Light, thin thermal-wet comfort multifunctional knitted fabric and preparation method thereof

A knitted fabric and comfort technology, applied in the field of knitted apparel fabrics, can solve the problems of poor anti-pilling performance, inability to change polyester fibers, and difficulty in the ability of the second yarn to wick and conduct moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

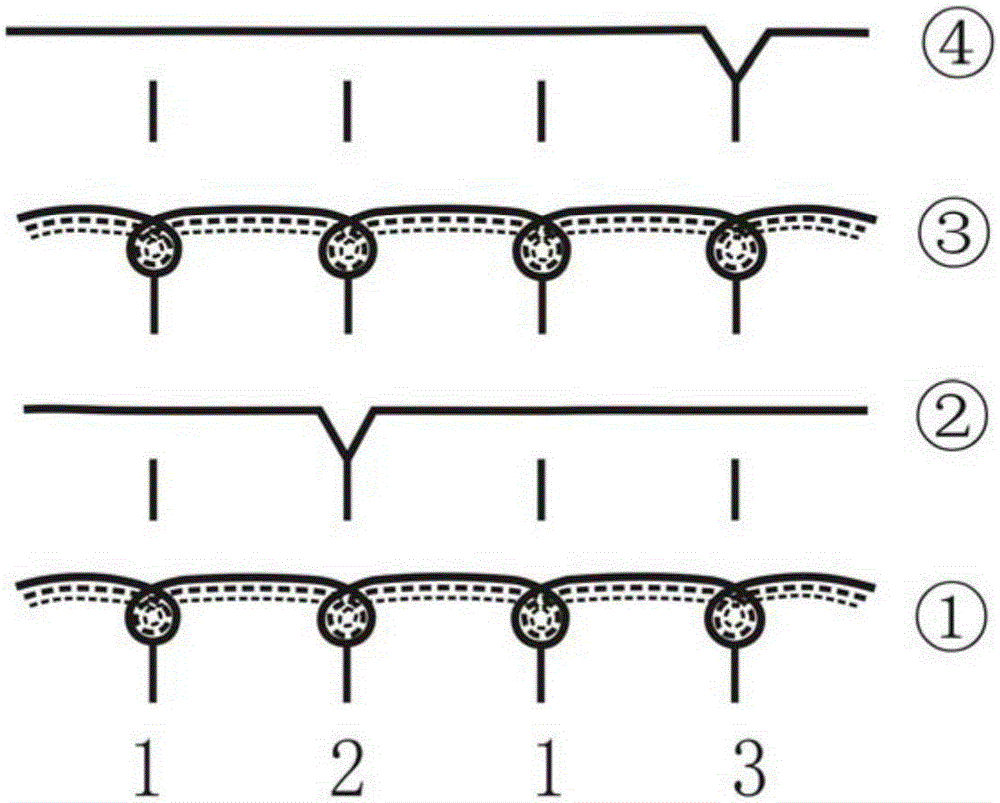

[0061] A lightweight thermal and moisture comfort multifunctional knitted fabric woven from four yarns. The first yarn is J40S Lenzing superfine modal Siro compact spun pure yarn, which is a kind of regenerated cellulose staple yarn; the second yarn is polyester matte air-jet spun yarn produced by Jiangsu Shenghong Chemical Fiber Co., Ltd. Elastic yarn 50D / 72F is a polyester fiber yarn with ultra-fine denier; the third yarn is 30D air-jet spinning spandex yarn produced by Korea Co., Ltd. Hyosung Spandex (Jiaxing) Co., Ltd., which is a polyurethane fiber yarn ; The fourth yarn is J32S cotton ring-spun combed yarn.

[0062] J40S Lenzing ultra-fine modal siro compact spinning pure spinning yarn converted into tex number is 590.5÷40=14.76tex, ultra-fine denier polyester fiber low elastic yarn 50D / 72F converted into tex number is 50÷ 9=5.56 tex, the linear density of the first yarn is 14.76÷5.56=2.65 times that of the second yarn.

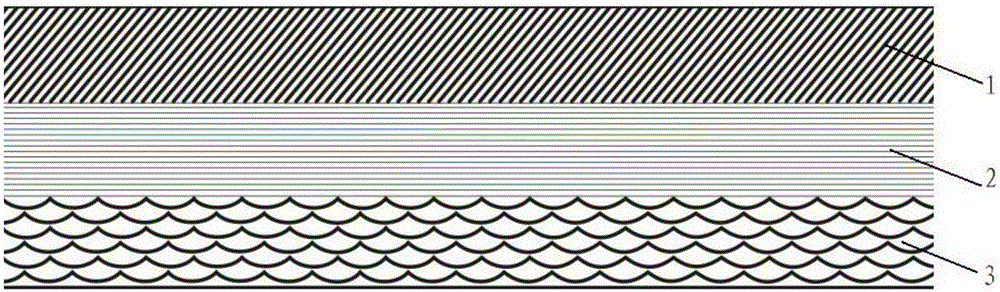

[0063] The fabric structure is as figure 1 As ...

Embodiment 2

[0081] A lightweight thermal and moisture comfort multifunctional knitted fabric woven from four yarns. The first yarn is J60S60% Lenzing superfine modal 40% long-staple cotton siro compact blended yarn, which is a regenerated cellulose fiber blended yarn; the second yarn is provided by Changzhou Guoxing Special Chemical Fiber Co., Ltd. The 50D / 72F fine denier antibacterial polypropylene low elastic yarn is a kind of fine denier polypropylene fiber yarn endowed with antibacterial function; the third yarn is 30D wrapping yarn ROICA produced by Japan Asahi Kasei Co., Ltd., which is a low temperature thermal Melt polyurethane fiber yarn; the fourth yarn is J40S70% combed cotton 30% milk protein fiber ring spinning combed blended yarn, in which 30% milk protein fiber is a kind of milk casein grafted with linear macromolecular structure polyacrylonitrile fibers.

[0082] J60S60% Lenzing superfine modal 40% long-staple cotton siro compact blended yarn converted into tex number is 5...

Embodiment 3

[0101] A lightweight thermal and moisture comfort multifunctional knitted fabric woven from four yarns. The first yarn is J60S70% Lenzing superfine viscose 30% fine linen siro compact blended yarn, which is a regenerated cellulose fiber blended yarn; the second yarn is Guangdong Xinhui Meida Nylon Co., Ltd. Dashuanglun 40D / 48F provided by the company, after vacuum sputtering nano-silver treatment, is a cross-section high moisture absorption and perspiration polyamide fiber yarn endowed with radiation protection function; the third yarn is INVISTA fiber 30D polyurethane fiber yarn produced by (Shanghai) Co., Ltd.; the fourth yarn is J40S70% combed cotton 30% SUPERCOOL ring-spun combed blended yarn, of which 30% SUPERCOOL is provided by Shanghai Guida Technology Co., Ltd. The utility model relates to a polyester staple fiber grafted with a Y-shaped cross-section of a hydrophilic group.

[0102] J60S70% Lenzing superfine viscose 30% fine linen siro compact blended yarn converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com