Patents

Literature

52results about How to "Improved thermal cycling stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

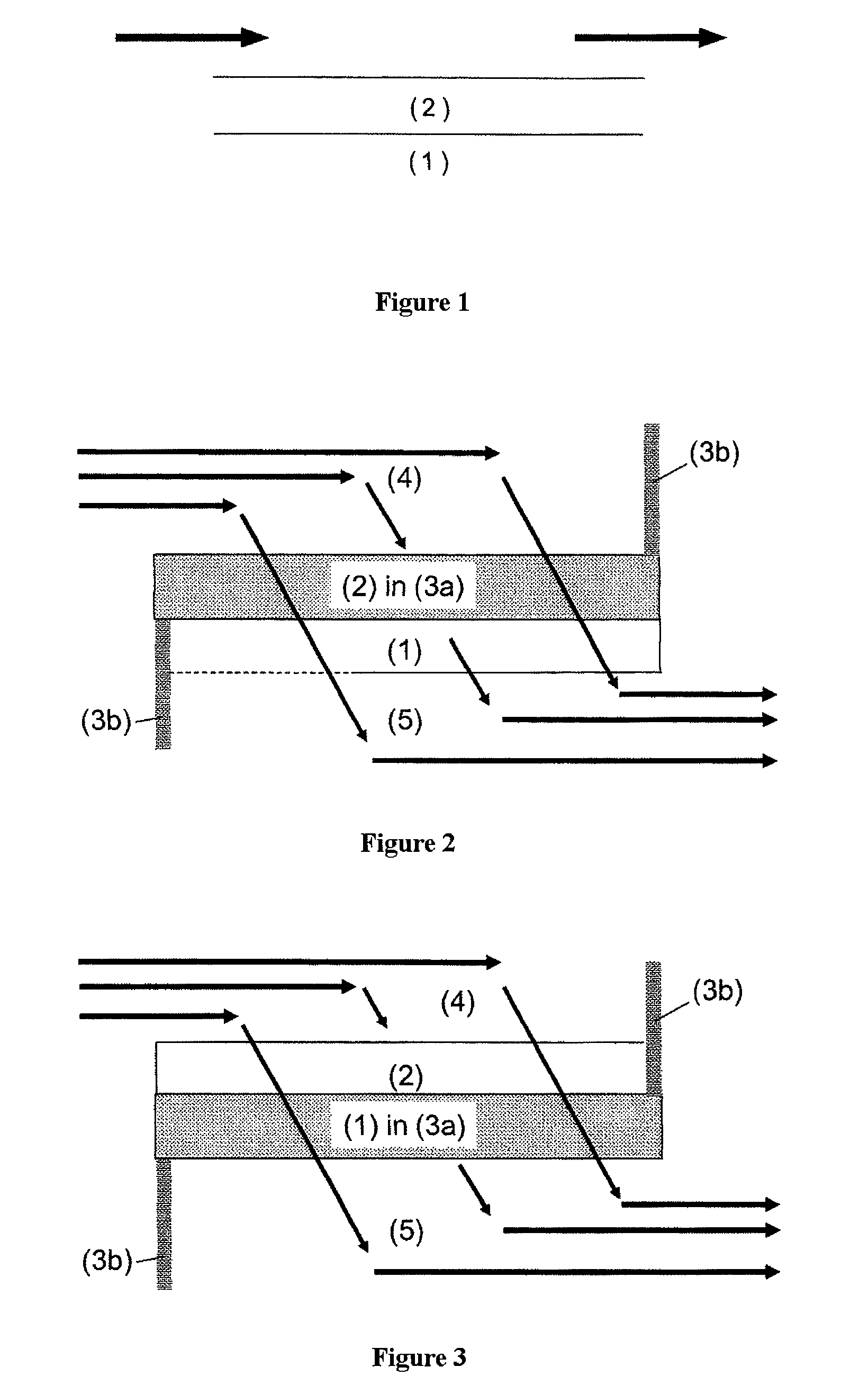

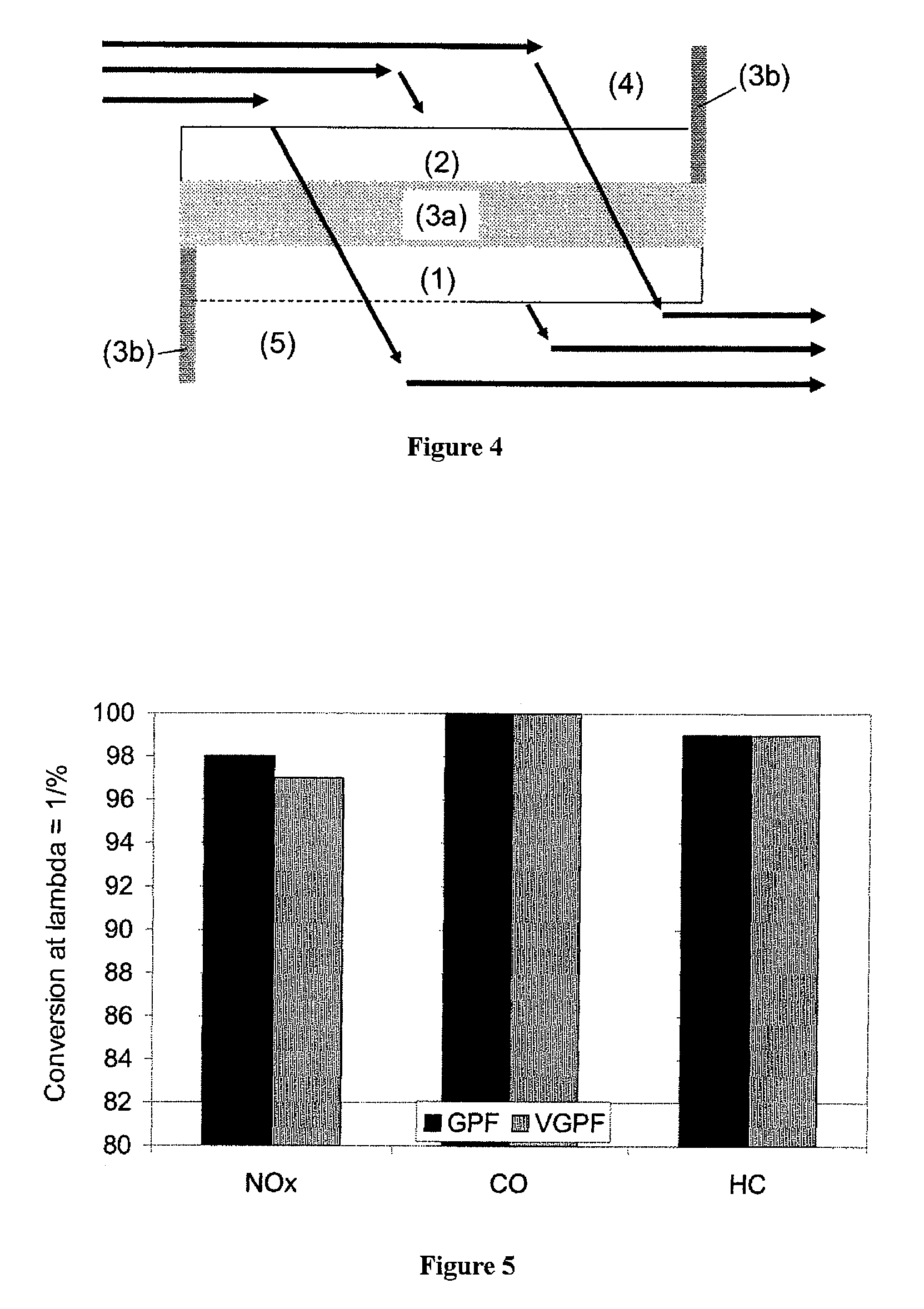

Removal of particulates from the exhaust gas of internal combustion engines operated with a predominantly stoichiometric air/fuel mixture

ActiveUS8066963B2Eliminate emissionsSmall sizeCombination devicesOrganic chemistryExternal combustion engineChemical measurement

The exhaust gas of internal combustion engines operated with a predominantly stoichiometric air / fuel mixture contains, as well as the gaseous hydrocarbon (HC), carbon monoxide (CO) and nitrogen oxide (NOx) pollutants, also ultrafine particulates. There is disclosed a catalytically active particulate filter, an exhaust gas cleaning system and a process for cleaning the exhaust gases of predominantly stoichiometrically operated internal combustion engines, as well as the gaseous CO, HC and NOx pollutants, also for removing particulates from the exhaust gas. The particulate filter comprises a filter body and a catalytically active coating consisting of two layers. Both layers contain alumina. The first layer contains palladium. The second layer contains rhodium. The latter is disposed above the first layer.

Owner:UMICORE AG & CO KG

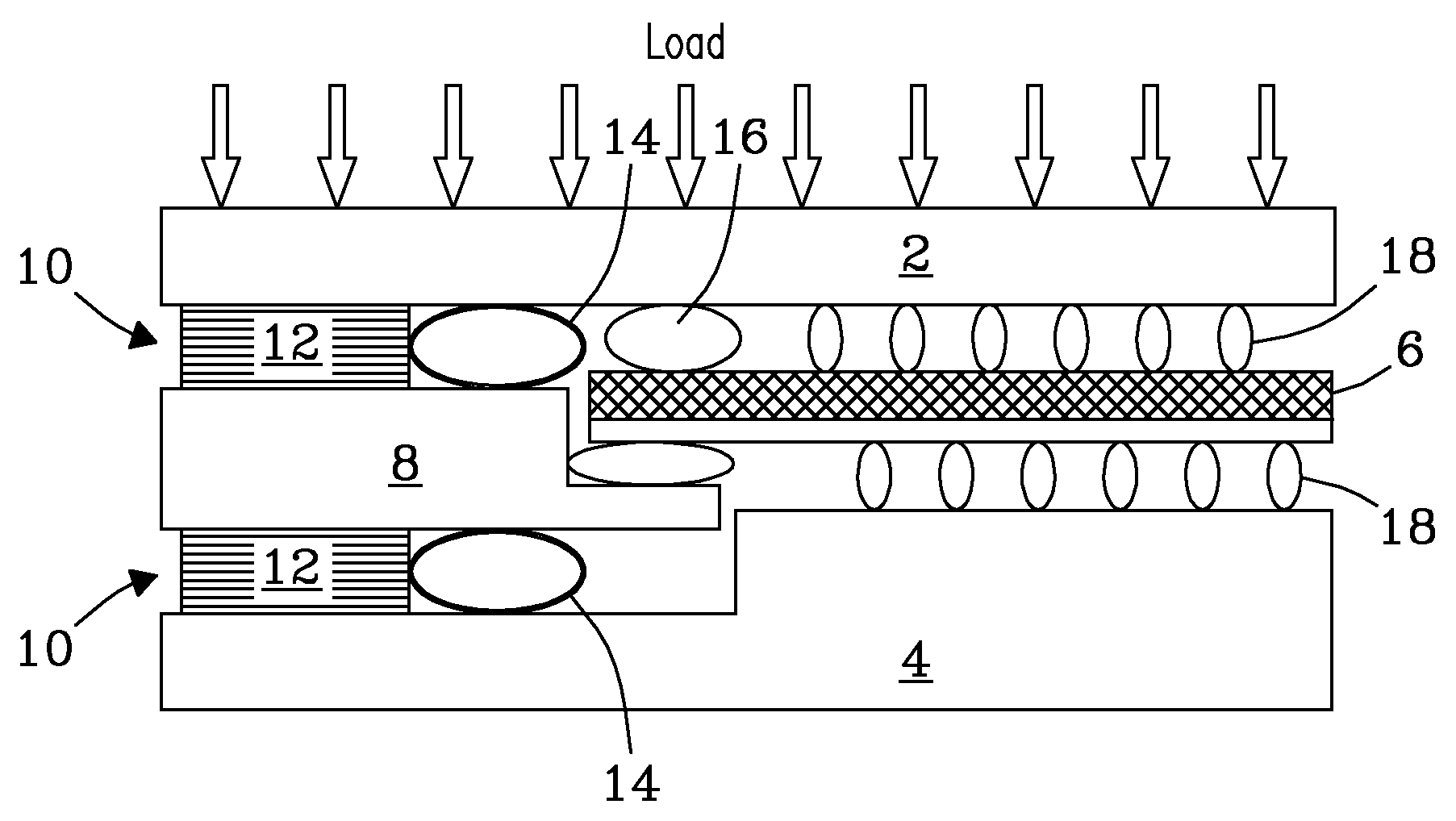

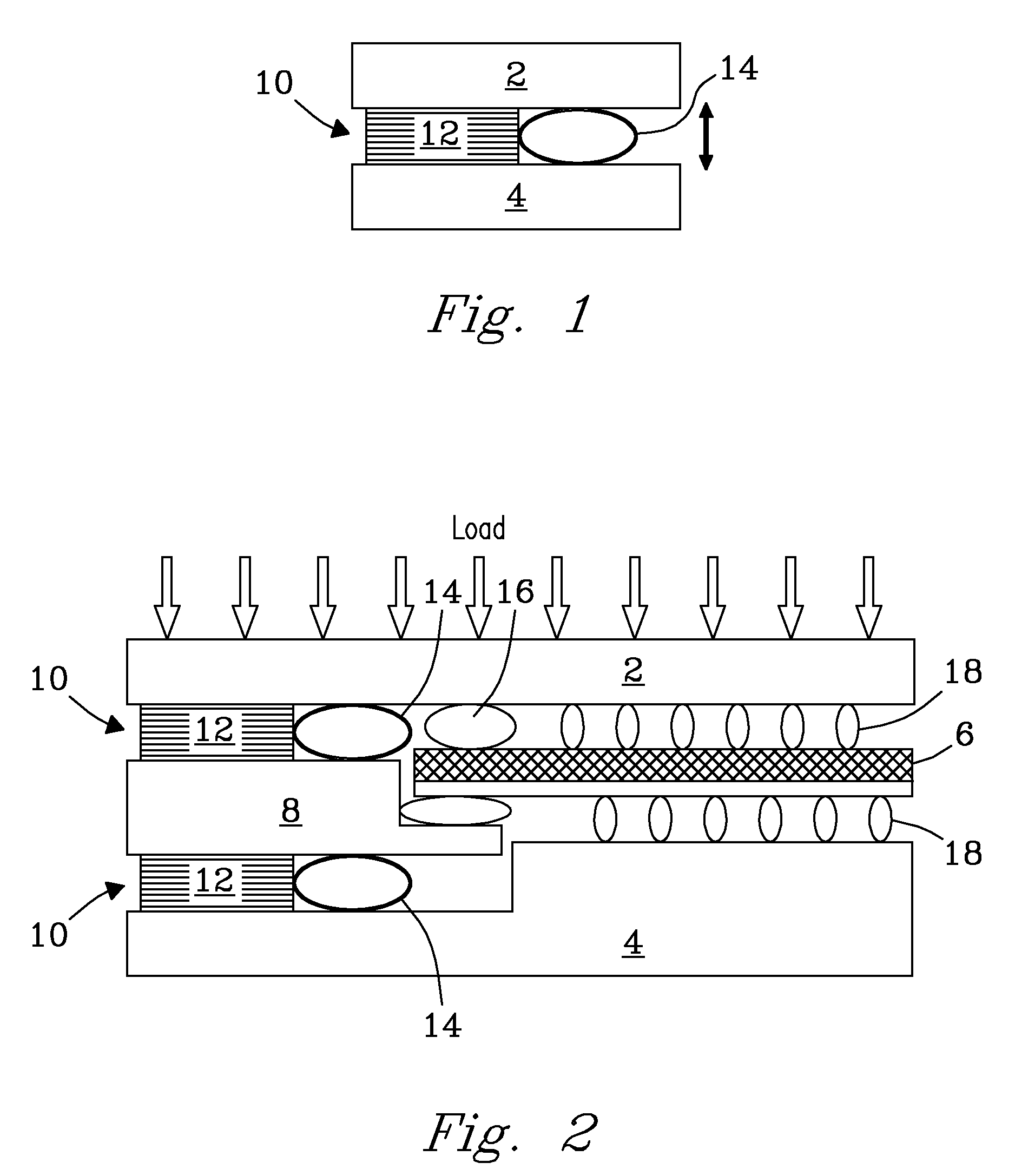

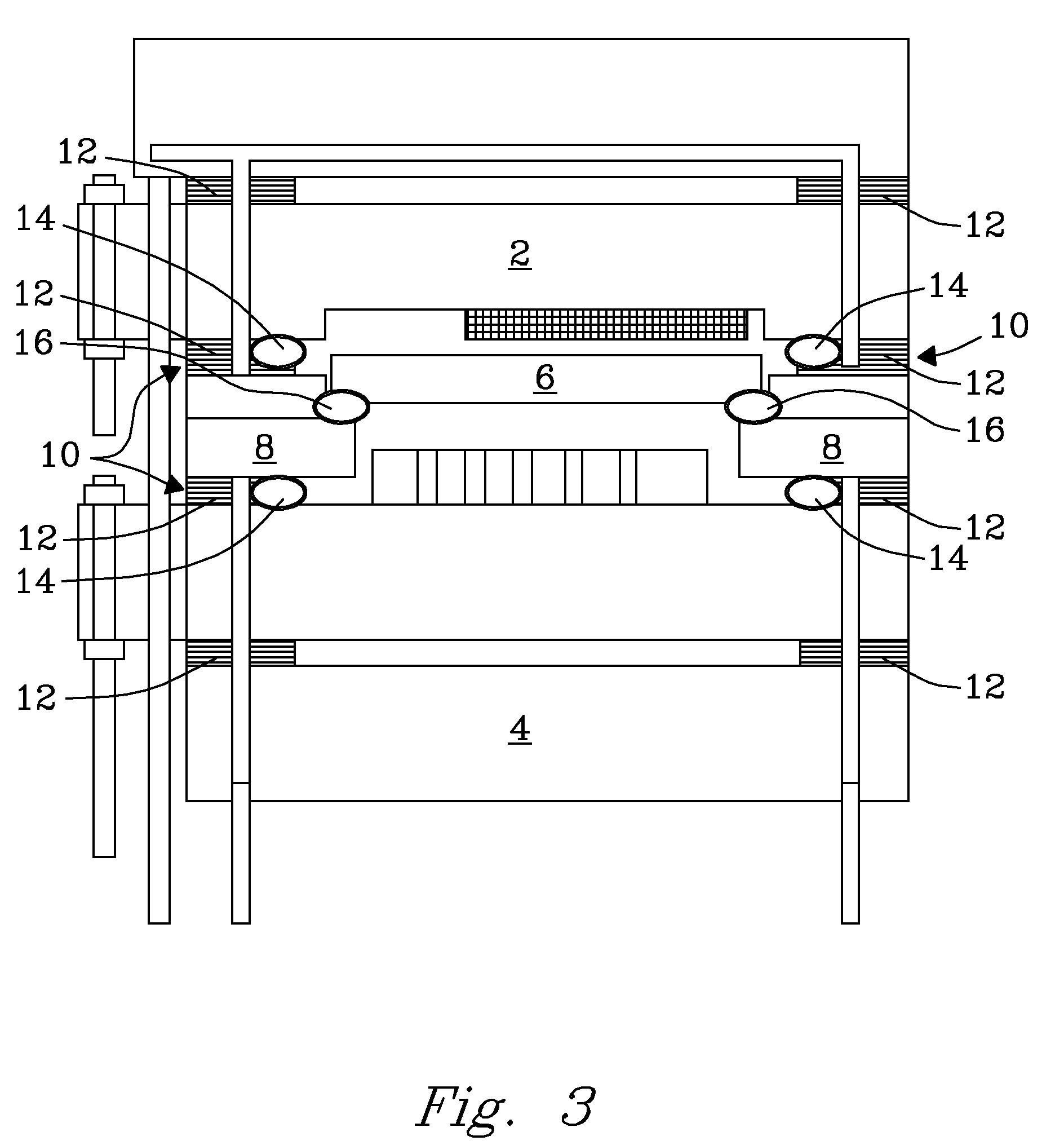

SOFC Double Seal with Dimensional Control for Superior Thermal Cycle Stability

InactiveUS20090311570A1Improved thermal cycling stabilityEngine sealsFuel cells groupingFuel cellsHermetic seal

A seal for devices such as a solid oxide fuel cells. The seal is a double seal having a first sealing material having a first preselected characteristic and a second sealing material having a second sealing characteristic. In one embodiment of the invention the first sealing material is a compressive sealing material and the second sealing material is a hermetic sealing material. In some embodiments a dimensional stabilizer may also be included as a part of the seal. In use these double seals provide superior thermal cycling stability in electrochemical devices where gasses must be separated from each other.

