Patents

Literature

4936 results about "Molecular materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hemostatic fibrous material

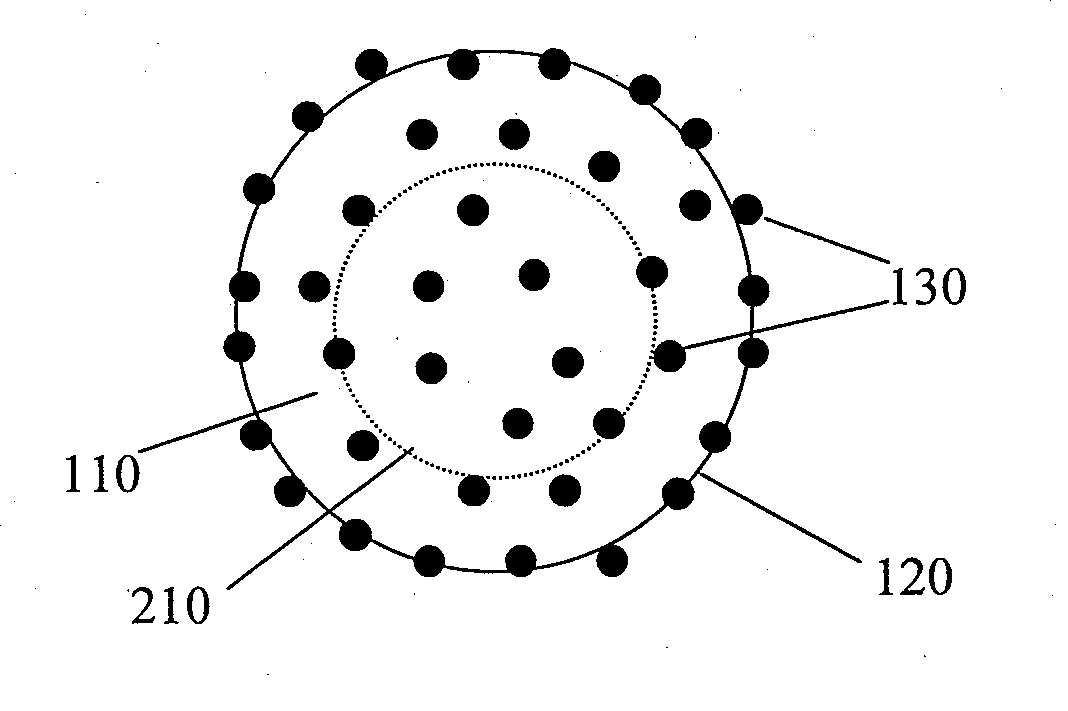

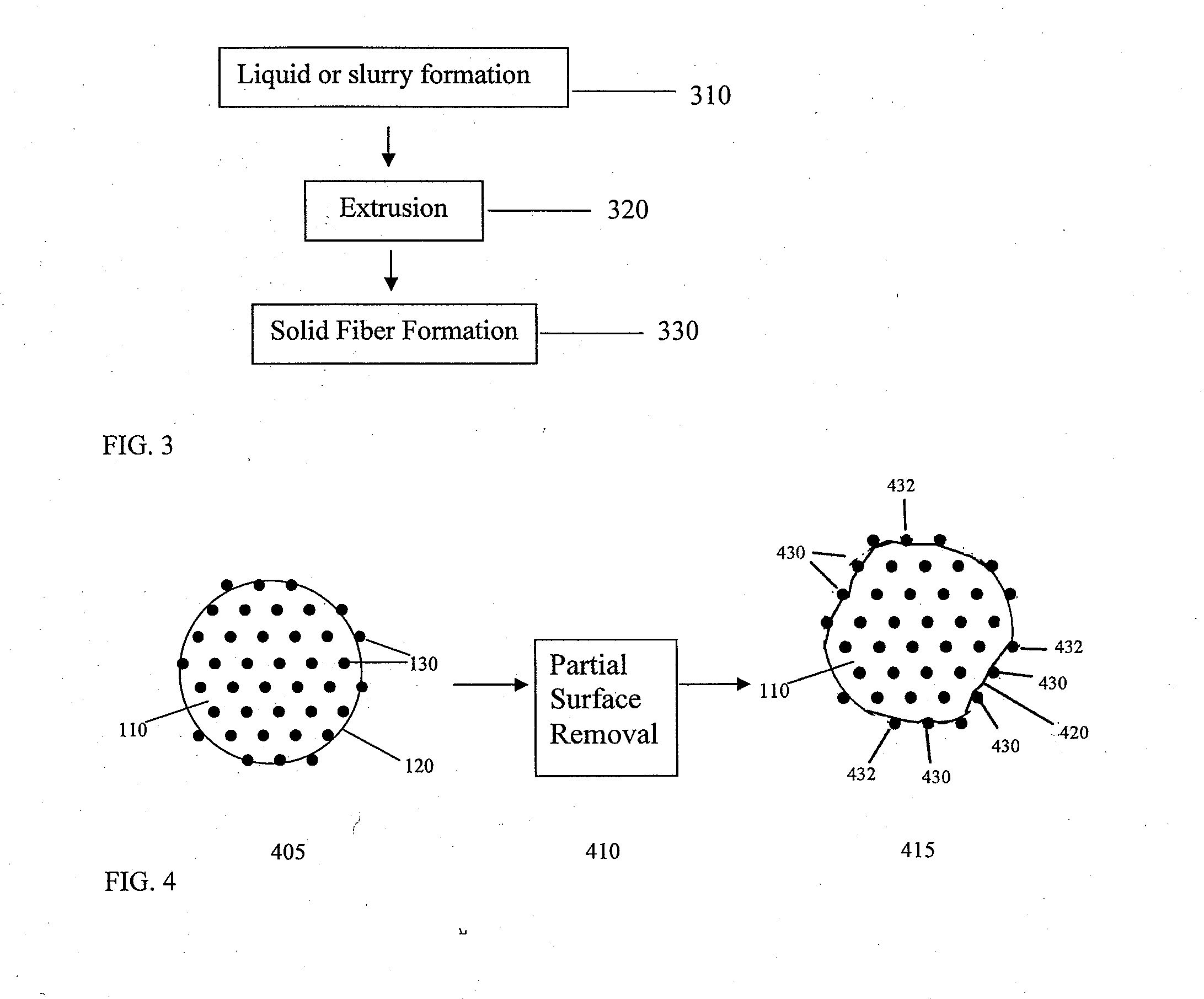

InactiveUS20120004636A1Promote blood clottingPromoting blood clottingBiocideDiagnosticsFiberMolecular materials

Owner:TELEFLEX LIFE SCI LTD

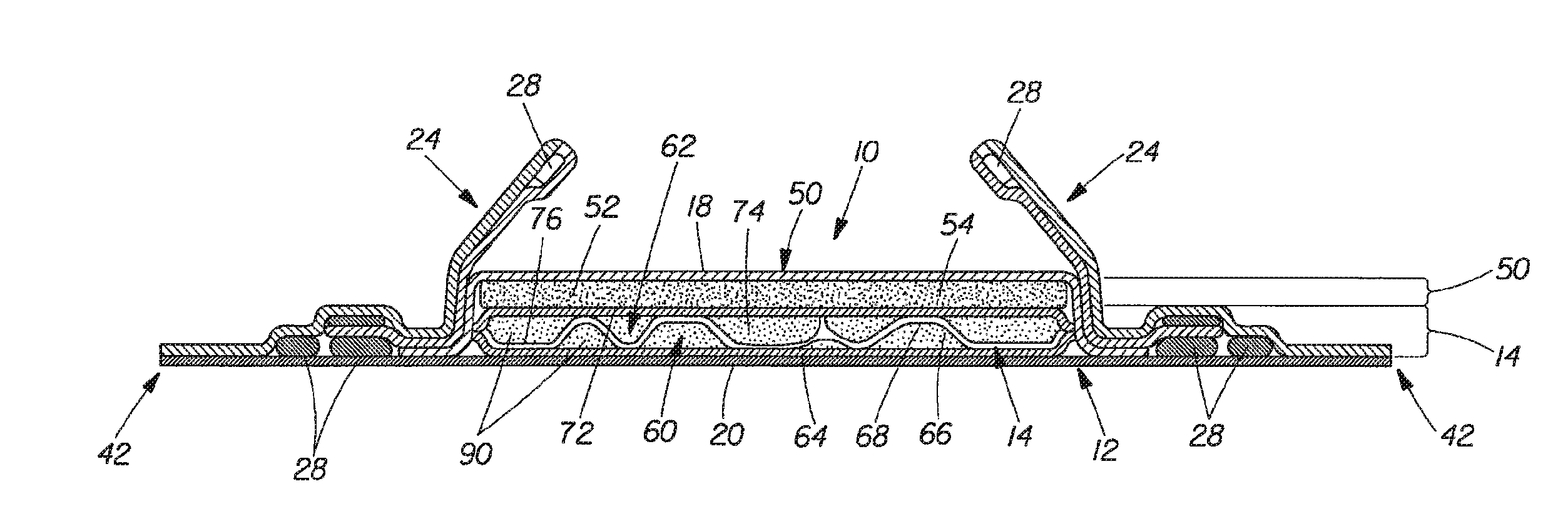

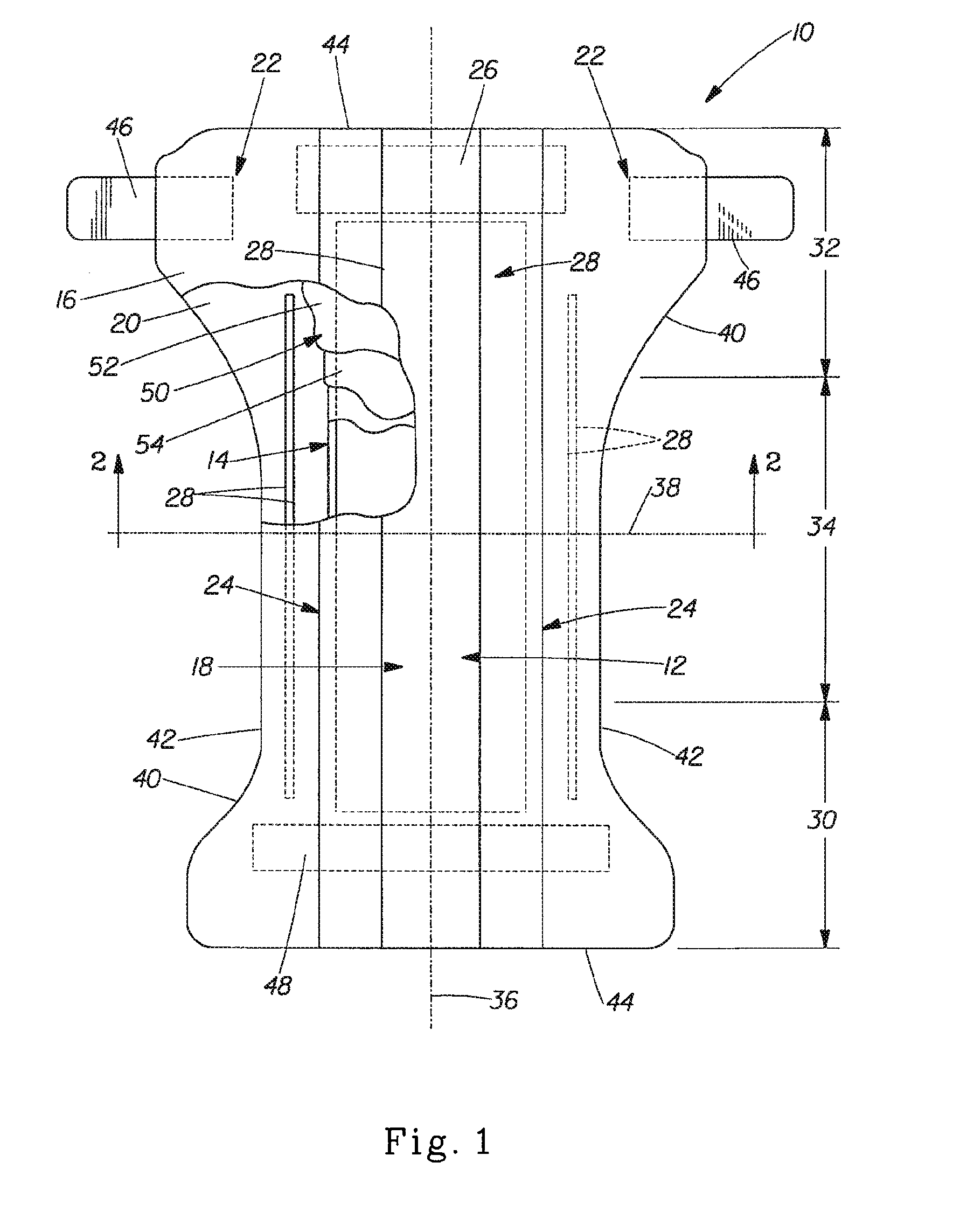

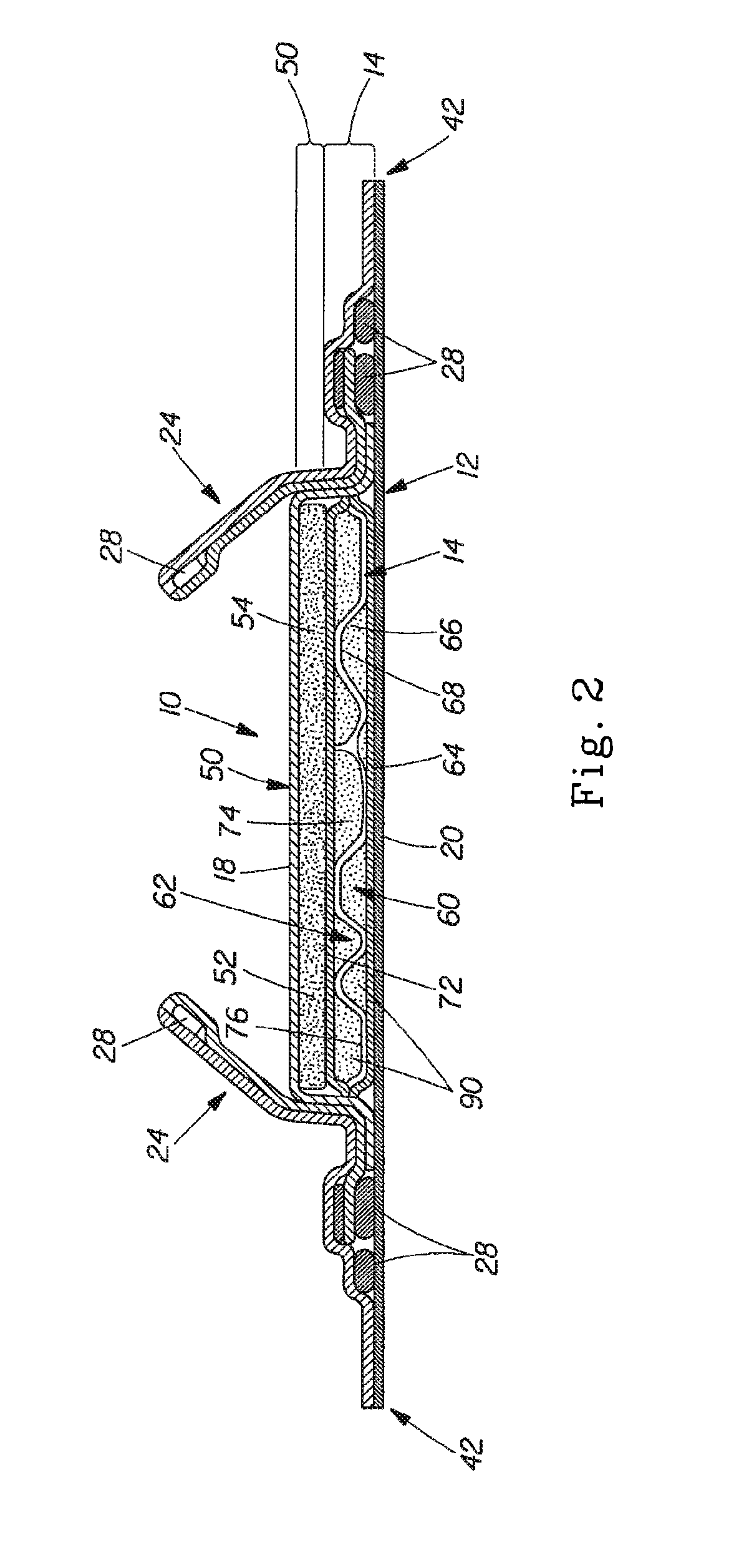

Better Fitting Disposable Absorbent Article With Absorbent Particulate Polymer Material

A disposable absorbent article includes an absorbent core that is substantially cellulose free and a chassis that includes a topsheet and a backsheet, with the absorbent core located between the topsheet and the backsheet. The chassis may include a pair of side panels joined with the chassis, the side panels extending laterally outwardly beyond the longitudinal edges, each side panel having at least one zone extensible in a direction having a vector component in the lateral direction.

