Patents

Literature

1357 results about "Float glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Float glass is a sheet of glass made by floating molten glass on a bed of molten metal, typically tin, although lead and other various low-melting-point alloys were used in the past. This method gives the sheet uniform thickness and very flat surfaces.

Electrochromic window fabrication methods

ActiveUS20120026573A1Maximize effective useLamination ancillary operationsLaminationEngineeringElectrochromism

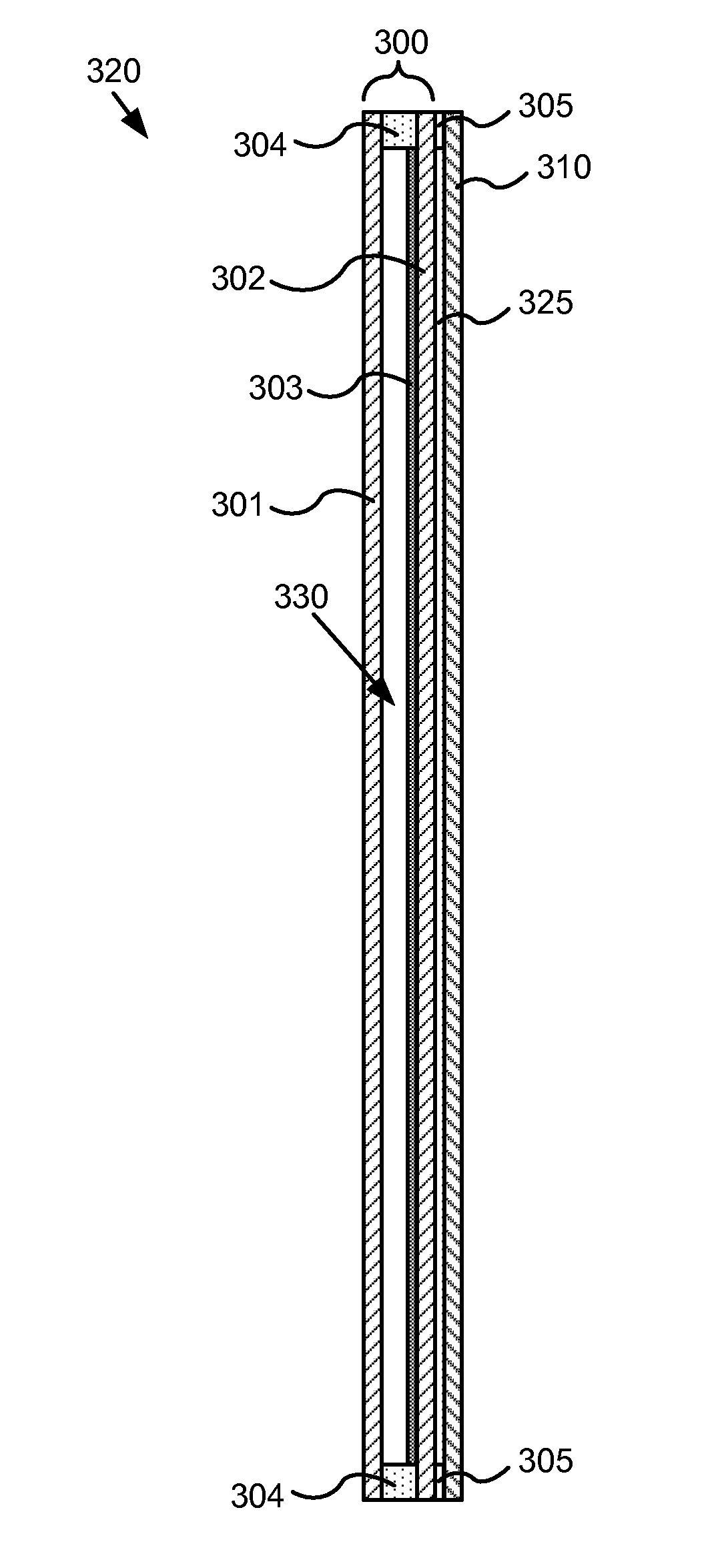

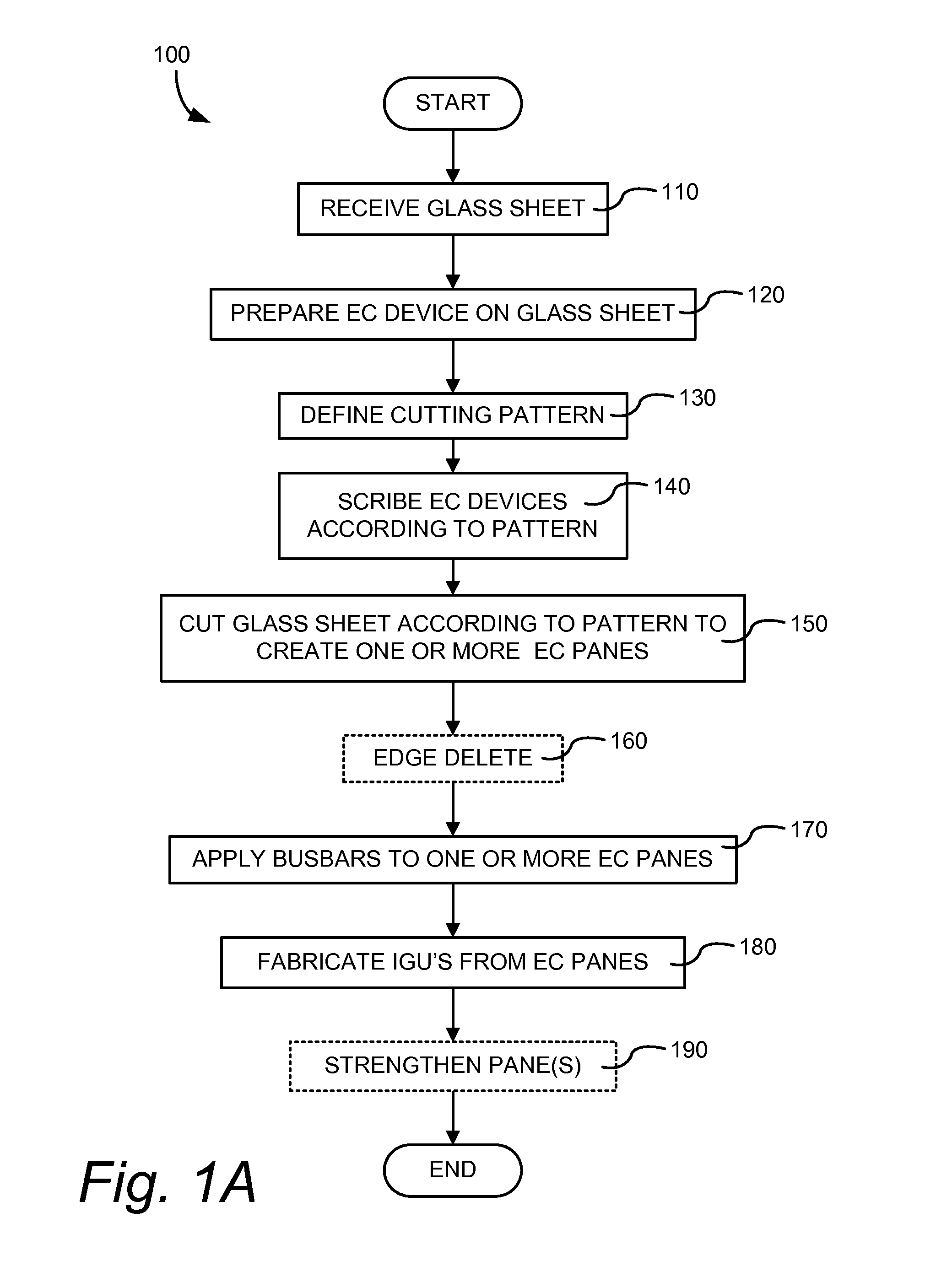

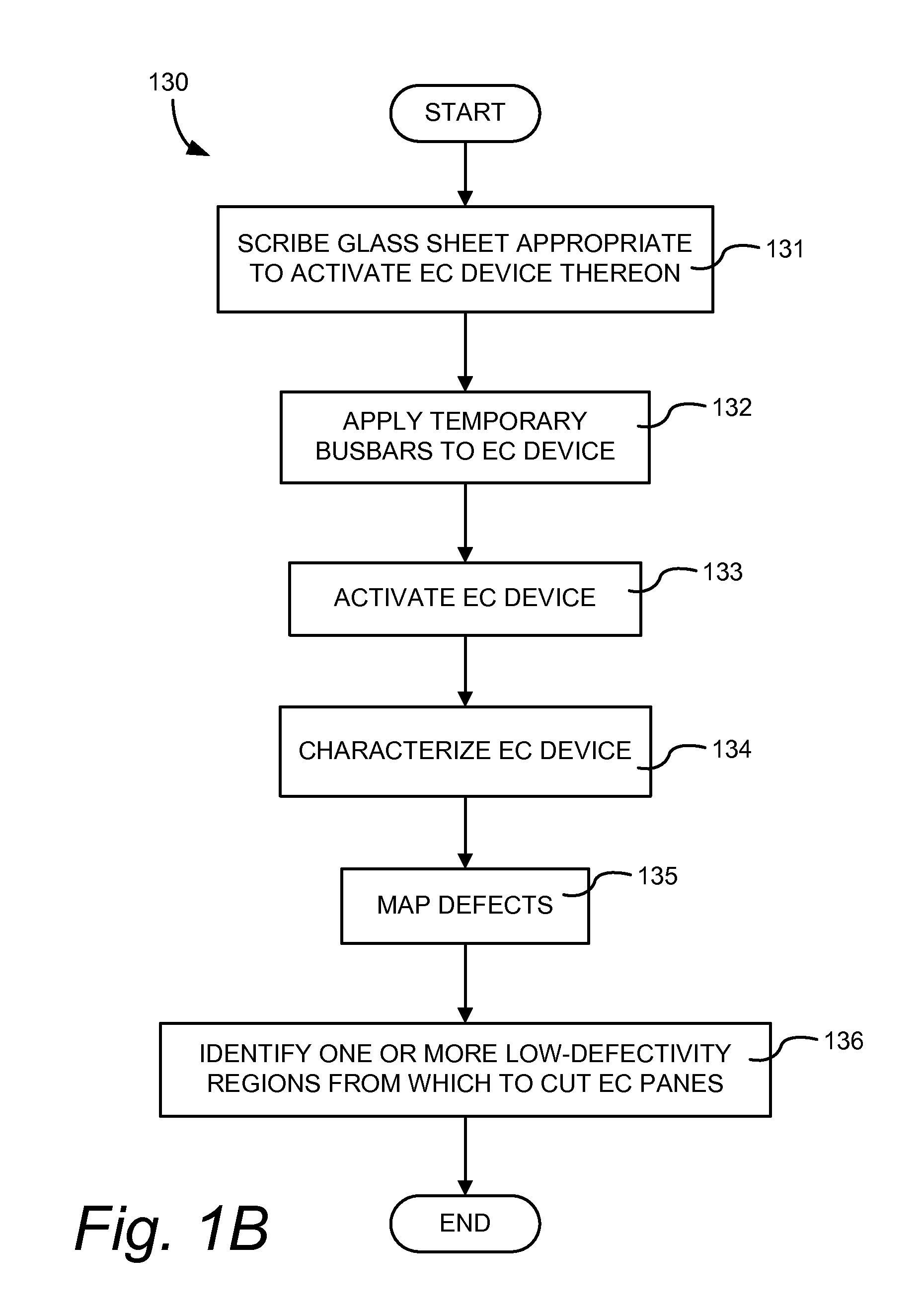

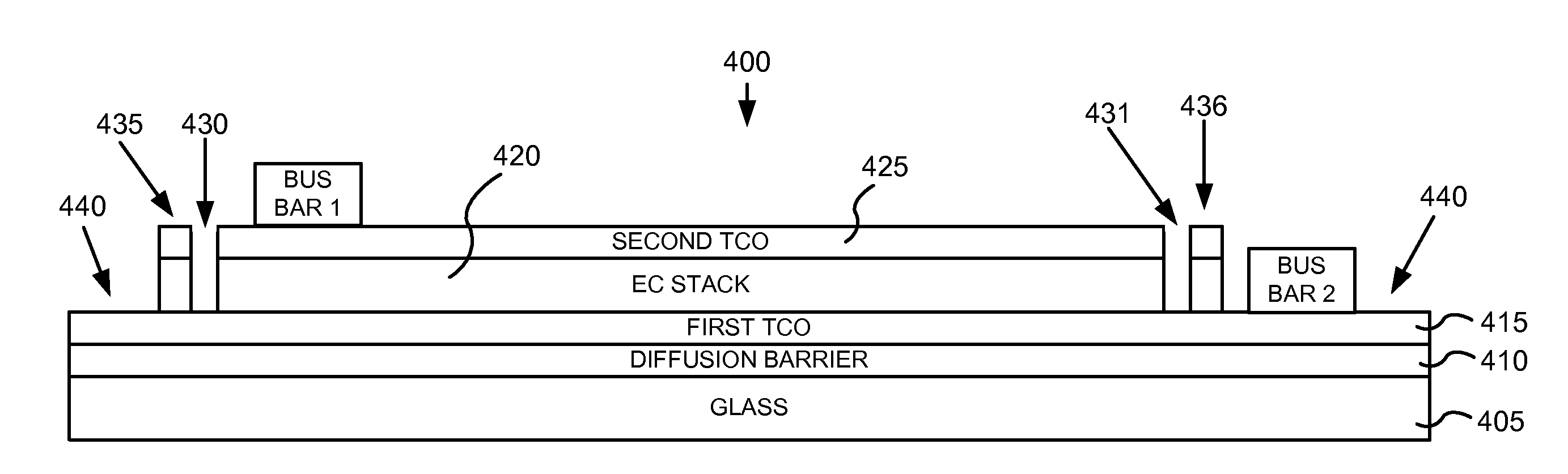

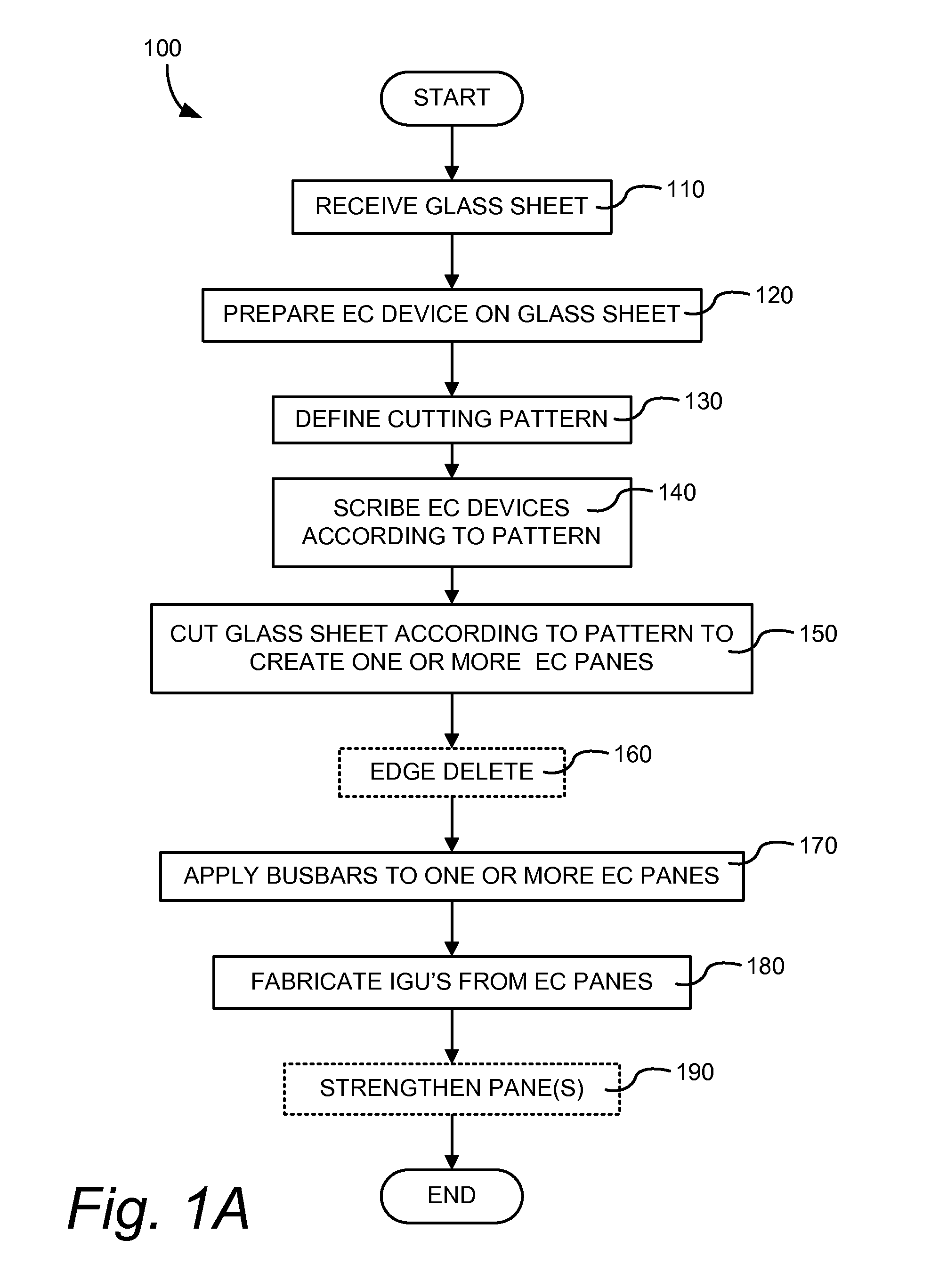

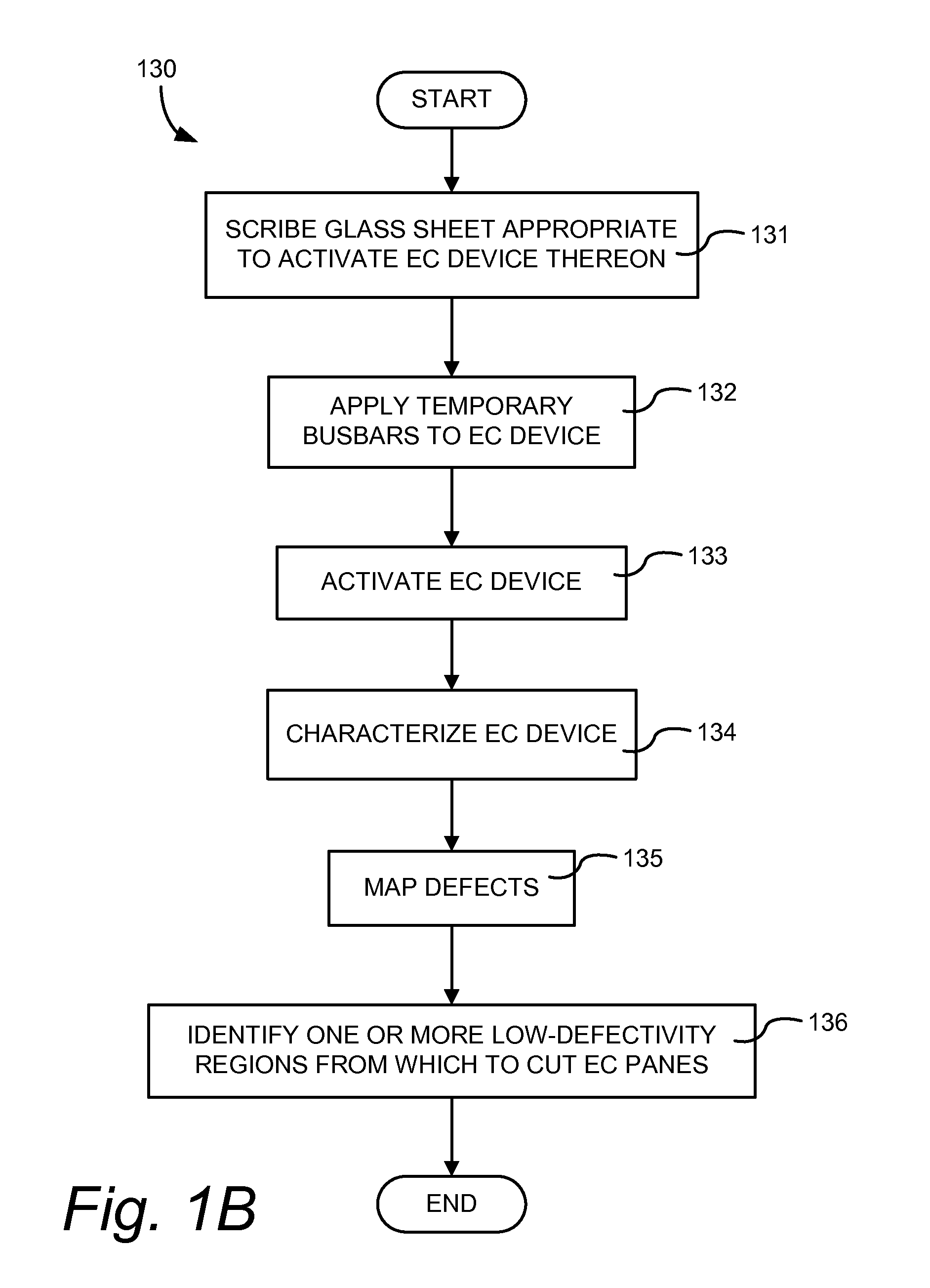

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

Flat float glass

InactiveUS6846760B2High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideTransmittance

