Patents

Literature

719results about How to "Realize recycling of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal heavy absorbent and preparation method and use thereof

InactiveCN102389776AEasy to operateImprove efficiencyOther chemical processesWaste water treatment from animal husbandryActive agentKaolin clay

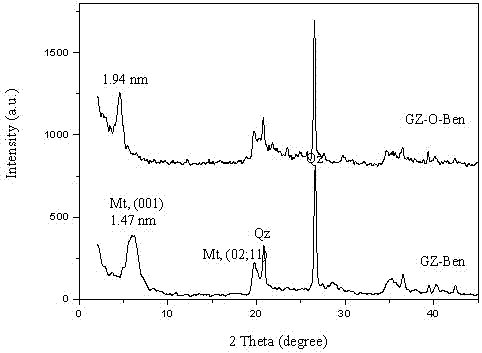

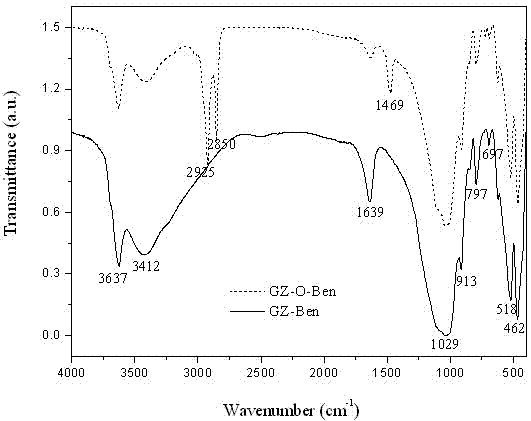

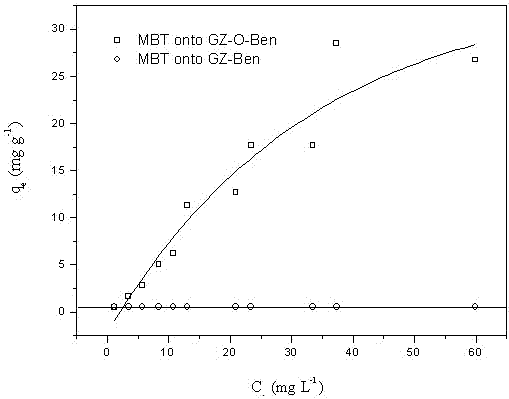

The invention discloses a heavy metal absorbent and a preparation method and use thereof. The heavy metal absorbent is prepared by using an inorganic mineral modified by a surfactant as a carrier and loading organic complexing agent on the carrier, wherein the inorganic mineral is bentonite, kaolin, kieselguhr, zeolite, aluminum oxide or iron oxide; the surfactant is cationic surfactant or nonionic surfactant; and the organic complexing agent is a compound containing a sulfydryl and an amino. The heavy metal absorbent has the advantages of stable performance, environment friendliness, high absorption capacity, high selectivity, convenient post-recovery treatment and the like. The absorption capacities of cadmium, mercury lead and other heavy metals all exceed 100mg / g, and the heavy metal absorbent can achieve good treatment effect in treatment of water and soil environments polluted by heavy metals.

Owner:上海伊克诺环境科技有限公司

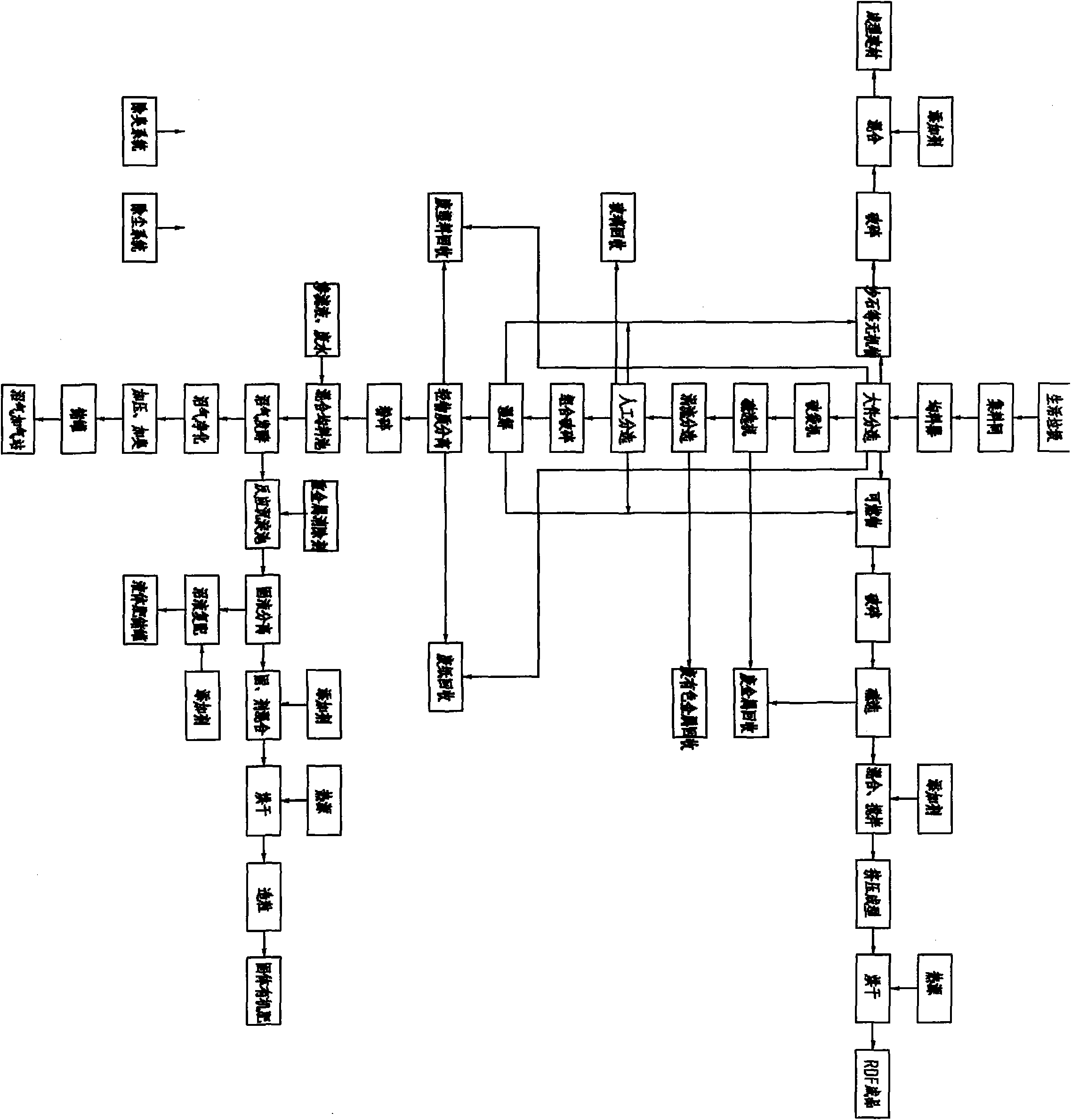

Technology for full classification recycling treatment on household waste

InactiveCN102728601ASolve problems in the treatment processRealize recycling of resourcesBio-organic fraction processingSolid waste disposalRefuse-derived fuelPlastic packaging

The invention discloses a technology for full classification recycling treatment on household waste and relates to the field of recycling integrated utilization of household waste. A main process route of the technology comprises that household waste is homogenized by a homogenizer, is subjected to large object sorting (wherein large objects comprise large combustibles and inorganic matters), is treated by a bag breaking device (for scratching a plastic packaging bag), is treated by a magnetic separator (for separating out magnetic materials), is treated by an eddy sorting machine (for separating out nonferrous metals), is subjected to artificial sorting, then is broken, is fed into a hydrothermal degradation tank, is treated by a light material separator (for separating out papers and plastics), and then is crushed; then mixed organic matters and percolate are mixed and then are subjected to methane fermentation so that methane is produced; and methane residues and a methane liquid are prepared into an organic fertilizer and inorganic matters are prepared into a building material and the combustibles are prepared into a refuse derived fuel (RDF). The technology really realizes reduction, harmlessness and recycling of waste.

Owner:张希曾 +1

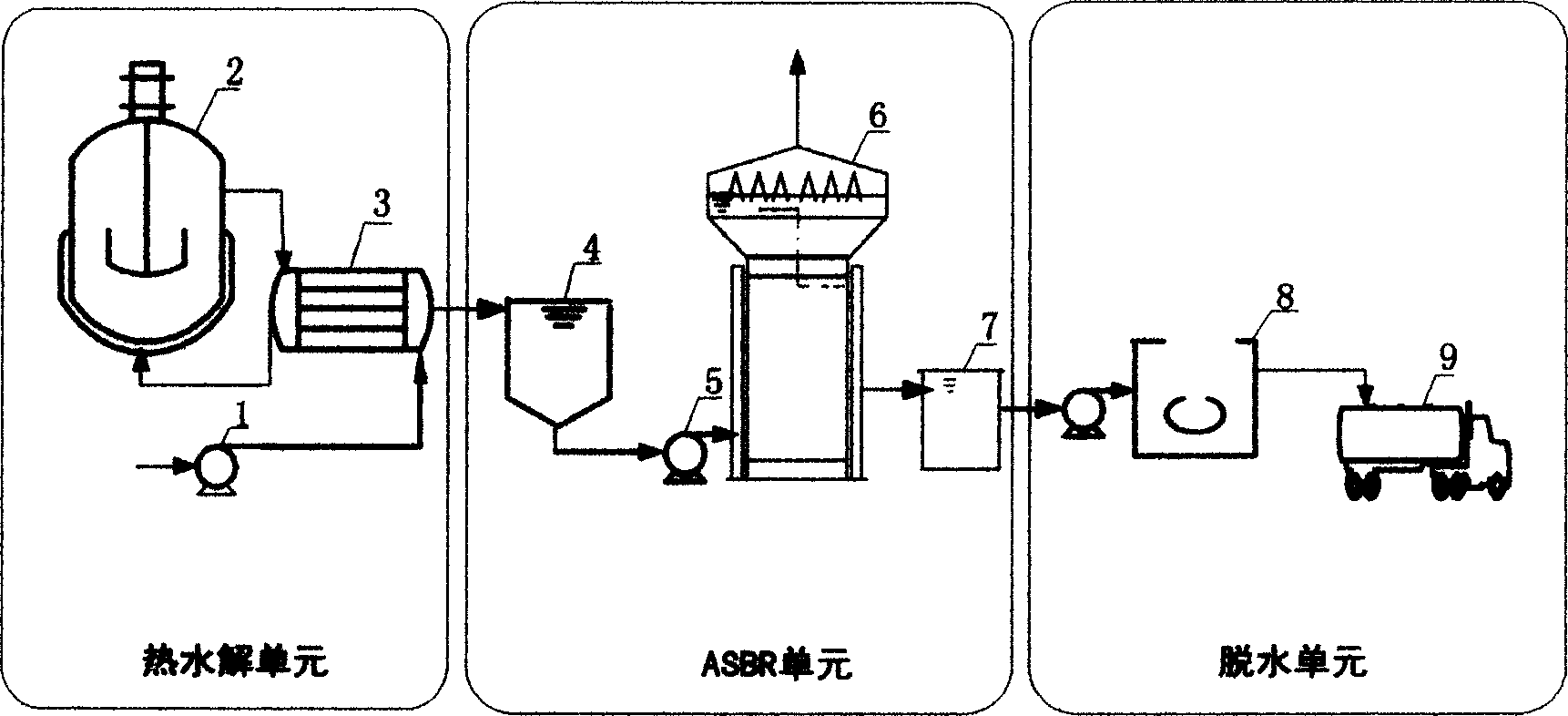

Process for treating excess sludge

ActiveCN1569699ARealize recycling of resourcesSmall volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMembrane bioreactorAnaerobic reactor

Disclosed is a method and equipment for treatment of polluted fluid, wherein ferrum family flocculating agents of a finite concentration are charged into the membrane bioreactor, in which they are subject to domestication and become compact biological ferrum sludge with improved property.

Owner:TSINGHUA UNIV

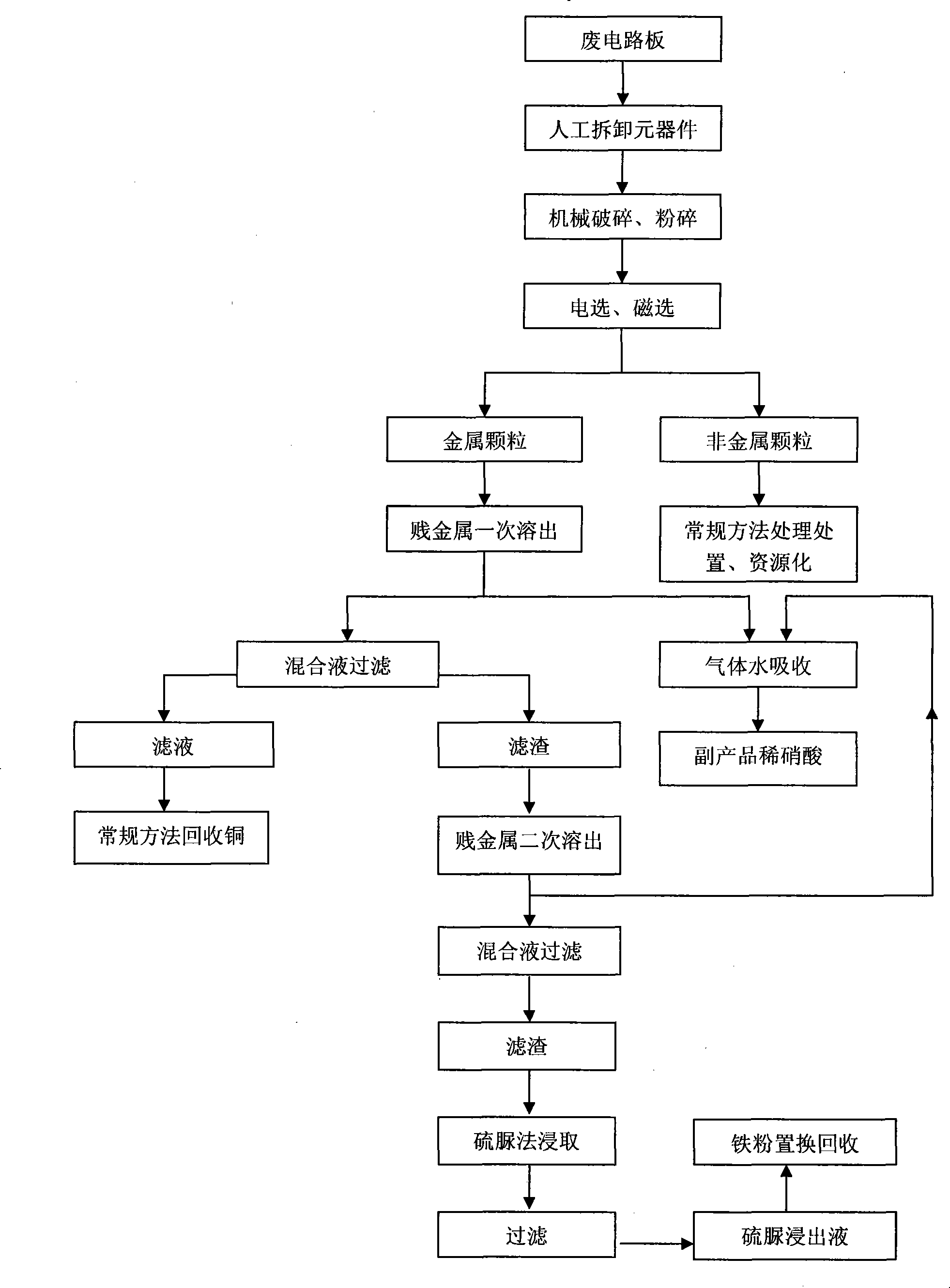

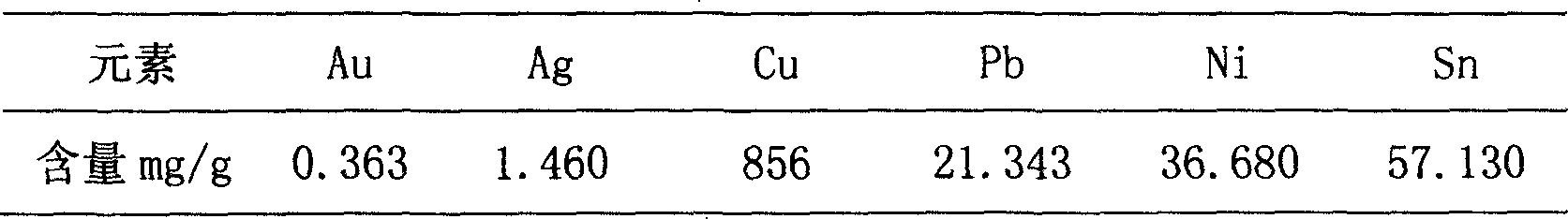

Method for extracting gold from waste circuit boards

InactiveCN101230421ALow cost of reagentsReduce the formation of nitrogen oxidesProcess efficiency improvementNitrogen oxidesPre treatment

The invention relates to a method by which gold can be extracted form waste circuit boards. Secondary acid dipping can be used for pre-processing metal particles of waste circuit boards. A first leaching uses mixed acid solution of nitric acid and sulphuric acid to leach out base metals which mainly is copper and can be used for wrapping gold in circuit boards. The diluted nitric acid solution can be used for dissolving out base metals secondarily to create favorite condition for the following gold extracting. A little nitrogen oxides can be absorbed by water, and then non-cyanogen complexing agent thiourea can be used for selectively leaching out gold and silver; finally, base-metal ferrous powder can be used for displacing gold and silver form the leaching solution, thereby realizing the source recycling of gold and silver. With simple equipment and convenient operation, the method has great potential in industrial promotion. The invention recycles copper and silver when gold is extracted form waste circuit boards, thereby having considerable economic, social and environmental benefits.