Owner:THE PROCTER & GAMBLE COMPANY

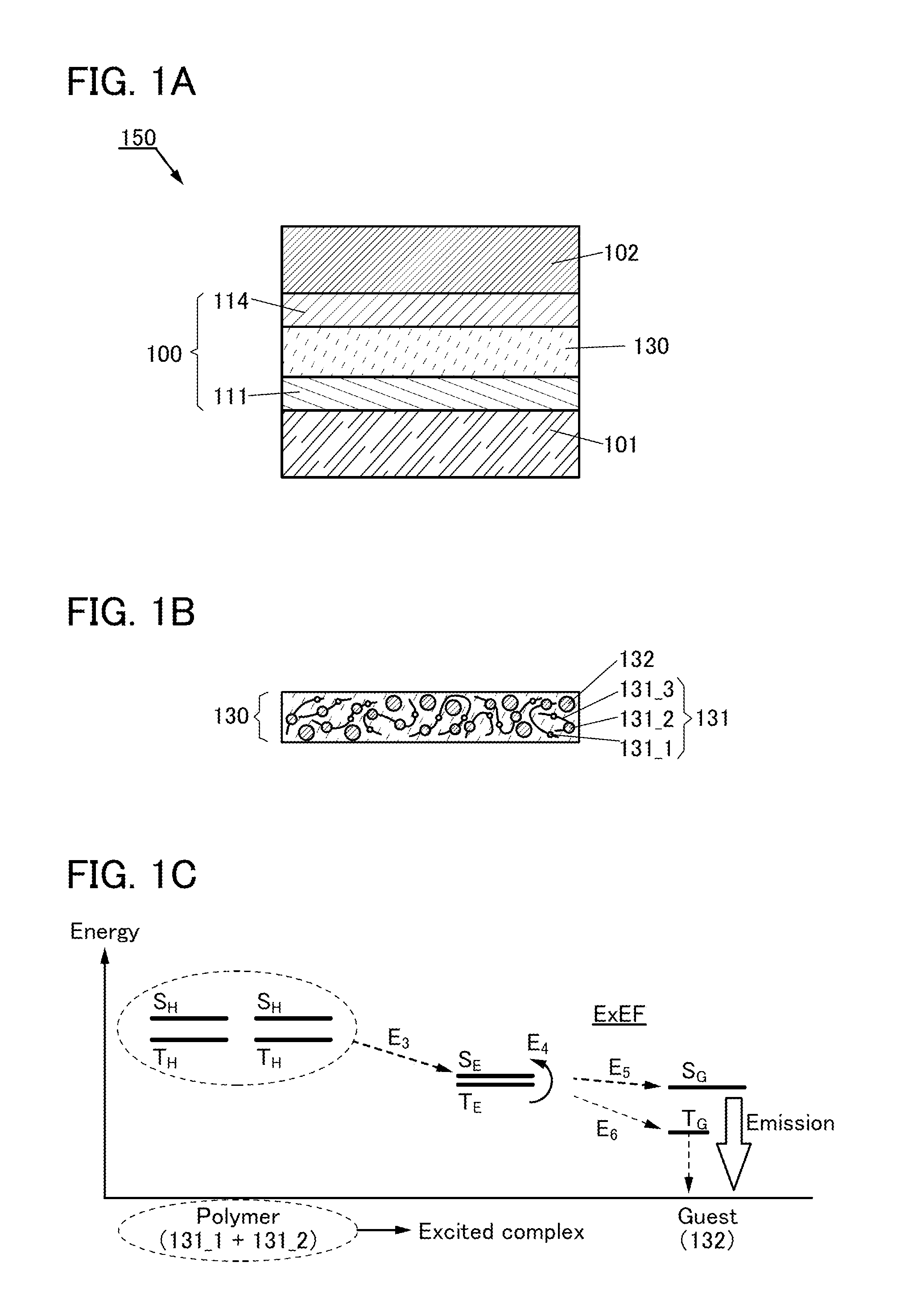

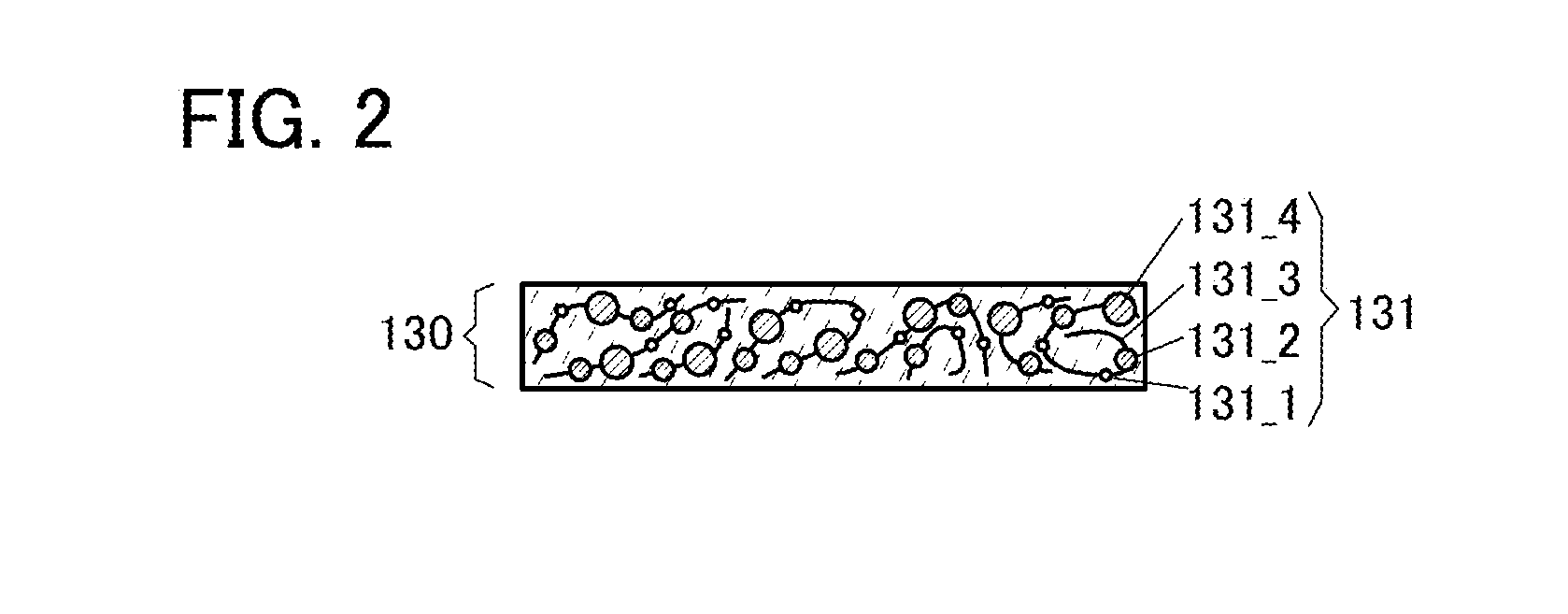

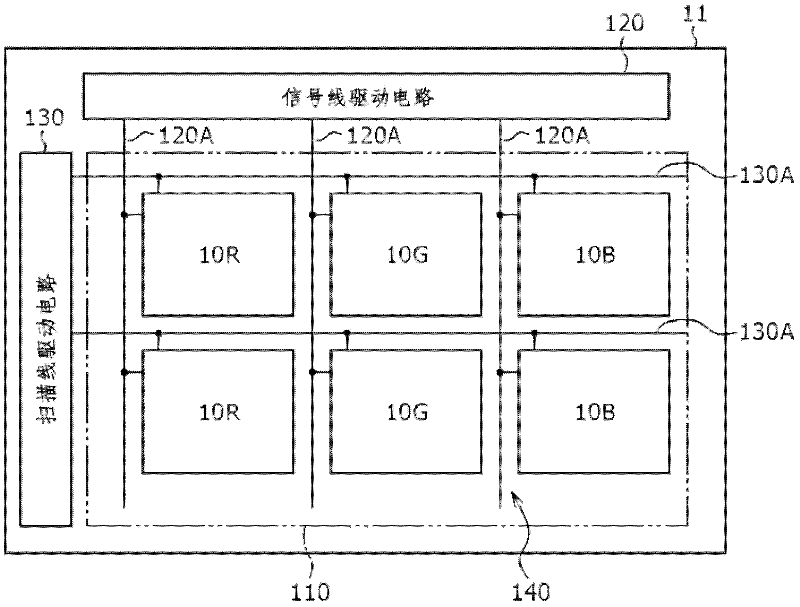

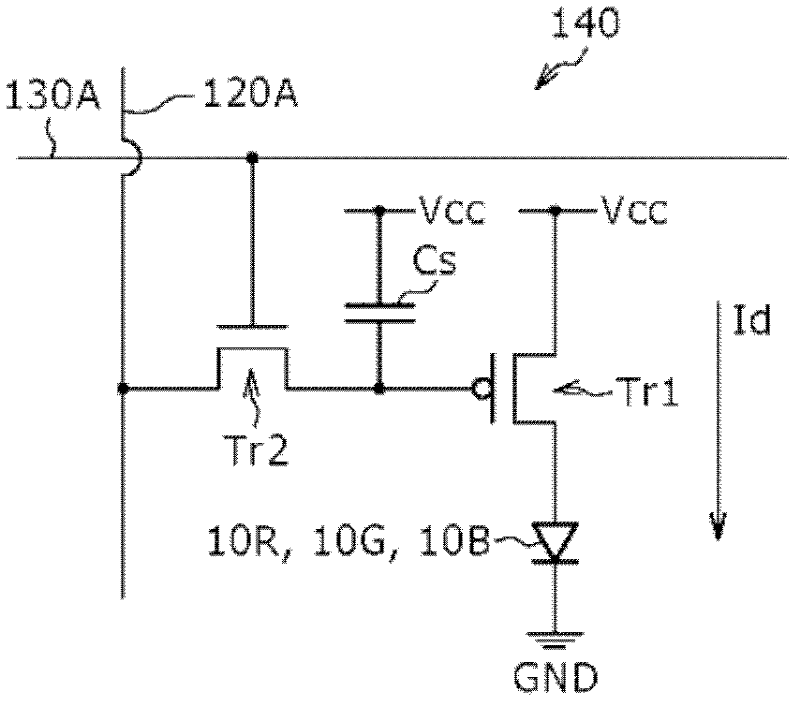

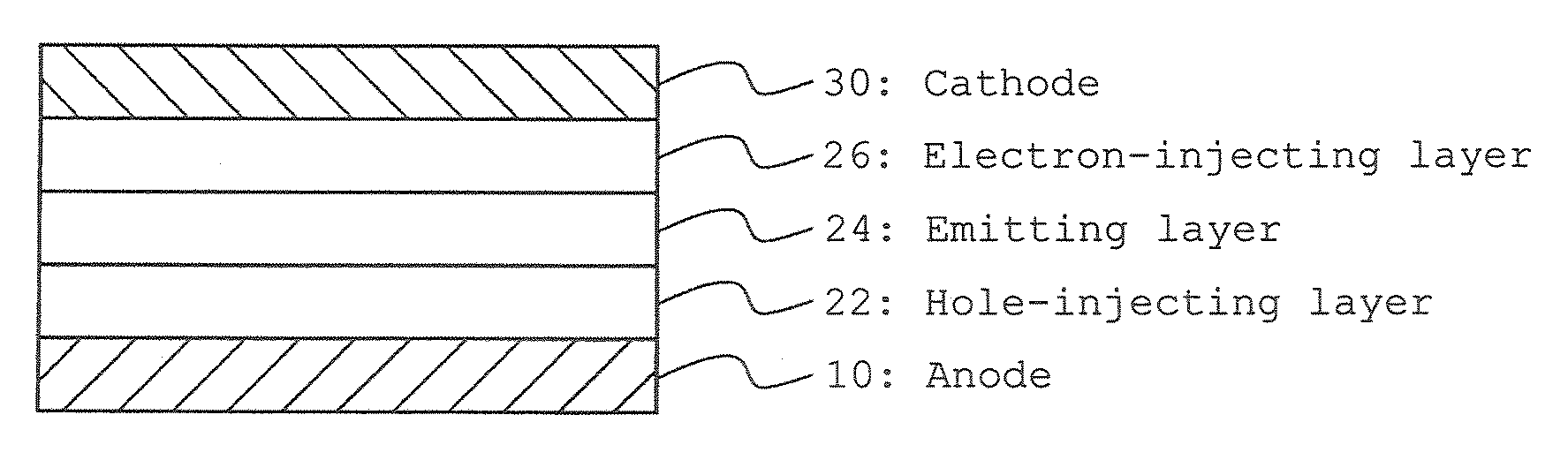

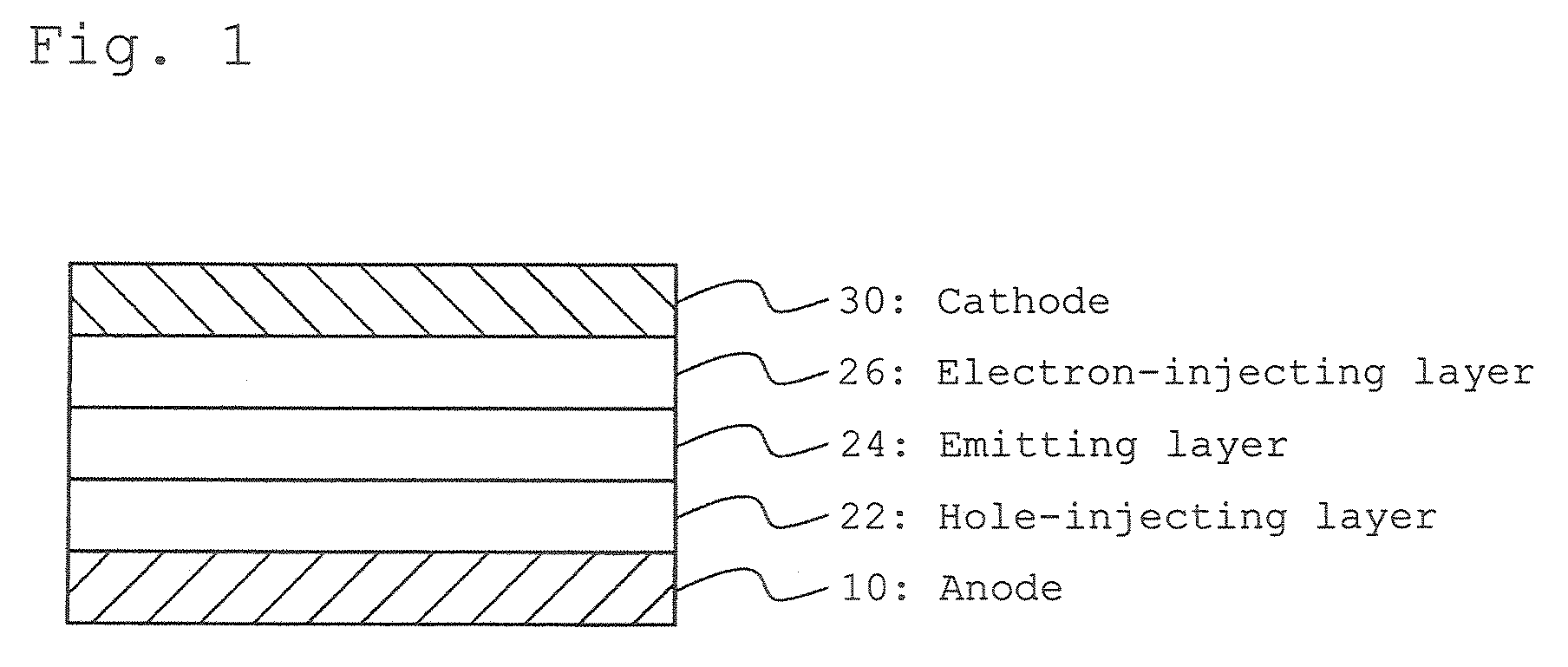

Light-emitting element, display device, electronic device, and lighting device

ActiveUS20160343949A1Improve luminous efficiencyReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingLight equipmentFluorescence

A light-emitting element containing a light-emitting material with high light emission efficiency is provided. The light-emitting element includes a high molecular material and a guest material. The high molecular material includes at least a first high molecular chain and a second high molecular chain. The guest material has a function of exhibiting fluorescence or converting triplet excitation energy into light emission. The first high molecular chain and the second high molecular chain each include a first skeleton, a second skeleton, and a third skeleton, and the first skeleton and the second skeleton are bonded to each other through the third skeleton. The first high molecular chain and the second high molecular chain have a function of forming an excited complex.

Owner:SEMICON ENERGY LAB CO LTD

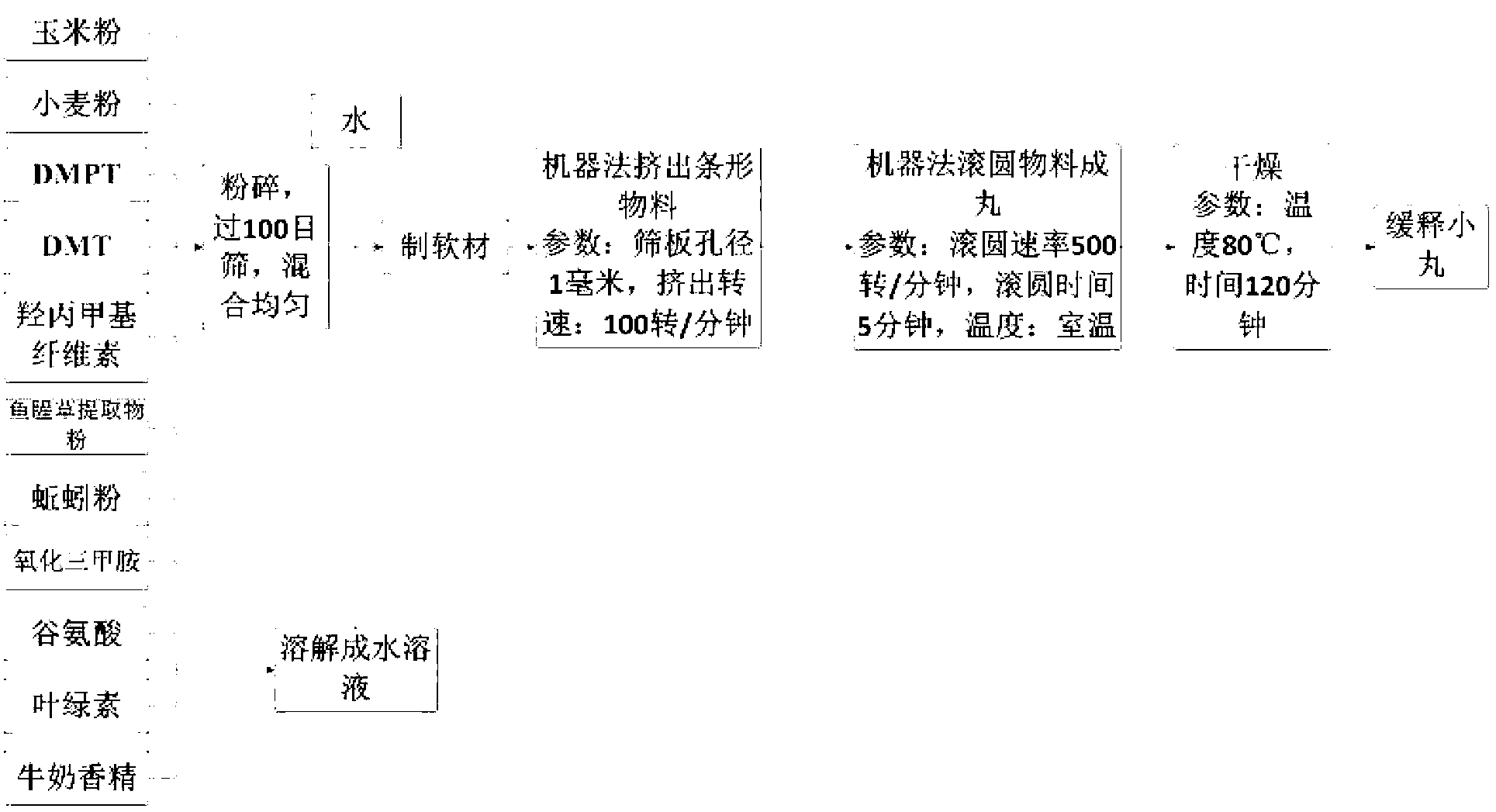

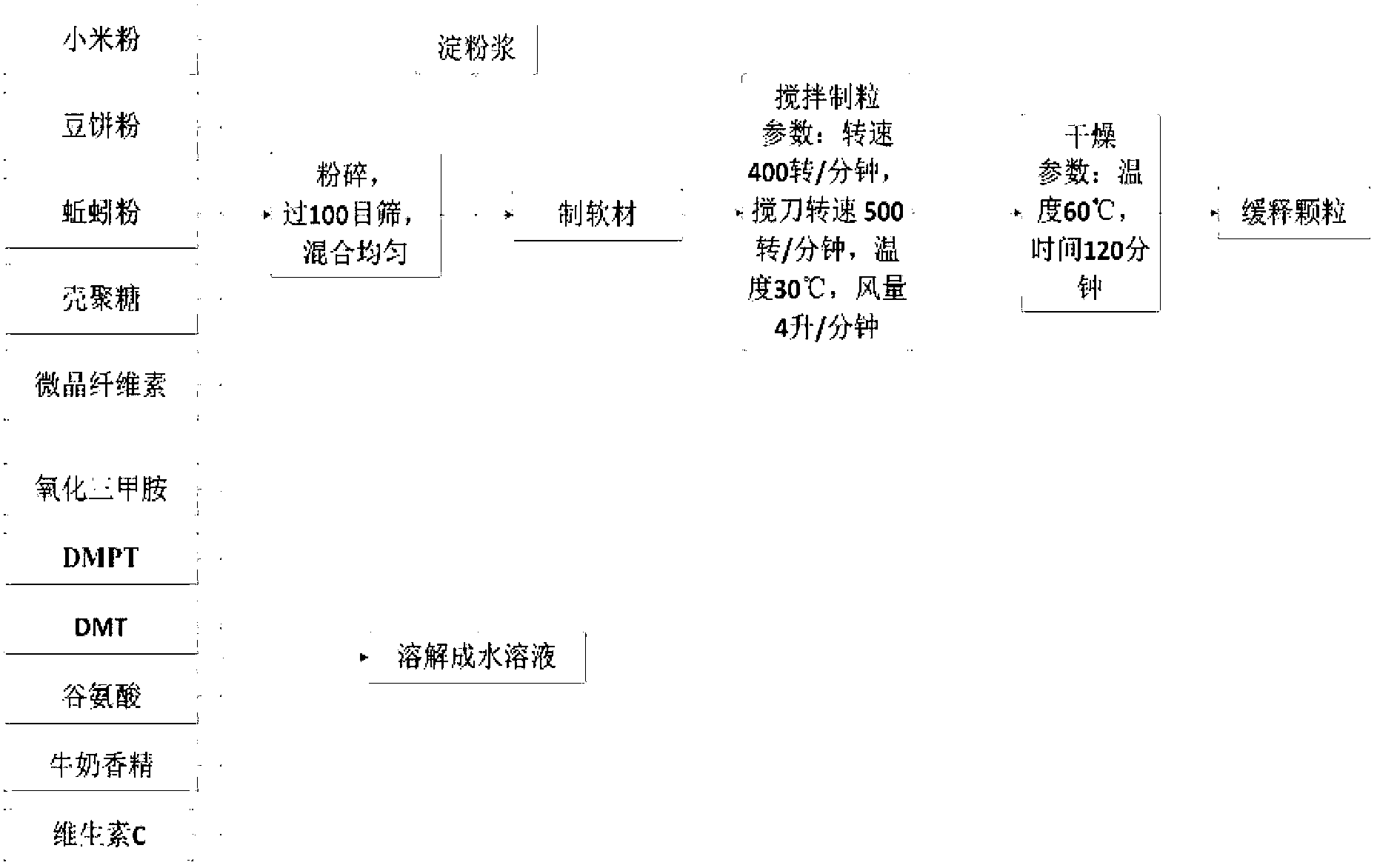

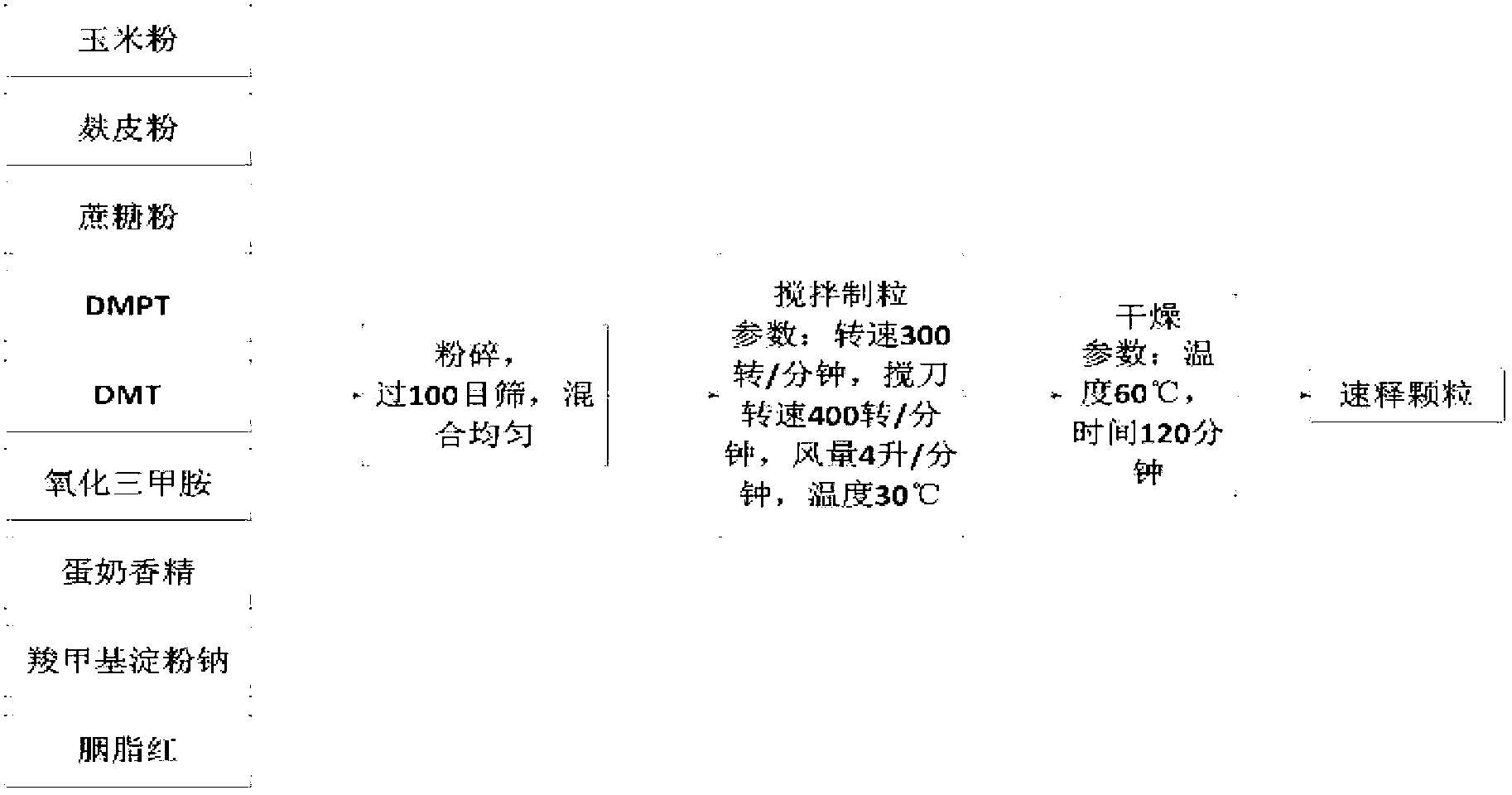

Controlled release bait material and preparation method thereof

InactiveCN103004717AQuick and long-lasting releaseFast and long-lasting effectOther angling devicesWater insolubleMicrosphere

The invention relates to a controlled release bait material and a preparation method thereof. The controlled release bait material refers to small pills, micro-pills, microcapsules, microspheres, particles or sticks prepared from raw materials including a basic material, a feed attractant, a bonding agent, a hydrophilic high-polymer material, a water-insoluble high-polymer material, a quick-release material, a filler, a colorant, a flavoring agent and the like through a preparation means; and the controlled release bait material can be coated for improving the controlled release effect. The invention further discloses a preparation method of the bait material. The controlled release material has rapid and lasting attracting force on fishes, the fish attracting time can be adjusted according to the habit of a fisherman and the habits of fishes, the food ration and frequency of fishes are increased, the fishing success rate can be increased, the food intake of fishes in cultivation of fishes can be increased, the corrosion ratios of remnant feeds and feeds in water bodies are reduced, the utilization ratios of feeds is increased, and the water body environmental pollution is lowered. The preparation method provided by the invention is suitable for industrial production.

