Patents

Literature

808results about How to "With thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight wall plaster

InactiveCN101691292AReduce lossWith thermal insulationSolid waste managementPlasterworkThermal insulation

The invention discloses a lightweight wall plaster which comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive, wherein the inorganic cementing material is a desulfurized plaster or a building plaster. The lightweight wall plaster is a single-component dry mixed material produced by a factory and can be used on a construction site by only adding water for stirring, the lightweight wall plaster has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional plastering mortar to be plastered on inner sides of external walls, partition walls, room separating walls, ceilings and other occasions and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

Lightweight leveling mortar

The invention discloses a lightweight leveling mortar material for a variety of wall surfaces and floors inside and outside buildings, and the lightweight leveling mortar material comprises the following components by weight percent: 65-90% of inorganic cementing material, 5-30% of lightweight aggregate, 0-30% of filler and 0-10% of functional additive. The lightweight leveling mortar material is a single-component dry-mixed material produced by a factory and can be used on a construction site by only adding water for stirring. The lightweight leveling mortar has a certain thermal insulation function and excellent fire prevention performance, the bonding performance is good, and the compressive strength is high, thereby being capable of replacing the traditional mortar to be plastered on a variety of wall surfaces and floors of buildings and further improving the thermal insulation performance of wall bodies.

Owner:谢日清

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190BStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberSodium Bentonite

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

Thermal insulation building mortar and preparation process thereof

InactiveCN101759416AWith thermal insulationWith phase change energy storageCement mixing apparatusSodium BentoniteThermal insulation

The invention discloses a thermal insulation building mortar. The thermal insulation building mortar is prepared by the mixing portland cement, pulverized fuel ash, calcium bentonite, re-scattering glue powder, hypromellose, polyacrylamide powder, polypropylene fibre, wood fiber, permeating crystal waterproof agent, air entraining agent, vitrified micro-bead, sizing phase-change material and hollow glass bead. A preparation process thereof comprises the steps of: a) preparing the sizing phase-change material, b) preparing the permeating crystal waterproof agent and c) preparing the thermal insulation building mortar. The mortar of the invention is characterized by the functions of thermal insulation, phase-change energy storage, temperature control, water resistance and energy saving, the wide application scope and low cost. The mortar is widely applied in thermal insulation work inside or outside the buildings and has a broad prospect.

Owner:唐山市思远涂料有限公司

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Crack self-repairing concrete using aerobic basophilic microorganisms and preparation method thereof

The invention relates to crack self-repairing concrete using aerobic basophilic microorganisms and a preparation method thereof. The concrete contains expanded perlite loading an aerobic basophilic microorganism repair agent, cement, pebbles, sand, silica fume, water, calcium lactate and water reducer. The crack self-repairing concrete has the crack self-repairing function and has heat-preservation and heat-insulation functions, the aerobic basophilic microorganisms serve as a crack repairing agent, calcium lactate serves as nutritional matter for microorganism metabolism, and expanded perlite serves as a carrier of the crack repairing agent. When concrete cracks, water and air enters the cracks so that resting microorganisms can restore the metabolism function, calcium lactate is converted into calcium carbonate precipitate, and accordingly the aims of automatically diagnosing and repairing the concrete cracks, preventing expansion of the cracks and improving concrete impermeability are achieved. The microorganism crack self-repairing concrete serves as a concrete material integrating the functions of crack self-diagnosis and self-repairing, lightweight, heat preservation and heat insulation, and has large research value and application potential.