Owner:DONGHUA UNIV

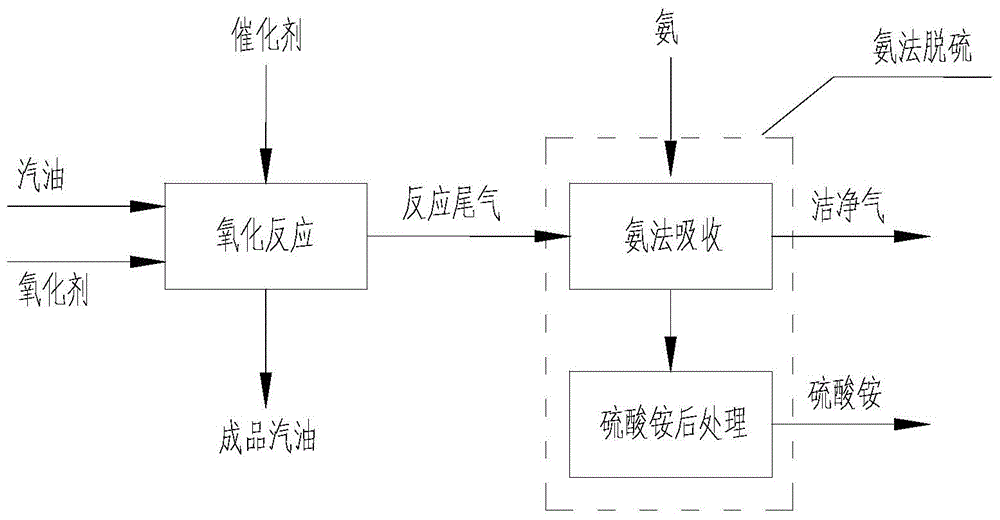

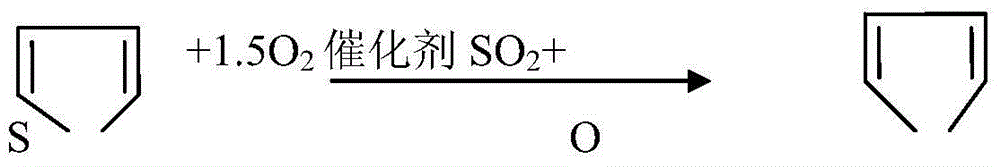

Gasoline-oxidation ammonia-process desulfurization method

InactiveCN104946296ARealize recycling of resourcesImprove desulfurization efficiencyRefining with oxygen compoundsDispersed particle separationGasolineComponents of crude oil

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

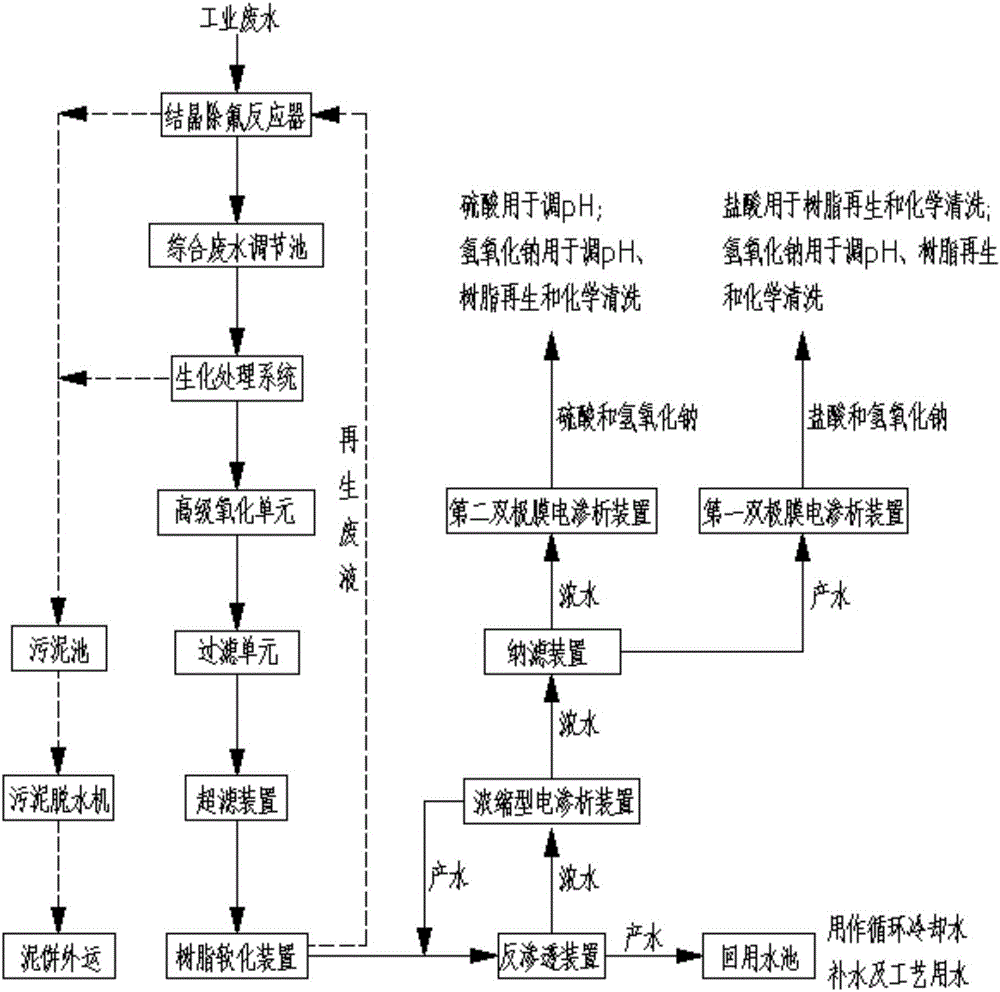

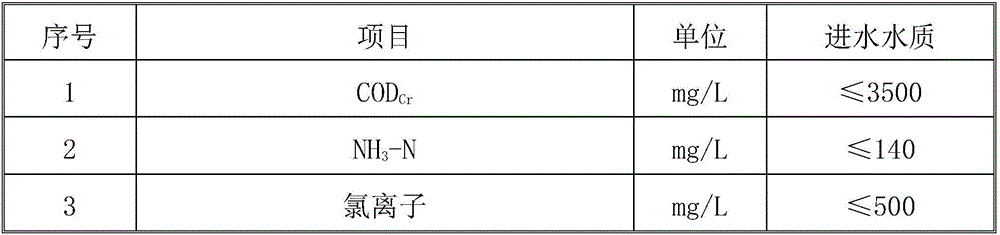

Resource recycling and treatment technology of high-concentration degradation-resistant salt-containing organic waste water

ActiveCN105800886ARealize inner loopImplement resourcesFatty/oily/floating substances removal devicesGeneral water supply conservationHigh concentrationWater quality

Provided is a resource recycling and treatment technology of high-concentration degradation-resistant salt-containing organic waste water.The technology comprises the following steps of the pretreatment process, the biochemical treatment process, the advanced pretreatment process, the advanced treatment process and the concentrated water treatment process.According to the technology, multiple process combinations are optimized, degradation-resistant organic matter and inorganic salts in the waste water can be removed step by step, and resource recycling of the high-concentration degradation-resistant salt-containing organic waste water is achieved on the basis of nearly zero emission; the recycling rate of produced water produced after the treatment process can reach 95% or above, and the produced water can be used as water for a production technology and replenishing water for circulating cooling water.According to the resource recycling and treatment technology of the high-concentration degradation-resistant salt-containing organic waste water, the water quality requirement of biochemical reaction inlet water is guaranteed; due to the fact that fluorine ions are removed through a fluorine removing reactor, and calcium and magnesium ions are removed through a resin softening device, the risk of inorganic salt scaling of a subsequent desalination system is greatly reduced; the risk of organic matter contamination of the subsequent desalination system is effectively reduced by means of biochemical treatment and an advanced oxidation reaction.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

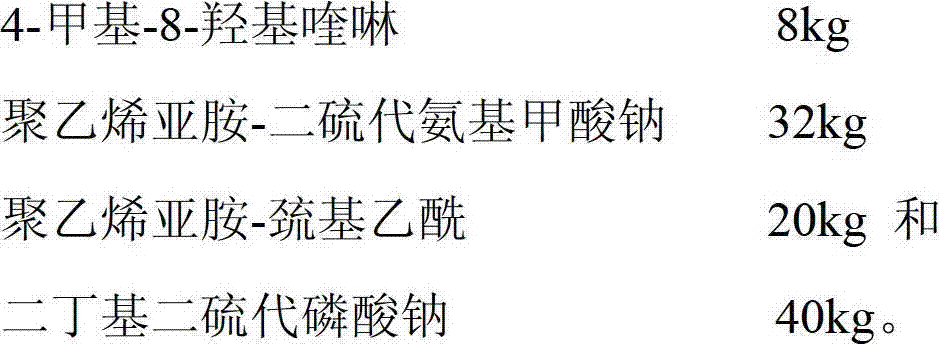

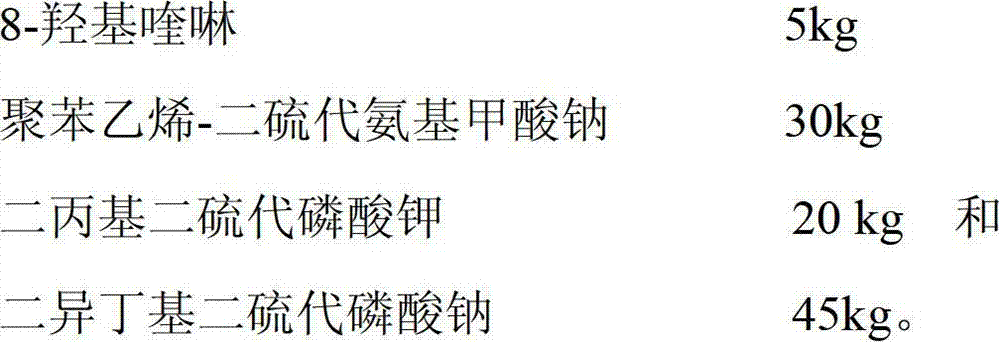

Pharmaceutical compound for treating wastewater containing complex heavy metals and/or radioactive substances and application of pharmaceutical compound

ActiveCN102730812AHas a bactericidal effectRapid sedimentation to removeWater/sewage treatment by flocculation/precipitationAutomatic controlDithiophosphoric acid

The invention discloses a pharmaceutical compound for treating wastewater containing complex heavy metals and / or radioactive substances and application of the pharmaceutical compound. The pharmaceutical compound comprises one of 8-hydroxyquinoline and derivatives of 8-hydroxyquinoline or a composition of any two of 8-hydroxyquinoline and the derivatives of 8-hydroxyquinoline, one of polyamine-dithiocarbamates or a composition of any two of the polyamine-dithiocarbamates, and one of dihydrocarbyl dithiophosphates or a composition of any two of the dihydrocarbyl dithiophosphates, wherein the mass fractions of the three components are respectively 1% to 90%, 1% to 90% and 1% to 98%. The pharmaceutical compound is dissolved in water and then the pharmaceutical compound solution is added into wastewater to be treated, and the amount of the pharmaceutical compound is 0.5 to 2 times larger than the theoretical amount of heavy metals and radioactive substances in the wastewater; and a metal complex is formed after sufficient stirring, and finally, the wastewater treatment can be completed by filtering separation. The pharmaceutical compound and the application of the pharmaceutical compound provided by the invention have the advantages of obvious effects, less investment, low cost, no site restriction, remote automatic control and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for recovering high-purity organic salt from phosphorous-containing industrial wastewater

ActiveCN103342398ARealize resource utilizationSolve processing problemsWater/sewage treatment by heatingInorganic saltsSaline water

The invention discloses a method for recovering a high-purity organic salt from phosphorous-containing industrial wastewater. The method comprises the following steps: evaporating and concentrating the phosphorous-containing high-salt industrial wastewater to obtain an organic salt rough product; washing the inorganic salt rough product by using a washing solution; removing phosphorous from the inorganic salt rough product; keeping the washed inorganic salt rough product in contact with oxygen-containing gas at the temperature of less than or equal to 1,000 DEG C; and carbonizing to obtain the high-purity inorganic salt, wherein the washing solution is salt water or industrial wastewater with high inorganic salt content. The method realizes resource recycling of industrial salt, phosphorous in the salt is removed by the high-salt wastewater, the treatment of wastes with wastes is realized, and the economic benefit is prominent; the method has the advantages of short process flow, no wastewater discharge, incapability of producing secondary pollution which is difficult to treat, recyclability of tail gas, obvious environmental protection effect and suitability for industrial application; meanwhile, the method is widely applied; and the purification of the industrial salt can be realized by using the method for all the pesticides and even high-salt wastewater in other industries.