Owner:李群益 +2

Water gel containing natural high molecule and its radiation preparing method

InactiveCN1944495AImprove water absorptionGood flexibilityOrganic active ingredientsAntipyreticCross-linkWound dressing

The present invention provides one kind of water gel containing natural high molecular material and its preparation process. The water gel has cross-linking degree of 70-95 % and water absorption of 500-80000 %, and contains natural high molecular material or its derivative selected from chitin, chitin derivative, chitosan, chitosan derivative, carrageenin, etc. The water gel may have synthetic high molecular material, inorganic filler, cross-linking sensitizer, medicine and other assistant added. It is prepared through radiation cross-linking, with the radiation dosage being 10-40 kGy. The water gel of the present invention has high water absorption, high flexibility, good medicine slow releasing performance, and may be used in wound dressing, etc.

Owner:厦门凝赋生物科技有限公司

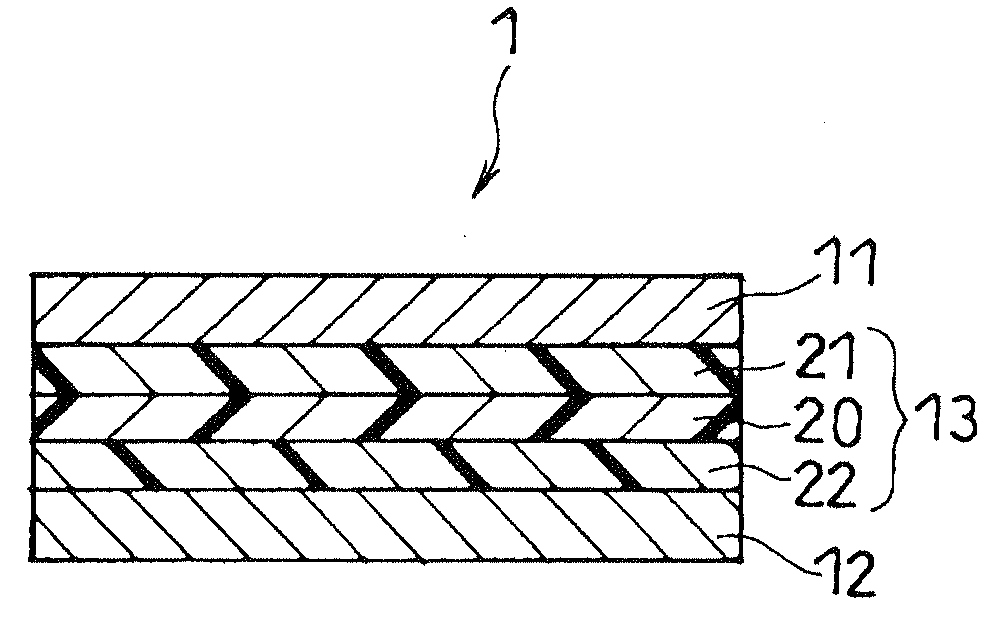

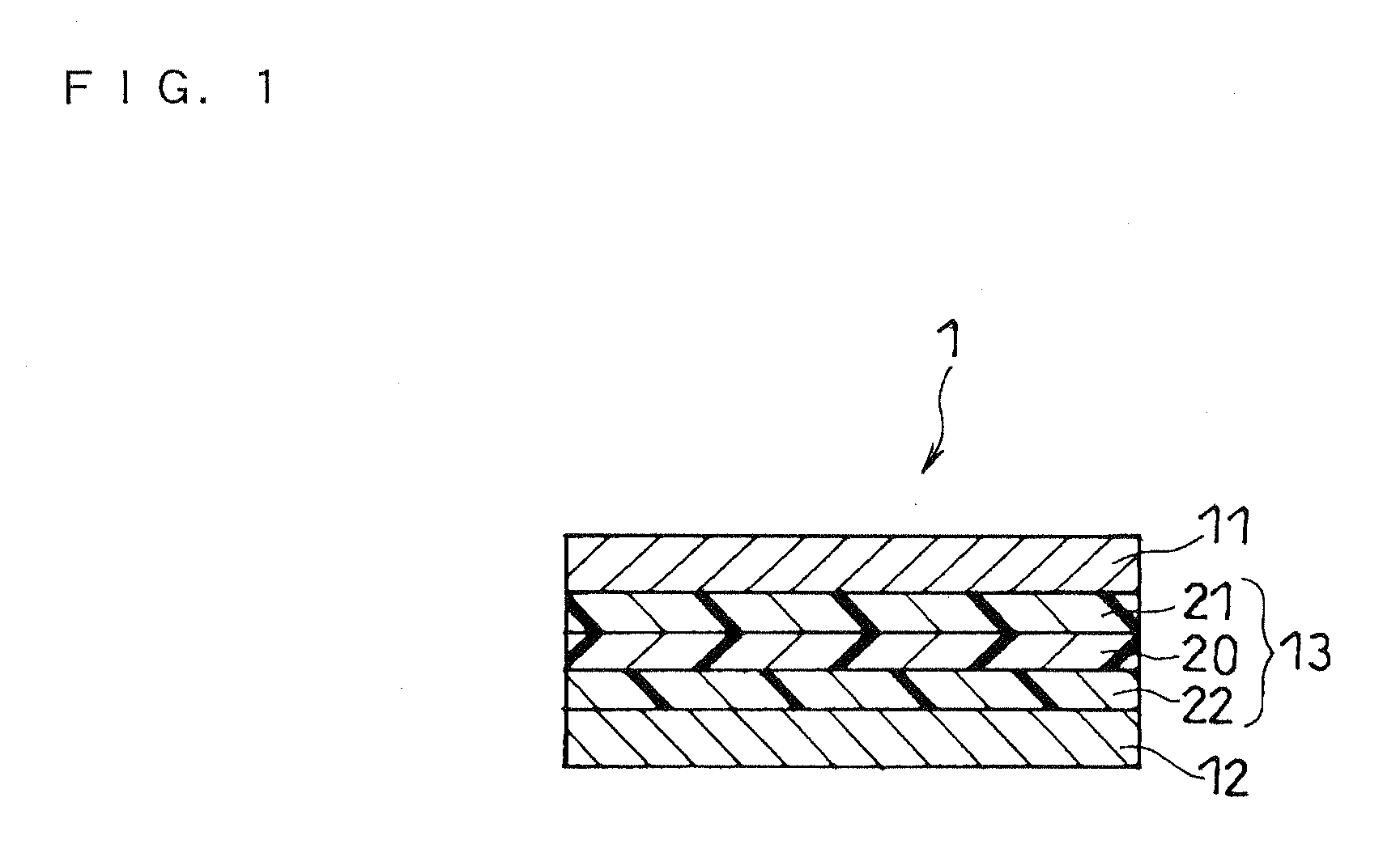

Separator for lithium secondary battery, method for producing the same, and lithium secondary battery including the same

InactiveUS20070281206A1Suppress occurrenceIncrease energy densityCell temperature controlPretreated surfacesPorous layerMolecular materials

A separator for a lithium secondary battery includes a high molecular porous film with a shut-down function and a heat-resistant porous layer integrally formed on each side of the high molecular porous film. The heat-resistant porous layers contain a heat-resistant high-molecular material and a ceramic filler. By using the separator, the occurrence of a short-circuit due to the melting and shrinkage of the high molecular porous film is prevented. Also, in the event of a short-circuit and the generation of heat higher than the melting point of the material of the high molecular porous film, the expansion of the short-circuit is prevented, so that the safety of the lithium secondary battery is improved.

Owner:PANASONIC CORP

Method for preparing graphene-carbon nano tube hybrid composite

InactiveCN101734650ALow costIncrease stiffnessNanostructure manufactureChemical industryCarbon nanotube

The invention provides a method for preparing a graphene-carbon nano tube hybrid composite and relates to a method for preparing a functional high molecular material and a device thereof. The method comprises the following steps of: carrying out the stirring and sonic oscillation treatment on graphene and carbon nano tubes to preform an entangled network structure, thoroughly mixing the entangled network structure and polymer particles, and thus obtaining an uniformly-mixed system in which the graphene-carbon nano tube network is coated on the surfaces of the polymer particles after removing the solvent; and putting the uniformly-mixed system in a mould, hot-compacting, and obtaining the graphene-carbon nano tube hybrid composite after cooling and demoulding. By mingling the graphene and the carbon nano tubes in advance to form the communicated network structure, the method realizes the advantage complementation of the graphene and carbon nano tube structures and enables the hybrid composite to have favorable electric conduction and heat conduction properties. The method can be widely used in the fields such as aviation, transportation and communication, electronic industry, civil facilities, construction, chemical industry and the like, can be produced in the industrial scale, and has the advantages of low cost and environmental friendliness.

