Patents

Literature

1434 results about "Textile industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

A kind of super imitation cotton polyester filament and its production process

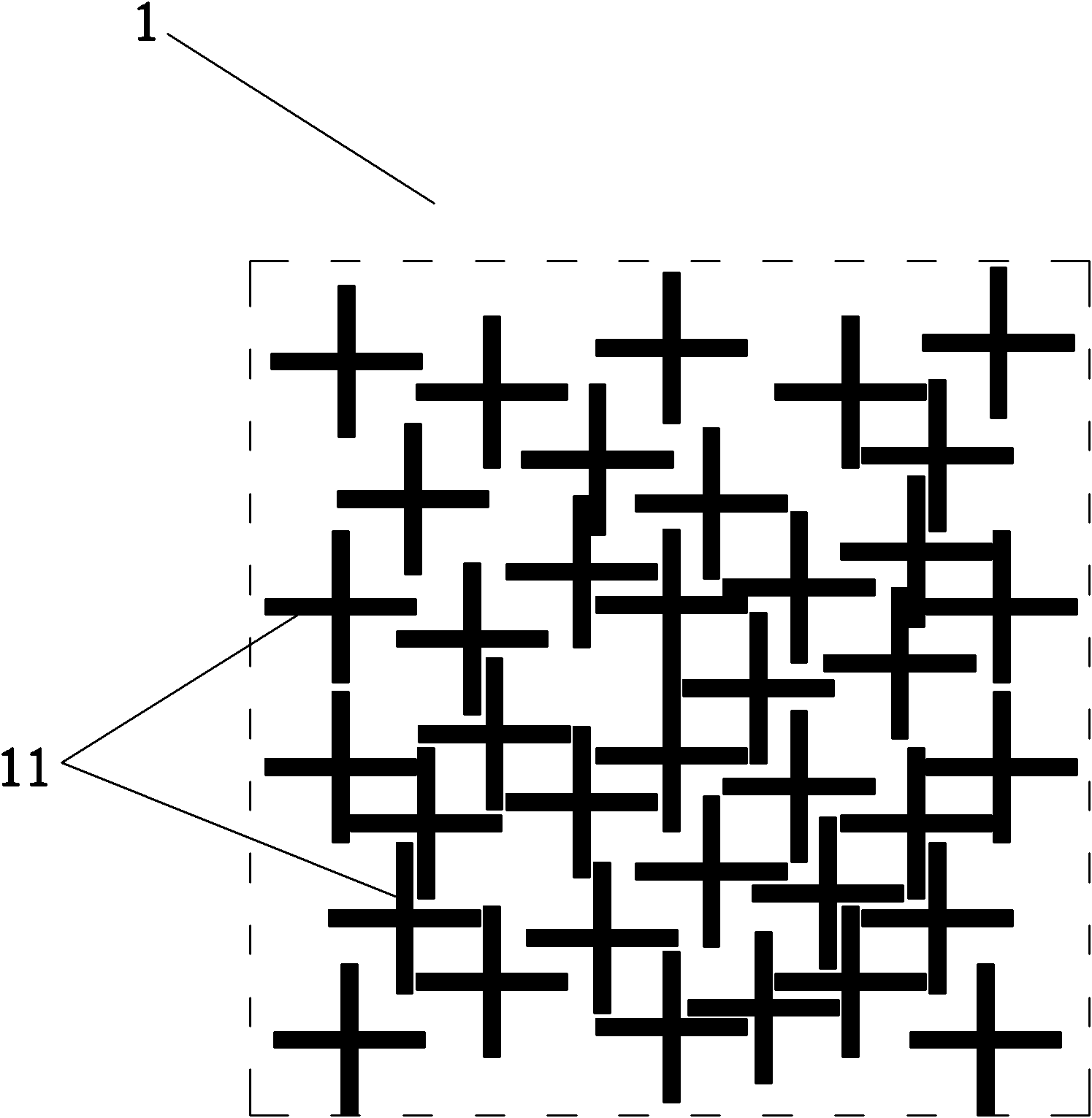

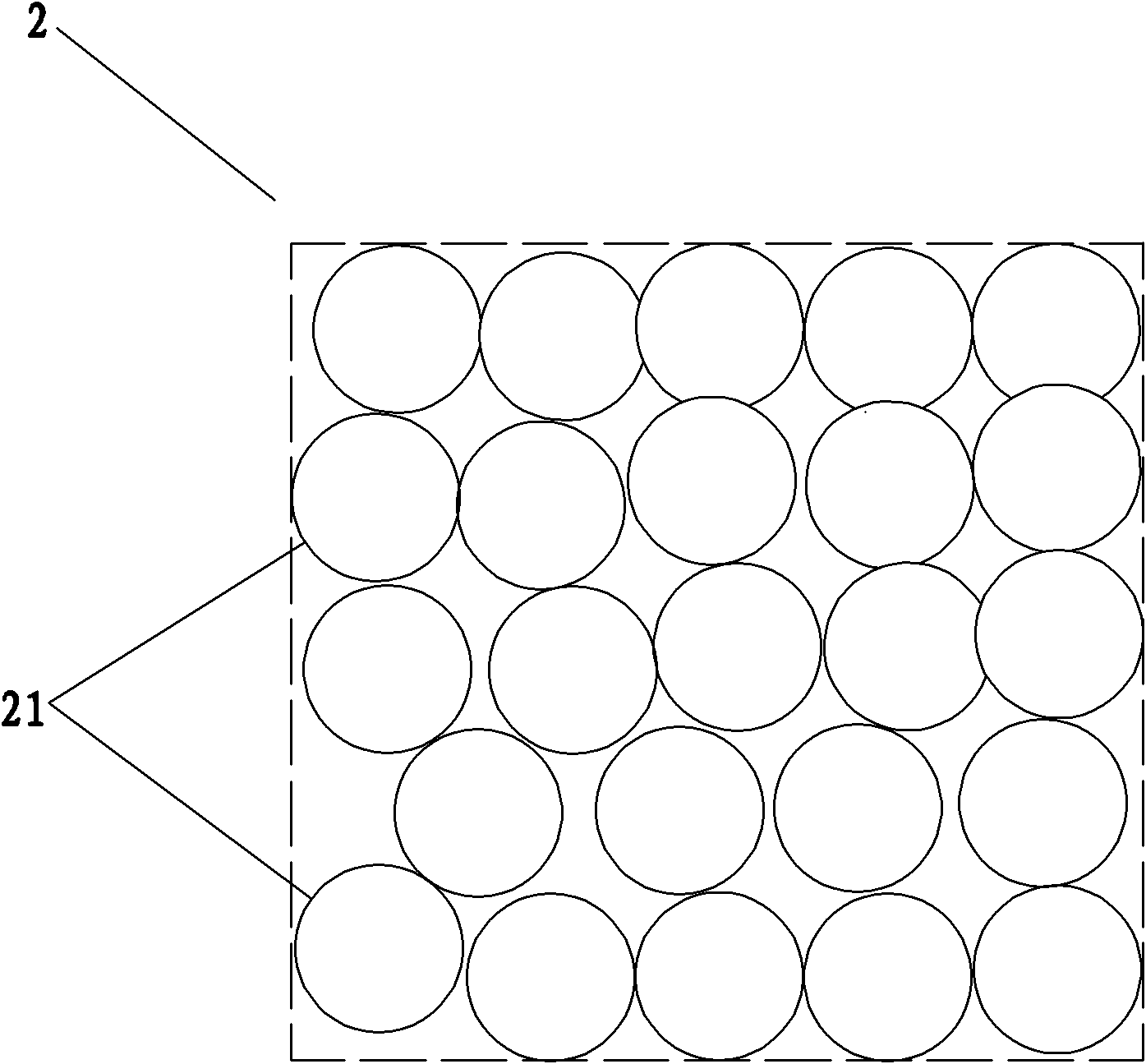

The invention provides a kind of super imitation cotton polyester filament, comprising polyester FDY yarn and superfine polyester POY yarn, polyester FDY yarn and superfine polyester POY yarn are composited together through false twist deformation processing, and the polyester FDY yarn has a fineness of 0.5-1.5D, semi-dull polyester FDY yarn with elongation at break of 25%-35%, the semi-dull polyester FDY yarn is a tow composed of several monofilaments, and the cross-sectional shape of the monofilament is cross-shaped; Superfine polyester POY yarn is full-dull superfine polyester POY yarn, the fineness of the full-dull superfine polyester POY yarn is 0.5-1.5D, and the elongation at break is 100%-135%. It is a tow composed of several monofilaments, and the cross-sectional shape of the monofilaments is circular. The beneficial effect of the present invention is that its softness, water absorption, moisture permeability and quick-drying property are all superior to those of pure cotton fiber, which can achieve the purpose of replacing cotton fiber, greatly reducing the dependence of the textile industry on natural cotton, and alleviating The problem of shortage of cotton resources.

Owner:福建百宏聚纤科技实业有限公司

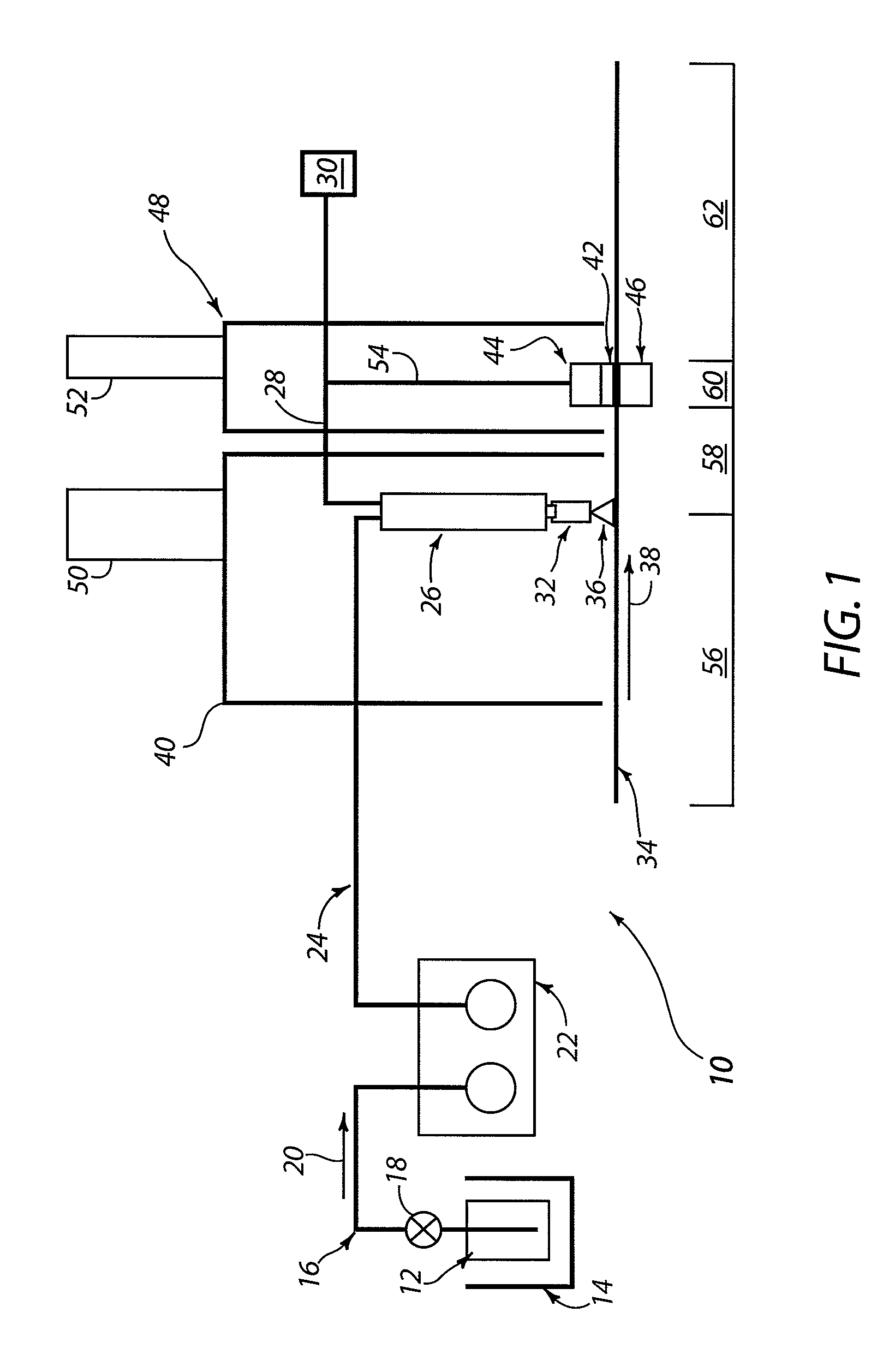

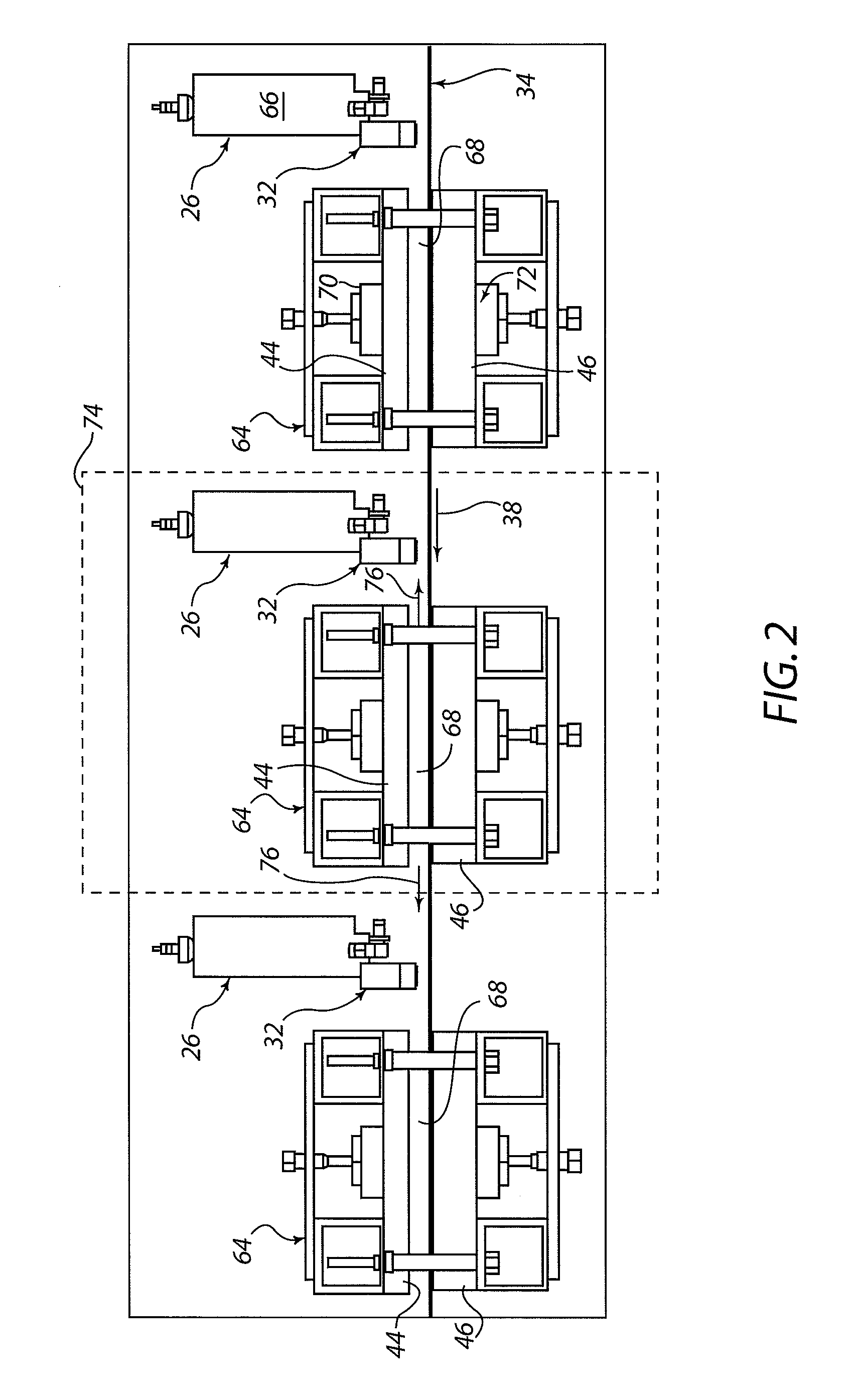

Treatment of fibrous materials using atmospheric pressure plasma polymerization

ActiveUS20080107822A1Suitable for useLiquid surface applicatorsPhysical treatmentTextile industryDry cleaning

An apparatus and method for plasma finishing of fibrous materials including paper and knitted, woven and non-woven fibrous substrates such that desired characteristics are imparted are described. The method includes depositing a monomer comprising at least one fluorocarbon monomer with chemical additives, as required, at atmospheric pressure onto the paper or knitted, woven or non-woven substrate; exposing the monomer on a single surface of the fibrous material to an inert gas, atmospheric-pressure plasma, thereby causing polymerization of the monomer species; and repeating this sequence using multiple sequential deposition and plasma discharge steps to create a layered surface having durability against abrasion for both water-based laundry methods and dry-cleaning methods, and normal wear, without affecting the feel, drape, appearance or breathability of the substrate material. The present method uses a high-power, continuously operating plasma that is 104 times more powerful than the prior art plasma sources utilized in the textile industry, and produces a durable finish with between 0.5 and 2 s of plasma exposure. This is sufficiently rapid to meet commercial fabric processing throughput, and repeated cleaning of the electrodes is not required.

Owner:APJET INC

Negative ion flame-retardant anti-bacterial fiber and preparation method thereof

InactiveCN101586267ASimple manufacturing methodWith mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolyester

The invention provides negative ion flame-retardant anti-bacterial fiber belonging to the field of textile industry technique and a and preparation method thereof, the weight percentages and components thereof are as follows: polyester fibre 92-99%, compound combustion inhibitor 0.6-6.4%, antimicrobial powder 0.1-1.6% and negative ion generating agent 0.1-1.6%. The method provided by the invention can prepare negative ion flame-retardant anti-bacterial fiber which can simultaneously reach national architectural material flame-retardant performance B1 grade standard and conform to national antimicrobial material specification, with 6140 / cm of negative ion generating number density.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Composite reagent for treating recycled water of printing and dyeing wastewater and application method of composite reagent

InactiveCN104108775AAchieve efficiencyAchieve economyWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolubilityFlocculation

The invention discloses a composite reagent for treating recycled water of printing and dyeing wastewater and an application method of the composite reagent. The composite reagent comprises the following components by weight percent: 20% to 70% of aluminum salt coagulant, 5% to 30% of iron salt coagulant, 5% to 40% of mineral material and 5% to 45% of activated carbon. The method comprises the following steps: preparing the composite reagent for treating the recycled water of the printing and dyeing wastewater into powder or an aqueous liquid in which the content of effective components accounts for 5% to 30%; regulating a pH value of effluent in a printing and dyeing wastewater biochemical system to be within 3 to 9; adding the powder or the aqueous liquid of the composite reagent into the effluent in the printing and dyeing wastewater biochemical system under the condition that the adding quantity of the effective components is between 20mg / L and 1000mg / L after the pH value of the effluent is regulated; and stirring for 0.2 to 2 hours and then standing so as to obtain the recycled water conforming to the water quality standard in textile industry. According to the method, macromolecular colloidal pollutants in the biochemical effluent of the printing and dyeing wastewater, which are difficult to degrade, can be removed by utilizing the coagulation / flocculation performance of aluminum salts and iron salts in the composite reagent; and meanwhile, soluble inert pollutants in the wastewater are removed by utilizing the adsorbability of the activated carbon and the mineral material in the composite reagent.