Owner:BATTELLE MEMORIAL INST

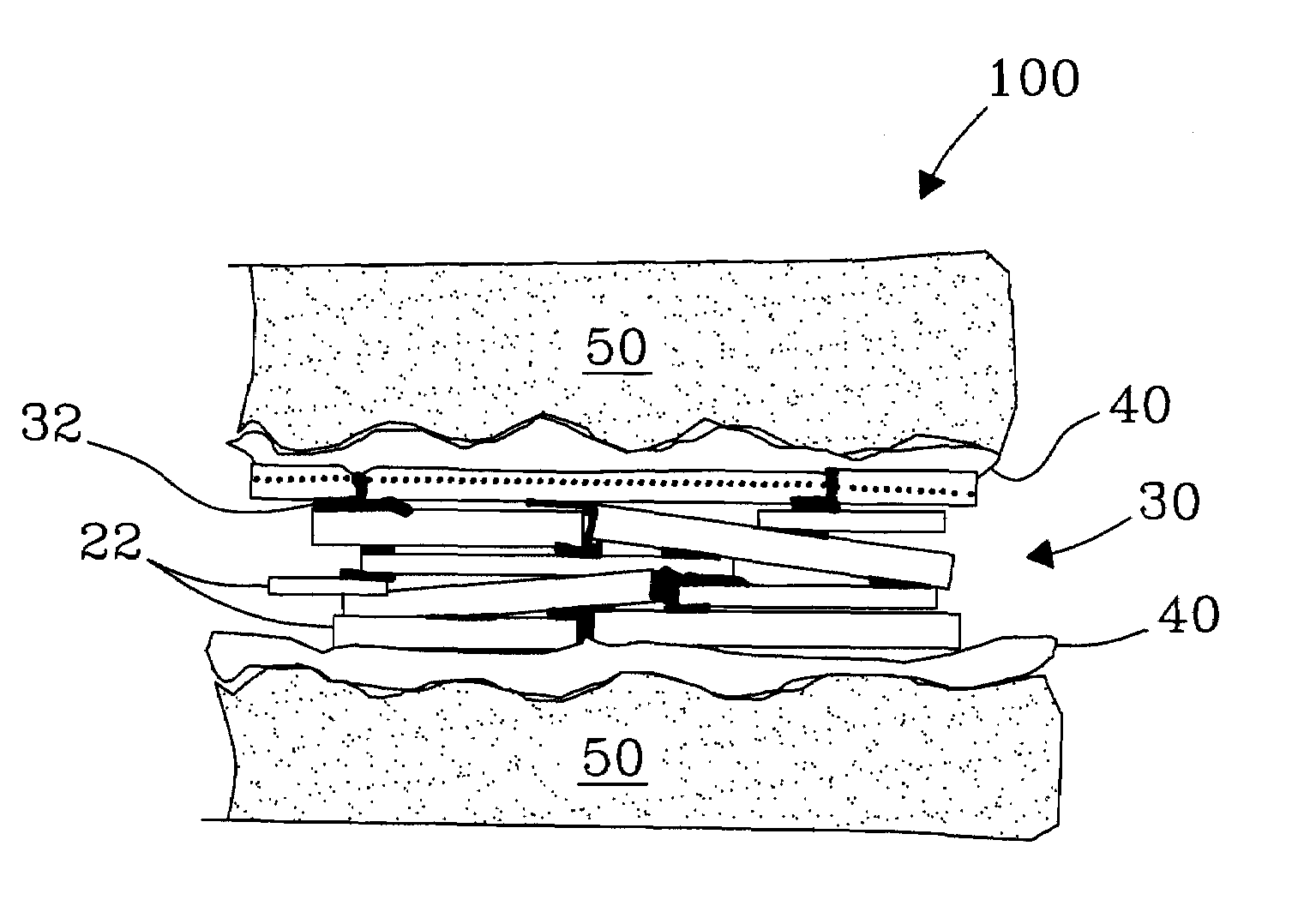

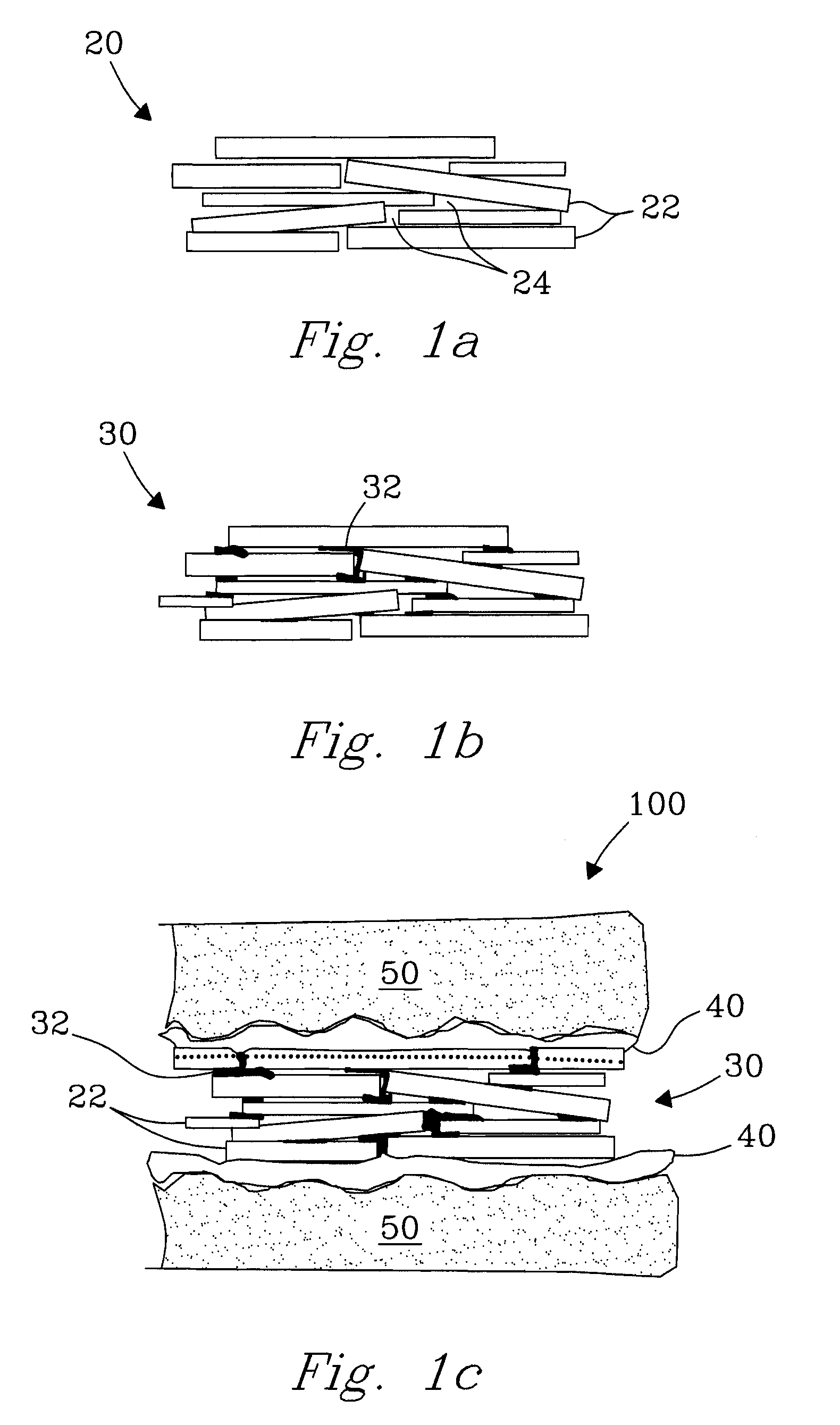

Multilayer compressive seal for sealing in high temperature devices

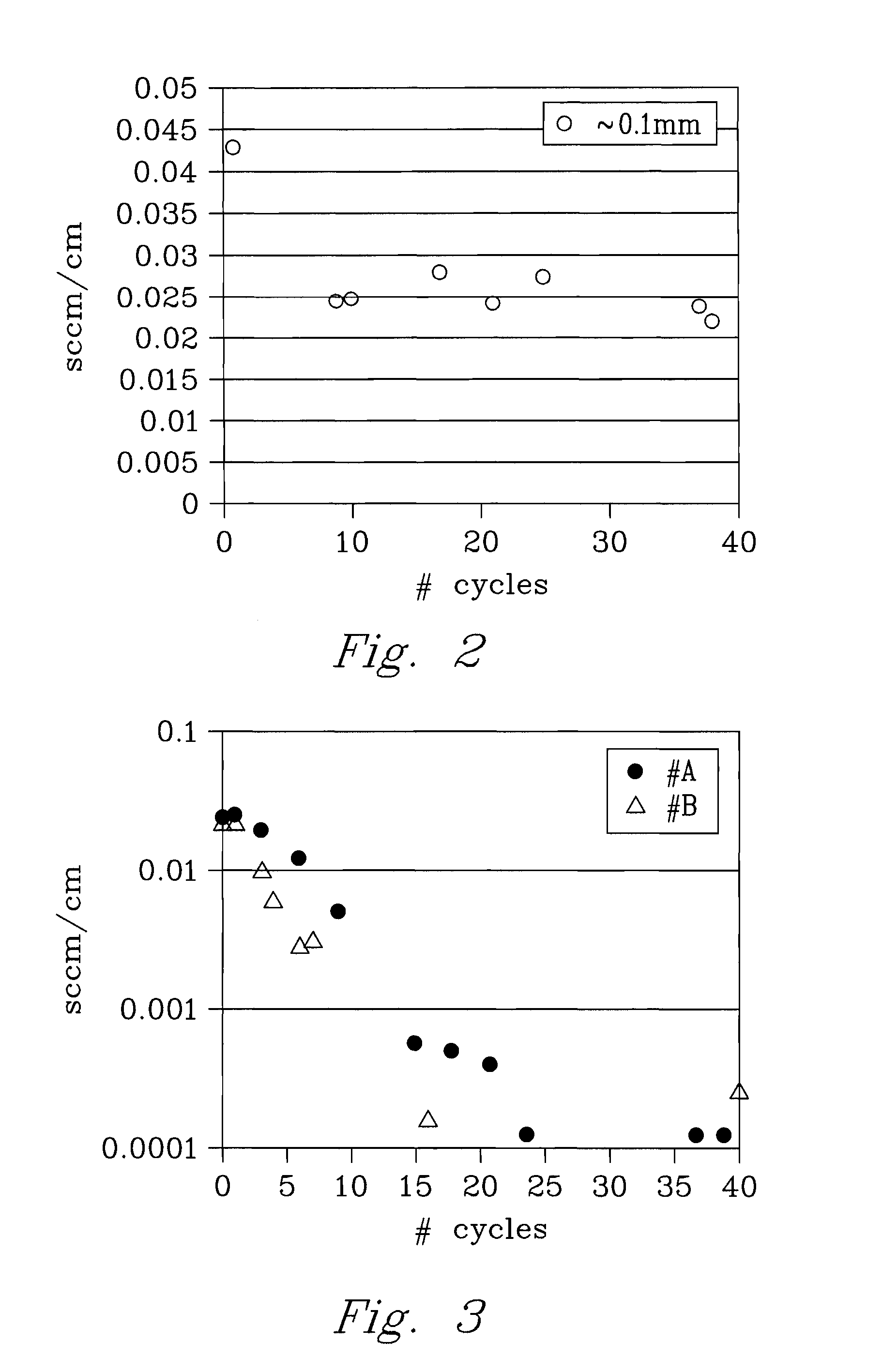

InactiveUS7258942B2Improved thermal cycling stabilityEffectively low leak rateEngine sealsFuel cells groupingEngineeringHot Temperature

A mica based compressive seal has been developed exhibiting superior thermal cycle stability when compared to other compressive seals known in the art. The seal is composed of compliant glass or metal interlayers and a sealing (gasket) member layer composed of mica that is infiltrated with a glass forming material, which effectively reduces leaks within the seal. The compressive seal shows approximately a 100-fold reduction in leak rates compared with previously developed hybrid seals after from 10 to about 40 thermal cycles under a compressive stress of from 50 psi to 100 psi at temperatures in the range from 600° C. to about 850° C.

Owner:BATTELLE MEMORIAL INST

Method for enhancing thermal conductivity of phase-change energy-storage superfine composite polyamide fiber and method for producing phase-change energy-storage superfine composite polyamide fiber

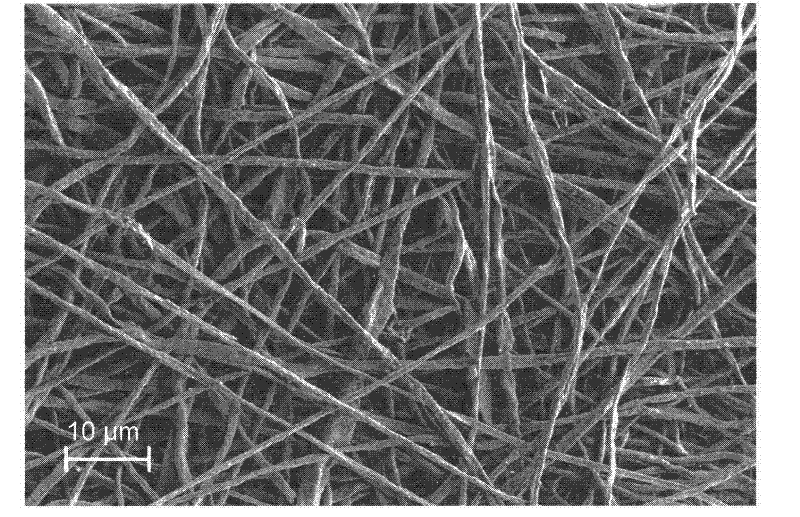

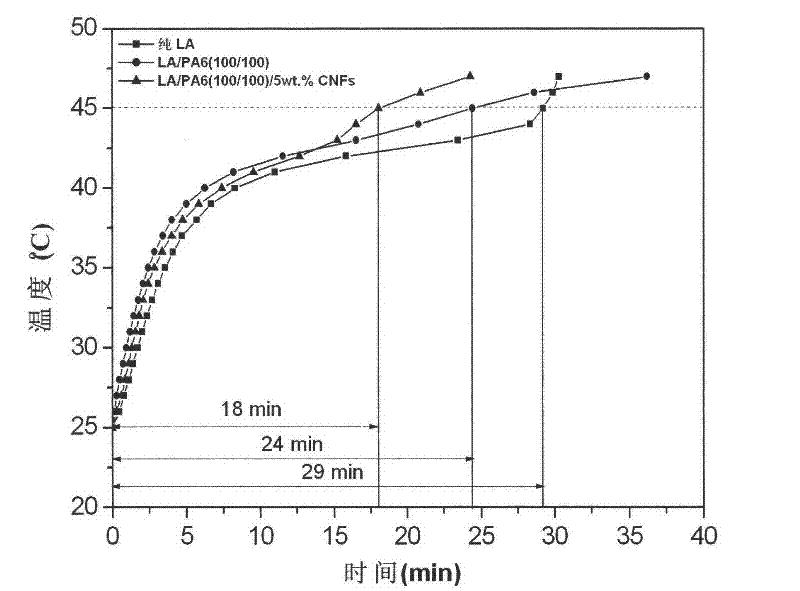

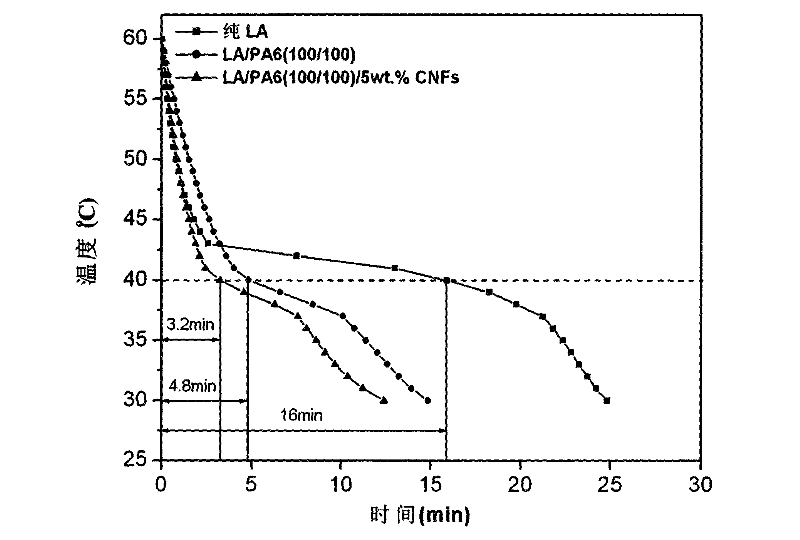

InactiveCN102517793APhase transition temperature is suitableHigh latent heat of phase changeFilament/thread formingNon-woven fabricsElectrospinningCarbon nanofiber

A production method for enhancing thermal conductivity of a fatty acid / polyamide-6 nano composite phase-change material belongs to the technical fields of nanocomposites, phase change materials, electrostatic spinning and the like, and particularly relates to a method of using an electrostatic spinning device to produce a nano composite fiber membrane of fatty acid / pollyamide-6 / carbon nano fibers. The production method is simple in process and easy in control. By effectively combining the production method with the electrostatic spinning technique, the produced fiber is small in diameter and uniform in distribution, the produced nano composite phase change material is uniform, stable and less prone to leakage, and has the thermal conductivity more evident than that of the conventional phase change material. Therefore, the material is more convenient in processing and application, and more widely applicable.

Owner:JIANGNAN UNIV

Heat conduction enhanced inorganic PCM (phase change material) and preparation method thereof

InactiveCN108997976AFast heat responseFast heat conductionHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced inorganic PCM (phase change material). The heat conduction enhanced inorganic PCM is prepared from an inorganic PCM as a core material and melamine resin containing heat conduction enhanced nano-particles as a wall material, wherein the heat conduction enhanced nano-particles are boron nitride, CNTs (carbon nano tubes) and graphene oxide that aremodified. A preparation method of the heat conduction enhanced inorganic PCM comprises the following steps: 1) modifying the heat conduction enhanced nano-particles; 2) preparing a prepolymer of the wall material added with the modified heat conduction enhanced nano-particles; 3) melting the inorganic PCM; and 4) preparing the heat conduction enhanced inorganic PCM. The heat conduction enhanced inorganic PCM has the advantages that 1) the heat response speed is high, i.e. the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and4) the technical characteristics that raw materials are safe and non-toxic and are not leaked easily are achieved. Therefore, the heat conduction enhanced inorganic PCM is better in heat conductivityand stability, the using ratio of energy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Boron nitride/graphene double-heat-conduction-base aerogel composite phase change material and preparation method thereof

ActiveCN111662688ALow densityContinuous network structureHeat-exchange elementsFreeze-dryingPyrrolidinones

The invention discloses a boron nitride / graphene double-heat-conduction-base aerogel composite phase change material. The material is formed by compounding modified boron nitride / graphene aerogel andn-octadecane by adopting a vacuum impregnation method. The double-heat-conduction aerogel is prepared by taking graphene oxide, modified boron nitride, polyvinylpyrrolidone and ethylenediamine as rawmaterials to prepare boron nitride / graphene hydrogel, freeze-drying the boron nitride / graphene hydrogel and then calcining the boron nitride / graphene hydrogel at a constant temperature. Polyvinylpyrrolidone is used as a cross-linking agent, and ethylenediamine is used as a reducing agent. A preparation method of the composite phase change material comprises the following steps: 1) preparing modified boron nitride; 2) preparing boron nitride / graphene double-heat-conduction-base aerogel; and 3) preparing the boron nitride / graphene double-heat-conduction-base aerogel composite phase change material. When the material is applied as a phase change material, the heat conductivity coefficient is 0.9-1.6 W / (m.K); wherein the phase change temperature is 19-32 DEG C, and the phase change latent heatis 200-220 J / g. The composite phase change material has the following advantages: 1, the heat conductivity coefficient is improved by 738%; 2, the leakage problem in the phase change process is effectively solved; and 3, the phase-change latent heat and the heat stability are high;

