Patents

Literature

177results about How to "No heat treatment required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

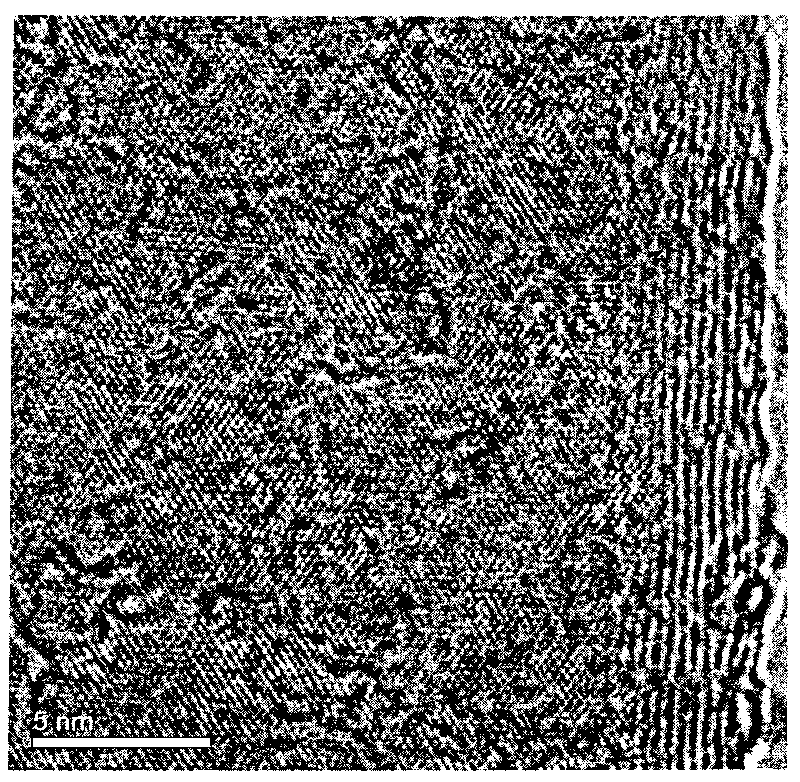

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

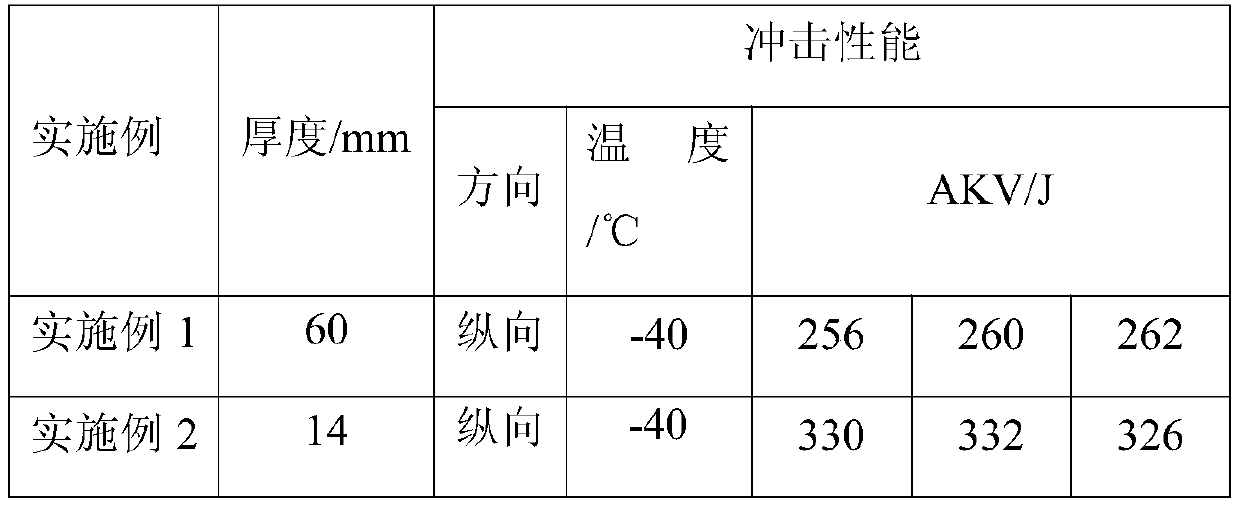

Low-cost steel plate for building structure and manufacturing method thereof

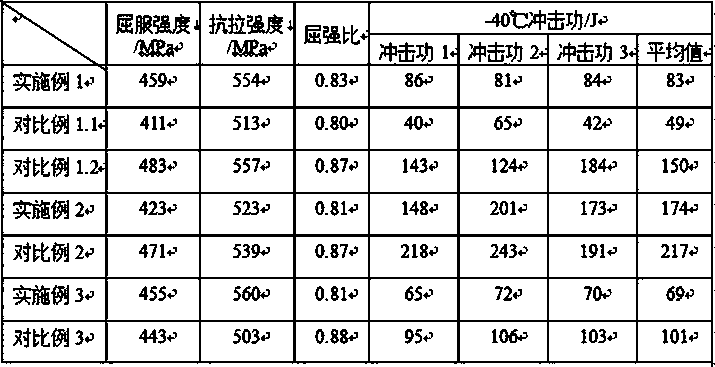

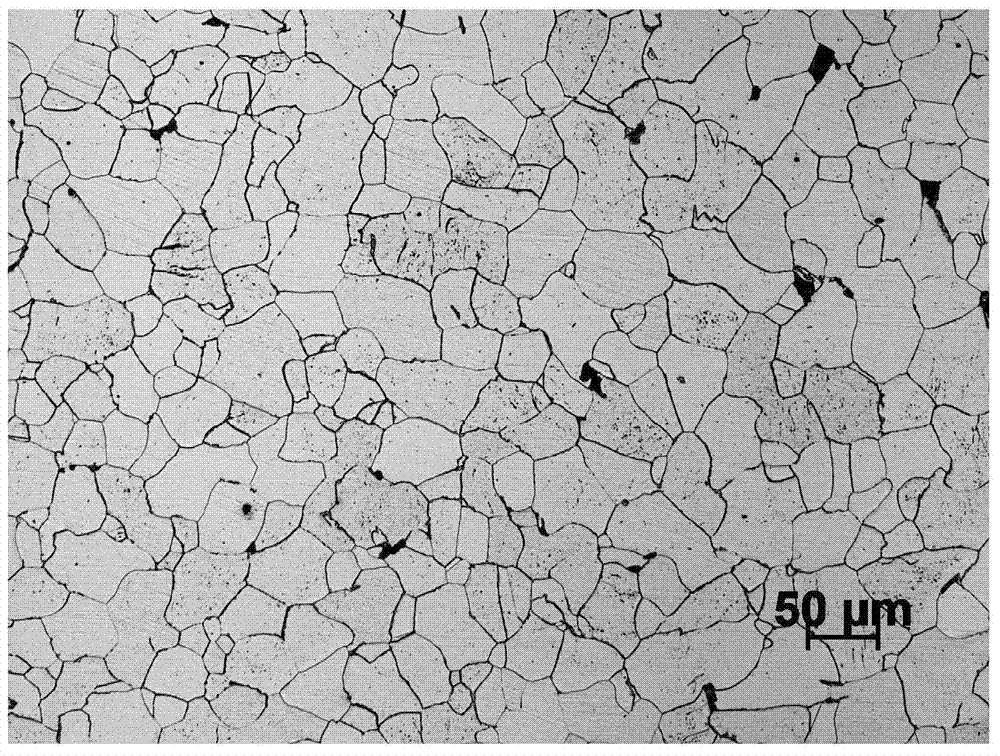

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

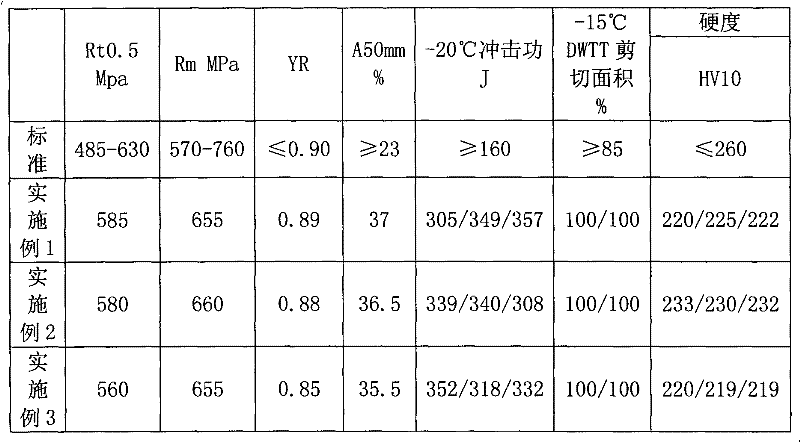

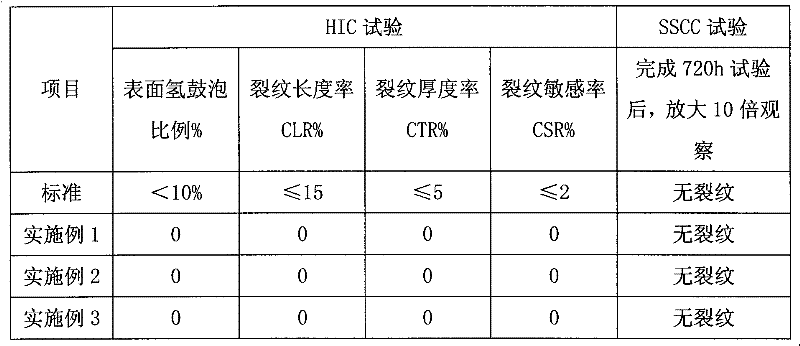

X70 pipeline steel hot rolled coil and manufacture method thereof

The invention relates to an X70 pipeline steel hot rolled coil and a manufacture method thereof. The coil comprises the following ingredients in percentage by weight: 0.02 to 0.05 percent of C, 0.10 to 0.30 percent of Si, 1.00 to 1.40 percent of Mn, at most 0.015 percent of P, at most 0.002 percent of S, 0.015 to 0.05 percent of Alt, 0.05 to 0.08 percent of Nb, 0.02 to 0.035 percent of V, 0.01 to 0.02 percent of Ti, 0.10 to 0.50 percent of Cr, at most 0.006 percent of Ca, 0.10 to 0.30 percent of Ni and 0.10 to 0.30 percent of Cu. The manufacture method is mainly characterized in that a, the laser fused (LF) refining is carried out outside a furnace: desulfurization is carried out until the weight percent of S is less than or equal to 0.0015 percent; b, the RH refining is carried out outside the furnace: Ca-Si lines are added before the vacuum smelting and steel outlet; c, the continuous casting temperature is 1553+ / -15DEG C; d, the continuous casting pulling speed is higher than or equal to 1.0 m / min; e, the plate blank heating temperature is lower than or equal to 1200 DEG C; f, the rough rolling terminating temperature is 930 to 1030 DEG C; g, the finish rolling terminating temperature is 780 to 850 DEG C; h, the steel band coiling temperature is 450 to 580 DEG C; and l, the cooling speed of the layer flow cooling is higher than or equal to 5 DEG C / s. The X70 pipeline steel hot rolled coil simultaneously meets the requirements of high toughness and hydrogen sulphide corrosion resistance of X70 pipeline steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

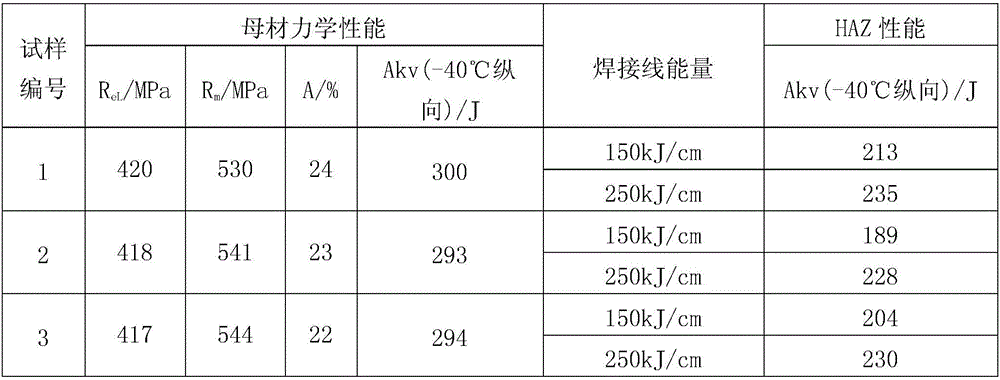

TMCP-state low-cost high-strength ship plate steel for high-heat input welding and manufacturing method of TMCP-state low-cost high-strength ship plate steel

ActiveCN106756543AReasonable ingredientsGood comprehensive mechanical propertiesSteel platesHeat treated

The invention discloses TMCP-state low-cost high-strength ship plate steel for high-heat input welding. The TMCP-state low-cost high-strength ship plate steel comprises the chemical components in percentage by weight: 0.04-0.12% of C, 0.15-0.35% of Si, 1.10-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.030-0.060% of V, 0.005-0.060% of Alt, 0.32-0.41% of Ceq, 0.005-0.030% of Ti, 0.0005-0.0040% of Ca, 0.05-0.40% of Ni and the balance of Fe and unavoidable impurities. The steel plate disclosed by the invention has the yield strength of larger than or equal to 400MPa and the tensile strength of larger than or equal to 510MPa, is suitable for high-strength ship plate steel with welding heat input being within the range of 150-250kJ / cm, the average impact power of HAZ of the steel plate under 40 DEG C is higher than 150J under the high-heat input welding conditions of 150kJ / cm and 250kJ / cm, heat treatment is not needed, and the production cost is low.

Owner:NANJING IRON & STEEL CO LTD

Phosphogypsum-based light-weight insulation board and preparation method thereof

InactiveCN105777039ALow densityImprove fire performanceLaminationLamination apparatusSurface layerSlurry

The invention relates to a phosphogypsum-based light-weight insulation board and a preparation method thereof. The phosphogypsum-based light-weight insulation board is prepared from the following raw material components in parts by weight: 100 parts of phosphorus building gypsum, 10-30 parts of high-strength gypsum, 3-12 parts of lightweight aggregates, 0.1-0.3 part of a dispersing agent, 0.3-0.5 part of a retarder, 0.2-0.4 part of a water-retaining agent and 0.1-0.3 part of an air entraining agent. The preparation method comprises the following steps: adding water into a stirring machine in a water-cement ratio of (0.70-0.80):1, adding the air entraining agent, the retarder, the dispersing agent and the water-retaining agent, stirring, then adding a dry material, obtained by uniformly mixing the phosphorus building gypsum, high-strength gypsum and lightweight aggregates, into the stirring machine, continuously stirring to obtain slurry, paving basalt fiber mesh cloth in a bottom die of a gypsum board forming die, pouring into the slurry, vibrating for 1 minute, then paving a layer of basalt fiber mesh cloth on the surface layer, closing a cover die of the gypsum board forming die, carrying out roller forming, taking apart the die after solidification, and drying, so that the phosphogypsum-based light-weight insulation board is obtained.

