Patents

Literature

70results about How to "High surface precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass ceramic and method of producing the same

ActiveUS20050096208A1High surface precisionThickness variationTransistorGlass tempering apparatusSolar cellGlass-ceramic

A glass ceramic comprises (in wt.-% on oxide basis): SiO2 35 to 60, B2O3>4 to 10, P2O5 0 to 10, Al2O3 16.5 to 40, TiO2 1 to 10, Ta2O5 0 to 8, Y2O3 0 to 6, ZrO21 to 10, MgO 6 to 20, CaO 0 to 10, SrO 0 to 4, BaO 0 to 8, ZnO 0 to 4, SnO2+CeO2 0 to 4, SO42−+Cl− 0 to 4, wherein the total content (SnO2+CeO2+S042−+Cl−) is between 0.01 and 4 wt.-%. The glass ceramic may be processed by the float glass method, may be transparent and is, inter alia, suitable as a substrate for thin film semiconductors, in particular for display applications, solar cells etc.

Owner:SCHOTT AG

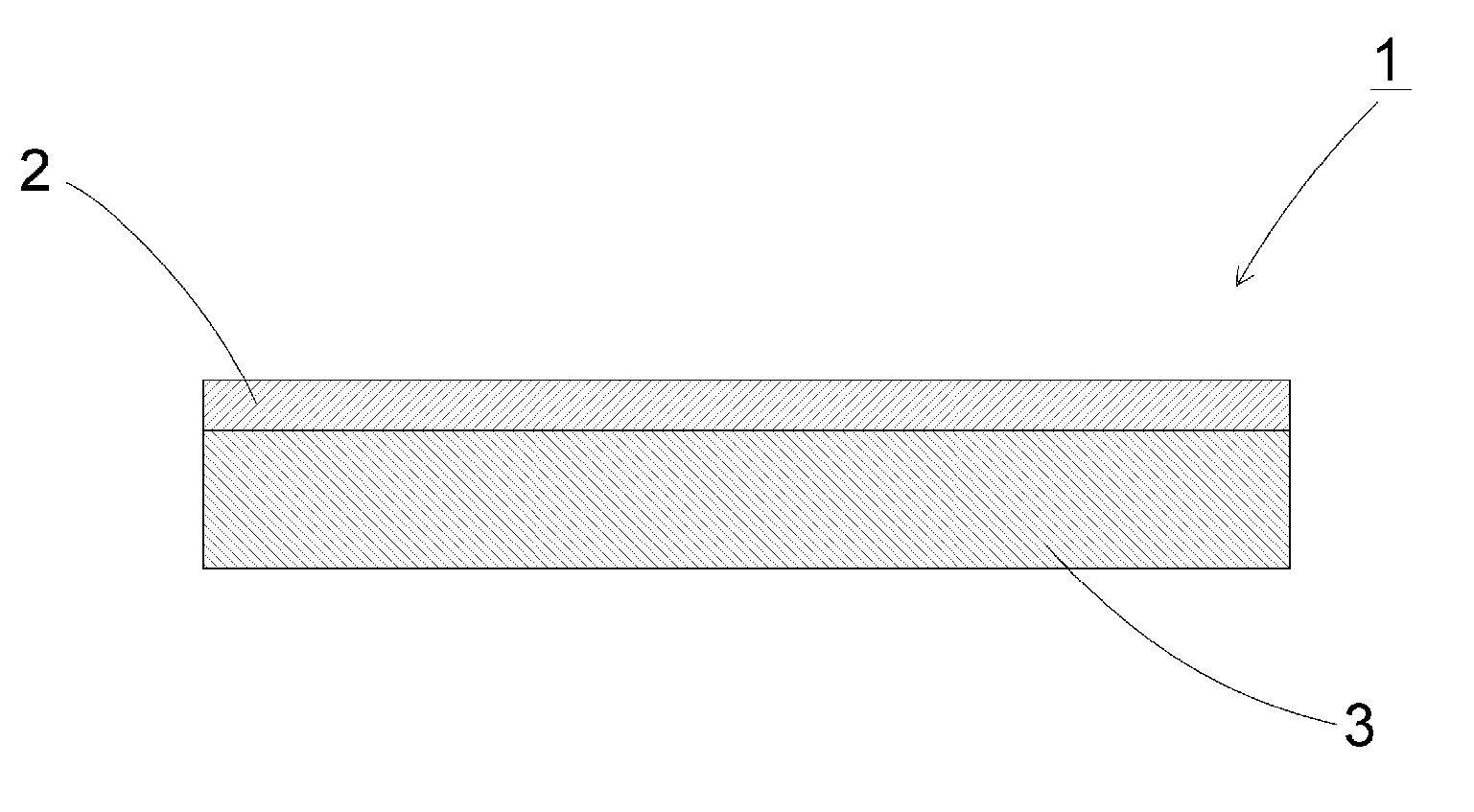

Glass film laminate

ActiveUS20110045239A1Enhances handling easinessWithout usingFinal product manufactureSolid-state devicesSurface roughnessGlass film

The glass film laminate comprises a glass film and a supporting glass. The glass film and the supporting glass have surfaces being brought into contact with each other, and each of the surfaces has a surface roughness Ra of 2.0 nm or less.

Owner:NIPPON ELECTRIC GLASS CO LTD

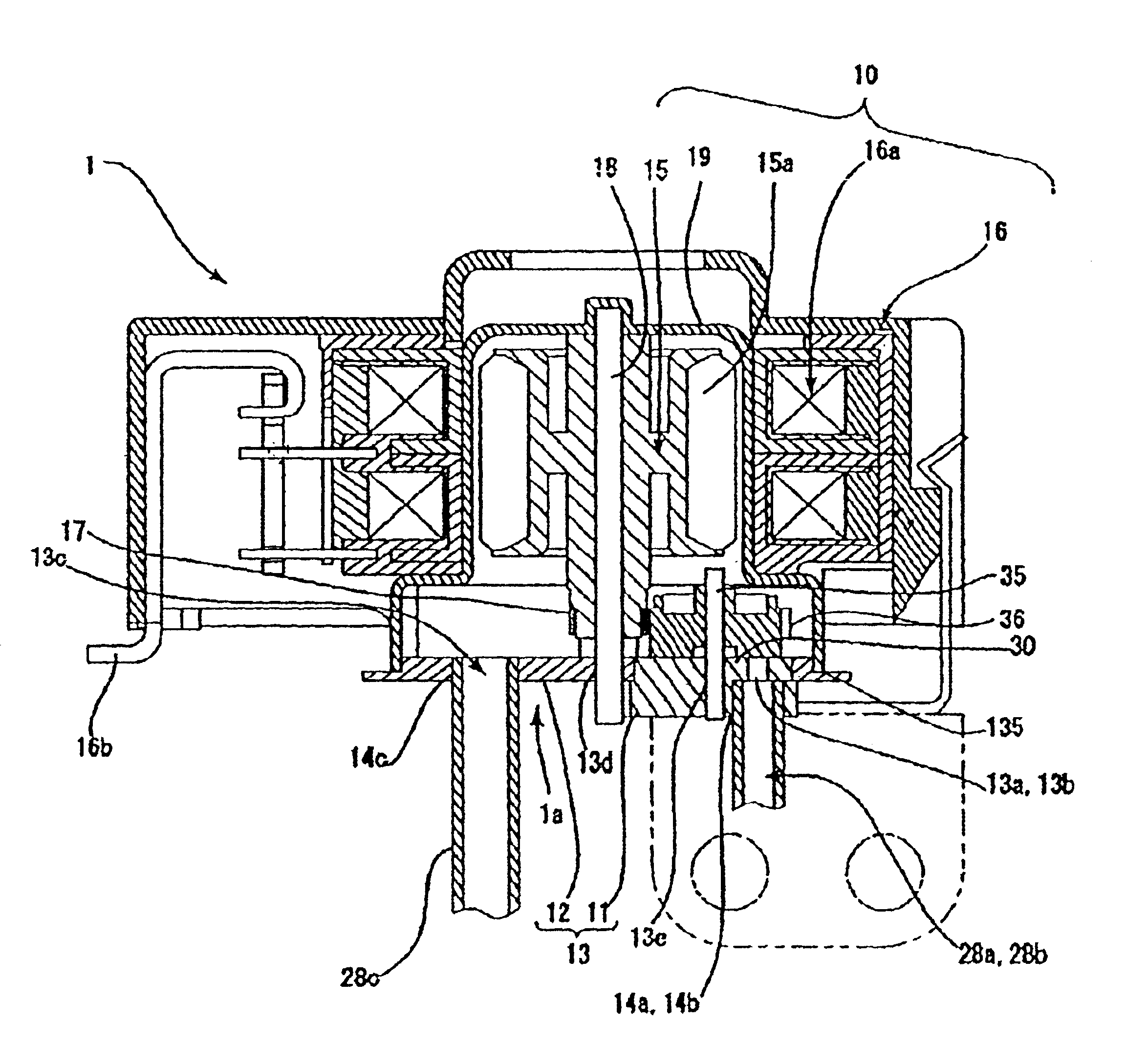

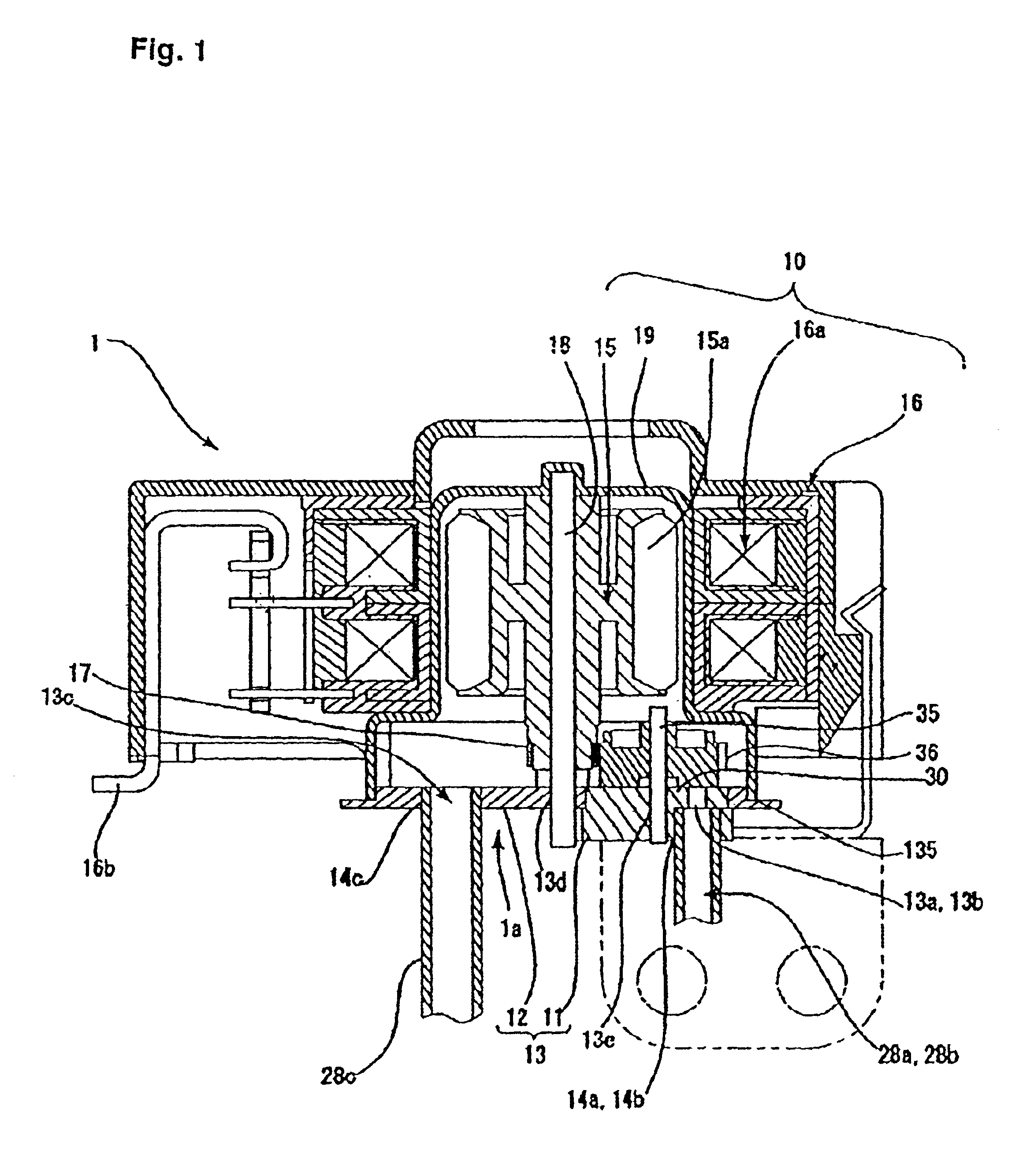

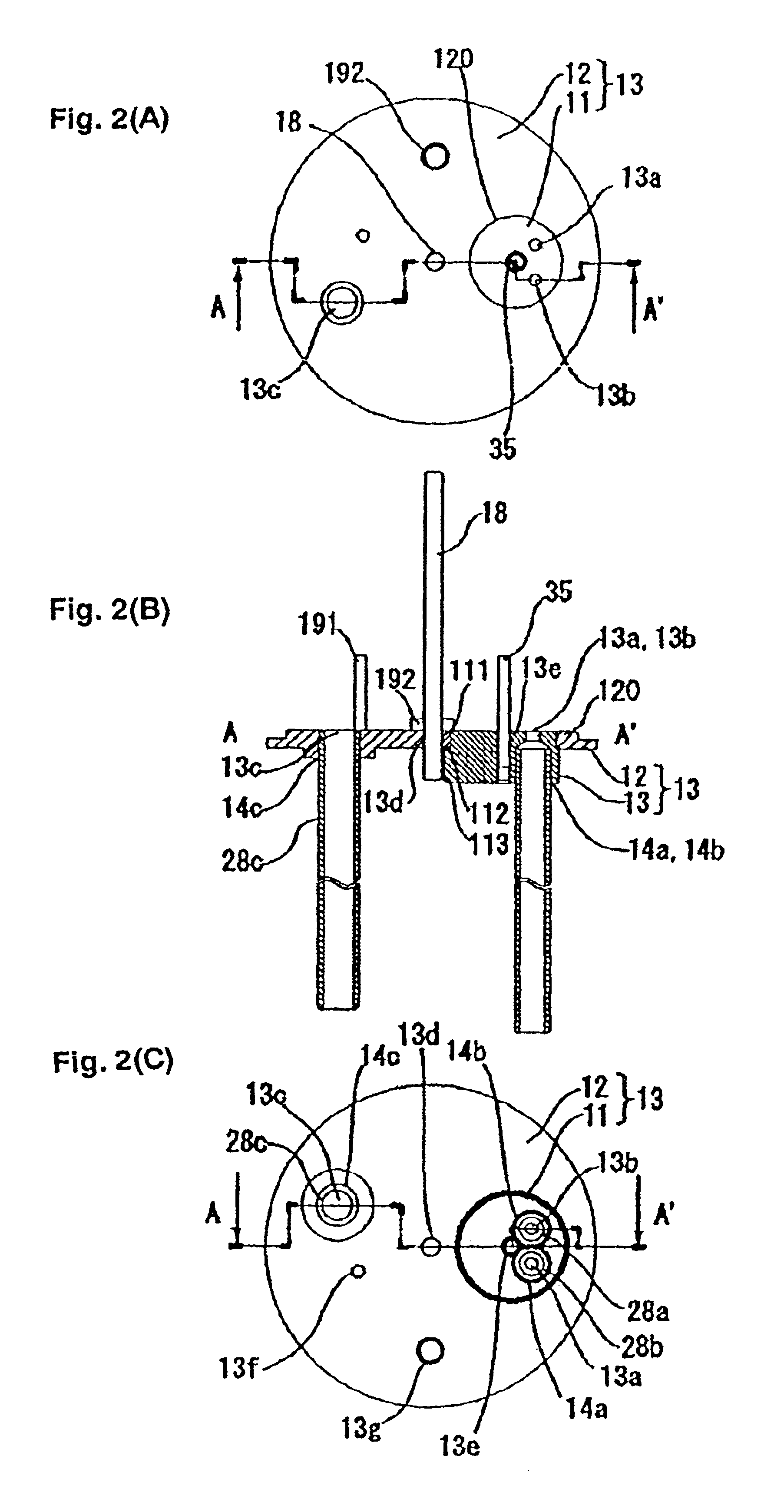

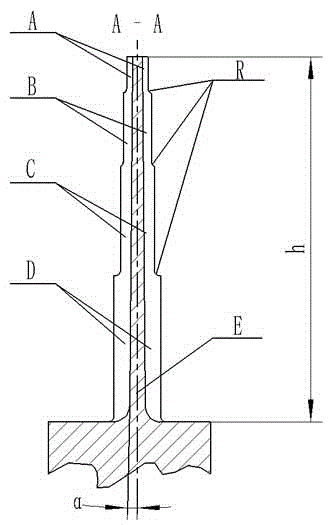

Valve device

ActiveUS6880802B2Improve flatnessAvoid changePlug valvesOperating means/releasing devices for valvesEngineeringVALVE PORT

A valve device having a novel vale seat plate is provided. The valve seat plate has an inlet opening, an outlet opening, a front side and a back side. A sealing case covers the front side and inlet and outlet pipes are attached to the back side to communicate respectively with the inlet and outlet openings. A valve element moves to cover the outlet opening on the front side to close the outlet opening. The novel valve seat plate includes at least two plates that are joined to each other. One plate forms the area around the outlet opening and the other plate forms other areas of the valve seat plate.