Owner:SHANDONG WEIFANG RAINBOW CHEM

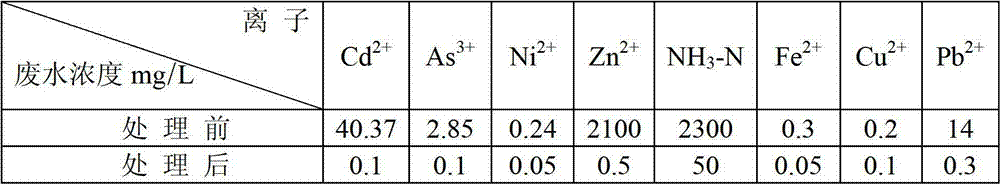

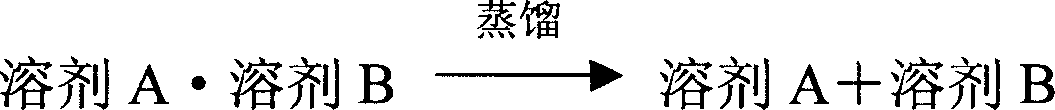

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

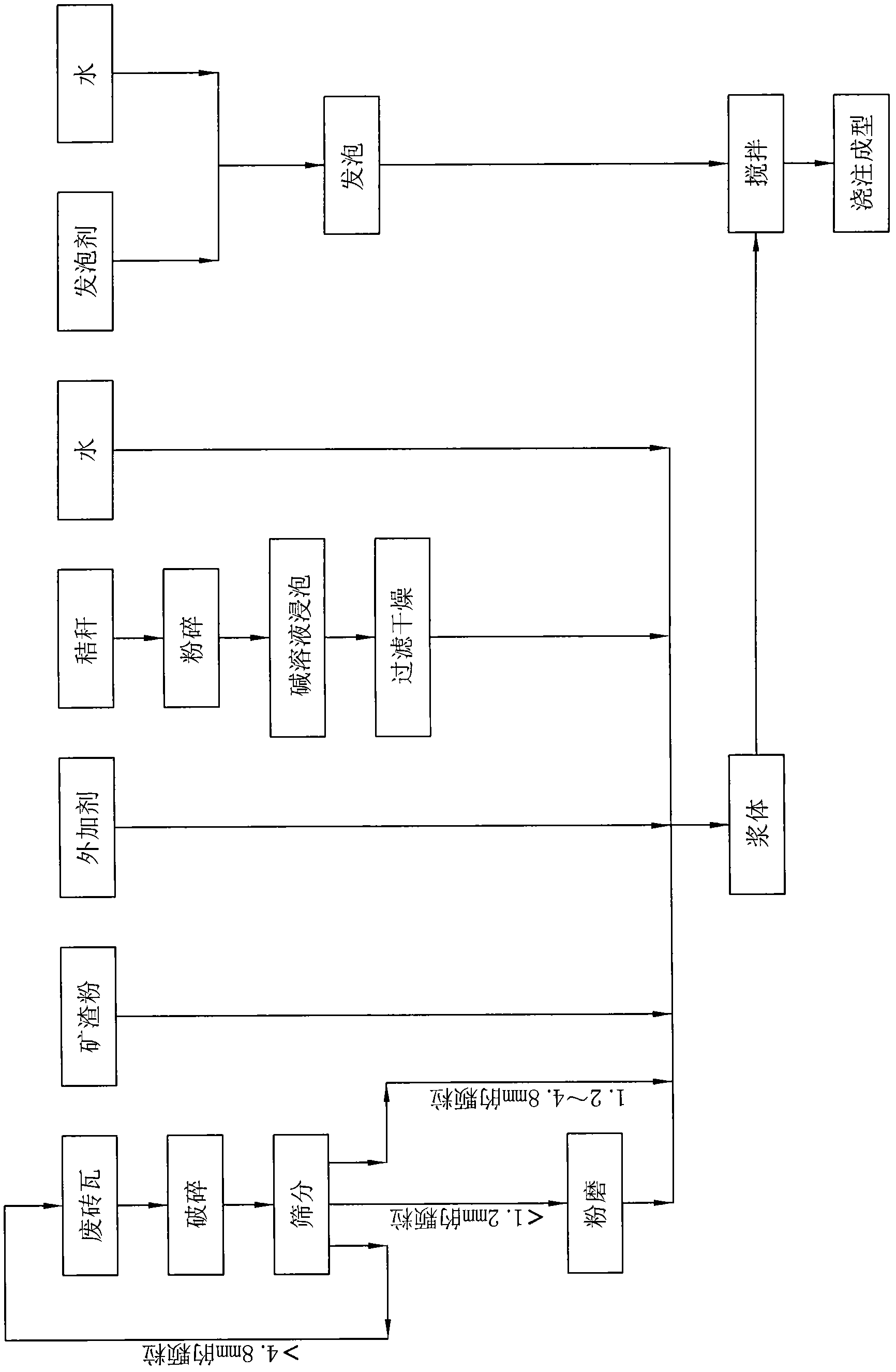

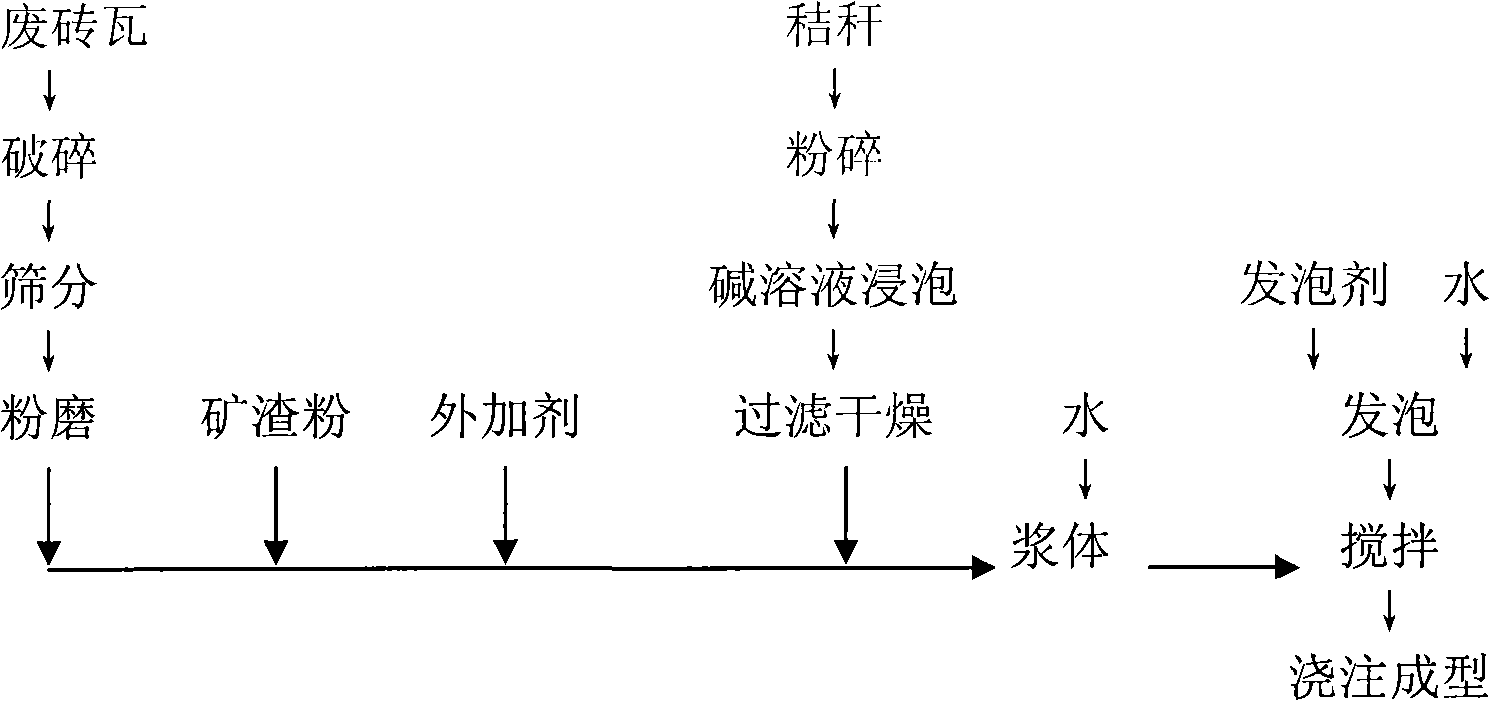

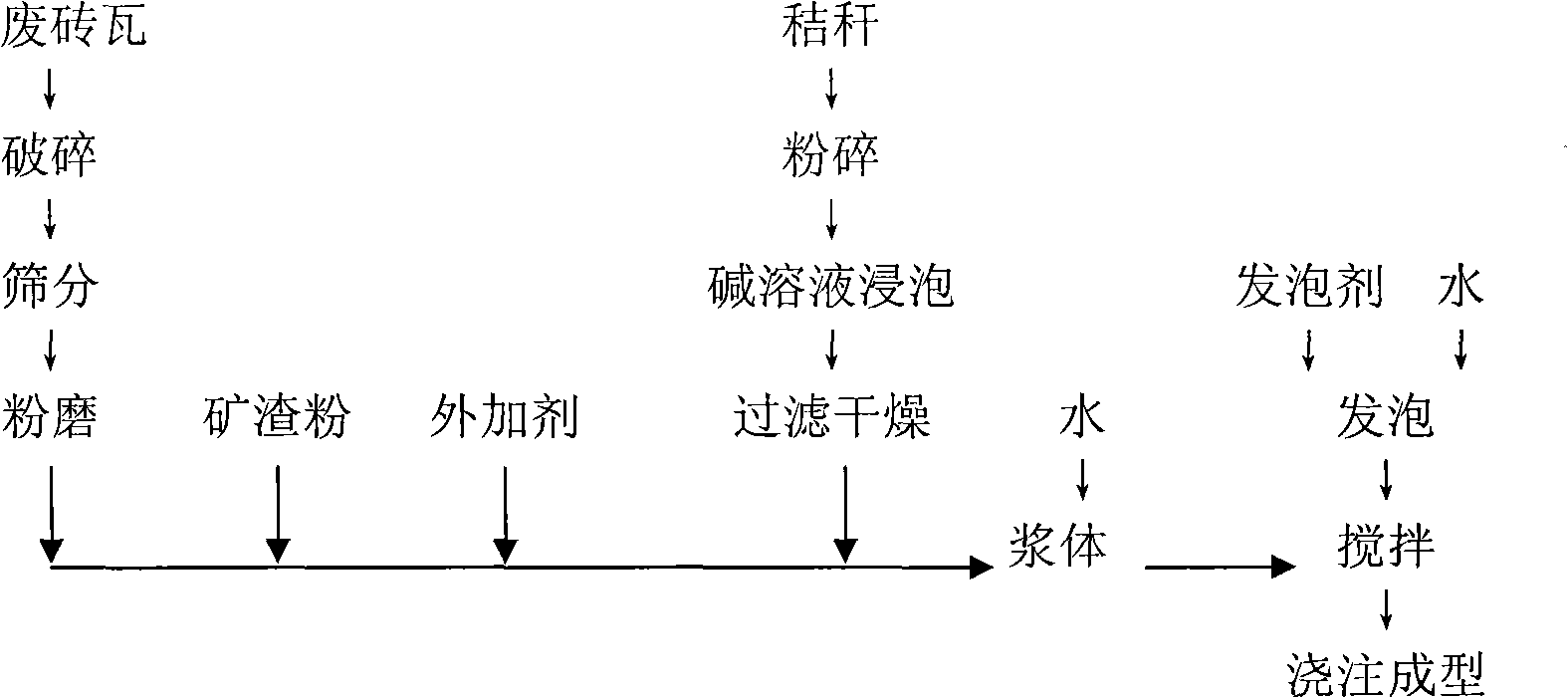

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

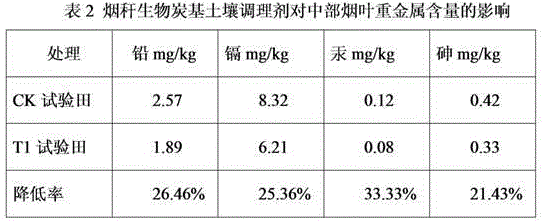

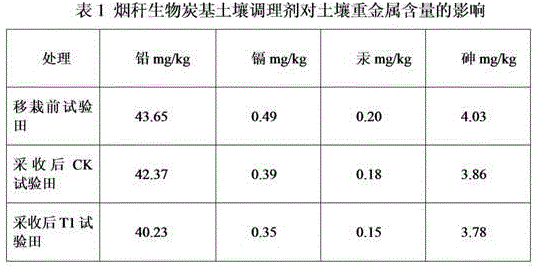

Tobacco stalk biochar soil conditioner and improvement method for tobacco field soil

ActiveCN104789229AReduce heavy metal activityEnhance metabolic functionOrganic fertilisersSoil conditioning compositionsSoil scienceEnvironmental engineering

The invention discloses a tobacco stalk biochar soil conditioner capable of reducing the content of heavy metals in tobacco, improving the tobacco quality and improving the soil environment, as well as an improvement method for tobacco field soil. The tobacco stalk biochar soil conditioner is prepared by mixing the following raw materials in parts by weight: 40-60 parts of tobacco stalk biochar and 40-60 g of a passivant. The tobacco stalk biochar soil conditioner is easy to obtain raw materials, simple in preparation method and low in cost, can effectively reduce the content of heavy metals in tobacco, and can improve the quality of tobacco field soil; a large number of waste tobacco stalks generated in tobacco growing areas are adopted as the raw material, the resource recycling of waste materials is realized, the sustainable development of the tobacco industry is facilitated, and the tobacco stalk biochar soil conditioner is suitable for large-scale popularization and application in the field of tobacco growing.

Owner:HENAN AGRICULTURAL UNIVERSITY

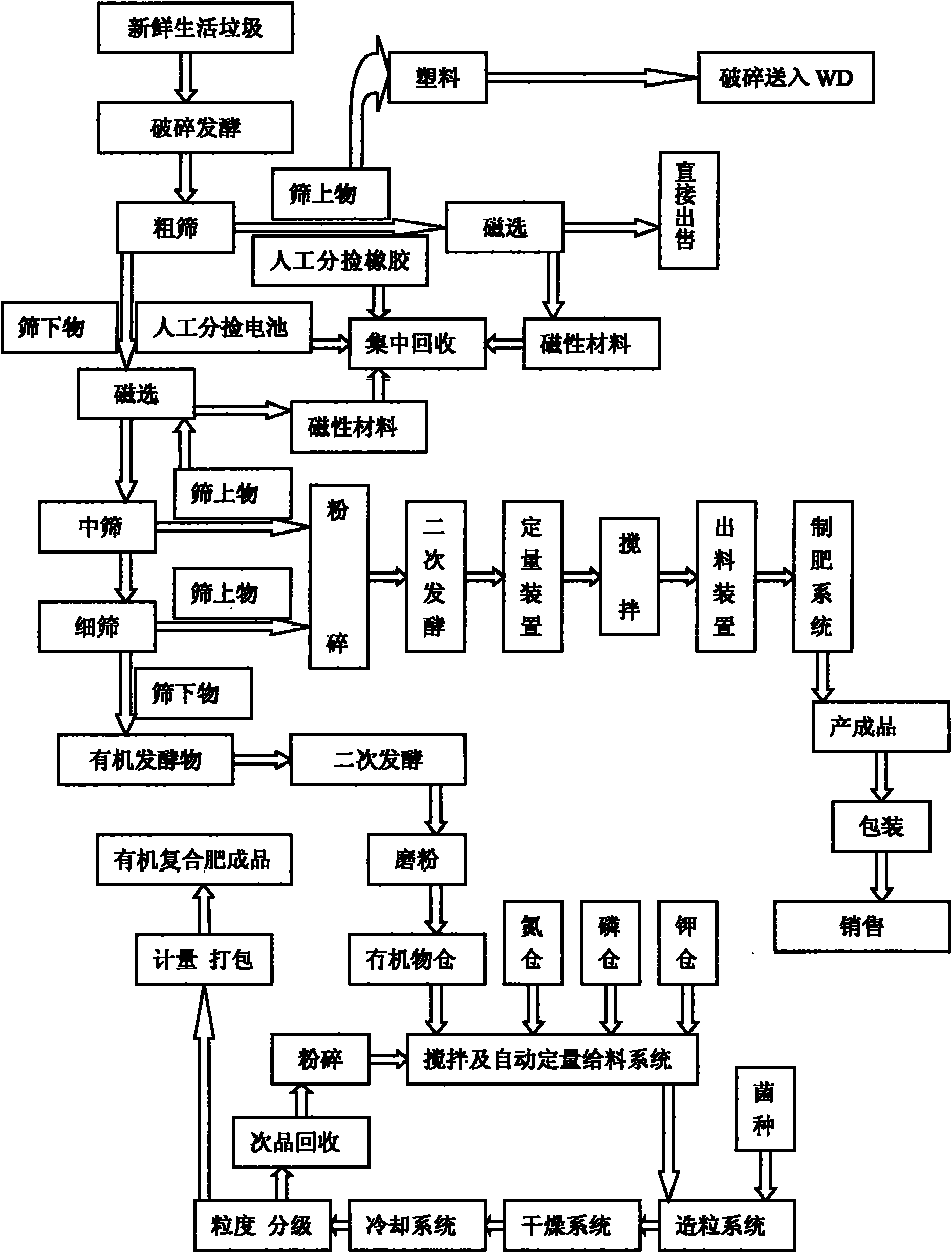

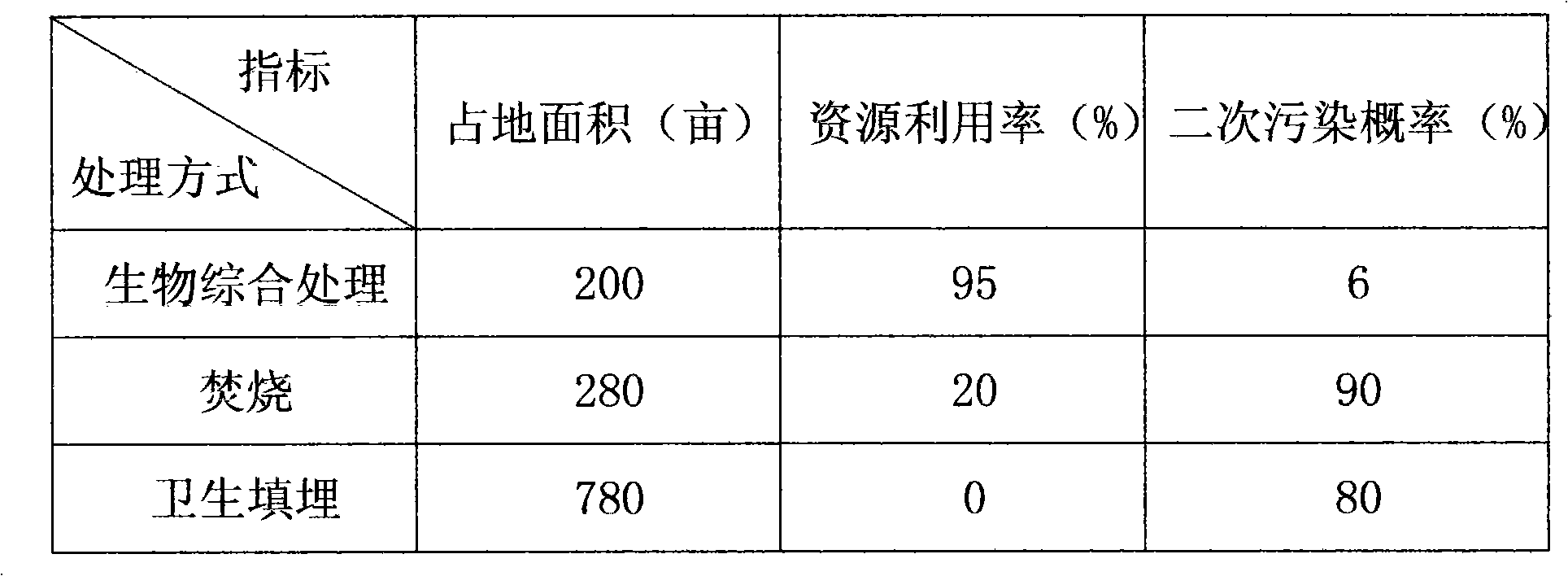

House refuse treatment method

InactiveCN102009057ASave spaceReduce the power requiredSolid waste disposalClimate change adaptationBrickCrushed stone

