Patents

Literature

137 results about "Heat responses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

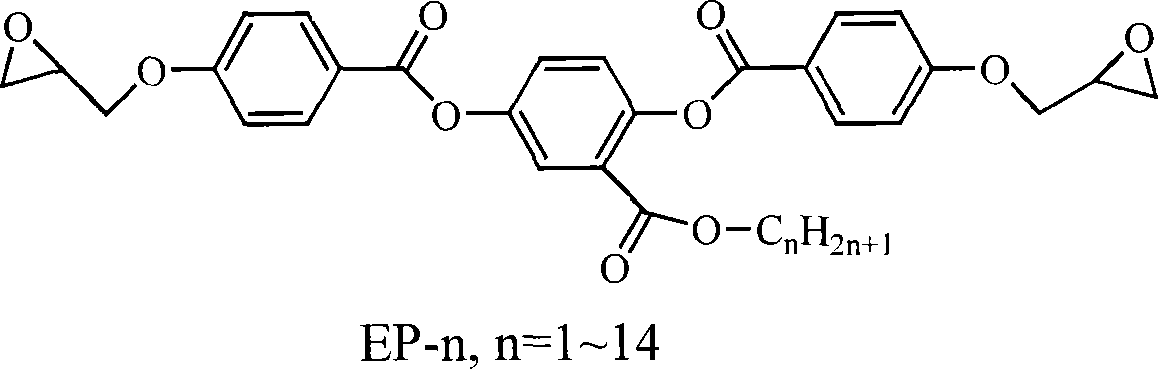

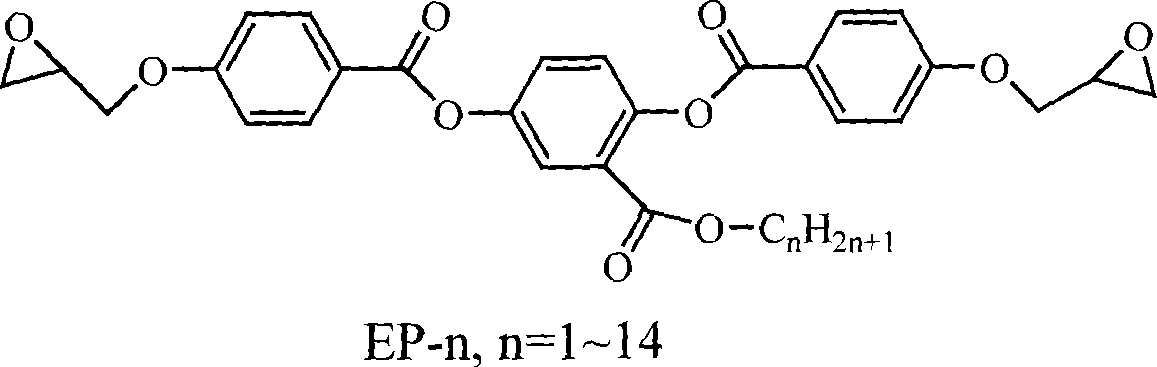

Epoxy resin shape memory polymer material and method for producing the same

InactiveCN101195701AThermal response temperature adjustableFast thermal response timeEpoxyMemory effect

The invention relates to a new epoxy resin shape memory macromolecule material and a relative preparation method, wherein the material contains liquid crystal epoxy resin monomer and curing agent at stoichiometry, which may further contains curing accelerator of 0-2% consumption of the total accounts of the liquid crystal epoxy monomer and curing agent. Compared with prior shape memory material, the inventive material has the advantages that (1), the thermal responsible temperature can be adjusted by adjusting the side chain and substituted chain of the liquid crystal epoxy monomer or by selecting curing agent, (2), the heat response time is short and the shape recover is rapid, (3), the product can realize saturated shape memory effect, (4) the product has simple preparation and clear structure.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

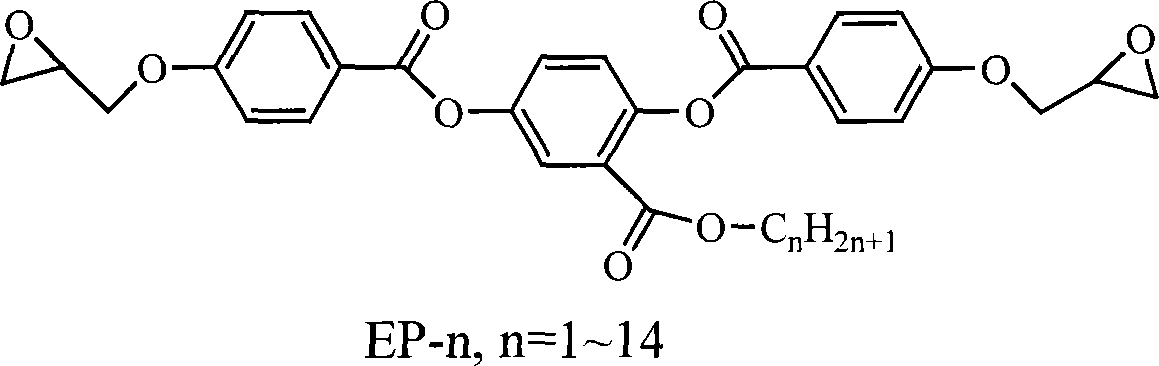

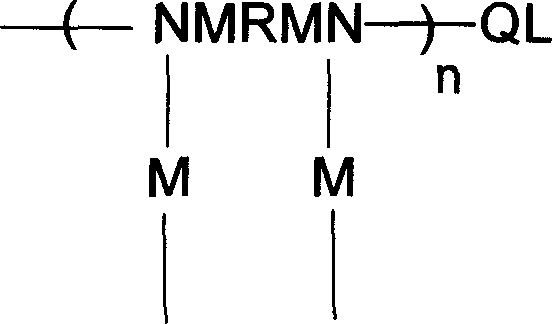

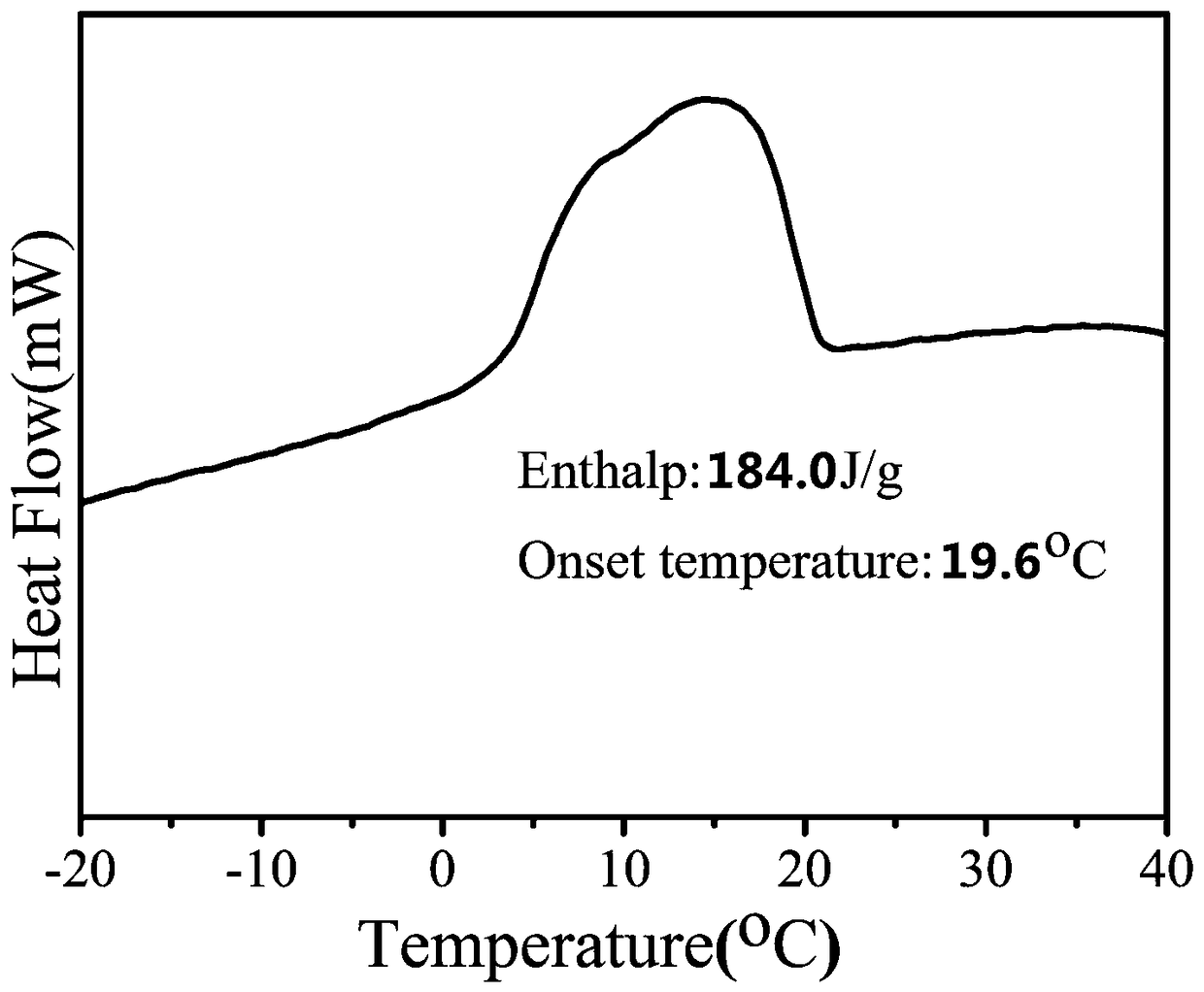

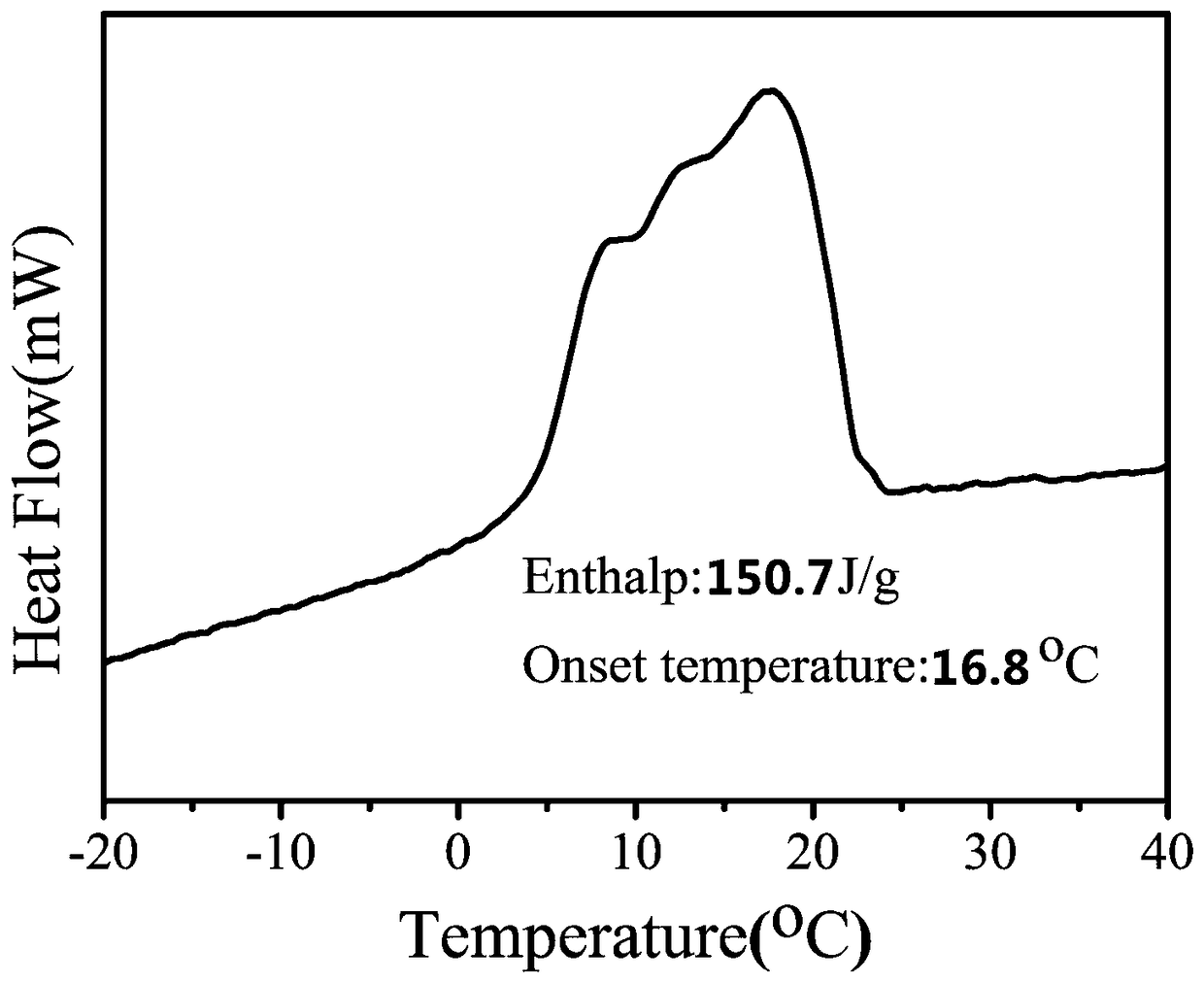

Energy storage material of solid - solid phase change in opal / polyurethane type, and preparation method

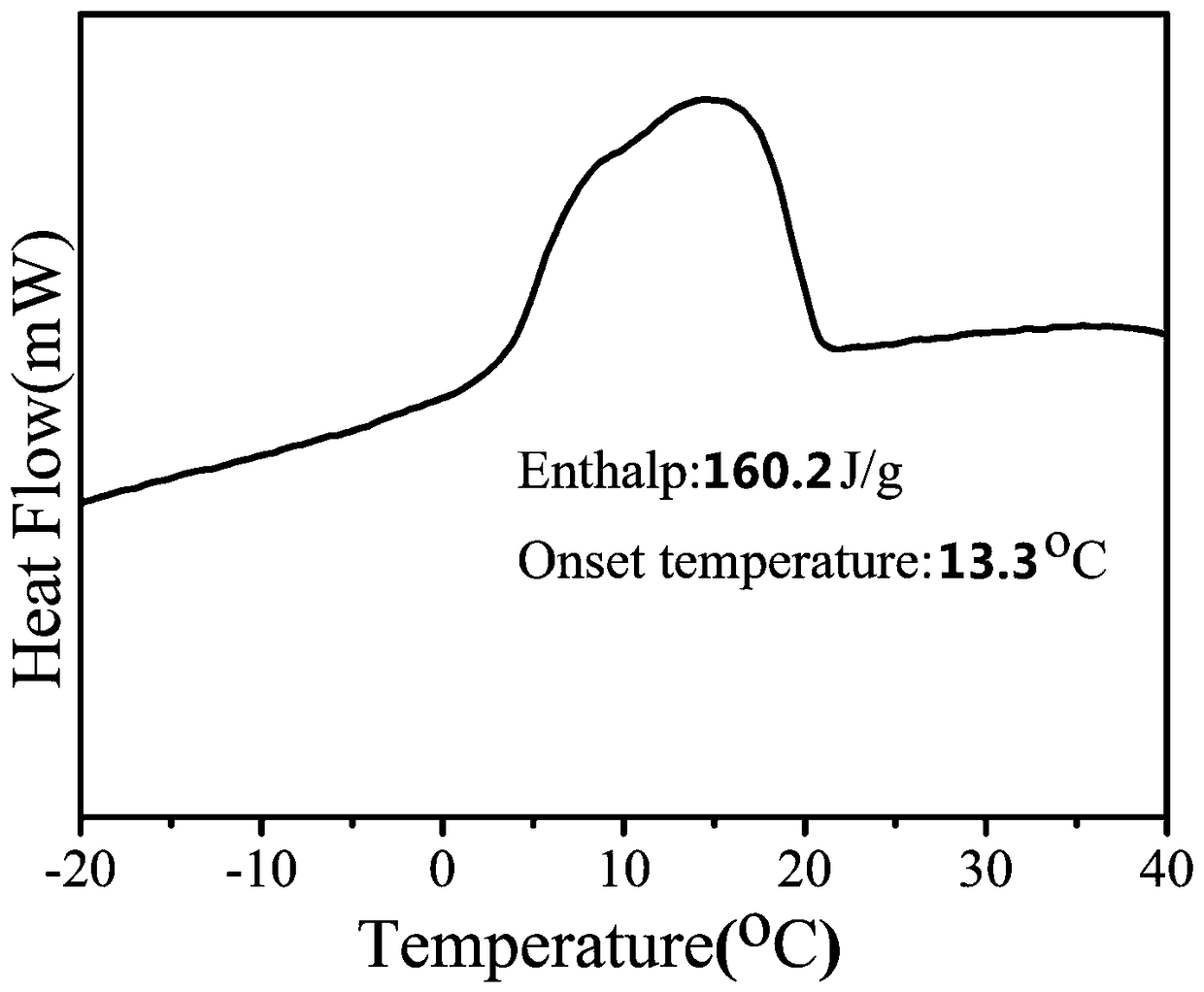

InactiveCN1958711ALarge specific surface areaHigh phase change enthalpyHeat-exchange elementsPolyethylene glycolGlycol synthesis

This invention relates to a method for preparing opal / polyurethane solid-solid phase transition energy-storage material. The molecular structure of the material is shown in formula I, where, poly (ethylene glycol) is the soft segment, while aliphatic and aromatic isocyanate, and trihydroxyl substance are the hard segments. The method comprises: (1) preparing prepolymer of poly (ethylene glycol) with terminal groups activated by isocyanate groups; (2) preparing opal / polyurethane solid-solid phase transition energy-storage material. The method has such advantages as low raw material cost, no toxicity of the product, and simple process. The addition of natural nanomaterial (opal) can increase the phase transition enthalpy value and heat response rate of the material, and can reduce the cost. The opal / polyurethane solid-solid phase transition energy-storage material can effectively save energy, and has potential applications in such fields as agriculture, energy resources, textile, construction and electronics.

Owner:DONGHUA UNIV

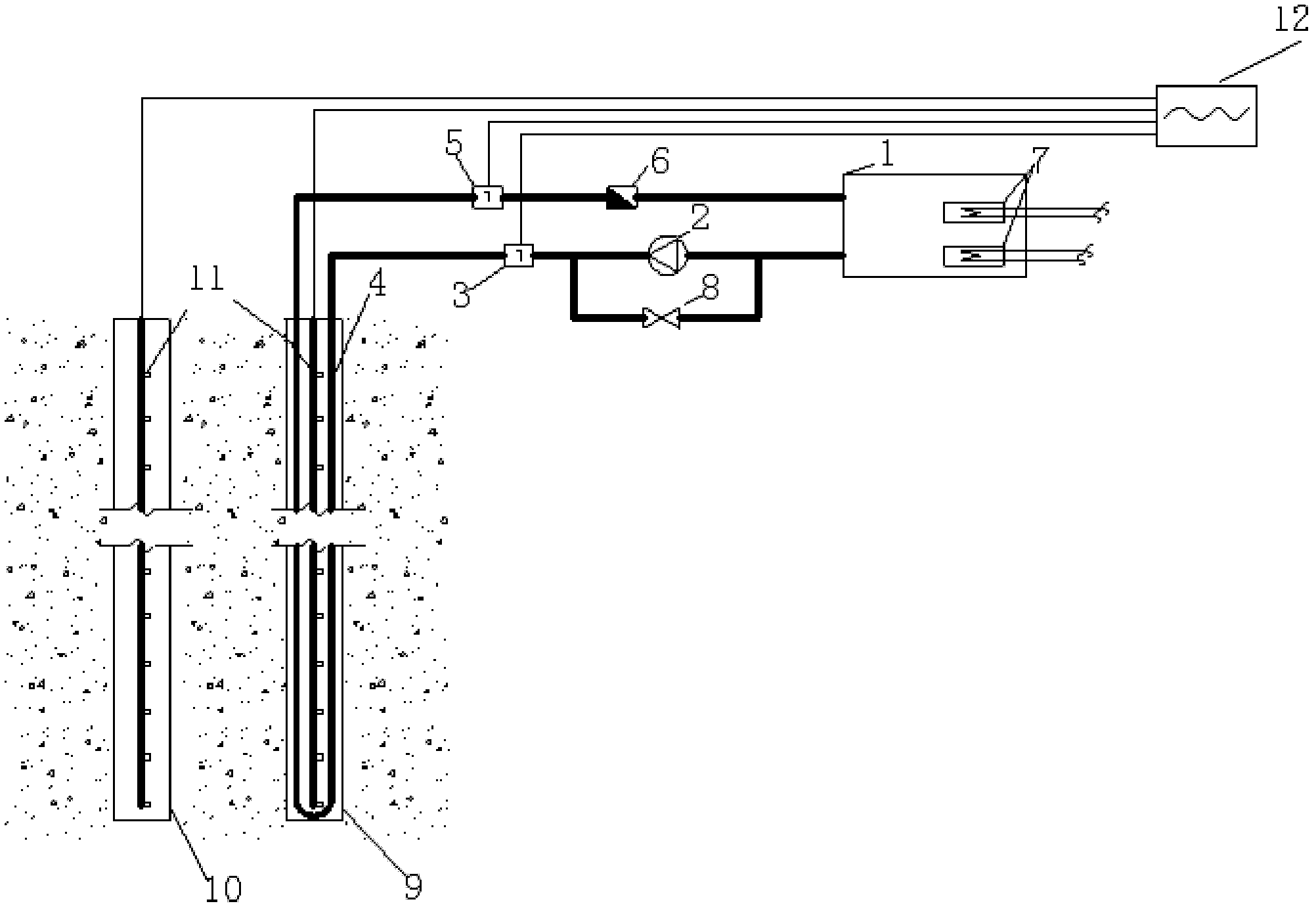

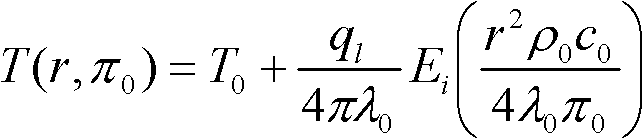

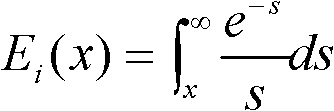

Ground source heat pump rock-soil heat response dynamic testing system and testing method

InactiveCN102590271ALearn more about heat transferRealize measurementMaterial heat developmentData acquisitionEngineering

The invention relates to a ground source heat pump rock-soil heat response dynamic testing system, which consists of a heating water tank, a circulating pump, a bypass-valve, a heating well, a U-shape pipe, a temperature monitoring well, a data acquisition analyzer, temperature sensors, flow sensors and a heater, and is characterized in that the temperature monitoring well is arranged in the position 0.3-1.2 m away from the heating well, a temperature sensor group identical to temperature sensors group on the heating well is arranged in the temperature monitoring well, and all the temperature sensors and flow sensors are connected with the data acquisition analyzer through signal lines. In testing, a rock-soil original temperature value data test, a basic heating process data test, a strengthened heating process data test and after heating stop data test are respectively carried out on the heating well and the temperature monitoring well. By the comparison of a calculation value and a measured value of a heat transfer model and the revision of rock-soil thermal conductivity, the actual rock-soil thermal productivity is ultimately approximated. The rock-soil temperatures in the heating well and the temperature monitoring well are monitored synchronously to shorten the test time; and the heat transfer conditions of rock-soil at different depths and the mutual influence of wells are accurately mastered to provide data for designing.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

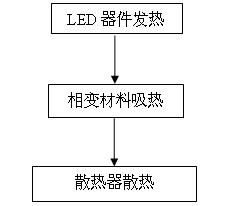

Heat dissipation method of LED (light-emitting diode) device and device

InactiveCN102155729AFast absorptionExtended service lifePoint-like light sourceLighting heating/cooling arrangementsJunction temperatureHeat sink

The invention discloses a heat dissipation method of an LED (light-emitting diode) device, which comprises the following steps of: conducting the heat of the LED device into a phase change material which emits heat with the external environment. The invention also discloses a heat sink of the LED device; the heat sink comprises a metal shell, a heat dissipation baseboard and a heat-conducting fin, wherein the metal shell is internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat-conducting fin. The invention also discloses another heat sink of the LED device; the heat sink comprise the metal shell, the heat dissipation baseboard, a heat pipe and a metal outer cover, wherein the metal shell and the metal outer cover are internally filled with the phase change material, and the heat dissipation baseboard is connected with the metal shell by the heat pipe. The phase change materials of the invention is a composite phase change material of an organic matter and an inorganic metal, has faster heat response rate and heat storage capacity, can rapidly absorb the heat generated by the LED device, and controls the junction temperature of the LED device to be within 60 DEG C, thereby avoiding the luminous decay phenomenon caused by the overheating of the LED device and prolonging the service life of the LED device.