Owner:HANGZHOU DIANZI UNIV

One-bath process continuous production process for treating cotton and its blended fabric before dyeing and printing

InactiveCN1515735AAchieving low alkali dischargeEmission reductionSucessive textile treatmentsBiochemical fibre treatmentWastewaterPulp and paper industry

The present invention relates to a pretreatment one-bath continuous production process before printing and dyeing cotton and blended fabric in dyeing and finishing production of textile industry. Three steps of desizing, refining and bleaching can be combined into one steop to implement, it utilizes biological enzyme and chelate dispersant WS to form the high-effective green pretreatment agent, adds hydroperoxide to prepare treatment liquor. The fabric can be undergone the processes of pad-steaming or pad-thermodepositing treatment on the continuous steaming long carriage, water-washing and drying or undergone the processes of dip dyeing on overflow dyeing machine or dip dyeing machine, water-washing and drying.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Method for producing dissolving pulp by oxygen continuous digesting method

InactiveCN101333778AReduce the degree of polymerizationAchieve continuous cookingPaper material treatmentCyclonic separationCooking methods

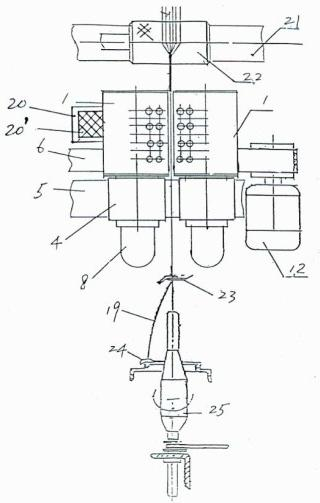

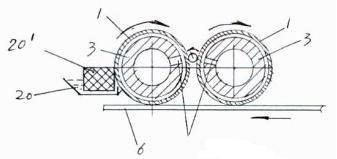

The invention relates to a production method for preparing a dissolving pulp by an oxygen-dissolving and continuous-cooking method, which applies the preparation of cotton linters in the production of viscose fibers in the textile industry, and the method comprises the following steps of: I. cotton linter pretreatments: including cotton linter loosening, cyclone separation and dust removal, feeding, two-roll grinding treatment, etc. to the cotton linters by a two-roll pulping machine; and II. oxygen dissolving and continuous cooking: a horizontal continuous cooking digester is adopted to realize the continuous, fast and low-pollution preparation of dissolving cotton pulp through the actions of high temperature, alkali, oxygen or hydrogen peroxide. The horizontal continuous cooking digester includes a pre-reaction bin, a two-roll gauge, a feeding screw, a T-shaped tube, a continuous-cooking tube and a cold discharge device. The method can effectively solve the problems of: cutting, tearing and cell primary wall breakage to the cotton linters by dry method after feed preparation, physical and chemical stripping to mass impurities in the cotton linters, fast accumulation reduction of the cotton linters in a continuous-cooking device and the purification of alpha cellulose under fast accumulation reduction, recycling of waste heat in the production link, and reduction of total amount of COD in a black liquor, and the method has advantages of even cooking and short cooking cycle.

Owner:宜宾长毅浆粕有限责任公司

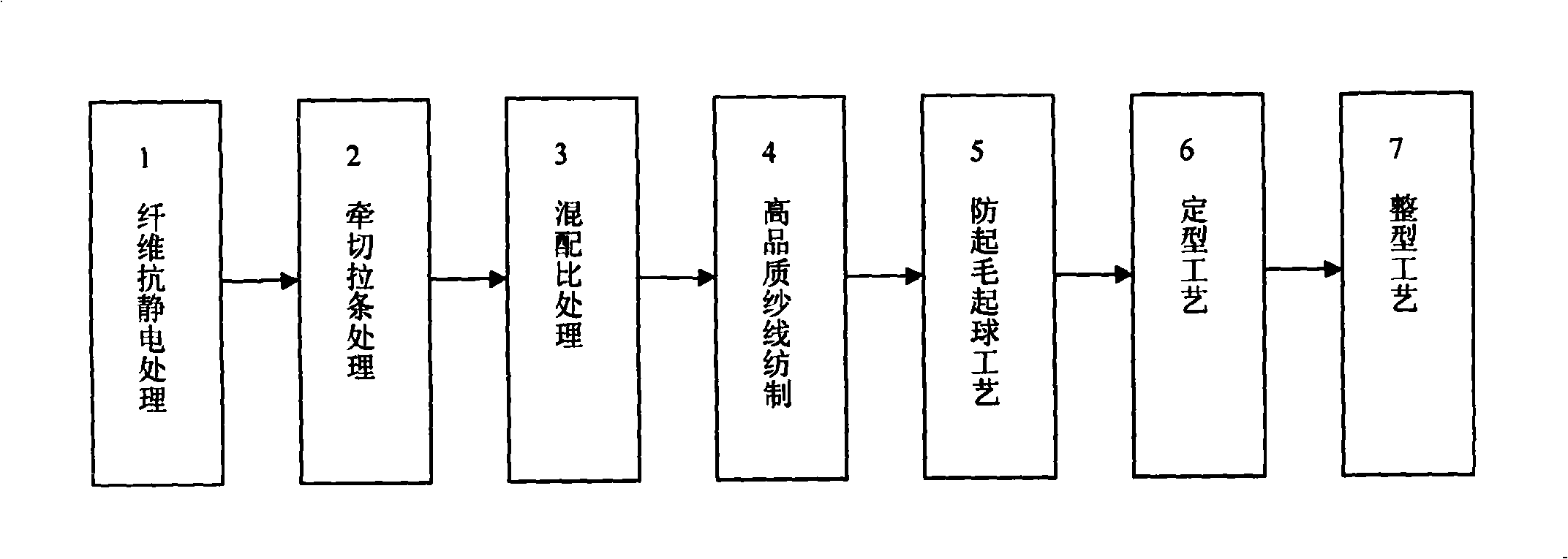

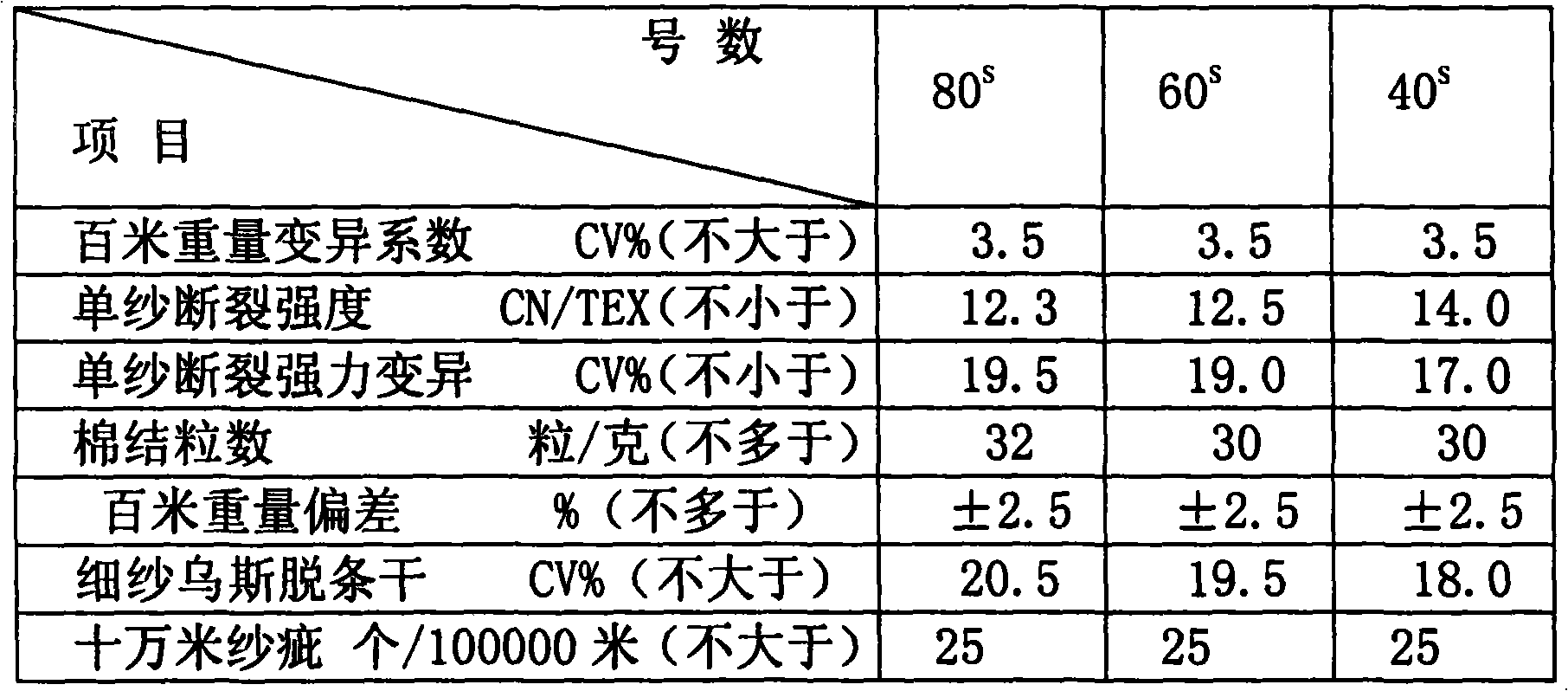

Clear and smooth blended yarn and production process thereof

The invention relates to a cotton textile-engineering field in the textile industry, in particular to a pure nylon blended yarn composed of the blended fabric of natural and chemical fibers and the production process of the pure nylon blended yarn, which has the technical scheme that through the changes of process parameters in the yarn spinning process and the special production processes of anti-static fiber blending treatment, yarn spinning twisting, double-twisting, modeling, integrating and other process steps in sequence, a special yarn with crepe twisting is produced in which the twisting coefficient range is 600 to 760 and the range of yarn count is 20s to 80s (yarns) is produced. The utility model is mainly to resolve the relevant technology issue that how to increase the twisting coefficient of spinning yarn substantially. The invention has the advantages that the twisting coefficient range of pure nylon blended yarn can reach 600 to 760 and the production yarn range thereof can reach the single and double yarns of 20s to 80s, which can be widely applied in circular knitting machines, flat knitting machines, tatting and other woven fabric series to fill in a gap in this domestic product category.. Therefore, the invention has the advantages the evaporation and permeability are increased with strong emotional cold feeling, unique luster, bright color and strong wear resistance. The moisture absorption and perspiration can be increased to facilitate the metabolic functions.

Owner:SHANGHAI HEYE TEXTILE

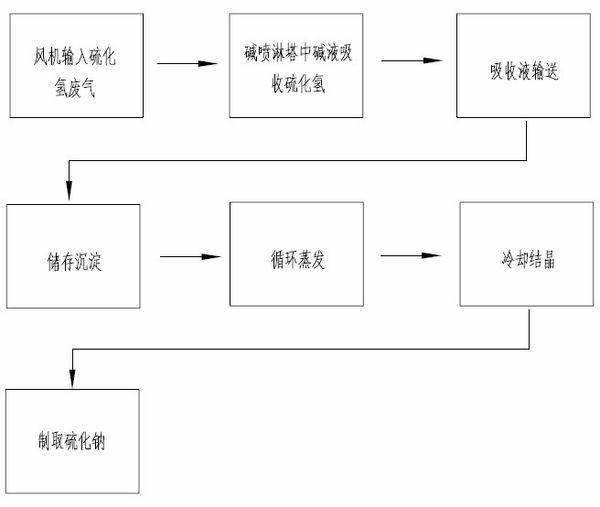

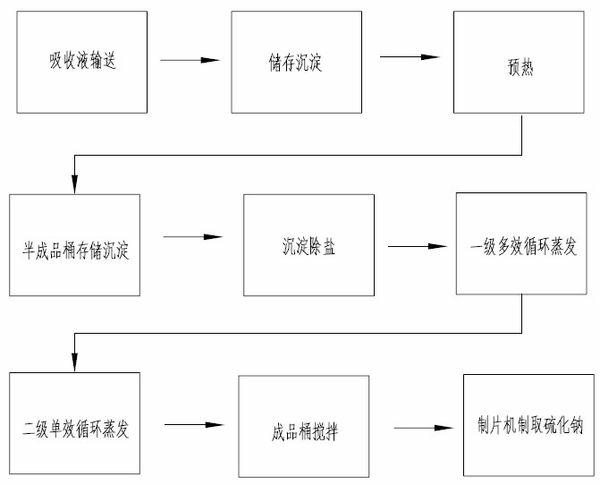

Method for preparing sodium sulfide from hydrogen sulfide waste gas produced in production of viscose fibre

InactiveCN102515112AAchieve optimized generationIncrease production costAlkali metal sulfides/polysulfidesImpurityWaste gas

The invention relates to the field of production of viscose fibre in the textile industry, in particular to a method for preparing sodium sulfide from hydrogen sulfide waste gas produced in the production of the viscose fibre. The method comprises the steps as follows: A, the waste gas is fed into an alkali spray tower; B, hydrogen sulfide is absorbed in an alkali liquor in the alkali spray tower; C, impurities are removed; D, a preheated absorption liquid is delivered into a primary multi-effect evaporator; E, a solution is subject to settlement and desalination; F, the desalinated solution is filled into a semi-finished product barrel, and caustic soda is added into the desalinated solution; G, the solution in the semi-finished product barrel is delivered into a secondary single-effect evaporator; H, after undergoing the secondary evaporation, the solution is filled into a finished product barrel, and then is stirred for crystallization; and I, crystal sodium sulfide is made into tablets. The method has the advantage of realizing the optimal generation of sodium sulfide through the setting of processing parameters such as the size of main equipment, the pore diameter of a delivery pipeline, wind volume, wind velocity, the concentration of the alkali liquor, absorption time, circulating evaporation time, evaporation temperature, evaporation vacuum degree, precipitation time, stirring velocity, the rotational speed of a tablet making machine, and the like.