Owner:SANKYO SEIKI MFG CO LTD

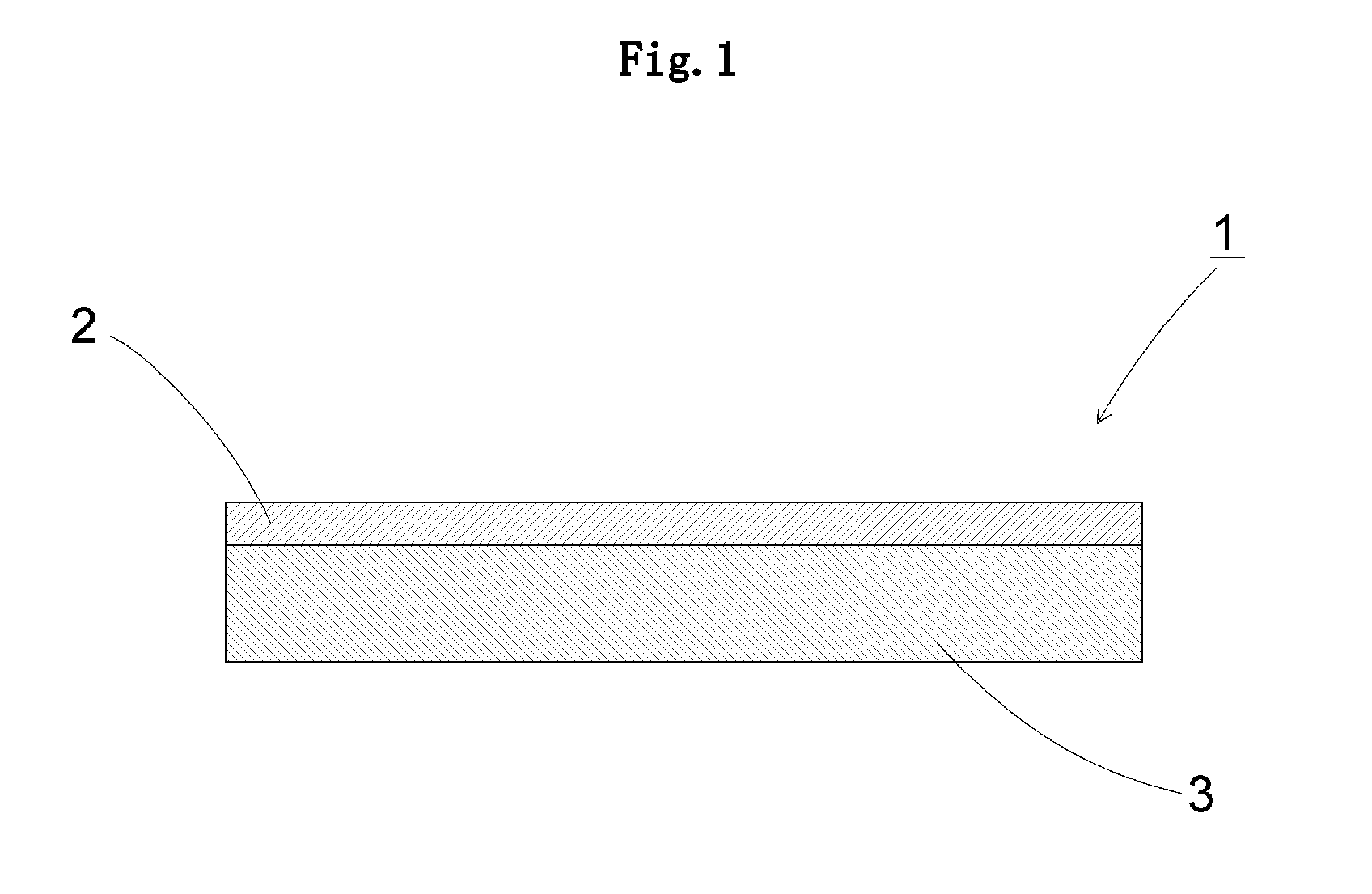

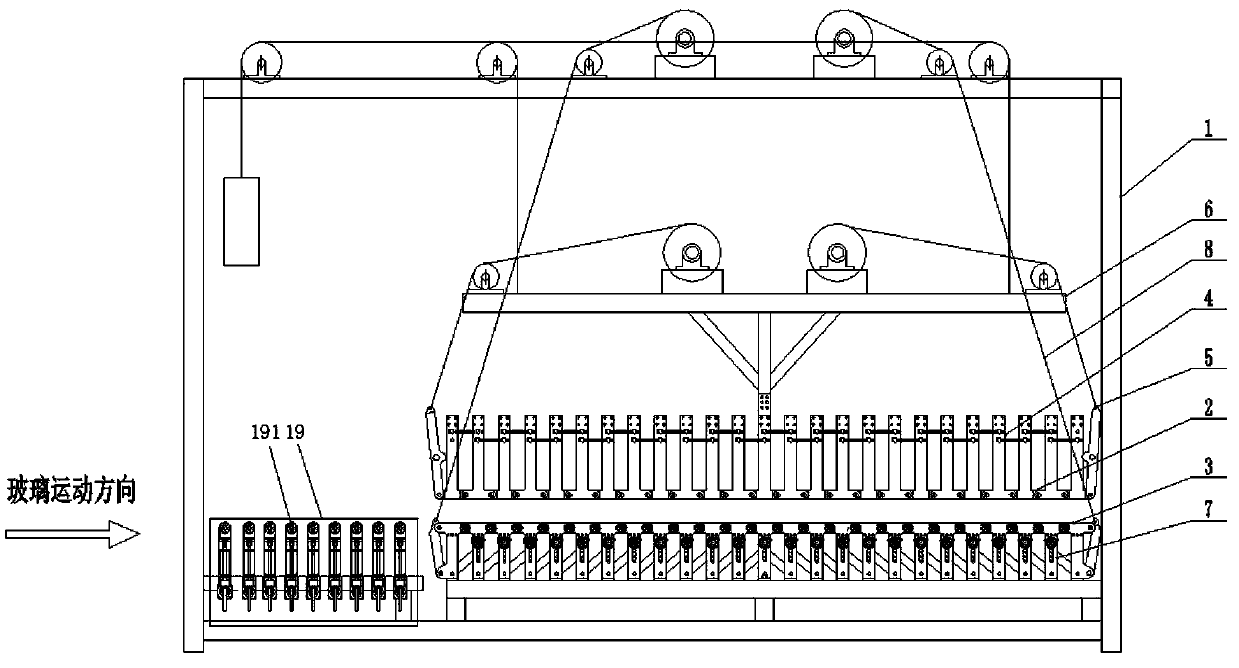

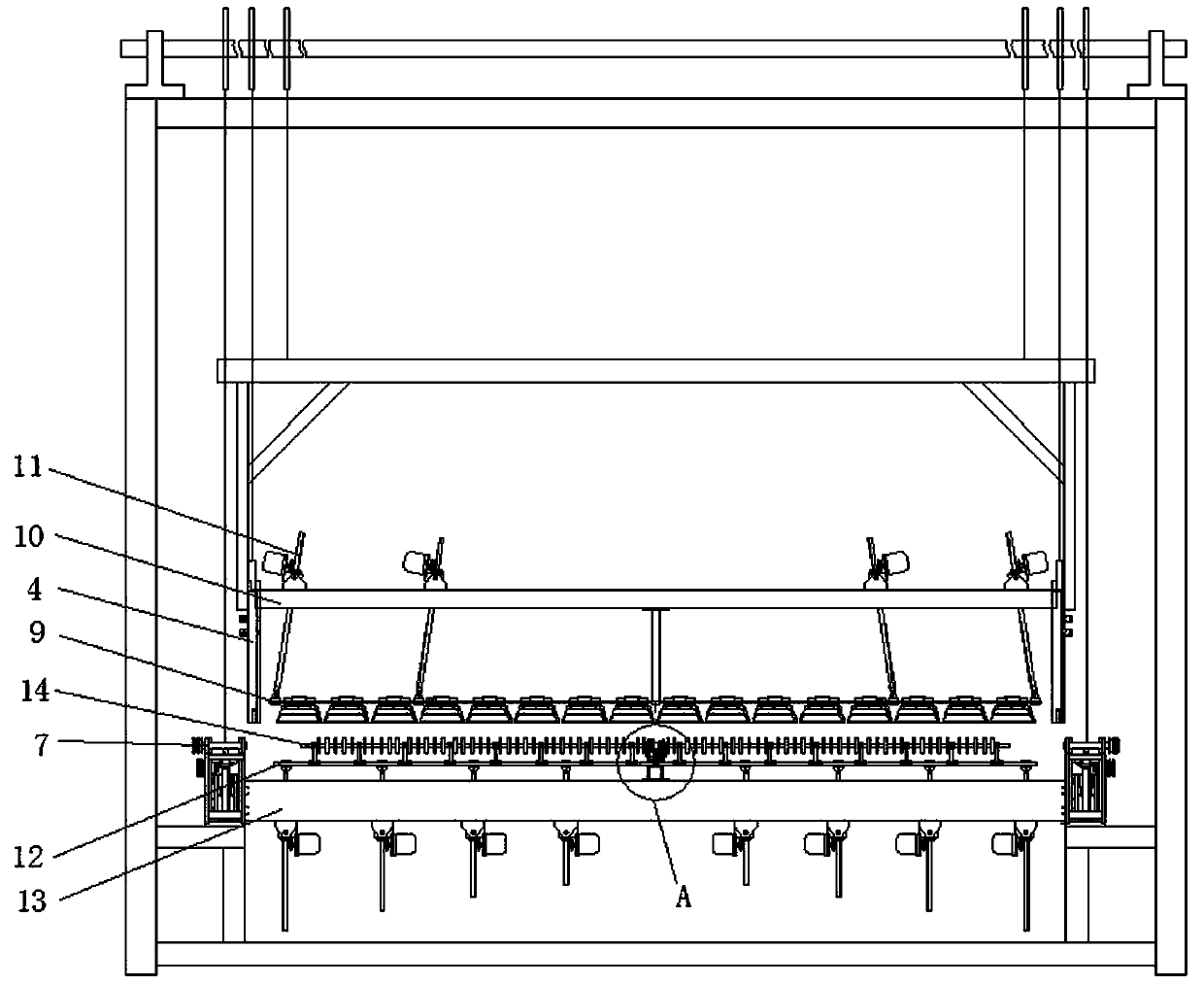

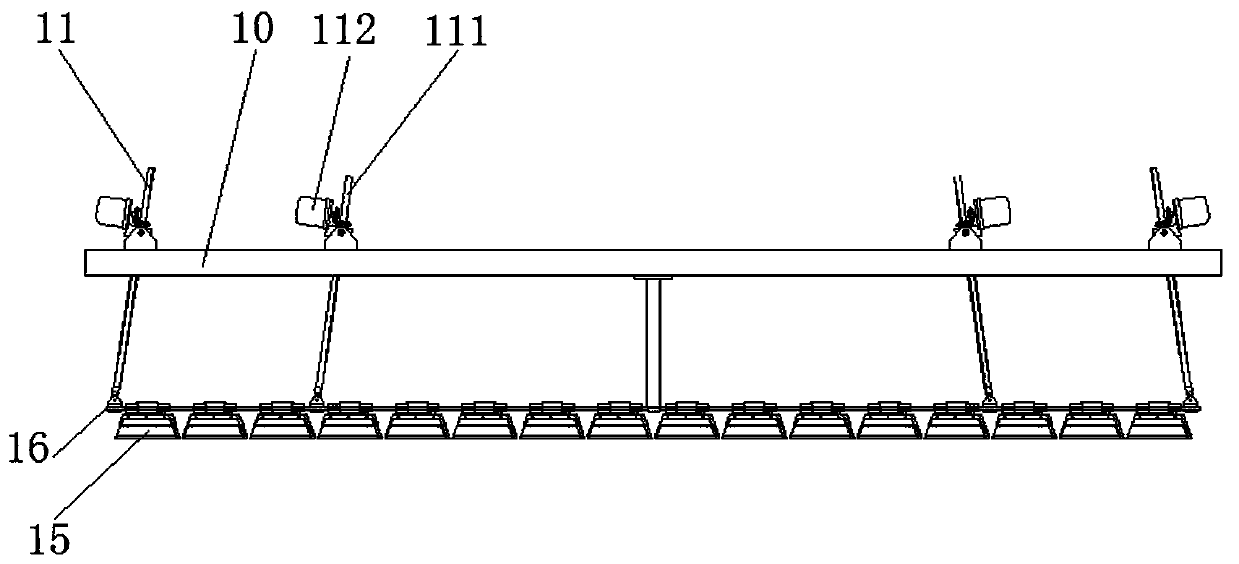

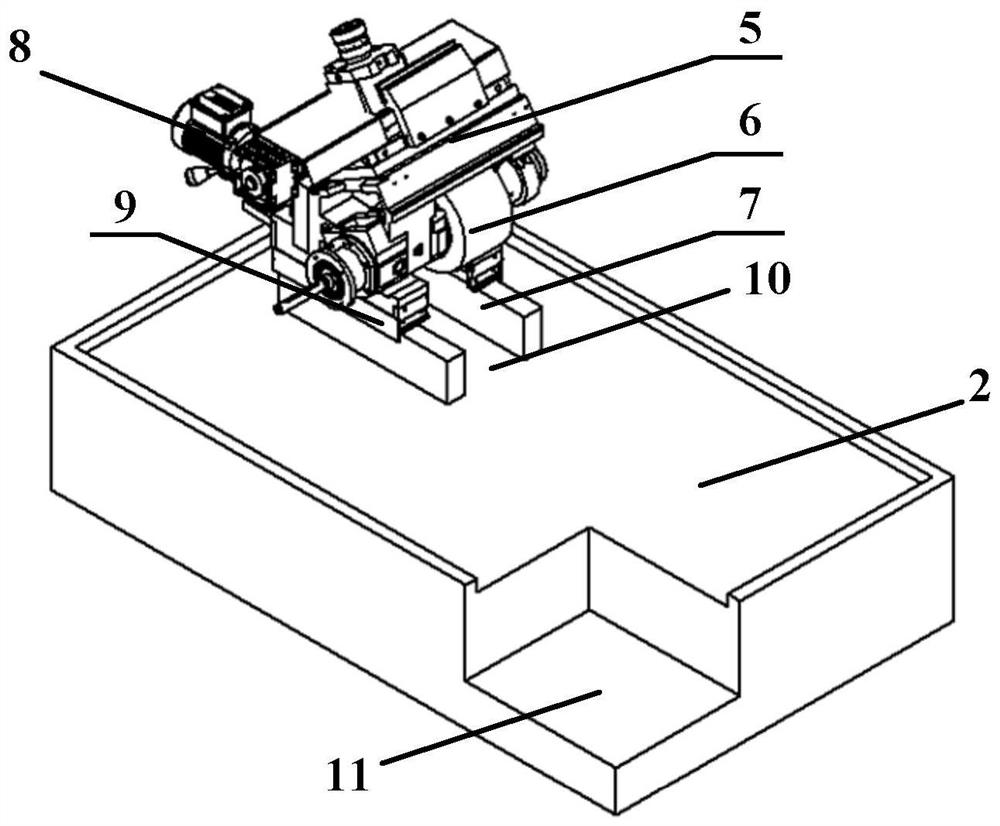

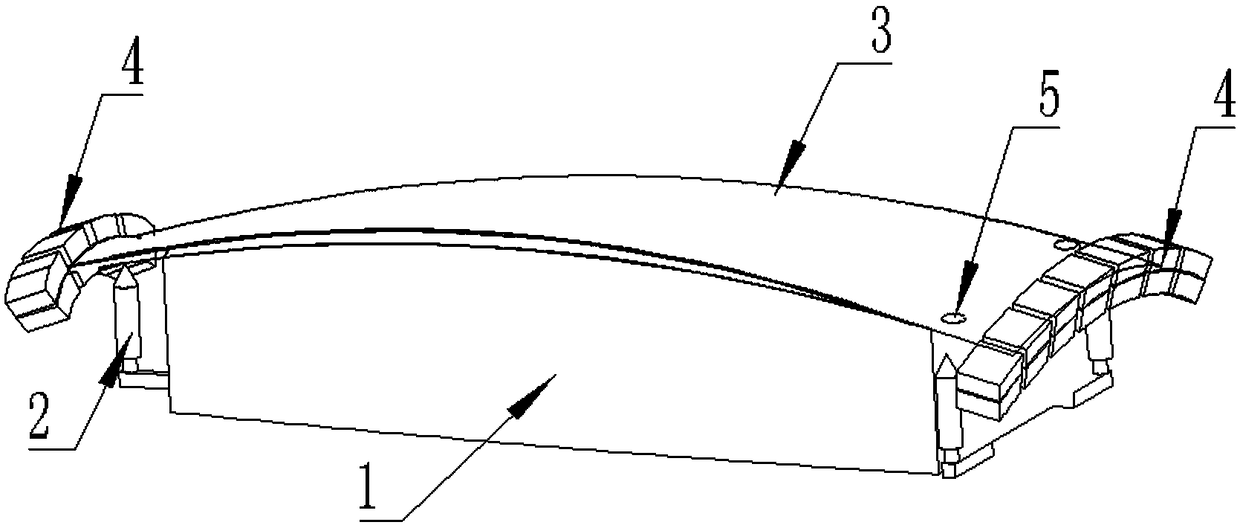

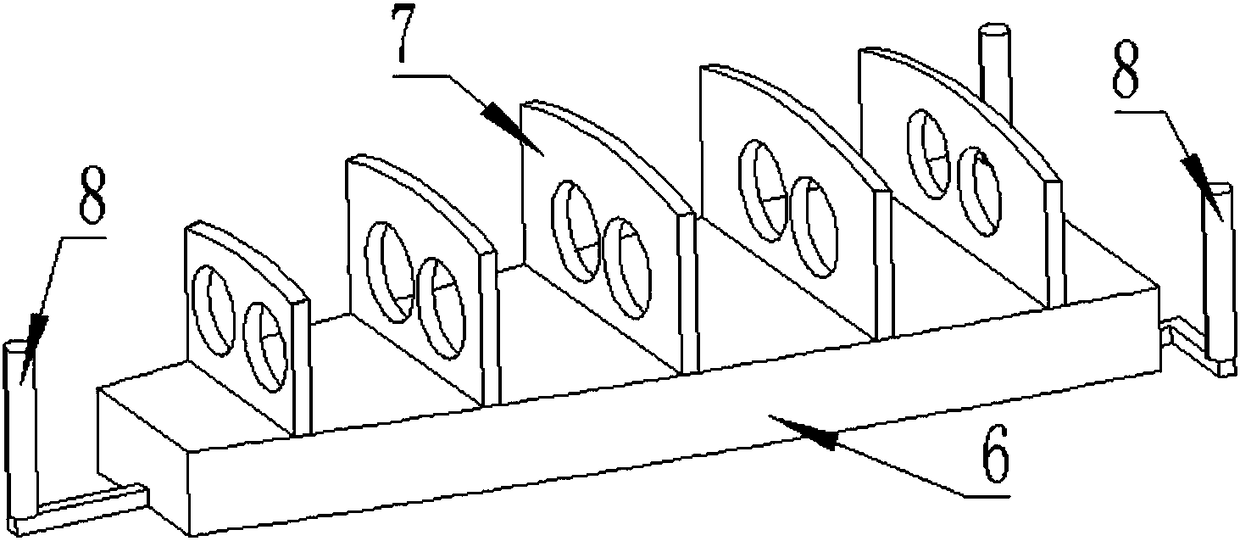

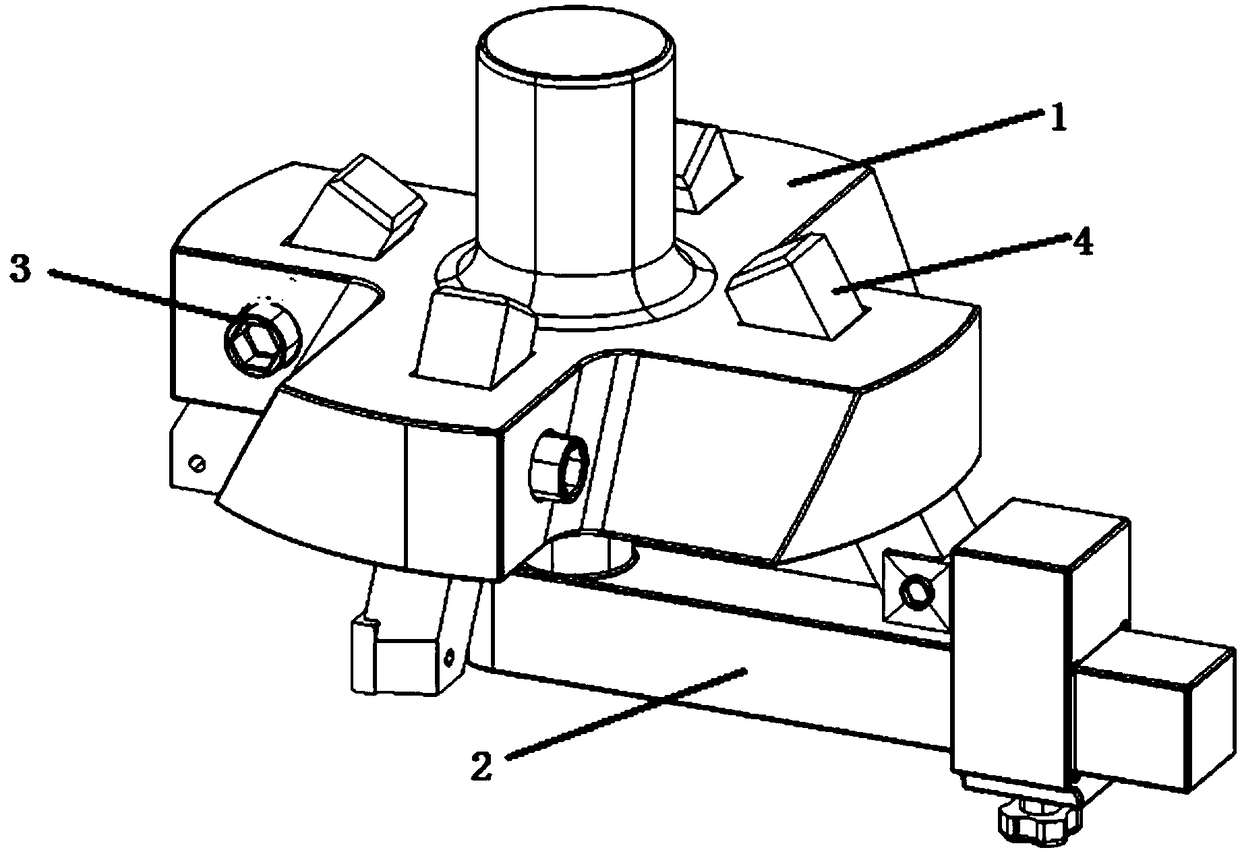

Bent toughened glass forming equipment and method

ActiveCN109748486AImprove general performanceQuick and easy molding adjustmentGlass transportation apparatusGlass reforming apparatusEngineeringToughened glass

The invention discloses bent toughened glass forming equipment. The bent toughed glass forming equipment comprises a rack, an air grid system and a forming system, wherein the air grid system comprises a plurality of upper air grids and a plurality of lower air grids; the upper air grids are mounted on the upper portion of the rack through a hoisting mechanism; the lower air grids are mounted in the forming system on the lower portion of the rack; a gradual transition section is arranged on the inlet side of the forming system, so that a glass plate is gradually changed into an arc in the transverse direction, and the glass plate which has been gradually changed into the arc is fed into the forming system; the forming system comprises two longitudinal forming arc-changing mechanisms and aplurality of transverse forming arc-changing mechanisms arranged in the conveying direction of the glass plate; the longitudinal forming arc-changing mechanism longitudinally bends and forms the glassplate; and the transverse forming arc-changing mechanisms are connected with the longitudinal forming arc-changing mechanisms through lower support cross beams, and the glass plate is transversely bent and formed. The equipment and the forming method provided by the invention can be used for processing various bent toughened glass without manufacturing a special mold, and have the advantages of rapid and convenient forming adjustment, stability, reliability, difficulty in deformation and high production efficiency.

Owner:LUOYANG LANDGLASS TECH CO LTD

Glass ceramic and method of producing the same

ActiveUS7300896B2High surface precisionThickness variationTransistorGlass tempering apparatusSolar cellGlass-ceramic

A glass ceramic comprises (in wt.-% on oxide basis): SiO2 35 to 60, B2O3>4 to 10, P2O5 0 to 10, Al2O3 16.5 to 40, TiO2 1 to 10, Ta2O5 0 to 8, Y2O3 0 to 6, ZrO2 1 to 10, MgO 6 to 20, CaO 0 to 10, SrO 0 to 4, BaO 0 to 8, ZnO 0 to 4, SnO2+CeO2 0 to 4, SO42−+Cl− 0 to 4, wherein the total content (SnO2+CeO2+SO42−+Cl−) is between 0.01 and 4 wt.-%. The glass ceramic may be processed by the float glass method, may be transparent and is, inter alia, suitable as a substrate for thin film semiconductors, in particular for display applications, solar cells etc.