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

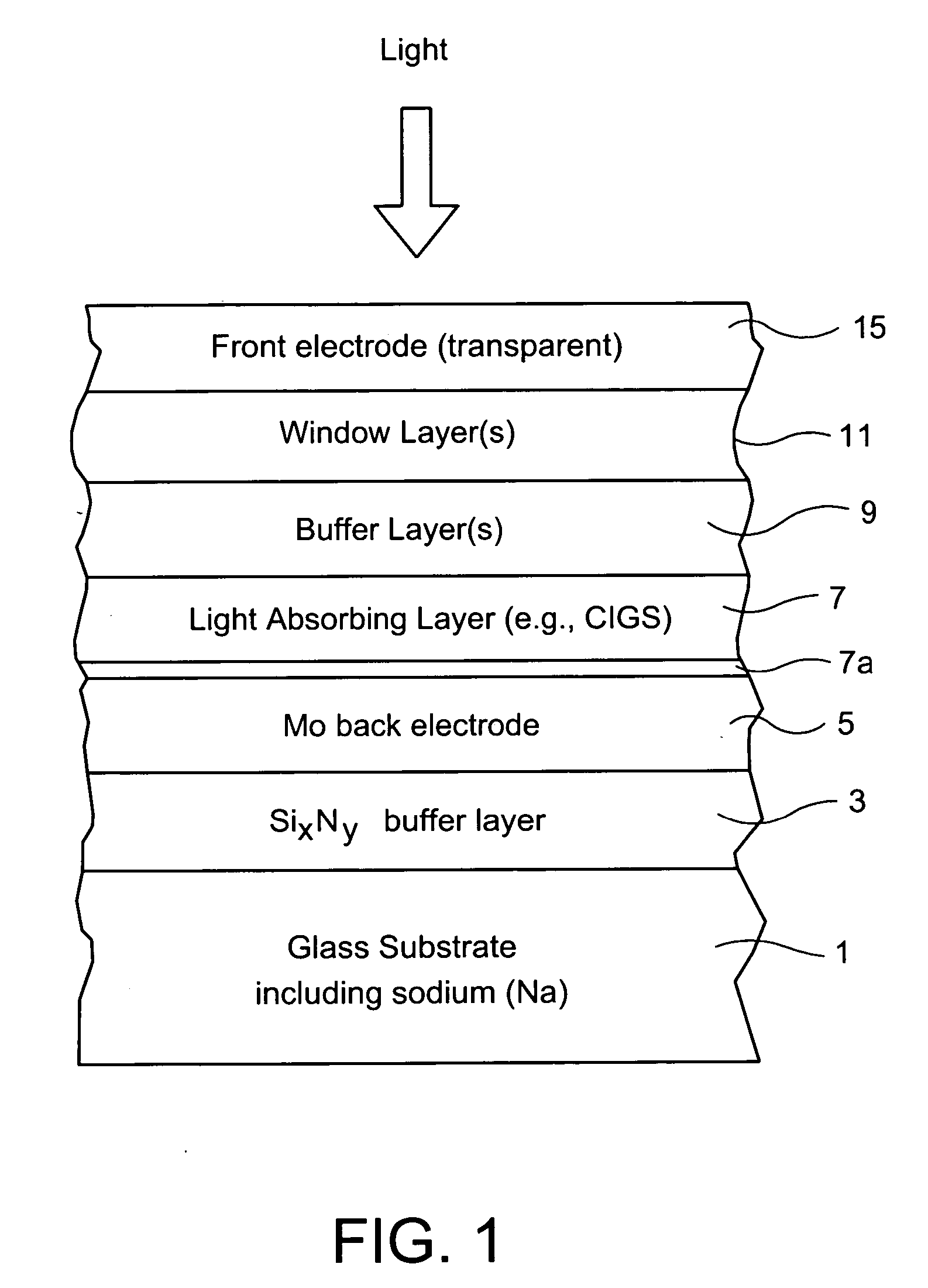

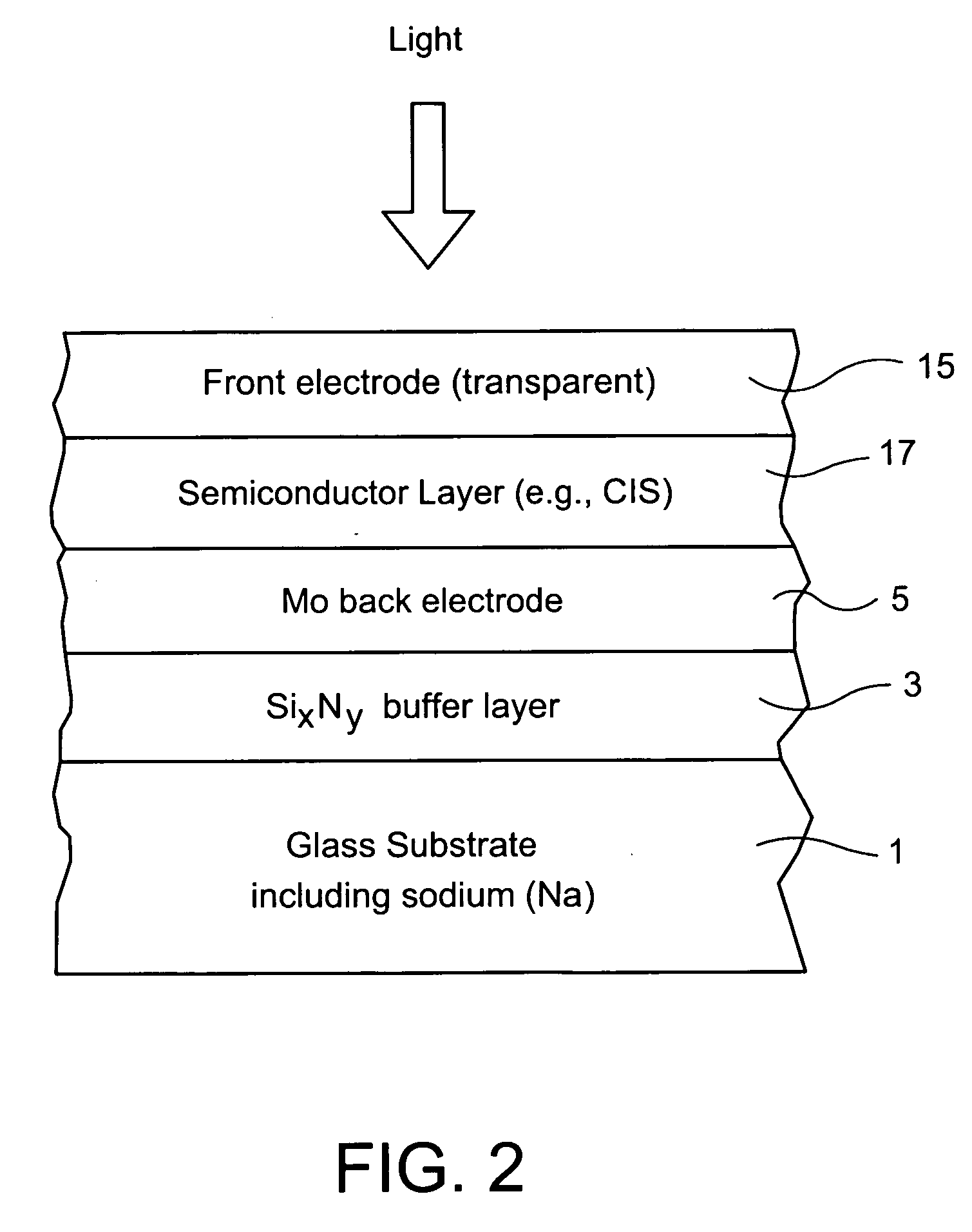

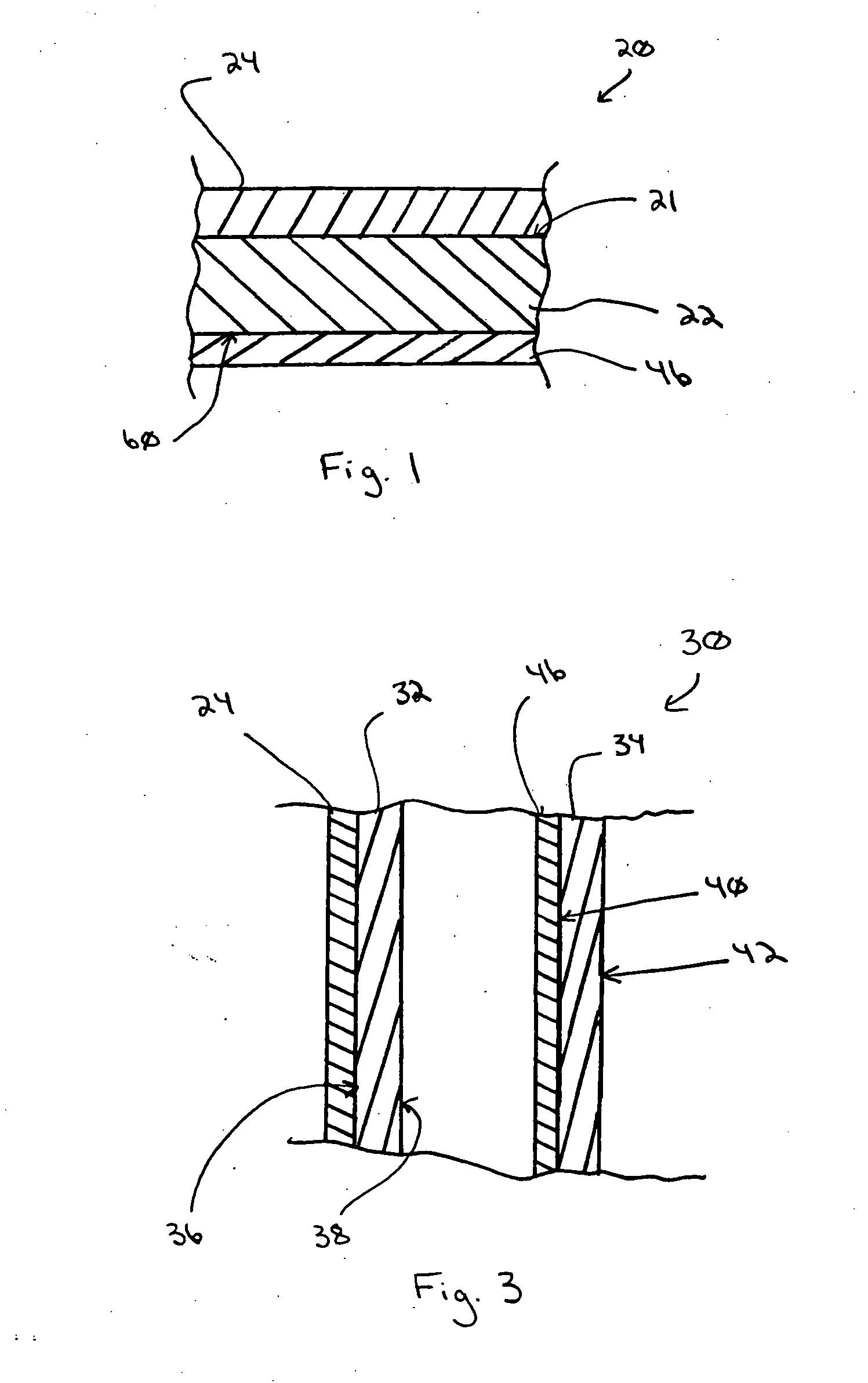

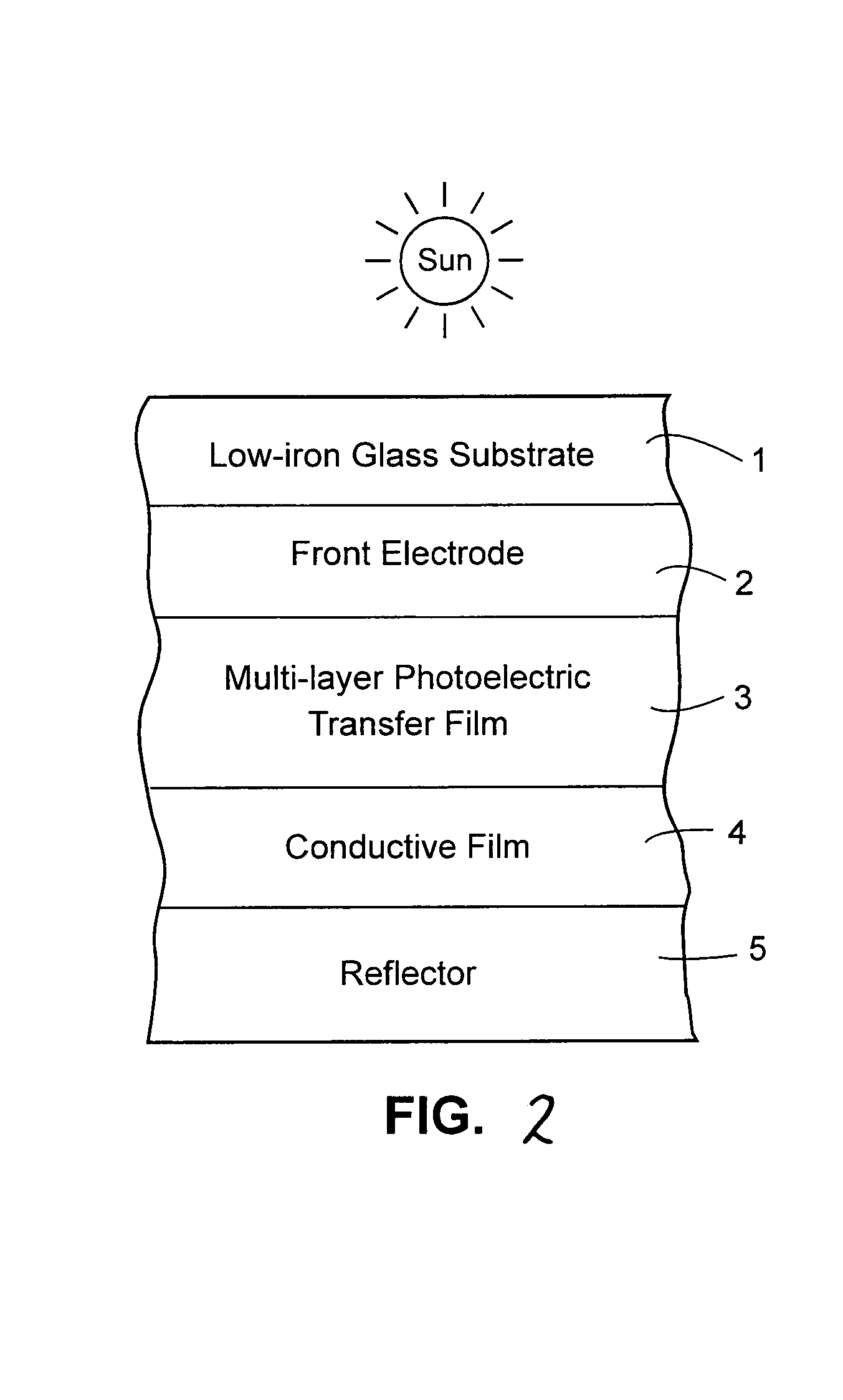

Electrode structure for use in electronic device and method of making same

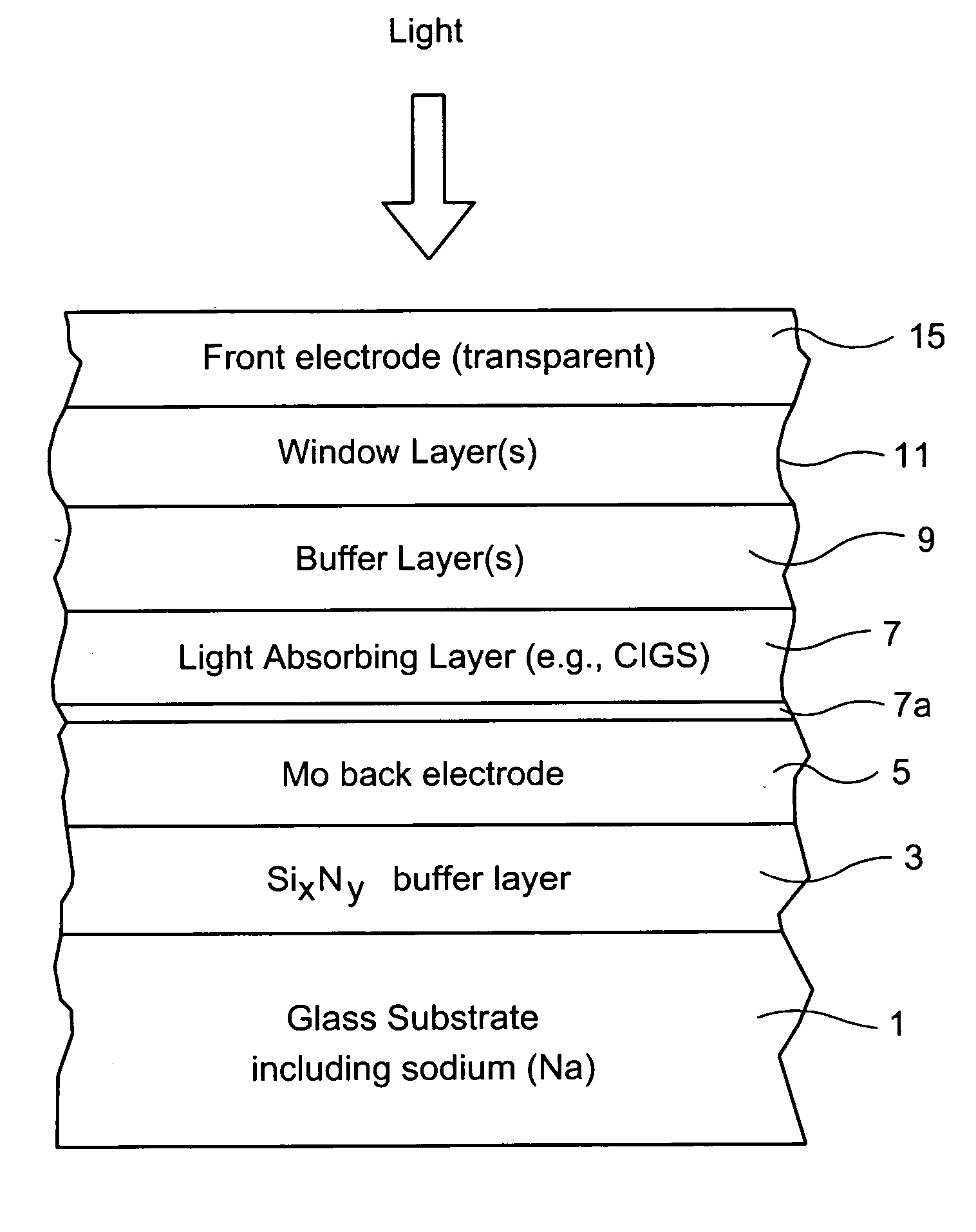

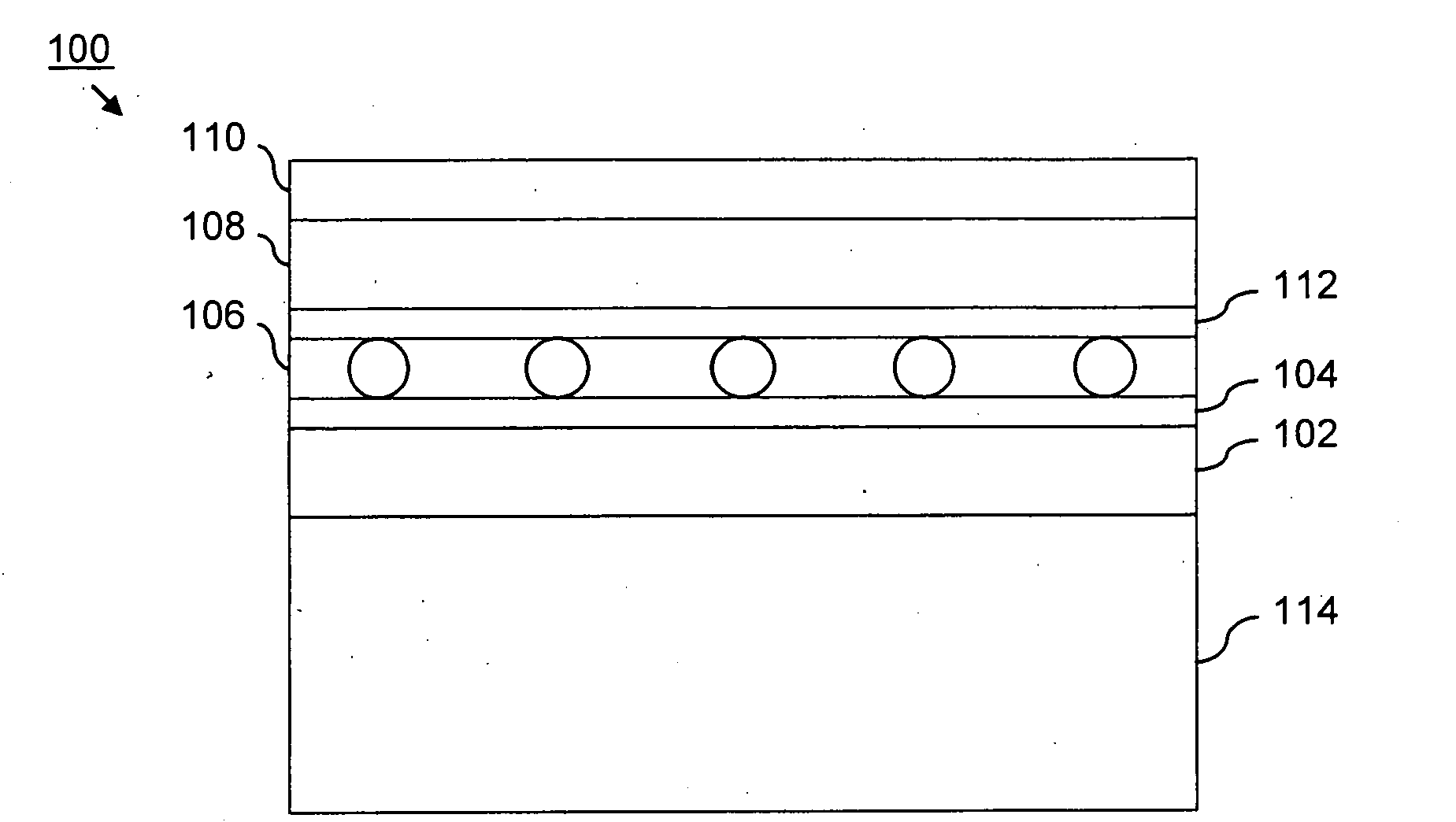

InactiveUS20070193623A1Reduce and prevent migrationControl of mechanical and efficiency propertyFinal product manufacturePhotovoltaic energy generationOptoelectronicsSoda lime

An electrode structure is provided for use in an electronic device. In certain example embodiments, an electrode structure includes a supporting glass substrate (e.g., soda-lime silica based float glass), a buffer layer (e.g., SixNy), and a conductive electrode (e.g., Mo) provided in this order. The buffer layer is advantageous in that it prevents or reduces sodium (Na) migration from the glass substrate into semiconductor layer(s) of the electronic device.

Owner:GUARDIAN GLASS LLC

Flat float glass

InactiveUS20020023463A1High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideThermal expansion