Owner:YIBIN HIEST FIBER +2

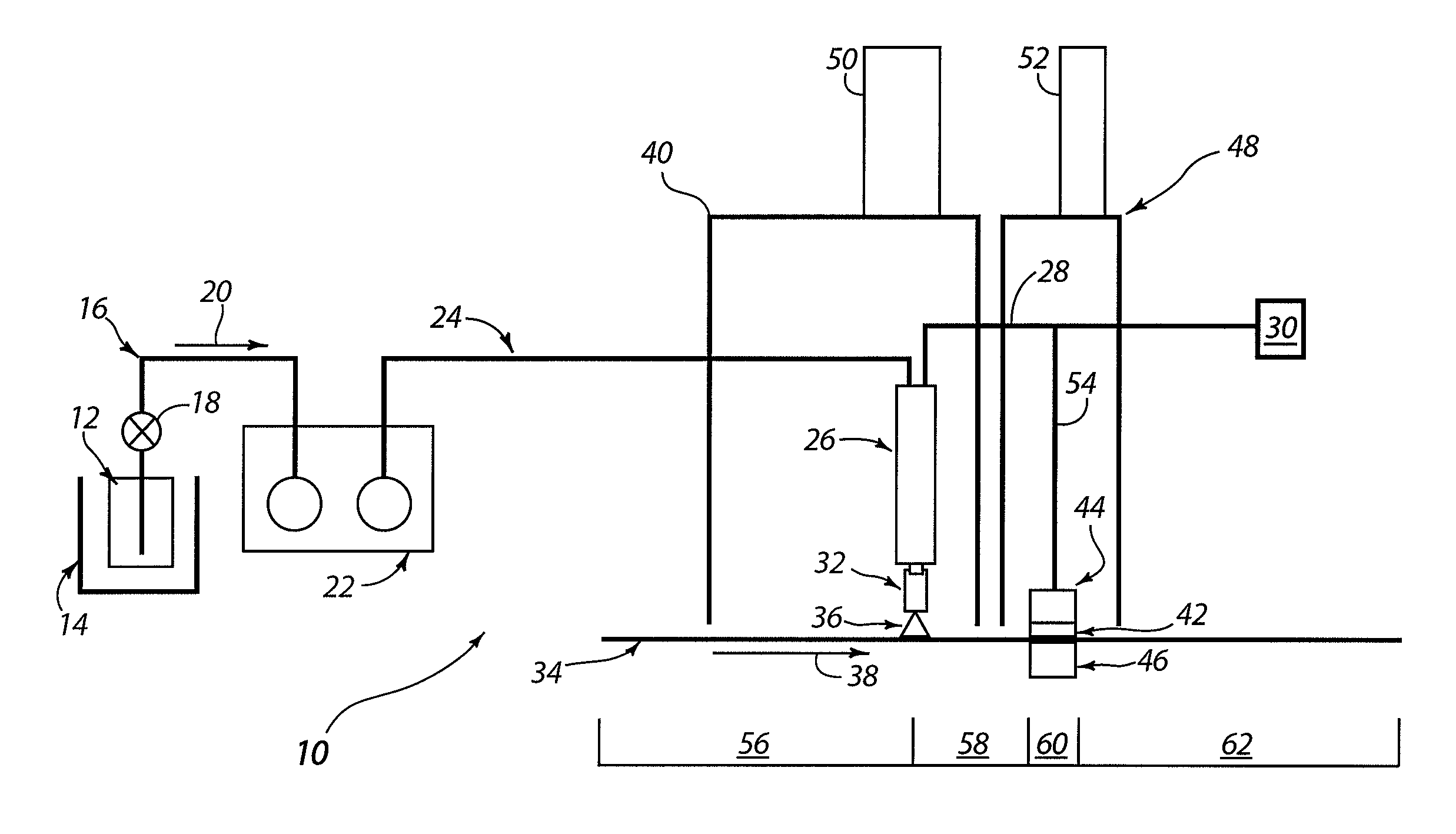

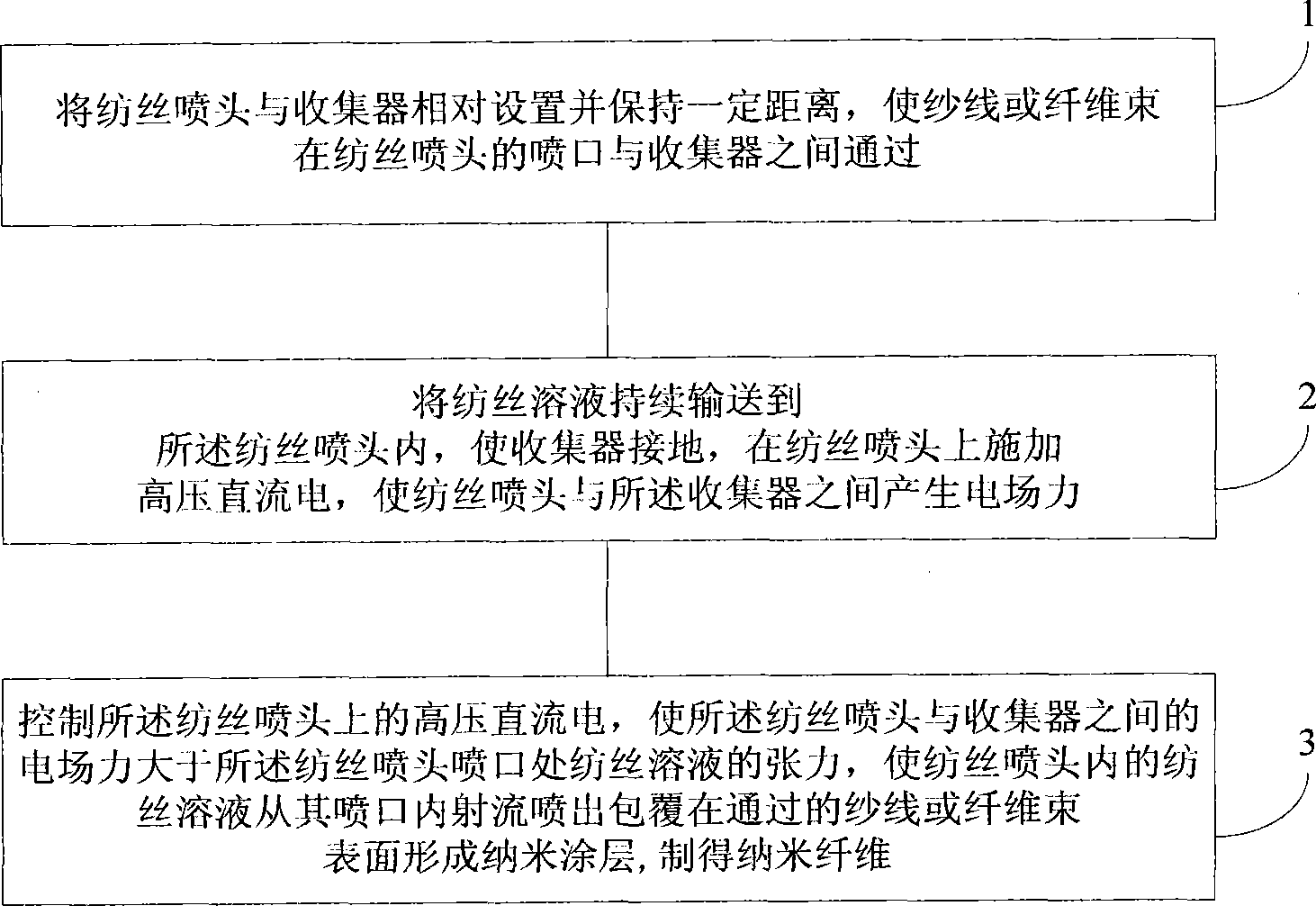

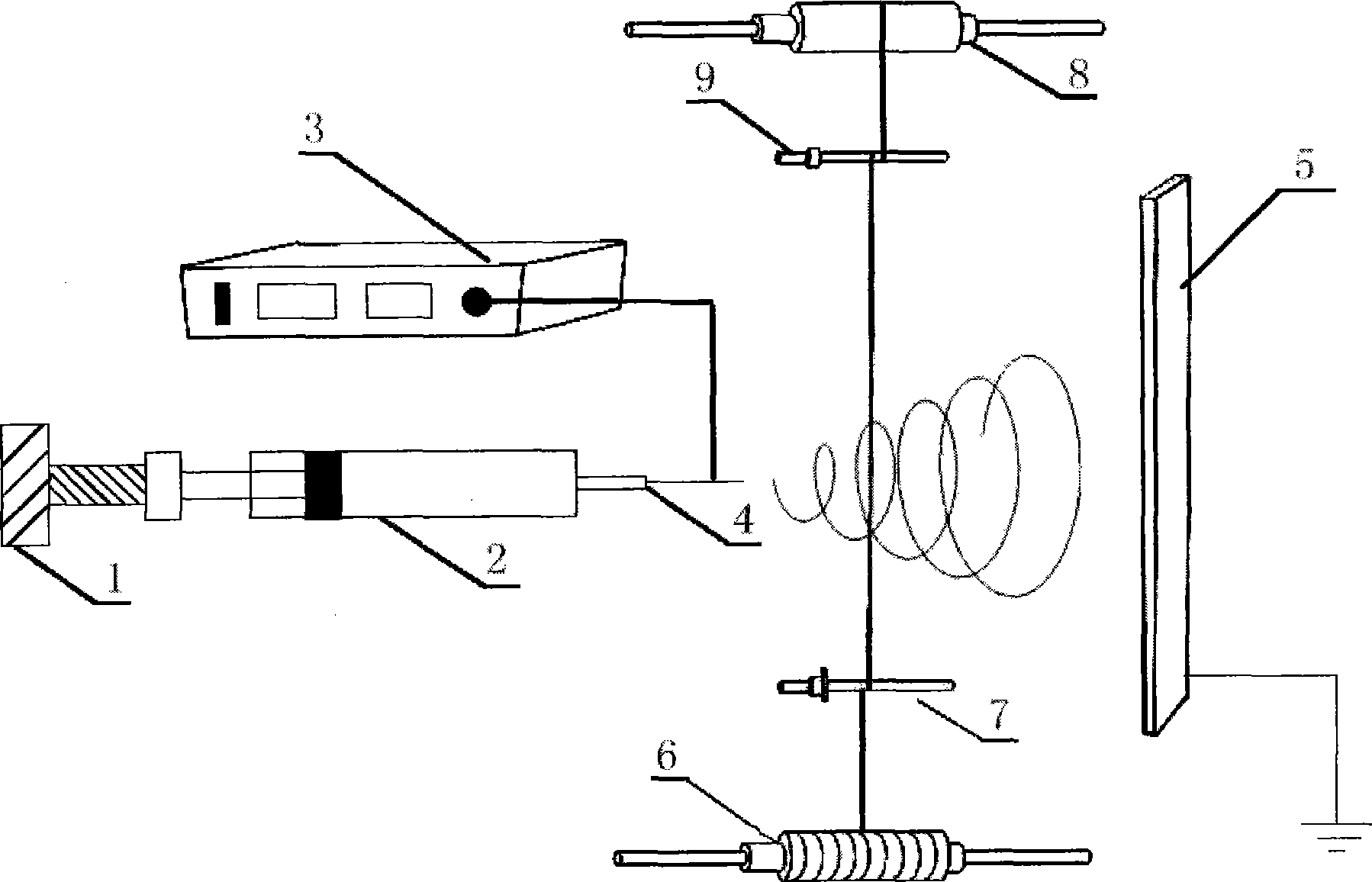

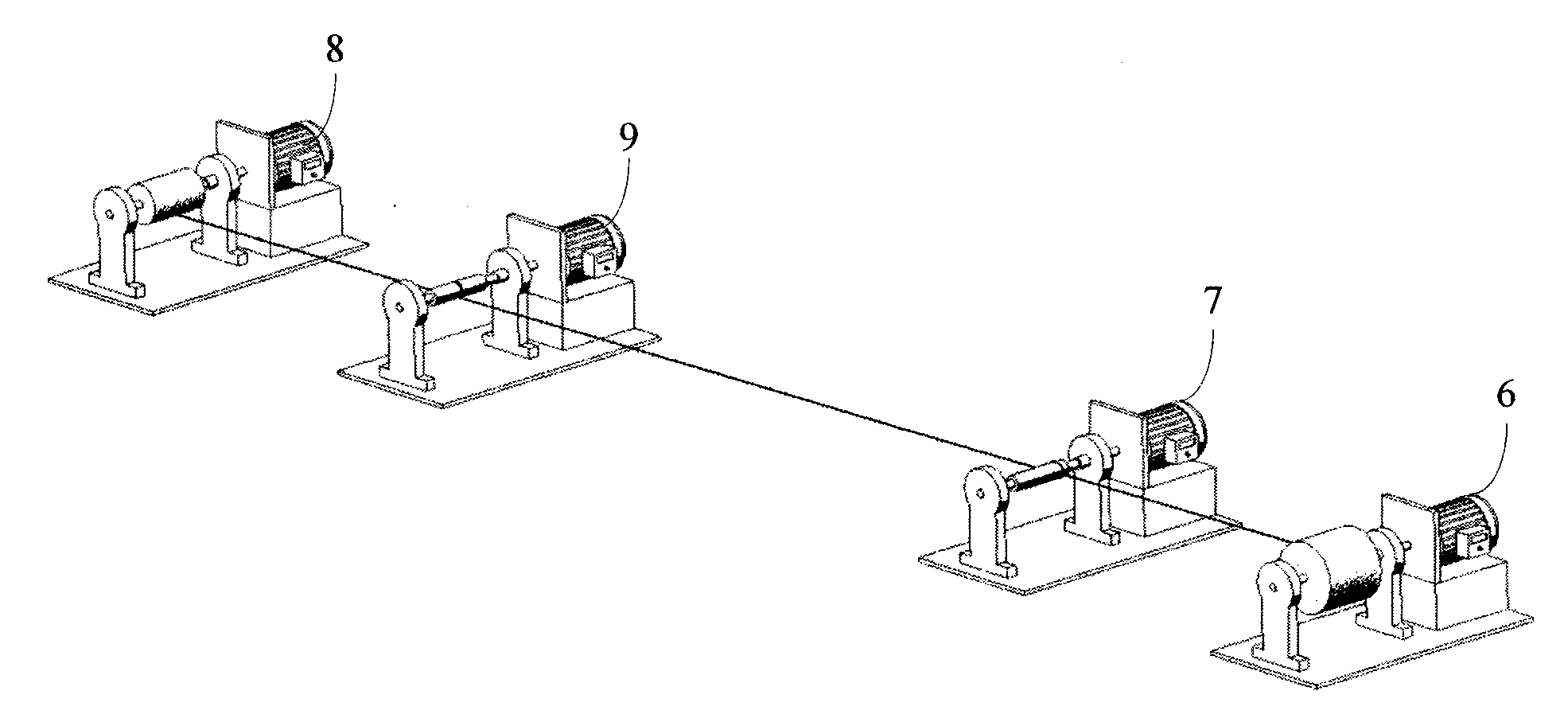

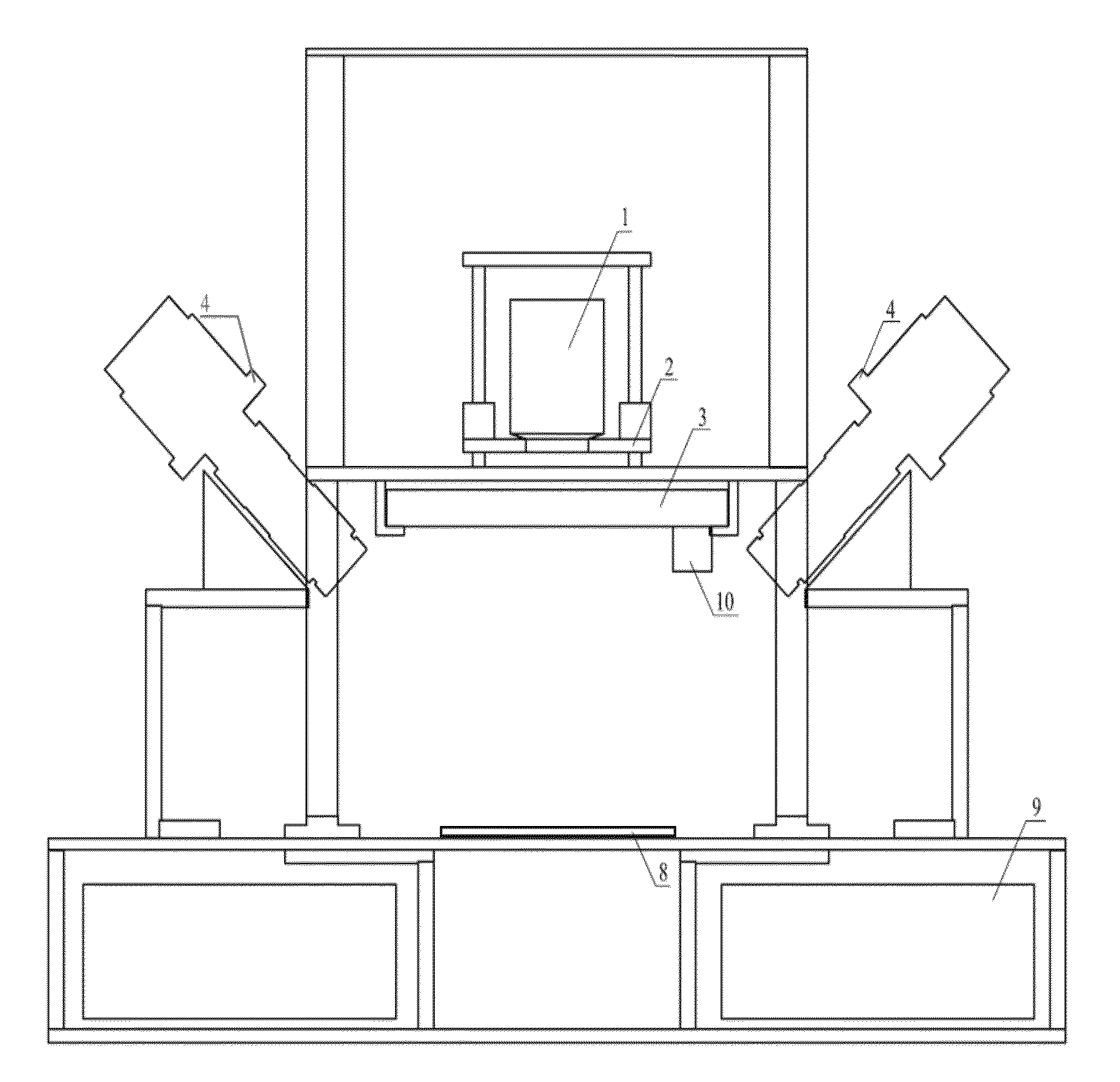

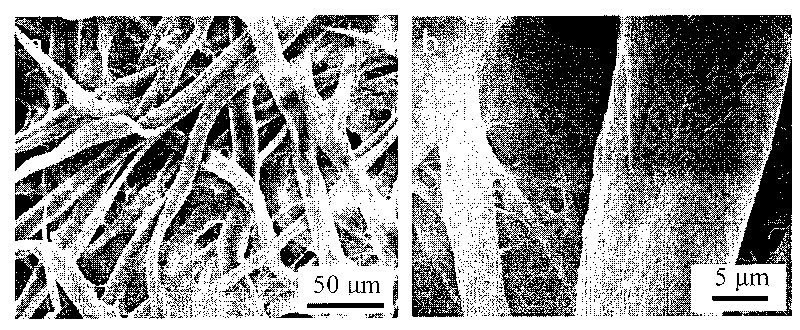

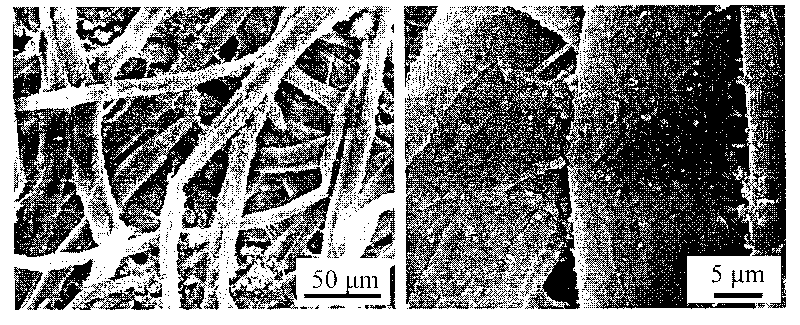

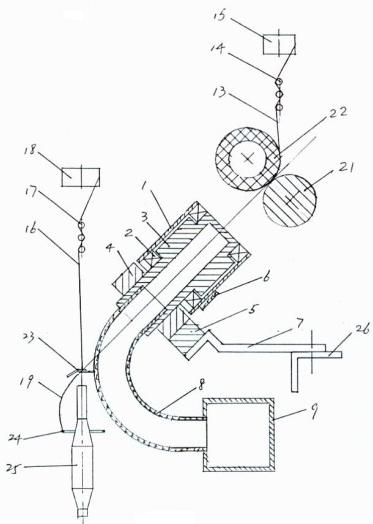

Method and system for preparing nanofiber coating on surface of yarn or fiber bundle

InactiveCN102912456AUniform diameter distributionImprove performanceLiquid surface applicatorsSpinnerette packsYarnFiber bundle

The invention discloses a method and a system for preparing a nanofiber coating on the surface of a yarn or a fiber bundle and belongs to the field of the textile industry. The method includes: arranging a spinning sprayer and a collector oppositely by a certain distance so that the yarn or the fiber bundle passes through between a nozzle of the spinning sprayer and the collector; continuously supplying spinning solution into the spinning sprayer by the aid of an automatic solution delivery device, enabling the collector to be grounded, applying high-voltage direct current on the spinning sprayer, and generating electric field force between the spinning sprayer and the collector; and controlling the high-voltage direct current on the spinning sprayer, enabling the electric field force between the spinning sprayer and the collector to be larger than surface tension of the spinning solution at the nozzle of the spinning sprayer, and enabling the spinning solution in the spinning sprayer to be sprayed out of the nozzle of the same by jet flow to be coated on the surface of the passing yarn or the passing fiber bundle so that a nano coating is formed, and the yarn with the nano coating formed on the surface is a prepared nano fiber. The method is simple in process steps, good in controllability and capable of producing nano fibers uniform in diameter distribution and excellent in performance with low cost.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Polysaccharides nano material with antibiotic function, preparing method and application thereof

InactiveCN101016391ARich varietyReduce usageOrganic active ingredientsBiocideWater soluble polysaccharidesAntibacterial activity

The invention discloses a polyose nanometer material possessing antibiotic function and preparing method and application, which comprises the following steps: choosing water-soluble polyose material incorporating carboxy group or sulfonic group as basis material; loading metallic ion possessing bacterial inhibition active in water solution; setting metallic ion load capacity at 10-500mg / g and bacterial inhibition active at 99.9%; centrifugal separating; ultrasonic dispersing; freezing or spraying; drying; getting end product with particle diameter at 20-800nm. This invention can be used to textile industry, animal husbandry and medicine domain as antiviral drug.

Owner:DONGHUA UNIV

High whiteness and strength adhesive short fiber and process for making same

ActiveCN1632189AImprove qualityHigh whitenessArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceAdhesive

The invention relates to a viscose staple fiber with high white strength and fine denier and a production process thereof, which belong to the viscose staple fiber and the production method of the textile spinning industry and the non-woven fabric industry. Its raw materials and weight percent content are: 86.7-92 percent of cellulose fiber, 7.7-13 percent of water, and 0.15-0.30 percent of oil agent. The raw materials are impregnated, squeezed, yellowed, spun, drawn, bundled, scoured, bleached twice with hydrogen peroxide, and dried to make finished products. The product of the present invention has finer denier, higher strength, higher yarn count and higher strength, and the garment fabric has higher strength, strong abrasion resistance, delicate hand feeling, wrinkle resistance and resistance to multiple deformations than ordinary viscose of the same process. Short fiber processing clothing fabrics and other advantages. High-count yarn products have thinner fabrics and lower grammage. The area of fabrics processed from raw materials of the same weight is increased and the cost is reduced.

