Patents

Literature

90results about How to "Uniform crosslinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrophotographic photoconductor, and image forming process, image forming apparatus and process cartridge for an image forming apparatus using the same

ActiveUS7175957B2Increase resistanceMaintain good propertiesElectrographic process apparatusElectrographic processes using charge patternElectrical conductorSurface layer

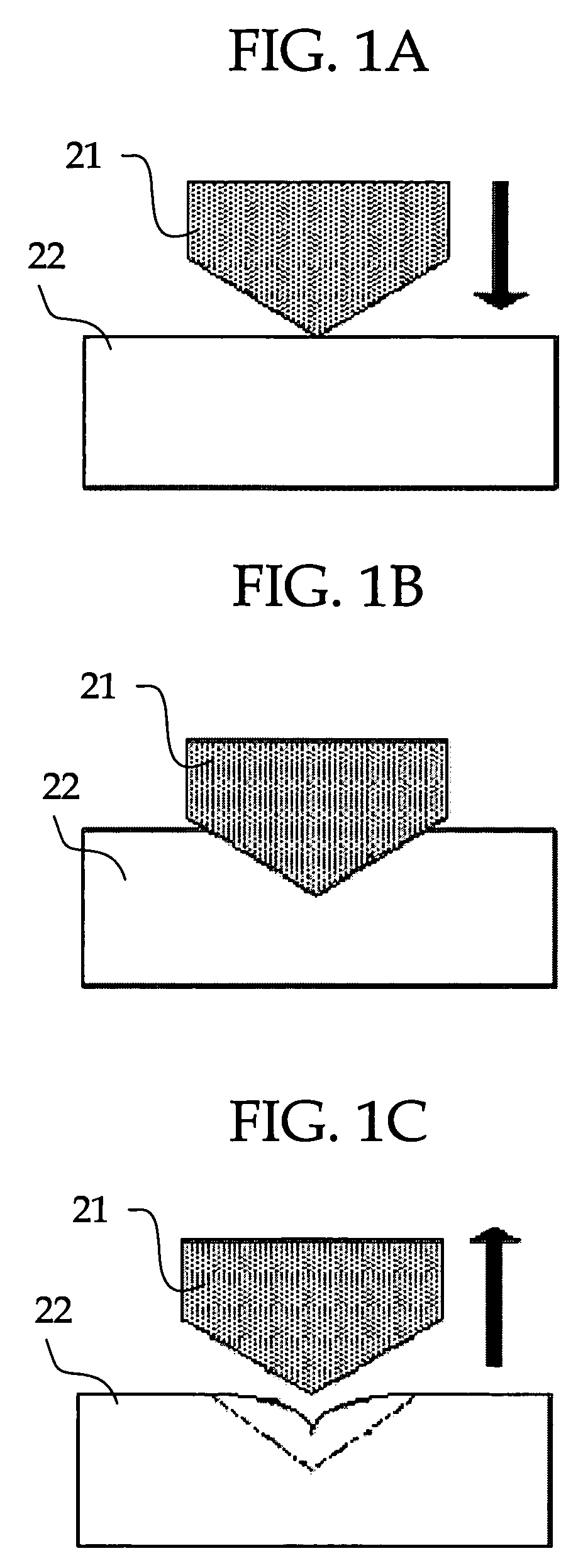

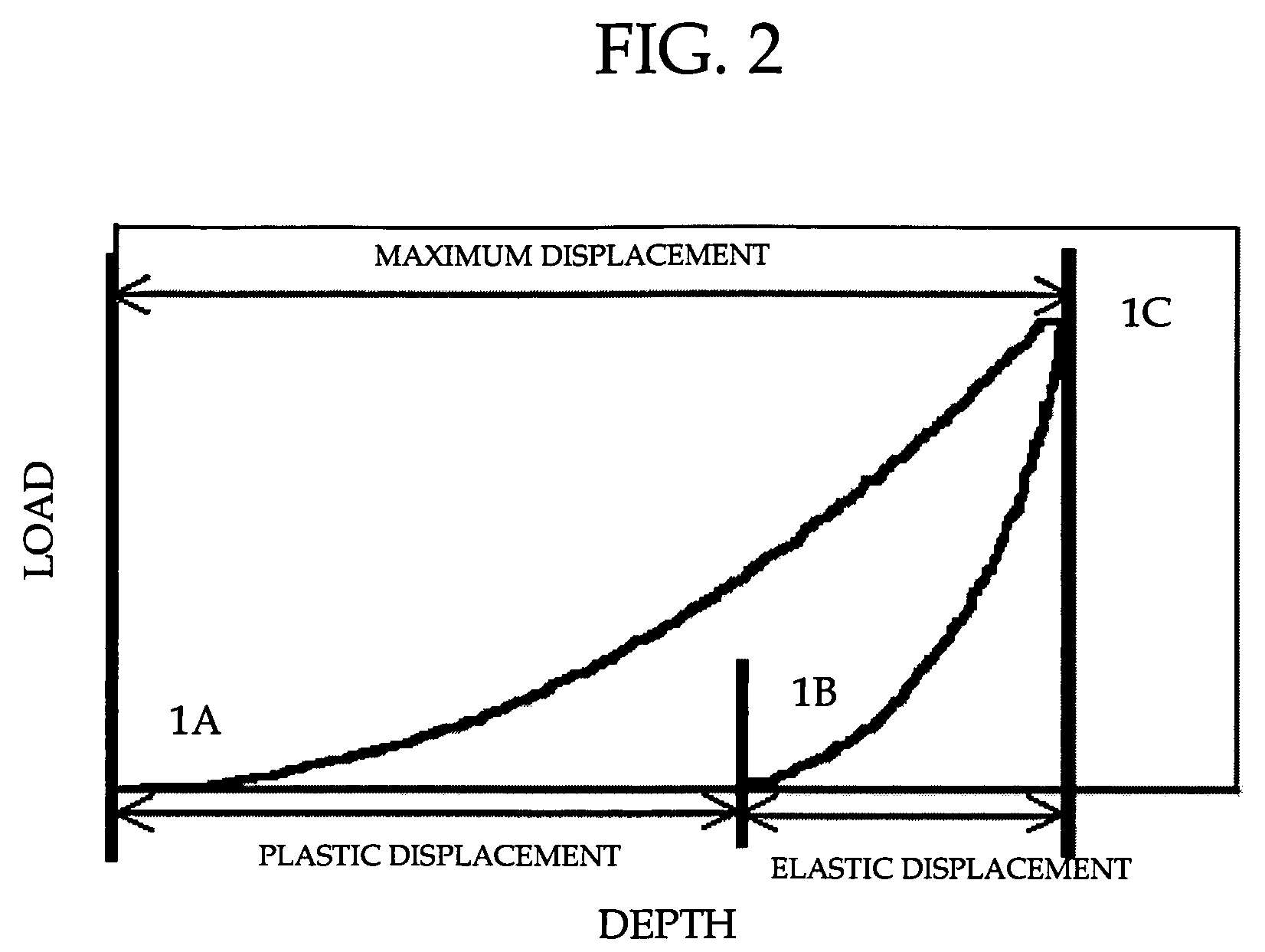

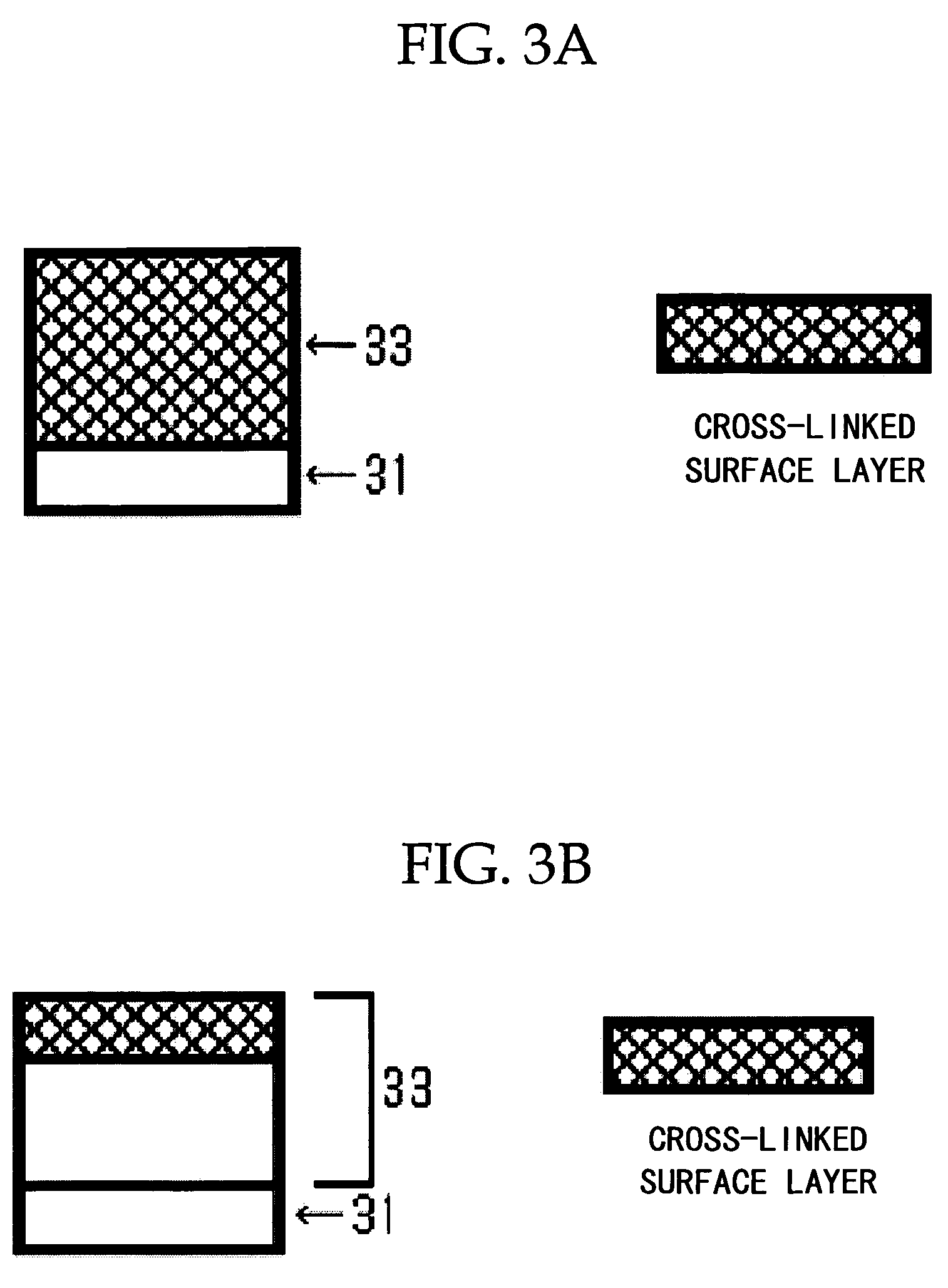

Disclosed is an electrophotographic photoconductor including at least a photoconductive layer on a conductive substrate, wherein the surface layer of the photoconductive layer contains at least a surface crosslinked layer formed by curing a tri- or more-functional radical polymerizable monomer without having a charge transporting structure and a mono-functional radical polymerizable compound having a charge transporting structure and the surface crosslinked layer has a surface roughness Rz of 1.3 μm or less.

