Patents

Literature

2005results about "Sludge treatment by pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

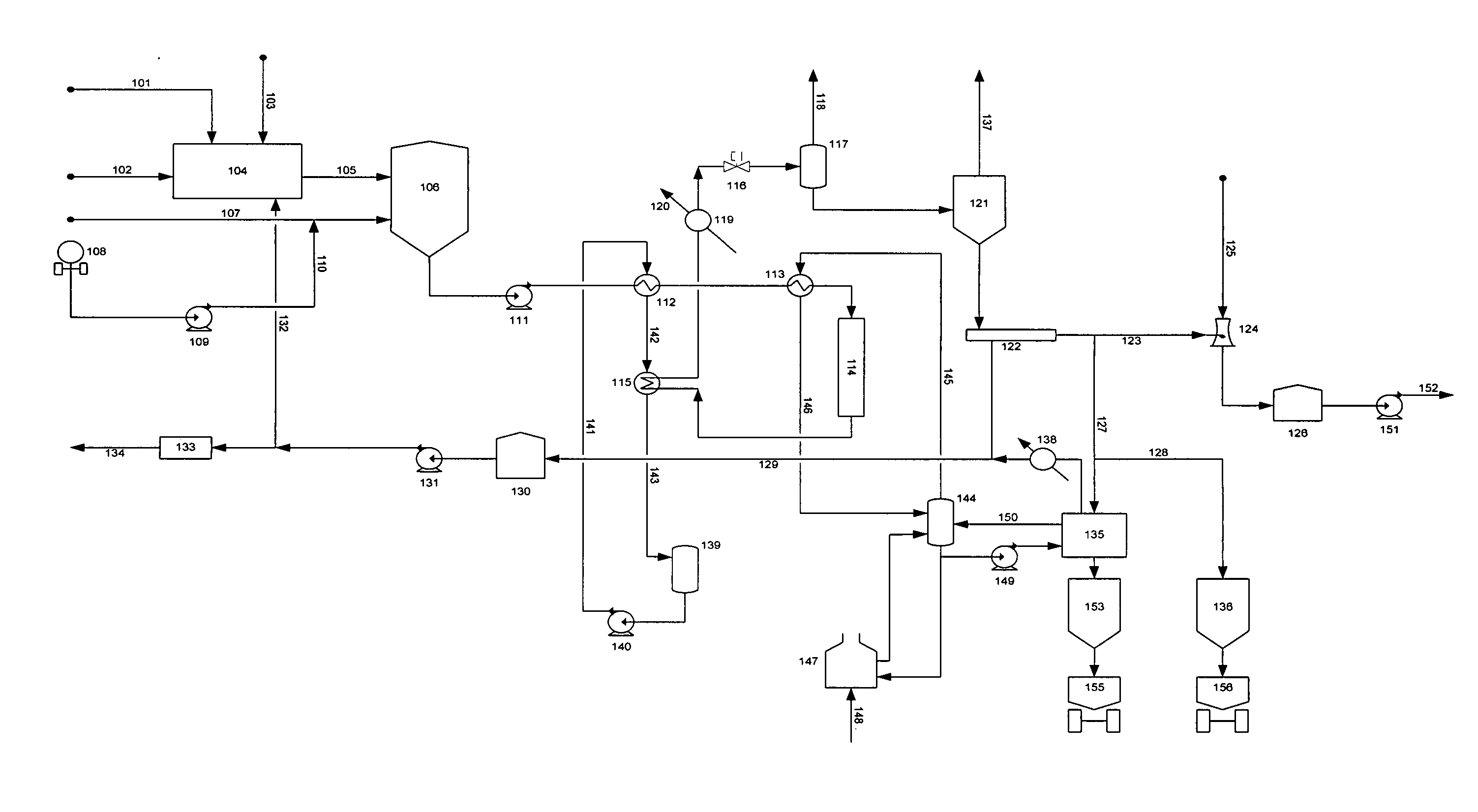

Slurry dewatering and conversion of biosolids to a renewable fuel

ActiveUS20060096163A1Readily removed mechanicallyLow oxygenBio-organic fraction processingBiofuelsEmission standardSlurry

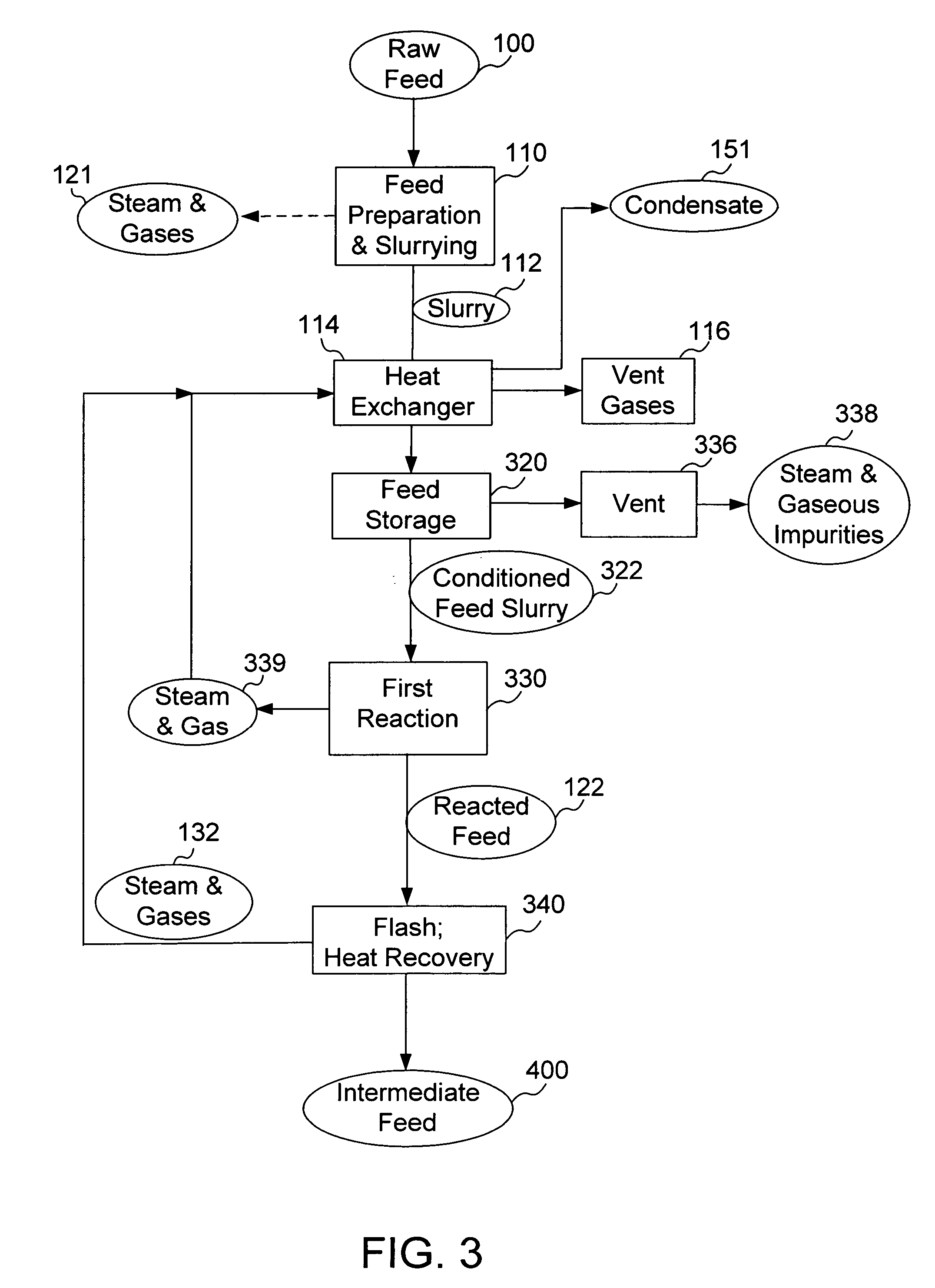

In the processes for treating municipal sewage and storm water containing biosolids to discharge standards, biosolids, even after dewatering, contain typically about 80% water bound in the dead cells of the biosolids, which gives biosolids a negative heating value. It can be incinerated only at the expense of purchased fuel. Biosolids are heated to a temperature at which their cell structure is destroyed and, preferably, at which carbon dioxide is split off to lower the oxygen content of the biosolids. The resulting char is not hydrophilic, and it can be efficiently dewatered and / or dried and is a viable renewable fuel. This renewable fuel can be supplemented by also charging conventional biomass (yard and crop waste, etc.) in the same or in parallel facilities. Similarly, non-renewable hydrophilic fuels can be so processed in conjunction with the processing of biosolids to further augment the energy supply.

Owner:SGC ADVISORS

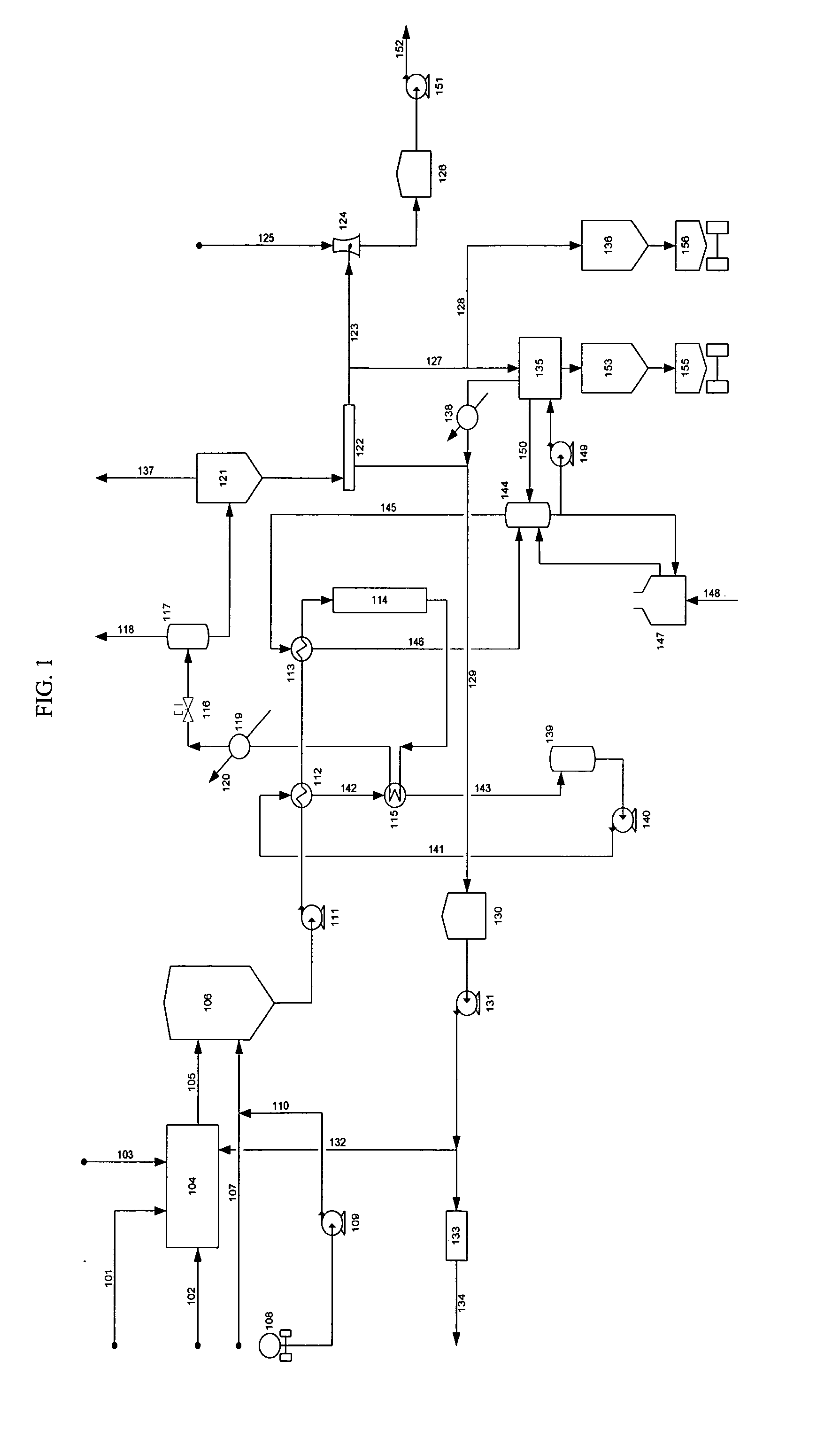

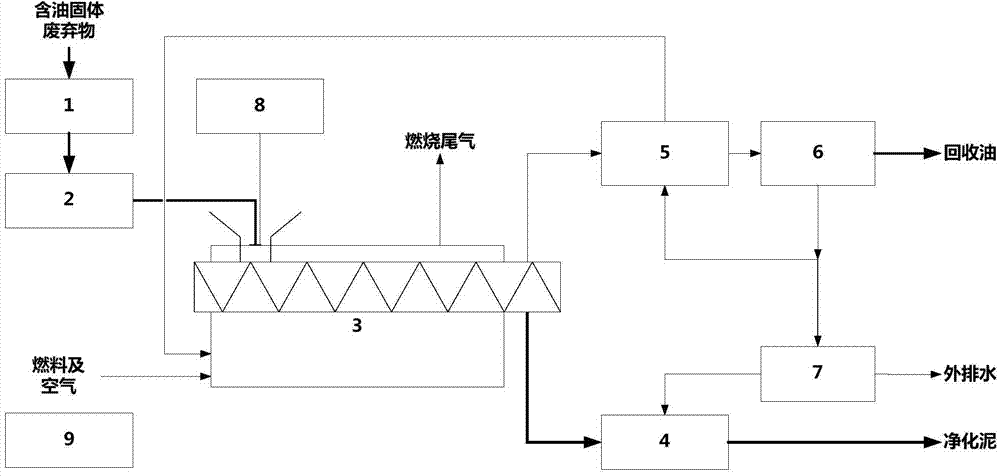

Method and system for processing oil field wastes

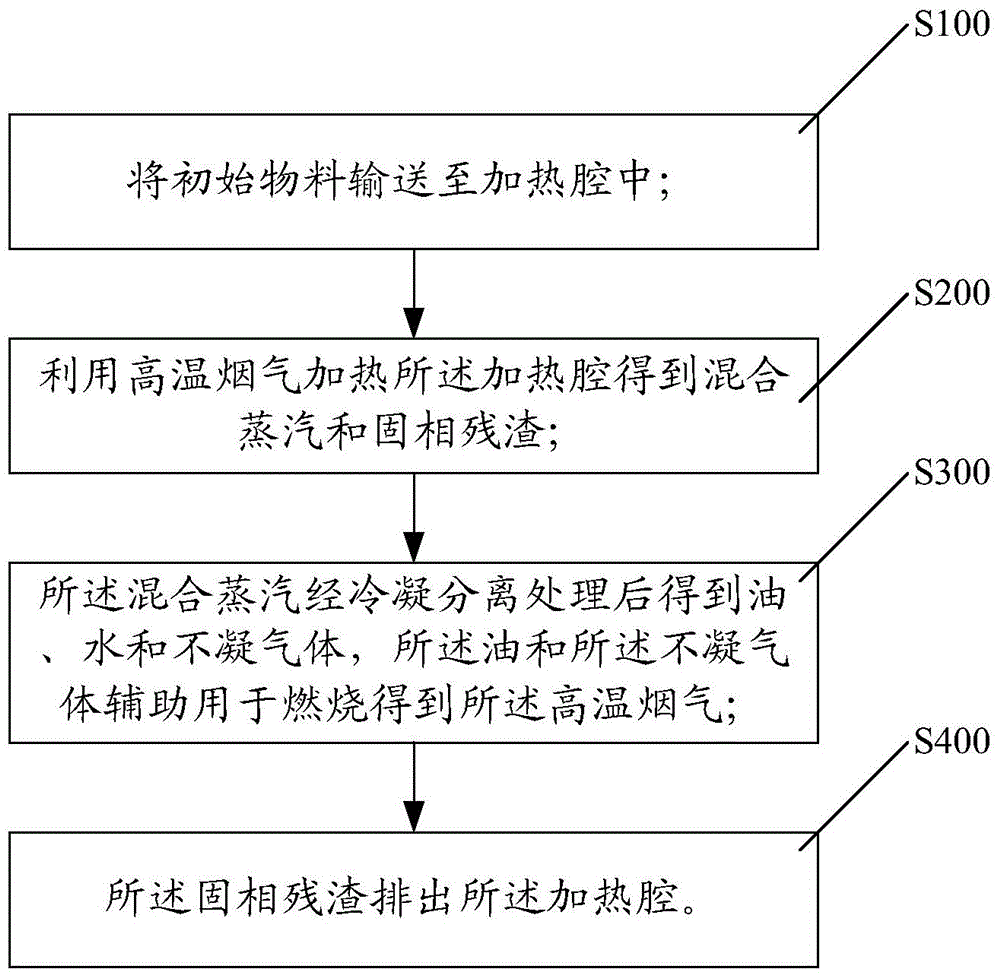

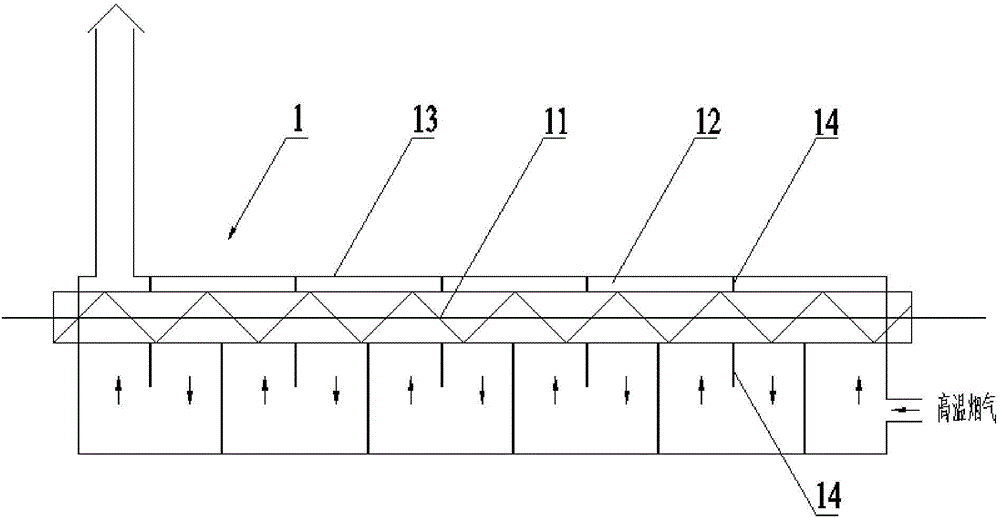

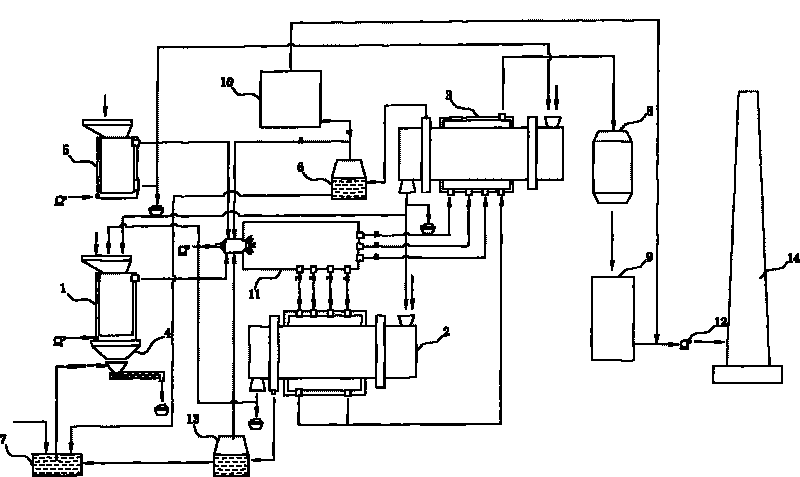

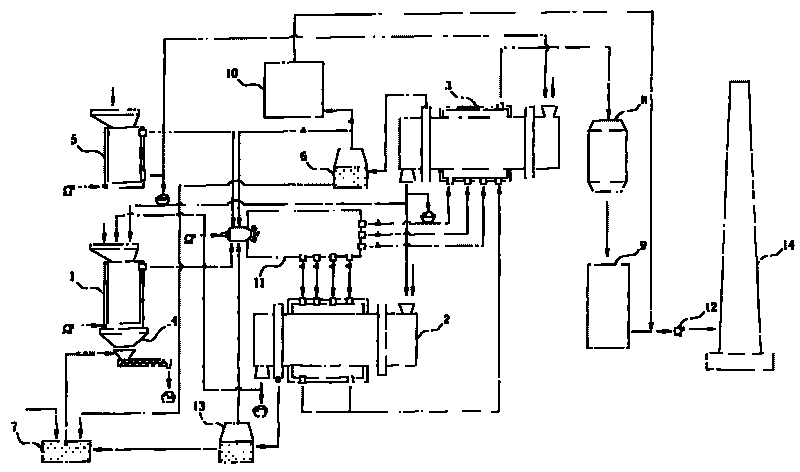

ActiveCN104150728AImprove versatilitySludge treatment by pyrolysisLiquid hydrocarbon mixture productionFlue gasDecomposition

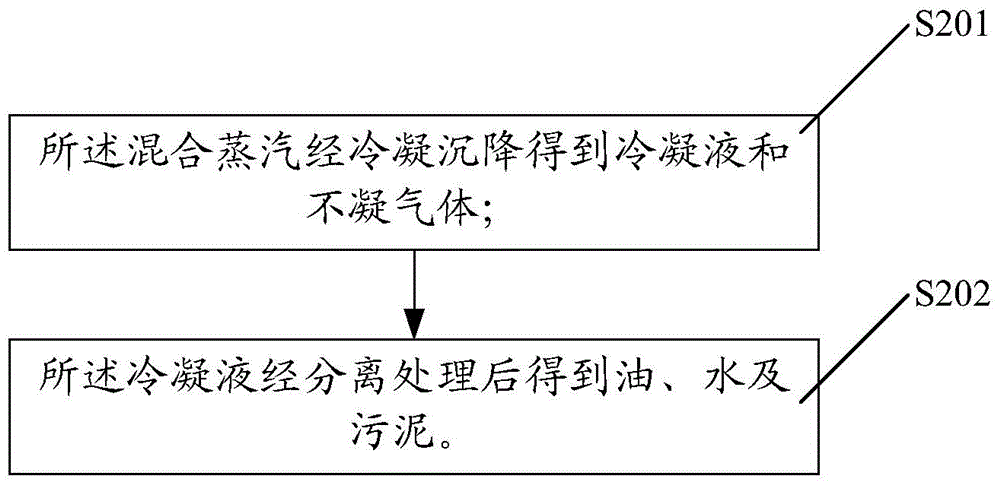

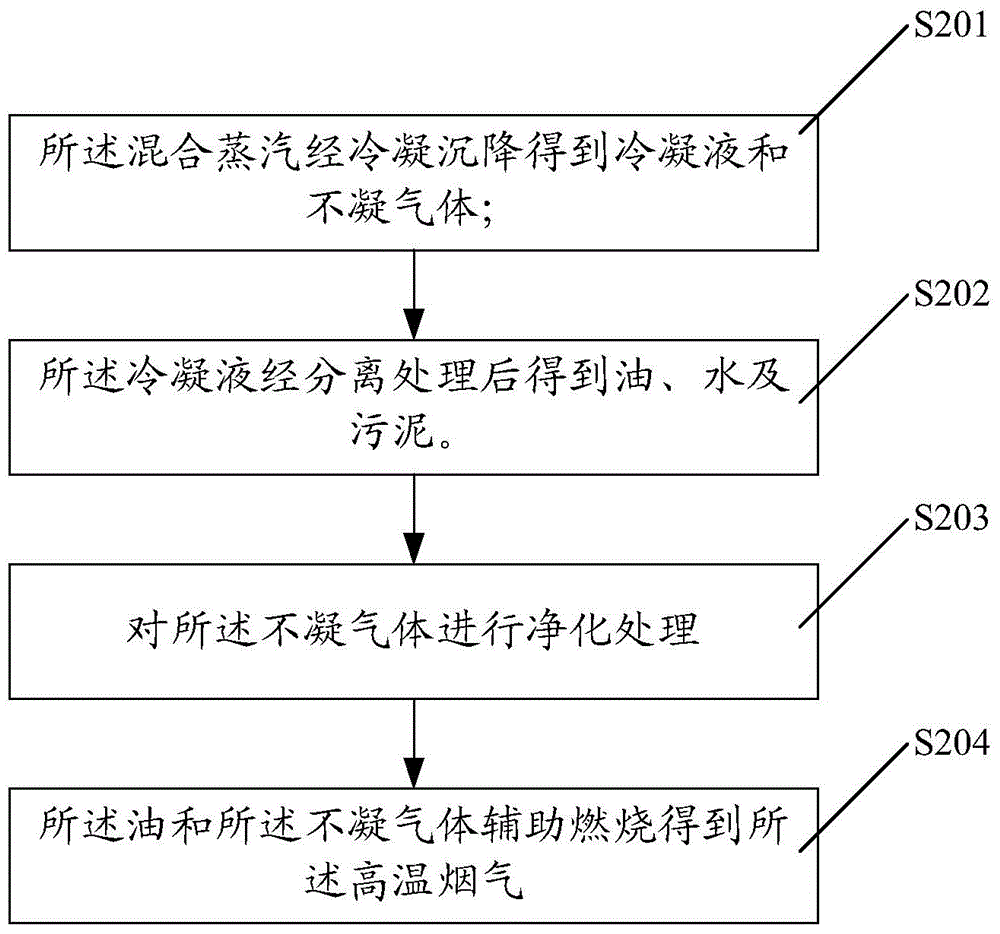

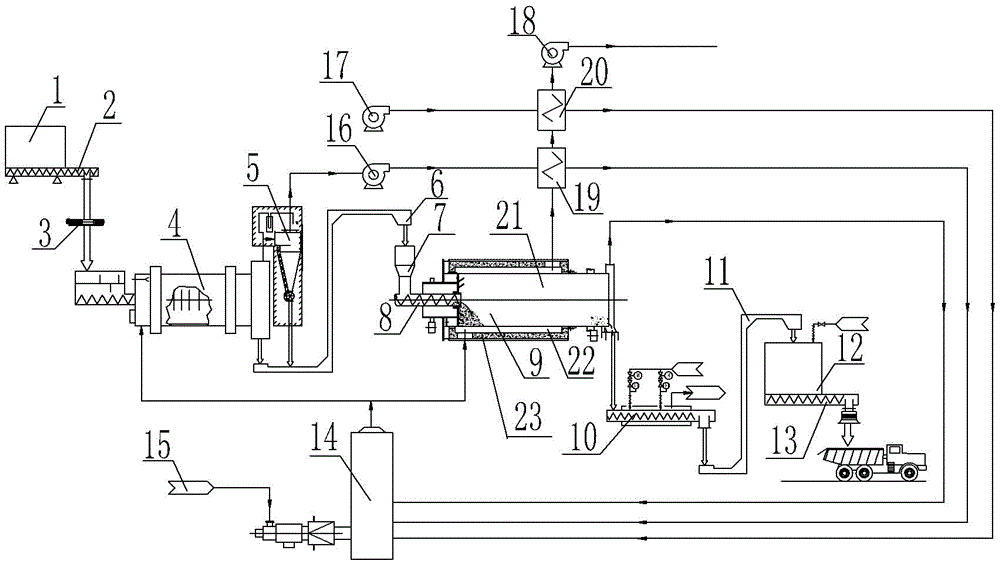

The embodiment of the invention discloses a method and a system for processing oil field wastes. The method for processing the oil field wastes comprises the following steps: conveying initial materials to a heating cavity, and heating the heating cavity by using high-temperature flue gas, so as to obtain mixed steam and solid residues; carrying out condensation and separation on the mixed steam, so as to obtain oil, water and a noncondensable gas, wherein the oil and the noncondensable gas are used for combusting to obtain the high-temperature flue gas, and the solid residues are discharged out of the heating cavity. According to the method, the heating cavity is indirectly heated by using the high-temperature flue gas, so that the initial materials inside the heating cavity are subjected to thermal decomposition, solid residues free of oil, the noncondensable gas and oil are obtained from the mixed steam generated by thermal decomposition after a series of treatments, and then the noncondensable gas and oil are used for combusting to generate the high-temperature flue gas. Compared with the prior art, the method disclosed by the invention has the advantages that decomposition is carried out without adding a cracking agent, and thermal decomposition can be directly carried out on the oil field wastes in different regions, therefore, the method and the system are better in universality.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

