Metal heavy absorbent and preparation method and use thereof

A heavy metal and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of inability to remove pollutants from the environment, troublesome treatment of plant residues, and small hyperaccumulated plant biomass. , to achieve the effect of realizing waste recycling, convenient and easy operation efficiency, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of heavy metal adsorbent

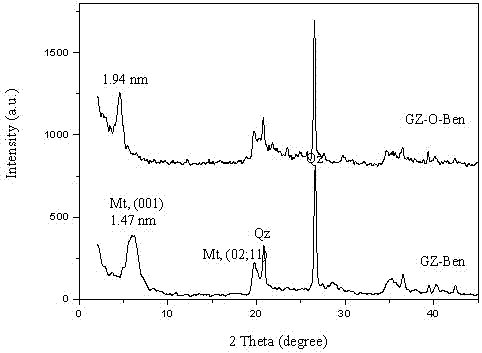

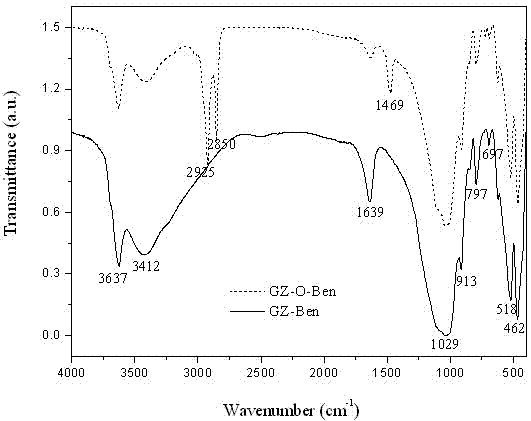

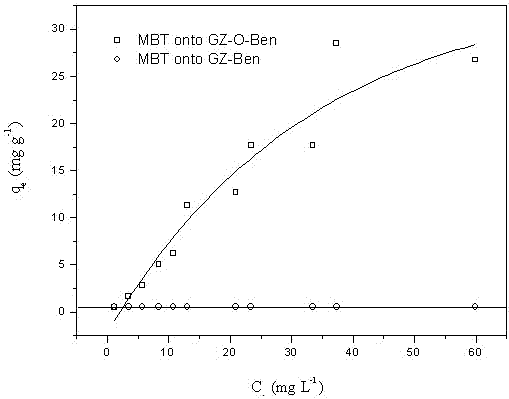

[0028] Select natural bentonite raw ore to grind, prepare cetyltrimethylammonium bromide (CTAB) solution equivalent to 100%~200% of bentonite CEC (exchange cation concentration), put the bentonite material in it, stir at room temperature for 24 hours and then filter , washed until no bromide ions were separated out to obtain organic bentonite, and X-ray diffraction analysis confirmed that the interlayer distance of bentonite was 1.47nm, which was increased to 1.94nm after organic modification ( figure 1 ), the infrared results showed that the hydroxyl groups on the surface of bentonite decreased sharply after organic modification ( figure 2 ), its lipophilicity and hydrophobicity are obviously enhanced. Tested under conditions such as water dispersion, it has high structural and compositional stability and does not precipitate surfactants. The organic bentonite is suitable for organic complexing agents containing mercapto (-...

Embodiment 2

[0039] (1) Adsorbent preparation

[0040] Select cheap, non-toxic and biodegradable Brij35, prepare 200ml of 0.1M solution, put 2 grams of kaolin in it, stir at room temperature for 24 hours, filter, wash until no surfactant is precipitated, and obtain organic kaolin, which is dispersed in water and other conditions It has high structural and compositional stability. The organic kaolin is mercaptoacetic acid, 2-mercaptobenzothiazole (MBT) and its derivatives and other organic complexing agents containing mercapto (-SH), polyacrylamide and its derivatives and other organic complexes containing amino groups (-NH) The complexing agent has a very high adsorption capacity (over 80mg / g).

[0041] Prepare 500 ml of 1M polyacrylamide solution, place organic kaolin in it, and stir at room temperature for 1 hour to obtain organic kaolin adsorption material loaded with polyacrylamide.

[0042] The obtained adsorbent can be granulated and shaped to obtain shaped materials with different...

Embodiment 3

[0052] (1) Adsorbent preparation

[0053] Prepare cetyltrimethylammonium bromide solution equal to clay mineral CEC100%-200%, put the clay material in it, stir at room temperature for 24 hours, filter, wash until no surfactant is precipitated, and obtain organic bentonite, which is dispersed by water and other conditions, it has high structural and compositional stability. The organoclay is suitable for organic complexing agents containing mercapto (-SH) groups such as thioglycolic acid, 2-mercaptobenzothiazole (MBT) and its derivatives, and organic compounds containing amino groups (-NH) such as polyacrylamide and its derivatives. The complexing agent has a high adsorption capacity (over 100mg / g).

[0054] The thioglycolic acid solution is prepared, the organoclay is placed in it, and stirred at room temperature to obtain the organoclay adsorption material loaded with mercapto groups.

[0055] The obtained adsorbent can be granulated and shaped to obtain shaped materials wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com