Owner:TAIYUAN UNIV OF TECH

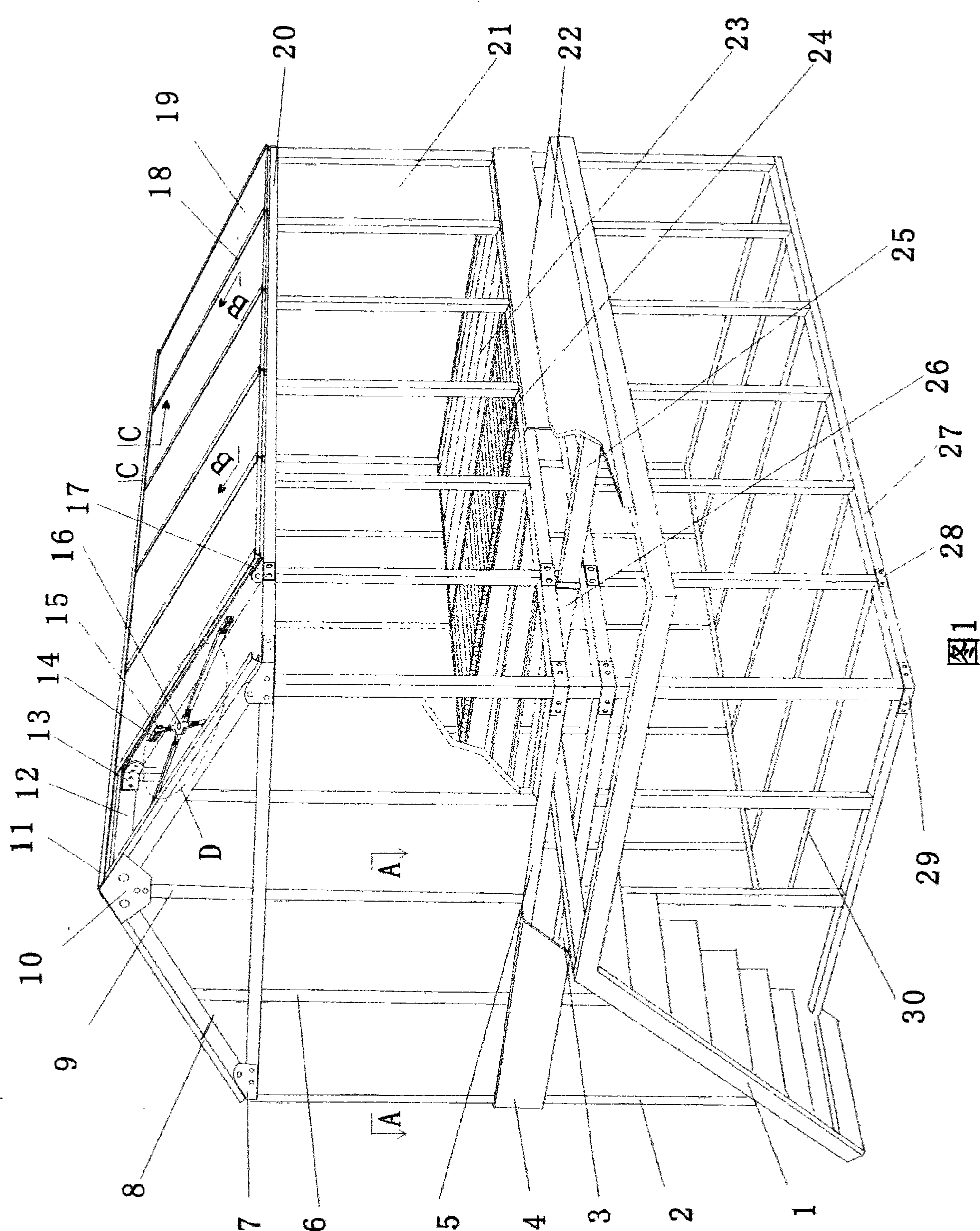

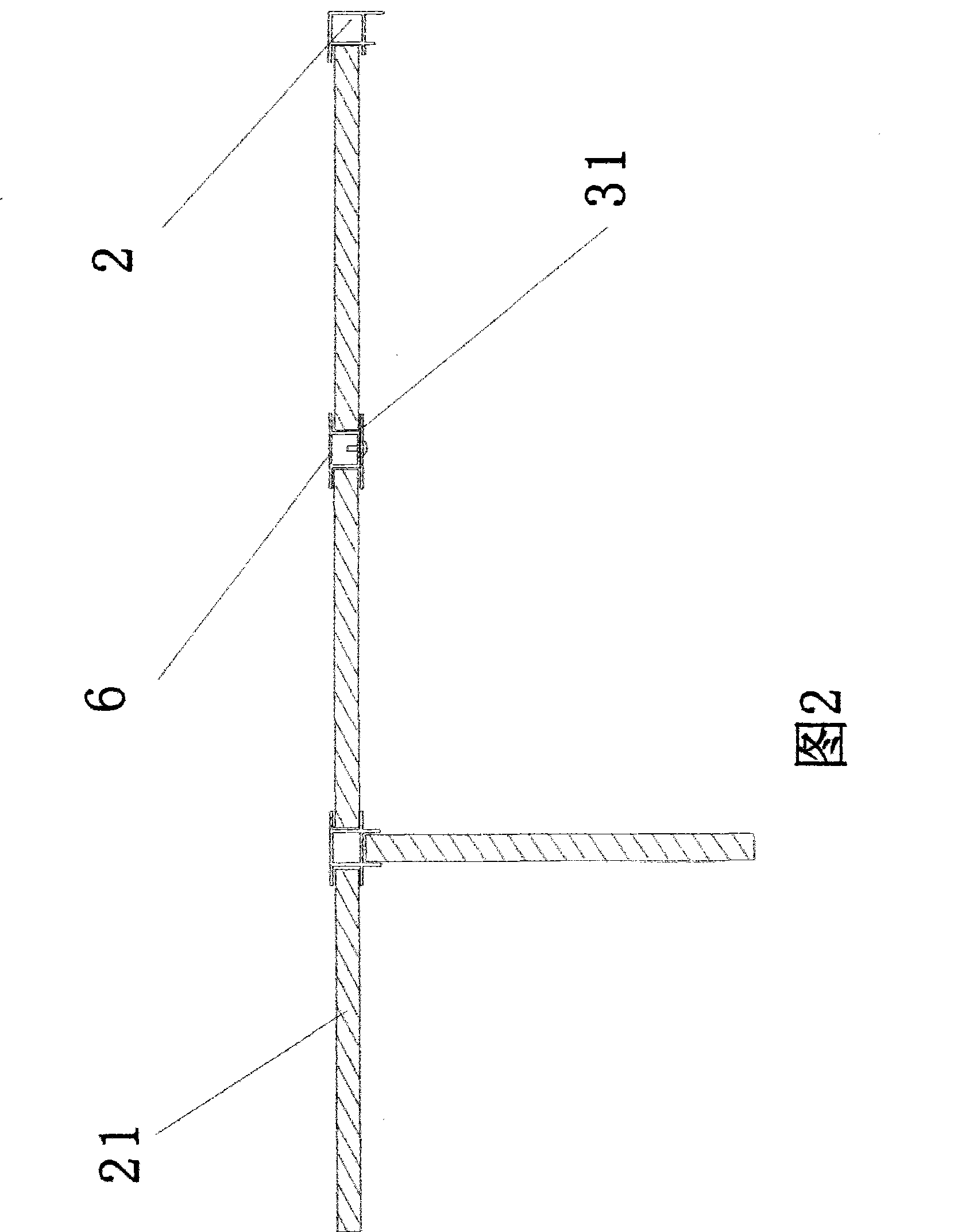

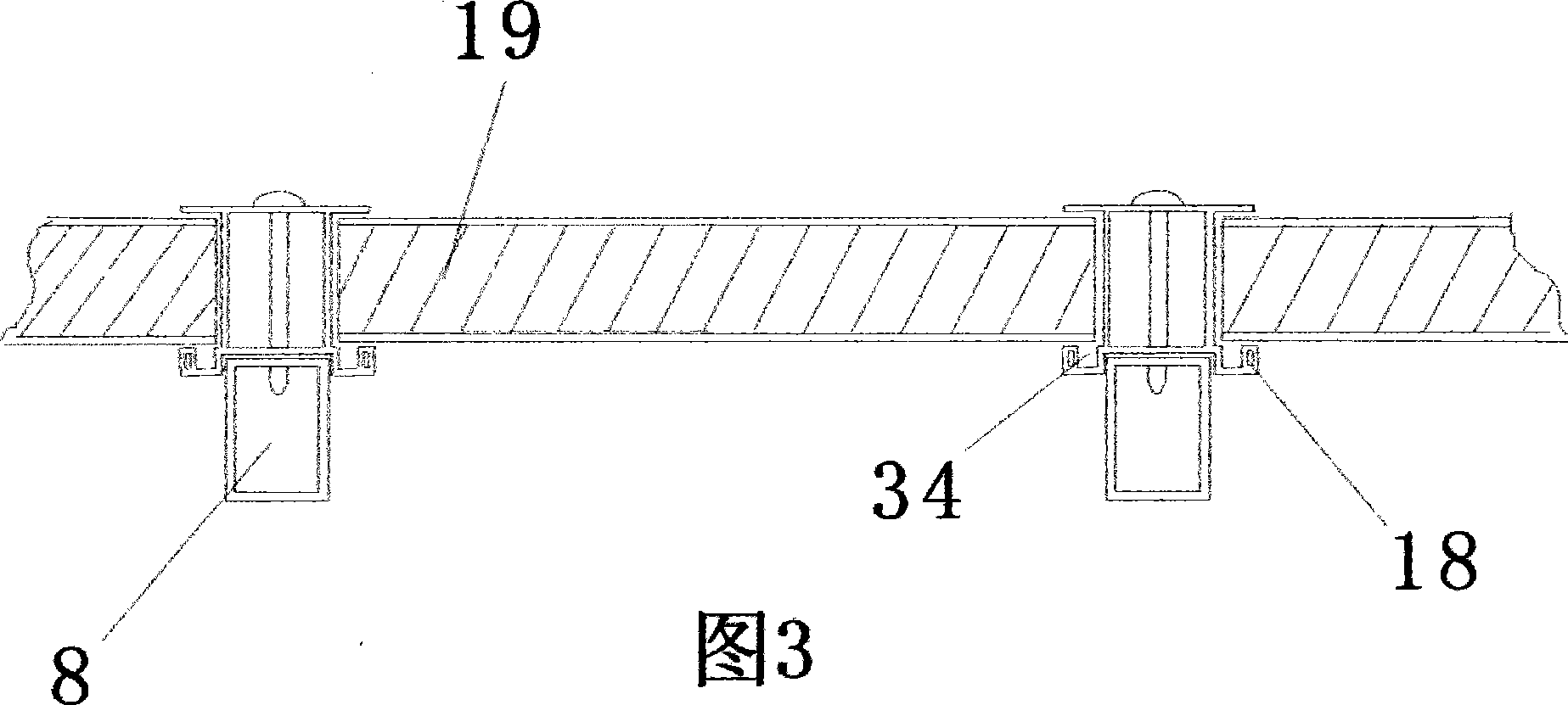

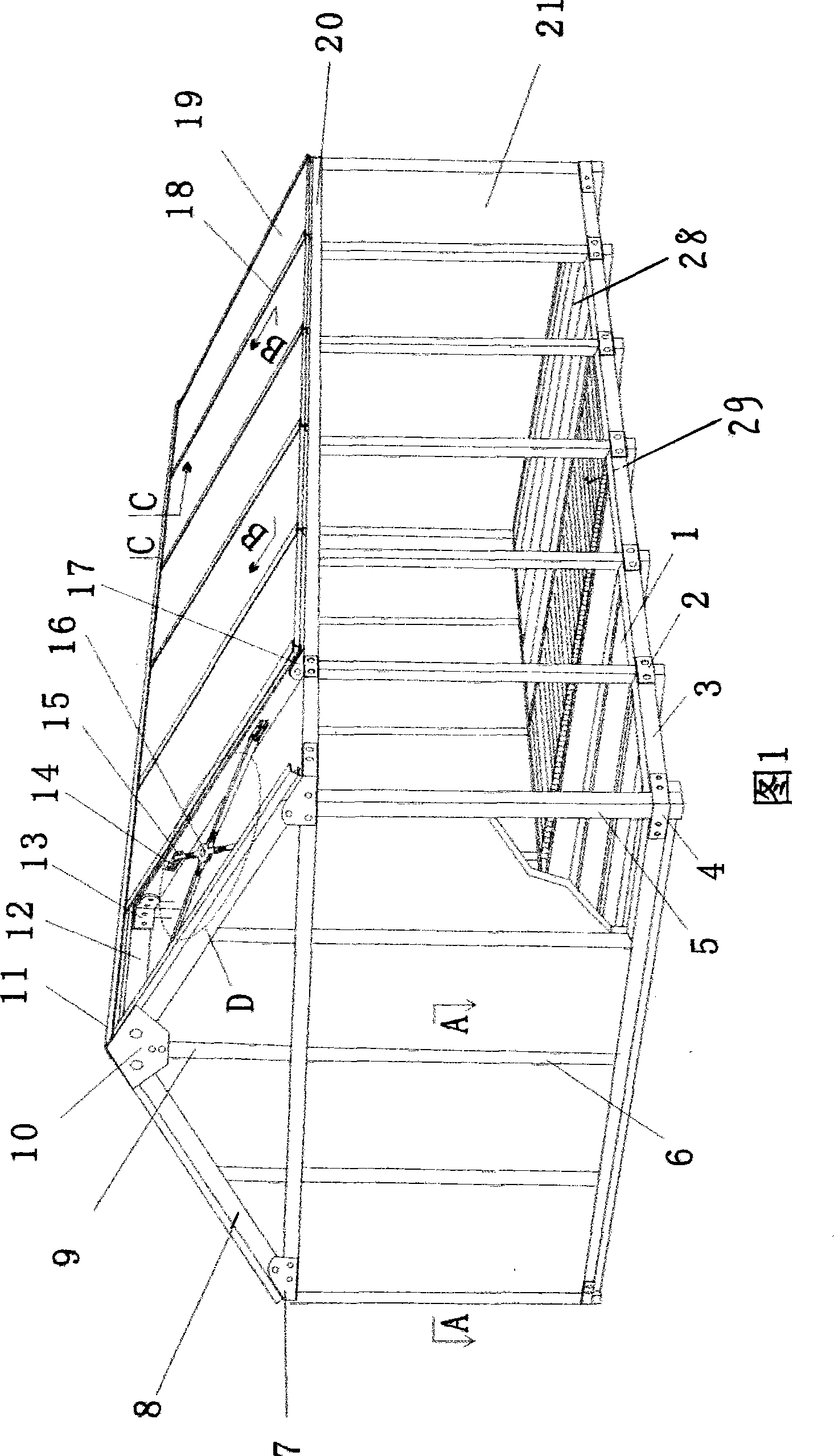

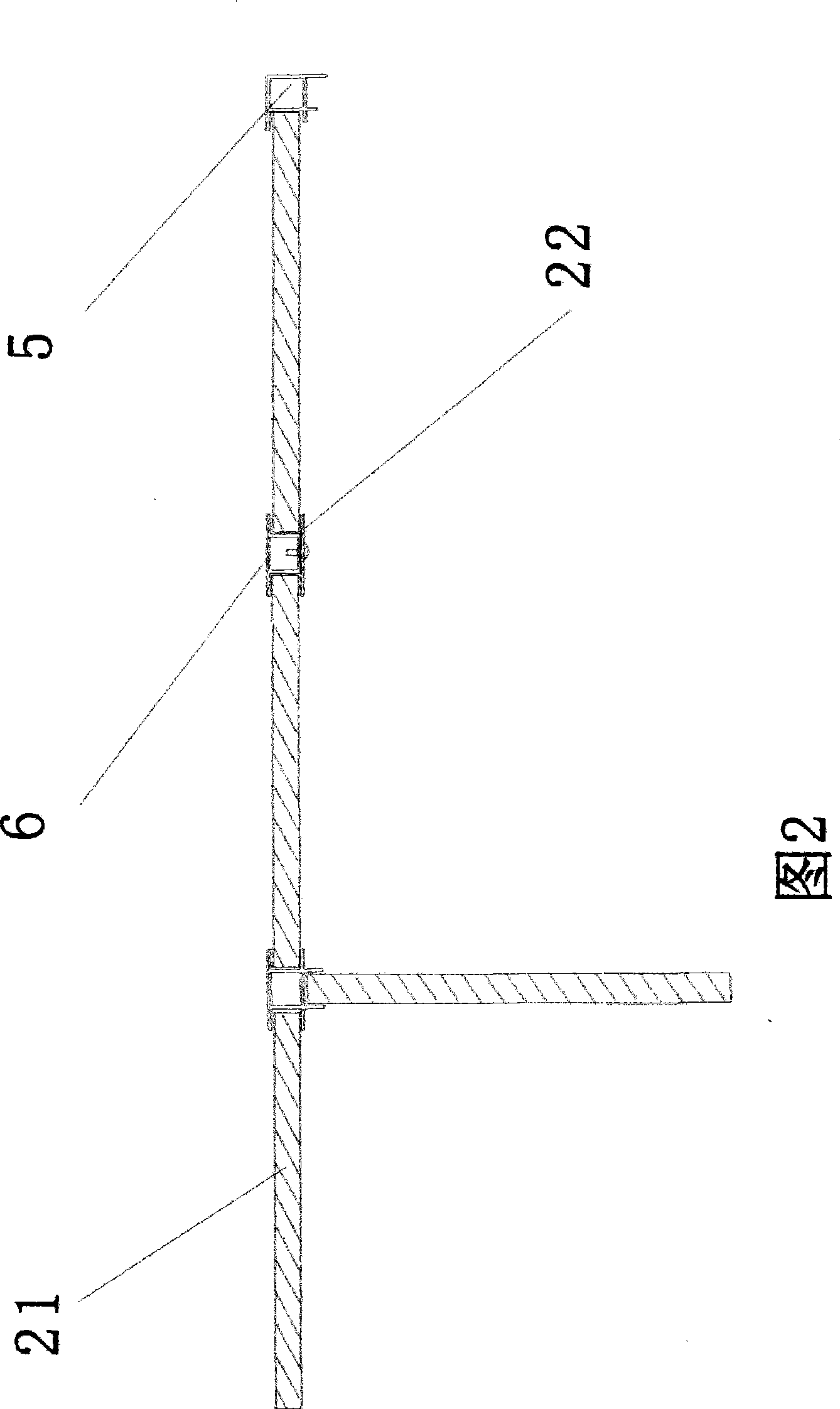

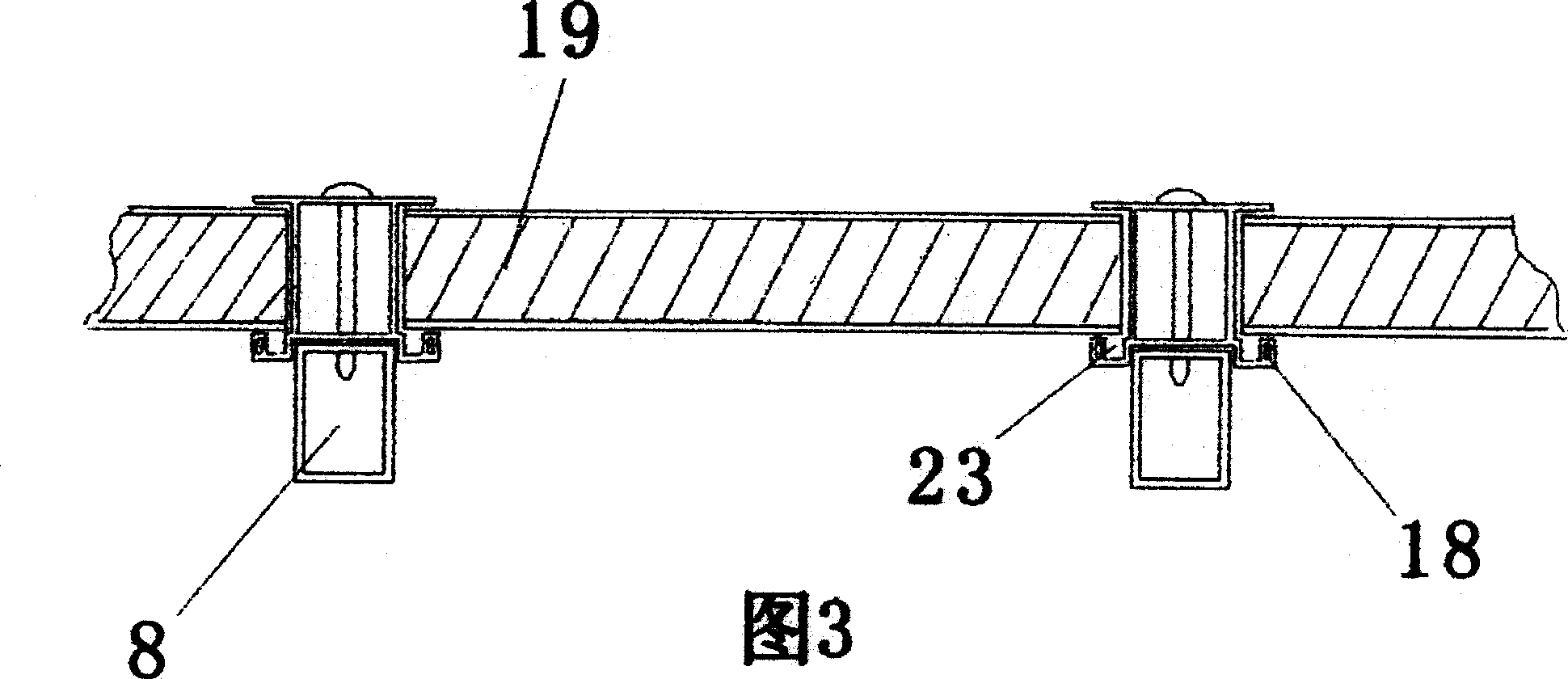

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

Method for preparing fiber wallboard through wet process

InactiveCN101638874ALarge stockWide variety of sourcesWater-repelling agents additionPaper/cardboardFiberHigh intensity

The invention discloses a method for preparing a fiber wallboard through a wet process. The method comprises the following steps: 1) pulping: mixing non-wood type natural plant fiber pulp with gramineous plant pulp according to a dry weight ratio of 1:0-1.5 and adding water into the raw materials to dilute the pulp; 2) storing the pulp: placing the obtained mixture pulp into a pulp storage pond and adding water for dilution; 3) carrying out suction filter and formation: inputting the pulp obtained from the previous step into a die cavity for cold-pressing, dehydration and formation so as to obtain a wet blank; and 4) carrying out hot-pressing formation and drying; transferring the wet blank into a hot-pressing mould for hot pressing, removing water generated during the hot pressing, and obtaining the fiber wallboard. The fiber wallboard obtained by using the method has the characteristics of environment-friendliness and high strength.

Owner:陈集双

Aerated concrete regenerative building block produced by using garbage clinkers and manufacturing method thereof

The invention relates to an aerated concrete regenerative building block produced by using garbage clinkers and a manufacturing method thereof. The manufacturing method comprises the following steps of: adopting the garbage clinkers, flying ash, river sand, silicate cement, lime, calcium sulfate, poly-carboxylate water reducing agent, aluminum powder, glcditsia sinensis powder, borax, sodium chloride and water as raw materials; stirring the raw materials into a paste by using a double-shaft hybrid stirring machine, and pouring the paste into a die; performing delaying curing for gas development and solidification; forming the paste through machinery cutting; putting the formed garbage clinker aerated concrete regenerative building block into a still kettle to perform steam curing; and raising the temperature to heat up the building block for 2 to 3 hours first, heating the building block for 5 to 8 hours at a constant temperature of between 95 and 100 DEG C, and then naturally cooling the building block for 1 to 2 hours to obtain a garbage clinker aerated concrete regenerative building block product. The product has the advantages and effects of light weight, high strength, no pollution, low cost and good benefit, and accords with a national prescription for saving energy, reducing emissions, developing low-carbon economy and protecting the environment.