Owner:SHENYANG JIANZHU UNIVERSITY

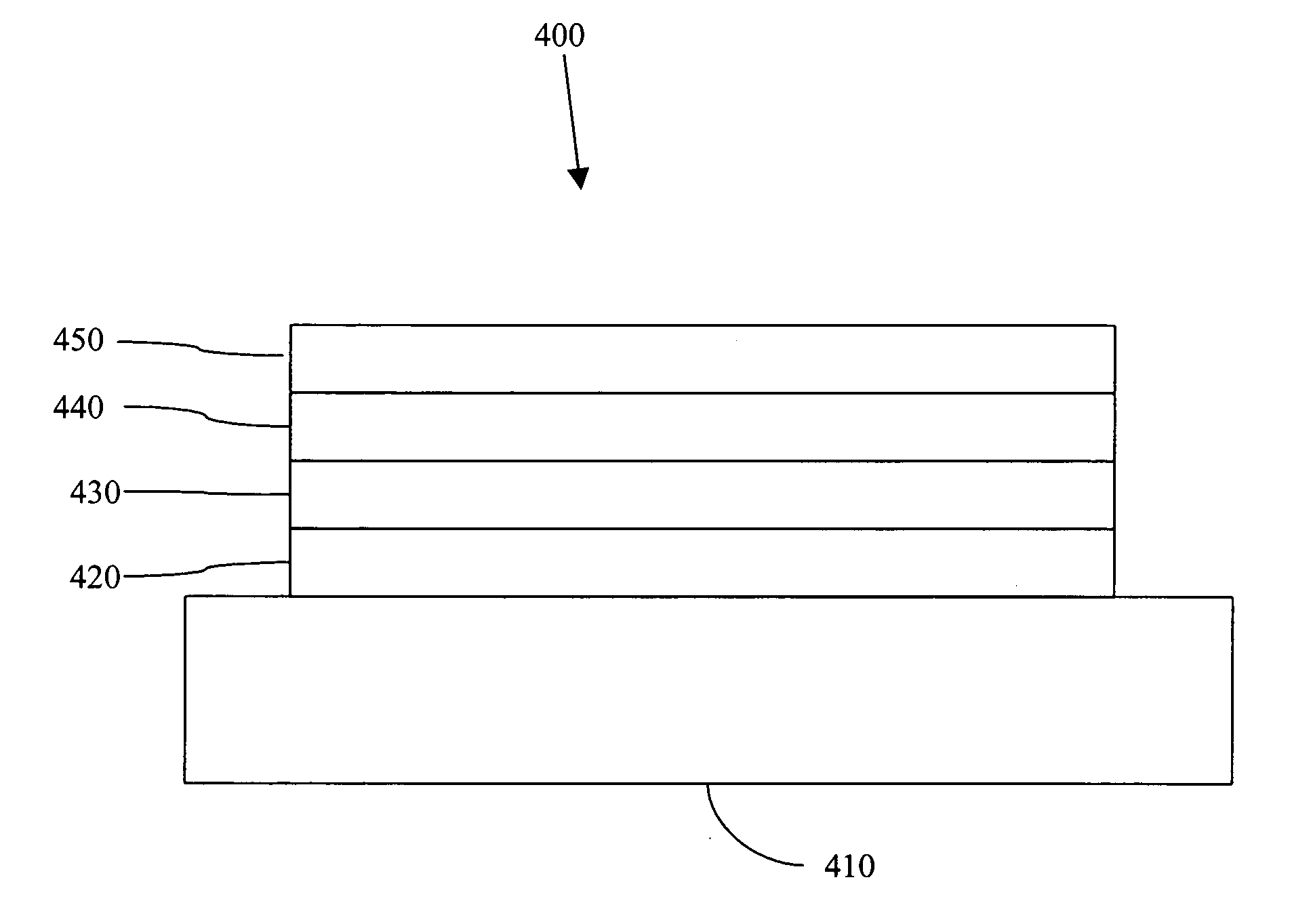

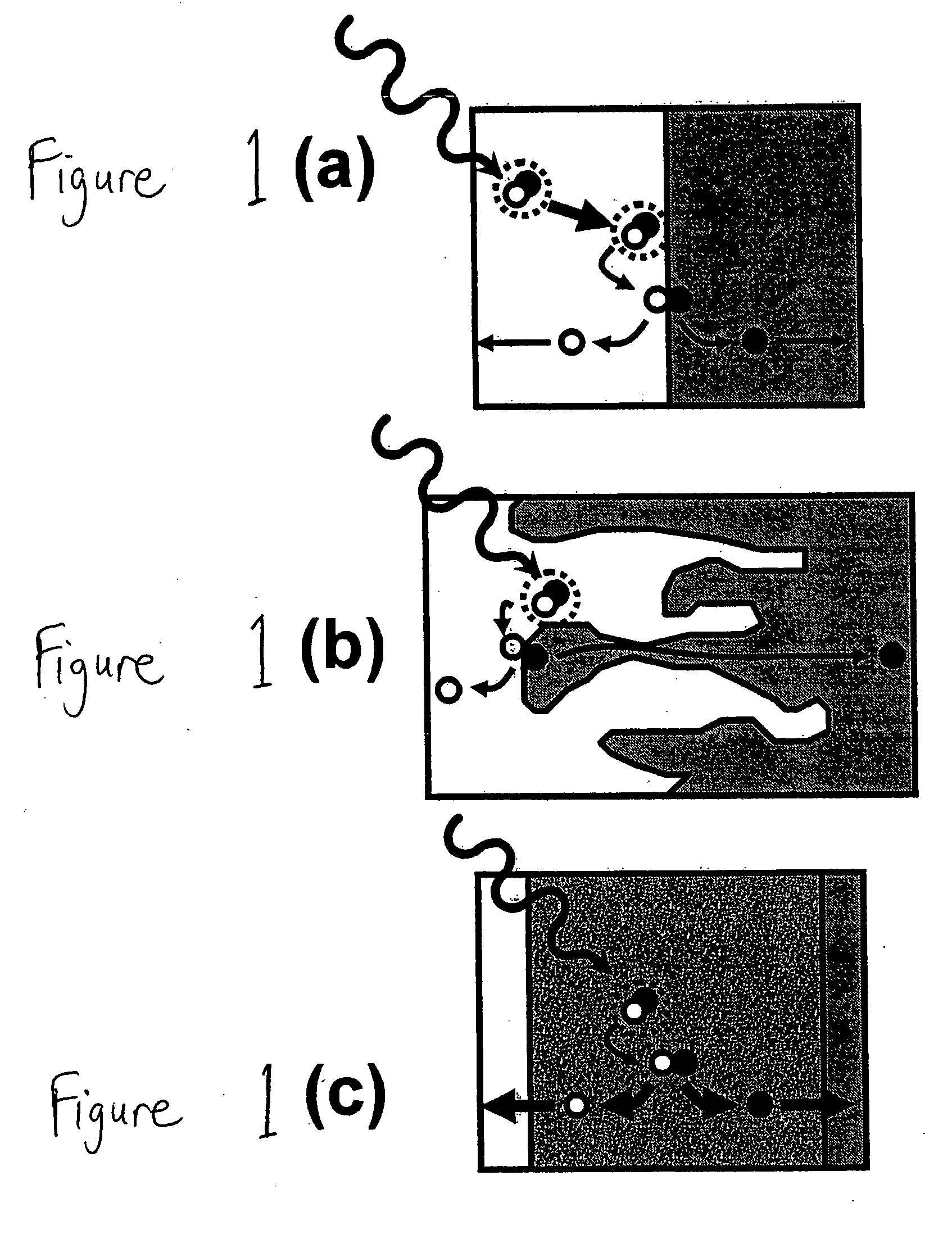

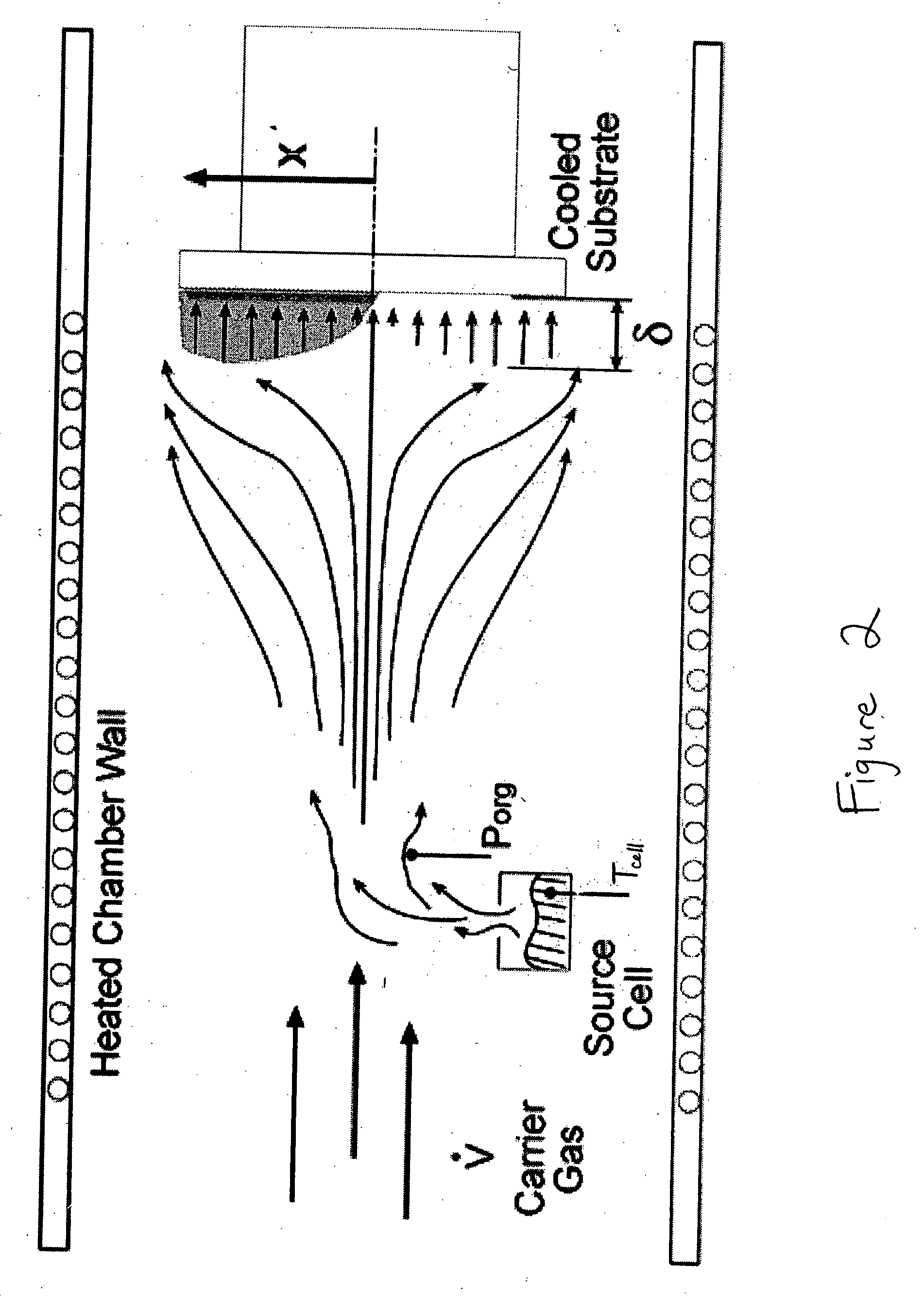

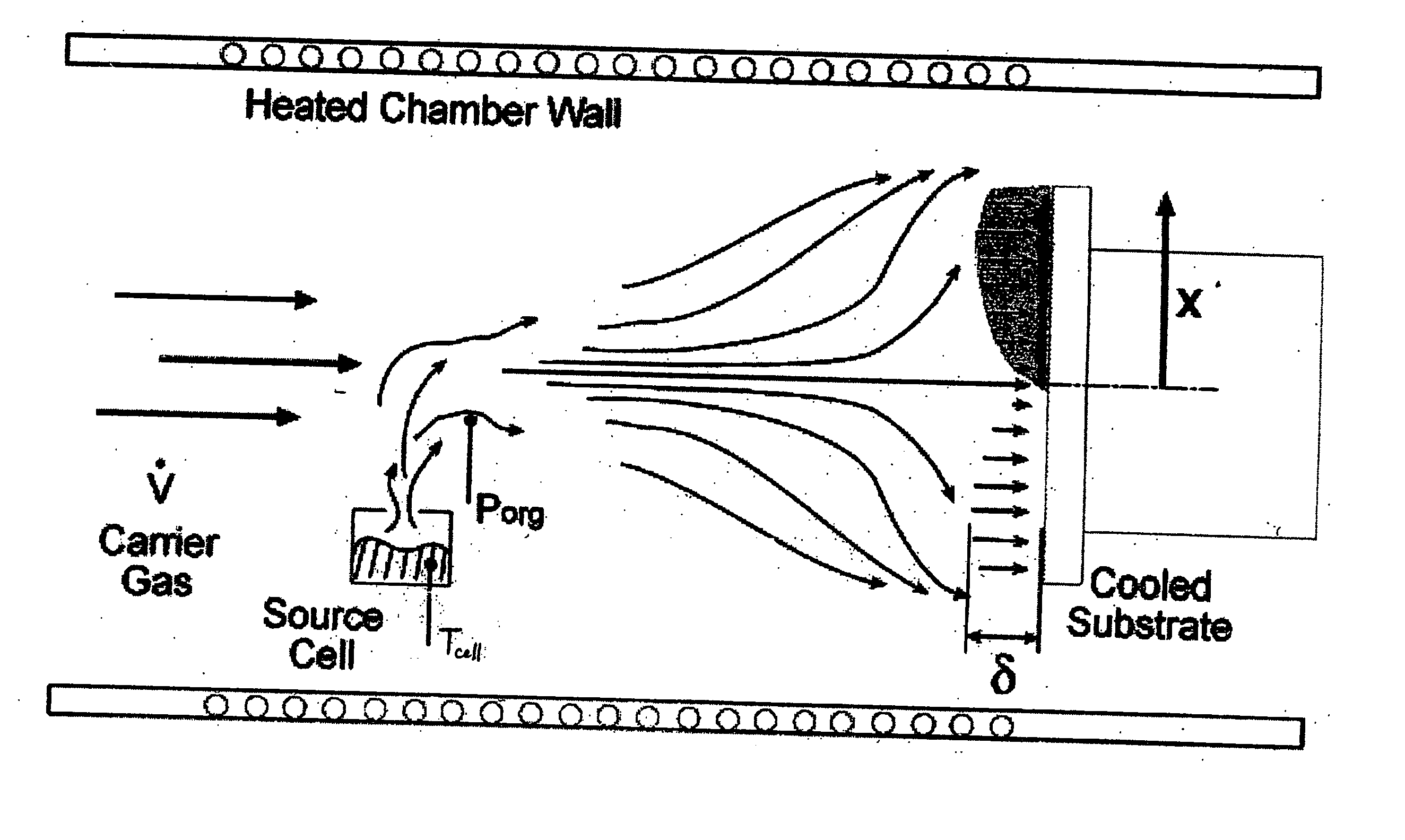

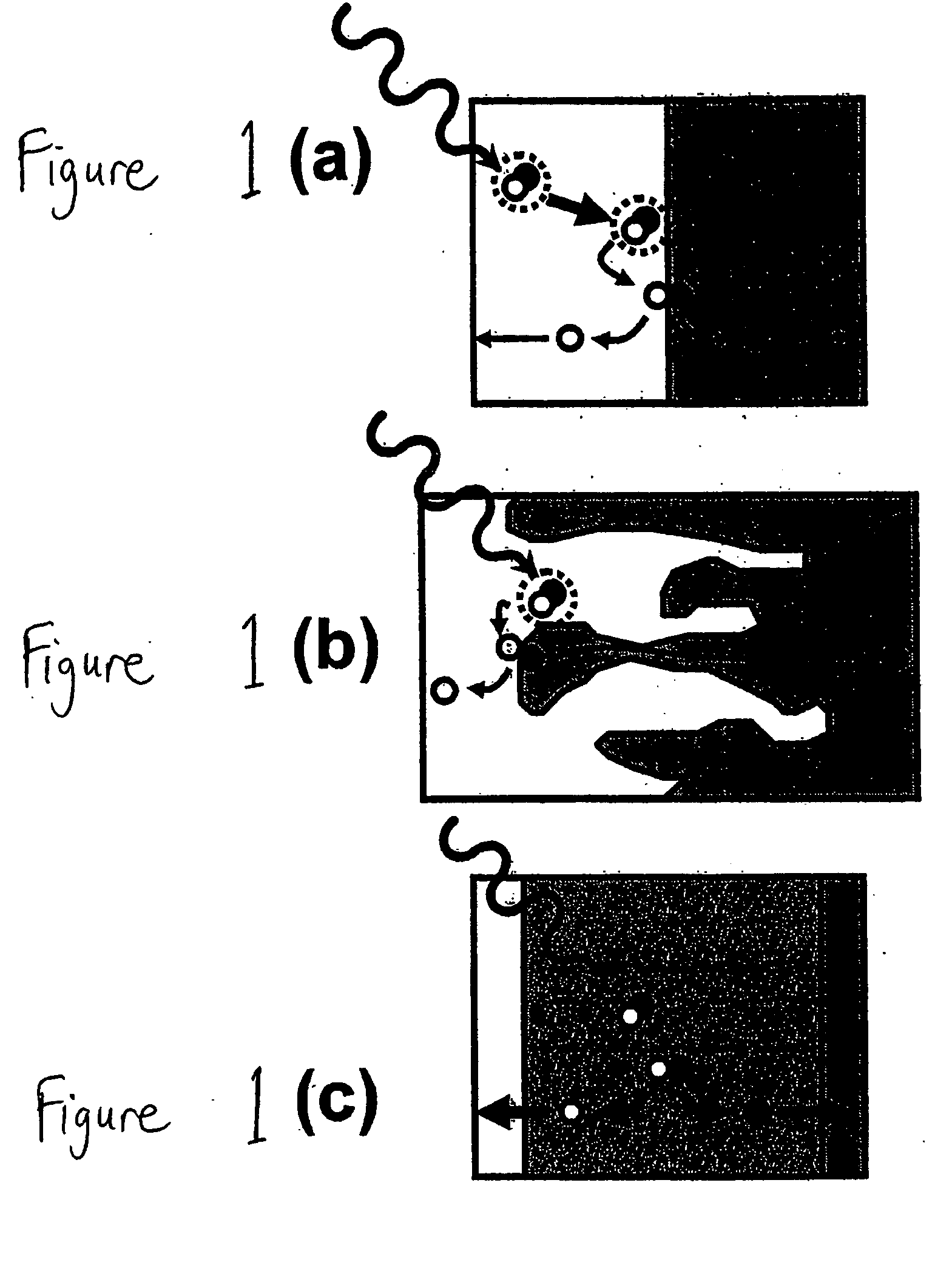

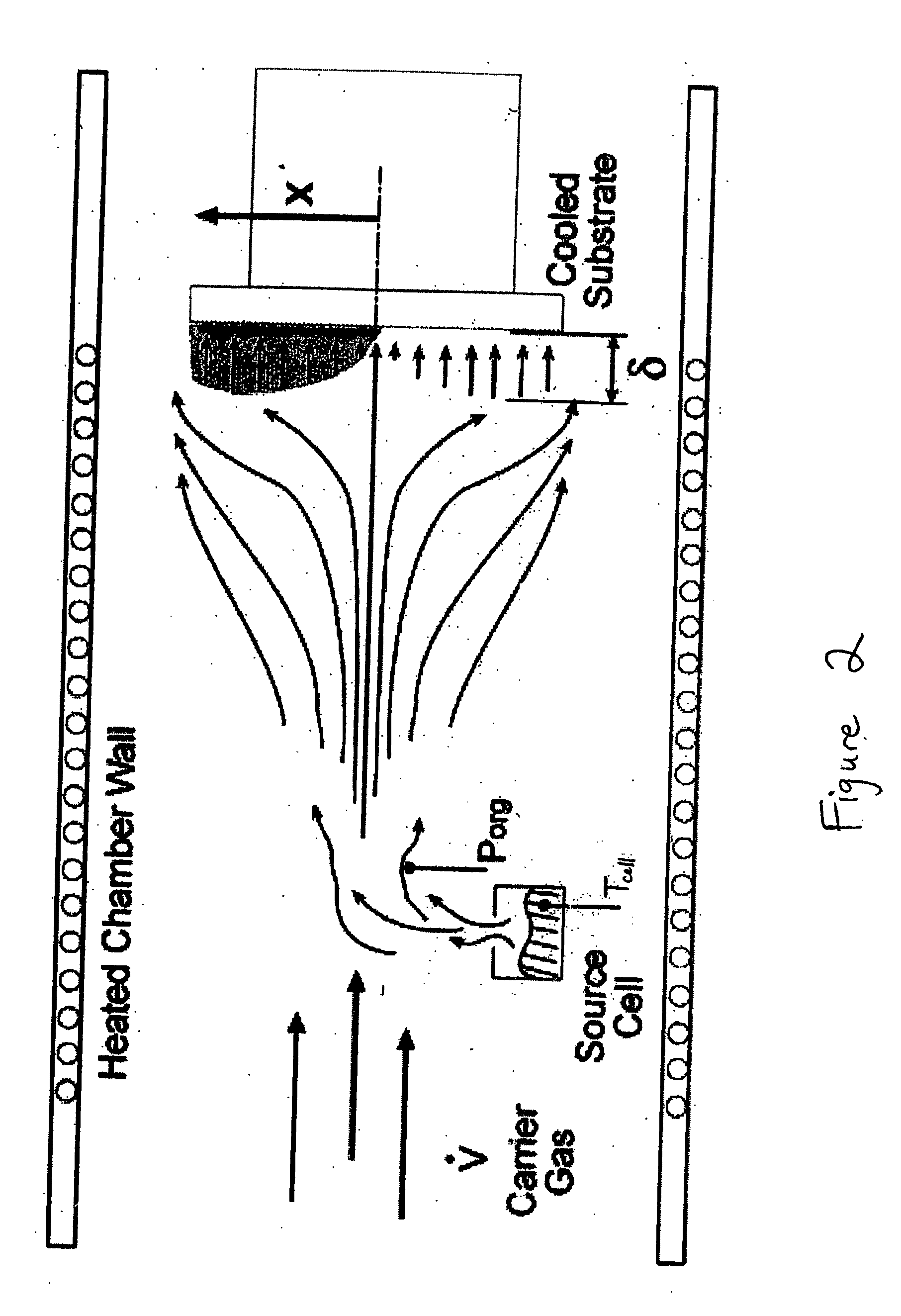

Method of fabricating an optoelectronic device having a bulk heterojunction

ActiveUS20050227406A1Acceptable power conversion efficiencyAcceptable quantum yieldMaterial nanotechnologyFinal product manufactureHeterojunctionElectron donor

A method of fabricating an organic optoelectronic device having a bulk heterojunction comprises the steps of: depositing a first layer over a first electrode by organic vapor phase deposition, wherein the first layer comprises a first organic small molecule material; depositing a second layer on the first layer such that the second layer is in physical contact with the first layer, wherein the interface of the second layer on the first layer forms a bulk heterojunction; and depositing a second electrode over the second layer to form the optoelectronic device. In another embodiment, a first layer having protrusions is deposited over the first electrode, wherein the first layer comprises a first organic small molecule material. For example, when the first layer is an electron donor layer, the first electrode is an anode, the second layer is an electron acceptor layer, and the second electrode is a cathode. As a further example, when the first layer is an electron acceptor layer, the first electrode is a cathode, the second layer is an electron donor layer, and the second electrode is an anode.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Fully-biodegradable PLA/PBAT composite film and making method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a PLA / PBAT composite film and a making method thereof. The composite film is made by using the following components, by weight, 10-90 parts of polylactic acid, 10-90 parts of PBAT, 0.04-2.5 parts of a compatibilizer A, 0.04-2.5 parts of a compatibilizer B, 0-3 parts of a lubricant, 0-3 parts of an antioxidant and 1-50 parts of a filler. A blend provided by the invention has a very good flexibility, and the made film can be fully biodegraded, and can be widely used in the field of films.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Antibiotic nanometer fibrous material and method for preparing the same

InactiveCN1467314ASimple processing technologyGood effectArtifical filament manufactureFiberRepair tissue

An antibacterial nano-class fibre material contains superfine high-molecular fibres (60-98 wt.%) and antibacterial agent (2-40 wt.%), and is prepared through dispersing or dissolving one or more high-molecular material in solvent to become transparent solution or mixture, dispersing the superfine particle of antibacterial agent (less than 20 microns) in said solution, and electric spinning. It can be used as protecting material, disinfecting filter material and tissue covering material for repairing tissue or promoting healing of tissue.

Owner:SOUTHEAST UNIV

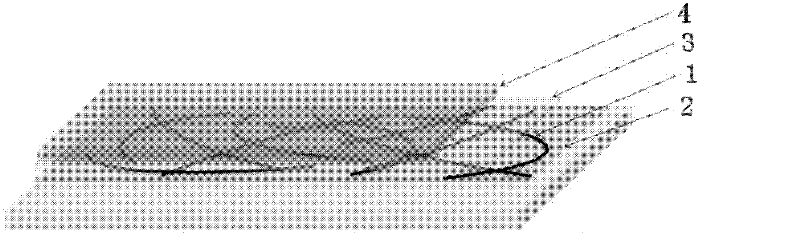

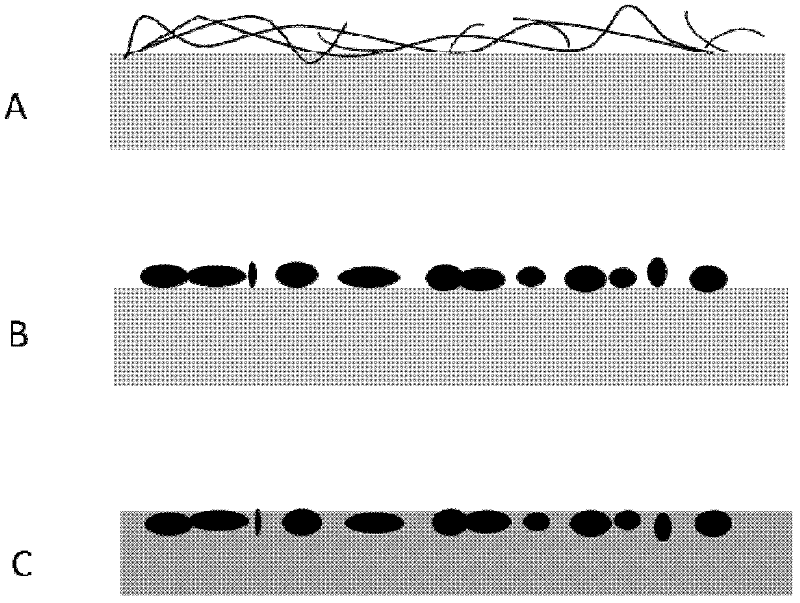

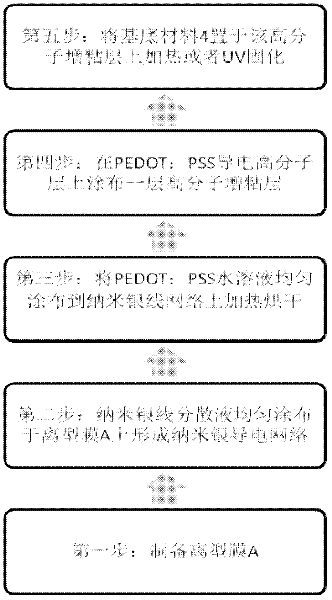

Nanometer silver transparent electrode material and preparation method thereof

ActiveCN102522145AEasy to manufactureTo prevent the phenomenon of insulationConductive layers on insulating-supportsCable/conductor manufactureElectricityHigh volume manufacturing

The invention discloses a nanometer silver transparent electrode material and a preparation method thereof. The nanometer silver transparent electrode material comprises the following four layers of structures: 1 a nanometer silver wire network, 2 poly(3,4-ethylenedioxythiophene) (PEDOT): an electricity conductive high molecular layer formed by evenly coating PSS aqueous solution, 3 a high molecular material tackifying layer and 4 a substrate. The nanometer silver wire transparent electrode is high in light transmitting rate, low in resistance, good in adhesion between the electricity conductive layer and the substrate, high in surface flatness degree, simple in preparation process and convenient for large-scale production and overcomes the shortcomings of being complex in a process for preparing the nanometer silver wire transparent electrode through a transfer method and not suitable for large-scale production.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

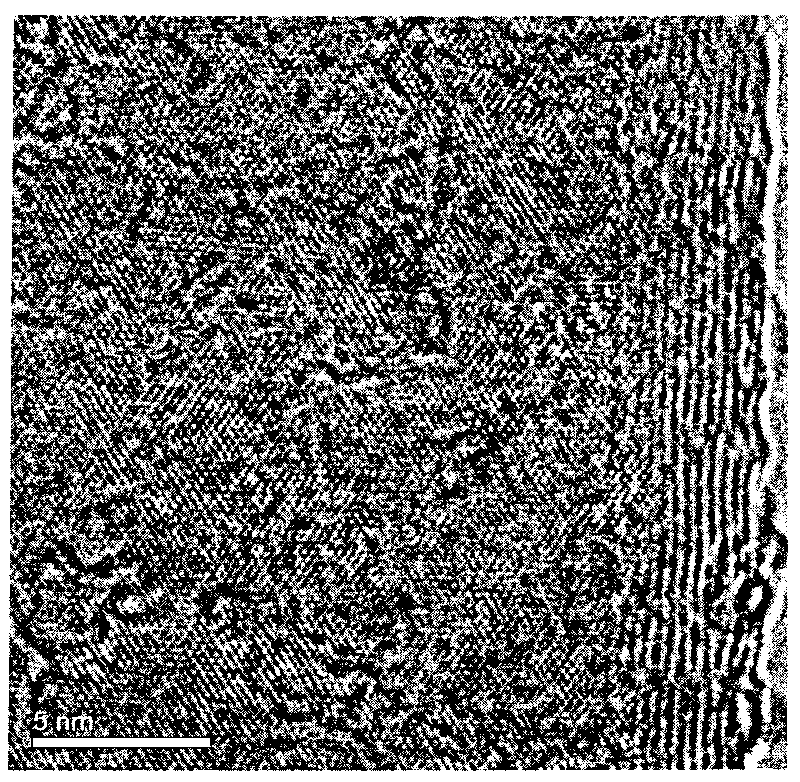

Method of fabricating an optoelectronic device having a bulk heterojunction

ActiveUS20050227390A1Acceptable power conversion efficiencyAcceptable quantum yieldMaterial nanotechnologyFinal product manufactureHeterojunctionMolecular materials

A method of fabricating an optoelectronic device comprises: depositing a first layer having protrusions over a first electrode, in which the first layer comprises a first organic small molecule material; depositing a second layer on the first layer such that the second layer is in physical contact with the first layer; in which the smallest lateral dimension of the protrusions are between 1 to 5 times the exciton diffusion length of the first organic small molecule material; and depositing a second electrode over the second layer to form the optoelectronic device. A method of fabricating an organic optoelectronic device having a bulk heterojunction is also provided and comprises: depositing a first layer with protrusions over an electrode by organic vapor phase deposition; depositing a second layer on the first layer where the interface of the first and second layers forms a bulk heterojunction; and depositing another electrode over the second layer.