Owner:SOUTH CHINA UNIV OF TECH

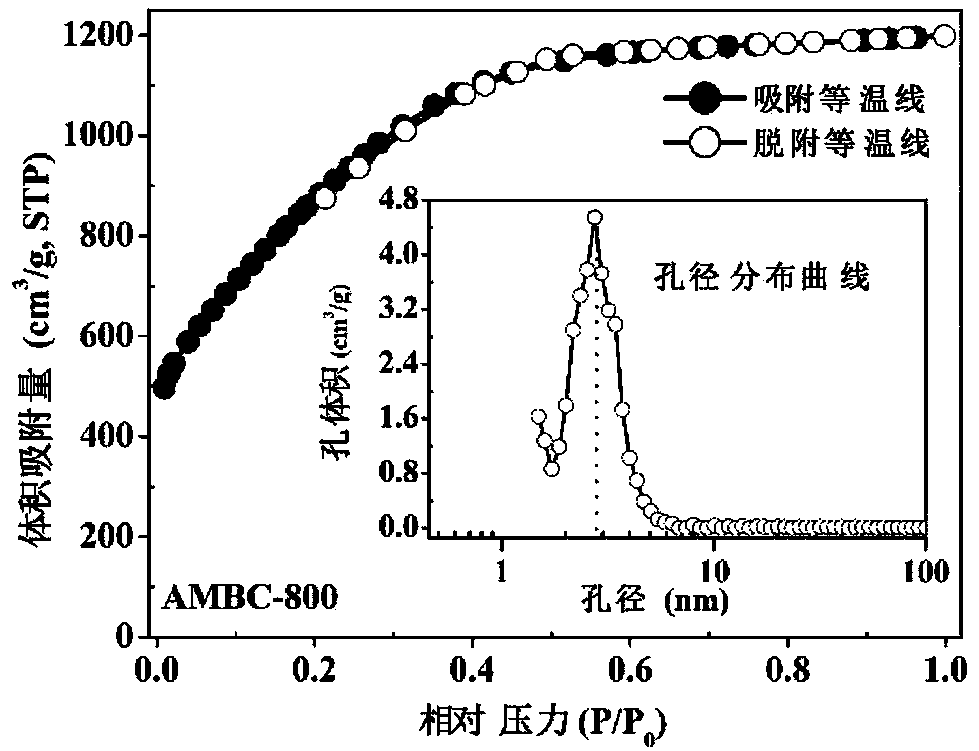

Preparation method of high mesoporous rate nitrogen doped carbon electrode material

ActiveCN108483442ALarge specific surface areaGood effectCarbon compoundsHybrid capacitor electrodesHigh current densityCapacitance

The invention provides a preparation method of a high mesoporous rate nitrogen doped carbon electrode material. The preparation method comprises the following steps: step one, pretreatment; step two,hydrothermal reaction: carrying out the hydrothermal reaction on bamboo shoot shells to obtain a hydrochar precursor; step three, carbonation reaction: filtering, washing and drying the hydrochar precursor and then carrying out low temperature carbonization treatment on the dried hydrochar precursor and a nitrogen source material to obtain carbide; step four, activating treatment: carrying out theactivating treatment on the carbide and an activator, carrying out acid pickling, washing with deionized water and drying to obtain the high mesoporous rate nitrogen doped carbon electrode material of which an aperture main peak is 2.8nm. A symmetric supercapacitor assembled by applying an electrode material provided by the invention has the effects that specific capacitance reaches as high as 209F / g when current density is 0.5A / g; especially when the high current density is 10A / g, the symmetric supercapacitor has excellent stability, and the capacitance still reaches as high as 95 percent ofinitial capacitance after 10,000 cycles of charge and discharge.

Owner:XIANGTAN UNIV

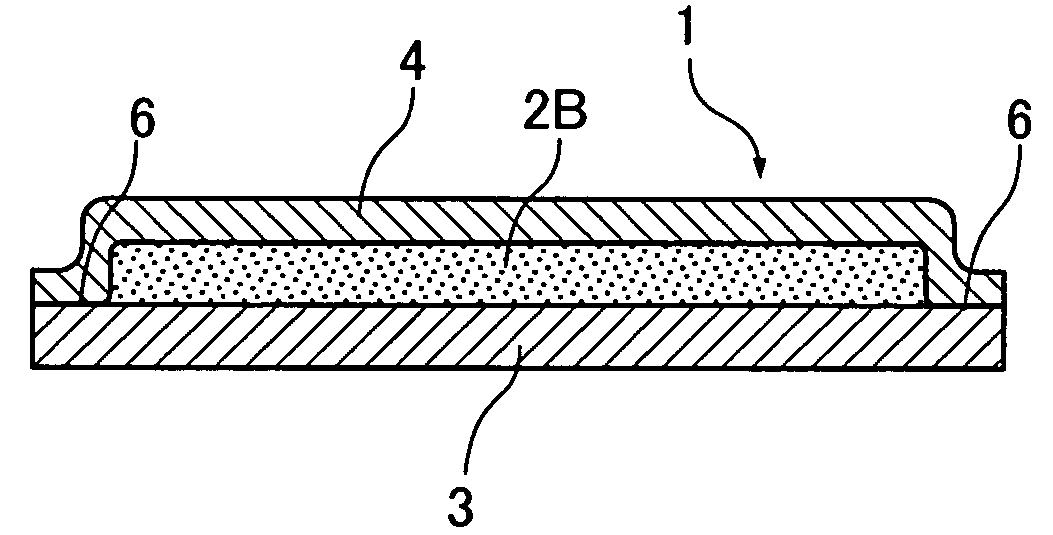

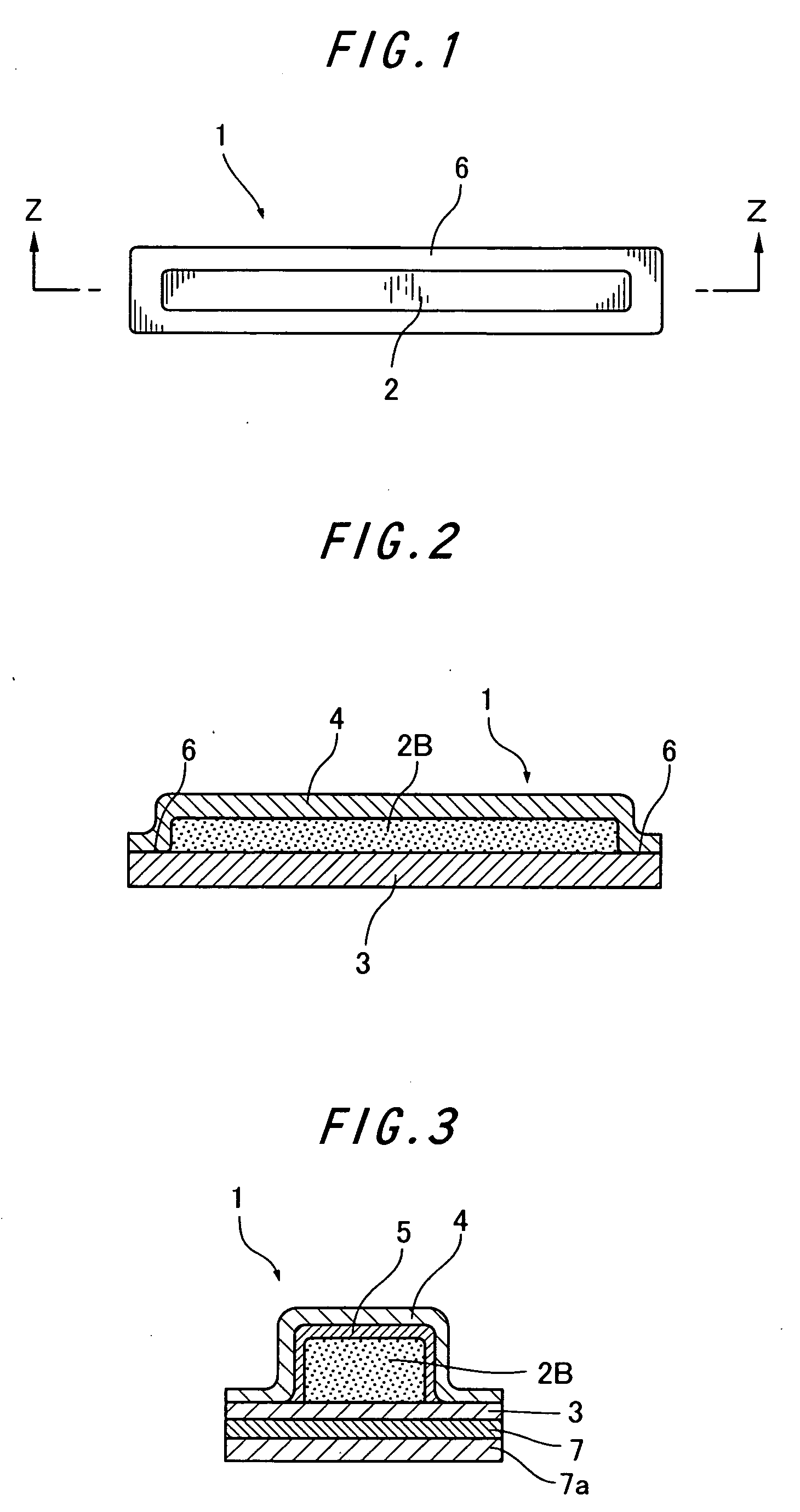

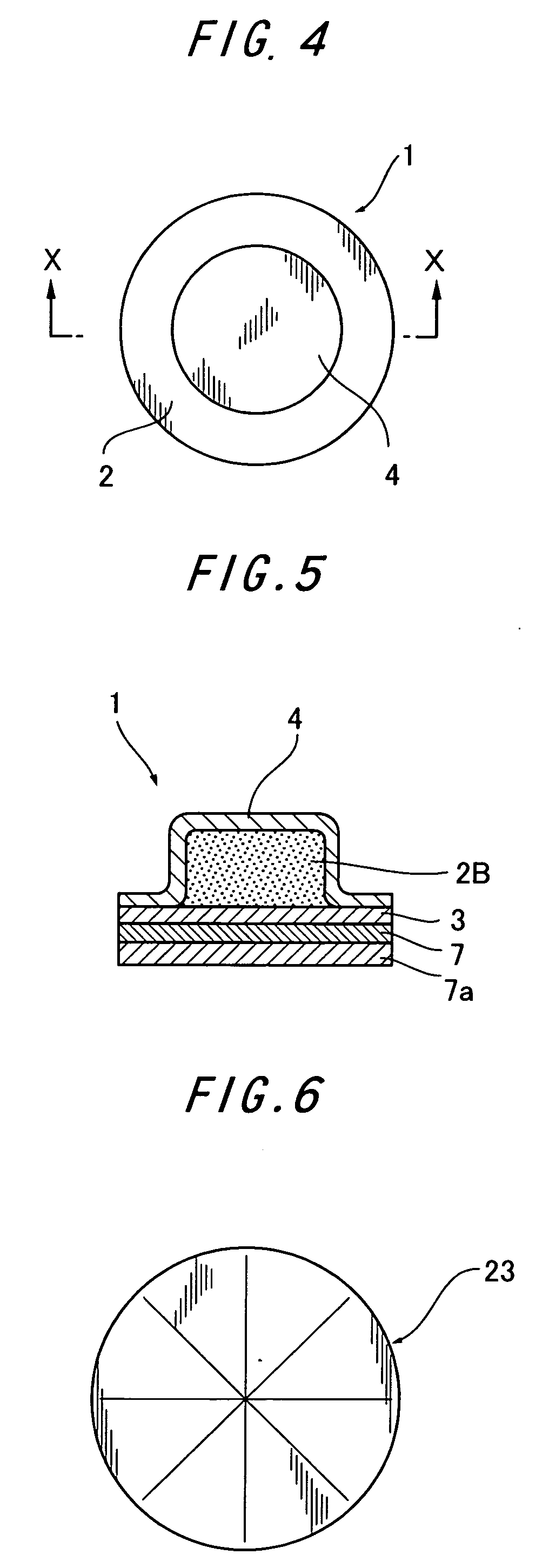

Microheater and Process For Producing the Same

InactiveUS20090000610A1High thermal moxibustion effectUniform and convenient and comfortable heatDevices for heating/cooling reflex pointsExothermal chemical reaction heat productionIron powderShell molding

To provide a microheater which gives a desired temperature and starts an exothermic reaction upon immediate contact with air and in which plural microheaters can be chained or incorporated in a packaging material.A microheater having a heat generating composition molded body made of a moldable heat generating composition containing surplus water as a connecting substance accommodated in an air-permeable accommodating bag, which is characterized in that the accommodating bag is made of a heat seal layer-containing substrate and a covering material and has an exothermic part as formed by laminating a heat generating composition molded body as molded on the substrate which is substantially planar and does not have a pocket, an accommodating division and an accommodating section, covering by the covering material and heat sealing the periphery of the heat generating composition molded body; that the moldable heat generating composition contains, as essential components, an iron powder, a carbon component, a reaction accelerator and water, has a content of water in the moldable heat generating composition of from 1 to 60%, does not contain a flocculant aid, a flocculant, an agglomeration aid, a dry binder, a dry binding agent, a dry binding material, a sticky raw material, a thickener and an excipient, contains surplus water so as to have a water mobility value of from 0.01 to 20, with the water in the heat generating composition not functioning as a barrier layer, and is capable of causing an exothermic reaction upon contact with air; that a volume of the heat generating composition molded body is from 0.1 to 30 cm3, and a ratio of a capacity of the exothermic part to the volume of the heat generating composition molded body is from 0.6 to 1.0; and that a maximum height of the exothermic part is from 0.1 to 10 mm.

Owner:MYCOAL PRODS CORP

Method for extracting xylose from poly pentose acidolysis liquid

ActiveCN101805378ASolve the disadvantage of increased burdenLow costSugar derivativesSugar derivatives preparationReverse osmosisStrong acids

The invention provides a method for extracting xylose from poly pentose acidolysis liquid, including the following steps: poly pentose acidolysis liquid is neutralized by calcium carbonate, then pre-destaining is carried out, and then active carbon is used for destaining; strong acid cation resin and weak base anion resin are sequentially used for carrying out ion exchange, and then reverse osmosis membrane is used for concentration; concentrated solution is destained by active carbon column and sequentially passes through the strong acid cation resin and weak base anion resin, and finally heat response concentration and crystallization are carried out. The invention overcomes the defect that content of acetate after concentration is improved by utilizing reverse osmosis membrane concentrated acidolysis liquid, cost is reduced, and dialysate thereof can be further taken as washing water in crystallization of wood sugar, thus cost is further reduced; besides, acid-base dosage of the method in the invention is less, the method is environmentally friendly, cost is lower, productivity is high, purity is good, and the method is applicable to industrialization production.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Heat conduction enhanced inorganic PCM (phase change material) and preparation method thereof

InactiveCN108997976AFast heat responseFast heat conductionHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced inorganic PCM (phase change material). The heat conduction enhanced inorganic PCM is prepared from an inorganic PCM as a core material and melamine resin containing heat conduction enhanced nano-particles as a wall material, wherein the heat conduction enhanced nano-particles are boron nitride, CNTs (carbon nano tubes) and graphene oxide that aremodified. A preparation method of the heat conduction enhanced inorganic PCM comprises the following steps: 1) modifying the heat conduction enhanced nano-particles; 2) preparing a prepolymer of the wall material added with the modified heat conduction enhanced nano-particles; 3) melting the inorganic PCM; and 4) preparing the heat conduction enhanced inorganic PCM. The heat conduction enhanced inorganic PCM has the advantages that 1) the heat response speed is high, i.e. the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and4) the technical characteristics that raw materials are safe and non-toxic and are not leaked easily are achieved. Therefore, the heat conduction enhanced inorganic PCM is better in heat conductivityand stability, the using ratio of energy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

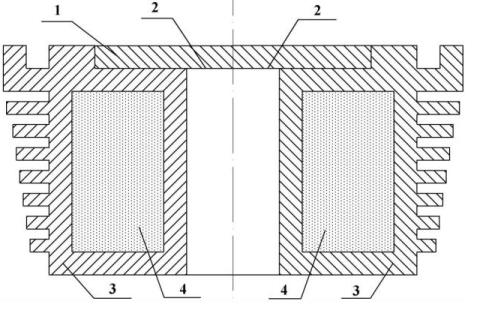

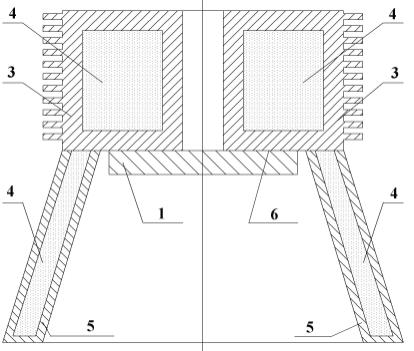

Quick response energy storing heat dissipation plate

ActiveCN103269571ASave energyReduce weightCooling/ventilation/heating modificationsHeat fluxEngineering

The invention discloses a quick response energy storing heat dissipation plate which comprises foam materials (1), a radiant plate (2) and phase-change materials (3). The radiant plate (2) comprises a plurality of inner cavities with regular shapes and even sizes. Some inner cavities are filled with the foam materials (1), and the rest of the inner cavities are filled with a large number of minitype heat pipes made of cycle fluid. The phase-change materials (3) are heated to be filled to the gaps of the foam materials (1) in a liquid state, and the periphery of the radiant plate (2) is sealed after the phase-change materials (3) are cooled and solidified. The quick response energy storing heat dissipation plate has the performance of large heat capacity, large thermal diffusivity and the like by utilizing the high heat-conducting property of the minitype heat pipes, the large specific surface area of the foam materials and the large phase-change latent heat of the phase-change materials. The quick response energy storing heat dissipation plate can be applied to electron devices for spaceflight, wherein the electron devices are small in size, high in heat flux and periodic in operation. The quick response energy storing heat dissipation plate has the advantages of being high in heat response speed and temperature control precision, large in short-term absorption heat, light in weight, reliable in system and the like.