Owner:清远绿由环保科技有限公司

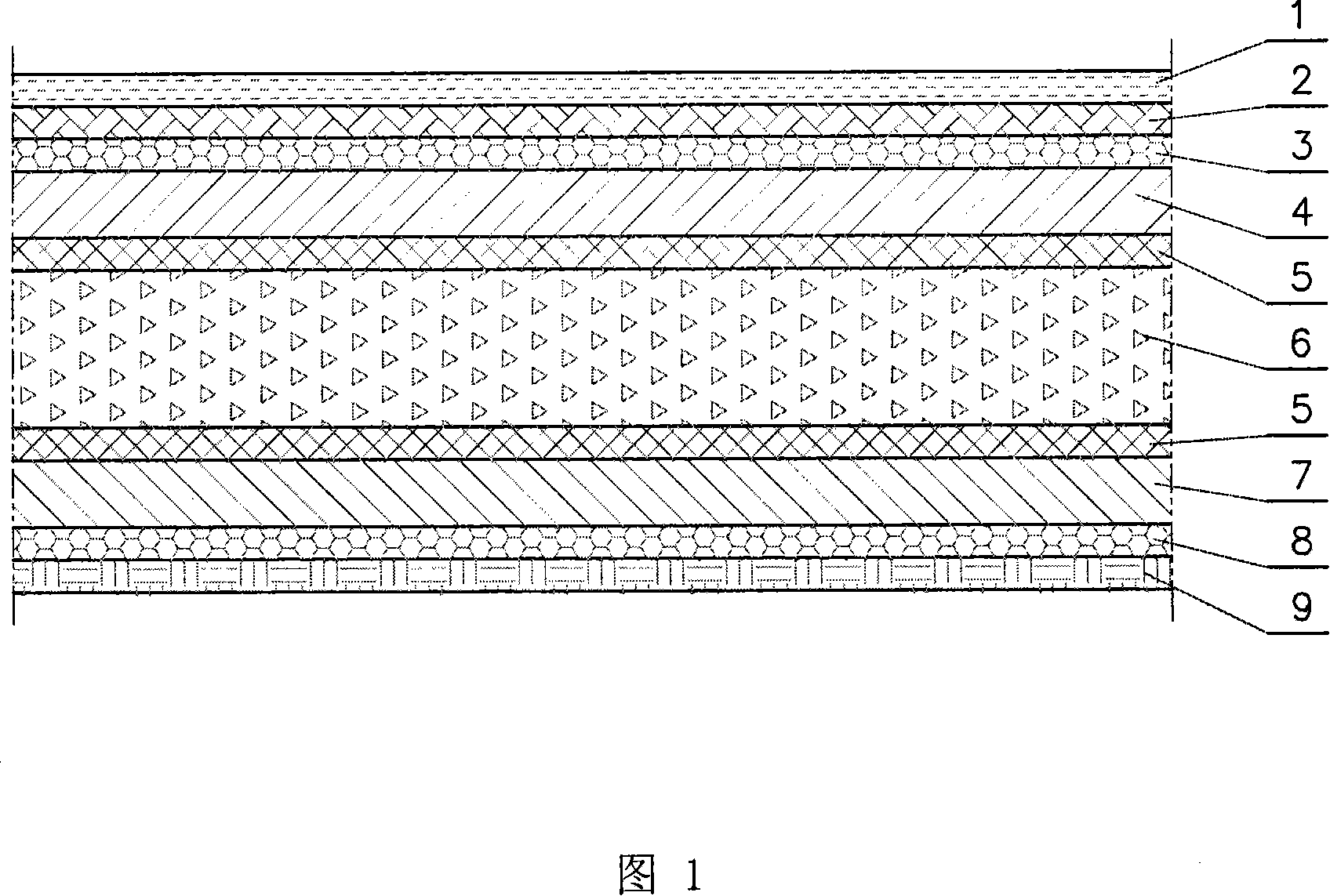

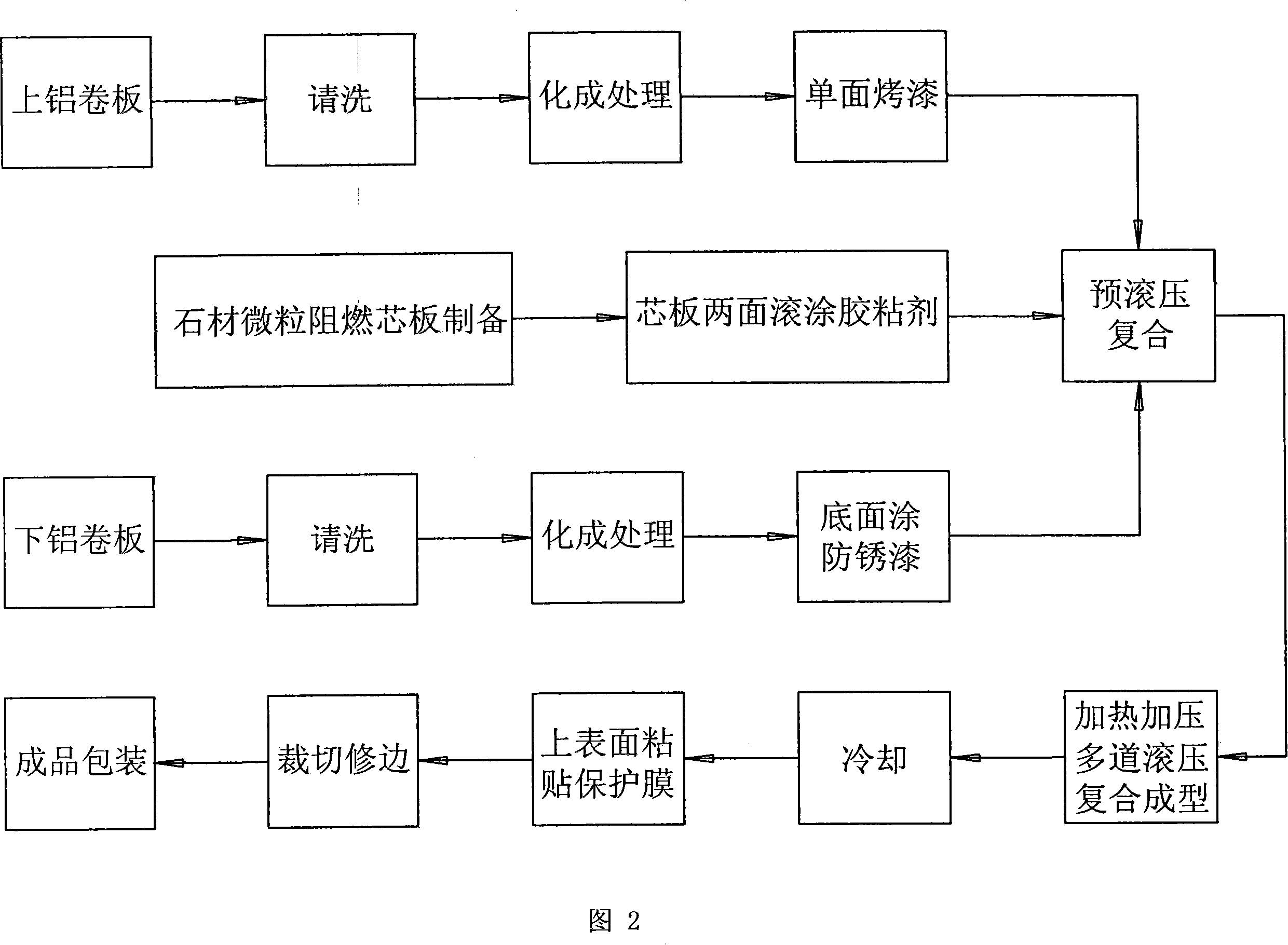

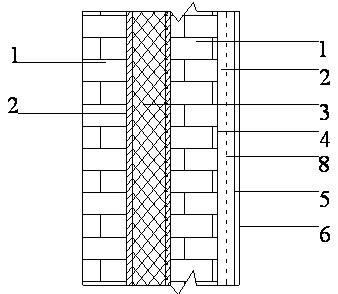

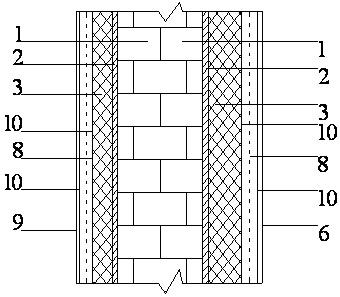

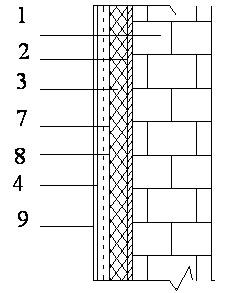

Metal composite plate with fireproof interlayer and manufacturing method thereof

ActiveCN101148936AWon't happenWith thermal insulationCovering/liningsLamination ancillary operationsTectorial membraneAdhesive

The present invention is one kind of composite metal plate with sandwiched fireproof layer and its making process. The composite metal plate with sandwiched fireproof layer consists of a protecting film layer, a baking varnish layer, a first chemically formed film layer, a first metal sheet, a first adhesive layer, a sandwiched fireproof layer, a second adhesive layer, a second metal sheet, a second chemically formed film layer and an antirust primer layer superposed successively and compounded integrally. Its making process includes the steps of: hot pressing the mixture of fine ore grains, fire retardant, coupling agent and adhesive to form the fireproof core board; treating the first metal sheet to form the first film layer and the baking varnish layer, and treating the second metal sheet to form the second film layer and the antirust primer layer; painting adhesive to two sides of the core board and hot pressing to combine the core board and two metal sheets; adhering the protecting film layer and cutting.

Owner:江阴新泓泰复合材料有限公司

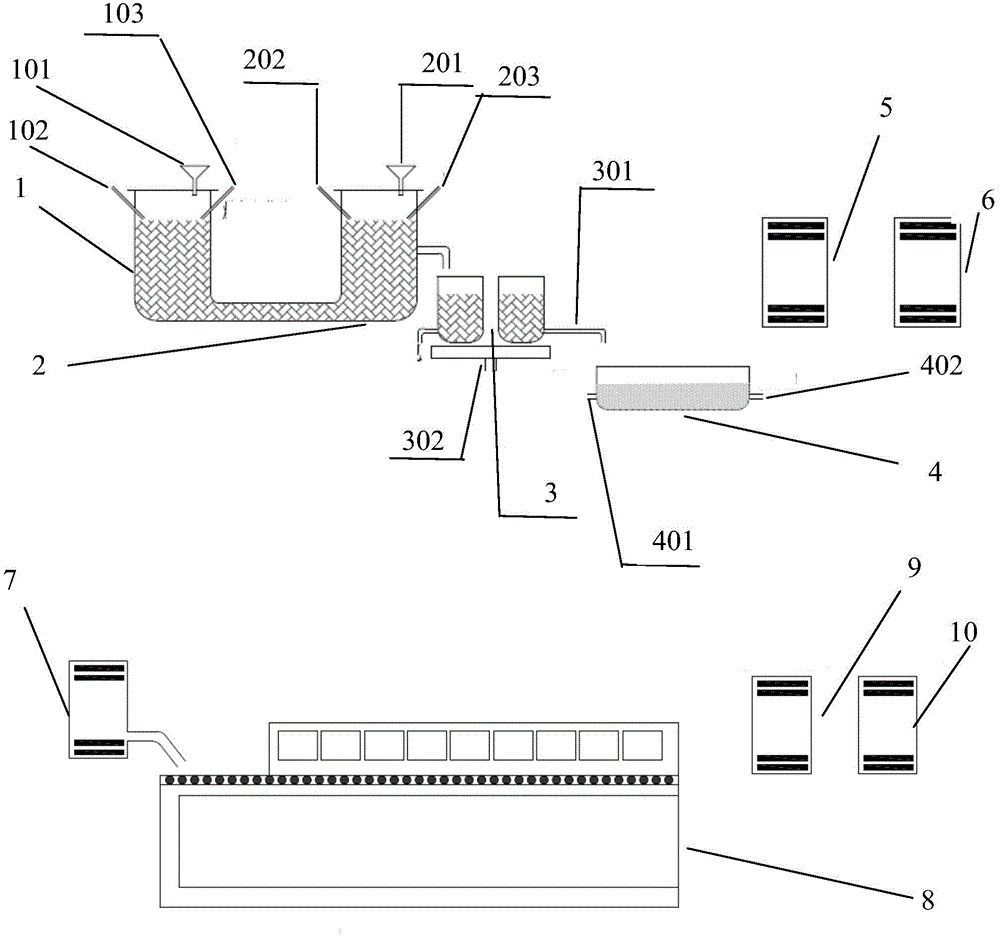

Method and device for preparing ceramsite from sludge pyrolytic biochar

ActiveCN106007776AAchieving mass utilizationEfficient curingCeramic materials productionCeramicwareSludgeBiochar