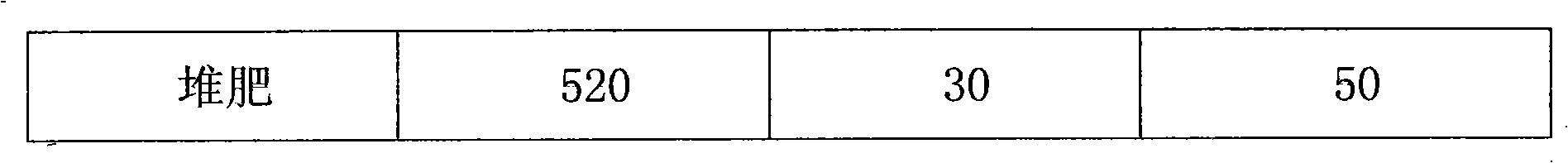

The invention discloses a house refuse treatment method, which comprises the following steps: crushing and fermenting refuse at normal pressure and under normal pressure; executing a screening process, crushing large or large-grain inorganic materials among oversize materials on a coarse screen, and making an urban coal material; coarsely screening, crushing stone and brick blocks among oversize materials on a medium screen, and making a roadbed material or pavior brick base material; making fertilizer by using organic materials or fermented products of the organic materials among the oversize materials and undersize materials of the medium screen and a fine screen, wherein materials with recycling value among magnetic materials screen out are sold directly, and materials without recycling value are collected and subjected to innocent treatment; and performing manual sorting, wherein materials with recycling value are directly sold. When the method is used for refuse treatment, the construction investment is small, the operation cost is low, the operation is simple, the treatment effect is desirable, and the resource recycling degree is high. The method can be widely used for treatment of refuse of different sizes and qualities without causing secondary pollution.

Owner:中山市祥源环保工程有限公司

Continuous sectioned crop straw pyrolysis circulation system

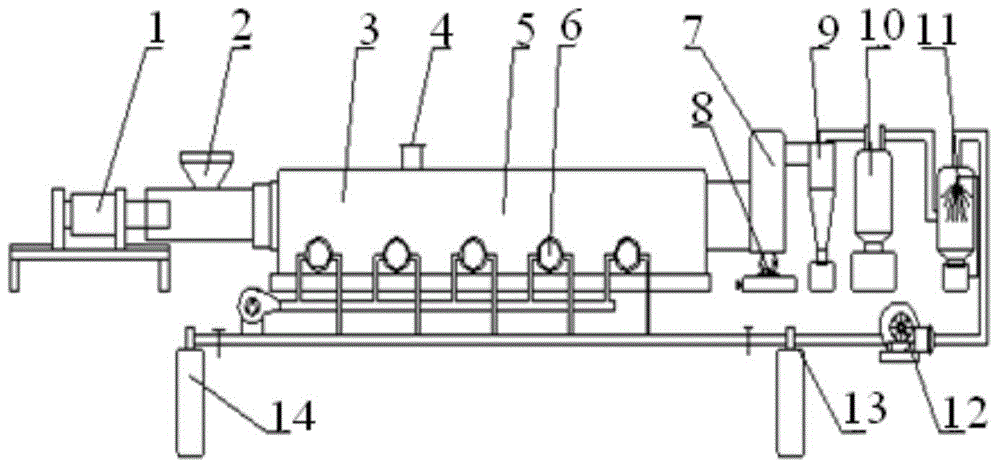

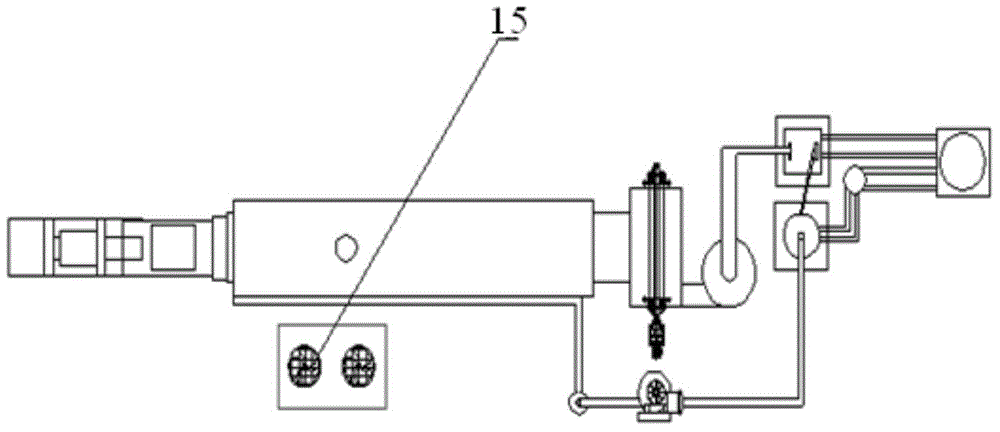

InactiveCN104629805AIncrease productivityReduce energy consumptionBiofuelsIndirect heating destructive distillationTarCollection system

The invention discloses a continuous sectioned crop straw pyrolysis circulation system which comprises six subsystems, namely a material delivery subsystem, a pyrolysis carbonization subsystem, a finished carbon collection subsystem, a tar collection subsystem, a wood vinegar collection subsystem and a gas collection subsystem, wherein the material delivery subsystem consists of a hydraulic push rod feeding device and a feeding bin; the carbonization subsystem comprises a furnace body and a combustion chamber; the carbon collection subsystem comprises a settling chamber, a screw feeder and a dust separator; the tar collection subsystem comprises a condenser; the straw vinegar fluid collection system comprises a sprayer; and the gas collection subsystem comprises an induced draft fan and a gas storage tank.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

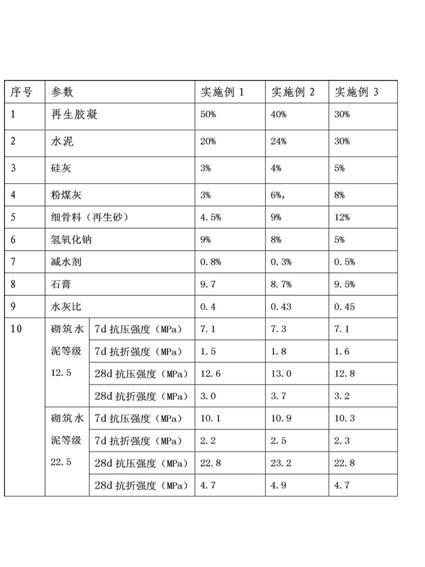

Construction regenerated binding material prepared from construction garbage and preparation method thereof

InactiveCN102432207AGreat renewable valueLarge specific surface areaCement productionSlagPre treatment

The invention discloses a construction regenerated binding material prepared from construction garbage, prepared by the following steps: putting the construction garbage in a reclamation machine to rub, impact, activate, and modify, using a micro powder extraction device to obtain regenerated micro powder, adjusting the proportion. The invention also discloses a preparation method of the material, comprising the following steps: pretreating construction garbage, reserving waste concrete, waste bricks, waste lime-sand mortar, and waste slag as raw materials; crushing and sieving raw materials to obtain particles; putting the particles in the reclamation machine for processing, removing inert membranes on sand grains, and activating the surface activity of particles; extracting micro powder by a dust collector, sieving the micro powder, and taking undersized parts to obtain regenerated micro powder; continuously crushing the unextracted particles, and extracting the regenerated micro powder when crushing; examining, and adjusting the components to obtain the construction regenerated binding material, wherein, the particles in the reclamation machine are regenerated sand. The construction regenerated binding material is used for replacing 50-70 % of ordinary portland cement to be as masonry cement.

Owner:云南华威废弃物资源化有限公司

Method and device for pyrolytic carbonizing treatment of sludge

ActiveCN104876414AWays to realize separate heatingControl and maintain temperatureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustorCombustion chamber

The invention relates to a method for pyrolytic carbonizing treatment of sludge. The method comprises: a heat supplying portion: arranging a combustor, and introducing a flaming port of the combustor into a combustion chamber to obtain high-temperature flue gas; a pre-treating portion: putting the sludge into a pre-treating chamber, and introducing the high-temperature flue gas of the heat supplying portion so as to heat the sludge to the temperature of 100-250 DEG C; a carbonizing treatment portion: feeding the pre-treated sludge into a carbonizing treatment chamber, and introducing the high-temperature flue gas of the heat supplying portion so as to heat the pre-treated sludge to the temperature of 450-650 DEG C; a gas treating portion: separately collecting gas-phase products generated from pre-treating and carbonizing treatment, and condensing the collected gas-phase products correspondingly by adopting a water spraying manner, so as to respectively obtain first oil, first noncondensable gas, second oil and second noncondensable gas; and a gas utilizing portion: introducing the second noncondensable gas into the combustion chamber of the heat supplying portion for combustion. The invention also provides a device for implementing the method. The method and the device have the advantages of simplified process, small equipment quantity, stability and reliability in operation, energy saving and environmental protection, high oil recovery ratio, and the like.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

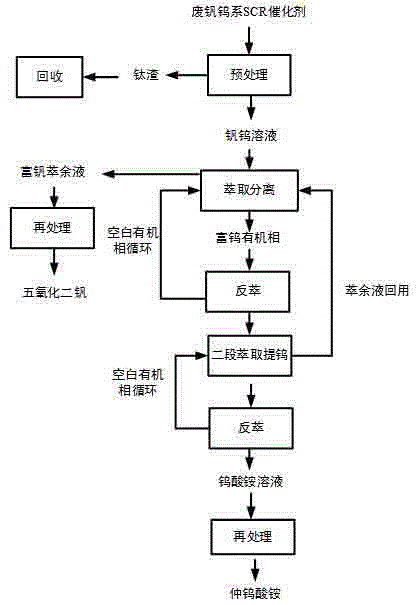

Vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts

ActiveCN104862485ARealize separation and recoveryRealize recycling of resourcesProcess efficiency improvementPtru catalystAmmonium paratungstate

The invention discloses a vanadium and tungsten separating and purifying method for spent vanadium and tungsten SCR (selective catalytic reduction) catalysts. The method comprises the following steps: a spent catalyst is pretreated to obtain titanium slag and a vanadium and tungsten solution; the vanadium and tungsten solution is extracted for separation, and an obtained vanadium-rich raffinate is treated again to obtain vanadium pentoxide; a tungsten-rich organic phase obtained through separation is subjected to two-stage extraction for tungsten extraction after back extraction, a product is subjected to back extraction again to obtain an ammonium tungstate solution, and the ammonium tungstate solution is treated to prepare ammonium paratungstate. The blank of lack of a vanadium and tungsten separating, purifying and recovering technology for the spent vanadium and tungsten SCR catalysts in the denitration industry is filled up completely, the recovery rates of vanadium and tungsten both exceed 95%, the obtained vanadium pentoxide and ammonium paratungstate products all meet the high-purity standard, and the purity is higher than 99%.

Owner:BOTREE CYCLING SCI &TECH CO LTD

Marbled glass ceramics directly employing fusion blast furnace slag and preparation method of marbled glass ceramics

ActiveCN106587634AImprove mechanical propertiesImprove the decorative effectCharging furnaceGlass productionSlagPotassium carbonate

The invention discloses marbled glass ceramics directly employing fusion blast furnace slag and a preparation method of the marbled glass ceramics. The marbled glass ceramics comprises the following raw materials, by mass, 55-75 parts of blast furnace slag flux and 25-45 parts of auxiliary material flux; and auxiliary materials comprise the following components, by mass, 8.5-19.5 parts of quartz sand, 0.5-5.5 parts of limestone, 1-5 parts of sodium carbonate, 2-5 parts of potassium carbonate, 1-4 parts of zinc oxide, 1-4 parts of ammonium di-hydrogen phosphate, 1-2 parts of spodumene, 2.5-5 parts of sodium fluosilicate, 0.5-1.5 parts of sodium fluoroaluminate and 0.5-1 part of borax. The preparation method is characterized in that through controlling the mixed melting temperature and time of the blast furnace slag flux and the auxiliary material flux, a flux mixture is obtained; through forming, annealing and microcrystallization heat treatment, the marbled glass ceramics is obtained. The molten blast furnace slag and the auxiliary materials are mixed in a flux form and the flux mixture having certain micro-inhomogeneity is obtained accurately, then with the combination of subsequent forming and heat treatment technologies and the like, the marbled glass ceramics is obtained, so that the technology is easy to implement, and the influence of uncertainty on a product in a mixing process is reduced.

Owner:WUHAN UNIV OF TECH

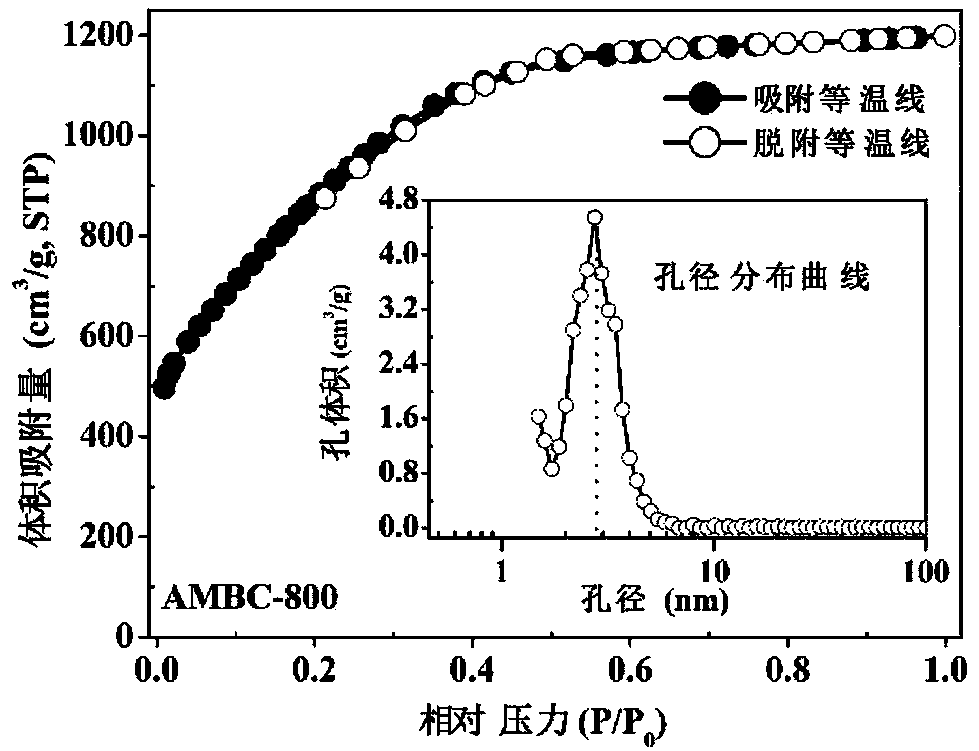

Preparation method of high mesoporous rate nitrogen doped carbon electrode material

ActiveCN108483442ALarge specific surface areaGood effectCarbon compoundsHybrid capacitor electrodesHigh current densityCapacitance

The invention provides a preparation method of a high mesoporous rate nitrogen doped carbon electrode material. The preparation method comprises the following steps: step one, pretreatment; step two,hydrothermal reaction: carrying out the hydrothermal reaction on bamboo shoot shells to obtain a hydrochar precursor; step three, carbonation reaction: filtering, washing and drying the hydrochar precursor and then carrying out low temperature carbonization treatment on the dried hydrochar precursor and a nitrogen source material to obtain carbide; step four, activating treatment: carrying out theactivating treatment on the carbide and an activator, carrying out acid pickling, washing with deionized water and drying to obtain the high mesoporous rate nitrogen doped carbon electrode material of which an aperture main peak is 2.8nm. A symmetric supercapacitor assembled by applying an electrode material provided by the invention has the effects that specific capacitance reaches as high as 209F / g when current density is 0.5A / g; especially when the high current density is 10A / g, the symmetric supercapacitor has excellent stability, and the capacitance still reaches as high as 95 percent ofinitial capacitance after 10,000 cycles of charge and discharge.