Owner:WUHAN UNIV OF TECH

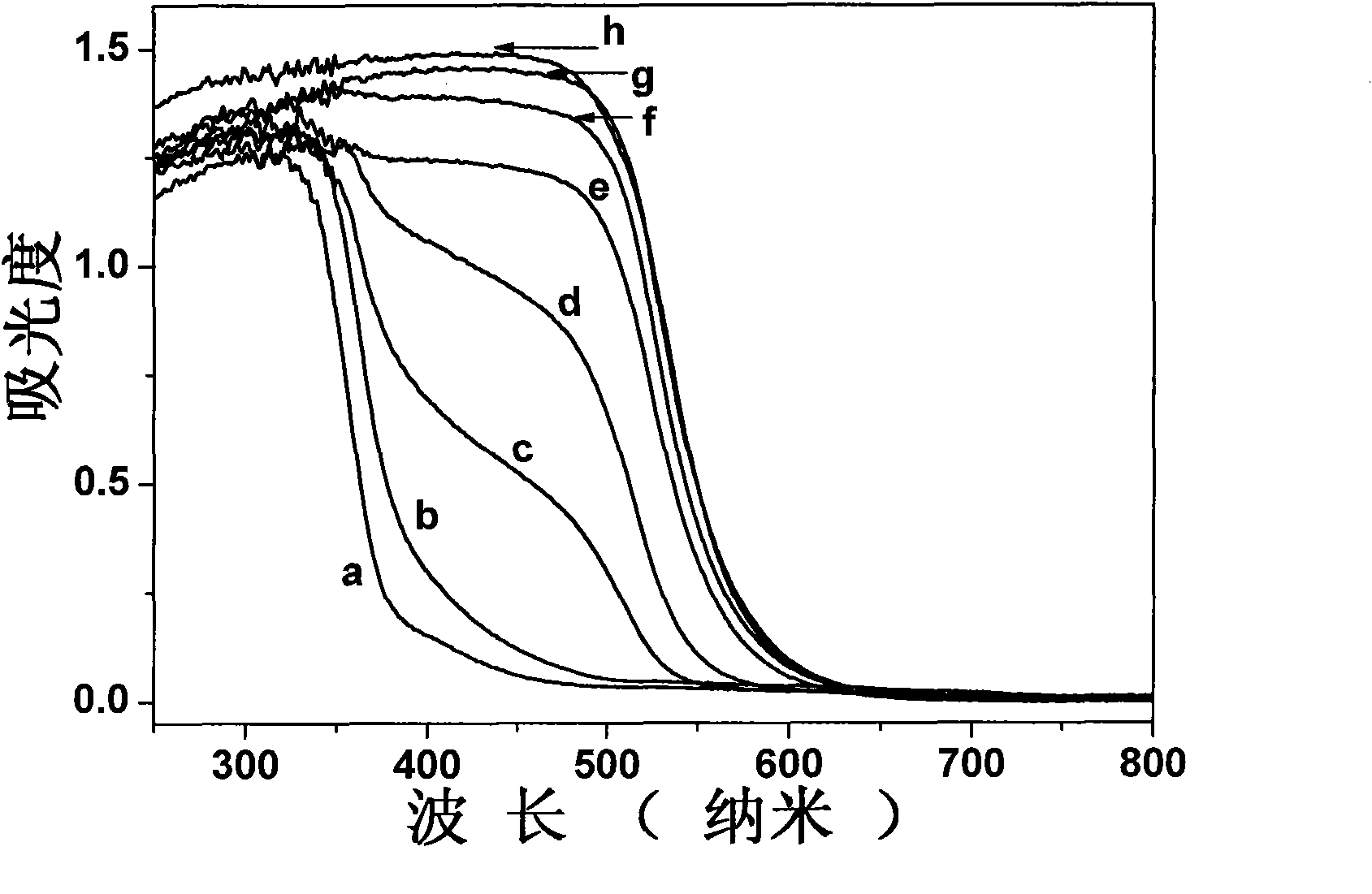

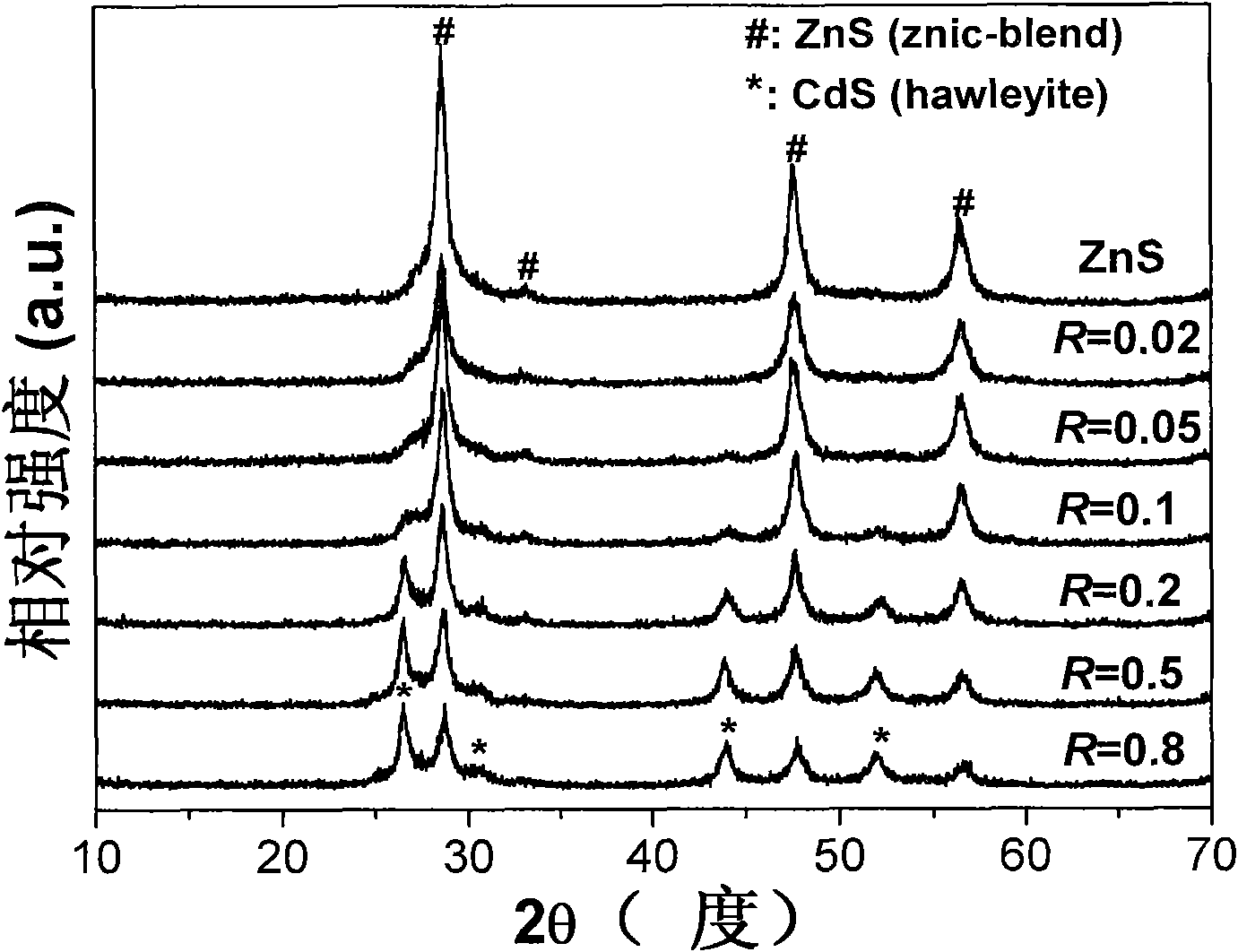

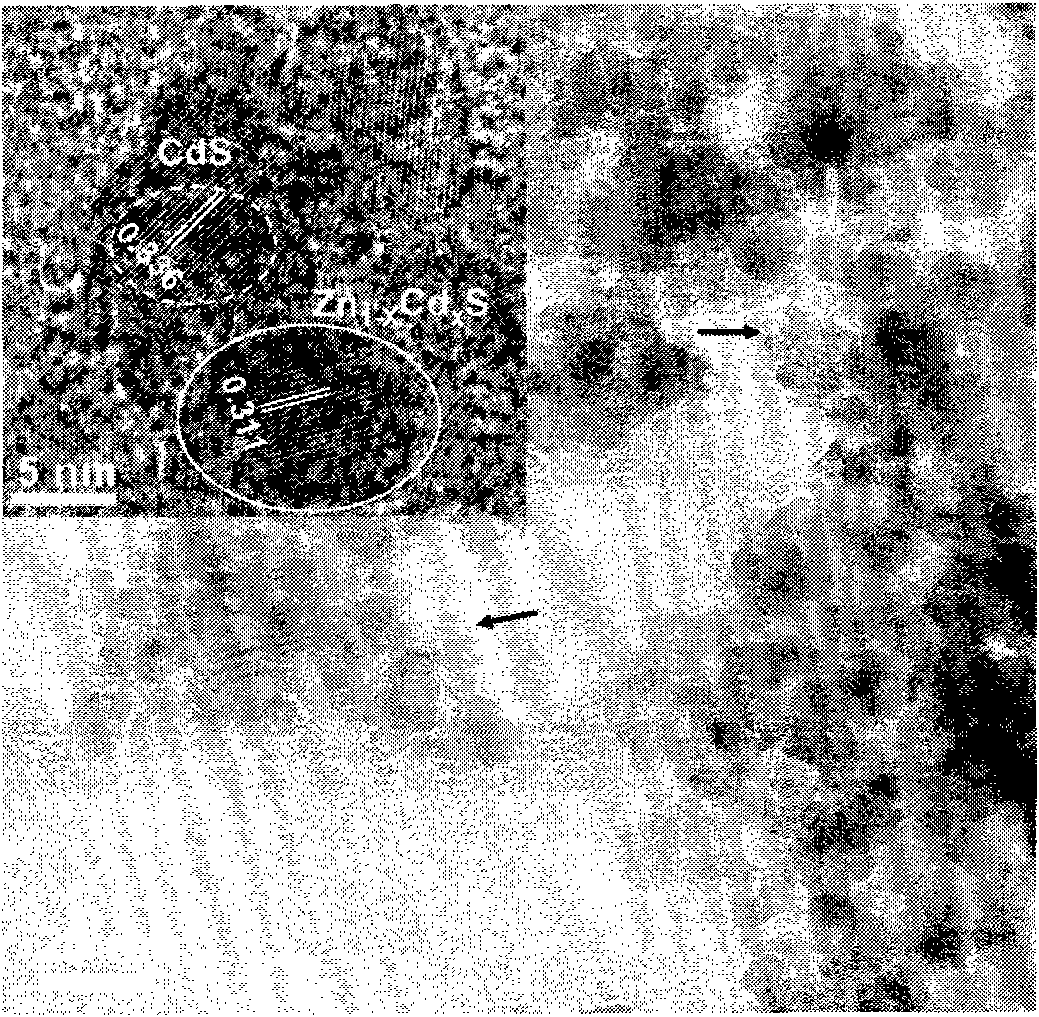

Preparation method for visible light photocatalyst prepared by CdS quantum dot sensitization Zn1-xCdxs and photodecomposition of water into hydrogen

InactiveCN101940933AEasy to operateNo heat treatment requiredCatalyst activation/preparationHydrogen productionGeneration rateDecomposition

The invention relates to a preparation method for a CdS quantum dot sensitization Zn1-xCdxs sosoloid photochemical catalyst (x is less than or equal to 0.02) having the visible light photocatalytic decomposition aquatic hydrogen activity. In a cation exchange hydrothermal method, ZnS nanoparticles and a cadmium nitrate solution are used as a precursor, and the preparation is carried out by controlling the proportioning of reactants, the reaction temperature, the reaction time, and the like. The preparation method comprises the following steps of: ultrasonically dispersing the ZnS nanoparticle precursor in deionized water; adding the cadmium nitrate solution until the atomicpercent of cadmium to zinc in the system is larger than 0 to 80%; stirring for 30 minutes at room temperature and then removing into a hydrothermal kettle of 100ml; carrying out a hydrothermal reaction for 5 to 24 hours at the temperature of 100 to 200 DEG C; successively washing the collected solid sediments with water and ethanol; and drying for 10 hours at the temperature of 60 DEG C to prepare the CdS quantum dot sensitization Zn1-xCdxs sosoloid visual light photocatalyst (x is less than or equal to 0.02). The invention can ensure that the CdS quantum dot sensitization Zn1-xCdxs sosoloid visual light photocatalyst (x is less than or equal to 0.02) has the advantages of high hydrogen generation rate and no noble metal load requirement; and the method has the advantages of simple operation, no high temperature processing requirement, friendly environment and low cost.

Owner:WUHAN UNIV OF TECH

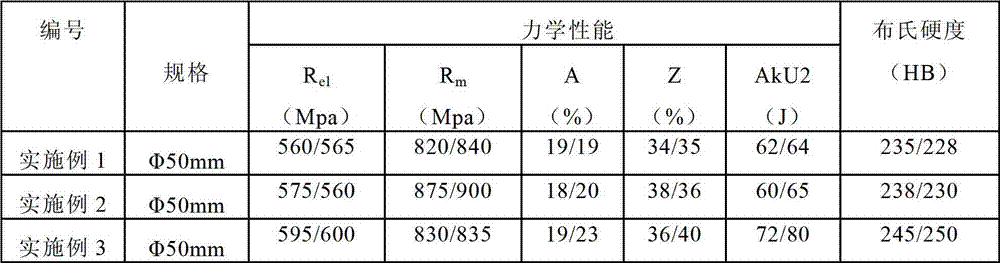

Non-quenched and tempered steel used for welding and electroplating hydraulic rod and production method thereof

The invention discloses non-quenched and tempered steel used for welding and electroplating a hydraulic rod and a production method thereof. The non-quenched and tempered steel consists of the following elements according to mass percentages: 0.28-0.35% of C, 0.30-0.80% of Si, 1.00-1.60% of Mn, 0.10-0.30% of Cr, 0.06-0.20% of V, 0.015-0.10% of Ti, less than or equal to 0.020% of P, 0.010-0.035% of S, 0.020-0.060% of Alt, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.10% of Mo, less than or equal to 15*10-4% of O and the balance of Fe and unavoidable impurities. The strength and plasticity index of the non-quenched and tempered steel reaches the level of 45 quenched and tempered steel, and the non-quenched and tempered steel is excellent in machinability and good in welding technological properties. The production method of the non-quenched and tempered steel solves the technical problems of low castability of molten steel caused by adding S and the like, and improves the purity of the steel. The non-quenched and tempered steel provided by the invention can be used for replacing the 45 quenched and tempered steel for manufacturing the hydraulic rod without thermal refining, thus belonging to energy-saving and environmentally-friendly steel.