The invention discloses a method and device for preparing ceramsite from sludge pyrolytic biochar. The method includes the steps that powder grinding, humidifying, pelleting, low-temperature drying, middle-temperature presintering, high-temperature sintering and cooling are carried out on the sludge pyrolytic biochar to obtain the ceramsite. The device comprises a quantitative feeding device, a water adding device, a humidifying device, a forming and pelleting device, a drying device, a middle-temperature presintering device, a high-temperature sintering device and a cooling device. The sludge pyrolytic biochar is used for preparing the ceramsite, large-scale utilization of the sludge pyrolytic biochar is achieved, heavy metal element in the sludge pyrolytic biochar is further efficiently solidified and passivated, potential heavy metal accumulated pollution of the sludge pyrolytic biochar in the land using process is avoided, and the method and device are particularly suitable for resource utilization of sludge pyrolytic biochar with heavy metal content exceeding standard. The method is simple, practical, low in equipment investment and low in cost and has good economic benefits and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

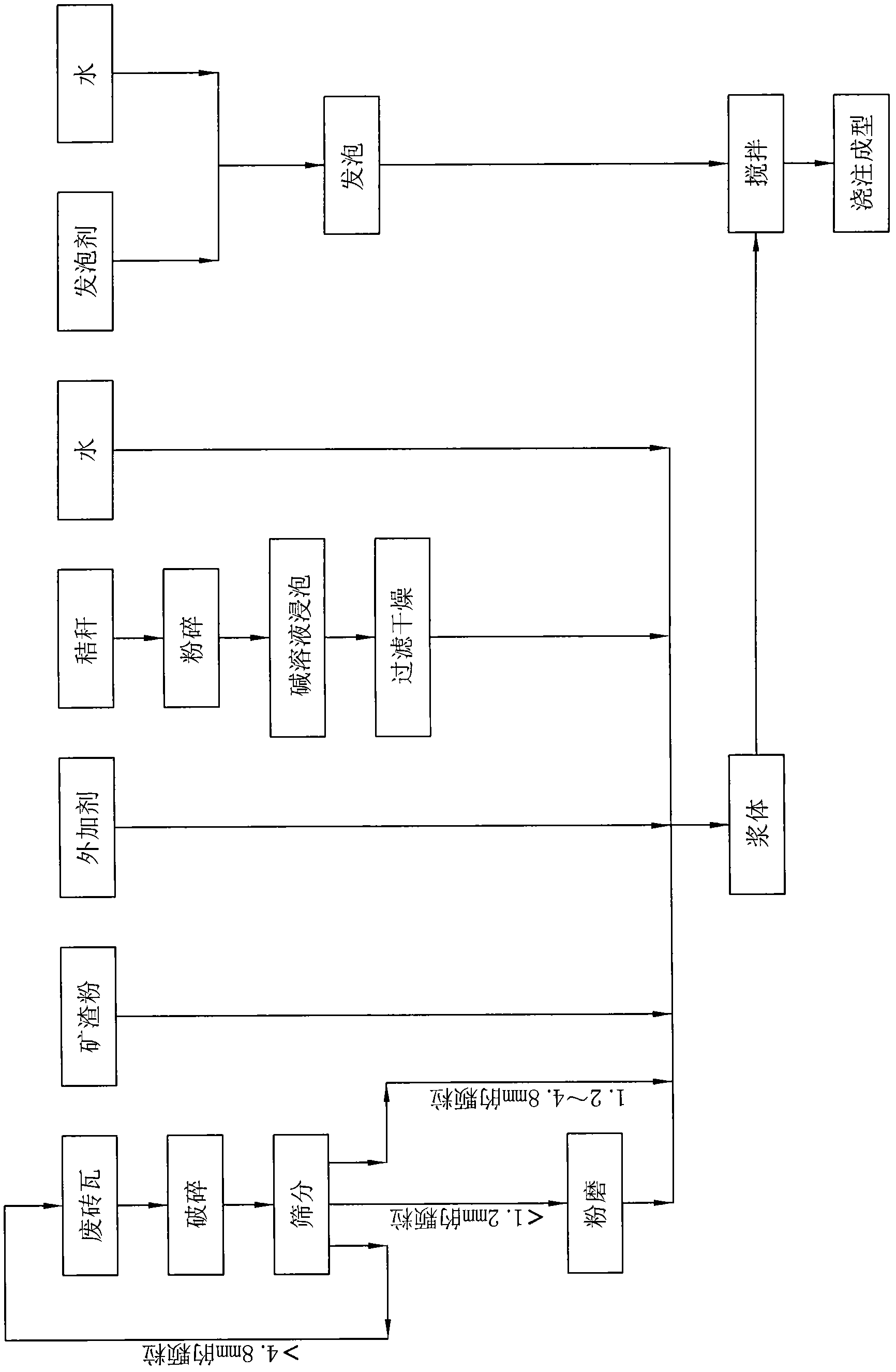

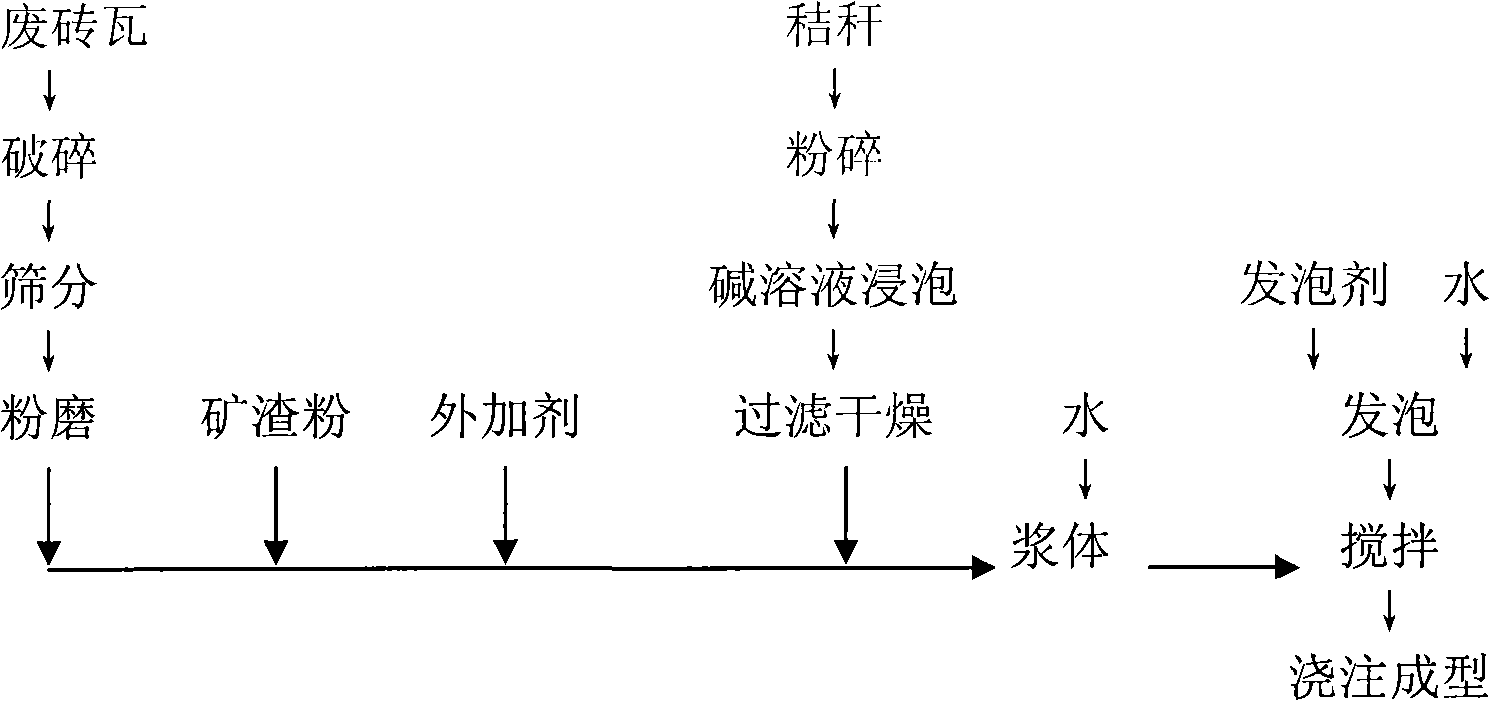

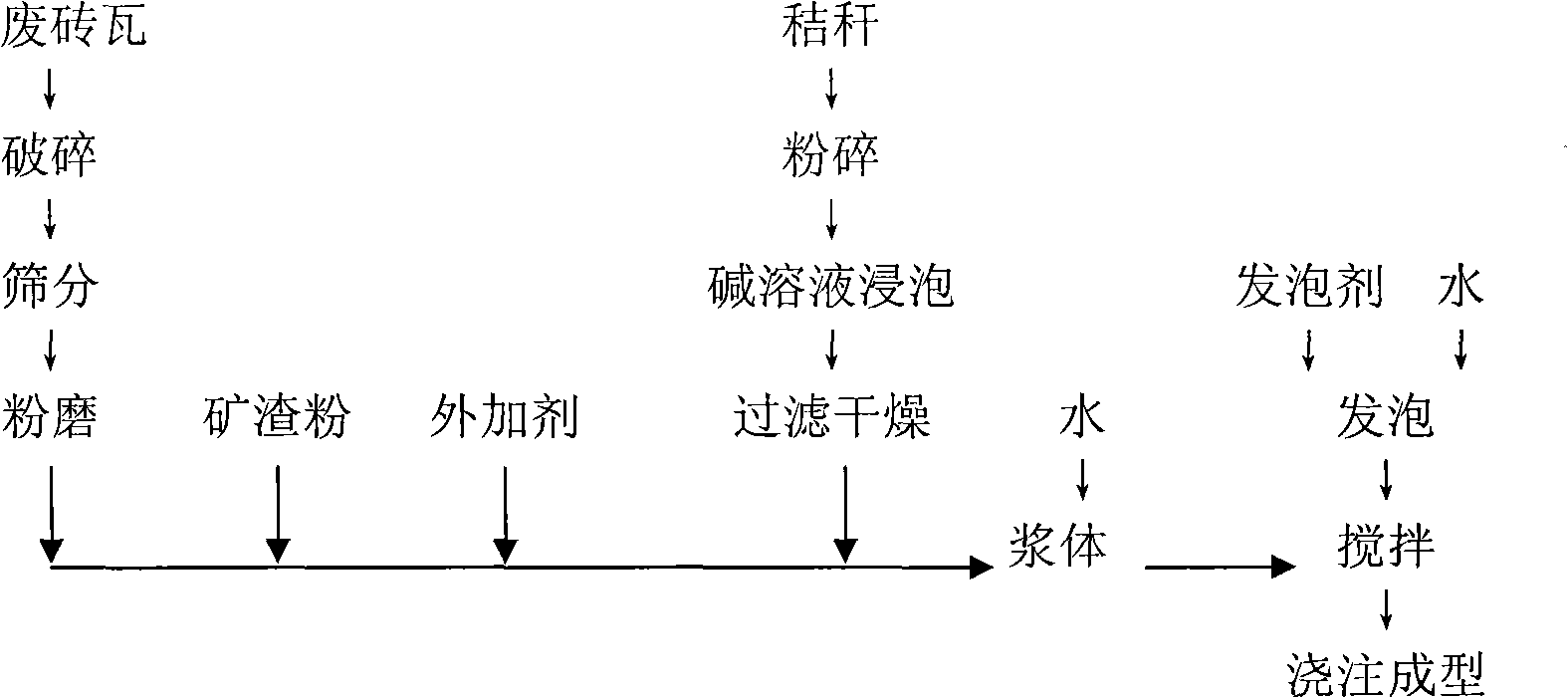

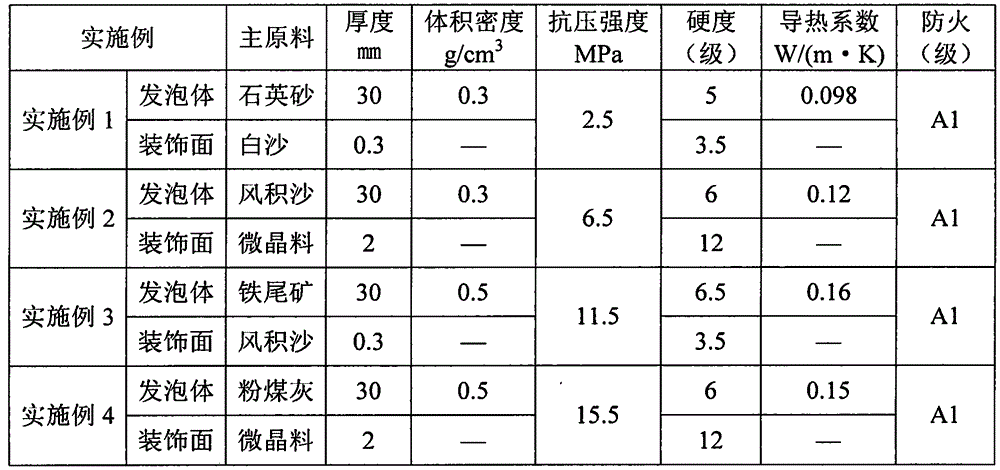

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

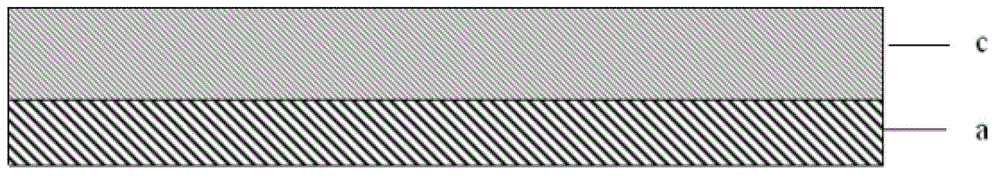

Heat insulating and preserving ceramic composite plate with decorative properties

ActiveCN102877614AReduce construction costWith thermal insulationCovering/liningsClaywaresCeramic compositeInsulation layer

The invention discloses a method for producing a heat insulating and preserving ceramic composite plate with decorative properties, comprising the following steps: preparing the powder of a decorative layer; preparing the powder of a heat insulating and preserving layer; loading the powder in a ceramic sagger in the secondary distribution way; sintering in a roller kiln in one time without drying and moulding by a ceramic pressing machine; demoulding, polishing and finishing the decorative surface, and determining the thickness and shape of the heat insulating and preserving surface by mechanical dry cutting. By the joint reaction of the ultrafine foaming agent, the dolomite, the diatomaceous earth and the polishing slag at high temperature, the heat insulating and preserving plate filled with tiny closed pores can be formed. The product has high strength, strong penetration resistance and lower thermal conductivity than the existing ceramic heat preserving material and has the characteristics of low production energy consumption, good decorative effect and prominent heat preservation, heat insulation and sound insulation effects.