Owner:SHANGHAI SATELLITE ENG INST

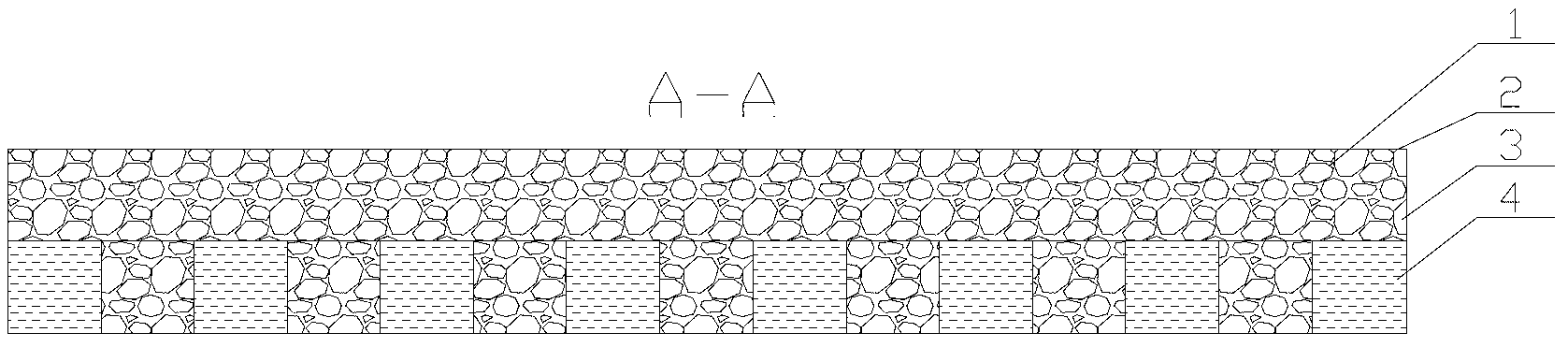

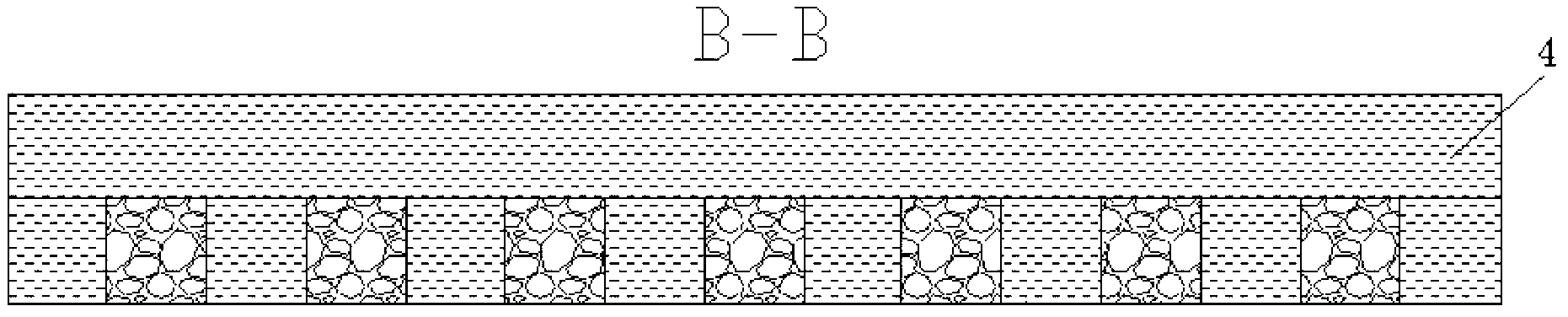

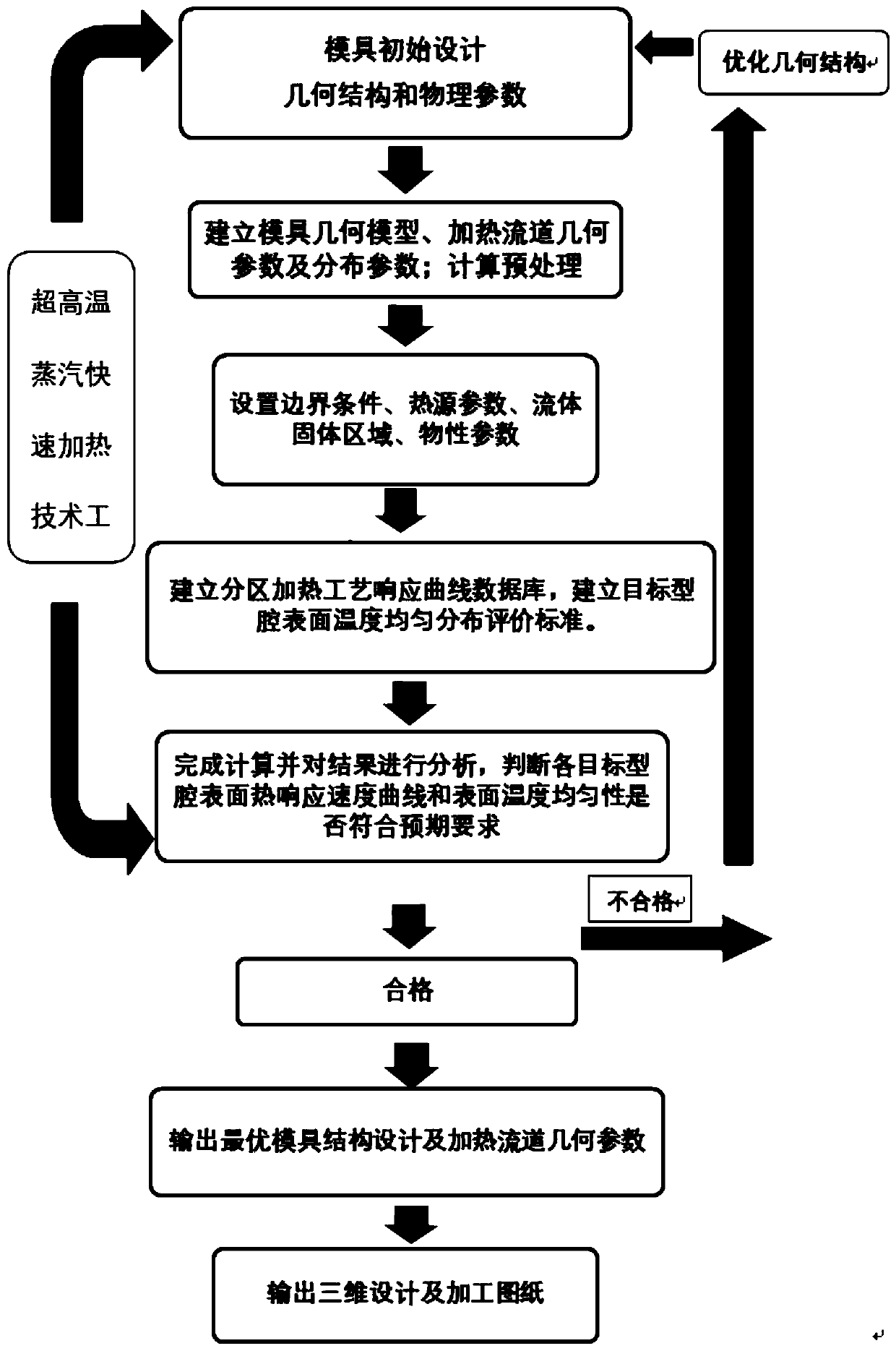

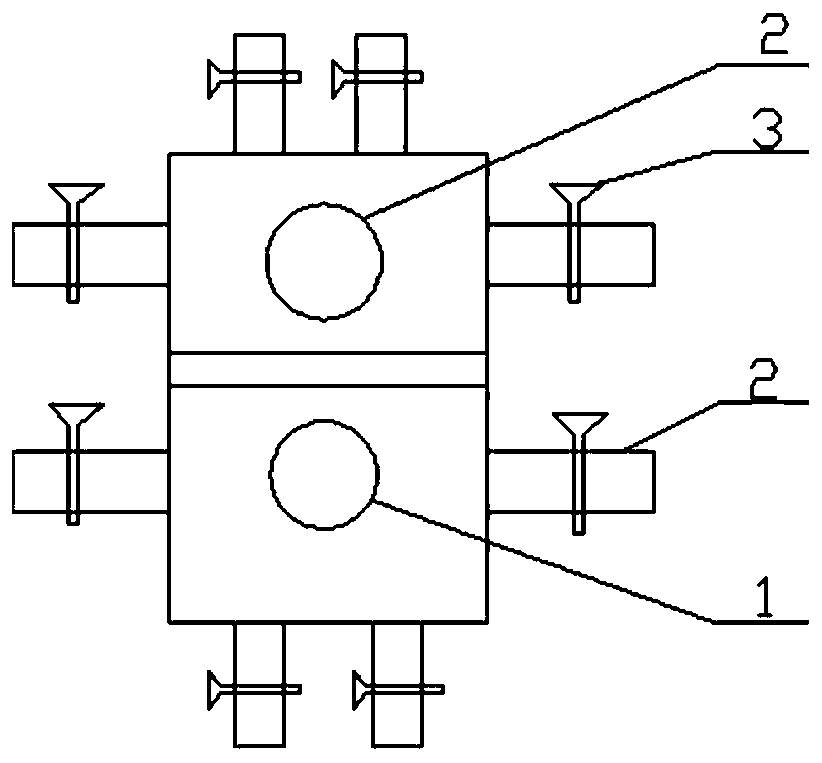

Mould preparation method, mould, mould heating system and heating controlling method

ActiveCN110027139AUniform temperatureMeet the needs of fast-changing mold temperatureThermometers using electric/magnetic elementsUsing electrical meansHot runnerModular unit

The invention discloses a mould preparation method, a mould, a mould heating system and a heating controlling method. The method comprises the following steps: S1, dividing heating areas; S2, pre-setting at least one heating flow channel in each of the heating areas, and the method for determining structural parameters of the heating flow channels comprises the following steps: S21, pre-setting the structural parameters of the heating flow channels; S22, obtaining an actual heating curve of each of the heating areas and actual temperature of each of position points of a mold cavity surface; S23, carrying out deviation analysis and adjusting the structural parameters of the heating flow channels according to a deviation analysis result; S24, repeatedly carrying out the steps S22 and S23; and S3, carrying out processing according to the structural parameters of the heating flow channels to form flow channels. The mould is heated in subareas, and the structural parameters of the flow channels are determined separately in each of the heating areas, so that the phenomena that the overall heat response speed of the mould and the temperature uniformity of the whole mold cavity can meet the requirement can be ensured, and by adopting the method, the requirement on quick change of the mould temperatures of complicated modular unit structures can be met, and subarea heating can be conveniently carried out.

Owner:宁波柚贝儿童用品有限公司

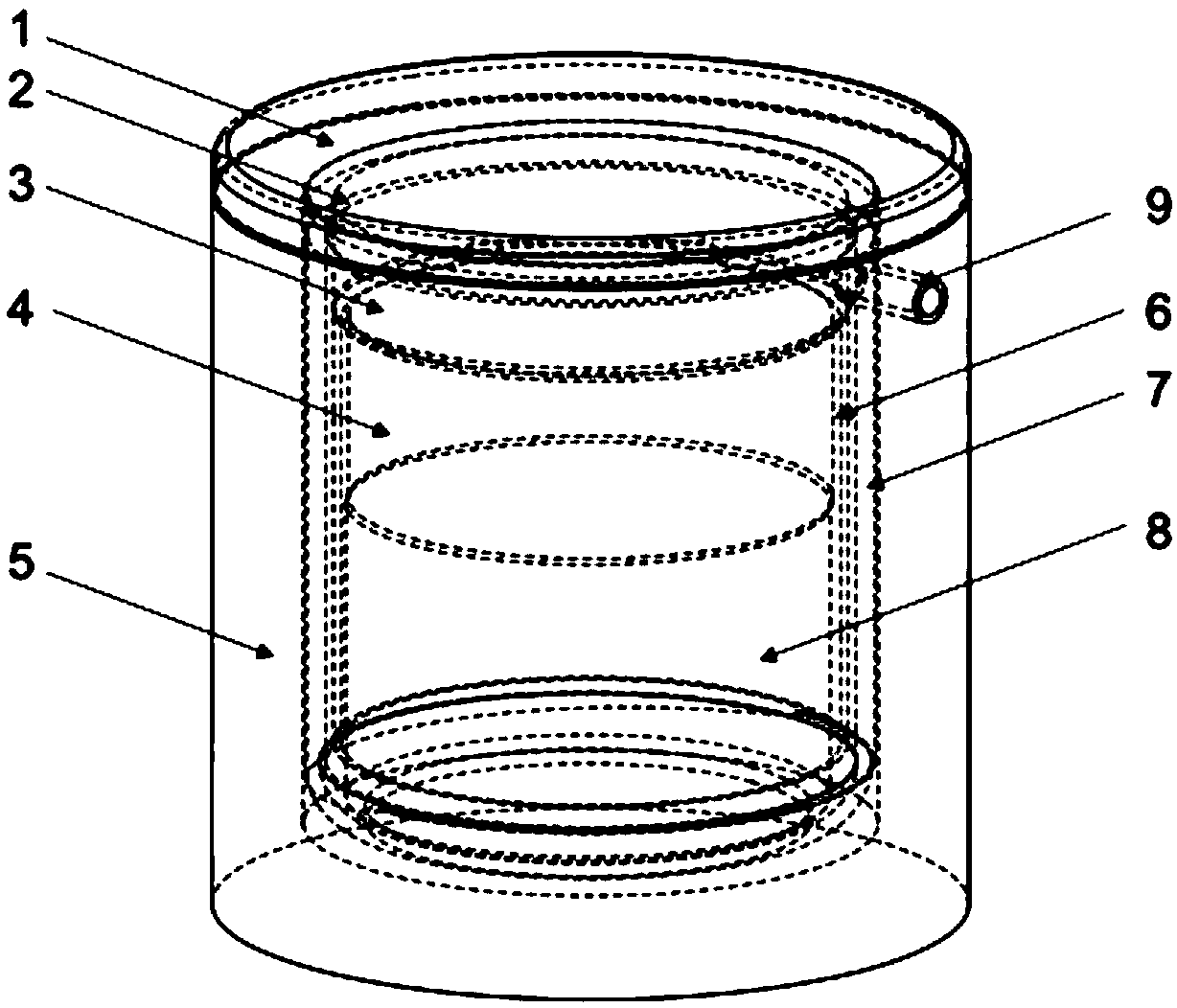

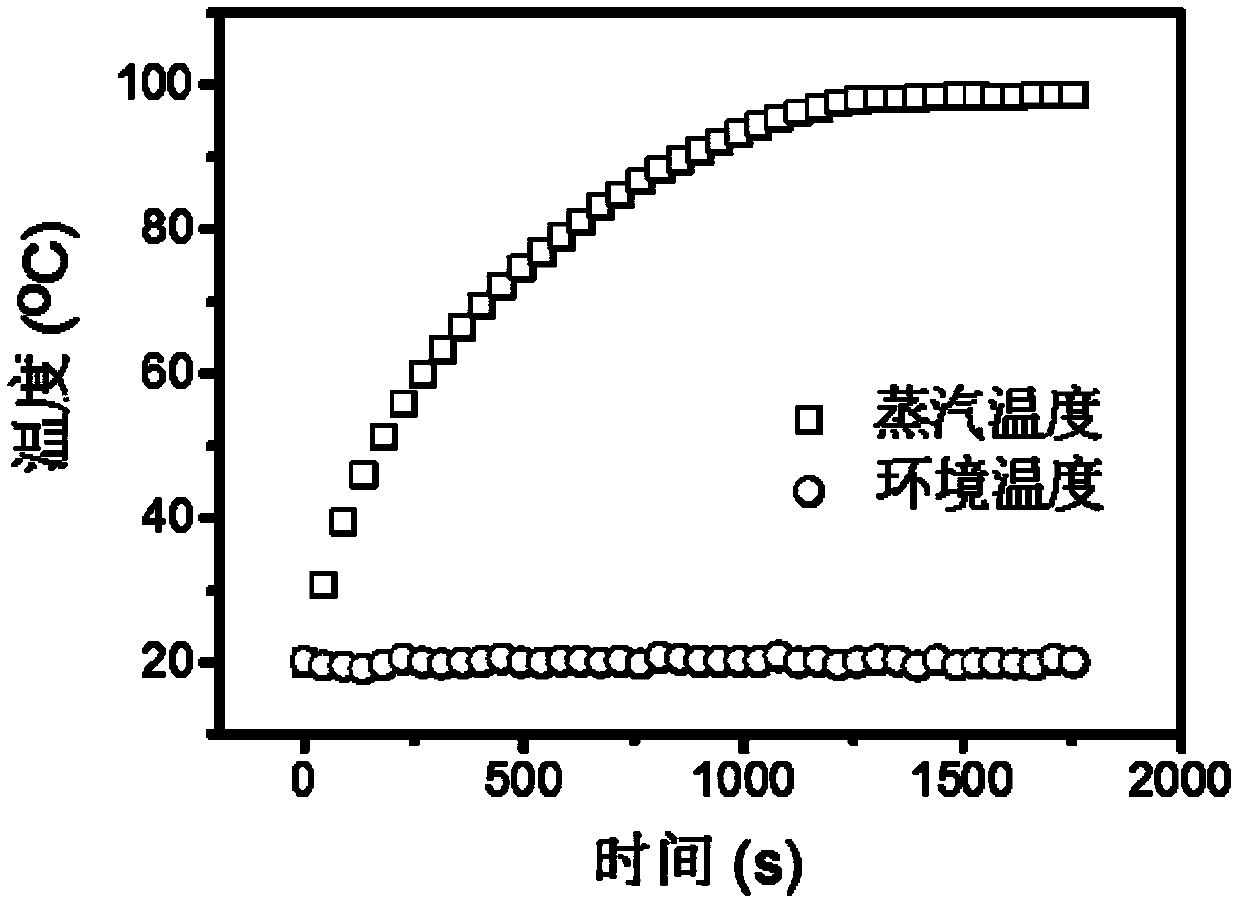

Efficient solar vapor generator based on interface evaporation

InactiveCN109630996AImprove light absorption capacityPromote absorptionSteam generation using solar heatEvaporationEngineering

The invention relates to an efficient solar vapor generator based on interface evaporation. The vapor generator comprises a container, water, a floating heat insulating material, a multi-hole evaporator, a light absorbing plate, and a capillary material, wherein the upper portion of the container is provided with an opening and covered with a transparent cover plate, the water, the floating heat insulating material, the multi-hole evaporator and the light absorbing plate are sequentially contained in the container from bottom to top, the capillary material penetrates through the floating heatinsulating material, one end of the capillary material is arranged in water, and the other end of the capillary material is connected with the multi-hole evaporator. A vapor outlet pipe connected withthe outside is led out of the interior of the multi-hole evaporator in the side direction. Compared with the prior art, the solar vapor generator has efficient solar photo-thermal conversion efficiency, vapor of 100 DEG C can be generated under low illumination intensity and normal pressure can be achieved, and the solar vapor generator has the advantages of being high in heat response speed, simple in structure, stable in operation, and capable of collecting the vapor easily.

Owner:SHANGHAI JIAO TONG UNIV

Epoxy resin with shape memory property and preparation method thereof

The invention relates to the technical field of high polymer materials, and particularly relates to an epoxy resin with the shape memory property and a preparation method thereof. The epoxy resin with the shape memory property comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 20.6-35.5 parts of sebacic monobasic amine, 14.4-20.3 parts of curing agent and 0.1-2.2 parts of curing catalyst, wherein the epoxy resin is bisphenols A epoxy resin and aliphatic epoxy resin blended resin. The influence temperature can be conveniently adjusted by changing the content and the alkyl group length of the sebacic monobasic amine or the content of the epoxy resin in the formula; the epoxy resin with the shape memory property is short in heat response time and fast in shape recovery rate and has a good shape memory effect after the shape memory repeatedly circulates; the forming process of the epoxy resin with the shape memory property is mature and low in cost; the epoxy resin with the shape memory property has relatively good mechanical property and thermal property, good chemical resistance and the characteristics of super toughness, impact resistance, wear resistance, low friction coefficient and the like and is difficult to deform, melt and burn at a high temperature environment.

Owner:DONGGUAN JIEYUE SHENGSHI SPORTS GOODS

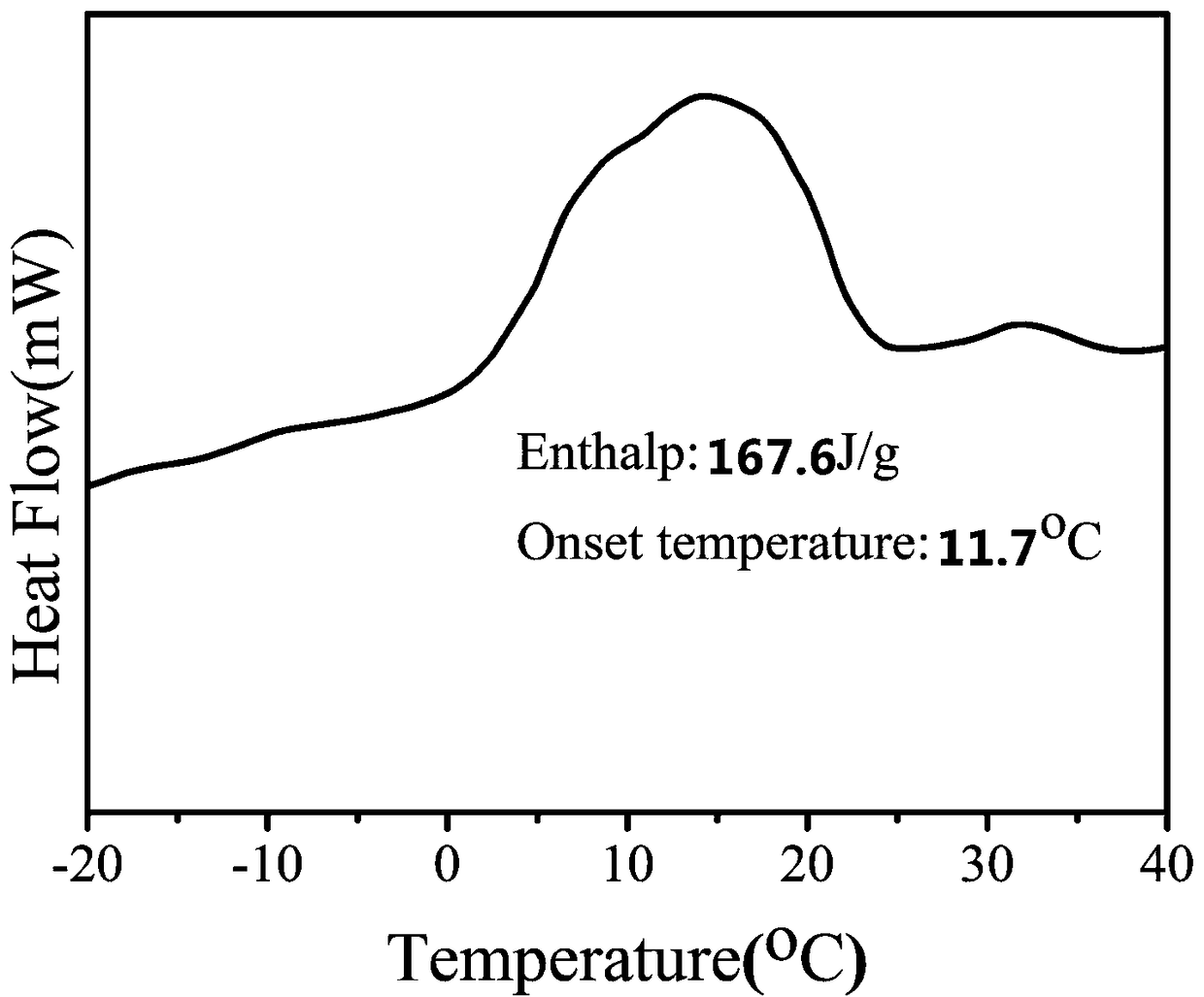

Heat conduction enhanced organic PCM (phase change material) and preparation method thereof

InactiveCN108997977AFast heat responseFast heat conductionChemical industryHeat-exchange elementsCarbon nanotubeBoron nitride

The invention discloses a heat conduction enhanced organic PCM (phase change material). The heat conduction enhanced organic PCM is prepared from an organic PCM containing nano-particles as a core material and a porous material as a wall material, wherein the nano-particles are boron nitride, CNTs (carbon nano tubes), expanded graphite and graphene oxide. A preparation method of the heat conduction enhanced organic PCM comprises the following steps: 1) a process of emulsifying the organic PCM; 2) a process of adsorbing the organic PCM containing the nano-particles by the porous material undera vacuum condition; and 3) a process of taking out a product obtained after vacuum adsorption. The heat conduction enhanced organic PCM has the advantages that 1) the heat response speed is high, i.e.the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and 4) raw materials are safe, non-toxic and non-corrosive, and the technical characteristics of being simple in preparation process and low in cost are achieved. Therefore, the heat conduction enhanced organic PCM is better in heat conductivity and stability, the using ratio ofenergy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

