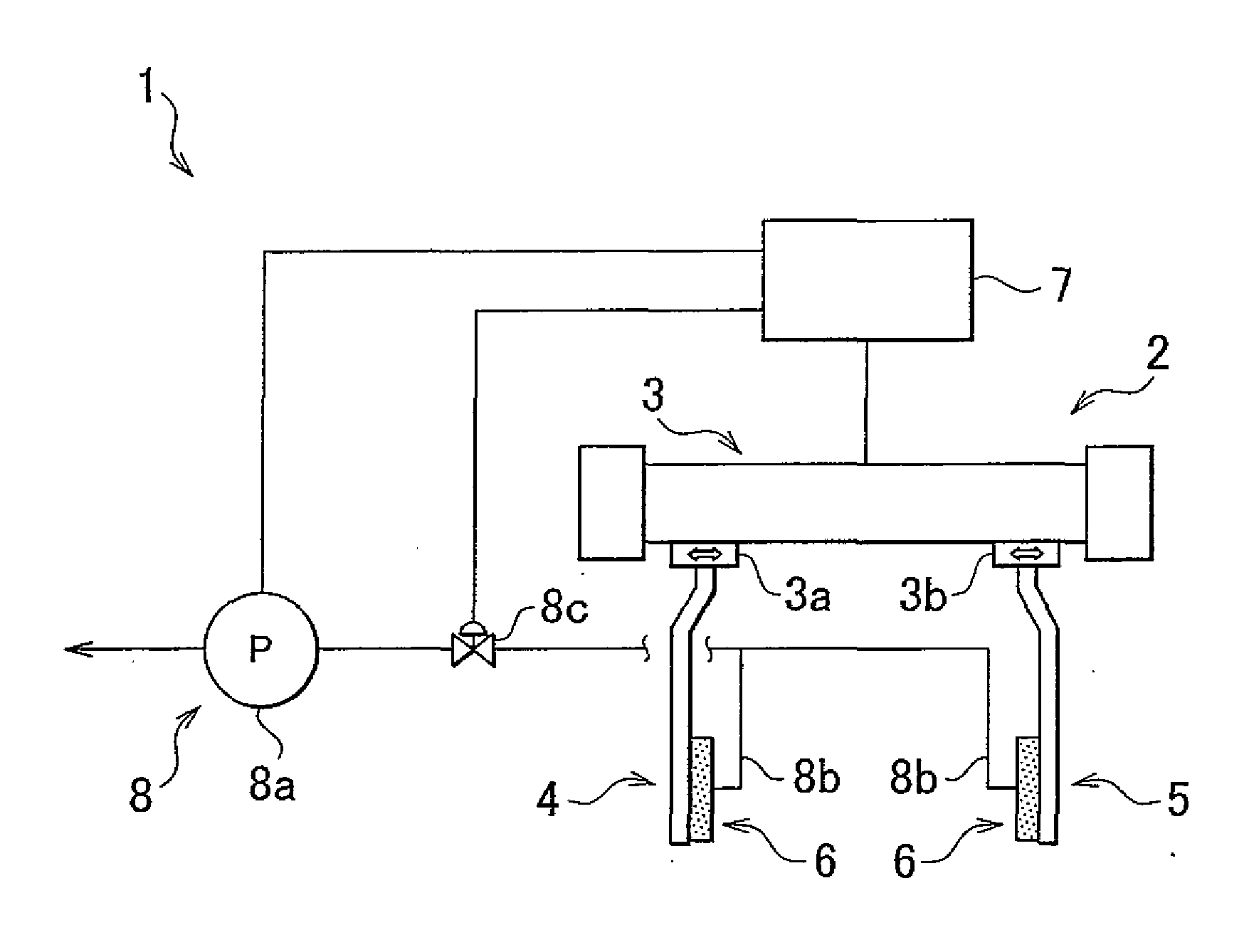

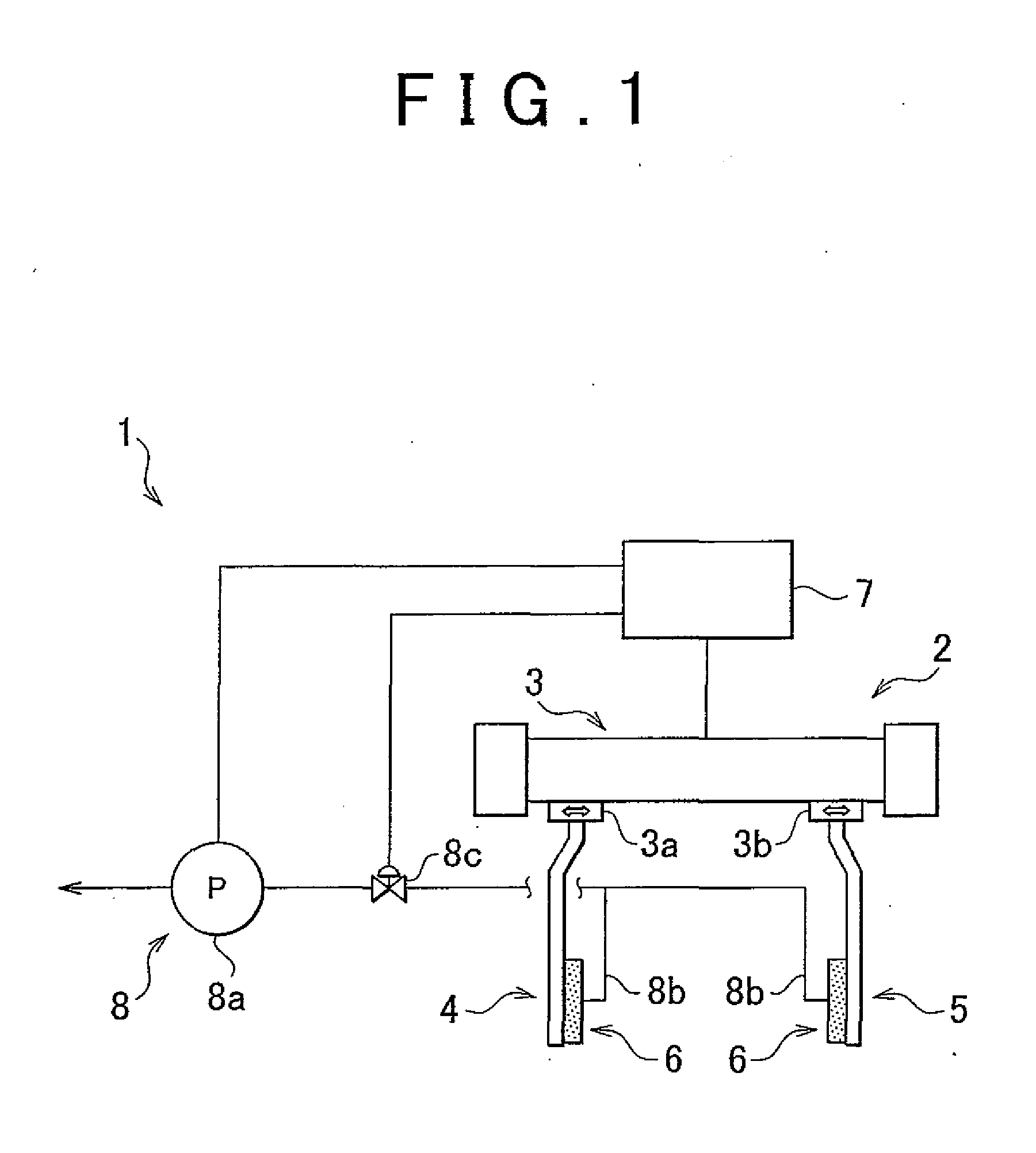

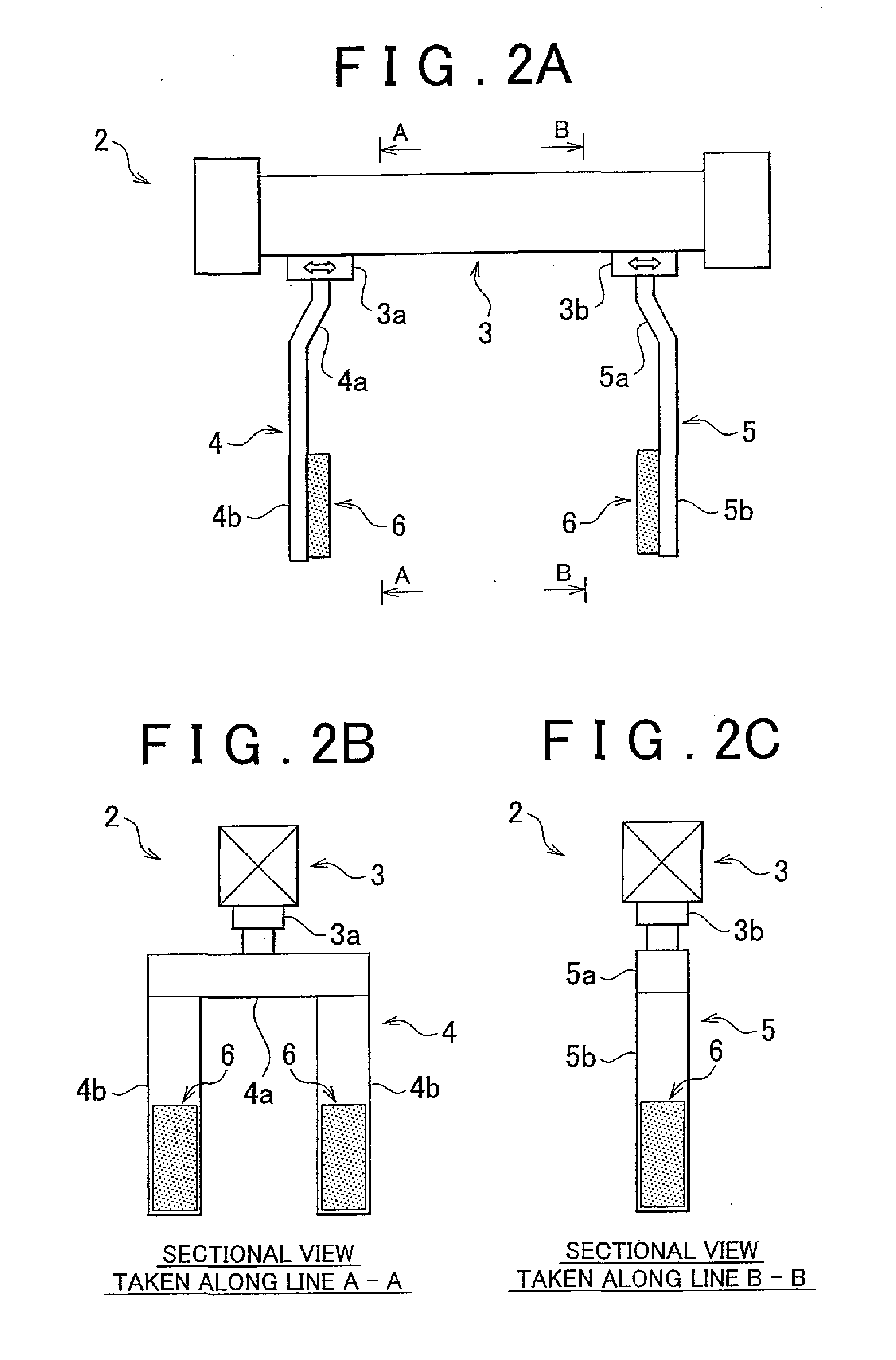

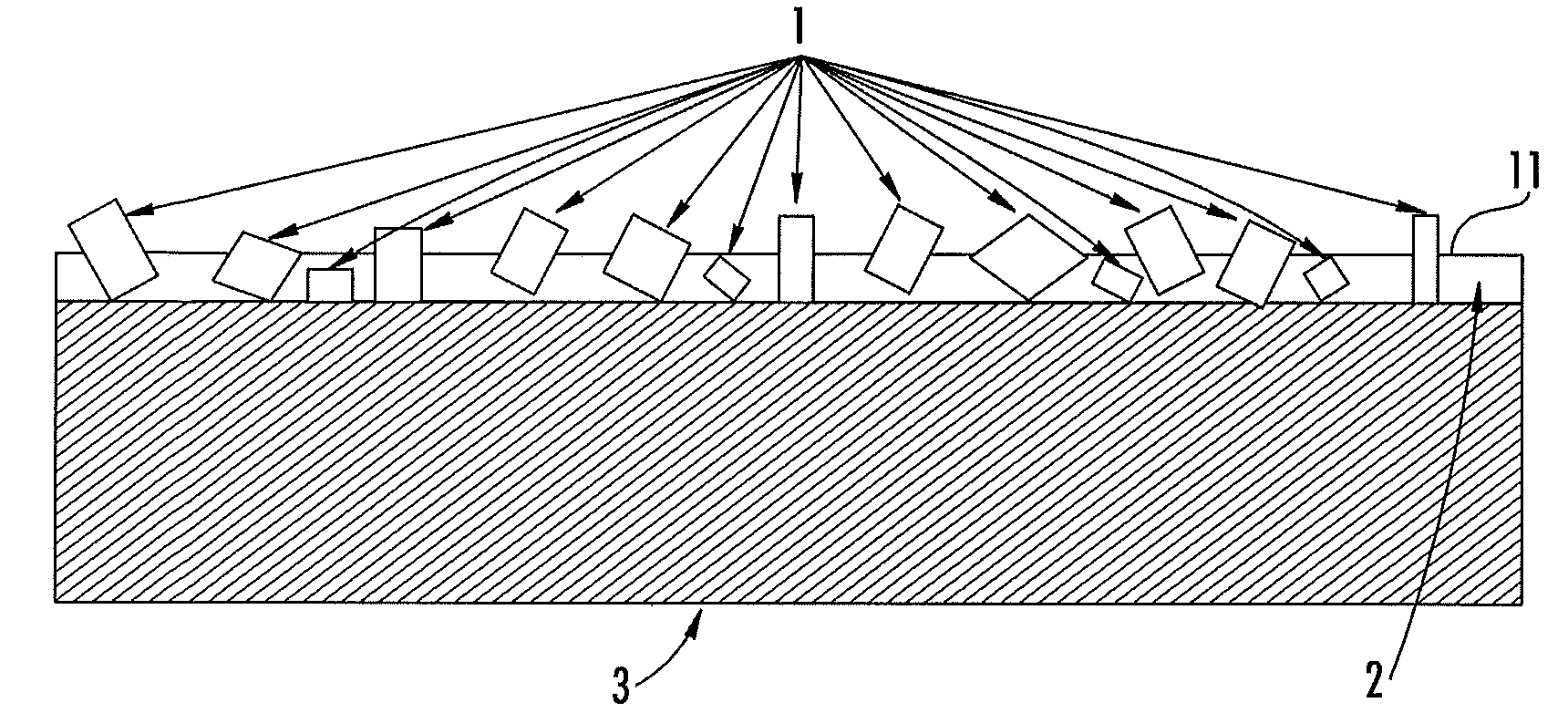

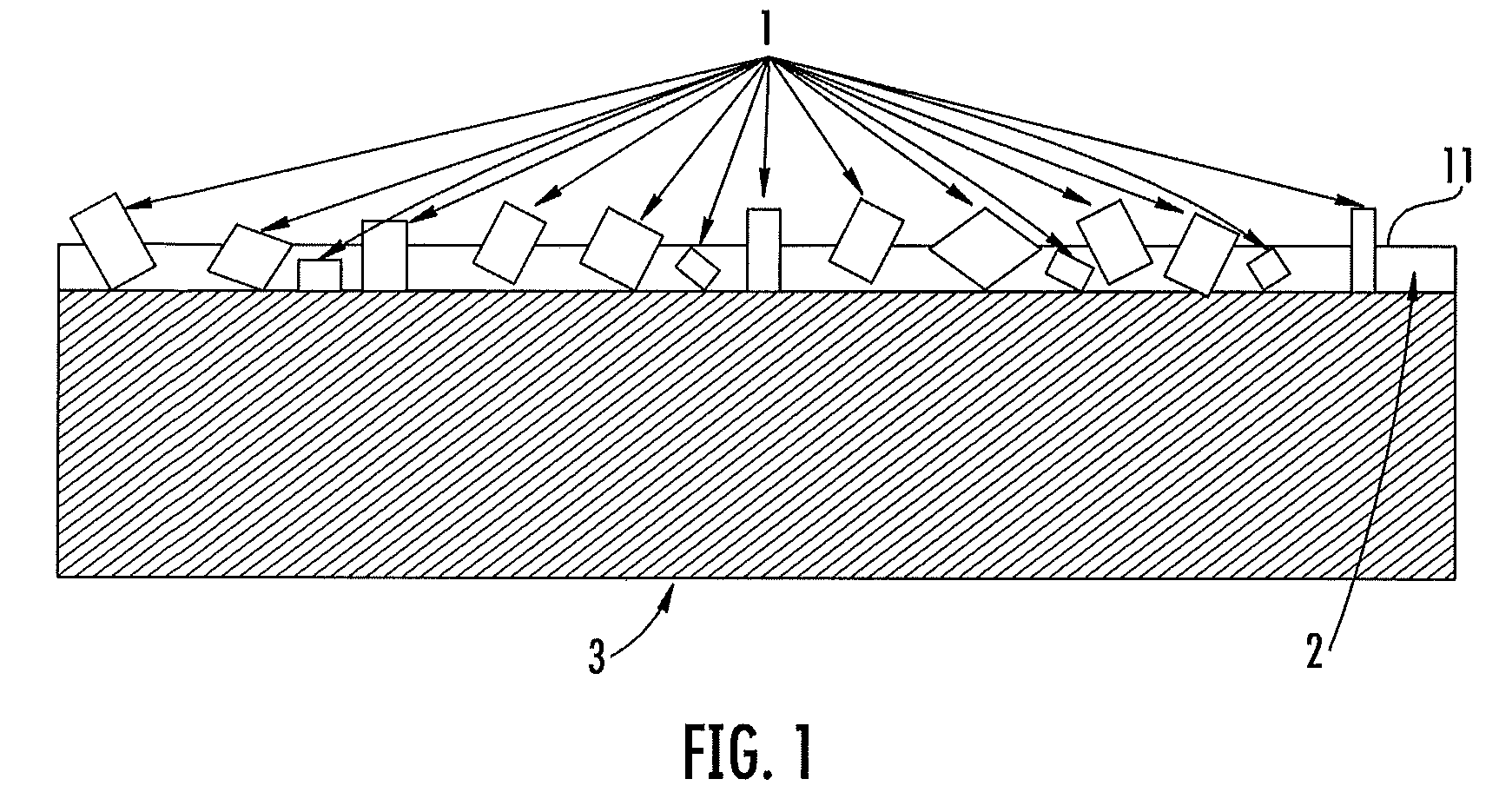

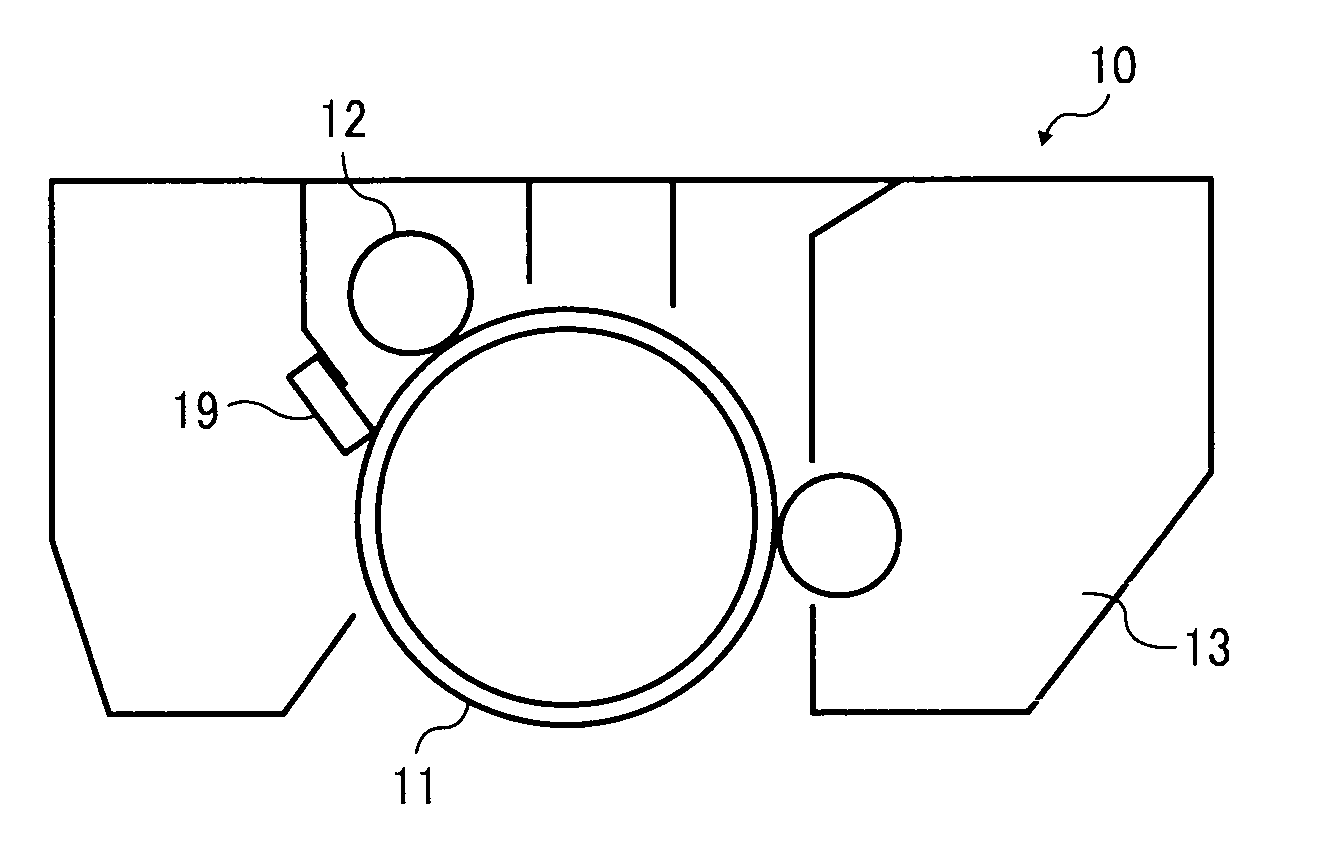

Grasping apparatus having bag members filled by a granular substance

ActiveUS20130033050A1Abrasion resistanceResistant to cuttingGripping headsLoad-engaging elementsStructural engineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