Owner:XIANGTAN UNIV

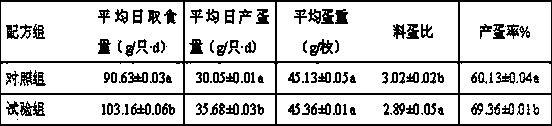

Feed formula of taking cordyceps militaris culture medium residue as material, and preparation method thereof

The invention discloses a feed formula of taking cordyceps militaris culture medium residue as a material, and a preparation method thereof, and solves the problems that the traditional feed is high in cost, and the quality of eggs cannot be well improved. The feed formula disclosed by the invention is prepared from cordyceps militaris culture medium residue powder, corn flour, wheat bran, bean pulp, salt, fish meal, bone powder, vitamin mixture, microelements, methionine and premix compound. The invention also provides the preparation method of the Chicken feed formula. In the components of the feed formula, industrial waste, namely residual solid culture medium residue after cordyceps militaris sporocarp is picked up is utilized; the industrial waste is fully recycled, so that the production cost of the feed is greatly reduced.

Owner:SICHUAN ACAD OF AGRI SCI SERICULTURE INST +1

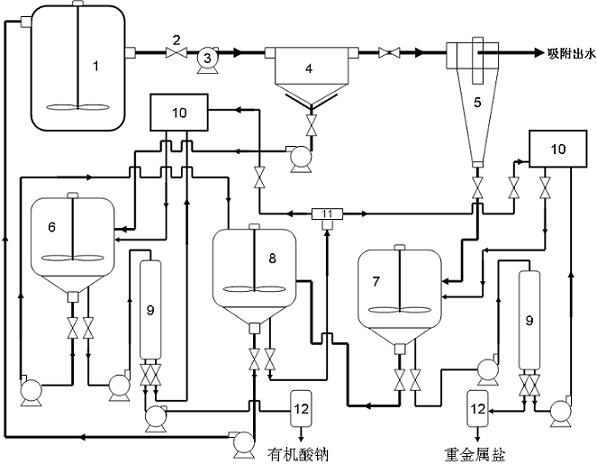

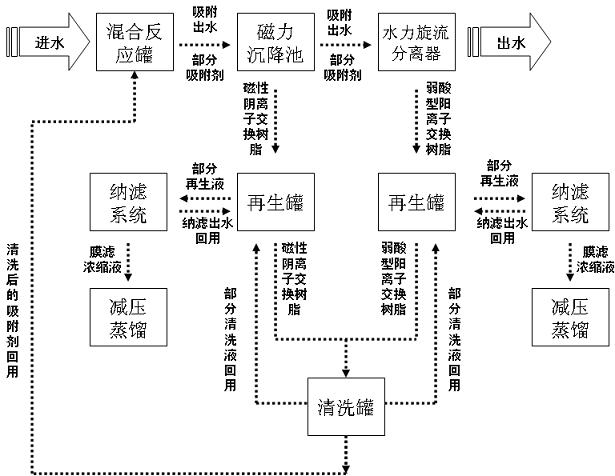

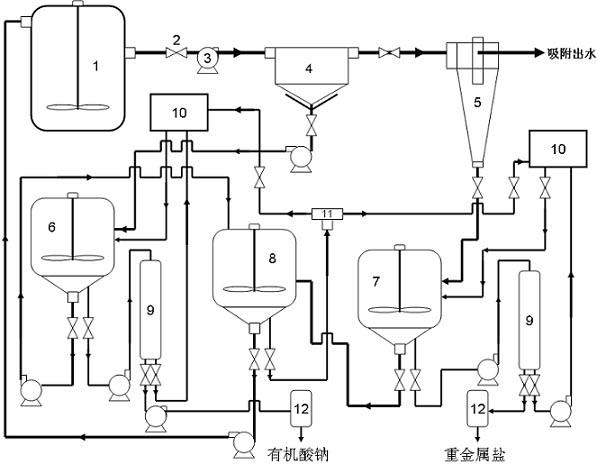

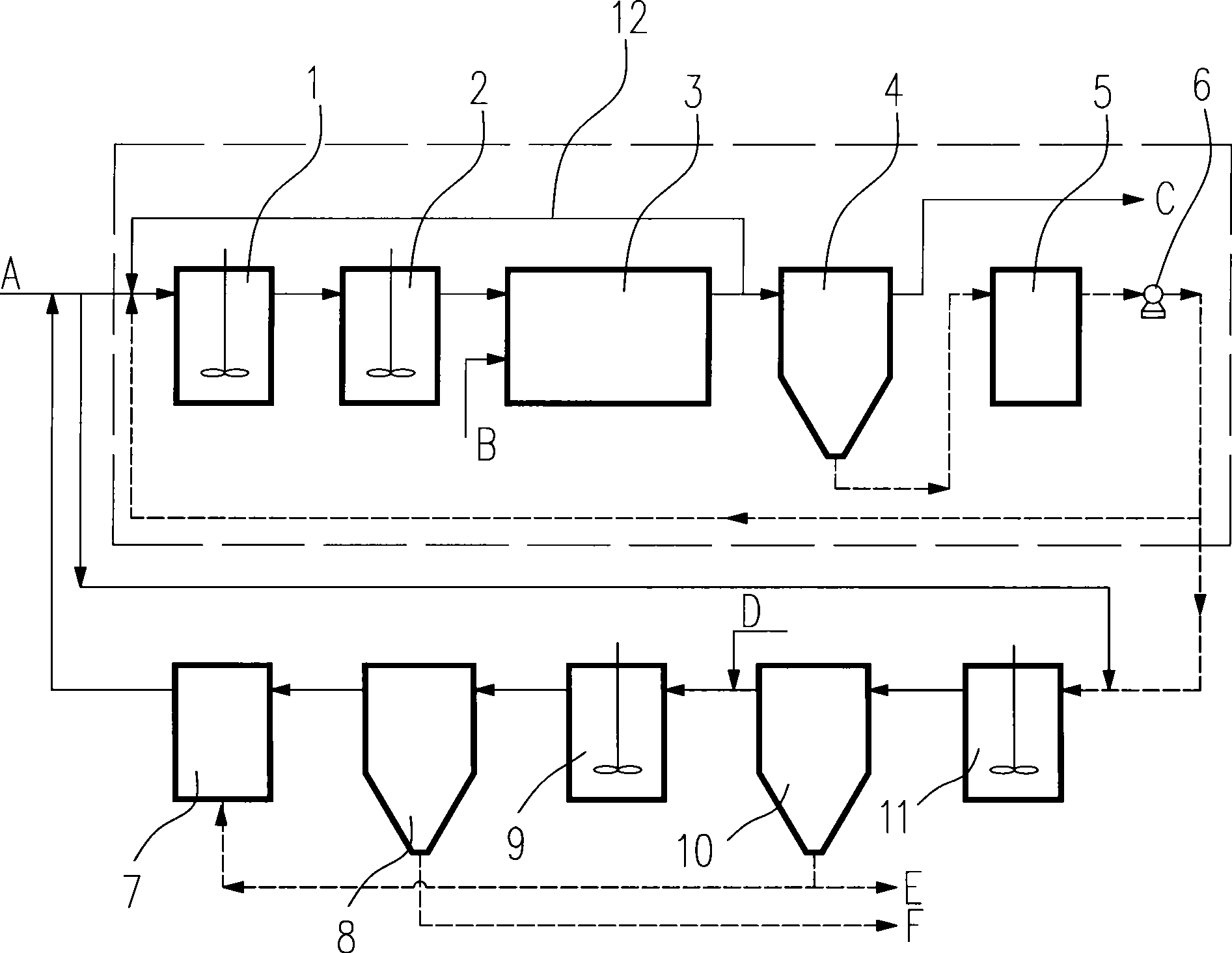

Continuous advanced treatment system of heavy metal ion-containing tail water and treatment method

ActiveCN101863530ARealize recycling of resourcesFast processingOrganic chemistryWater/sewage treatment by magnetic/electric fieldsOrganic acidSorbent

The invention discloses a continuous advanced treatment system of heavy metal ion-containing tail water and a treatment method, belonging to the field of tail water advanced treatment. The system comprises a mixed reaction tank and a regeneration tank, wherein the mixed reactor is connected with a magnetic force sedimentation tank which is respectively connected with a gravity type hydrocyclone and the regeneration tank, and the regeneration tank is respectively communicated with a rinse tank and a nanofiltration system. The treatment method comprises the following steps: pretreating, adsorbing by the mixed reaction of magnetic anion exchange resin and weak acid cation exchange resin, yielding water, separating adsorbent, separating solid from liquid, transporting resin to the regeneration tank, regenerating resin, cleaning, and disposing resin desorption liquid. The invention mixes the weak acid cation exchange resin with the magnetic anion exchange resin in the same mixed reactor for the first time to treat the heavy metal ion tail water, can remove heavy metal ions and natural organic acid in tail water at the same time in shorter time and can unify high-efficiency tail water treatment and resource recycling.

Owner:NANJING UNIV

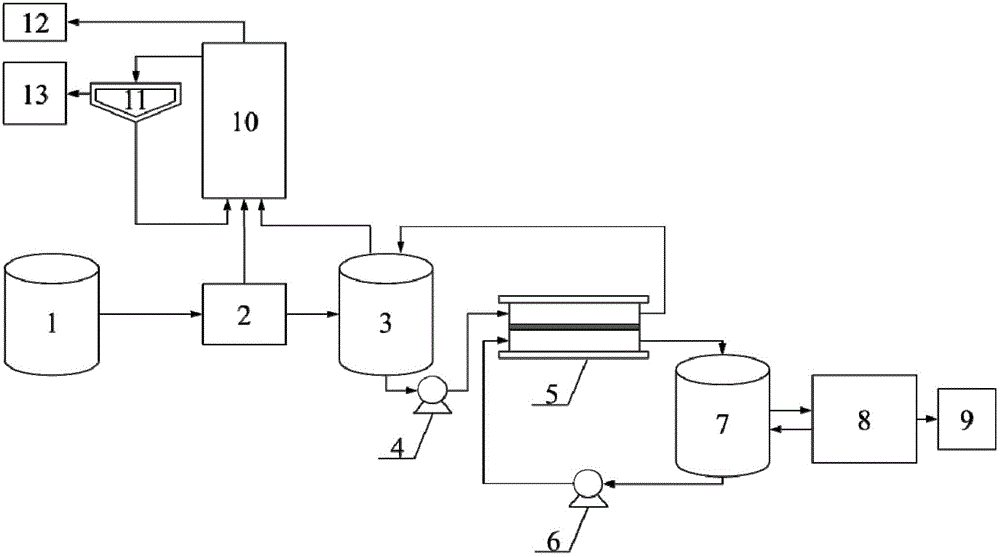

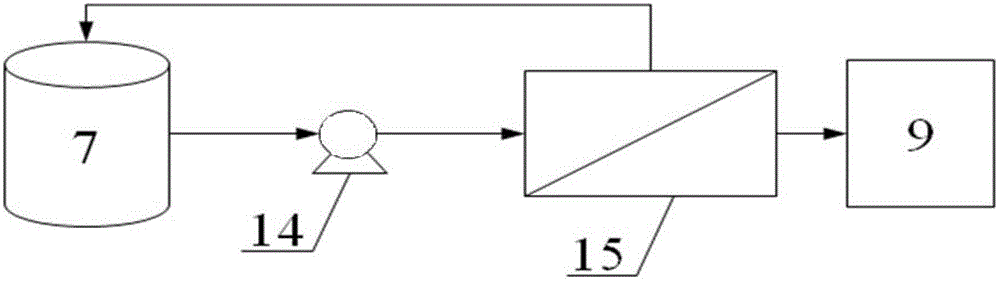

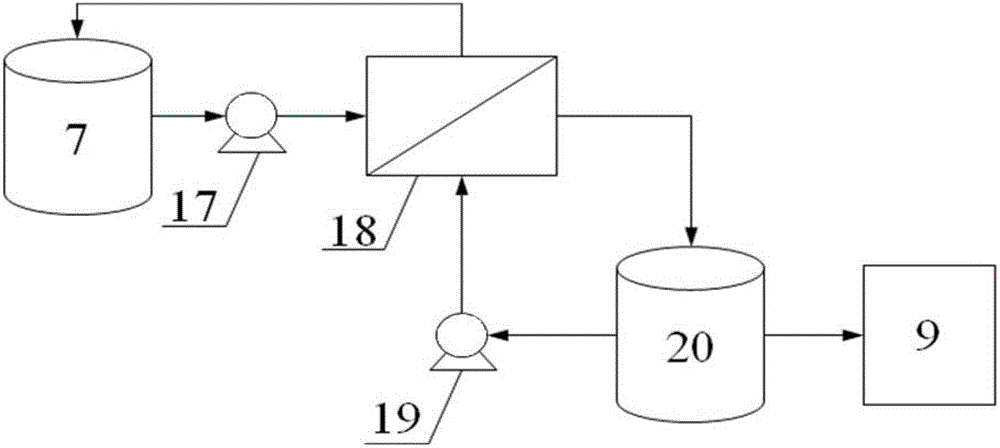

Method and device for recovering carbon source in urban sewage

InactiveCN103145219AReduce processing costsAchieve desalinationGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWater desalinationWater flow

The invention relates to a method and a device for recovering a carbon source in urban sewage. The method comprises the following steps: by taking urban sewage as raw material liquid, after the urban sewage is filtered, feeding the filtered urban sewage into one side of a forward osmosis membrane assembly, and then feeding the filtered urban sewage into an absorbed liquid barrel at the other side of the forward osmosis membrane assembly under the action of absorbed liquid at the other side of the forward osmosis membrane assembly, wherein the absorbed liquid is seawater; and feeding the diluted seawater in the absorbed liquid barrel into a membrane separation assembly, collecting produced water at a produced water outlet of the membrane separation assembly, and flowing concentrated water back to the absorbed liquid barrel. According to the invention, urban sewage as raw material liquid and seawater as absorbed liquid enter a forward osmosis system, water in the raw material liquid seeps through a forward osmosis membrane, and pollutants are intercepted, so that the urban sewage is concentrated, the seawater is diluted, thereby simultaneously achieving effects of sewage concentration and seawater desalination, reducing the processing cost of the urban sewage, and realizing the recovery of organic carbon sources; and the diluted seawater is easy to desalinate, thereby reducing the cost of seawater desalination.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

