Patents

Literature

144results about How to "Good anti-pilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

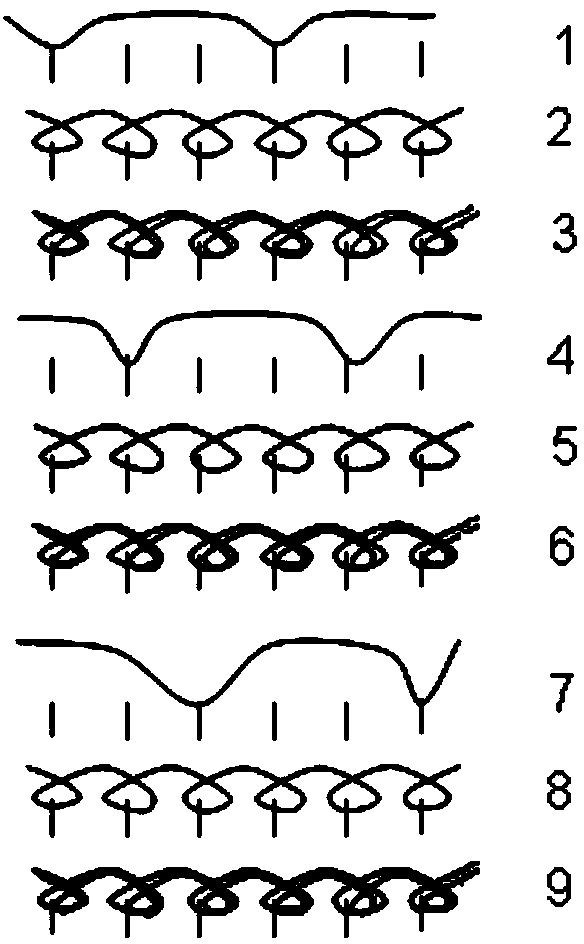

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

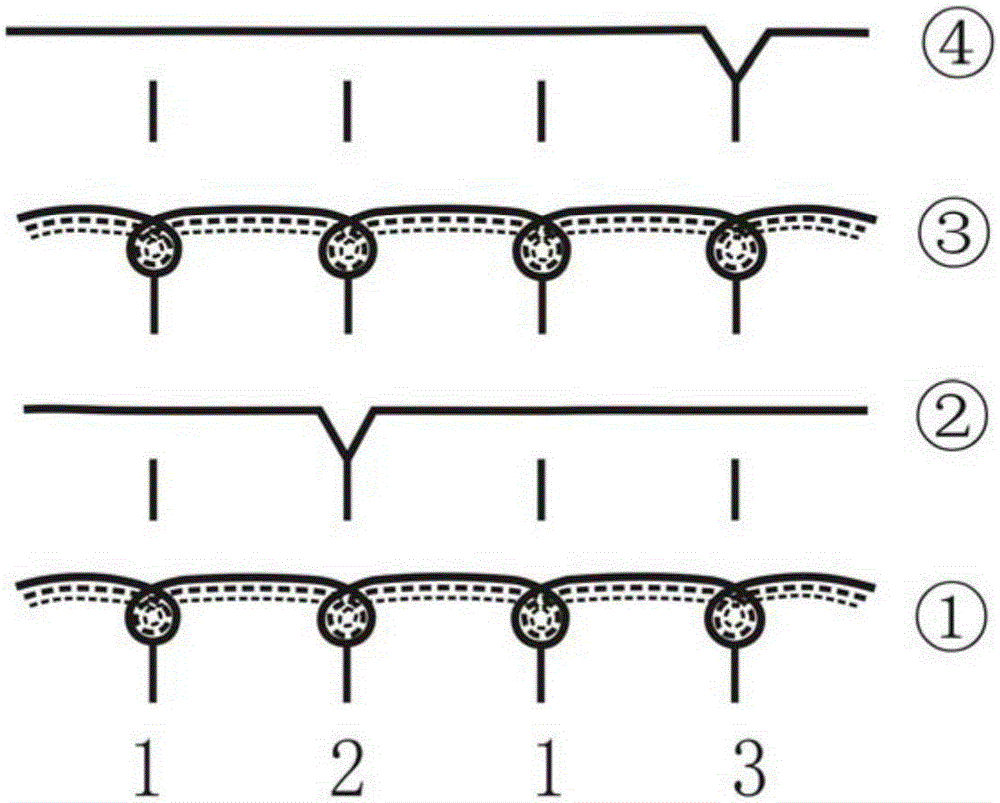

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

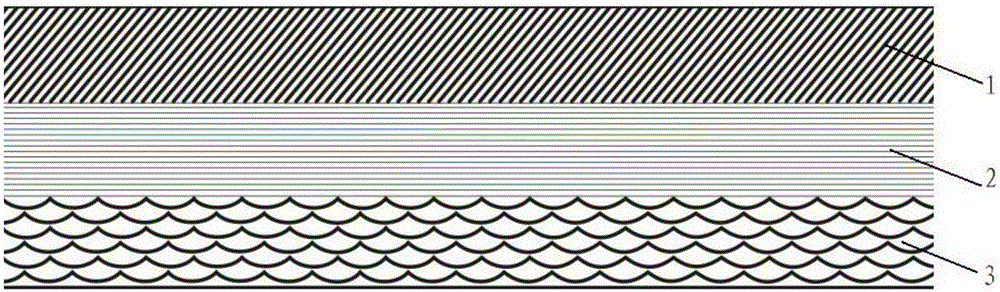

Light, thin thermal-wet comfort multifunctional knitted fabric and preparation method thereof

ActiveCN105220336AGood moisture absorption and heating performanceOne-way moisture guide function is goodWeft knittingDyeing processYarnMoisture absorption

The invention provides light, thin thermal-wet comfort multifunctional knitted fabric and a preparation method thereof. The fabric is formed by weaving first yarn, second yarn, third yarn and fourth yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer. The outer layer is formed by weaving the first yarn. The middle layer is formed by weaving the second yarn and the third yarn. The inner layer is formed by weaving the fourth yarn. The moisture-absorption and heat-generating heating up value of the fabric meets the standard requirements in the textile industry, moisture adsorption performance, quick drying performance, comprehensive sweat-discharge quick drying performance and other indexes meet values required by national standards before and after the fabric is washed, and the heat-preserving rate index meets the values required by the national standards; meanwhile, the fabric has a good moisture retention function, moisture needed by human skin is locked, and human skin aging can be effectively relieved.

Owner:武汉爱帝针纺实业有限公司

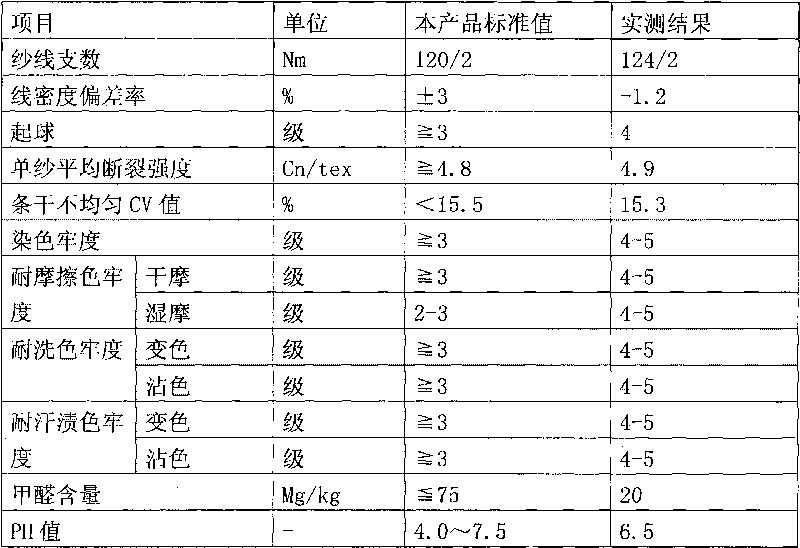

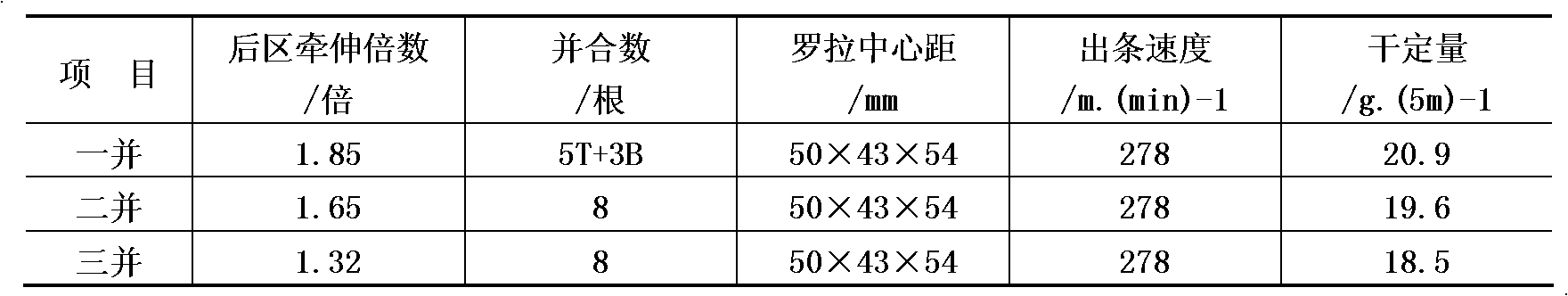

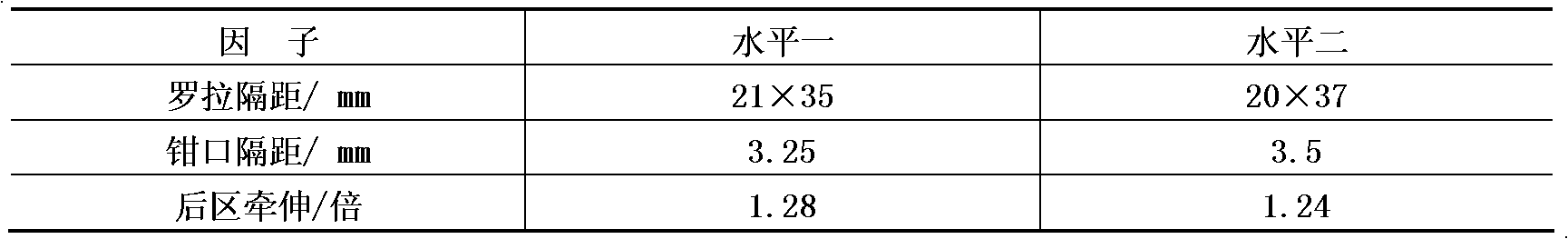

Superfine wool yarn and manufacturing method thereof

InactiveCN101709522AGood anti-pillingImprove effective controlDrafting machinesYarnInternational standardEngineering

The invention discloses a superfine wool yarn and a manufacturing method thereof. The superfine wool yarn comprises 100-120Nm / 2 of yarn counts, 1050-1200t / m of single twist with a twist direction of Z and 480-550t / m of plied twist with a twist direction of S. The manufacturing method comprises the process steps of wool top recombing, primary silver mixing, secondary silver mixing, quartic gilling, triple roving, spun yarn, spooling, doubling, two-for-one twisting, reeling silk, checking and the like. In the invention, raw materials of the superfine wool are selected, and the reasonable yarn counts and the twist are determined at the same time. By adopting some special measures on the spinning process and optimizing the technological parameters, the excellent and low-consumption superfine wool yarn with the yarn counts of 120Nm / 2, and the yarn levelness of less than 15 percent and anti-pilling of more than or equal to the third level is successfully manufactured; and the number of the cross-section fibers of the fine yarn is only 28, which is far lower than the limit of the number of 36 in the international standard. The invention not only provides a new yarn product with excellent quality and high cost performance, but also provides a beneficial spinning method for sufficiently utilizing and reasonably developing tight wool resources.