Owner:唐山三友集团兴达化纤有限公司

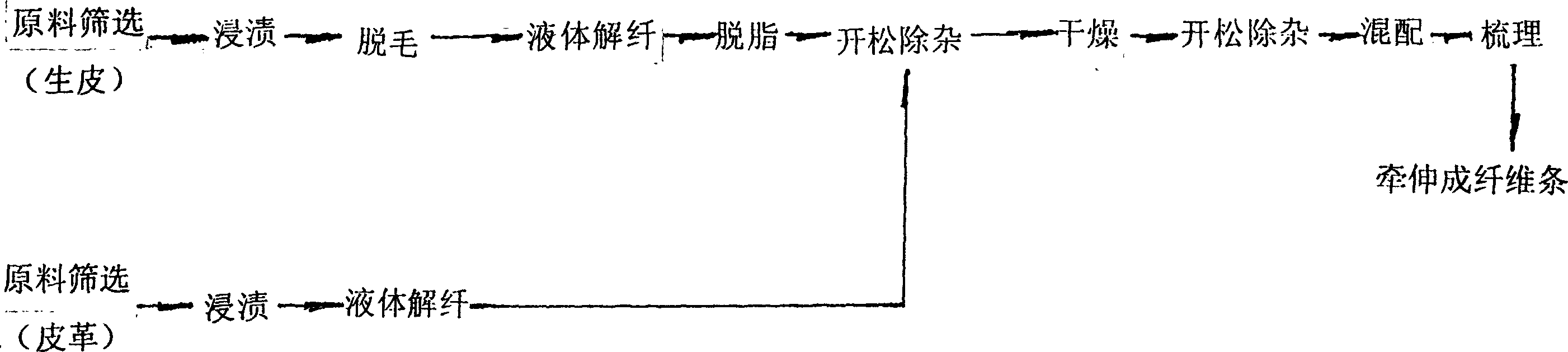

Fabric strip for spinning and its processing method

The invnetion relates to a spinning fiber rod comprised of 5-100% collagen fiber and residual textile fiber. Wherein, the process method comprises: screening material, dipping, defibering, degreasing, cleaning, dewatering, drying, opening to remove impurity, mixing, carding, and drafting. This invention can obtain material from wide source, has well applicability, high tensile strength, well moisture / oil absorption properties, and fit to spread in textile industry.

Owner:张立文

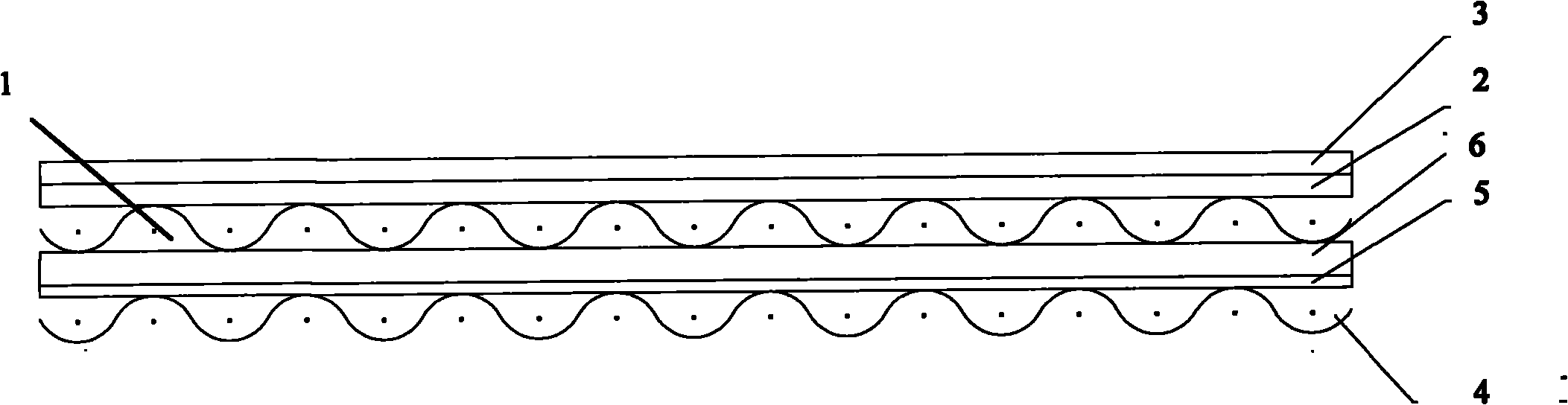

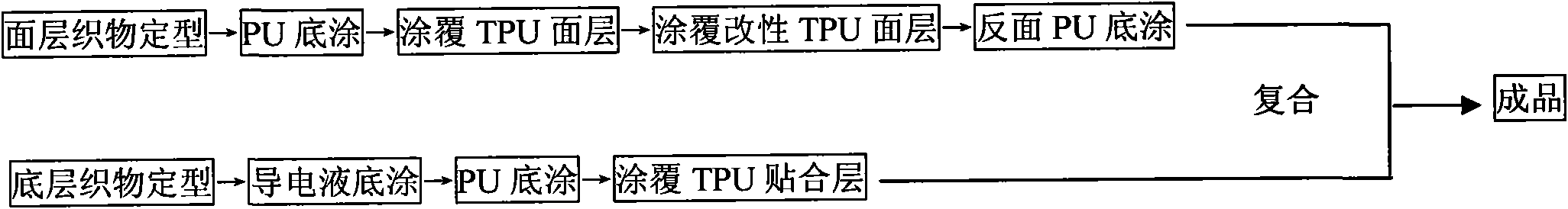

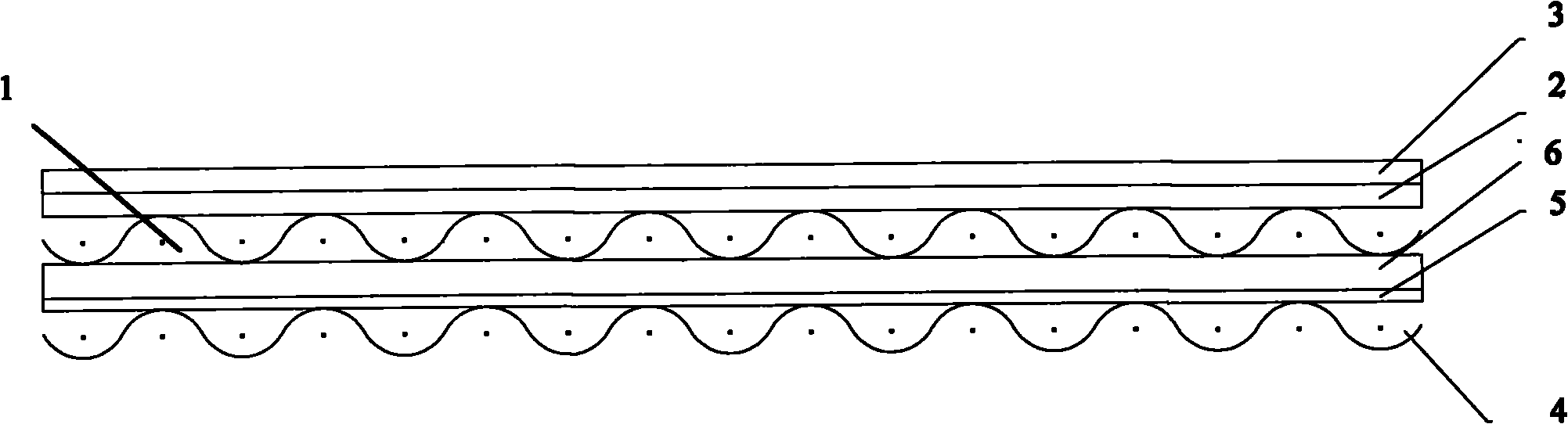

Highly anti-static thermoplastic polyurethane (PU) conveyer belt for textile industry and preparation method thereof

ActiveCN101844666AMeet needsImprove antistatic performanceConveyorsFibre treatmentPolymer scienceOrganic solvent

The invention relates to a highly anti-static thermoplastic polyurethane (PU) conveyer belt for the textile industry and a preparation method thereof. The upper surface of a facing fabric is sequentially coated with a PU bottom coating, a TPU (Thermoplastic Polyurethane) surface layer and a carbon nano tube modified TPU surface layer from bottom to top, and the lower surface of the facing fabric is coated with a PU bottom coating; a bottom fabric is a fabric containing conductive fibers, and the upper surface of the bottom fabric is sequentially coated with a conductive liquid coating, a PU bottom coating and a TPU laminating layer from bottom to top; and the conductive liquid is a solution of carbon nano tube modified TPU in an organic solvent. The preparation method comprises the following steps of: coating the PU bottom coating, the TPU surface layer and the carbon nano tube modified TPU surface layer on the upper surface of the facing fabric, and coating the PU bottom coating on the lower surface of the facing fabric; coating the conductive liquid coating, the PU bottom coating and the TPU on the upper surface of the bottom fabric and carrying out heat setting to form the laminating layer; and superposing and compounding the fabrics up and down to prepare the conveyer belt. The conveyer belt has the advantages that the surface resistance of the conveyer belt reaches 103 omegas and the bottom resistance reaches 105 omegas, which sufficiently meet the requirement on the textile industry.

Owner:SHANGHAI YONGLI BELTING +1

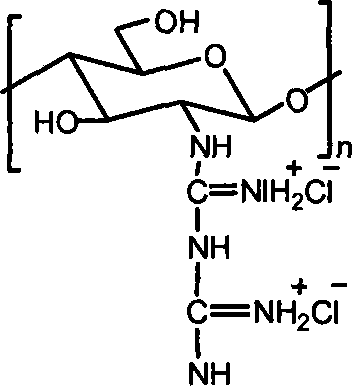

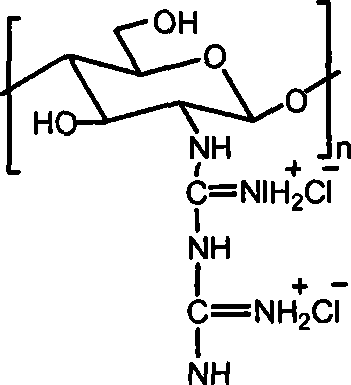

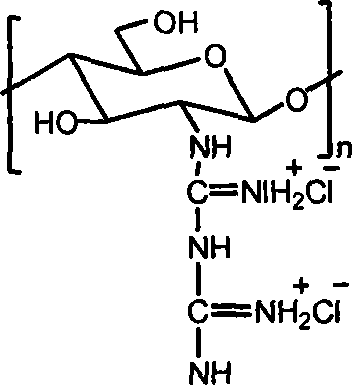

Chitosan biguanide hydrochloride, preparation method and use thereof

InactiveCN101033264AStrong and broad-spectrum antibacterial activityRich sourcesBiocideDisinfectantsSolubilitySide effect

The invention provides a new chitosan derivate-chitosan biguanide muriate, its preparation and usage, in which, the repeat unit is 2-biguanide glucose muriate, the substitution degree of guanidine is 15-50%, and the molecular weight is 0.5-25 ten thousand. This invention uses the reaction of chitosan and dicyandiamide to prepare chitosan biguanide muriate, and has advantages of mild reaction conditions and fewer side effects. The product has good antibacterial activity and water solubility, and can be widely used in medicine, textile industry, agriculture and other fields.

