Patents

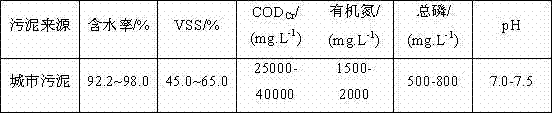

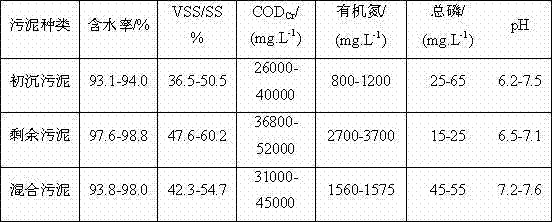

Literature

61results about How to "Improved Anaerobic Digestion Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis

InactiveCN101524699AImproved Anaerobic Digestion PerformanceShortened hydrolysis efficiencySolid waste disposalBiological sludge treatmentMicrowaveRoom temperature

The invention relates to a method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis, and the method belongs to the technical field of solid waste treatment. Alkaline solution is firstly added in the sludge with the solid concentration of 7 percent-10 percent for controlling the pH value of the sludge, the mixing is carried out after adding the alkaline solution, the alkalified sludge is placed in a pressure-bearing reactor, the heating is carried out in a microwave field with the frequency of 2450MHz, the sludge heated by microwave is cooled to the room temperature, and the anaerobic digestion treatment is carried out on the sludge after the cooling. More than 60 percent of organic matters in the sludge which is treated by the method are converted to liquid phase; during anaerobic digestion, the conversion efficiency of the organic matters of the sludge is improved, thereby being an effective means for realizing the whole process pollution control, the energy conservation and the emission reduction of sewage treatment.

Owner:TSINGHUA UNIV

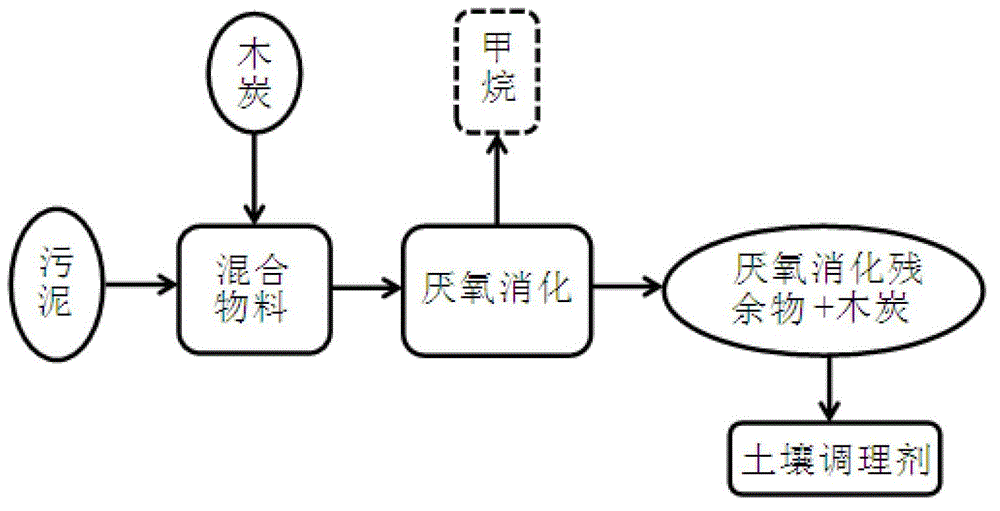

Method using charcoal for promoting anaerobic digestion of sludge to produce methane

InactiveCN104150730AIncreased anaerobic digestionImprove soil physical and chemical propertiesWaste based fuelBiological sludge treatmentAerobic digestionChemistry

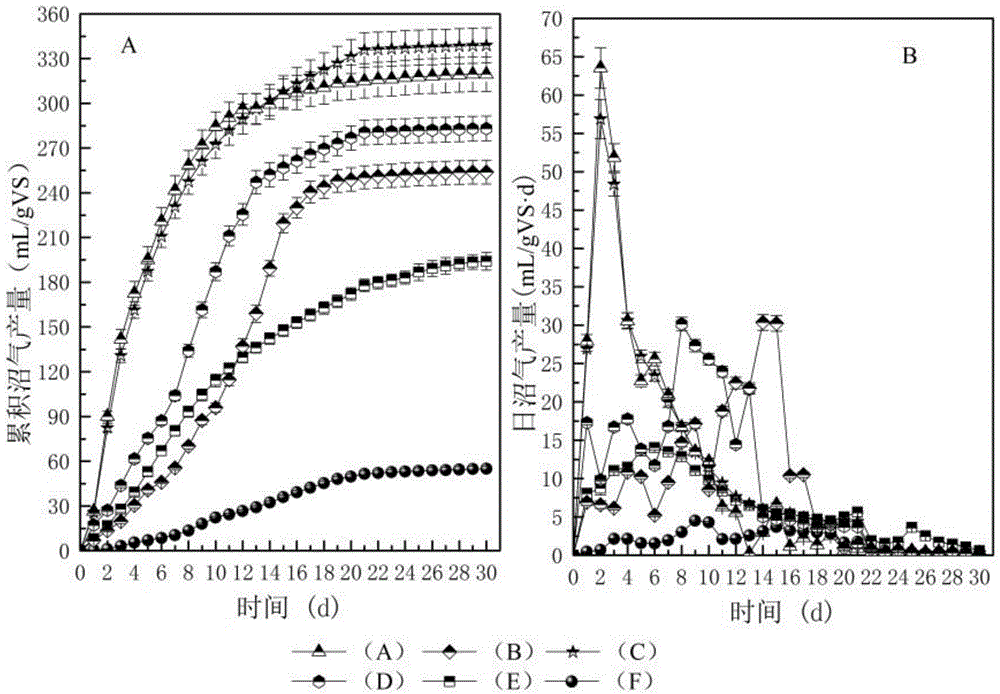

The invention relates to a method using charcoal for promoting anaerobic digestion of sludge to produce methane, and the method comprises the following steps: (1) adding 0.5 to 5% by volume of the dry charcoal powder into the sludge to obtain a mixed material, adjusting the mixed material pH value to 7.5-8; and (2) putting the mixed material into a sealed anaerobic digestion device for anaerobic digestion of the sludge in the condition of an intermediate temperate of 30-40 DEG C or a high temperature of 50 to 60 DEG C by means of stirring. Compared with the prior art, the charcoal powder is used as an adding material, organic matters in the sludge are fully recycled and reused, the environment pollution is reduced, the sludge anaerobic digestion time is brought forward by 15-25%, the methane production yield is increased by 40-60%; the method is simple in operation, low in investment and treatment cost, and conductive to reducing environment pollution of the sludge, separation of organic remains produced by the anaerobic digestion of the sludge and the charcoal is not needed, and the organic remains can be directly applied to soil as a soil conditioner.

Owner:TONGJI UNIV

Sludge dewatering integrated process

InactiveCN101786787ARaise the pHReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge cakeBrick

The invention discloses a sludge dewatering integrated process, which is characterized by adopting the following steps: (1), pumping sludge from a secondary sedimentation tank behind an aeration tank into a sludge concentration tank with a sludge lifting pump to concentrate the sludge for 13 to 20 hours so as to reduce volume of the sludge primarily; (2), pumping the sludge subjected to primary volume reduction into a quality-regulating tank with the sludge lifting pump, adding burnt lime in an amount of 1 to 3 percent based on the total weight of the sludge and alkaline industrial waste residue in an amount of 2 to 6 percent based on the total weight of the sludge into the quality-regulating tank, and stirring the mixture at a low speed to regulate quality for 4 to 6 hours; (3), dewatering the sludge subjected to quality regulation with a dewaterer to make sludge cakes; (4), naturally drying the dewatered sludge cakes for about 10 days; and (5), burning the naturally dried sludge cakes into raw materials for preparing cement, processing the naturally dried sludge cakes into raw materials for preparing bricks, processing the naturally dried sludge cakes into autoclaved geotechnical engineering materials or curing the naturally dried sludge cakes into daily covering materials for refuse landfills. The process of the invention has the advantages of effectively reducing water content of sludge, along with low processing cost.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

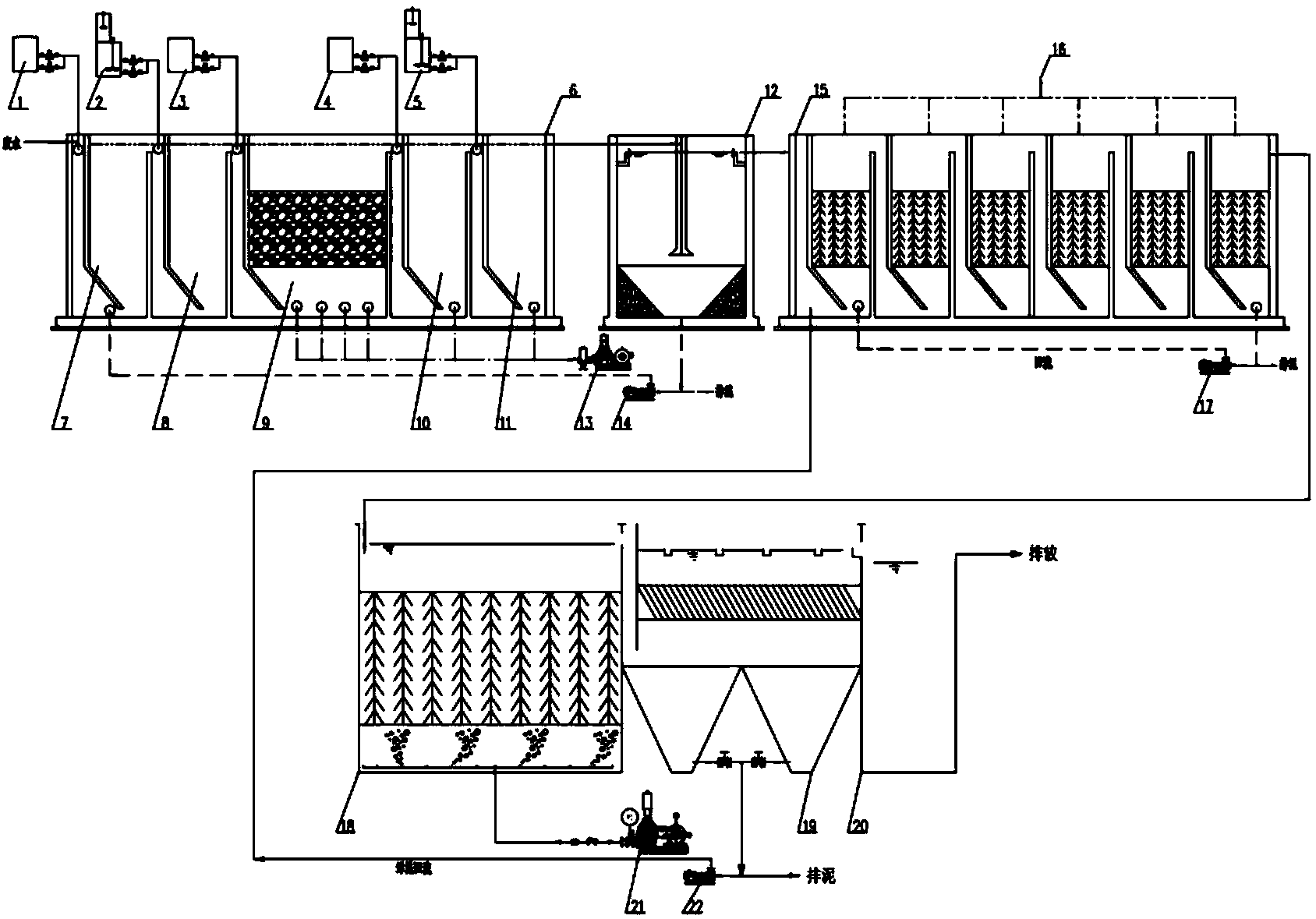

Advanced oxidation-biological treatment device for non-biodegradable waste water

ActiveCN103755097AImprove the efficiency of drug useReduce energy consumptionMultistage water/sewage treatmentAnaerobic digestionReclaimed water

The invention relates to an advanced oxidation-biological treatment device for non-biodegradable waste water. The device comprises a baffle plate Fenton reactor (6), a precipitating pond (12), a baffle plate anaerobic pond (15) and a contact oxidization pond (18). Waste water to be treated flows through each reaction pond of the baffle plate Fenton reactor in sequence, reacts and enters the precipitating pond for precipitating, supernate in the precipitating pond enters each compartment of the baffle plate anaerobic pond in sequence for undergoing anaerobic digestion, water undergoing anaerobic treatment in the baffle plate anaerobic pond enters the contact oxidation pond for undergoing aerobic treatment, treated effluent enters an oblique-tube precipitating pond, and sludge undergoing secondary precipitation in the oblique-tube precipitating pond returns to the foremost end of the baffle plate anaerobic pond through a sludge reflux pump to realize reduction of the residual sludge, and treated water is stored in the reclaimed water pond. Compared with the prior art, the advanced oxidation-biological treatment device has the advantages of high agent use efficiency, low energy consumption, simple structure and remarkable increase of the sludge digesting efficiency and the gas yield.