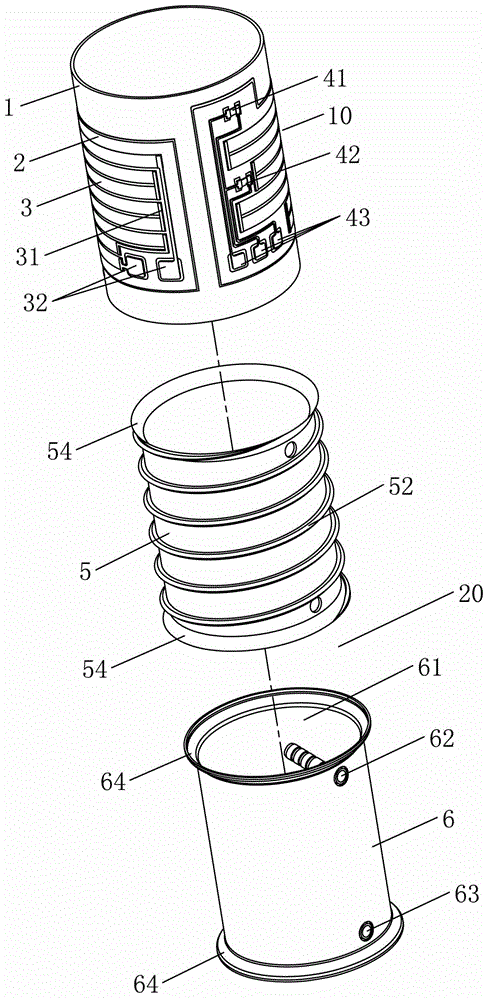

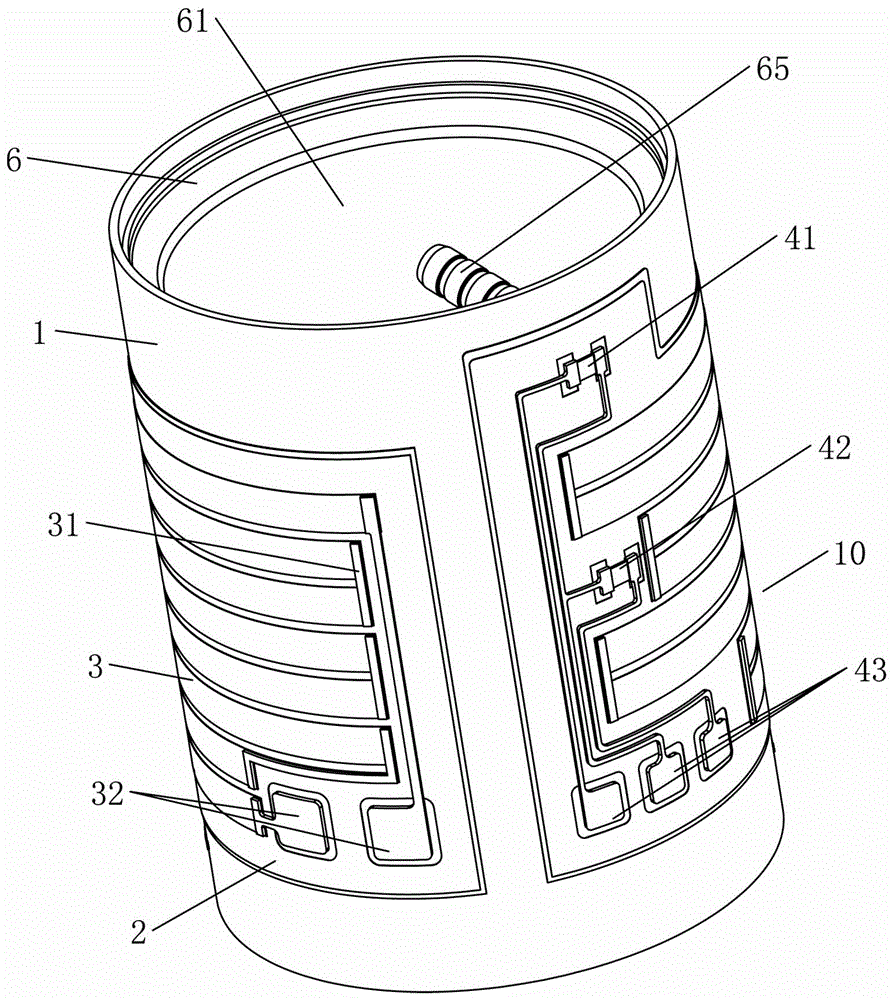

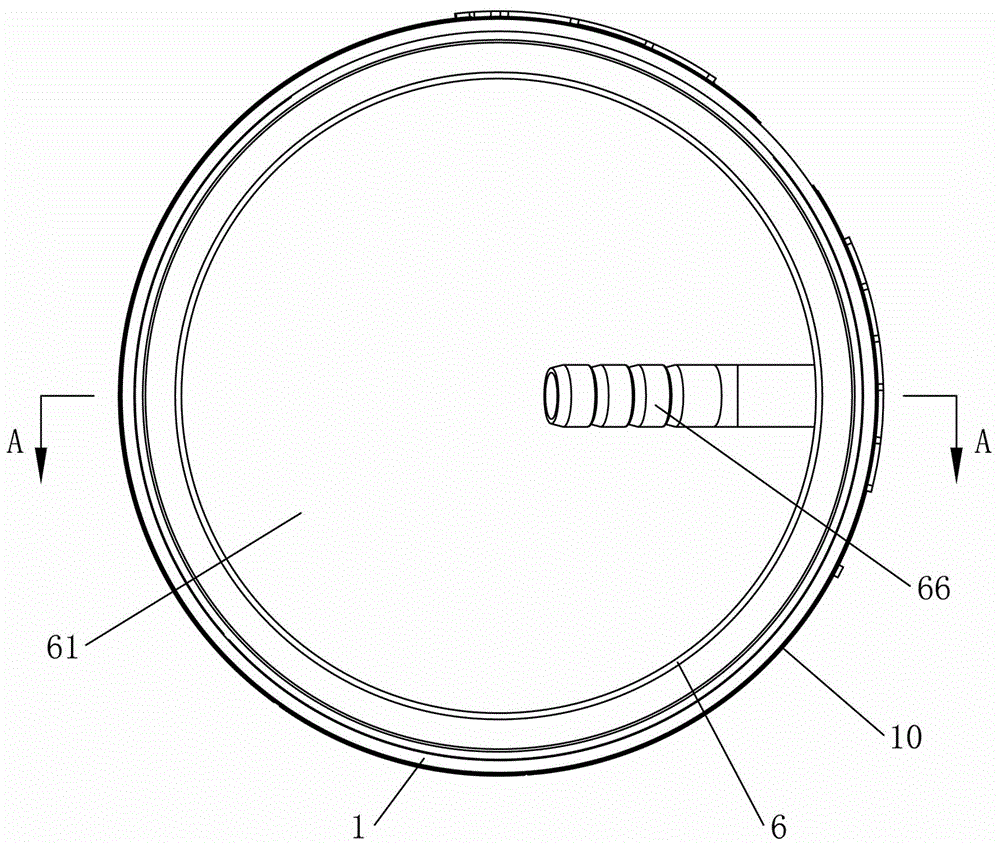

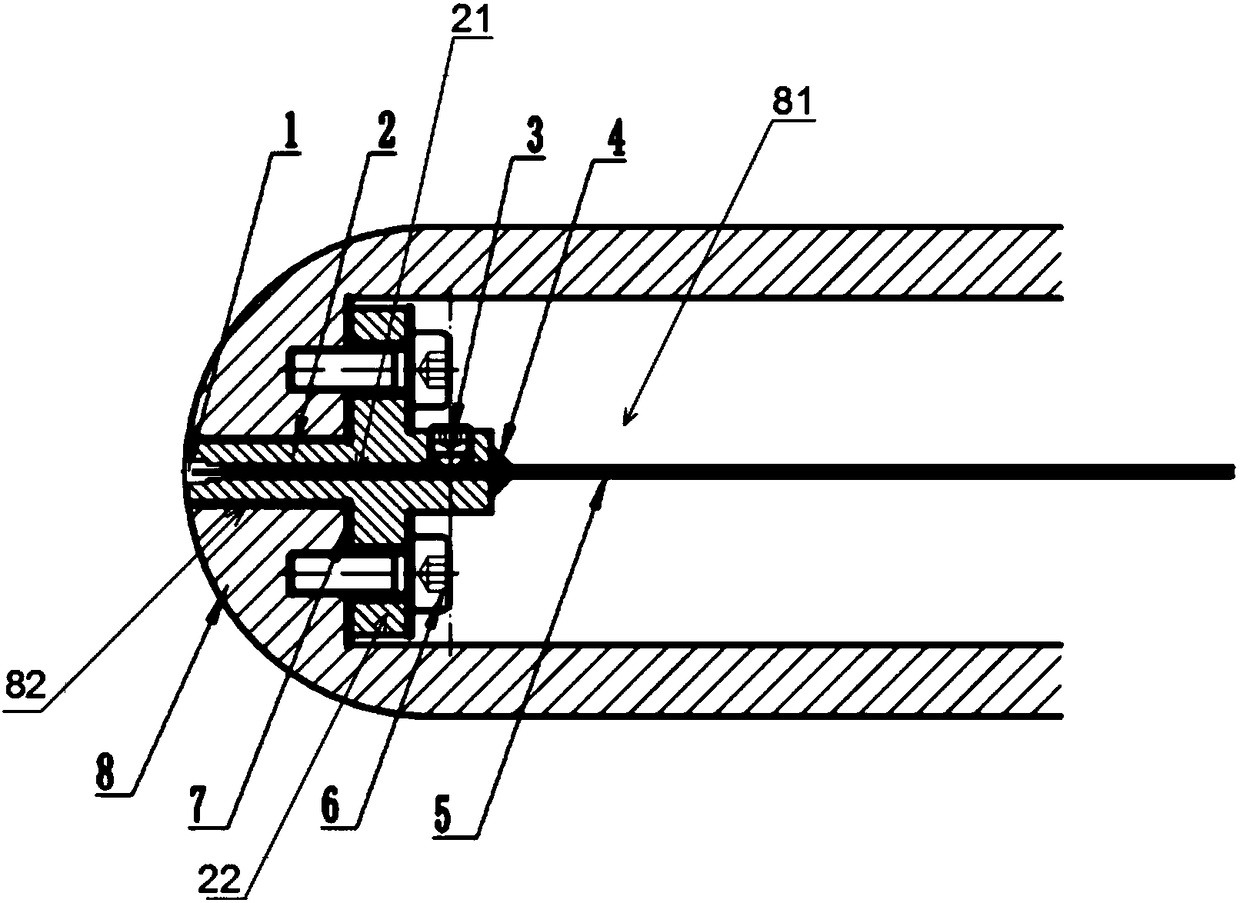

Liquid heating device

ActiveCN105716269AReduce the waiting time for booting up and warming upStable temperatureHeating element shapesWater heatersEngineeringSilica gel

The invention relates to a liquid heating device which comprises a body of a cylindrical structure and a heating element of a cylindrical structure. The surface of the body is sleeved with the heating element. The heating element is composed of an outer pipe and a heating circuit printed on the outer surface of the outer pipe. The body is composed of an inner pipe and a silica gel sleeve. The two ends of the inner pipe are matched with the two ends of the outer pipe in a sealed manner. An inner cavity is formed between the outer pipe and the inner pipe. The silica gel sleeve is arranged on the outer side of the inner pipe in a sleeving manner and sealed in the inner cavity. Protruding edges are arranged on the outer surface of the silica gel sleeve and matched with the inner wall of the outer pipe in a sealed manner. A liquid circulating route is defined jointly by the outer surface of the silica gel sleeve, the protruding edges and the inner wall of the outer pipe. The body is provided with a liquid inflow channel and a liquid outflow channel which correspond to the liquid circulating route. The liquid heating device has the beneficial effects of being simple and reasonable in structure, high in heating response speed, low in energy consumption and the like.

Owner:广西桂仪科技有限公司

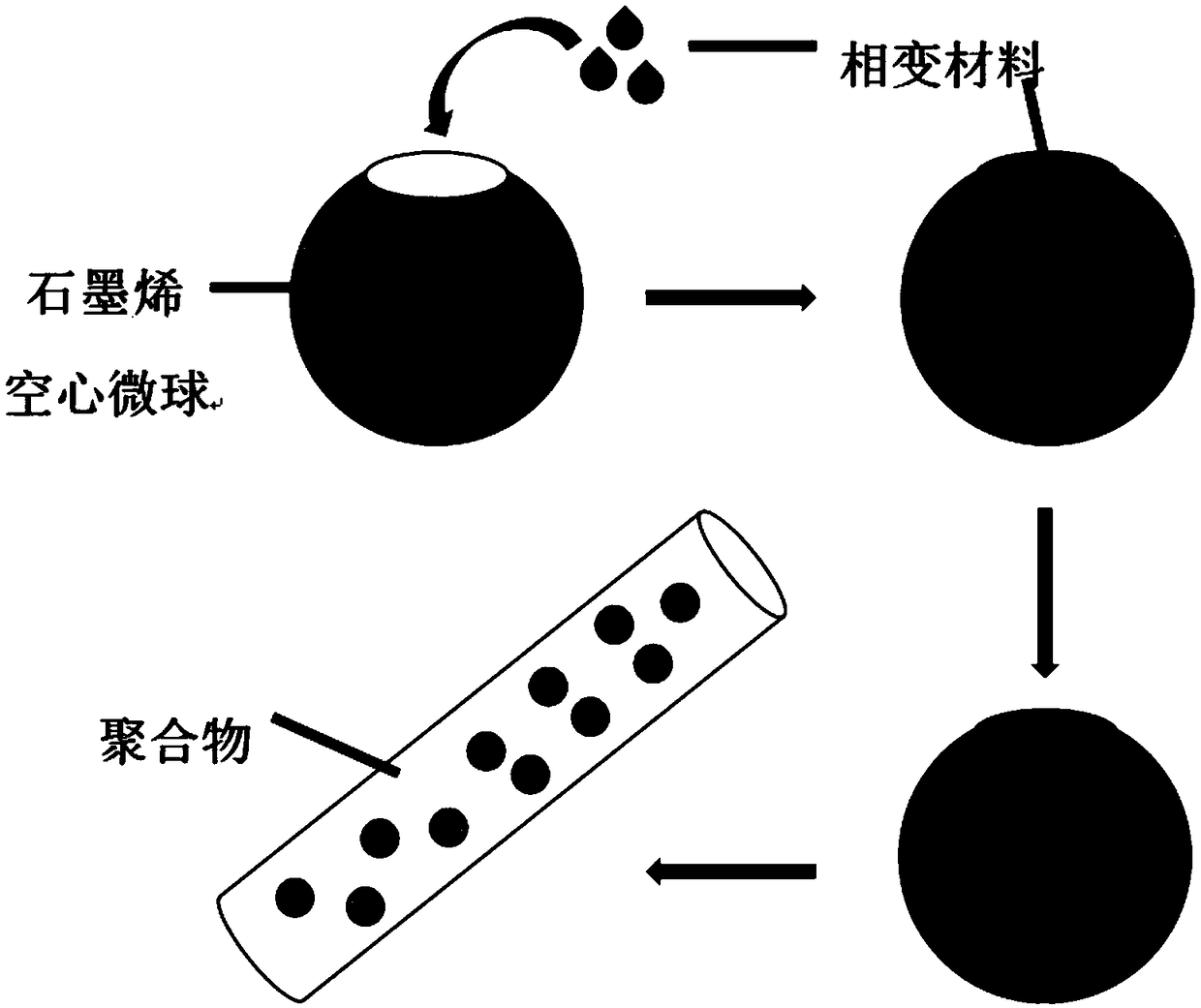

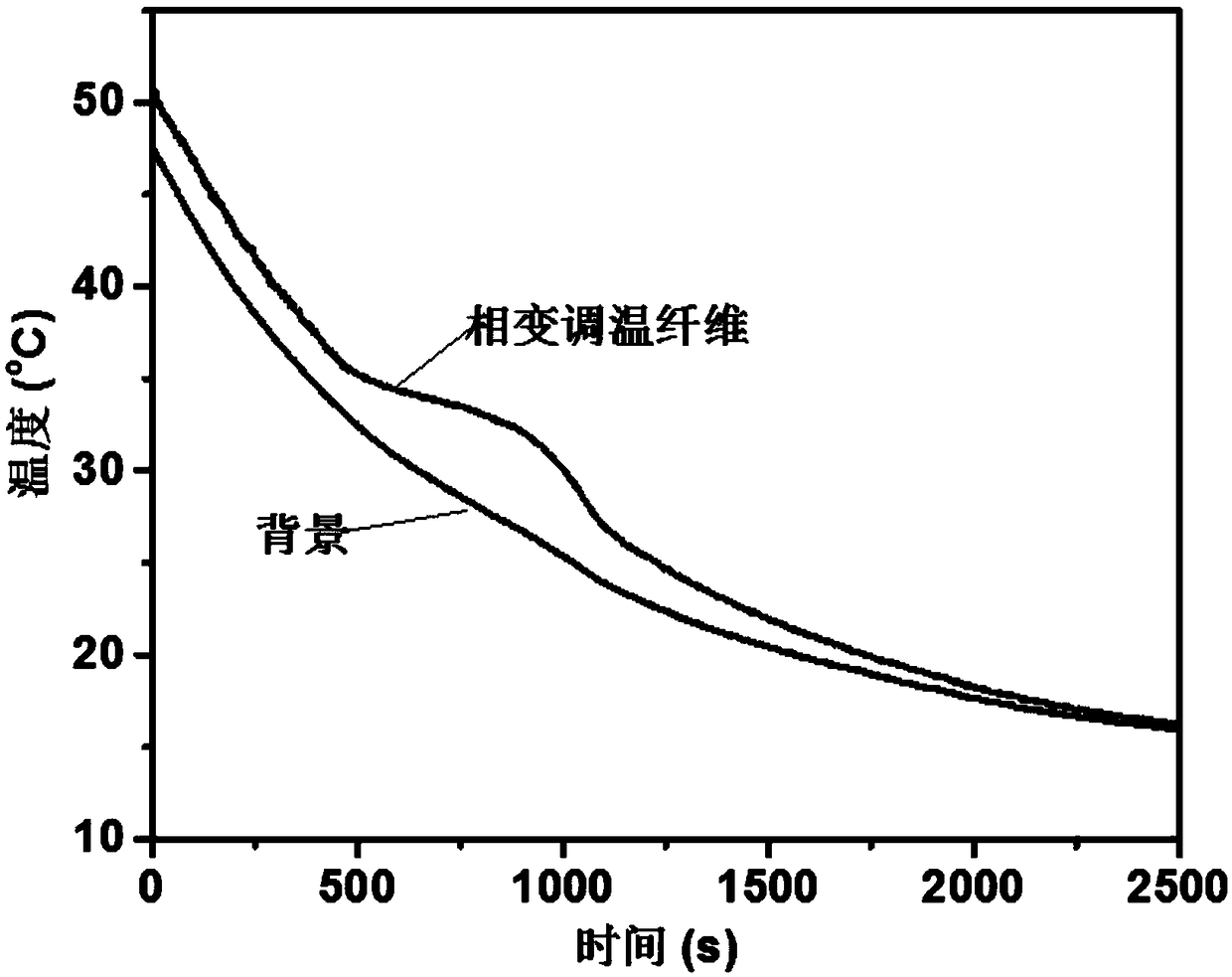

Phase change microspheres, intelligent temperature-adapting fiber and preparation methods thereof