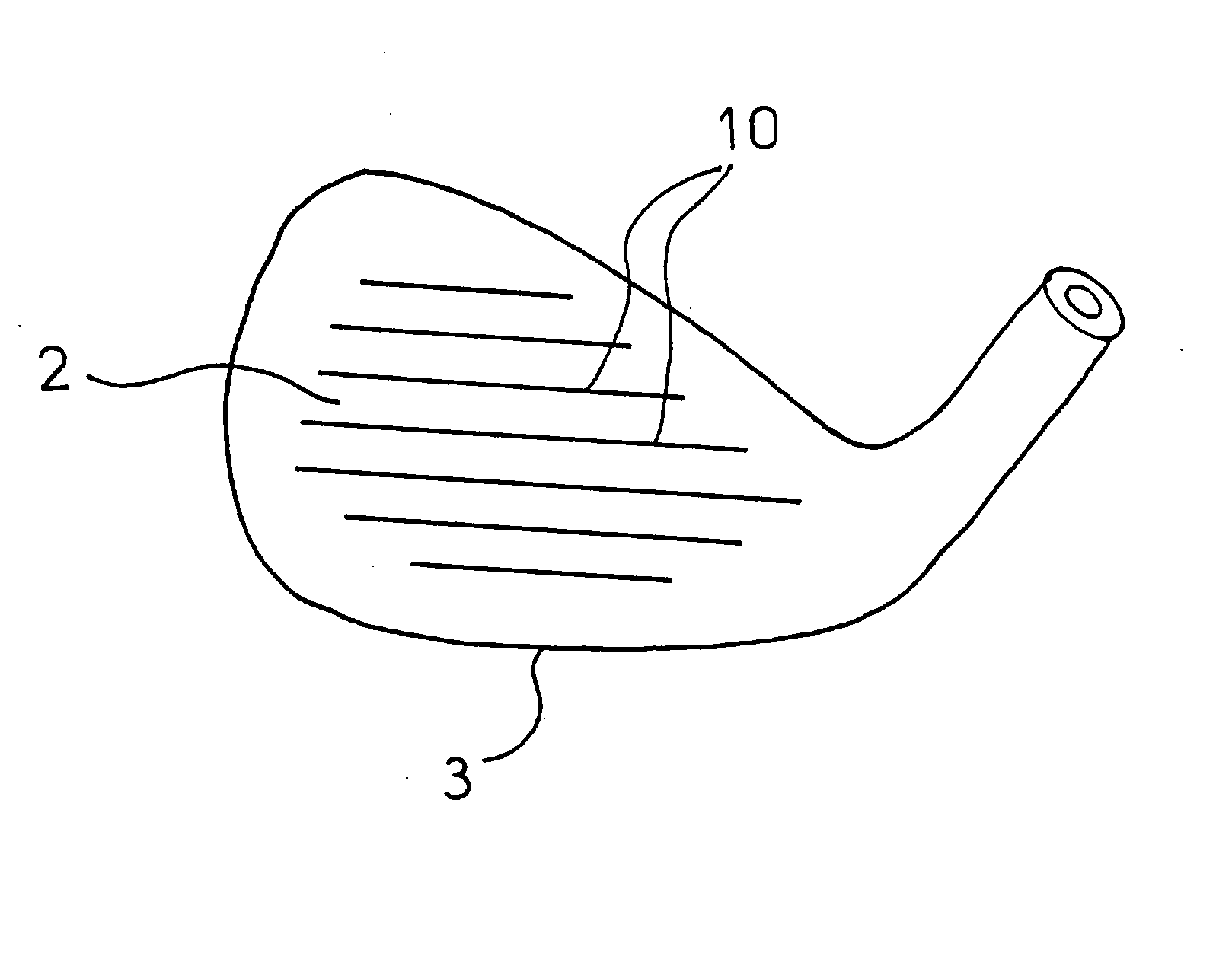

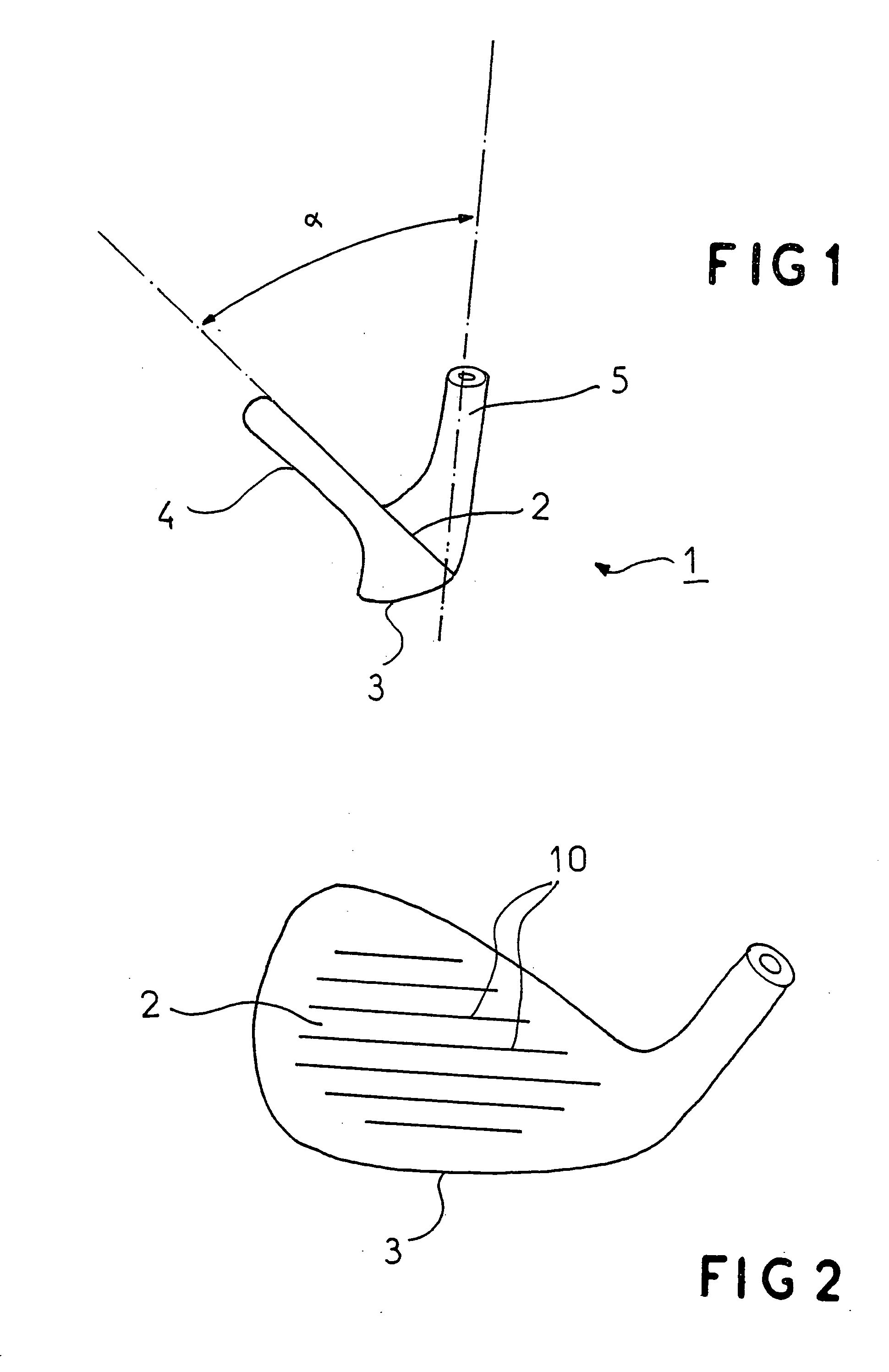

Golf clubhead

InactiveUS20040127300A1Increasing backspin effectEasy to controlGolf clubsGolfing accessoriesSurface roughnessEngineering

Golf clubhead (1) made from metal, having a strike face (2) which has a loft angle alpha of greater than 45°°, said strike (2) face having has a plurality of parallel grooves (10), characterized in that the strike face (2) has a surface roughness Ra of less than 0.25 micrometre, and in that the Vickers hardness of the strike face (2) is greater than 5 GigaPascal.

Owner:ROGER CLEVELAND GOLF

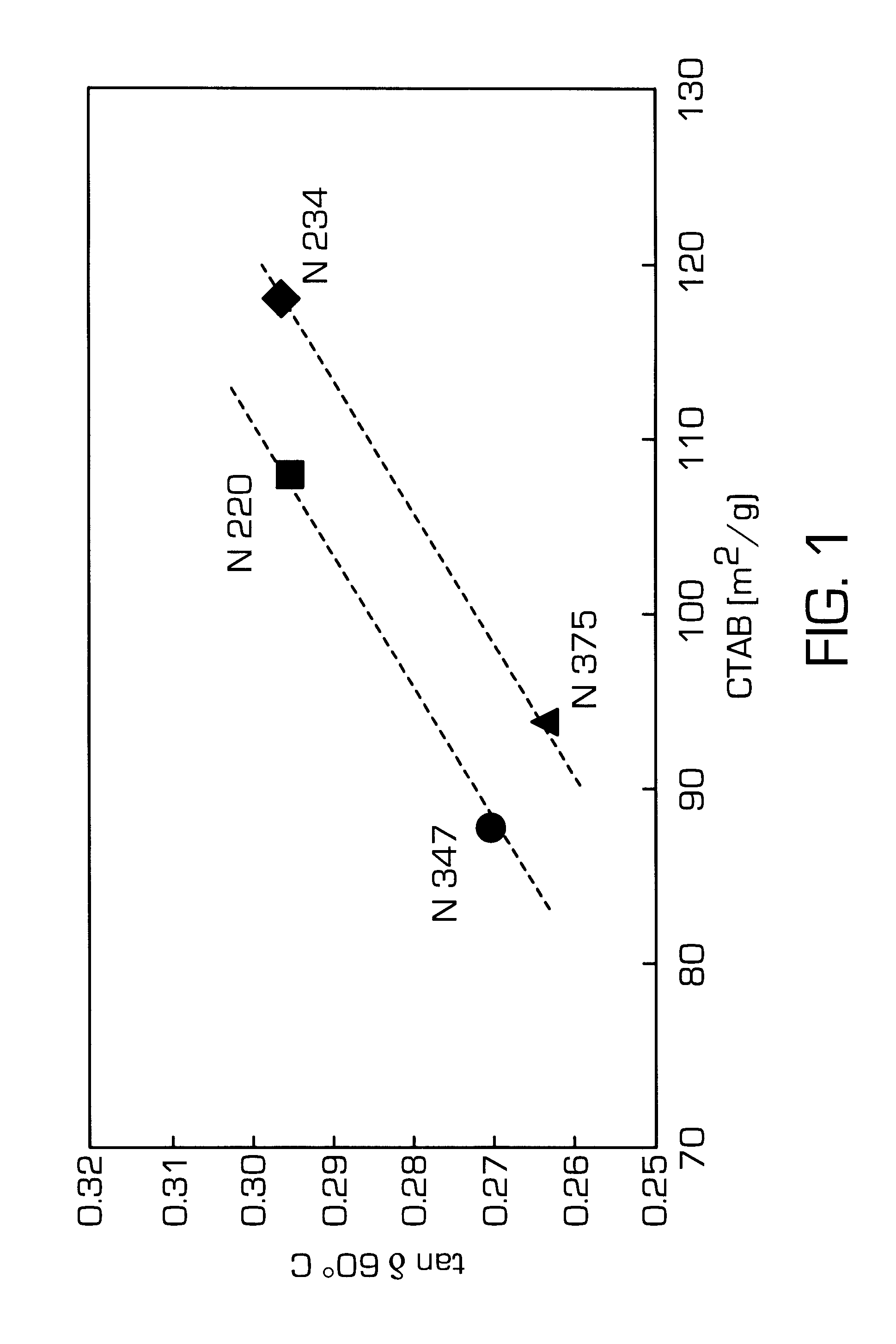

Inversion carbon blacks and method for their manufacture

InactiveUS6251983B1Improve rolling resistanceReduce heat buildupPigmenting treatmentAlkali metal halidesCombustion chamberRolling resistance

Inversion carbon blacks and a method for their manufacture are disclosed. The inversion carbon blacks have a lower rolling resistance with identical or improved wet skid behavior. The particle size distribution contains a smaller proportion of particles with large diameters. This leads to an improved abrasion behavior of rubber compounds which were prepared using these carbon blacks. The inversion carbon blacks can be manufactured in conventional carbon black reactors by controlling the combustion in the combustion chamber in such a manner that carbon black nuclei form, which are immediately brought into contact with the carbon black raw material. The carbon blacks present a lower proportion of larger particles if the additions of combustion air and carbon black raw material are increased in an appropriate manner.

Owner:UBS AG

Method for embedding a marking substance in a device such as an insertion tube

InactiveUS20050003103A1Abrasion resistanceResistant to chemical degradationSurgeryEndoscopesEngineeringEnergy analysis

Owner:OPTIM

Painted glass tiles, panels and the like and method for producing painted glass tiles and panels

InactiveUS20060115651A1Reduce and minimize corrosionAbrasion resistanceCovering/liningsSpecial ornamental structuresProduction lineBrick

A process and apparatus for painting float glass in particular using a production line that may also be used as or is similar to a mirror line, to produce decorative glass panels. In an embodiment of the invention, painted glass tiles are cut from the glass panels after the paint has dried / cured using a typical glass panel cutter. As such, a mass production technique is provided for making painted glass tiles, particularly for residential use.

Owner:GUARDIAN GLASS LLC

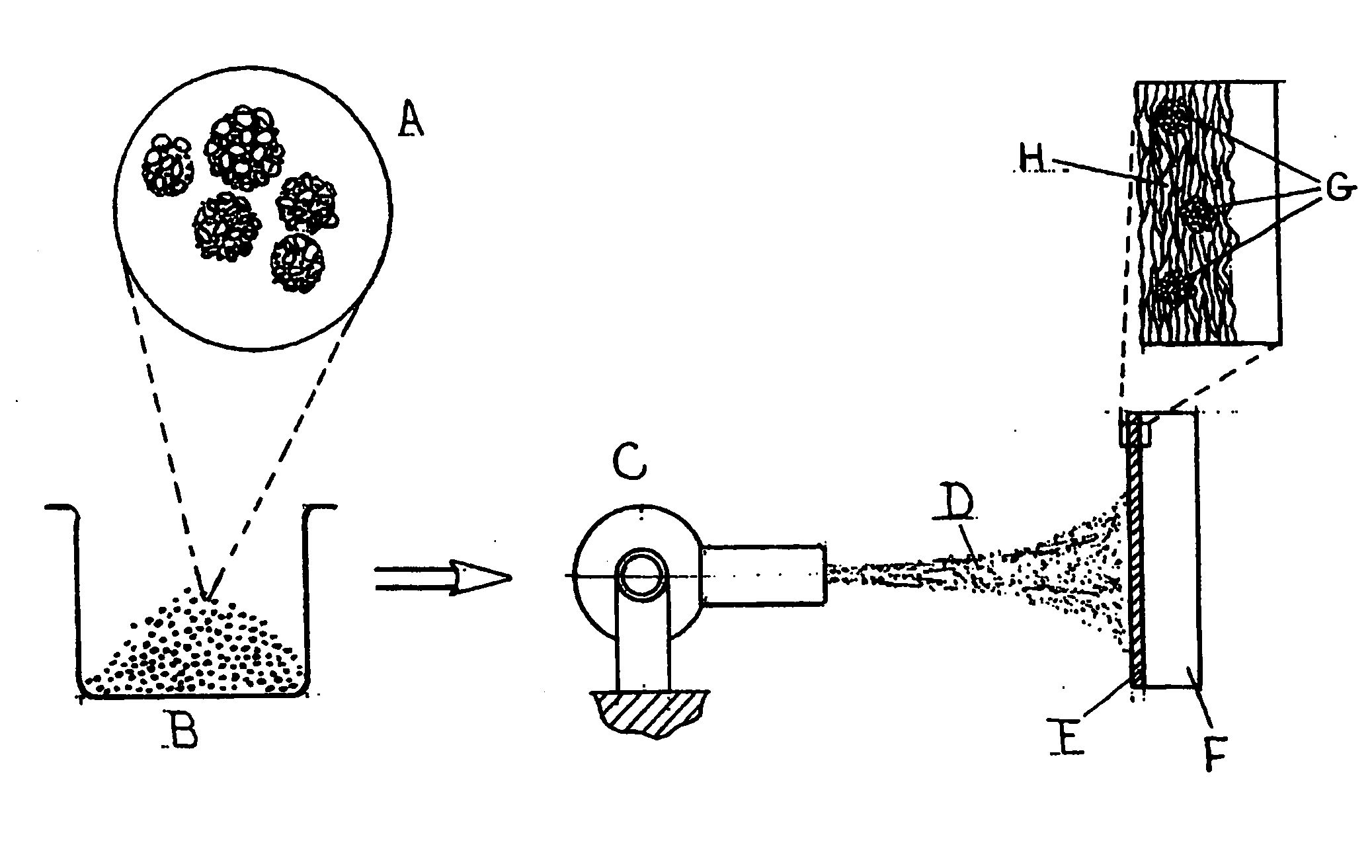

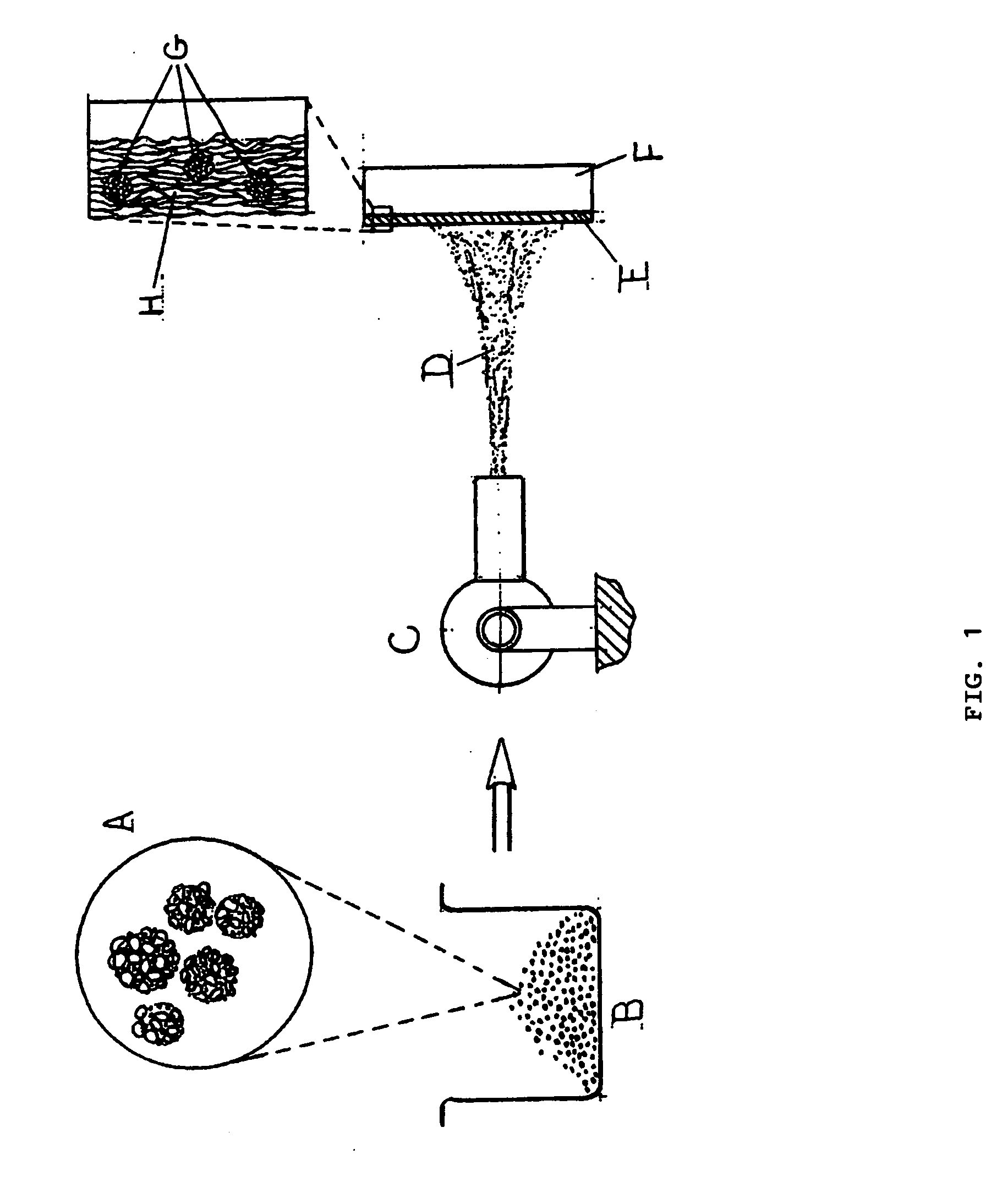

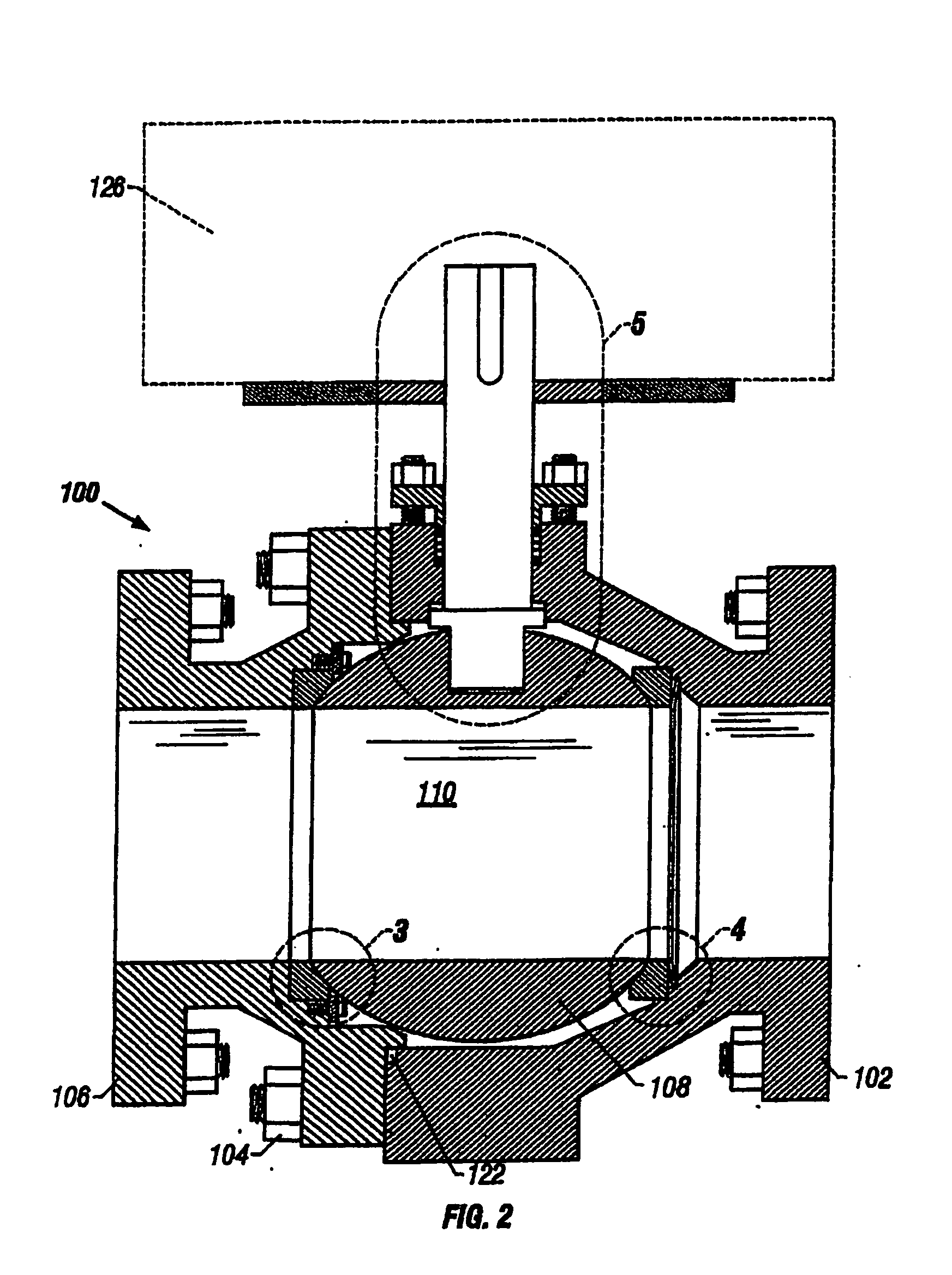

Coatings, their production and use

InactiveUS20080182114A1Improve the immunityAbrasion resistancePlug valvesLiquid surface applicatorsThermal sprayingNanostructure

Disclosed herein are agglomerate blends suitable for application to a surface of a substrate by thermal spray, thereby to produce coatings, typically nanostructured coatings, that exhibit desirable properties such as erosion, abrasion, or corrosion resistance. Such coatings have many useful applications, including but not limited to an enhancement of valve reliability and durability. For example, the nanostructured coatings may be applied to valve components (i.e., balls and seats) via thermal spray processes, wherein the feedstock powder used in thermal spray may be composed, for example, of a chromium oxide composite material that meets the protective requirements against the wear and corrosion of the valve service. The thermal spray process may involve, but is not limited to, either a plasma spray or high-velocity combustion process. Through their enhanced properties, the coatings can provide superior reliability and extended life to components such as valves. Also disclosed are methods for producing the coatings, and correspondingly coated components.

