Concrete construction method for curved roof

A construction method and concrete technology, which are applied to roofs, roof coverings, and roofs using sealed aggregates, etc., can solve the problems of low precision of curved surfaces and poor construction quality of concrete slabs, so as to improve the precision of curved surfaces and improve construction quality. and curve surface accuracy, improve the effect of repeated utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

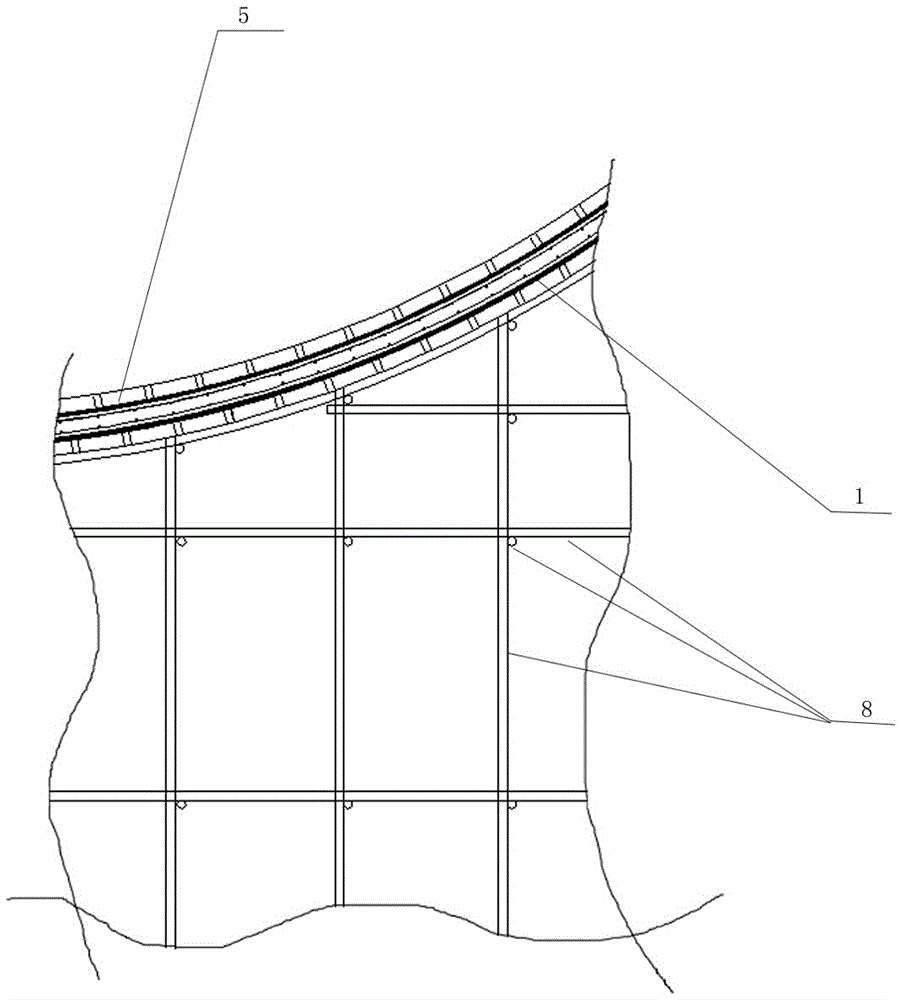

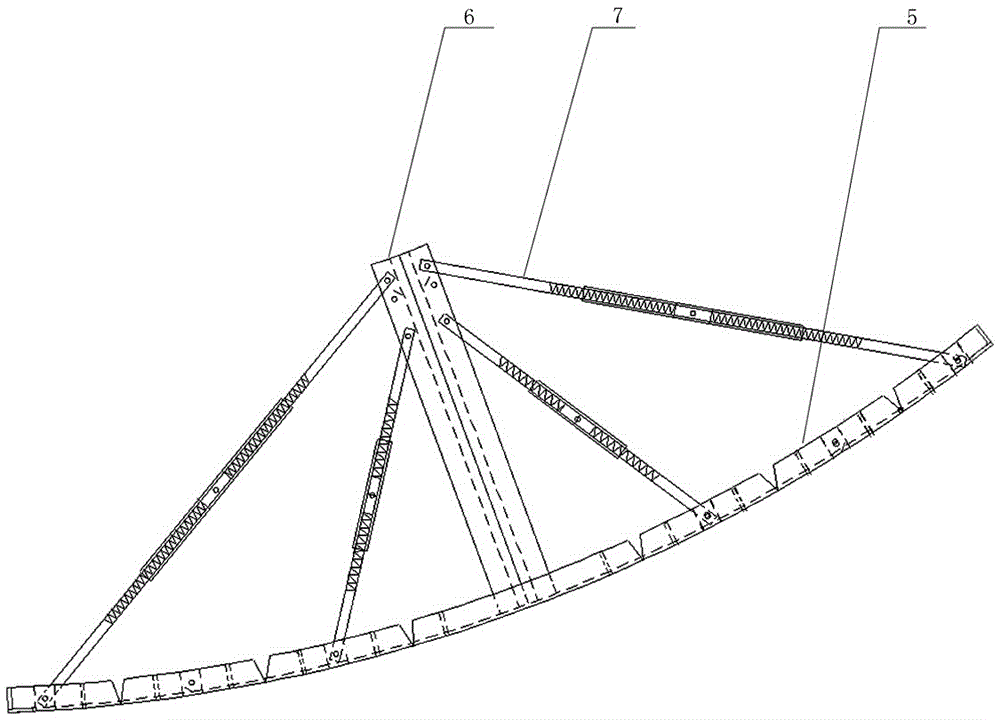

[0026] Such as Figure 1~Figure 5 As shown, a concrete construction method for a curved roof includes the following steps:

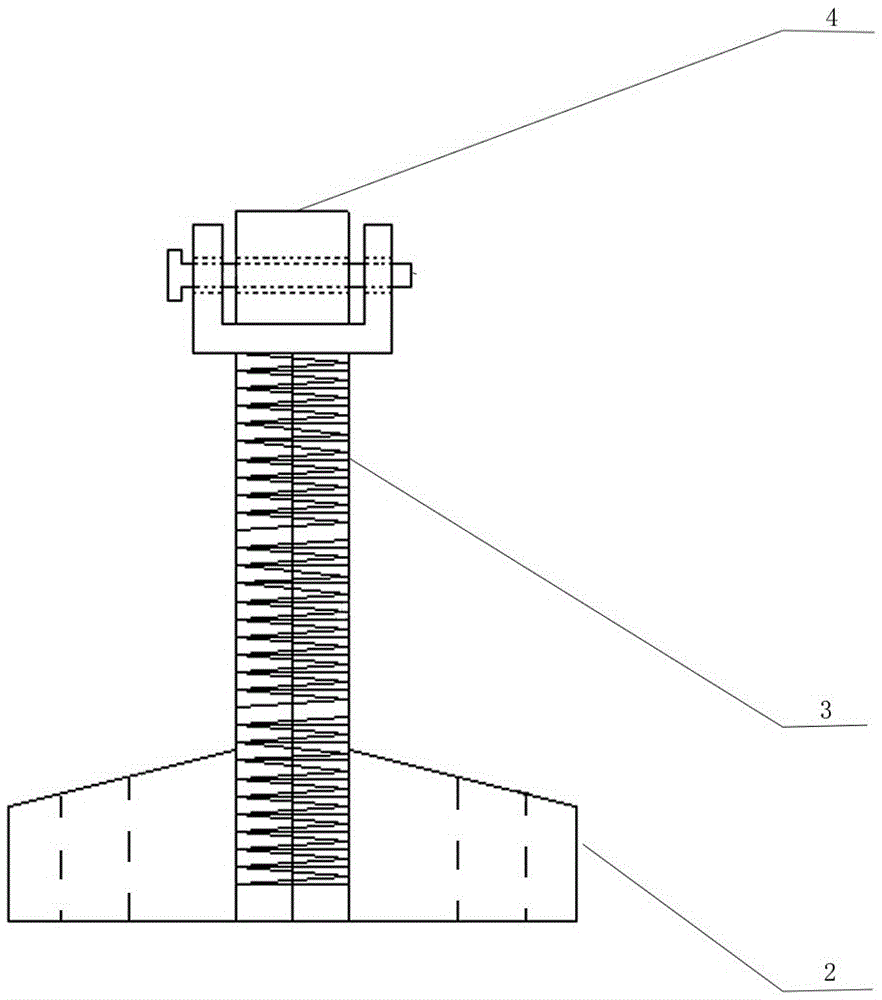

[0027] a. Install sliding guide rail 4: On the pre-laid roof wooden formwork 1, a plurality of parallel track centerlines are evenly popped up along the radian direction of the roof, and on the centerline of each track on the roof wooden formwork 1, along the direction of the track centerline A plurality of fixed supports 2 are evenly arranged, and the fixed supports 2 adopt rubber fixed supports 2, and the fixed supports 2 are fixed and installed on the roof wooden formwork 1 through steel nails, and the fixed supports 2 set on the center line of the same track The distance between the adjacent fixed support 2 is 1 meter. An adjusting screw 3 perpendicular to its bottom surface is installed on the fixed support 2, and the adjusting screw 3 is fixedly connected with the top of the fixed support 2 through threaded connection, and a track for accommodatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com