Sludge treatment and resource utilization method based on thermal hydrolysis and its application

A thermal hydrolysis and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Short time, low equipment cost and other problems, to achieve the effect of improving anaerobic digestion performance, improving dehydration performance and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

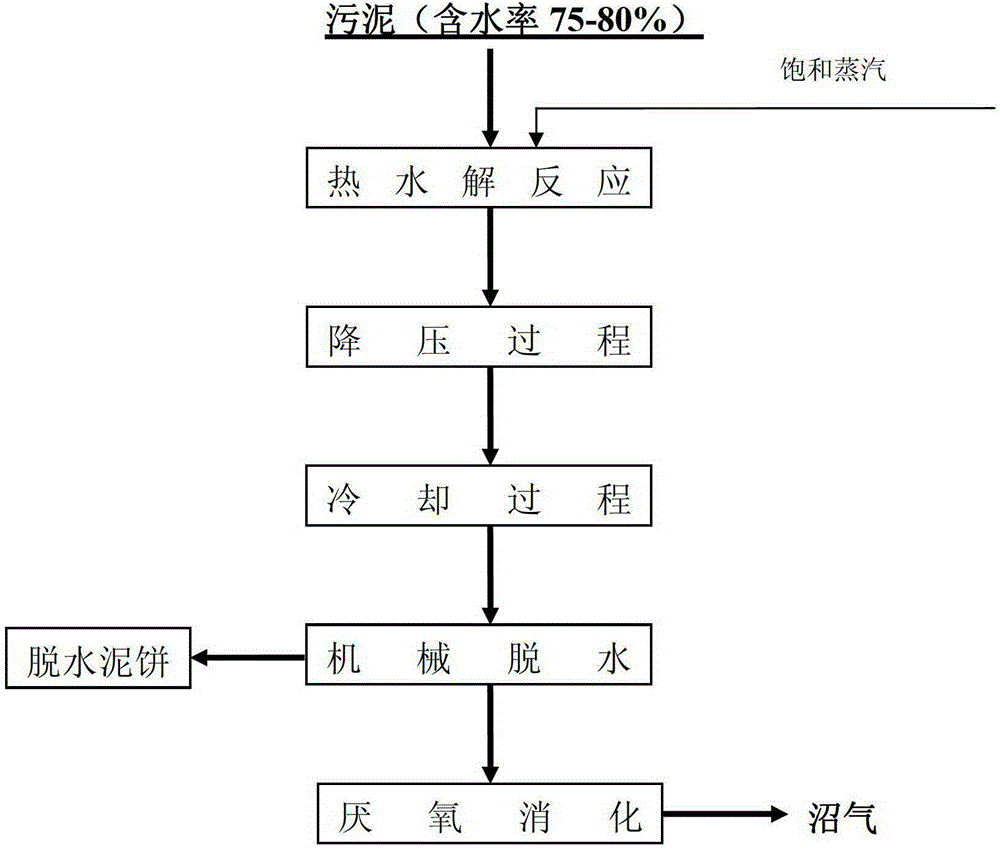

[0038] Such as figure 2 As shown, inject the sludge with a moisture content of 75-80% into the reactor, close the feed port of the reactor, and start the stirring device in the reactor; inject 1.5-1.7MPa sludge from the upper part of the reactor from the steam boiler Saturated steam to heat the sludge in the reactor; detect the real-time temperature of the sludge in the lower part of the reactor, when the temperature of the sludge reaches 185°C, stop injecting saturated steam and keep it for 5-10 minutes; then open the pressure relief valve and start to discharge Steam pressure relief, when the pressure in the reactor drops below 0.05MPa, open the discharge valve to discharge the mud obtained by thermal hydrolysis treatment; after the mud is cooled, it enters the filter press for mechanical dehydration, and the removal liquid and water content are respectively obtained 45-50% dehydrated cake; the dewatered liquid is further anaerobically digested to produce biogas. At this p...