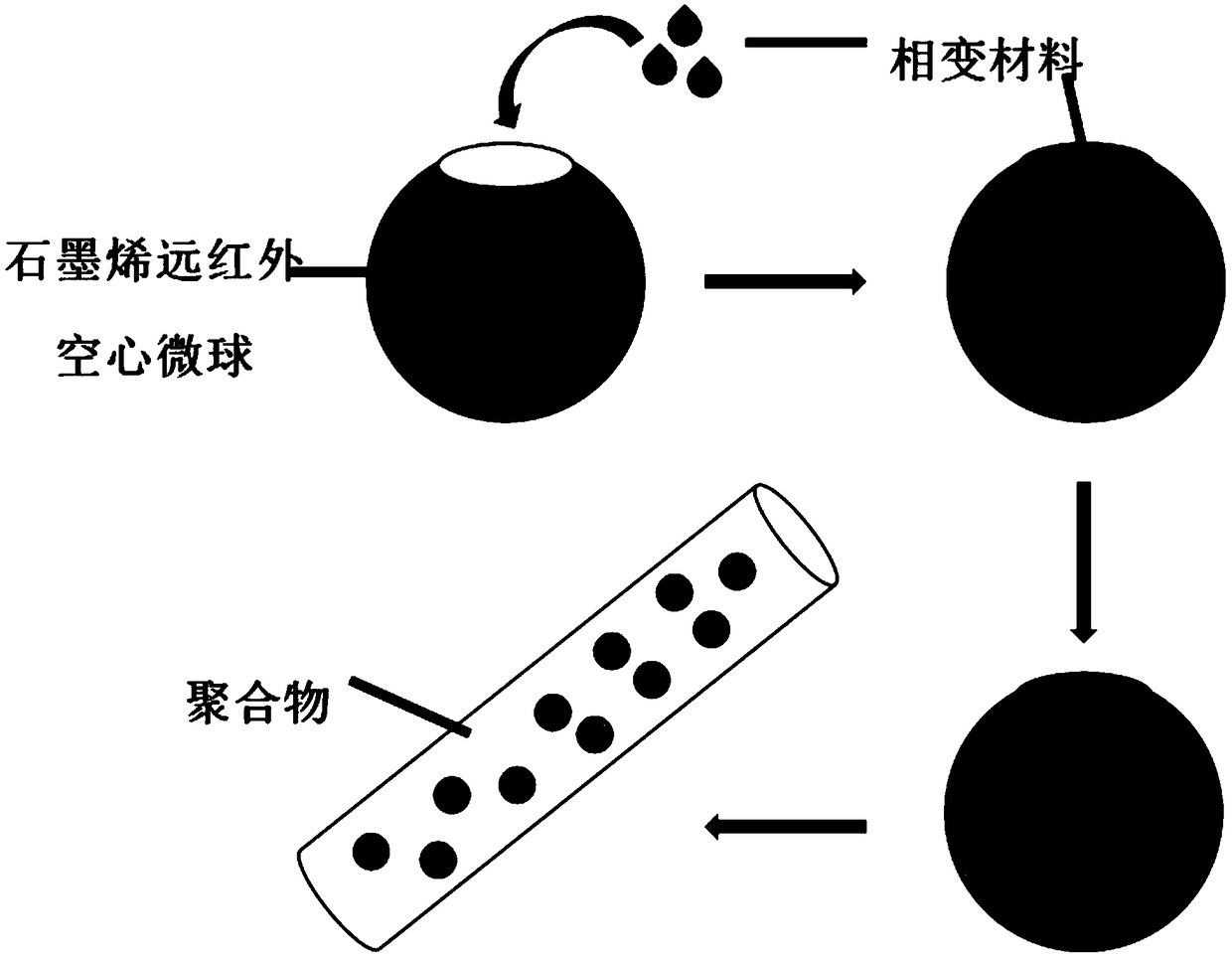

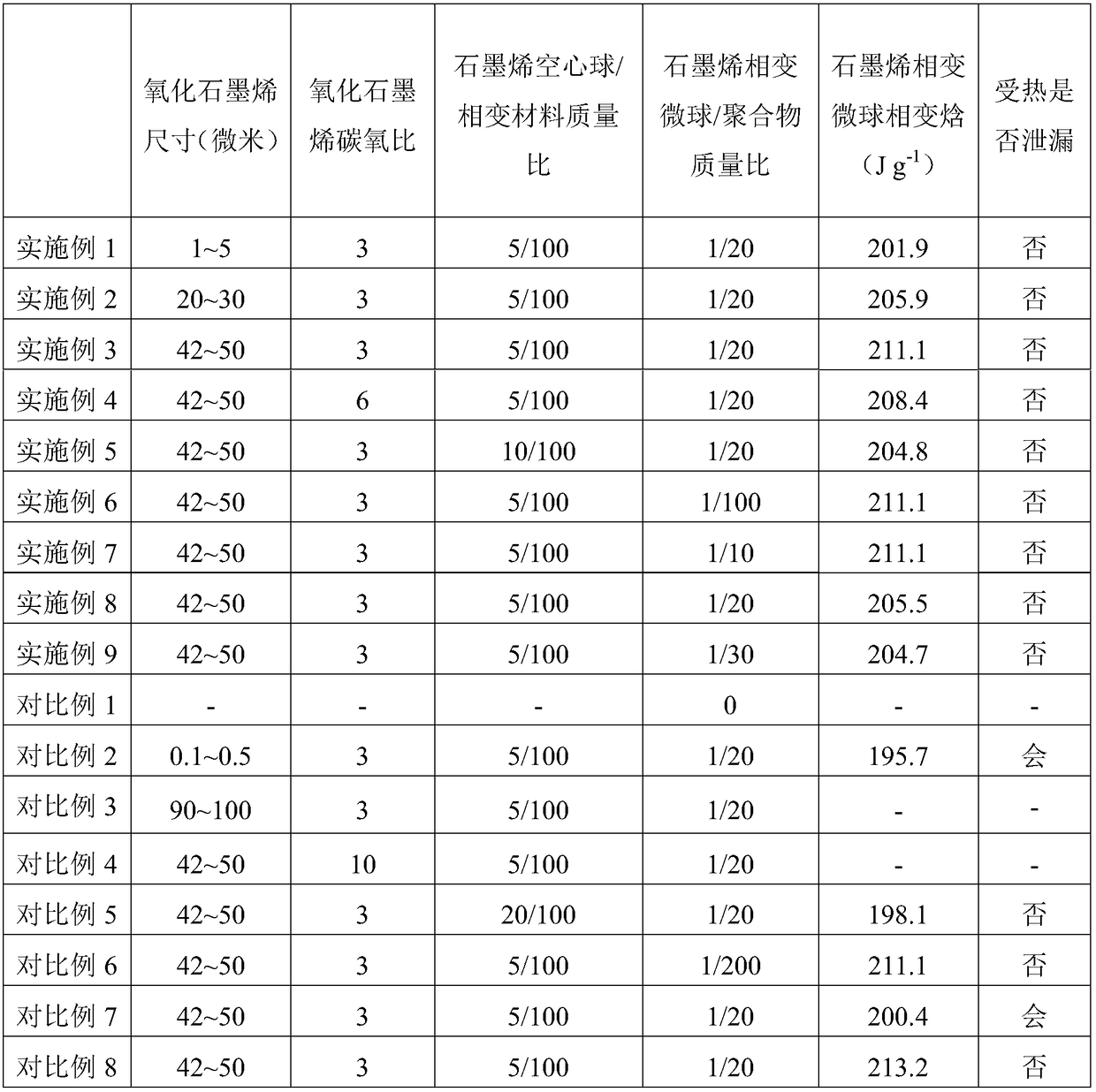

InactiveCN109234825AEnsure coverageImprove mechanical propertiesArtifical filament manufactureMonocomponent polyamides artificial filamentFiberMicrosphere

The invention discloses phase change microspheres, intelligent temperature-adapting fiber and preparation methods thereof. Firstly, graphene far-infrared microspheres adopting mesoporous structures are prepared, then a phase change material is melted and fully the phase change material is infiltrated into cavities of the graphene microspheres to obtain the phase change microspheres adopting core-shell structures. The excess phase change material on the surfaces of the phase change microspheres is removed through pressure filtration, and after cooling, melt blending and spinning are performed on the phase change microspheres and spun-grade polymer chips to obtain composite fiber with an intelligent temperature-adjusting function. Through use of the graphene hollow spheres for wrapping the phase change material, leakage of the phase change material during using is greatly reduced, so that the service life can be significantly prolonged; high heat conductivity of graphene can effectivelypromote heat exchange between the environment and fabric and between the fabric and the surface of a human body, so that the heat response speed of heat storage fabric can be increased; the graphene and nanometer far-infrared powder have a high-efficiency far-infrared radiation function, so that the temperature of the body surface can be increased, and blood circulation is promoted.

Owner:HANGZHOU GAOXI TECH CO LTD

Transient heat flow sensor

PendingCN108344521AReduce the difficulty of manufacturing processSimple welding processThermometers using electric/magnetic elementsUsing electrical meansHeat flowFusion welding

The invention discloses a transient heat flow sensor which comprises a heat measuring probe outer shell and a heat flow sensor body, the heat flow sensor body comprises an oxygen-free copper heat transfer body, an end-exposed type armored thermocouple, and a pure silver plunger. A containing through hole is formed in the center of the oxygen-free copper heat transfer body and the inner diameter ofthe position, close to the front end of the oxygen-free copper heat transfer body, of the containing through hole is increased, and the oxygen-free copper heat transfer body is connected in the heatmeasuring probe outer shell by arranging a flange structure. The end-exposed type armored thermocouple is fixed in the containing through hole of the oxygen-free copper heat transfer body, and the temperature measuring point of the end-exposed type armored thermocouple is located in the center of the containing through hole of the oxygen-free copper heat transfer body, and the head part has a certain distance away from the outlet position of the containing through hole. The pure silver plunger is connected at the output position of the containing through hole of the oxygen-free copper heat transfer body by means of casting or fusion welding, and is integrated with the head part of the end-exposed type armored thermocouple. The transient heat flow sensor of the novel structure has the advantages of being simple in processing and assembling process, being easy to achieve quality control, and improving the heat response speed and the test accuracy of the sensor.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Hollow heat-retaining putty

InactiveCN101555366ALow water absorptionReduce coefficient of frictionFilling pastesFiberCrack resistance

The invention relates to hollow heat-retaining putty which is prepared by the following steps: mineral fiber, heat-response powder and base material gluing auxiliary powder are evenly mixed with a weight proportion of 1.0-2.0:0.2-0.8:89.5-137.3 to prepare the putty, ant the putty is weighted and packaged by bags. The putty overcomes the defects that the prior product has large blocking force, is easy to sag and can not ensure the blow thickness of a coat when being used in construction, the grains of the product are easy to smash when being stirred and blown, and the adhesive force is unsteady. The invention has fire resistance, heat insulation, heat preservation, sound insulation, crack resistance and yellowing resistance, steady structure, long quality guarantee period and low cost, thereby being particularly suitable for the actual need of energy saving in construction engineering.

Owner:胡建中

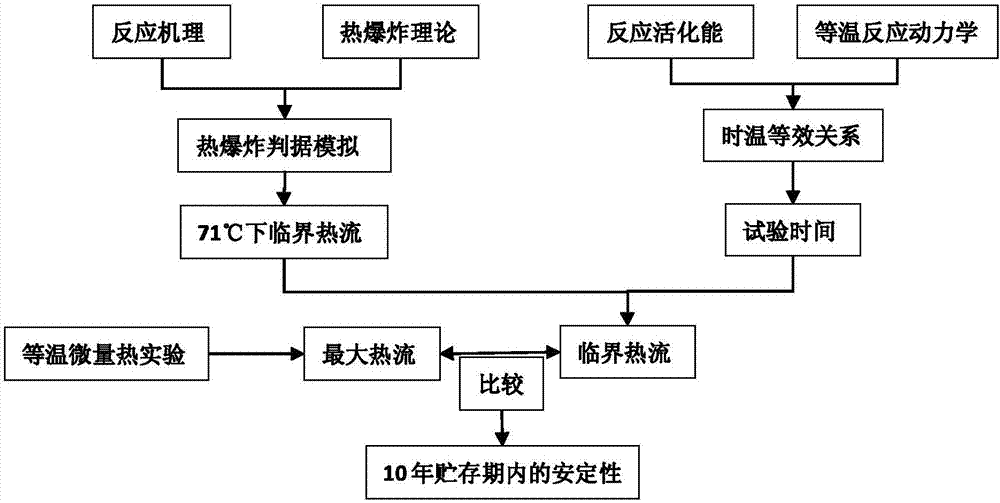

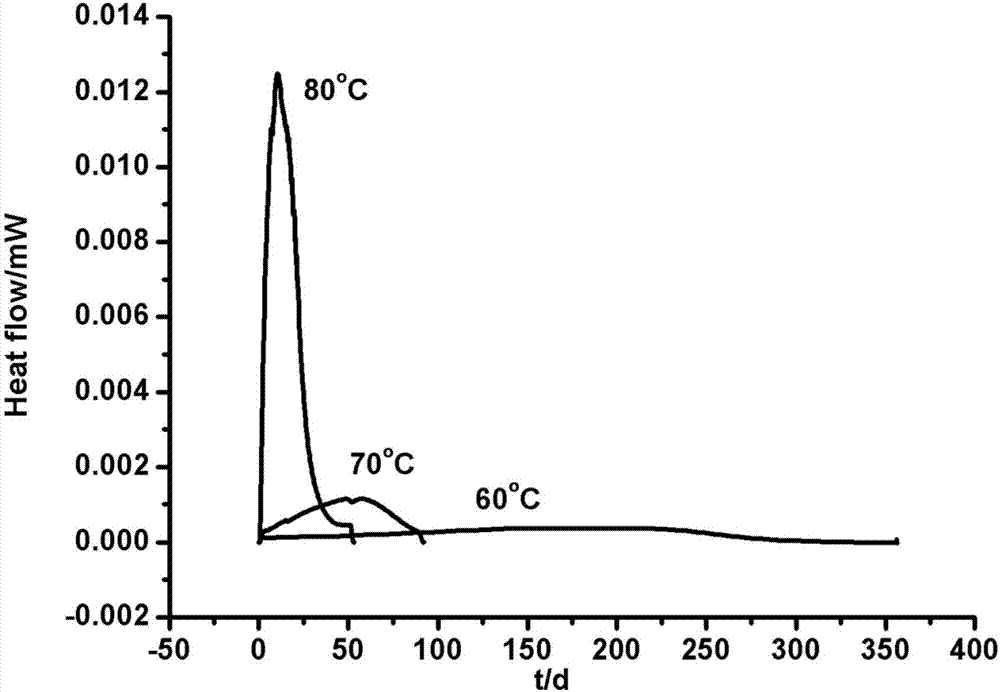

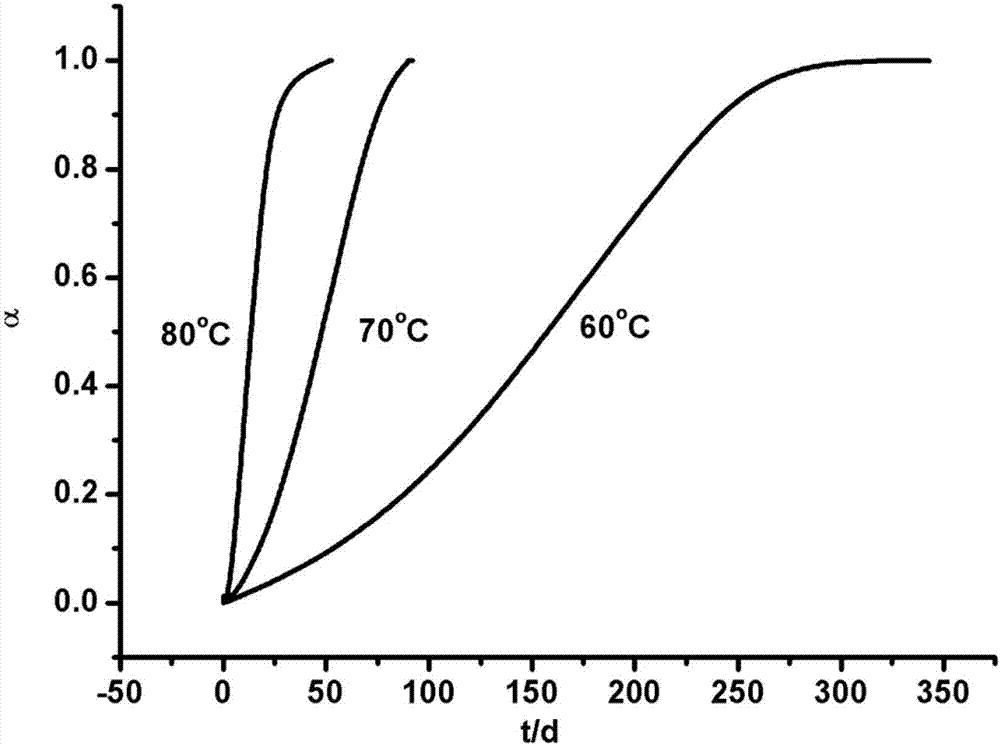

Novel method for evaluating stability of one-base propellant within 10-year storage period through microcalorimetry

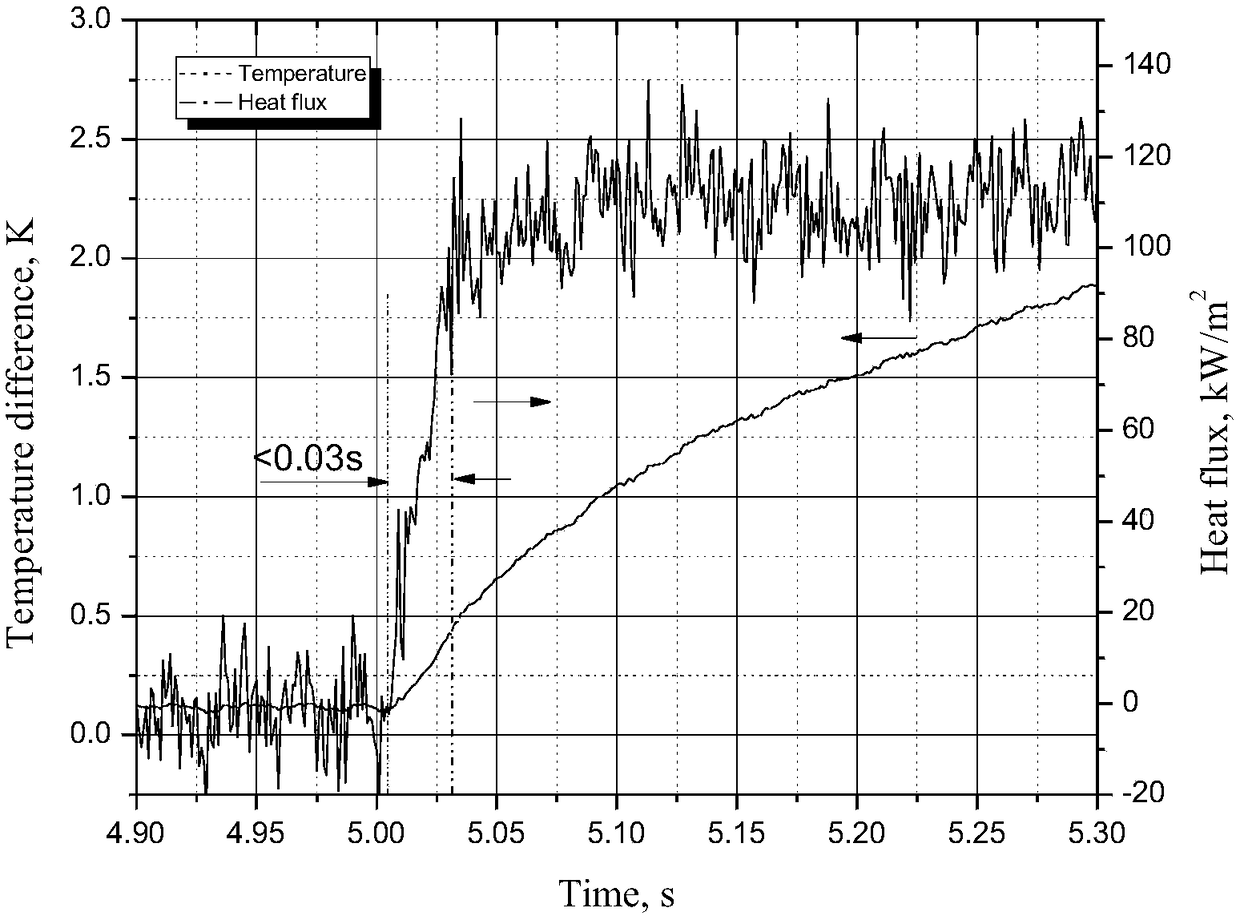

ActiveCN107478674AHigh risk of samplingPracticalMaterial heat developmentEngineeringHeat balance equation

The invention discloses a novel method for evaluating stability of a one-base propellant within a 10-year storage period through microcalorimetry. The method is characterized in that the stability reaction kinetics is researched by tracking micro heat released or absorbed by the one-base propellant at every moment, a time-temperature equivalent relation of the storage process is established, the heat accumulation effect is researched according to a heat balance equation established through heat generation and heat conduction, thus, a heat explosion critical criterion is obtained, microcalorimetry evaluation rules, covering size effects, about storage safety of the one-base propellant are formed, the evaluation rules are compared according to heat response signals output according to a microcalorimetry test when storage safety is evaluated, and the evaluation result of the stability within the 10-year storage period is given. The stability of the one-base propellant within the 10-year storage period is evaluated through microcalorimetry, the stability within 10-year storage period can be given within 10 days, and the measurement process is rapid, safe, nondestructive, environmentally friendly and convenient.

Owner:XIAN MODERN CHEM RES INST

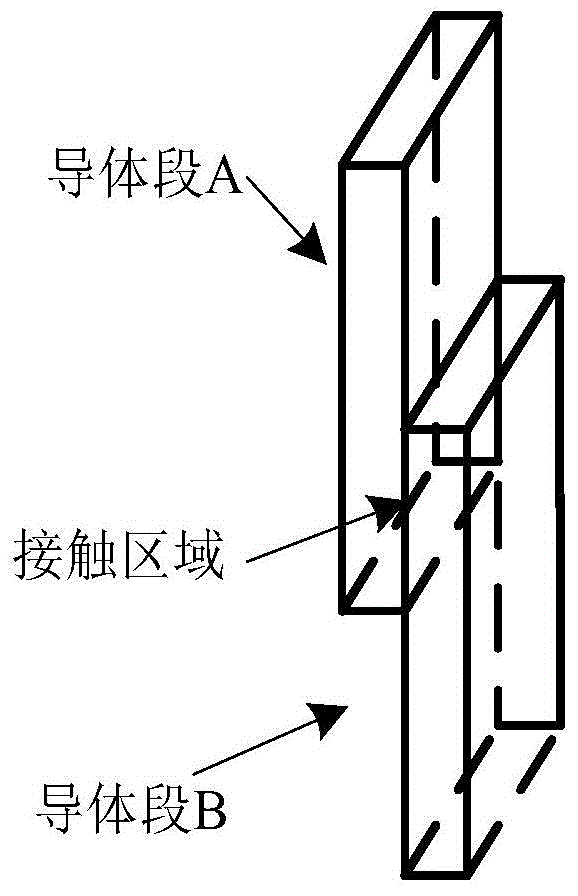

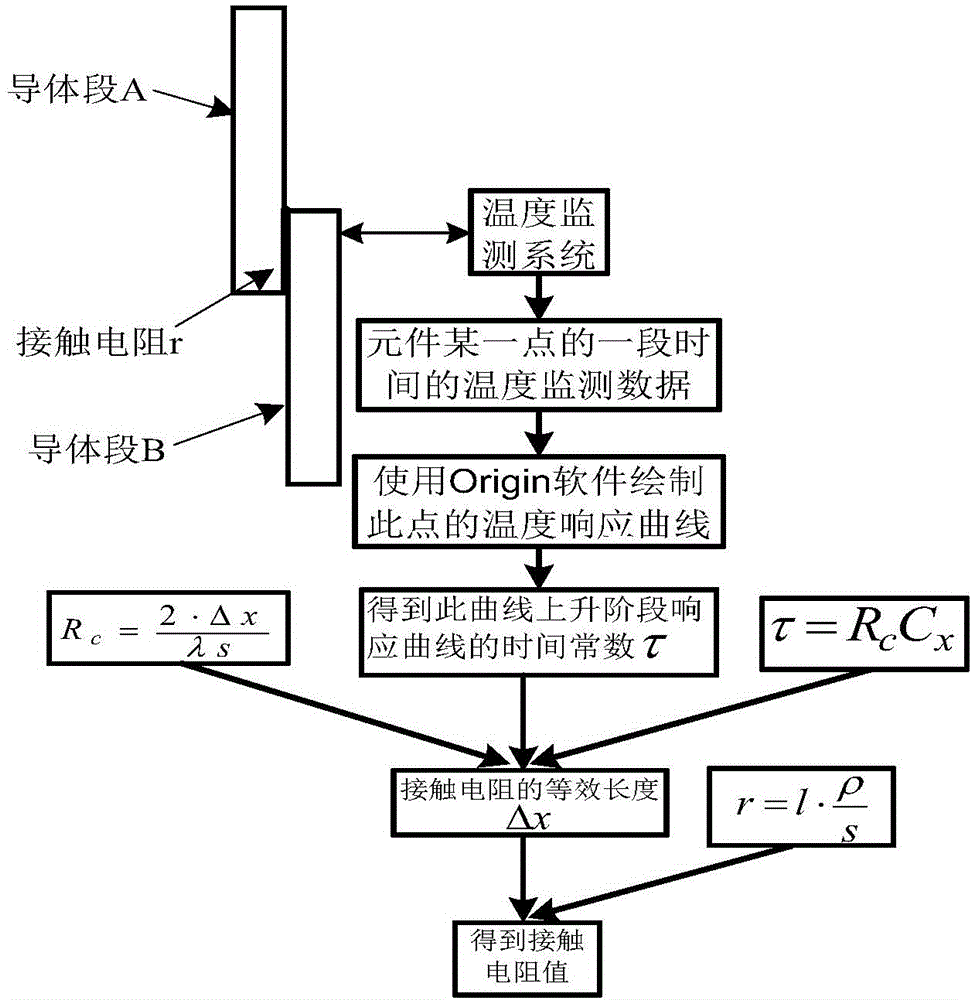

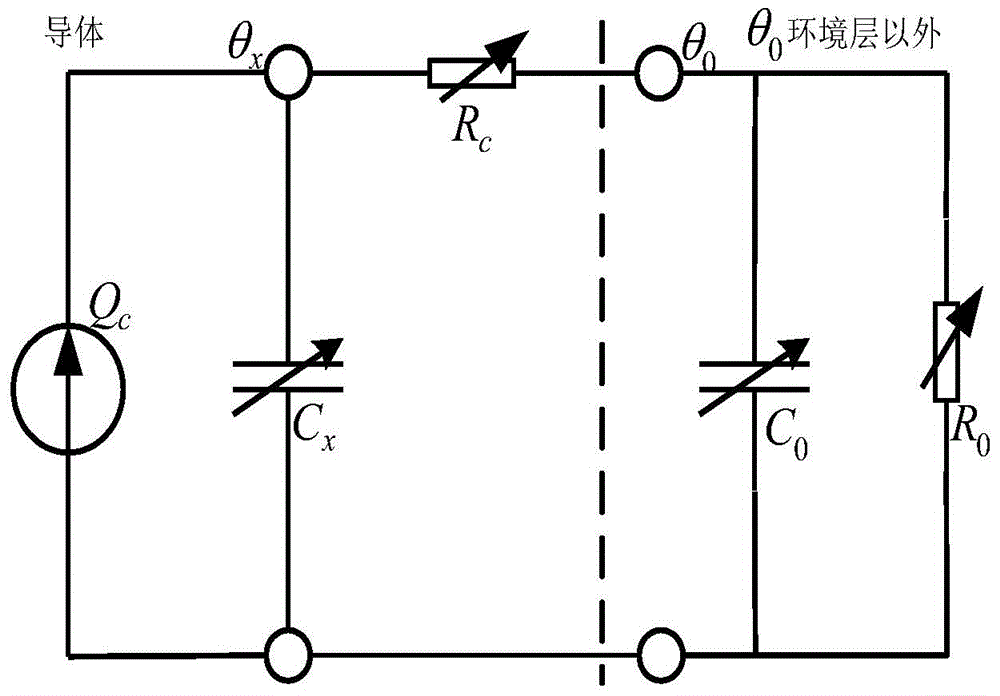

Method for measuring contact resistance on line

ActiveCN104062323AReliable temperature dataAccurate calculation of sizeMaterial impedanceTemperature responseBusbar

The invention discloses a method for measuring contact resistance on line. The method comprises the following steps: firstly, measuring the real-time temperature of a surface point, close to a heat source area, of a contact element to be measured, so as to obtain temperature data, subsequently calculating heat response constant of the contact element according to a temperature response curve drawn according to the temperature data by using an established first-order heat path model equation and Origin software, and finally deriving according to the equation so as to obtain the contact resistance of the contact element. By adopting the method, the contact resistance of electric connectors, such as high voltage switch cabinet busbar connectors, switch connectors and knife switches can be accurately measured on line, and data reference is provided for practical application such as state monitoring, analysis and fault treatment on electric equipment.

