Preparation method of calcium alginate electrically-driven film adopting microwave vacuum low-temperature drying technology

A microwave vacuum and calcium alginate technology, which is applied in manufacturing tools, program-controlled manipulators, and sustainable manufacturing/processing, can solve the problems of poor mechanical strength, difficult operation, and cumbersome post-processing of calcium alginate hydrogels. Achieve the effect of uniform internal network structure, wide source of raw materials, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

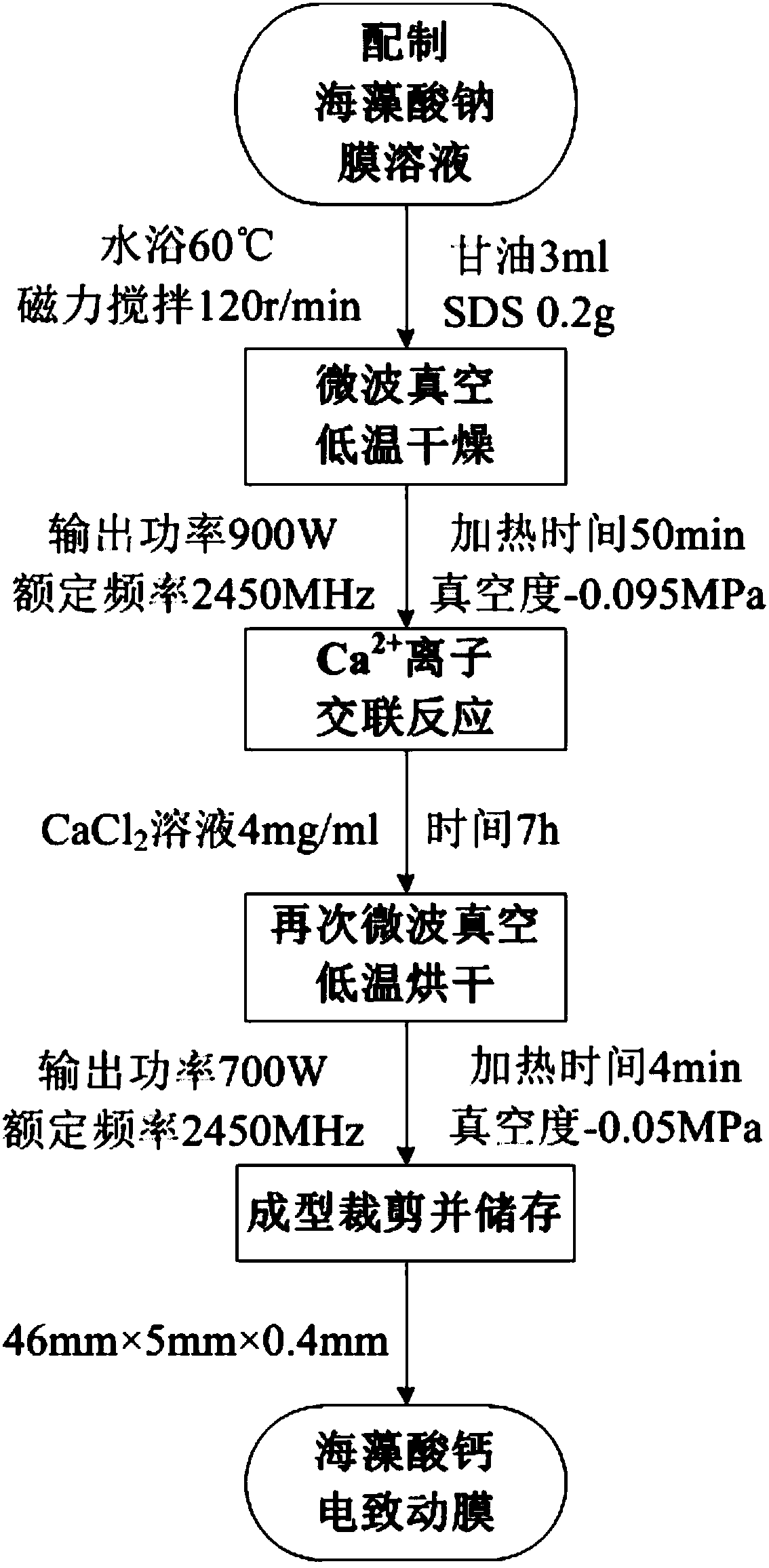

[0018] A method for preparing calcium alginate electro-actuated film using microwave vacuum low-temperature drying technology, using sodium alginate as the main material for film formation, adding plasticizer glycerin and plasticizer sodium dodecyl sulfate (SDS), Prepare the membrane solution; then put it into a microwave vacuum drying oven for microwave vacuum low-temperature drying to form a hierarchical porous membrane structure; after it is completely dried and formed into a membrane, take it out and immerse it in a CaCl2 solution for ion crosslinking reaction to generate a calcium alginate electro-actuated membrane with a three-dimensional network gel structure (commonly referred to as an "egg box" structure); finally, microwave vacuum drying is performed again at low temperature, and then cut into shape and stored. The above mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com