Owner:GUILIN UNIV OF ELECTRONIC TECH

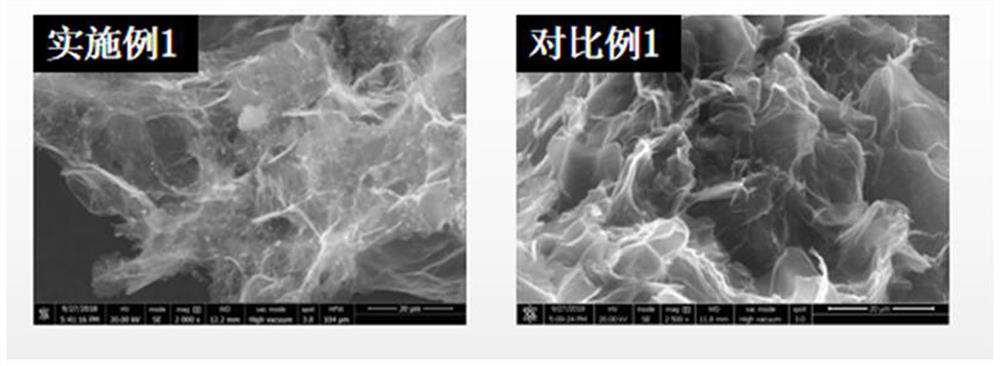

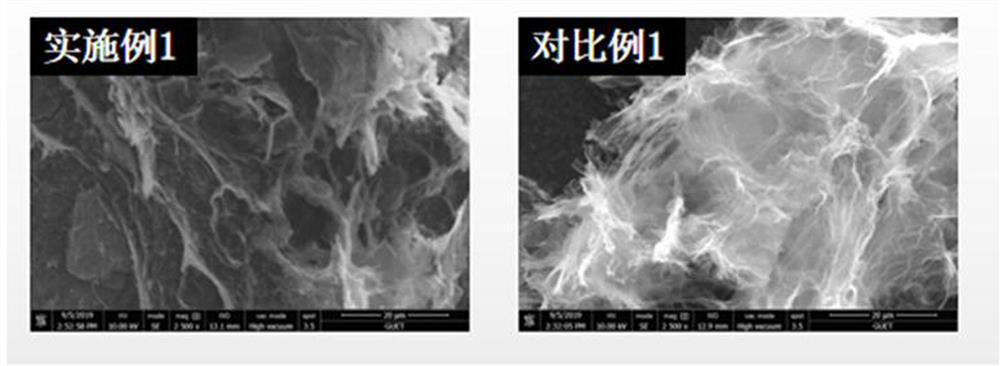

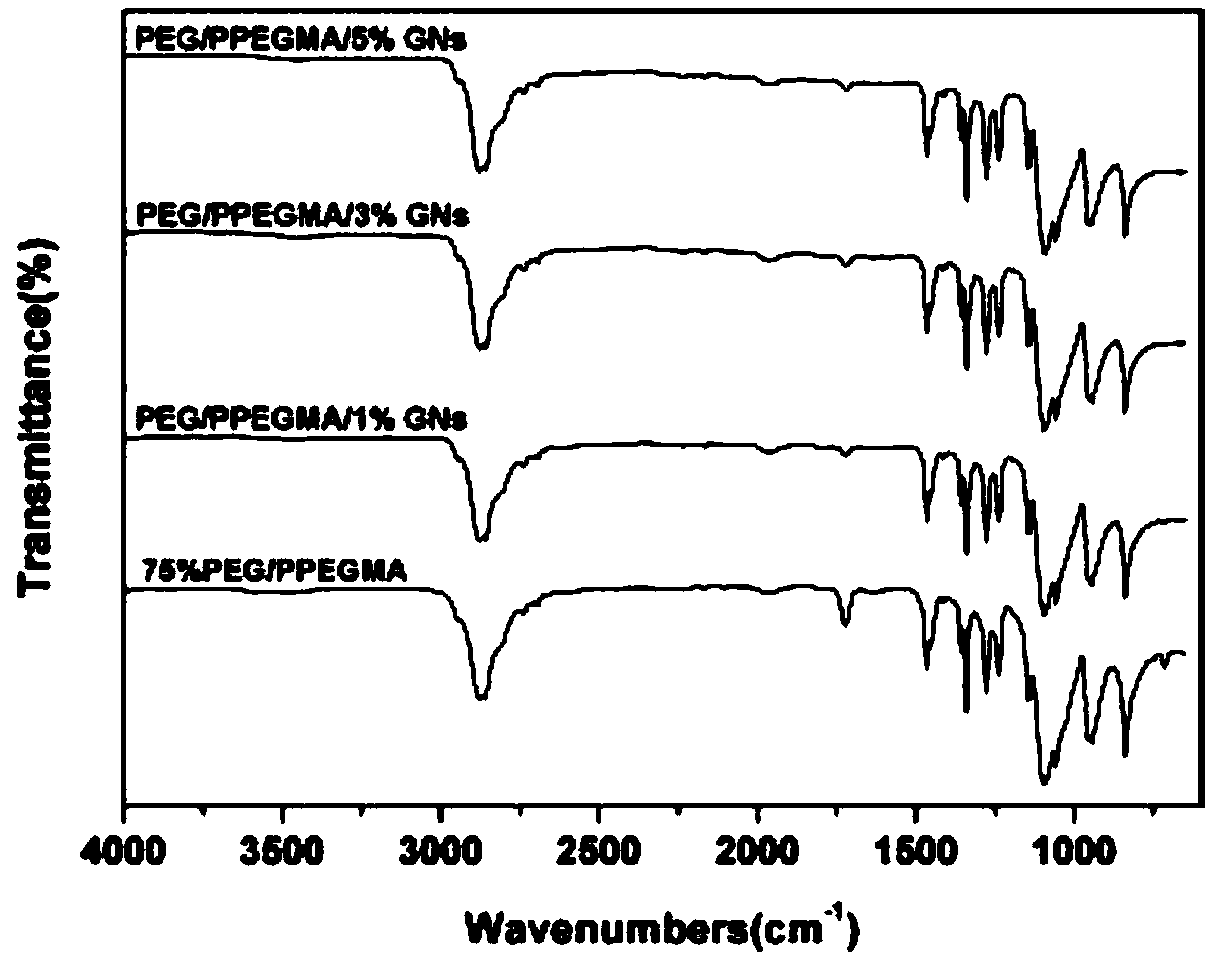

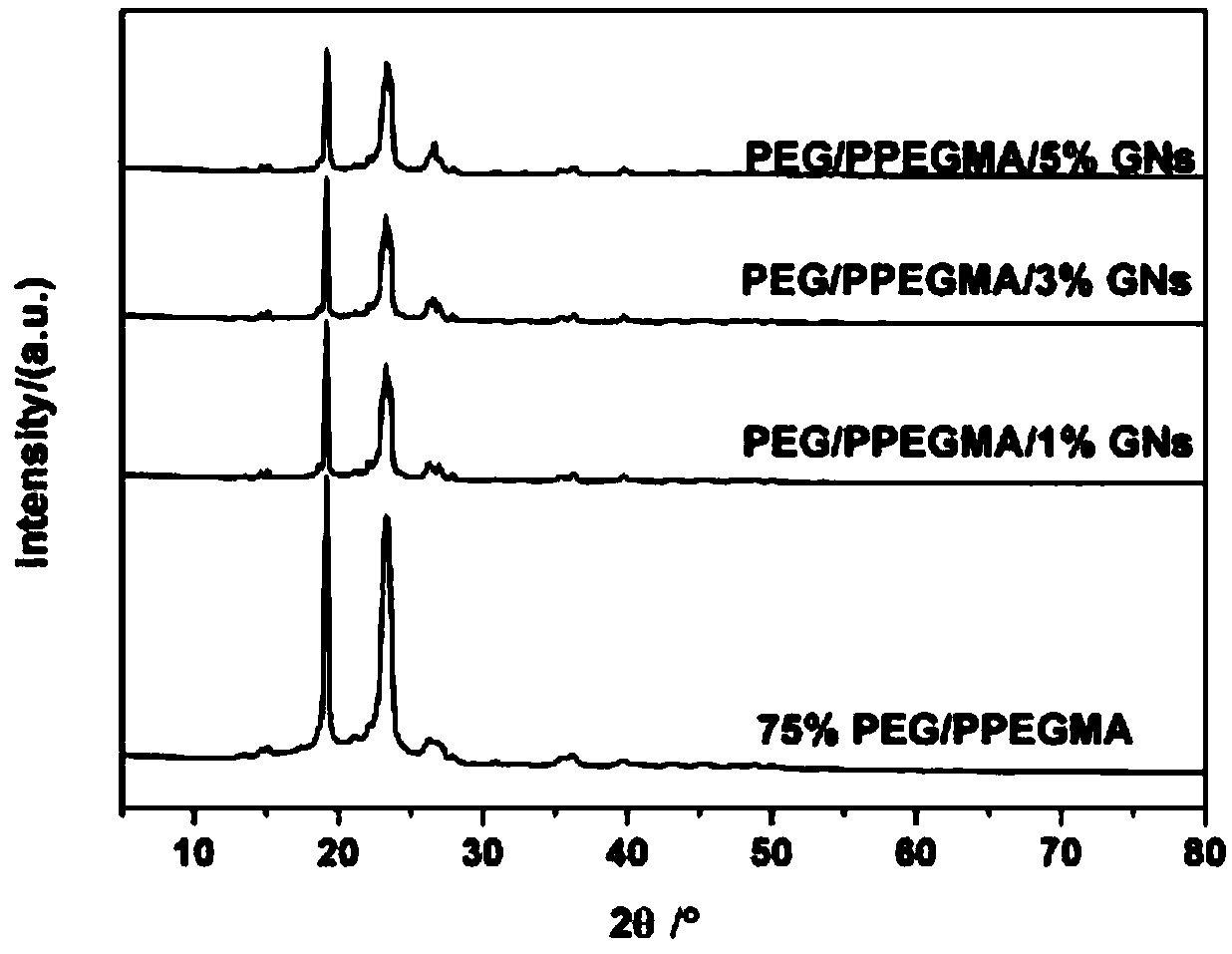

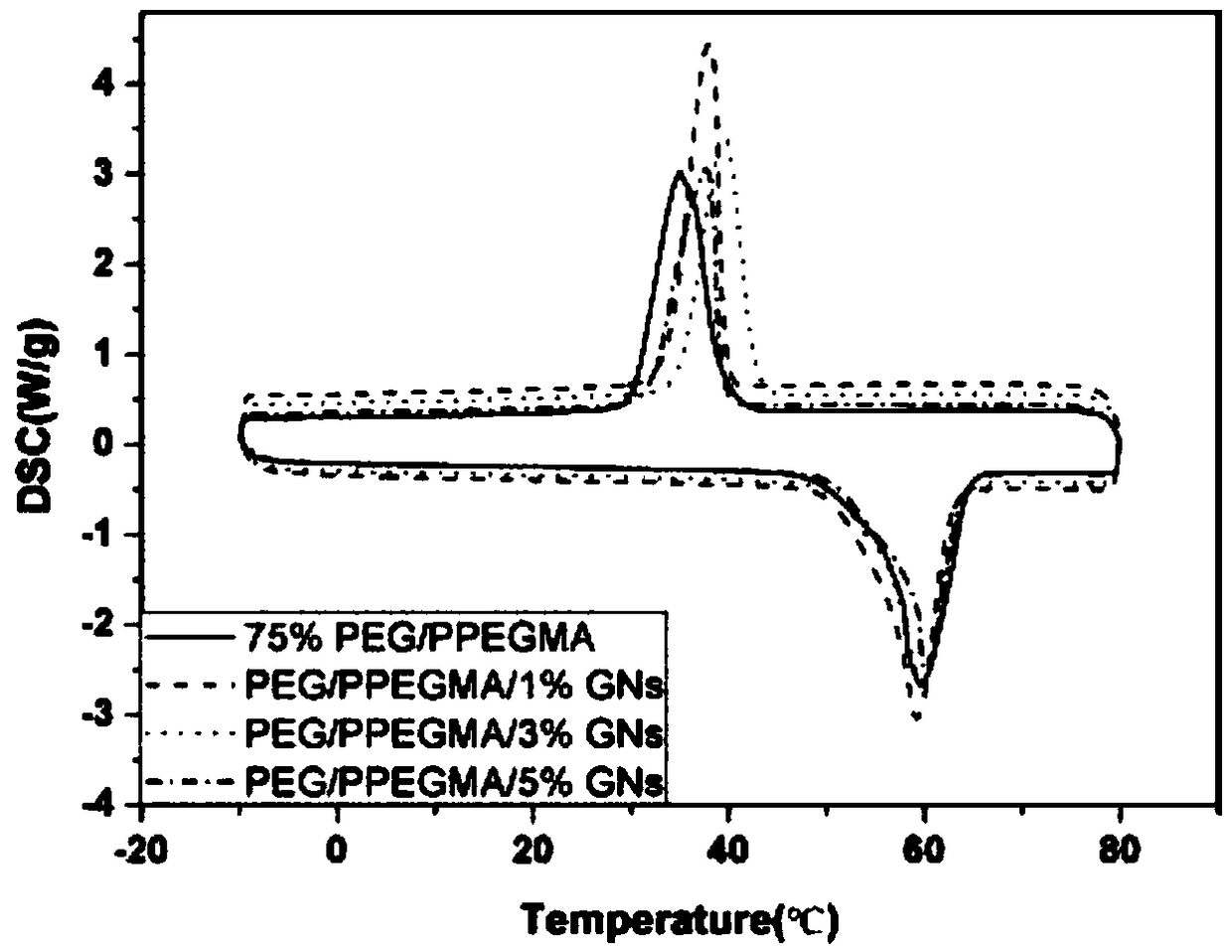

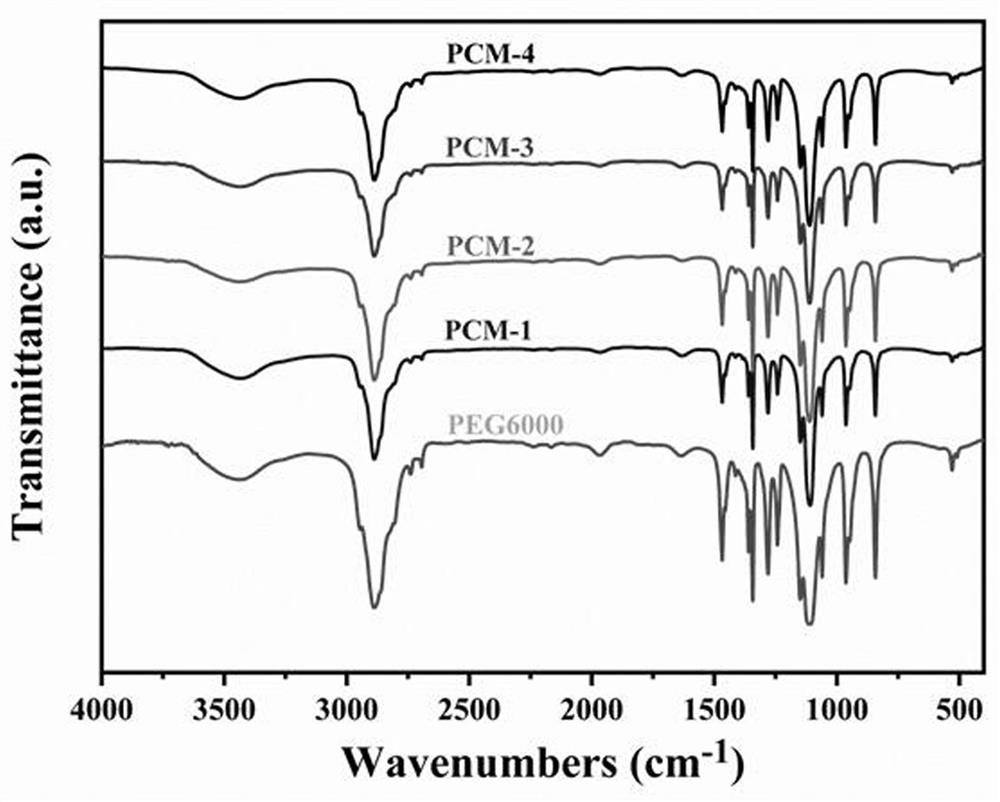

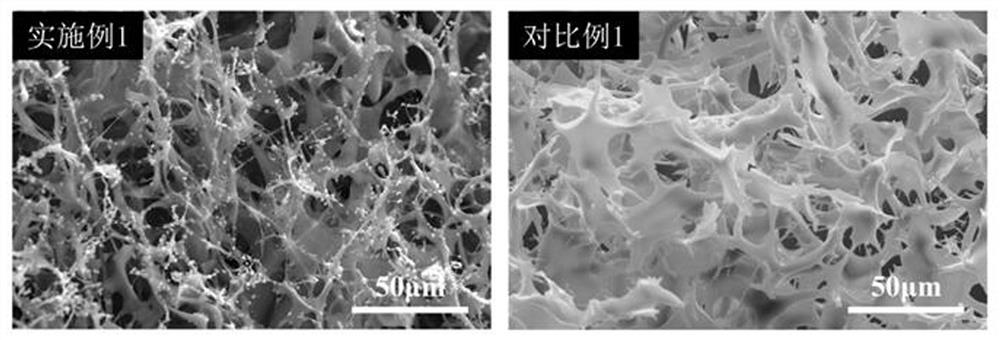

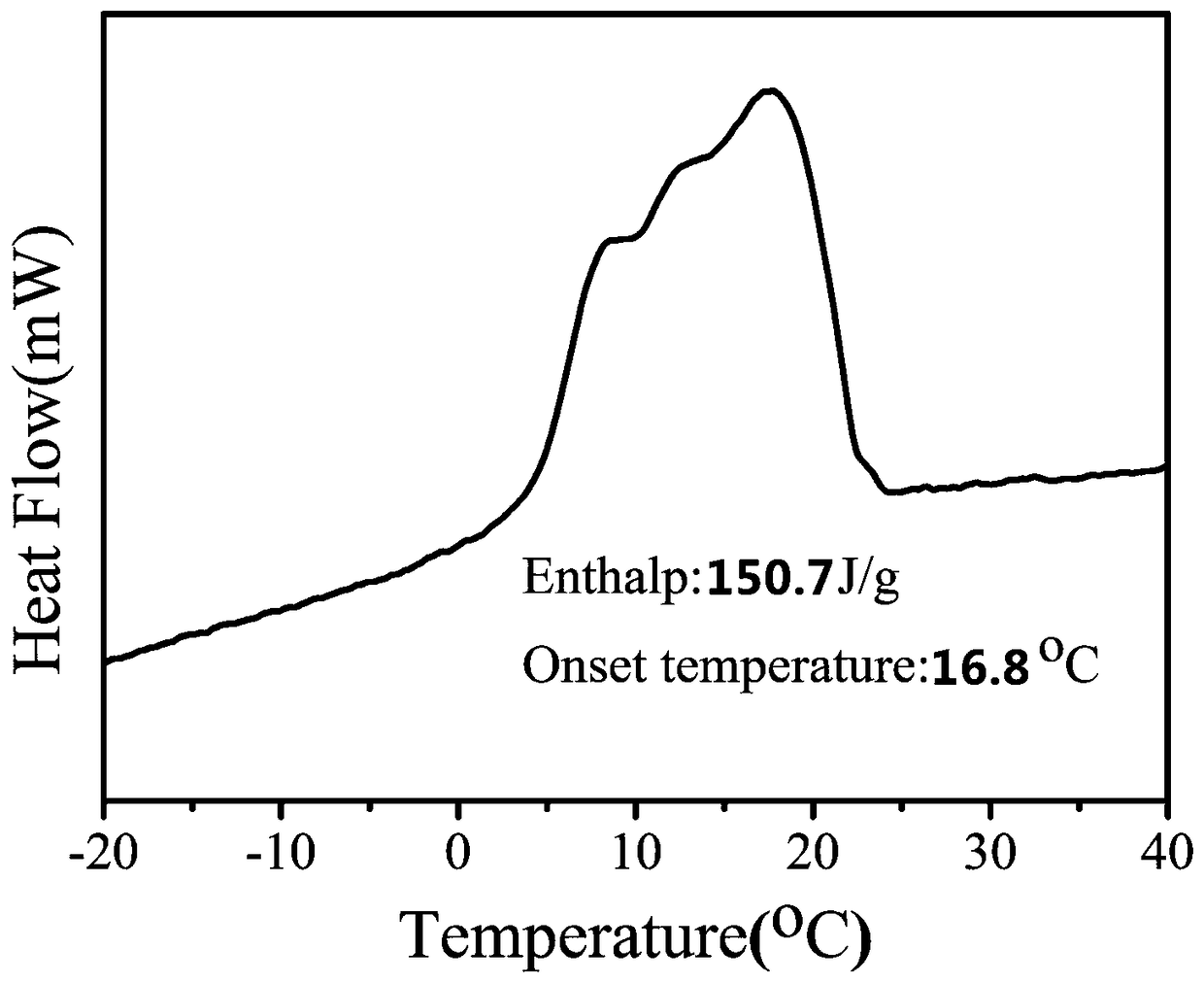

Polyether-based composite phase change energy storage material and preparation method thereof

ActiveCN109504351AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsPolymer sciencePolyethylene glycol

The invention relates to a polyether-based composite phase change material and a preparation method thereof, and belongs to the technical field of novel materials. The polyether-based composite phasechange material comprises the following components in percent by mass: 23-70% of a phase change supporting material, 1-7% of a carbon material and 30-75% of polyethylene glycol, wherein the phase change supporting material is a polyacrylate polymer, and a monomer structure of the olyacrylate polymer is as shown in the specification, wherein n is 5-90, m is 50-1000, R1 is -H or -CH3, and R2 is -CH3or -CH2CH3; and the carbon material is graphene or graphene oxide. The novel heat storage material is high in energy storage density, high in heat conductivity coefficient, good in heat stability, simple in synthesis technology and good in shaping performance, so that the novel heat storage material has very strong practicability.

Owner:DALIAN UNIV OF TECH

Heat conduction enhanced organic PCM (phase change material) and preparation method thereof

InactiveCN108997977AFast heat responseFast heat conductionChemical industryHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced organic PCM (phase change material). The heat conduction enhanced organic PCM is prepared from an organic PCM containing nano-particles as a core material and a porous material as a wall material, wherein the nano-particles are boron nitride, CNTs (carbon nano tubes), expanded graphite and graphene oxide. A preparation method of the heat conduction enhanced organic PCM comprises the following steps: 1) a process of emulsifying the organic PCM; 2) a process of adsorbing the organic PCM containing the nano-particles by the porous material undera vacuum condition; and 3) a process of taking out a product obtained after vacuum adsorption. The heat conduction enhanced organic PCM has the advantages that 1) the heat response speed is high, i.e.the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and 4) raw materials are safe, non-toxic and non-corrosive, and the technical characteristics of being simple in preparation process and low in cost are achieved. Therefore, the heat conduction enhanced organic PCM is better in heat conductivity and stability, the using ratio ofenergy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

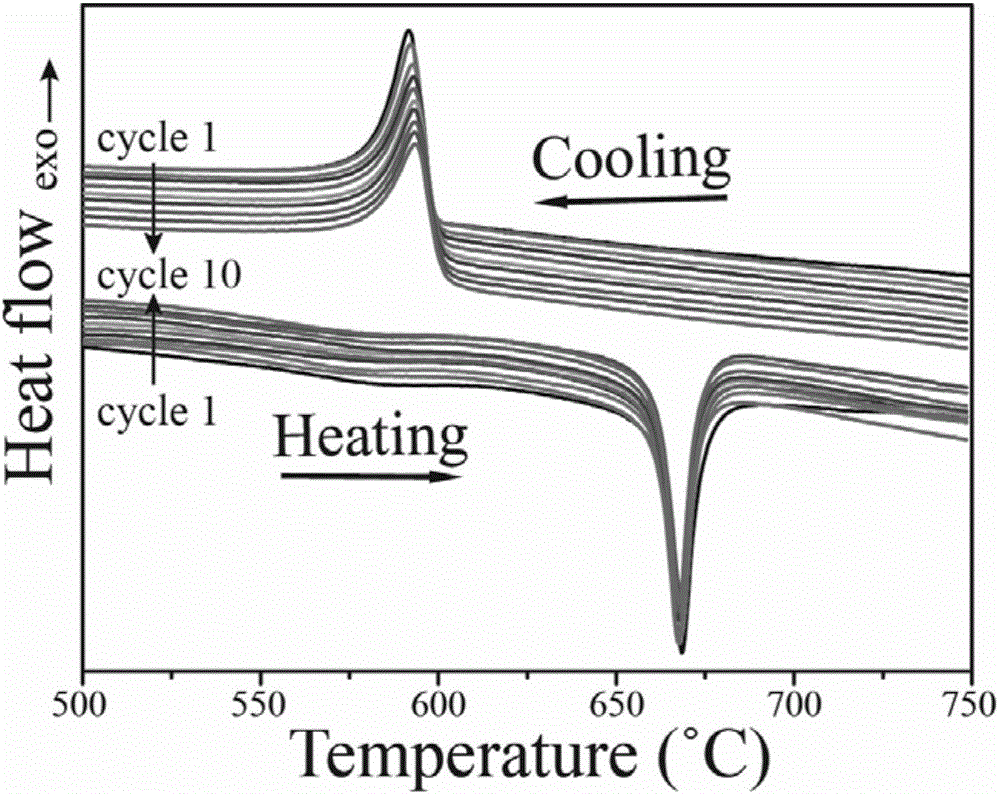

High-temperature heat-storage material and uses thereof

InactiveCN101225492AHigh energy storage densityImproved thermal cycling stabilityHeat storage materialSolar power

The invention relates to a high temperature heat accumulation material and the application, which is characterized in that: the high temperature heat accumulation material is an aluminum alloy material with a melting point arranging from 450 to 800 degree centigrade and is one material of the following six materials: 1) Al-Cu alloy with a Cu mass percent of 20% to 61% and a Al mass percent of 39% to 80%; 2) Al-Mg alloy with a Mg mass percent of 16% to 55% and a Al mass percent of 45% to 84%; 3) Al-Si alloy with a Si mass percent of 3% to 26% and a Al mass percent of 74% to 97%; 4) three component aluminum alloy with a chemical expression of Al-x% Si-y% Cu, x between 6 and 27 and y between 0 and 5; 5) three component aluminum alloy with a chemical expression of Al-x% Si-y% Mg, x between 0 and 20 and y between 0 and 40; the aluminum alloy material is used in solar power generation as a heat accumulation material. The high temperature heat accumulation material has the advantages of high phase transition latent heat, good phase transition stability and long service life.

Owner:WUHAN UNIV OF TECH

Phase-change high-thermal-conductivity interface material and preparation method thereof

InactiveCN107722942AReduce thermal contact resistancePlay a protective effectHeat-exchange elementsPolyethylene terephthalatePhase change

The invention relates to a phase-change high-thermal-conductivity interface material and a preparation method thereof. The phase-change high-thermal-conductivity interface material comprises a phase-change high-thermal-conductivity interface material layer, wherein protective film layers are arranged on the upper side and bottom side of the phase-change high-thermal-conductivity interface materiallayer and refer to one or several in PET (Polyethylene Terephthalate) release films, PE release films and release paper; and the phase-change high-thermal-conductivity interface material layer comprises a main composite phase-change base material, high-thermal-conductivity filler particles and performance additives. The phase-change high-thermal-conductivity interface material disclosed by the invention has excellent thermal cycling stability and impact resistance.

Owner:SUZHOU ENBRIGHTECH

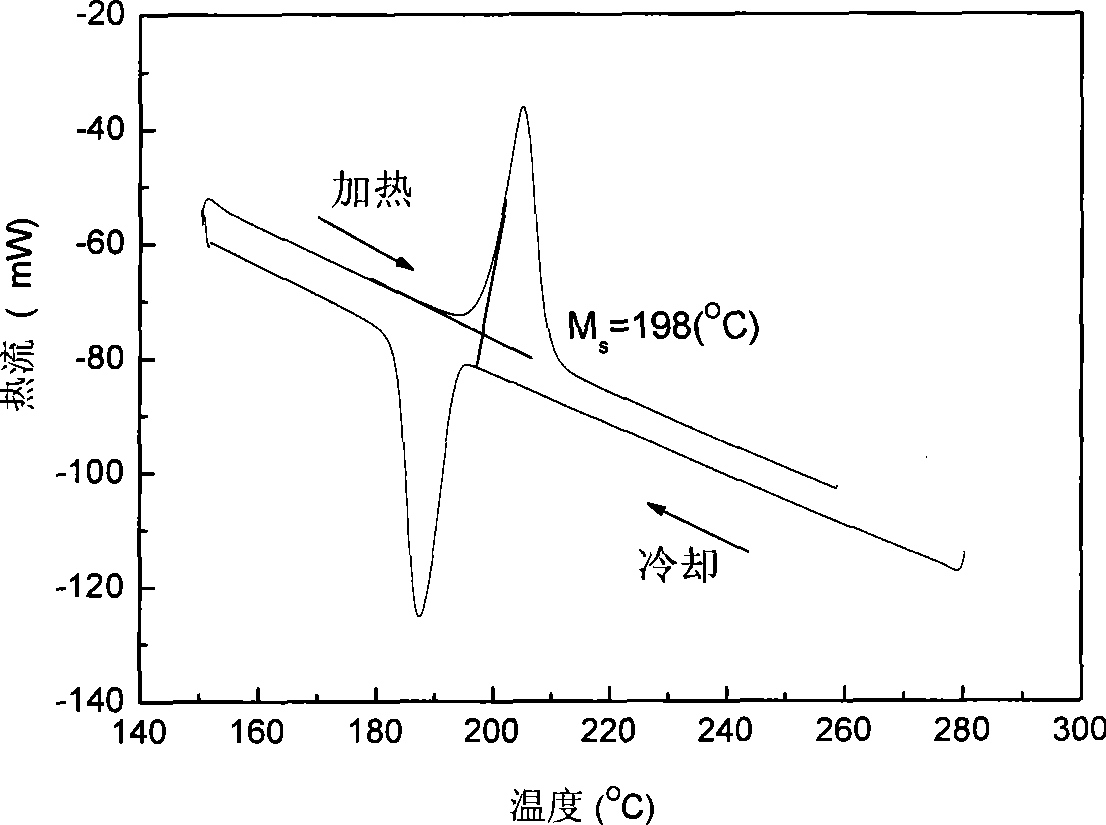

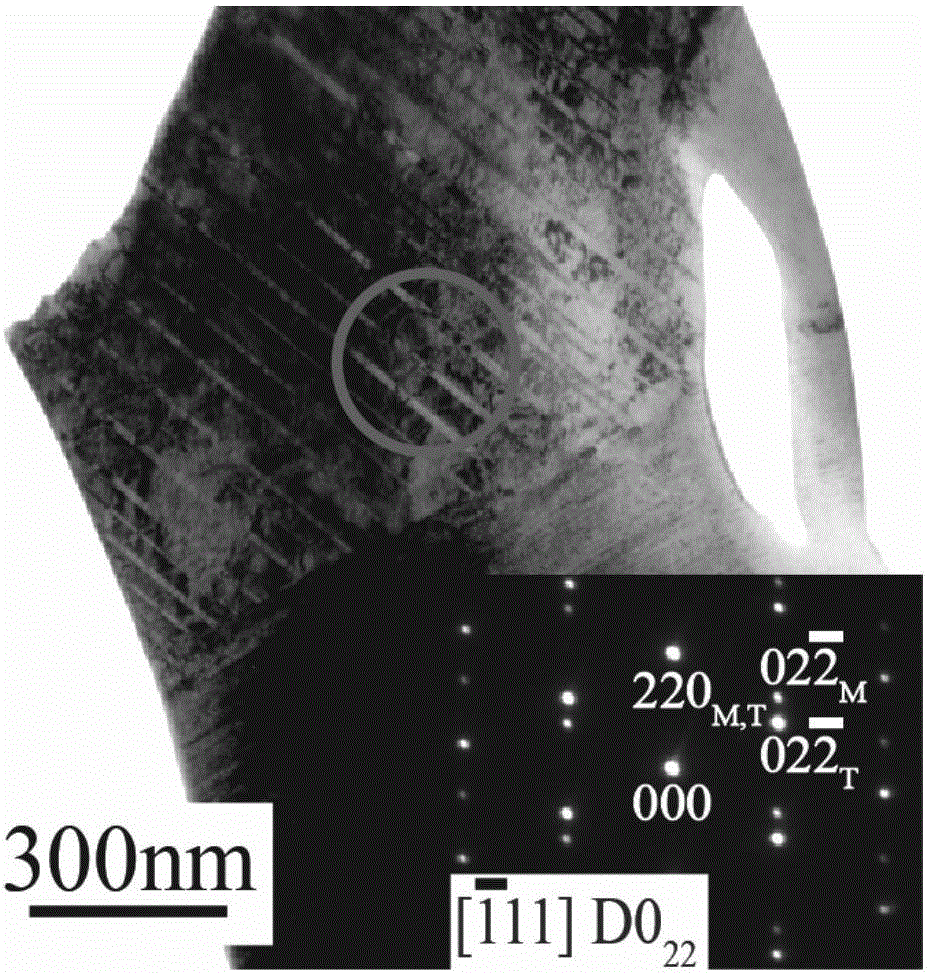

NiMnGaCu high temperature shape-memory alloy and manufacturing method thereof

InactiveCN101463445AHigh phase transition temperatureImproved thermal cycling stabilityMartensite transformationMemory effect

The invention provides a NiCoMnSn high temperature shape memory alloy and a preparation method thereof. Ni, Co and Sn are weighted according to the atomic percent of Ni43Co7Mn<50-x>Sn<x>; wherein, X equals to 7-10; the raw materials of Ni, Co, and Sn weighted in the first step are put in a no consumable vacuum arc furnace, vacuumed to cause that the vacuum degree of the background reaches 2*10<-2> - 5*10<-3>Pa, and then charged with high-purity argon till 500 Pa; the raw materials are melted to NiCoMnSn button-type cast ingot by using high temperature voltaic arc; a vacuum suction mold device is used for preparing a bar-shaped cast ingot with the 10mm diameter, thus obtaining the Ni43Co7Mn<50-x>Sn<x> high temperature shape memory alloy. The martensitic phase transformation temperature of the NiCoMnSn prepared by the invention ranges from 120 DEG C-300 DEG C; the alloying elements of the raw materials are relatively cheap. The preparation method is simple and the alloy has uniform components; therefore, the follow-up heat treatment is not needed. The shape memory effect can reach up to 3.8%. The stability of the thermal circulation is high. The alloy is a new high temperature shape memory alloy with the application prospect.