Owner:SCI VALVE & SEAL

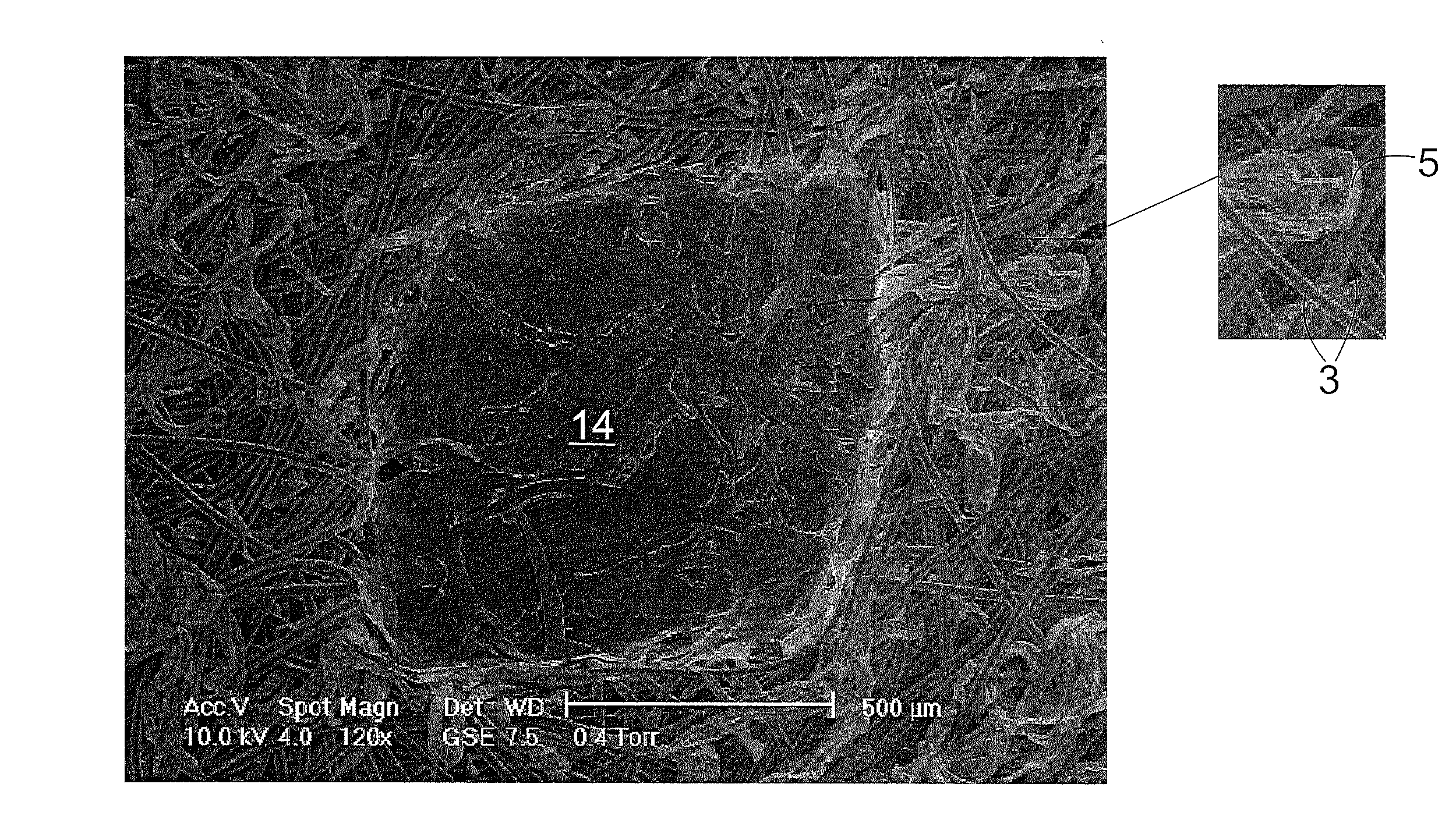

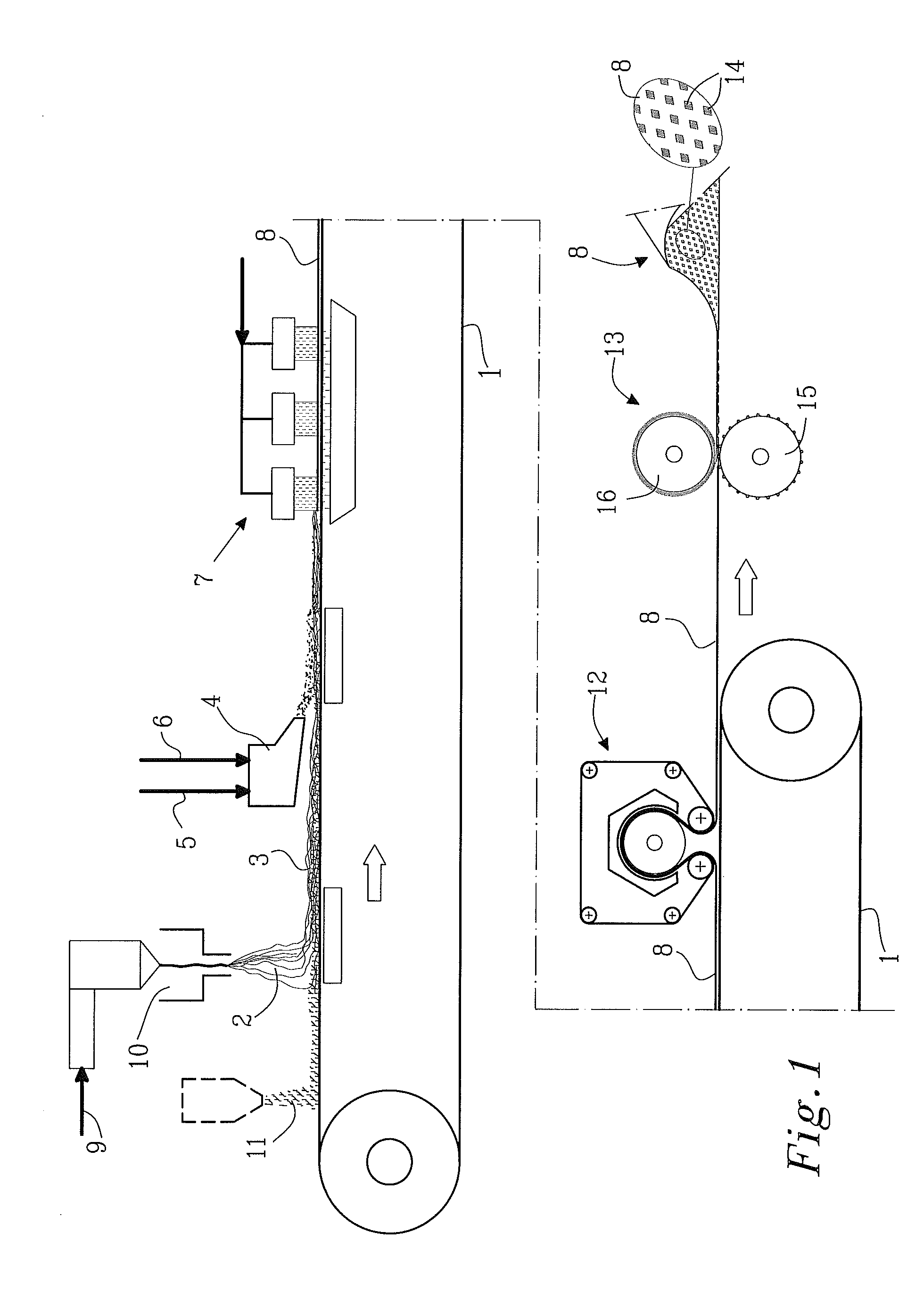

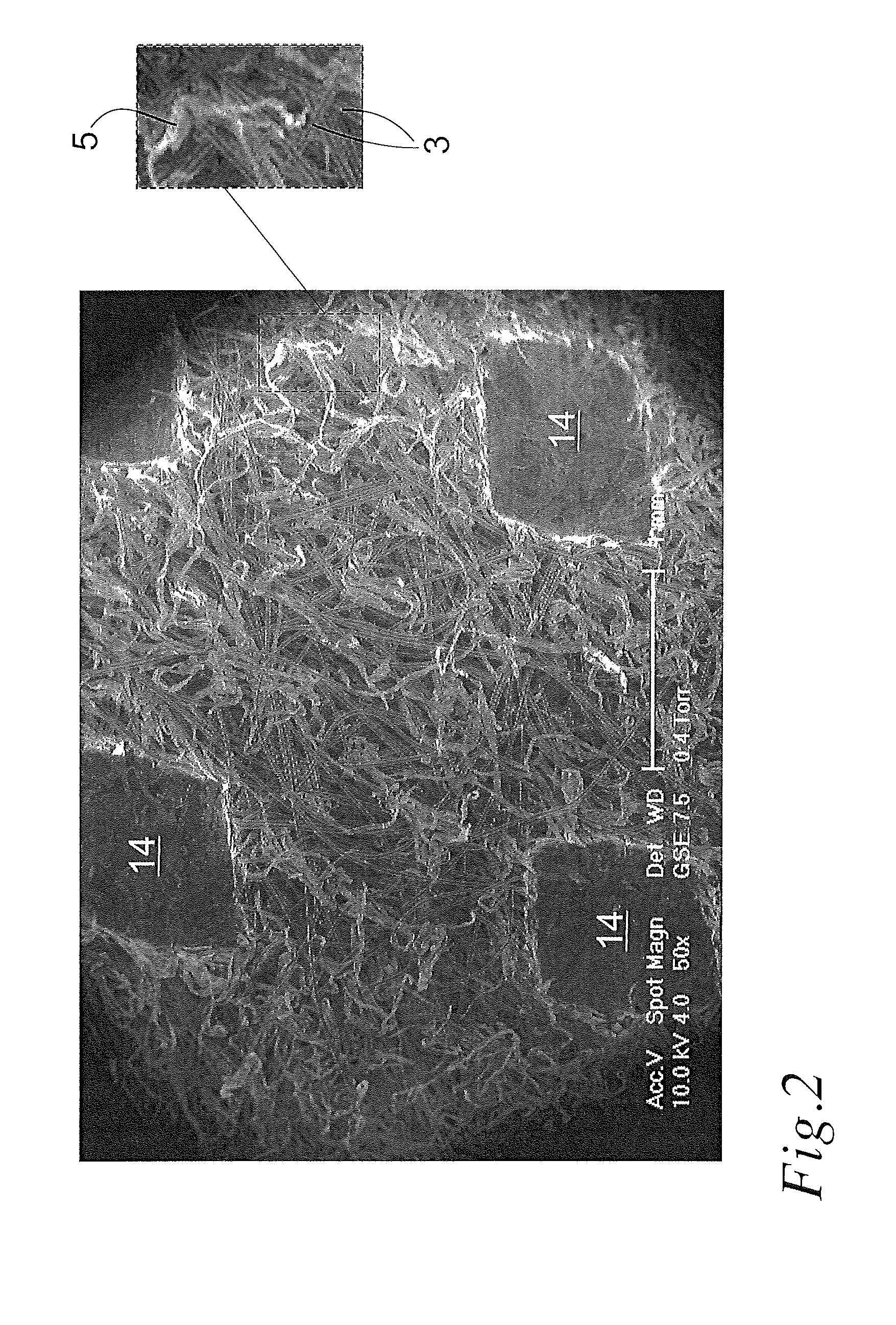

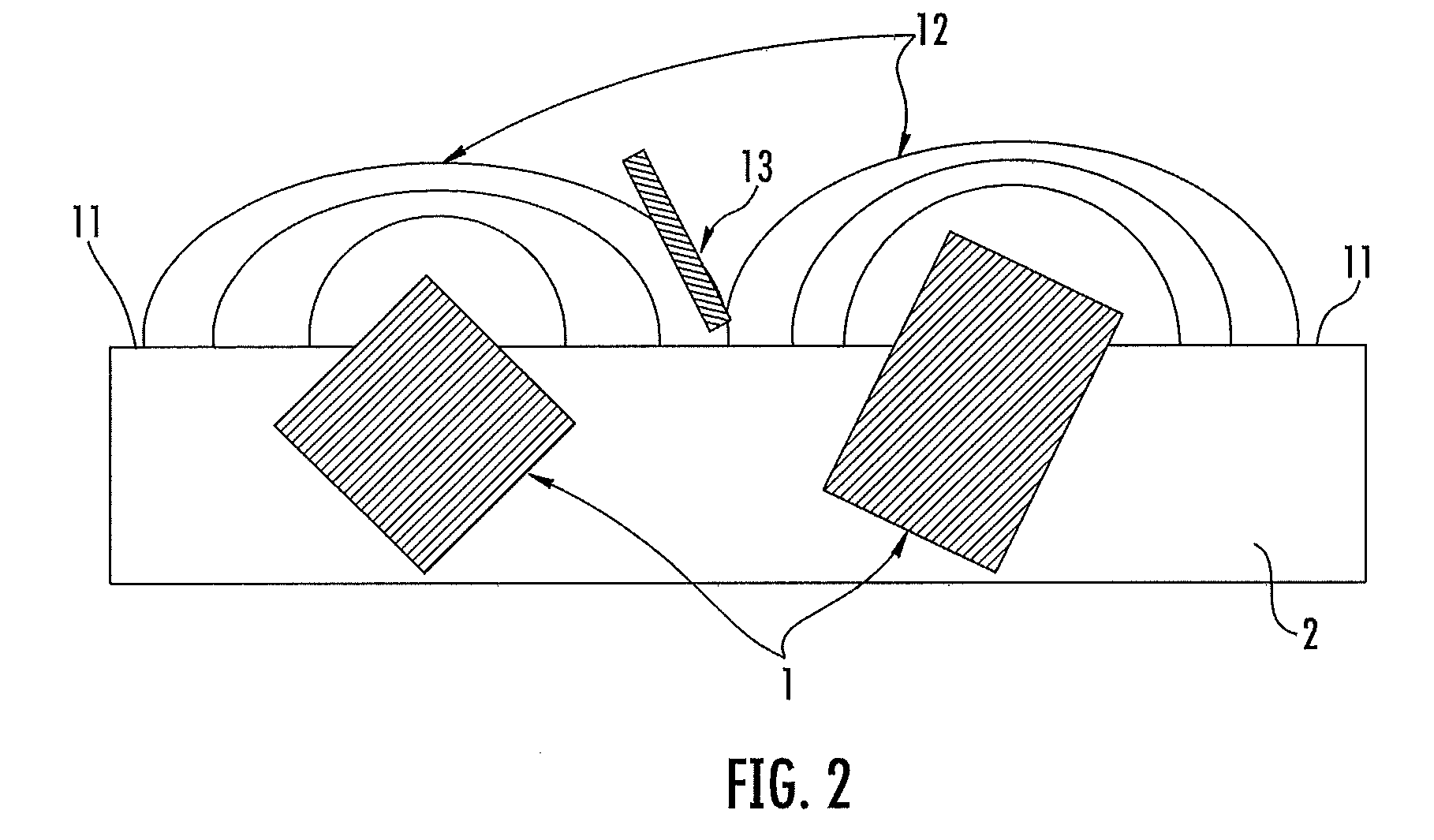

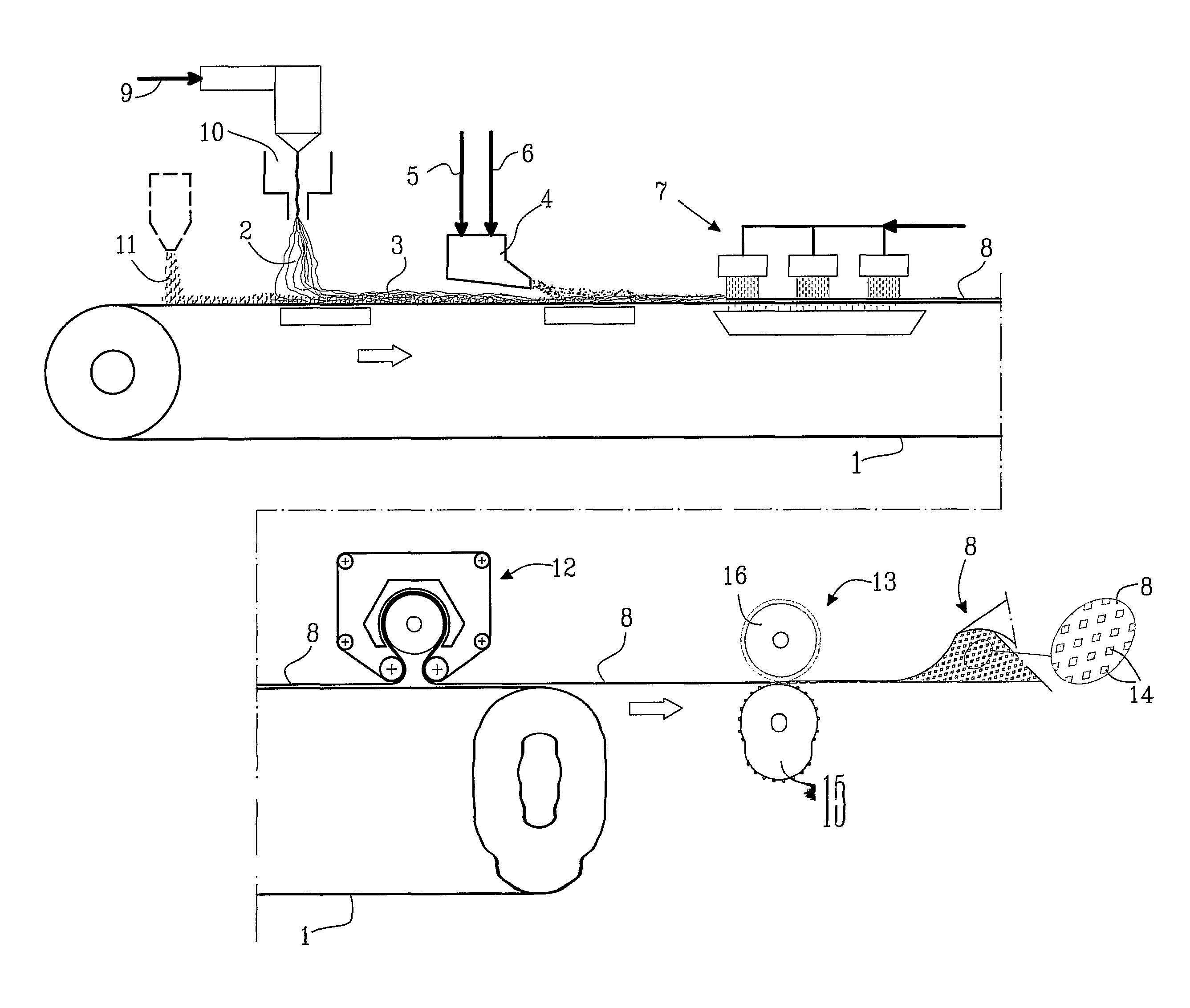

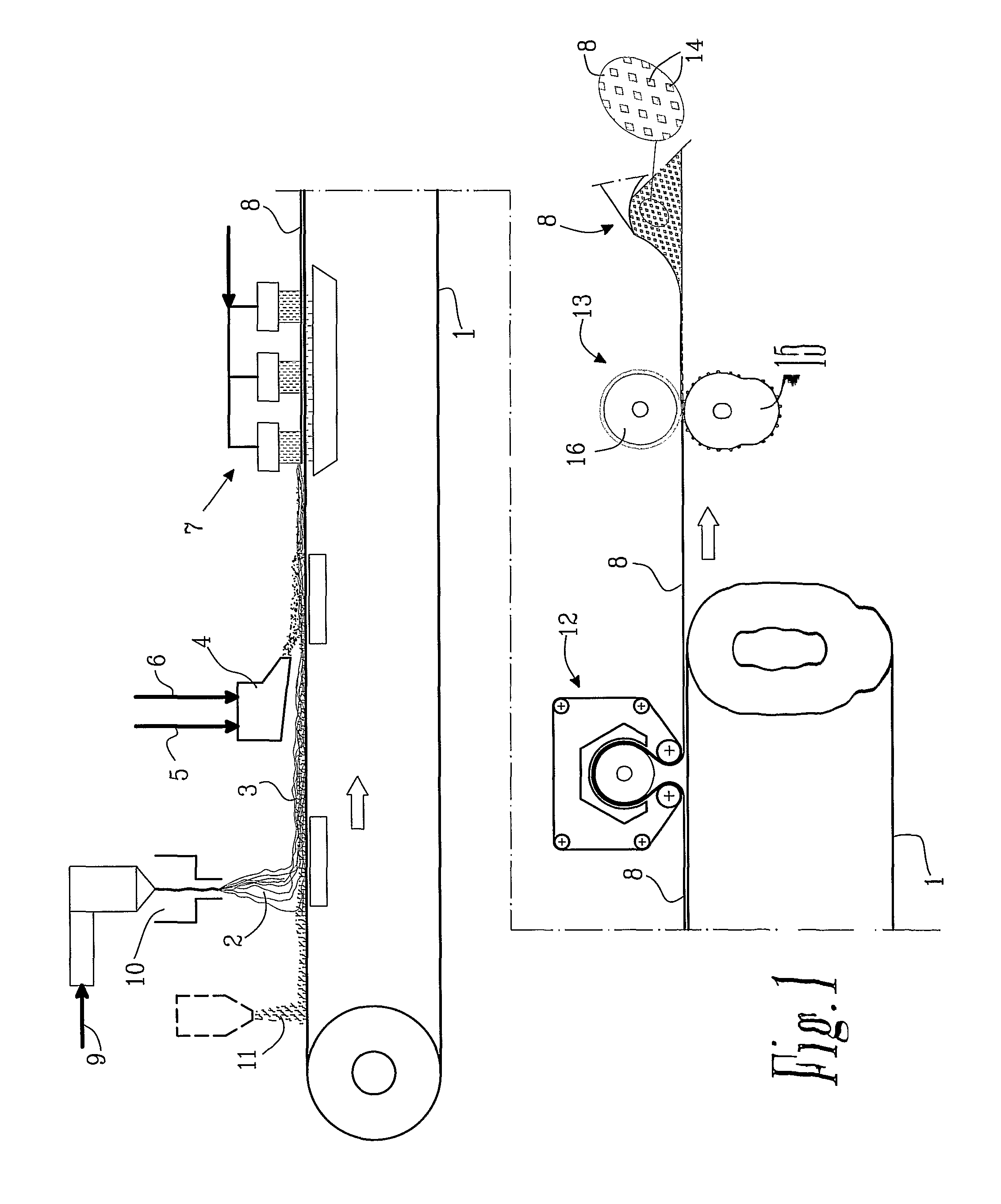

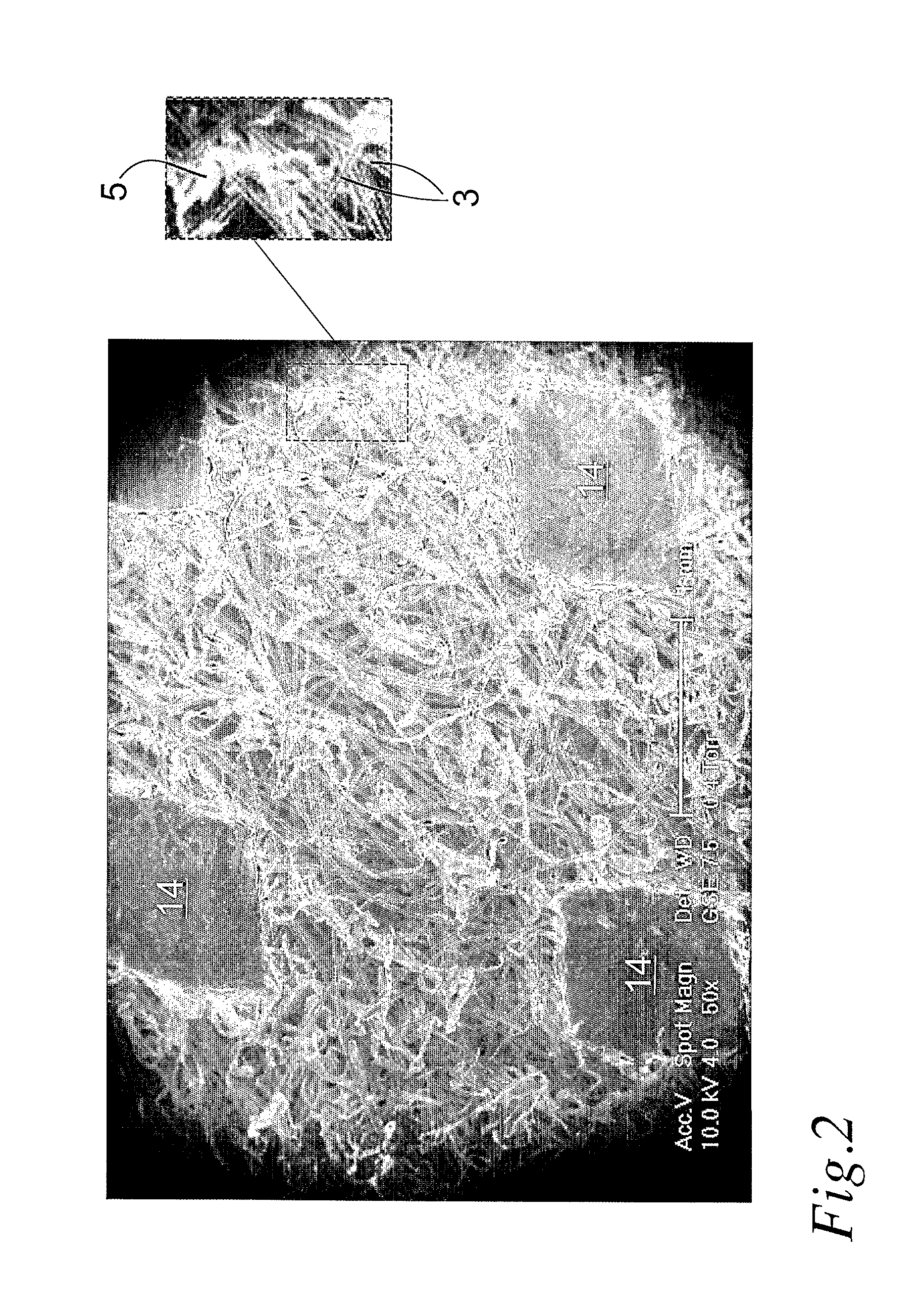

Hydroentangled nonwoven material

InactiveUS20100075120A1Less sensitive to pillingAbrasion resistanceSynthetic resin layered productsLaminationPolymer scienceNonwoven fabric

A hydroentangled nonwoven material (8), includes a mixture of randomized continuous filaments (3) and natural fibres (5), wherein at least part of the staple fibres and / or the continuous filaments includes thermoplastic material. The nonwoven material is bonded in a non-random bonding pattern including a plurality of bonding sites (14) in which thermoplastic material included in the nonwoven material has been caused to at least partly soften or melt to create thermal bonds between the continuous filaments. The nonwoven material includes no other thermal bonds between the filaments than provided by the non-random bonding pattern. The nonwoven material may also contain synthetic staple fibers (6).

Owner:SCA HYGIENE PROD AB

Method for producing artificial teeth

ActiveUS20160184189A1Excellent in aesthetic propertyImprove functionalityImpression capsAdditive manufacturing apparatusSimple Organic CompoundsHardness

To provide a method for producing an artificial tooth which is excellent in strength, abrasion resistance, hardness, low water absorption, aesthetic property, functionality, and the like within a short time, especially less than 1 hour, smoothly and simply, without requiring skill using a dental photocurable resin composition.[Solution]Disclosed is a method for producing an artificial tooth, which includes the steps of:(a) accommodating a liquid dental photocurable resin composition containing a radical polymerizable organic compound (A), a filler (B), and a photosensitive radical polymerization initiator (C) in a shaping container having a light permeable bottom face, and irradiating the dental photocurable resin composition in