Owner:SCHOTT AG

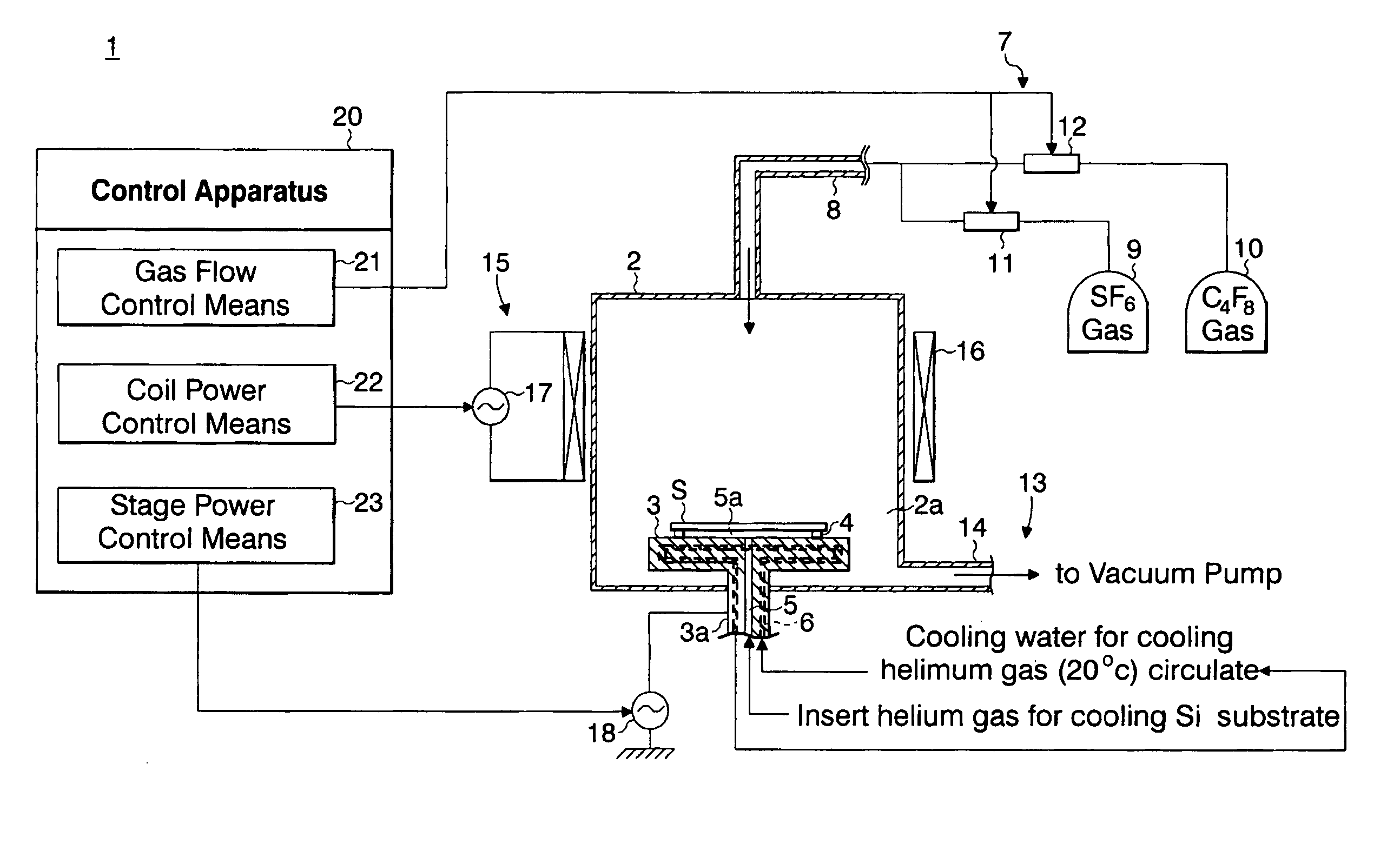

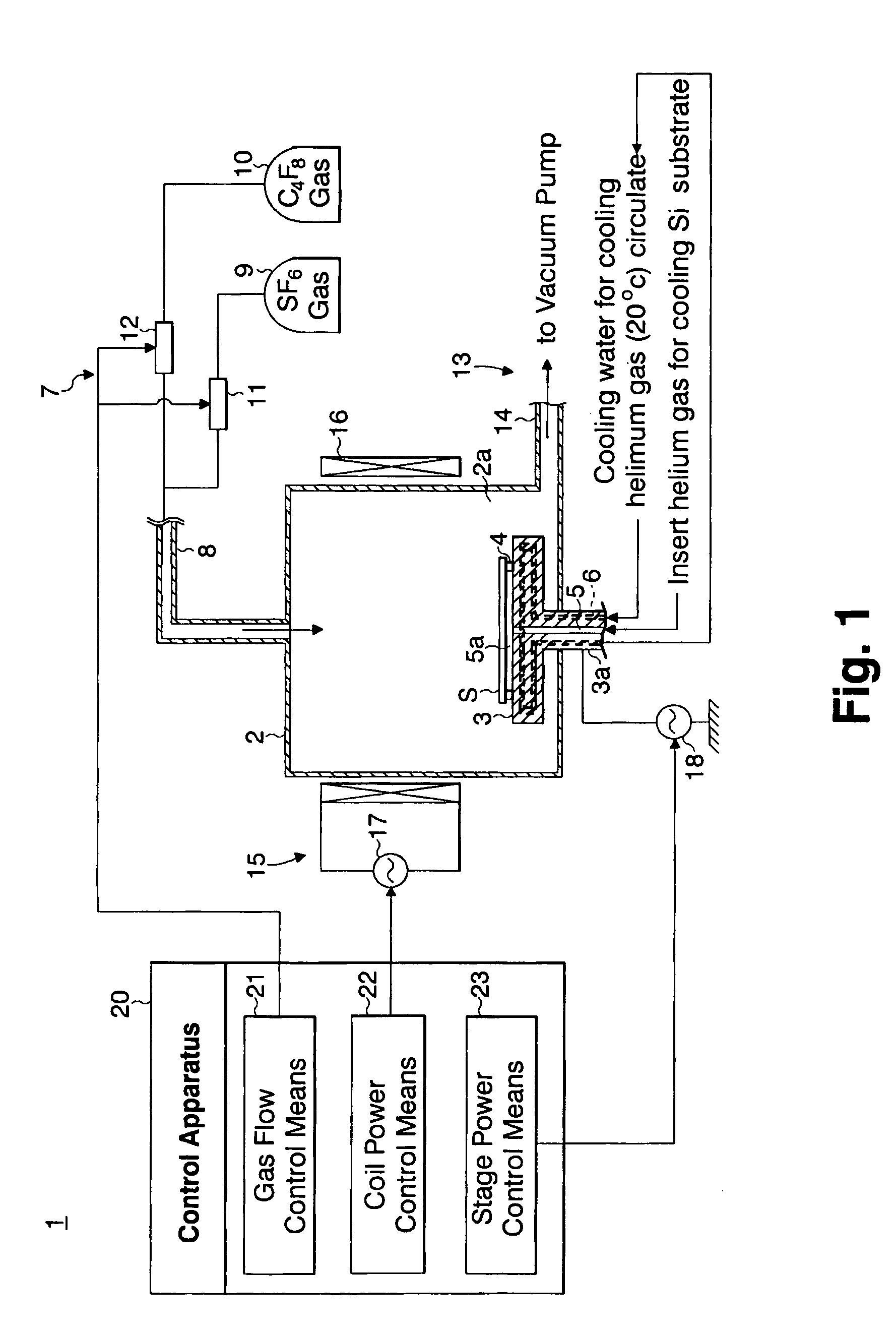

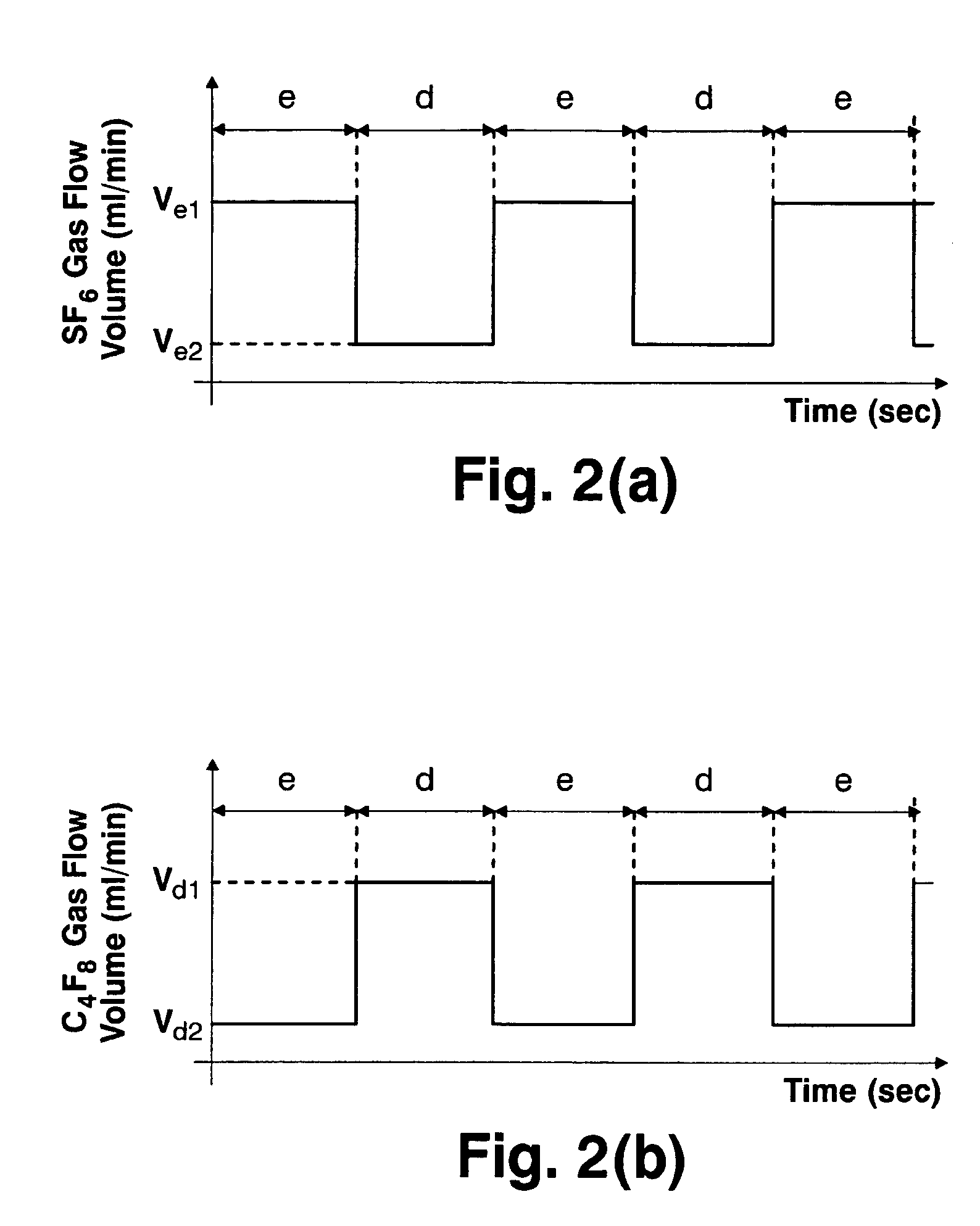

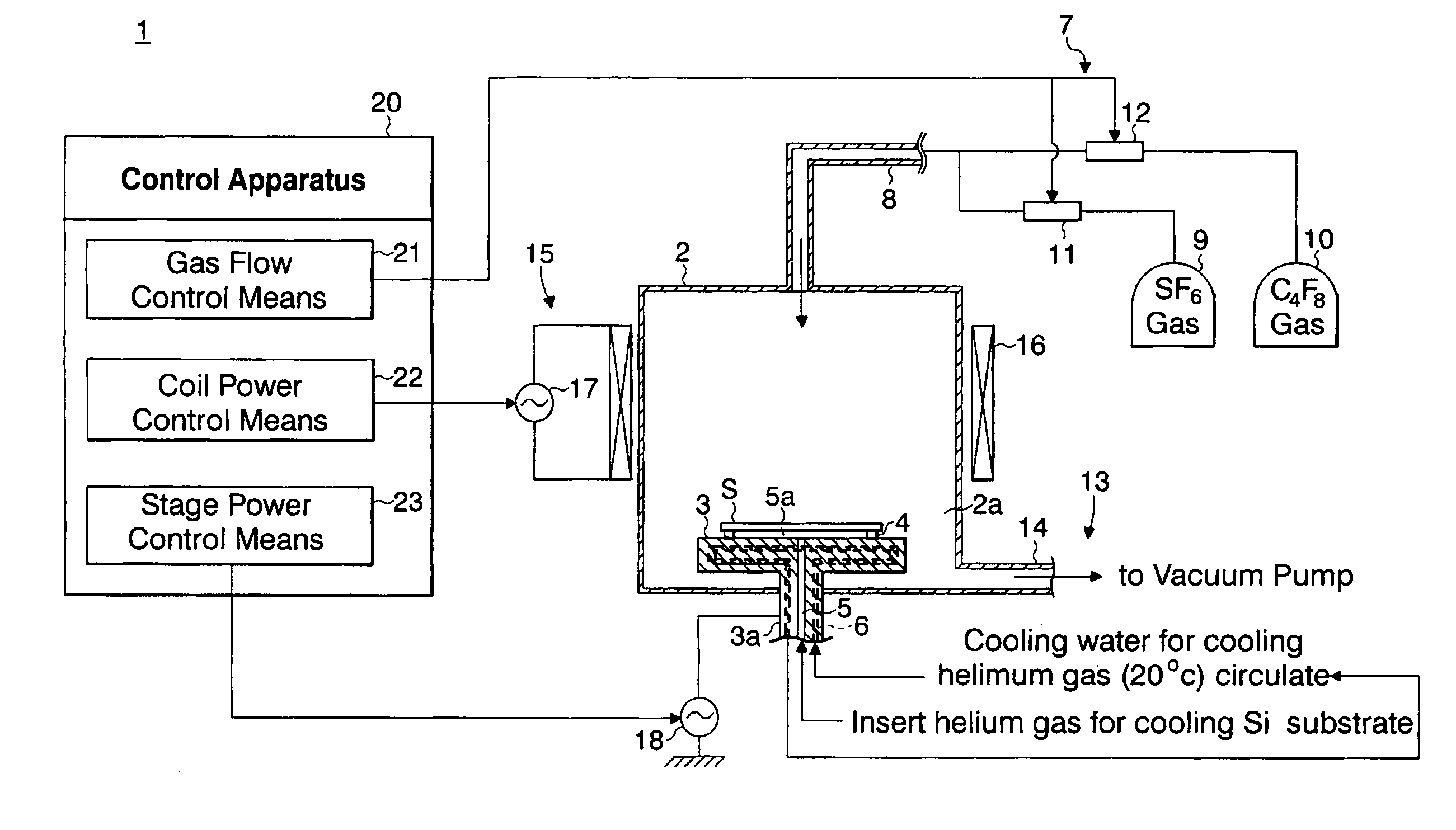

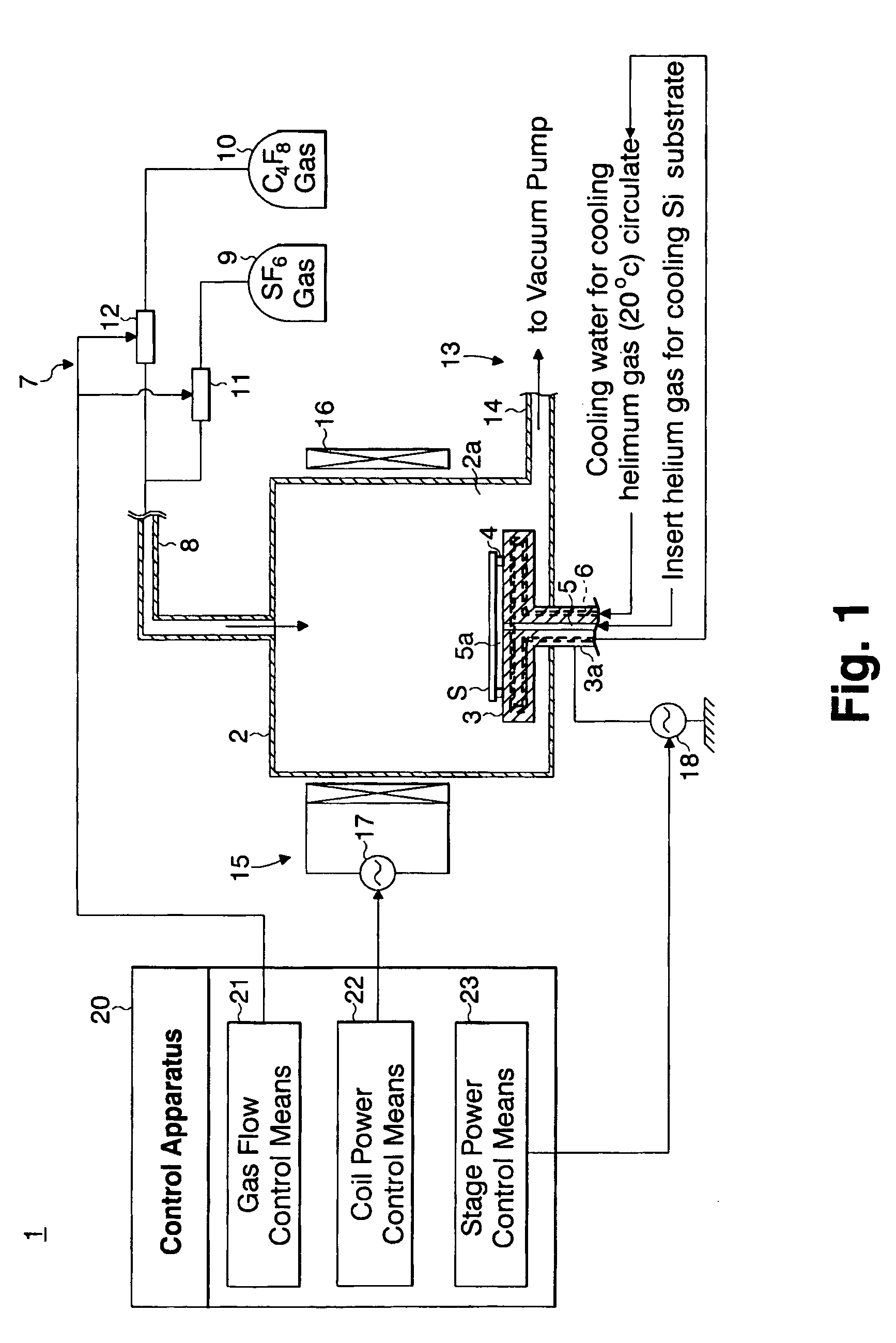

Method for etching of a silicon substrate and etching apparatus

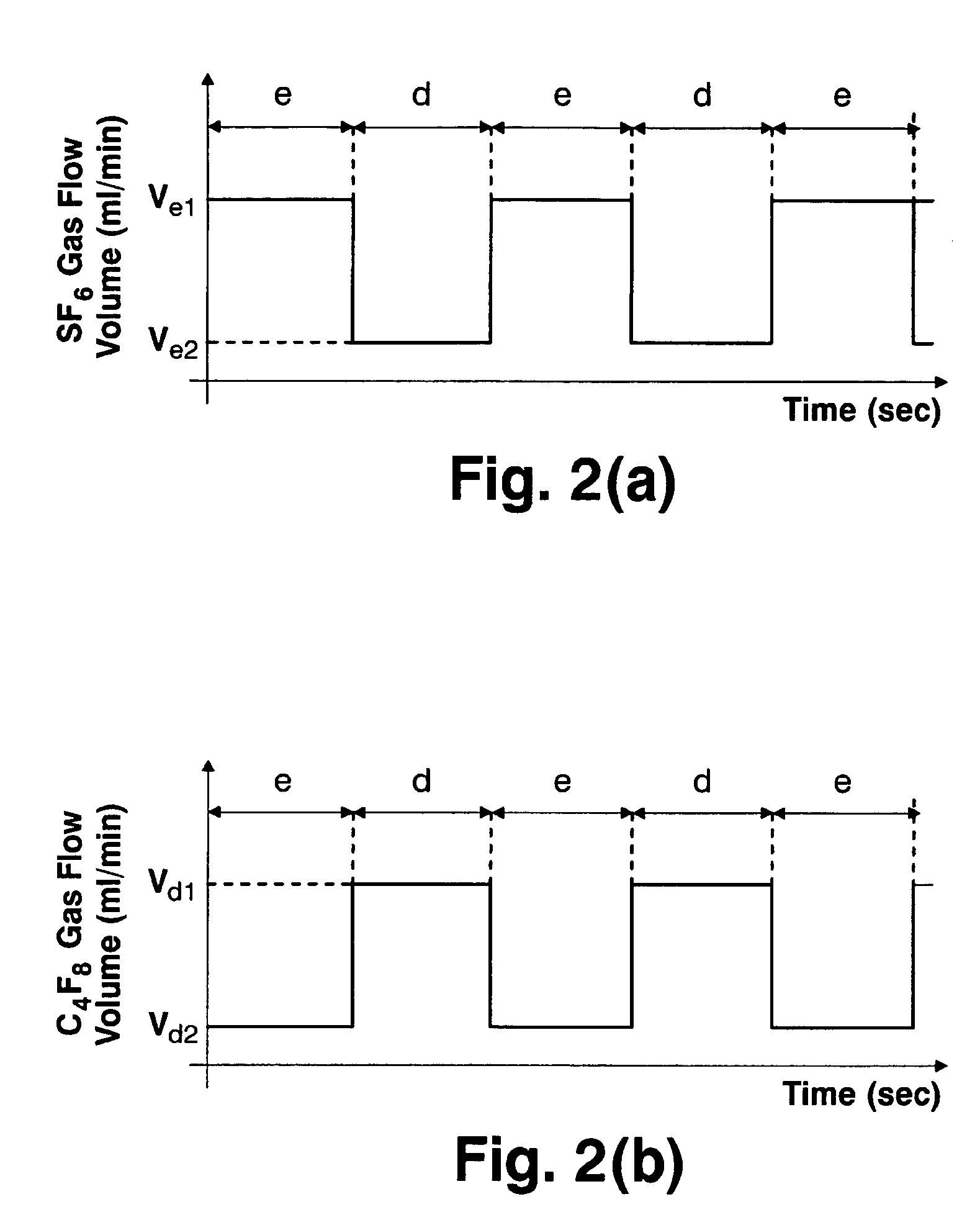

ActiveUS20050130436A1Sufficiently smoothExcellent perpendicularity without reducing the etching speedDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Fluorocarbon

A method for etching a silicon substrate is presented in which fast etching speed and etching structures with smooth and perpendicular wall surfaces are achieved. In the etching step, a constant electric power is applied to the silicon substrate to provide a bias potential. Using a mixture of SF6 gas and fluorocarbon gas, there is a step mainly for the progression of dry etching of the etching ground surface. Similarly, using a mixture gas, there is a step mainly for forming a protective layer on the structure surfaces which are perpendicular with respect to the etching ground surface. These two steps are repeated one after the other. In the step for dry etching, the mixture gas is 5-12 volume of fluorocarbon gas with respect to 100 volume SF6 gas. The mixture gas in the protective film formation step is a mixture of 2-5 volume of SF6 gas with respect to 100 volume fluorocarbon gas.

Owner:SUMITOMO PRECISION PROD CO LTD

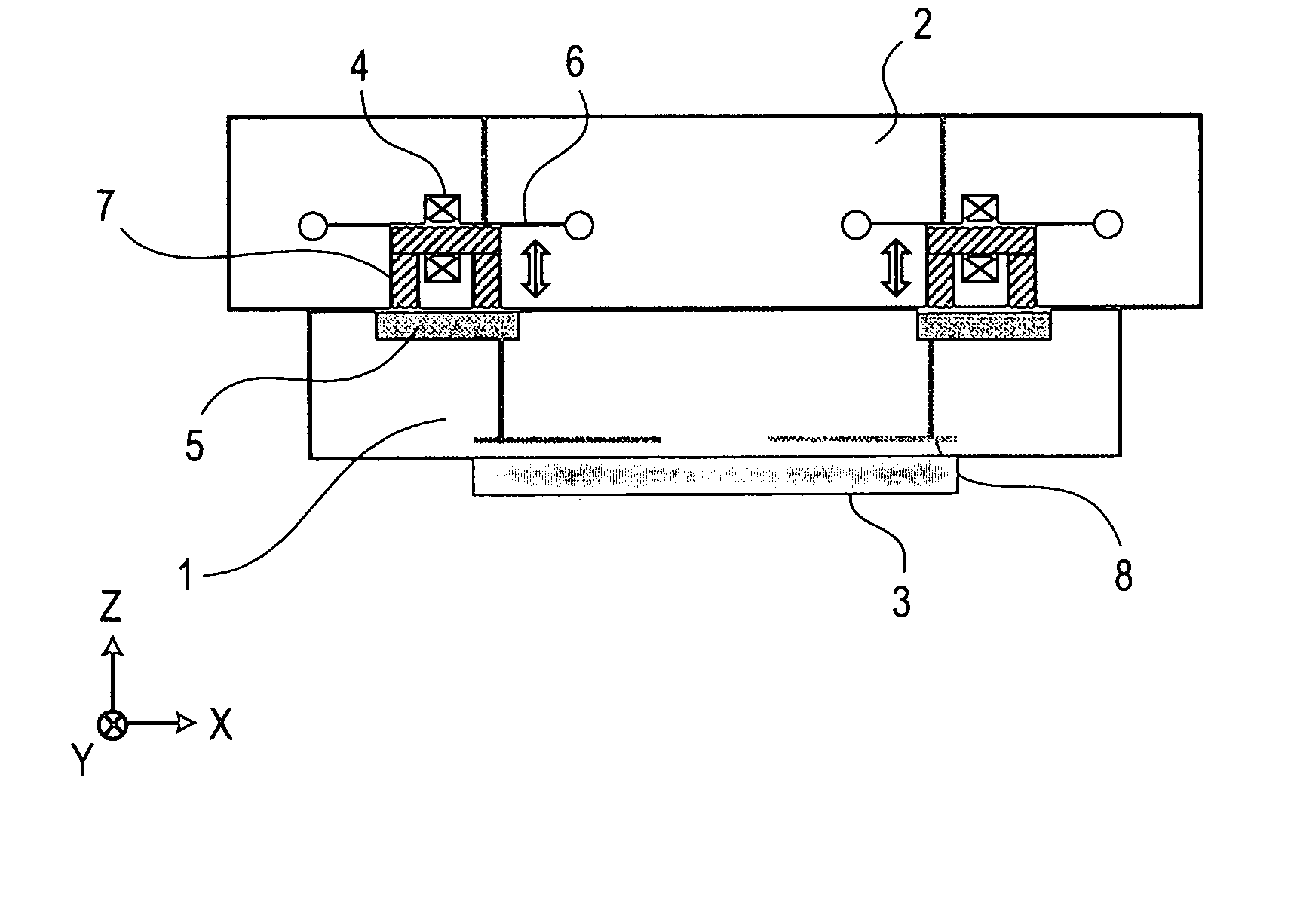

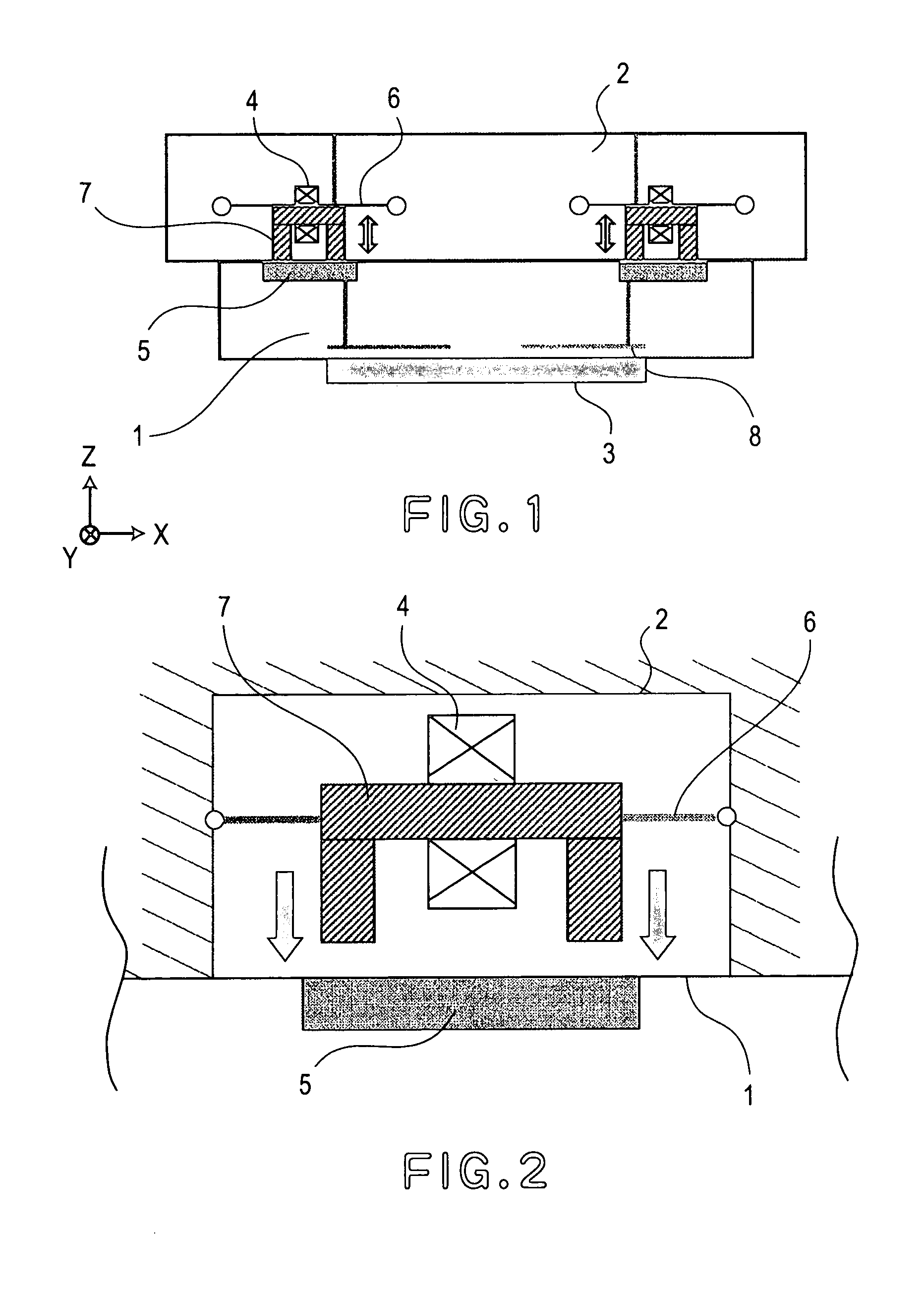

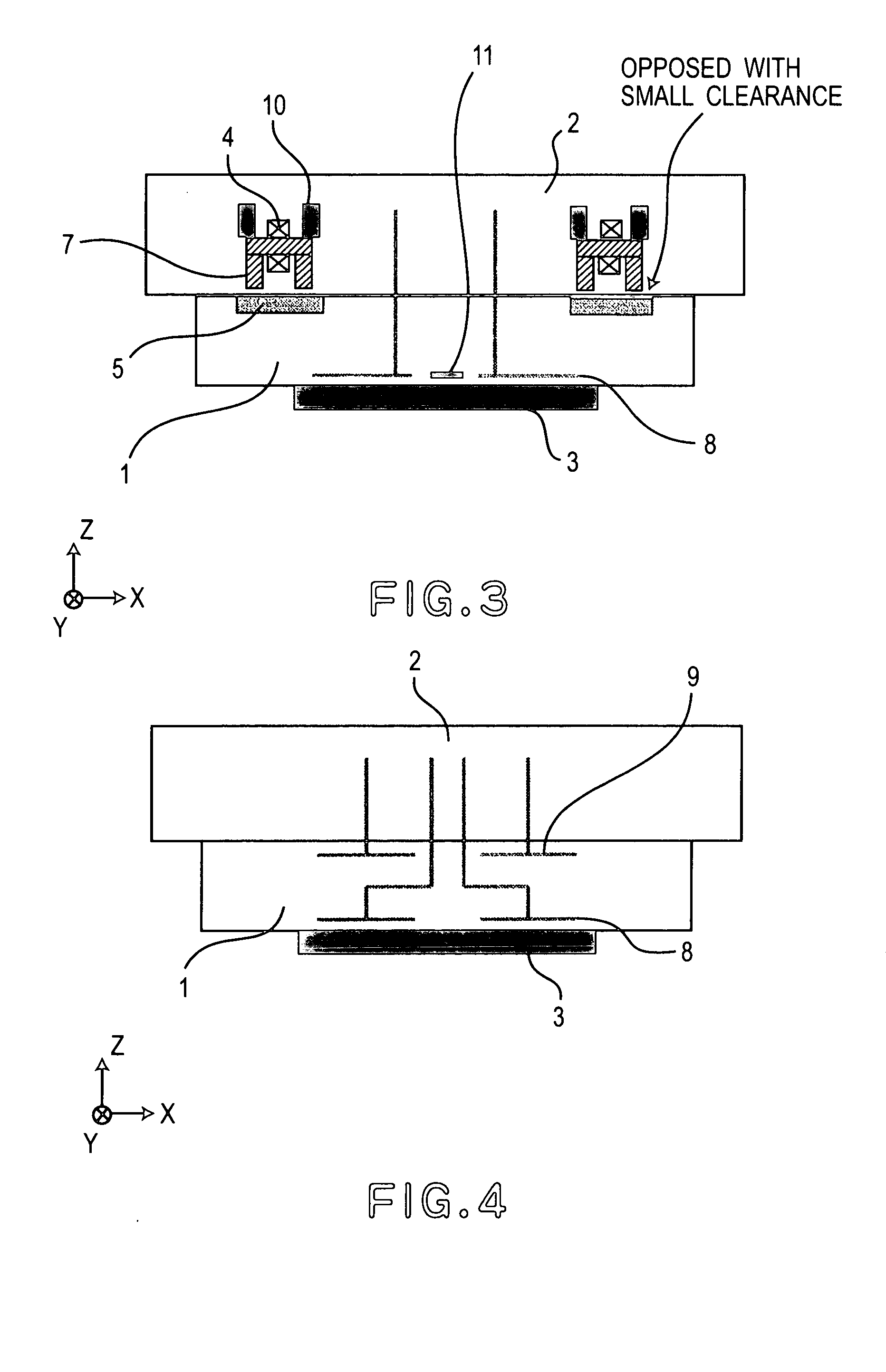

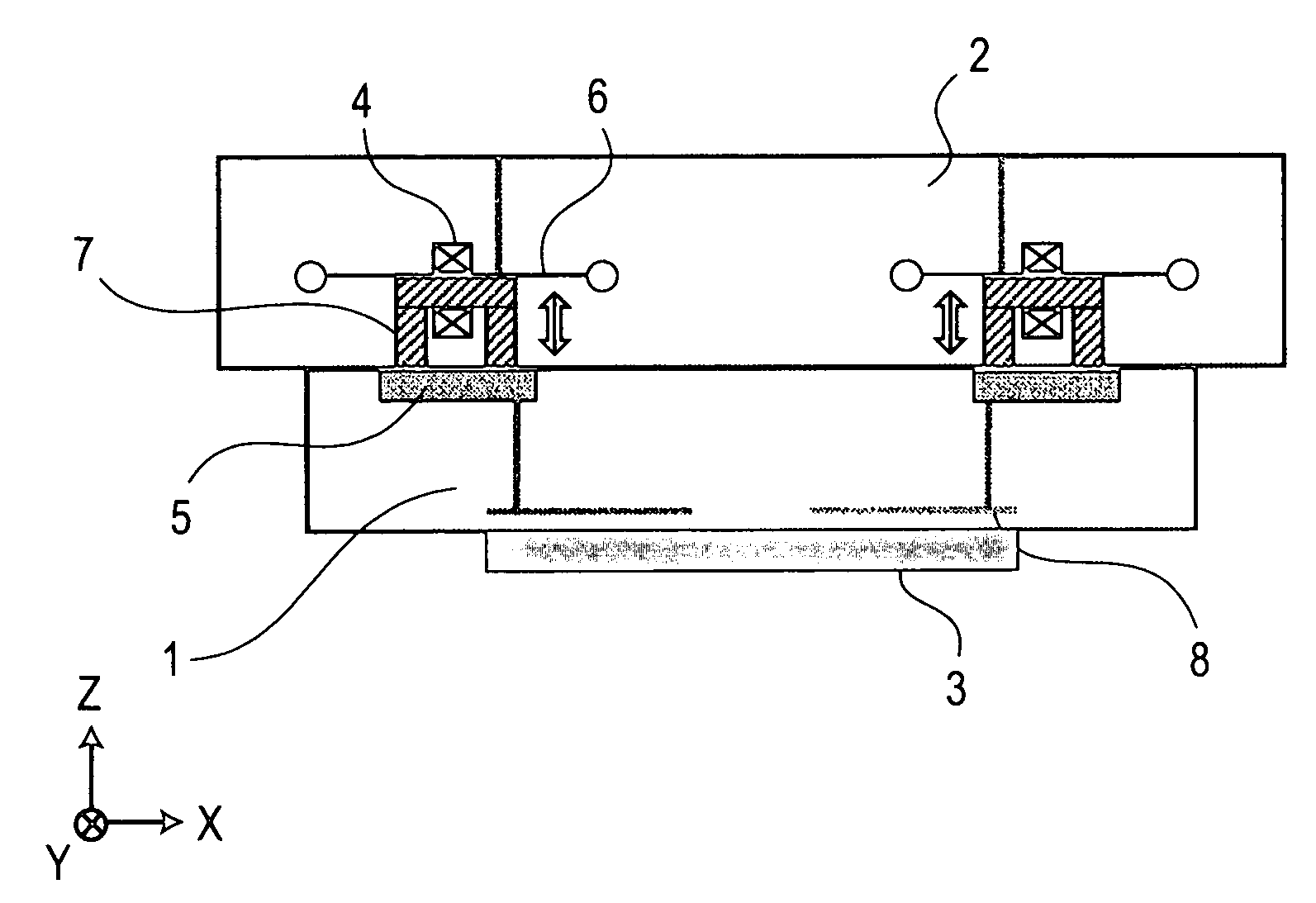

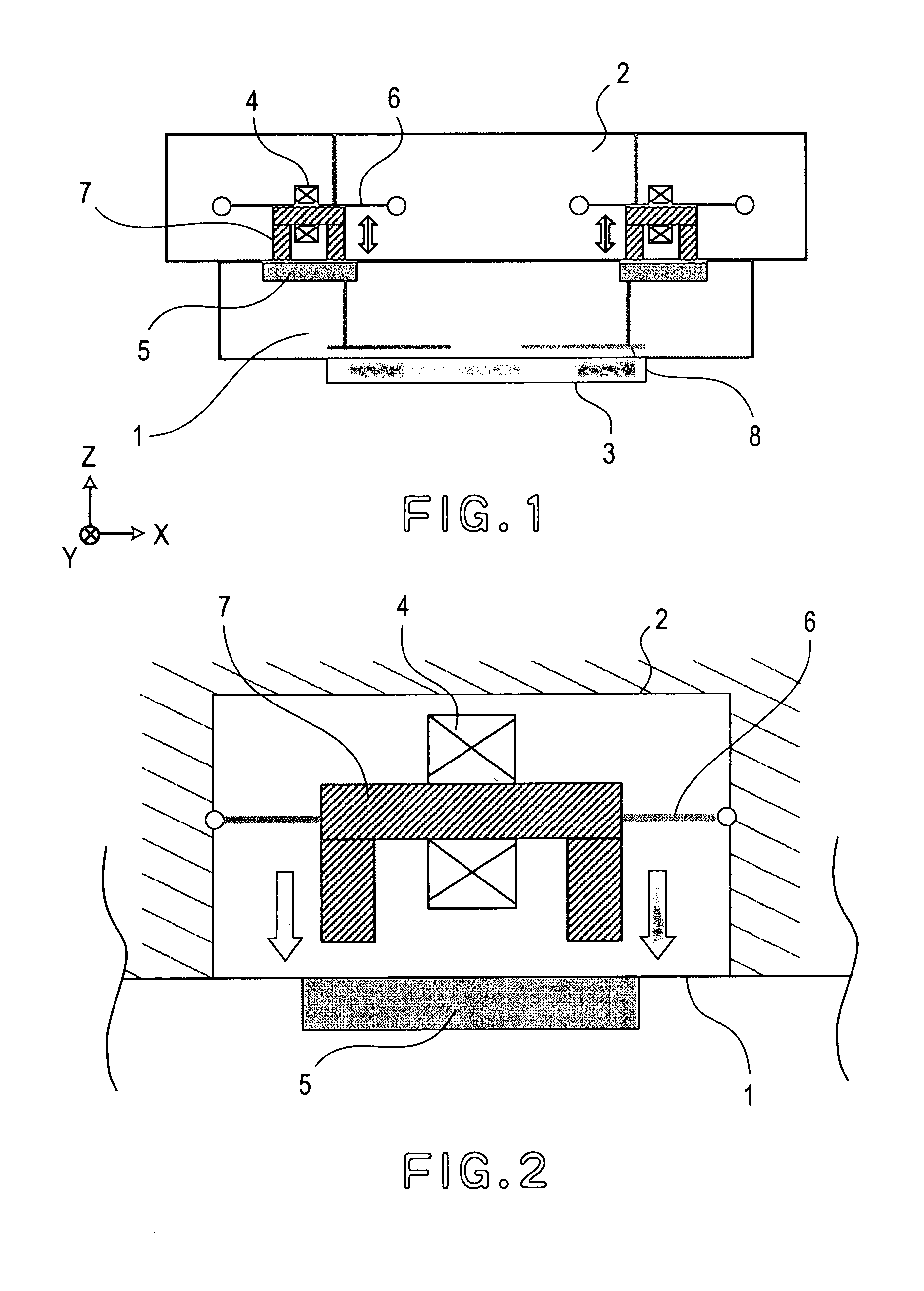

Substrate holding technique

InactiveUS20050093666A1High surface precisionElectromagnets without armaturesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Disclosed is technology for holding a substrate and, specifically, an object holding apparatus including a chuck for holding an object, a holding unit for holding the chuck, a generating unit provided in the holding unit, for generating a field related to an attraction force, a member provided in the chuck and attracted by the generating unit in accordance with the field, and a supporting unit for supporting one of the generating unit and the member, for movement at least in a direction nearing the other and in a direction away from the other.

