Method and device for preparing ceramsite from sludge pyrolytic biochar

A technology of biochar and pyrolysis, which is applied in the production of clay products, ceramic products, ceramic materials, etc., can solve the problem of low level of large-scale comprehensive utilization, and achieve the effect of large-scale utilization and high-efficiency solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Preparation of ceramsite by 100% sludge pyrolysis biochar

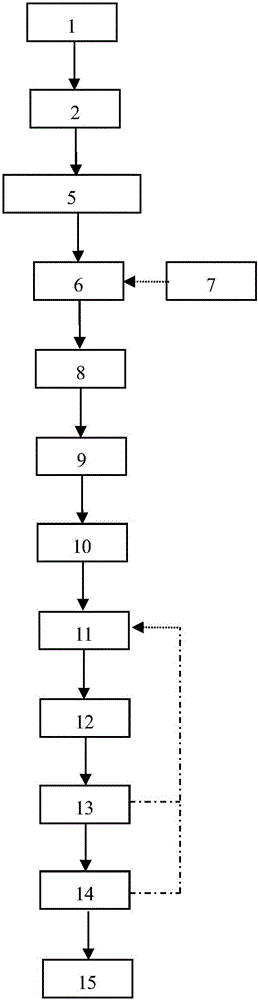

[0055] figure 1 It is a diagram of the device for preparing ceramsite by pyrolyzing biochar from sludge. The labels in the attached drawings indicate: 1. Storage bin for biochar from sludge pyrolysis; 2. 1# quantitative feeding device; 5. Grinding device; 6. Humidity control 7. Water adding device; 8. 1# conveying device; 9. Forming and granulating device; 10. 2# conveying device; 11. Drying device; 12. 3# conveying device; 13. Medium temperature pre-burning device; 14. High temperature Pre-burning device; 15. Cooling device.

[0056] Such as figure 1 As shown, firstly, the sludge pyrolysis biochar in the sludge pyrolysis biochar storage bin 1 is sent to the 1# quantitative feeding device 2, and the sludge biochar of a certain quality is weighed and sent to the grinding device 5 for pulverization. Grinding, controlling the particle size of the grinding material to be less than 100 mesh, and determ...

Embodiment 2

[0058] Example 2: 80% sludge pyrolysis biochar + 20% fly ash to prepare ceramsite

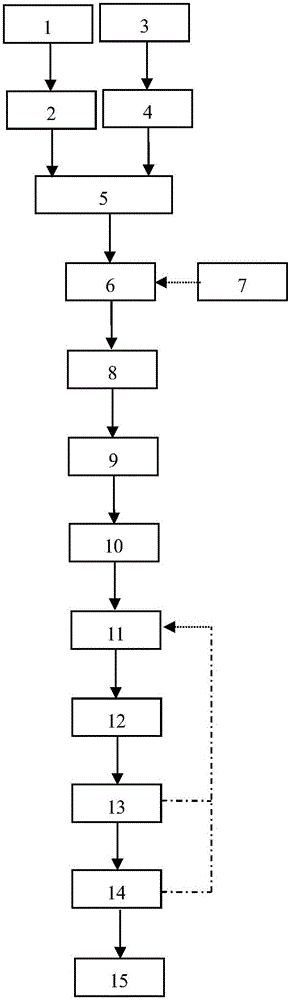

[0059] figure 2It is a diagram of the device for preparing ceramsite by pyrolyzing biochar from sludge. The reference numbers in the attached drawings indicate: 1. Storage bin for sludge pyrolysis biochar; 2. 1# quantitative feeding device; 3. Storage bin for other auxiliary materials; 4. 2# Quantitative feeding device; 5. Grinding device; 6. Humidity control device; 7. Water adding device; 8. 1# conveying device; 9. Forming and granulating device; 10. 2# conveying device; 11. Drying device; 12. 3# conveying device; 13. Medium-temperature pre-burning device; 14. High-temperature pre-burning device; 15. Cooling device.

[0060] Such as figure 2 As shown, firstly, the sludge pyrolysis biochar in the sludge pyrolysis biochar storage bin 1 is sent to the 1# quantitative feeding device 2, and 80% of the sludge pyrolysis biochar weighing 80% is sent to the grinding device 5, Simultaneously, the ...

Embodiment 3

[0064] Example 3: 70% sludge pyrolysis biochar + 20% fly ash to prepare ceramsite + 10% kaolin

[0065] Such as figure 2 As shown, firstly, the sludge pyrolysis biochar in the sludge pyrolysis biochar storage bin 1 is sent to the 1# quantitative feeding device 2, and the sludge pyrolysis biochar weighing 70% is sent to the grinding device 5, At the same time, the mixture of fly ash and kaolin with a mixing ratio of 2:1 in the storage bin 3 of other auxiliary materials is sent to the grinding device 5 for mixing and grinding through the 2# quantitative feeding device 4 weighing 30% of the fly ash , the particle size of the powder and abrasive is controlled to be less than 300 mesh, and the main chemical composition range of the mixture of sludge pyrolysis biochar and fly ash is determined as follows: SiO 2 : 46%, A1 2 o 3 : 19%, Fe 2 o 3 : 7%, CaO+MgO: 6%, K 2 O+Na 2 O: 6%, C: 12%; continue to send the mixed powder and abrasive to the humidity control device 6, add wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com