Owner:RICOH KK

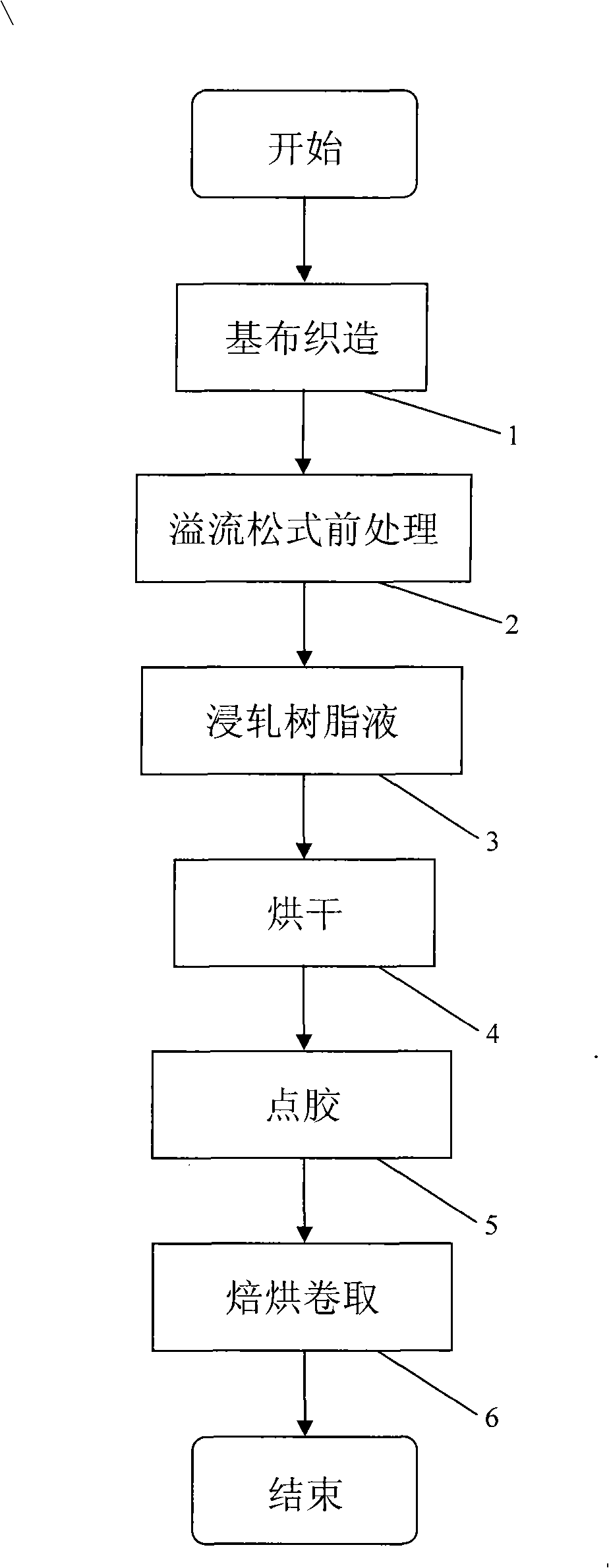

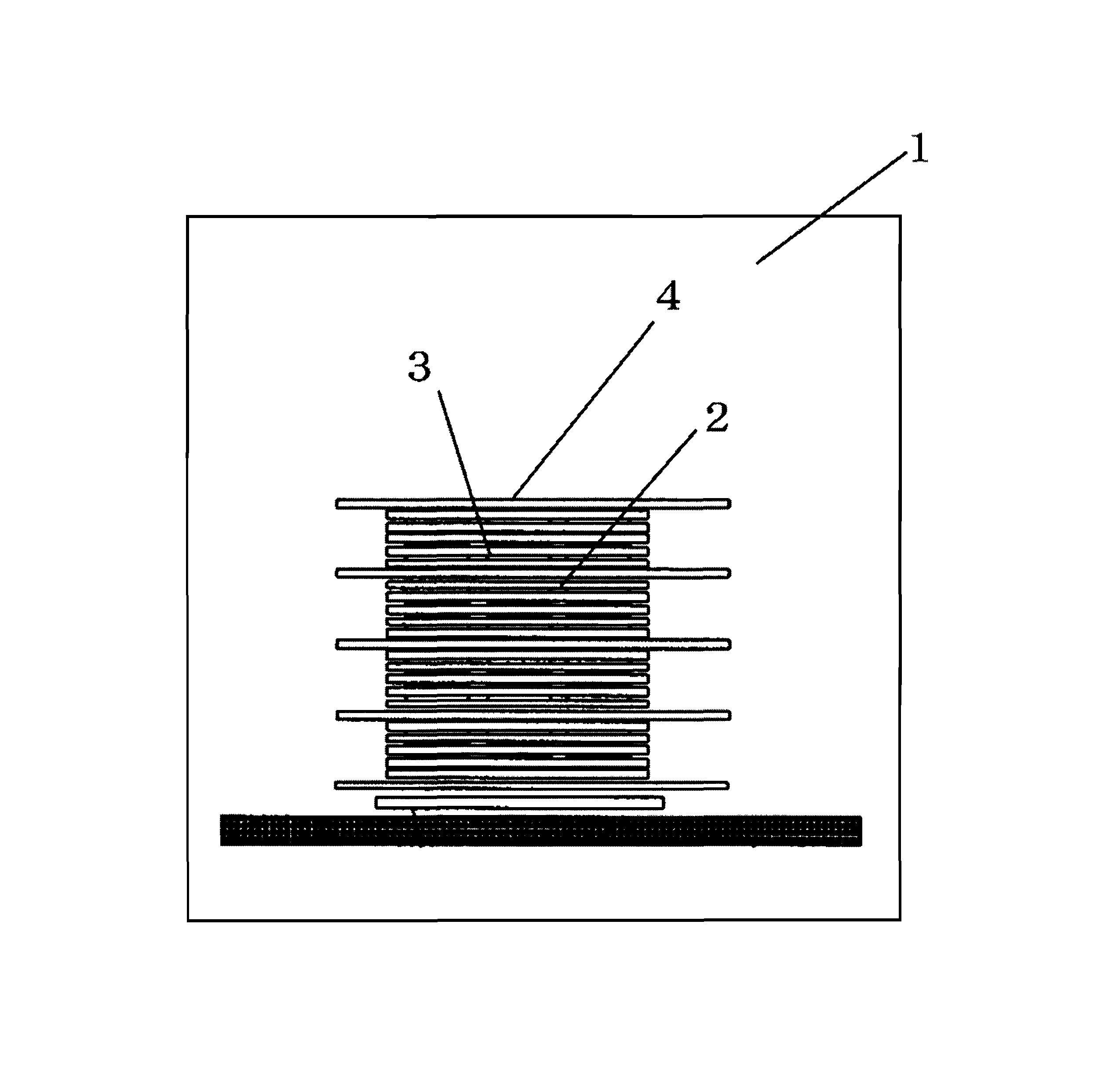

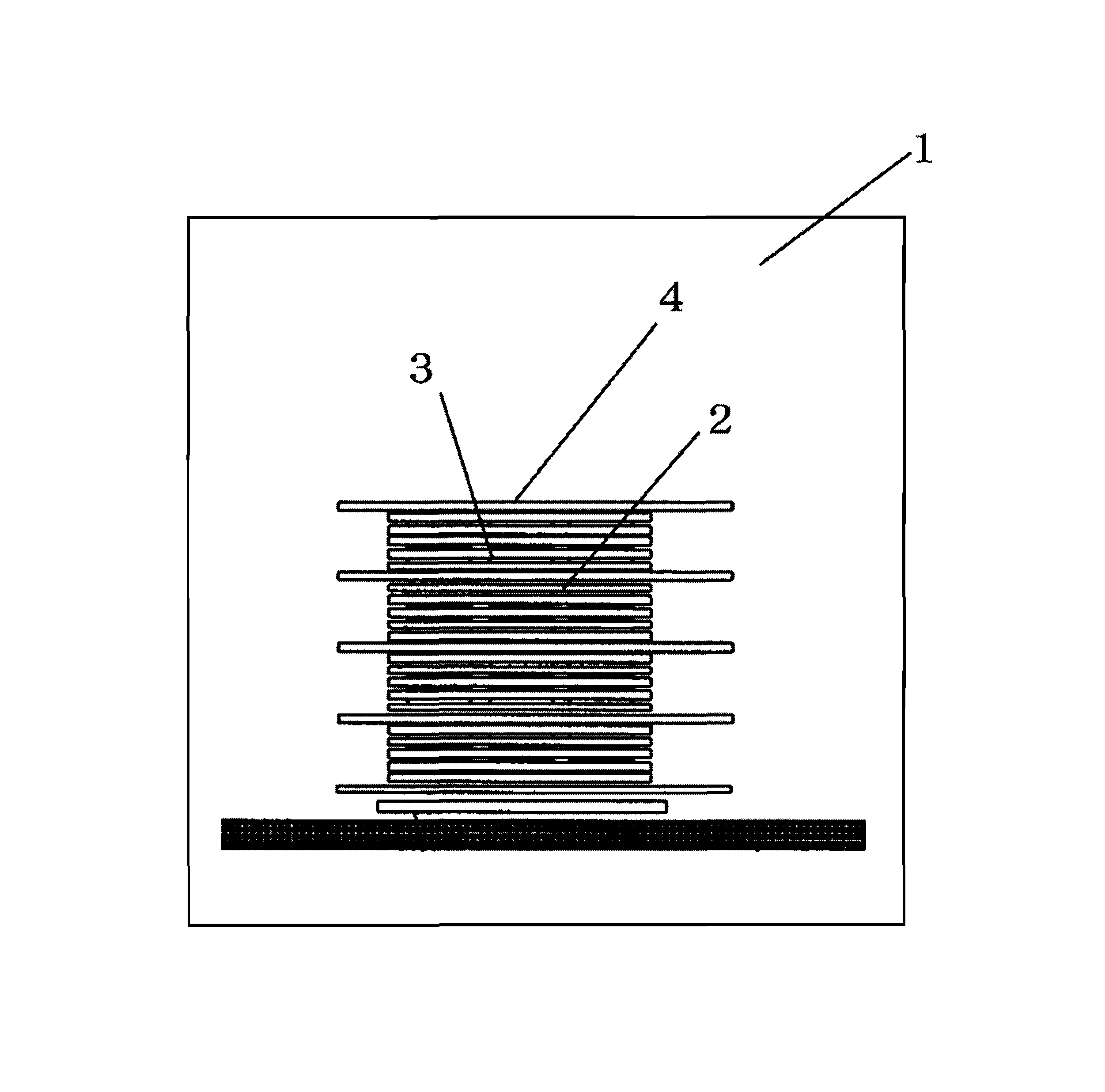

Manufacturing technique of crease-shedding uniforms lining

InactiveCN101288507AImprove deformation recovery performanceImproves wrinkle recoveryGarmentsVegetal fibresFiberPolyamide

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Owner:严华荣

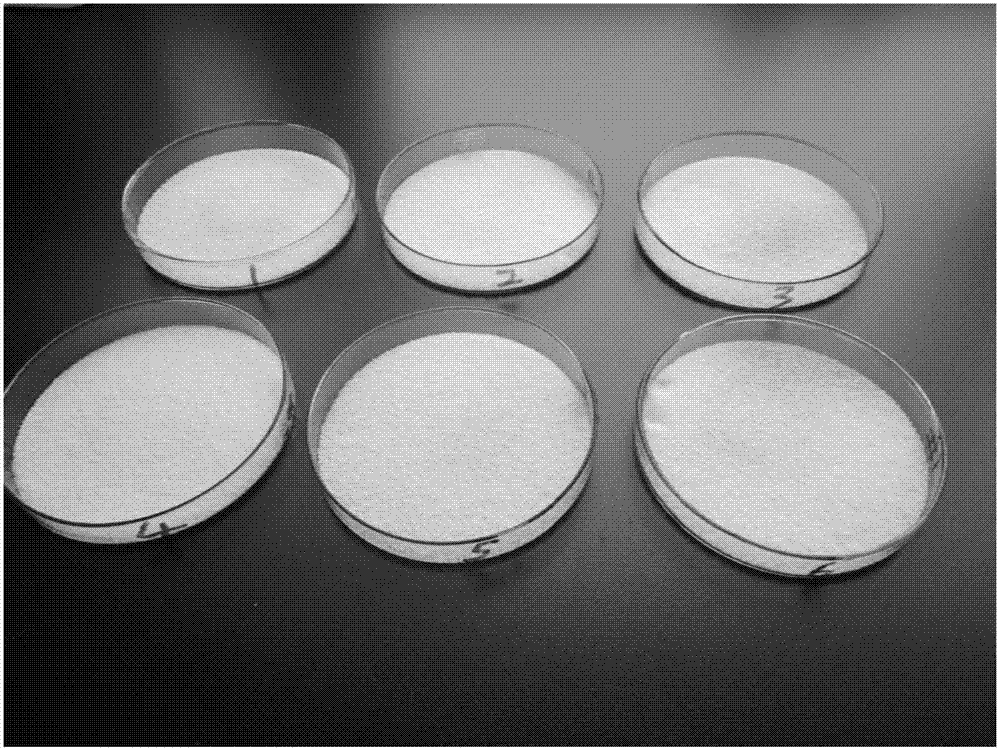

Gelatin embolism microsphere and preparation method and application thereof

ActiveCN102585258AUniform crosslinkingControl degradation timePowder deliverySurgeryMicrosphereDistilled water

The invention provides a gelatin embolism microsphere and a preparation method and an application thereof. The preparation method of the gelatin embolism microsphere comprises the following steps of: (1) preparing a gelatin aqueous solution of which the concentration is 10-50 percent g / ml; (2) adding the gelatin aqueous solution prepared in the step (1) into an emulsifier-containing oil phase of which the temperature is 50-60 DEG C, stirring for 10 minutes, lowering the temperature to 2-5 DEG C, stirring for 30 minutes at the stirring speed of 100-900 revolutions per minute, and standing to precipitate the microsphere; (3) pouring the oil phase out, repeatedly washing the oil phase left on the surface of the microsphere with acetone, and filtering the microsphere out; and (4) adding the microsphere obtained in the step (3) into a crosslinking agent aqueous solution of which the pH is 8-9 and the concentration is 1-15 percent g / ml, reacting at the temperature of 4 DEG C for 0.5-25 hours, and washing the microsphere with distilled water. The gelatin embolism microsphere provided by the invention is crosslinked uniformly, is regularly spherical, and is convenient for screening grading and accurate marking of the particle diameter; and the degradation time and elasticity of the gelatin embolism microsphere are more suitable for clinical application.