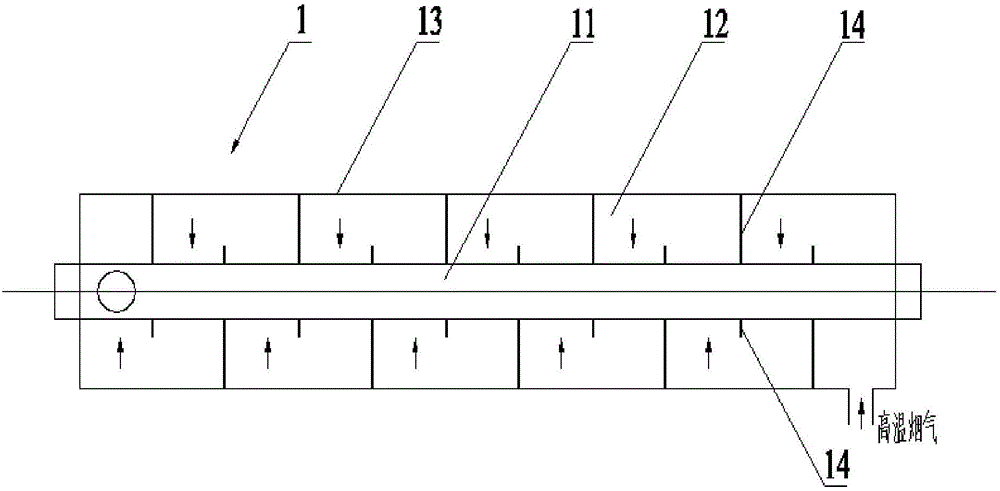

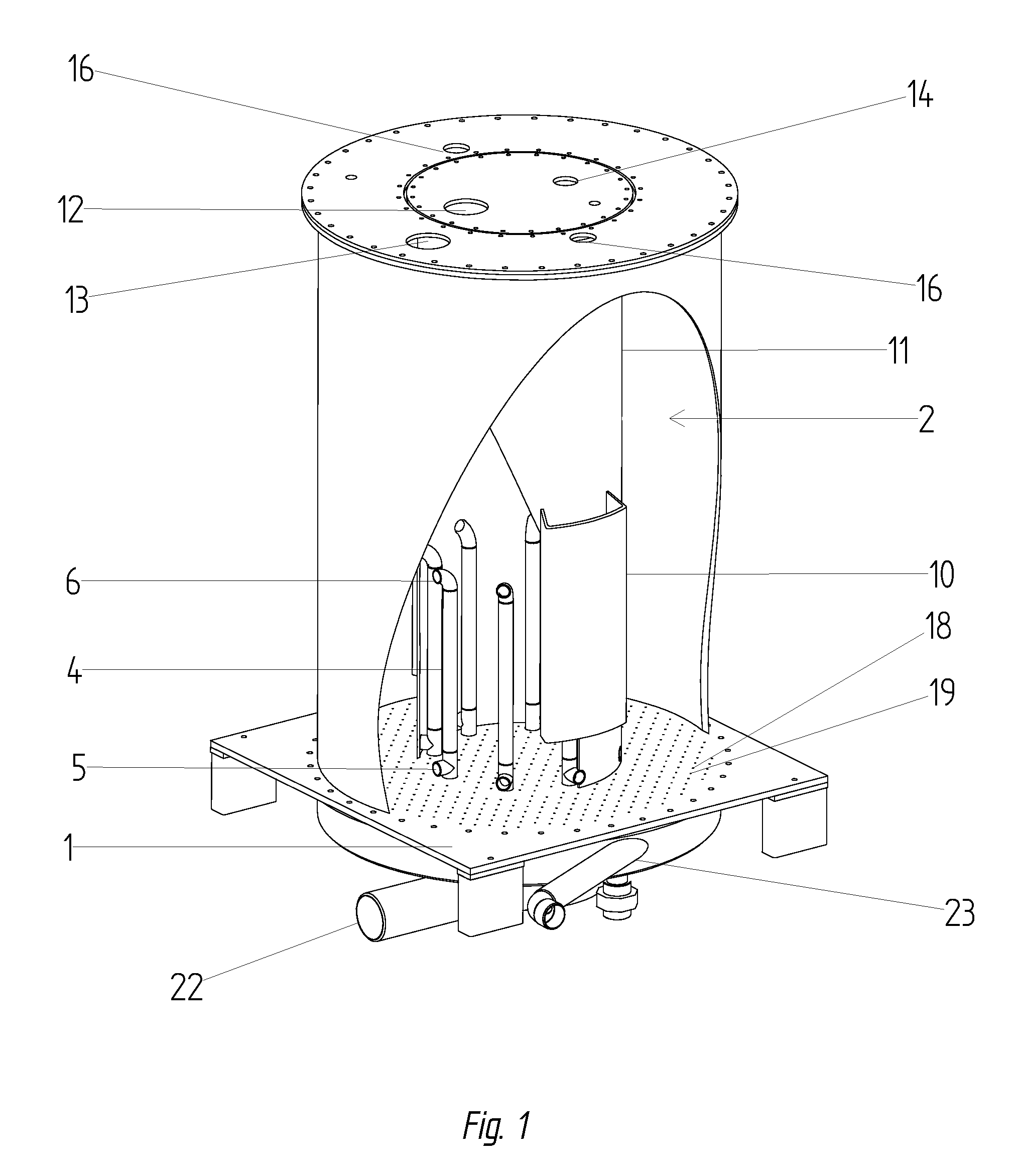

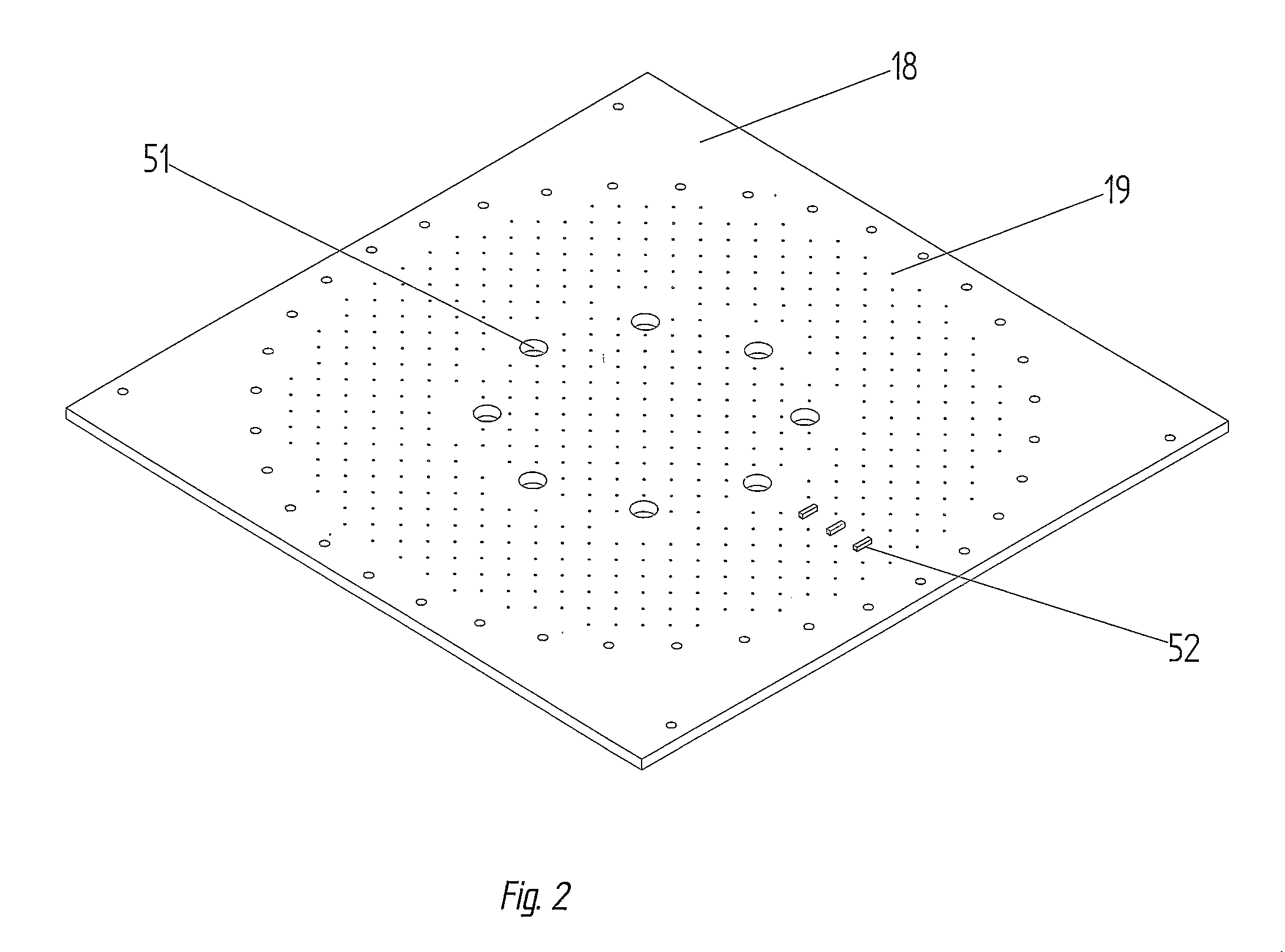

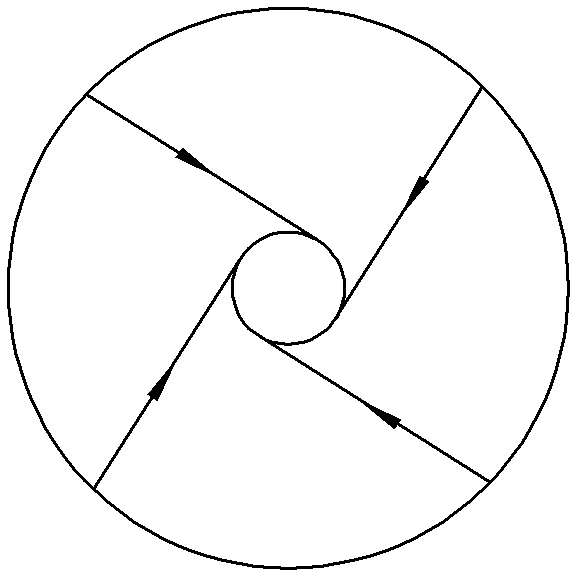

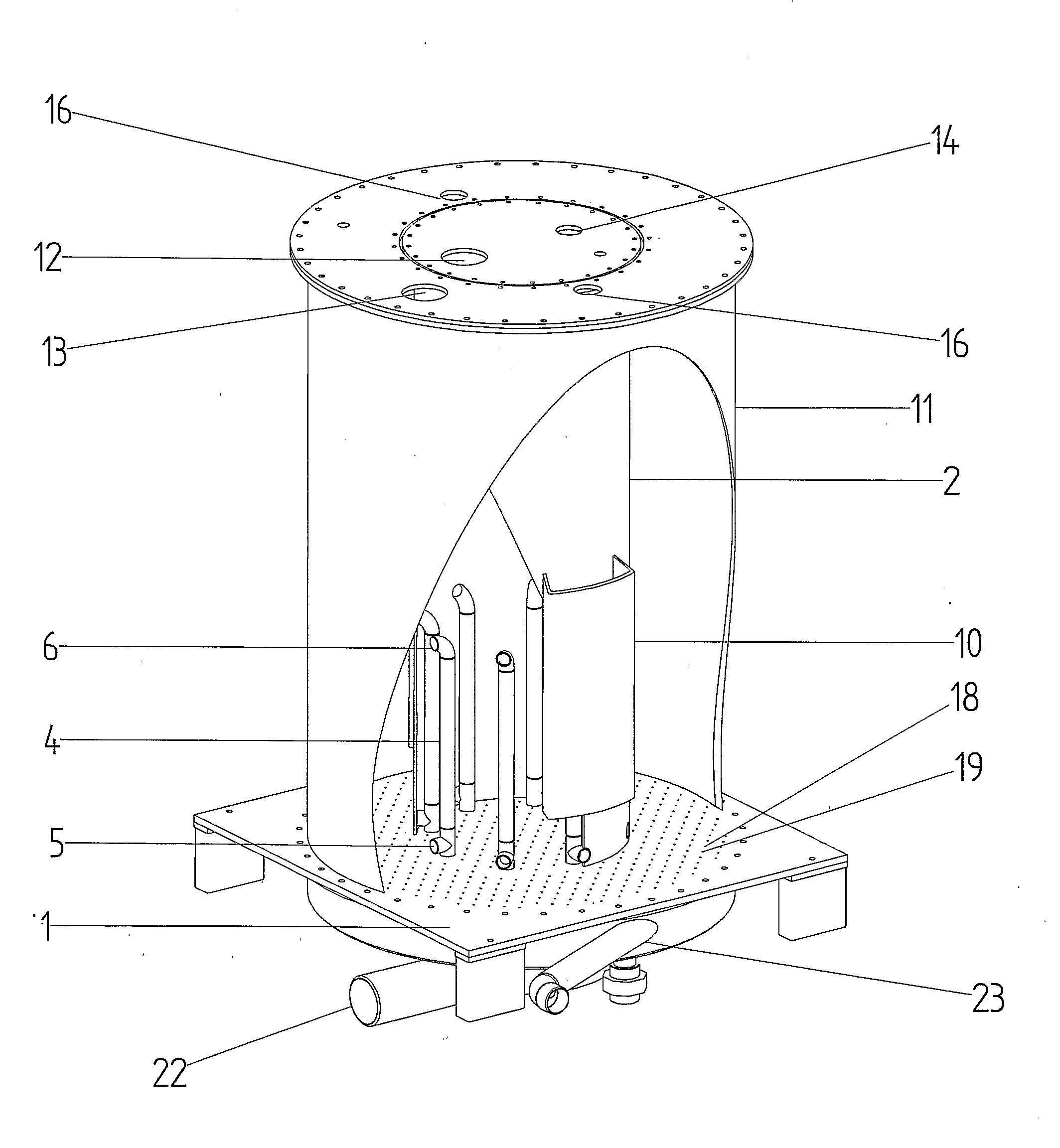

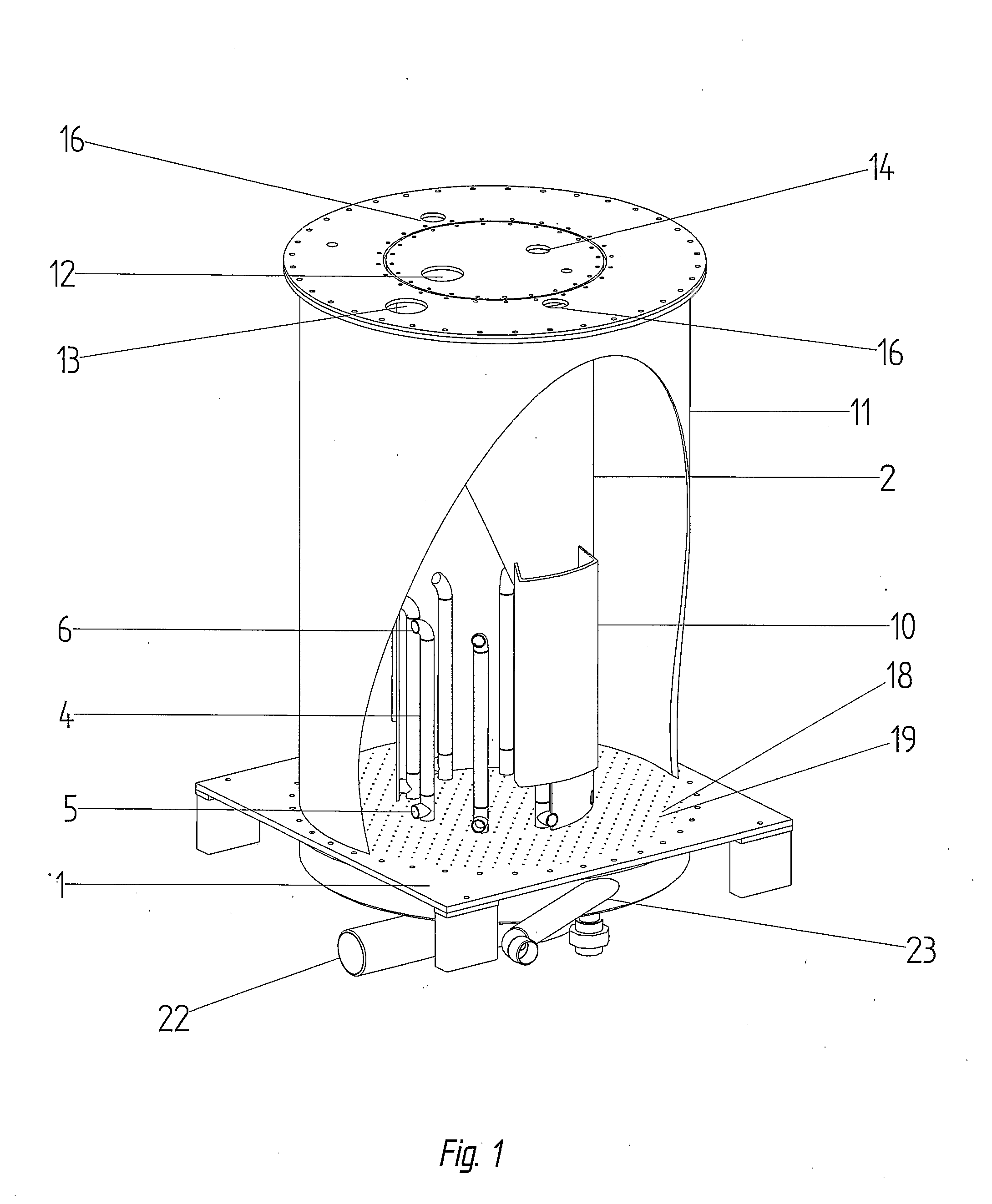

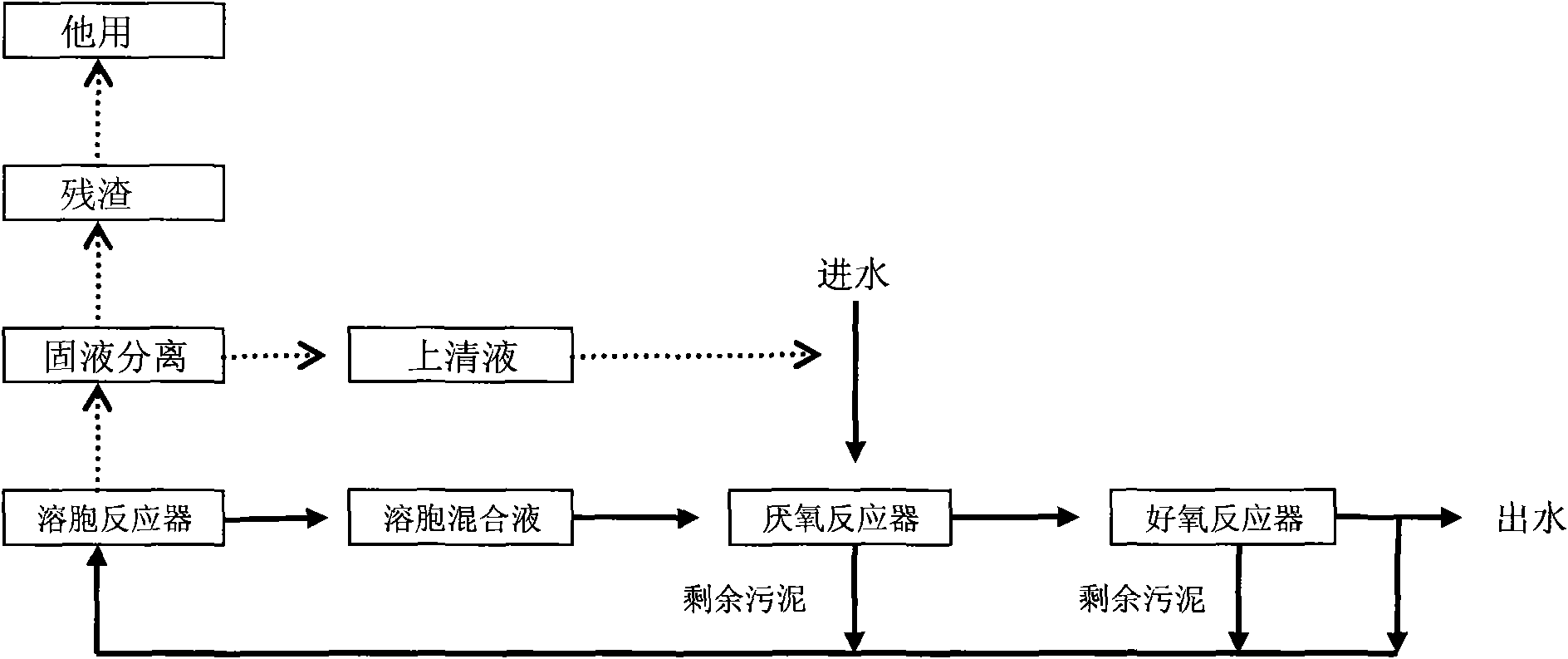

Thermal decomposition device of oil field waste

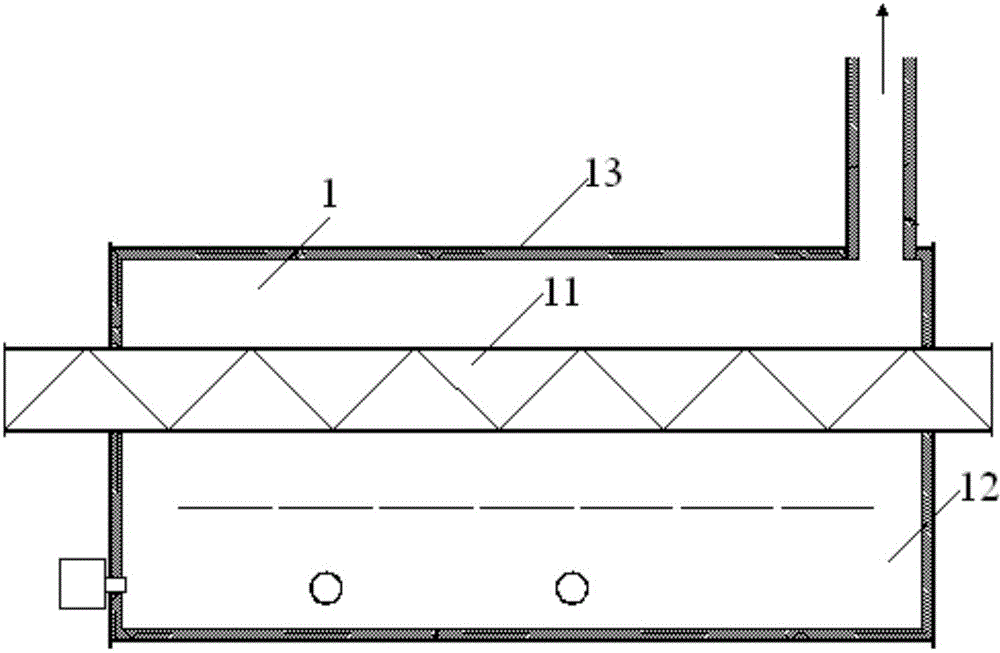

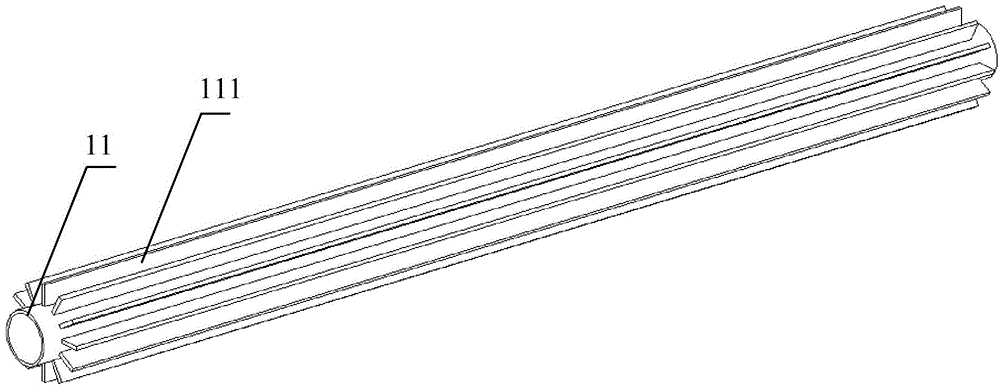

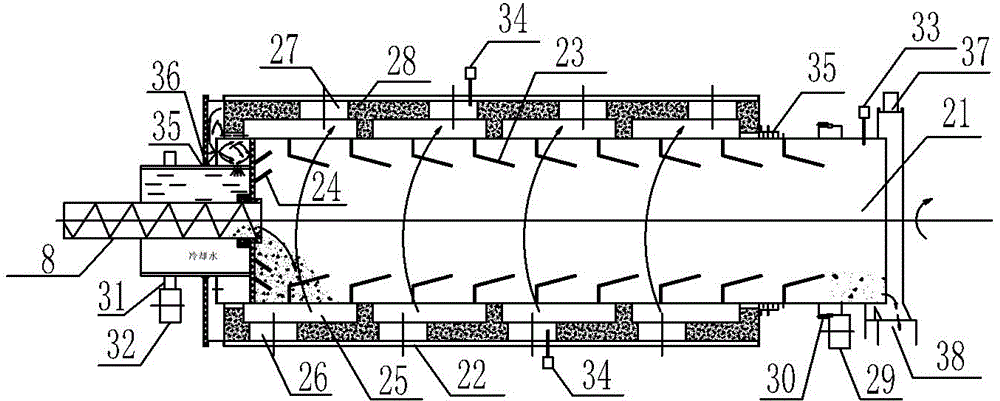

InactiveCN104402186AImprove heat transfer efficiencyIncrease the effective heat transfer areaWaste water treatment from quariesSpecific water treatment objectivesOil fieldEngineering

The invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue; ribs are arranged on the casing with the heating cavity. Fume inside the flue flashes the casing with the heating cavity, so that the heat can be conducted; due to adoption of the ribs on the casing with the heating cavity, the heat exchange area is effectively increased when being compared with that of the prior art, and the heat exchange efficiency of the thermal decomposition device is improved.