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

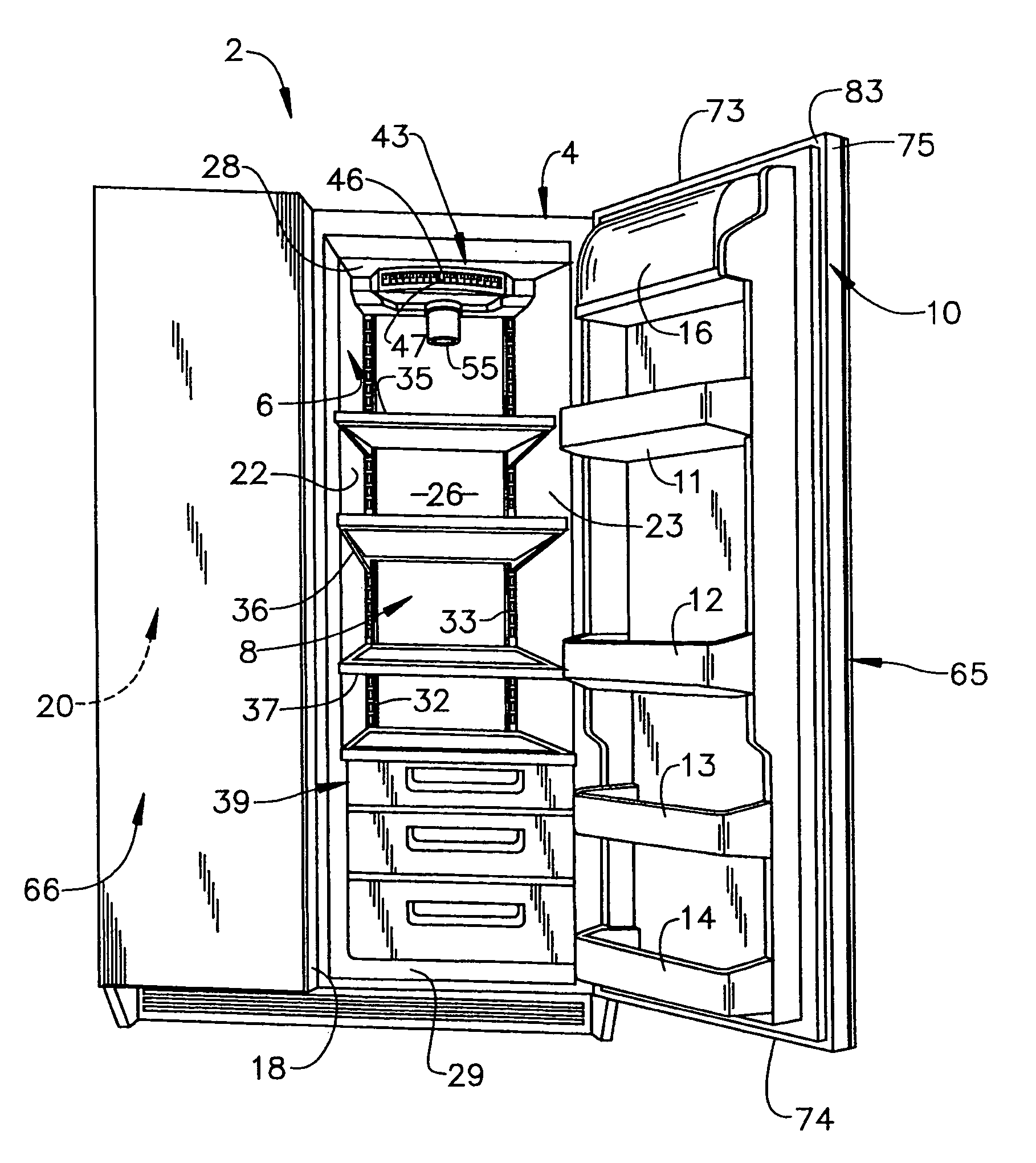

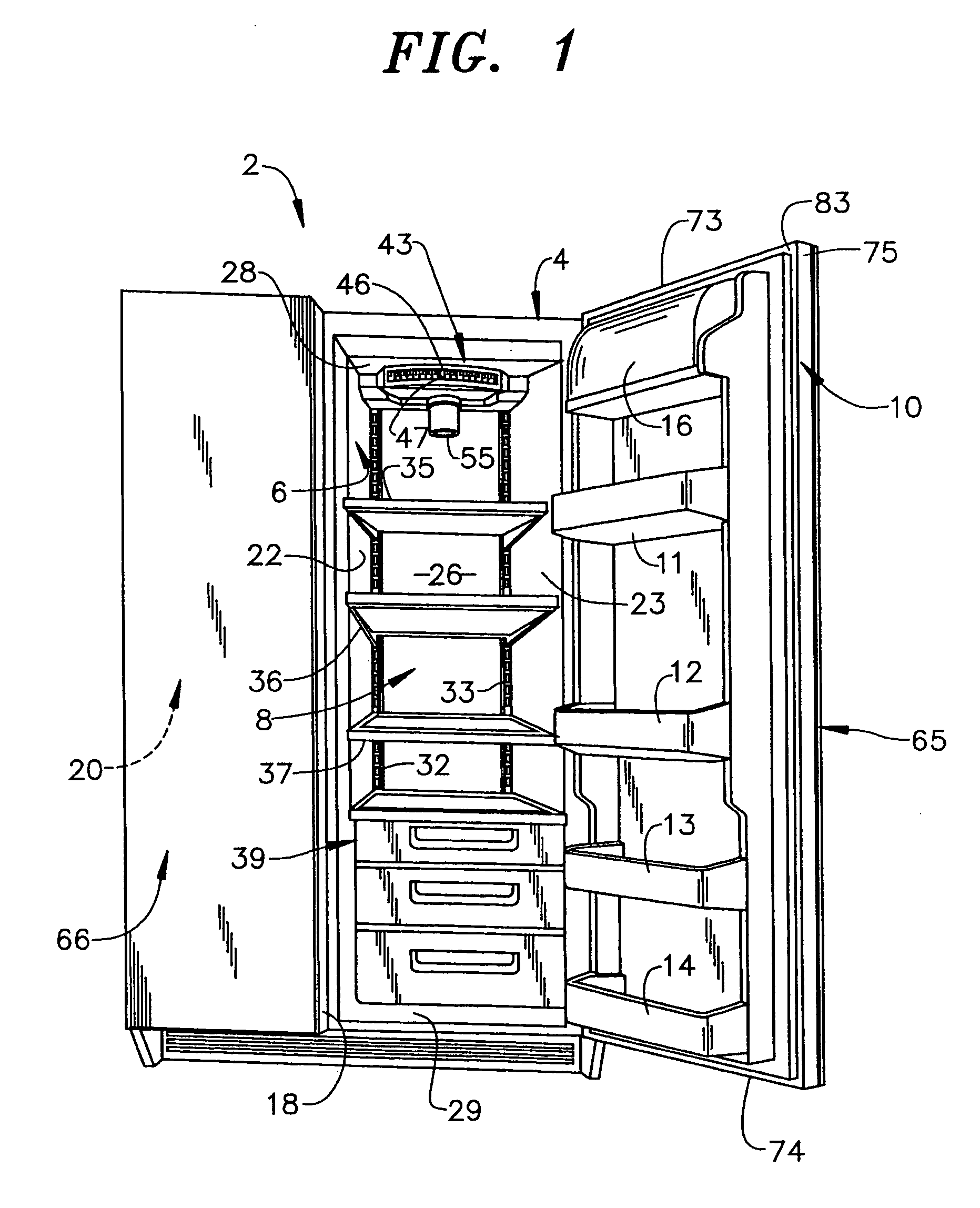

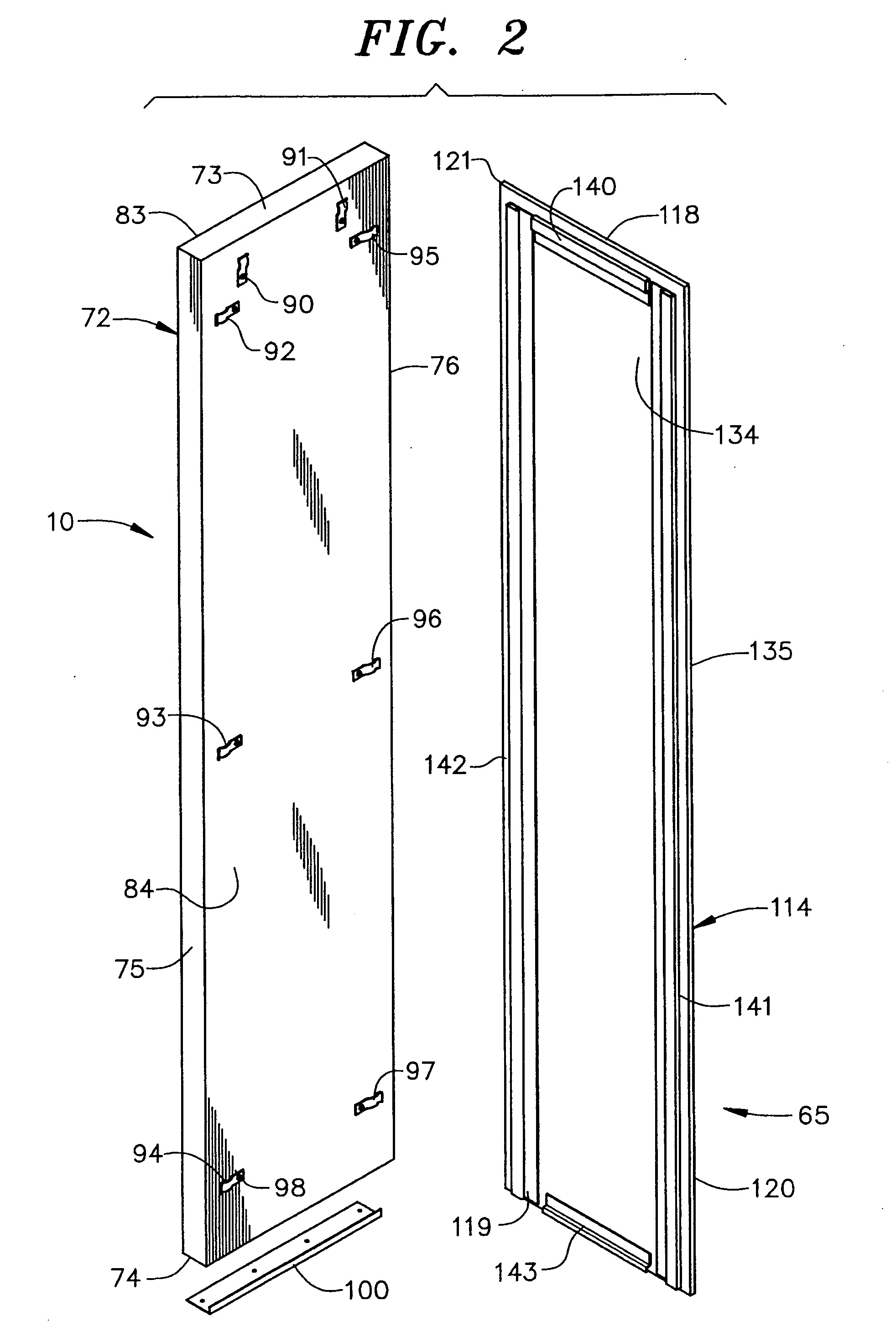

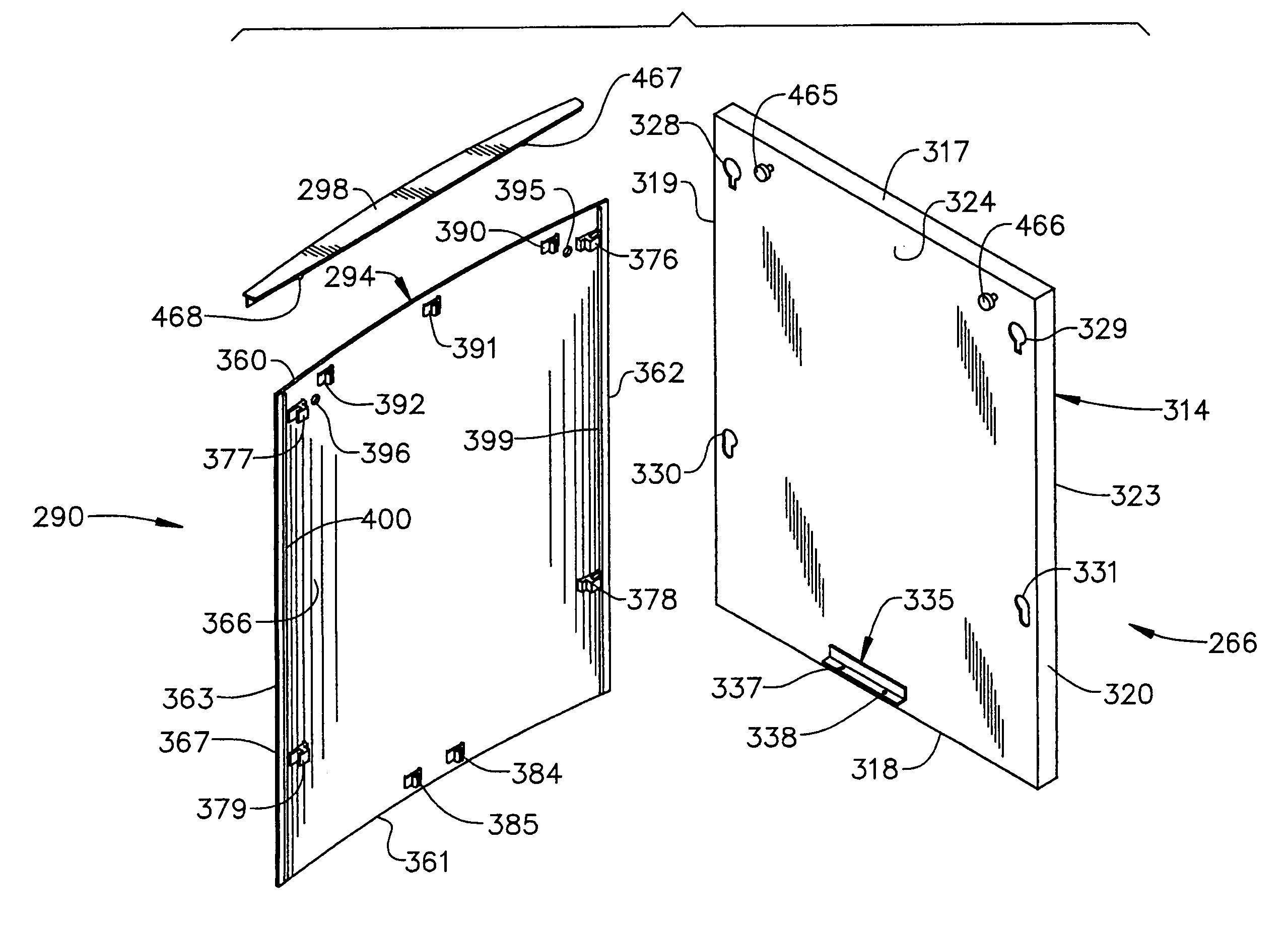

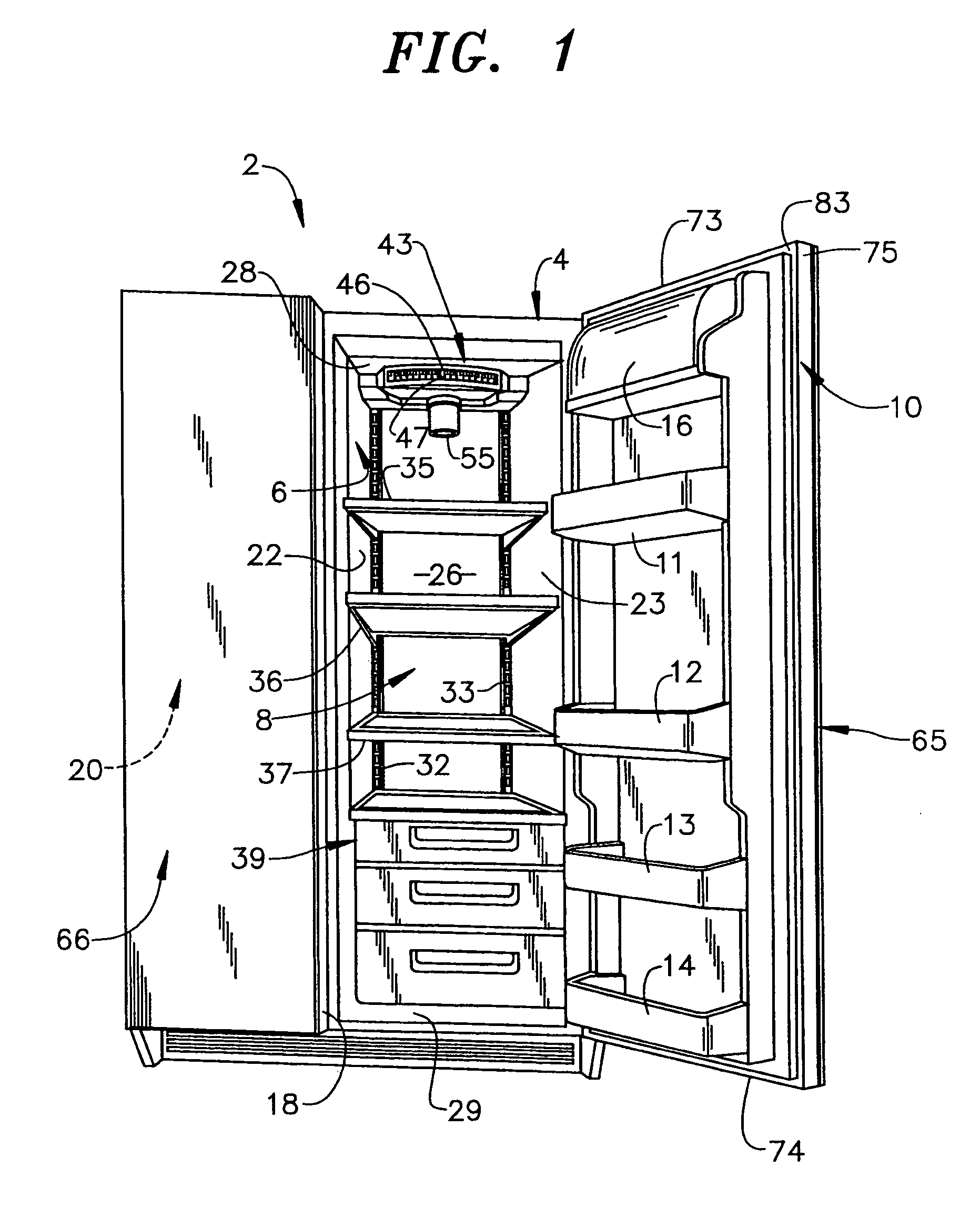

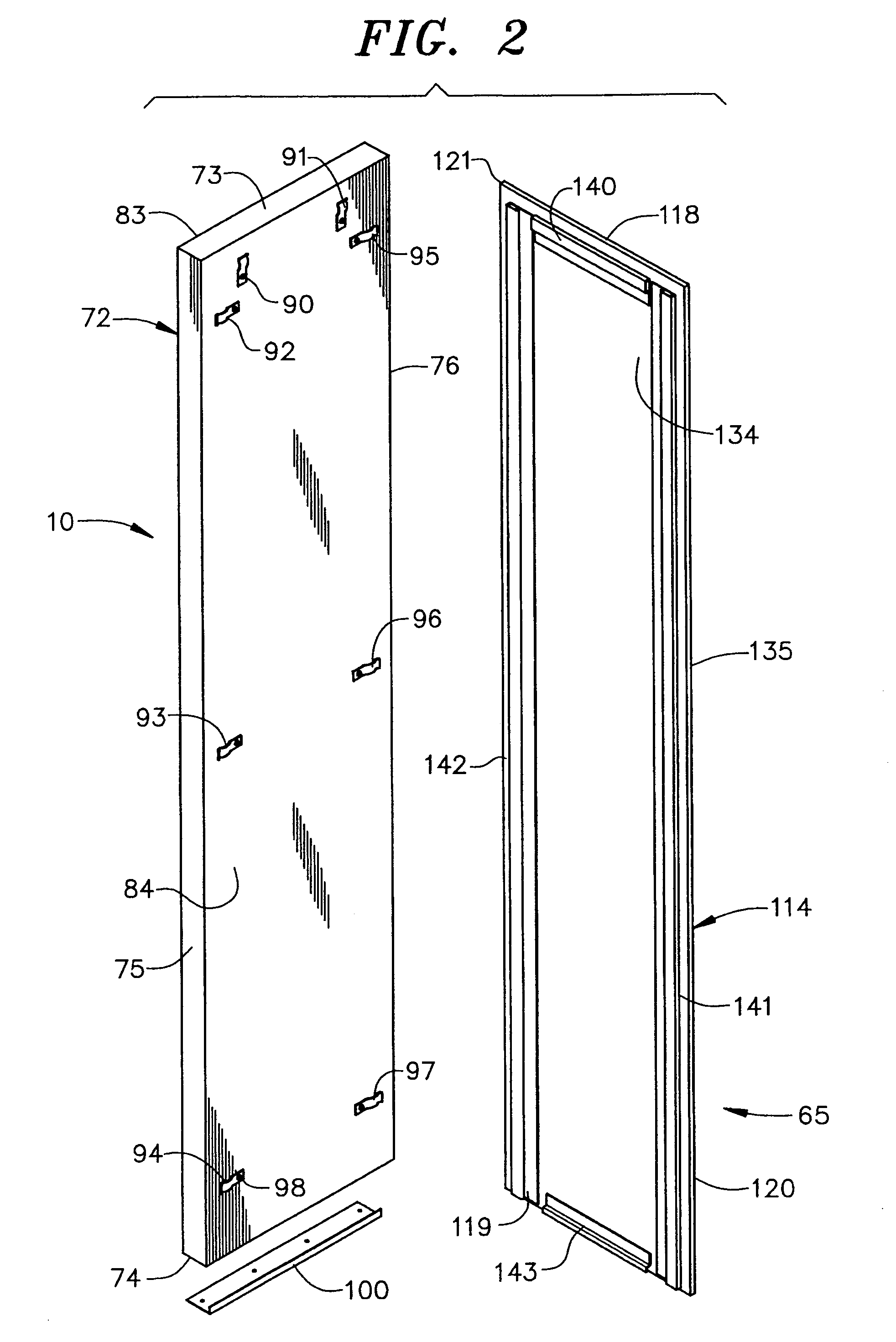

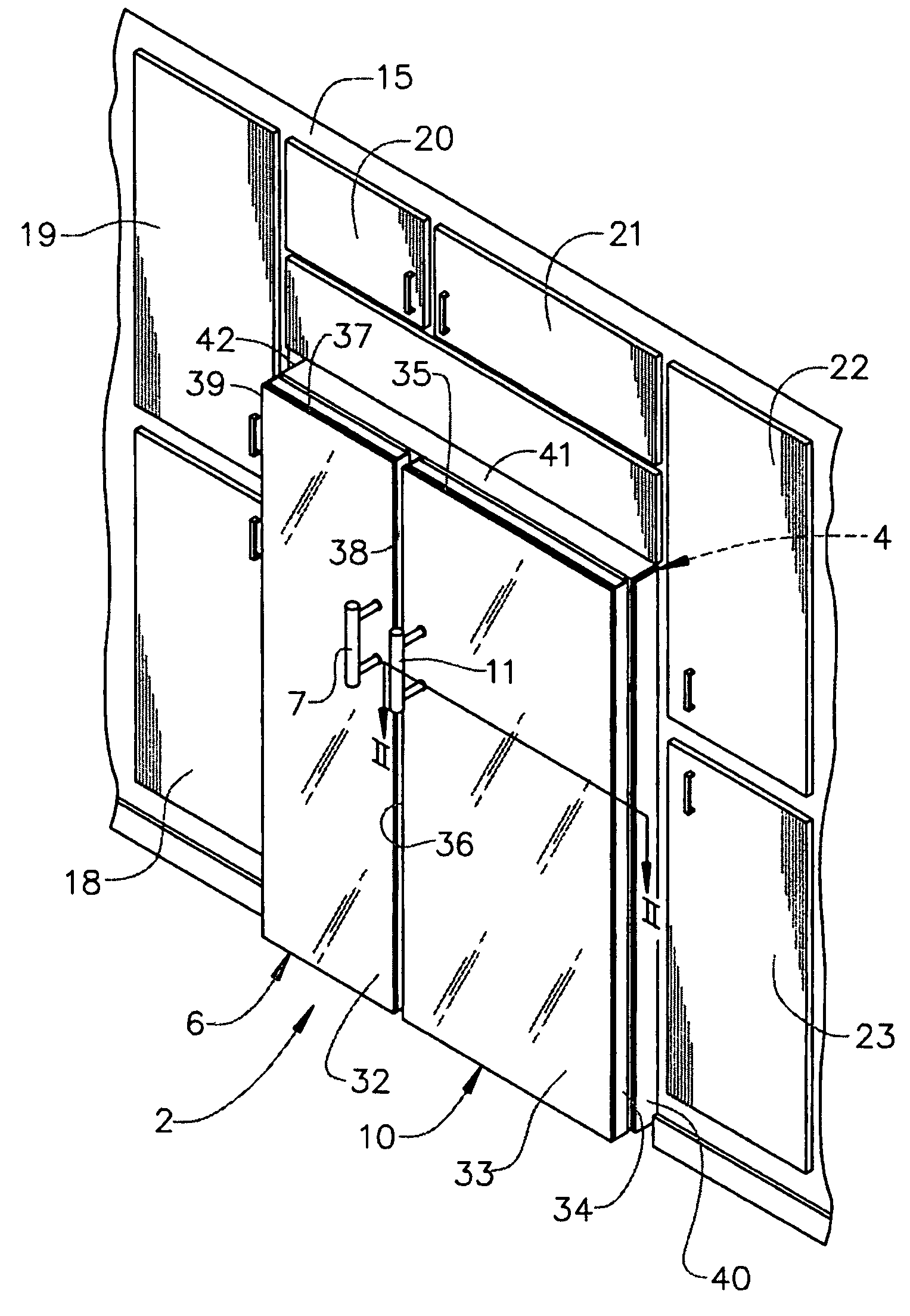

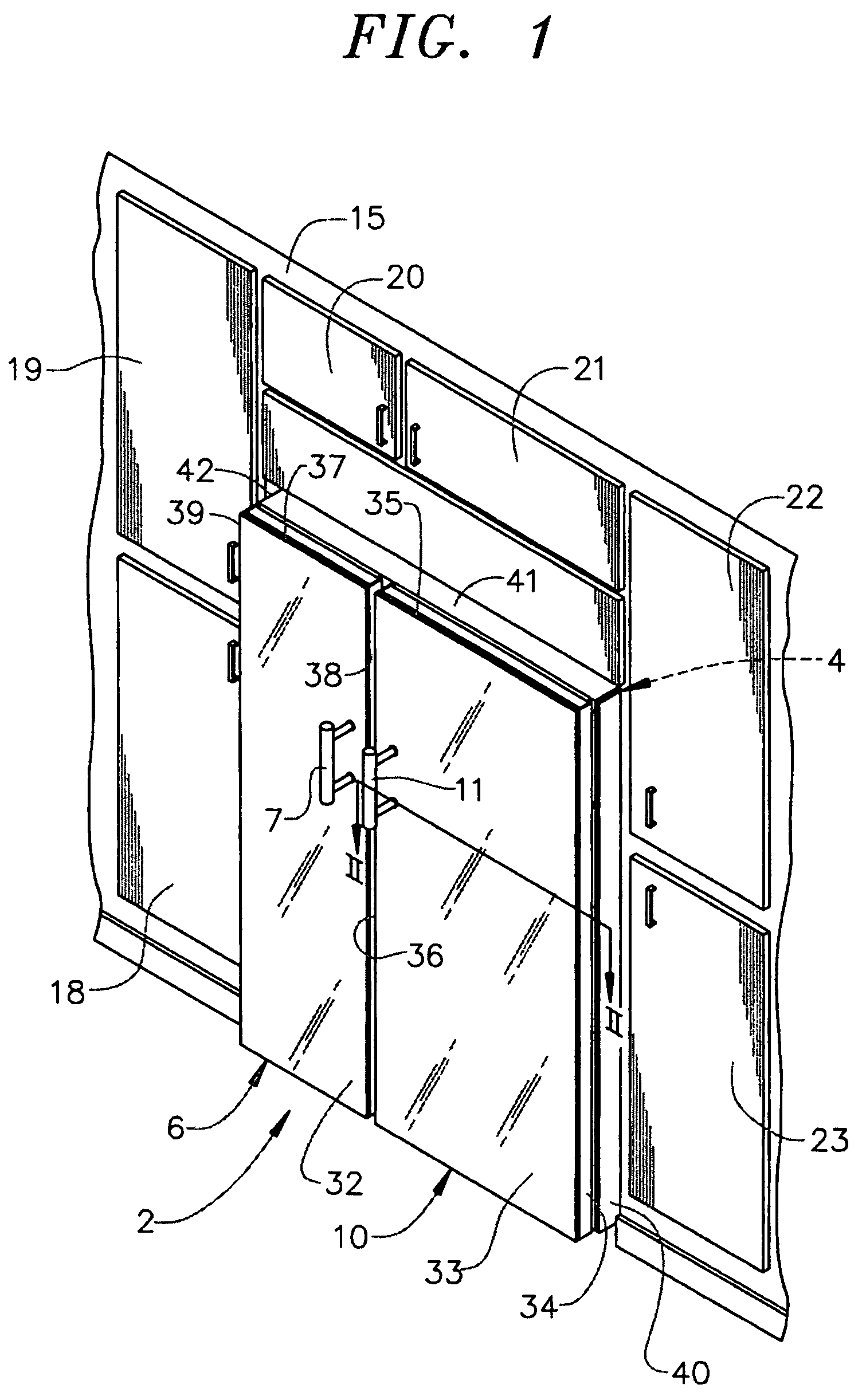

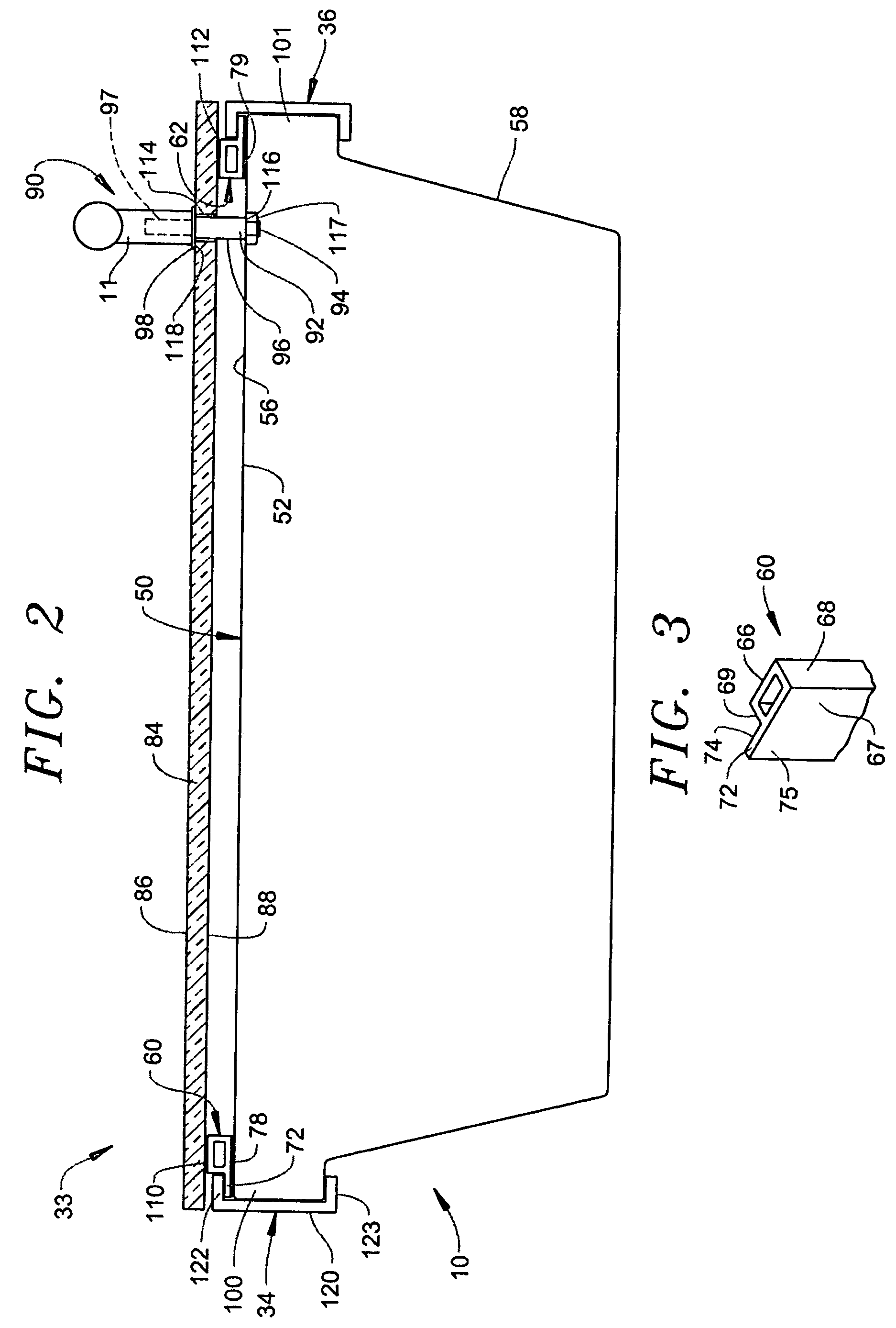

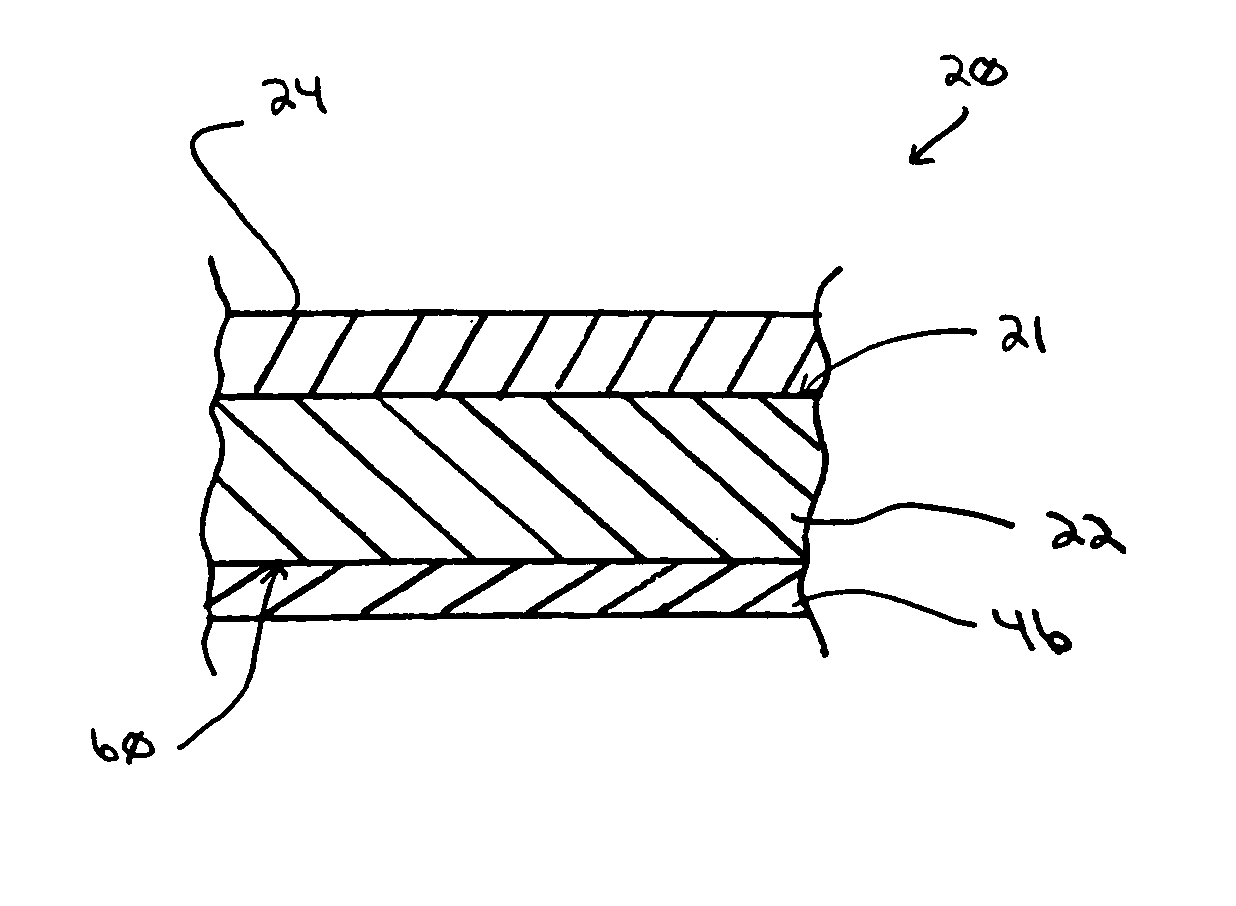

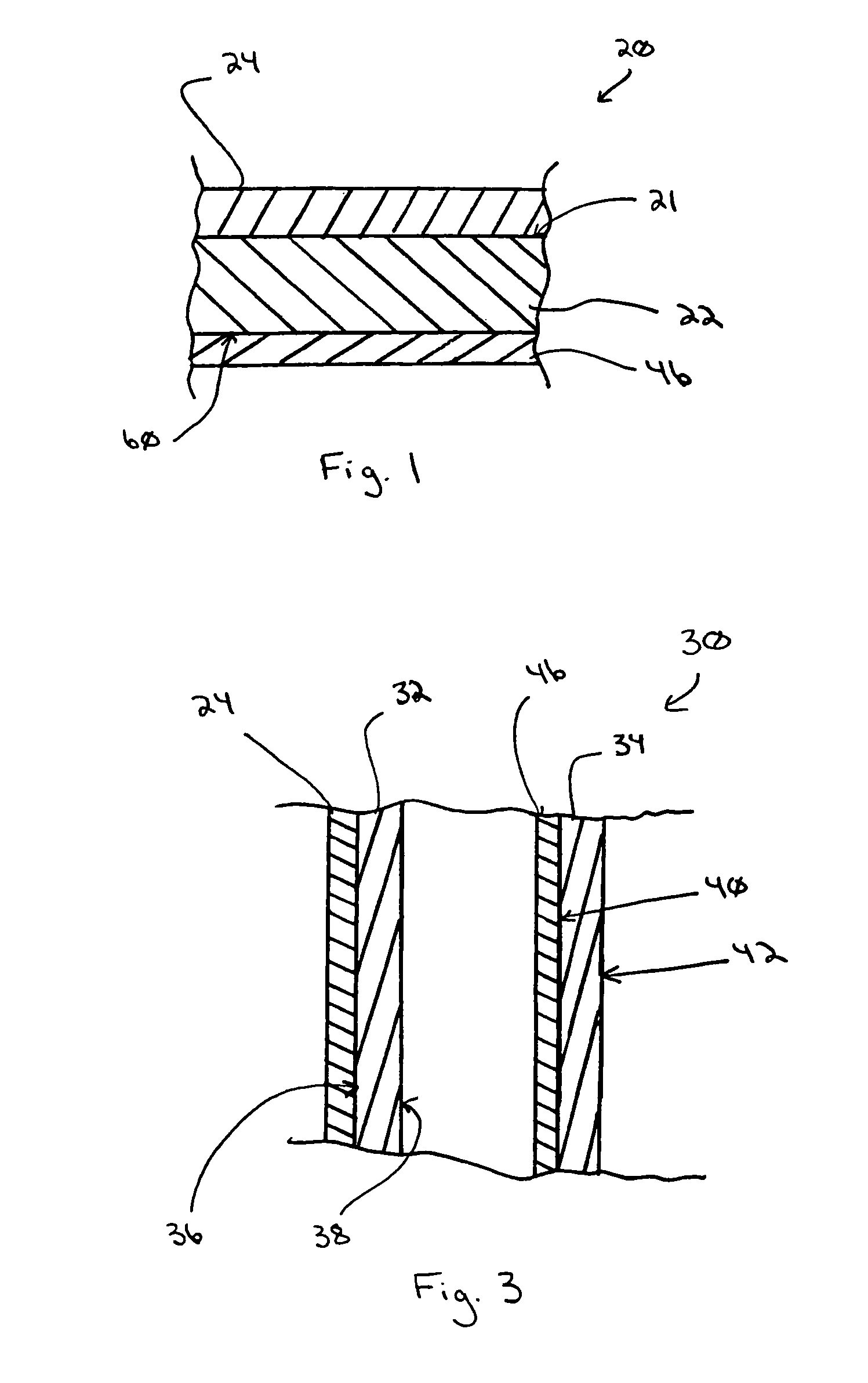

Kitchen appliance having floating glass panel

ActiveUS20070188059A1Domestic stoves or rangesLighting and heating apparatusKitchen utensilsEngineering

A kitchen appliance includes a door having an outer panel portion and an inner panel portion, with a plurality of mounting members being spaced about the outer panel portion of the door. A glass panel assembly, including a glass panel and a plurality of mounting elements, is detachably mounted to the door through the interengagement of the plurality of mounting elements with the plurality of mounting members. The mounting elements are adhesively secured to the glass panel. Neither the plurality of mounting members nor the plurality of mounting elements are readily visible normally when viewing the kitchen appliance such that the glass panel appears to float relative to the door.