Owner:SHANGHAI JIAO TONG UNIV

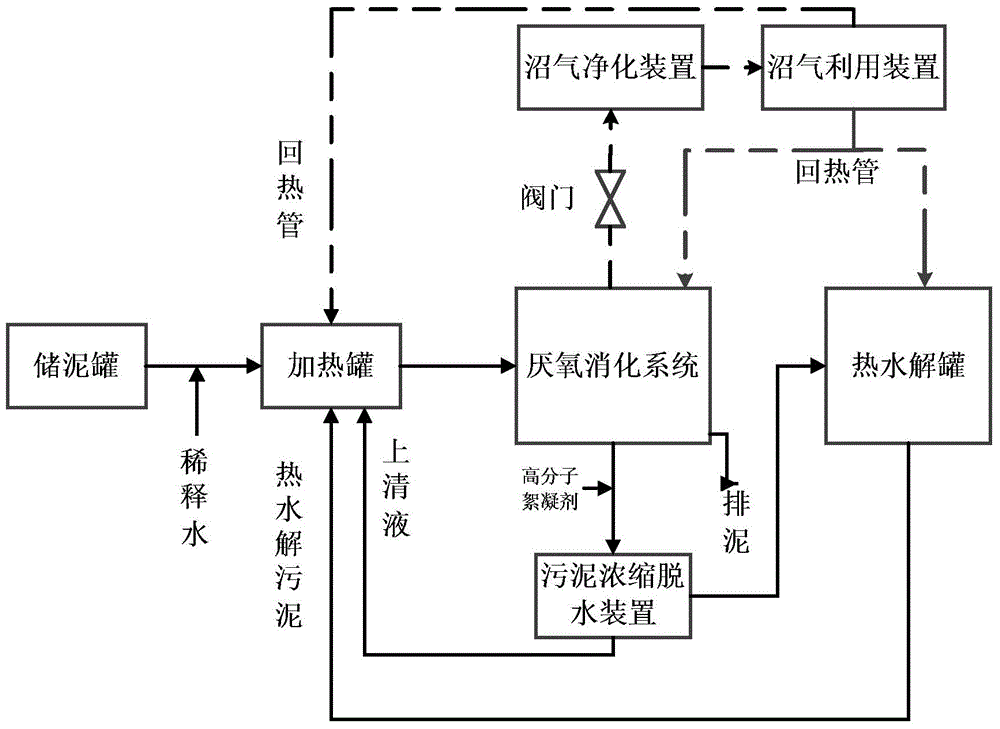

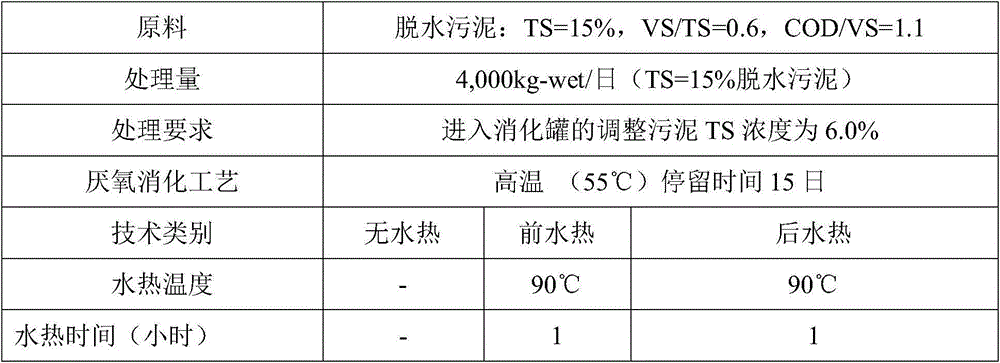

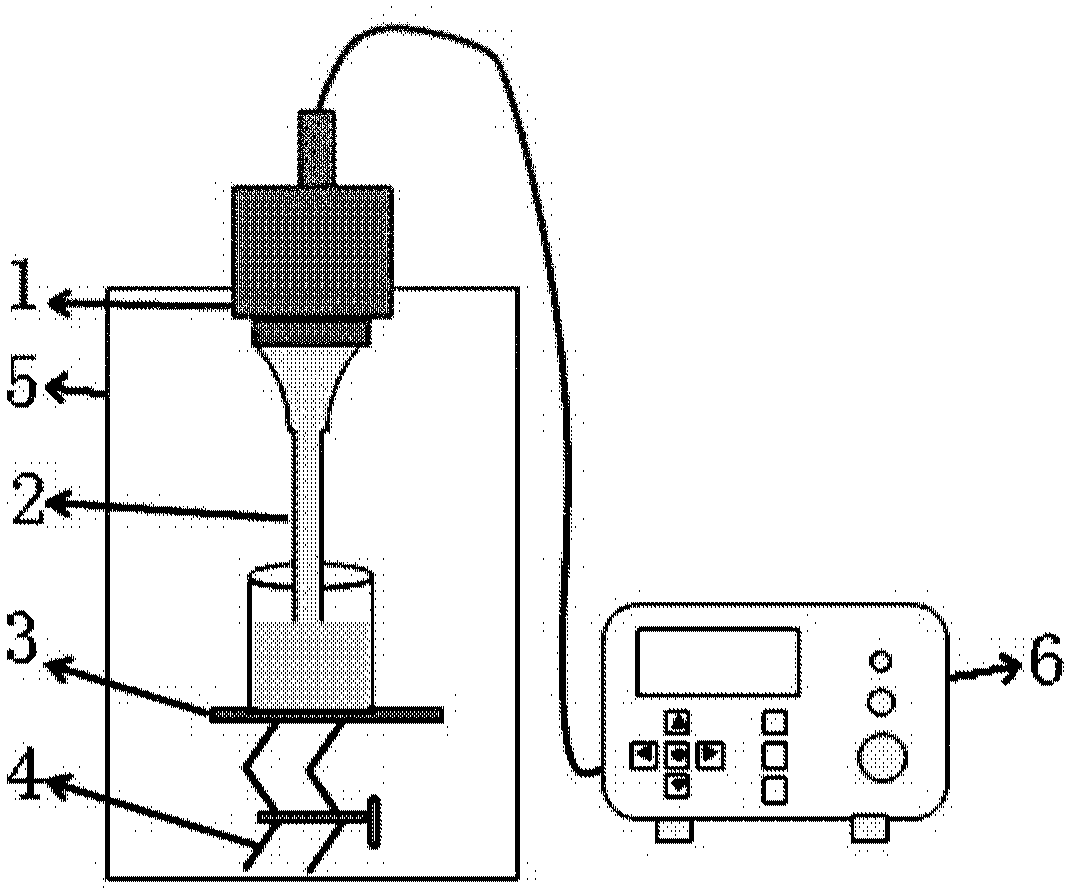

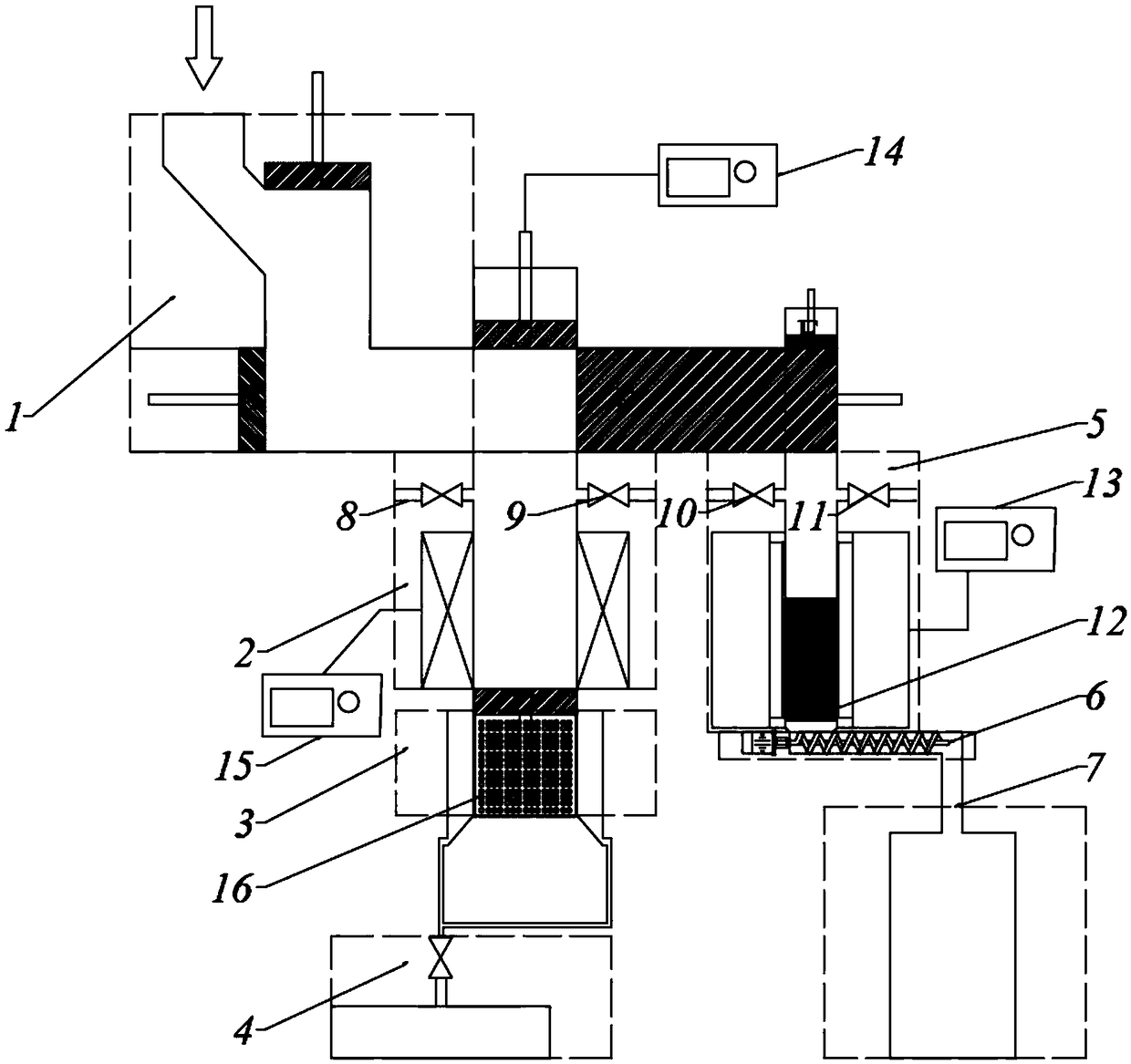

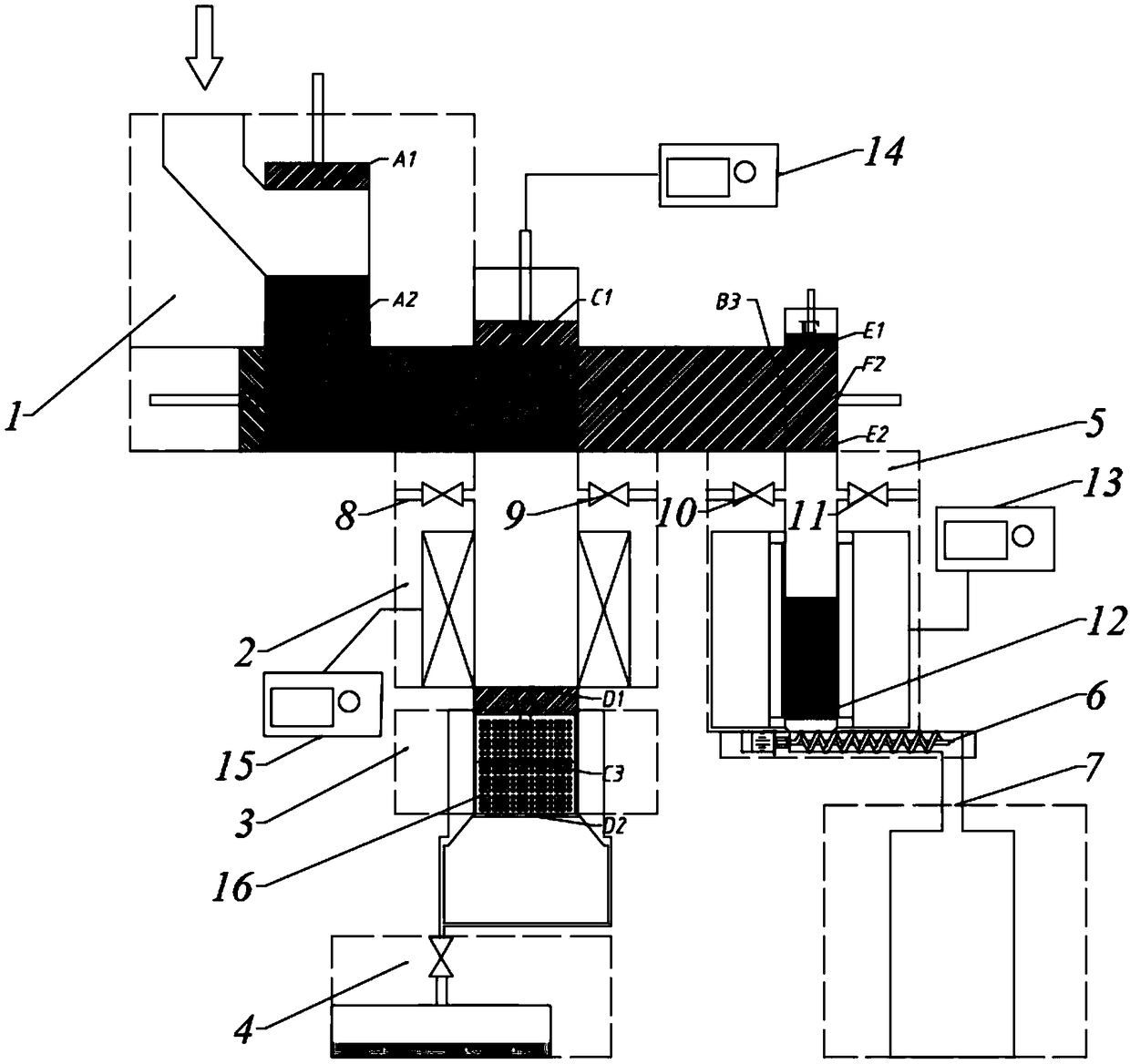

Anaerobic digestion sludge conditioning system and method

InactiveCN104909530AImproved Anaerobic Digestion PerformanceAchieve reductionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisEnergy transferBiogas production

The invention provides an anaerobic digestion sludge conditioning system. The anaerobic digestion sludge conditioning system comprises a sludge storage tank, a heating tank, an anaerobic digestion system, a methane purification device, a methane utilization device, a sludge concentration dewatering device, and a pyrohydrolysis reaction tank; the sludge storage tank, the heating tank, and the anaerobic digestion system are communicated successively; the anaerobic digestion system is communicated with the methane purification device and the sludge concentration dewatering device respectively; the sludge concentration dewatering device is communicated with the heating tank and the pyrohydrolysis reaction tank respectively; the methane purification device is communicated with the methane utilization device; the methane utilization device is communicated with the anaerobic digestion system and the pyrohydrolysis reaction tank respectively; and the pyrohydrolysis reaction tank is communicated with the heating tank. According to the anaerobic digestion sludge conditioning system, postposition pyrohydrolysis is adopted, so that energy consumed on the part of sludge easy for biodegradation in the prior art is transferred to the part of sludge difficult for biodegradation, biogas production efficiency is increased, energy utilization efficiency is increased greatly, and a large amount of operation cost is reduced for practical engineering.

Owner:SOUTHEAST UNIV

Method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge

ActiveCN103880259AEliminate Pollution PotentialImprove the efficiency of anaerobic digestionWaste based fuelBiological sludge treatmentBiogasAerobic digestion

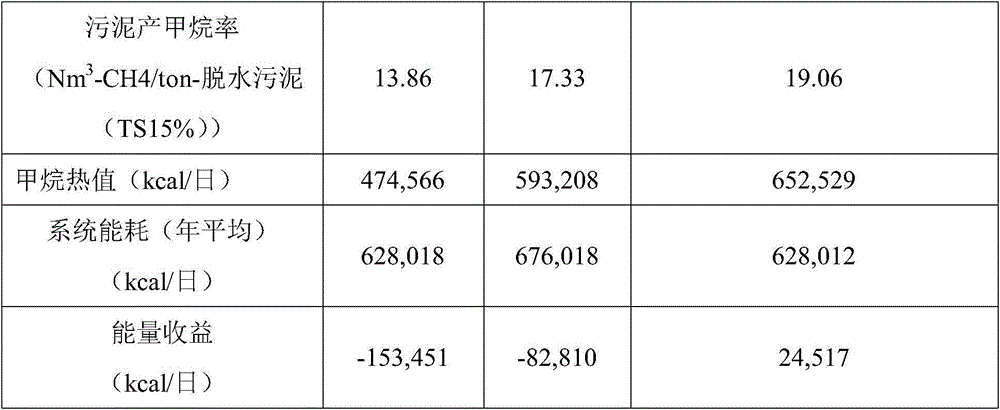

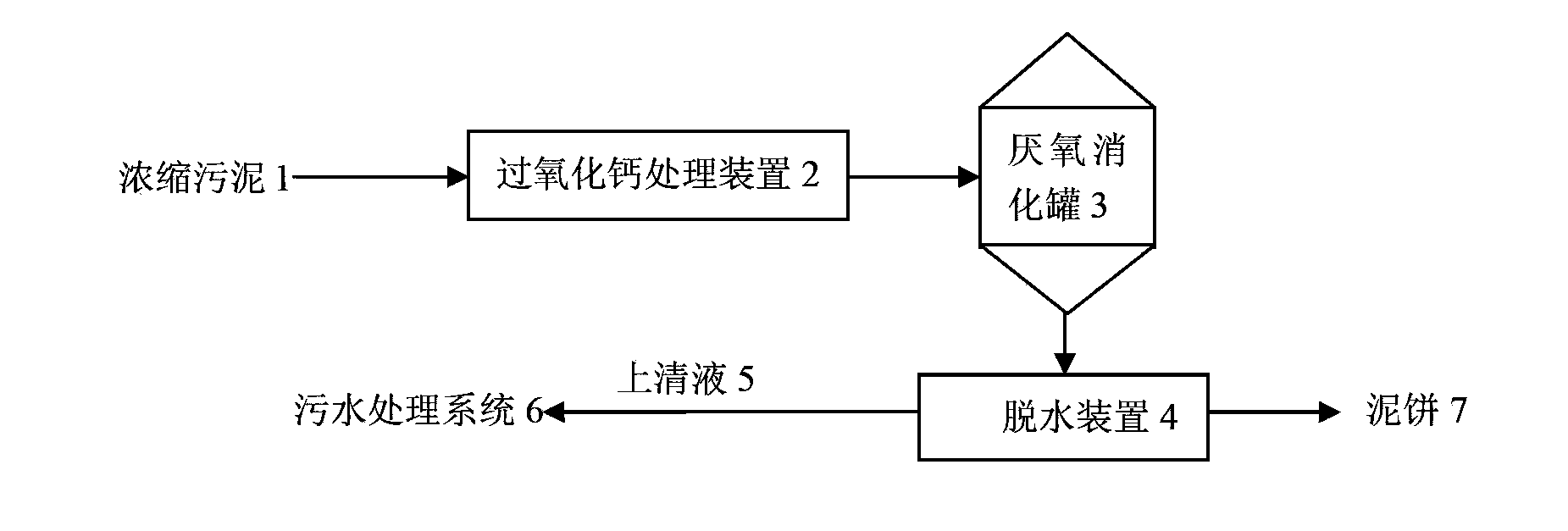

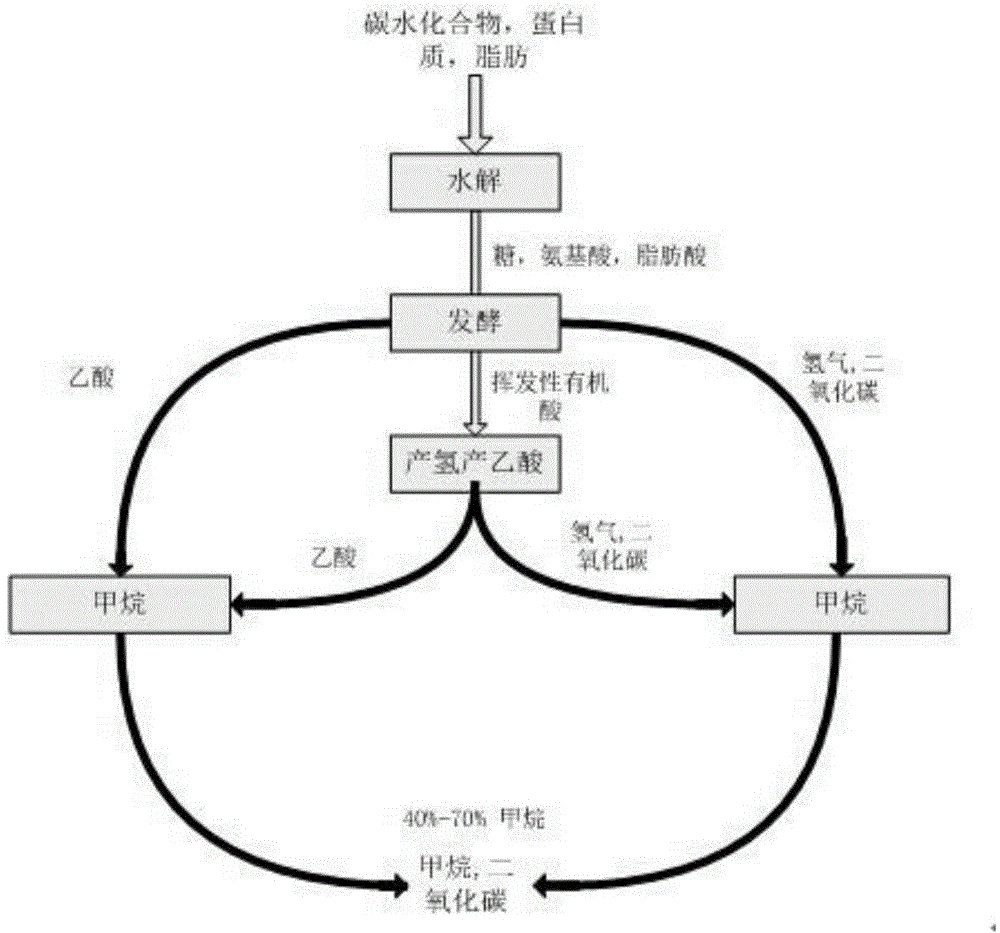

The invention relates to a method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge, which comprises the following steps: 1)a calcium peroxide processing unit: placing the calcium peroxide in the sludge, wherein the mass ratio of calcium peroxide to sludge is 0.01: 1-0.6:1, reacting for 1-24 hours, and hydrolyzing the sludge; and 2)an anaerobic digestion unit: after processing the calcium peroxide, performing anaerobic digestion on sludge under the effect of anaerobe and amphimicrobe in an anaerobic digestion tank, rapidly using an organic compound in the sludge, conversing to methane, carbon dioxide and water, increasing the sludge biogas output and then realizing the quantitative reduction. Compared with the prior art, the method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge has the advantages of low cost, shortened digestion time and easy enforcement.

