Waste brick tile/straw foam concrete and preparation method thereof

A technology of foam concrete and waste bricks and tiles, which is applied in the field of lightweight building materials, can solve the problems of high price, high cost, and high thermal conductivity, and achieve the effects of protecting the ecological environment, simple manufacturing process, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

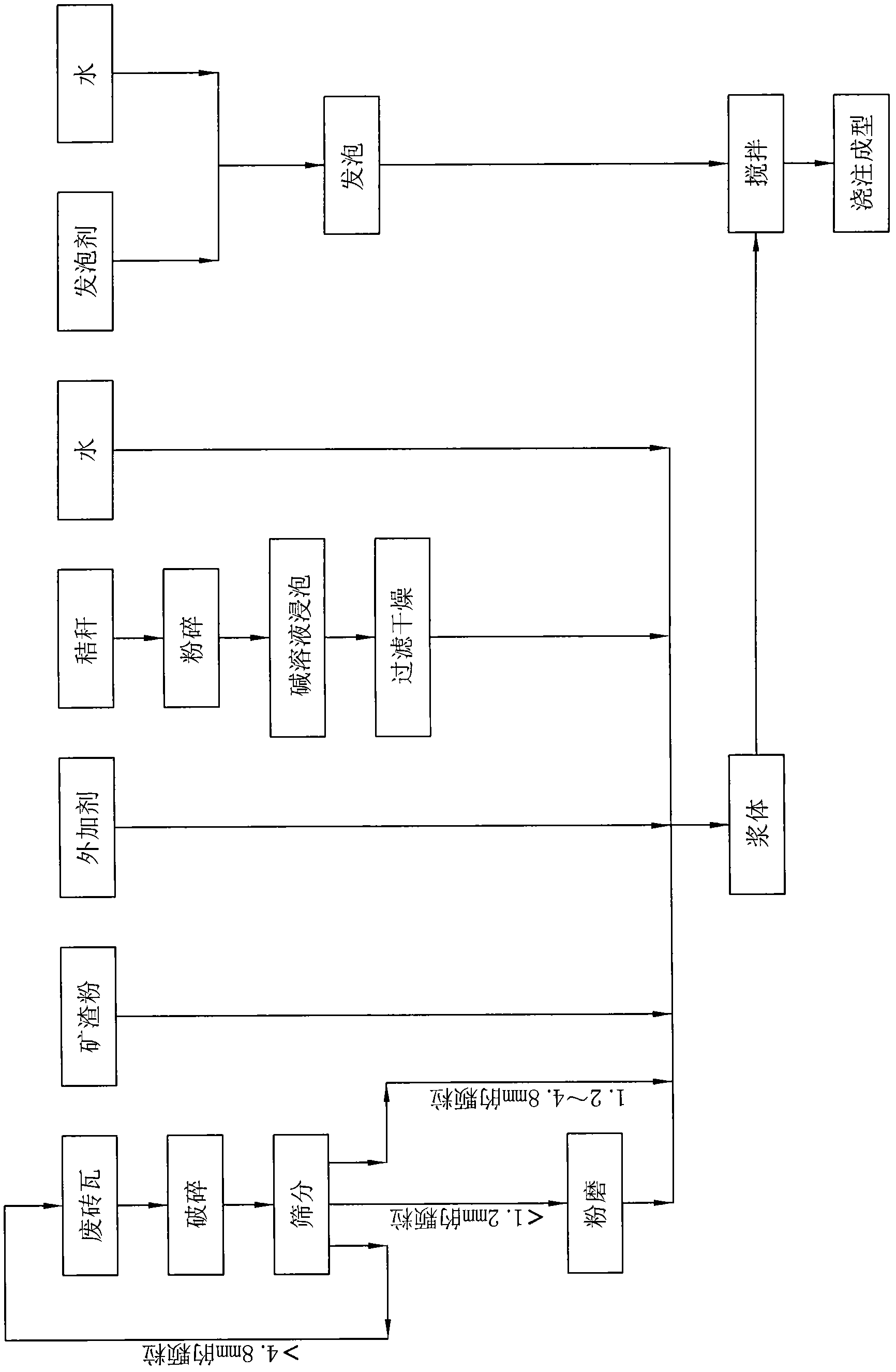

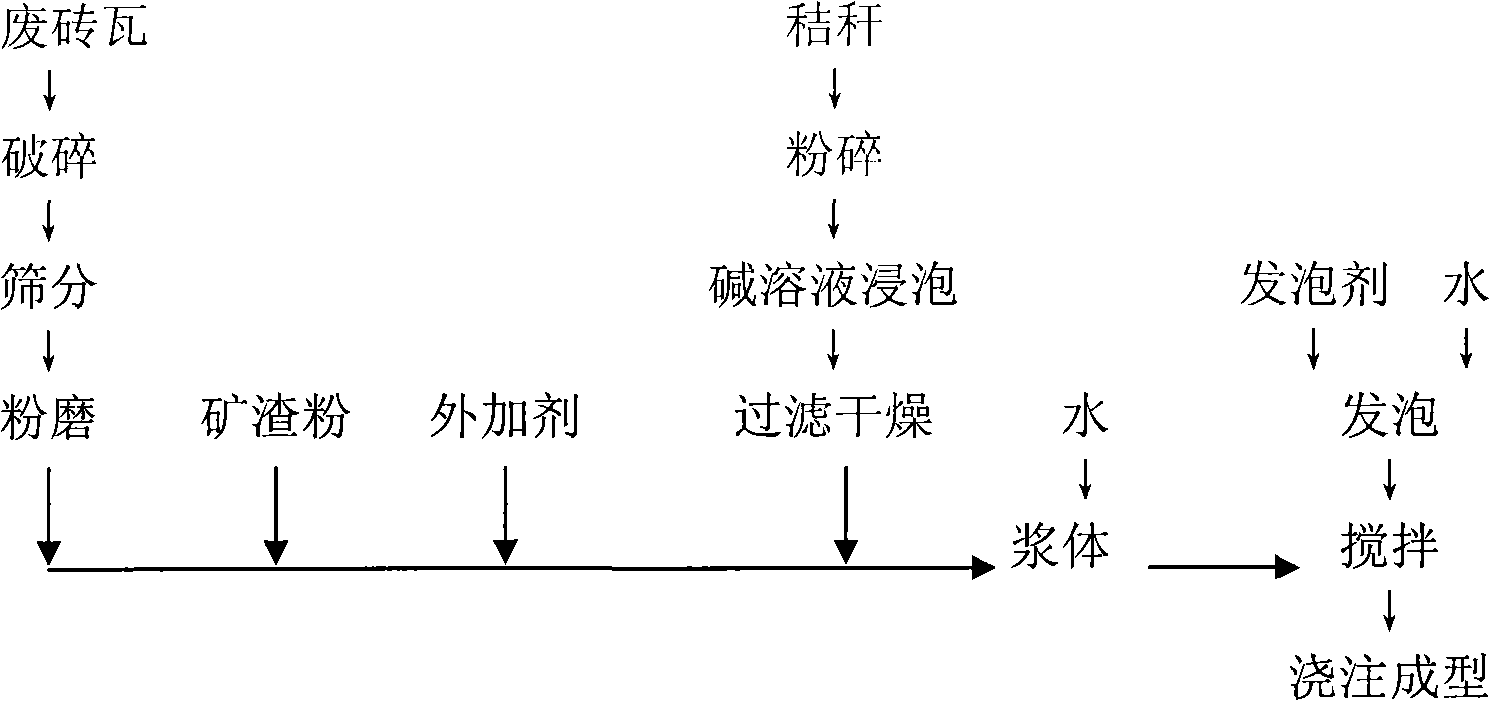

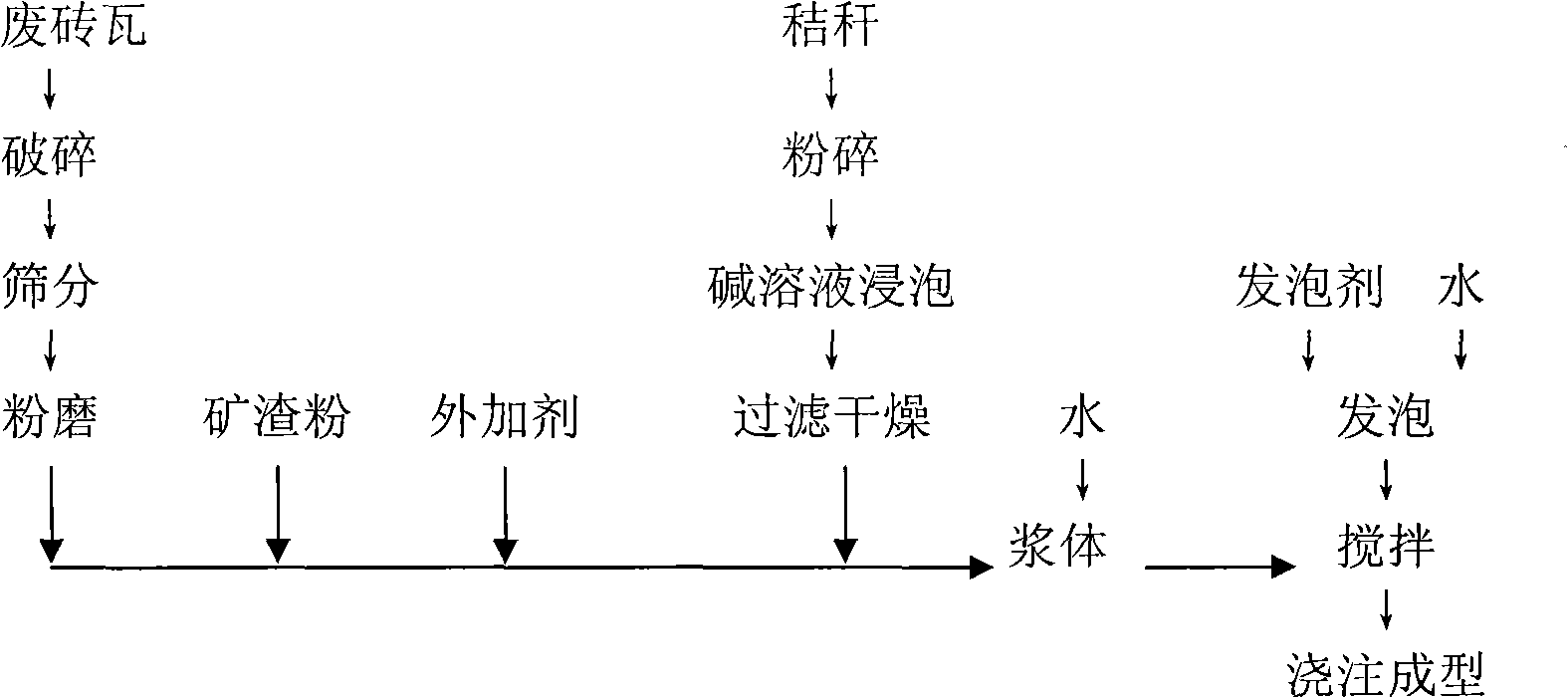

[0020] A waste brick tile / straw foam concrete and a preparation method thereof, comprising the following steps:

[0021] 1. Sorting waste bricks and tiles from construction waste, crushing large pieces of waste bricks and tiles with a crusher, and then screening with a sieve hole of 4.8mm