Owner:LAIWU IRON & STEEL GRP

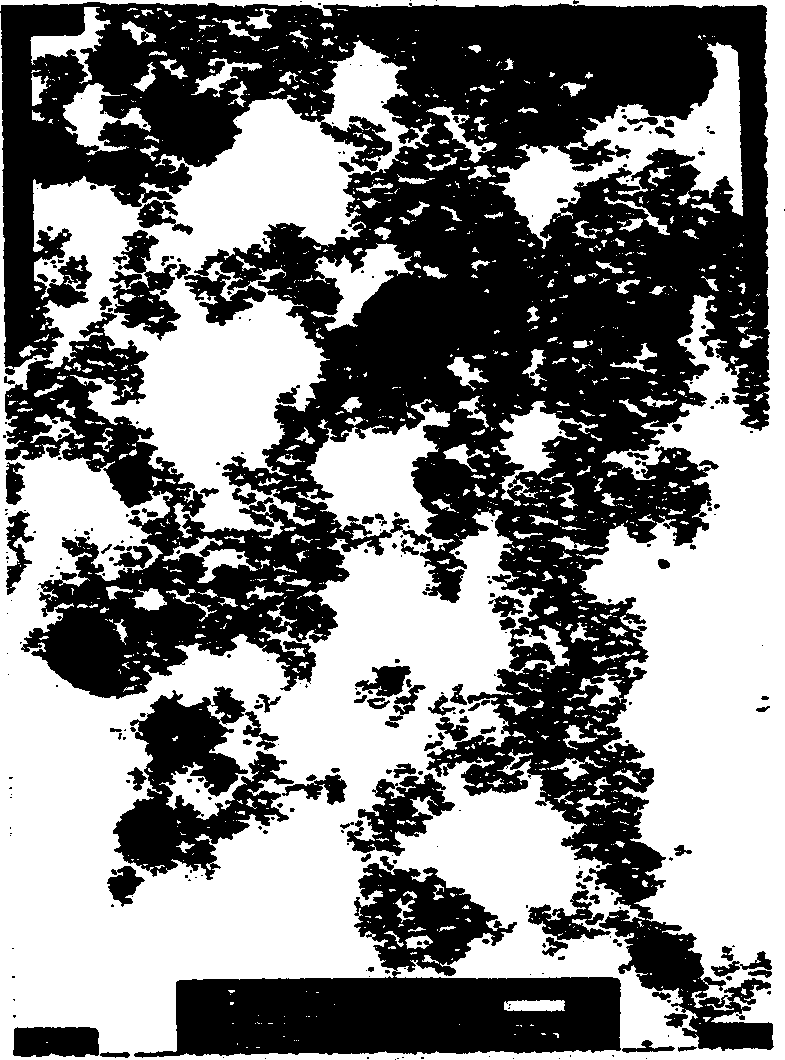

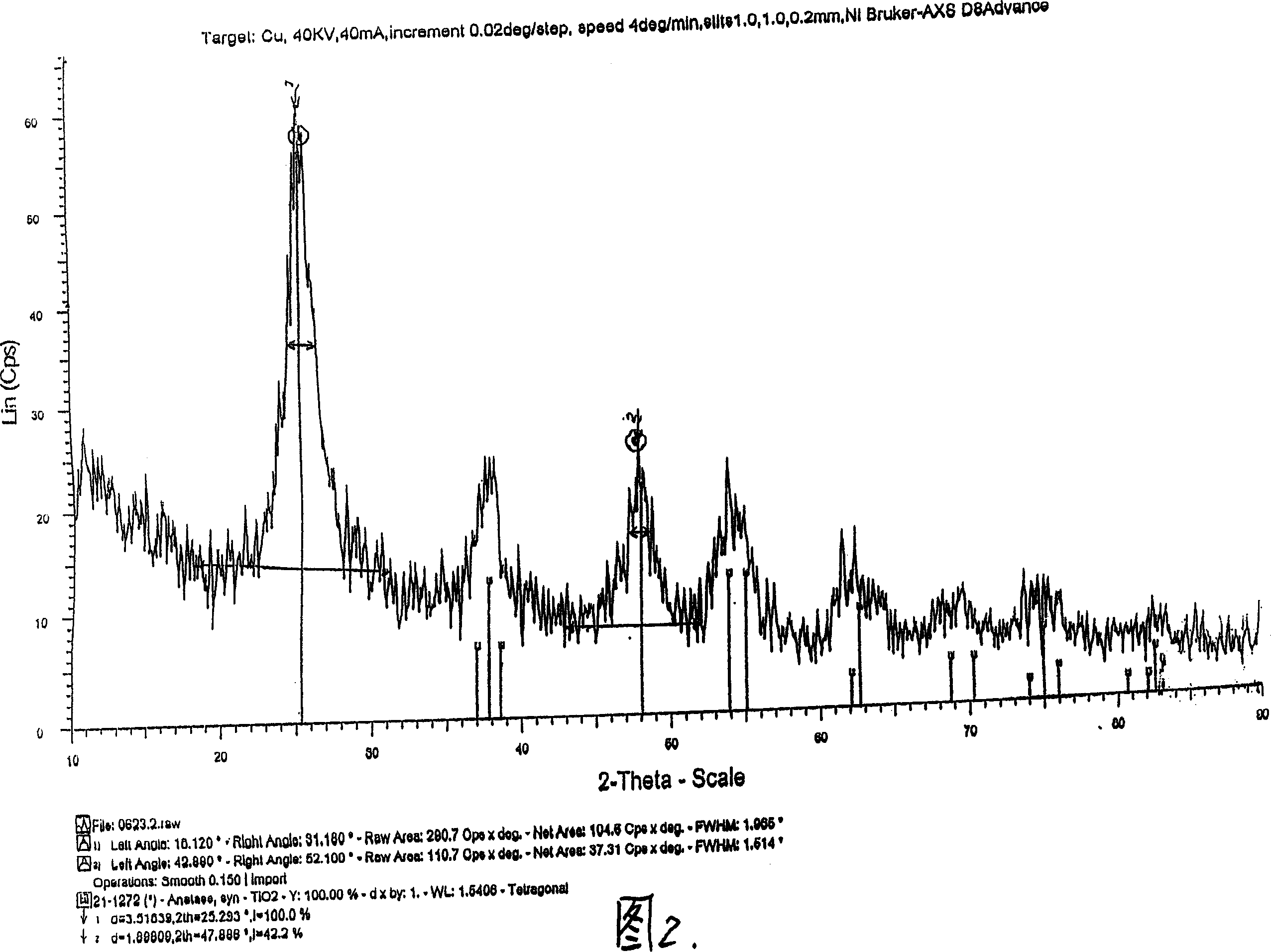

Method for preparing nano titanium dioxide photocatalyst and its product

InactiveCN1891335ASimple processNo heat treatment requiredCatalyst activation/preparationTitanium dioxideMixed type

This invention provides a method and a product for modulating and preparing optical catalyst of nm TiO2 taking TiCL4 as the raw material to realize inside dope of lattices and outside cover at the surface by secondary hydrolyzation, in which the catalyst prepared in this method is the acute Ti type or crystal-mixed type, the particle size is <=20nm, no hard agglomeration, scattering property is excellent and the light catalyzing efficiency is high radiated by ultraviolet light, visual light or glimmer.

Owner:范莉 +1

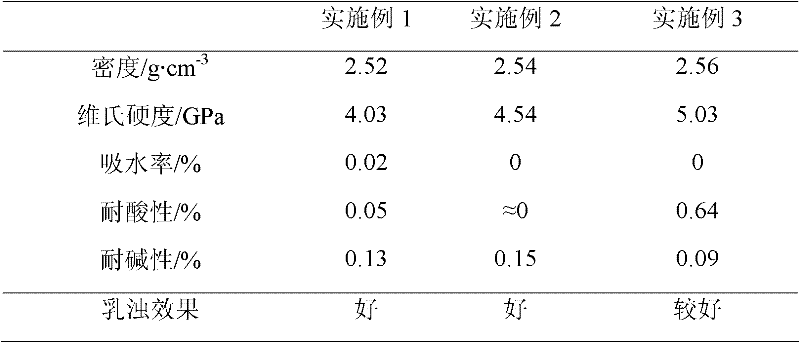

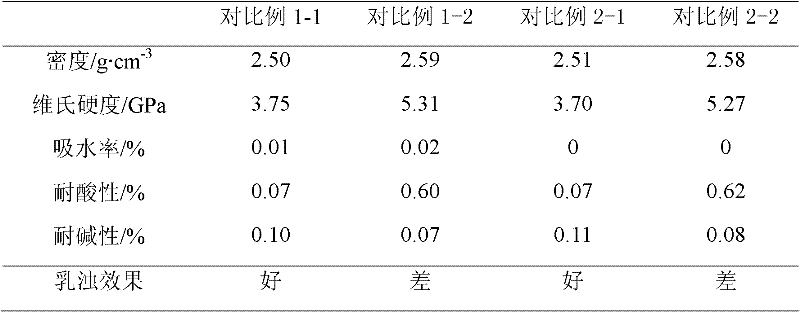

Na2O-CaO-SiO2 opaque glass and preparation method thereof

The invention discloses Na2O-CaO-SiO2 opaque glass, which consists of the following components in percentage by weight: 59 to 70 percent of SiO2, 6.0 to 10 percent of CaO, 16 to 24 percent of Na2O, 1 to 2 percent of Al2O3, 0.5 to 3 percent of K2O, 1 to 3 percent of MgO, 1.0 to 5.0 percent of P2O and 1.0 to 5.0 percent of ZrO. The invention also discloses a method for preparing the opaque glass, which comprises the following steps of: 1) mixing materials, wherein Na2O is replaced by Na2CO3 with equal molar weight and K2O is replaced by K2CO3 with equal molar weight; 2) heating the mixed materials in a furnace to the temperature of between 1,420 and 1,470 DEG C for melting, and keeping the temperature for 2.8 to 3.2 hours; and 3) pouring molten glass obtained in the step 2) into a mould for forming, and naturally and slowly cooling to room temperature to obtain the milky opaque glass.

Owner:ZHEJIANG UNIV

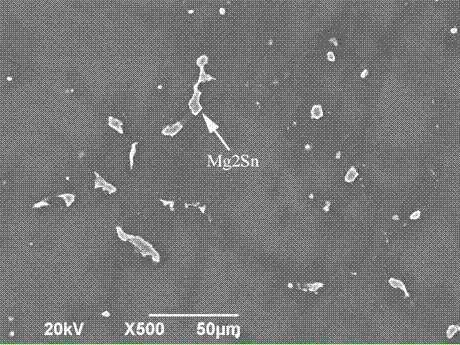

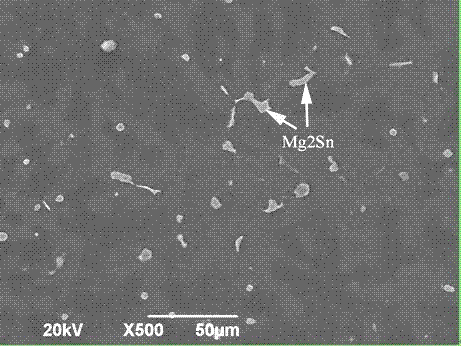

High-plasticity casting Mg-Sn-Zn-Al series magnesium alloy

The invention relates to a high-plasticity casting Mg-Sn-Zn-Al series magnesium alloy with low cost. The chemical formula and specific chemical components of the series alloy are as follows: Mg-xSn-yZn-zAl, wherein x is not less than 2.0 wt.% and not more than 7.0 wt.%, y is not less than 0.5 wt.% and not more than 6.0 wt.%, z is not less than 0.5 wt.% and not more than 6.0 wt.%, y+z is not less than 1.0 wt.% and not more than 7.0 wt.% and the balance is Mg. The alloy provided by the invention has substantive characteristics and obvious progresses; under a room temperature casting condition, the tensile strength of the series alloy can reach 210-240 MPa, and the elongation can reach 18-22%; and the alloy has the characteristics of higher strength, excellent plasticity, no need of thermal treatment, simplicity and reliability for preparation technique and easiness for popularization and application.