the shaping container with light in a predetermined shape pattern through the light permeable bottom face of the shaping container in accordance with slice data every one layer based on three-dimensional CAD data relating to a tooth to form a cured resin layer having a shape pattern for one layer;(b) lifting up the cured resin layer for one layer formed in the step (a), thereby allowing the liquid dental photocurable resin composition to flow into the space between the lower face of the cured resin layer and the bottom face of the shaping container, and irradiating the dental photocurable resin composition between the lower face of the cured resin layer and the bottom face of the shaping container with light through the light permeable bottom face of the shaping container in accordance with slice data every one layer based on three-dimensional CAD data relating to a tooth to further form a cured resin layer having a shape pattern for one layer; and(c) repeating the operation of the step (b) until the objective artificial tooth is obtained.

Owner:DWS SRL

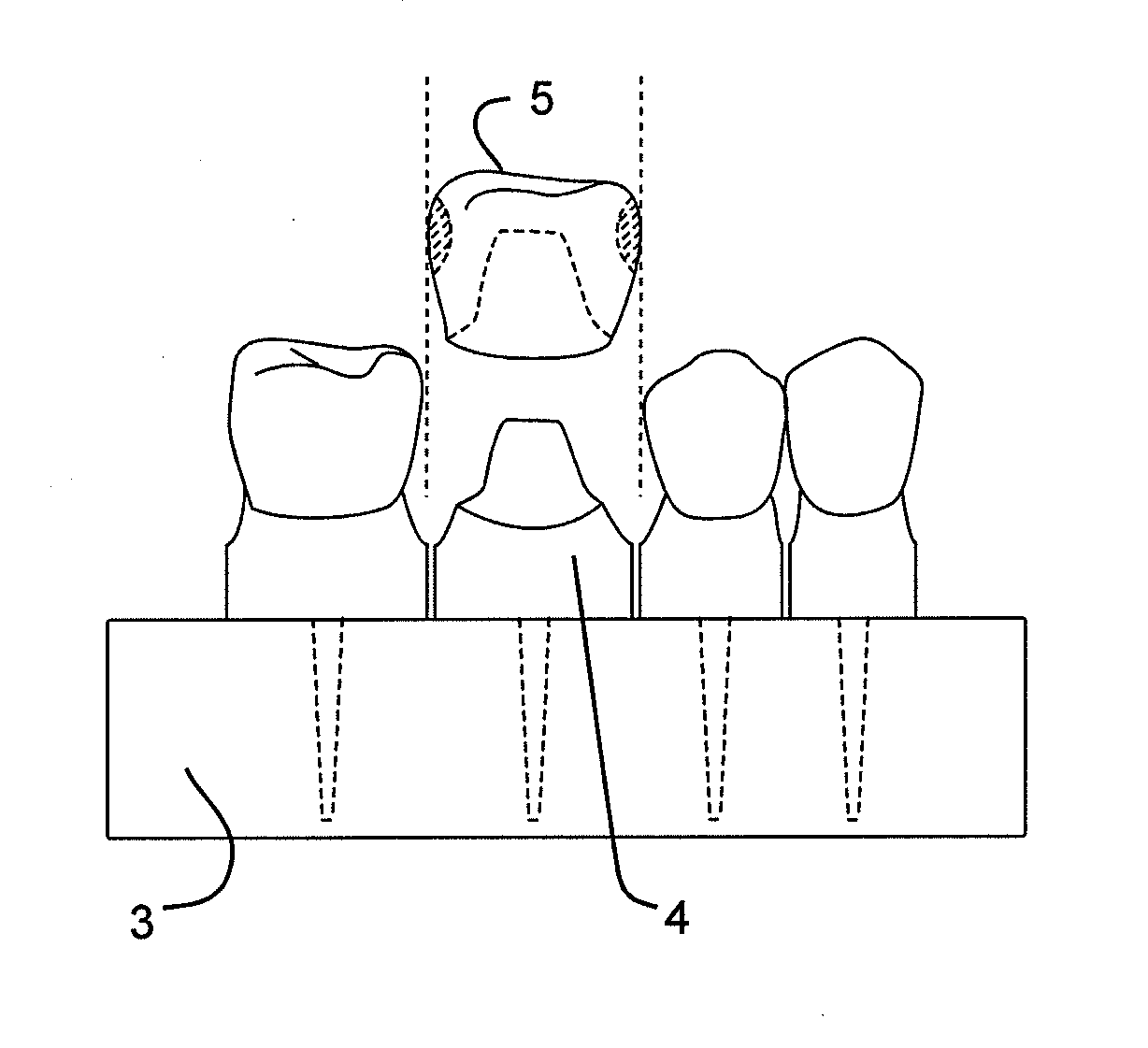

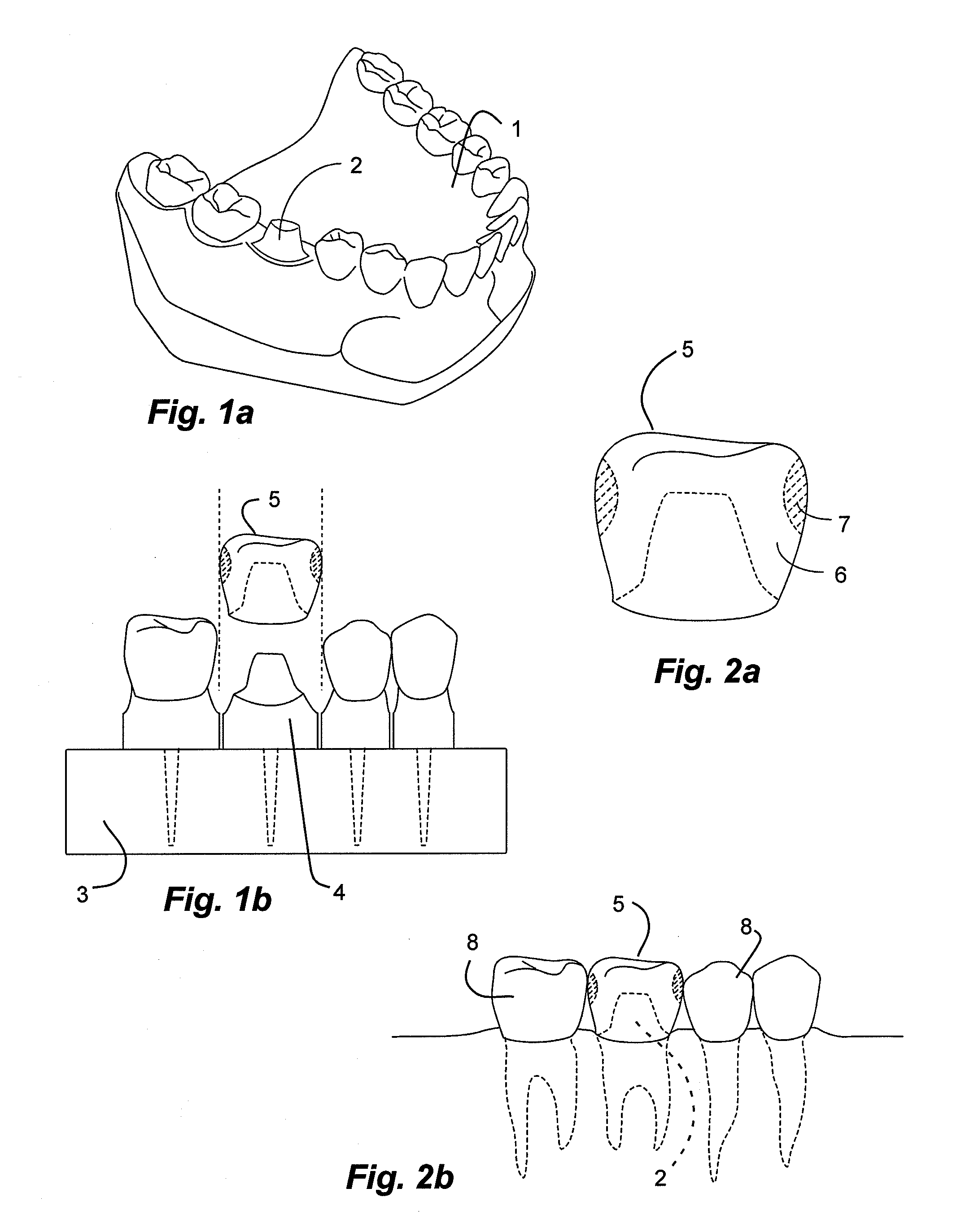

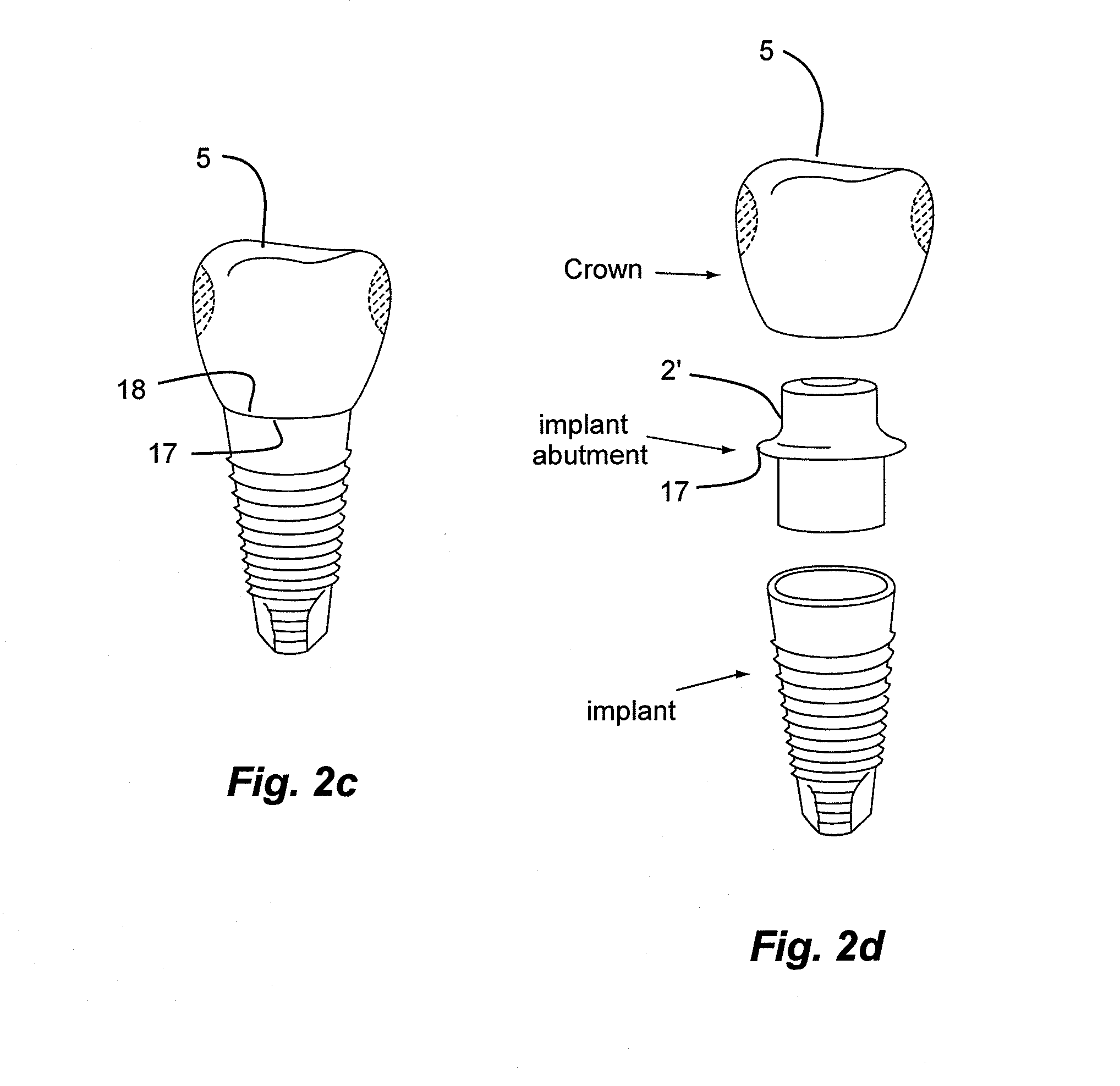

Method of making a dental prosthesis

ActiveUS20150111172A1Improve flexural strengthReduce generationImpression capsFastening prosthesisRestorative materialDentures

A method of making a dental crown or bridge restoration comprises forming a precursor crown outside of a patient's mouth with a first restorative material, with a buccal contour on the buccal wall substantially the same as a buccal contour on a final crown restoration, and an open space on or around at least one of the mesial side wall or the distal side wall; and filling and securing a second material, different from the first restorative material, inside the open space or pocket of the precursor crown while outside the patient's mouth, and with the precursor crown having a strength substantially equivalent to the final crown restoration, and with the buccal contour being substantially the same as the buccal contour on the final crown, prior to filling and securing the second material.