Owner:HYGEA MEDICAL TECH CO LTD

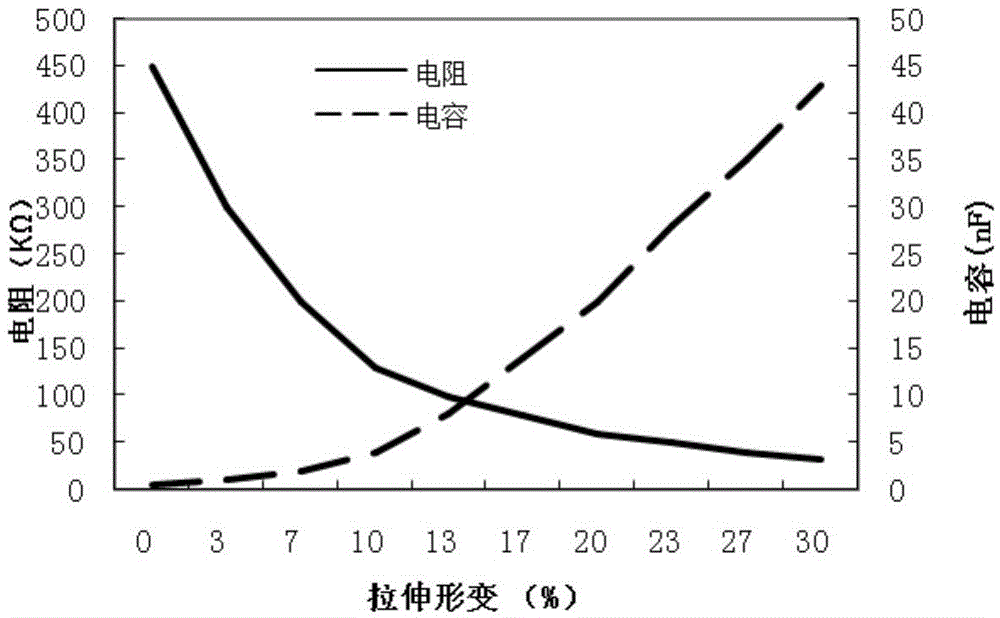

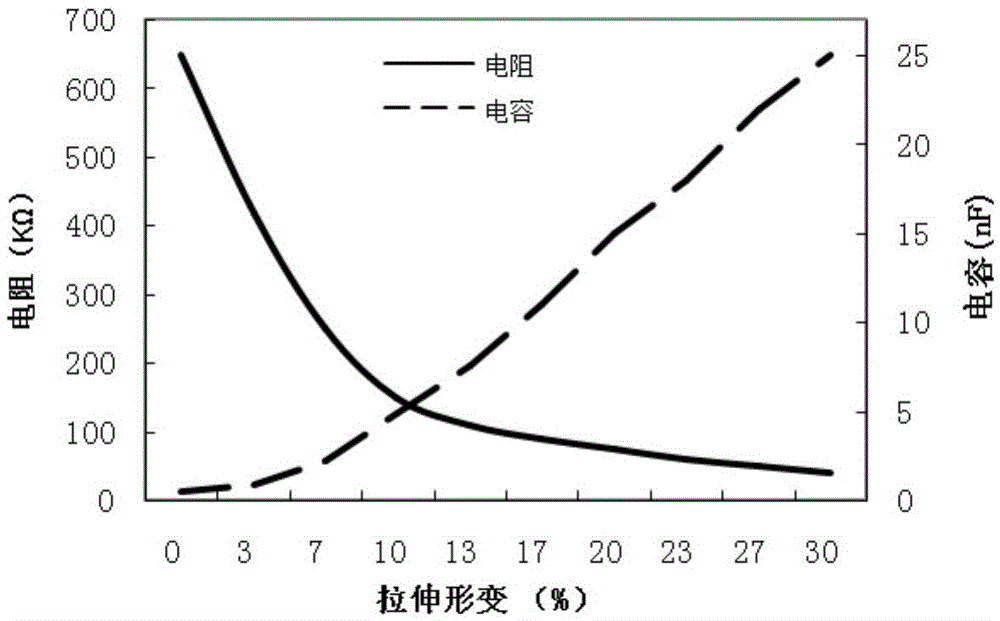

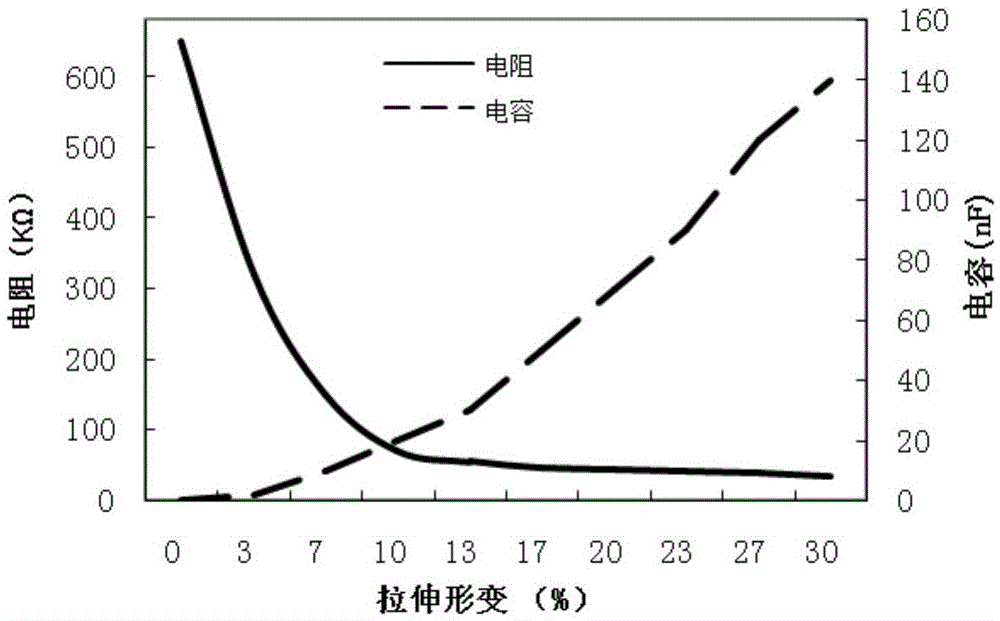

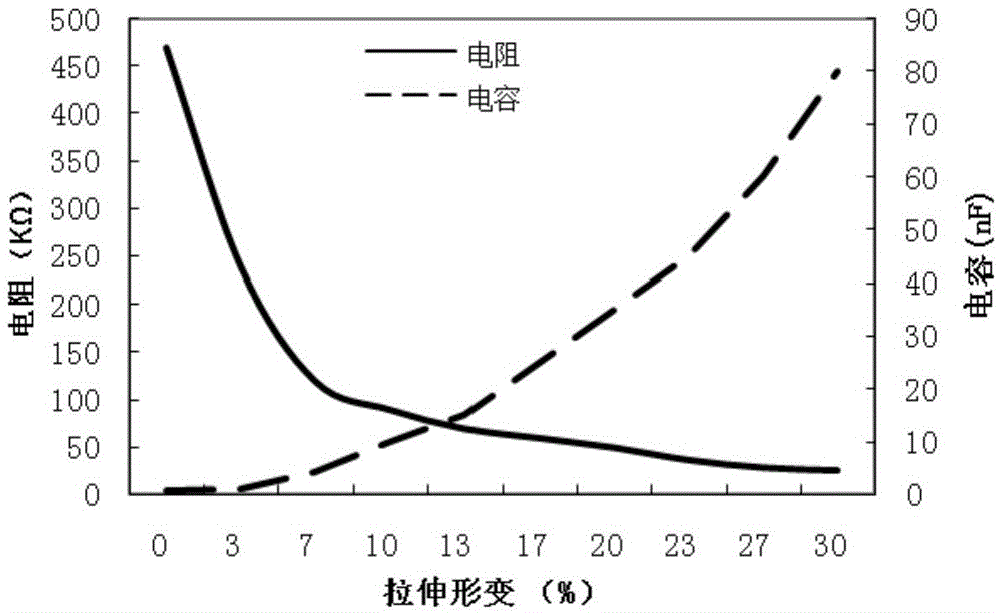

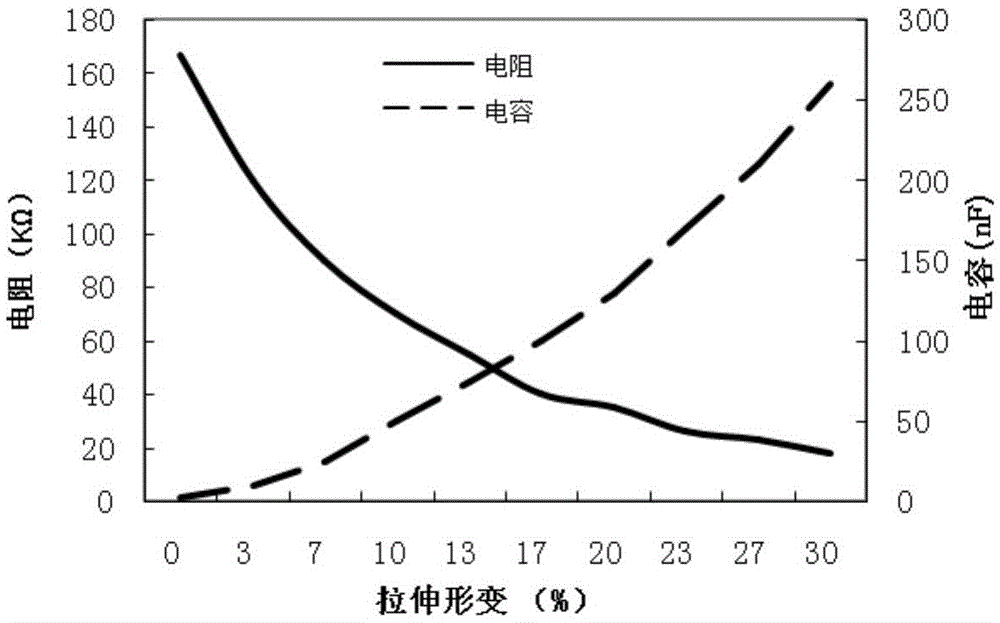

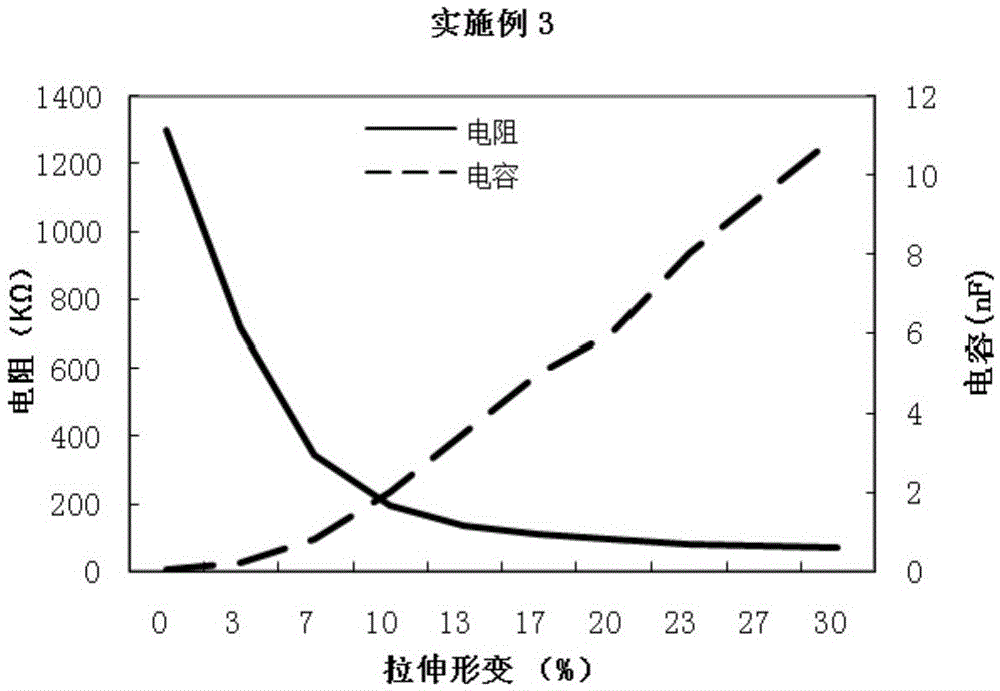

Conductive rubber material for flexible sensor and preparation method and application of conductive rubber material

InactiveCN105482176ANarrow resistance distributionReduce pollutionForce measurementRubber materialEngineering

The invention is applicable to the field of flexible sensors and provides a conductive rubber material for a flexible sensor and a preparation method and application of the conductive rubber material. The conductive rubber material comprises, by weight, 100 parts of rubber base bodies and conductive filler, wherein the conductive filler comprises, by weight, 5-50 parts of conductive black and / or 20-100 parts of silver-containing conductive filler bodies; the conductive rubber material is made in the mode that the conductive filler is dispersed in the rubber material, and radiation crosslinking is conducted through electron beams or gamma rays.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

Preparation and its products for composite nanometer filter membrane

InactiveCN1745885AUniform cross-linkingEasy to operateSemi-permeable membranesAqueous solutionPolymethacrylic Acids

A process for preparing the composite nano-class filtering membrane includes such steps as providing the ultra-filter membrane made of polysulfone or poly vinylidene fluoride as substrate, dipping in the aqueous solution of aminoester polyacrylate polymers chosen from polymethyl acrylate-N, N-dimethylamino ethylester, polymethyl acrylate-N, N-dimethylamino methylester, polymethyl acrylate-N, N-diethylamino methylester, etc, drying, and beta-ray irradiating for cross-linking.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

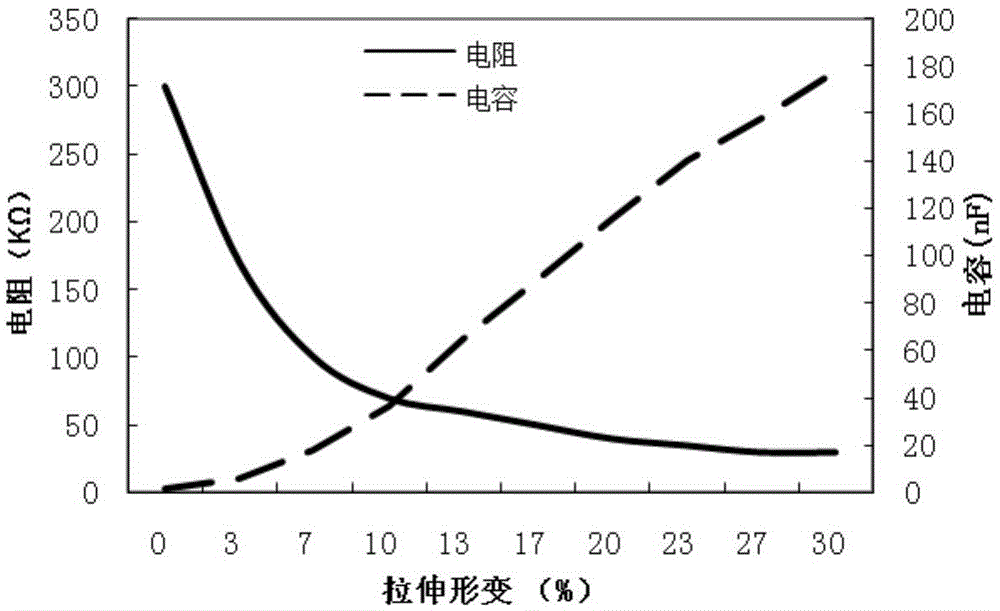

Conductive rubber material for flexible sensors and preparation method and application thereof

InactiveCN105647030ANarrow resistance distributionReduce pollutionNon-conductive material with dispersed conductive materialRubber materialEngineering

The invention is suitable for the field of flexible sensors and provides a conductive rubber material for flexible sensors and a preparation method and application thereof. The conductive rubber material is prepared from, by weight, 100 parts of rubber matrixes and 5-200 parts of conductive filler. The conductive rubber material is prepared in the mode that the conductive filler is dispersed in a rubber material and subjected to radiation crosslinking of electron beams or gamma rays.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

