Phase change energy storage material based on MOFs and preparation method thereof

A technology of phase change energy storage material and inorganic phase change material, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low force between wall material and core material, leakage of core material, etc. The effect of raw material safety and high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Preparation method of phase change energy storage materials based on MOFs:

[0023] Step 1, melting of the inorganic phase change material, mixing the inorganic phase change material with a nucleating agent with a mass fraction of 1% and heating until the inorganic phase change material is completely melted;

[0024] Step 2, take a clean and dry beaker, add MOFs materials, and dry in an oven at 110°C for 30 minutes;

[0025] Step 3, add the dried MOFs material obtained in step 2 to the molten inorganic phase change material obtained in step 1, and perform ultrasonic mixing for 10 min to mix the inorganic phase change material and MOFs material evenly; put the mixed sample at 70 °C Vacuum oven, vacuum adsorption for 8 hours, during which every 2 hours, the sample was taken out for magnetic stirring to promote the full adsorption of MOFs materials to phase change materials;

[0026] In step 4, the sample is taken out and naturally cooled to room temperature to obtain the...

PUM

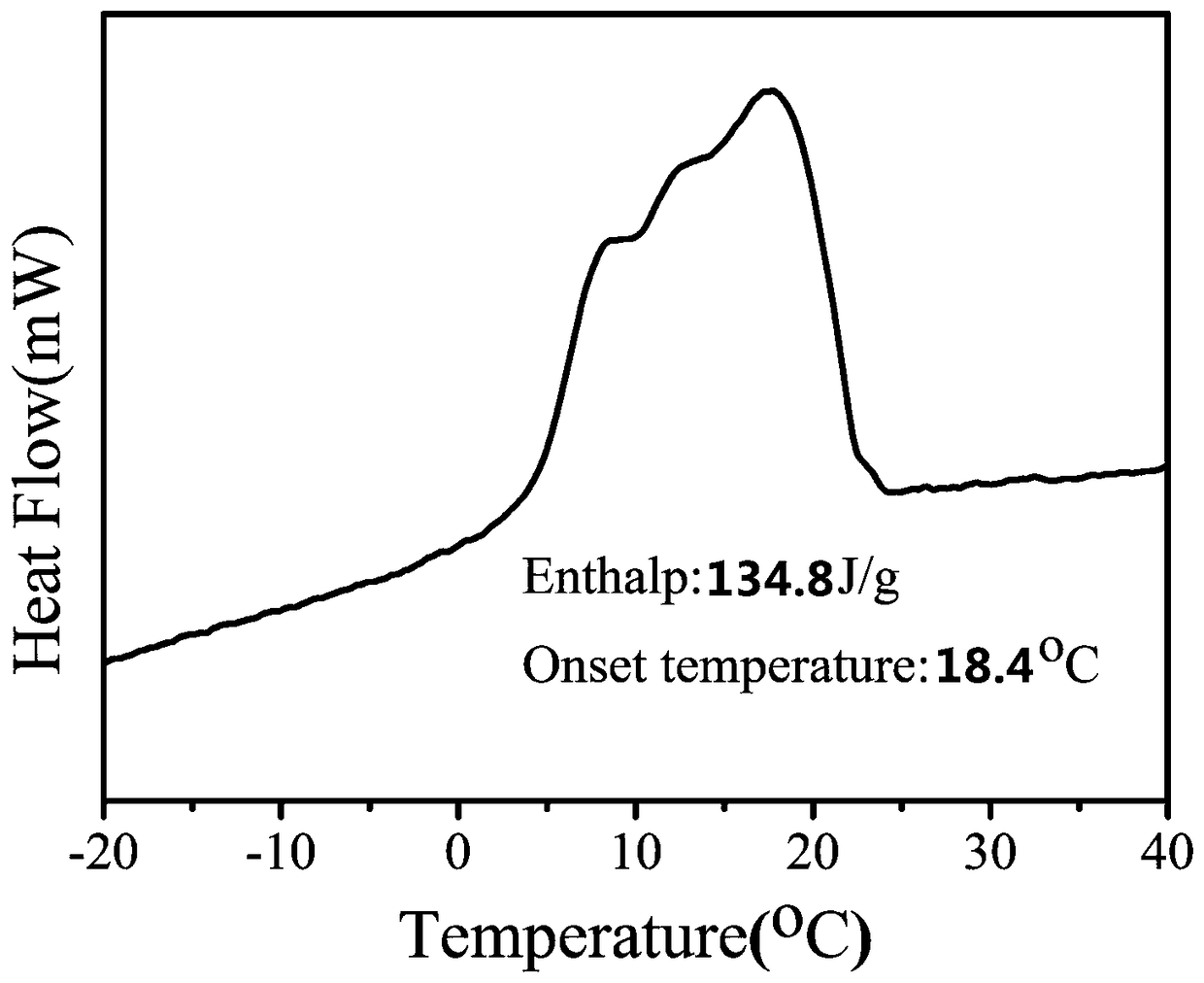

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com