Owner:TONGJI UNIV

Method for producing methane through mixed slaking of straw stalks subjected to alkali treatment and surplus sludge

ActiveCN104099374AIncrease productionSimple processWaste based fuelFermentationResource utilizationSludge

The invention discloses a method for producing methane through the mixed slaking of straw stalks subjected to alkali treatment and surplus sludge, and belongs to the technical field of solid waste disposal control and environment-friendly purification treatment. According to the invention, the mixed anaerobic fermentation is adopted to produce methane, the harmless disposal and resource utilization of wastes are realized while the straw stalks and surplus sludge are effectively treated, the system is stable in operation, the energy recovery rate is high, and a better treatment effect is achieved in the situation that the raw material sources are complex.

Owner:JIANGNAN UNIV

Multistage anaerobic digestion strengthened gas production method

ActiveCN103553289AEnhanced anaerobic digestion processImprove stabilityBiological sludge treatmentHigh pressureAerobic digestion

The invention relates to a multistage anaerobic digestion strengthened gas production method mainly comprising the steps of front-stage anaerobic digestion, high-temperature and high-pressure thermal hydrolysis and back-stage anaerobic digestion. After sludge is subjected to the front-stage anaerobic digestion treatment, easily-degraded organic matters are sufficiently decomposed and converted into marsh gas, the residual part mainly comprises difficultly-biodegraded organic matters and facultative bacteria which adapt to the anaerobic environment and can not be digested and utilized, and the organic matters account for over 50% of the total organic matters in the sludge and restrict the development of anaerobic digestion. The discharged material subjected to the front-stage anaerobic digestion is subjected to the high-temperature and high-pressure thermal hydrolysis treatment to force a cell wall to crack, substances in a cell to be dissolved out and a colloid structure of an extracellular polymer to be broken, so that parts of difficultly-biodegraded organic matters are converted into the easily-degraded organic matters; the sludge subjected to the thermal hydrolysis treatment is added into a back-stage anaerobic digestion system to further realize the degradation and anaerobic gas production of the organic matters. By using the multistage anaerobic digestion strengthened gas production method, the degradation rate and gas production rate of the organic matters in the sludge are radically increased, the quantity and volume of the sludge are reduced, the sludge stabilizing effect is enhanced, and the quality of anaerobic digestion sludge is improved.

Owner:TONGJI UNIV

Method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide

InactiveCN102424506AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentChemistryAerobic digestion

Belonging to the technical field of solid waste treatment, the invention relates to a method for promoting anaerobic digestion of excess sludge through pretreatment of ultrasonic waves and hydrogen peroxide. The method comprises: subjecting the excess sludge of an urban sewage treatment plant to gravity thickening, then adding a certain amount of hydrogen peroxide, conducting rapid stirring and sending the sludge into an ultrasonic reactor for ultrasonic treatment, in which the combined action of ultrasonic waves and hydrogen peroxide destroys the bacterial cell wall structure of the sludge, thus leading to leakage of the cell contents and content increase of dissolved organic matters in water, then sending the treated sludge into an anaerobic digestion reactor for subsequent mesophilic anaerobic digestion; delivering the biogas generated from anaerobic digestion to a gas collection gas for comprehensive utilization. After treatment, the concentration of SCOD (soluble chemical oxygen demand) in the liquid phase sludge can be increased by 23.83 times to 41.18 times, the biogas output can be increased by 17.40%-55.37%, and the methane content of the biogas can be increased by 10%-20%, thus reducing the energy consumption of ultrasonic treatment. For sewage treatment plants of different scales, only by making corresponding modification on existing facilities can good effects be achieved.

Owner:NANKAI UNIV

Method for utilizing enhanced pretreatment to promote anaerobic digestion of excess sludge

InactiveCN102424507AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentSolubilityChemical oxygen demand

Owner:NANKAI UNIV

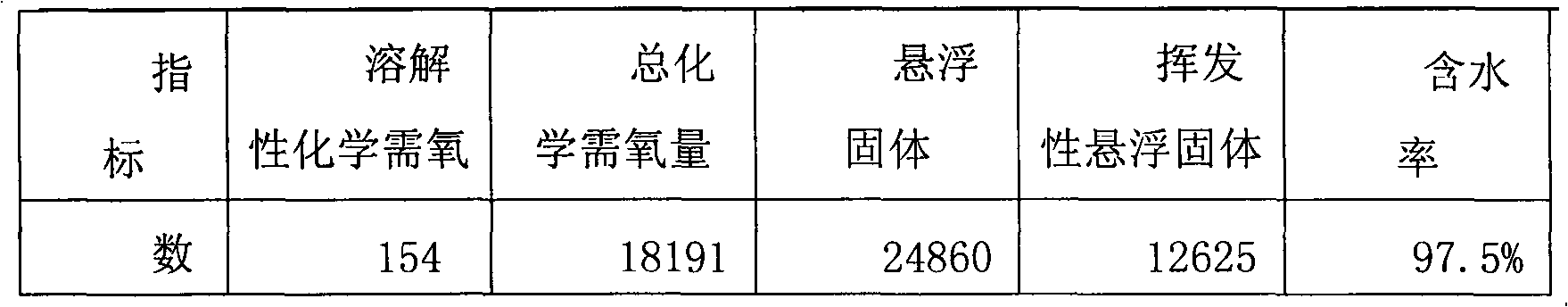

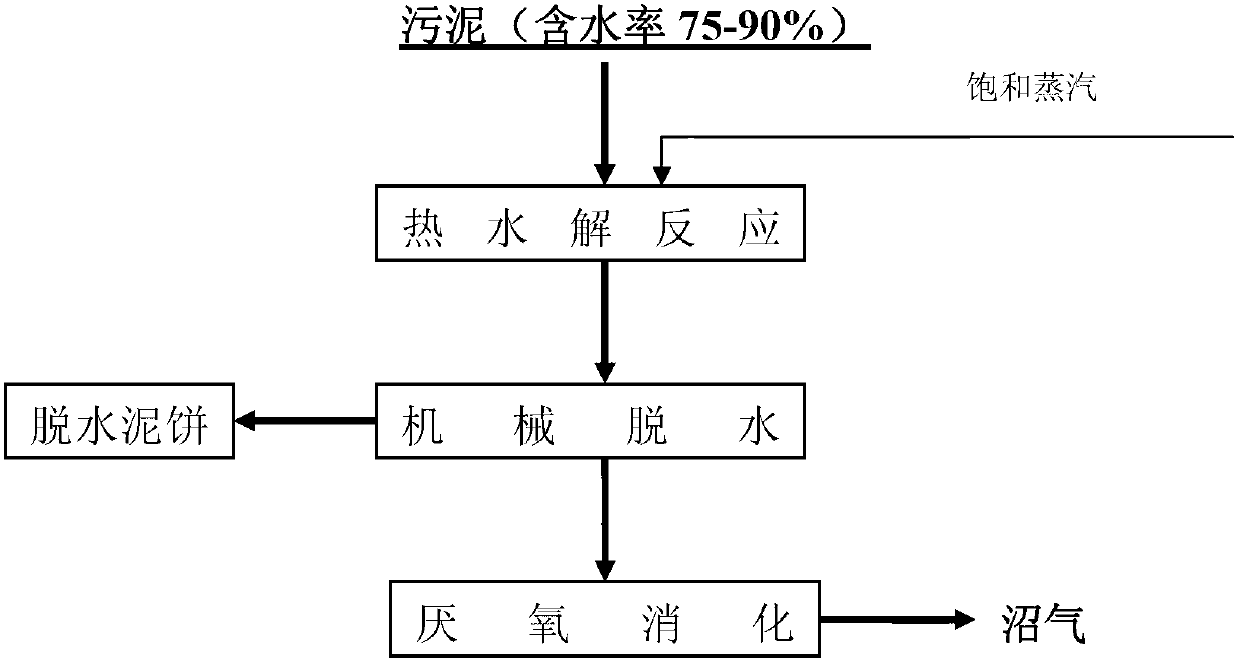

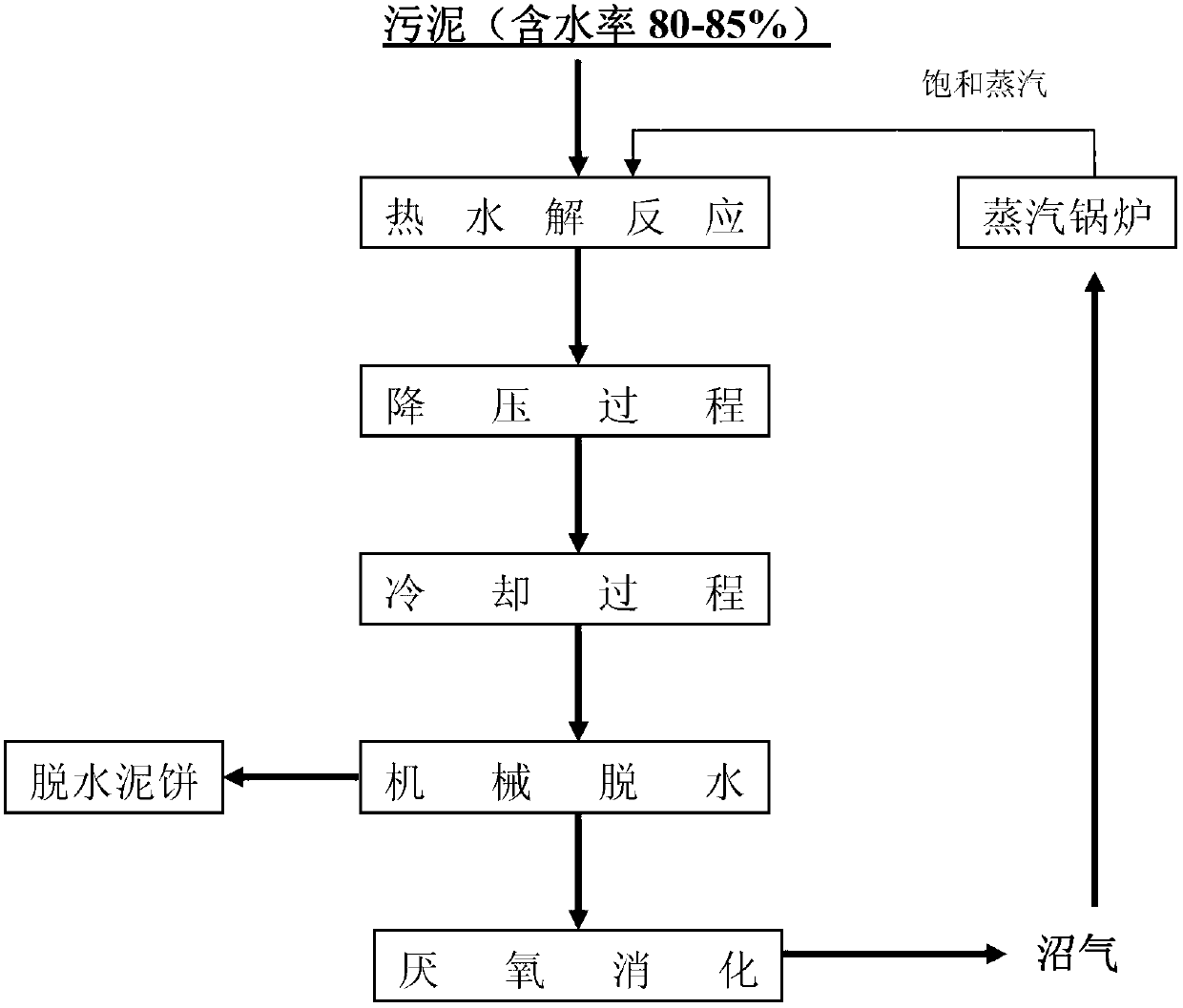

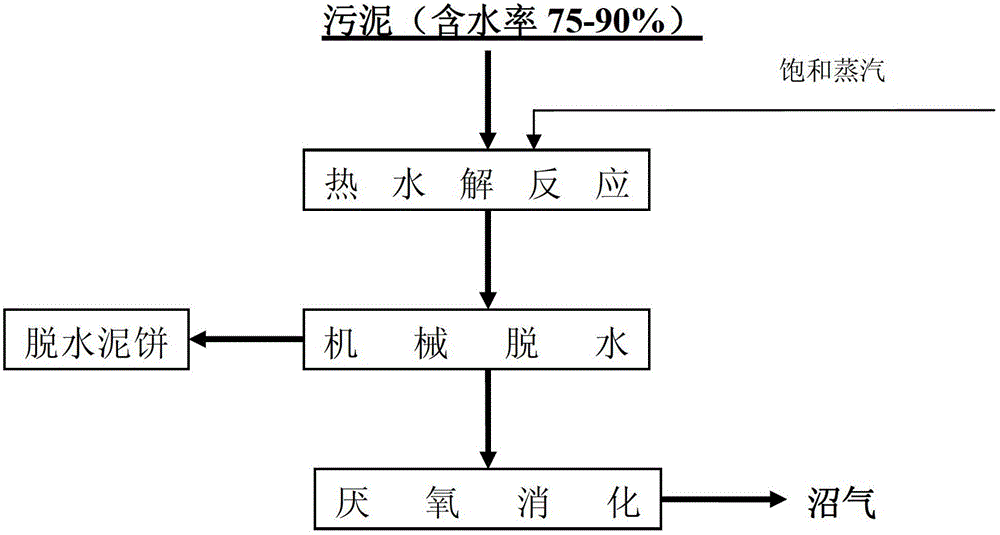

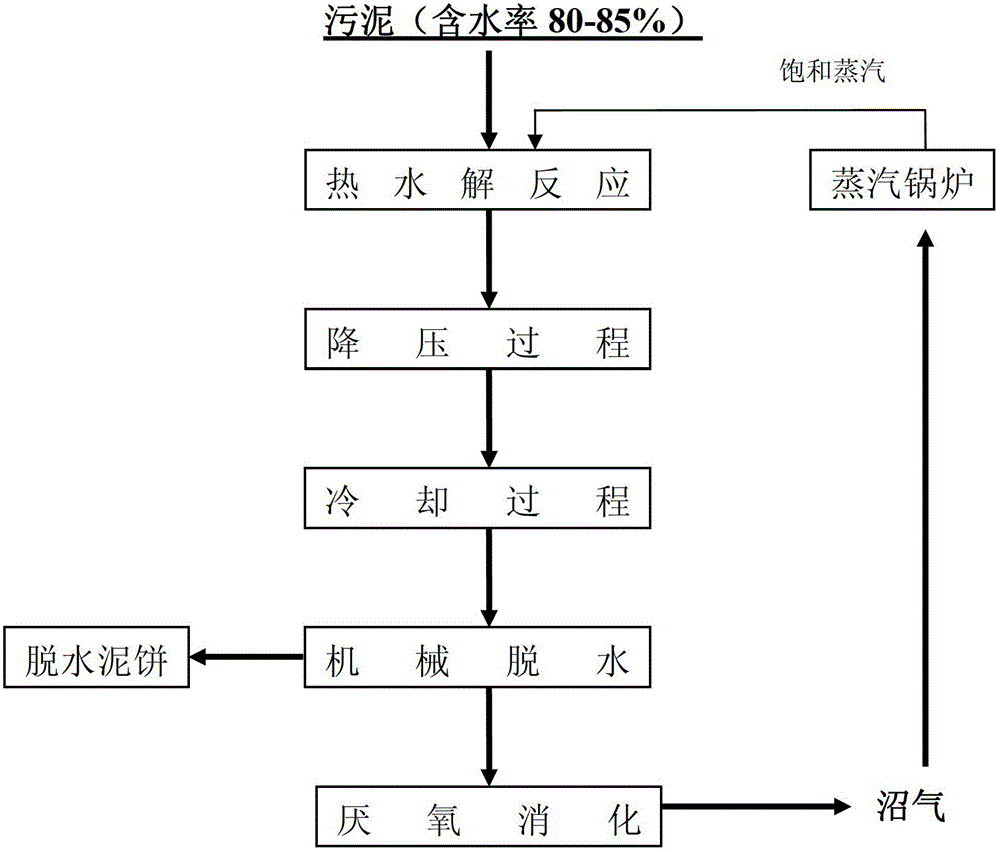

Sludge treatment and resource utilization method based on pyrohydrolysis and application thereof