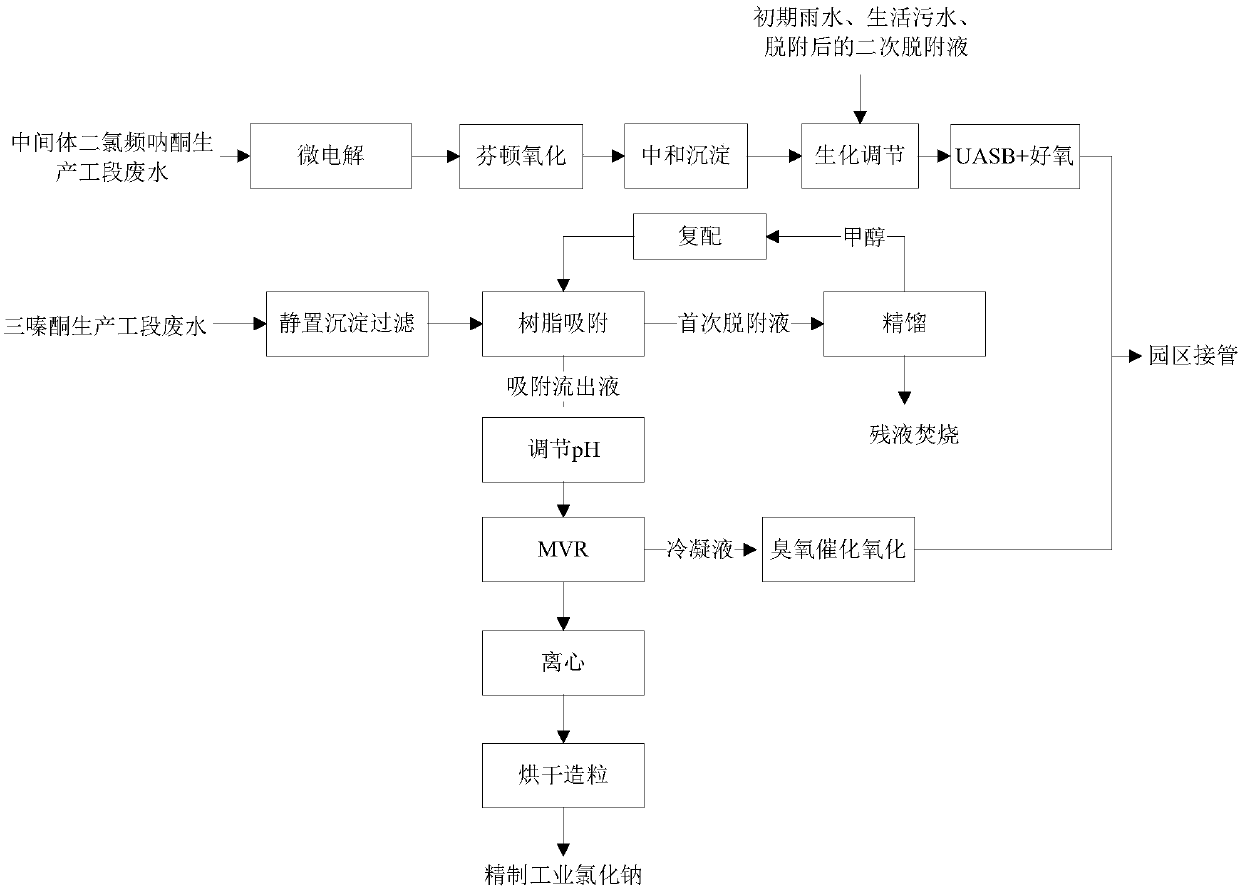

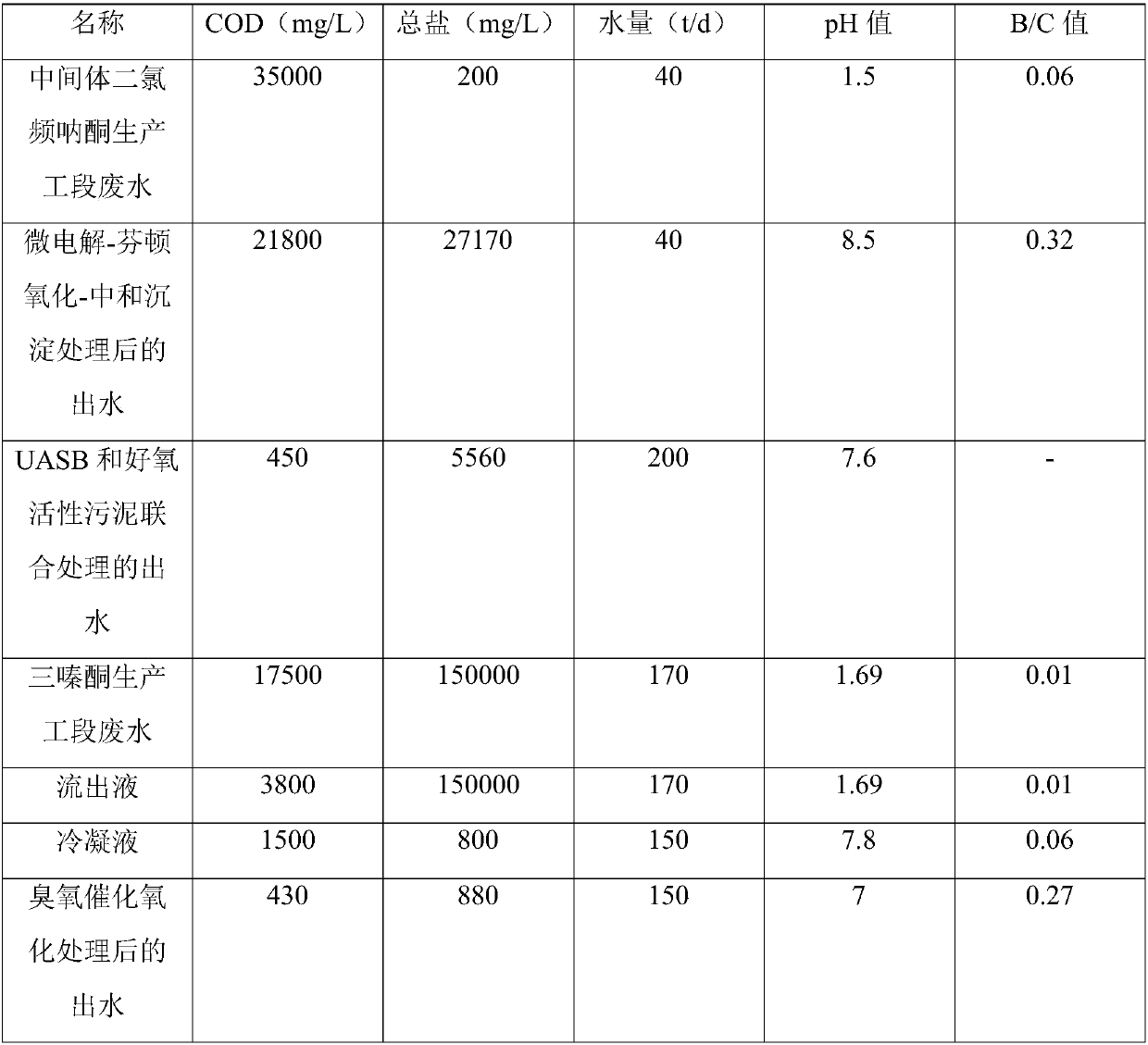

Triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method

ActiveCN107935308ARealize recycling of resourcesEasy to handleWater contaminantsTreatment with aerobic and anaerobic processesChemistryPesticide

The invention discloses a triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method and belongs to the technical field of pesticide wastewater treatment. The method comprises the following steps: separately collecting and treating wastewater of a triazone pesticide preparation process, performing combined treatment of microelectrolysis-Fenton oxidation-neutralization and sedimentation treatment and UASB (Upflow Anaerobic Sludge Blanket) and aerobiotic activity sludge on wastewater of an intermittent dichloropinacolin production section, performing resinadsorption treatment on wastewater of a triazone production section, recycling sodium chloride, finally combining effluents of the two modes, and accessing to a garden tube network for garden management. By adopting the triazone pesticide wastewater up-to-standard emission synergistic salt recycling treatment method disclosed by the invention, efficient and stable treatment on high-salt, high-COD(Chemical Oxygen Demand) and biorefractory wastewater is achieved, and the purpose of up-to-standard emission of triazone pesticide wastewater is achieved; the method is simple and convenient to operate and has the advantages of high efficiency, low consumption, high stability, convenience of maintenance, and the like, and sodium chloride in the wastewater can be recycled and reused.

Owner:江苏南大华兴环保科技股份公司

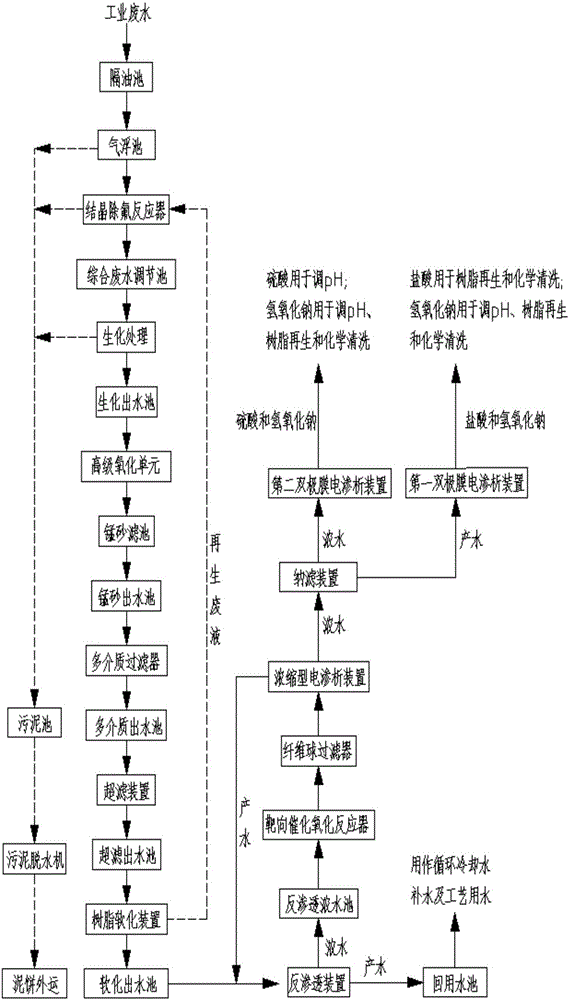

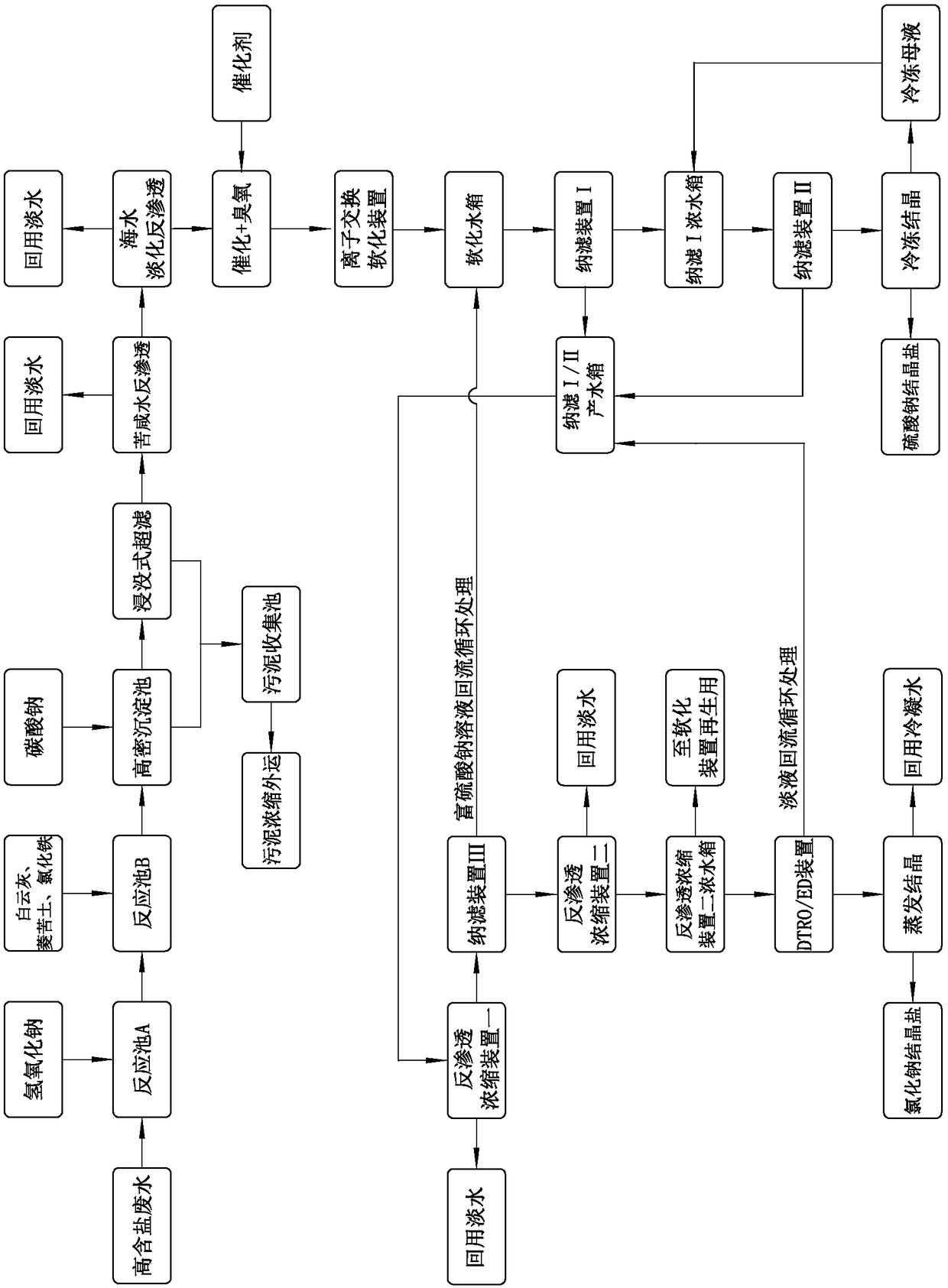

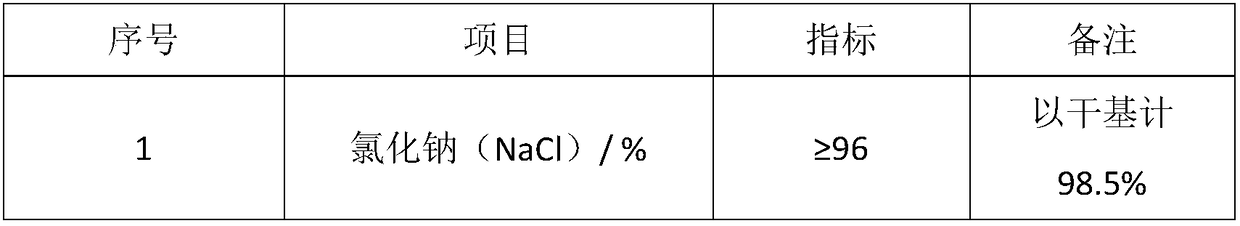

Zero discharge process for high-salt wastewater discharged from titanium dioxide production

ActiveCN108529802AAvoidance of foulingAvoid foulingGeneral water supply conservationWater softeningUltrafiltrationCatalytic oxidation

The invention relates to a zero discharge process for high-salt wastewater discharged from titanium dioxide production, and the steps are as follows: high-salt wastewater, removal of silicon by a magnesium agent, medicinal agent softening, high-density precipitation, immersion-type ultrafiltration, brackish water reverse osmosis membrane concentration, seawater desalination reverse osmosis membrane concentration, reduction of COD by catalytic oxidation, ion exchange softening, multi-stage nanofiltration salt separation, high pressure reverse osmosis membrane concentration, DTRO / ED electrodialysis concentration, and evaporation crystallization / freezing crystallization. The zero discharge process adopts corresponding treatment processes separately, realizes for the first time the zero discharge of the high-salt wastewater of titanium dioxide by a detailed control technology of each specific process in the system, ensures the normal and smooth operation of the system, and recovers a largeamount of fresh water resources and industrial salts. The purpose of resource recycling of the titanium dioxide production wastewater is realized, and on the basis of creating of certain economic benefits, significant environmental and social benefits are reflected.