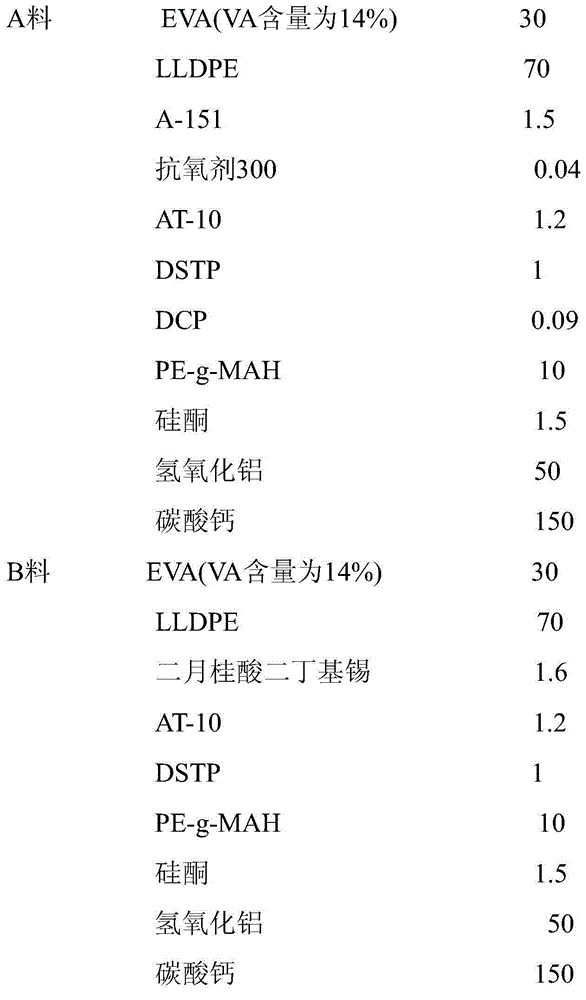

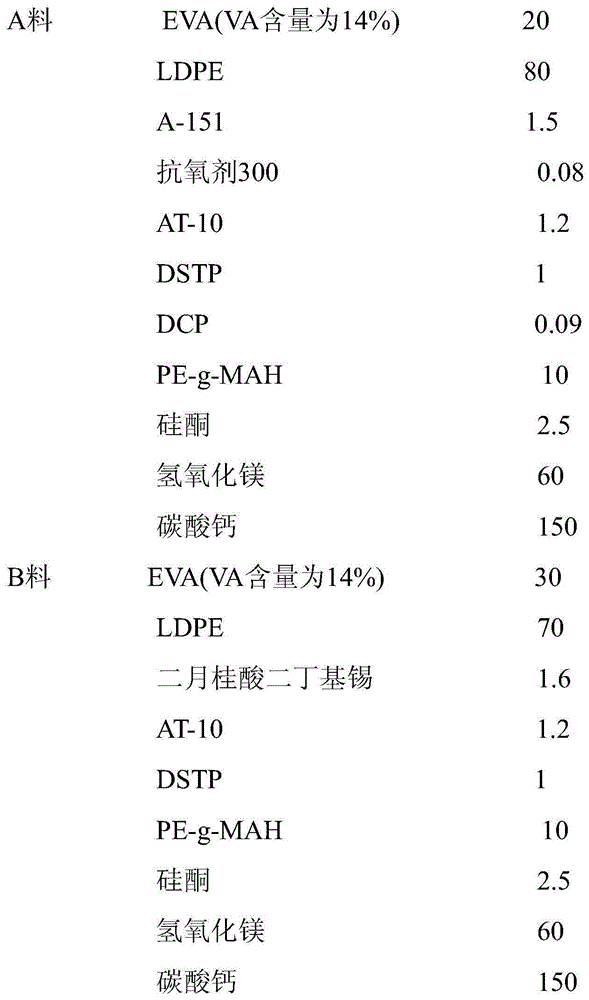

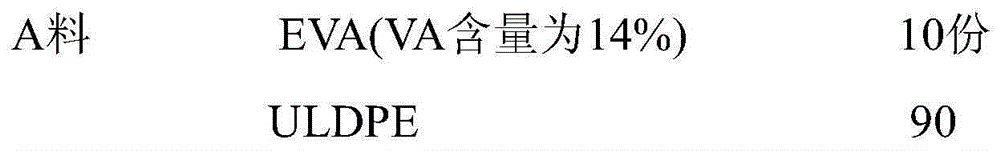

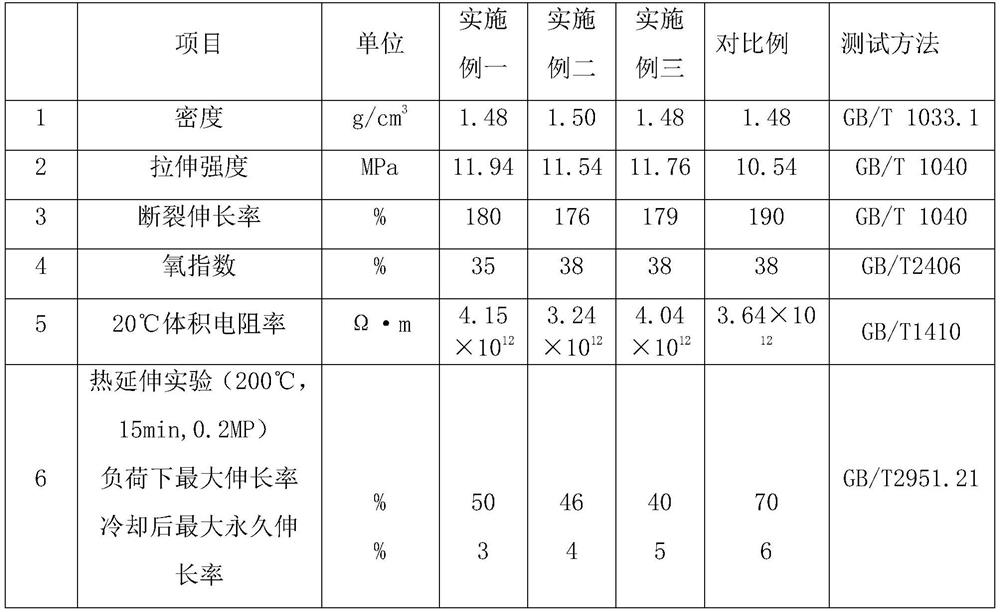

Easy-peel highlighted silane crosslinking flame-retardant polyolefin insulation material, preparation method and application thereof

InactiveCN105037911AEnhanced ease of peelingIncrease success ratePlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention relates to an easy-peel highlighted silane crosslinking flame-retardant polyolefin insulation material, a preparation method and application thereof, and aims to provide the polyolefin insulation material relatively good in mechanical property and electrical property. A prepared insulating layer of a low-smoke halogen-free flame-retardant cable is uniform in crosslinking, excellent in temperature endurance and easy to peel after being made into the cable, and in a high-speed paying-off situation, the cable surface is free of melt fracture, smooth, highlighted and easy to peel. The technical scheme is as follows: the polyolefin insulation material comprises an A material and a B material, wherein the A material comprises the following components: EVA, PE, a silane coupling agent, a primary antioxidant, an auxiliary antioxidant, an initiator, a compatilizer, a lubricating agent, a fire retardant and a filler; the B material comprises the following components: EVA, PE, a catalyst, a primary antioxidant, an auxiliary antioxidant, a compatilizer, a lubricating agent, a fire retardant and a filler.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

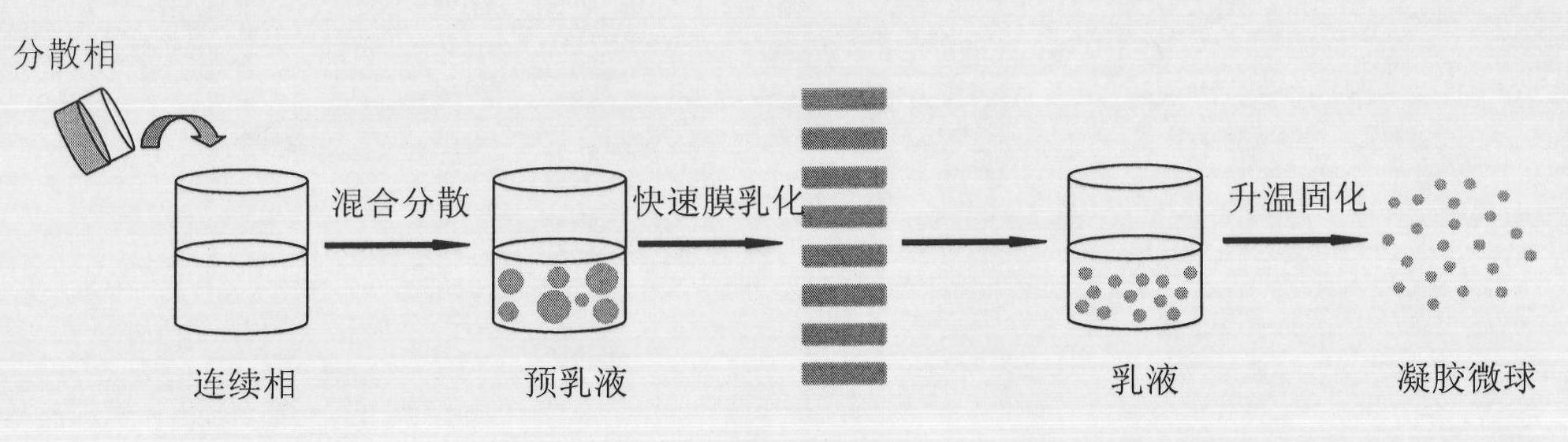

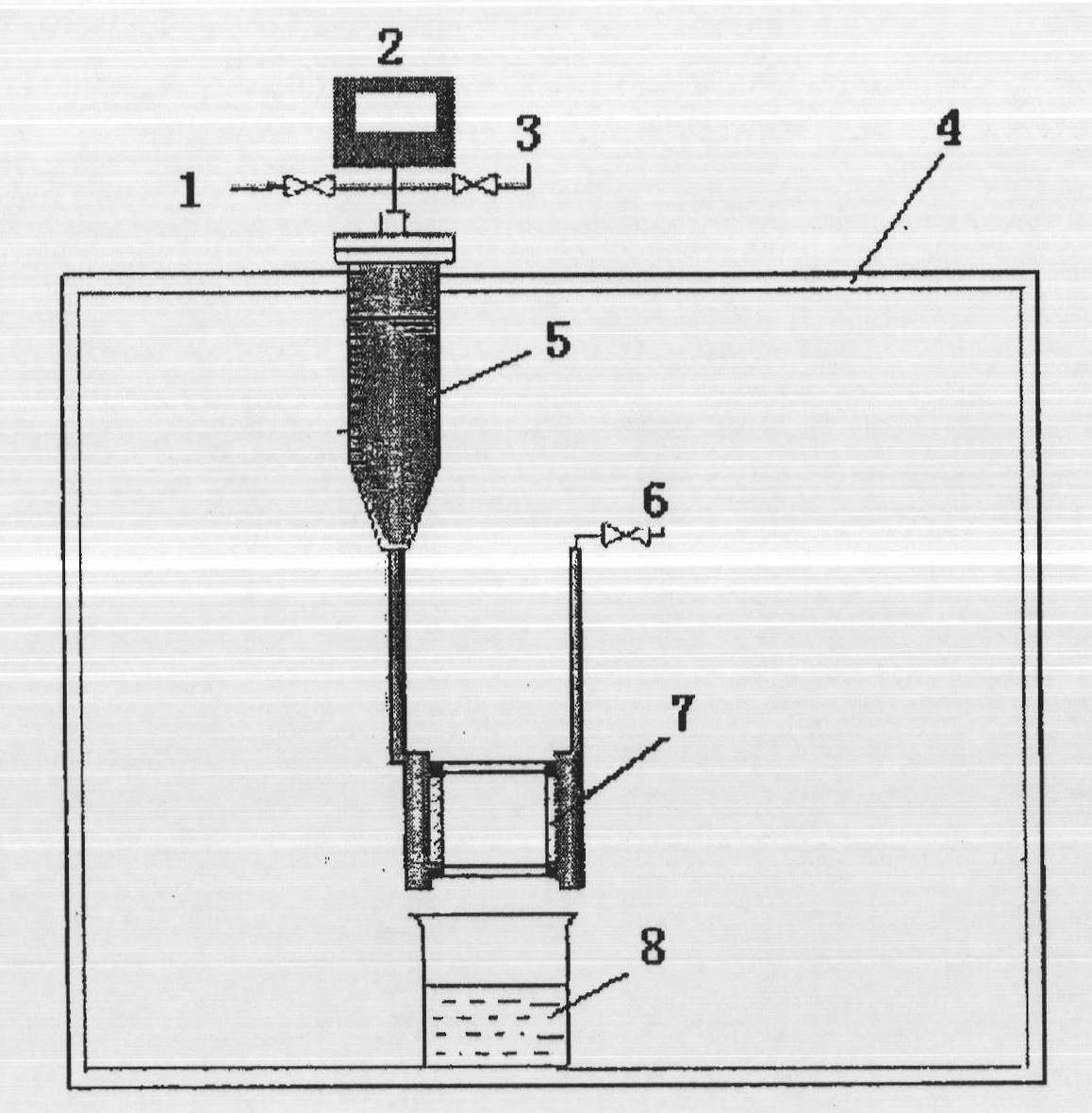

Self-solidified microspheres and preparation method and application thereof

ActiveCN102138904AImprove biological activityPromote biological responseCosmetic preparationsToilet preparationsEmulsionMicrosphere

The invention provides self-cured microspheres, which are prepared from a temperature-sensitive material with a lower critical soluble temperature, wherein the average particle size of the self-cured microspheres is in the range of 50nm to 100 microns, and the particle size distribution coefficient of the self-cured microspheres is smaller than 20%. The self-cured microspheres are prepared by thefollowing steps of: 1) providing a solution of the temperature-sensitive material added with bioactive substances or functional components as a dispersed phase; 2) providing emulsifying agent dissolved solvents which are dispersed and are insoluble with each other as continuous phases; 3) dispersing the dispersed phase in step 1) into the continuous phases in step 2) to obtain a pre-emulsion; 4) enabling the pre-emulsion in step 3) to pass through a microporous membrane for one time or a plurality of times under a pressure to obtain an emulsion; 5) heating the emulsion in step 4) to above thelower critical soluble temperature of the adopted temperature-sensitive material, so that liquid drops are cured to obtain the microspheres. The self-cured microspheres is suitable for serving as carriers of bioactive substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

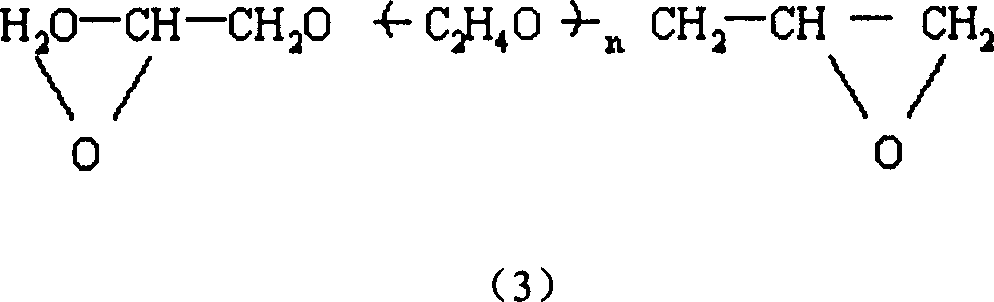

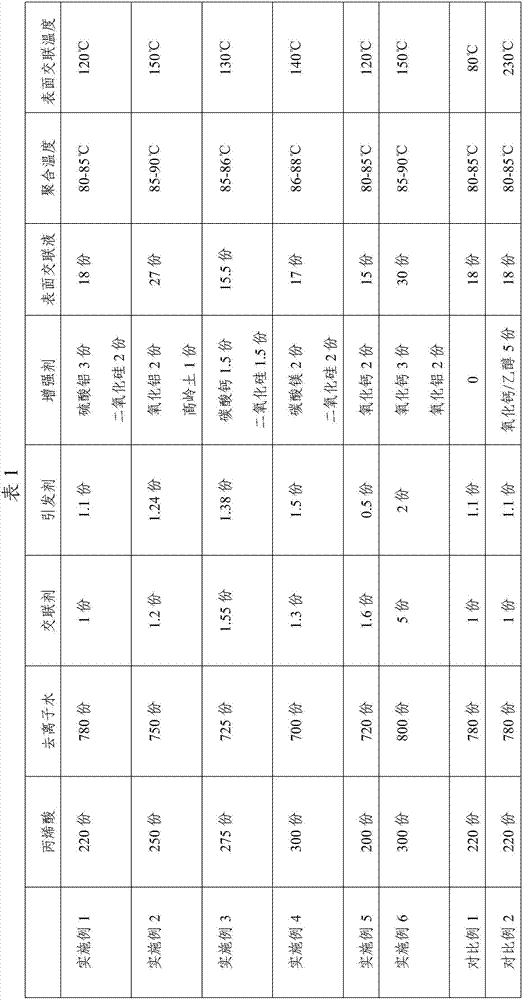

Preparation method of antibacterial super absorbent resin

The invention discloses a preparation method of antibacterial super absorbent resin. The preparation method comprises the following steps: firstly adding acrylic acid and deionized water into a reactor, adding 50% sodium hydroxide solution for neutralization, and adding acryloyl morpholine, ultrafine silicon dioxide and a complex cross-linking agent; then introducing nitrogen to remove oxygen for 30 min, adding an initiator to initiate a polymerization reaction at 20-30 DEG C, and regarding that the reaction is completed when the temperature does not rise; pelleting, drying and crushing gel to obtain water-absorbent resin particles; finally carrying out high-temperature processing at 120 DEG C on the resin particles through ethylene glycol, a nano-silver antibacterial and 25% aluminum sulfate for 2-5 hours to obtain the antibacterial super absorbent resin. The reparation method adopts a new antibacterial polymeric monomer, and the resin particles can reach a good antibacterial and sterilizing effect; a high low temperature compound type cross-linking agent is adopted, so that the cross-linking of molecules is more uniform; suspended silicon dioxide particles can guarantee good conductivity among the resin particles. No azo initiator is used, so that the antibacterial super absorbent resin is free of azo substance residues.

