Microalloyed magnesium alloy sheet with high formability and preparation method thereof

A technology of microalloying and magnesium alloying, applied in the field of microalloying magnesium alloy sheet with high formability and its preparation, can solve the problems of poor room temperature plasticity, achieve high room temperature formability, reduce original cost, and increase work hardening index Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

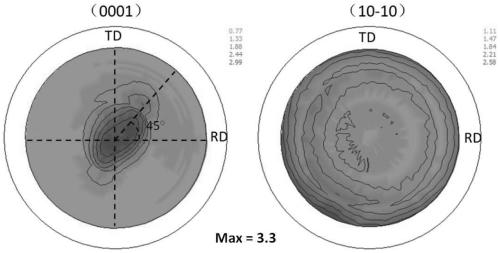

Image

Examples

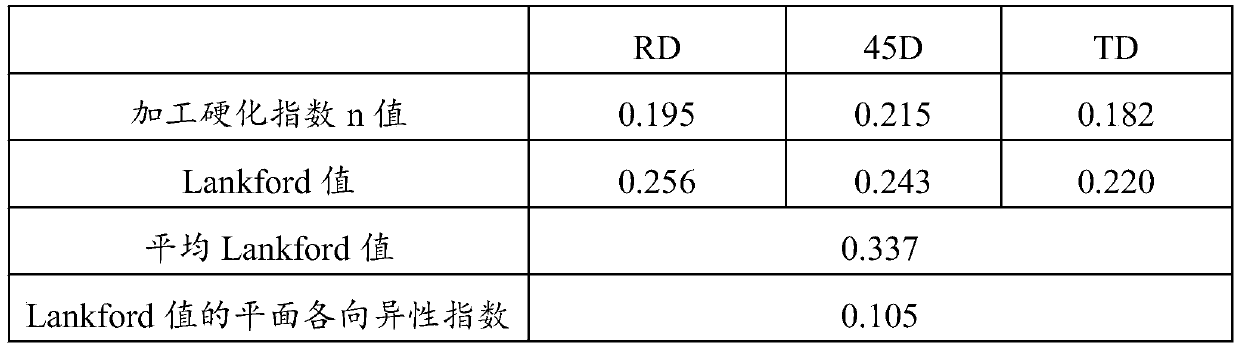

Embodiment 1

[0063] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 1.0% zinc, 0.6% ytterbium, 0.4% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0064] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0065] Step 1. Melting process

[0066] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

Embodiment 2

[0080] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 0.5% zinc, 0.3% ytterbium, 0.2% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0081] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0082] Step 1. Melting process

[0083] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

Embodiment 3

[0097] A micro-alloyed magnesium alloy thin plate with high formability, its composition and the mass percentage of each component are: 0.5% zinc, 0.5% ytterbium, 0.3% zirconium, and the balance is magnesium and unavoidable impurity elements.

[0098] A method for preparing a micro-alloyed magnesium alloy thin plate with high formability, the steps are as follows:

[0099] Step 1. Melting process

[0100] Weigh the corresponding raw materials according to the alloy composition and the content of each component, melt the prepared industrial pure magnesium, industrial pure zinc, magnesium-ytterbium master alloy, and magnesium-zirconium master alloy in an ordinary resistance furnace, and add industrial The addition temperature of pure magnesium, industrial pure zinc and magnesium-ytterbium master alloy is 730°C, and the addition temperature of magnesium-zirconium master alloy is 760°C. After the alloy elements are completely melted, high-purity argon is continuously introduced in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com