Owner:CANON KK

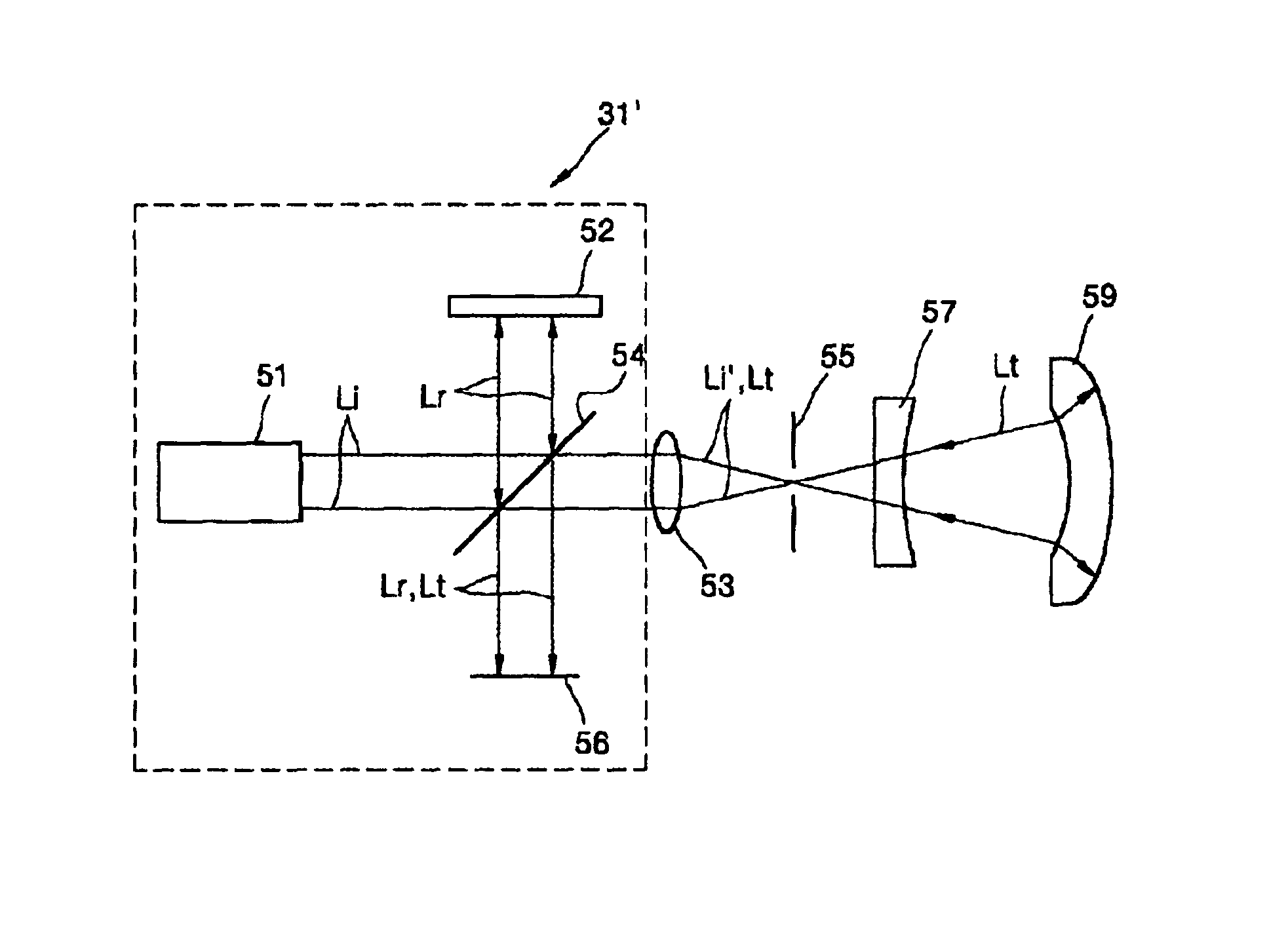

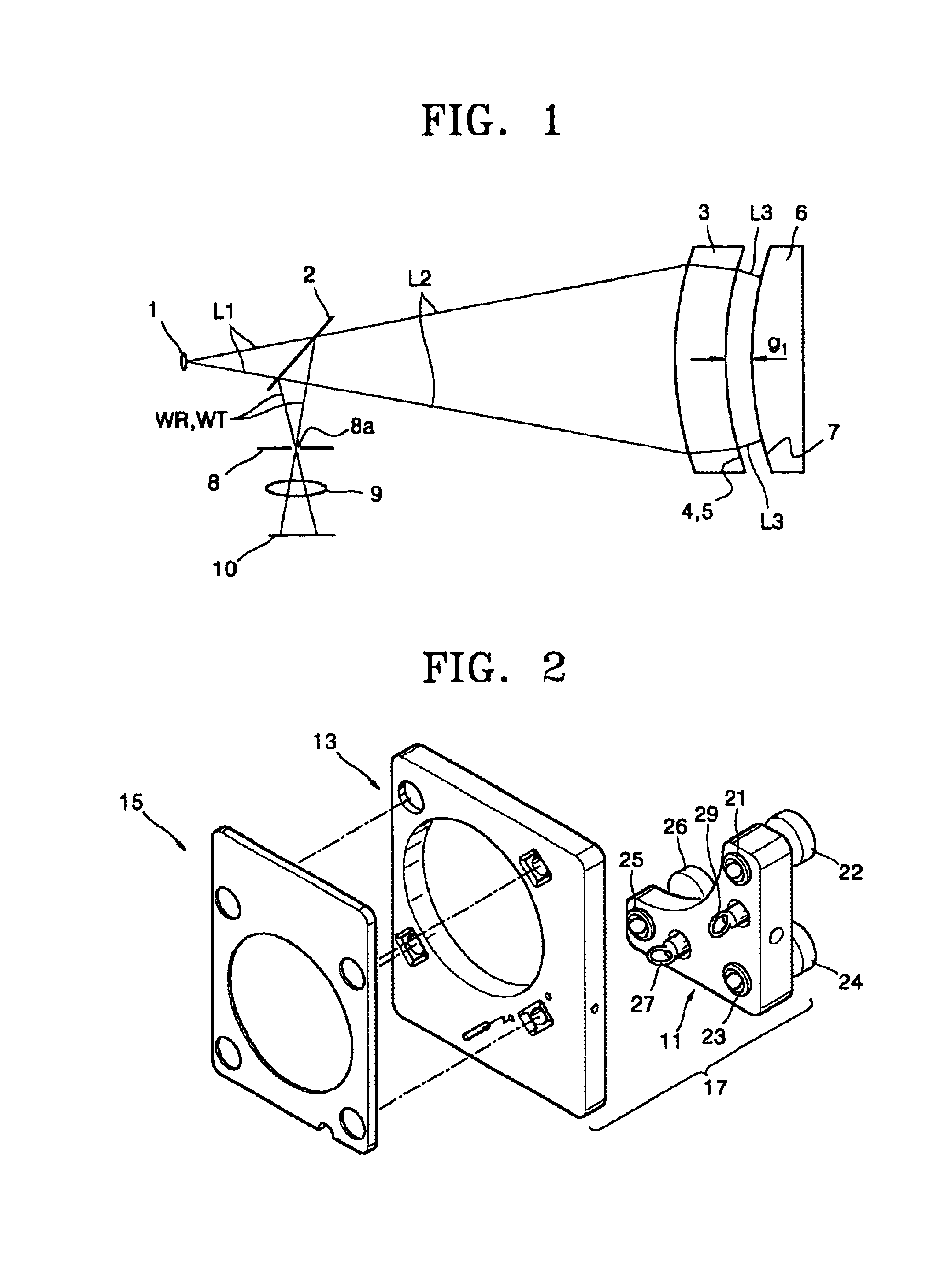

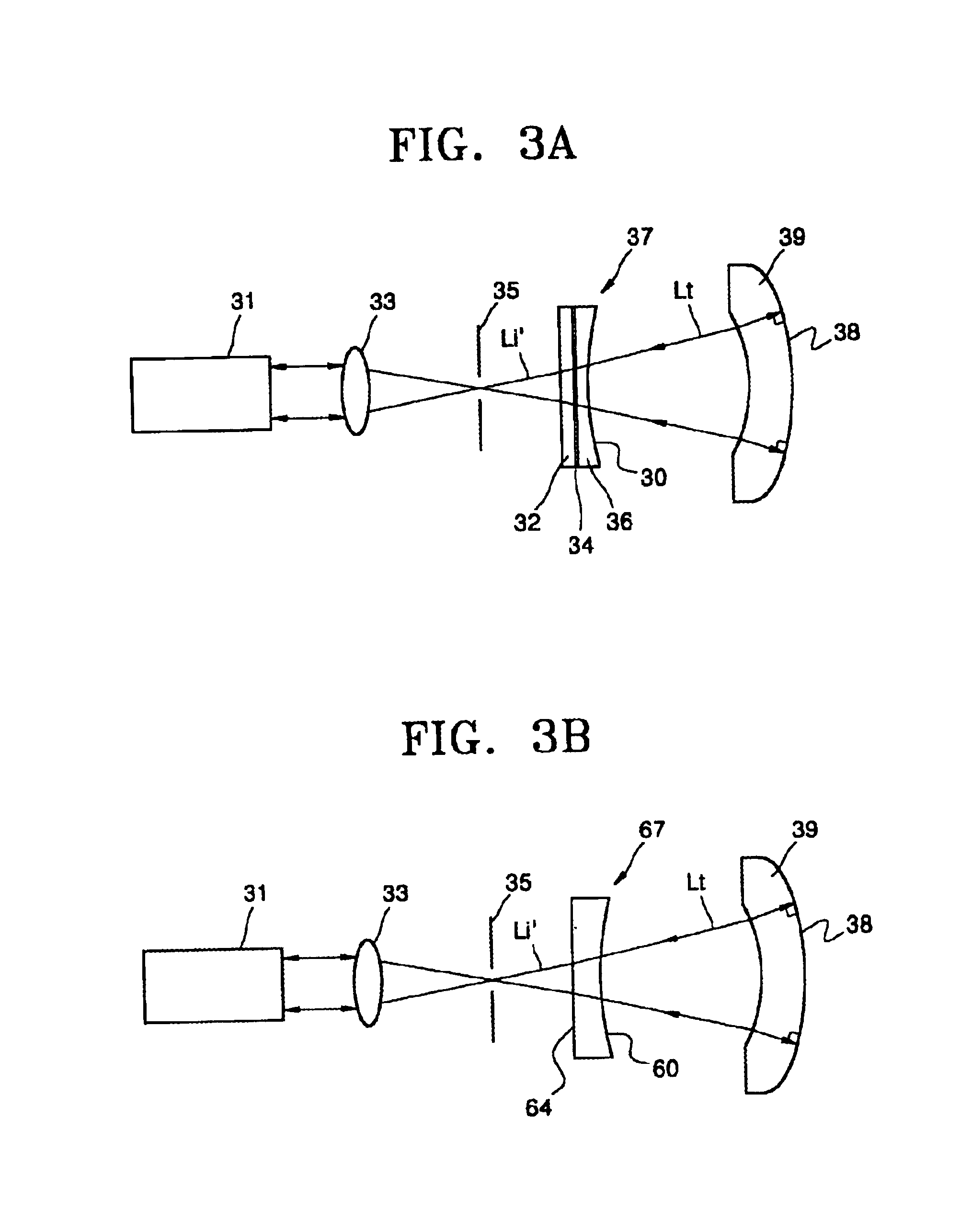

Apparatus for and method of measurement of aspheric surfaces using hologram and concave surface

InactiveUS7072042B2Large gratingHigh surface precisionUsing optical meansGeometric properties/aberration measurementAspheric lensLight Testing

An aspheric surface measuring apparatus includes an interferometer which generates incident light; a test piece having an aspheric surface from which the incident light is reflected as test light; a first optical element disposed on an optical path of the incident light, having at least one surface with a hologram for diffracting the incident light toward the test piece; and a second optical element disposed after the first optical element, which transmits the incident light toward the aspheric surface and has a concave surface to reduce an incident angle of the test light entering the hologram after having been reflected from the aspheric surface. Alternatively, a single optical element with a hologram and a concave surface can be used instead of the separate first and second optical elements. An extremely aspheric lens can be precisely measured using the apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

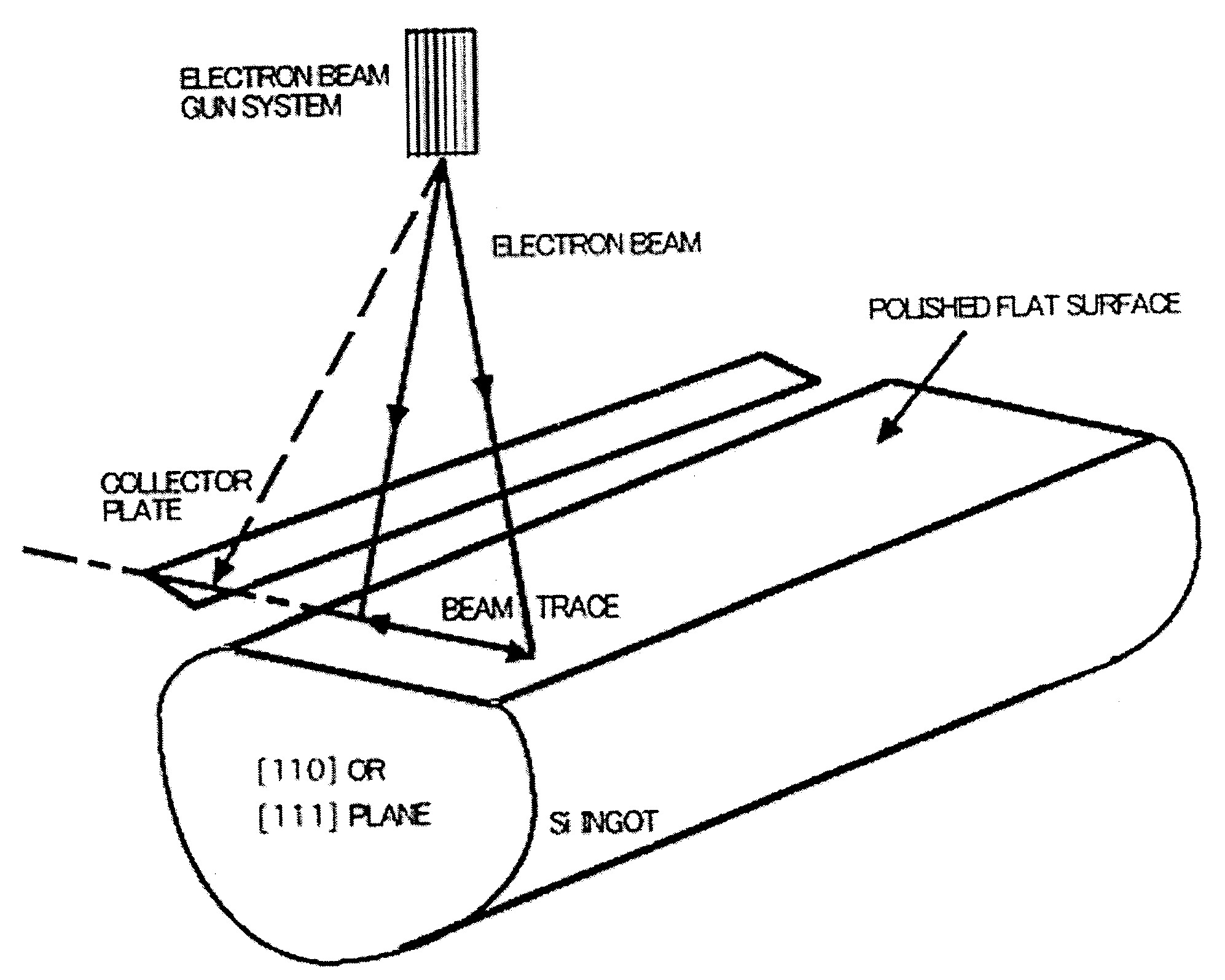

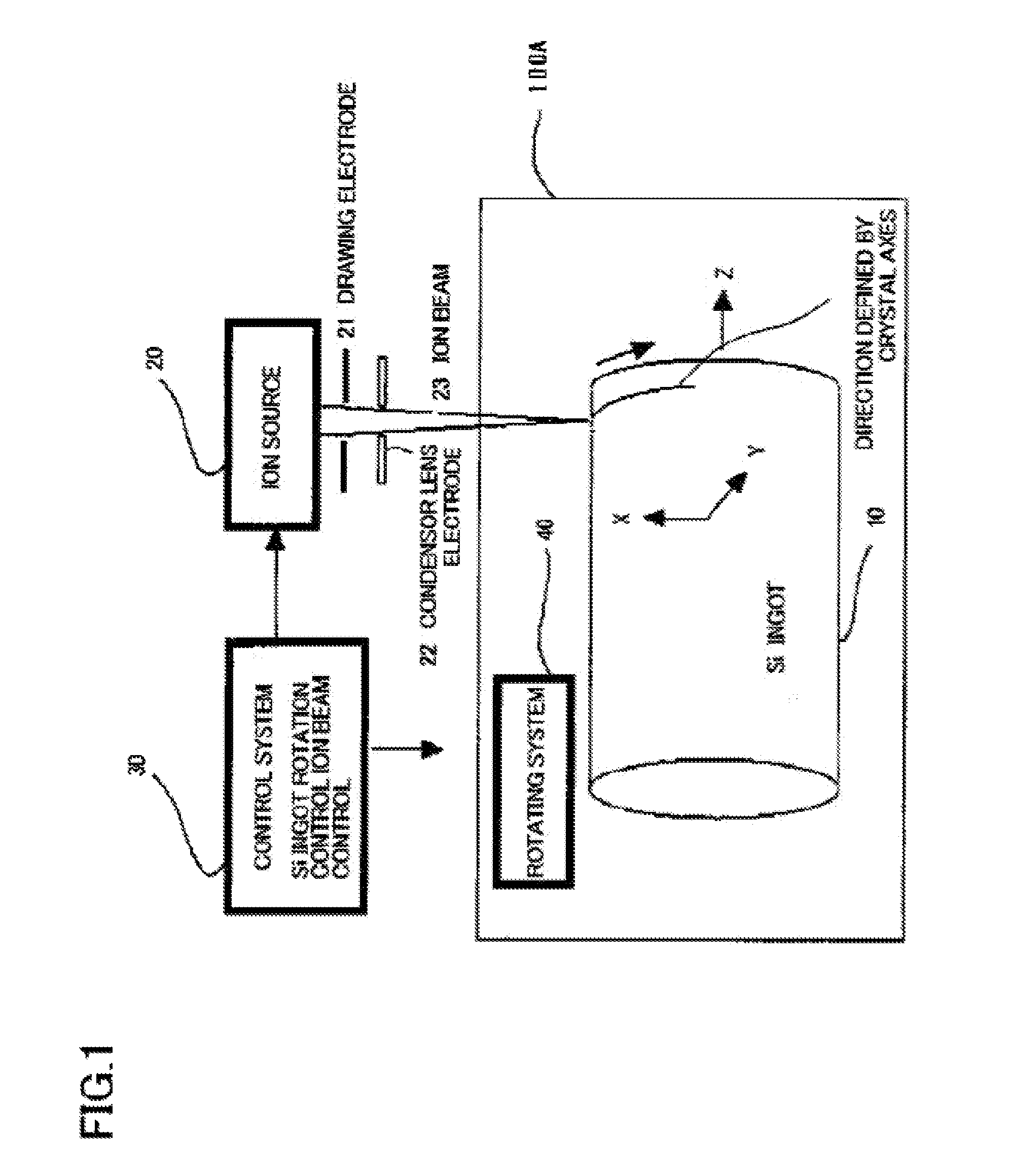

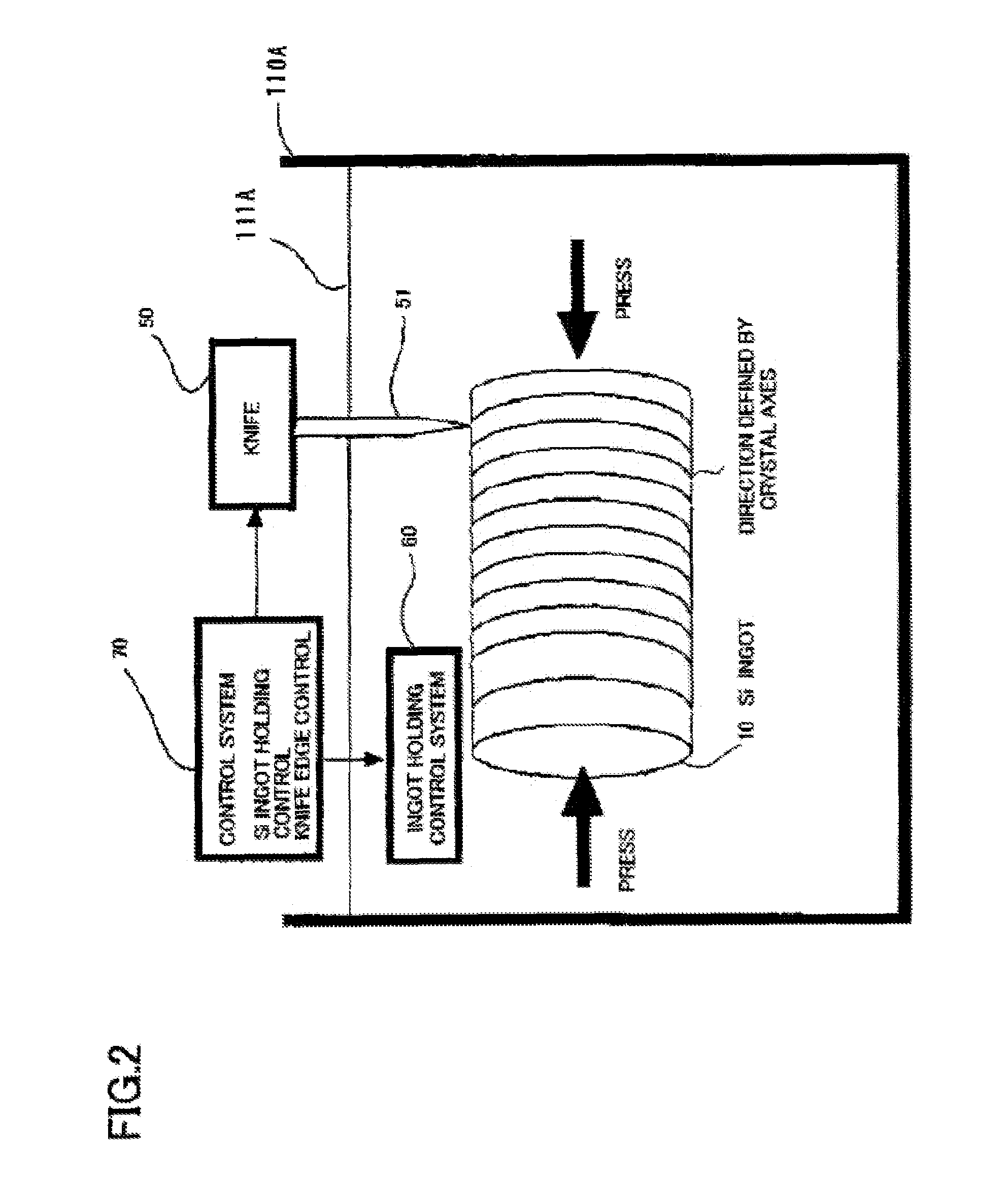

Cutting method and apparatus for ingot, wafer, and manufacturing method of solar cell

InactiveUS7351282B2Shorten the timeHigh surface precisionFinal product manufactureBy zone-melting liquidsLattice defectsIon beam

Cutting method of ingot into wafers along cleavage plane. Onto surface of single crystal ingot 10 is implanted ion beam 23 to generate lattice defects in a direction defined by the crystal axes that corresponds to the cleavage plane. Cleavage is generated by applying a shock by a knife edge to the position of the lattice having a cutting face as a cleavage plane. Production time of waters is reduced with a more numbers of sliced wafers from one ingot.

Owner:Y Y L

Sol of spinous inorganic oxide particles, method of producing the sol, and polishing agent containing the sol

ActiveUS20080131571A1Suppress generationImprove surface accuracyPigmenting treatmentOther chemical processesSilicic acidCentrifugation

The present invention provides a sol of spinous inorganic oxide particles not containing coarse particles, in which particles having extremely homogeneous particles are dispersed in a solvent. An acidic silicic acid is added to a dispersion liquid of core particles to grow core particles, and then again the acidic silicic acid is added at the addition rate 1.2 to 1.8 higher than that in the previous step to prepare a sol of spinous inorganic oxide particles. Then the sol is subjected to centrifugation to remove coarse particles having the diameter of 800 nm or more, thus spinous inorganic oxide particles having peculiar form such as a spinous one being obtained.

Owner:JGC CATALYSTS & CHEM LTD

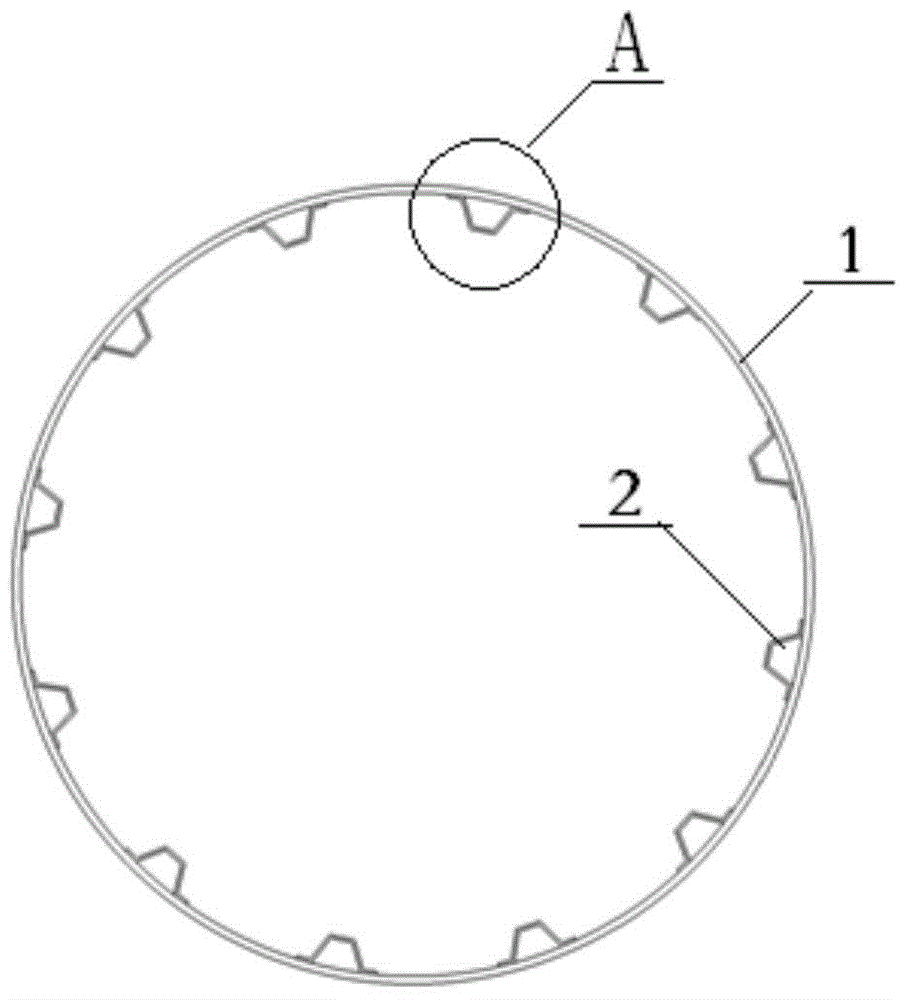

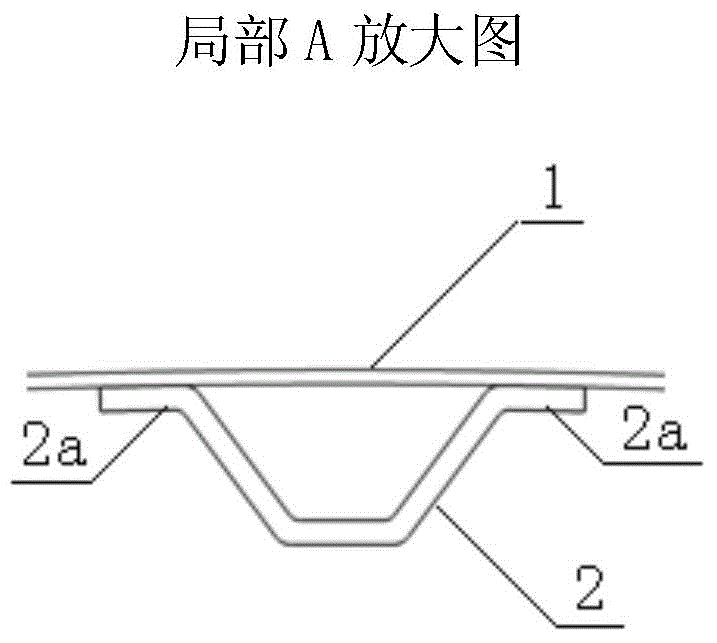

Molding method of integral composite material reinforced cylinder, laying tool, curing mold and stringer positioning device

The invention belongs to a composite material molding technology, and relates to a molding method of an integral composite material reinforced cylinder, a laying tool, a curing mold and a stringer positioning device. The method comprises the molding steps of: assembly of a laying mold; adjustment of a movable mold (6a); sealing of the laying mold; laying of a skin (1); installation of the curing mold; extraction of the laying mold; curing of the skin; adjustment of the stringer positioning device (7); bonding of an adhesive film on a stringer; positioning of the stringer; and curing. The invention proposes the molding method of the integral composite material reinforced cylinder, the laying tool, the curing mold and the stringer positioning device; the appearance surface precision of the cap-shaped stringer and the cylinder is greatly improved; the stringer positioning method is simplified; the demolding difficulty is solved; and the product pass percent is improved.

Owner:AVIC COMPOSITES

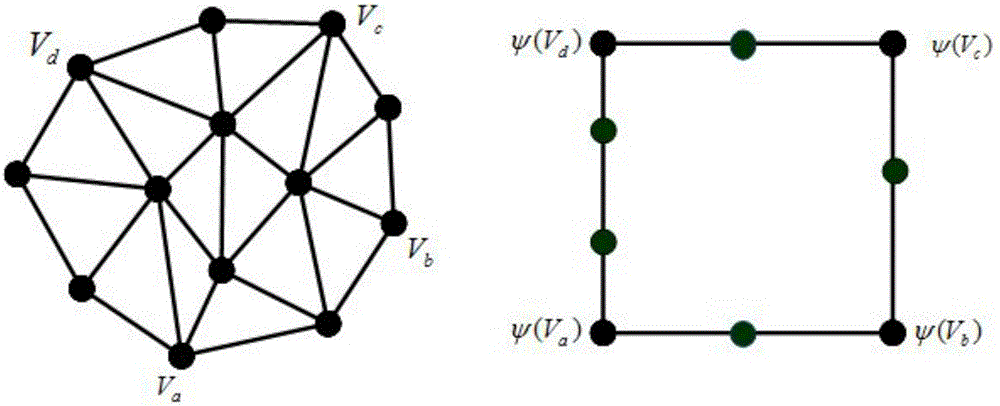

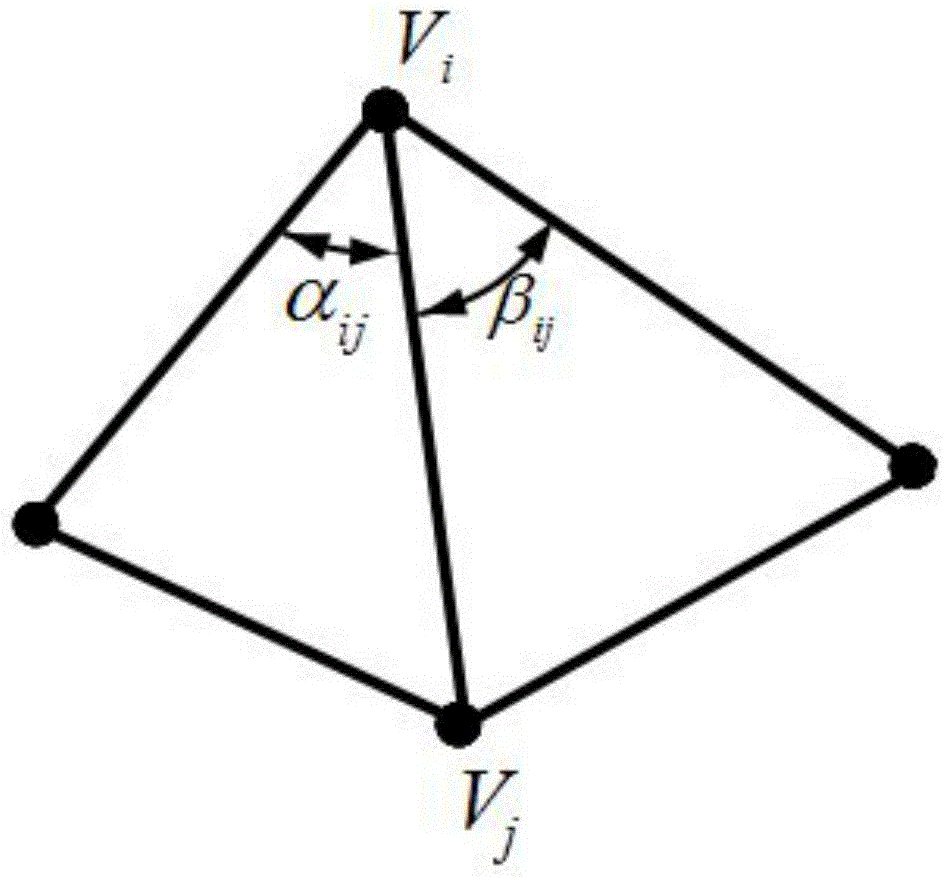

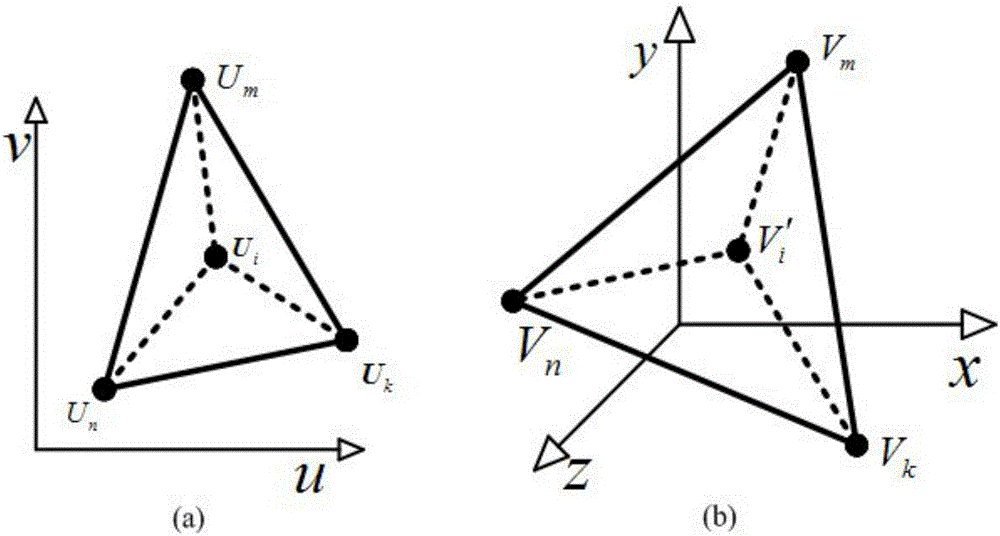

Parametric surface reconstruction method for false tooth discrete data

InactiveCN105118093ASpline surface with high precisionHigh surface precisionSpecial data processing applications3D modellingReconstruction methodMean value coordinates