Owner:SICHUAN UNIV

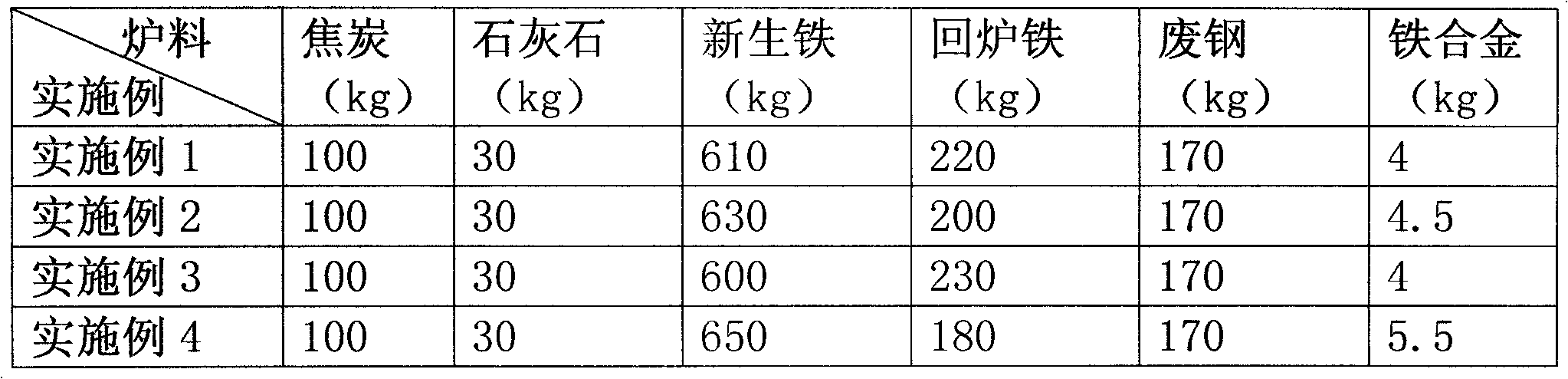

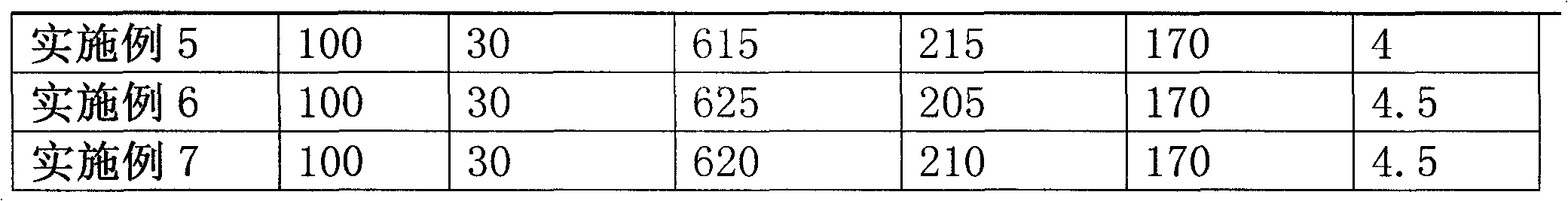

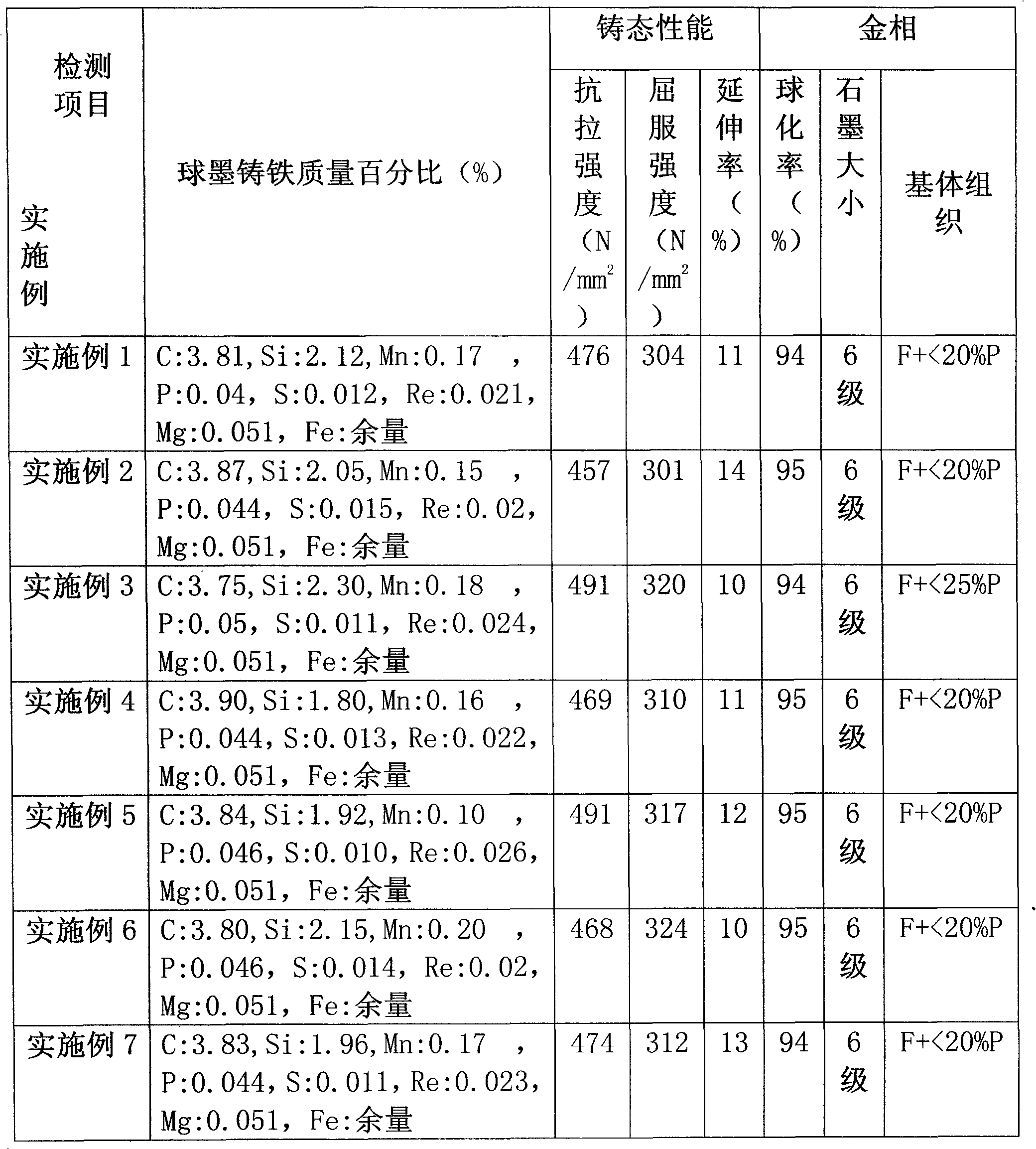

Preparation method of nodular cast iron

The invention discloses a preparation method of nodular cast iron, belonging to the technical field of metallurgy manufacture, and solving the defects in the prior art that the preparation flow cycle of the nodular cast iron is long, and the mechanical performance of the prepared nodular cast iron can not meet requirements. The preparation method of the nodular cast iron comprises the following steps: material smelting, spheroidization and a first time of inoculation, a second time of inoculation, and a third time of inoculation. The preparation method of the nodular cast iron is low in production cost and short in production cycle, and does not need thermal treatment. The produced nodular cast iron has stable quality and high toughness, and is especially suitable for castings of machine dies with high impact force and high strength.

Owner:宁波康发铸造有限公司

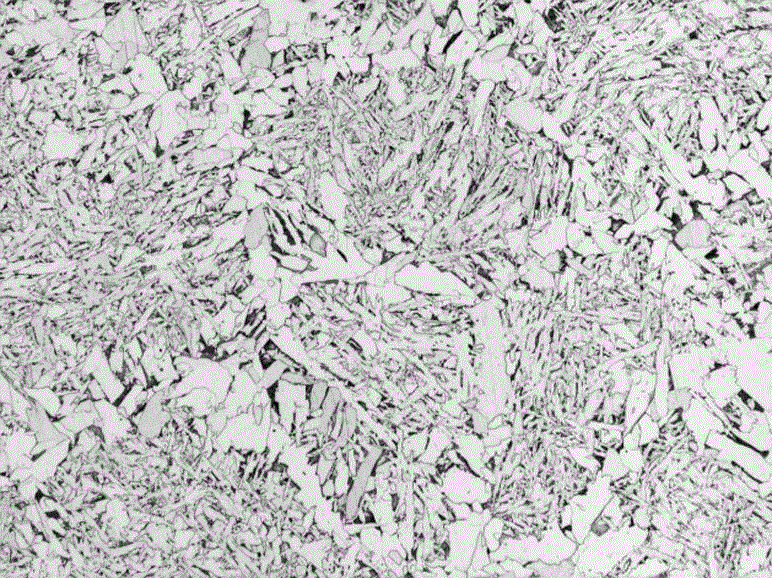

Production method of pipeline steel plate with excellent impact toughness

ActiveCN103014497AImprove impact toughnessSimplify the production processTemperature control deviceSteel platesSmelting process

The invention discloses a production method of a pipeline steel plate with excellent impact toughness. The pipeline steel plate comprises the following components in percentage by weight: 0.02-0.07% of C, 0.10-0.40% of Si 1.00-1.80% of Mn, not more than 0.015% of P, not more than 0.0050% of S, 0.030-0.060% of Nb, 0.006-0.020% of Ti, not more than 0.30% of Ni, 0.012-0.050% of Al, and the balance of Fe and impurities. According to the invention, by means of composition control of extremely low content of S and low contents of P, O, N and H, the smelting process of calcium treatment and combination with a pouring process under dynamic soft reduction, processes of precise rolling and precise cooling control are adopted to improve the toughness of the steel plate, so that the center macroscopic and microscopic segregation grades of a cast blank are reduced effectively, ferrites with more tough tissues are obtained, the impact toughness performance of the steel plate is improved, and in addition, the production method is simple in production process and lower in cost.

Owner:NANJING IRON & STEEL CO LTD

Heated pour-in beverage production with flavouring inpouring

The present invention is flavored beverage producing process and system. The flavoring agent is added into the base beverage through pasteurization and other treatment in an alone step. After the base beverage is produced in a stable process, the flavoring agent is added in the downstream flavoring agent adding part. The present invention makes it easy for the beverage producing line to convert from producing the beverage with one first flavoring agent to producing the beverage with one second flavoring agent.

Owner:THE QUAKER OATS CO

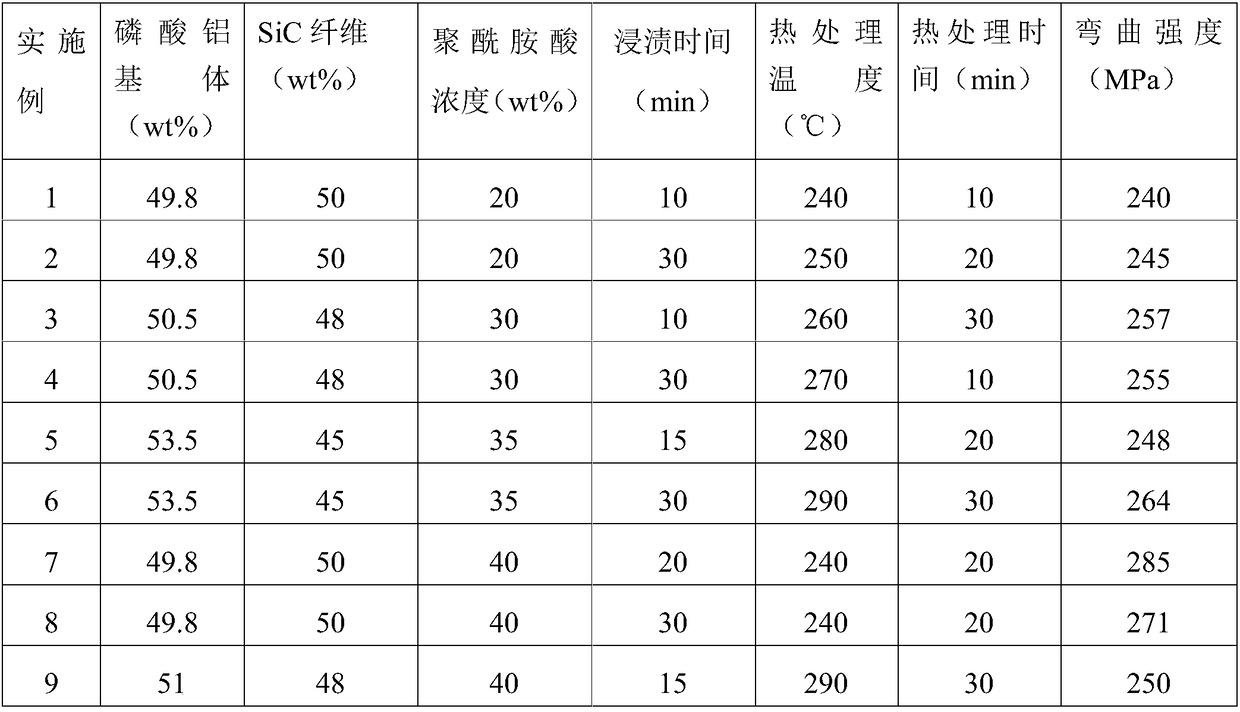

Silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and preparation method thereof

The invention relates to a silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and a preparation method thereof. The silicon carbide fiber reinforced aluminium phosphate ceramic-based composite comprises the following components in percentage by mass of 40% of silicon carbide fiber cloth, 45%-55% of an aluminium phosphate basal body, and 5%-15% of a polyimide resin basal body. The preparation method comprises the preparation steps of putting silicon carbide fiber cloth in a polyamic acid solution for immersing for 10-30min after the silicon carbide fiber cloth is degummed and dried, then taking out the immersed silicon carbide fiber cloth, and performing solidifying to obtain the silicon carbide fiber cloth containing an oxidation resistant coating; uniformly coating an aluminium phosphate sizing agent onto the outer surfaces of the silicon carbide fiber cloth containing the oxidation resistant coating, then stacking up the silicon carbide fiber cloth coated with the aluminium phosphate sizing agent, and then performing vacuum immersing and die pressing, so that the silicon carbide fiber reinforced aluminium phosphate ceramic-based composite is obtained. The combination effect of fibers and the basal body is good, so that the intensity and the tenacity of the composite are improved, and under the high-pressure oxygen-free environment, the composite canalso maintain high mechanical properties.

Owner:QINGHAI UNIVERSITY

Method for rapidly preparing three-dimensional porous gold-silver alloy nanometer material

The invention discloses a method for rapidly preparing a three-dimensional porous gold-silver alloy nanometer material, which comprises the following steps: adding silver nitrate and ascorbic acid into a gold nano octahedral colloidal solution and reacting for 30 minutes under the condition of 50-80 DEG C so as to prepare a gold@silver nano cubic colloidal solution; uniformly mixing the gold@silver nano cube cubic colloidal solution with deionized water under the action of stirring and irradiating with a laser with a power of 670-680 volts for 60 -90 seconds so as to prepare a gold-silver alloy nanosphere colloidal solution; adding nitric acid into the gold-silver alloy nanosphere colloidal solution and reacting for 0.5-hours to obtain the three-dimensional porous gold-silver alloy nanometer material. The method not only can rapidly prepare the three-dimensional porous gold-silver alloy nanomaterial at room temperature and greatly shorten the preparation time, but also realizes the complete alloying of gold and silver elements; the three-dimensional porous gold-silver alloy nanomaterial has uniform size, large specific surface area, and good monodispersity; the preparation processis simple and easy to operate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

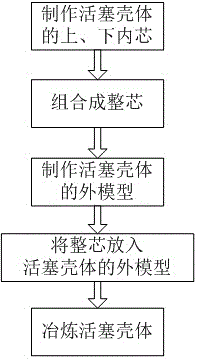

Casting process for piston shell

ActiveCN102744373AExtended service lifeMeet the requirementsFoundry mouldsFoundry coresFerrochromeHeat treated

The invention discloses a casting process for a piston shell. The process is as follows: an upper inner core and a lower inner core of the piston shell are fabricated at first and then are combined together to form an integral core that is put into a piston shell mold later, which enables the success rate of product casting to be improved; raw materials added during melting comprise, by weight, 34% of pig iron, 26% of steel scrap, 33% of returns, 1.4% of ferromanganese, 0.8% of ferromolybdenum, 0.5% of copper, 0.6% of ferrovanadium, 1.5% of ferrochrome and 0.8% of ferronickel; a silicon calcium barium inoculant is added at the front of a furnace for multiple inoculation. A separately cast test bar obtained after pouring has a tensile strength under a cast condition of more than 380 MPa and a hardness of 255 to 270 HB, a graphite grade is grade 5 and pearlite reaches over 97%; thus, the test bar totally meets requirements by customers, has good processing performance, needs no heat treatment, enables production cost to be reduced and effectively prolongs the service life of the piston shell.