Owner:ZHEJIANG ZHONGXIN WOOL TEXTILE

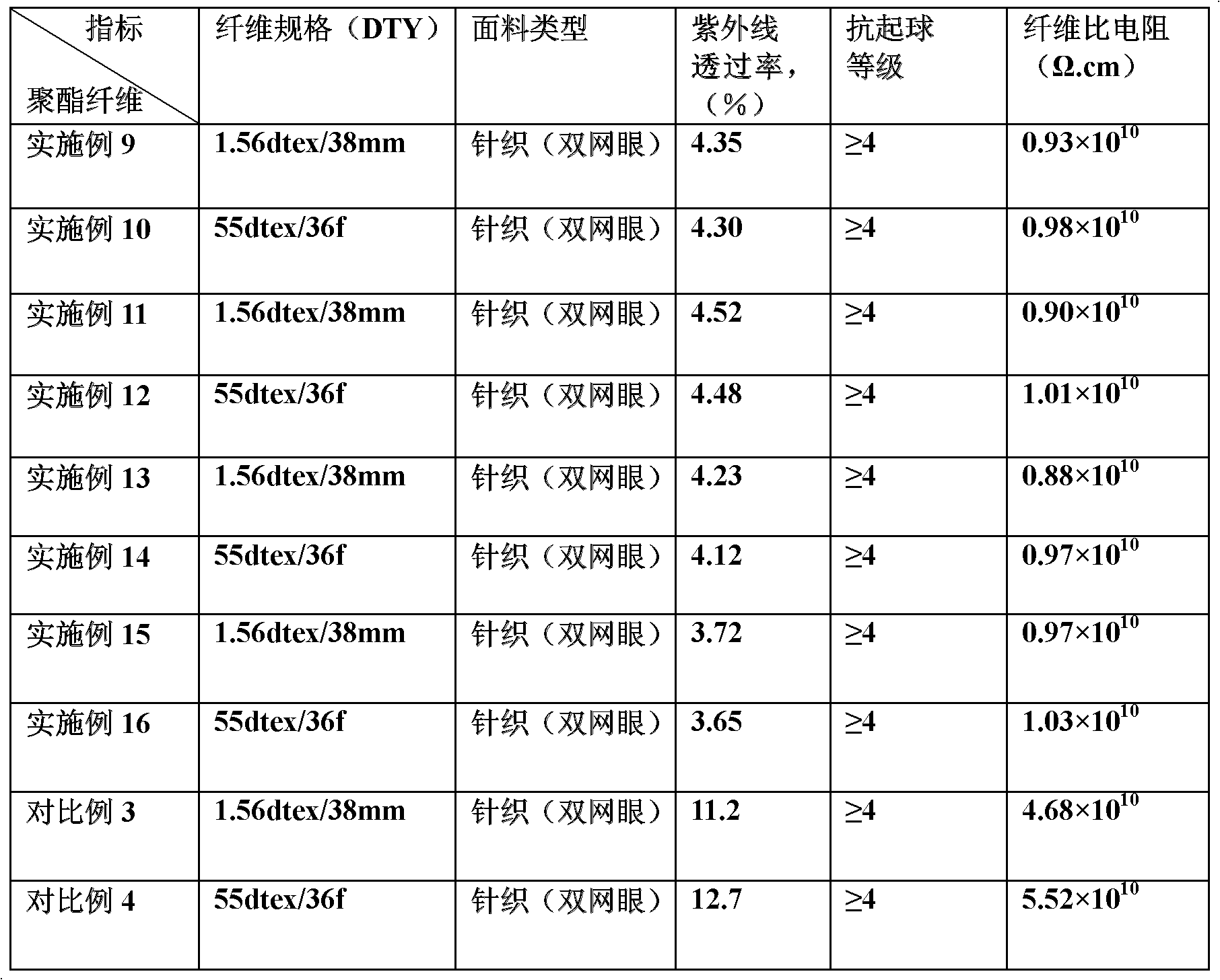

Method for treating anti-lousiness-pilling for cashmere fabric

InactiveCN1508352AGood anti-pillingImprove anti-pilling performancePhysical treatmentWastewaterEngineering

The invention relates to a processing method to resist the fluffing and pilling of pashm textile. It places the pashm textile in low-temperature plasm processing cavity, then pumps the pressure in the processing cavity to lower than or equal to 10Pa, inputs non-polymeric gas to adjust the pressure in the processing cavity to 10-20Pa and exerts voltage on electrodes to make low-temperature plasm processing for 10-600s under 10-200W power to obtain excellent finished product. It can further make softened finish, shrinkproof finish or other functional finishes on the processed pashm textile.