Owner:JEREH ENERGY SERVICES

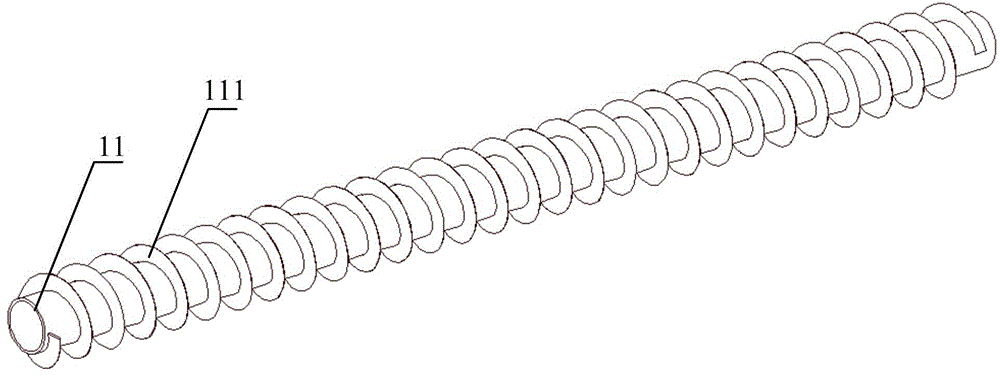

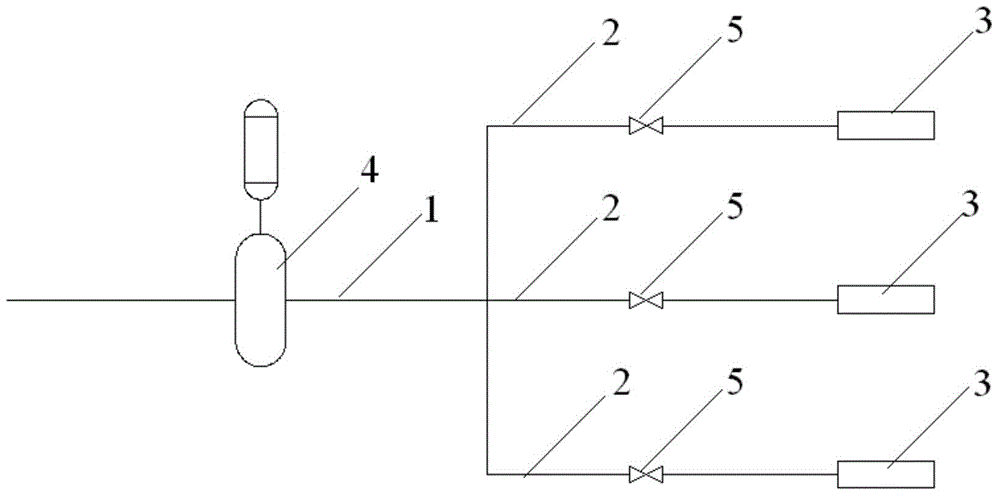

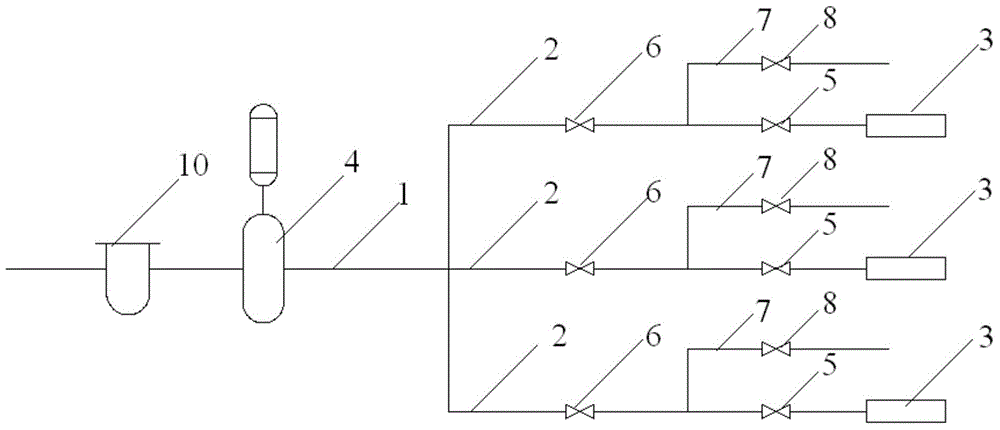

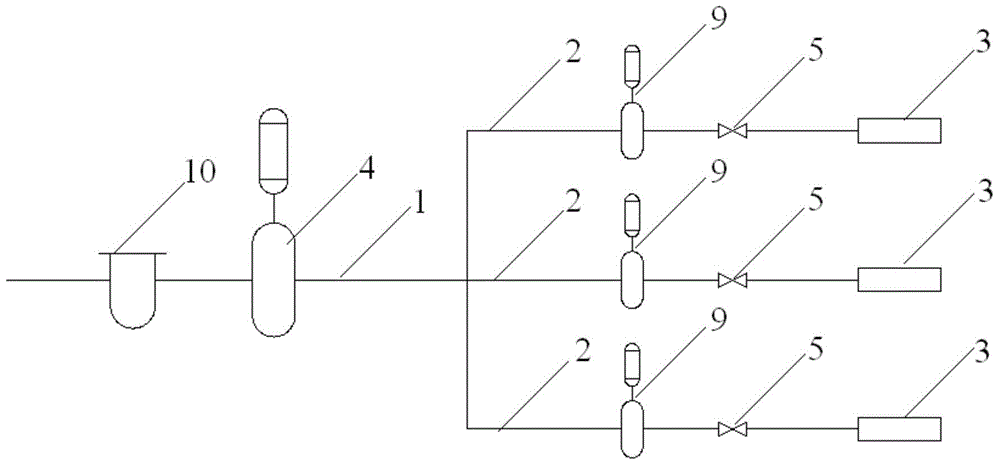

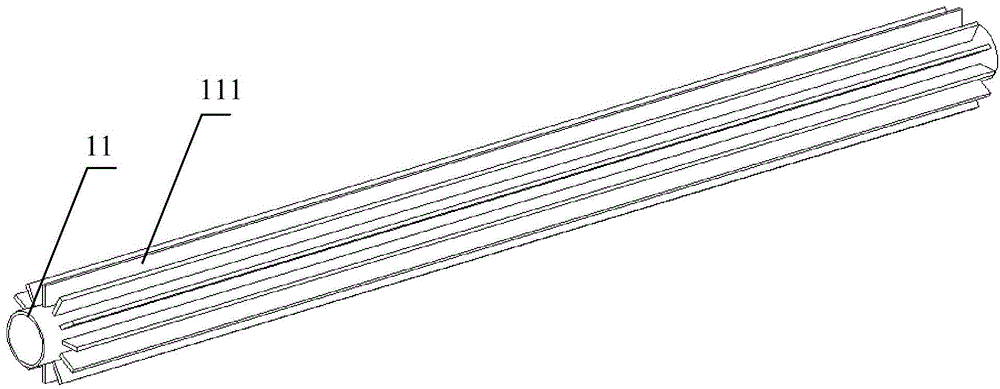

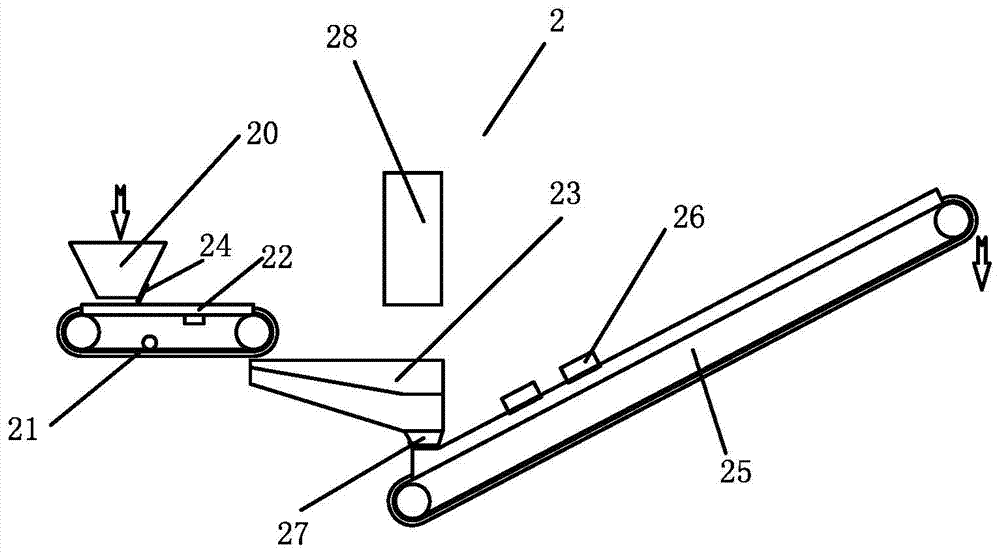

Feeding device for oil field waste treatment system and work method of feeding device

ActiveCN104803568AStrong continuity of processing operationsRealize deliverySludge treatment by pyrolysisCombustorWaste treatment

A feeding device for an oil field waste treatment system comprises a main pipe and multiple branch pipes, wherein front ends of the branch pipes are all connected with the rear end of the main pipe, and rear ends of the branch pipes are all connected with corresponding heating cavities; a main slurry pump which is a positive displacement pump is mounted on the main pipe; root valves are mounted on all of the branch pipes. The feeding device for the oil field waste treatment system adopts the positive displacement pump for pumping, materials with higher fluidity can be conveyed and distributed, and the feeding quantity can be measured, so that a proper quantity of materials are conveyed into the heating cavities, the materials are completely treated, the heat energy of a burner can be more efficiently utilized, and the treatment efficiency is improved. The materials can be constantly conveyed into the heating cavities quantitatively at a constant speed for a long time through measurement of calibration ports and regulation of branch regulation valves, the continuity of waste treatment work can be higher, and the work efficiency is further improved.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Thermal decomposition device of oil field waste

InactiveCN104402185AImprove heat transfer efficiencyEnhanced turbulence effectWaste water treatment from quariesSludge treatment by pyrolysisRetention timeOil field

The embodiment of the invention discloses a thermal decomposition device of oil field wastes. The thermal decomposition device comprises a casing, wherein a flue and a heating cavity are formed inside the casing; the heating cavity is isolated from the flue. The oil field waste thermal decomposition device is characterized in that a plurality of partitioning plates are arranged on the inner wall of the casing; the flue is of a snakelike structure through the adoption of the partitioning plates. Through the adoption of the partitioning plates on the inner wall of the casing of the thermal decomposition device disclosed by the invention, the flue inside the casing is of the snakelike structure, so that the flowing direction and the flowing speed of fume are changed, the turbulent flow effect is improved, the retention time is prolonged, and the heat exchange efficiency of the heating cavity and the fume is improved.

Owner:JEREH ENERGY SERVICES

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

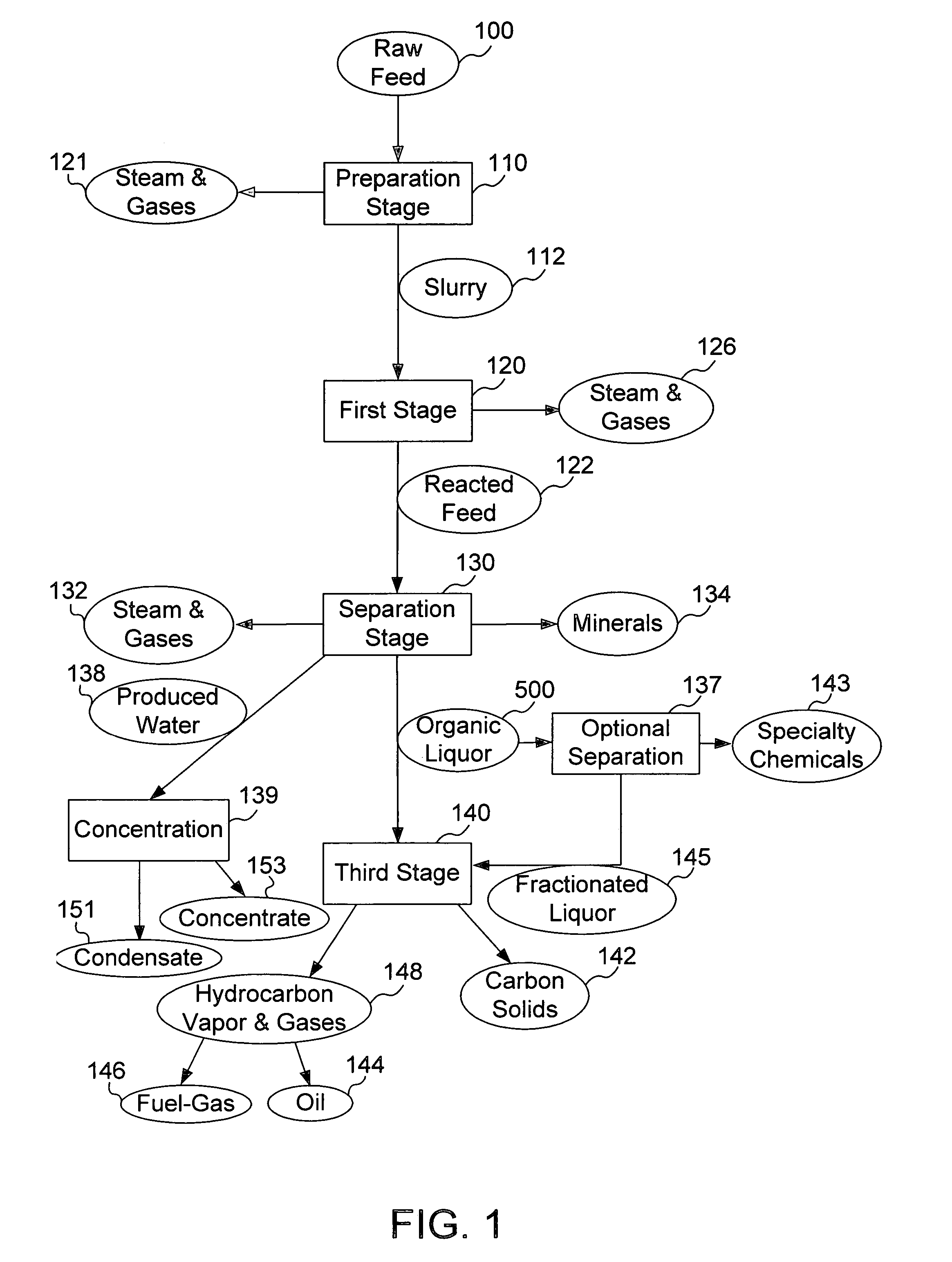

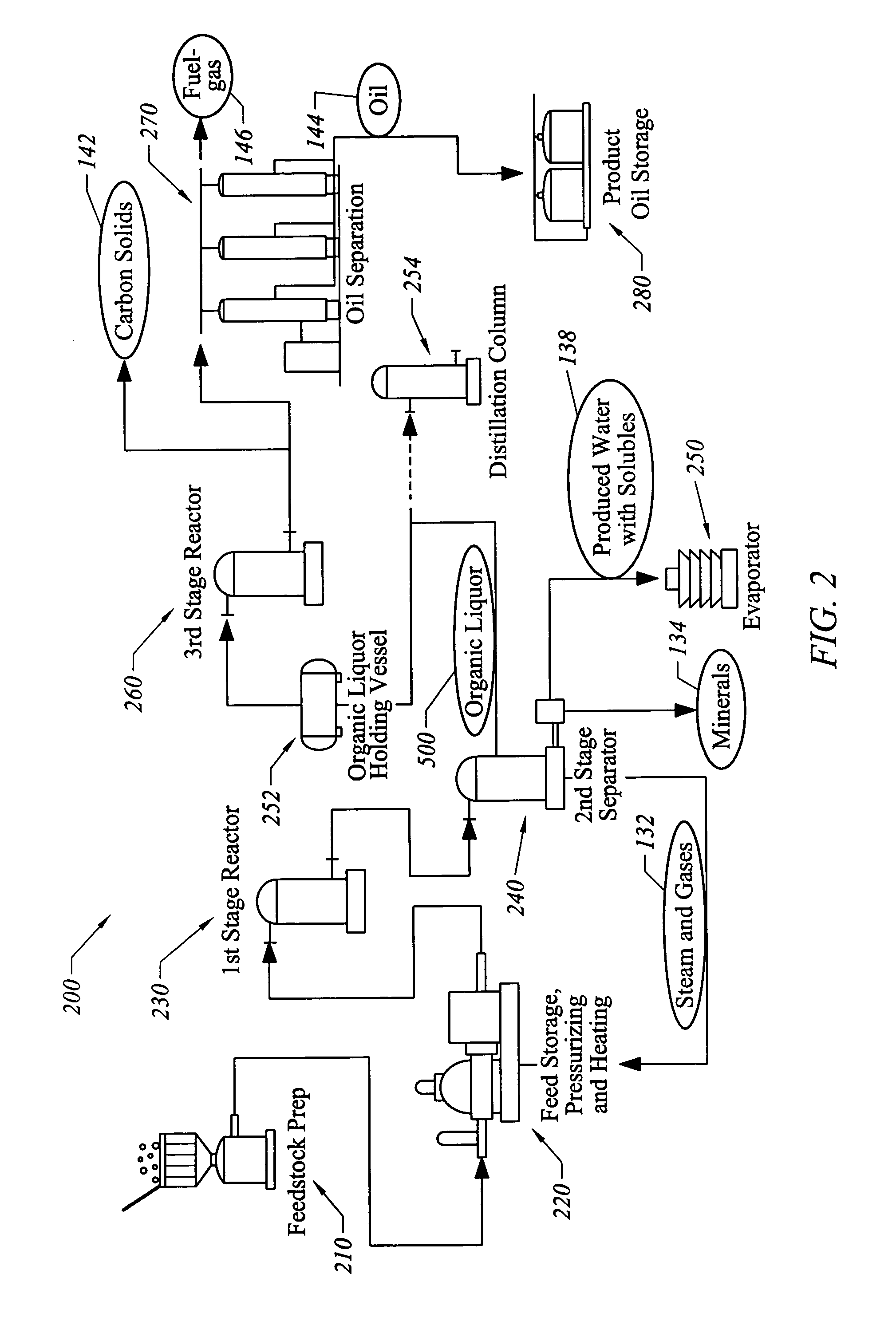

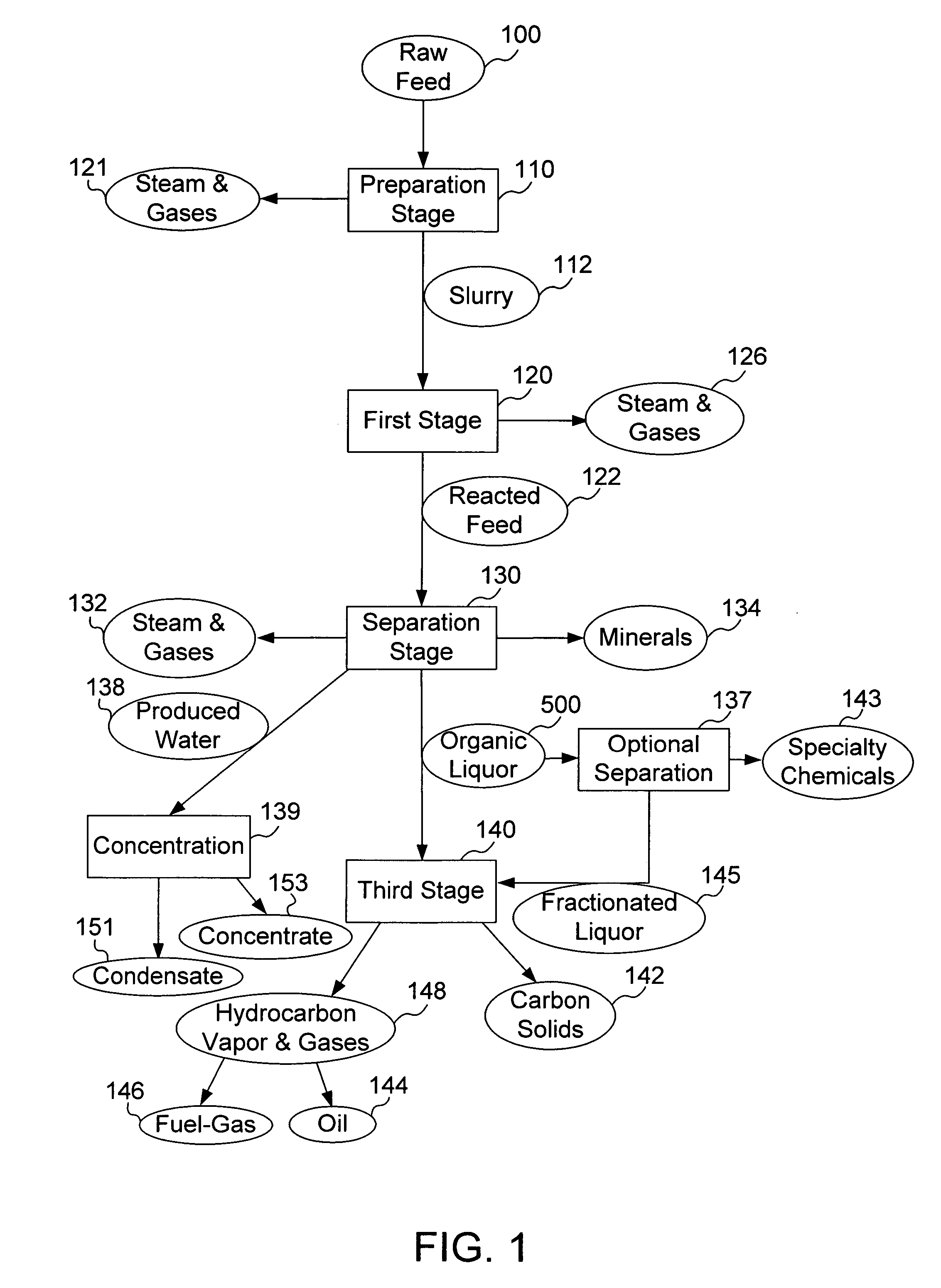

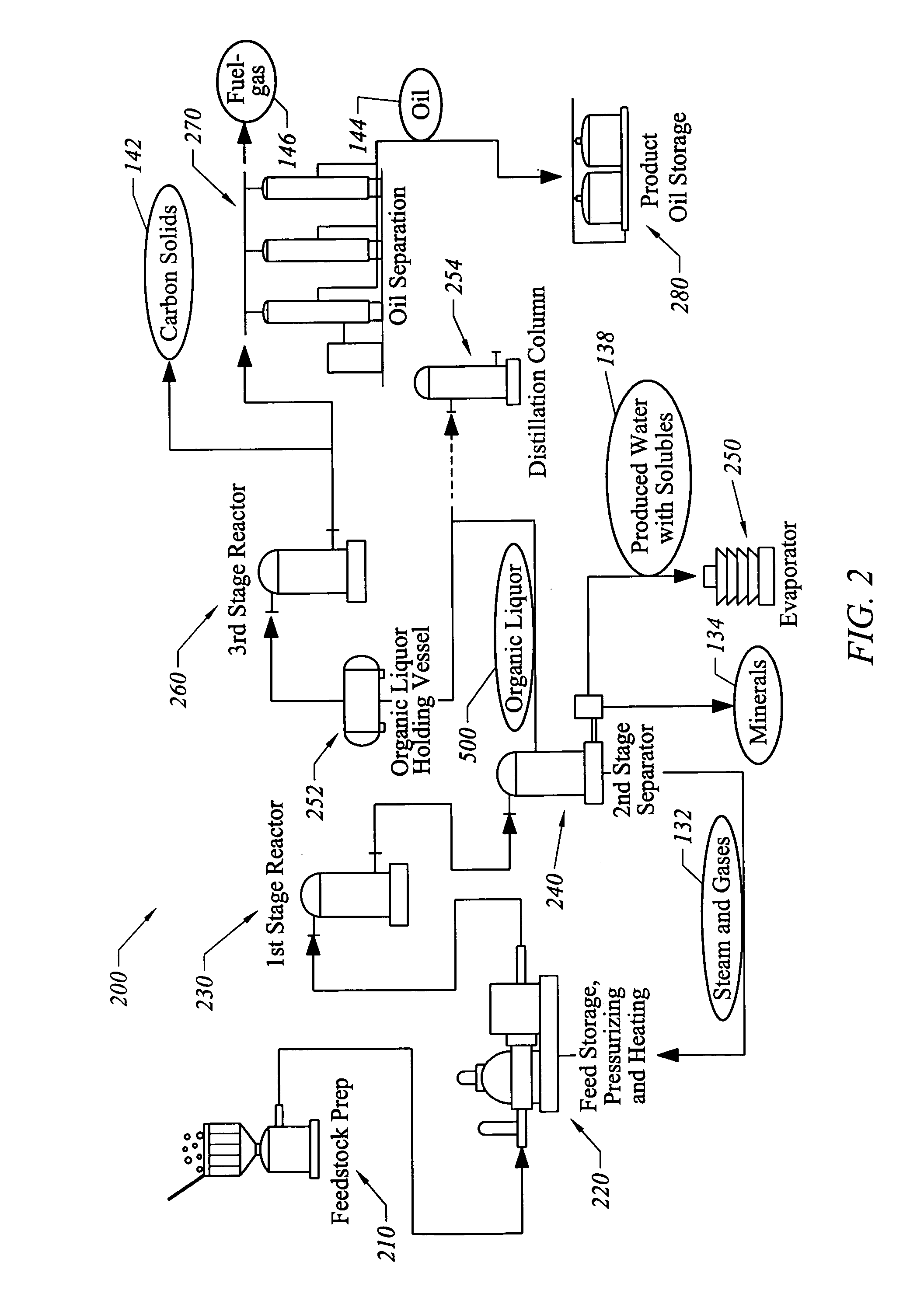

Apparatus and process for converting a mixture of organic materials into hydrocarbons and carbon solids

