Polyacrylonitrile fiber duplex metal complexes catalyst and preparation method thereof

A polyacrylonitrile fiber and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of popularization and application, poor reusability, and applicability No high-level problems, to achieve the effect of simple process, high reuse rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Pretreatment of polyacrylonitrile fiber: Wash the polyacrylonitrile fiber yarn with nonionic surfactant JFC aqueous solution containing volume concentration of 2.0g / L for 30 minutes, take it out, wash it twice with water, and dry it for later use.

[0035] 2. Modification reaction of polyacrylonitrile fibers: Accurately weigh the above-mentioned pretreated polyacrylonitrile yarns to a specified weight, and immerse them in hydrazine hydrate with a volume concentration of 30g / L and hydroxylamine hydrochloride with a volume concentration of 42g / L. In the mixed aqueous solution, the bath ratio (referring to the ratio of the weight of the fiber used to the volume of the mixed aqueous solution) is 1:40, and the pH value of the mixed aqueous solution is adjusted to 9.5 with sodium hydroxide, and then reacted at 98°C under stirring conditions After 2 hours, the light yellow modified polyacrylonitrile fiber was taken out, washed repeatedly with distilled water for 3 times, and...

Embodiment 2

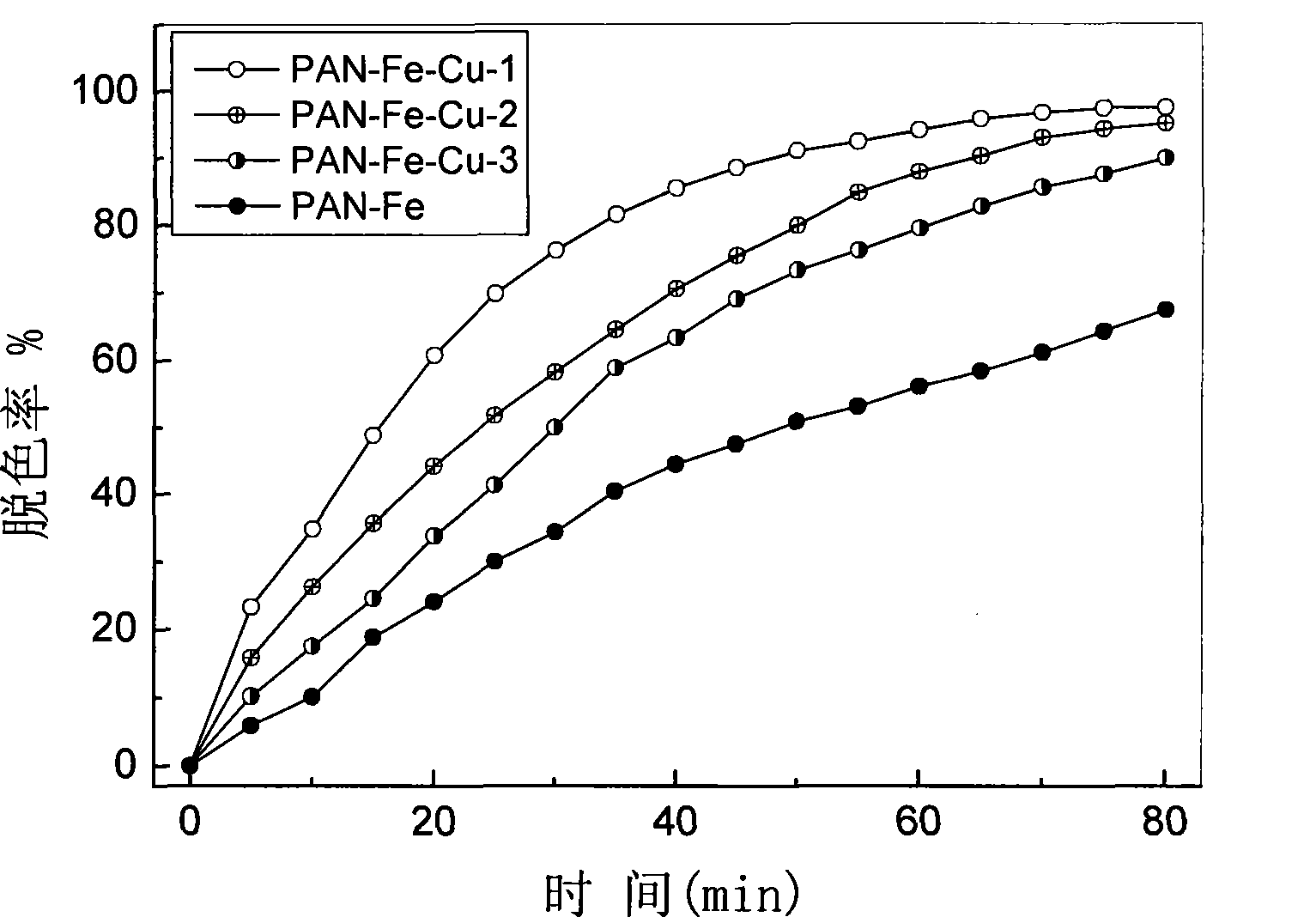

[0040] The volume concentration of the mixed aqueous solution of hydrazine hydrate and hydroxylamine hydrochloride in Example 1 is adjusted to 25g / L and 55g / L respectively, and the pH value is adjusted to 9.2; the molar concentration ratio of iron ion and copper ion in the metal ion mixed solution Adjusted to 3:1, that is, the volume concentration of the ferric chloride aqueous solution and the copper sulfate aqueous solution are 0.075mol / L and 0.025mol / L respectively, and the rest are the same as in Example 1, that is, the second polyacrylonitrile fiber bimetallic complex catalyst is prepared (Denoted as PAN-Fe-Cu-2).

[0041] Through measurement and calculation, the contents of iron ions and copper ions in the catalyst are 25.84mg / g and 11.91mg / g respectively.

Embodiment 3

[0043] The volume concentration of the mixed aqueous solution of hydrazine hydrate and hydroxylamine hydrochloride in Example 1 is adjusted to 45g / L and 40g / L respectively, and the pH value is adjusted to 9.8; the molar concentration ratio of iron ions and copper ions in the metal ion mixed solution is adjusted It is 1:3, namely ferric chloride aqueous solution and copper sulfate aqueous solution volume concentration are respectively 0.025mol / L and 0.075mol / L, all the other are with embodiment 1, promptly prepare the 3rd kind of polyacrylonitrile fiber bimetallic complex catalyst ( Recorded as PAN-Fe-Cu-3).

[0044] Through measurement and calculation, the contents of iron ions and copper ions in the catalyst are 11.69mg / g and 27.52mg / g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com