Owner:INST OF CHEM CHINESE ACAD OF SCI

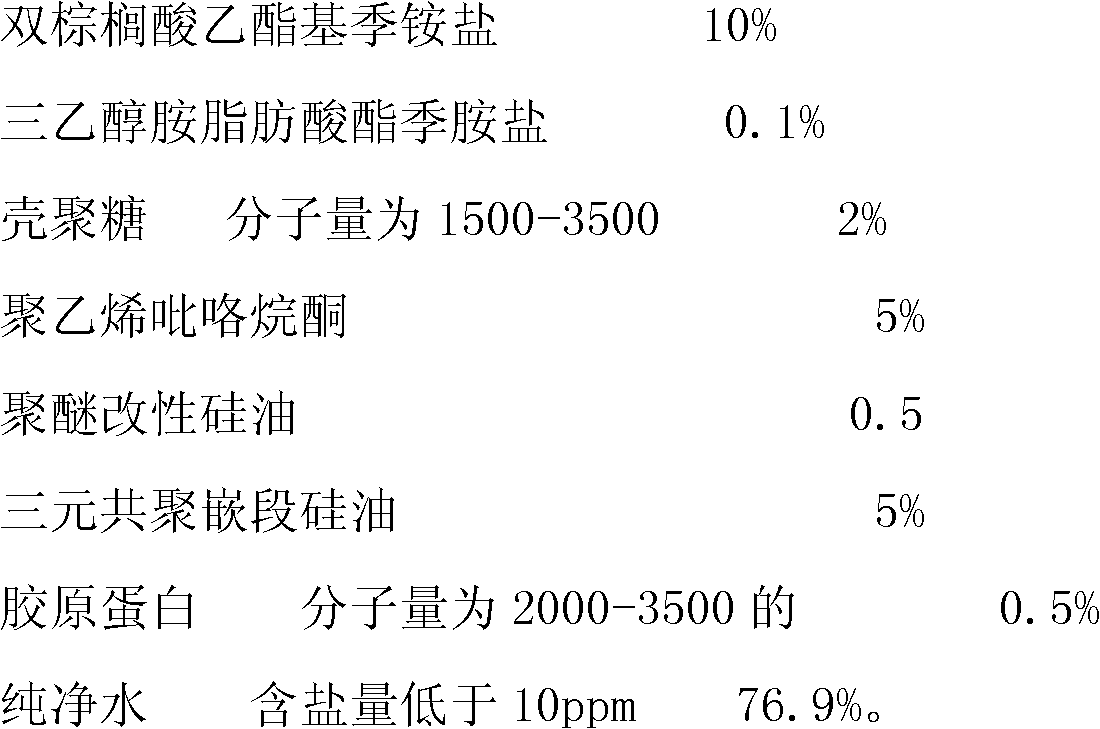

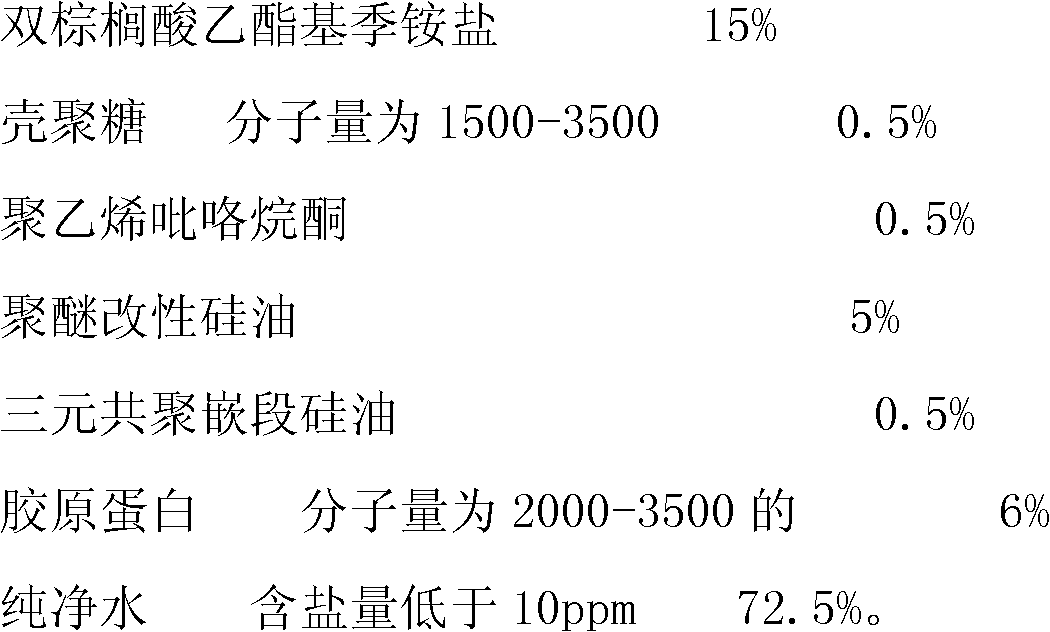

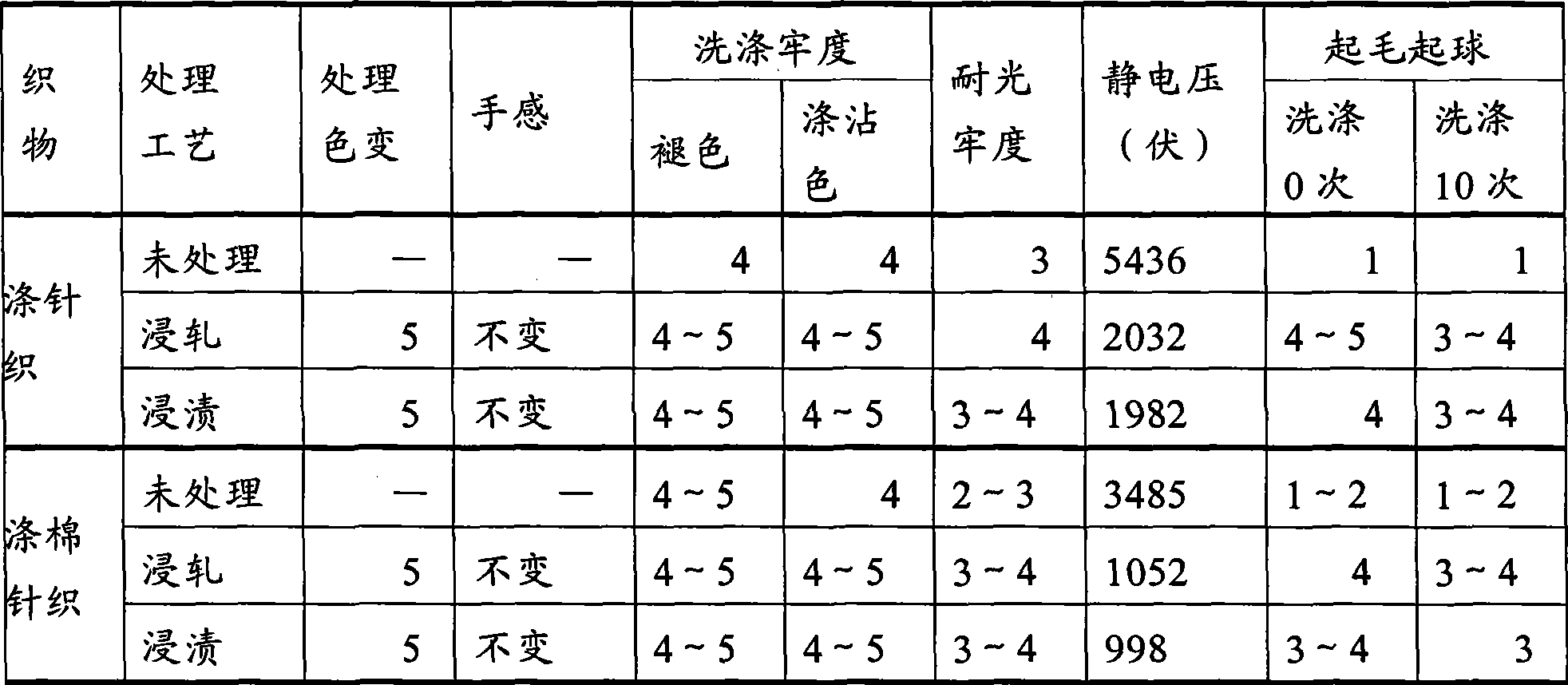

Softening agent capable of improving sublimation fastness of disperse dye and wet friction fastness of reactive dye

The invention relates to the field of textile dyeing of polyester and dark fabrics such as blended fabrics, pure cotton, adhesives and hemp, in particular to a softening agent capable of improving the sublimation fastness of a disperse dye and the wet friction fastness of a reactive dye. The softening agent is characterized by mainly comprising the following raw materials in percentage by weight: bi-ethyl palmitate based quaternary ammonium salt, triethanolamine fatty acid ester quaternary ammonium salt, chitosan, polyvinyl pyrrolidone, polyether modified silicone oil, ternary polymerization block silicon oil, collagen and purified water. Compared with the prior art, the softening agent has the advantages that the sublimation fastness of the disperse dye can be improved by 0.5 to 1 grade and the wet friction fastness of the reactive dye can be improved by 0.5 grade after the sizing of a dyed fabric; and simultaneously, the neatened fabric is endowed with elastic and exquisite handfeel, so that the fabric is high in pollution resistance, dust resistance, shrinkage resistance, pilling resistance and static electricity resistance.

Owner:祝洪哲

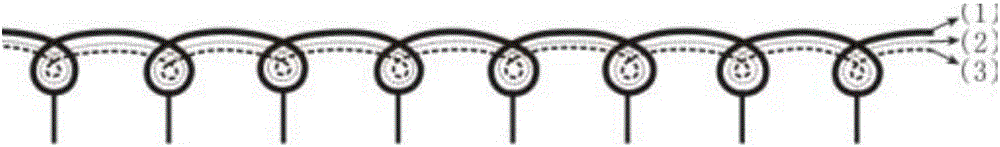

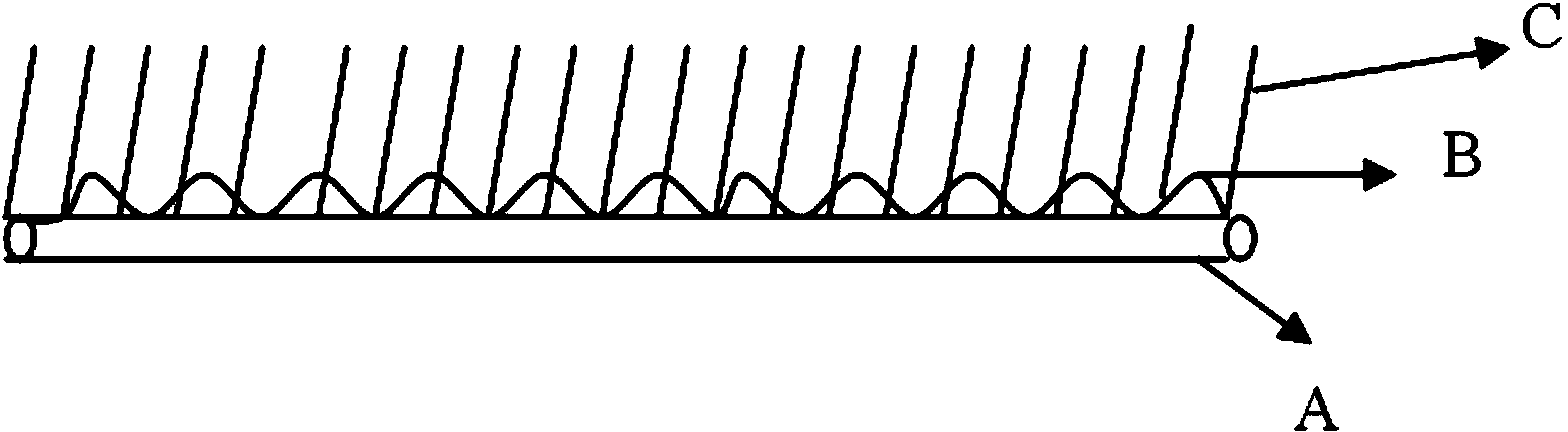

High-elastic warming gigging knitted fabric and manufacturing method thereof

The invention provides high-elastic warming gigging knitted fabric and a manufacturing method thereof. The high-elastic warming gigging knitted fabric comprises three layers, the first layer is a flat weft plain stitch layer, the intermediate reinforcing layer is wavy, and the gigging layer is shaped in fluffy polar fleece. The fabric is knitted by chinlon filaments, naked spandex filaments and polyester filaments. Elasticity of the fabric is improved and production cost is reduced by an independent naked spandex filament feeding method. Loops of a gigging surface of the fabric are lengthened, the fabric has excellent extensibility and fluffy sense of the fabric is improved. The chinlon filaments are used for the surface layer of the fabric, and pilling resistance is better. Furthermore, a weft-knitting loop knitting machine is adopted in the manufacturing method, gram weight of the fabric can be controlled better, and the manufactured fabric is more uniform.

Owner:NINGBO DAQIAN TEXTILE

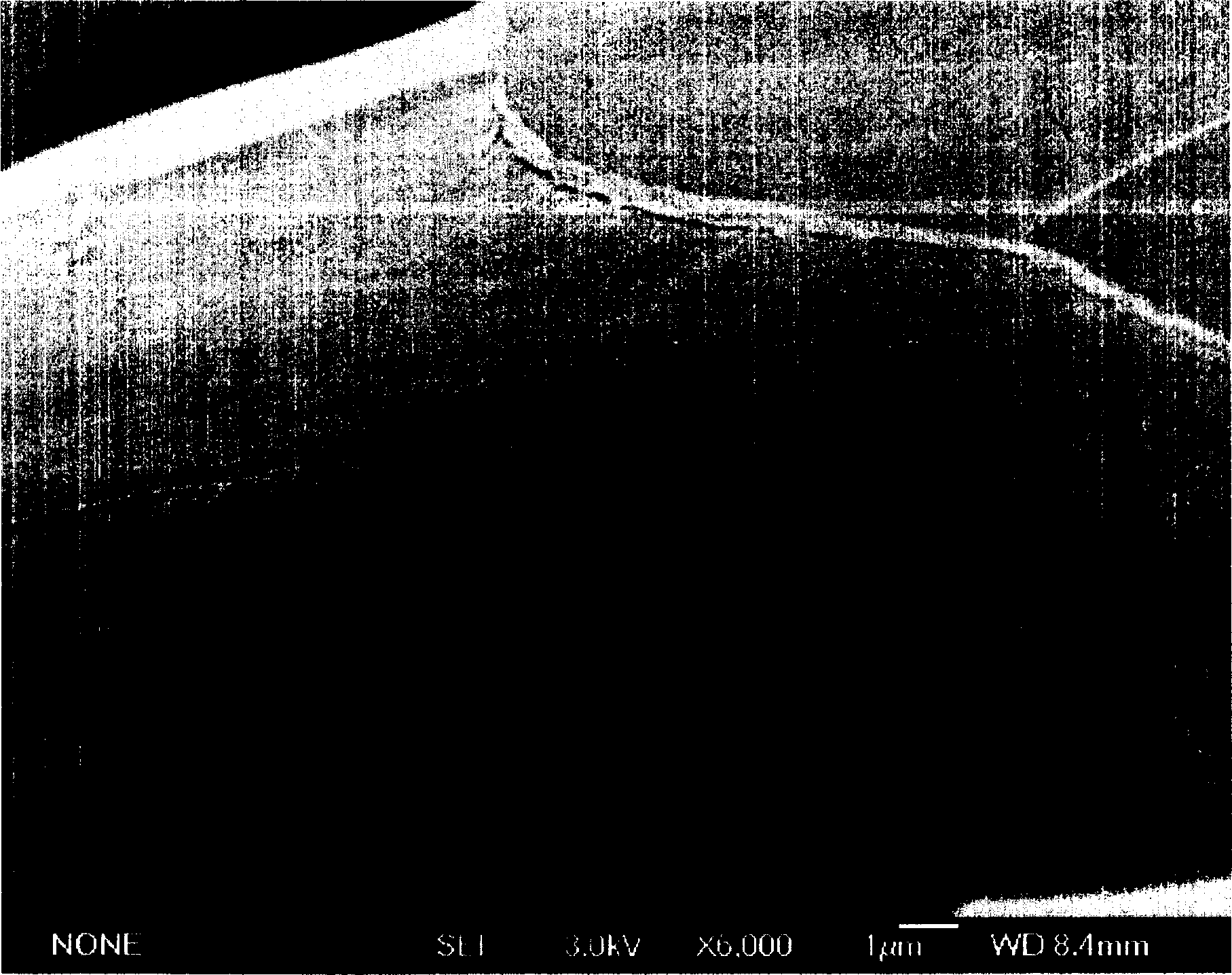

No-fluff wool fabric of fiber with surface nano structure and its prepn

InactiveCN1548643ALarge specific surface areaImprove cohesionUltrasonic/sonic fibre treatmentWastewaterLow temperature plasma

The present invention belongs to the field of functional fabric, and is especially no-fluff wool fabric of fiber with surface nano structure and its preparation. After wool fabric is set inside low temperature plasma processing cavity, the pressure inside the cavity is first pumped to not higher than 10 Pa and then regulated with introduced non-polymerizing gas to 10-170 Pa and the wool fabric is discharged for low temperature plasma processing at power of 10-300 w for 1-60 min, so as to form nano level embossed structure in the surface of wool fiber, to produce hydrophilic radical in the surface of wool fiber for fast escape of water and to obtain wool fiber with excellent fluff resisting performance. The wool fabric through the low temperature plasma processing may be further finished via softening, etc.