Owner:西安兴汇电力科技有限公司

Heat conduction enhanced MOFs (metal-organic frameworks) PCM (phase change material) and preparation method thereof

InactiveCN108997975AHigh heat storage densityImproved thermal cycling stabilityChemical industryHeat-exchange elementsMetal-organic frameworkVolumetric Mass Density

The invention provides a heat conduction enhanced MOFs (metal-organic frameworks) PCM (phase change material). The heat conduction enhanced MOFs PCM is prepared from an organic PCM containing heat conduction enhanced nano-particles as a core material and a MOFs material as a wall material. A preparation method of the heat conduction enhanced MOFs PCM comprises the following steps: 1) a process ofemulsifying the organic PCM; 2) a process of adsorbing the organic PCM containing the nano-particles with the MOFs material under a vacuum condition; and 3) a process of taking out a product obtainedafter vacuum adsorption. The heat conduction enhanced MOFs PCM has the advantages that 1) the heat response speed is high, i.e. the heat conduction property is high; 2) the heat accumulation density is high; 3) the heat cycling stability is high; and 4) raw materials are safe, non-toxic and non-corrosive, and the technical characteristics of being simple in preparation process and low in cost areachieved. Therefore, the heat conduction enhanced MOFs PCM is higher in heat conductivity and stability, the using ratio of energy sources is improved, and the application prospect is wide.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

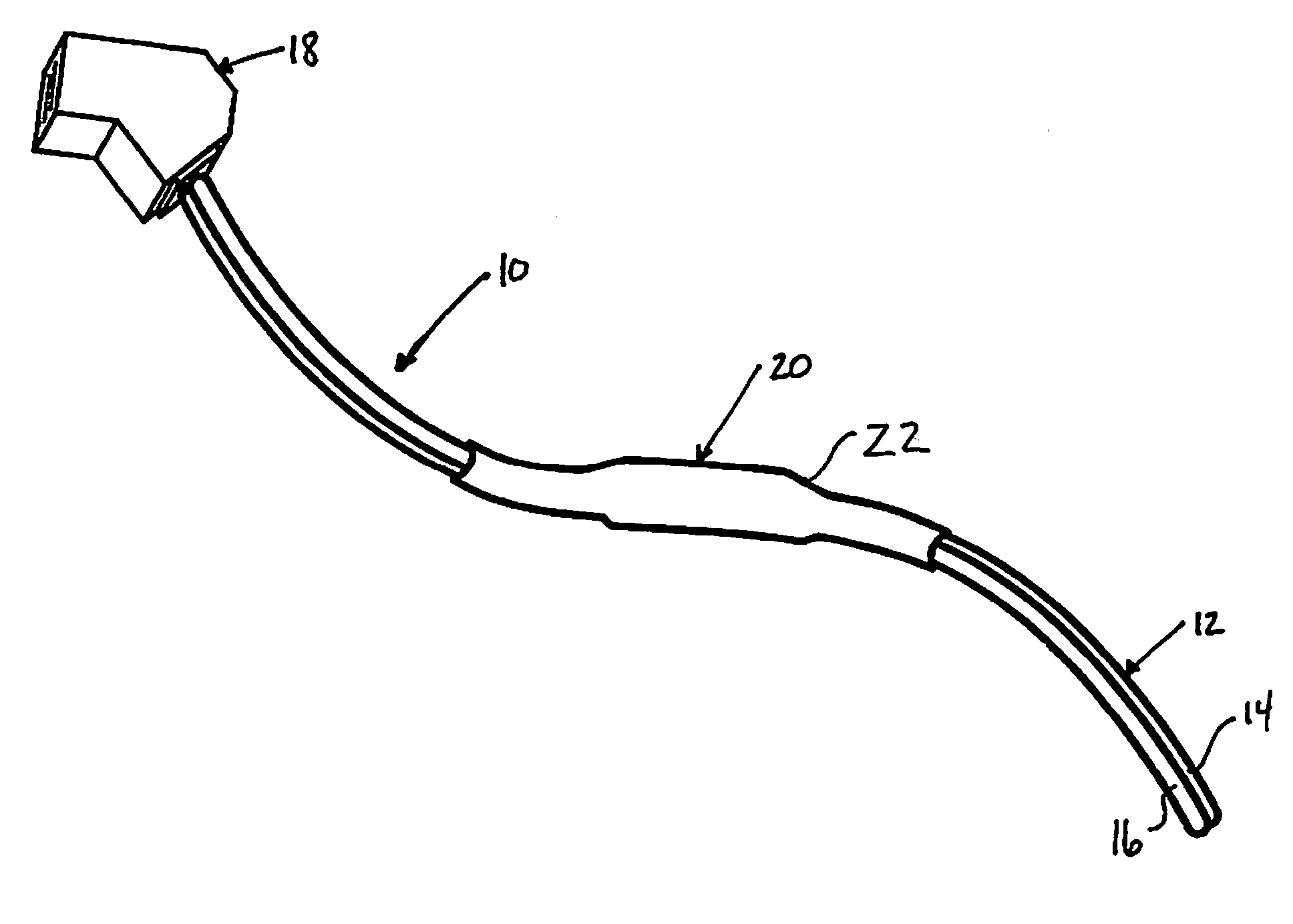

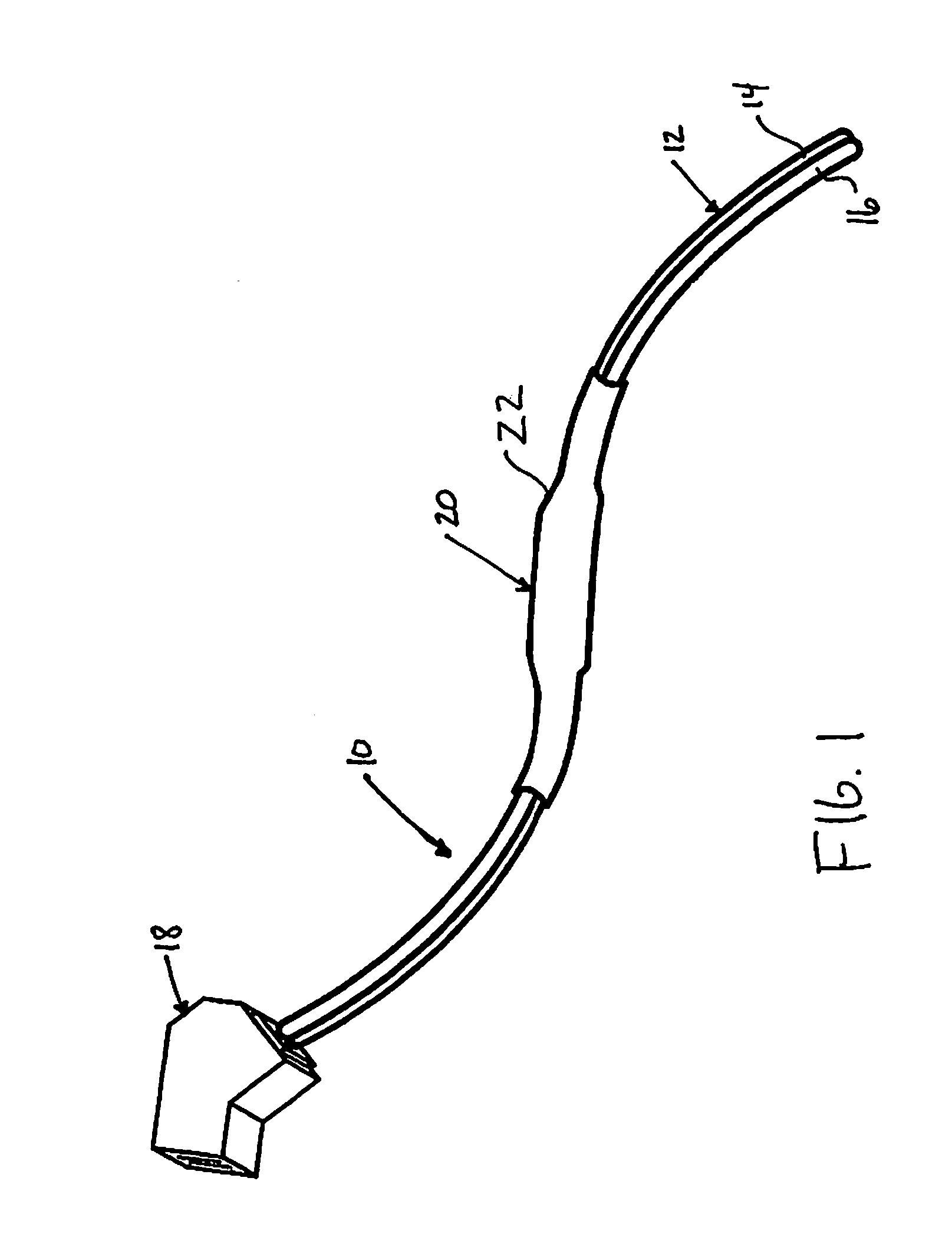

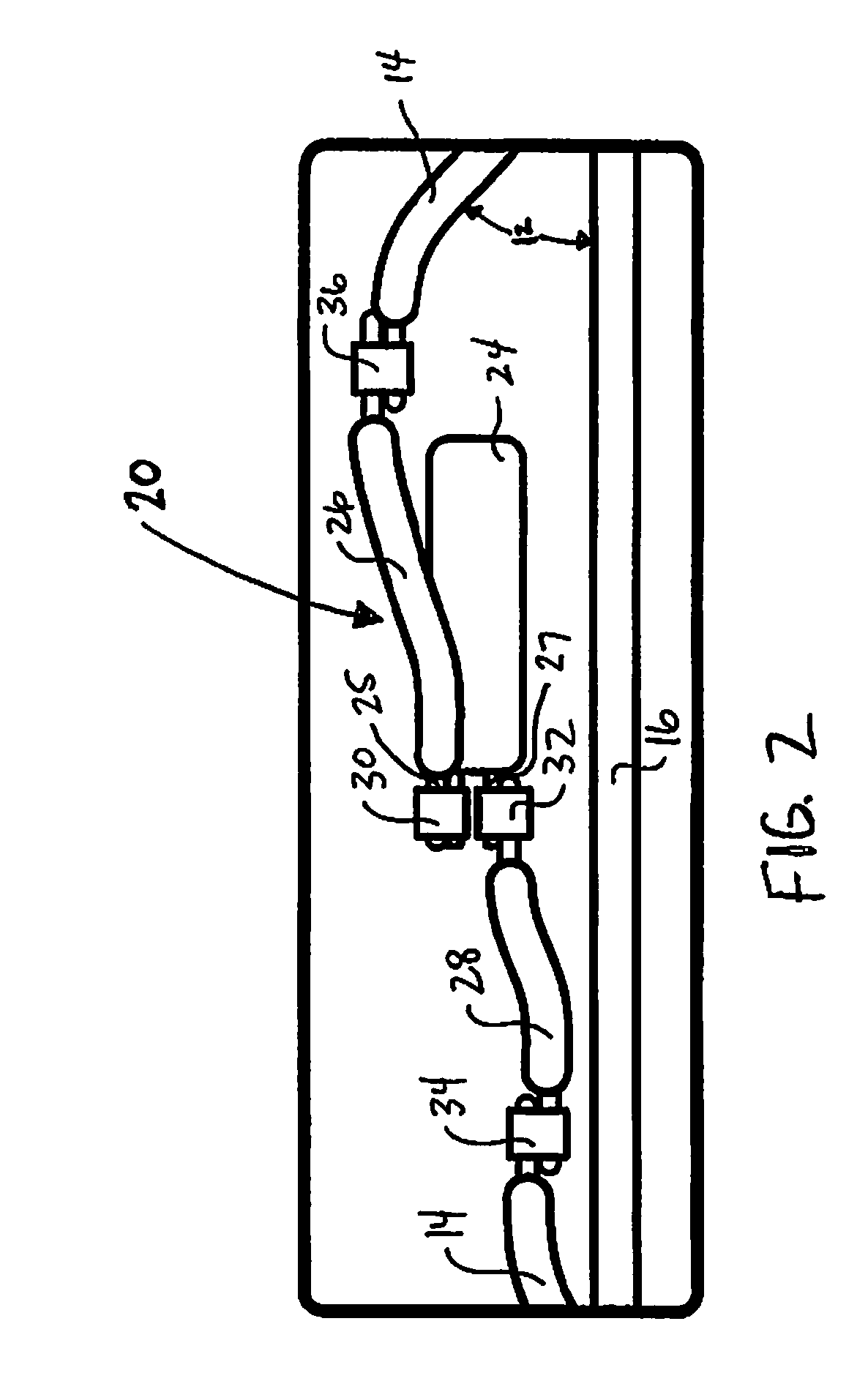

Power Cord with Thermal Control

InactiveUS20110095621A1Reduce energy consumptionSimple designBoards/switchyards circuit arrangementsThermally actuated switchesElectrical conductorAlternating current

The present invention relates to a cord for powering a cooling element including a thermally-actuated switch assembly and a method of controlling a cooling element through a power cord including a thermally-actuated switch assembly in an alternating current (AC) circuit. The cord assembly includes a multiple conductor wire for carrying power and a heat reactive element. The heat reactive element is connected in line and integral with one of the conductors of the wire. The heat reactive element functions as a switch to conduct power through the wire in one state and to interrupt power through the wire in a second state. The heat reactive element changes from one state to the other state in response to ambient air temperature.

Owner:GARDTEC

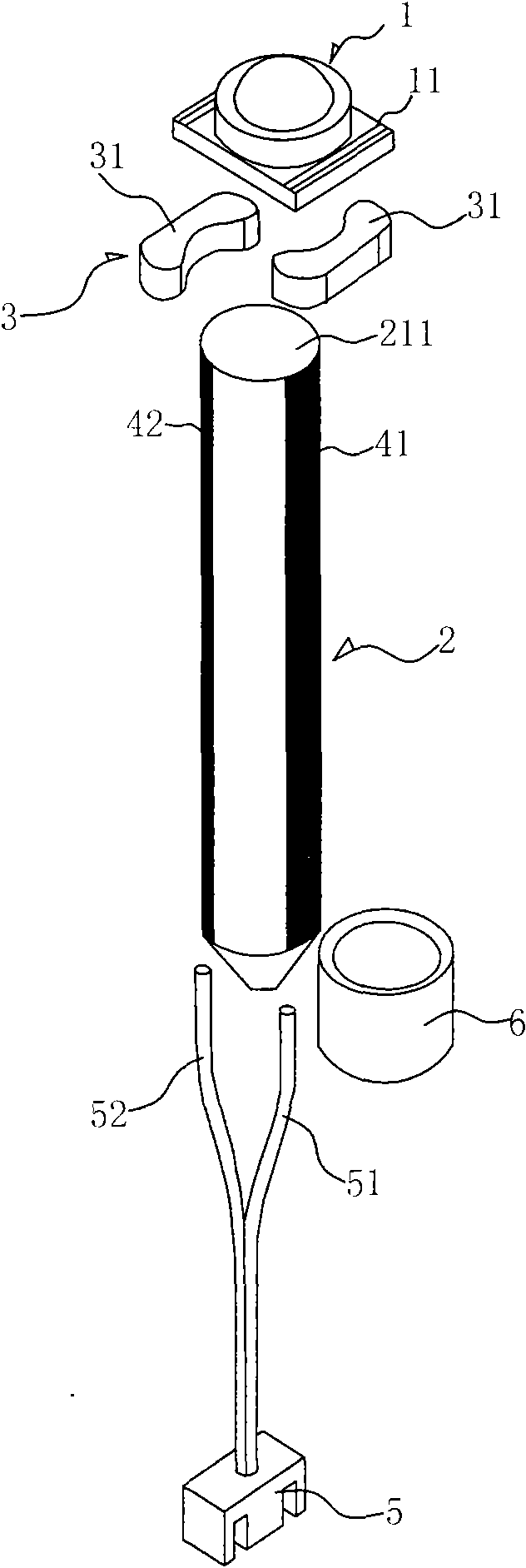

LED heat radiating device

The invention relates to an LED heat radiating device capable of effectively enhancing heat radiating efficiency and simplifying circuit connection, relating to the technical field of LED heat radiating technologies. The LED heat radiating device comprises an LED and a heat-conducting heat pipe, wherein the heat-conducting heat pipe is connected with an LED substrate; the LED substrate is fixed to one end of the heat-conducting heat pipe; and conducting wires are coated on the surface of the heat-conducting heat pipe and electrically connected with the LED. The heat-conducting heat pipe is adopted as a heat-conducting main body, therefore, the invention has the advantages of high heat conductivity, good isothermality, fast heat response, simple structure, no additional electric drive, and the like and becomes an ideal heat-conducting heat-radiating element of the traditional LED chip with high heat density; and in addition, in the invention, the heat-conducting heat-radiating heat pipe used as the heat-conducting main body not only plays a heat-conducting role, but also is used as a transmission carrier of current and a signal, thereby preventing the leads from being used for connection and enabling an integral LED product to be simpler and more attractive.