Owner:WUHAN UNIV

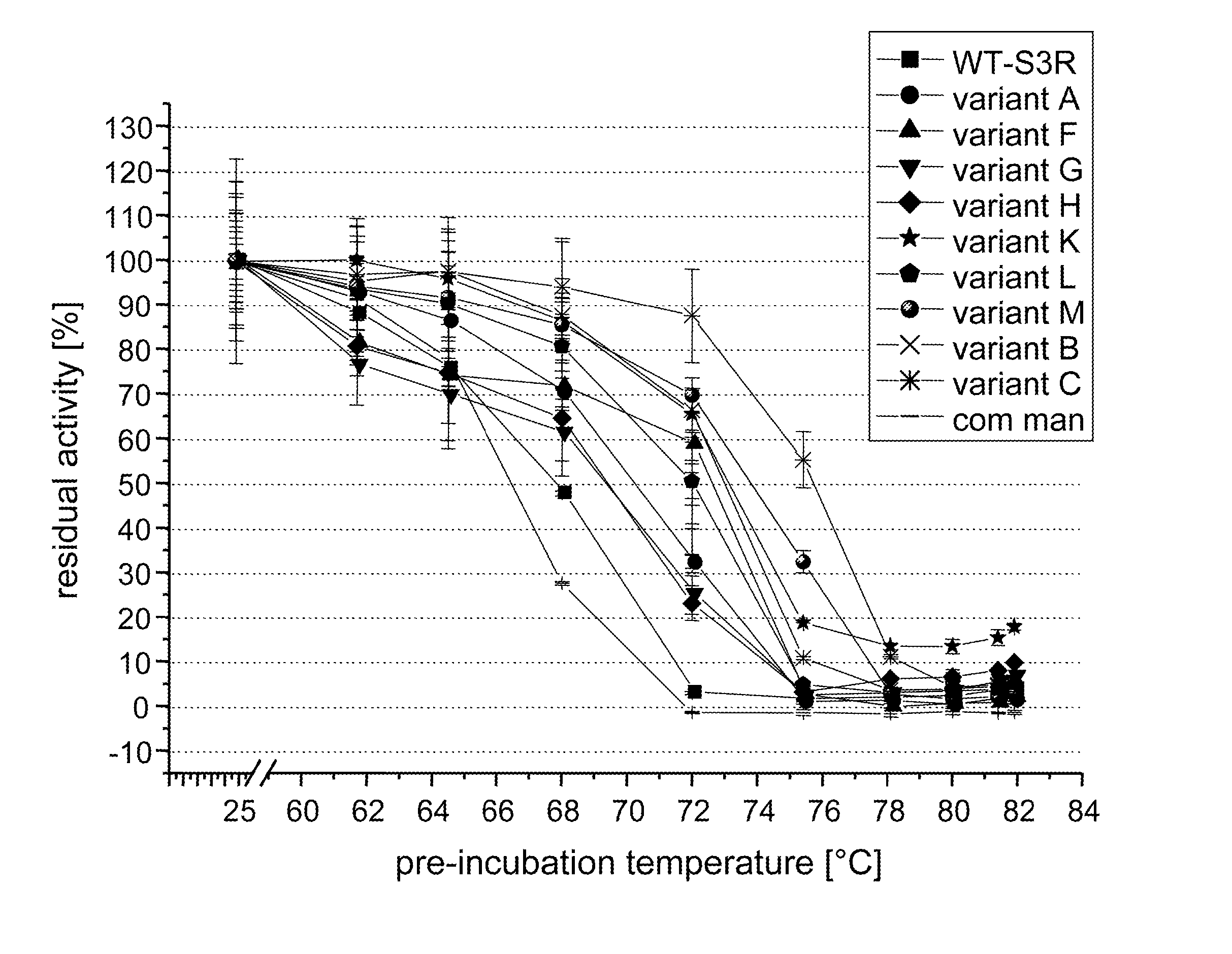

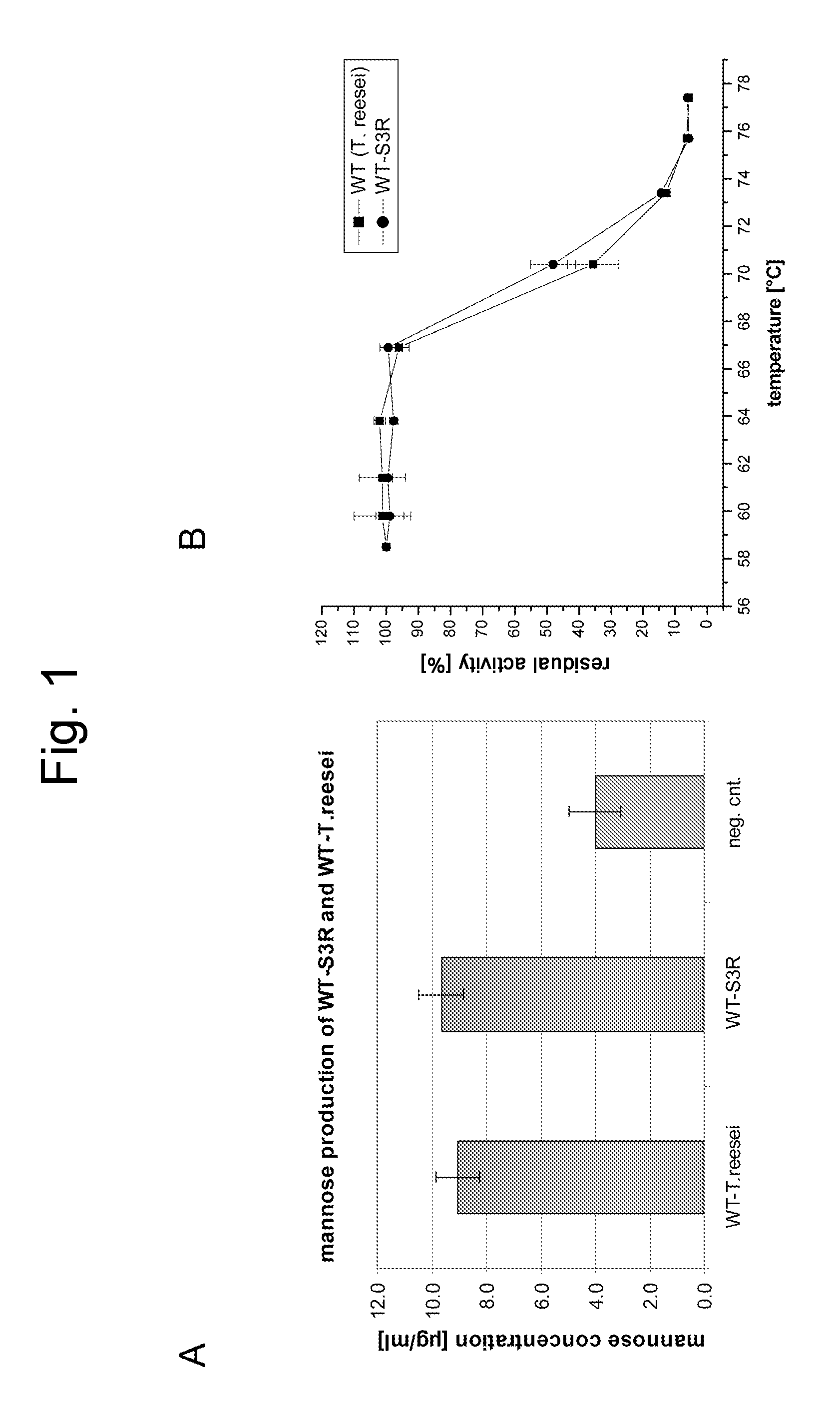

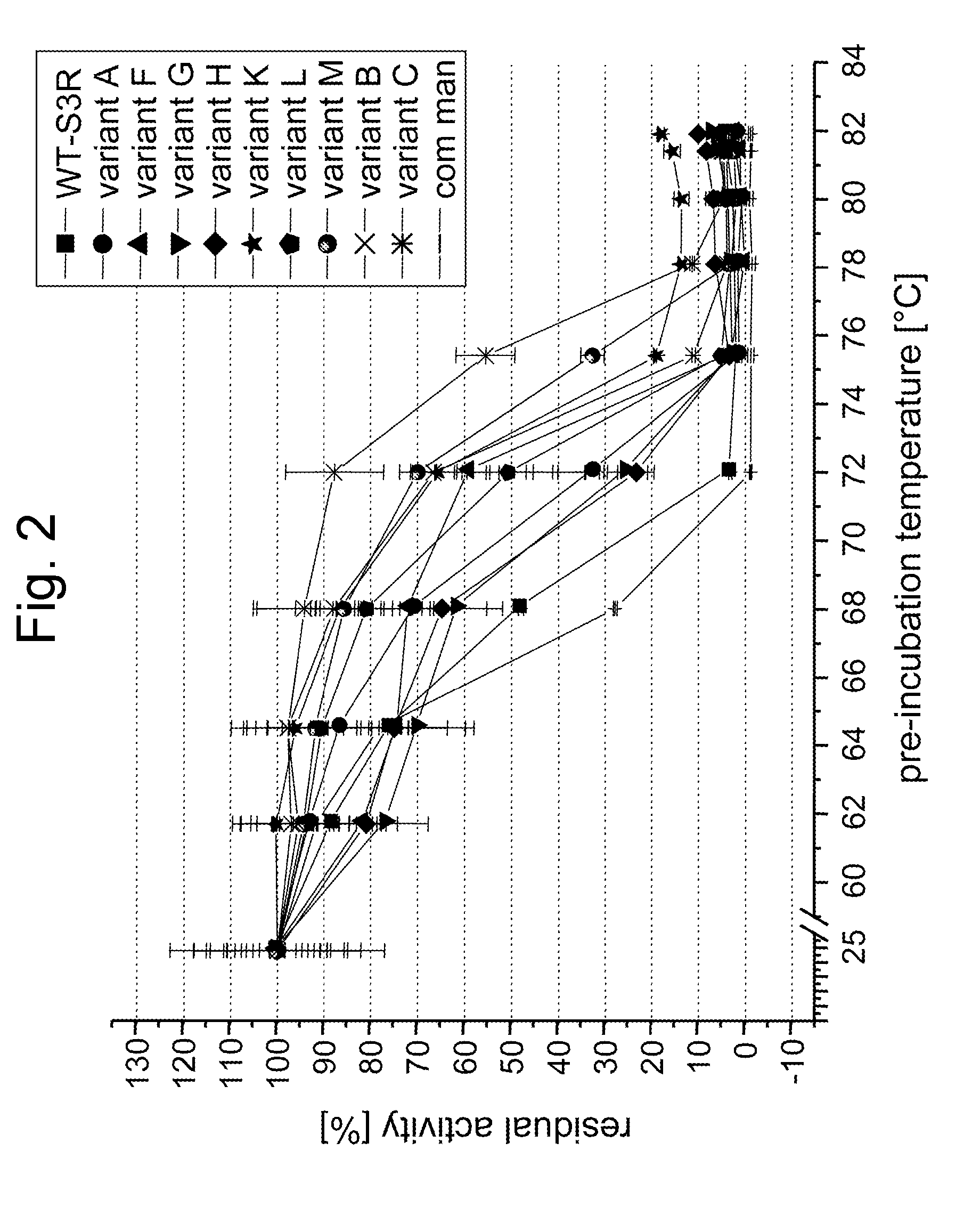

Mannanases

ActiveUS20080064064A1Precise and reproducible enzyme dosagePrevent steppingTissue cultureFlushingBleachWild type

The present invention provides an insertion, deletion and / or substitution mutein of wild-type Trichoderma reesei β-mannanase having enhanced thermostability, proteolytic stability, specific activity and / or stability at low pH, a nucleic acid molecule encoding said mannanase mutein, a composition comprising said mannanase mutein; a method for its preparation, and its use for food and feed processing, for coffee extraction and the processing of coffee waste, as a supplement to food and feed, for enzyme aided bleaching of paper pulps, as bleaching and / or desizing agent in textile industry, for oil and gas well stimulation by hydraulic fracturing, as detergent, for removal of biofilms and in delivery systems, or for the processing of renewable resources intended for the production of biological fuels.

Owner:BASF AG

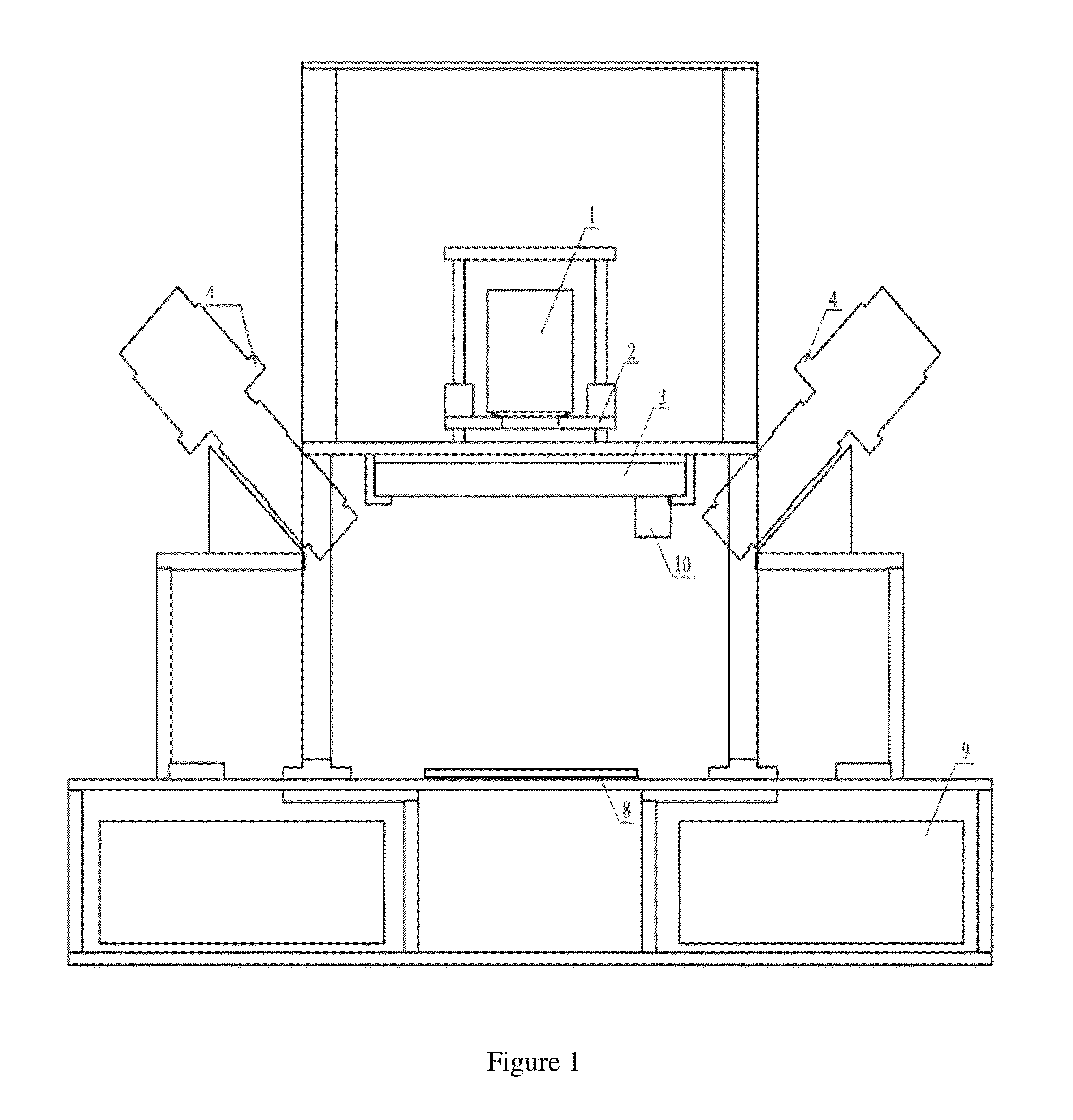

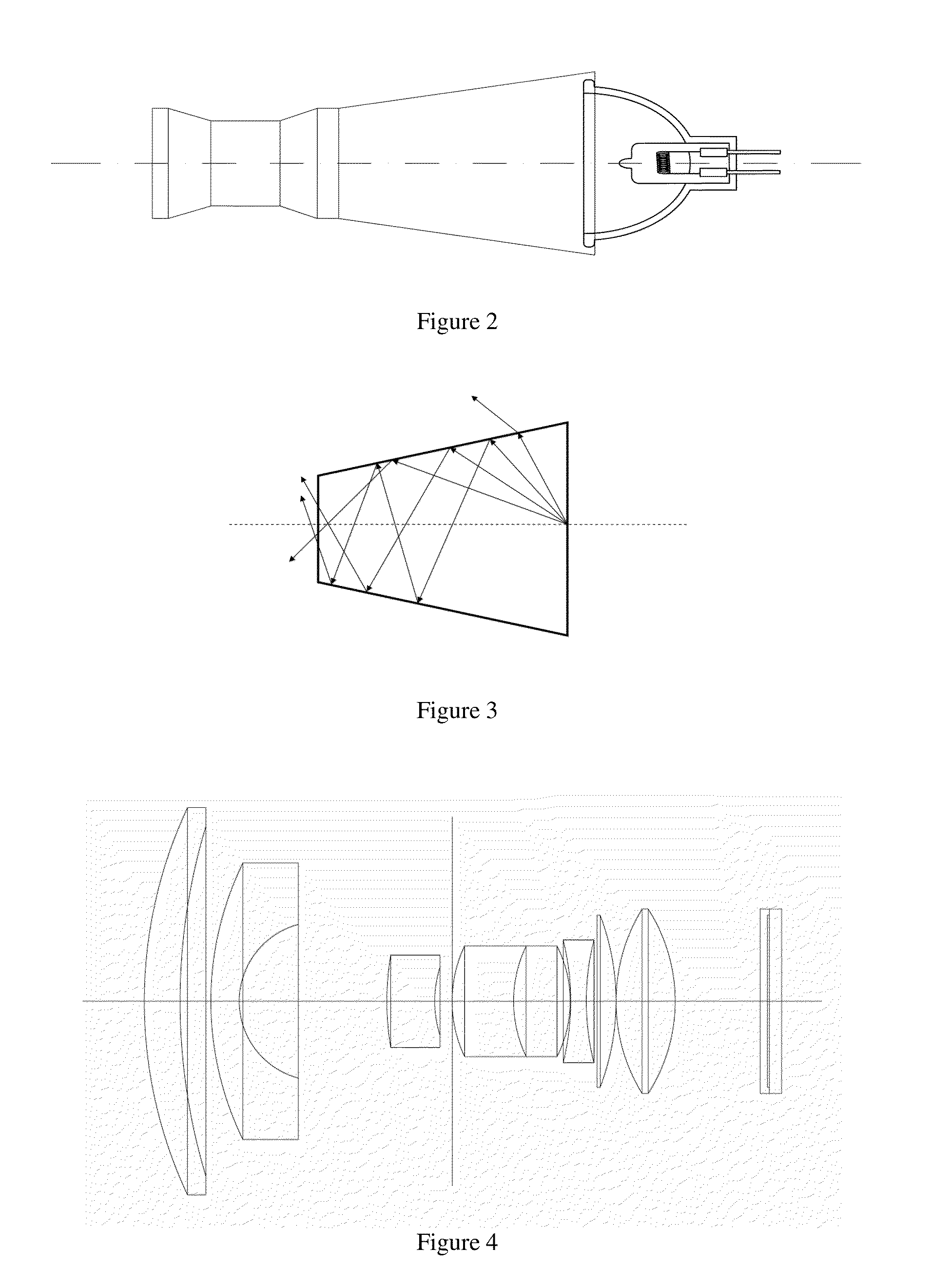

Multispectral imaging color measurement system and method for processing imaging signals thereof

ActiveUS20130293702A1Overcome inaccuraciesImprove spatial resolutionColor signal processing circuitsSpectrum investigationDigital imagingMultispectral image

A multispectral imaging color measurement system, comprising a dark room, a sample platform and an imaging device for capturing said object being measured; a controllable illumination device, a filter wheel unit, an imaging signal processing unit and an electronic control unit. A method for processing imaging signals of the multispectral imaging color measurement is also proposed. The multispectral imaging color measurement system and the method for processing imaging signals thereof can overcome the inaccuracy of traditional digital imaging systems and the limits of spectrophotometer systems and provide users in the textile industry with highly accurate color measurement and evaluation.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Method for preparing super-hydrophobic nano modified cellulose material

InactiveCN101694057AStrong toughnessHigh mechanical strengthDry-cleaning apparatus for textilesVegetal fibresCellulose fiberNatural fiber

The invention relates to a method for preparing a super-hydrophobic nano modified cellulose material, which comprises the following steps: adopting tetrabutyl titanate as a precursor, adopting a natural cellulose fiber as a substrate substance and depositing a nano-layer titanium dioxide film on the surface of the natural cellulose fiber by a sol-gel method; and then self-assembling a silane single layer containing long chain alkyl to obtain the super-hydrophobic nano modified cellulose material. The nano modified cellulose material has obvious super-hydrophobicity, durable chemical stability and self-cleaning capacity and wide application prospect in the production of the fiber materials for preventing water, damp, dirt, dust, and the like in a textile industry.

Owner:ZHEJIANG UNIV

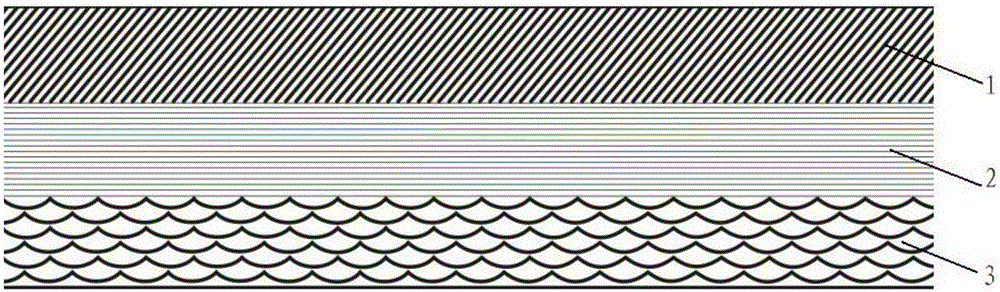

Light, thin thermal-wet comfort multifunctional knitted fabric and preparation method thereof

ActiveCN105220336AGood moisture absorption and heating performanceOne-way moisture guide function is goodWeft knittingDyeing processYarnMoisture absorption

The invention provides light, thin thermal-wet comfort multifunctional knitted fabric and a preparation method thereof. The fabric is formed by weaving first yarn, second yarn, third yarn and fourth yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer. The outer layer is formed by weaving the first yarn. The middle layer is formed by weaving the second yarn and the third yarn. The inner layer is formed by weaving the fourth yarn. The moisture-absorption and heat-generating heating up value of the fabric meets the standard requirements in the textile industry, moisture adsorption performance, quick drying performance, comprehensive sweat-discharge quick drying performance and other indexes meet values required by national standards before and after the fabric is washed, and the heat-preserving rate index meets the values required by the national standards; meanwhile, the fabric has a good moisture retention function, moisture needed by human skin is locked, and human skin aging can be effectively relieved.

Owner:武汉爱帝针纺实业有限公司

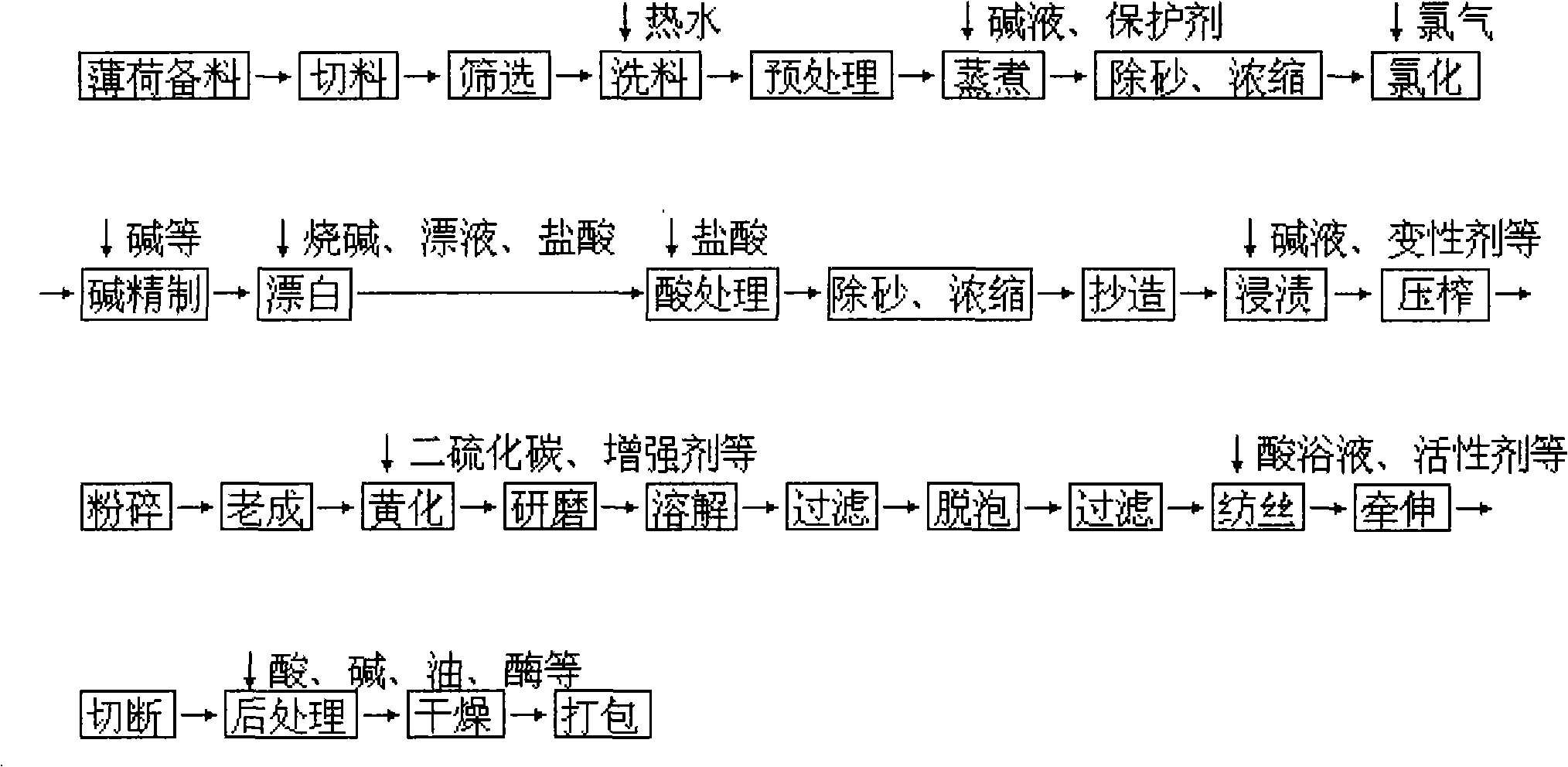

Corn mint cellulose viscose manufacturing technique

InactiveCN101265615AAvoid harmAbundant storageBiochemical fibre treatmentArtificial filaments from viscoseCelluloseMenthone

The invention relates to a viscose fiber produced by utilizing mint and the process engineering thereof. The process includes: mint preparing, cropping, screening, washing, pre-treating, boiling, desanding and concentrating, chloridizing, alkali refining, bleaching, acid treating, desanding and concentrating, papermaking, dipping, pressing, crushing, maturing, yellowing, rubbing, dissolving, filtrating, debubbling, filtrating, spinning, drafting, severing, post-treating, drying, and packing; in the production process, a relaxative pulp technology is adopted, a preservative agent is added, and an enzyme treatment working procedure is added. The invention utilizes mint as the raw material to produce the viscose fiber, which is a creation of applying mint in the textile industry; and the original special matter of the mint, menthol and menthone, are kept, as well as the characteristics of sterilization, balminess, coolness, environmental protection, mosquito repelling, and so on; so that the fiber products thereof have the natural refreshing healthcare function and create a novel field for the development of the viscose fiber and the functional products thereof.