Owner:如皋市生产力促进中心

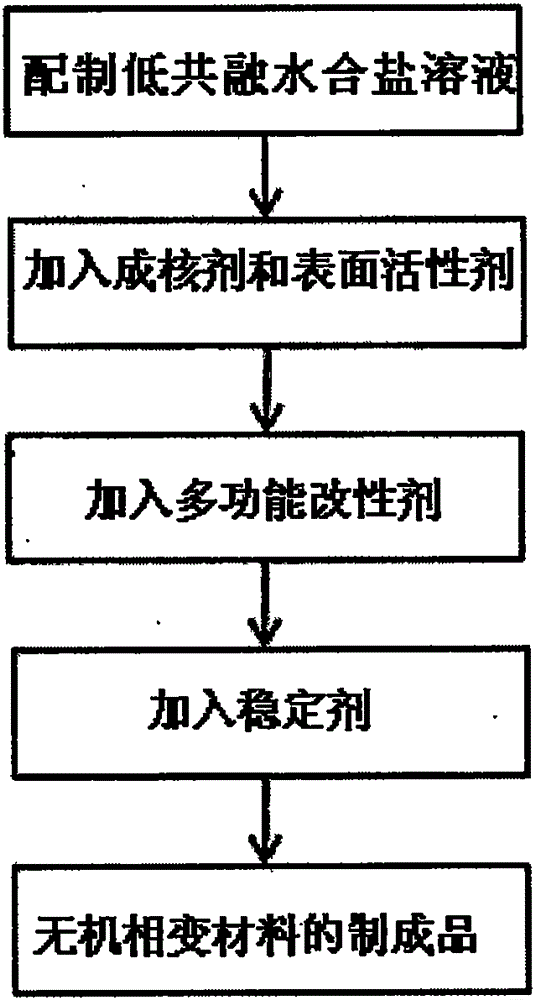

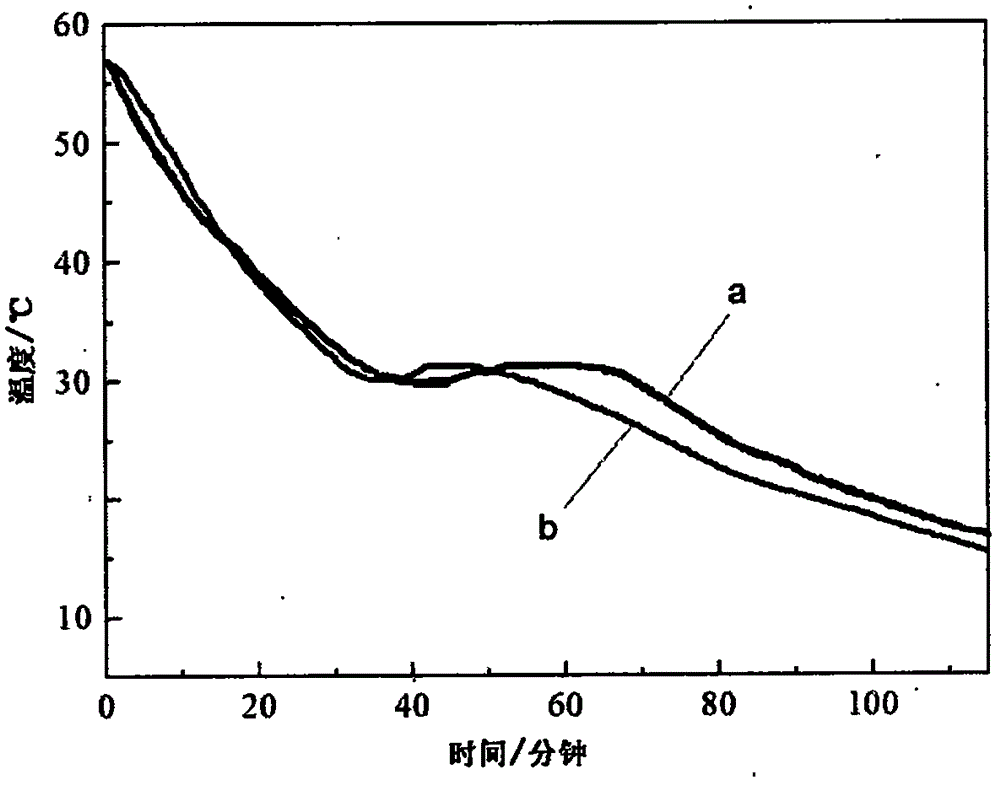

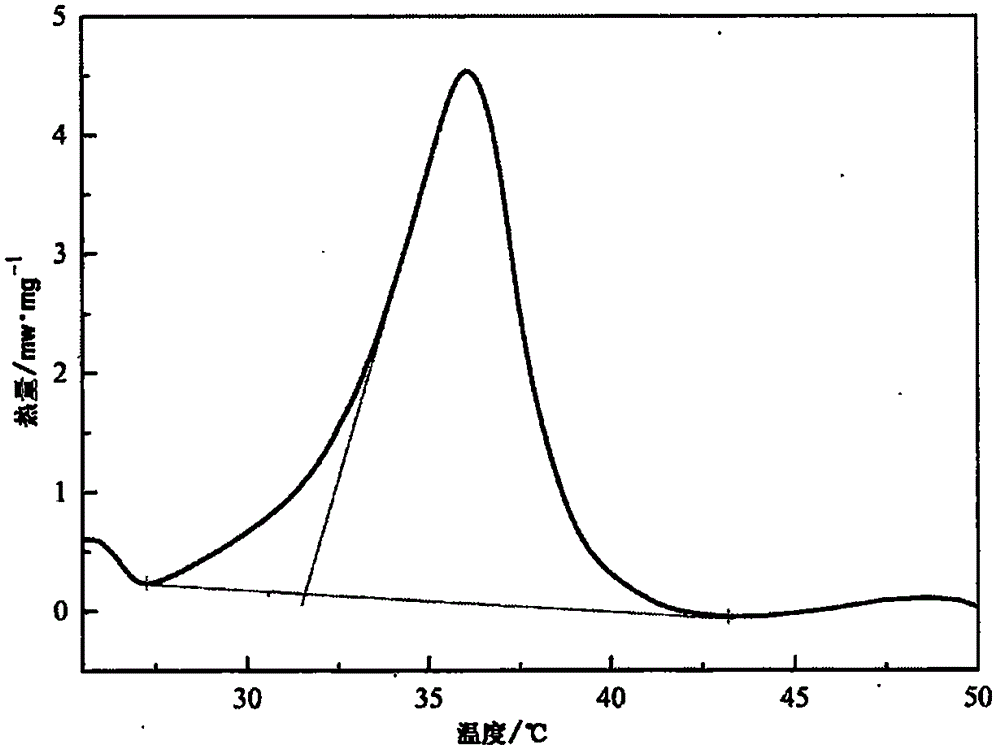

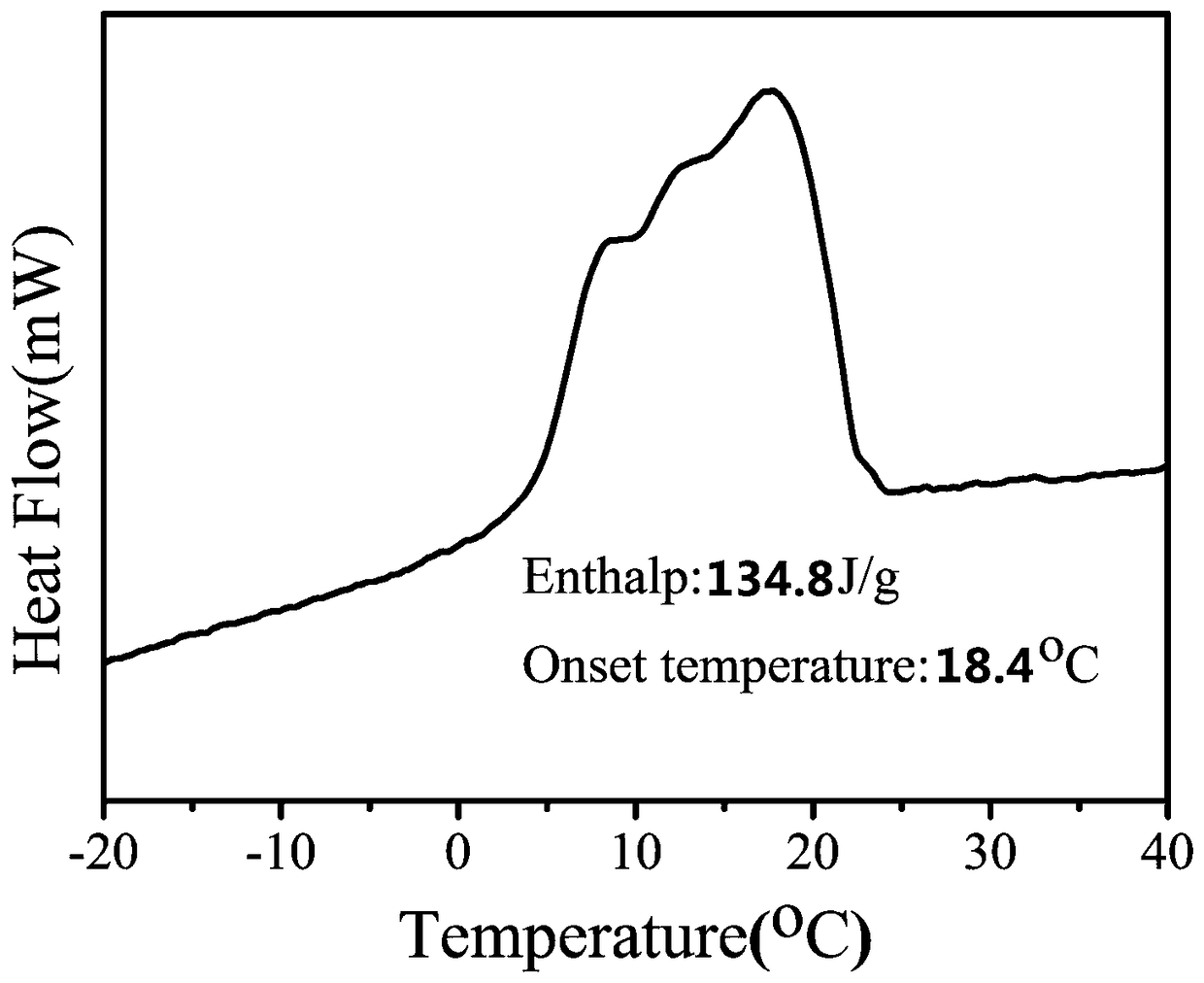

Binary low-eutectic hydrated salt phase-change material with high heat conductivity and preparation method thereof

ActiveCN107523272AGood dispersionReduce subcoolingHeat-exchange elementsHydration reactionSurface-active agents

The invention discloses a binary low-eutectic hydrated salt phase-change material with high heat conductivity and a preparation method thereof and relates to an inorganic hydrated salt phase-change material and a preparation method thereof. The existing hydrated salt phase-change material with the phase-change temperature of about 30 DEG C has the defects of lower heat conductivity, high supercooling degree and phase layering in the use process, and is tedious in preparation process and complex in operation. The binary low-eutectic hydrated salt phase-change material is a solution with the following components in parts by weight: 23-26 parts of mirabilite, 70-75 parts of disodium hydrogen phosphate dodecahydrate, 0.5-1.5 parts of nucleating agent, 1-2.25 parts of surface active agent, 3-4.5 parts of multifunctional modifier and 1-2.25 parts of stabilizer. The preparation method is a process with the following steps: gradually mixing and dissolving mirabilite, disodium hydrogen phosphate dodecahydrate, the nucleating agent, the surface active agent, the multifunctional modifier and the stabilizer, and finally forming a binary low-eutectic hydrated salt phase-change solution with high heat conductivity. The invention is used in the technical field of material chemistry.

Owner:HARBIN INST OF TECH

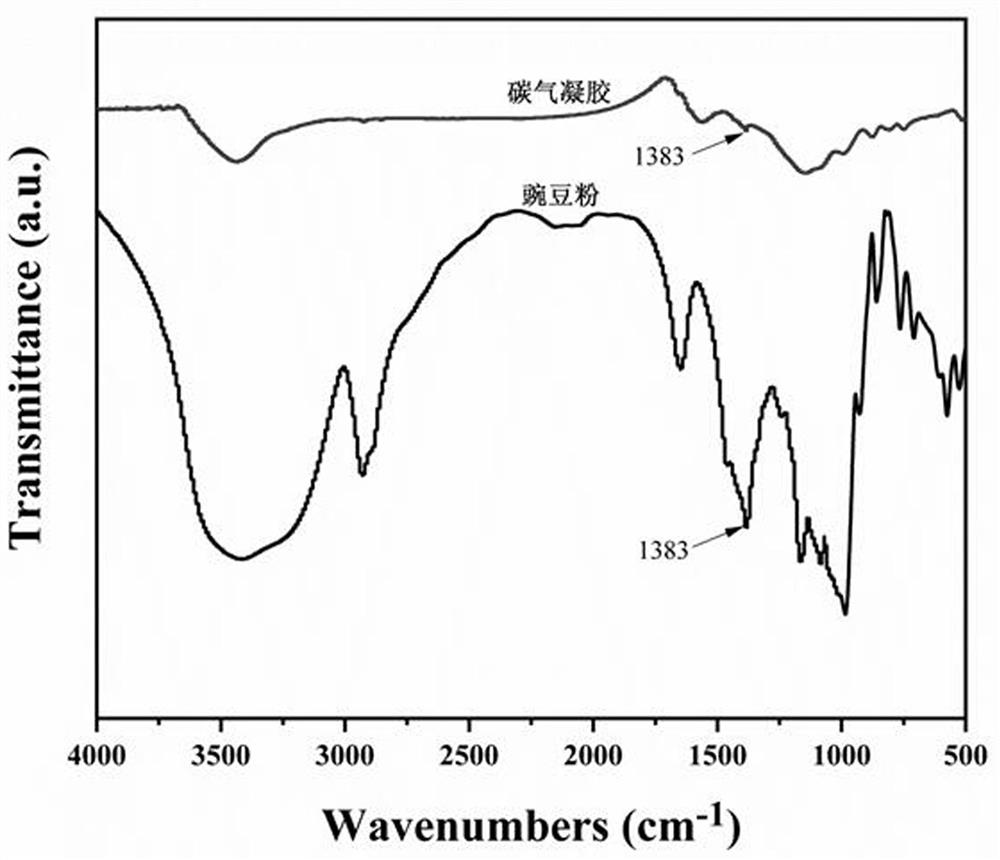

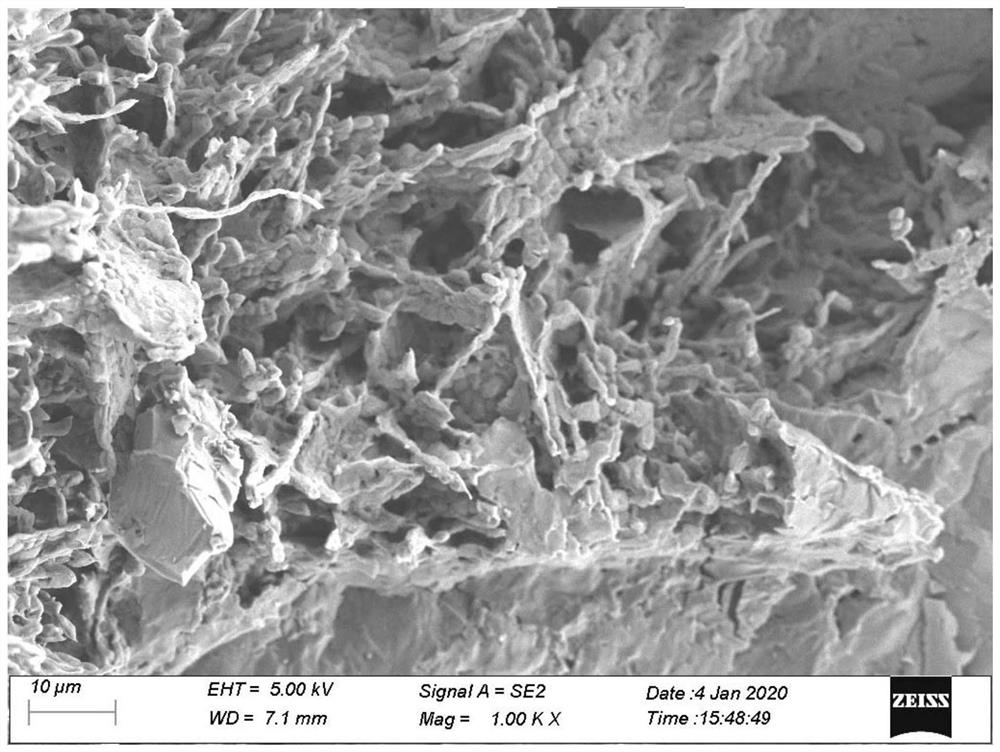

Boron nitride/pea meal double-heat-conduction-base carbon aerogel as well as preparation method and application thereof

InactiveCN113150746AIncrease added valueImprove adsorption capacityNitrogen compoundsCarbon preparation/purificationMetallurgyFreeze-drying

The invention relates to a boron nitride / pea meal double-heat-conduction-base carbon aerogel. According to the invention, boron nitride, pea meal and a cross-linking agent are used as raw materials, the boron nitride is firstly prepared into modified two-dimensional nano lamellar boron nitride, then the modified two-dimensional nano lamellar boron nitride, the pea meal and the cross-linking agent are subjected to a water bath curing reaction, freeze drying and low-temperature calcination. The preparation method comprises the following steps: 1) preparing modified two-dimensional nano lamellar boron nitride; and (2) preparing the boron nitride / pea meal double-heat-conduction-base carbon aerogel. According to the application of the product as a phase change material, the boron nitride / pea meal double-heat-conduction-base carbon aerogel composite phase change material is obtained by compounding with polyethylene glycol, the phase change temperature is 39-55 DEG C, the phase change latent heat is 168-171J / g, and the heat conductivity coefficient is 0.46-0.58 W / (m.K). The method has the following advantages: 1, the raw materials are low in cost, easy to obtain and environment-friendly; 2, the heat conductivity coefficient is improved by 187%; 2, the leakage problem is avoided; and 3, the phase change latent heat and the thermal stability are high;.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Heat conduction enhanced MOFs (metal-organic frameworks) PCM (phase change material) and preparation method thereof

InactiveCN108997975AHigh heat storage densityImproved thermal cycling stabilityChemical industryHeat-exchange elementsMetal-organic frameworkVolumetric Mass Density

The invention provides a heat conduction enhanced MOFs (metal-organic frameworks) PCM (phase change material). The heat conduction enhanced MOFs PCM is prepared from an organic PCM containing heat conduction enhanced nano-particles as a core material and a MOFs material as a wall material. A preparation method of the heat conduction enhanced MOFs PCM comprises the following steps: 1) a process ofemulsifying the organic PCM; 2) a process of adsorbing the organic PCM containing the nano-particles with the MOFs material under a vacuum condition; and 3) a process of taking out a product obtainedafter vacuum adsorption. The heat conduction enhanced MOFs PCM has the advantages that 1) the heat response speed is high, i.e. the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and 4) raw materials are safe, non-toxic and non-corrosive, and the technical characteristics of being simple in preparation process and low in cost areachieved. Therefore, the heat conduction enhanced MOFs PCM is higher in heat conductivity and stability, the using ratio of energy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

Oxidation-resistant high energy density magnesium alloy for 500-600 degrees and process thereof

The invention discloses oxidation-resistant high energy density magnesium alloy for 500-600 degrees and a process thereof. The alloy comprises the following components by weight: Li: 2.0-3.0%, Al: 5.0-6.0%, In: 1.0-1.2%, Zn: 2.5-2.8%, B: 0.10.2%, Sn: 1.0-1.2%, Bi: 5.0-6.0%, Sb: 2.4-2.5% and the balance magnesium. A multi-element near-eutectic alloy solution for the oxidation-resistant high energydensity magnesium alloy for 500-600 degrees in the field of alloy energy storage is provided. Alloy melt has excellent oxidation resistance, thermal cycle performance and thermophysical performance. The alloy can effectively overcome the defect of innovation shortage of novel alloy materials in the field of energy storage, and is expected to obtain great market value while solving industrial problems.

