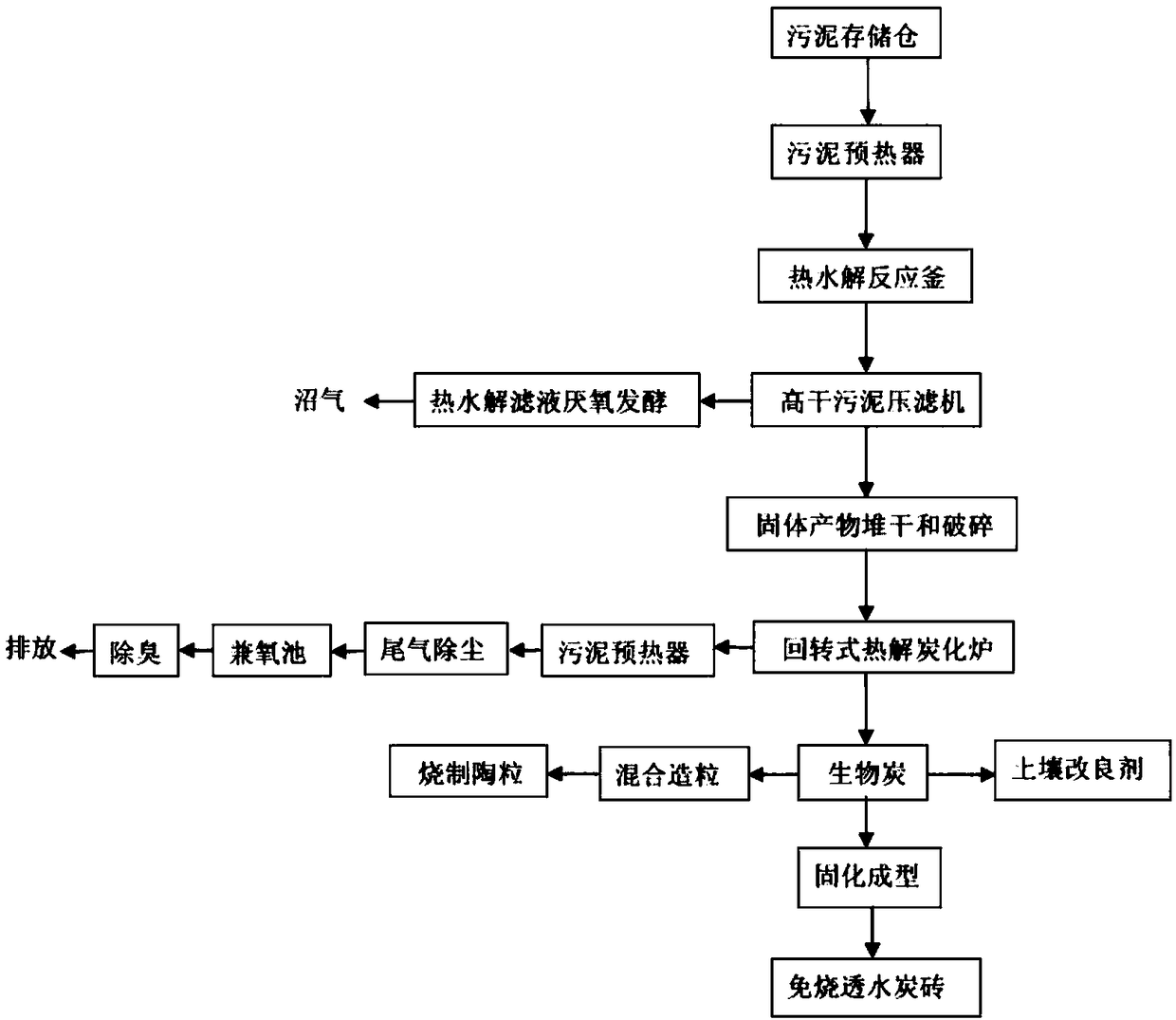

Resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization

A technology of pyrolysis carbonization and thermal hydrolysis, applied in the fields of pyrolysis treatment of sludge, chemical instruments and methods, water/sludge/sewage treatment, etc. Higher problems, achieve the effect of high level of sludge energy utilization, low operating cost, and overcome excessive moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

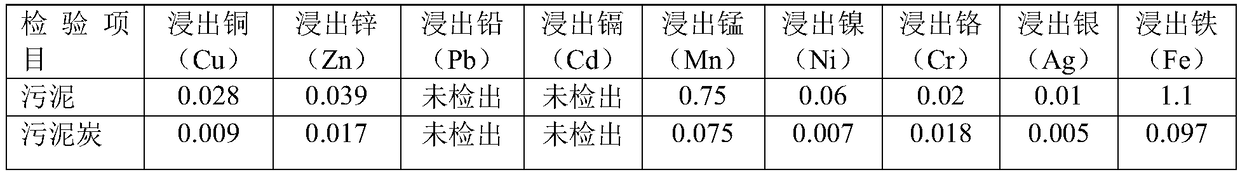

[0035] The moisture content of the sludge in an urban sewage treatment plant is 78% after mechanical dehydration. After the wet sludge is preheated by the preheater, the temperature reaches 83°C. The preheated sludge is sent to the sludge thermal hydrolysis reactor, and the The reaction temperature is 185°C, the pressure is 1.8MPa, and the ribbon-screw agitator in the reactor is stirred at 80rpm for 1.2h to discharge the material to obtain a thermal hydrolysis product, and the moisture content drops to 37% after passing through a high-dry sludge filter press. %, after further natural heap drying for 2 days, the moisture content drops to 28%, then the dried solid product is broken, and 0.2% potassium hydroxide and 0.85% potassium carbonate activator of sludge dry weight are added to mix and granulate evenly. Send it into a rotary controllable pyrolysis carbonization furnace, control the temperature rise rate of the carbonization furnace to 7°C / min, and the pyrolysis temperature ...

Embodiment 2

[0041] The water content of the sludge in a mixed urban and industrial sewage treatment plant is 82% after mechanical dehydration. After the wet sludge is preheated by the preheater, the temperature reaches 88°C, and the preheated sludge is sent to the thermal hydrolysis reaction of the sludge Reactor, at a reaction temperature of 210°C and a pressure of 2.2MPa, the ribbon-screw agitator in the reactor stirred and reacted for 1.4 hours at 120rpm and discharged to obtain a thermal hydrolysis product. After passing through a high-dry sludge filter press, the moisture content was Reduce to 32%, further natural heap drying after 2 days, the moisture content drops to 26%, then break the dried solid product, add 0.1% potassium hydroxide and 0.25% potassium carbonate activator of sludge dry weight and mix evenly Granulate and send into the rotary controllable pyrolysis carbonization furnace, control the temperature rise rate of the carbonization furnace to 8.5°C / min, and the pyrolysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com