Owner:THE TRUSTEES FOR PRINCETON UNIV

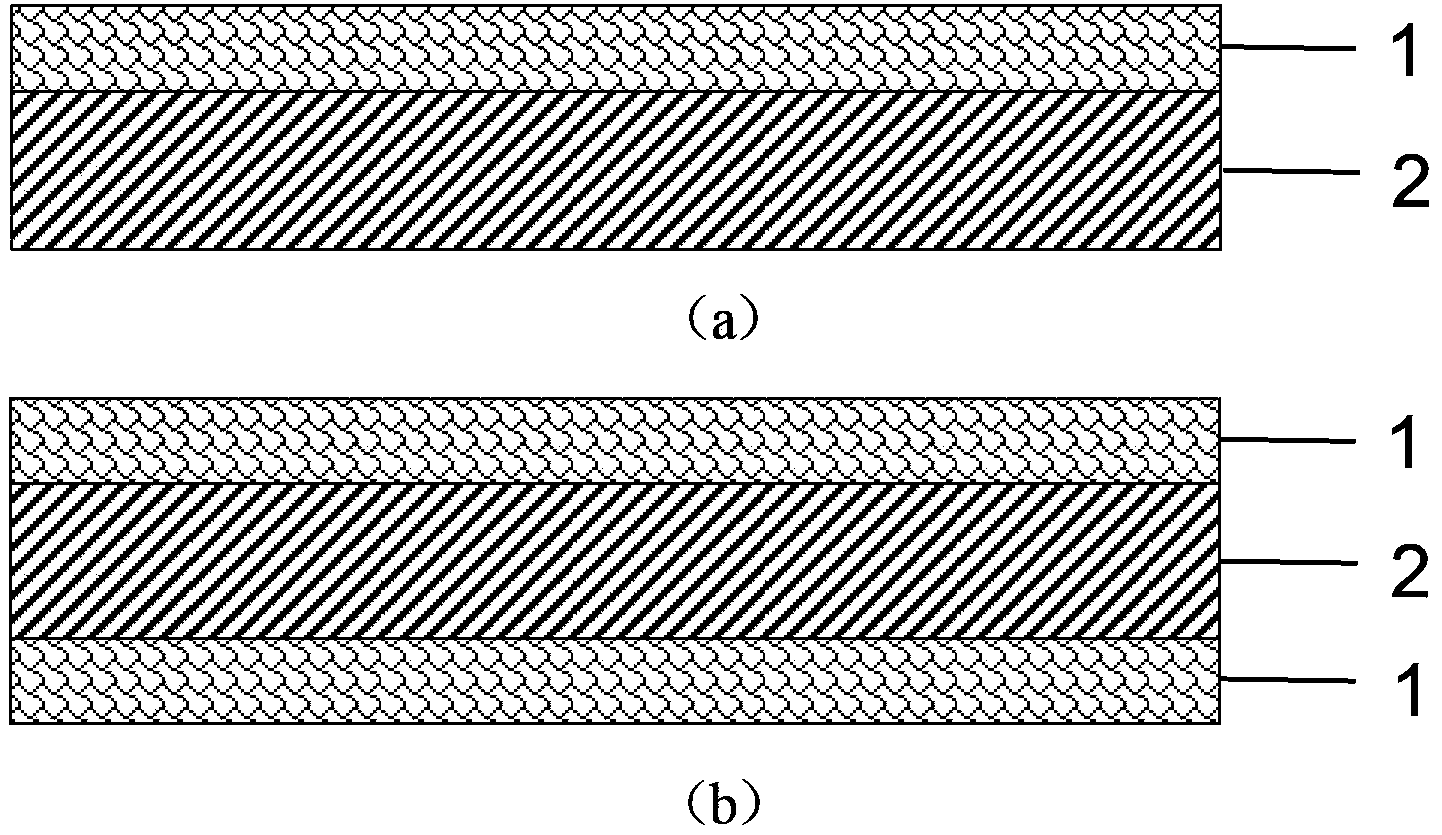

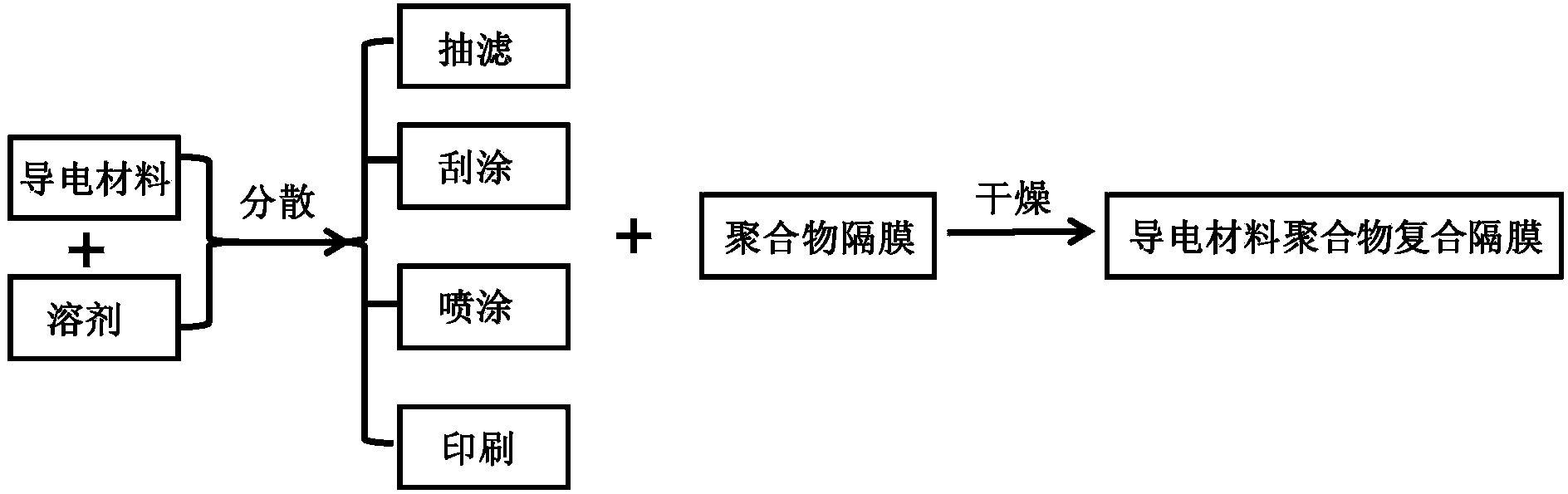

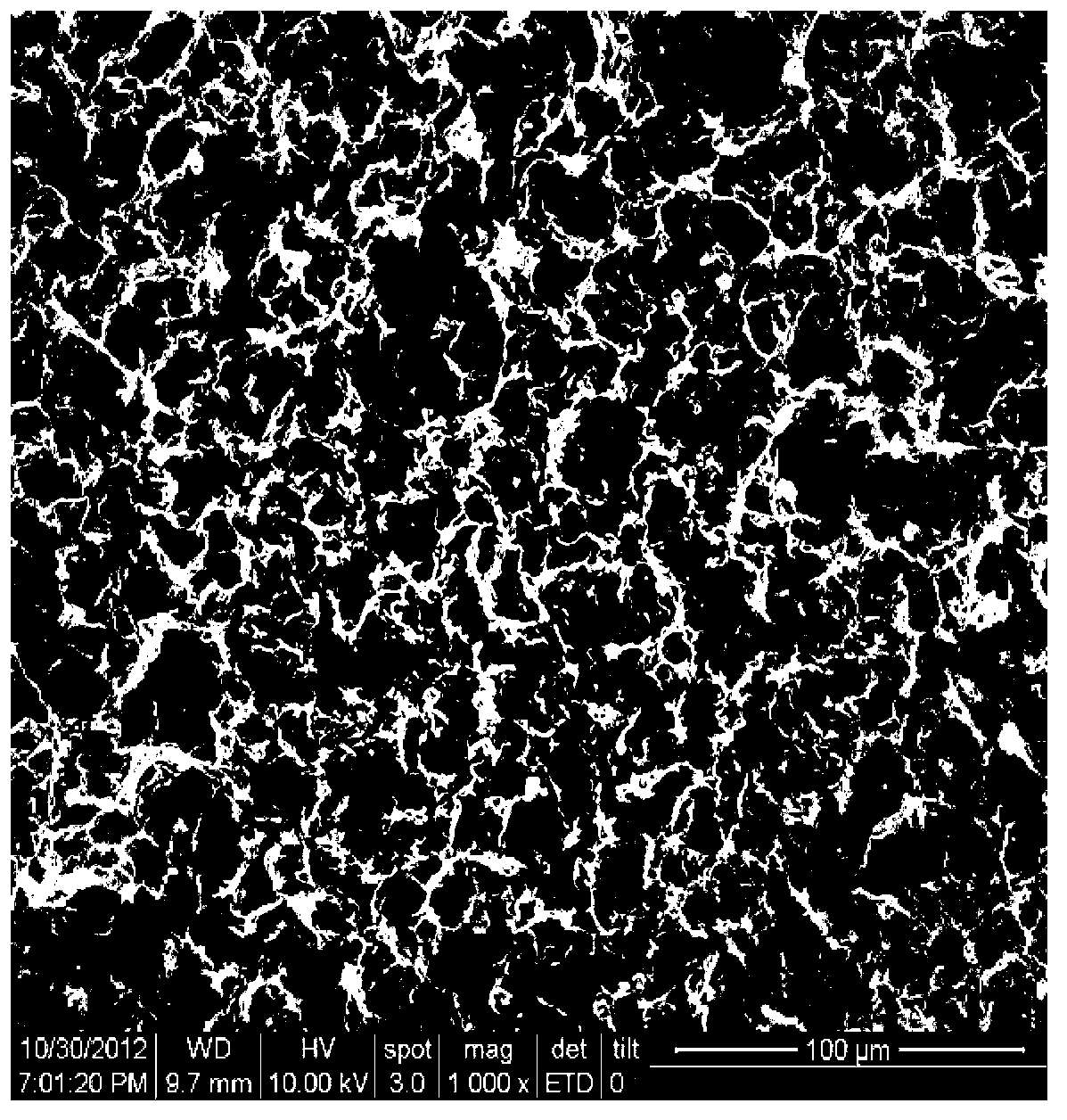

Composite diaphragm for battery and preparation method thereof

InactiveCN104103791ALower internal resistanceIncrease contactCell component detailsMetallic lithiumDiaphragm structure

The invention discloses a composite diaphragm for a battery and a preparation method thereof, belonging to the field of electrochemical cells. The composite diaphragm is a multilayer composite diaphragm structure composed of a conducting layer / a polymer layer or a conducting layer / a polymer layer / a conducting layer, wherein the conducting layer mainly comprises a carbon material or a conductive polymeric material and forms a film on a single surface or double surfaces of a polymer diaphragm. The composite diaphragm has the following characteristics: the conducting layer has strong electrolyte adsorption and storage capability, the process of ion transport is shortened, and large-current charge and discharge performance of the battery is improved; when the composite diaphragm is used in a metallic lithium battery, the conducting layer in the composite diaphragm contacting with metallic lithium can alleviate nonuniform corrosion on the surface of lithium and inhibit formation of lithium dendrite crystals. The preparation method for the composite diaphragm is simple and easily controllable, can realize large-quantity and low-cost industrial preparation of the composite diaphragm and has a high application value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of three-dimensional graphene or composite system thereof

The invention discloses a preparation method of three-dimensional graphene or a composite system thereof. The preparation method comprises the steps of: by taking a transition metal elementary substance and / or a compound containing a transition metal element as raw materials, preparing a three-dimensional porous metal catalyst template through high-temperature reduction; growing the three-dimensional graphene by utilizing a chemical vapor phase deposition method to obtain the three-dimensional graphene with a catalyst framework; furthermore, etching the three-dimensional graphene with the catalyst framework to obtain three-dimensional graphene powder; and furthermore, compositing the three-dimensional graphene powder with metal, a macromolecular material, a biomolecular material and the like to form a composite material system. The preparation method is simple in technique, capable of fast and massively preparing high-quality and high-density three-dimensional graphene or composite material thereof, and has wide application prospects on the aspects of water treatment, biomedicines, energy generation and conversion and energy accumulation devices, static resistance, thermal management, heat conduction and dissipation, sensors, electromagnetic shielding, wave absorption, catalysis and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Modular Bioresorbable or Biomedical, Biologically Active Supramolecular Materials

The present invention relates to a modular supramolecular bioresorbable or biomedical material comprising (i) a polymer comprising at least two 4H-units and (ii) a biologically active compound. Optionally, the supramolecular bioresorbable or bio medical material comprises a bioresorbable or biomedical polymer as third component to tune its properties (mechanical and bioresorption properties). The supramolecular bioresorbable or biomedical material is especially suitable for biomedical applications such as controlled release of drugs, materials for tissue-engineering, materials for the manufacture of a prosthesis or an implant, medical imaging technologies.

Owner:SUPRAPOLIX

High-thermal-diffusion-coefficient high molecular material and preparation method thereof

InactiveCN104559148AImprove thermal conductivityGood radiation cooling performancePolymer scienceAntioxidant

The invention discloses a high-thermal-diffusion-coefficient high molecular material and a preparation method thereof. The high-thermal-diffusion-coefficient high molecular material is prepared from the following steps: 20-65 parts of matrix resin, 35-65 parts of high-thermal diffusion heat-conducting filler, 0.1-5 parts of carbon fiber composite, 0.1-10 parts of a flexibilizer, 0.1-2 parts of coupling agent, 0.1-2 parts of antioxidant and 0.1-15 parts of other auxiliaries. According to the high-thermal-diffusion-coefficient high molecular material, the heat conduction capability of the high molecular material is remarkably enhanced by virtue of the positive synergetic hybrid effect of a three-dimensional heat-conducting network formed by the high-thermal-diffusion-coefficient heat-conducting fillers different in shape in the processing course, and therefore the problems of poor heat conduction and thermal diffusion properties of the high molecular material for the existing LED lamp cooling housing are solved; in the preparation process, the compatibility between the surface modified high-thermal-diffusion-coefficient high molecular material and a resin matrix is improved, the viscosity of the synthetic resin melt is reduced and the dispersity of the filler is improved to enhance the processability; as a result, the product has excellent surface quality and mechanical properties; the high molecular material further has the advantages of high thermal conductivity and high tenacity.

Owner:HUIZHOU KINGBALI TECH

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

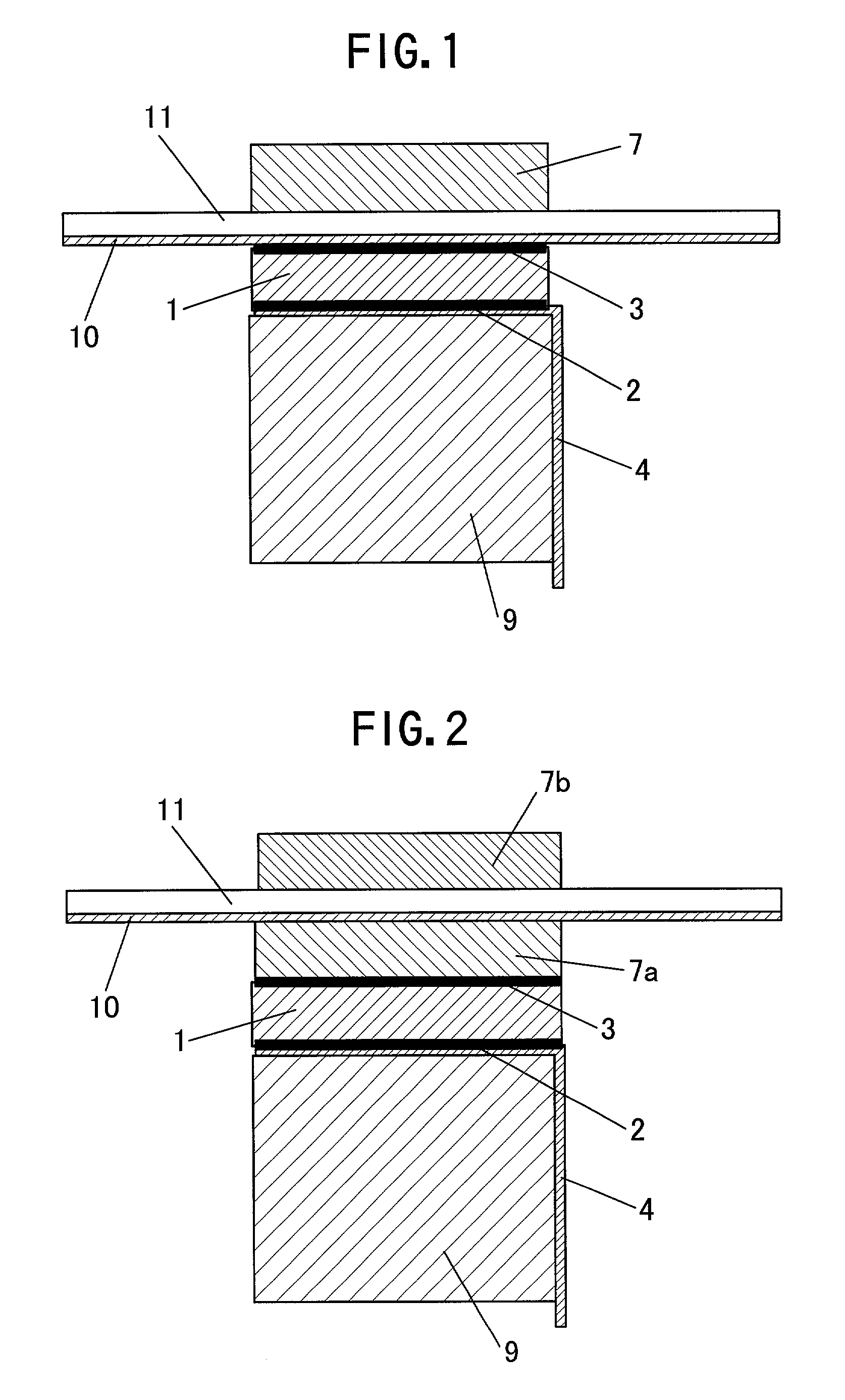

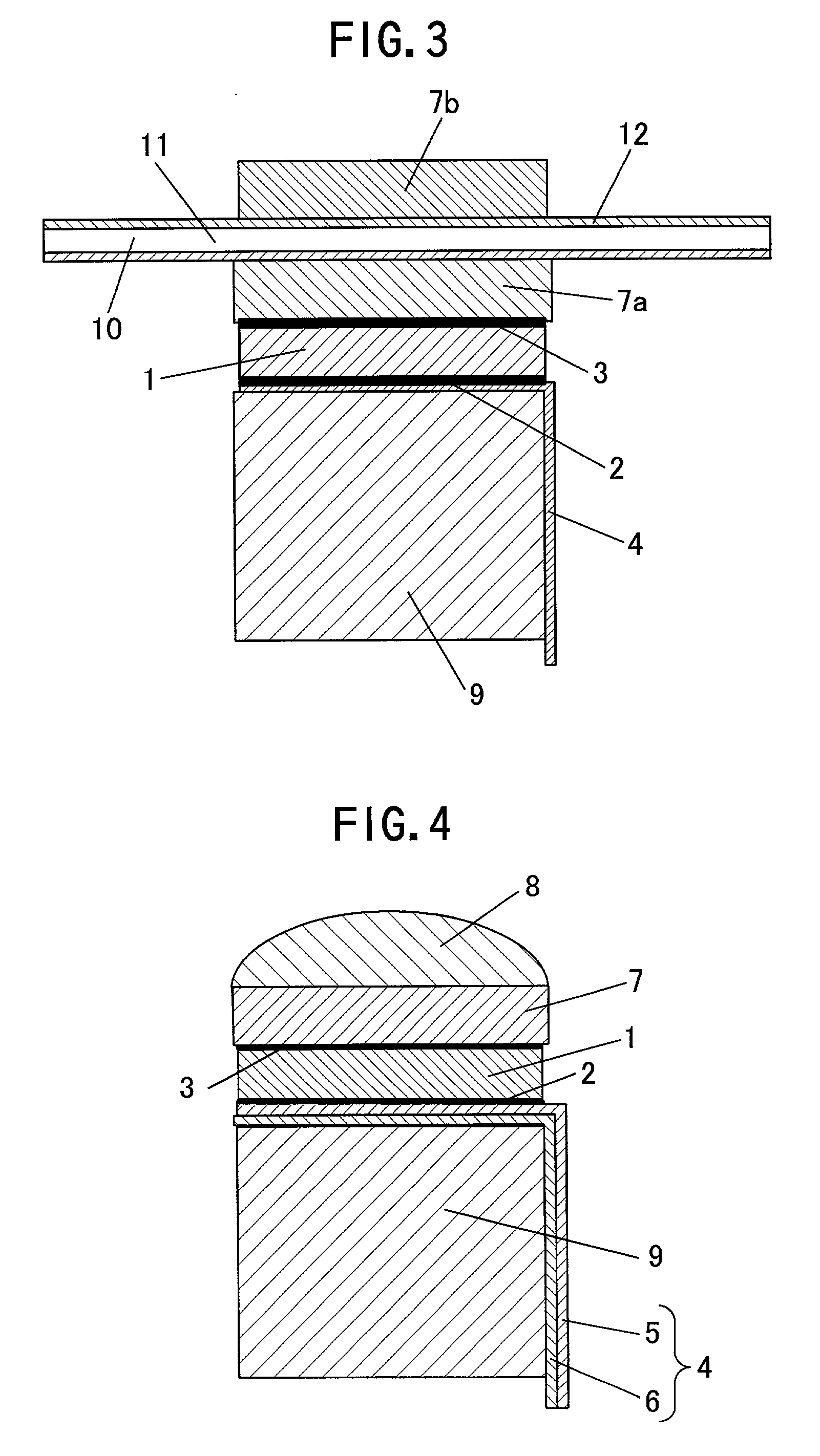

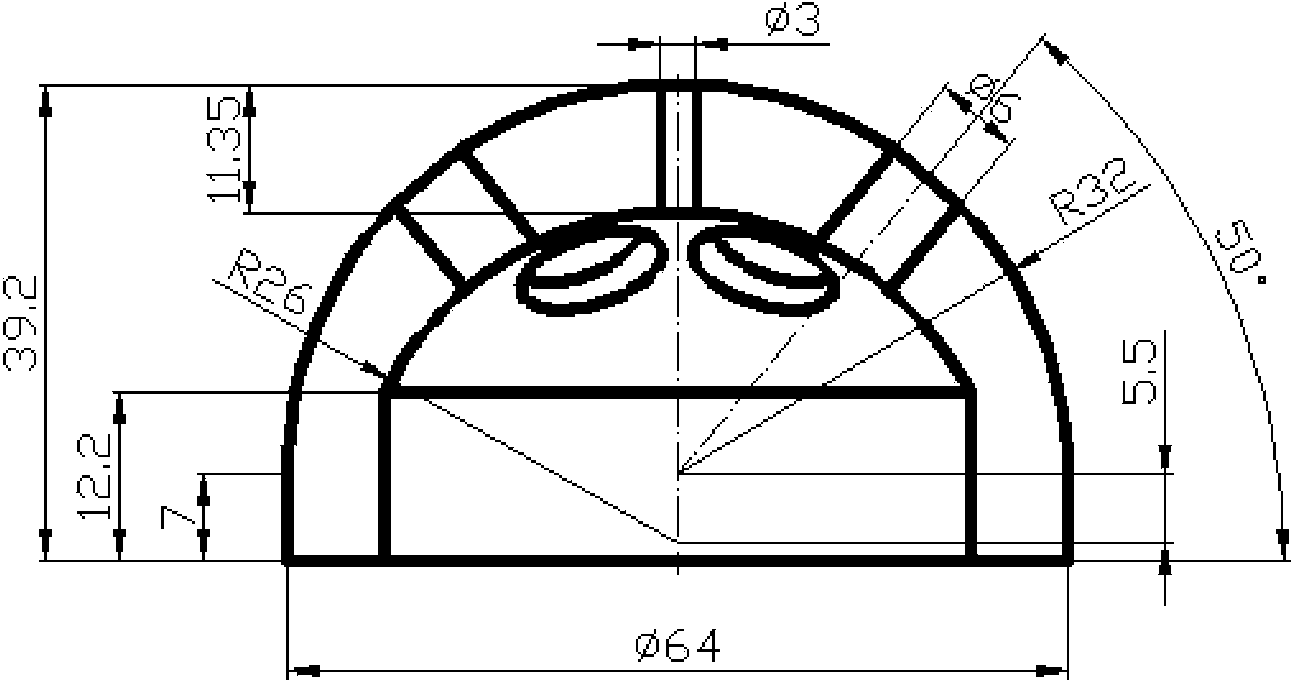

Ultrasonic probe

InactiveUS20010021807A1Quality improvementUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesElectricityElectrical Problem

The object of the present invention is to provide an ultrasonic probe of high performance and high quality. Disclosed is an ultrasonic probe comprising a high molecular material 11 having a conductive layer 10 and is disposed between a piezoelectric element 1 and an acoustic matching layer 7, wherein the high molecular material has an acoustic impedance substantially equal to that of the acoustic matching layer 7. The ultrasonic probe configured as above can be formed into a slim shape which is easy to operate without degrading the performance thereof such as sensitivity, frequency characteristic or the like. The ultrasonic probe is structured so as not to cause electrical problem due to breaking of wire even if the piezoelectric element is cracked by a mechanical impact or the like, and thus a high quality ultrasonic probe can be provided, and the noise can be reduced.