Embodiment 2

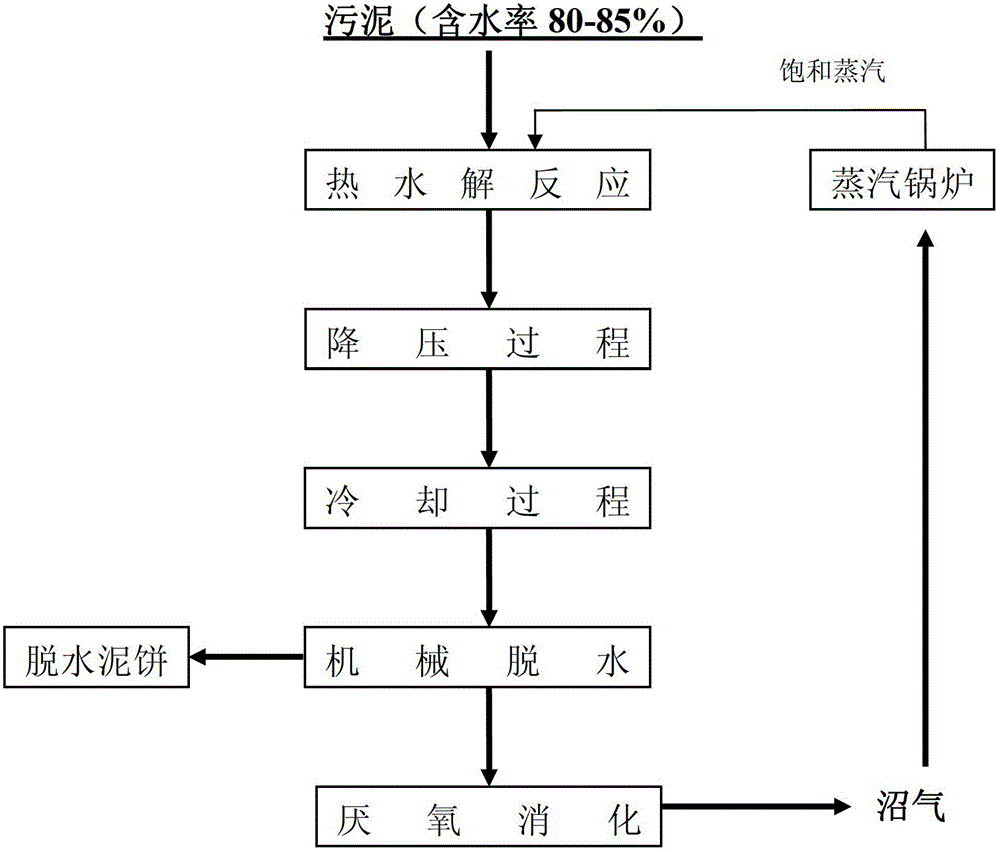

[0040] Such as image 3 As shown, inject the sludge with a moisture content of 80-85% into the reactor, close the feed port of the reactor, and start the stirring device in the reactor; inject 1.8-2.0MPa sludge from the upper part of the reactor from the steam boiler Saturated steam to heat the sludge in the reactor; detect the real-time temperature of the sludge in the lower part of the reactor, and when the temperature of the sludge reaches 170°C, stop injecting saturated steam and keep it for 15-20 minutes; then open the pressure relief valve to start discharging Steam pressure relief, when the pressure in the reactor drops below 0.05MPa, open the discharge valve to discharge the mud obtained by thermal hydrolysis treatment; after the mud is cooled, it enters the filter press for mechanical dehydration, and the removal liquid and water content are respectively obtained 40-45% dehydrated cake; the removal liquid is further subjected to anaerobic digestion to generate biogas,...

Embodiment 3

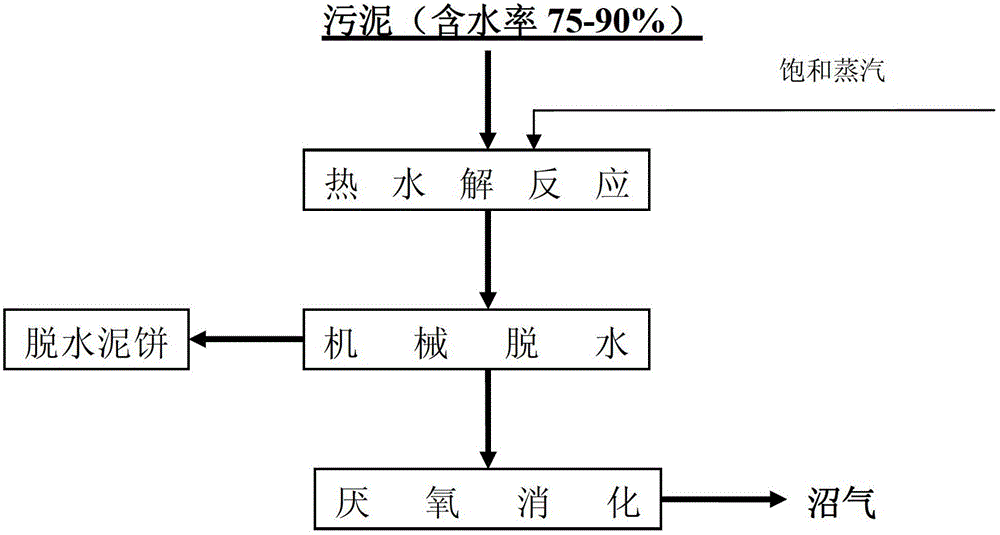

[0042] Inject the sludge with a moisture content of 85-90% into the reactor, start the stirring device in the reactor at the same time, close the feed port of the reactor; inject 2.1-2.3MPa sludge from the upper and lower parts of the reactor at the same time from the steam boiler Saturated steam to heat the sludge in the reactor; detect the real-time temperature of the sludge in the middle of the reactor, when the temperature of the sludge reaches 165°C, stop injecting saturated steam and keep it for 0-5 minutes; then open the pressure relief valve to start discharging Steam pressure relief, when the pressure in the reactor drops below 0.05MPa, open the discharge valve to discharge the mud obtained by thermal hydrolysis treatment; after the mud is cooled, it enters the filter press for mechanical dehydration, and the removal liquid and water content are respectively obtained 43-48% dehydrated cake; the removal liquid further enters the anaerobic digestion equipment, and genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com