Owner:广州智择物业管理有限责任公司

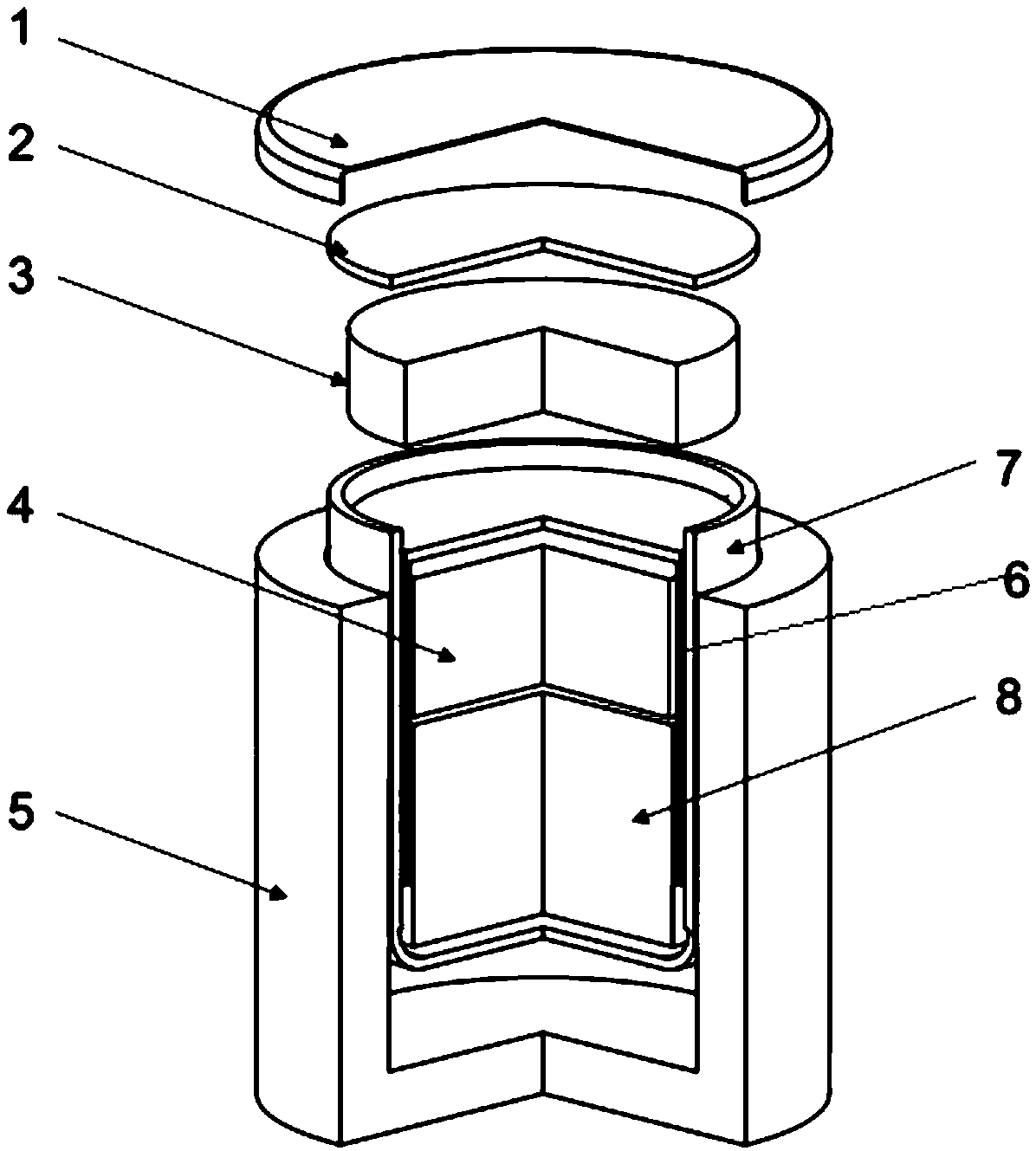

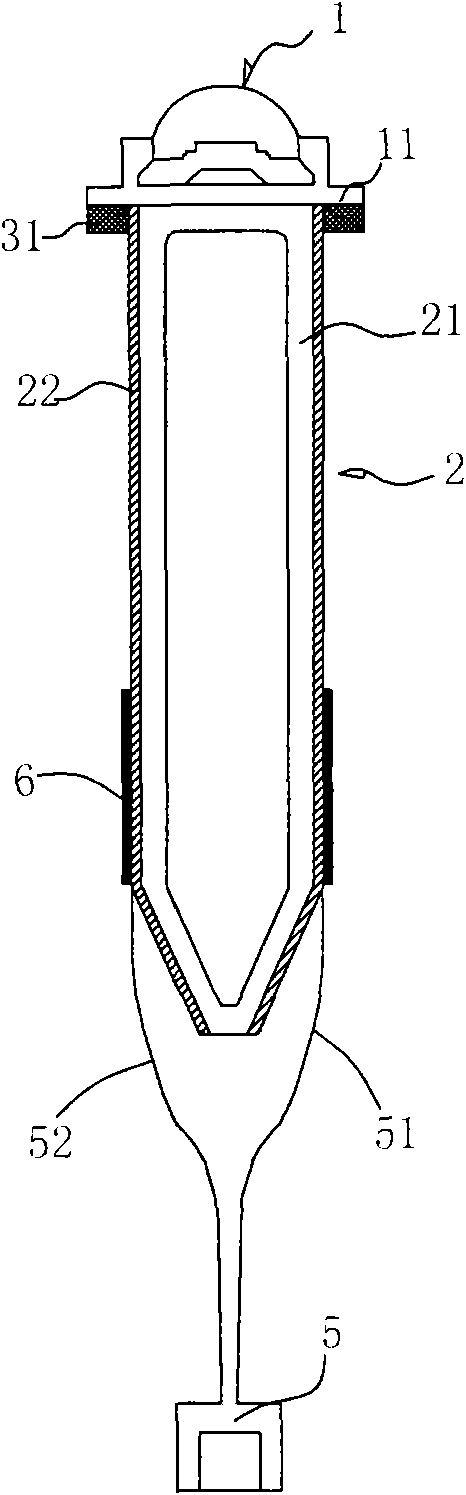

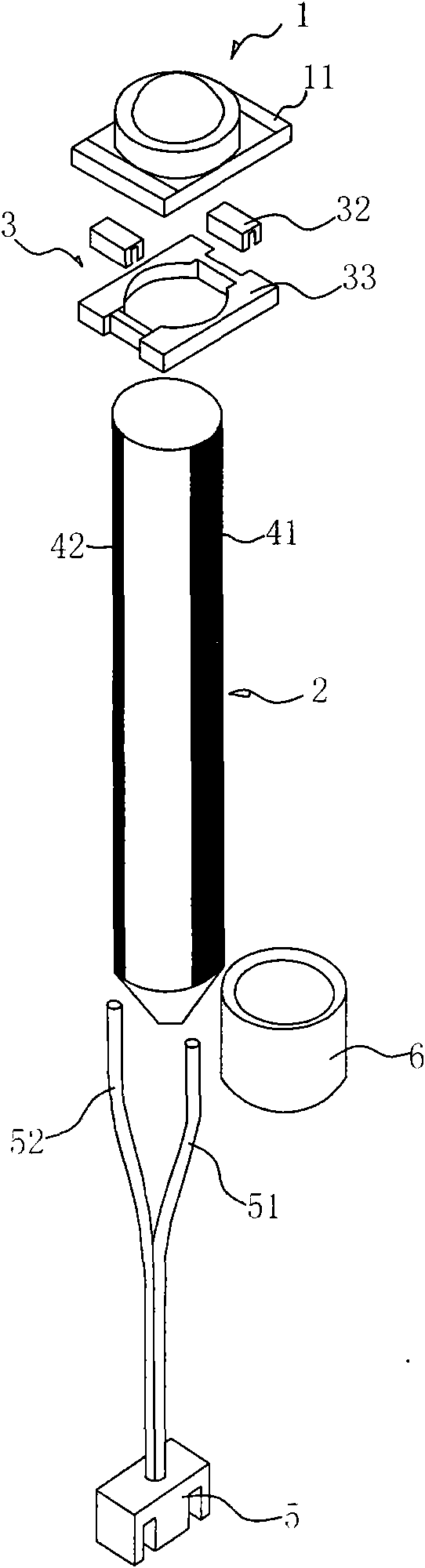

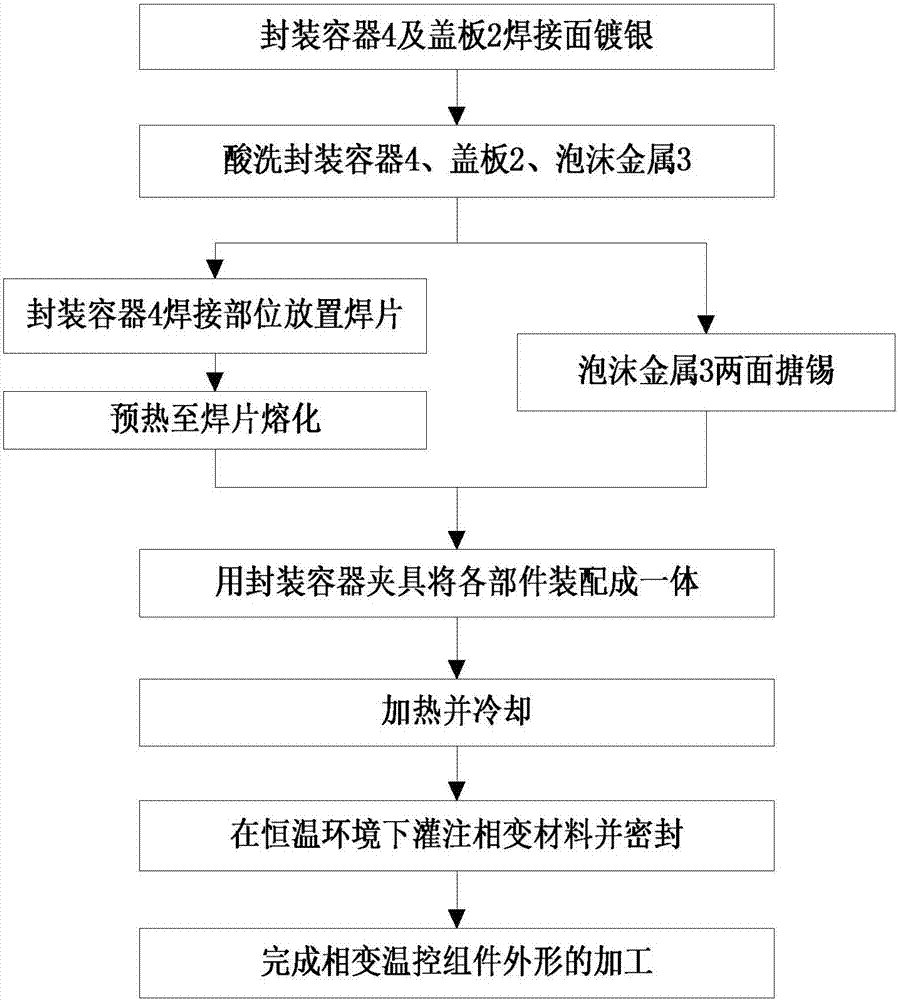

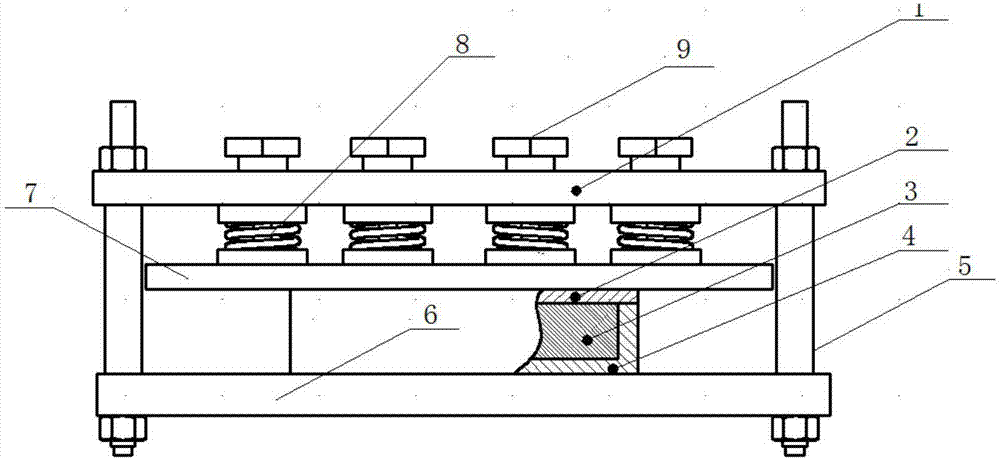

Method for integrated preparing of foam metal phase change temperature control assembly

InactiveCN107116279AOvercome failureImprove the equivalent thermal conductivityHeating appliancesWelding/soldering/cutting articlesTemperature controlEngineering

The invention provides a method for integrated preparing of a foam metal phase change temperature control assembly and aims at providing a technology method for solving the problem that in a phase change temperature control assembly, a gap exists between foam metal and a base body material, and the heat response rate is influenced. The method is achieved through the following technical scheme that according to the boundary dimension of a packaging container, a packaging container clamp is prepared; a cavity used for welding the foam metal is machined in the packaging container in advance, a layer of welding piece is laid on the inner side welding face of the cavity of the packaging container, and the contact interface of the foam metal is subjected to tin lining; the foam metal is compressed to the cavity size; the packaging container, the foam metal and the clamp are assembled into a whole and heated, and after cooling, a formed phase change temperature control assembly blank is taken out of the clamp of the packaging container; in the constant-temperature environment, a liquid phase change material is poured into the phase change temperature control assembly from a pouring port in the bottom of the packaging container; and finally, the pouring port is sealed, and machining of the appearance of the temperature control assembly is finished.

Owner:10TH RES INST OF CETC

Instantaneous-heating type heater

PendingCN106969489AShort vertical lengthImprove heating efficiencyLavatory sanitoryVolume/mass flow by mechanical effectsThermodynamicsControl power

The invention relates to an instantaneous-heating type heater. The instantaneous-heating type heater is characterized by comprising a body, a control part, a water inlet end, a water outlet end and a water channel. The water inlet end and the water outlet end are arranged on the body. The water channel communicates with the water inlet end and the water outlet end and is provided with two heating bars arranged side by side, and the two heating bars are arranged in a preheating cavity and a heating cavity. The preheating cavity and the heating cavity communicate with each other in the upstream and downstream direction of water flow and communicate with the water inlet end and the water outlet end correspondingly. The control part is used for controlling power supplied to the heating bars from a supply power source. The instantaneous-heating type heater has the advantages of being compact in structure, fast in heating response, high in heating power control precision, stable in water outlet temperature, good in safety and the like.

Owner:XIAMEN JIAPULE ELECTRONICS TECH

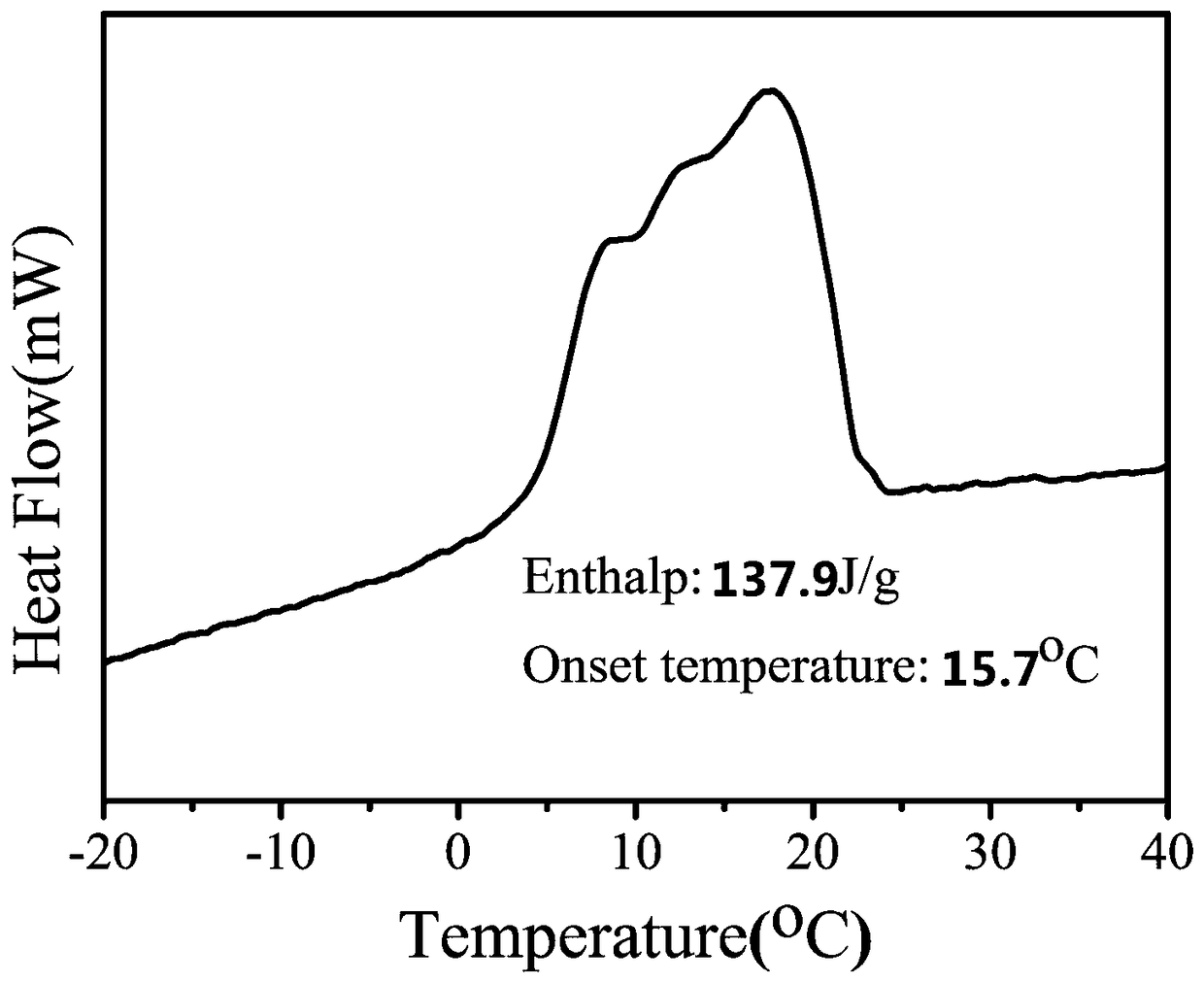

High-heat conductivity polyurethane solid-solid phase change material and preparation method thereof

ActiveCN108383968AHigh latent heat of phase changeFast thermal responseHeat-exchange elementsVoid ratioHeat stability

The invention discloses a high-heat conductivity polyurethane solid-solid phase change material. The high-heat conductivity polyurethane solid-solid phase change material comprises, by mass, 60-95% ofpolyethylene glycol, 2-30% of isocyanate, 0-9% of a chain extender, 0-5% of a surfactant and 0.5-8% of a heat conduction medium. The invention also discloses a preparation method of the high-heat conductivity polyurethane solid-solid phase change material. The high-heat conductivity phase change energy storage material with the advantages of high phase change latent heat, good heat stability andfast heat response rate is obtained through ingeniously combining adsorption loading, stable state shaping and heat conduction channel construction by physical loading and chemical crosslinking with expanded graphite having a large void ratio as a loading body and the heat conduction medium and a polyurethane material having a phase change function as a matrix, and the application prospect of thephase change energy storage material in fields of aviation, industrial heat storage, construction and solar energy storage is widened.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