Owner:KONICA MINOLTA INC

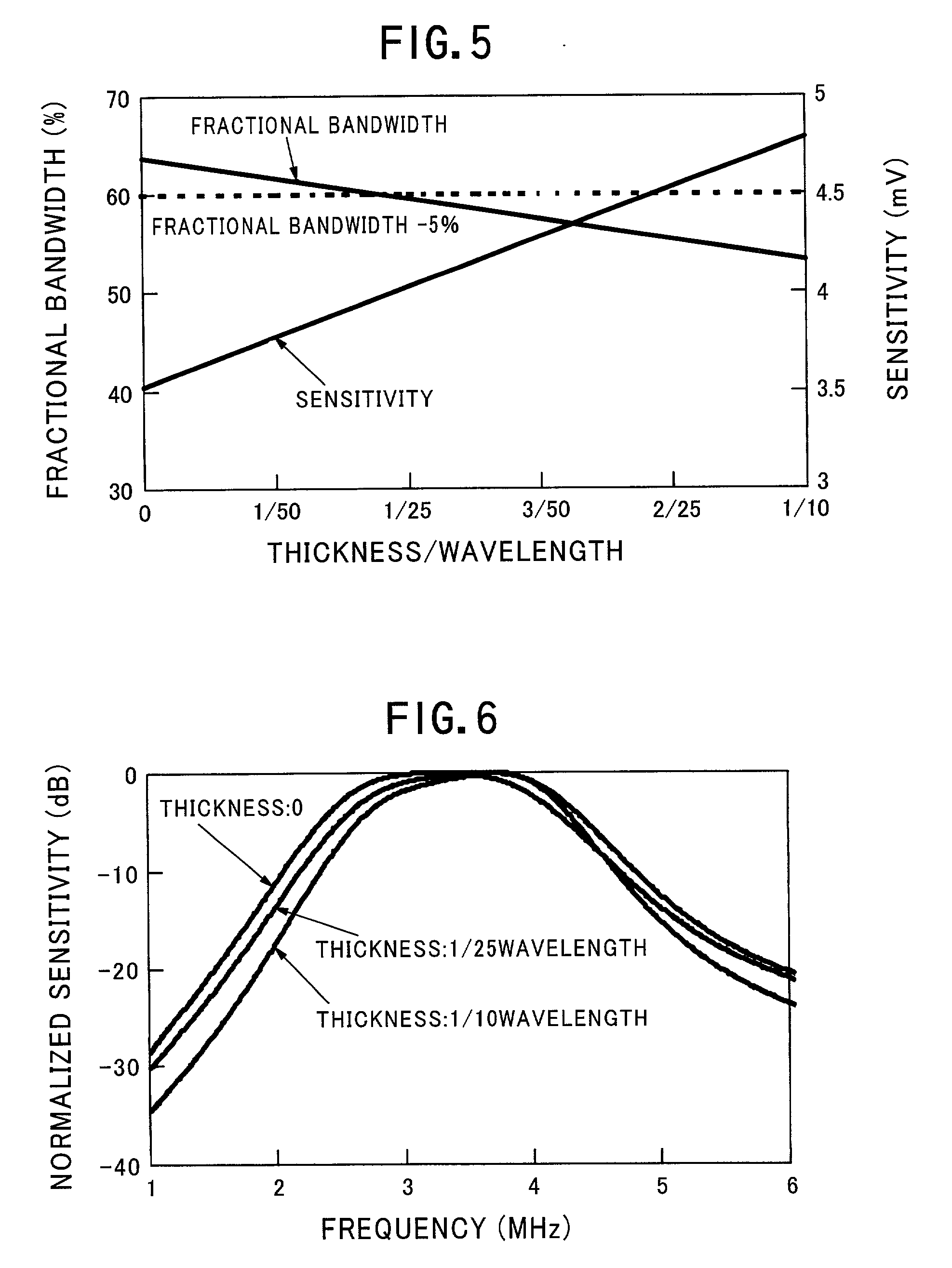

Preparation method of three-dimensional artificial random porous structure tissue engineering scaffold

The invention relates to a preparation method of a three-dimensional artificial random porous structure tissue engineering scaffold, belonging to the technical field of biomaterials. The invention aims to solve the design and manufacturing problems of the bionic structure of tissue engineering scaffold, provides a design method for constructing a random distributed scaffold porous structure with a bionic shape under expected porosity and pore size requirements, and molds by using a 3D additive manufacturing method to produce tissue substitute. The preparation method provided by the invention has the following advantages that the scaffold has a 3D through-hole structure meeting bionic requirements, and ensures nutrient substance transfer and waste metabolism and has certain bionic mechanical properties; the porosity and pore size distribution range of the scaffold can be conveniently controlled, and the random pore structure with expected function gradient is constructed to realize the bionic characteristic of the structure; and the method is suitable for a large range of materials such as metal materials, non-metal materials and medical high molecular materials, and can meets user-personalized tissue repair requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

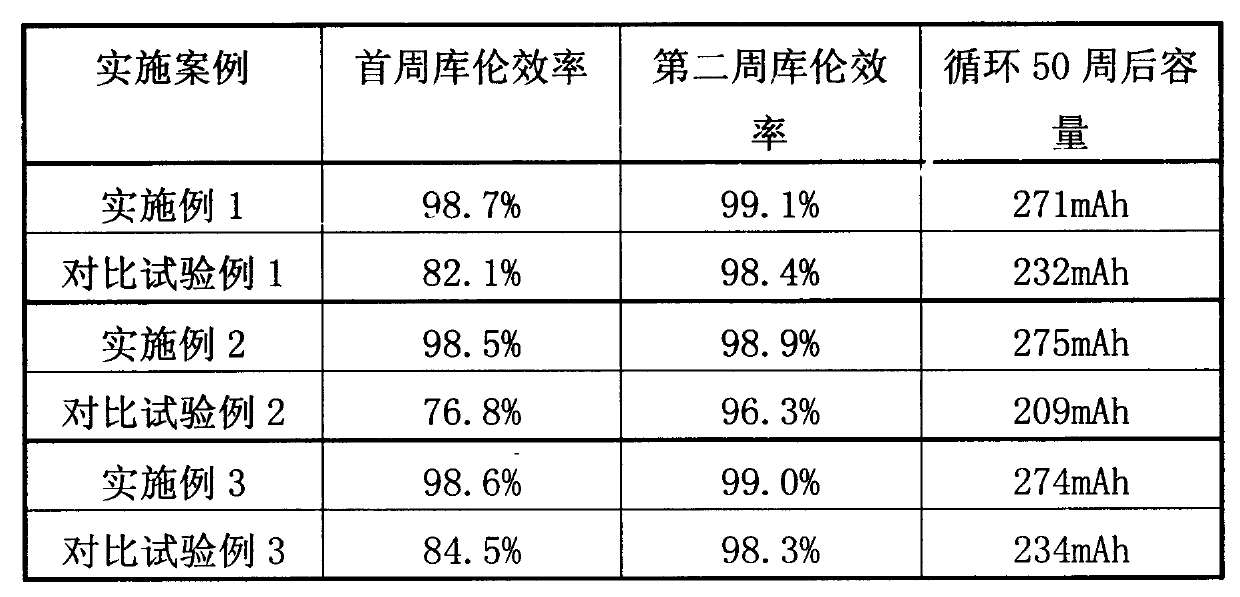

Method for pre-lithiating electrode material of lithium ion battery

InactiveCN104201320AIncrease profitLow costFinal product manufactureCell component detailsElectrical conductorElectrical battery

The invention relates to an electrode material of a lithium ion battery, in particular to a method for pre-lithiating a cathode material. The method comprises the steps that an electrolytic cell cathode cavity is made of the electrode material such as a lithium ion cathode material and arranged in a lithium ion conductive organic electrolyte; an anode cavity is an aqueous solution containing lithium salt or an organic solution; the anode cavity is separated from the cathode cavity by a lithium ion conductor ceramic membrane or a composite membrane of lithium ion conductor ceramic and a high molecular material; an electric potential and current density are controlled by external circuit charge and discharge equipment to allow lithium ions to migrate to a cathode from an anode through the membrane; and an SEI (Solid Electrolyte Interphase) membrane is formed on the surface of the material; or the electrode material is pre-lithiated. According to the method, a cheap and safe lithium ion saline solution serves as a source of the lithium ion; the SEI membrane is generated for the cathode of the lithium ion battery in advance; or lithium is supplemented to the electrode material; the coulombic efficiency and cycling stability of the cathode material can be improved; a formation process in production of the lithium ion battery in the prior art is simplified; the electrode material and cost are saved; and the method is safe and efficient and has a large-scale application prospect.

Owner:赵前永

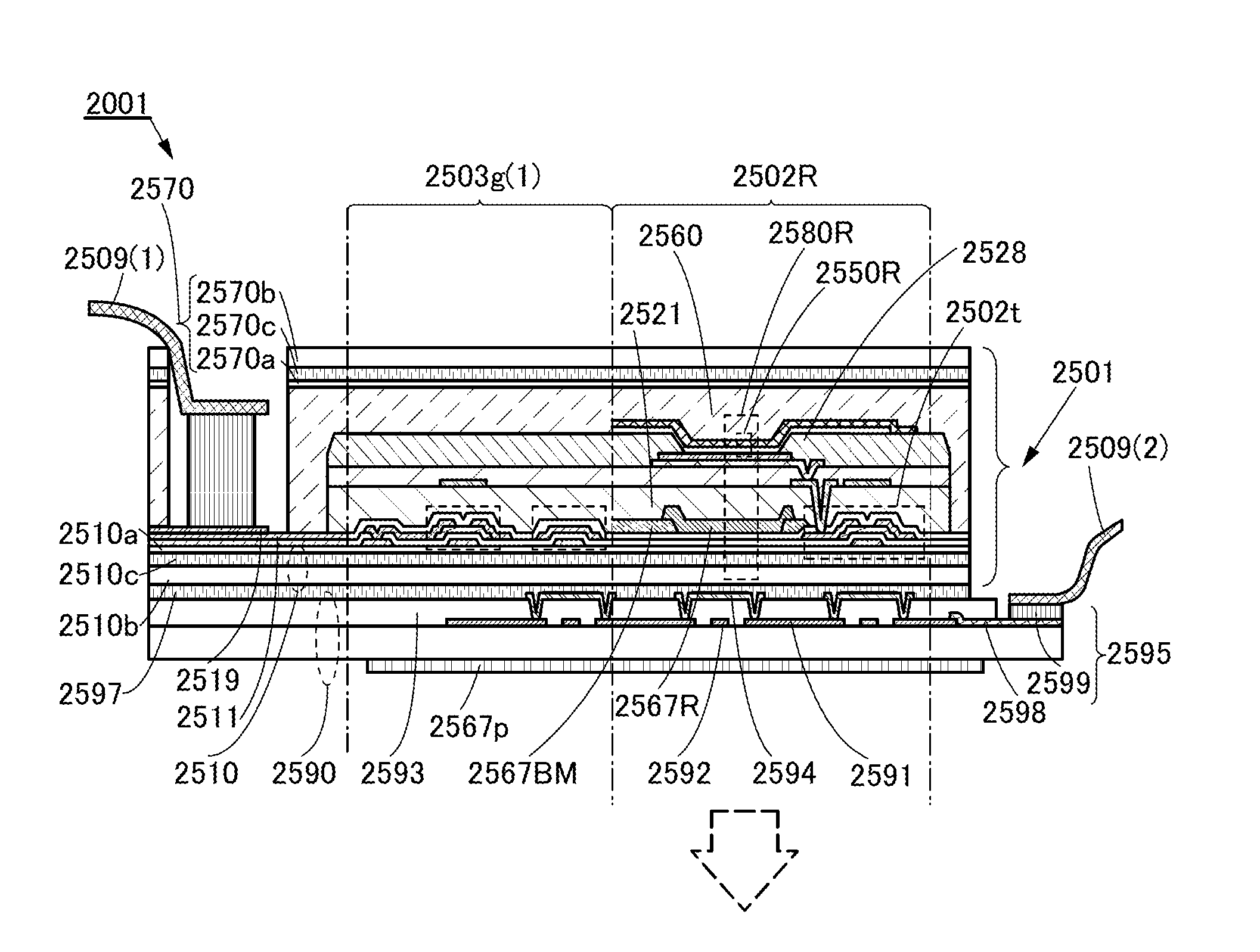

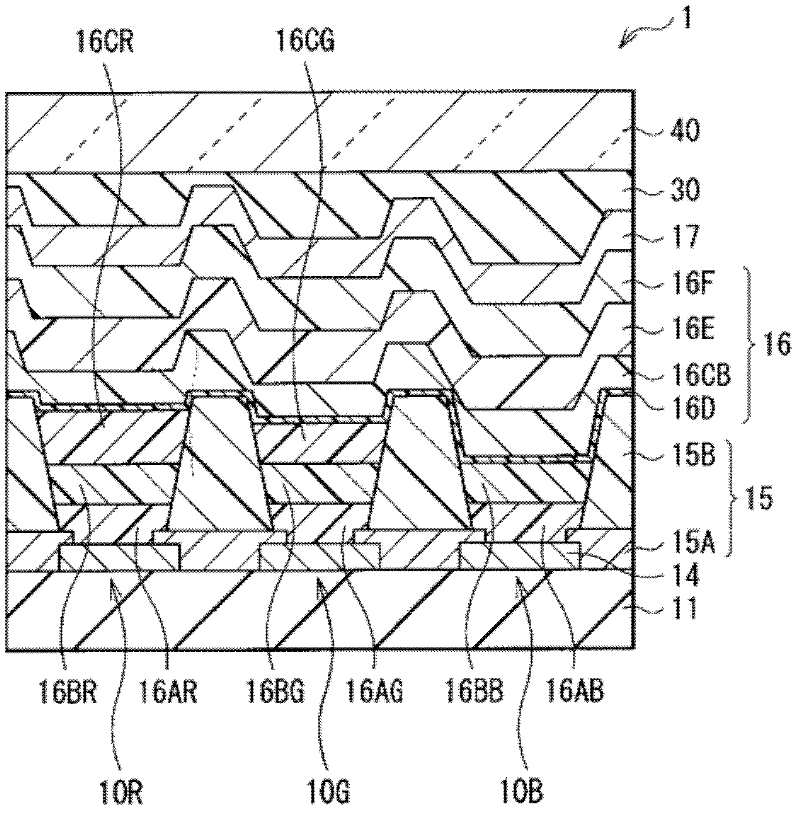

Organic el display device and method of manufacturing the same

ActiveCN102655164AImprove luminous efficiencyHigh color puritySolid-state devicesSemiconductor/solid-state device manufacturingTransport layerElectron injection

Disclosed herein is an organic EL display device, including: a lower electrode provided every first organic EL element for a blue color and every second organic EL element for another color on a substrate; a hole injection / transport layer provided every first and second organic EL elements; a second organic light emitting layer for another color provided on said hole injection / transport layer for said second organic EL element; a connection layer made of a low-molecular material and provided over an entire surface of said hole injection / transport layer for said second organic light emitting layer and said first organic EL element; a first organic light emitting layer for a blue color provided over an entire surface of said connection layer; and an electron injection / transport layer and an upper electrode provided over an entire surface of said organic light emitting layer in order.