Owner:GUANGZHOU YUZHI TECH CO LTD

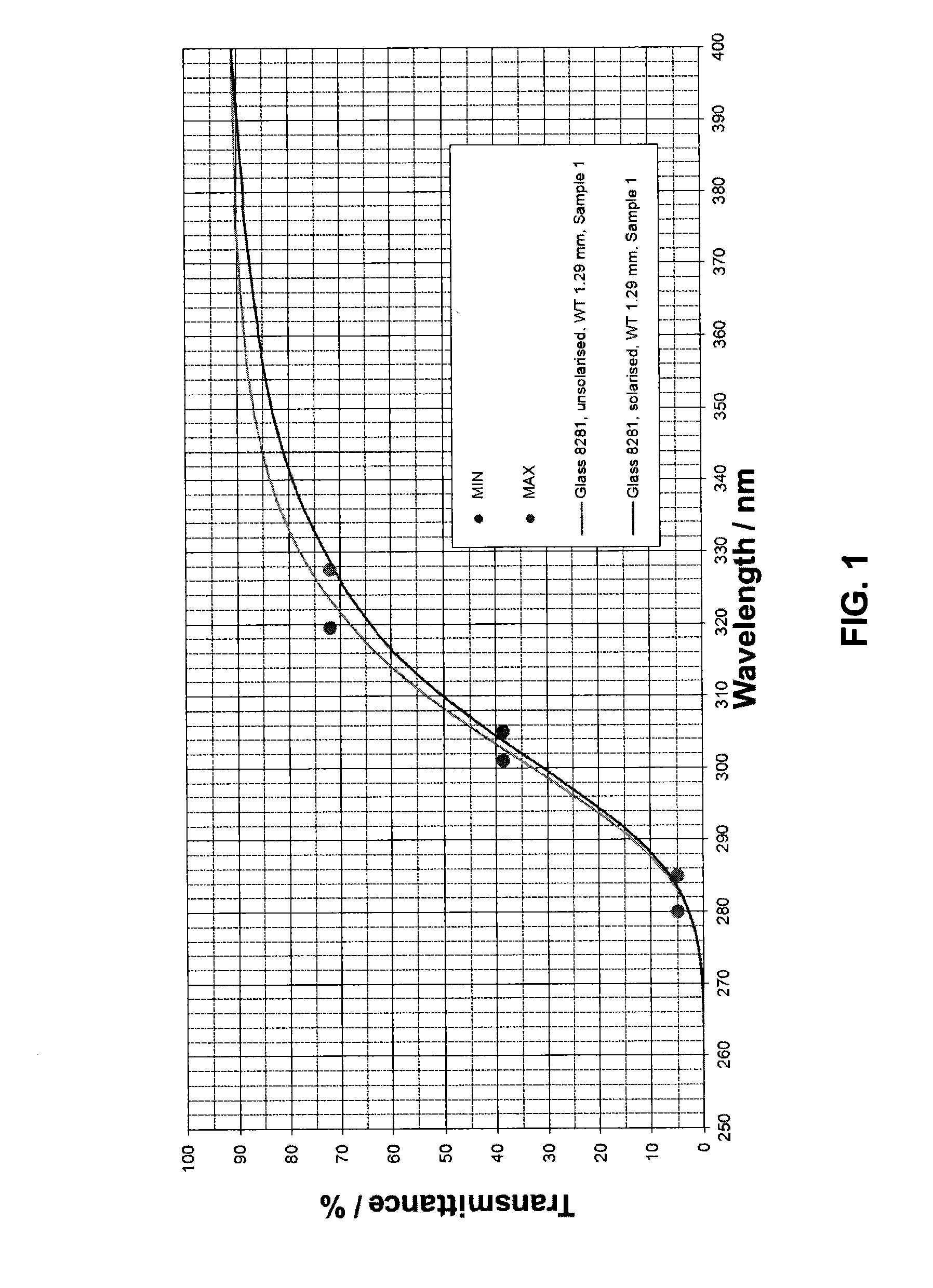

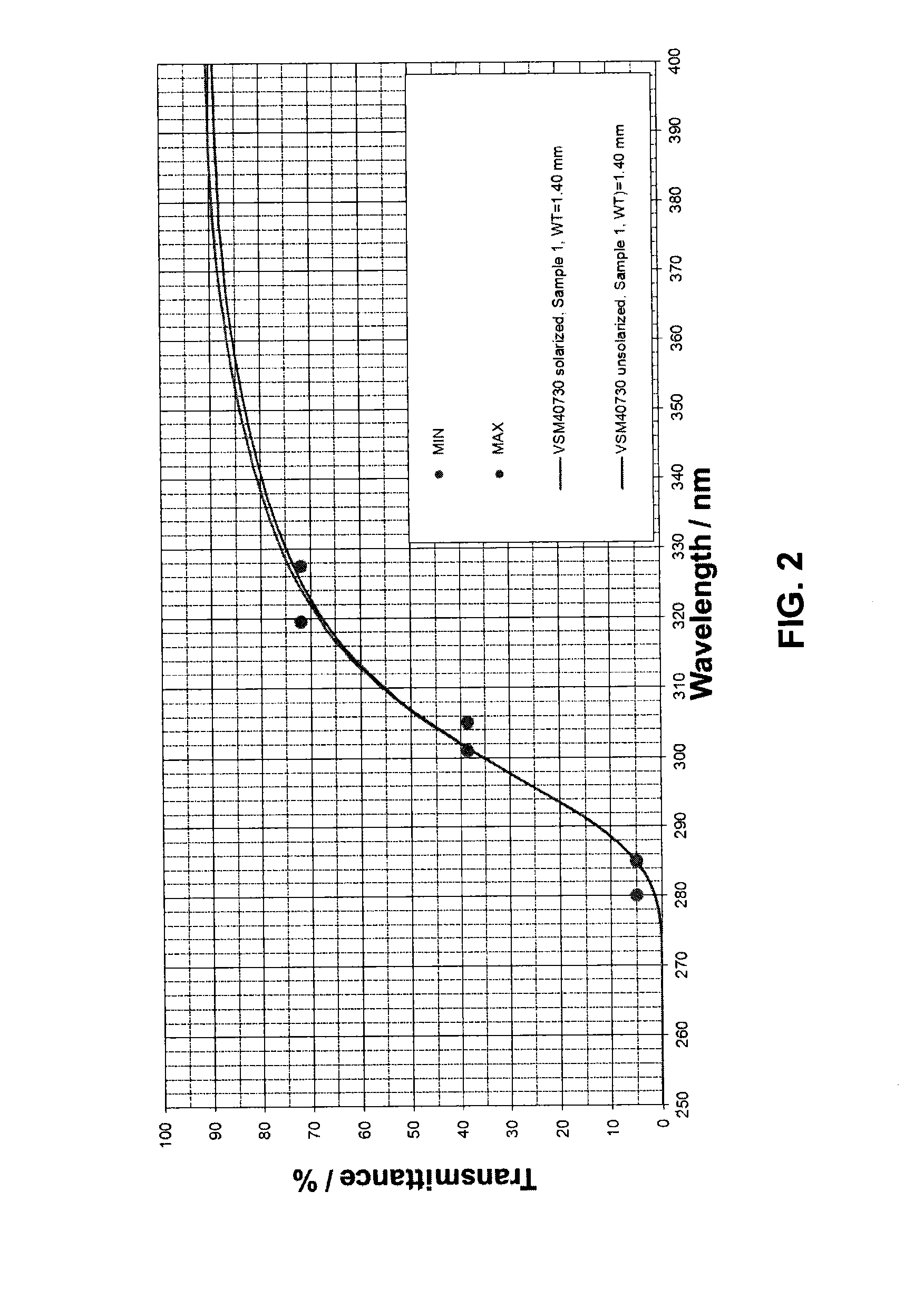

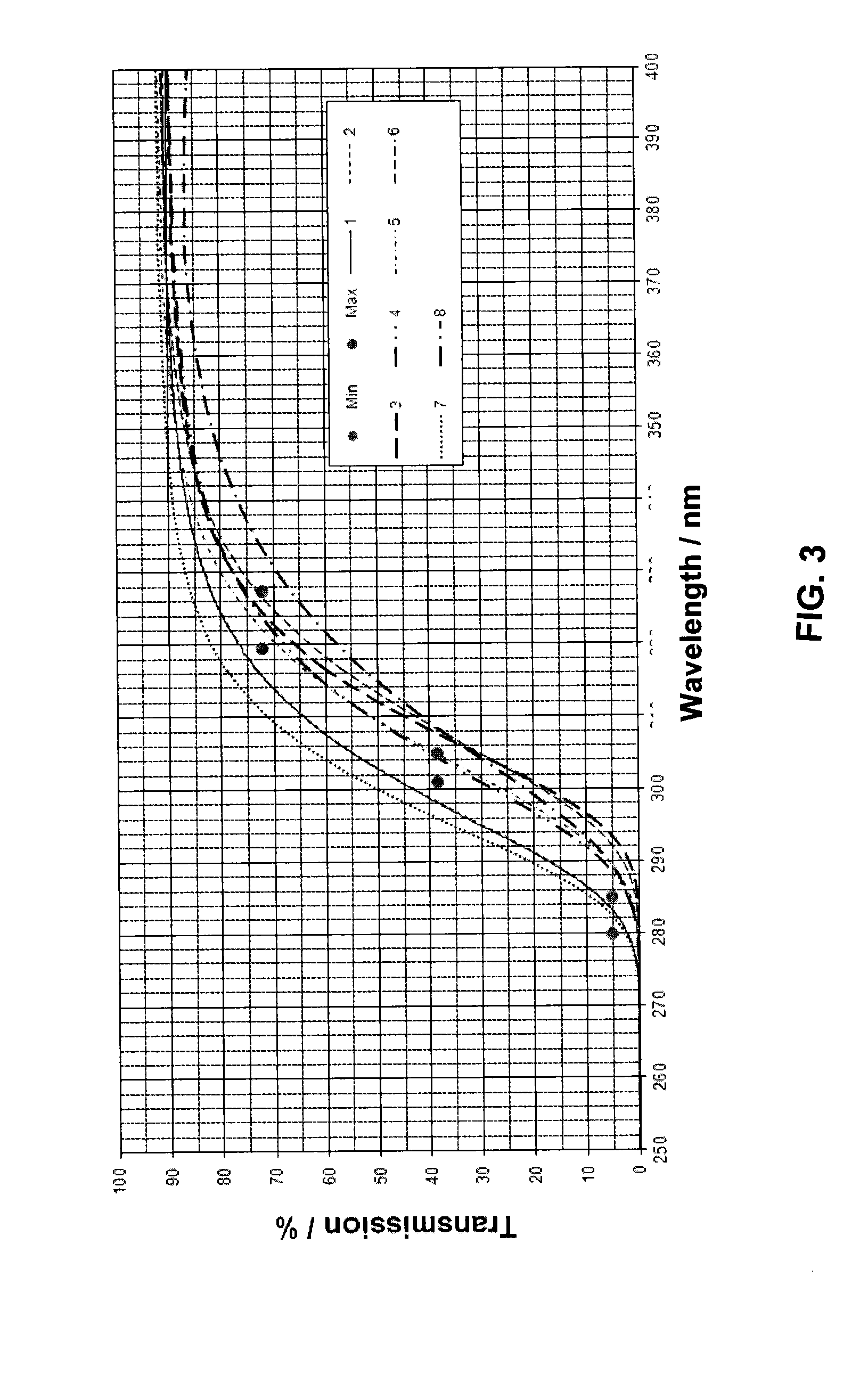

Solarization-resistant borosilicate glass and use thereof for production of glass tubes and lamps and in irradiation units

ActiveUS20140117294A1Improve sun resistanceReduction factorGlobesSpectral modifiersSilicate glassIrradiation

A borosilicate glass is provided that has high solarization resistance and a defined position of the UV edge. The borosilicate glass includes the following constituents, in percent by weight based on oxide, of:SiO2 65-85%;B2O3 7-20%;Al2O3 0-7%;Li2O 0-2%;Na2O 0-8%;K2O 0-12%;BaO 0-5%;CaO 0-2%;MgO 0-2%;ZnO 0-2%;TiO2 0.05-0.4%;MoO3 0.025-0.3%; andV2O5 0.001-0.01%.

Owner:SCHOTT AG

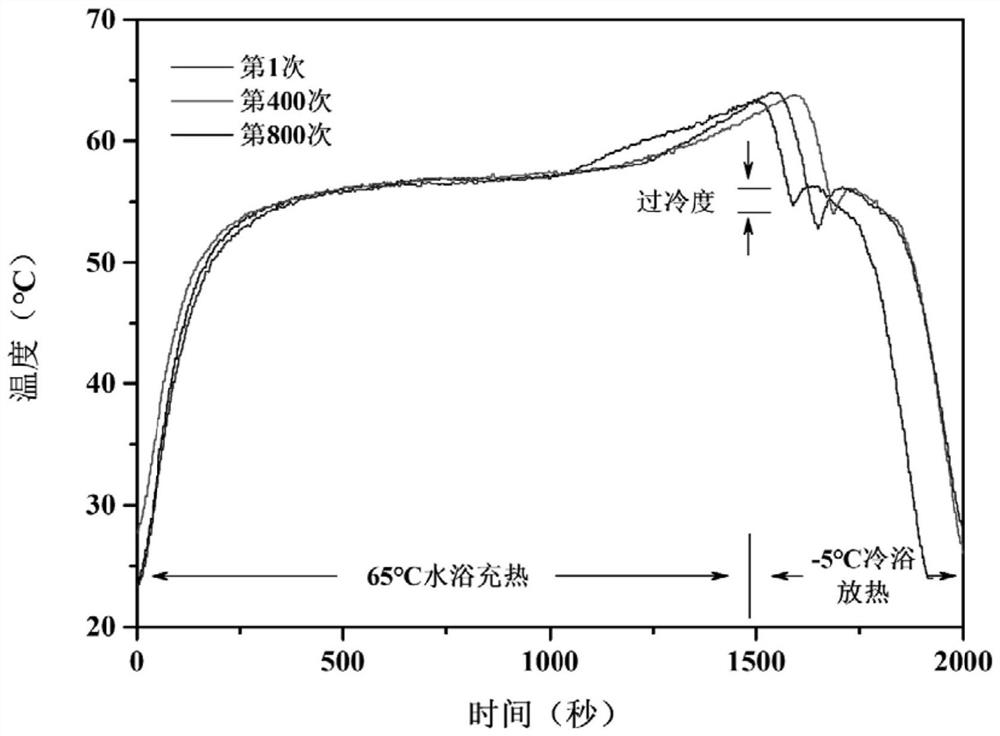

Nano-modified sodium acetate trihydrate phase change heat storage material and preparation method thereof

ActiveCN111621264AReduced nucleation workHigh viscosityHeat-exchange elementsCelluloseChemical reaction

The invention discloses a nano-modified sodium acetate trihydrate phase change heat storage material and a preparation method thereof. The material is composed of, by mass, 90-99 parts of sodium acetate trihydrate, 0.5-2 parts of nano-particles, 0.5-2.5 parts of cellulose and 5-10 parts of graphite, wherein the nano-particles are at least one or a composition of neutral particles and polar particles, the nano-particles do not chemically react with water, and the average particle size of the nano-particles is smaller than 50nm. The phase change temperature is 54-58 DEG C, the degree of supercooling is less than 4 DEG C, and the latent heat of phase change is more than 200kJ / kg. The nano-particles are adopted for modification, the thermal cycle stability of the sodium acetate trihydrate phase change material is improved, and no thermal performance attenuation exists after the material is subjected to 800 times or more of heat charging and discharging cycle tests. The phase change material is green and environmentally friendly, the preparation method is simple, batch production is easy to achieve, stable access of heat is facilitated, and the heat conversion efficiency is improved.

Owner:NARI TECH CO LTD

Heat storage concrete and preparation method thereof

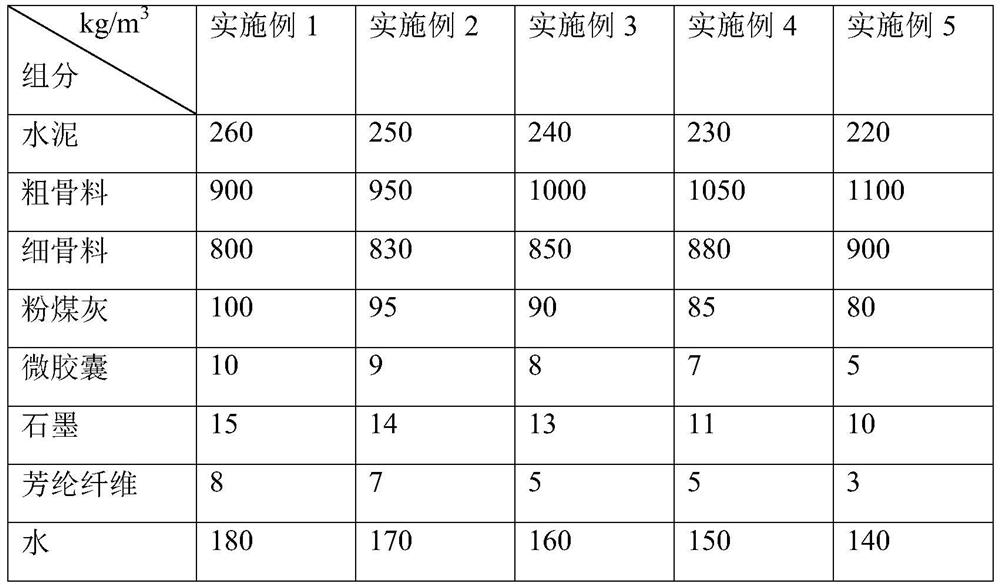

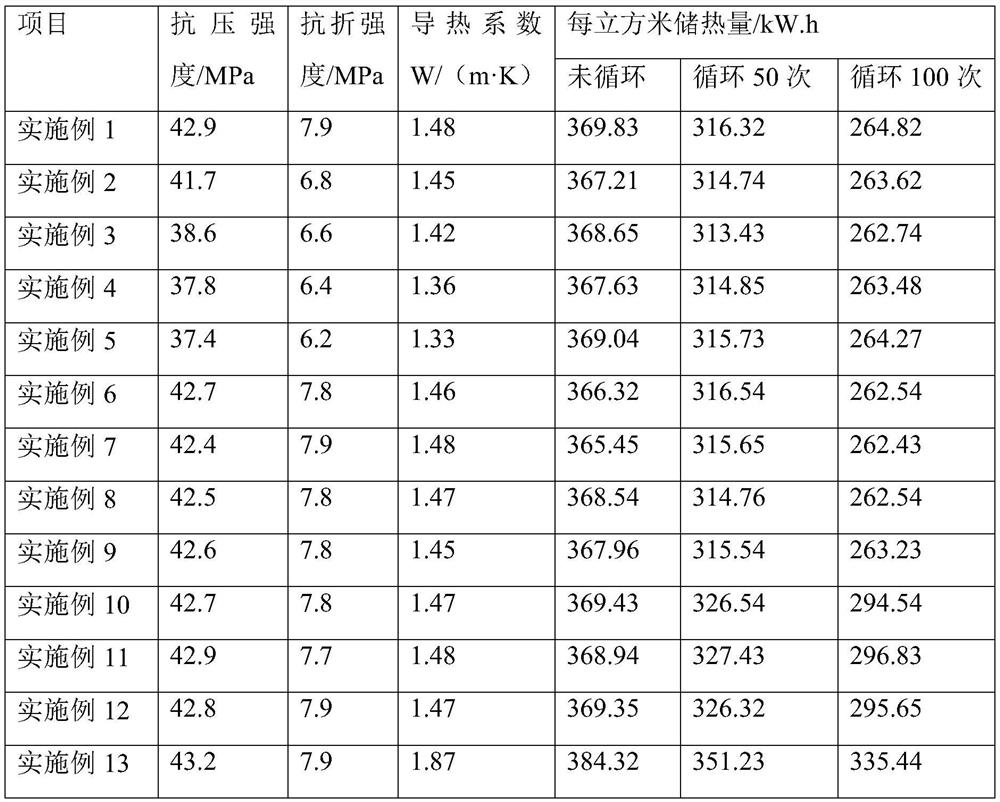

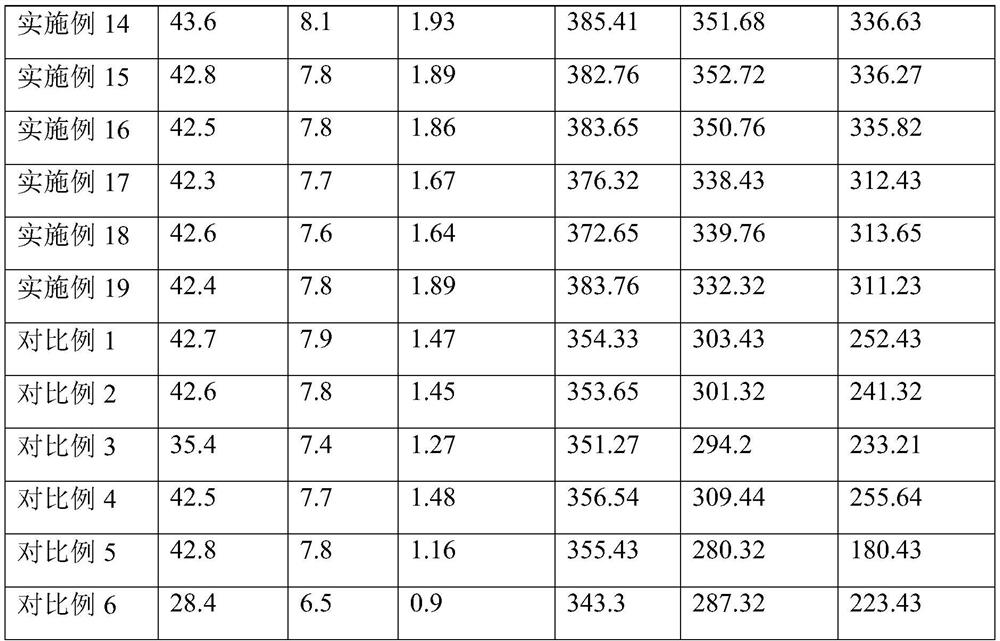

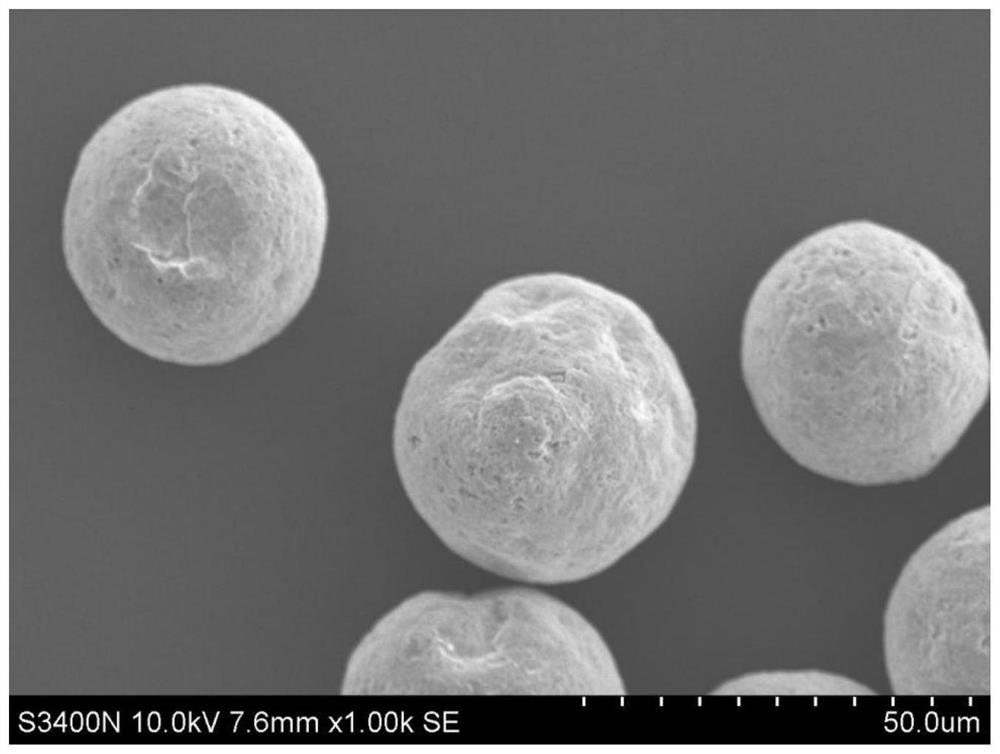

ActiveCN113372065AReduce the possibility of exudationIncreased permeation path lengthSolid waste managementSilane couplingBuilding material

The invention relates to the field of building materials, and particularly discloses heat storage concrete and a preparation method thereof. The heat storage concrete is prepared from the following components in parts by weight: 220 to 260 parts of cement, 900 to 1100 parts of coarse aggregate, 800 to 900 parts of fine aggregate, 140 to 180 parts of water, 4.8 to 8 parts of additive, 80 to 100 parts of fly ash, 3 to 8 parts of aramid fiber, 10 to 15 parts of graphite and 5 to 10 parts of microcapsule. A phase change core material of the microcapsule comprises paraffin, a wall material of the microcapsule comprises silicon dioxide, and the mass ratio of the phase change core material to the wall material is (3-5):10; and the paraffin is prepared from the following components in parts by weight: 2-6 parts of graphite oxide, 5-10 parts of water, 0.2-0.4 part of a silane coupling agent and 5-10 parts of paraffin. The heat storage concrete has the advantages of being good in heat storage performance, still high in heat storage and release efficiency after multiple cycles, good in durability, long in service life and high in heat cycle stability.

Owner:北京民佳混凝土有限公司

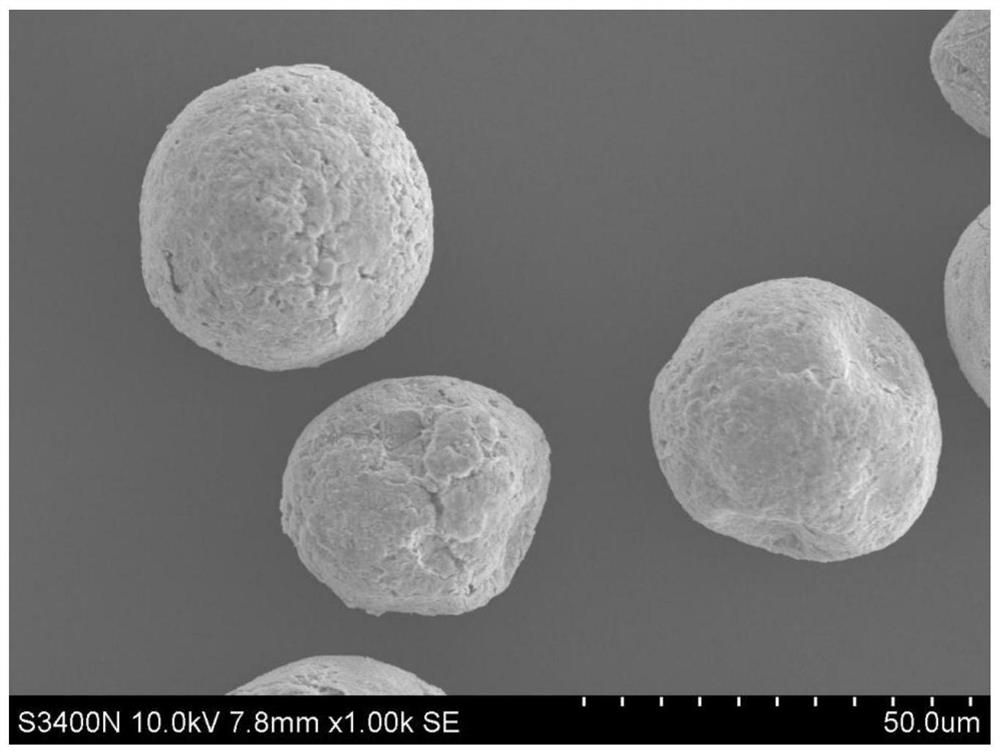

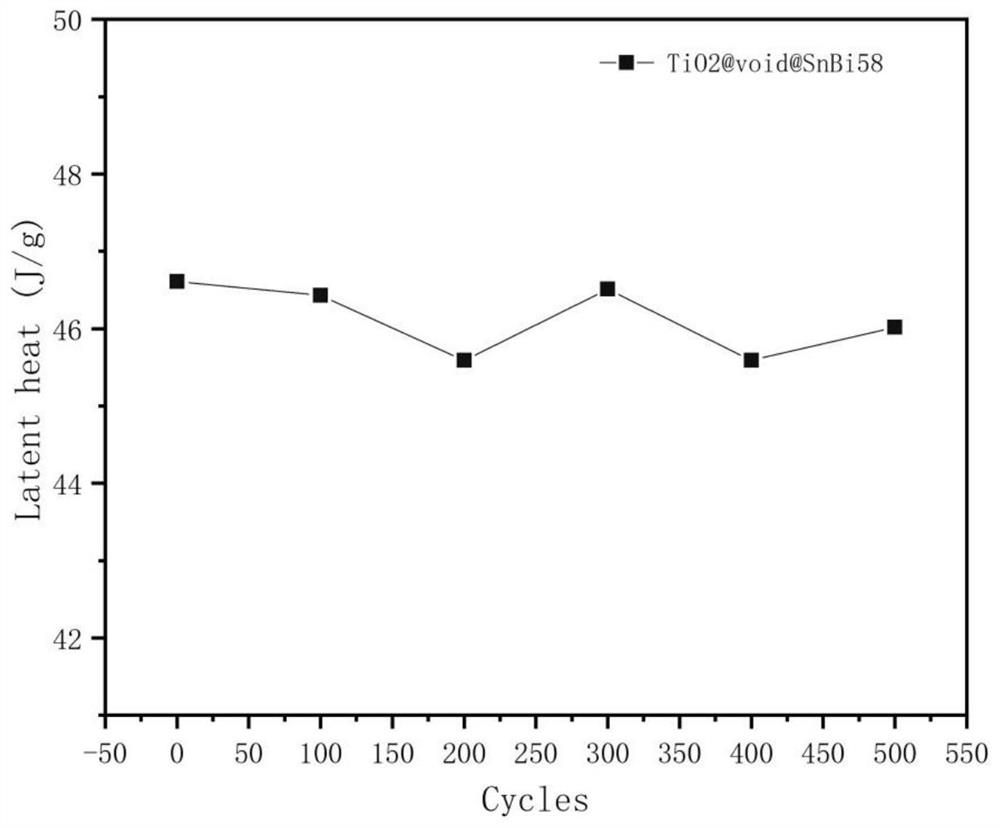

Metal phase change microcapsule with thermal expansion cavity and preparation method of metal phase change microcapsule

ActiveCN112473579ASolve the ruptureBreak through the bottleneck of preparation technologyHeat-exchange elementsMicroballoon preparationThermal electronMetal particle

The invention discloses a metal phase change microcapsule with a thermal expansion cavity, the microcapsule takes metal particles as a core material, the core material is coated with a porous inorganic wall material layer, and a layer of thermal expansion cavity is arranged between the core material and the porous inorganic wall material layer; the thermal expansion cavity and the porous inorganicwall material layer are subjected to thermal treatment through an organic layer and an inorganic layer which are coated outside the core material, and organic matters in the organic layer are decomposed into gas which escapes from the inorganic layer. The metal phase change microcapsule provided by the invention provides a thermal expansion space for metal, solves the problem of microcapsule breakage caused by metal thermal expansion from the source, greatly improves the thermal cycle stability, breaks through the technical bottleneck of metal microcapsule preparation, has good heat conduction, energy storage and temperature adjustment functions and the like, and can be widely applied to the fields of heat storage, electronic equipment heat dissipation and the like.