Owner:B & D DENTAL

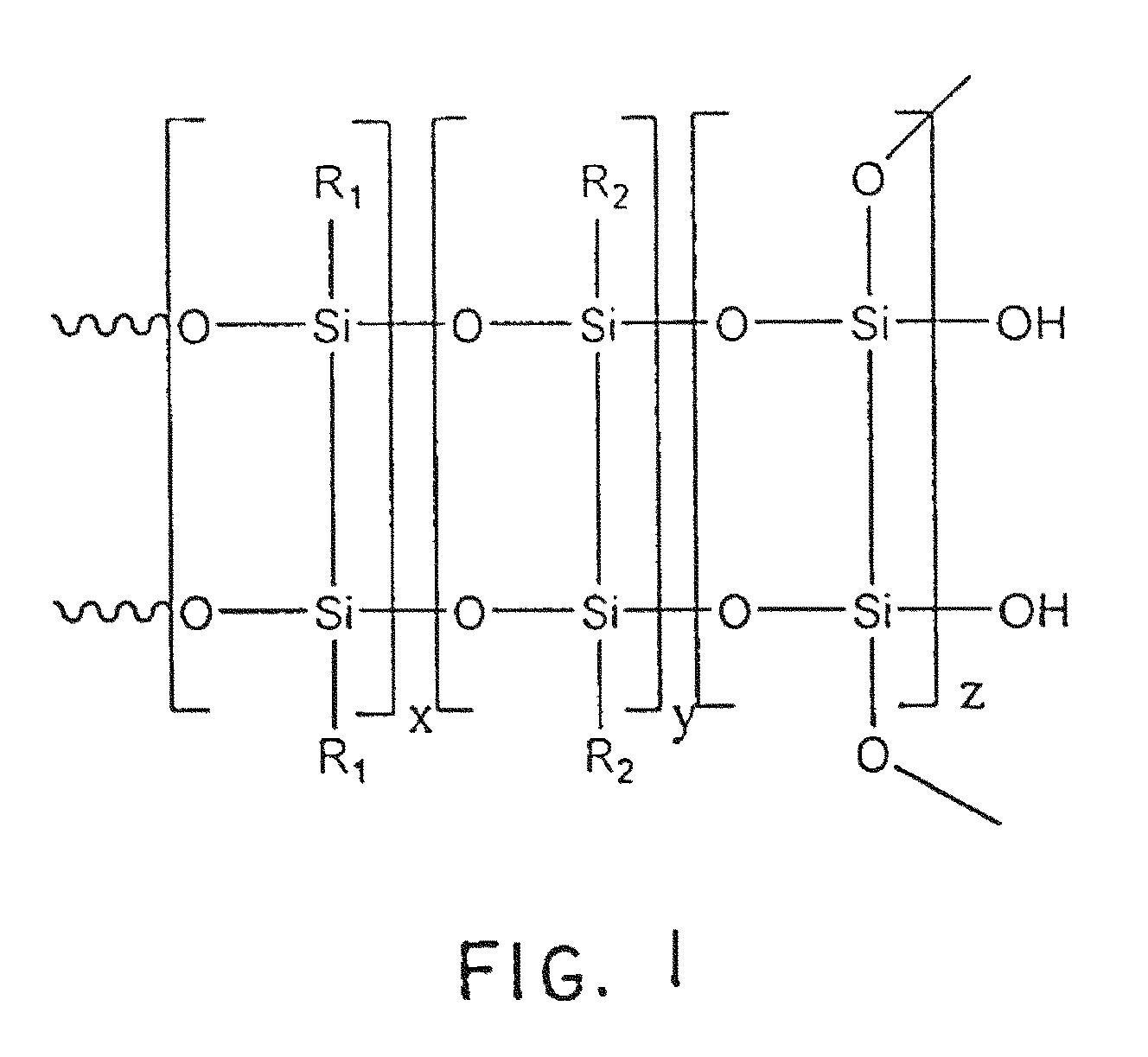

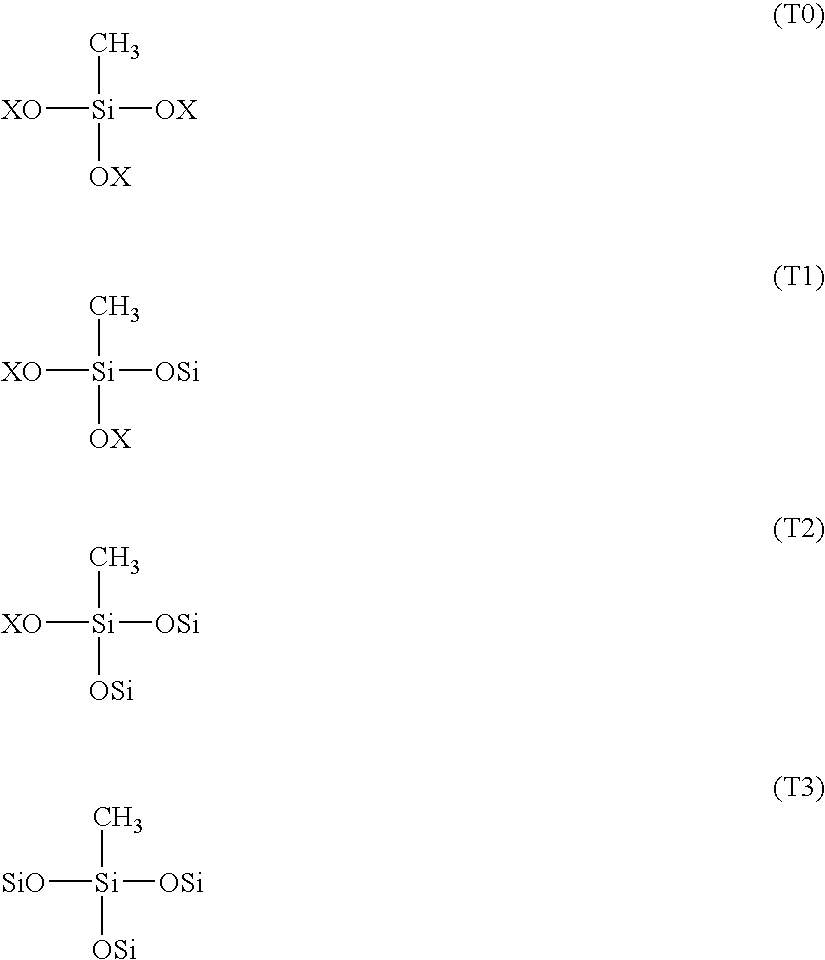

Hardcoat compositions and hardcoated articles

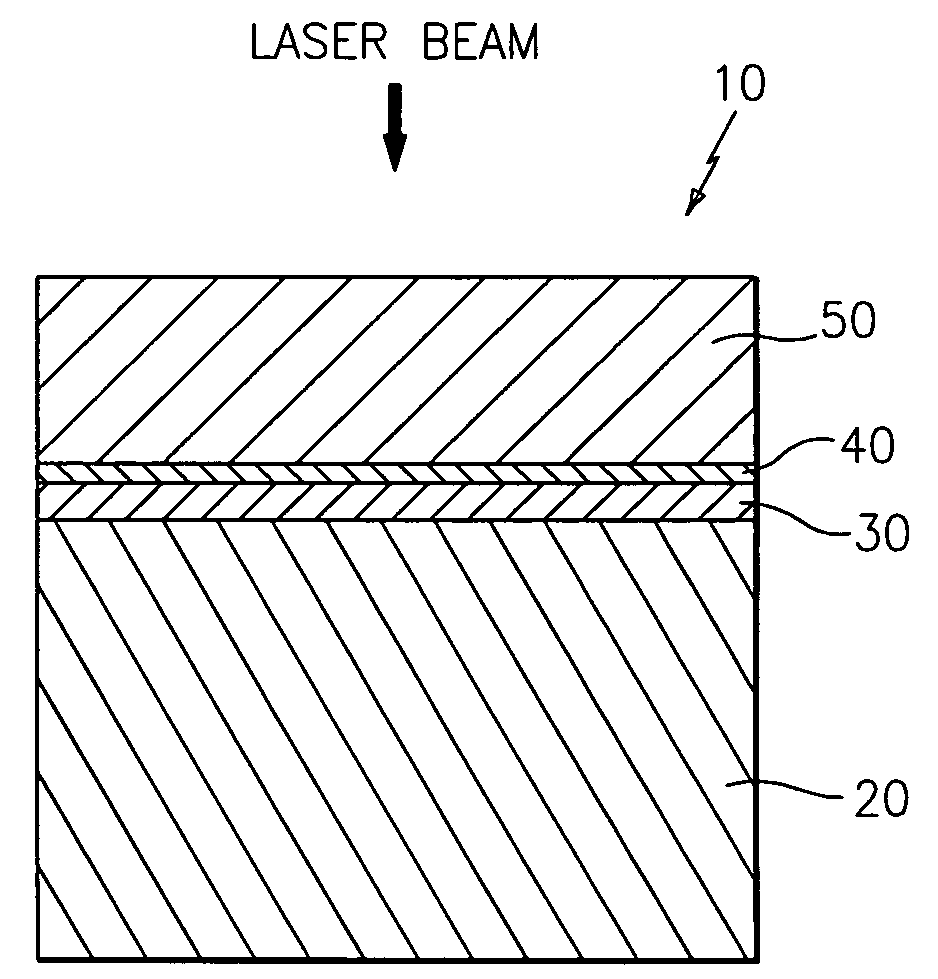

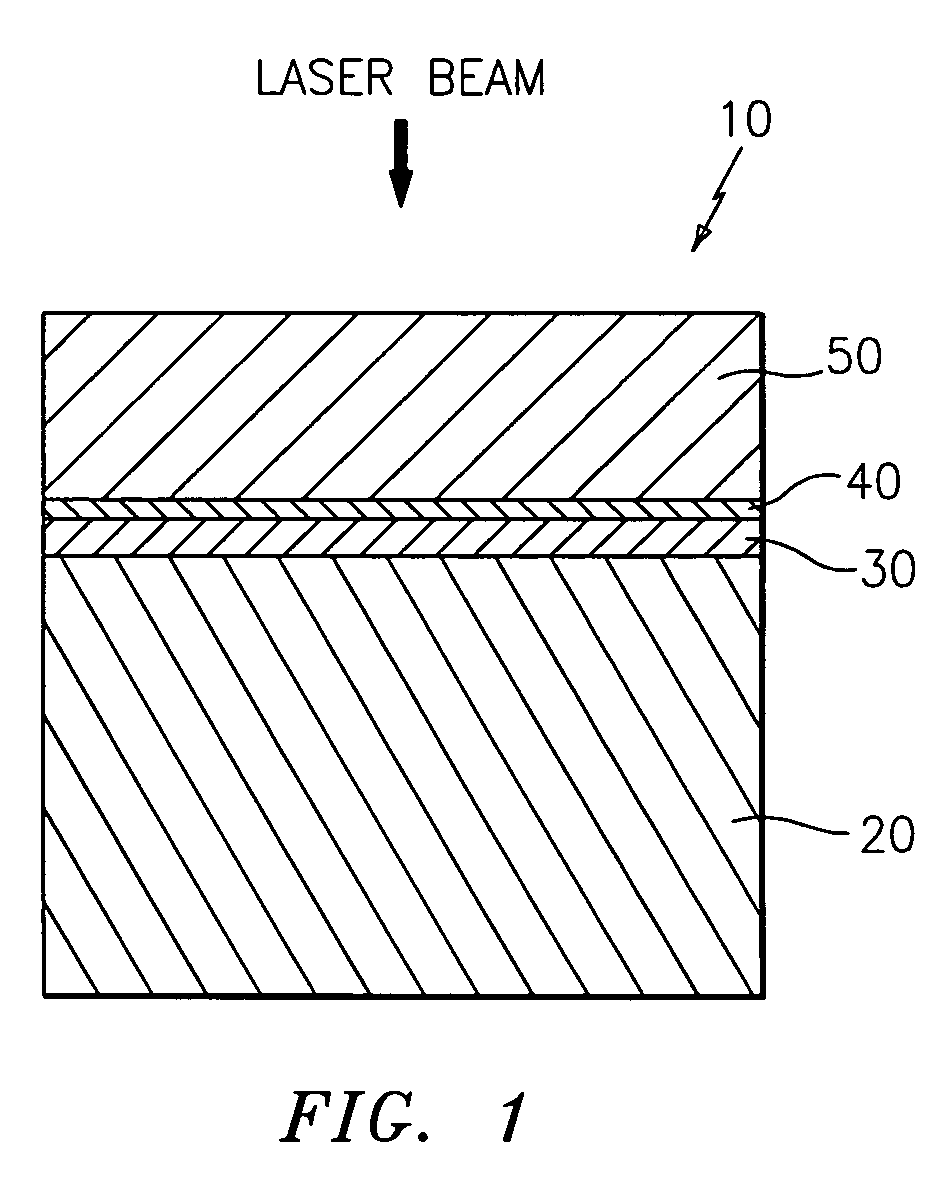

ActiveUS7052770B2Satisfactory hardnessSatisfactory transparencySynthetic resin layered productsCoatingsHardnessSilicon

A hardcoat composition comprising (A) a hydrolytic condensate of a hydrolyzable silicon compound of formula: R1aSiX(4-a) with at least 1 mole of water per mole of hydrolyzable group X, (B) a metal oxide, (C) a siloxane resin of formula: R2bSi(OR3)c(OH)dO(4-b-c-d) / 2 and having a Mw of at least 2,000, which is solid at a temperature of not higher than 40° C., and (D) a curing catalyst forms a hardcoat film having satisfactory hardness, transparency and adhesion as well as improved weather resistance and presenting a surface that is repellent to marker ink.

Owner:SHIN ETSU CHEM IND CO LTD

Method of manufacturing antimicrobial coating

InactiveUS20100034900A1Easy to controlLimited amountBiocideInorganic active ingredientsCoated surfaceMaterials science

A method of coating a substrate with the biocide particles dispersed into a coating permitting the antimicrobial particles to be positioned on the substrate such that they are in contact with the environment is provided. In the method, one or more biocides agents are dispersed into a coating. The coating with the biocide agent is applied to a substrate at a thickness such that at least some of the individual biocide particles extend beyond the surface of the coating.

Owner:MADICO INC

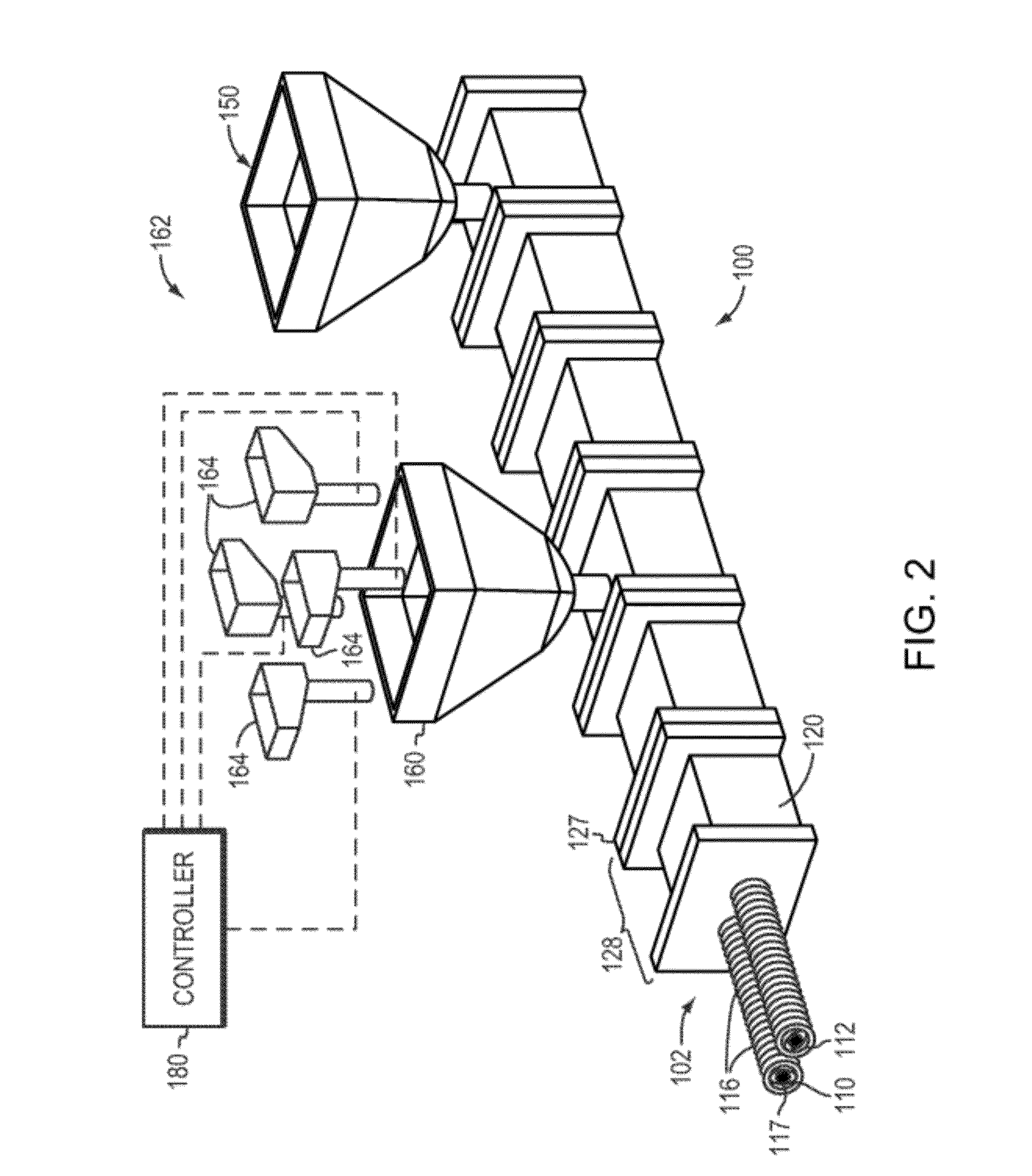

Composites Utilizing Polymeric Capstocks and Methods of Manufacture

InactiveUS20120315471A1Improve skid resistanceIncrease coefficient of frictionSynthetic resin layered productsCellulosic plastic layered productsElastomerFilling materials

An extruded composite adapted for use as a building material includes a core having a base polymer and a filler material in a substantially homogeneous mixture and a polymeric capstock modified with an elastomer and / or a plastomer. To improve adherence of the polymeric capstock to the base polymer, the capstock can include a capstock polymer that is similar or substantially similar the base polymer. Additionally, various additives may be mixed with the capstock material to improve visual aesthetics of the product and performance of the building material, especially over time.

Owner:MANCOSH DOUGLAS +1

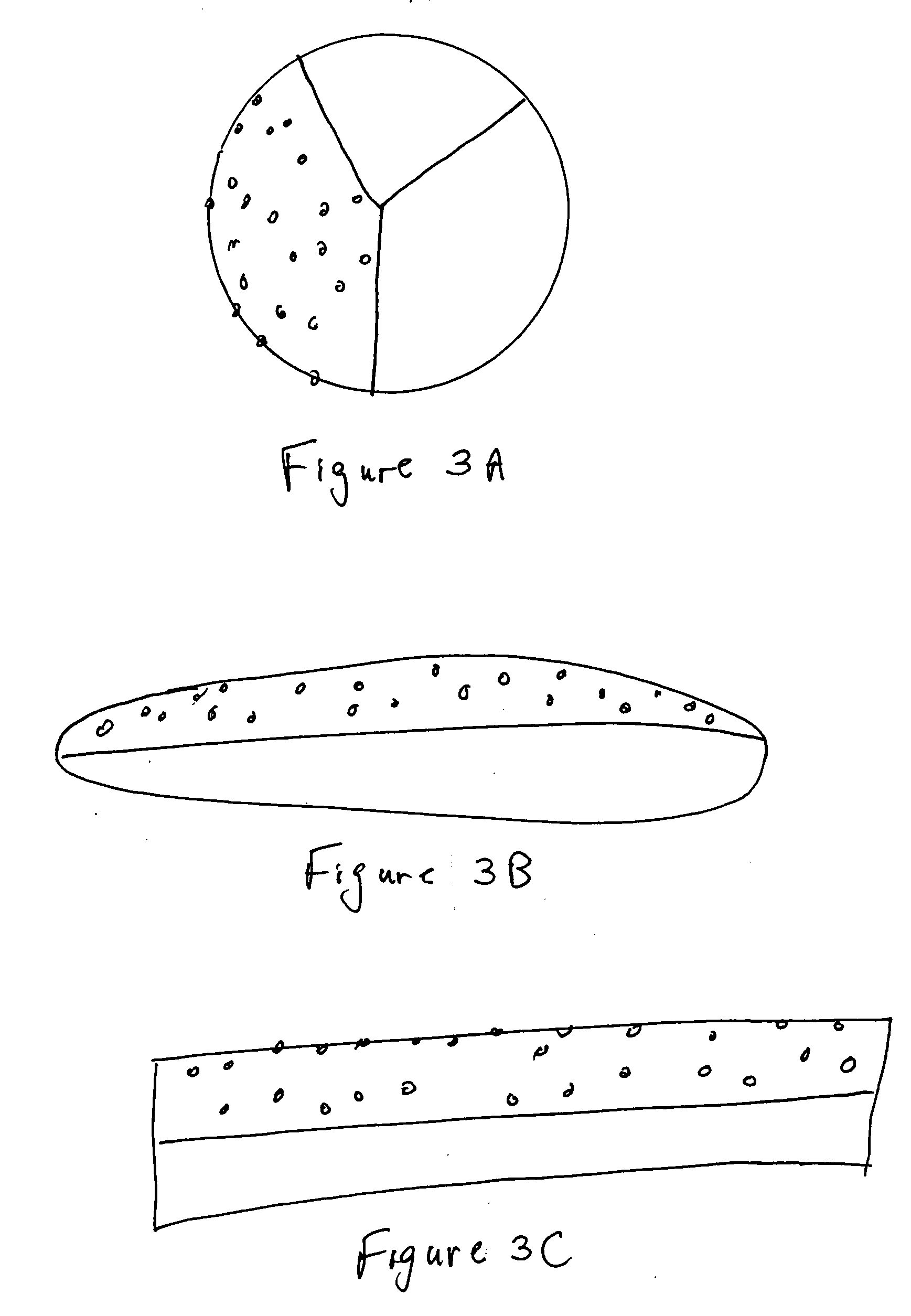

Synthetic fibers modified with PTFE to improve performance

InactiveUS20050100733A1Improve hydrophilicityImprove stain resistanceConjugated synthetic polymer artificial filamentsYarnPolyesterUV degradation

Synthetic plastic fibers are enhanced by inclusions therein of micro-polyester particles (4), preferably sized or otherwise optimized to enhance surface (10) characteristics (abrasion resistance, hydrophilicity, coating receptiveness, increase dullness), reduce UV degradation. The synthetic plastic matrix is preferably polyester but can be any synthetic plastic. The invention is preferentially implemented in multi-component fibers (e.g. core (6)-sheath (8) bi-component fibers (3)) with the inclusions entirely or primarily in one or some, but not all such components. The PTFE inclusions, sizing, concentration, morphology can be adjusted to optimize their enhancing effects, reduce costs and enhance throughput of fiber production. Co-inclusions can be made with the PTFE including anti-microbial and / or coloring agents and with synergistic effects.