Owner:中科纳米技术工程中心有限公司

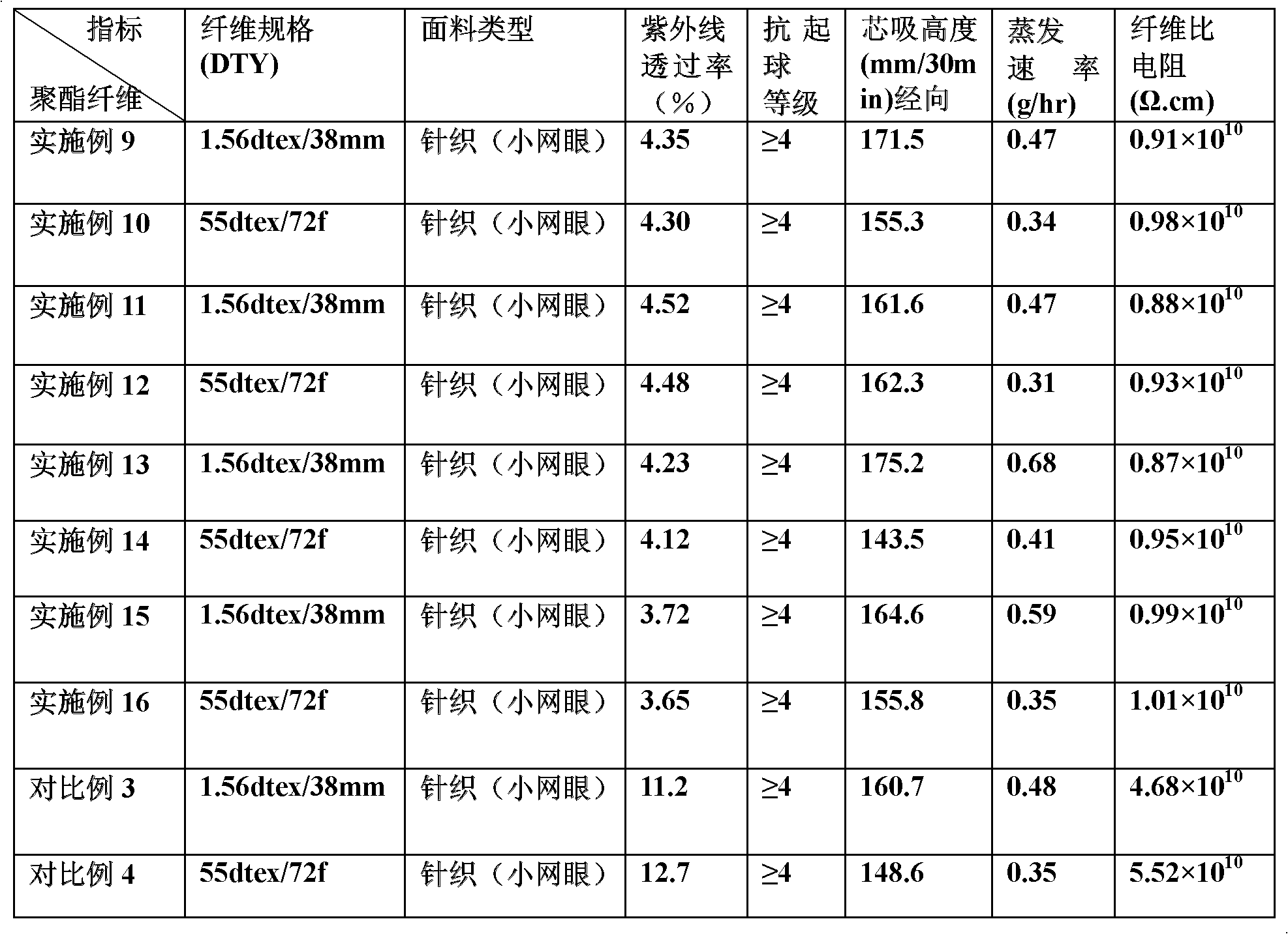

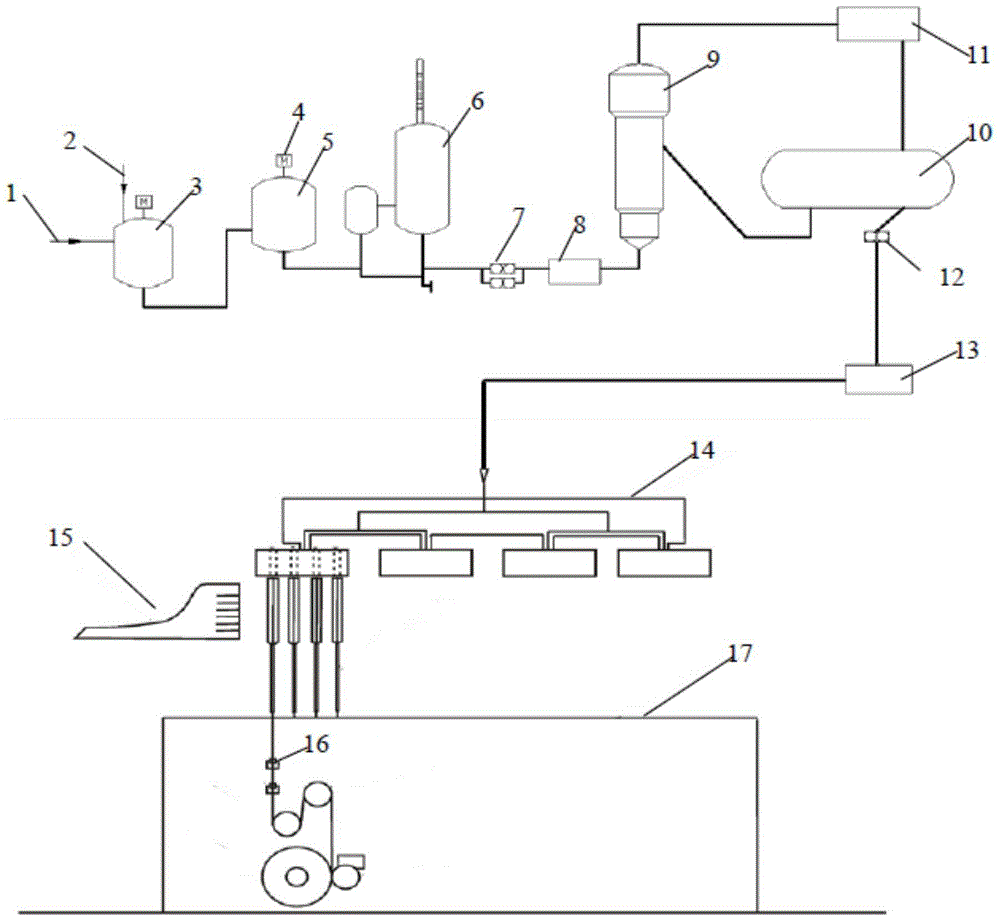

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

Anti-fuzzing and anti-pilling finishing agent for fabric

The invention relates to an auxiliary agent in the printing and dyeing industry, in particular to a surface finishing auxiliary agent for fabric. An anti-pilling finishing agent for the fabric is nonionic macromolecular polymer, and is characterized in that the anti-pilling finishing agent for the fabric is formed by copolymerizing 10 to 20 portions of high-hydro silicone oil, 30 to 50 portions of polyurethane prepolymer and 30 to 50 portions of polypropylene ester copolymer under the conditions of catalyst and heating; and the portion is weight portion. The fabric anti-pilling finishing agent is suitable for various fibers and fabrics; and in particular, polyester fabric treated by the anti-pilling finishing agent has basically unchanged tone and handfeel, improves the fastness to washing and light fastness, greatly improves the antistatic performance, has certain dust resistance and obviously improves the anti-pilling performance.

Owner:上海德桑精细化工有限公司

Sirospun yarn and spinning method thereof

The invention discloses a sirospun yarn and a spinning method thereof. The yarn consists of 25-35 wt% of coffee carbon fiber, 25-35 wt% of bamboo-carbon fiber and 30-40 wt% of cotton fiber, wherein the fibers are spun into the yarn through a siro spinning process. The spinning method sequentially comprises a loose fiber dyeing process, a cotton carding process, a drawing process, a roving process, a fine yarn siro spinning process and a spooling process. The yarn is formed by blending various fibers, the characteristics of each fiber are highlighted by reasonably setting the weight proportion of each fiber, the advantages of various fibers are integrated, the basic performance of the yarn is kept, the propagation of bacteria is restrained, the release of odor ammonia is reduced, and peculiar smell of alcohol, tobacco and the like can also be effectively removed. Compared with the conventional spinning process, the sirospun yarn disclosed by the invention has less hairness than the ordinary ring spun yarn, particularly the long hairness longer than 3mm is well improved, the method has greater advantages in size dyeing, weaving, singeing and other processes, and the woven fabric has a good wear-resisting property, a good anti-pilling performance and better surface handfeel and softness.