ActiveCN103130388AHarmlessImproved Anaerobic Digestion PerformanceBio-organic fraction processingSolid waste disposalResource utilizationDesorption

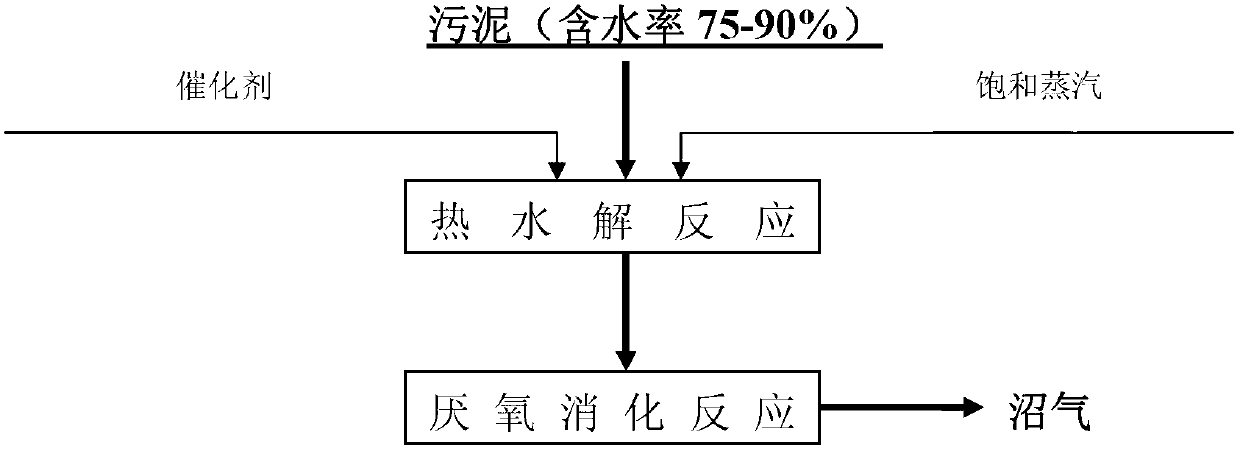

The invention belongs to the technical field of sludge treatment, and discloses a sludge treatment and resource utilization method based on pyrohydrolysis and application of the sludge treatment and resource utilization method based on the pyrohydrolysis. The sludge treatment and resource utilization method based on the pyrohydrolysis comprises injecting sludge with moisture content of 75%-90% into a reaction kettle, then injecting saturated steam with pressure of 1.5MPa-2.5MPa into the reaction kettle, stopping injecting the saturated steam when the temperature of the sludge reaches 150DEG C-185DEG C, maintaining the state for 0-25min, and obtaining slurry of the pyrohydrolysis; carrying out mechanical dehydration on the slurry, and obtaining desorption liquid and dehydration mud cakes; and carrying out an anaerobic digestion reaction on the desorption liquid, and obtaining methane. Processing temperature of the pyrohydrolysis is low, heating time of the sludge and total processing time of the sludge treatment and resource utilization method can remarkably reduced, processing efficiency is improved, energy consumption is reduced, and cost is saved. The dehydration mud cakes obtained by the sludge treatment and resource utilization method can serve as raw materials of organic fertilizer, the obtained methane can be used for fuel of a boiler system, and finally reduction, harmless performance and recycling of the sludge are achieved.

Owner:SHENZHEN ECO SOLUTION TECH CORP

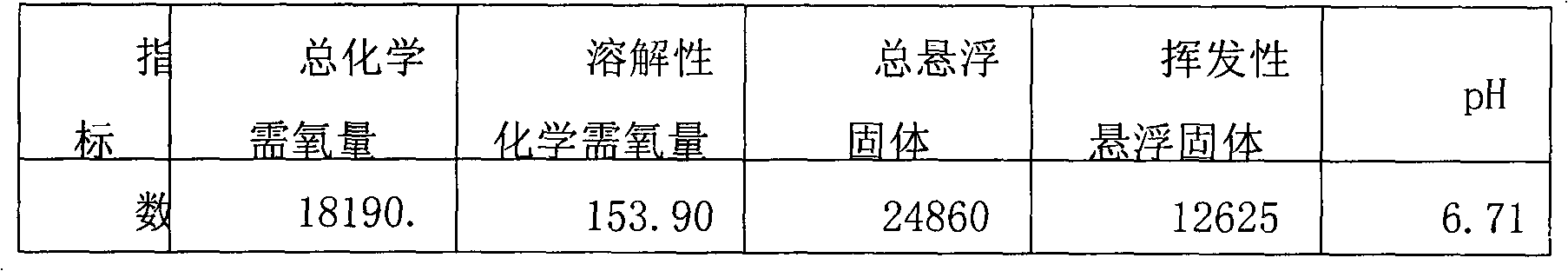

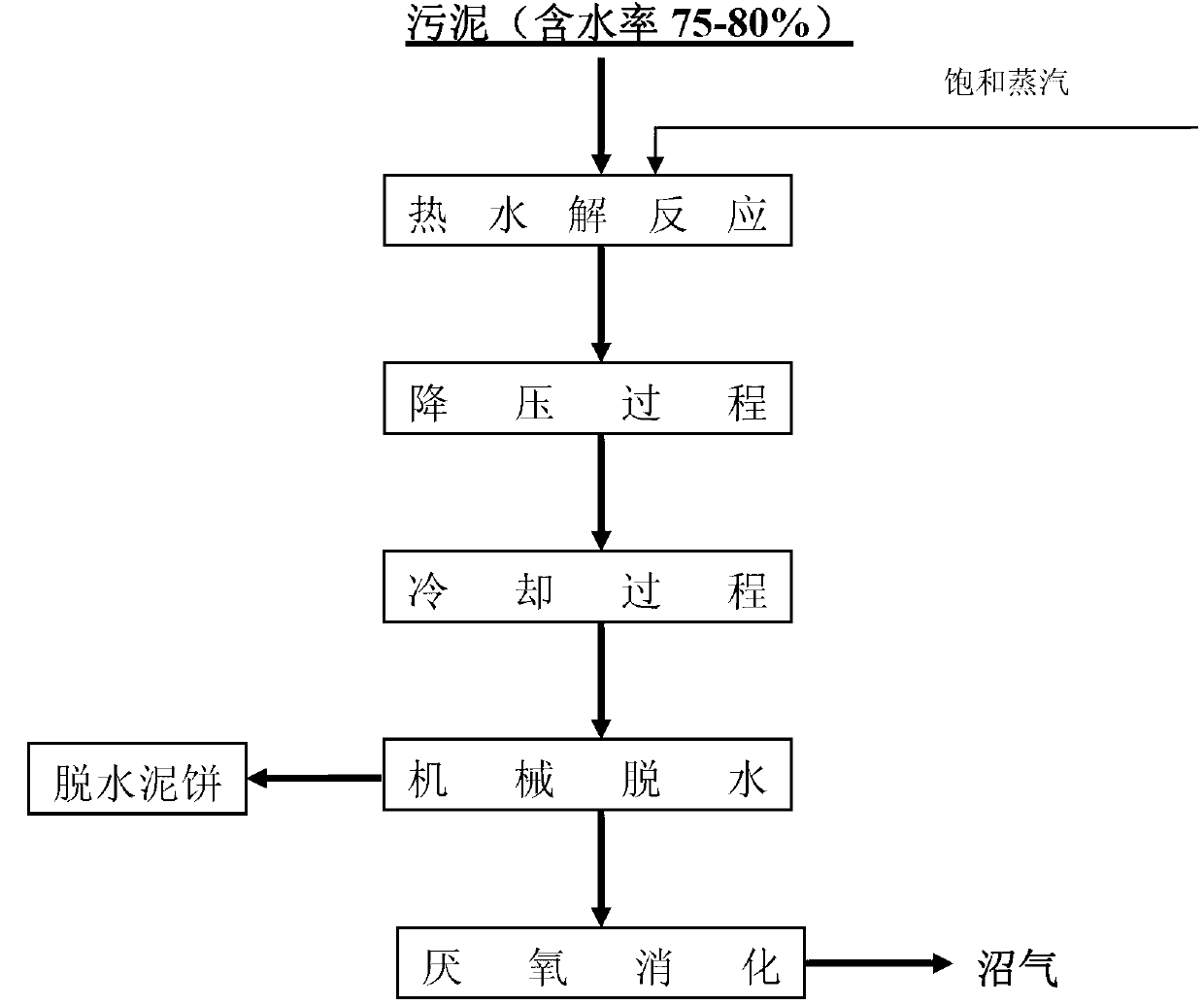

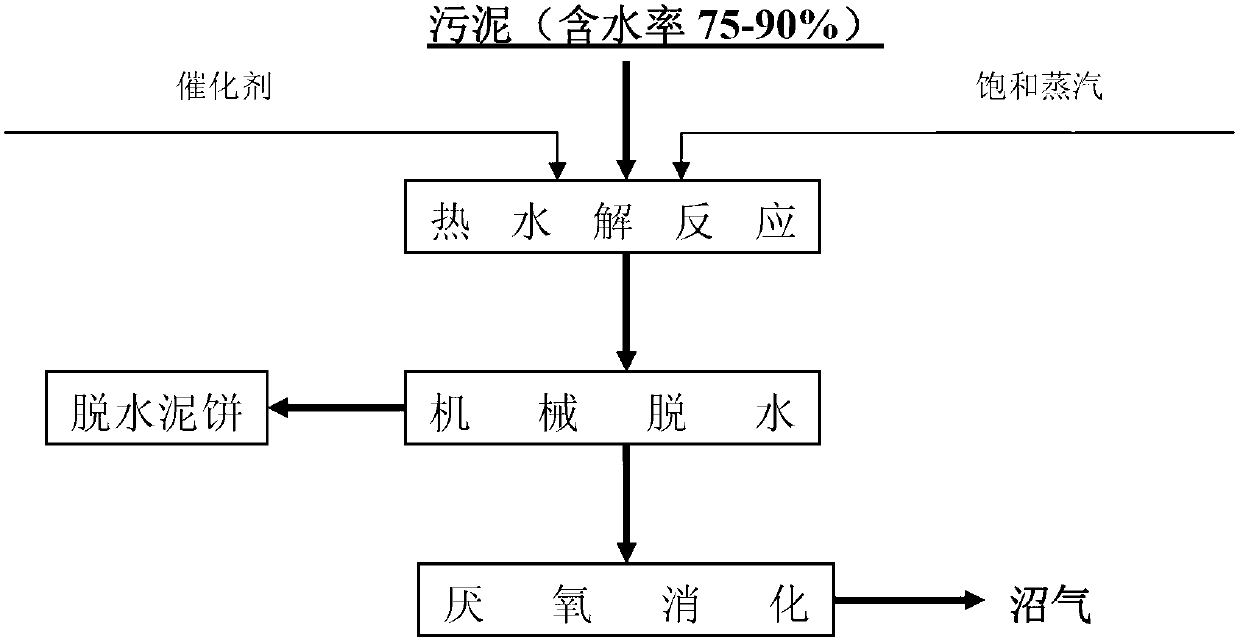

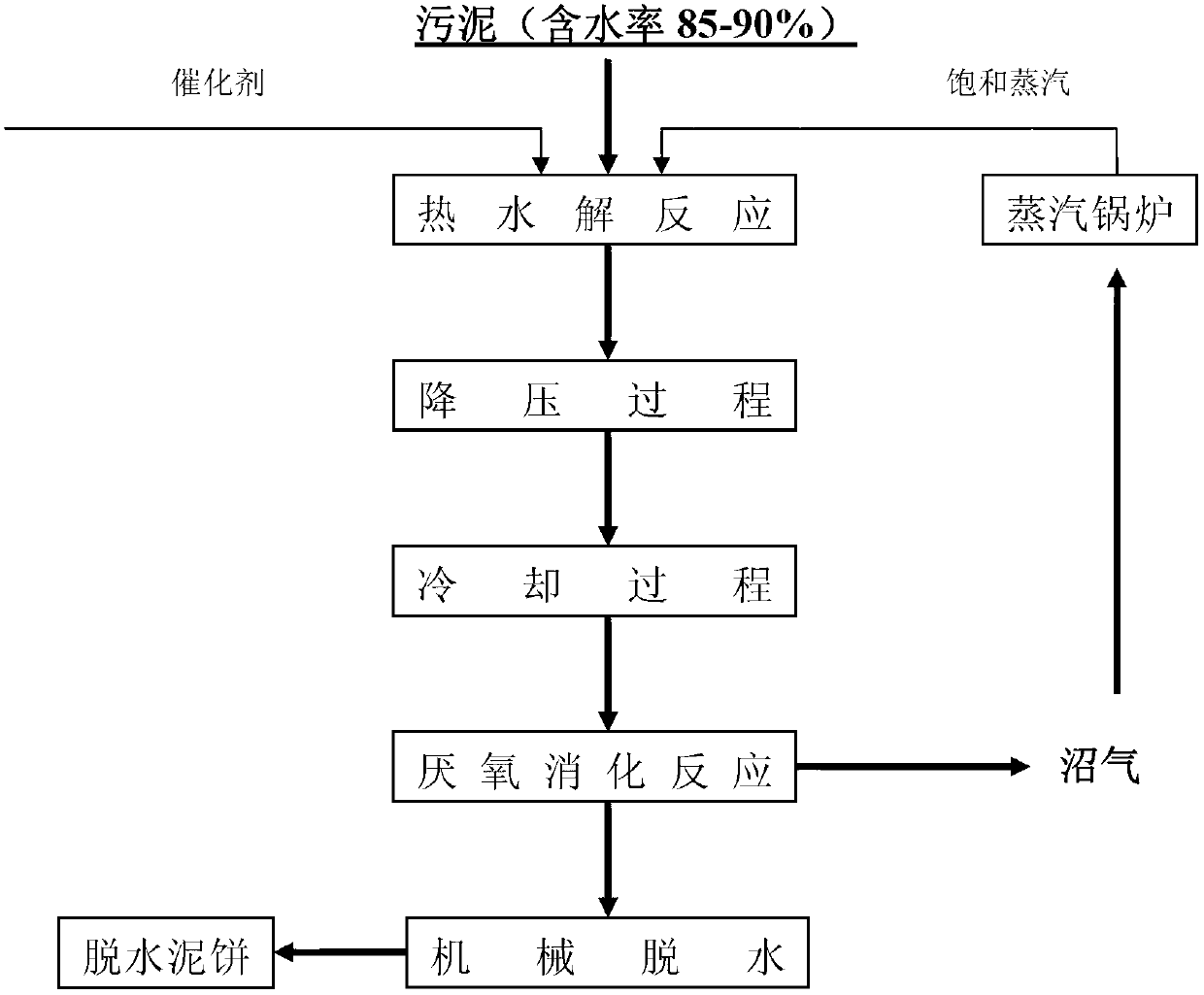

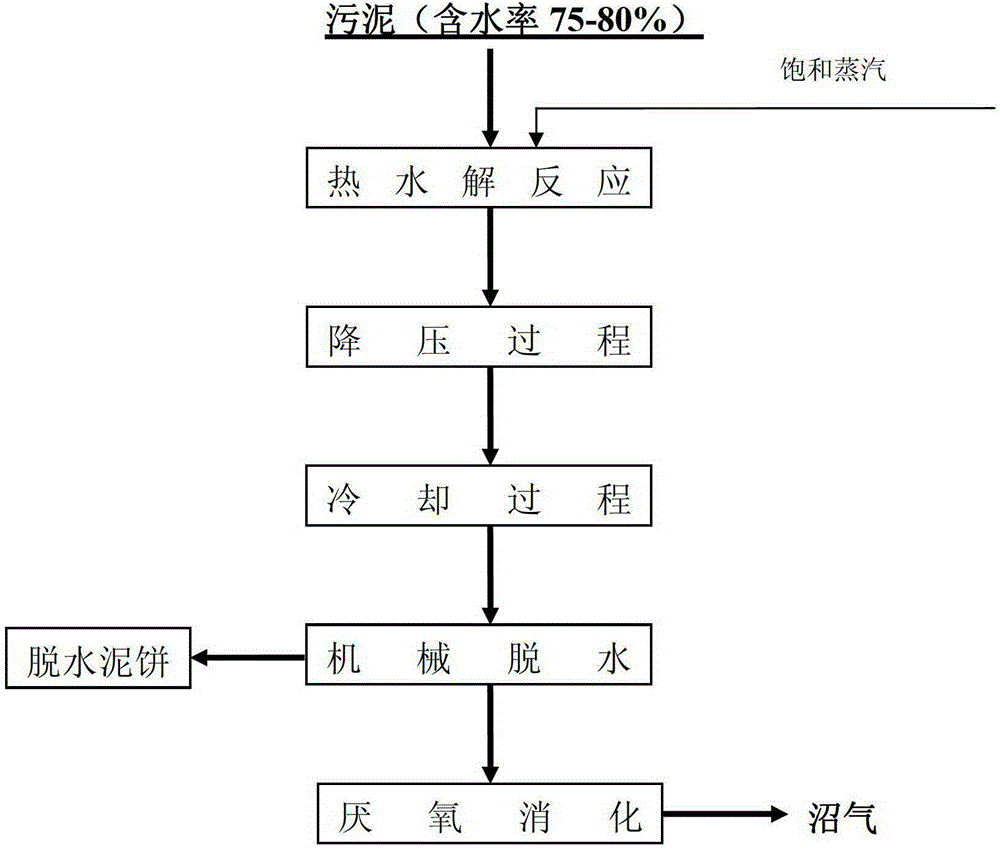

Method for treatment and resource utilization of sludge based on low-pressure catalytic thermal hydrolysis and application of method