Owner:SHANDONG YUXIN ENVIRONMENTAL SCI & TECH

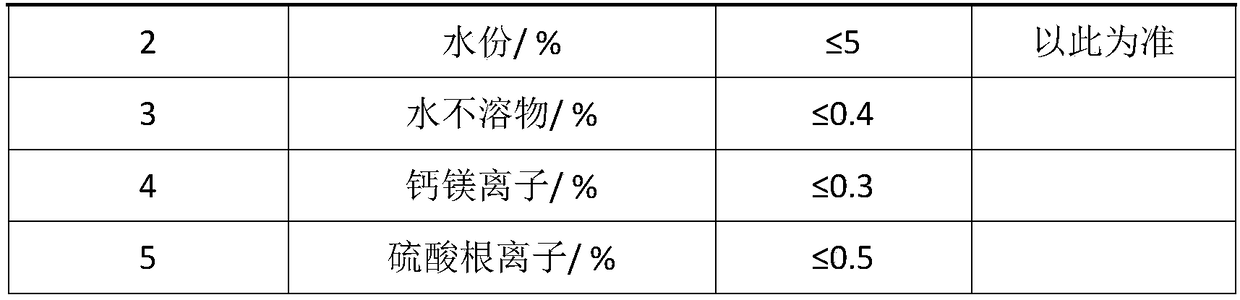

Alkali deweighting wastewater processing method and device

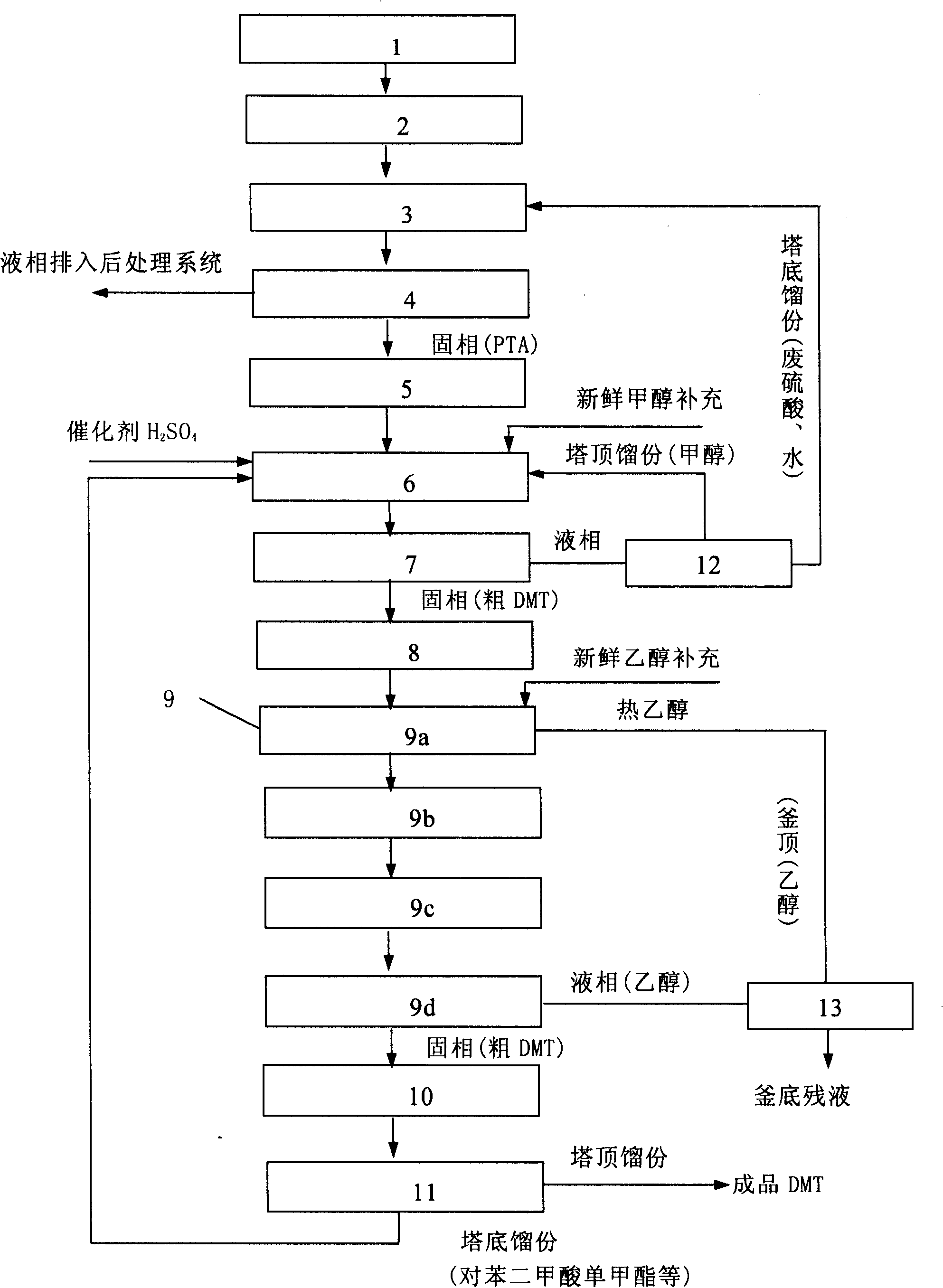

InactiveCN101244857AEliminate purification processEliminate polluting emissionsOrganic chemistryWater contaminantsDimethyl terephthalateIndustrial effluent

The invention provides a processing method for alkali-minimization wastewater, comprising a plurality of steps: (a) adjusting the PH value of alkali-minimization wastewater into 6.5 to 7, using the method of acid precipitation to obtain liquid phase and the solid phase with terephthalic acid; (b) carrying out esterification reaction for the solid phase from the procedure (a) in the presence of methanol to obtain a crude dimethyl terephthalate product. The method recovering terephthalic acid from alkali-minimization wastewater makes CODcr value of the wastewater removal of more than 75% and modifies the wastewater into Biodegradable industrial wastewater and at the same time changes the phthalic acid into dimethyl terephthalate.

Owner:SHAOXING COUNTY JINGSHENG RESIN TECH CO LTD

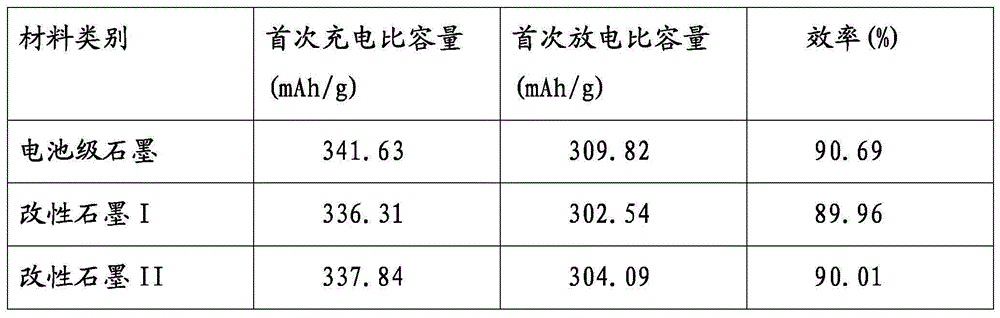

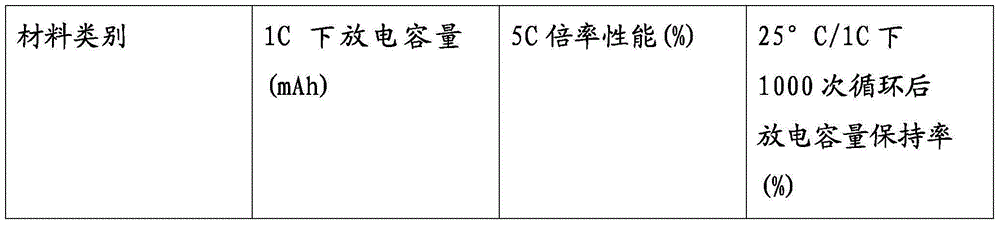

Recycling method for anode graphite material for invalid prismatic lithium-ion battery

ActiveCN105186059AReduce reaction energy consumptionRealize recycling of resourcesWaste accumulators reclaimingBattery recyclingWater bathsFiltration

The invention discloses a recycling method for an anode graphite material for an invalid prismatic lithium-ion battery. The method comprises the following steps: completely discharging the invalid prismatic lithium-ion battery, dismantling a negative pole piece and putting the negative pole piece into a dilute hydrochloric acid solution for ultrasonic dissolution; stopping ultrasound after completely separating graphite flakes from a current collector, taking out the separated current collector, and finishing recovery of the current collector after washing and drying; carrying out filtration, low-temperature vacuum drying and sieving on residual graphite slurry to obtain primarily purified graphite material, carrying out ultrasonic treatment on an oxidizing agent solution in a water bath, and carrying out centrifuging, washing, low-temperature vacuum drying and sieving to obtain secondarily purified graphite material; and carrying out ultrasonic reaction in low-temperature nitrogen atmosphere when steeping the graphite material into a reducing solution in the water bath, repairing the graphite material in the nitrogen atmosphere through thermal treatment, and cooling and sieving the graphite material, so as to obtain battery-grade modified graphite powder. The energy consumption of the reaction in the method is relatively low; and recovery is efficient.

Owner:安徽巡鹰新能源集团有限公司

Sewage disposal system with biological phosphorus removal and chemical phosphorus removal bypass and disposal method

InactiveCN101381183ARealize recycling of resourcesSolving the Contradiction of Biological Phosphorus and Nitrogen RemovalTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeSewage

The invention discloses a system and a method for treating sewage with biological phosphorus removal and bypath chemical phosphorus removal. The system comprises a nitrogen-phosphorus removal subsystem and a bypath phosphorus removal subsystem, wherein the nitrogen-phosphorus removal subsystem is formed by connecting an anaerobic tank, an anoxic tank, an aeration tank, a sedimentation tank, a sludge return tank and a sludge return pump in turn, wherein the water outlet of the sludge return tank is connected to a sewage inlet of the anaerobic tank through a sludge return pump via pipelines; the bypath phosphorus removal subsystem is formed by connecting a mixing tank, an anaerobic phosphorus release sedimentation tank, a mixing reaction tank and a second sedimentation tank in turn; and the water outlet of the sludge return tank of the nitrogen-phosphorus removal subsystem is communicated with the water inlet of the mixing tank through the sludge return pump. The treatment system is simple in structure, organically combines the biological phosphorus removal with the chemical phosphorus removal, effectively solves the disadvantages that the biological phosphorus removal is low in efficiency and the pure chemical phosphorus removal remains high in operation cost, and has the advantages of good phosphorus removal effect and less medicament cost than the pure chemical phosphorus removal.

Owner:BEIJING YIPU INT WATER AFFAIRS

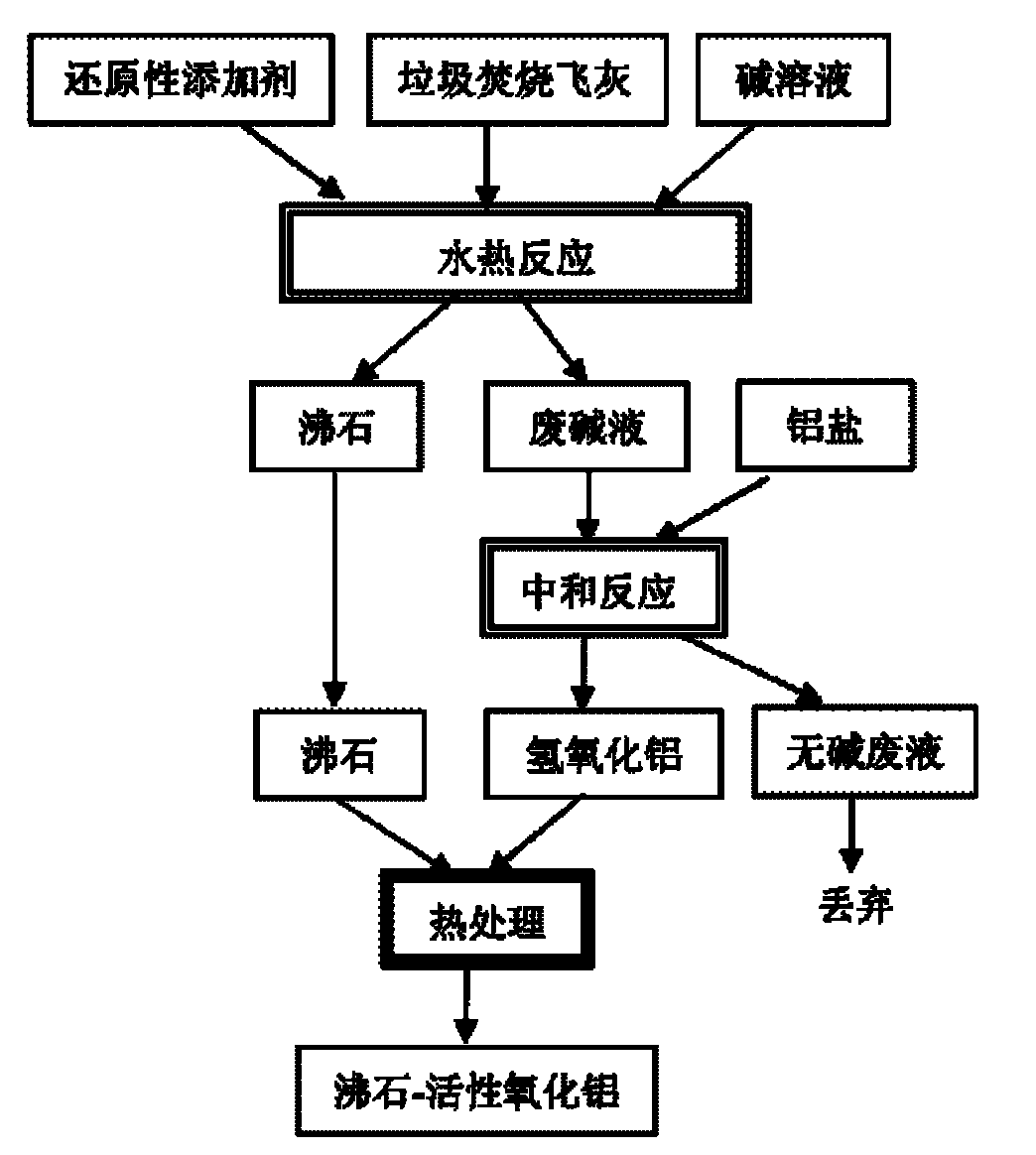

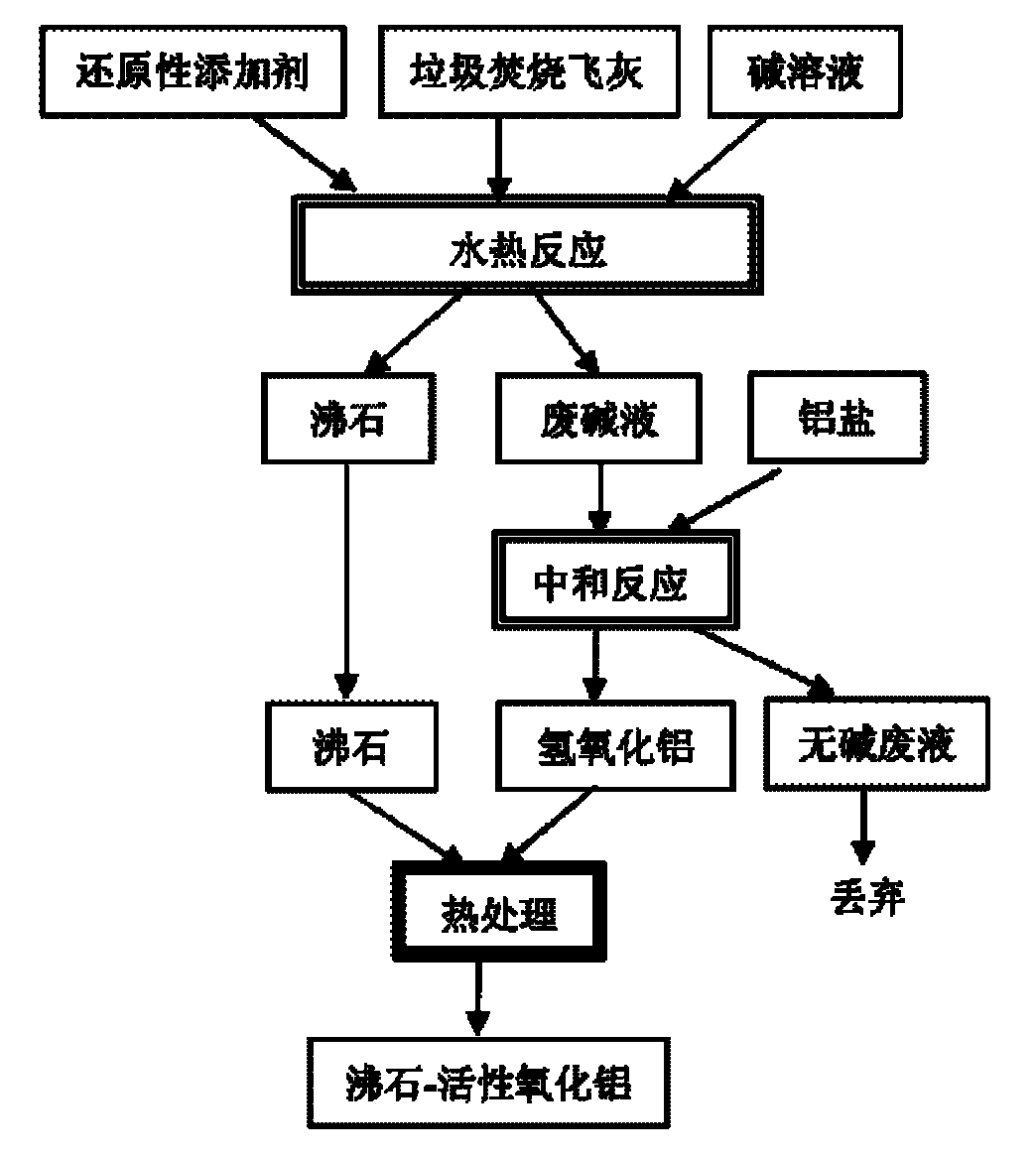

Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

InactiveCN102206757AWith resource recyclingAchieving harmlessnessOther chemical processesSolid waste disposalSorbentWater soluble

The invention relates to a heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash in the technical field of treatment for environmental protection. After an alkali solution and hydrazine substances are added to the MSWI fly ash and heated, and a water-soluble aluminum salt solution is further dripped; finally, after solid and liquid separation is conducted, heat treatment is carried out on an obtained solid phase to obtain a zeolite-active alumina compound absorbant; and the absorbant is put into sewage full of heavy metal to absorb and recycle the heavy metal. In the preparation process of the absorbant provided by the invention, dioxin in the MSWI fly ash is decomposed and removed; the MSWI fly ash is recycled as resources, and the heavy metal in the MSWI fly ash and the heavy metal in the sewage are recycled as the resources; and because the dioxin is decomposed and removed and the heavy metal is also extracted, the recycling method provided by the invention is safer and more reliable compared with the traditional treatment manner.