Owner:JIANGNAN UNIV +1

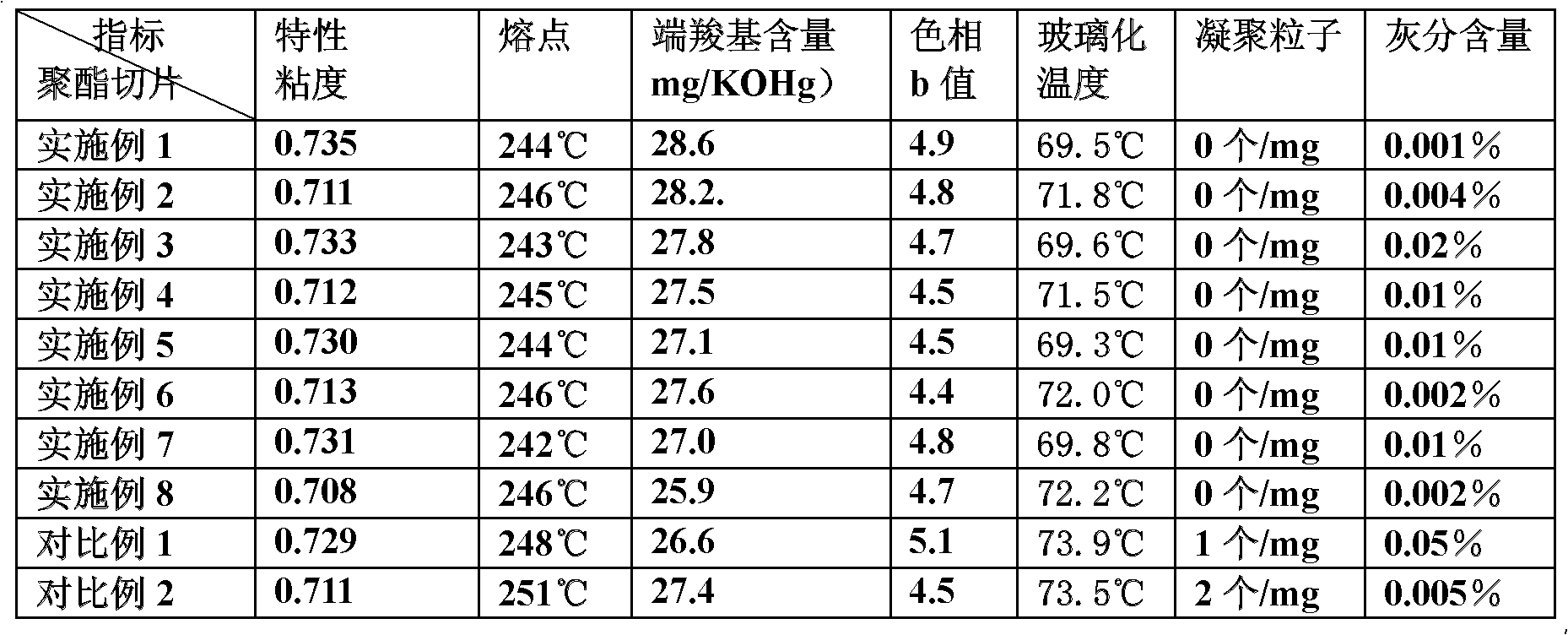

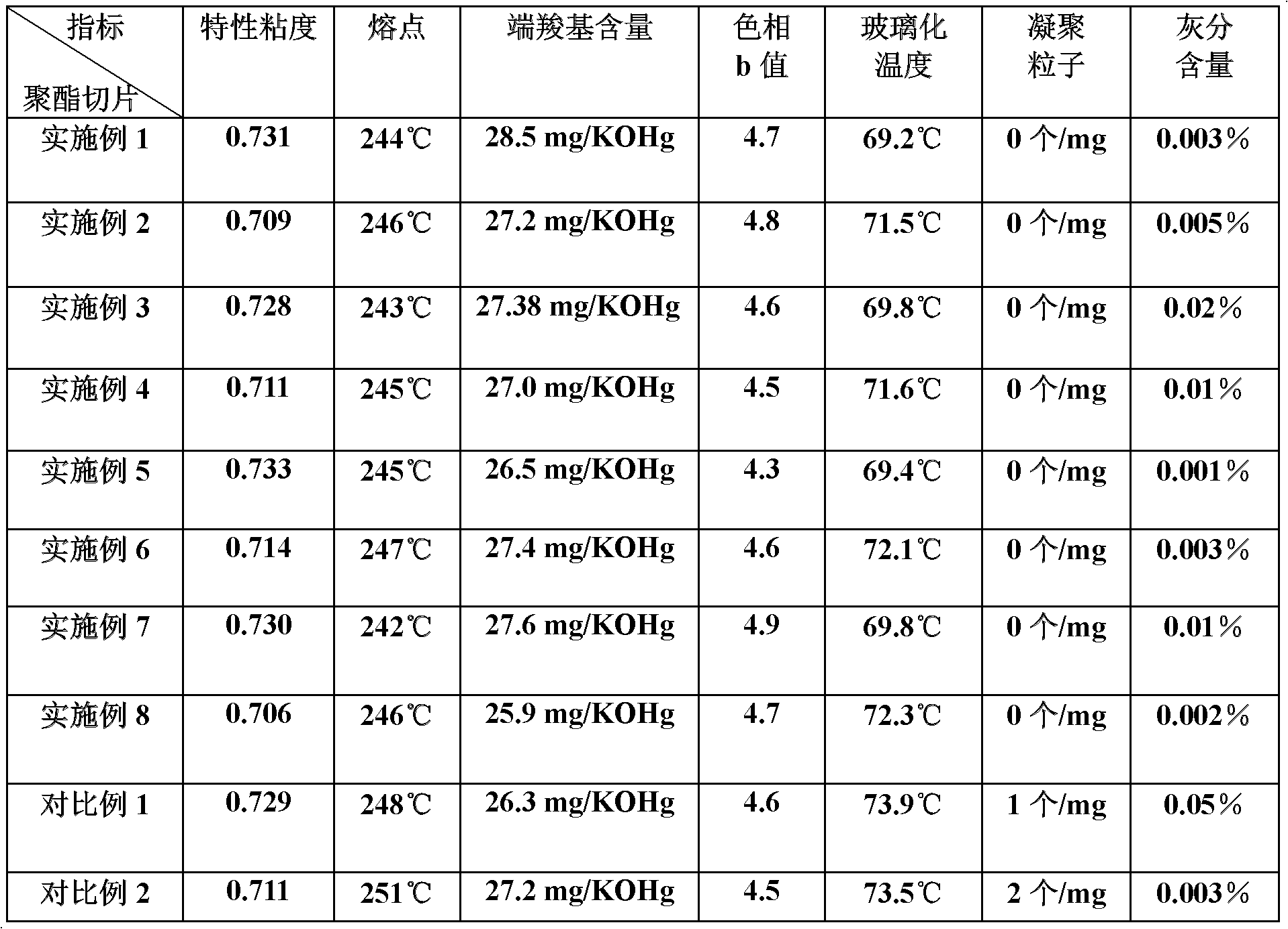

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

Fine-denier flat yarn and manufacturing method thereof

InactiveCN103603071AImprove unevennessImprove inner qualityFilament forming substance formingArtificial thread manufacturing machinesFiberYarn

The invention relates to the field of polyester fiber production and particularly discloses a fine-denier flat yarn and a manufacturing method thereof. The fine-denier flat yarn has good properties such as glare performance, fluffiness, soiling resistance, pilling resistance and dyeing easiness. According to the manufacturing method, after being pressurized by a booster pump and cooled by a melt cooler through a melt conveying pipeline, spinning melt is distributed into spinning boxes through a distribution valve, then measured through a measuring pump and sent into a special shape yarn spraying assembly for filtering and extrusion and then cooled through circular air blowing to obtain primary fiber; after being processed by an oiling unit, yarn guide hooks, yarn guide plates a pre-weaving unit and the like, the primary fiber enters a winder at a certain tension to obtain the multi-aperture superfine-denier flat yarn. The fine-denier flat yarn has good properties such as glare performance, fluffiness, soiling resistance, pilling resistance and dyeing easiness, overcomes wax type soft and smooth feeling of fabric woven from round-section fiber, provides a specific style and excellent properties for the fabric and is a novel polyester fiber with high added value.

Owner:TONGXIANG ZHONGCHEN CHEM FIBER

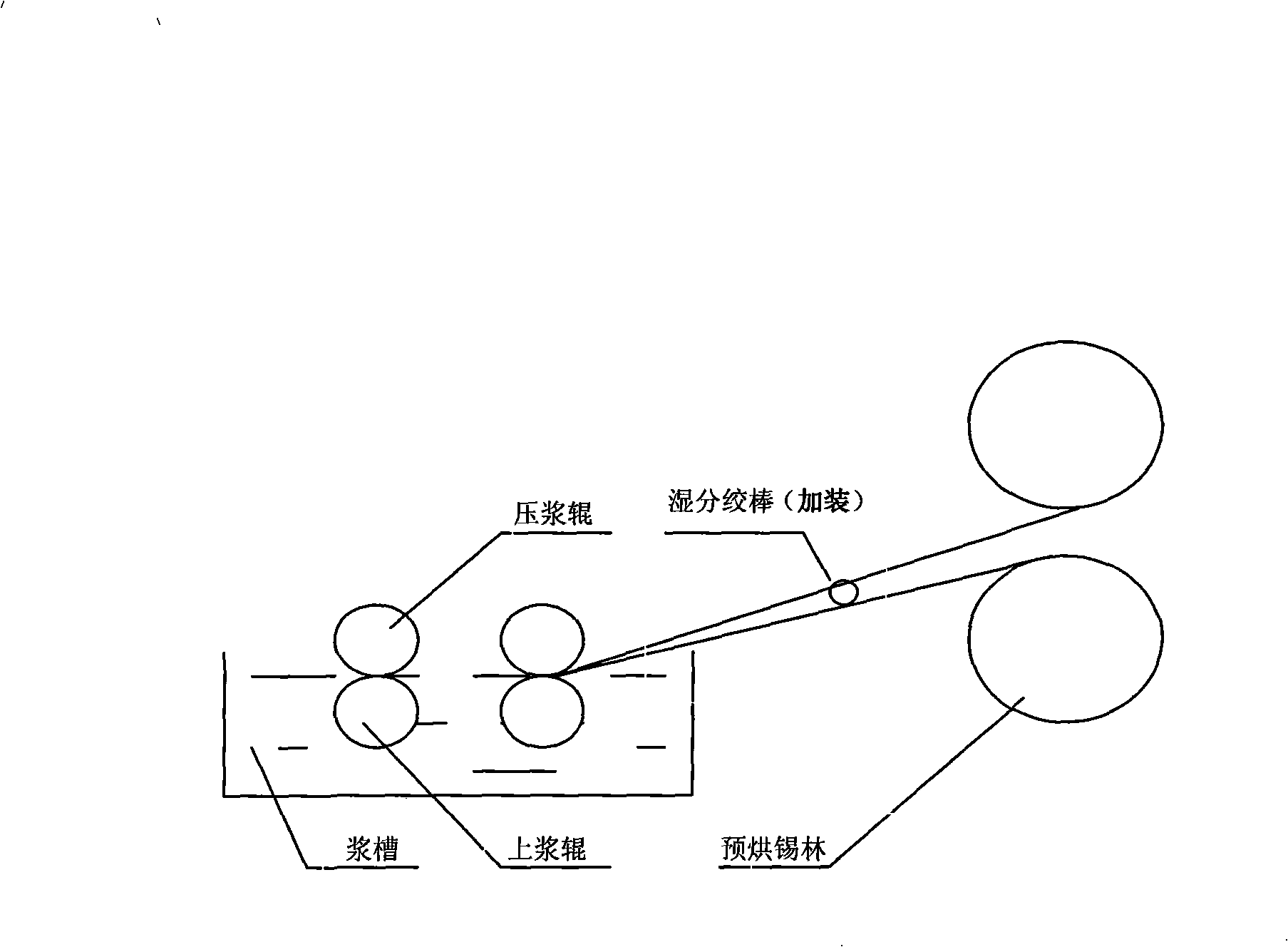

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

Preparation method of multifunctional cotton and linen blended compound yarns

InactiveCN105839256AIncrease comfort and tinting strengthSolve the lack of cohesionBiochemical treatment with enzymes/microorganismsYarnAnti bacterialYarn