InactiveCN103121778AHarmlessImproved Anaerobic Digestion PerformanceSludge treatment by de-watering/drying/thickeningSolid waste disposalWater contentChemistry

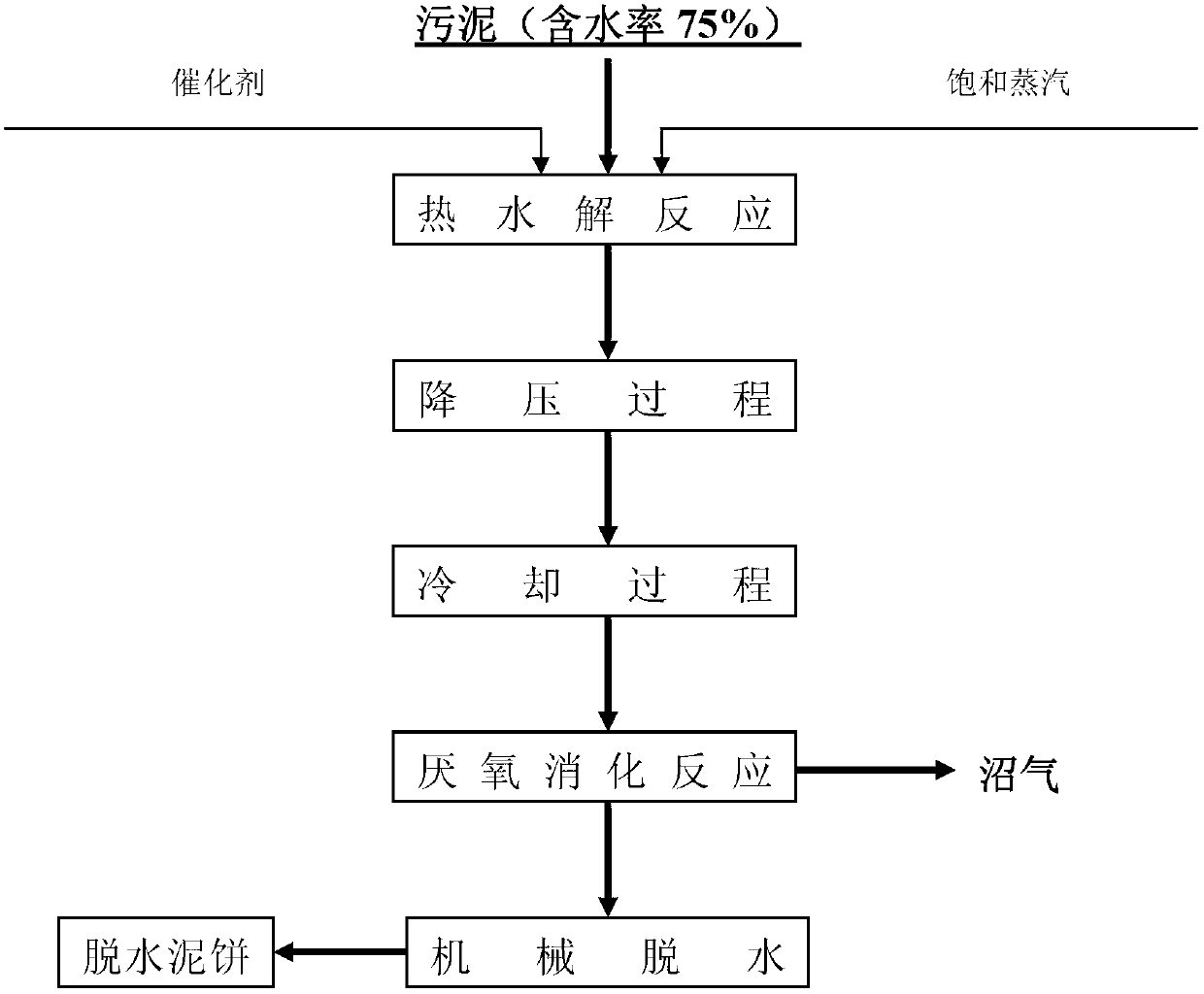

The invention belongs to the technical field of sludge treatment, and discloses a method for treatment and resource utilization of sludge based on low-pressure catalytic thermal hydrolysis and an application of the method. The method comprises the following steps of: injecting a catalyst and sludge with the water content of 75-90% into a reaction kettle, then injecting saturated steam with the pressure of 1.0-1.59MPa into the reaction kettle, and heating the sludge mixed with the catalyst, thus obtaining slurry after reaction; performing mechanical dehydration on the slurry to obtain removing liquid and dehydrated mud cakes; and performing anaerobic digestion reaction on the removing liquid to prepare a marsh gas. According to the method, the treatment time can be greatly shortened and the treatment efficiency can be improved by adding the catalyst, and the energy consumption and the running and investment costs are reduced at the same time. The marsh gas prepared by the method can be used as a fuel for a steam boiler in a system or can be sold; the dehydrated mud cakes can be prepared into a biomass fuel which can be used by boilers in the system or can be sold; and meanwhile, the mud cakes can also be used as an organic fertilizer raw material sold to fertilizer plants, so that the thorough harmlessness and recycling of the sludge are realized.

Owner:SHENZHEN ECO SOLUTION TECH CORP

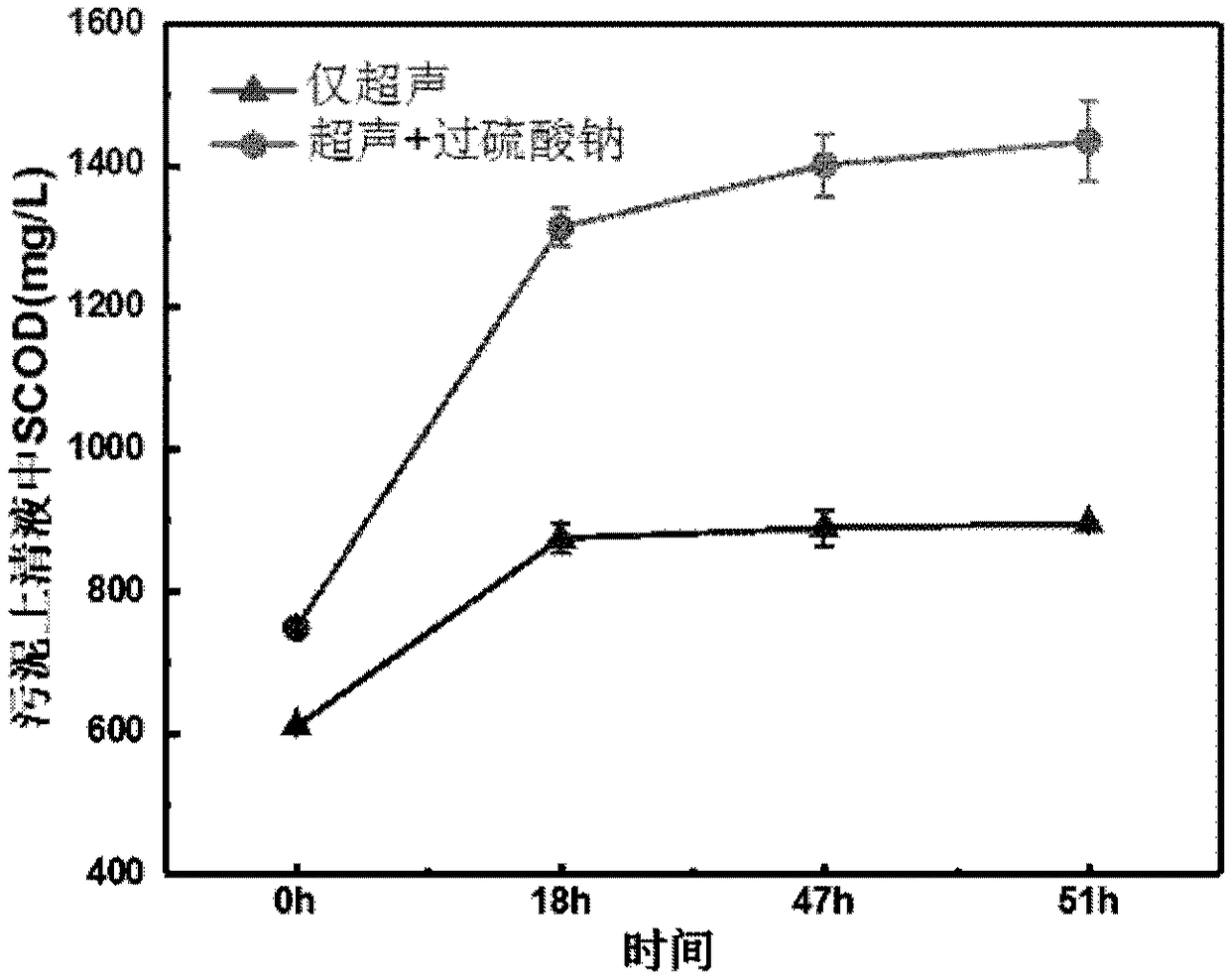

Sludge pretreatment method and method of producing acid by anaerobic fermentation of sludge

InactiveCN109354349AGood cracking effectCrack thoroughlySludge treatment by oxidationSpecific water treatment objectivesPretreatment methodSulfate

A sludge pretreatment method and a method of producing an acid by anaerobic fermentation of sludge are provided. The sludge pretreatment method includes: adding a persulfate into sludge, and mixing well to obtain mixed sludge; ultrasonically treating the mixed sludge. Further, the invention provides the method of producing an acid by anaerobic fermentation of sludge; after sludge is subjected theaforementioned pretreatment, the sludge is subjected to anaerobic fermentation. sludge floc disintegration is enhanced by advanced oxidation in combination with ultrasonic treatment, sludge disintegration degree is greatly increased, sludge biodegradability is improved, rich substrate is provided for subsequent hydrolysis stage of anaerobic fermentation, and the yield of volatile acids in the subsequent anaerobic fermentation of sludge is greatly increased.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