Owner:SHANDONG NUOER BIOLOGICAL TECH

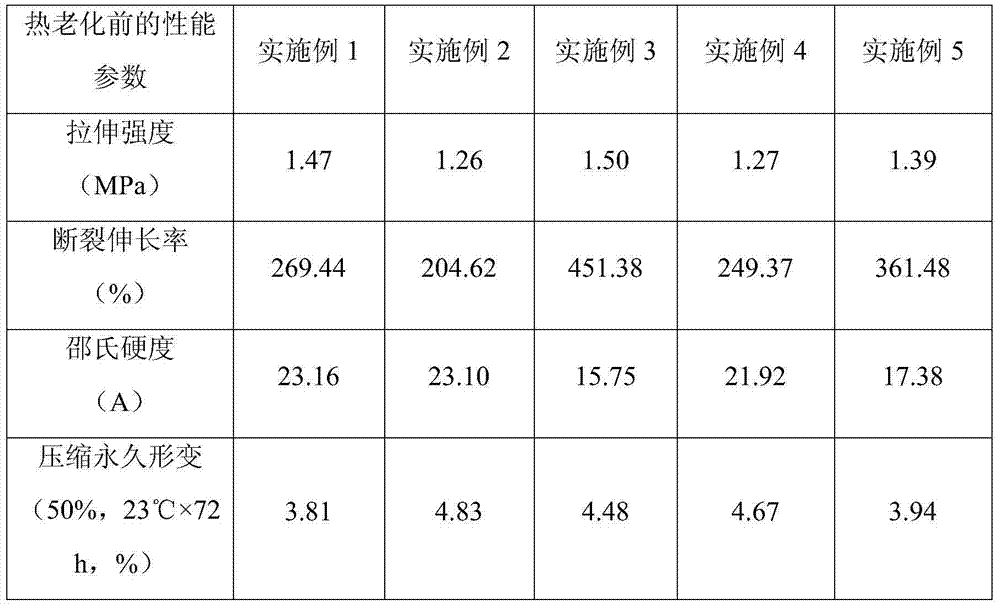

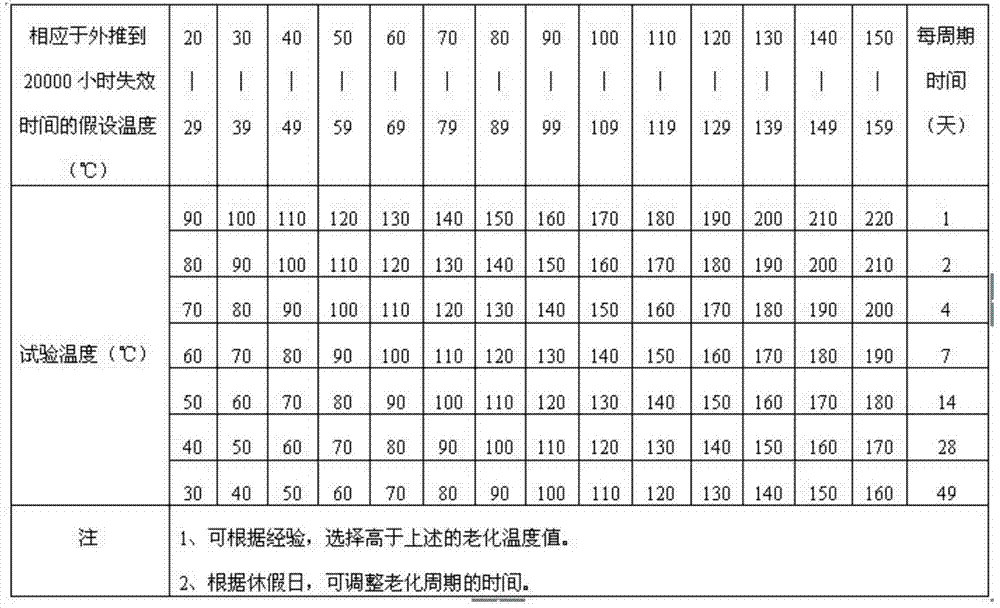

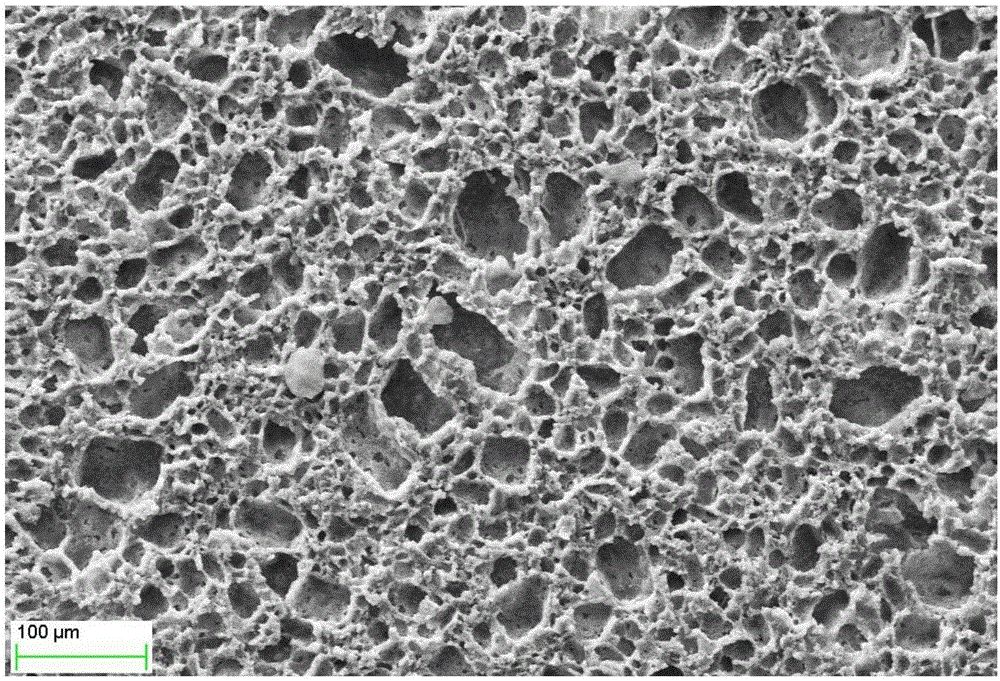

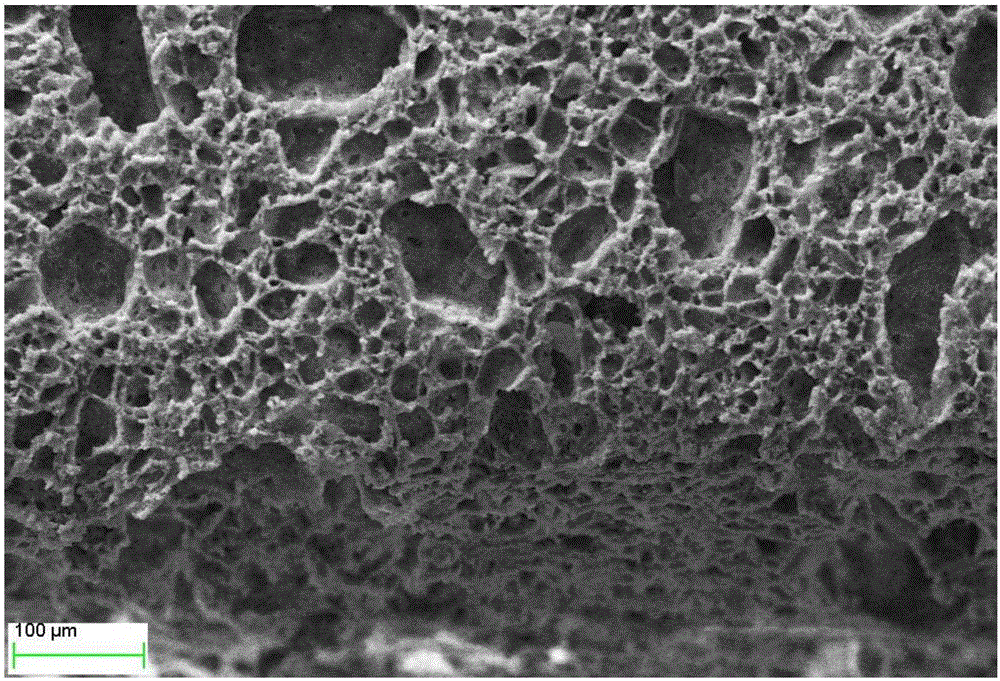

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Organic peroxide master batches and preparation method thereof

The invention discloses organic peroxide master batches and a preparation method of the master batches. The master batches take polyolefine elastomer (POE), ethylene-vinyl acetate copolymer (EVA), ethylene-propylene-butadiene ethylene-propylene diene monomer (EPDM) and other polymer as a substrate resin; and the selected peroxide is required to cross-link the substrate resin. The substrate resin granules are added in a liquid emulsion medium, which contains 0-98% of peroxide; at certain temperature and after enough long time, the polymer granules absorb the peroxide to prepare the peroxide master batches with 20-50% high concentration; and after the peroxide is absorbed, the liquid medium is required to exist around the polymer granules at certain quantity. The peroxide master batches disclosed by the invention are mainly used for the cross-linking process of polymers, thus the dispersion of the peroxide in a substrate material is improved, the organic peroxide is well dispersed in the substrate material and the material cross-linking is more uniform.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Low-density and high-porosity silicone rubber foam material and preparation method thereof

The invention discloses a low-density and high-porosity silicone rubber foam material and a preparation method thereof. The method is characterized by comprising the following steps: 100 parts of silicone rubber, 10 to 50 parts of a reinforcing agent, 1 to 7 parts of a control agent, 200 to 600 parts of a pore-forming agent, and 0 to 5 parts of a sensibilizer are mixed and molded, and then are radiated through gamma ray, so as to be subjected to crosslinking; the amount of radiation absorber is 30 to 100kGy; then the low-density and high-porosity silicone rubber foam material with excellent performance is obtained after elution and freeze drying. The material has the advantages that the technology is simple, complex chemical control process or professional auxiliary equipment is not needed, simple equipment, such as a two-roll mill, is only needed, and the cost is low; the silicone rubber foam material has the characteristics of low density and high porosity, is soft in material and excellent in elasticity, and can serve as a filling, positioning, sound-proof and vibration-absorptive material.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Self-adhesion silicon rubber material and preparation method thereof

InactiveCN106380860AUniform crosslinkingEasy to controlBulk chemical productionChemistryPolytetrafluoroethylene

The invention discloses a self-adhesion silicon rubber material and a preparation method thereof. The preparation method is characterized in that 100 parts of silicon rubber, 10 to 80 parts of a reinforcing agent, 1 to 9 parts of a controlling agent and 0 to 5 parts of a sensitizing agent are mixed and formed, and then are subjected to gamma-ray radiation to be crosslinked to obtain the self-adhesion silicon rubber material with excellent performance, wherein the radiation absorbed dose is 30 to 100 kGy. The self-adhesionsilicon rubber material and the preparation method thereof have the advantages that the process is simple, complex chemical raw materials and process control or professional auxiliary equipment are not needed, and the cost is relatively low; and the prepared silicon rubber material can be well adhered to various components or assemblies, such as metal, glass, polyethylene, polytetrafluoroethylene and the like, can maintain lasting adhesion, and can effectively prevent the components or the assemblies from falling off or sliding.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