Owner:FOSS MFG CO LLC

Electrical wire marker

InactiveUS7320553B1Abrasion resistanceResist damageBrushesInk reservoir pensElectrical conductorElectric wire

Owner:NUNEZ EFREM

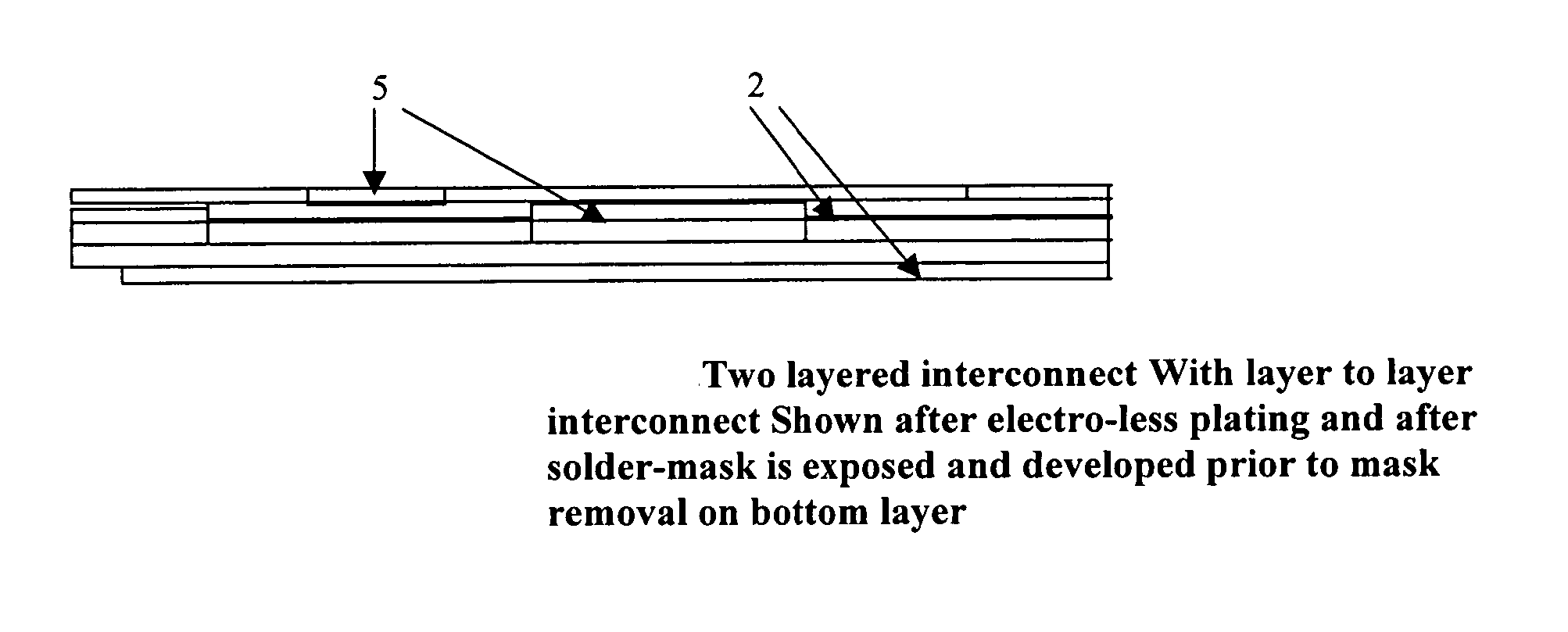

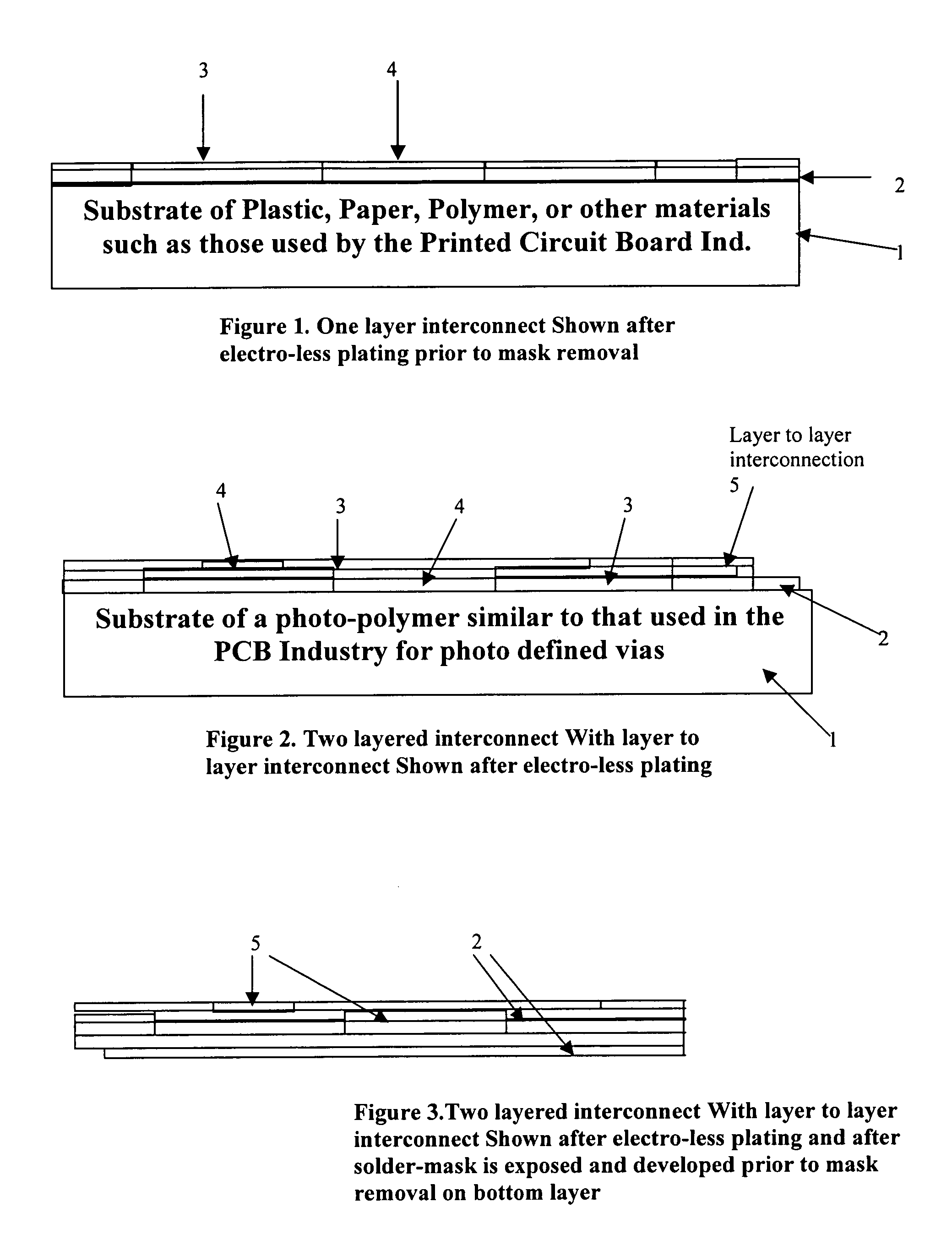

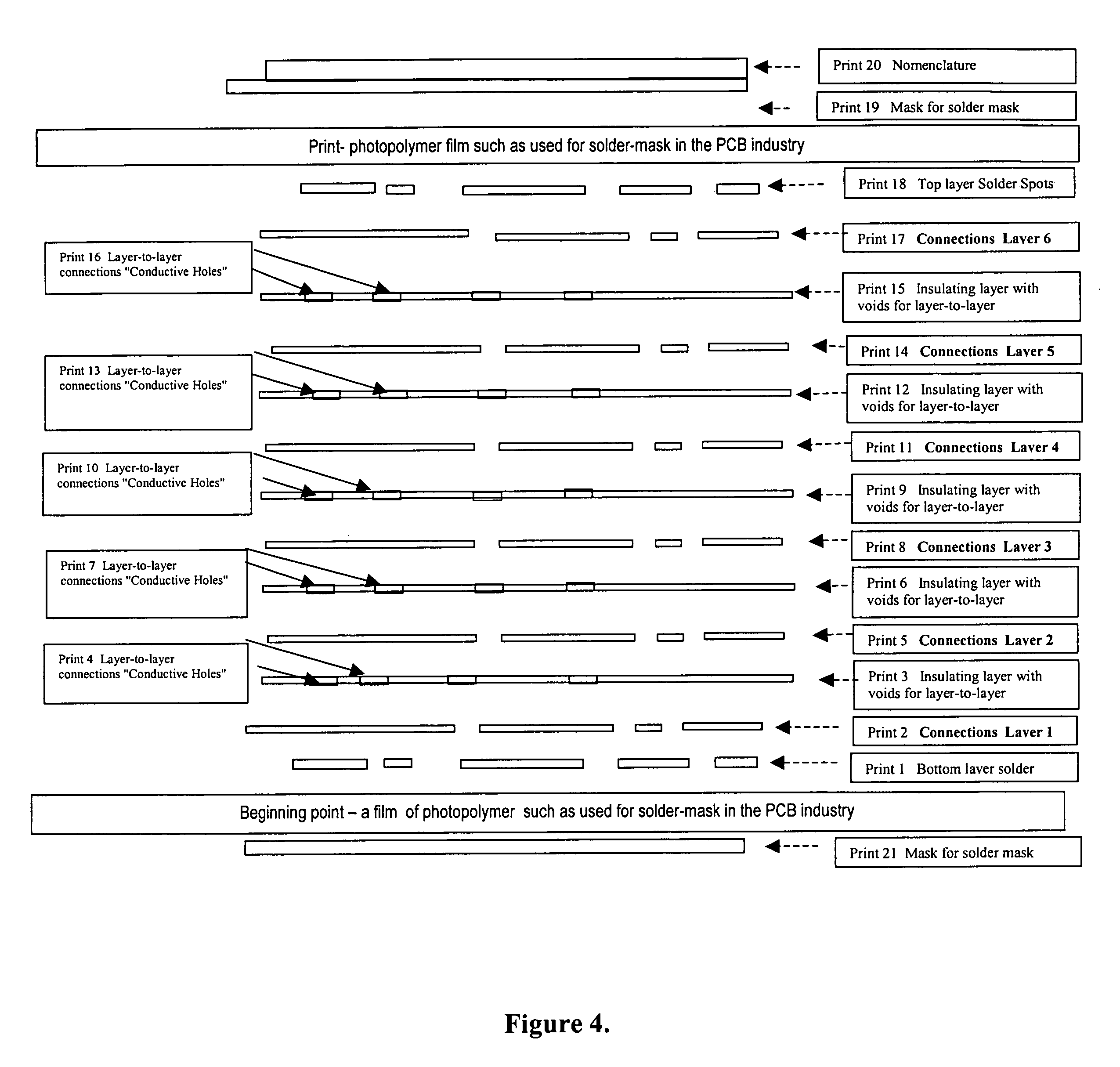

Process for fabrication of printed circuit boards

InactiveUS20050227049A1Less expensiveReduce chemical processingDecorative surface effectsDuplicating/marking methodsPolymer scienceConductive polymer

A method of making a printed circuit board by coating a surface of a substrate with an electrically conductive polymer and curing or setting the polymer on the substrate. The polymer coating is laced with a catalytic reducing agent.

Owner:BOYACK JAMES R +2

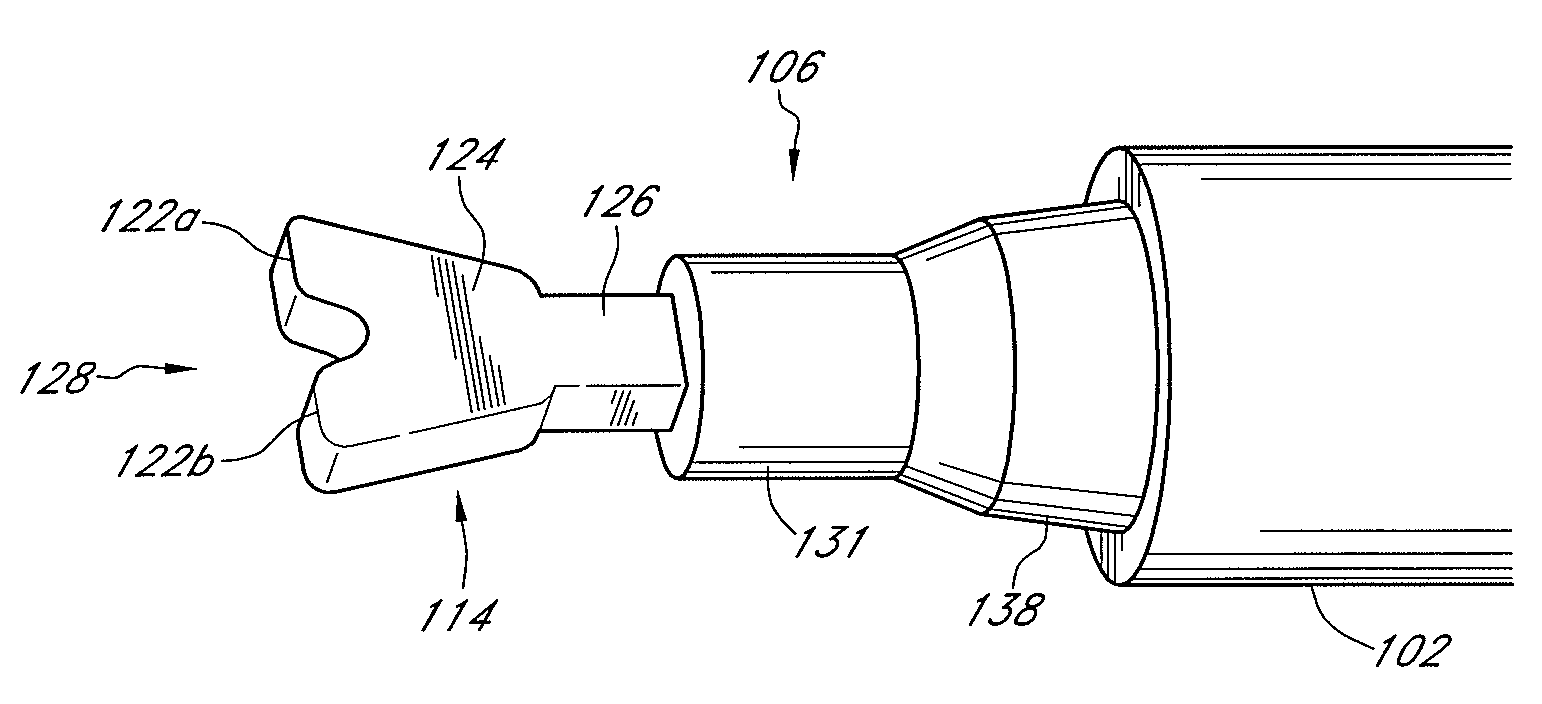

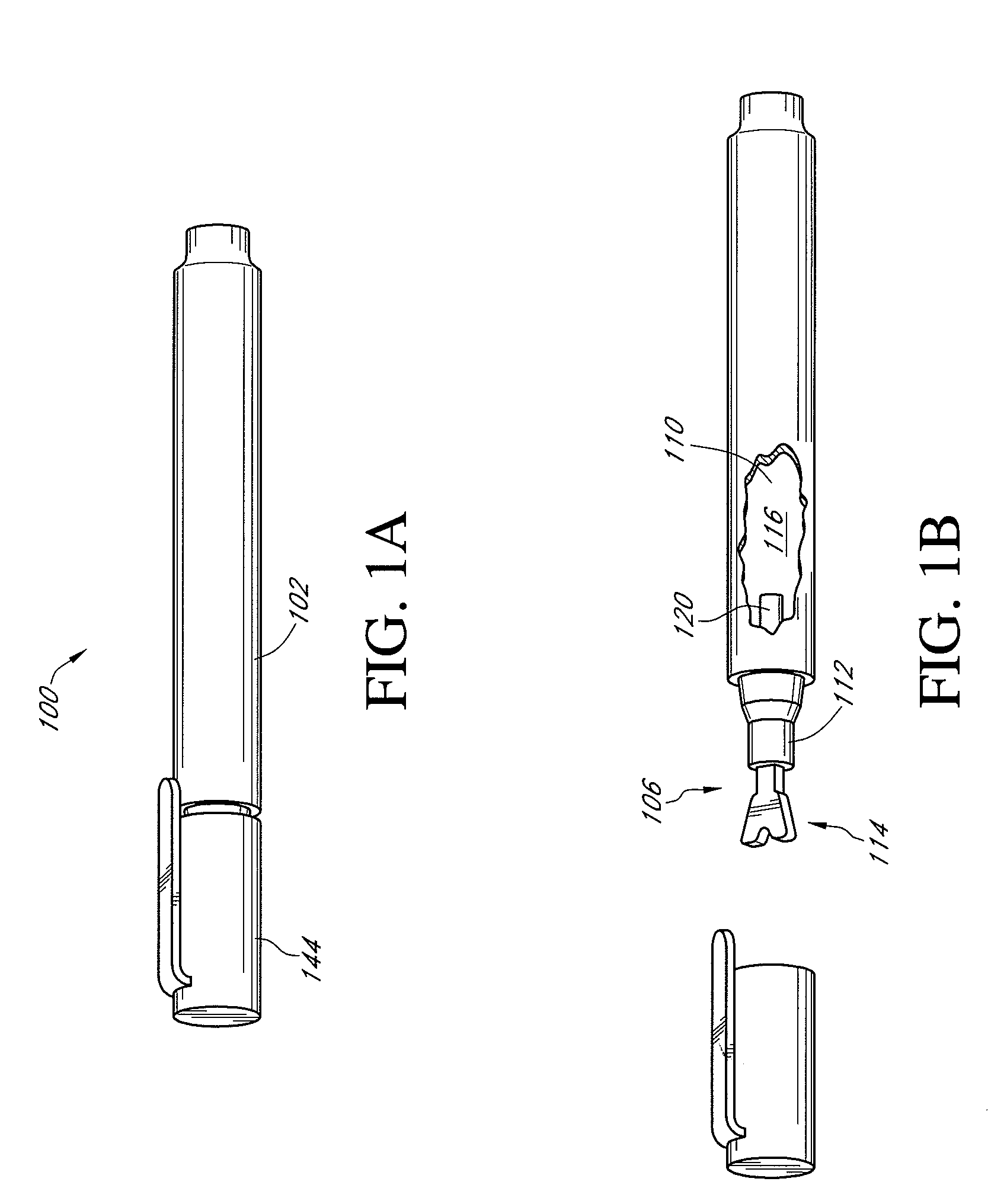

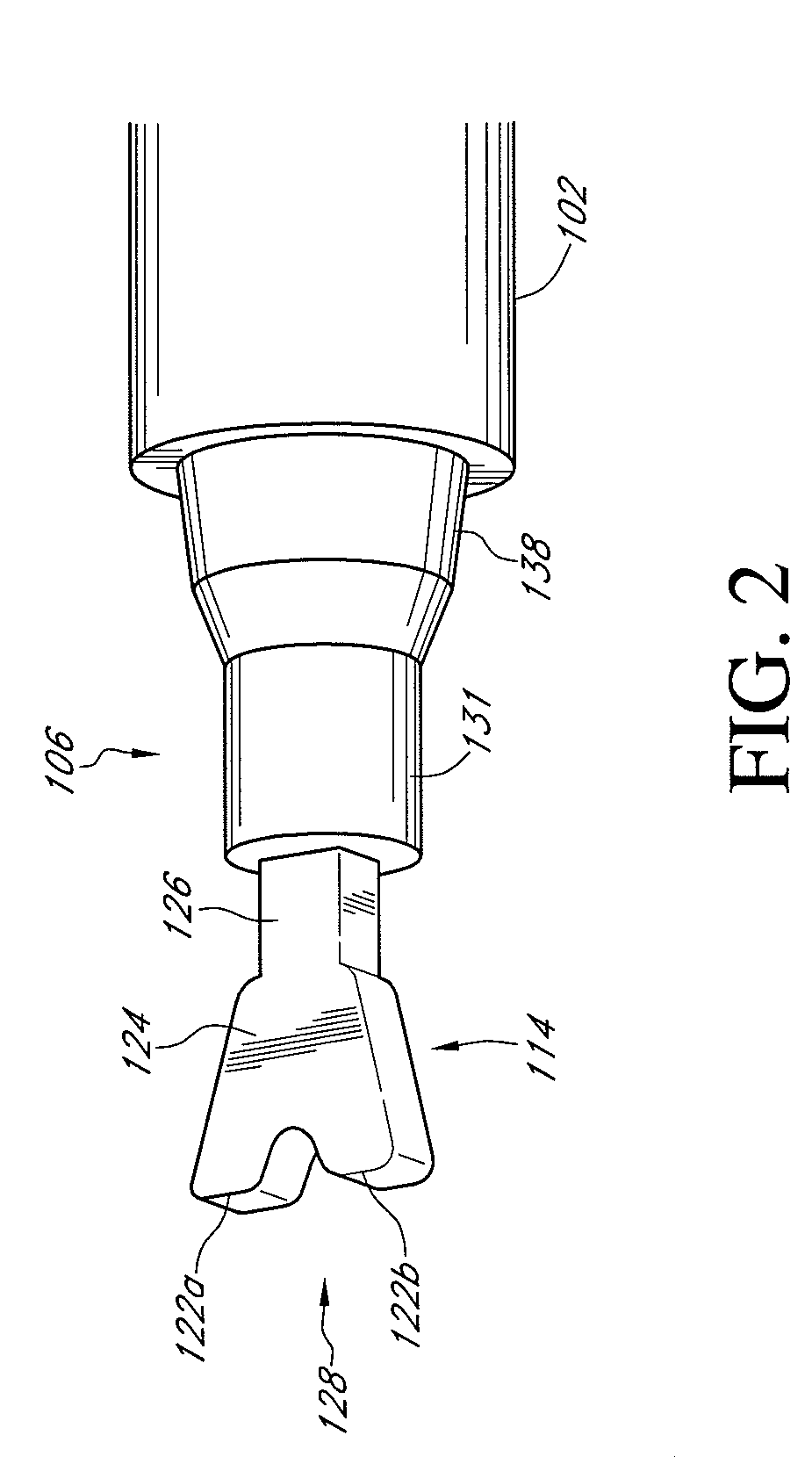

Inflatable device for use in surgical protocol relating to fixation of bone

InactiveUS20070299455A1Easy to compressEasy to foldInternal osteosythesisSurgical furnitureBone CortexTrabecular bone

A balloon for use in compressing cancellous bone and marrow (also known as medullary bone or trabecular bone). The balloon comprises an inflatable balloon body for insertion into said bone. The body has a shape and size to compress at least a portion of the cancellous bone to form a cavity in the cancellous bone and / or to restore the original position of the outer cortical bone, if fractured or collapsed. The balloon desirably incorporates restraints which inhibit the balloon from applying excessive pressure to various regions of the cortical bone. The wall or walls of the balloon are such that proper inflation of the balloon body is achieved to provide for optimum compression of the bone marrow. The balloon can be inserted quickly into a bone. The balloon can be made to have a suction catheter. The balloon can be used to form and / or enlarge a cavity or passage in a bone, especially in, but not limited to, vertebral bodies. Various additional embodiments facilitate directionally biasing the inflation of the balloon.