Owner:SHANGHAI JIAO TONG UNIV

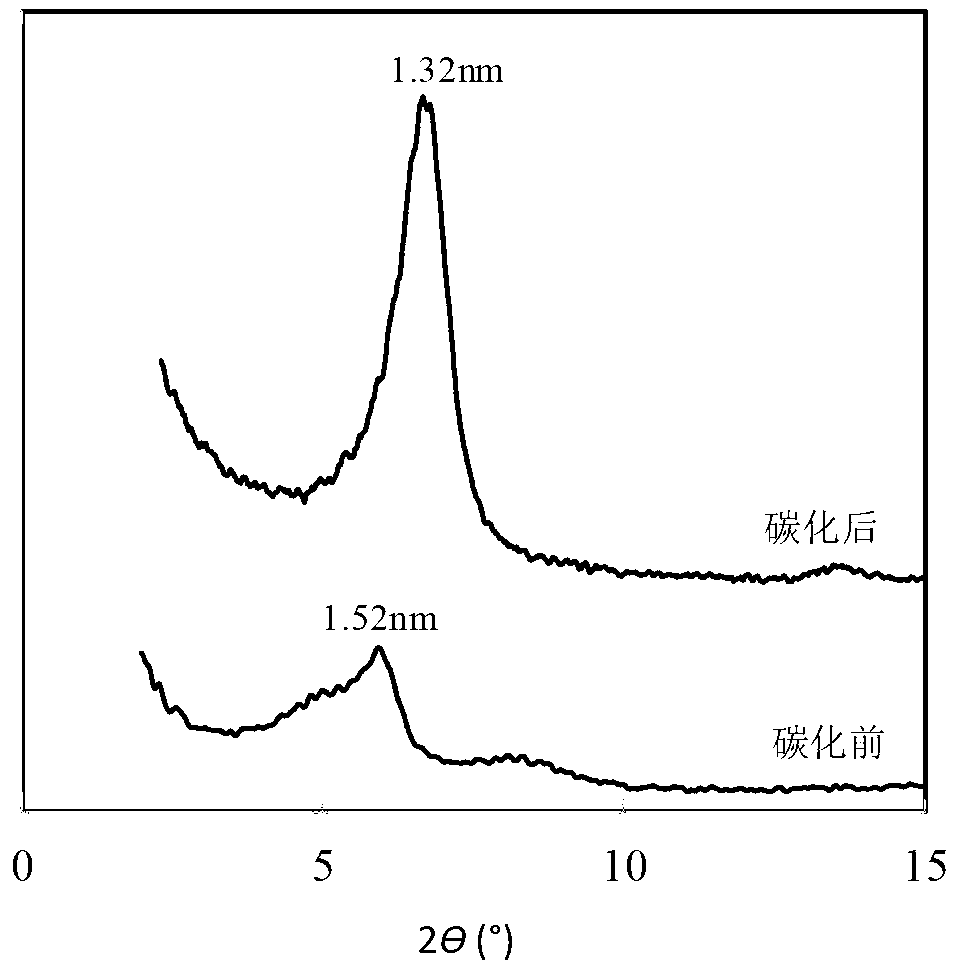

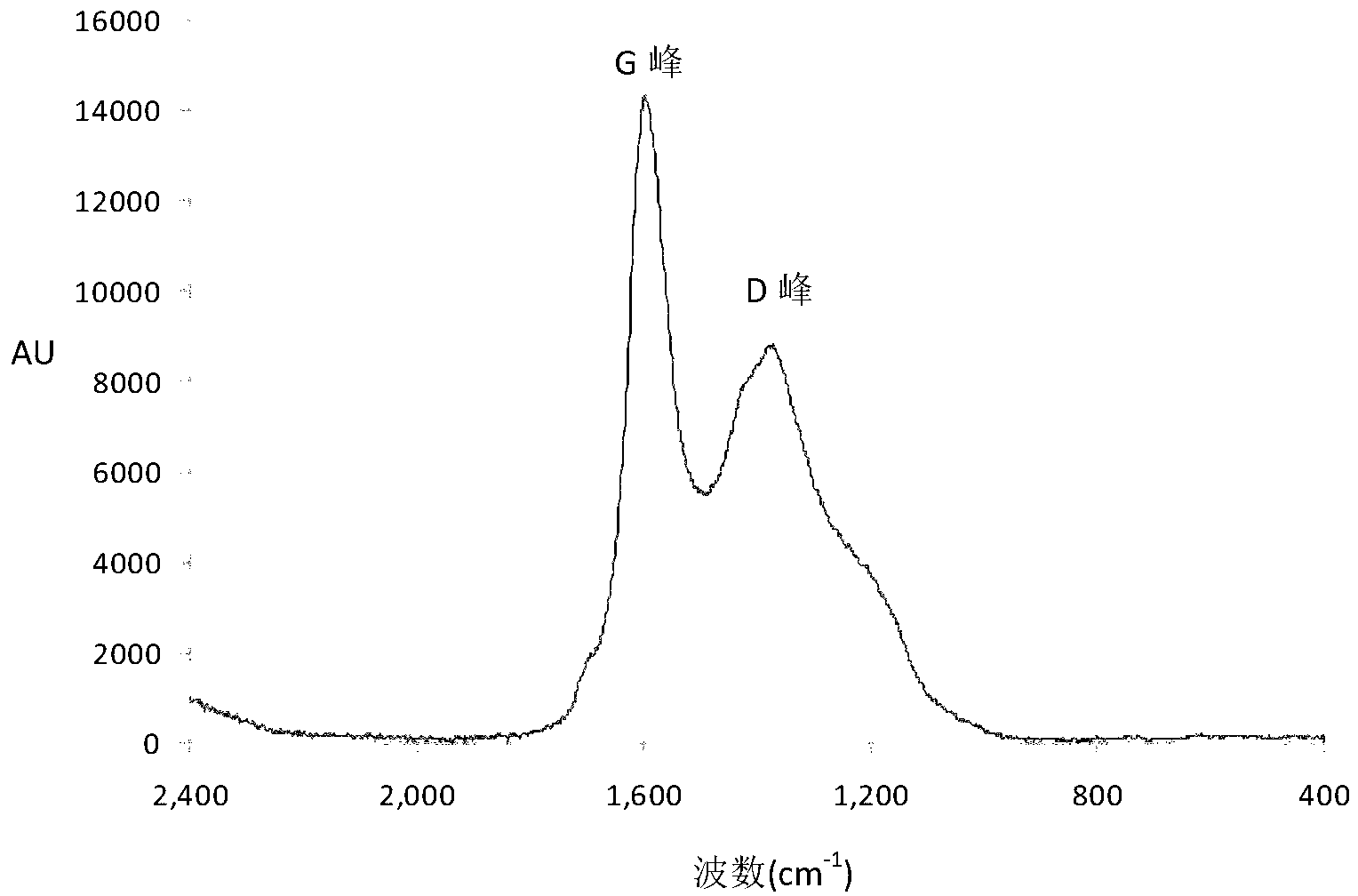

Preparation method for nano-carbon material having graphene-like structure

InactiveCN103058168ARealize recycling of resourcesMaterial nanotechnologyNano-carbonResource recoveryPhysical chemistry

The present invention discloses a preparation method for a nano-carbon material having a graphene-like structure. The preparation method comprises: sequentially performing drying, grinding, carbonizing, acidification washing, and drying to bentonite with dyes adsorbed therein to obtain the nano-carbon material having graphene-like structure. In the present invention, waste bentonite is used as a raw material, and a novel nano layered carbon material having a large specific surface area is prepared via a simple method; and at the same time, a new way for resource recovery and utilization of bentonite with dyes adsorbed therein is provided, thus achieving resource utilization of bentonite after being used for wastewater treatment after, and helping to promote the applications of the bentonite in dye / printing and dyeing wastewater treatment.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

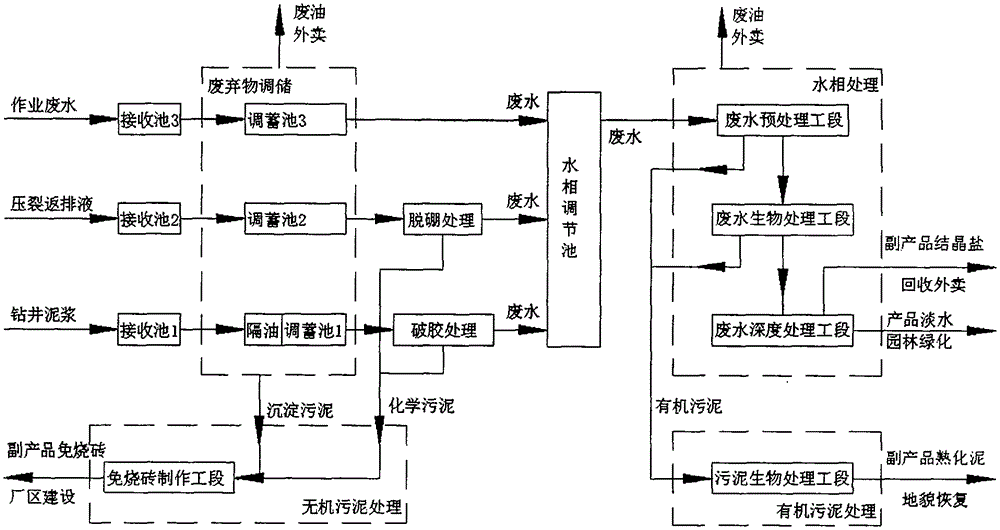

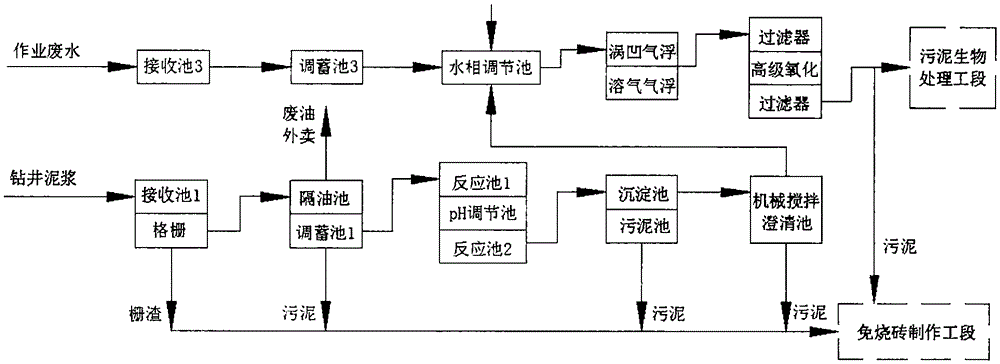

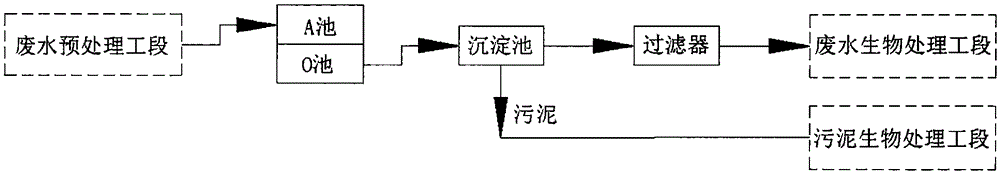

Resource utilization technology of drilling well wastes

ActiveCN105540994ASignificant environmental benefitsGreat social benefitsSolid waste disposalMultistage water/sewage treatmentSolid phasesThree-phase

The invention discloses a resource utilization technology of drilling well wastes. The resource utilization technology comprises three phases: pretreatment, biochemical treatment and deep treatment. In the pretreatment phase, the solid-liquid separation of drilling well slurry and fracturing flow-back fluid is realized by the physical and chemical methods, the solid phase is introduced into a baking-free brick preparation section and a sludge processing section, the liquid phase and operation wastewater are introduced into a blending and storing tank and mixed, pollutants are removed from the mixed liquid through a physical method, and then the mixed liquid is subjected to an iron-carbon micro-electrolysis treatment. In the biochemical treatment section, a hydrolysis acidification-contact oxidation technology is adopted to reduce the COD of biochemical effluent to less than 100 mg / L. In the deep treatment section, an ozone catalytic oxidization method and a BAF bio-filter technology are used together to degrade organic substances in water body, then the water body is processed in a membrane processing module to obtain fresh water and thick water; the fresh water can be used for afforesting in factory, and the thick water can be processed by a MVR mechanical evaporation system to produce cooling water, which can be used for afforesting in factory.

Owner:INNER MONGOLIA HENGSHENG ENVIRONMENTAL PROTECTION TECH ENG CO LTD

Recycling separation process of electrode component materials of used lithium batteries

InactiveCN101692510ARealize recycling of resourcesSimple processWaste accumulators reclaimingProcess efficiency improvementCrusherMaterials science

The invention relates to a recycling separation process of electrode component materials of used lithium batteries, which comprises shearing detached cathode materials of used lithium batteries into sheets and placing the sheets in a hammer crusher for stripping carbon powder and acetylene black powder which are attached on the surface of cathode copper foil by hamming and vibrating, wherein the lower part of the hammer crusher is provided with a sieve plate, hammer-crushed cathode particles having a diameter smaller than the bore diameter of the sieve plate fall into sieving equipment under the sieve plate through the pores of the sieve plate, cathode material having a diameter larger than the bore diameter of the sieve plate is circularly crushed by hammering in the hammer crusher till the diameter of the cathode material is smaller than the bore diameter of the sieve plate, and due to the size and shape differences between the particles, the crushed particles which fall into the sieving equipment and are non-metal carbon power and acetylene black powder are separated from metal copper through vibration sieving after the stripping by hammering and vibrating; and shearing the anodes of used lithium batteries into sheets and delivering the sheets into drum-type pyrolysis equipment for processing, wherein an organic bonder bonding aluminum foil, lithium cobaltoxide and acetylene black is decomposed under heat, the battery anode material of which component materials are stripped mutually is continuously discharge out from the other end of the pyrolysis equipment, and thus the separation of the anode aluminum foil from the lithium cobaltoxide and the acetylene black is realized through vibrating, impacting and sieving in the follow-up sieving equipment with an impacting member. The process has the advantage of simplicity, high efficiency, easy control, cleanness and environmental protection.

Owner:TONGJI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com