Owner:NINGBO UNIV

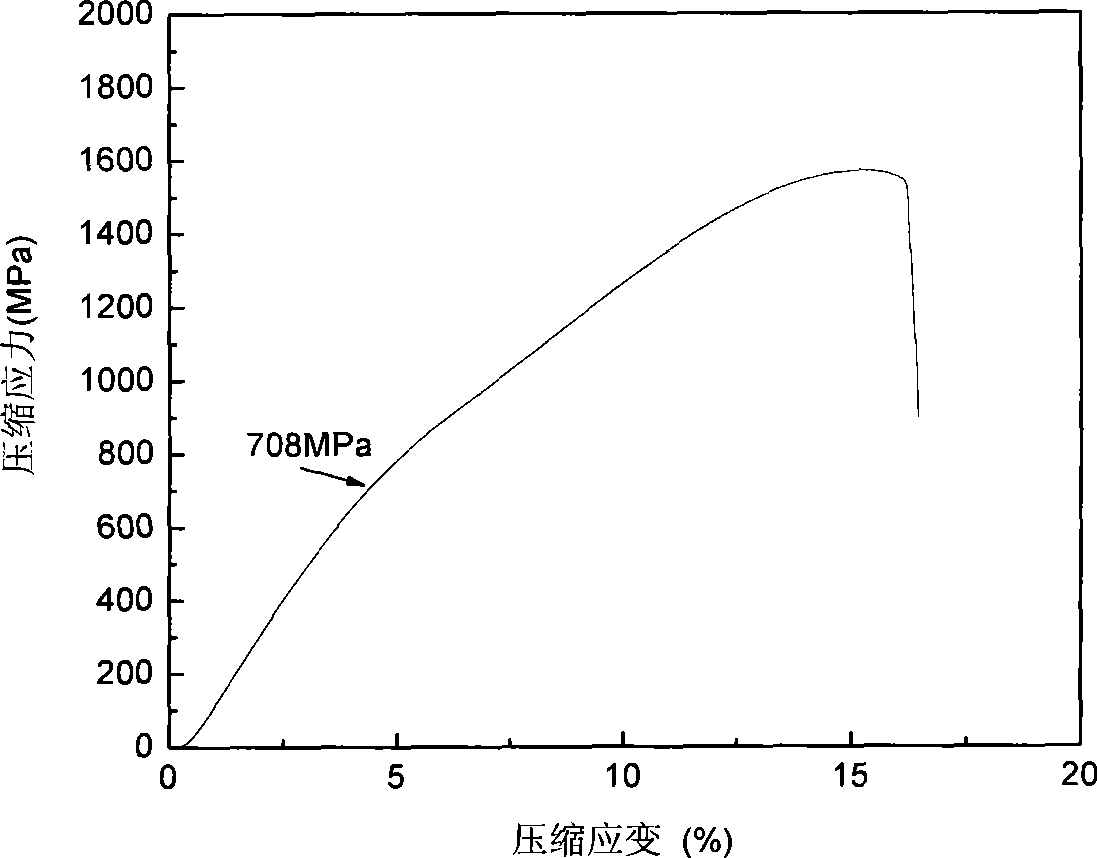

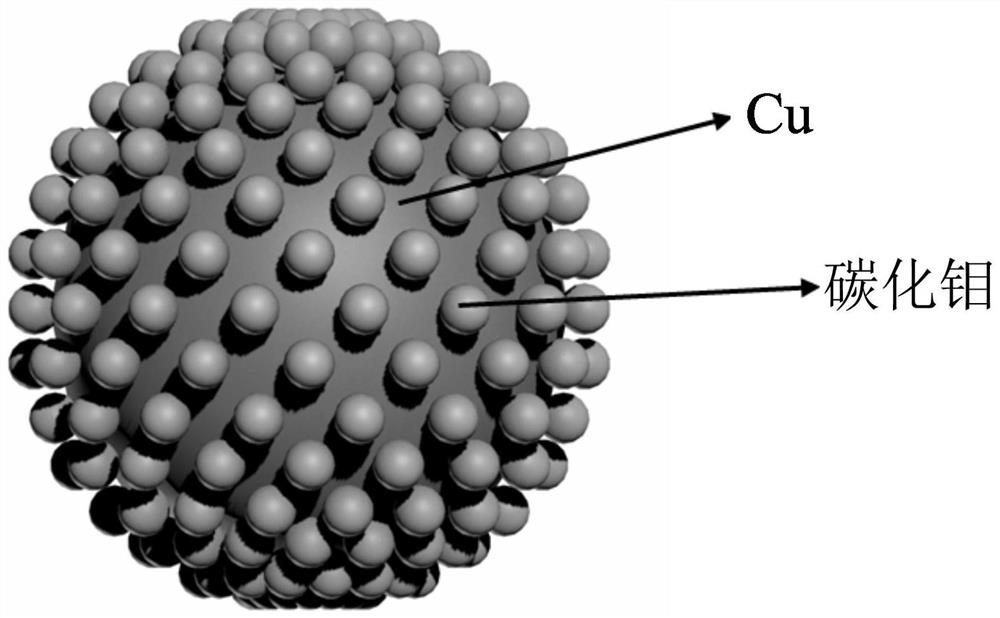

Soldering paste and preparation method thereof, device and welding method

ActiveCN112846563AHigh hardnessHigh melting pointWelding/cutting media/materialsSoldering mediaMolybdenum carbideCopper

The invention discloses a soldering paste. The soldering paste is prepared from copper powder, molybdenum carbide, a diluent, a dispersing agent and a binder, the molybdenum carbide is adsorbed on the surface of the copper powder, the molybdenum carbide is in a nanometer level, the copper powder is in any one or more of the nanometer level and the micrometer level, and the particle size of the copper powder is larger than that of the molybdenum carbide. The invention further discloses a preparation method of the soldering paste. The invention further discloses a device. The device comprises a substrate and a chip, and the substrate and the chip are welded through the soldering paste. The invention further discloses a welding method. The welding method comprises the following steps that the welding paste is applied between the substrate and the chip, and pre-sintering is carried out at the pre-sintering temperature of 65-180 DEG C for 5-120 seconds; and after presintering is finished, the temperature is immediately increased to the secondary sintering temperature for secondary sintering, the secondary sintering temperature ranges from 250 DEG C to 320 DEG C, and the secondary sintering time ranges from 5 minutes to 30 minutes.

Owner:SONGSHAN LAKE MATERIALS LAB +1

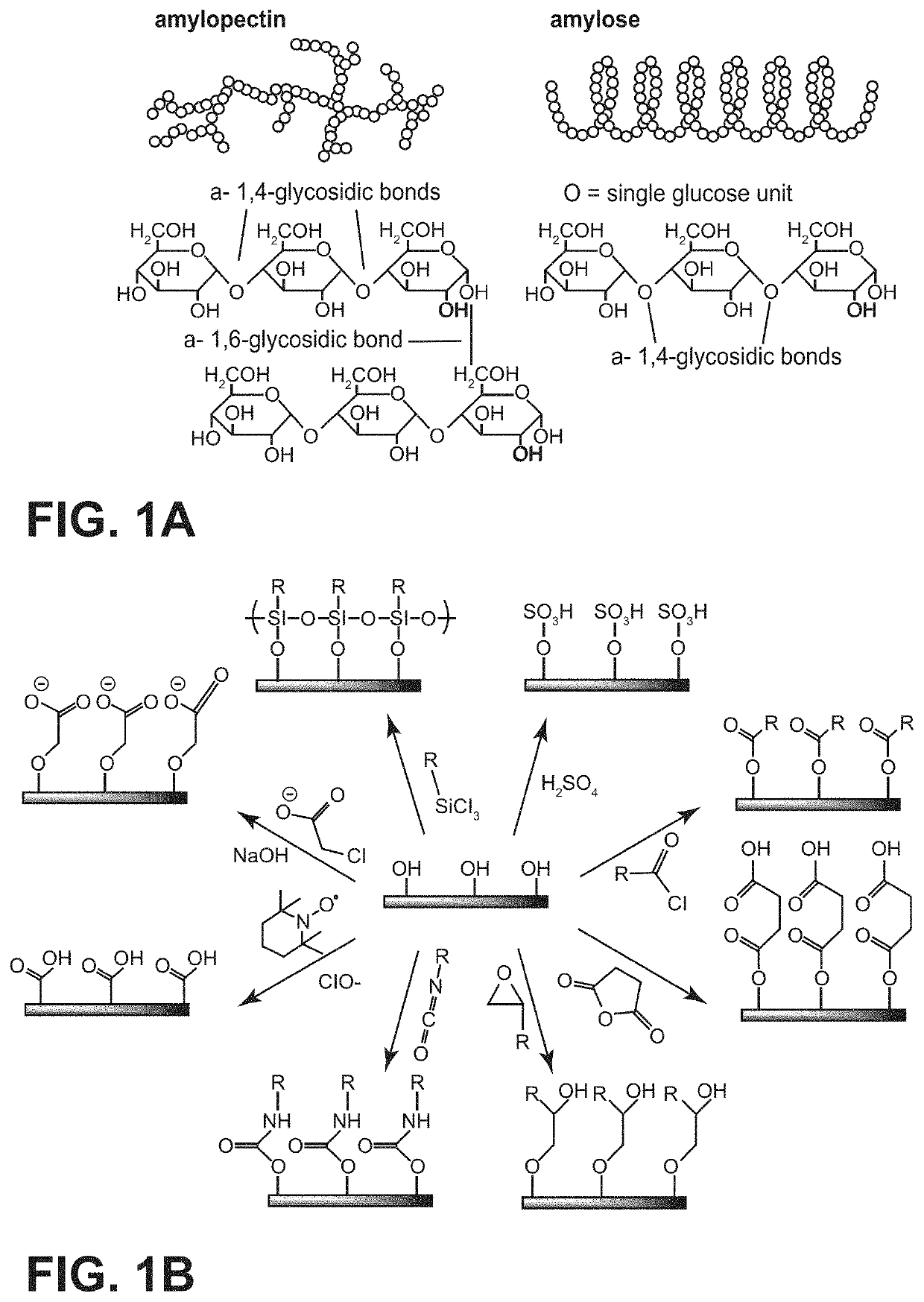

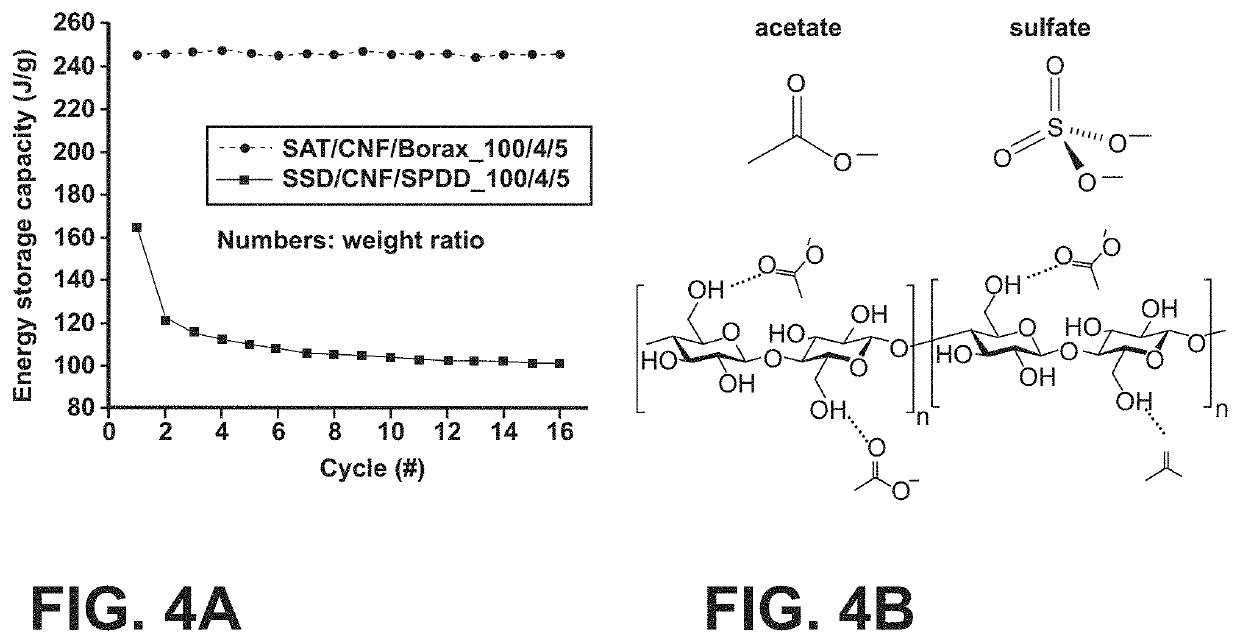

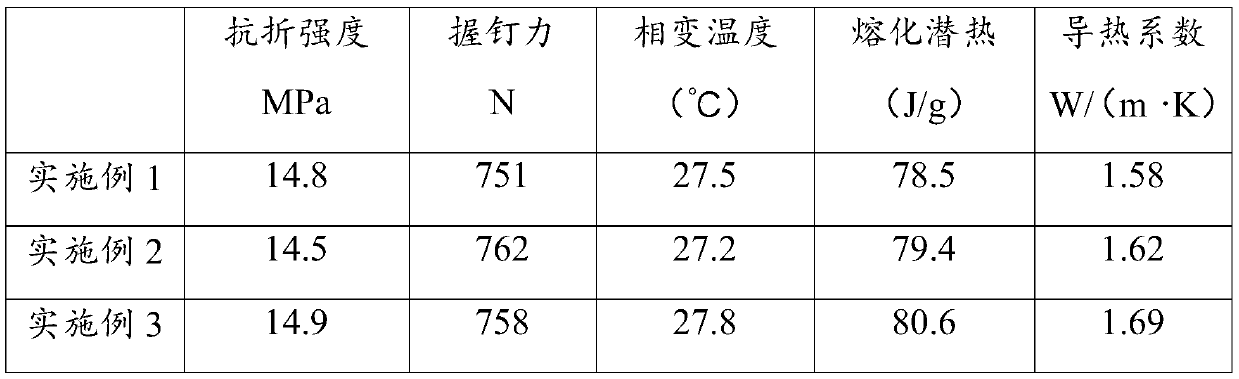

Stable salt hydrate-based thermal energy storage materials

ActiveUS20210340423A1Excellent thermal cycling stabilityHigh energy storage capacityHeat-exchange elementsChemistryLatent heat storage

A phase change material composition for latent heat storage is provided. In one embodiment, the phase change material includes a salt hydrate having a melting temperature (Tm) of from 1° C. to 100° C. as determined in accordance with ASTM E793. The phase change material further includes a stabilizing matrix including a polysaccharide selected from the group of a nanocellulose, a sulfonated polysaccharide, a starch, a glycogen, a chitin, and combinations thereof. A composite article including the phase change material composition is also provided.

Owner:UT BATTELLE LLC

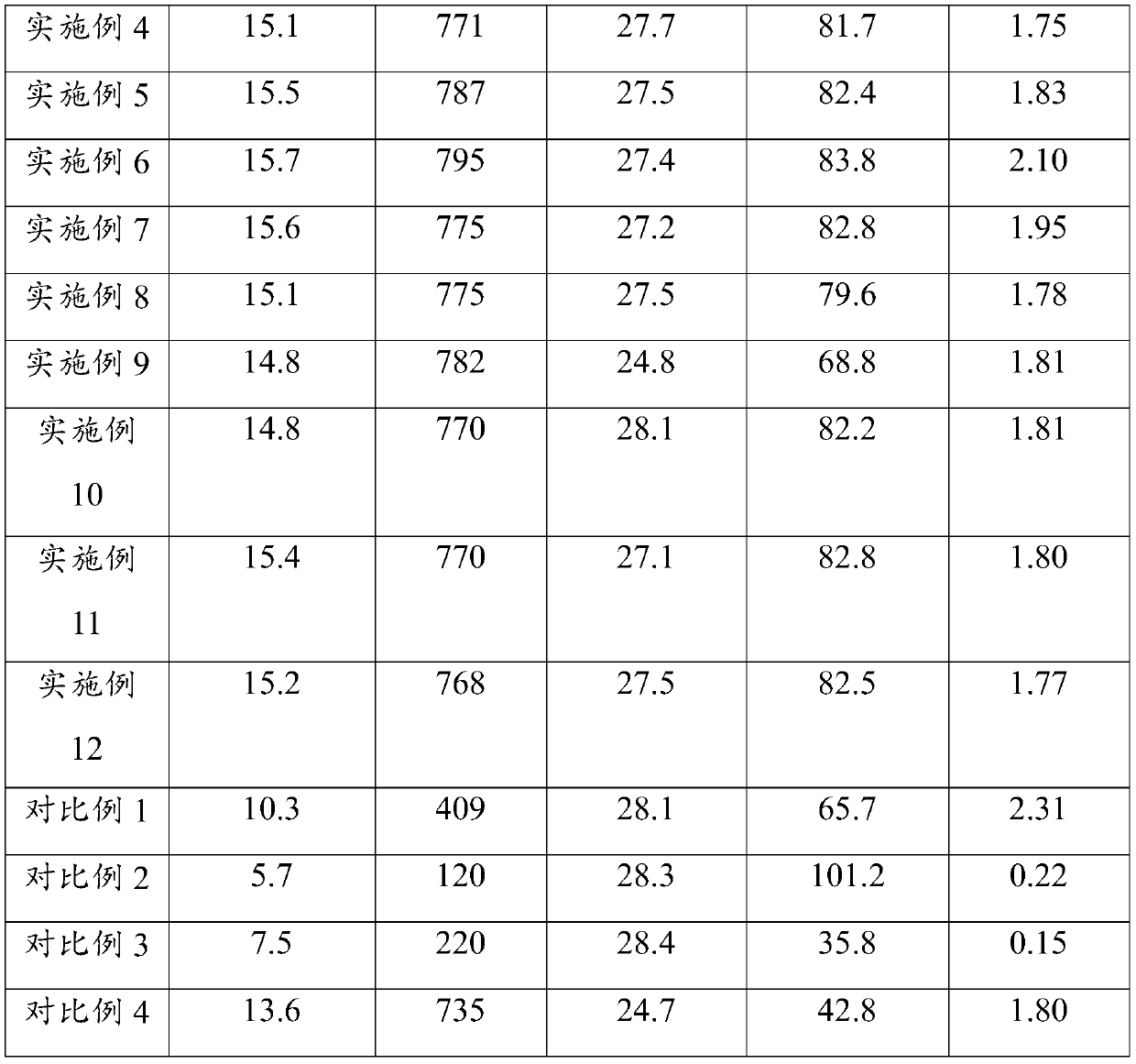

Phase-change thermal storage calcium silicate board and raw materials, preparation method and application thereof

InactiveCN110407554APrevent leakageEfficient energy conversionLaminationLamination apparatusCalcium in biologyEnvironmentally friendly

The invention relates to the field of non-metallic mineral materials, in particular to a phase-change thermal storage calcium silicate board and raw materials, a preparation method and application thereof. The raw materials of the phase-change thermal storage calcium silicate board comprise a component A and a component B. By weight, the component A includes 20-35 parts of silicon raw materials, 20-35 parts of calcium raw materials, 30-45 parts of organic phase-change materials, 1-5 parts of carbon materials, 5-15 parts of an inorganic fiber filler, 1-5 parts of wood fiber and 1-3 parts of a thickener; by weight, the component B includes 30-45 parts of silicon raw materials, 30-40 parts of calcium raw materials, 10-15 parts of an inorganic fiber filler, 5-10 parts of wood fiber and 1-3 parts of a thickener. When the raw materials are used for preparing the phase-change thermal storage calcium silicate board, leakage of the phase-change material is prevented, the mechanical properties,the heat conduction rate and the phase-change latent heat effect are significant, and the phase-change thermal storage calcium silicate board can be widely used in the field of buildings and interiordecoration and has the advantages of saving energy, being environmentally friendly, purifying air and improving the indoor environment.

Owner:梁泽雄

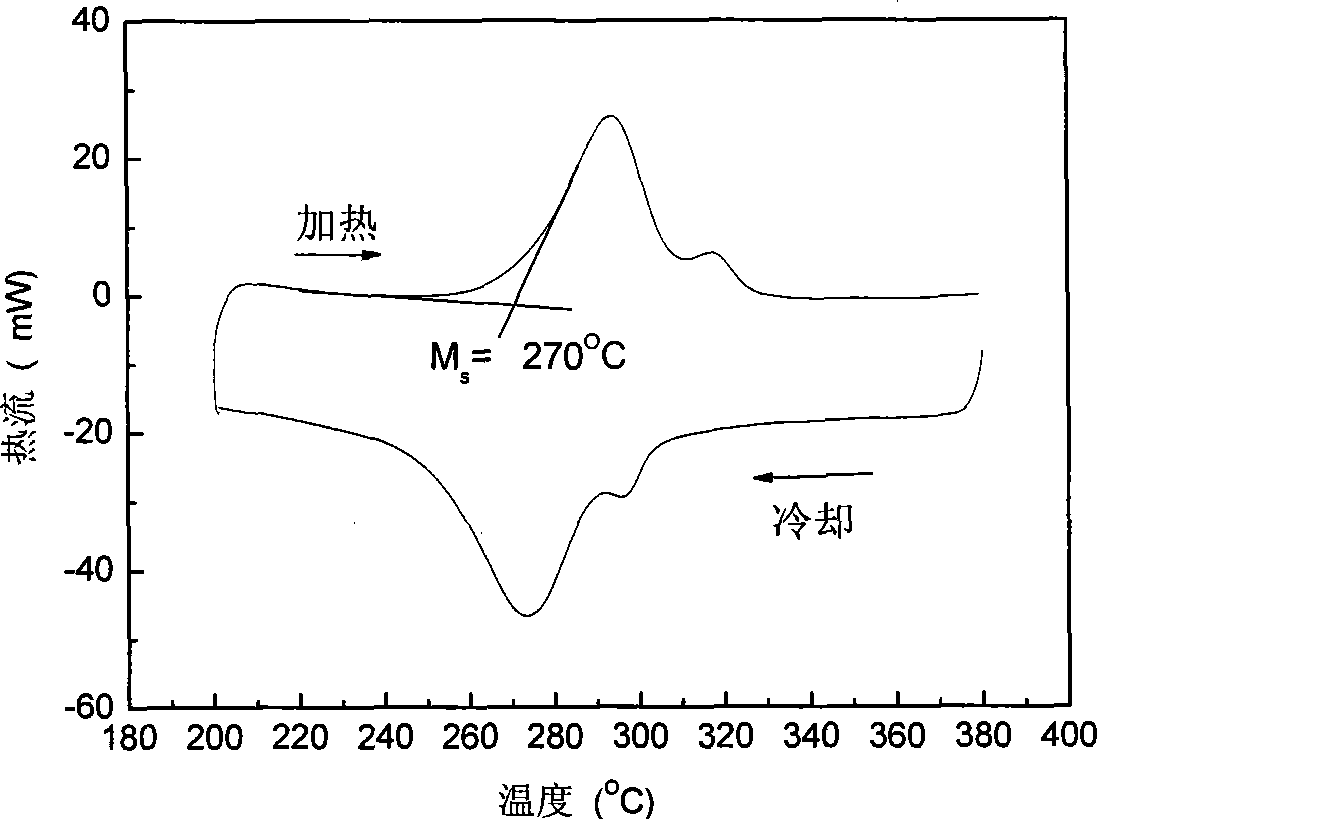

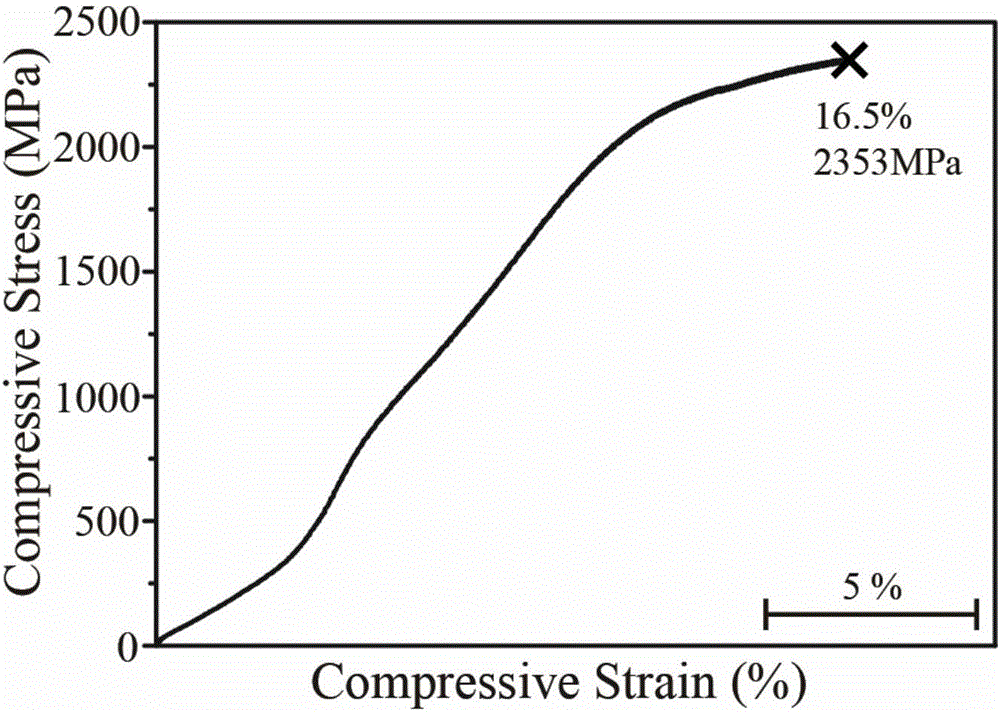

Cobalt-vanadium-silicon-gallium base high-temperature shape memory alloy

ActiveCN106521245AHigh martensitic transformation temperatureImproved thermal cycling stabilityShape-memory alloyIngot

The invention discloses a cobalt-vanadium-silicon-gallium base high-temperature shape memory alloy, and relates to an alloy. The cobalt-vanadium-silicon-gallium base high-temperature shape memory alloy comprises the following components according to atomic percentages: 60-70% of cobalt, 10-20% of vanadium, 15-25% of silicon, 2-8% of gallium, and 0-1% of one of gadolinium, dysprosium and tantalum. A preparation method comprises the following steps: all the raw materials are put in an arc smelting furnace for vacuumizing; then, argon is introduced for arc striking; a magnetic stirring switch is opened; the current is gradually increased to 250-350 A; after once smelting is finished, an obtained alloy ingot is overturned by a manipulator; the smelting is repeated by 4-5 times; and the prepared alloy ingot is machined as a needed shape by an electrospark cutting machine, is put in a quartz tube, is filled with argon after vacuumizing, is homogenized by 4-24 h at 1000-1200 DEG C, and is quenched by ice water to obtain the cobalt-vanadium-silicon-gallium base high-temperature shape memory alloy. The cobalt-vanadium-silicon-gallium base high-temperature shape memory alloy is excellent in comprehensive performance.