Owner:FANCHANG COUNTY JINKE CASTING

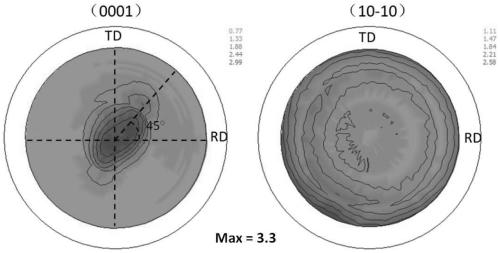

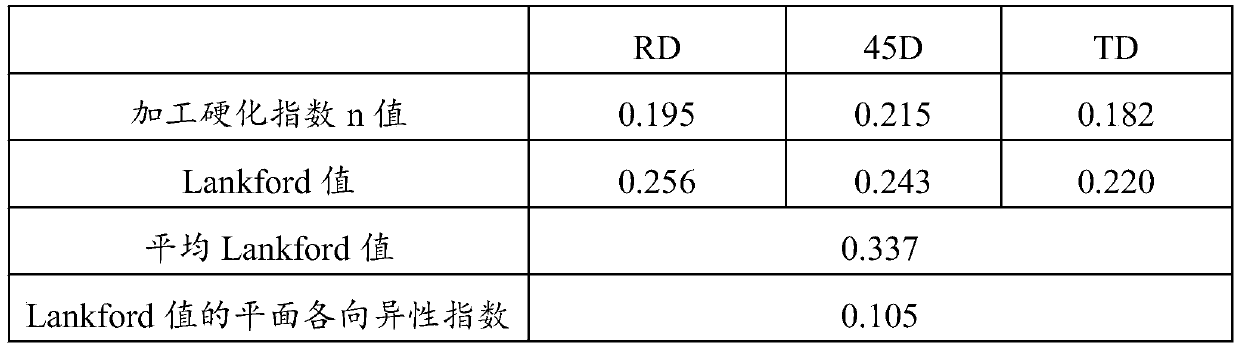

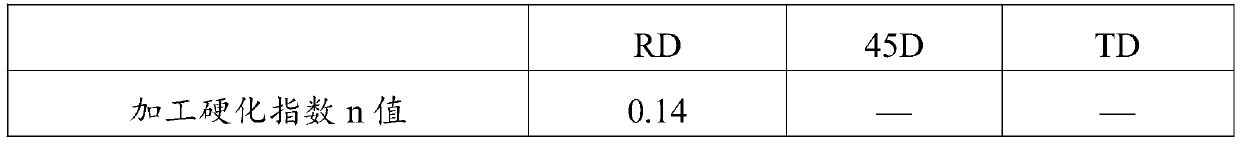

Microalloyed magnesium alloy sheet with high formability and preparation method thereof

The invention discloses a microalloyed magnesium alloy sheet with high formability and a preparation method thereof, and belongs to the nonferrous metal material and machining field, which solves theproblem of poor room temperature plasticity existing in magnesium alloy sheets. The microalloyed magnesium alloy sheet with high formability comprises, by mass percent, 0.5-1.0% of zinc, 0.3-0.6% of ytterbium, 0.2-0.4% of zirconium, and the balance magnesium and inevitable impurity elements. A weak base surface texture is showed through the sheet formed by synchronous cross rolling, the elongations in the rolling direction, 45-degree rolling direction and transverse direction are about 30%, the erishen value is 8.11 mm, and the room temperature formability is good. The key preparative techniques comprise smelting, casting, rolling and annealing, and has the advantages of being efficient, rapid, low in cost, high in operability, good in process stability, capable of realizing batch production easily, energy-saving and environment-friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

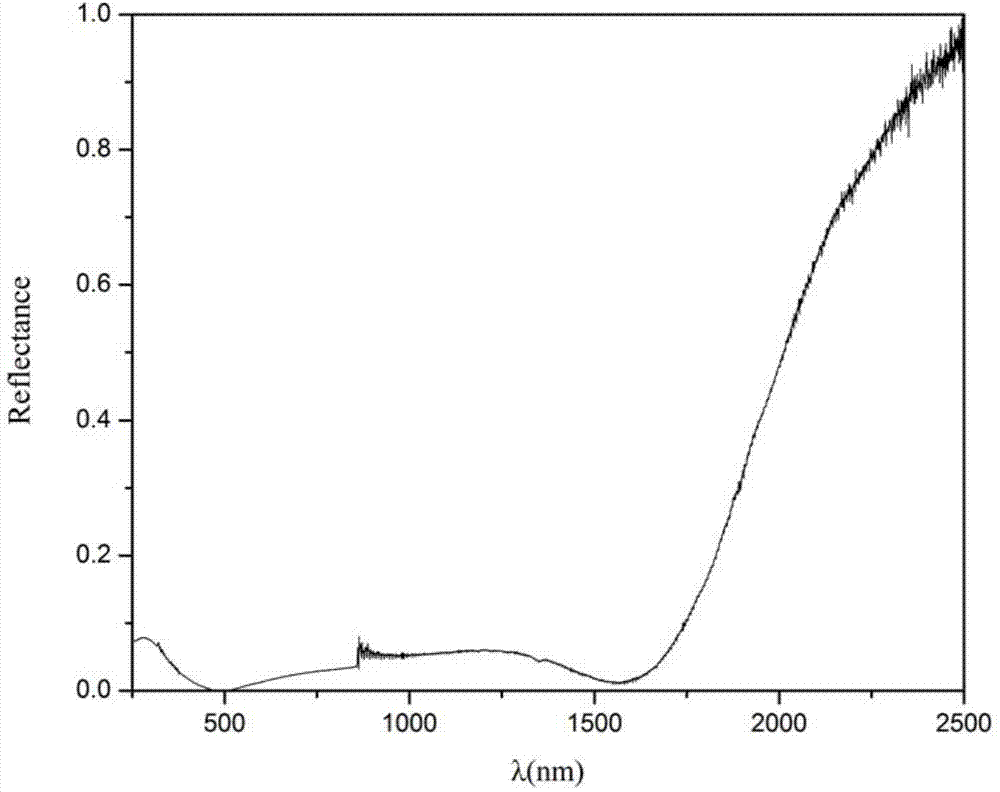

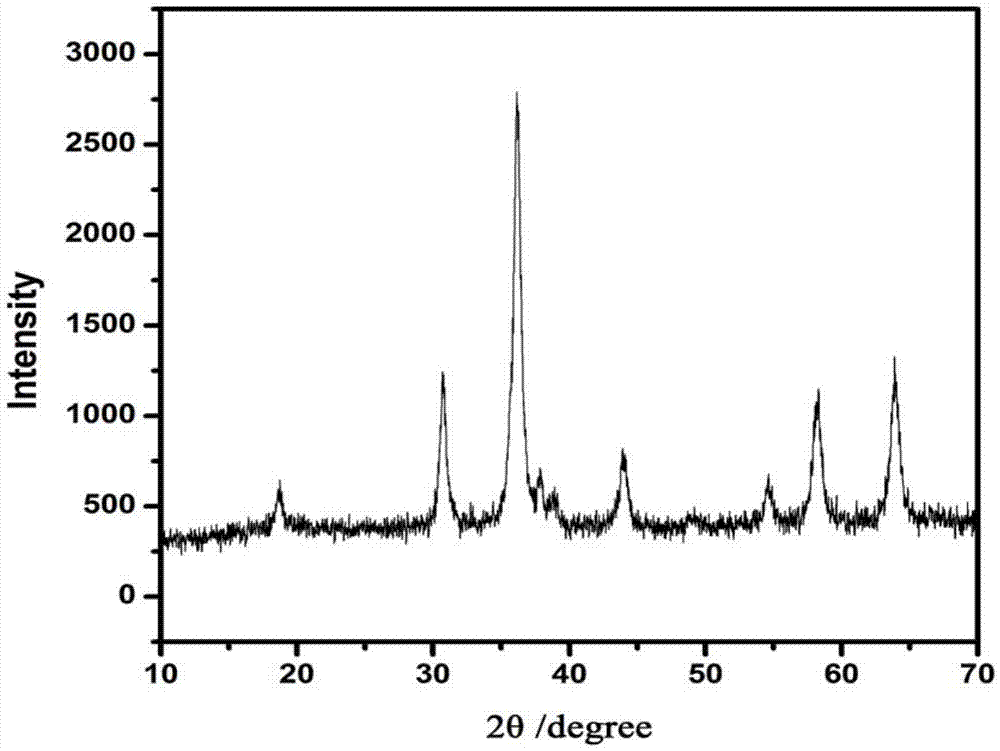

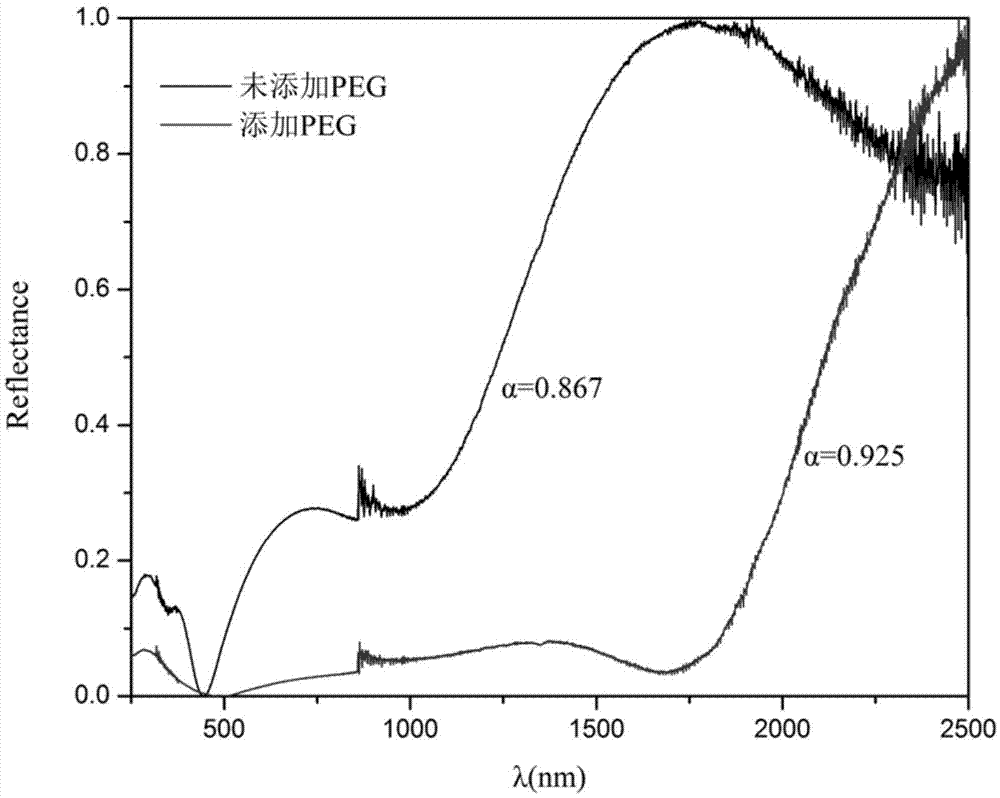

Preparation method of solar selective-absorption thin film with spinel structure

InactiveCN103691647ANo heat treatment requiredNo oxidation problemsPretreated surfacesRadiation-absorbing paintsLow emissivityPolyethylene glycol

The invention belongs to the field of solar heat utilization, and discloses a preparation method of a solar selective-absorption thin film with a spinel structure. The selective-absorption thin film is subjected to pulling and film plating through a sol-gel method and is formed by roasting. The preparation method is characterized in that metal salt of copper, cobalt and manganese is used as a sol precursor body, alcohol is used as a solvent, metal sol impregnation liquid is prepared by mixing the sol precursor body and the solvent with hydroxyl carboxylic acid and polyethylene glycol 200 according to a certain ratio, a layer of thin film can be plated on a metal substrate having an infrared reflection characteristic by adopting a pulling method after a film forming agent is added, an obtained thin film has higher solar absorption rate (0.90-0.93) and lower emissivity (0.05-0.07) after being subjected to 80-100 DEG C solidification for 30-60 minutes and then being subjected to 500 DEG C heat treatment for 30-60 minutes, and the photo-thermal conversion efficiency of a solar heat collector can be effectively increased.

Owner:CHANGZHOU UNIV

Low-cost high-strength and high-toughness bridge steel and preparation method thereof

The invention provides low-cost high-strength and high-toughness bridge steel and a preparation method thereof, and is mainly used in the field of manufacturing bridge structural parts. The low-cost high-strength and high-toughness bridge steel comprises the following chemical components of, in percentage by weight, 0.10% - 0.13% of C, 0.10% - 0.30% of Si, 1.30% - 1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015% - 0.0.045% of Al, less than or equal to 0.035% of Nb, less than or equal to 0.04% of V, 0.010% to 0.025% of Ti, and the balance Fe and inevitable impurities. The preparation method comprises the following production process flow of hot metal pretreatment -> BOF steelmaking -> LF refining -> RH vacuum treatment -> continuous casting -> slow cooling -> casting blank inspection, cleaning and judgment -> heating -> descaling -> rolling -> water cooling -> flaw detection -> spray marking -> cutting and sampling -> warehousing. The low-cost high-strength and high-toughness bridge steel and the preparation method thereof has low production cost, excellent low temperature impact toughness, excellent welding performance of steel plate, and can simplify the welding process.