Owner:FOSHAN RONGZHOU NO 2 BUILDING CERAMICS FACTORY

Lightweight fireproof foaming cement door inner filling material and preparation method thereof

InactiveCN101143777AIncrease gas productionWith thermal insulationSolid waste managementCeramicwareReducing agentWeight light

The invention discloses a lightweight flame retardant and foamy filling material of cement doors and manufacturing method thereof, comprising magnesium oxide, magnesium sulphate, fly ash, high alumina refractory cement, calcium chloride, water proofing agent, water reducing agent and foaming agent, with bulk density ranging between 200 kg / m3 and 500kg / m3; the ingredients are formulated by weight at a rate of: magnesium oxide (40 percent -55 percent), magnesium sulfate (15 percent-40 percent), fly ash (5 percent-20 percent), high alumina refractory cement (5 percent-20 percent), calcium chloride (2 percent-6 percent), water proofing agent (2 percent5 percent), water reducing agent (0.2 percent1.5 percent) and foaming agent (0.1 percent-0.5 percent). With the technical solution, the product has the advantages of high strength, light weight, flame retardancy, sound insulation, weather resistance, thermal resistance, energy efficient, freedom from toxicity, harm and irradiation, low manufacturing cost, simple process, etc, which can be widely employed for fire / theft proof metal interior door, building material and like sectors.

Owner:ZHEJIANG MEIXIN IND CO LTD

Rubber reinforced cement functional composite material and preparation method thereof

InactiveCN101857399AWith noise reductionWith sound insulationSolid waste managementNoise barrierAdhesive

The invention discloses a rubber reinforced cement functional composite material and a preparation method thereof. The rubber reinforced cement functional composite material is prepared from waste rubber and cement or cement mortars by the following steps of: applying coupling adhesives to surfaces of waste rubber grains and / or powder by using coupling agents; mixing the waste rubber grains and / or powder with the cement or the cement mortars; adding water into the rubber-cement mixed materials for uniform stirring, and performing pavement, pressing, demoulding and maintaining to obtain the functional composite material product having a high mechanical strength and endurance. The composite material has the characteristics of noise reduction, sound isolation, high impact resistance, damping vibration attenuation, wear resistance, static resistance, water resistance and the like, has the advantages of insulation, environmental protection and the like and can be used in the field of functional materials, such as buildings, roads, railways, tunnels, noise barriers and the like. The functional composite material and the method thereof also provide a new way for solving the global problem of 'black pollution' of increasing waste tyres and have a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

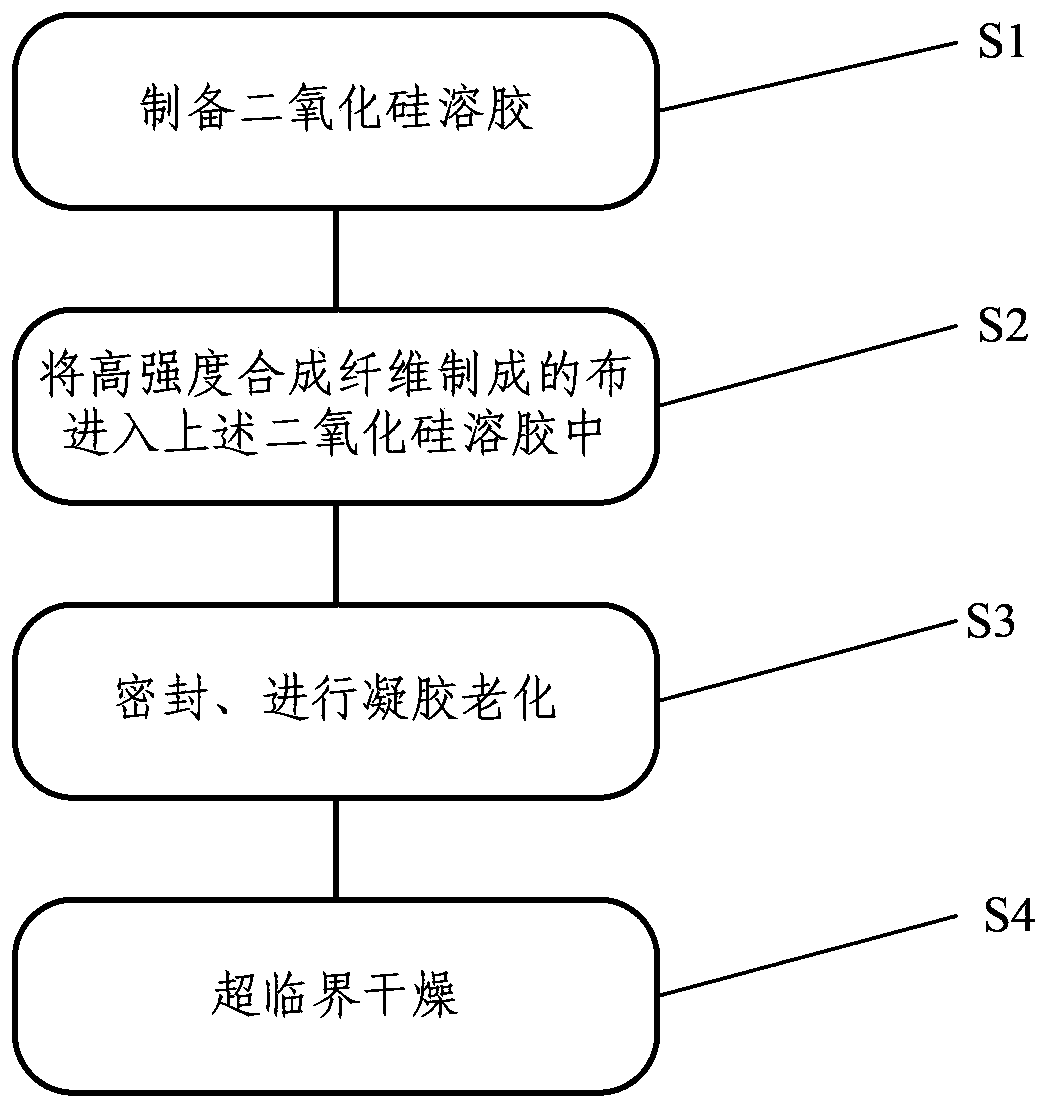

Silicon dioxide aerogel compound fabric, preparation method and military tent cloth

ActiveCN103397516ALow densityLow thermal conductivity at room temperatureCarbon fibresSupercritical dryingPolyester

The invention relates to the field of silicon dioxide aerogel, and particularly discloses a silicon dioxide aerogel compound fabric, a preparation method and a military tent cloth. The preparation of the silicon dioxide aerogel compound fabric comprises the following steps of: soaking a cloth made from high-strength synthetic fibers into a silicon dioxide sol; after the surface of the cloth is completely soaked, sealing the cloth soaked with the silicon dioxide sol and made of the high-strength synthetic fibers, and aging by a gel; finally supercritically drying. The military tent cloth comprises an outer layer, an interlayer and an inner layer, wherein the outer layer is a camouflage cloth coated with vinyl polyester fibers; the interlayer is a silicon dioxide aerogel compound fabric part; the inner layer is a military dacron cloth. The silicon dioxide aerogel compound fabric provided by the invention has the advantages of light weight, good heat-insulating property and extremely high absorption property on high-strength impact force and has the characteristics of good heat-insulating property, light weight and anti-explosion property.