Owner:ORTHOPHOENIX

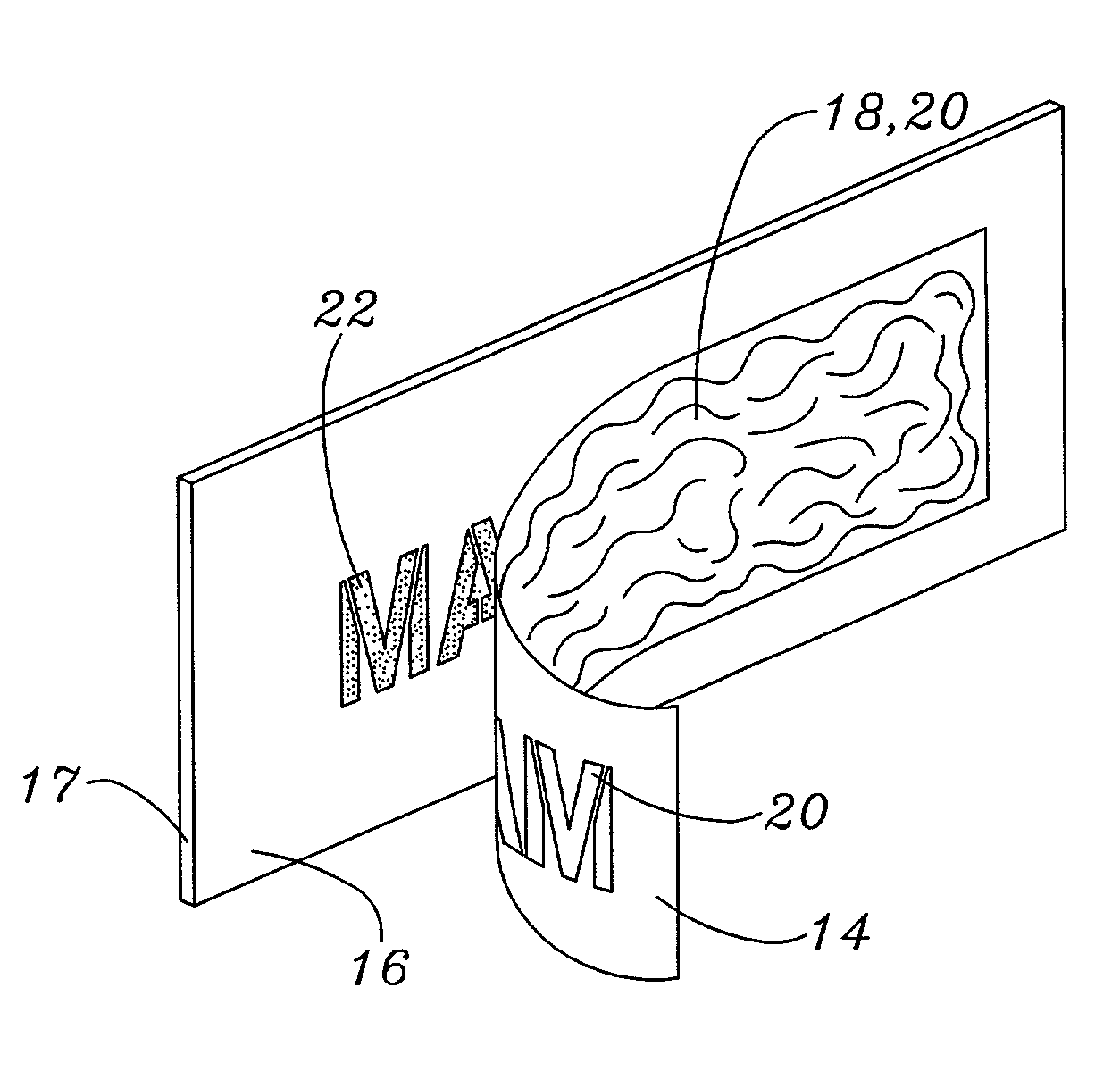

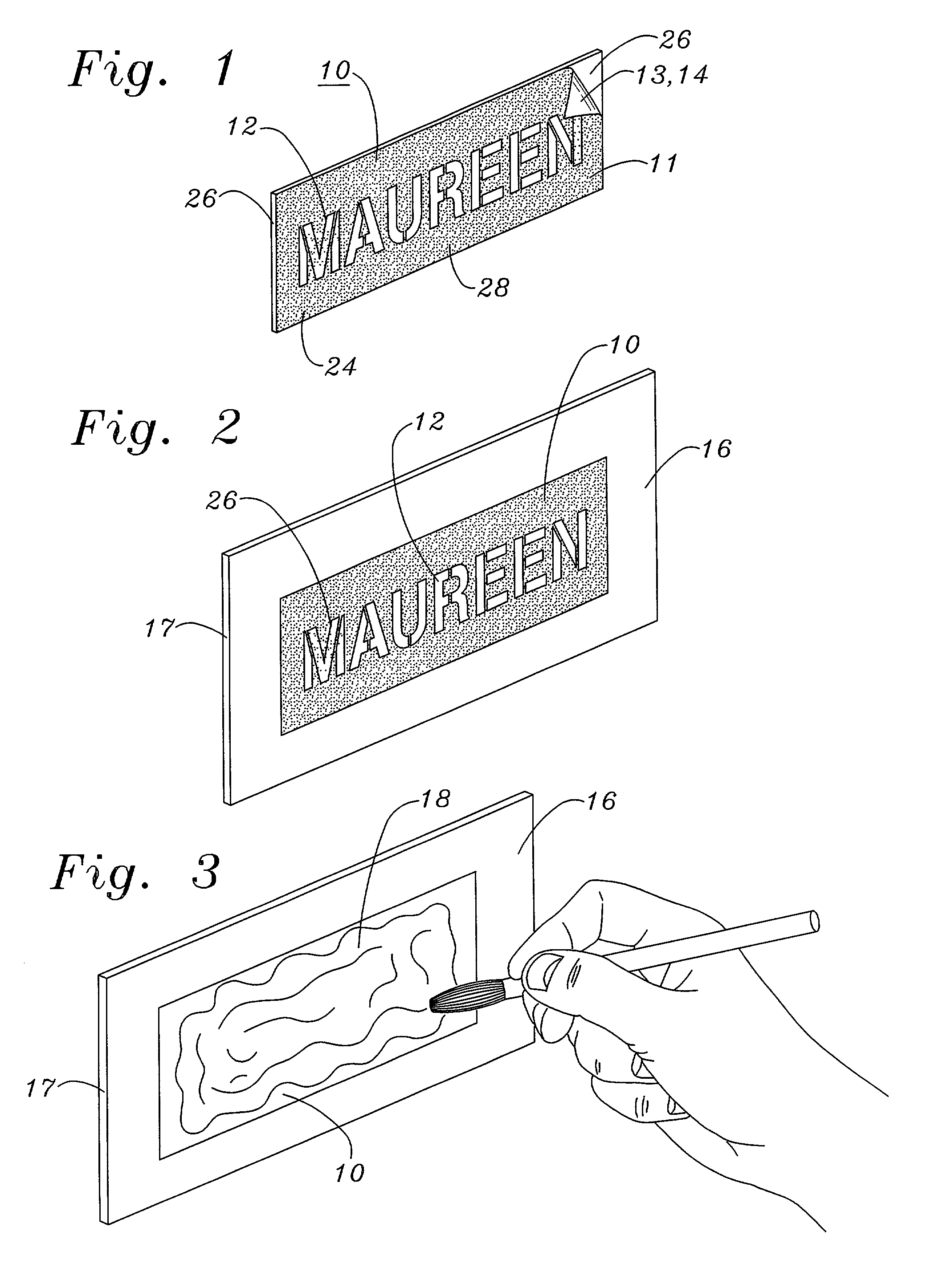

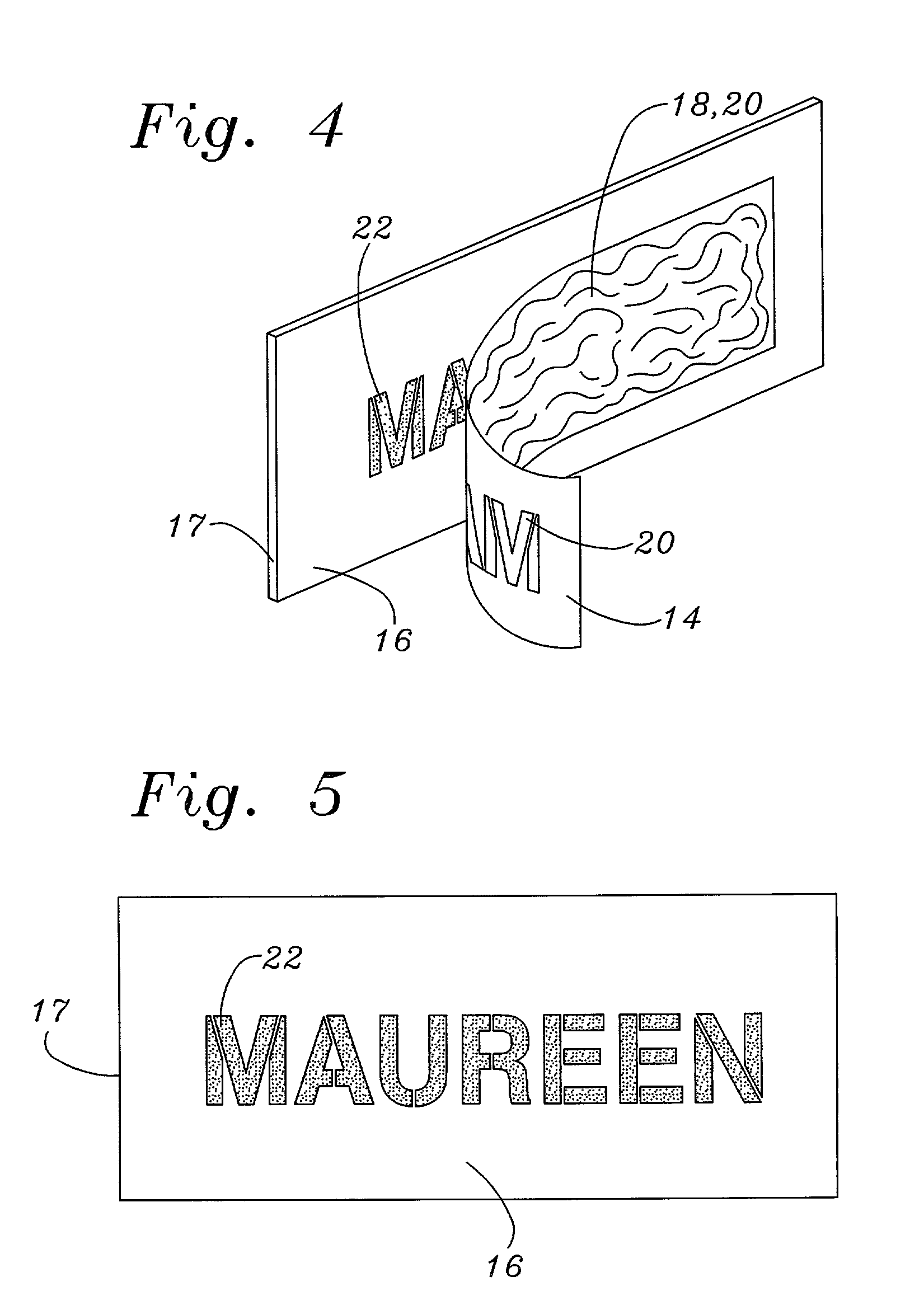

Peelable stenciling ink and method of using

A peelable stenciling ink for imprinting indicia such as letters, numbers and symbols on a surface of an article such as a sport ball made of leather or a synthetic polymer, e.g., a thermoplastic material, consists of a solvent, a dye dispersed in the solvent, and a film-forming polymer soluble in the dye-solvent solution to form a thick paste and hardenable into a solid, flexible film upon evaporation of the solvent from a thin layer of ink applied to an article surface. A method of using the ink comprises the steps of temporarily adhering a stencil sheet in fluid-tight contact to an article surface by a pressure-sensitive adhesive layer, smearing a layer of the ink on the obverse surface area of the stencil sheet through indicia-shaped openings through the sheet onto the article surface, allowing sufficient time for dye in the ink to penetrate the article surface, and for the solvent to evaporate and cause the film-forming substance to harden into a solid film peelable from the article surface, and peeling the stencil sheet and solid film together from the article surface, thereby leaving indicia markings imprinted on and dye-penetrated beneath the article surface, thus making the markings resistant to obliteration by scuffing or abrasion.

Owner:WYNNE JOHN H

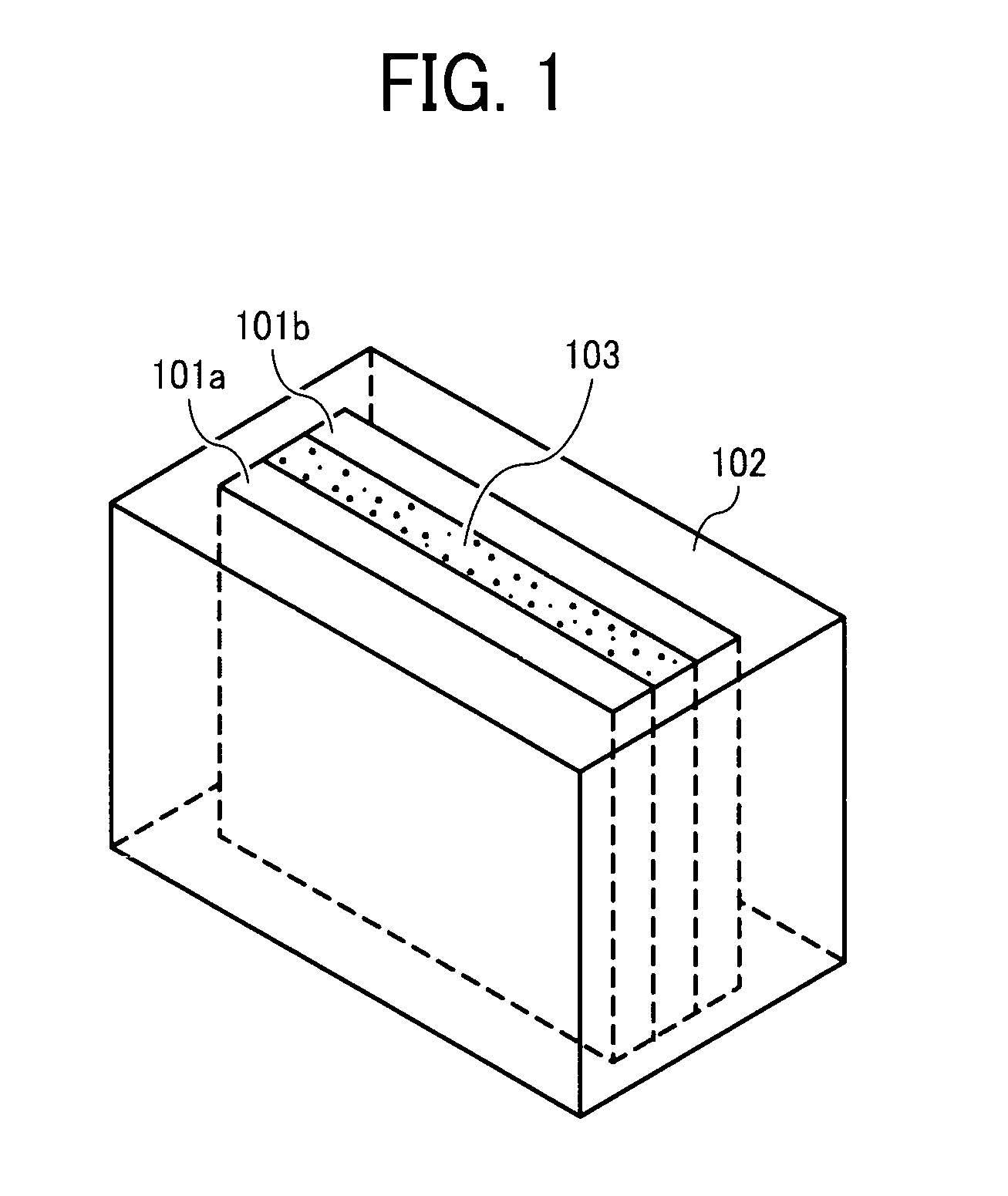

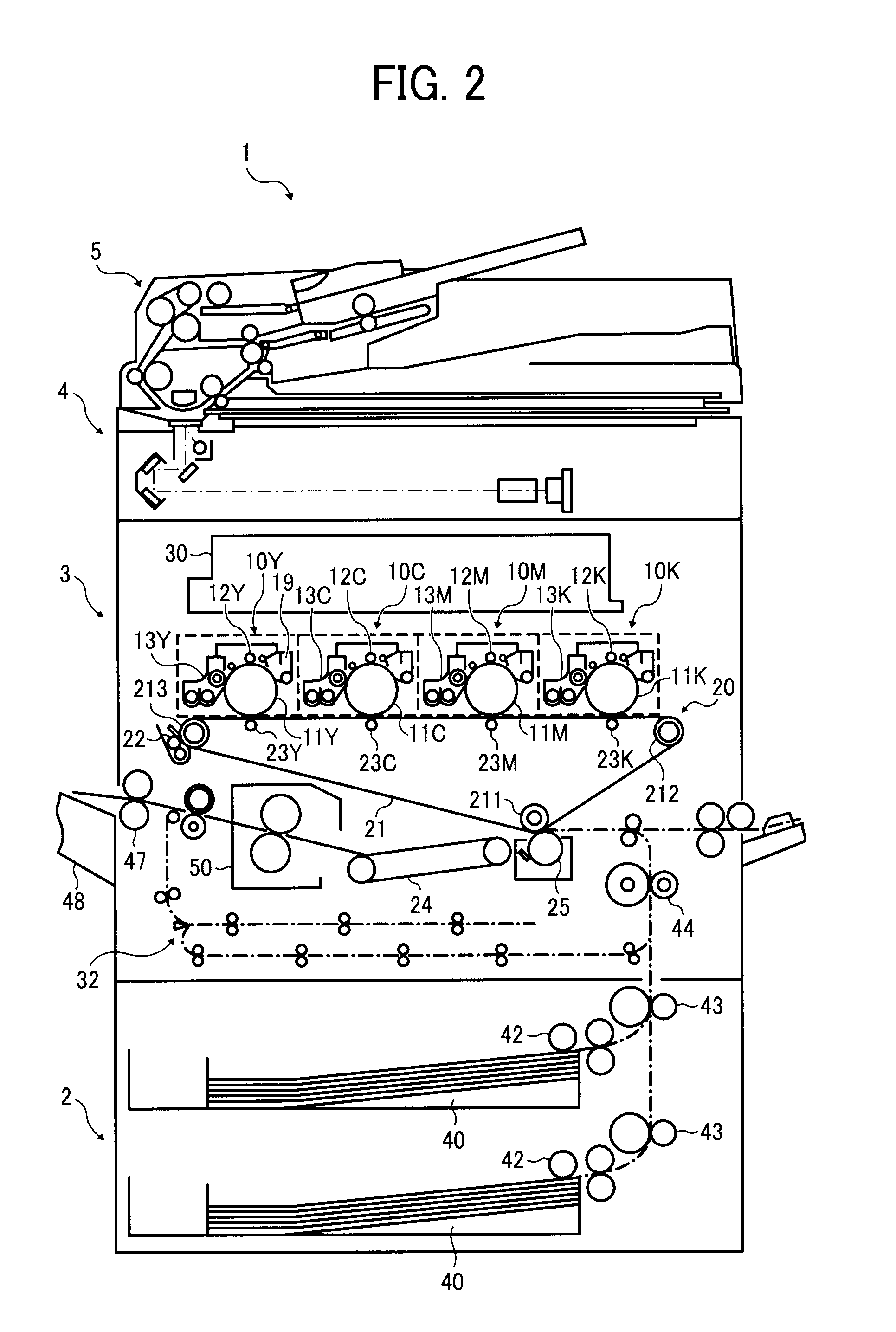

Carrier, developer, method of manufacturing carrier, developer container, image forming method, process cartridge, image forming apparatus, and supplemental developer

ActiveUS20120057898A1Abrasion resistanceResistant to adherenceElectrographic process apparatusDevelopersFluorescencePhysical chemistry

A carrier including a magnetic core particle and a resin layer covering a surface of the magnetic core particle. The magnetic core particle is a ferrite particle including strontium in an amount of 0.005 to 3% by mass, measured by fluorescent X-ray spectroscopy. The resin layer comprises a resin obtained by heating a copolymer comprising a silicon-containing unit A and another silicon-containing specific unit B.

Owner:RICOH KK

Substrate possessing a transparent protective layer derived from a radiation-curable acrylate composition

InactiveUS20080020170A1Increase elasticityLow modulusSynthetic resin layered productsCoatingsPhotoinitiatorChemistry

A substate possesses a transparent protective layer derived from a radiation-curable acrylate composition which comprises:a) at least one urethane polyacrylate possessing a number average molecular weight of at least about 400 per acrylate group and having a Tg of not greater than about 40° C.;b) at least one crosslinking polyacrylate having a Tg of at least about 50° C.;c) at least one hydrophobic monoacrylate; and,d) at least one photoinitiator.

Owner:GENERAL ELECTRIC CO +1

Hydroentangled nonwoven material

InactiveUS8389427B2Less sensitive to pillingAbrasion resistanceSynthetic resin layered productsLaminationPolymer scienceNatural fiber

A hydroentangled nonwoven material (8), includes a mixture of randomized continuous filaments (3) and natural fibers (5), wherein at least part of the staple fibers and / or the continuous filaments includes thermoplastic material. The nonwoven material is bonded in a non-random bonding pattern including a plurality of bonding sites (14) in which thermoplastic material included in the nonwoven material has been caused to at least partly soften or melt to create thermal bonds between the continuous filaments. The nonwoven material includes no other thermal bonds between the filaments than provided by the non-random bonding pattern. The nonwoven material may also contain synthetic staple fibers (6).