The invention relates to a parametric surface reconstruction method for false tooth discrete data. The method comprises the following steps: quickly reconstructing a triangular mesh model of a false tooth by utilizing a circumsphere criterion; mapping top points of the triangular mesh model of the false tooth to a unit square of a planar parameter domain in a one-to-one manner with a mean value coordinate parameterization method; according to an inverse mapping technology, mapping regular sampling points on the unit square of the planar parameter domain to the triangular mesh model; and obtaining regular sampling points of the triangular mesh model and obtaining a B-spline surface of the false tooth with a B-spline surface interpolation algorithm. According to the method, the oral repair cycle can be shortened and the pain of oral patients can be relieved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

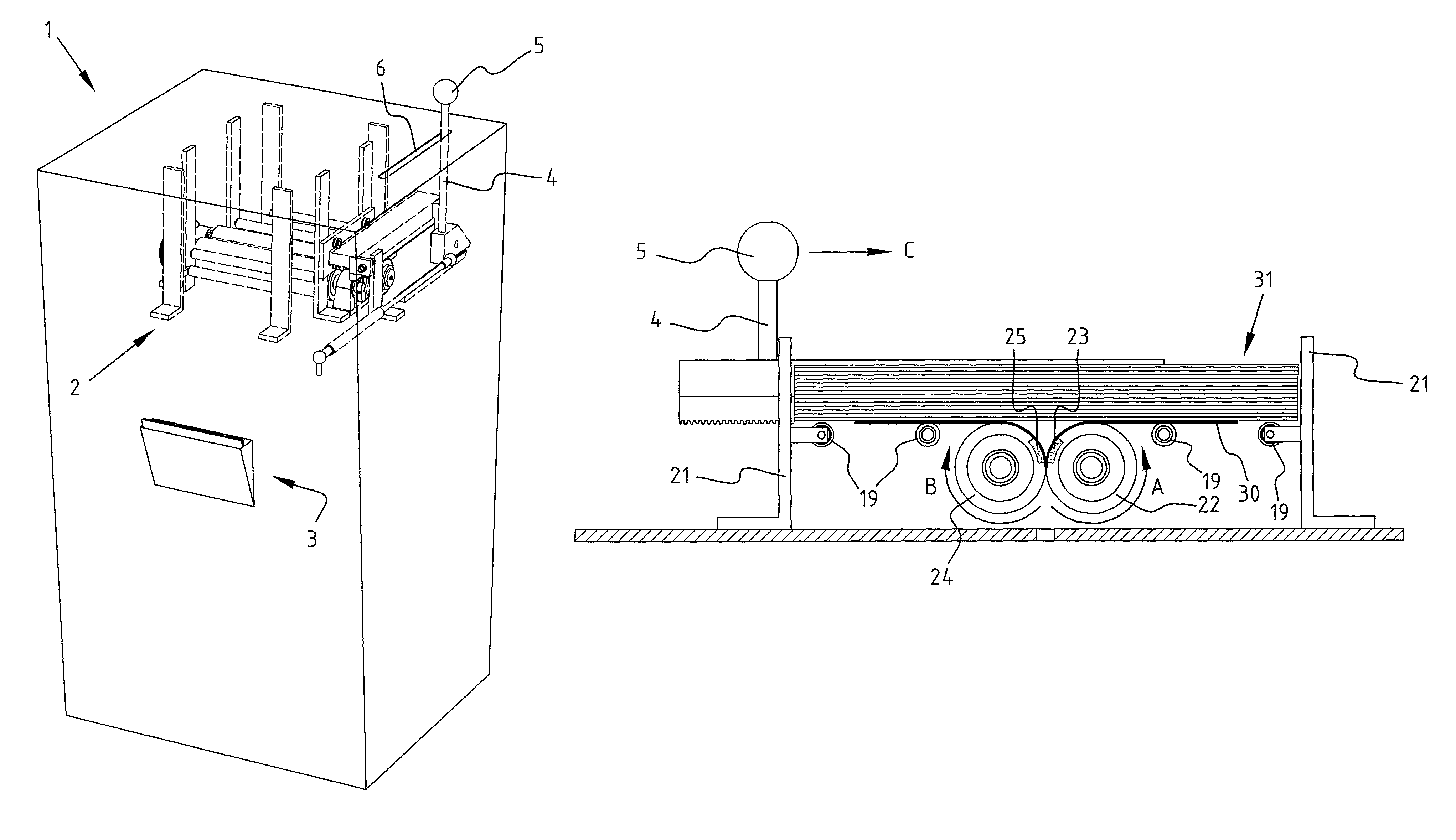

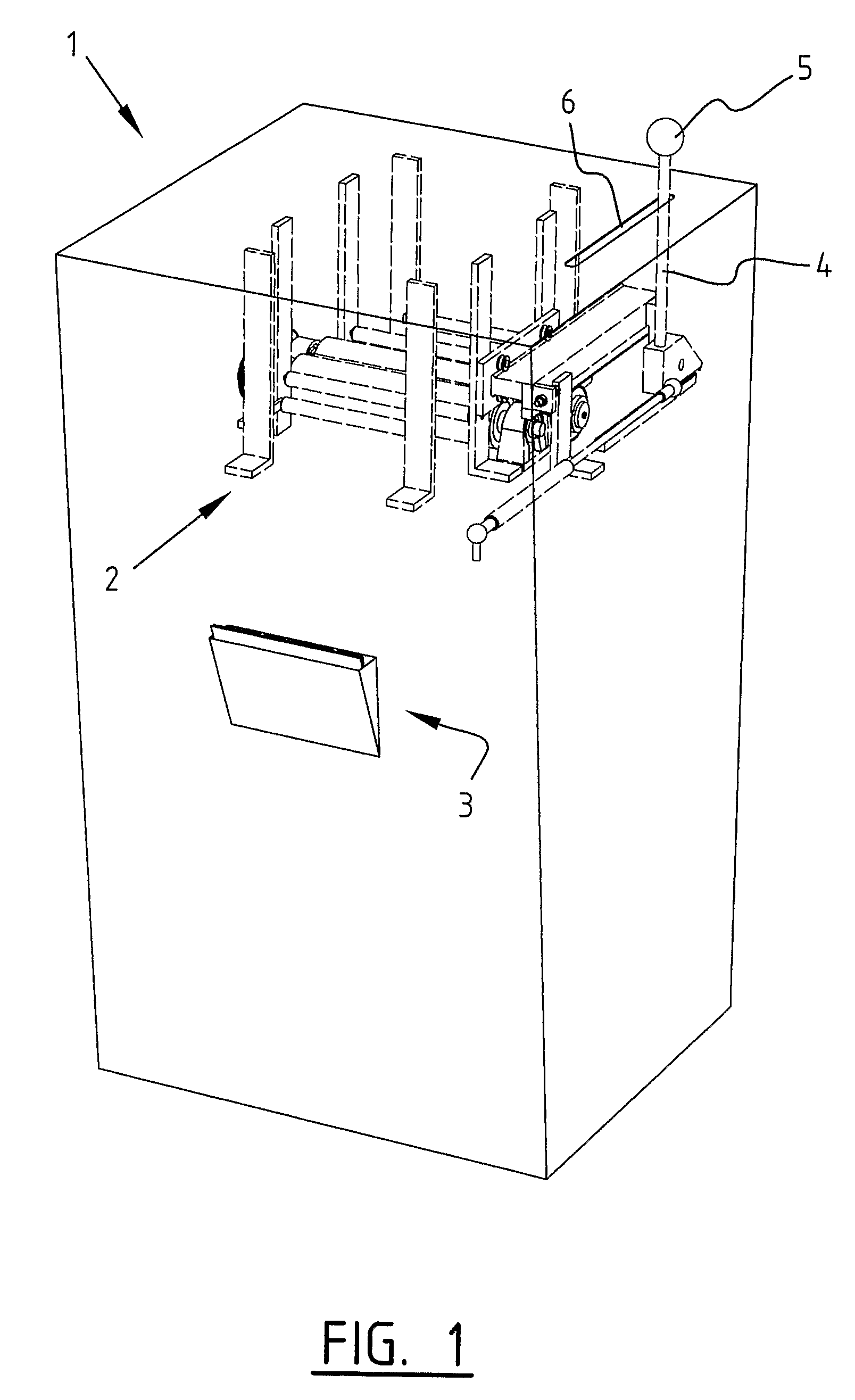

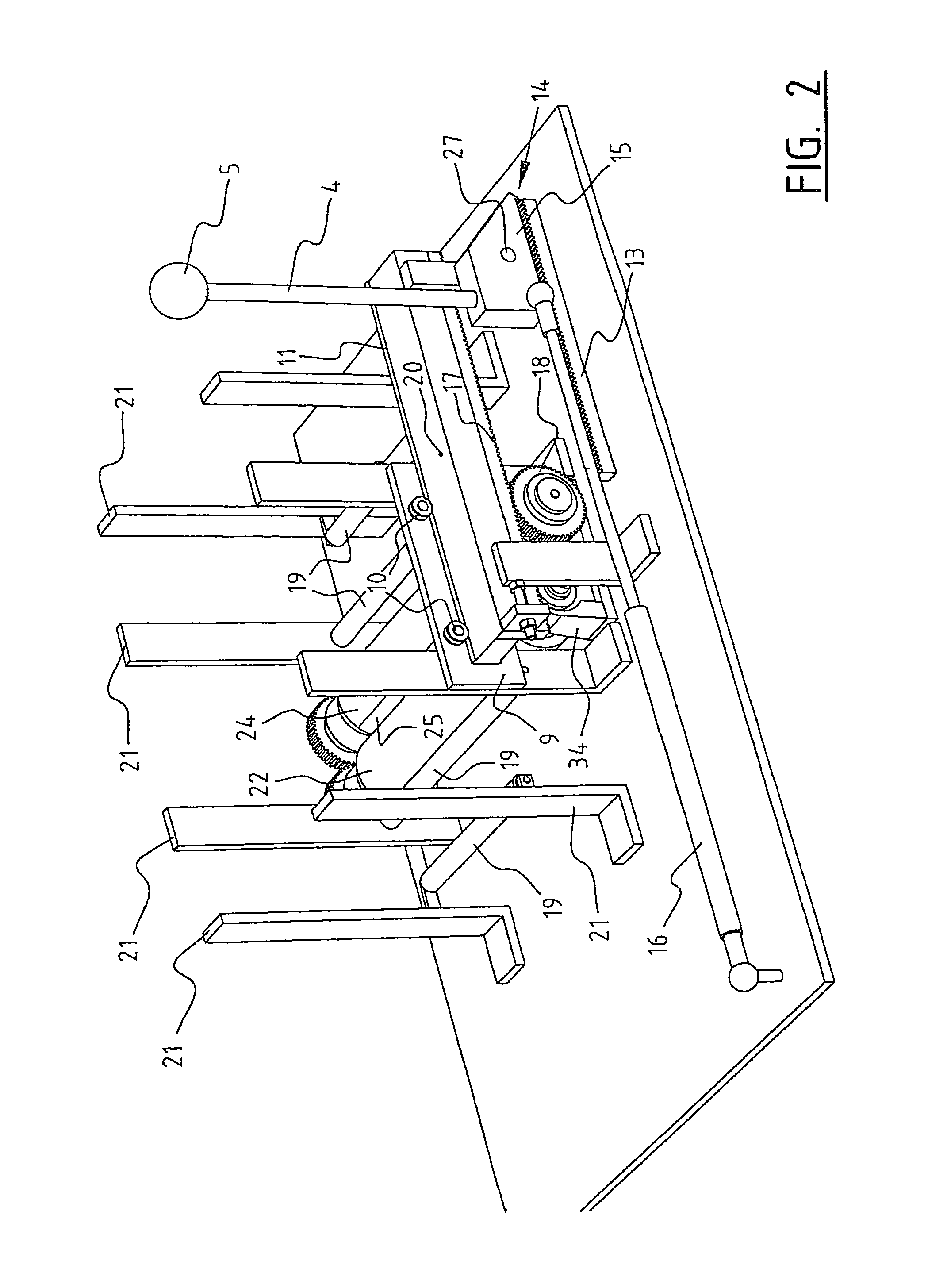

Apparatus and method for dispensing and folding of sheets from a stack

InactiveUS8662346B2Prevent removalIncrease frictionCoin-freed apparatus detailsFolding thin materialsEngineeringMechanical drive

A removing mechanism is disclosed for removing the bottom or top sheet from a stack of sheets; a delaying member for a delay of a predetermined time between the dispensing of two successive sheets; and an actuating mechanism for driving the removing mechanism, wherein the actuating mechanism is driven via a physically supplied mechanical drive force of an operator of the dispensing apparatus.

Owner:INFOSTOP

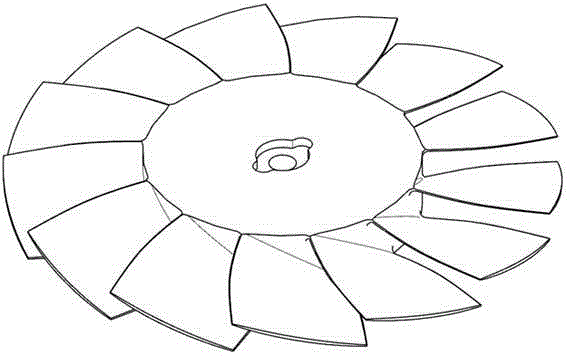

Process for strengthening milling rigidity of aluminum-alloy ultrathin-blade integral impeller

The invention discloses a process for strengthening the milling rigidity of an aluminum-alloy ultrathin-blade integral impeller. The process comprises the following steps: firstly layering the ultrathin blade of the integral impeller; reserving rough machining allowance; and carrying out layered finish machining on the ultrathin blade. According to the invention, resonance of the whole blade is reduced via non-uniform allowance and transition fillets between each layer, so vibration of the ultrathin-blade integral impeller caused by influence of cutting force in cutting can be effectively reduced, the molded surface quality and curved surface precision of the blade milled by a cutter and dimensional stability of the impeller are improved, and cutting efficiency is significantly enhanced.

Owner:SHANGHAI INST OF TECH

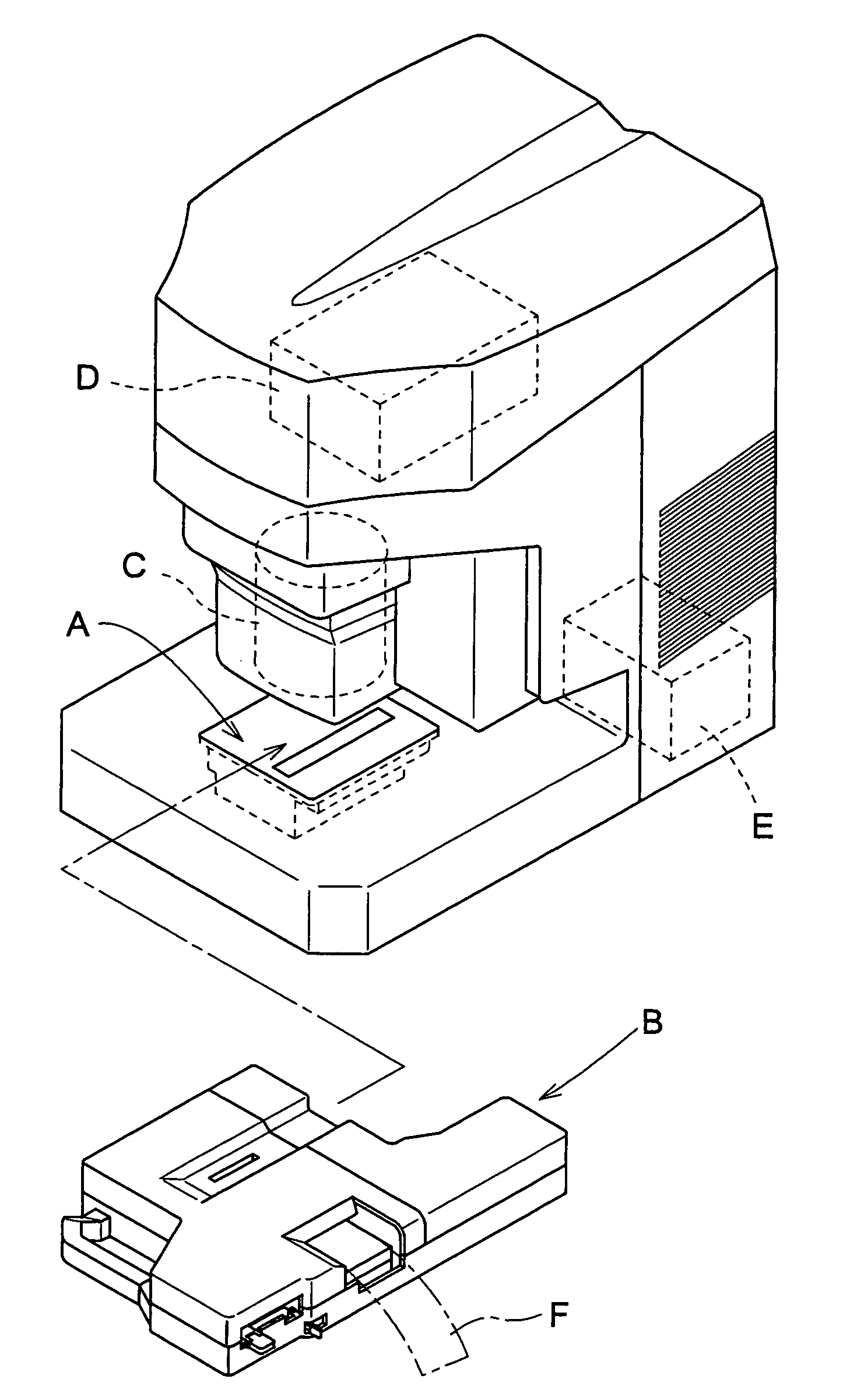

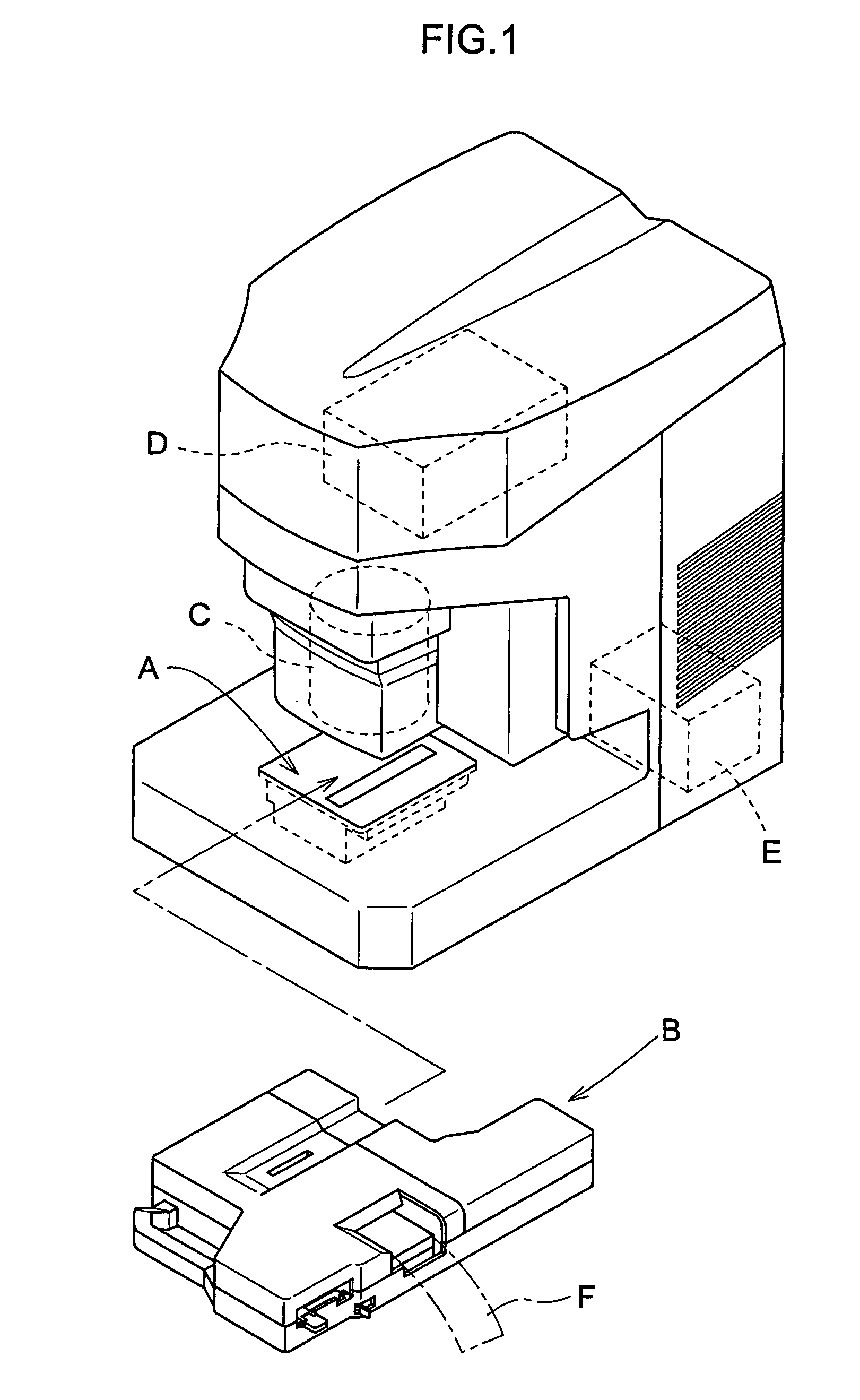

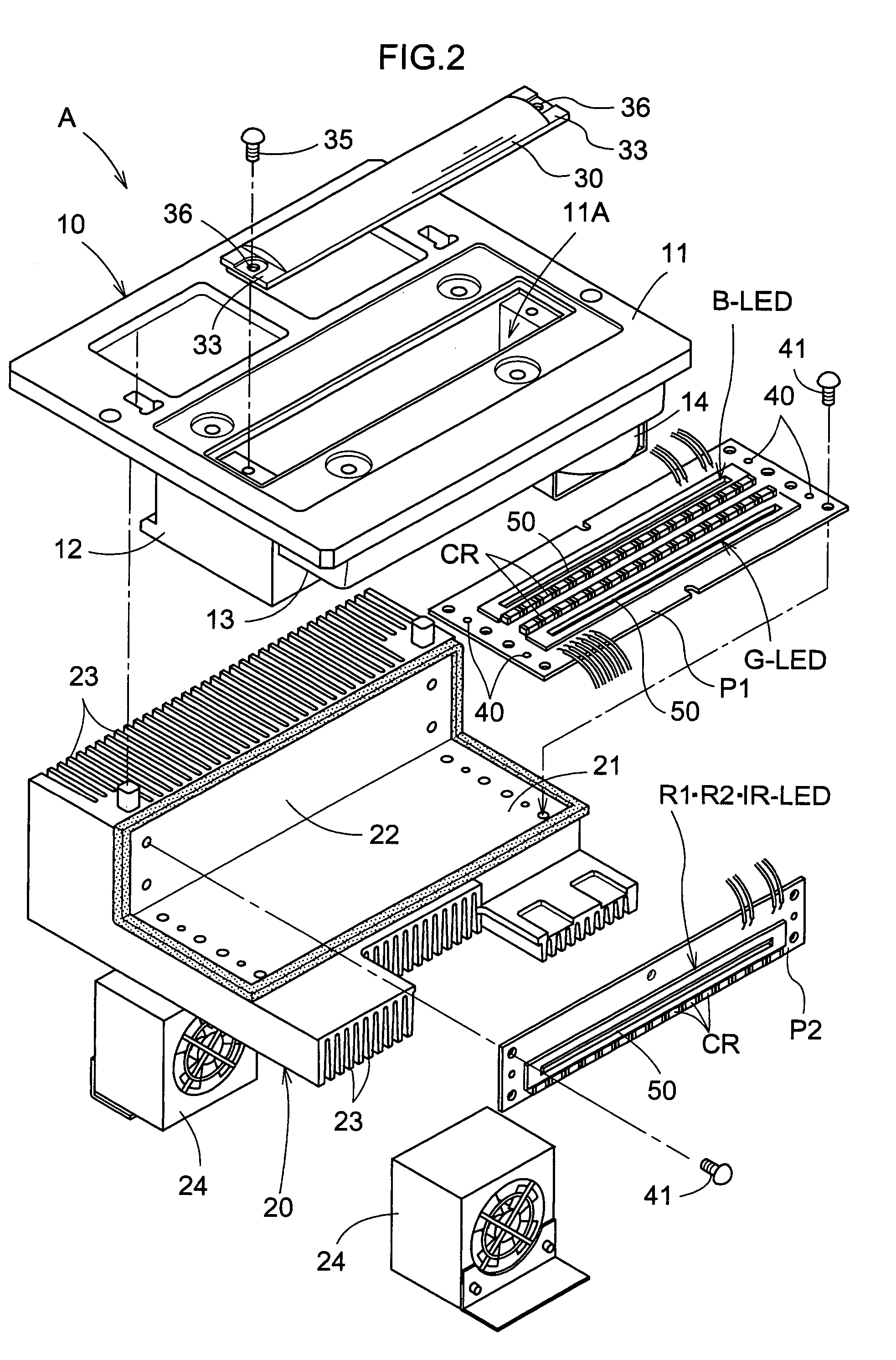

Light-emitting diode light source unit

InactiveUS7018065B2Improve reflective effectHigh surface precisionPoint-like light sourceLighting support devicesLight beamEngineering

A light-emitting diode (LED) light source unit includes a printed circuit board mounting LED elements thereon. The LED elements are arranged in the form of an array and mounted on a bottom face of a straight groove defined in the printed circuit board by a groove forming technique. A lateral face of the groove acts as a reflecting face for reflecting beam from the LED elements toward an object to be illuminated.

Owner:NORITSU PRECISION CO LTD

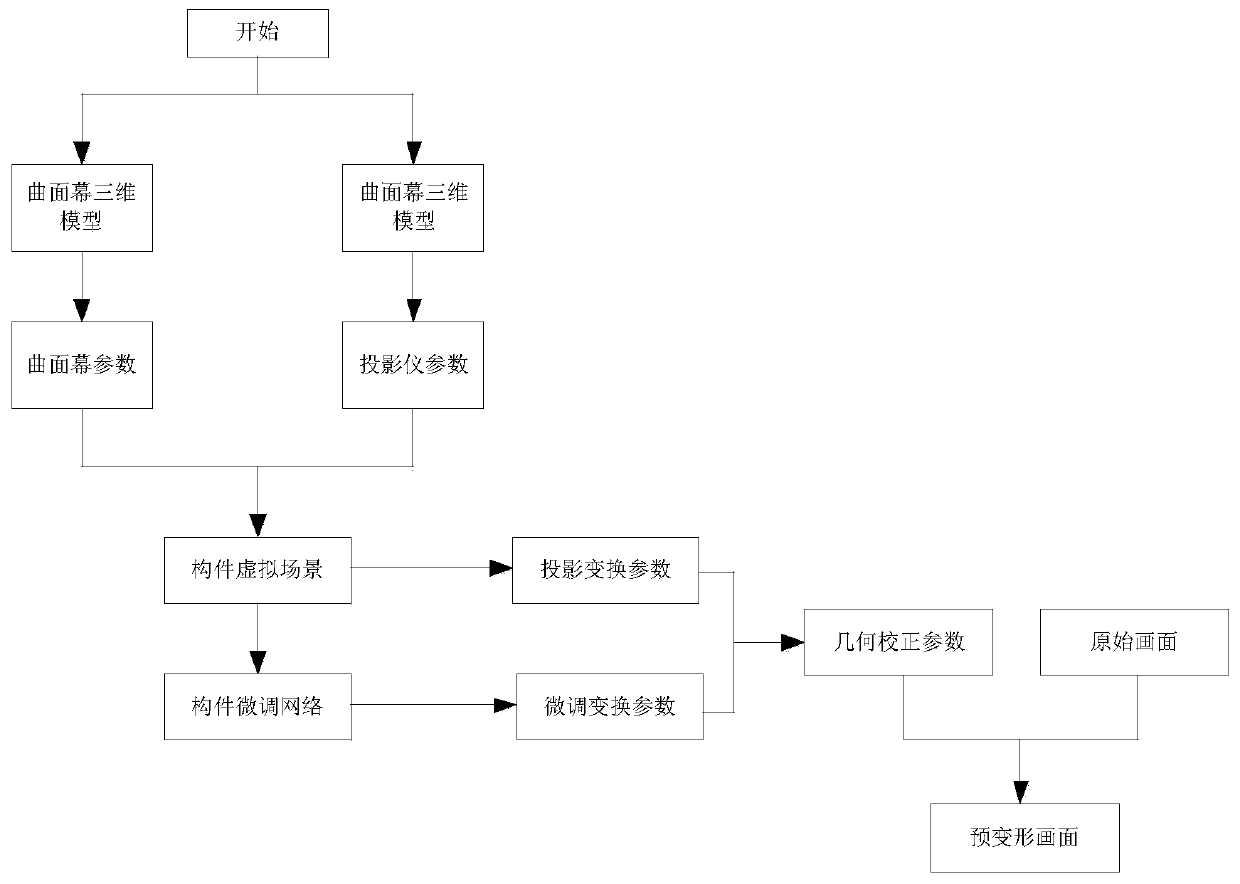

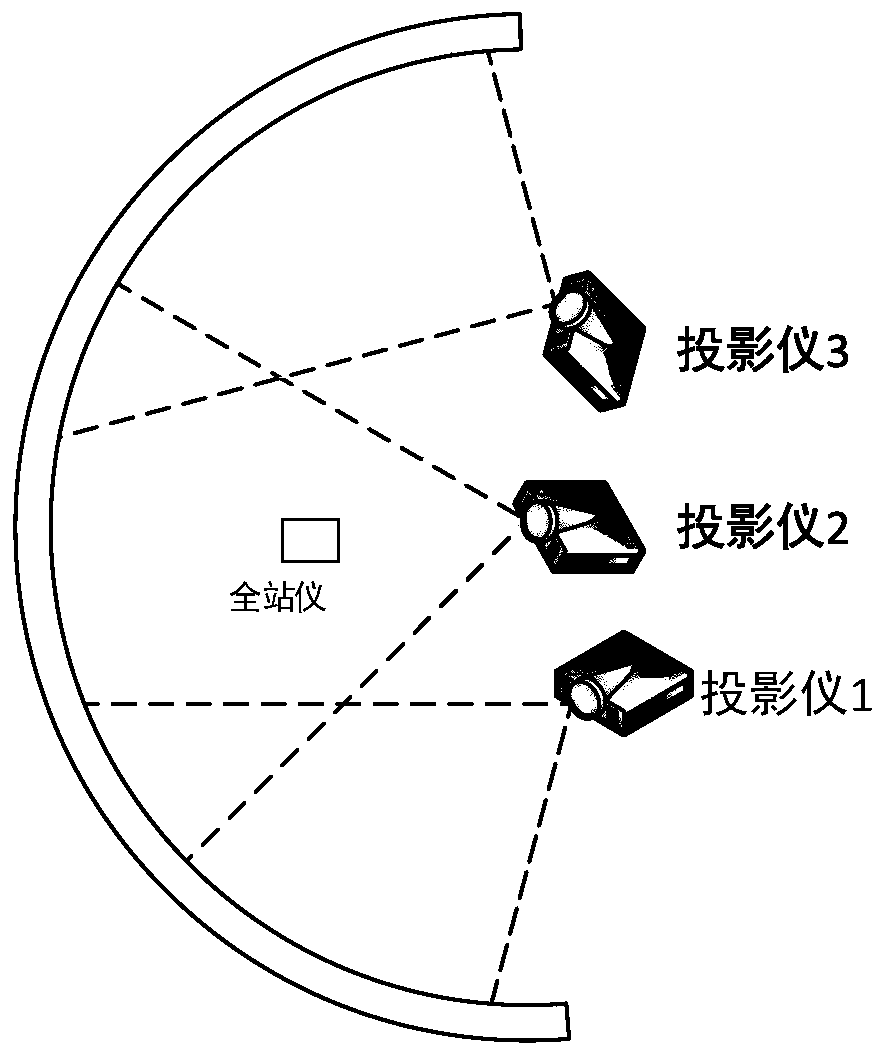

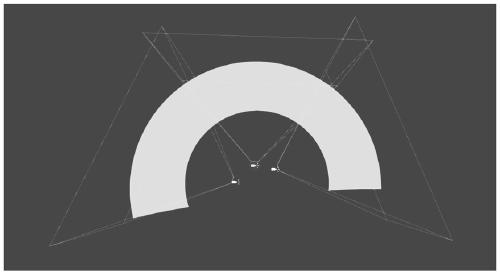

Multi-channel correction splicing method for curved screen

ActiveCN111062869AHigh surface precisionHigh measurement accuracyImage enhancementSustainable transportationMorphingTransformation parameter

The invention discloses a multi-channel correction splicing method for a curved screen, and the method comprises the following steps: firstly obtaining the parameters of the curved screen, measuring the positions and posture parameters of all projectors relative to the curved screen, and unifying a coordinate system; then constructing a virtual scene containing a virtual curved screen and a virtual projector, calculating a picture deformation relationship when a projector picture is projected to the dome screen, and obtaining a projection transformation relationship; and finally, constructingan interpolation grid in a screen space of the projector; obtaining the interpolation grids required by fine adjustment of the screen space of each projector through the above mode; then, performing fine tuning and forming a fine tuning transformation parameter table; integrating two-dimensional mapping tables obtained by projection transformation and micro-calibration transformation; rendering the picture by using the geometric correction parameters to obtain a pre-deformed picture projected by each projector; and finally, projecting a pre-deformed picture by the projector to finish splicingcorrection. According to the invention, only one-time initial calibration is needed, and part of measurement errors, construction errors, settlement errors caused by overlong service life of equipmentand the like are solved through micro calibration.

