Method for preparing multi-layer graphene

A multi-layer graphene and expanded graphite technology, applied in the field of carbon materials, can solve the problems of single-layer graphene with many structural defects, unsuitable for large-scale production, complex process conditions, etc., and achieves easy popularization and application, high electromagnetic wave absorption, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

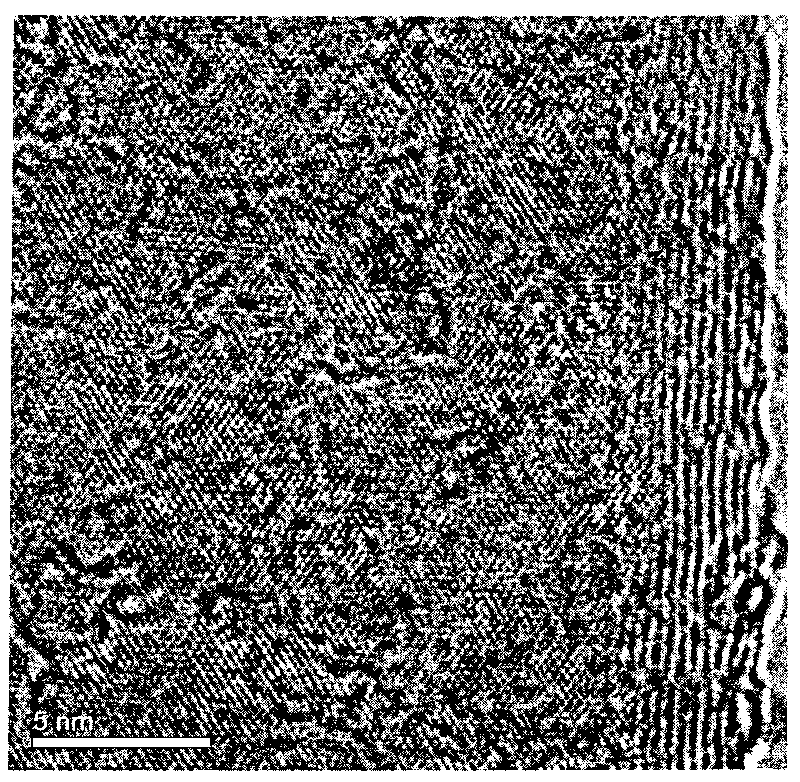

Image

Examples

Embodiment 1

[0023] The concrete steps of a kind of multilayer graphene preparation method are as follows:

[0024] (1) Ultrasonic vibration dispersion

[0025] According to the mass (g) of expanded graphite: the volume (ml) ratio of dehydrated alcohol solvent is the ratio of 1: 20, the expanded graphite is put into dehydrated alcohol solvent, after stirring evenly, under the ultrasonic output frequency is 100kHz, carries out Ultrasonic dispersion for 60 minutes to obtain a suspension dispersed in expanded graphite;

[0026] (2) Solid-liquid separation

[0027] After the step (1) is completed, the suspension prepared in the step (1) is subjected to solid-liquid separation by filtration, the solvent and the solid residue are collected respectively, and the collected absolute ethanol solvent is recovered and reused;

[0028] (3) dry

[0029] After step (1) is completed, the solid residue collected in (2) is dried at a temperature of 120° C. for 120 minutes to prepare multilayer graphene; ...

Embodiment 2

[0031] The concrete steps of a kind of multilayer graphene preparation method are as follows:

[0032] (1) Ultrasonic vibration dispersion

[0033] With embodiment 1, wherein: the mass (g) of expanded graphite: the volume (ml) ratio of acetone solvent is 1: 50, and ultrasonic frequency is 50Hz, and ultrasonic separation time is 100 minutes;

[0034] (2) Solid-liquid separation

[0035] With embodiment 1, wherein: adopt centrifugation to carry out solid-liquid separation by the suspension liquid that (1) step makes in centrifuge;

[0036] (3) dry

[0037] Same as Example 1, wherein: drying at a temperature of 80° C. for 30 minutes;

Embodiment 3

[0039] The concrete steps of a kind of multilayer graphene preparation method are as follows:

[0040] (1) Ultrasonic vibration dispersion

[0041] With embodiment 1, wherein: the mass (g) of expanded graphite: the volume ratio of toluene solvent is 1: 1, and ultrasonic frequency is 500kHz, and ultrasonic separation time is 30 minutes;

[0042] (2) Solid-liquid separation

[0043] With embodiment 1;

[0044] (3) dry

[0045] Same as implementation 1, wherein: drying at a temperature of 100°C for 60 minutes;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com