ActiveUS7476296B2Low viscosityInhibition formationAnimal corpse fertilisersMultiple-effect/fractional condensationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

Sludge or organic garbage high-low temperature coupling themolysis method

InactiveCN101708938AFlexible to adapt to changes in natureSimple processSludge treatment by pyrolysisBiofuelsSludgeCarbonization

The invention provides a sludge or organic garbage high-low temperature coupling themolysis method which is characterized in that: the method comprises the following steps: step I: the sludge or organic garbage is fed in a low temperature drying depolymerizing furnace; material with partial carbonization is used as raw material of soil organic fertilizer; step II: the material with partial carbonization, generated in pyrolysis, is fed into a middle temperature carbonizing furnace for carrying out carbonization; the obtained bio-organic carbon is used as raw material of soil organic fertilizer or soil conditioner; step III: the material with partial carbonization, bio-organic carbon and one or more than two mixtures of the sludge, straws or organic garbage are fed in a high-temperature pyrolysis furnace for gasification; step IV: fixed carbon remained in a high-temperature depolymerizing furnace after aerogenesis is fed in a high-temperature sub-fusion activated device, and then oxygen-enriched air enters in, and then liquid in a regulating solution storage tank is prayed in for regulation, and then, compound charcoal is obtained after being cooled. The method has high efficiency, simple steps and diversified products.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

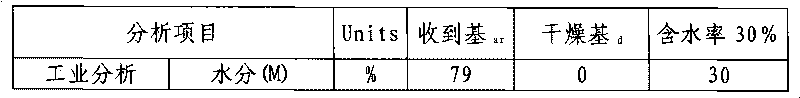

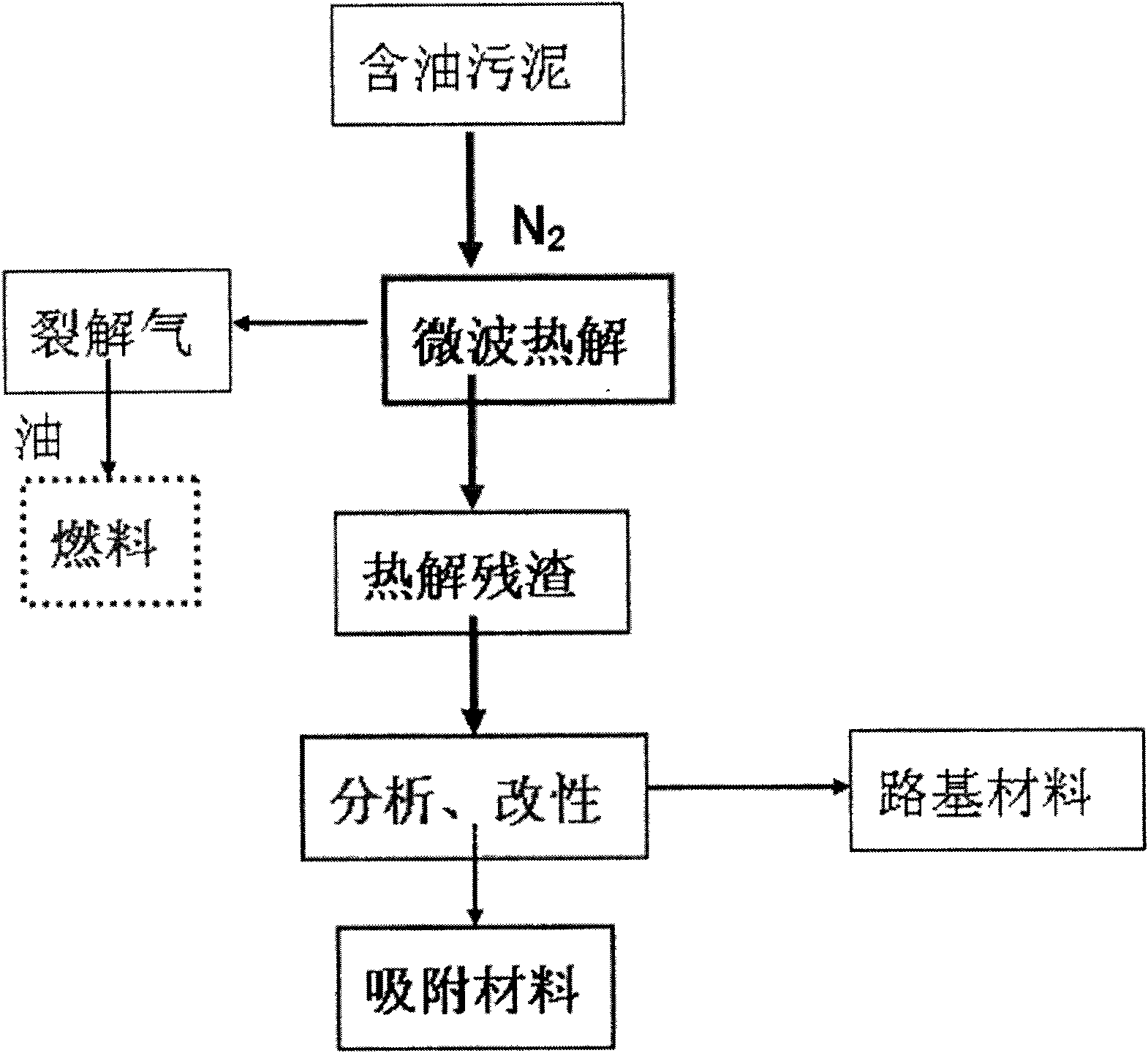

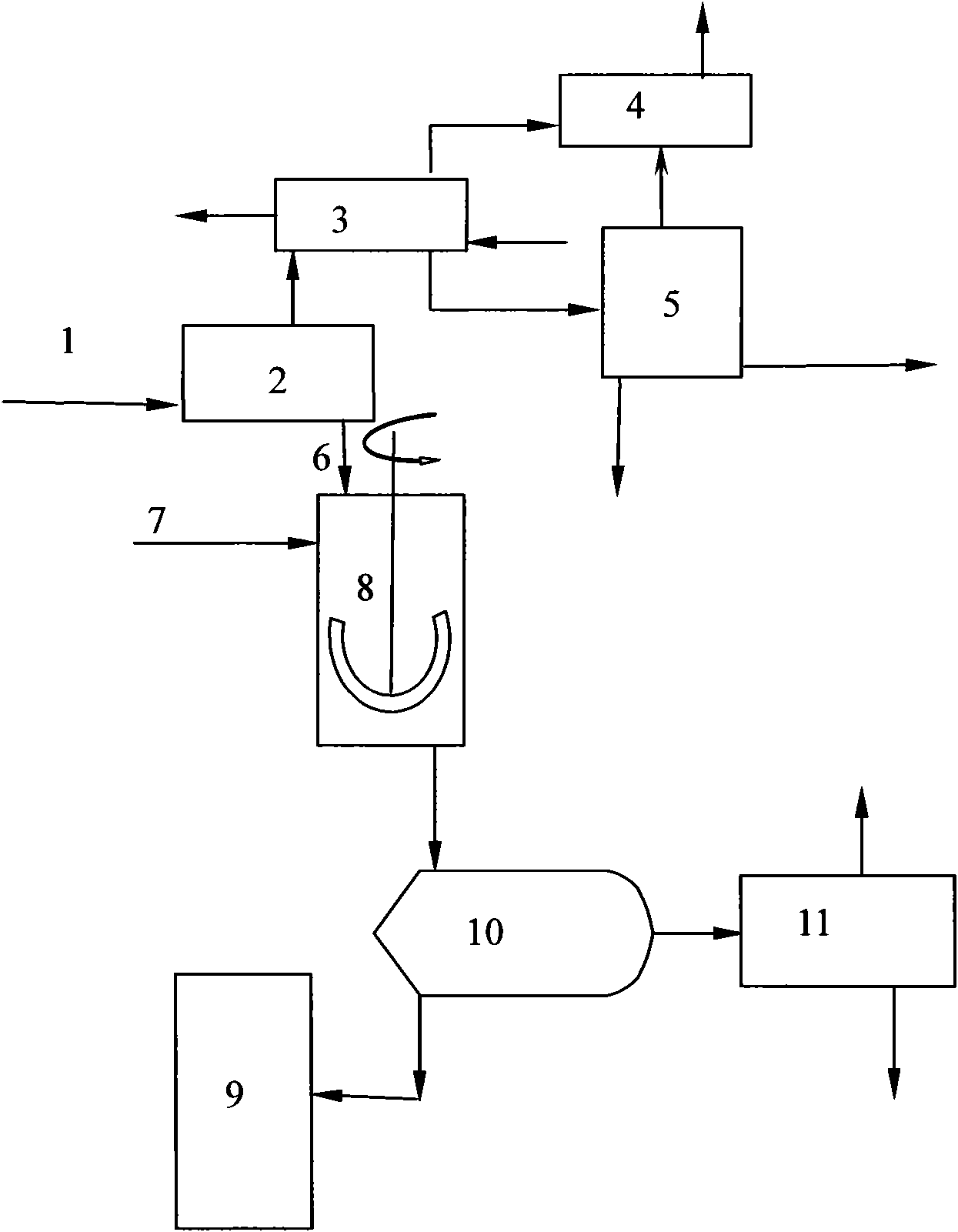

Resourceful treatment method and device for oil-containing sludge in oil fields by microwave pyrolysis

ActiveCN101838094ASolve pollutionAvoid Hazardous Waste Sewage FeesOther chemical processesSludge treatment by pyrolysisMicrowave pyrolysisSludge

The invention discloses a resourceful treatment method and a resourceful treatment device for oil-containing sludge in oil fields by microwave pyrolysis. The oil-containing sludge is conveyed into an enclosed reactor heated by microwaves, and is subjected to pyrolysis treatment at the temperature of between 200 and 900 DEG C; oil, gas and water generated by the pyrolysis treatment are recycled; the residue after the pyrolysis is used as a roadbed material or modified by nitric acid or NaOH alkali; and the modified residue is used as an adsorbing material. After the method and the device are implemented, over 75 percent of crude oil in the oil-containing sludge can be recycled, the pollution fee of 1,000 yuan / t can be saved, the social and economic benefits are obvious, and the method and the device have wide market application prospect.

Owner:CHINA PETROCHEMICAL CORP +2

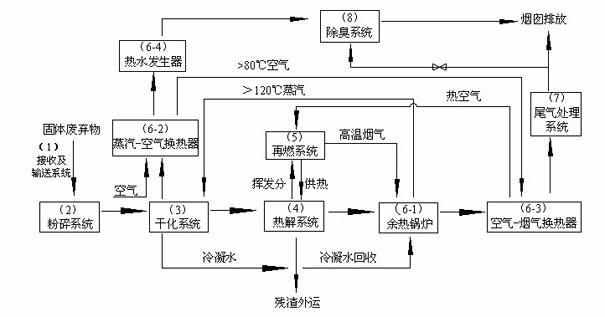

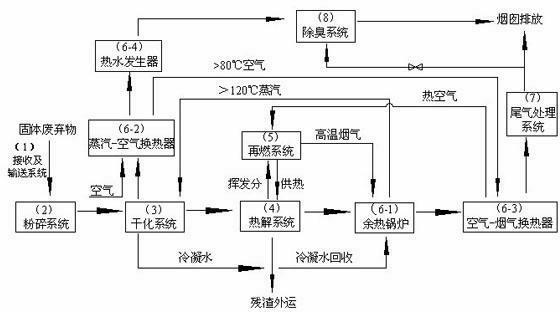

Novel process for pyrolysis of solid wastes

InactiveCN102537973AHas waste heat utilization valueAvoid consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionRoom temperature

The invention discloses a novel process for pyrolysis of solid wastes. According to the existing pyrolysis technology, the solid wastes with low calorific values and high moisture content are difficult to treat, and effects of being completely harmless, reduced and recycled cannot be achieved. The novel process provided by the invention comprises the following steps of: uniformly crushing the solid wastes by a crushing system and conveying the crushed solid wastes to a drying system to be dried; carrying out the pyrolysis in a pyrolysis system and treating a pyrolyzed product by a re-burning system to provide energy needed by the pyrolysis system; conveying high-temperature smoke into a residual heat boiler to generate saturated vapor with a temperature which is higher than 1000 DEG C; carrying out heat exchange on the vapor by a vapor-air heat exchanger; after raising the temperature of normal-temperature air, conveying the air into the vapor-air heat exchanger to carry out the heat exchange with output smoke of the residual heat boiler; conveying the hot air into the pyrolysis system and carrying out processes of cooling combustion smoke, de-acidifying and removing dust on the smoke of the residual heat boiler through an exhaust gas treatment system; receiving uncondensed gas in condensed odor vapor by the deodorization system, carrying out final treatment on the uncondensed gas and exhausting. According to the invention, the residual heat value of the high-moisture solid wastes is sufficiently utilized and the utilization is not limited by types of the solid wastes, so that the energy source and the operation cost are saved.

Owner:ZHONGCHANG ENVIRONMENT PROTECTION GROUP +1

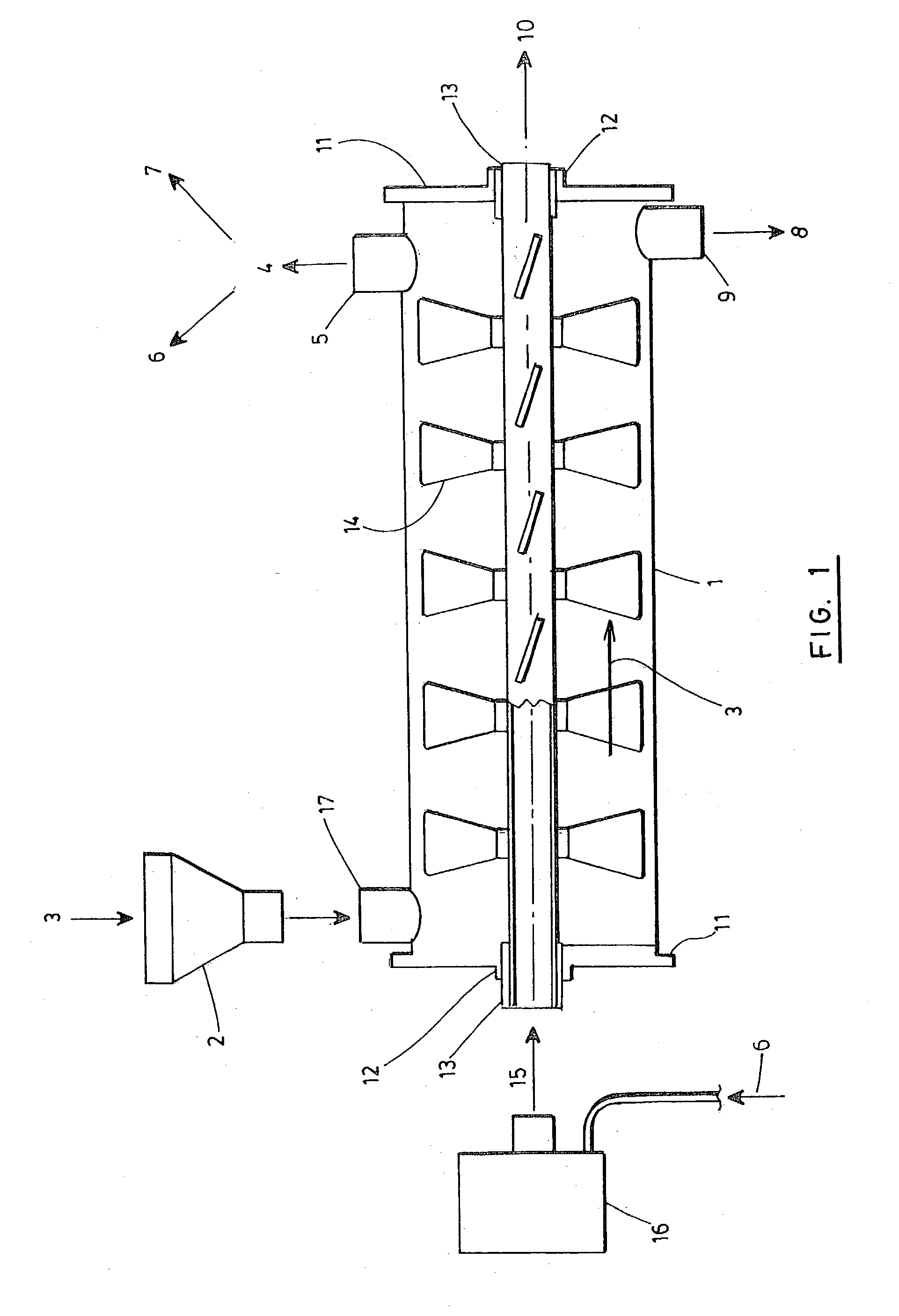

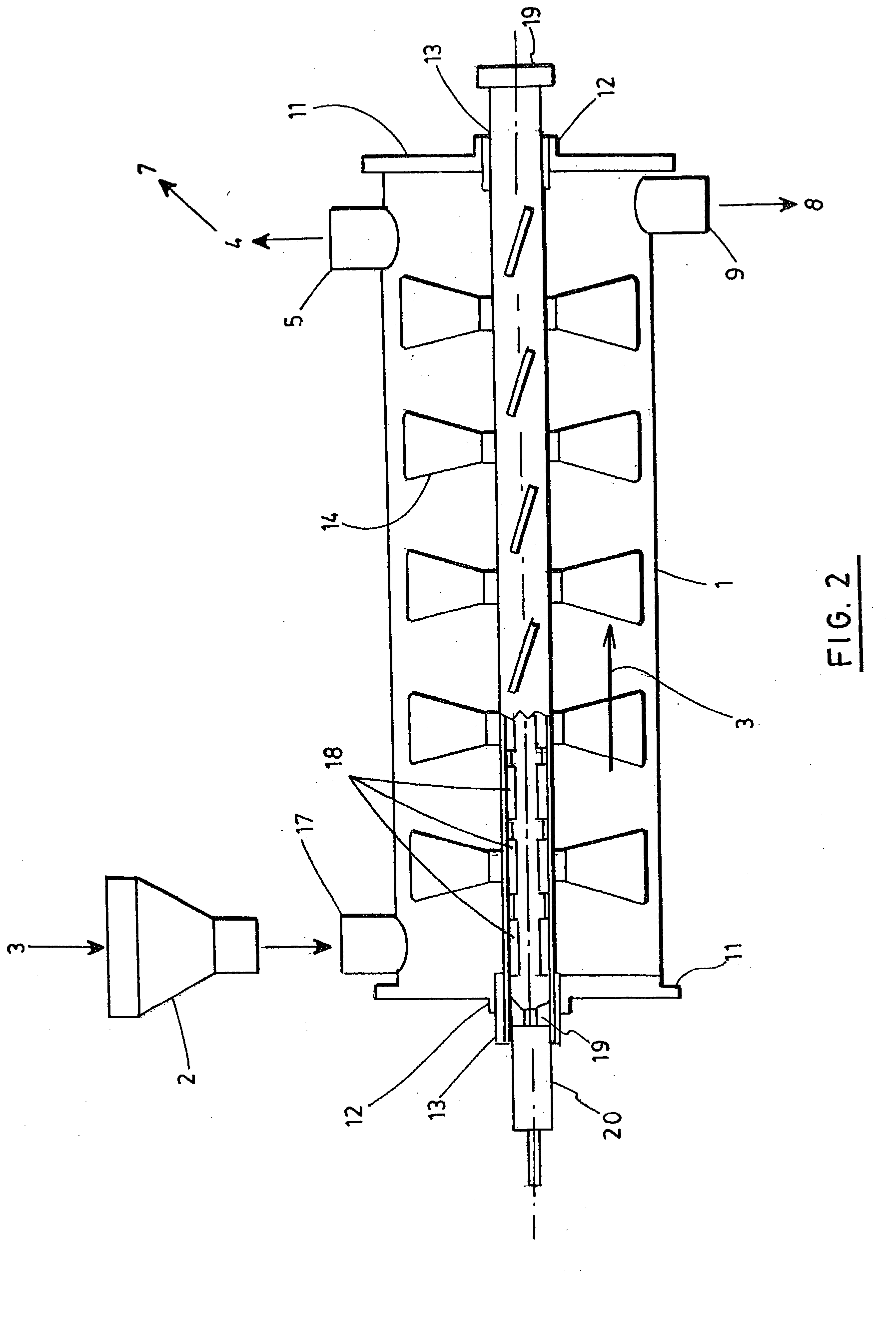

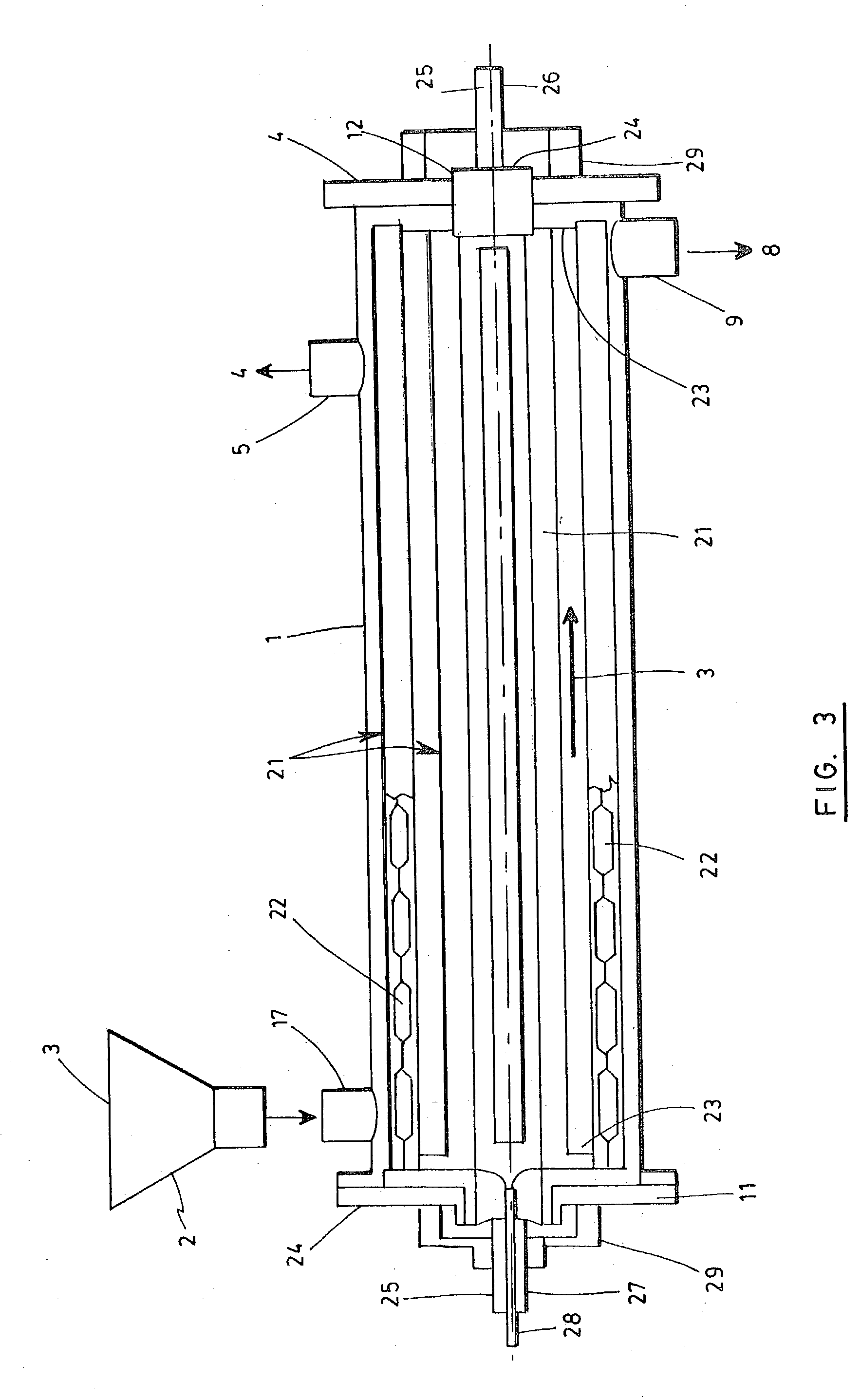

Pyrolysis system

InactiveUS20030138365A1Minimize introduction of airSecure safe and good operationMechanical conveying coke ovensRotating receptacle mixersProduct gasOxygen

A pyrolysis system includes a generally cylindrical reactor chamber having two opposite ends and a longitudinal axis. The chamber has an inlet for receiving biomass, the inlet being adapted to prevent air from entering the chamber and being located at a first opposite end; a gas outlet for recuperating biogas produced in the reactor chamber, the gas outlet being adapted to prevent air from entering the chamber and being located at a second opposite end; and a solid outlet for recuperating charcoal produced in the reactor chamber, the solid outlet being adapted to prevent air from entering the chamber and being located at the second opposite end. The biomass is then subjected to indirect heating supplied by a heated rotor that decomposes the biomass in the absence of air or oxygen into a biogas and charcoal. A controller for controlling a rate of feed of biomass, extracted carbon residue and a temperature inside the reactor chamber is also provided. In a preferred embodiment, the shaft is heated by a portion of the energy recuperated from the pyrolysis system.