Owner:北京东方瑞丰航空技术有限公司

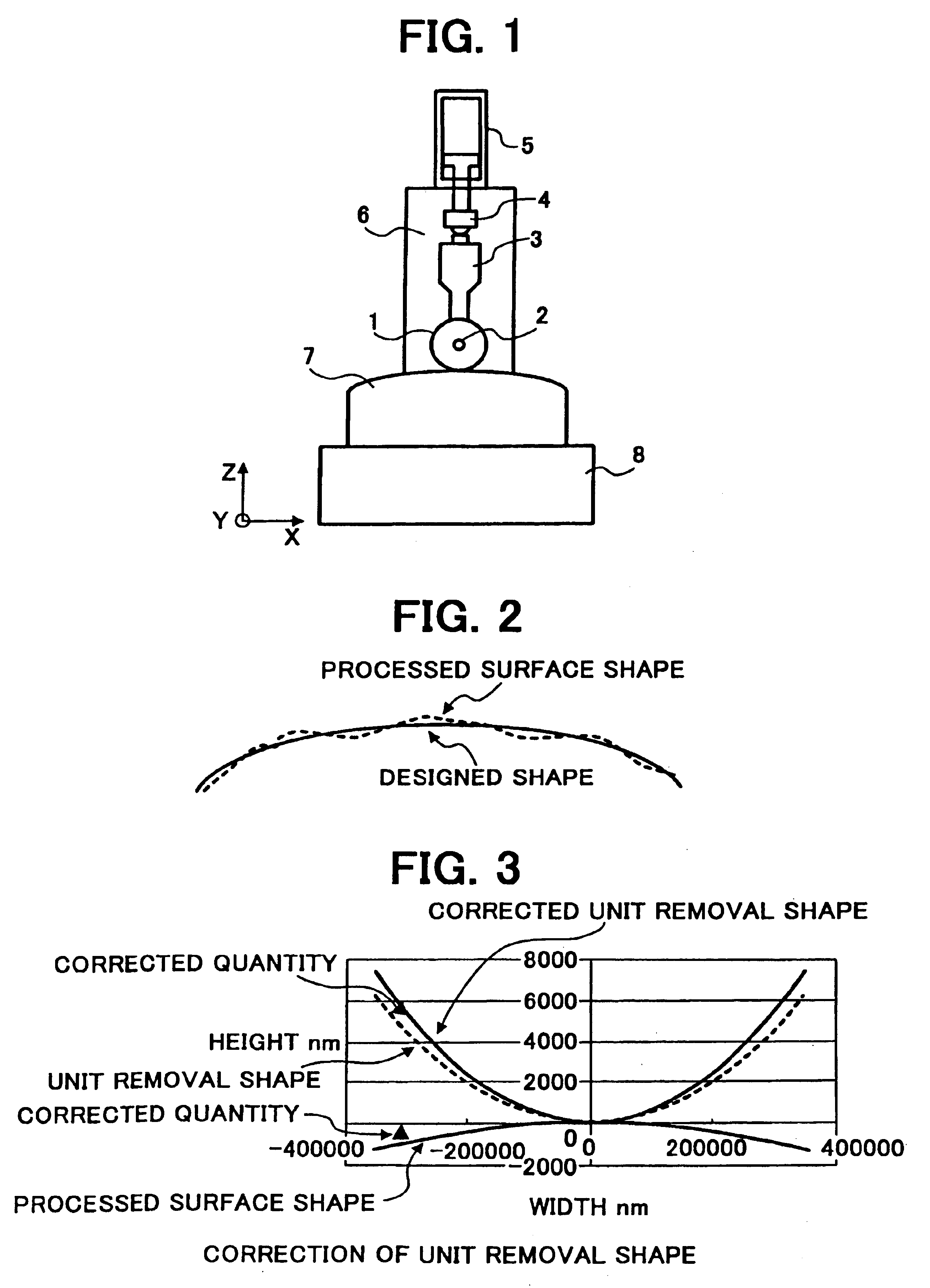

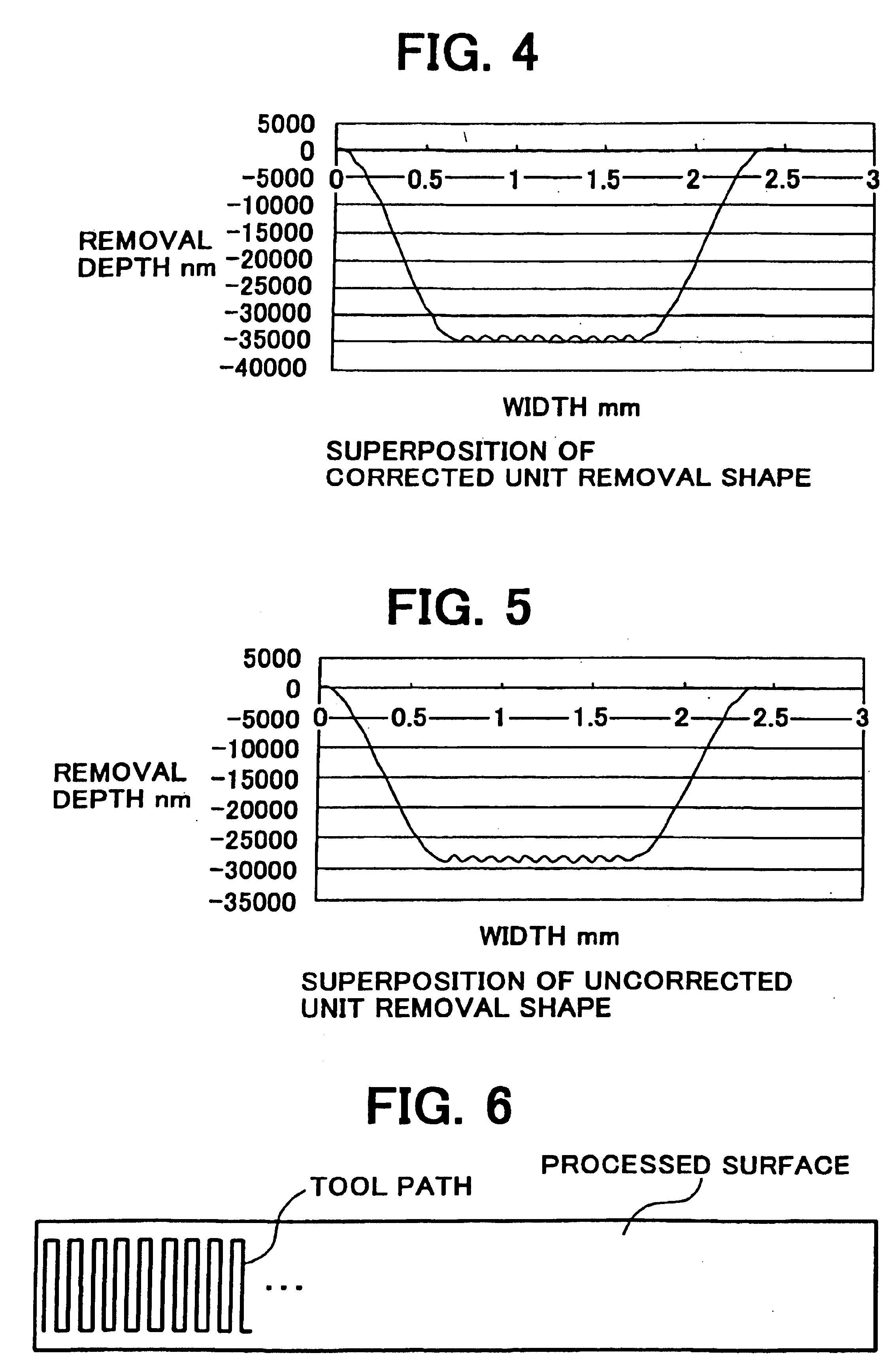

Method for processing surface and apparatus for processing same

InactiveUS6889112B2High surface precisionProgramme controlAutomatic control devicesComputer scienceReference surface

A method for processing a surface corrects a relationship between a processing condition and a removal quantity (polished removal quantity) or a removal depth (polished removal depth) in accordance with a worked surface to obtain desired removal quantity or removal depth in processing the worked surface irrespective of the shape of the worked surface, forms a reference surface in a simple shape to obtain the relationship between the processing condition and the removal quantity or the removal depth readily, and executes such correction of the relationship between the processing condition and the removal quantity or the removal depth and such correction of unit removal shapes readily for a short time.

Owner:RICOH KK

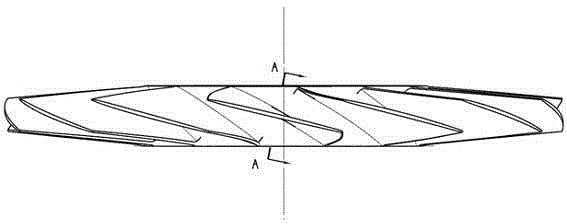

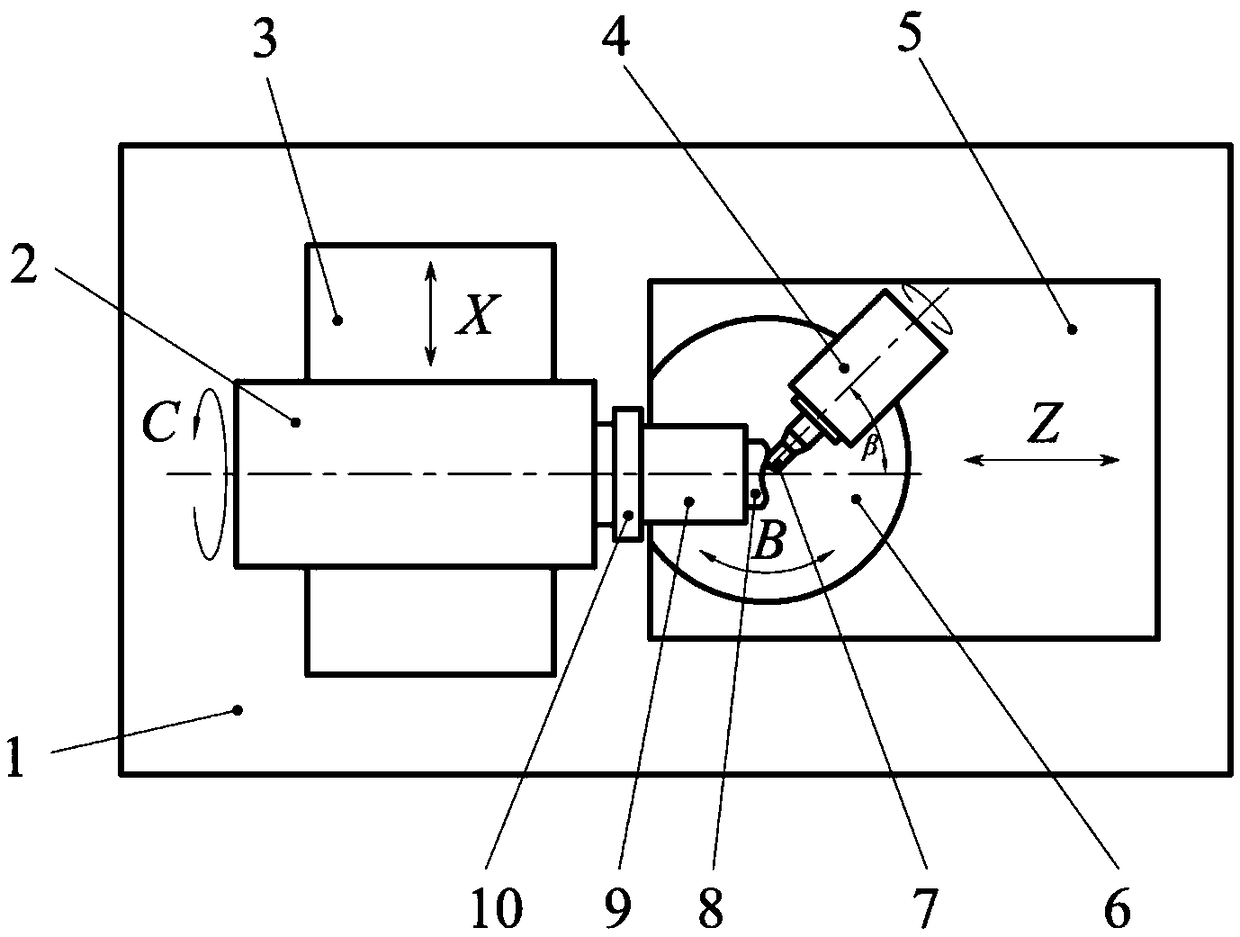

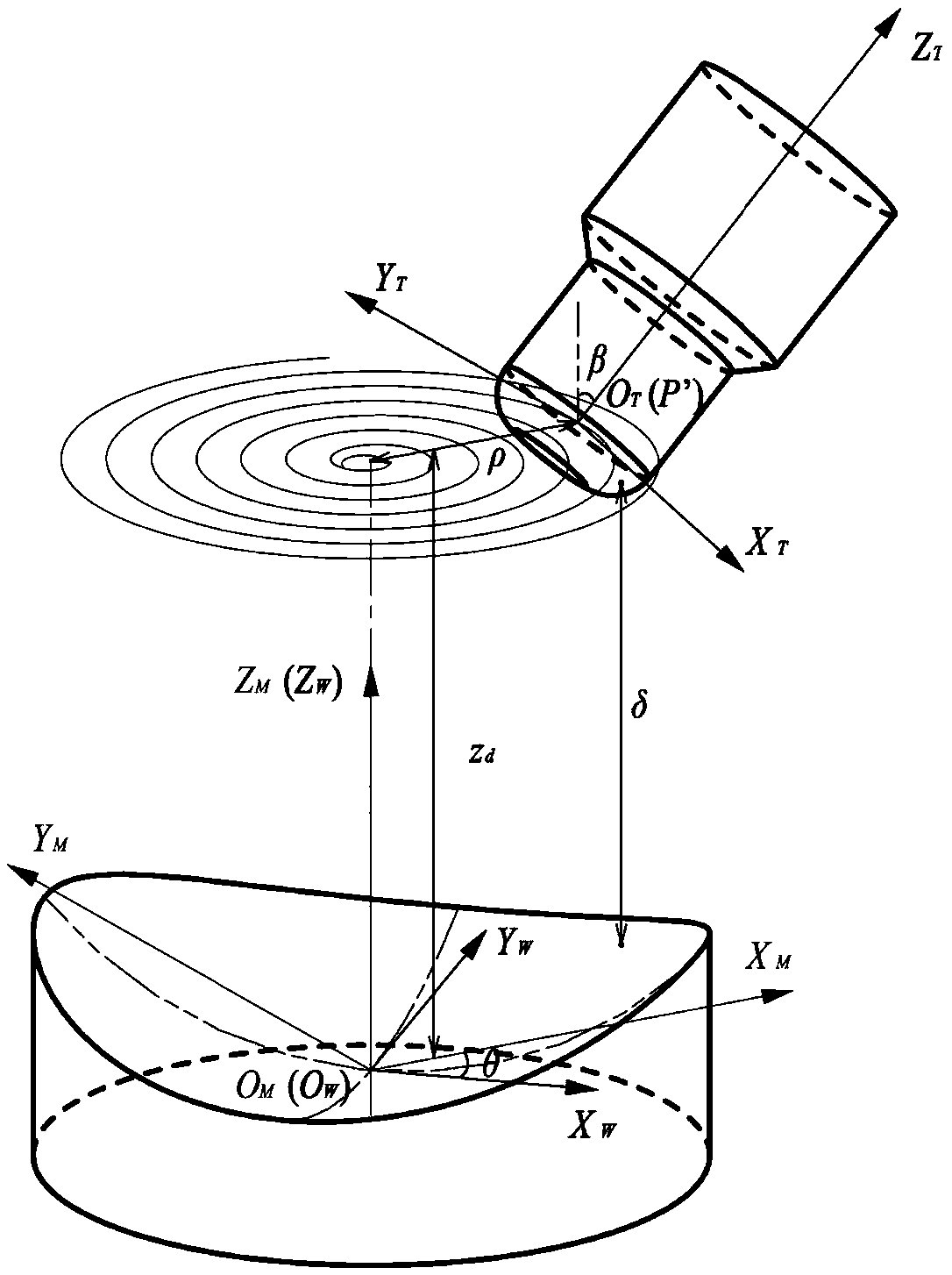

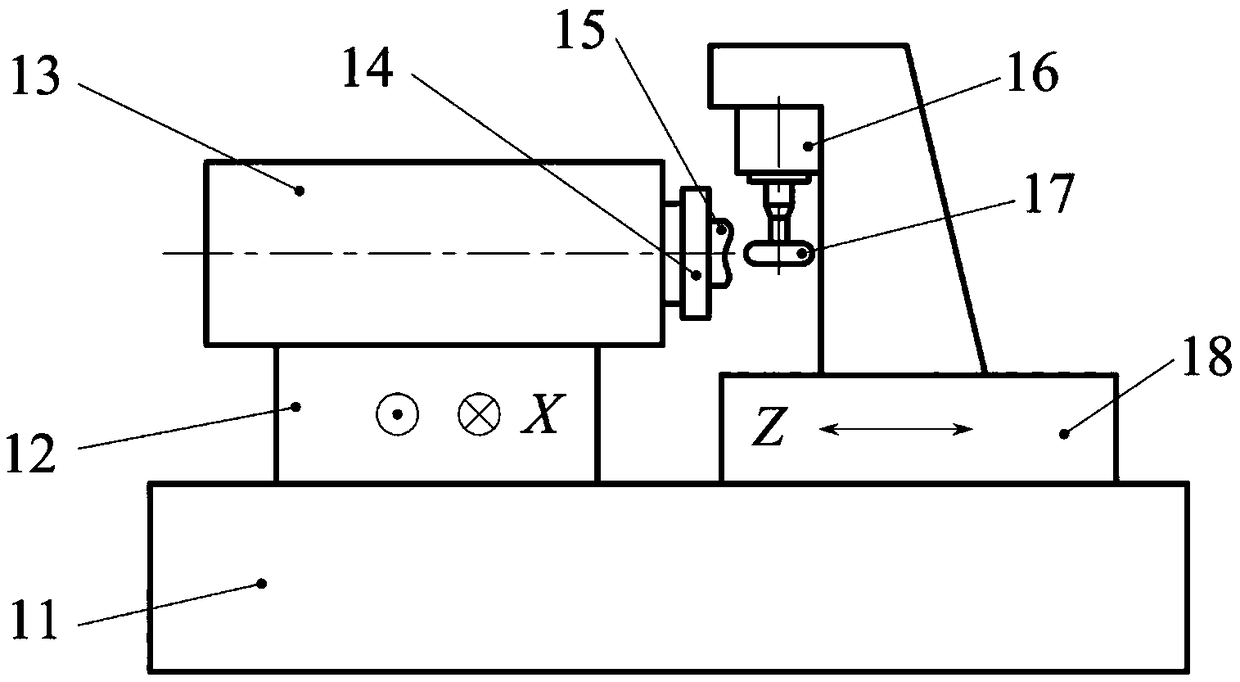

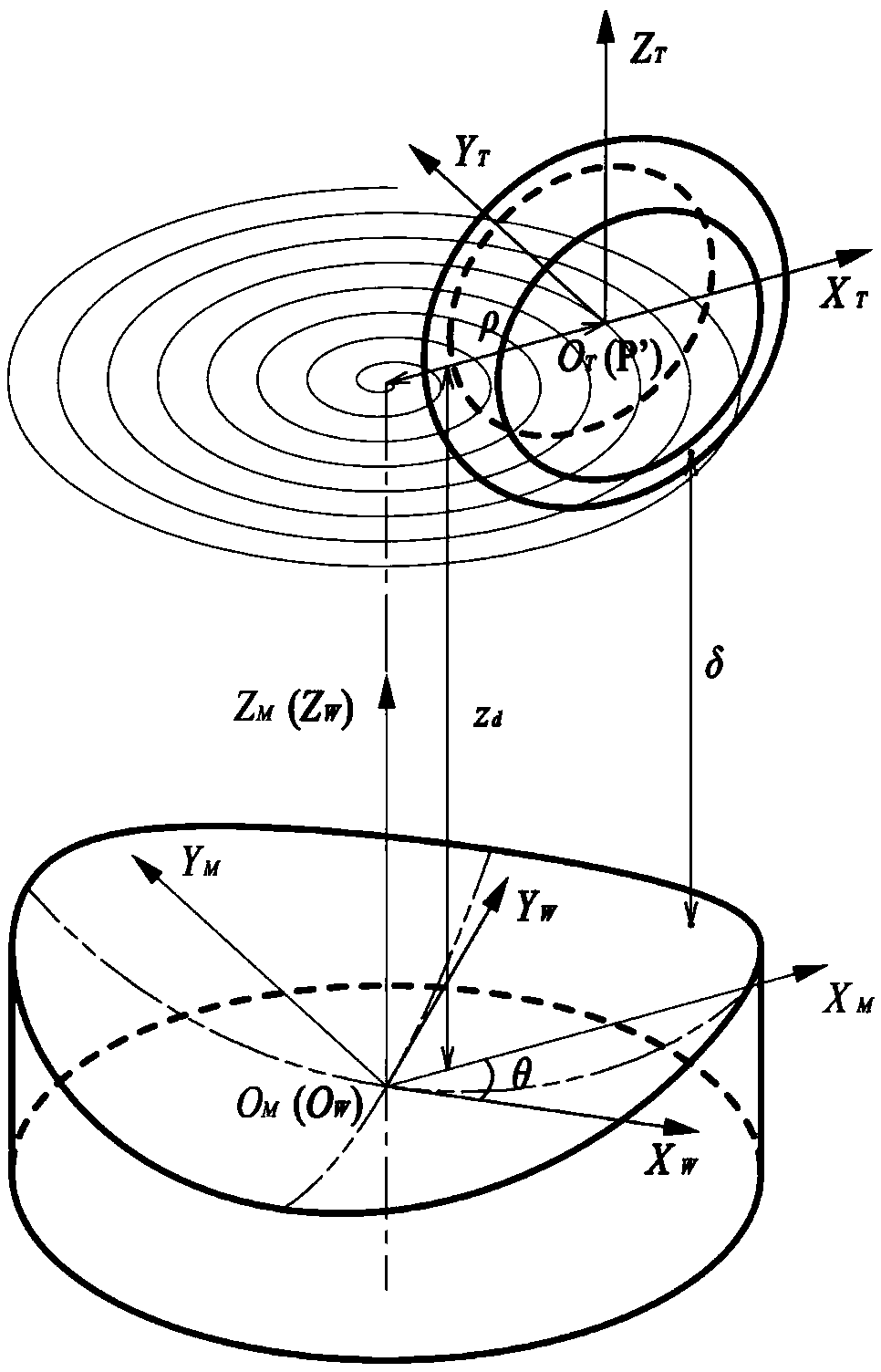

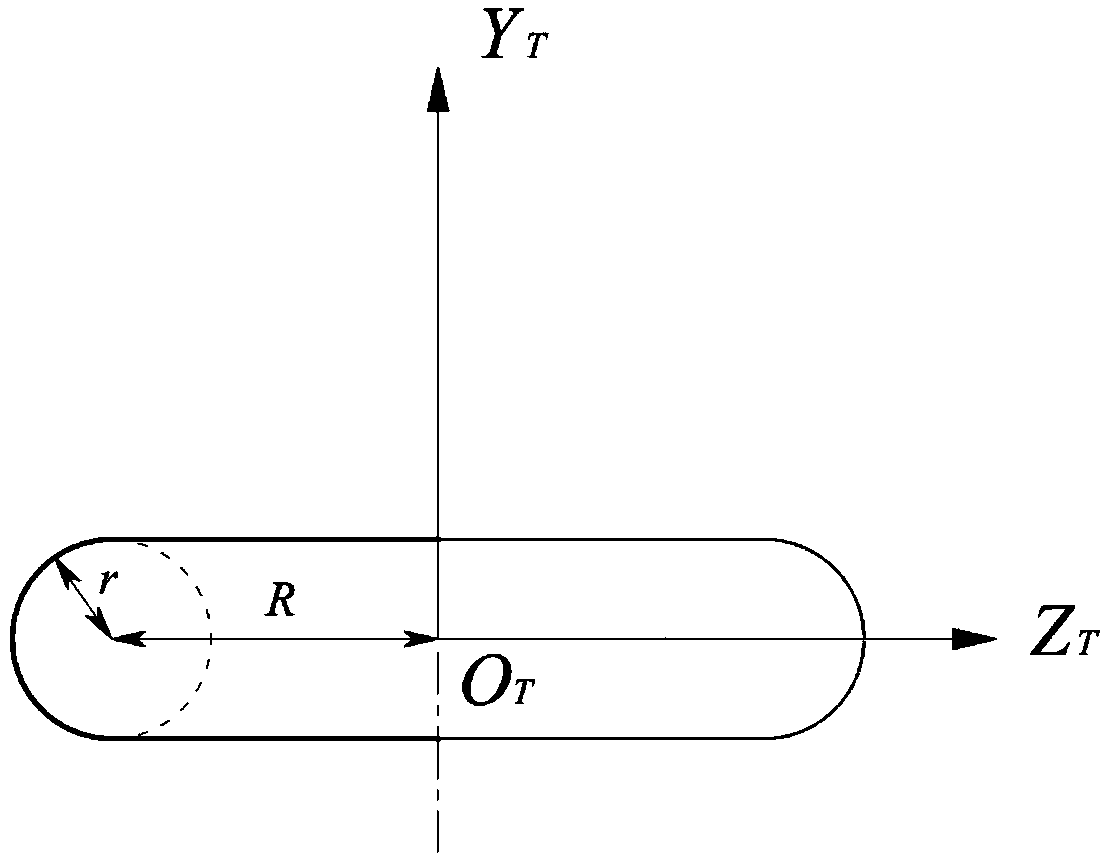

Grinding wheel path generation method for tilting-axis single-point grinding of free-form curved surface

ActiveCN109176224AGuaranteed stabilityReduced dynamic response performance requirementsOptical surface grinding machinesGrinding drivesFree formPath generation

The invention relates to a grinding wheel path generation method for tilting-axis single-point grinding of a free-form curved surface. The method comprises the steps that a plane perpendicular to theZ axis of a workpiece coordinate system is established at the position zd by a certain distance above the free-form curved surface to be processed in the workpiece coordinate system, an equidistant spiral line is generated in the plane and discretized, points are converted into cylindrical-coordinate system forms (rho, theta and zd) after discretization, the free-form curved surface to be processed is rotated by the angle theta around the Z axis, the minimum distance delta and the B-axis rotation angle beta between the grinding wheel processing curved surface and the rotated free-form curved surface to be processed at each point of the equidistant spiral line in the Z direction are obtained, then coordinates (rho, 0 and zd-delta) of a grinding wheel control point are obtained, specifically, a grinding wheel is a circular-bead columnar grinding wheel, and the inclination angle between the grinding wheel axis and the workpiece rotation shaft axis is beta and changes along with rotation of a workpiece so that it can be ensured that the contact point of the workpiece and the grinding wheel is kept unchanged. According to the method, the projection drive track of the grinding wheel control point is optimally generated, smoothness of feeding motion of the grinding wheel in the X direction is ensured, and the requirement for dynamic response performance of a machine tool is reduced; and meanwhile, as the grinding point of the grinding wheel is kept unchanged, the contour error of the grinding wheel cannot be copied to the workpiece, and accordingly the quality of the processing surface can be further improved.