Owner:MAYTAG

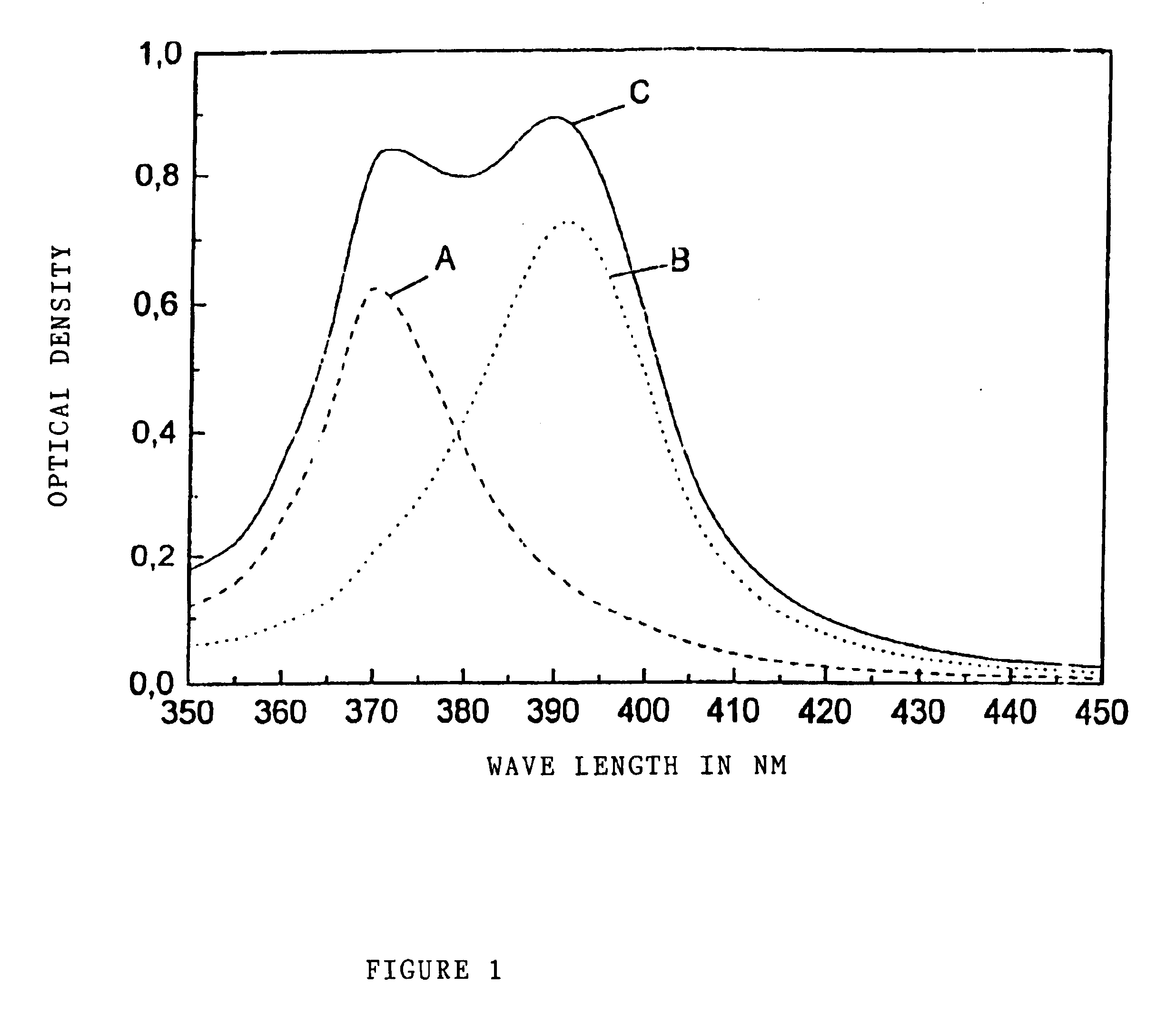

Method for producing UV polarizers

The invention relates to a method for producing UV polarizers, according to which spheroid particles situated near the surface of the glass are incorporated into the support material (primarily standard float glass) in a novel arrangement. According to the method for producing UV polarizers, after the introduction of metal ions (e.g., silver ions) into the glass surface, a large size distribution of particles is achieved by multiple alternation of a heat treatment for separating out spherical metal particles, followed by the renewed introduction of metal ions and a subsequent heat treatment. A deformation of the glass produces spheroid particles of various sizes and different semi-axis relationships. The particles are characterized by their large size distribution and are deformed differently in relation to their spheroid shape. In this way UV polarizers are produced which have a wide absorption range since the absorption bands having different maximum positions overlap.

Owner:F O B GES ZUR FERTIGUNG FARBIGER OPTOELEKTRONISCHER BAUELEMENTE

Photo-induced hydrophilic article and method of making same

InactiveUS20070218265A1Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

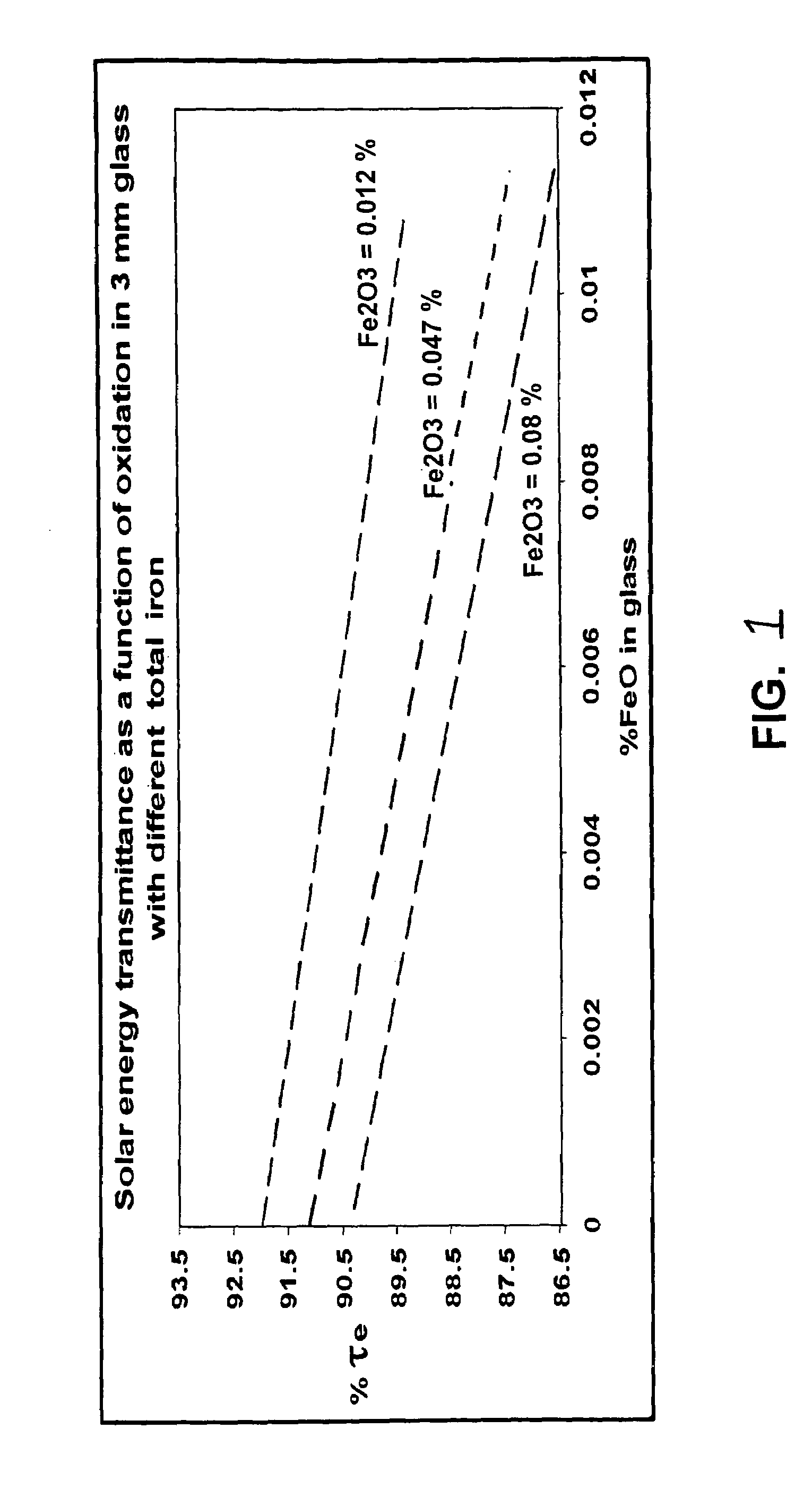

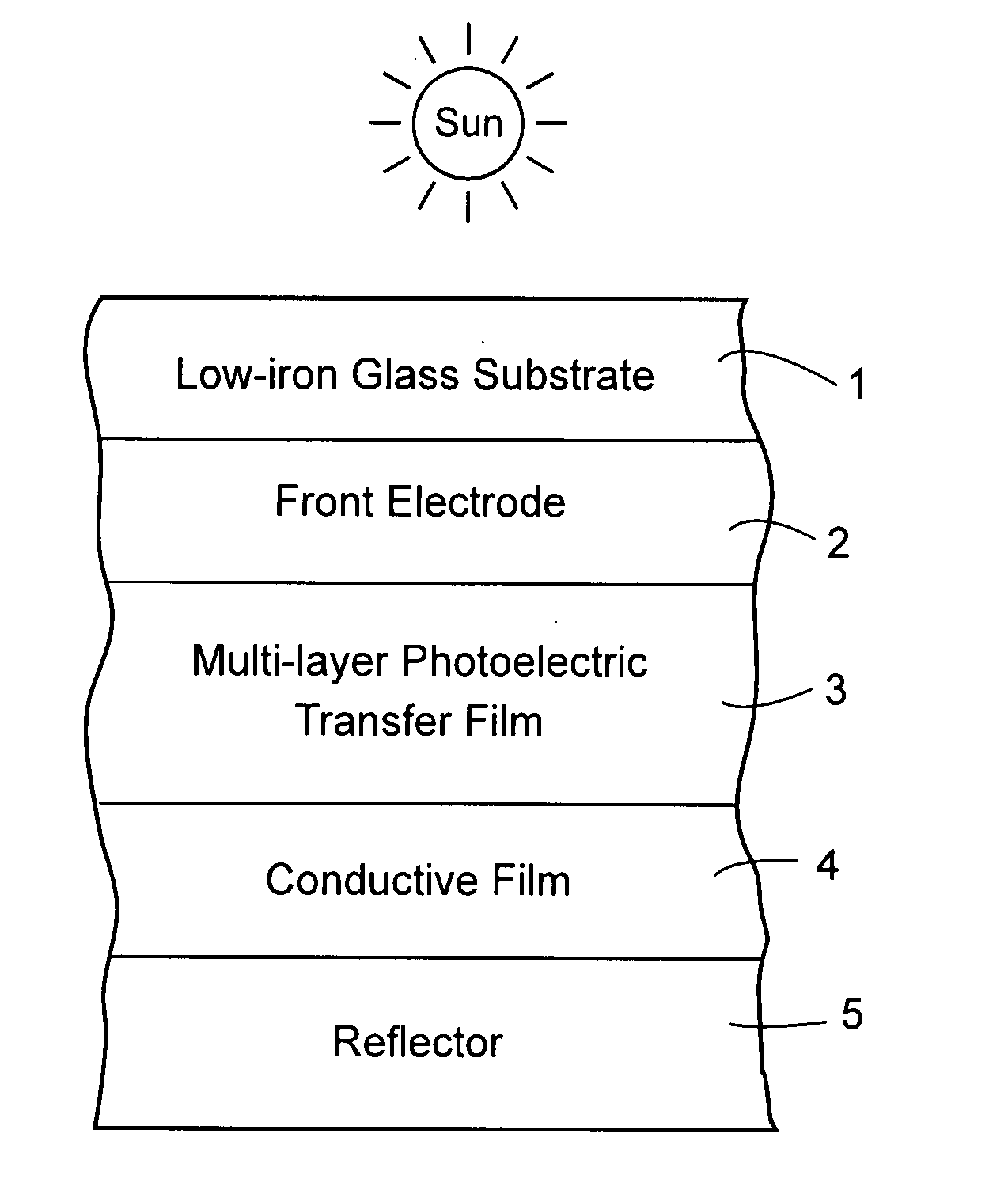

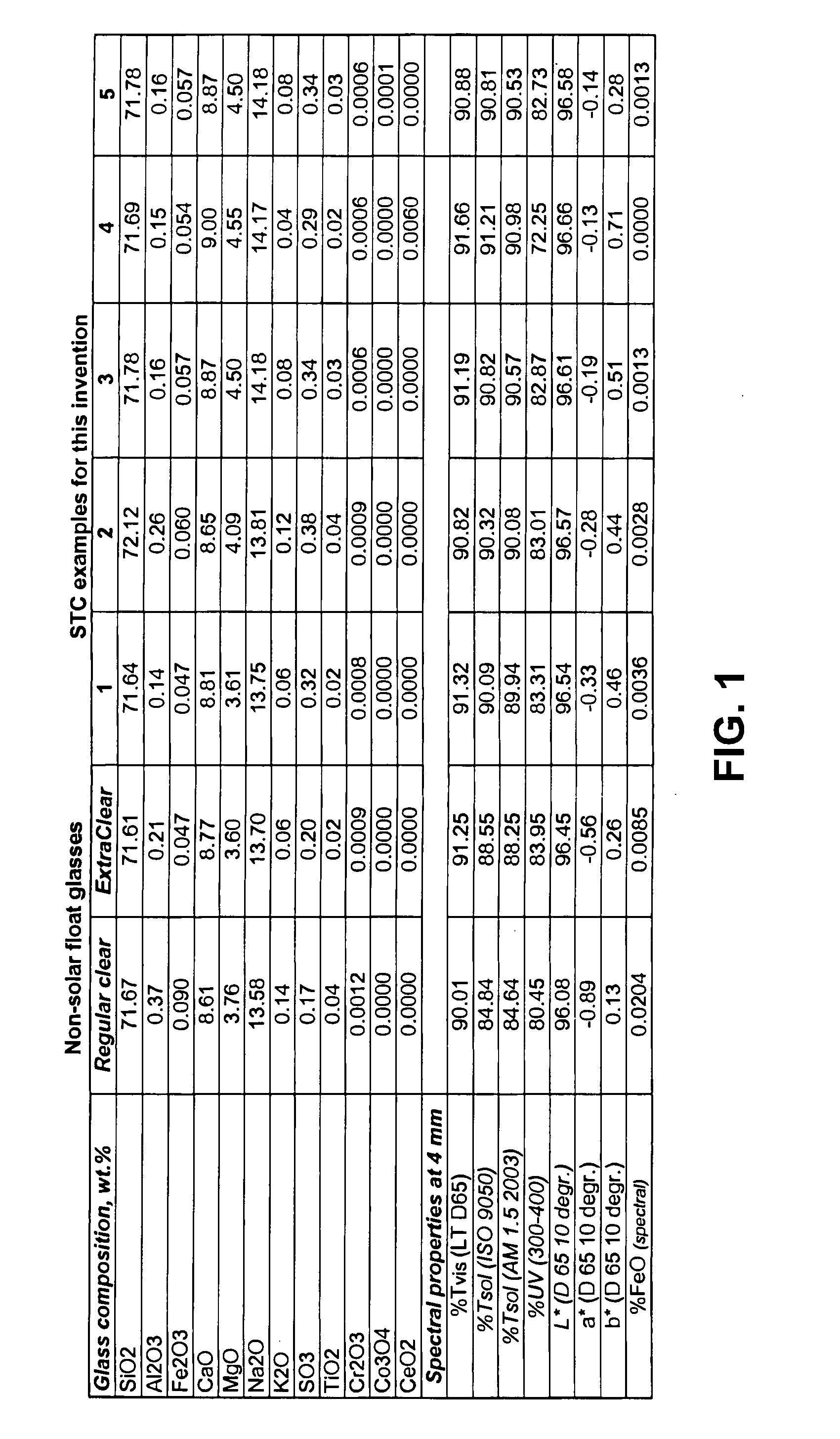

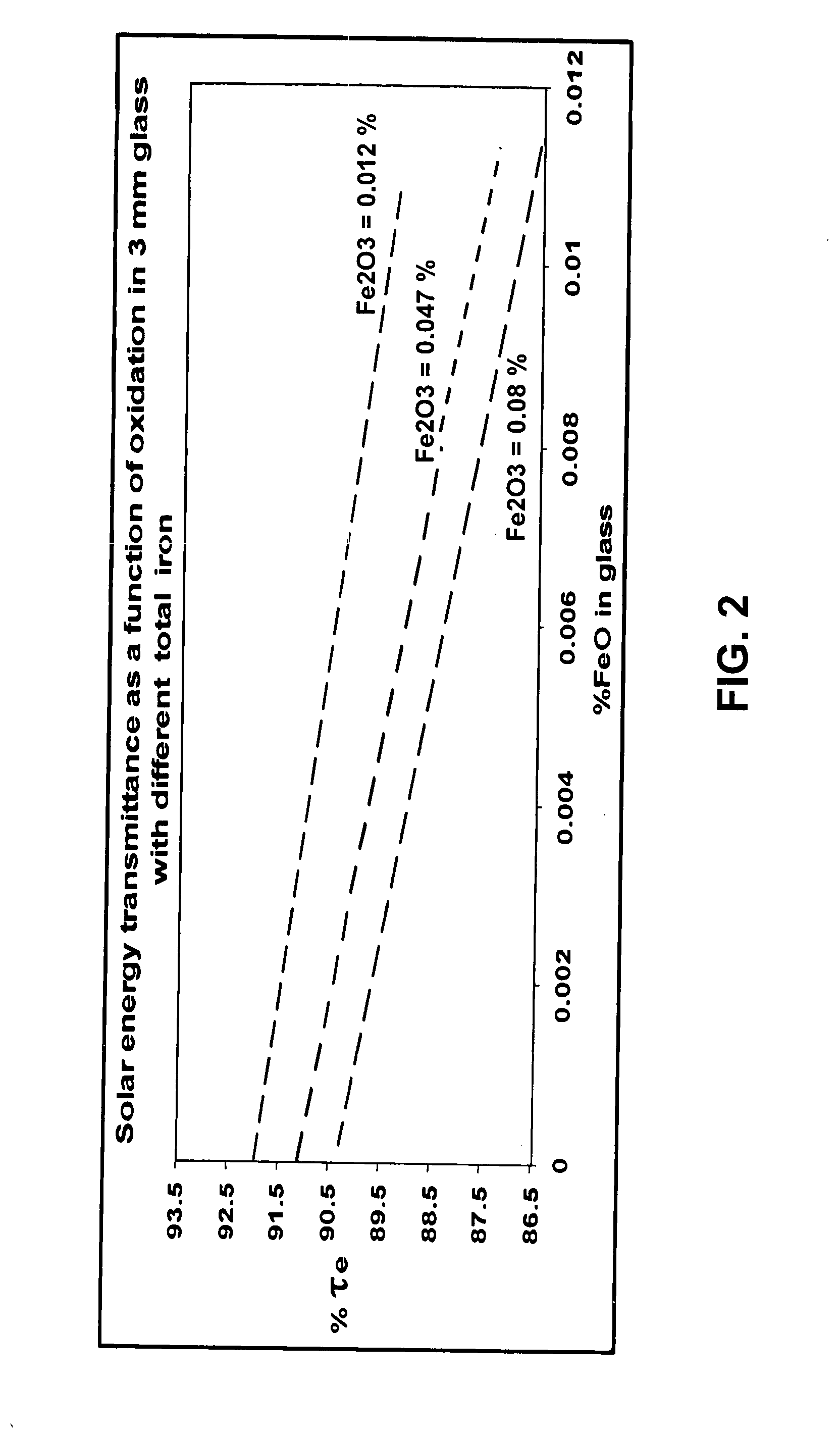

Low iron high transmission float glass for solar cell applications and method of making same

Certain example embodiments of this invention relate to a high transmission low iron glass, which is highly oxidized and made using the float process, for use in photovoltaic devices such as solar cells or the like. In certain example embodiments, the glass composition used for the glass is made via the float process using an extremely high and positive batch redox in order to reduce % FeO to a low level and permit the glass to consistently realize a combination of high visible transmission (Lta or Tvis), high infrared (IR) transmission, and high total solar (TS) transmission. The glass substrate may be patterned or not patterned in different example embodiments of this invention.