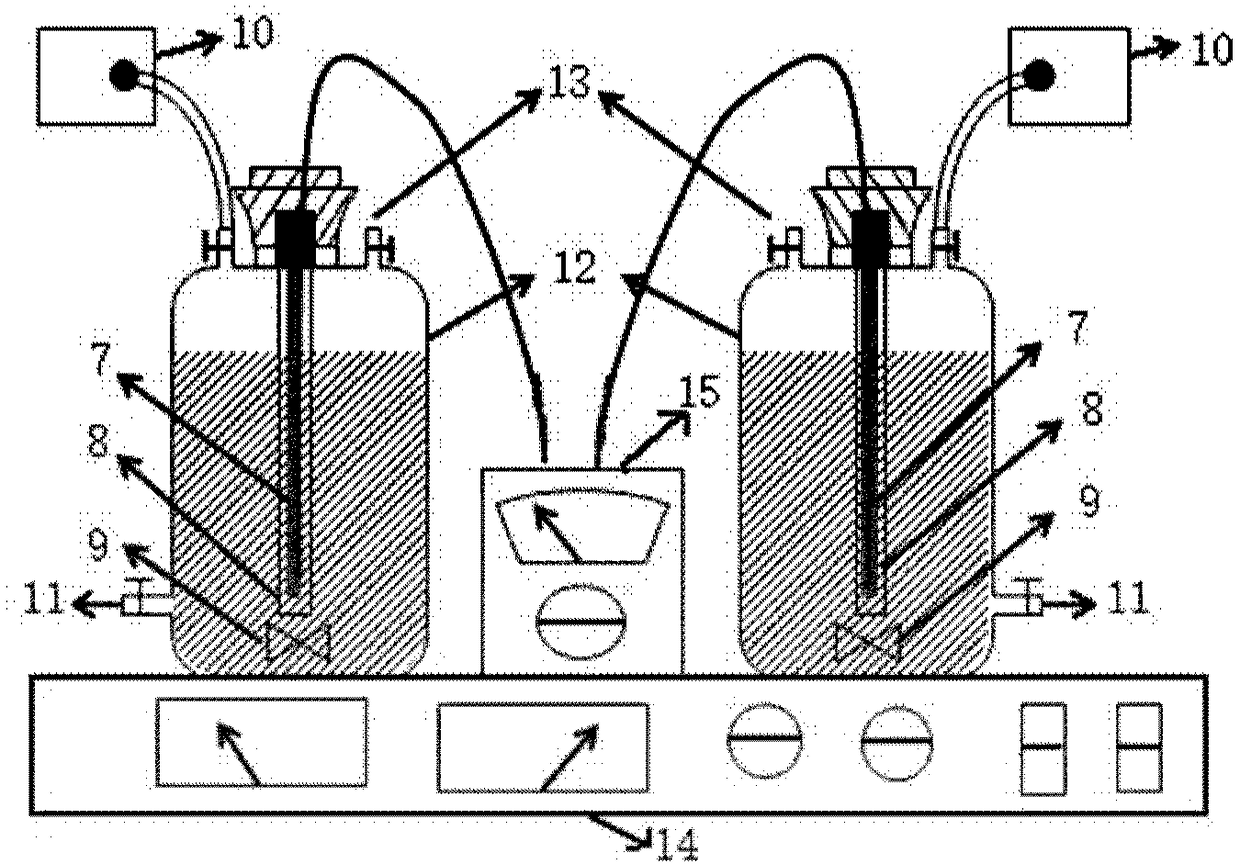

Mud-water separation type sludge anaerobic digestion treatment system and method

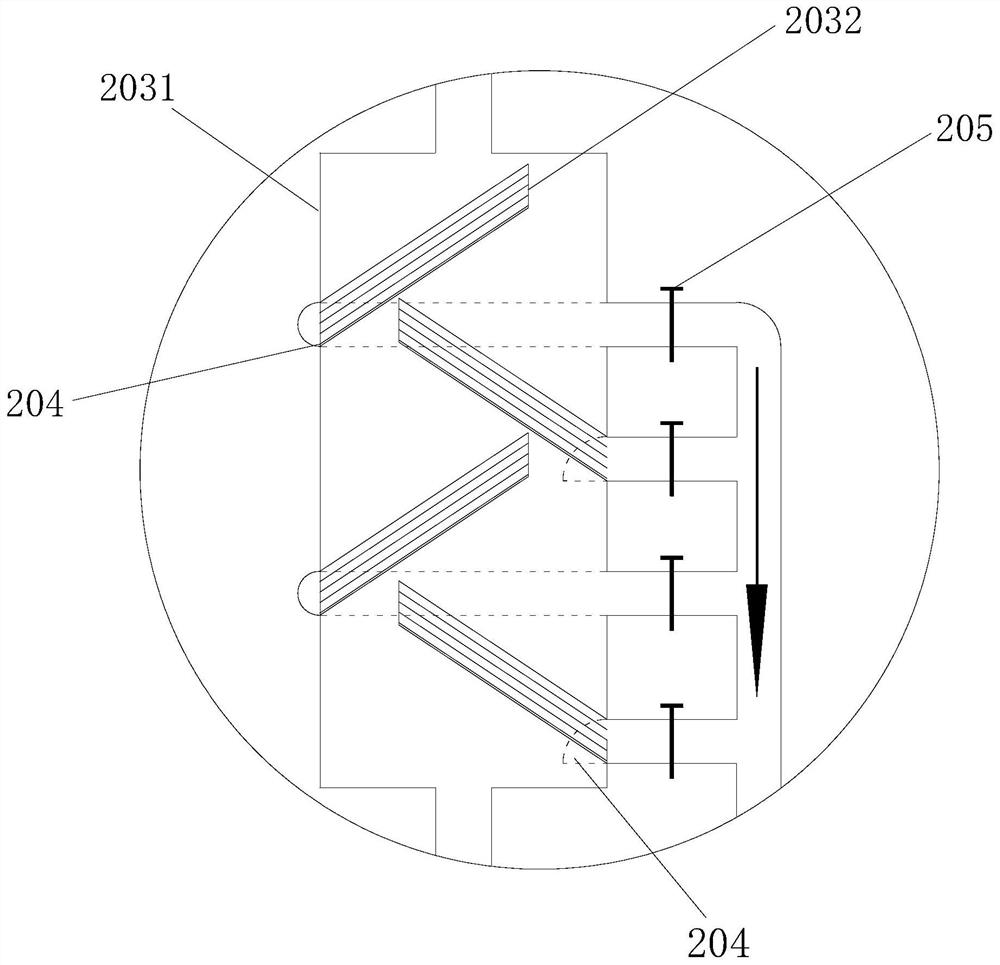

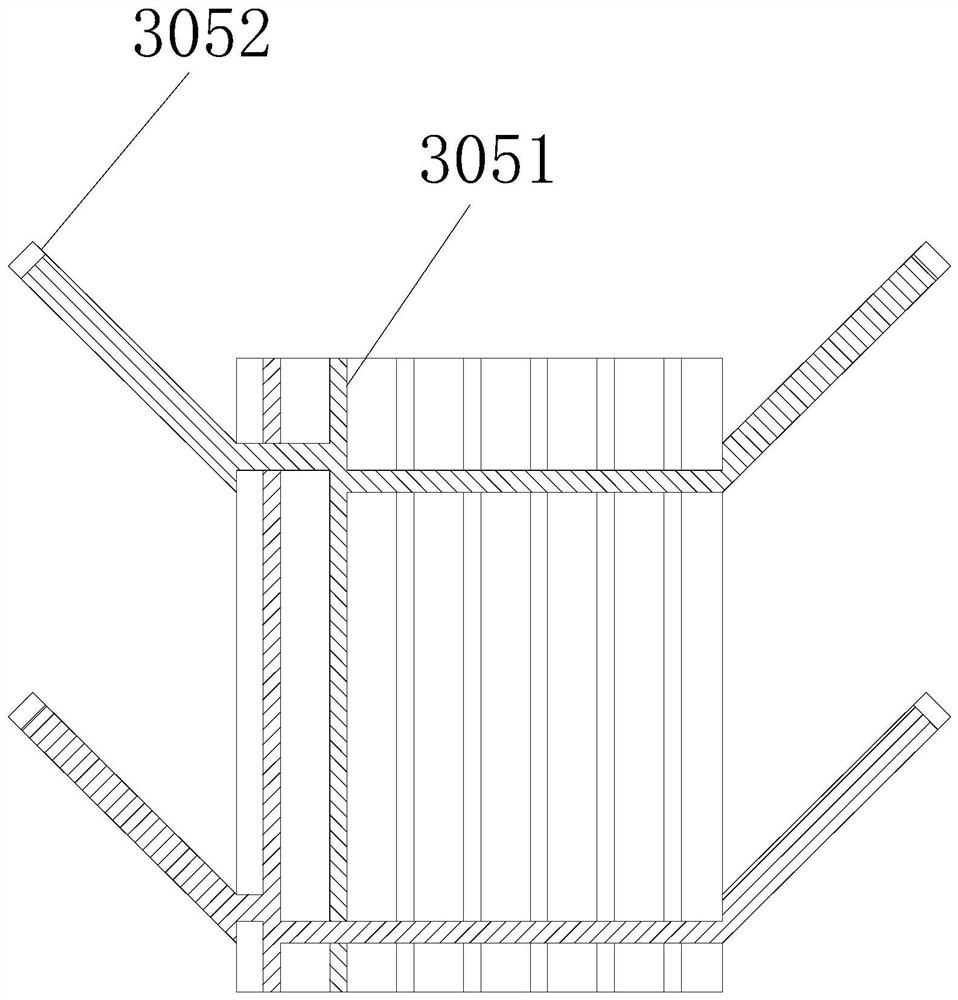

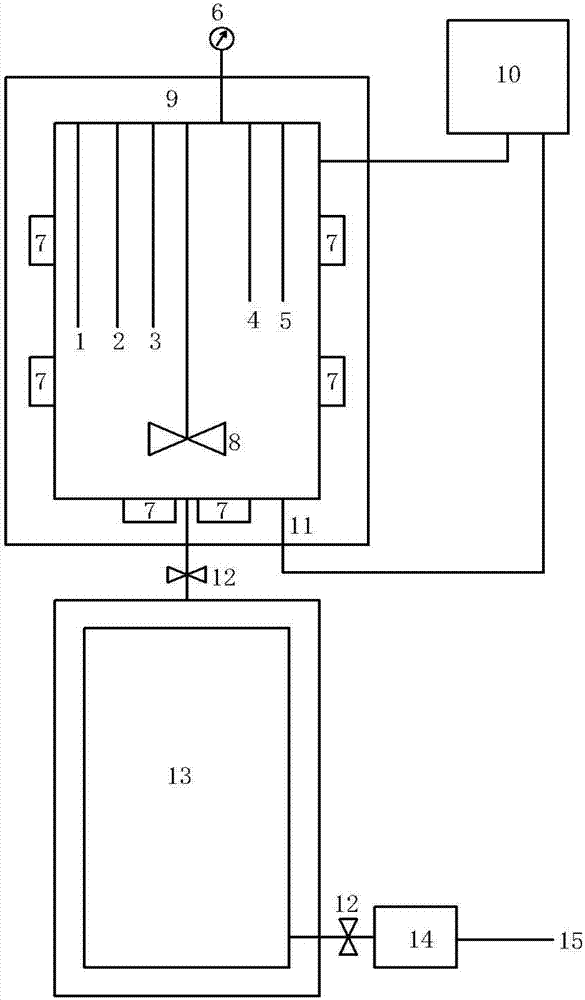

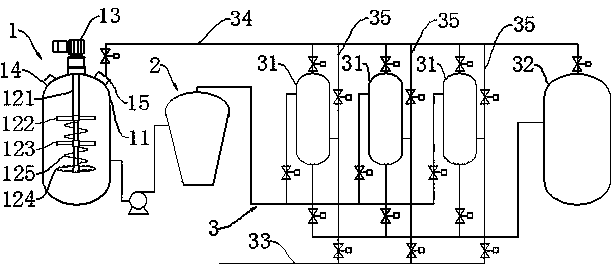

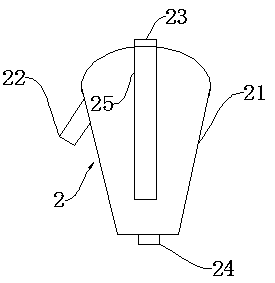

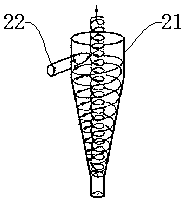

ActiveCN112794596AImprove the mixing effectFully anaerobic digestion reactionWater/sewage treatment by centrifugal separationWaste based fuelDigestion TreatmentProcess engineering

The invention discloses a mud-water separation type sludge anaerobic digestion treatment system, which comprises a sludge anaerobic digestion tank, a drainage assembly and a cyclone for mud-water separation. The sludge anaerobic digestion tank is provided with a sludge inlet pipeline, a sludge circulation stirring assembly and a detection element. The cyclone is respectively connected with the drainage assembly and the sludge inlet pipeline. A mechanical stirring assembly and a biogas circulating stirring assembly are arranged in the sludge anaerobic digestion tank, the mechanical stirring assembly is arranged at the side part of a tank body, and the biogas circulating stirring assembly not only collects biogas in the tank, but also stirs sludge by using the biogas. The sludge circulating stirring assembly is used for realizing circulating stirring of sludge in the tank and discharging the sludge out of the tank. The detection element is used for detecting the liquid level, the temperature, the pressure, the viscosity and the potential of the sludge. The treatment system has the advantages of flexibility in disassembly and assembly, small occupied area, high space utilization rate and the like. The invention further discloses a sludge-water separation type sludge anaerobic digestion treatment method. The anaerobic digestion efficiency and dehydration performance of the sludge are improved, and the sludge volume is reduced.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

Pretreatment method of two-stage electrochemical reinforcement of anaerobic digestion performance of sludge

ActiveCN106396322AImproved Anaerobic Digestion PerformanceEasy to destroySpecific water treatment objectivesWaste based fuelPretreatment methodRetention time

The invention discloses a pretreatment method of two-stage electrochemical reinforcement of the anaerobic digestion performance of sludge. The method is composed of two parts, i.e., two-stage electrochemical pretreatment and anaerobic fermentation of sludge. Through the electrochemical pretreatment, residual sludge of a sewage treatment plant is improved in the performance of anaerobic digestion for production of biogas. Specifically, residual sludge from the sewage treatment plant is concentrated, then subjected to the two-stage electrochemical pretreatment and then added into an anaerobic fermentation tank. Through reinforcement of the two-stage electrochemical pretreatment, the accumulative methane output after anaerobic digestion of the residual sludge from the sewage treatment plant is increased by 0.5 to 1.5 times and retention time needed for stabilization of the sludge is reduced by 5 to 9 d compared with one-stage electrochemical pretreatment with same energy consumption. The method is applicable to treatment of the residual sludge of the sewage treatment plant and recovers biomass energy included in organic matters in recovered sludge in the form of methane; and the method is also applicable to reconstruction of conventional anaerobic digestion systems for sludge so as to improve the benefits of anaerobic digestion of sludge.

Owner:SHANGHAI JIAO TONG UNIV

Method for pretreating sludge by high-pressure microwaves

ActiveCN107055986AImprove reaction efficiencyImproved Anaerobic Digestion PerformanceSludge treatment by thermal conditioningSpecific water treatment objectivesMicrowaveLysis

The invention relates to a method for pretreating sludge by high-pressure microwaves. The method comprises the following specific steps of: (1) adding monoatomic base into concentrated remaining sludge in a secondary sedimentation tank, and adjusting pH to 9-11 to obtain a sludge-water mixture; (2) stirring the sludge-water mixture obtained in the step (1), carrying out microwave treatment, when the temperature of the sludge-water mixture reaches 75-85 DEG C, temporarily stopping radiation heating, adding a hydrogen peroxide solution with the concentration of 30% according to the mass ratio of H2O2 / TS of 0.15-0.25, slowly stirring, continuously carrying out radiation heating to 130-150 DEG C, and ensuring that the pressure of microwave treatment is more than 3bar, so as to obtain sludge digestive liquid; and (3) carrying out flashing evaporation treatment on the sludge digestive liquid obtained in the step (2), so as to obtain discharged sludge. The method has the advantages that the cell lysis of the sludge can be effectively enhanced, reducing and recycling utilization of the sludge is realized, the effect is stable, and no secondary pollution is caused.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

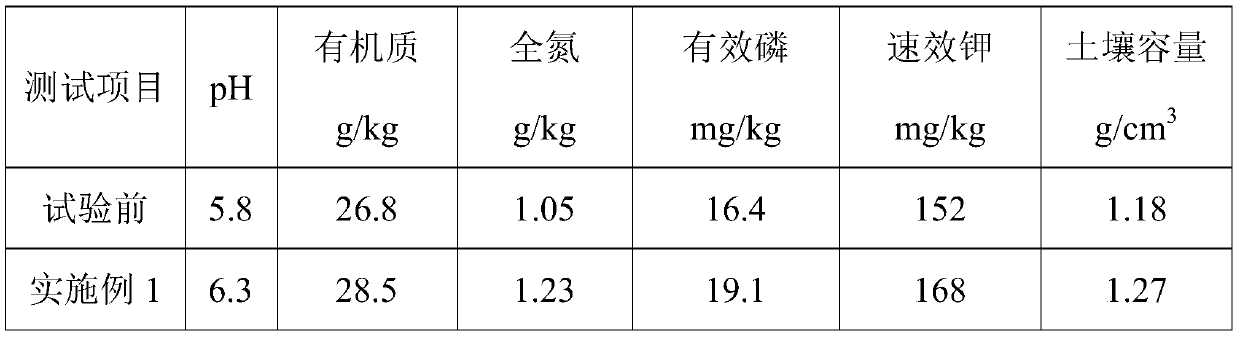

Soil remediation fertilizer prepared from kitchen waste as well as preparation method and application thereof

InactiveCN111320497AShort processing timeHigh recovery rateClimate change adaptationOrganic fertilisersBiological propertySoil remediation

The invention provides a soil remediation fertilizer prepared from kitchen waste as well as a preparation method and an application of the soil remediation fertilizer. The soil remediation fertilizeris prepared from kitchen waste subjected to anaerobic heat treatment, a complex microbial inoculant and a synergistic component. The soil remediation fertilizer prepared from the kitchen waste can reduce resource waste and effectively improve the problems of grease, germs and worm eggs of the kitchen waste, so that the physical, chemical and biological properties of soil are effectively improved,soil nutrients are maintained, and the utilization rate of the soil nutrients is increased.

Owner:时科生物科技(上海)有限公司

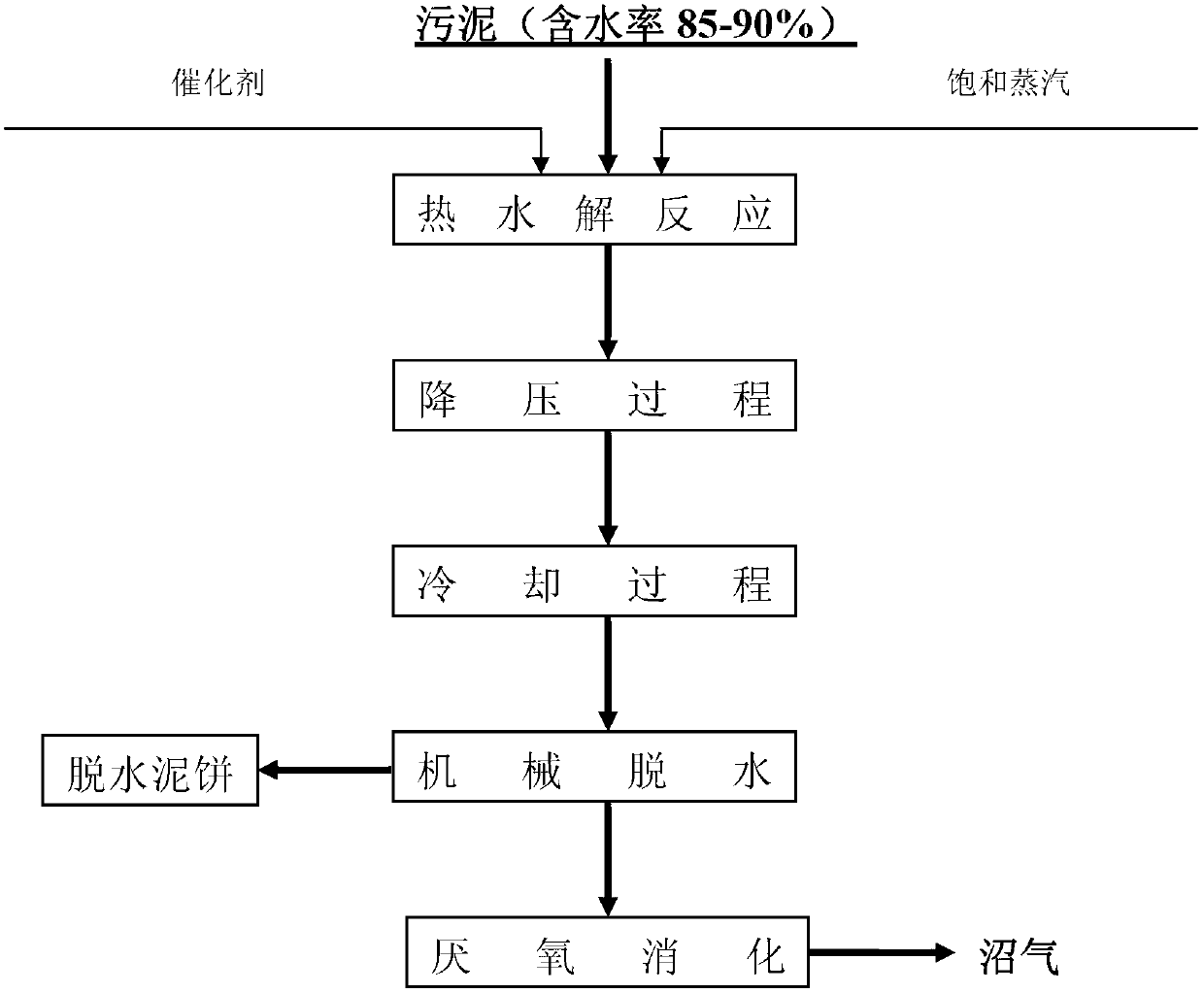

Method for treatment and comprehensive utilization of sludge based on low-pressure catalytic thermal hydrolysis and application of method

InactiveCN103121784AHarmlessImproved Anaerobic Digestion PerformanceSludge treatment by pyrolysisSlurryThermal water

The invention belongs to the technical field of sludge treatment, and discloses a method for treatment and comprehensive utilization of sludge based on low-pressure catalytic thermal hydrolysis and an application of the method. The method comprises the following steps of: injecting a catalyst and sludge with the water ratio of 75-90% into a reaction kettle, then injecting saturated steam with the pressure of 1.0-1.59MPa into the reaction kettle, stopping injecting the saturated steam when the temperature of the sludge reaches 60-80 DEG C, and maintaining the situation for 2 to 25 minutes, thus obtaining slurry after reaction; and performing anaerobic digestion reaction on the slurry to prepare a marsh gas. According to the method, the thermal hydrolysis time can be greatly shortened and the treatment efficiency can be improved by adding the catalyst, so that the energy consumption, the running cost, the equipment investment cost and the maintenance cost are reduced. The marsh gas prepared by the method can be used as a fuel for a steam boiler in a system or can be sold, and the purchased energy sources required by sludge treatment are reduced when the marsh gas is used as the fuel for the steam boiler in the system, so that the treatment cost is reduced, and the thorough harmlessness and recycling of the sludge are realized.