Owner:TIANJIN UNIV

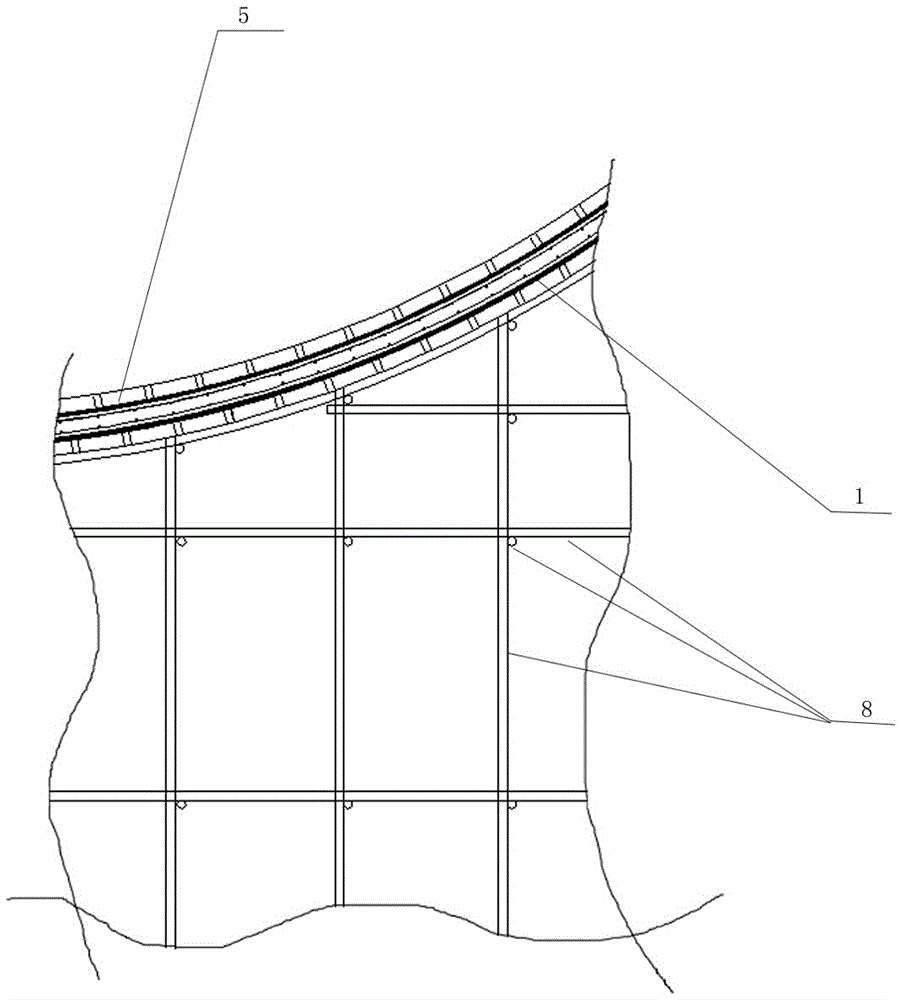

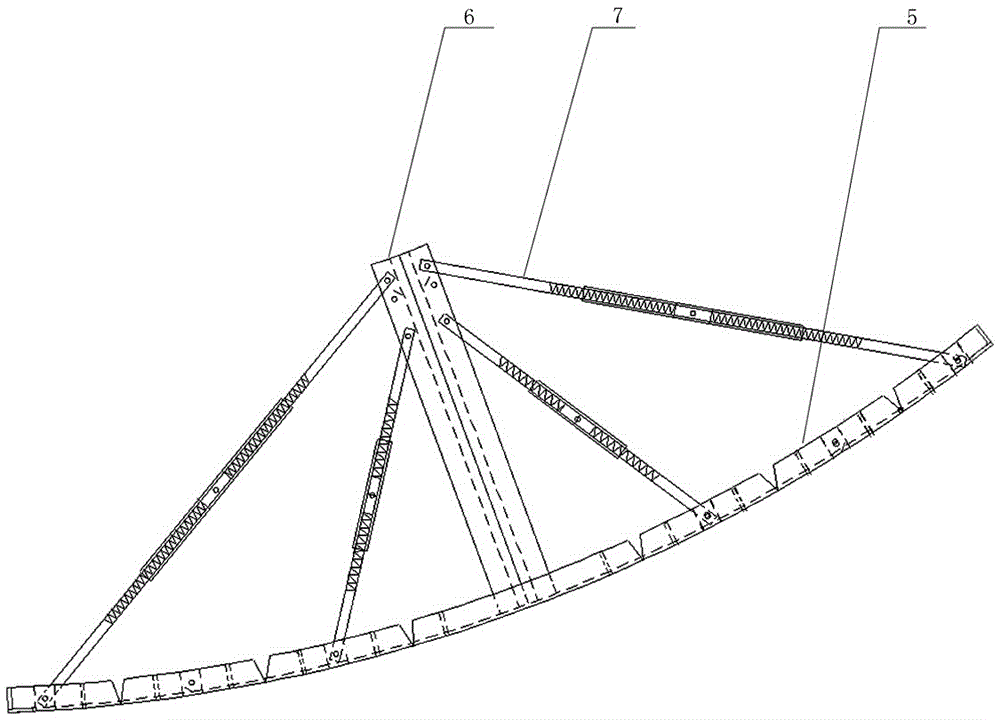

Concrete construction method for curved roof

ActiveCN106836662AHigh reuse rateHigh surface precisionBuilding roofsRoof covering using sealantsTower craneUltimate tensile strength

The invention provides a concrete construction method for a curved roof, the concrete construction method for the curved roof comprises the following steps of a, installing a slide rail; b, assembling and installing a steel framework; c, adjusting the radian of the steel framework; d, installing a framework moving mechanism on the steel framework; e, installing a plate vibrator on an assembled steel framework; f, checking the framework moving mechanism; g, pouring concrete on roof after finishing the framework moving mechanism; h, lifting the steel framework integrally to the next pouring area through a tower crane, and repeating steps F and G for concrete pouring until the entire roof is poured; and removing the steel framework after the entire roof is poured and the concrete reaches certain strength. The concrete construction method of the curved roof solves the problems of forming difficulty in concrete pouring of the curved roof, the construction quality and curve surface accuracy of curved roof concrete slabs are improved, and it is effectively guaranteed that the design thickness of the curved roof concrete and the compactness of the concrete meet the design requirements.

Owner:CHINA MCC20 GRP CORP +1

Grinding wheel route generation method for low-speed servo grinding of free-form surface

ActiveCN109129031AAchieve ultra-precision grindingGuaranteed stabilityGrinding carriagesGrinding drivesHelical lineLow speed

The invention relates to a grinding wheel route generation method for low-speed servo grinding of a free-form surface. A plane perpendicular to the Z axis of a workpiece coordinate system is established at the position, a certain distance zd above a to-be-machined free-form surface, in the workpiece coordinate system; an isometric helical line is generated in the plane and is discretized, and points obtained after discretization are converted into a cylindrical coordinate system form (rho, theta, zd); the to-be-machined free-form surface is rotated around the Z axis by the angle theta; and theminimum distance delta, between the grinding wheel machining curved surface and the rotated to-be-machined free-form surface in the Z direction, at the position of each point on the isometric helicalline is calculated, and the coordinate of the grinding wheel control point is obtained to be (rho, 0, zd-theta). A grinding wheel is an annular grinding wheel. The axis of the grinding wheel is perpendicular to the axis of a workpiece rotation shaft. According to the method, the projection drive track of the grinding wheel control point is generated preferentially, and stability of the feeding movement, in the X direction, of the grinding wheel is ensured; and the machining efficiency is higher, and precision of machined surfaces is higher.

Owner:TIANJIN UNIV

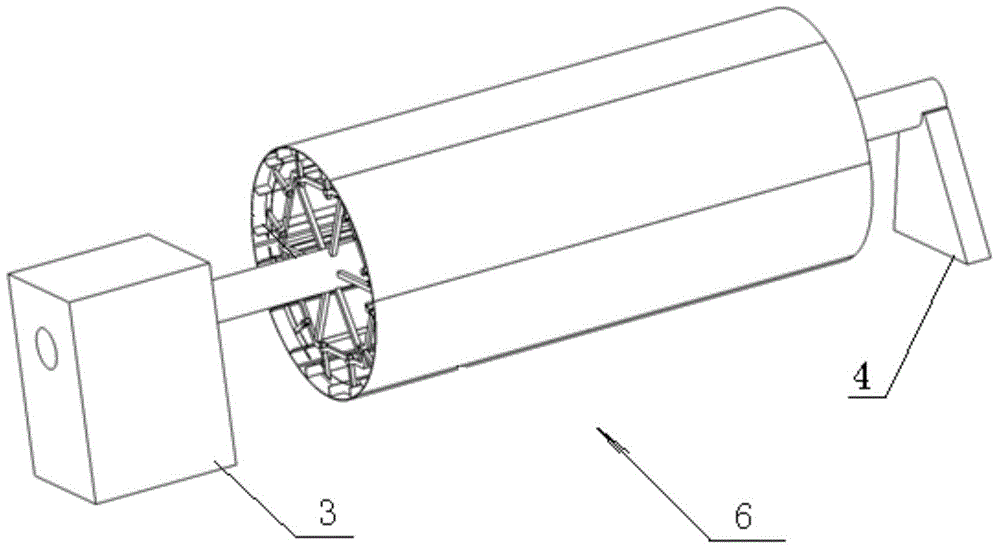

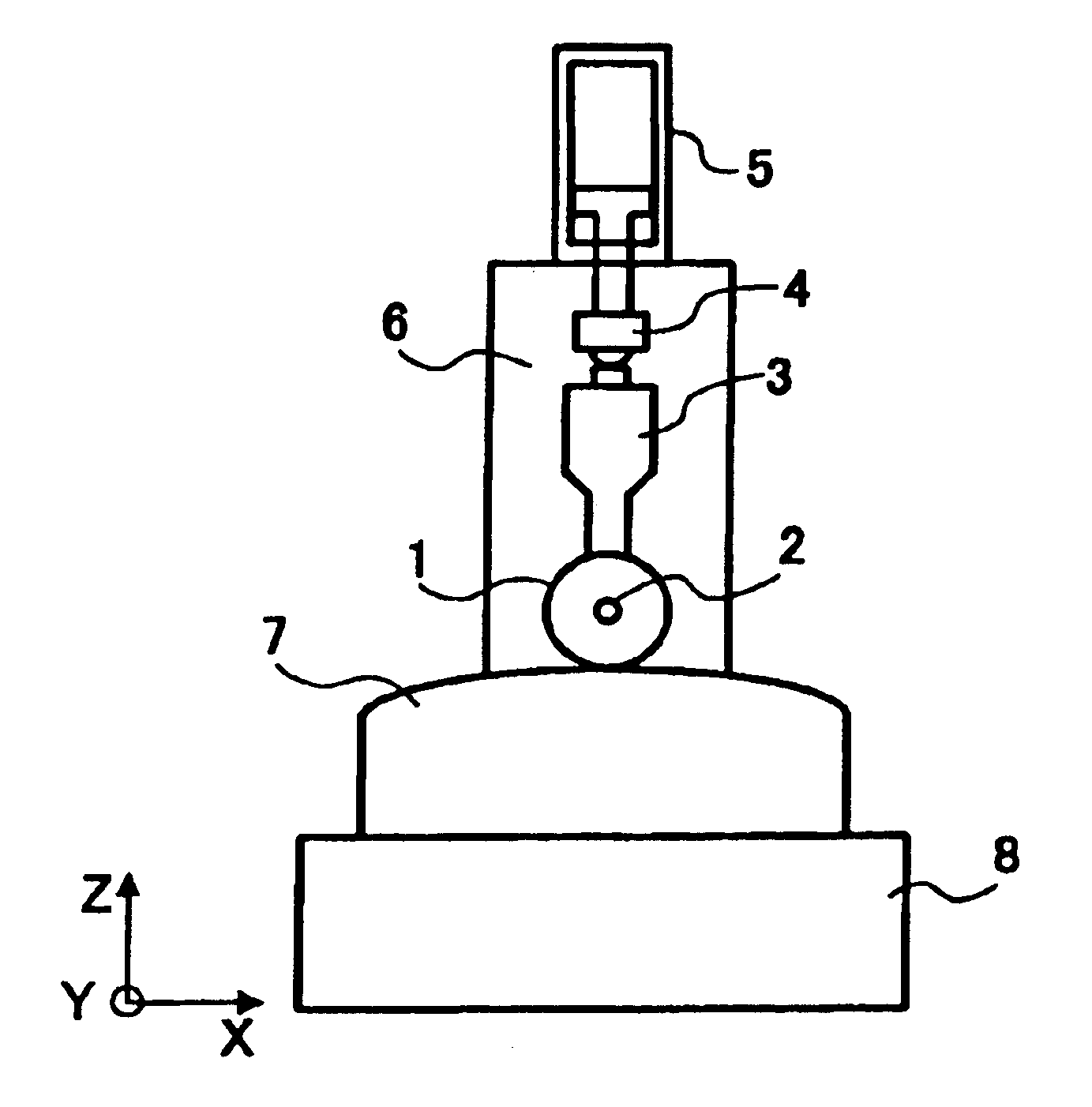

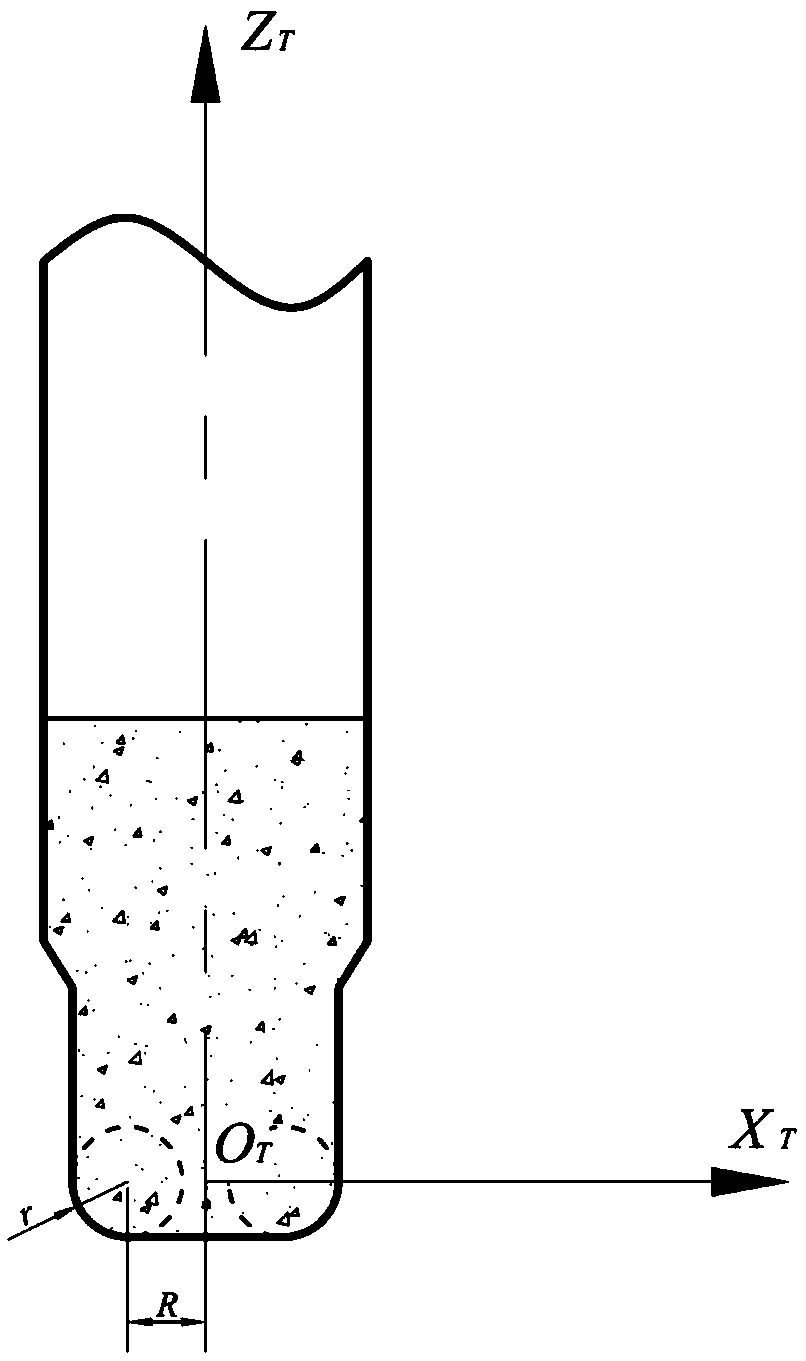

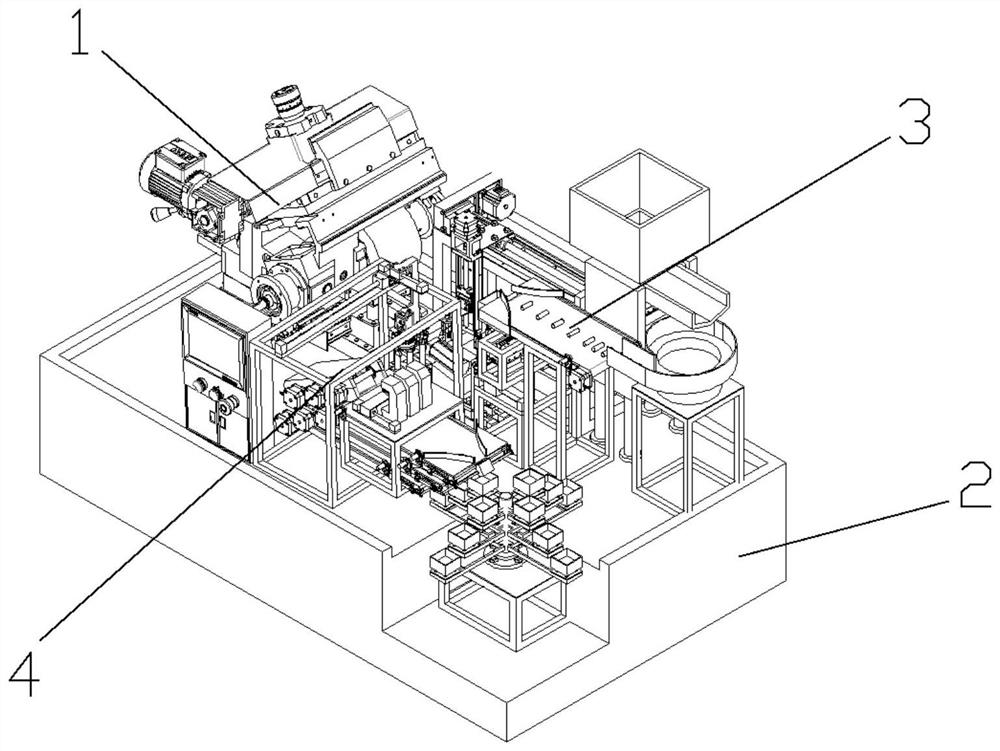

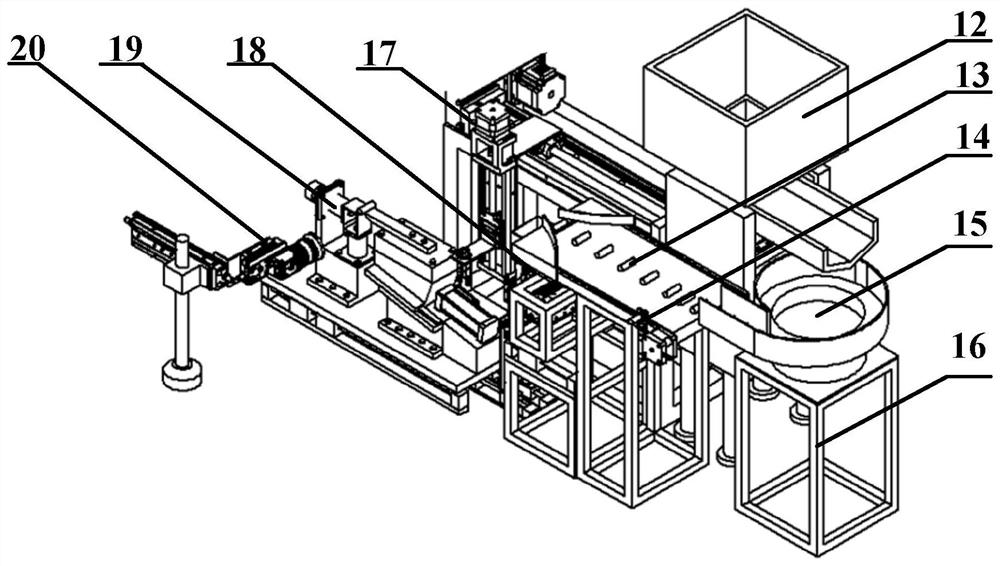

Full-automatic grinding machine for ultrasonic vibration auxiliary grinding of outer circle of hard and brittle single crystal cylinder

ActiveCN111805309ARealize automatic feeding processImprove work efficiencyGrinding carriagesGrinding feed controlMachine partsEngineering

The invention discloses a full-automatic grinding machine for ultrasonic vibration auxiliary grinding of an outer circle of a hard and brittle single crystal cylinder, and relates to the technical field of mechanical equipment. The full-automatic grinding machine aims to solve the problems in the prior art that when the outer circle surface of the hard and brittle single crystal cylinder is ground, the adopted grinding liquid is alkaline or acidic, a machine tool can be corroded after long-term use, the clamping precision of a workpiece is reduced, the surface precision of a machined part is reduced, and the working efficiency is low due to the fact that feeding is carried out in a manual mode. An automatic feeding mechanism and an automatic classifying and storing mechanism are distributed in parallel, the full-automatic grinding machine is perpendicular to the automatic feeding mechanism and the automatic classifying and storing mechanism, a storage mechanism base table is arranged at one corner of the upper surface of a grinding machine base, and the upper surface of the storage mechanism base table is lower than the upper surface of the grinding machine base and is used for containing the automatic classifying and storing mechanism. The full-automatic grinding machine is suitable for grinding the outer circle surface of the hard and brittle single crystal cylinder.

Owner:HARBIN INST OF TECH

Method for etching of a silicon substrate and etching apparatus

ActiveUS7220678B2Excellent perpendicularity without reducing the etching speedSufficiently smoothDecorative surface effectsSemiconductor/solid-state device manufacturingProduct gasTwo step

A method for etching a silicon substrate is presented in which fast etching speed and etching structures with smooth and perpendicular wall surfaces are achieved. In the etching step, a constant electric power is applied to the silicon substrate to provide a bias potential. Using a mixture of SF6 gas and fluorocarbon gas, there is a step mainly for the progression of dry etching of the etching ground surface. Similarly, using a mixture gas, there is a step mainly for forming a protective layer on the structure surfaces which are perpendicular with respect to the etching ground surface. These two steps are repeated one after the other. In the step for dry etching, the mixture gas is 5–12 volume of fluorocarbon gas with respect to 100 volume SF6 gas. The mixture gas in the protective film formation step is a mixture of 2–5 volume of SF6 gas with respect to 100 volume fluorocarbon gas.

Owner:SUMITOMO PRECISION PROD CO LTD

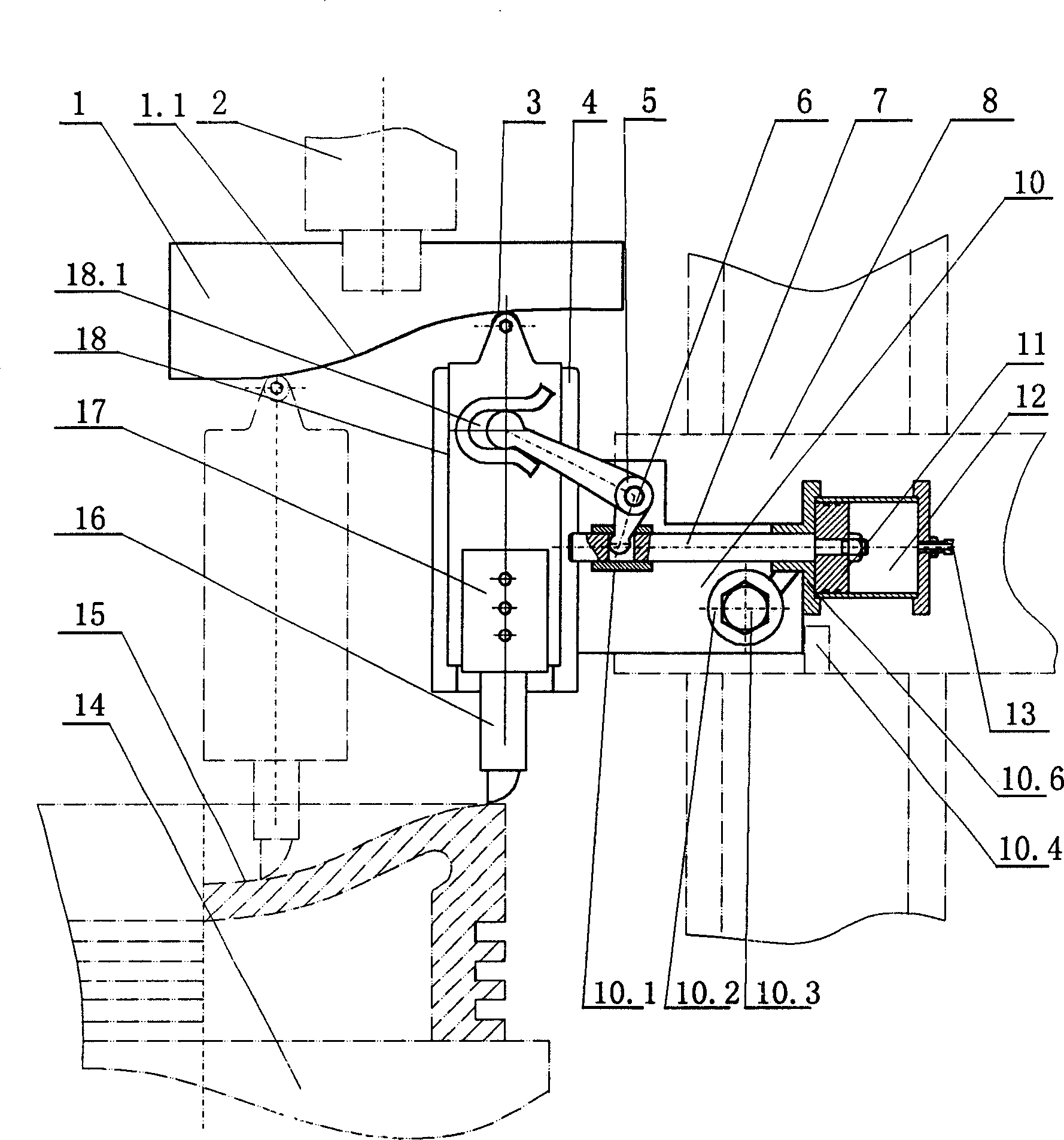

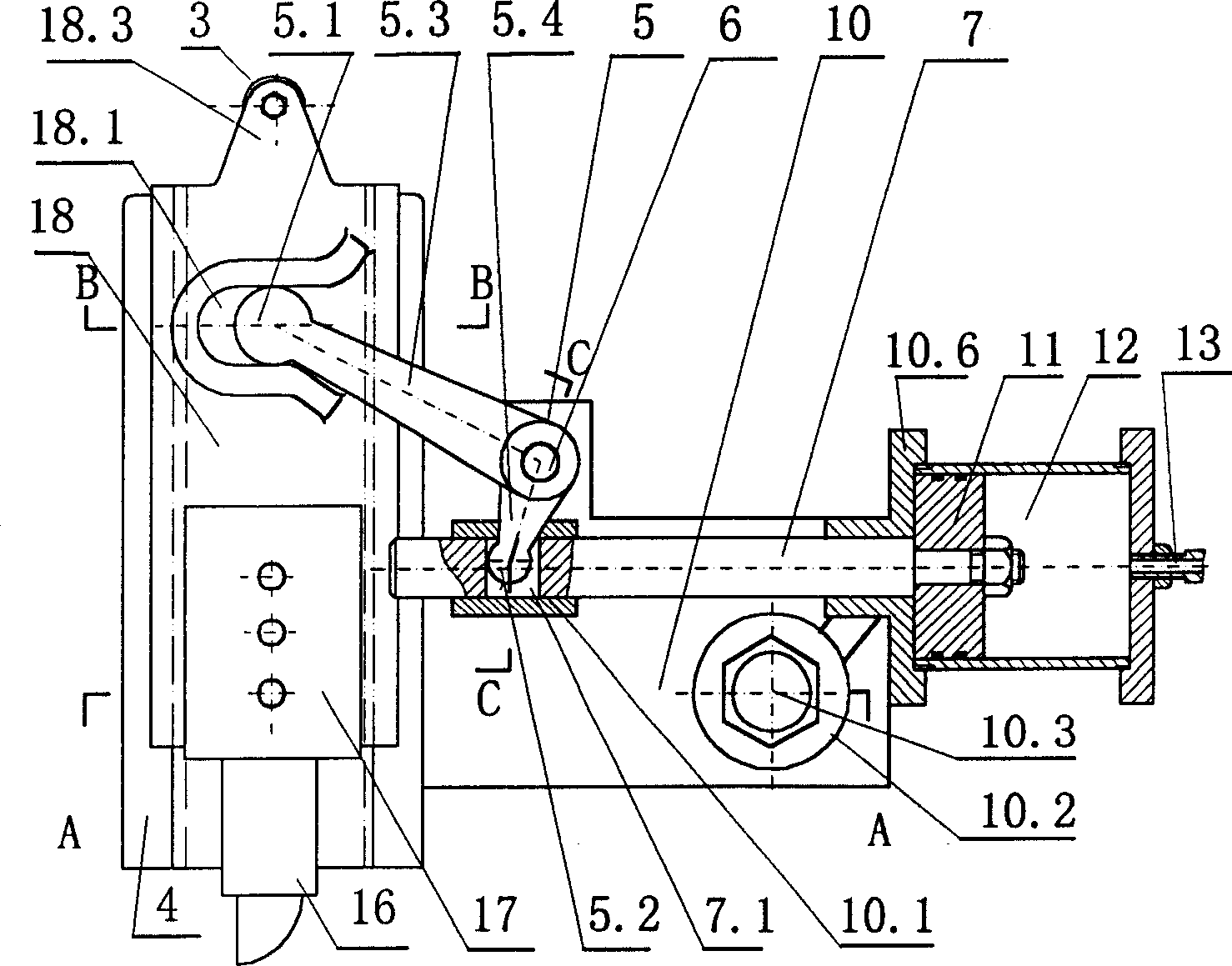

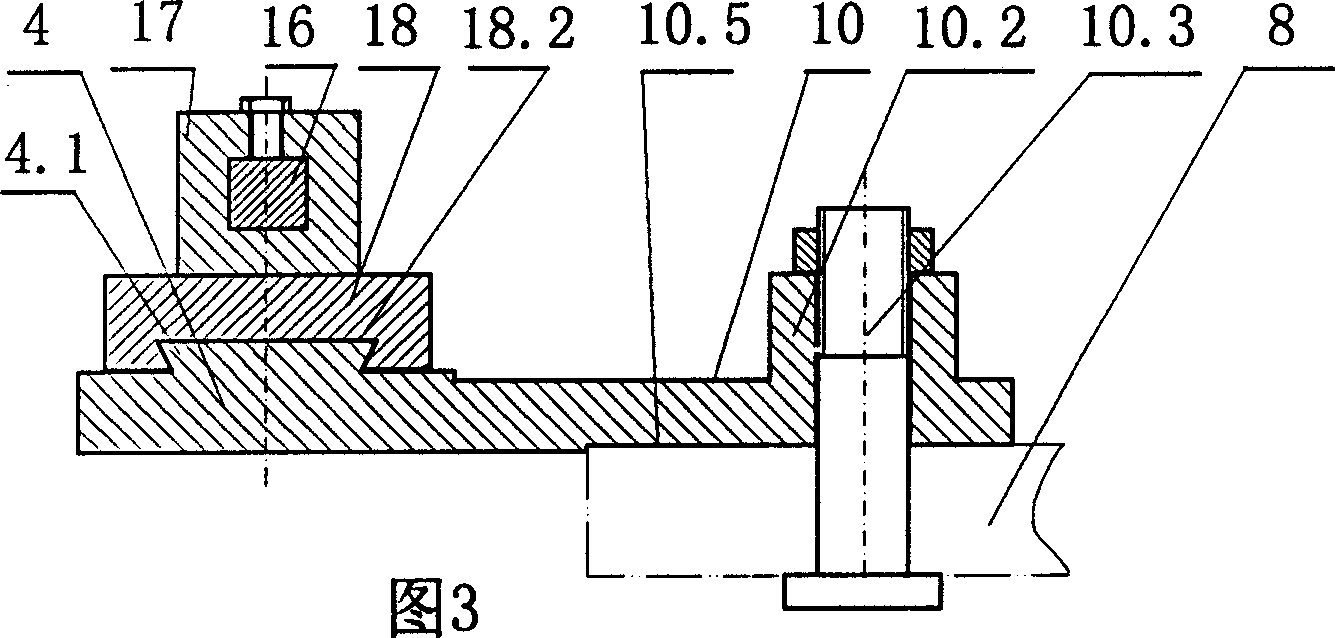

Piston top curved surface processing device for verticle lathe

A mechanism of vertical lathe for machining the curved surface on the top of piston is composed of vertical tool carrier, copying plate for said curved surface, linkage plate, power cylinder on said linkage plate, slide plate sliding up and down for installing tool carrier on it, and fulcrum with curved arm, lateral branch arm and lower branch arm.