Owner:GUARDIAN GLASS LLC

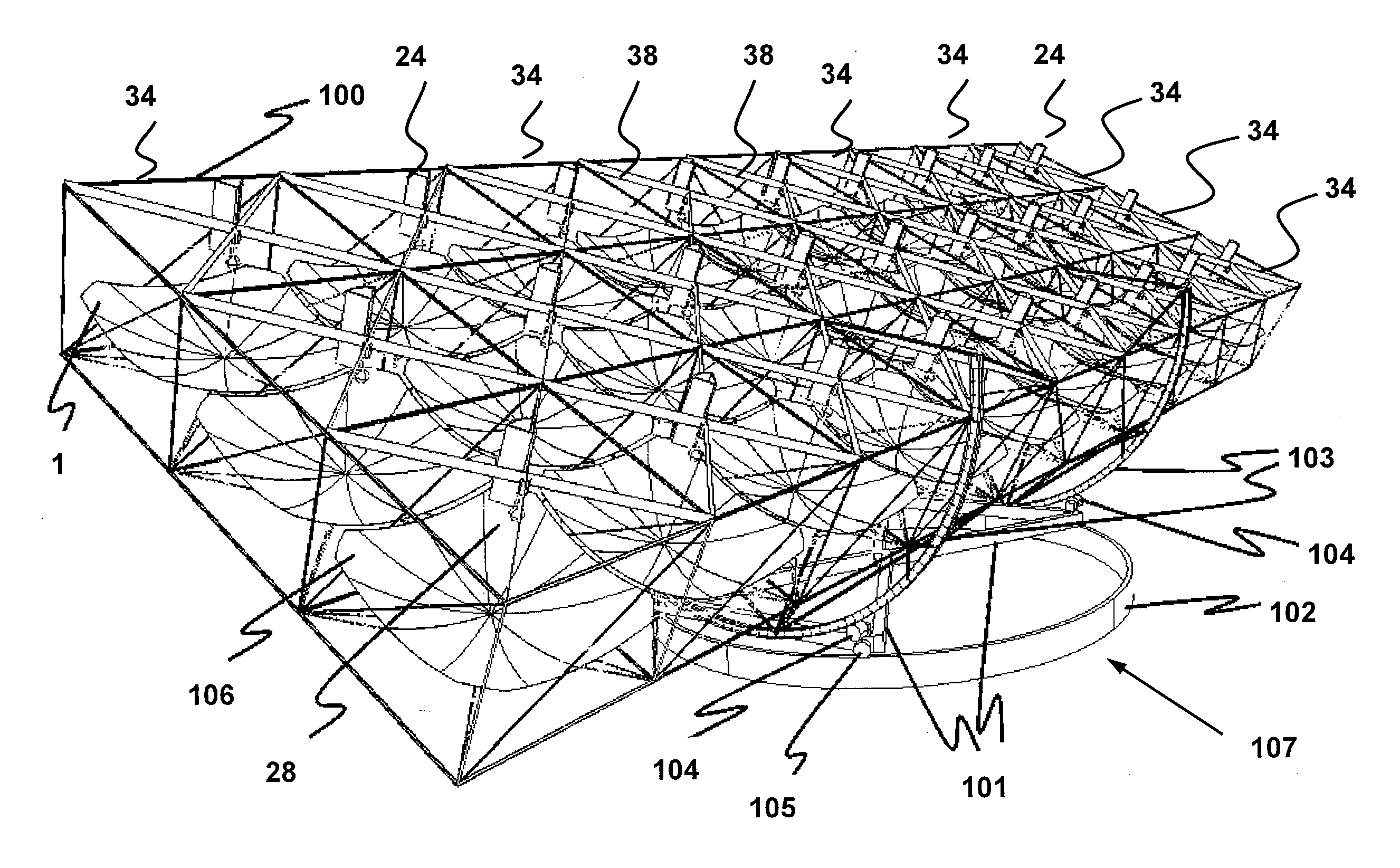

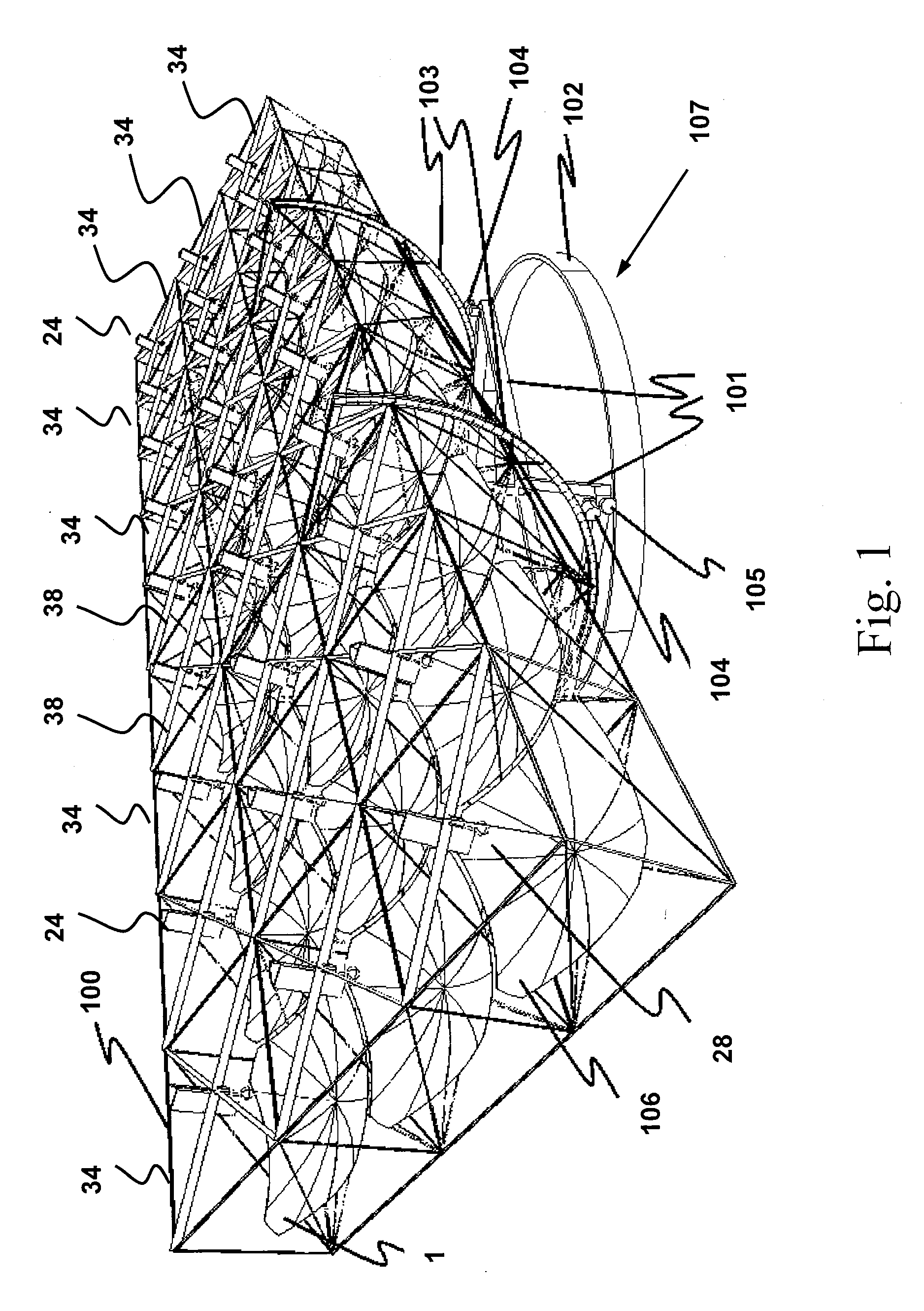

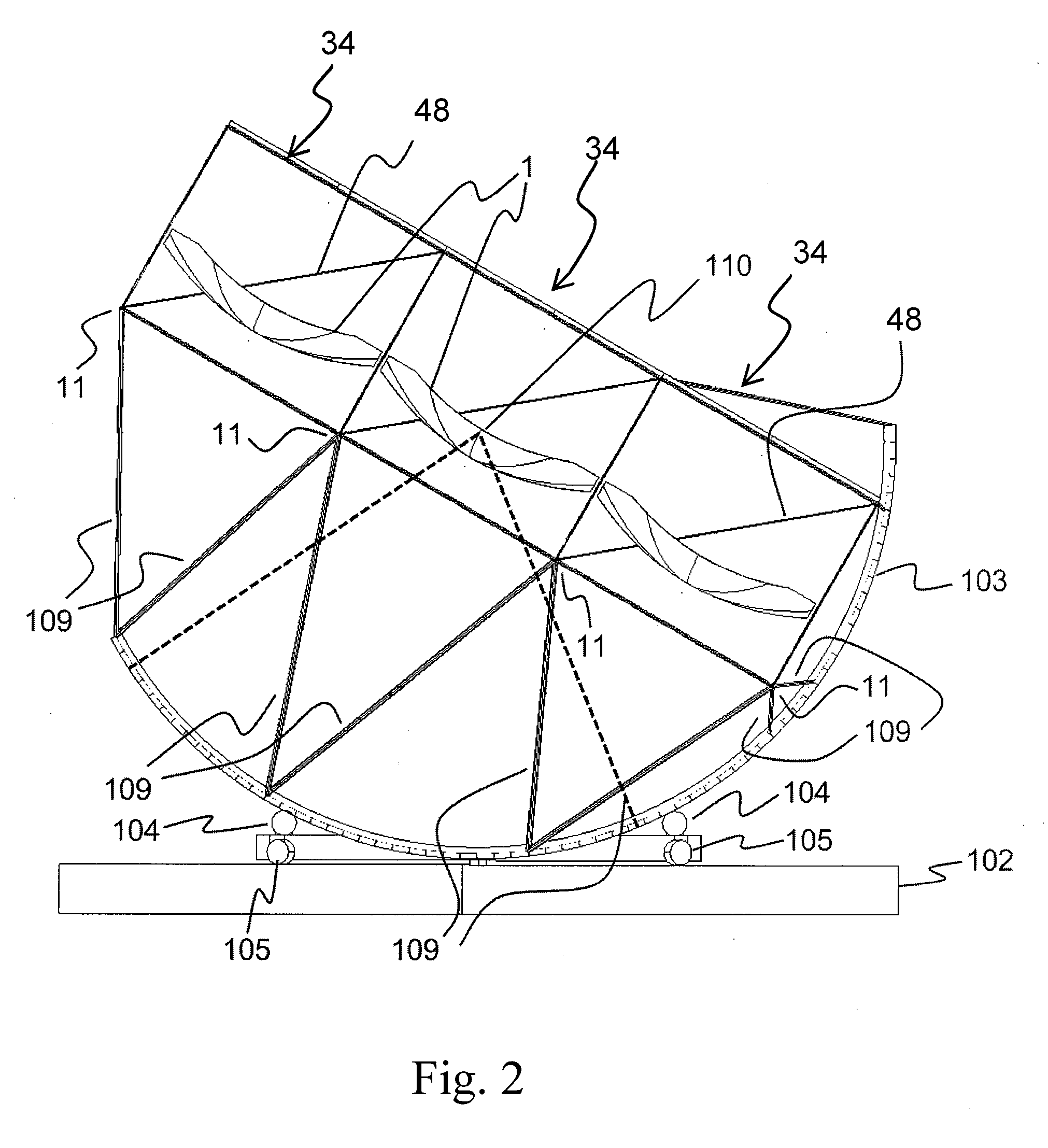

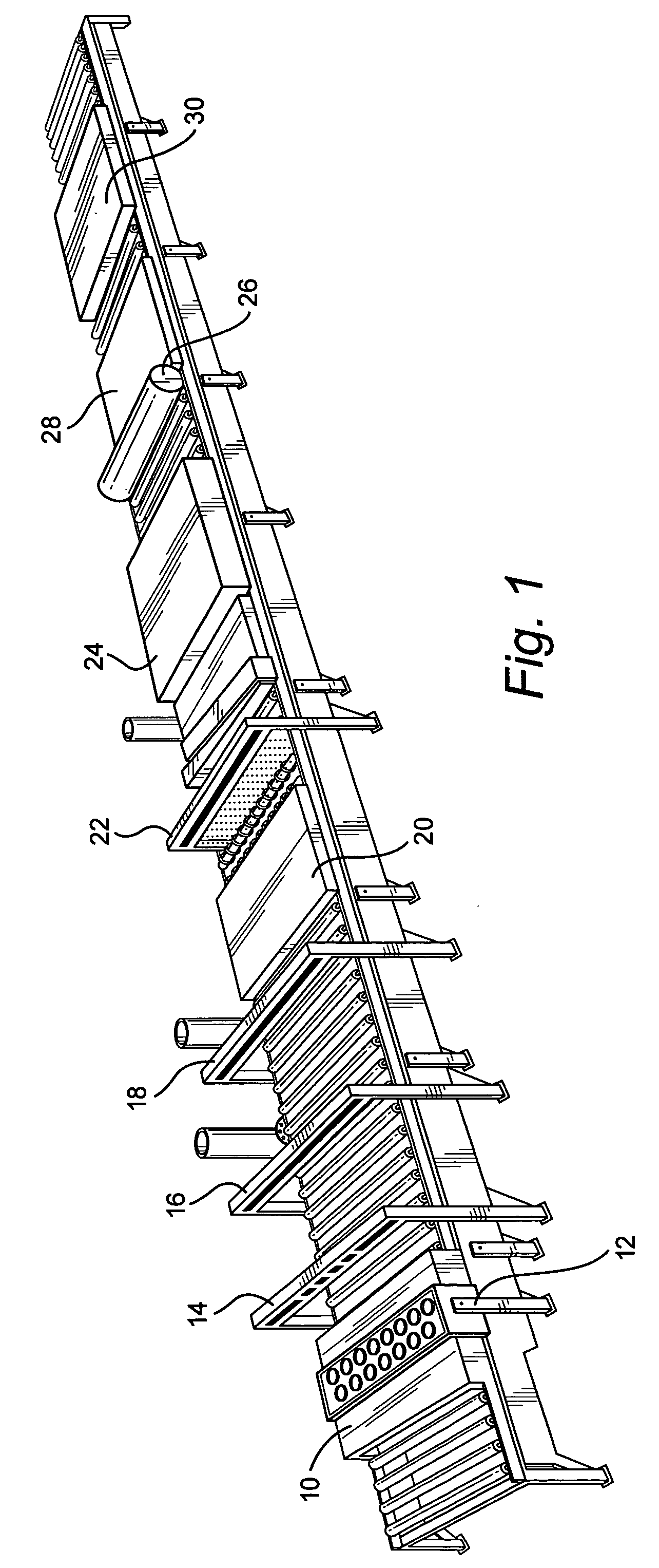

Method of manufacturing large dish reflectors for a solar concentrator apparatus

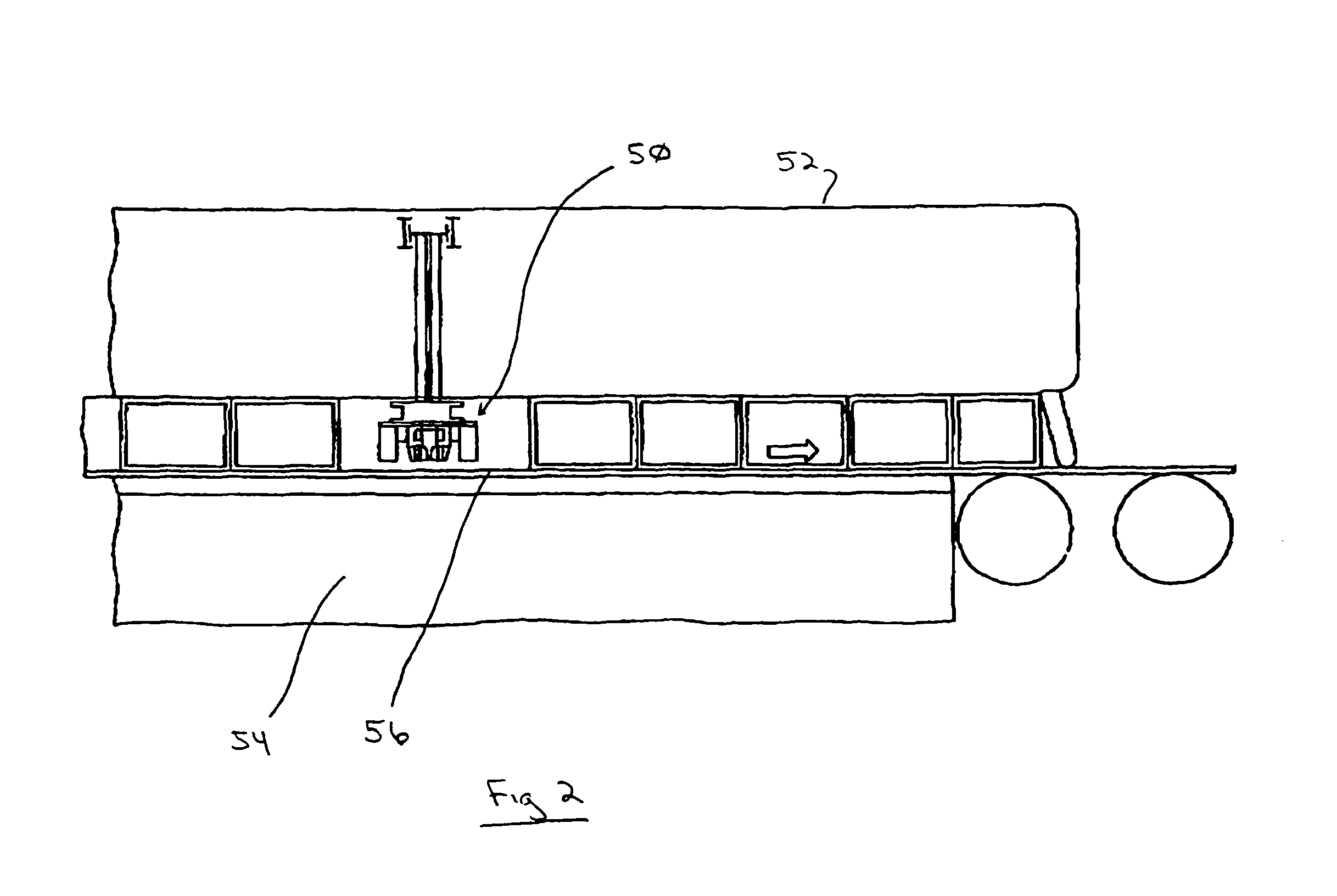

ActiveUS20090277224A1Reduce supporting costsMaximizes stiffnessSolar heating energySolar heat devicesProduction rateProduction line

A method of manufacturing monolithic glass reflectors for concentrating sunlight in a solar energy system is disclosed. The method of manufacturing allows large monolithic glass reflectors to be made from float glass in order to realize significant cost savings on the total system cost for a solar energy system. The method of manufacture includes steps of heating a sheet of float glass positioned over a concave mold until the sheet of glass sags and stretches to conform to the shape of the mold. The edges of the dish-shaped glass are rolled for structural stiffening around the periphery. The dish-shaped glass is then silvered to create a dish-shaped mirror that reflects solar radiation to a focus. The surface of the mold that contacts the float glass preferably has a grooved surface profile comprising a plurality of cusps and concave valleys. This grooved profile minimizes the contact area and marring of the specular glass surface, reduces parasitic heat transfer into the mold and increases mold lifetime. The disclosed method of manufacture is capable of high production rates sufficiently fast to accommodate the output of a conventional float glass production line so that monolithic glass reflectors can be produced as quickly as a float glass production can make sheets of float glass to be used in the process.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Low iron high transmission float glass for solar cell applications and method of making same

Certain example embodiments of this invention relate to a high transmission low iron glass, which is highly oxidized and made using the float process, for use in photovoltaic devices such as solar cells or the like. In certain example embodiments, the glass composition used for the glass is made via the float process using an extremely high and positive batch redox in order to reduce % FeO to a low level and permit the glass to consistently realize a combination of high visible transmission (Lta or Tvis), high infrared (IR) transmission, and high total solar (TS) transmission. The glass substrate may be patterned or not patterned in different example embodiments of this invention.

Owner:GUARDIAN GLASS LLC

Kitchen appliance having floating glass panel

A kitchen appliance includes a door having an outer panel portion and an inner panel portion, with a plurality of mounting members being spaced about the outer panel portion of the door. A glass panel assembly, including a glass panel and a plurality of mounting elements, is detachably mounted to the door through the interengagement of the plurality of mounting elements with the plurality of mounting members. The mounting elements are adhesively secured to the glass panel. Neither the plurality of mounting members nor the plurality of mounting elements are readily visible normally when viewing the kitchen appliance such that the glass panel appears to float relative to the door.

Owner:MAYTAG

Glass ceramic and method of producing the same

ActiveUS20050096208A1High surface precisionThickness variationTransistorGlass tempering apparatusSolar cellGlass-ceramic

A glass ceramic comprises (in wt.-% on oxide basis): SiO2 35 to 60, B2O3>4 to 10, P2O5 0 to 10, Al2O3 16.5 to 40, TiO2 1 to 10, Ta2O5 0 to 8, Y2O3 0 to 6, ZrO21 to 10, MgO 6 to 20, CaO 0 to 10, SrO 0 to 4, BaO 0 to 8, ZnO 0 to 4, SnO2+CeO2 0 to 4, SO42−+Cl− 0 to 4, wherein the total content (SnO2+CeO2+S042−+Cl−) is between 0.01 and 4 wt.-%. The glass ceramic may be processed by the float glass method, may be transparent and is, inter alia, suitable as a substrate for thin film semiconductors, in particular for display applications, solar cells etc.

Owner:SCHOTT AG

Chemically and thermally pre-stressable lithium aluminosilicate float glass of high temperature resistance

ActiveCN1693247AGood quality bubblesImprove heat resistanceBase layers for recording layersGlass tempering apparatusArsenic oxideTemperature resistance

The invention provides a lithium aluminosilicate flat float glass with a high thermal stability which can be chemically and thermally tempered and is suitable for economical and environmentally friendly production. The lithium aluminosilicate flat float glass which can be chemically and thermally tempered, is refined without using a standard refining agent such as arsenic oxide and / or antimony oxide and has excellent thermal stability is constituted so as to contain 2.5-6.0 wt.% Li2O, 0<4 wt.% in total of Na2O+K2O, 0-4 wt.% B2O3, 15-30 wt.% Al2O3, 55-75 wt.% SiO2and <2 wt.% in total of TiO2+ZrO2(the undesirable crystallization of [beta]-quartz and / or keatite solid solution is prevented) as main components per the weight of the total compositions.

Owner:SCHOTT AG

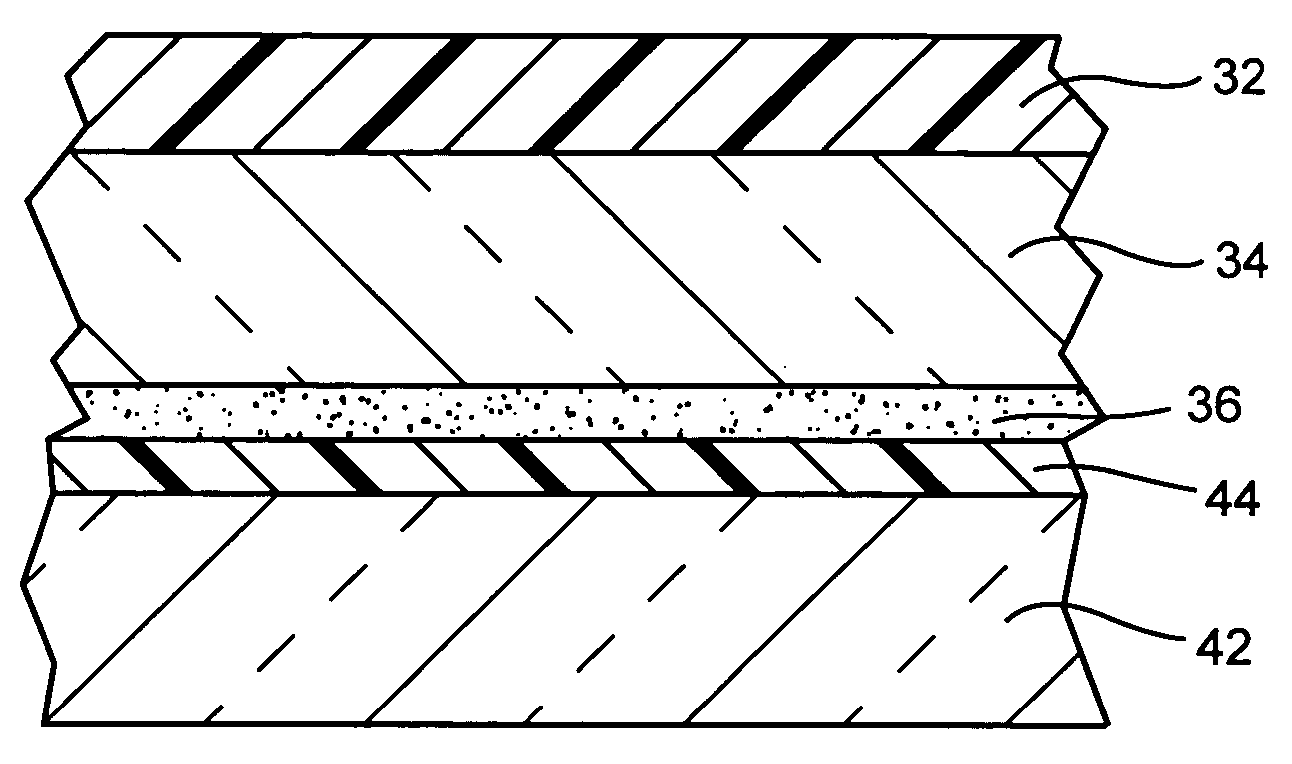

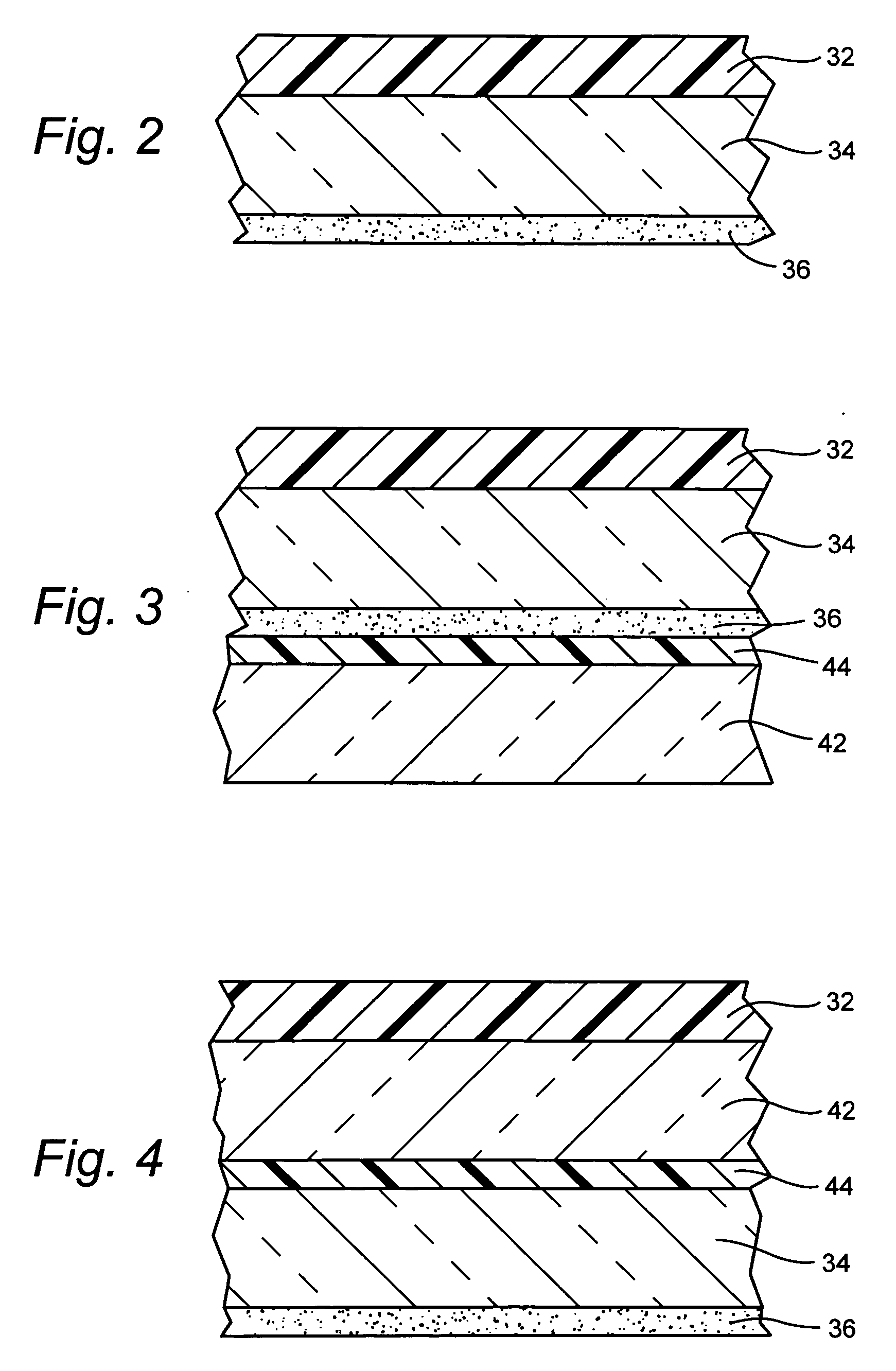

Electrochromic window fabrication methods

ActiveUS20120182593A1Maximize effective useLamination ancillary operationsLight protection screensInsulated glazingEngineering

Methods of manufacturing electrochromic windows are described. An electrochromic device is fabricated to substantially cover a glass sheet, for example float glass, and a cutting pattern is defined based on one or more low-defectivity areas in the device from which one or more electrochromic panes are cut. Laser scribes and / or bus bars may be added prior to cutting the panes or after. Edge deletion can also be performed prior to or after cutting the electrochromic panes from the glass sheet. Insulated glass units (IGUs) are fabricated from the electrochromic panes and optionally one or more of the panes of the IGU are strengthened.