Owner:SD STEEL RIZHAO CO LTD

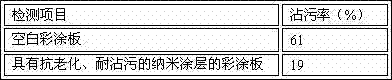

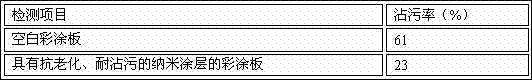

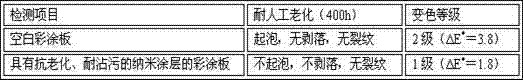

Nano-sol for forming anti-aging and stain-resistant nano-coating and preparation method and application thereof

The invention discloses nano-sol for forming an anti-aging and stain-resistant nano-coating and a preparation method thereof. The nano-sol for forming the anti-aging and stain-resistant nano-coating comprises the following components in percentage by weight: 0.1-10% of nano-TiO2 sol, 0.1-20% of sodium silicate, 0.1-5% of cerium oxide sol, 0-0.1% of colorant and the balance of water or mixed solution consisting of ethanol and water. The preparation method comprises the steps of firstly preparing the nano-TiO2 sol by adopting a sol-gel method, then preparing the Ce2O3 sol, then adding sodium silicate and the Ce2O3 sol into the nano-TiO2 sol, uniformly stirring, further adding the colorant, and finally adding the balance of water or the mixed solution consisting of ethanol and water to obtain the nano-sol for forming the anti-aging and stain-resistant nano-coating. The nano-coating which is used for a color-coated plate and obtained by coating has the properties of aging resistance, stain resistance, corrosion resistance and the like, and the service life of the color-coated plate can be prolonged.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Wear-resistant coating and preparation method thereof, cutter ring of shield hobbing cutter, shield hobbing cutter and shield tunneling machine

ActiveCN110468406ARelieve heat stressInhibition of germinationMetallic material coating processesTunnelsHobbingAlcohol

The invention provides a wear-resistant coating and a preparation method thereof, a cutter ring of a shield hobbing cutter, the shield hobbing cutter and a shield tunneling machine. The wear-resistantcoating comprises at least two brazing filler metal coatings basically identical in structure. Each brazing filler metal coating comprises, by mass part, 3-10 parts of diamond micro-powder, 2-6 partsof an alcohol solvent, 1-5 parts of sodium fluoride and 81-93 pars of nickel-based brazing filler metal. According to the wear-resistant coating, a gradient transition coating is formed by the multi-pass basically identical thin coatings, the thermal stress problem generated when a thick coating is prepared through a surfacing welding method is relieved, and initiation and extension of cracks areinhibited to a certain degree; and meanwhile, the uniform distribution degree of the hard phase diamond micro-powder can be improved, and the advantages of being small in thermal injury, uniform in hard phase distribution and not likely to fall off are achieved. According to the shield hobbing cutter, the surface of the cutter ring is coated with the wear-resistant coating, the wear resisting performance of the cutter ring is effectively improved, and the service life of the cutter ring is prolonged.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

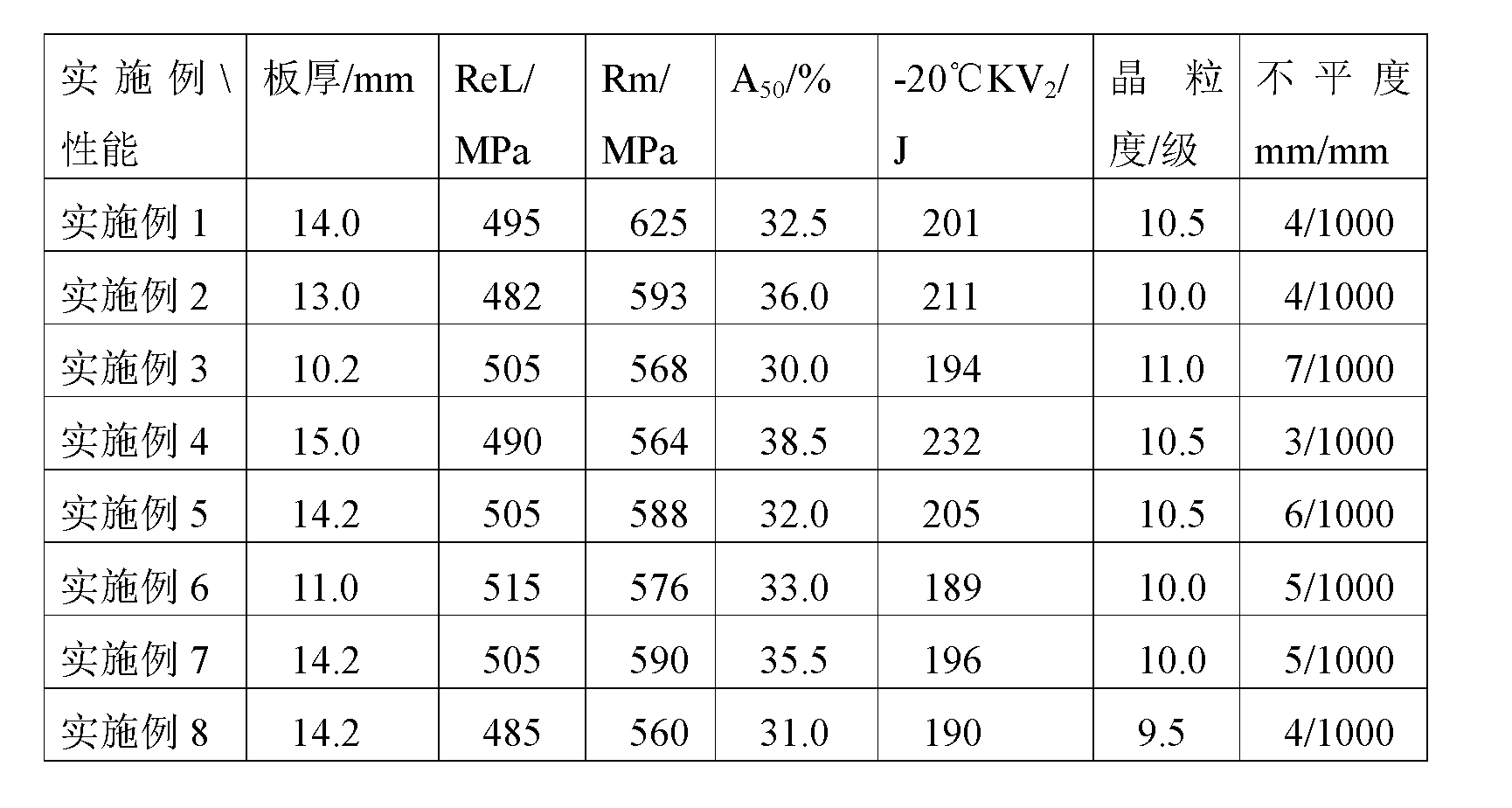

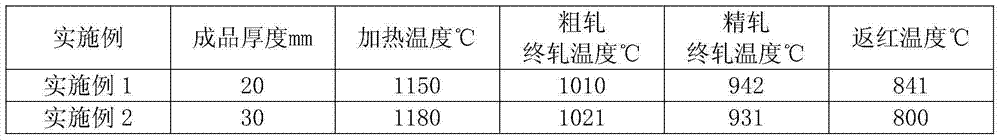

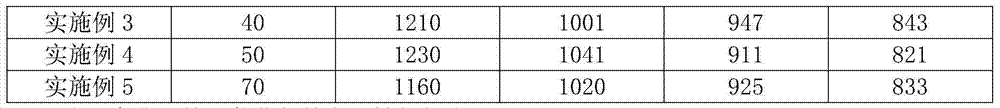

High-strength thin-specification steel plate with excellent shape and production method thereof

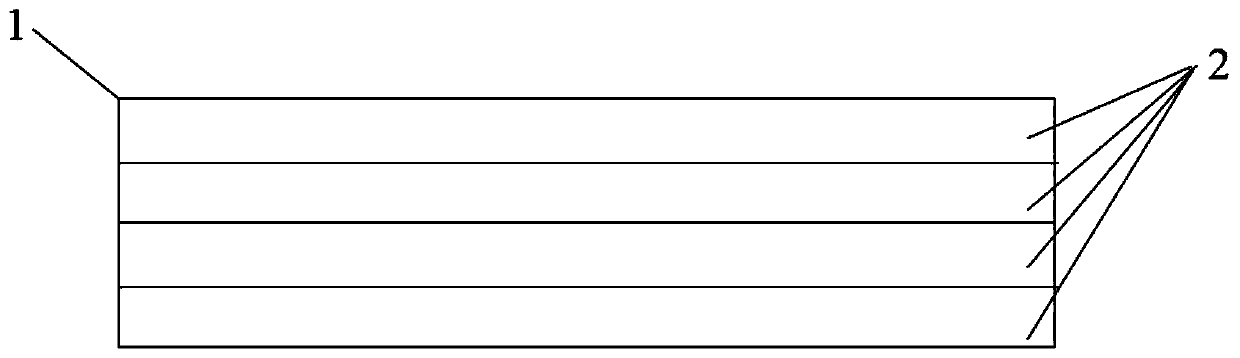

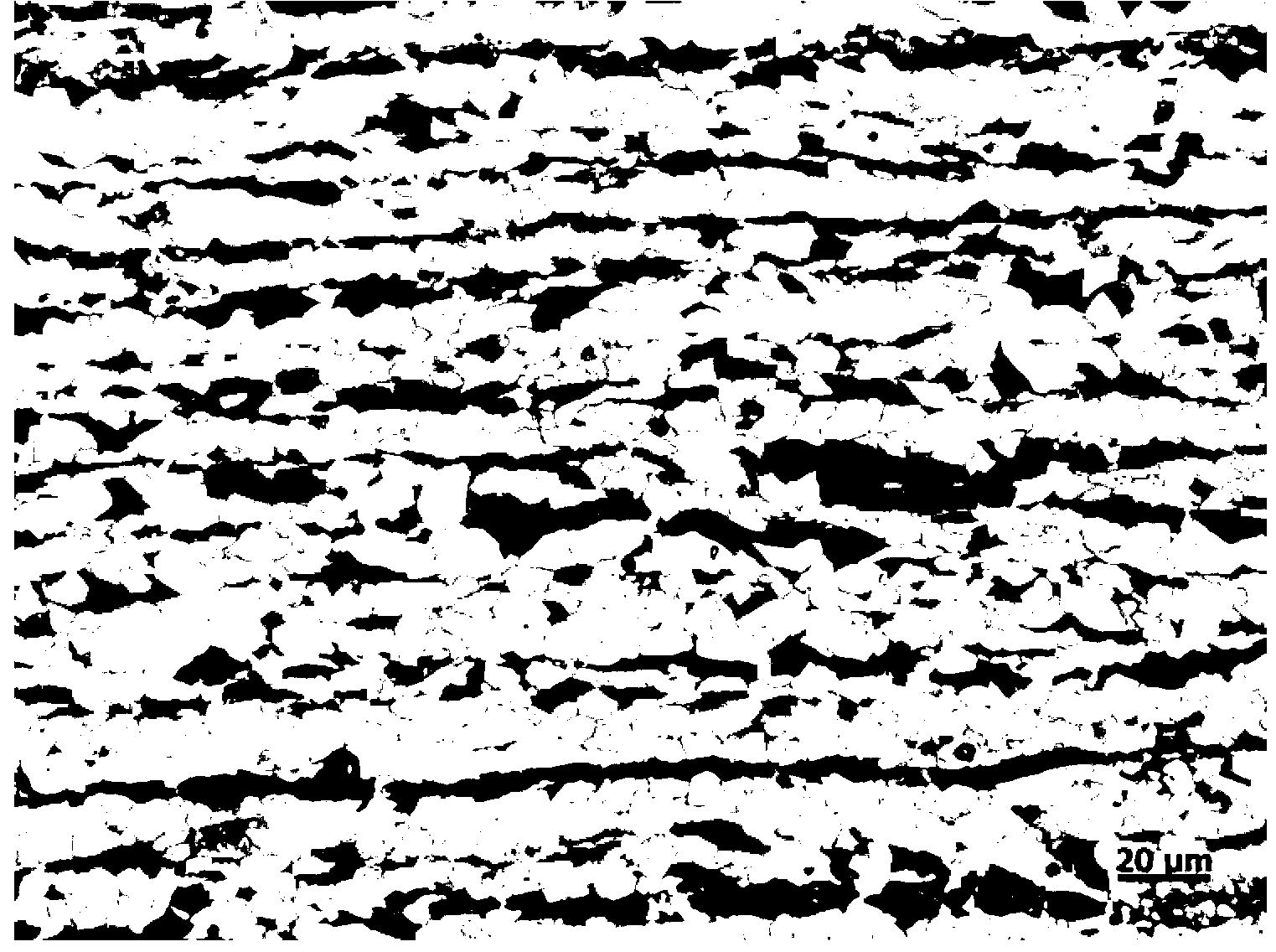

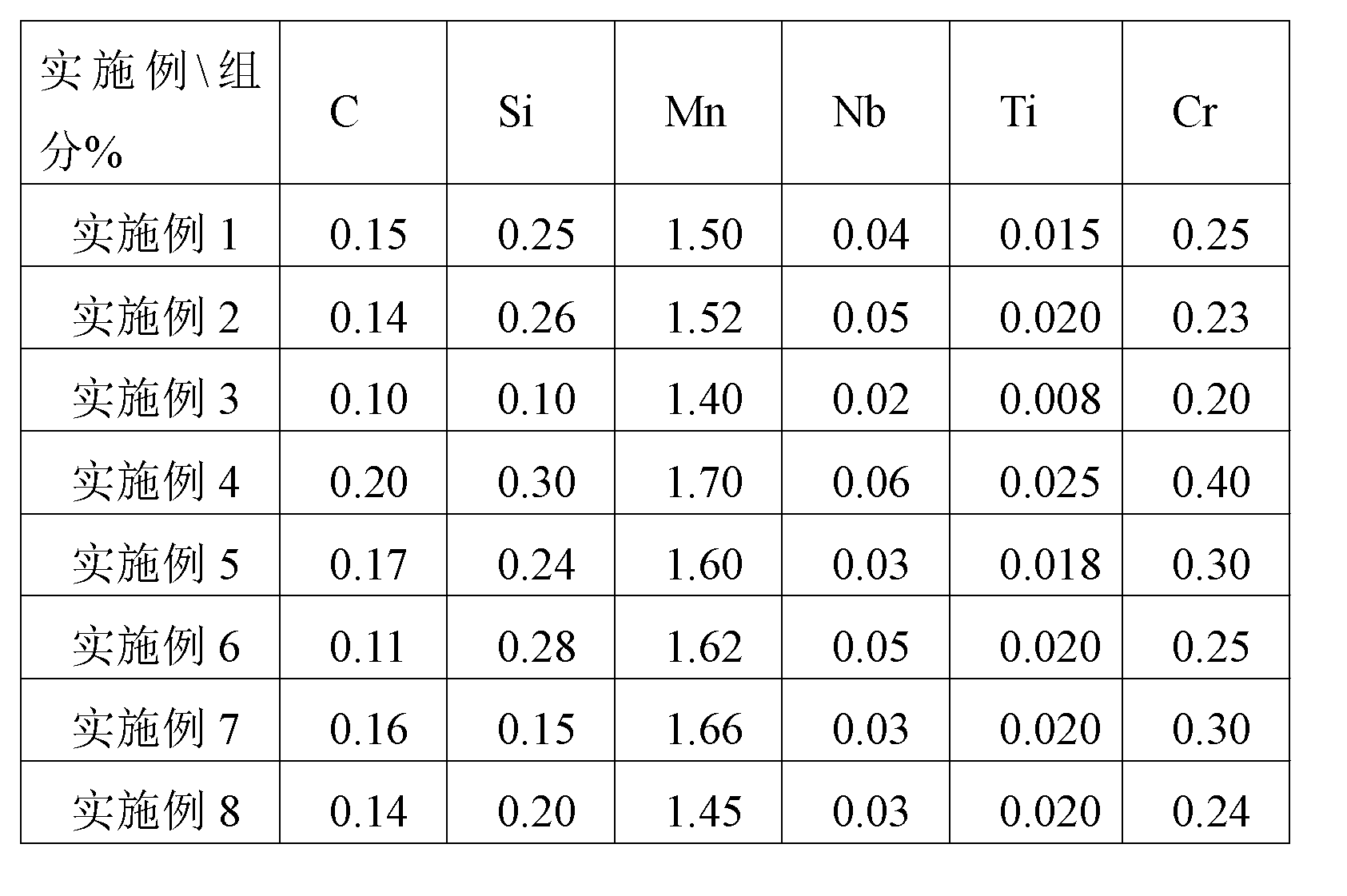

ActiveCN103233169ASimple ingredientsHigh strengthHeat treatment process controlSheet steelChemical composition