Owner:STRUDES

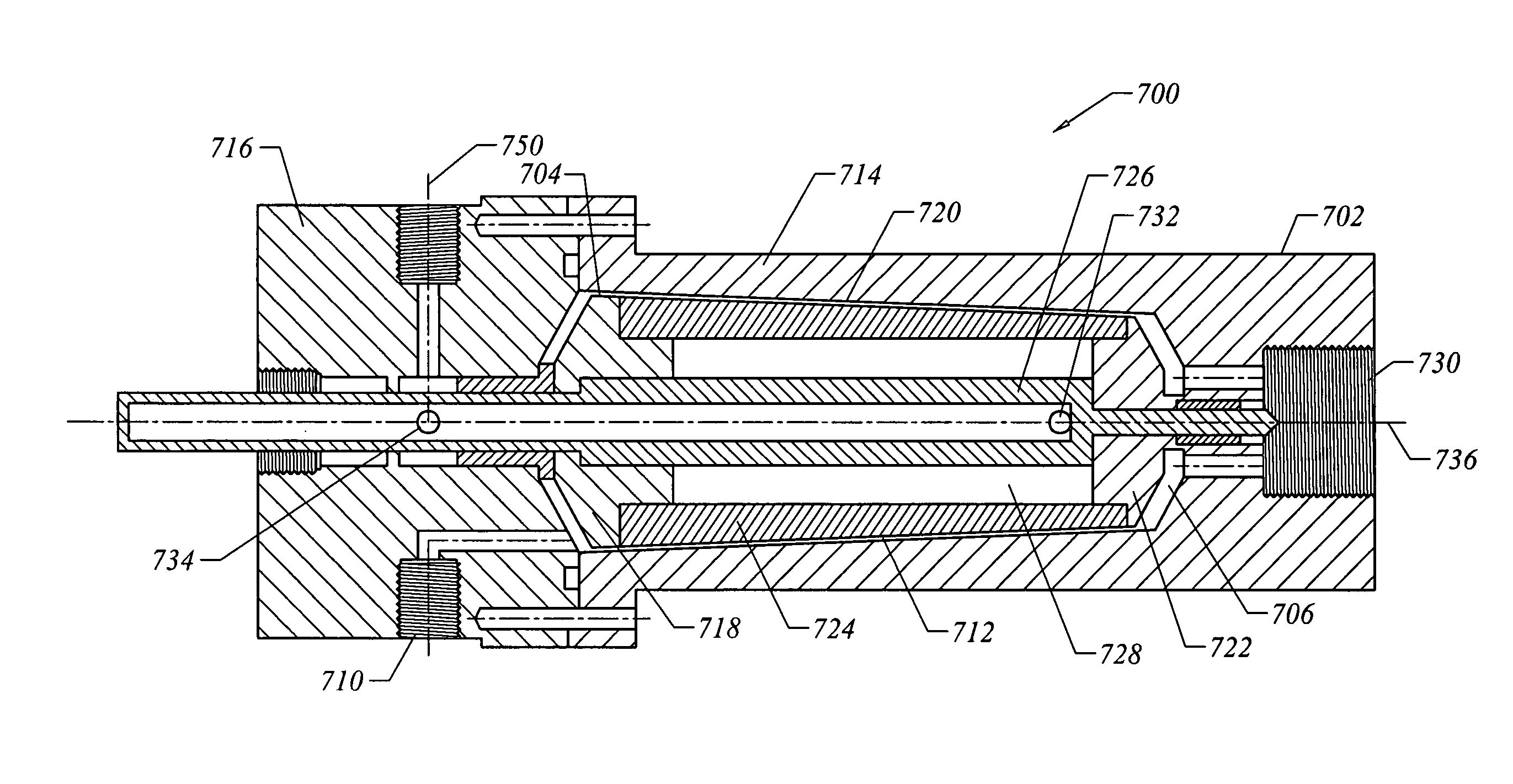

Apparatus for separating particulates from a suspension, and uses thereof

InactiveUS7179379B2Stir wellDiscouraging decarboxylation reactionMultiple-effect/fractional condensationAnimal corpse fertilisersParticulatesSpeciality chemicals

The present invention includes an apparatus for separating particulates from a fluid in a suspension, comprising: a housing defining a frusto-conically shaped inner chamber with an inner wall, an inlet and a first outlet communicating with the chamber, and a second outlet; and a spinning assembly with a hollow interior mounted in the chamber, the assembly being shaped to define an annular gap with the chamber inner wall, the hollow interior communicating with the second outlet, and the hollow interior communicating with the annular gap for flow of fluid materials from the gap into the interior and out of the second outlet in response to rotation of the spinning assembly. The separator finds application in the preparation of waste products such as municipal sewage sludge for processes that produce useful materials including gas, oil, specialty chemicals, fertilizer, and carbon solids, in reliable purities and compositions, and with high energy efficiency.

Owner:AB CWT LLC

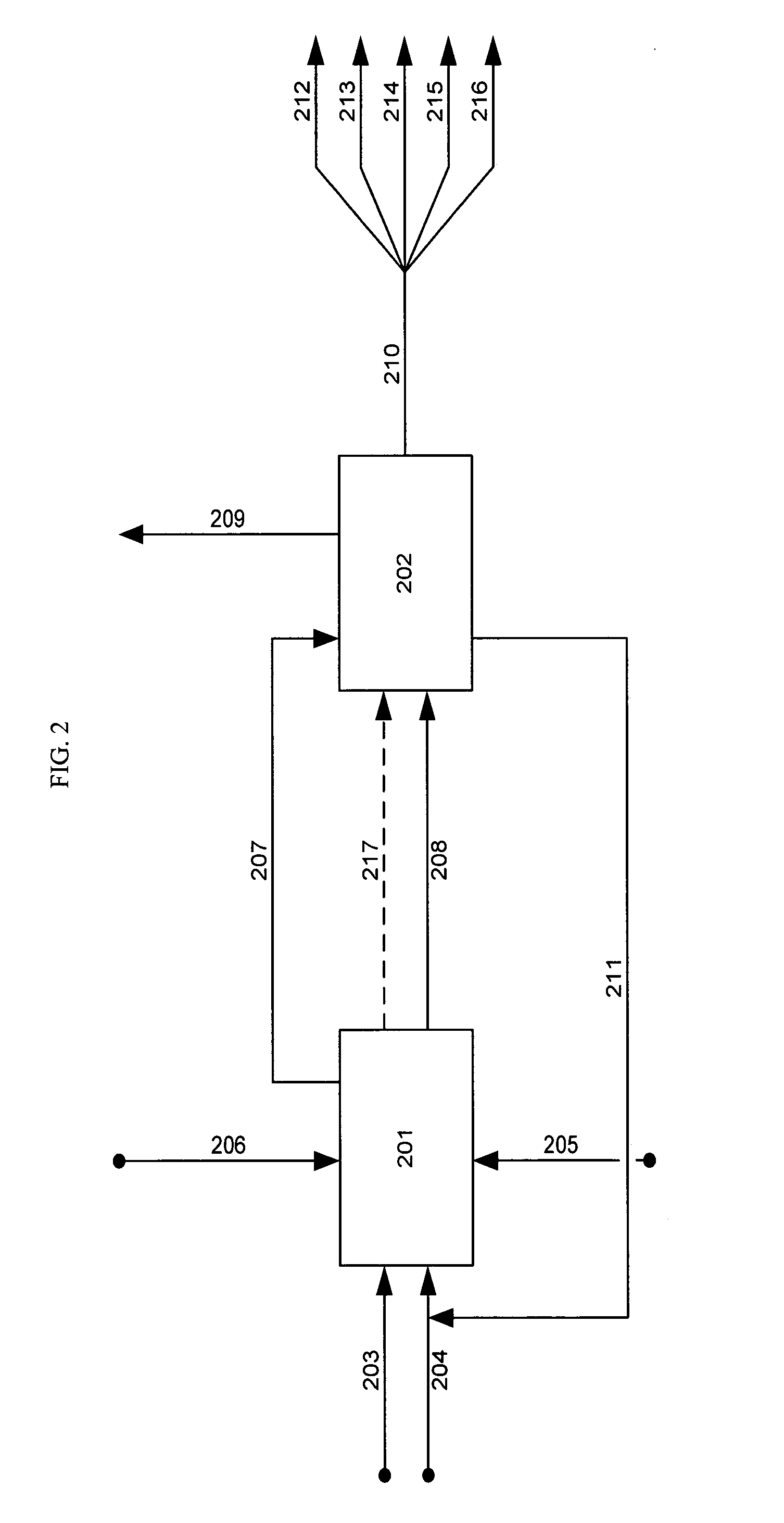

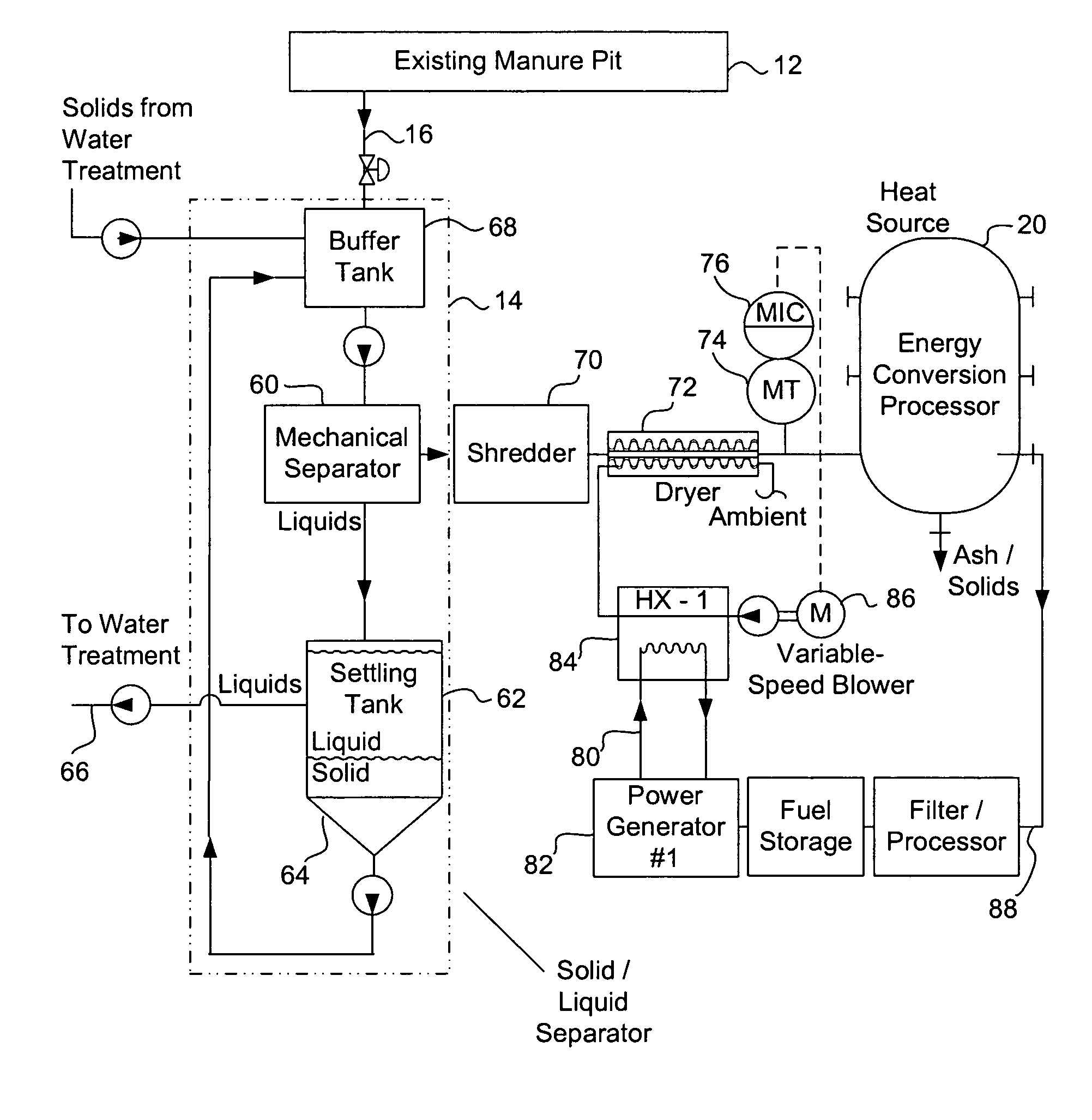

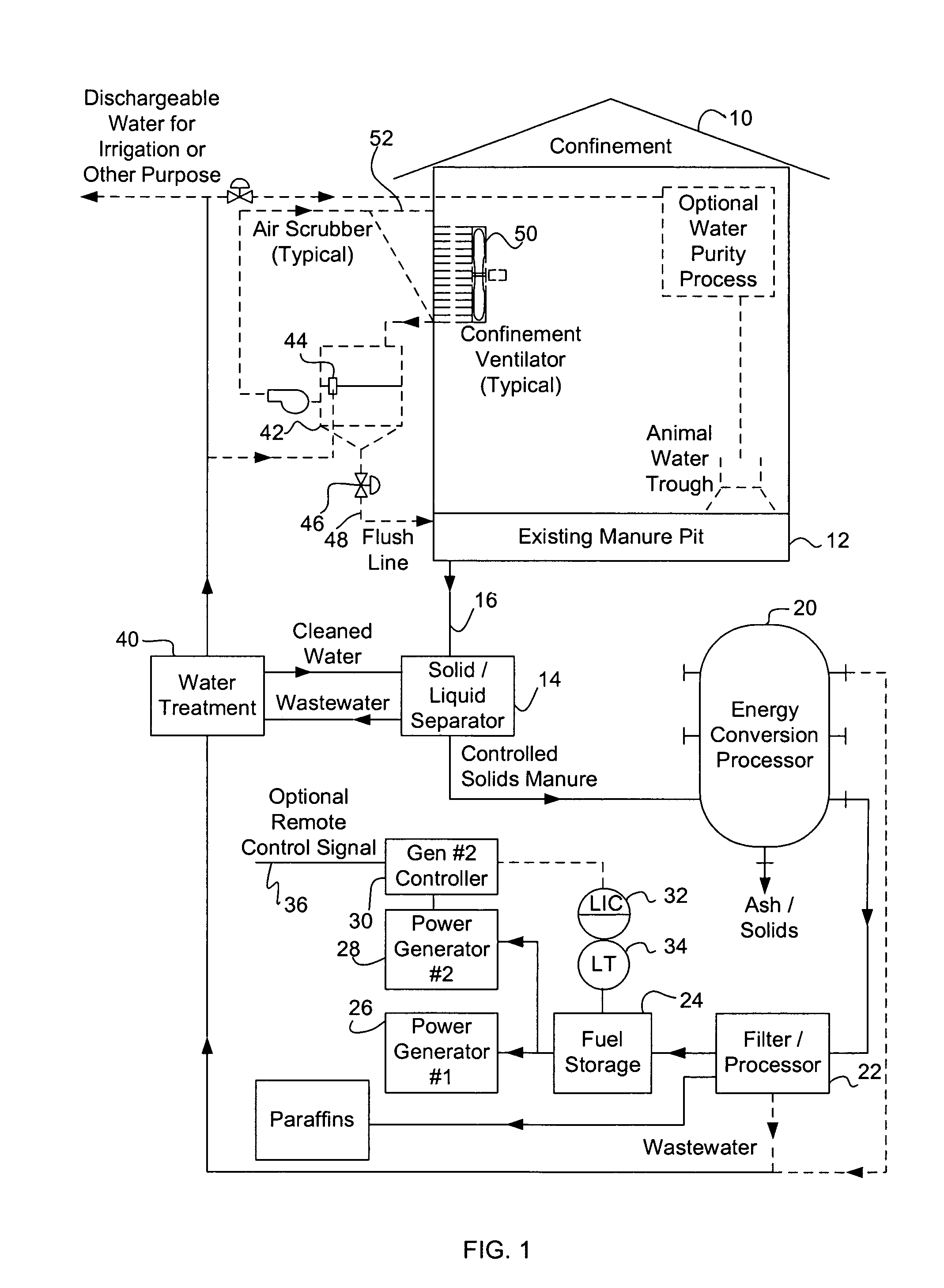

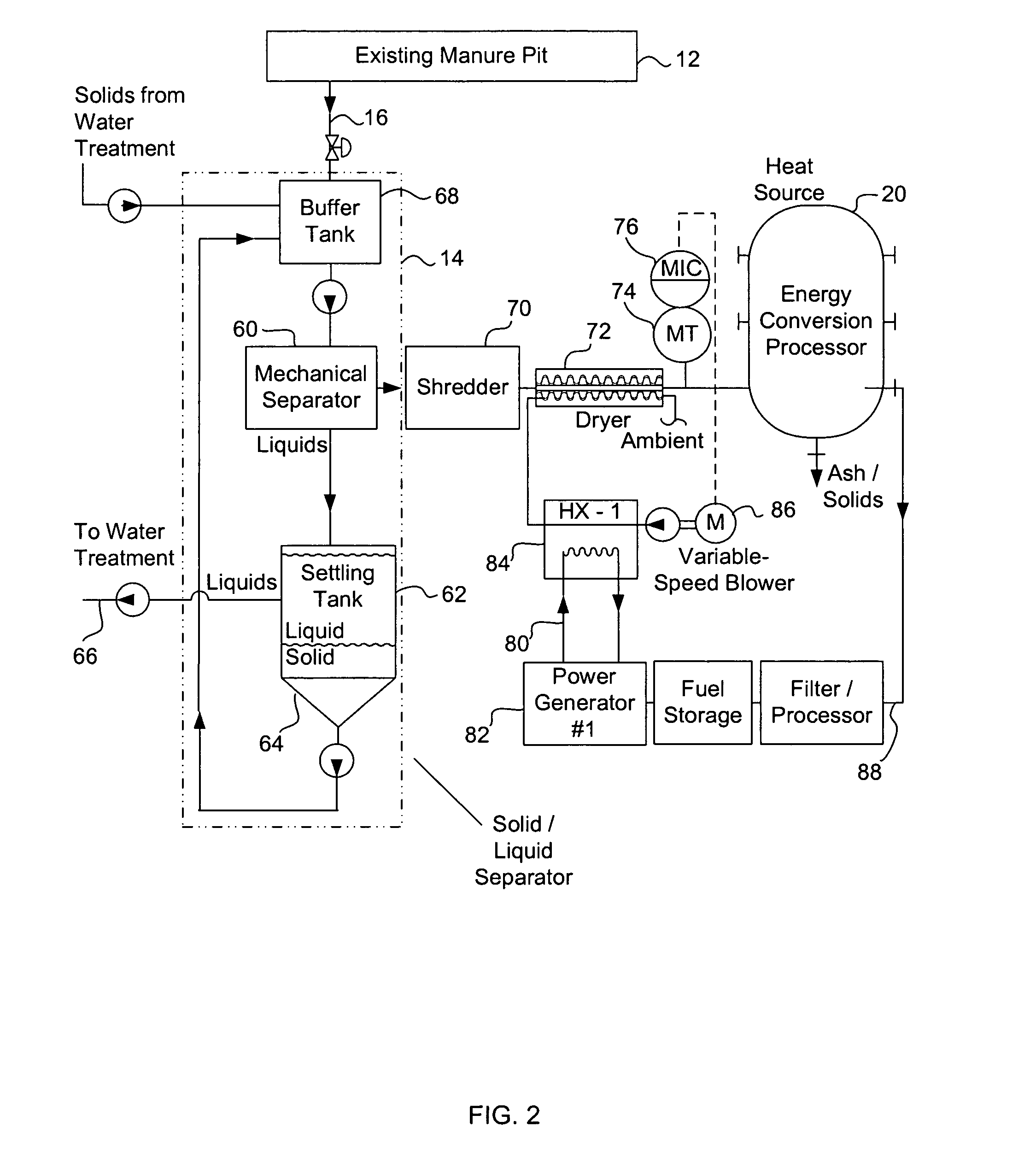

Methods and systems for converting waste into energy

A method for receiving animal waste from animal confinements or other concentrated animal waste sources and for converting the waste into a usable form is described. The waste contains both liquids and solids. The method includes separating the liquids and solids into separate waste streams, controlling an amount of moisture in the solids waste stream such that the amount of moisture in the solid waste stream is compatible with a selected energy conversion process, and feeding the moisture controlled solid waste into the energy conversion process.

Owner:SNAPSHOT ENERGY LLC

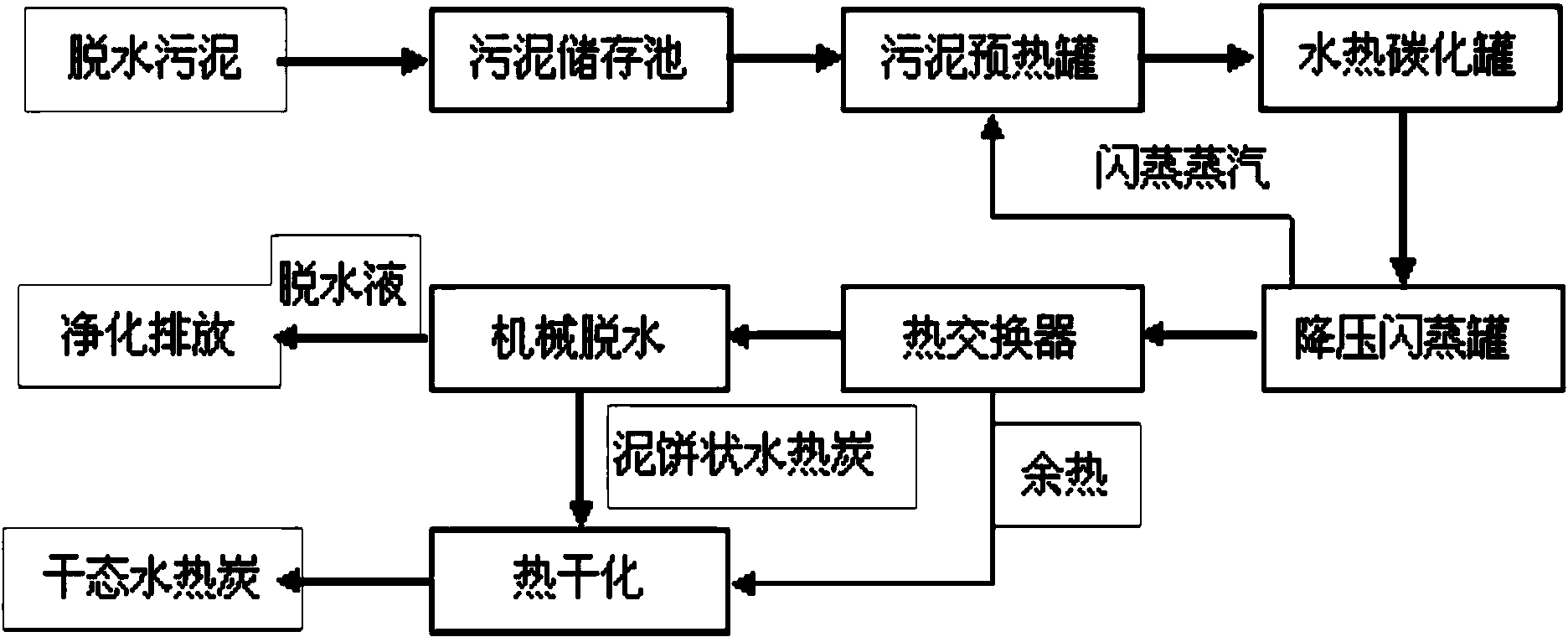

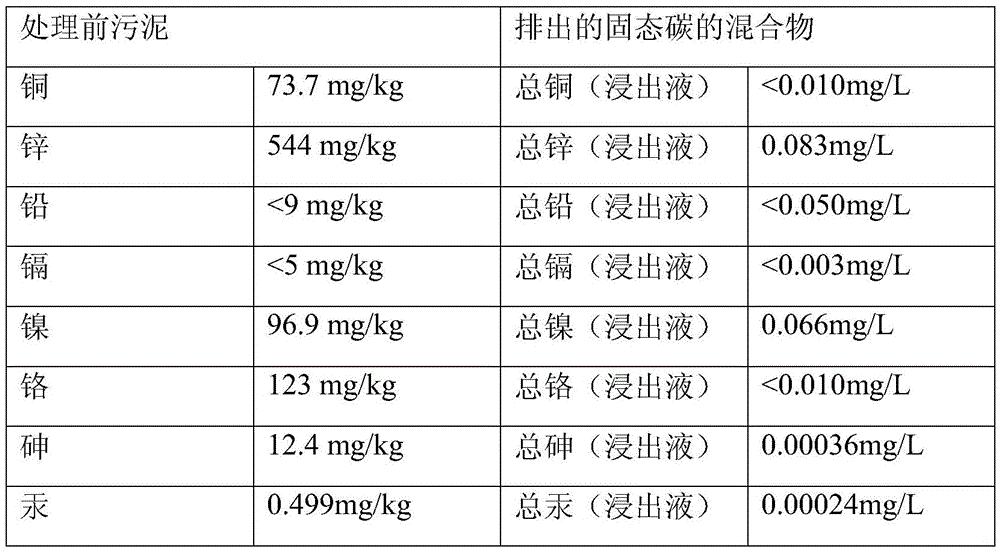

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

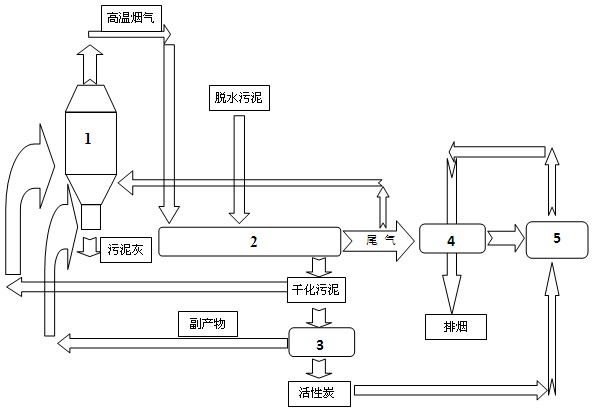

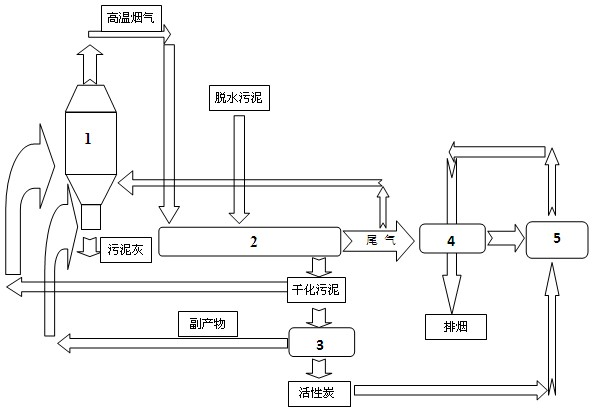

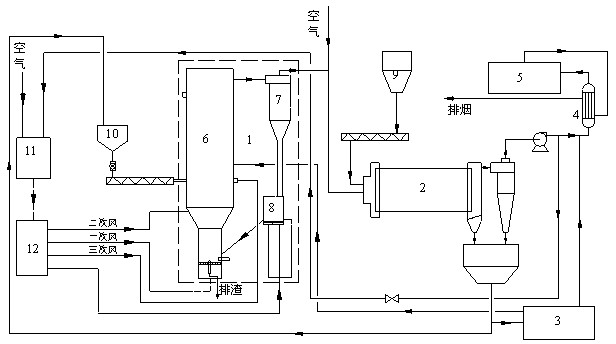

Municipal sludge drying and incineration system and treatment process thereof

ActiveCN101813316AReduce oxygen concentrationImproved Temperature UniformitySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisExhaust gasActivated carbon