Owner:陕西盟创纳米新型材料有限责任公司

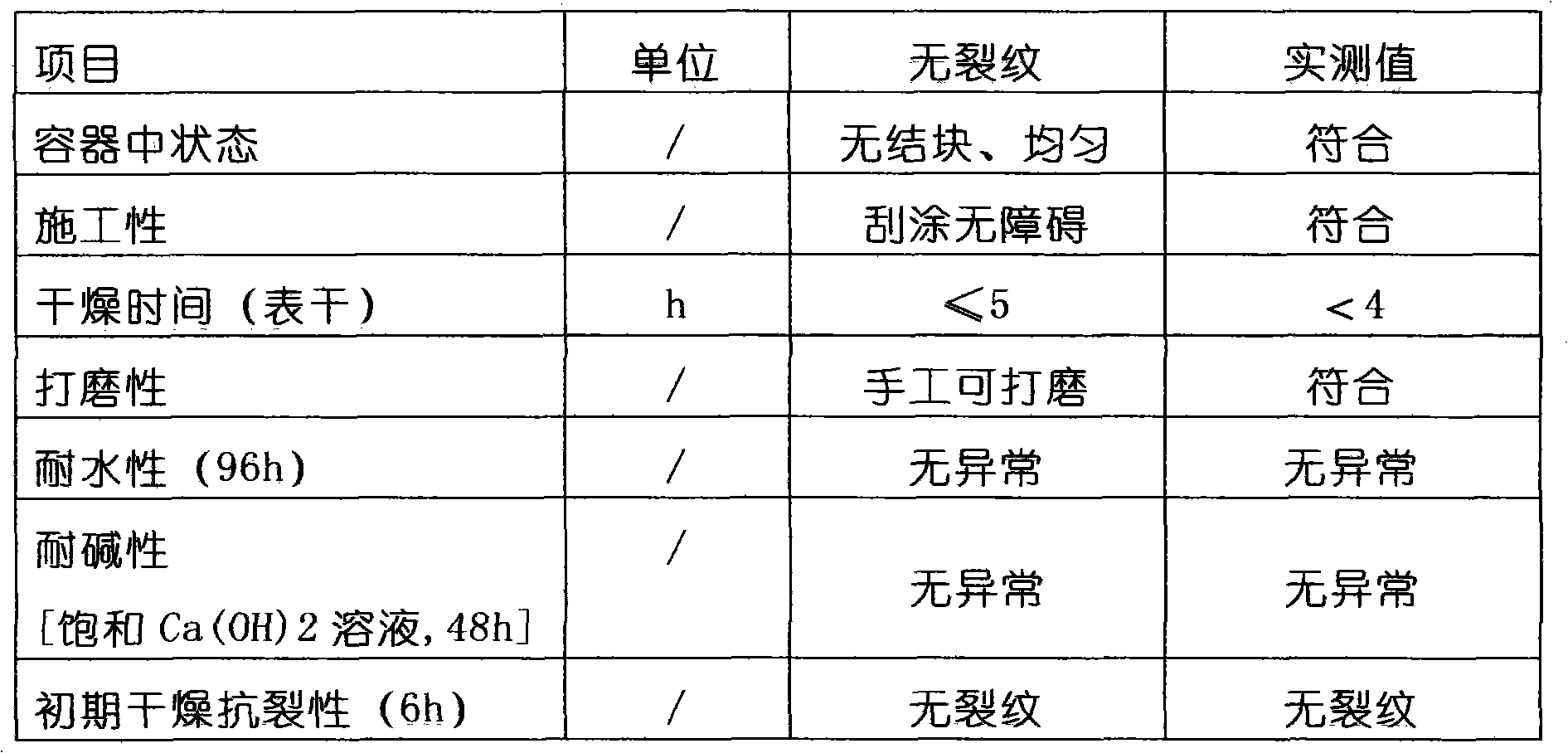

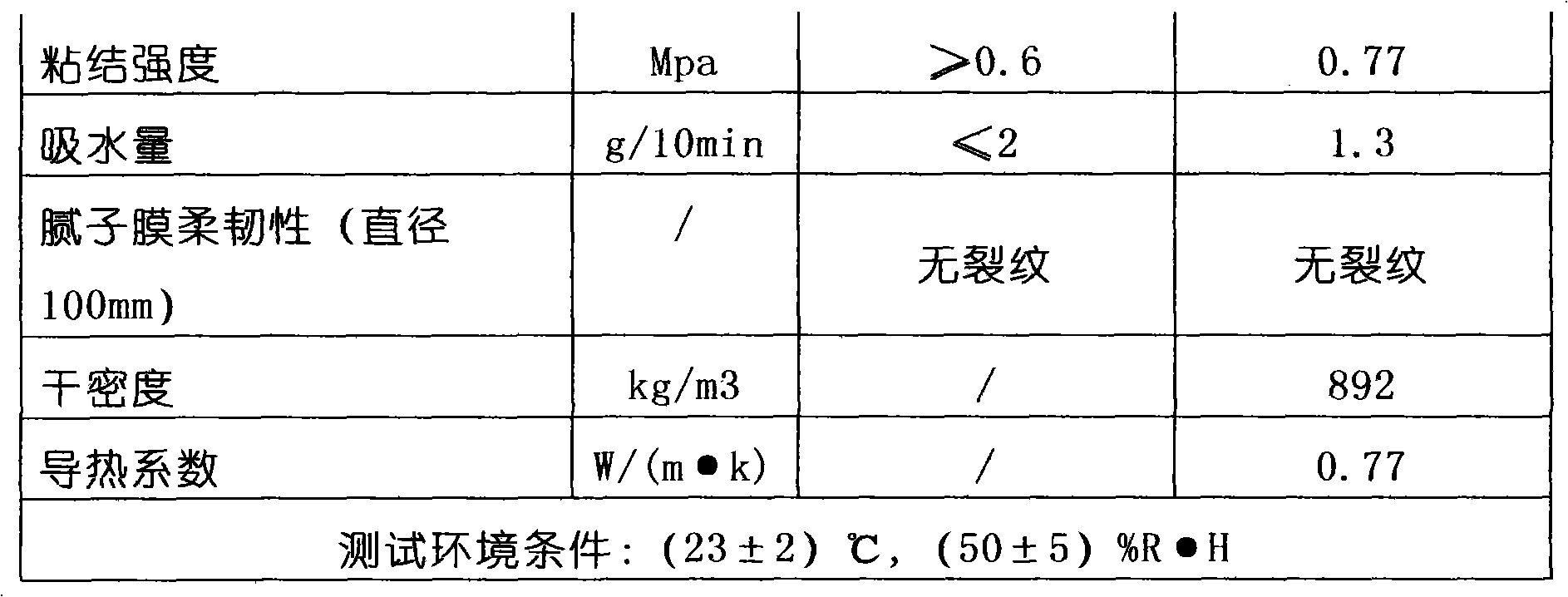

Energy-saving leveling putty powder

The invention relates to energy-saving leveling putty powder, which is characterized by being prepared from the following raw materials in percentage by weight: 20 to 30 percent of white cement, 5 to 10 percent of gray calcium powder, 40 to 60 percent of heavy calcium carbonate powder, 5 to 15 percent of 50 to 100-mesh light sand, 0.1 to 1 percent of reinforcing fiber, 0.1 to 1.5 percent of polyvinyl alcohol, 0.1 to 1.8 percent of cellulose and 1 to 3 percent of polymer powder, wherein the light sand is polyphenyl particles, vitrified micro bubbles or expanded perlite; the reinforcing fiber is 2-mm polypropylene fiber; and the cellulose is carboxymethyl cellulose. The energy-saving leveling putty powder has the characteristics of high strength, high water resistance, no toxicity or odor, yellowing resistance and the like; moreover, by adding the light sand with heat preservation and thermal insulation function, the putty powder has the obvious characteristics of light weight, heat preservation, high thermal insulation, abrasion resistance, corrosion resistance, high electric insulating performance, radiation protection and the like, while the basic performance is ensured.

Owner:陈文光

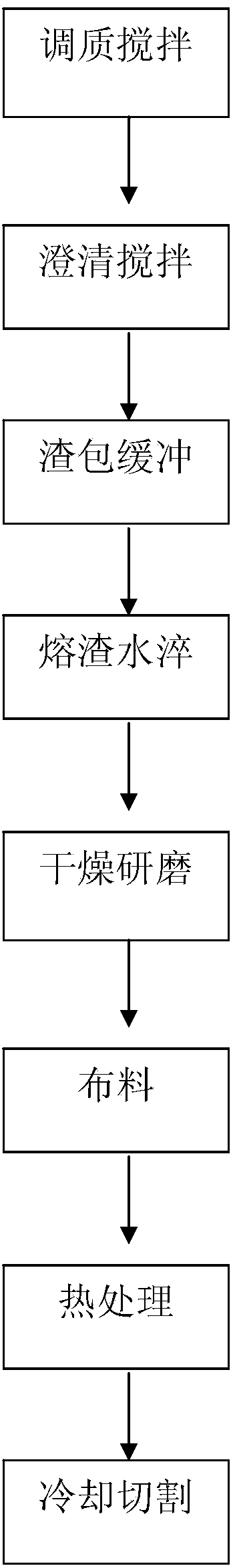

Method for using blast furnace slag to produce micro-crystalline light brick

The invention discloses a method for using blast furnace slag to produce a micro-crystalline light brick. The light brick uses the blast furnace slag as main raw material. The method for using the blast furnace slag to produce the micro-crystalline light brick includes that tempering and clearing the blast furnace slag to obtain slag with qualified ingredients, feeding to a water quenching pool to form micro-crystalline particles through water quenching, grinding and sieving the micro-crystalline particles to obtain micro-crystalline particles with proper granularity, uniformly mixing with foaming agent, putting the mixture in a casting mould, and sintering to form the micro-crystalline light brick with uniform air bubbles and stable ingredients. Compared with the traditional clay brick, the micro-crystalline light brick has lower density and higher intensity, so that the micro-crystalline light brick has better bearing ability, and moreover, the micro-crystalline light brick has good heat preservation effect and sound insulation effect due to the uniform air hole structure, so that the micro-crystalline light brick can replace the clay brick or ordinary light brick in a certain degree to serve as novel building material.

Owner:江西璞晶新材料股份有限公司

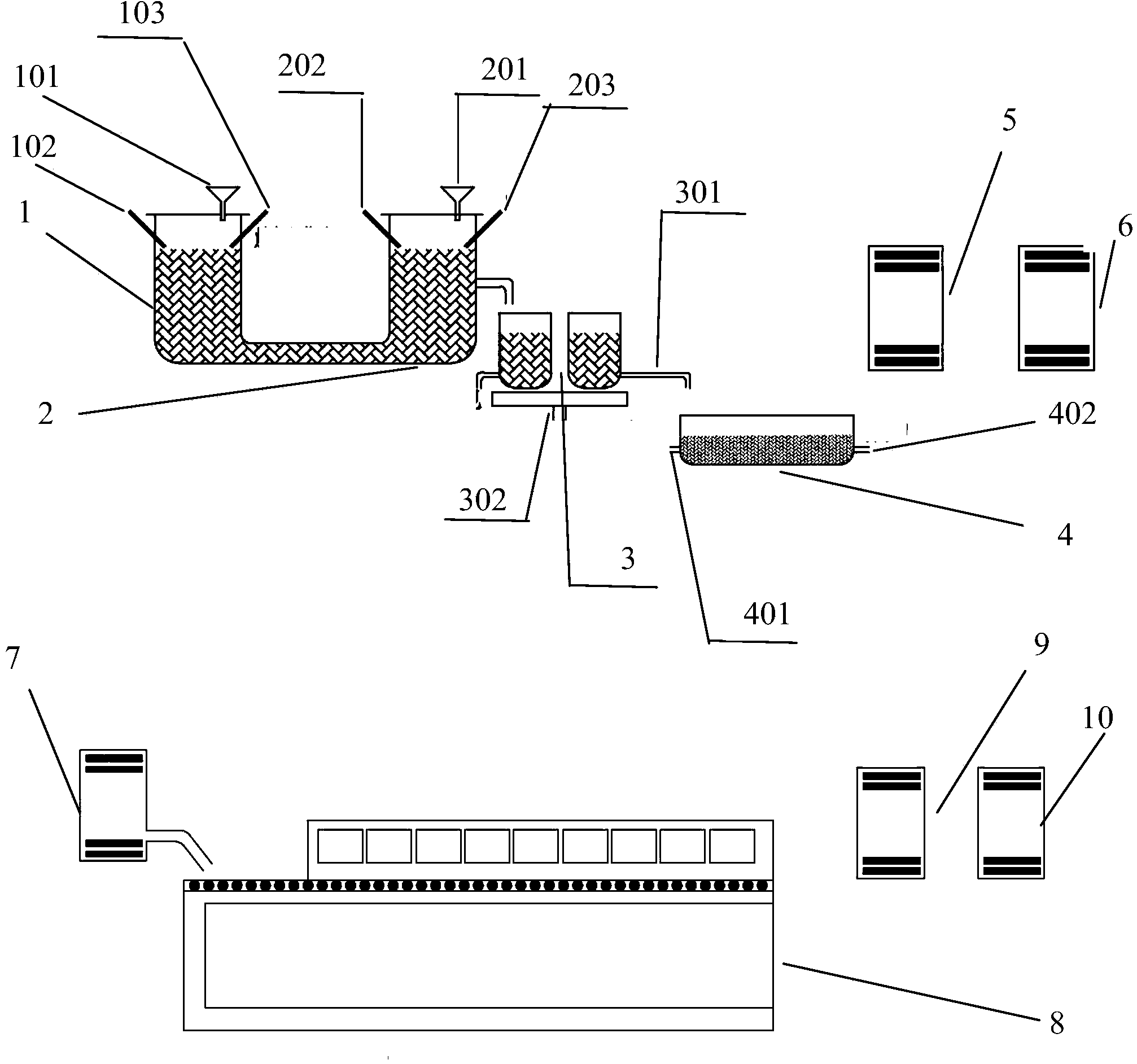

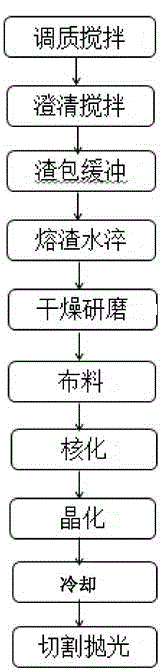

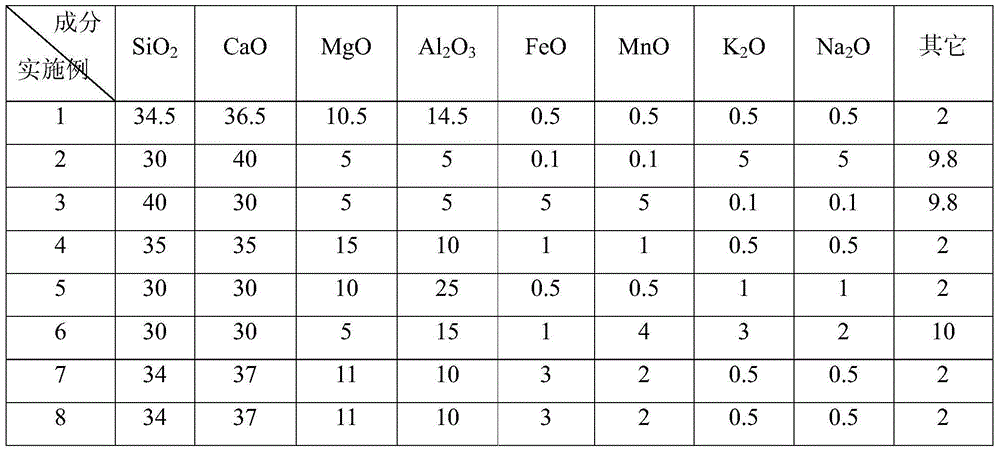

Method for producing micro-crystal foamed glass plate by using molten slag of blast furnace and equipment used in method

The invention belongs to the fields of metallurgy and inorganic nonmetallic materials and provides a method for producing a micro-crystal foamed glass plate by using molten slag of a blast furnace. The method comprises the following steps of (1) transferring molten slag of the blast furnace to a component tempering stirring tank, adding a modifier, and uniformly stirring to ensure the temperature of the molten slag; (2) transferring the molten slag to a clarification tank, adding a clarifying reagent, and uniformly stirring to ensure the temperature of the molten slag; (3) enabling the molten slag to enter a water quenching tank to be subjected to water quenching to form micro-crystal grains; (4) drying the micro-crystal grains, grinding, and then, sieving the micro-crystal grains with different particle sizes; (5) adding a foaming agent into the qualified micro-crystal grains and uniformly stirring; (6) spreading the micro-crystal grains on a refractory slab, and preserving the heat in a nucleation region for a certain period of time; (7) preserving the heat in a crystallization region for a period of time; (8) cooling in a cooling region to obtain a finished product of micro-crystal foamed glass. The method is capable of sufficiently utilizing the molten slag of the blast furnace, solid waste resources and the energy of the molten slag of the blast furnace, high in product strength, low in density, resistant to corrosion and capable of insulating heat and noise.

Owner:江西璞晶新材料股份有限公司

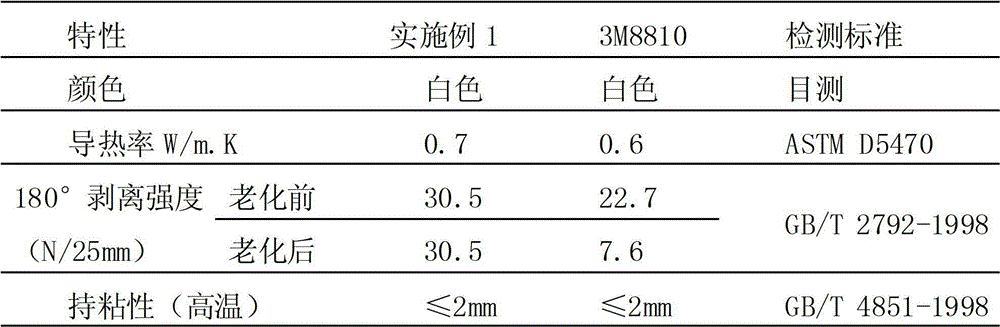

Heat-conducting insulated pressure sensitive tape and preparation method thereof

ActiveCN102746799AWith thermal insulationSensitive to pressureNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingHeat sink

The invention relates to a heat-conducting insulated pressure sensitive tape and a preparation method of the tape. The principal technical features are as follows: the heat-conducting insulated pressure sensitive tape comprises a heat-conducting insulated pressure sensitive tape without a base material and a heat-conducting insulated pressure sensitive tape with the base material; and the preparation method comprises the following steps: (1) preparing a polyacrylate adhesive; (2) preparing modified heat-conducting filler dispersion liquid; and (3) mixing the polyacrylate adhesive prepared in the step (1) with the modified heat-conducting filler dispersion liquid prepared in the step (2), coating wet glues with different thicknesses onto a release protection layer by a film coater, and drying in a gradually heating way to prepare the heat-conducting insulated pressure sensitive tape without the base material; or bonding with the both faces of the base material to prepare the heat-conducting insulated pressure sensitive tape with the base material. The heat-conducting insulated pressure sensitive tape is high in heat conductivity, good in bonding performance and excellent in ageing resistance, has excellent die cutting processability, and can be widely applied to bonding of heat radiating fins and heating devices such as a CPU (central processing unit), a power tube, a module power supply and the like, as well as bonding of screens, frames and injection molded boards in electronic products such as a mobile phone, an LED (light emitting diode) device and the like.