Owner:南京辉恒纺织服装有限公司

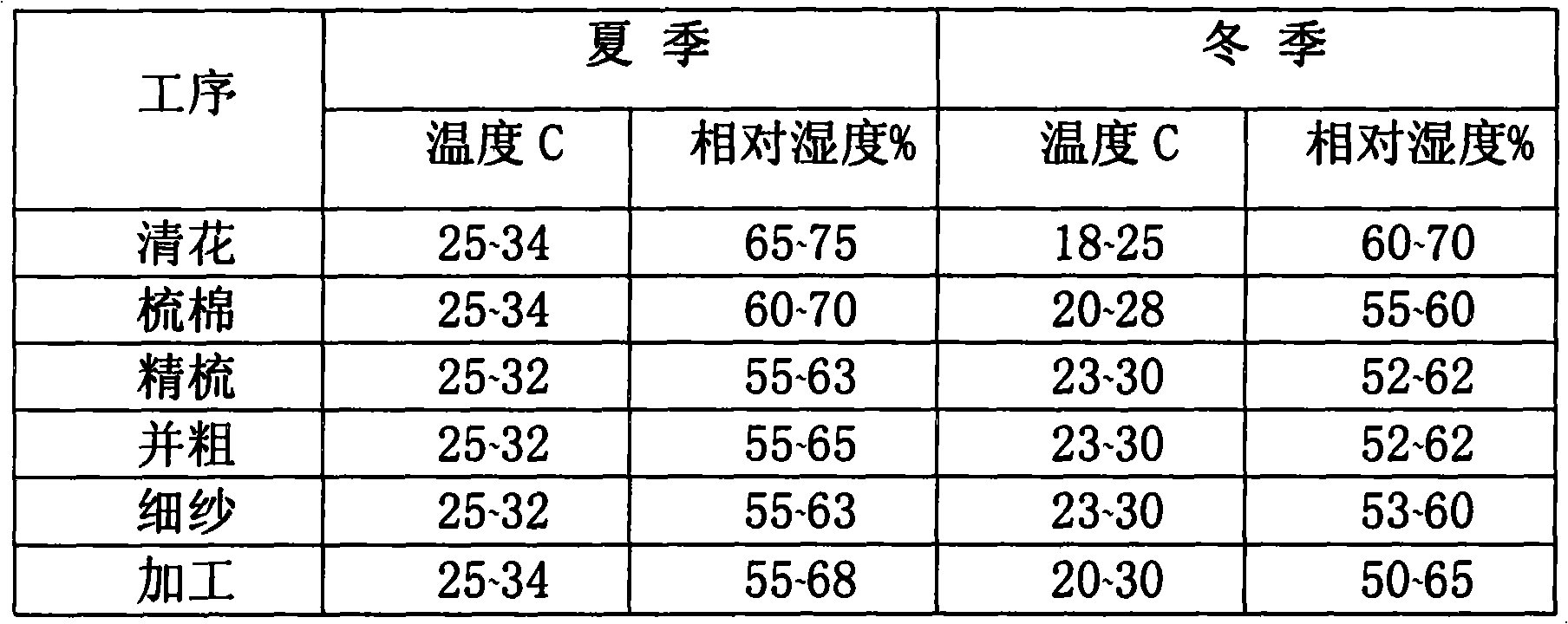

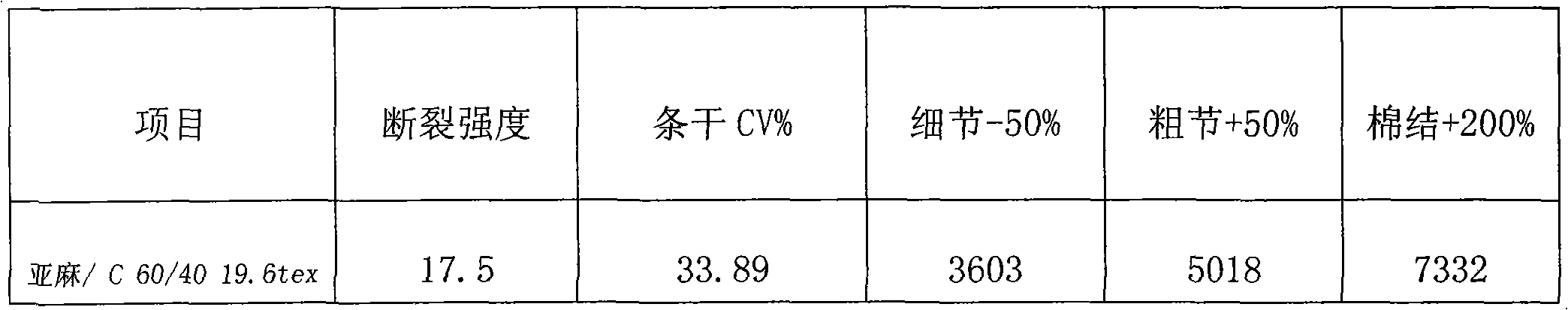

Blended yarn of flax fibers and cotton fibers and preparation process thereof

The invention discloses a blended yarn of selected flax fibers with superior count and cotton fibers and a preparation process thereof. The blended yarn consists of the flax fibers with superior count and the cotton fibers, wherein the flax fiber content accounts for 20 to 60 percent of the total weight of the blended yarn, and the cotton fiber content accounts for 40 to 80 percent of the total weight of the blended yarn. The preparation process comprises the following steps of: dividing the flax fibers with superior count and carded sliver or combed sliver into small heaps by proportioning; preparing uniform aqueous solution; and performing steps of fiber mixing, cleaning, cotton carding, drawing, roving and spinning to prepare the blended yarn of flax fibers and cotton fibers, wherein the relative humidity for the production environment of each step is 58 to 65 percent. The product produced by the invention can be made into various blended fabrics and thus provides a purely natural and comfortable textile product for the field of textile industry.

Owner:JIHUA 3542 TEXTILE CO LTD

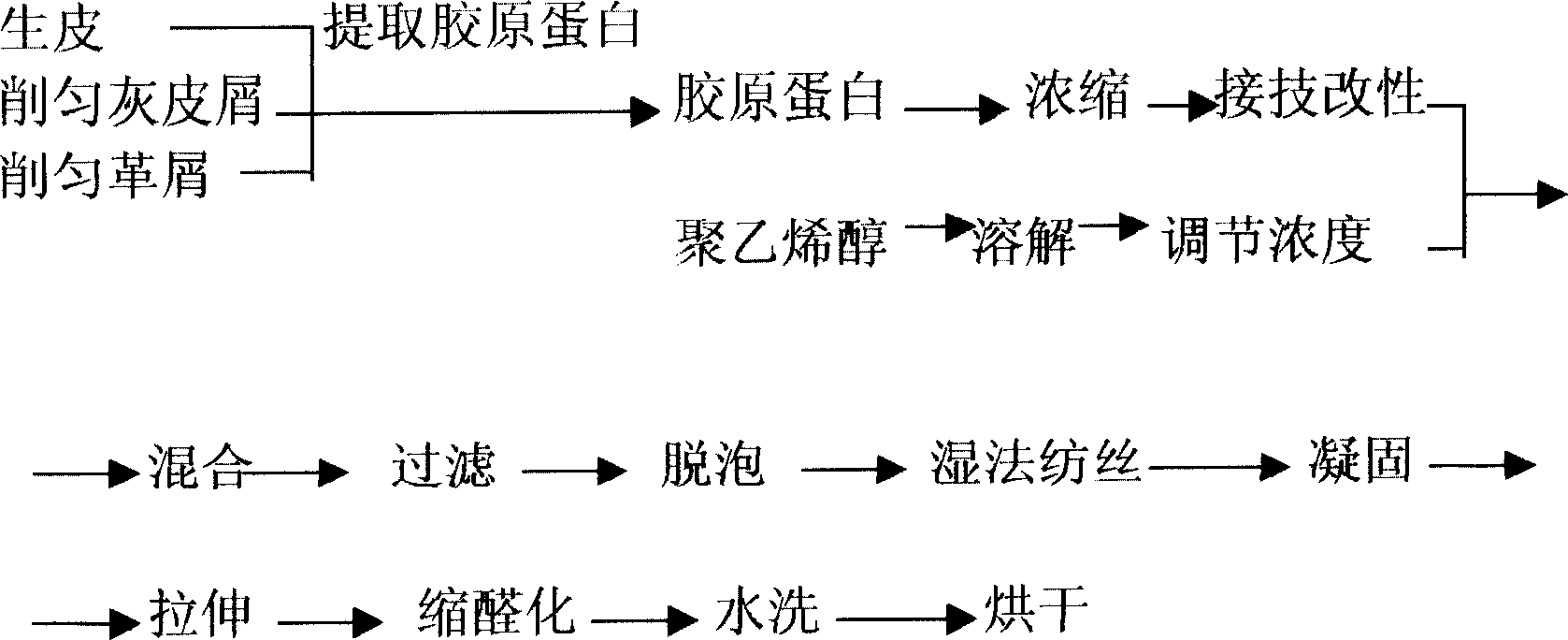

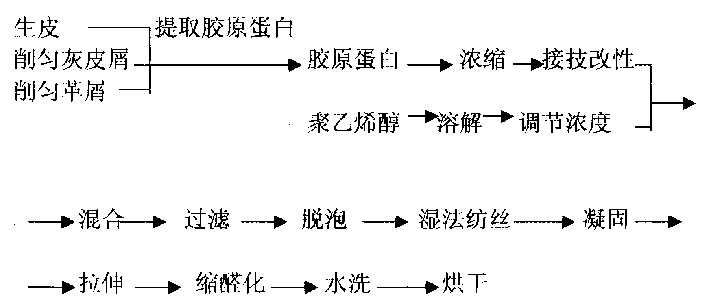

Collagen protein composite fiber and its producing method

InactiveCN1492087AComfortable to wearGood hygroscopicityConjugated artificial filamentsLeather industryPolyvinyl alcohol

The present invention relates to new material in textile industry. Collagen protein extracted from animal skin or leather industry leftover is grafting modified with olefin monomer and mixed with PVA to form spinning liquid with certain density and viscosity; and through further wet spinning, solidification, stretching and acetalization, the composite collagen protein fiber for textile industry is produced. The composite collagen protein fiber consists of collagen protein 10-45 wt%, olefin monomer modifier 5-20 wt% and PVA 50-85 wt%. The composite collagen protein fiber has excellent affinity to human skin, high hygroscopicity, wearing comfort and easy colorizing.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