Owner:JOLED INC

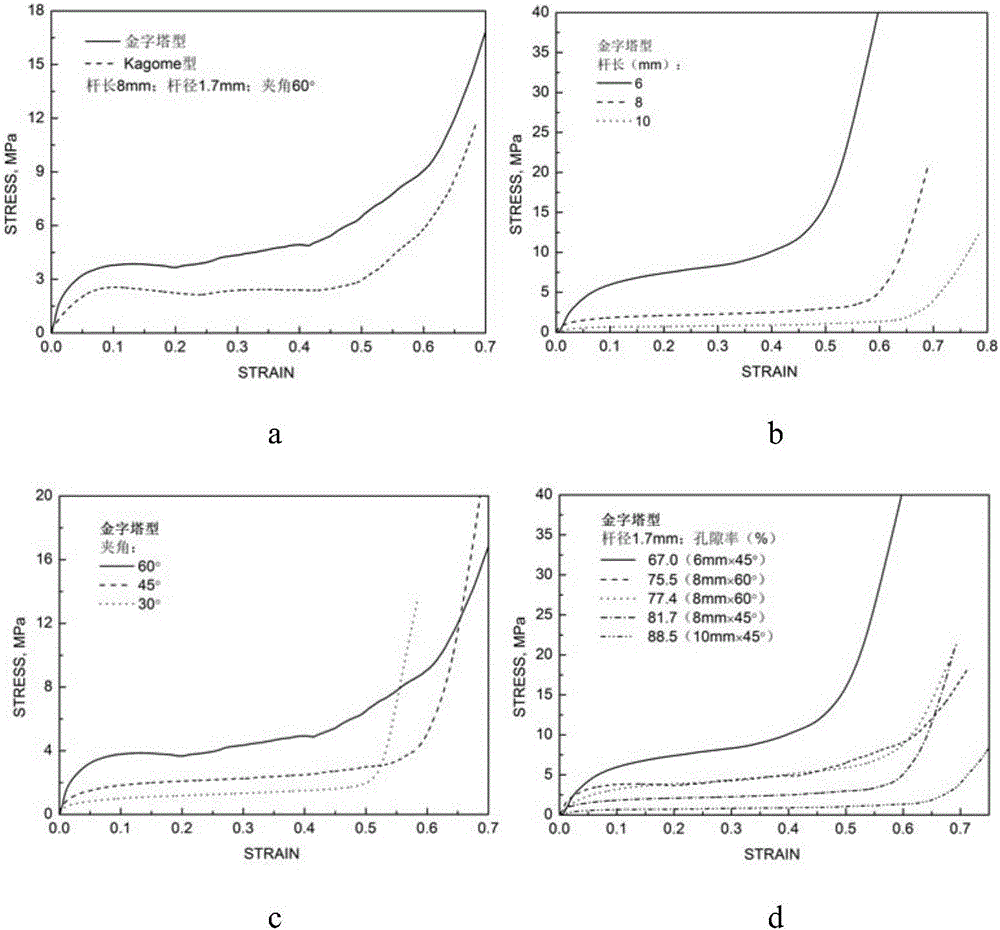

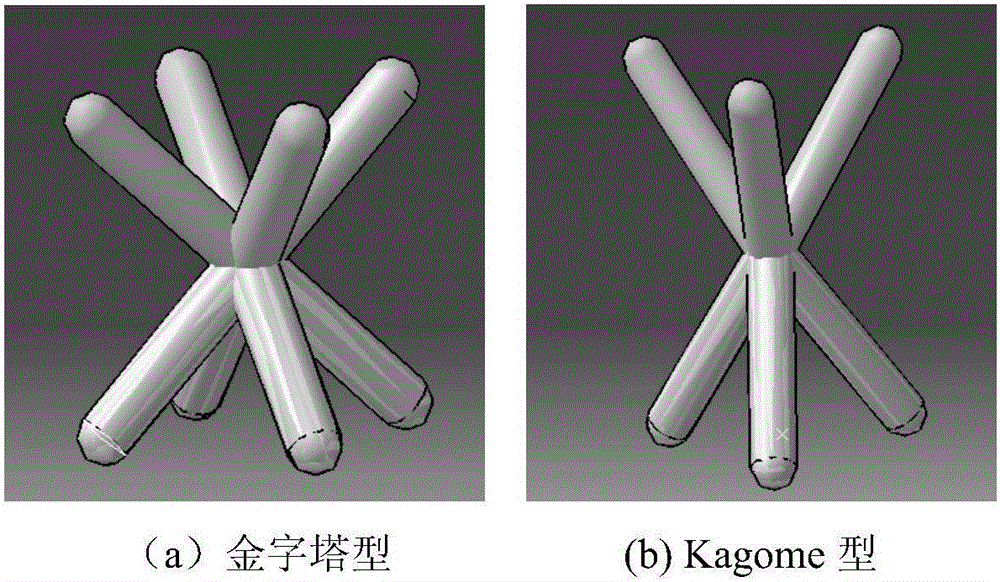

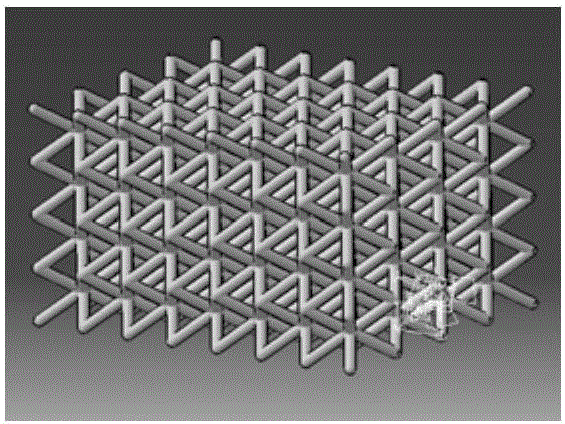

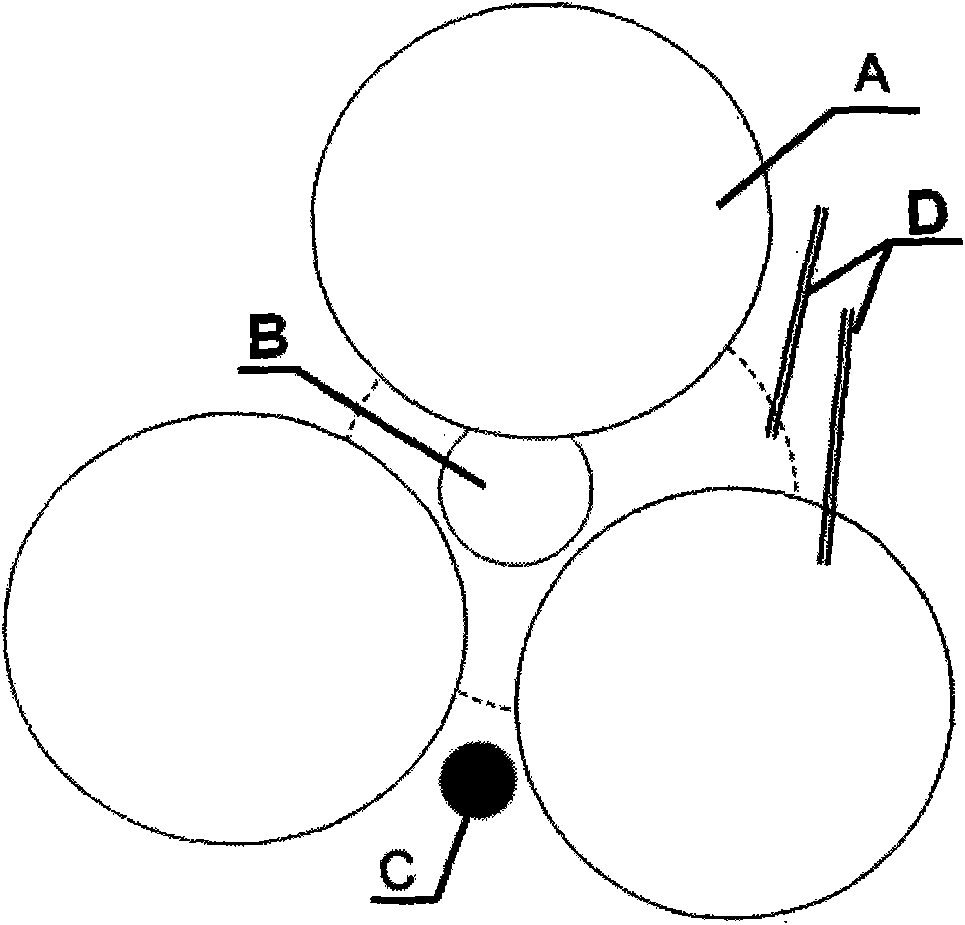

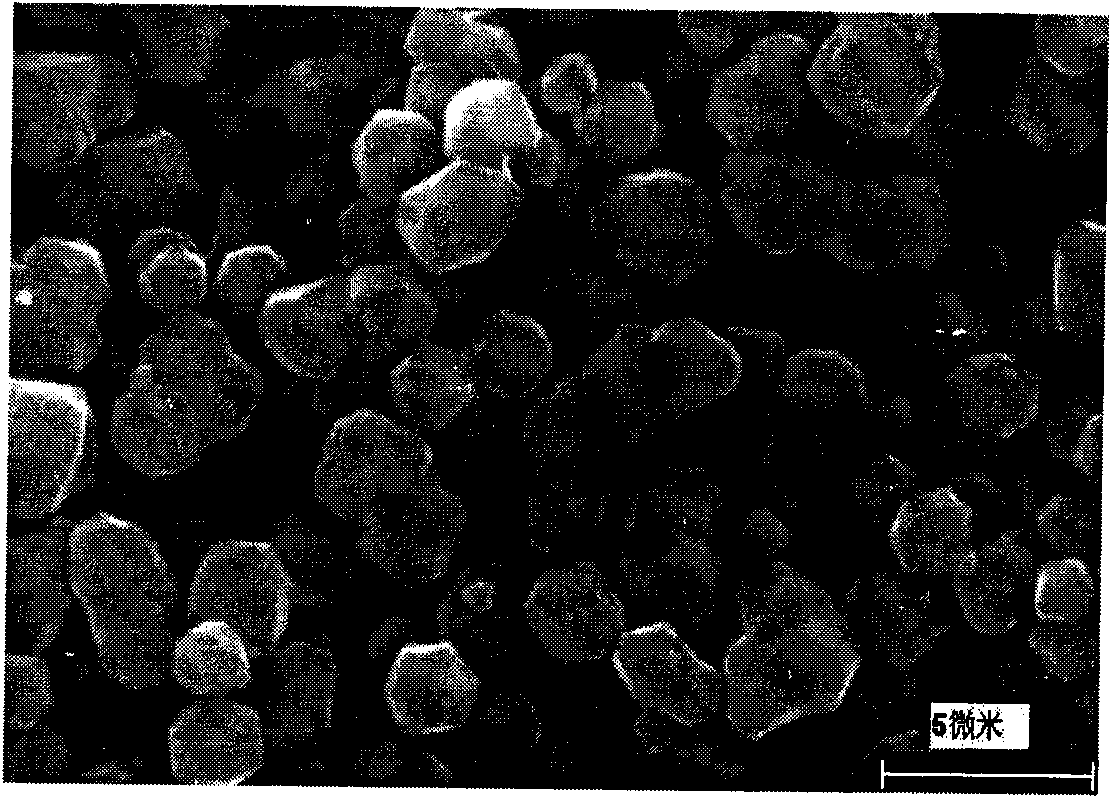

Aluminum-based dot matrix material based on 3D printing technology and preparation method thereof

InactiveCN105033188ARich configurationAdjustable structureFoundry mouldsFoundry coresGratingDot matrix

The invention discloses an aluminum-based dot matrix material based on 3D printing technology. In the dot matrix material, industrial pure aluminum or any aluminum alloy is employed as a base body. Unit cell configuration and a periodic structure thereof are modeled and designed with CATIA software and the model is produced from high-molecular materials through the 3D printing technology. An investment casting shell mould is prepared from soluble gypsum and the aluminum-based dot matrix material is prepared through an air-pressure seepage process. The aluminum-based dot matrix material can be in a pyramid type, a Kagome type and a grating type in the unit cell configuration. The invention also provides a sandwiched plate composite structure composed of the dot matrix material and a compact surface plate. The diameter of a unit cell bar is 0.5-5.0 mm, the length of the unit cell bar is 0.5-15.0 mm, and an included angle between the unit cell bar and a protective surface is 30-70 degrees. The compact surface plate is made from industrial pure aluminum, aluminum alloy, iron alloy or high-molecular materials. The dot matrix material with the industrial pure aluminum as the base body can reach higher than 5 MPa / g*cm<-3> in specific compressive strength.

Owner:INST OF SOLID PHYSICS ACAD SINICA

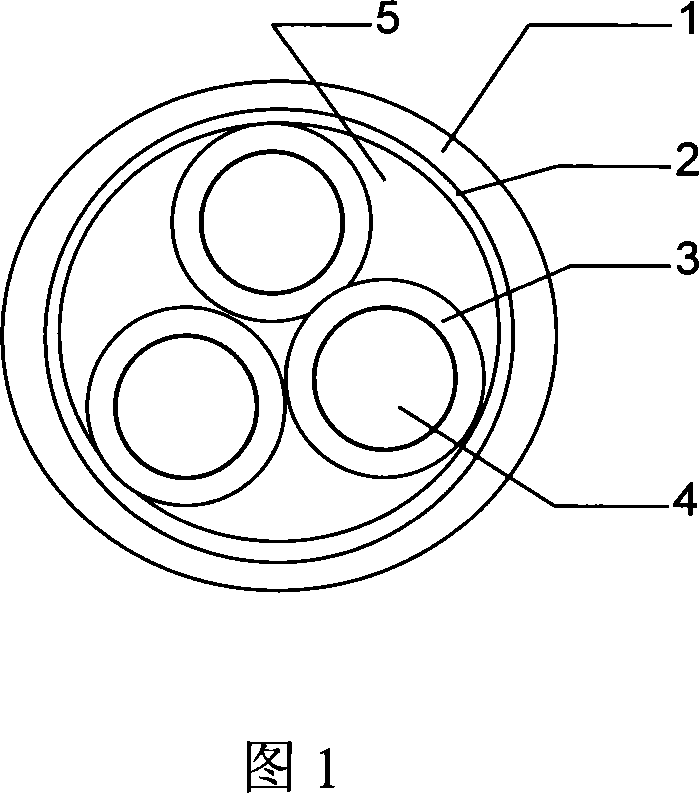

Halogen-free flame-retardant electric wire and cable sheath polymer material and uses thereof

ActiveCN101205324ASolve the problem of unsatisfactory flame resistanceNormal channel workInsulated cablesInsulated conductorsMolecular materialsElectrical polarity

The invention relates to a high molecular material of the halogen-free fire retardant sheath for wire cable and the application thereof. The invention solves the problem of bad fire retardant performance of the existing flame-retardant wire cable. The high molecular material of the invention is characterized in that the material comprises the following components by weight: a) 8-50 per cent of halogen-free expansive flame retardant pretreated by coupling agent occupying 0.1-3 wt per cent of the halogen-free expansive flame retardant; b) 0.5-10 per cent of graft polymer of the polar compound; c) 5-30 per cent of inorganic padding pretreated by coupling agent occupying 0.1-3 wt per cent of the inorganic padding; and d) at least one organic polymer for the rest.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

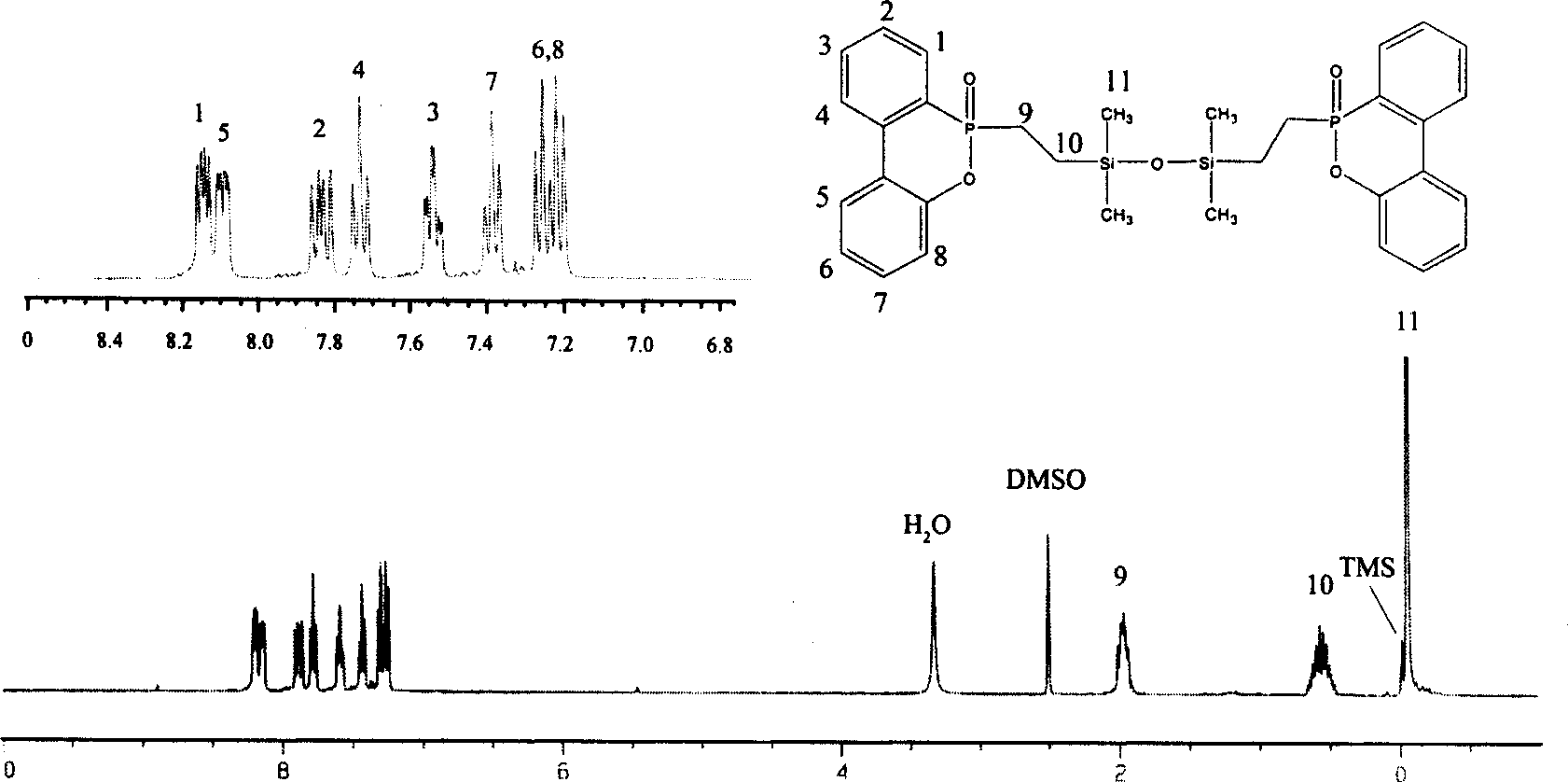

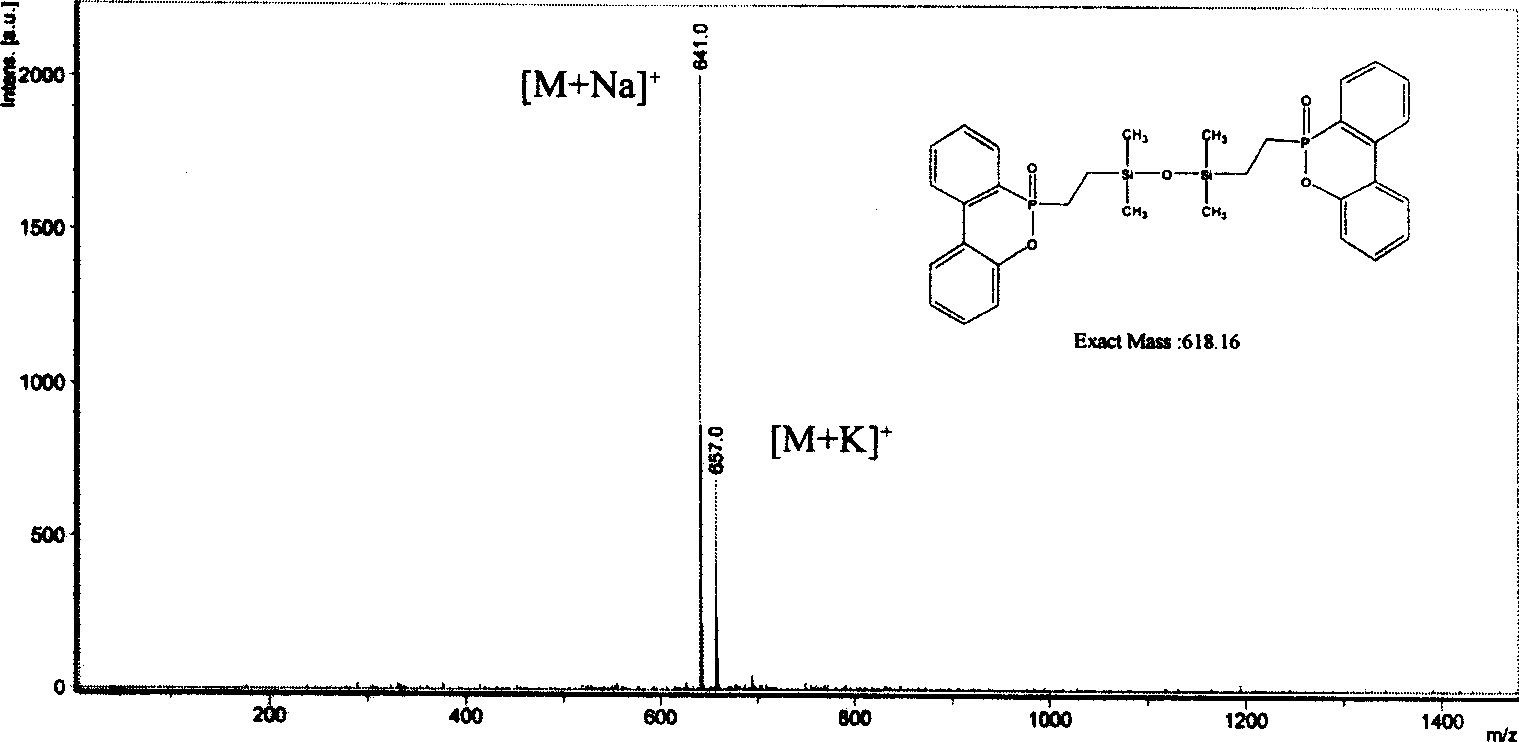

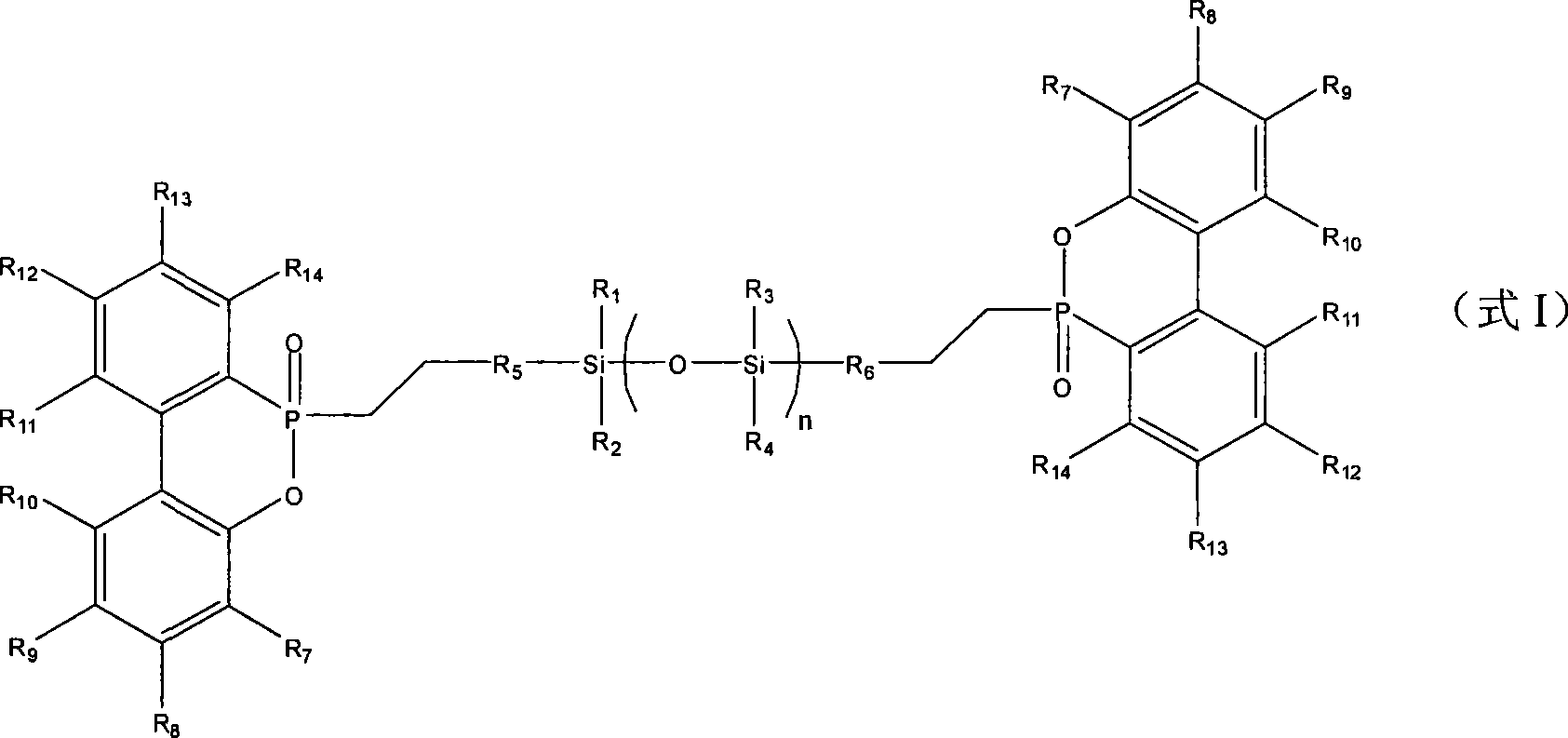

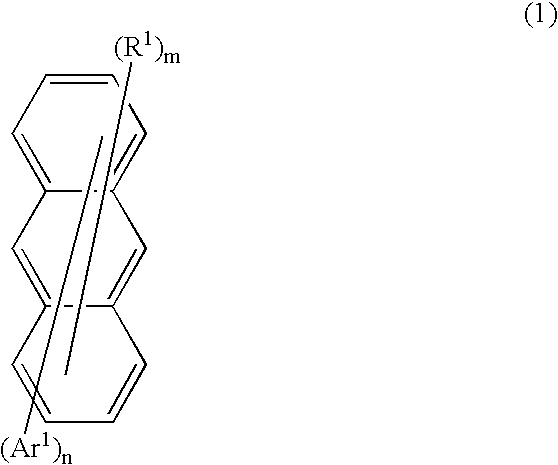

Phosphoric organic silicon compound, preparation method and application thereof

The invention discloses a phosphoric organic silicon compound, a preparation method and application thereof. The structural formula of the phosphoric organic silicon compound is shown as Figure 1, wherein, R1, R2, R3 and R4 are selected from C1-C5 alkyl, C1-C5 alkoxy, aryl, aryl substituted by halogen and aroxy; R5 and R6 are C0-C5 alkylidene groups; R7-R14 are selected from hydrogen atom, C1-C5 alkyl, nitro, the C1-C5 alkoxy, aryl, the aryl substituted by the halogen and the aroxy; and n is 1-10. The preparation method comprises performing an addition reaction of an active phosphorus-hydrogen bond in a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative and siloxane containing two carbon-carbon double bonds to produce the novel phosphoric organic silicon compound. The compound contains two elements namely phosphorus and silicon which have flame retardant property, and can be taken as an additive flame retardant for inflaming retarding of high molecular materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Gel polymer electrolyte containing natural high molecular material as well as preparation method and application thereof

PendingCN103441300AGood biocompatibilityImprove conductivityFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesPolymer science

The invention belongs to the technique fields of high molecular materials and batteries and in particularly relates to a gel polymer electrolyte as well as a preparation method and an application thereof. The gel polymer electrolyte is composed of a liquid electrolyte and a material containing natural high molecules, and has characteristics of not only higher ionic conductivity, better safety performance, better compatibility with an electrode material, better circularity and better multiplying power performance, but also better compatibility with a creature, degradability and environmental friendliness, and can be used as an electrolyte and a membrane barrier of a primary or secondary battery.