Owner:TIANJIN BOYUAN NEW MATERIALS

Environment-friendly flame-retardant thermal insulation mortar adopted with rice hulls

The invention belongs to the technical field of building materials, and particularly relates to an environment-friendly flame-retardant thermal insulation mortar adopted with rice hulls. The preparation method includes taking ordinary Portland cement, coal ash and slag powder as cementing materials and the rice hulls and sand as fine aggregates; adding a water reducing agent, redispersible latex powder and a graft copolymer (CMC-g-PMMA) of carboxymethyl cellulose and methyl methacrylate as plant fiber surface treating agents. The environment-friendly flame-retardant thermal insulation mortar adopted with the rice hulls has the advantages of being simple in construction, low in cost, small in self-weight, environment-friendly and energy-saving due to the full usage of crop waste, good in economical and social benefits, provided with performances of damp and moth proofing, frame retardance and thermal insulation, and suitable for building and plastering construction of wall materials.

Owner:TONGJI UNIV

Light-weight concrete for 3D printing, and preparation method and application thereof

ActiveCN105948668AShort initial setting timeSolve the problem of special-shaped formworkAdditive manufacturing apparatusPortland cementUltimate tensile strength

The invention provides a light-weight concrete for 3D printing, and a preparation method and application thereof. The light-weight concrete is prepared from the following raw materials in parts by weight: 100 parts of 52.5R ordinary Portland cement, 6-12 parts of quick-setting sulfoaluminate cement with the strength level of not less than 42.5, 7-10 parts of fly ash, 100-250 parts of composite inert light-weight filler, 1.2-6.5 parts of polypropylene fiber, 0.06-0.2 part of viscosity modifier, 0.5-1.5 parts of flexibility modifier and 25-40 parts of water. Compared with the traditional concrete material, the dead weight of the material is obviously lowered by 25-40%, the pressure deformation from the upper layer material to the lower layer material in the printing process is greatly reduced, and the number of layers of one-step continuous printing can be further increased, thereby shortening the construction period. Besides, the material has certain heat-shielding and heat-insulating properties, so that the light-weight concrete is more energy-saving and environment-friendly when being applied to the field of buildings.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

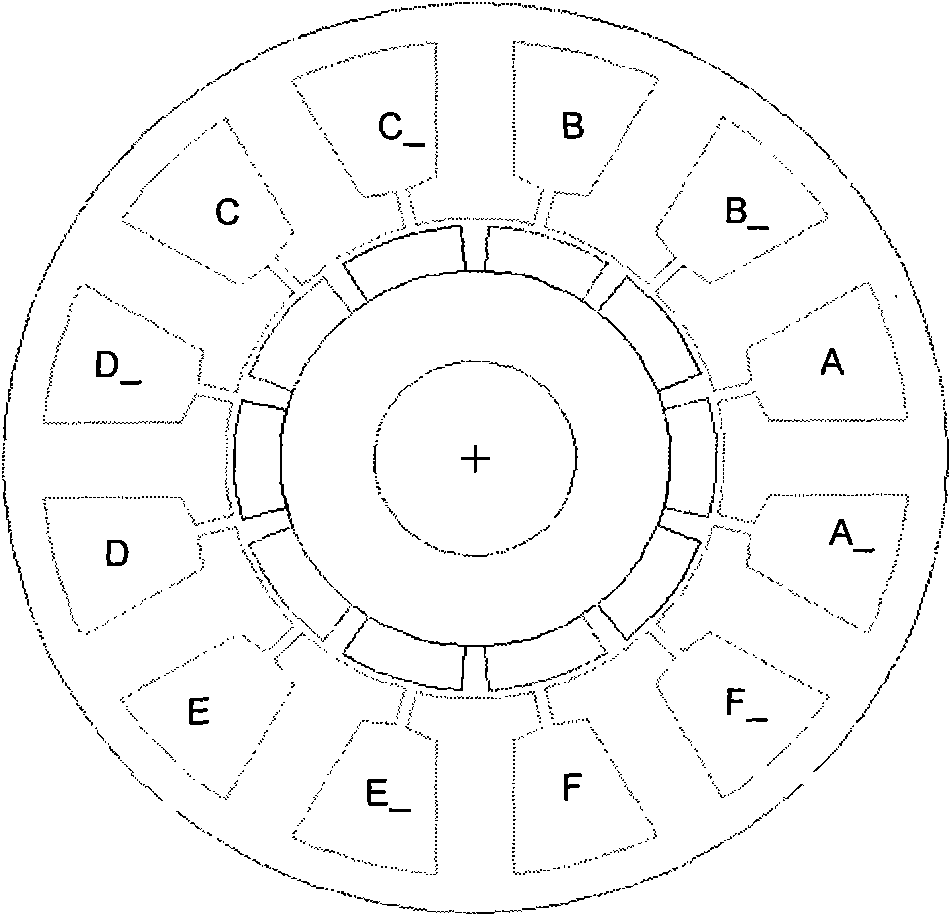

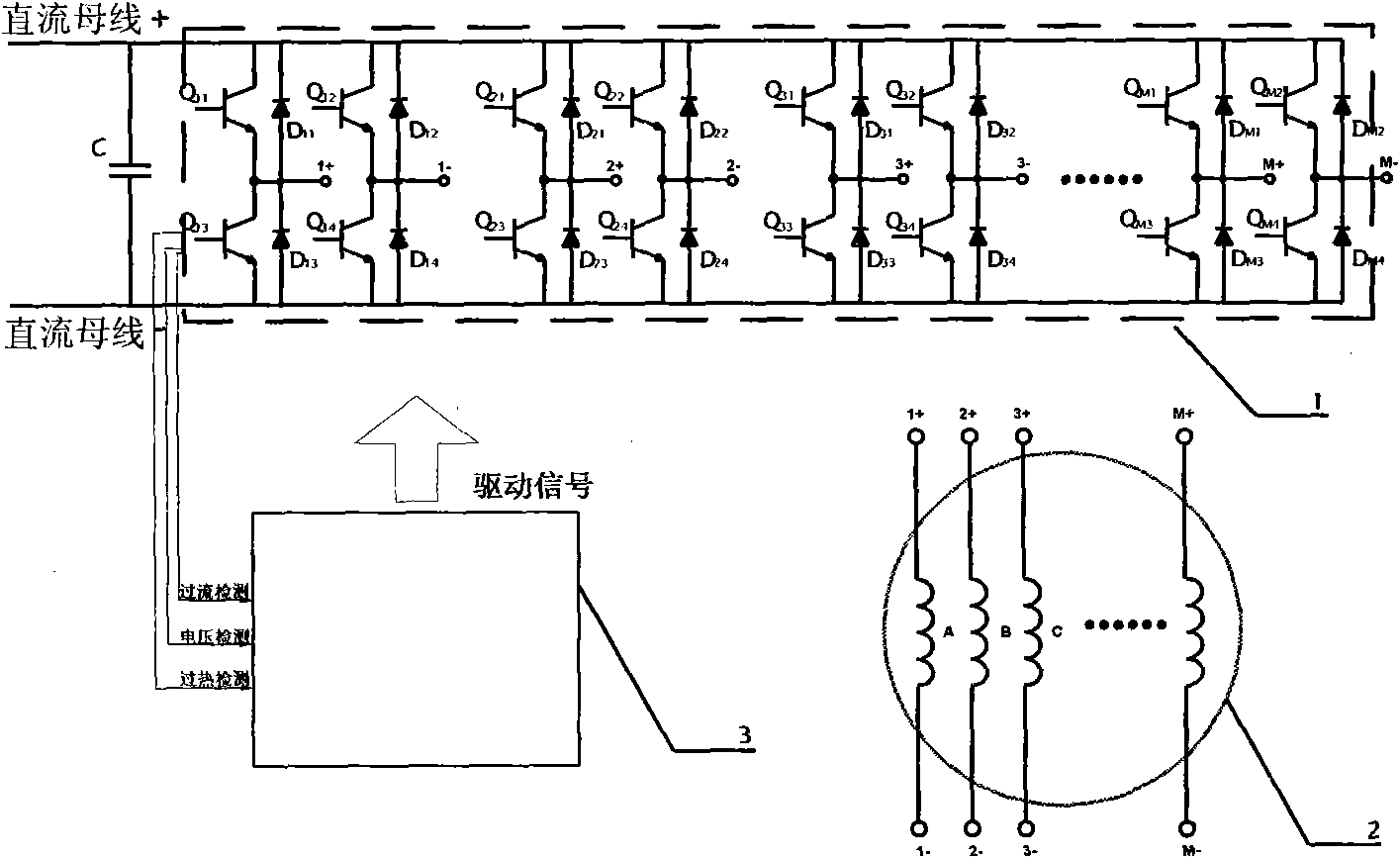

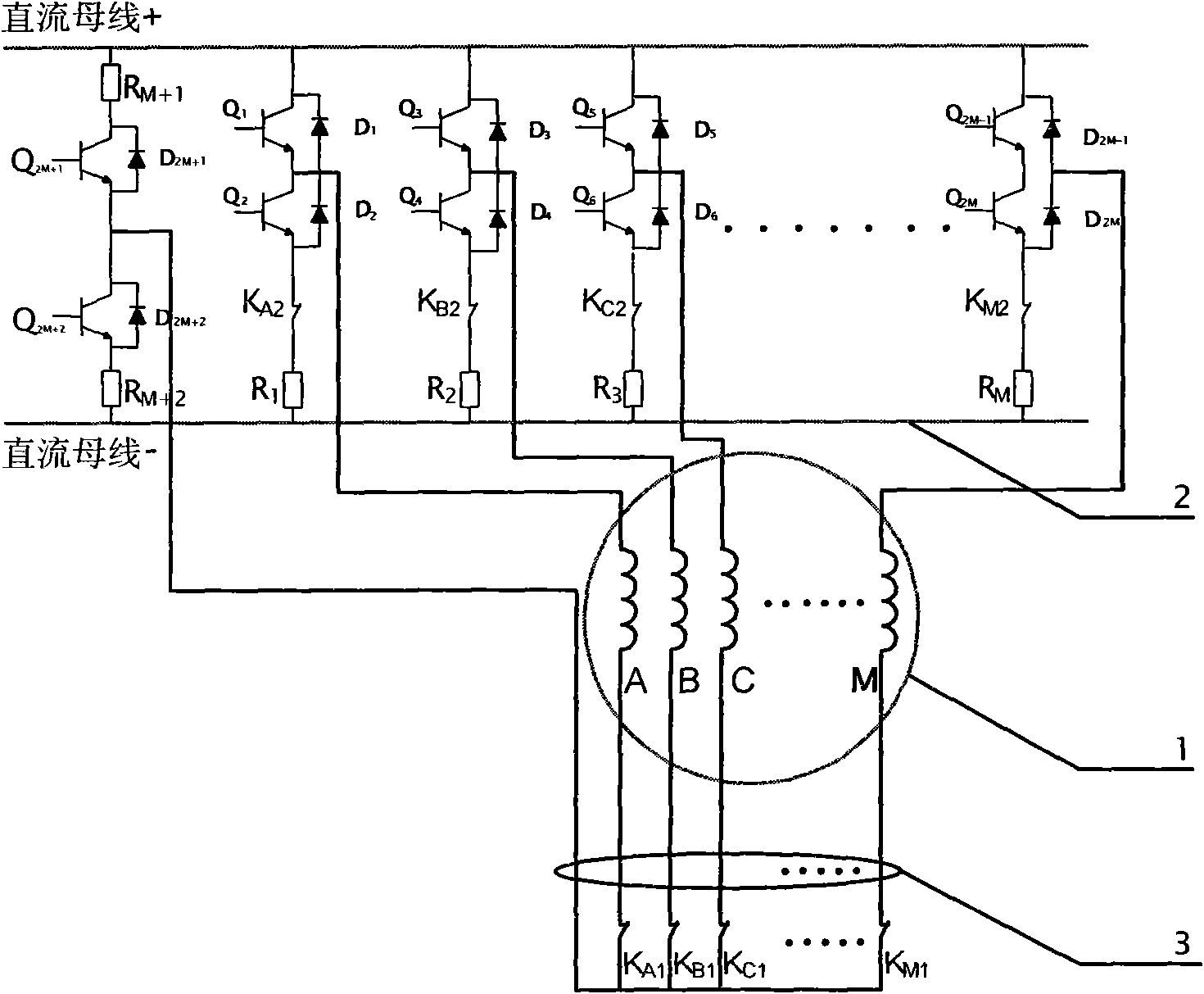

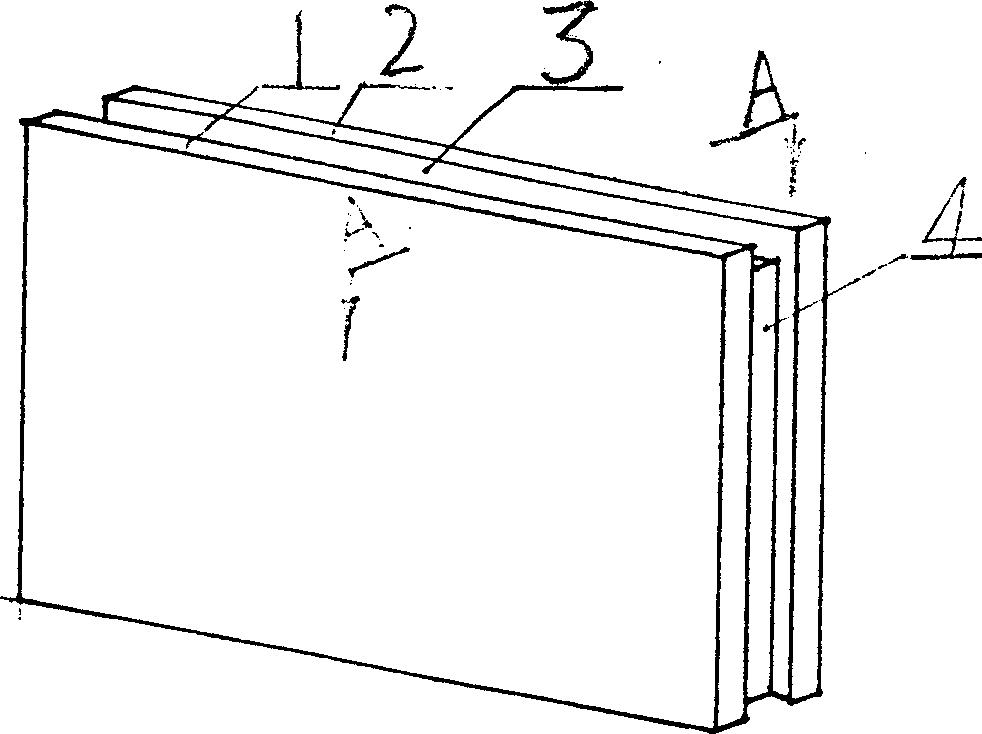

Multiphase permanent magnet fault-tolerant motor control system in half-bridge structure