The invention discloses a municipal sludge drying and incineration system. The system comprises an incinerator, wherein a smoke outlet of the incinerator is communicated with a sludge dryer; a tail gas outlet of the sludge dryer is connected with a heat exchanger and the incinerator respectively; the heat exchanger is communicated with a tail gas treatment system; one path of a discharge port of the sludge dryer is communicated with the incinerator, while the other path is communicated with a pyrolyzing furnace; and a discharge port of the pyrolyzing furnace is respectively communicated with an activated carbon tail gas treatment system and the incinerator. The invention also discloses a process for treating the municipal sludge drying and incineration system. The system has the advantages of simple system formation, small energy consumption in sludge treatment process, no secondary pollution, concise whole processing procedure, low failure rate and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

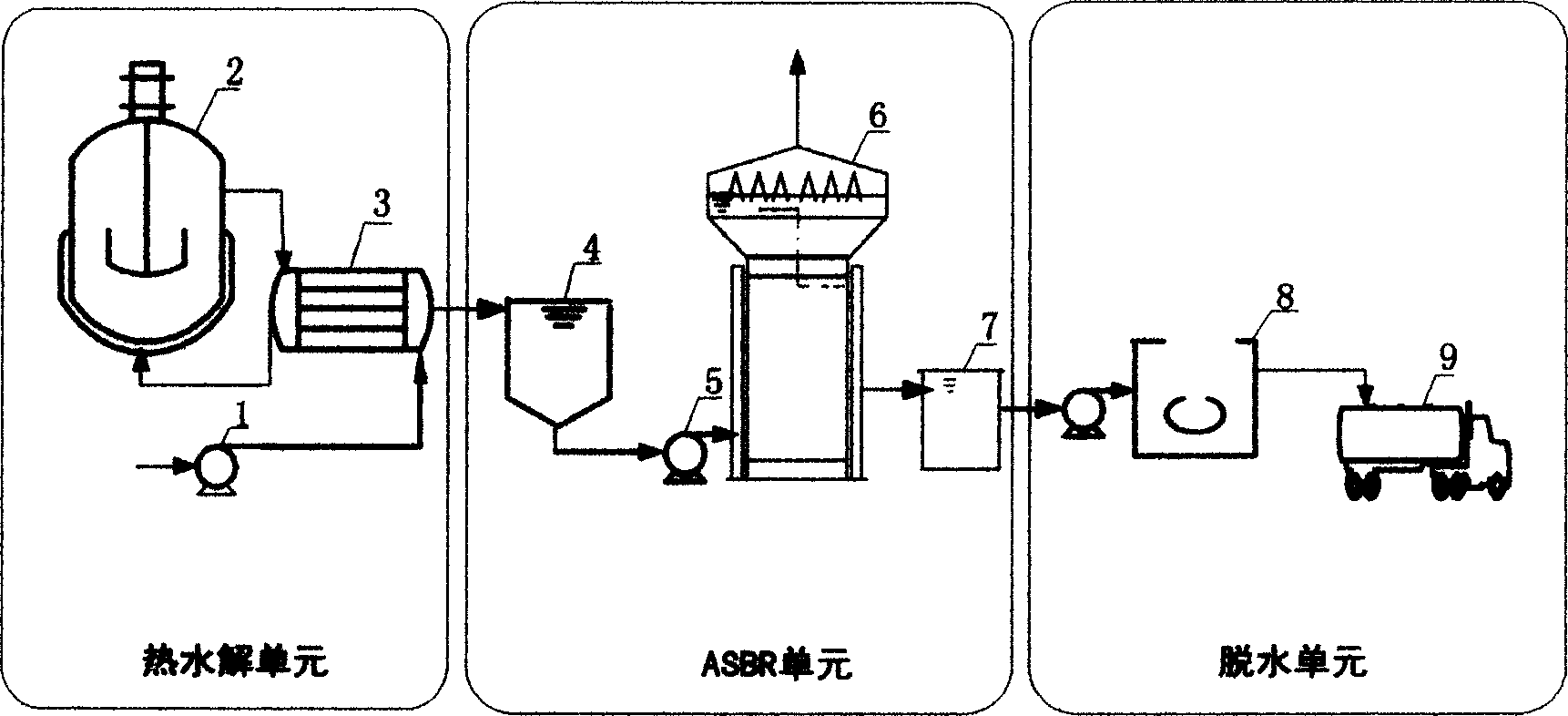

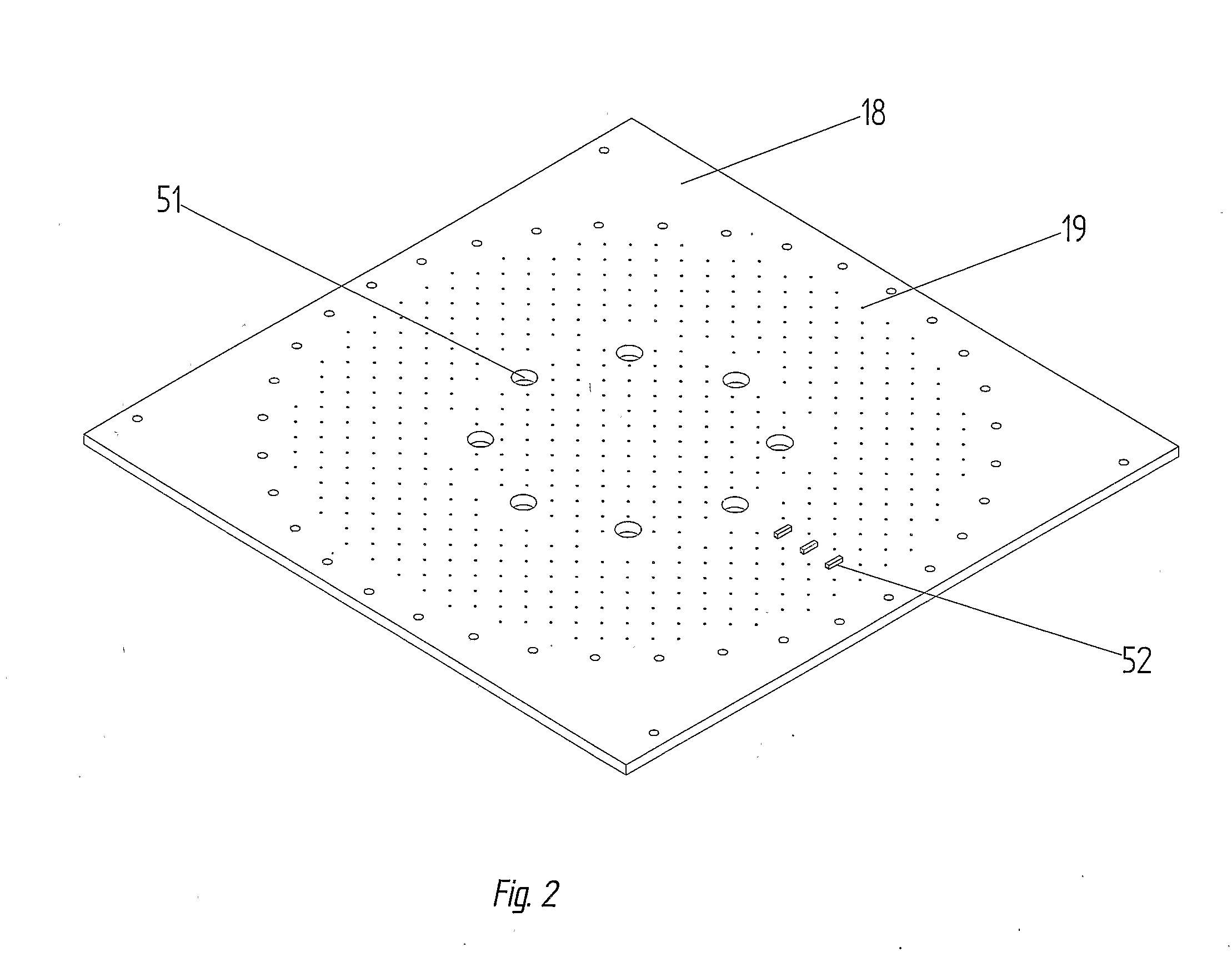

Process for treating excess sludge

ActiveCN1569699ARealize recycling of resourcesSmall volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMembrane bioreactorAnaerobic reactor

Disclosed is a method and equipment for treatment of polluted fluid, wherein ferrum family flocculating agents of a finite concentration are charged into the membrane bioreactor, in which they are subject to domestication and become compact biological ferrum sludge with improved property.

Owner:TSINGHUA UNIV

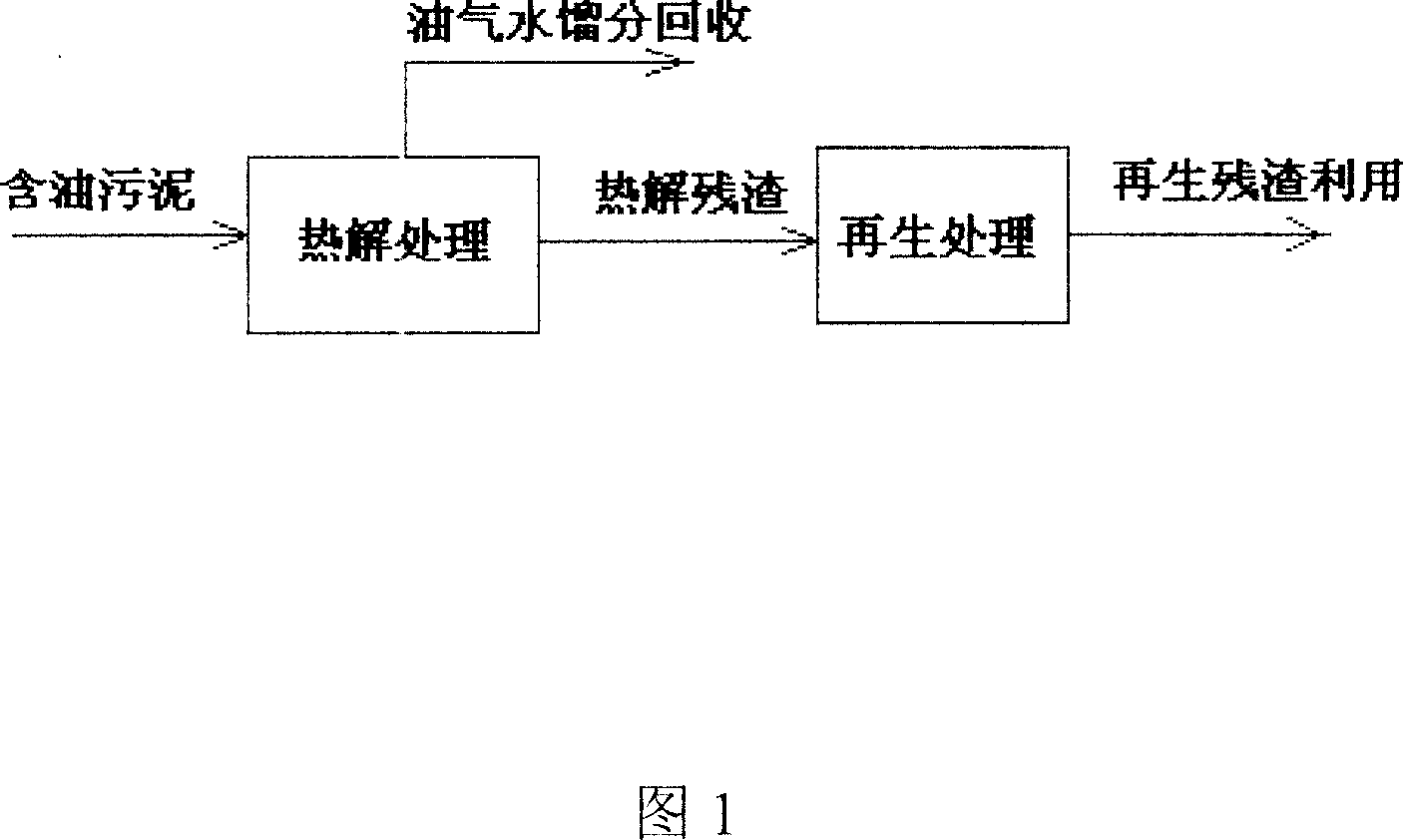

Resource treating method for oil-containing sludge

ActiveCN101113067ASolve pollutionReduce doseSludge treatment by pyrolysisByproduct vaporizationClay mineralsIron salts

The invention relates to a resource processing method for oily sludge. First, the oily sludge is sent to a closed retorting cracking furnace to be pyrolyzed, and the pyrolyzed period is 1-5 hours under 200-600 DEG C, then the oil, gas, and water are recovered. Second, sulfate or hydrochloride is put into the pyrobitumen of sludge containing inorganic aluminum salt or iron salt flocculant according to the chemical equivalent of the aluminum salt or iron salt 1 to 1-1.5 to do acid-soluble processing. The products after the two processes can be reclaimed and used as the flocculant of the sewage processing system, or reclaimed as the concentrating agent of sludge. The pyrobitumen containing mostly clay mineral can be used as decolorizing and absorbing material of waste water and oil, or used as absorbent for lube-oil complementing and refining process. The method used in oilfield gathering transportation and treatment system can realize zero discharge in course of the gathering transportation and treatment, and can effectively solve the pollution problem of the oily sludge and find the automate answer for the oily sludge. Meanwhile, by adopting the method, the cost for the treatment of sewage flocculation and for adding sludge concentration agent can be reduced and the energy material can be reclaimed from sludge and the wastage of oil can be reduced.

Owner:PETROCHINA CO LTD

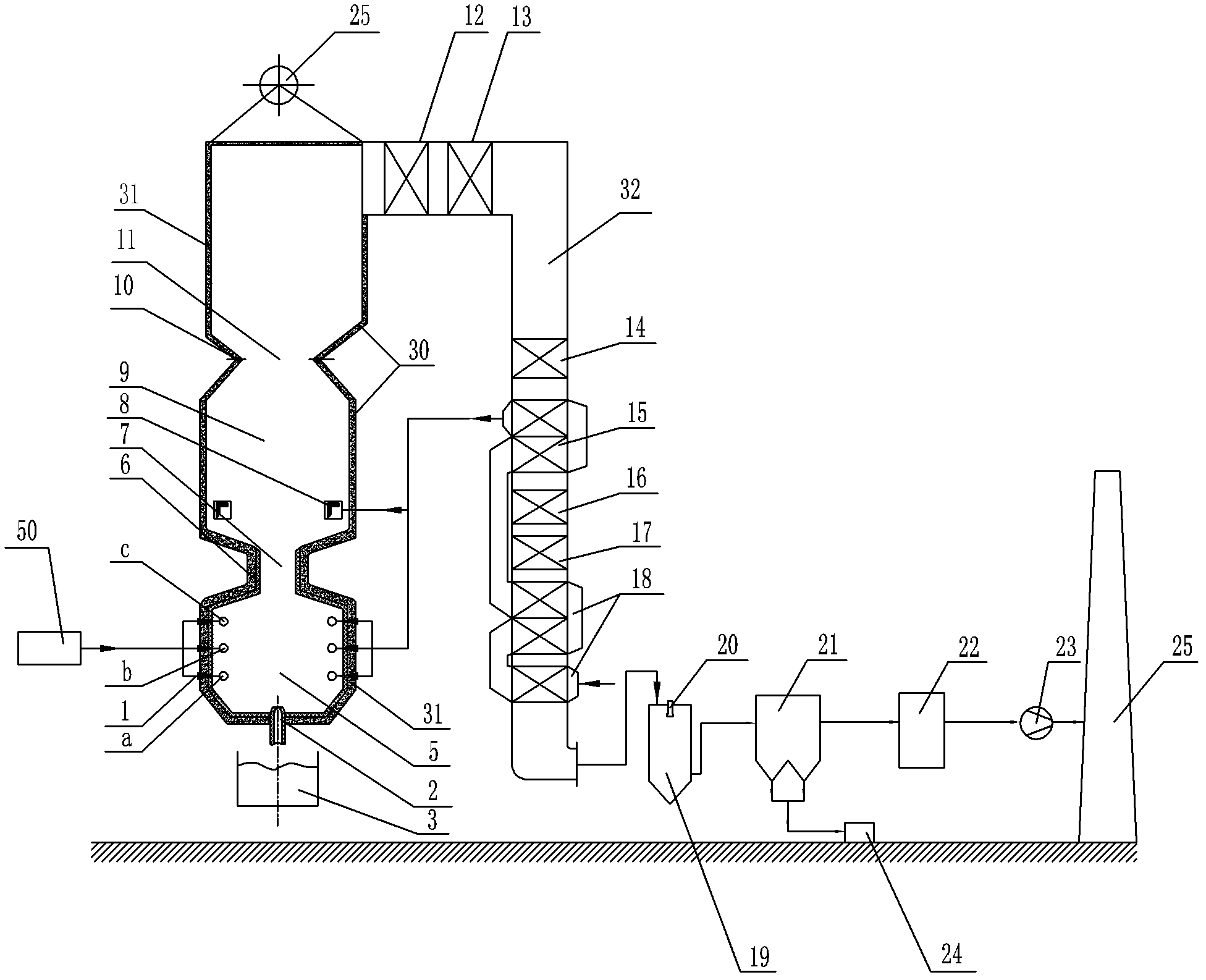

High-temperature melting treatment system and method for sludge

ActiveCN102537980ALow running costEmission reductionCombination devicesSludge treatment by pyrolysisAir preheaterCooling tower

The invention discloses a high-temperature melting treatment system and a method for sludge, and relates to a sludge treatment system and a sludge treatment method. The system and the method solve the problem that dioxine exists in sludge incineration methods in prior arts. A first device comprises a melting chamber with a furnace body integrally manufactured from a lower side to an upper side, a shrinking section smoke outlet and a secondary combustor, high temperature and low temperature superheaters arranged in a smoke duct, high temperature and low temperature coal economizers, high temperature and low temperature air preheaters, and an SCR (selective catalytic reduction) denitration system, wherein the smoke duct is communicated with a smoke fast cooling tower, the smoke fast cooling tower is communicated with a bag-type dust collector, and the bag-type dust collector is communicated with a chimney by a smoke wet desulphurization system and a draught fan. The first method comprises the steps of feeding dry sludge powder into the melting chamber for burning to a high-temperature melting state, recycling liquid-state slag and reusing, treating high-temperature smoke after entering the smoke duct, and discharging. The differences between a system in a second scheme and the first device are as follows: the high temperature and low temperature superheaters and the high temperature and low temperature coal economizers are not arranged, and a steam heat exchanger is additionally arranged. A difference between a system in the third scheme and the second scheme is as follows: a multistage sludge dryer is additionally arranged. The high-temperature melting treatment system and method for the sludge are used for high-temperature melting treatment of the sludge.