The invention belongs to the technical field of spinning and in particular relates to a preparation method of multifunctional cotton and linen blended compound yarns. The preparation method comprises the following steps: (1) preparing cotton and linen blended functional yarns; (2) preparing cotton and linen yarns; (3) preparing the compound yarns. The disadvantage that the cohesive force of traditional cotton and linen blended yarns is not enough is effectively overcome, and the prepared compound yarns have an excellent antibacterial property; the antibacterial rate of escherichia coli is 99.9 percent; meanwhile, a preparation process of antibacterial functional mother liquid is also simple, and the storage stability is good. The doubled and twisted compound yarns provided by the invention are stable in structure and moderate in tightness, and a textile has good anti-fluffing and anti-pilling properties.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

Jade fiber siro spinning cool antimicrobial yarn and spinning technology thereof

The invention discloses a jade fiber siro spinning cool antimicrobial yarn and a spinning technology of the jade fiber siro spinning cool antimicrobial yarn. The yarn comprises, by weight, 30-50% of jade fibers, 25-35% of bamboo fibers and 25-35% of modal. The fibers are spun into the yarn through the siro spinning technology. Blended yarns with different functions can be obtained through mixing of different proportions. The spinning procedure sequentially comprises the cotton carding process, the drawing process, the roving process, the spun yarn siro spinning process and the spooling process. The yarn is formed by blending multiple kinds of fibers, the characteristic of each kind of fibers stands out by reasonably arranging the weight proportion of each kind of fibers, the advantages of all the kinds of fibers are integrated, and therefore the basic performance of the yarn is kept, and the cool functionality and the antimicrobial functionality are achieved.

Owner:JIANGNAN UNIV +1

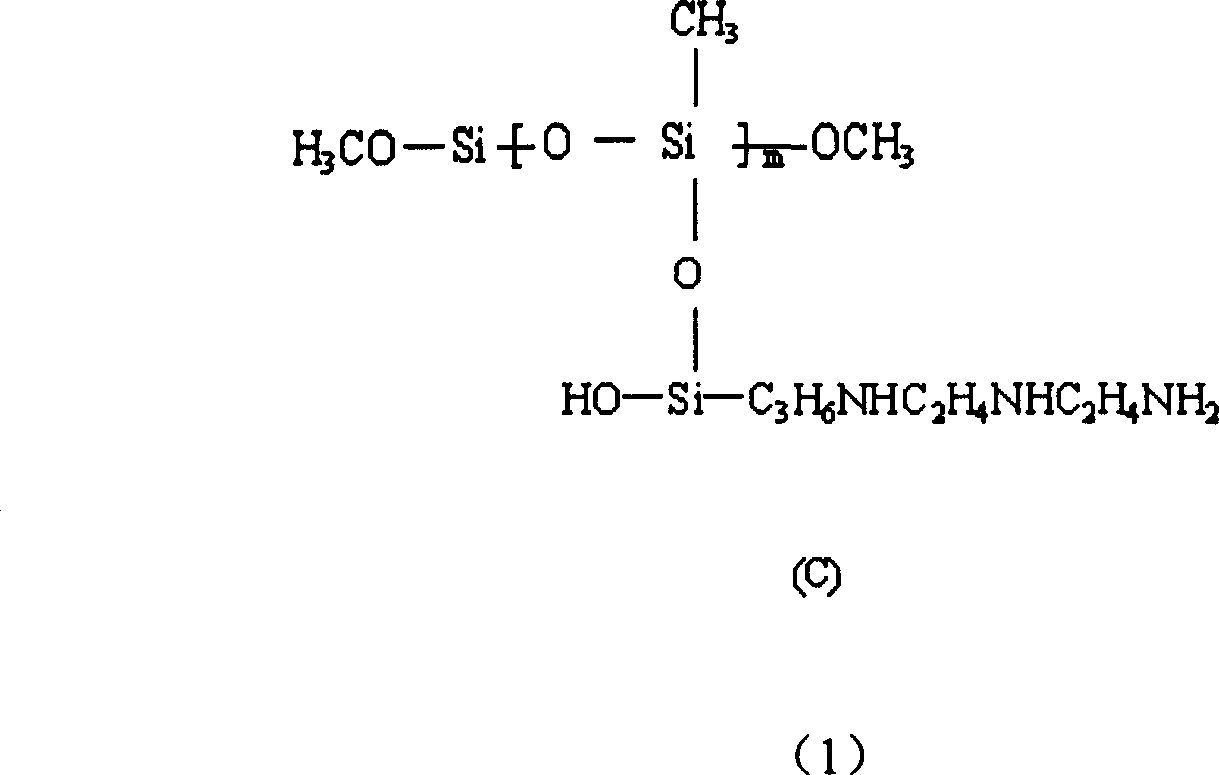

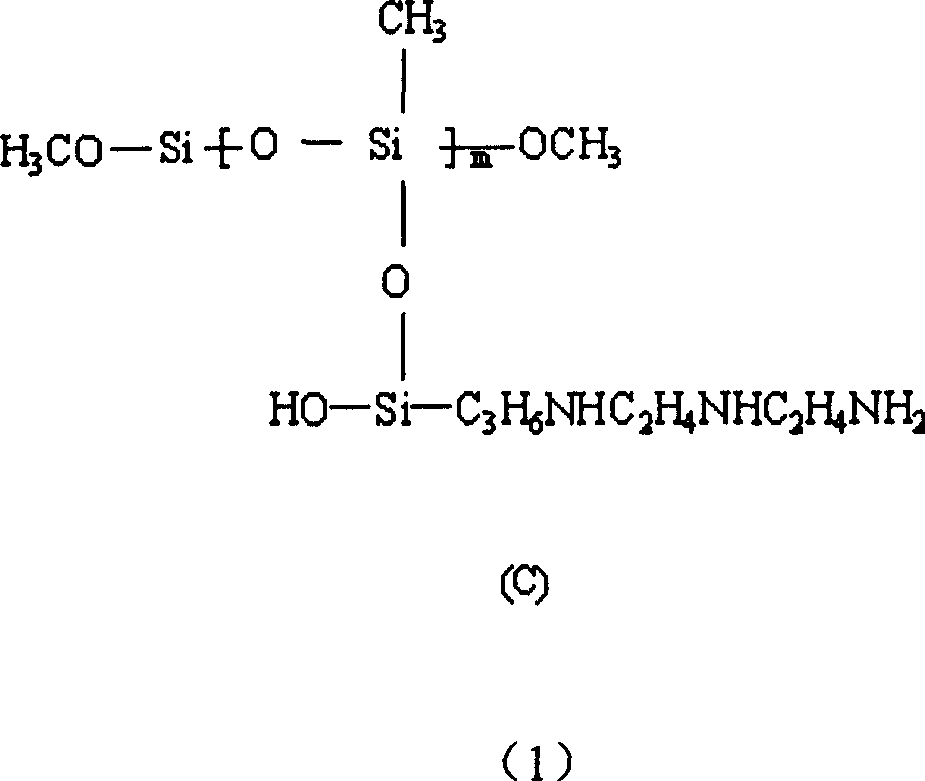

Wool fabric soft finish and application therefor

InactiveCN1970877AUniform crosslinkingGood color uniformity qualityFibre treatmentPerformance indexEngineering

The invention discloses a soft finishing agent for wood fabric and the application. The agent in the invention is suitable for softening finishing of wood fabric. Performance indexes of the wood fabric in the invention, such as softness (pure bending, shearing performance, drape coefficient), anti-pilling (pilling index), machine washing performance (total shrinkage and relaxed shrinkage) and so on, are superior to the related standard of international woodmark and nation. The invention is provided with good quality for color even degree in vision, good performance for anti-teasing and anti-pilling, good handle feeling and good softness degree. There is no international forbidden material in it and when finishing there is no poisonous gas with strong odor discharging. It is in favor of environmental protection.

Owner:SHANGHAI SANMAO ENTERPRISE GROUP

Blended yarn with natural bamboo fiber and anti-pilling polyester fiber and production process thereof

The invention discloses a blended yarn with natural bamboo fiber and anti-pilling polyester and a production process thereof. The blended yarn is an 18-20tex blended yarn and comprises 30-50 percent of natural bamboo fiber and 50-70 percent of anti-pilling polyester. The process for production of the blended yarn with the natural bamboo fiber and the anti-pilling polyester comprises preparation prior to spinning, scutching, carding, drawing, roving, spinning and winding. The blended yarn has the advantages of good warmth, comfortableness, softness, air permeability and anti-bacterial effects, superior anti-pilling properties and ideal use effects.

Owner:HUZHOU FUSHUNDA SILK TEXTILE

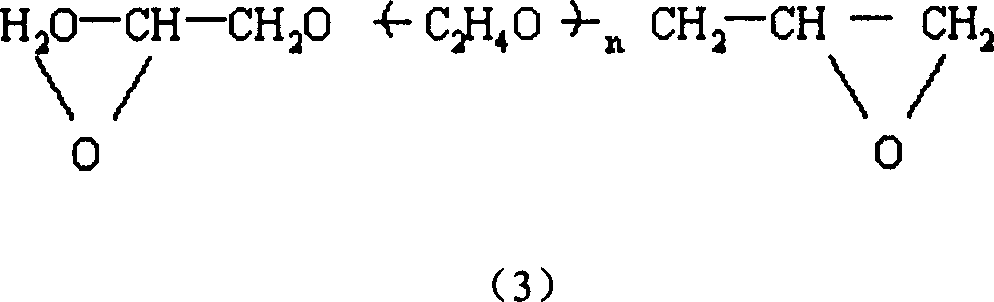

Fuzzing, pilling and ultraviolet-prevention finishing agent and preparation method and application

InactiveCN102154829AImproves UV resistanceImproves anti-pilling propertiesVegetal fibresOrganic solventSilicon alkoxide

The invention discloses a fuzzing, pilling and ultraviolet-prevention finishing agent and preparation method and application. The finishing agent is prepared by the method comprising the following steps: (1) dissolving titanium alkoxide in an organic solvent, adding the obtained solution into acid aqueous solution and stirring uniformly to obtain a mixture; and (2) adding silicon alkoxide into the mixture obtained in the step (1), and stirring uniformly to obtain transparent solution; or (1) sequentially dissolving acid and silicon alkoxide in water, and stirring uniformly to obtain a mixture; and (2) dissolving titanium alkoxide in an organic solvent, adding the obtained solution into the mixture obtained in the step (1), and stirring uniformly to obtain transparent solution. The finishing agent disclosed by the invention is simple in preparation and short in the finishing process, and meets the requirements of water and energy conservation, low carbon and environmental protection.