Owner:DKJ NEW ENERGY S & T CO LTD

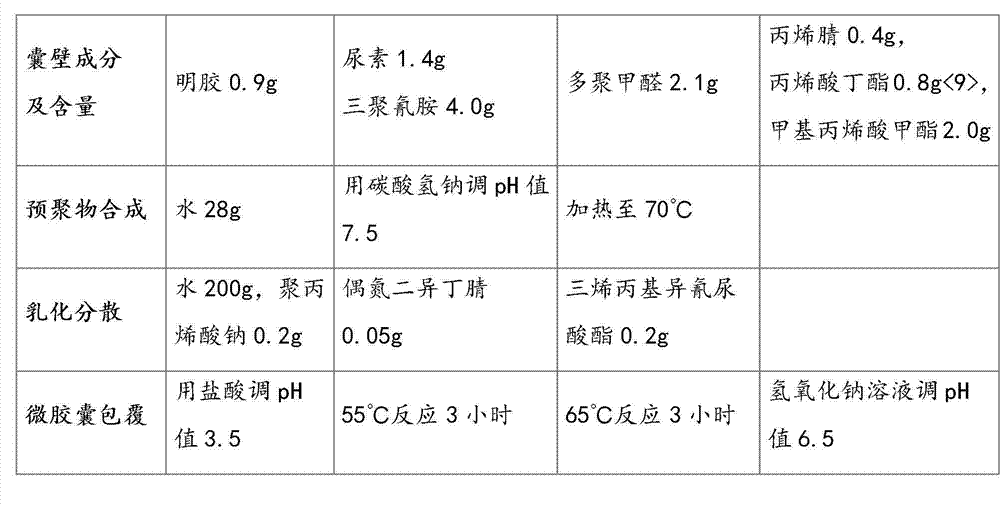

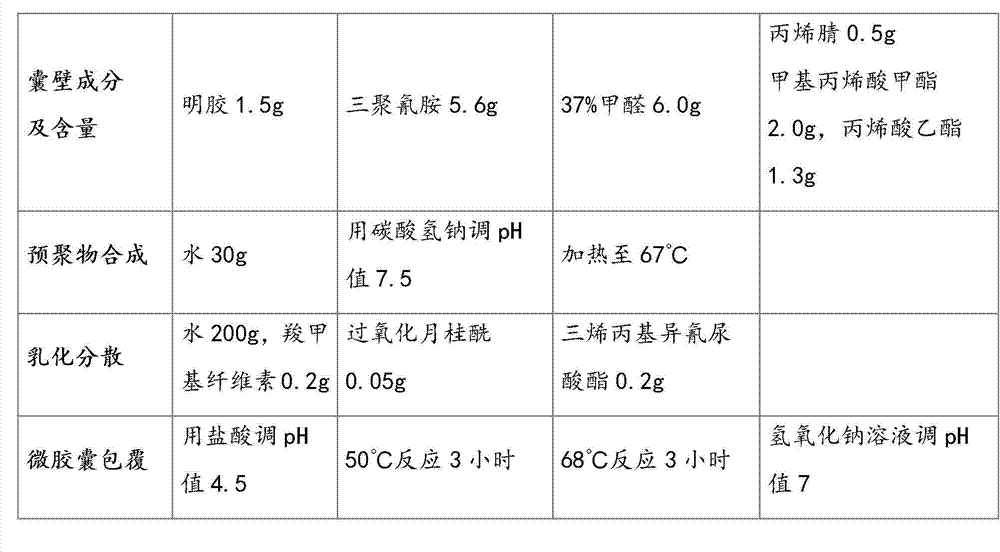

Double-layer coated essence microcapsule and preparation method thereof

ActiveCN102899168AMeet heat resistanceFulfil requirementsEssential-oils/perfumesMicroballoon preparationAcrylate polymerMechanical property

The invention discloses a double-layer coated essence microcapsule and a preparation method thereof. The essence microcapsule takes an oil soluble liquid essence as a capsule core, a gelatin modified amino resin composite material as a first-layer capsule wall and an acrylate polymer as a second-layer capsule wall, wherein a grafting transition area is formed by graft copolymerization of gelatin and acrylate between the first-layer capsule wall and the second-layer capsule wall. The preparation method comprises a step of prepolymer compounding, emulsification dispersion, microcapsule continuous double-layer coating and post-treatment. Compared with a single-layer coated microcaposule, the essence microcapsule has the advantages that the slow release performance, the heat resistance performance and the capsule wall material mechanical property are greatly improved, and the essence microcapsule can be used for most of microencapsulated essence products processed by heat extrusion molding of high molecular materials.

Owner:湖南方税达科技有限公司 +1

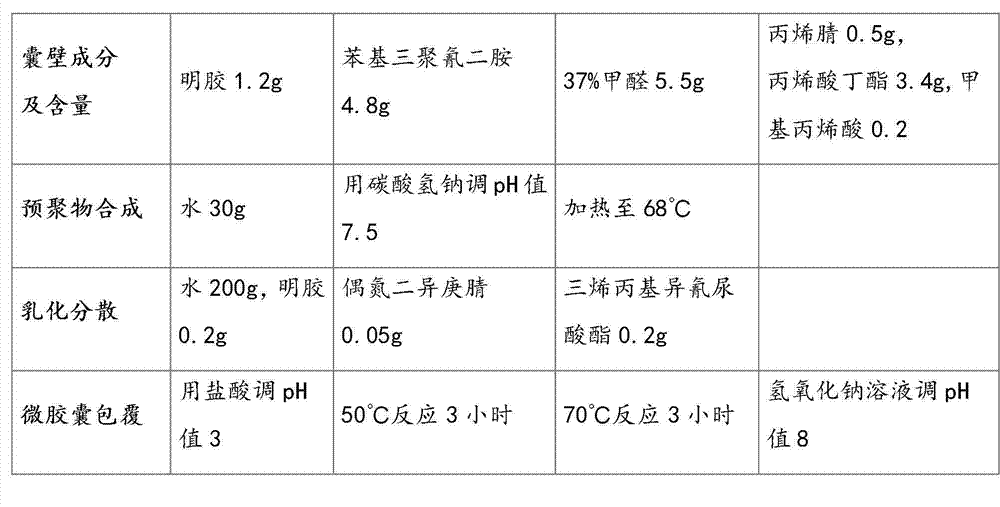

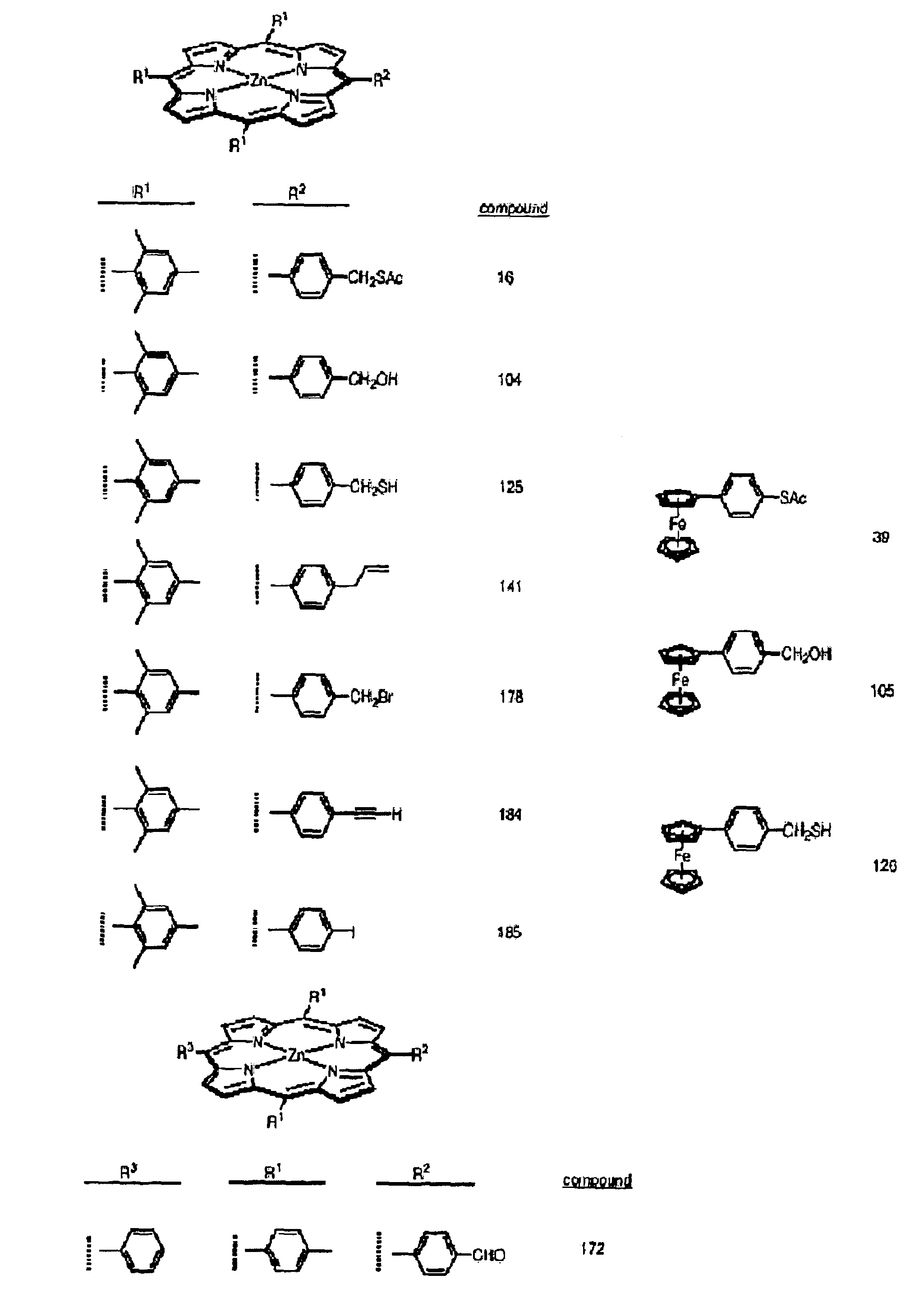

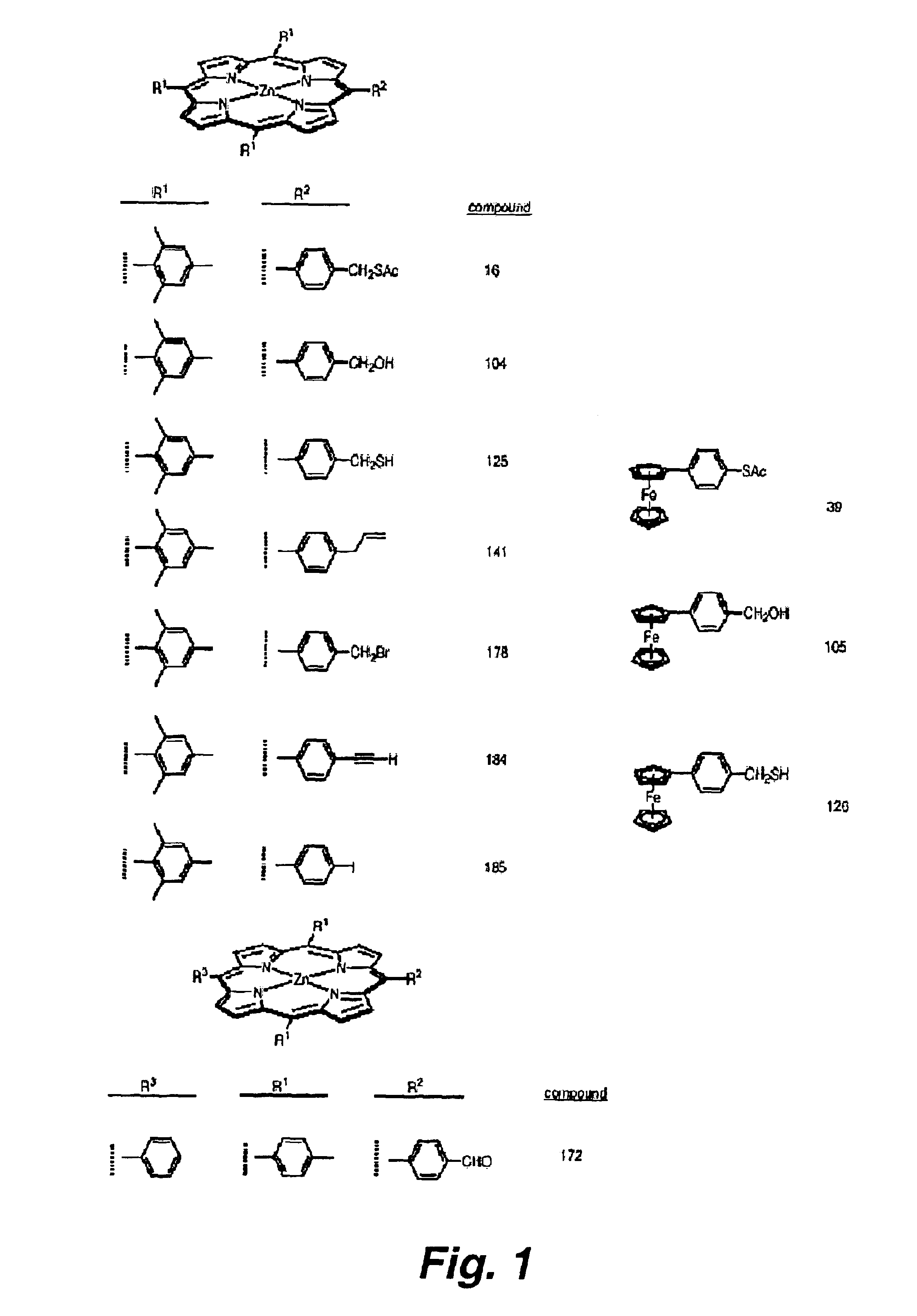

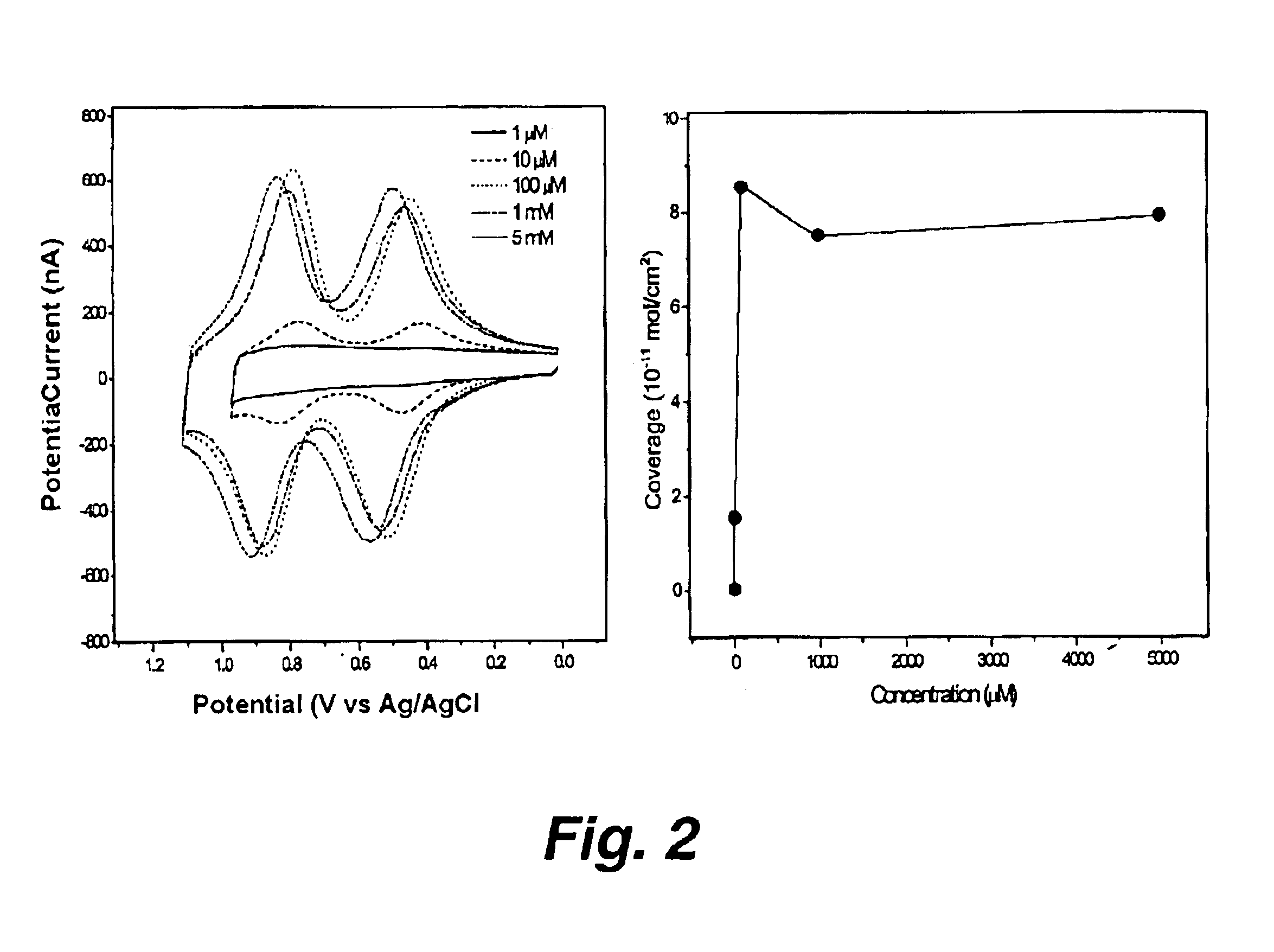

Attachment of organic molecules to group III, IV or V substrates

This invention provides a new procedure for attaching molecules to semiconductor surfaces, in particular silicon. The molecules, which include, but are not limited to porphyrins and ferrocenes, have been previously shown to be attractive candidates for molecular-based information storage. The new attachment procedure is simple, can be completed in short times, requires minimal amounts of material, is compatible with diverse molecular functional groups, and in some instances affords unprecedented attachment motifs. These features greatly enhance the integration of the molecular materials into the processing steps that are needed to create hybrid molecular / semiconductor information storage devices.

Owner:CALIFONRIA UNIV OF RGT +1

Luminescent Ink Composition for Organic Electroluminescent Device

InactiveUS20080001123A1Well formedIncrease contentMethine/polymethine dyesElectroluminescent light sourcesAnthraceneSolubility

A luminescent ink composition for an organic EL device which can form thin films by a wet process easily due to a high solubility of a low-molecular material is provided in order to form an organic thin film containing a luminescent low-molecular material by a wet method with a high productivity. A luminescent ink composition for an organic electroluminescent device comprising: (A) an anthracene derivative represented by the following formula (1); (B) a condensed aromatic ring compound substituted with an arylamino group and / or a styryl derivative substituted with an arylamino group; and (C) an organic solvent.

Owner:GLORY KOGYO KK +1

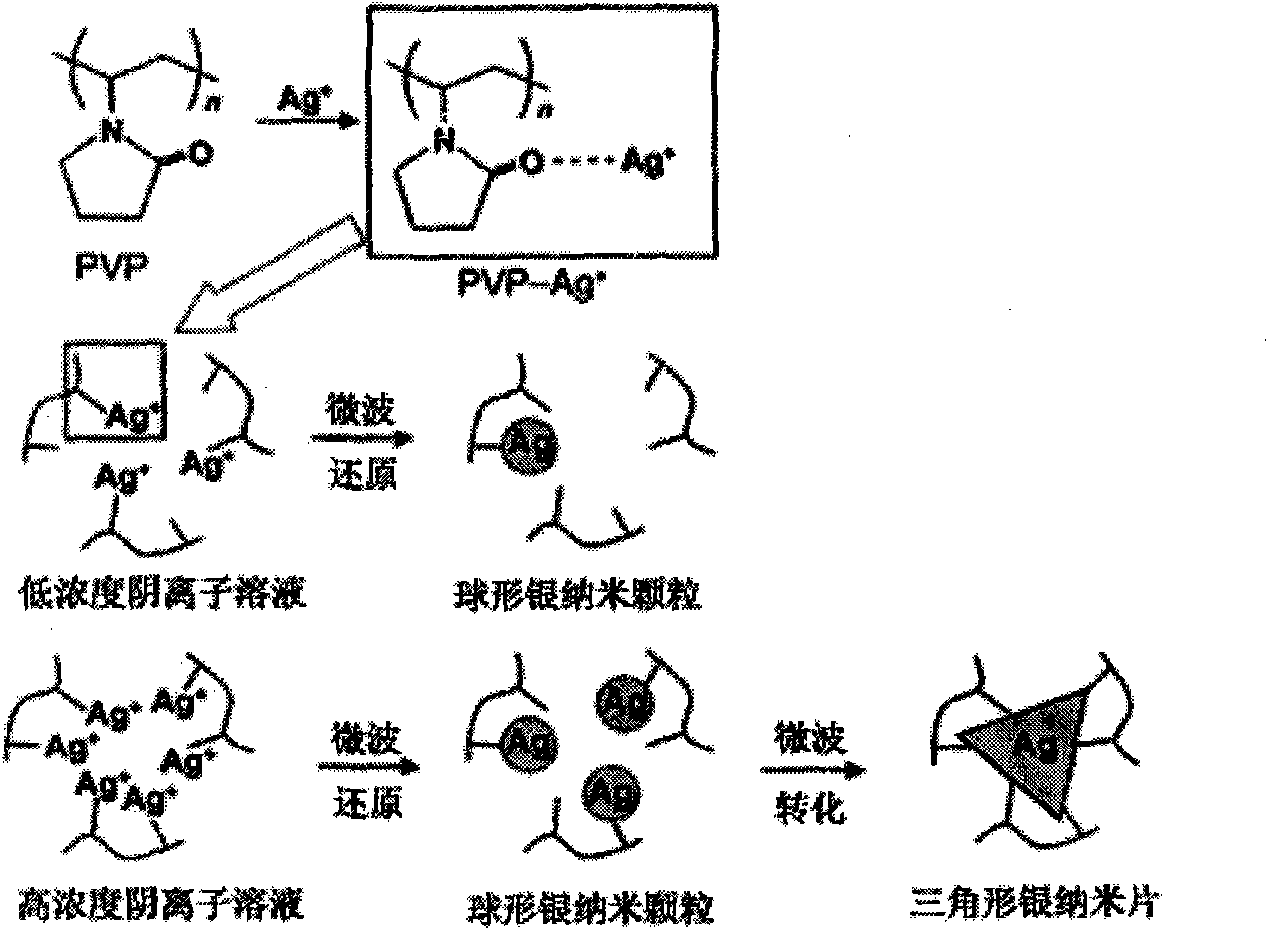

Nano conductive adhesive and preparation method thereof

InactiveCN101629057AImprove performanceImprove conductivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMicrowave methodAdhesive

The invention provides a nano conductive adhesive. The conductive adhesive is a uniform mixture of one of or two, three or four of micron-grade silver powder, submicron-grade silver powder, nano silver powder or a nano silver wire, and a high molecular material, solvent and a curing agent. The invention also provides a preparation method of the nano conductive adhesive, which comprises the following steps: 1. preparing the micron-grade silver powder, the submicron-grade silver powder, the nano silver powder and the nano silver wire by a microwave method; and 2. mixing the components in different proportions with the high molecular material, the solvent and the curing agent. The invention has the advantages of even diameter of a conductive silver particle obtained by the microwave method and simple preparation. The conductive adhesive performance can be improved by the optimal design of the particle proportion. The conductive adhesive with high conductive performance is prepared by three silver powder particles and one nano silver wire in certain size selection and proportion. The prepared conductive adhesive has stable performance and high rheological property.

Owner:漳立冰

Thermal interface material and method for making the same

ActiveUS20060219689A1Smooth connectionSemiconductor/solid-state device detailsSolid-state devicesFiberLiquid state

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com