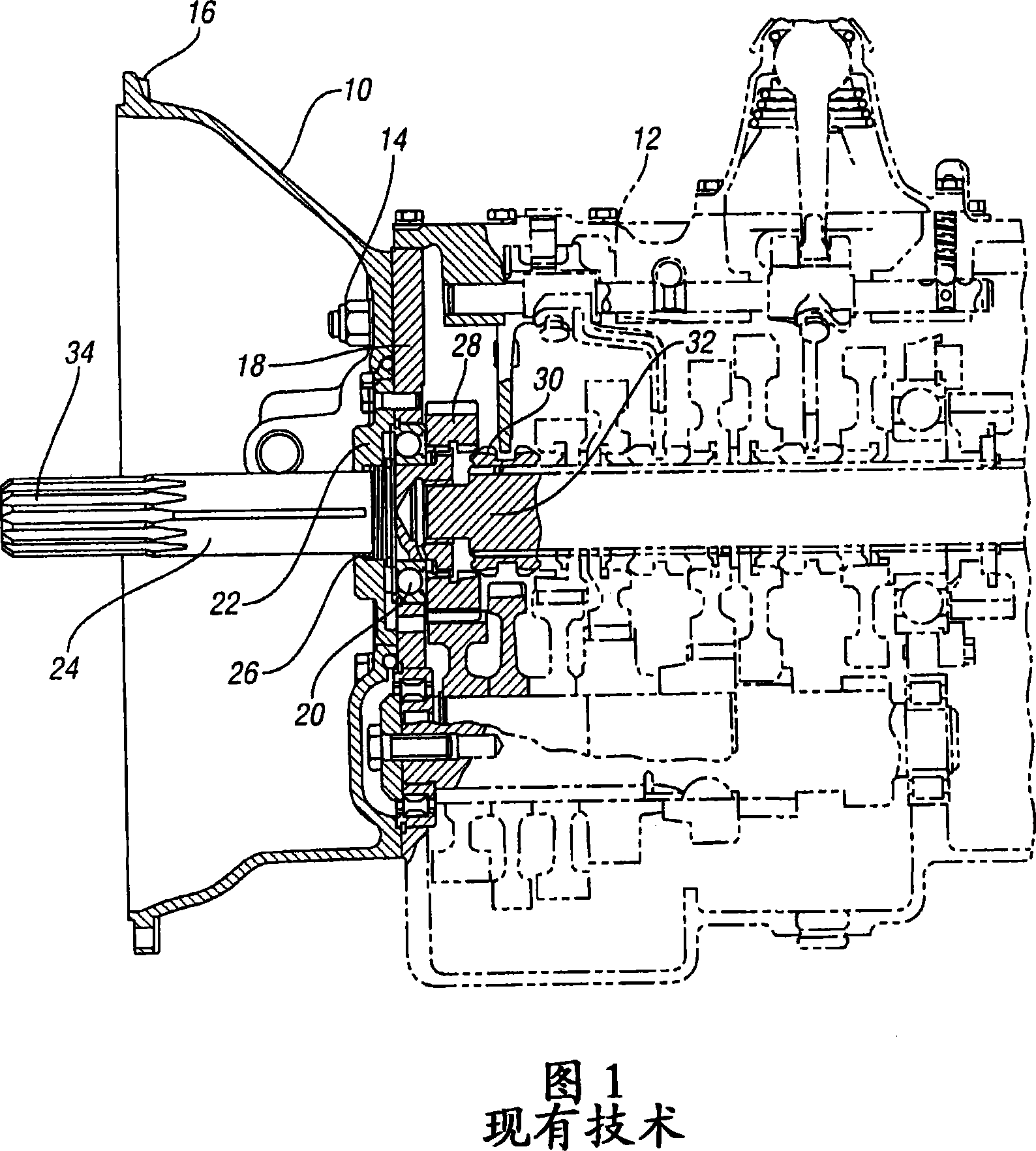

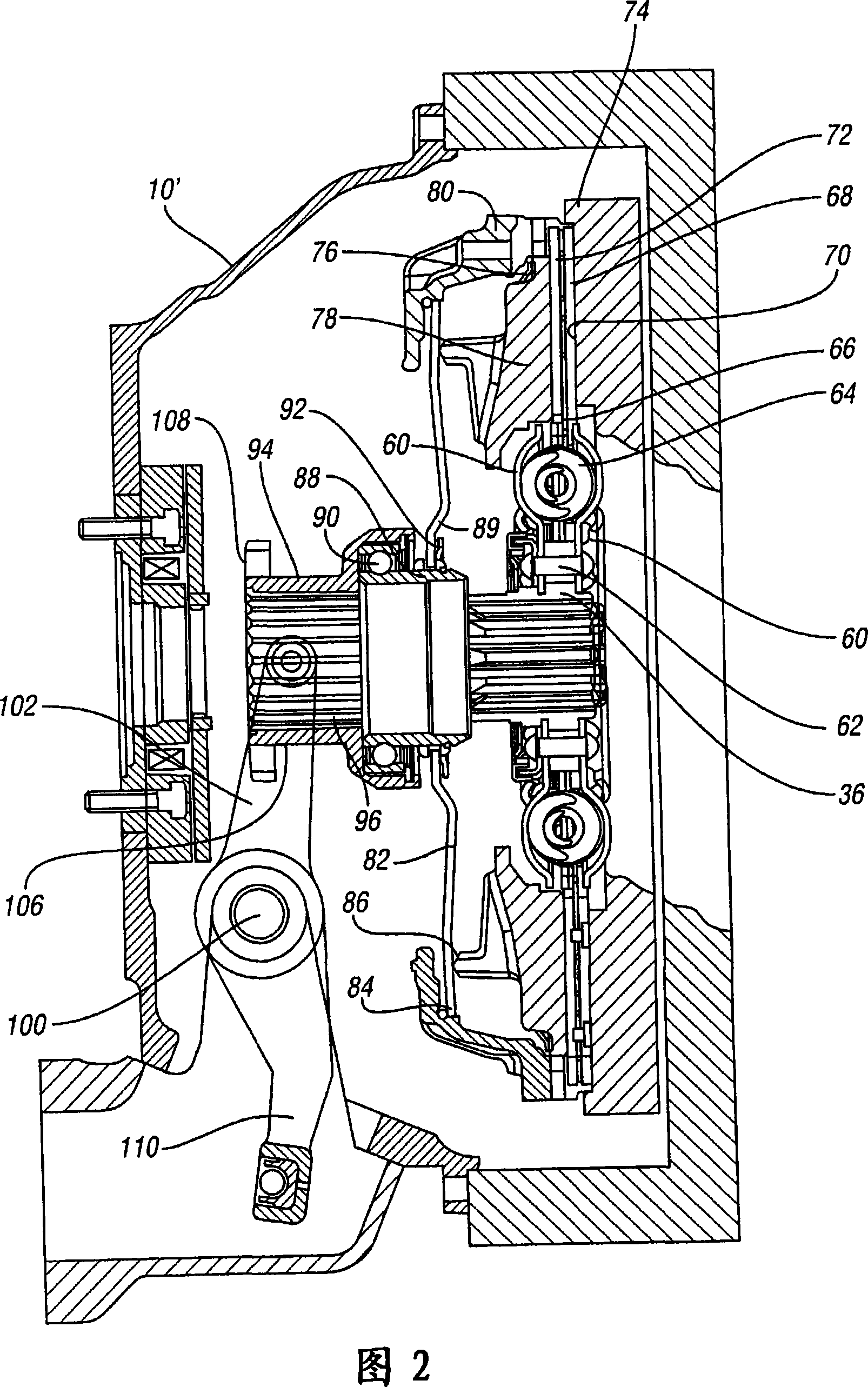

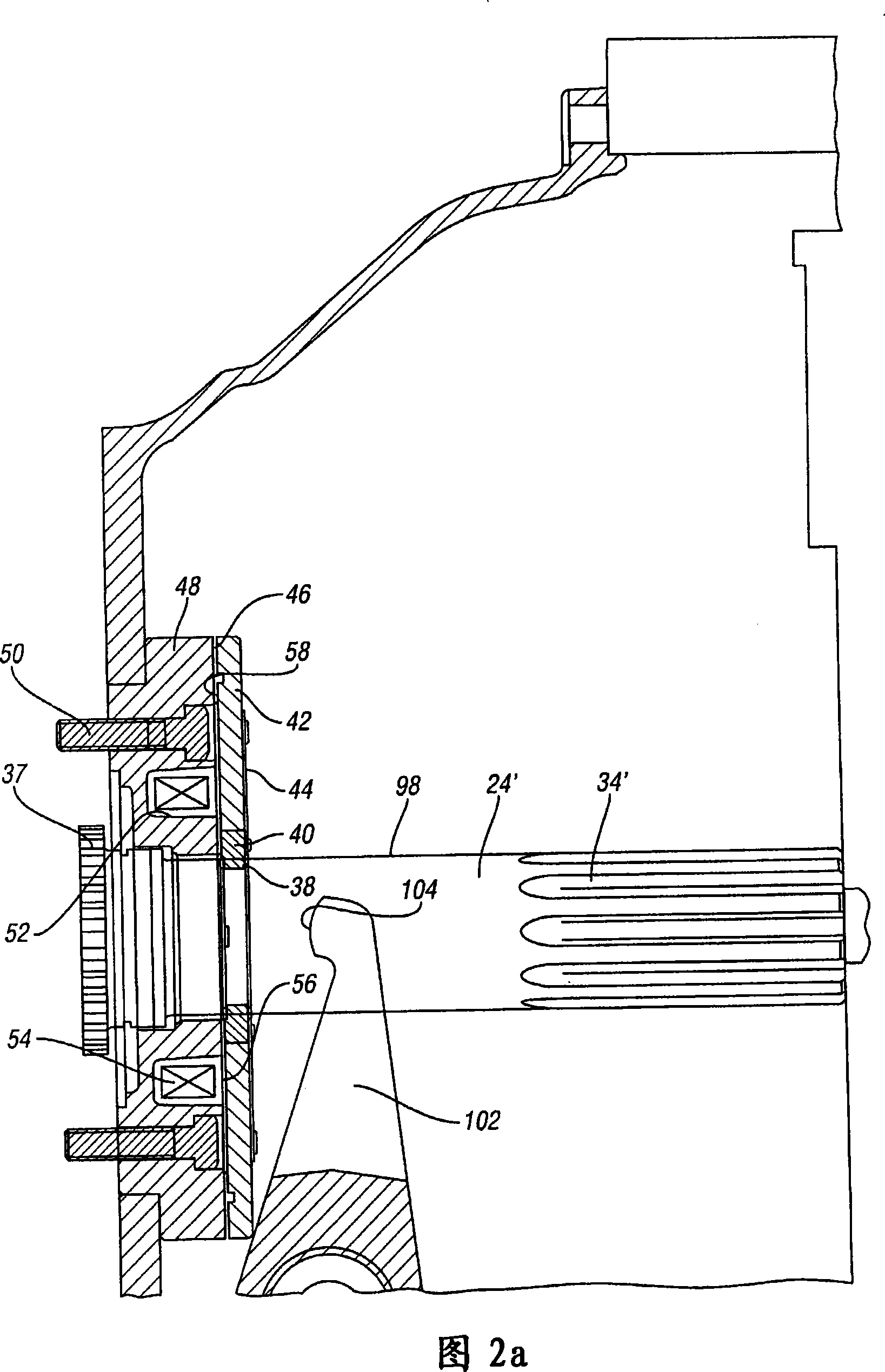

Control for an electromagnetic brake for a multiple-ratio power transmission in a vehicle powertrain

InactiveCN101079569ADynamo-electric brakes/clutchesBrake actuating mechanismsControl systemStator coil

The invention relates to the control of an electromagnetic brake used for a multi-gear power transmission of a vehicle transmission system. A control system (shown in drawing 8, drawing 9 and drawing 10) used for electromagnetic brakes (120, 122, 124) comprises an electromagnetic brake excitation coil (120) which is used for the multi-gear transmission (shown in drawing 1) in the vehicle transmission system and surrounds a power input shaft (124). The electromagnetic flux circuit (shown in drawing 7) of the excitation coil (120) is electrically insulated with the other elements of the power input shaft (24) and the transmission system, thus avoiding residual magnetization. The coil circuit is internally provided with a heat response circuit protector (154) which detects the temperature of a stator coil (120), thus avoiding the over-heat of the coil. The invention also provides an over-current protector (152) used for disconnecting the stator coil circuit when the current in the stator coil (120) exceeds the prearranged value.

Owner:EATON CORP

Phase-change microsphere, multifunctional phase-change temperature-adjustment fiber, preparation method for phase-change microsphere and preparation method for multifunctional phase-change temperature-adjustment fiber

InactiveCN108977910AEnsure coverageImprove mechanical propertiesArtifical filament manufactureMonocomponent polyamides artificial filamentFiberFiltration

The invention discloses a phase-change microsphere, a multifunctional phase-change temperature-adjustment fiber, a preparation method for the phase-change microsphere and a preparation method for themultifunctional phase-change temperature-adjustment fiber. The preparation method for the phase-change microsphere comprises the steps that firstly, spray drying and thermal expansion treatment are carried out on a graphene oxide aqueous solution so as to obtain a graphene microsphere body with a mesoporous structure, and then phase-change materials are melted and fully permeate into a cavity of the graphene microsphere body so as to obtain the phase-change microsphere with a core-shell structure. The preparation method for the multifunctional phase-change temperature-adjustment fiber comprises the steps that redundant phase-change materials on the surfaces of phase-change microspheres are removed through a pressure filtration method, cooling is carried out, and then the phase-change microspheres and spinning-grade polymer slices are melted and blended for spinning so as to obtain the multifunctional phase-change temperature-adjustment fiber. The phase-change microsphere, the multifunctional phase-change temperature adjustment fiber, the preparation method for the phase-change microsphere and the preparation method for the multifunctional phase-change temperature-adjustment fiber have the advantages that the graphene hollow spheres are wrapped around the phase-change materials, so that the leakage of the phase-change materials in the use process is greatly reduced, and the service life can be remarkably prolonged; the thermal conductivity of graphene is high, so that the heat exchange between the environment and fabric as well as between the fabric and the human body surface can be effectively promoted, and the heat response speed of the heat storage fabric can be increased; and in addition, the graphene has the characteristics of being high in conductivity, antibacterial, ultraviolet-proof and capable of realizing far-infrared emission, so that the fabric can be endowed with multiple new functions.

Owner:HANGZHOU GAOXI TECH CO LTD +1

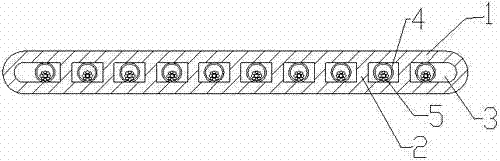

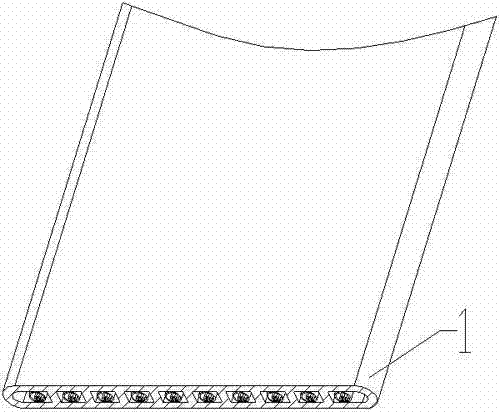

Composite microarray flat heat pipe

InactiveCN102401588AUniform temperature distributionReduce thermal resistanceIndirect heat exchangersHeat resistanceEngineering

The invention discloses a composite microarray flat heat pipe, comprising a flat hollow shell, wherein the hollow shell is provided with a plurality of supporting structures, the cavity of the shell body is divided into a number of relatively independent channels by the supporting structures, the channels run through from front to back and are arranged side by side, metal networks are arranged inside the channels, multiple strands of metal wires are arranged in the metal networks ; the channels are also arranged with working medium , and two ends of the channels are sealed by seal structures. The invention of the composite microarray flat heat pipe is characterized by uniform temperature distribution, small heat resistance, fast thermal response, large heat transfer (making use of latent heat ), light weight and small volume ( hollow container ), simple structure, and being capable of operating in the absence of gravity.

Owner:苏州雪林电器科技有限公司

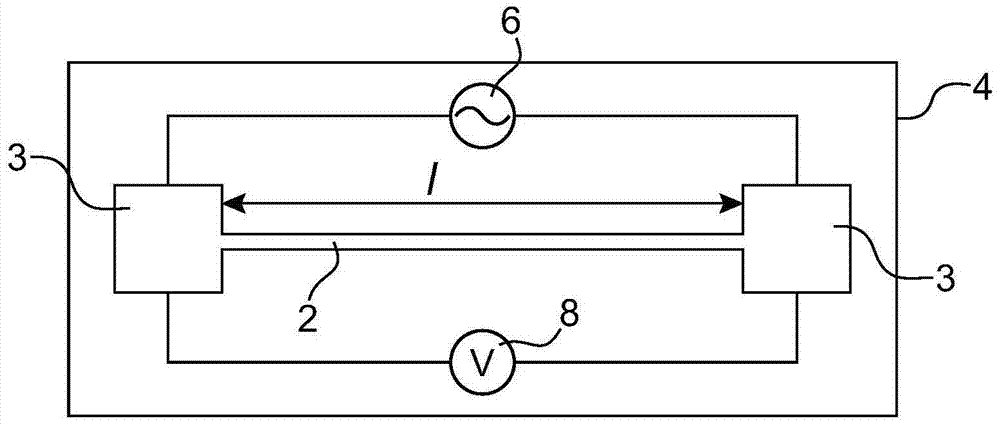

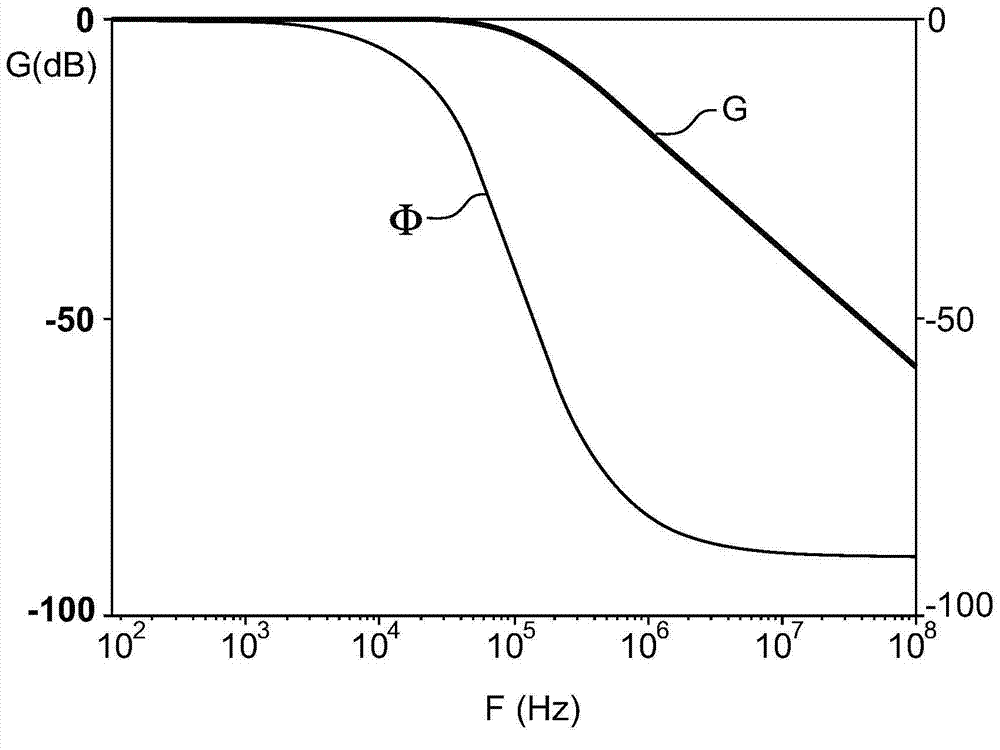

Gas concentration sensor with a suspended structure

ActiveCN104849302AHigh resolutionComponent separationDispersed particle separationPhase shiftedConductive materials

A concentration sensor for at least one given gas comprising at least one suspended structure (2) with respect to a support, said suspended structure (2) being of an electrically conductive material and said structure having a low heat response time, means for biasing said suspended element (2) and means (8) for measuring the variation of the electric voltage at the terminals of the suspended structure (2), the biasing means (6) being formed by an alternating current source the intensity of which heats the suspended structure (2) and the frequency of which gives rise to a phase shift between a signal of the biasing means and a signal measured by the measuring means, and means for determining a phase shift variation due to a gas concentration variation and means for determining the concentration variation of said gas from the phase variation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

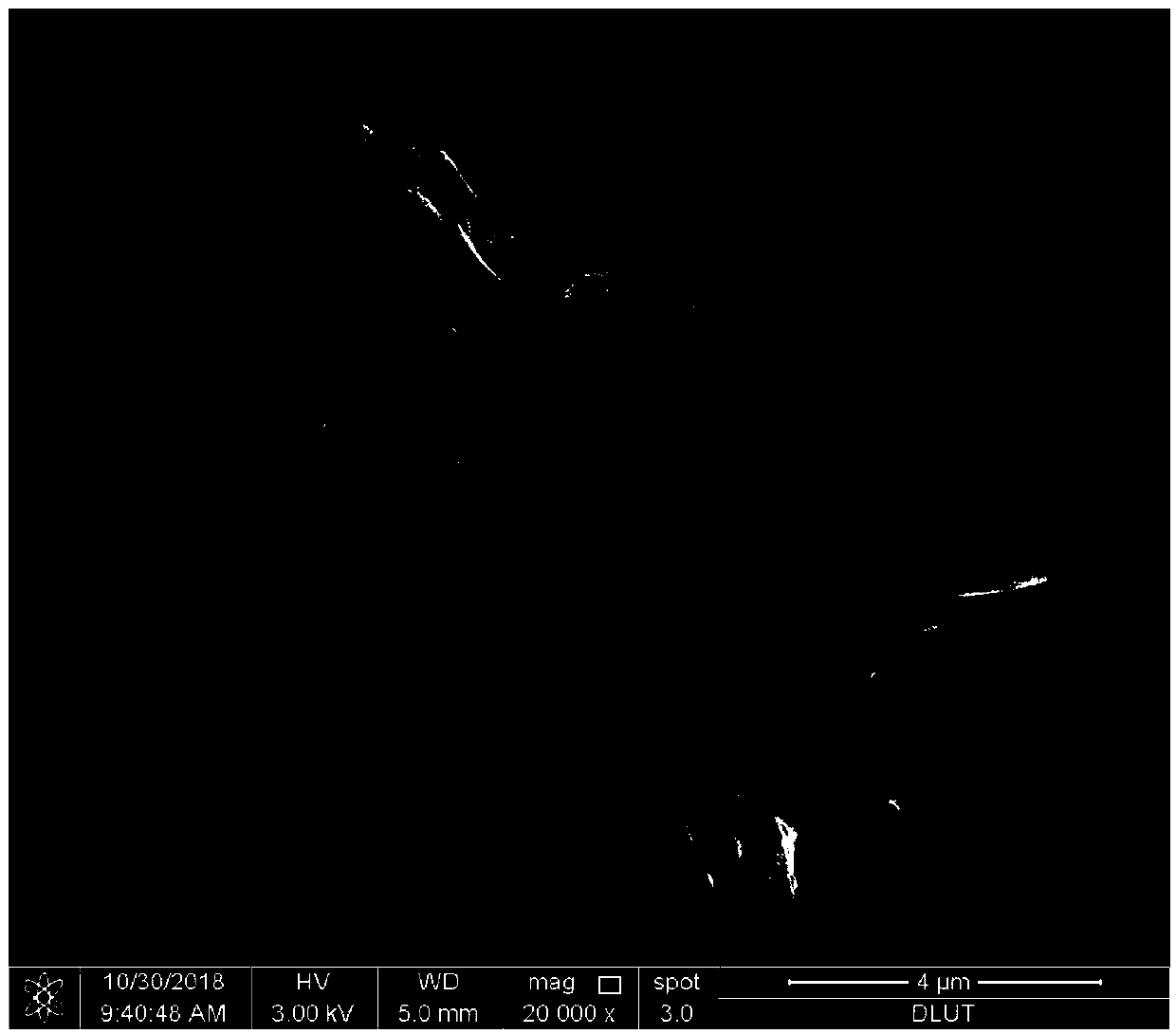

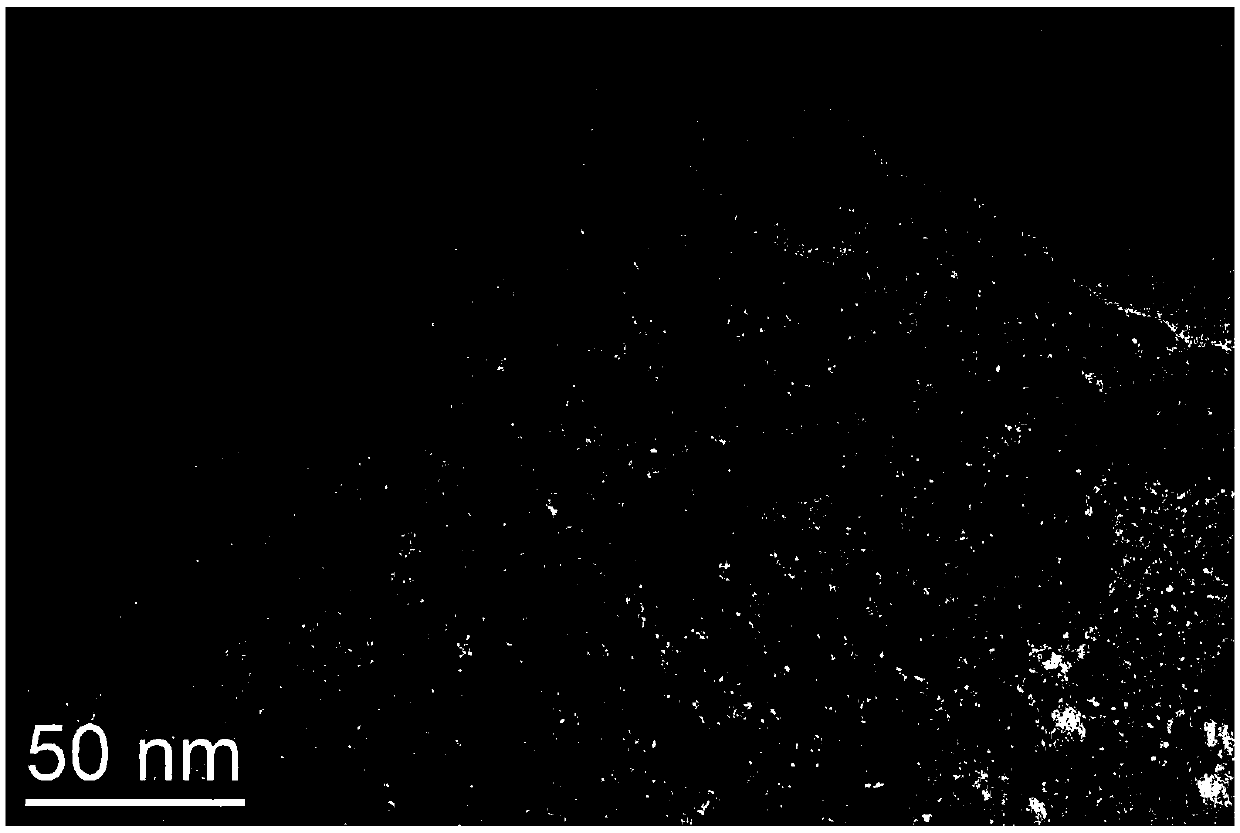

Nitrogen dioxide gas sensor based on flower-shaped SnSe2/SnO2 heterojunction, and preparation technology and application of nitrogen dioxide gas sensor

The invention belongs to the technical field of electronic components, and discloses a nitrogen dioxide gas sensor based on a flower-shaped SnSe2 / SnO2 heterojunction, and a preparation technology andapplication of the nitrogen dioxide gas sensor. The nitrogen dioxide gas sensor comprises a gas sensitive material and an interdigital electrode plate, and the surface of the interdigital electrode plate is coated with the gas sensitive material, wherein the coating thickness is 1-100 [mu]m; and the gas sensitive material is a flower-shaped SnSe2 / SnO2 nano-material. The flower-shaped nano heterojunction is obtained through a hydrothermal method and a thermal oxidation method, raw materials are convenient to obtain, low in cost and simple in preparation process, equipment investment is small, and the process flow is simple. The nitrogen dioxide sensor made of the flower-shaped SnSe2 / SnO2 nano-material selects a silicon substrate, the material and silicon-based microelectronics are integrated, and the micro hot plate type nitrogen dioxide gas sensor having the advantages of low heating power consumption, small heat loss, short heat response time, compatibility with a CMOS process, easy integration with other microelectronic devices and the like is prepared.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com