Owner:XIAMEN UNIV

Phase change energy storage material based on MOFs and preparation method thereof

InactiveCN108997974AHigh heat storage densityImproved thermal cycling stabilityHeat-exchange elementsVolumetric Mass DensityPhase change

The invention discloses a phase change energy storage material based on MOFs. The phase change energy storage material based on MOFs is formed by using an inorganic phase change material as a core material and a MOFs material as a wall material. A preparation method of the phase change energy storage material based on MOFs comprises the steps of 1) melting of the inorganic phase change material; 2) a process of using the MOFs material to adsorb the inorganic phase change material; and 3) a process of taking out a product after vacuum adsorption. The phase change energy storage material based on MOFs has the advantages that 1) the heat response speed is high and the heat conductivity is high; 2) the heat storage density is large; 3) the phase change material adsorption performance is good and the phase change material is uneasy to leak; and 4) raw materials are safe, nontoxic and non-corrosive, the preparation process is simple, and the cost is low. Therefore, the phase change energy storage material based on MOFs has the advantages that the heat conductivity and stability are better, the energy utilization efficiency is enhanced, and broad application prospect is realized.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

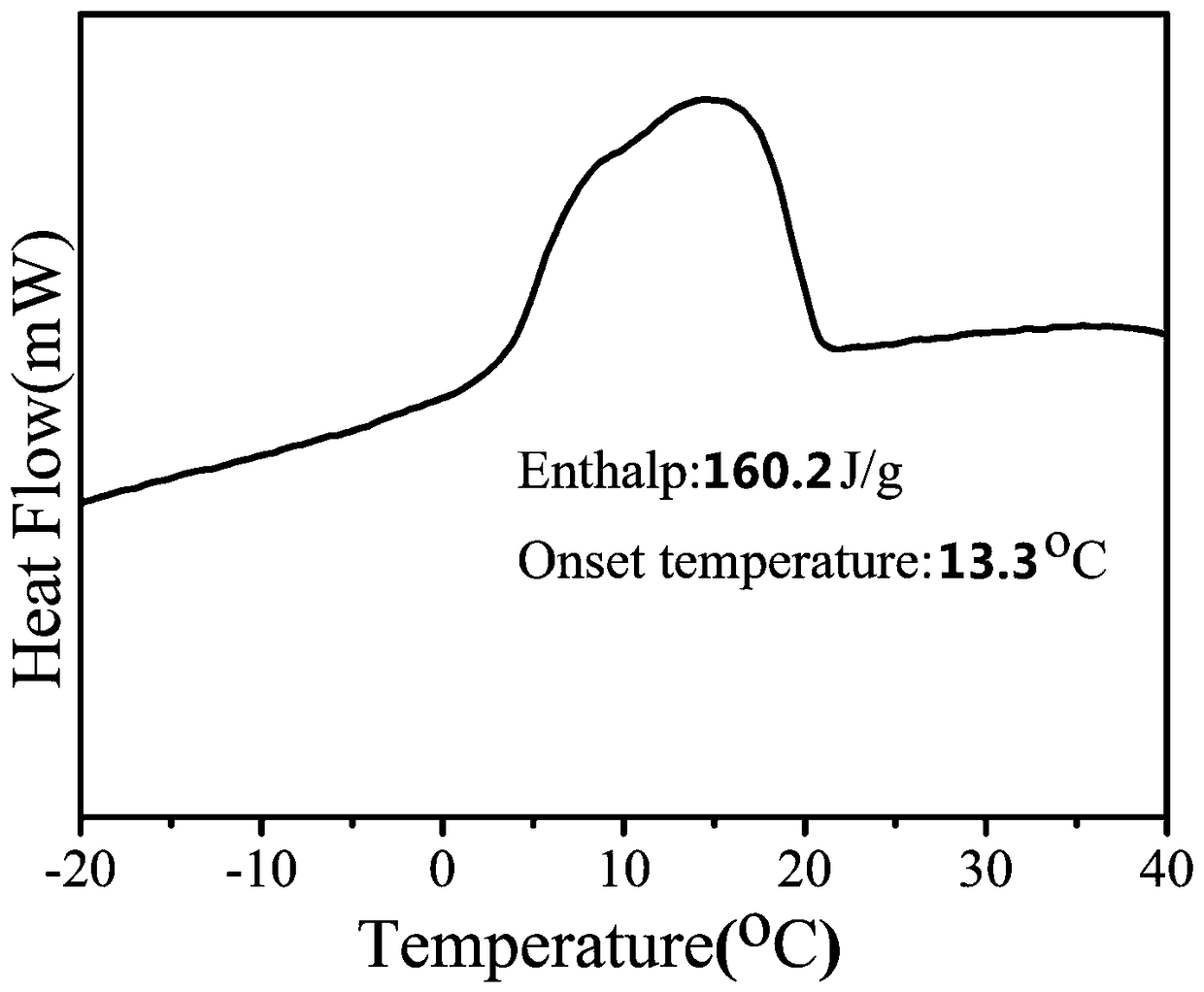

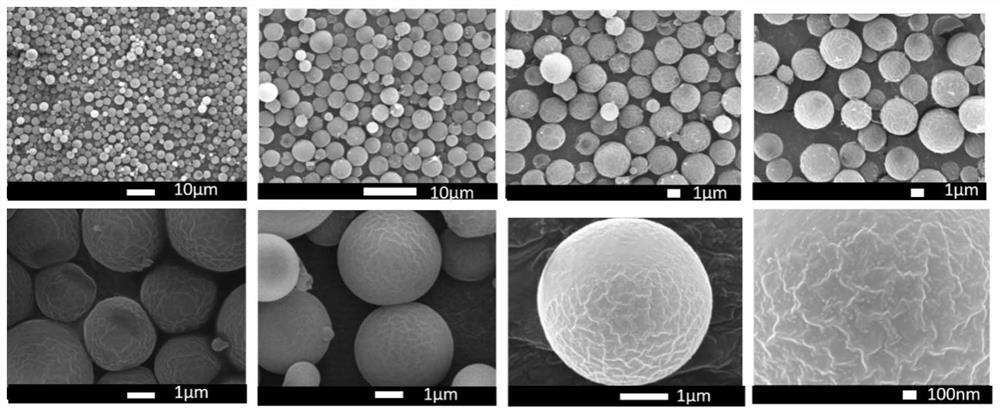

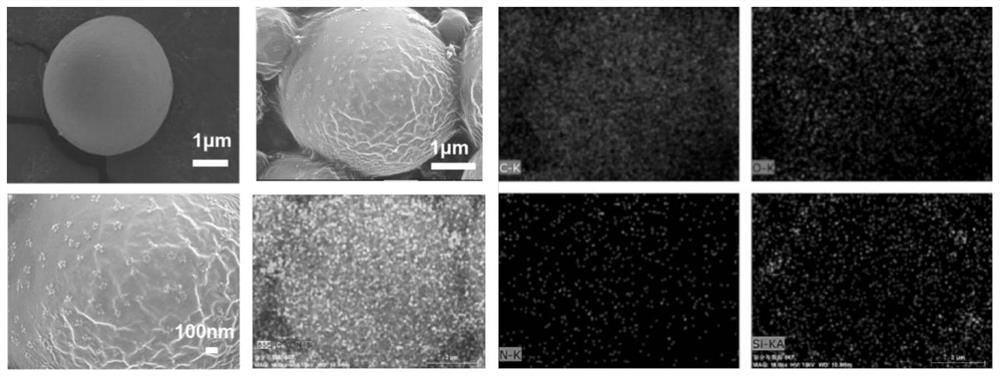

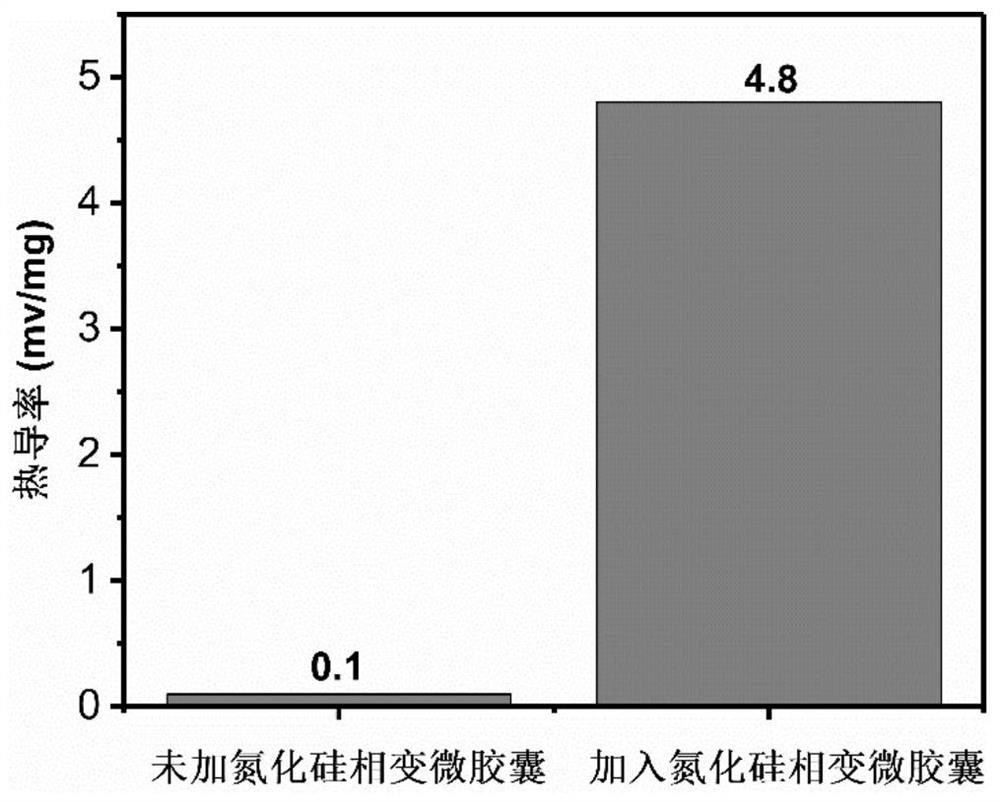

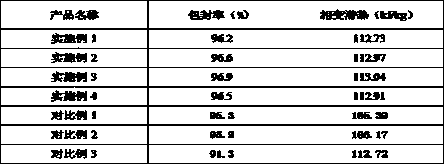

Organic phase-change microcapsule with high coating rate, high thermal conductivity and high thermal cycling stability, and preparation method thereof

ActiveCN113881404APrevent implosionIncrease coverageHeat-exchange elementsMicroballoon preparationPhase change enthalpyAlkane

The invention provides an organic phase-change microcapsule with high coating rate, high thermal conductivity and high thermal cycling stability, and a preparation method thereof, and relates to the field of phase-change microcapsule materials. According to the organic phase-change microcapsule, a dispersant aqueous solution, methyl methacrylate, a cross-linking agent, an initiator, modified silicon nitride and a C14-C25 straight-chain alkane are directly mixed uniformly, and are subjected to reaction polymerization, and by adjusting the reaction conditions and dosage and uniformly grafting the modified silicon nitride on the surface of the organic shell, the heat-conducting property of the organic shell is improved, and finally the purpose of improving the thermal property of the microcapsule is achieved. The heat conductivity of the prepared microcapsule reaches 4.80 W / m.K, the phase change enthalpy value is larger than or equal to 210 J / g, the phase change enthalpy value is larger than or equal to 200 J / g after 500 times of cold and heat cycles, the coating rate is 82.5% or above, and the microcapsule has the effects of being high in latent heat and good in heat cycle stability.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of spherical phase change microcapsule

InactiveCN108410429AIncrease heat transfer areaPrevent leakageHeat-exchange elementsWater bathsFiltration

The invention provides a preparation method of a spherical phase change microcapsule. The preparation method includes the steps: (1) uniformly mixing n-dodecanol, beewax, polyethylene glycol, melissicacid, lauric acid, cationic modified styrene, acrylonitrile, acrylic acid and co-emulsifiers to obtain solution A; (2) mixing and stirring 2,2'-azobis[2-methylpropionamidine] dihydrochloride, emulsifiers and deionized water to obtain solution B; (3) adding the solution A into the solution B to perform pre-emulsification; (4) transferring the solution into an ultrasonic cell crusher to perform ultrasonic dispersion; (5) transferring the solution into a three-necked flask with a reflux condensing tube, a mechanical stirrer and a thermometer, heating the solution and performing thermostatic water-bath reaction; (6) naturally cooling the solution to room temperature and adding ethanol solution containing 2wt% calcium chloride to perform demulsification and suction filtration; (7) sequentiallywashing a product with ethanol solution and distilled water and drying the product to obtain the spherical phase change microcapsule. The spherical phase change microcapsule prepared by the method has quite high encapsulation efficiency and is high in phase change latent heat and excellent in energy-saving effect.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