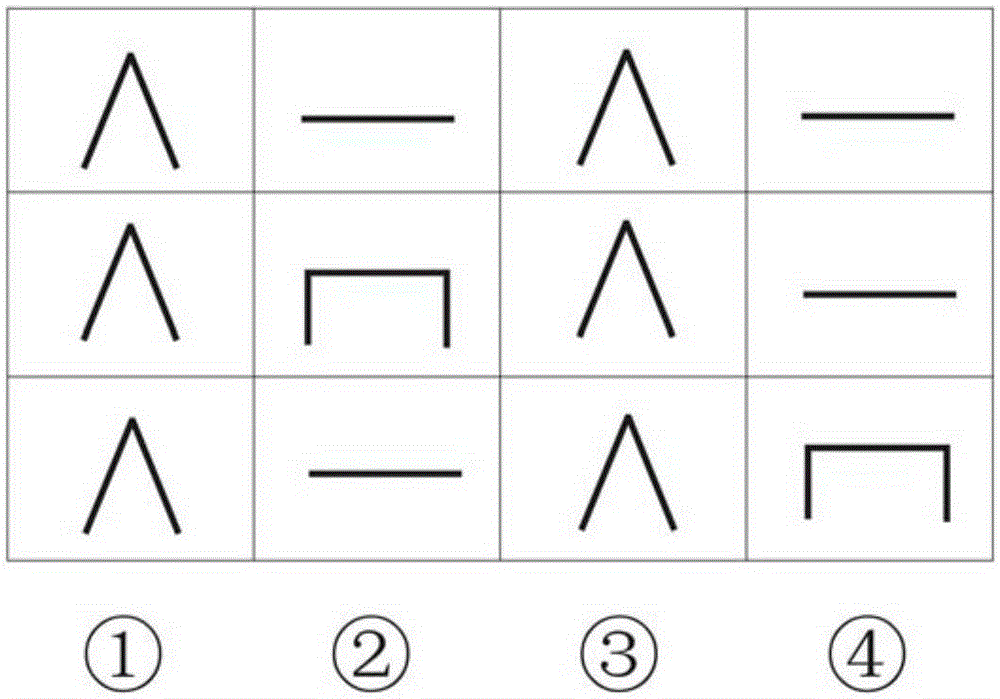

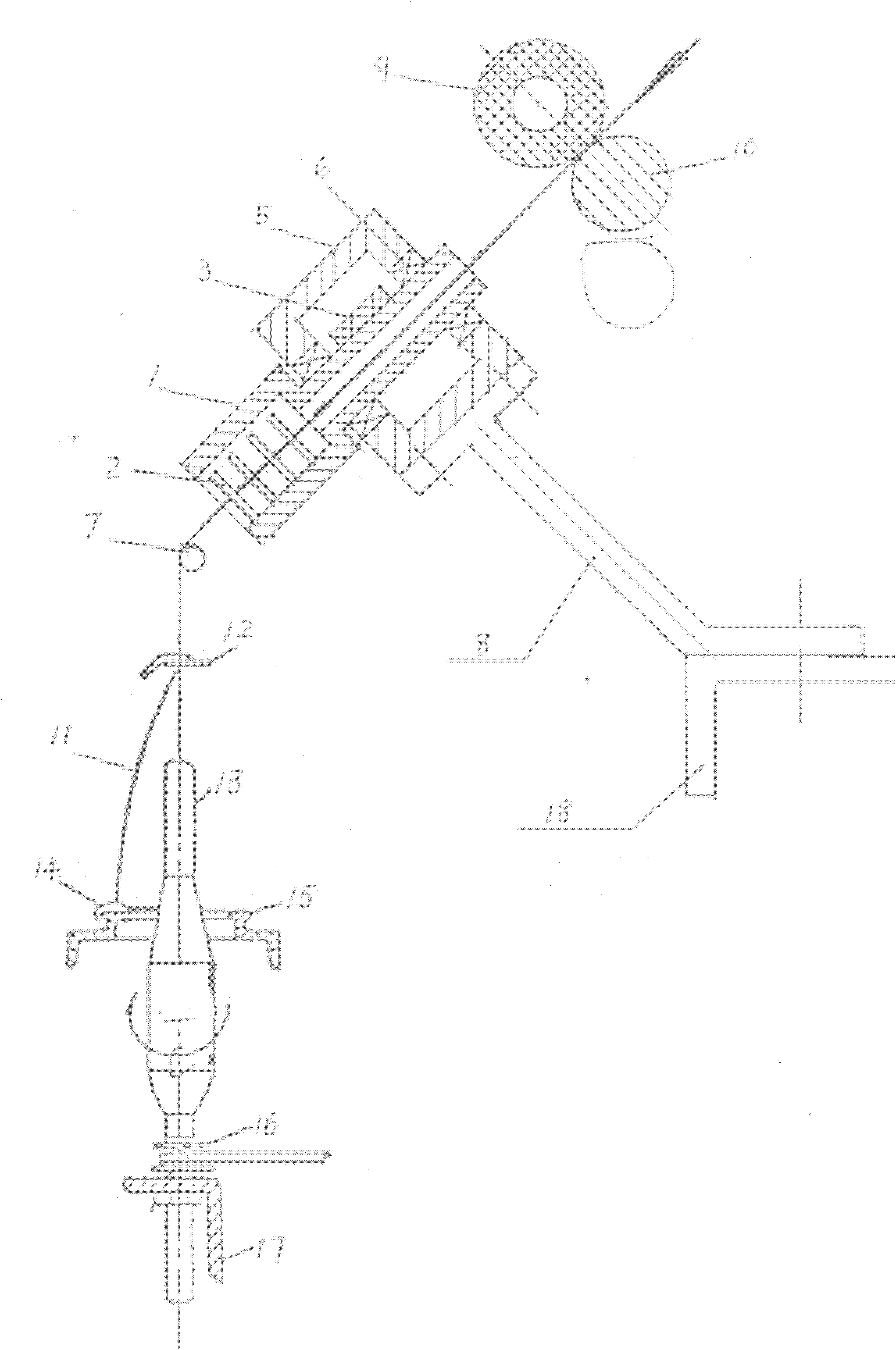

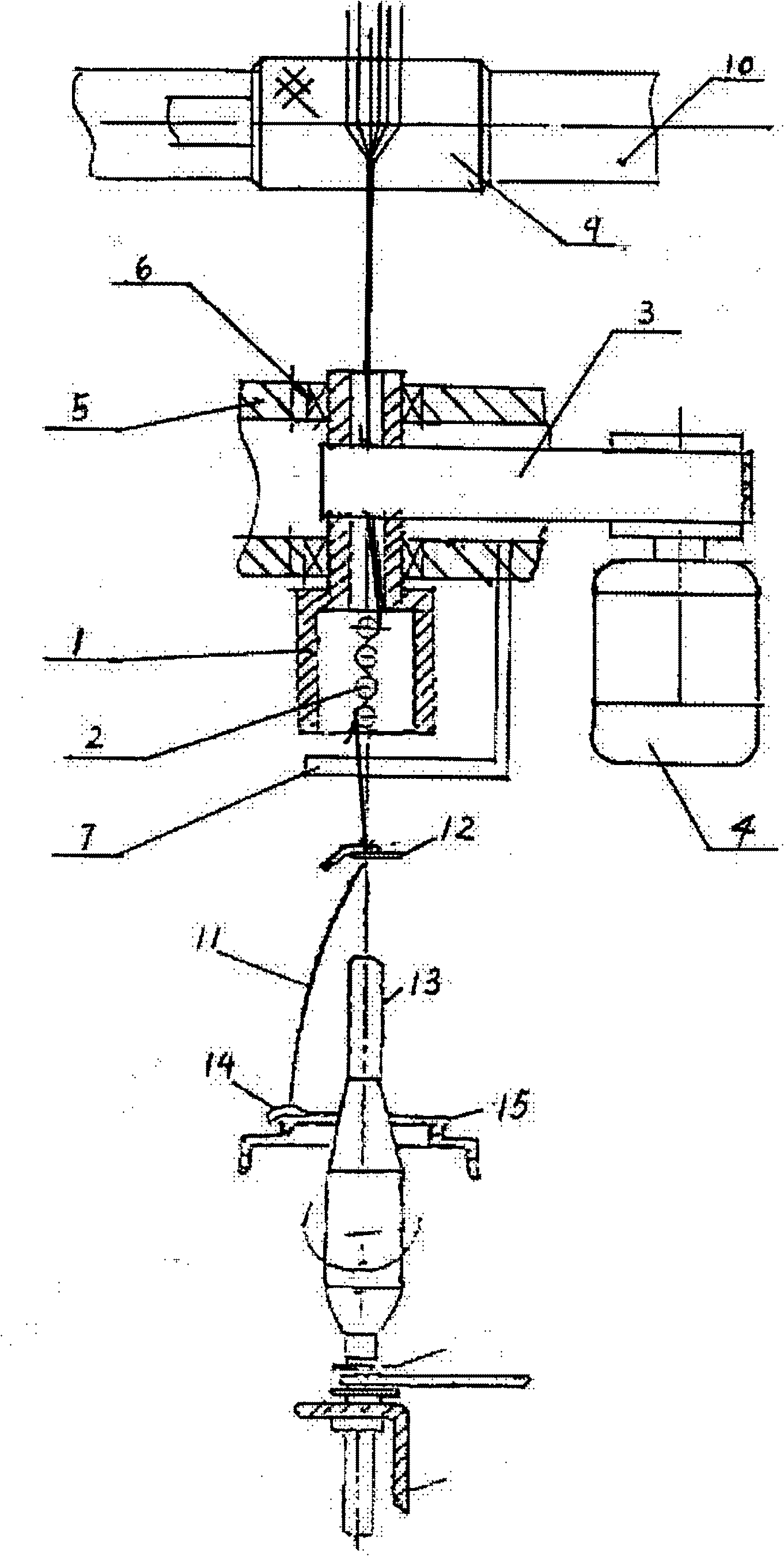

High-tenacity and low-tension spinning device

ActiveCN101892533AHigh strengthReduce spinning tensionDrafting machinesContinuous wound-up machinesEngineeringHardness

The invention relates to a high-tenacity and low-tension spinning device, which is used for ring spinners in textile industry. In the invention, a frame member is arranged along the length direction of a ring spinner in the middle of a spinning section between a front jaw and a yarn guide hook, a false twisting unit arranged corresponding to a spindle is fixed on the two borders of the frame member by two bearings and makes tangential transmission by a driving belt driven by a motor, and a yarn tension damping needle rod is arranged in the false twisting unit. By using the invention, the spinning tenacity is greatly improved, the spinning tension is reduced, and the spinning tension difference of large cop, middle cop and small cop is reduced, thereby realizing low-tension spinning; yarn filoplume is reduced, rubber roller is not wound by fibre frequently, and flyings are reduced, thereby improving spinning environment and spinning quality; heavy twist torsional moment is featured, the device can be applied to yarn with bigger hardness and cruder fibre, fibre material scope is enlarged, and raw material cost is reduced; and installation of the low-tension spinning device keeps the mechanism of the traditional ring spinners unchanged and is fit for modification of ring spinners for cotton / yarn / ramie / silk spinning.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

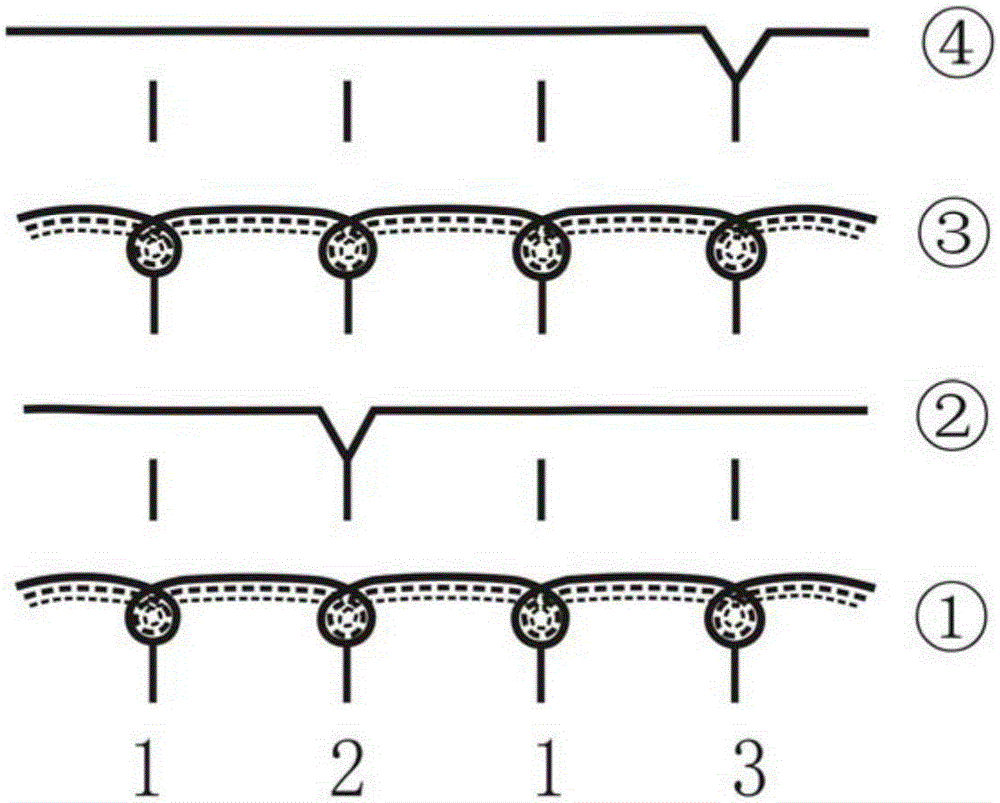

Polysulfonamide core-spun and wrapped composite yarns and conditioning friction tight composite spinning device thereof

The invention relates to polysulfonamide core-spun and wrapped composite yarns produced in the textile industry. Core-spun yarns consist of core yarn polyester yarns and externally-wrapping polysulfonamide fibers, and flame-retardant viscose filaments wrap the core-spun yarns. A conditioning friction tight composite spinning device for the composite yarns comprises a pair of dust cage friction false twisters corresponding to each spinning spindle, wherein a dust cage consists of two thin-wall sleeves and is fixed on an internal air suction pipe; the internal air suction pipe is connected with a main air suction pipe through a rubber pipe; the main air suction pipe is connected with a negative pressure fan; a conditioning groove is formed above the dust cage; a core yarn tensioner and a core yarn bobbin are arranged above a front roller and a front rubber roller; and a wrapped yarn tensioner and a wrapped yarn bobbin are arranged above a yarn guide hook. The invention has the advantages that: the polysulfonamide core-spun and wrapped composite yarns have a unique structure, a few hairs and high strength and can replace the conventional plied yarns, doubling and twisting processes are eliminated, the ration of coarse yarns can be improved by 40 percent compared with that of the conventional process, the tearing strength of the prepared fabric can be improved, and the structure of a ring spinning frame is not changed when the device is adopted.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD +1

Preparing method of high-strength regenerated cellulose fiber

InactiveCN106435799AGood physical and mechanical propertiesSimple processArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthPolymer science

The invention relates to a preparing method of a high-strength regenerated cellulose fiber. The preparing method of the high-strength regenerated cellulose fiber is characterized by comprising the steps of preparing cellulose sulphonate, preparing a spinning solution, spinning, conducting drafting and postprocessing. The preparing method is simple in technology and convenient to carry out. Compared with a traditional regenerated cellulose fiber, the high-strength regenerated cellulose fiber obtained through the preparing method is high in dry and wet strength and has a good spinning property; in addition, physical and mechanical properties of the fiber are excellent, the dry breaking strength is 3.40 CN / dtex or above, the dry elongation at break is 13-16%, the wet breaking strength is 2.0 CN / dtex or above, and the wet breakage modulus is 0.45 CN / dtex or above. The high-strength regenerated cellulose fiber can be applied to textile industries of textile and garment materials, underwear and the like.

Owner:山东银鹰化纤有限公司

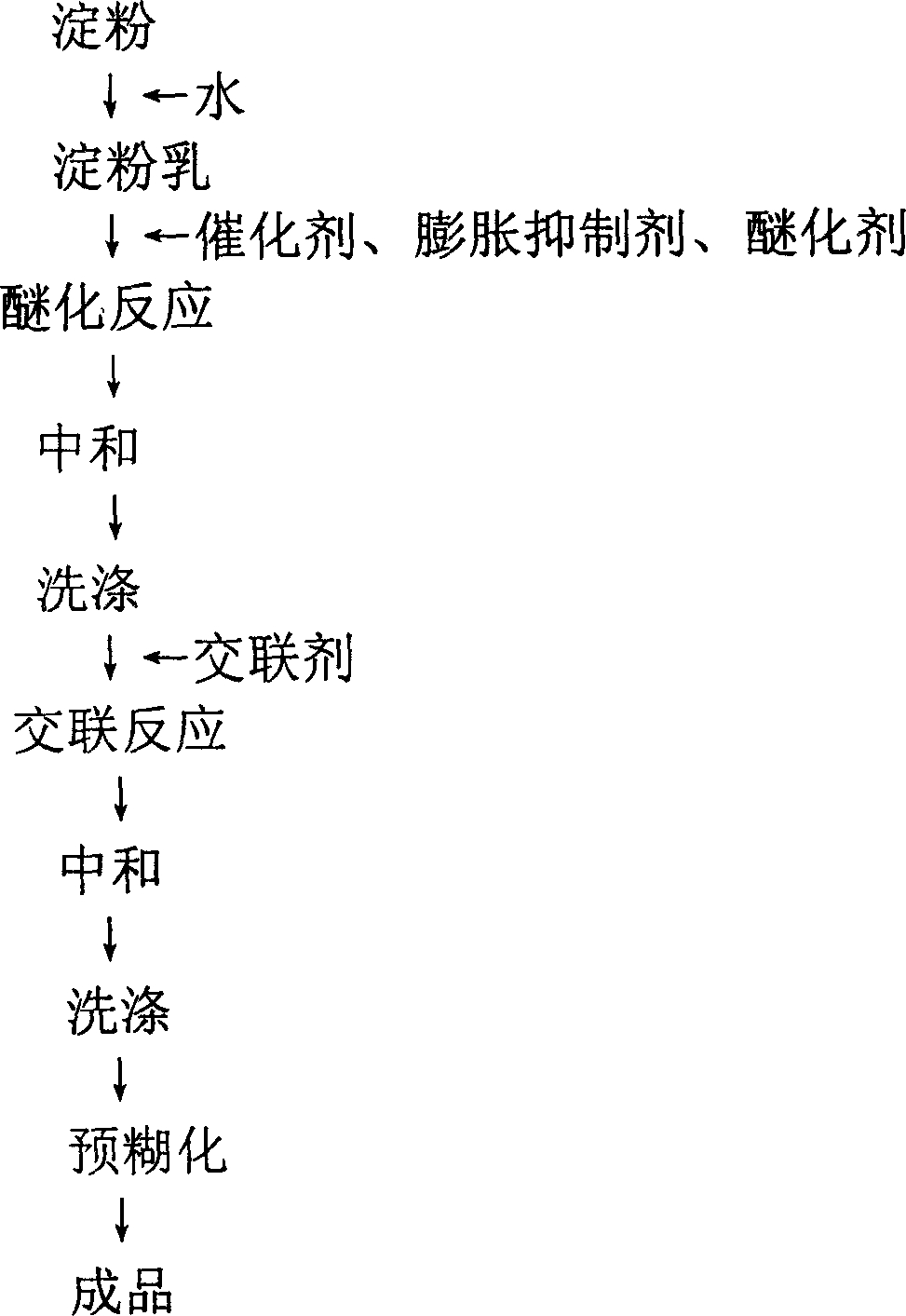

Etherified-cross linked-pregelated ternary composite modified starch, its preparing process and application

The invention discloses an etherified - cross bond - pregelatinized ternary composite modified starch, its preparing process and application, wherein the product is prepared through the simultaneous process of etherification, cross bonding and pre-gelatinization denaturization to the starch, the product can be used for thickening and stabilizing the high acid, high salt and frozen food in food-processing industry, and also as the sizing agent in paper making and textile industry.