Owner:VIEW INC

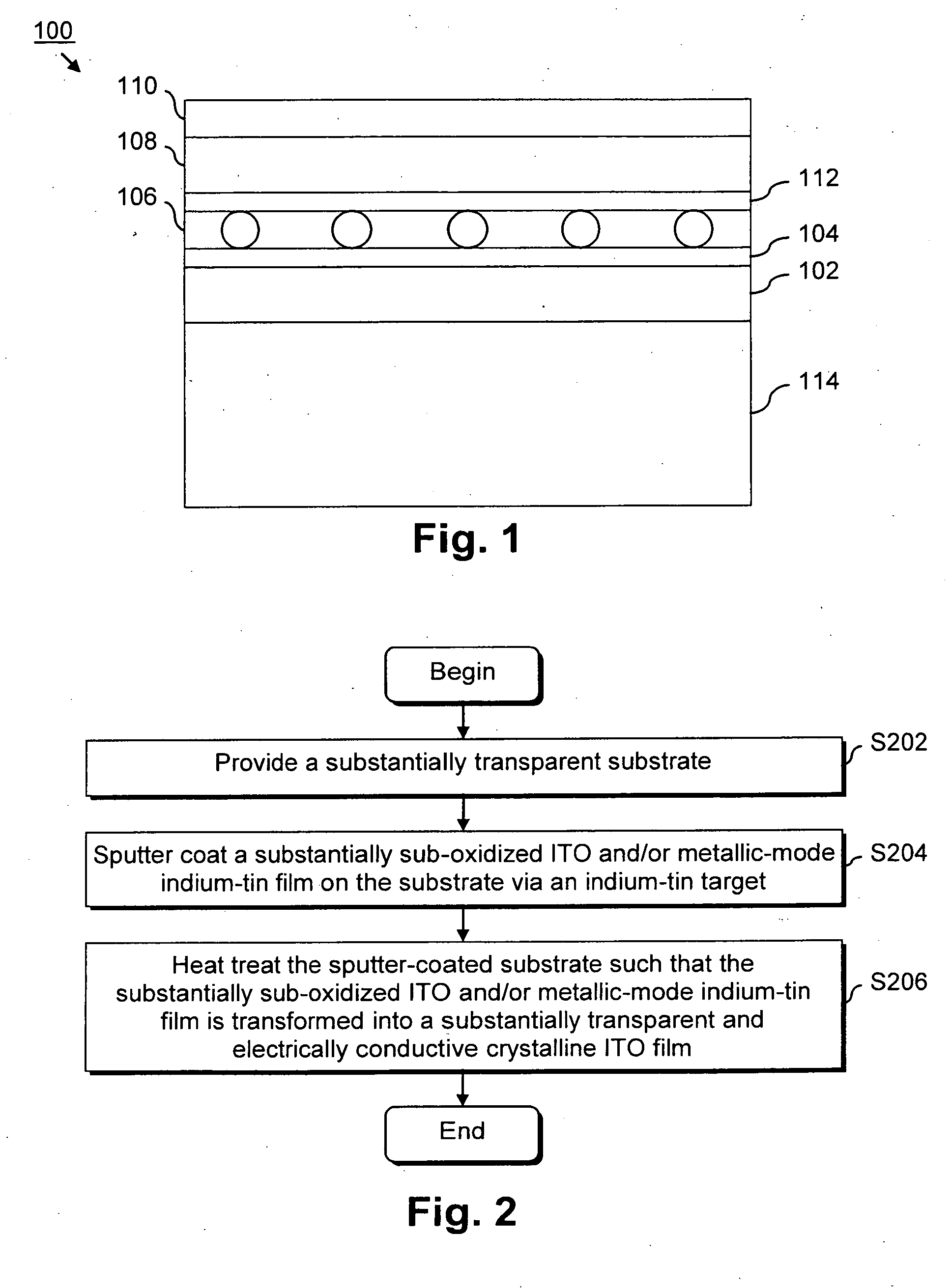

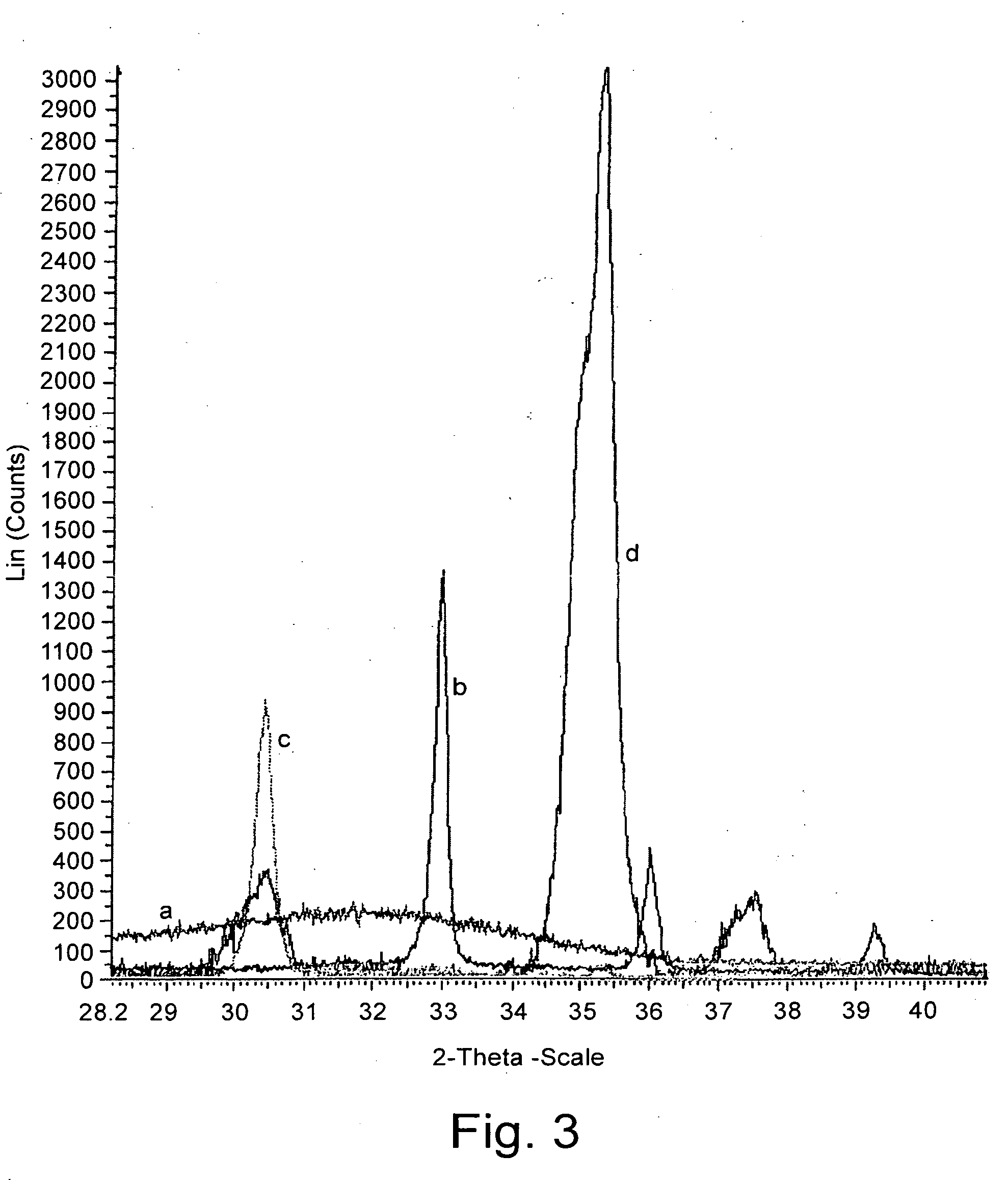

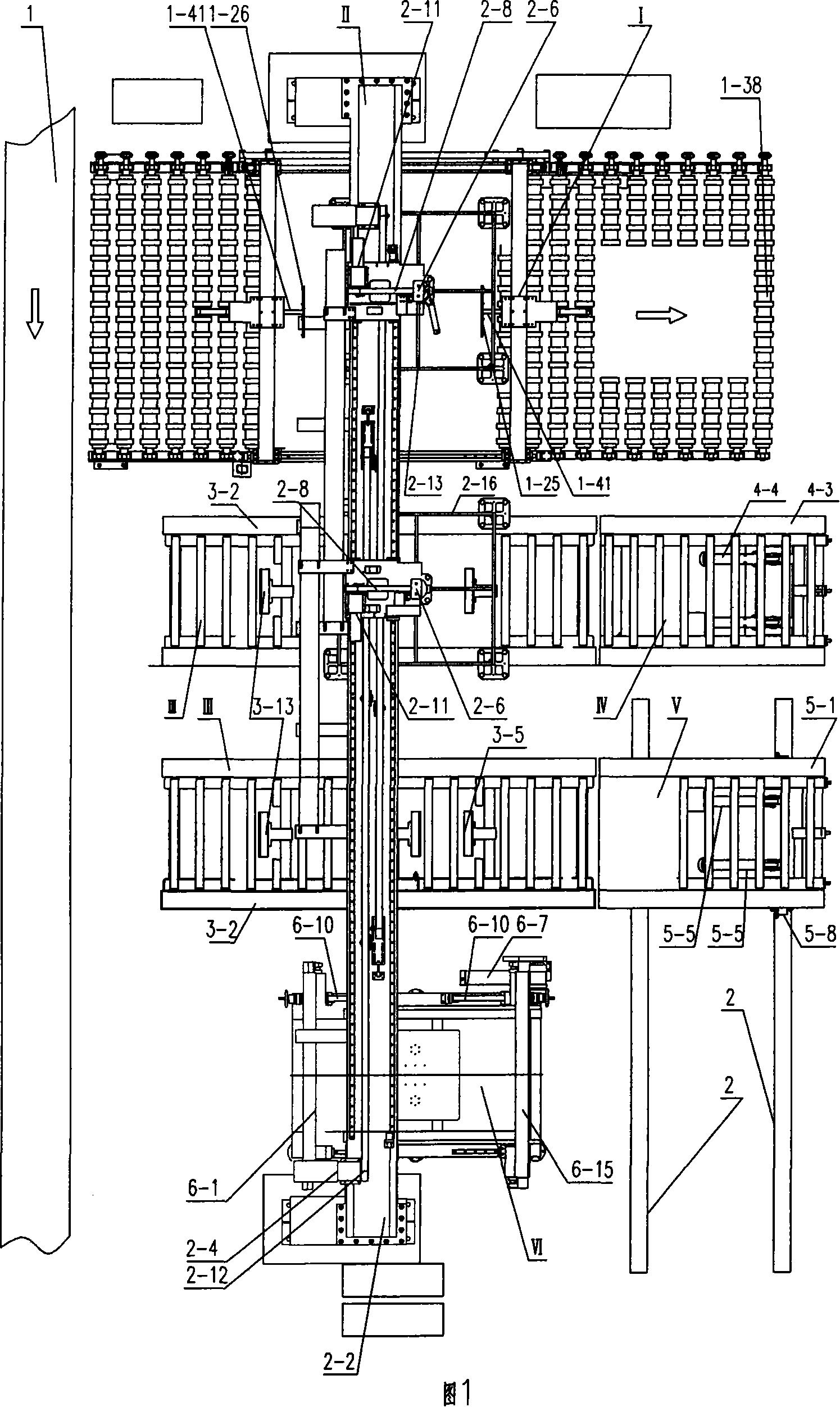

ITO-coated article for use with touch panel display assemblies, and/or method of making the same

ActiveUS20100122900A1Increase production costLow costVacuum evaporation coatingSputtering coatingIndiumIndium tin oxide

Certain example embodiments of this invention relate to techniques for making a coated article including a transparent conductive indium-tin-oxide (ITO) film supported by a heat treated glass substrate. A substantially sub-oxidized ITO or metallic indium-tin (InSn) film is sputter-deposited onto a glass substrate at room temperature. The glass substrate with the as-deposited film thereon is subjected to elevated temperatures. Thermal tempering or heat strengthening causes the as-deposited film to be transformed into a crystalline transparent conductive ITO film. Advantageously, this may reduce the cost of touch panel assemblies, e.g., because of the higher rates of the ITO deposition in the metallic mode. The cost of touch-panel assemblies may be further reduced through the use of float glass.

Owner:GUARDIAN GLASS LLC

Preparation method of self-cleaning ceramic nanometer glass antireflective coating material and preparation method of reflection deducting coating

InactiveCN102061111AWith self-cleaning effectHas surface antistatic propertiesCoatingsWater basedTin dioxide

The invention discloses a preparation method of a self-cleaning ceramic nanometer glass antireflective coating material and a coating preparing technique thereof. The reflection deducting coating is formed by coating a composite of amorphous porous silicon dioxide and one or a plurality of titanium dioxide, zirconium dioxide, tin dioxide, ceria, yttria, and the like on the surface of photovaltic glass or common float glass, the reflection deducting coating coated on the surface of the glass has the characteristics of self-cleaning effect, high ceramic hardness and wear resistance. surface antistatic property of dust protection, aging resistance and zero-decrement, can be used for 25 years; and within 250nm-2500nm, the degree of transparency of the photovoltaic glass coated with the reflection deducting coating can be improved by 2.5%-3.5%, and the degree of transparency of the common glass coated with the reflection deducting coating can be improved by 2.8%-3.8%. The nanometer antireflective coating material provided by the invention is a water-based paint, the three wastes are not generated in the preparing course, the preparation method is simple, and the cost is low; and the coating preparing technical process is low in requirement and simple and easy to operate, the energy is saved, thereby being suitable for industrial production in large scale.

Owner:中山市旌旗纳米材料科技有限公司

Deposition of silicon oxide coating on glass

Owner:PILKINGTON PLC

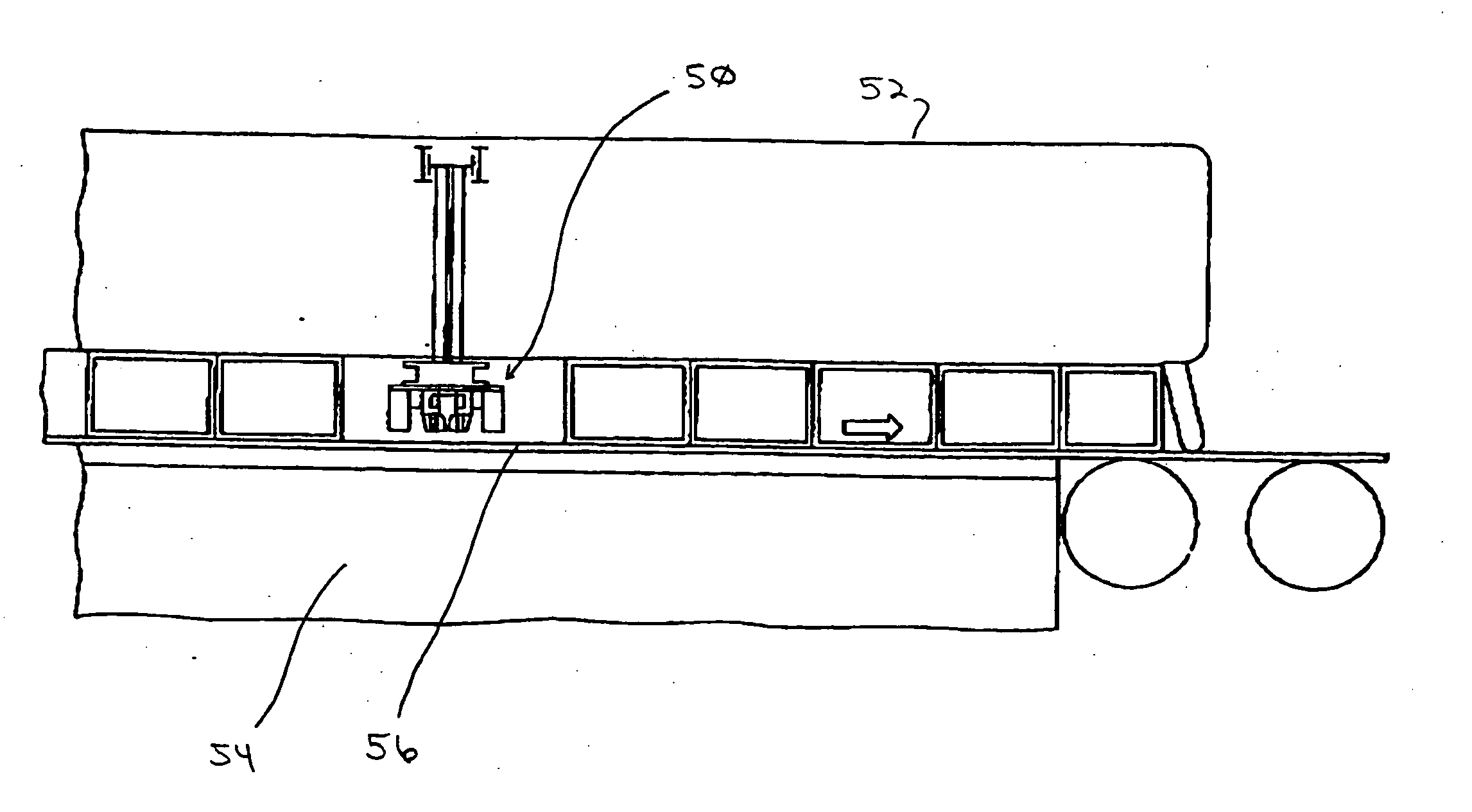

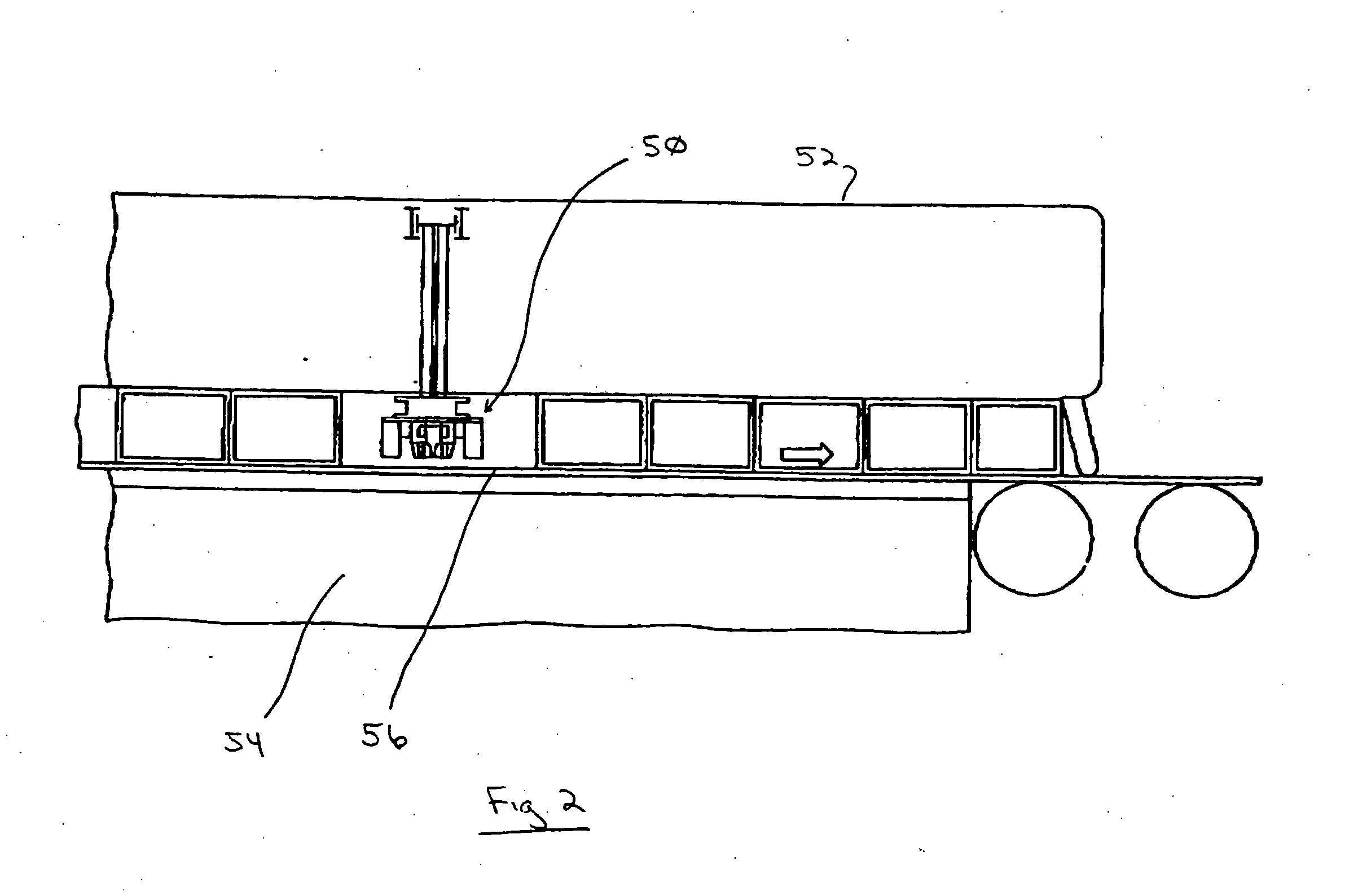

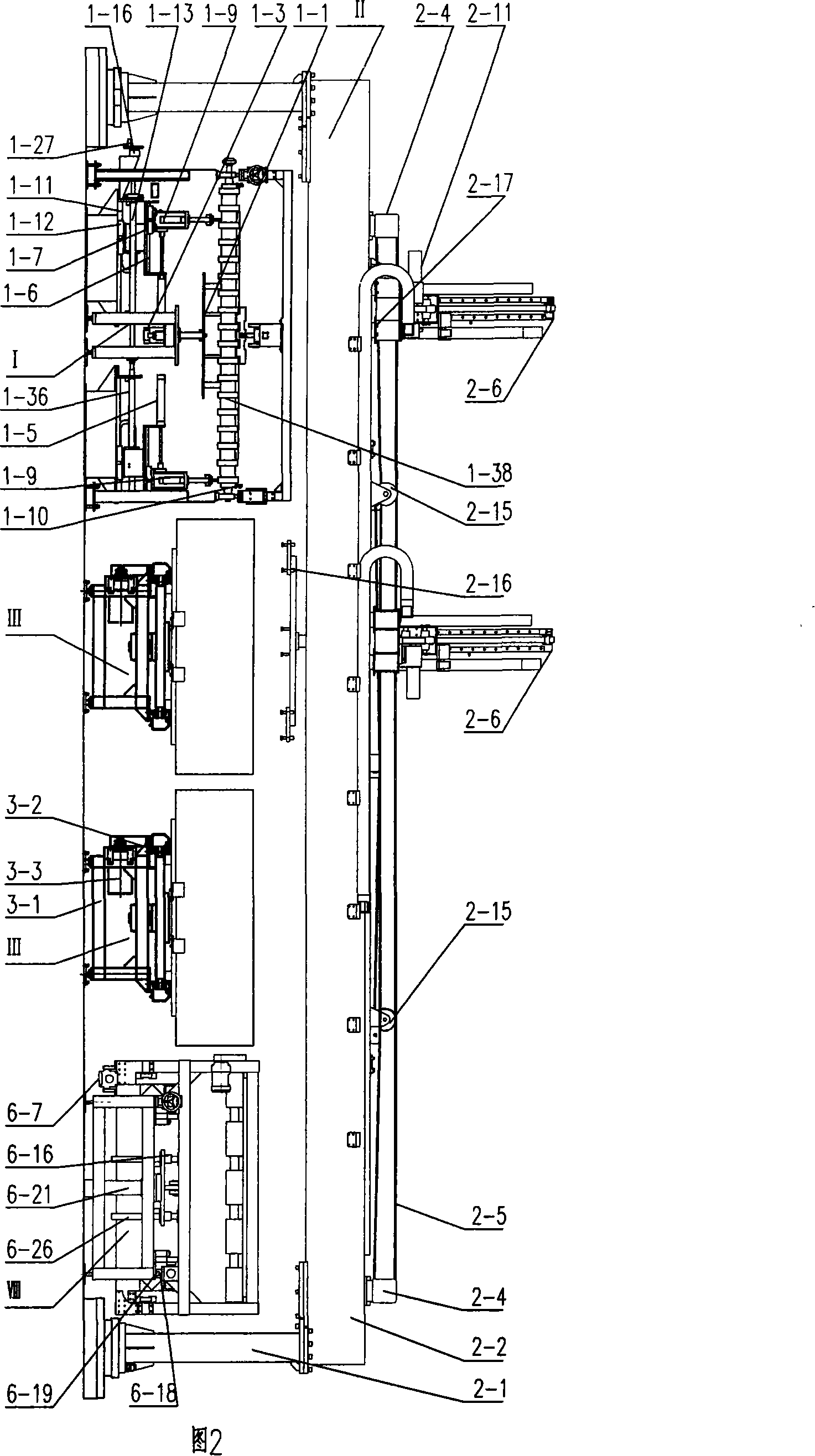

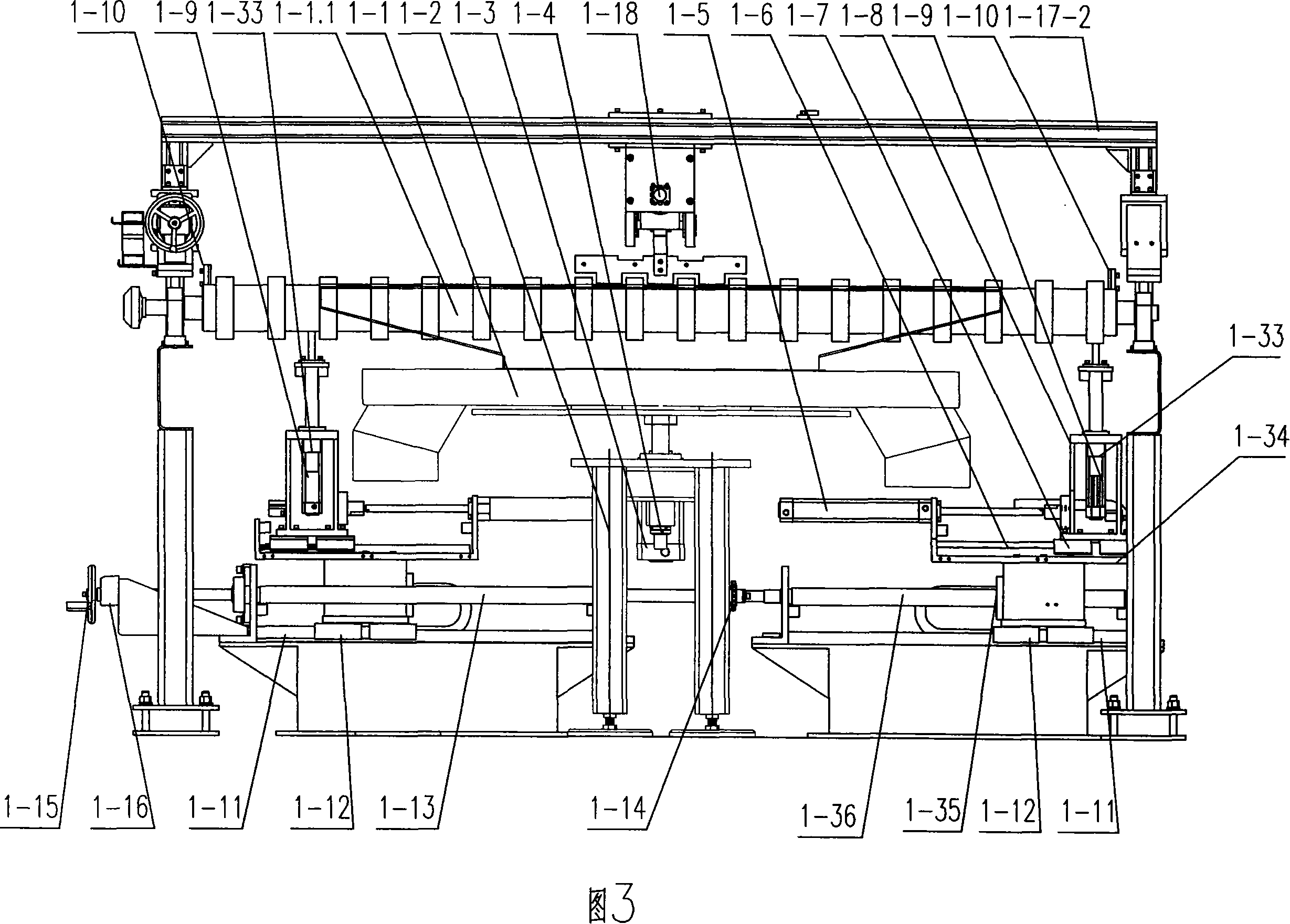

Automatic sheet-fetching system of ultra-thin glass

ActiveCN101139015ATimely crawlSolve the key technical problems of offlineRegistering devicesCharge manipulationEngineeringThin glass

The present invention discloses a ultra-thin glass automatic slicing system and comprises a glass transmission branch, a clean transportation robot and a packing box fixed turnover unit as well as a glass centering positioning unit, a packing box transmission positioning unit, a packing box moving turnover unit and a septum paper supplying unit. A glass transmission main line is vertical to the glass transmission branch and the glass centering positioning unit is arranged above and below the glass transmission branch; two packing box transmission positioning units are arranged in parallel with the glass transmission branch, wherein, the terminal of the packing box transmission positioning unit arranged close to the glass transmission branch is provided with the packing box fixed turnover unit; the terminal of the packing box transmission positioning unit far away from the glass transmission branch is provided with the packing box moving turnover unit; the septum paper supplying unit is arranged in parallel to the packing box transmission positioning unit; the present invention can meet the quality standard of glass in electronic industry and packing requirement of ultra-thin glass storage and transmission at the same time, and improve yield and packing quality of ultra-thin float glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Silicone rubber based pressure sensitive adhesive sheet

ActiveUS20060008662A1Improve adhesionThin material handlingPressure sensitive film/foil adhesivesPolymer sciencePlatinum catalyst

There are disclosed a silicone rubber based pressure sensitive adhesive sheet comprising a transparent substrate film and a silicone rubber layer which is formed by coating the surface of the transparent substrate film with silicone rubber in an amount of 5 to 100 g / m2 (after drying) containing addition type organopolysiloxane composed of organopolysiloxane having a siloxane bond as a principal skeleton and bearing an alkenyl group and of organohydrogenpolysiloxane, the silicone rubber further containing 0.01 to 3.0 parts by mass of a platinum catalyst based on 100 parts by mass of the addition type organopolysiloxane, and then by curing the resultant coating, and which has adhesion for float glass in accordance with JIS Z 0237 being in the range of 10 to 1000 mN / 25 mm, holding power (load of one kg) of at least 24 hours and a 100% modulus in the range of 0.3 to 1.5 MPa. The resultant silicone rubber based pressure sensitive adhesive sheet is imparted with strong holding power, sufficient adhesiveness to the substrate film and sufficient removability from an adherend enabling repeated sticking even if an additive such as an adhesion improving agent is not blended, and at the same time which makes it possible to use as a releasing film, an inexpensive film not subjected to a releasing treatment.