InactiveCN101667804AImprove reliabilityImprove fault toleranceAC motor controlEmergency protective circuit arrangementsControl theoryConductor Coil

The invention relates to a novel multiphase permanent magnet fault-tolerant motor control system in a half-bridge structure, which has the characteristic of failure isolation. The system comprises anM-phase permanent magnet fault-tolerant motor (1) and an M+1-phase half-bridge inverting circuit (2). One end of each phase winding of a permanent magnet fault-tolerant motor is connected with a midpoint of a corresponding half bridge, and the lower end of a bridge arm of the half bridge is connected with the negative end of a bus after being connected in series with a normally-closed contact point and a PTC resistor; the other ends of all the windings are connected to form a * shape connecting method after being connected in series with the other normally-closed contact point; and the two normally-closed contact points with the same phase belong to the same double-connecting relay. A midpoint of the * shape connecting method is also connected with the midpoint of a redundant phase half bridge, and the phase is a midpoint control bridge arm; both an upper bridge arm and a lower bridge arm are connected with the bus after being connected in series with the PTC resistor, and the lower end of the bridge arm is not connected in series with the normally-closed contact point. When any phase generates failure, the two normally-closed contact points of the phase are opened to isolate the failure phase, a motor system carries out unsymmetrical running and controls current flowing through the midpoint by combining a fault-tolerant control algorithm through the midpoint control bridge arm, and the motor system enters a fault-tolerant running state.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Washable ecologic wall material capable of decomposing formaldehyde

ActiveCN101935190AStrong water absorptionHigh decolorizing powerOther chemical processesDispersed particle separationFiberAdhesive

The invention relates to a washable ecologic wall material capable of decomposing formaldehyde. The invention not only can be used for decomposing and absorbing the formaldehyde, improving indoor moisture and absorbing indoor water content, but also is very convenient to wash and brings great convenience for people to clean the wall. The washable ecologic wall material capable of decomposing the formaldehyde is characterized by being prepared from the following components in percentage by weight: 18-29 percent of diatomite, 25-30 percent of quartz sand, 0.1 percent of fiber, 15-18 percent of bentonite, 1-3 percent of adhesive, 12-17 percent of ash calcium, 13-18 percent of water retention agent, 5-8 percent of formaldehyde purifier, 3-6.1 percent of titanium dioxide and 3-7 percent of anion powder. The invention further improves a traditional original wall material to satisfy the market needs and bring convenience and benefits to the life of people.

Owner:氧宜多硅藻新材料(宜昌)有限责任公司

Self-insulation wall material

InactiveCN102795818AWith thermal insulationImprove fire and water resistanceClimate change adaptationPassive housesFiberThermal insulation

The invention discloses a self-insulation wall material. The self-insulation wall material comprising the following components in proportion: 30-90 parts by weight of high-performance cement or high-efficiency concrete admixture, 5-40 parts by weight of aggregate, 0.1-5 parts by weight of air entraining agent, 0-8 parts by weight of expanding agent, 0-2 parts by weight of waterproof agent, and 0-20 parts by weight of anti-crack fiber. The self-insulation wall material disclosed by the invention has thermal insulation and insulating performance similar to that of the organic insulation material, the strength of a material which can be used as a building enclosure, as well as the comprehensive performances of uniform and single material, convenience in construction, good durability, good fireproof and waterproof performance, resistance to deformation, and non-crack and non-leakage; and the invention provides an appropriate self-insulation material for saving more than 50% and 65% of building energy.

Owner:万俊松

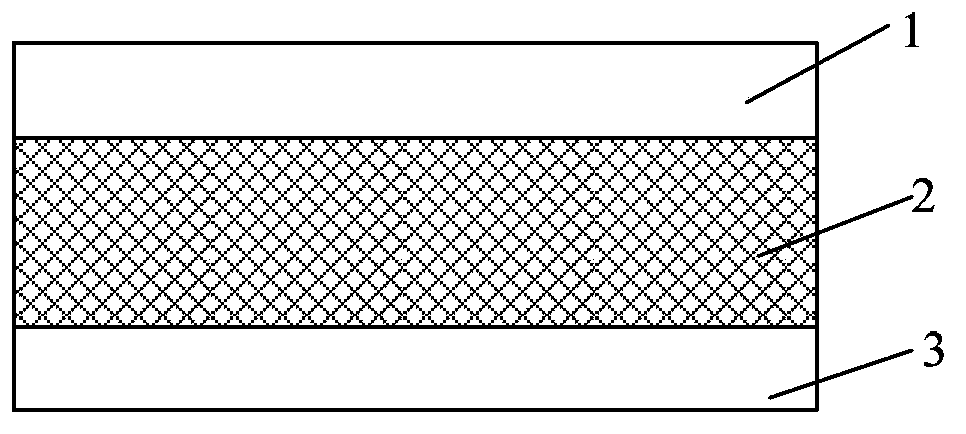

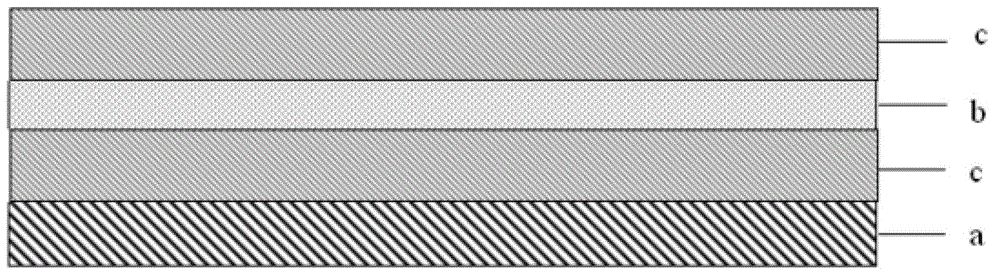

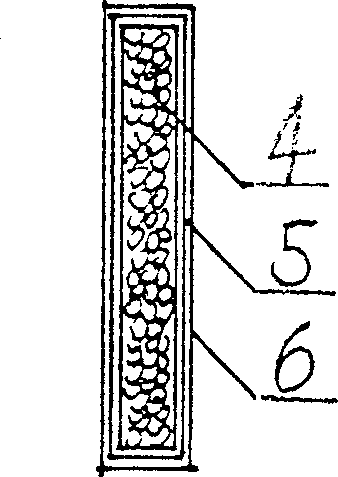

Insulation board made of fiber reinforced composites and preparation method of insulation board

InactiveCN102797299ADimensionally stableImprove impact resistanceHeat proofingWater-setting substance layered productFiberglass meshGlass fiber

The invention discloses an insulation board made of fiber reinforced composites. The insulation board is characterized in that enhancement layers are paved on an upper layer and a lower layer of an insulation layer, and are of glass fiber gridding cloth. The invention also discloses a preparation method of the insulation board made of fiber reinforced composites. The preparation method comprises the steps of mixing all raw materials of the insulation layer with water uniformly; pouring the slurry mixed uniformly into a mold, wherein the glass fiber gridding cloth is paved at the bottom of the mold; paving a layer of glass fiber gridding cloth on the upper layer of the slurry; after the paving, pressing and molding the slurry. Due to the mode, the double layers of glass fiber gridding cloth are adopted for enhancing, so that the size stability, the shock resistance and the crack resistance of the insulation plate are improved obviously; the requirement on the insulation and fire resistance of an outer wall are met by adopting the technology that inorganic bond materials wrap the insulation fillers; and the service life of the insulation board is long and basically keeps the pace with that of a building.

Owner:JIANGSU NIGAO SCI & TECH +1

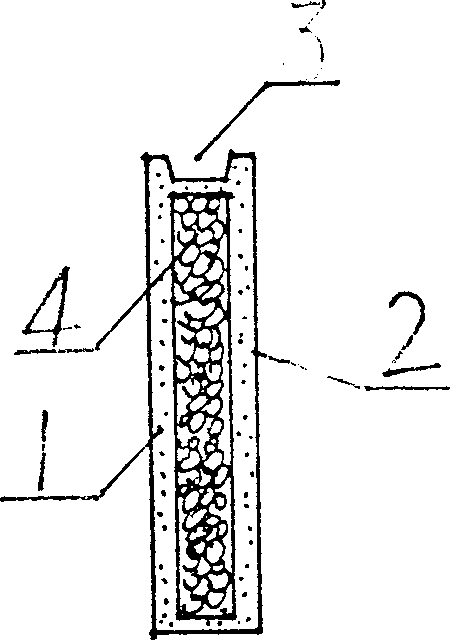

Light-weight small building block as sandwich of wall and its production method

InactiveCN1391017AFacilitate factory processing and productionSimple production processConstruction materialCeramic shaping apparatusRebarReinforced concrete

A light small building block with sandwich for wall is composed of rectangular sandwich board and two rectangular surface slabs made of concrete, and features that its each edge has a slot for casting the reinforced concrete. Its advantages are good insulation of heat and sound, and less possessed area.

Owner:李顺安 +2

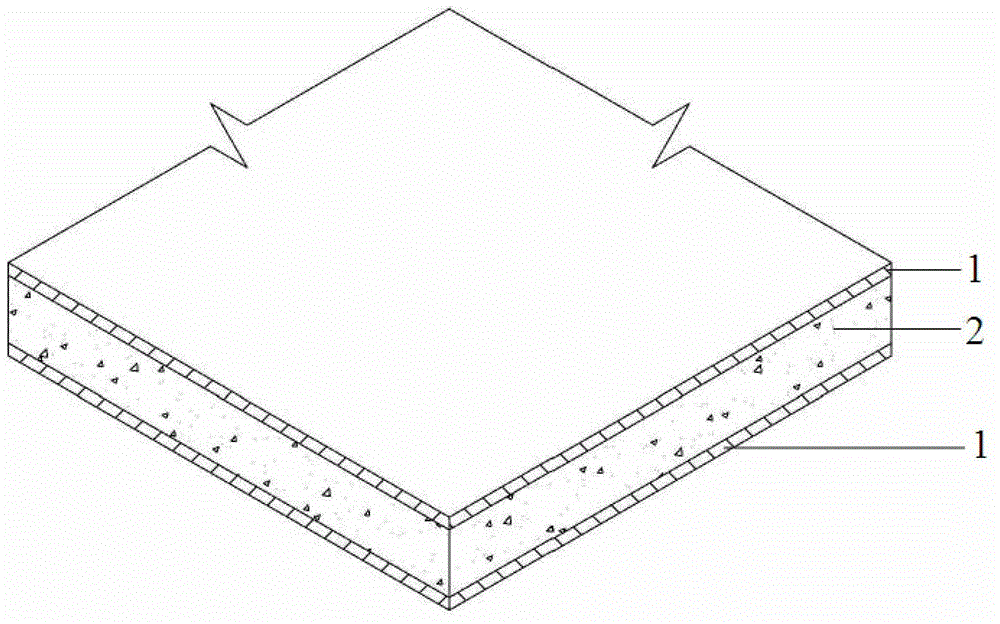

Foam concrete light compound wall board and preparation method thereof

InactiveCN102979241AEasy constructionCivilization ConstructionConstruction materialCeramicwareCalcium silicateFoam concrete

The invention relates to a foam concrete light compound wall board and a preparation method thereof. The wall board comprises upper and lower surface layers and a middle layer filled between the upper and lower surface layers; the upper and lower surface layers are calcium silicate boards and the middle layer is a foam concrete layer; the thickness of the compound wall board is 60-112 mm and the thickness of the calcium silicate boards is 15-16 mm; and the thickness of the foam concrete layer is 30-80 mm. Compared with the prior art, the recycling way of waste slurry is expanded and the damage of the waste slurry to the environment is reduced; the foam concrete light compound wall board has the advantages of light weight, heat preservation and heat insulation, sound insulation and fireproof performance, low elasticity and vibration absorption, waterproof and damp-proof performance, environmental friendliness and energy saving and the like; and the construction is convenient and the civilized, sanitary and efficient construction can be realized.

Owner:SHANGHAI ZHONGJIN CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com