Owner:LANGZI CO LTD

Blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns

The invention relates to a blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns. The method comprises following steps: selecting alginate fibers and cotton fibers; carrying out blowing, combing and pre-drawing operation on alginate fibers and combining them with combed fine-fleece cotton and long stapled cotton on a drawing machine; and producing cone yarns through roving, spun-yarn and spooling procedures with the blending proportion of alginate, combed long stapled cotton and combed fine-fleece cotton being 50 / 30 / 20. The blending method of alginate fibers, combed fine-fleece cotton and long stapled cotton for production of top-grade knitting yarns has following beneficial effects: cone yarns have cotton texture due to addition of combed cotton and fine staple cotton so that woven fabric has few hair and shows great piling resistance and high strength and is fluffy, soft and elastic; cotton fabric is not easily wrinkled and has fixed size so that comfort and warm-keeping ability are further enhanced; the cotton fabric can be made into underwear, vests, T-shirts, shorts, and pajamas and shows great warm-keeping ability; and functions of protecting and moistening skin and health-care are fulfilled.

Owner:JIHUA 3509 TEXTILE

Cation dacron bamboo fiber blended yarn

The invention provides a cation dacron bamboo fiber blended yarn which contains the flowing compositions by weight percent: 65-75% of 1.5D*38mm normal temperature and pressure dyed dacron fiber and 25-35% of 2D*51mm bamboo fiber. The cation dacron bamboo fiber blended yarn has the technical effects of good warm keeping performance, good air permeability, excellent pilling resistance and good sense of fur texture and is soft, bright in dyeing, mothproof and ultraviolet-proof.

Owner:NANTONG SUZHONG TEXTILE

Pilling resistant agent emulsion for wool fabrics and preparation method thereof

InactiveCN103044627AGood anti-pillingNo emissionsAnimal fibresPolymer scienceEmulsion polymerization

The invention discloses pilling resistant agent emulsion for wool fabrics and a preparation method thereof. The emulsion comprises the following raw materials in percentage by weight: 2-8 percent of ethyl hexyl acrylate monomer, 6-16 percent of butyl acrylate monomer, 2-8percent of hydroxyl ester acrylate monomer, 0.1-1.5 percent of anionic surfactant, 0.1-1.5 percent of non-ionic emulsifier, 0.01-0.1 percent of initiator, 0.8-5 percent of siloxane monomer, 5-15 percent of vinyl-contained silane coupling agent, 0.1-1 percent of silane hydrolysis inhibitor and 50-70 percent of de-ionized water; and the emulsion is prepared by adopting the semi-continuous seed emulsion polymerization technique. The pilling resistant agent emulsion has the characteristics of small particle size, low emulsion dosage, easy control of reaction process, no environmental pollution and the like. The pilling resistant grade of the wool fabrics which are treated by the pilling resistant agent emulsion is improved by more than 2 grades; the hydrophily is basically not changed; and the original hand feel and style of the fabrics are little influenced.

Owner:SUZHOU UNIV +1

Sorona/bast fiber blended fabric preparation method

The invention discloses a Sorona / bast fiber blended fabric preparation method. Bast fiber, Sorona fiber and other fiber are adopted for blending; the method particularly comprises the steps that the bast fiber is subjected to pretreatment, and the bast fiber, the Sorona fiber and the other fiber are subjected to mixing, opening picking, carding, combing, drawing, roving, spinning, self-spooling, slashing, weaving and quality inspection. Accordingly, the fabric not only has enough elasticity so as to ensure that the woven fabric is worn comfortably, but also has the advantages of being naturally antimicrobial, environmentally friendly and the like, and the certain health-care function is achieved; in addition, the product contains cotton, viscose, lyocell and other fiber, the product has the multifunctionality, and the adaptability of the product is improved.

Owner:浙江吉麻良丝新材料股份有限公司

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

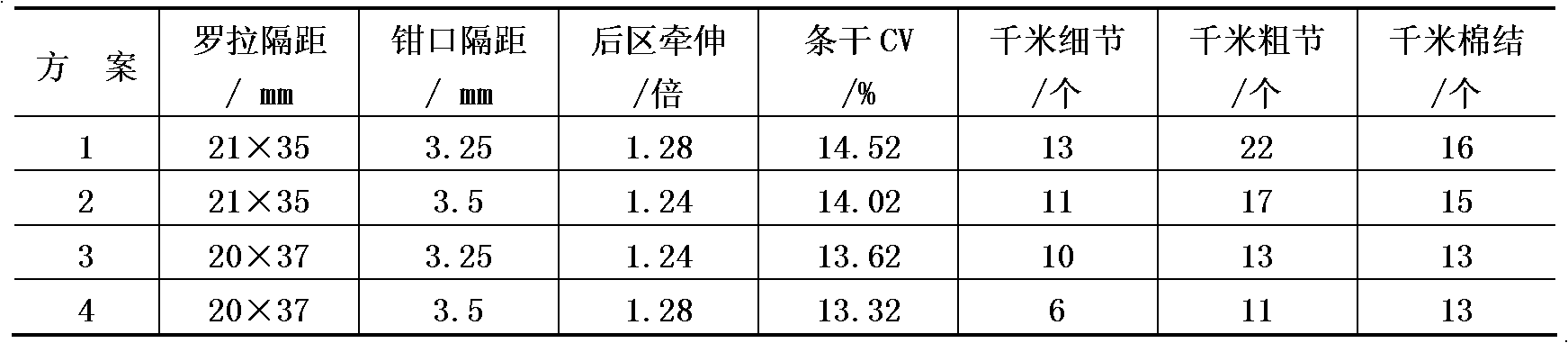

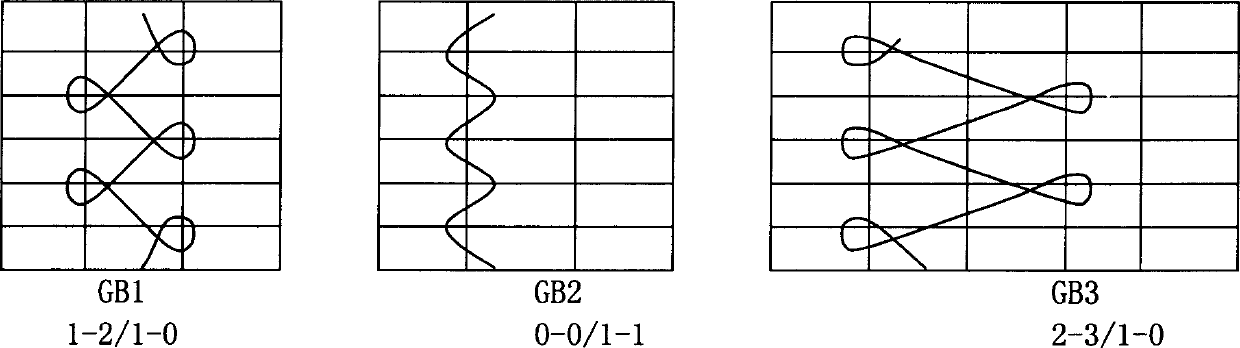

Antistatic warp-knitted face fabric

The invention discloses an antistatic warp knitted face fabric, which comprises electric conductive yarn higher than 0.02%, cotton yarn higher than 12% and delustring terylene higher than 80%. The face fabric has good skin touch feeling, hygroscopic property and air permeability.