Owner:LINTEC CORP

Kitchen appliance having a floating glass panel

A glass panel assembly for kitchen appliances includes a glass panel and a plurality of spacers. The spacers are mounted to an outer surface of the appliance and an inner surface of the glass panel. Preferably, the spacers are adhesively secured to the glass panel and are not visible when viewing the kitchen appliance from the front. Trim pieces fit between the glass panel and the appliance door to cover and further hide the spacers from view. The glass panel can be mounted to any outer surface of the appliance such as an appliance door, side walls or even a top wall. The particular construction of the spacers, in combination with the trim pieces creates an illusion that glass panel appears to float relative to the appliance.

Owner:MAYTAG

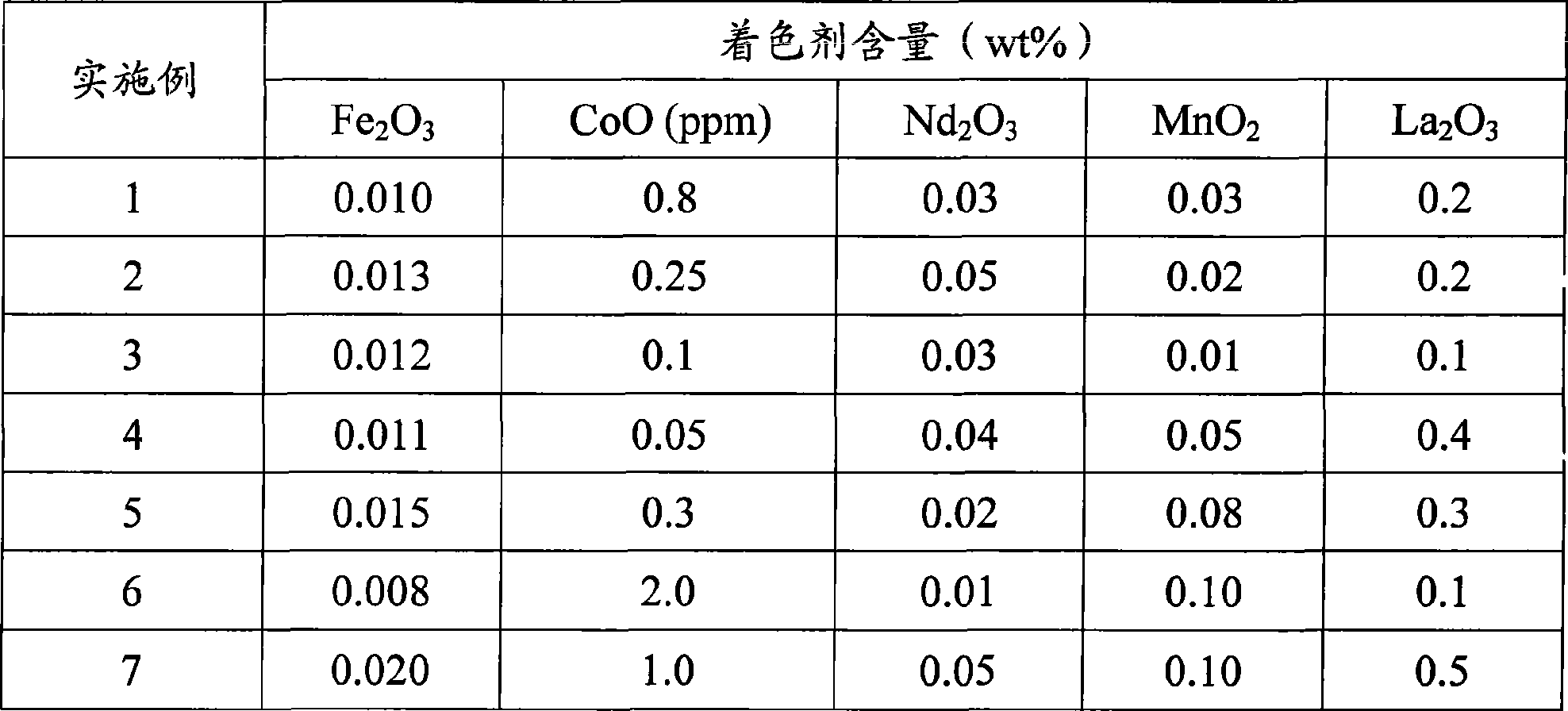

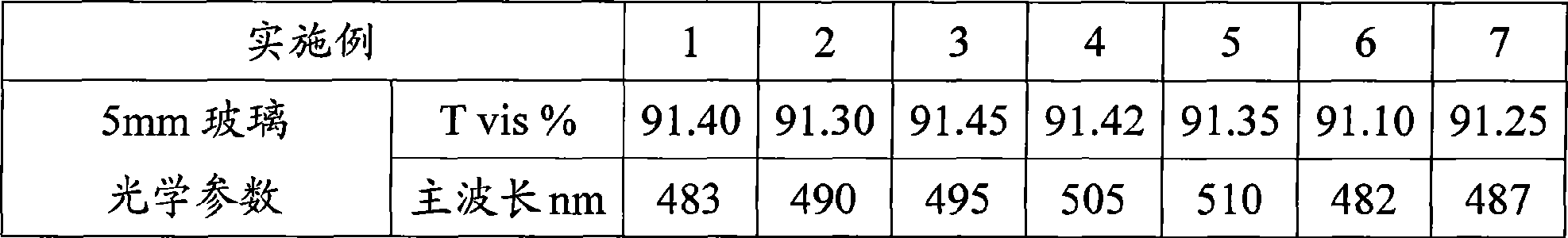

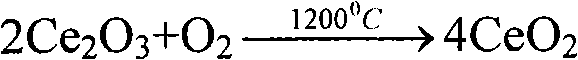

Ultra-white float glass

The invention relates to super-white float glass comprising a basic glass part and a colorant part, wherein the basic glass part comprises the following components: 65 to 75 weight percent of SiO2, 10 to 20 weight percent of Na2O, 5 to 15 weight percent of CaO, 0 to 5 weight percent of MgO, and 0 to 5 weight percent of Al2O3; and the colorant part comprises the following components counted by weight of the basic glass: 0 to 0.02 weight percent of Fe2O3, 0 to 2ppm of CoO, 0 to 5 weight percent of Nd2O3, 0 to 5 weight percent of La2O3, and 0 to 0.1 weight percent of MnO2. The finished product of the super-white float glass has the dominant wavelength range of between 480 and 510nm under the condition of the conversion into 5mm equivalent thickness, the visible light transmission rate of above 91 percent, and the light blue edge color.

Owner:CSG HOLDING

Photo-induced hydrophilic article and method of making same

InactiveUS7960043B2Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

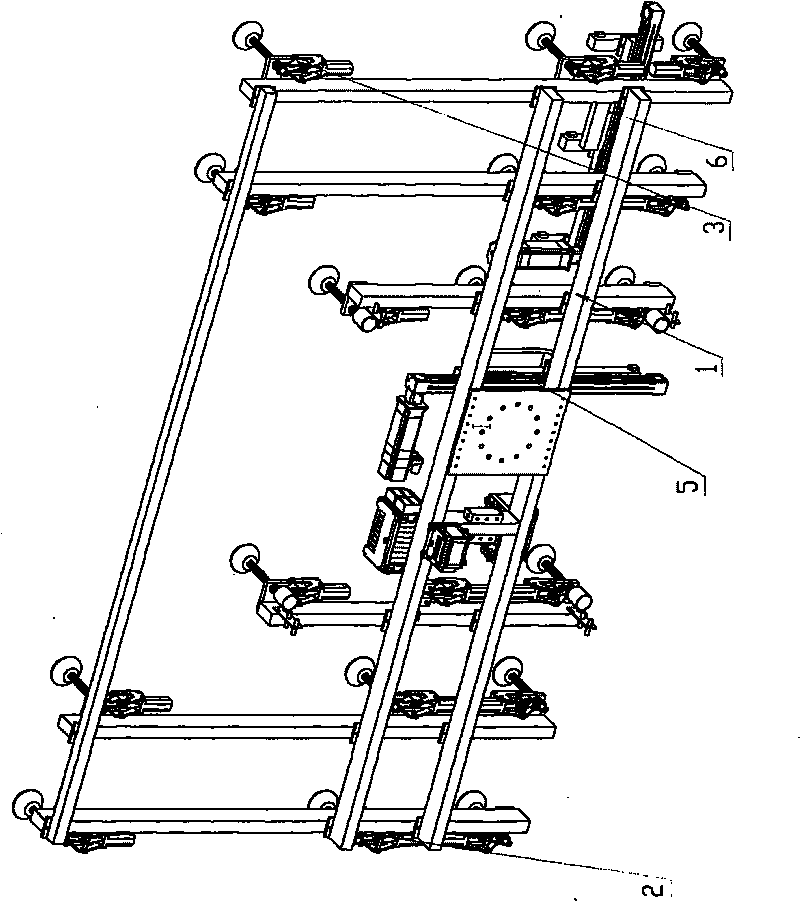

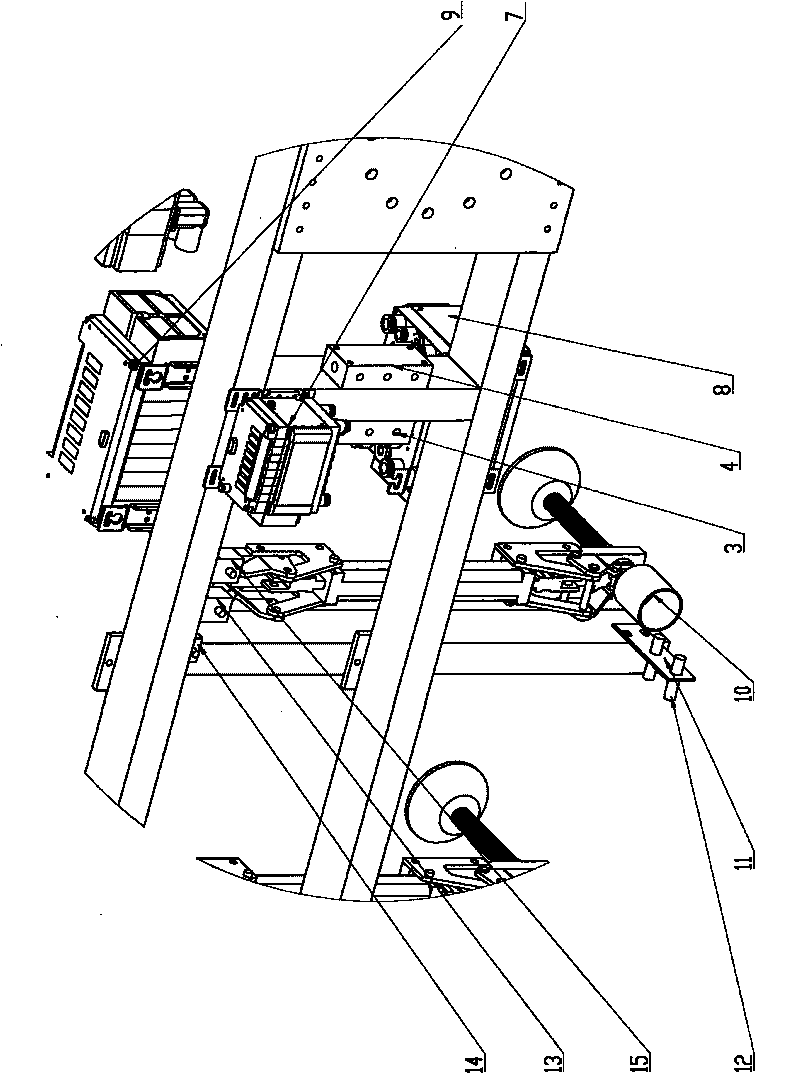

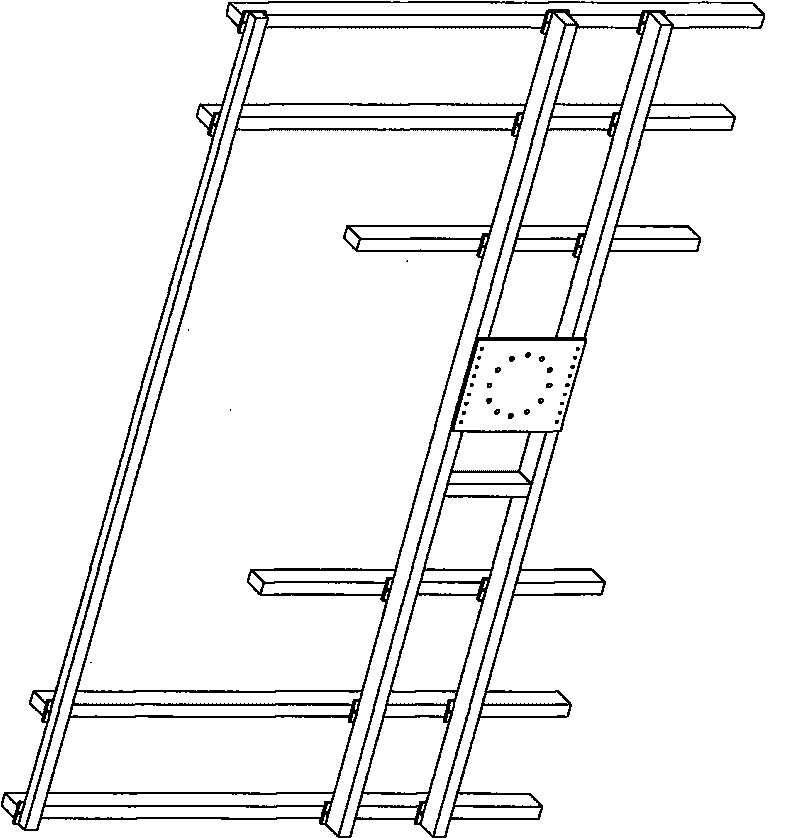

Sucking disc assembling bracket for float glass production line cold side glass stacking

ActiveCN101723182ARelative position deviation correctionAvoid smashingGlass transportation apparatusCharge manipulationCold sideProduction line

The invention relates to a sucking disc assembling bracket for float glass production line cold side glass stacking, comprising a sucking disc bracket (1), a plurality of groups of sucking disc mechanisms (2), a set of two-point detection component (6), a set of one-point detection component (5) and four sets of anti-collision detection components (10, 11, 12); a plurality of groups of the sucking disc mechanisms (2) are arranged at the bottom part of the sucking disc bracket (1), each group of the sucking disc mechanism (2) comprises a bottom plate (2.1), a bracket(2.2), a movable plate (2.3),an air cylinder (2.4), a sucking disc (2.5), a sucking disc rod (2.6), a sucking disc rod guide sleeve (2.7), a guide sleeve fixed nut (2.8) and a spring (2.9); the two-point detection component (6) is laterally arranged at the bottom part of the sucking disc bracket (1); the one-point detection component (5) is longitudinally arranged at the bottom part of the sucking disc bracket (1), and four sets of the anti-collision detection components are arranged on the sucking disc bracket (1) in a rectangle way. The sucking disc assembling bracket for float glass production line cold side glass stacking can automatically suck the glass, after suction is carried out, the glass is detected and placed on the bracket, and the anti-collision detection is carried out in the whole process.

Owner:JIANGSU JINMING IND ROBOT AUTOMATION

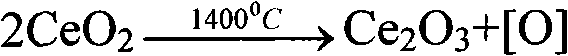

Ultra-white glass

The invention relates to ultra-white glass, belonging to the preparation field of glass. The preparation method of the ultra-white glass is as follows: La2(CO3)3, Ce2(CO3)3, Nd2(CO3)3, MnO2, CoO and CuSO4 are added in common float glass to perform compound clarification and decoloring, wherein under the combined action of chemical decoloring and physical decoloring, the thickness of the molten glass is 4mm, the visible light transmittance is more than 94.5% under the wavelength of 380-780nm, the whiteness is less than 0.082, the flexural strength is more than 380MPa and the microhardness is more than 8320MPa. The ultra-white glass has the advantages of higher visible light transmittance, low whiteness, high flexural strength and higher microhardness; and the quality of the white float glass can be obviously increased. The ultra-white glass can be widely used in the fields such as building glass, photovoltaic technology, experimental apparatus and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