The invention discloses a high-strength thin-specification steel plate with an excellent shape. The steel plate comprises the following chemical components by weight percent: 0.10 to 0.20 percent of C, 0.10 to 0.30 percent of Si, 1.4 to 1.70 percent of Mn, 0.02 to 0.06 percent of Nb, 0.008 to 0.025 percent of Ti, 0.20 to 0.40 percent of Cr and the balance of Fe and inevitable impurities, a metallographic structure is ferrite and pearlite, and the grain size is more than or equal to level 9.5. The production method comprises the steps of smelting in a converter, continuous casting, heating, rolling and cold control, and the heating temperature is controlled between 1150 DEG C and 1190 DEG C; the segmented rolling is adopted, the rolling temperature is controlled to be more than or equal to 1080 DEG C at the rough rolling stage, the pressing rate of each pass is not less than 15 percent, the rolling temperature is controlled at 900 to 950 DEG C at the fine rolling stage, and the final rolling temperature is controlled at 760 to 800 DEG C; the cooling speed is controlled to be less than or equal to 10 DEG C per second when controlling the coldness, the red returning temperature of the steel plate is controlled at 500 to 600 DEG C; and the steel plate is cooled in the air to the room temperature. The performances such as high strength, high flexibility and low uneveness are integrated on the thin-specification steel plate, the production process is simple, the heat treatment does not needed, and the yield is increased.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

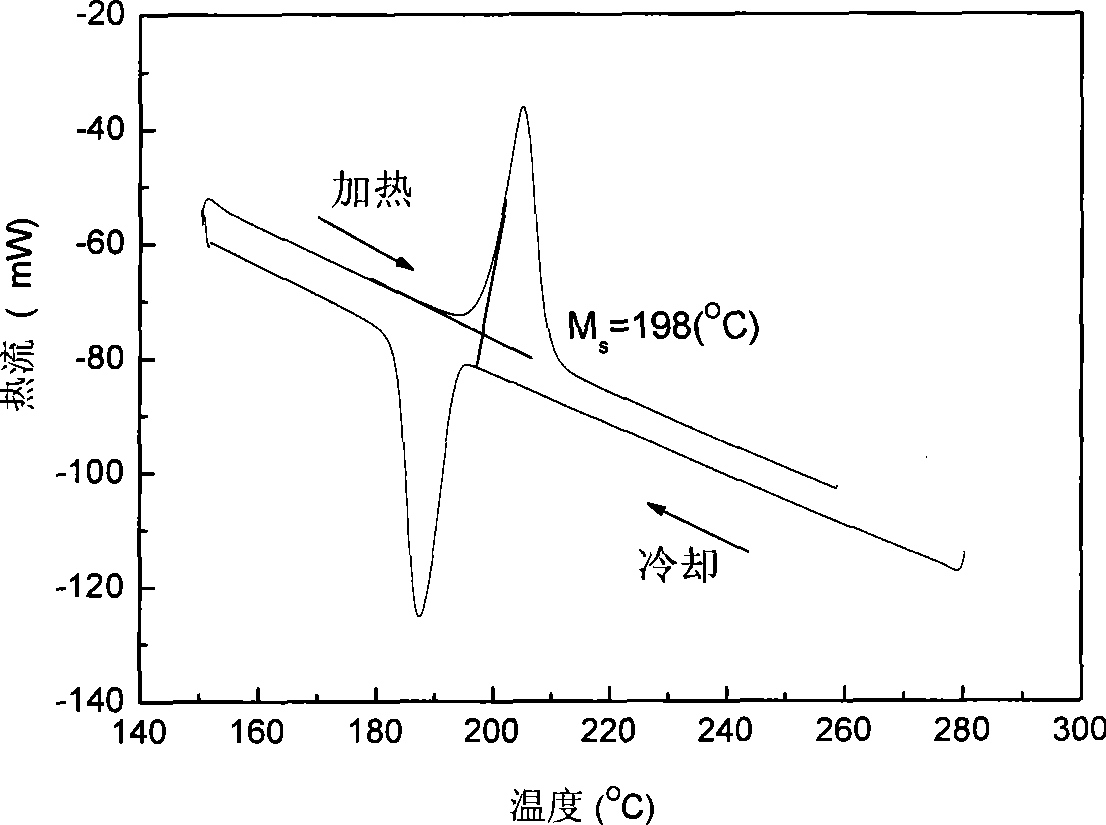

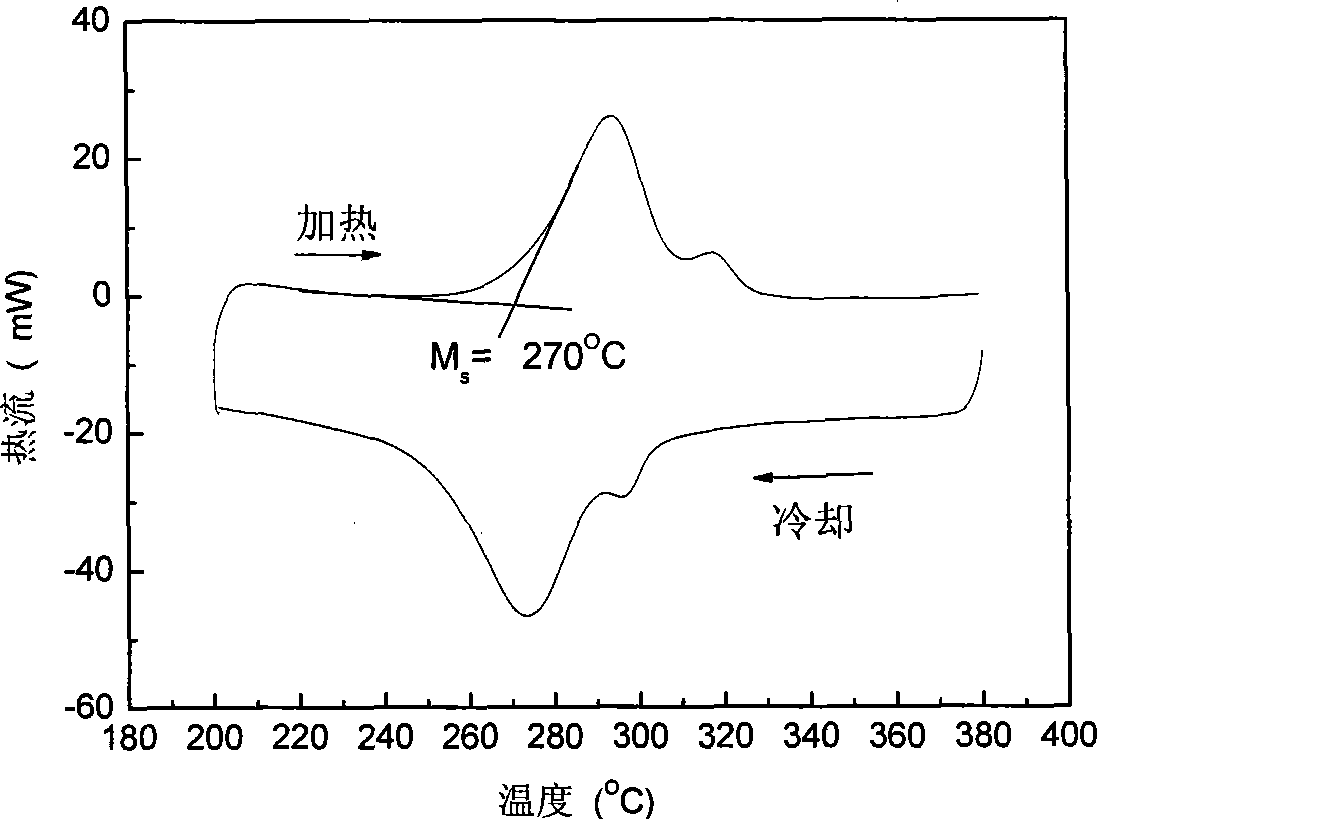

NiMnGaCu high temperature shape-memory alloy and manufacturing method thereof

InactiveCN101463445AHigh phase transition temperatureImproved thermal cycling stabilityMartensite transformationMemory effect

The invention provides a NiCoMnSn high temperature shape memory alloy and a preparation method thereof. Ni, Co and Sn are weighted according to the atomic percent of Ni43Co7Mn<50-x>Sn<x>; wherein, X equals to 7-10; the raw materials of Ni, Co, and Sn weighted in the first step are put in a no consumable vacuum arc furnace, vacuumed to cause that the vacuum degree of the background reaches 2*10<-2> - 5*10<-3>Pa, and then charged with high-purity argon till 500 Pa; the raw materials are melted to NiCoMnSn button-type cast ingot by using high temperature voltaic arc; a vacuum suction mold device is used for preparing a bar-shaped cast ingot with the 10mm diameter, thus obtaining the Ni43Co7Mn<50-x>Sn<x> high temperature shape memory alloy. The martensitic phase transformation temperature of the NiCoMnSn prepared by the invention ranges from 120 DEG C-300 DEG C; the alloying elements of the raw materials are relatively cheap. The preparation method is simple and the alloy has uniform components; therefore, the follow-up heat treatment is not needed. The shape memory effect can reach up to 3.8%. The stability of the thermal circulation is high. The alloy is a new high temperature shape memory alloy with the application prospect.