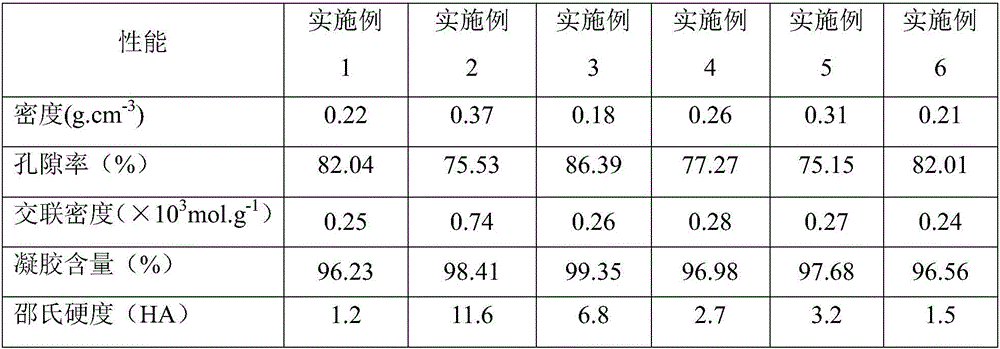

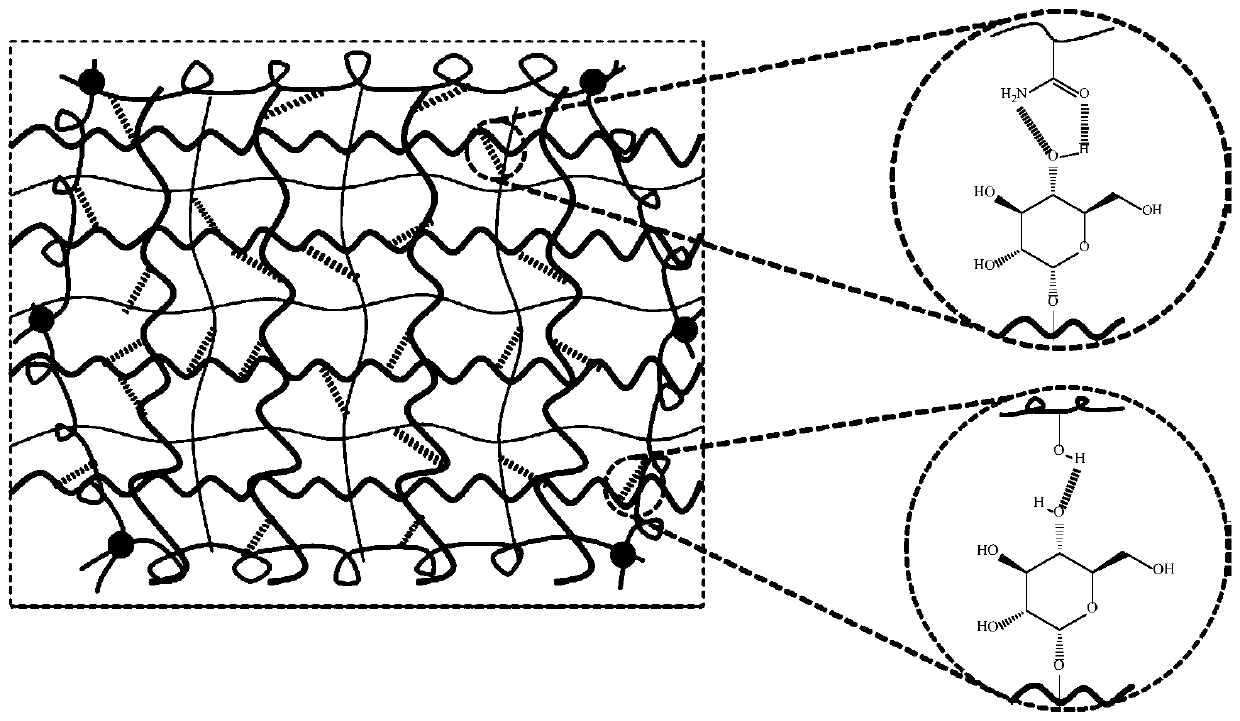

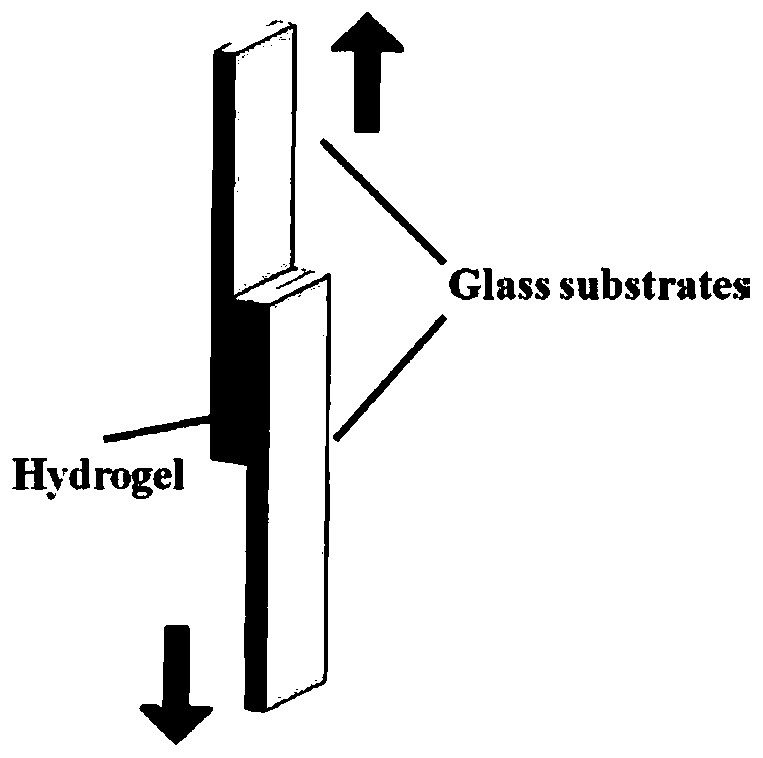

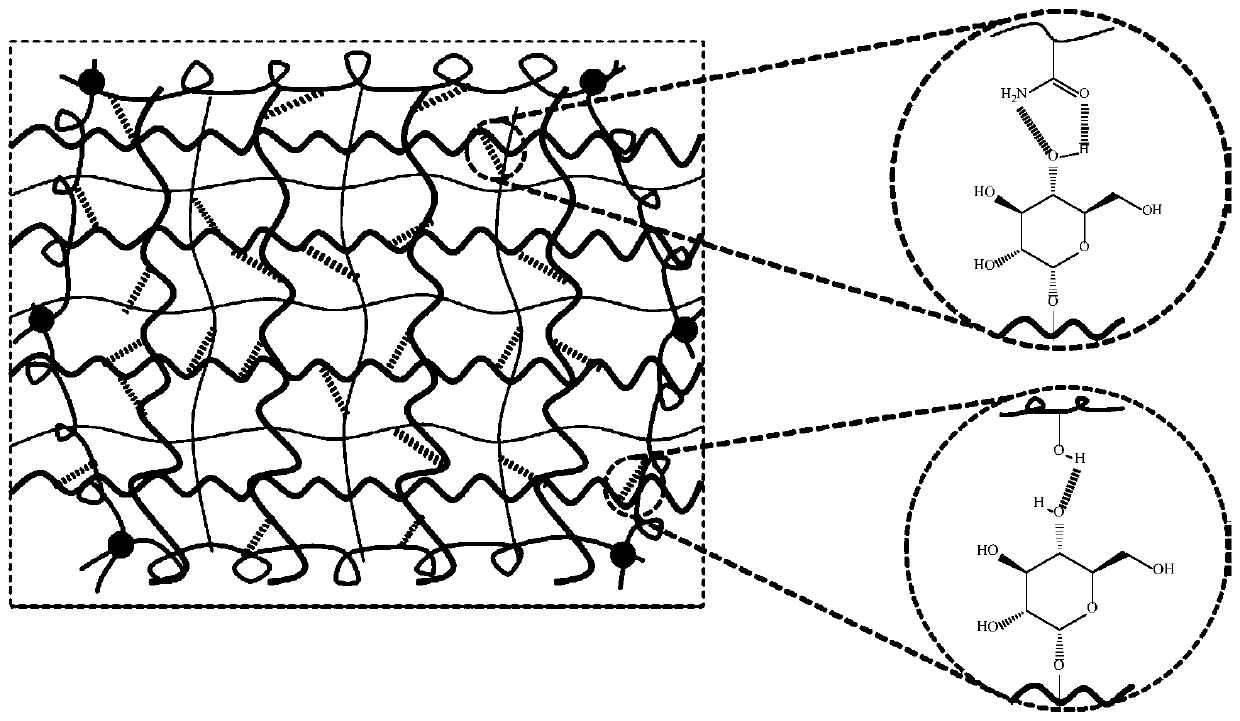

Preparation method of high-strength and high-adhesion branched starch composite hydrogel with strong hydrogen bonding effect

The invention discloses a preparation method of a high-strength and high-adhesion branched starch composite polyacrylamide / polyvinyl alcohol hydrogel with a strong hydrogen bonding effect, the methodcomprises the following steps: branched starch, polyvinyl alcohol, polymer monomer acrylamide and a photoinitiator are dissolved to obtain a uniform mixed solution, firstly, the uniform mixed solution is initiated under the condition of ultraviolet light, so that the acrylamide is polymerized, micro-crystals are formed in a polyvinyl alcohol network in the freezing and unfreezing process, a multi-hydrogen bond interaction can be formed between molecular chains of the branched starch and molecular chains of the polyacrylamide and molecular chains of the polyvinyl alcohol, and under the doubleactions of multiple hydrogen bonds and the micro-crystals, multi-physical-bond cooperative cross-linking is realized. The preparation process is simple and convenient to operate, and the prepared hydrogel has relatively high mechanical strength and excellent adhesion property on the surface of glass, and can be used as a preferred material of a soft robot.

Owner:HUBEI UNIV OF TECH

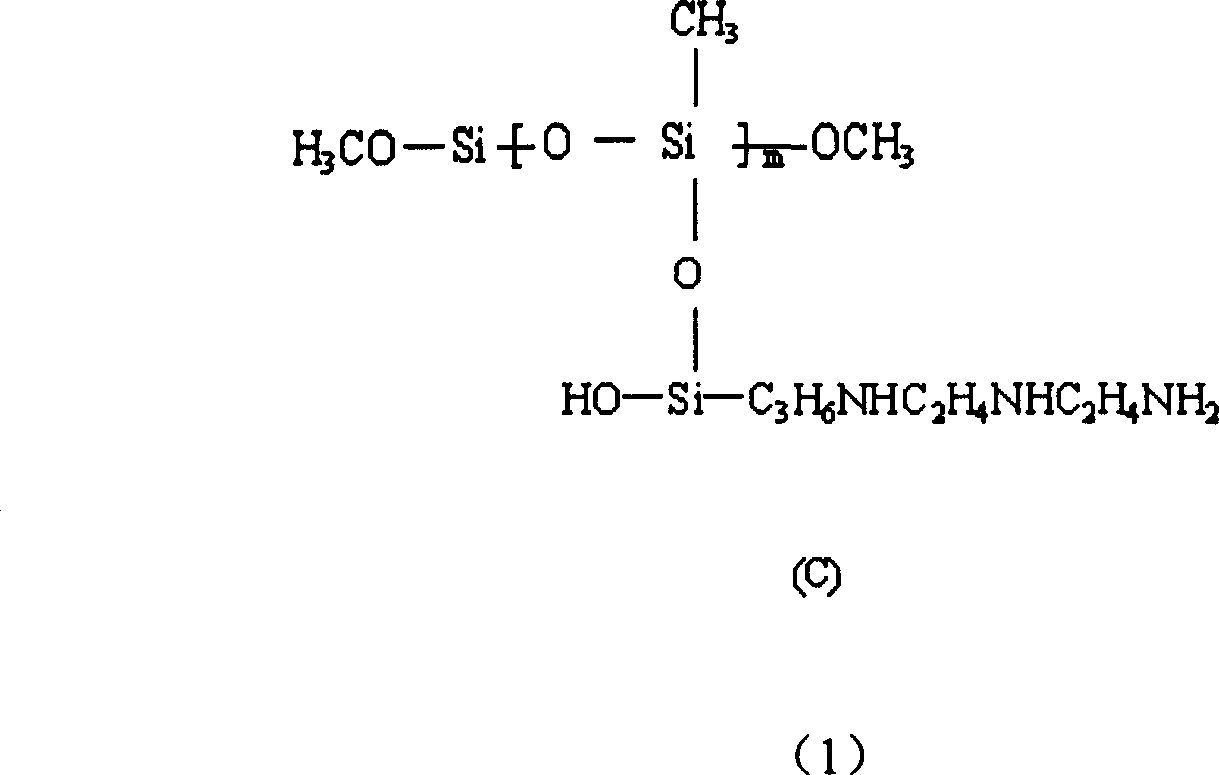

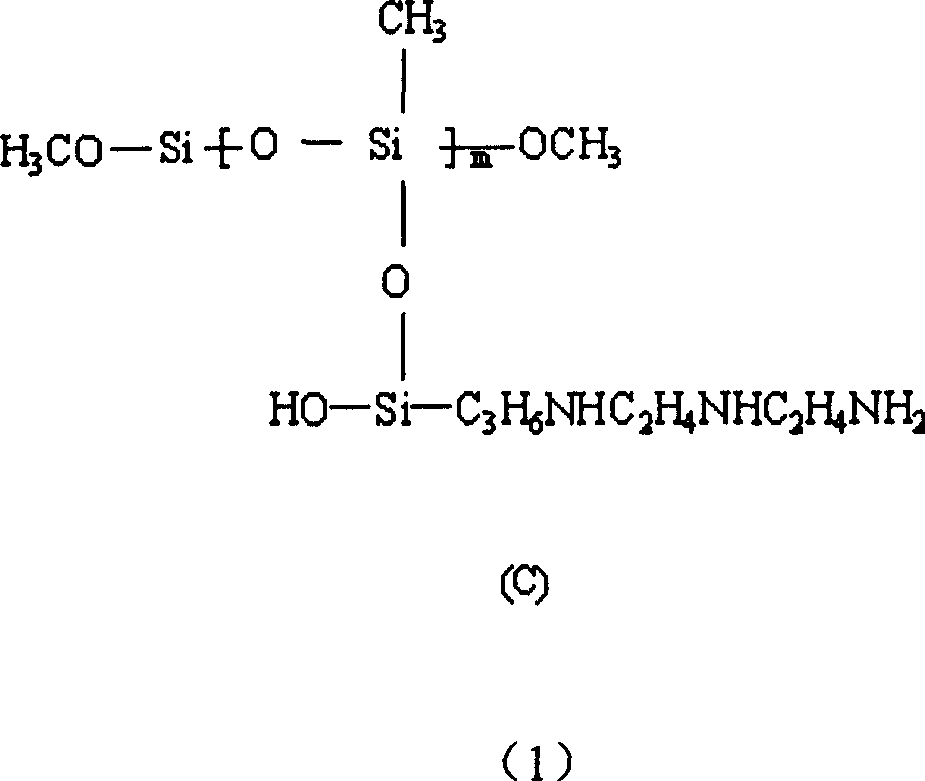

Wool fabric soft finish and application therefor

InactiveCN1970877AUniform crosslinkingGood color uniformity qualityFibre treatmentPerformance indexEngineering

The invention discloses a soft finishing agent for wood fabric and the application. The agent in the invention is suitable for softening finishing of wood fabric. Performance indexes of the wood fabric in the invention, such as softness (pure bending, shearing performance, drape coefficient), anti-pilling (pilling index), machine washing performance (total shrinkage and relaxed shrinkage) and so on, are superior to the related standard of international woodmark and nation. The invention is provided with good quality for color even degree in vision, good performance for anti-teasing and anti-pilling, good handle feeling and good softness degree. There is no international forbidden material in it and when finishing there is no poisonous gas with strong odor discharging. It is in favor of environmental protection.