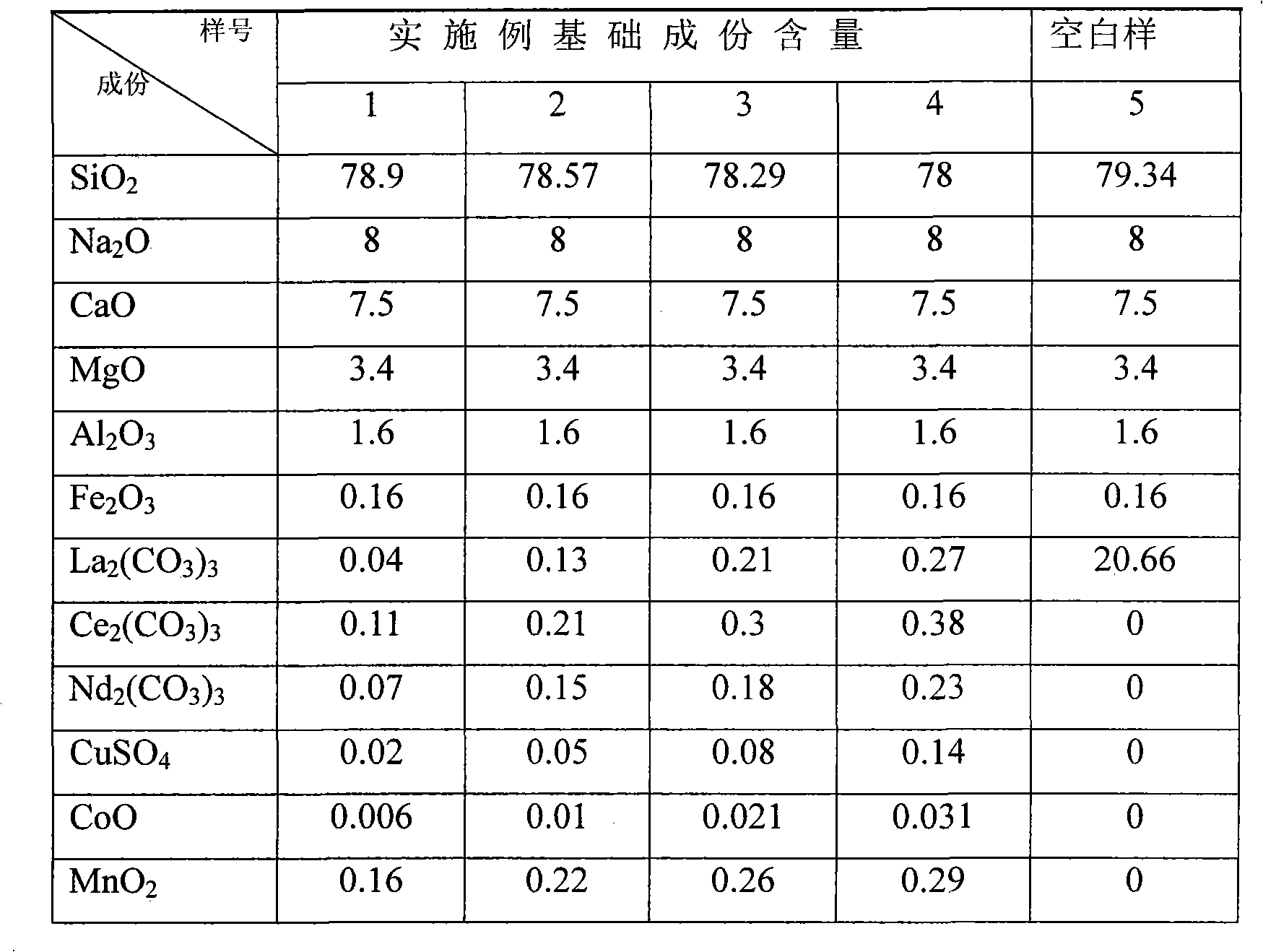

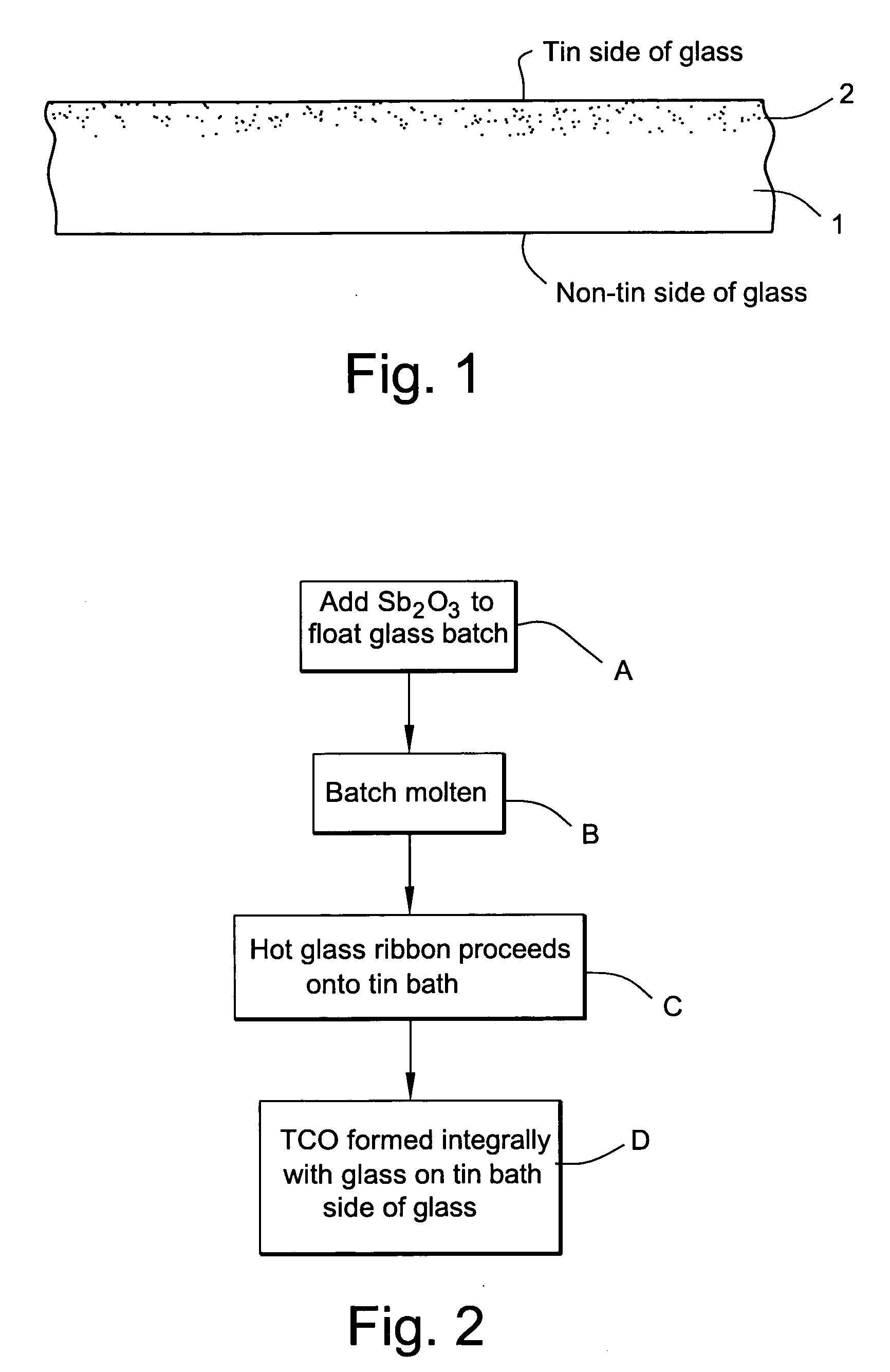

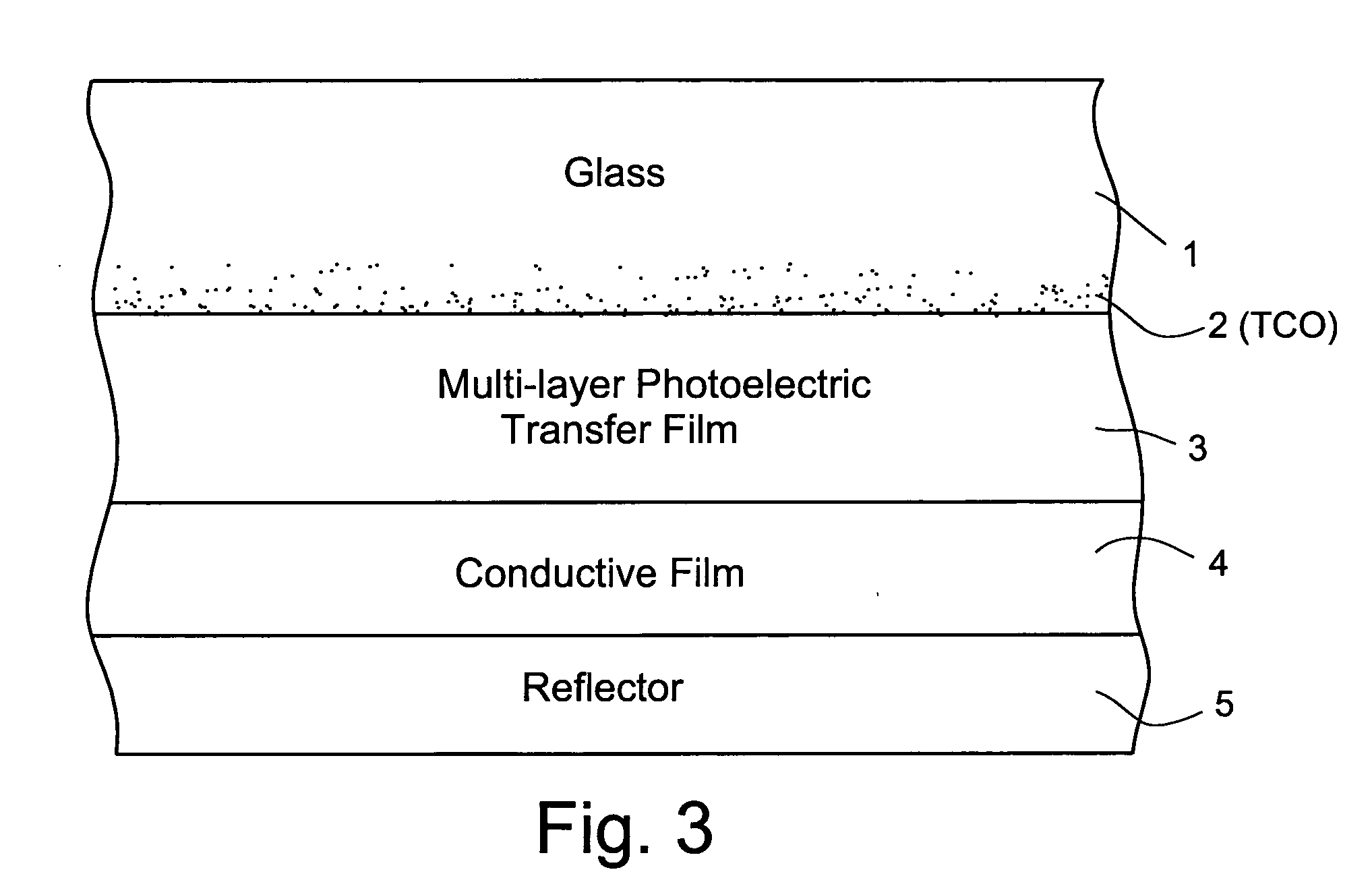

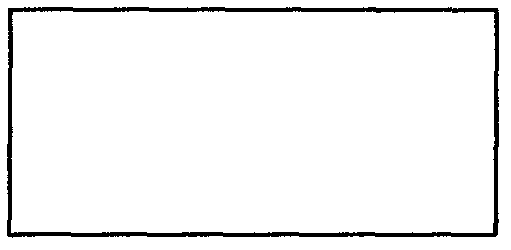

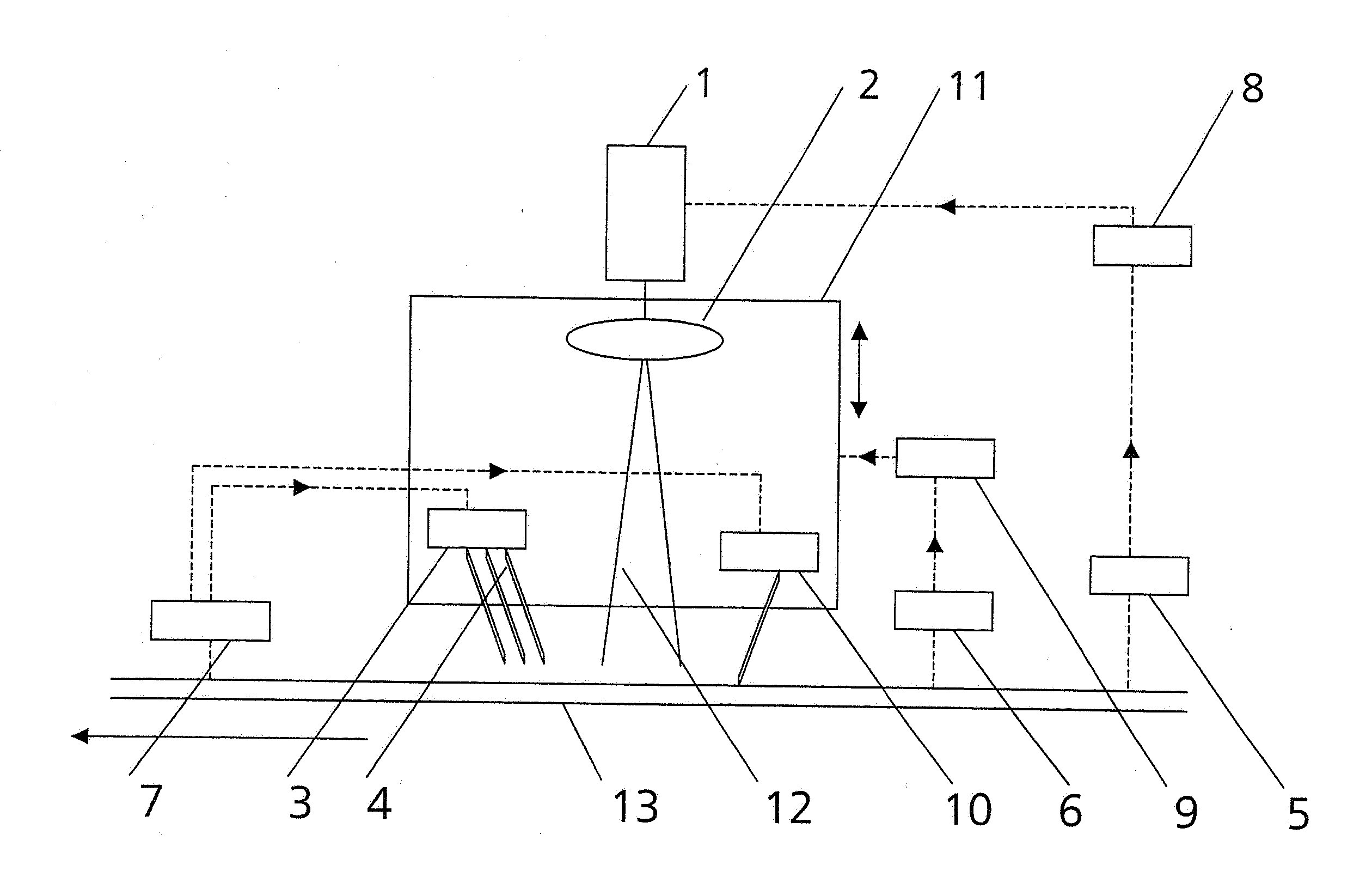

Method of making float glass with transparent conductive oxide (TCO) film integrally formed on tin bath side of glass and corresponding product

A method of making float glass is provided that results in a transparent conductive oxide (TCO) films being integrally formed with the float glass at the tin side thereof. In particular, a donor(s) such as antimony and / or an oxide thereof is added to the glass batch during the process of manufacture. The donor diffuses into the tin oxide inclusive layer adjacent the tin bath during the “float” manufacturing process, thereby increasing the number of electrons in the tin oxide inclusive layer so as to form a TCO film at the tin side of the glass.

Owner:GUARDIAN GLASS LLC

Manufacturing method of fireproof glass

The invention relates to a manufacturing method of fireproof glass. The method comprises: first conducting chemical tempering and physical tempering respectively on float glass that undergoes edge polishing after cutting, and specifically employing a high temperature salt solution of cesium and potassium to perform soaking during chemical tempering so as to realize chemical tempering of the glass; and then using a tempering furnace to carry out sharp air cooling molding. By means of precise control of the heating time of different thickness glass, and adjustment of the upper and lower air grid positions, air speed, and air pressure, the method provided in the invention can make the tempering cold air uniform, and performs arc-shaped tracking air cooling on glass corners, so that the compressive stress of the glass can reach 190-210MPa.

Owner:杭州福隆鼎门窗幕墙有限公司

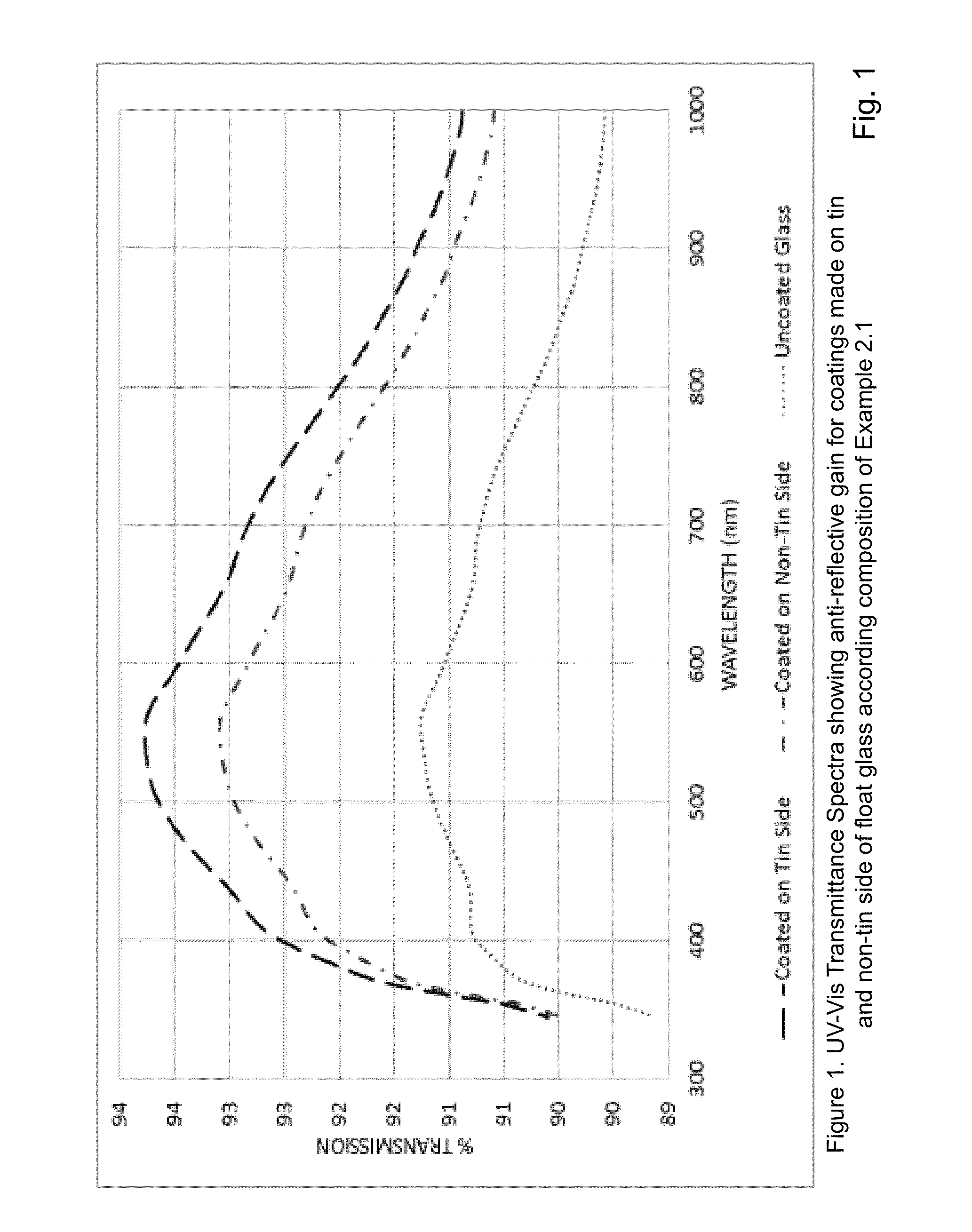

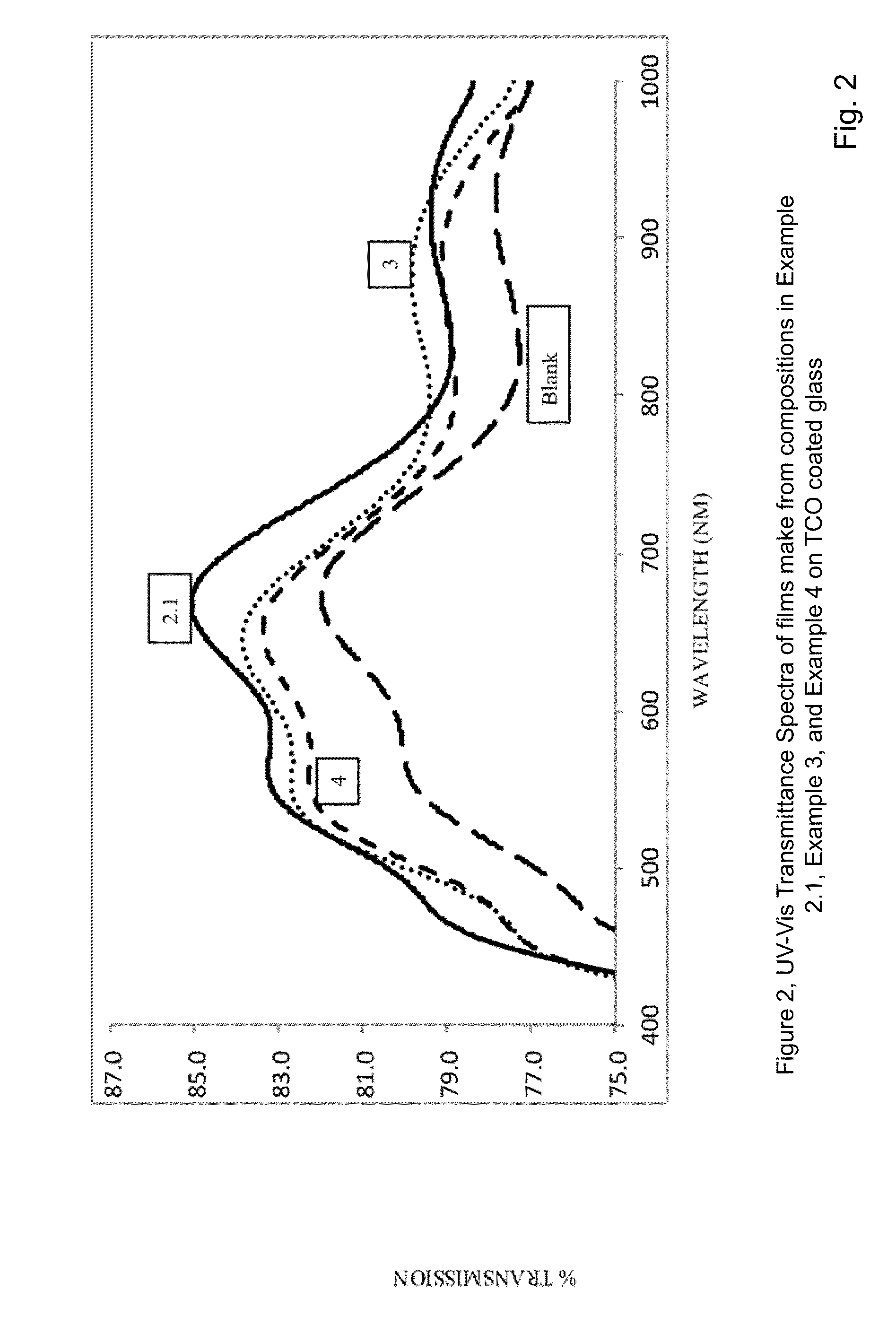

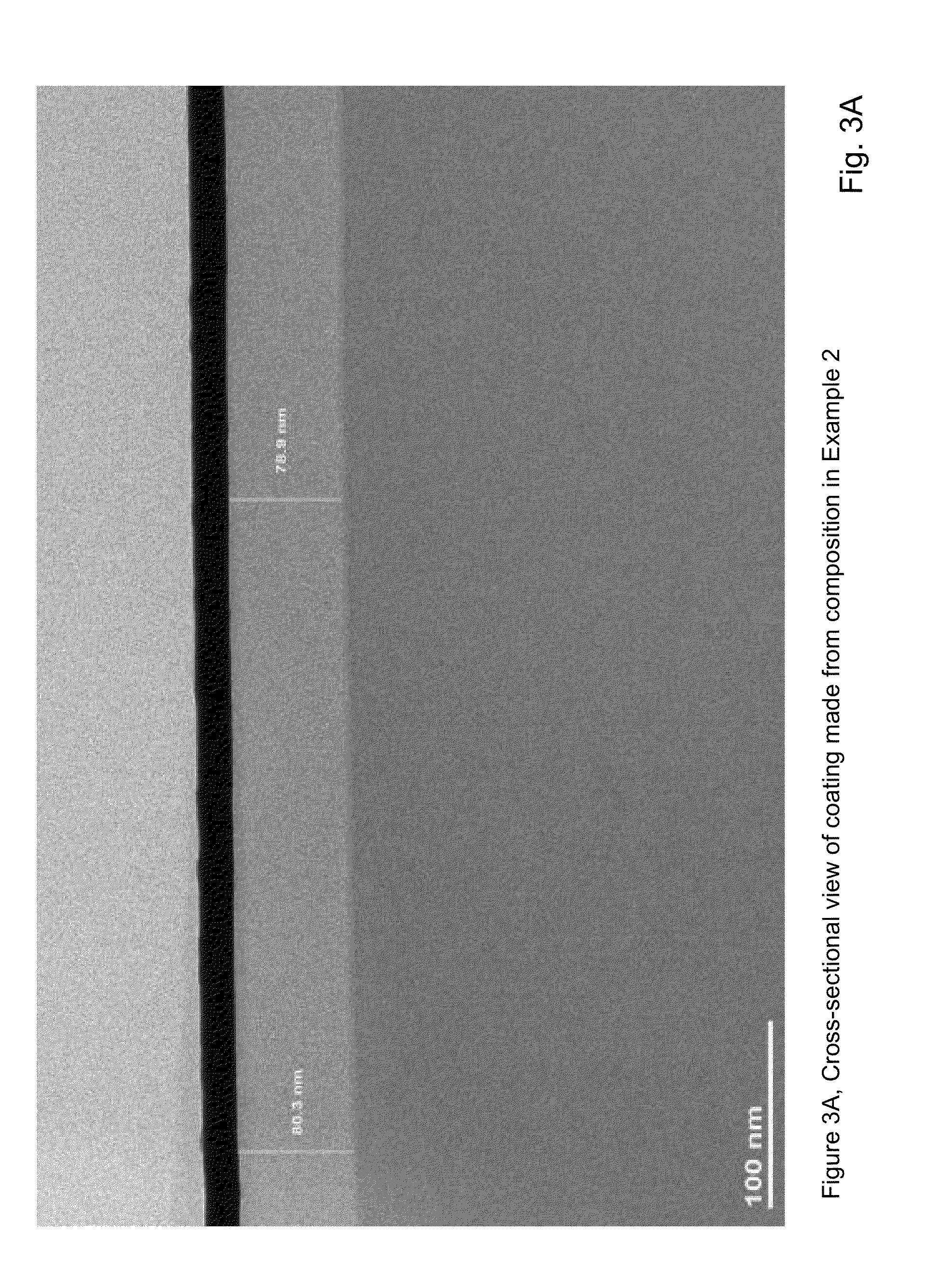

Tuning the Anti-reflective, abrasion resistance, Anti-soiling and self-cleaning properties of transparent coatings for different glass substrates and solar cells

InactiveUS20140261615A1Improve transmittanceEnhanced interactionMirrorsPV power plantsSoil propertiesSilanes

Functionalized coatings preferentially coated on the tin-side of float glass used in solar and other applications are disclosed. Coating compositions include silane-based precursors that are used to form coatings through a sol-gel process including hydrolyzed alkoxysilane-based sols. The coatings are characterized by anti-reflective, abrasion resistant, and anti-soiling properties and the tunability of those properties with respect to different applications. The coatings formed from the compositions described herein have wide application, including, for example, use as abrasion resistant coatings on the outer glass of solar modules, wherein the coating adheres through siloxane linkages. In some embodiments, when applied to glass and cured at a temperature of less than 300° C., the dried sol gel has abrasion resistance sufficient to pass standard EN-1096-2 with a loss of transmission of no more than 0.5% and enables a post-test light transmission gain of greater than 1% as compared to uncoated glass.

Owner:ENKI TECH

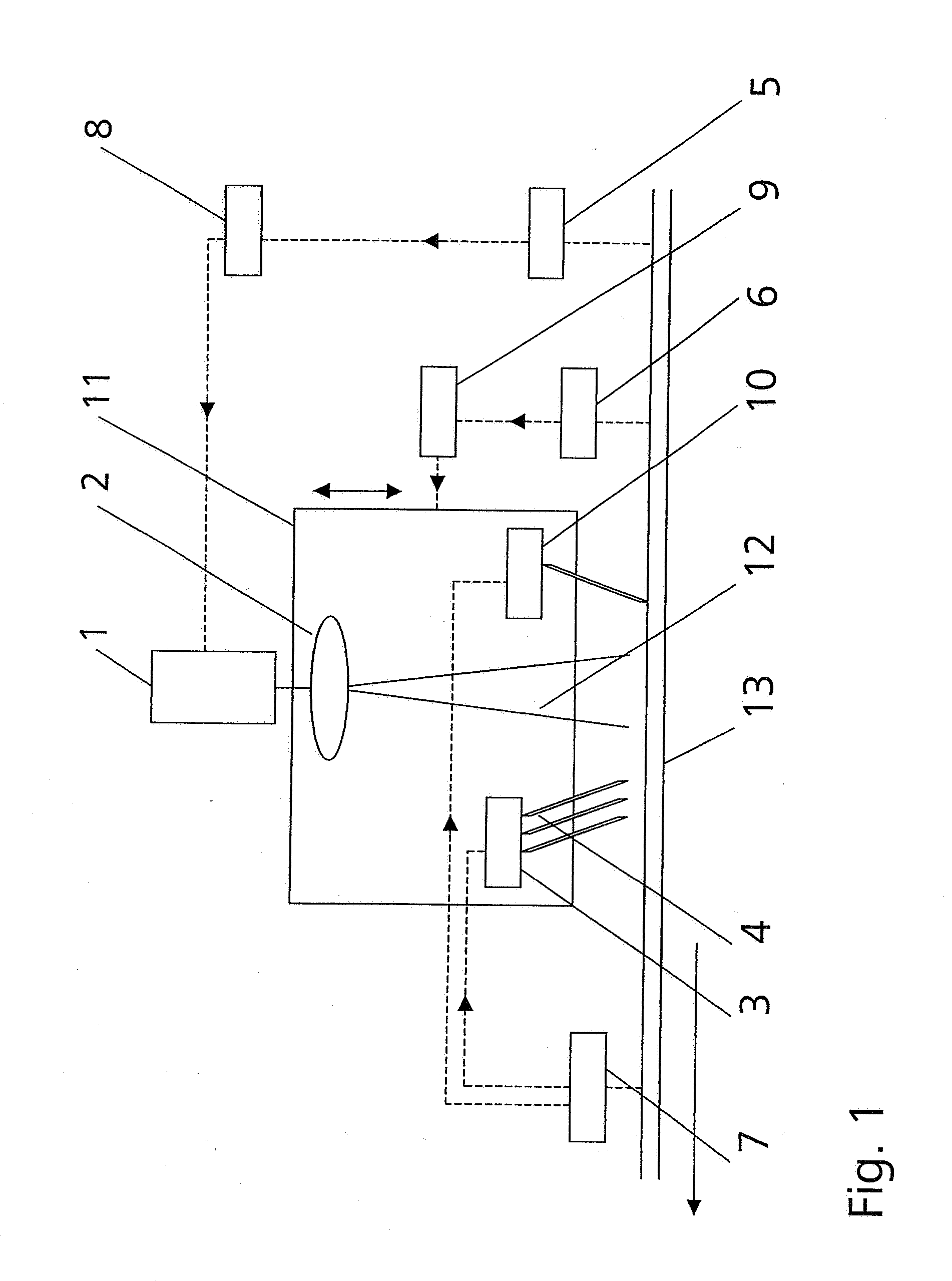

Method and apparatus for trimming the edges of a float glass ribbon

InactiveUS20070275338A1Speed up the processCharge manipulationDrying machines with progressive movementsEngineeringBeam shaping

A method and apparatus for trimming the edges of a float glass ribbon whose thickness can vary between 0.4 mm and 24 mm in which a specific depth crack is generated for the respective thickness. The depth of the crack is actively influenced by energy introduced by means of a laser which is controlled as a function of the surface temperature of the float glass ribbon and by a subsequent cooling whose acting period is variable. To ensure a permanently reliable process, the severing crack and the thickness of the float glass ribbon are detected in order to initiate a new initial crack immediately in the event that the severing crack should break up and so that a cutting unit comprising the scribing device, the beam-shaping optics and the cooling nozzles is always at a constant vertical distance from the surface of the float glass ribbon. The method and apparatus are distinguished particularly by the fact that only a low laser power is required.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

Painted glass tiles, panels and the like and method for producing painted glass tiles and panels

InactiveUS20060115651A1Reduce and minimize corrosionAbrasion resistanceCovering/liningsSpecial ornamental structuresProduction lineBrick

A process and apparatus for painting float glass in particular using a production line that may also be used as or is similar to a mirror line, to produce decorative glass panels. In an embodiment of the invention, painted glass tiles are cut from the glass panels after the paint has dried / cured using a typical glass panel cutter. As such, a mass production technique is provided for making painted glass tiles, particularly for residential use.

Owner:GUARDIAN GLASS LLC

Sun blocking stack

The invention relates to a multilayer sun blocking stack formed on a sheet of vitreous material, comprising at least one functional layer made from a material that reflects infrared radiation and comprising at least two dielectric coatings, each functional layer being surrounded by the dielectric coatings. Said stack, when it is placed on an ordinary clear float sodiocalcic glass sheet having a width of 6 mm, has a solar factor FS of less than 45 % and a light transmission TL of less than 70 %. According to the invention, the stack comprises an essentially metallic absorbent material based on the following elements: Pd, Pt, Au, Ir, Rh, Ru, Os, Co, Ni, Cu, Cr, La, Ce, Pr, Nd, W, Si, Zn, Mo, Mn, Ti, V, Nb, Hf, Ta and alloys thereof, placed in immediate proximity to the functional layer or included in this functional layer. The invention is particularly advantageous for forming selective glazings exhibiting a high level of sun blocking and having a nice aesthetic appearance and, in particular, glazings having been subjected to a high-temperature tempering and / or bending heat treatment.

Owner:AGC GLASS EUROPE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com