Owner:SCA HYGIENE PROD AB

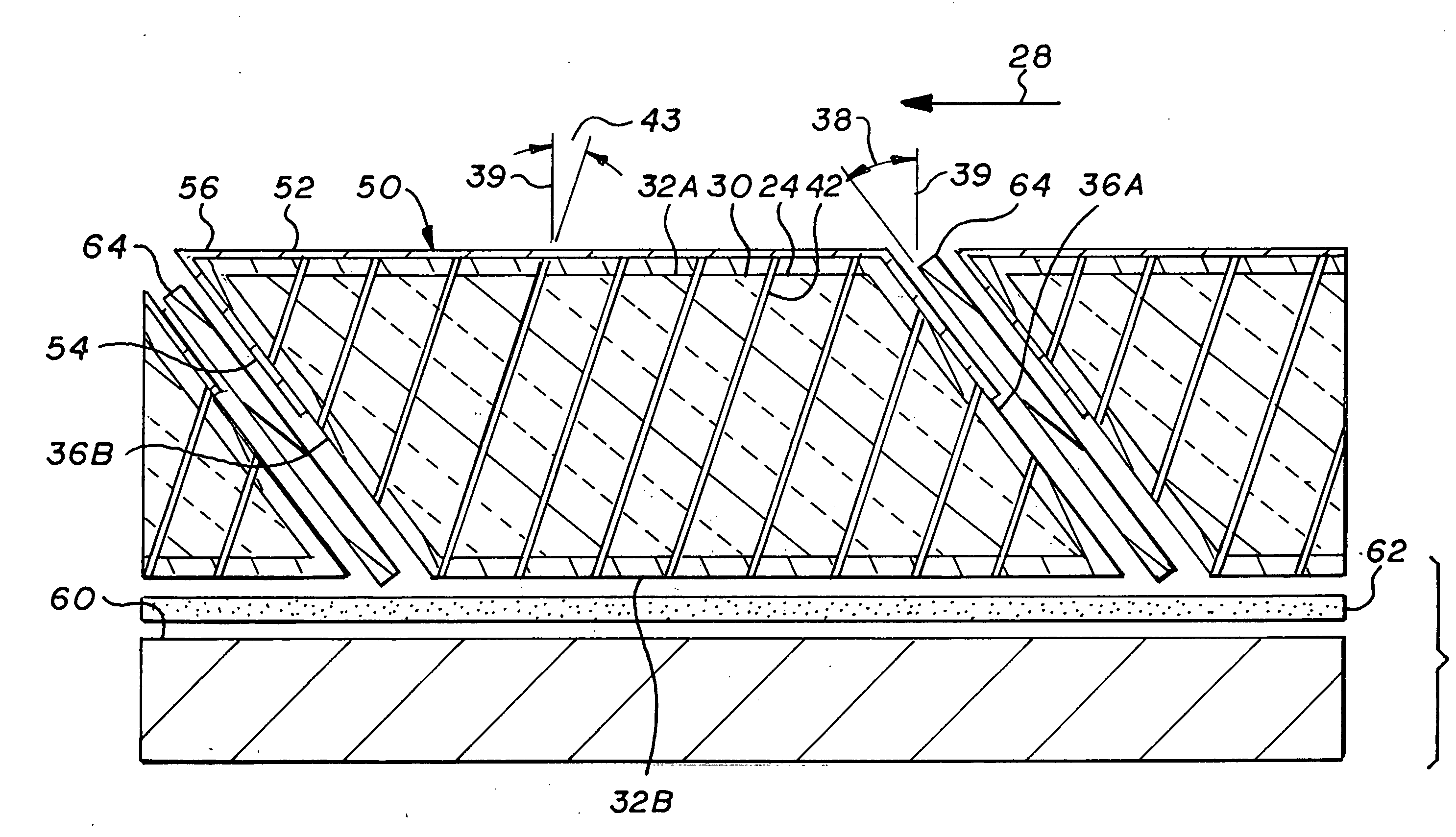

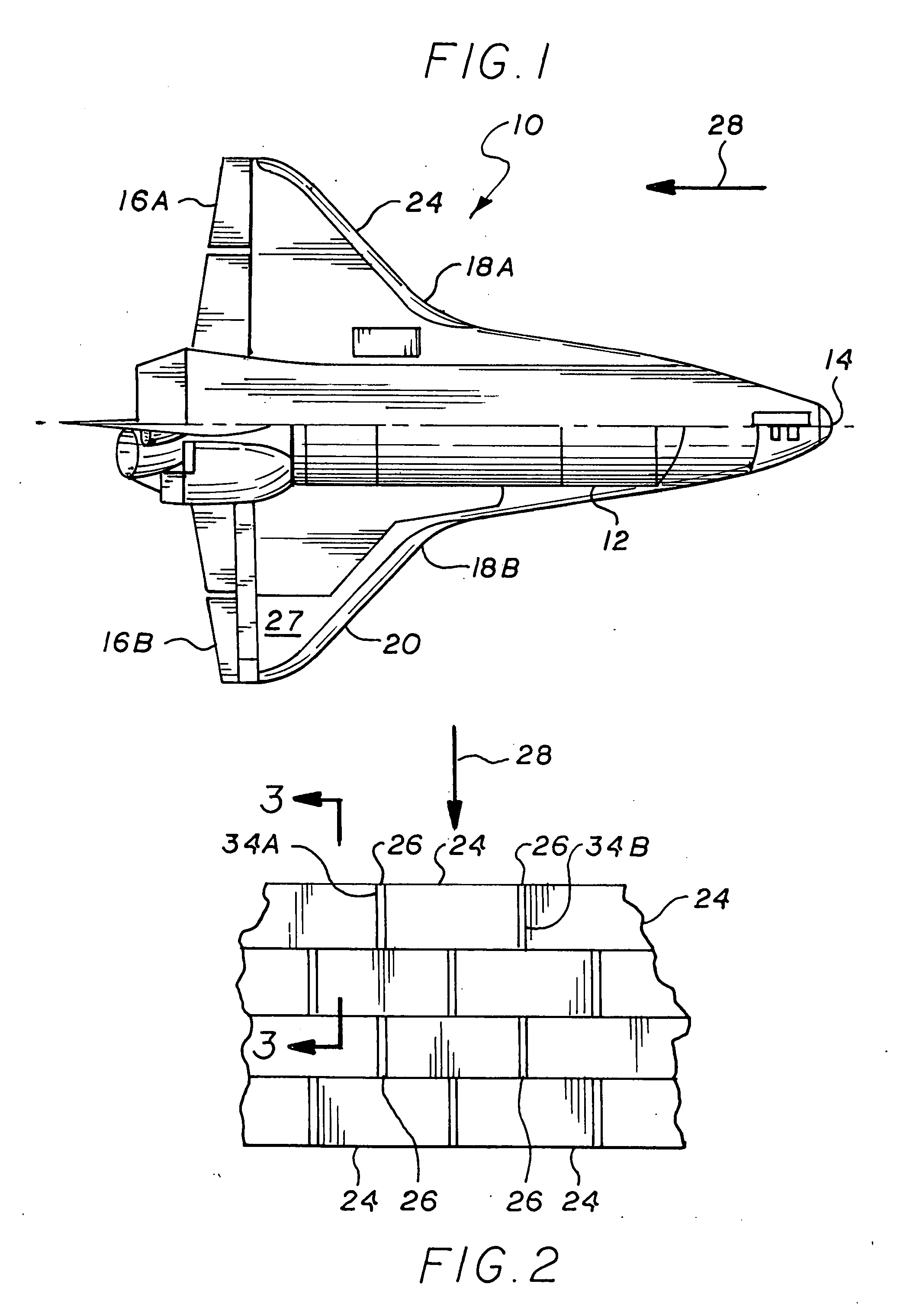

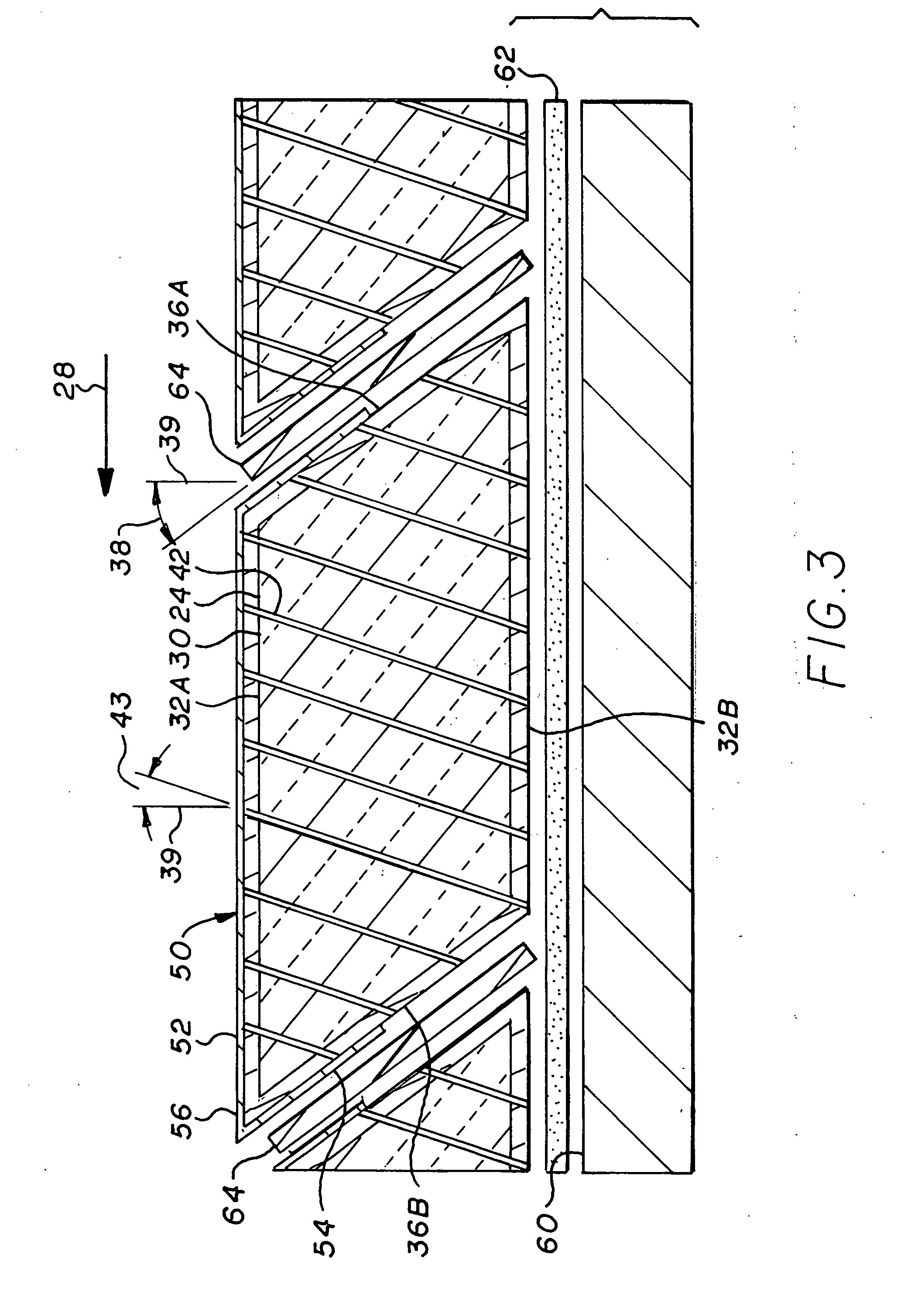

Thermal protection system for a vehicle

ActiveUS20070292654A1Light weightHigh strengthLayered productsCosmonautic thermal protectionBrickThermal insulation

The invention is a thermal insulation tile for providing thermal protection of the external surface of a vehicle. In detail, the tile includes a rigid ceramic core having top and bottom surfaces, side surfaces and parallel front and rear surfaces at a 15 to 45 degree angle to said top surface. A cover completely surrounds the core and is bonded thereto. A plurality of rigid rods extends through the core and the cover and are bonded thereto. The rods are at an angle of between 10 and 30 degrees to the top surface of the core, with the angle thereof in an angular direction opposite to the front and rear surfaces of the core.

Owner:NORTHROP GRUMMAN SYST CORP

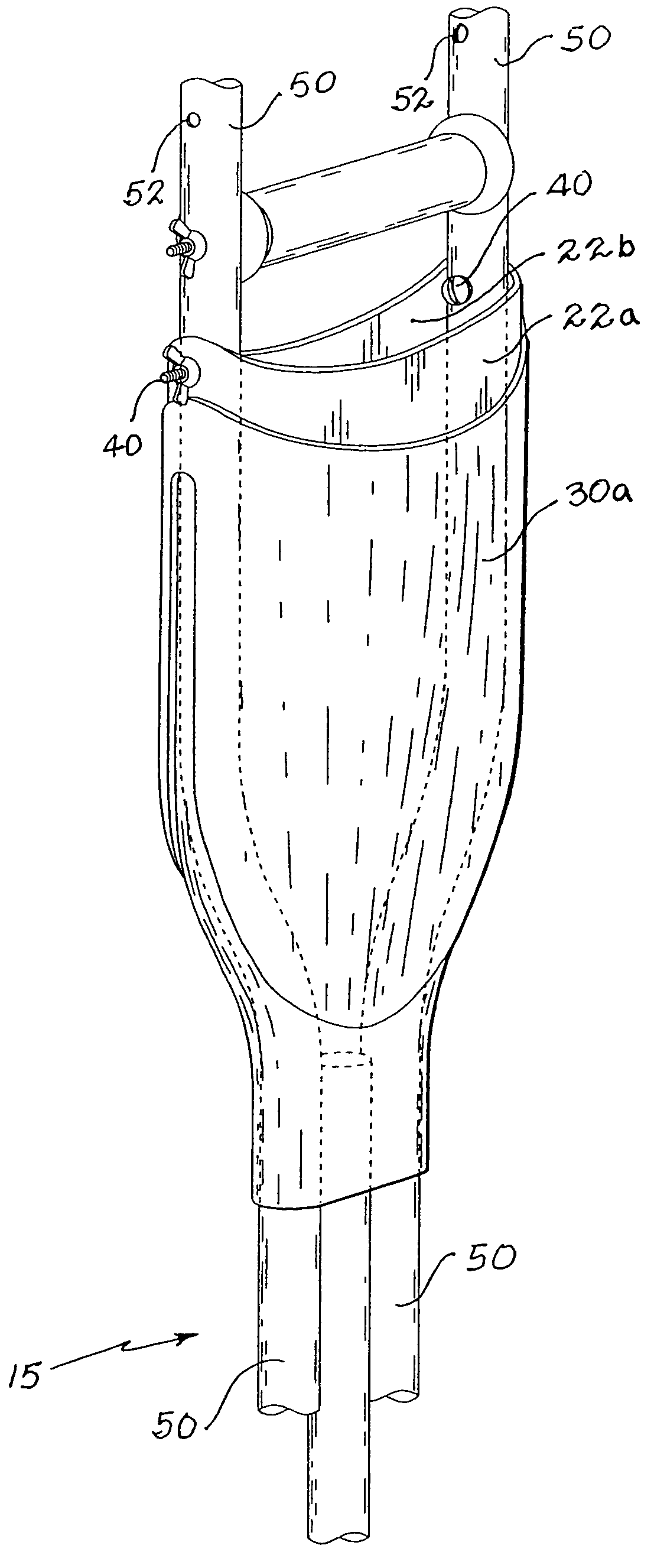

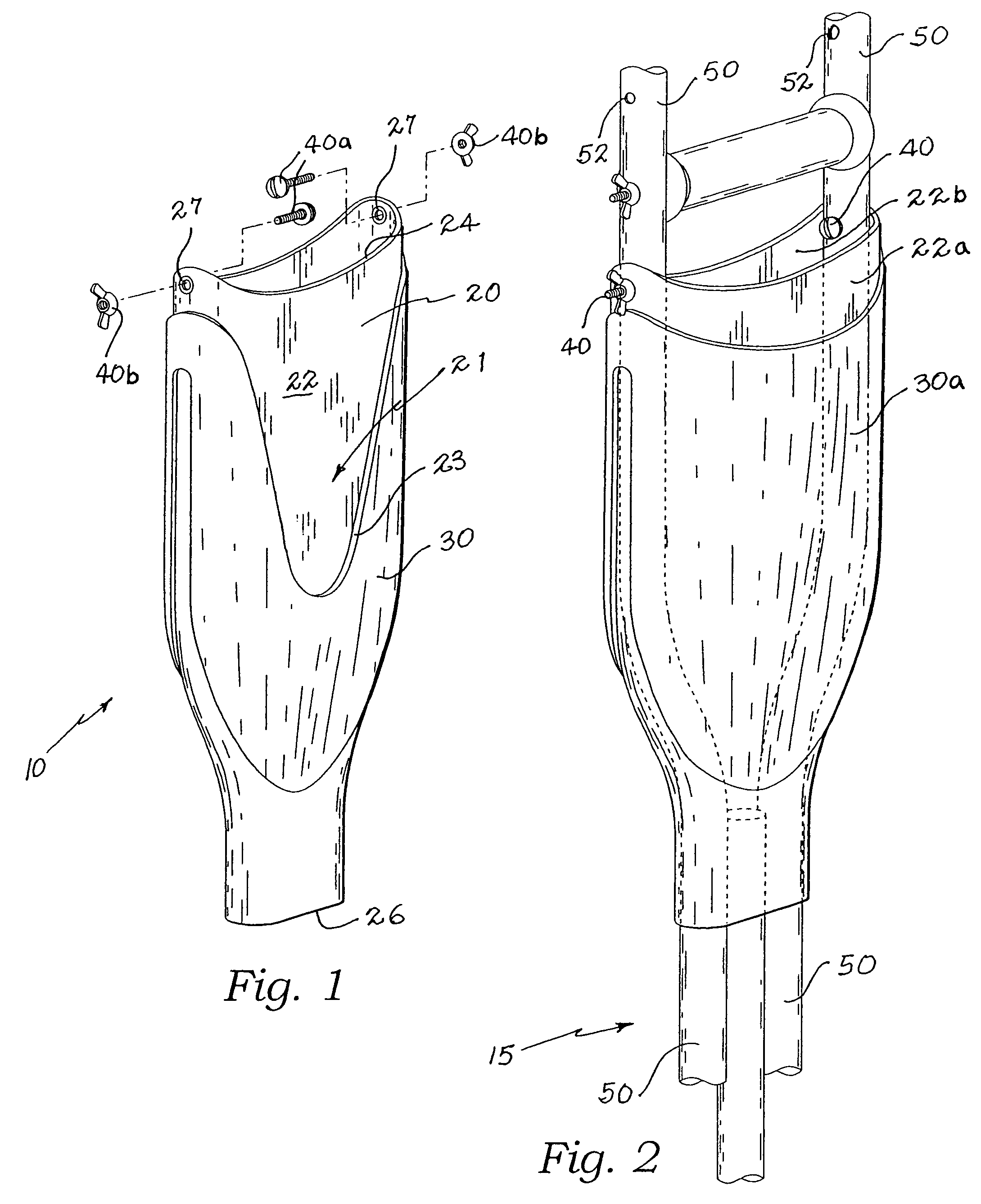

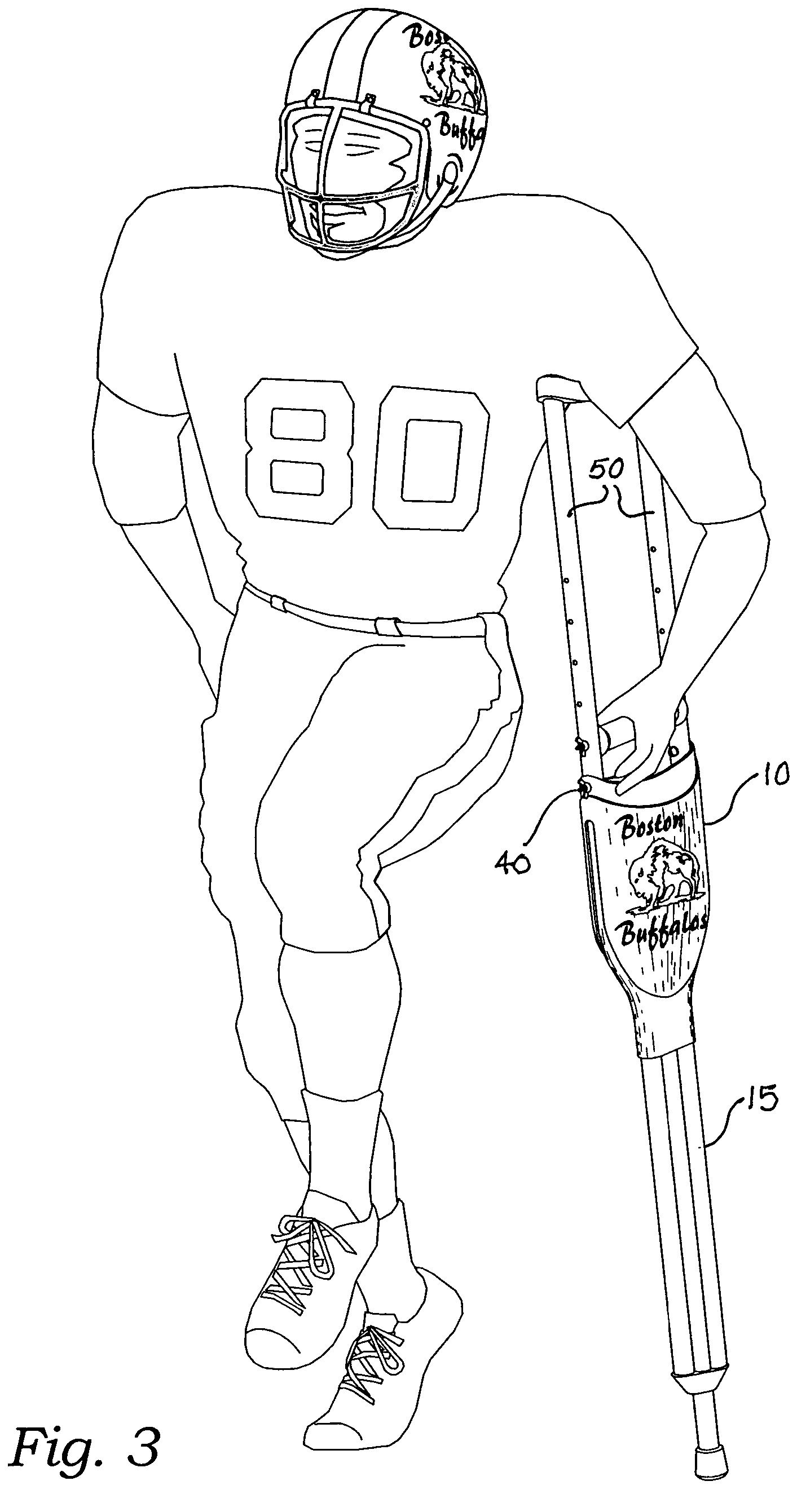

Crutch bag

A crutch has dual spaced apart upright struts, each providing vertically spaced apart fastener receivers. A sleeve of a flexible and elastic material has an open top and bottom rims. A side wall of the sleeve converges downwardly with the open top rim larger than the bottom rim. A pair of opposing outer panels of a flexible and abrasion resistant material are sewn conformingly exterior to the sleeve. At least one of the outer panels provides an open notch adjacent the open top rim so as to better enable the open top rim of the sleeve to be expanded for receiving articles into the apparatus for carrying. A pair of fasteners are fixed in opposing positions adjacent to the open top rim, the fasteners engaged with the fastener receivers of the crutch for holding the carry bag on the crutch.

Owner:FLORIANI DAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com