Owner:如皋市生产力促进中心

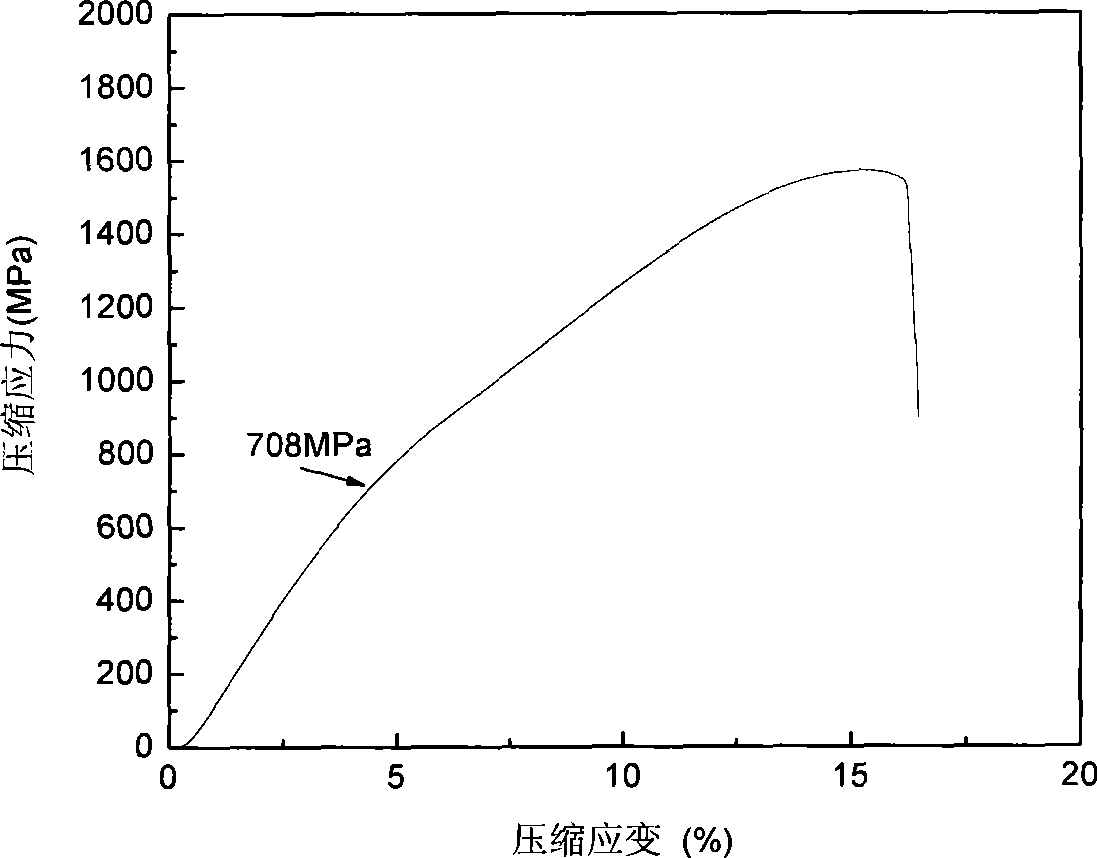

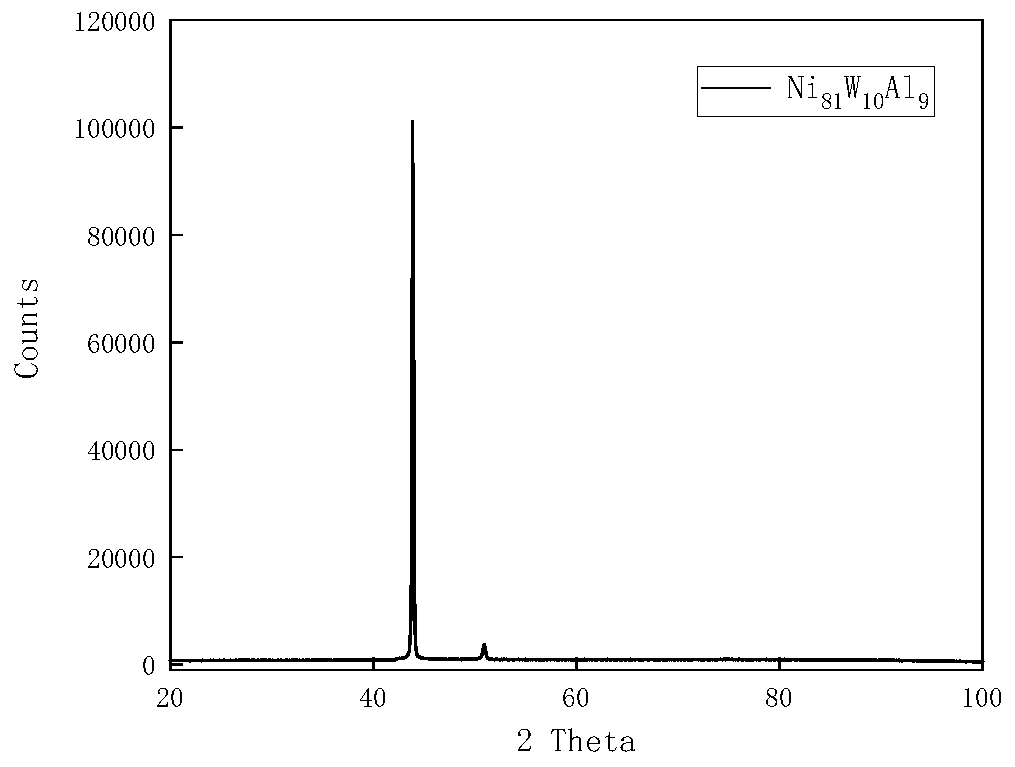

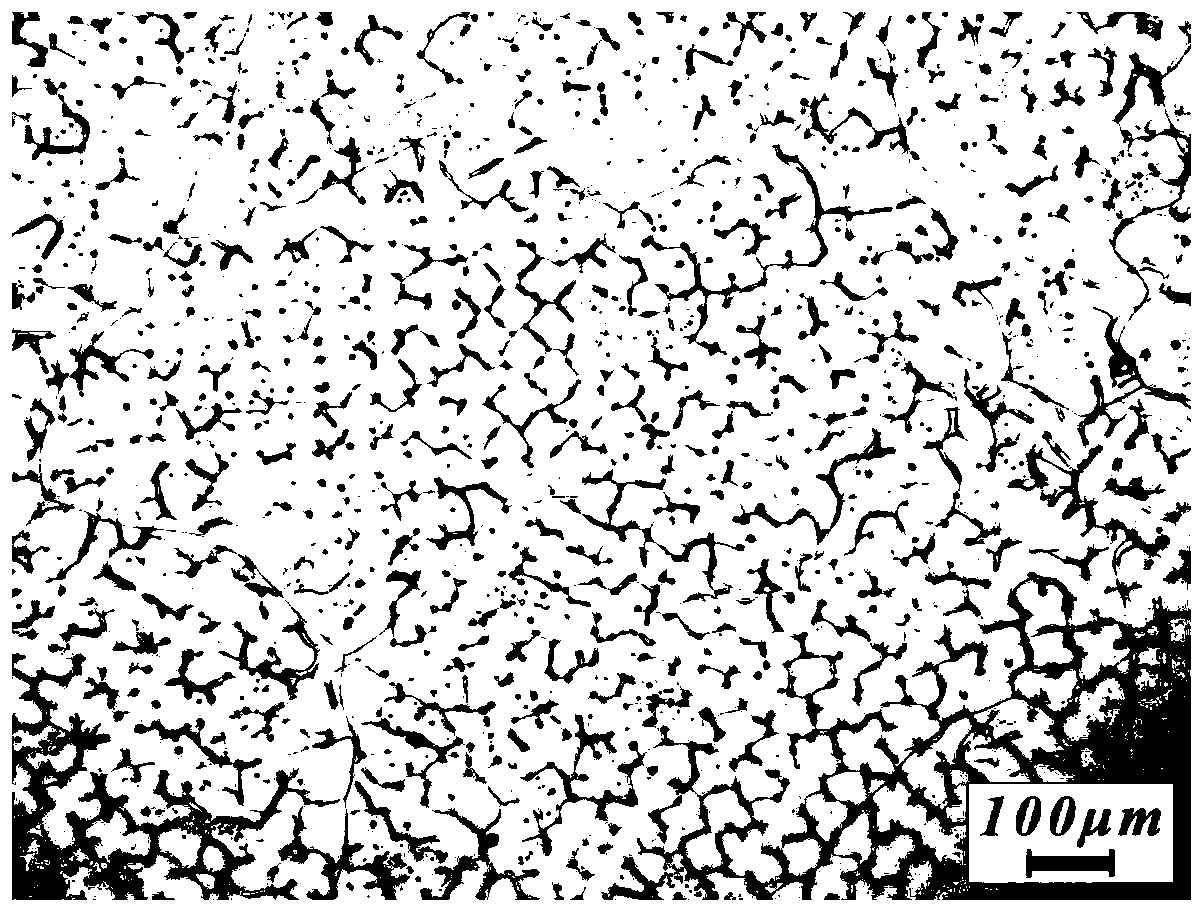

Preparation method of high-strength high-plasticity Ni-W-X alloy

The invention relates to a preparation method of high-strength high-plasticity Ni-W-X alloy. The high-strength and high-plasticity of the alloy means that the cast-state yield strength is larger thanor equal to 500 MPa, the tensile strength is larger than or equal to 800 MPa, and the elongation is 30-50%. The preparation method belongs to the technical field of metal material preparation, and when the ratio of raw materials is different, the density of the obtained casting alloy can be continuously adjusted in the range of 8.8-12.1 g / cm<3>. The forming technique of the invention does not needforging and heat treatment, and has important significance for industrial production. Through the selection of components and the preparation method, the alloy can have the high strength, the high plasticity and continuously adjustable density in the cast state.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Simple preparation method of coating photocatalyst containing titanium dioxide nano-crystal grains

InactiveCN101554580ASimplify process equipment and operating techniquesFresh smellPhysical/chemical process catalystsIonPhotocatalysis

The invention discloses a simple preparation method of a coating photocatalyst containing titanium dioxide nano-crystal grains. The method comprises the following steps: preparing TiOSO4.2H2O into clear solution; taking deionized water as base solution; titrating TiOSO4 settled solution and 3mol / L ammonia into the base solution, keeping pH in the range from 8 to 9 to obtain precipitate suspension; stirring and aging for 30min; washing with the deionized water for 3-5 times to eliminate NH4 and SO4; separating solid from liquid; diluting precipitate to 0.05-0.2mol / L; selecting H2O2 solution as a peptizing agent, dropping the peptizing agent into the suspension with the Ti / H2O2 mol ratio of 1:4-6, and stirring; standing the reaction solution for 24h; processing the reaction solution by hot water of 93-100 DEG C for 4-10h, cooling to the room temperature to obtain coating titanium dioxide photocatalyst containing nano-crystal grains and having higher visible light activity. The method is realized by a normal-pressure low-temperature water processing and aging technology, and the obtained photocatalyst is free from organic solvent, has low cost, substantially neutral spraying agent and strong adhesion on a plurality of base materials.

Owner:TIANJIN UNIV

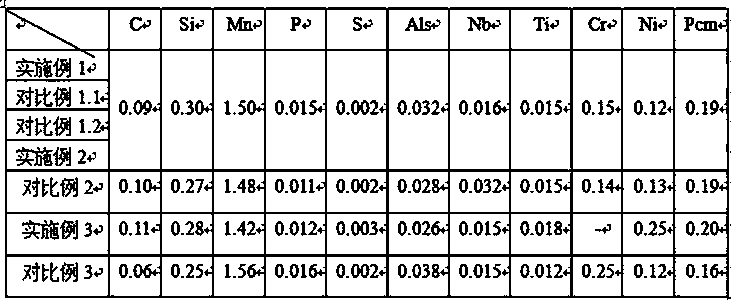

Production method for thin specification Q370qE steel plate

InactiveCN108486474ANo heat treatment requiredThe manufacturing process is simple and controllableShape changeChemical composition

The invention discloses a production method for a thin specification Q370qE steel plate. The thickness of the steel plate is 6-10 mm. Steel comprises chemical components including, by weight percent,0.08-0.12 of C, 0.15-0.40 of Si, 1.20-1.60 of Mn, smaller than or equal to 0.02 of P, smaller than or equal to 0.01 of S, 0.01-0.05 of Als, 0.010-0.020 of Nb, 0.006-0.025 of Ti, smaller than or equalto 0.30 of Cr, smaller than or equal to 0.30 of Ni, smaller than or equal to 0.20 of Pcm, and the balance Fe and inevitable impurity elements. According to the production method, the single-phase austenite area rolling and 1-2-pass two-phase area rolling technology is adopted, a mixed structure including 40%-60% of air-cooled ferrite grains with the grain size being the eighth-tenth level, 30%-45%of shape change induction ferrite grains with the grain size being the tenth-twelfth level and 10%-15% of pearlite is obtained. The produced thin specification bridge structure steel plate can combine good impact toughness and the low yield ratio under limitation of Pcm, meanwhile, the production cost is low, the technology is simple and controllable, and the plate shape is easy to control.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Ultralow cost low yield point steel and production method thereof

The invention relates to an ultralow cost low yield point steel and a production method thereof. The ultralow cost low yield point steel comprises the following chemical components in percentage by weight: 0.005-0.05% of C, 0.15-0.25% of Si, 0.1-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of Fe and inevitable impurity elements. The production method comprises a smelting process, a continuous casting, a rolling process and a thermal treatment process, in the rolling process, the heating temperature of a continuous cast blank before being rolled is 1150-1250 DEG C, a TMCP (Thermal Mechanical Control Processing) process is adopted for production, the rolling temperature at a first stage is controlled to be 1000-1050 DEG C, the rolling pass reduction rate is 15-20%, the rolling temperature at a second stage is controlled to be 900-950 DEG C, the rolling pass reduction rate is 10-15%, subsequently water-cooling is performed, and the self-tempering temperature is controlled to be 800-850 DEG C. The ultralow cost low yield point steel with stable property is obtained.

Owner:NANJING IRON & STEEL CO LTD

High-strength and high-toughness anti-alumina magnesium alloy material for 5G mobile phone middle plate and preparation method thereof

The invention discloses a high-strength and high-toughness anti-alumina magnesium alloy material for a 5G mobile phone middle plate and a preparation method thereof, and relates to an aluminum alloy material. The high-strength and high-toughness anti-alumina magnesium alloy material for the 5G mobile phone middle plate and preparation method thereof aims to solve the technical problem that in theprior art, when an alloy material for a mobile phone middle plate is smelted, and the alloy material is easy to oxidize and form oxide inclusions. The high-strength and high-toughness anti-alumina magnesium alloy material for the 5G mobile phone middle plate comprise the following chemical elements of, in percentage by mass, 2.0-5.5% of Si, 5.5-12.0% of Mg, 0.60-1.20% of Mn, 0.01-0.35% of Ti, 0.001%-0.04% of Be, 0.01-0.30% of Ce, less than or equal to 0.40% of Fe, less than or equal to 0.50% of inevitable impurities and the balance aluminum. the preparation method comprises the following stepsof melting a pure aluminum ingot, adding silicon, manganese and a titanium additive, so that the pure aluminum ingot is alloyed; (2) adding aluminum beryllium and an aluminum-cerium alloy, and melting to obtain an alloy melt; (3) adding a pure magnesium ingot, completely melting, and refining by using a sodium-free refining agent in an argon atmosphere. According to the invention, and the alloy material is mainly applied to a mobile phone middle plate.

Owner:范卫忠

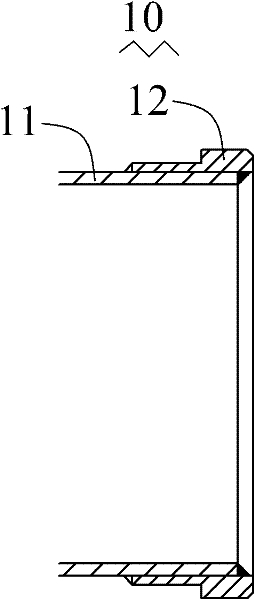

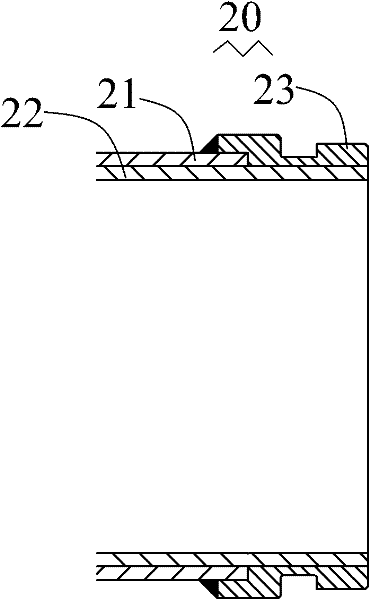

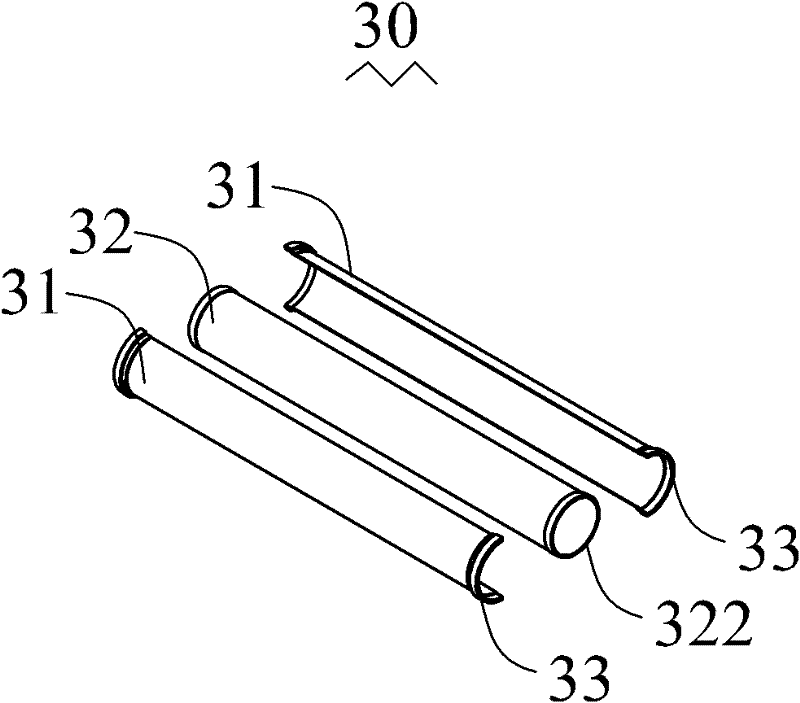

Material conveying machine, composite structure conveying pipe and manufacture method thereof

ActiveCN102537533AHigh strengthReduce toughnessFlanged jointsBulk conveyorsWear resistantShear capacity

The invention discloses a composite structure conveying pipe and a manufacture method of the conveying pipe. The composite structure conveying pipe comprises an outer pipe and an inner pipe, wherein the outer pipe is made of a light alloy material; the inner pipe is made of a light wear-resistant material; and the inner pipe is arranged in the outer pipe. In addition, the invention also discloses a material conveying machine including the composite structure conveying pipe. According to the invention, the outer pipe of the composite structure conveying pipe made of the low-density, high-strength and high-toughness material can provide enough strength and toughness at a lighter weight so as to prevent deformation and burst of the conveying pipe, and has higher shear resistance, less possibility of damages caused by bumping or dropping and lower cost in comparison with the composite material; and the inner pipe made of the light wear-resistant material can provided enough wear resistance at a lighter weight. Therefore, the overall weight of the product is reduced by more than 50% in comparison with that of a steel conveying pipe so as to facilitate assembly and disassembly, greatly improve efficiency and safety and simplify the process, and subsequent heat treatment for the inner layer is obviated.

Owner:ZOOMLION HEAVY IND CO LTD

Popular searches

Excellent electromagnetic wave absorption performance Improve wear resistance Reduce production energy consumption Promote environmental protection Less production equipment Suitable for mass production Good atmospheric corrosion resistance Improve welding efficiency Shorten the production cycle Good lamellar tear resistance

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com