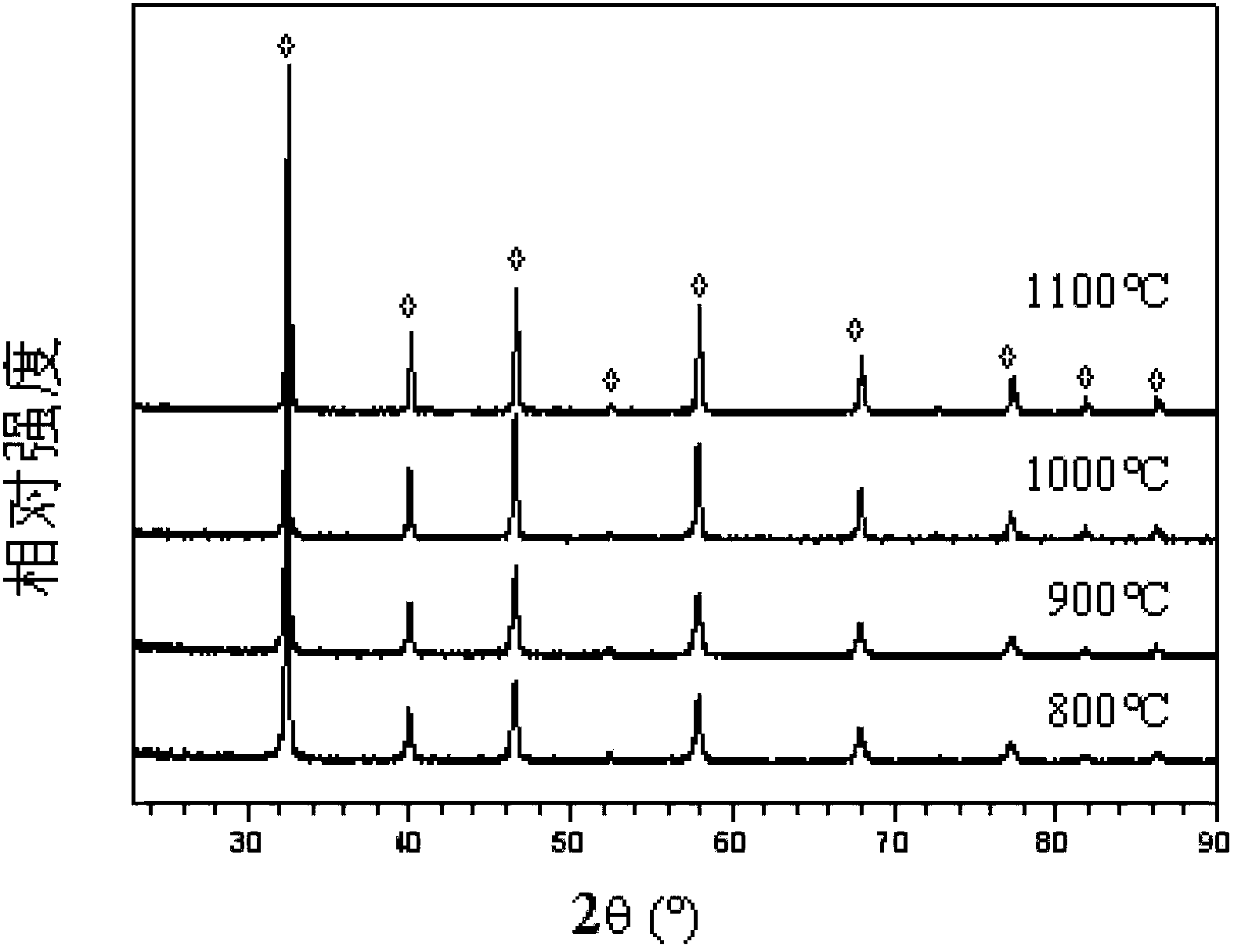

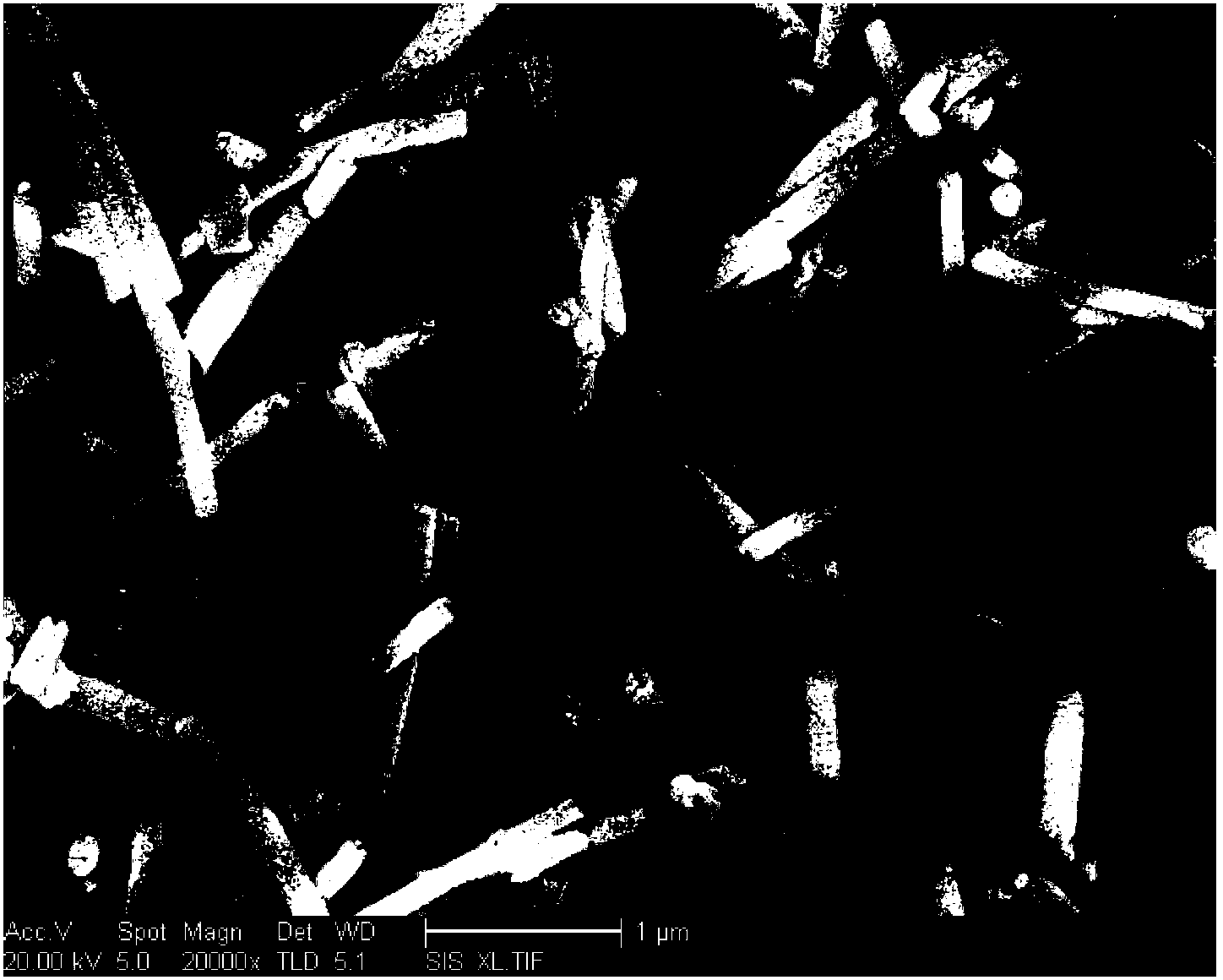

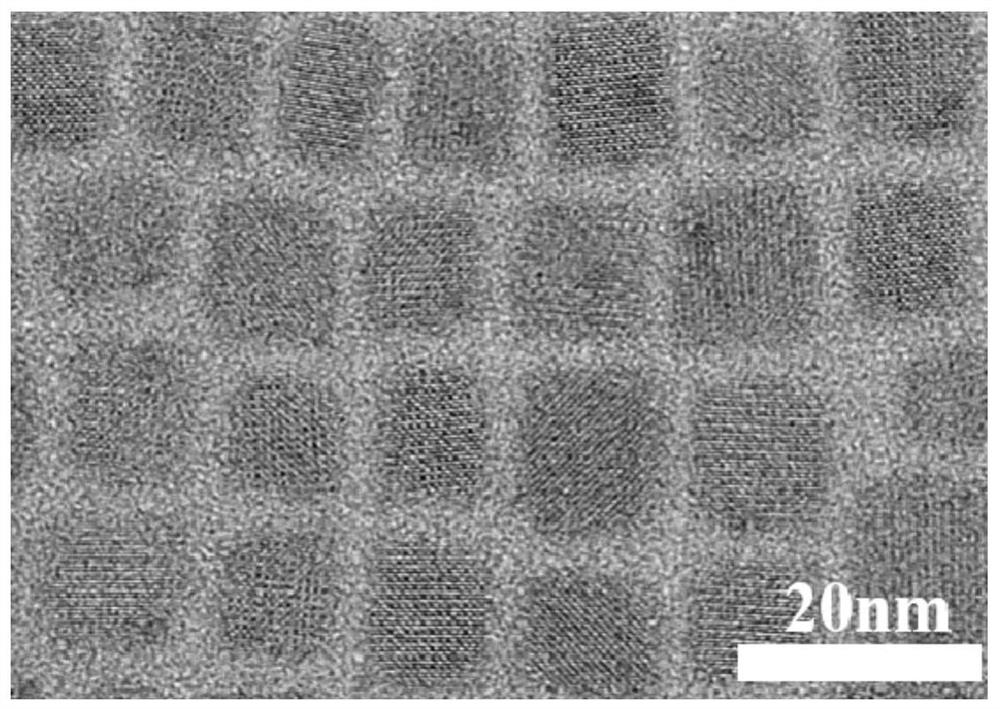

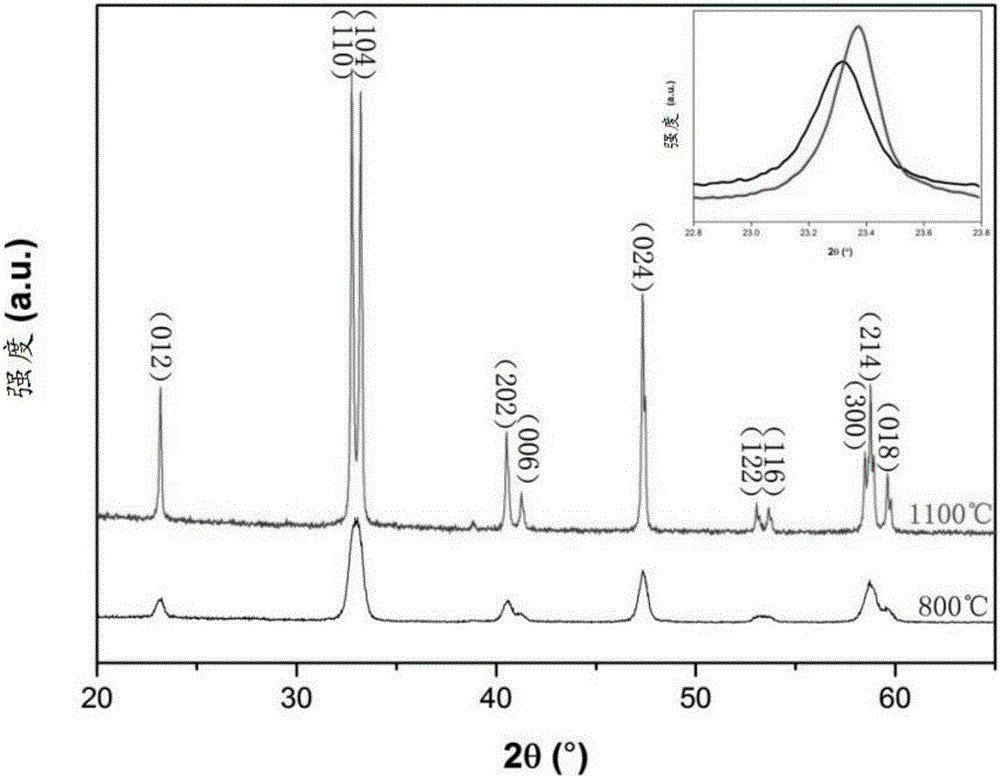

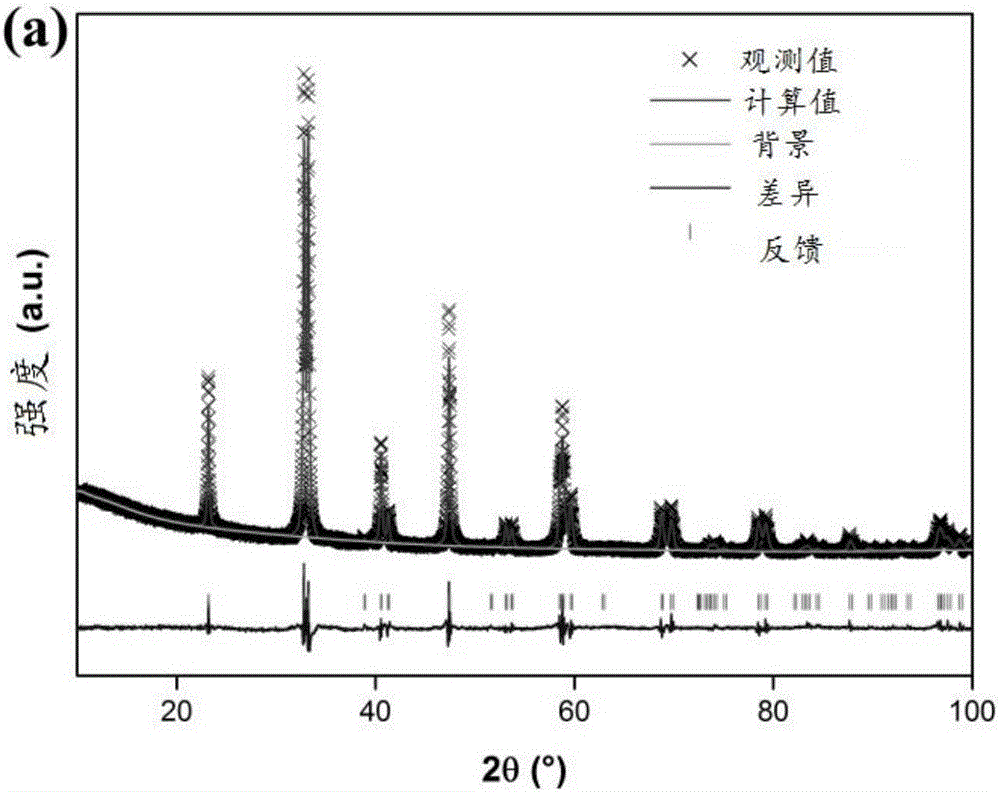

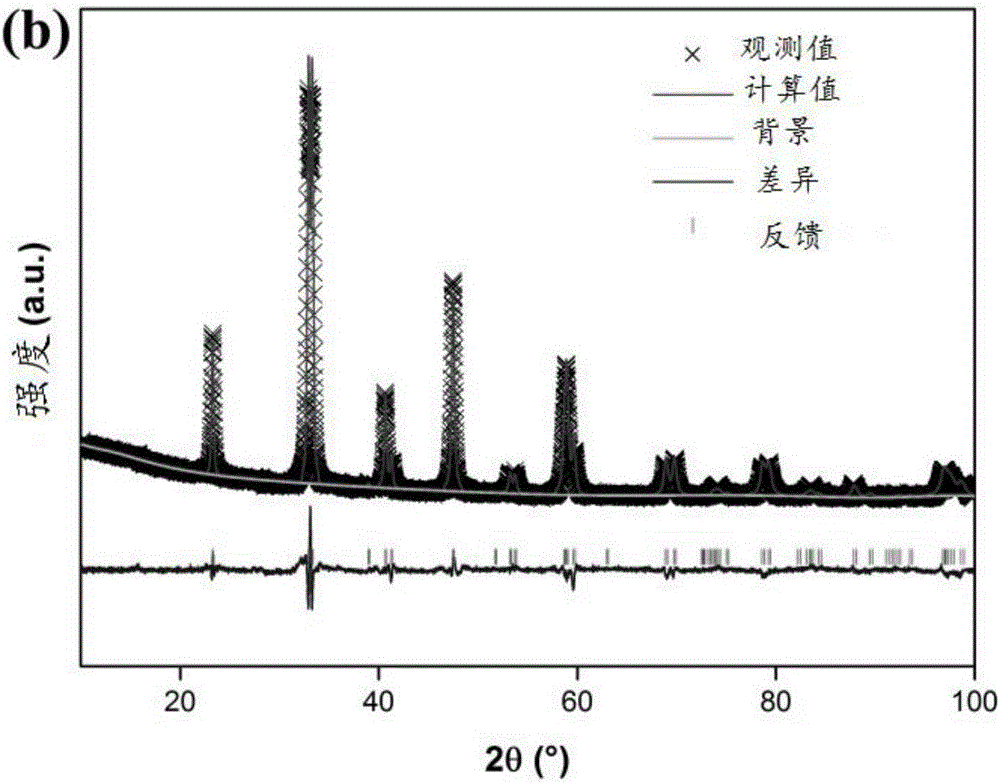

preparation method of composite anode by one-dimensional nano fibrous lanthanum strontium titanate (LST) anode material

ActiveCN103117404BSuitable electron conductivityImprove electronic conductivityCell electrodesSolid electrolyte fuel cellsFiberSlurry

The invention relates to a one-dimensional fibrous lanthanum strontium titanate (LST) anode material, a preparation method thereof, a composite anode utilizing the anode material and a preparation method of the composite anode, and relates to an anode material, a composite anode and a preparation method. The invention aims at solving the problems of reasonability in selection of the anode material and insufficiency in preparation technique that when a solid oxide fuel cell (SOFC) utilizes carbon-based fuel, the reduction of a three-phase interface caused by the carbon precipitation phenomenon and the clustering phenomenon of nickel after being deactivated by sulfur compounds on a nickel-based anode influences the working performances of the electrode. The one-dimensional fibrous LST anode material is LaxS(r1-x)TiO3 and obtained by preparing one-dimensional nano fibers through an electrostatic spinning technique and then sintering the one-dimensional nano fibers. The one-dimensional fibers are made into anode slurry to be coated on an electrolyte, cathode or anode supporting body, and a one-dimensional fibrous LST-based LST-GDC composite anode is prepared by adopting a method for combining the electrostatic spinning technique and dipping electrolyte precursor solution. The composite anode can be used in a low-medium-temperature solid oxide fuel cell.

Owner:HARBIN INST OF TECH

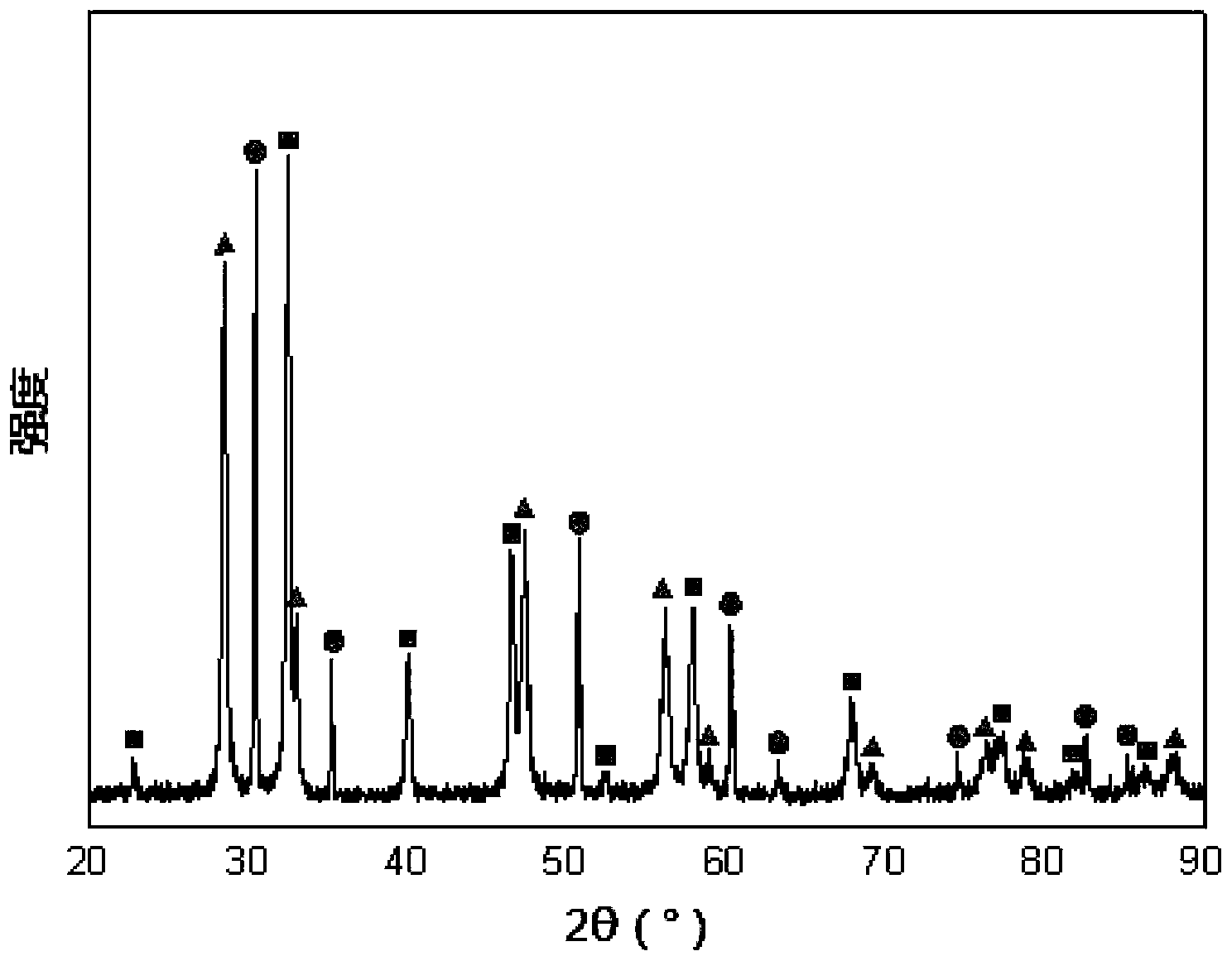

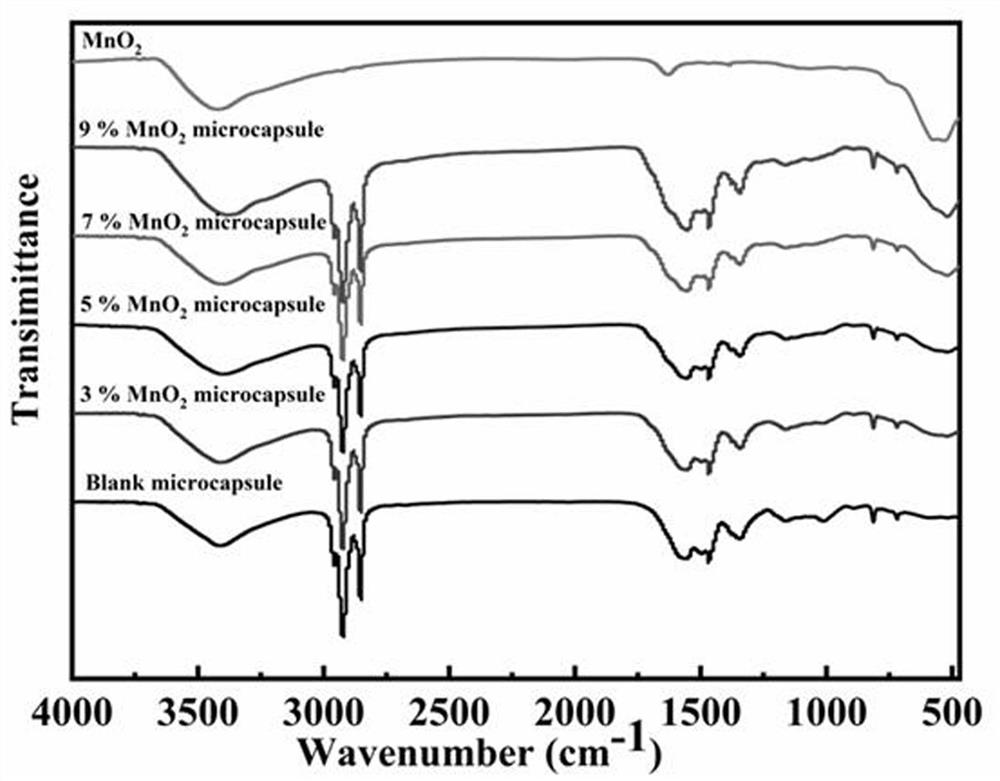

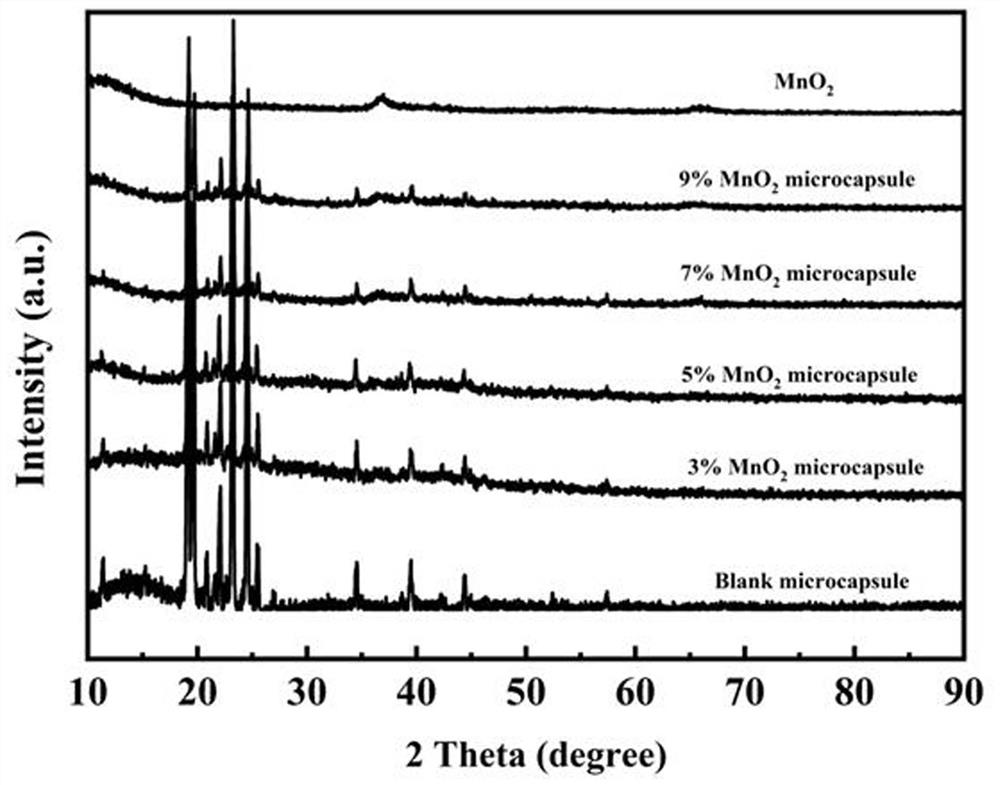

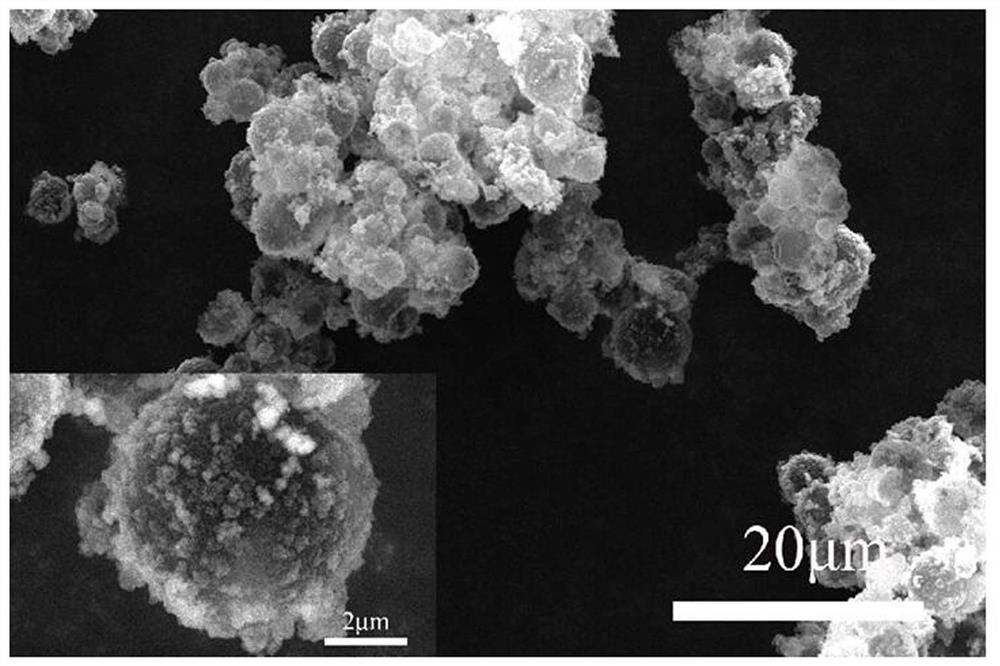

Manganese dioxide-melamine formaldehyde resin double-shell composite phase change material and preparation method thereof

ActiveCN112375545AExcellent photothermal performanceHigh photothermal conversion efficiencyMaterial nanotechnologyManganese oxides/hydroxidesNanowireHeat stability

The invention discloses a manganese dioxide-melamine formaldehyde resin double-shell composite phase-change material, which is prepared by the following steps: preparing melamine-formaldehyde resin microcapsules by using an oxidation-reduction method and an electrochemical adsorption method, and constructing MnO2 nano layers on the surfaces of the microcapsules to form a double-shell spherical structure, wherein the microcapsules are negatively charged through surface modification, the MnO2 nano layer is further constructed through an oxidation-reduction reaction, and the microstructure of theMnO2 nano layer is composed of nano particles and nano wires. The preparation method comprises the following steps: 1) pretreating raw materials;2) preparing microcapsules; and 3) preparing a MnO2 shell layer. According to the invention, the photo-thermal conversion efficiency of the phase change material is 93-99%, the phase change temperature is 10-29 DEG C, and the phase change latent heat is116-169 J / g; and the phase change material has the advantages that the problem of leakage in the phase change process is effectively solved, the photo-thermal conversion efficiency is high, and the phase change latent heat and the thermal stability are high.

Owner:GUILIN UNIV OF ELECTRONIC TECH

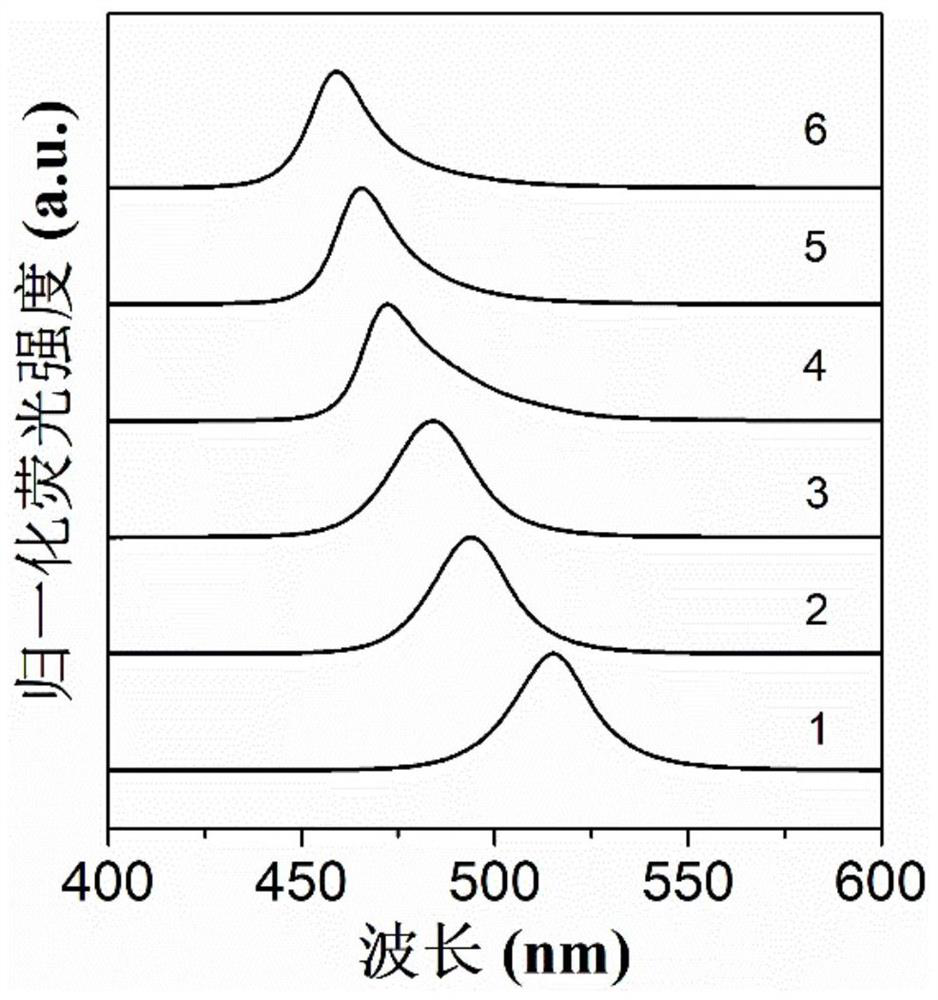

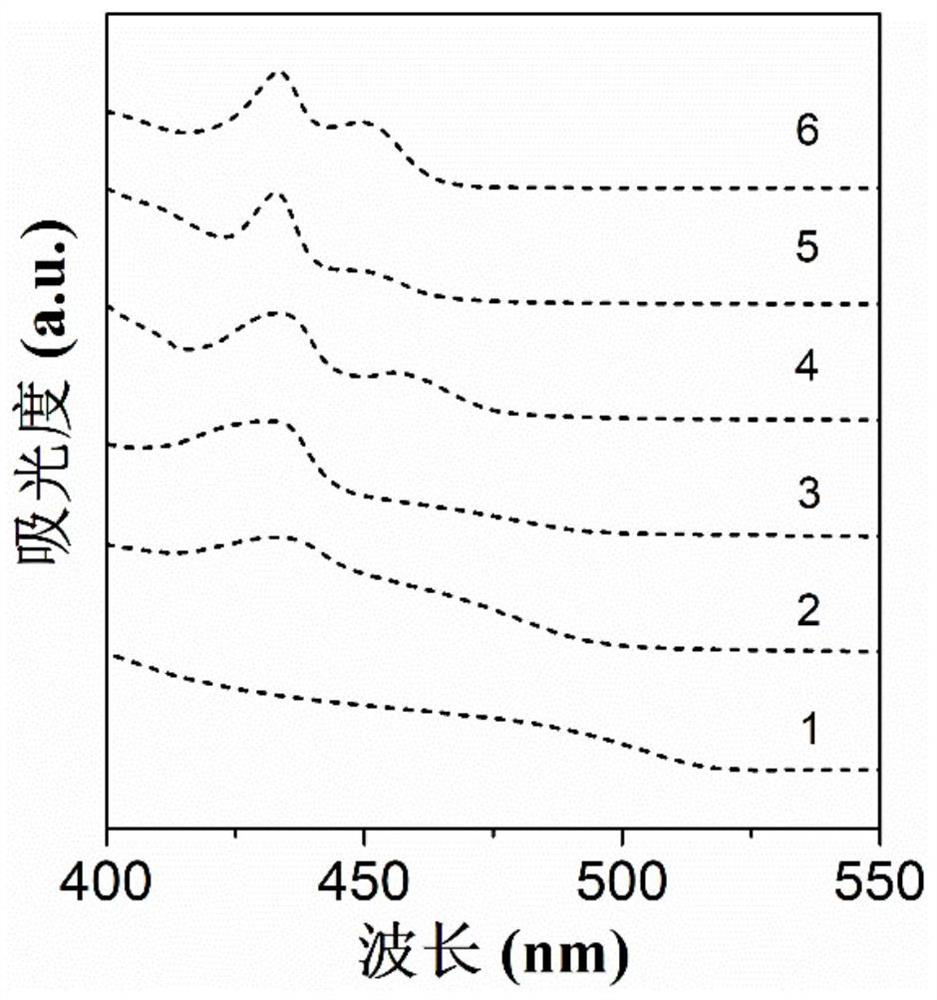

A kind of controllable neodymium-doped high light-efficiency blue perovskite quantum dots and preparation method thereof

ActiveCN111410957BIncrease the intrinsic bandgap widthEffective blue shift adjustmentNanoopticsLuminescent compositionsQuantum yieldGreen-light

The invention belongs to the technical field of photoelectric material preparation, and specifically relates to a controllable neodymium-doped high-efficiency blue perovskite quantum dot and a preparation method thereof. body, using dimethylformamide or dimethyl sulfoxide as a solvent, using a ligand-assisted method to in-situ synthesize neodymium-doped blue perovskite quantum dots in toluene solution, the quantum dots are efficient and stable, and can be solution-processed. Easy and fast. By introducing neodymium doping, the fluorescence quantum yield of perovskite quantum dots can be improved. For single bromine halogen perovskite quantum dots, the controllability of the fluorescence peak of perovskite quantum dots can be achieved by changing the doping ratio of neodymium in the precursor solution. Blue shift, blue-green luminescence peak between 459nm-520nm, for neodymium-doped bromine-lead perovskite quantum dots at 459nm luminescence peak, its fluorescence quantum yield is as high as 90% and the half-wave width is only 19nm.

Owner:FUDAN UNIV

Preparation method of novel negative electrode contact material for solid oxide fuel cell

InactiveCN106654293AImproved thermal cycling stabilityCell electrodesSolid electrolyte fuel cellsUltrasound attenuationFuel cells

The invention discloses a preparation method of a novel negative electrode contact material for a solid oxide fuel cell. A novel negative electrode contact layer is designed according to different physicochemical properties of the same LCN powder at different temperatures, and the respective advantages of coarse powder and fine powder are brought into full played, so that the negative electrode contact layer has high thermal cycling stability. The average performance attenuation rate of a single cell taking the combination of the coarse powder and the fine powder as the negative electrode contact layer in each thermal cycle is 0.46 percent, being far lower than the standard value of 1 percent. The single cell having the negative electrode contact layer is higher than the conventional single cell having a negative electrode contact layer prepared from pure coarse powder and pure fine powder on the aspect of thermal cycling stability.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com