Owner:SHANGHAI SANMAO ENTERPRISE GROUP

Preparation method of super absorbent resin resistant to moisture absorption and caking

The invention relates to a preparation method of super absorbent resin resistant to moisture absorption and caking. The preparation method comprises the following steps: introducing nitrogen to removal oxygen after mixing acrylic acid, water and a cross-linking agent, then adding an initiating agent until the temperature is not increased, and then preserving the temperature to obtain a product; treating the obtained product to obtain resin particles; adding reinforcing agent powder into the resin particles to be mixed uniformly, then adding a surface cross-linking solution to be stirred uniformly, preserving the temperature at the temperature of 120 to 200 DEG C to obtain the super absorbent resin, wherein the reinforcing agent is selected from one or more of calcium oxide, kaoline, silica, aluminum sulfate, aluminum oxide, calcium carbonate and magnesium carbonate. The super absorbent resin synthesized by using the method is highly uniform in surface cross-linking degree and high in strength, is not easy for moisture absorption and caking in air, can be stored for longer time, is unlikely to cause gel blockage after liquid absorption, and has good liquid flowing performance and conduction performance.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Low-smoke zero-halogen flame-retardant polyolefin thermoplastic elastomer and preparation method thereof

InactiveCN103435903AIncrease elasticityImprove wear resistanceRubber insulatorsPlastic/resin/waxes insulatorsInsulation layerPolymer science

The invention relates to a low-smoke zero-halogen flame-retardant polyolefin thermoplastic elastomer and a preparation method thereof and particularly relates to an elastic polyolefin particle for preparing a soft movable low-smoke zero-halogen flame-retardant cable insulation layer or sheath layer and a preparation method thereof. The low-smoke zero-halogen flame-retardant polyolefin thermoplastic elastomer is prepared by mixing raw materials such as an ethylene-octene copolymer, an ethylene propylene diene monomer, ethylene-vinyl acetate copolymerization resin, aluminum hydroxide, magnesium hydrate, magnesium stearate, an antioxidant, polyethylene wax, a crosslinking agent, a vulcanizing agent and the like, and extruding by using a six-temperature-stage double-screw extruder. When used for manufacturing electric wires and cables, the low-smoke zero-halogen flame-retardant polyolefin thermoplastic elastomer has the characteristics of simple machining process, low smoke, zero halogen, flame retardance, softness, good elasticity, good wear resistance and the like.

Owner:WUXI JAKE PLASTIC

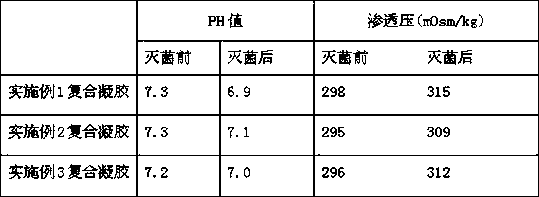

Preparation method and application of hyaluronic acid plural gel

ActiveCN105504313AImprove homogeneityUniform crosslinkingSurgeryPharmaceutical delivery mechanismMedicineHyaluronic acid

The invention relates to the field of hyaluronic acid plural gel and particularly relates to a preparation method of hyaluronic acid plural gel. According to the preparation method, homogenizing of a crosslinking system and the prepared gel is realized through the combination of multiple parameters in multiple time periods, and sufficient uniform mixing of the system is realized through low-temperature and high-frequency oscillation in earlier stage; and in the middle and later stages, different oscillation frequencies are set to promote reactions producing gel and reduce gel damage in the preparation process so as to obtain a new plural gel. The invention also provides an application of the plural gel in medical treatment or prevention.

Owner:HANGZHOU SINGCLEAN MEDICAL PROD

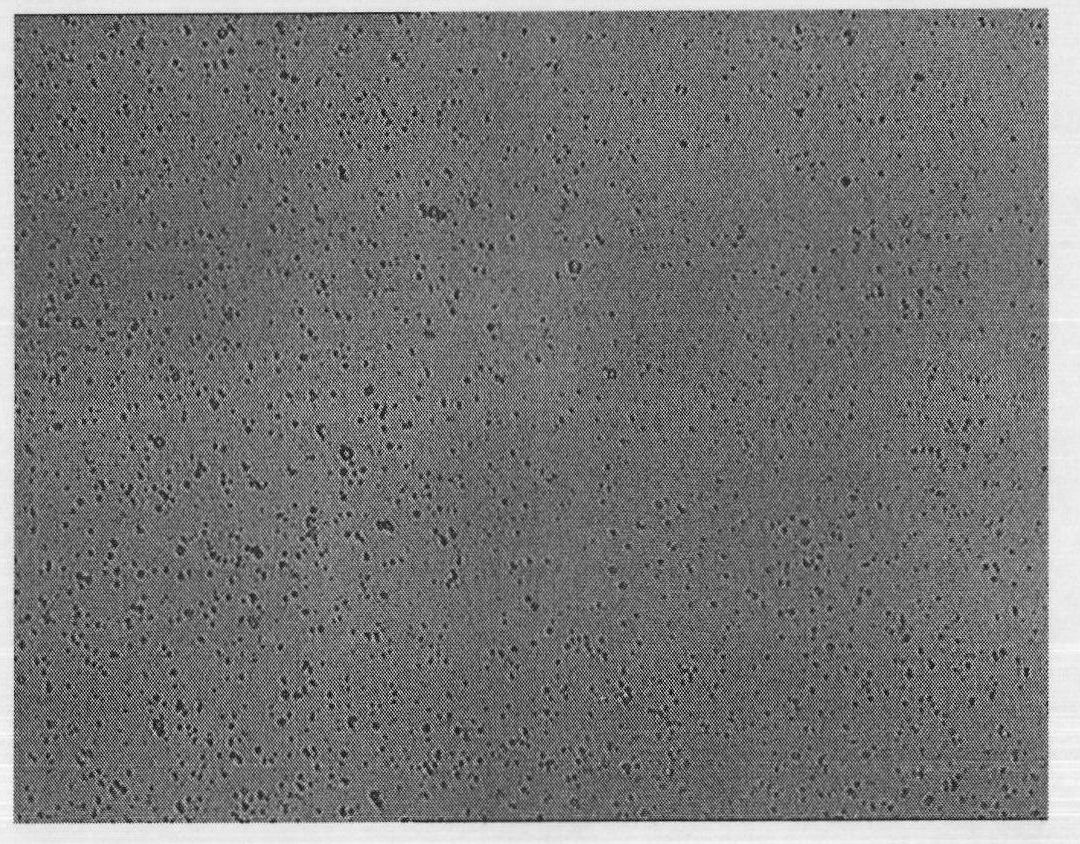

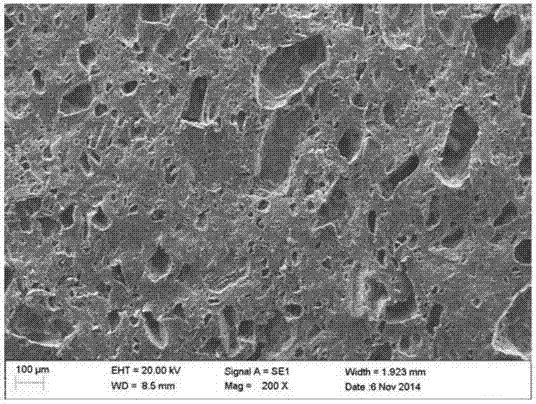

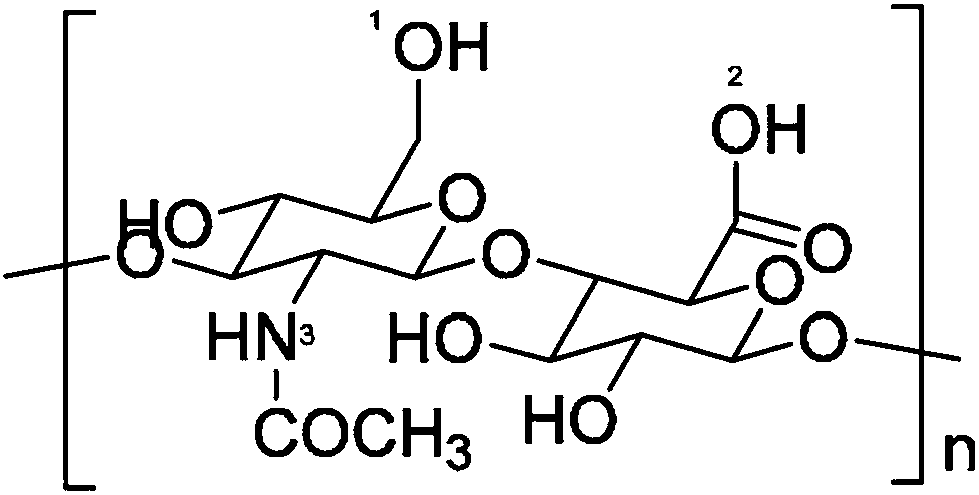

Preparation method and application of cross-linked hyaluronic acid gel microspheres

ActiveCN108478875AUniform crosslinkingThe particle distribution is round and uniformPharmaceutical delivery mechanismProsthesisCross-linkTissue repair

The invention discloses a preparation method and application of cross-linked hyaluronic acid gel microspheres. The preparation method comprises the steps that a hyaluronic acid alkaline solution withthe concentration being 5-30% g / ml is prepared, inorganic dispersants are added into organic phase cyclohexane under stirring, full stirring is conducted, and thus the inorganic dispersants are uniformly dispersed. By adopting the technical scheme, the preparation method is simple, products are controllable in particle size, intact in form, low in impurity content, high in purity and highly transparent, and meanwhile, the degradation period can also be controlled within the range of 30-300 days. In the preparation method and the application of the cross-linked hyaluronic acid gel microspheres,the cross-linked hyaluronic acid gel microspheres prepared through the preparation method can be used for producing medical or prevention products and used for injection, tissue repair and tissue strength in animals and especially in humans; and because of the extremely-low impurity content, the products have good biocompatibility and degradability, and clinical safety is ensured.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Efficient ultraviolet crosslinking low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

PendingCN112300478AUniform crosslinkingImprove stabilityPlastic/resin/waxes insulatorsPolyethylene vinyl acetateElastomer

The invention relates to an efficient ultraviolet crosslinking low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable material comprises the following components in parts by weight: 30-50 parts of polyethylene vinyl acetate resin, 20-30 parts of elastomer resin, 15-25 parts of a compatilizer, 5-15 parts of polyethylene resin, 1-2 parts of an antioxidant, 1-2 parts of a lubricant, 2-4 parts of a photoinitiator, 3-5 parts of a crosslinking agent and 150-200 parts of a flame retardant. The raw material components are simple and easy to obtain,the preparation method is simple, and the crosslinking efficiency of the polyolefin cable material is improved by utilizing the combination of multiple free radical photoinitiators; on the premise ofensuring the mechanical properties and aging resistance of the material, a proper amount of halogen-free flame retardant is added, so that the material has high flame retardancy, the finally preparedcable material is uniform in crosslinking, high in stability and high in crosslinking efficiency, and the production efficiency of wires and cables is improved in a disguised manner.

Owner:WUXI JAKE PLASTIC

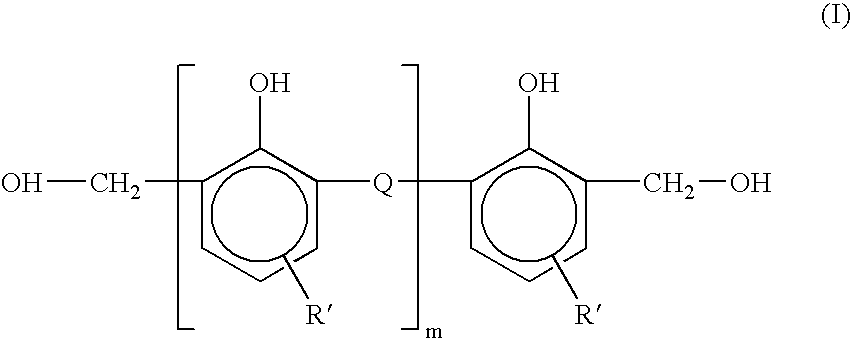

Resin composition

A resin composition comprises (a) 100 parts by weight of at least one compound selected from the group consisting of phenol resins and brominated phenol resins, (b) 20 to 500 parts by weight of a crystalline olefin resin, provides that copolymers of ethylene with unsaturated carboxylic acid ester or vinyl acetate are precluded, and (c) 0 to 300 parts by weight of a non-aromatic softening agent for rubber. The resin composition is easy to handle in dynamic cross-linking of rubber or a thermoplastic elastomer to give uniform cross-linking. A cross-linked rubber composition or thermoplastic elastomer composition has improved compression set and moldability.

Owner:RIKEN TECHNOS CORP

Injectable self-healing hydrogel with conductivity and preparation method thereof

The invention relates to injectable self-healing hydrogel with conductivity and a preparation method thereof. The method comprises the steps that firstly, a methacrylic anhydride modified natural polymer is adopted, then, pyrrole is added into a modified natural polymer solution, stirring is performed for 1-3 h, then, an initiator is added, and after a reaction is ended, dialysis and freeze dryingare performed to obtain a polypyrrole grafted natural polymer; then, the polypyrrole grafted natural polymer is dissolved into ultra pure water, and then, due to the Fe3+ cross linking effect, the injectable self-healing hydrogel with the conductivity is prepared. The prepared self-healing hydrogel has the advantages of conductivity and injectability, the hydrogel can be implanted into the body in a minimally invasive mode, the irregular defect part is restored, and meanwhile wound healing is promoted. The injectable self-healing hydrogel has the potential application prospect in the field ofbiology medicine materials.