Owner:JIANGNAN UNIV

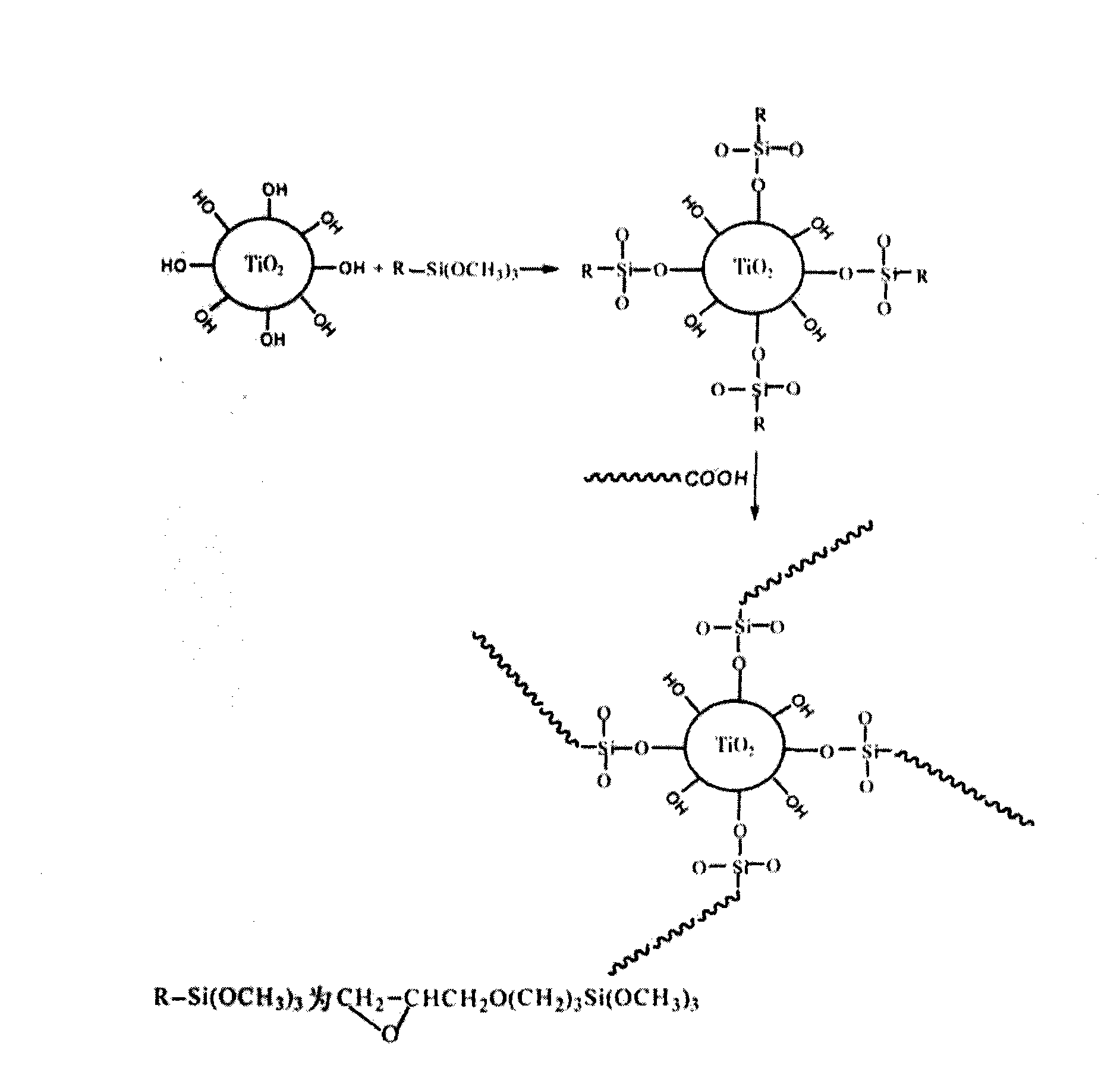

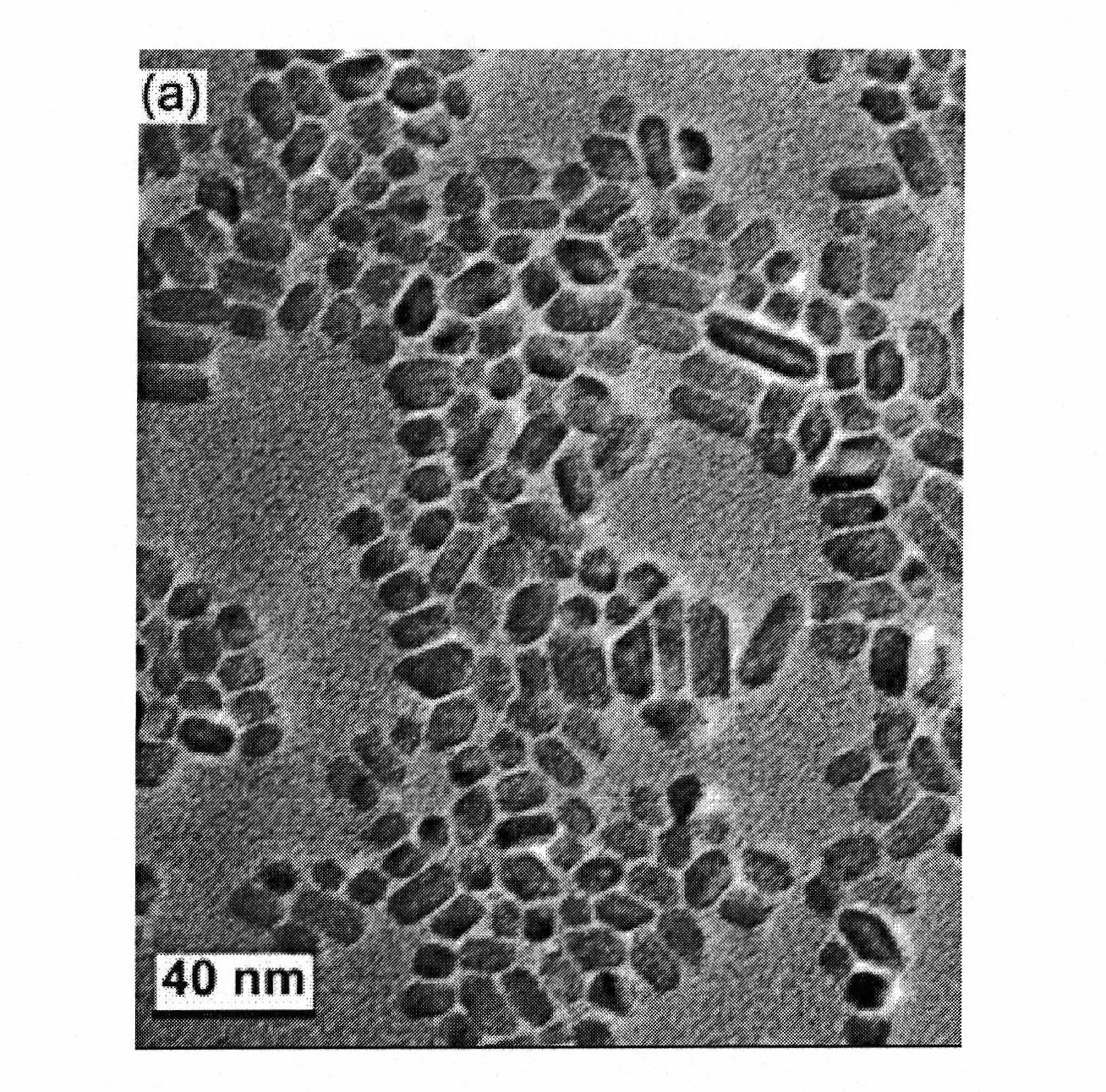

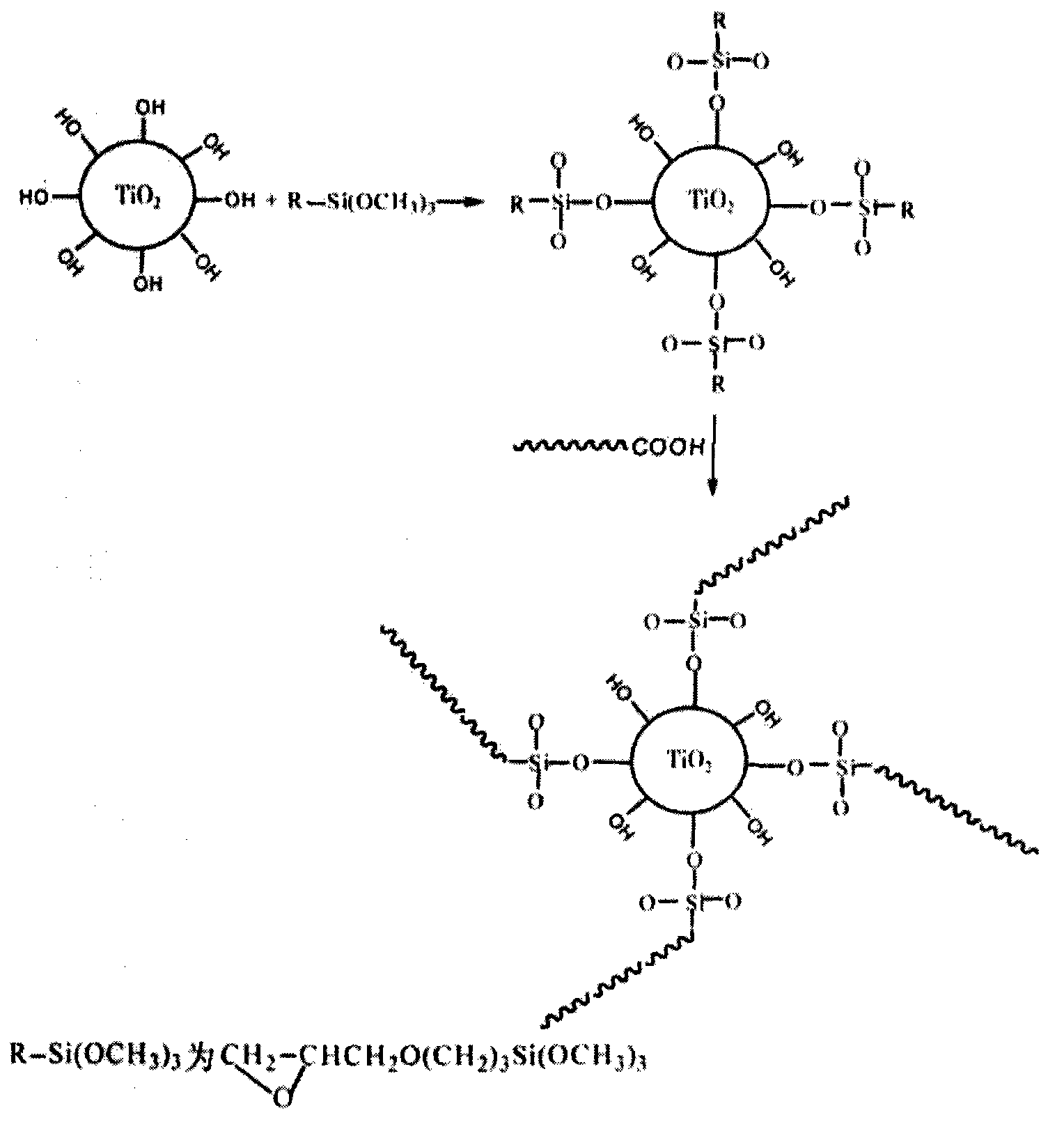

Method for preparing finishing agent of modified nano titanium dioxide coating layer of electromagnetic shielding fabric

InactiveCN101768853AImprove performanceNot easy to reuniteMagnetic/electric field screeningFibre treatmentCross-linkUltraviolet

The invention relates to a method for preparing a finishing agent of a modified nano titanium dioxide coating layer of an electromagnetic shielding fabric. The technical problem of the invention to be solved is that the method for preparing the finishing agent of the modified nano titanium dioxide coating layer of the electromagnetic shielding fabric is provided, so that the electromagnetic shielding fabric has excellent performance of ultraviolet ray resistance, antibacterium, self-cleaning and the like, and the original characteristic of low surface resistance can be maintained at the same time. The technical scheme for solving the problem is that nano TiO2 is modified by a special process, and then the modified nano TiO2 is mixed uniformly with resin and a cross-linking agent according to the proportion, so that the finishing agent of the modified nano titanium dioxide coating layer of the electromagnetic shielding fabric is obtained. The invention can be used for the textile industry of the electromagnetic shielding fabric.

Owner:ZHEJIANG SAINTYEAR ELECTRONICS TECH

Method for conducting wool fabric anti-felting treatment through two-bath process by using imidazolium chloride ionic liquid/protease

InactiveCN101781852AReduced felt shrinkageSolve pollutionBiochemical fibre treatmentAnimal fibresYarnSwelling capacity

The invention relates to a method for conducting wool textile anti-felting treatment through a two-bath process by using imidazolium chloride ionic liquid / protease, belonging to the application field of wool fabric dyeing and finishing in the wool textile industry. The method is characterized in that chloroform / methanol is used to extract impurities on the surface of the fabric first, then the strong dissolving / swelling capacity of the imidazolium chloride ionic liquid is used to modify the surface layer of wool yarn scales and finally protease is used to trim the fabric to obtain the goal of improving the anti-felting effect of the wool fabric treated by using protease. Moreover, the ionic liquid used for pretreatment can be repetitively utilized after the ionic liquid is distilled under reduced pressure, so the environmental pollution is reduced. The invention solves the problems that the anti-felting effect of the wool fabric treated by using the existing single protease is bad and serious pollution is caused by the DCCA / protease anti-felting technology.

Owner:JIANGNAN UNIV

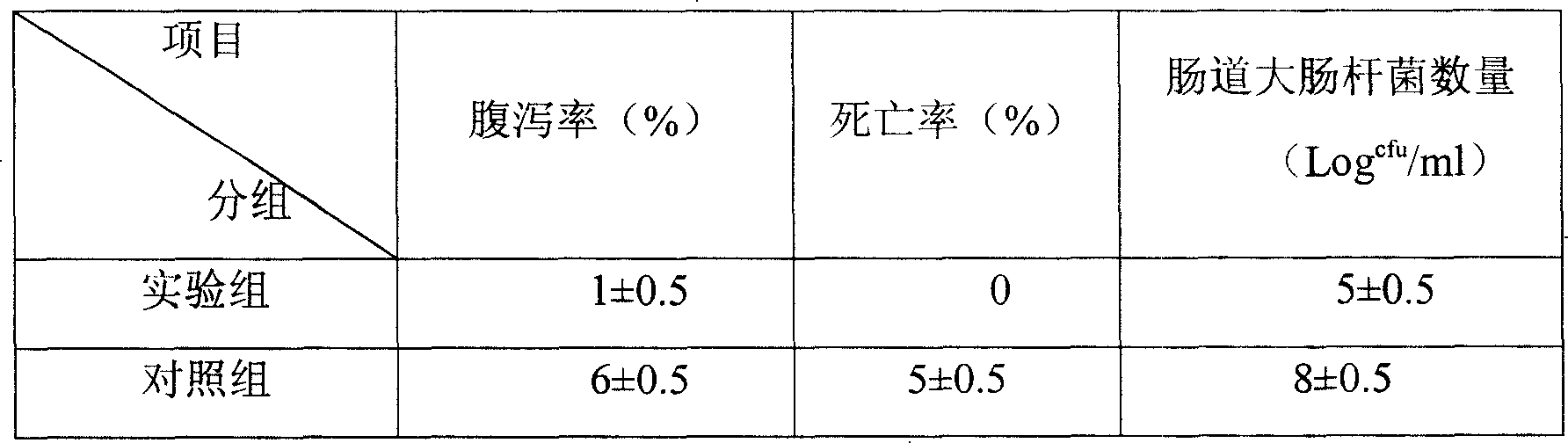

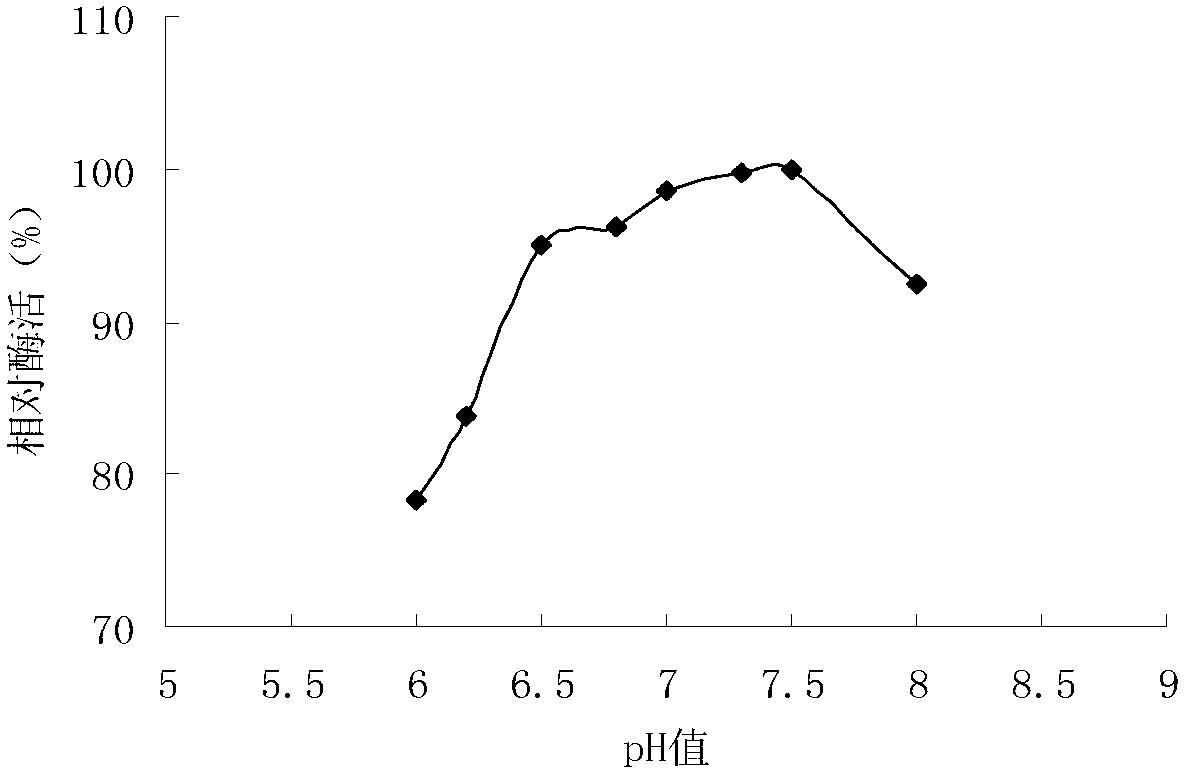

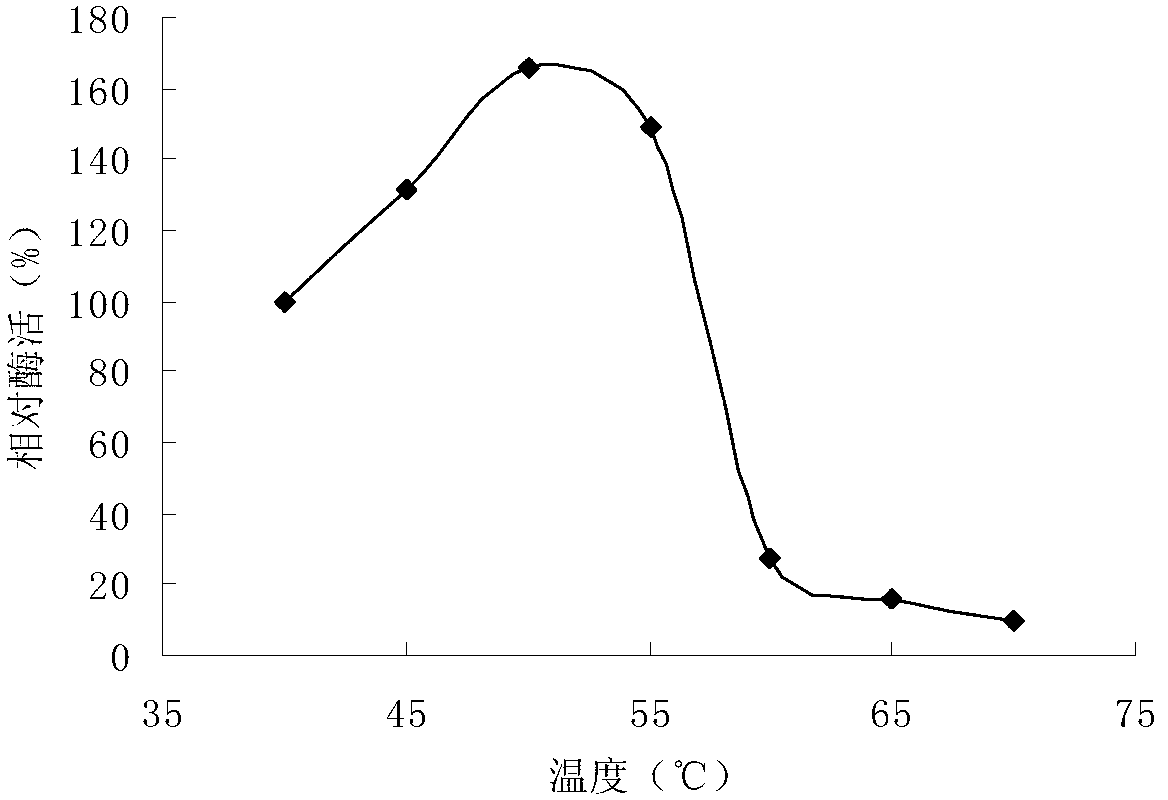

Aspergillus oryzae bacterial strain giving high yield of neutral protease and liquid fermentation method thereof

The invention relates to an aspergillus oryzae mutant bacterial strain giving high yield of neutral protease and a liquid fermentation method thereof. The enzymatic activity of the neutral protease produced by the aspergillus oryzae bacterial strain is more than 20,821 u / mL. The liquid fermentation method for the neutral protease by using the aspergillus oryzae mutant bacterial strain CGMCC 6848 comprises the following steps: 1), seed culture; 2), liquid fermentation; and 3), extraction and refining of the neutral protease. According to the liquid fermentation method for the neutral protease, the fermentation activity is 25,000 u / mL, the residual enzyme activity is 91% after the produced neutral protease is subjected to heat preservation at the temperature of 40 DEG C for 1h, and the aspergillus oryzae mutant bacterial strain has good heat resistance and can be applied widely in industries such as the food industry, the feed industry and the textile industry.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Method for dying cotton fiber by utilizing tea vegetable dye

ActiveCN101956334AHas antibacterial effectHigh color fastnessDyeing processVegetal fibresFiberSocial benefits

The invention provides a method for dying cotton fiber by utilizing tea vegetable dye. In the method, natural tea vegetable dye is extracted from fresh tea leaves, and is utilized to dye cotton fiber by different mordanting methods. After being dyed by the method the invention, the cotton fiber has the advantages of good dyeing color fastness, more color spectrums and good bacteriostatic effect. Through the method, multiple colors can be dyed, the color and lustre are soft, archaic and natural, thus people can feel natural and healthy; the dyed cotton fiber has the characteristics of good dyeing fastness, washing and wear resistance, strong repeatability and uniform dyeing; the existing dyeing equipment is used to dye directly without adding equipment and increasing cost; the method is environmentally friendly and is beneficial to human health; and the method can be applied to clean production of textile industry and can realize large-scale production. The method can efficiently use resources of summer tea and autumn tea, develop and produce tea-dyeing cotton textiles which are environmentally friendly and have archaic, simple and elegant colors and bacteriostatic effect, and the market prospect is broad, thus being capable of not only generating great economic benefits but also obtaining great social benefits.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI +1

Method for manufacturing high-performance electromagnetic wave shielding fabric

InactiveCN101302719AImprove folding resistanceImprove oxidation discolorationPhysical treatmentMagnetic/electric field screeningSputteringFolding endurance

The invention discloses a production method for a high-efficiency electromagnetic wave shielding fabric in the production of textile industries, comprises the working procedures of vacuum sputtering metallic film plating, chemical metallic film plating and protective layer applying of a fabric substrate, and is characterized in that an applied protective layer takes mixed wave absorbing materials, which comprises acrylic ester paste, carbon powder, ferrite, nano ferrite, titanium dioxide, an organic silicone softening agent and an dispersing agent, the mixed wave absorbing materials are applied onto the surface of a fabric that passes through the vacuum sputtering metallic film plating and the chemical metallic film plating through the ways of extrusion coating with a serum roller, blade coating with a knife or printing coating with a circular screen, and are solidified at high temperature. The invention has the advantages that the high-efficiency electromagnetic wave shielding fabric produced achieves the superimposed effect of electromagnetic wave reflecting and absorbing and plasma activating, improves the electromagnetic wave shielding performance further to be larger than 90 dB, simultaneously raises the combining fastness between a plated film and the fabric substrate, and improves the folding resistance of the product and the oxidative stain property of the metallic film.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com