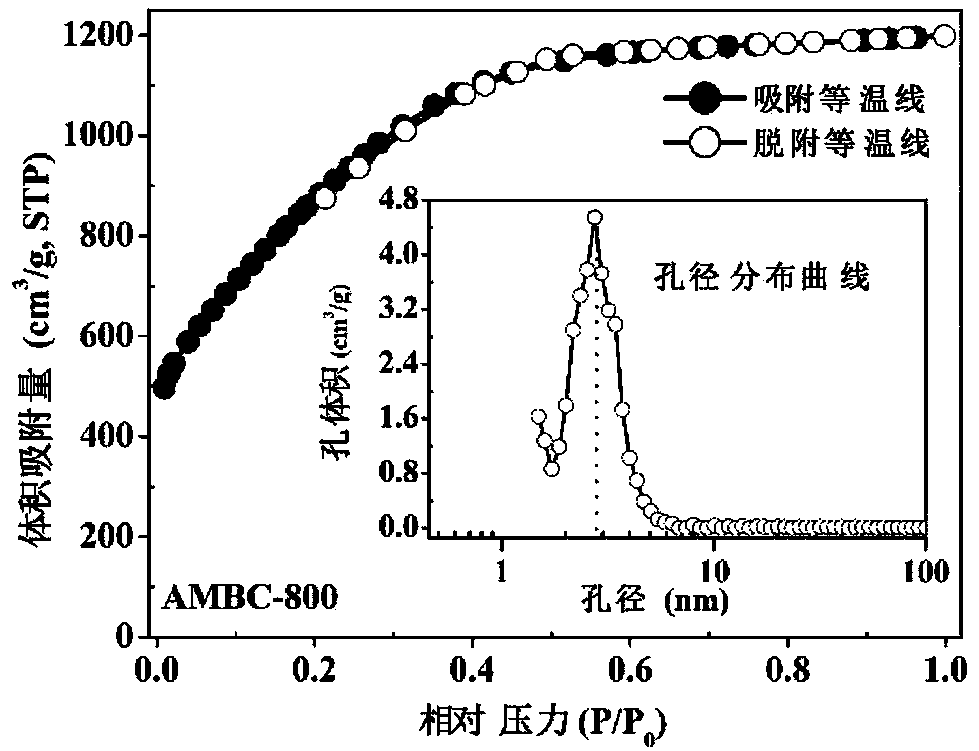

Preparation method of high mesoporous rate nitrogen doped carbon electrode material

A technology of nitrogen doping and carbon electrodes, applied in the field of materials, can solve the problems of morphology, pore structure and surface chemical properties, such as the difficult and precise macro-control, to achieve excellent electrochemical performance, promote diffusion, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a high-mesopority nitrogen-doped carbon electrode material, specifically as follows:

[0037] Pretreatment, specifically: peel off the collected bamboo shoot shells from the same batch of bamboo shoots, wash away impurities such as sand and dust with deionized water, dry them in an oven at 80°C overnight, cut them into small pieces and pulverize them with a pulverizer;

[0038] Hydrothermal reaction, specifically: accurately weigh 4g of bamboo shoot shell powder and mix it with 75mL of 1mol / L dilute sulfuric acid solution, mix it evenly, seal it in a 100mL polytetrafluoroethylene reactor, and react in a programmed temperature oven at 200°C for 24h , to obtain the hydrothermal carbon precursor;

[0039] Carbonization reaction, specifically: after filtering the hydrothermal carbon precursor, washing with deionized water, and drying overnight at 120°C, weigh 1g of the dry hydrothermal carbon precursor and 4g of melamine, mix and grind it, and place i...

Embodiment 2

[0051] The difference between Example 2 and Example 1 lies in the difference in activation temperature, that is, in this example, the activation treatment was performed at 600° C. for 1 hour under a nitrogen atmosphere. The specific implementation process is to peel off the same batch of bamboo shoot shells collected from the bamboo shoots, wash away impurities such as sand and dust with deionized water, dry them in an oven at 80°C overnight, cut them into small pieces and pulverize them with a pulverizer; 4g of bamboo shoot shell powder was mixed with 75mL of 1mol / L dilute sulfuric acid solution, stirred evenly, sealed in a 100mL polytetrafluoroethylene reactor, and reacted at a constant temperature of 200°C in a programmed temperature oven for 24h to obtain a hydrothermal carbon precursor; After the hot charcoal precursor is filtered, washed with deionized water and dried overnight at 120 °C, weigh 1 g of the dry hydrothermal charcoal precursor and 4 g of melamine, mix and gr...

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1 is: the activator is different, that is, the present embodiment adopts potassium oxalate (K 2 C 2 o 4 ) as an activator. The specific implementation process is to peel off the same batch of bamboo shoot shells collected from the bamboo shoots, wash away impurities such as sand and dust with deionized water, dry them in an oven at 80°C overnight, cut them into small pieces and pulverize them with a pulverizer; 4g of bamboo shoot shell powder was mixed with 75mL of 1mol / L dilute sulfuric acid solution, stirred evenly, sealed in a 100mL polytetrafluoroethylene reactor, and reacted at a constant temperature of 200°C in a programmed temperature oven for 24h to obtain a hydrothermal carbon precursor; After the hot charcoal precursor is filtered, washed with deionized water and dried overnight at 120 °C, weigh 1 g of the dry hydrothermal charcoal precursor and 4 g of melamine, mix and grind it, place it in a tube furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com