Owner:四川创智炜业科技有限公司

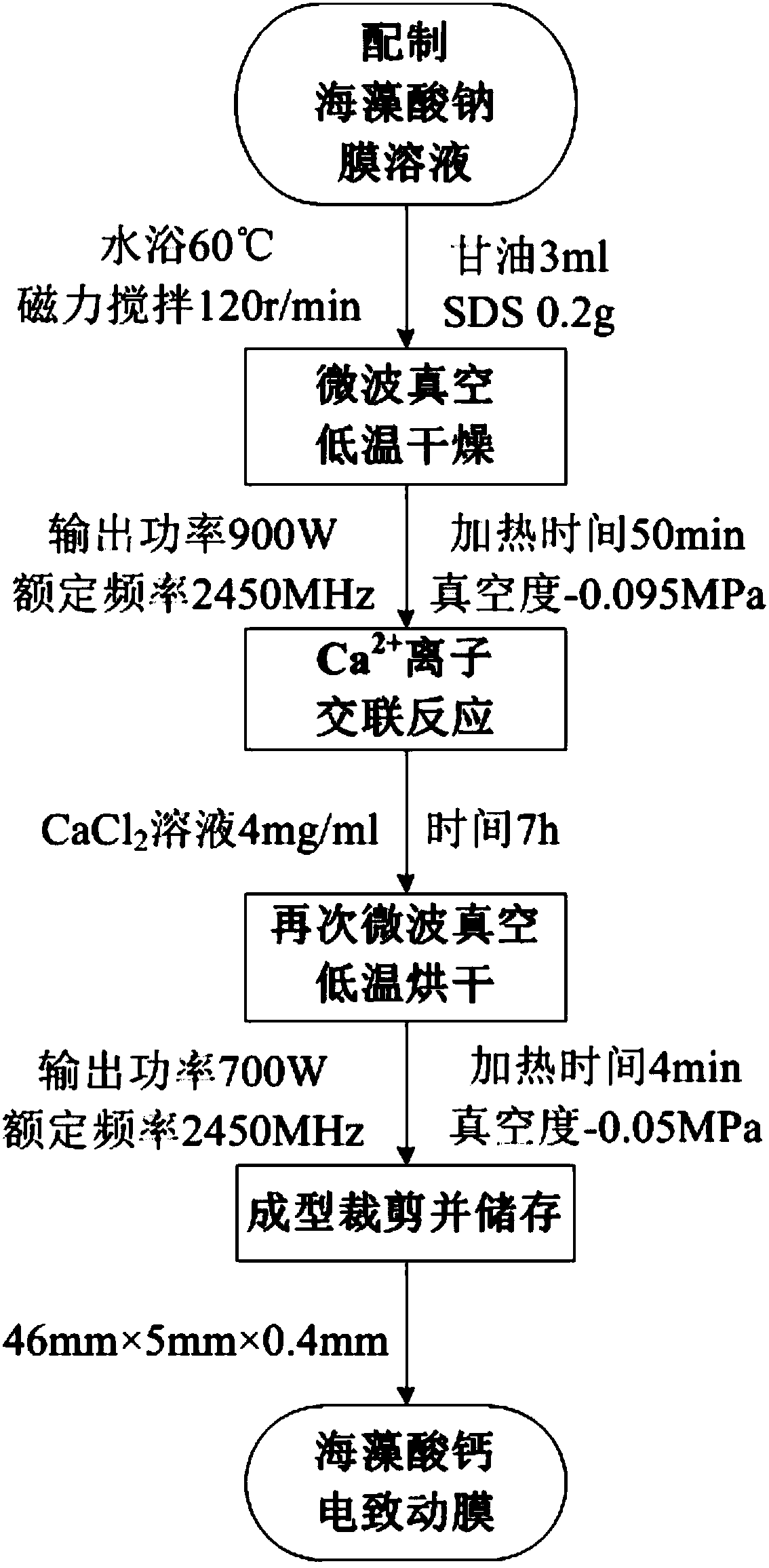

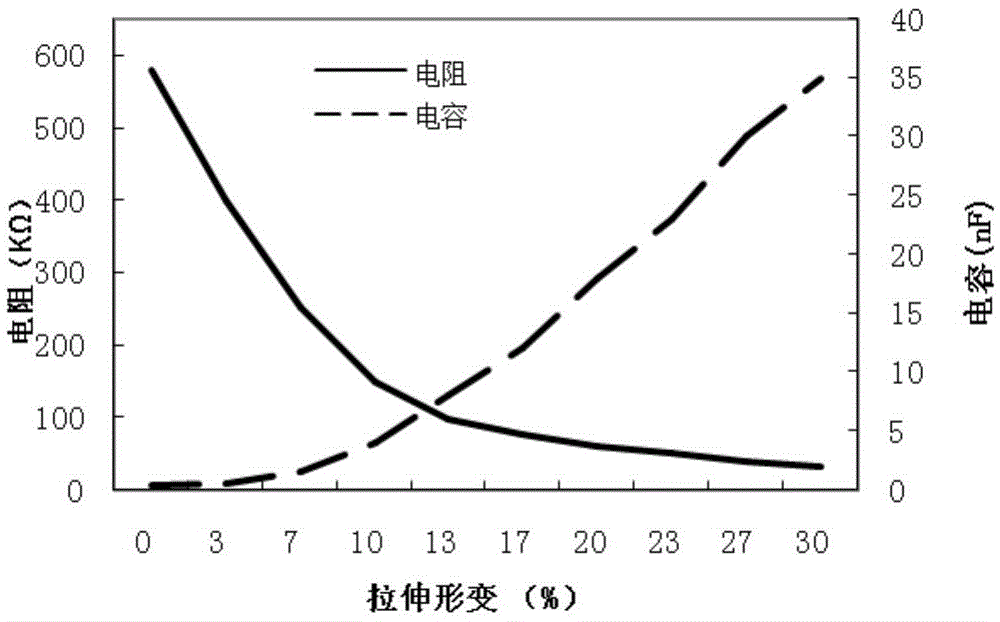

Preparation method of calcium alginate electrically-driven film adopting microwave vacuum low-temperature drying technology

InactiveCN108484955AFlat surfaceReduced diffusion rateProgramme-controlled manipulatorChemical industryCross-linkPolymer science

The invention provides a preparation method of a calcium alginate electrically-driven film adopting a microwave vacuum low-temperature drying technology. The microwave vacuum low-temperature drying technology is adopted, and through the combination with the two technologies of microwave drying and vacuum drying, the advantages of the two technologies are sufficiently and comprehensively developed.The preparation method comprises the following steps: using natural macromolecular biological materials of sodium alga acid as a film forming main material and a cross-linking agent CaCl2, and addingplasticizer glycerinum and plastic assisting agent lauryl sodium sulfate so as to prepare the calcium alginate electrically-driven film of a three-dimensional network gel structure. The raw materialsare wide in sources and low in cost, and the obtained electrically-driven film is non-toxic, tasteless and biodegradable. After microwave vacuum drying, hierarchical pore structures are connected with one another and are regular, the ionic cross-linking of Ca<2+> on the inner layer and the outer layer is comprehensive and uniform, and the electrically-driven film is excellent and controllable inelectrically-driven performance and long in service life. The microwave vacuum low-temperature drying technology of the calcium alginate electrically-driven film prepared in the invention is energy-saving, efficient and free of pollution, and is mostly beneficial for high molecular material synthesis and curing reaction with extremely high requirement for heating rate and uniformity.

Owner:HARBIN ENG UNIV

Preparation method of edible collagen membrane

The invention discloses a preparation method of an edible collagen membrane. The method comprises the following steps: first, performing a reaction on animal collagen dissolved by an acetic acid solution and hydroxycarboxylic acid-N-hydroxysuccinimide ester, removing bubbles, performing film forming and drying to obtain a transparent collagen membrane, soaking the obtained transparent collagen membrane in a solution containing oxidase for a reaction, after the reaction is finished, performing washing by water and performing drying to obtain the edible collagen membrane. In the method provided by the invention, with the adoption of step-by-step crosslinking modification on a collagen membrane, the system is uniform in crosslinking, the membrane is more uniform and compact, and the crosslinking degree is higher, so that the tensile strength of the membrane can be greatly improved, and meanwhile, the membrane is transparent in color, and is more suitable for being used as a packaging material for highlighting the color of packaged objects. The method provided by the invention is simple in method and easy in operation and is easy for popularization and application.

Owner:SICHUAN UNIV

Cable insulating material with good thermal stability and corrosion resistance

InactiveCN106317630AHigh mechanical strengthGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideChlorinated paraffins

The invention discloses a cable insulating material with good thermal stability and corrosion resistance. The cable insulating material is prepared from raw materials in parts by weight as follows: 15-35 parts of polyvinyl chloride thermoplastic elastomers, 15-25 parts of polypropylene, 10-20 parts of high density polyethylene, 5-10 parts of heavy calcium carbonate, 4-12 parts of glass fibers, 3-8 parts of barium sulfate, 2-8 parts of wollastonite, 1-6 parts of mica powder, 1-5 parts of modified lecithin, 0.5-1.5 parts of disproportionated rosin, 0.5-1.5 parts of chlorinated paraffin, 0.2-0.8 parts of liquid coumarone, 0.2-0.8 parts of pine tar, 0.2-0.8 parts of cresyl diphenyl phosphate, 1.2-1.8 parts of an antioxidant 1010, 1.2-1.8 parts of a stabilizer, 1-2 parts of an antistatic agent and 1-2 parts of a colorant. The cable insulating material has good thermal stability, high mechanical strength and excellent corrosion resistance.

Owner:ANHUI LAND GRP

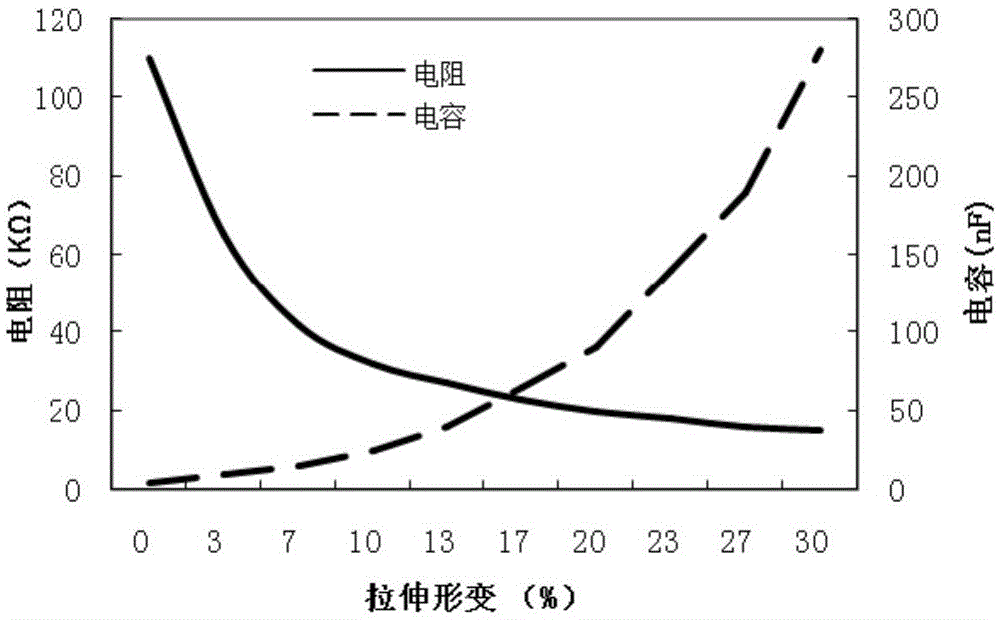

Conductive rubber material used for flexible sensor as well as preparation method and application of conductive rubber material

InactiveCN105542246ANarrow resistance distributionReduce pollutionForce measurementNon-conductive material with dispersed conductive materialRubber materialEngineering

The invention provides a conductive rubber material used for a flexible sensor as well as a preparation method and application of the conductive rubber material, and is applicable to the field of flexible sensors. The conductive rubber material is prepared from the following components in parts by weight: 100 parts of a rubber base body and 5 to 100 parts of conductive fillers, wherein the rubber base body is a rubber base body containing cis-1,4-isoprene structure; the conductive rubber material is prepared by dispersing the conductive fillers into a rubber material, radiating by electronic beams or gamma rays and crossly linking.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

Parallel bundle-assembled overhead insulation cable and production process thereof

ActiveCN106298014AHigh breaking forceIncrease the installation distanceFlexible cablesFlexible conductorsYarnFiber

The invention relates to a parallel bundle-assembled overhead insulation cable and a production process thereof. The parallel bundle-assembled overhead insulation cable comprises compression conductors, the compression conductors are formed by twisting of circular carbon fiber yarns and irregular hard aluminum wires arranged at outer walls of the circular carbon fiber yarns, outer walls of the compression conductors are provided with insulating layers, the insulating layers are connected with connecting ribs, and the upper surfaces of the connecting ribs are provided with marking lines. The production process of the parallel bundle-assembled overhead insulation cable comprises wire drawing, wire twisting, extrusion molding, and crosslinking. The cable and the production process thereof are advantageous in that the production efficiency is high, the service lifetime is long, the overall cost is low, and the promotion is facilitated.

Owner:HENAN LESHAN CABLE

A kind of preparation method of antibacterial superabsorbent resin

The invention discloses a preparation method of antibacterial super absorbent resin. The preparation method comprises the following steps: firstly adding acrylic acid and deionized water into a reactor, adding 50% sodium hydroxide solution for neutralization, and adding acryloyl morpholine, ultrafine silicon dioxide and a complex cross-linking agent; then introducing nitrogen to remove oxygen for 30 min, adding an initiator to initiate a polymerization reaction at 20-30 DEG C, and regarding that the reaction is completed when the temperature does not rise; pelleting, drying and crushing gel to obtain water-absorbent resin particles; finally carrying out high-temperature processing at 120 DEG C on the resin particles through ethylene glycol, a nano-silver antibacterial and 25% aluminum sulfate for 2-5 hours to obtain the antibacterial super absorbent resin. The reparation method adopts a new antibacterial polymeric monomer, and the resin particles can reach a good antibacterial and sterilizing effect; a high low temperature compound type cross-linking agent is adopted, so that the cross-linking of molecules is more uniform; suspended silicon dioxide particles can guarantee good conductivity among the resin particles. No azo initiator is used, so that the antibacterial super absorbent resin is free of azo substance residues.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Anti-adhesion membrane

ActiveUS8741969B2Uniform crosslinkingHigh strengthBiocideConnective tissue peptidesDry weightPhosphate

An object of the present invention is to provide an anti-adhesion membrane that has no toxicity to a living body, has flexibility allowing itself to fit an affected part as a hydrated gel, is uniformly crosslinked, and is immediately absorbed in a living body after maintaining its shape in the living body for a certain period of time.The present invention provides anti-adhesion material, which comprises a thermally crosslinked gelatin film, and has a water content of 60 to 85% calculated by the following formula (1):water content (%)=[(Ws−Wd) / Ws]×100(%) (1),in the formula (1), Ws representing a weight (wet weight) of the anti-adhesion material immersed in a phosphate buffered saline solution at a temperature of 25° C. for one hour, and Wd representing a weight (dry weight) of the anti-adhesion material dried completely using a vacuum drying apparatus.

Owner:GUNZE LTD

Super-hydrophobic antifouling ceramic tile

InactiveCN112322185AImprove hydrophobicityUniform crosslinkingAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention relates to a super-hydrophobic antifouling ceramic tile which is characterized in that the surface of the ceramic tile is coated with a super-hydrophobic fluorosilicone resin ceramic antifouling agent by about 1-2g / cm < 2 >, and the super-hydrophobic antifouling ceramic tile is obtained. According to the super-hydrophobic fluorosilicone resin ceramic antifouling agent, perfluoro hydrogen-containing polymethylhydrosiloxane is used as matrix resin, amino-substituted polyhedral oligomeric silsesquioxane and polyisocyanate are used as cross-linking catalysts, and nano aluminum oxideis used as reinforcing filler so that the super-hydrophobic fluorosilicone resin antifouling agent which is cured at normal temperature is generated. The super-hydrophobic antifouling ceramic tile issmall in glossiness influence, excellent in hydrophobicity and good in antifouling effect.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com