Owner:QINGDAO PORT GRP

Substrate for biochip and biochip

ActiveUS20100184622A1Easy to fixEasy to manufactureSequential/parallel process reactionsOrganic compound librariesCarbon layerFluorescence

A substrate for biochips with which immobilization is easy, which does not exhibit self-fluorescence, which is easy to manufacture, and which is excellent in flatness and surface precision, is disclosed. A substrate having a substrate body of the biochip, which is made of a metal, and a carbon layer having functional groups formed on the metal substrate body is used as a substrate for biochips. Since the substrate body of the substrate for biochips is made of a metal, the substrate is not only easy to manufacture, but also free from cracking and chipping, so that it allows easy handling, and high flatness and surface precision can be attained. Therefore, the problem that the optical system is hard to focus when detecting fluorescence does not occur. Moreover, since the substrate body is made of a metal, it does not emit fluorescence by itself. In addition, since the carbon layer has functional groups such as amino groups, biologically relevant substances can be easily immobilized.

Owner:HIPEP LAB +1

Pectin-modified micro-emulsion cutting fluid

InactiveCN106635355AImprove high temperature resistanceImprove toughnessLubricant compositionGlycerolCocamidopropyl betaine

The invention discloses pectin-modified micro-emulsion cutting fluid. The pectin-modified micro-emulsion cutting fluid is prepared from the following raw materials: refined mineral oil, TEA-lauryl sulfate, polyoxyethylene lauryl ether, cocamidopropyl betaine, fatty alcohol-polyoxyethylene ether, triethanolamine, antifoaming agent, amide borate, palmitic acid, sodium chloride, glycerol, tetraethoxysilane, oleic acid, acrylamide, azodiisobutyronitrile 3-4, aluminum borate whisker, pectin, dihydroxyl pentasulfide, a proper amount of ethyl acetate, a proper amount of ammonia water, a proper amount of absolute ethyl alcohol and a proper amount of deionized water. The prepared micro-emulsion cutting fluid has very high anti-friction extreme pressure performance, can be used for preventing adhesive wear of tools, increasing surface machining accuracy and prolonging the service lives of the tools, can meet the cooling performance in a machining process, and has a good cleaning effect; through a unique formula design, the pectin-modified micro-emulsion cutting fluid has very high biological stability and a long life cycle, and is free from irritation and pollution.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Manufacturing method for high-precision single-curved surface aluminum alloy skin

The invention discloses a manufacturing method for a high-precision single-curved surface aluminum alloy skin, and belongs to the technical field of skin machining. The manufacturing method comprisesthe steps of aluminum alloy panel preparing, quenching heat treatment, panel stretching through a stretching tire, panel positioning through a cutting tire, panel cutting through numerical control cutting equipment and the like. According to the method, the skin machining precision is greatly improved, the original manual positioning manner is changed, the skin positioning efficiency and positioning accuracy are improved, and the manufacturing method is an important improvement on the prior art.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Substrate holding technique

InactiveUS7212277B2High surface precisionElectromagnets without armaturesSemiconductor/solid-state device manufacturingEngineeringElectric generator

An object holding apparatus including a chuck for holding an object, a holder configured to hold the chuck, a generator provided in the holder and configured to generate a field related to an attraction force, a member provided in the chuck and configured to be attracted by the generator in accordance with the field, and a support configured to support one of the generator and the member. The support is configured to allow the one to move toward the other and away from the other, and the support includes a leaf spring.

Owner:CANON KK

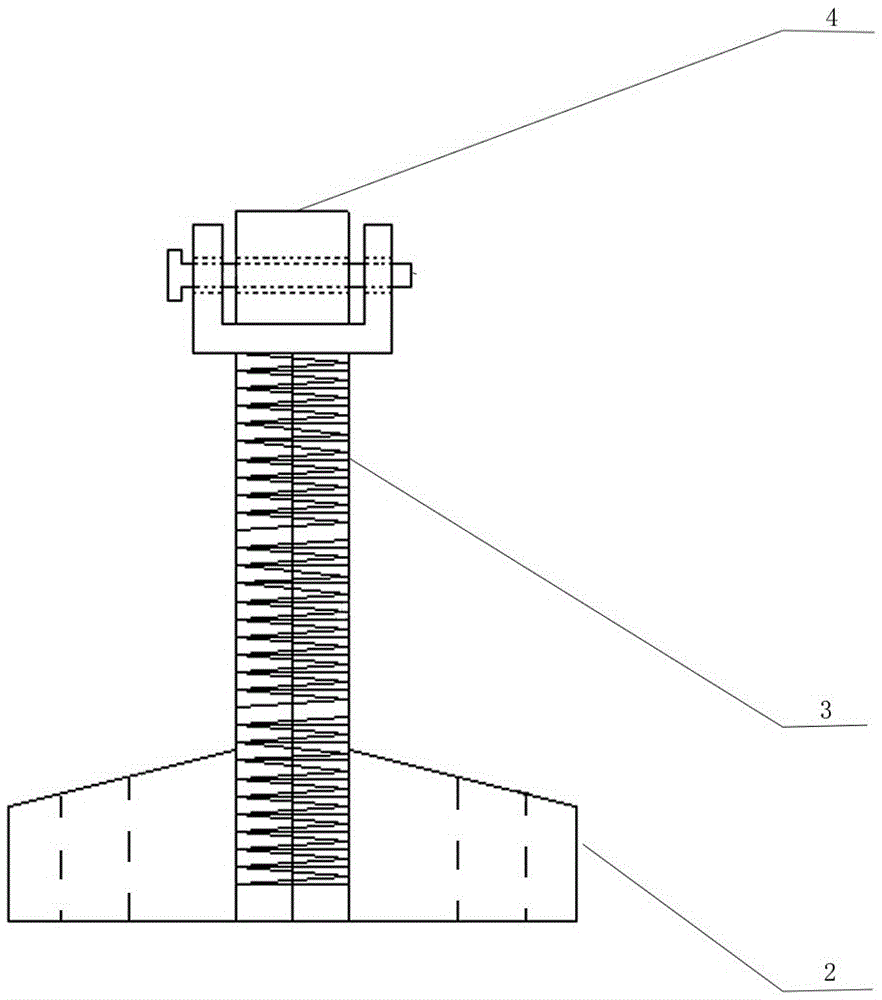

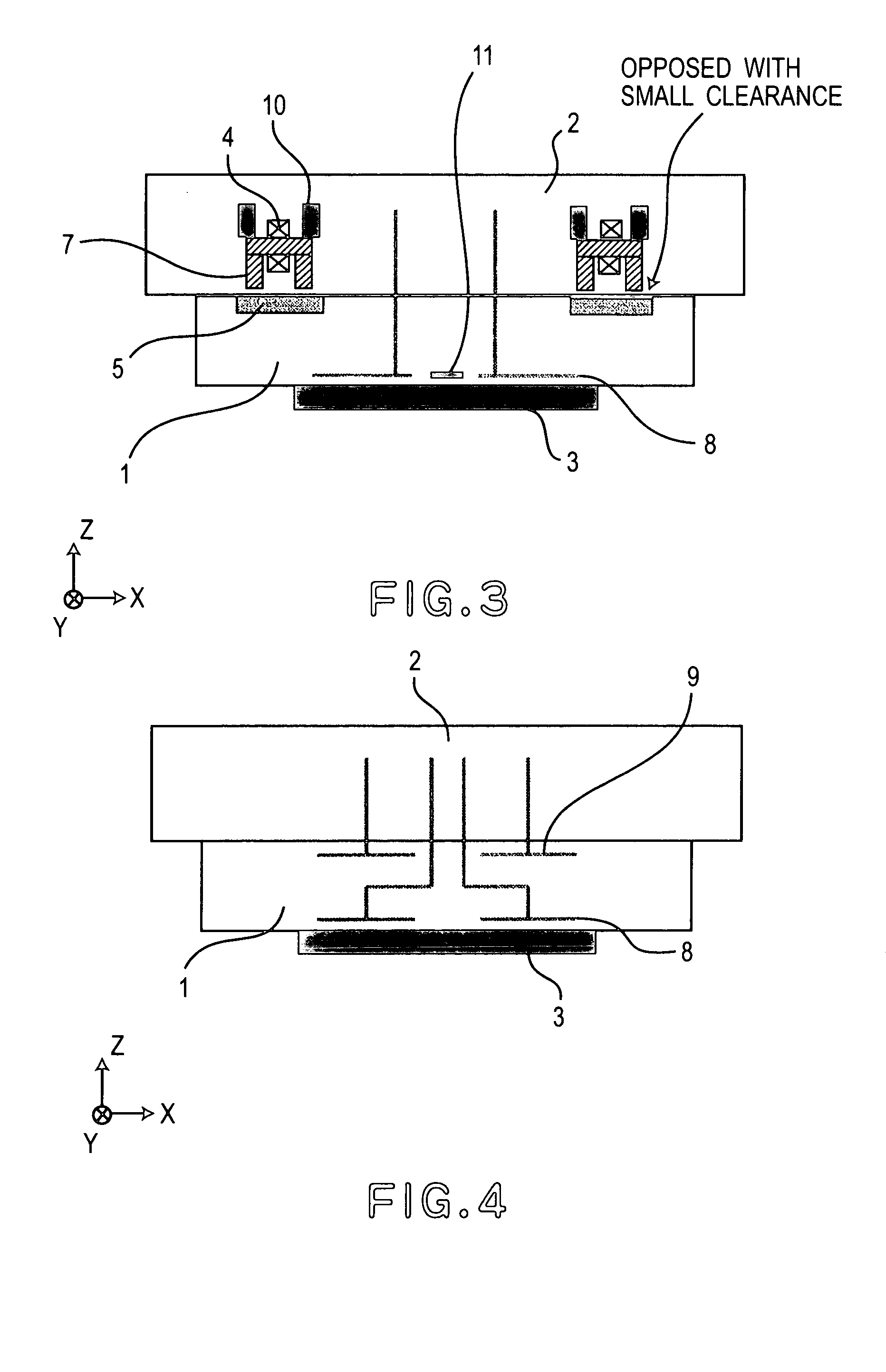

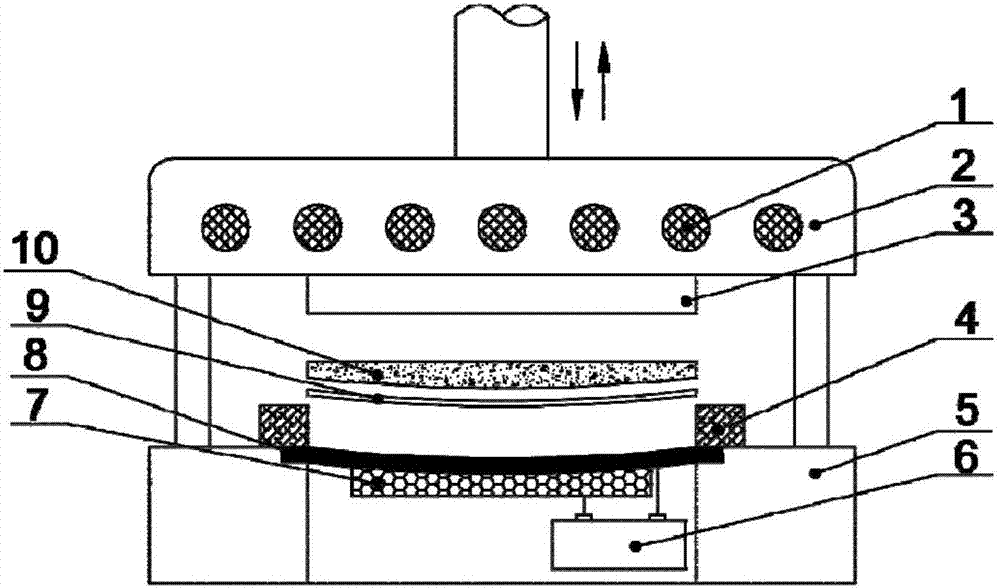

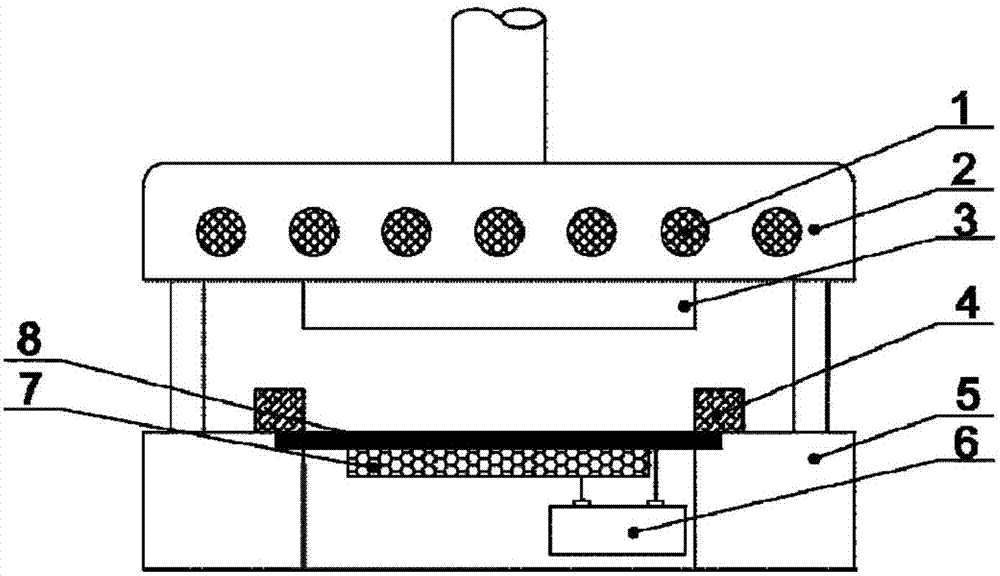

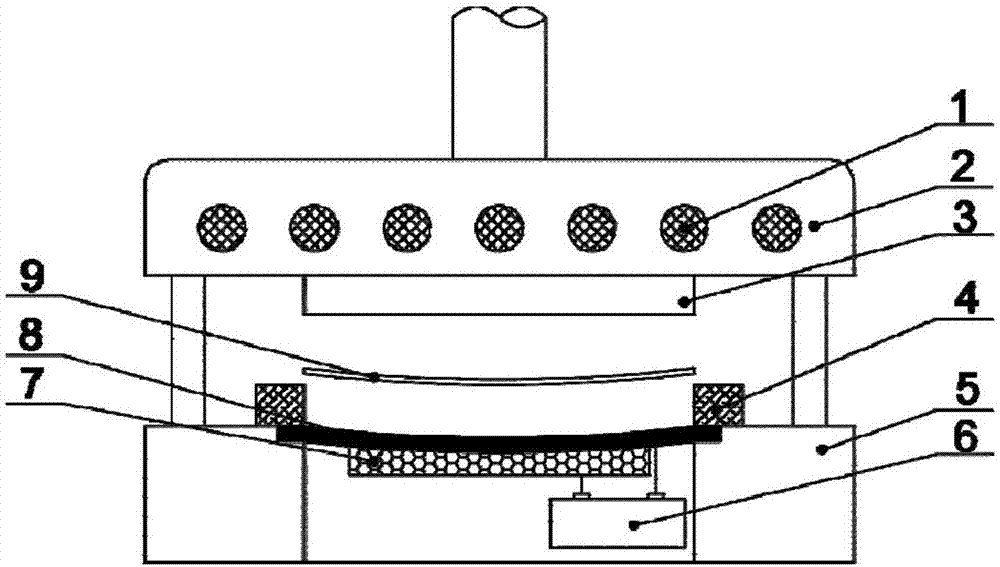

Electric control variable-curved-surface fluorescent membrane die-pressing method and apparatus

ActiveCN107123724AMeet diverse production requirementsShorten the timeSemiconductor/solid-state device manufacturingSemiconductor devicesFluorescenceEngineering

The invention discloses an electric control variable-curved-surface fluorescent membrane die-pressing method and apparatus. The apparatus comprises a heating apparatus (1), an upper pressing die substrate (2), an upper pressing die (3), a box dam (4), a lower pressing die substrate (5), a voltage-adjustable direct current power supply (6), a piezoelectric material (7), an elastic deformable slice (8) and a separation membrane (9). According to the die-pressing method based on the apparatus, by adjusting the voltage value and direction of the voltage-adjustable direct current power supply (6), the piezoelectric material (7) generates deformation of different degrees; and the elastic deformable slice (8) is deformed to form a fluorescent membrane die-pressing surface with different curved surface shapes so that the fluorescent membranes with different curved surfaces can be prepared. The apparatus is high in controllability; and the deviation values of the curved surface shapes of the produced membrane are detected, and the value and the direction of the input voltage can be adjusted according to the deviation values, so that the deviation values in fluorescent membrane production can be compensated rapidly, the production quality and yield of the fluorescent membrane can be improved, and small-batch, and multi-model membrane production efficiency is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Sol of spinous inorganic oxide particles, method of producing the sol, and polishing agent containing the sol

ActiveUS8187351B2Suppress generationHigh surface precisionPigmenting treatmentOther chemical processesCentrifugationSilicic acid

The present invention provides a sol of spinous inorganic oxide particles not containing coarse particles, in which particles having extremely homogeneous particles are dispersed in a solvent. An acidic silicic acid is added to a dispersion liquid of core particles to grow core particles, and then again the acidic silicic acid is added at the addition rate 1.2 to 1.8 higher than that in the previous step to prepare a sol of spinous inorganic oxide particles. Then the sol is subjected to centrifugation to remove coarse particles having the diameter of 800 nm or more, thus spinous inorganic oxide particles having peculiar form such as a spinous one being obtained.

Owner:JGC CATALYSTS & CHEM LTD

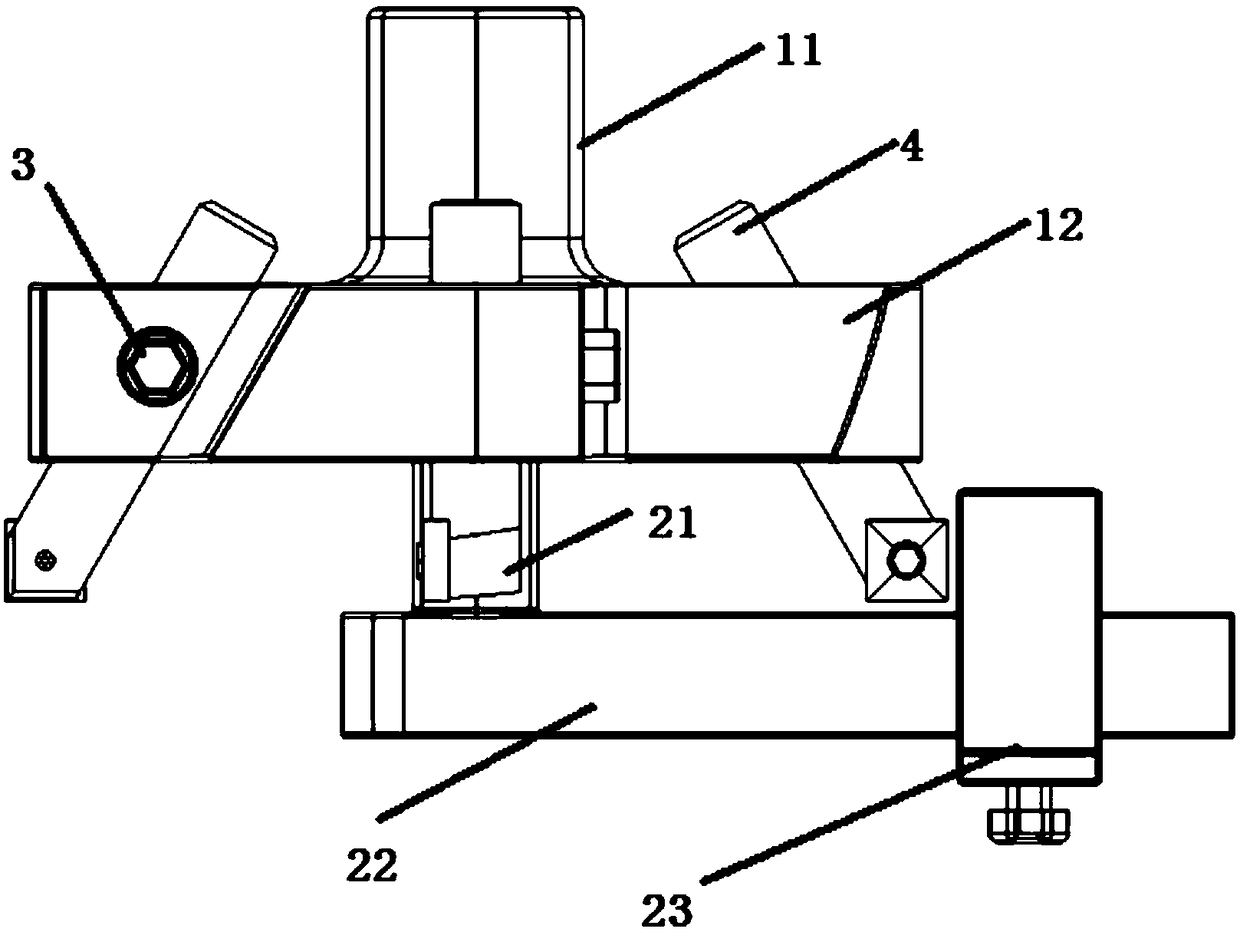

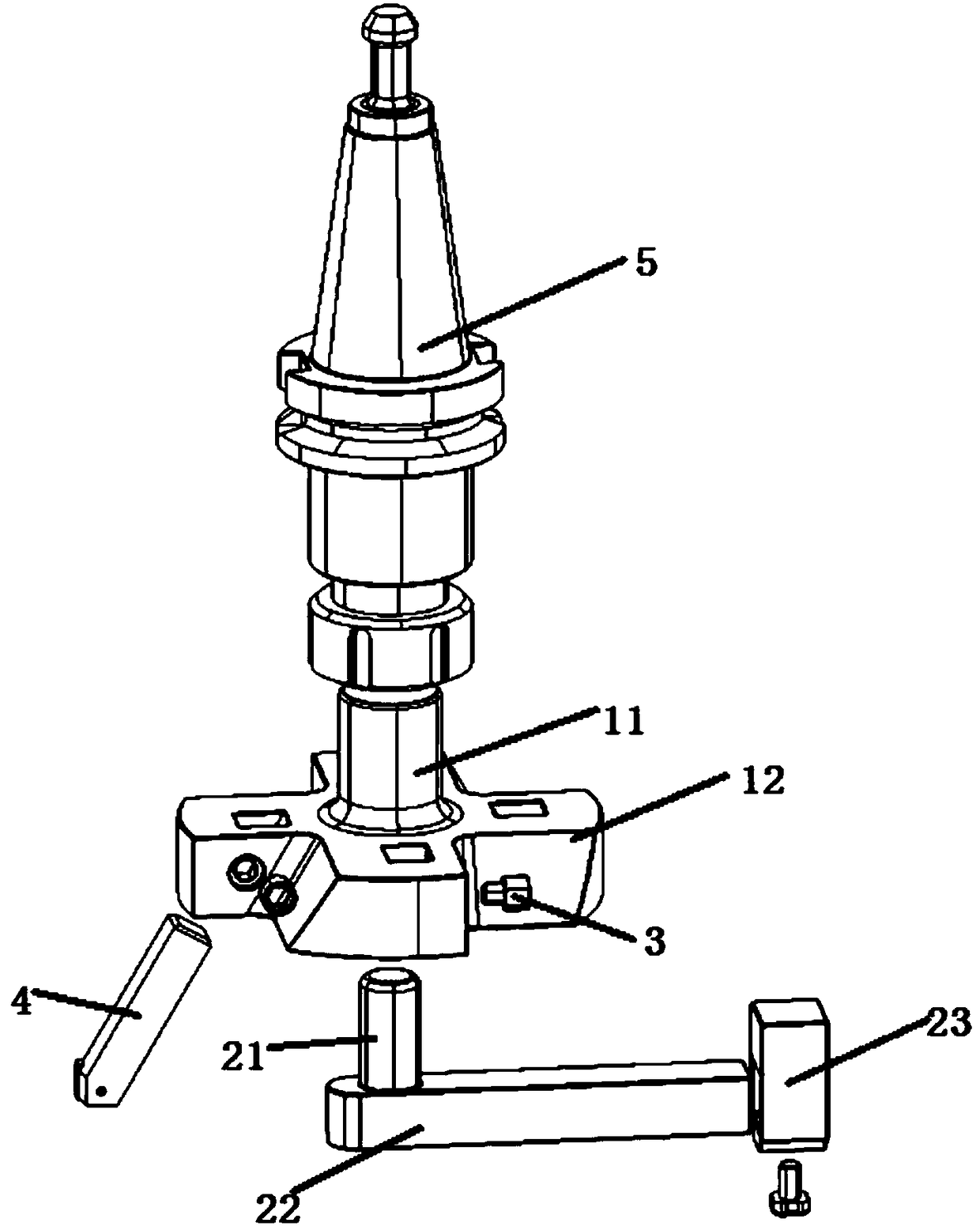

Variable-diameter disc milling cutter hilt tool

ActiveCN109500442AHigh surface precisionExtended service lifeMilling cuttersEngineeringMilling cutter

The present application discloses a variable-diameter disc milling cutter hilt tool, and belongs to the field of mechanical processing technology. The tool includes a cutter head, machining cutter bars and a first locking mechanism, wherein the cutter head (1) includes a center cylinder (11) connected with a milling cutter hilt (5) and a plurality of mounting bosses (12) distributed on the circumferential side of the center cylinder (11); through holes are formed in each mounting boss (12); the axis of the through holes and the axis of the center cylinder (11) intersect at the surface where the cutter head (1) faces the milling cutter hilt (5); the machining cutter bars (4) are slidably arranged in the through holes; and the first locking mechanism is used for fixing the machining cutter bars after the machining cutter bars (4) are moved to a set position. The machining cutter bars slide along the oblique angle of the through holes; different radius values have different cutter tip heights; in this way, the layered cutting of the variable-diameter disc milling cutter head with different cutting depths during feeding per revolution can be realized; and the precision of machined surfaces is improved.

Owner:SHAANXI AVIATION ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com