and 1.2mm, the material with particles of 4.8-1.2mm is used as foam concrete The aggregates; the particles larger than 4.8mm are returned to the crusher for crushing, and the waste brick and tile particles smaller than 1.2mm are fed into the ball mill for grinding, and the fineness is controlled at 360-400m 2 / kg;

[0022] 2. Blast furnace slag powder has a specific surface area of 450-500m 2 / kg;

[0023] 3. The straw is pulverized into straw fibers with a length of less than 2 cm, then soaked in 1 to 2% NaOH solution for 6 to 12 hours, and filtered to dry;

[0024] 4. Mix and stir the materials and admixtures in steps 1 to 3 evenly, add appropriate amount of water and stir to form a sl...

Embodiment 1

[0029] 55 parts by weight of waste brick and tile powder, 20 parts by weight of blast furnace slag powder, 5 parts by weight of waste brick and tile particles, 10 parts by weight of straw, 8.0 parts by weight of additives (quick lime, sodium silicate and latex powder), 1.8 parts by weight of blowing agent parts by weight. After testing, the dry apparent density is 350kg / m 3 , 28-day compressive strength 0.5MPa, thermal conductivity 0.061W / (m·K).

Embodiment 2

[0031]49 parts by weight of waste brick and tile powder, 24 parts by weight of blast furnace slag powder, 8 parts by weight of waste brick and tile particles, 8 parts by weight of straw, 9.4 parts by weight of admixture (quicklime, sodium silicate and latex powder), 1.6 parts by weight of blowing agent parts by weight. After testing, the dry apparent density is 500kg / m 3 , 28-day compressive strength 2.5MPa, thermal conductivity 0.079W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com