Owner:HARBIN INST OF TECH

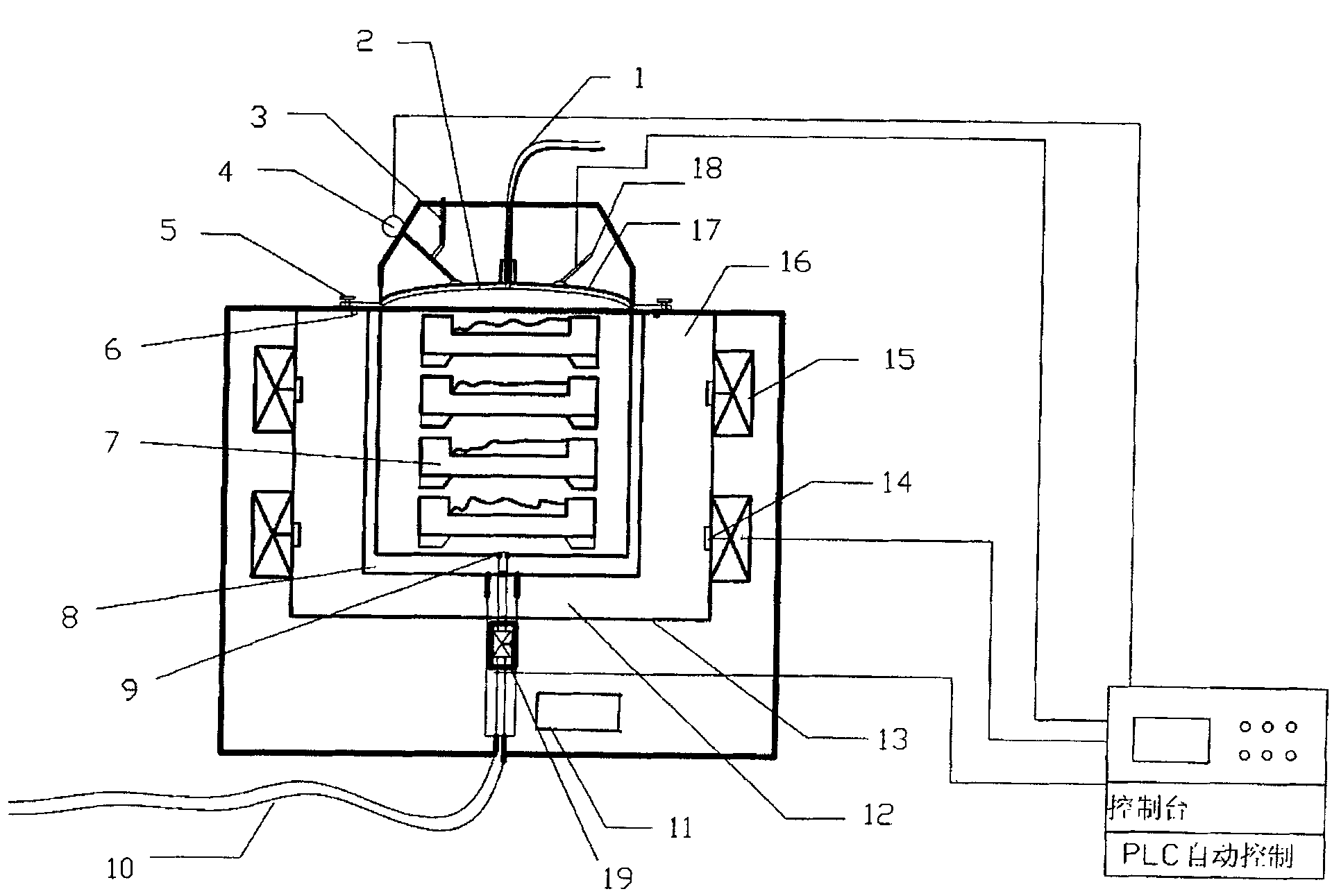

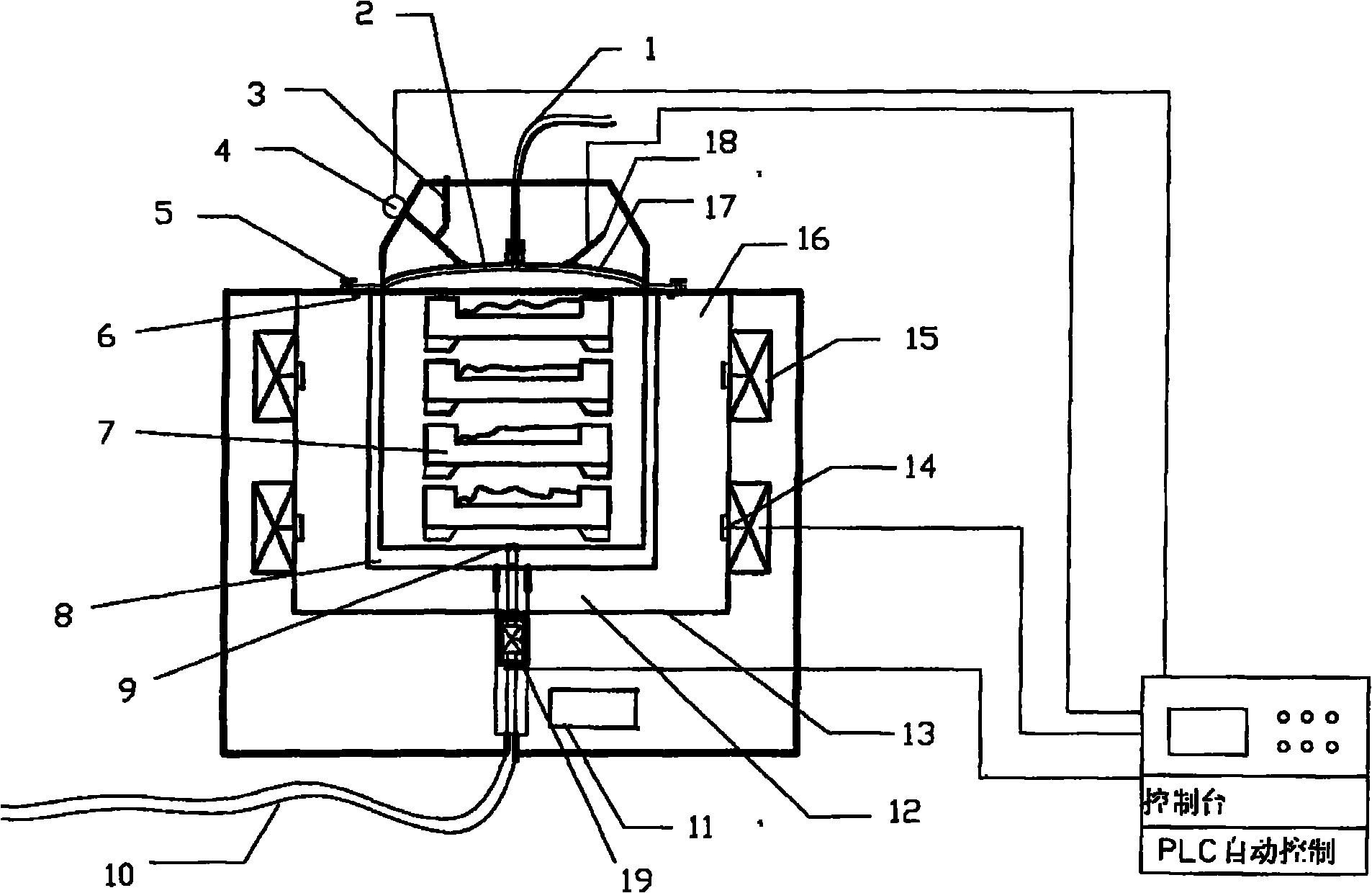

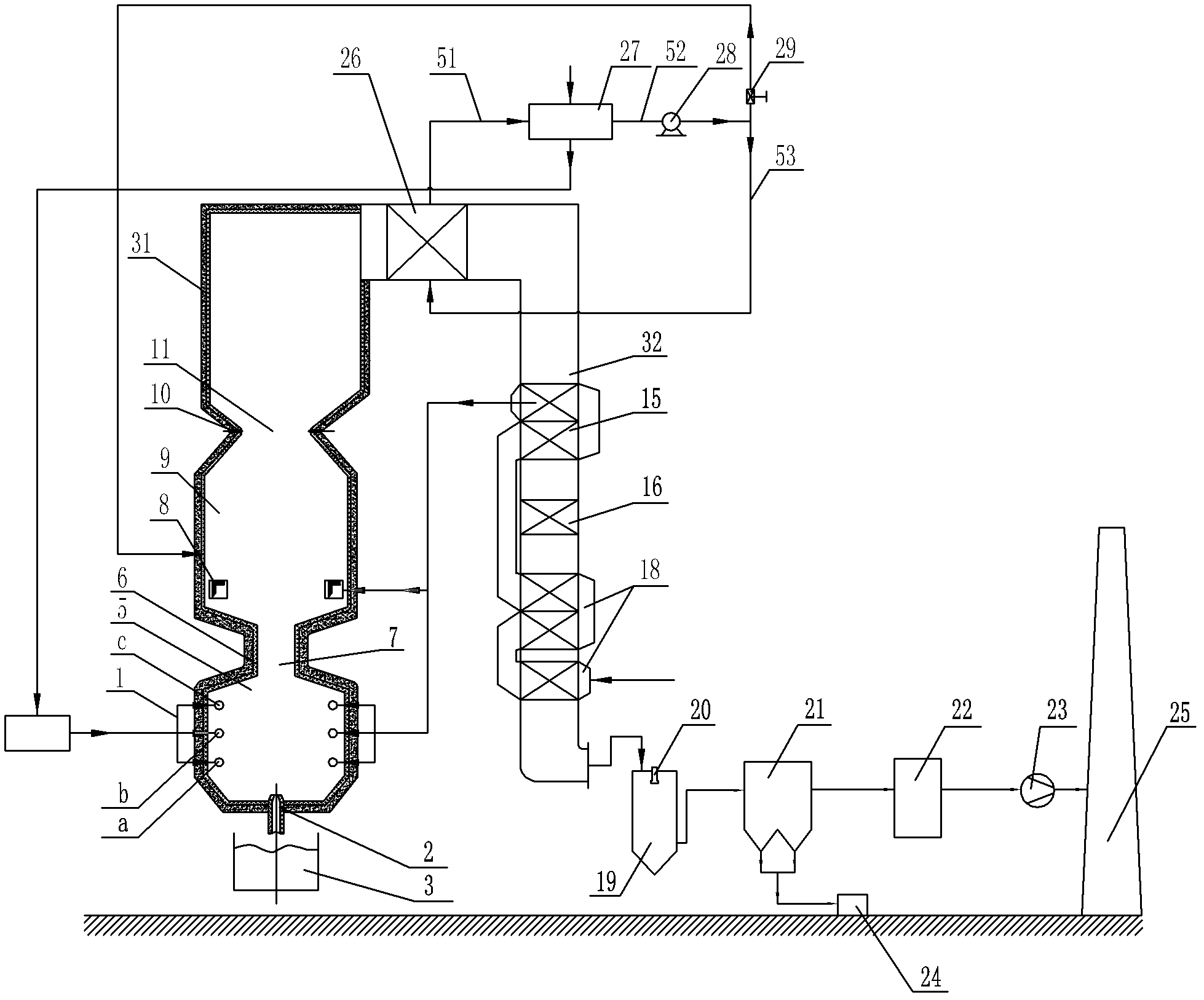

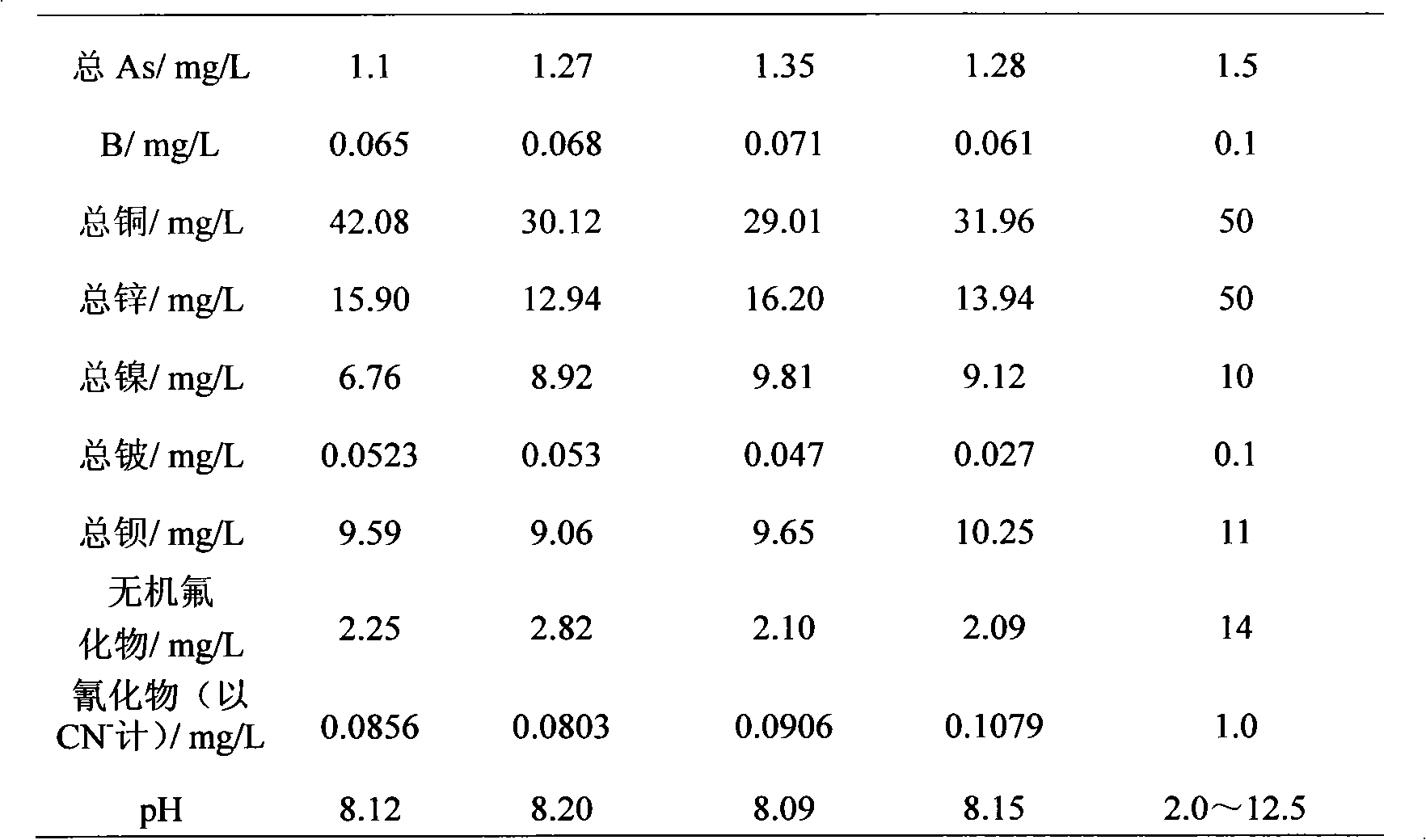

Indirect heating and thermal desorption treatment device and method for oily solid waste

ActiveCN104496136AHarmlessRealize resourcesSludge treatment by pyrolysisMultistage water/sewage treatmentAutomatic controlEngineering

The invention discloses an indirect heating and thermal desorption treatment device and method for oily solid waste. The device comprises an automatic control unit, a feeding pretreatment unit, a feeding metering and protecting unit and an indirect heating and thermal desorption unit, wherein the feeding pretreatment unit, the feeding metering and protecting unit and the indirect heating and thermal desorption unit are sequentially communicated with one another through an oily solid waste material conveying mode; a desorbed gas and oil gas outlet of the indirect heating and thermal desorption unit is connected with a desorbed gas separating and purifying unit; a discharge hole of the indirect heating and thermal desorption unit is connected with a muck post-treatment unit; the indirect heating and thermal desorption unit is composed of a heating cavity and a thermal desorption cavity; a heated part of the thermal desorption cavity is arranged in the heating cavity; and an internal space of the thermal desorption cavity and the internal space of the heating cavity are two cavities which are independently separated and are not communicated. The invention further discloses a method using device.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

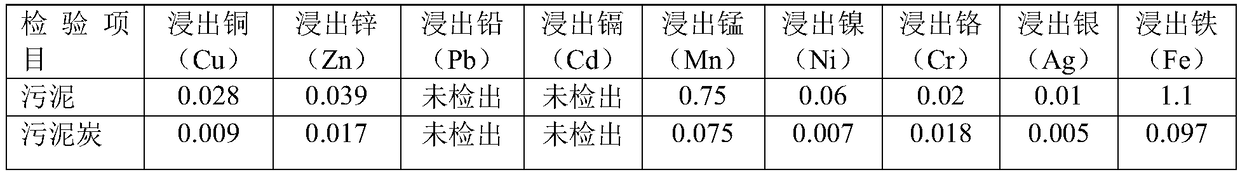

Method for preparing magnetic sludge-based biochar material from sludge and application of magnetic sludge-based biochar material

ActiveCN112354516AEasy to separateLarge specific surface areaOther chemical processesSludge treatment by pyrolysisSludgeRed mud

The invention discloses a method for preparing a magnetic sludge-based biochar material from sludge and the application of the magnetic sludge-based biochar material, and belongs to the technical field of sludge resource utilization. The invention aims to fully utilize municipal and industrial wastes such as sewage sludge, hematite, rust, Bayer process red mud, high-iron-content fly ash, picklingwastewater and the like, and prepare magnetic sludge-based biochar from a solid waste iron source: dried sludge with the water content of less than 15% and a solid iron source are mechanically crushedand uniformly mixed; continuous pyrolysis is carried out, the pyrolysis temperature is 400-800 DEG C, the solid material stays in the device for 20-120 min, and fine ball milling and smashing are carried out until the particle size is 100 [mu] m or below; in the nano Fe3O4 / magnetic sludge-based biochar core-shell material prepared by the method, both the material core and the shell have magnetism, so that efficient recycling can be realized.

Owner:SHANGHAI FUTING TECH CO LTD

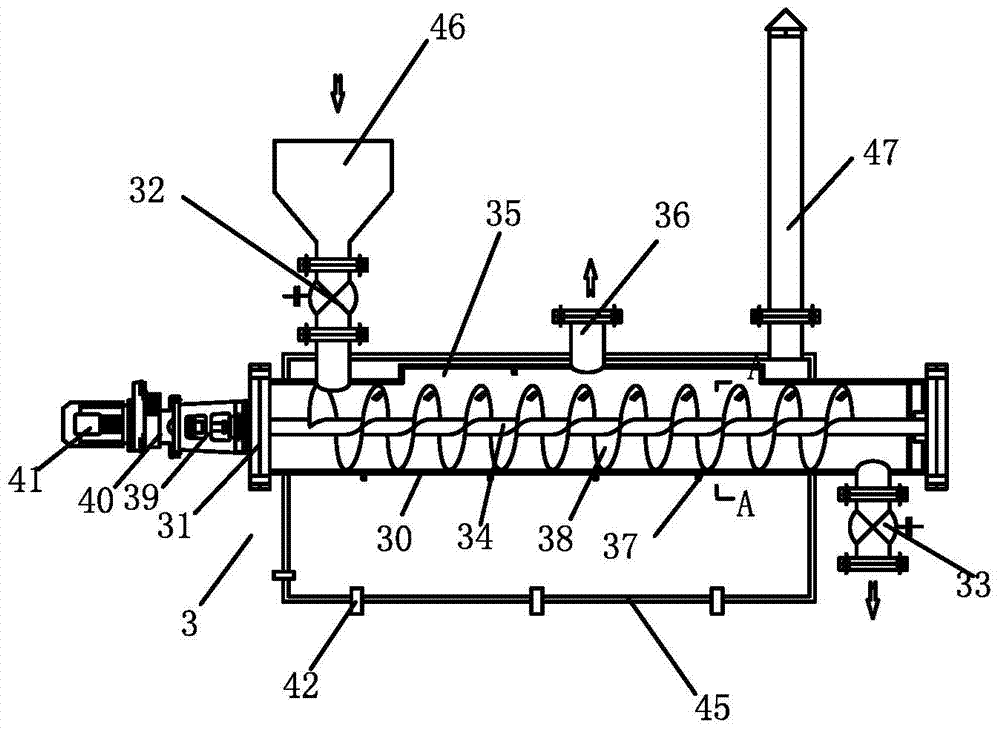

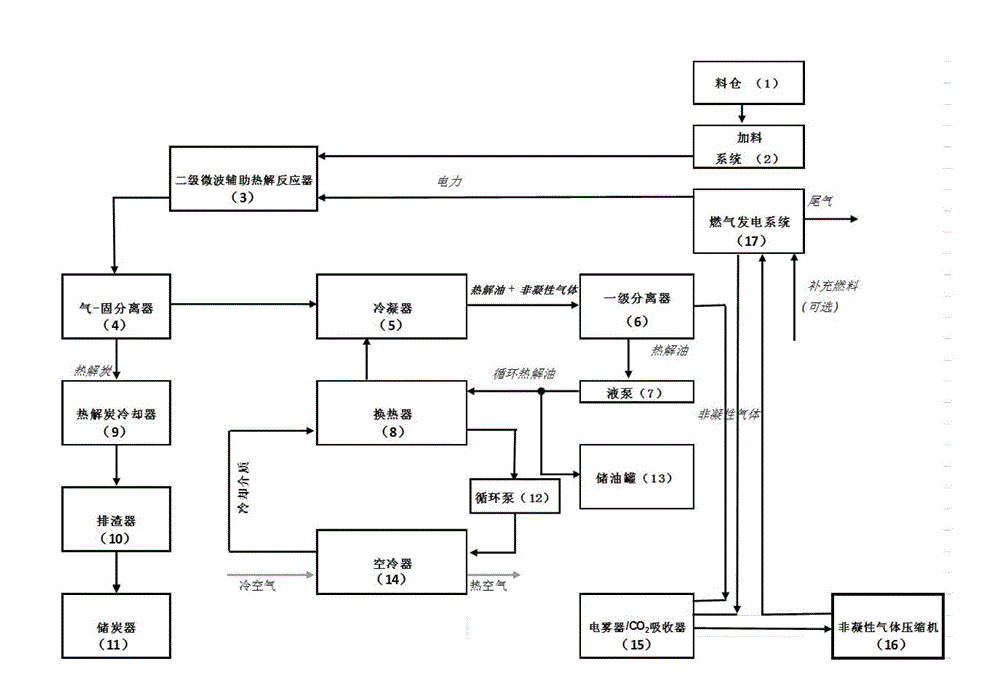

Pyrolysis device and method for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis

ActiveCN102718383ASolve the difficulty of large-scale collectionSolve the inconvenience of storage and transportationSludge treatment by pyrolysisByproduct vaporizationSlagChar

The invention discloses a pyrolysis device for in-situ conversion of carbon-containing resources by microwave-assisted pyrolysis. The device comprises a microwave-assisted pyrolysis reactor, a solid outlet of the reactor is connected with an inlet of a pyrolytic carbon cooler, an outlet of the pyrolytic carbon cooler is connected with a slag storer through a deslagging machine, a gas outlet of the reactor is connected with an inlet of a condenser through a pipeline, the condenser is provided with a gas-liquid separator, a gas outlet of the condenser is connected with a gas purifier, an outlet of the gas purifier is connected with a gas compressor, a liquid outlet of the condenser is connected with a liquid circulating pump, then one branch of the condenser is connected with an oil storage tank, and the other branch of the condenser is connected back to the condenser through a cooling medium circulating system. The invention further discloses a method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis. By the pyrolysis device and the method for the in-situ conversion of the carbon-containing resources by the microwave-assisted pyrolysis, various low-grade carbon-containing resources can be collected, stored and continuously produced at an economic scale.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

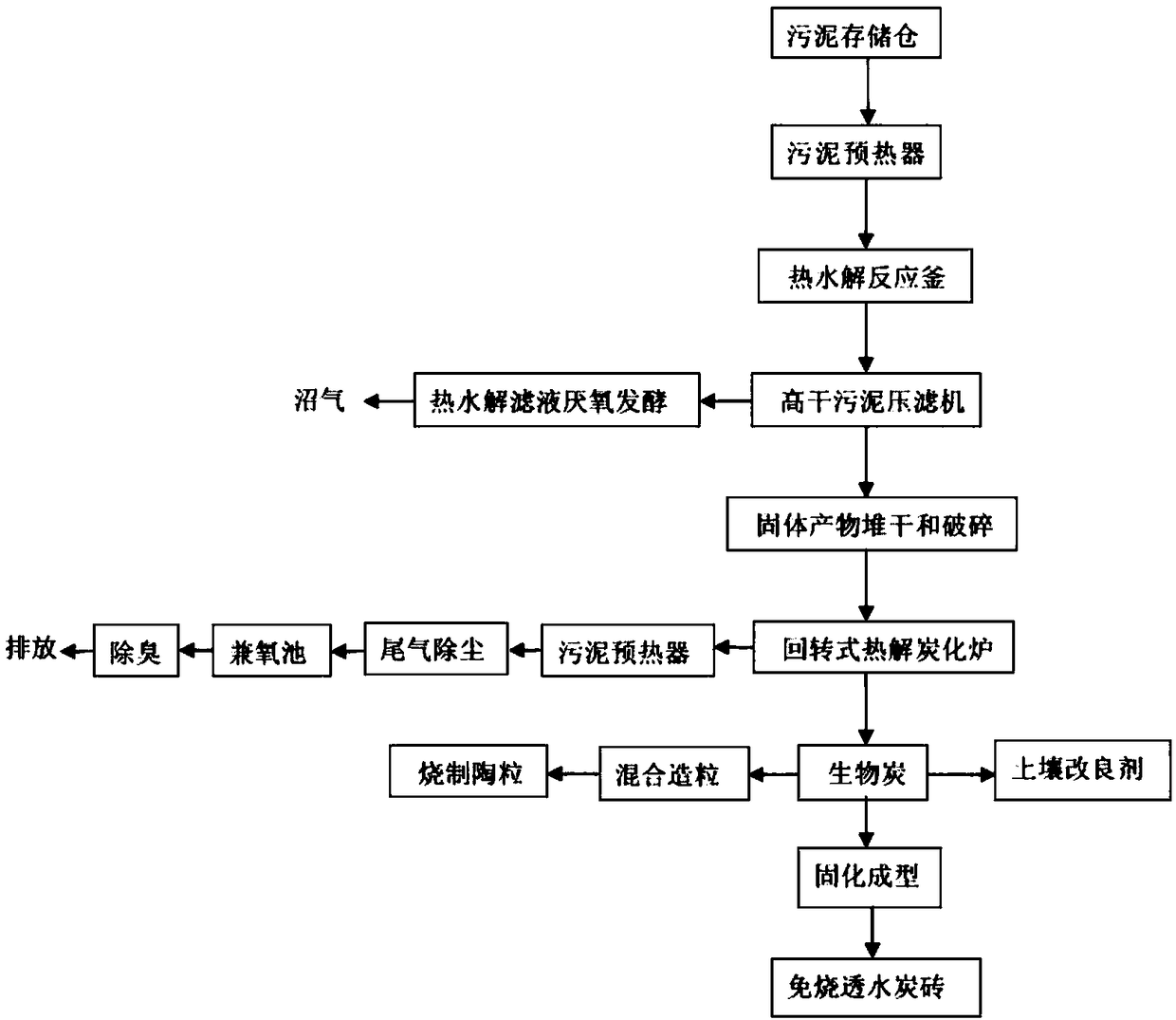

Resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization

InactiveCN108423959AImproved Anaerobic Digestion PerformanceImprove dehydration effectWater treatment parameter controlSpecific water treatment objectivesSludgeHigh energy

The invention discloses a resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization. The method includes the steps of: (1) transporting dehydrated sludge to a sludge preheater; (2) sending the preheated sludge into a sludge thermal hydrolysis reaction kettle; (3) subjecting the thermal hydrolysis product to solid-liquid separation to obtain thermal hydrolysis filtrate and a solid product; (4) carrying out natural heap drying, crushing, activation and granulation on the solid product successively, then conveying the product to a rotary controllable pyrolysis carbonization furnace by a spiral conveyer, and conducting high-temperature rapid pyrolysis to obtain biochar, tar and high-temperature waste gas, introducing the high-temperature waste gas into the sludge preheater, and subjecting the biochar to resource comprehensive utilization; and (5) subjecting the thermal hydrolysis filtrate to anaerobic fermentation, and using the generated biogas as the fuelof the pyrolysis carbonization furnace. The method provided by the invention overcomes the problems of high energy consumption of the sludge carbonization process and nonstandard resource utilizationmethod of sludge biochar in sewage treatment plants at present, and realizes reduction, stabilization, harmless and resource comprehensive utilization of sludge in sewage treatment plants.