Owner:SHENZHEN ECO SOLUTION TECH CORP

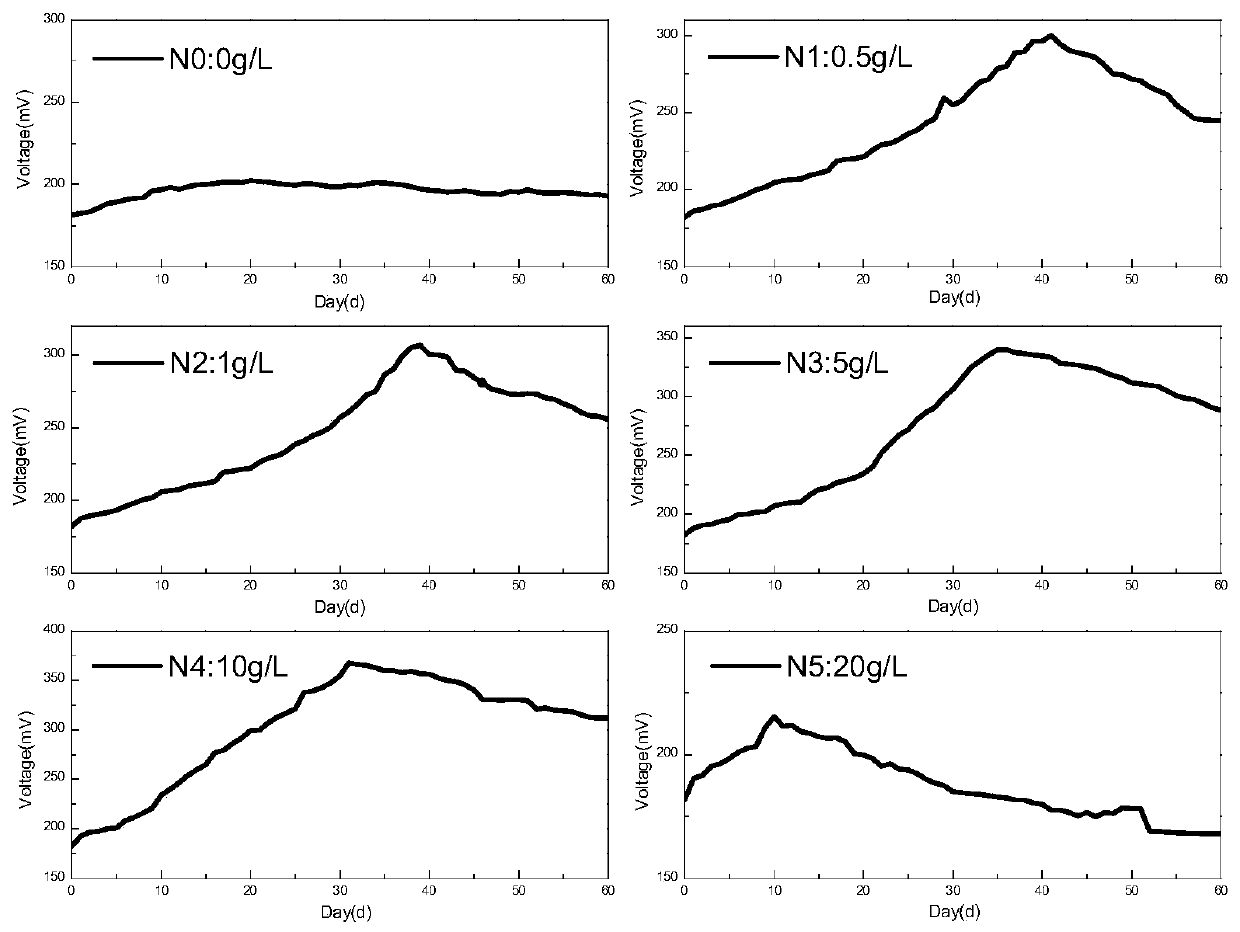

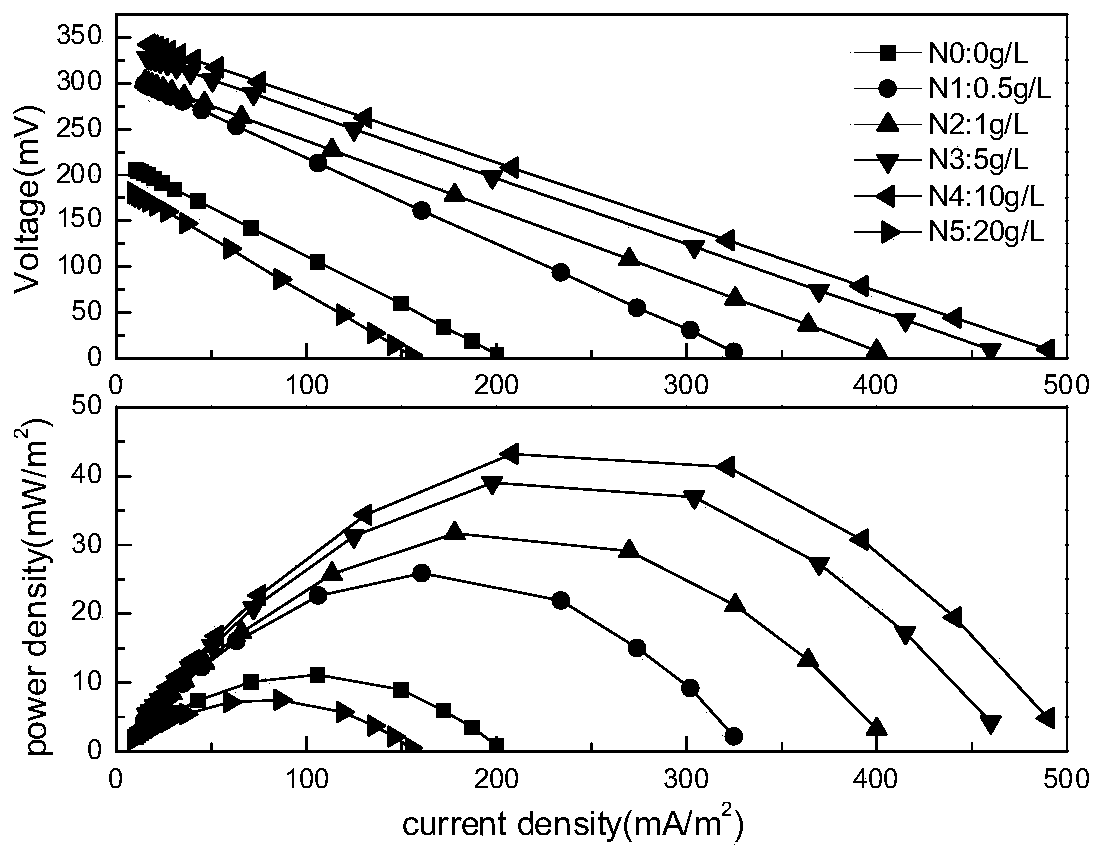

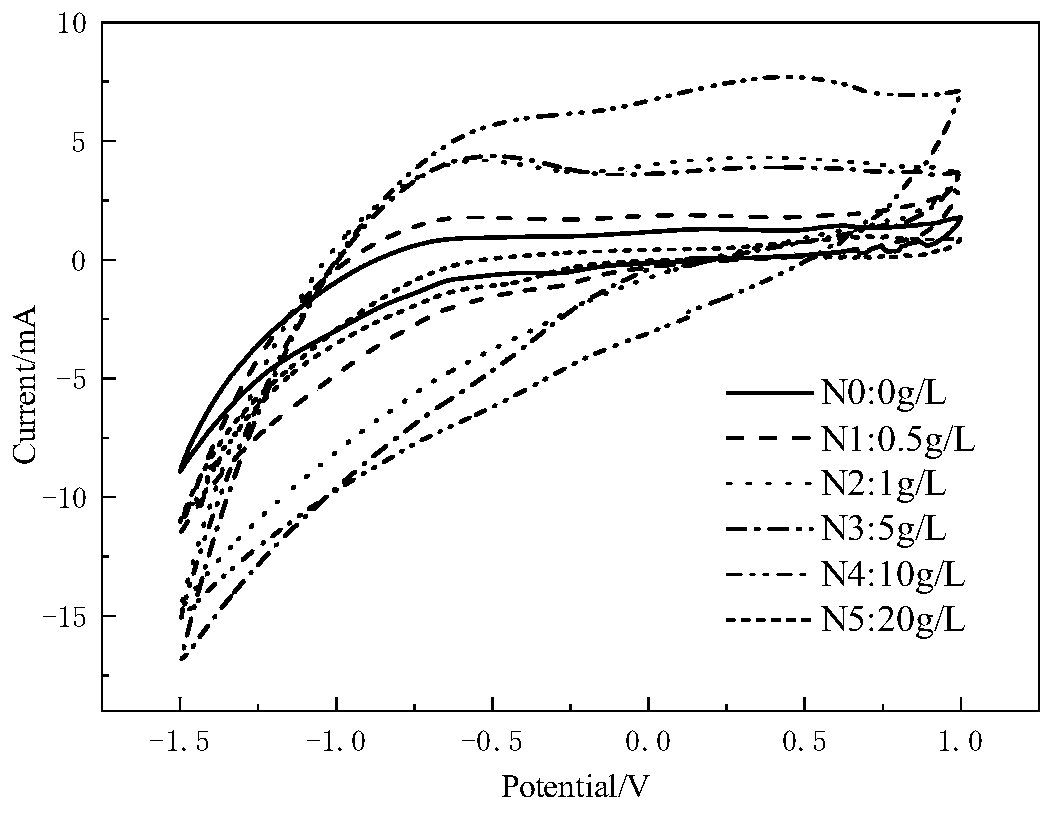

Sludge MFC-anaerobic digestion coupling system and performance enhancing method thereof

InactiveCN111170599AImprove weight reduction effectImprove power generation performanceWaste based fuelBiological sludge treatmentCarbon feltMethane gas

The invention discloses a sludge MFC-anaerobic digestion coupling system and a sludge MFC-anaerobic digestion coupling method. The system comprises a closed anaerobic anode chamber and an aerated cathode chamber, which are connected through a communicating pipeline; a proton exchange membrane is arranged in the communicating pipeline, a carbon felt anode in the anode chamber is connected with a carbon felt cathode in the cathode chamber through an alligator clip wire, an outer resistor is arranged between the anode and the cathode, and a circular hole is formed in the anode cover surface and connected with a gas collecting bag and used for collecting methane gas generated by anode anaerobic sludge fermentation. The invention further provides a method for strengthening the performance of the sludge MFC-anaerobic digestion coupling system, wherein waste iron scraps are added into anode anaerobic sludge of the sludge MFC-anaerobic digestion coupling system to obtain iron-containing sludge, and the iron-containing sludge serves as an anode substrate to domesticate electrogenesis bacteria and anaerobic digestion bacteria in the anode anaerobic sludge.

Owner:HOHAI UNIV

Three-step two-stage method for producing marsh gas from municipal sludge by anaerobic fermentation

InactiveCN102775037AImproved Anaerobic Digestion PerformanceReduce volumeWaste based fuelBiological sludge treatmentChemical oxygen demandSlag

The invention relates to a three-step two-stage method for producing marsh gas from municipal sludge by anaerobic fermentation, which comprises the following steps: carrying out anaerobic digestion on municipal sludge at 33-37 DEG C or 53-57 DEG C for 15-90 days; putting residual marsh slag in the anaerobic digestion step in a loading reactor to carry out wet oxidation, wherein the temperature is set at 120-320 DEG C according to different sludge properties, an oxidizer is introduced until the gas pressure is 0.5-20 MPa, and the reaction time is 20-90 minutes; cooling the marsh slag subjected to wet oxidation to room temperature, and carrying out anaerobic digestion at 33-37 DEG C or 53-57 DEG C for 15-90 days; and collecting marsh gas generated by digestion by using a gas collection device, and determining the methane content. After the sludge is subjected to anaerobic digestion, the VS (VSS) removal rate is enhanced from 40-50% to 70%, and the COD (chemical oxygen demand) removal rate is up to more than 90%; the dehydration property of the digested sludge is obviously improved; and after dehydration and dewatering, the volume of the sludge can be reduced by more than 85%, and the main components are inorganic substances, thereby efficiently implementing reduction, stabilization and recycling of sludge, and having wide application prospects.

Owner:TONGJI UNIV

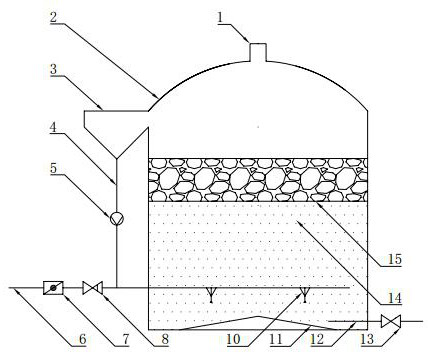

Solar septic tank apparatus and treatment process for pretreating domestic sewage

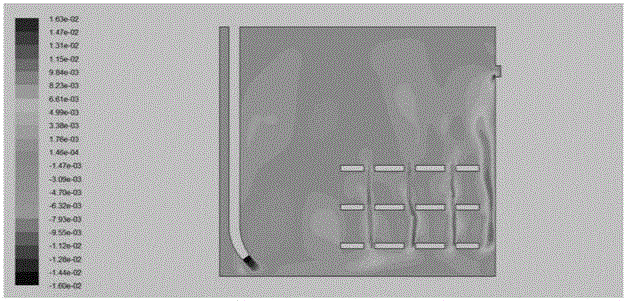

InactiveCN105967454AReduce hydraulic dead zonePlay a role in removalWater treatment parameter controlWater contaminantsMicroorganismSewage

The invention discloses a solar septic tank device for pretreatment of domestic sewage and a treatment process thereof, which is suitable for small-scale distributed domestic sewage. Wherein the septic tank device includes a solar energy system and a septic tank, and the septic tank includes a first cell, a second cell and a third cell separated by a first partition and a second partition, the first cell It is a water inlet cell, the second cell is a transition cell, and the third cell is a filter cell; a multi-layer heating plate is arranged in the first cell, and at least one circle of evenly distributed heating plates is provided on each layer of the heating plate A small hole; a second water inlet pipe and a filter layer are arranged on the third compartment, the water inlet of the second water inlet pipe is connected to the second water inlet, and the water outlet of the second water inlet pipe is located in the filter bottom of the layer. Compared with the traditional septic tank, the invention is not limited by the influence of the environment temperature, and the effect of anaerobic digestion is enhanced through the regulation and control of the temperature field and the flow field, and the degradation ability of microorganisms and the removal efficiency of pollutants are improved.

Owner:SOUTHEAST UNIV +1

Method for treating residual active sludge

ActiveCN109912139AReduce dosageKeep aliveSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisActivated sludgeSewage

The invention discloses a method for treating residual active sludge. The method comprises: feeding remaining active sludge into a homogenization groove, adding a treatment agent to the homogenizationgroove, treating, carrying out thermal hydrolysis wall breaking treatment on the treated sludge, feeding the wall-broken sludge into a sludge dewatering machine, dewatering to obtain dewatered mud cake and sewage, feeding the sewage to a sewage treatment plant so as to be further treated, and carrying out molding drying on the obtained dewatered mud cake to obtain dried sludge. With the method ofthe present invention, the water content of the remaining sludge can be reduced to less than 15%, the volume of the sludge can be greatly reduced, and the dried sludge can be used as the further resource raw material or can be incinerated.

Owner:CHINA PETROLEUM & CHEM CORP +1

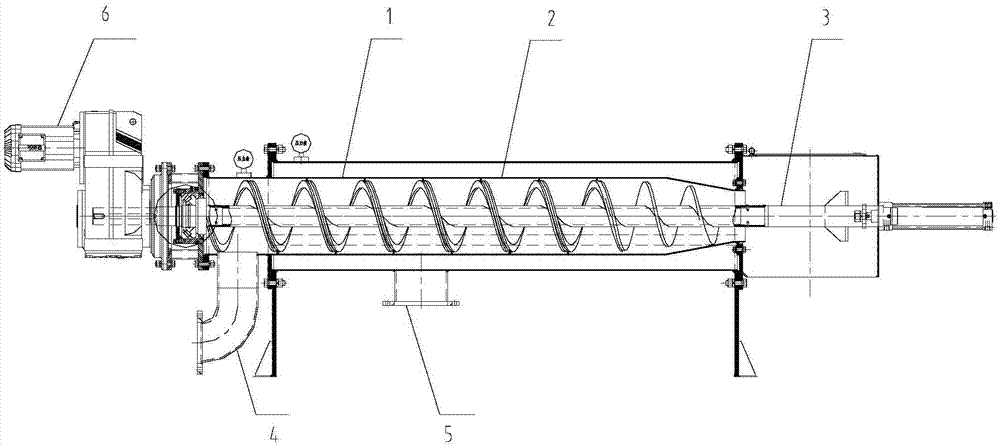

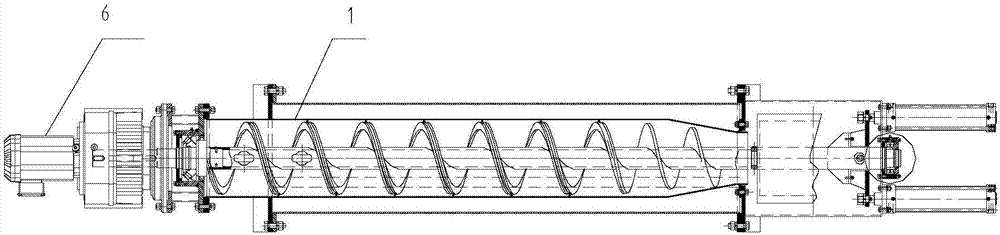

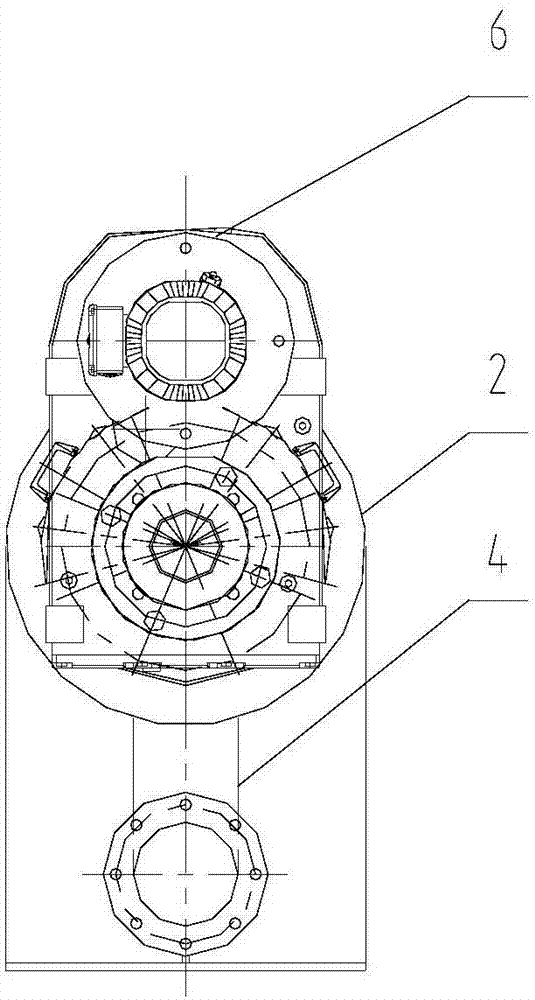

Pipeline type sludge slag removal automation control system and control method

ActiveCN107352763AEfficient separationSimple structural designSludge treatment by thermal conditioningSpecific water treatment objectivesElectricityControl system