Owner:HAINING WANFANG WARP KNITTING +1

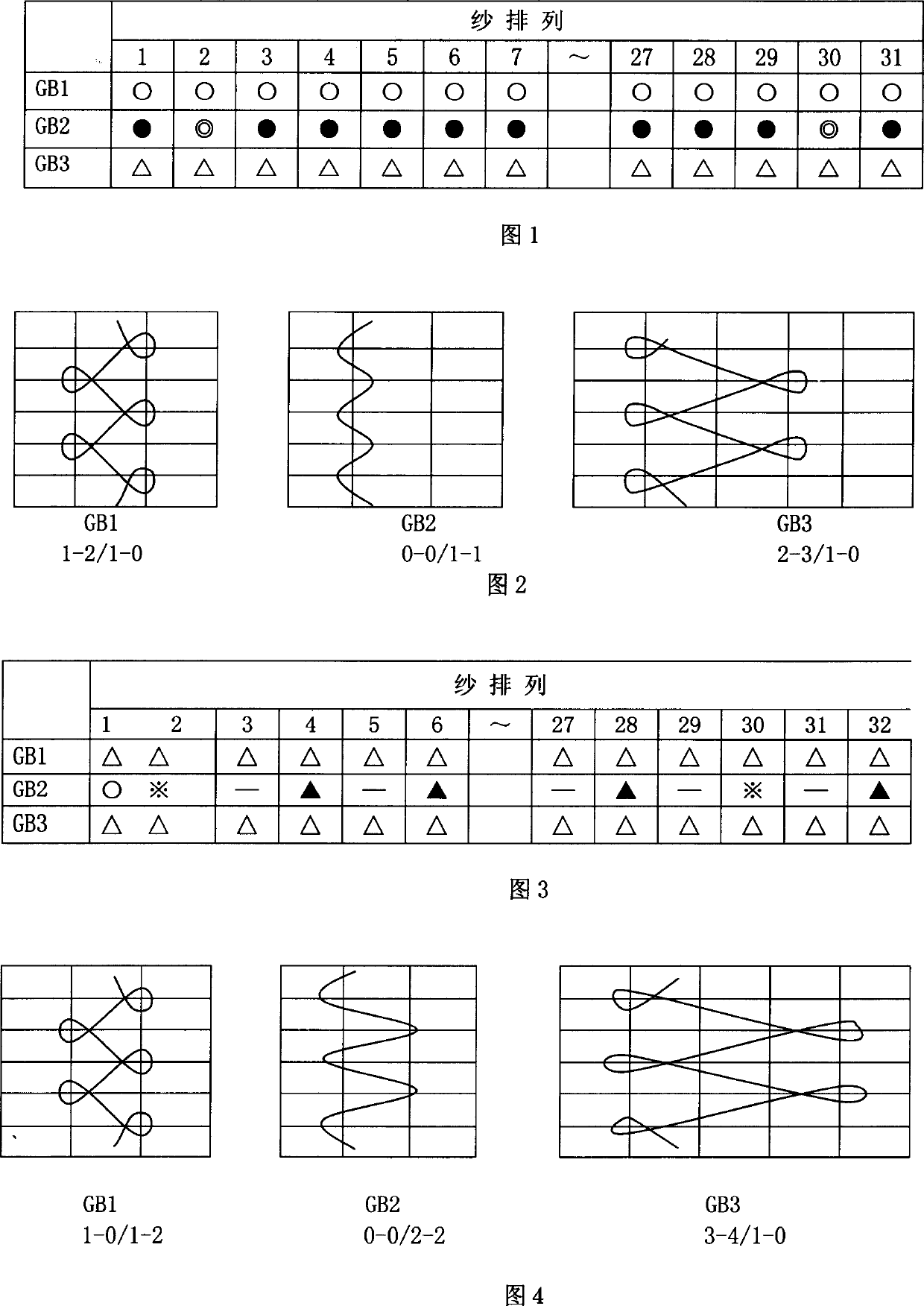

Air layer fabric and production method and application thereof

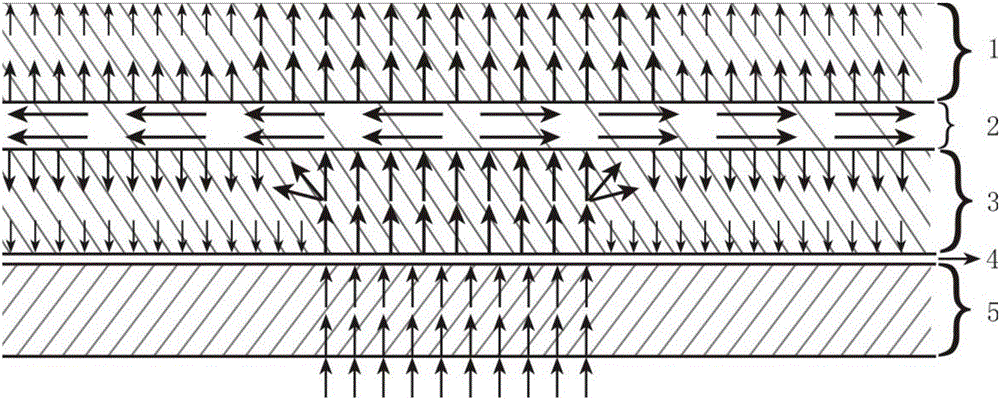

PendingCN111020837AGood anti-snagImprove pilling performanceWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention relates to an air layer fabric and a production method and an application thereof. The air layer fabric comprises an outer layer, a secondary outer layer, a middle layer, a secondary inner layer and an inner layer; the outer layer and the inner layer are of a knitted weft flat tissue structure composed of cotton yarns; the secondary outer layer is composed of a first polyester yarn and a coil of the outer layer in a tucking manner; the secondary inner layer is composed of a second polyester yarn and a coil of the inner layer in a tucking mode; and the middle layer is formed by sleeving the first polyester yarn of the secondary outer layer and the second polyester yarn of the secondary inner layer by a third polyester yarn in a tucking manner. The fabric and the clothing provided by the invention have good anti-hooking and pilling performance and the anti-napping performance of the fabric, and is capable of effectively improving the wearability of the fabric.

Owner:台巨纺织(上海)有限公司

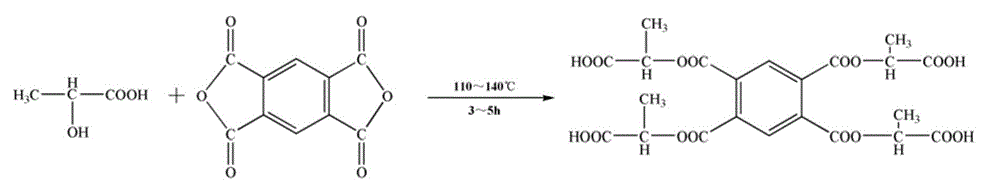

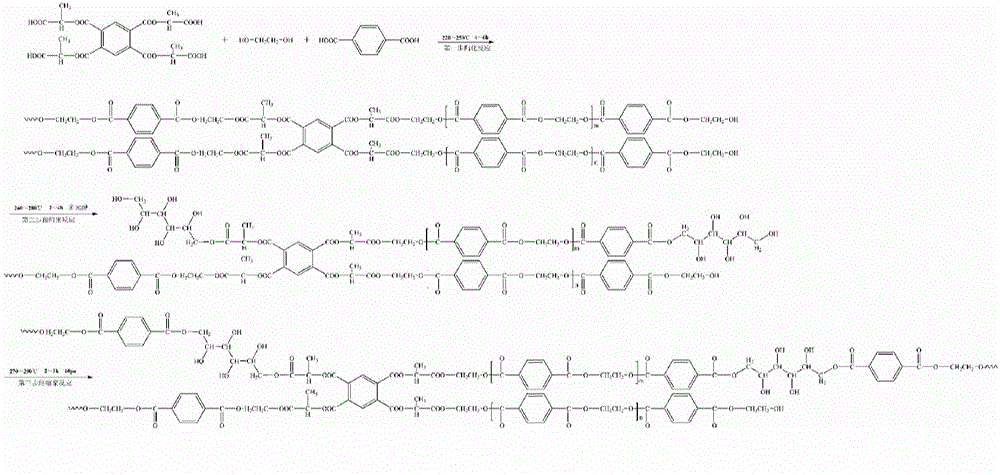

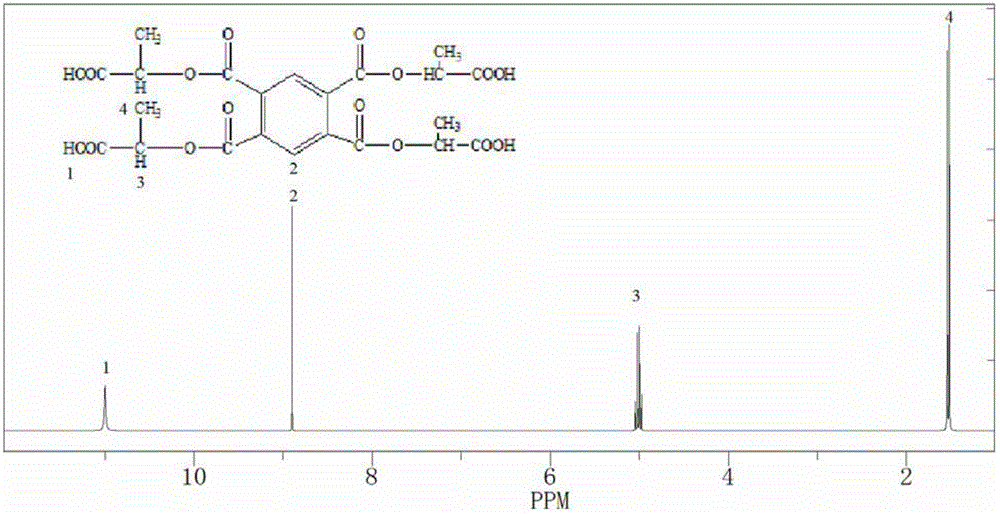

Branched chain type degradable hydrophilic polyester master batch and preparation method thereof

The invention provides a branched chain type degradable hydrophilic polyester master batch and a preparation method thereof. A degradable lactic acid group with a multi-branched chain structure and polyalcohol with a polyhydroxyl structure are introduced into a chain segment, excellent biodegradability and hygroscopicity are given to polyester, the degradability of polyester is further improved, a static contact angle of the surface of a copolyester chip is less than 60 degrees, and intrinsic viscosity is 0.45-0.52dL / g. The invention also provides a preparation method of branched chain type degradable hydrophilic polyester. The preparation method comprises the steps that reaction is carried out on benzenetetracarboxylic anhydride and lactic acid for preparing a branched chain monomer, then primary esterification reaction is carried out on the branched chain monomer, terephthalic acid and ethylene glycol, and then polyalcohol is added in a secondary prepolycondensation process for carrying out copolycondensation, and final polycondensation is carried out for preparing the branched chain type degradable hydrophilic polyester. The prepared polyester has the advantages of good hydrophility, fast biodegradation and the like and can be widely applied to the fields of home textiles, clothing, plastics and the like.

Owner:POLY PLASTIC MASTERBATCH SUZHOU +1

Anti-pilling and shrink-resistant woolen sweater treatment agent containing lauryl sodium sulfate

InactiveCN103437169ALow shrinkageGood anti-pillingAnimal fibresCarboxymethyl starchMonopotassium phosphate

The invention relates to an anti-pilling and shrink-resistant woolen sweater treatment agent containing lauryl sodium sulfate, which comprises the following components in parts by weight: 5-9 parts of lauryl sodium sulfate, 3-7 parts of n-butyl alcohol, 2-4 parts of monopotassium phosphate, 3-4 parts of sodium carboxymethyl starch, 2-4 parts of potassium tartrate and 100-110 parts of water. The prepared woolen sweater treatment agent has anti-pilling and shrink-resistant functions.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

Smooth memory knitted fabric and preparation method

ActiveCN103556377AFunction increaseThe preparation process is scientific and environmentally friendlyWeft knittingDeodorantEngineering

The invention relates to a smooth memory knitted fabric and a preparation method thereof. The smooth memory knitted fabric comprises an outer layer and an inner layer, the outer layer is composed of super fine denier polyester fibers, and the inner layer is composed of Modal fiber staple yarns and polyurethane fiber filaments. The preparation method includes that (1) after structural design, a weft knitting single-sided multi-needle-track high needle pitch knitting machine is used for weaving with weft knitting number 28-32G to obtain a knitted fabric, and (2) the obtained knitted fabric is subjected to presetting, pre-processing, polyester fiber dyeing, Modal fiber overdyeing, color fixing, water scrubbing, repeatedly setting and finally drying. The smooth memory knitted fabric has the advantages that the smooth memory knitted fabric is highly elastic, fine, smooth, quickly dry when absorbing water, antimicrobial, deodorant, not prone to deformation after washed, light, convenient and comfortable if a user wears clothes made of the fabric, and capable of overcoming defects of poor hand feel, creased cloth surfaces, insufficient wet permeability, tendency to stink and the like in terms of traditional fabrics.

Owner:NINGBO DAQIAN TEXTILE

Method for producing high-efficiency thermal protection high hygroscopic perspiration-discharging weaving terylene face fabric

The invention relates to a manufacturing method of woven polyester fabric that effectively preserves heat and absorbs moisture well. The manufacturing method comprises procedures as follows: spinning, weaving and finishing. As the surface and the section of fiber adopted by the invention has honeycombed microcellular texture, the specific surface-area is larger and has good hollowness. The manufacturing method has the characteristics as follows: (1) the fiber has a capillary effect and good moisture absorption and sweat discharging; (2) as the inner part of the fiber has continuous hollow space, the specific weight of the fiber is decreased and the fiber effectively preserves heat; (3) the fiber has a good anti-pilling effect; and (4) the fiber is dyed easily.

Owner:DANYANG DANSHENG TEXTILE

Composite functional fabric with multiple cotton-hemp blends and functional fibers

ActiveCN105839272AImprove intrinsic performanceImprove comfortBiochemical treatment with enzymes/microorganismsWoven fabricsHemp fiberWeft yarn

The invention belongs to the technical field of textiles, and particularly relates to a composite functional fabric with multiple cotton-hemp blends and functional fibers. The fabric is formed by blending hemp fibers, cotton fibers, bamboo fibers and wool fibers; warp yarns of the fabric are formed by blending the hemp fibers, the bamboo fibers and the wool fibers according to the proportion of (1-3):1:1; weft yarns of the fabric is formed by blending the cotton fibers, the bamboo fibers and the wool fibers according to the proportion of (2-6):1:1. According to the fabric provided by the invention, the functional fibers such as the bamboo fibers and the wool fibers are optimized, so that the inner performances of the fabric are improved, the finally produced fabric has the characteristics of softness and smoothness of cottons as well as slipperiness, moisture absorption and sweat releasing, antibacterium and health, and the like of the hemp, and the comfort of the fabric is improved. According to the composite functional fabric with the multiple cotton-hemp blends and the functional fibers provided by the invention, after the hemp fibers and the cotton fibers are modified by biological enzyme, the dyeing effect of the yarns can be also improved.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com