Owner:浙江合泽环境科技有限公司

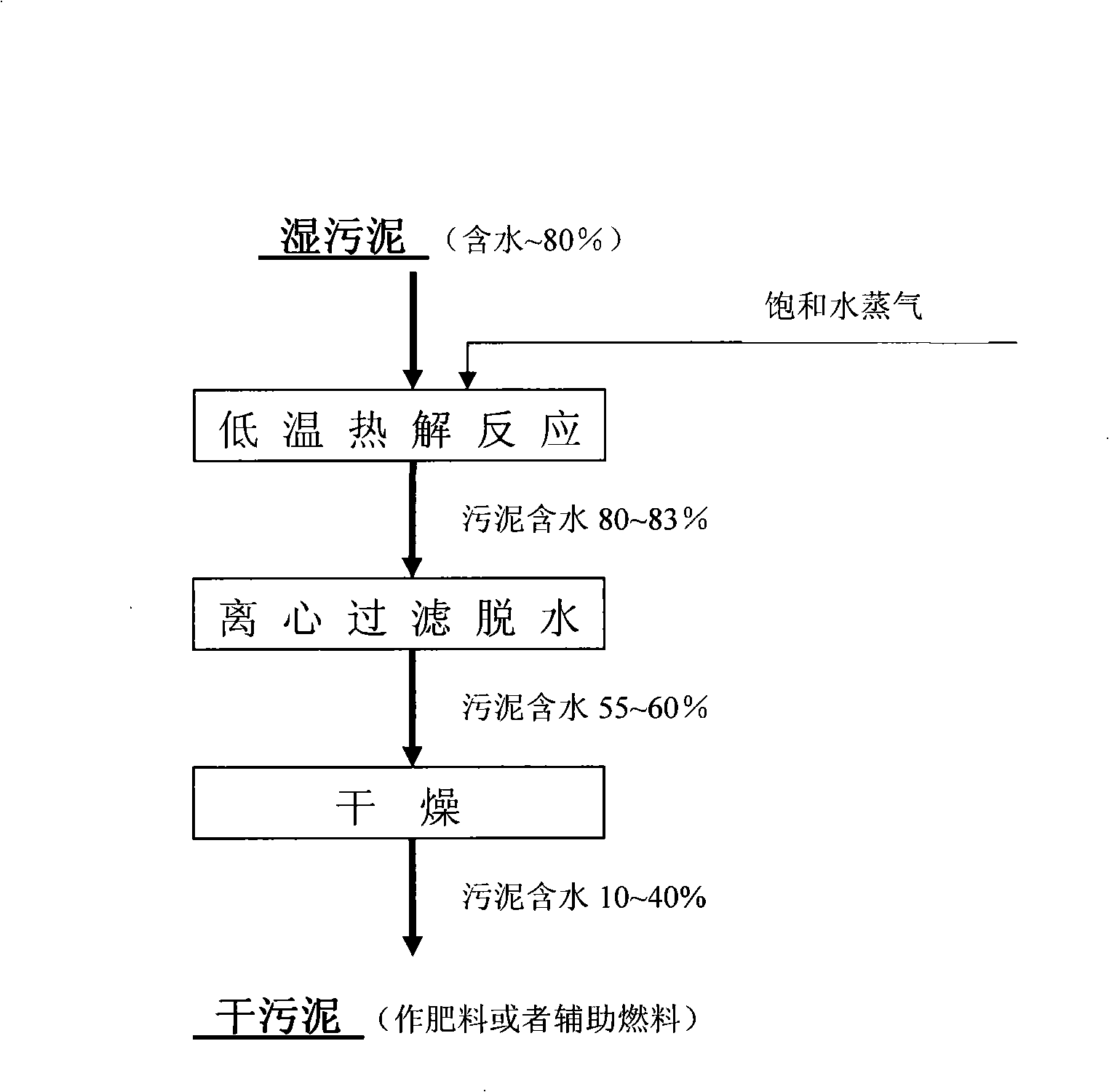

System and process for anhydration treatment of wet sludge

ActiveCN101289267AAvoid it happening againNo odorSludge treatment by de-watering/drying/thickeningWaste processingResource utilizationSludge

The invention relates to a wet sludge anhydration treatment system which comprises a low-temperature pyrolysis reaction device which is used for carrying out the low-temperature pyrolysis reaction of wet sludge and saturated water vapor to convert macromolecular organics in the wet sludge into low-molecular organics, a spiral centrifugal filtering device which is used for carrying out centrifugal filtering and dehydration to the wet sludge after the pyrolysis in a mechanical separation manner so as to obtain semi-dry sludge with the water content of 55 percent to 60 percent, and a drying device which is used for drying and removing the water in the semi-dry sludge after the filtering and hydration so as to obtain dried-sludge solid fuel with the water content of 10 percent to 40 percent. Meanwhile, the invention also relates to a wet sludge anhydration treatment technology by adopting the treatment system. The system and the technology of the invention can solve the problem of renewable resource of sludge in a method of environment protection, energy saving, high resource utilization and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

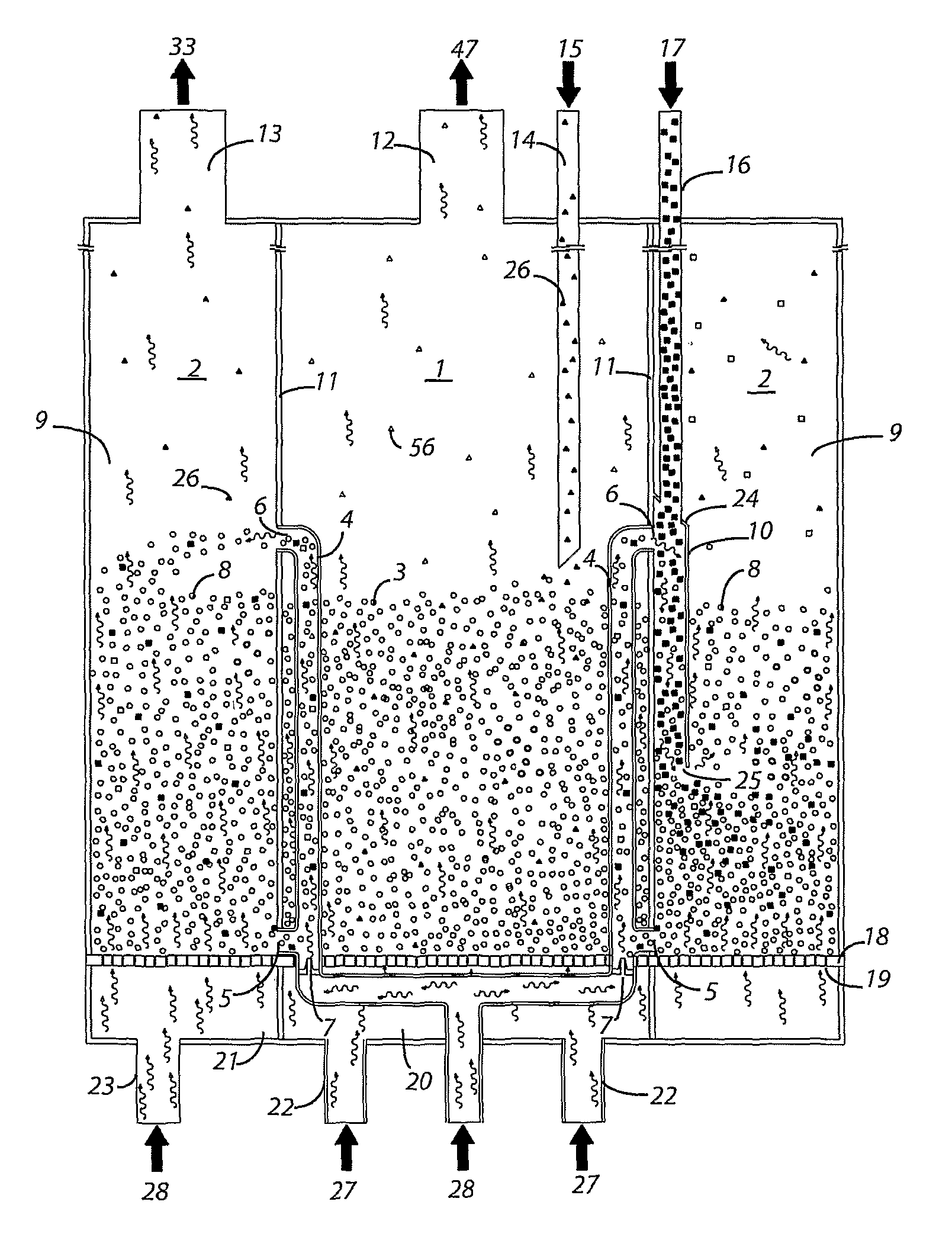

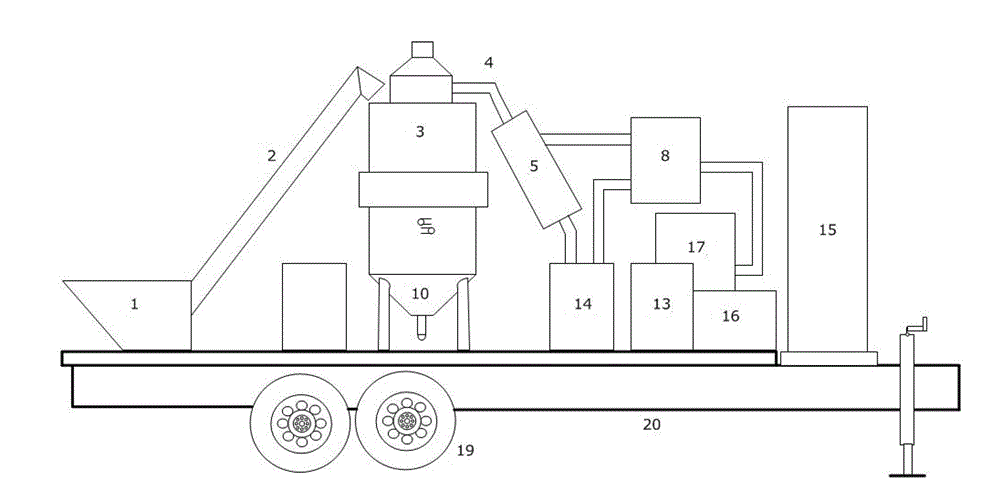

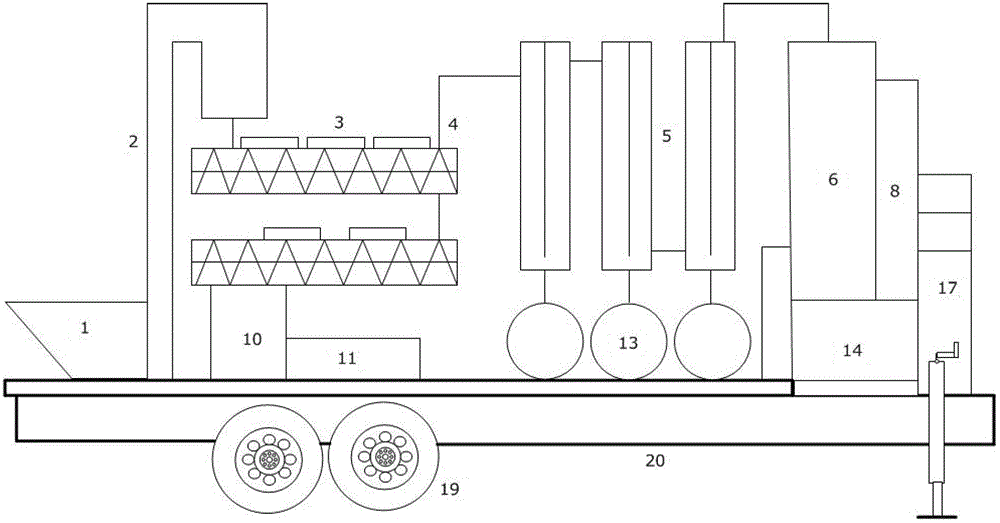

Apparatus and Process for the Pyrolysis of Agricultural Biomass

InactiveUS20080197012A1Prevent escapeFast heat transferFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

Method for strengthening biological treatment of organic wastewater difficult to degrade

InactiveCN101602547AReduce exogenous nutrientsImprove biological treatment efficiencySludge treatment by pyrolysisTreatment with aerobic and anaerobic processesDetonatorDissolution

Owner:DALIAN UNIV OF TECH

High temperature carbonization system of sludge and carbonization process

InactiveCN103145307ATo achieve the purpose of energy savingReduce volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCarbonizationExhaust fumes

Owner:CECEP BOTH HUBEI ENVIRONMENT ENG & TECH

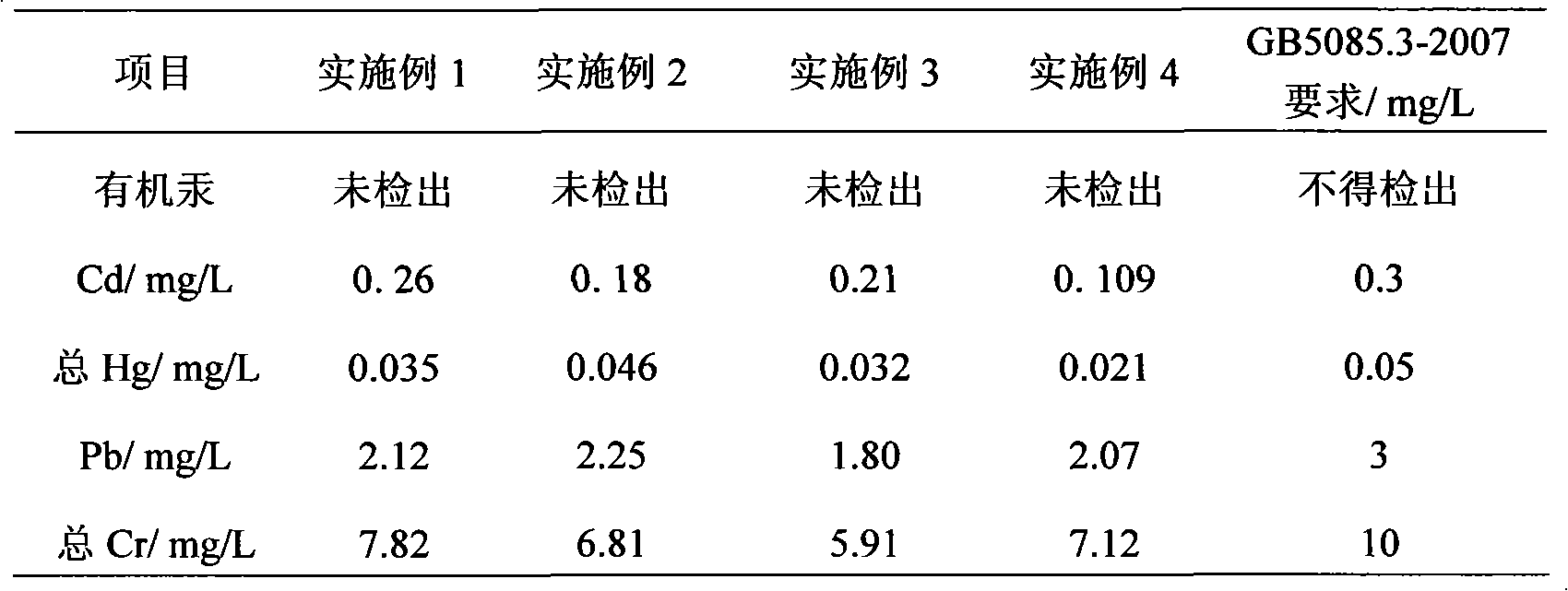

Treatment method of oily sludge

ActiveCN102050556AReduce volumeReduce quality problemsThermal non-catalytic crackingSludge treatment by de-watering/drying/thickeningTherapeutic effectOil sludge

The invention relates to a treatment method of oily sludge, which is particularly suitable for oily sludge generated during the sewage treatment process of a refinery plant. The method comprises the following steps: after centrifugal dewatering, the oily sludge is dehydrated through rotary dehydration equipment under the control of a certain negative pressure and a certain temperature, so as to destroy the water, oil and solid stable system in the oily sludge; parts of oil and water in the oily sludge are distilled out; the coke generated after dehydration is extracted with a solvent; after extraction, the material undergoes the solid-liquid separation; the separated liquid phase is delivered to a delayed coking device; the separated solid phase is dehydrated to form the residues that meet the discharge standards for solids; and the wastewater generated during the process is biochemically treated and then discharged after reaching the discharge standards. The invention is mainly characterized in that the sludge treatment process is short, the speeds and the efficiencies of sludge dehydration and extraction are high, the effect is good, the operational condition is moderate, the energy consumption is reduced, the oily sludge treatment effect is good, and the operating maintenance of the equipment is simple.

Owner:PETROCHINA CO LTD

Sludge pyrolysis carbonization technique and device

ActiveCN105601075AStable stateSimple production processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSolid carbonWater vapor

The invention discloses a sludge pyrolysis carbonization technique and device. The technique comprises the following steps: sludge is pressed by a press, pulverized by a pulverizer, mixed by a mixer, dried in an internal heating rotary kiln drying machine, sent into a storage bin, and sent into a pyrolysis carbonization furnace; the sludge is subjected to pyrolysis carbonization in the pyrolysis carbonization furnace; the product solid carbon mixture is sent out of the system, and the products vapor and pyrolytic gas enter a separation purification tower to be separated and purified; the purified combustible gas is sent into a combustor and combusted into an internal heating rotary kiln drying machine delivery heat source, and the purified heavy components are sent into the mixture and mixed with the sludge to perform secondary pyrolysis; the flue gas generated by the heating furnace is discharged into a hot-blast furnace to perform secondary ablation; and the exhaust generated by the whole device is discharged by an outlet I of the internal heating rotary kiln drying machine, and is treated and discharged after reaching the standard. The device has the advantages of simple production technique, stable product state and no secondary pollution, and implements the reduction, harmless treatment and recycling of sludge treatment.

Owner:刘晓静

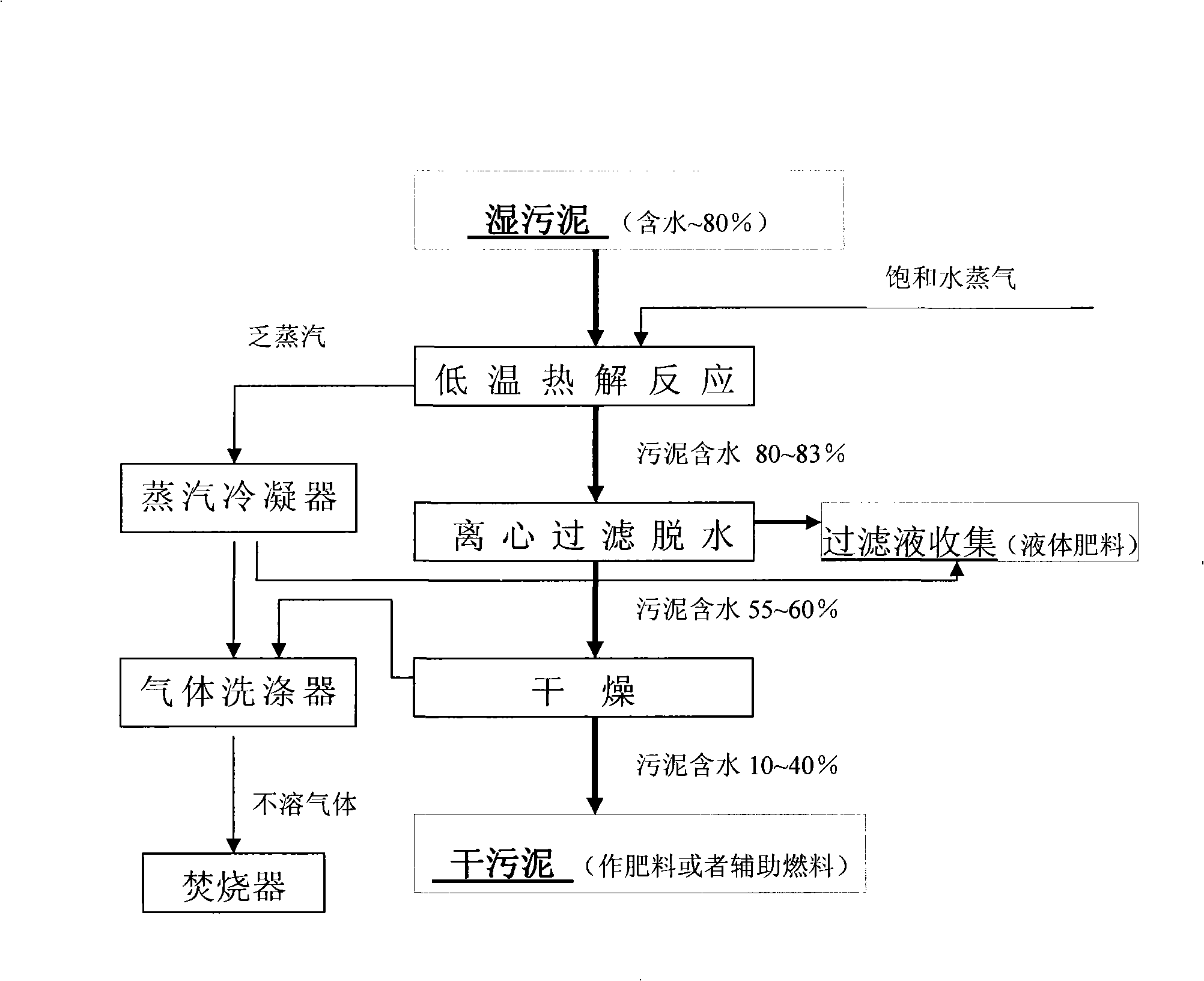

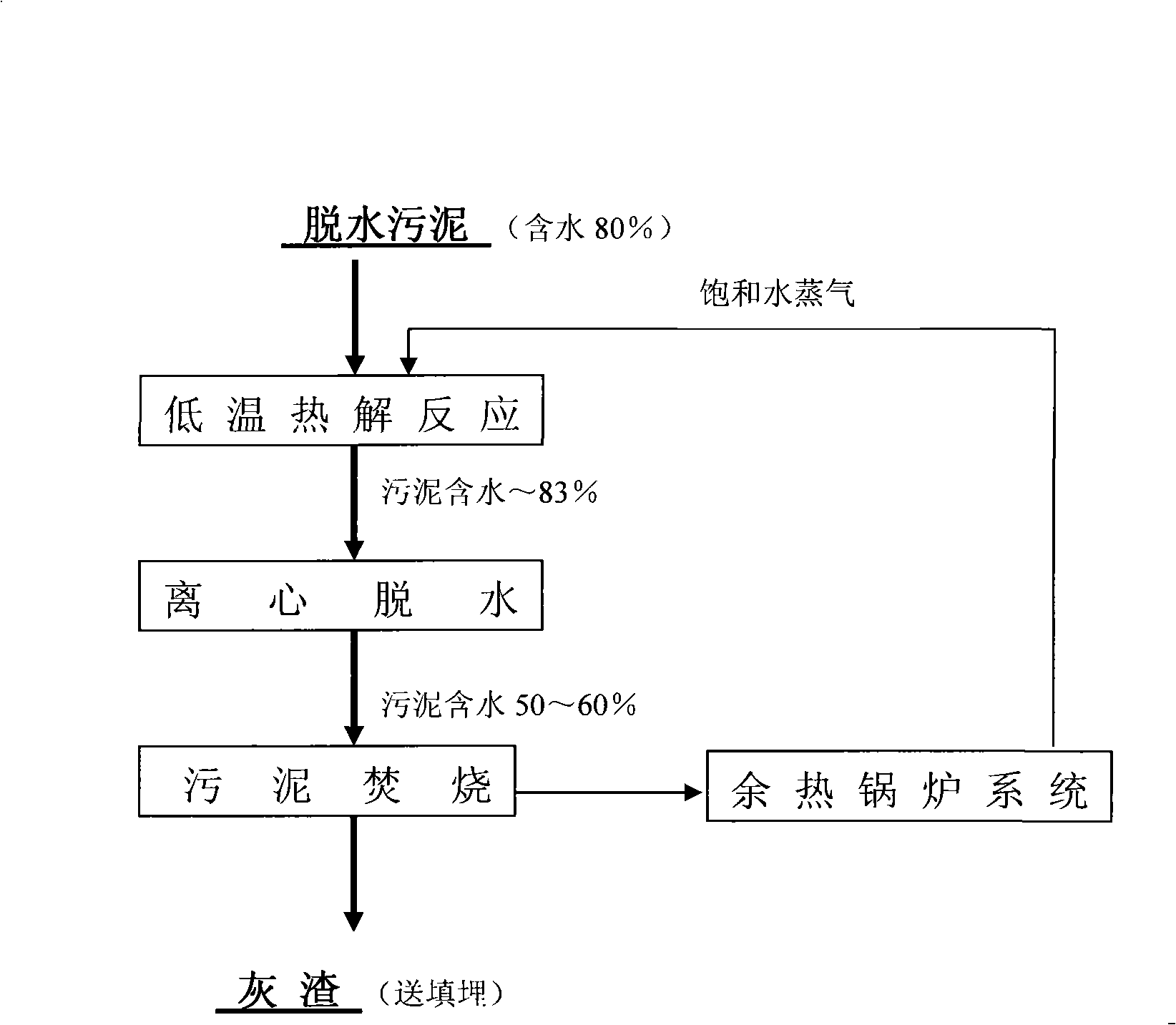

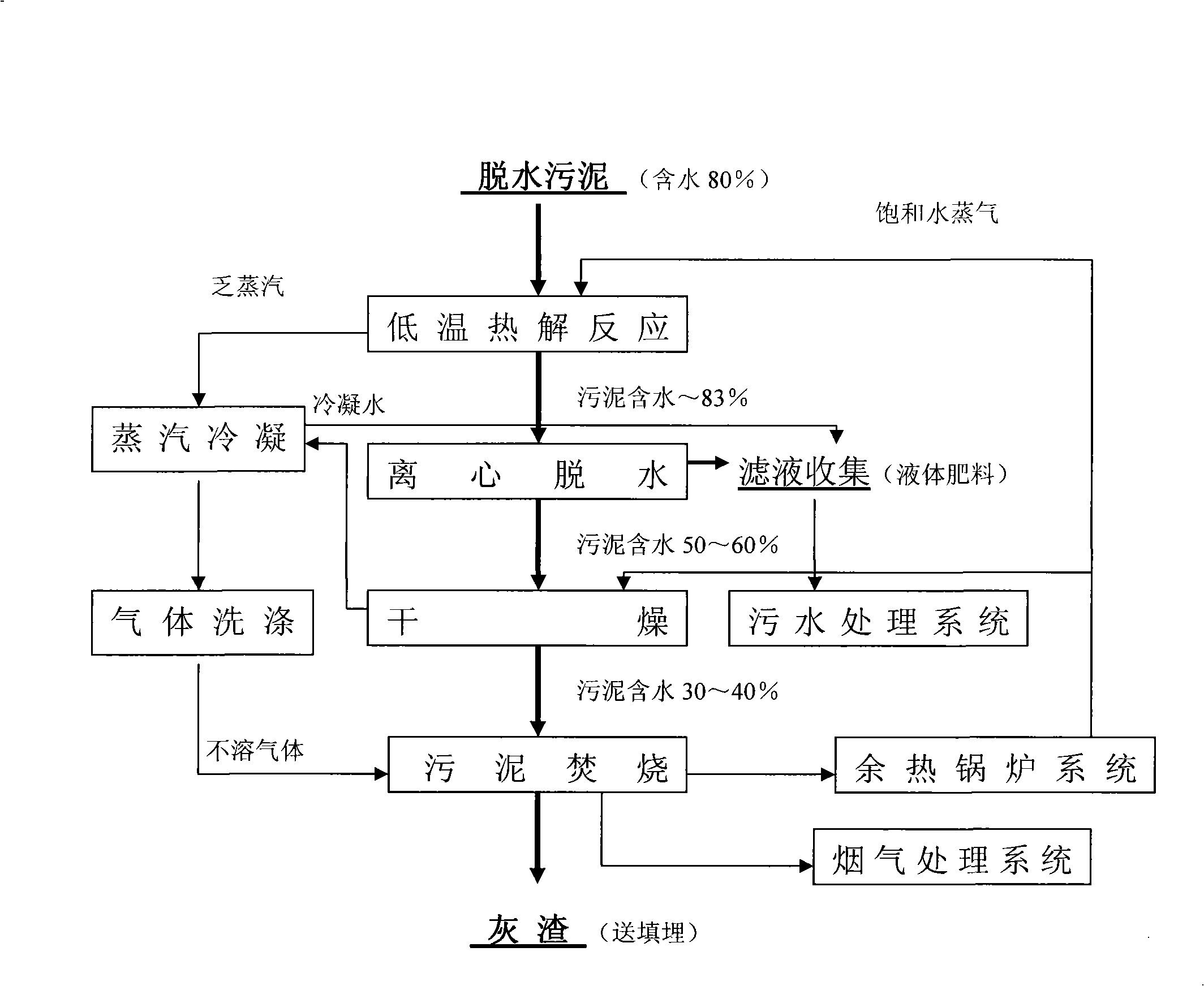

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com