The invention relates to a pipeline type sludge slag removal automation control system and a control method thereof. The system comprises a pipeline type sludge slag removal machine and a waterproof electric control box, wherein the pipeline type sludge slag removal machine comprises a multifunctional filter tube in horizontal transverse arrangement and a dewatering extrusion device arranged in the multifunctional filter tube; a sludge inlet and a sludge outlet are formed in the multifunctional filtering tube; a spiral type conveying assembly is transversely arranged in an inside cavity of a tube body of the multifunctional filter tube and is electrically connected with a driving device; the spiral type conveying assembly comprises a slag spiral conveying rod and a sludge filtering net; the slag is conveyed to the dewatering extrusion device through a spiral conveying rod; the dewatering extrusion device is connected with a slag outlet discharging device arranged at the outer side of the pipe body. The system and the method have the advantages that the structure is simple; the design is reasonable; the operation is reliable and stable; the automation degree is high; the stirring efficiency is high; the later-stage maintenance cost is low; the installation and the use are convenient and fast; the sludge can be effectively subjected to slag removal, recovery and reutilization, and the like.

Owner:BEIJING DRAINAGE EQUIP

Biomass waste treatment system and method

PendingCN109454092AImproved Anaerobic Digestion PerformanceIncrease resourcesSolid waste disposalTransportation and packagingEnvironmental resistanceEnvironmental engineering

The invention discloses a biomass waste treatment system and method, and relates to the technical field of environmental protection. The biomass waste treatment system comprises a flow control unit, ademulsification tank, a cyclone separator and a hydrothermal reaction unit, and the demulsification tank, the cyclone separator and the hydrothermal reaction unit are sequentially connected. The flowcontrol unit is connected to the demulsification tank, the cyclone separator and the hydrothermal reaction unit separately so as to control the working processes of the demulsification tank, the cyclone separator and the hydrothermal reaction unit. The inner diameter of the cyclone separator is sequentially reduced from top to bottom, and the cyclone separator is also provided with a material inlet, a liquid phase outlet and a solid phase outlet. The material inlet is formed in the upper side wall and is tangent to the side wall, the solid-phase outlet is formed in the bottom of the cyclone separator, and the liquid phase outlet is formed in the top of the cyclone separator. The method is based on the system. The biomass waste treatment system and method are used for multi-stage treatmentof biomass waste, and the dehydration property and anaerobic digestion performance of the biomass waste are improved, so that the harmless and recycling effects of the biomass waste are improved.

Owner:四川深蓝环保科技有限公司

Method for treating biochemical sludge

InactiveCN108002671AImprove processing efficiencyEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisRoom temperatureTherapeutic effect

The invention discloses a method for treating biochemical sludge. The method comprises (1) diluting biochemical sludge through water so that the solid content is 5% to 15%, (2) carrying out pyrohydrolysis on the diluted biochemical sludge and then naturally cooling the diluted biochemical sludge to the room temperature, wherein the pyrohydrolysis temperature is in a range of 140-200 DEG C and pyrohydrolysis time is in a range of 20-90min, (3) carrying out anaerobic digestion post-treatment on the biochemical sludge and (4) press-filtering the treated biochemical sludge through a plate-and-frame filter press to obtain dehydrated sludge. The method has simple processes, high sludge treatment efficiency and good treatment effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

UBF anaerobic reactor based on biochar carrier

InactiveCN113060832AImproved Anaerobic Digestion PerformanceIncrease the number ofTreatment with anaerobic digestion processesTreatment with microorganism supports/carriersBiofilmMicroorganism

The invention discloses a UBF anaerobic reactor based on a biochar carrier. The UBF anaerobic reactor comprises a reaction tank, a biological filler layer is arranged on the upper portion of the reaction tank, a water inlet pipe is arranged on one side of the reaction tank, a sludge discharge pipe is arranged on the other side of the reaction tank, and the sludge discharge pipe, a water distributor, a granular sludge layer, the biological filler layer, an effluent weir and a gas collection port are sequentially arranged on the reaction tank from bottom to top. The anaerobic digestion capability of anaerobic microorganisms on sewage is improved through the biochar, and the anaerobic microorganisms in the reaction tank mainly exist in a biological membrane on the surface of a filter material through the biological filler layer, so that the quantity and activity of the microorganisms in the reaction tank are improved; according to the invention, the sewage treatment capability, the pollutant load impact resistance and the stability of a traditional UBF anaerobic reactor are improved, and the UBF anaerobic reactor has the characteristics of simplicity in operation, high treatment efficiency and the like.

Owner:NORTHWEST A & F UNIV

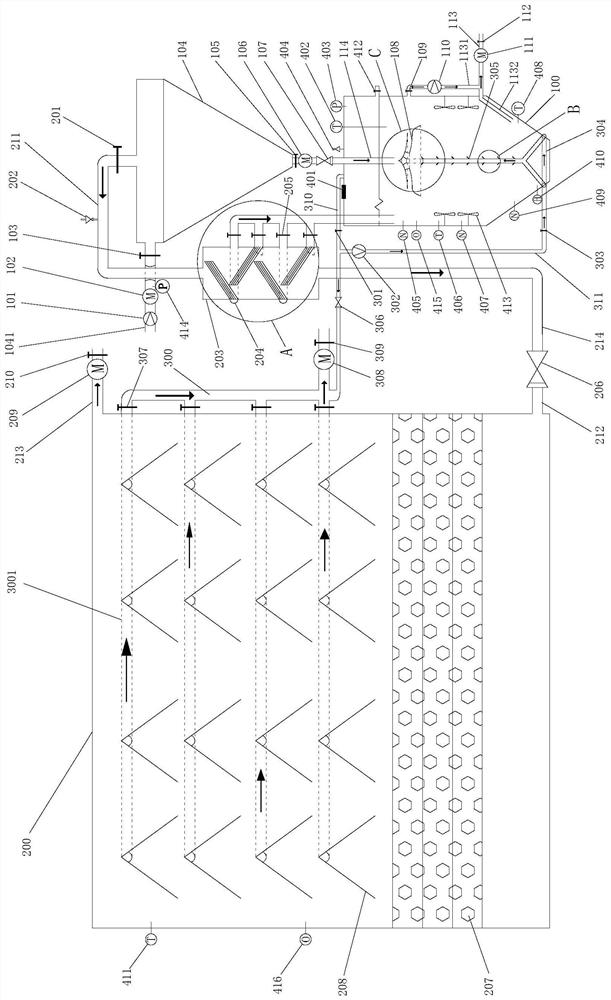

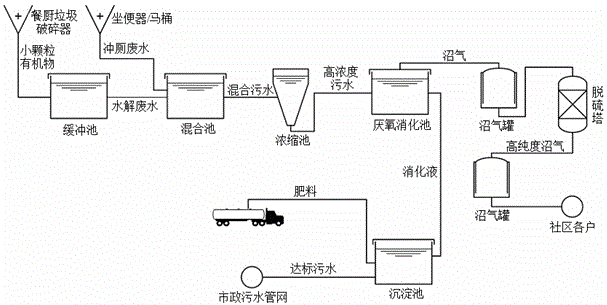

Method and system for recycling urban community organic waste

InactiveCN104556560AShort processReduce processing costsBio-organic fraction processingSolid waste disposalWastewaterMunicipal sewage

The invention relates to a method and system for recycling urban community organic waste, which comprises the following steps: crushing kitchen waste from all families in the community into 2-3mm-granule organic waste, hydrolyzing, mixing the hydrolysis wastewater with toilet flushing water of all families in the community, concentrating to obtain high-concentration sewage with the organic matter concentration of 10-15%, carrying out anaerobic digestion on the high-concentration sewage to obtain marsh gas and a digestive fluid, carrying out desulfurization purification on the marsh gas to obtain pure marsh gas, treating the digestive fluid to obtain a fertilizer and acceptable sewage, and discharging the acceptable sewage into a municipal sewage pipe network. The waste is pretreated at the generation source, and subjected to anaerobic digestion treatment in situ, and thus, the method has the advantages of short process and low treatment cost. Various types of waste are not piled or transported, thereby avoiding environment pollution. The treatment object only comprises kitchen waste and toilet flushing waste generated in the community, so the component is simple; and therefore, the method has favorable anaerobic digestion effect.

Owner:WISDRI ENG & RES INC LTD

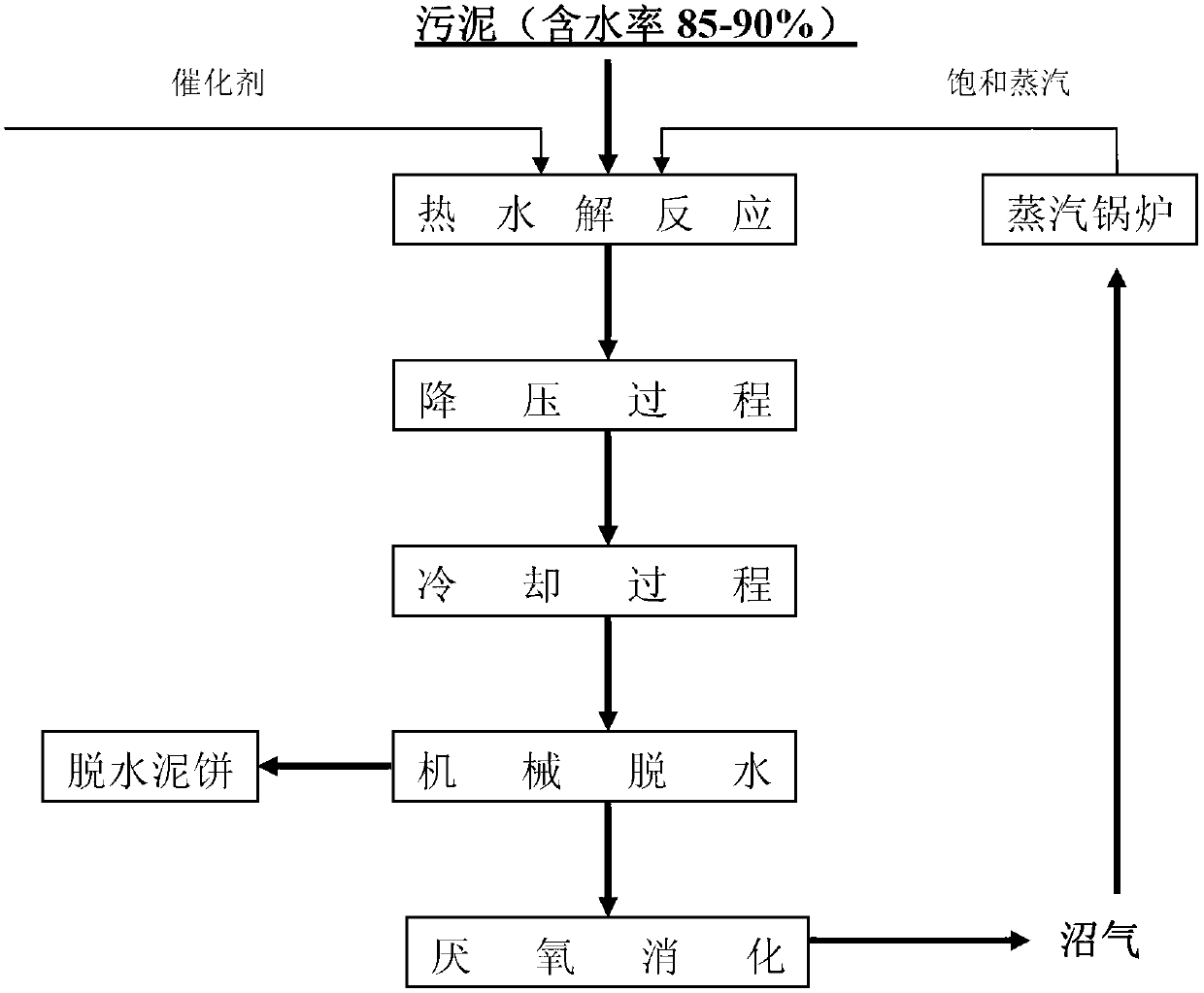

Sludge treatment and resource utilization method based on thermal hydrolysis and its application

ActiveCN103130388BHarmlessImproved Anaerobic Digestion PerformanceBio-organic fraction processingSolid waste disposalHeating timeResource utilization

The invention belongs to the technical field of sludge treatment, and discloses a sludge treatment and resource utilization method based on pyrohydrolysis and application of the sludge treatment and resource utilization method based on the pyrohydrolysis. The sludge treatment and resource utilization method based on the pyrohydrolysis comprises injecting sludge with moisture content of 75%-90% into a reaction kettle, then injecting saturated steam with pressure of 1.5MPa-2.5MPa into the reaction kettle, stopping injecting the saturated steam when the temperature of the sludge reaches 150DEG C-185DEG C, maintaining the state for 0-25min, and obtaining slurry of the pyrohydrolysis; carrying out mechanical dehydration on the slurry, and obtaining desorption liquid and dehydration mud cakes; and carrying out an anaerobic digestion reaction on the desorption liquid, and obtaining methane. Processing temperature of the pyrohydrolysis is low, heating time of the sludge and total processing time of the sludge treatment and resource utilization method can remarkably reduced, processing efficiency is improved, energy consumption is reduced, and cost is saved. The dehydration mud cakes obtained by the sludge treatment and resource utilization method can serve as raw materials of organic fertilizer, the obtained methane can be used for fuel of a boiler system, and finally reduction, harmless performance and recycling of the sludge are achieved.

Owner:SHENZHEN ECO SOLUTION TECH CORP

Device and method for treating organic matter with high water content

ActiveCN109052892AIncrease moisture contentImprove qualitySludge treatment by de-watering/drying/thickeningTemperature controlSoil organic matter

The invention discloses a device and a method for treating organic matter with high water content. The device comprises a material charge unit, a hydrothermal drying unit, a press filtering unit, a liquid storage unit, a thermal conversion unit and a solid storage unit, wherein the to-be-treated organic matter with high water content can be sequentially sent into the material charge unit, the hydrothermal drying unit, the press filtering unit and the thermal conversion unit; the hydrothermal drying unit is provided with an air inlet, an air outlet, a first heating device and a second heating device; the press filtering unit is a mechanical press filtering unit; the thermal conversion unit comprises a second heating device and a second temperature control device. The device has the advantages that the water content of the organic matter with high water content can be well reduced via the in-situ hydrothermal dewatering, and the organic matter with high water content after reducing of water content is thermally converted to obtain the product with higher quality; the device is an integral combined device, so that the operation is convenient, and the treatment efficiency of the organic matter with high water content is higher.

Owner:XI AN JIAOTONG UNIV

Sludge pretreatment combined method

ActiveCN101348316BImprove efficiencyQuick breakdownSludge treatment by oxidationBiological sludge treatmentCombined methodWaste treatment

The invention relates to the waste treatment technical field, in particular to a combined method used for sludge pretreatment. The combined method comprises the following steps that excess sludge generated during sewage treatment is adjusted to the appropriate concentration, pH value and temperature, and is conveyed to an ultrasonic / ozone reactor; and after treated with both ultrasonic wave and ozone, the excess sludge is finally conveyed to a sludge anaerobic digestion reactor so as to undergo post treatment or is directly dewatered to be made into agricultural fertilizer. The combined method has the advantages that the method applies ultrasonic wave and ozone to sludge pretreatment for the first time; after treatment, the dissolution rate of solid phase COD is between 5 and 35 percent, and the output of methane is increased by 50 to 75 percent; compared with treatment carried out through adopting ultrasonic wave or ozone independently, the removal rate of benzo [a] pyrene in the sludge can reach 4 to 10 percent, and energy consumption is reduced by 5 to 20 percent; therefore, the method reduces the cost in sludge treatment, and is suitable for the treatment of sludge in a sewageplant and a sewage treatment station; moreover, the method can be used in sludge pretreatment for manufacturing agricultural fertilizer, and has broad application prospect.

Owner:SUZHOU QINGRAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com